Environmental protection type HPVC door frame

An environmentally friendly, PVC resin powder technology, applied in the field of plastic materials, can solve the problems of excessive harmful substances and affecting the export of products to the EU, and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

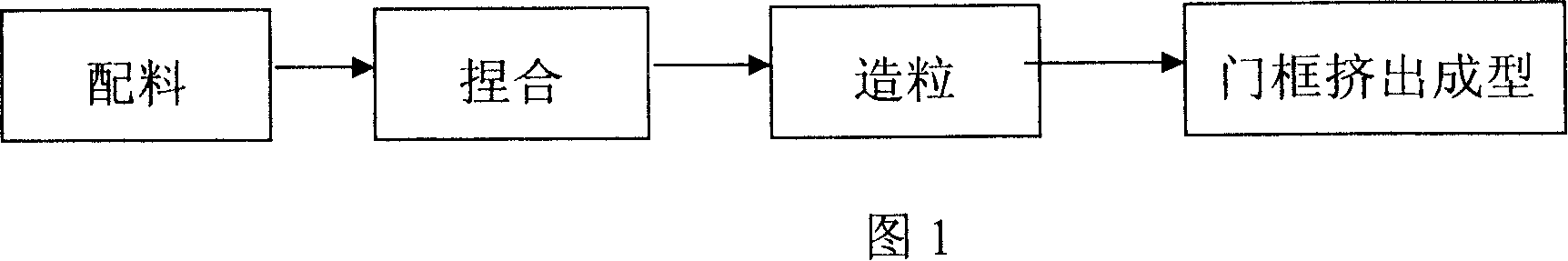

Method used

Image

Examples

Embodiment approach 1

[0014] Get 54 parts of PVC resin powder, 3 parts of non-toxic calcium-zinc composite stabilizer, 4 parts of CPE (chlorinated polyethylene), 0.4 part of stearic acid, 0.6 part of polyethylene wax, EBS lubricant (ethylene bis stearamide) 0.4 parts, 3 parts of ACR (acrylic ester copolymer), 13 parts of activated calcium carbonate, 0.6 parts of dioctyl phthalate, 0.6 parts of epoxy soybean oil, 0.6 parts of triphenyl phosphite, 0.6 parts of toner. Add the above-mentioned PVC resin powder, non-toxic calcium-zinc composite stabilizer and various additives into a high-speed mixer for kneading. When the temperature of the mixture reaches 120°C, it is discharged into a low-speed cold mixer to continue mixing, and the temperature is cooled to below 50°C for discharge. Enter the granulation process. The granulation process is carried out by a conical twin-screw extruder, and the processing temperature is six temperature sections, from the fuselage to the machine head, respectively 1#170-...

Embodiment approach 2

[0016] The process of processing is identical with embodiment one, and the parts by weight of each raw material is as follows: 50 parts of PVC resin powders, 1.3 parts of nontoxic calcium-zinc composite stabilizers, 4 parts of CPE (chlorinated polyethylene), 0.25 parts of stearic acid, 0.3 parts of polyethylene wax, 0.3 parts of EBS lubricant (ethylene bis stearamide), 2 parts of ACR (acrylate copolymer), 15 parts of activated calcium carbonate, 0.5 parts of dioctyl phthalate, epoxy large 0.8 parts of soybean oil, 0.4 parts of triphenyl phosphite, and 0.5 parts of toner.

[0017] The above materials can be used to obtain PVC door frames with good performance, and the specific performance data are as follows:

[0018] project name

[0019] The environment-friendly door frame prepared by the above method can be applied to products such as refrigerators, freezers, or disinfection cupboards, and has high practical value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com