Patents

Literature

594 results about "Triphenyl phosphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Triphenyl phosphite is the chemical compound with the formula P(OC₆H₅)₃. This colourless viscous liquid is the ester of phosphorous acid and phenol. It is used as a ligand in organometallic chemistry. Nickel complexes of this ligand are homogeneous catalysts for the hydrocyanation of alkenes.

Method for preparing aldehyde through linear chain olefin hydroformylation

InactiveCN102911021AReduce dosageGuaranteed uptimeOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionFormylation reactionDiphosphines

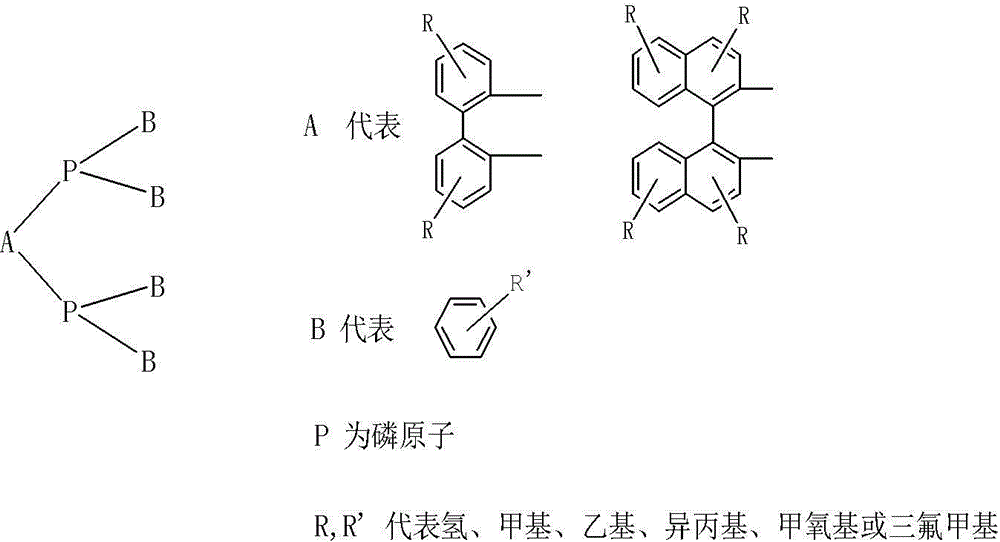

The invention relates to a method for preparing aldehyde through linear chain olefin hydroformylation. According to the method, a continuous reaction mode is used for performing olefin hydroformylation reaction in a homogeneous catalyst system; a catalyst is a composite catalysis system composed of a rhodium complex, a biphenyl backbone or biphenyl backbone diphosphine ligands and triphenylphosphine or triphenyl phosphate monophosphorous ligands; a reaction solvent comprises butyraldehyde, valeraldehyde, toluene or isodecanol; when the catalyst system uses propylene or butene-1 as raw materials under the condition of a low molar ratio of the diphosphine ligands to the rhodium complex, contents of the aldehyde generated by hydroformylation of the propylene and the butene-1 is larger than 97% and 95% respectively; and when the catalyst system uses a mixture of the butene-1 and butene-2 as raw materials, and the content of n-valeraldehyde in hydroformylation reaction products can reach above 85%.

Owner:QINGDAO SANLI BENNUO CHEM IND +1

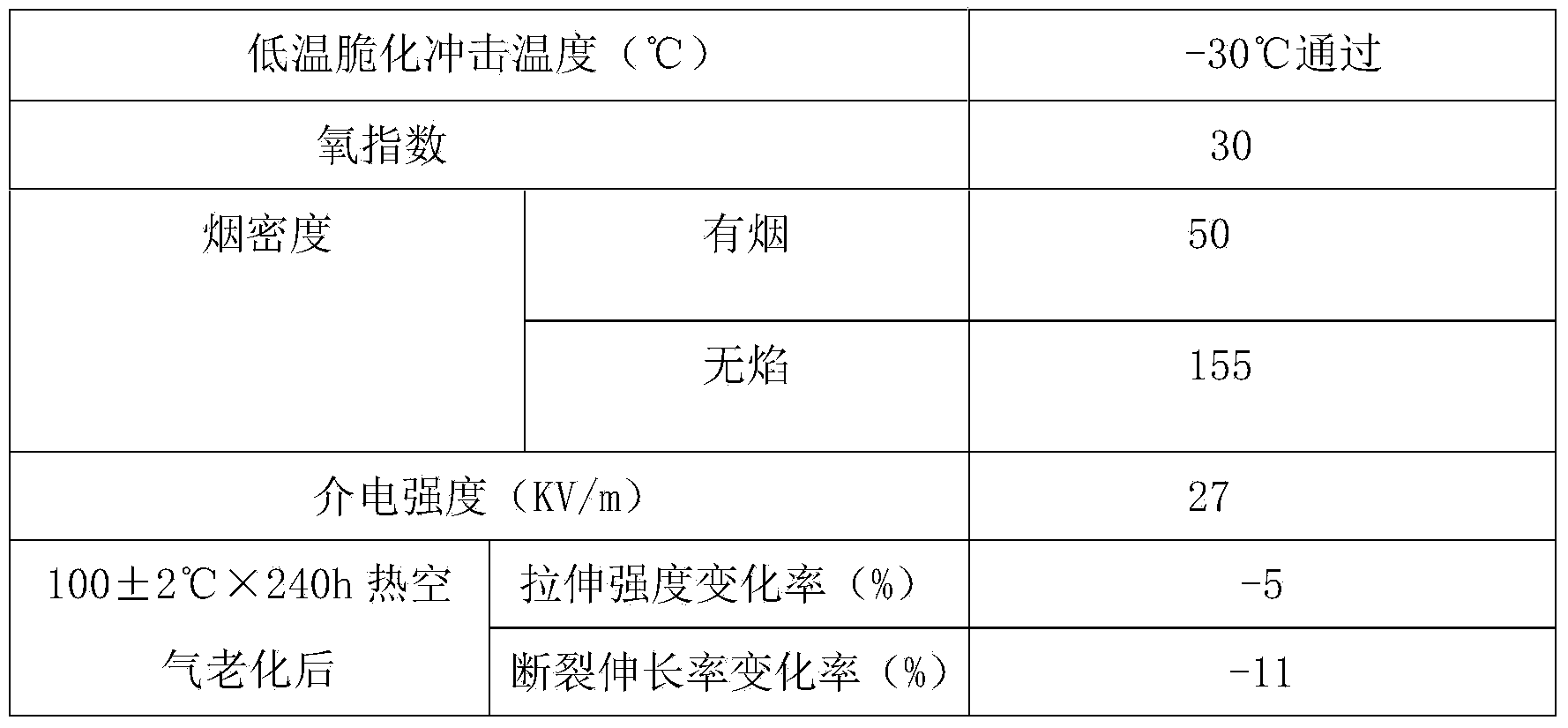

Environmental-friendly halogen-free low-smoke flame retardant material for coaxial cable and preparation method thereof

InactiveCN101608032AGood effectEnvironmental protection is goodInsulated cablesInsulated conductorsAluminium hydroxideMixed materials

The invention relates to an environmental-friendly halogen-free low-smoke flame retardant material for a coaxial cable and a preparation method thereof. The environmental-friendly halogen-free low-smoke flame retardant material comprises the following materials with the content by weight percent: 15 to 30 percent of ethane-vinyl acetate copolymer, 8 to 15 percent of linear low-density polythene, 25 to 60 percent of fire retardant aluminium hydroxide, 10 to 20 percent of fire retardant magnesium hydroxide, 5 to 10 percent of compatilizer ethane-vinyl acetate copolymer graft maleic anhydride copolymer or ethane graft maleic anhydride copolymer, 0.2 to 0.8 percent of antioxygen triphenyl phosphate, 0.4 to 1 percent of surface active agent ethenyl (beta-methoxyl ethyoxyl) trisilane and 0.5 to 1.2 percent of lubricant zinc stearate. The preparation method of the environmental-friendly halogen-free low-smoke flame retardant material comprises the following steps: firstly, mixing the fire retardant aluminium hydroxide at high speed in a high-speed mixing machine till the temperature of the fire retardant aluminium hydroxide achieves 80 to 90 DEG C; using the surface active agent ethenyl (beta-methoxyl ethyoxyl) trisilane to carry out spraying preprocessing after dehydration; adding the materials by weight percent into the high-speed mixing machine to be stirred at high speed for 3 to 5 minutes so that the materials are uniformly mixed; then delivering the mixed materials into a twin-screw extruder to be processed and prilled, wherein the temperature of each section of a screw is as follows: the temperature of a material feeding section is 90 to 110 DEG C, the temperature of a delivering section is 120 to 130 DEG C, the temperature of a plasticizing section is 130 to 140 DEG C, and the temperature of a machine head is 135-145 DEG C; and drying particles after the mixed materials are prilled so as to obtain finished products.

Owner:SUZHOU HENGLI COMM MATERIAL

Packing leather cup rubber for hydraulic mount and preparation method thereof

The invention discloses packing leather cup rubber for hydraulic mount. The packing leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of isoprene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorosilicone rubber, 3-5 parts of natural rubber, 20-30 parts of high abrasion furnace black N330, 10-15 parts of modified white carbon black, 3-4 parts of antimony trioxide, 8-10 parts of modified wood ash, 4-6 parts of attapulgite, 4-6 parts of meerschaum, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of vulcanizing agent TMT, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BZ, 1-2 parts of calcium stearate, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of polyethylene wax, 1-2 parts of triphenyl phosphite, 1-2 parts of anti-aging agent RD, 2-3 parts of vinyl-tris(beta-methoxyethoxy)silane and 16-18 parts of butyl epoxy oleate. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

Method for preparing functionalization polyolefin resin

The preparation process of functional polyolefin resin includes electronic beam or gamma-ray pre-irradiation treatment of functional polyolefin resin; mechanical mixing of polyolefin resin after pre-treatment, functional monomer and electron donor reagent; and reacting extrusion for the polyolefin resin in molten state and functional monomer to produce grafting reaction. The polyolefin resin includes polyethylene, polypropylene, ethylene-propylene copolymer, ethylene-styrene copolymer, polystyrene, etc; the functional monomer is unsaturated organic acid or its derivative with amino group, isocyanate, hydroxyl group or other reactive functional group; and the electron donor reagent includes electron-rich compound with P, N, S or O element, p-benzoquinone, triphenyl phosphite, triphenyl phosphate, etc.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Polyester resin for low-temperature cured powder paint and preparation method of polyester resin

ActiveCN102718952ARaise the conversion temperatureLow hydroxyl valuePowdery paintsPolyester coatingsPhosphorous acidPolymer science

The invention relates to polyester resin for low-temperature cured powder paint and a preparation method of the polyester resin. The polyester resin is characterized by comprising the following ingredients in percentage by mass: 0 to 10 percent of ethylene glycol, 10 to 40 percent of neopentyl glycol, 0 to 8 percent of 1,6-ethylene glycol, 0 to 5 percent of 1,4-cyclohexanedimethanol, 20 to 60 percent of terephthalic acids, 2 to 15 percent of adipic acid, 0.05 to 0.2 percent of monobutyltin oxide, 0.02 to 0.15 percent of triphenyl phosphate, 0 to 5 percent of adipic acid, 2 to 40 percent of m-phthalic acid and 0 to 5 percent of methacrylic acid. The polyester resin and the preparation method have the advantages that the curing at the low temperature condition of 130 DEG C to 140 DEG C can be realized, in addition, the storage stability is good, and the like.

Owner:广东伊诗德新材料科技有限公司

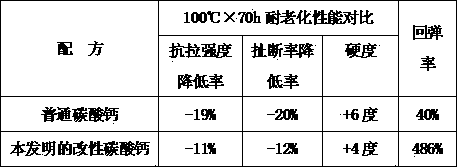

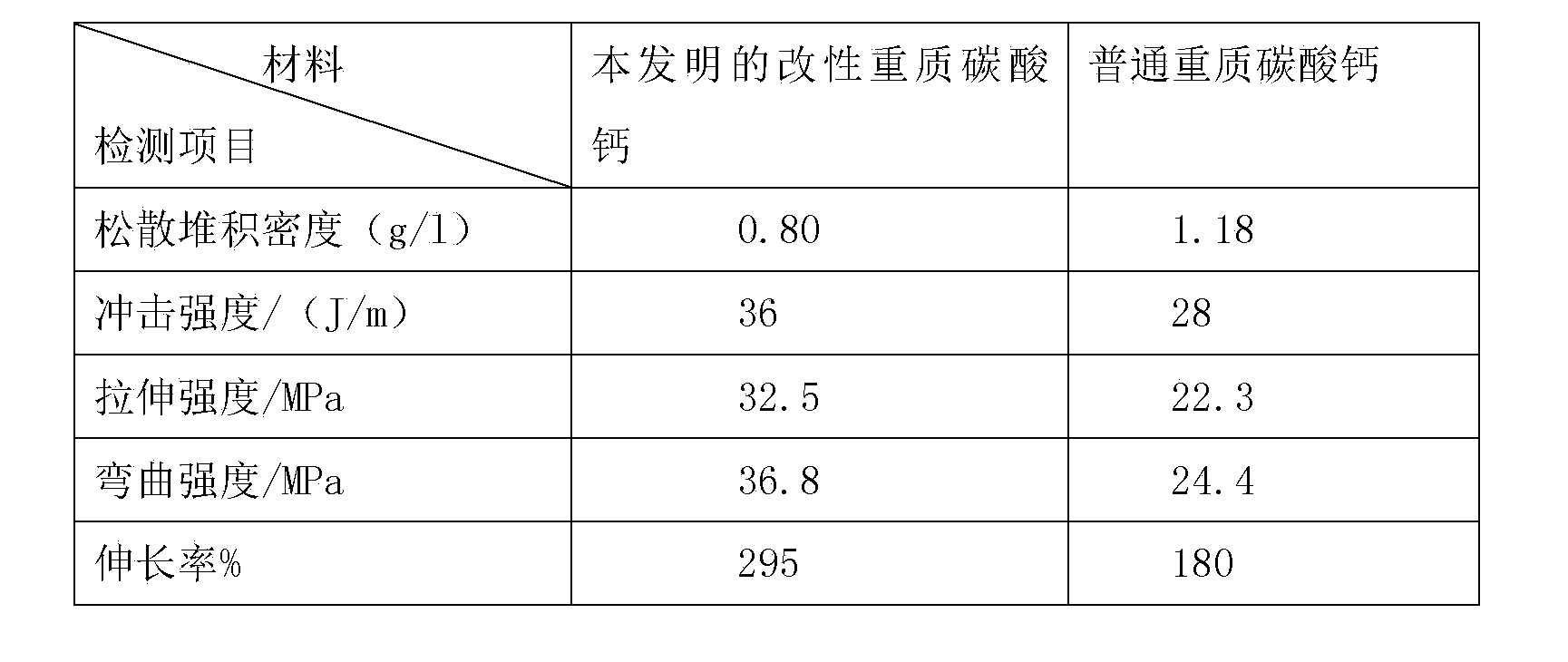

Modified calcium carbonate for wear-resistant rubber shoe soles and preparation method thereof

ActiveCN103408801AUniform particle sizeLarge specific surface areaSolesPigment treatment with macromolecular organic compoundsDispersityRubber material

The invention provides a modified calcium carbonate for wear-resistant rubber shoe soles, which is prepared from the following raw materials in parts by weight: 95-100 parts of ground calcium carbonate, 0.2-0.3 part of stearyl alcohol based polyethenoxy ether, 0.3-0.4 part of polyoxyethylene sorbitan fatty acid ester, 0.1-0.4 part of PE (polyethylene) wax, 0.5-0.8 part of triphenyl phosphite, 0.5-1 part of teflon micropowder, 0.1-0.3 part of ananti-aging agent 4020, 1-2 parts of ABS (acrylonitrile-butadiene-styrene) high rubber powder, 0.2-0.5 part of high-wear-resistance carbon black, 0.1-0.2 part of zirconium fluoride, 1-2 parts of dioctyl terephthalate (DOTP), 0.5-0.6 part of polyvinyl alcohol and 1-2 parts of a titanate coupling agent TMC-TTS. The preparation method comprises the following steps: drying calcium carbonate, proportionally and sequentially adding the other raw materials in batches, thoroughly mixing in a high-speed stirrer, drying and grinding. The modified calcium carbonate provided by the invention has the advantages of favorable dispersity and favorable wear resistance, and can lower the cost and enhance the working properties and wear resistance of shoe rubber when being used in shoe sole rubber materials.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

Polyolefin Compositions for Film, Fiber and Molded Articles

ActiveUS20130190434A1Good processing characteristicsExcellent gas fade resistanceHollow articlesFiberPolymer science

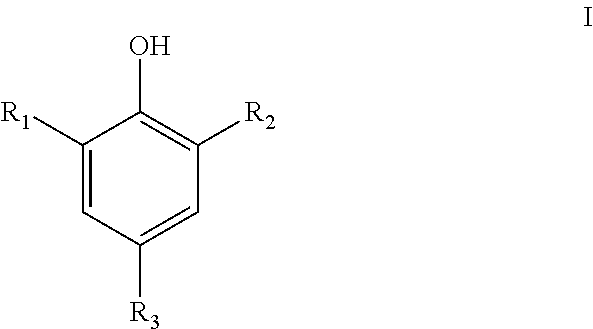

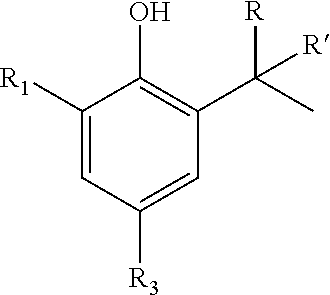

Polyolefin compositions prepared by processing a polyolefin resin and a mixture of a select hindered phenol and select liquid phosphite above the melting point of the polyolefin contain a higher amount of retained active phosphorus than when other common phosphites are used. The compositions, and films, fibers and other molded articles prepared from the compositions show improved stabilization against NOX discoloration and long term oxidation. The select liquid phosphite consists mainly of a mixture of triphenyl phosphite derivatives wherein the phenyl groups are substituted by different numbers of butyl and / or amyl substituents.

Owner:SI GROUP INC

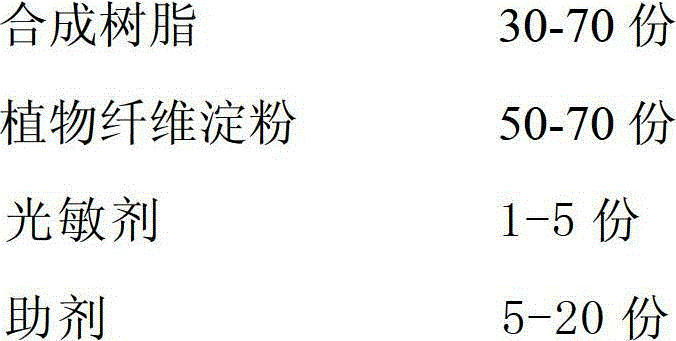

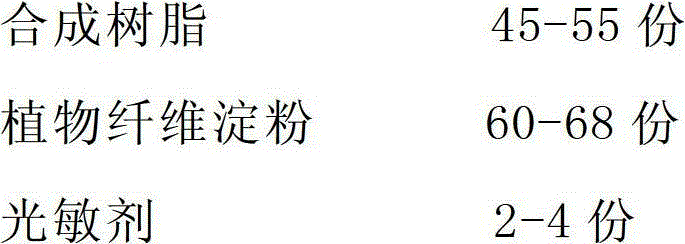

Degradable plastic

The invention provides a degradable plastic which is composed of, by weight, 30 to 70 parts of synthetic resins, 50 to 70 parts of plant fiber starch, 1 to 5 parts of photo-sensitizer and 5 to 20 parts of additives. The synthetic resins are selected from the combination of propene polymer (PP) resins and polylactic acids; the plant fiber starch is selected from garden wastes, in particular to leaves, weeds, limbs and the like; the additives include plasticizers, lubricants and heat stabilizers; the plasticizers are selected from one of tributyl citrate, mineral oil, acetic acid tributyl ester, urea and formamide; the lubricants are magnesium stearate; and the heat stabilizers are triphenyl phosphate. The degradable plastic has the advantages of biodegradation and light degradation, and the degradation is thorough; the starch is selected from the plant fiber starch, and the garden wastes are used, accordingly, both environmental problems are solved, and the cost of the degradation plastic is reduced; and components are simple, the cost is low, and the plastic is easy to produce.

Owner:TIANJIN LISHUN PLASTIC PRODS

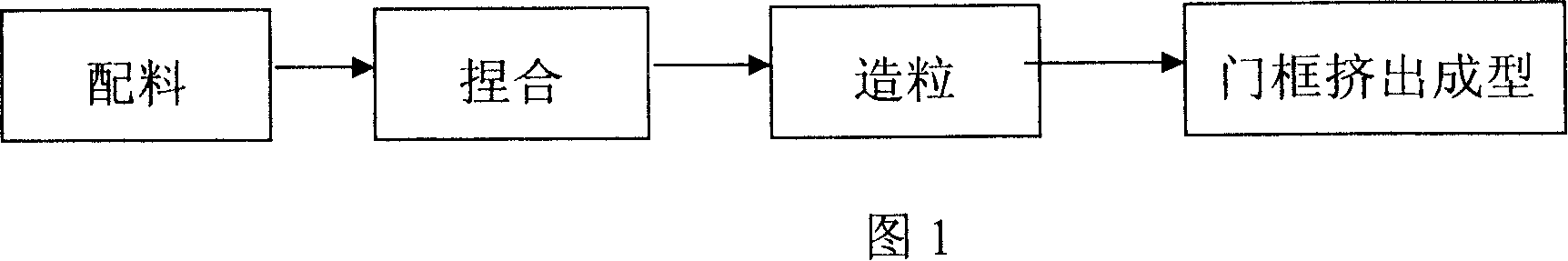

Environmental protection type HPVC door frame

InactiveCN101121802AComply with RoHS Directive requirementsDoes not affect processing performanceDomestic cooling apparatusLighting and heating apparatusAdditive ingredientStearic acid

The invention discloses an environment-friendly HPVC door frame, which is obtained by kneading and extruding. The main raw materials include PVC, a stabilizer, and a surface treatment agent, and are composed of the following substances by weight: PVC resin powder: 45-55, calcium Zinc composite stabilizer: 1-6, chlorinated polyethylene: 1-6, stearic acid: 0.1-1 part, polyethylene wax 0.1-1 part, ethylene bisstearamide: 0.1-0.8 part, acrylate copolymer Matter: 1-3, active calcium carbonate: 8-20, dioctyl phthalate: 0.1-1.5, epoxy soybean oil 0.3-1.2, triphenyl phosphite: 0.2-1.2, toner: 0.2-1 . The preparation method includes the steps of compounding, kneading, granulation and door frame extrusion. The performance index of the environment-friendly door frame prepared according to the invention meets the requirements of the RoHS directive, and the new formula does not affect the processing performance of the original equipment; the raw materials of the formula are easy to obtain and the price is low, and are suitable for industrial production.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

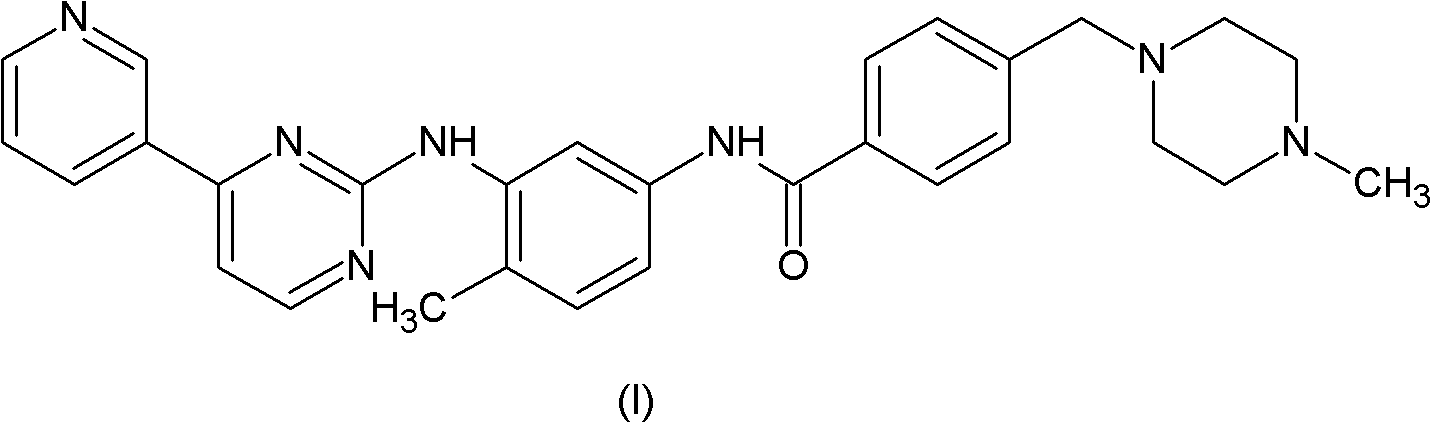

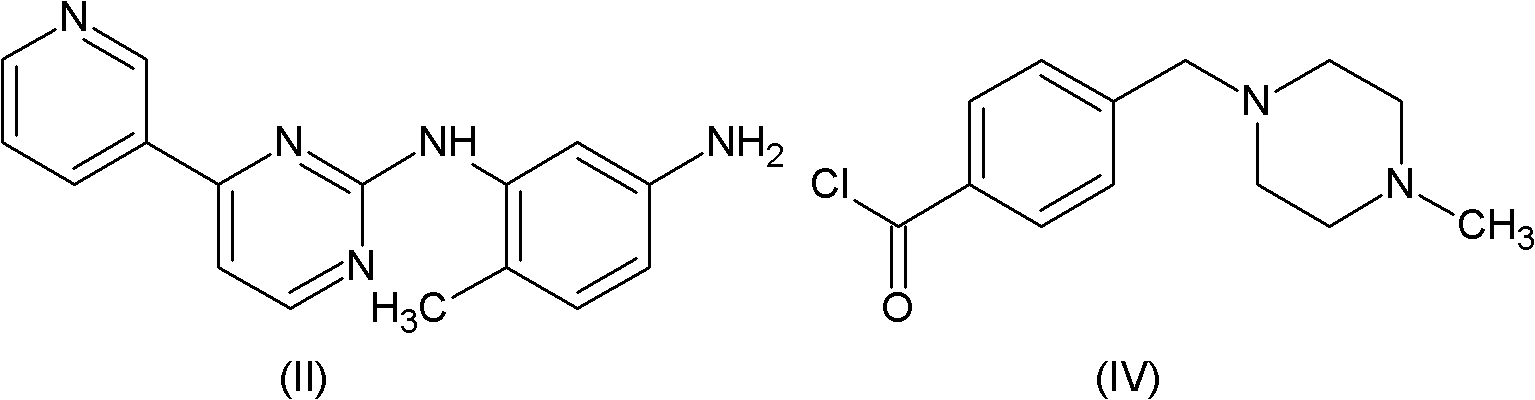

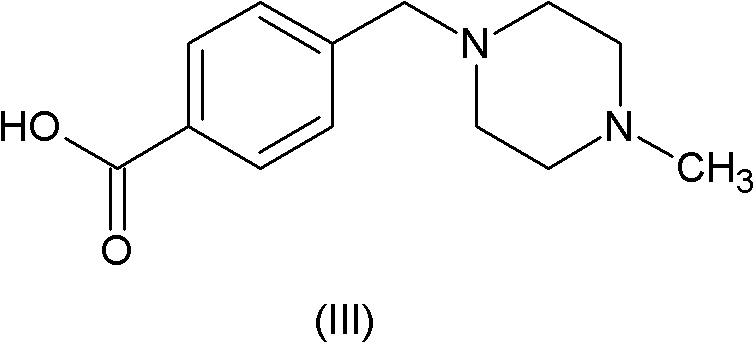

Method for preparing imatinib

ActiveCN101921260AThe reaction steps are simpleShorten the production cycleOrganic chemistryBenzoic acidN dimethylformamide

The invention relates to a method for preparing imatinib, which comprises the following steps of: with a compound N-(5-Amino-2-methylphenyl)-4-(3-pyridyl)-2-pyrimidineamine shown as the structural formula (II) and a compound 4-[(4-Methylpiperazin-l-yl)methyl]benzoic acid shown as the structural formula (III) as initial raw materials, dropwise adding phosphite ester at 50-90 DEG C for 1-2 hours inthe presence of a catalyst in an organic solvent; and continuously insulating and reacting at 50-90 DEG C to obtain the compound imatinib shown as the structural formula (I). The organic solvent is N,N-dimethylformamide, N,N-dimethylacetylamide or N-methylpyrrolidone. The catalyst is pyridine; and the phosphite ester is trimethyl phosphate, triethyl phosphate or triphenyl phosphate. The technical scheme of the invention has the advantages of simple reaction step, easy control of reaction, short production cycle, low toxicity of used raw materials, less pollution to the environment and higher product quality, and the yield can reach 95 percent, and the purity reaches 99.5 percent.

Owner:山东金城昆仑药业有限公司

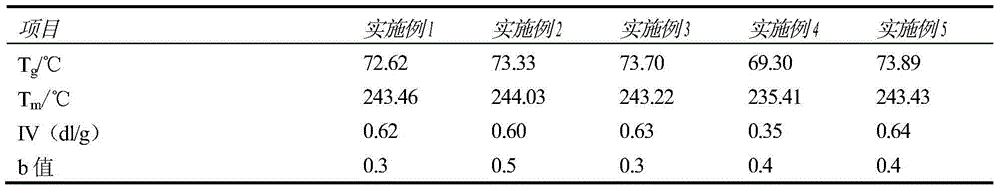

Synthetic method of polyethylene glycol terephthalate from biomass glycol

The invention discloses a synthetic method of polyethylene glycol terephthalate from biomass glycol. The glycol is prepared in to biomass through a chemical conversion method, and subjected to synthesis polyester reaction with terephthalic acid, wherein a catalyst is a composite catalyst. The biomass glycol and terephthalic acid in the molar ratio of 1.2:1-1.5:1 are added into a reaction kettle for esterification, wherein a stabilizer is triphenyl phosphate; and finally obtained by a condensation polymerization is carried out to obtain the polyester. glycol accounts for 95%-99.9% in the biomass glycol, and the trace alcohols are ethanol, 1, 2-propylene glycol, 1,2-butanediol, 1,2-pentadiol and 1,2-hexanediol. The technology of the invention is mainly to solve the influence of fusel on PET synthesis, and can synthesize PET polyester with quality standards satisfied from fusel-containing glycol.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

PET compound of heat and ageing resistant insulation film, and preparation method thereof

ActiveCN105778435APromotes Oxygen and Water Vapor PermeationOxygen and water vapor barrierPentaerythritolInorganic particle

The invention relates to a PET compound of a heat and ageing resistant insulation film. Raw materials of the PET compound comprise, by mass, 100 parts of PET resin slices, 0.1-1.0 part of a nanoparticle nucleating agent, 10-15 parts of ultrafine nylon powder, 0.1-1.0 part of ammonium polyphosphate, 1-10 parts of pentaerythritol and 1-6 parts of triphenyl phosphite, wherein the nanoparticle nucleating agent is a silane coupling agent with the content of 4-6%, the silane coupling agent comprises a fluorine-containing silane coupling agent and an active silane coupling agent according to a mass part ratio of 0.6-1.2:1, and the ultrafine nylon powder is 600-2000 mesh nylon powder. The method has simple process flow, the dispersibility of the nanometer inorganic particle nucleating agent is easy to regulate, and the PET compound has excellent high temperature and ageing resistance.

Owner:JIANGSU YUXING FILM TECH

Nano silicon dioxide modified polyurethane composite material

The invention discloses a nano silicon dioxide modified polyurethane composite material comprising the raw materials: polytetrahydrofuran glycol, hydroxyl-terminated polyepichlorohydrin, isocyanate, epoxy resin, a chain extender, 1H,1H,8H,8H-dodecafluoro-1,8-octanediol, a catalyst, polypropylene, a maleic anhydride grafted ethylene-octene copolymer, an acrylonitrile-styrene-butadiene copolymer, ethylene-propylene-diene rubber, organic modified nano silicon dioxide, tetrapod-like zinc oxide whiskers, graphene oxide, carbon nanotubes, expanded graphite, tris(2-chloroethyl) phosphate, triphenyl phosphite, tris(2,4-di-tert-butylphenyl)phosphite, di(octane phenol polyoxyethylene)phosphate, polythiazole, and a silane coupling agent. The nano silicon dioxide modified polyurethane composite material provided by the invention has the advantages of excellent heat resistance, good flame retardancy, good water resistance, and high strength.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

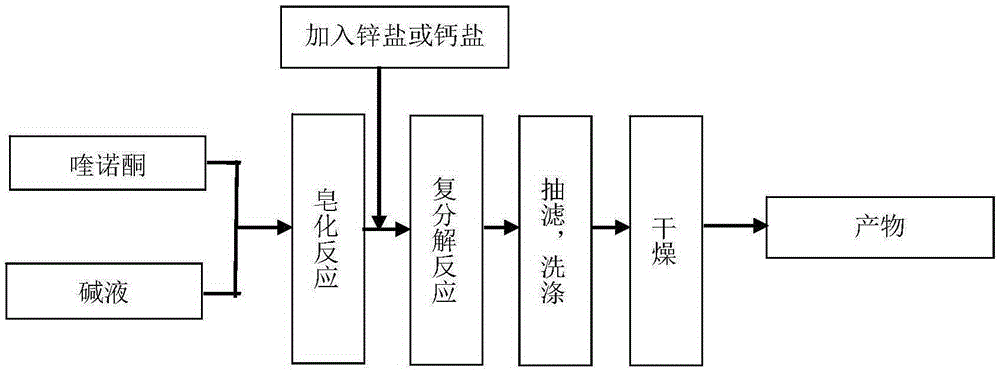

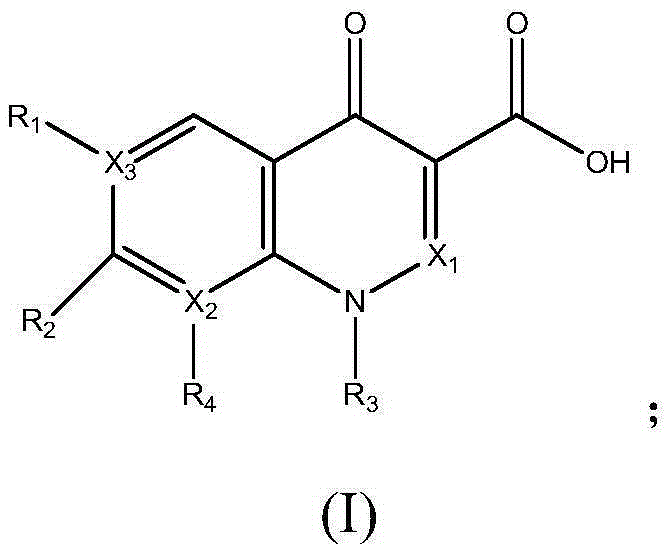

Calcium and zinc heat stabilizer for PVC and application of calcium and zinc heat stabilizer

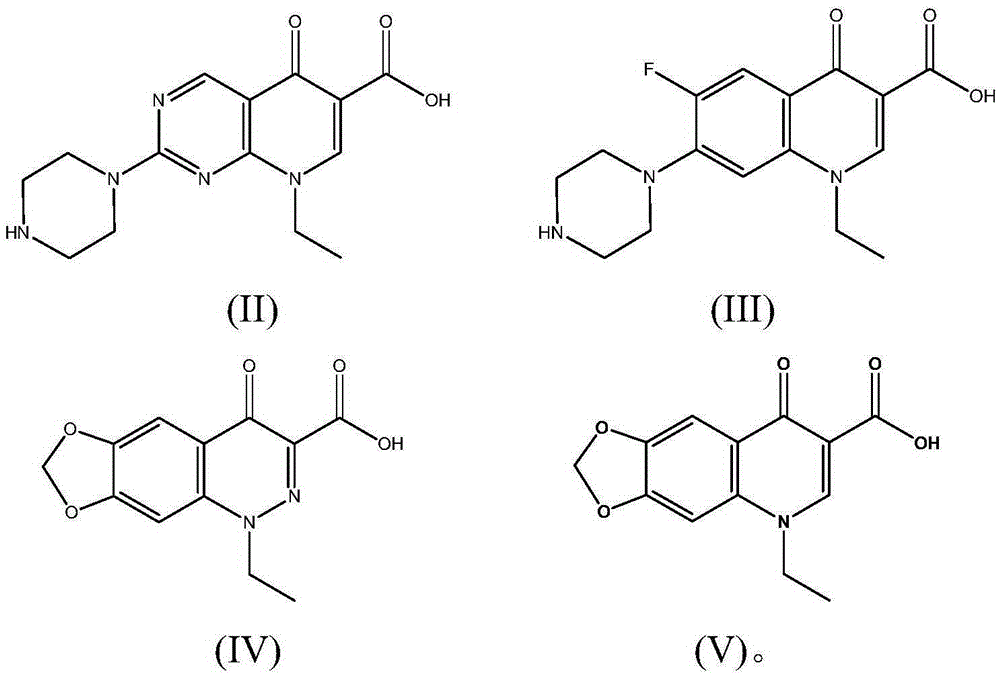

ActiveCN105315574AGood PVC thermal stabilityGood surface antibacterial functionOrganic chemistryPentaerythritolUracil

The invention provides a calcium and zinc heat stabilizer for PVC and application of the calcium and zinc heat stabilizer. The calcium and zinc heat stabilizer is prepared from 50-80 parts of main stabilizer and 20-50 parts of auxiliary stabilizer. The main stabilizer is prepared from 10-50 parts of quinolone zinc salt and 10-70 parts of quinolone calcium salt. The auxiliary stabilizer is a compound prepared from one or two or more of triphenyl phosphite, epoxidized soybean oil, 2-ethylhexyl epoxystearate, pentaerythritol, dipentaerythritol, sorbitol, trimethylolpropane, dibenzoyl methane, stearoylbenzoylmethane and uracil according to any proportion. The calcium and zinc heat stabilizer for PVC has good PVC heat stabilizing performance and meanwhile has the excellent surface bacterium resisting function.

Owner:ZHEJIANG UNIV OF TECH

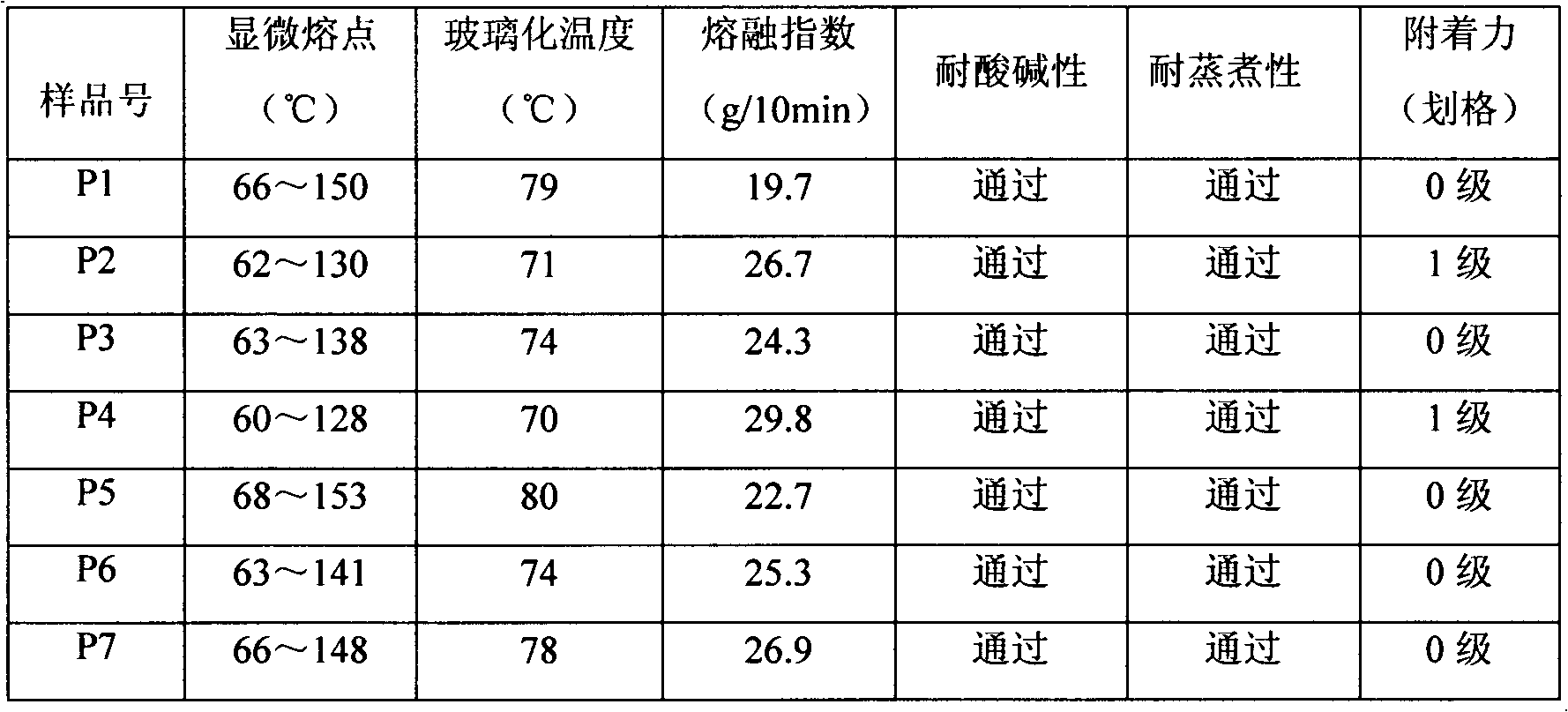

Preparation method of copolyester for metal powder coating

ActiveCN102492125AHigh viscosity strengthRetortPowdery paintsPolyester coatingsTransesterification reactionBisphenol A

The invention relates to a preparation method of a copolyester for a metal powder coating, mainly comprising the following steps of: (1) carrying out transesterification reaction between terephthalic acid, isophthalic acid, hydroxyethyl bisphenol A and C2-C6 dihydric alcohol under the action of a tetrabutyl titanate / butylhydroxyoxo-stannane catalyst; and (2) adding a stabilizer triphenyl phosphite into the product obtained from Step (1) at atmospheric pressure and carrying out decompressing copolycondensation at 230-250 DEG C and at 80-130 Pa to obtain the copolyester. The obtained copolyester has advantages of steaming and boiling resistance, acid and alkali resistance and strong adhesive force. The coating provided by the invention can be applied in the field of metal can coating.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

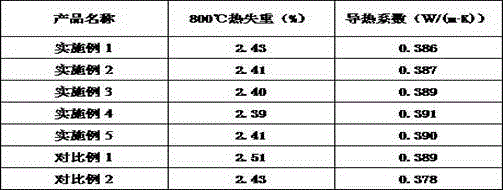

Heat-conducting electronic packaging composite and preparation method thereof

ActiveCN105754297AImprove thermal stabilityImprove thermal conductivityLithium chlorideHeat conducting

The invention provides a heat-conducting electronic packaging composite and a preparation method thereof. The preparation method comprises the following steps: mixing nano-alumina, nano-silica, a silane coupling agent KH-551, a gamma-aminopropyltriethoxysilane and water at first, and stirring; drying after filtering; mixing with N-methyl pyrrolidone, pyridine and triphenyl phosphate for reaction; adding lithium chloride and methyl alcohol for further reaction; filtering, flushing with N-dimethyl formamide and drying; re-adding acetone for ultrasonic dispersion; mixing bisphenol A epoxy resin, Neodymium(III) 2,4-pentanedionate and water, heating, and stirring for dissolution; mixing the two mixtures, and stirring while performing ultrasonic treatment; performing water bathing, adding 3,5-diaminobenzoic acid, N-aminoethylpiperazine and trimethyl hexamethylene diamine, stirring, and then conducting vacuum degassing; finally, pouring the mixture into a die for curing to obtain the heat-conducting electronic packaging composite. The heat-conducting electronic packaging composite has excellent heat stability, and meanwhile, has very good heat conductivity and a good heat dissipation effect.

Owner:深圳市锦昊辉实业发展有限公司

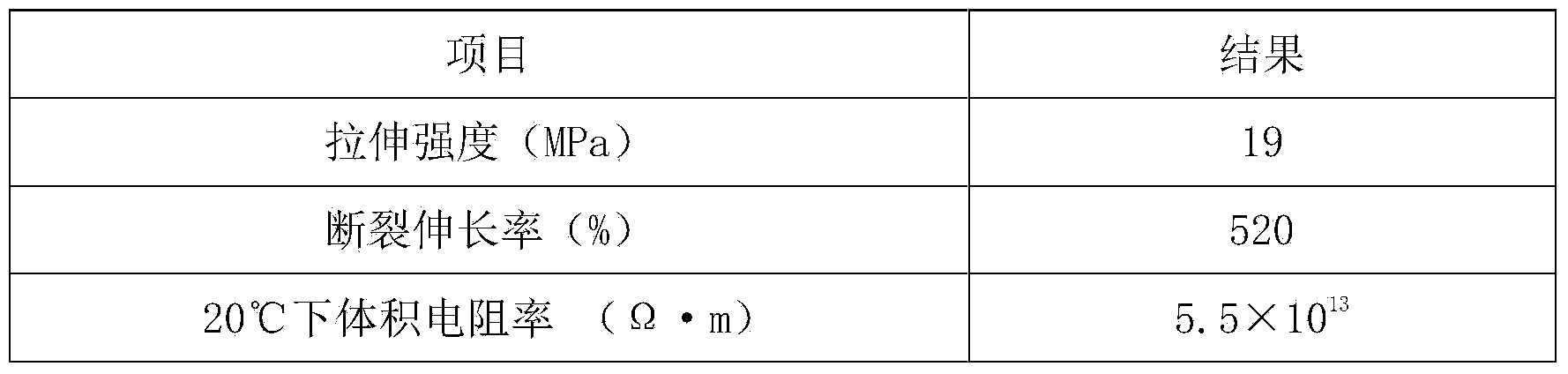

Flexible polyvinyl chloride (PVC) soft cable material

ActiveCN103524942AHigh elongationHigh tensile strengthPlastic/resin/waxes insulatorsInsulated cablesPolyvinyl chlorideStearic acid

The invention provides a flexible polyvinyl chloride (PVC) soft cable material which is prepared from the following component raw materials: by weight, 50-60 parts of PVC resin, 20-40 parts of polyester resin, 10-20 parts of organic silicone resin, 10-15 parts of precipitated white carbon black, 5-10 parts of wollastonite powder, 4-6 parts of dolomite, 4-6 parts of bauxite, 4-6 parts of molybdenum disulfide, 3-5 parts of pentaerythritol, 0.5-1.0 part of triphenyl phosphate, 0.1-0.2 part of antioxidant 1035, 0.1-0.2 part of antioxidant 168, 0.2-0.4 part of ferrocene, 0.1-0.3 part of stearic acid amide, 0.2-0.3 part of zinc stearate, 0.1-0.3 part of calcium stearate, 0.1-0.3 part of barium stearate, 0.1-0.2 part of phenyl methyl silicone oil and 10-15 parts of a modified filler. A plastic high mixing machine is used for mixing the formula components, after plasticizing granulation by use of a plastic extruding machine, the flexible polyvinyl chloride (PVC) soft cable material has excellent elongation and a greatly improved elastic property, and under the condition of ensuring product electrical performances, the elongation and tensile strength of a finished product can be improved.

Owner:广东佰佳电线电缆实业有限公司

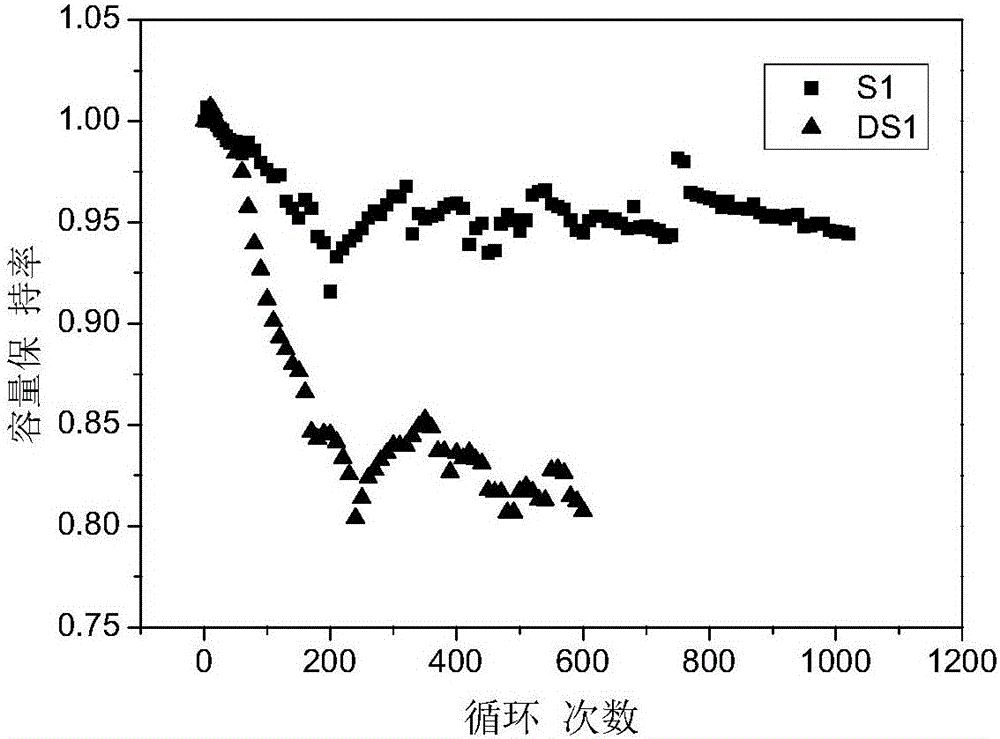

High-stability lithium ion battery electrolyte

ActiveCN106252721ATaking into account the cycle performanceSuppress chroma riseSecondary cellsPhysical chemistryLithium-ion battery

The invention discloses a high-stability lithium ion battery electrolyte. The high-stability lithium ion battery electrolyte is prepared from, by mass, 14-18% of lithium hexafluorophosphate, 71-79% of a non-aqueous organic solvent, 3.5-6% of an electrolyte stabilizer and 3.5-5% of additives, wherein the non-aqueous organic solvent is at least one of carboxylic ester, halogenated carbonate, aromatic hydrocarbon and aryl halides, and halogen substitutes in the halogenated carbonate and the aryl halides are at least one of F, Cl and Br; the electrolyte stabilizer is formed by combination of hexamethyl disilazane, ethanol amine and triphenyl phosphate in a mole ratio of 1:(0.5-0.68):(0.25-0.35); the additives are at least one of maleic anhydride, methylene methanedisulfonate, ammonium acetate, fluorocarbonate, fluoroether and phosphazene and derivatives thereof. The high-stability lithium ion battery electrolyte is stable in chromaticity, and prepared batteries are excellent in cycle performance.

Owner:ZHEJIANG JINKAILAI NEW ENERGY TECH

Chromatophilous polyurethane resin for synthetic leather and preparation method of polyurethane resin

The invention relates to chromatophilous polyurethane resin for synthetic leather and a preparation method of the polyurethane resin. The polyurethane resin comprises the following components by mass percentage: 15-20% of polyester polyol EG1000, 3-5% of polyester polyol PCL2000, 15-20% of diphenyl-methane-diisocyanate (MDI), 0.1-0.2% of epoxy resin, 0.05% of triphenyl phosphite, 0.02% of dibutyltin dilaurate, 0.01% of silicone oil, 0.8-1.5% of glycol, 2-3% of 1,4-butanediol, 0.4-0.6% of alcohol, and the balance of solvent, wherein the solvent comprises the following components by mass percentage: 20-25% of dimethyl formamide (DMF), 15-20% of butanone, and the balance of methylbenzene. The chromatophilous polyurethane resin for the synthetic leather and the preparation method have the benefits that the polyurethane resin synthesized by the preparation method is chromatophilous, high in fixation, and uniform in coloring, and has good mechanical properties such as water resistance, solvent resistance, cold resistance and folding resistance after being produced into the leather.

Owner:JIANDE BAISHA CHEM

Preparation method of polypropylene beta crystalline nucleating agent

ActiveCN102040532AEasy to recycleGood repeatabilityOrganic compound preparationCarboxylic acid amides preparationDicarboxylic acidSolvent

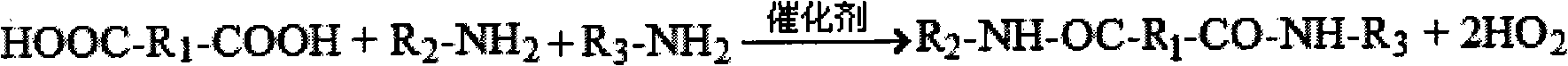

The invention relates to a preparation method of a polypropylene beta crystalline nucleating agent, comprising the following steps of: contacting dicarboxylic acid with amine to carry out condensation reaction in the presence of a catalyst and a solvent, wherein the amine is primary amine and / or secondary amine, the catalyst is one or more of phosphorus pentoxide, polyphosphoric acid and triphenyl phosphate, the solvent is pyridine, and the mole ratio of the using amounts of the catalyst to the pyridine is 1: (10-30). The preparation method can be used for sufficiently preparing the amides polypropylene beta crystalline nucleating agent from the primary amine and / or the secondary amine under normal pressure.

Owner:CHINA PETROLEUM & CHEM CORP

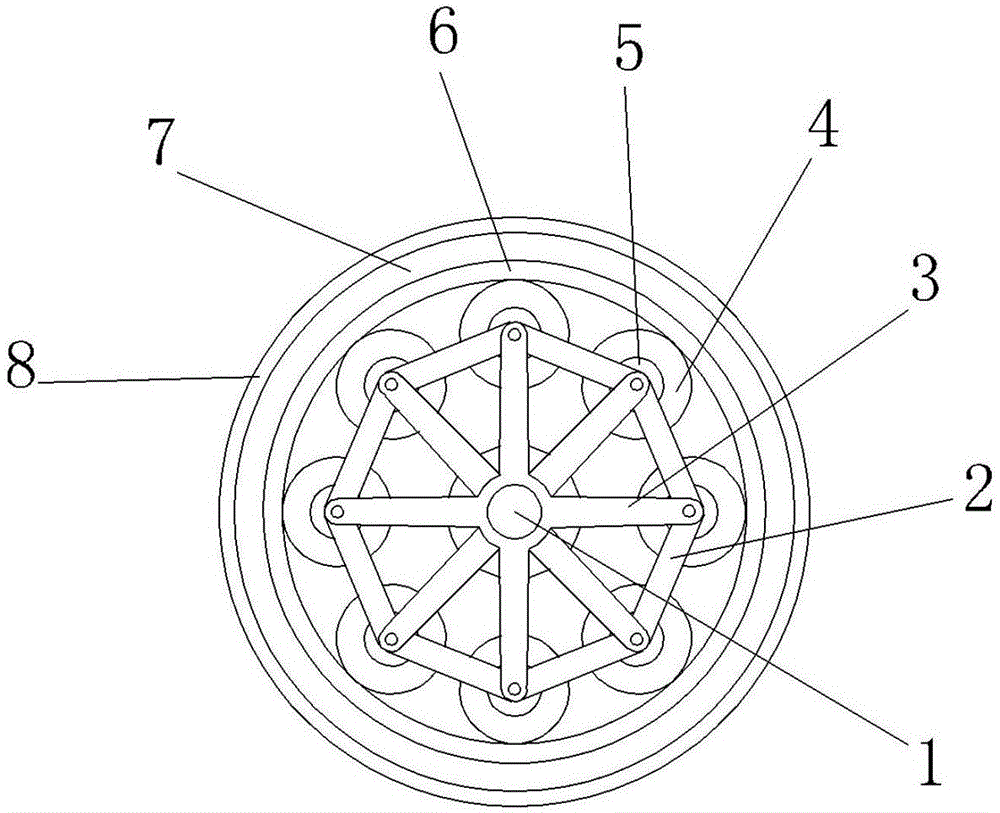

Mining anti-extrusion high-wear-resistance cable

InactiveCN105111538AEasy to fixImprove stabilityRubber insulatorsClimate change adaptationAntioxidantEngineering

The invention discloses a mining anti-extrusion high-wear-resistance cable comprising a supporting core, a connecting ring, a supporting rod, a cable core, multiple axes, an insulating layer, a jacket layer, an armored layer and a filling body, wherein the jacket layer comprises the following raw materials in parts by weight: 90 parts of butadiene-nitrile rubber, 45 parts of chloroprene rubber, 40 parts of ethylene propylene diene rubber, 35 parts of chlorinated polyethylene, 19 parts of maleic anhydride grafted EVA (ethylene vinyl acetate copolymer), 7.5 parts of zinc oxide, 3 parts of chlorinated paraffin, 5.5 parts of calcium stearate, 7.5 parts of white carbon black, 10 parts of talc powder, 9 parts of active kaolin, 5 parts of antimony trioxide, 4.5 parts of triphenyl phosphite, 4 parts of magnesium hydroxide, 4.5 parts of aluminum oxide, 5.5 parts of an anti-aging agent RD, 3.5 parts of an N,N'-di-sec-butyl-p-phenylenediamine antioxidant, 4 parts of a curing agent DTDM and 5.5 parts of a curing agent PDM. The cable is excellent in extrusion resistance and wear resistance.

Owner:ANHUI MENTOR CABLE GROUP

Anti-aging modified calcium carbonate for paint-latex paint and preparation method thereof

ActiveCN103408971AImprove anti-agingEasy constructionEmulsion paintsPigment treatment with macromolecular organic compoundsDispersityMilk paint

The invention provides an anti-aging modified calcium carbonate for a paint-latex paint. The modified calcium carbonate is prepared from the following raw materials in parts by weight: 95-100 parts of 800-mesh ground calcium carbonate, 1-3 parts of polyoxyethylene oleate, 0.5-0.8 part of polyethylene wax, 1-2 parts of styrene, 0.3-0.5 part of aluminum nitride powder, 1-3 parts of triphenyl phosphite, 0.2-0.4 part of aziridine crosslinking agent XR-100, 0.1-0.3 part of polyvinyl alcohol, 2-3 parts of silane coupling agent KH550, 0.3-0.5 part of styrene-acrylic emulsion, 2-3 parts of emulsifier OP-10, 0.4-0.6 part of aluminum oxide, 1-2 parts of nano silicon dioxide (VK-SP30), 1-2 parts of epoxy soybean oil, 0.5-0.6 part of ammonium polyphosphate and 0.8-1.2 parts of zinc powder. The preparation method comprises the following steps: drying calcium carbonate, proportionally and sequentially adding the other raw materials in batches, thoroughly mixing in a high-speed stirrer, drying and grinding. The modified calcium carbonate provided by the invention has the advantages of favorable dispersity and favorable wear resistance, and can lower the cost and enhance the workability of the paint when being used in paint materials; and the paint film has high glossiness.

Owner:青阳县恒源化工原料有限责任公司

Degradable environment-friendly plastic and preparing method thereof

The invention relates to a degradable environment-friendly plastic prepared from the following raw materials in parts by weight: 53-90 parts of film level polyethylene, 48-85 parts of microcrystalline cellulose, 48-85 parts of thermoplastic starch, 45-90 parts of ethylene and acrylic copolymer, 45-90 parts of polyvinyl alcohol, 42-70 parts of film level polylactic acid, 36-65 parts of polyhydroxyalkanoate, 36-65 parts of triphenyl phosphite, 20-30 parts of plasticizer, 15-30 parts of xylogen, and 12-30 parts of vegetable dyes. The invention further discloses a preparing method of the degradable environment-friendly plastic. A plastic product manufactured by the method can be self-degraded, cannot pollute the environment or damage a soil structure, and is a true green plastic. The plastic product has good flexibility, oil resistant property, and heat sealability. The added vegetable dyes not only have a coloring effect, but also have a certain antibacterial property.

Owner:GUANGXI UNIV

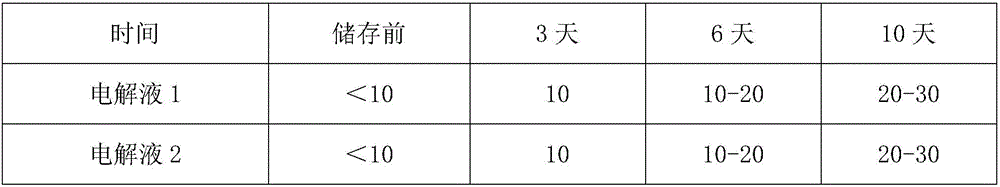

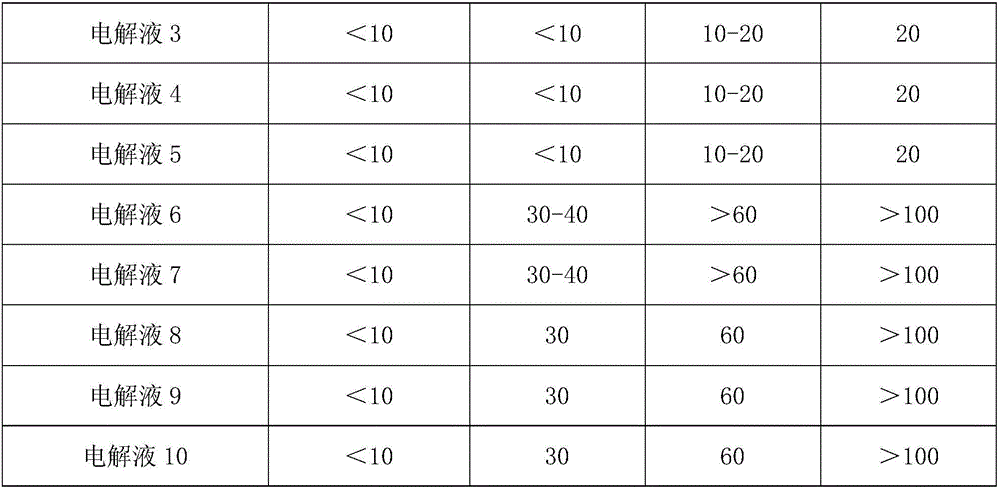

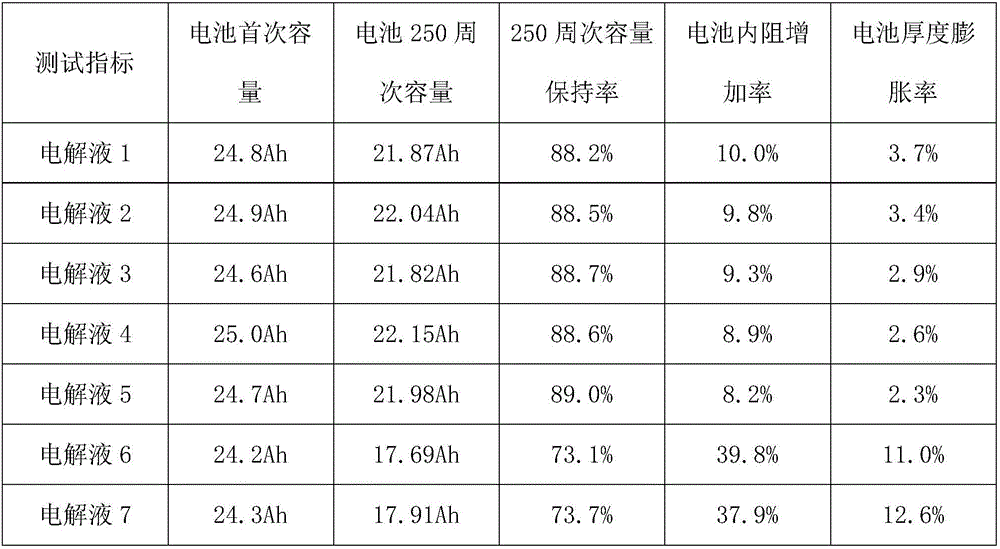

Electrolyte for high-capacity lithium ion battery, preparation method and lithium ion battery

InactiveCN106299324AImprove shrinkageImprove high temperature resistanceCell electrodesSecondary cellsHigh temperature storageSolvent

The invention discloses an electrolyte for a high-capacity lithium ion battery. The electrolyte is prepared from an non-aqueous solvent, lithium hexafluorophosphate, an anode film forming additive, an air bulking inhibiting additive, a cathode surface film stabilizer and a moisture stabilizer; the anode film forming additive is prepared from one or two of fluoroethylene carbonate and vinylene carbonate which account for 1%-15% of the total mass of the electrolyte; the air bulking inhibiting additive is prepared from a sultone compound accounting for 0.5%-5% of the total mass of the electrolyte; the cathode surface film stabilizer is prepared from a lithium borate salt compound accounting for 0.2%-3% of the total mass of the electrolyte; the moisture stabilizer is prepared from one or two of triphenyl phosphite and triphenyl phosphate which account for 0.1%-1% of the total mass of the electrolyte. The electrolyte can improve the normal-temperature cycle performance and the high-temperature storage performance of the battery. Meanwhile, the invention discloses a preparation method of the electrolyte and the high-capacity lithium ion battery adopting the electrolyte.

Owner:GUANGZHOU TINCI MATERIALS TECH

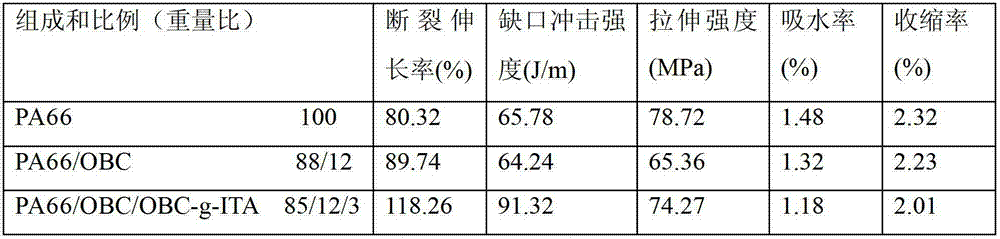

Preparation method of itaconic acid grafted ethylene-octylene block copolymer granules

InactiveCN102766239AImproved thermoforming processabilityHigh elongation at breakPolymer scienceItaconic acid

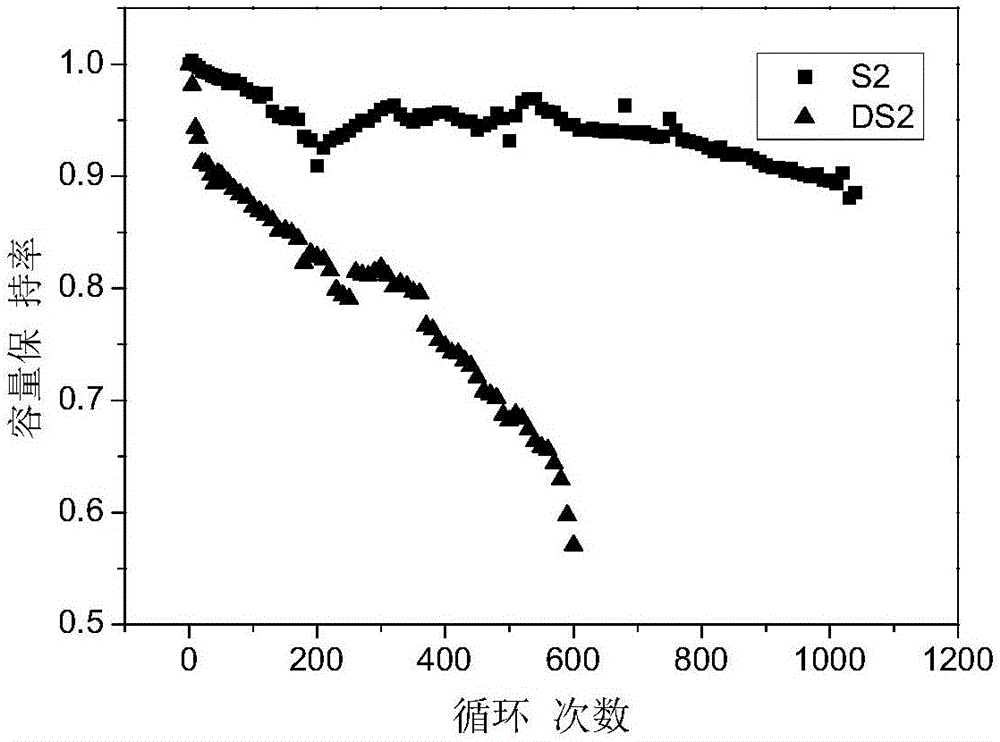

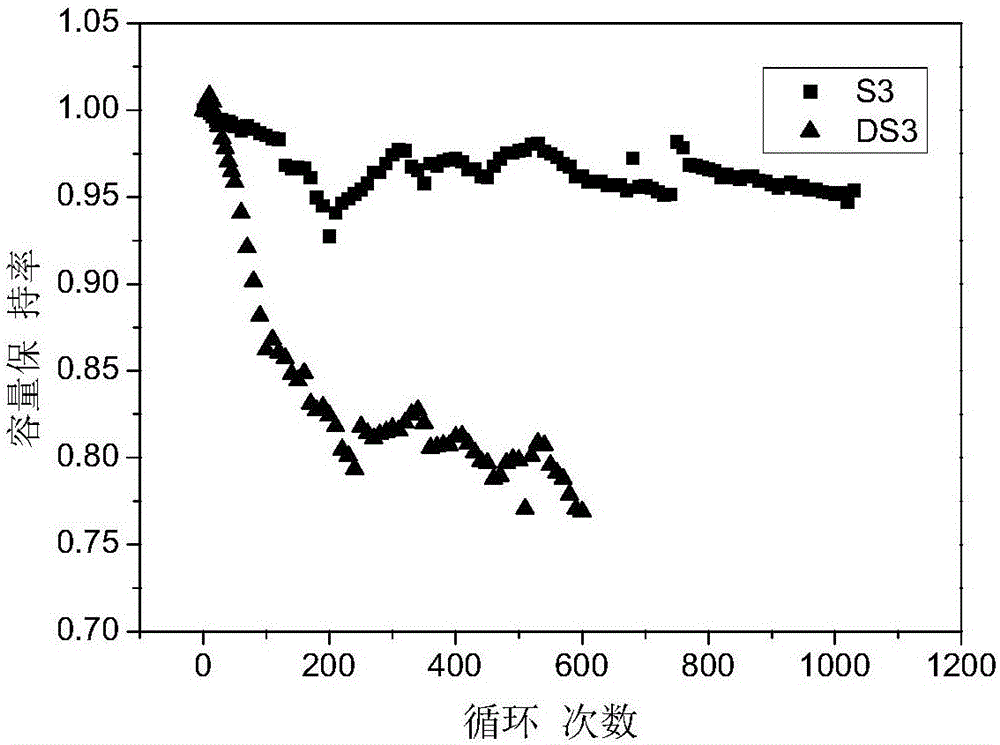

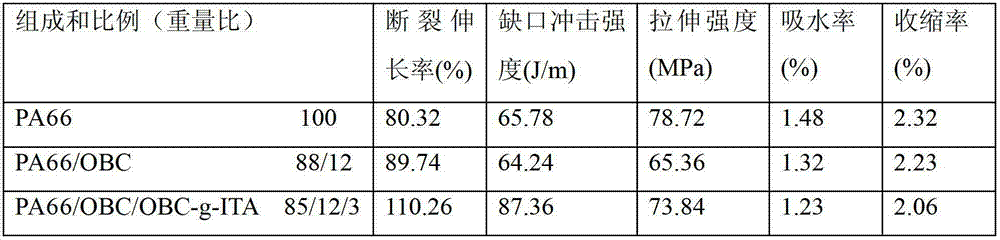

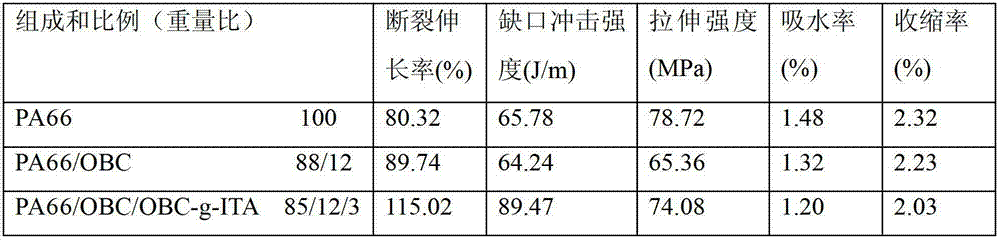

The invention relates to a preparation method of itaconic acid grafted ethylene-octylene block copolymer granules. The method comprises steps of: based on 93.0-96.5 parts by weight of ethylene-octylene block copolymer as a base material, adding 3.0-6.0 parts by weight of itaconic acid, 0.15-0.35 parts by weight of dibenzoyl peroxide and 0.35-0.65 parts by weight of triphenyl phosphate, mixing under stirring, and carrying out double-screw extrusion melt grafting reaction to prepare the itaconic acid grafted ethylene-octylene block copolymer granules. The grafting rate of the granules prepared by using the preparation method is 1.35%-1.65%; when the granules serve as a compatilizer of PA (polyamide) 66 and OBC (ethylene-octylene block copolymer) blended alloy materials, compared with pure PA66, the prepared PA66 / OBC / OBC-g-ITA (itaconic acid) alloy material has the advantages that the elongation at break is improves by 35%-48%, notch impact strength is improved by 30%-40%, the impact toughness is obviously improved, and the water absorption rate and shrinkage factor are obviously reduced.

Owner:FUJIAN NORMAL UNIV

Preparation method of high-efficiency compound stabilizer of chlorinated paraffin

A preparation method of a high-efficiency compound stabilizer of chlorinated paraffin comprises the following steps of: (1) uniformly mixing 50-55 parts by weight of glycol diglycidyl ether and methyltin, adding triphenyl phosphite, after intensive and uniform mixing, adding a catalyst, slowly heating to 145-150 DEG C, holding the temperature for 3h, rising the temperature to 160-170 DEG, holding the temperature for 30min, cooling to the room temperature to form a solution A, (2) pouring epoxy soybean oil into the solution A, then adding chlorinated paraffin-52 into the solution A to form a solution B, and (3) slowly heating the solution B to raise the temperature to 50-60 DEG C, continuing stirring for 15-20min, adding an ultraviolet absorber and an antioxidant, and stirring to complete dissolution to form the high-efficiency compound stabilizer of the chlorinated paraffin. The inventor of the invention finds that the solution can form a stable system and the storage stability is better via many repeated tests.

Owner:衡阳市骏杰化工有限公司

Antifouling scale-inhibiting anti-aging exterior wall coating and preparation method thereof

The invention provides an exterior wall coating which is composed of the following raw materials in parts by weight: 84-90 parts of water-based acrylic emulsion, 10-15 parts of styrene-acrylic emulsion, 16-50 parts of hydrotalcite powder, 4-6 parts of nano silicon dioxide, 0.1-0.2 part of triallyl isocyanurate, 3-4 parts of acrylic acid, 1-2 parts of aluminium nitride, 1-2 parts of dimethylethanolamine, 0.7-1 part of ureidopropyltriethoxysilane, 1-2 parts of sodium tripolyphosphate, 1-2 parts of polyvinylpyrrolidone, 1-2 parts of para toluene sulfonamide, 1-2 parts of ammonium dihydrogen phosphate, 0.4-0.6 part of triphenyl phosphite, 2-3 parts of absolute ethyl alcohol, 3-5 parts of coalescing agent, 0.1-0.2 part of polyoxypropylene glycerol ether and 10-20 parts of deionized water. The coating provided by the invention has the advantages of low raw material loss, low gel production, simple process, hard coating film, good glossiness, strong impact resistance, low cracking rate, soft texture, excellent decorative property, high weather resistance, scrubbing resistance, high adhesion force and long service life; and the coating is free of special smell and contains no heavy metals such as mercury and lead and also does not contain formaldehyde volatile, and thus the coating meets the technical requirements of an environment-friendly coating.

Owner:CHUZHOU MAISITE NEW BUILDING MATERIAL

Adhesive of hot melting coating for laminated steel process and preparation method thereof

InactiveCN102766430AReduce surface tensionImprove wettabilityPolyureas/polyurethane adhesivesEpoxy resin adhesivesAntioxidantNeopentyl glycol

The invention discloses an adhesive of a hot melting coating for a laminated steel process and a preparation method of the adhesive. The adhesive is synthesized by mixing and reacting polyester polyol, 4,4'-diphenylmethane diisocyanate, 2,2-dipropane or 4-hydroxyphenyl propane, an organic solvent, a bisphenol-A epoxy resin and a silane coupling agent as raw materials under the action of etrabutyl titanate and triethylamine as a mixed catalyst, wherein the solid content of the adhesive is 25-35%, the viscosity is 300-500mPa.s, and the hydroxyl value is 10-20mgKOH / g; and the polyester polyol is prepared by performing a primary esterification and a polycondensation for the components through taking terephthalic acid, m-phthalic acid, hexane diacid, neopentyl glycol, ethylene glycol and diethylene glycol as raw materials, stannous octoate or tetrabutyl titanate as a catalyst, and triphenyl phosphate as an antioxidant. The adhesive does not rise at 9 mm in a laminated steel product cup drawing experiment and does not bubble within 240 h in a salt spray resistance experiment, thereby reaching the requirements of applying the laminated steel products.

Owner:BEIJING COMENS NEW MATERIALS

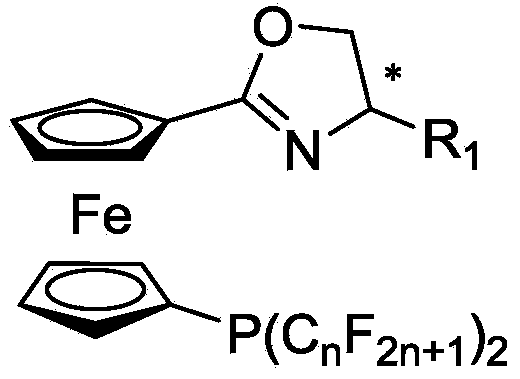

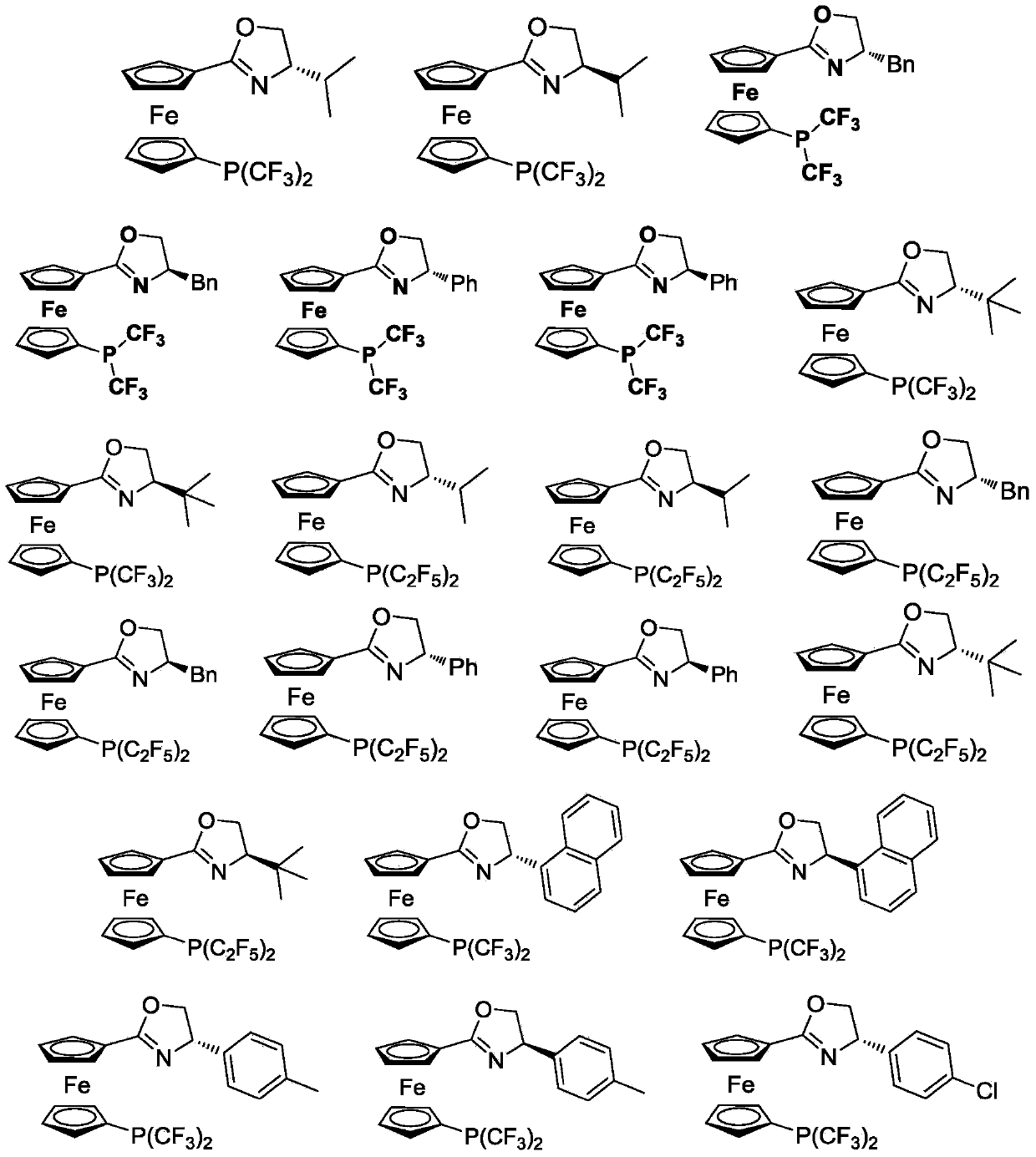

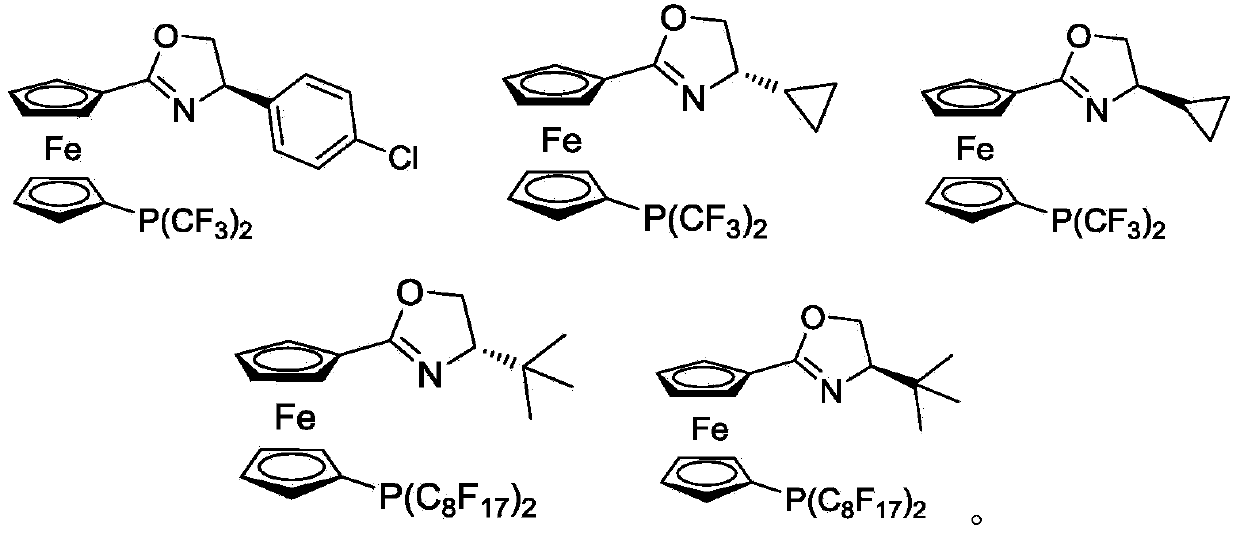

1, 1'-ferrocene perfluoroalkyl phosphine nitrogen ligand as well as preparation method and application thereof

ActiveCN103772445AEasy to synthesizeGood effectOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDiphenyl phosphiteDisplacement reactions

The invention relates to a 1, 1'-ferrocene perfluoroalkyl phosphine nitrogen ligand as well as a preparation method and an application thereof. The preparation method of the 1, 1'-ferrocene perfluoroalkyl phosphine nitrogen ligand comprises the following steps: (1) reacting oxazoline bromoferrocene with a butyl lithium compound in an organic solvent under the condition of existence of an additive; (2) mixing reaction liquid obtained in the step (1) with triphenyl phosphite; and (3) in the solvent, reacting an isodecyl diphenyl phosphite derivative obtained in the step (2) and cesium fluoride with TMSCnF2n+1. The invention also relates to the application of the ligand in an asymmetric allyl displacement reaction catalyzed by metallic palladium. The ligand provided by the invention can be used for catalyzing the allyl displacement reaction of single substituted allyl carbonic ester in a high domain selectivity and high enantioselectivity manner. The synthetic method is simple, mild in conditions, high in yield, convenient in purification and suitable for industrial production; starting materials are low in cost and easy to obtain.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Preparation method of 4-bromocarbazole

ActiveCN103936656AImprove the coordination effectHigh yieldOrganic chemistryChemical synthesisPhosphorous acid

The invention discloses a preparation method of 4-bromocarbazole, which belongs to the field of organic chemical synthesis. The method comprises the following steps: by using o-bromophenylboronic acid as a raw material, a DMSO (dimethylsulfoxide) solvent and o-chloronitrobenzene to generate Suzuki reaction in the presence of combined catalysis of palladium metal and an organic phosphine ligand so as to obtain 2-bromine-2'-nitrobiphenyl; and then synthesizing a product 4-bromocarbazole, from 2-bromine-2'-nitrobiphenyl by using triphenyl phosphite as a reductant. During reaction, side reactions are few, the method is simple to operate and the yield is high. The synthesized 4-bromocarbazole can be used in the fields of organic photoelectric materials, medicines and the like, and is an important intermediate for carbazole photoelectric materials, medicines and presides.

Owner:PUYANG HUICHENG ELECTRONICS MATERIAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com