Preparation method of copolyester for metal powder coating

A metal powder, copolyester technology, applied in powder coatings, polyester coatings, coatings, etc., to achieve the effect of high viscosity strength and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

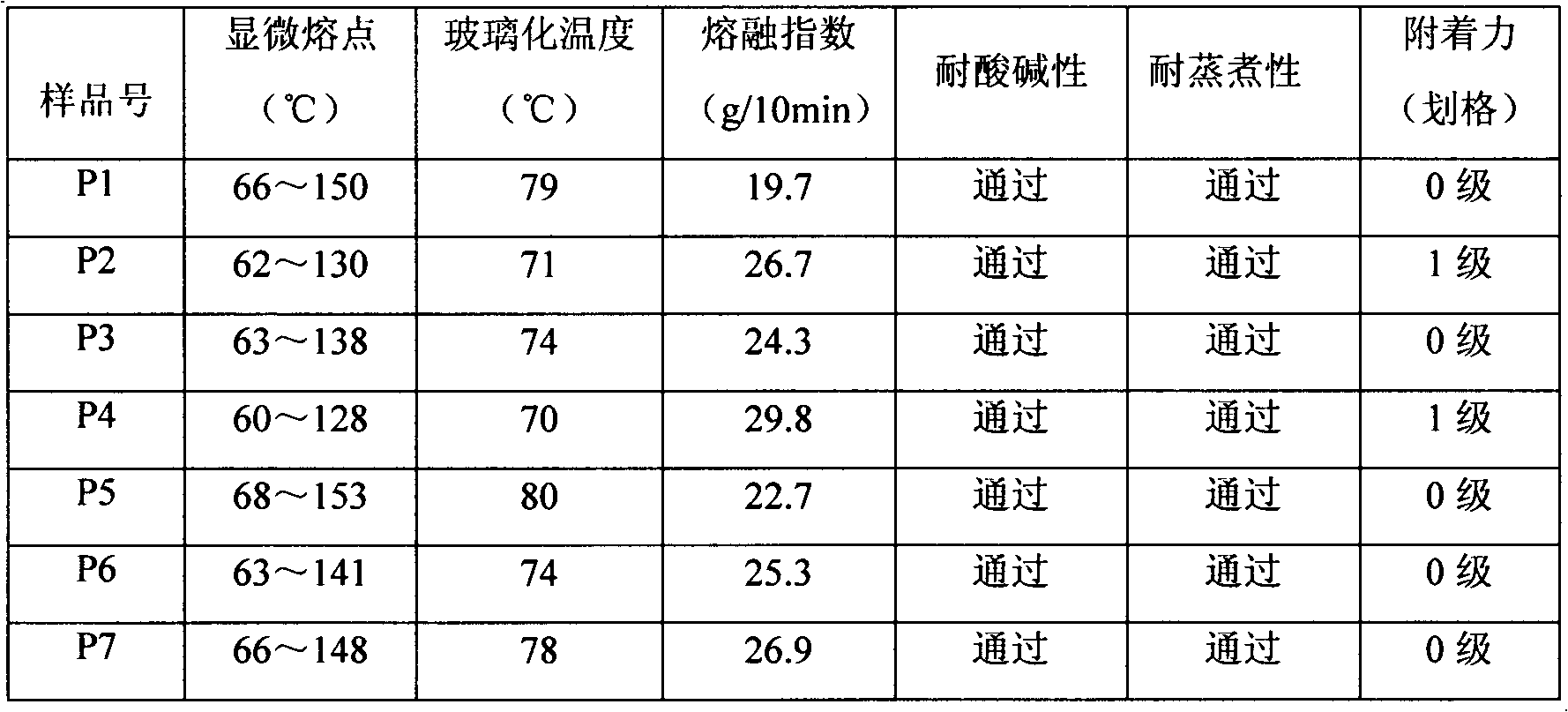

Examples

Embodiment 1

[0018] In a 2.0L polymerization reactor with a distillation device, add terephthalic acid (244.28g), isophthalic acid (24.92g), ethylene glycol (97.29g), 2-methyl-1,3-propanediol (102.74g), hydroxyethylated bisphenol A (44.89g), butyl stannoic acid (0.45g) and tetrabutyl titanate (0.07g), when the internal temperature of heating reaches 180°C, water begins to distill out, and the temperature continues to rise To 210 ° C, when the distilled water reaches 92% of the theoretical amount, the esterification reaction ends. Then add 0.12 g of triphenyl phosphite, raise the temperature to 240° C., keep the system pressure at 80 Pa, and react for 1 hour to obtain the copolyester product P1.

Embodiment 2

[0020] In a 2.0L polymerization reactor with a distillation device, add terephthalic acid (199.36g) isophthalic acid (49.84g), ethylene glycol (51.36g) 2-methyl-1,3-propanediol (154.11 g) Hydroxyethylated bisphenol A (89.78g), butyl stannoic acid (0.44g) and tetrabutyl titanate (0.08g), when heated to 183°C, water began to distill, continue to heat up to 200°C, wait When the distilled water reaches 90% of the theoretical amount, the transesterification reaction ends. Then add 0.11 g of triphenyl phosphite, raise the temperature to 230° C., keep the system pressure at 110 Pa, and react for 1.5 h to obtain the copolyester product P2.

Embodiment 3

[0022] In a 2.0L polymerization reactor with a distillation device, add terephthalic acid (174.44g), isophthalic acid (74.76g), ethylene glycol (85.60g), 2-methyl-1,3-propanediol ( 116.80g), hydroxyethylated bisphenol A (59.54g), butyl stannoic acid (0.44g) and tetrabutyl titanate (0.08g), when heated to 180°C, water began to distill out, and the temperature continued to rise to 210°C , when the water to be distilled reaches 92% of the theoretical amount, the esterification ends. Then add 0.1 g of triphenyl phosphite, raise the temperature to 250° C., the system pressure is 100 Pa, and react for 1.3 h to obtain the copolyester product P3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com