Low-odor and low-voc automotive paper honeycomb composite panel and its dry forming process

A technology of paper honeycomb and composite board, applied in paper/cardboard layered products, vehicle parts, adhesive additives, etc., can solve the problems of affecting the driver's sight, occupant's physical injury, uncomfortable smell, etc., to improve heat transfer efficiency and Cross-section diameter, improvement of load carrying capacity, effect of improvement of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

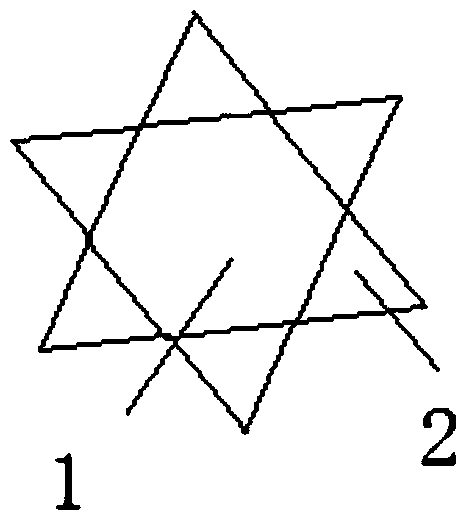

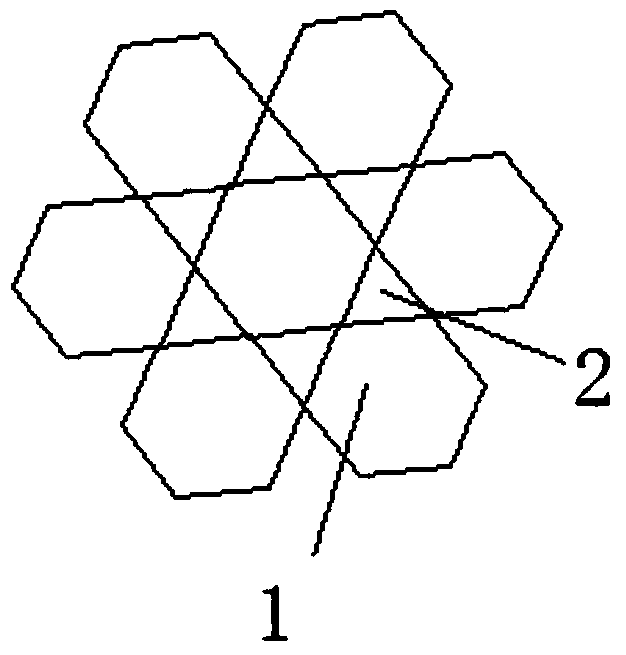

[0028] The low-odor and low-VOC automobile paper honeycomb composite board of the present embodiment, the composite board comprises a paper honeycomb core layer, a hot-melt adhesive film layer bonded to the upper and lower surfaces of the paper honeycomb core layer, and a hot-melt adhesive film bonded to the The non-woven fabric layer on the surface and the surface layer material covered on the non-woven fabric layer, the paper honeycomb core layer is a honeycomb structure composed of hexagonal cells and triangular cells, the surface layer material and the non-woven There is a tooth-like bonding structure between the cloth layers, and the raw material of the hot melt adhesive film includes the following components by weight: 10 parts of polyneopentyl adipate-1,6-hexanediol ester diol, polyoxygen 5 parts of ethylene-polystyrene-polyoxyethylene triblock copolymer, 5 parts of polyethylene acrylate, 3 parts of pentaerythritol, 2 parts of neopentyl glycol, 1 part of hexadecanoic aci...

Embodiment 2

[0034] The low-odor and low-VOC automobile paper honeycomb composite board of the present embodiment, the composite board comprises a paper honeycomb core layer, a hot-melt adhesive film layer bonded to the upper and lower surfaces of the paper honeycomb core layer, and a hot-melt adhesive film bonded to the The non-woven fabric layer on the surface and the surface layer material covered on the non-woven fabric layer, the paper honeycomb core layer is a honeycomb structure composed of hexagonal cells and triangular cells, the surface layer material and the non-woven There is a tooth-like bonding structure between the cloth layers, and the raw material of the hot-melt adhesive film includes the following components by weight: 20 parts of polyneopentyl adipate-1,6-hexanediol ester diol, polyoxygen 10 parts of ethylene-polystyrene-polyoxyethylene triblock copolymer, 10 parts of polyethylene acrylate, 7 parts of pentaerythritol, 6 parts of neopentyl glycol, 3 parts of hexadecanoic ...

Embodiment 3

[0040] The low-odor and low-VOC automobile paper honeycomb composite board of the present embodiment, the composite board comprises a paper honeycomb core layer, a hot-melt adhesive film layer bonded to the upper and lower surfaces of the paper honeycomb core layer, and a hot-melt adhesive film bonded to the The non-woven fabric layer on the surface and the surface layer material covered on the non-woven fabric layer, the paper honeycomb core layer is a honeycomb structure composed of hexagonal cells and triangular cells, the surface layer material and the non-woven There is a tooth-like bonding structure between the cloth layers, and the raw material of the hot melt adhesive film includes the following components by weight: 10 parts of polyneopentyl adipate-1,6-hexanediol ester diol, polyoxygen 10 parts of ethylene-polystyrene-polyoxyethylene triblock copolymer, 5 parts of polyethylene acrylate, 7 parts of pentaerythritol, 2 parts of neopentyl glycol, 3 parts of hexadecanoic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com