Patents

Literature

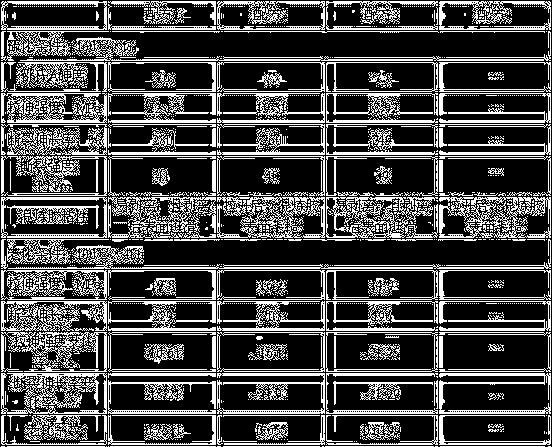

66 results about "Dibutylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dibutylamine is an amine used as a corrosion inhibitor, in the manufacture of emulsifiers, and as a flotation agent. It is flammable and toxic.

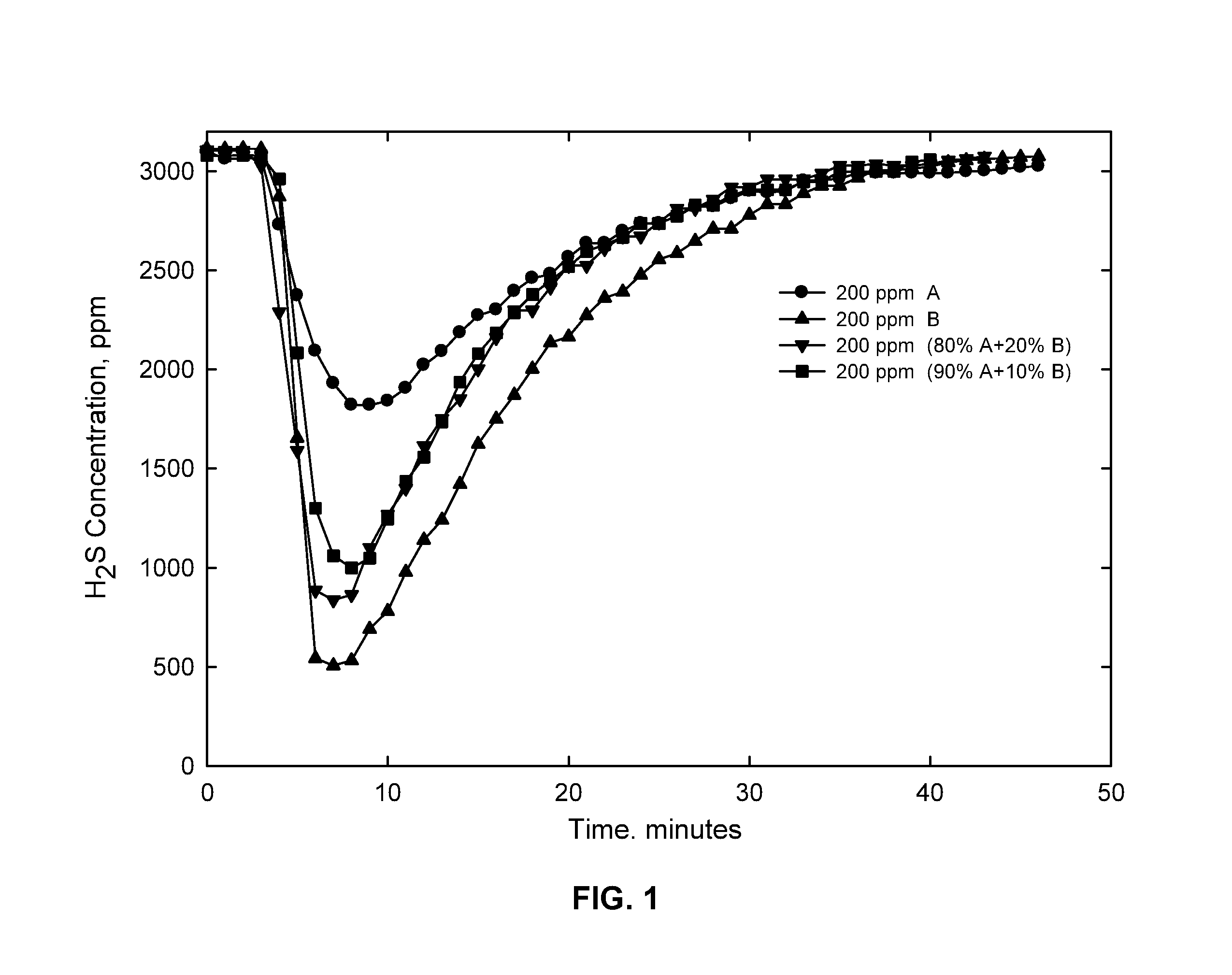

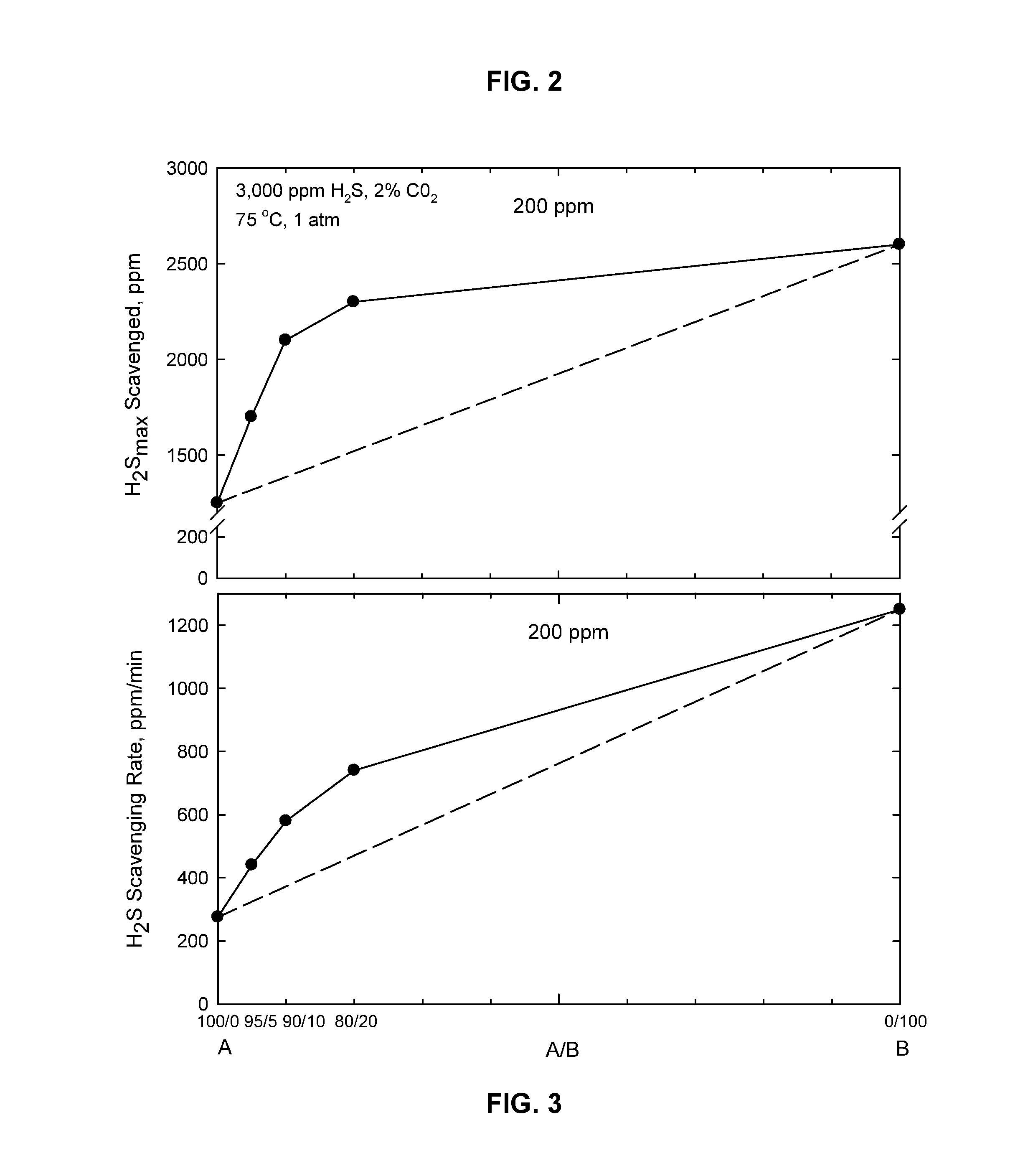

Synergistic H2S Scavengers

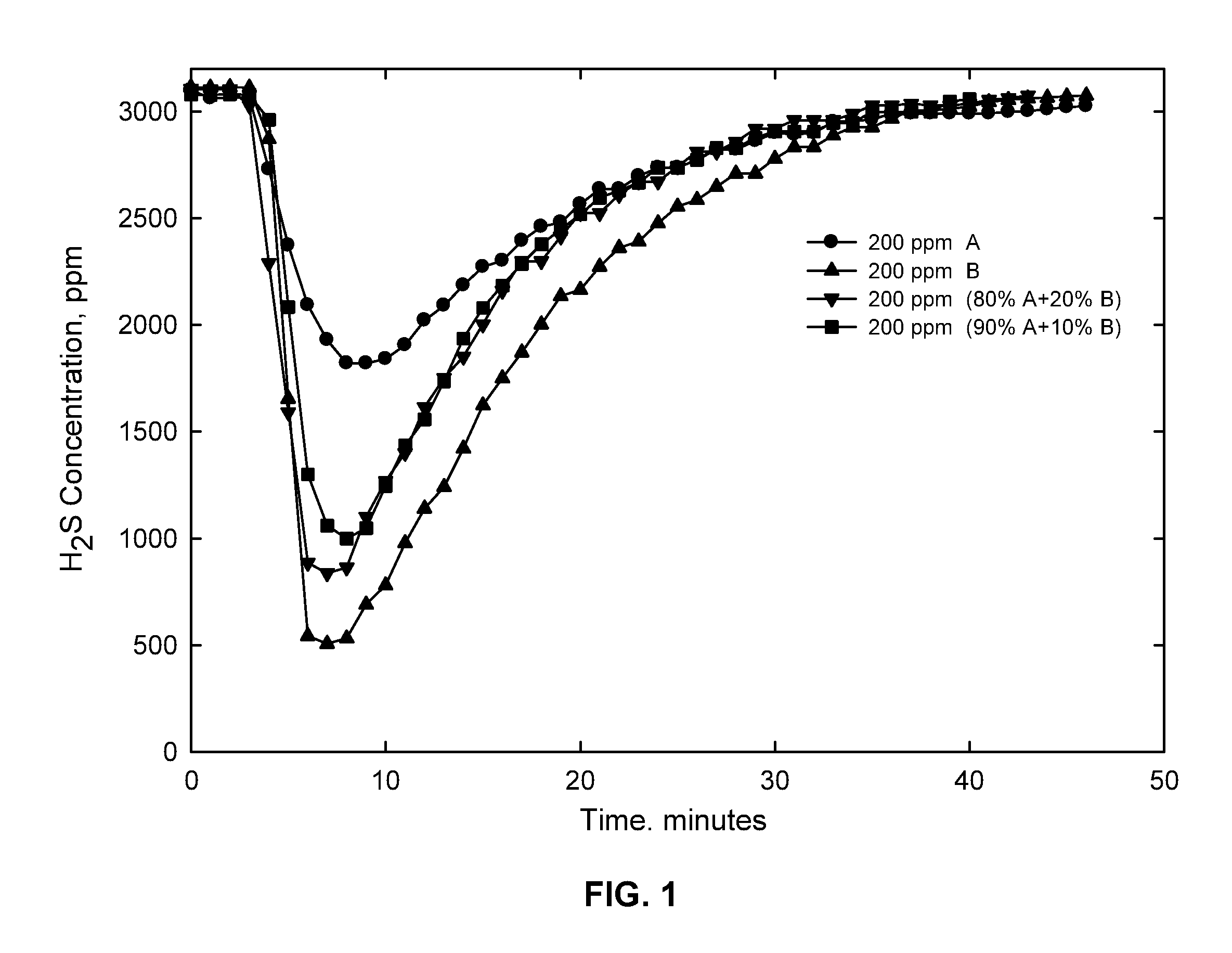

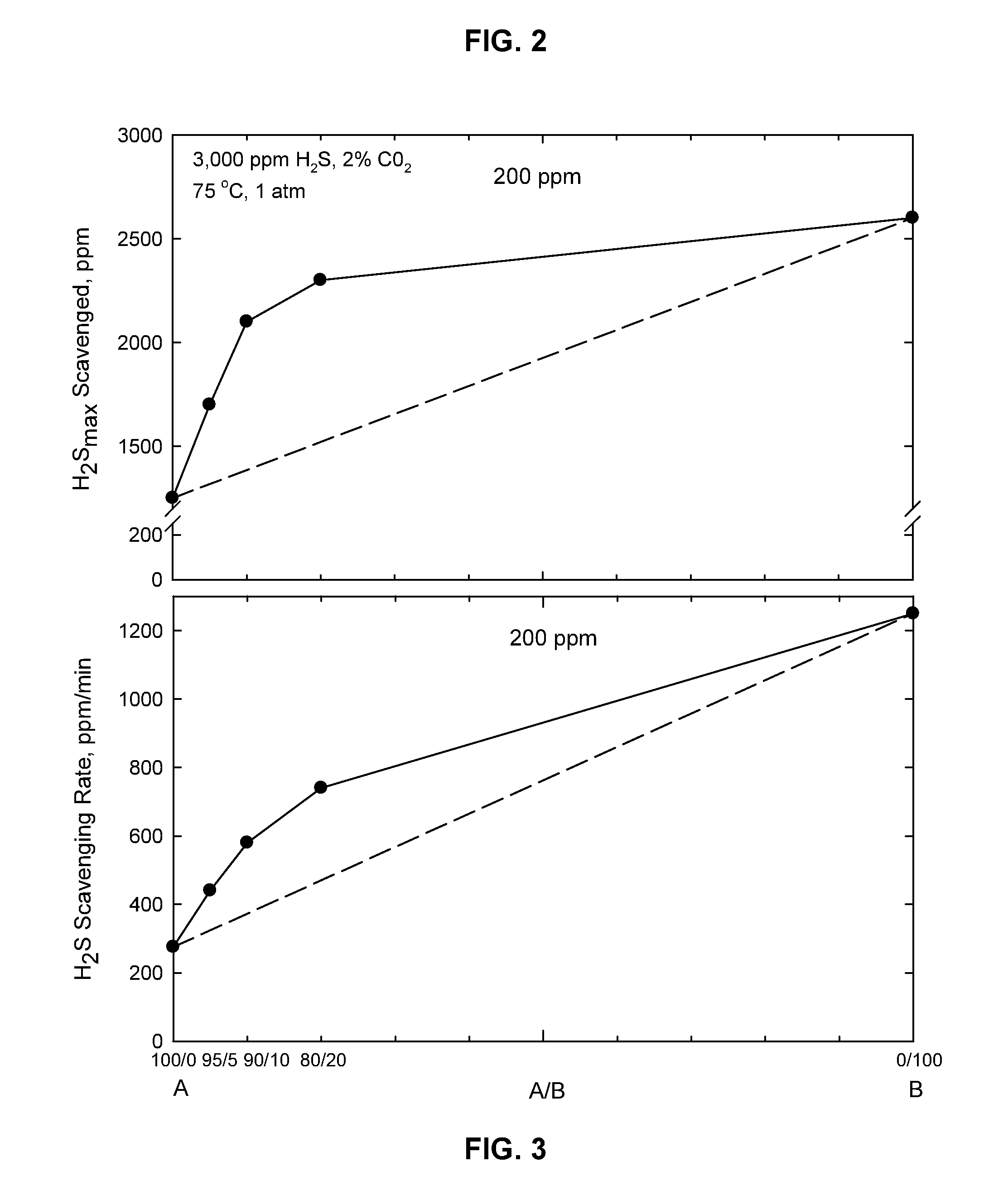

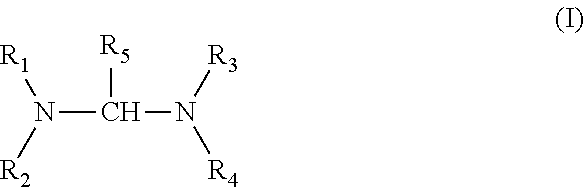

The use of a composition that includes a metal salt and an oil soluble amine formaldehyde reaction product scavenges H2S that is present in aqueous fluids (e.g. produced water liquid streams), natural gas and in oil and mixtures thereof (e.g. mixed production streams that contain all three phases) better than either component when used alone. The resulting scavenger combination significantly increases the reaction rate and the overall scavenging efficiency, i.e. capacity over each component when used alone, in the same total amount. Non-limiting examples of the metal salt include zinc or iron carboxylates, and a non-limiting example of an oil soluble amine formaldehyde reaction product is the reaction product of dibutylamine with formaldehyde.

Owner:BAKER HUGHES INC

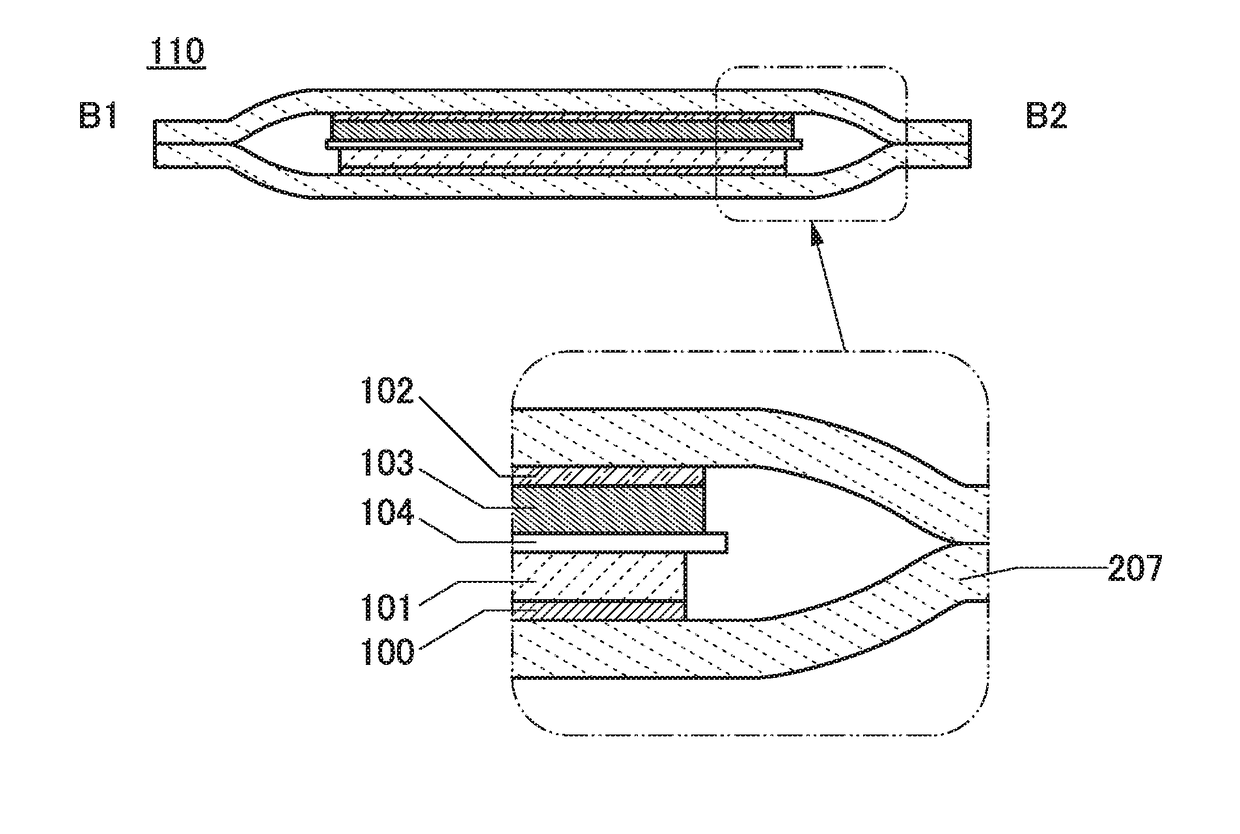

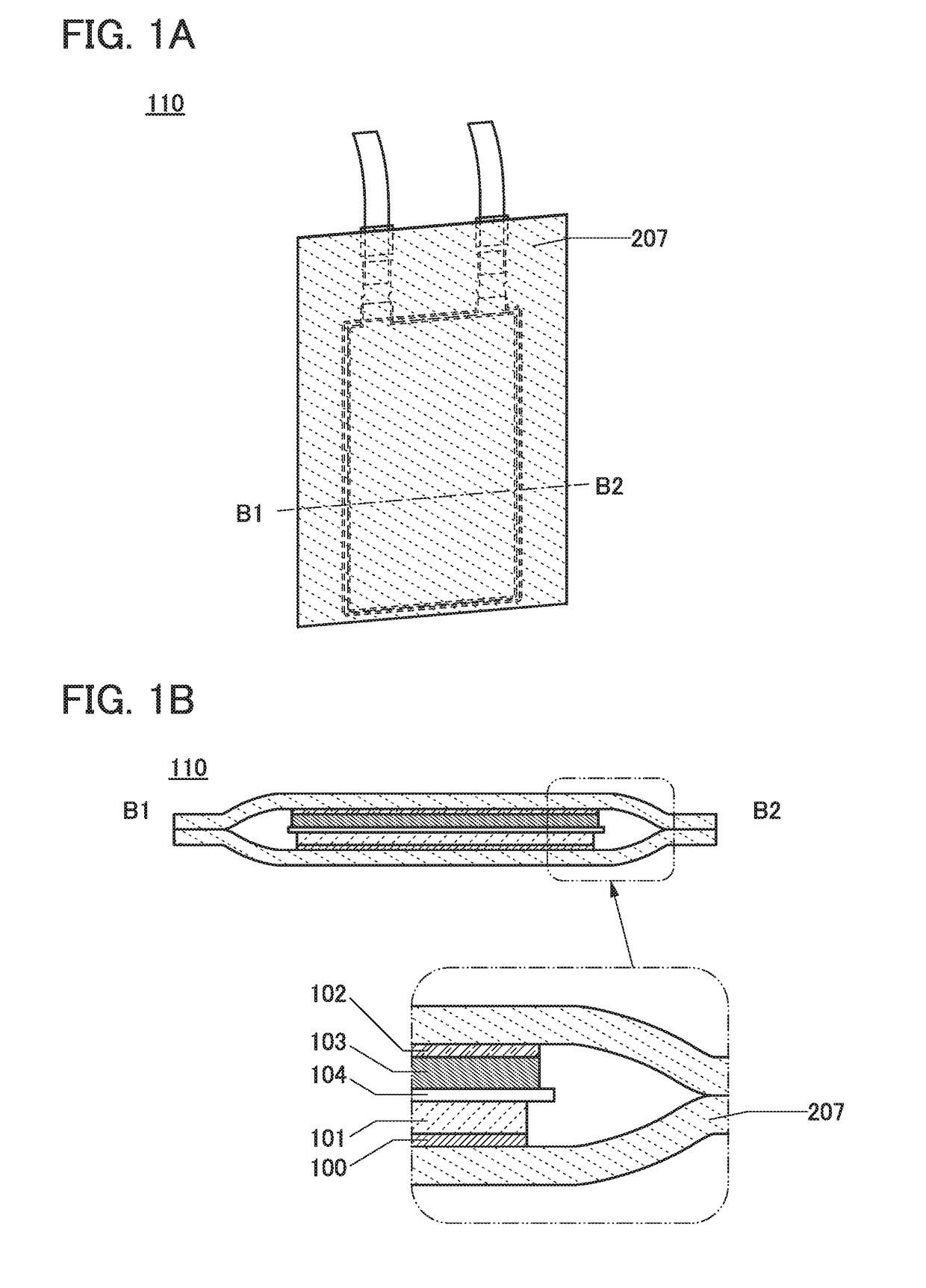

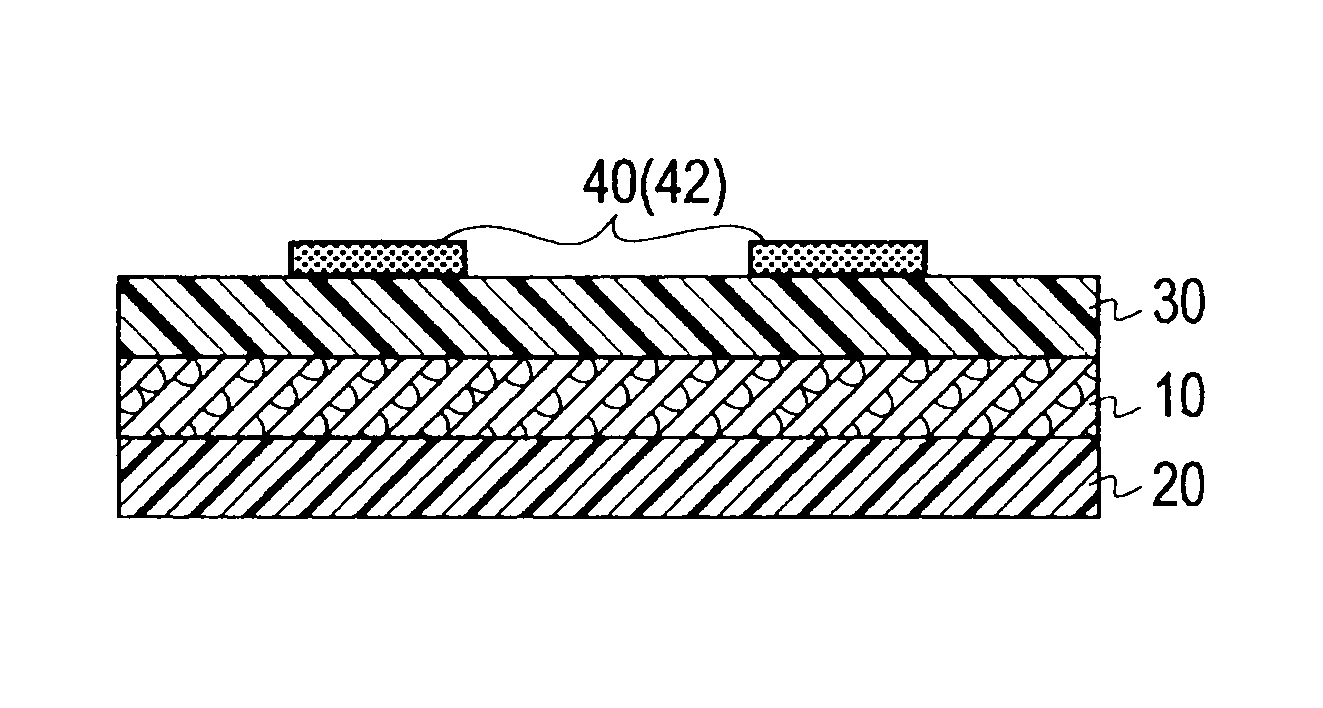

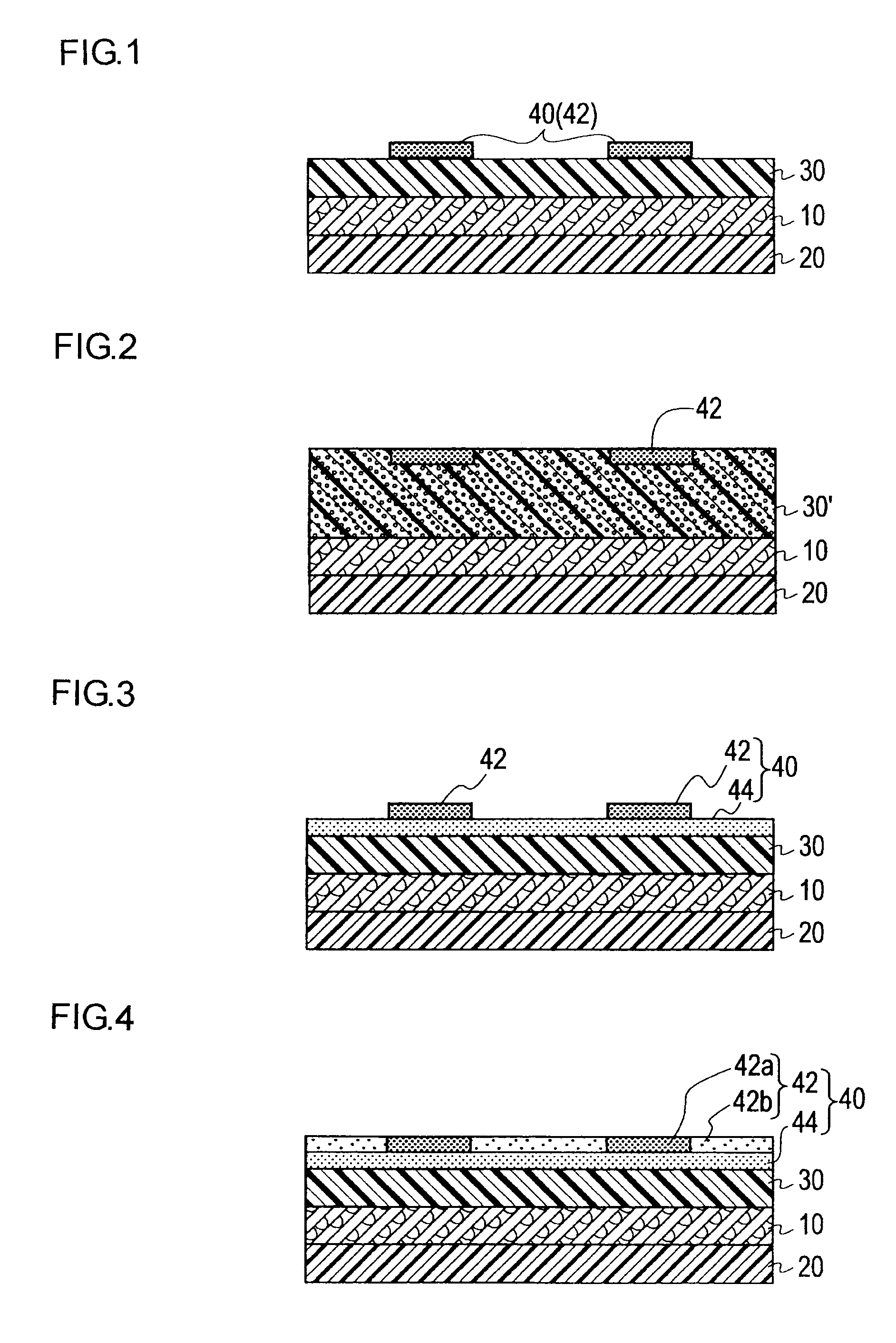

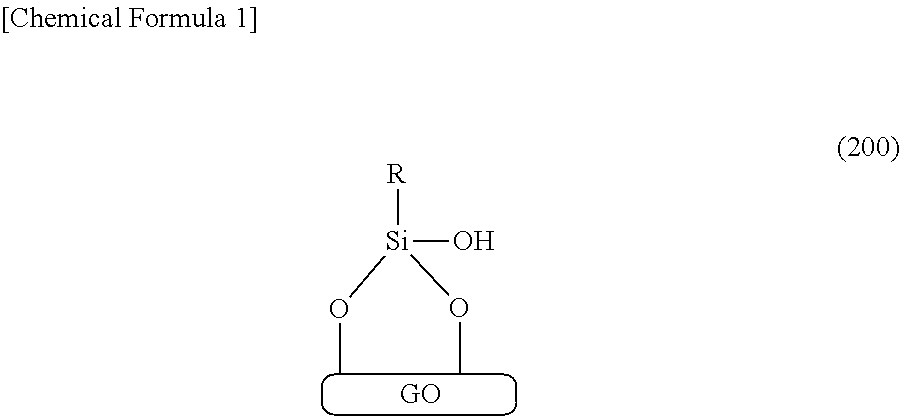

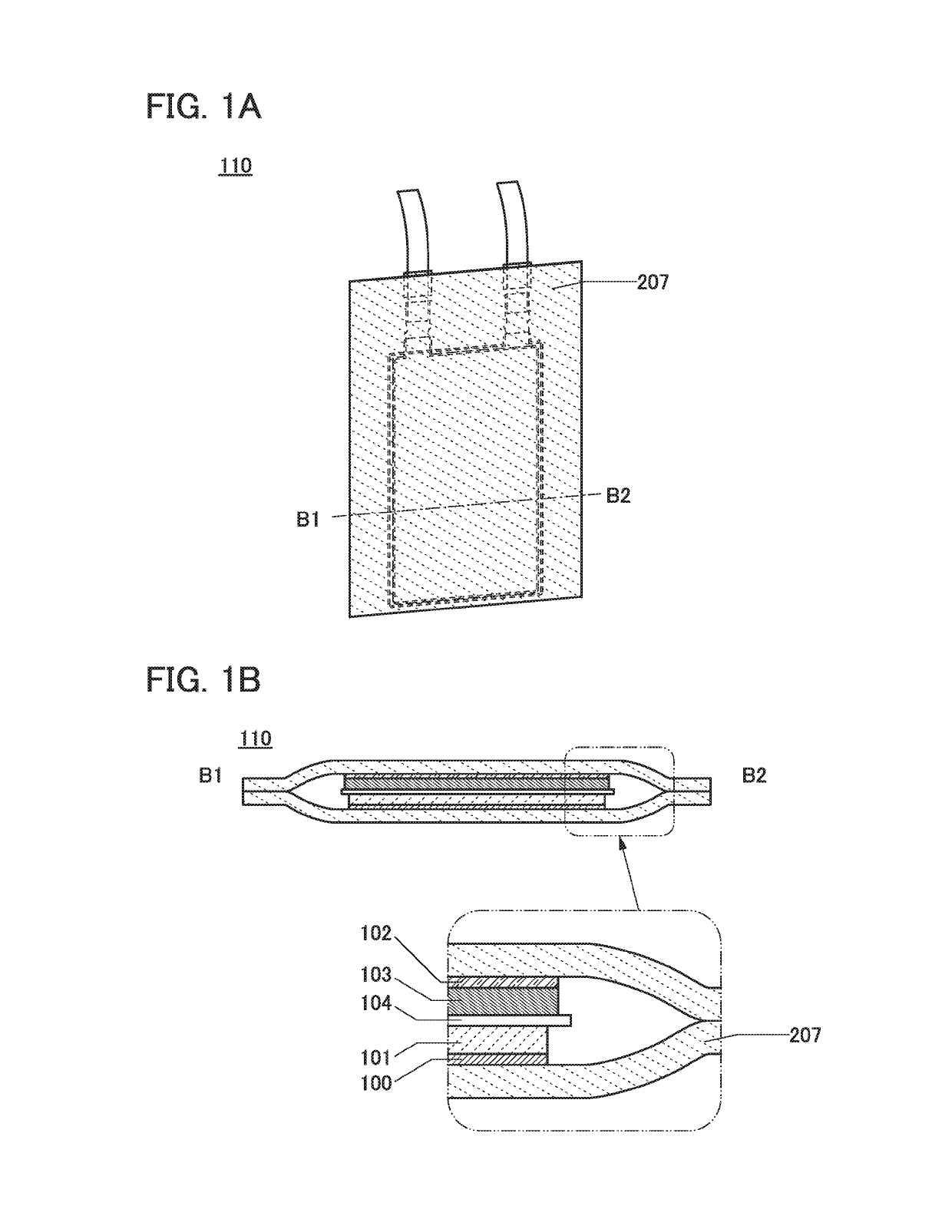

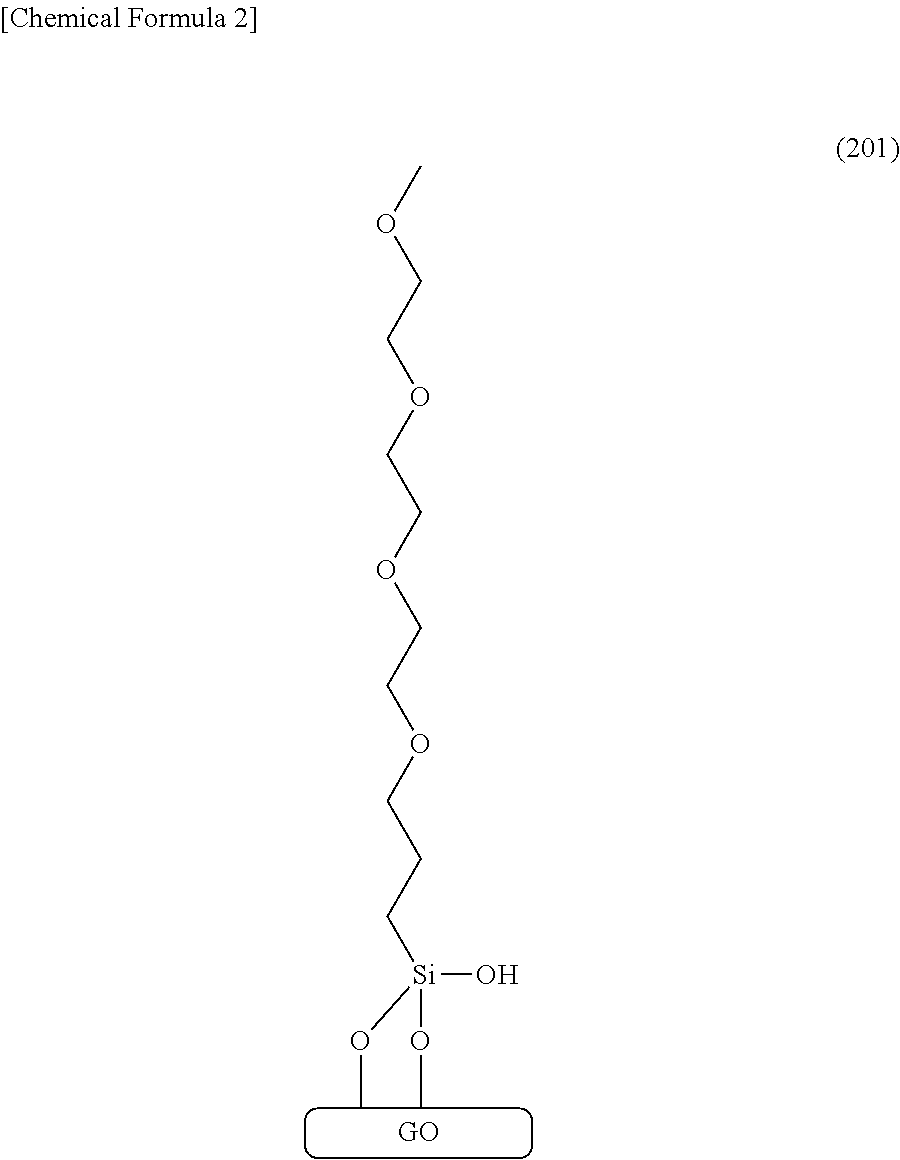

Graphene compound, method for forming graphene compound, and lithium-ion storage battery

ActiveUS20170256817A1Prevent short-circuitingImprove conductivitySolid electrolytesGraphiteNitrogen gasSilylation

A material that can be used in a wide temperature range is provided. A graphene compound includes graphene or graphene oxide and a substituted or unsubstituted chain group, the chain group includes two or more ether bonds, and the chain group is bonded to the above graphene or graphene oxide through a Si atom. Alternatively, a method for forming a graphene compound includes a first step and a second step after the first step. In the first step, graphene oxide and a base are stirred under a nitrogen stream. In the second step, the mixture is cooled to room temperature, a silylating agent that has a group having two or more ether bonds is introduced into the mixture, and the obtained mixture is stirred. The base is butylamine, pentylamine, hexylamine, diethylamine, dipropylamine, dibutylamine, triethylamine, tripropylamine, or pyridine.

Owner:SEMICON ENERGY LAB CO LTD

Preparation method of tetrabutyl urea

InactiveCN1394852ANo pollution in the processNo three wastes and no pollutionUrea derivatives preparationOrganic compound preparationChemical synthesisOrganic solvent

The preparation method of organic compound tetrabutyl carbamide uses dibutylamine and trichloromethyl carbonate as raw material, and makes synthesis is organic solvent to obtain the invented product. Said method is safe, has no production of three wastes, its raw materials are non-toxic, its reaction yield is high and quality is good.

Owner:SINO FOREIGN JOINT HUZHOU JICHANG CHEM

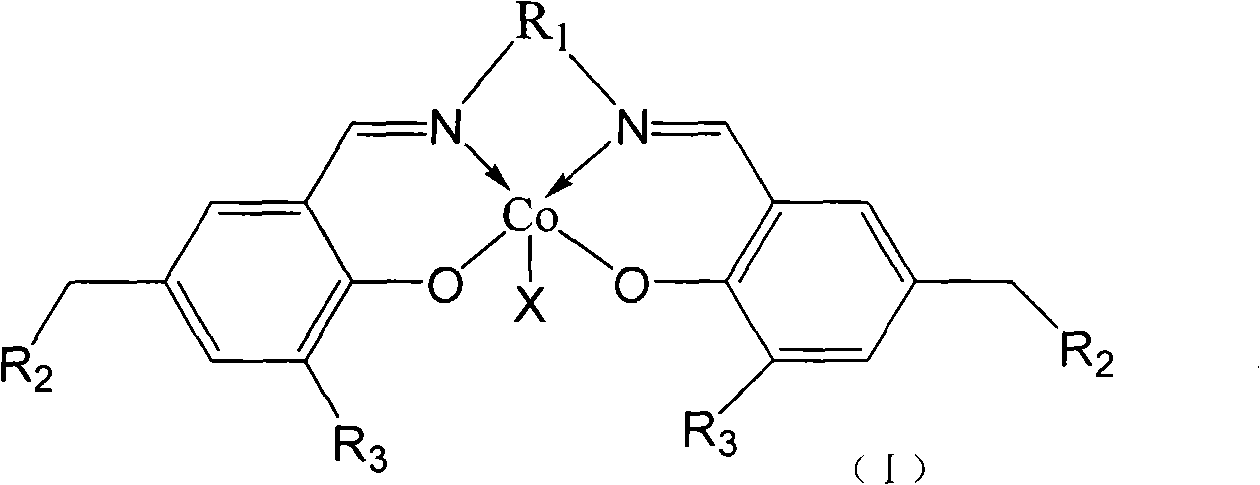

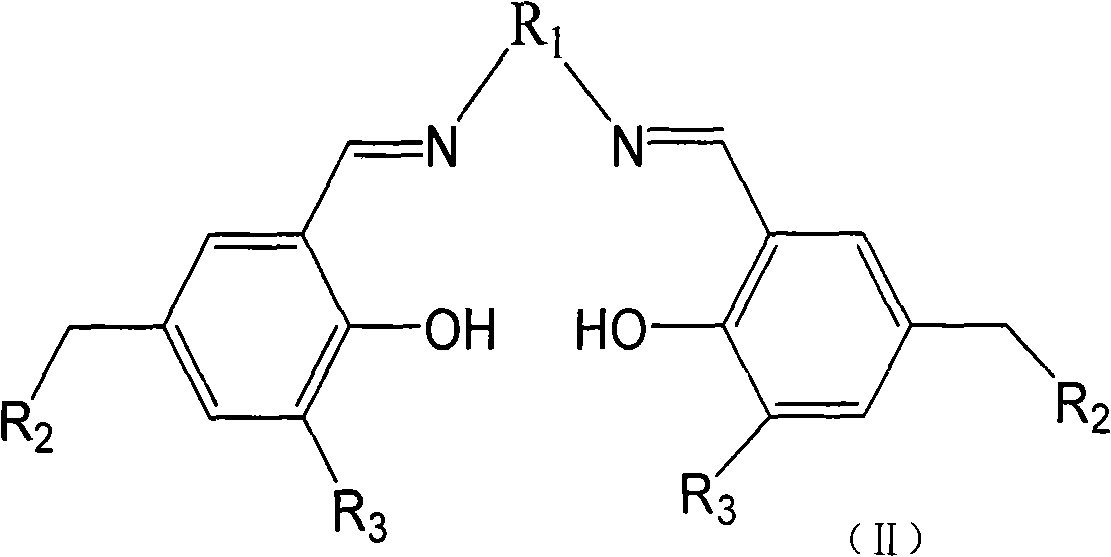

Catalyst for copolymerization of carbon dioxide and epoxy compounds, preparation method and applications thereof

InactiveCN101565502ASimple preparation stepsLow costCobalt organic compoundsEpoxyBulk polymerization

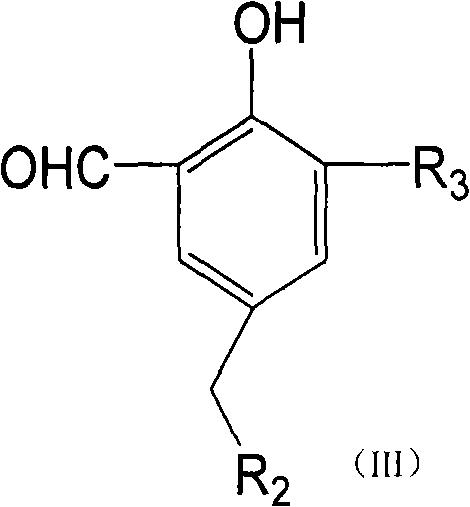

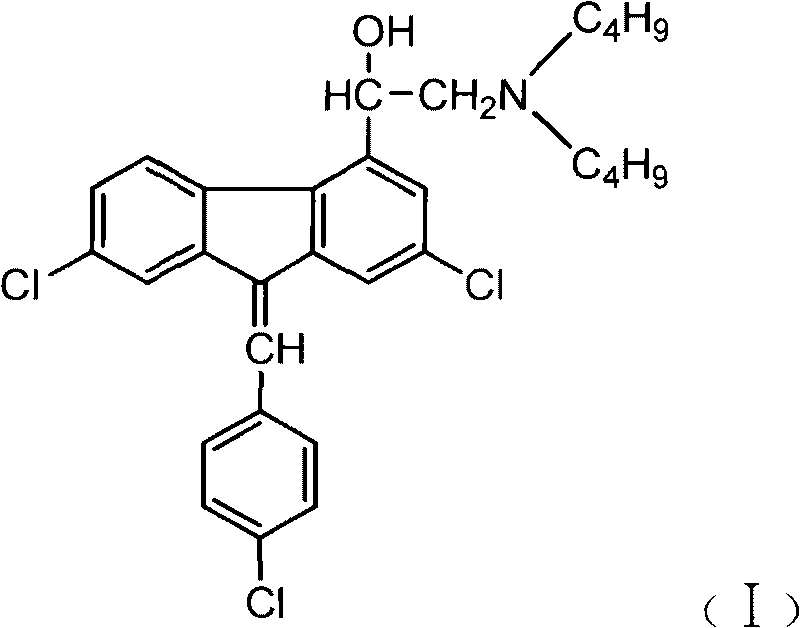

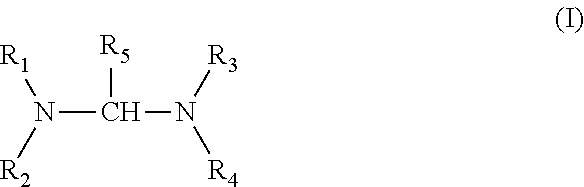

The invention relates to a catalyst for copolymerization of carbon dioxide and epoxy compounds, a preparation method and applications thereof. The structural formula of the catalyst is compound (I) at the right side, wherein X refers to halogen, nitrate radical, azide group or trifluoroacetic acid group; R1 is 1, 2-site disubstituted cyclohexyl or 1, 2-site disubstituted 1, 2-diphenyl-ethyl; R2 is N substituted pyrrolidine, piperidyl, morpholinyl, dibutylamine or 4- methylamino-pyridyl; R3 is tert-butyl group. The preparation method of the catalyst for the copolymerization of carbon dioxide and epoxy compounds comprises the two preparation steps of a ligand and the catalyst. The catalyst preparation method has simple preparation steps, low cost and good catalysis efficiency and product selectivity. Under the noumenon polymenrism or the solution polymenrism, the carbon dioxide and epoxy compounds are polymerized under the lower polymenrism of carbon dioxide (optimal pressure is 30 atm) and simultaneously the copolymer with the content of the polycarbonate unit of more than 98% and the catalyst with the catalytic efficiency of 60-214g polymer / g are obtained.

Owner:HEBEI UNIV OF TECH

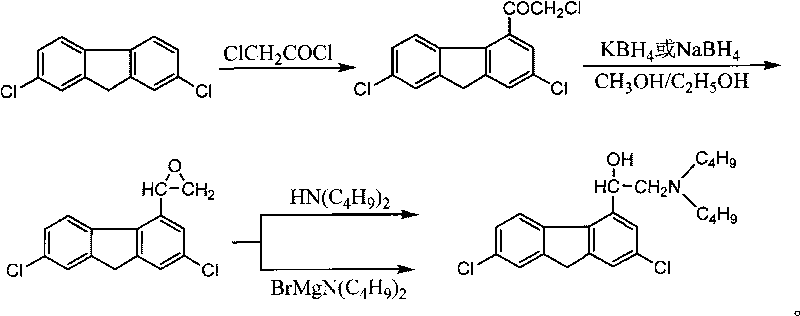

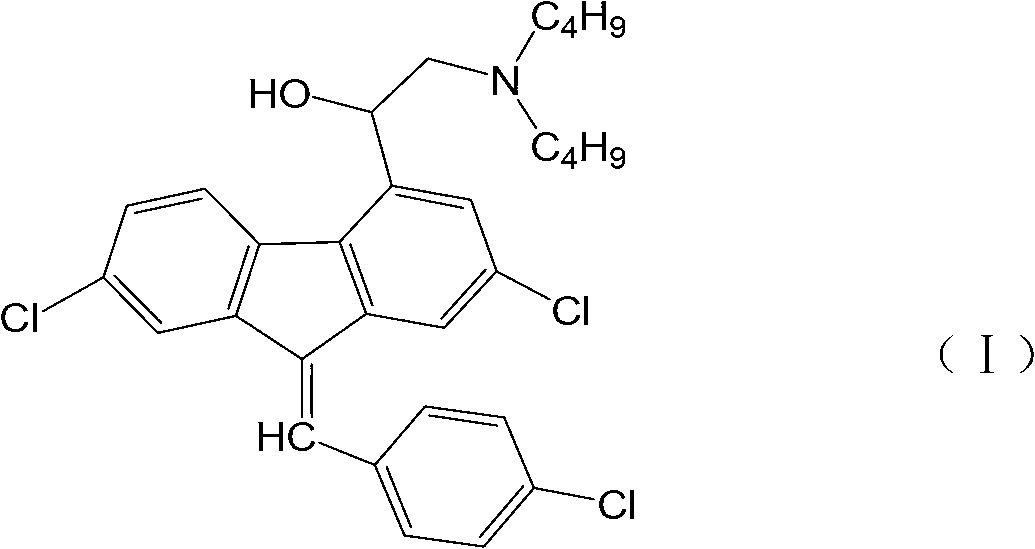

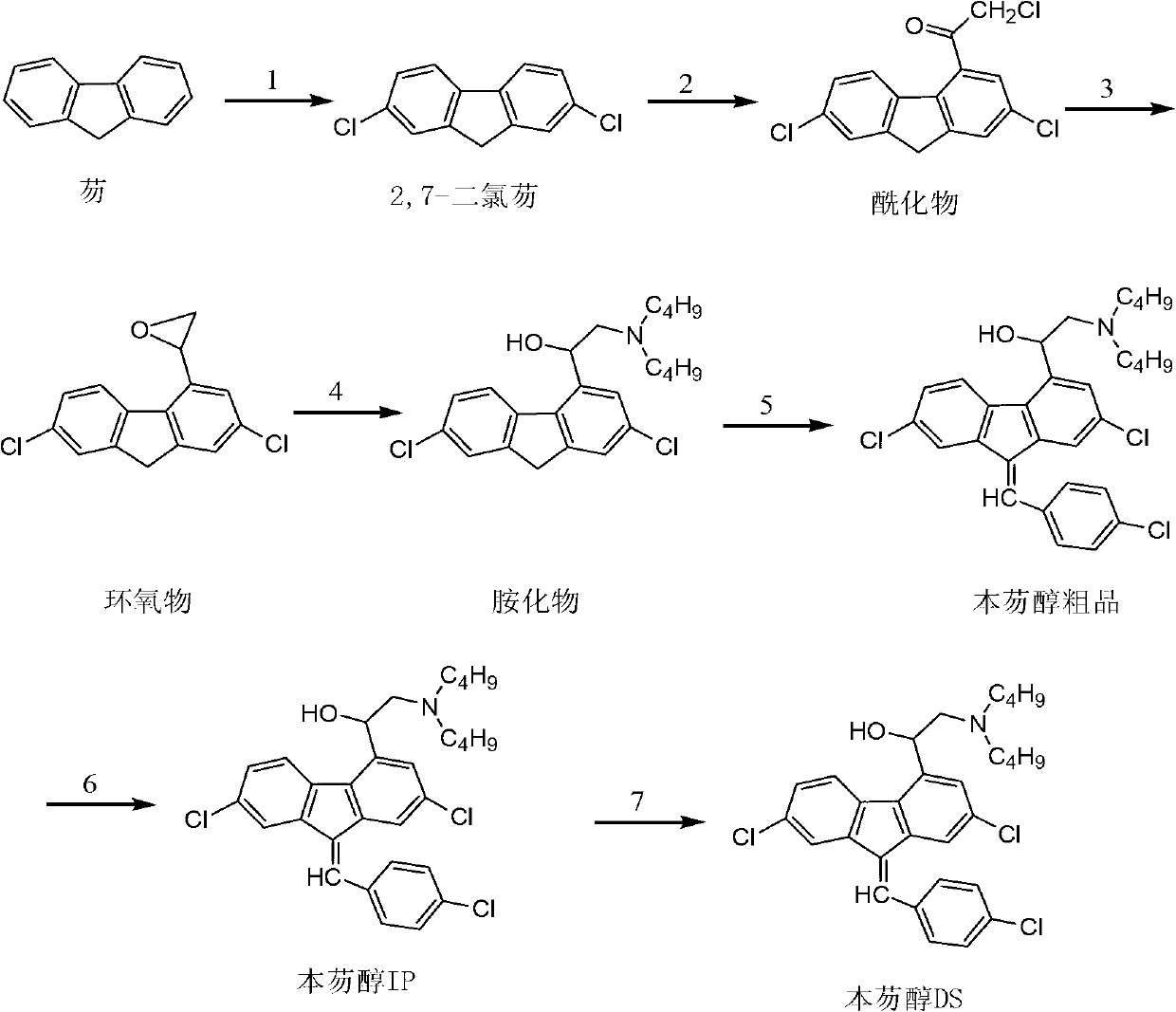

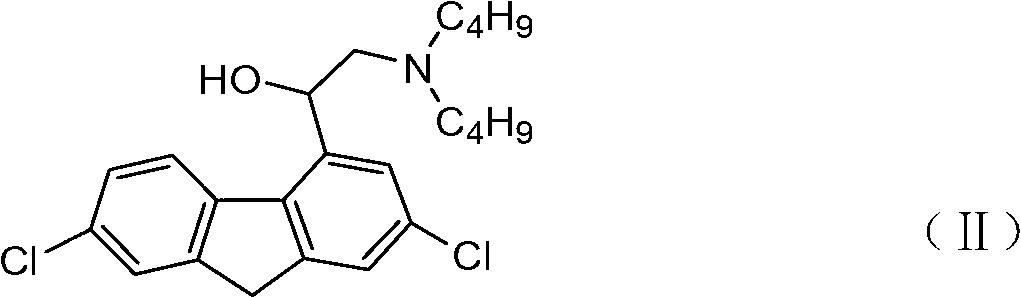

Method for preparing alpha-(di-n-butylaminomethyl)-2,7-dichloro-4-fluorenemethanol and the hydrochloride thereof

InactiveCN101747210AInexpensive and easy to use raw materialsMild reaction conditionsOrganic compound preparationAmino-hyroxy compound preparationPotassium borohydrideEthyl acetate

The invention discloses a method for preparing benflumetol intermediate alpha-(di-n-butylaminomethyl)-2, 7- dichloro-4-fluorenemethanol and the hydrochloride thereof. The alpha-(di-n-butylaminomethyl)-2, 7- dichloro-4-fluorenemethanol is obtained by directly reacting 2, 7-Dichlorofluoren as raw material with the chloroacetyl chloride, then reducing the obtained mixture with potassium borohydride or sodium borohydride for 10 to 24 hours, washing the obtained solids with water, then adding the obtained solids into recycled ethanol mother solution concentrate, adding N-Dibutylamine into the mother solution concentrate and the target product is separated from the reaction mixture; the hydrochloride of the alpha-(di-n-butylaminomethyl)-2, 7- dichloro-4-fluorenemethanol is obtained by adding chlorhydric acid into the reaction mixture to salify the reaction mixture and then crystallizing the reaction mixture. The method has cheap raw materials, simple and convenient operations and high yield factor and in particular greatly reduces the production cost by reusing the ethanol mother solution.

Owner:GUILIN PHARMA

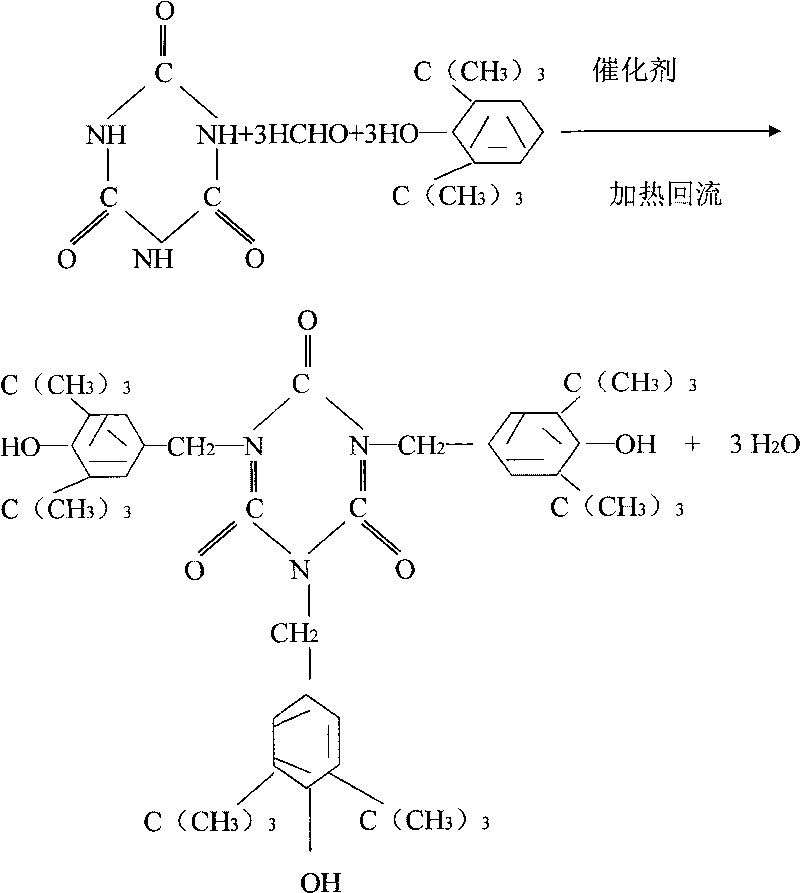

Method for preparing antioxidant

A method for preparing 1.3.5-tri(3.5-di tert butyl-4-hydroxybenzaldehyde)1.3.5-s-triazine.2.4.6-(1H, 2H, 3H) triketone is characterized by adding isopropanol and distilled water into a reactor, adding cyanuric acid and paraformaldehyde under stirring, adding catalysts including triethylamine and dibutylamine after uniform dispersion, after uniform stirring, raising the temperature to 60-80 DEG C under the protection of nitrogen, after adding 2.6-di tert butyl phenol, continuing raising the temperature until the reflux state, naturally cooling after reacting for 10-12h, carrying out pumping filtration after cooling to 10 DEG C, drying to obtain the crude product and obtaining the product through recrystallization and refining. The method has the following advantages and benefits: 1. the production technology process is more reasonable and convenient and the production efficiency is improved; 2. the pollution to the environment is lightened and the harm to the production workers is reduced; and 3. the yield of the product is improved and the total yield is over 90%.

Owner:天津市北方金恒新材料有限责任公司

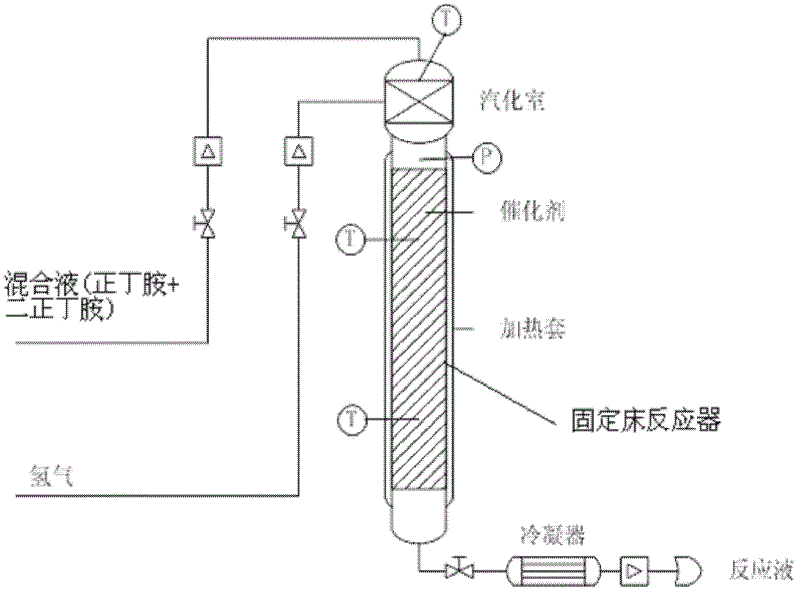

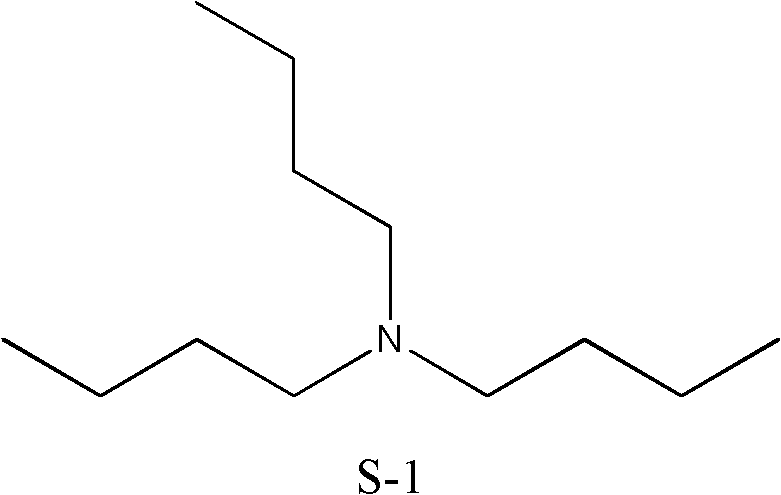

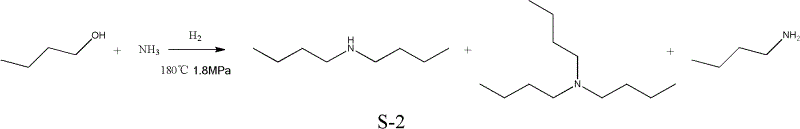

Method for combining tributylamine and used catalyst

ActiveCN102614893AModerate reaction conditionsHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by disproportionationPlatinumHydrogen

The invention discloses a load type catalyst, which utilizes roasted gama-alumina as a carrier. An active component is loaded on the carrier to obtain the load type catalyst. The active component is composed of nickel, copper, iron and platinum. The weight sum of the nickel, the copper, the iron, the platinum and the roasted gama-alumina is the total weight. The nickel occupies 15% to 25% of the total weight, the copper occupies 5% to 12% of the total weight, the iron occupies 0.5% to 1% of the total weight, and the platinum occupies 0.5% to 1% of the total weight. A preparation method of the load type catalyst and a method for preparing tributylamine by using the load type catalyst are further disclosed. Butylamine and dibutylamine are mixed in a mixed cylinder to obtain mixed liquid, the mixed liquid is gasified and then passes through a fixed bed reactor containing an activated load type catalyst, catalyst reaction is conducted under the hydrogen condition, and a product is collected after condensation to obtain the tributylamine.

Owner:ZHEJIANG JIANYE CHEM

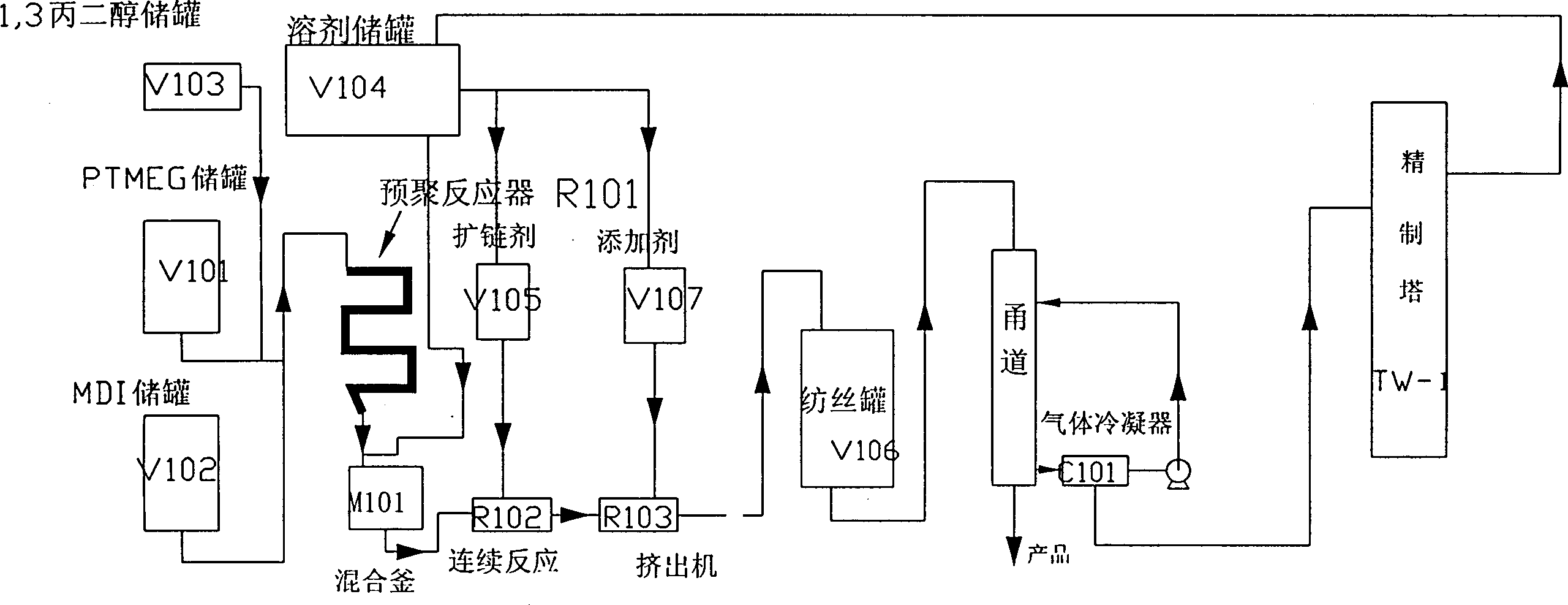

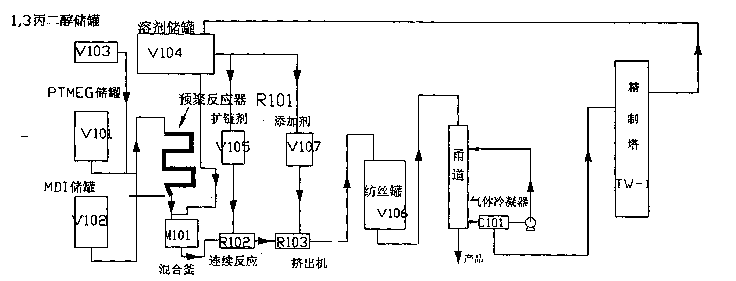

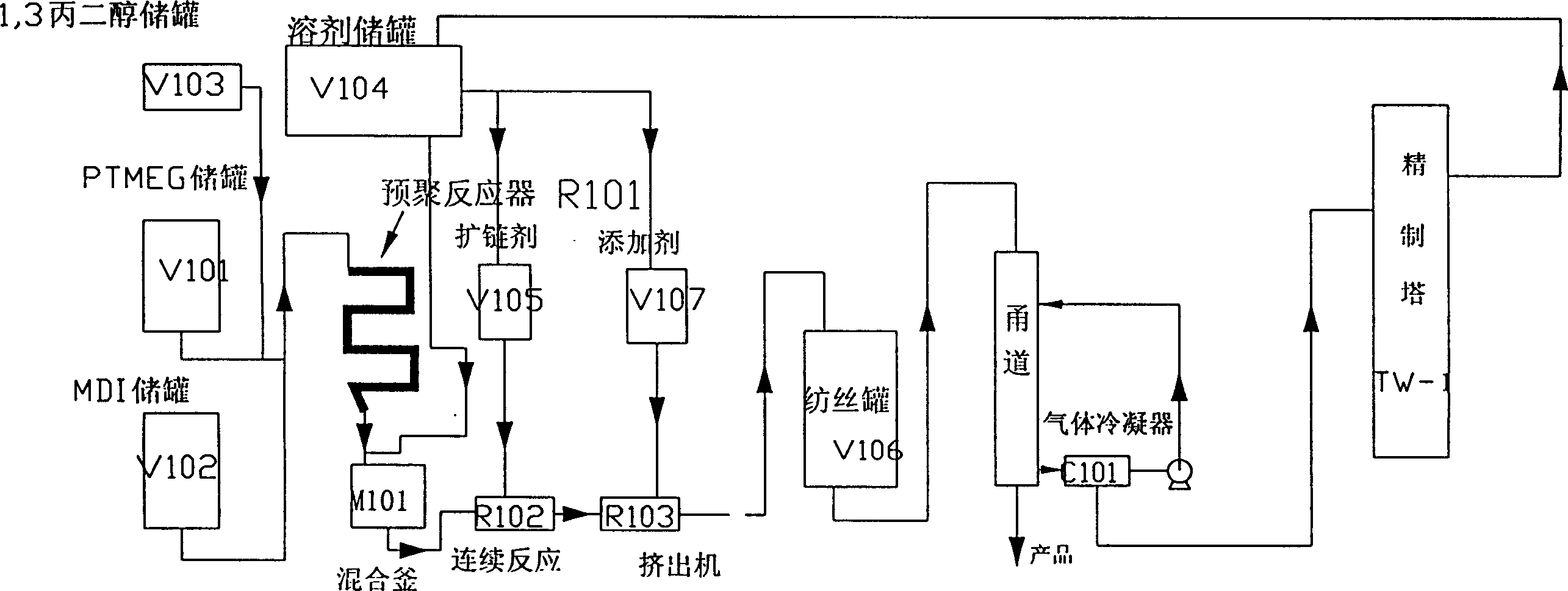

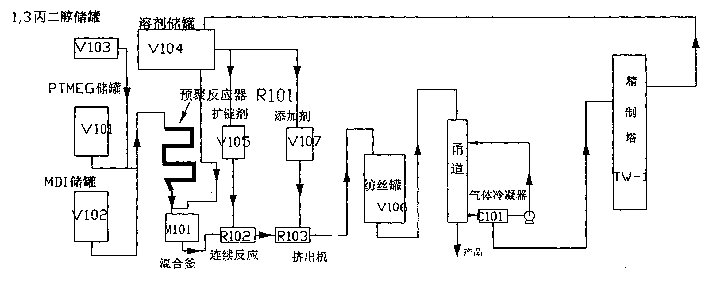

Prepn process and apparatus of polyurethane fiber

InactiveCN1403642AHigh elongationIncrease elasticityMonocomponent polyurethanes artificial filamentFiberPolymer science

The present invention relates to preparation process and apparatus of polyurethane fiber. The preparation process includes: mixing PTMEG, MDI and 1,3-propylene glycol in a prepolymerizing reactor; and pre-polymerization in the prepolymerizing reactor separated into two sections, including a front main section to the material to the reaction temperature of 70-75 deg.c via 80-90 deg.c hot water led into its jacket and a back section to cool and stabilize the prepolymer via 5 deg.c cooling water led into its jacket. The solvent used is pyrrolidone, which can makes the chain-expanding reaction smooth, eliminate gel and raise the concentration of spinning liquid and the chain expanding agent used is benzene diamine and dibutylamine to raise the strength and dyeing performance of the fiber.

Owner:中国中化股份有限公司 +1

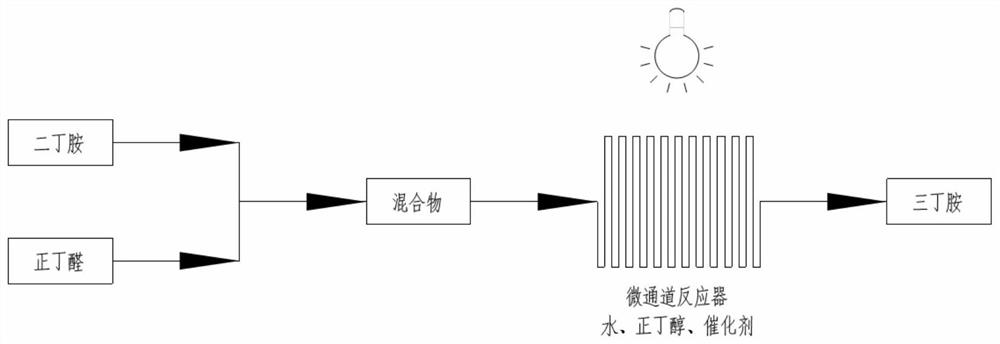

Synthesis process of tetrabutylammonium bromide

ActiveCN111960948AHigh yieldHigh purityOrganic compound preparationChemical/physical/physico-chemical microreactorsAminationButyraldehyde

The invention discloses a synthesis process of tetrabutylammonium bromide. The process is characterized by comprising the following steps: (1) taking dibutylamine and n-butyraldehyde as initial raw materials, taking water as a hydrogen source and butanol as a sacrificial reagent under the action of a modified titanium dioxide photocatalyst, and preparing tributylamine by a photocatalytic continuous micro-channel reactor through a reductive amination mechanism; and (2) after concentrating the obtained tributylamine, making the tributylamine directly dissolved in the solvent and mixed with a certain proportion of n-bromobutane, and then enter the next step continuous micro-channel reactor, such that the target product TBAB can be obtained at the high yield after the reaction is performed for3-5 h at the temperature of 60-90 DEG C. Compared with the kettle type reaction, the continuous reaction temperature is low, the reaction time is short, and the process is safe and efficient.

Owner:KENTE CATALYSTS INC

Synergistic H2 S scavengers

The use of a composition that includes a metal salt and an oil soluble amine formaldehyde reaction product scavenges H2S that is present in aqueous fluids (e.g. produced water liquid streams), natural gas and in oil and mixtures thereof (e.g. mixed production streams that contain all three phases) better than either component when used alone. The resulting scavenger combination significantly increases the reaction rate and the overall scavenging efficiency, i.e. capacity over each component when used alone, in the same total amount. Non-limiting examples of the metal salt include zinc or iron carboxylates, and a non-limiting example of an oil soluble amine formaldehyde reaction product is the reaction product of dibutylamine with formaldehyde.

Owner:BAKER HUGHES INC

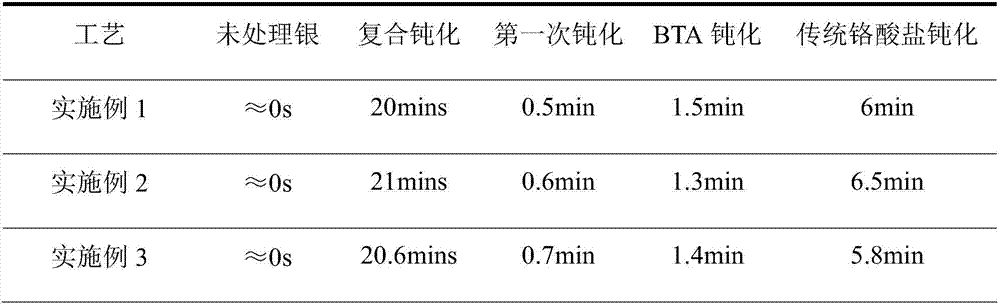

Silver and silver alloy passivation process

ActiveCN107022756AExcellent corrosion protectionNo pollution in the processMetallic material coating processesThiolComposite film

The invention belongs to the technical field of silver or silver alloy surface passivation and particularly discloses a silver and silver alloy passivation process. The silver and silver alloy passivation process comprises the steps of conducting passivation treatment on the clean surface of silver or silver alloy with a 6-N,N-dibutylamine-1,3,5-triazine-2,4-thiol solution as a first passivation solution for the first time; conducting solidification treatment on a first passivation film obtained after passivation treatment for the first time and solidifying the first passivation film into a net structure film; and conducting passivation treatment on the surface of the net structure film for the second time to obtain a compact composite film with a solution containing thiol and benzotrizaole as a second passivation solution. The process is free of environmental pollution. Complicated equipment is not needed in the whole passivation process. Operability is high. A duplex film comprising the net structure passivation film and the compact composite film has a good corrosion protection effect.

Owner:依波精品(深圳)有限公司 +1

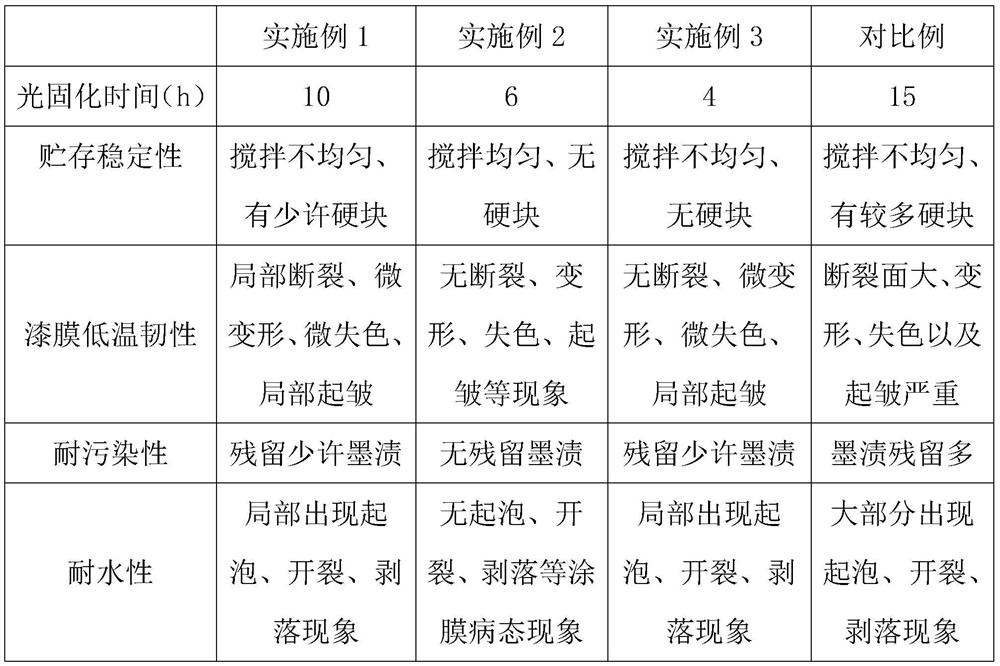

Waterborne polyurethane industrial paint and preparation method thereof

InactiveCN112080185AImprove low temperature toughnessShort curing timeAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

The invention discloses waterborne polyurethane industrial paint and a preparation method thereof, and particularly relates to the technical field of polyurethane paints. The waterborne polyurethane industrial paint is prepared from the following raw materials in parts by weight: 5 to 8 parts of polyether glycol, 3 to 5 parts of castor oil, 8 to 15 parts of isophorone diisocyanate, 10 to 15 partsof dibutyltin dilaurate, 0.5 to 1.5 parts of 1,4-butanediol, 1 to 3 parts of dimethylolpropionic acid, 2 to 4 parts of epoxy resin, 1 to 2 parts of trimethylolpropane, 25 to 40 parts of methyl methacrylate, 1 to 2 parts of triethylamine, 1 to 2 parts of ethylenediamine, 0.8 to 1.2 parts of a photoinitiator, 0.5 to 1 part of a coalescing agent, 0.3 to 0.6 part of a leveling agent, 0.3 to 0.8 part of a thickener, a proper amount of an external cross-linking agent, a proper amount of dibutylamine and sufficient dry nitrogen. And production is carried out through the processes of prepolymerization, emulsification, emulsion modification treatment and paint preparation. The waterborne polyurethane industrial paint is high in storage stability, a formed paint film is not prone to breakage, and the waterborne polyurethane industrial paint is high in water resistance and pollution resistance.

Owner:湖北奥斯鸣环保科技有限公司

Polymer for increasing speed for spinning fine-denier filaments in Nisshinbo dry process

InactiveCN103194814AIncrease concentrationStable spinning dopeArtifical filament manufactureMonocomponent polyamides artificial filamentPolymer scienceSpinning

Owner:浙江四海氨纶纤维有限公司

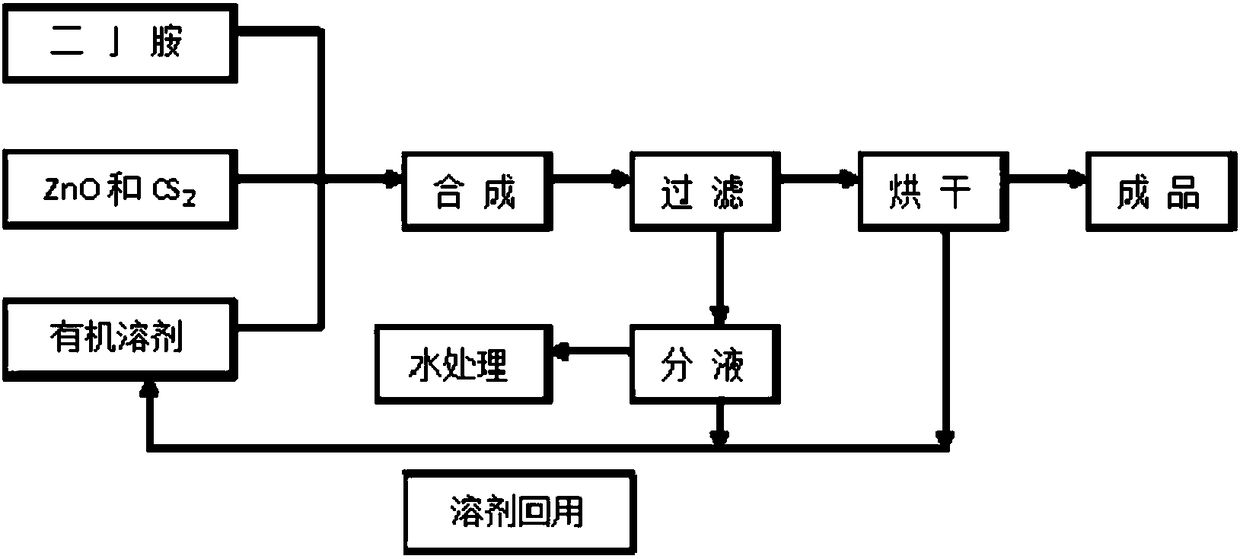

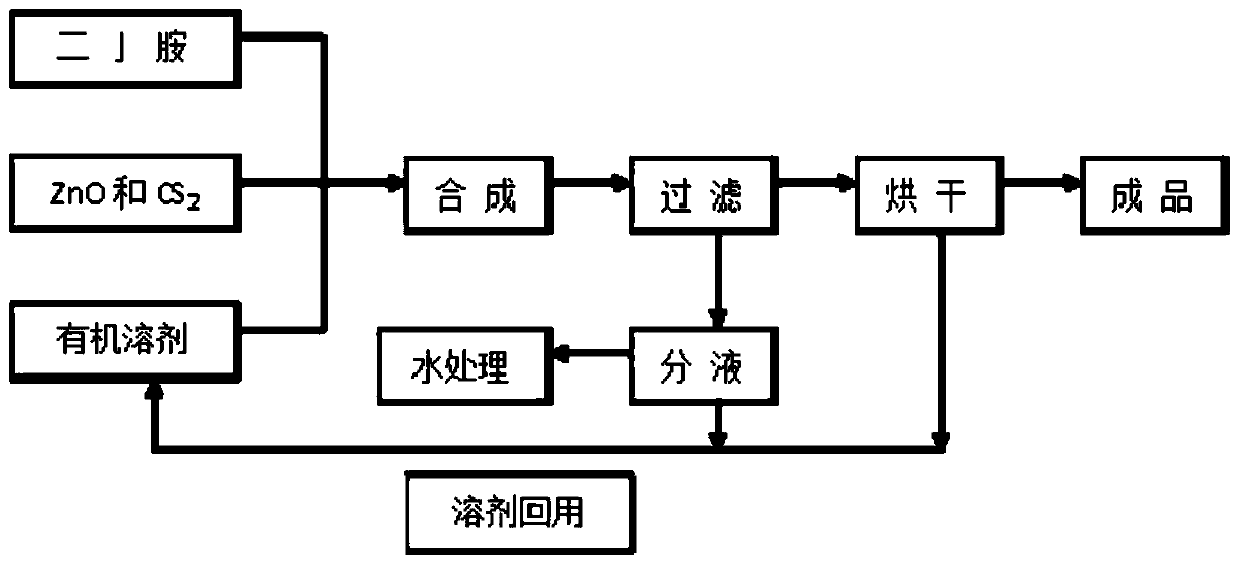

Preparation method of zinc dibutyldithiocarbamate

The invention relates to the field of rubber vulcanizing promoter and particularly relates to a preparation method of zinc dibutyldithiocarbamate. The preparation method comprises the following stepsof: dropping carbon disulfide into reaction solution containing zinc oxide, dibutylamine, a dispersing agent and a first organic solvent to carry out reaction, and after reaction is ended, obtaining the zinc dibutyldithiocarbamate, wherein the first organic solvent is insoluble in water and the obtained zinc dibutyldithiocarbamate is insoluble or slightly soluble in the first organic solvent. Thepreparation method of the zinc dibutyldithiocarbamate has the beneficial effects that an anhydrous solvent method is adopted to prepare the zinc dibutyldithiocarbamate, so that the generation of salt-containing waste water is avoided; since the first organic solvent is insoluble in water, the first organic solvent and the water can be separated by liquid-separating operation; the first organic solvent after water removal can be repeatedly utilized, so that the solvent cost is reduced and simultaneously the yield of a product is increased; the operation is simple and convenient, the generationof the salt-containing waste water is avoided, and the method is a cleaning environment-friendly new method, and is easily applied in large-scale production practice.

Owner:WILLING NEW MATERIALS TECH CO LTD

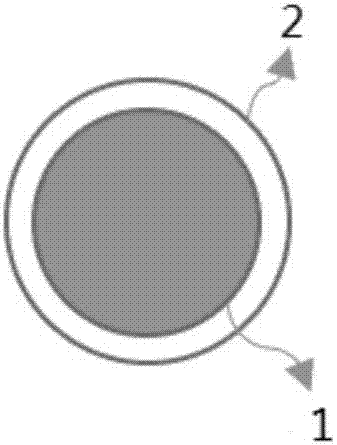

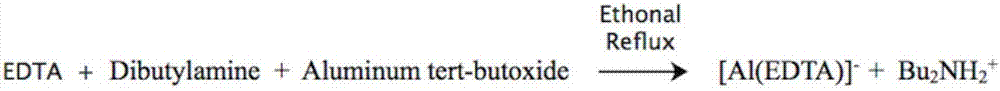

Method for wrapping silicon dioxide particle surface with aluminum oxide

InactiveCN107032358AFacilitate contact areaSimple manufacturing methodSilicaAluminum IonParticulates

The invention discloses a method for coating aluminum oxide on the surface of silicon dioxide particles. A wet chemical method is used to add tert-butoxyaluminum to a solution of ethylenediaminetetraacetic acid and dibutylamine under heating and stirring conditions. , to obtain an organic ion solution containing aluminum, and then add silica powder to the organic ion solution, heat and stir to dry to obtain a gel, and then put the gel into a muffle furnace for roasting, and the silica particles can be The surface is covered with a layer of aluminum oxide. The composite material of the present invention is in granular form, the particle size is determined by the particle size of the initial silicon dioxide, and the thickness of the aluminum oxide coating layer can be adjusted according to requirements. The aluminum oxide-coated silicon dioxide composite material of the invention is very suitable for preparing silicon dioxide structural materials with high tridymite phase and high cristobalite phase content, has simple preparation and easy process control, and is very suitable for large-scale production.

Owner:HUAQIAO UNIVERSITY

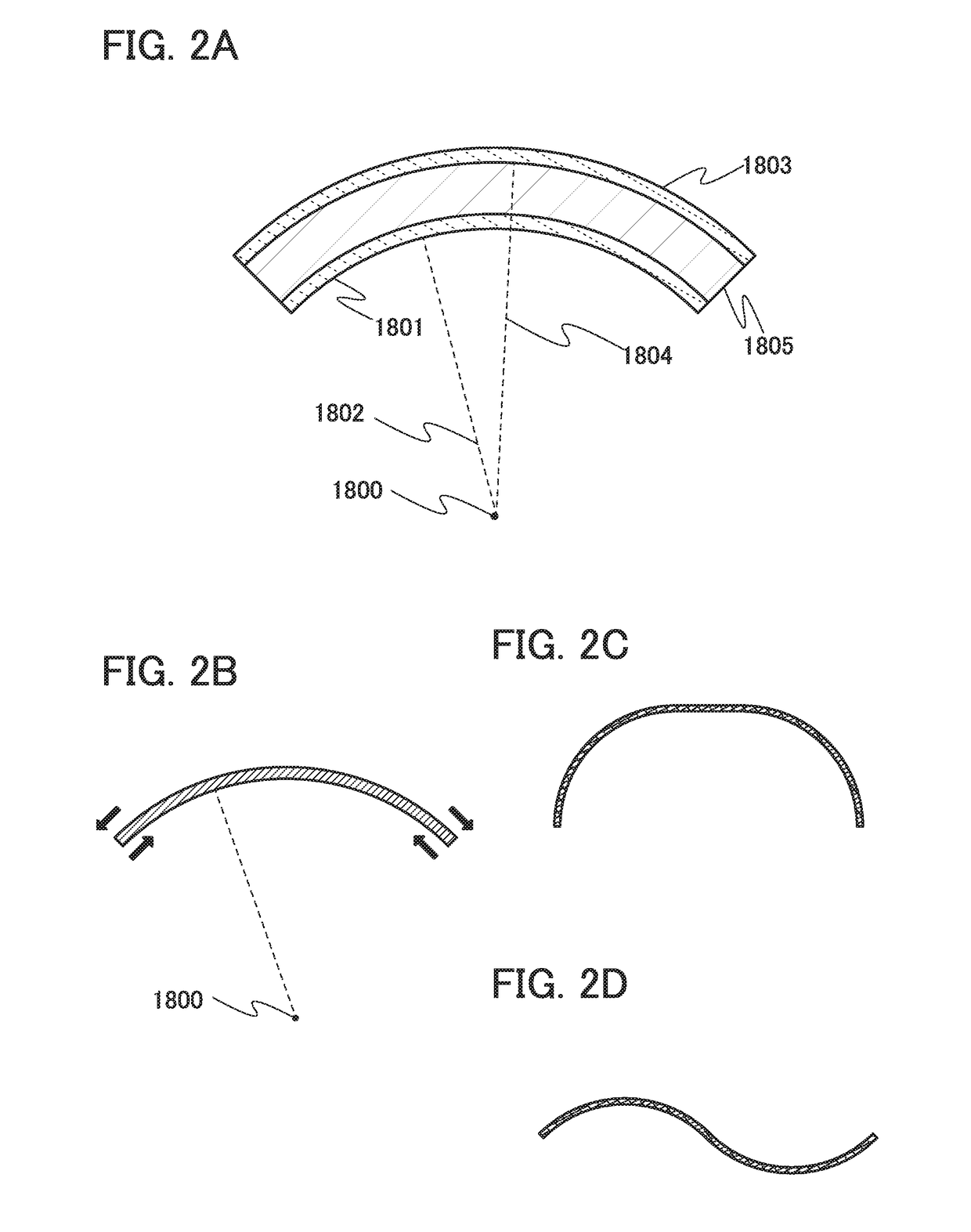

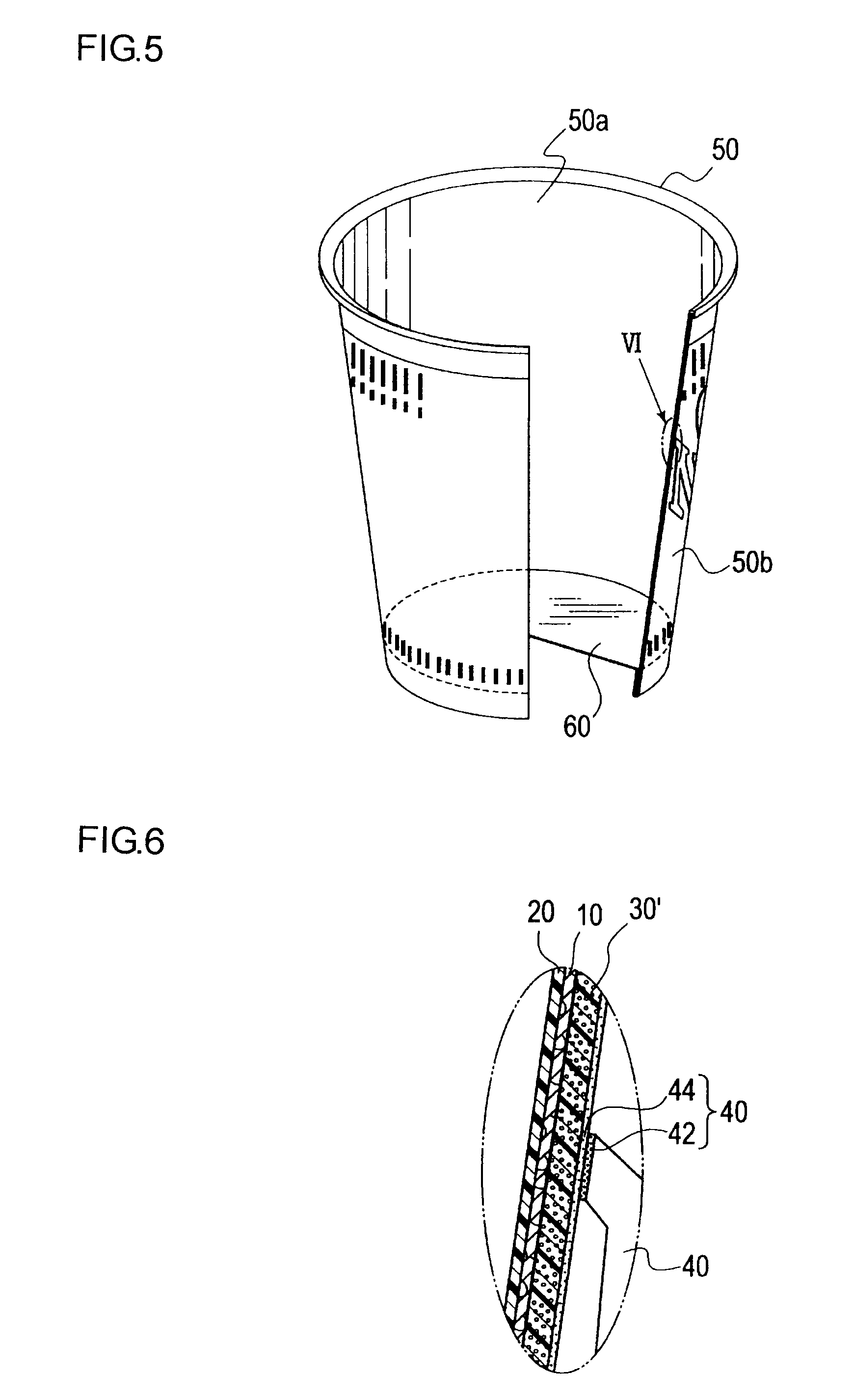

Ink composition for printing, paper container material using the ink composition, and heat insulating foamed paper container

ActiveUS8431195B2Reduce surface unevennessLarge suppressive powerPattern printingPreformed elementsCarbamateSolvent

An ink composition having a colorant; a binder resin; and a solvent; wherein the elongation ratio of the binder resin is 400% to 3,000%; wherein the binder resin comprises a urethane resin and a vinyl chloride / vinyl acetate copolymer, and the mixing ratio of the urethane resin:vinyl chloride / vinyl acetate copolymer relative to the total weight of the urethane resin and the vinyl chloride / vinyl acetate copolymer is 50:50 to 99:1; and wherein the urethane resin comprises a urethane-urea resin that is obtained by a process comprising reacting dibutylamine and a urethane prepolymer obtained by a process comprising reacting a polymeric polyol component having a number average molecular weight of 500 to 10,000 and an organic diisocyanate component having terminal isocyanate groups. A heat insulating foamed paper container material having at least one print pattern formed from said ink composition.

Owner:NISSIN YORK +1

Prepn process and apparatus of polyurethane fiber

InactiveCN1147628CHigh elongationIncrease elasticityMonocomponent polyurethanes artificial filamentFiberPolymer science

The present invention relates to preparation process and apparatus of polyurethane fiber. The preparation process includes: mixing PTMEG, MDI and 1,3-propylene glycol in a prepolymerizing reactor; and pre-polymerization in the prepolymerizing reactor separated into two sections, including a front main section to the material to the reaction temperature of 70-75 deg.c via 80-90 deg.c hot water led into its jacket and a back section to cool and stabilize the prepolymer via 5 deg.c cooling water led into its jacket. The solvent used is pyrrolidone, which can makes the chain-expanding reaction smooth, eliminate gel and raise the concentration of spinning liquid and the chain expanding agent used is benzene diamine and dibutylamine to raise the strength and dyeing performance of the fiber.

Owner:中国中化股份有限公司 +1

The preparation method of zinc dibutyl dithiocarbamate

Owner:WILLING NEW MATERIALS TECH CO LTD

Preparation technology of tetrabutyl urea

InactiveCN106699607AImprove product qualityRaw materials are cheap and easy to getUrea derivatives preparationOrganic compound preparationOrganic solventCarbonyl chloride

The invention provides a preparation technology of tetrabutyl urea synthetized by a phosgene method. The tetrabutyl urea is synthetized from dibutylamine and carbonyl chloride as main materials in an alkaline organic solvent. The technology comprises the following steps: (1) adding dibutylamine, carbonyl chloride and the organic solvent according to a ratio to a reaction container; (2) adjusting the temperature of an acylation reaction, and controlling the time of the acylation reaction so as to obtain a tetrabutyl urea crude product; and (3) enabling the tetrabutyl urea crude product to be subjected to standing, separation, distillation, and purification so as to obtain the finished product of the tetrabutyl urea. The preparation method disclosed by the invention is simple in operation steps, the raw materials are low in price and easy to obtain, products are high in quality, the reaction yield reaches 90% or above, and the purity reaches 99% or above.

Owner:QINGDAO SENMEIKE CHEM TECH CO LTD

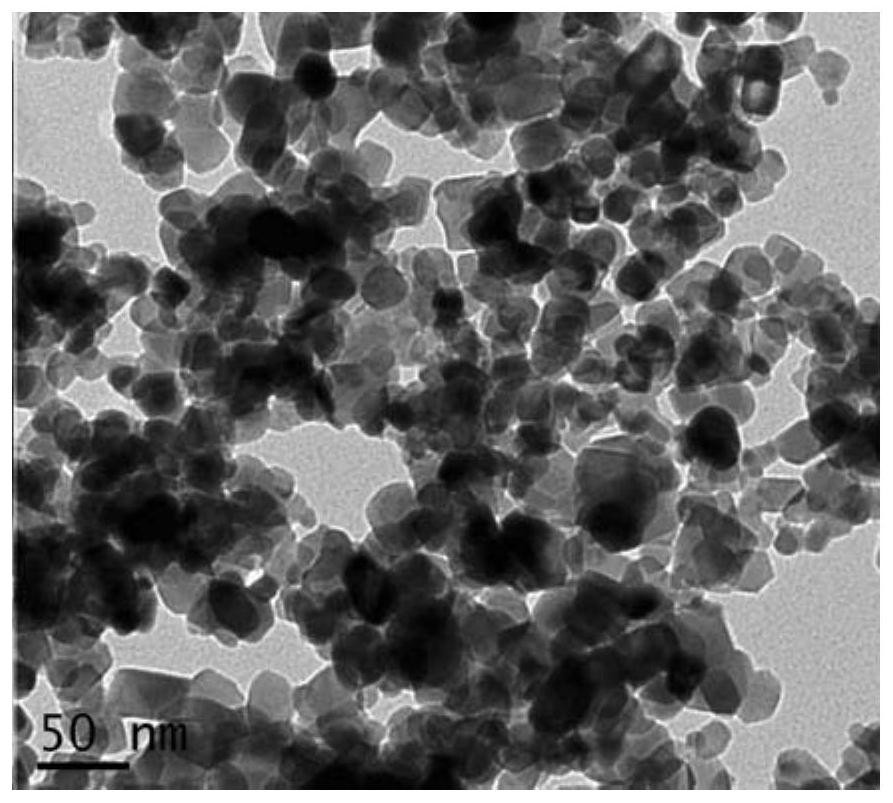

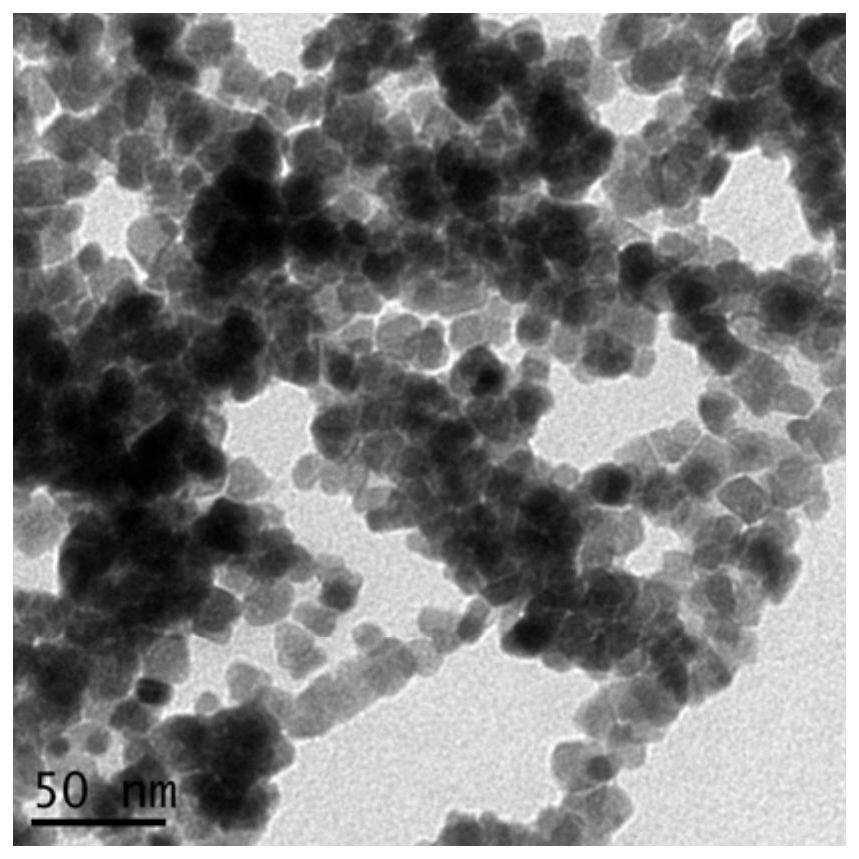

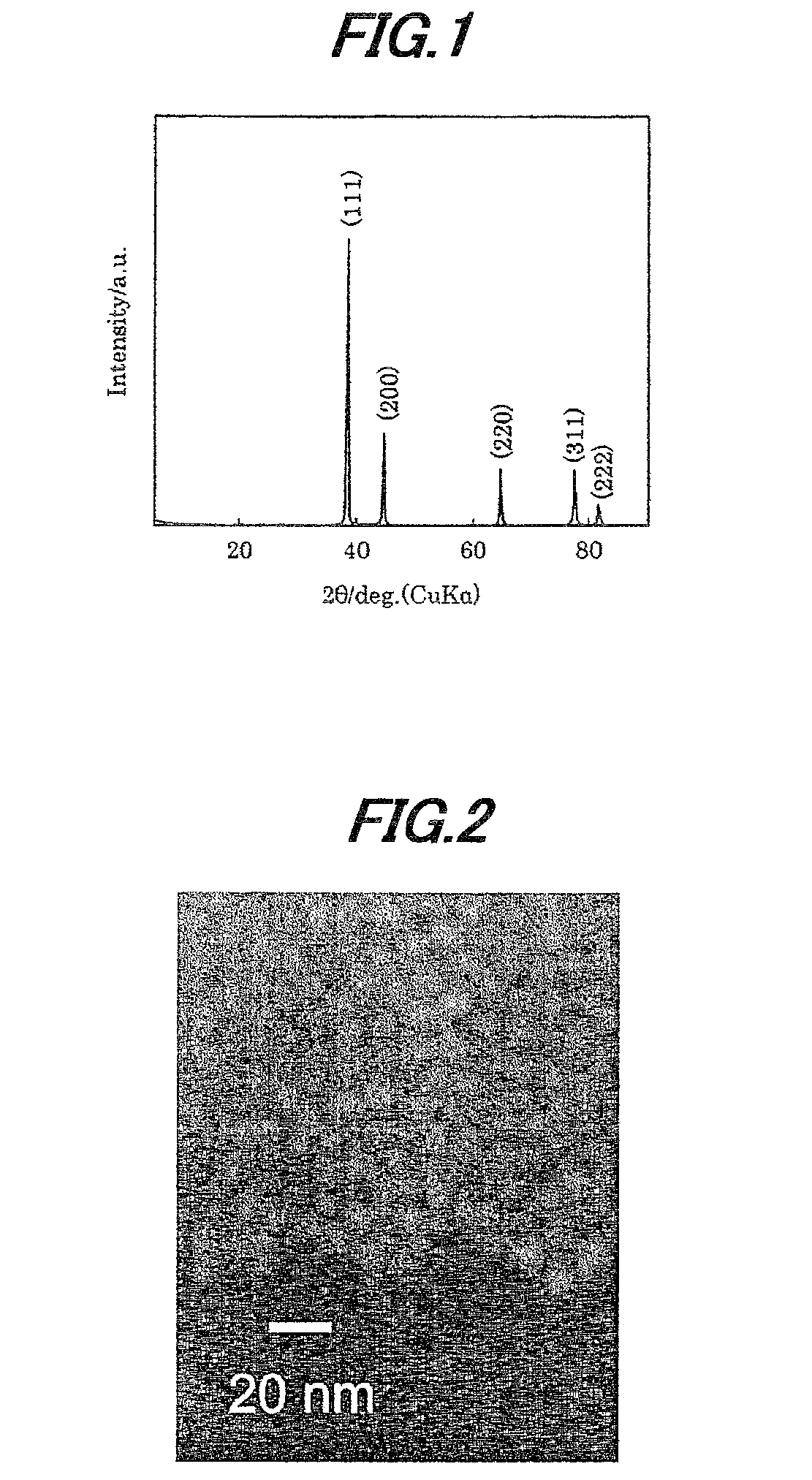

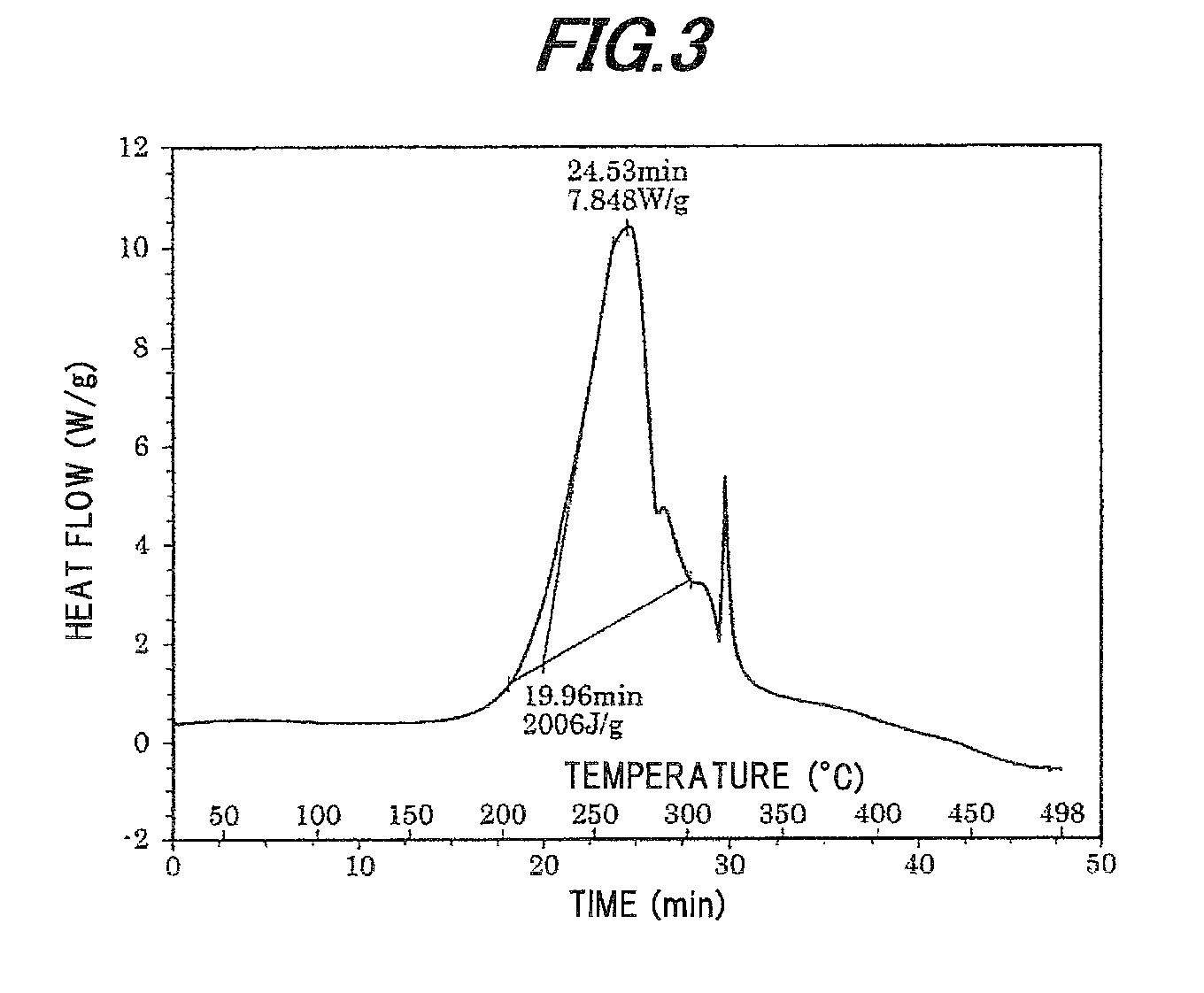

Metal fine particle for conductive metal paste, conductive metal paste and metal film

ActiveUS8852463B2Decrease in required calcination timeNanotechConductive materialMicroparticleButanethiol

A metal fine particle for a conductive metal paste includes a protective agent covering a surface of the metal fine particle. An amount of heat generated per unit mass (g) of the metal fine particle is not less than 500 J at a temperature of an external heat source temperature in a range of 200° C. to 300° C. when being calcined by the external heat source. The protective agent includes at least one selected from the group consisting of dipropylamine, dibutylamine, triethylamine, tripropylamine, tributylamine, butanethiol, pentanethiol, hexanethiol, heptanethiol, octanethiol, nonanethiol, decanethiol, undecanethiol and dodecanethiol. The content of the protective agent is in a range of 0.1 to 20% by mass with respect to the mass of the metal fine particle.

Owner:HITACHI METALS LTD

Preparation method for 2-dibutylamido-1-1(2,7- dichloro-9H-fluorine-4base)-ethanol

InactiveCN102993029AReduce dosageAvoid lostOrganic compound preparationAmino-hyroxy compound preparationBiochemical engineeringCombinatorial chemistry

The invention discloses a preparation method for 2-dibutylamido-1-1(2,7- dichloro-9H-fluorine-4base)-ethanol. In an existing method, the yield is low, or the yield is high, but new impurities are generated, and yield is still needed to be improved. The preparation method comprises the following steps of: using 2,7-dichlorofluorene as a material; and carrying out an acylation reaction, reduction reaction and amination in sequence to obtain 2-dibutylamido-1-1(2,7- dichloro-9H- fluorine-4base)-ethanol, wherein the molar ratio of reducing agent in the reduction reaction to 2,7-dichlorofluorene is (0.4-1.3):1; and the molar ratio of amination accelerator in amination reaction to the 2,7-dichlorofluorene is (0.4-1.3):1. The preparation method avoids the problems such as product loss, health damage, environment pollution and the like caused by separating, purifying and drying steps of the acylation reaction and reduction reaction, further simplifies process steps, shortens a production period, reduces production cost and remarkably improves the yield and the product quality.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

Graphene compound, method for forming graphene compound, and lithium-ion storage battery

ActiveUS10396397B2Prevent short-circuitingImprove conductivitySolid electrolytesGraphiteSilylationNitrogen gas

A material that can be used in a wide temperature range is provided. A graphene compound includes graphene or graphene oxide and a substituted or unsubstituted chain group, the chain group includes two or more ether bonds, and the chain group is bonded to the above graphene or graphene oxide through a Si atom. Alternatively, a method for forming a graphene compound includes a first step and a second step after the first step. In the first step, graphene oxide and a base are stirred under a nitrogen stream. In the second step, the mixture is cooled to room temperature, a silylating agent that has a group having two or more ether bonds is introduced into the mixture, and the obtained mixture is stirred. The base is butylamine, pentylamine, hexylamine, diethylamine, dipropylamine, dibutylamine, triethylamine, tripropylamine, or pyridine.

Owner:SEMICON ENERGY LAB CO LTD

Compound fuel oil

The invention discloses a compound fuel oil which is prepared from the following components in parts by weight: 30-70 parts of methyl alcohol, 20-50 parts of gasoline and 10-22 parts of additives, wherein the additives comprise the following components in parts by weight: 1-2 parts of dodecane, 0.5-1.5 parts of oleic acid, 0.5-1.5 parts of xylenol, 3-10 parts of petroleum ether, 1-2 parts of n-butyl alcohol, 1-2 parts of isopropyl alcohol, 0.1-0.5 part of methoxyphenol, 0.5-1.5 parts of iso-butylamine, and 0.5-2 parts of dibutylamine. The compound fuel oil can be stored for more than a year and does not layer or deteriorate, the octane value is up to 100-115, the water resistance property can reach 15%, and the combustion performance is excellent.

Owner:广西丰泰能源防爆科技有限公司

Preparation method of cationic asphalt emulsifier with corrosion inhibition function

InactiveCN107814770AEasy to prepareImprove surface activityOrganic chemistryBuilding insulationsDistillationEvaporation

The invention discloses a preparation method of a cationic asphalt emulsifier with corrosion inhibiting function, comprising the following steps: (1) mixing lauric acid, tetraethylenepentamine and xylene, stirring and reacting, distilling, and heating at 0.092MPa, 230-250°C Under the conditions of reaction for 3.5-4h, long-chain alkyl imidazolines are obtained; (2) Dibutylamine and epichlorohydrin are mixed, and absolute ethanol is used as a solvent, and hydrochloric acid solution is added dropwise until the pH is 5-6, and the reaction is completed Finally, rotary evaporation, and then dry in vacuo to obtain N-butyl-N, N-two (3-chloro-2-hydroxypropyl) butane-1 ammonium salt; (3) N-butyl-N, N-bis(3-chloro-2-hydroxypropyl) butane-1 ammonium salt is mixed with long-chain alkyl imidazoline, and isopropanol is added as a solvent. After the reaction is completed, vacuum distillation is completed. The preparation method of the invention is simple, and the synthetic product has good corrosion inhibition performance under different pH value environments.

Owner:SHAANXI HUANKE BIOLOGICAL TECH CO LTD

Special protective material for polar rubber and preparation method thereof

The invention discloses a special protective material for polar rubber and a preparation method thereof. The protective material is composed of the following components (in parts by weight): 40-50 parts of nickel dibutyldithiocarbamate; 30 to 40 parts of nickel terephthalate; and 10 to 30 parts of calcium terephthalate. The preparation method of the protective material comprises the following steps: (1) mixing alkali deweighting wastewater, dibutylamine, carbon disulfide and caustic soda according to a certain ratio, dissolving, and filtering with activated carbon to obtain a clarified solution; (2) reacting the solution obtained in the step (1) with a nickel chloride solution to obtain slurry A; (3) reacting the alkali deweighting water filtered by the activated carbon with a calcium chloride solution to obtain slurry B; and (4) uniformly mixing the slurry A in the step (2) and the slurry B in the step (3), separating, washing and drying to obtain a target product. The protective material disclosed by the invention is moderate in price, good in dispersity in a rubber material and excellent in protective performance, and can also improve the defect that the rubber material is easyto adhere.

Owner:常州市五洲化工有限公司

Synthesis technology of twin-tailed hydrophobic monomer based on drying time control

InactiveCN103833580AImprove performanceThe synthesis steps are simpleOrganic compound preparationCarboxylic acid amides preparationWater bathsDistillation

The invention discloses a synthesis technology of a twin-tailed hydrophobic monomer based on drying time control. The technology comprises the following steps: 1, dissolving acryloyl chloride in a dichloromethane solution; 2, adding the above obtained acryloyl chloride and dichloromethane mixed solution, dibutylamine and an aqueous solution of NaOH into a reaction container, and fully shaking; 3, placing the reaction container in a water bath; 4, stirring, and letting in an inert gas; 5, separating out an organic layer, and washing; 6, drying for 10-20min, and carrying out reduced pressure distillation to vaporize a solvent in order to obtain a light yellow oily liquid; and 7, adding a polymerization inhibitor, and carrying out reduced pressure distillation under a certain degree of vacuum at a certain temperature to obtain a colorless oily liquid which is a target product. The twin-tailed hydrophobic monomer can be successfully synthesized through the technology, and the synthesized twin-tailed hydrophobic monomer has the advantages of excellent performances, simple synthesis steps and substantially reduced synthesis cost; and the drying time in the synthesis process is controlled to improve the yield and the quality of the product.

Owner:谭正怀

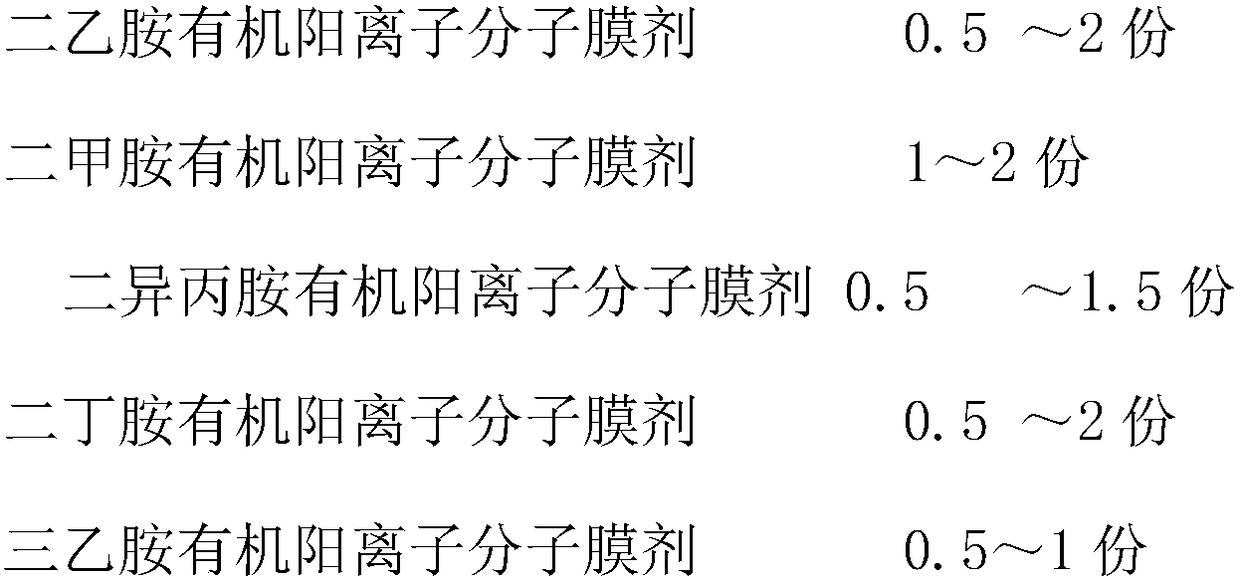

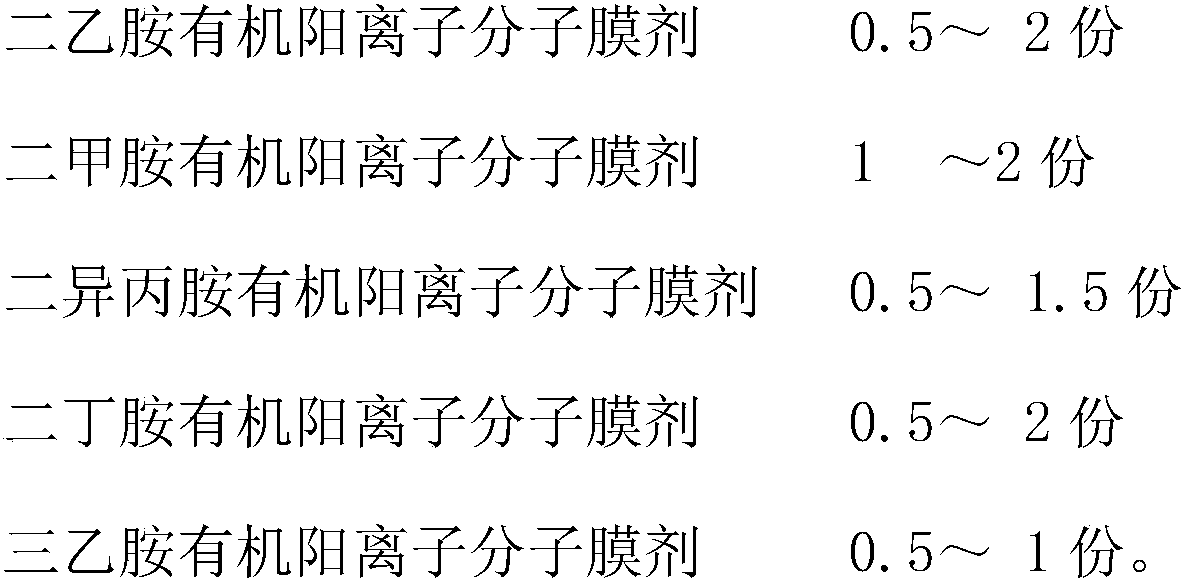

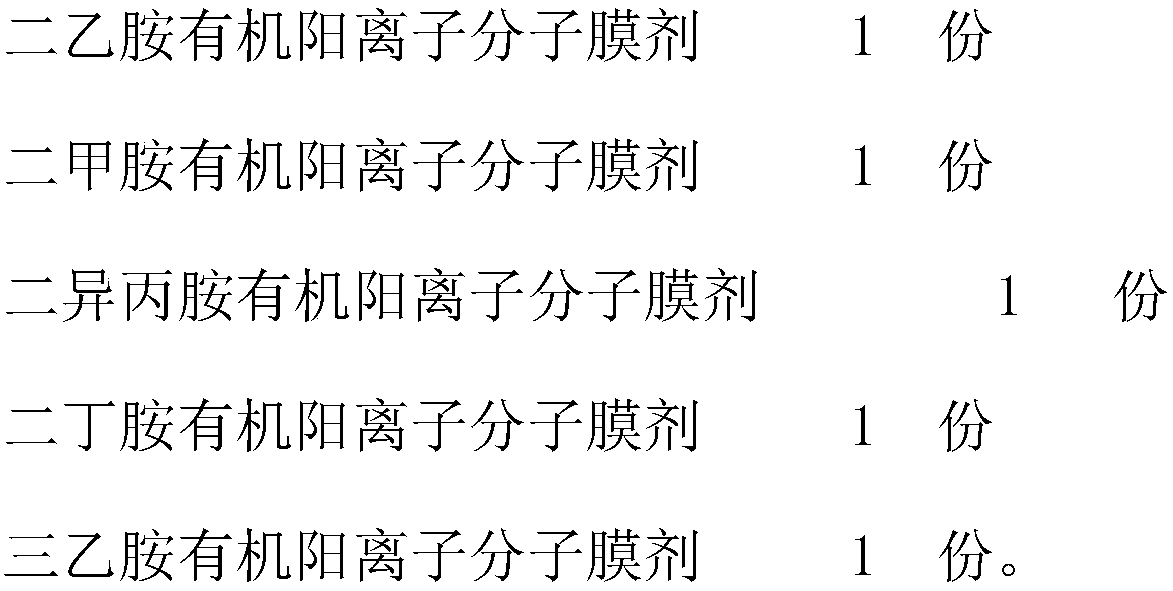

Separating agent and method for separating petroleum from petroleum sludge

InactiveCN109279744ALow residual oil rateSave raw materialsWater contaminantsSludge treatment with immiscible liquidsDiisopropylamineResidual oil

The invention relates to a separating agent and method for separating petroleum from petroleum sludge. The separating agent is prepared by mixing 0.5-2 parts by mass of a diethylamine organic cationicmolecular film agent, 1-2 parts by mass of a dimethylamine organic cationic molecular film agent, 0.5-1.5 parts by mass of a diisopropylamine organic cationic molecular film agent, 0.5-2 parts by mass of a dibutylamine organic cationic molecular film agent, and 0.5-1 part by mass of a triethylamine organic cationic molecular film agent. The thermochemical separating agent for oily sludge preparedby the method is cheap in raw materials, easy in preparation method, stable in properties and good in oil washing effect, and can be used for treating oily sludge, specially oil tank bottom sludge. Compared with a conventional separating agent, a residual oil rate of the tank bottom oily sludge can be reduced to 0.5% at the minimum.

Owner:XIAN LANDARUI NEW ENERGY CO LTD

Synthesis technology of twin-tailed hydrophobic monomer based on distillation pressure control

InactiveCN103833574AImprove performanceThe synthesis steps are simpleOrganic compound preparationCarboxylic acid amides preparationWater bathsDistillation

The invention discloses a synthesis technology of a twin-tailed hydrophobic monomer based on distillation pressure control. The technology comprises the following steps: 1, dissolving acryloyl chloride in a dichloromethane solution; 2, adding the above obtained acryloyl chloride and dichloromethane mixed solution, dibutylamine and an aqueous solution of NaOH into a reaction container, and fully shaking; 3, placing the reaction container in a water bath; 4, stirring, and introducing an inert gas; 5, separating out an organic layer, and washing; 6, drying, and distilling under 0.2-0.6atm to vaporize a solvent in order to obtain a light yellow oily liquid; and 7, adding a polymerization inhibitor, carrying out reduced pressure distillation under a certain degree of vacuum at a certain temperature to obtain a colorless oily liquid which is a target product. The twin-tailed hydrophobic monomer can be successfully synthesized through the technology, and the synthesized twin-tailed hydrophobic monomer has the advantages of excellent performances, simple synthesis steps and substantially reduced synthesis cost; and the distillation pressure in the synthesis process is controlled to improve the yield and the quality of the product.

Owner:谭正怀

Synthesis technology of twin-tailed hydrophobic monomer based on stirring time control

InactiveCN103833575AImprove performanceThe synthesis steps are simpleOrganic compound preparationCarboxylic acid amides preparationWater bathsDistillation

The invention discloses a synthesis technology of a twin-tailed hydrophobic monomer based on stirring time control. The technology comprises the following steps: 1, dissolving acryloyl chloride in a dichloromethane solution; 2, adding the above obtained acryloyl chloride and dichloromethane mixed solution, dibutylamine and an aqueous solution of NaOH into a reaction container, and fully shaking; 3, placing the reaction container in a water bath; 4, stirring for 20-40min, and introducing an inert gas; 5, separating out an organic layer, and washing; 6, drying, and distilling to vaporize a solvent in order to obtain a light yellow oily liquid; and 7, adding a polymerization inhibitor, and carrying out reduced pressure distillation under a certain degree of vacuum at a certain temperature to obtain a colorless oily liquid which is a target product. The twin-tailed hydrophobic monomer can be successfully synthesized through the technology, and the synthesized twin-tailed hydrophobic monomer has the advantages of excellent performances, simple synthesis steps and substantially reduced synthesis cost; and the stirring time in the synthesis process is controlled to improve the yield and the quality of the product.

Owner:谭正怀

Synthesis technology of twin-tailed hydrophobic monomer

InactiveCN103833579AImprove performanceThe synthesis steps are simpleOrganic compound preparationCarboxylic acid amides preparationWater bathsDistillation

The invention discloses a synthesis technology of a twin-tailed hydrophobic monomer. The technology comprises the following steps: 1, adding dichloromethane, dibutylamine and an aqueous solution of NaOH into a reaction container, and fully shaking; 2, placing the reaction container in a water bath; 3, stirring, introducing an inert gas, adding a dichloromethane solution containing acryloyl chlorine, and stirring for a certain time; 4, separating out an organic layer, and washing; 5, drying, and carrying out reduced pressure distillation to vaporize a solvent in order to obtain a light yellow oily liquid; and 6, adding a polymerization inhibitor, and carrying out reduced pressure distillation under a certain degree of vacuum at a certain temperature to obtain a colorless oily liquid which is a target product. The twin-tailed hydrophobic monomer can be successfully synthesized through the technology, and the synthesized twin-tailed hydrophobic monomer has the advantages of excellent performances, simple synthesis steps and substantially reduced synthesis cost.

Owner:谭正怀

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com