Patents

Literature

108results about "Sludge treatment with immiscible liquids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphate recovery from sludge

A process for recovering reusable materials, in particular phosphate, from sewage sludge products, namely sewage sludge, sewage sludge ash or sewage sludge slag, by extraction, in which a suspension of the sewage sludge product is produced in water, alcohol, water-alcohol mixture or an aqueous solution, gaseous carbon dioxide (CO2) or supercritical carbon dioxide (scCO2) is introduced as an extraction agent into the suspension of the sewage sludge product, undissolved solids are separated from the liquid suspension agent, carbon dioxide is removed from the suspension agent, and reusable materials dissolved in the suspension agent are precipitated and separated from the suspension agent.

Owner:CHEM FAB BUDENHEIM AG

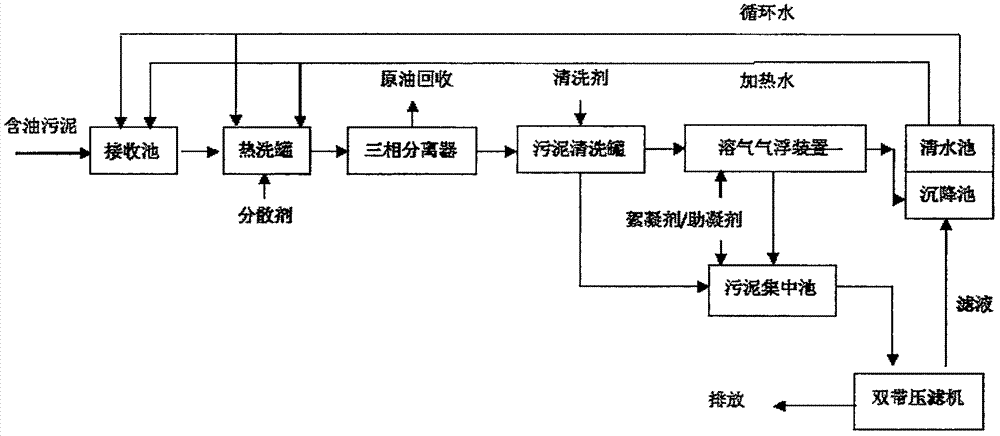

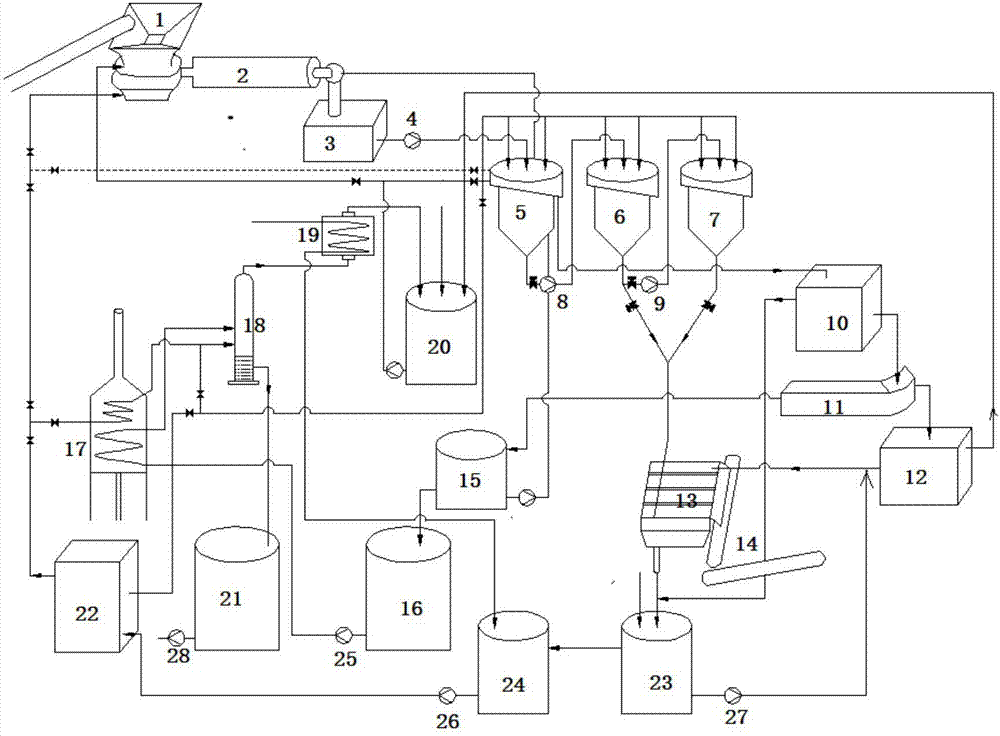

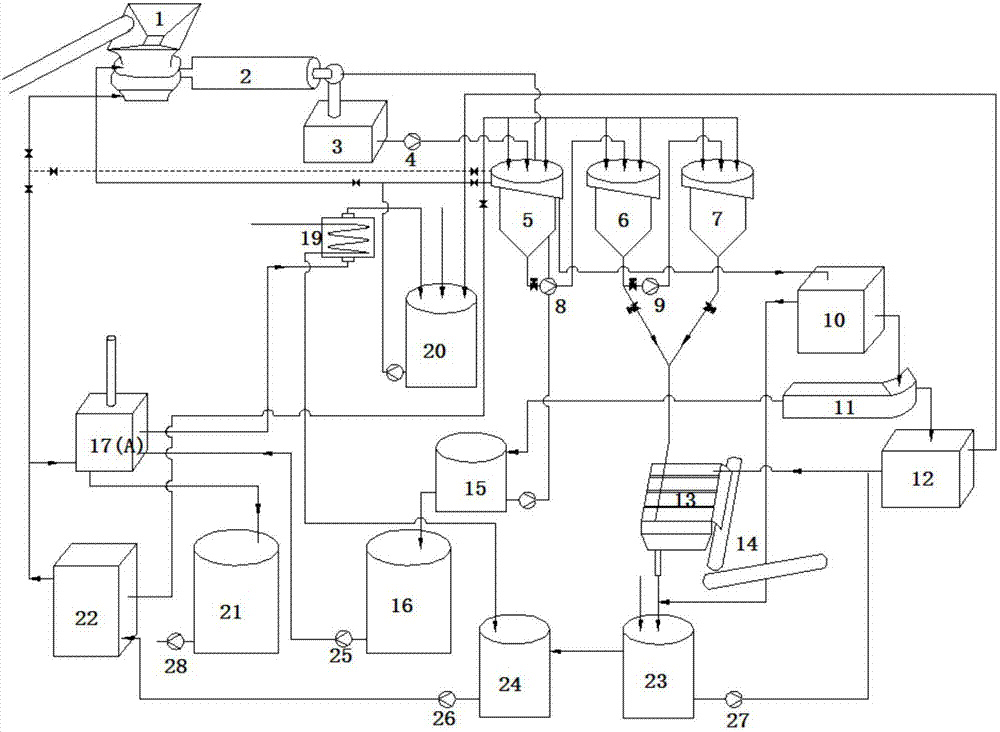

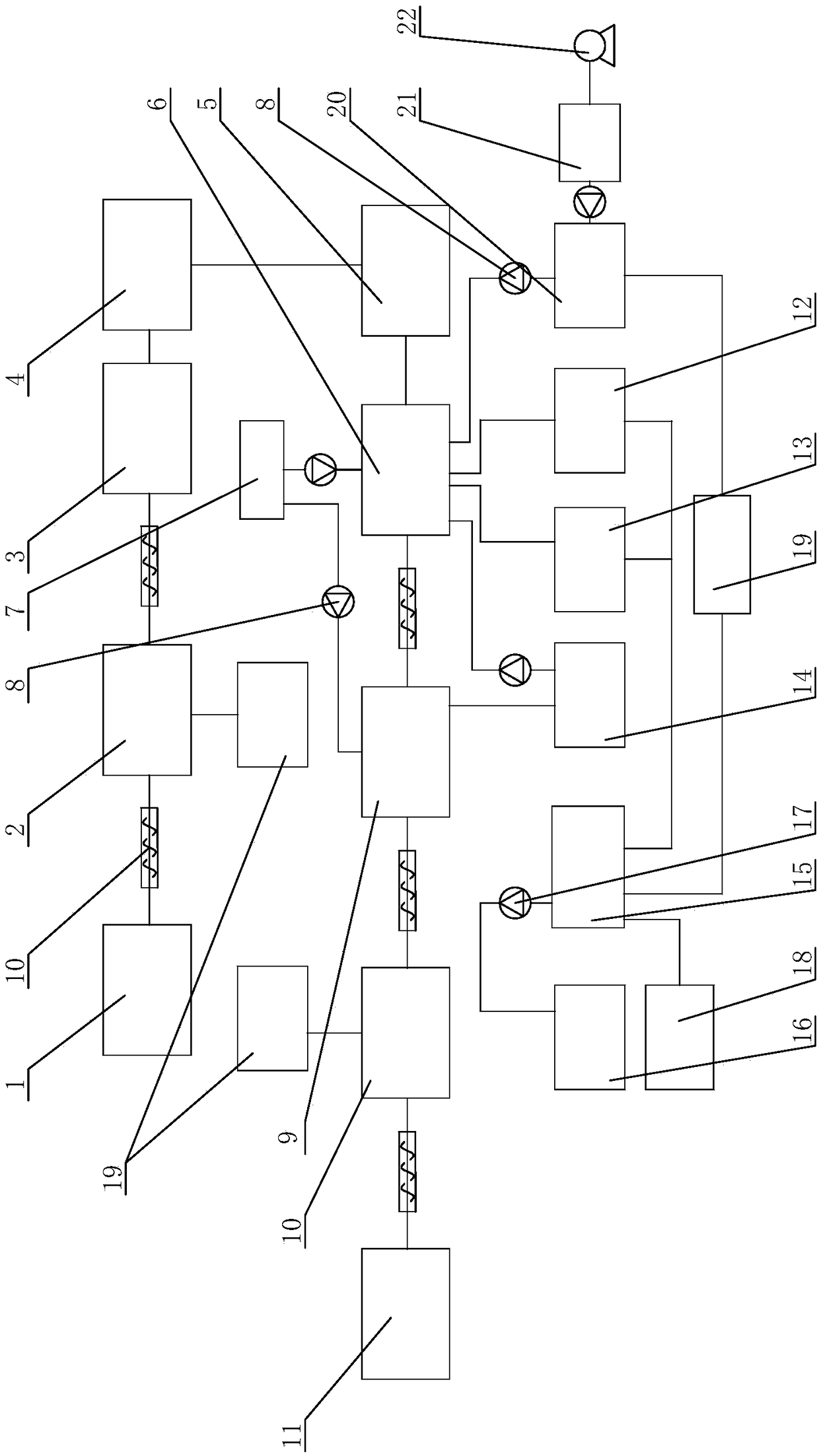

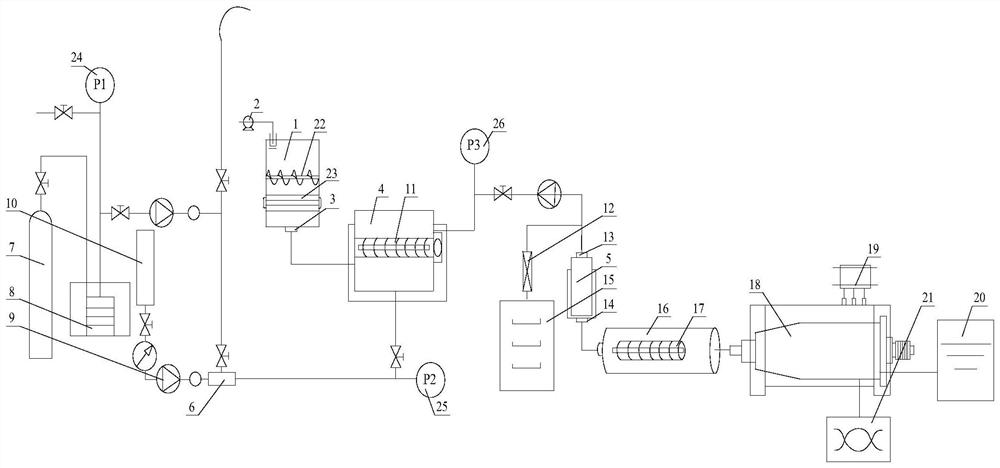

Harmless and recycling treatment method and process for oily sludge

InactiveCN106904801APromote sustainable developmentSolve the use problemWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningSludgeThree-phase

The invention relates to a hot washing separation treatment method for the oily sludge. The hot washing separation treatment method comprises steps as follows: (1) the oily sludge is introduced into a receiving tank and diluted with circulating water, and enters a hot washing tank through a lift pump after being in a fluid state; (2) a dispersant is added to the hot washing tank, so that crude oil is separated from the sludge and enters a three-phase separator; and the like. The treatment method has the advantages that oil, water and sludge in the oily sludge are separated, secondary pollution cannot be caused, comprehensive utilization can be realized, the treatment amount is large, large-scale production can be realized, the treatment cost can be reduced, the pollution problem of the oily sludge is thoroughly solved, harmlessness, recycling and reduction of the oily sludge are realized, the environment can be protected, and sustainable development of an oil field is facilitated.

Owner:XIAN HUANUO ENVIRONMENTAL PROTECTION CO LTD

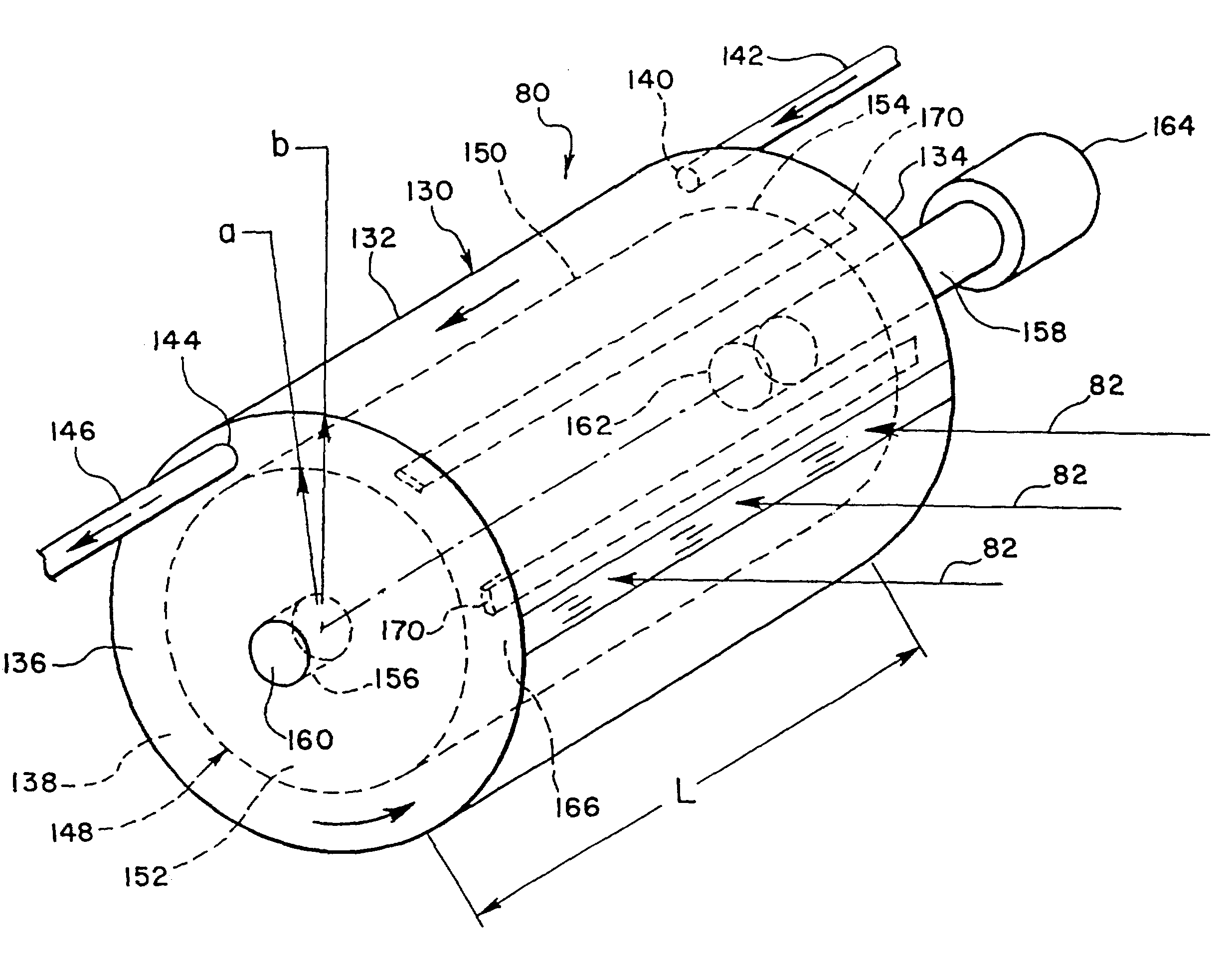

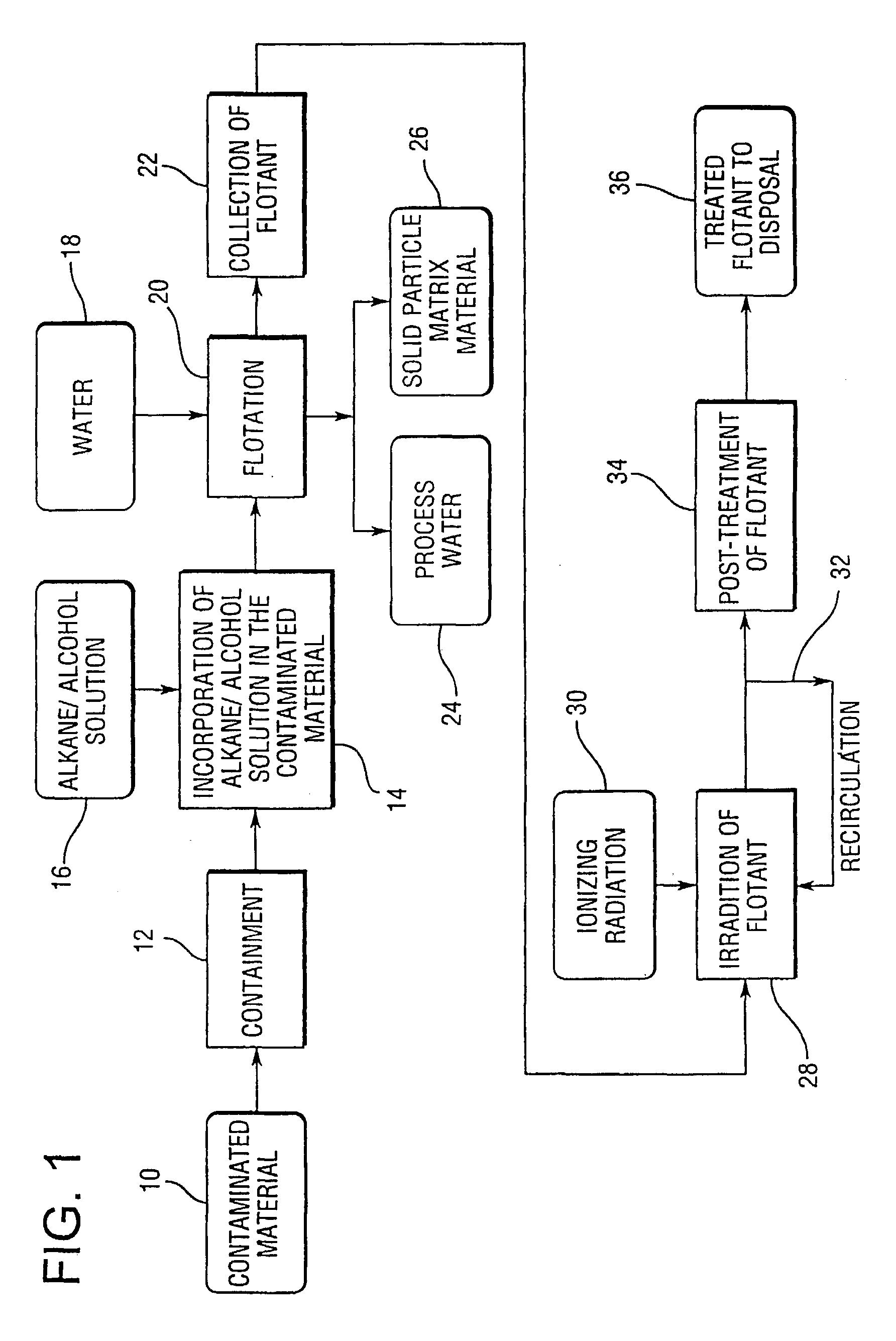

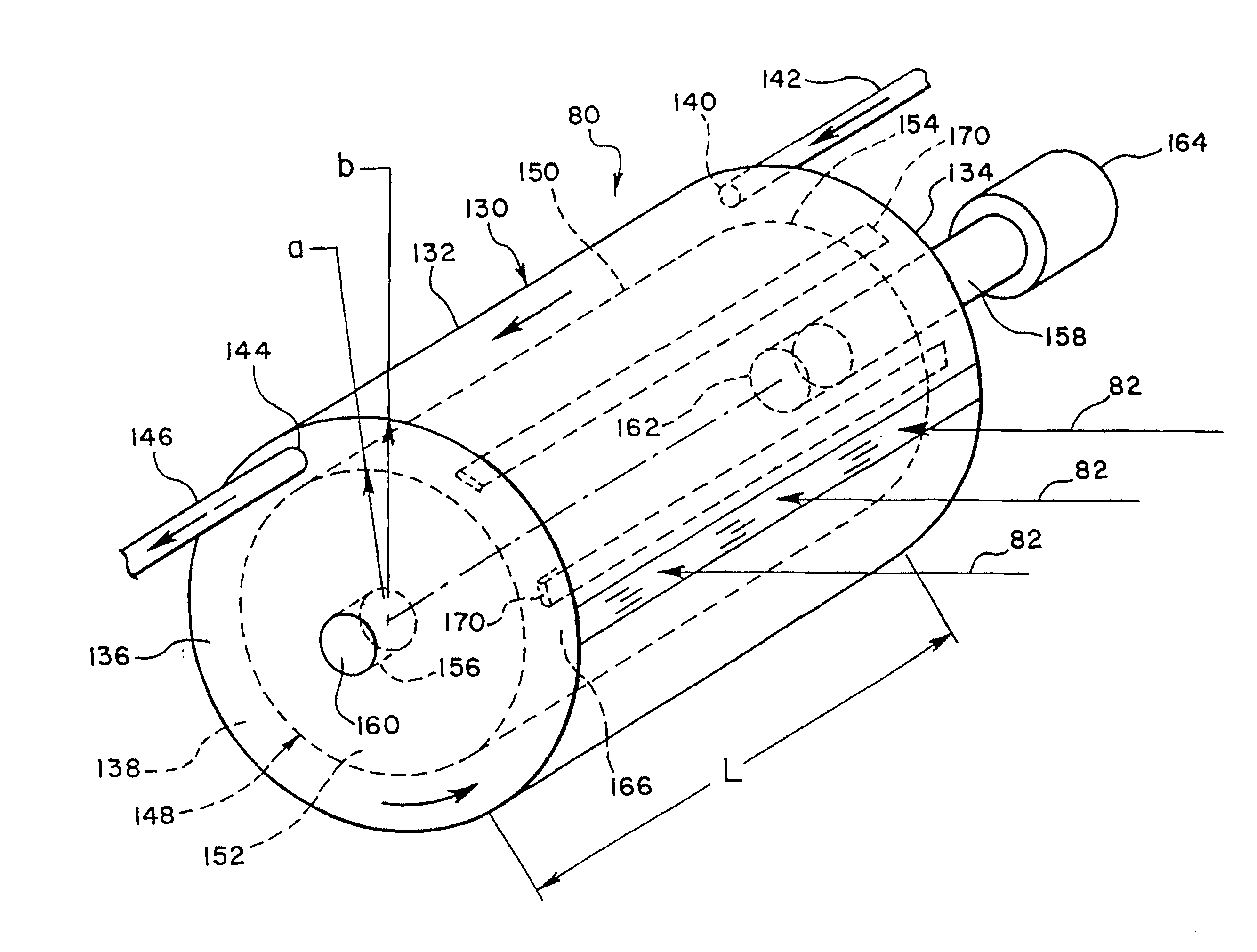

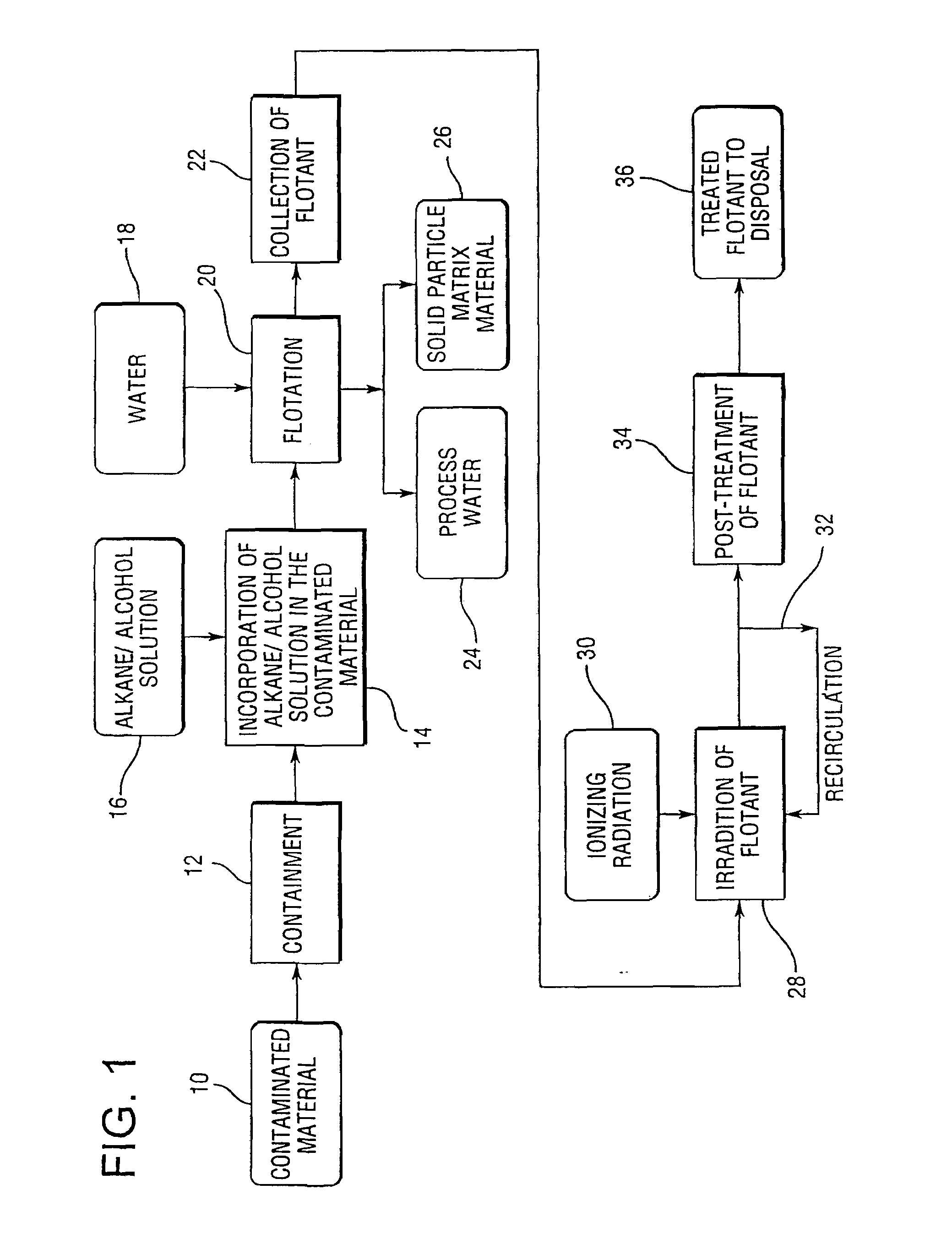

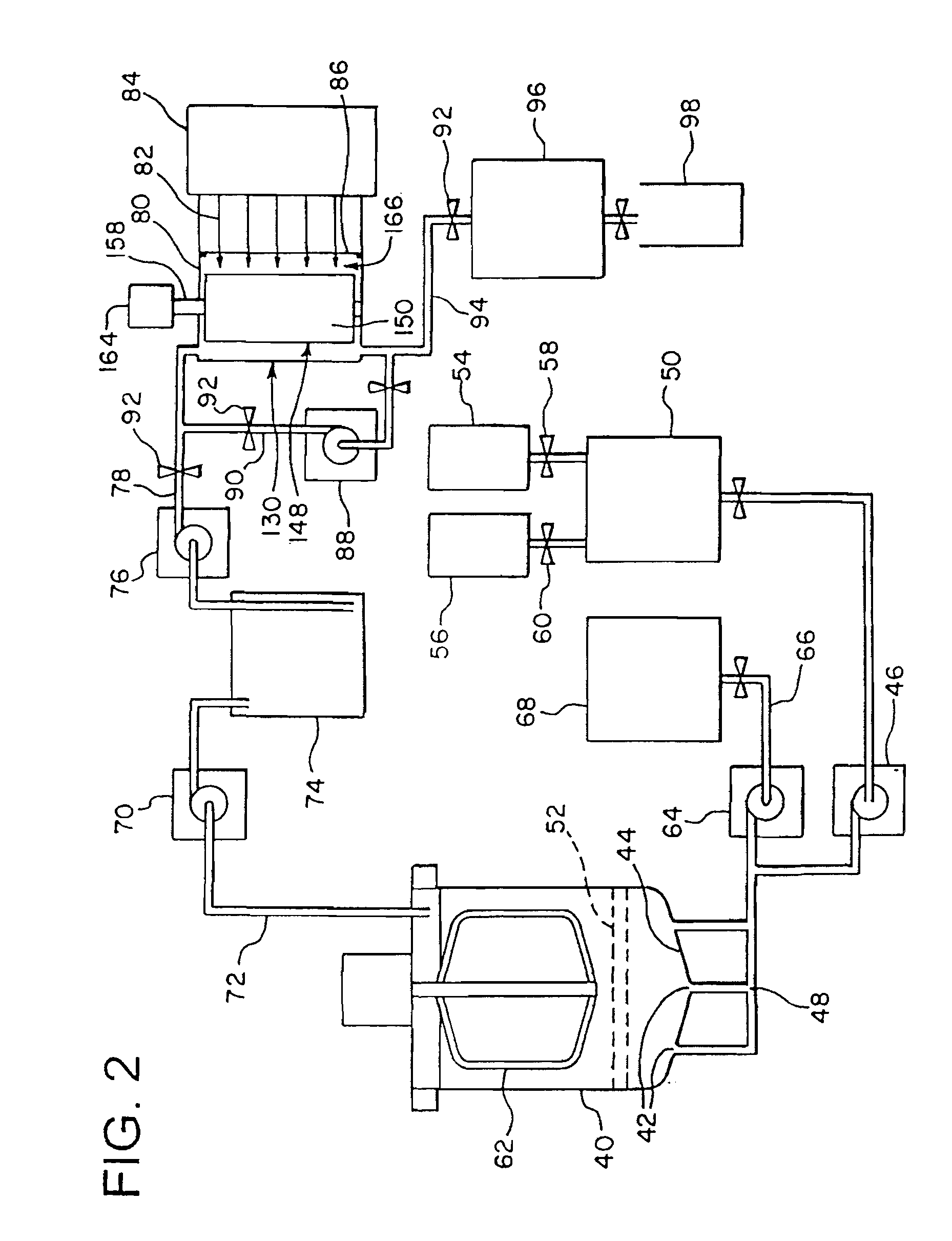

Process for the solvent extraction for the radiolysis and dehalogenation of halogenated organic compounds in soils, sludges, sediments and slurries

InactiveUS7175816B2Highly uniform radiation doseEfficiency and output powerSolvent extractionTransportation and packagingAlkaneSludge

A process of extracting halogenated organic compounds, and particularly PCBs, from soil, sediment, slurry, sludge and dehalogenating the compounds contacts a contaminated soil sample with an extraction medium of a mixture of an alkane and a water miscible alcohol. The organic compounds dissolve in the extraction medium which is separated from the soil by passing water upwardly through the soil. The extraction medium floats to the surface of the water and is separated. Thereafter, the extraction medium containing the halogenated organic contaminants is subjected to ionizing radiation to radiolytically dehalogenate the compounds.

Owner:CLEAN EARTH TECH

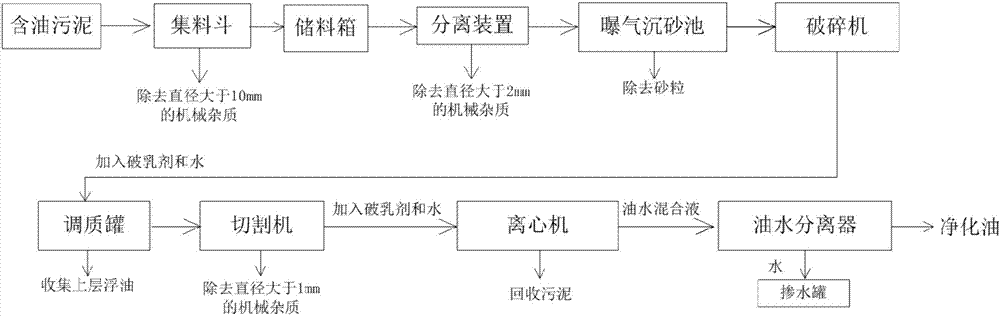

Treatment method of oily sludge

InactiveCN107253810AEfficient use ofTake advantage ofSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningDemulsifierSludge

The invention discloses a treatment method of oily sludge, and belongs to the sludge treatment field. The method includes steps of removing mechanical impurities of which diameter in the oily sludge is more than 2 mm; performing aeration and sand setting treatment on the oily sludge; smashing the oily sludge after the sand setting treatment, and then adding demulsifier and water to perform the first oil water separating treatment, so as to collect upper floating oil in the oily sludge; cutting, mixing and extruding the oily sludge after removing the upper floating oil, and removing the mechanical impurities of which diameter in the oily sludge is more than 1 mm; further adding the demulsifier and water and performing a second oil water separating treatment; collecting oil water mixture from the oily sludge; mixing the upper floating oil with the oil water mixture and performing a third oil water separating treatment; acquiring purified oil. The treatment method of oily sludge has good treatment effect of the oily sludge, and can fully use the purified oil, water and mud after being treated.

Owner:PETROCHINA CO LTD

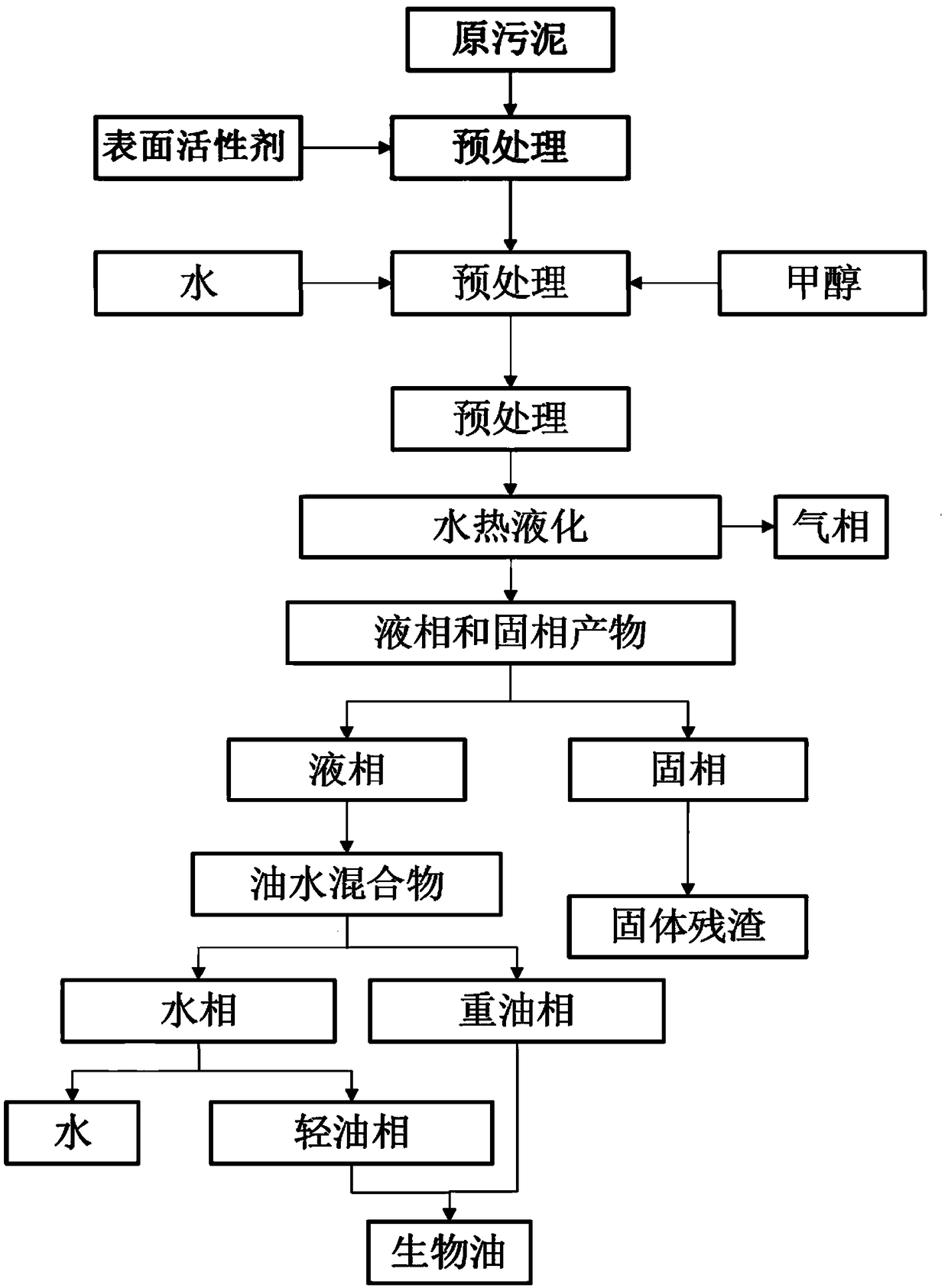

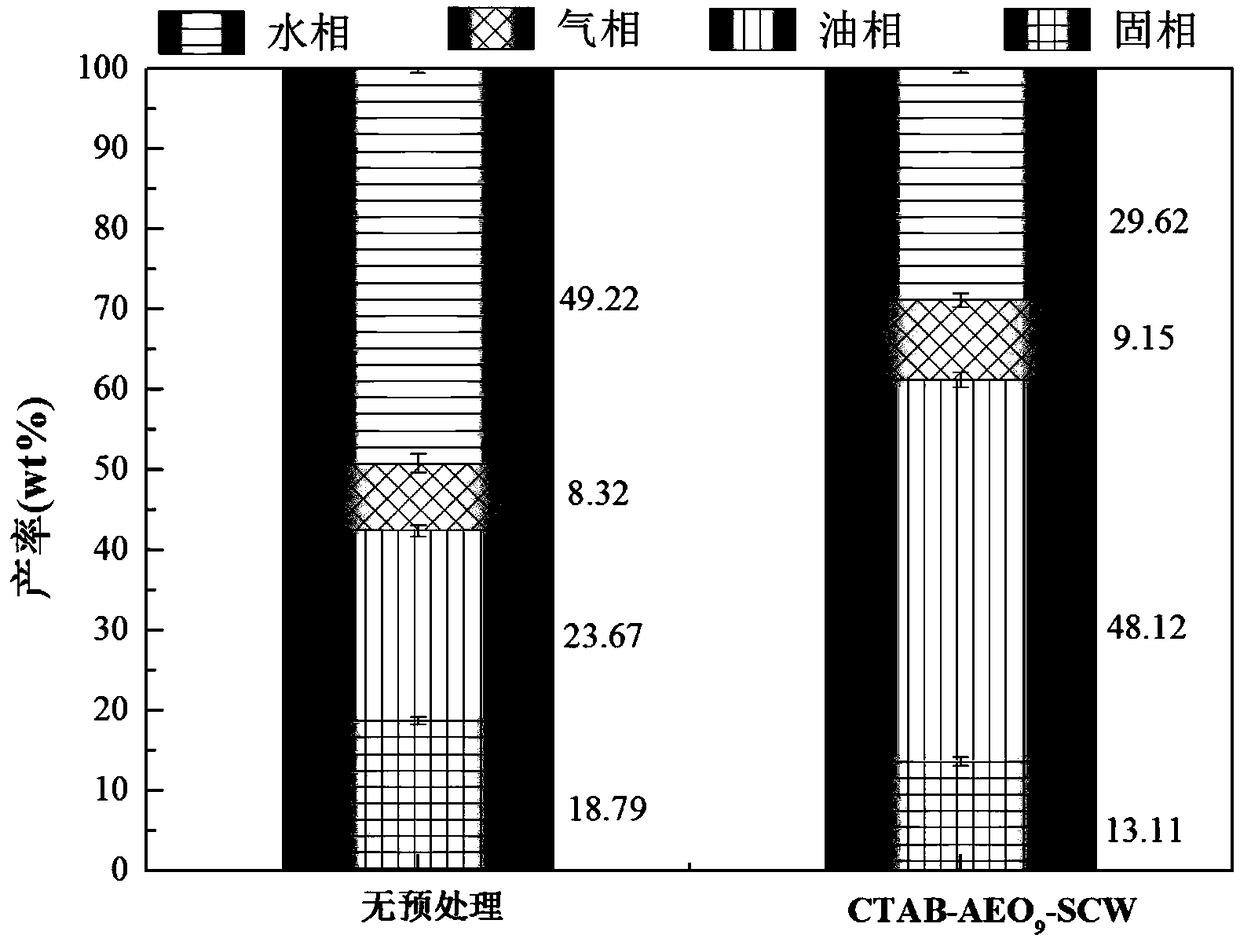

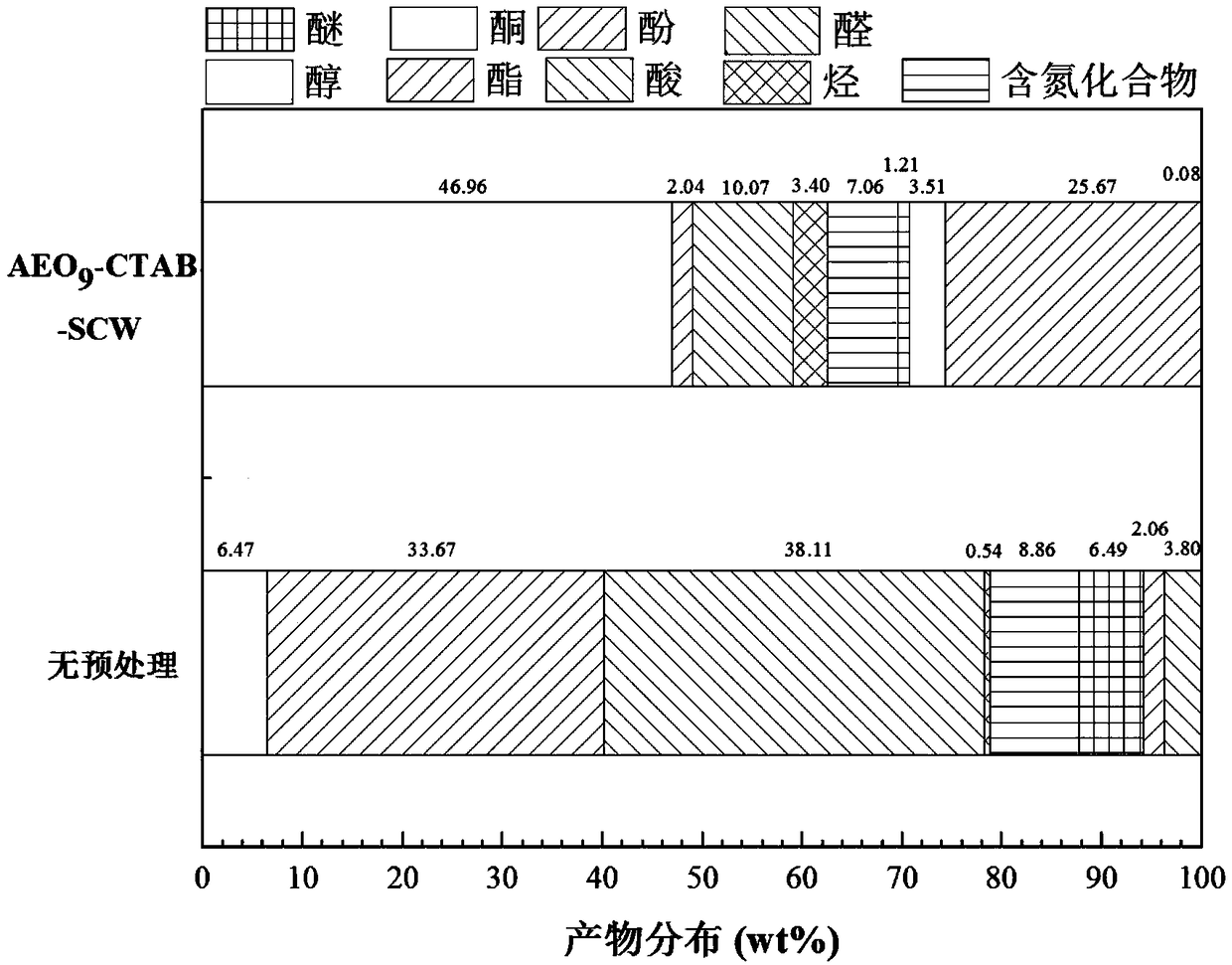

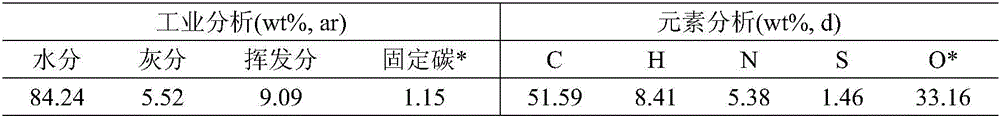

Method of preparing bio-oil through raw material pretreatment and hydrothermal liquefaction

InactiveCN108659876ASource not requiredReduce consumptionWater contaminantsLiquid hydrocarbon mixture productionBound waterSludge

The invention belongs to the technical field of environmental protection and new energy and relates to a novel method of improving quality of biological fuel produced by a biomass hydrothermal liquefaction method, in particular to a method of preparing bio-oil through raw material pretreatment and hydrothermal liquefaction. In order to solve the problems of lower bio-oil productivity and too complicated oil ingredients of the existing sludge hydrothermal liquefaction method, the novel method of preparing biological fuel through chemical pretreatment-hydrothermal liquefaction is developed according to a removal effect of two-step pretreatment of CTAB, AEO9 and subcritical water on bound water in sludge and a modification effect of a methanol cosolvent on the bio-oil.

Owner:SHENYANG AEROSPACE UNIVERSITY

Biological cleaning agent for treating oily sludge and use method

ActiveCN108298780AGood cleaning activityEasy to manufactureSludge treatment with immiscible liquidsEnvironmental resistanceSludge

The invention belongs to the field of solid waste treatment and particularly relates to a biological cleaning agent for treating oily sludge and a use method. The active component of the biological cleaning agent is mono-rhamnolipid, and the concentration of mono-rhamnolipid in the biological cleaning agent is 0.01wt%-0.2wt%. The cleaning agent for the oily sludge is green, environment-friendly, convenient to prepare, good in cleaning effect and wide in application range. The cleaning method based on the cleaning agent has low consumption and can be used for treating oily sludge produced during petroleum extraction, gathering and transportation, refinement and the like.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

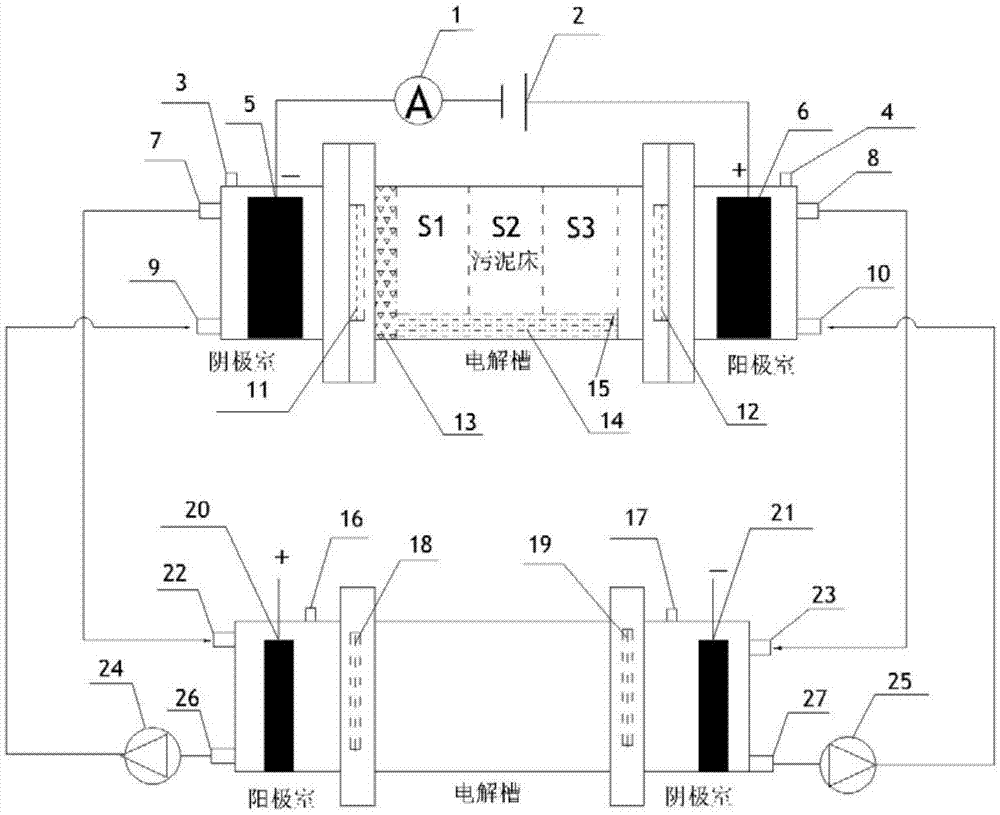

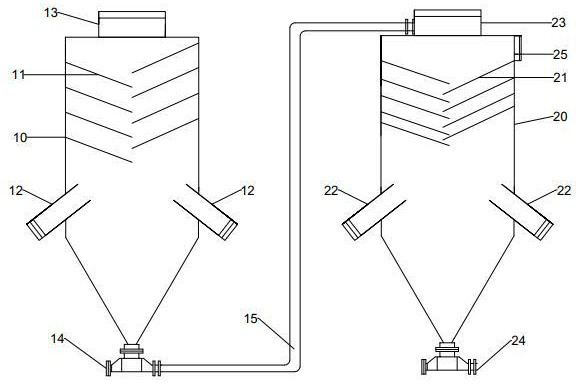

Electrokinetic remediation enhancing device and method using same to remove heavy metal in sludge

ActiveCN106904799AImprove electric repair rateSolving Migration DifficultiesWater contaminantsSludge treatment with immiscible liquidsTransfer cellSludge

The invention discloses an electrokinetic remediation enhancing device and a method using same to remove heavy metal in sludge. The electrokinetic remediation enhancing device comprises an electrokinetic remediation system and a pH (potential of hydrogen) control system, wherein the electrokinetic remediation system comprises an electrokinetic remediation electrolytic bath, a cathode electrolytic cell and an anode electrolytic cell; the cathode electrolytic cell and the anode electrolytic cell are positioned at two ends of the electrokinetic remediation electrolytic bath; an ion enhancing transfer cell and activated carbon are arranged in the electrokinetic remediation electrolytic bath. The method using the electrokinetic remediation enhancing device to remove the heavy metal in the sludge comprises the following steps of (1) sludge pretreatment: pretreating a wet sludge sample by 0.5 to 3mol / L of sulfuric acid, so as to obtain the sludge with the water content of 70 to 85%; (2) putting the pretreated sludge into the ion enhancing transfer cell of the electrokinetic remediation electrolytic bath layer by layer; (3) energizing for 3 to 10 days under the condition of potential gradient of 0.5 to 2V / cm, and controlling the pH (potential of hydrogen) value of a catholyte to 2 to 4. The electrokinetic remediation enhancing device and the method have the advantages that the problem of difficulty in transfer of metal ions in the sludge is solved, and the electrokinetic remediation rate of the heavy metal in the sludge is improved.

Owner:有研资源环境技术研究院(北京)有限公司

Method for treating oily sludge by biological extraction agent and application of method

ActiveCN106977064AImprove cleaning rateCause secondary pollutionLiquid hydrocarbon mixture productionSludge treatment with immiscible liquidsOil sludgePetrochemical

The invention provides an application method and a process for a biological extraction agent in oily sludge treatment. Lemon olefins are adopted for treating oily sludge at the bottoms of tanks for petroleum, petrochemical and coal chemical industries, impurity oily sludge of pipelines and soil polluted by the oily sludge; the application method and the process are used for treating the oily sludge of different types, extracting petroleum from oil sand, and the like. The application method and the process disclosed by the invention are also suitable for extracting crude oil in oil sand, have the characteristics of high recovery rate, low energy consumption and short soil second ploughing time, and have no secondary pollution to environment.

Owner:柴海林

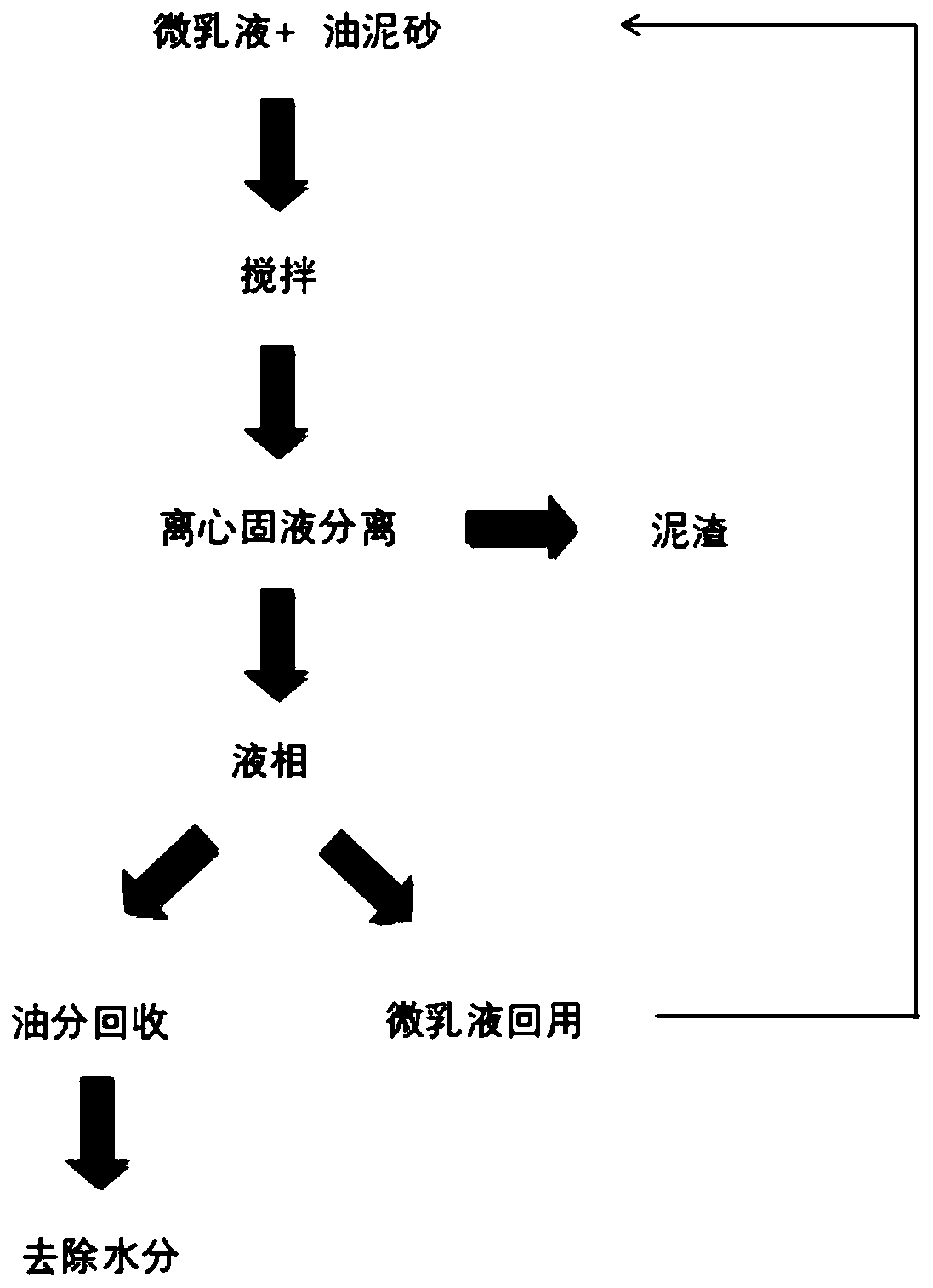

Method for cleaning oiled sand and recovering crude oil

ActiveCN110760328AReduce adhesionEfficient removalWaste water treatment from quariesLiquid hydrocarbon mixture productionInorganic saltsFluid phase

The invention relates to a method for cleaning oiled sand. The method comprises the following steps: (1) mixing a surfactant, an oil phase, an aqueous phase, an inorganic salt and a co-surfactant so as to prepare a microemulsion; (2) mixing the microemulsion prepared in the step (1) with to-be-cleaned oiled sand in a container, and sealing the container; (3) stirring the mixture in the step (2) soas to achieve elution of oil in the oiled sand through the microemulsion; (4) performing centrifugal separation on the washed mixture in the step (3) so as to achieve solid-liquid separation and obtain oil-removed sand and a liquid phase, wherein the liquid phase is a mixture of the microemulsion and oil; (5) separating the oil from the liquid phase separated in the step (4) so as to obtain the microemulsion which is used once; (6) repeating operation from the step (2) to the step (5) on the microemulsion which is obtained in the step (5) and is used once; and (7) merging the oil separated inthe step (5), and removing water.

Owner:CHINA PETROLEUM & CHEM CORP +1

PHOTOCHEMICAL PROCESS FOR THE LIQUID PHASE DESTRUCTION OF POLYCHLORINATED BIPHENYL COMPOUNDS, POLYCHLORINATED DIBENZO-p-DIOXIN, AND POLYCHLORINATED DIBENZOFURAN CONTAMINATED SLUDGES AND SOILS

InactiveUS20150136710A1Improve efficiencyExcellent solventSludge treatment by de-watering/drying/thickeningWater/sewage treatment by irradiationPolychlorinated biphenylSludge

A method or process is provided for treating contaminated sludge or soil that includes adsorbed polychlorinated biphenyl compounds (PCB) and polychlorinated dibenzo-p-dioxins and polychlorinated dibenzofurans (collectively termed “dioxin-furans compounds”), the method includes pulverizing the sludge or soil and thereafter directing the sludge or soil to an extraction tank where the PCB and dioxin-furan compounds are extracted from the sludge or soil and are caused to become dissolved in a solvent. The treated sludge or soil is separated from the solvent and the solvent is subjected to an ultraviolet irradiation process that destroys the PCB and dioxin-furan compounds.

Owner:AIR CONTROL TECHN P C

Oily sludge treatment agent, use method and oily sludge cleaning method

InactiveCN111333289AHigh viscosity reduction propertiesEasy to cleanSludge treatment by oxidationWater contaminantsSludgeActive agent

The invention relates to an oily sludge treatment agent, which comprises the following components based on the mass of oily sludge: 1-4wt% of a viscosity reducer, 1-6wt% of mahogany petroleum sulfonate, 1-6wt% of sodium dodecyl benzene sulfonate, 2-6wt% of sodium silicate and 1-3wt% of an oxidant. Specifically, the viscosity reducer can effectively reduce the viscosity of oily sludge caused by long-time storage, and the stripping effect of the crude oil after viscosity reduction is remarkable. The oxidant effectively decomposes microbial metabolites wrapped on the surfaces of sludge particlesunder the action of heating and ultrasonic reaction, so that the cleaning effect of the oily sludge is improved. An emulsifying agent, a surfactant, a dispersing agent and other surfactants can effectively emulsify the crude oil to achieve the effects of solid-liquid layering, crude oil recovery and sediment solidification. The oily sludge treatment agent provided by the invention has a remarkabletreatment effect on oil field oily sludge sediment like landing mud and tank bottom mud, and the oil content of the treated sludge sediment is smaller than 2%, thus meeting the national standard.

Owner:中洁环淼(江苏)环境科技有限公司

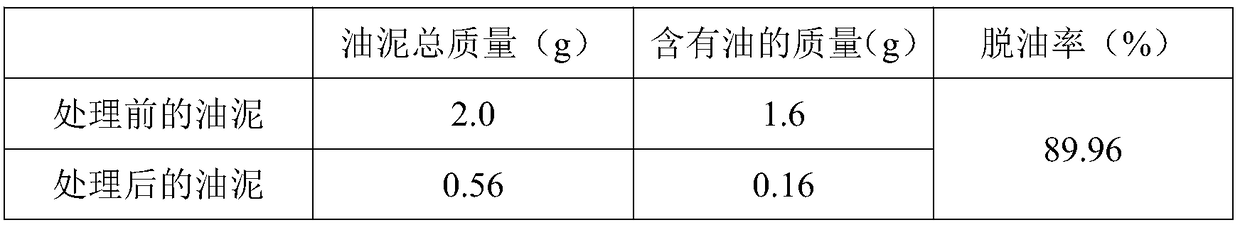

Oil-containing sludge cleaning agent, and cleaning method

ActiveCN109179929AImprove environmental friendlinessRaw materials are easy to getWater contaminantsSludge treatment with immiscible liquidsSodium bicarbonateSludge

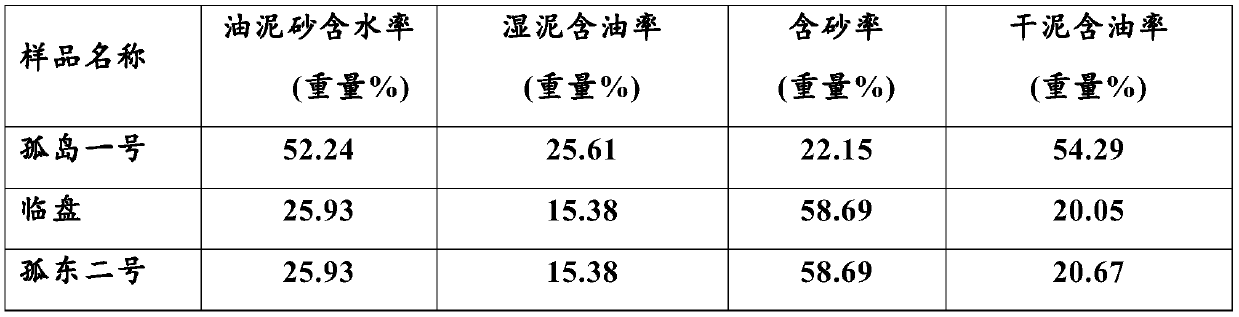

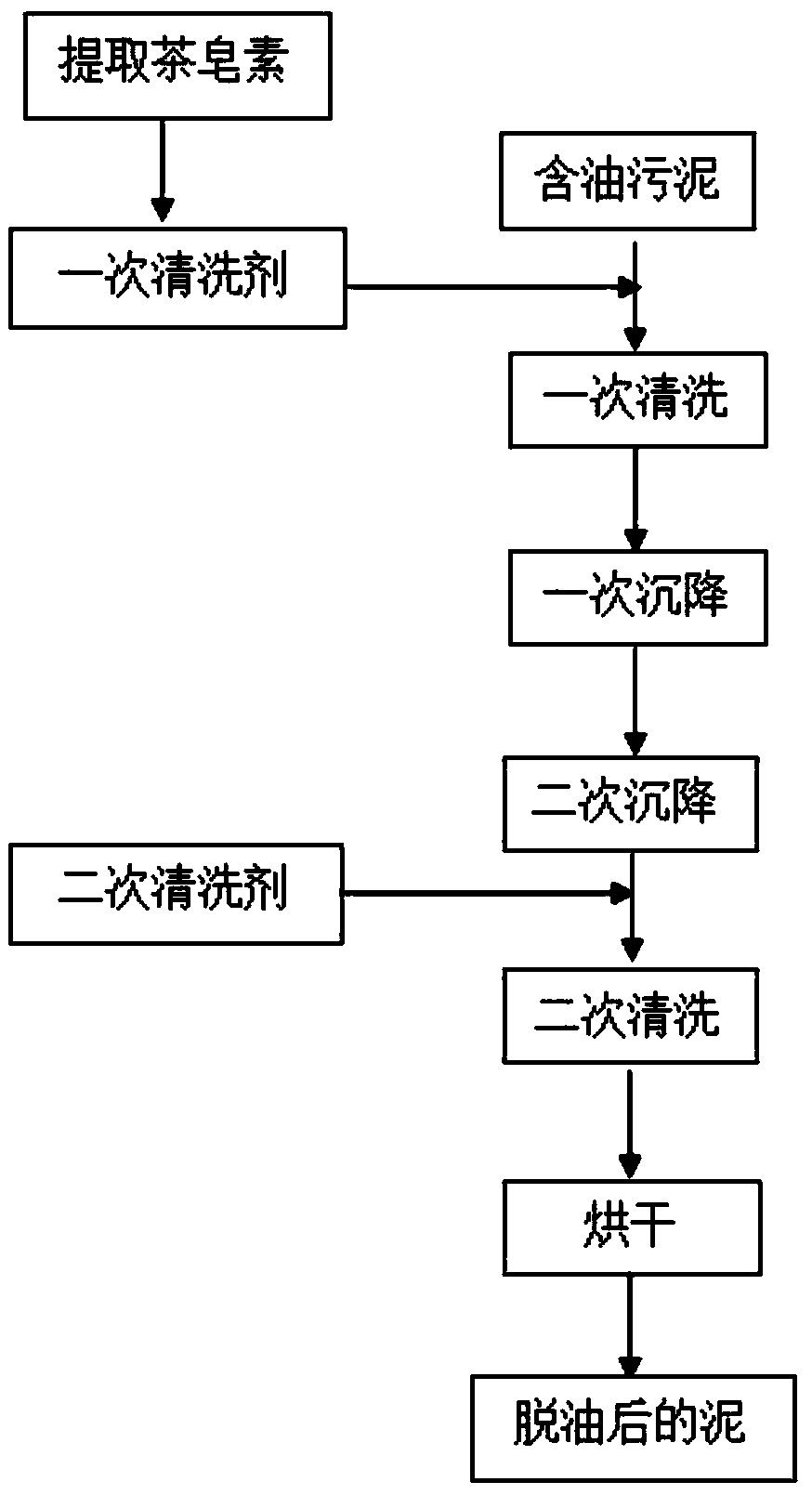

The invention discloses an oil-containing sludge cleaning agent. The oil-containing sludge cleaning agent comprises a primary cleaning agent and a secondary cleaning agent; the primary cleaning agentcontains tea saponin, sodium silicate, fatty alcohol polyoxyethylene ether, and sodium bicarbonate; the secondary cleaning agent comprise fatty alcohol polyoxyethylene ether, and sodium bicarbonate; the primary cleaning agent is prepared through dissolving of tea saponin, sodium silicate, fatty alcohol polyoxyethylene ether, and sodium bicarbonate in water; and the secondary cleaning agent is prepared through dissloving fatty alcohol polyoxyethylene ether, and sodium bicarbonate in water. The cleaning method used for washing oil-containing sludge comprises following steps: primary cleaning, primary settlement, secondary settlement, secondary cleaning, and drying. The oil-containing sludge cleaning agent cleaning process is simple, is high in efficiency, and low in comprehensive energy consumption; 80 to 90% of oil in oil-containing sludge can be washed away, and the highest oil removing rate is 90% or higher.

Owner:SOUTHWEST PETROLEUM UNIV

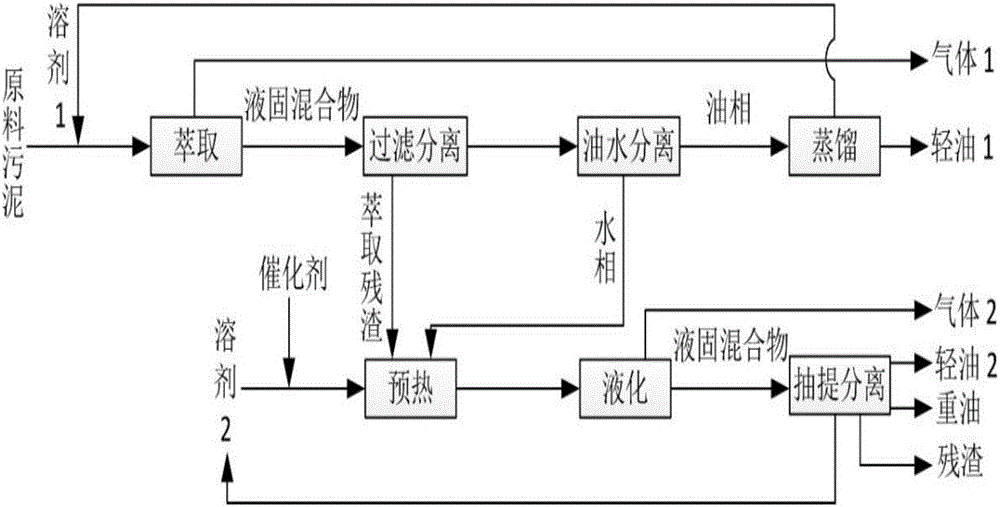

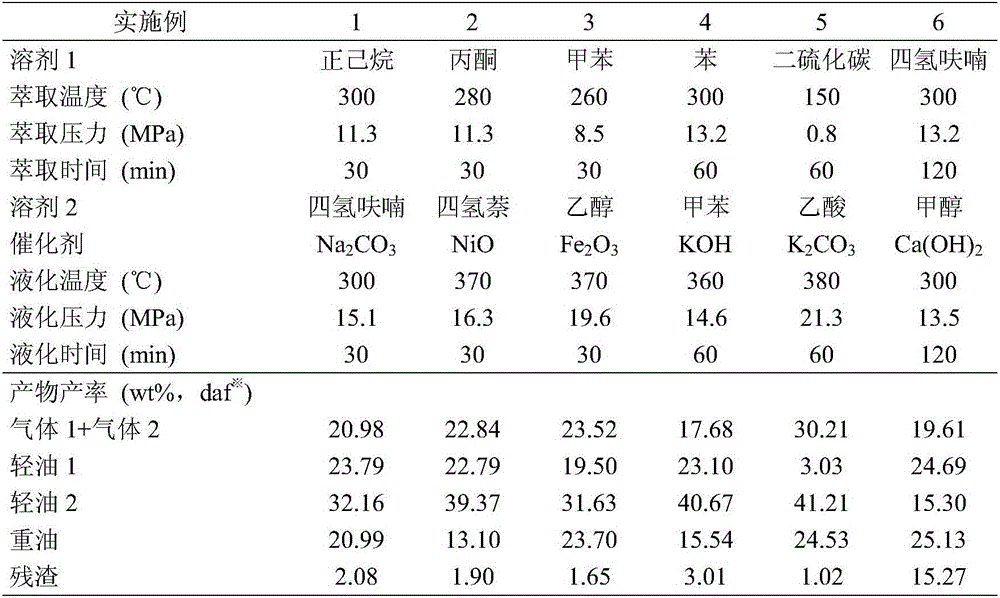

Technique for producing liquid fuel by graded conversion of sludge

InactiveCN106477831ARealization of resource conversionRealize energy utilizationLiquid hydrocarbon mixture productionSludge treatment with immiscible liquidsSludgeLiquid fuel

The invention discloses a technique for producing liquid fuel by graded conversion of sludge, comprising the steps of proportionally mixing sludge and solvent 1, performing extractive reaction at certain temperature, and isolating to obtain gas 1, extraction liquid mixture and extraction residue, subjecting the extraction liquid mixture to phase isolation to obtain oil and water, distilling the oil to obtain the solvent 1 and light oil 1, performing liquefaction reaction on the water, extraction residue, a catalyst and solvent 2 under certain conditions, and isolating to obtain gas 2, the solvent 2, light oil 2, heavy oil and residue. Light organic components in sludge are directly extracted as liquid fuel under mild temperature and pressure; water and residue produced by extracting are mixed for liquefaction reaction under high temperature and pressure to further produce liquid fuel, to be specific, organic components in the sludge are isolated and then subjected to graded conversion through two-step process, and high-added-value liquid fuel is finally obtained.

Owner:EAST CHINA UNIV OF SCI & TECH

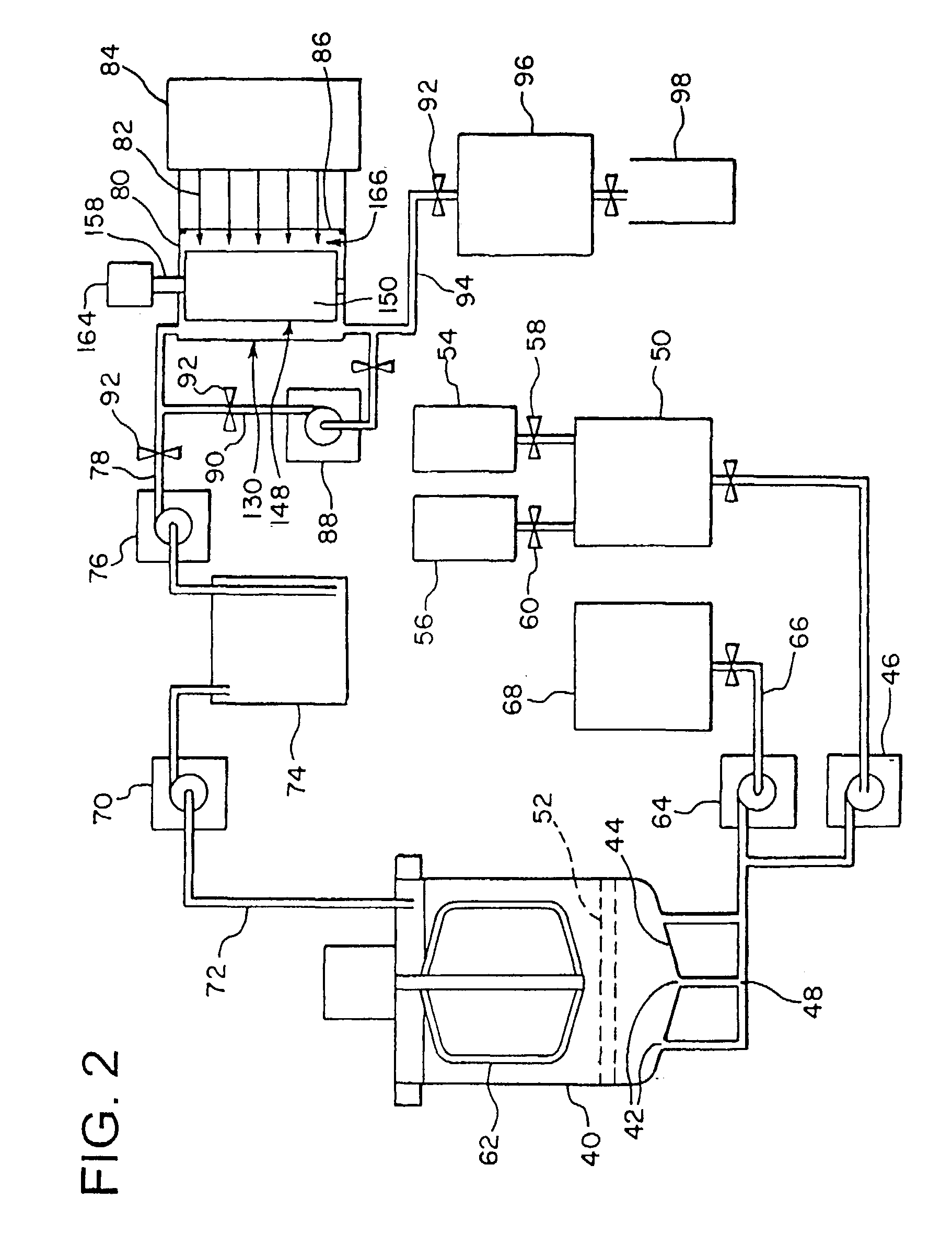

Hydrocarbons environmental processing system method and apparatus

InactiveUS9669340B2Reduce stepsDisintegration is not improvedSolid sorbent liquid separationLoose filtering material filtersCost effectivenessFiltration

Owner:ROBINSON DAVID

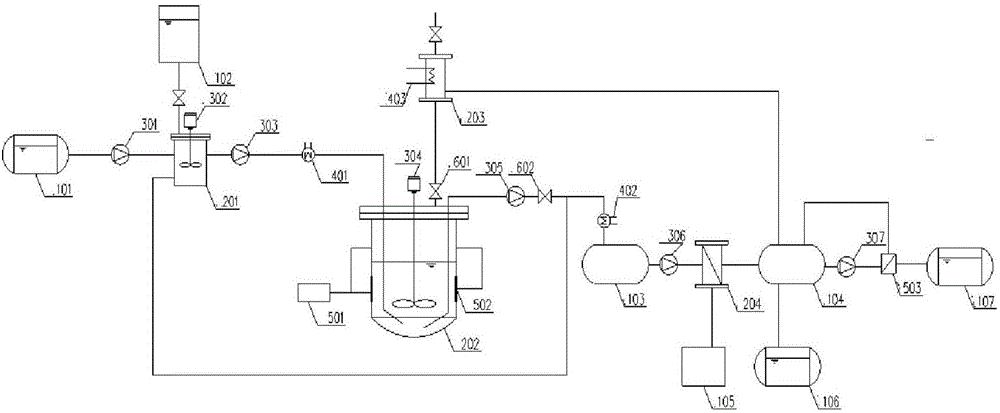

Device and process for treating chemical dangerous and waste sludge

ActiveCN106277676AAvoid corrosionAvoid the problem of industrial scale-upSludge treatment by thermal conditioningSludge treatment with immiscible liquidsSludgeHigh pressure

The invention belongs to the technical field of chemical sludge treatment, and particularly relates to a device and process for treating chemical dangerous and waste sludge. The device comprises a storage trough A, a high-position storage trough, a storage tank, a mixed oil tank, a storage trough B, a finished oil storage trough, a sewage storage tank, a mixed tank, a reaction still, a condensation tank, a screw pump, a stirrer A, a high-pressure plunger pump, a stirrer B, a high-pressure pump, a sludge pump, a chemical pump, a preheater, a circulating water cooling device, a circulating water condensation device, an ultrasonic generator, a transducer, a cross-flow ceramic film assembly and a reducing valve. Compared with the prior art, the device and process have the advantages that the problems of reaction still corrosion and hard industrial amplification caused by super criticality are avoided; generated solid waste is reduced; a reflux device is additionally arranged, the use amount of a solvent is reduced, and the solvent residual amount in oil and water is reduced; the problems of high cost and large secondary pollution are avoided.

Owner:王焕升

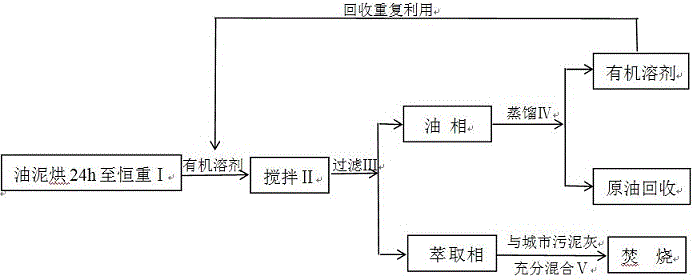

Method for recovering crude oil in petroleum oil sludge and comprehensively recycling residual mud and sand

InactiveCN105621833AAvoid secondary pollutionAvoid wastingSludge treatment by de-watering/drying/thickeningLiquid hydrocarbon mixture productionOrganic solventDistillation

The invention discloses a method for recovering crude oil in petroleum oil sludge and recycling residual mud and sand. The method comprises the steps of A, pretreatment-crude oil extraction-co-incineration: drying the oil sludge to a constant weight at a certain temperature and measuring a heat value of the oil sludge; B, a crude oil extraction process: mixing the oil sludge with an organic solvent according to a certain weight ratio, stirring at a certain temperature, and filtering to obtain oil phase and raffinate phase oil sludge; C, an organic solvent recovery process: selecting a boiling point of the organic solvent, recovering the organic solvent at 100 DEG C under the normal pressure through a distillation recovery device, and recycling the organic solvent; and D, a co-incineration process: drying the raffinate phase oil sludge, mixing the dried raffinate phase oil sludge with municipal sludge ash according to a certain ratio, measuring a heat value of a mixture, and performing incineration at 800-1,000 DEG C. The method is easy to implement and simple and convenient to operate; the crude oil subjected to extraction is recycled; the residual raffinate phase oil sludge still can take effects and is subjected to co-incineration together with the municipal sludge ash; and the heat value of the oil sludge is fully utilized.

Owner:WUHAN TEXTILE UNIV

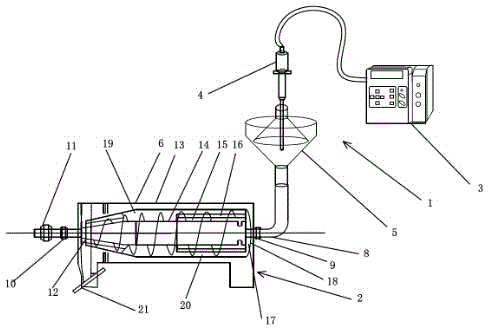

Treatment technology for recovering and separating oily sludge

ActiveCN104556599AFast separationEasy to separateSpecific water treatment objectivesLiquid hydrocarbon mixture productionSludgeActive agent

The invention relates to the technical field of petroleum separation, in particular to a treatment technology for recovering and separating oily sludge. The treatment technology comprises the following specific steps: firstly, adding 50 parts of oily sludge, 50 parts of a sodium hydroxide solution with the pH of 12 and 2.6 parts of an active agent to a sludge hopper, carrying out mixing treatment by virtue of an ultrasonic extracting instruction at the frequency below 20KHz for 10-30 minutes, and feeding a mixture into a centrifugal separator, wherein the rotating speed of a spiral pushout rod in the centrifugal separator is 4,000-5,000r / min; the treatment time of the mixture in the centrifugal separator is 10-20 minutes; and the temperature in the centrifugal separator is controlled to 50-60 DEG C. The technology disclosed by the invention is high in separation speed and good in separation effect, and can reach 95% of separation effect.

Owner:浙江金成环保科技工程有限公司

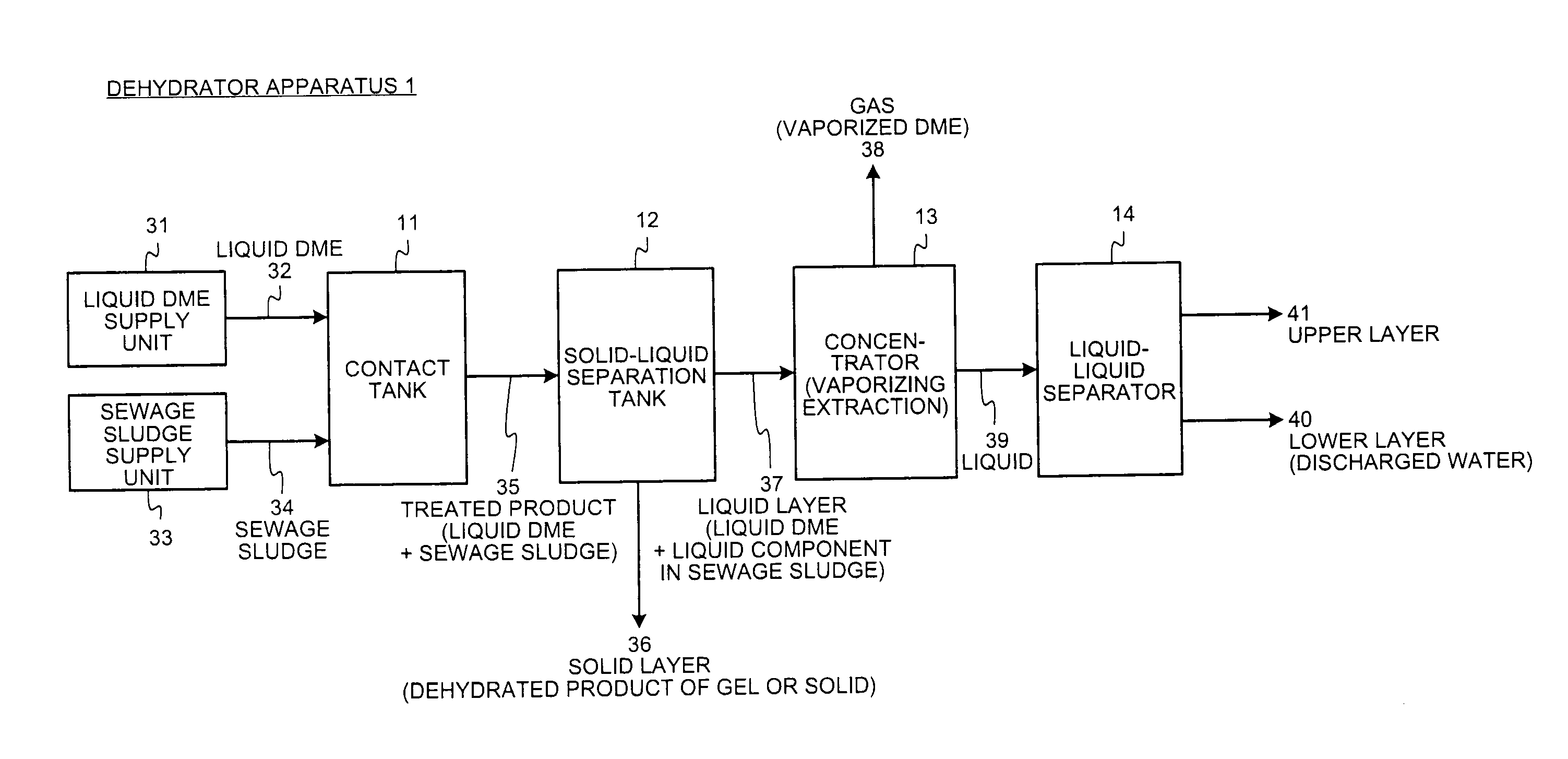

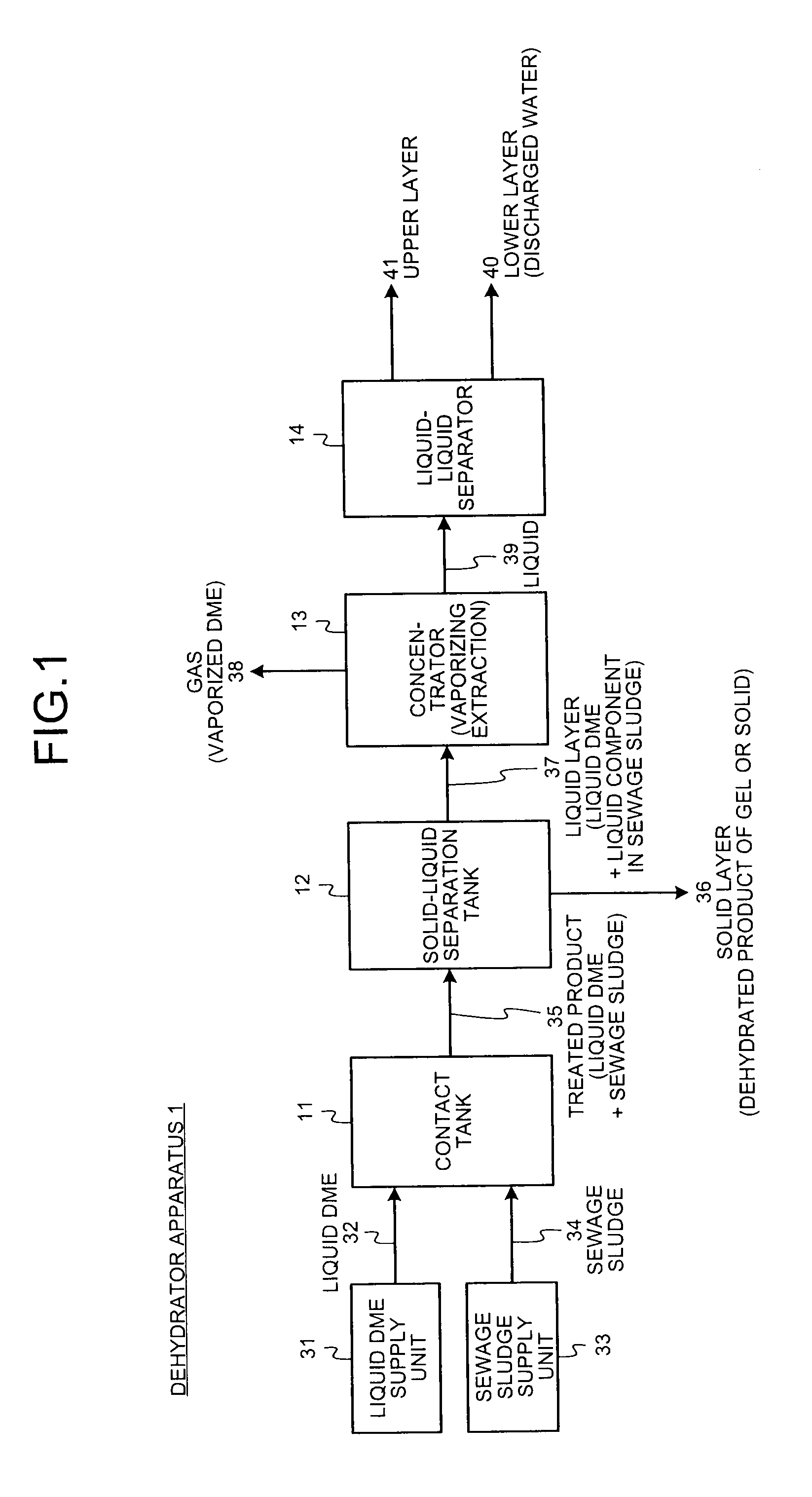

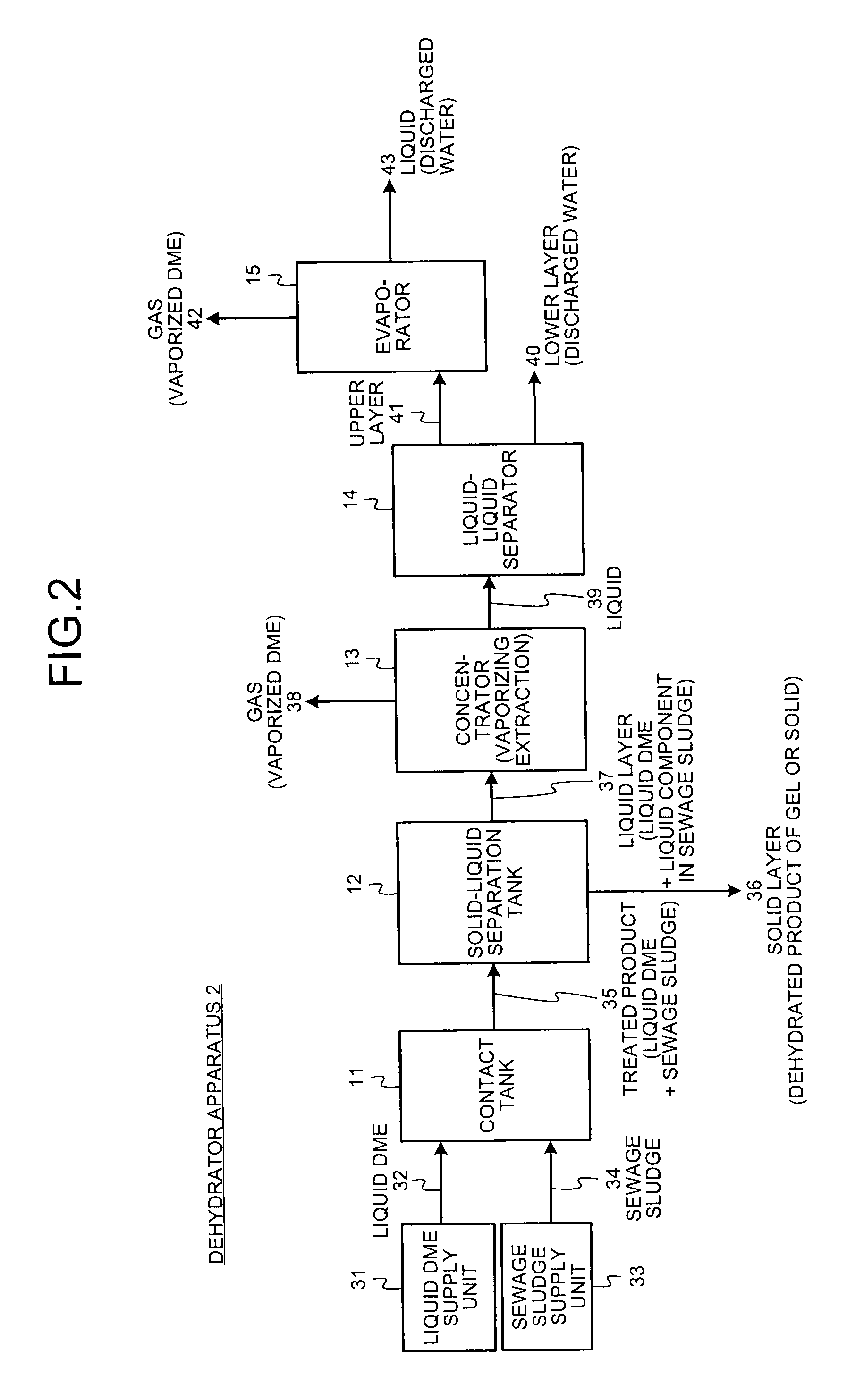

Method for treatment of water-containing material

InactiveUS20100108600A1Easy to transportReduce weightSludge treatment by de-watering/drying/thickeningLiquid degasificationLiquid layerPhysical chemistry

A method and apparatus for treatment of a water-containing material. The method includes: (A) bringing a liquid of a substance in a gaseous state under normal temperature and pressure conditions into contact with a water-containing material; (B) obtaining a liquid layer through solid-liquid separation from a treated product resulting from (A); (C) vaporizing and extracting at least a portion of the substance that is in the gaseous state under normal temperature and pressure conditions as gas from the liquid layer obtained from (B); and (D) collecting a lower layer resulting from liquid-liquid separation conducting on a liquid layer resulting from (C). The method and apparatus achieve efficient treatment of a water-containing material and allow the material after the treatment to be recycled as a resource.

Owner:TSUKISHIMA KIKAI CO LTD

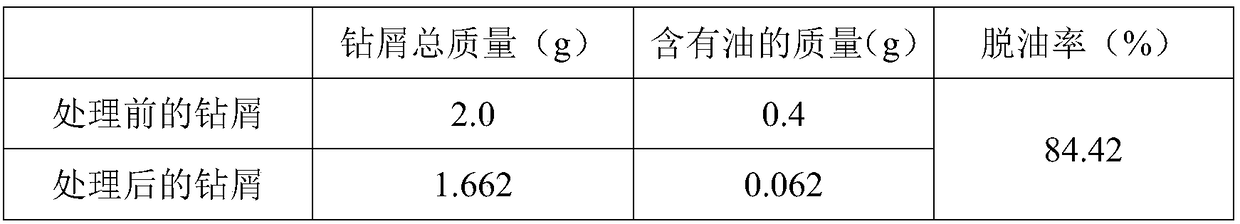

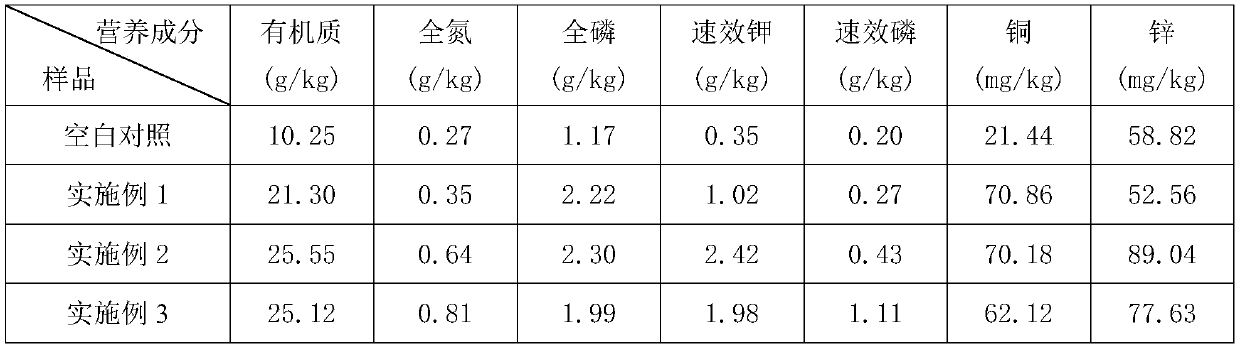

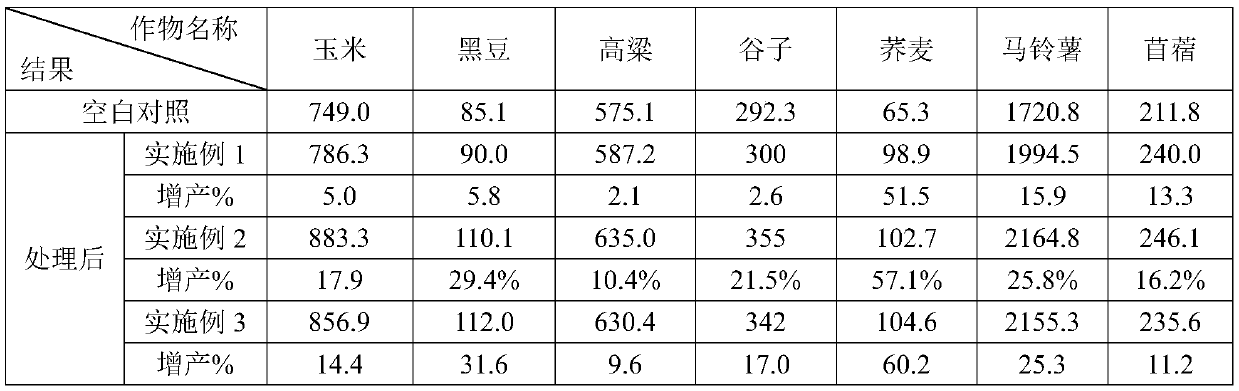

Treatment method for drilling mud cuttings in oil and gas fields

ActiveCN110092554AImprove attributesImprove aggregate structureAgriculture tools and machinesOther chemical processesWell drillingMicrobiologic agent

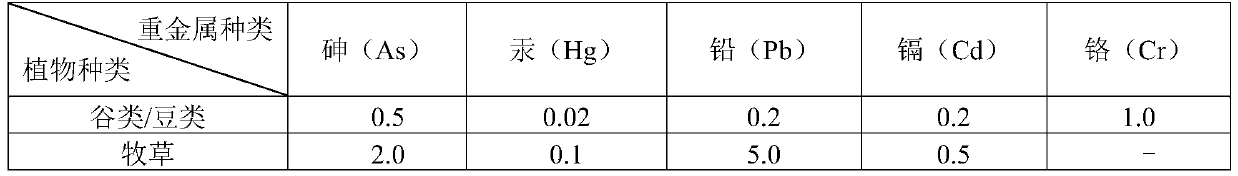

The invention discloses a treatment method for drilling mud cuttings in oil and gas fields, and the treatment method is specifically implemented according to the following steps: step 1, adding crushed straw into the drilling mud cuttings generated in a drilling site, and uniformly stirring; step 2, adding humic acid into the drilling mud cuttings treated in the step 1 to complexe heavy metal ionsin the drilling mud cuttings; and step 3, inoculating the drilling mud cuttings treated in the step 2 with a microbial preparation to finish the treatment of the drilling mud cuttings. The treated drilling mud cuttings are suitable for the production of plants, and improve the yield, quality and nutritional components of the plants, the heavy metal content is within the safety and quality index range of agricultural products, the treated drilling mud cuttings are suitable for planting, waste is changed into valuables, and the treated drilling mud cuttings are environment-friendly and have lowcost.

Owner:陕西同泽人居工程科技有限公司

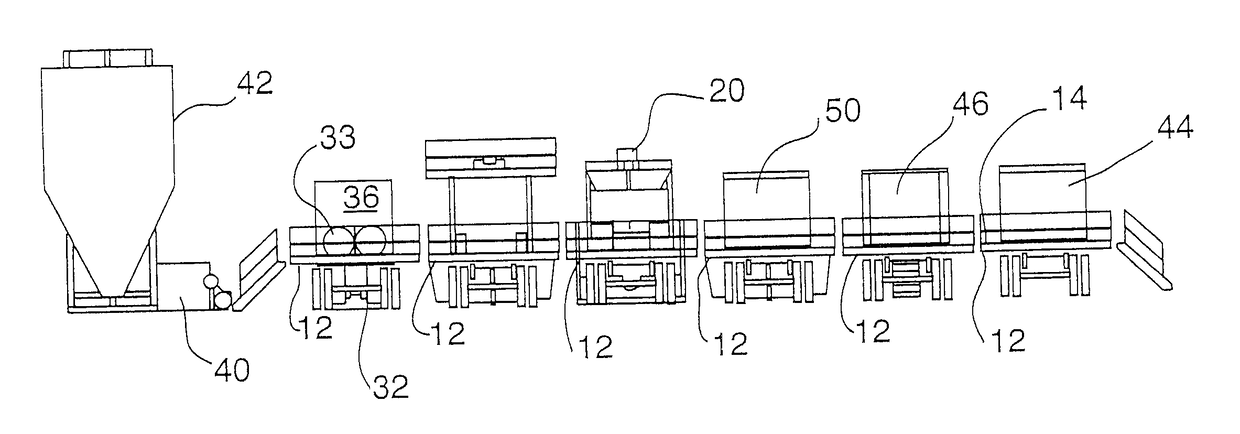

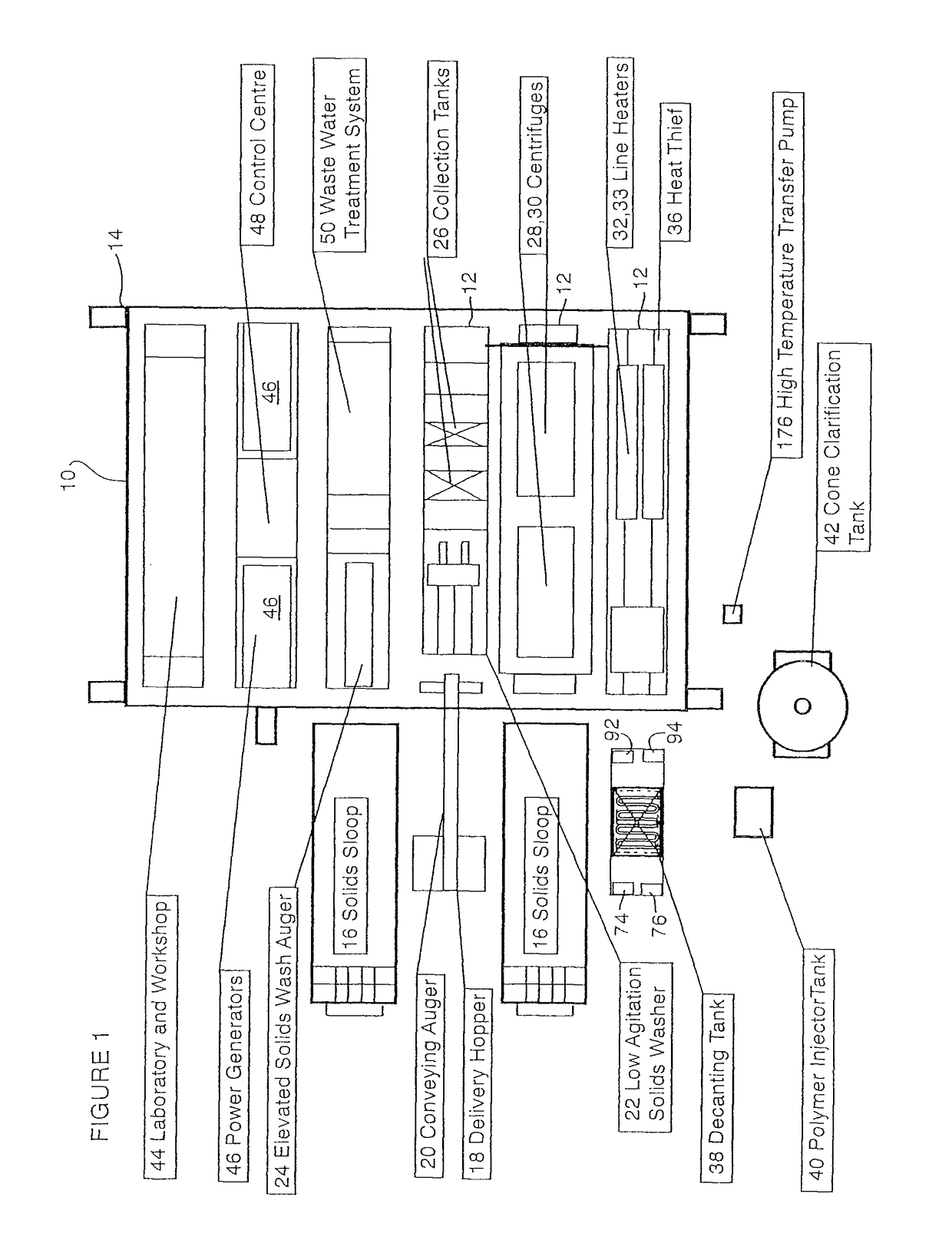

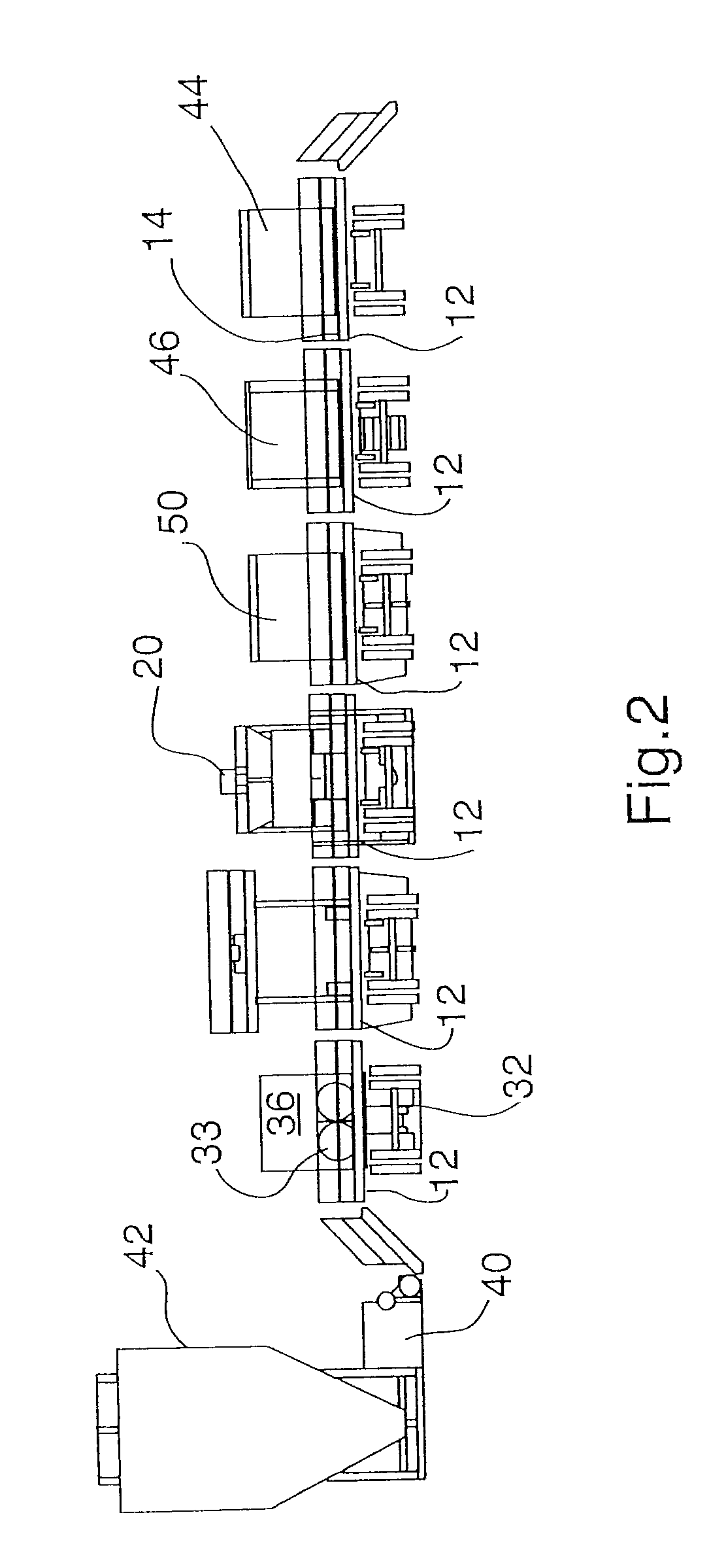

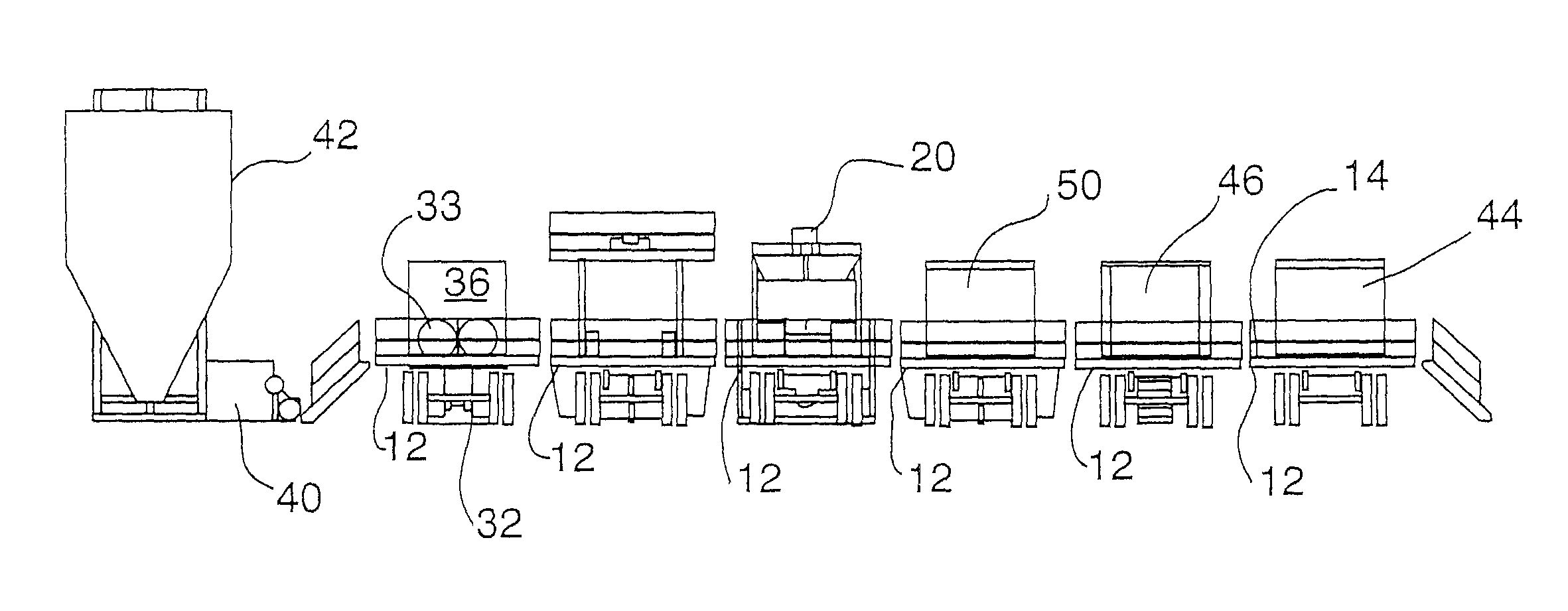

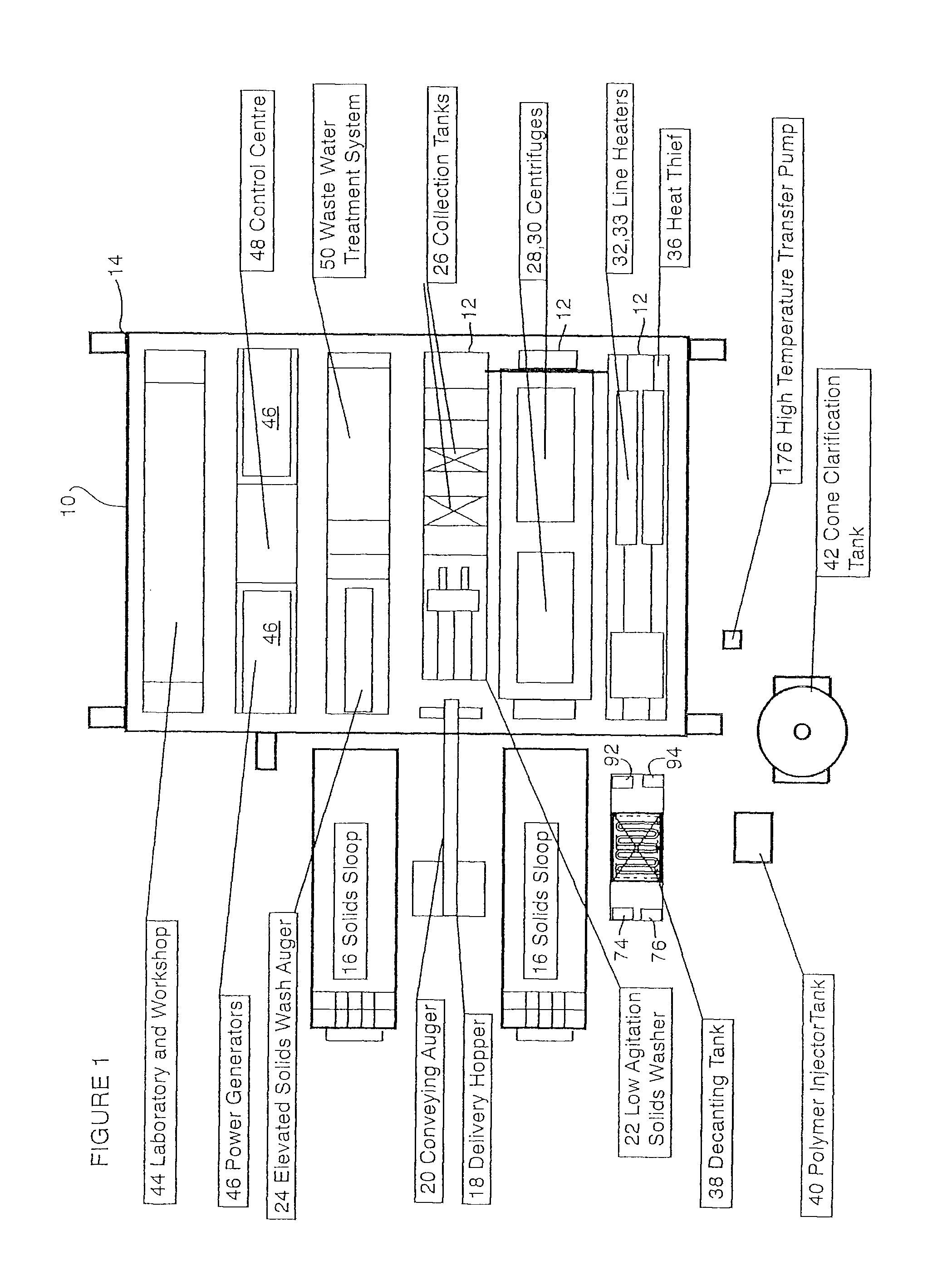

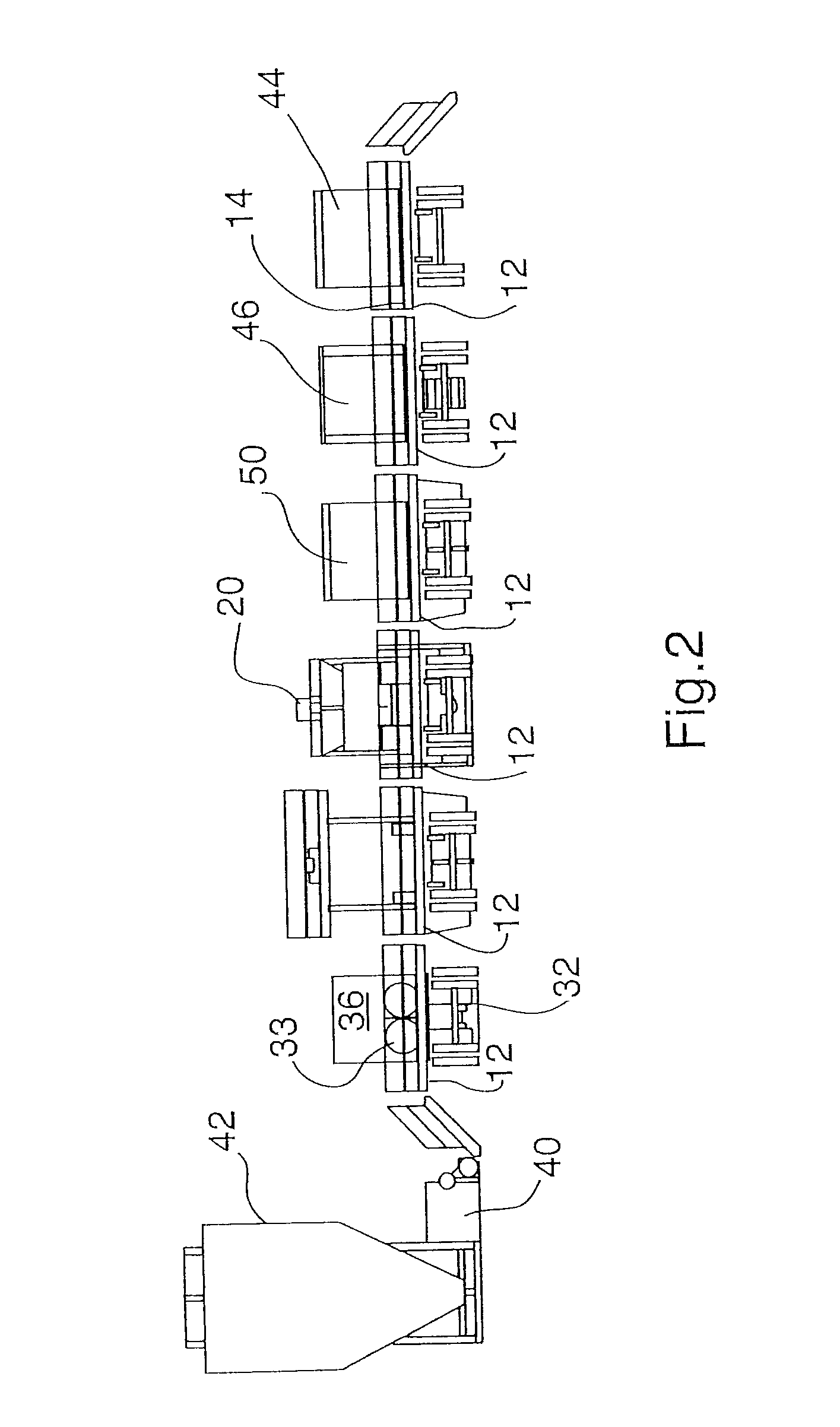

Hydrocarbons Environmental Processing System Method and Apparatus

InactiveUS20130270183A1Reduce stepsDisintegration is not improvedSolid sorbent liquid separationLoose filtering material filtersCost effectivenessFiltration

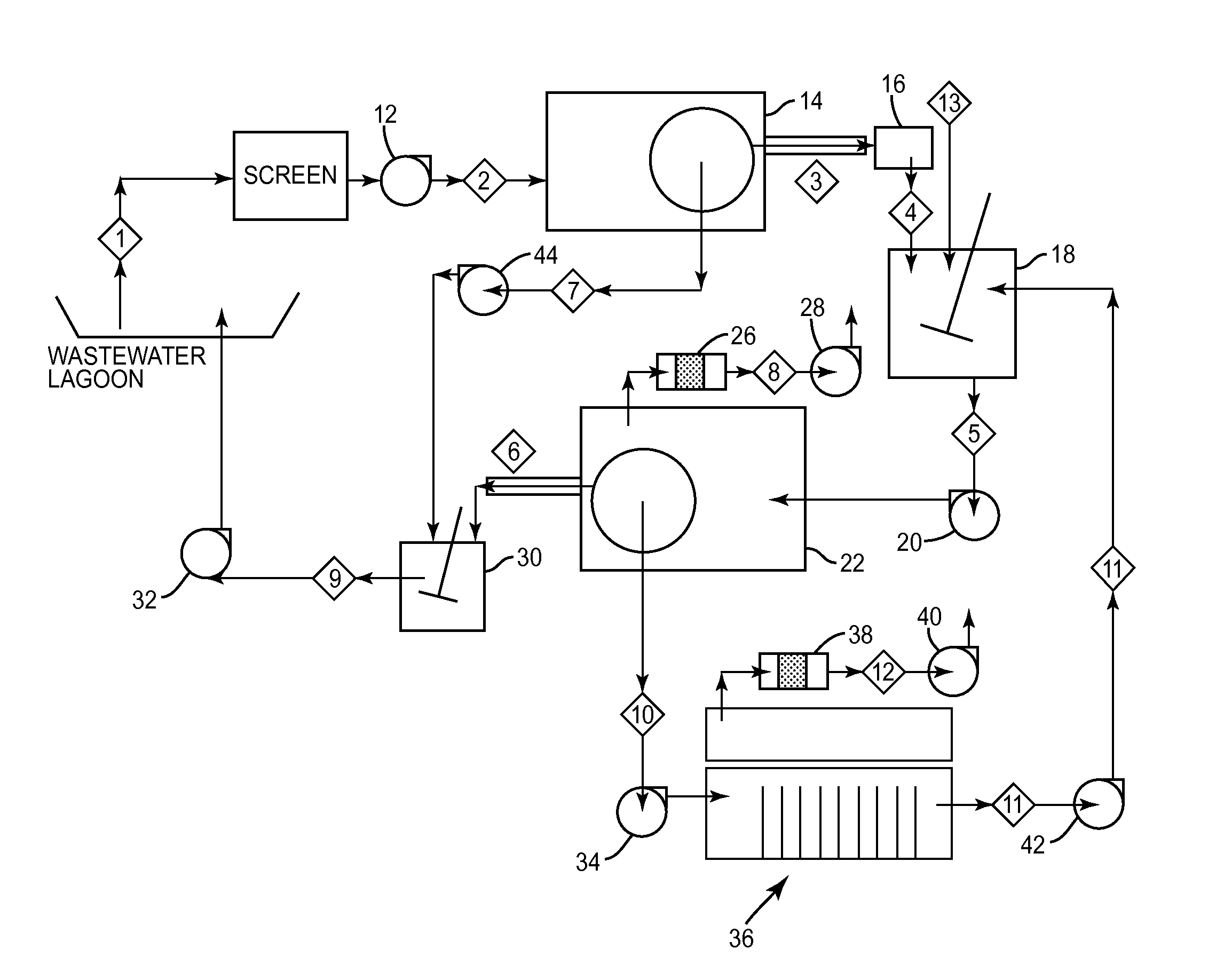

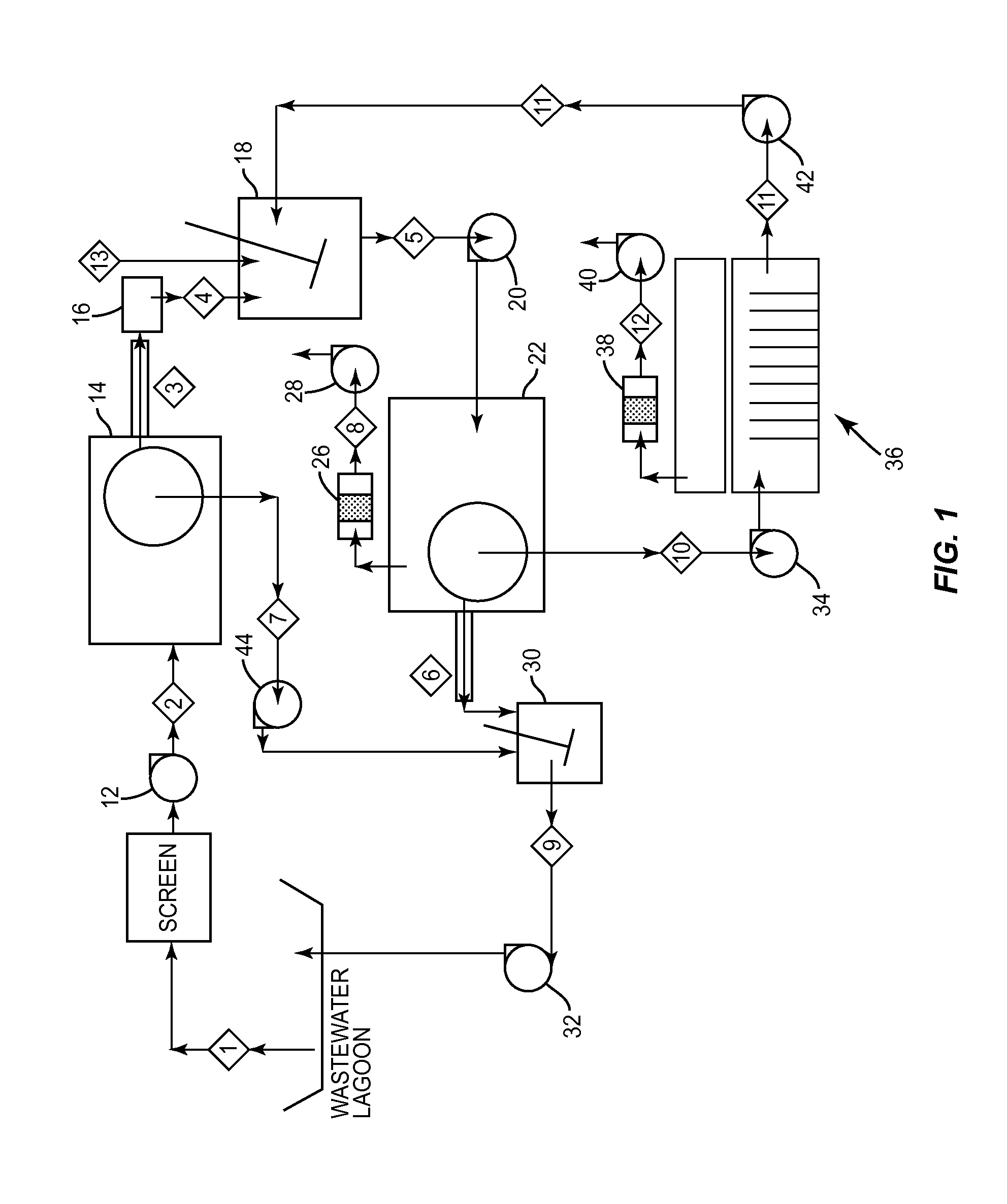

A system, components of the system and methods for processing, combinations of hydrocarbons, water, solids and contaminants, to separate extract, recover, filter and treat the constituent elements to enable the recovery of valuable hydrocarbons, the treatment of solids for environmentally sustainable discharge, the filtration and treatment of water for reuse, or environmentally sustainable discharge, and the extraction of contaminants. The integrated method and system incorporates alternative processing modes, each of which is optimized for the intake and processing of a materials stream which is predominately solids, or predominately water or predominately hydrocarbons, respectively. The system can dynamically adjust to accommodate variations in the composition of the intake materials stream in any particular mode. The system can be implemented in a portable, modular configuration which is cost effective, energy efficient and scalable to enable processing of any volume of materials.

Owner:ROBINSON DAVID

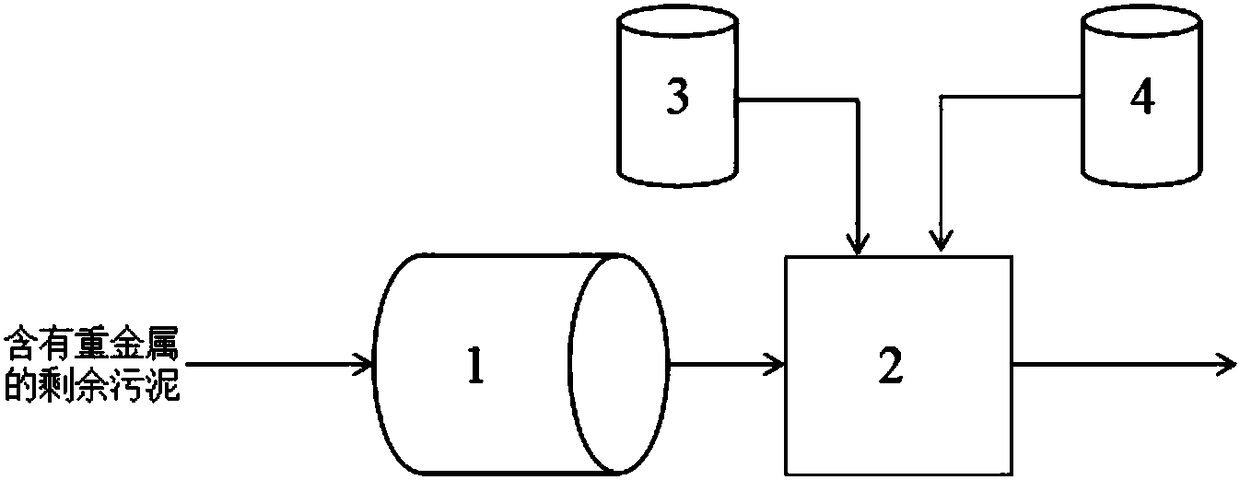

Heavy metal sludge harmless treatment system and method

InactiveCN108726821APromotes anaerobic digestionPromotes anaerobic fermentationWater treatment parameter controlWater treatment compoundsCalcium hydroxideAnaerobic reactor

The invention belongs to the technical field of environment protection difficult treatment heavy metal treatment, and relates to a method for promoting heavy metal treatment in rest sludge. The concrete method comprises the following steps of performing ultrasonic pretreatment on the rest sludge containing heavy metal; then, charging the materials into an anaerobic reaction; adding biosurfactantsand calcium hydroxide into the reactor; performing stirring so that the substances in the reactor are uniformly mixed; meanwhile, controlling the fermentation temperature. The method provided by the invention has the advantages that the treatment and immobilization of the heavy metal in the sludge can be effectively promoted; the pollution of the heavy metal on the environment can be relieved; thefoundation is laid or the land utilization after the anaerobic treatment of the rest sludge; meanwhile, the positive guidance and reference significance can be realized on how to efficiently remove other heavy metal contaminants in the rest sludge.

Owner:HUNAN UNIV

A recycling treatment method for oil field sludge

ActiveCN107098554AAchieve separationHigh recovery rateWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningRotary evaporatorOil sludge

A recycling treatment method for oil field sludge is disclosed. The method is characterized in that the method includes sieving, drying, extraction with petroleum ether being adopted as a solvent, heating and concentration with a rotary evaporator, and vibration and settlement by using a chromatography column; a solid phase which can be used as horticultural soil is obtained after leaching is finished; and a liquid phase is heated and concentrated by the rotary evaporator, a product is collected, and petroleum ether is added into the collected product for cyclic utilization. Solute separation is achieved at the same time of solvent extraction. Through continuous cyclic extraction, the sludge can be used as the horticultural soil, the oil separating and recovering rate is increased, and the treatment process of the oil sludge is overcome.

Owner:武汉巨正环保科技有限公司 +1

Treatment method of oily sludge and sand

ActiveCN113121076AImprove liquidityGuaranteed separation effectSpecific water treatment objectivesLiquid hydrocarbon mixture productionOil sludgeWasher

The invention relates to a treatment method of an oily sludge and sand, which comprises the following steps of: adding oily sludge and sand into a specially designed feeder, forcibly mixing the oily sludge and sand with water after passing through a distribution plate to obtain homogenization treatment, conveying the treated material to a specially designed sand washer, separating out large-particle-size coarse sand particles under the impact of a multi-stage distribution plate and inlet water, conveying to an impeller agitator, under the action of microbubbles generated by an impeller, and settling the materials in a grading manner, wherein the upper scum layer is high-oil-content sludge, and the lower settling layer is low-oil-content sludge. According to the feeder and the sand washer, oil sludge and sand are fully homogenized through the arrangement of multi-stage distribution plates and a water inlet mixing mode, and coarse sand separation is achieved. The oil content of the high-oil-content sludge separated by the method is greater than or equal to 40%, and the water content is less than or equal to 50%; the oil content in the low-oil-content sludge is less than or equal to 6%, and the water content is less than or equal to 40%.

Owner:CHINA PETROLEUM & CHEM CORP +1

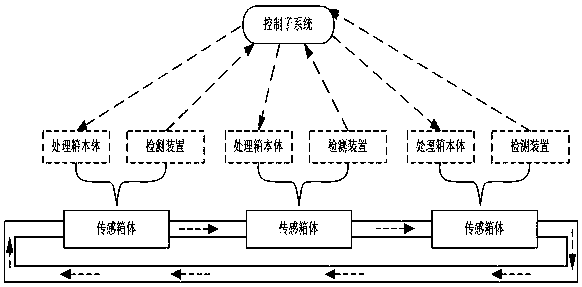

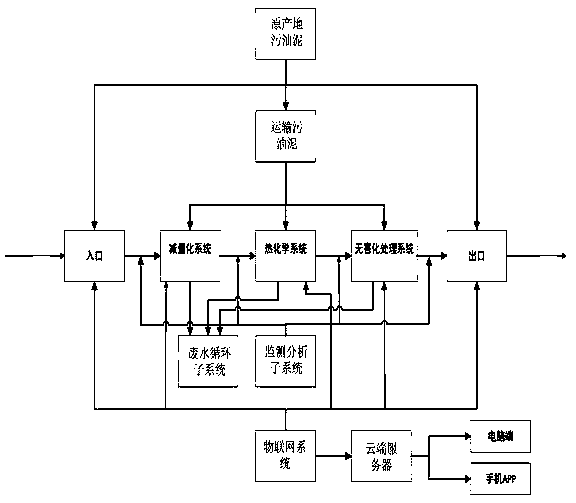

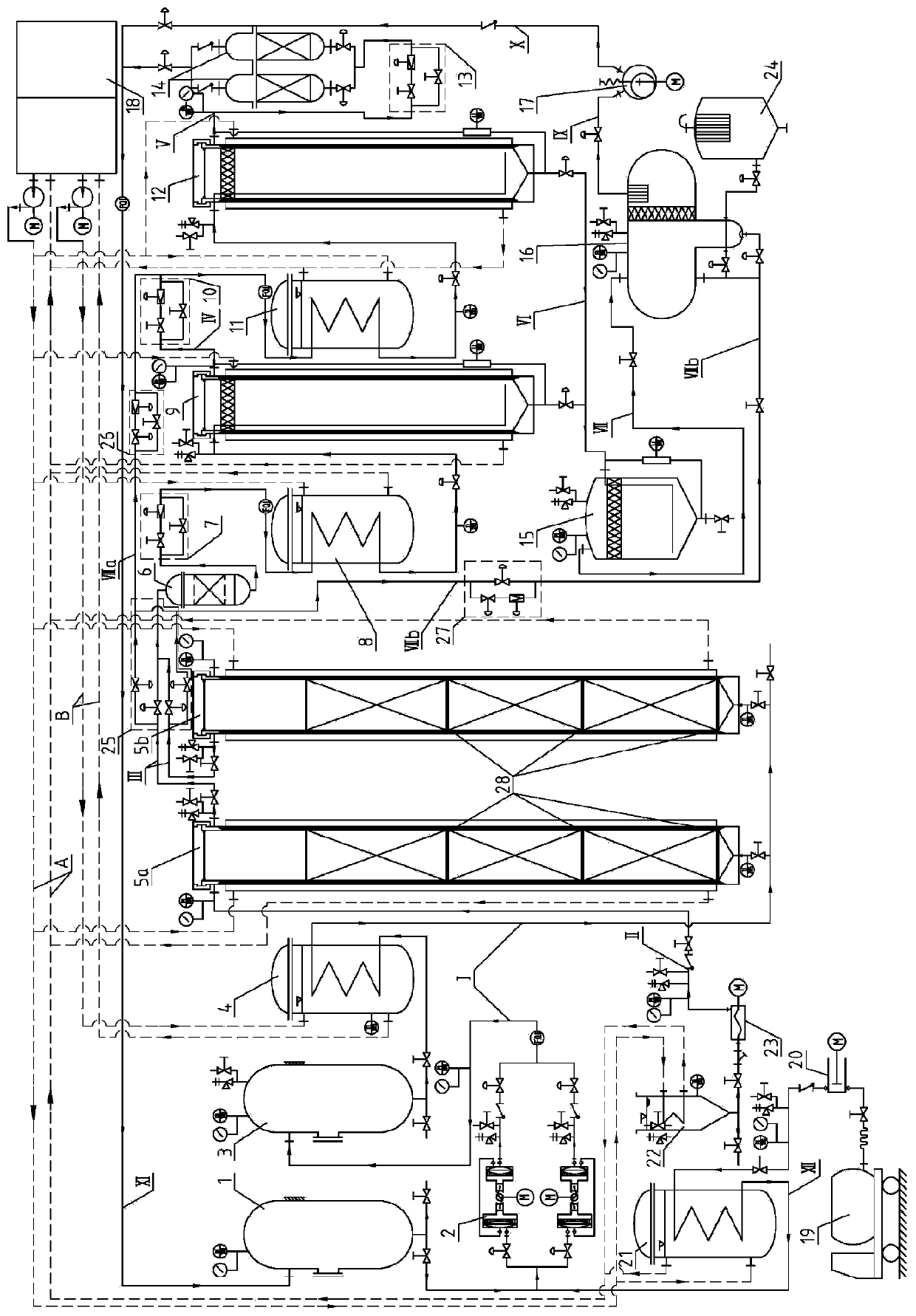

Oil-field oil sludge factory-like comprehensive treatment system based on Internet of Things technology

InactiveCN109052876AGet rid of situations where guardians observe and manipulateImprove efficiencyWaste water treatment from quariesSludge treatment with immiscible liquidsOil fieldThe Internet

The invention provides an oil-field oil sludge factory-like comprehensive treatment system based on the Internet of Things technology. The system comprises m sensing box bodies and a control sub-system, wherein each sensing box body comprises a treatment box body and a detection device arranged in the treatment box body; a treatment device is arranged on each treatment box body; the detection devices communicate with the control sub-system respectively; each detection device acquires and sends the data of oil sludge in the treatment box body; the control sub-system receives and processes the data transmitted by the detection devices and controls corresponding treatment device to work; m treatment box bodies are communicated in turn; a controller also controls the oil sludge reaching the standard in the first treatment box body to enter the second treatment box body for further treatment, and so on, wherein m is greater than or equal to 2. According to the system disclosed by the invention, oil sludge equipment is integrated in one place, and batch long-term harmless and recycling production of the oil sludge treatment is realized through the Internet of Things technology.

Owner:马睿

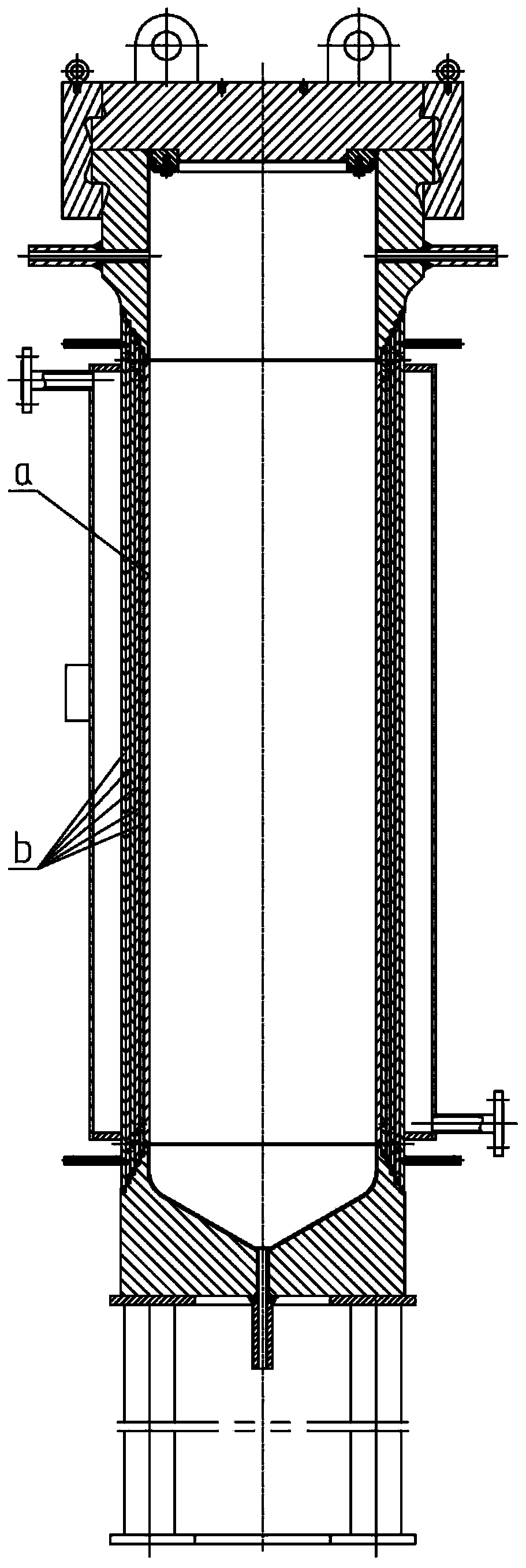

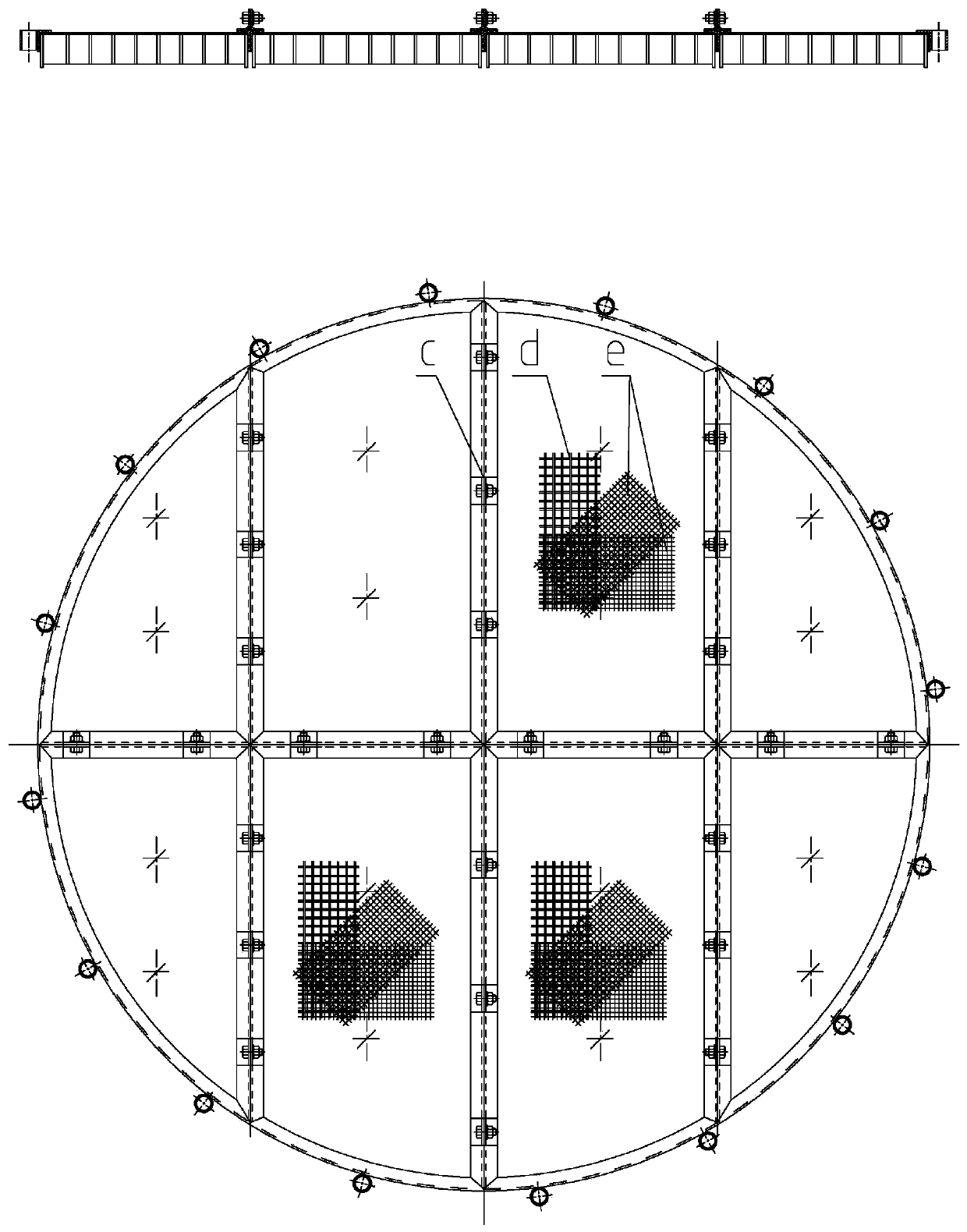

Oil-based drilling waste supercritical treatment system

ActiveCN110451745ALow viscosityContinuous extraction operationWaste water treatment from quariesSpecific water treatment objectivesEnvironmental resistanceHigh water content

The invention relates to an oil-based drilling waste supercritical treatment system. The oil-based drilling waste supercritical treatment system mainly comprises an extraction unit, a separation unit,an extractant recovery unit and a corresponding control unit. The extraction unit comprises an extraction kettle, an extractant storage tank, a metal diaphragm compressor, an extractant buffer tank,a pre-extraction cooler, a waste storage tank and a screw pump. The separation unit comprises an extraction kettle outlet pipeline switching valve group, a filter, a first-stage pressure reducing valve group, a first-stage separation heater, a first-stage separation kettle, a second-stage pressure reducing valve group, a second-stage separation heater and a second-stage separation kettle; the extractant recovery unit includes a first residual extractant recovery line, a second residual extractant recovery line, an extractant decompression recovery line, and a solute collection line. The systemrealizes the continuous, high-efficient and environmental protection treatment of oil-based drilling waste with high oil content, high water content, high solid content and low fluidity by adjustingand switching the corresponding valves on the pipeline.

Owner:HEFEI GENERAL MACHINERY RES INST +1

Composition and Process for Conversion of Paint Sludge Into Reusable Paint

InactiveUS20090221727A1Sludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeChemistry

The present invention relates to a composition for the conversion of paint sludge into reusable paint, to a process for the preparation of said composition and to a process for the conversion of waste paint sludge back to useful paint. The sludge conversion process of the invention consumes the environmentally hazardous sludge collected from paint application systems by converting this paint sludge into a reusable paint.

Owner:MAHARANI PAINTS (INDIA) PVT LTD

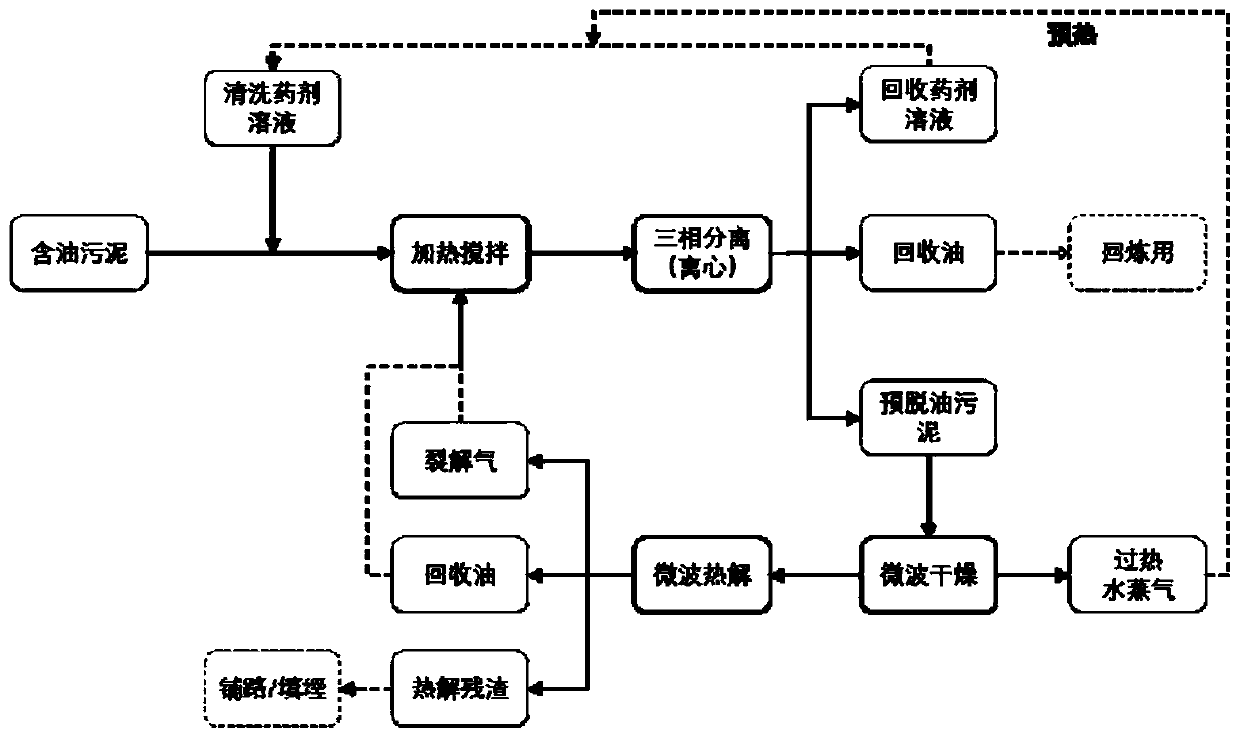

Treatment method of oily sludge

ActiveCN110590087AEasy to separateHeating fastSludge treatment by pyrolysisByproduct vaporizationMicrowaveSludge

The invention relates to a treatment method of oily sludge. The method comprises the following steps that a, the oily sludge is treated by hot washing with a chemical agent, then the heat washed sludge is stratified to form an upper layer oil phase, a middle layer water phase and lower layer sludge, and the upper layer oil phase, the middle layer water phase and lower layer sludge are collected respectively after separation; b, the lower layer sludge is subjected to two successive stages of microwave heat treatment; the first stage is heated for 150-220 DEG C, and an evaporated gas phase is collected in the first stage; and heating is continued to 580-600 DEG C for thermal decomposition in the second state, then generated non condensable gas and condensate are cooled and recovered, and finally, sludge residues after pyrolysis are collected. The treatment method of the oily sludge realizes the goal of reducing, harmlessness and resource treatment of the oily sludge.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Process for the Solvent Extraction for the Radiolysis and Dehalogenation of Halogenated Organic Compounds in Soils, Sludges, Sediments, and Slurries

InactiveUS20070148059A1Uniform radiation doseEfficient radiolytic dehalogenationWater/sewage treatment by irradiationSolvent extractionAlkaneSludge

A process of extracting halogenated organic compounds, and particularly PCBs, from soil, sediment, slurry, sludge and dehalogenating the compounds contacts a contaminated soil sample with an extraction medium of a mixture of an alkane and a water miscible alcohol. The organic compounds dissolve in the extraction medium which is separated from the soil by passing water upwardly through the soil. The extraction medium floats to the surface of the water and is separated. Thereafter, the extraction medium containing the halogenated organic contaminants is subjected to ionizing radiation to radiolytically dehalogenate the compounds.

Owner:GOLDEN JEFFRY

Oily sludge treatment equipment for oil field

InactiveCN108751635AAchieve separationReduce qualitySludge treatment by de-watering/drying/thickeningSludge treatment with immiscible liquidsAfter treatmentSlurry

The invention provides oily sludge treatment equipment for an oil field, and belongs to the field of sludge treatment of the oil field. The oily sludge treatment equipment comprises a stacked spiral type dehydrater; the oily sludge is dehydrated by the stacked spiral type dehydrater, and sent into a blade wet oil sludge dryer to dry; after the oily sludge is dried by the blade wett oil sludge dryer, the oily sludge is sent into a oil sludge pulping machine to pulp, and then sent into a dirt oil sludge slurry tank; the oily sludge is sent into a stirring and shearing extractor by a screw pump,and the stirring and shearing extractor is communicated with an extracting liquid tank; the sludge is crushed and extracted by the stirring and shearing extractor, and then sent into an automatic discharge centrifugal machine; the sludge is treated by the automatic discharge centrifugal machine, and sent into a sludge extracting rake type vacuum dryer; the sludge is dried by the sludge extractingrake type vacuum dryer, and sent to a dry sludge stacking yard. The oily sludge treatment equipment has the advantages that the solvent extracting technique is adopted; the oil in the oil sludge is extracted by the extracting liquid, so that the oil is completely separated from the sediment; the residues after treatment can be directly applied to other crops, except vegetables and grains.

Owner:潍坊力德电器有限公司

Oily sludge treatment system based on ultrasonic waves and process thereof

PendingCN112876036AEfficient extractionSmall intermolecular forceWater treatment parameter controlSludge treatment by de-watering/drying/thickeningDemulsifierSludge

The invention discloses an oily sludge treatment system based on ultrasonic waves and a process thereof, belongs to the technical field of oily sludge treatment, and solves the problems of large chemical reagent consumption, poor dehydration effect and small treatment capacity in the oily sludge treatment process in the prior art. The oily sludge treatment system comprises a pretreatment unit, a supercritical CO2 extraction unit, an ultrasonic treatment unit and a post-treatment unit which are connected in sequence, and the pretreatment unit comprises a pretreatment pool, the supercritical CO2 extraction unit comprises an extraction reaction kettle, the bottom of the extraction reaction kettle is connected with a supercritical CO2 generation module, and the other side of the extraction reaction kettle is connected with a separation kettle. The treatment mode of supercritical extraction and high-power ultrasonic deep treatment is adopted, the oil content of the oil-containing sludge is reduced, the dryness of the sludge is improved, three-phase separation is effectively achieved, a demulsifier does not need to be added, the requirement for chemical reagents is reduced, meanwhile, after the sludge is subjected to high-power ultrasonic treatment, intermolecular gaps become small, agglomeration is good, and the dependence on a flocculating agent is reduced.

Owner:扬州阿鲁达环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com