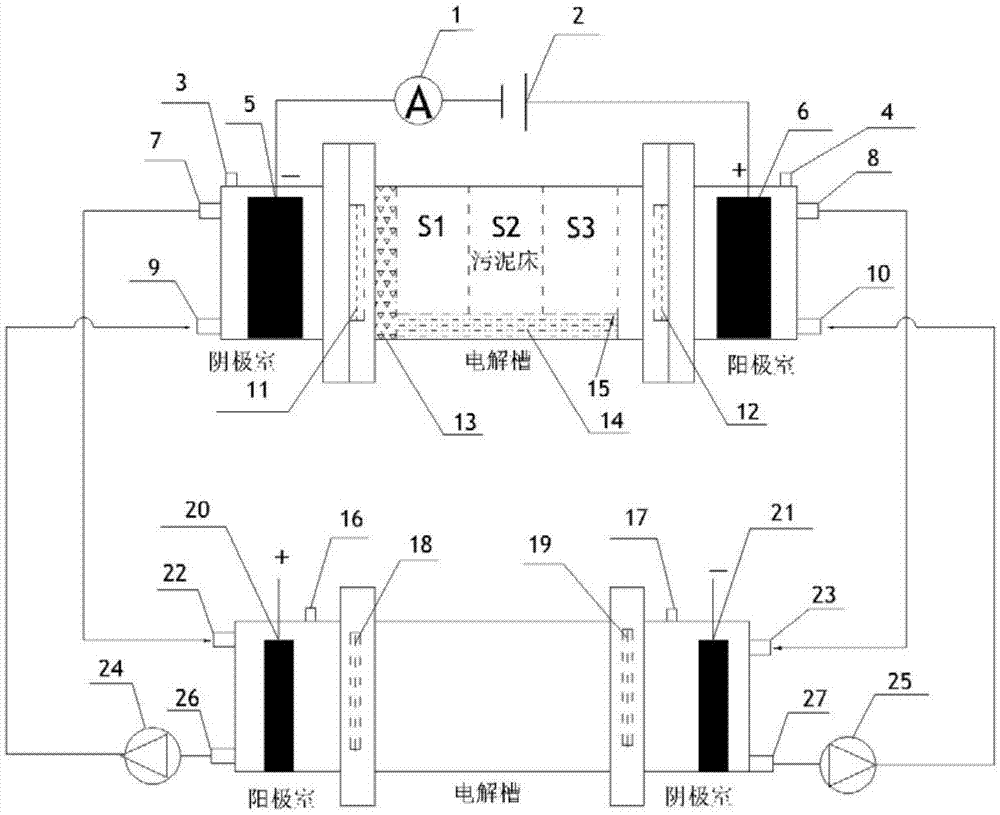

Electrokinetic remediation enhancing device and method using same to remove heavy metal in sludge

A technology of electric repair and strengthening device, which is applied in the field of secondary resource recovery and environmental engineering, can solve the problem of low removal rate of heavy metals, and achieve the effect of improving the electric repair rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Sludge pretreatment: Take 400g of smelting wastewater sludge from the wet sludge sample by nine grid method. The main metal content in the smelting wastewater sludge is Cu 5.01%, Ni 0.61%, Pb 0.68%, Cr 0.028%, Ca 8.56%.

[0031] (2) Pretreat the sludge with sulfuric acid with a concentration of 2mol / L. The pretreatment method is to stir with a magnetic stirrer for 0.5h at a speed of 250 / min. The water content of the pretreated sludge is 80%, and the initial pH value is 6.

[0032] (3) Loading into the electrolytic cell: layer the pretreated sludge in (1) into the rectangular box in the middle of the electric restoration electrolytic cell, press evenly, and put activated carbon into the cathode side of the electrolytic cell.

[0033] (4) Inject distilled water into the cathodic electrolytic cell and the anode electrolytic cell, and replace the distilled water with the electrolyte after standing for 24 hours until osmotic equilibrium, the catholyte and the anolyte ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com