Patents

Literature

486results about "Electrochemical sludge treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for promoting anaerobic digestion of residual activated sludge to generate methane by pretreatment combined electrochemical technology

InactiveCN105621826AImprove biodegradabilityAchieve reductionSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesHydrogenResource utilization

The invention discloses a method for promoting anaerobic digestion of residual activated sludge to generate methane by a pretreatment combined electrochemical technology. The method comprises the following steps: 1) concentration treatment of sludge; 2) combined pretreatment of sludge: performing ultrasonic pretreatment of sludge and alkaline pretreatment to obtain pretreated sludge; and 3) microbial electrolysis cell coupling with anaerobic digestion of sludge to generate methane: feeding the sludge after the combined pretreatment into a MEC-AD coupling reactor and fermenting to generate methane. In the method, the pretreatment combined microbial electrolysis cell hydrogen generation technology is used for the first time, and the reduction and resource utilization of the sludge from a municipal sewage treatment plant are realized.

Owner:LIAONING UNIVERSITY

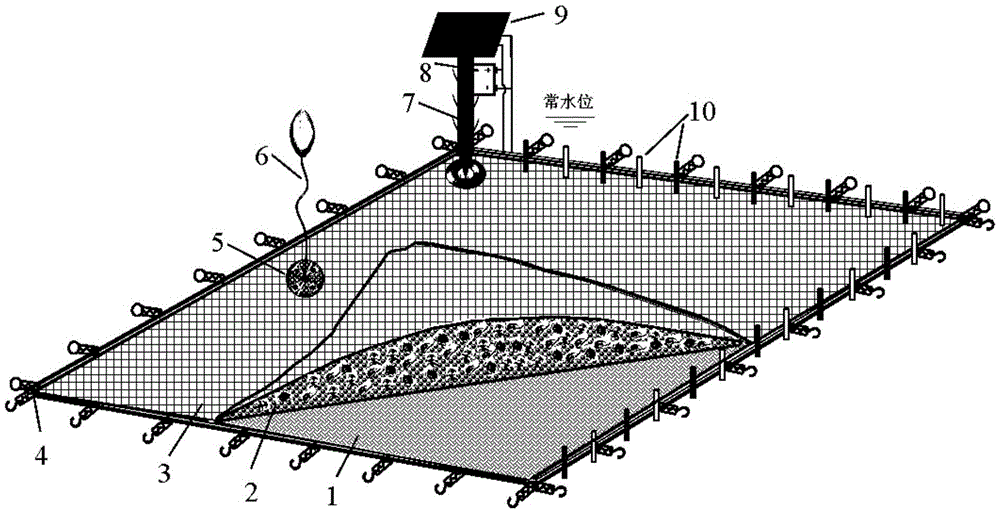

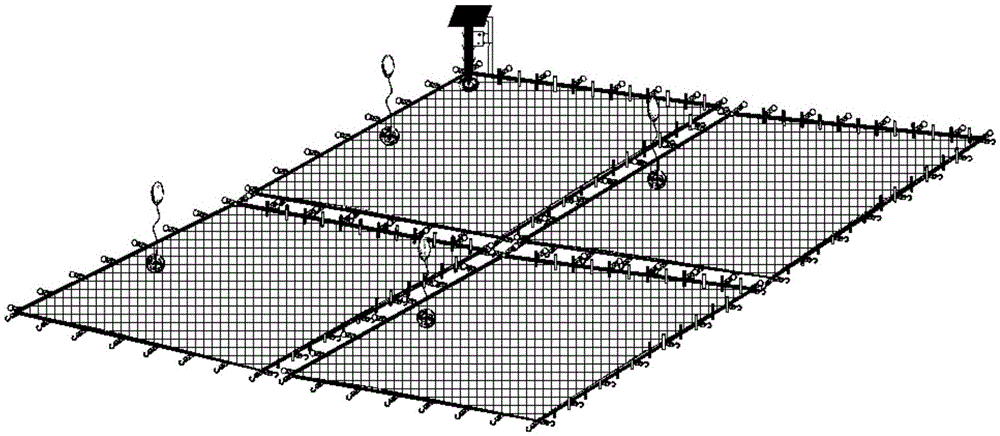

Polluted sediment ecological coverage carpet capable of inhibiting original algae from revival and growth and application method thereof

ActiveCN105645563AExtended service lifeReduce the amount of adsorption saturationTreatment by combined electrochemical biological processesCoastlines protectionFiberEutrophication

The invention provides a polluted sediment ecological coverage carpet capable of inhibiting original algae from revival and growth and an application method thereof, belonging to the field of sediment in-situ restoration and algae control of a eutrophied water body. The invention aims to solve the problems of ecological potential safety hazards, low restoration efficiency, incapability of reutilization and the like in the existing sediment coverage technique. The ecological coverage carpet comprises a thin fiber inverted filter layer, a biological-matrix combined restoration layer, a fabric layer, a quick connection hook, an embedded matrix frame, floaters, stay piles, a microcurrent electrolyzer, solar panels and electrodes. The application method comprises the following steps: analyzing the varieties of algae hypopuses and pollutants in the superficial deposit, selecting the restoration region, laying in the dormancy interval that blue algae do not revive to the water body, analyzing the pollutant content and adsorption characteristics of the adsorptive filter material in the embedded matrix frame, and determining whether to replace the filler or reap the plants. The carpet can be used in sediment improvement and ecological restoration in lakes, ponds, landscape water and other polluted water bodies.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

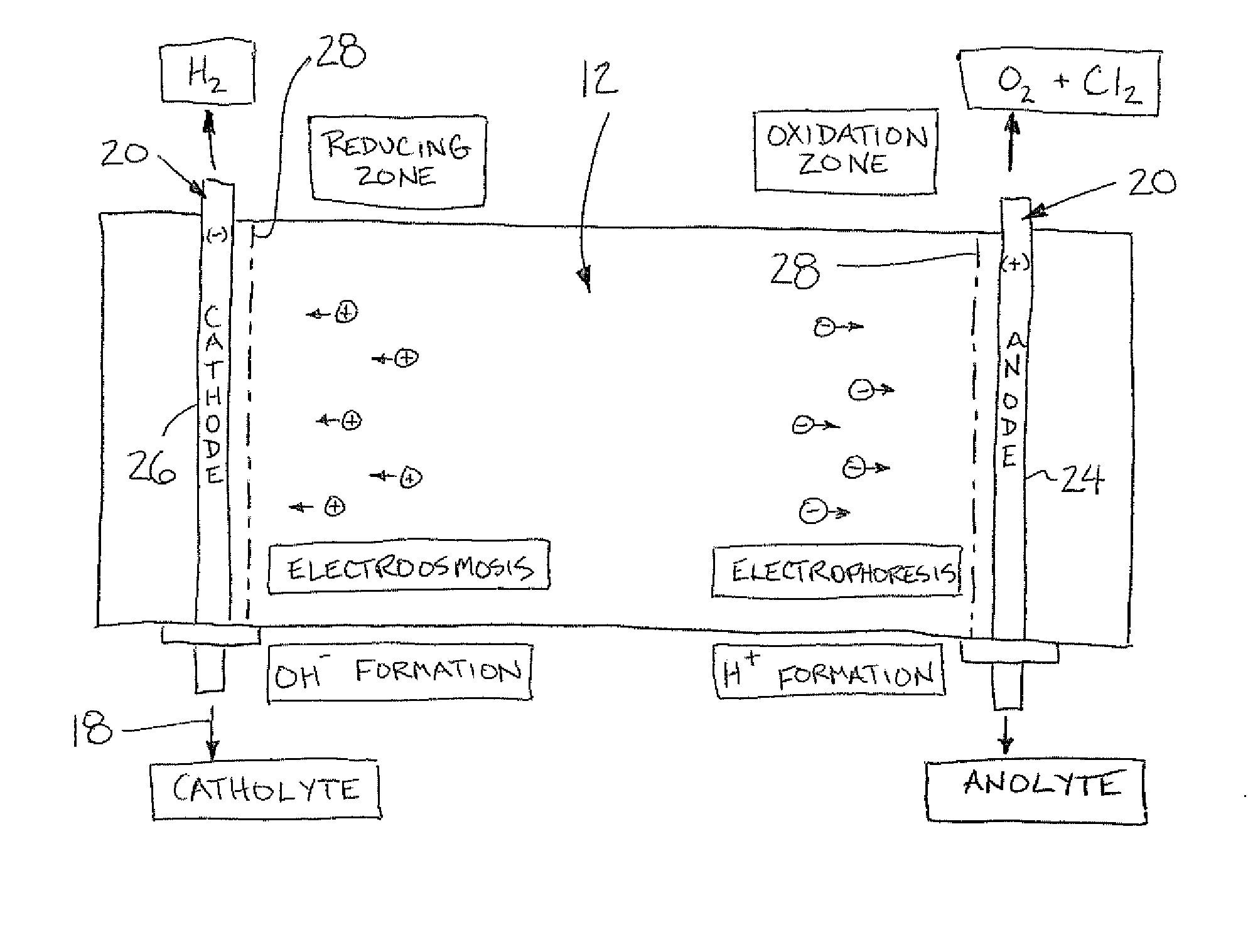

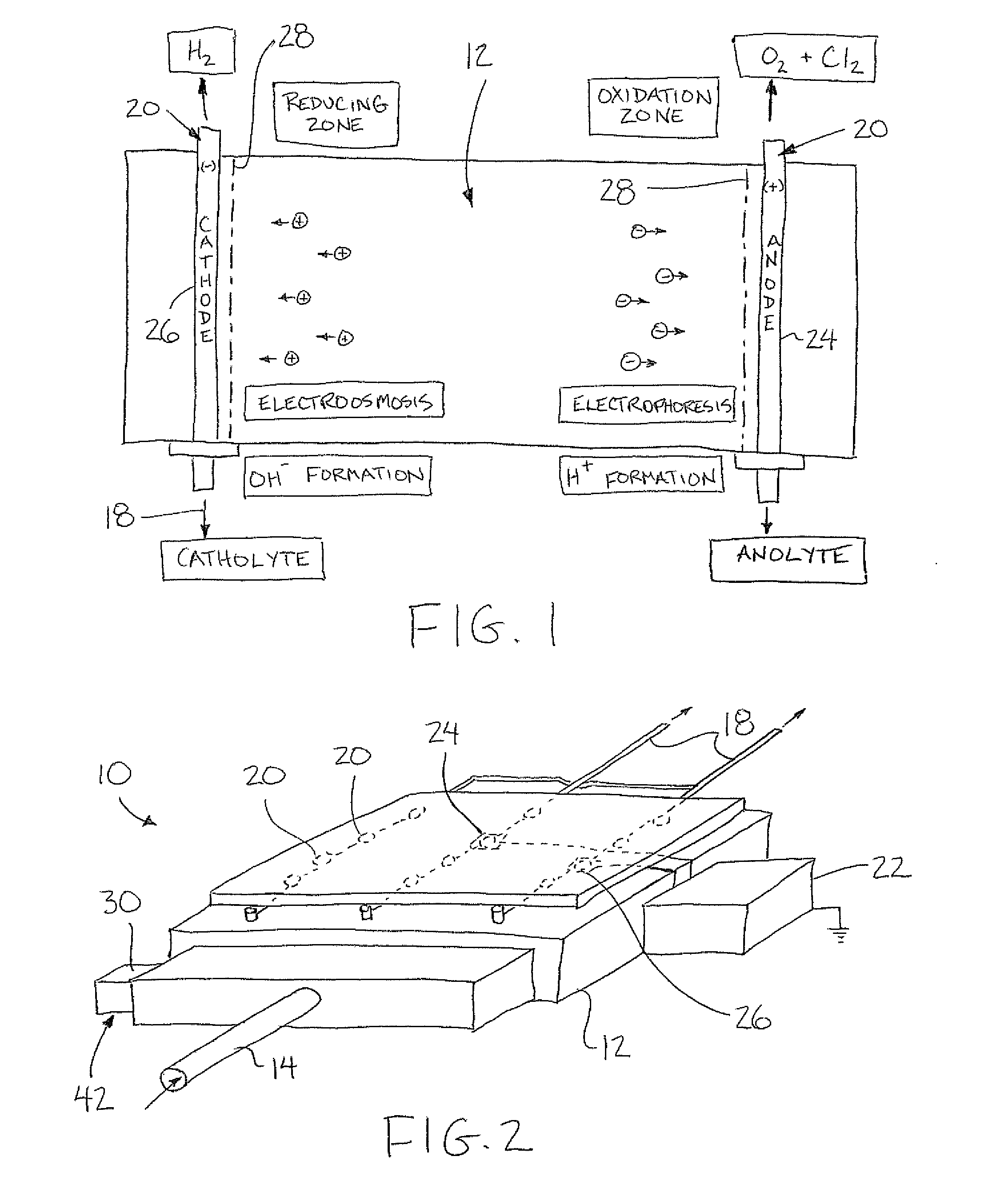

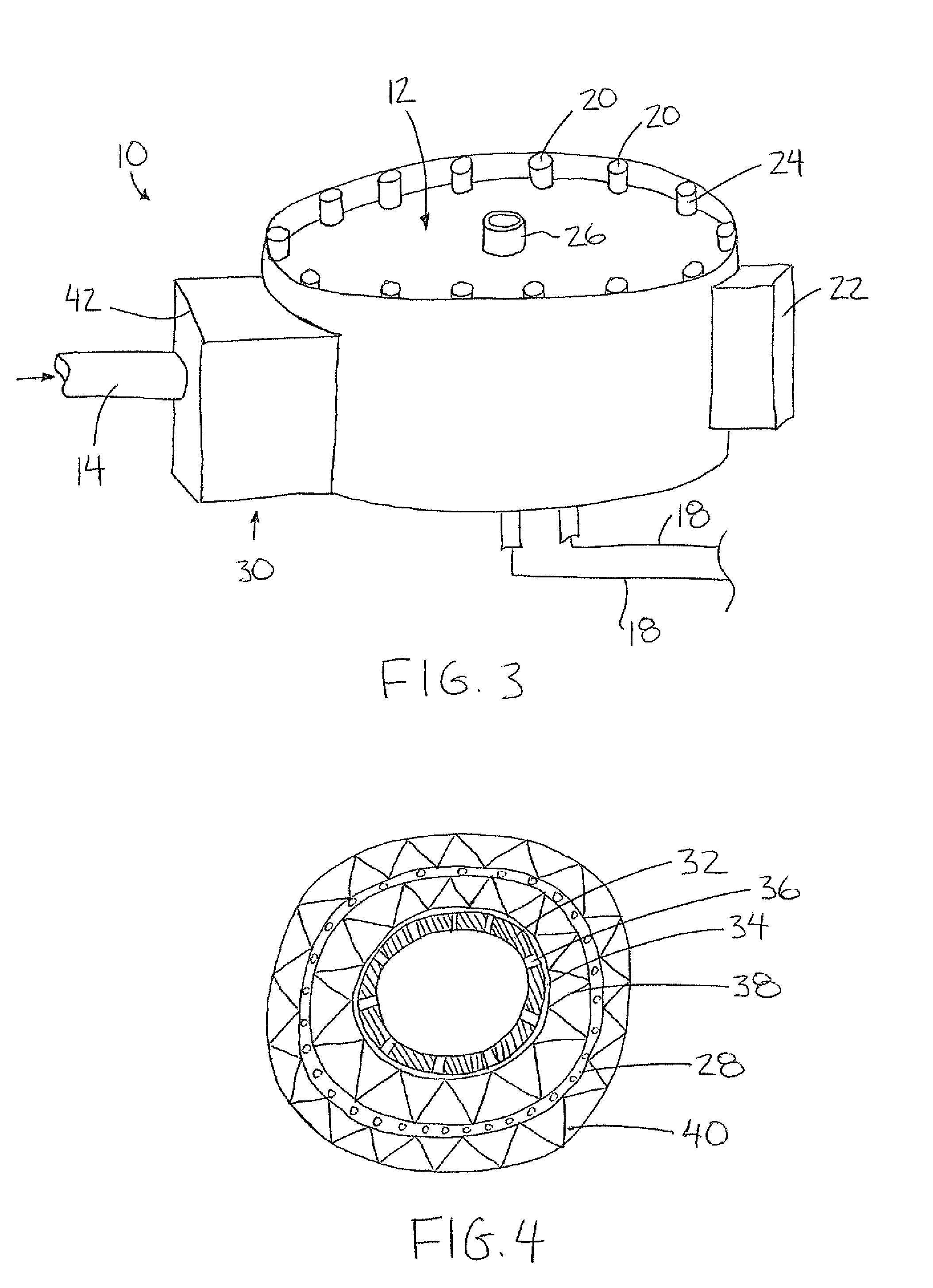

Method of Treating Sludge Material Using Electrokinetics

ActiveUS20100078389A1Effective distributionHigh gradientSludge treatment by de-watering/drying/thickeningWater treatment compoundsPower flowSludge

Sludge is treated in a treatment chamber by providing a pair of electrodes in the treatment chamber and applying an electrical current between the electrodes such that one of the electrodes functions as an anode and one of the electrodes functions as a cathode in proximity to the outlet. A flow of water is induced from the sludge towards the outlet by the electrical current. An ion exchange textile comprising exchangeable functional groups grafted thereon is located in proximity to at least one of the electrodes such that the ionic forms of the metals are exchanged with the functional groups on the ion exchange textile. Accordingly the sludge is dewatered and metals in the sludge are captured commonly in the treatment chamber while the electrical current simultaneously inactivates pathogens in the treatment chamber.

Owner:ELEKTOROWICZ MARIA +1

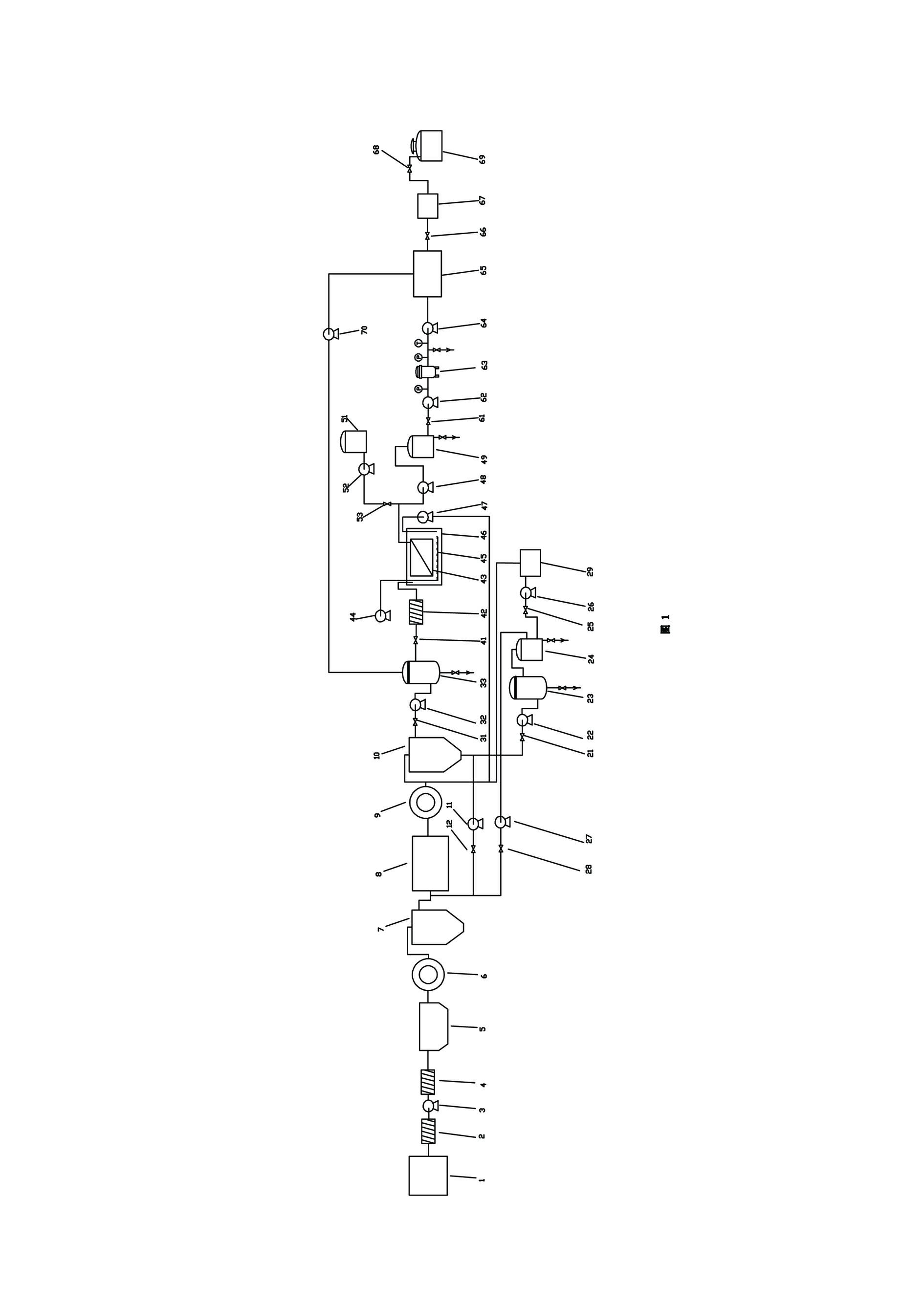

Sewage treatment and regeneration cyclic utilization device and sewage treatment and regeneration cyclic utilization method

InactiveCN102674628AImprove the efficiency of sewage treatmentTo achieve the effect of double treatmentSludge treatment by de-watering/drying/thickeningWater/sewage treatment by irradiationCapacitanceElectrolysis

The invention relates to a sewage treatment and regeneration cyclic utilization device, which is provided with a biochemical system, an electrolysis system, a membrane biological reactor (MBR) system and a deep processing system. A sewage treatment and regeneration cyclic utilization method comprises the following steps of (1) biochemical treatment; (2) electrolysis; (3) MBR system filtering; (4) capacitance desalting and sterilization; and (5) sludge treatment. The device and the method can overcome the defects that in the existing sewage regeneration technology, the quality of the regeneration water is poor, the water consumption water quality requirements are difficult to meet, the investment is high, the operation cost is high, the secondary pollution is caused on the environment, and the like. The sewage discharge can be reduced, the utilization efficiency of the water is improved, meanwhile, the regeneration and the reutilization on the sludge are realized, and the harm possibly caused by the sludge to the environment is eliminated.

Owner:BOYING XIAMEN SCI & TECH

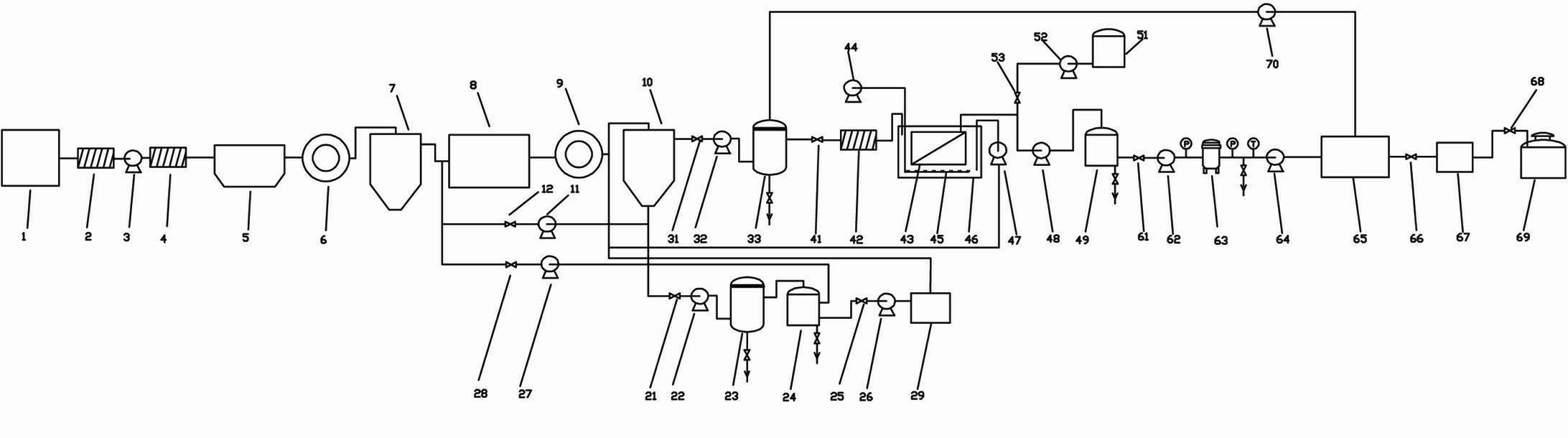

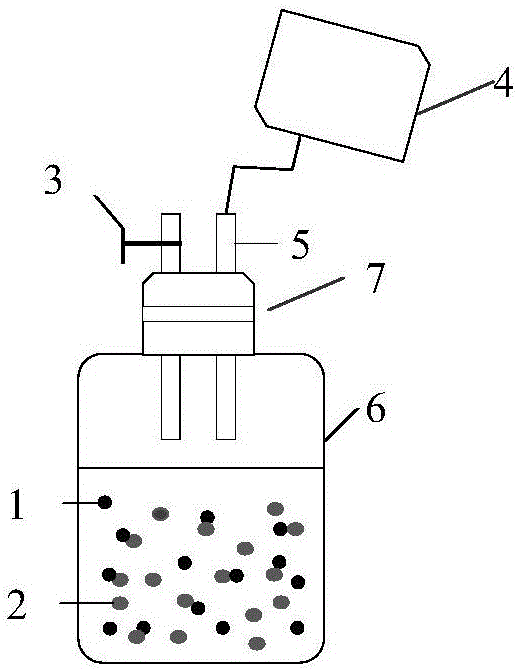

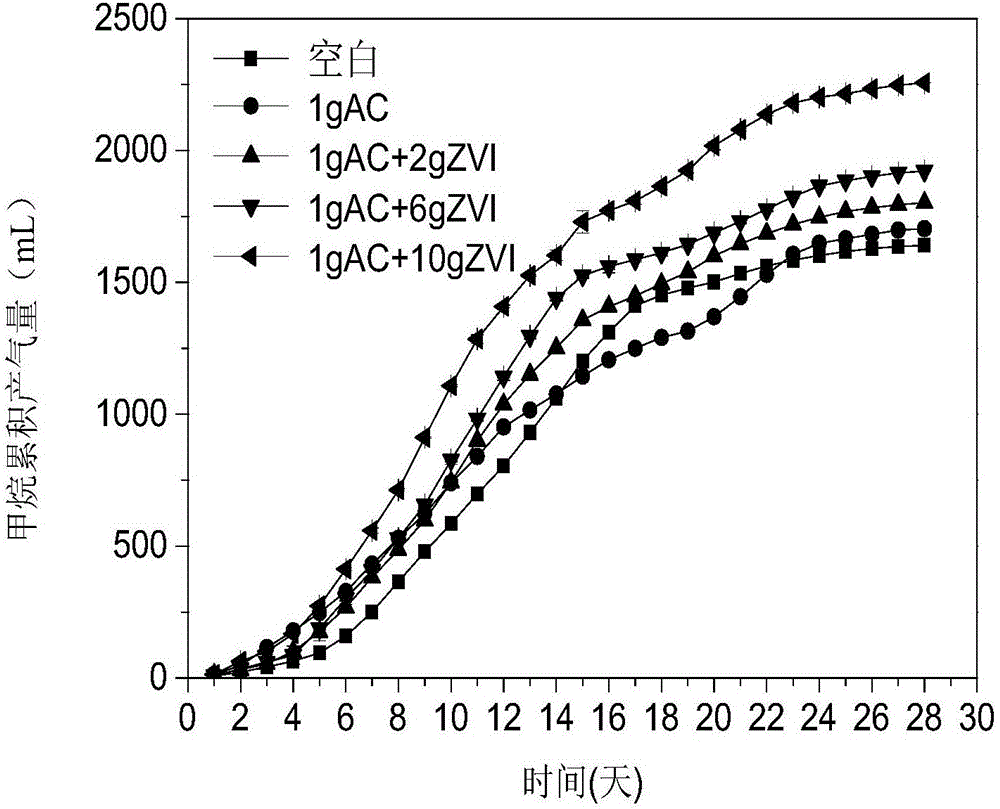

Method for enhancing anaerobic digestion and methane production of excess sludge by zero-valent iron and activated carbon

InactiveCN107522375AIncrease contactPromote decompositionWater treatment parameter controlWater treatment compoundsActivated carbonSocial benefits

The invention belongs to the technical field of sludge treatment and recycling and discloses a method for enhancing anaerobic digestion and methane production of excess sludge by zero-valent iron and activated carbon. The method comprises steps as follows: (1), the excess sludge, inoculated sludge and water are mixed, pH is regulated to 6-7.5, solid content of a mixture is enabled to be 8%-12%, and mixed sludge is obtained; (2), the mixed sludge, activated carbon and zero-valent iron are added to an anaerobic digestion device, and anaerobic digestion is implemented; (3), gas produced in the anaerobic digestion process is collected. According to the method, the anaerobic digestion is better promoted by adding activated carbon and zero-valent iron simultaneously; the method is simple, reaction conditions are mild, a gas producing effect is better than that of a traditional method, recycling, harmless and reducing treatment of the excess sludge of a sewage treatment plant is realized, and the method has good economic and social benefits.

Owner:SOUTH CHINA UNIV OF TECH

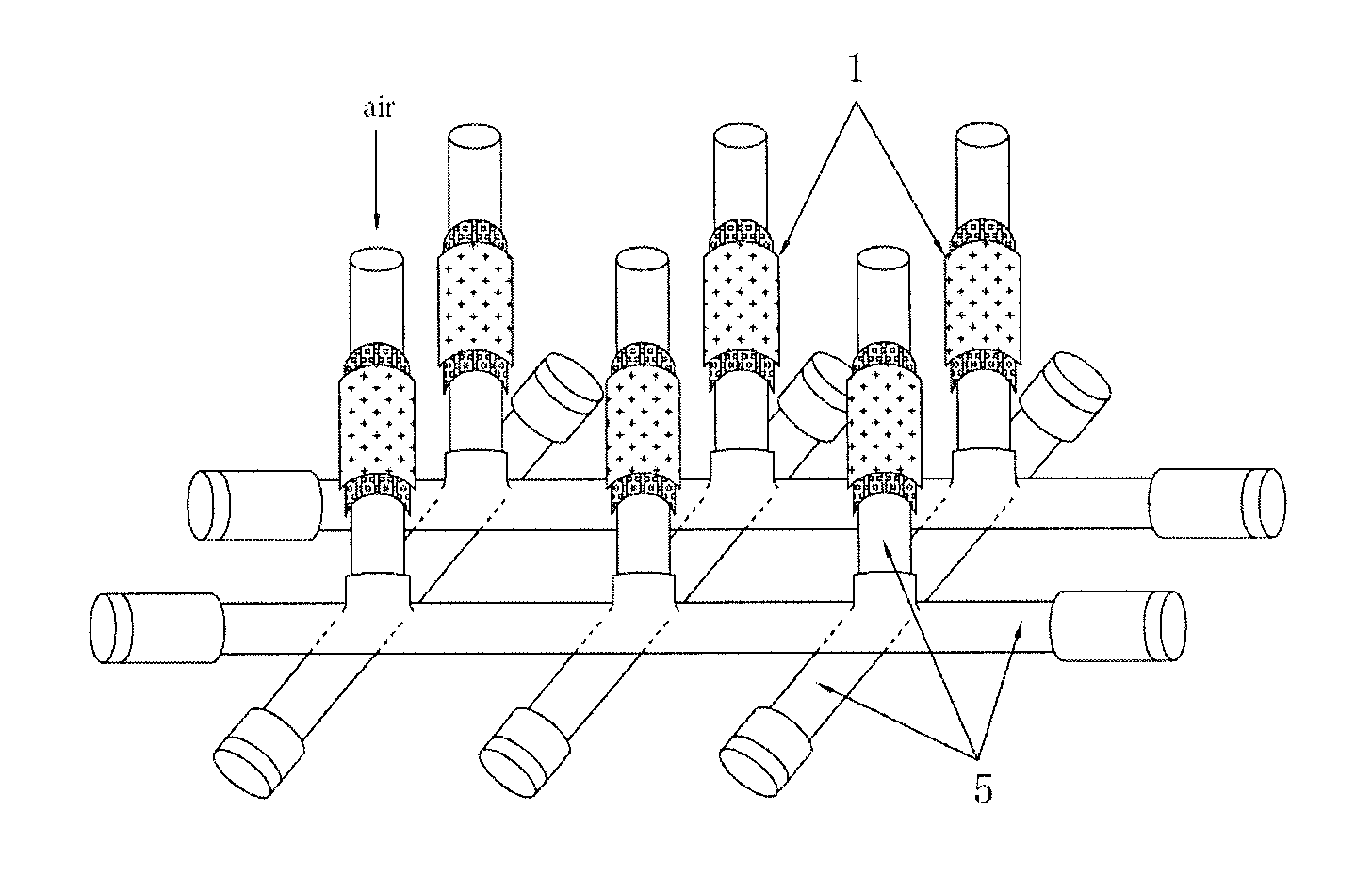

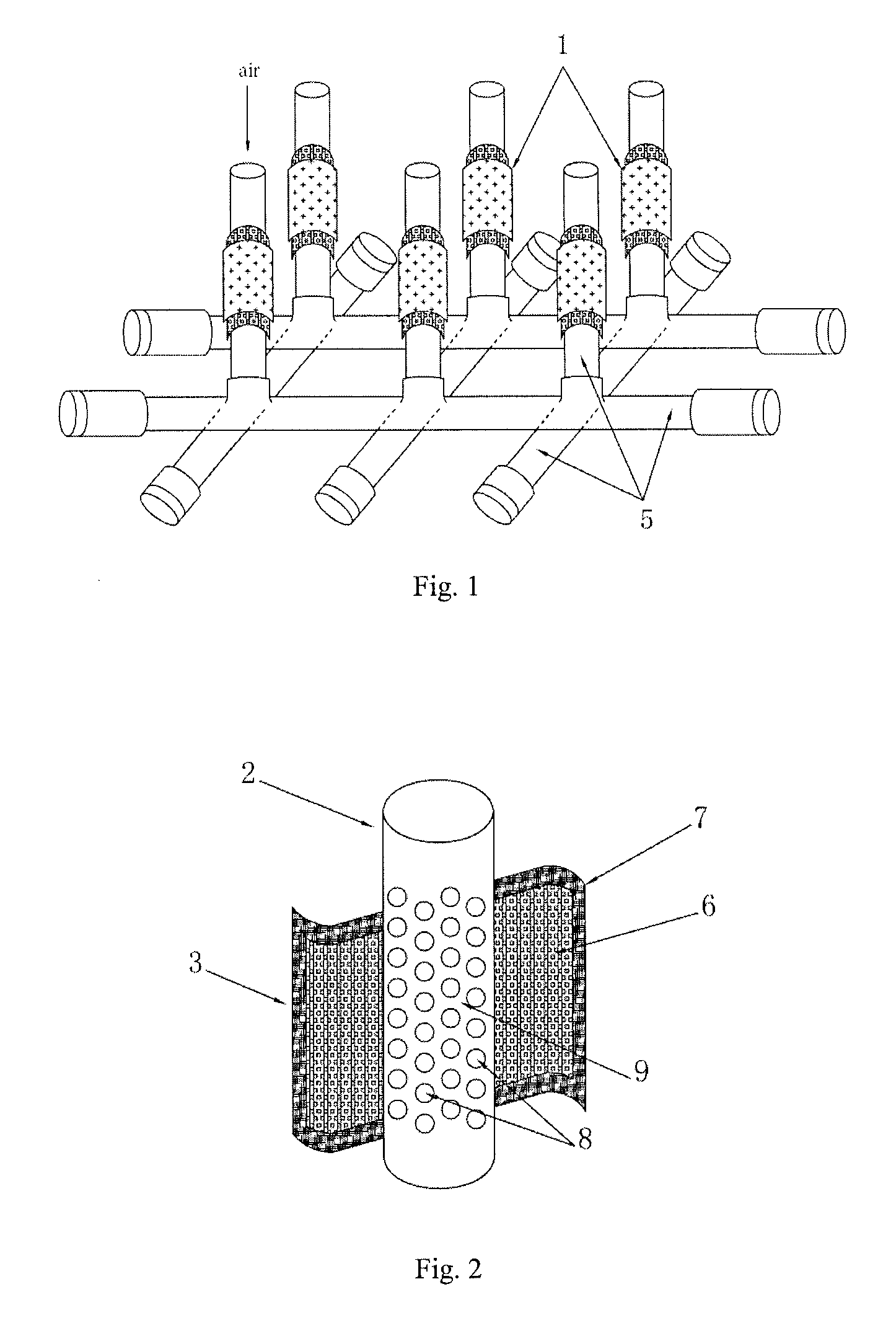

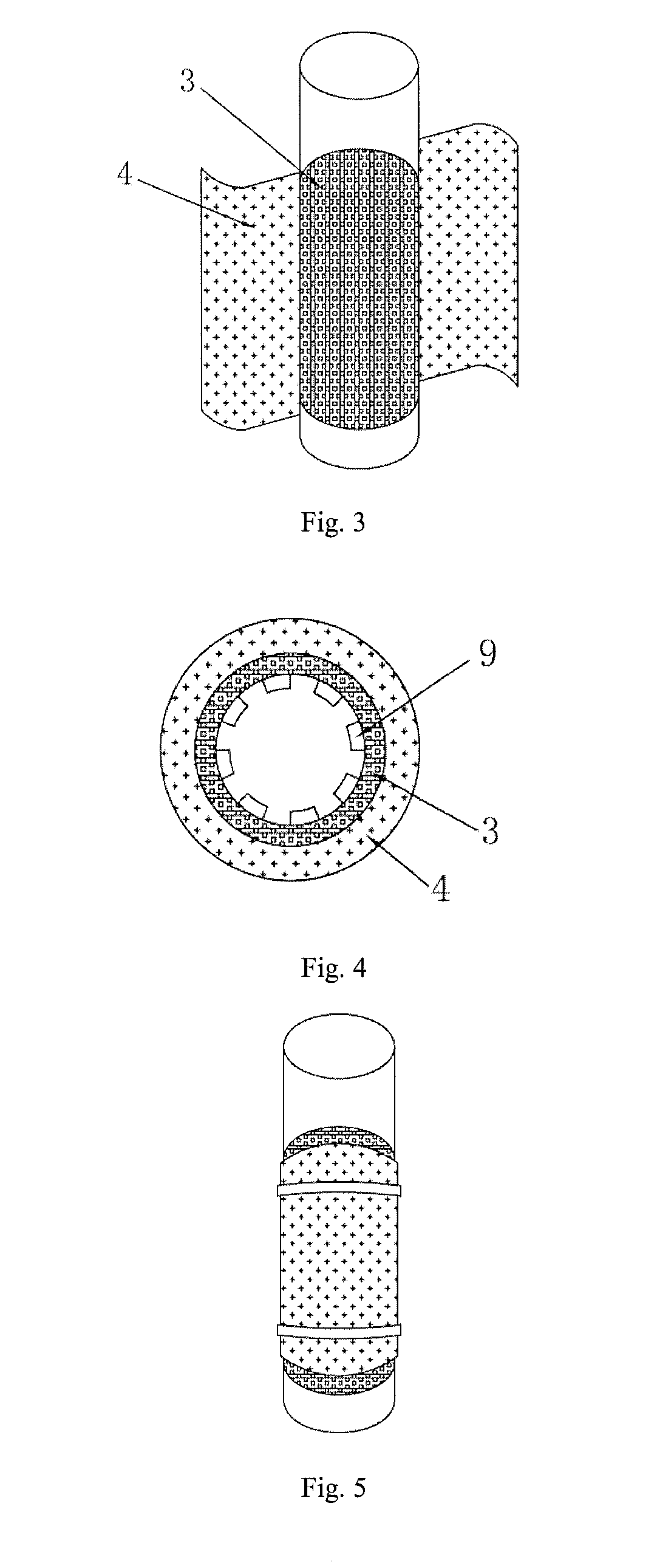

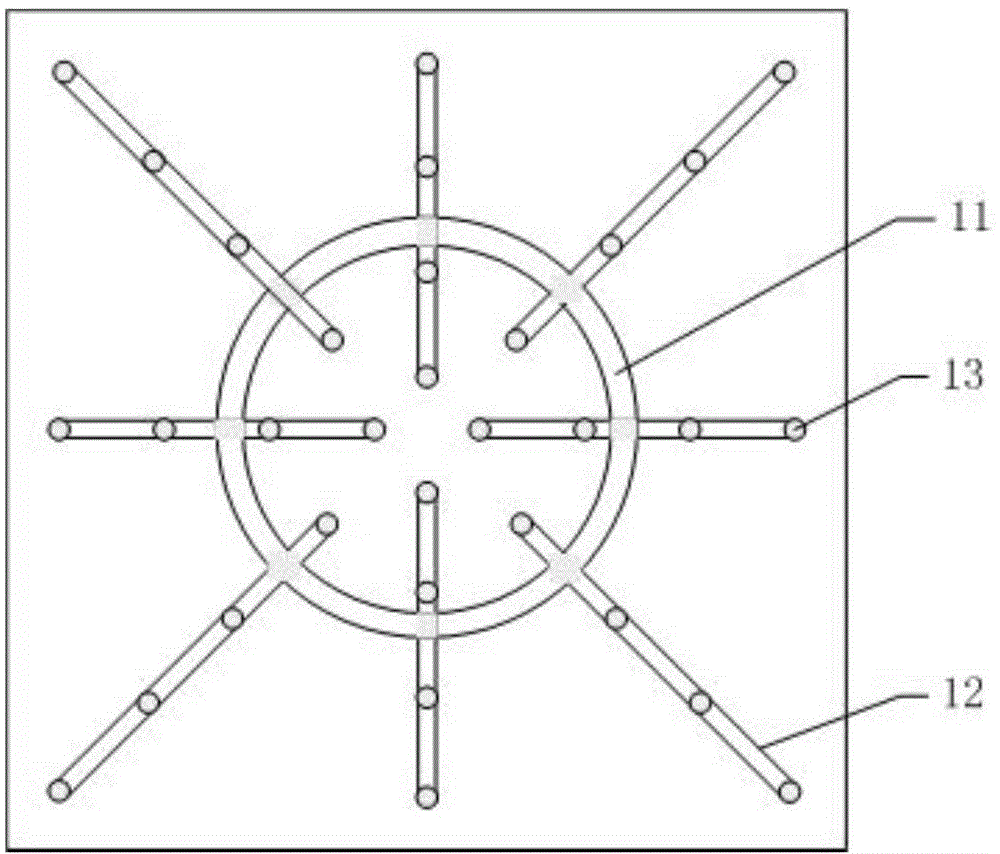

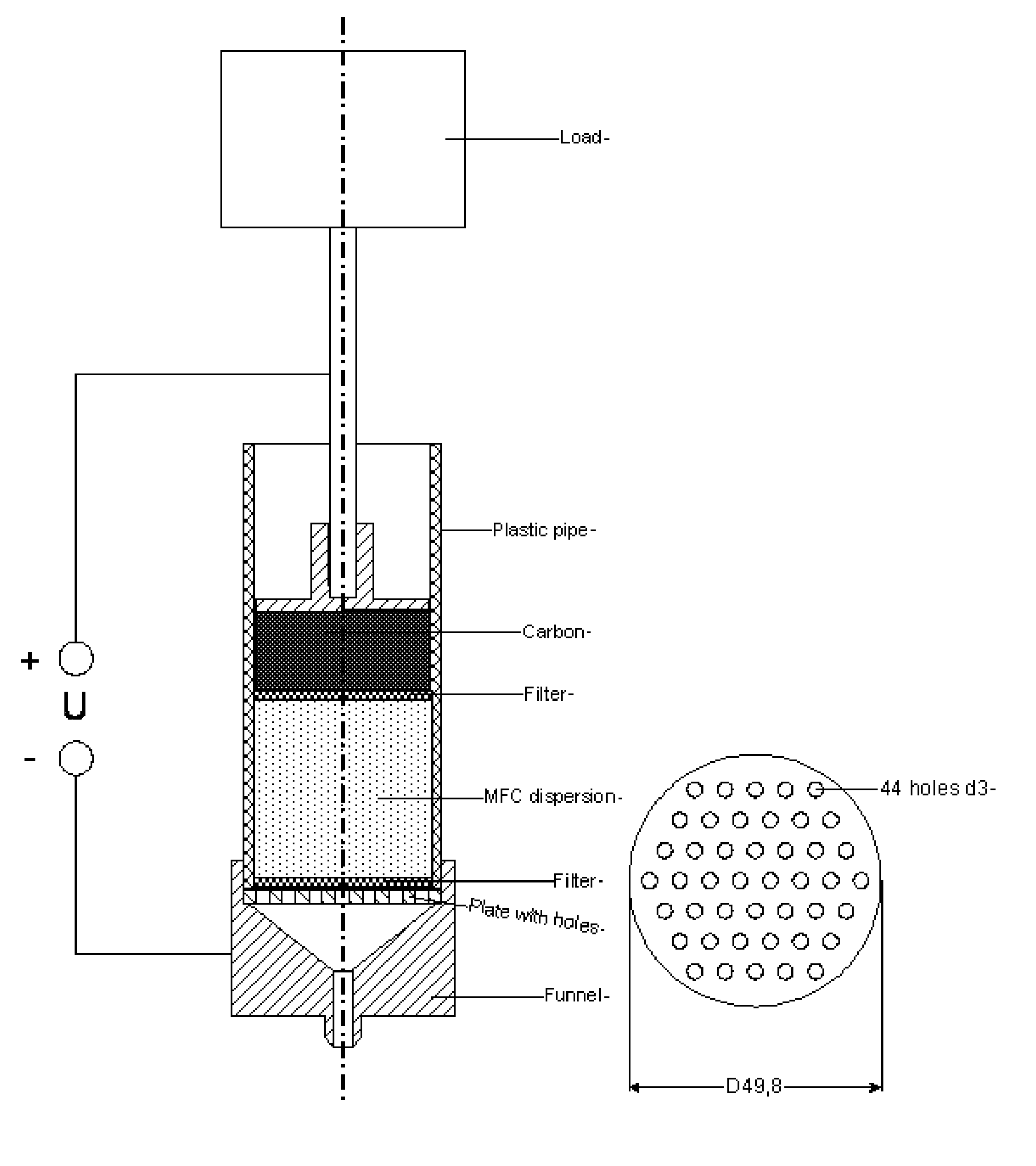

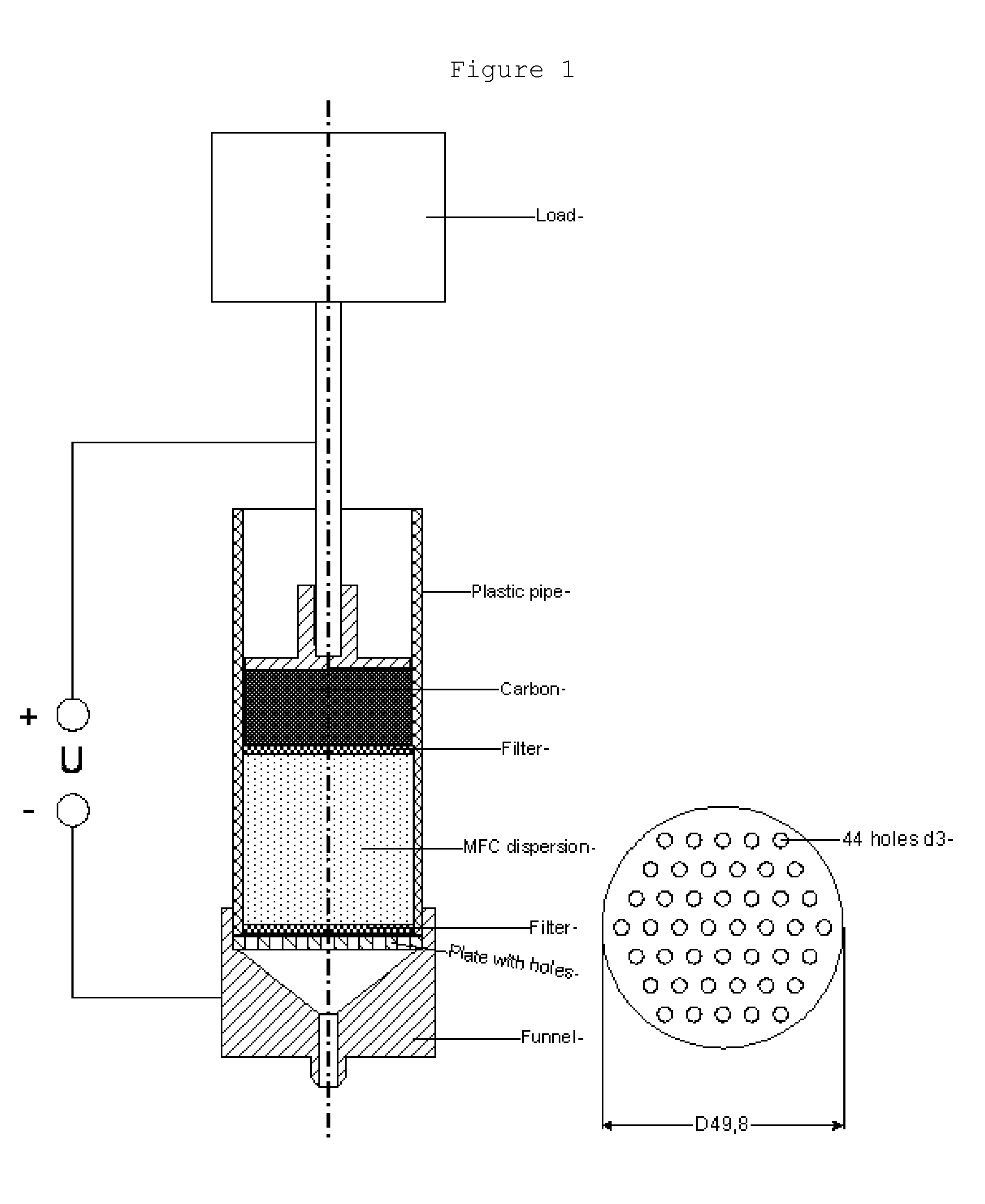

Methods and devices for in-situ treatment of sediment simultaneous with microbial electricity generation

ActiveUS20120276418A1Easy to placeGood effectTreatment by combined electrochemical biological processesFinal product manufactureEnvironmental resistanceMicrobial fuel cell

A method for in-situ treatment of sediment simultaneous with microbial electricity generation is provided, comprising steps of constructing a microbial fuel cell, placing the microbial fuel cell in the sediment, forming a cell circuit, and cultivating microorganisms to generate electrical power. The method overcomes shortcomings found in the prior art and uses organics in the sediment as fuels to in-situ treat the sediment with simultaneous electricity generation. A device for implementing the method is also provided, which can be expanded in different directions as needed and is easy to maintain during long-term operation. The device has many advantages including compact structure, easy operation, low cost, high output power density, significant reduction in sediment COD, no influence on water flow, and environment-friendly

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

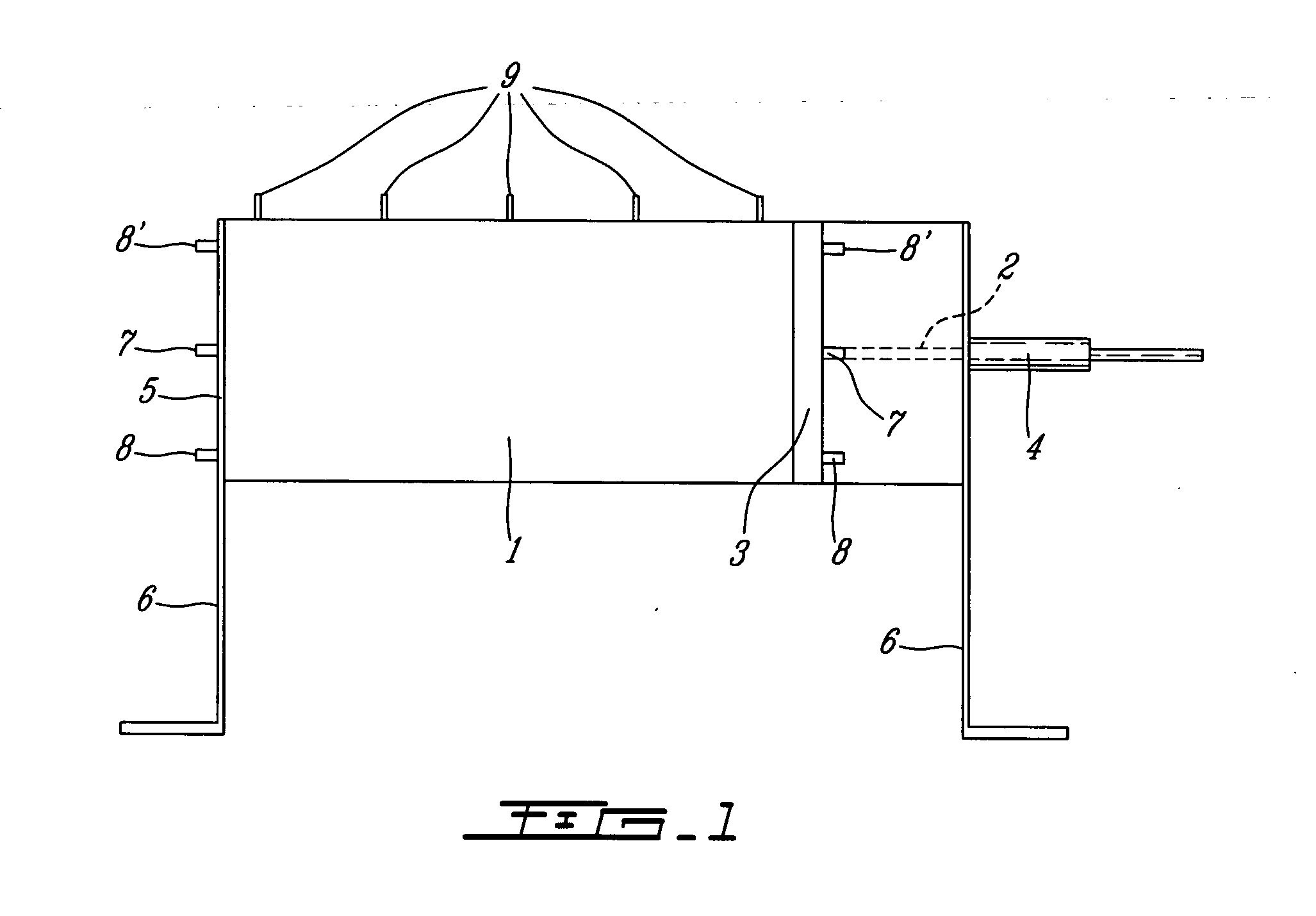

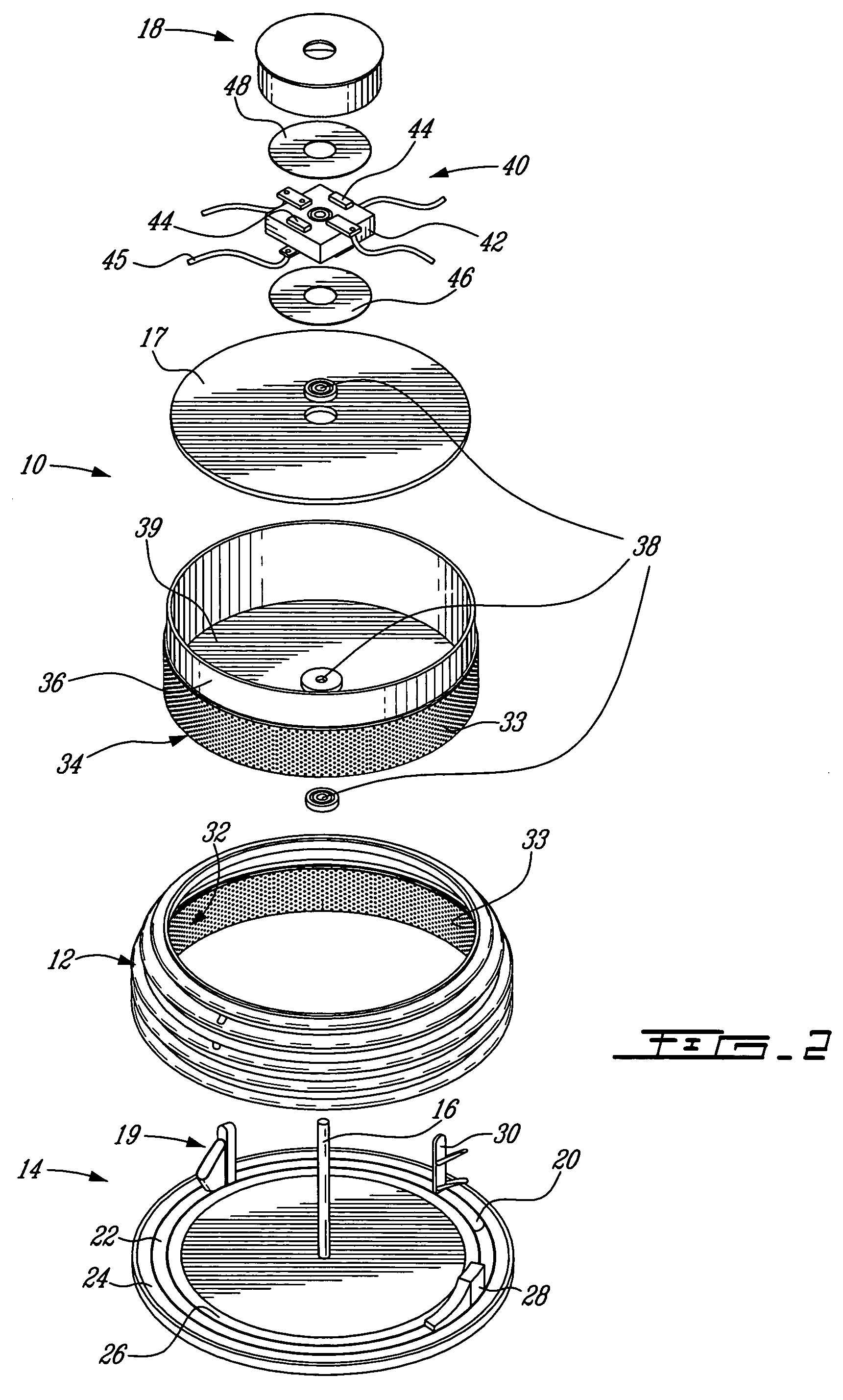

Process and apparatus for treating sludge by the combined action of electro-osmosis and pressure

InactiveUS20050016870A1Easy to dehydrateReduce distanceCellsPolycrystalline material growthSludgeEngineering

The present invention relates to a process for treating sludge by the combined action of electro-osmosis and pressure. This process comprises providing a cell for treating the sludge, the cell comprising at least two electrodes including at least one cathode and at least one anode. At least one of the electrodes is movable, and at least one of the electrodes is perforated so as to drain effluents. Then, the sludge is introduced into the cell between the at least two electrodes, each of the electrodes defining a surface adapted to constantly contact the sludge. Then, the sludge is submitted to an electric current by applying a voltage to the electrodes, and applying a pressure to the sludge. by means of the at least one movable electrode so as to permit a constant contact between the surfaces and the sludge. An apparatus for carrying out such a process is also disclosed.

Owner:GL&V CANADA INC

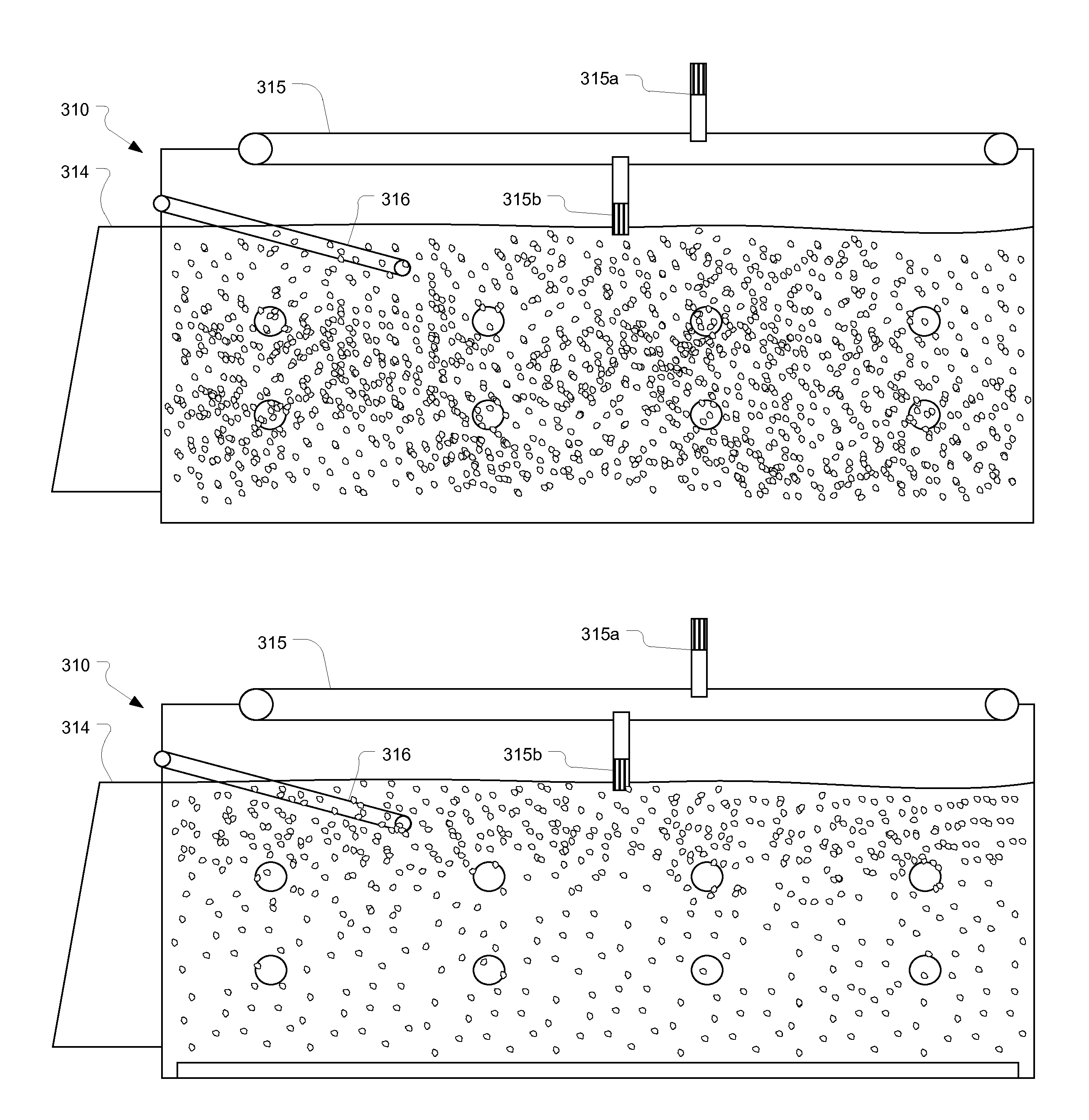

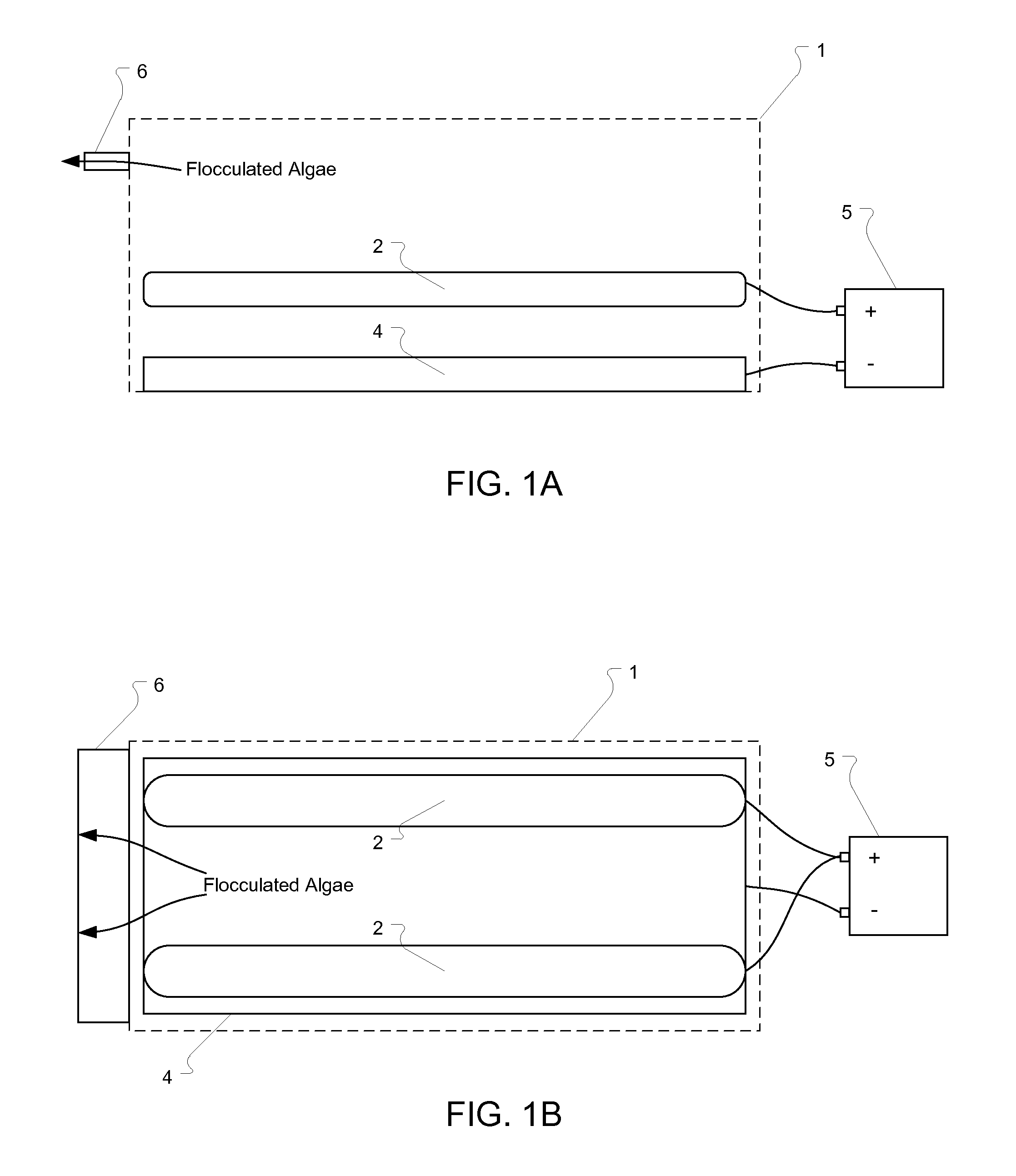

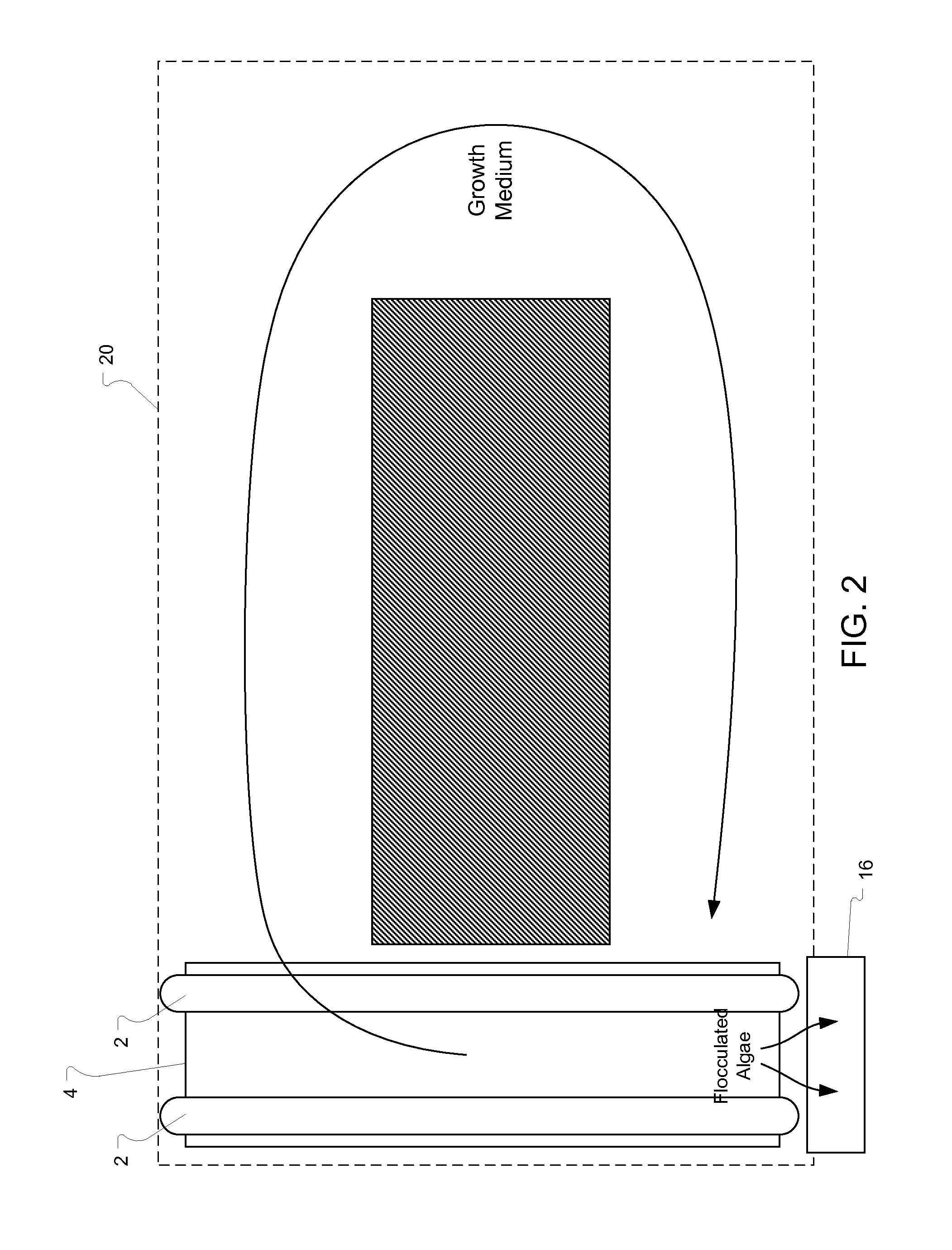

Systems and methods for harvesting and dewatering algae

InactiveUS20130192130A1Simple and low cost approachLow costSeed and root treatmentMicroorganism separationMicro bubbleCell culture media

Owner:ORGINOIL INC

Method for treating black and odorous water body bottom mud through microelectrolysis material

ActiveCN105502867ASludge treatment by oxidationElectrochemical sludge treatmentSelf purificationOxygen

The invention discloses a method for treating black and odorous water body and bottom mud thereof. The method comprises the following steps that 1, a microelectrolysis material is added to the bottom mud of the black and odorous water body, and the microelectrolysis material is mixed with the black and odorous water body bottom mud, wherein the dosage of the microelectrolysis material is 0.1%-5% of the weight of the bottom mud of the black and odorous water body; 2, an oxidant is injected into or sprayed in the black and odorous water body bottom mud with the microelectrolysis material, wherein the dosage of the oxidant is 0.1%-1% of the weight of the black and odorous water body. By means of the method for treating the black and odorous water body and the bottom mud thereof, desulphuration and denitrification of the bottom mud can be achieved, the situation that the bottom mud is converted into a facultative state from an anaerobic state is facilitated, black-odor of the water body can be eliminated rapidly, and the water body self-purification function is restored. The method for treating the black and odorous water body and the bottom mud thereof is suitable for comprehensive treatment of the black and odorous water body and a river channel.

Owner:广东灵捷制造化工有限公司

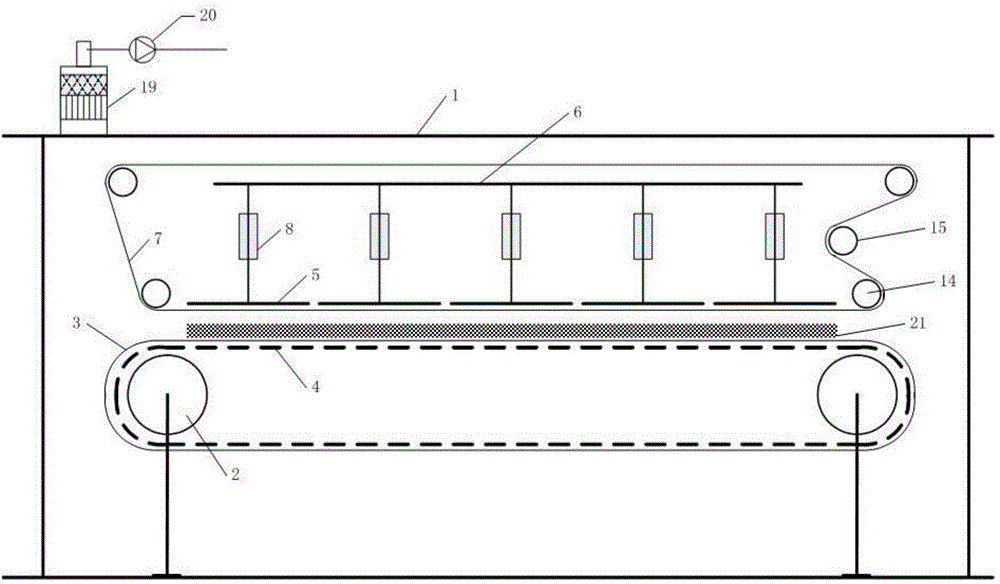

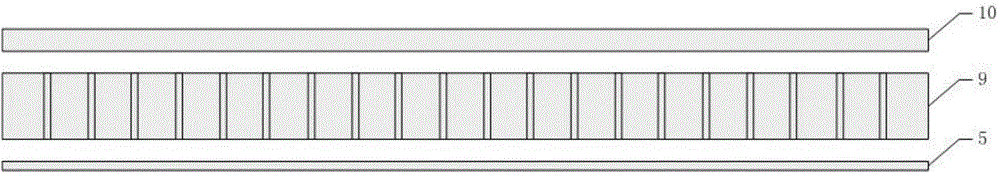

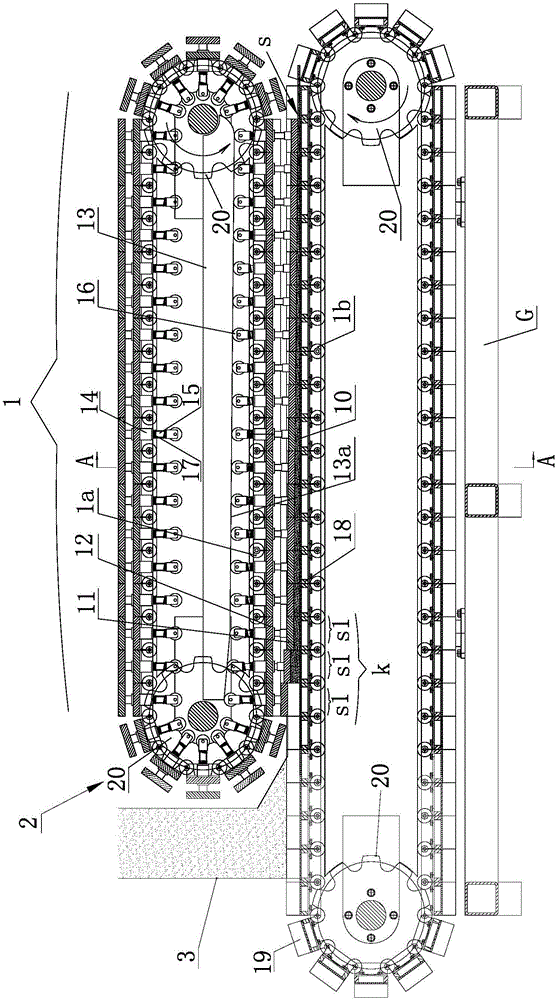

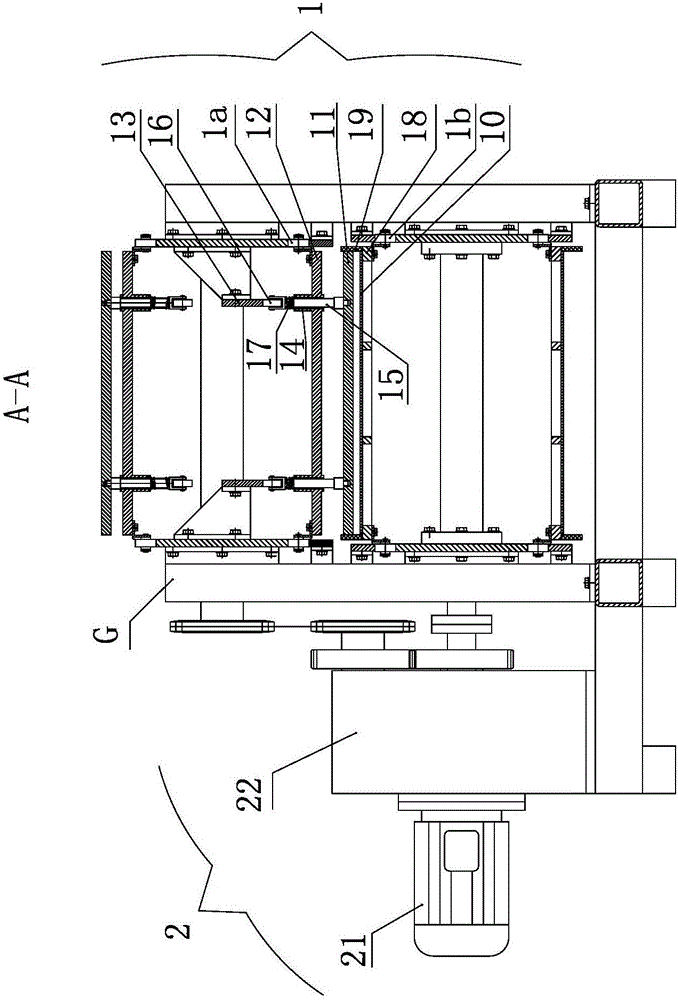

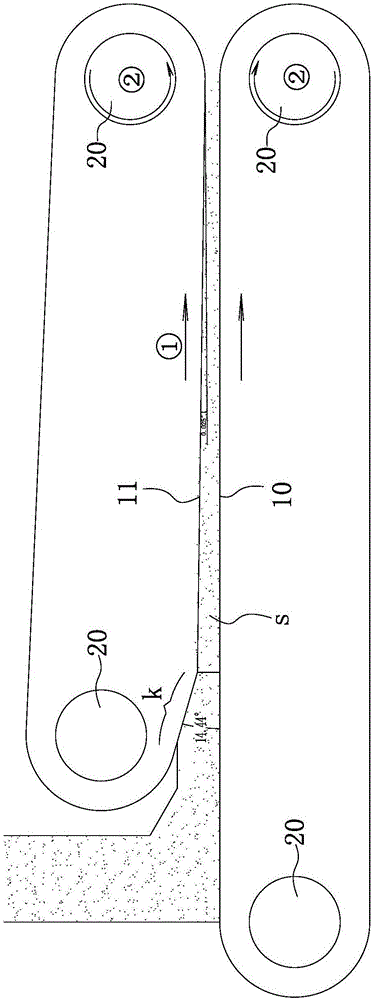

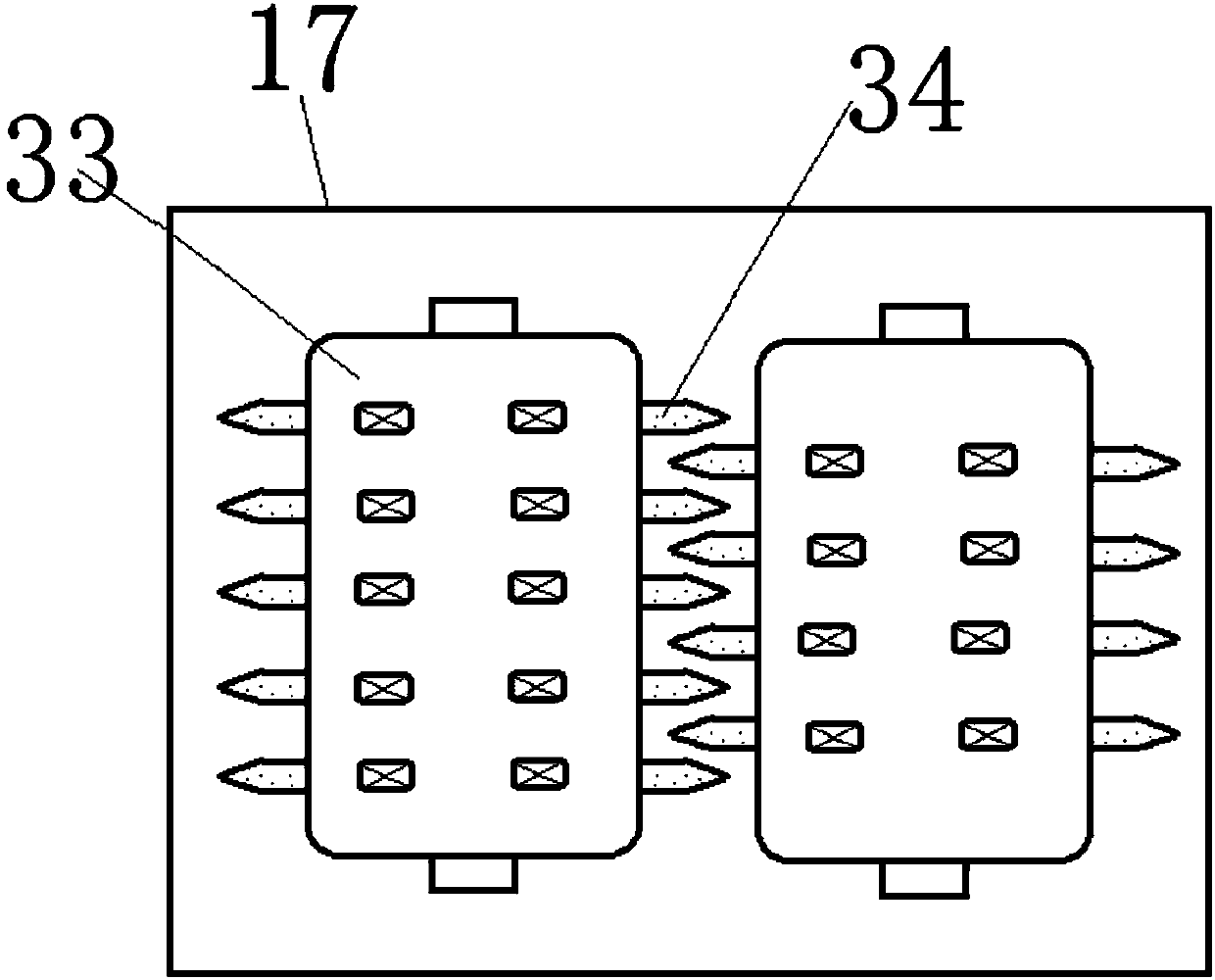

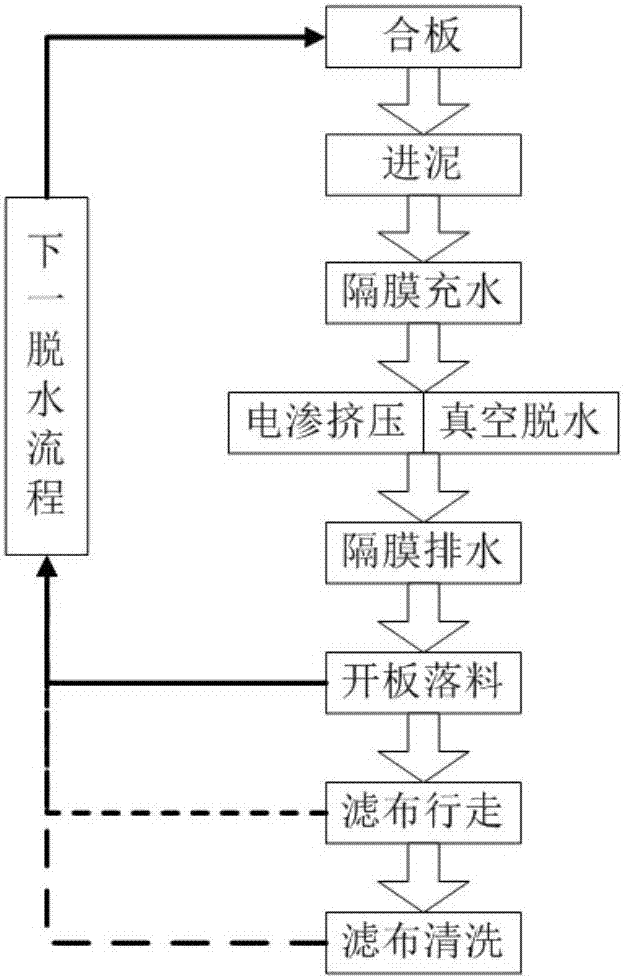

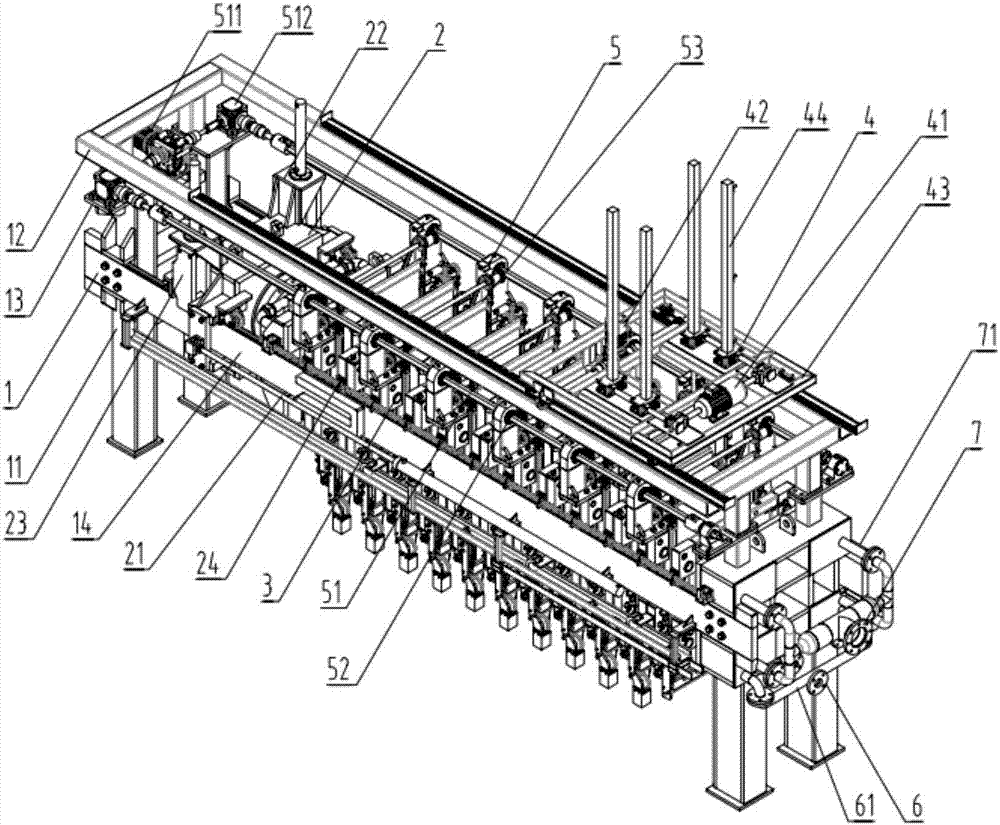

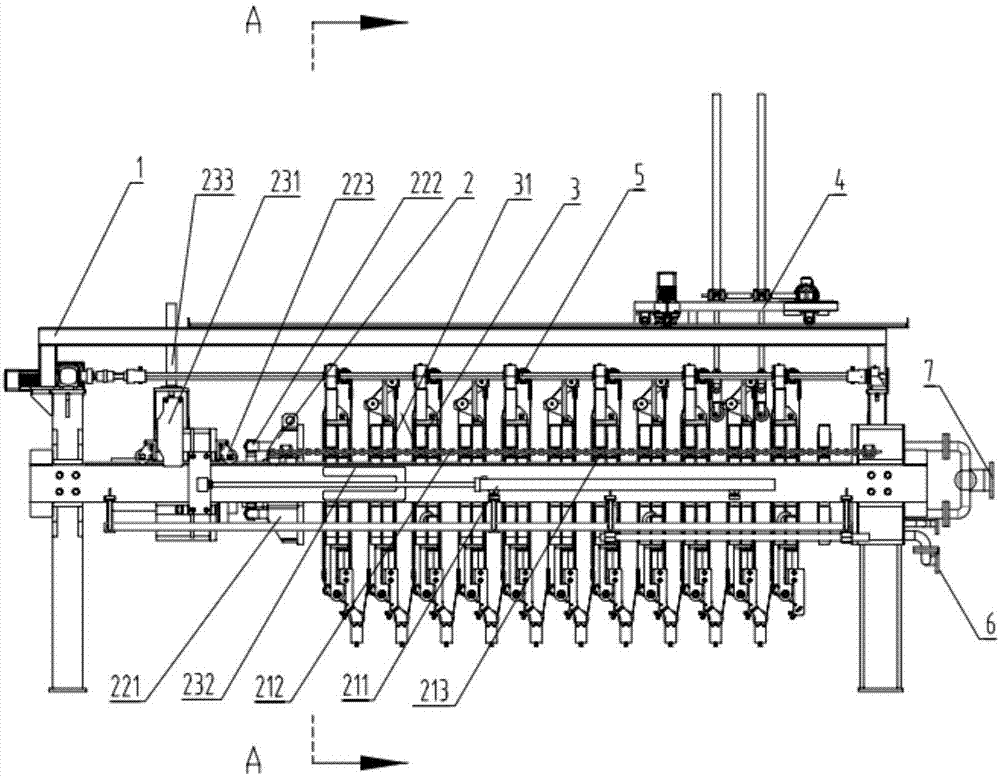

Sequencing batch sludge deep dewatering equipment and method adopting electroosmosis

ActiveCN104671632AReduce consumptionExtend anode lifeSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentEnd stagesDrive wheel

The invention relates to sequencing batch sludge deep dewatering equipment and method adopting electroosmosis. The equipment comprises a closed frame, wherein an anode assembly and a cathode assembly are arranged in the frame; the cathode assembly comprises a driving wheel set supported at the lower part of the frame, the driving wheel set is sleeved with annular cathode filter cloth connected end to end, and cathode plates are arranged on the inner side of the cathode filter cloth; the anode assembly comprises a group of anode plates opposite to the cathode plates and a fixed seat supported at the upper part of the frame, and the anode plates are supported on the fixed seat respectively through driving pieces; anode filter cloth is arranged on one side, back to the corresponding driving piece, of each anode plate; sludge treatment space is formed between the anode plates and the cathode plates; and a middle layer and a surface active layer are arranged on the surface of each anode plate sequentially. The method comprises a start stage, a normal circulation work stage and an end stage. The service life of an anode can be prolonged, the electric energy consumption can be reduced, and biochemical sludge with the moisture content of 80%-85% can be dewatered until the moisture content reaches 55%-60%.

Owner:南京赛佳环保实业有限公司

Efficient electroosmotic sludge dehydrator

ActiveCN106630541AImprove dehydration effectImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentConductive materialsEngineering

The invention relates to an efficient electroosmotic sludge dehydrator, comprising a frame, a sludge dehydration unit, a drive mechanism that powers the sludge dehydration unit, and a power source; the sludge dehydration unit comprises a plurality of moving mesh plates and extrusion plates movably arranged at lower and upper portions of the frame respectively along set trajectories, both the moving mesh plates and the extrusion plates are made of conductive material and are communicated with a cathode and anode of the power source respectively, a horizontally extended sludge extrusion passage is formed between the extrusion plates and the moving mesh plates, and the sludge extrusion passage narrows gradually from its inlet end to its outlet end and forms a quick extrusion area close to its inlet end; the narrowing rate of the sludge extrusion passage corresponding to the quick extrusion area is greater than that of the other area of the sludge extrusion passage. Compared with a dehydrator of ZL201310285709.6, the efficient electroosmotic sludge dehydrator has dehydration efficiency increased by about 30% with the dehydration effect unchanged, and is easier to popularize.

Owner:浙江科力尔环保设备股份有限公司

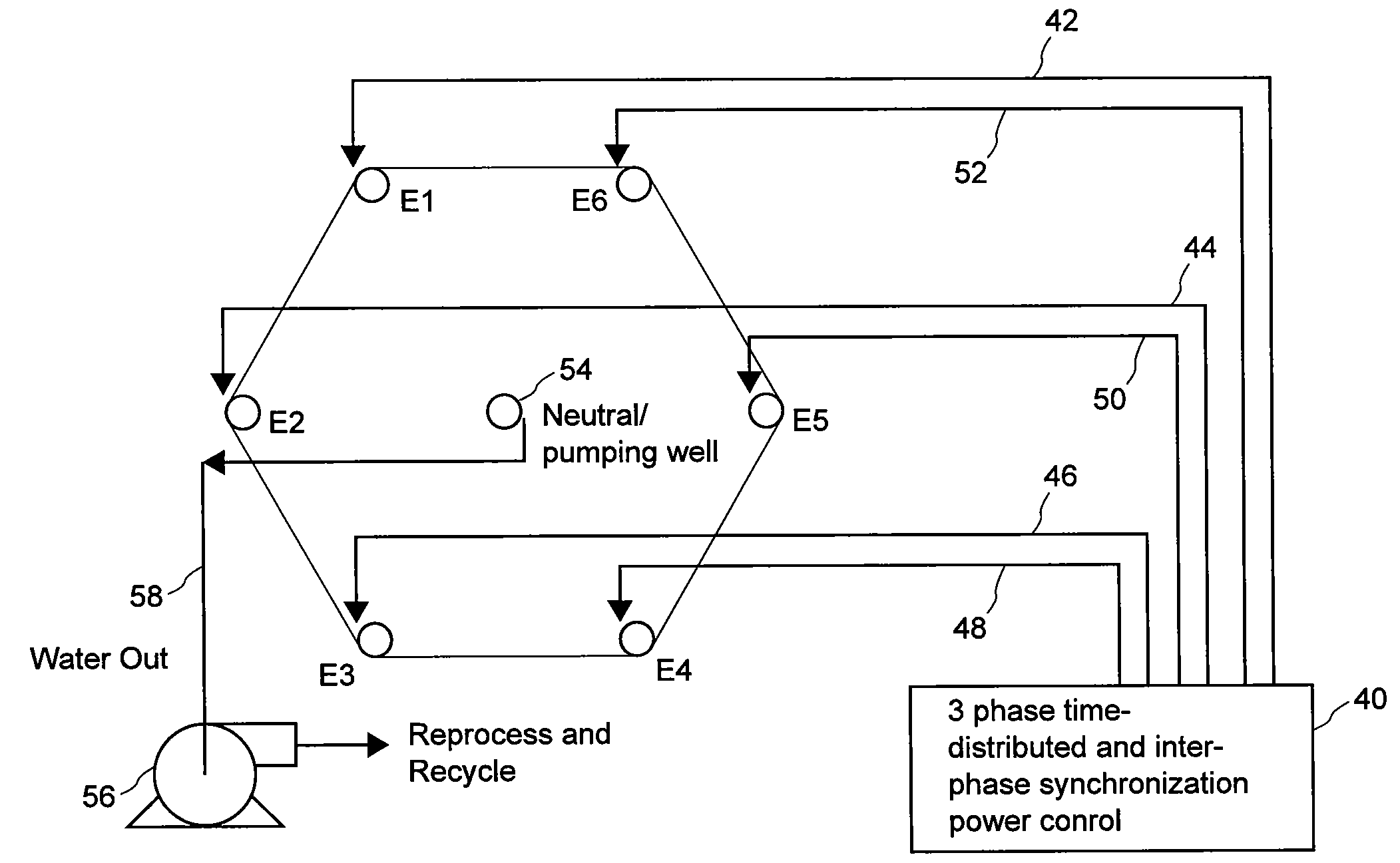

Electrokinetic Process And Apparatus For Consolidation Of Oil Sands Tailings

InactiveUS20120255872A1Increase capacityFree up spaceWaste water treatment from quariesCellsFlocculationEngineering

A method is provided of treating liquid tailings using electro-kinetics by creating a variable voltage between two electrodes in the tailings. Flocculation and water release from the tailings is induced by establishing an electrical field between the two electrodes. The electrodes are connected to an electrical power source having the variable voltage to create a cathode and an anode. Compacting the flocculation solids and removing further water released from the compacting solids allows for the creation of a compacted material having a desired load bearing capacity.

Owner:ELECTRO KINETIC SOLUTIONS

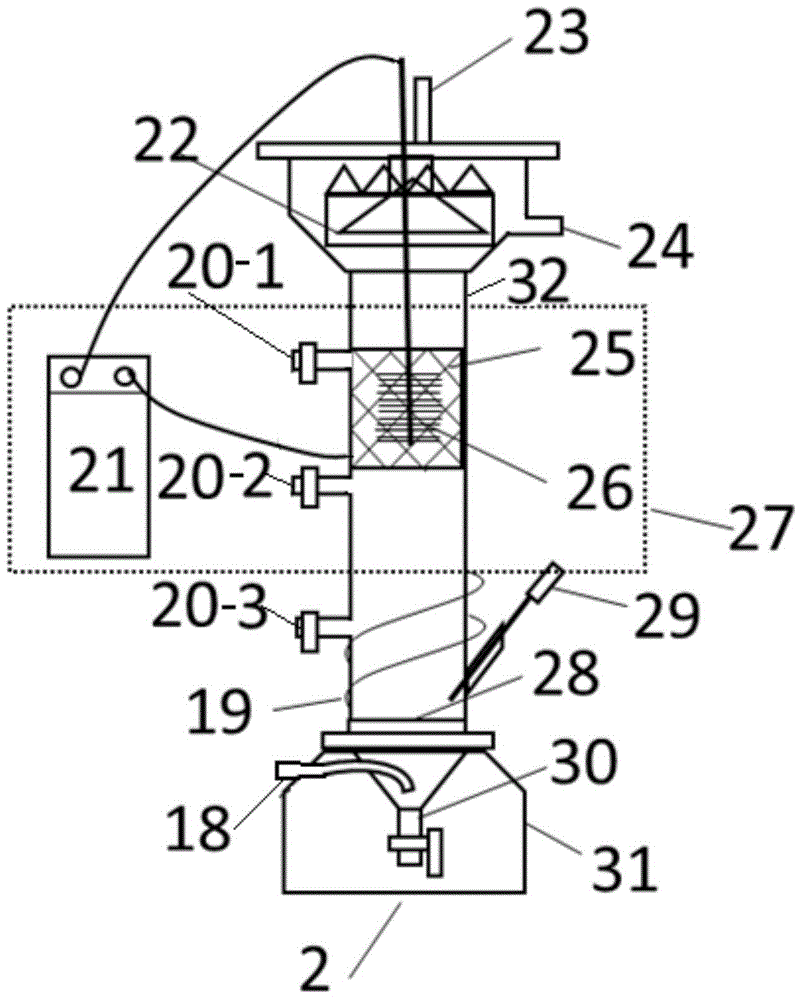

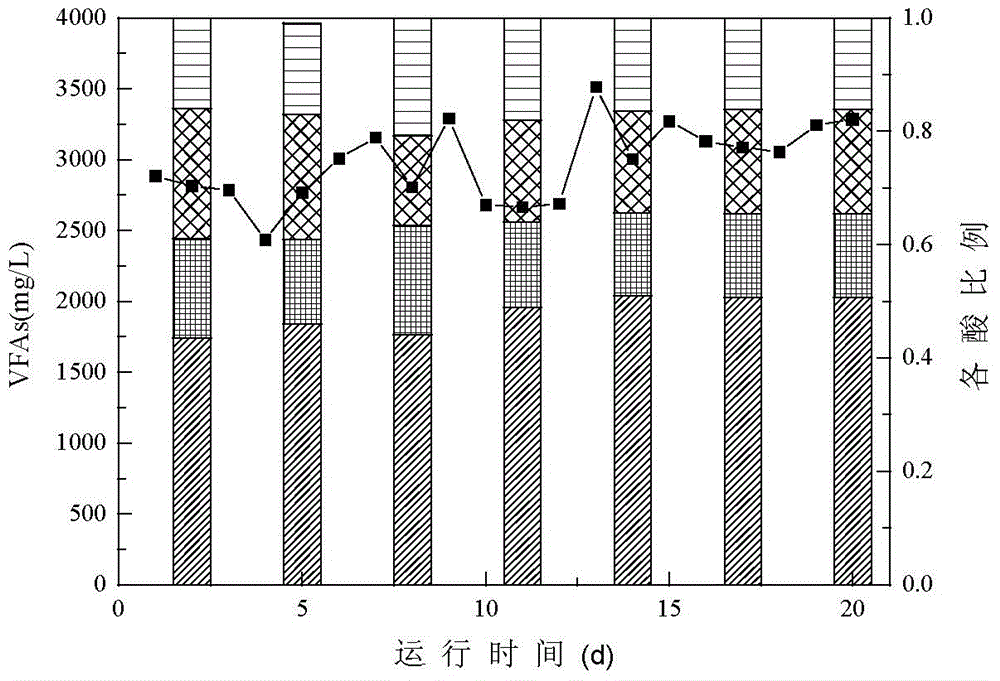

Microbial electrolysis two-section type sludge anaerobic digestion device and method for producing methane by using microbial electrolysis two-section type sludge anaerobic digestion device

ActiveCN104478178AImprove the breaking effectImprove utilization and removal rateSpecific water treatment objectivesWaste based fuelElectrolysisBiomass degradation

The invention discloses a microbial electrolysis two-section type sludge anaerobic digestion device and a method for producing methane by using the microbial electrolysis two-section type sludge anaerobic digestion device, relating to an improved two-section type anaerobic digestion device and a method for producing methanol from sludge. The purpose of the microbial electrolysis two-section type sludge anaerobic digestion device is to solve the technical problems of long fermentation cycle, low methanol yield and difficult biomass degradation and application in an existing residual sludge anaerobic digestion process. The microbial electrolysis two-section type sludge anaerobic digestion device consists of a continuous stirring type acidogenic reactor and a microbial electrocatalysis assisted upflow methane-producing reactor. The method comprises the following steps: starting a microbial catalytic electrolysis unit; producing acid by fermenting the residual sludge; and producing methanol. According to the microbial electrolysis two-section type sludge anaerobic digestion device and method disclosed by the invention, an acid production stage in a treatment process of the residual sludge only needs 5 to 8 days, a methanol production stage adopts continuous flow operation, the hydraulic retention time can be reduced to less than 1 day, and the operation cycle of sludge anaerobic digestion can be greatly shortened by adopting the device and method disclosed by the invention. The device and method disclosed by the invention belong to the field of sludge anaerobic digestion.

Owner:HARBIN INST OF TECH

Process for treating cellulose and cellulose treated according to the process

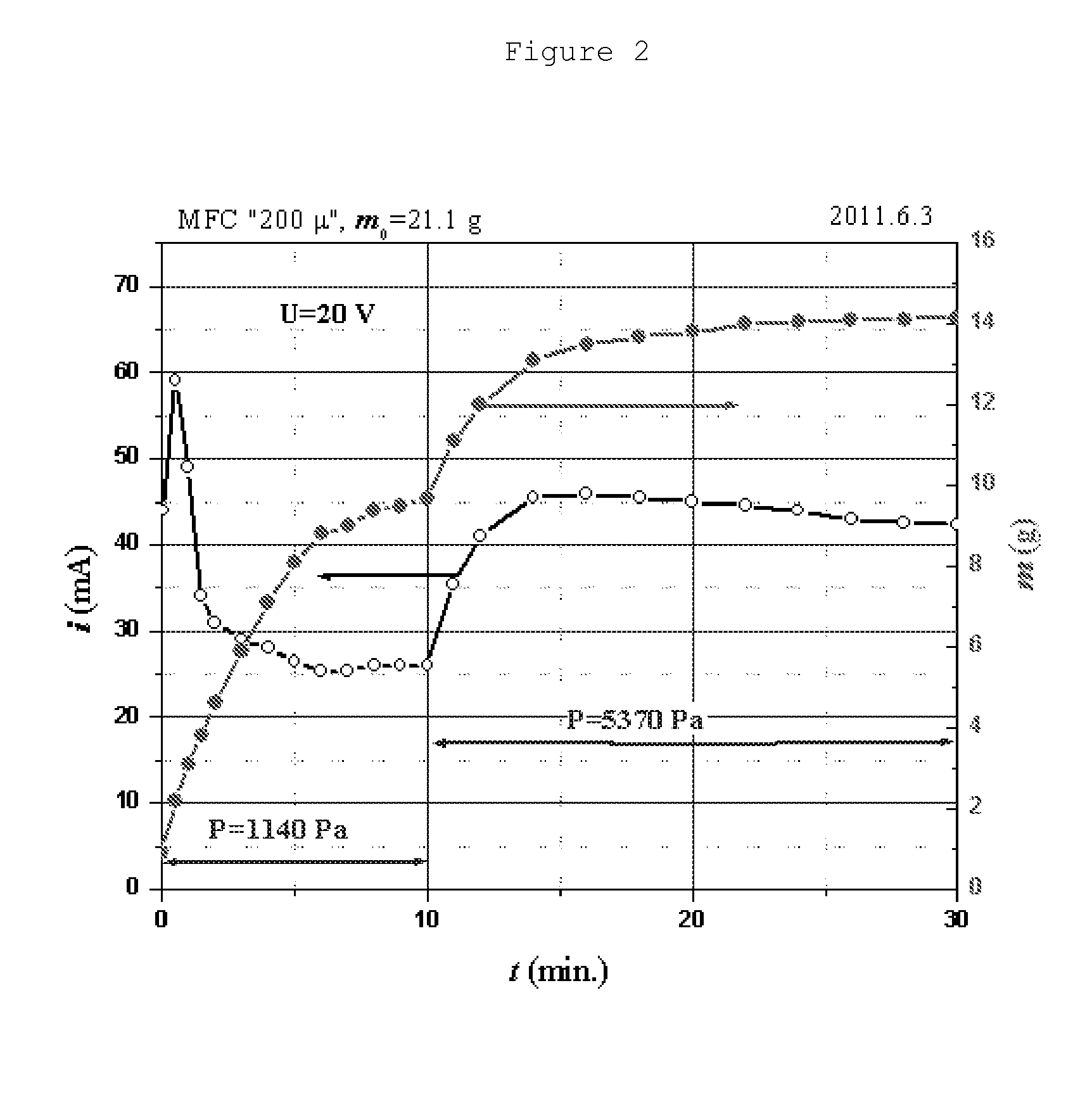

ActiveUS20140073774A1Improve responseWay of increaseSolidificationLiquefactionCelluloseOrganic solvent

The present invention relates to a process for purifying a slurry comprising cellulose, such as microfibrillated cellulose, wherein the process comprises the following steps: —providing a slurry comprising cellulose and liquid,—subjecting the slurry to an electric field inducing the liquid of the slurry to flow, —separating the liquid from the cellulose thus obtaining a liquid depleted slurry, —adding a washing liquid, such as an organic solvent, to the liquid depleted slurry—subjecting the liquid depleted slurry to an electric field inducing the washing liquid of the slurry to flow and—separating the washing liquid from the cellulose, thus obtaining a purified cellulose. The invention also relates to cellulose such as microfibrillated cellulose obtainable from said process.

Owner:STORA ENSO OYJ

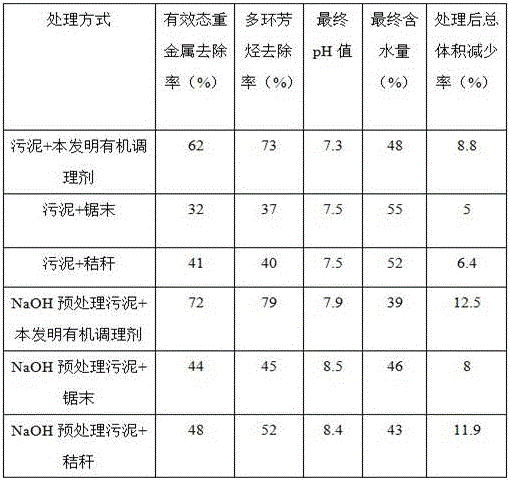

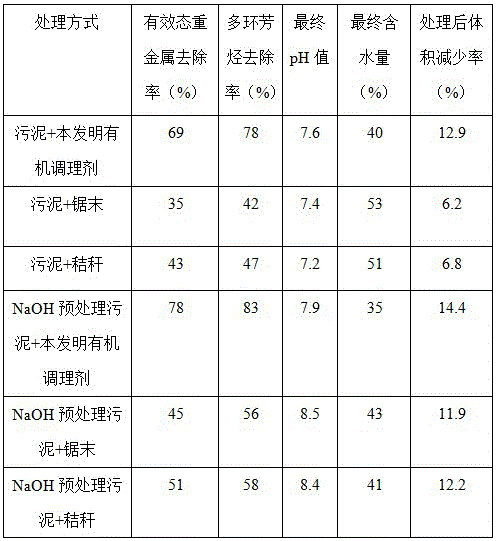

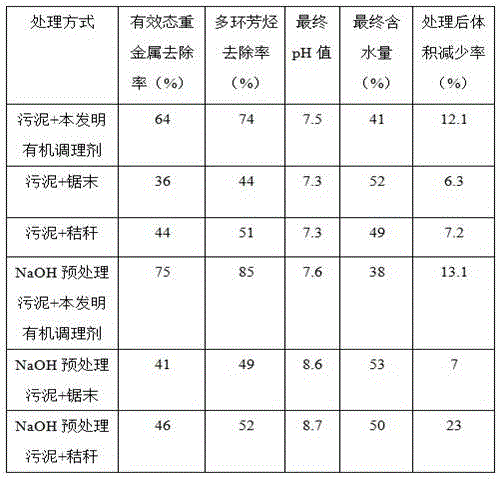

Municipal excess sludge biologic drying organic conditioning agent and preparation method thereof

ActiveCN105837005ARealize resource utilizationFast growthSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesIron powderSludge

The invention relates to a municipal excess sludge biologic drying organic conditioning agent and a preparation method thereof, and belongs to the technical field of environment engineering. Cellulose fermenting rest waste fungi residues and furfural residues are used as main substrates; after baking and carbonization, polysporus trichoderma conidial powder, iron powder and the like are added; through compounding and briquetting, the materials are prepared into the organic conditioning agents for rest sludge biologic drying. The organic conditioning agent has the beneficial effects of obviously promoting the starting of the sludge biologic drying process, improving the degradation efficiency of partial contaminants in sludge, passivating heavy metal and the like. The prepared organic conditioning agent can be used in the field of municipal excess sludge treatment and disposal.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

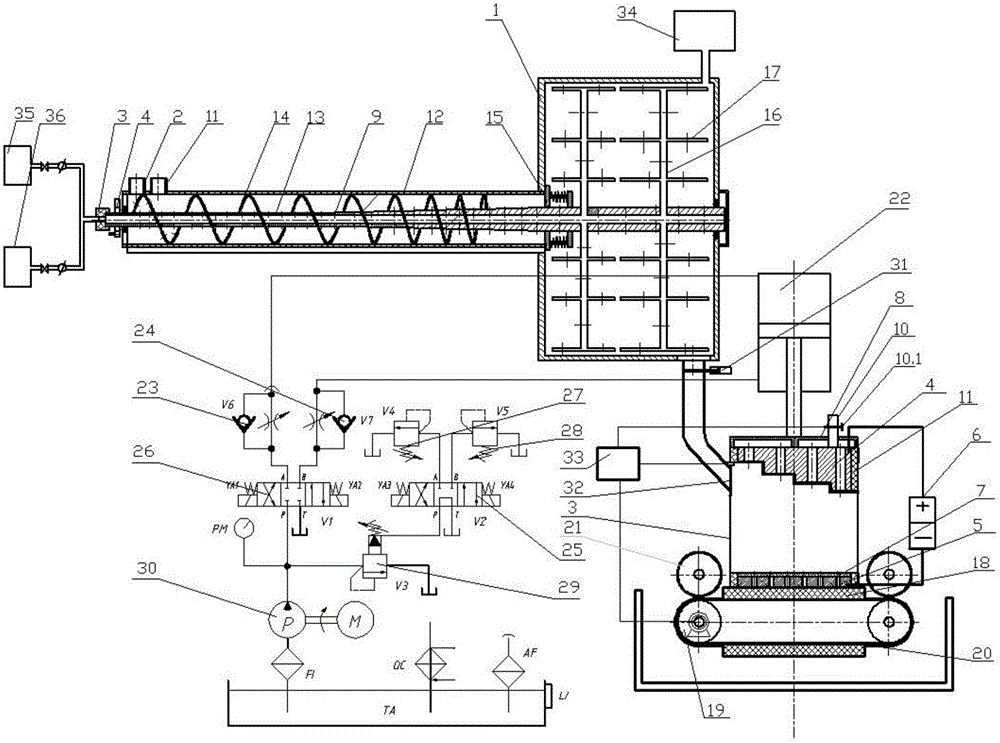

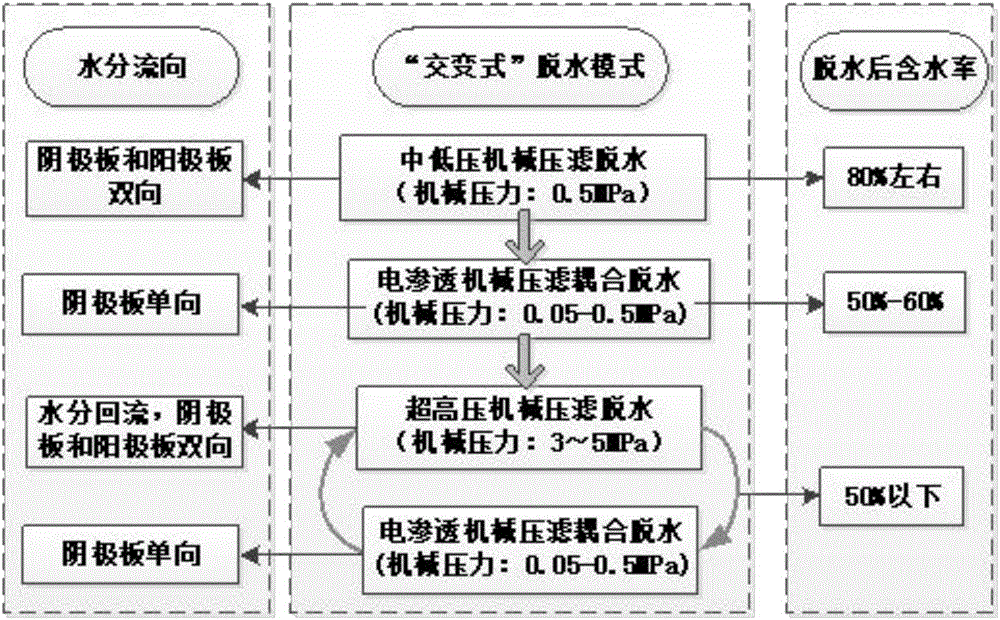

Sewage sludge dewatering device based on cooperation of oxidization, electroosmosis and mechanical filter pressing

InactiveCN105923968AReduce moisture contentImprove contact tightnessSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgeSewage

The invention discloses a sewage sludge dewatering device based on cooperation of oxidization, electroosmosis and mechanical filter pressing. The sewage sludge dewatering device comprises a spiral filter pressing device, an oxidation cylinder and an electroosmosis extrusion dewatering device, wherein a sewage sludge inlet is formed in the front end of the spiral filter pressing device; the rear end of the spiral filter pressing device is connected with the oxidation cylinder; the oxidation cylinder is communicated with the electroosmosis extrusion dewatering device; the electroosmosis extrusion dewatering device comprises an electroosmosis extrusion container, an anode plate, a cathode plate and a hydraulic system; the anode plate and the cathode plate are arranged in the electroosmosis extrusion container; after electroosmosis dewatering is completed by the electroosmosis extrusion dewatering device, the sludge water content of the anode plate is low, electroosmosis dewatering can be stopped, and pressure between the anode plate and the cathode plate is enlarged, so that ultrahigh pressure filter pressing dewatering is realized; the hydraulic system is connected with the anode plate, and the hydraulic system comprises a hydraulic oil cylinder and a high-low pressure regulating device. According to the sewage sludge dewatering device disclosed by the invention, high-water content sludge can be directly treated, and the dewatering energy consumption and the sludge water content are reduced through a multi-cooperation dewatering mode.

Owner:CHINA JILIANG UNIV

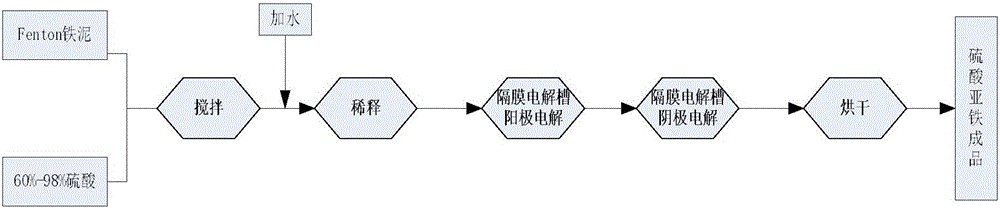

Method for resource utilization of Fenton iron mud

ActiveCN105836987AReduce pollutionReduce energy consumptionWater contaminantsIron sulfatesFerrous sulfate ironSulfate

The invention discloses a method for resource utilization of Fenton iron mud. The method comprises the following steps: adding sulfuric acid to the Fenton iron mud, converting Fe(OH)3 into Fe2(SO4)3 wholly, adding water to dilute after dissolving until the concentrations of iron ions are 70 to 98g / L to obtain a treatment solution I; adding the obtained treatment solution I to an anode chamber of a diaphragm electrolyzer, carrying out oxidation treatment on organic matters in the Fenton iron mud firstly, and then pumping into a cathode chamber of the diaphragm electrolyzer to carry out electroreduction treatment to obtain an Fe<2+> reducing solution; carrying out concentrated crystallization on the Fe<2+> reducing solution under the protection of an inert gas to prepare an industrial product, namely the ferrous sulfate product. According to the invention, the industrial ferrous sulfate is produced through electroreduction, so that the iron mud is fully subjected to resource utilization.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

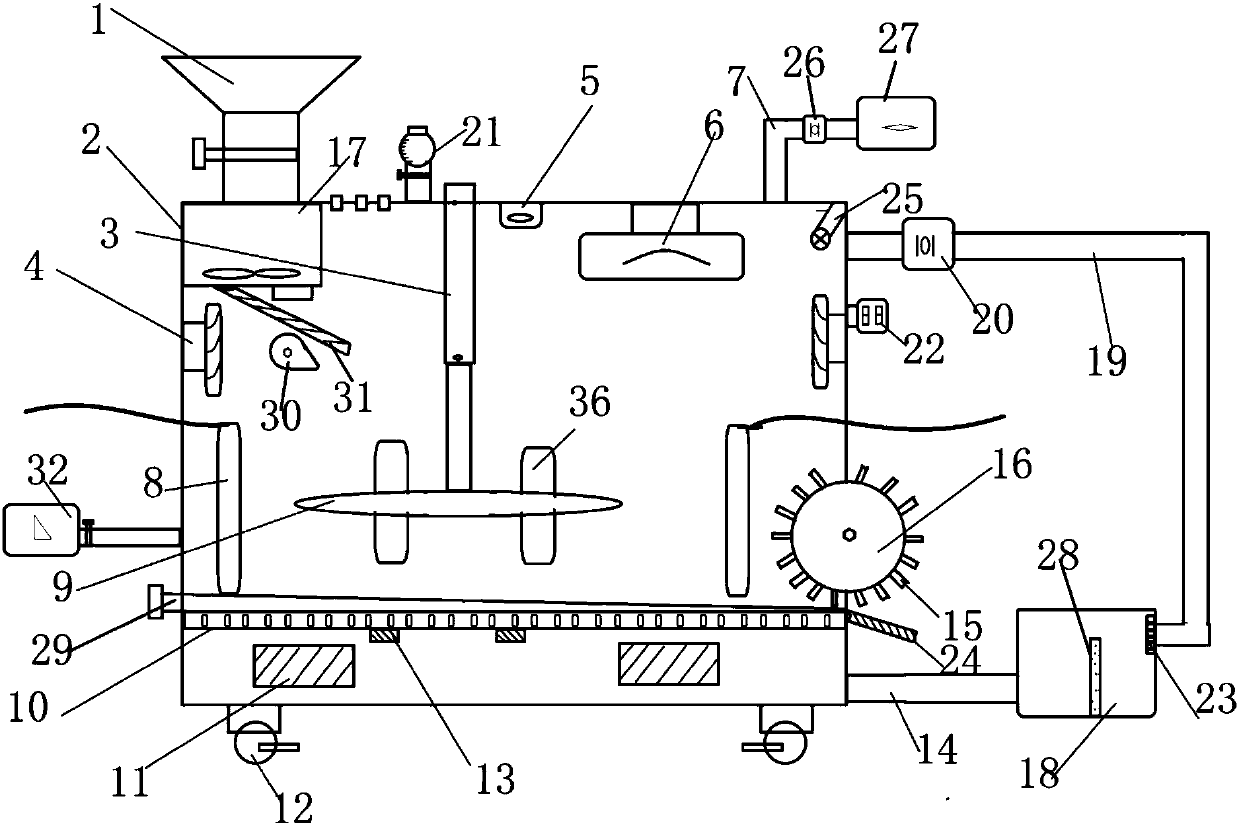

Efficient safety environment-friendly sludge treatment apparatus

InactiveCN107804956AReduce falling speedEasy dischargeSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesImpellerSludge

The invention discloses a high-efficiency, safe and environmentally friendly treatment equipment for sludge, which includes a feeding port, a treatment box, a rotating shaft, a UV violet lamp, a camera, a fan, an electrode, an impeller, a filter plate, a heater, a guide wheel, a drain pipe, a runner and sedimentation The top of the treatment box is provided with a feeding port, the outlet of the feeding port is provided with a pulverizer, the processing box is provided with a rotating shaft, an impeller is installed on the rotating shaft, a fan is provided on the inner wall of the top of the processing box, and a UV purple light is also provided on the inner wall of the processing box. There are electrodes in the treatment box, a filter plate at the bottom of the treatment box, a heater under the filter plate, a drainage pipe at the bottom of the treatment box, and the drainage pipe is set under the filter plate, and the drainage pipe is connected with the sedimentation tank. The side wall of the box is provided with runners. The invention sterilizes the bacteria and viruses in the sludge, reduces its diffusion, reduces the damage to people and the environment, separates the heavy metal ions in it, and prevents them from polluting other soil sources during landfill or other treatments. It has a simple structure and is easy to use. Good for promotion.

Owner:广西综改咨询服务有限公司

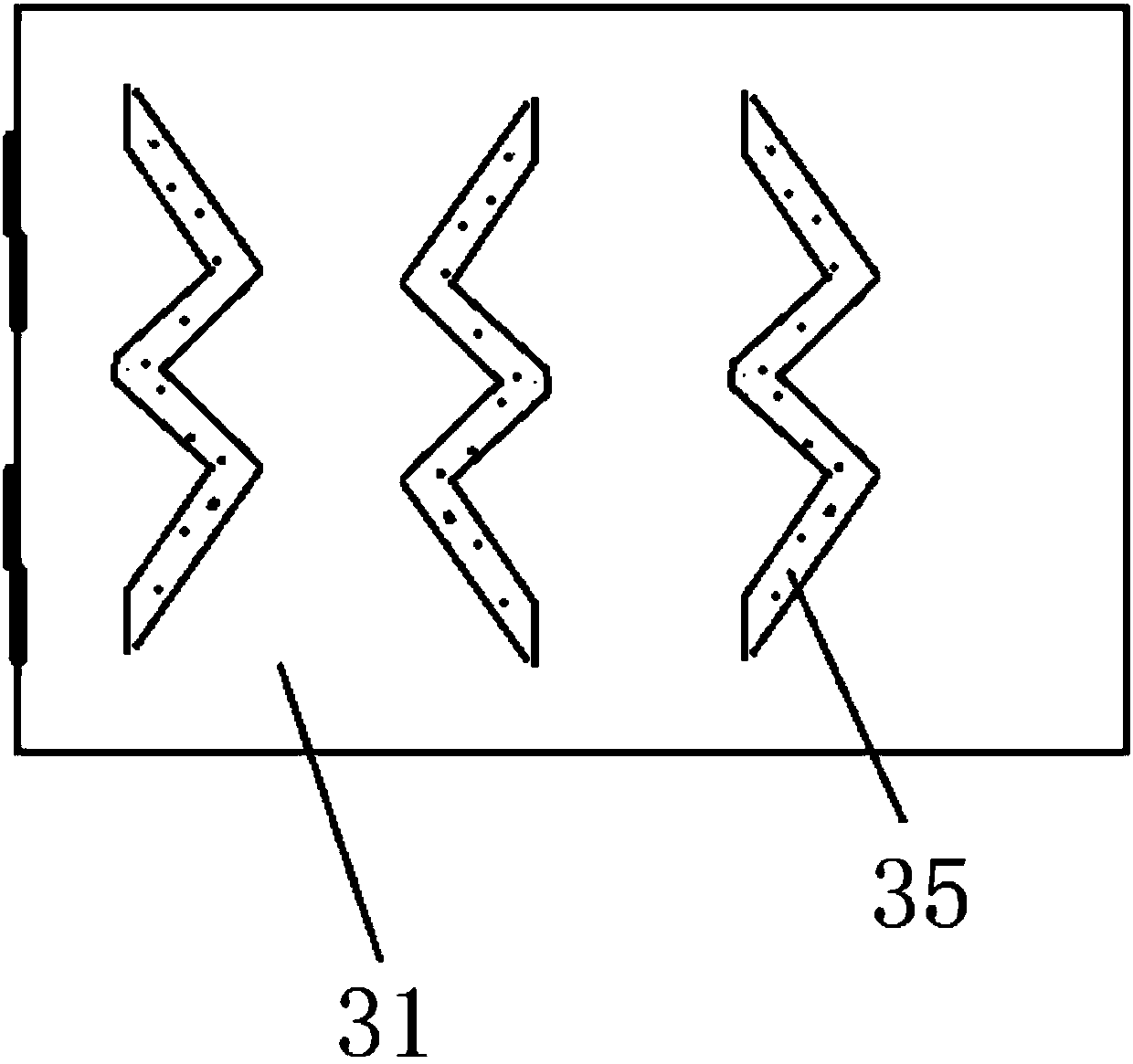

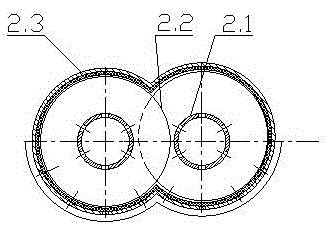

Filter plate and pressing filter assembly for electroosmotic sludge high-dryness dewatering equipment

ActiveCN105967489AHigh pressing pressureReduce moisture contentSludge treatment by de-watering/drying/thickeningWaste based fuelSludgeEngineering

The invention provides a pressing filter plate for electroosmotic sludge high-dryness dewatering equipment. The pressing filter plate comprises a filter plate frame, filter cloth, a filter disc and sludge conveying concentric holes, wherein the front surface of the filter plate frame unidirectionally sinks to form a pressing filter chamber; the filter disc is arranged at the bottom of the pressing filter chamber; the filter cloth is arranged on the filter disc; a cathode conductive filter screen connected with a cathode copper row is arranged between the filter disc and the filter cloth; an anode plate is arranged at the back of the plate frame; a cavity into which liquid or gas can be charged is formed between the filter disc and the plate frame; a push plate device is further arranged between the cavity and the filter disc; the cavity consists of a drum membrane, an inner steel base plate and an outer steel base plate; and the drum membrane is arranged on the inner peripheries of the steel base plates. By charging water to pressurize the cavity, a sludge pressing pressure is increased; meanwhile, through the push plate device, the uniformity of a pressing force is ensured and whole-process pressing is achieved; therefore, the moisture content of the sludge is further reduced.

Owner:EGUARD NEW ENERGY AUTOMOBILE CO LTD +1

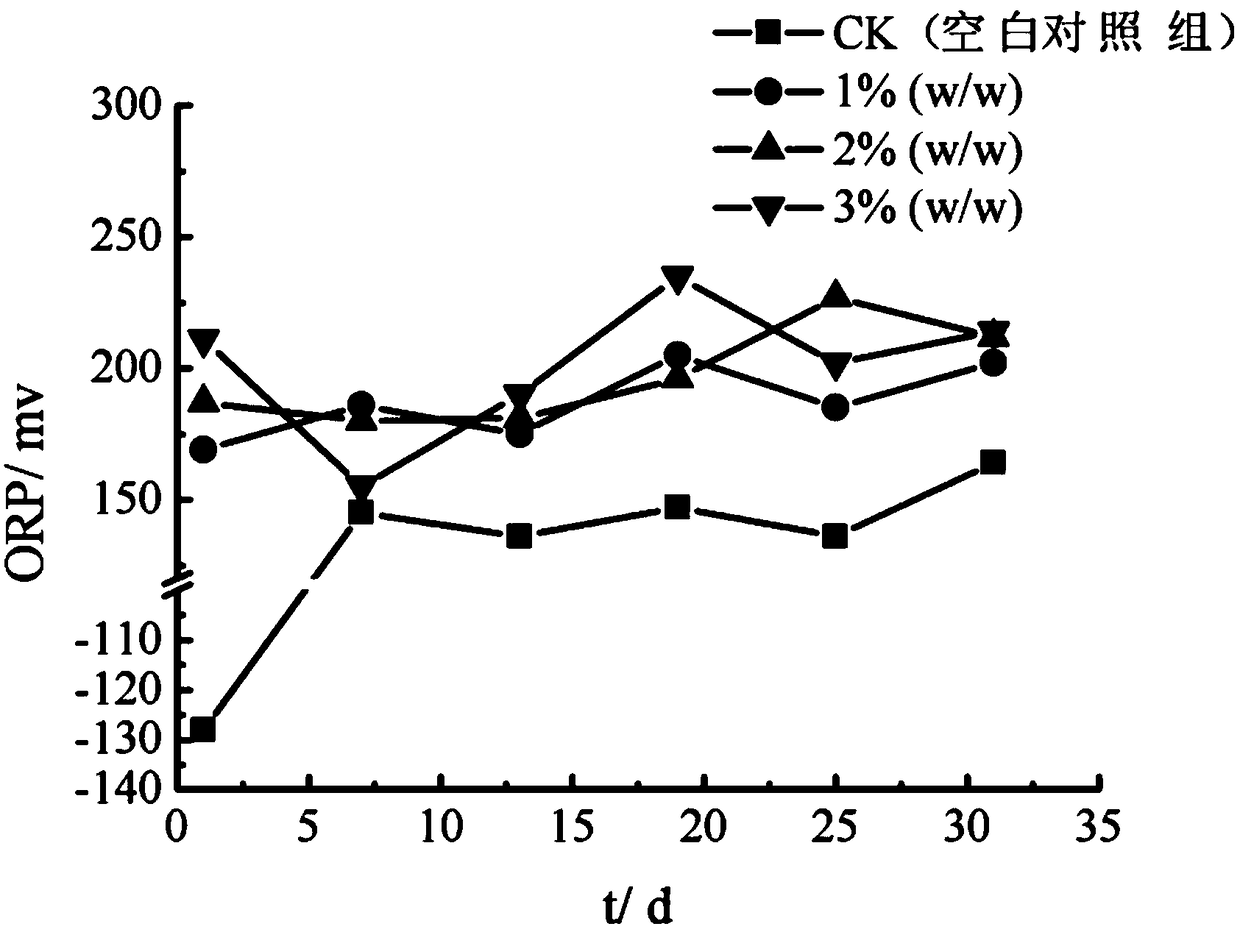

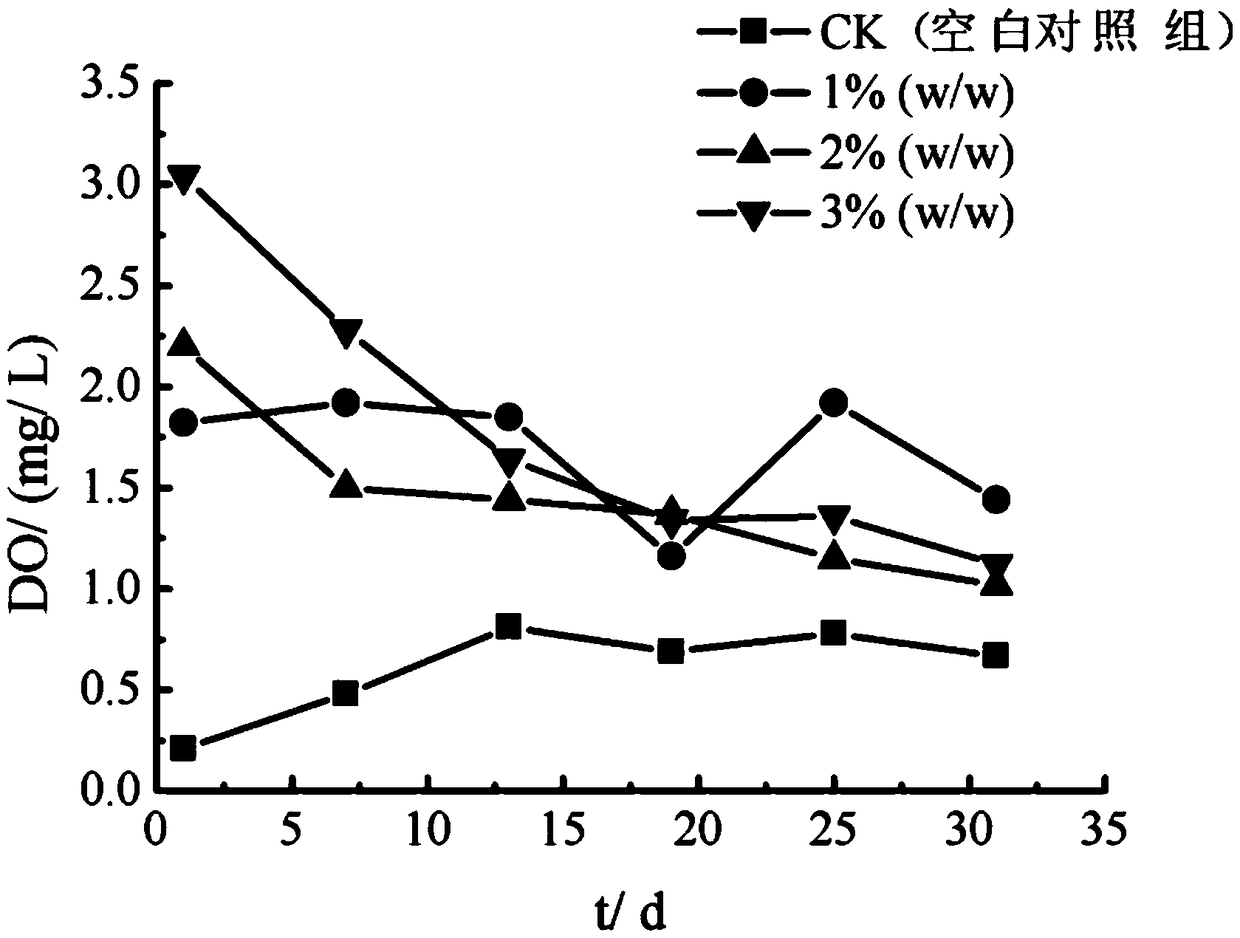

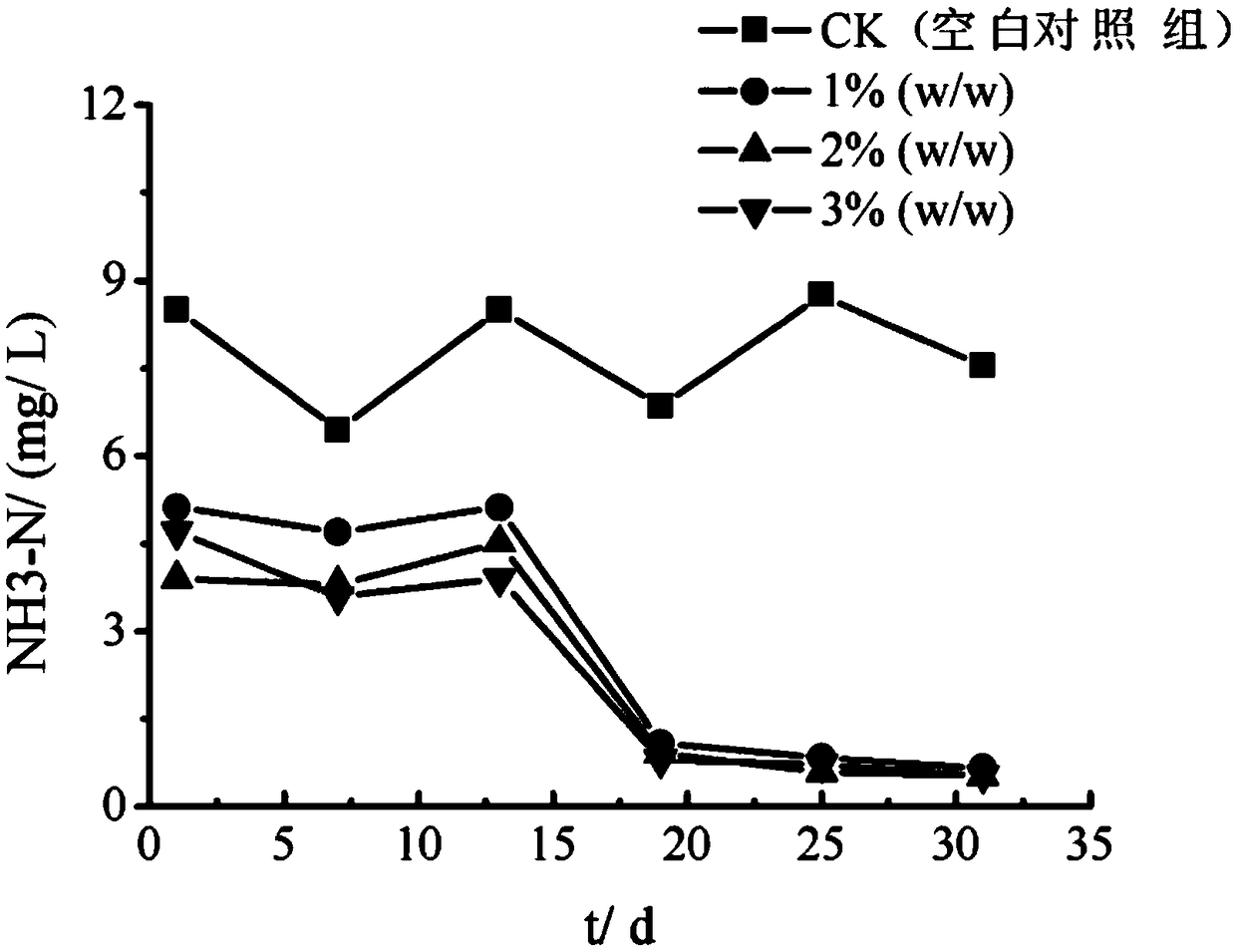

Sediment improving material for black and odorous water body and use method

PendingCN109133551AIncreased redox potentialEliminate black and odor phenomenonWater treatment parameter controlSludge treatment by oxidationIron powderNatural mineral

The invention relates to the field of black and odorous water body remediation, in particular to a sediment improving material for a black and odorous water body and a use method, and aims to providea sediment improving material capable of fundamentally eliminating black and odorous phenomena of the water body for the black and odorous water body. The sediment improving material is prepared from1-30 parts by weight of a sediment improving material A and 0.5-10 parts by weight of a sediment improving material B, wherein the sediment improving material A comprises iron powder, carbon powder, aluminium oxide, natural minerals and / or silica; the sediment improving material B comprises calcium nitrate, calcium peroxide and / or chitosan.

Owner:广州润方环保科技股份有限公司

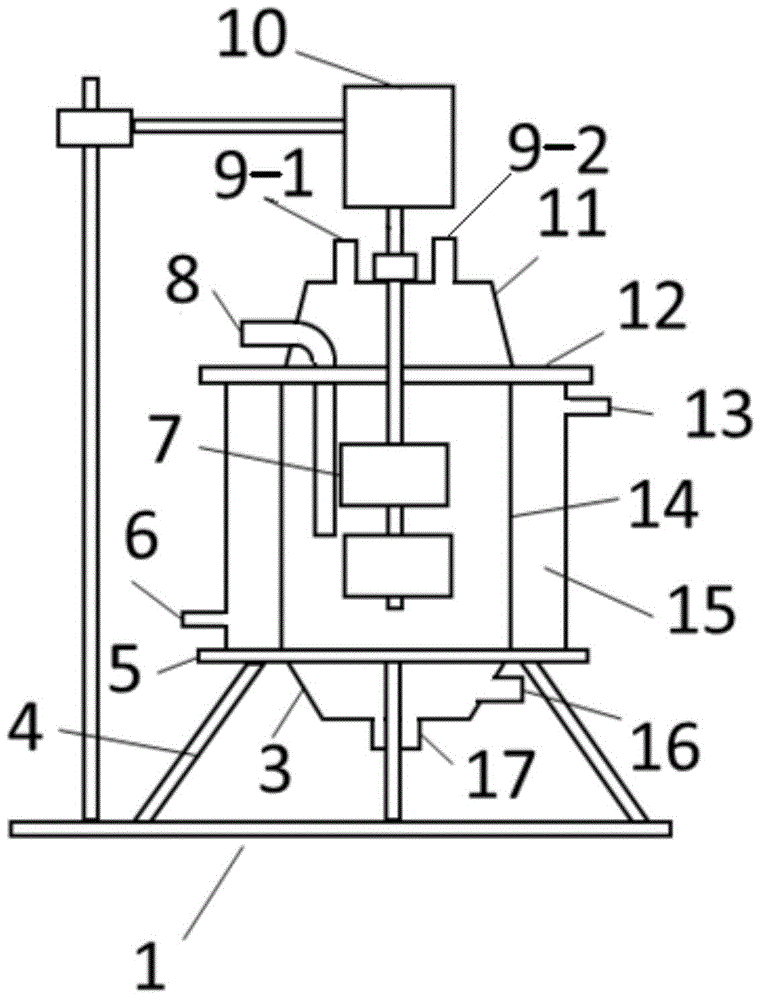

Vacuum electroosmosis sludge drying equipment and method thereof

ActiveCN106865944ACompact structureHigh degree of automationSludge treatment by de-watering/drying/thickeningElectrochemical sludge treatmentSludge cakeSteam pressure

The invention relates to vacuum electroosmosis sludge drying equipment and a method thereof. The vacuum electroosmosis sludge drying equipment and the method thereof are applied to treating sludge in environment protection industry and achieve sludge dehydration and drying. The vacuum electroosmosis sludge drying equipment comprises a support platform, a mechanical extruding device, an electroosmosis dehydrating device and a vacuum low-temperature evaporating and dehydrating device, wherein the mechanical extruding device, the electroosmosis dehydrating device and the vacuum low-temperature evaporating and dehydrating device are integrated to be an integrated structure and arranged on the support platform. The vacuum electroosmosis sludge drying equipment can mechanically extrude and dehydrate the sludge and perform electroosmosis treatment and vacuum low-temperature evaporation treatment at the same time. The vacuum electroosmosis sludge drying method mainly comprises the steps of utilizing mechanical extrusion among filter chambers to treat sludge into even sludge cake, performing electroosmosis dehydration and vacuumized dehydration at the same, reducing saturated steam pressure of water and accelerating water evaporation in an electroosmosis process. As three technologies are combined, the moisture content of sludge is effectively reduced, and the vacuum electroosmosis sludge drying equipment has the advantages of energy conservation, environmental friendliness, strong generalizability and the like.

Owner:北京海斯顿水处理设备有限公司

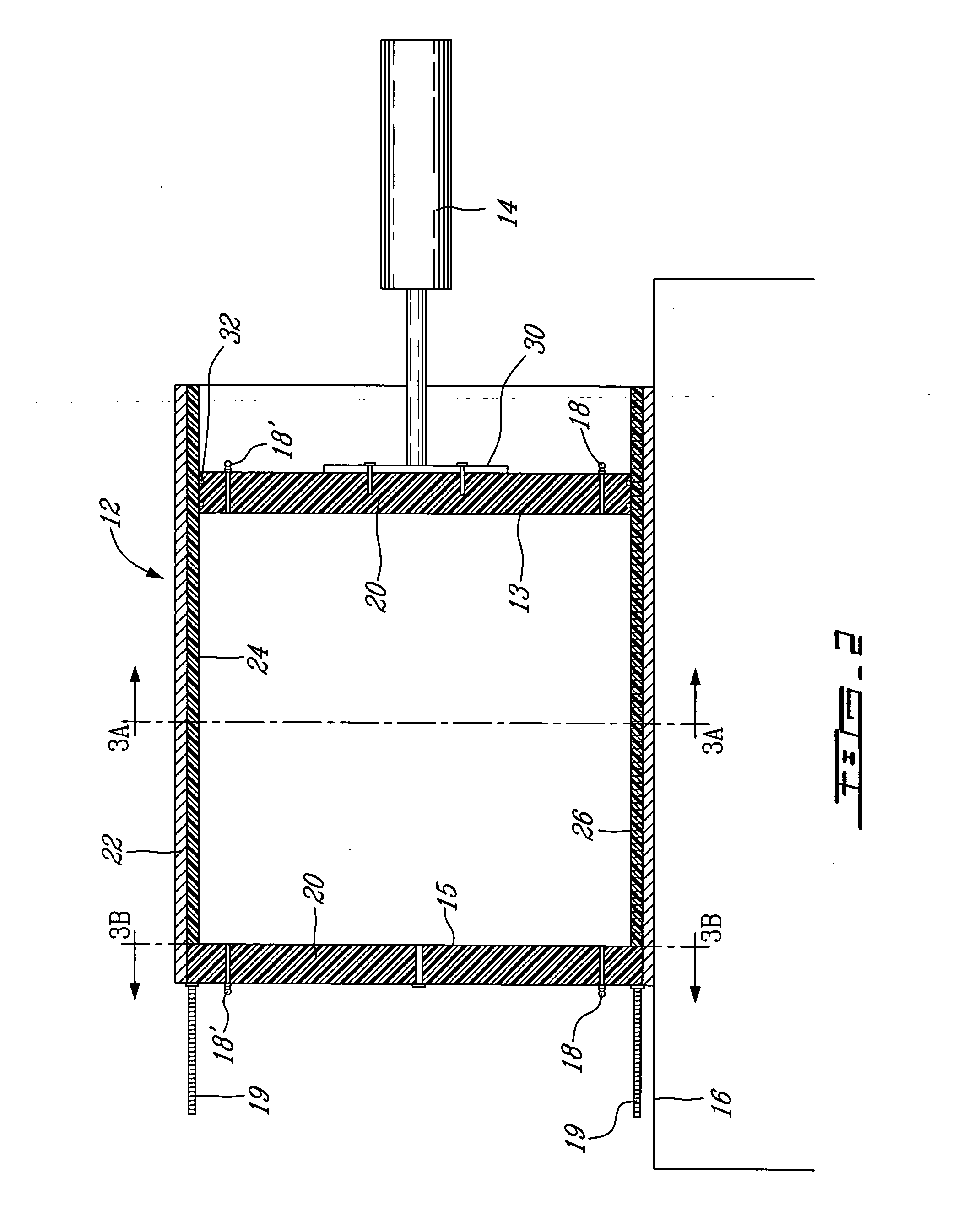

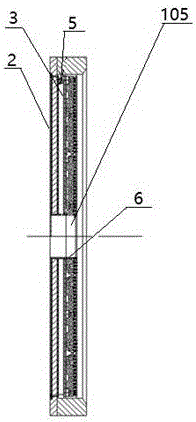

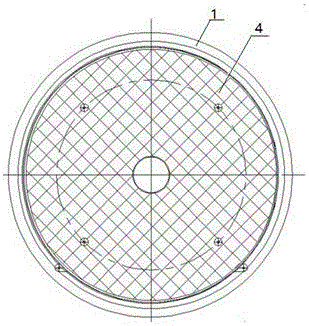

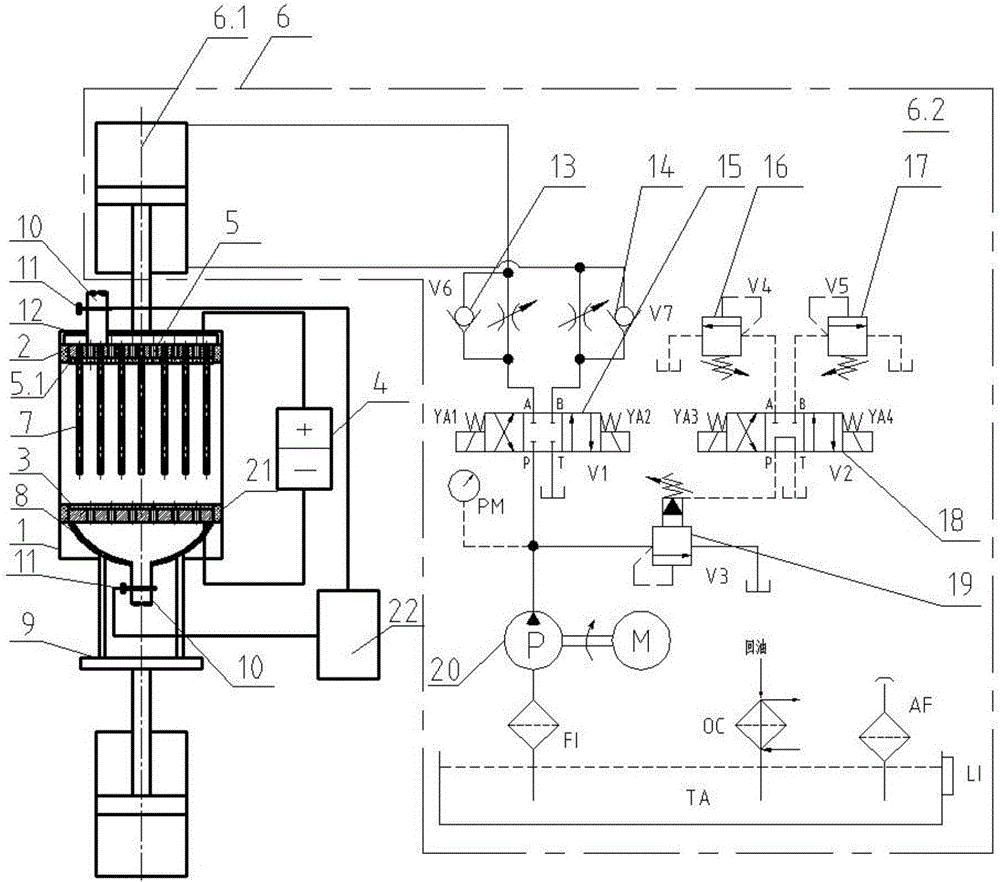

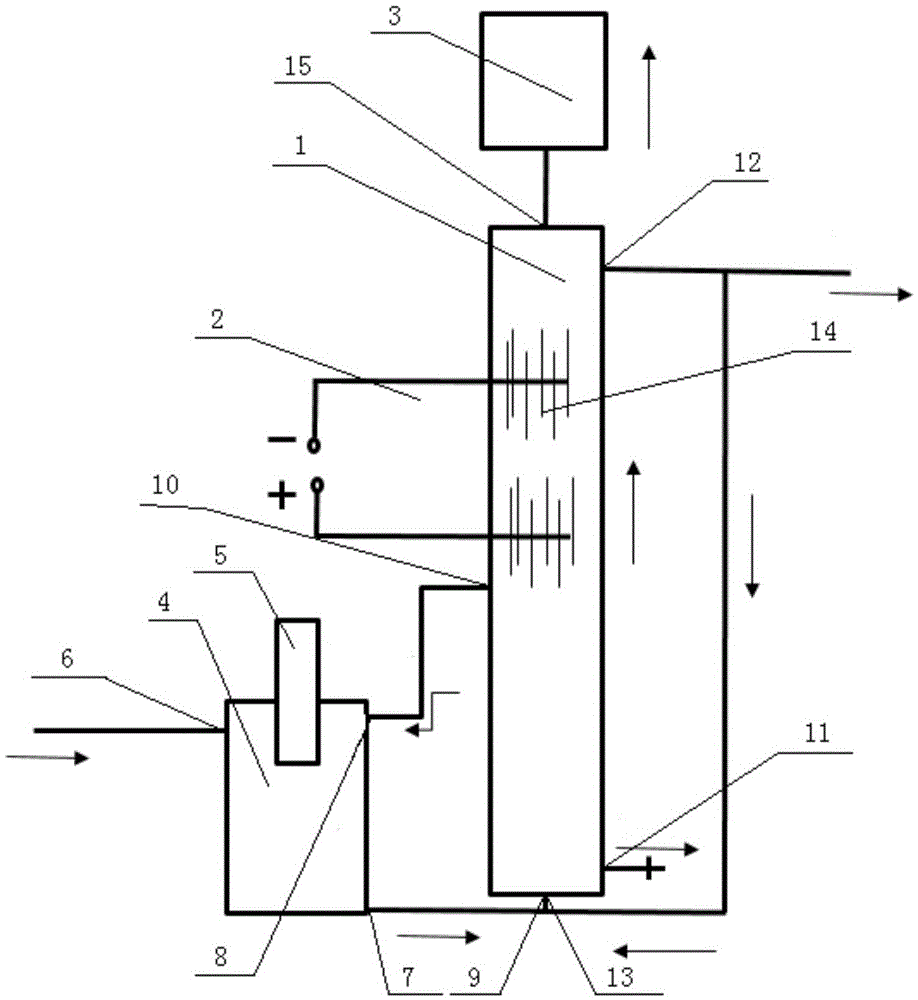

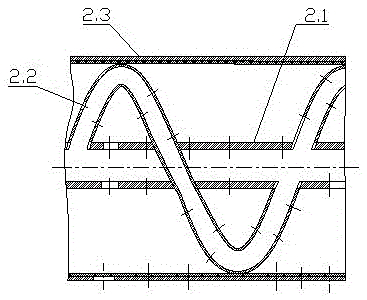

A sewage and sludge dehydrating device coupling electroosmosis and mechanical pressure filtration

InactiveCN106396303AUniform moisture contentEven distribution of moisture contentSludge treatment by de-watering/drying/thickeningElectrochemical sludge treatmentElectricitySludge

A sewage and sludge dehydrating device coupling electroosmosis and mechanical pressure filtration is disclosed. The device includes a pressure filtration container (1), an anode plate (2), a cathode plate (3) and a direct current source (4). The anode plate (2) is disposed at the upper part of the pressure filtration container (1). The cathode plate (3) is disposed at the lower part of the pressure filtration container (1). The cathode and anode of the direct current source (4) are respectively electrically connected to the anode plate (2) and the cathode plate (3). The anode plate (2) and the cathode plate (3) are provided with water outlet holes (5) on which filter cloths (5.1) are paved. The cathode plate (3) is connected to a hydraulic system (6) used for driving the cathode plate (3) to move. Through adoption of the device, sludge resistance in an anode layer is slow in increase, dehydration effects are good, and the water content distribution at the sludge thickness direction is uniform.

Owner:CHINA JILIANG UNIV

Anti-corrosion conductive ceramic electrode material for sewage and sludge treatment and preparation method thereof

ActiveCN105523761AGood for anodizingUnique electrochemical performanceWater/sewage treatment by electrochemical methodsElectrochemical sludge treatmentFiberEpoxy

The invention discloses an anti-corrosion conductive ceramic electrode material for sewage and sludge treatment and a preparation method of the anti-corrosion conductive ceramic electrode material. The anti-corrosion conductive ceramic electrode material is characterized in that carbon is used as aggregate; the anti-corrosion conductive ceramic electrode material is prepared from artificial graphite, graphitized mesocarbon microbeads, a reinforcement binder, graphitized carbon fiber and E-44 epoxy resin. The preparation method comprises the following steps of adding a Ti4O7 functional additive having strong electrode performance, simultaneously adding one or several of ceramic anti-wear-corrosion components of TiB2, TiO2, TiC, B2O3, SiO2 and SiC, carrying out solidification, compression molding and high-temperature sintering after adding a mixing solvent and completely mixing the mixture, and finally preparing the anti-corrosion conductive ceramic electrode material. According to the anti-corrosion conductive ceramic electrode material and the preparation method, disclosed by the invention, aiming at an actual working situation of a sewage and sludge treatment environment, unique anti-corrosion components are added while low specific resistance of the anti-corrosion conductive ceramic electrode material is ensured, not only are wearing resistance and corrosion resistance of traditional ceramics obtained, but also excellent conductivity and excellent electrochemical performance are obtained, and the service life is up to more than 3500 hours.

Owner:JIANGSU UNITED CERALLOY MATERIALS TECH

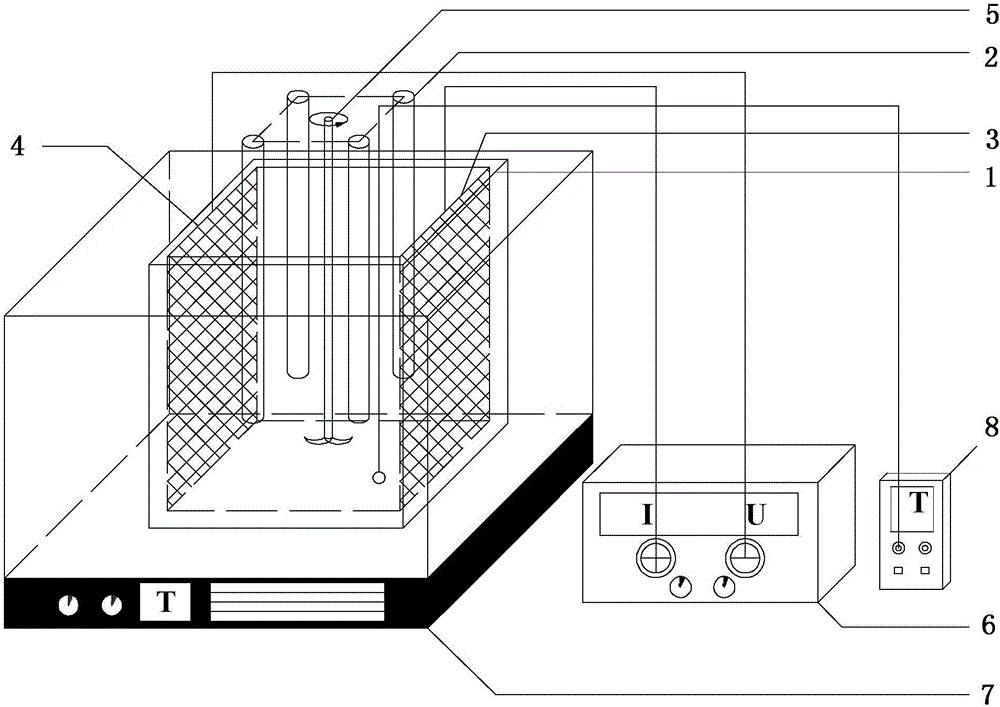

Sludge treatment method and electrochemical appliance

ActiveCN106219916AGood cracking effectAchieve activitySludge treatment by de-watering/drying/thickeningSludge treatment by oxidationActivated sludgeElectrolysis

The invention discloses a sludge treatment method and an electrochemical appliance. The sludge treatment method includes: mixing sodium sulfate with activated sludge to obtain a mixture; placing the mixture into an electrolytic bath, placing an activator between the anode and the cathode of the electrolytic bath and performing electrochemical treatment; continuously adding framework materials in the mixture subjected to the electrochemical treatment prior to stirring to complete treatment of sludge. The electrochemical appliance comprises the electrolytic bath and an iron rod, an anode plate and a cathode plate are arranged in the electrolytic bath, the iron rod is arranged between the anode plate and the cathode plate, the anode plate is of an IrO2-RuO2 / Ti electrode plate, and the cathode plate is of a Ti electrode plate. On the basis of electrochemistry-advanced oxidation-framework combined sludge treatment method, sludge dewatering property can be remarkably improved, and the sludge can be odorless after dewatering and stable in property.

Owner:HUNAN UNIV

Method for removing and recovering heavy metal in sludge through electrolytic method

InactiveCN105884157AShorten migration distanceHigh removal rateWater contaminantsElectrochemical sludge treatmentElectrochemical responseElectrolysis

The invention discloses a method for removing and recovering heavy metal in sludge through an electrolytic method. The method includes the steps that the water content of the sludge is adjusted to 90%, then the sludge is stirred; a chemical agent is selectively added, stirred and pretreated; an electrolyzer is assembled and stirs the sludge for electrolysis; the heavy metal is recovered finally. The sludge is directly put in an anode region, the sludge is directly acidized with H+ generated through water electrolysis through an anode, acid does not need to be added additionally, secondary pollution is reduced, and the removal rate of the heavy metal is increased. In addition, the sludge is directly put in the anode region, an electrode can make full contact with the sludge, the current efficiency is fully used, and the electrolysis efficiency is high. The action of electrochemical reaction of a cathode and anode is used well, the membrane exchange area between the sludge and electrolyte is increased, the ionic migration distance is reduced, the heavy metal removal rate is high, the electric energy use ratio is large, the problem of heavy metal recovery is improved, the dual purposes of reducing pollution and recovering resources can be achieved, and environment value and economic benefits are achieved.

Owner:ZHEJIANG UNIV

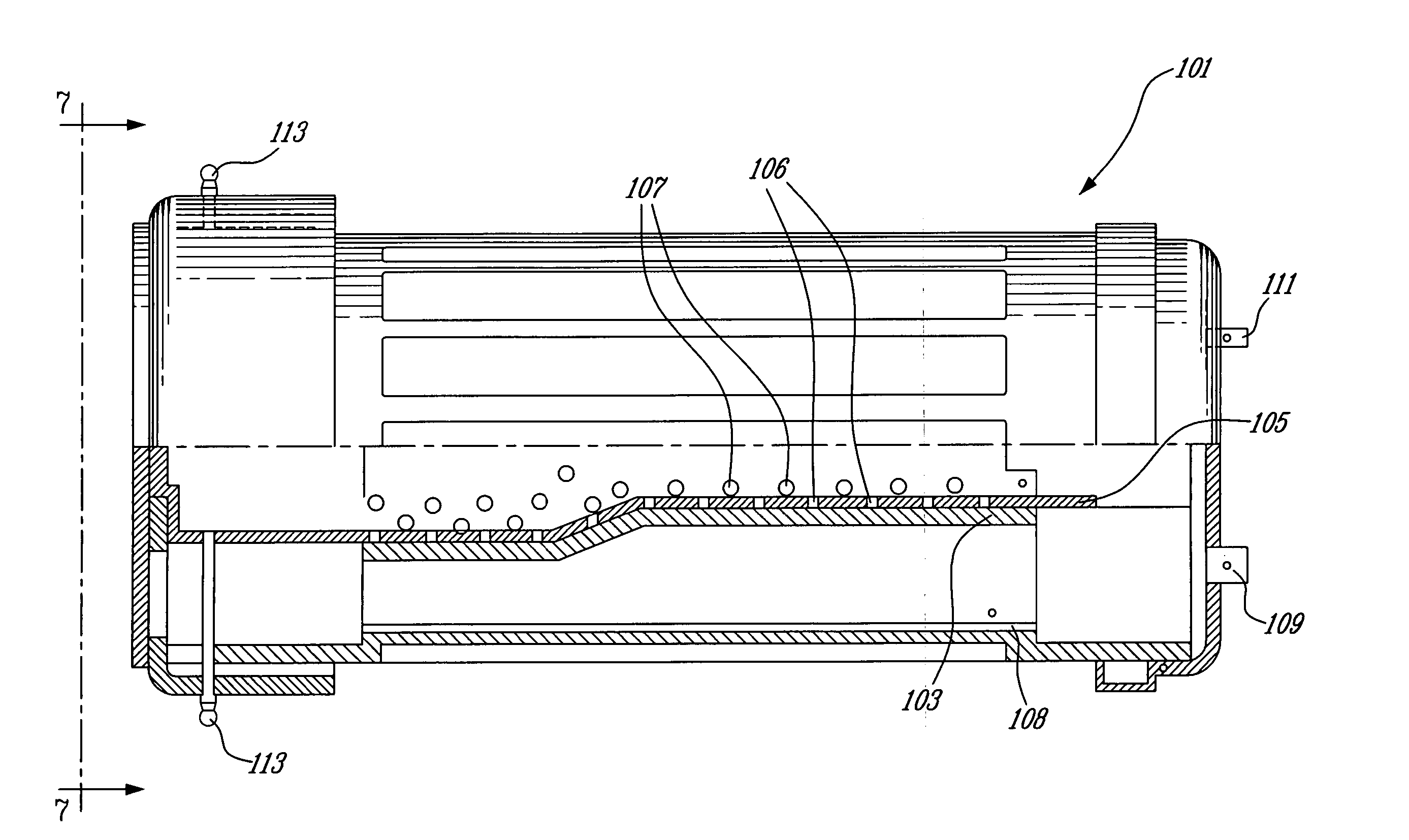

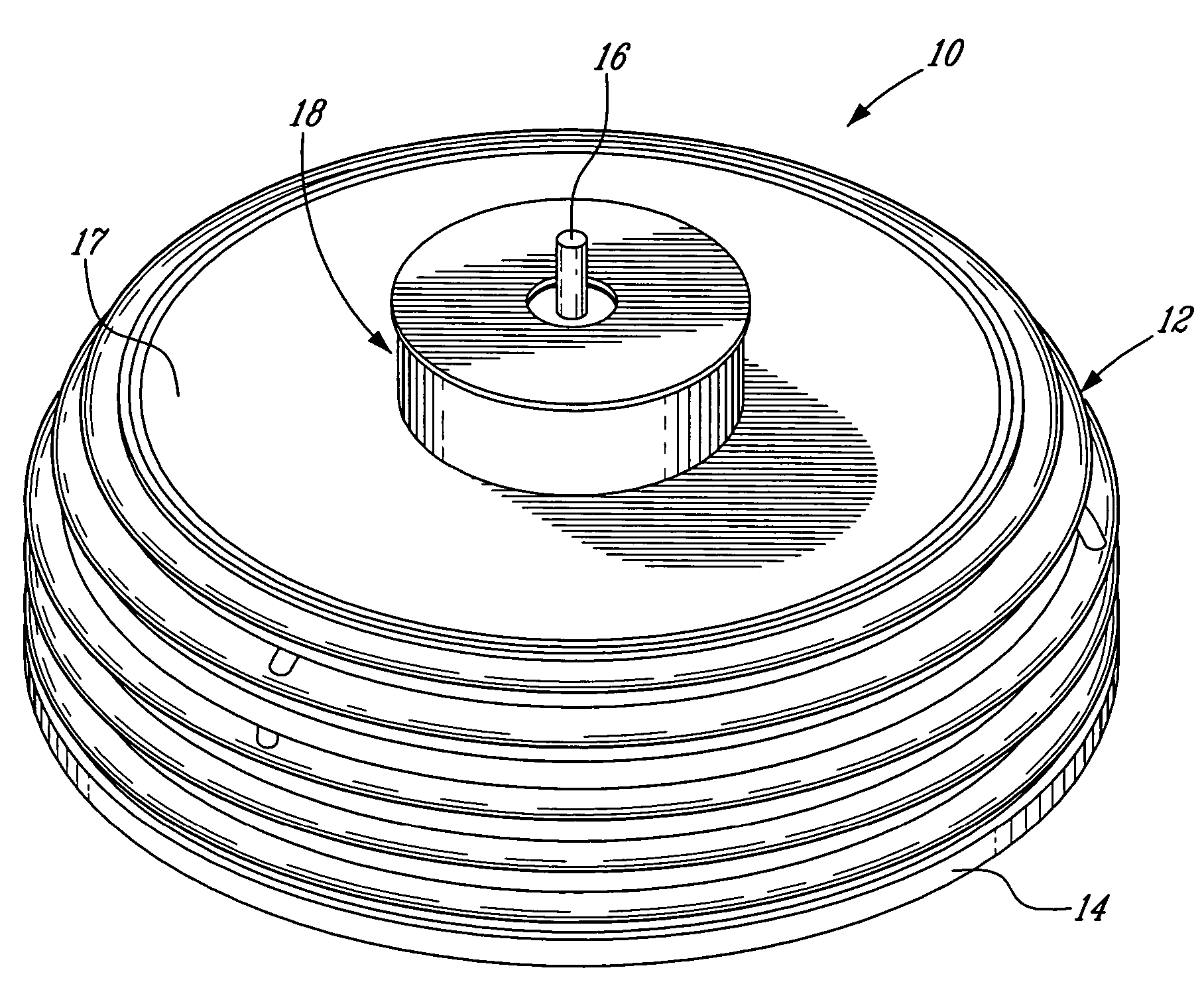

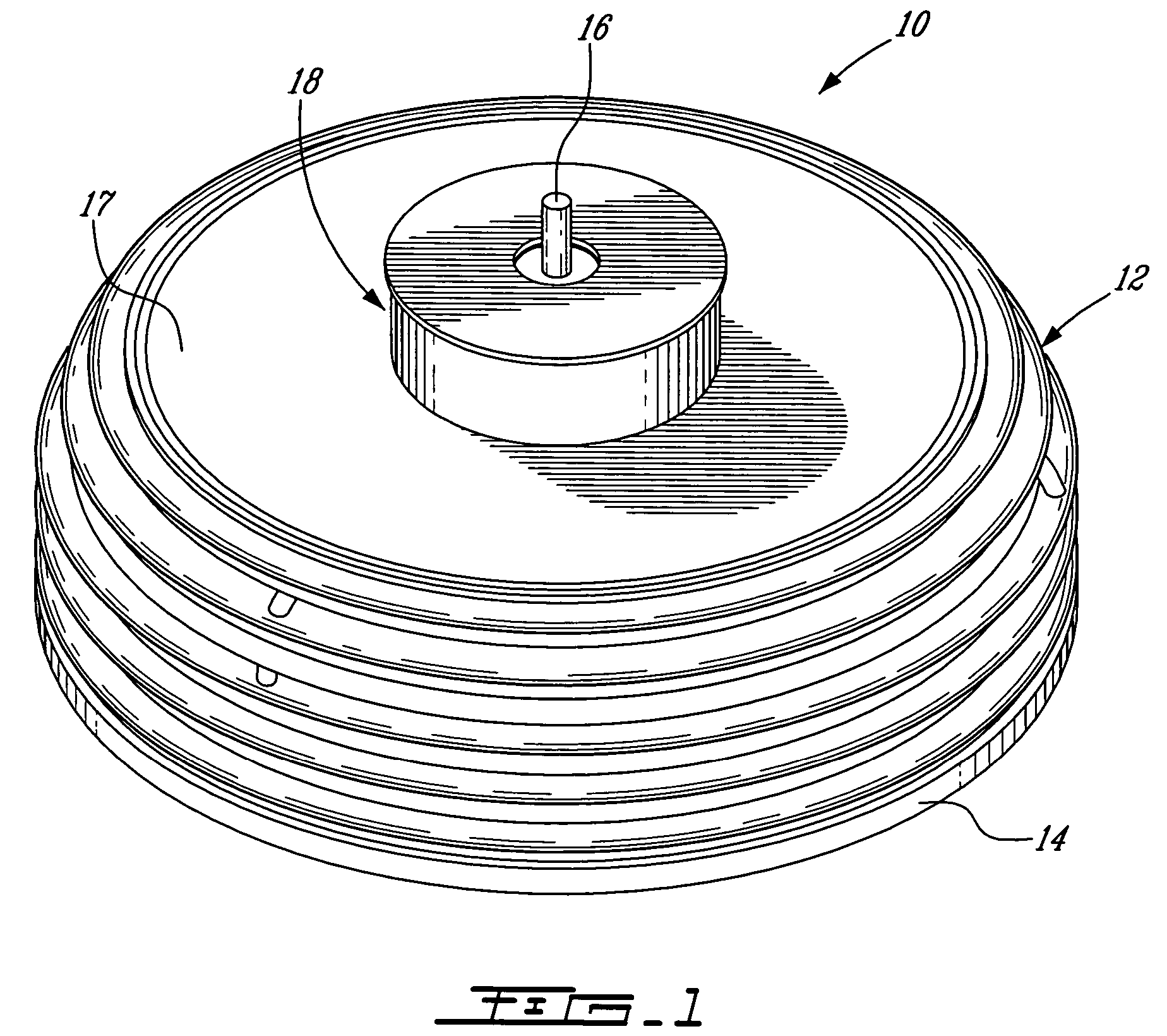

Process and apparatus for treating sludge

InactiveUS7578918B2Maintain curative effectKeep dryLiquefactionVolume/mass flow measurementEngineeringSludge dewatering

The present invention relates to an apparatus for treating sludge comprising electrodes including at least one anode and at least one cathode. The electrodes define therebetween a space adapted to receive the sludge so as to submit the sludge disposed within the space to an electric current, thereby dehydrating the sludge and generating an effluent. The apparatus also comprises an inlet for receiving the sludge and an outlet for evacuating the treated sludge. The inlet and the outlet are in communication with the space. The apparatus also comprises compression means for compacting the sludge so as to permit a contact substantially constant between the electrodes and the sludge when the sludge is submitted to the electric current and rotated around a rotation axis. The invention also relates to a process for treating sludge. The invention is useful for treating various types of sludge in order to dehydrate and decontaminate the sludge.

Owner:GL&V CANADA INC

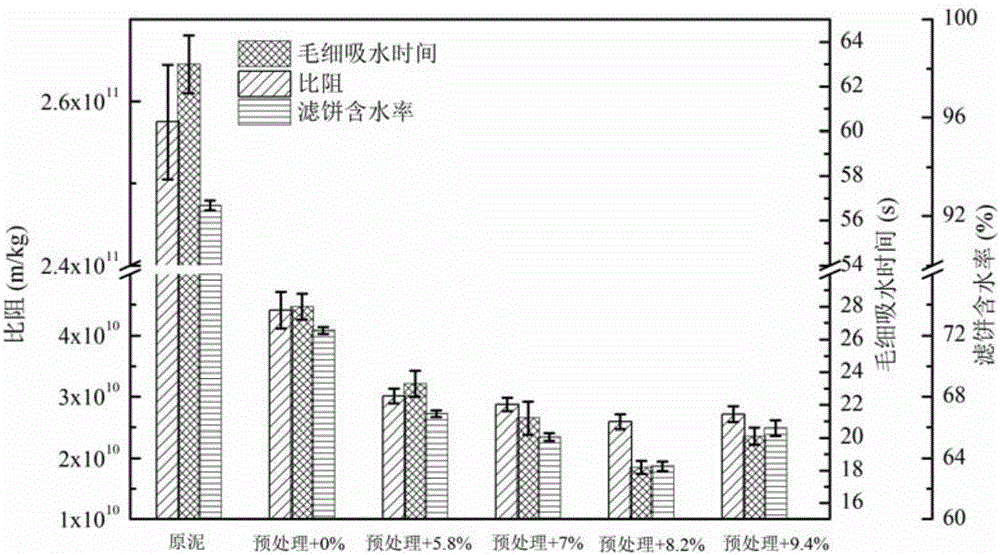

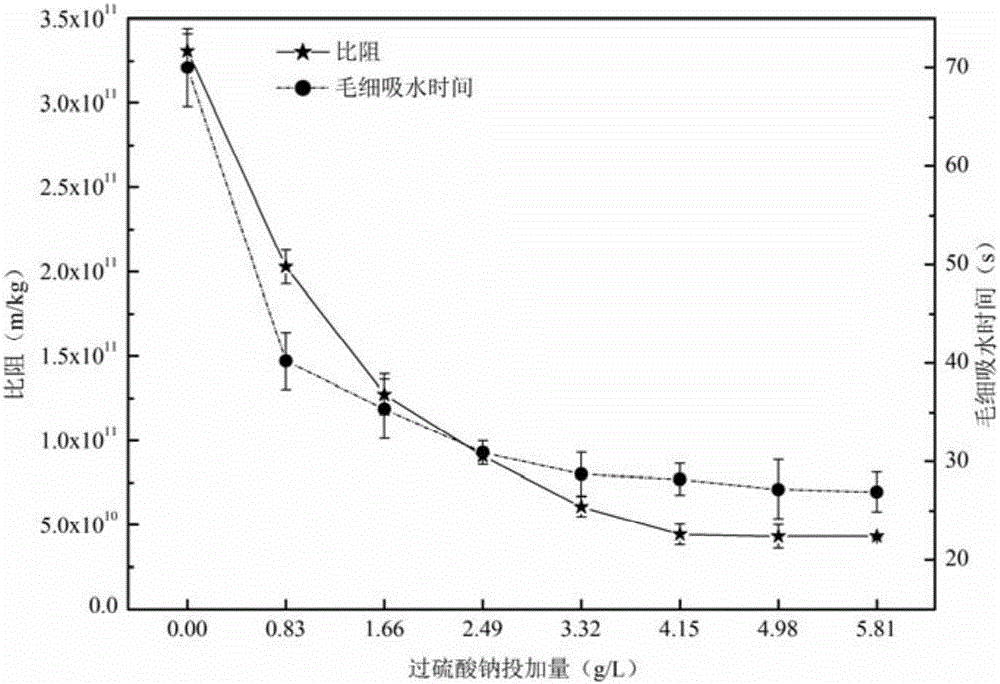

Method for conditioning urban sludge by agent compounding

InactiveCN108083609AImprove dehydration effectCalorific valueSludge treatment by de-watering/drying/thickeningElectrochemical sludge treatmentDewatered sludgeMoisture

The invention discloses a method for conditioning urban sludge by agent compounding. The method comprises (1) adjusting pH through an acid solution, then adding iron powder and activated carbon powderinto sludge, carrying out full stirring mixing, starting an aeration device to condition and transferring a part of substances in the sludge into the liquid phase, (2) adding a persulfate into the sludge conditioned in the previous step, activating the persulfate through ferrous ions, oxidizing to break the sludge so that combined water, adsorbed water, interstitial water and free water in the sludge are partially separated, the dewaterability is improved and SCOD, proteins and polysaccharide in the sludge are increased, and (3) after sludge conditioning, carrying out mechanical dewatering toobtain dewatered sludge. The method can reduce the moisture content of the urban sludge from 97 to 99% to 55 to 60%, greatly reduce the specific resistance and volume of the sludge, greatly improve the combustion calorific value, realize harmlessness, stabilization, reduction and recycling of sludge and has a wide application prospect.

Owner:NANCHANG HANGKONG UNIVERSITY

Device and method for degrading excess sludge through pretreatment-EGSB-microorganism-electrochemistry integration

ActiveCN105541059AChange natureReduce the difficulty of crackingTreatment by combined electrochemical biological processesSpecific water treatment objectivesParticulatesHigh concentration

An objective of the invention is to process excess sludge to achieve reduction, harmlessness, and recycling of the sludge. The invention provides a device and method for degrading excess sludge through pretreatment-EGSB-microorganism-electrochemistry integration, and belongs to the technical filed of recycling and reduction of excess sludge. The device includes a crushing-anaerobic-digestion integrated pre-processor, an EGSB anaerobic processor, a microorganism electrochemical reactor, and a gas collector. The method comprises: performing anaerobic digestion and crushing on the sludge in anaerobic sludge to enable solid particles in a sludge suspending liquid to be crushed and partially dissolved in an aqueous phase and to form high-concentration organic waste water containing a certain amount of solid particles; degrading pre-treated sludge through anaerobic granular sludge in the EGSB anaerobic processor; and performing further degradation through microorganism electrochemistry. Through the device, the water content in sludge is made to satisfy an emission standard, and organic matters are released in a gas manner, such as CO2, CH4, and H2, thereby effectively improving the reduction and recycling efficiency of the excess sludge and achieving a harmlessness objective.

Owner:NORTHEASTERN UNIV

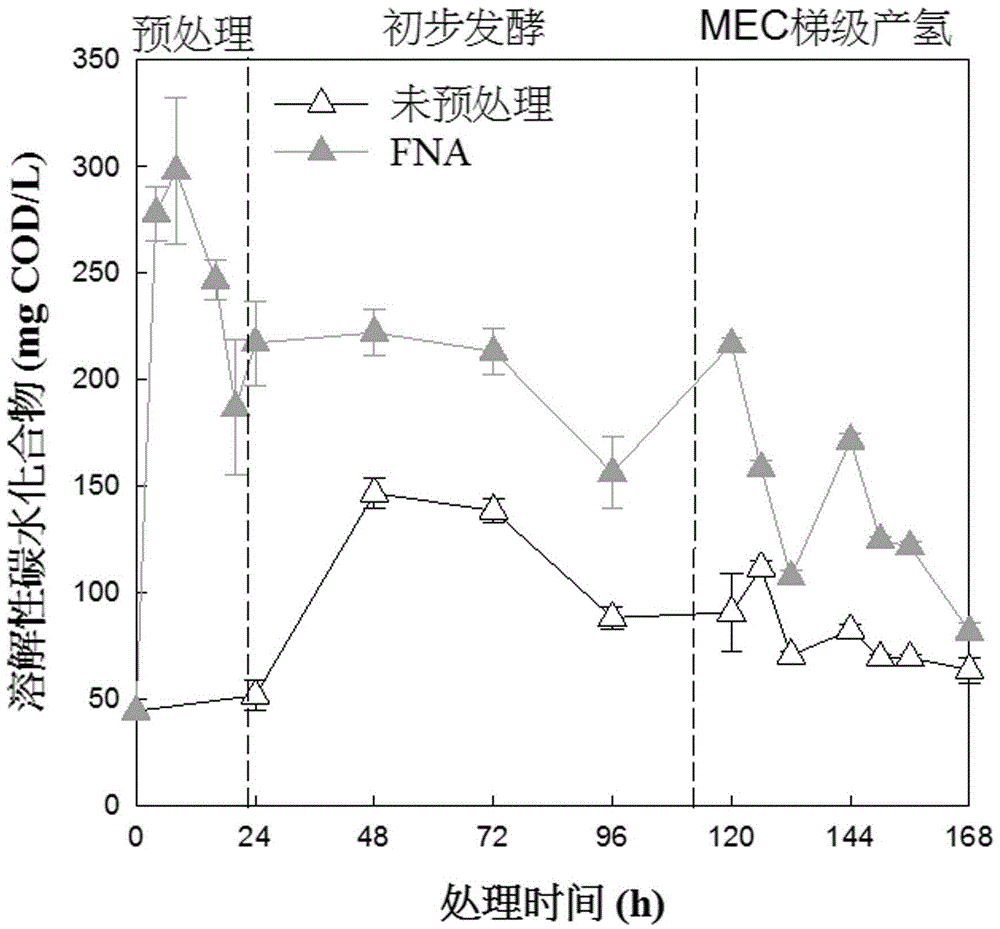

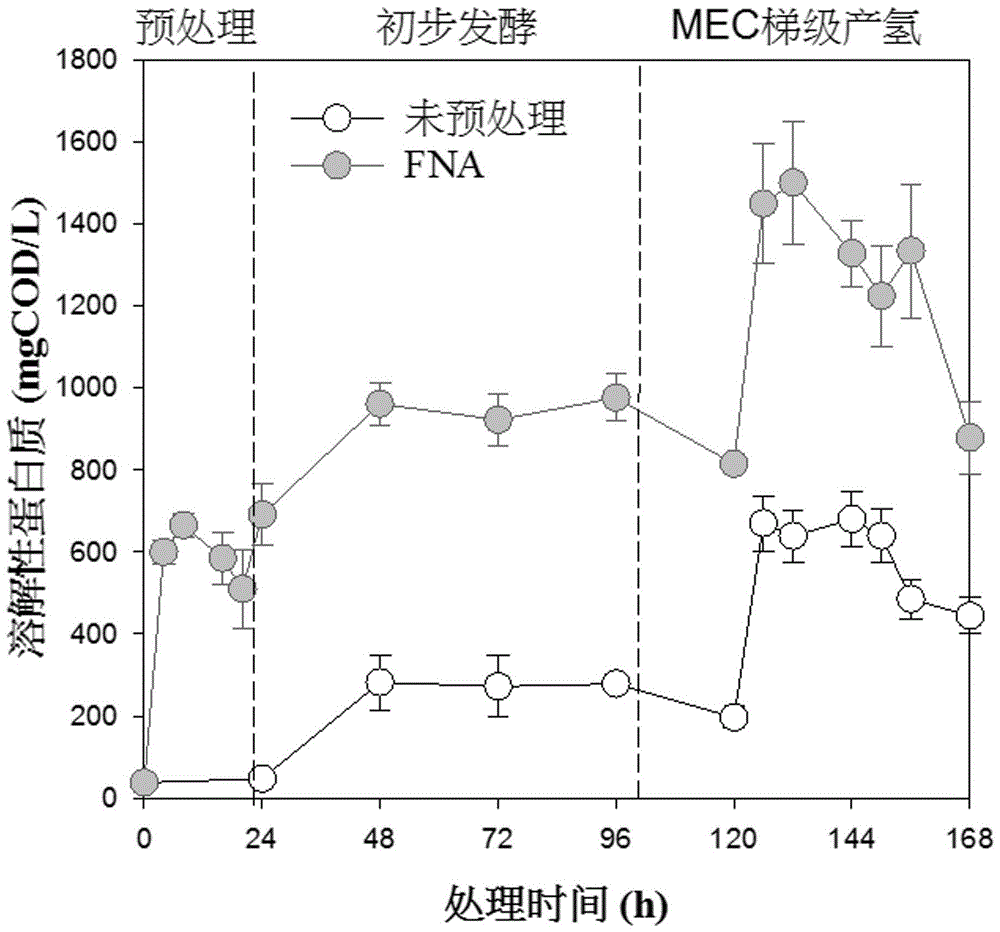

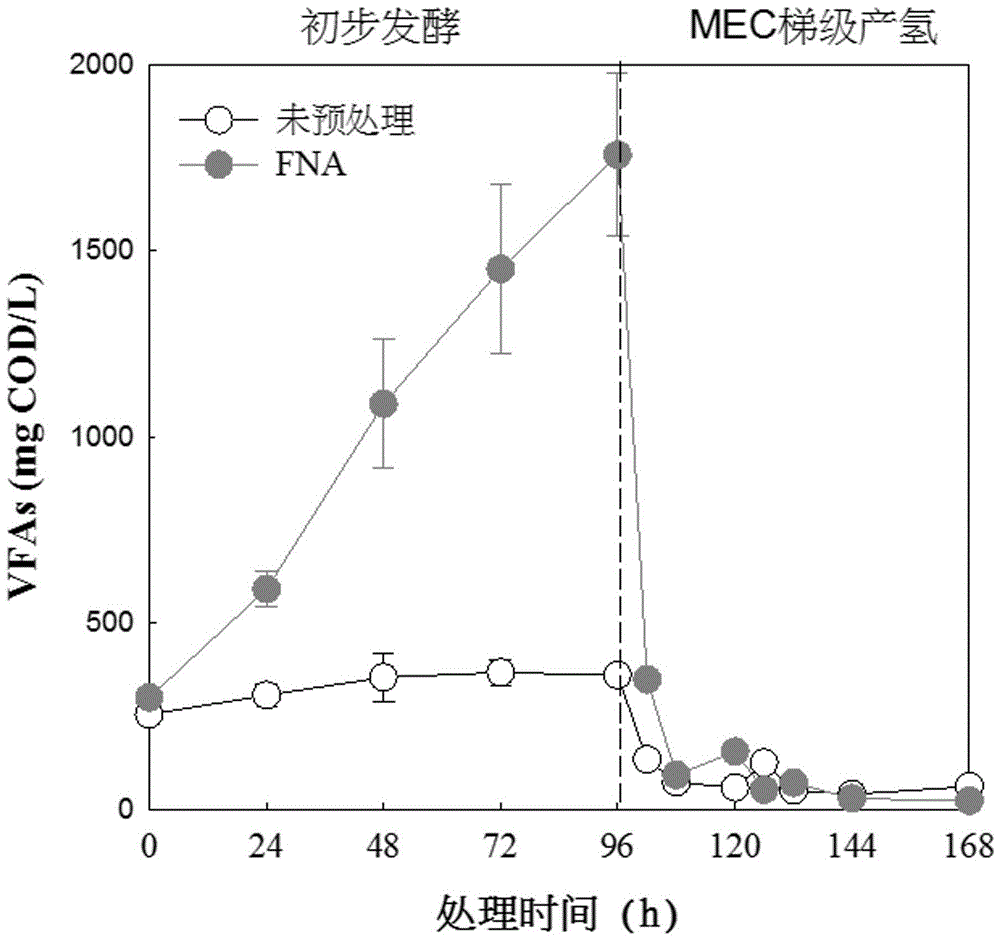

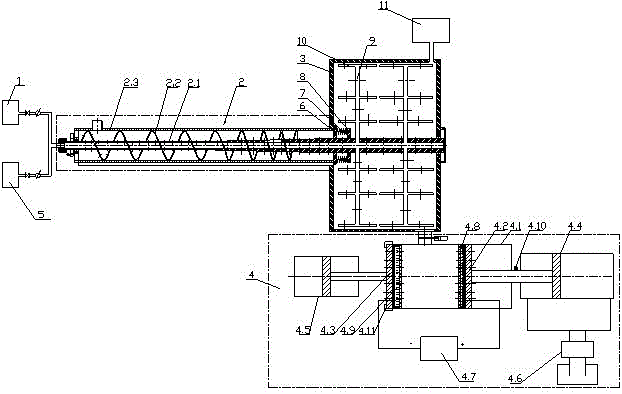

Hydrogen production and struvite recovery method for sludge by adopting FNA (free nitrous acid) reinforced microbial electrolysis

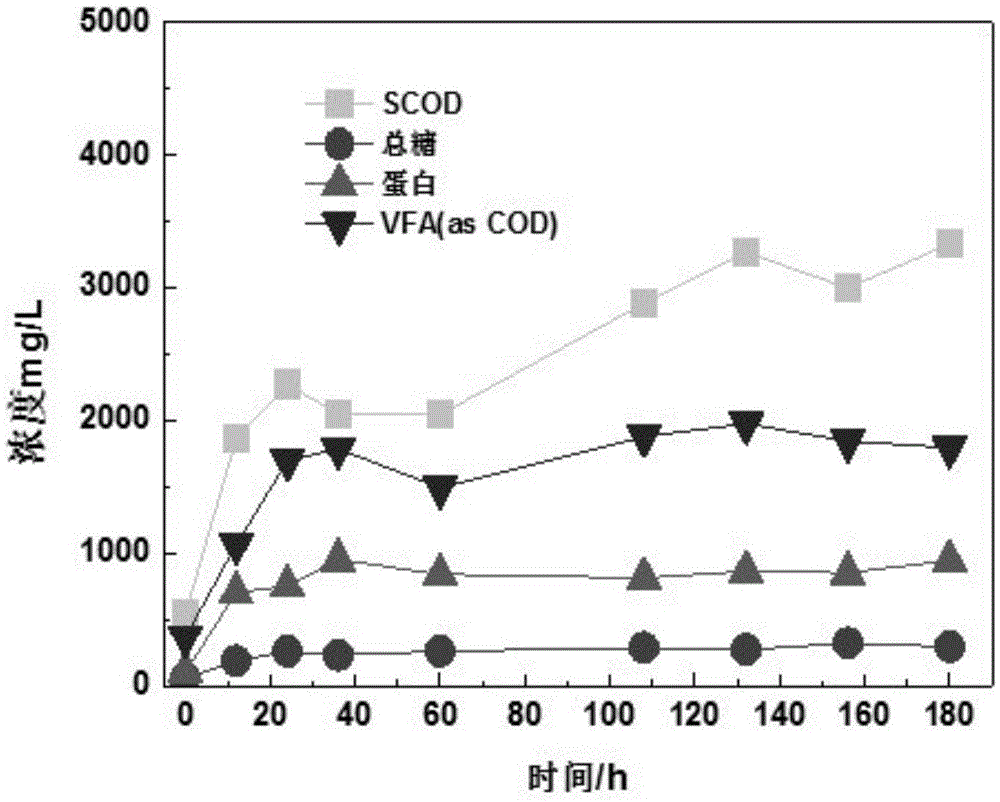

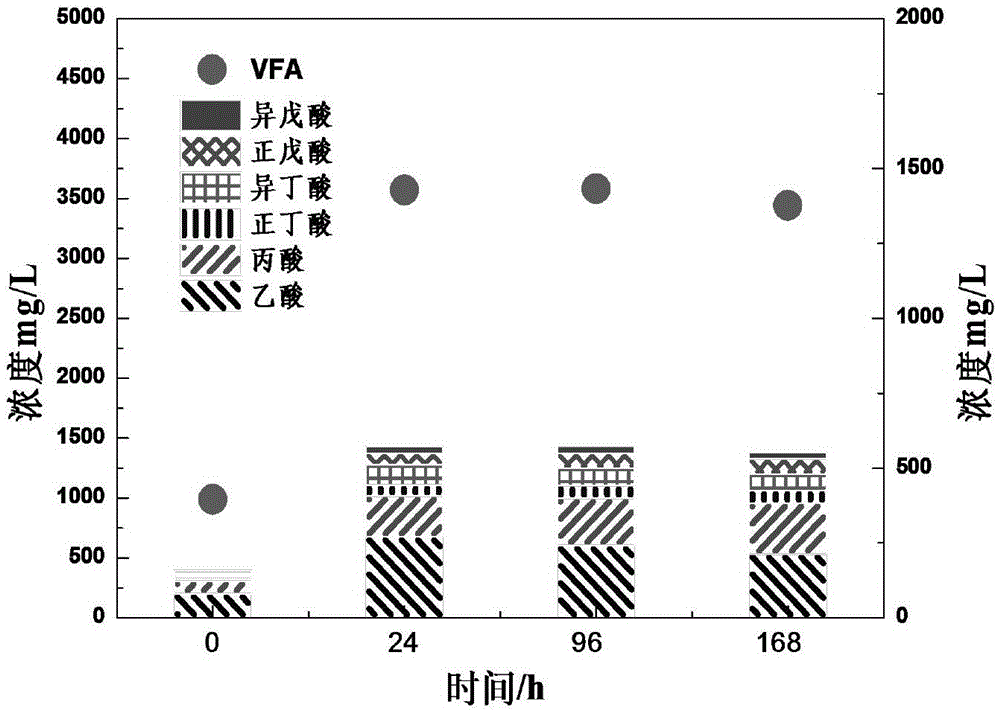

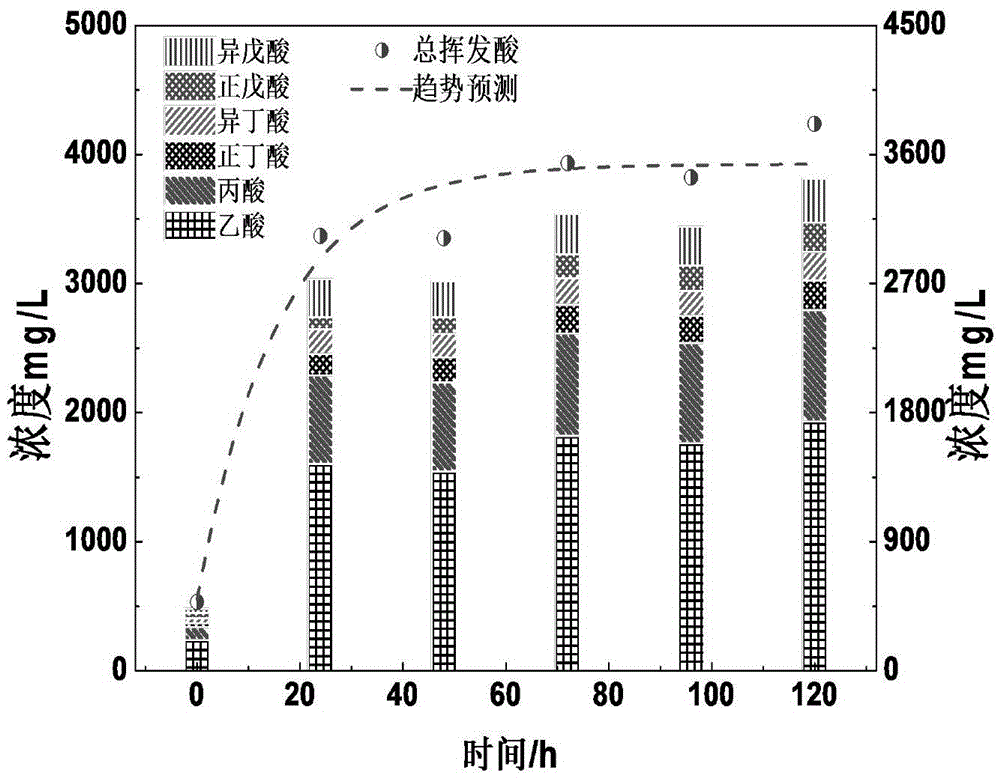

ActiveCN106477846ASludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesRecovery methodPretreatment method

The invention discloses a hydrogen production and struvite recovery method for sludge by adopting FNA (free nitrous acid) reinforced microbial electrolysis, aims to realize utmost synchronous recovery of C, N and P by coupling FNA pretreatment and an electrochemical system to solve the problem of incomplete recycling of C, N and P in sludge at present. The method comprises the following steps: 1, FNA pretreatment of residual sludge; 2, anaerobic preliminary fermentation of the sludge; 3, MEC (microbial electrolysis cell) starting and functional microbial acclimation; 4, MEC step utilization of fermented 4d sludge; 5, synchronous N and P recovery adopting struvite. FNA pretreatment for the residual sludge is a novel sludge pretreatment method, has the advantages of being low in cost, free of secondary pollution and the like compared with the traditional pretreatment method, and the cell breaking rate can reach 80% or higher. Anaerobic treatment and the MEC are used for step utilization of FNA pretreated sludge for hydrogen production, N and P in a sludge digestion liquid are recovered with a struvite precipitation method, and C, N and P in the sludge are synchronously recovered.

Owner:TAIYUAN UNIV OF TECH

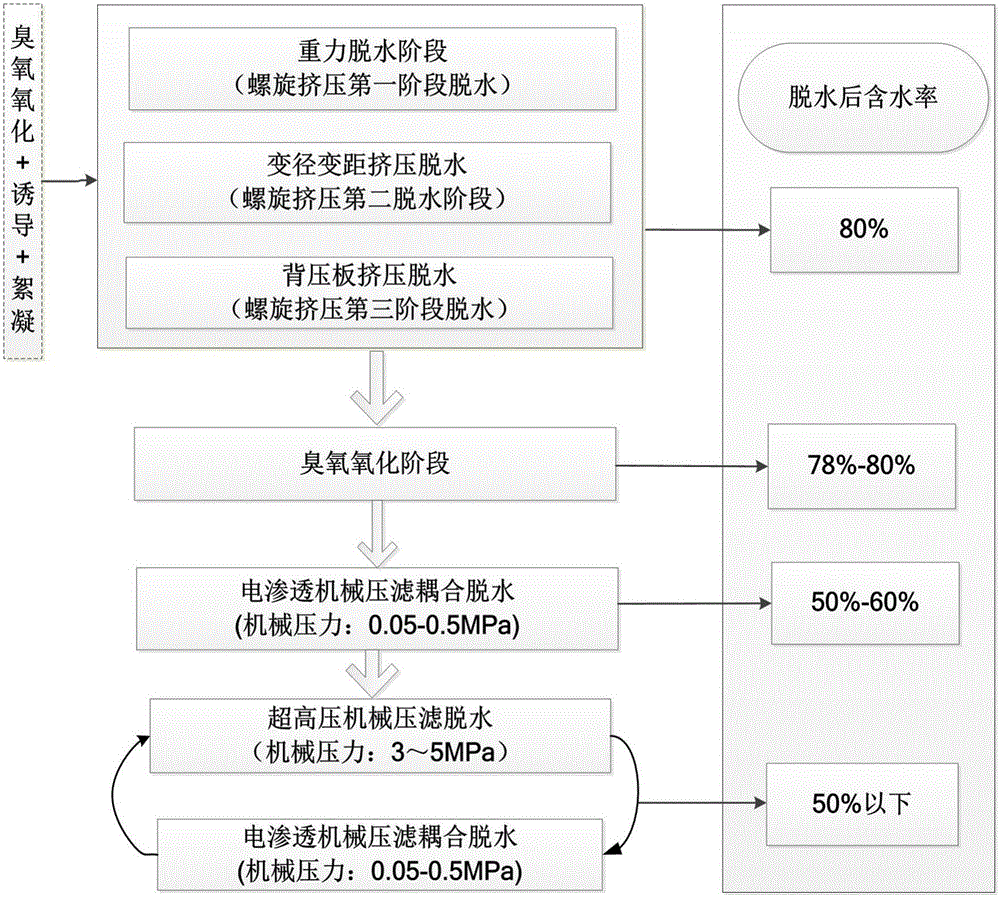

High-dryness sewage sludge treatment method

InactiveCN105819638AAchieve high dryness dehydrationFavorable effect follow-up treatmentSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSpiral bladeSewage

The invention discloses a high-dryness sewage sludge treatment method. According to the method, an active gas generator introduces active gas into a spiral shaft, sewage sludge enters a spiral filtering apparatus, and in the front section of the spiral filtering apparatus, sewage sludge undergoes dehydration under the action of the gravity of sewage sludge; the spiral shaft rotates to drive sewage sludge to move forward, and in the rear section of the spiral filtering apparatus, sewage sludge is extruded between spiral blades and a spiral drum so as to realize spiral dehydration; sewage sludge having undergone spiral dehydration enters an oxidation drum and further undergoes full oxidation under the action of active gas; and sewage sludge from the oxidation drum enters an ultrahigh-voltage electro-osmosis dehydration apparatus and undergoes electro-osmosis and ultrahigh voltage coupled dehydration so as to obtain high-dryness sludge. The high-dryness sewage sludge treatment method provided by the invention has a wide application scope and low energy consumption, is beneficial for sludge reduction and enables treated sludge to have low water content.

Owner:CHINA JILIANG UNIV

Popular searches

Biological sludge treatment Sludge processing Treatment with aerobic and anaerobic processes Dispersed particle separation Solid sorbent liquid separation Water/sewage treatment by ion-exchange Water/sewage treatment by neutralisation Water/sewage treatment by substance addition Cation exchangers Water/sewage treatment apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com