Sequencing batch sludge deep dewatering equipment and method adopting electroosmosis

A technology of deep dehydration and electroosmosis, applied in electrochemical sludge treatment, dehydration/drying/thickened sludge treatment, energy wastewater treatment, etc. Power consumption and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

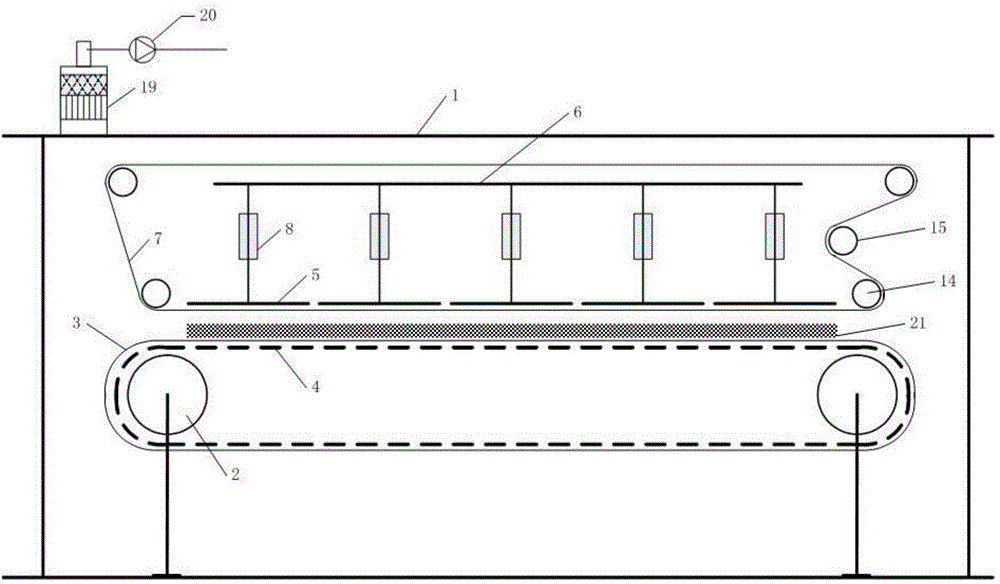

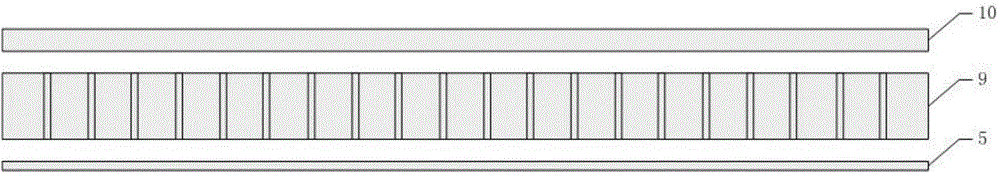

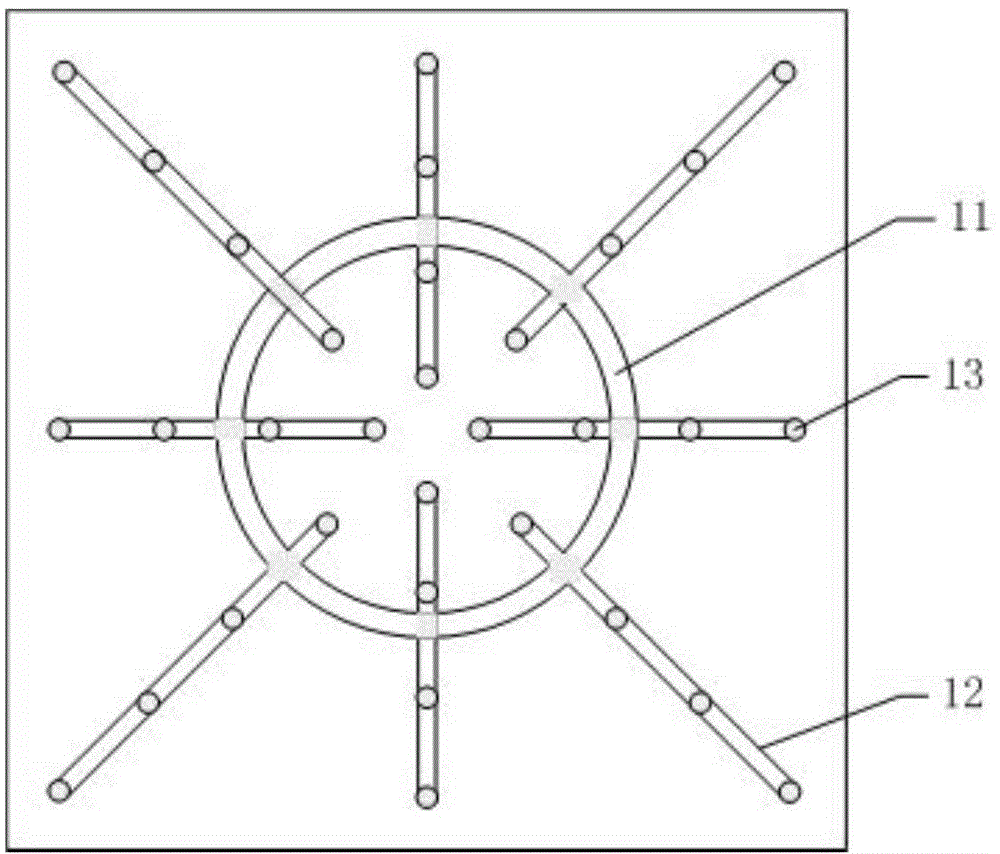

[0057] Such as figure 1 As shown, the sequence batch type electro-osmotic sludge deep dewatering equipment in this embodiment includes a closed frame 1, and an anode assembly and a cathode assembly are arranged in the frame 1; the cathode assembly includes a drive wheel set 2 supported on the lower part of the frame 1, and the drive wheel set 2. A cathode filter cloth 3 connected end to end in a ring shape is set on the top, and a cathode plate 4 is arranged on the inner side of the cathode filter cloth 3; The seat 6 and the anode plate 5 are respectively supported on the fixed seat 6 through the transmission part 8; the side of the anode plate 5 facing away from the transmission part 8 is provided with an anode filter cloth 7; a sludge treatment space is formed between the anode plate 5 and the cathode plate 4; The material of the anode plate 5 is a titanium metal material, and the surface of the anode plate 5 is provided with an intermediate layer and a surface active layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com