Sewage treatment and regeneration cyclic utilization device and sewage treatment and regeneration cyclic utilization method

A sewage treatment and sludge treatment technology, which is applied in water/sewage treatment, biological water/sewage treatment, light water/sewage treatment, etc., can solve the problems of poor quality of regenerated water, high operating cost, and difficult to meet, so as to reduce production , Improve biodegradability and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1000 tons / day sewage treatment and recycling project.

[0052] The water quality of the sewage is shown in Table 2.

[0053] Table 2 Water quality of sewage

[0054] serial number project unit measured value serial number project unit measured value 1 COD Cr mg / L 350 5 Turbidity NTU 19 2 BOD 5 mg / L 180 6 Chroma times 50 3 SS mg / L 270 7 pH — 7.5 4 TN mg / L 30 8 Conductivity μS / cm 380

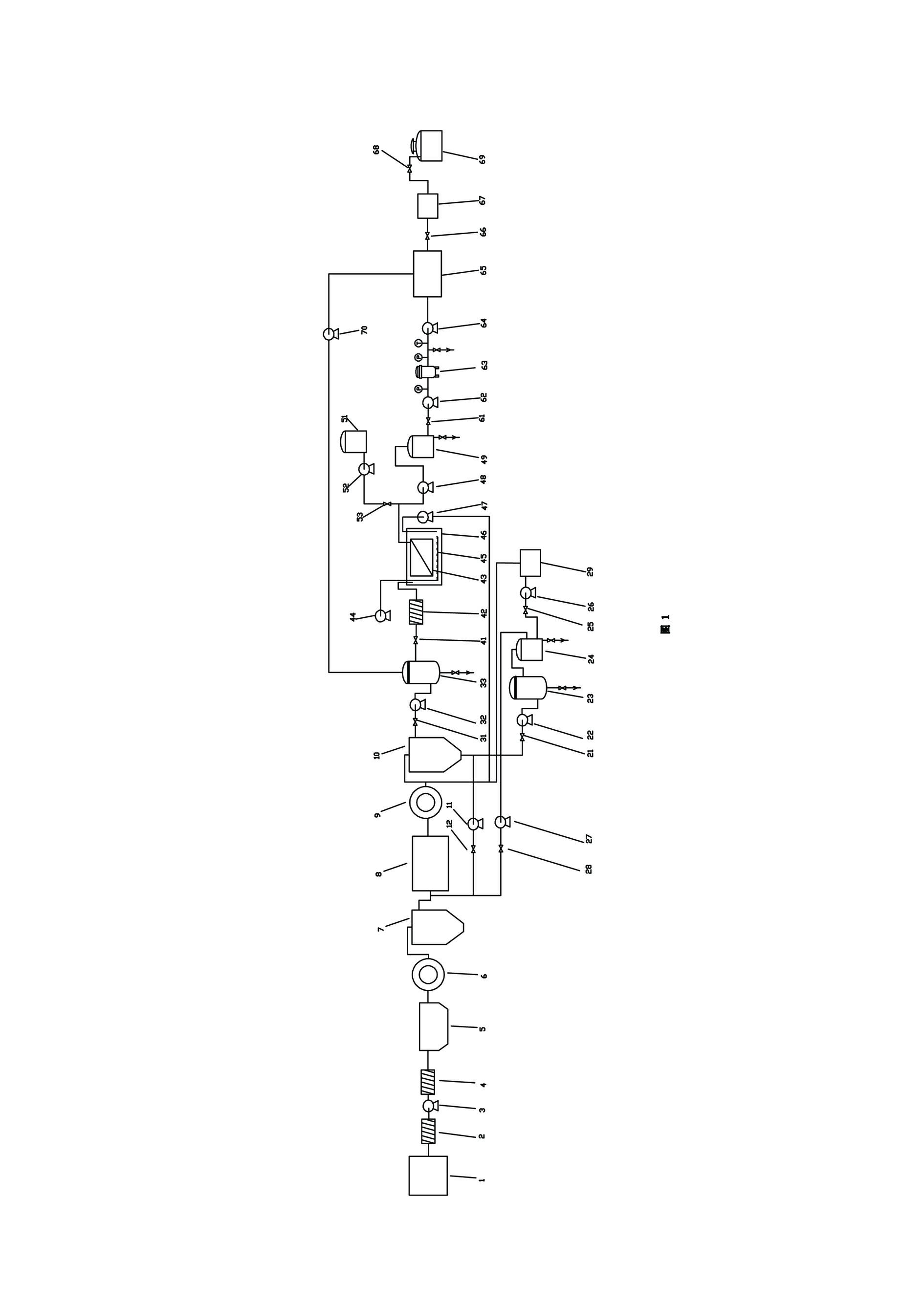

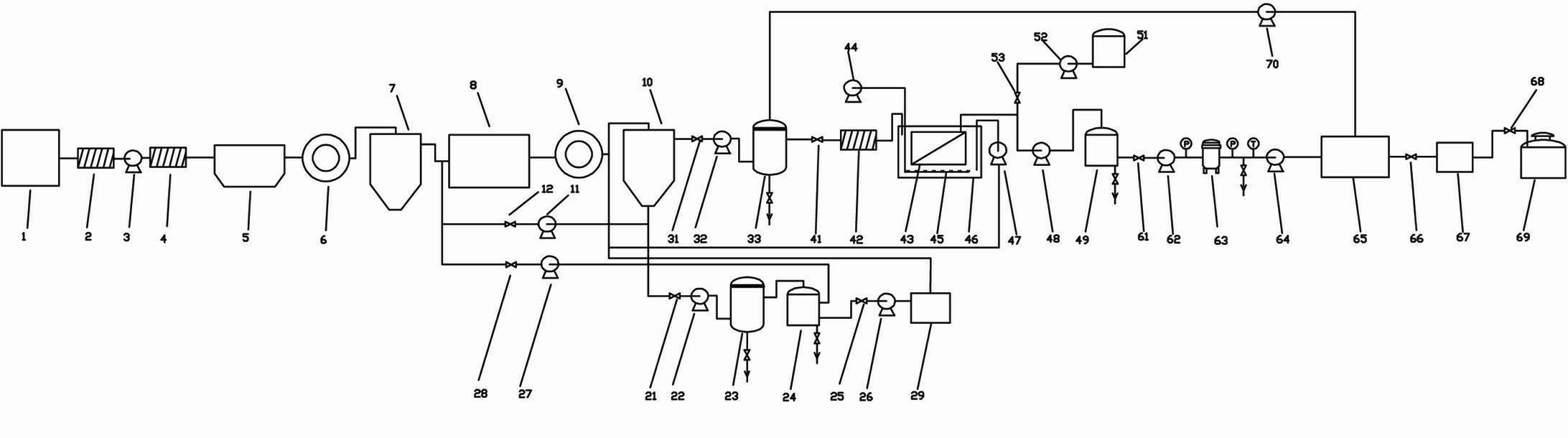

[0055] Step 1. Biochemical treatment: Sewage enters the biochemical system through the interception well 1, and then passes through the coarse screen 2, lifting pump 3, fine screen 4, grit chamber 5, primary water distribution well 6, primary sedimentation tank 7, and biological treatment equipment 8. The treatment of the secondary water distribution well 9 and the secondary sedimentation tank 10, so that all indicators can reach the third-level discharge standard of GB 18918-2002 "Pollutant Discharge ...

Embodiment 2

[0069] Deep purification regeneration and recycling project of 5000 tons / day sewage.

[0070] The water quality of the sewage is shown in Table 4.

[0071] Table 4 Water quality of sewage

[0072] serial number project unit measured value serial number project unit measured value 1 COD Cr mg / L 289 5 Turbidity NTU 16 2 BOD 5 mg / L 114 6 Chroma times 80 3 SS mg / L 250 7 pH — 7.4 4 TN mg / L 42 8 Conductivity μS / cm 510

[0073] Step 1. Biochemical treatment: Sewage enters the biochemical system through the interception well 1, and then passes through the coarse screen 2, lifting pump 3, fine screen 4, grit chamber 5, primary water distribution well 6, primary sedimentation tank 7, and biological treatment equipment 8. The treatment of the secondary water distribution well 9 and the secondary sedimentation tank 10, so that all indicators can reach the third-level discharge standard of GB 18918-20...

Embodiment 3

[0087] Deep purification regeneration and recycling project of 10,000 tons / day sewage.

[0088] The water quality of the sewage is shown in Table 6.

[0089] Table 6 Water quality of sewage

[0090] serial number project unit measured value serial number project unit measured value 1 COD Cr mg / L 259 5 Turbidity NTU 15 2 BOD 5 mg / L 99 6 Chroma times 80 3 SS mg / L 300 7 pH — 7.7 4 NH 3 -N mg / L 45 8 Conductivity μS / cm 440

[0091] Step 1. Biochemical treatment: Sewage enters the biochemical system through the interception well 1, and then passes through the coarse screen 2, lifting pump 3, fine screen 4, grit chamber 5, primary water distribution well 6, primary sedimentation tank 7, and biological treatment equipment 8. The treatment of the secondary water distribution well 9 and the secondary sedimentation tank 10, so that all indicators can reach the third-level discharge standard of GB 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com