Patents

Literature

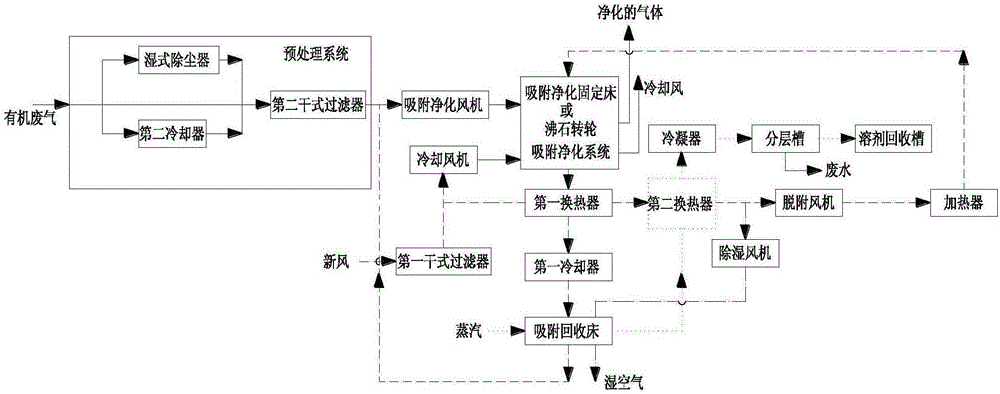

151results about How to "To achieve the purpose of cleaner production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

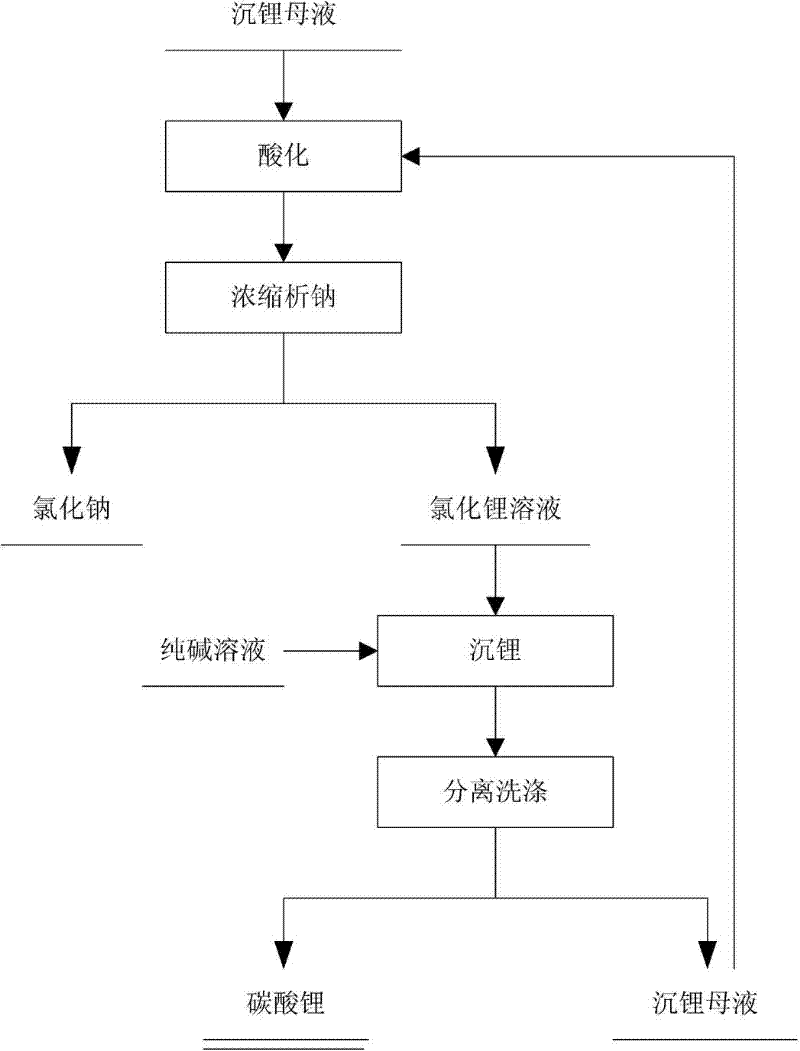

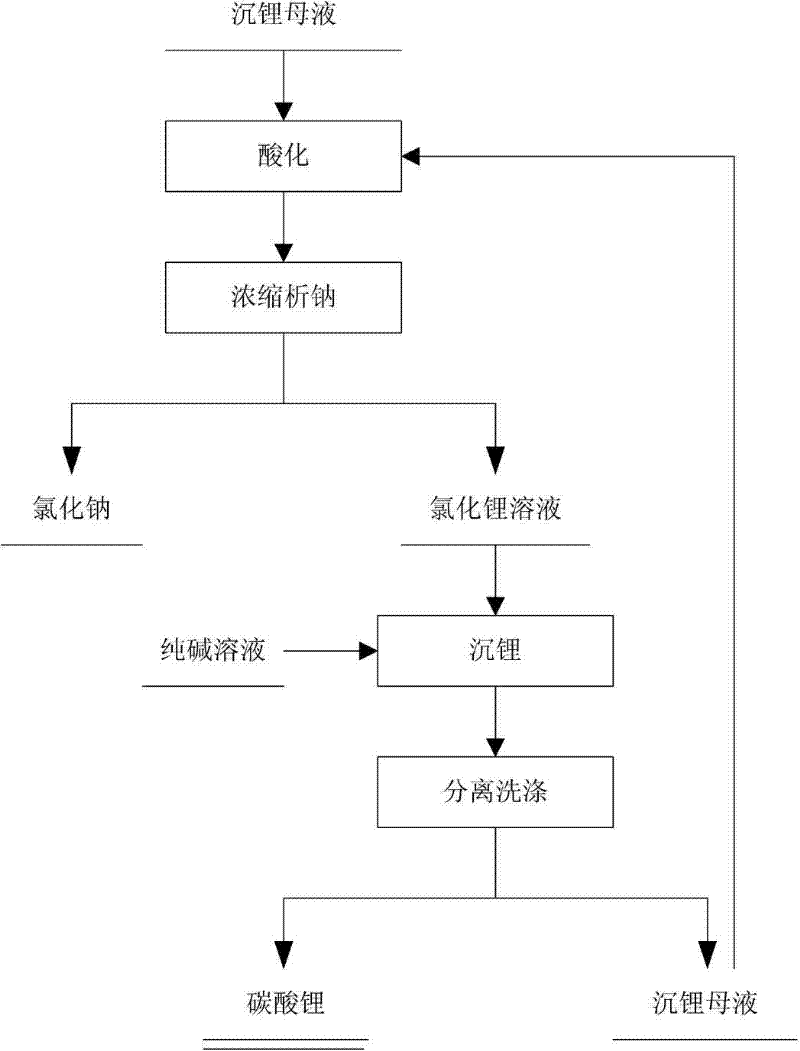

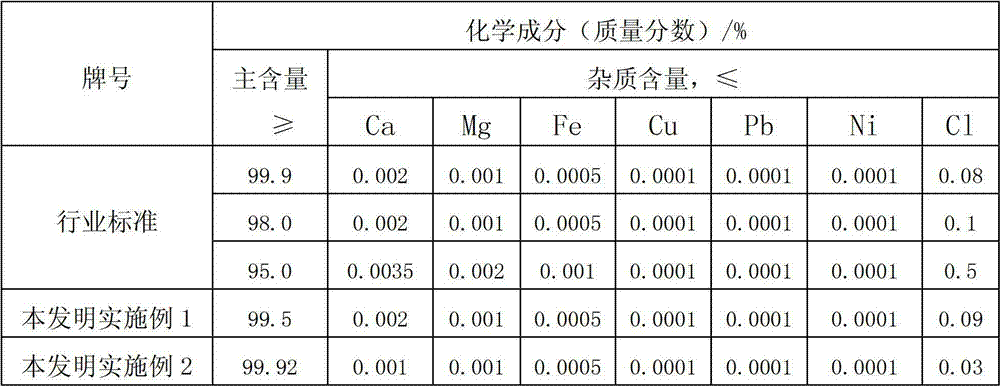

Method for processing battery-level lithium carbonate mother liquor

ActiveCN102249471AIncrease productionHigh recovery rateMultistage water/sewage treatmentAlkali metal chloridesLithium carbonateChemistry

The invention discloses a method for processing battery-level lithium carbonate mother liquor. The processing method comprises the following process follow: A. acidizing lithium deposition mother liquid; B. evaporating, condensing and separating out sodium; C. depositing lithium; and D circulating: circularly carrying out steps from A to C on liquid obtained by dewatering in step B and leaching in the step C and the mother liquor subjected to lithium deposition. By the adoption of the method for processing battery-level lithium carbonate mother liquor, which is disclosed by the invention, the quality of lithium chloride can be guaranteed, and lithium recovery rate can be improved greatly on the basis of the formed sealed circulation. In addition, no the industrial three wastes are discharged, therefore the purpose of clean production is achieved.

Owner:GANFENG LITHIUM CO LTD

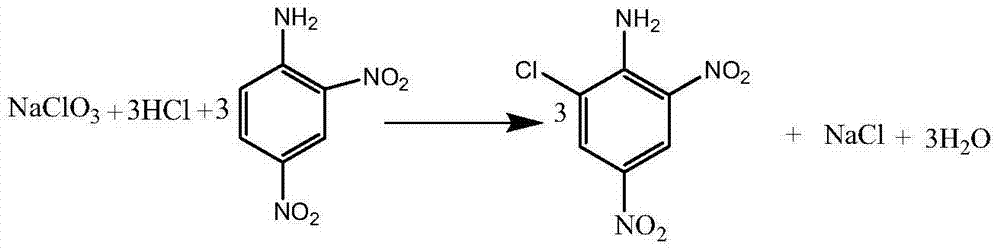

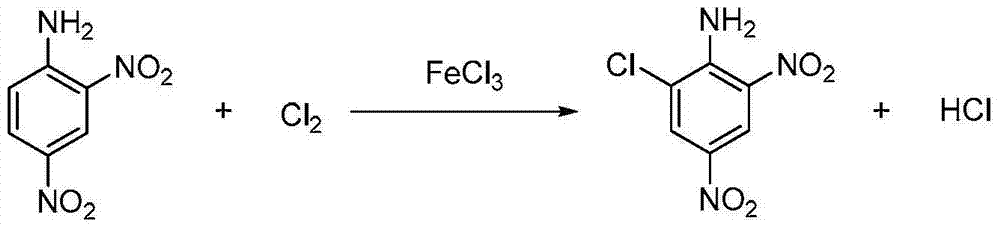

Clean production process of 6-chloro-2,4-dinitroaniline

ActiveCN103539680AFast responseLess side effectsOrganic compound preparationAmino compound preparationChemistryMother liquor

The invention discloses a clean production process of 6-chloro-2,4-dinitroaniline. The clean production process of 6-chloro-2,4-dinitroaniline comprises the following steps: 1, dispersing 2,4-dinitroaniline into hydrochloric acid solution for pulping, then introducing chlorine gas into the solution for reacting, and thus obtaining intermediate reaction solution; and 2, adding the intermediate reaction solution obtained in the step 1 into sodium chlorate solution for reacting, after the reaction is completed, processing the reaction solution to obtain the 6-chloro-2,4-dinitroaniline and mother solution, and returning the mother solution to the step 1 to serve as the hydrochloric acid solution. According to the production process, the chlorine gas and the sodium chlorate are sequentially employed as chloride agents for chlorinating in steps, so that the product purity and yield are improved and the cost of material is reduced; and the quantity of hydrochloric acid after the reaction is completed is kept stable basically, so that the mother solution is convenient to recycle for use and the pollution to environment is reduced.

Owner:浙江大井化工有限公司

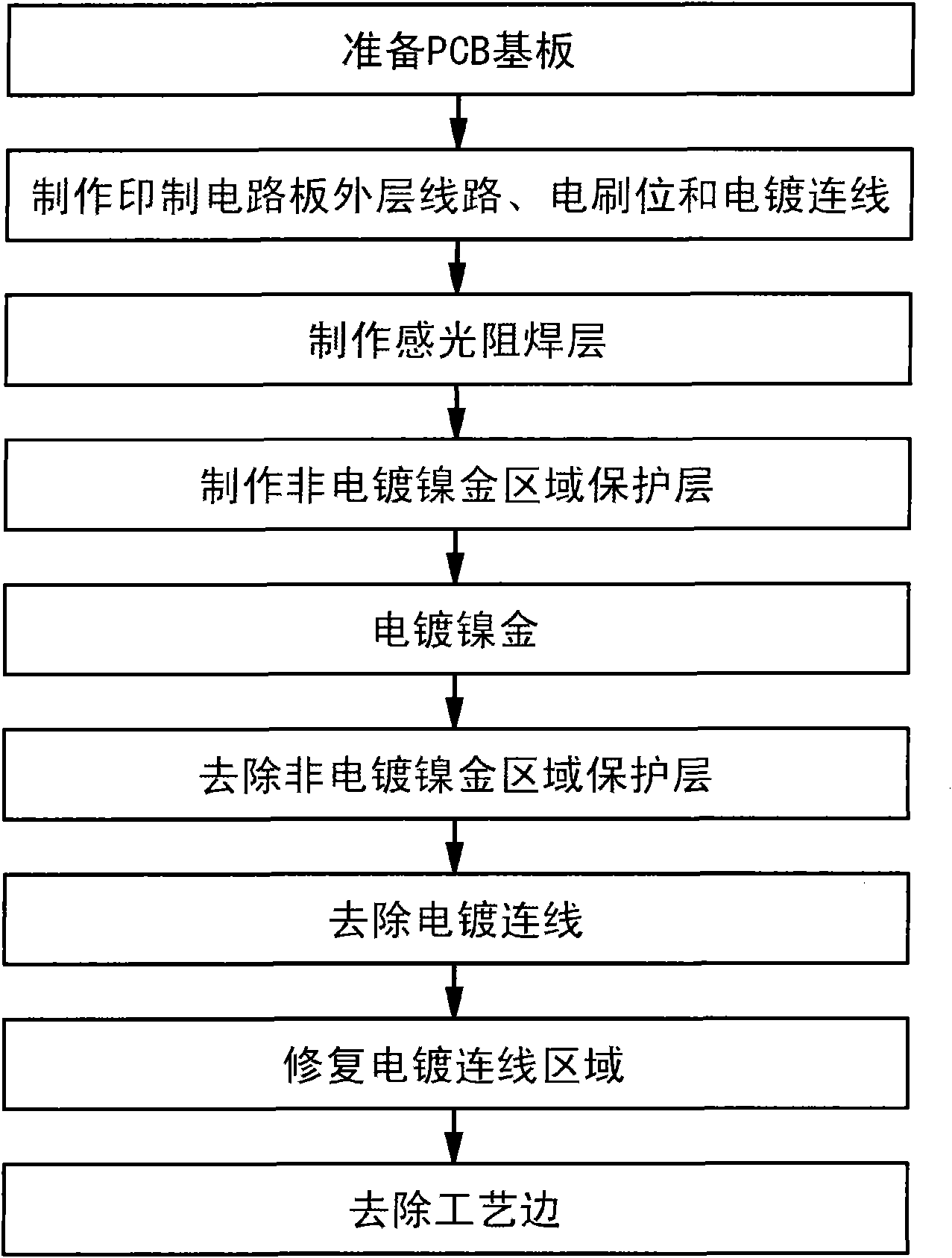

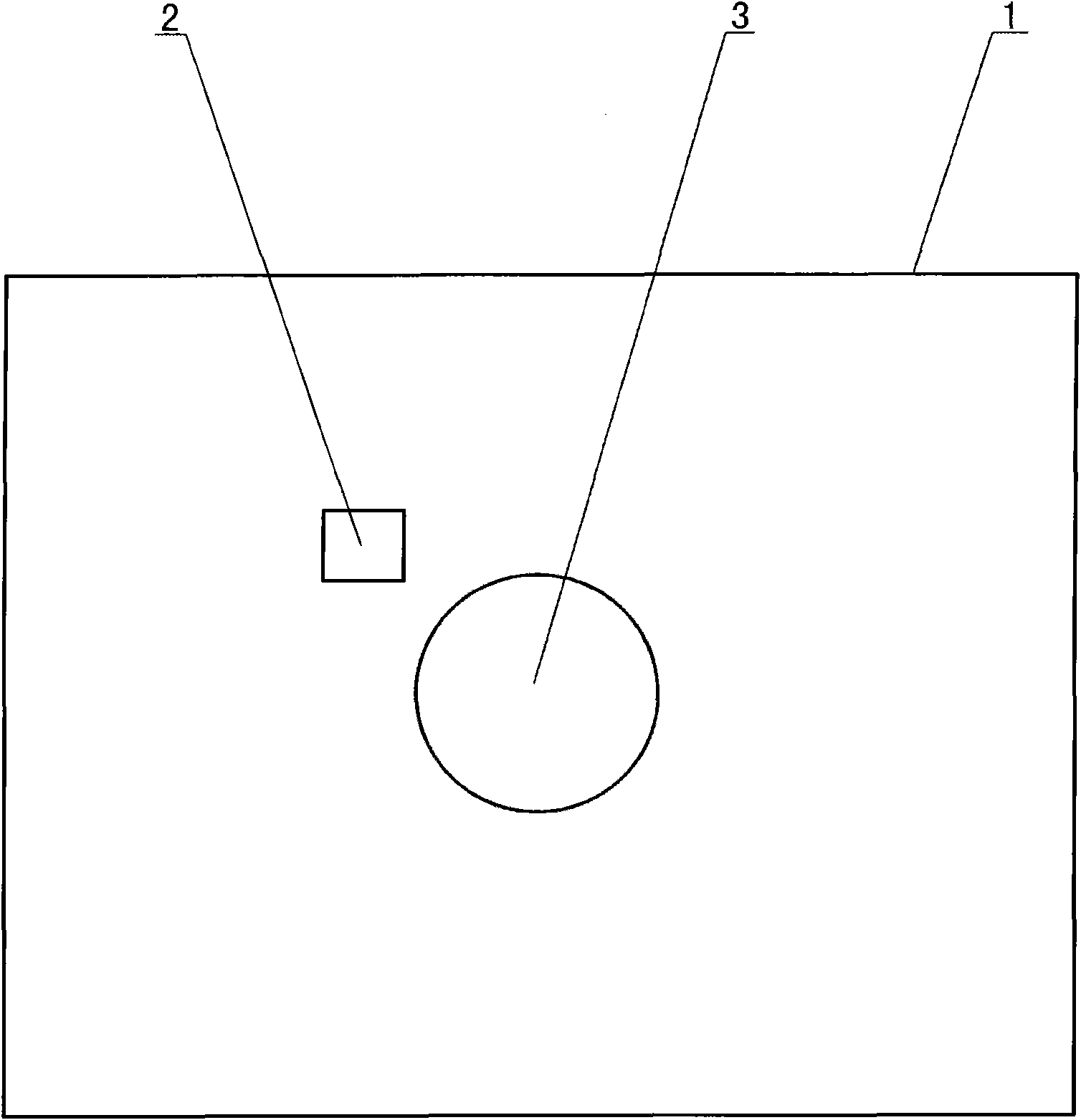

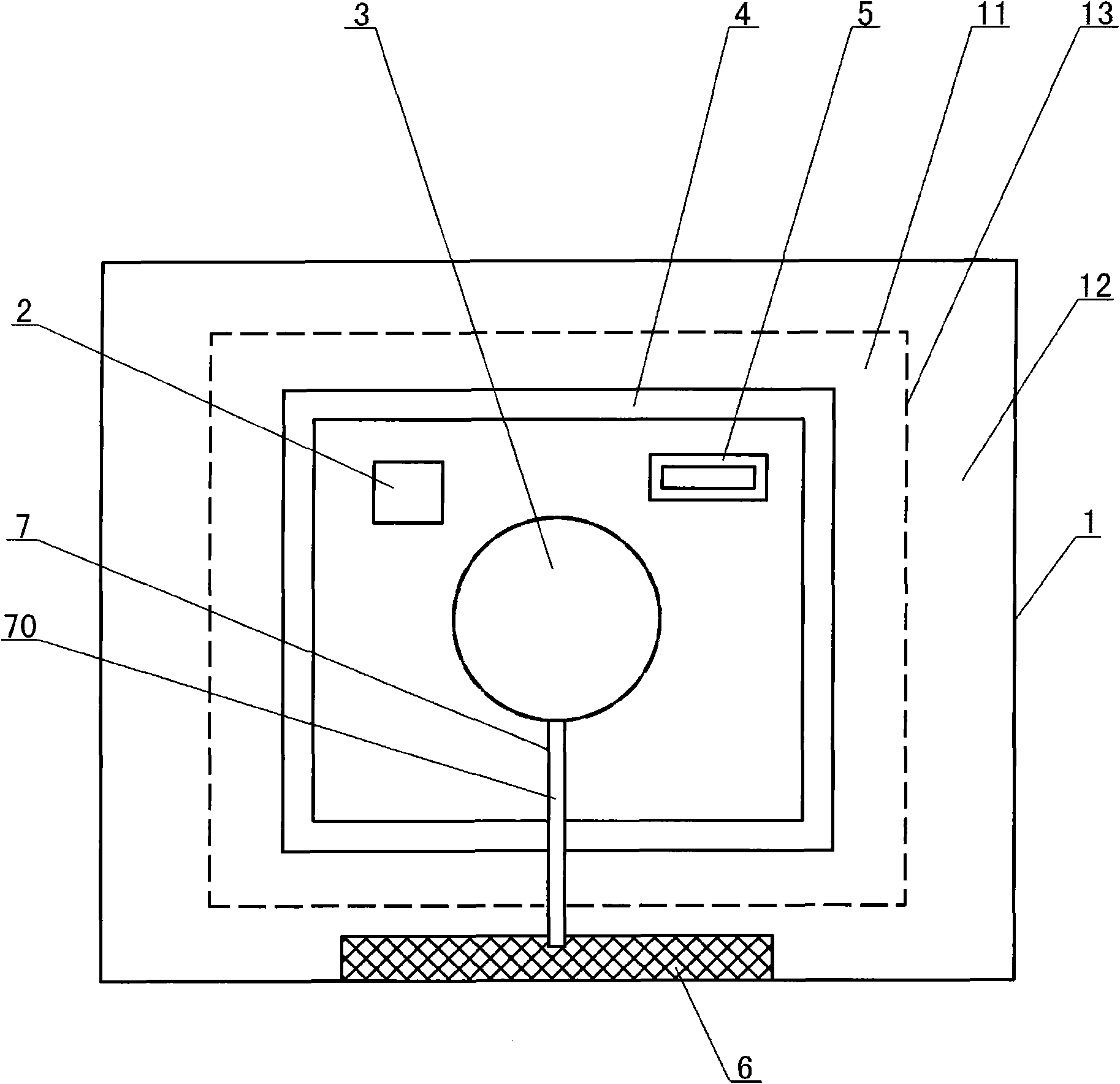

Nickel-gold electroplating process of PCB

InactiveCN101835346AHigh feasibilityAvoid residuePrinted circuit secondary treatmentElectricityEngineering

The invention relates to a nickel-gold electroplating process of a PCB, which comprises the following steps of: (1) preparing a PCB substrate; (2) making an outer circuit, an electric brush part and an electroplating connecting line of the PCB; (3) making a photosensitive soldering-resistant layer; (4) making a non-nickel-gold electroplating region protection layer; (5) electroplating nickel and gold; (6) removing the non-nickel-gold electroplating region protection layer; (7) removing the electroplating connecting line; (8) repairing an electroplating connecting line region; and (9) removing a process edge. In the nickel-gold electroplating process, the electric brush part on the process edge is communicated with a non-marginal to-be-electroplated region by the designed electroplating connecting line to electroplate a non-marginal region on the PCB, the electroplating connecting line is removed after nickel-gold electroplating, and the electroplating connecting line region is repaired to avoid the problem of electroplating connecting line residue and ensure the reliability of the PCB. Meanwhile, the non-marginal to-be-electroplated region and the electroplating connecting line can be freely selected according to actual needs. Accordingly, the nickel-gold electroplating process has high practicability.

Owner:CHINA CIRCUIT TECH SHANTOU CORP

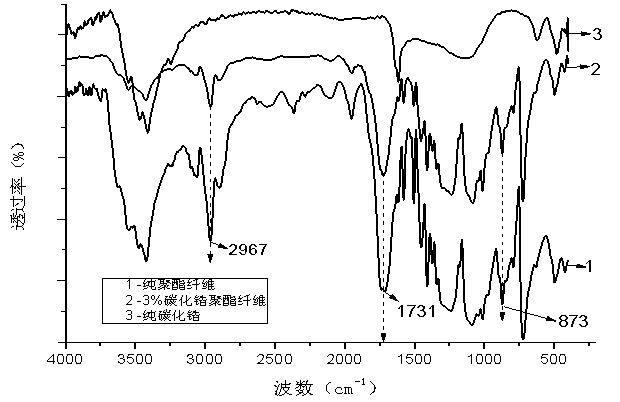

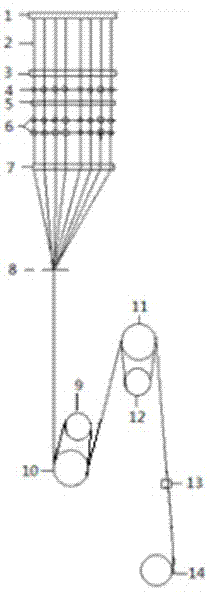

Nano zirconium carbide induction type heat-storage heat-preservation polyester fiber and preparation method thereof

InactiveCN103132177AAdjust and control the effect of induction thermal storage insulationEasy to carryFilament forming substance formingArtificial thread manufacturing machinesFiberPolyester

The invention relates to a nano zirconium carbide induction heat-storage heat-preservation polyester fiber and a preparation method thereof. The preparation method comprises the steps of: adding 1.0-8.0% of nano zirconium carbide using as an additive in an online manner to evenly blend and fuse together with a polyester chip in a screw rod, extruding blend melt from a spinneret micro-hole, winding the extruded blend melt at the winding speed of 3000-3200m / min to prepare a POY (polyester pre-oriented yarn) silk tube by using the processes of cooling, curing, oiling and bundling by a nozzle, stretching to deform after balancing, so as to prepare the nano zirconium carbide induction heat-storage heat-preservation polyester fiber. The nano zirconium carbide induction heat-storage heat-preservation polyester fiber has the functions of efficiently and selectively absorbing visible light and a near infrared ray in a solar radiation ray, and reflecting the heat radiation of a human body, so as to have the functions of two-way temperature induction adjustment and heat preservation, changes the heat-storage mode of cold protective clothing, and has the characteristics of being high in additional value, good in quality and significant in cost performance.

Owner:SUZHOU UNIV

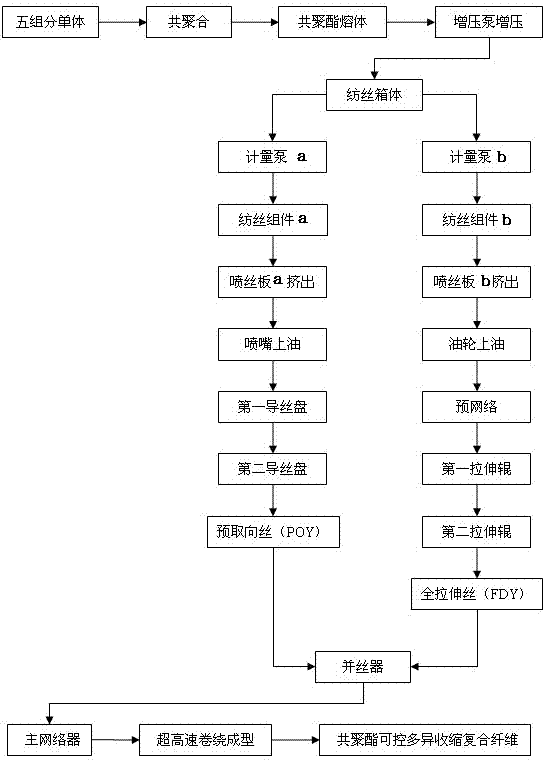

Controllable multiple-differential-shrinkage composition fiber made from copolyester melt through ultra-fast direct spinning, and preparation method of composition fiber

InactiveCN103484967AIncrease spinning speedIncrease added valueArtificial filament heat treatmentMonocomponent copolyesters artificial filamentYarnFiber

The invention relates to a controllable multiple-differential-shrinkage composition fiber made from a copolyester melt through ultra-fast direct spinning, and a preparation method of the composition fiber. The copolyester melt, which is made from five components including terephthalic acid, ethylene glycol, poly ethylene glycol, diethylene glycol and pentaerythritol, is pressurized by a booster pump and transported through a melt pipeline into a spinning box body, and is then divided by two measuring pumps into two branches, which enter a spinning component and a spinneret respectively and finally be extruded. After cooling and curing, two yarns are formed, wherein one yarn is subject to oiling by an oil wheel, pre-entwining, stretching and thermoforming to obtain an FDY yarn, and the other yarn is subject to oiling by an oil nozzle, and is guided to two spinning discs to obtain a POY yarn; the two yarns are simultaneously input into a doubling device and a main entwining device for combination, and are formed through the ultra-fast rolling, so as to obtain the composition fiber. The composition fiber has the characteristics of relatively good micro three-dimensional morphological structure, moisture absorption property, moisture preservation property, air permeability and antistatic property, easiness in dyeing, uniform dyeing, high coloration uniformity and the like; the composition fiber is high in processing speed, high in yield, low in consumption, low in manufacturing cost, high in value added, high in product functions, good in quality, and obvious in advantage of performance price ratio.

Owner:SUZHOU UNIV

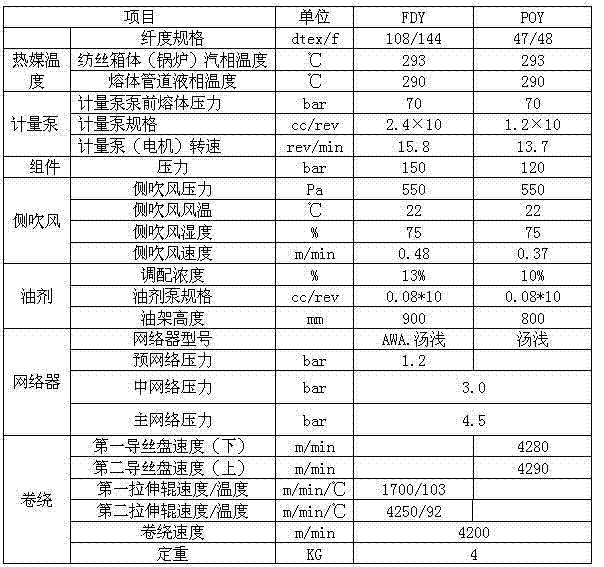

Efficient energy-saving large-air-quantity low-concentration organic waste gas recovery and treatment device and method

ActiveCN105169886AReduce energy consumptionImprove recycling efficiencyDispersed particle separationSolventChemistry

The invention discloses an efficient energy-saving large-air-quantity low-concentration organic waste gas recovery and treatment device and method. The recovery and treatment device comprises a pretreatment system and an adsorption and purification device, the output end of the pretreatment system is connected with a waste gas inlet of the adsorption and purification device through an adsorption and purification fan, and the adsorption and purification device is an adsorption and purification fixed bed or a zeolite rotary wheel adsorption and purification system. A recovery device further comprises a first heat exchanger, a first cooler, an adsorption recovery bed, a condenser, a layering tank, a solvent recovery tank, a heater, a first dried filter, a dehumidifying fan and a cooling fan. The recovery and treatment method includes the steps of firstly, pretreatment, secondly, adsorption and purification, thirdly, adsorption and concentration, fourthly, cooling and adsorption and fifthly, adsorption and recovery. By means of multi-stage reuse of heat and multi-stage adsorption of organic waste gas, the effects of reducing energy consumption and improving recovery efficiency are achieved, the device and method are particularly suitable for large-air-quantity low-concentration organic waste gas recovery and treatment, the aim of clean production is achieved, recycling of resources are achieved, and environment protection is achieved while energy is saved and emission is reduced.

Owner:黄文科

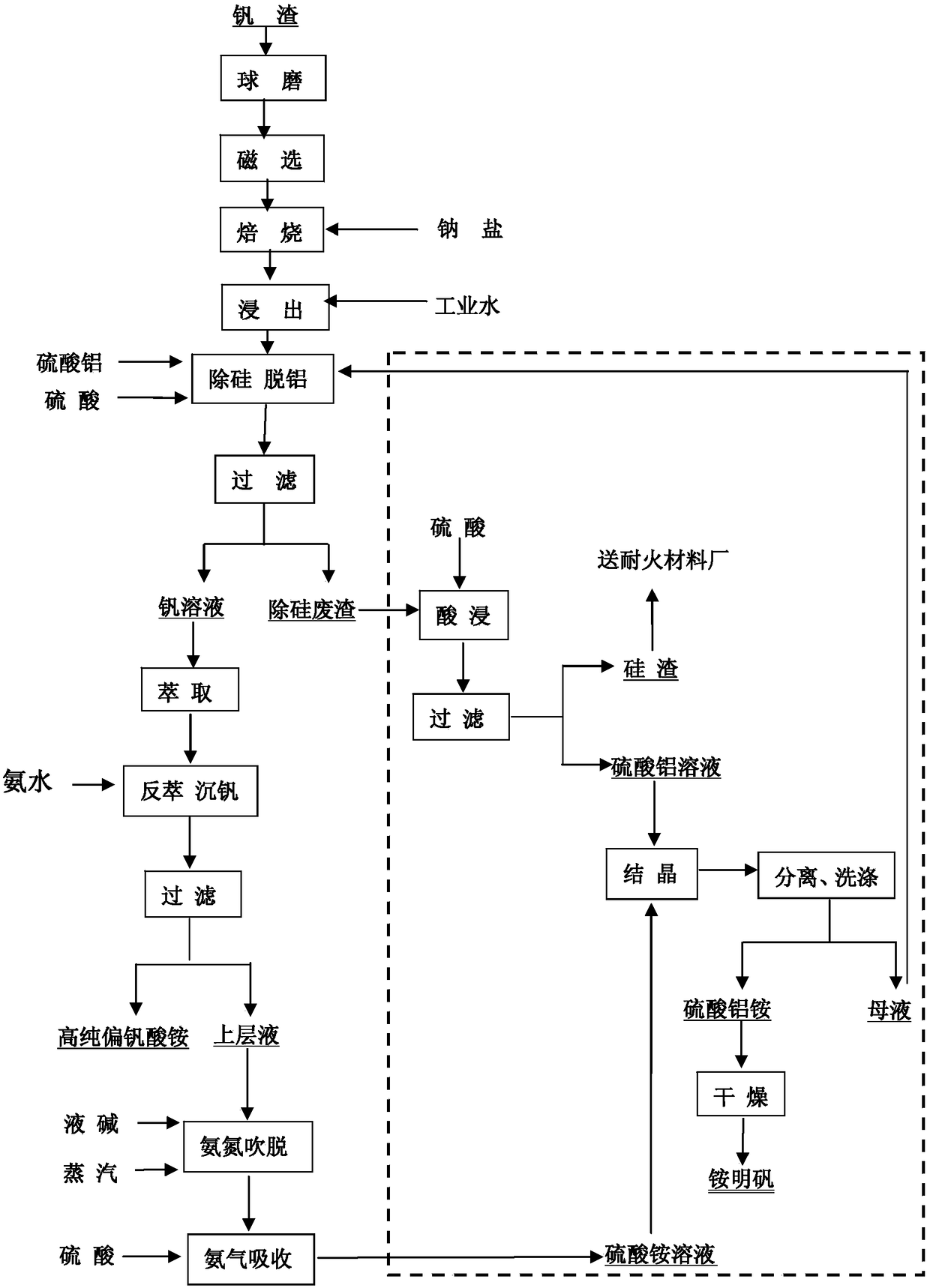

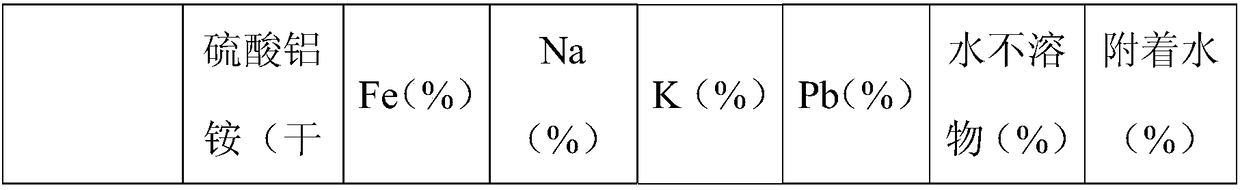

Preparation method of vanadium containing solution

ActiveCN108359815AHigh recovery rateSolve the pollution of the environmentVanadium oxidesCeramic materials productionResource utilizationAluminum ammonium sulfate

The invention provides a preparation method of a vanadium containing solution. The preparation method comprises the following steps that vanadium containing lixivium is subjected to silicon removal and dealumination to obtain the vanadium containing solution and silicon removal waste residues; the silicon removal waste residues are leached through concentrated sulfuric acid to obtain an acid leaching solution; after the acid leaching solution is precisely filtered, silicon residues and an aluminum sulfate solution are obtained; and the aluminum sulfate solution and an ammonium sulfate solutionare mixed, recooling crystallization is carried out after reacting, aluminum ammonium sulfate crystals and crystallization mother liquor are obtained through second solid-liquid separation, and the crystallization mother liquor is used for replacing part or all of aluminum salt to be mixed with a silicon-chrome-silicon containing solution for silicon removal. According to the method, the siliconremoval waste residues can be subjected to resource utilization, and an aluminum ammonium sulfate product high in additional value can be obtained; meanwhile, the consumption of the aluminum salt canbe reduced, high-purity ammonium metavanadate can be prepared continuously and stably, and therefore a high-purity vanadium pentoxide product with the purity not smaller than 99.9% is prepared, and the vanadium recovery rate is increased; and the process is simple, the cost is low, and energy consumption is low.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

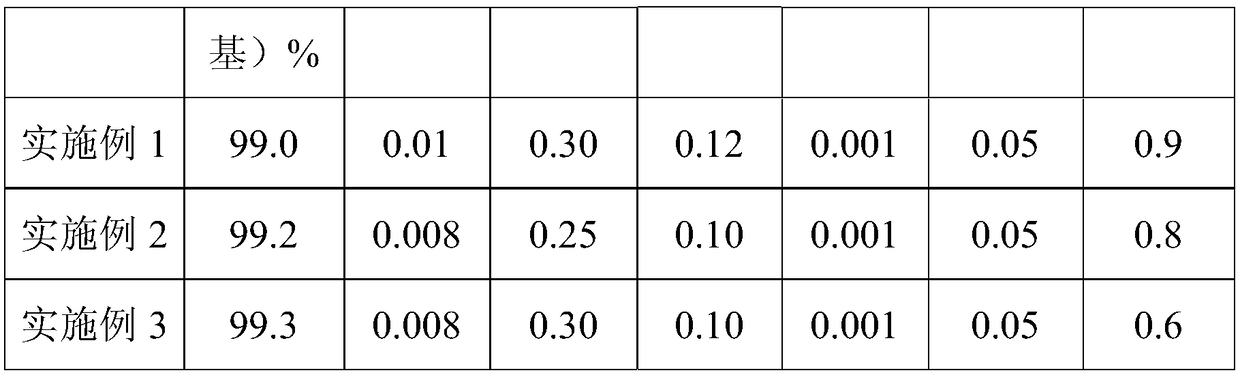

Clean production method of N-cyanoethylaniline

ActiveCN102241606AReduce adverse effectsEasy dischargeCarboxylic acid nitrile preparationOrganic compound preparationSodium bicarbonateHigh concentration

The invention discloses a clean production method of N-cyanoethylaniline. The method comprises the following steps: synthesizing N-cyanoethylaniline by utilizing aniline and acrylonitrile as raw materials in the presence of hydrochloric acid and zinc chloride; after the reaction, adding sodium bicarbonate into the mixture of which the water layer is separated out so as to recycle acrylonitrile, pumping steam into the mixture without acrylonitrile to distill, adding sodium carbonate or sodium bicarbonate after distillation, and evenly mixing the solution to obtain N-cyanoethylaniline; and recycling aniline and N-cyanoethylaniline from the distillate of distillation, and recycling water generated in the reaction. In the method, according to the practical applications of N-cyanoethylaniline, the content of aniline in a product is reduced to eliminate the negative influences on the subsequent application of N-cyanoethylaniline; and the output of high concentration wastewater can be reduced in the production, the design of the reaction steps is reasonable and the aim of clean production can be effectively achieved.

Owner:JIANGSU HELIRUI TECH DEV CO LTD

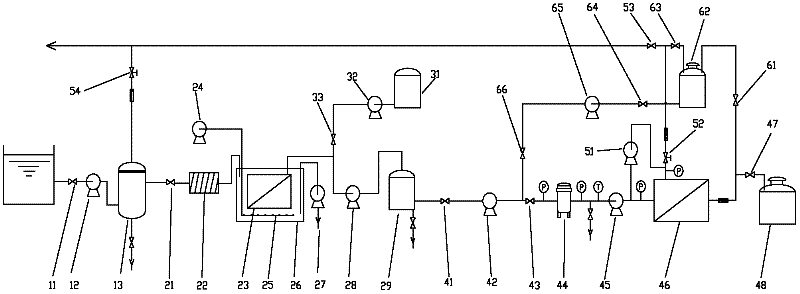

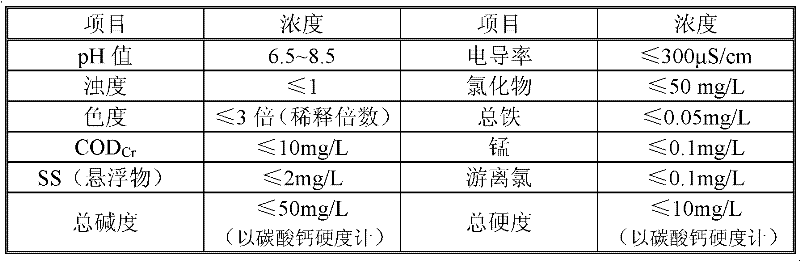

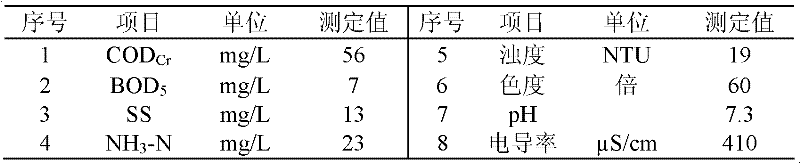

A regenerated water manufacturing device and method based on electrolysis and double-membrane technology

InactiveCN102260013AImprove water qualityTo achieve the purpose of cleaner productionWater/sewage treatmentMultistage water/sewage treatmentWater basedWater quality

Provided is an apparatus for producing reclaimed water based on electrolysis and double membrane technologies. The apparatus is disposed with an electrolysis system, an MBR system and a reverse osmosis system. Further provided is a method for producing reclaimed water using the apparatus, comprising the following steps: retrieving biochemical sewage through a water pump (12) and inputting the biochemical sewage into an electrolysis apparatus (13) of the electrolysis system to be electrolyzed, then enabling the sewage to enter an MBR reaction tank (26) through a grid (22) to obtain primary reclaimed water, pumping the primary reclaimed water into the reverse osmosis system with a high pressure pump (45) to separate dialysis water and concentrated water, enabling the dialysis water to enter a reclaimed water storage tank (48) to obtain ultrapure reclaimed water, enabling a part of the concentrated water to flow back for cyclic membrane filtering and separation, enabling a part of the concentrated water to flow back to enter an electrolysis procedure for cyclic use, and discharging the rest part of the concentrated water.

Owner:BOYING XIAMEN SCI & TECH

Method of high effect preparing tea polyphenol

InactiveCN1534034ASimple processShorten the production cycleOrganic chemistryChemical recyclingAcetic acidSlurry

A process for effectively preparing the theapolyphenol includes mixing fresh tea leaves with solvent, homogenizing, solid-liquid extracting, filtering, mixing dregs with solvent, solid-liquid extracting, collecting the liquid extract, concentrating, mixing with dichloromethane solution, liquid-liquid extracting, centrifugal treating, mixing the liquid extract with ethyl acetate, liquid-liquid extracting, centrifugal treating, filtering, concentrating, drying and purifying. Its advantages are short period and high output rate.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

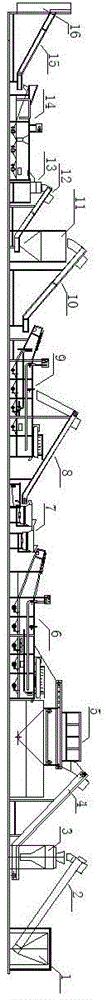

Efficient environmental-friendly automatic processing control system for dehydrated vegetables

ActiveCN104799419AHigh in nutrientsHigh spicinessVegetable peelingFood treatmentStone removalAutomatic processing

The invention discloses an efficient environmental-friendly automatic processing control system for dehydrated vegetables. The processing process of the efficient environmental-friendly automatic processing control system is characterized by concretely comprising the following steps: (1) feeding; (2) sectioned peeling; (3) primary rinsing; (4) stone removal; (5) secondary rinsing; (6) temporary material storage; (7) slicing; (8) drying. A slicer is connected with a conveying belt for a drying box. Slices are free of cleaning before drying, various nutrients in the product are kept, the strong taste of the product is promoted, the yield of primary product reaches to 32 percent and is increased by 5 percent compared with the same industry, and the use of raw materials is saved. A novel drying machine has the advantages of high heat utilization rate, high yield, uniform product color and constant water, adopts natural gas or electricity as a heat source, and achieves the target of clean production. The novel processing process for the dehydrated vegetables is high in yield of primary product, keeps the original nutritional value, and is wide in applicability.

Owner:QINGDAO UNISONECO FOOD & TECH CO LTD

Method for producing high-purity inulin

InactiveCN101955553AHigh degree of polymerizationSolve the problem of hydrolysisFiltrationStrong acids

The invention provides a method for producing high-purity inulin, which comprises the following steps of: a, performing cleaning, shredding, countercurrent leaching, flocculation and impurity removal, and filtration on jerusalem artichoke or chicory serving as a raw material to obtain inulin feed solution; b, making the inulin feed solution obtained in the step a pass through macroporous decolorization resin, strong acid resin, and strong base resin for decoloration in turn at a linear speed of 2-3 meters / second, and performing ion exchange to obtain inulin solution, wherein the macroporous decolorization resin, the strong acid resin, and the strong base resin are respectively added with 8 to 12 weight percent sodium chloride solution in an amount which is 2 to 4 times volume thereof for regeneration; and c, performing nanofiltration on the inulin solution by using a nanofiltration membrane, eluting monosaccharide and sodium chloride by using purified water, concentrating, and performing spray drying to obtain the product. The method has the advantages of avoiding hydrolysis caused by reduced pH value of the inulin solution, regenerating and recycling ion exchange resin, and realizing comprehensive utilization, clean production and pollution-free emission in the whole production process.

Owner:SHANDONG NINE RING GASOLINEEUM MACHINERY

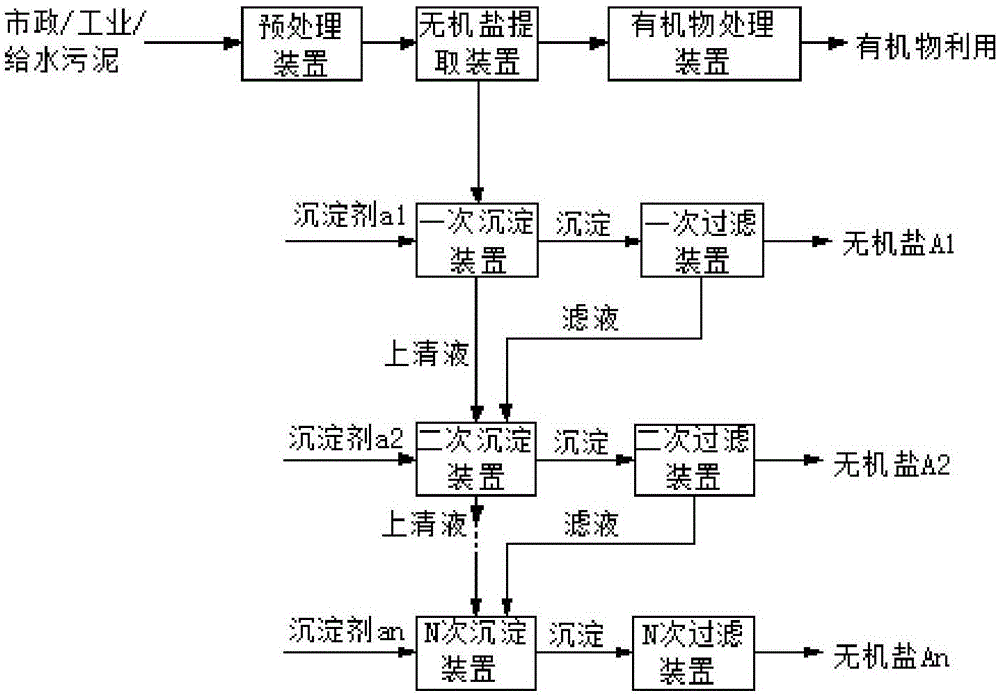

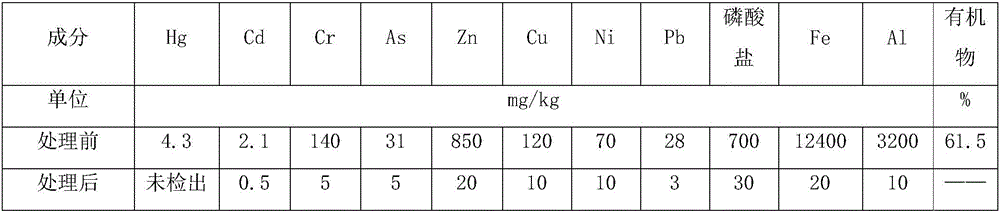

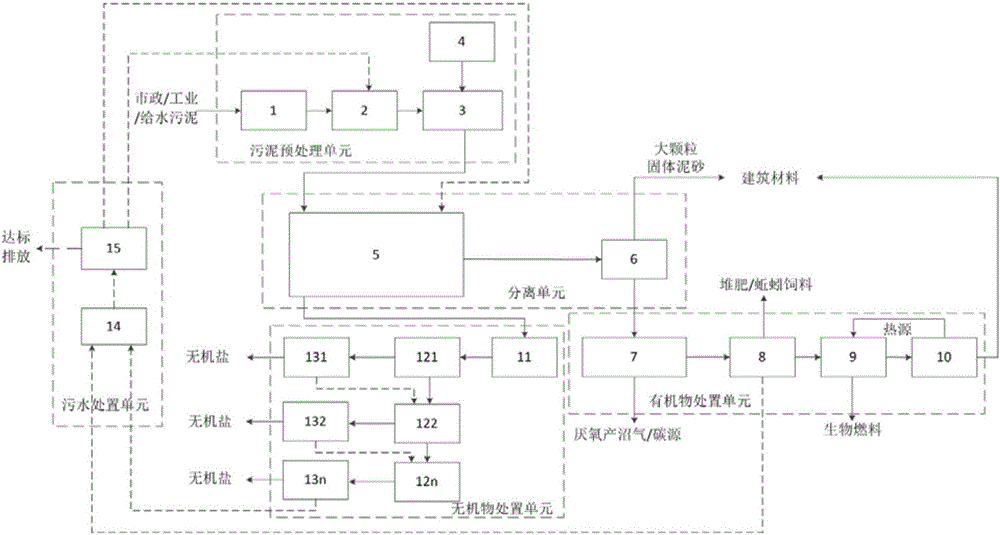

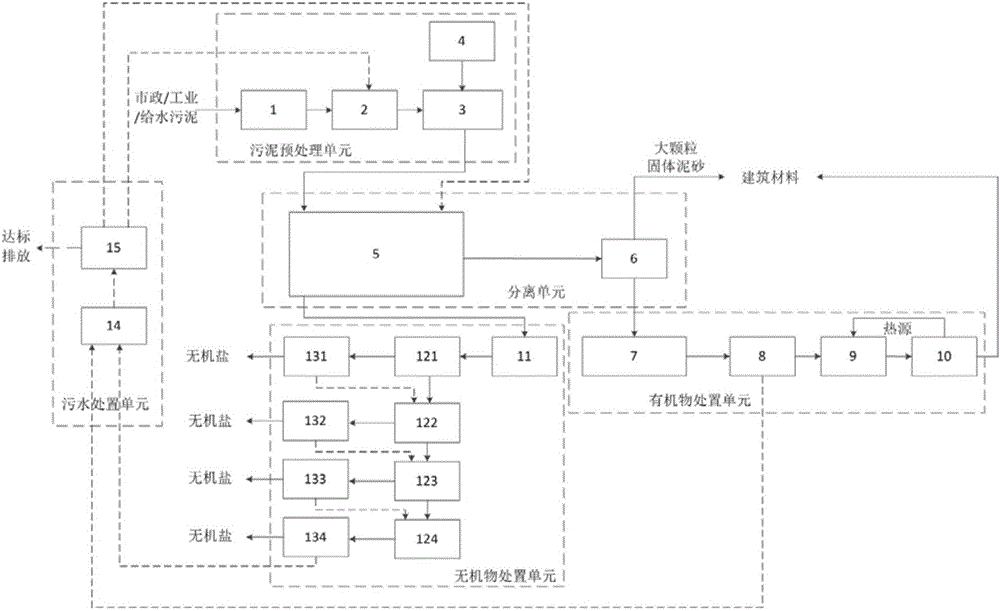

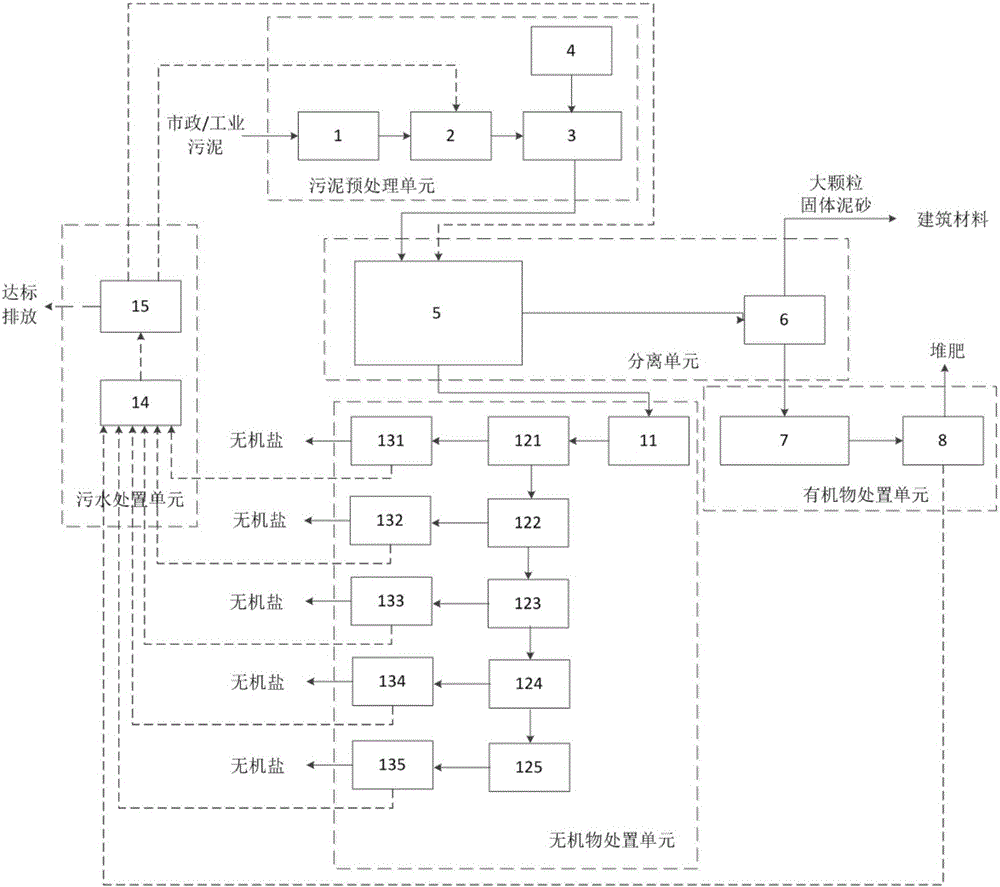

Method and device for respectively extracting and using inorganic matters in sludge

InactiveCN106007292ALow impurity contentHigh puritySludge treatmentLead hydroxidesInorganic saltsResource utilization

The invention provides a method for respectively extracting and using inorganic matters in sludge, and belongs to the technical field of sludge treatment. The method comprises the following steps: (1) pretreating the sludge; (2) extracting inorganic salt from a sludge solution subjected to pretreatment; (3) adding a precipitant a1 into the inorganic salt extracting solution obtained in the step (2) till precipitates are separated, and forming inorganic salt A1 for recycling; (4) adding a precipitant a2 into precipitate-removed supernate in the step (3) till precipitates are separated, and forming inorganic salt A2 for recycling; (5) by parity of reasoning, adding a precipitant an into the precipitate-removed supernate in the former step till precipitates are separated, forming inorganic salt An for recycling. According to the method, the inorganic matters in the sludge are respectively recycled, so that weight reduction for the sludge is realized, and resource utilization of the sludge is also realized; the method is simple in process, high in applicability, simple and convenient to operate, easy to control, low in operating cost, good in treatment effect, wide in application range and easy to popularize and use.

Owner:TIANJIN ENEW ENVIRONMENTAL PROTECTION ENGCO LTD

Method for extracting lactoflavin

InactiveCN101412716AReduce degradationEmission reductionOrganic chemistryMetabolism disorderWastewaterSewage

The invention relates to a method for extracting riboflavin, in particular to the method for extracting the riboflavin from a riboflavin fermentation broth. The invention provides the method for extracting the riboflavin from the riboflavin fermentation broth to reduce the steps for extracting the riboflavin, reduce the production cost and achieve clean production. The method has the advantages of online control of the production process, short basic time, less degradation of the riboflavin, no acid-soluble back dissolving process, no generation of waste acid, less wastewater discharge, less equipment corrosion, mother liquor reclamation, pressure reduction on sewage treatment, product recycling, and improved yield by about 5 percent.

Owner:山东恩贝生物工程有限公司

Polyester fully-drawn slub yarn and preparation method thereof

InactiveCN102828278AGood orientationEnsure productivityNew-spun product collectionFilament forming substance formingPolyesterBreaking strength

The invention discloses a polyester fully-drawn slub yarn and a preparation method thereof. On the basis of not changing the conventional FDY (fully-drawn yarn) production device, the polyester fully-drawn slub yarn is produced by using a one-step method implemented through adding a polymethyl methacrylate additive (mass percentage: 0.5-3.0%) into a polyester chip and then carrying out drawing on an obtained mixture at a drawing speed of 4600-5000m / min. The radial fineness ratio of the obtained slub yarn is 1.20-1.60 / l, the length of a thick section of the slub yarn is 15-40mm, and the slub density is 5-15 / m; and the breaking strength is 2.70-3.40 cN / dtex, and the breaking elongation is 40-80%. The polyester fully-drawn slub yarn prepared by using the technical scheme of the invention has the characteristics of high output, low cost, good quality, stable performance, high added values of products, and obvious price-performance advantages, and achieves the purposes of energy conservation, emission reduction, environmental protection, clean production and benefit incensement.

Owner:SUZHOU UNIV

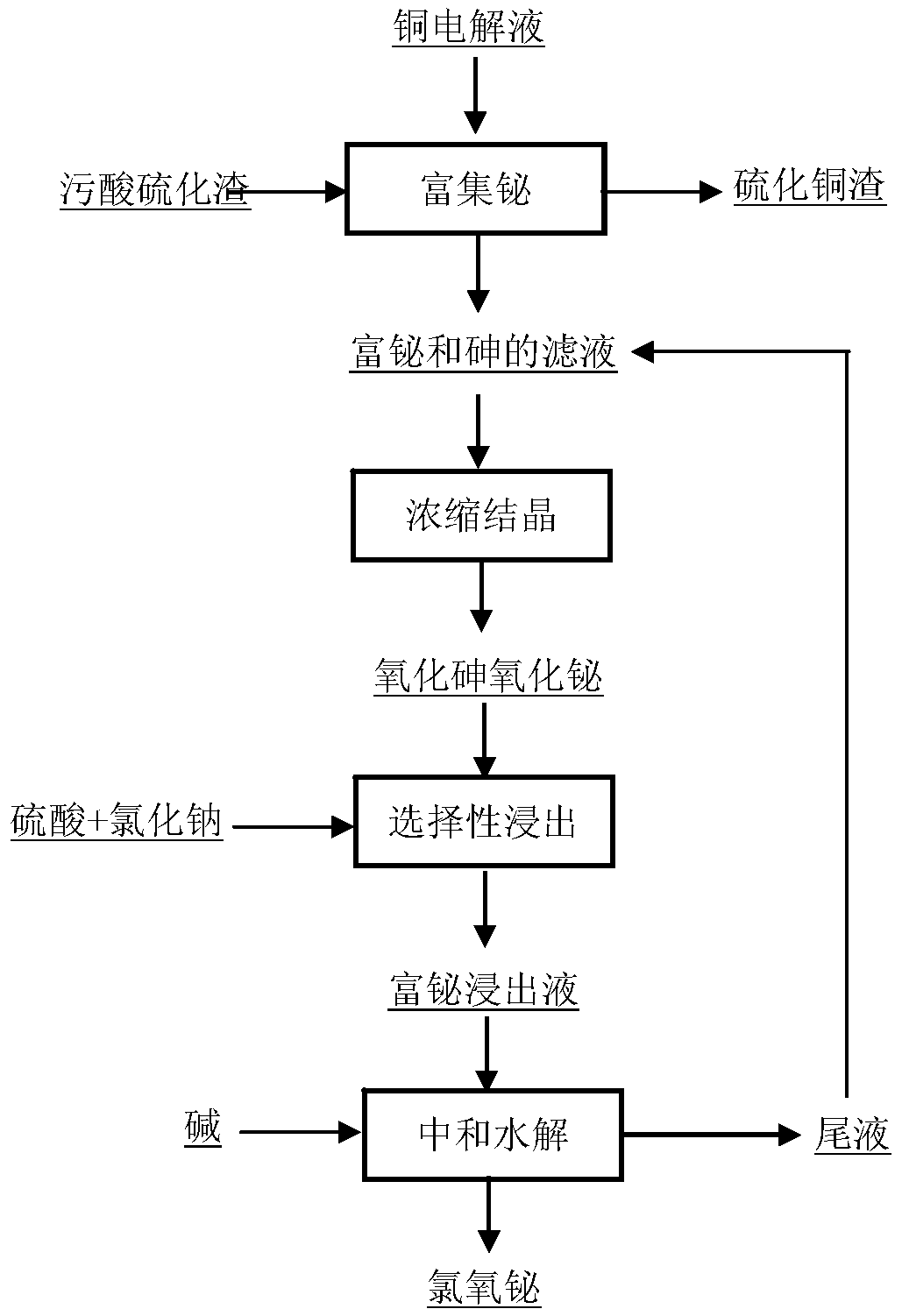

Method for enriching and recycling bismuth from waste acid sulfide residues

ActiveCN105568002AAchieve reductionReduce processing costsProcess efficiency improvementArsenic oxideSulfide

The invention discloses a method for enriching and recycling bismuth from waste acid sulfide residues. The method comprises the following steps: 1) adding the waste acid sulfide residues into copper electrolyte, controlling reaction conditions, introducing bismuth and arsenic in the waste acid sulfide residues into a solution, replacing and enriching sulfides in copper waste acid sulfide residues in electrolyte to obtain copper sulfide residues; 2) evaporating and concentrating the solution which is rich in bismuth and arsenic in step 1), and separating out a mixture of bismuth oxide and arsenic oxide from the solution by crystallizing the solution after cooling the solution; 3) adding sodium chloride into sulfuric acid to selectively leach bismuth in the mixture of the bismuth oxide and the arsenic oxide, and filtering the mixture to bismuth-rich leaching liquor; and 4) regulating the pH value of the bismuth-rich leaching liquor for neutralizing and hydrating the bismuth-rich leaching liquor to generate bismuth chloride oxide precipitates, standing the bismuth chloride oxide precipitates for certain time, filtering the bismuth chloride oxide precipitates to obtain bismuth chloride oxide and tail liquor, and returning the tail liquor into a solution which is rich in bismuth and arsenic in the step 1) for circulating. The method not only can realize recycling waste acid sulfide residues in a smelting system, but also efficiently enriches and recycles the bismuth, and has a relatively high practical value.

Owner:CENT SOUTH UNIV +1

Food wrapper and manufacturing method thereof

ActiveCN101555672AEmission reductionAvoid damageFlexible coversNatural cellulose pulp/paperFiberBleach

The invention relates to a food wrapper and a manufacturing method thereof. Burst index of the food wrapper is not lower than 3kPa.m / g, longitudinal tensile strength thereof is not lower than 3.0KN / m, lead content thereof is not higher than 5.0mg / kg and arsenic content is not higher than 1.0mg / kg; decoloring testing proves negative; fluorescent matter is not contained; pathogen can not be detected; whiteness of the wrapper ranges from 20% to 30%; the wrapper is brown; the manufacturing method comprises the following steps: DDS displacement cooking, washing screen, oxygen delignification and hydrogen peroxide bleaching are carried out on wood fibrous material to be prepared into micro-bleach pulp with a whiteness of 22% to 36%; beating, desanding, flovoring, fine sizing by a pressurized screen, wiring and moulding, pressing, drying, reeling, rewinding and packaging are carried out on the pulp, thus obtaining the food wrapper.

Owner:YUEYANG FOREST & PAPER CO LTD

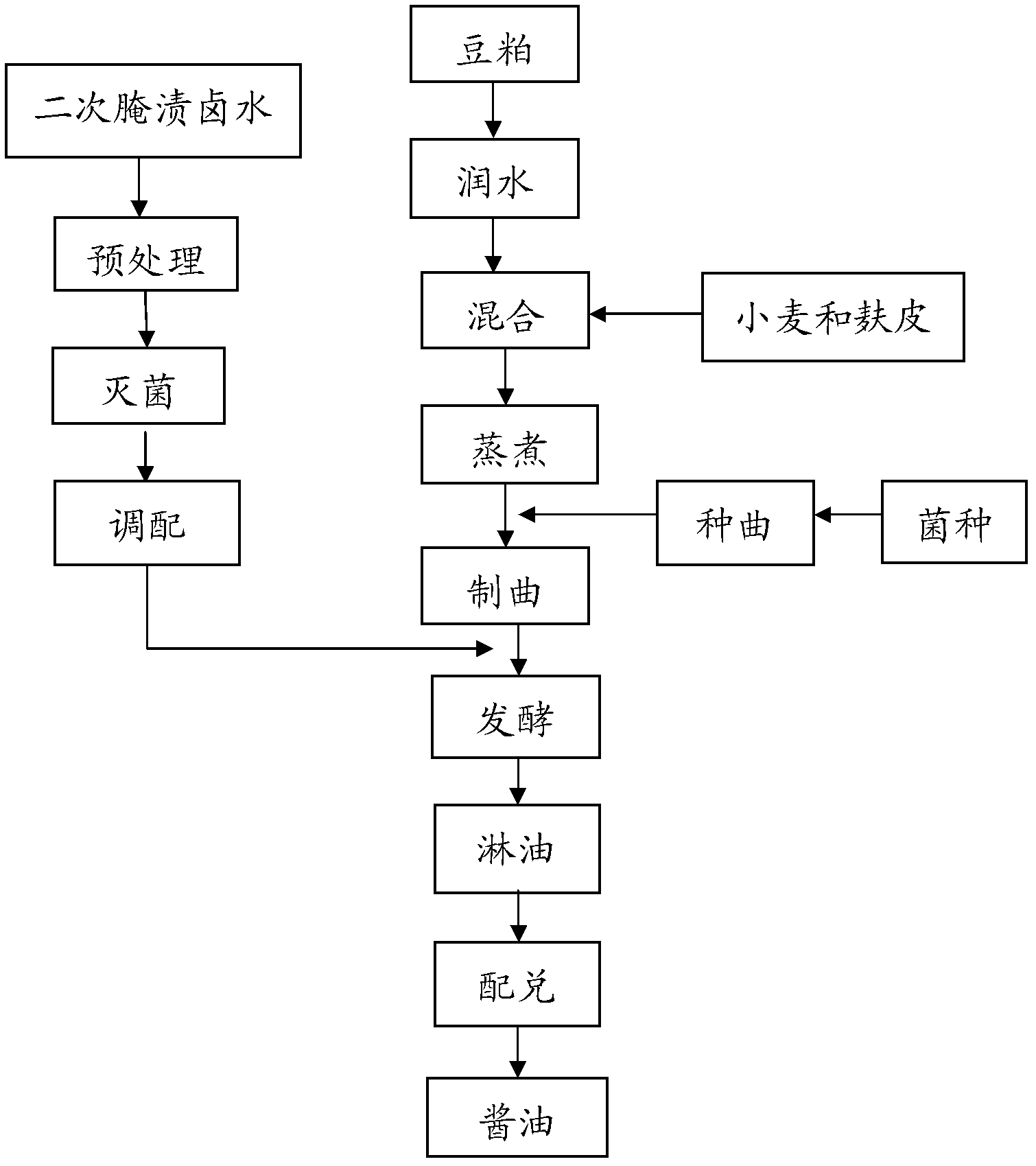

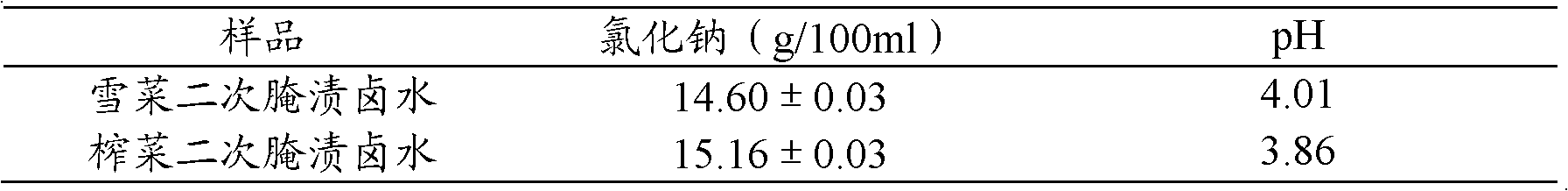

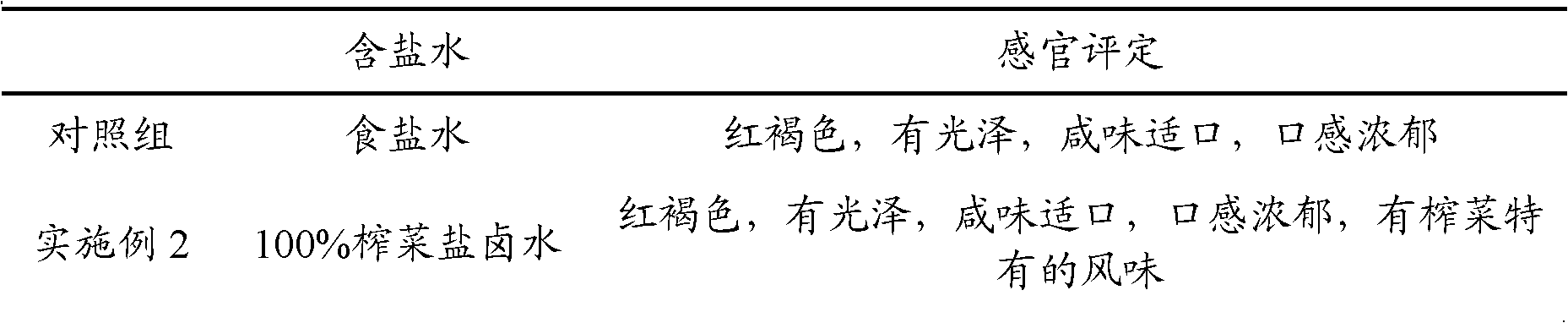

Method for preparing soy sauce by recycling vegetable pickling brine

The invention discloses a method for preparing soy sauce by recycling vegetable pickling brine, which comprises the following steps of: recycling secondary pickling brine produced in the vegetable pickling process, sterilizing and separating supernate out to obtain bittern; taking raw materials of the sauce, stewing and cooking the raw materials and then inoculating aspergillus for starter propagation to obtain finished koji; and adding saline to the finished koji and fermenting, and then pouring oil and mixing to obtain the soy sauce, wherein the saline is bittern or a mixture comprising thebittern and a salt solution. The method for preparing the soy sauce by recycling vegetable pickling brine is a soy sauce production method which is short in fermentation time, low in cost, economic and effectively, environment-friendly and energy-saving. According to the method disclosed by the invention, the secondary pickling brine produced in the vegetable pickling process is recycled, zero emission is achieved, the pollution of the secondary pickling process on environment is reduced, and salt and nutritional ingredients in the bittern are utilized to the greatest extent; and the secondary pickling brine is added to the finished koji according to the appropriate proportion, the normal fermentation of the soy sauce cannot be influenced, and the fermented soy bean which has good quality, rich nutritional ingredients, long quality guarantee period and qualified quality can be produced.

Owner:ZHEJIANG UNIV

Clean production method for perfluoroalkyl acrylate

InactiveCN102229530AImprove conversion rateAdequate responseOrganic compound preparationCarboxylic acid esters preparationAlcoholOrganosolv

The invention relates to a clean production method for perfluoroalkyl acrylate, which belongs to the field of preparation of intermediates containing fluorine. The technical scheme for the method is as follows: in a reaction vessel with a negative pressure water separator, under the condition of a negative pressure of -0.04 to -0.085 Mpa and a temperature of 110 to 120 DEG C, under the action of an alkali metal acid salt catalyst and a polymerization inhibitor, perfluoro alcohol reacts with acrylic acid or homologues thereof to generate perfluoroalkyl acrylate, wherein perfluoro alcohol refers to fluorine-containing alcohol which has a general formula of F(CF2CF2)n(CH2)mOH, n therein is a positive integer from 1 to 10, m therein is 1 or 2 or 3, and alkali metal acid salt is potassium bisulfate or sodium bisulfate. According to the invention, the negative pressure water separator is used to separate resultant moisture in time, which enables a more adequate reaction and a high conversion rate of acrylic acid; no azeotropic organic solvent is used and water generated in the reaction can be recycled directly; after the reaction ends, the catalyst precipitates with the decrease of temperature and can be removed by merely filtering, thereby achieving the purpose of clean production.

Owner:山东中氟化工科技有限公司

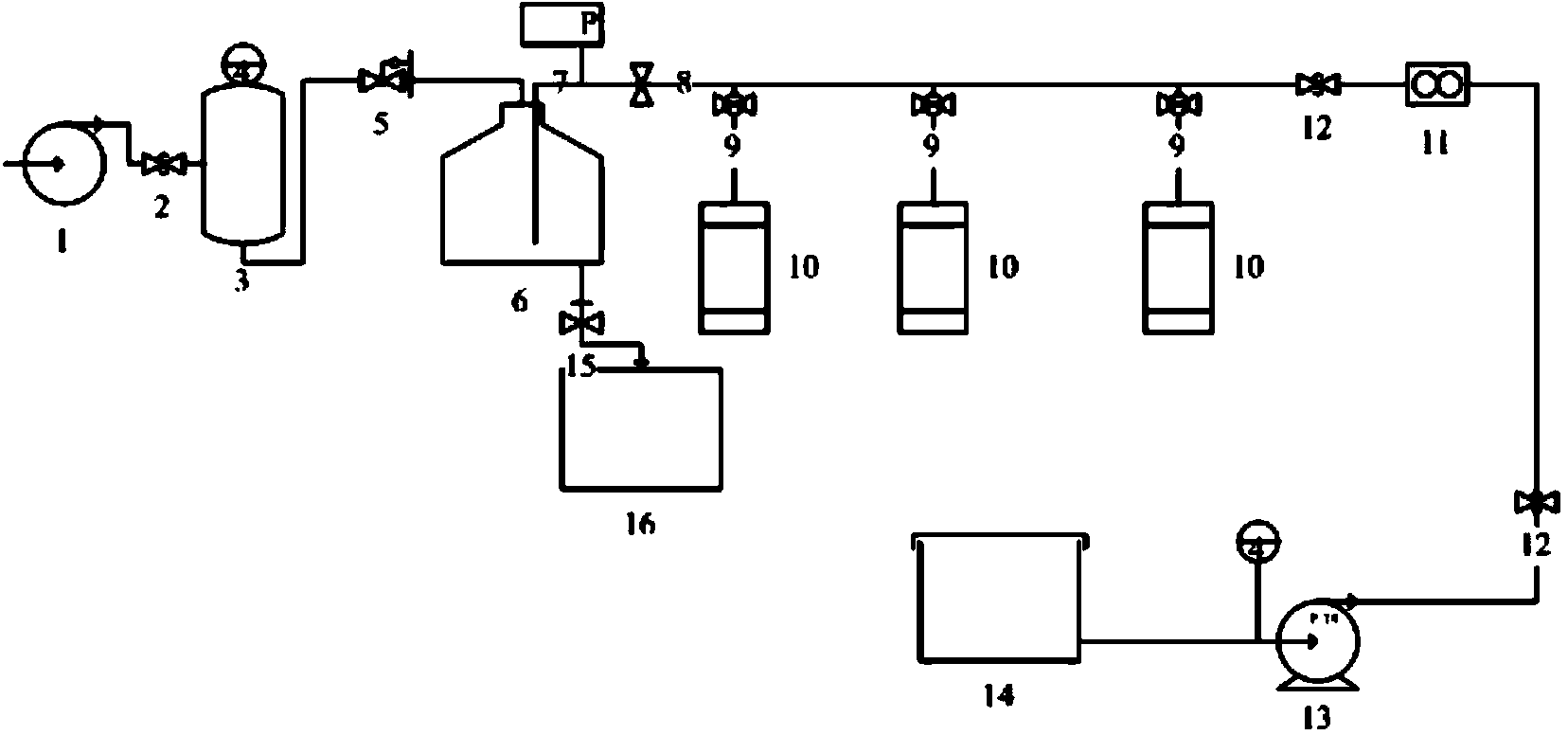

Waste and old hard-case power lithium ion battery electrolyte displacement apparatus and displacement method thereof

InactiveCN103825063AHarm reductionTo achieve the purpose of cleaner productionWaste accumulators reclaimingCell component detailsSolenoid valveDistillation

The invention relates to a waste and old hard-case power lithium ion battery electrolyte displacement apparatus and a displacement method thereof, which belongs to the lithium ion battery recovery and cleaning production fields. According to the invention, an electrolyte flowed in the cell is extracted from an explosion-proof valve port through a vacuum system, cleaning fluid is introduced in the cell through a liquid inlet system, after standing, the inner liquid of the cell is extracted through the vacuum system, and most volatile electrolyte and the solvent can be brought out if the steps are repeated. Through the pre-processing, the harmful gas to human body and environment when the cell is disassembled can be reduced. The extracted electrolyte enables cycle utilization through steps such as distillation, and the addition amount of the cleaning fluid can be controlled through a flowmeter and a solenoid valve.

Owner:BEIJING UNIV OF TECH +1

Green synthesis method of D-calcium pantothenate

InactiveCN108129346AEasy to operateMild reaction conditionsOrganic compound preparationCarboxylic acid amide separation/purificationFilter cakeCalcium

The invention discloses a green synthesis method of D-calcium pantothenate. The green synthesis method of D-calcium pantothenate provided by the invention comprises the steps that beta-alanine is added into methyl alcohol; then, a calcium source is added; temperature rise and stirring are performed for reaction; filtering is performed; filter liquid is collected; filter liquid is subjected to temperature cooling; then, D-pantolactone is added; stirring reaction is performed; seed crystals are added; stirring reaction is continuously performed; after the reaction is finished, water is added; crystallization is continuously performed at -15 DEG C to -20 DEG C; then, filtering and washing are performed; filtering cake and filtering liquid are respectively collected; the filtering cake is dried; the filtering liquid is subjected to acid hydrolysis; DL-pantolactone is recovered. The green synthesis method has the advantages that the D-calcium pantothenate is prepared from calcium pantothenate; the process route operation is simple; the reaction conditions are mild; safety is realized; the environment is protected; the raw materials are cheap and can be easily obtained; the industrial adaptability is high; the wastes are few; the used raw materials can be recovered and utilized; the goal of clean production is reached.

Owner:CHONGQING BEISHENG PHARMA TECH CO LTD

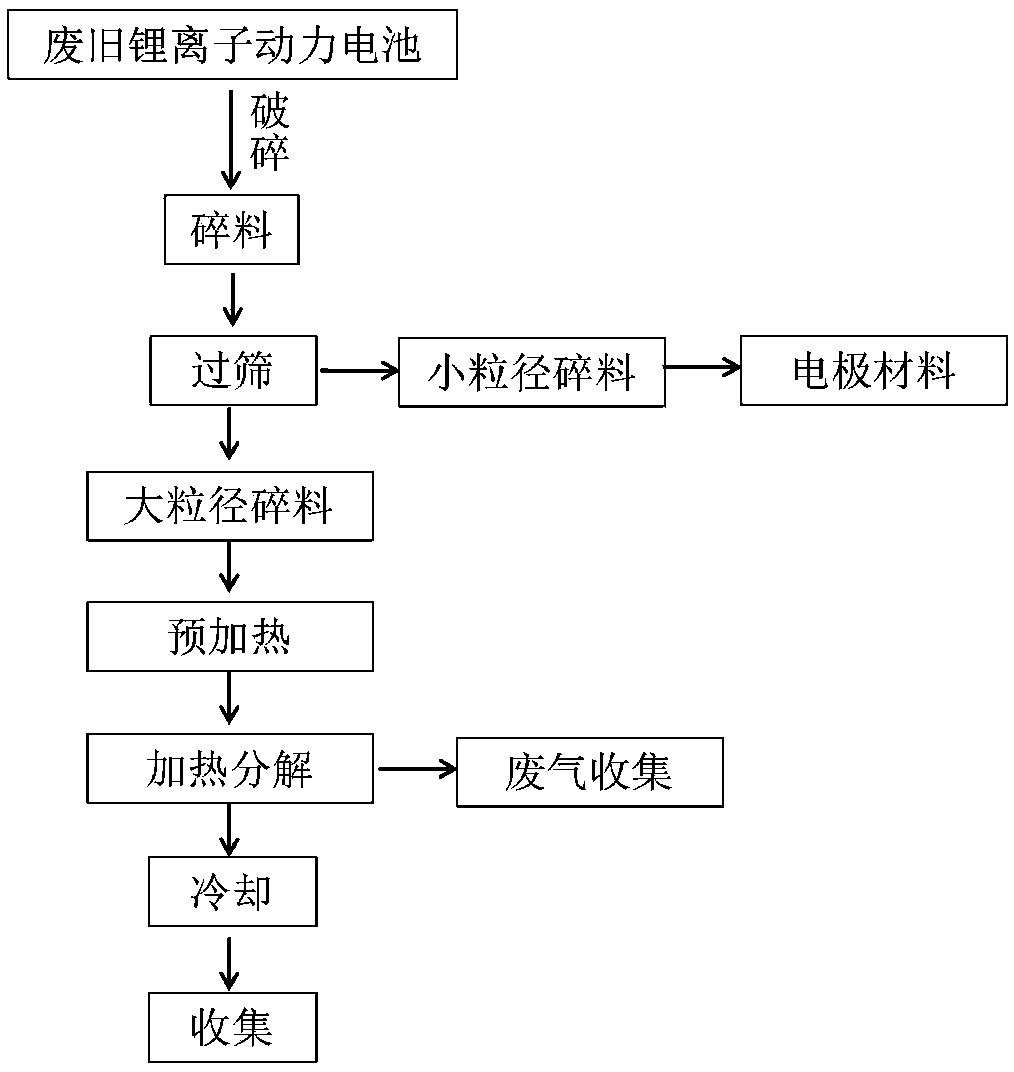

Method for removing a separator in a waste lithium ion power battery

ActiveCN109273791AImprove pyrolysis efficiencySolve removal puzzlesWaste accumulators reclaimingBattery recyclingDecompositionScrap

The invention discloses a method for removing a separator in a waste lithium ion power battery, which comprises the following steps: crushing the waste lithium ion power battery into crumbs and passing through a 5-mesh screen to obtain small crumbs with a particle size less than 5 mesh and large crumbs with a particle size greater than 5 mesh; Preheating the large particle size crushed material, and controlling the preheating temperature at 100-300 DEG C; Heating and decomposing the crumbs obtained after the preheating is completed until the thermal decomposition of the diaphragm in the crumbsis complete and the temperature of the thermal decomposition is controlled at 300 to 500 DEG C; cooling and recovering The scrap obtained after decomposition. The method adopts two-stage heating design, improves the pyrolysis efficiency of the separator in the scrap material, the pyrolysis of the separator is more complete, the separator in the waste lithium ion power battery can be directly decomposed and removed, and the problem of removing the separator in the scrap material after the scrap material of the waste power battery is broken is solved; At that same time, the process method is simple to operate and easy to industrialize.

Owner:ZHUZHOU DINGDUAN EQUIP CO LTD

Tape base paper and production method thereof

InactiveCN102041744AReduce energy consumptionReduce emissionsSpecial paperReinforcing agents additionHydrogen peroxideFiber

The invention provides tape base paper and a production method thereof. As for the tap base paper, the fracture length is more than or equal to 6.0km; the tensile strength is more than or equal to 1.5kN / m; the moisture content is within the range of 7-10%; the tightness is more than or equal to 0.62g / cm<3>; the wet strength is more than or equal to 0.33kN / m; and the whiteness is within the range of 17-25%. The production method of the tape base paper comprises the following steps: carrying out low-energy consumption displacement cooking, oxygen-alkali delignification and hydrogen peroxide bleaching processes on a wood fiber raw material to produce micro-bleaching pulp, wherein the whiteness of the bleached pulp is 19-27%, the beating concentration of the bleached pulp is 2.5-4.5%, the beating degree of the bleached pulp is 26-32 degree SR, and the wet weight of the bleached pulp is 10.5-15g; and the pulp is formed by beating, degritting, adding a wet strength agent, carrying out fine screening with a pressurized screen, forming on a mesh, squeezing, drying, reeling, rewinding, and packaging.

Owner:YONGZHOU XIANGJIANG PAPER CO LTD

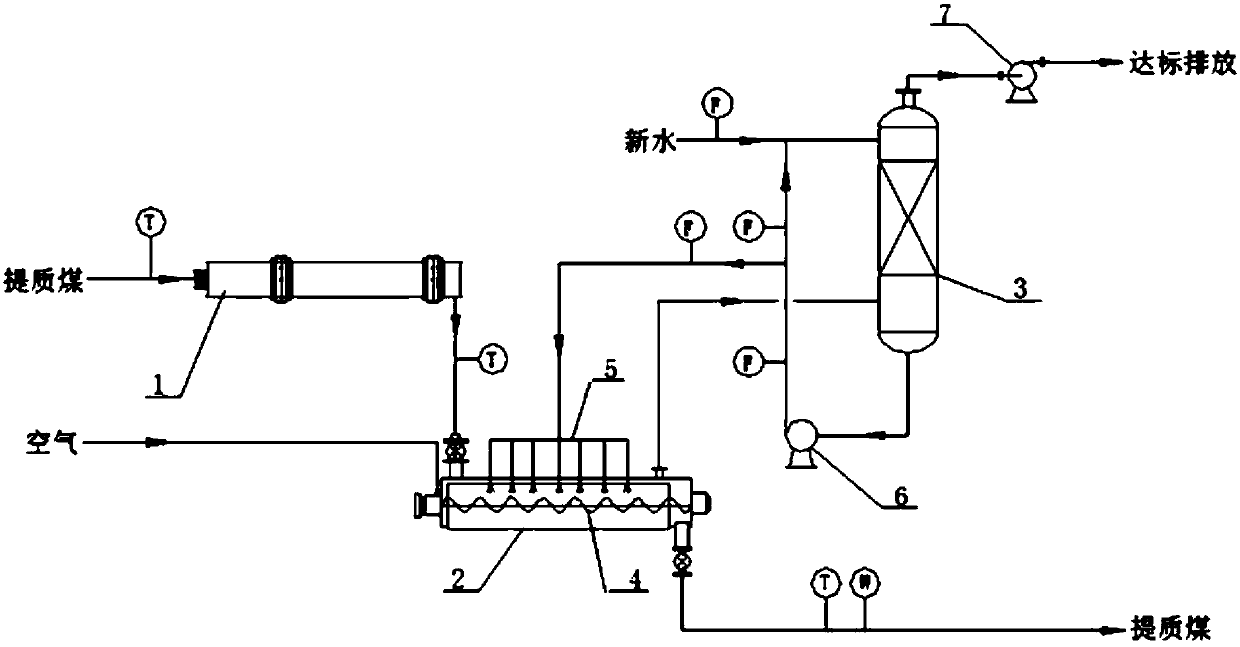

Upgraded coal cooling and humidifying device

PendingCN107937008AMeet the requirements of subsequent processesReduce loadCoke ovensUsing liquid separation agentTowerCirculating pump

The invention relates to an upgraded coal cooling and humidifying device which comprises a rotary cooler, a humidifier and a scrubbing tower, wherein an upgraded coal discharging hole of the rotary cooler is connected with an upgraded coal inlet in one side on the top of the humidifier; an upgraded coal outlet is formed in the other side at the bottom of the humidifier; a water spraying device isarranged on the top of the humidifier; an air inlet is formed in one end of the humidifier close to one side of the upgraded coal inlet; a tail gas outlet is formed in the top of the humidifier closeto the upgraded coal outlet; the tail gas outlet is connected with the tower column on the lower part of the scrubbing tower by virtue of a pipeline; at least two stages of spraying devices are arranged on the upper part of the scrubbing tower; a net gas outlet is formed in the top of the scrubbing tower; a washing water outlet is formed in the bottom of the scrubbing tower and connected with thespraying device by virtue of a washing water circulating pipeline; and a circulating pump and a washing water supply inlet are arranged on the washing water circulating pipeline. By virtue of a methodfor combining indirect cooling and humidification cooling, the temperature and moisture of the upgraded coal meet the requirements. Meanwhile, dust-containing steam produced in the humidification cooling process is effectively treated, and up-to-standard discharge is achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

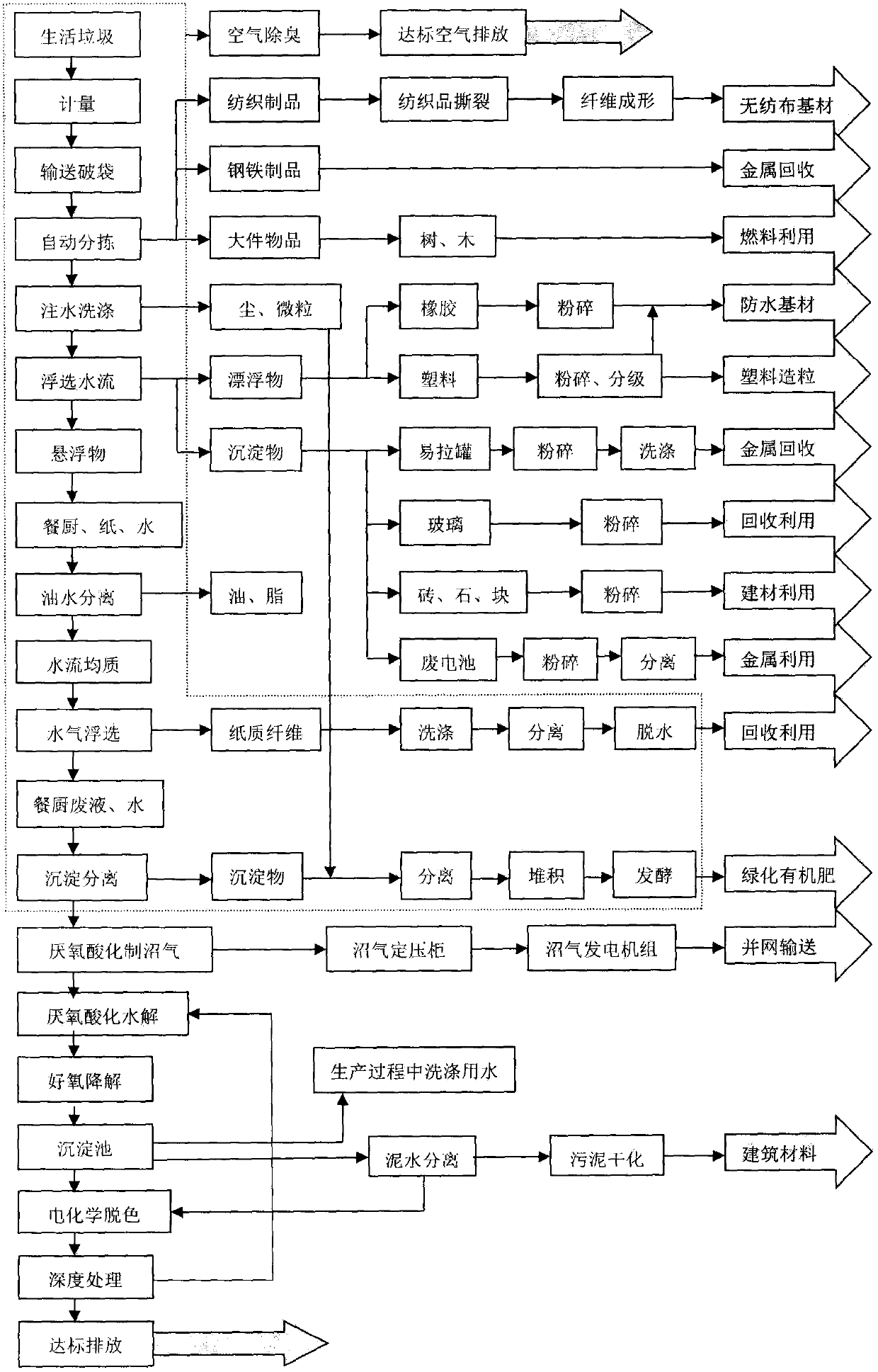

Household garbage resource recycling process

PendingCN105363758AEliminate secondary pollutionSave land resourcesWaste processingSolid waste disposalSewageMethane

The invention relates to a household garbage resource recycling process. According to the household garbage resource recycling process, household garbage is separated and classified step by step through hydraulic flotation until being recycled after being washed and sorted; meanwhile, washing wastewater is subjected to an anaerobic acidification process, and generated methane is recovered in a centralized mode for power generation; odor generated in the production process is cleaned by a low-temperature plasma oxidation deodorization technology; and at last, surplus wastewater is subjected to electrochemical decoloration to achieve emission on standard. According to the circulation, the purpose of purifying and recycling the household garbage can be achieved. According to the household garbage resource recycling process, the household garbage generated in every day of a city is all subjected to reduction, harmlessness and resource treatment, dioxin and secondary pollution are avoided, and accordingly the purpose of cleaner production is achieved.

Owner:江苏中证金鹏环保集团有限公司

Method for recycling secondary pickling brine in primary pickling

InactiveCN103099161AReduce processing costsReduce pollutionFruit and vegetables preservationFood processingWastewaterEnergy conservation

The invention relates to the technical fields of processing of pickled foods and comprehensive utilization of waste water and particularly relates to a method for recycling secondary pickling brine in primary pickling. The method is performed according to the following steps of: selecting and treating raw materials, performing primary pickling, performing secondary pickling, recycling and reusing. According to the method disclosed by the invention, energy can be saved and recontamination can be reduced.

Owner:HANGZHOU ZIXIANG FOODS GRP

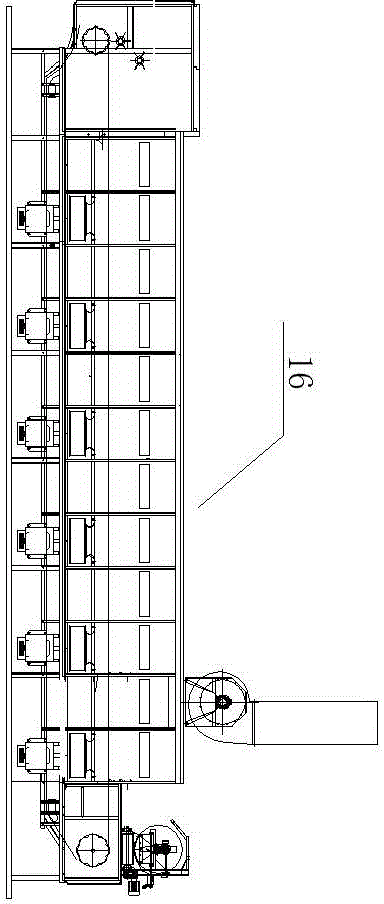

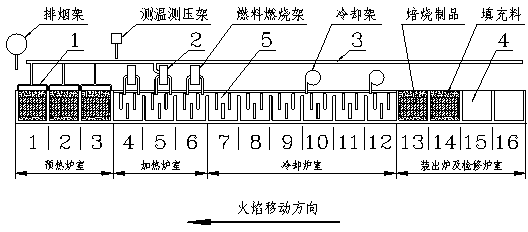

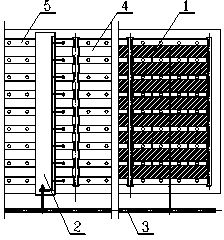

Ring-type baking furnace for carbon production

The present invention discloses a ring-type baking furnace for carbon production. According to the ring-type baking furnace, a plurality of furnace chambers are subjected to head-tail connection combination to form a ring; a material box (4) and a fire channel (5) are separately arranged; the upper portion of the preheat furnace chamber material box (4) is provided with a furnace cover (1); a volatilization component pipeline (3) is arranged between the two rows of the furnace chambers; the upper portion of a heat furnace chamber is provided with volatilization component combustion frames (2); the furnace cover (1) and the volatilization component combustion frames (2) are connected with the volatilization component pipeline (3); the volatilization component combustion frame (2) is connected with the fire channel (5) of the heat furnace chamber; the furnace cover (1) is provided with asphalt volatilization component discharge ports; and furnace cover volatilization component discharge ports and inlets of the volatilization component combustion frames (2) are connected through the volatilization component pipeline (3). With the present invention, the condition that harmful asphalt volatilization components enter baking flue gas so as to cause pollution can be avoided, baking energy consumption can be reduced, benzopyrene can be effectively treated, a clean production purpose can be achieved, and the condition that the too high temperature at the preheat stage causes the baking product to generate cracks can further be avoided.

Owner:GUIYANG AL-MG DESIGN & RES INST

Method for producing lithium phosphate by using lithium-containing waste liquid

ActiveCN102815680AImprove conversion rateReduce manufacturing costPhosphorus compoundsLiquid wastePhosphoric acid

The present invention relates to a method for producing lithium phosphate by using a lithium-containing waste liquid. The method specifically comprises the following steps: adding industrial phosphoric acid to a lithium-containing waste liquid according to a molar ratio of lithium content in the lithium-containing waste liquid to the phosphoric acid of 3:(1-1.05); carrying out a reaction for 1-5 hours at a temperature of 70-90 DEG C; filtering after carrying out the complete reaction; washing the resulting filter cake; and drying to obtain the lithium phosphate finished product. The method of the present invention has the following significant advantages that: with different dissolubilities of the products, the lithium resource in the waste liquid is reasonably converted into the lithium phosphate with a high added value so as to follow a "3R" principle of circular economy and correspondingly save the lithium resource; conversion rate is high, and the lithium resource is completely utilized so as to correspondingly save production cost of the lithium product; the method of the present invention has characteristics of simple process, easy operation, and easy industrial production; and the lithium-containing waste liquid is completely utilized and meets the discharge standard so as to achieve a purpose of cleaning production.

Owner:BAIYIN ZHONGTIAN CHEM

Clean method for preparing low-sulfur chromium oxide green

InactiveCN101993112AEasy to achieve zero emissionsEasy to industrializeChromium trioxideHydrogenSulfur

The invention discloses a clean method for preparing low-sulfur chromium oxide green. The chromium salt is taken as a raw material and a reducing gas is taken as a reducing agent; and the method comprises the following steps of: performing reaction on the chromium salt and the reducing gas at the temperature of between 300 and 800 DEG C for 0.5 to 5 hours; cooling, washing the reaction mixture with water, filtering, and drying to obtain an intermediate product; performing ball milling on the intermediate product at a rotating speed of 0 to 500rpm / min for 0 to 5 hours; hydrothermally leaching the ball milling product at the temperature of between 100 and 250 DEG C for 0 to 30 hours, washing, filtering and drying to obtain a leacheate; and calcining the leacheate at the temperature of between 600 and 1,300 DEG C in protective atmosphere to obtain the low-sulfur chromium oxide green and a byproduct of chromium-free sodium hydroxide. The chromium salt is sodium dichromate or sodium dichromate; and the reducing gas is hydrogen, natural gas, ammonia gas, coal gas or a mixture thereof.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

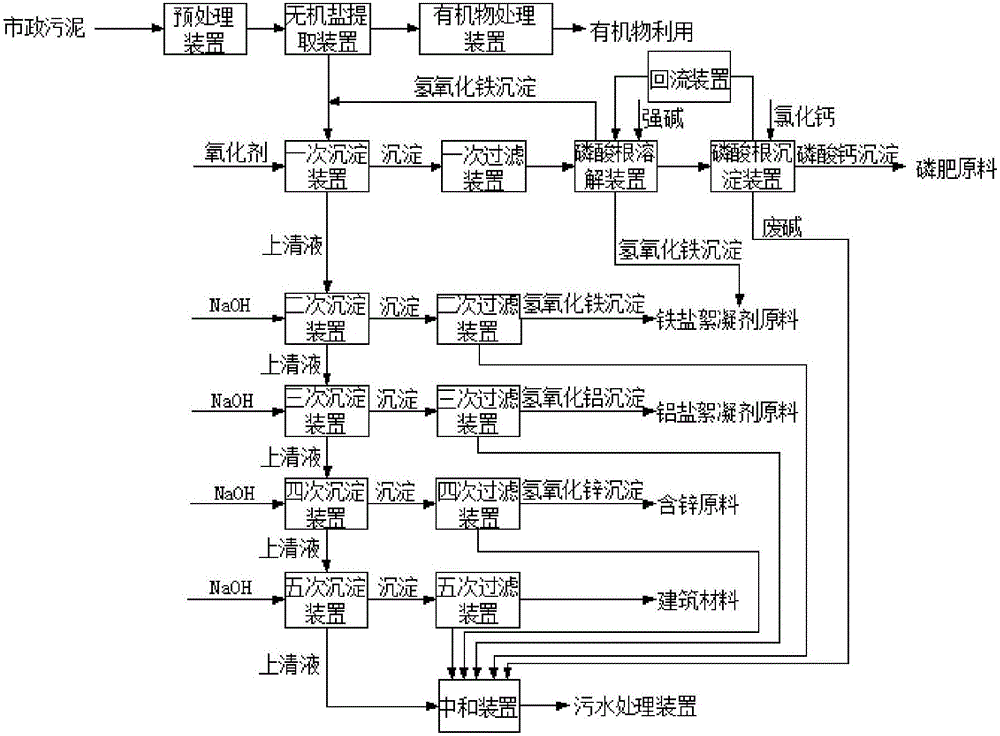

Novel recycling sludge treatment system and treatment method

InactiveCN106045249ATake advantage ofLow viscositySpecific water treatment objectivesWaste based fuelInorganic saltsSewage

The invention provides a novel recycling sludge treatment system and belongs to the technical field of sludge treatment. A sludge pretreatment unit comprises a sludge storage bunker, an adjustment device and an inorganic salt dissolving device which are sequentially connected, a separation unit comprises an inorganic salt extraction device and a desanding device, an organic matter treatment unit comprises an organic matter sludge solution storage tank, a dehydration device, a drying device and an incinerator which are sequentially connected, an inorganic matter treatment unit comprises an inorganic matter solution storage tank, a primary sedimentation device and a primary sedimentation filtering device which are sequentially connected, the primary sedimentation device is connected with a secondary sedimentation device, the secondary sedimentation device is connected with a secondary sedimentation filtering device, and a sewage treatment unit comprises a sewage storage tank and a sewage treatment system. Inorganic matters and organic matters in the sludge are effectively separated and respectively utilized, the harmless treatment of the sludge is implemented while sludge recycle and reduction is achieved, the purpose of cleaner production is achieved, and economic, social and environmental benefits are remarkable.

Owner:TIANJIN ENEW ENVIRONMENTAL PROTECTION ENGCO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com