Patents

Literature

32results about How to "Solve removal puzzles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

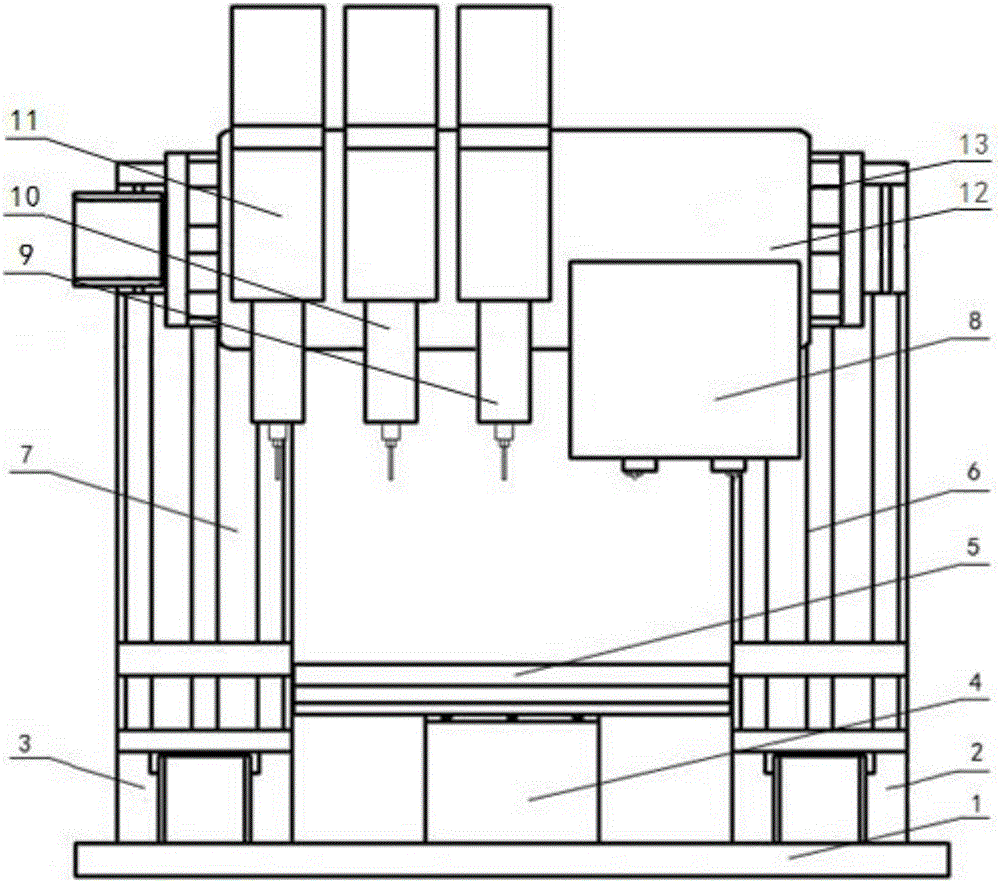

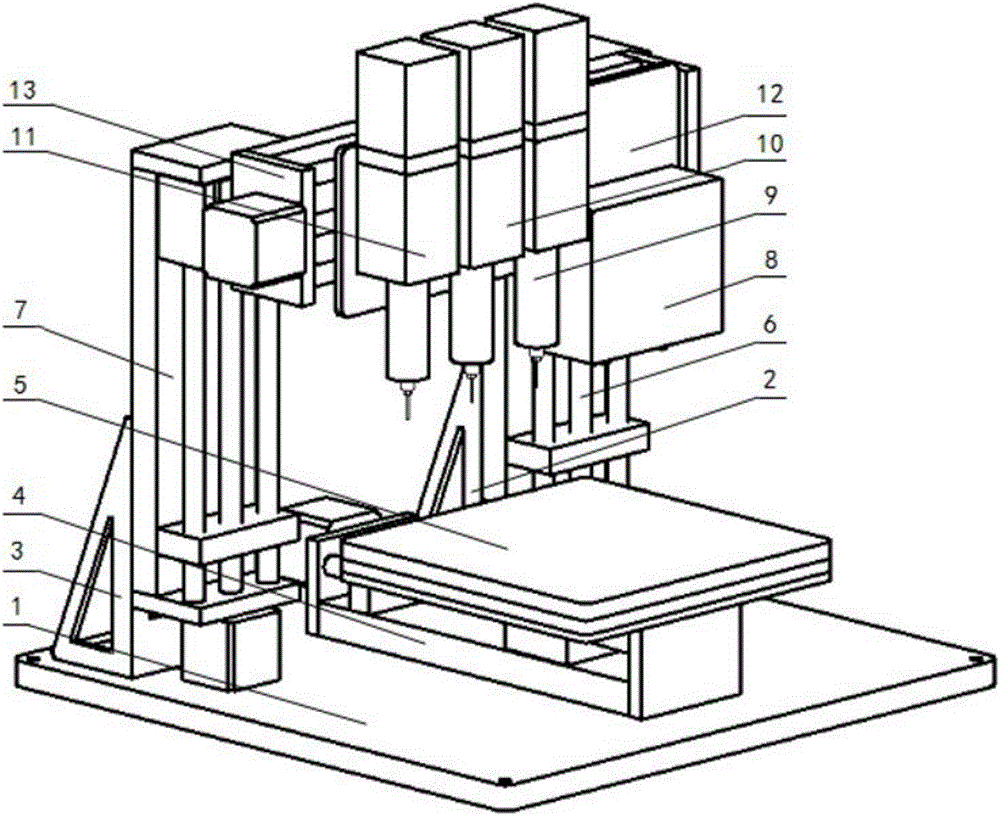

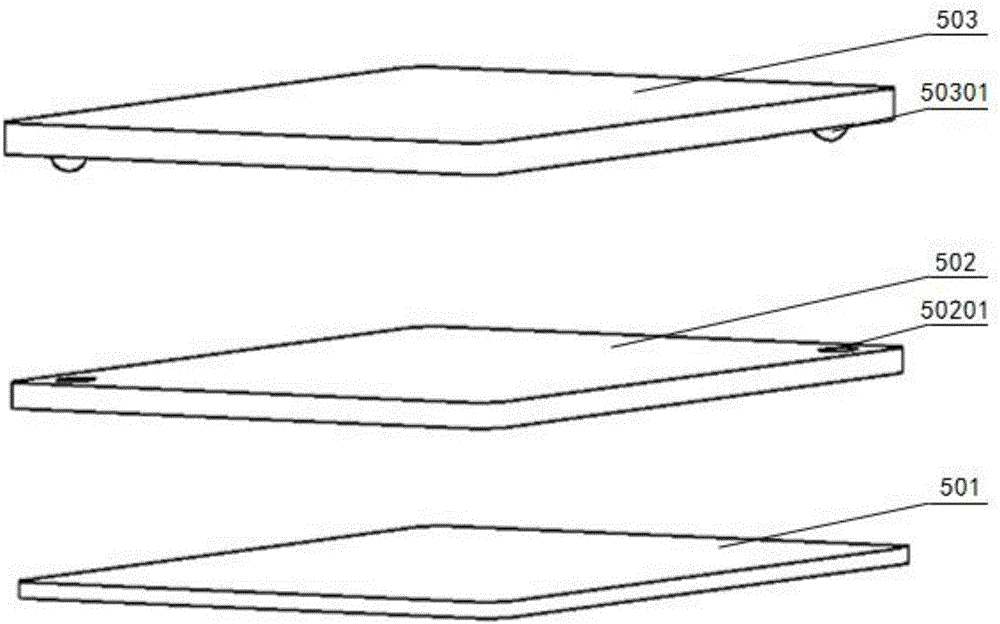

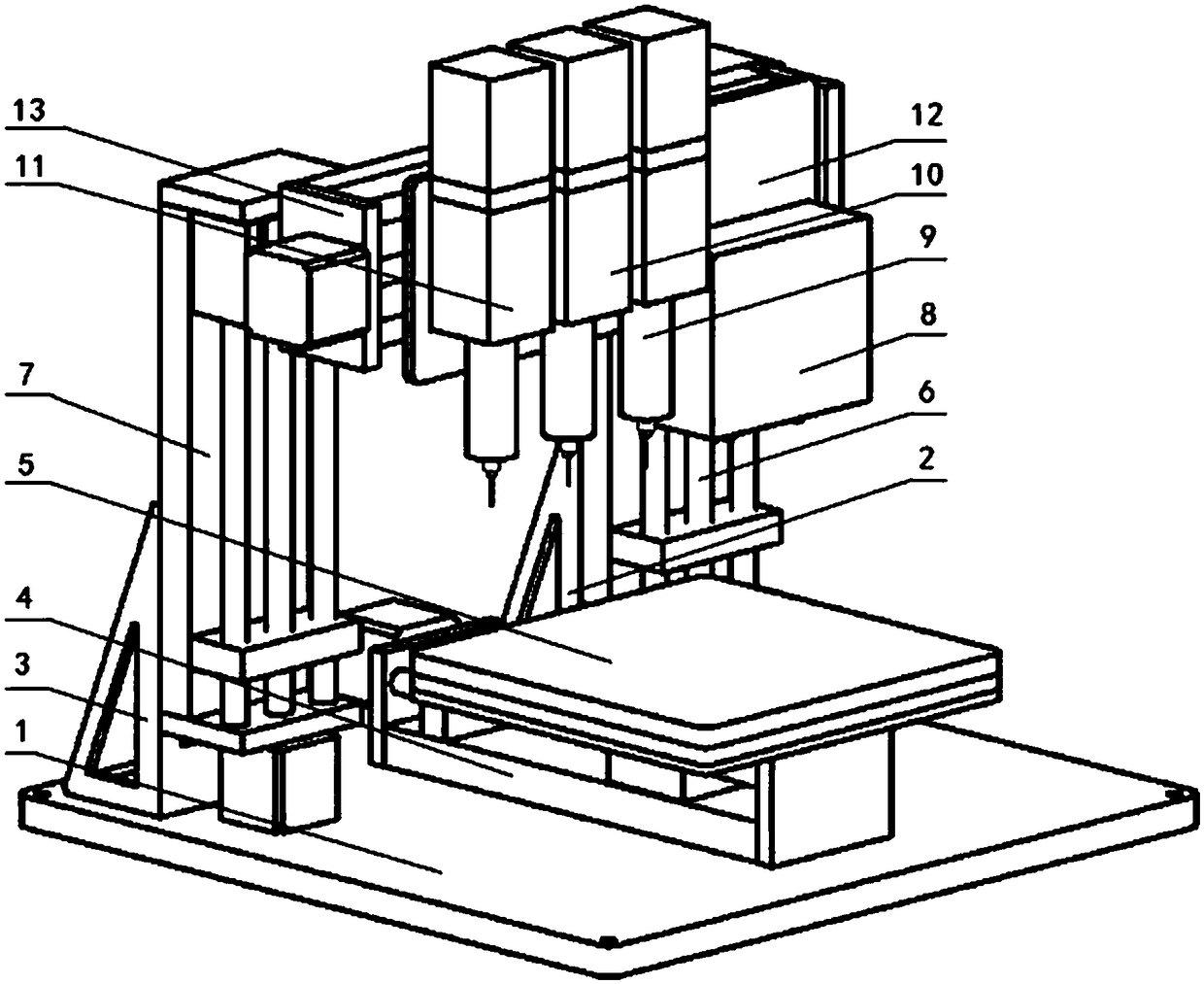

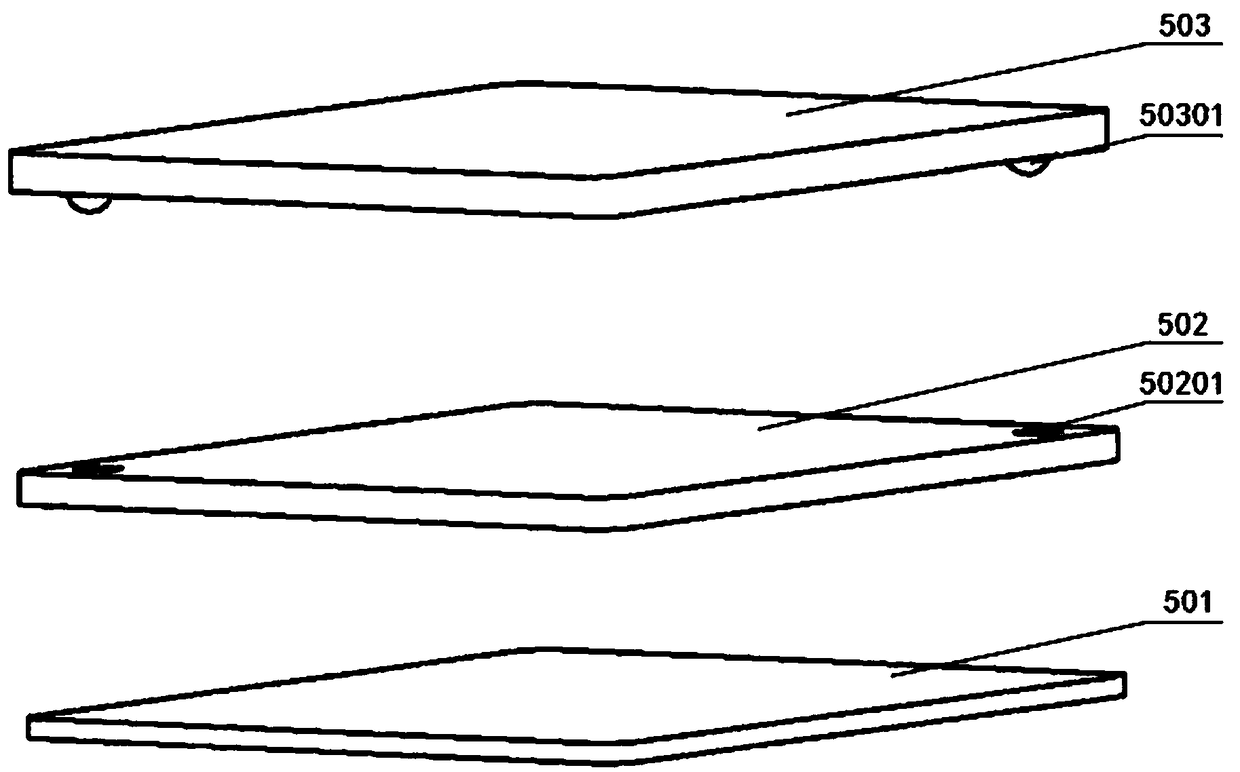

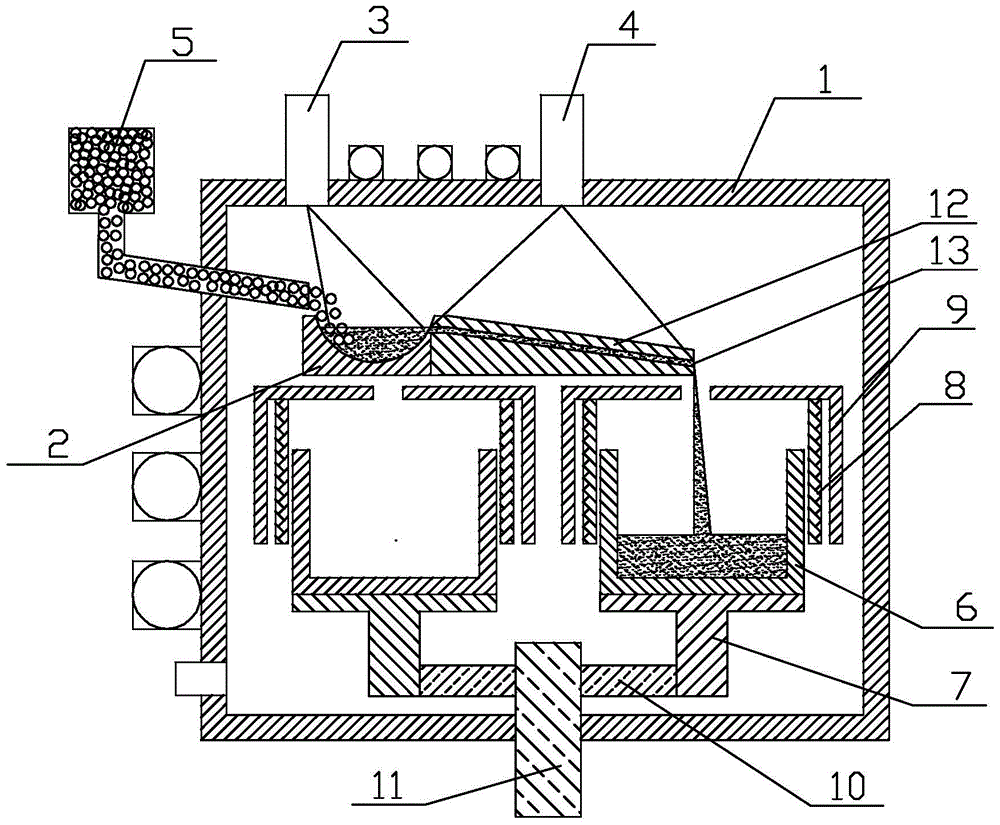

3D printing method for embedded electronic product and 3D printer

ActiveCN106493939AEfficient integrated manufacturingLow costAdditive manufacturing apparatus3D object support structuresComputer printingHemt circuits

The invention discloses a 3D printing method for an embedded electronic product and a 3D printer. After each layer of structure material is printed, a layer of release material is arranged around a support reserved position in a jet printing manner, support printing is conducted, and when the set of structure layers are printed, supports of reserved holes and grooves are removed, an electronic component is embedded, printing of the set of electric conduction layer structure, jet printing of electric conduction circuits and jet printing of dielectric materials between the electric conduction circuits are sequentially conducted, the process is repeatedly conducted till the last set of electric conduction layer structure is printed, and the electronic product is packaged through printing structure materials. The release material is introduced between the structure material and a support material, the support material is easy to remove, on one hand, removal of the supports through an ultrasonic alkaline solution is avoided (a traditional support removing technology is not allowed to be adopted in the embedded electronic product), and on the other hand, influences on a printed electric conduction circuit from support removal are avoided. The problem about support removal in the embedded electronic product manufacturing process is effectively solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Waste plastic recycling process method

InactiveCN102443210ASave production spaceDoes not pollute the environmentPlastic recyclingPlasticizerAntioxidant

The invention provides a waste plastic recycling process method, aiming to solve the problems of occupation of land resources and environmental pollution caused by waste plastic recycling at present. In the technical scheme, the waste plastic recycling process method comprises the following steps: (1) crushing waste polyethylene plastic, cleaning with a washing barrel, rinsing again in a water tank, drying, and obtaining waste polyethylene plastic particles; and (2) uniformly mixing the waste polyethylene plastic particles with raw polyethylene materials, activators, compatilizers, plasticizers, antioxidants and lubricants, carrying out plasticization and filtration, and finally cutting to obtain granulated plastic. The waste polyethylene plastic and other raw materials are mixed according to the following weight percentage: 60-65 percent of the waste polyethylene plastic, 15-16 percent of the raw polyethylene materials, 15-20 percent of fillers, 1 percent of the compatilizers, 1 percent of the plasticizers, 1 percent of the antioxidants, 0.5-1 percent of the activators and 0.5-1 percent of the lubricants.

Owner:郧县金龙工贸有限公司

Preparation method of 3-guanidino propanoic acid

InactiveCN103288685AReduce use costReduce recycling costsOrganic chemistryOrganic compound preparationPropanoic acidIon exchange

The invention relates to a preparation method of 3-guanidino propanoic acid. The preparation method comprises the following steps of: adding 3-aminopropionic acid to methanol, thereby obtaining a solution a at 15 DEG C; putting monocyanamide into methanol, thereby obtaining a solution b; feeding the solution b to the solution a, thereby obtaining a solution c at a temperature within 15 DEG C and PH in the range from 7.5 to 8.0; performing vacuum concentration on the solution c and filtering at -5 DEG C, thereby obtaining a crude product of sodium 3-guanidine propionate; preparing the crude product into an aqueous solution of sodium 3-guanidine propionate, thereby obtaining a solution d2; filling H type weakly acidic cation exchange resin into an ion exchange column, and feeding the solution d2 into the ion exchange column and detecting no 3-guanidino propanoic acid; blending the exchange solution collected by the step e and performing decompression concentration on the exchange solution, feeding methanol, reducing the temperature to -10 DEG C for crystallization, thereby obtaining a crystalline mixed liquid f; and then filtering and drying the crystalline mixed liquid f to obtain 3-guanidino propanoic acid. The problem of removing sodium ions during the production of 3-guanidino propanoic acid is solved through exchange treatment of the weakly acidic cation exchange resin; as methanol is taken as a solvent, the utilization and recovery cost of the solvent is lower and the preparation method is safer to operate; side-reactions are few; the 3-guanidino propanoic acid is extracted by ion resin exchange; and the yield of the 3-guanidino propanoic acid is 76.0% and the purity of the 3-guanidino propanoic acid is 99.0%.

Owner:郭礼强

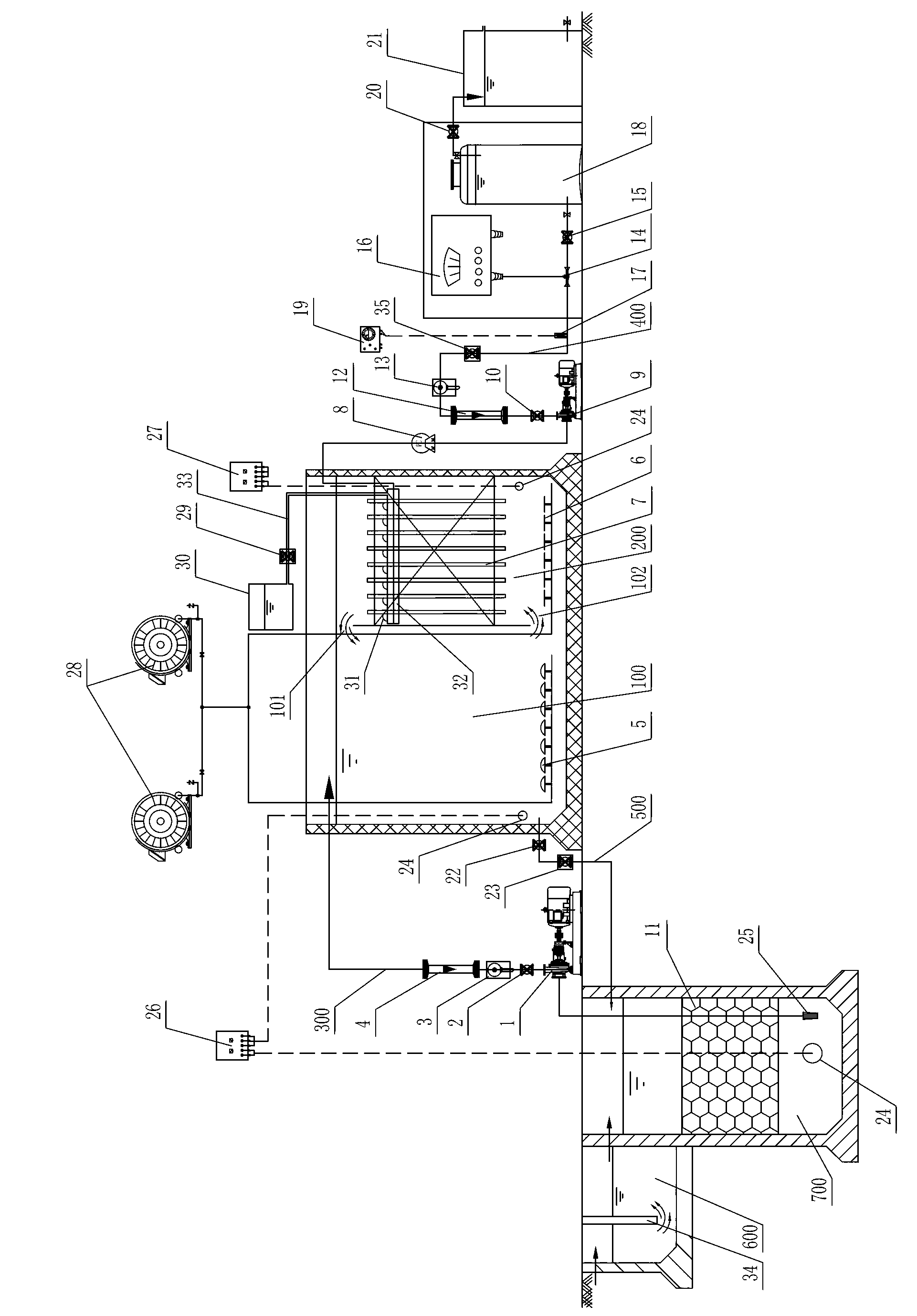

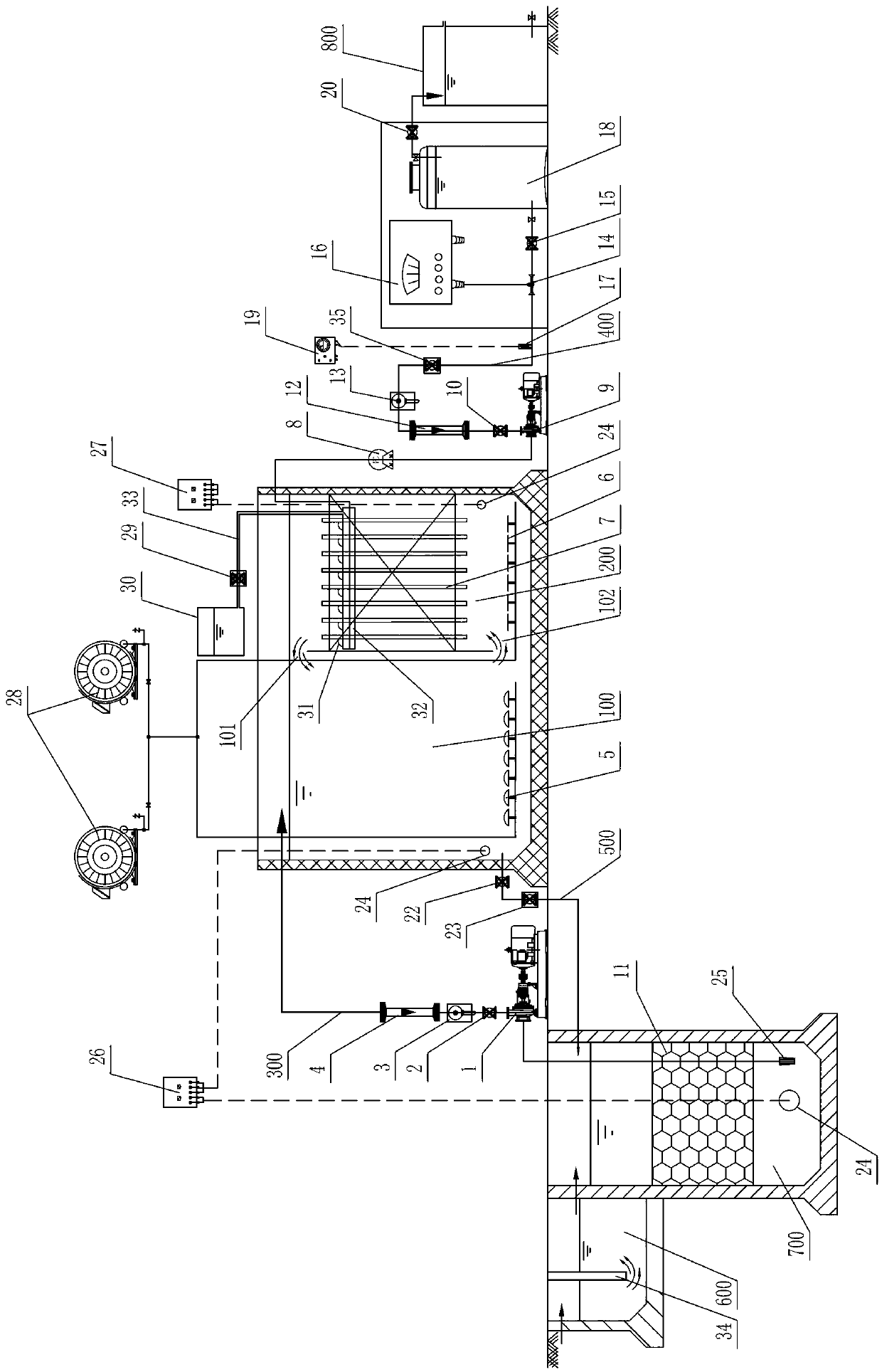

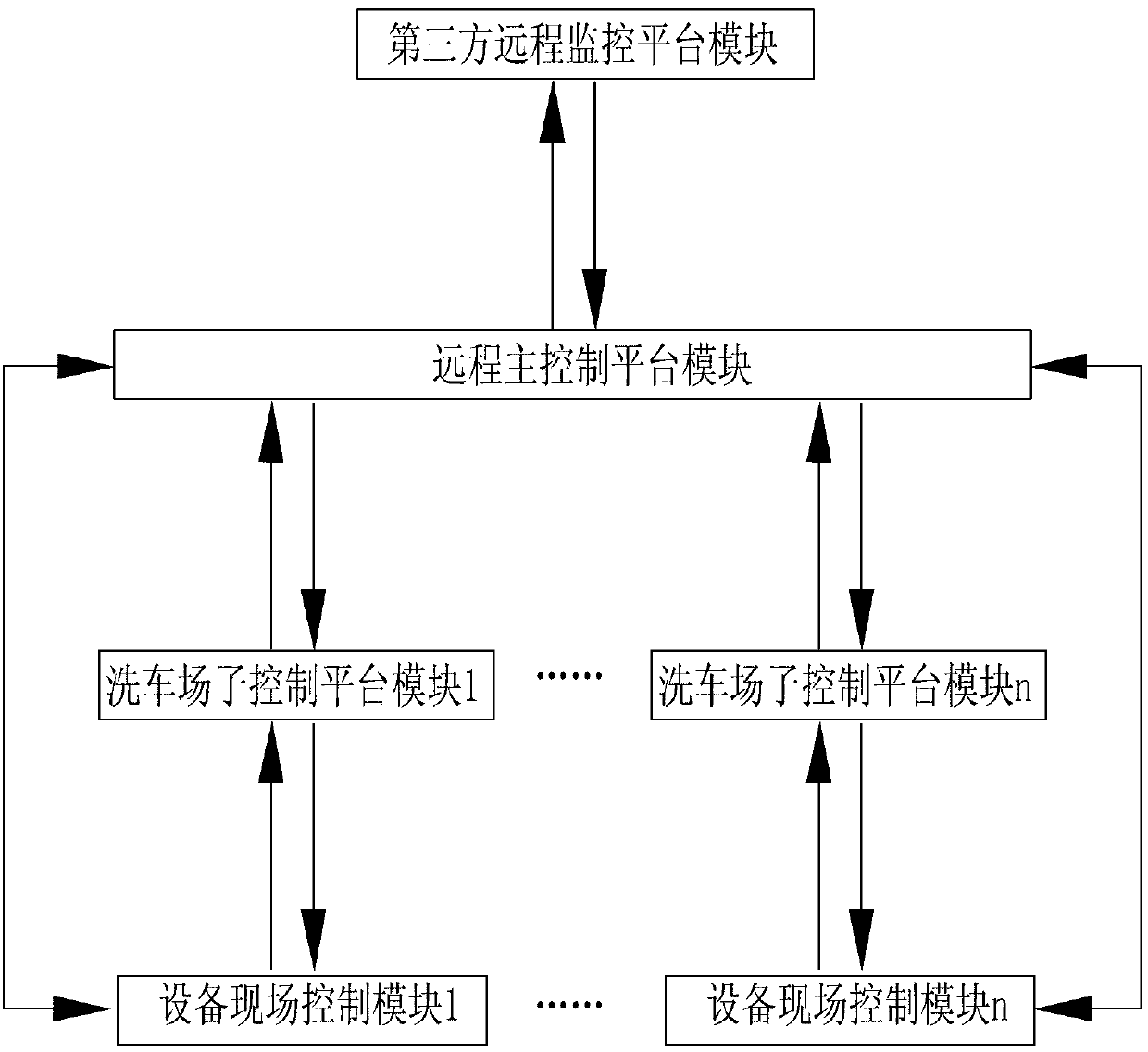

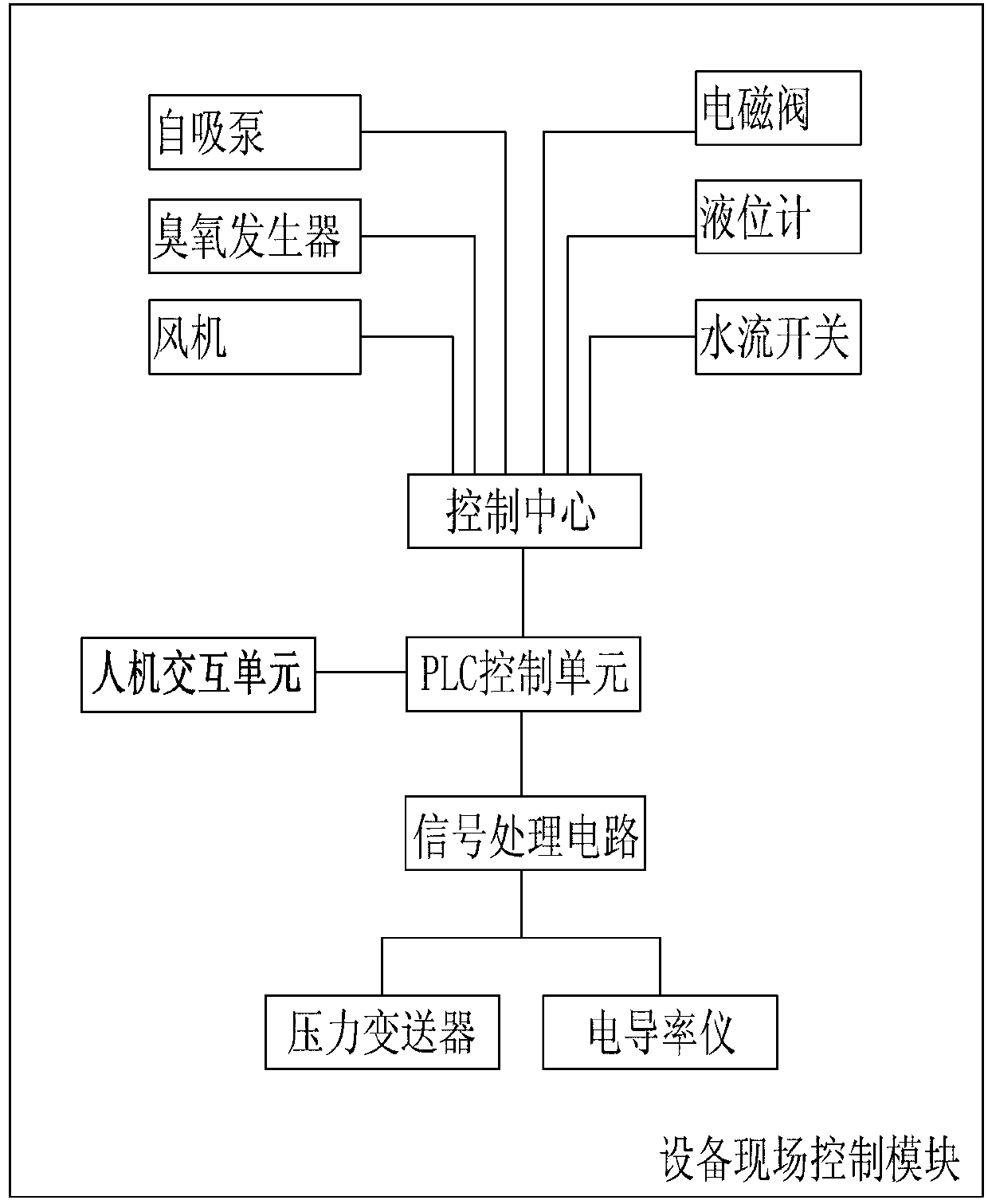

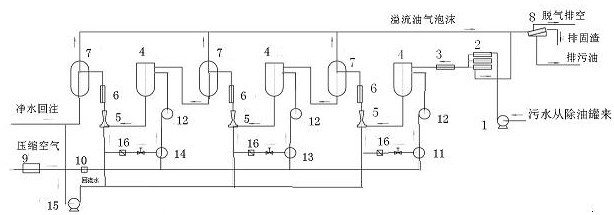

Treatment equipment for recycling car washing waste water and automatic control system

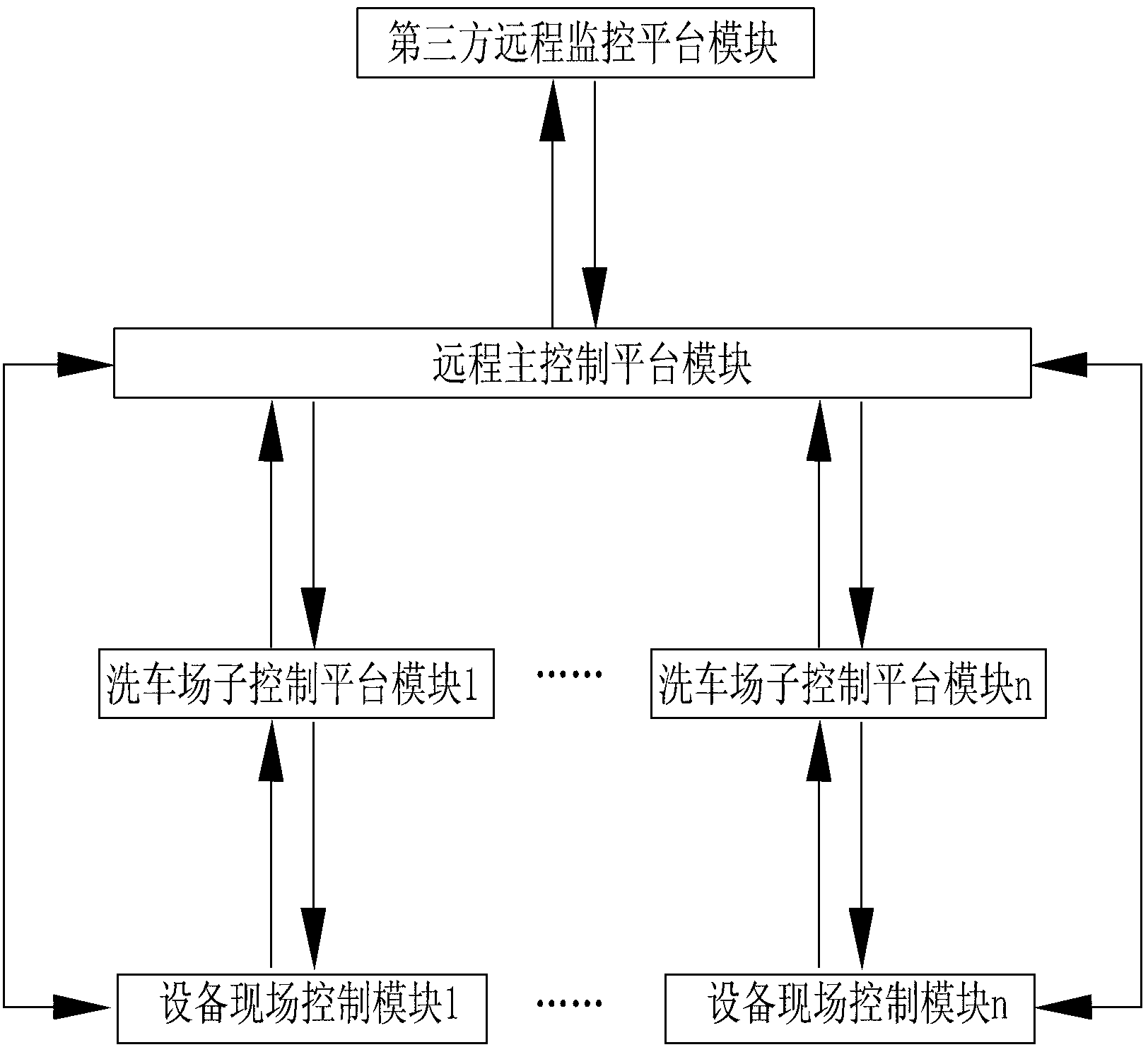

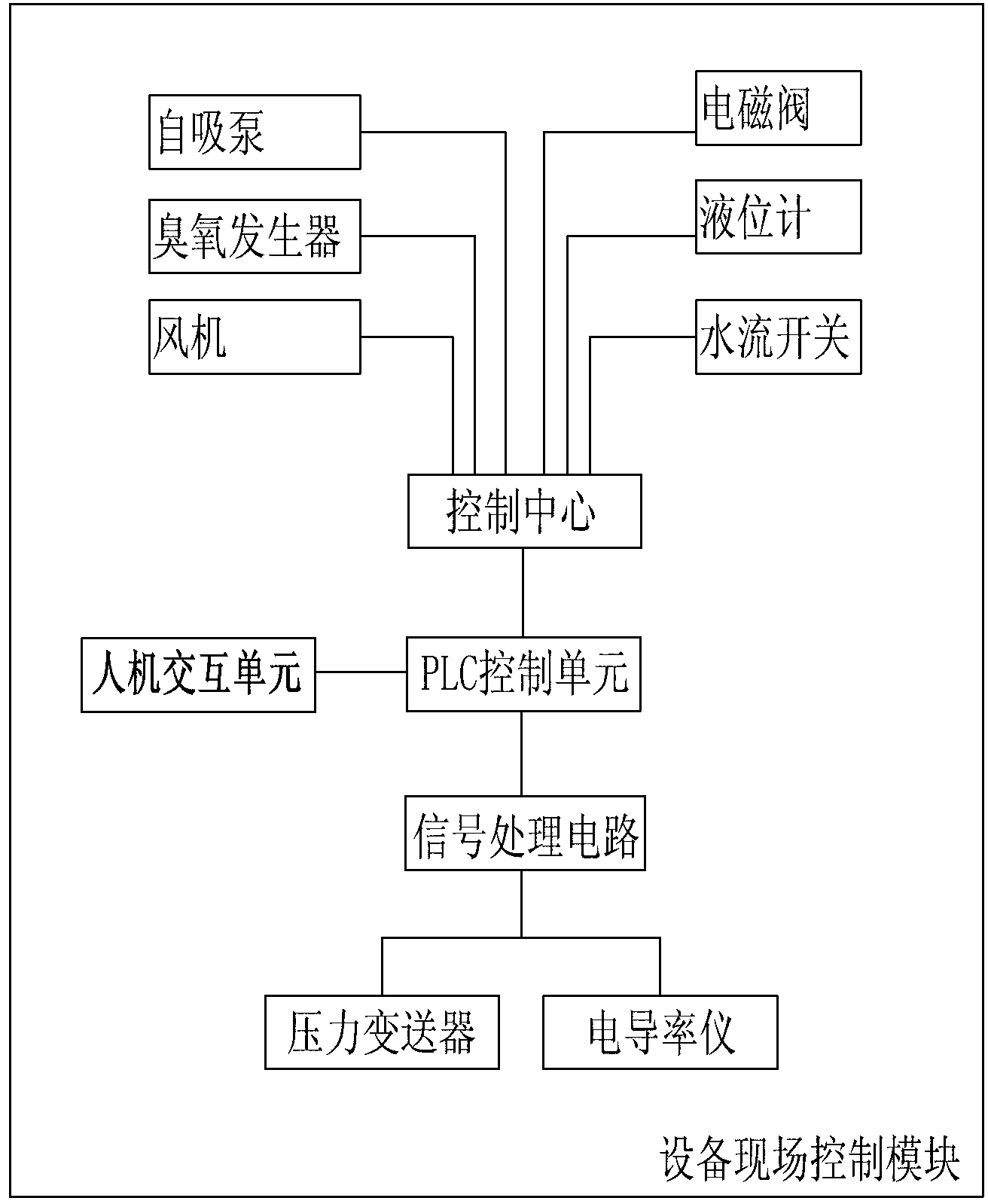

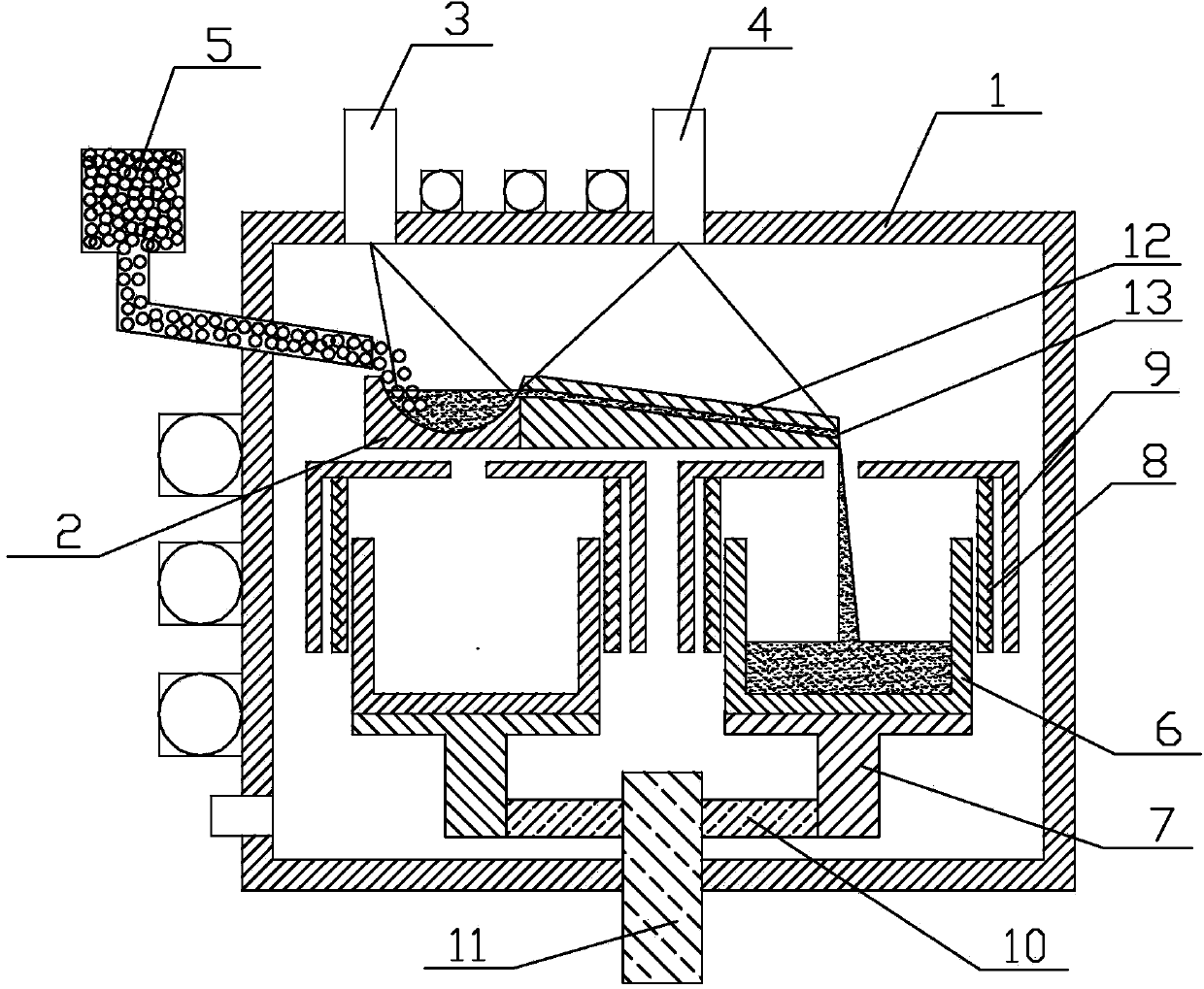

ActiveCN102701516AImprove water qualitySmall water qualityMultistage water/sewage treatmentProgramme control in sequence/logic controllersThird partyOzone generator

The invention discloses treatment equipment for recycling car washing waste water and an automatic control system. The treatment equipment comprises a combined tank, an ozone generator, an ozone mixed disinfection tank and a recycling water tank, wherein the combined tank consists of an oil-removal grit tank, an anaerobic adjusting tank, a biochemical reaction tank and a flat-panel membrane bioreactor (MRB) tank; an aeration head and an aeration pipe are respectively arranged in the biochemical reaction tank and the flat-panel MRB tank; a flat panel membrane, a suction pipe and a suction hoseare arranged in the flat-panel MRB tank; a membrane cleaning medicine liquid storage tank is connected with the suction pipe; the inlet of a water inlet self-sucking pump is communicated with the anaerobic adjusting tank; the outlet of the water inlet self-sucking pump is connected with the biochemical reaction tank; a inlet of a water outlet self-sucking pump is connected with the suction pipe; the outlet of the water outlet self-sucking pump is connected with the inlet of the ozone mixed disinfection tank through a water outlet pipe; the outlet of the ozone mixed disinfection tank is connected with the recycling water tank; the ozone generator is connected with the water outlet pipe through a jet device; and the biochemical reaction tank is communicated with the anaerobic adjusting tankthrough a discharge pipe. The control system comprises an equipment field control module, a sub-control platform module for a car washing station, a remote main control platform module and a third-party remote monitoring platform module. The treatment equipment and the automatic control system can be applied to the field of recycling of the car washing waste water.

Owner:SHENZHEN HUIQING TECH

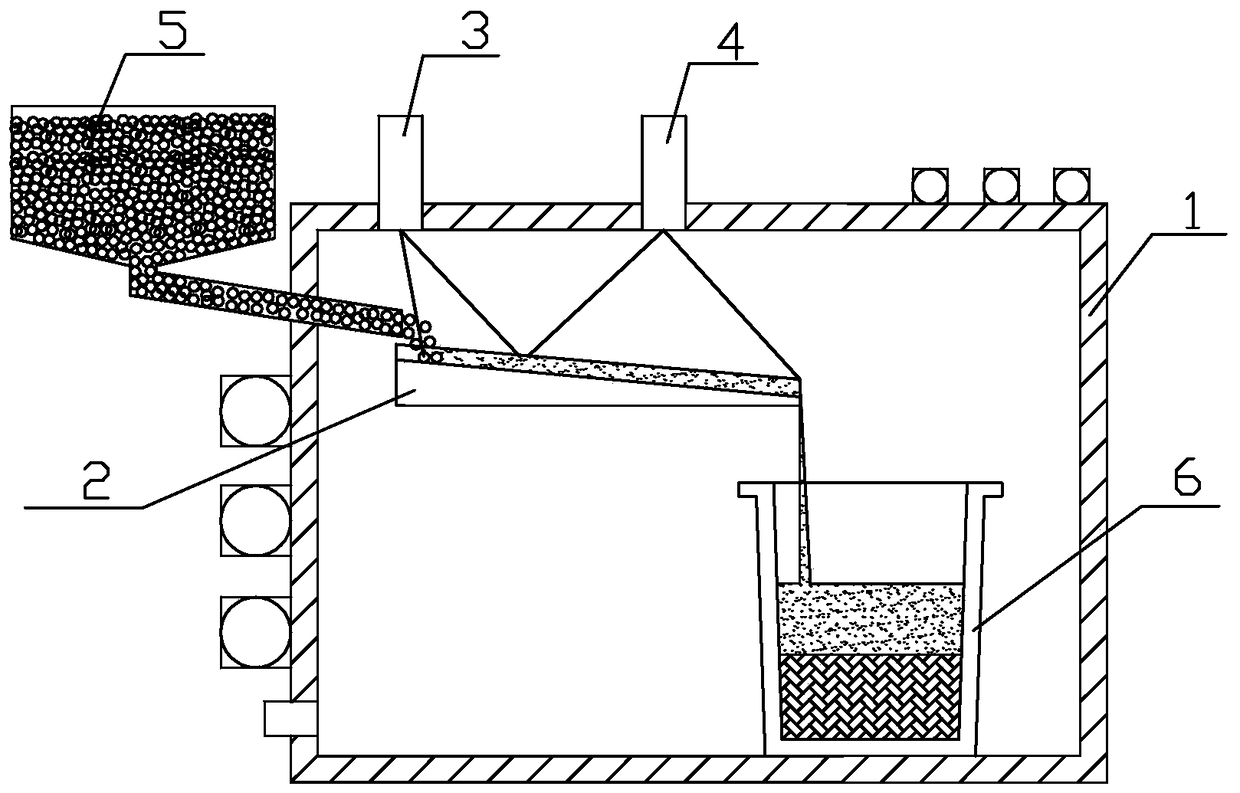

Method and device for electron beam melting to remove oxygen from polysilicon and continuous ingot casting

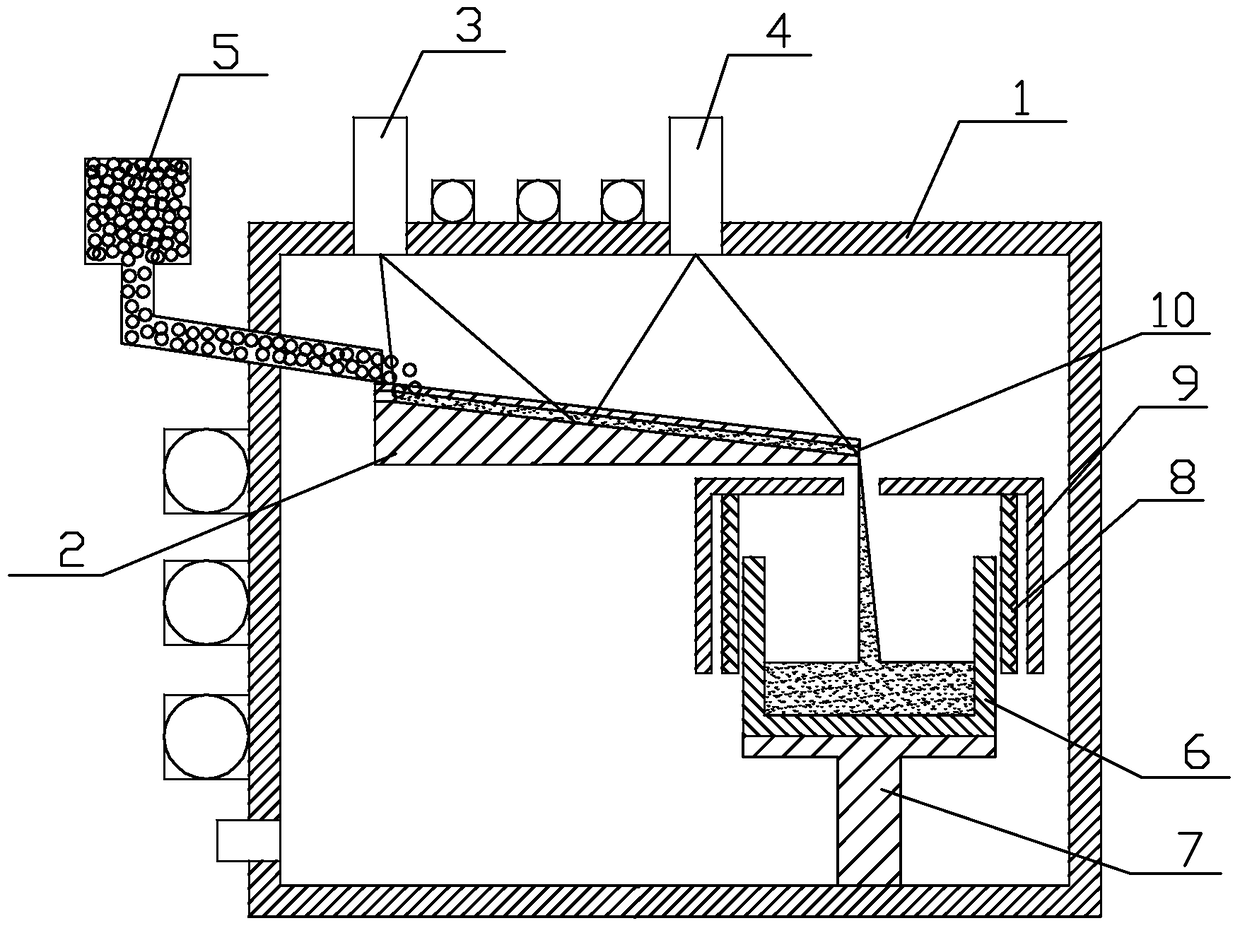

InactiveCN103741210AShorten the timeReduce energy consumptionPolycrystalline material growthSilicon compoundsOxygenElectron

Belonging to the field of metallurgical melting, the invention in particular relates to a method and a device for electron beam melting to remove oxygen from polysilicon and continuous ingot casting. The method includes: subjecting a furnace body and an electron gun to vacuum pumping, starting a electron gun for melting to conduct electron beam melting on a polysilicon material, and preliminarily removing impurity oxygen; under the action of an electron gun for radiation, keeping a liquid state and further conducting oxygen removal, and finally leading the polysilicon liquid into ingot casting equipment through a water-cooled transmission belt to carry out a directional crystal growth ingot casting process so as to obtain a polysilicon cast ingot till the end of directional crystal growth ingot casting processes in all ingot casting equipment. The device includes an electron beam melting assembly and a continuous ingot casting assembly. The electron beam melting assembly comprises a water-cooled melting crucible and the water-cooled transmission belt disposed on one side of the melting crucible. 3-6 ingot casting equipment is fixedly mounted on a rotating platform. The invention puts forward the technological method and application of electron beam melting for oxygen removal, realizes the effects of oxygen removal by electron beams. At the same time, by combining continuous ingot casting, the energy consumption needed by heating the raw materials of ingot casting is reduced, and the production efficiency is greatly improved.

Owner:QINGDAO XINSHIJI SOLAR ENERGY TECH CO LTD

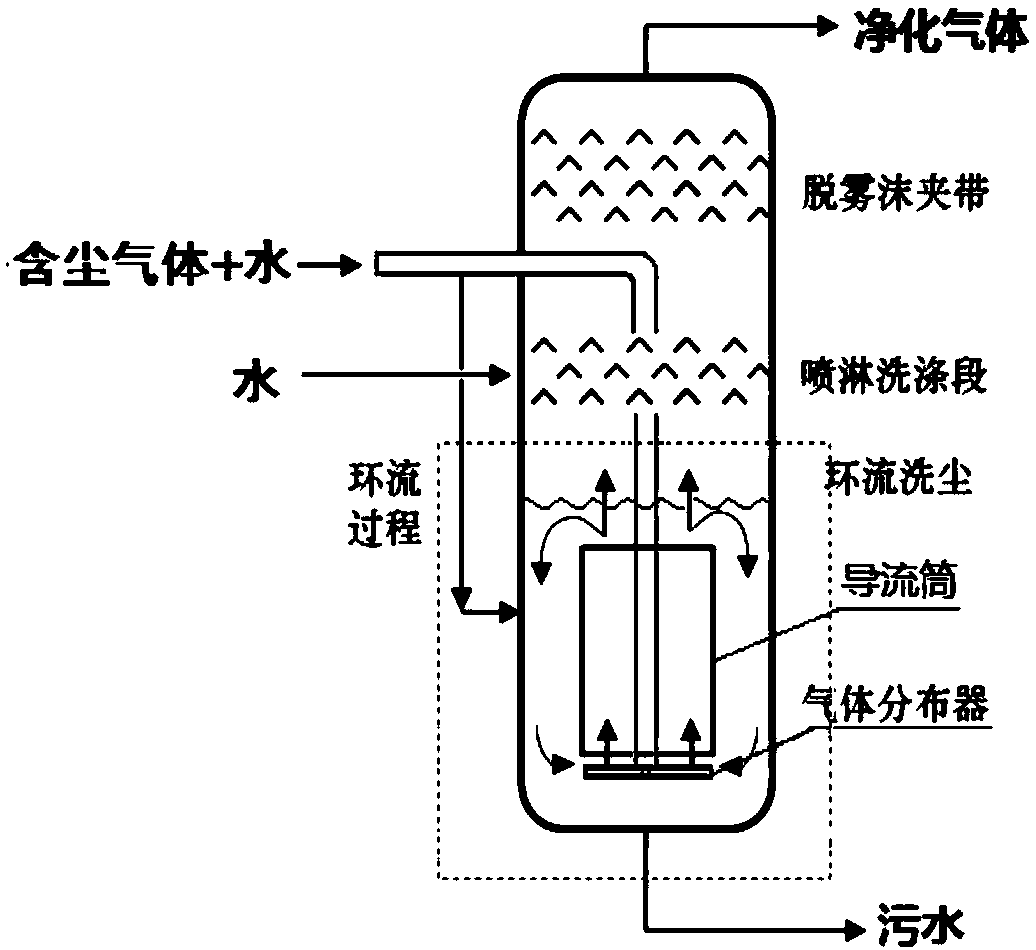

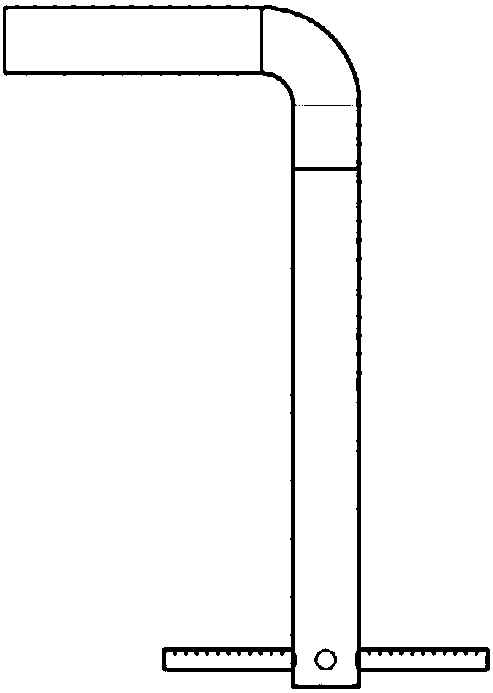

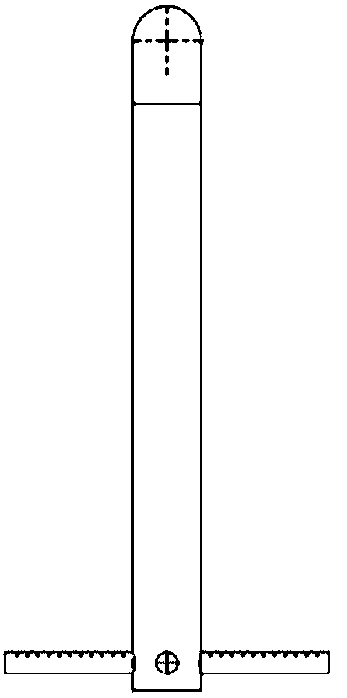

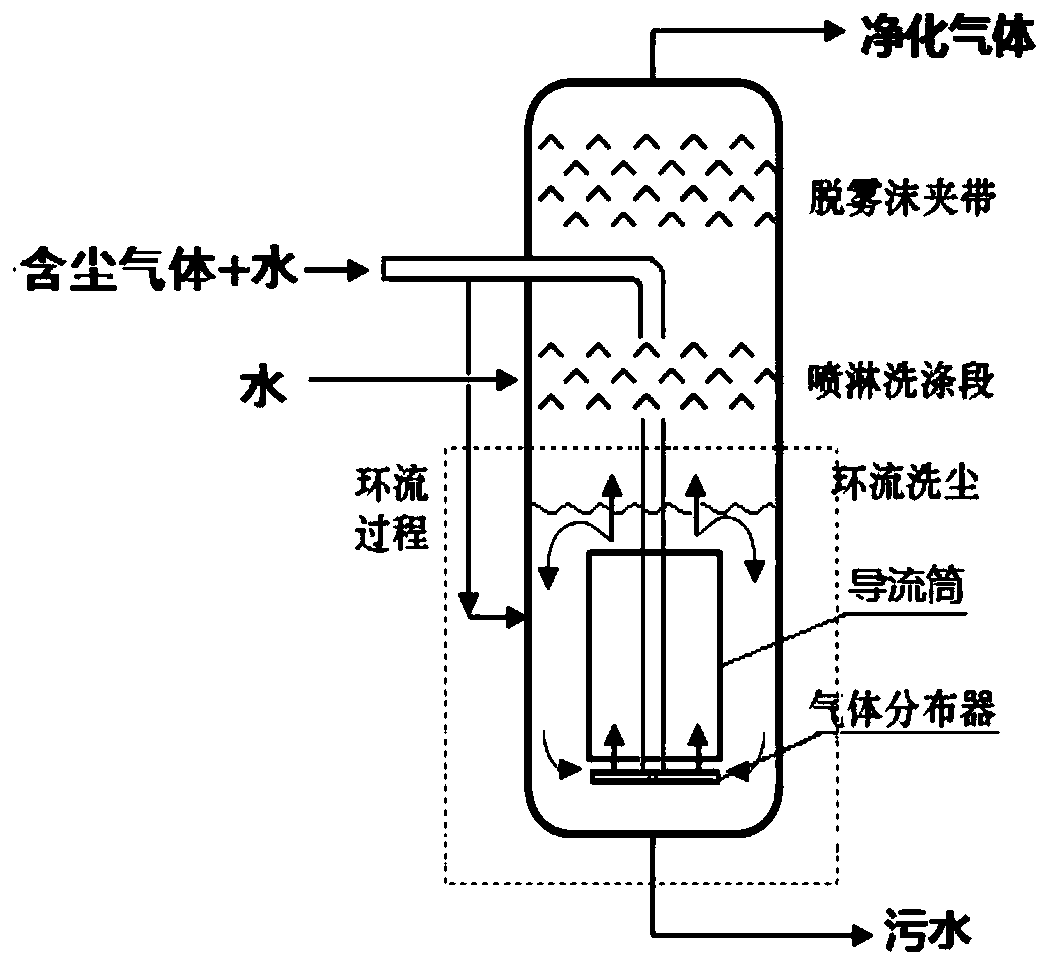

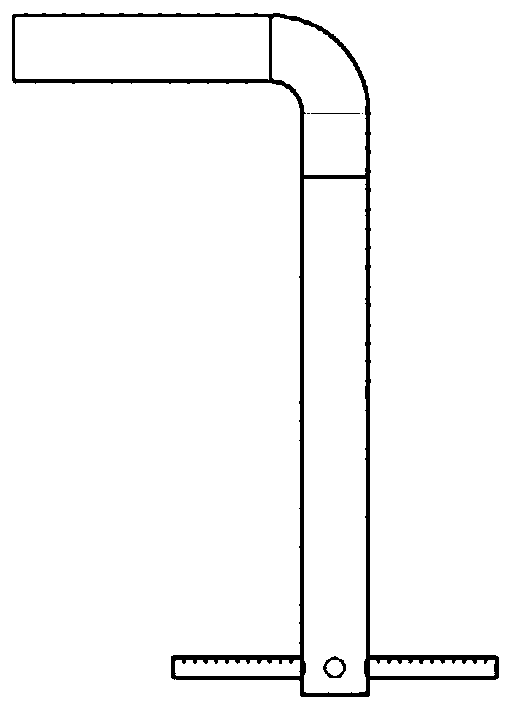

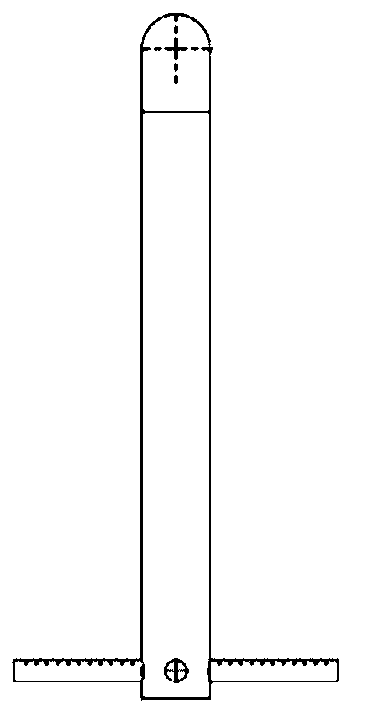

Gas distributor for circulating-flow scrubbing tower and design method of gas distributor

ActiveCN108079708AThe hydraulic index is consistentSimplify the design processUsing liquid separation agentLiquid layerEngineering

The invention provides a gas distributor for a circulating-flow scrubbing tower and a design method of the gas distributor. The gas distributor is of a branch-shaped distributor structure and is provided with a central gas inlet pipe and at least one branch pipe, wherein the branch pipes are connected with the central gas inlet pipe, a blind plate is arranged at the tail end of the central gas inlet pipe, liquid discharging holes are formed in the blind plate at the tail end of the central gas inlet pipe, and liquid discharging holes are also formed near the lowest ends or the tail ends of thebranch pipes; gas spraying holes are formed in the pipe walls of the branch pipes, and blind plate holes are formed in the tail ends of the branch pipes, or Venturi-type spraying nozzles are arrangedin the branch pipes. The pressure drop and the gas velocity of the spraying holes are adopted as the overall design and control indexes of the gas distributor, the design process is simple and easy to implement, and the diameter distribution and phase interface of bubbles can be controlled; a circulating flow can be formed in a flow guiding canister of the scrubbing tower, the standing time of gas at a liquid layer is prolonged, and the humidity of the gas at the liquid layer and the scrubbing efficiency are improved; even distribution of the gas flow is ensured, discharging of liquid and solid sediments is facilitated at the same time, and the gas distributor is applicable to large-scale gas-liquid-solid three-phase separation equipment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

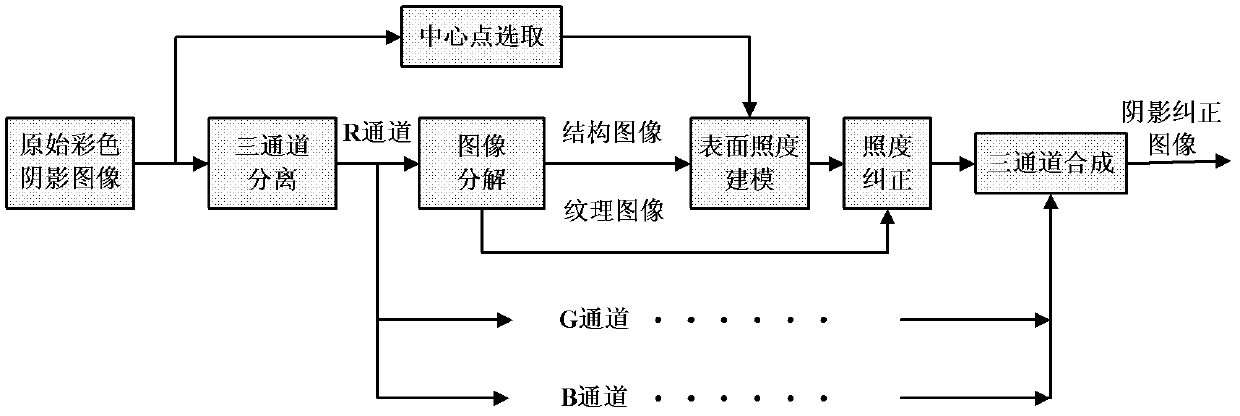

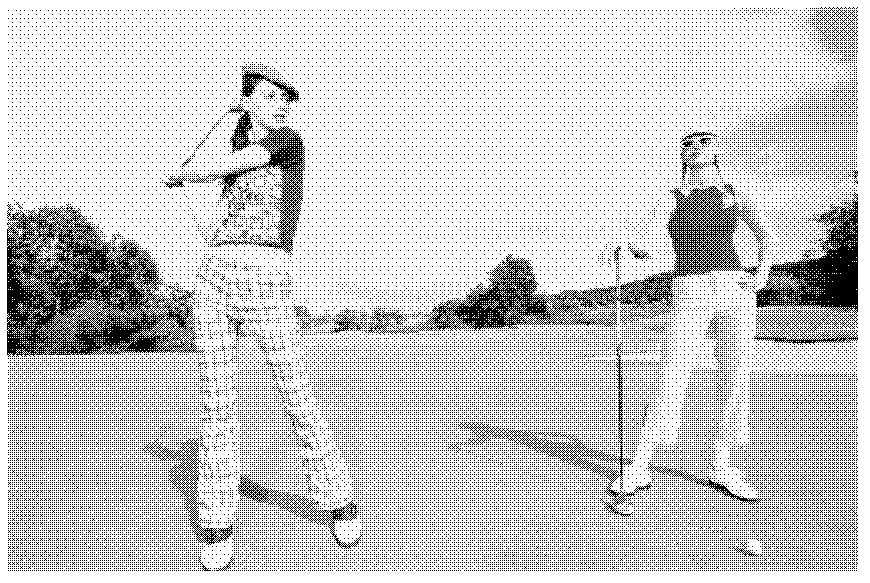

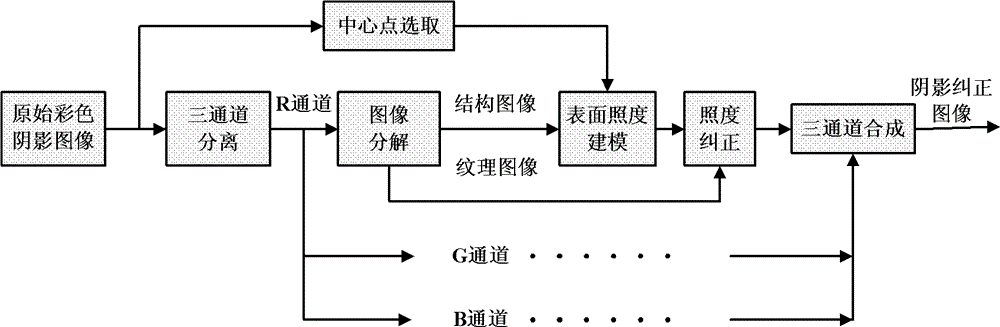

Single color image shadow removal method based on illumination surface modeling

The invention belongs to the computer image processing field and relates to a single color image shadow removal method based on illumination surface modeling. The method comprises the following steps: carrying out structure and texture decomposition on an original color shadow image and acquiring structure images in three color channels: R, G and B and corresponding texture images respectively; selecting central points uniformly in a non-shadowed region of the image and calculating a radial distance between any two central points; modeling the structure images in the three color channels respectively and acquiring illumination distribution of shadow regions in the three color channels; adding texture images in each channel to the three color channels respectively so as to obtain the image after illumination correction. The method of the invention has a strong adaptability. Too much manual interventions are not needed. The illumination modeling and central point selection adopt an adaptive algorithm. The method can be used for automatically removing the actual image shadow.

Owner:天津渤化安创科技有限公司

Method and device for efficient removal of impurity oxygen from polysilicon by electron beam melting

Belonging to the field of polysilicon purification, the invention in particular relates to a method and device for efficient removal of impurity oxygen from polysilicon by electron beam melting, and breaks the traditional electron beam melting mode to carry out electron beam deoxygenation smelting by means of a diversion trench rather than in a melting crucible. As a silicon liquid can spread in a diversion area, the specific surface area increases, and the electron beam melting deoxygenation effect can be better. According to the method and device provided by the invention, (1) the technological method and use of electron beam deoxygenation are put forward, the problem of difficult removal of impurity oxygen from polysilicon is solved, and the oxygen content can be reduced to less than 0.0571ppmw, thus meeting the requirement of solar cells for polysilicon ingot oxygen content; (2) the polysilicon material efficient banded deoxygenization technology can increase the silicon liquid surface area by over 30% and shorten the deoxygenation time by more than 20%; and (3) continuous production can be realized, and the production efficiency can be improved by more than 35%.

Owner:QINGDAO NEW ENERGY SOLUTIONS

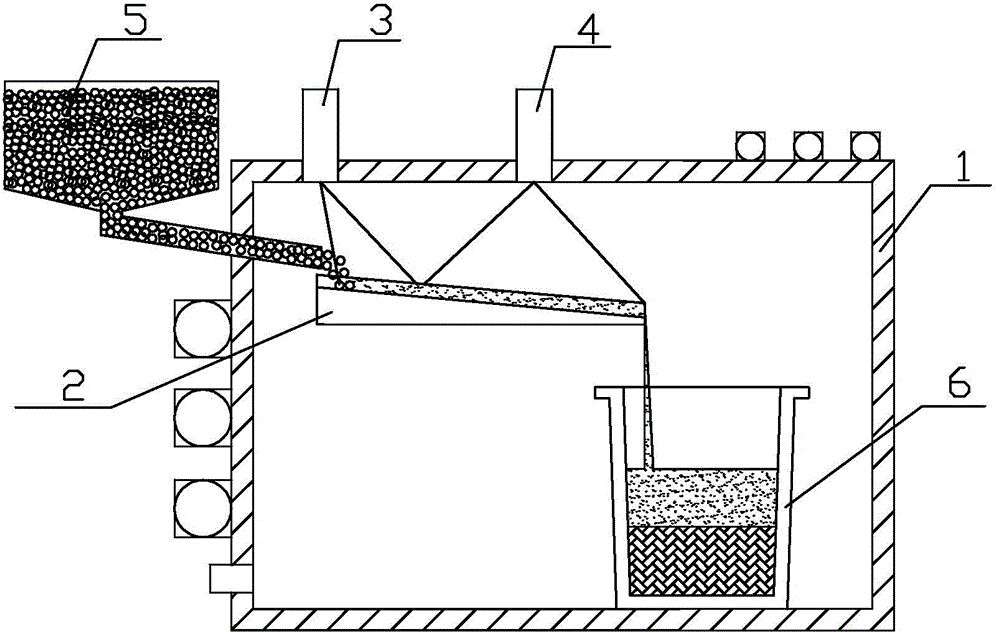

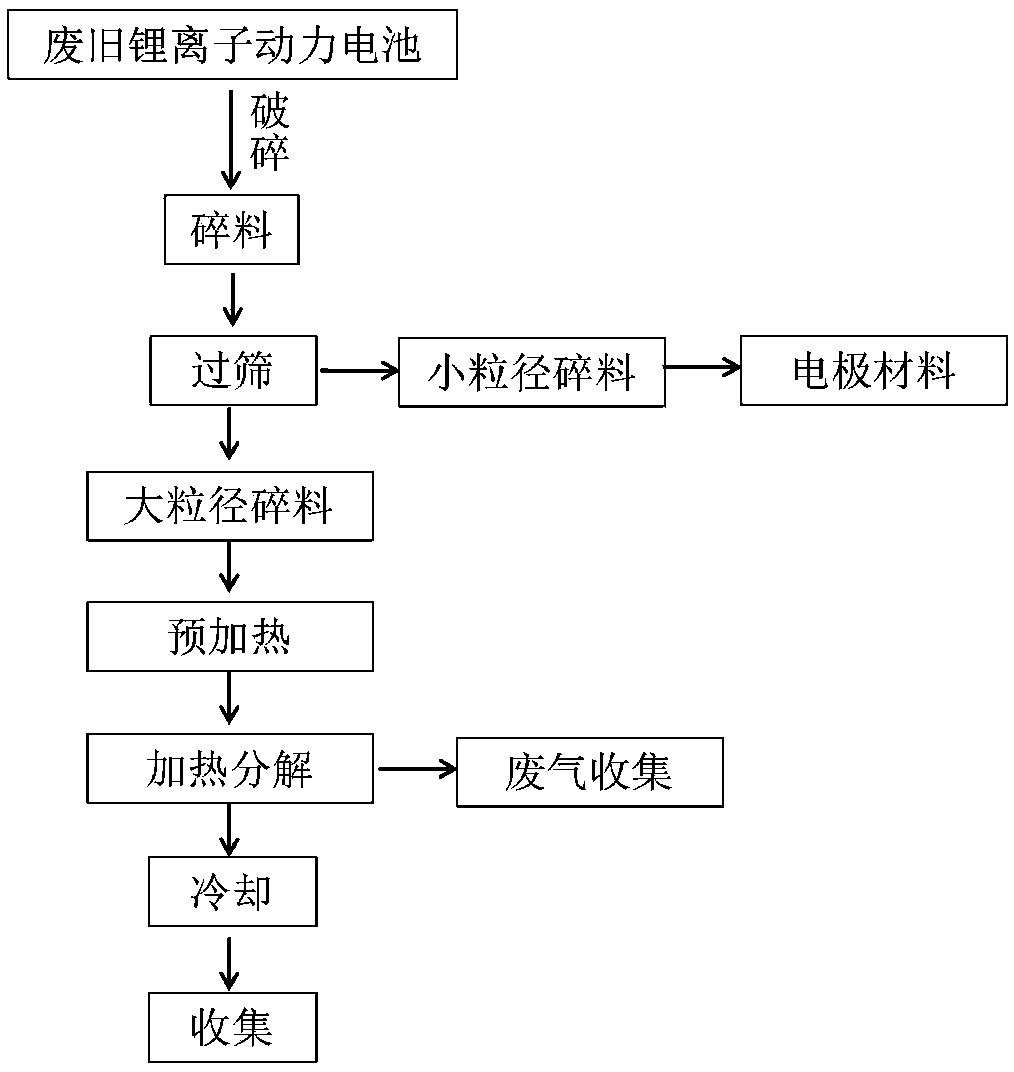

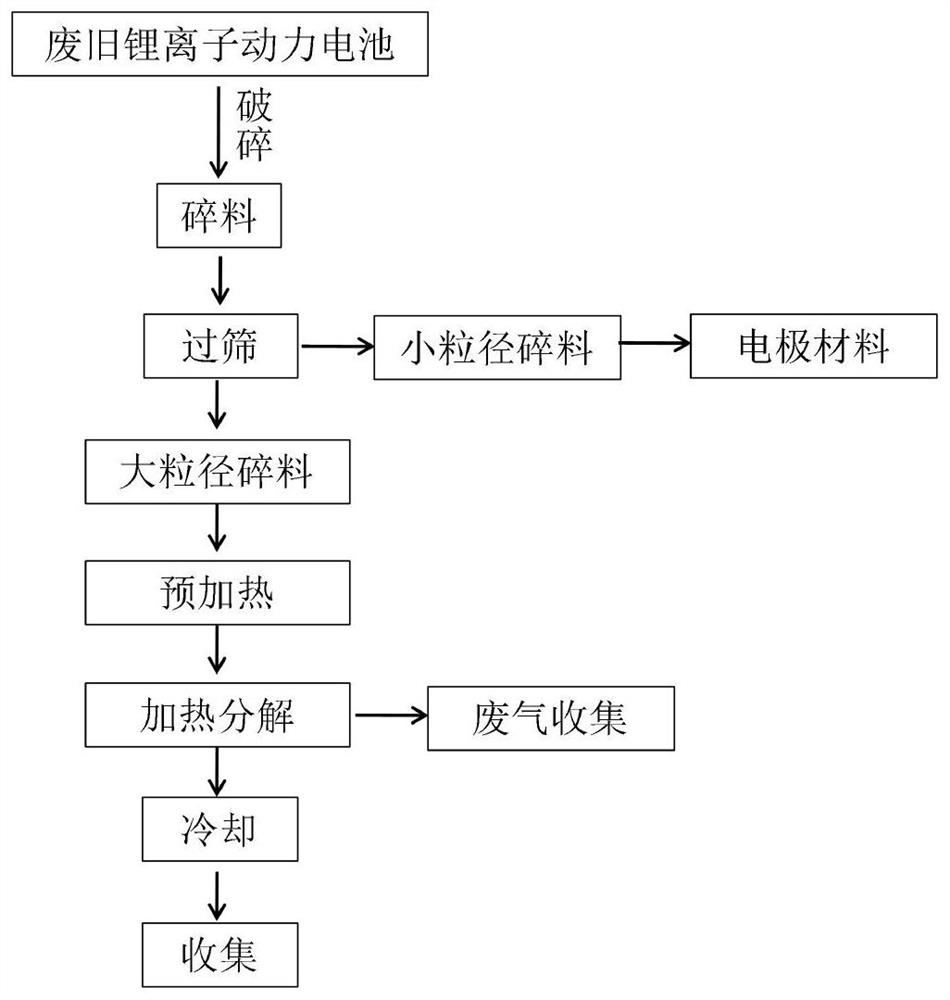

Method for removing a separator in a waste lithium ion power battery

ActiveCN109273791AImprove pyrolysis efficiencySolve removal puzzlesWaste accumulators reclaimingBattery recyclingDecompositionScrap

The invention discloses a method for removing a separator in a waste lithium ion power battery, which comprises the following steps: crushing the waste lithium ion power battery into crumbs and passing through a 5-mesh screen to obtain small crumbs with a particle size less than 5 mesh and large crumbs with a particle size greater than 5 mesh; Preheating the large particle size crushed material, and controlling the preheating temperature at 100-300 DEG C; Heating and decomposing the crumbs obtained after the preheating is completed until the thermal decomposition of the diaphragm in the crumbsis complete and the temperature of the thermal decomposition is controlled at 300 to 500 DEG C; cooling and recovering The scrap obtained after decomposition. The method adopts two-stage heating design, improves the pyrolysis efficiency of the separator in the scrap material, the pyrolysis of the separator is more complete, the separator in the waste lithium ion power battery can be directly decomposed and removed, and the problem of removing the separator in the scrap material after the scrap material of the waste power battery is broken is solved; At that same time, the process method is simple to operate and easy to industrialize.

Owner:ZHUZHOU DINGDUAN EQUIP CO LTD

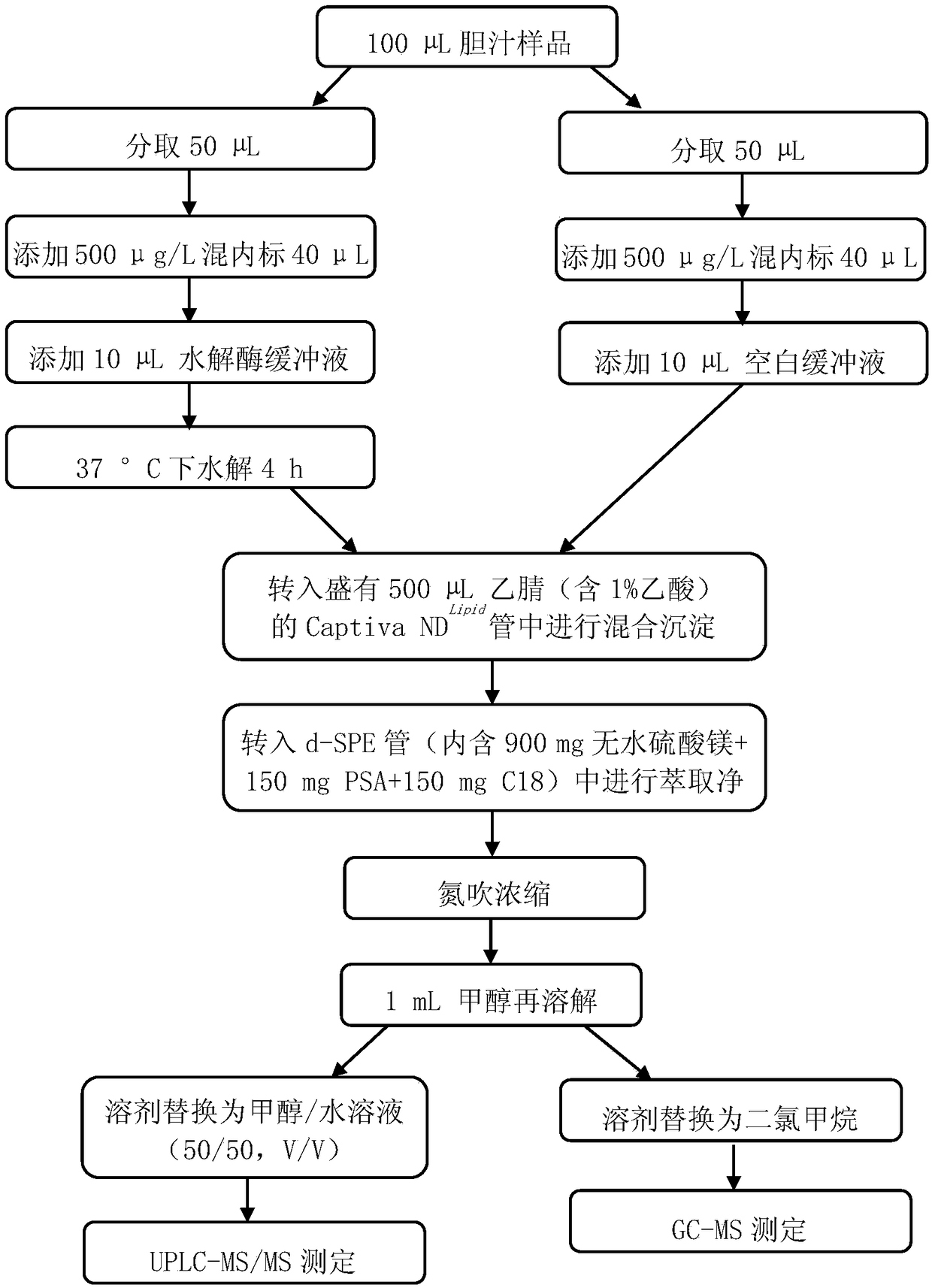

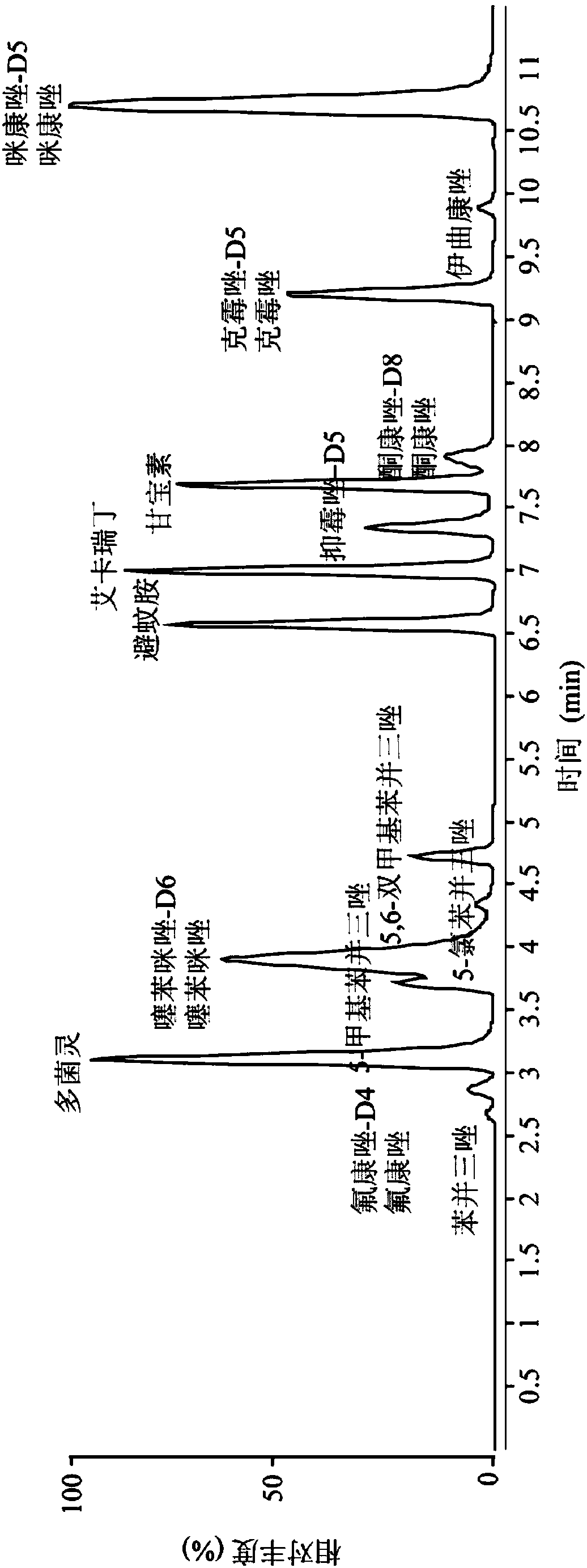

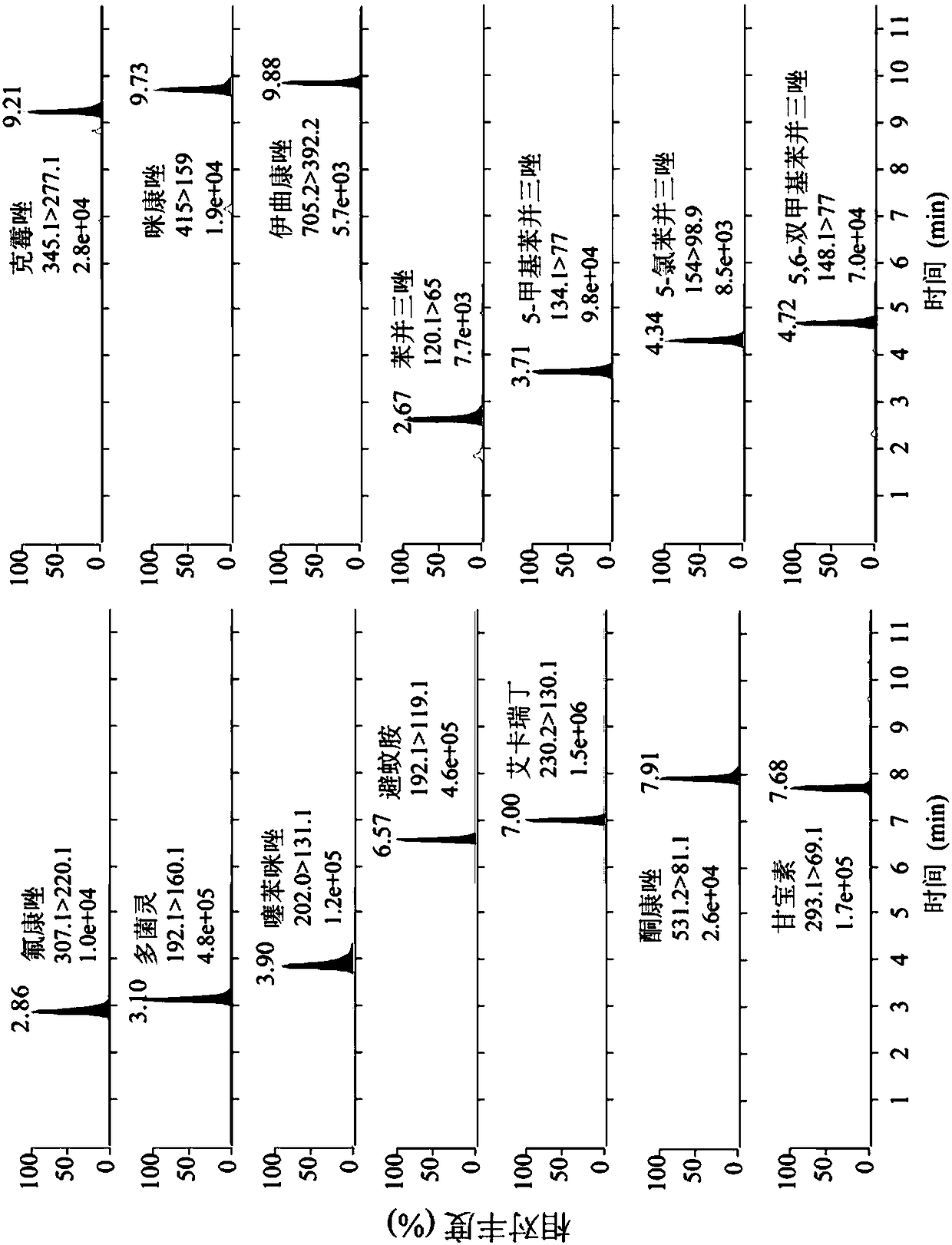

Method for detecting PCPS (personal care products) in fish bile

The invention relates to a method for detecting personal care products in fish bile. The method mainly comprises the following steps: adding internal standards into samples, hydrolyzing the samples, extracting, purifying, analyzing and detecting the samples. The method is characterized by extracting and purifying bile samples by using an optimum protein and phospholipid removal tube and a d-SPE tube based on a multi-isotope internal standard analysis method, measuring the concentration of personal care products (PCPs) in the purified samples by using a UPLC-MS / MS instrument and a GC-MS instrument, avoiding the problems of short sample storage time, high detection limit and serious interference of complex matrix, and establishing a detection method which is simple and rapid and is high in accuracy and sensitivity. In addition, the method is capable of adding or not adding hydrolase into the bile samples before extracting and purifying, comparing and measuring the total concentration andthe free-state concentration of the PCPs in the bile and facilitating the show of the existence forms of the PCPs in the fish bile.

Owner:SOUTH CHINA NORMAL UNIVERSITY +2

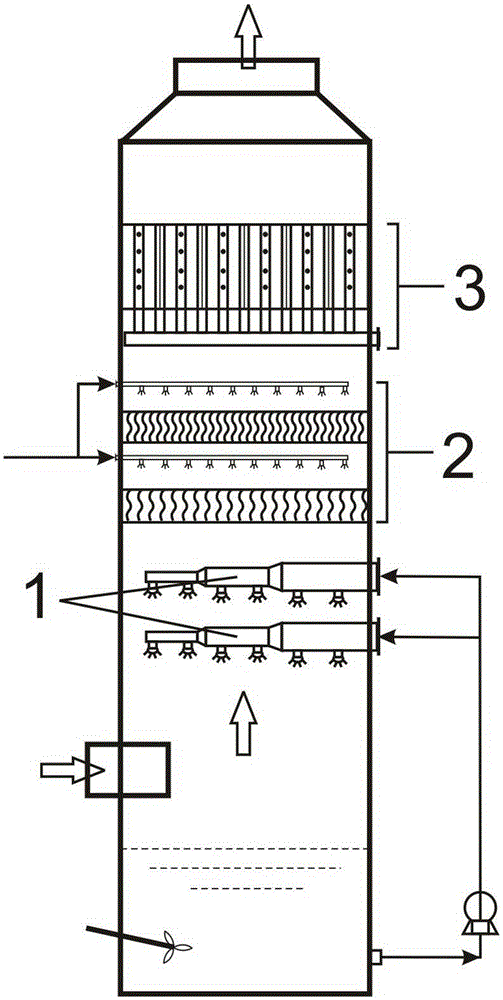

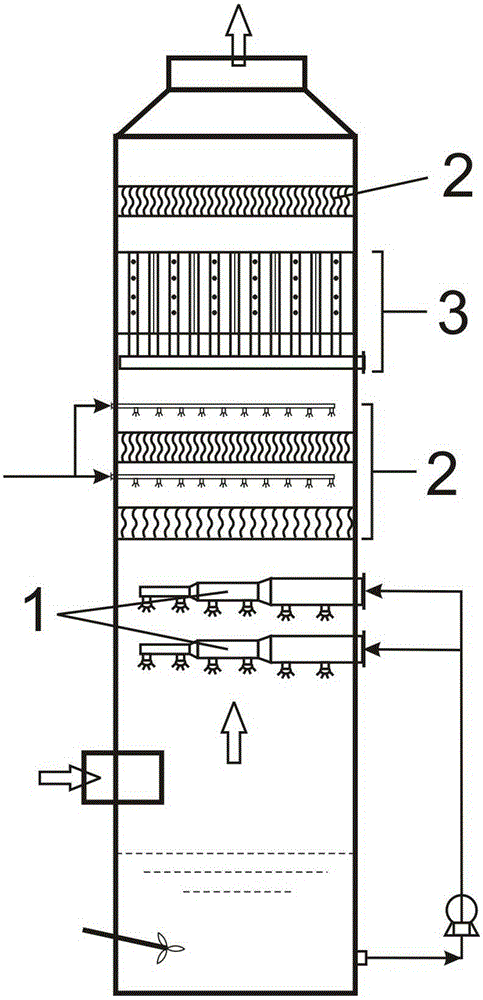

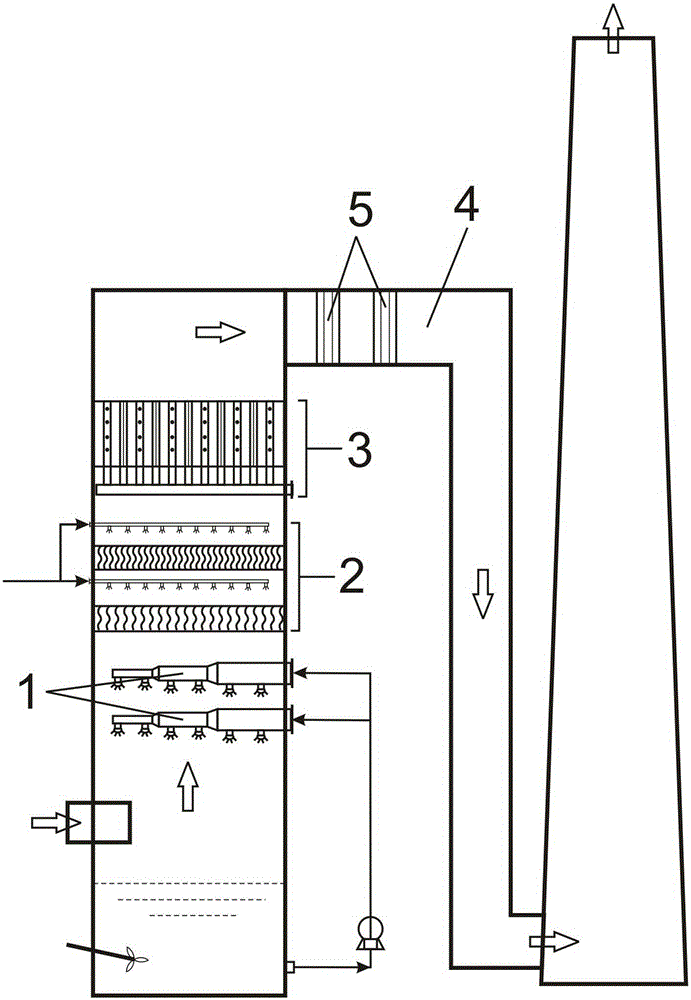

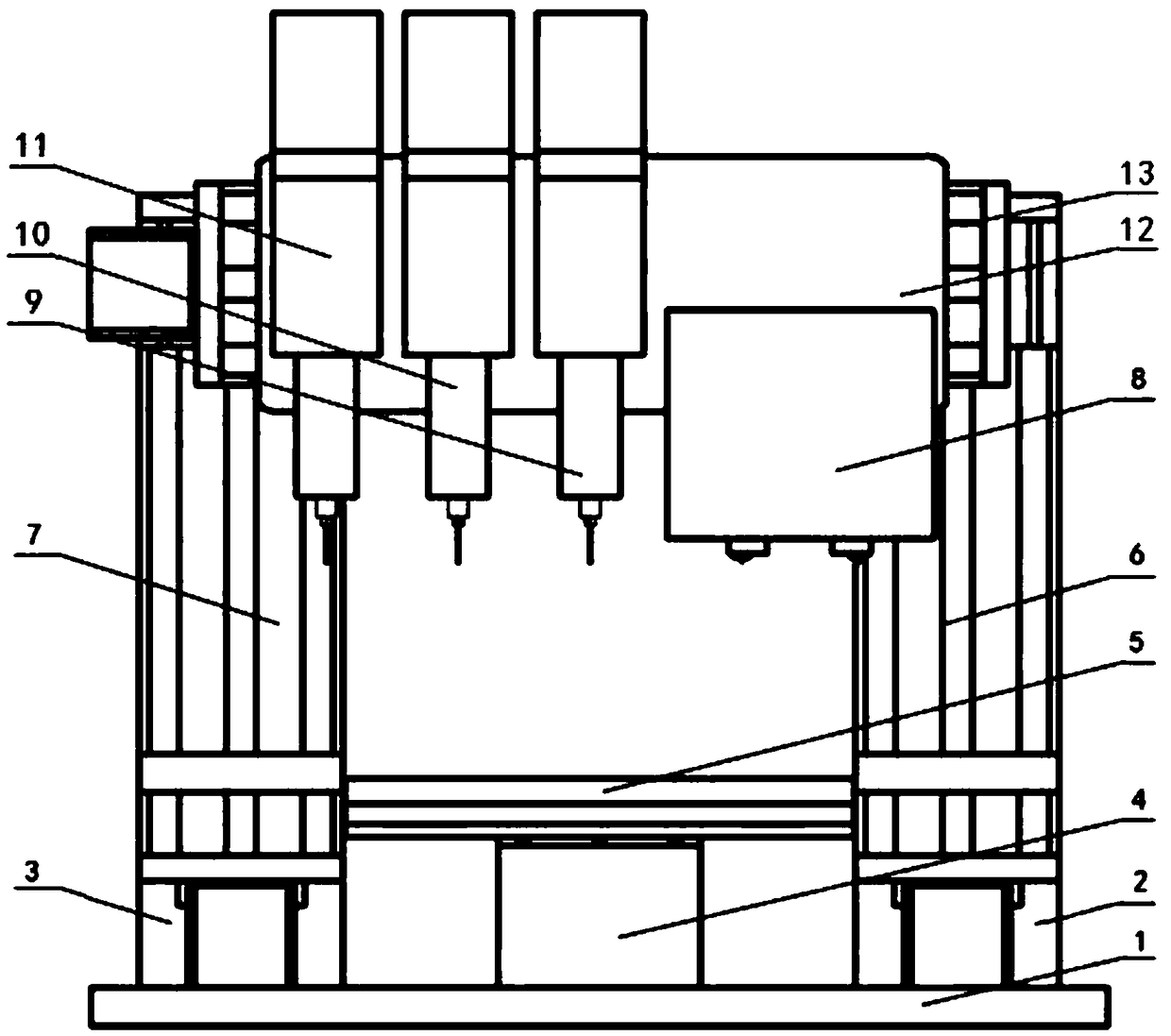

Wet flue gas desulphurization dedusting tower and wet flue gas desulphurization dedusting method

InactiveCN105214425ASolve removal puzzlesSimple structureCombination devicesFlue gasProcess engineering

The invention provides a wet flue gas desulphurization dedusting tower. The tower comprises a tower body, a spraying layer (1) and a demister layer (2) which is above the spaying layer. The tower is characterized in that: a bubbling system (3) special for wet flue gas desulphurization dedusting is arranged above the demister layer (2), wherein the bubbling system (3) special for wet flue gas desulphurization dedusting comprises several flue gas pipes (31) which are combined parallally, bubbling pipes (32) which are arranged between the flue gas pipes or on the pipe walls, and wetting liquid absorption and conveying subsystems (33); liquid steam bubble discharging apparatuses (321) are arranged on the bubbling pipes (32) and are used for discharging liquid steam bubbles to the flue gas pipes (31), and the lower ends or the upper ends of the bubbling pipes (32) are connected with the wetting liquid absorption and conveying subsystems (33). In the flue gas pipes (31), rising flue gas and dense steam bubbles are merged and blended, so that flue gas and steam bubbles are in full contact, a small amount of residual SO2 in the flue gas is absorbed, at the same time ultrafine particles in the flue gas are absorbed or wetted, so that the ultrafine particles either enter liquid, or agglomerate into droplets as a result of wetting, and separation becomes easier. The invention also relates to a wet flue gas desulphurization dedusting method by using the technology.

Owner:ZHEJIANG HONGDIAN ENVIRONMENTAL PROTECTION & TECH CO LTD

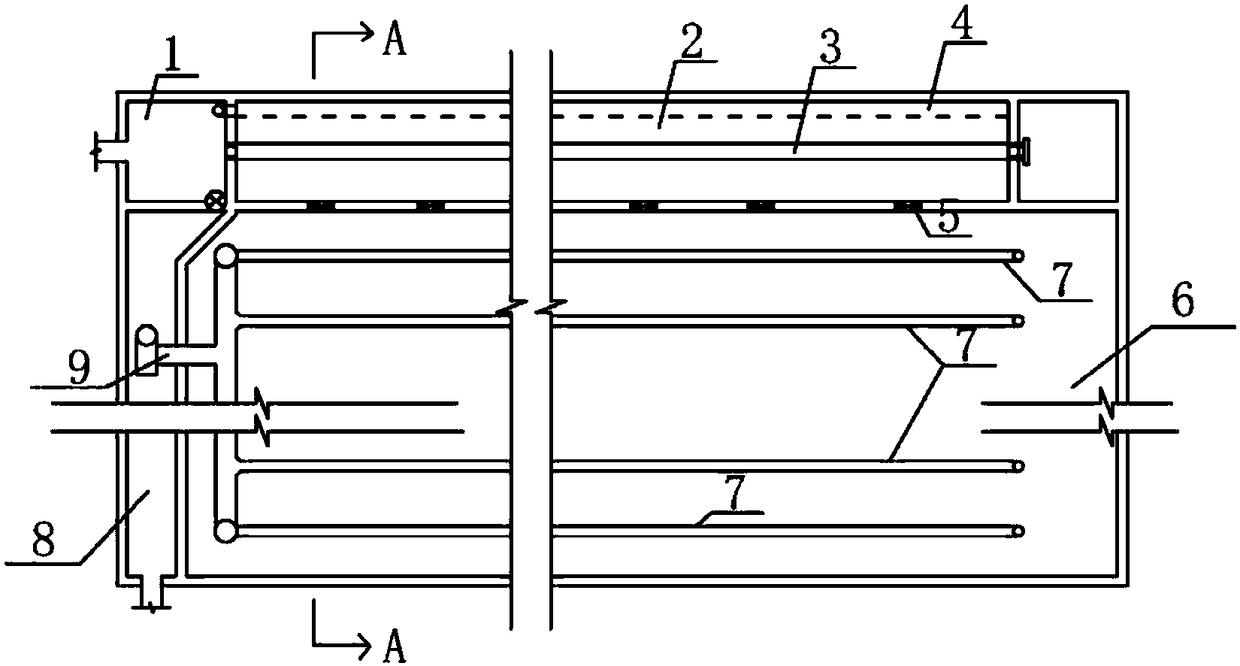

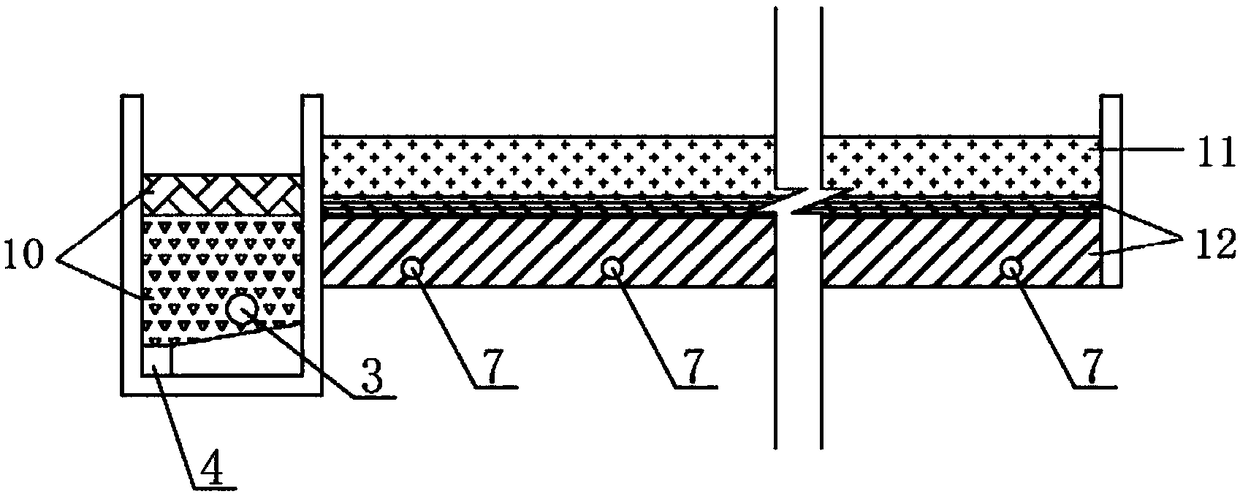

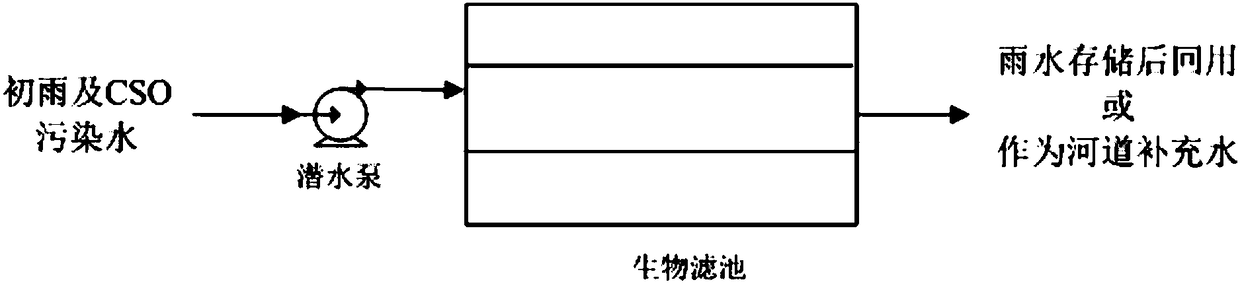

Method for purifying and processing city non-point source pollution

InactiveCN109384347AReduce runoffSolve removal puzzlesWater treatment parameter controlWater contaminantsRainfall runoffSewage

The invention provides a method for purifying and processing city non-point source pollution. The method comprises following steps: collecting rainfall runoff and / or merging sewage overflowed from pipelines, providing a bio-filter; introducing sewage into the bio-filter; filtering the sewage by the bio-filter to obtain purified water; and recovering and using the purified water. After rainfall runoff and / or merged sewage overflowed from pipelines are processed by the provided method, COD removal rate can reach 80 to 85%; SS removal rate can reach 80 to 90%; NH3-N removal rate can reach 70 to 80%, and TP removal rate can reach 40 to 60%.

Owner:光大水务科技发展(南京)有限公司 +1

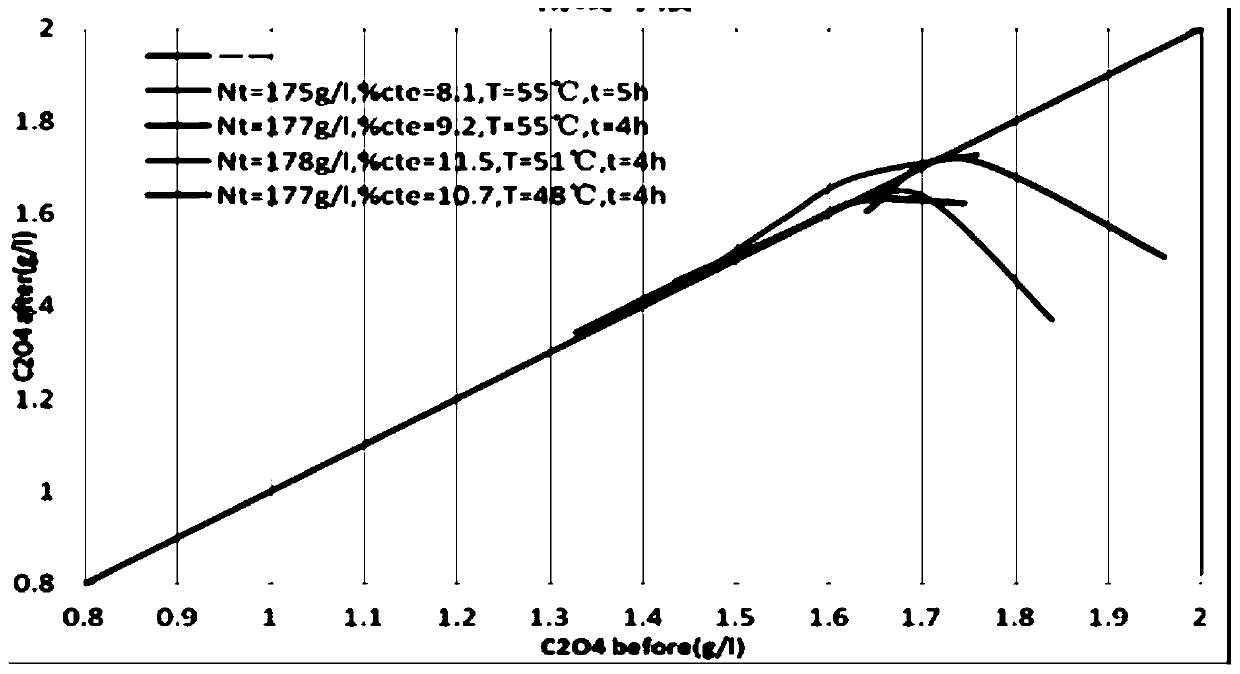

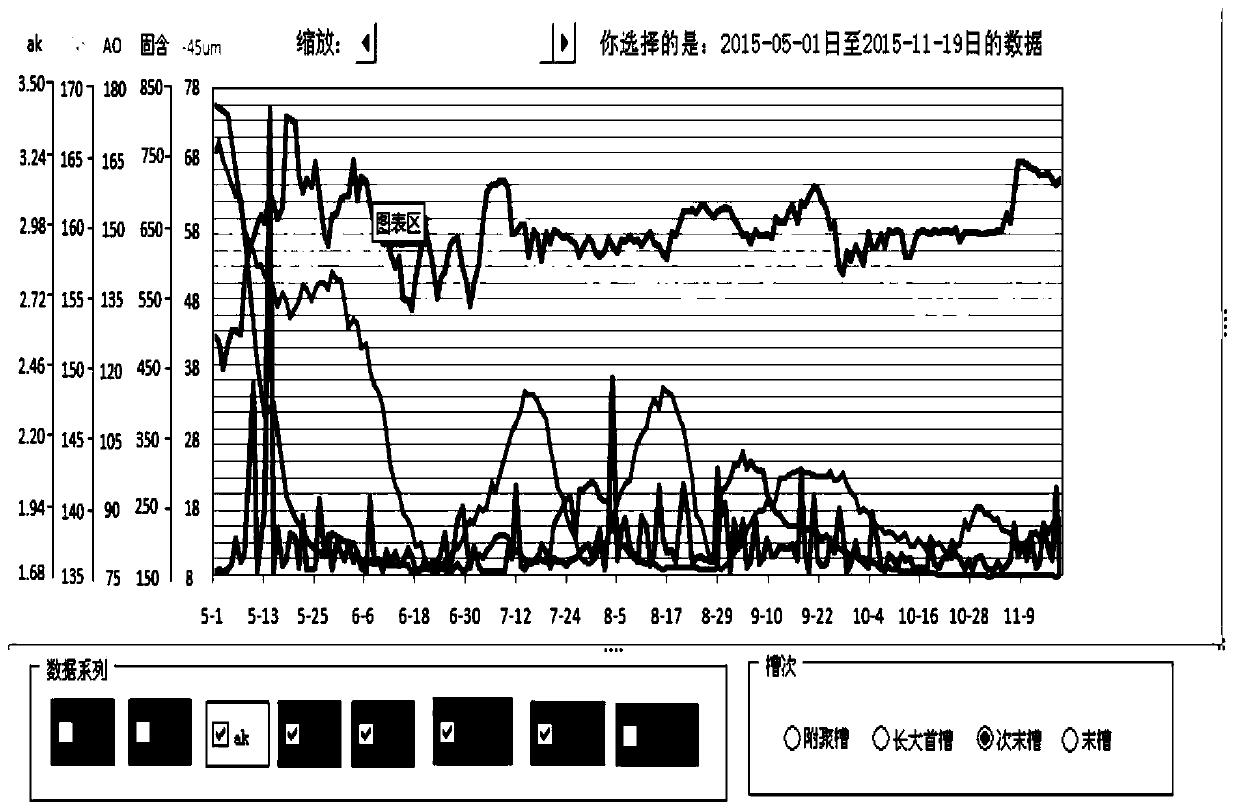

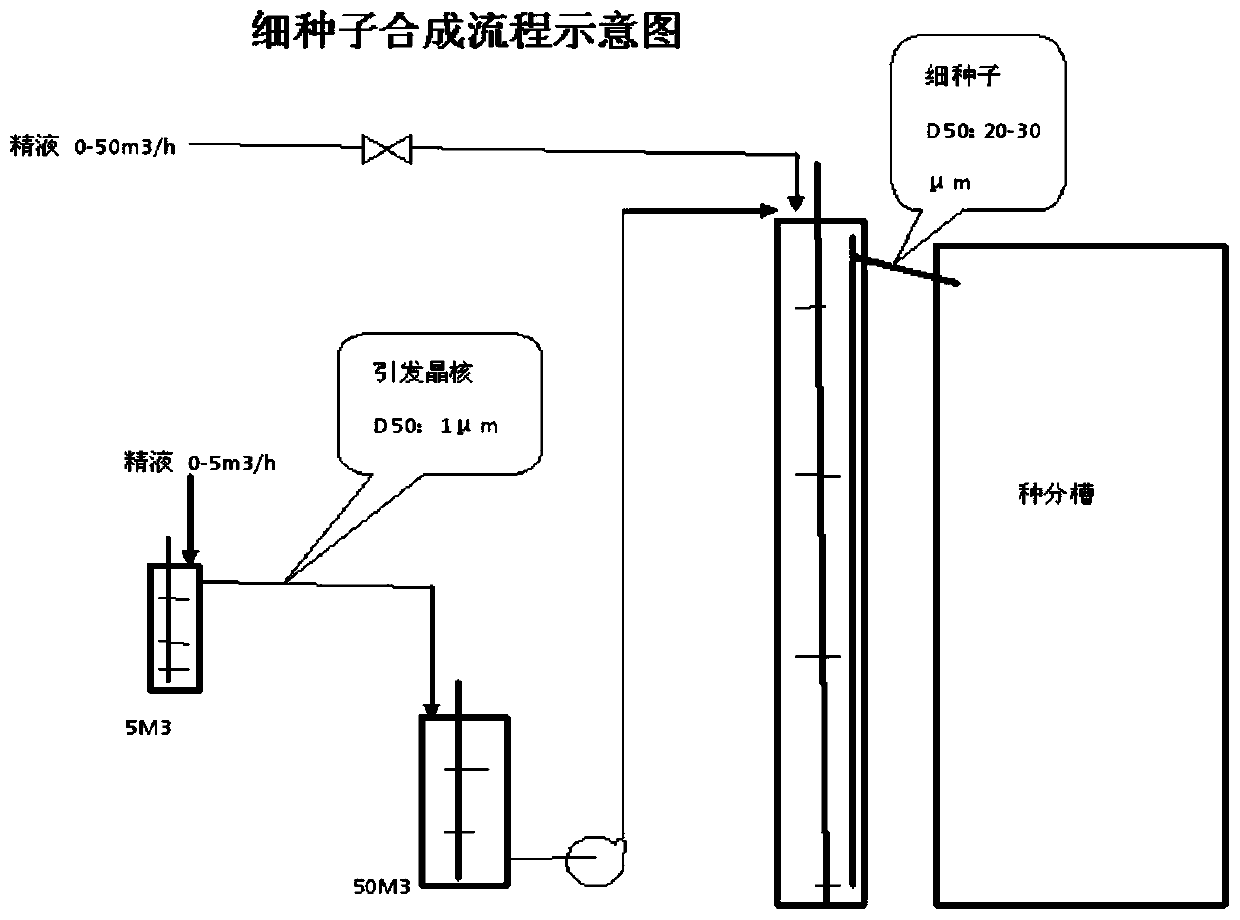

Seed precipitation decomposition process for high-content total organic carbon in low-temperature Bayer process

PendingCN110844927AImprove the decomposition rate of speciesPrevent precipitationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationOxalateAluminium hydroxide

The invention provides a seed precipitation decomposition process for high-content total organic carbon in low-temperature Bayer process, belonging to the field of aluminum oxide production. The seedprecipitation decomposition process is a one-stage decomposition process and comprises the following steps of: reducing the concentration of oxalate in circulating mother liquor to obtain low-oxalate-content mother liquor; adjusting the concentration of caustic alkali in the circulating mother liquor, subjecting the adjusted circulating mother liquor to batching so as to obtain batched ore, and performing bauxite dissolution, red mud separation and washing on the batched ore to obtain a sodium aluminate solution; reducing the concentration of oxalate in the sodium aluminate solution to obtaina low-oxalate-content sodium aluminate solution; and adding seeds into the low-oxalate-content sodium aluminate solution for decomposition to obtain aluminum hydroxide crystals, wherein the aluminum hydroxide crystals comprise coarse-grained aluminum hydroxide crystals and fine-grained aluminum hydroxide crystals, and the content of the fine-grained aluminum hydroxide crystals is controlled.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Treatment equipment for recycling car washing waste water and automatic control system

ActiveCN102701516BImprove water qualitySmall water qualityMultistage water/sewage treatmentProgramme control in sequence/logic controllersAutomatic controlControl system

The invention discloses treatment equipment for recycling car washing waste water and an automatic control system. The treatment equipment comprises a combined tank, an ozone generator, an ozone mixed disinfection tank and a recycling water tank, wherein the combined tank consists of an oil-removal grit tank, an anaerobic adjusting tank, a biochemical reaction tank and a flat-panel membrane bioreactor (MRB) tank; an aeration head and an aeration pipe are respectively arranged in the biochemical reaction tank and the flat-panel MRB tank; a flat panel membrane, a suction pipe and a suction hose are arranged in the flat-panel MRB tank; a membrane cleaning medicine liquid storage tank is connected with the suction pipe; the inlet of a water inlet self-sucking pump is communicated with the anaerobic adjusting tank; the outlet of the water inlet self-sucking pump is connected with the biochemical reaction tank; a inlet of a water outlet self-sucking pump is connected with the suction pipe; the outlet of the water outlet self-sucking pump is connected with the inlet of the ozone mixed disinfection tank through a water outlet pipe; the outlet of the ozone mixed disinfection tank is connected with the recycling water tank; the ozone generator is connected with the water outlet pipe through a jet device; and the biochemical reaction tank is communicated with the anaerobic adjusting tank through a discharge pipe. The control system comprises an equipment field control module, a sub-control platform module for a car washing station, a remote main control platform module and a third-party remote monitoring platform module. The treatment equipment and the automatic control system can be applied to the field of recycling of the car washing waste water.

Owner:SHENZHEN HUIQING TECH

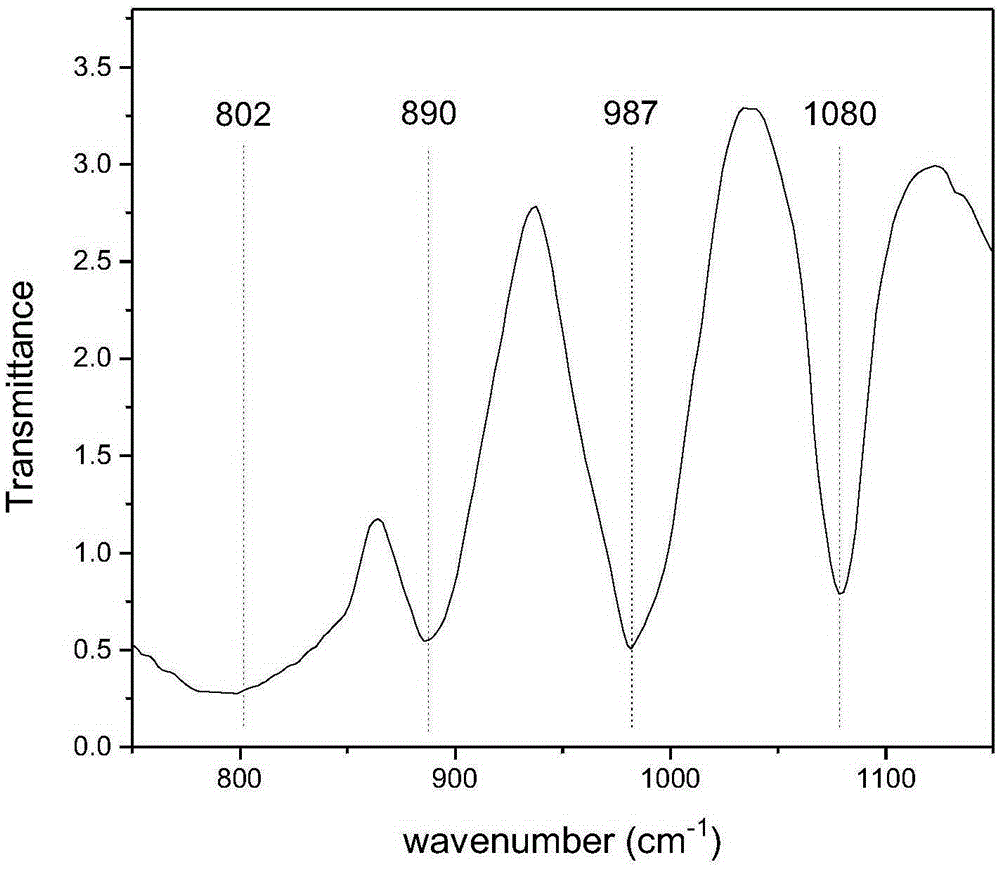

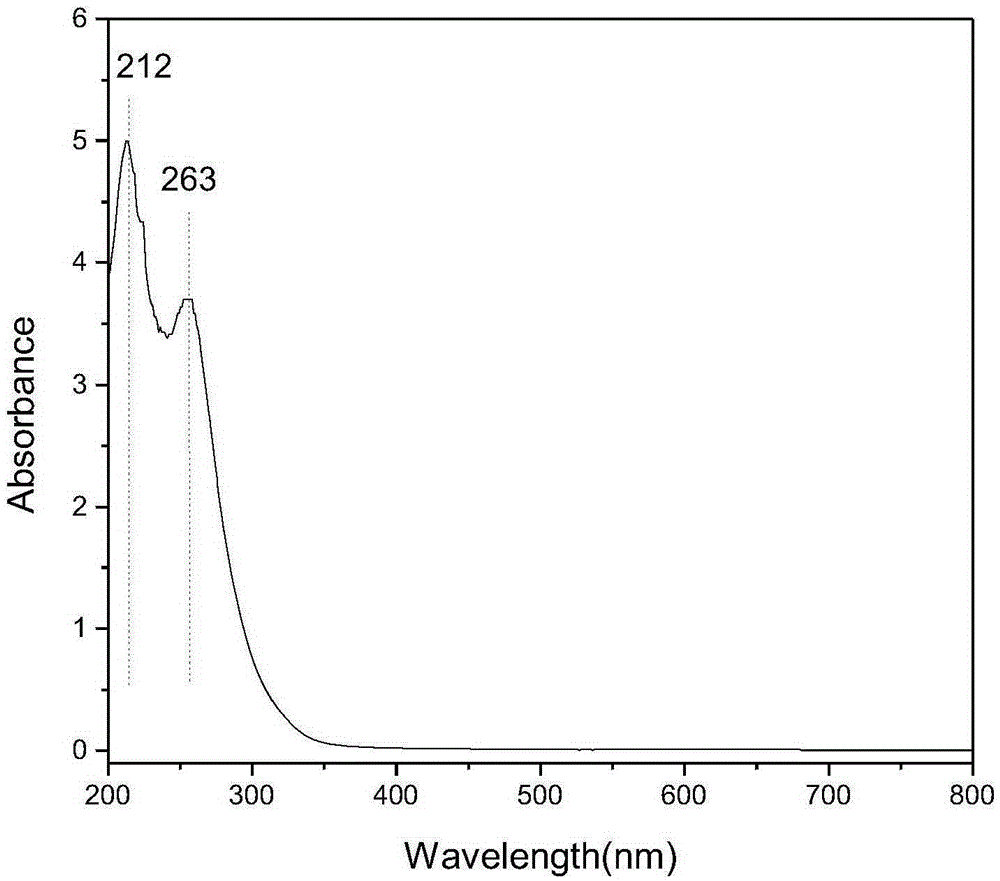

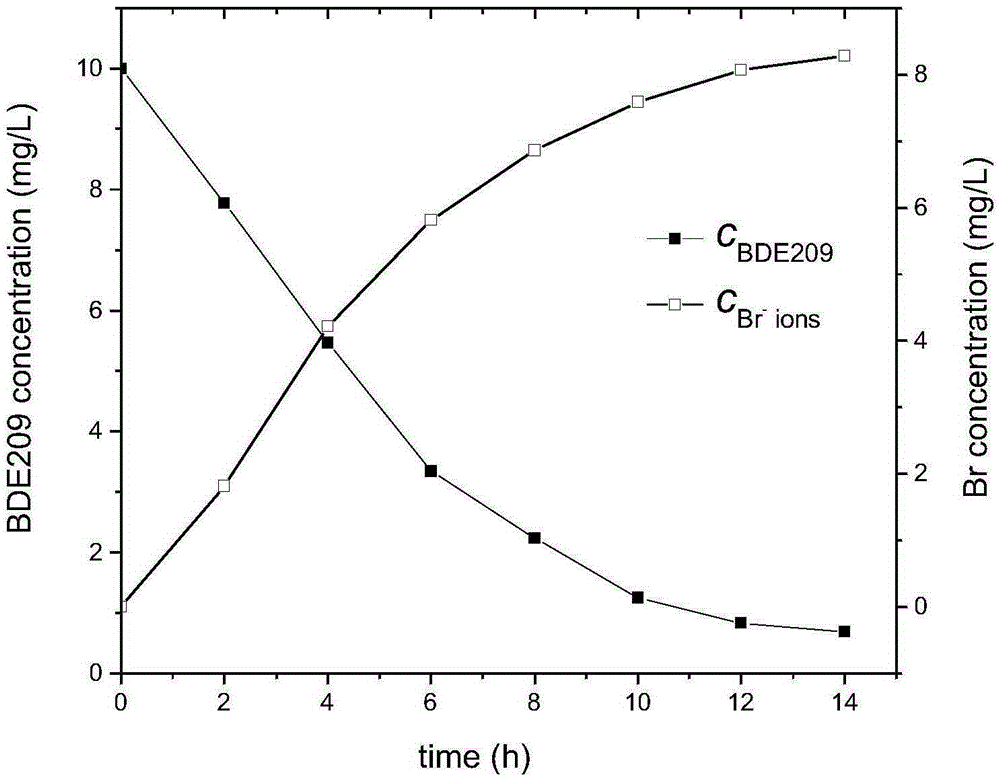

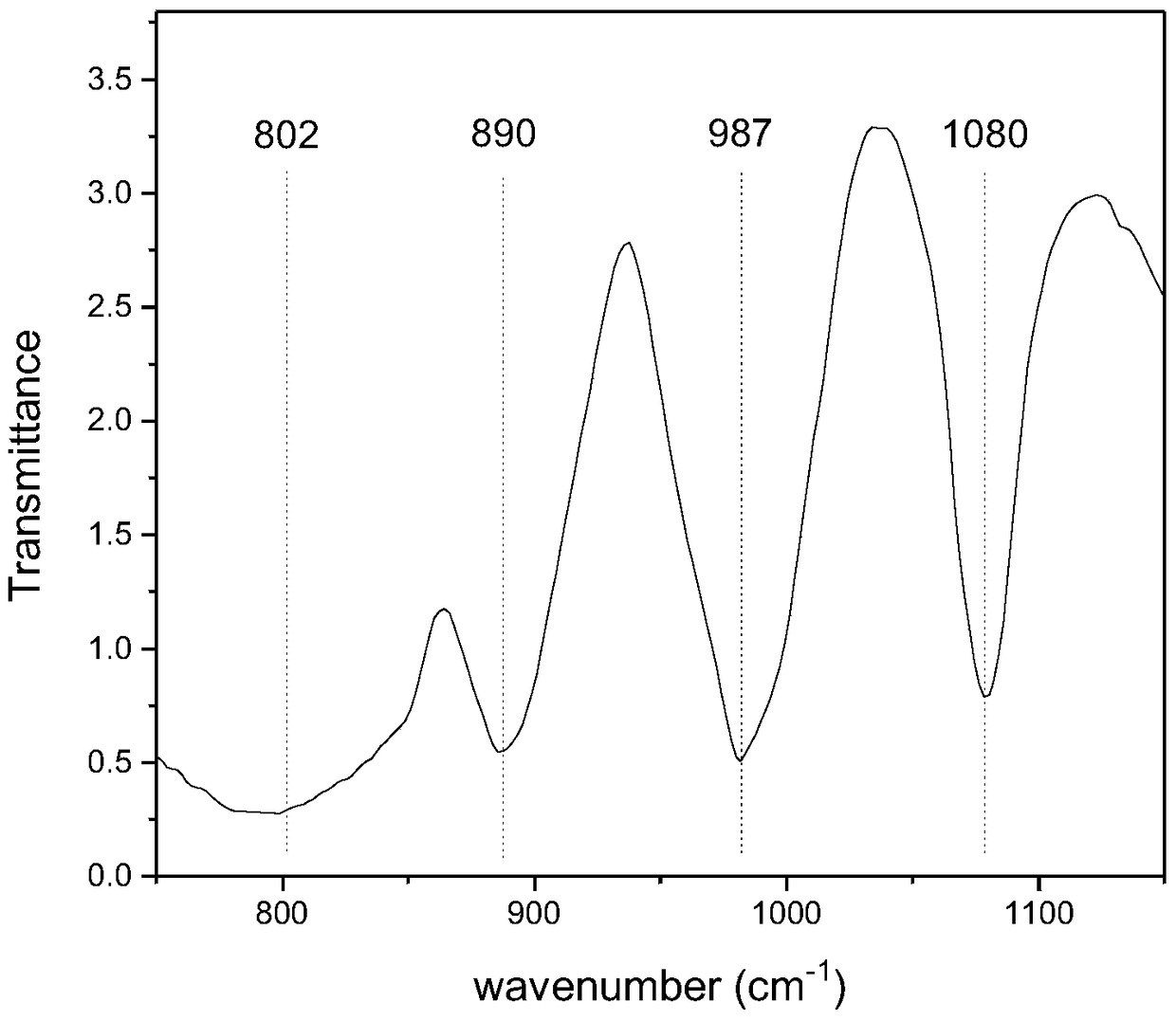

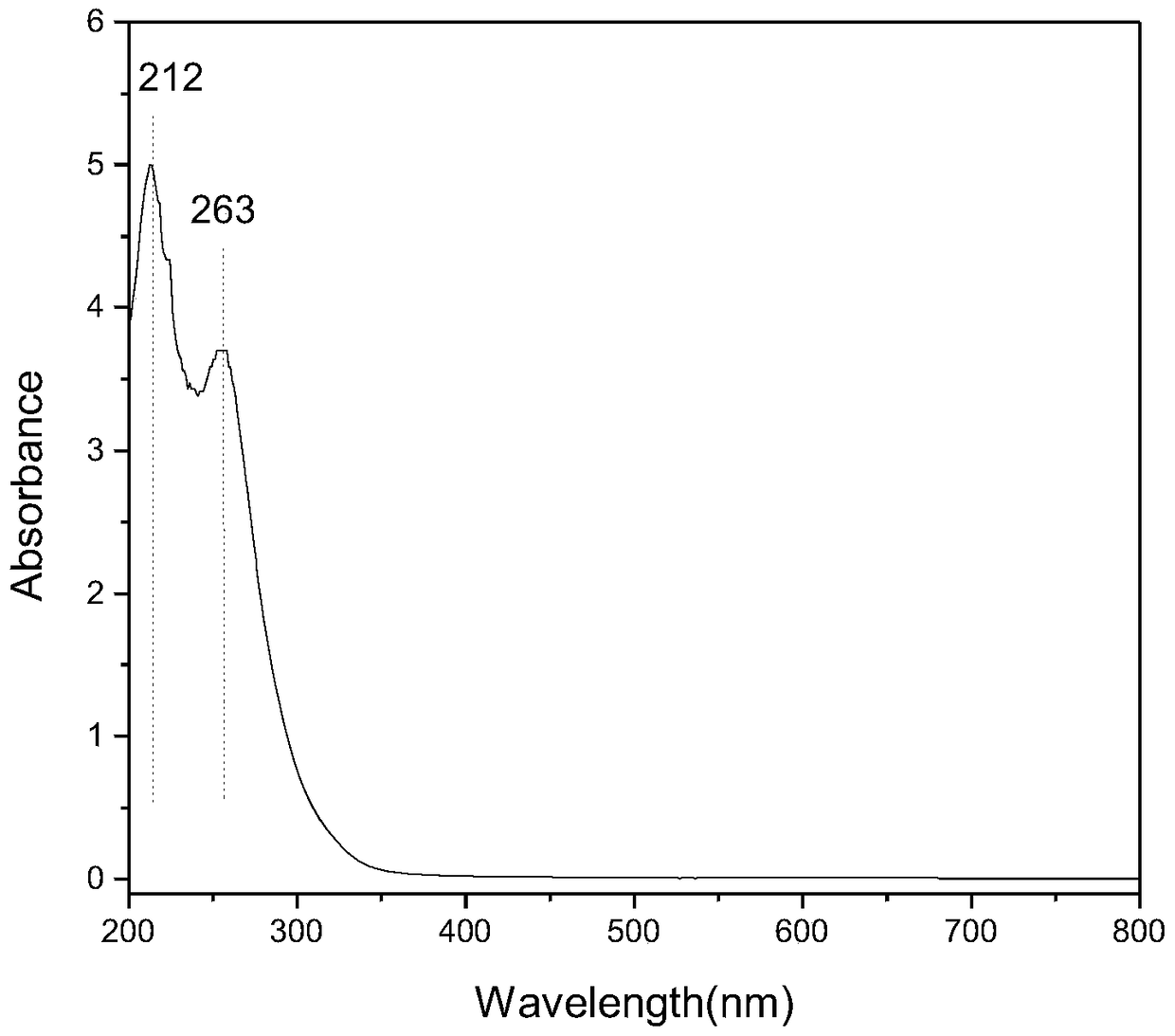

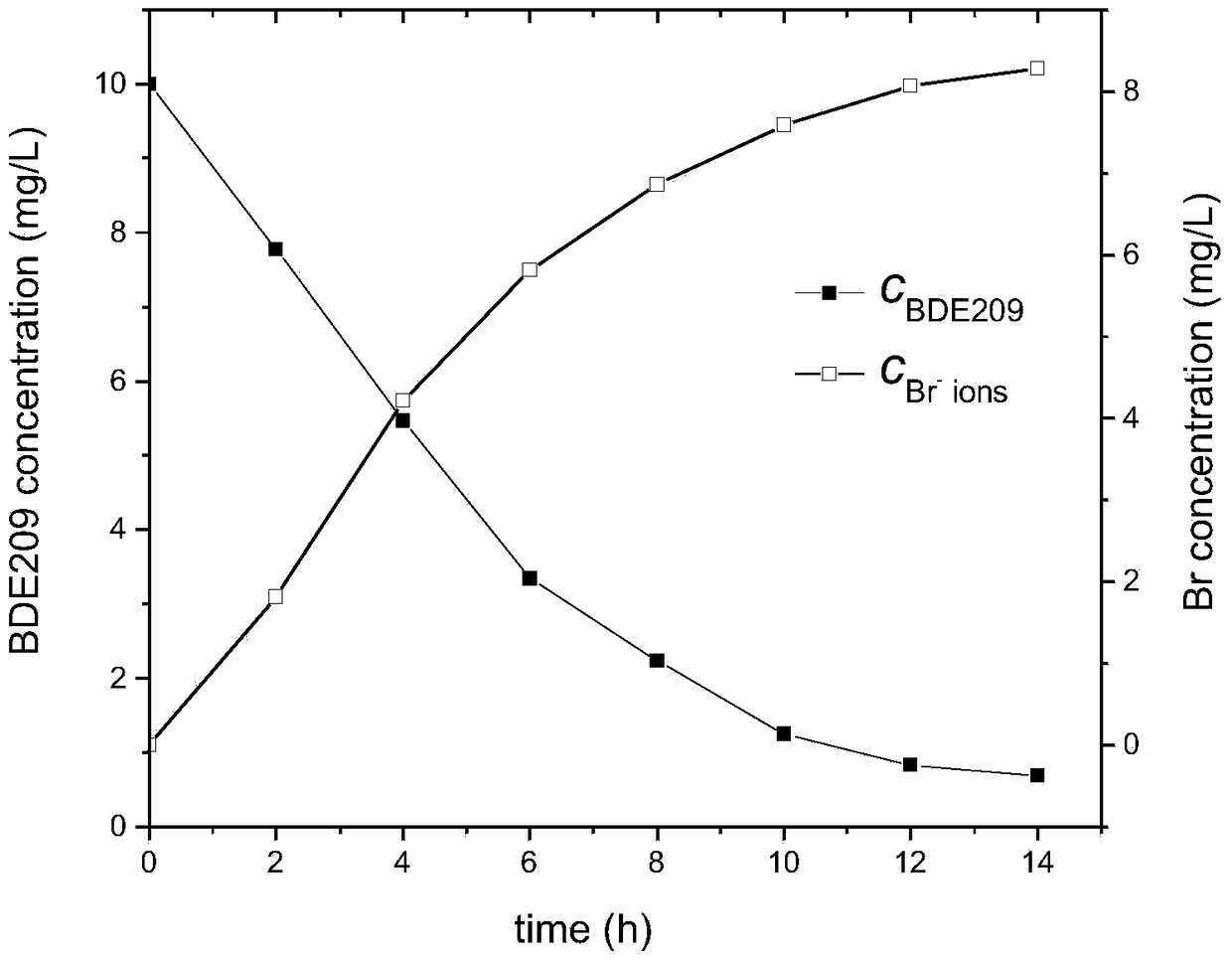

Homogeneous catalysis technology of degrading organic pollutant decabromodiphenyl ether by using Keggin type heteropoly compound H3PW12O40 as catalyst

InactiveCN105288929AIncrease profitSolve removal puzzlesChemical protectionProcess equipmentCatalyst degradation

The invention discloses a homogeneous catalysis technology of degrading organic pollutant decabromodiphenyl ether by using Keggin type heteropoly compound H3PW12O40 as a catalyst. The homogeneous catalysis technology is characterized by comprising the steps of synthesis of the Keggin type heteropoly compound H3PW12O40 serving as the catalyst, characterization of the Keggin type heteropoly compound H3PW12O40 serving as the catalyst, homogeneous catalysis of the organic pollutant decabromodiphenyl ether, analysis of homogeneous catalysis degradation effects and degradation products and the like. The homogeneous catalysis technology has the advantages of scientific and reasonable process flow, simple process equipment, high degradation efficiency, low energy consumption, high comprehensive utilization ratio of the catalyst, good environmental protection effect and the like and solves the difficult problem of removing the organic pollutant decabromodiphenyl ether in the environment field.

Owner:NORTHEAST DIANLI UNIVERSITY

Method for preparing low-arsenic oyster protein peptide through targeted nano silica gel material adsorption

PendingCN113854473ASolve removal puzzlesEasy to operateFatty-oils/fats refiningPeptide preparation methodsFood safetySilica gel

The invention belongs to the technical field of food processing, and particularly relates to application of a targeted nano silica gel material to removal of heavy metal arsenic in oyster protein peptide powder, and a preparation method of the oyster protein peptide powder with low arsenic content by adopting targeted nano silica gel material. The preparation method comprises the following steps: adding a targeted nano silica gel material into an aqueous solution or an acid solution containing oyster protein crude peptide, refluxing and stirring at 0-100 DEG C for 0.25-12 hours, and filtering; and drying the filtering solution, obtaining the oyster protein peptide with the arsenic content smaller than 1 ppm by adding the filtrate into the oyster protein peptide powder, and converting the oyster protein peptide powder originally containing 12 mg / kg of arsenic into a product containing 1 mg / kg or below of arsenic, so that the content of arsenic in the oyster protein peptide powder is greatly reduced, and the food safety is remarkably improved. The method is simple and convenient to operate, the used reagent is easy to obtain, the adsorption cost is low, the effect is excellent, the problem about arsenic removal in the oyster protein peptide powder is solved, and the excellent arsenic removal effect is achieved.

Owner:无锡定象生物科技有限公司

A method and equipment for electron beam smelting polysilicon deoxidation and ingot coupling

InactiveCN104651929BSolve removal puzzlesMeet oxygen requirementsPolycrystalline material growthSilicon compoundsOxygenDeoxygenation

The invention belongs to the field of metallurgic melting, and especially relates to an electron beam melting polysilicon deoxygenation and ingot casting coupling method and an apparatus thereof. The method comprises the following steps: carrying out vacuum pumping on a furnace body and electron guns, starting a melting electron gun to carry out electron beam melting on a polysilicon material, and melting to preliminarily remove impurity oxygen; maintaining a liquid state under the action of a radiation electron gun to further remove oxygen, guiding the obtained material to enter an ingot casting device through a water cooled conveyor belt, and carrying out oriented crystal growth to obtain polysilicon cast ingots. The apparatus comprises an electron beam melting assembly and an ingot casting coupling assemble, the ingot casting coupling assembly comprises the ingot casting device, the ingot casting device is positioned under the water cooled conveyor belt, and the flow guiding opening of the water cooled conveyor belt is positioned over the center of the quartz crucible of the ingot casting device. The electron beam melting deoxygenation method and a use thereof are provided for the first time, electron beam deoxygenation is realized, and ingot casting coupling is combined, so energy required by ingot casting heating of the raw material is reduced, and the production efficiency is greatly improved.

Owner:QINGDAO NEW ENERGY SOLUTIONS

Single color image shadow removal method based on illumination surface modeling

The invention belongs to the computer image processing field and relates to a single color image shadow removal method based on illumination surface modeling. The method comprises the following steps: carrying out structure and texture decomposition on an original color shadow image and acquiring structure images in three color channels: R, G and B and corresponding texture images respectively; selecting central points uniformly in a non-shadowed region of the image and calculating a radial distance between any two central points; modeling the structure images in the three color channels respectively and acquiring illumination distribution of shadow regions in the three color channels; adding texture images in each channel to the three color channels respectively so as to obtain the image after illumination correction. The method of the invention has a strong adaptability. Too much manual interventions are not needed. The illumination modeling and central point selection adopt an adaptive algorithm. The method can be used for automatically removing the actual image shadow.

Owner:天津渤化安创科技有限公司

3j1 Removal method of oxide skin on the surface of the part of the tie wire

The invention belongs to a surface treatment technique, and relates to a method for removing the oxide skin from the surface of a workpiece of a 3J1 bundle. The method for removing the oxide skin fromthe surface comprises the following steps of preparing an etching solution; degreasing the 3J1 bundle; blow-drying; removing the oxide skin; cleaning; and inspecting. The invention provides the method for removing the oxide skin from the surface of the workpiece of the 3J1 bundle, the problem of removing the oxide skin from the 3J1 bundle is solved, the removal effect is increased, base materialsare prevented from being damaged, and the electroplating quality is guaranteed.

Owner:BEIJING SHUGUANG AERO ELECTRICAL

A method for advanced treatment of ASP flooding produced water with micro-bubbles

ActiveCN110510798BNo costGood effect in removing suspended solidsWaste water treatment from quariesWater treatment parameter controlMicrobubblesFiltration

The present invention relates to a method for deep treatment of produced water of ASP flooding with micro-bubbles. The method comprises the steps of sewage filtration to remove suspended solids ≥ 40 μm; electromagnetic anti-scaling; generation of micro-bubbles, mixing of micro-bubbles and water, and pressurization of sewage jets. , Suspension of oil droplets and microbubble coalescence, cyclone separation as a treatment unit, according to the microbubble particle size <4μm, <10μm, <25μm, <60μm, respectively generated and used, the sewage treatment is divided into corresponding The processing units are processed step by step from small to large. The microbubbles of each level of treatment unit occur at this level; the microbubbles mix and coalesce with the oil beads and suspended particles; the hydrocyclone separates the oil-water cyclone; the invention uses mechanical or physical methods to treat sewage, which is technically economical Good performance, safety and environmental protection, suitable for advanced treatment of ASP flooding produced water, polymer flooding produced water, heavy oil produced water, also suitable for the treatment of other similar sewage containing fine suspended solids, highly emulsified and high viscosity.

Owner:兰州正丰石油化工技术装备有限责任公司

Homogeneous Catalytic Process for Degradation of Organic Pollutant Decabromodiphenyl Ether Using Keggin Type Heteropoly Compound H3PW12O40 as Catalyst

InactiveCN105288929BIncrease profitSolve removal puzzlesChemical protectionProcess equipmentCatalyst degradation

The invention is a homogeneous catalytic process for degrading organic pollutants decabromodiphenyl ether using Keggin type heteropoly compound H3PW12O40 as a catalyst. The characterization of H3PW12O40, the homogeneous catalysis of the organic pollutant decabromodiphenyl ether, the homogeneous catalytic degradation effect and the analysis of the degradation products have scientific and reasonable process flow, simple process equipment, high degradation efficiency, less energy consumption, and the catalyst With the advantages of high comprehensive utilization rate and good environmental protection effect, it solves the problem of removing organic pollutant decabromodiphenyl ether in the environmental field.

Owner:NORTHEAST DIANLI UNIVERSITY

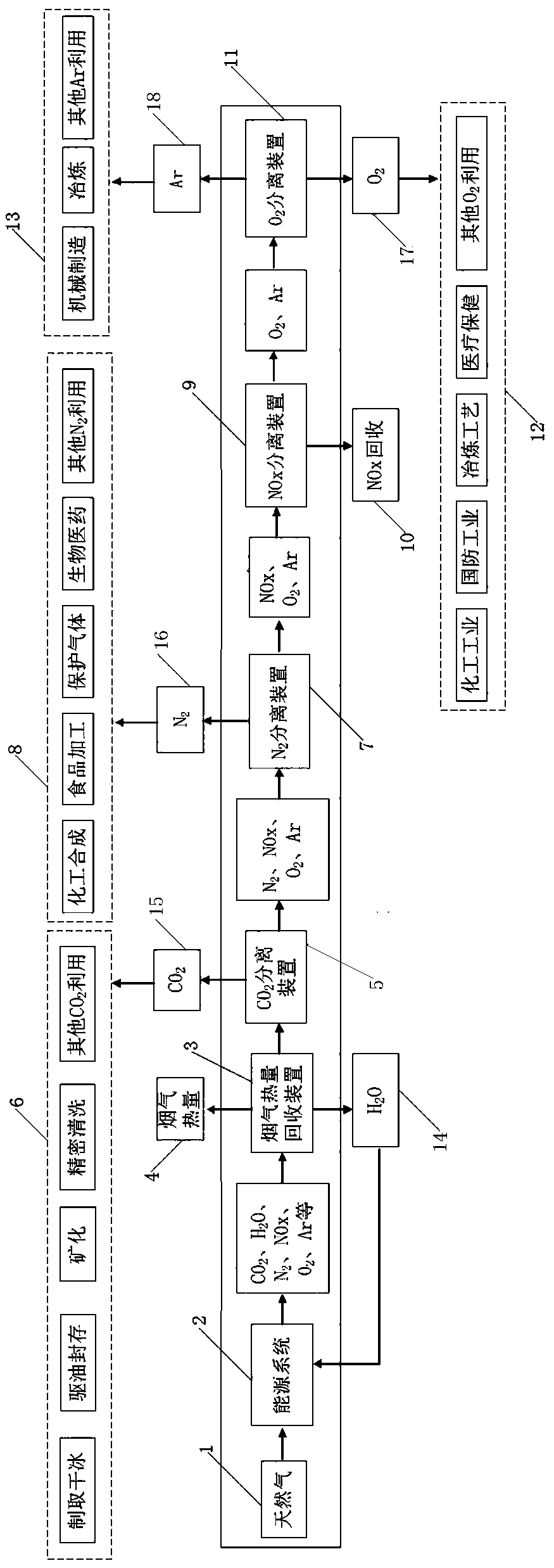

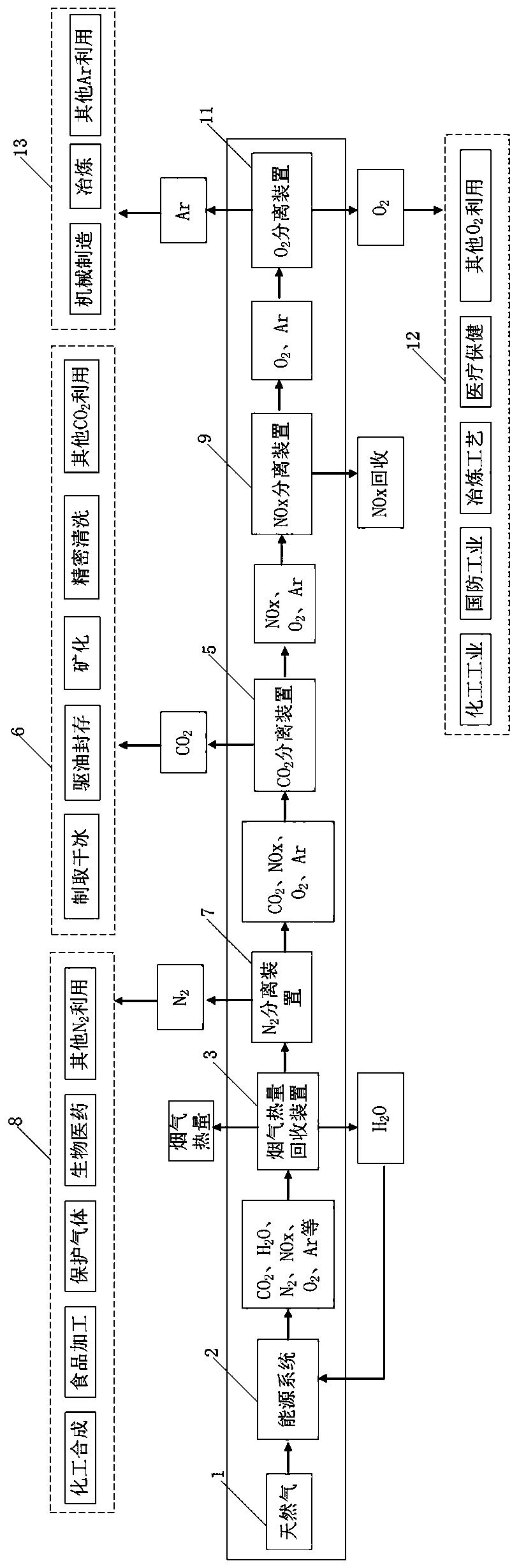

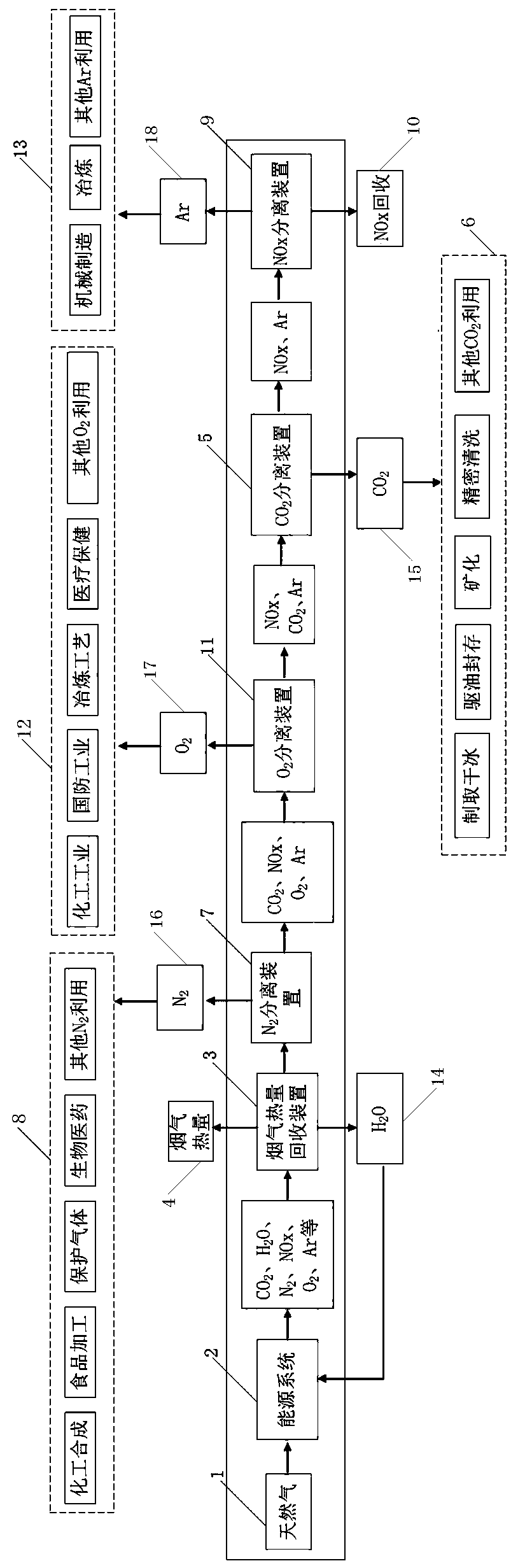

Low carbon, clean and efficient distributed energy source system and operation method thereof

PendingCN108905488AReduce the impactImprove use valueGas treatmentDispersed particle separationFlue gasProcess engineering

The invention relates to a low carbon, clean and efficient distributed energy source system and an operation method thereof, and belongs to the field of distributed energy sources. In the prior art, the development of the distributed energy source system is faced with many challenges such as carbon dioxide emission control, nitrogen oxide emission control, system efficiency improvement, heat island effect, and no comprehensive treatment method can solve the problems. The low carbon, clean and efficient distributed energy source system comprises a natural gas device, a gas distributed energy source system, a flue gas heat recovery device, a flue gas heat utilization device, a CO2 separation device, a CO2 supply terminal, a N2 separation device, a N2 supply terminal, a NOX separation device,a NOX recovery device, an O2 separation device, an O2 supply terminal and an Ar supply terminal. The low carbon, clean and efficient distributed energy source system can effectively solve the problems of carbon dioxide emission control, nitrogen oxide emission control, system efficiency improvement, heat island effect and the like, and can reasonably and effectively utilize flue gas generated bythe gas distributed energy source system.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Method and device for efficiently removing impurity oxygen in polysilicon by electron beam smelting

Belonging to the field of polysilicon purification, the invention in particular relates to a method and device for efficient removal of impurity oxygen from polysilicon by electron beam melting, and breaks the traditional electron beam melting mode to carry out electron beam deoxygenation smelting by means of a diversion trench rather than in a melting crucible. As a silicon liquid can spread in a diversion area, the specific surface area increases, and the electron beam melting deoxygenation effect can be better. According to the method and device provided by the invention, (1) the technological method and use of electron beam deoxygenation are put forward, the problem of difficult removal of impurity oxygen from polysilicon is solved, and the oxygen content can be reduced to less than 0.0571ppmw, thus meeting the requirement of solar cells for polysilicon ingot oxygen content; (2) the polysilicon material efficient banded deoxygenization technology can increase the silicon liquid surface area by over 30% and shorten the deoxygenation time by more than 20%; and (3) continuous production can be realized, and the production efficiency can be improved by more than 35%.

Owner:QINGDAO NEW ENERGY SOLUTIONS

Method for arsenic removal treatment of euphausia superba extract and application of adsorbent in arsenic removal

The invention relates to a method for removing heavy metal arsenic in euphausia superba extract. The method comprises the following steps: (1) dispersing euphausia superba peptide powder in water or an acid solution to obtain a mixed solution I; (2) mixing the mixed solution I with an adsorbent, carrying out arsenic removal treatment, and removing the adsorbent to obtain a mixed solution II; (3) desolventizing the mixed solution II to obtain arsenic-removed euphausia superba peptide powder; or (1) dissolving the euphausia superba oil in an organic solvent to obtain a mixed solution A; and (2) mixing the mixed solution A with an adsorbent, and carrying out reflux stirring, rotary evaporation and filtration to obtain the arsenic-removed euphausia superba oil. The content of total arsenic in the euphausia superba extract is greatly reduced, and the safety of the euphausia superba extract is remarkably improved. The method is simple and convenient to operate, the used reagent is easy to obtain, the adsorption effect is excellent, the problem about total arsenic removal in the euphausia superba extract is solved, and the excellent arsenic removal effect is achieved.

Owner:无锡定象生物科技有限公司

A gas distributor for a circulation scrubber and its design method

ActiveCN108079708BThe hydraulic index is consistentSimplify the design processUsing liquid separation agentLiquid layerSpray nozzle

The invention provides a gas distributor for a circulating-flow scrubbing tower and a design method of the gas distributor. The gas distributor is of a branch-shaped distributor structure and is provided with a central gas inlet pipe and at least one branch pipe, wherein the branch pipes are connected with the central gas inlet pipe, a blind plate is arranged at the tail end of the central gas inlet pipe, liquid discharging holes are formed in the blind plate at the tail end of the central gas inlet pipe, and liquid discharging holes are also formed near the lowest ends or the tail ends of thebranch pipes; gas spraying holes are formed in the pipe walls of the branch pipes, and blind plate holes are formed in the tail ends of the branch pipes, or Venturi-type spraying nozzles are arrangedin the branch pipes. The pressure drop and the gas velocity of the spraying holes are adopted as the overall design and control indexes of the gas distributor, the design process is simple and easy to implement, and the diameter distribution and phase interface of bubbles can be controlled; a circulating flow can be formed in a flow guiding canister of the scrubbing tower, the standing time of gas at a liquid layer is prolonged, and the humidity of the gas at the liquid layer and the scrubbing efficiency are improved; even distribution of the gas flow is ensured, discharging of liquid and solid sediments is facilitated at the same time, and the gas distributor is applicable to large-scale gas-liquid-solid three-phase separation equipment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A method for removing diaphragms in waste lithium-ion power batteries

ActiveCN109273791BImprove pyrolysis efficiencyFully pyrolyzedWaste accumulators reclaimingBattery recyclingPower batteryThermodynamics

The invention discloses a method for removing a separator in a waste lithium ion power battery, which comprises the following steps: crushing the waste lithium ion power battery into crumbs and passing through a 5-mesh screen to obtain small crumbs with a particle size less than 5 mesh and large crumbs with a particle size greater than 5 mesh; Preheating the large particle size crushed material, and controlling the preheating temperature at 100-300 DEG C; Heating and decomposing the crumbs obtained after the preheating is completed until the thermal decomposition of the diaphragm in the crumbsis complete and the temperature of the thermal decomposition is controlled at 300 to 500 DEG C; cooling and recovering The scrap obtained after decomposition. The method adopts two-stage heating design, improves the pyrolysis efficiency of the separator in the scrap material, the pyrolysis of the separator is more complete, the separator in the waste lithium ion power battery can be directly decomposed and removed, and the problem of removing the separator in the scrap material after the scrap material of the waste power battery is broken is solved; At that same time, the process method is simple to operate and easy to industrialize.

Owner:ZHUZHOU DINGDUAN EQUIP CO LTD

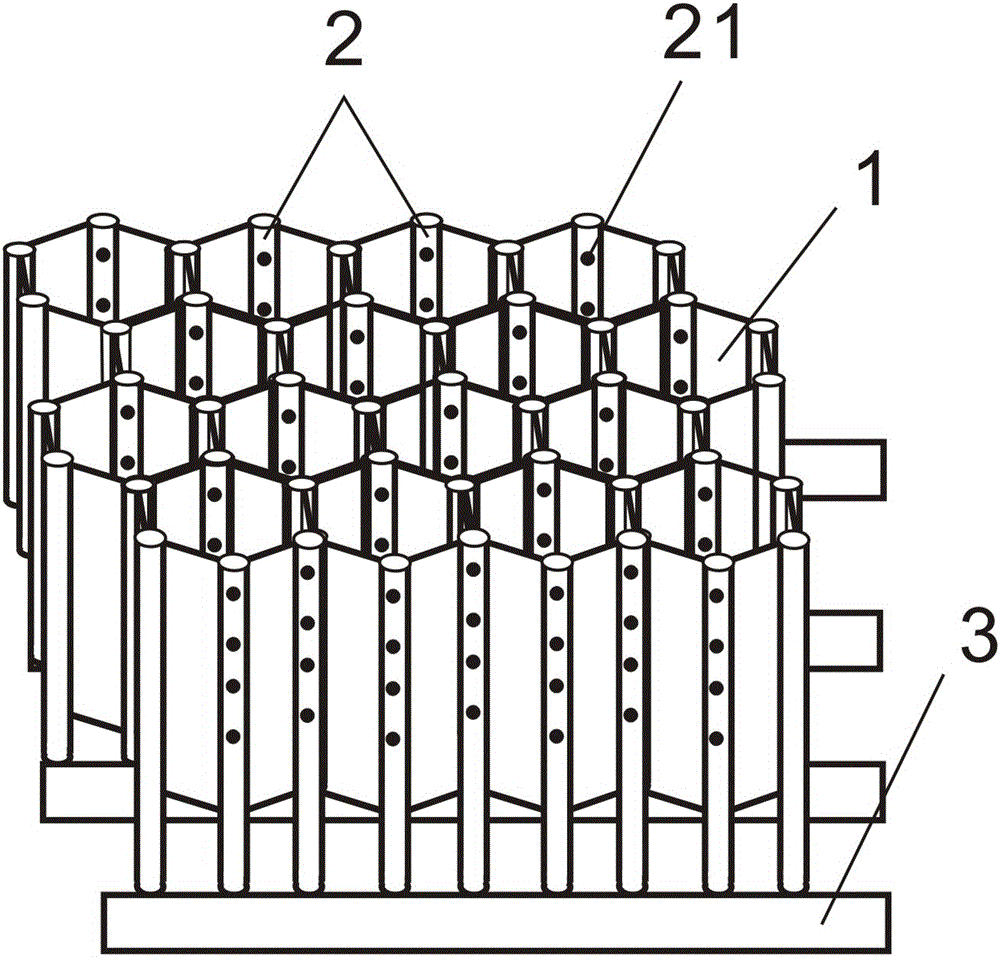

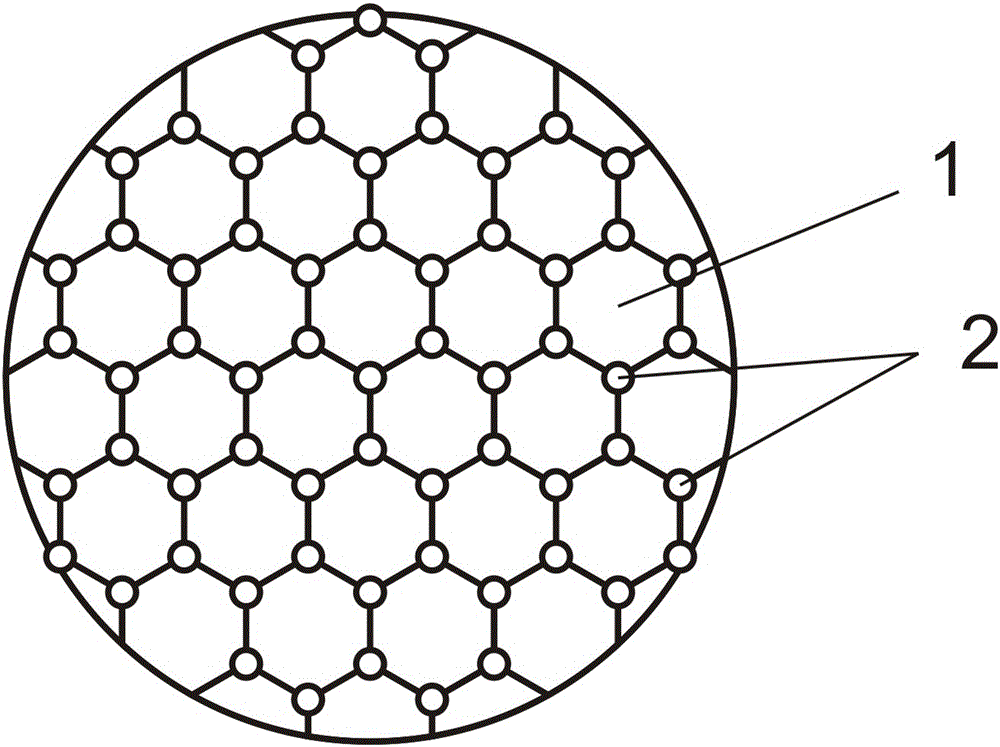

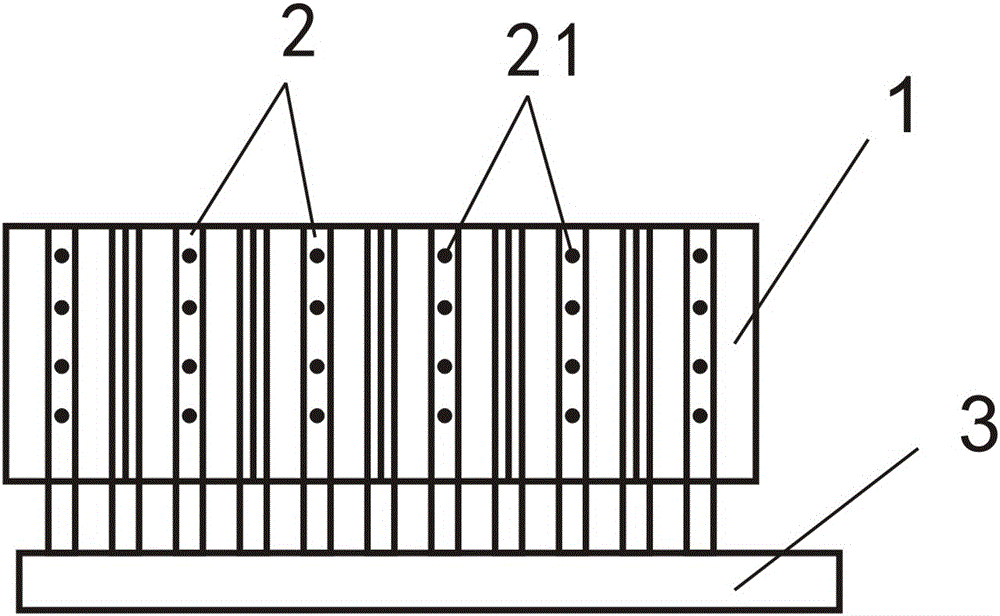

Special bubbling system for dust removal by wet flue gas desulfurization

InactiveCN105107342ASolve removal puzzlesSimple structureCombination devicesParticulatesActive agent

The invention relates to a special bubbling system for dust removal by wet flue gas desulfurization. The bubbling system comprises a plurality of flue gas pipes (1), bubbling pipes (2) and absorption wetting liquid delivery subsystems (3), wherein the bubbling pipes (2) are arranged on the side walls of the flue gas pipes (1); liquid-vapor bubble releasing devices (21) are arranged on the bubbling pipes and used for emitting liquid-vapor bubbles to be released into the flue gas pipes (2); the lower ends or the upper ends of the bubbling pipes (2) are connected with the absorption wetting liquid delivery subsystems (3); the absorption wetting liquid delivery subsystems (3) enable absorption wetting liquid containing an alkaline active agent to form intensive bubbles in the bubbling pipes (2) by certain air pressure, and inject the bubbles into the flue gas pipes (1) through the liquid-vapor bubble releasing devices (21) on the bubbling pipes (2); in the flue gas pipes (1), rising flue gas and intensive bubbles are converged and blended, so that flue gas can be in full contact with the bubbles, a small amount of residual SO2 in flue gas can be absorbed, and at the same time superfine particulate matters in wetting flue gas can be absorbed, the superfine particulate matters can be enabled to enter liquid or wetted to coagulate to form fogdrops , so as to be easily separated.

Owner:ZHEJIANG HONGDIAN ENVIRONMENTAL PROTECTION & TECH CO LTD

Preparation method of 3-guanidino propanoic acid

InactiveCN103288685BReduce use costReduce recycling costsOrganic chemistryOrganic compound preparationPropanoic acidIon exchange

The invention relates to a preparation method of 3-guanidino propanoic acid. The preparation method comprises the following steps of: adding 3-aminopropionic acid to methanol, thereby obtaining a solution a at 15 DEG C; putting monocyanamide into methanol, thereby obtaining a solution b; feeding the solution b to the solution a, thereby obtaining a solution c at a temperature within 15 DEG C and pH in the range from 7.5 to 8.0; performing vacuum concentration on the solution c and filtering at -5 DEG C, thereby obtaining a crude product of sodium 3-guanidine propionate; preparing the crude product into an aqueous solution of sodium 3-guanidine propionate, thereby obtaining a solution d2; filling H type weakly acidic cation exchange resin into an ion exchange column, and feeding the solution d2 into the ion exchange column and detecting no 3-guanidino propanoic acid; blending the exchange solution collected by the step e and performing decompression concentration on the exchange solution, feeding methanol, reducing the temperature to -10 DEG C for crystallization, thereby obtaining a crystalline mixed liquid f; and then filtering and drying the crystalline mixed liquid f to obtain 3-guanidino propanoic acid. The problem of removing sodium ions during the production of 3-guanidino propanoic acid is solved through exchange treatment of the weakly acidic cation exchange resin; as methanol is taken as a solvent, the utilization and recovery cost of the solvent is lower and the preparation method is safer to operate; side-reactions are few; the 3-guanidino propanoic acid is extracted by ion resin exchange; and the yield of the 3-guanidino propanoic acid is 76.0% and the purity of the 3-guanidino propanoic acid is 99.0%.

Owner:郭礼强

3D printing method and 3D printer for embedded electronic products

ActiveCN106493939BEfficient integrated manufacturingLow costAdditive manufacturing apparatus3D object support structuresSupport removalEngineering

The invention discloses a 3D printing method for an embedded electronic product and a 3D printer. After each layer of structure material is printed, a layer of release material is arranged around a support reserved position in a jet printing manner, support printing is conducted, and when the set of structure layers are printed, supports of reserved holes and grooves are removed, an electronic component is embedded, printing of the set of electric conduction layer structure, jet printing of electric conduction circuits and jet printing of dielectric materials between the electric conduction circuits are sequentially conducted, the process is repeatedly conducted till the last set of electric conduction layer structure is printed, and the electronic product is packaged through printing structure materials. The release material is introduced between the structure material and a support material, the support material is easy to remove, on one hand, removal of the supports through an ultrasonic alkaline solution is avoided (a traditional support removing technology is not allowed to be adopted in the embedded electronic product), and on the other hand, influences on a printed electric conduction circuit from support removal are avoided. The problem about support removal in the embedded electronic product manufacturing process is effectively solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

A method and equipment for electron beam smelting polysilicon deoxidation and continuous ingot casting

InactiveCN103741210BSolve removal puzzlesMeet oxygen requirementsPolycrystalline material growthSilicon compoundsVacuum pumpingIngot casting

Belonging to the field of metallurgical melting, the invention in particular relates to a method and a device for electron beam melting to remove oxygen from polysilicon and continuous ingot casting. The method includes: subjecting a furnace body and an electron gun to vacuum pumping, starting a electron gun for melting to conduct electron beam melting on a polysilicon material, and preliminarily removing impurity oxygen; under the action of an electron gun for radiation, keeping a liquid state and further conducting oxygen removal, and finally leading the polysilicon liquid into ingot casting equipment through a water-cooled transmission belt to carry out a directional crystal growth ingot casting process so as to obtain a polysilicon cast ingot till the end of directional crystal growth ingot casting processes in all ingot casting equipment. The device includes an electron beam melting assembly and a continuous ingot casting assembly. The electron beam melting assembly comprises a water-cooled melting crucible and the water-cooled transmission belt disposed on one side of the melting crucible. 3-6 ingot casting equipment is fixedly mounted on a rotating platform. The invention puts forward the technological method and application of electron beam melting for oxygen removal, realizes the effects of oxygen removal by electron beams. At the same time, by combining continuous ingot casting, the energy consumption needed by heating the raw materials of ingot casting is reduced, and the production efficiency is greatly improved.

Owner:QINGDAO XINSHIJI SOLAR ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com