Patents

Literature

74results about How to "Does not pollute the environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

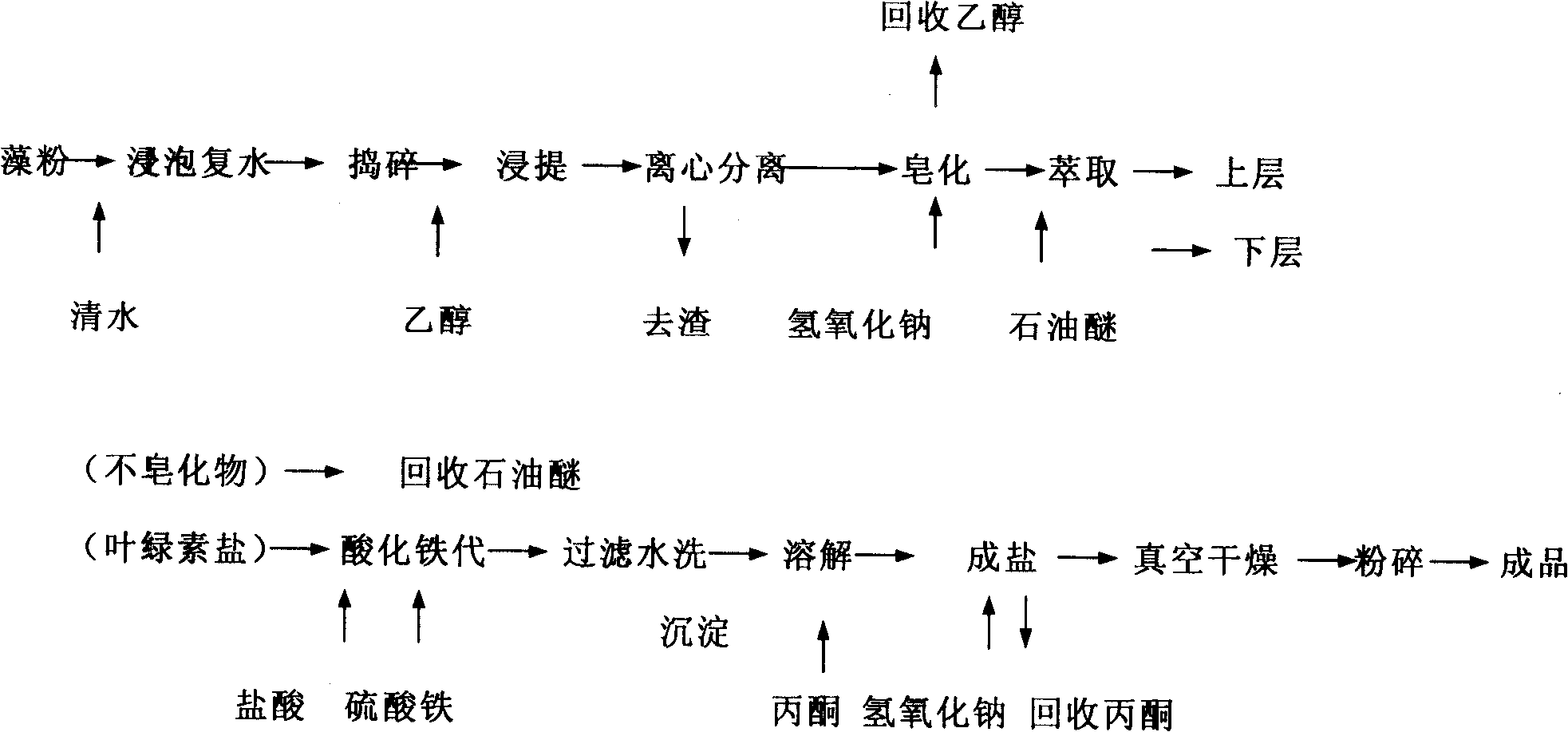

Cleaning and blockage relieving technology of gathering and transportation system for oil and natural gas field highly containing sulfuric acid

InactiveCN103143533ADoes not pollute the environmentStrong ability to dissolve sulfur scalePipeline systemsCleaning processes and apparatusNatural gas fieldChemistry

The invention relates to a cleaning and blockage relieving technology of a gathering and transportation system for natural gas field highly containing sulfuric acid. The cleaning and blockage relieving technology of the gathering and transportation system for the natural gas field highly containing the sulfuric acid comprises a three-section technology, including replacement deodorization, cleaning for blockage relieving and passivation protection. The main technology process comprises a first step of replacement deodorization: scavenging the gathering and transportation system by adopting nitrogen or purified natural gas to replace sulfur-containing gas therein so as to reach the safety standard, circularly filling and soaking the system with alkaline liquid, neutralizing for deodorization and passivating ferrous sulfide; a second step of cleaning for blockage relieving: circularly filling a sulfur scale dissolving and removing agent into the system for 2-6 hours so as to dissolve, disperse and remove corrosive scale and other sulfur-containing accumulated scale in pipelines, wherein the cleaning temperature is controlled within the range of 30 to 90 DEG C at this stage; and a third step of passivation protection: coating cleaned pipeline equipment with a passivating agent or a film forming agent for protection. With the adoption of the blockage relieving technology of the gathering and transportation system for the natural gas field highly containing the sulfuric acid, the inner-wall accumulated scale of the sulfur-containing gathering and transportation pipeline equipment can be completely cleaned away.

Owner:PUYANG BAOJIE WANJIA IND

Excretion fermented seedling compound fertilizer and preparation method thereof

InactiveCN103553794ANo side effectsDoes not pollute the environmentFertilizer mixturesRiver sandEffective microorganism

The invention discloses an excretion fermented seedling compound fertilizer. The compound fertilizer is prepared from the following raw materials in parts by weight: 500-600 parts of livestock excretion, 120-140 parts of water hyacinth powder, 100-120 parts of castor stems, 100-120 parts of silkworm excrement, 100-120 parts of corn stalk, 80-90 parts of cottonseed cake, 40-50 parts of tobacco stems, 30-40 parts of pulverized fuel ash, 12-15 parts of river sand, 20-25 parts of calcium superphosphate, 15-20 parts of urea, 8-12 parts of potassium chloride, 1-2 parts of compound sodium nitrophenolate, 2-3 parts of copper sulfate, 6-9 parts of EM (effective microorganism) bactericide, 5-7 parts of microbial starter, 10-15 parts of soil conditioner, and a proper amount of water. The fertilizer adopts livestock excretion and the like as main raw materials through microbial fermentation, is rich in organic fertilizer, inorganic fertilizer and various nutrition, does not have toxic or side effect, does not pollute environment, can remarkably supply nutrition required by seedlings, can improve the soil structure, promote growth and development of seedlings, and improve the resilience of disease resistance, insect resistance, drought resistance, water logging resistance, cold resistance, salt alkali resistance, lodging resistance and the like.

Owner:ANHUI WANLI ECOLOGICAL LANDSCAPE

Method for hunting mosquitoes and the device

InactiveCN101204148AReduce mosquito damageDoes not pollute the environmentInsect catchers and killersAgainst vector-borne diseasesElectronic circuitDigital circuitry

The invention relates to a method for killing mosquito and a killer, which uses a method and an apparatus of physical instrument to kill the mosquito. The invention makes use of ecological habits of the mosquito, by using techniques of micro electron, digital circuit and solar cell, to all-weather and omnidirectional kill the mosquito in an automatic operation way. The invention comprises a tripping box, an induction factor generating device, a water containing and relevant processing device, a disturbing device and a killing device, and is controlled by electronic circuit according to set program in operation process. The invention can realize automatic monitoring over the mosquito by automatic shooting or specific chemical marker and corresponding detecting circuit.

Owner:康强胜

Method for extracting theanine from tea

InactiveCN1587258ALow costDoes not pollute the environmentCarboxylic acid amide separation/purificationSolventChemistry

The process of extracting theanine from tea includes the following steps: soaking tea with deionized water to obtain extracted solution; exchange absorbing of the extracted solution with cationic resin and elution with ammonia water to obtain theanine eluate; and decompression evaporating theanine eluate to obtain coarse theanine product. The present invention can utilize various kinds of tea material in extracting theanine, and has simple operation, low cost and no environmental pollution. The coarse theanine product is suitable for further processing and has purity of 10-30 %.

Owner:ZHEJIANG UNIV

Waste plastic recycling process method

InactiveCN102443210ASave production spaceDoes not pollute the environmentPlastic recyclingPlasticizerAntioxidant

The invention provides a waste plastic recycling process method, aiming to solve the problems of occupation of land resources and environmental pollution caused by waste plastic recycling at present. In the technical scheme, the waste plastic recycling process method comprises the following steps: (1) crushing waste polyethylene plastic, cleaning with a washing barrel, rinsing again in a water tank, drying, and obtaining waste polyethylene plastic particles; and (2) uniformly mixing the waste polyethylene plastic particles with raw polyethylene materials, activators, compatilizers, plasticizers, antioxidants and lubricants, carrying out plasticization and filtration, and finally cutting to obtain granulated plastic. The waste polyethylene plastic and other raw materials are mixed according to the following weight percentage: 60-65 percent of the waste polyethylene plastic, 15-16 percent of the raw polyethylene materials, 15-20 percent of fillers, 1 percent of the compatilizers, 1 percent of the plasticizers, 1 percent of the antioxidants, 0.5-1 percent of the activators and 0.5-1 percent of the lubricants.

Owner:郧县金龙工贸有限公司

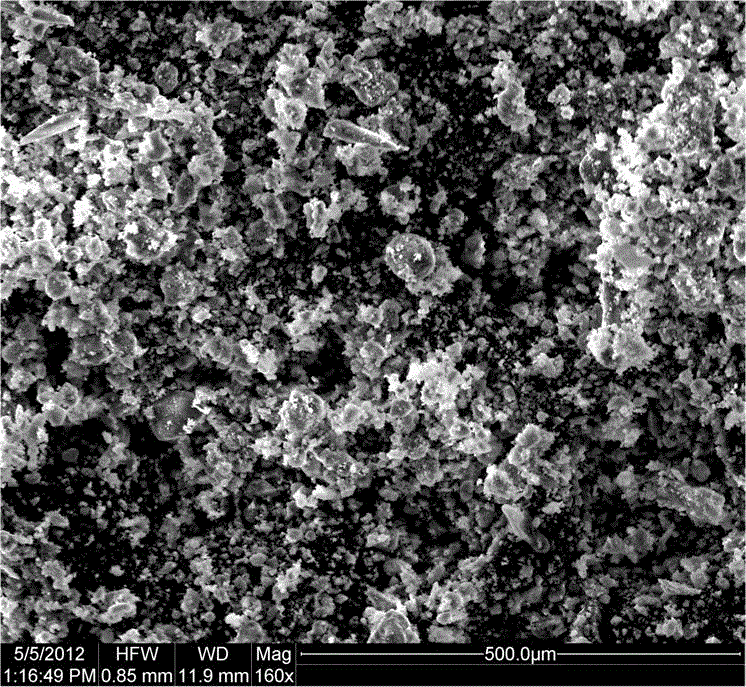

Spirulina extract and preparation thereof

ActiveCN101348754ADoes not pollute the environmentEasy to operatePeptide preparation methodsFermentationSpirulina maximaPhycocyanin

The invention provides extracting solution for a spirulina maxima and a preparation method thereof. The nutrient content in the extracting solution mainly comprises chlorophyl of the spirulina maxima, phyeoeyani of the spirulina maxima, and polyhexose of the spirulina maxima, and so on, wherein the content of the chlorophyll of the spirulina maxima is higher than 8 percent. The preparation method mainly comprises the processes of extracting the chlorophyll, extracting the phyeoeyanin, extracting free amino acid, oligopeptides and oligose, and extracting the polyhexose of the spirulina maxima, and so on; particularly, the gummeline embedding process is performed in the process of extracting the chlorophyll of the spirulina maxima. The preparation method extracts sufficiently, reserves the ingredient of the chlorophyll of the spirulina maxima, can be applied to the beverage addition, particularly the beer addition, does not pollute the environment, has convenient operation and is easily applied to the industrial production.

Owner:TSINGTAO BREWERY

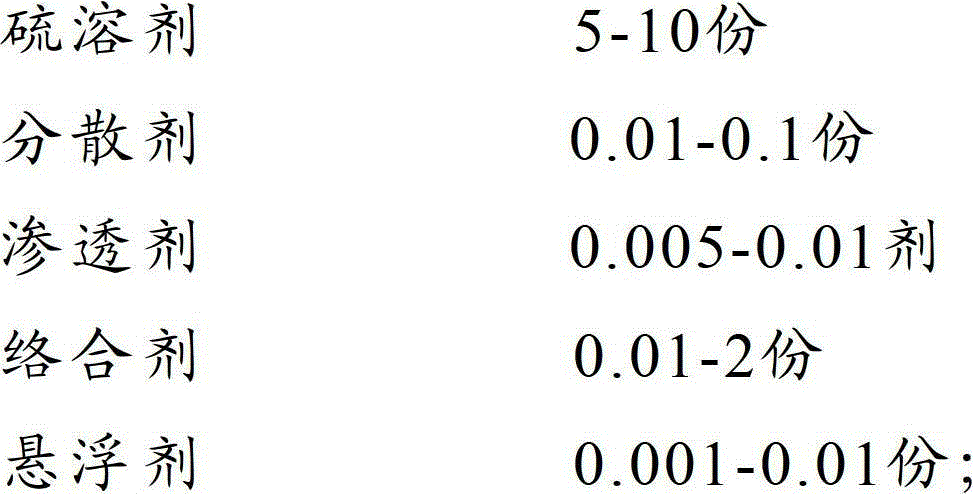

Nuisanceless high-efficient vegetal pesticide

InactiveCN101036475ANo pesticide residueDoes not pollute the environmentBiocideAnimal repellantsStemonaMutation

The invention is a harmless high-efficient vegetative pesticide, which is composed of active ingredient and aid, wherein the active ingredient is mainly composed of matrine, and the aid is composed of Cymanchum komarovii extract, nicotine, bitter fruit, bitter orange peel, pyrethrum, radix stemonae stemona, and thyme extract. Usually, the medicine effect release of the vegetative pesticide is slower than the chemical pesticide and the vegetative pesticide has low knock down rate, which can be solved by using the invention. In the invention, the knock down time is shortened to 6 hours, and the effect of the vegetative pesticide is better than the chemical pesticide. The invention is provided without harm to human, animal, and crop, pesticide residue, environmental pollution, and 'three genicity' to human body (deformity, cancer, and mutation).

Owner:孙伟年

Plant anti-freezing agent

InactiveCN104671943ADoes not pollute the environmentEasy to useBiocidePlant growth regulatorsBudFreeze injury

The invention discloses a plant anti-freezing agent which comprises the following preparation components in percentage by weight: 0.1-0.2 percent of fulvic acid, 0.1-0.25 percent of compound sodium nitrophenolate, 0.05-0.1 percent of chitosan oligosaccharide, 1-3 percent of propylene glycol, 5-10 percent of glycerin, 0.5-1 percent of glucose, 0.01-0.02 percent of monopotassium phosphate and 86-93 percent of water. The plant anti-freezing agent disclosed by the invention does not have any toxicity or damage, does not pollute the environment, can be directly sprayed on leaves, flowers and flower buds of plants, is easy to use, simple in preparation method and low in cost and has the effective anti-freezing period of 15-20 days; the resistance of the plants on low-temperature freeze injury is improved; and the freeze injury can be rapidly alleviated by using the anti-freezing agent after freeze injury. According to the plant anti-freezing agent disclosed by the invention, a protective film is formed on a plant surface, and the anti-freezing agent protects the plants against cold and has a disease prevention effect.

Owner:朱全顺

Novel fertilizer and production method thereof

InactiveCN102942394AImprove fertilizer efficiencyDoes not pollute the environmentProductsBio-organic fraction processingFuel woodNutrient

The invention provides a novel fertilizer which comprises biomass power plant ash and binders. The biomass power plant ash is formed by burning chicken manure, rice hull, moso bamboos and fuel woods. The mass ratio of the chicken manure, the rice hull, the moso bamboos to the fuel woods is (30-50): (10-40): (2-20): (10-30). The mass ratio of the biomass power plant ash to the binders is (300-990): (10-30). The invention further provides a production method of the novel fertilizer. The production method comprises the steps of putting the biomass power plant ash and the binders according to a mass ratio of (300-990): (10-30) into a granulator, adding water, and stirring the mixture fully and evenly, and subjecting the resultant to dry crushing, dedusting and cooling to obtain novel granule-shaped fertilizers. The novel fertilizer has the advantages that the fertilizer is taken from the field and used in the field, does not damage soil element balance and has no hormones and germs, is lasting in fertilizer efficiency and does not pollute the environment. Besides, the novel fertilizer has a slow releasing effect, and the nutrient releasing speed is faster than that of organic fertilizers.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

Method for separating free carbon from ultra-fine silicon carbide powder

ActiveCN103008093ADoes not pollute the environmentSimple process operationWet separationSeparating agentSocial benefits

The invention relates to a method for separating free carbon from ultra-fine silicon carbide powder. The method comprises the steps of: 1, placing the ultra-fine silicon carbide powder containing free carbon into a separating container, adding pure water and a separating agent, mixing, and keeping static for stratification; 2, pumping clear solution in Step 1 with a pump into a circulating container; 3, inserting an over-frequency vibratory rod into the ultra-fine silicon carbide powder layer for vibration; 4, scraping and collecting free carbon on the surface of sediment obtained after vibration in Step 3; and 5, pumping the clear solution which is pumped into the circulating container in Step 2 into the separating container again, repeating mixing and maintenance of the static state in Step 1, repeating Step 2, Step 3 and Step 4 until no obvious black aggregates exist on the surface of the ultra-fine silicon carbide powder, thereby completing separation of the free carbon from the ultra-fine silicon carbide powder. No hidden safety risks or environmental pollution can be caused in recovery of fine silicon carbide powder; and the process is simple and convenient to operate, the labor intensity of workers can be reduced, the working efficiency can be increased, the production cost can be decreased, and economic benefits and social benefits can be improved.

Owner:PINGDINGSHAN YICHENG NEW MATERIAL

Environmental-friendly casein insulating paste

InactiveCN102120919ADoes not pollute the environmentEasy to degradeNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveChemistryParaffin oils

The invention discloses an environmental-friendly casein insulating paste, which is prepared by adopting the steps of: adding water in casein for dissolving, regulating pH value to 7.5-8.0, enabling a solution to be integrally shaped as a colloid when stirring and raising the temperature to 55-65 DEG C, and continuously stirring at constant temperature until casein particles are completely dissolved; sequentially adding acrylate, starch, zinc oxide, urea, dimethyl oxidized silicone oil, paraffin oil and ethylparaben, stirring and raising temperature; after auxiliary materials are completely dissolved, raising the temperature to 80-85 DEG C, stirring at constant temperature for 30-45min, and keeping pH value between 7.5 and 8.0; reducing the temperature to 35-40 DEG C, and filtering to obtain milk white or light yellow uniform semi-transparent viscous fluid without impurities; and packaging, closely storing, and placing and ageing for 24-72h at normal temperature to obtain a finished product of the environmental-friendly casein insulating paste. The environmental-friendly casein insulating paste is prepared from the raw material of casein in the milk, has the characteristics of no toxicity, no taste, easy degradation, no pollution to environment, and the like, can be used for replacing chemically synthesized glue of epoxy resins, urea-formaldehyde resin adhesives, amino resins, polyvinyl alcohols, and the like, and can be widely applied to fields of electric appliances, laminated plates and the like.

Owner:甘肃省商业科技研究所有限公司

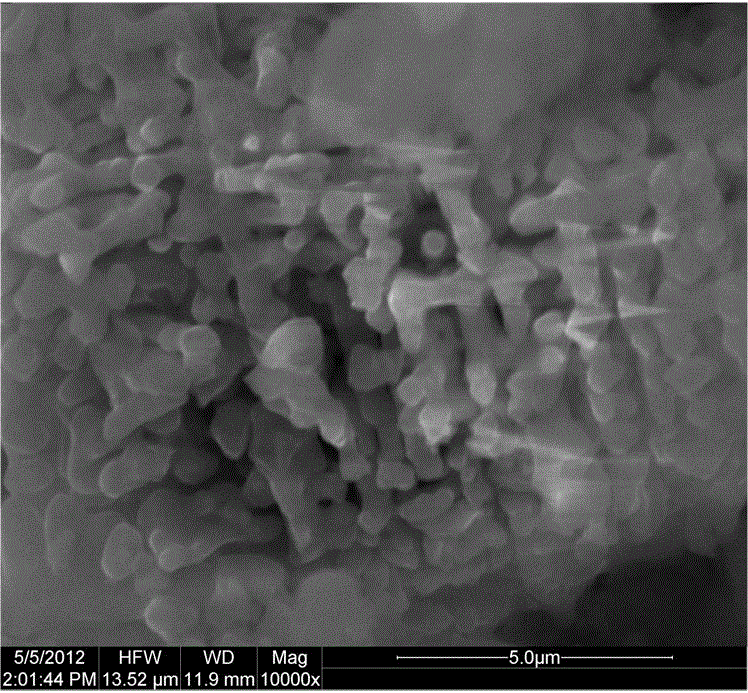

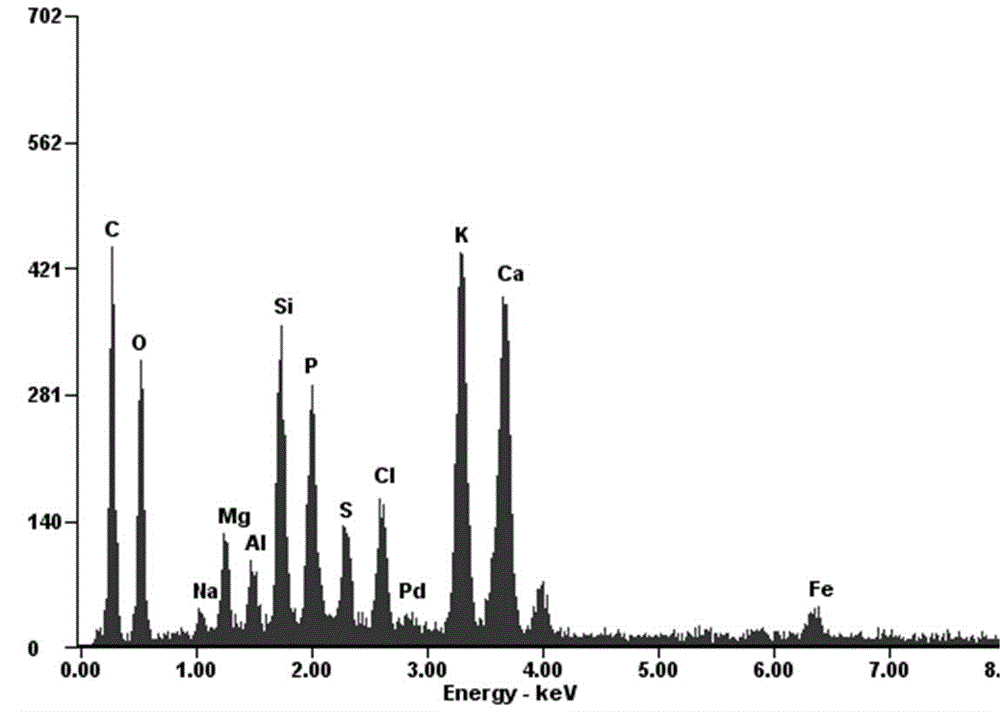

Aluminum and aluminum alloy refining agent and aluminum alloy melting refining technology using same

The invention relates to an aluminum and aluminum alloy refining agent and an aluminum alloy melting refining technology using the same, and belongs to the technical field of aluminum alloy machining. The refining agent comprises, by mass, 20-28% of K, 10-18% of Na, 2.3-3.0% of Ca, 3.2-5.0% of Al, 30-35% of F, 2.5-3.0% of Si, 4.0-6.0% of O, 0.3-0.8% of C and 10-16% of Cl. The aluminum and aluminum alloy refining agent contains no chlorine. Even though the aluminum and aluminum alloy refining agent contains NaCl and KCl salt, the NaCl and KCl salt do not react with Al chemically, so that production environment is innocuous, dust is greatly reduced, environmental pollution is avoided, and health of workers is facilitated. The specific refining agent is used for carrying out smelting refining on aluminum alloy to replace a refining method using chlorine. By means of the aluminum and aluminum alloy refining agent and the aluminum alloy melting refining technology using the same, aluminum alloy cast-rolling coils meeting quality requirements of aluminum foil, PS plates and CTP plates are obtained, environmental protection safety is high, and metal loss is reduced by 0.2-0.5%.

Owner:浙江中金铝业有限公司

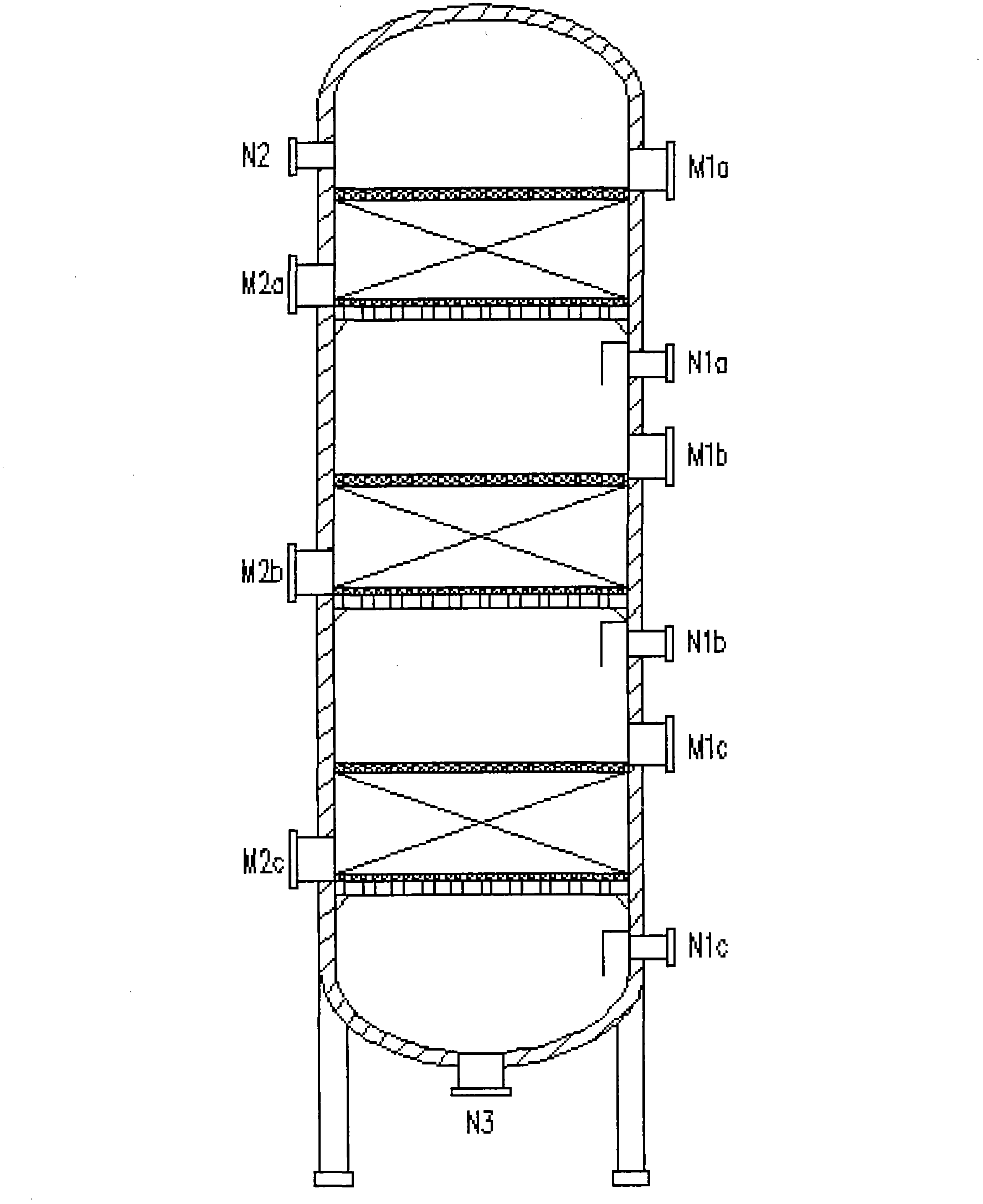

Multi-stage catalyzed sorption reactor

ActiveCN103007747AReduce exhaust gas treatment investmentDoes not pollute the environmentDispersed particle separationExhaust gasActivated carbon

The invention discloses a multi-stage catalyzed sorption reactor which comprises a reactor body, catalyzed sorption beds, charging holes, discharge holes, gas inlets and a gas outlet, wherein the catalyzed sorption beds are fixed in the reactor body to divide the interior of the reactor body into independent catalyzed sorption spaces; the discharge holes are formed in the reactor body on the upper surfaces of the catalyzed sorption beds; the charging holes are formed in the reactor body in the middles of the independent catalyzed sorption spaces formed by the upper surfaces of the catalyzed sorption beds; the gas inlets are formed in the reactor body on the lower surfaces of the catalyzed sorption beds; and the gas outlet is formed at the upper part of the reactor body. The charging holes and the discharge holes are used for filling high-efficiency converted-sorption activated carbon desulfurizing agents; acid gas enters the reactor body through the gas inlets, and conducts sorption and catalysis with the high-efficiency converted-sorption activated carbon desulfurizing agents through the catalyzed sorption beds; the high-efficiency converted-sorption activated carbon desulfurizing agents convert sulfur-bearing matters in the acid gas to simple sulfur, simple sulfur is sorbed in micropores of a catalyst; and desulfurized tail gas is discharged out of the reactor body through the gas outlet of the reactor body.

Owner:JIANGSU HENGXIN ENERGY TECH

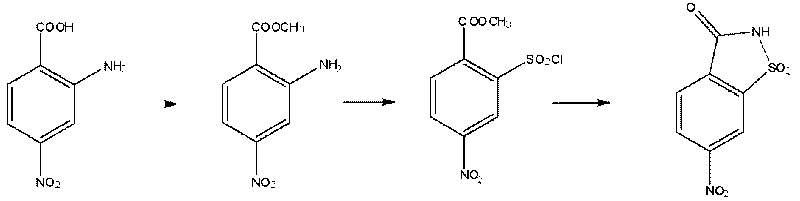

Preparation method of 6-nitrosaccharin

ActiveCN101735167ASimple operationDoes not pollute the environmentOrganic chemistryCopper chlorideNitrobenzoic acid

The invention discloses a preparation method of 6-nitrosaccharin, which comprises the following steps of: adding 2-amino-4-nitrobenzoic acid into excessive methanol for carrying out reflow esterification under the catalysis of an acidic catalyst to obtain 2-amino-4-nitro methyl benzoate through postprocessing; carrying out diazotization reaction on the 2-amino-4-nitro methyl benzoate and a sodium nitrite solution in an acidic medium under the temperature of 0-20 DEG C; then adding a glacial acetic acid solution of copper chloride into a system under the temperature of 20-30 DEG C to generate 2-chloro sulfonyl-4-nitro methyl benzoate; and reacting the 2-chloro sulfonyl-4-nitro methyl benzoate with ammonia water under the temperature of 0-40 DEG C to obtain the 6-nitrosaccharin. The method has simple reaction operation, no environment pollution, wide sources and low cost of the 2-amino-4-nitrobenzoic acid as the raw material, lower production cost and suitability for industrialized production.

Owner:江苏省农用激素工程技术研究中心有限公司

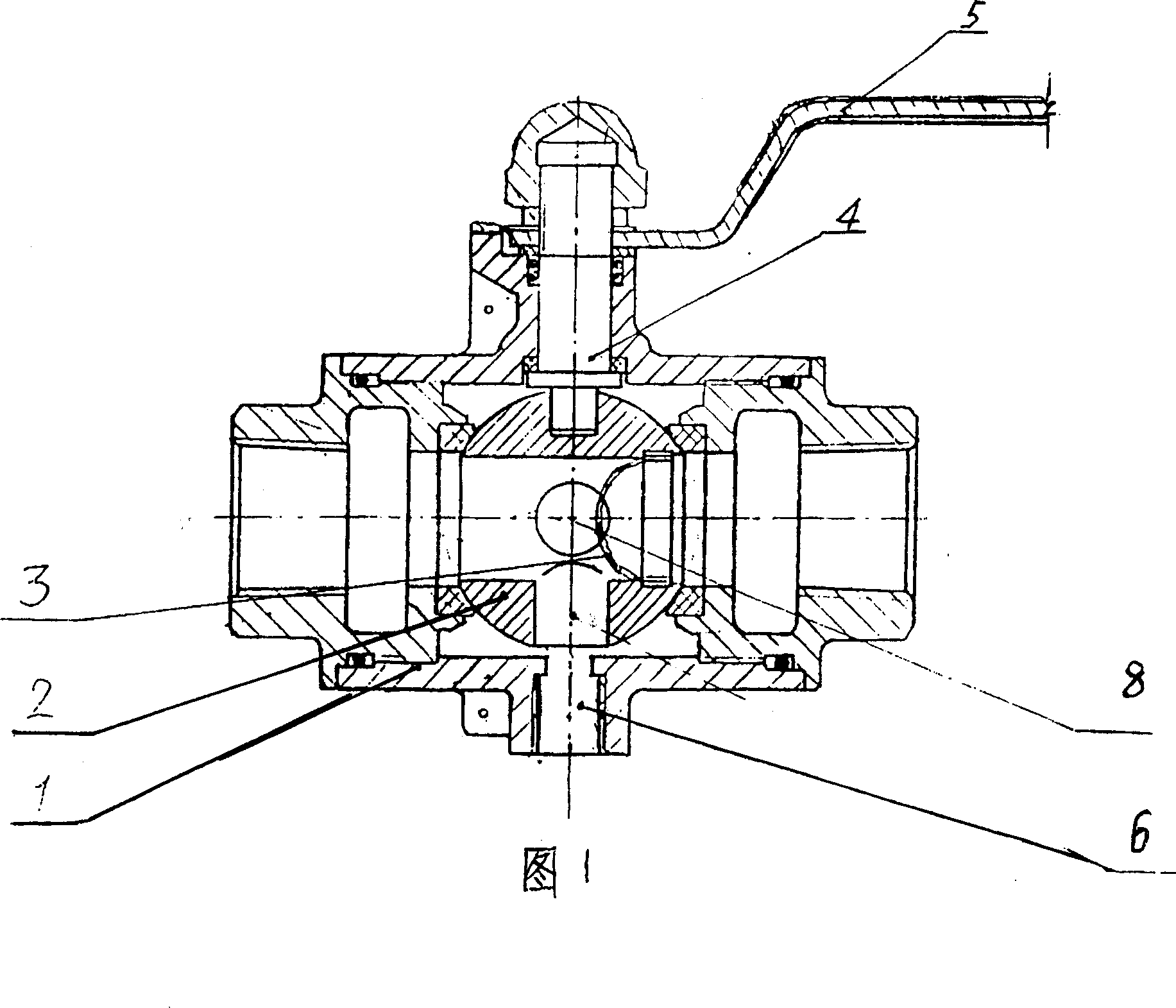

Heat supply system block-proof device

InactiveCN101122344ADoes not pollute the environmentExtended service lifePlug valvesFiltration separationEngineeringSieve

The invention is an anti-blocking device of a heat supply system. A waste discharging and back washing hole is drilled at the back of a spherical valve core, and communicates directly with a drift diameter hole. A temperature sensor insertion hole is drilled under the spherical valve core, and communicates directly with the drift diameter hole. A hemispherical sieve projecting inwards is arranged at a mouth of the drift diameter hole at the water inlet side of the spherical valve core. The invention is provided with the advantage that the device can discharge sundries quickly without changing a part, the device is safe and causes no pollution to the environment, and the usable life of the device is prolonged.

Owner:TIANJIN JINNAN KAIDA ELECTRONIC CO LTD

Adhesive for trapping and killing flies

InactiveCN104472553ADoes not pollute the environmentLow toxicityBiocidePest attractantsRosinFish meal

The invention discloses an adhesive for trapping and killing flies, and belongs to medicine products in the field of chemical engineering. The adhesive contains cyhalothrin, rosin resin, polyvinyl alcohol, fish meal, brown sugar, floral perfume, sex pheromone, calcium oxide and talcum powder. The adhesive for trapping and killing flies disclosed by the invention is low in toxicity, pollution-free, rapid in efficacy, long in efficacy lasting period, capable of rapidly and comprehensively killing flies, good in fly trapping effect, good in adhesion, long in usable time, suitable for families, hotels, public places and other places, convenient to use, and simple to operate.

Owner:杨秋慧 +1

Aloe paint formula and preparing process

InactiveCN101328326ADoes not pollute the environmentSafe to useEmulsion paintsAloinPlant composition

The invention relates to a paint formulation and a preparation process thereof, in particular to a formulation of aloe paint and a preparation process thereof. The formulation of the aloe paint consists of the following compositions according to the following weight percentage: 5 to 30 percent of latex, 2 to 20 percent of titanium pigment, 10 to 30 percent of powder filler, 2 to 10 of extraction products of aloe, Panax notoginseng and mint, and 20 to 30 percent of water. The preparation method comprises the following steps of: adding the titanium pigment, the powder filler, the extraction products of the aloe, the Panax notoginseng and the mint, and the water into a dispersing kettle for even stirring and dispersing; then injecting the dispersed slurry material into a grinding machine for grinding; adding the latex into the ground mixture for dispersing after the grinding is finished; and then checking the normal indexes of viscosity, contrast ratio, fineness and application property, and packaging and warehousing after being qualified. The extraction products of the aloe, the Panax notoginseng and the mint are natural plant compositions. The aloe paint is an environmental-friendly product which does not contain any constituent harmful to the environment and human bodies.

Owner:MCD PAINT DONGYING

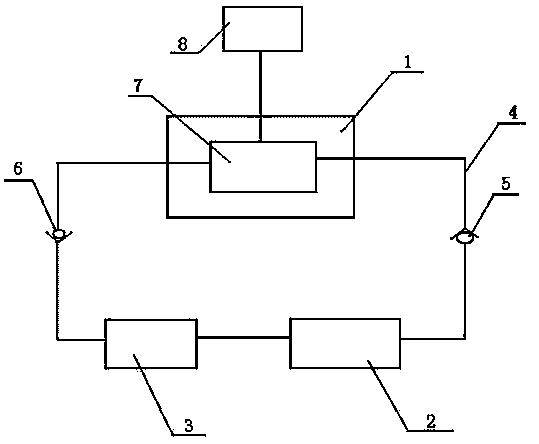

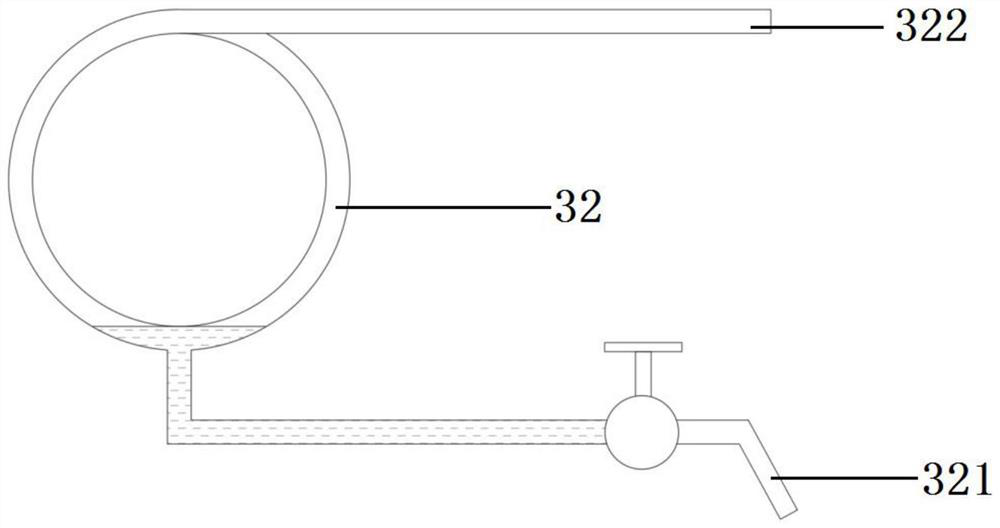

Solar solid absorption air conditioner refrigeration system

InactiveCN103851824ATight supply of electricity slows downDoes not pollute the environmentFluid circulation arrangementAir conditioning systemsMoving partsSolar thermal collector

The invention relates to a solar solid absorption air conditioner refrigeration system. Air conditioners become necessary household appliances along with the improvement of people living standards; however, great damage is caused to the environment due to the large-range utilization of traditional refrigeration modes. The system is characterized by comprising a cooling system, an evaporator, a condenser and a solar heat collector. The cooling system is connected with the condenser through a pipe, the condenser is connected with the evaporator through a pipe, the cooling system is connected with the evaporator through a pipe, and the solar heat collector is connected with the cooling system through a pipe. The system is high in safety, free of moving parts and wide in application.

Owner:XIAN RAY VISION ELECTRONICS TECH

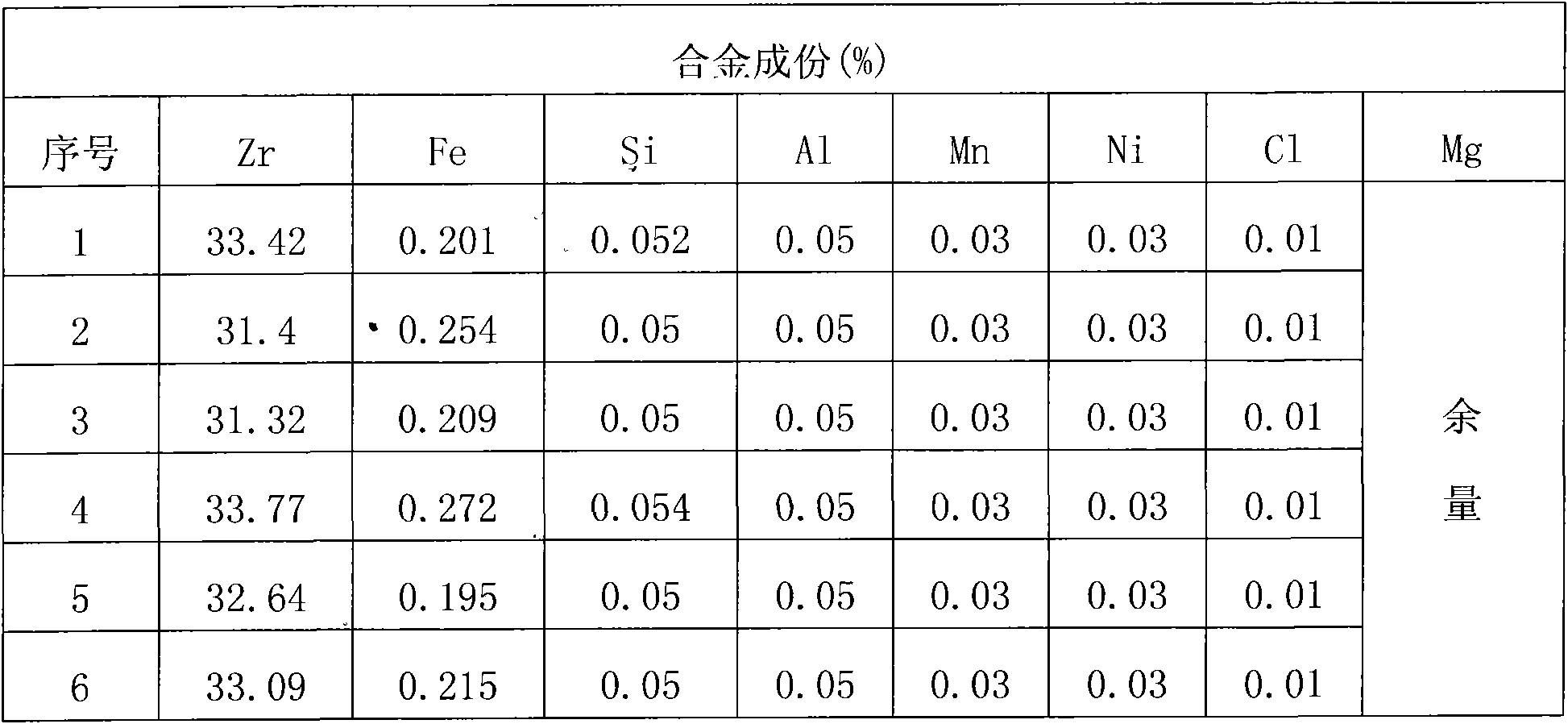

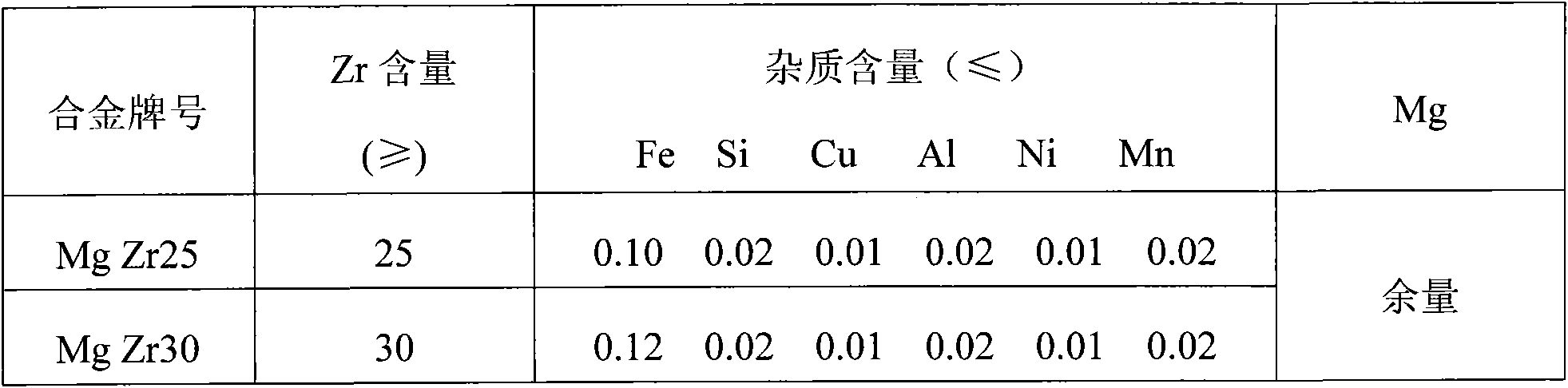

Secondary smelting method for producing magnesium-zirconium intermediate alloy

The invention discloses a secondary smelting method for producing a magnesium-zirconium intermediate alloy, which comprises the following steps of: adding 100 to 200 kg of potassium chloride into a pot, raising the temperature to between 880 and 910 DEG C in 25 to 35 minutes, and performing slagging-off; adding 60 to 195 kg of potassium fluozirconate with stirring by using a mechanical nickel rod, wherein the adding time is 10 to 30 minutes; when the furnace temperature reaches the temperature of between 880 and 910 DEG C, performing slagging-off again, and adding magnesium, wherein the addition of the magnesium is based on the weight ratio of K2ZrF6 to Mg of 1.2-1.5:1; after the magnesium is completely dissolved, spreading a protective flux, and stirring for 10 to 20 minutes by using the mechanical nickel rod, standing for 4 to 10 hours, cooling to normal temperature, and brewing by using vapor and cold water; and removing and washing the slag on the alloy, performing remelting refining and slagging-off at the temperature of between 680 and 700 DEG C, and finally ingoting and testing to obtain the finished product. The secondary smelting method for producing the magnesium-zirconium intermediate alloy has the advantages of simple operation, no environmental pollution, low content of impurities in the product, a few flux impurities, high effective content of zirconium and magnesium, fine components, high uniformity, and stable performance.

Owner:LOUDI XINGXIN ALLOY

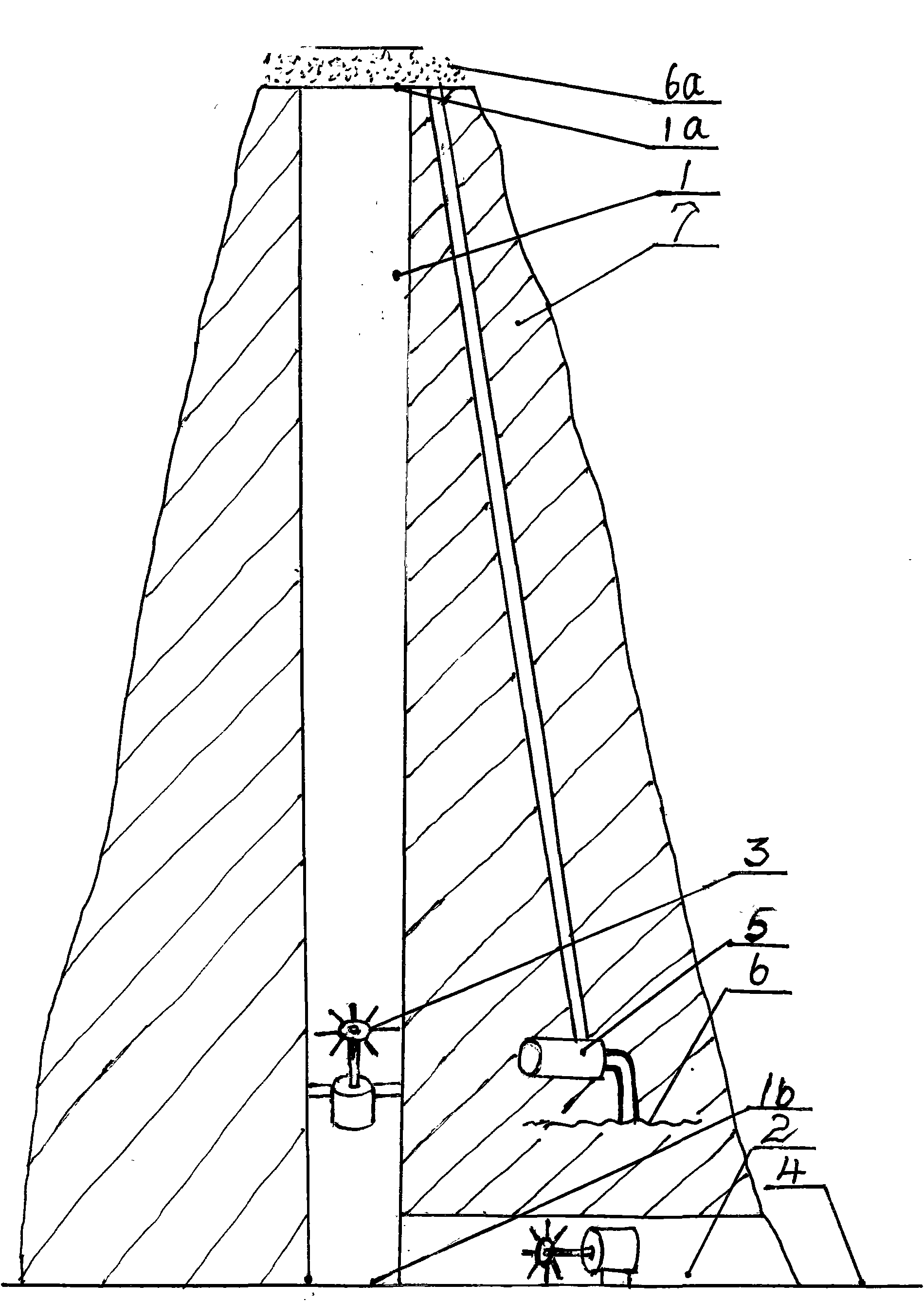

Solar wind power station in perpendicular cave

InactiveCN101598112ASolve technical problemsDoes not pollute the environmentEnergy industryMachines/enginesTerrainWind force

The invention relates to a method for constructing a solar wind power station in a perpendicular cave by utilizing high mountain terrain. The solar wind power station comprises a perpendicular cave (1), a top (1a), a bottom (1b), a horizontal lead-in wind tunnel (2), a wind generating set (3), a solar heat-absorbing surface (4), a pump set (5), water (6) and a mountain (7). The invention solves the technical problems in actually constructing the solar wind power station with a chimney, and has the advantages of no environmental pollution, safe operation and low cost of power generation.

Owner:欧阳宝武

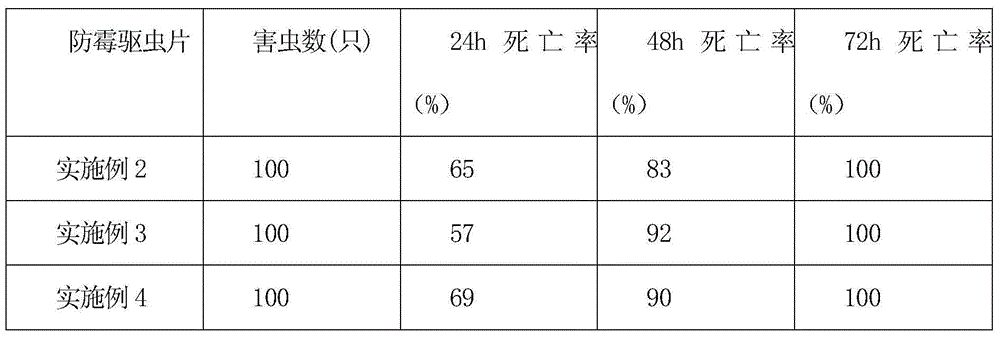

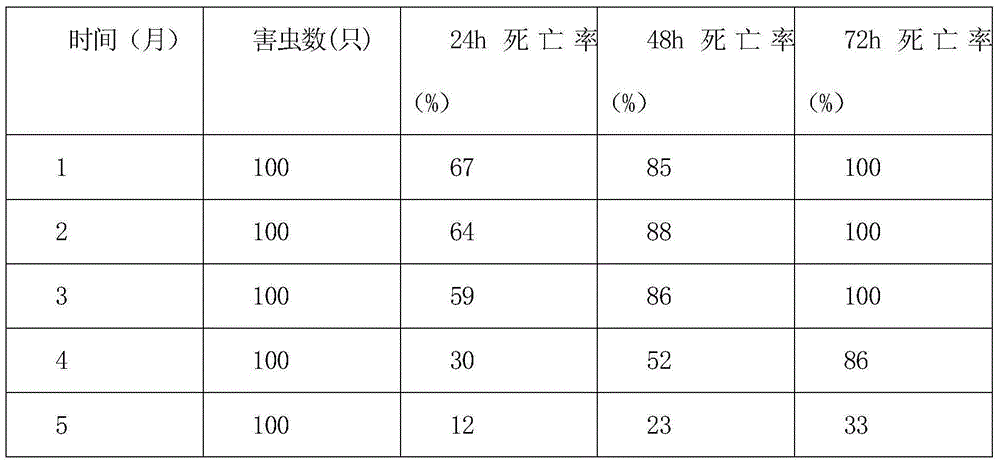

Mould-proof repellent mat for files and preparation method thereof

The invention discloses a mould-proof repellent mat for files. The mould-proof repellent mat for the files comprises medicinal effective constituents and a carrier, wherein the effective constituents comprise the following components with the content: 10 to 30 percent of pyrethrum extracts, 10 to 20 percent of folium artemisiae argyi extracts, 5 to 10 percent of atractylodes chinensis extracts, 10 to 15 percent of calamus extracts, 5 to 10 percent of wild tobacco extracts, 5 to 10 percent of alum, 5 to 10 percent of turpentine, and 5 to 10 percent of lavender oil; the carrier is adsorption paper with plastic paper attached to two faces or limestone, a plurality of small holes are distributed on the plastic paper, the effective constituents are dropwise added on the adsorption paper so as to be slowly released from the small holes on the surface of the adsorption paper, and the pesticide effect can be prolonged for three months. The mould-proof repellent mat is convenient to use, lasting in pesticide effect, remarkable in effect and small in occupied space, and can be widely used for storing the school files.

Owner:陈永强

Preparation method of Camellia oleifera fertilizer with high utilization rate

InactiveCN107721546ASave pesticidesDoes not pollute the environmentCalcareous fertilisersAlkali orthophosphate fertiliserWollastonitePeanut meal

The invention discloses a preparation method of a Camellia oleifera fertilizer with high utilization rate. The method comprises the following steps: bentonite, Chinese medical stone powder, and diatomite are mixed and grinded, water, brassinolide, mint essential oil, and forchlorfenuron are added with stirring, and spray drying is carried out in order to obtain a first material; turfy soil, coppersulphate, magnesium nitrate, gypsum powder, and wollastonite powder are mixed, and water is added with uniform mixing in order to obtain a second material; biogas residues, cassava residues, cottonseed meal, fermented peanut meal and wheat bran are added into the first material with mixing, water is added with uniform mixing, a second material, urea, potassium nitrate, and diammonium phosphate are added with uniform mixing, granulation is carried out, and drying is carried out in order to obtain the Camellia oleifera fertilizer with high utilization rate.

Owner:安庆市望马楼生态农业发展有限公司

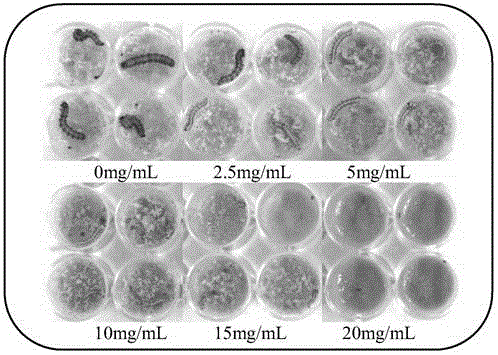

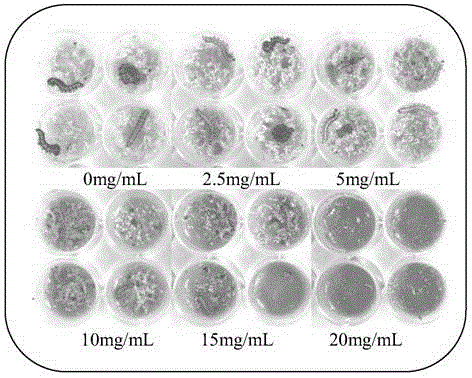

Method of artificially restraining cladophora disaster from being generated in sea cucumber aquaculture pool

InactiveCN103098692ADoes not pollute the environmentBroad market prospectClimate change adaptationExcrement fertilisersMass propagationSea cucumber

The invention discloses a method of artificially restraining cladophora disaster from being generated in a sea cucumber aquaculture pool. The method of artificially restraining cladophora disaster from being generated in the sea cucumber aquaculture pool has the following advantages: firstly, nutritive salt content in pond water is gradually increased by putting in biofertilizer such as fermentation chicken manure, meanwhile, micro algae in the sea cucumber aquaculture pool is enabled to keep superiority by putting in chlorella vulgaris; secondly, through mass propagation of floating algae, transparency of the pond water is reduced, sunlight can not shine into the bottom of a sea, the cladophora can not acquire enough sunlight so that the cladophora can not grow; the method of artificially restraining cladophora disaster from generating in the sea cucumber aquaculture pool is a full-biological method, free of environment pollution and harmless to aquaculture animals. Due to the fact that after the floating micro algae dies and subsides, the floating micro algae serve as bait of aquaculture sea cucumbers. The method of artificially restraining cladophora disaster from being generated in the sea cucumber aquaculture pool has the advantages of being green, environment-friendly and circulatory. Therefore, the method of artificially restraining cladophora disaster from being generated in the sea cucumber aquaculture pool has various advantages, particularly suitable for popularization and application in the field and broad in market prospect.

Owner:DALIAN OCEAN UNIV

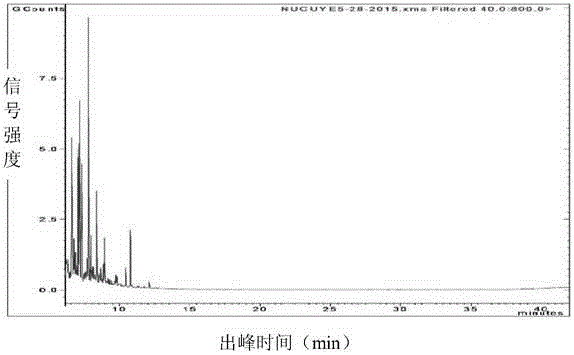

Mongolian oak wood vinegar extract, preparation method and application thereof and harmless insecticide

ActiveCN105638737ADoes not pollute the environmentDo not destroy the ecological balanceBiocideAnimal repellantsChemistryKetone

The invention discloses Mongolian oak wood vinegar extract and a preparation method thereof. The Mongolian oak wood vinegar extract is prepared from, by weight, 50-70% of phenols, 20-30% of ethers, 5-15% of aldehydes, 2-6% of ketone and the balance impurities. The method includes the steps that a Mongolian oak wood vinegar crude product is subjected to reduced pressure distillation to obtain first deep color liquid; the first deep color liquid is dissolved in water, insoluble particles are removed, and then second deep color liquid is obtained; the second deep color liquid is extracted with organic solvent, an organic solvent layer after extraction is collected, the organic solvent is removed through reduced pressure distillation, and then third deep color liquid is obtained; the third deep color liquid is dissolved in water, insoluble particles are removed, and fourth deep color liquid is obtained; selectively, water is removed from the fourth deep color liquid, and then fifth deep color liquid is obtained.

Owner:抚顺市世纪东方生物质综合技术开发有限公司

Traditional Chinese medicinal preventer for Chinese prickly ash felt fungus

InactiveCN107094815ADoes not pollute the environmentGood control effectBiocideDead animal preservationTigridia pavoniaAgriculture

The invention provides a traditional Chinese medicinal preventer for Chinese prickly ash felt fungus and belongs to the technical field of agriculture. The traditional Chinese medicinal preventer for the Chinese prickly ash felt fungus is prepared from the following raw materials in parts by weight: 10-15 parts of madder, 5-8 parts of common andrographis herb, 4-6 parts of polygala tenuifolia, 3-4 parts of liquorice, 4-5 parts of Chinese gall, 6-8 parts of turmeric, 3-5 parts of rhizoma anemarrhenae, 4-6 parts of sweet wormwood herb, 2-4 parts of asarum, 1.5-3.0 parts of cortex dictamni, 1.8-2.5 parts of moutan bark, 2-3 parts of pericarpium granati, 4-5 parts of coptis chinensis, 5-7 parts of fructus cnidii, 4-6 parts of wild asparagus cochinchinensis, 3-5 parts of arisaema japonicum, 2-3 parts of garden balsam stem, 3-4 parts of pinellia ternate, 1-2 parts of tigridia pavonia, 4-6 parts of Chinese tallowtree leaves, 0.8-1.2 parts of sophora flavescens, 5-8 parts of thunder god vines, 1-2 parts of red-knees herb, 5-7 parts of purslane, 2-3 parts of ailanthus altissima and 6-8 parts of pyrethrum. The traditional Chinese medicinal preventer provided by the invention is nontoxic, has no residue and does not pollute the environment, the control efficiency is excellent by virtue of dual prevention and control of pathogenic bacteria basidiomycetes of the felt fungus and pathogenic bacterium symbiotic scale insects, and stress-resistant capability of Chinese prickly ash can also be enhanced, so that the yield and quality of the Chinese prickly ash are improved, and the traditional Chinese medicinal preventer provided by the invention has good economic benefit.

Owner:平凉锐博知识产权服务有限公司

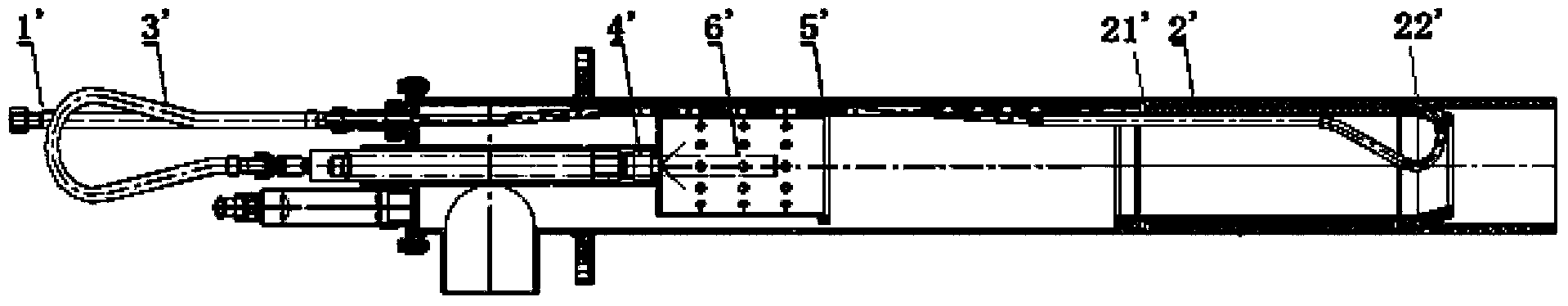

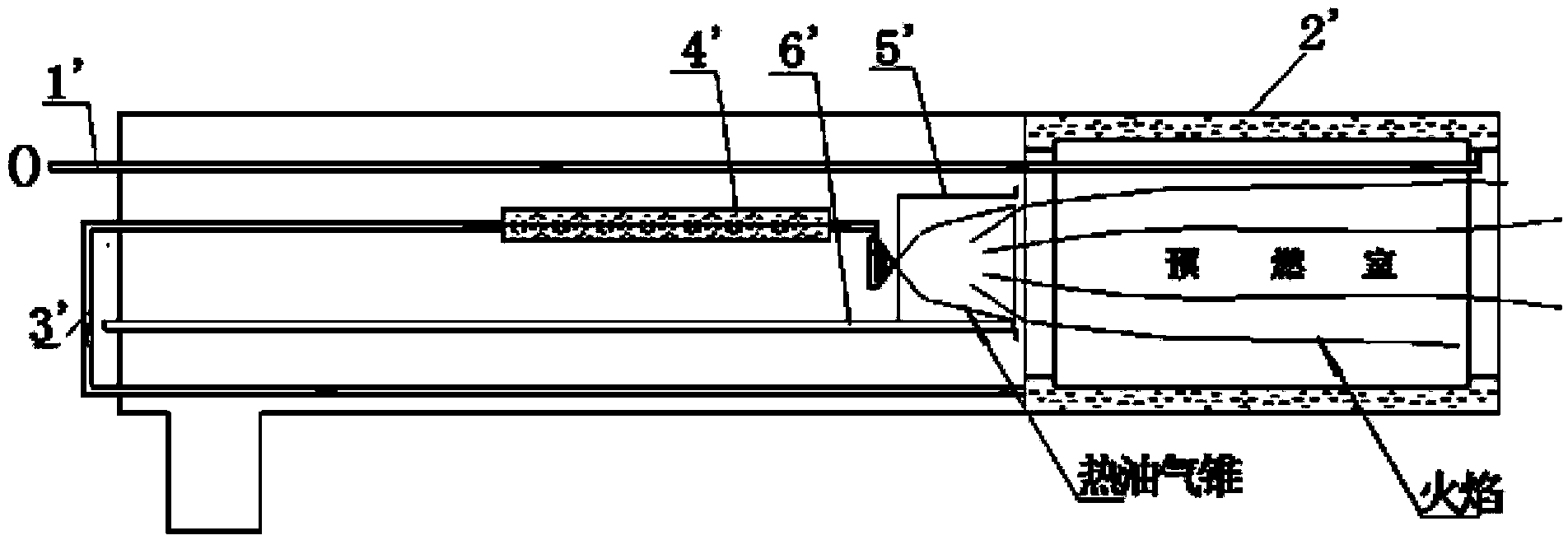

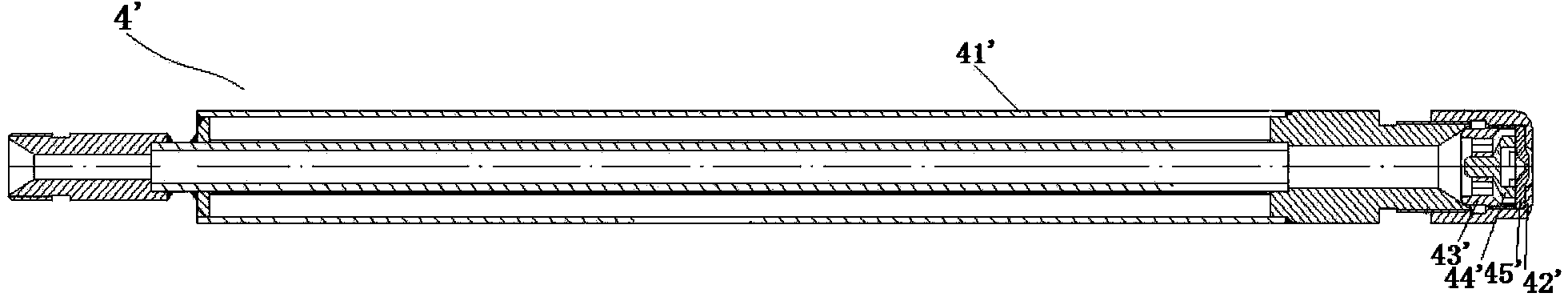

Electric heating mechanical type micro-oil-gasification combustor

ActiveCN104279557ADoes not pollute the environmentImprove combustion efficiencyPulverulent fuel combustion burnersSpray nozzleElectric heating

The invention relates to an electric heating mechanical type micro-oil-gasification combustor. The electric heating mechanical type micro-oil-gasification combustor comprises a four-head spiral groove gasification device, an air distribution barrel, a combustion stabilization device, an ignition gun, a mechanical atomization oil gun, a first oil inlet pipe and a second oil inlet pipe. The mechanical atomization oil gun comprises a gun rod and a rotational flow disc spray nozzle assembly. The gun rod comprises an inlet end and an outlet end. The rotational flow disc spray nozzle assembly is arranged at the outlet end of the gun rod. The mechanical atomization oil gun further comprises a base and a heating element. The base is arranged at the inlet end of the gun rod. The heating element is fixedly connected with the base and is located in an inner cavity of the gun rod. Cold fuel oil sequentially passes through the four-head spiral groove gasification device and the second oil inlet pipe through the first oil inlet pipe, enters an inner cavity of the gun cavity, and is heated through the heating element to form hot oil gas; the hot oil gas enters the rotational flow disc spray nozzle assembly, forms hot oil mist again, and is sprayed out. At the initial ignition stage, the combustion efficiency is high, and the problems that at the low-temperature cold state initial ignition stage, an existing electric heating mechanical type micro-oil-gasification combustor is prone to oil dripping and black smoke emission are solved.

Owner:YANTAI LONGYUAN POWER TECH

Monitoring and trap-killing technology for bradysia odoriphaga

ActiveCN104170814ADoes not pollute the environmentPromote crop growthBiocidePlant growth regulatorsPromotion effectPopulation

A monitoring and trap-killing technology for bradysia odoriphaga takes sugar-acetic acid-ethanol as a trapping test solution, a newly prepared sugar-acetic acid-ethanol is added into an open basin in an arch shed, an additive is added, and a standard trapping basin is made and placed in a field of leeks. On the basis that the cost is not increased, the new technology can improve the monitoring and trap-killing effect of bradysia odoriphaga, is suitable for monitoring the pest occurrence rule by a grassroots plant protection department, and is particularly suitable for controlling pests by grassroots farmers. The sugar-acetic acid-ethanol used in the technology is non-toxic and harmless and has a good promotion effect on growth of plant; and a method adopted by the technology is a more accurate test method for monitoring pest population dynamics and performing trap-killing control.

Owner:QINGDAO AGRI UNIV

Skin disinfectant

ActiveCN102697943ANo side effectsDoes not pollute the environmentAntiinfectivesDermatological disorderSkin disinfectionGardenia gummifera

The invention provides a skin disinfectant, which is prepared from the following bulk pharmaceuticals in parts by weight: 5-10 parts of belvedere fruit, 10-20 parts of baikal skullcap root, 5-15 parts of coptis root, 2-10 parts of heartleaf houttuynia herb, 15-25 parts of weeping forsythia, 5-10 parts of plantain herb, 5-10 parts of fructus gardenia, 5-10 parts of lightyellow sophora root, 5-10 parts of selinum japenious seed and 5-15 parts of mint. The skin disinfectant provided by the invention is a pure Chinese medicinal preparation, has no toxic and side effects on human bodies, is corrosion-resistant and environment-friendly, has a good disinfecting effect and strong sterilizing power, and is worthy of clinical popularization and application.

Owner:南通洋口港劳务服务有限公司

Vertical rice whitener for rice with germ

InactiveCN105413787AImprove automationDoes not pollute the environmentGrain huskingGrain polishingAgricultural engineeringAgricultural science

The invention discloses a vertical rice whitener for rice with germ. The vertical rice whitener for rice with germ is composed of belt wheels, a motor, a spiral push sheet, milling ribs, a box body, a rice outlet, an upper end cover, a main shaft, a pressure door, a bran removal fan, a charge port, a lower end cover and a belt, wherein the spiral push sheet and the milling ribs are welded on the main shaft respectively; the main shaft penetrates in the box body; the rice outlet and the lower end cover penetrate in the upper end and the lower end of the main shaft respectively, and are connected and fastened with the box body; the upper end cover sleeves the uppermost end of the main shaft, and is connected and fastened with the rice outlet; the pressure door is installed on the rice outlet; the bran removal fan is installed on the box body; and the two belt wheels are installed at the lower end of the main shaft and the output shaft of the motor respectively, and are connected through the belt. The vertical rice whitener for rice with germ, which is disclosed by the invention, realizes high-degree automation, and is capable of completely reserving germs, and pollution-free to environment.

Owner:HARBIN MIMI RICE IND TECH CO LTD

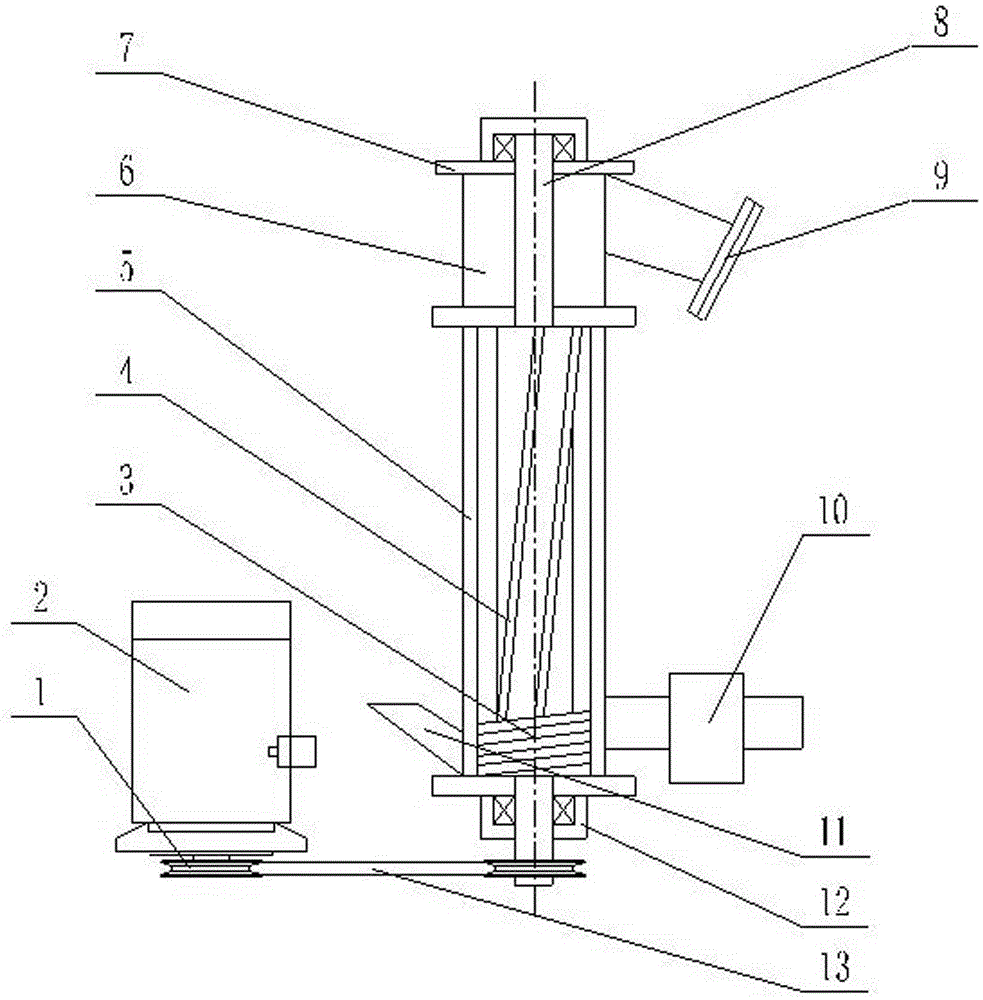

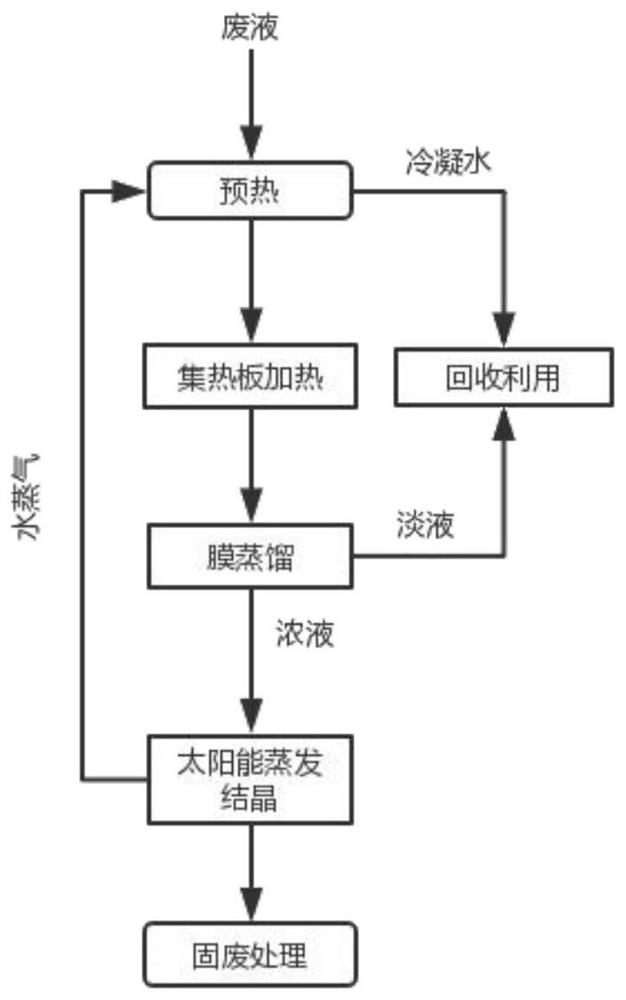

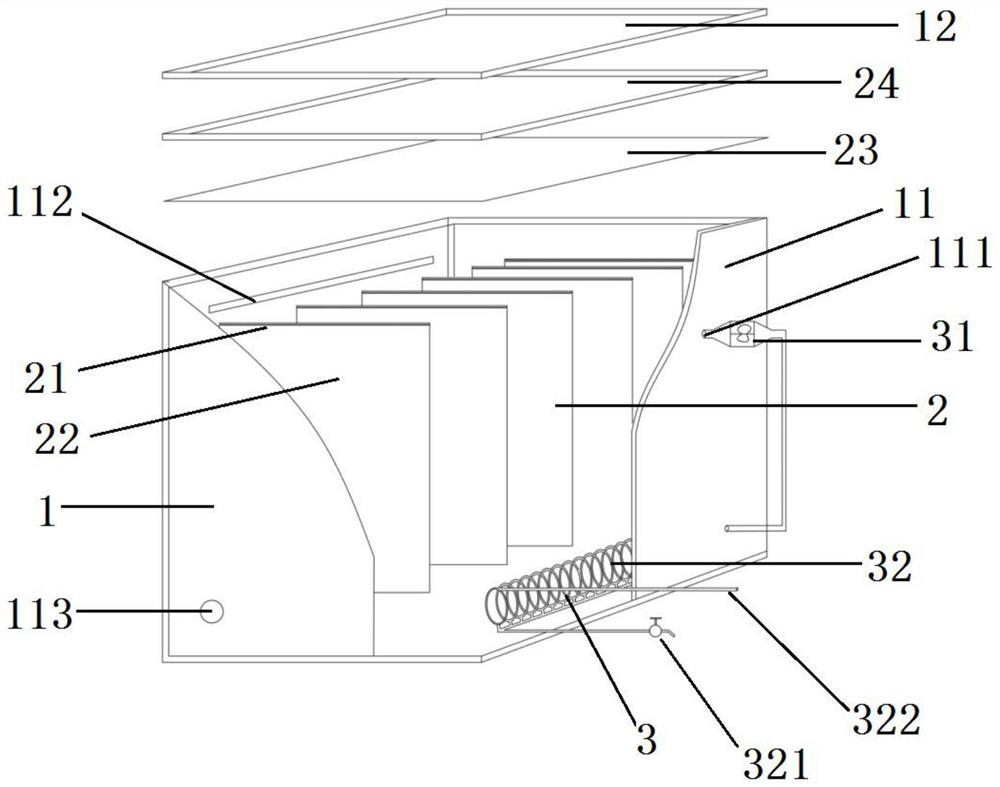

Process for treating radioactive wastewater

ActiveCN111883278AGood light absorption performanceEnhance light absorptionEnergy based wastewater treatmentRadioactive decontaminationMembrane distillationWaste treatment

The invention discloses a process for treating radioactive salt-containing wastewater. The process comprises the following procedures: a heating procedure, a membrane distillation procedure, an evaporative crystallization procedure, a solid waste treatment procedure and a recycling procedure. The method specifically comprises the following steps: (1) introducing radioactive salt-containing wastewater into a heater for heating; (2) enabling the heated radioactive salt-containing wastewater to enter a membrane distillation process to obtain a concentrated solution and first condensed water; (3)introducing the concentrated solution obtained in the step (2) into an evaporation salt collection device for evaporative crystallization to generate steam and solid wastes, performing a solid waste treatment process on the obtained solid wastes, and then collecting radioactive solids; and (4) introducing the first condensed water obtained in the step (2) into a recycling process. According to theprocess, the solar energy utilization rate is increased through the heat collecting plate, the wastewater evaporation rate is increased through membrane distillation, and finally solid-liquid separation is achieved through the evaporation salt collecting device. The process greatly improves the natural evaporation rate, accelerates the wastewater treatment, and greatly reduces the energy consumption by using solar energy.

Owner:TIANJIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com