Vertical rice whitener for rice with germ

A germ and rice machine technology, applied in the direction of grain degermination, grain processing, application, etc., can solve problems such as difficult to meet standards, and achieve the effect of high automation and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

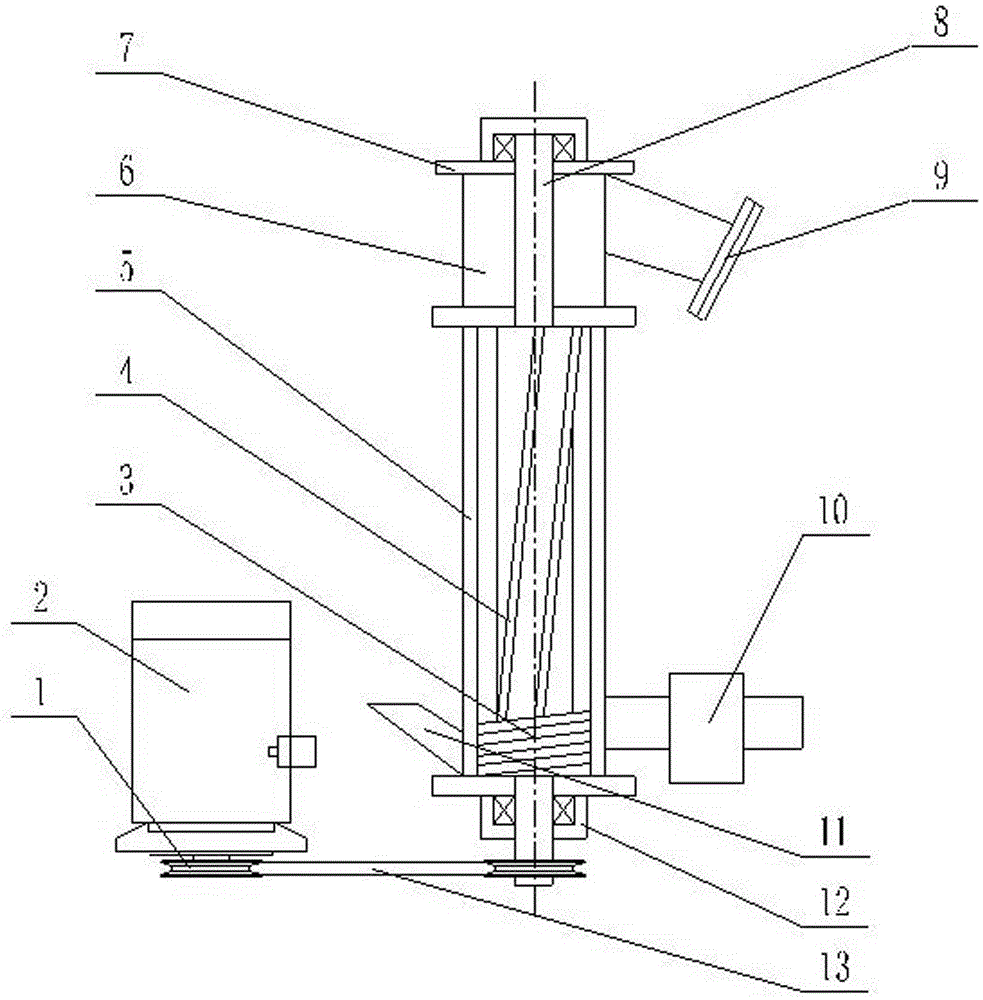

[0012] figure 1 Among them, a vertical germ rice machine, which consists of a pulley 1, a motor 2, a screw push piece 3, a mill bar 4, a box body 5, a rice outlet 6, an upper end cover 7, a main shaft 8, a pressure door 9, and a bran removal fan 10. The feed port 11, the lower end cover 12, and the belt 13 are composed; the screw push piece 3 and the milling bar 4 are respectively welded to the corresponding positions of the main shaft 8, the main shaft 8 is inserted into the box body 5, and the rice outlet 6 is connected to the lower end cover. 12 are respectively worn on the upper and lower ends of the main shaft 8 and fastened with the box body 5, the upper end cover 7 is set on the uppermost end of the main shaft 8 and fastened with the rice outlet 6, and the pressure door 9 is installed on the rice outlet 6 First, install the bran removal fan 10 on the box body 5, install the two pulleys 1 on the lower end of the main shaft 8 and the output shaft of the motor 2, and co...

Embodiment 2

[0014] A kind of vertical germ rice machine of the present invention, when working, motor 2 drives main shaft 8 to rotate through belt 13, adopts the feeding way of lowering, and brown rice is put into feeding port 11, and brown rice flows in counter-gravity direction in box body 5, and Under the action of the screw push piece 3 and the brown rice's own weight, the brown rice fills the entire box 5 and moves upward; the four milling bars 4 on the main shaft 8 grind and rub the brown rice, so that the cortex of the brown rice is broken and peeled off to be whitened; The rice bran peeled off is sucked out of the machine from the box body 5 holes by the bran removal fan 10; the rice outlet 6 automatically keeps the pressure of the box body 5 relatively stable by adjusting the pressure door 9, and controls the rice outlet 6 flow rate simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com