Patents

Literature

402 results about "White rice" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

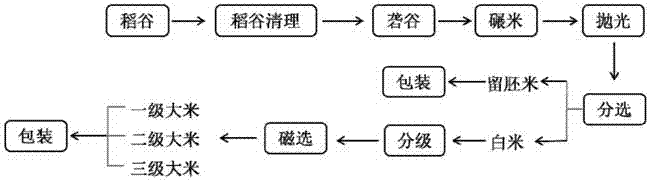

Processing method allowing lower broken rice rate

The invention relates to a processing method allowing lower broken rice rate and belongs to the technical field of rice processing. The processing method includes the steps of rice screening, stone removal, magnetic separation, moisture measurement and drying or atomizing, hulling, husked rice separation, thickness classification, moisture measurement and drying or atomizing, rolling, white rice classification, cooling, polishing, color sorting, water content detection, and sterilizing and packaging. The rice processed by the processing method is low in broken rice rate, long in shelf life and good in glossiness, and flavor of the rice is rarely lost.

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

Nutrient meal-following food and producing method thereof

ActiveCN103053938AGuaranteed normal operationSmooth dischargeFood preparationPolygonum fagopyrumPlant cell

The invention discloses a nutrient meal-following food and a producing method thereof. The nutrient meal-following food is characterized by comprising the following components in parts by weight: 0.5-1.5 parts of polished round-grained rice, 0.5-1.5 parts of white rice, 0.5-1.5 parts of black rice, 0.5-1.5 parts of barley, 1.5-2.5 parts of buckwheat, 0.5-1.5 parts of wheat, 1.5-2.5 parts of oats, 1.5-2.5 parts of coix seeds, 1.5-2.5 parts of millets, 1.5-2.5 parts of corns, 1.5-2.5 parts of broomcorn and 1.6-2.4 parts of sesames. The producing steps are as follows: (1) mixing and cleaning the raw materials, and then soaking the mixture for 8-12 hours (2) steaming the raw materials thoroughly and then airing the raw materials to 30 DEG C; (3) adding fermentation strains and the raw material soaking water in the step (1) into the raw materials in the former step and mixing uniformly; (4) fermenting at a constant temperature of 30 DEG C for 30-35 hours; (5) repeating the step (3); (6) fermenting at a constant temperature of 30 DEG C for 24-30 hours; (7) grinding the well-fermented raw materials into paste; (8) drying the paste into powder and packaging the powder in a sealing manner. The nutrient meal-following food has rational allocation, results in no digestion discomfortableness to the intestines and stomach as the surfaces of the coarse grains are softened through biological fermentation, and is better for the absorption of an organism as the plant cell walls are destroyed by enzymes under the action of microorganisms.

Owner:姜桂英

Rice processing method

InactiveCN104028327AReduce manufacturing costReduce broken rice rateGrain treatmentsBroken riceWhite rice

The invention relates to a rice processing method and belongs to the technical field of rice processing. The rice processing method includes the following steps of rice screening, stone removing, magnetic separation, rice hulling, husked rice separation, thickness grading, rice milling, rice grading, rice cooling, polishing, color sorting, second-time rice grading, sterilizing and packaging. The rice processing method is simple in procedure and high in milled rice rate, production cost of rice processing enterprises can be lowered, and rice produced by the method is clean, high in smoothness and low in broken rice rate.

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

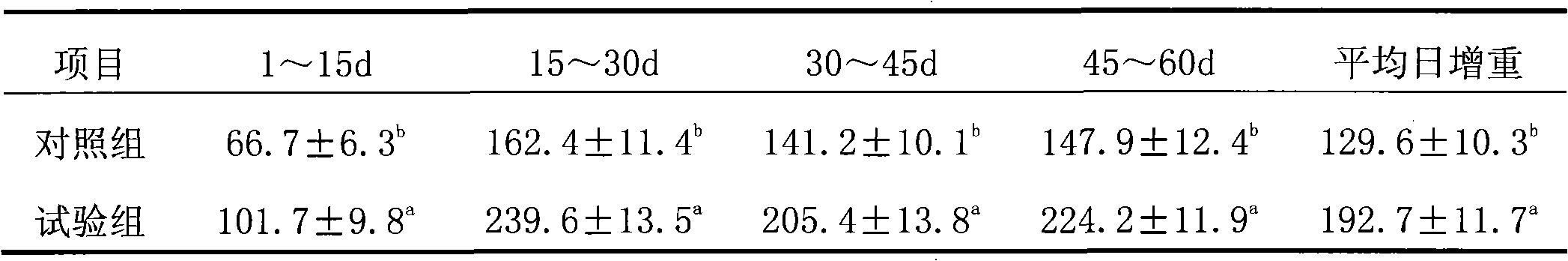

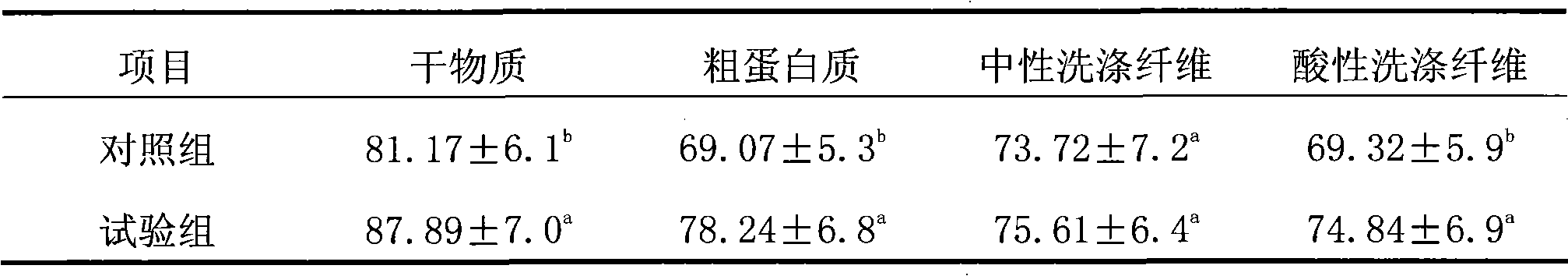

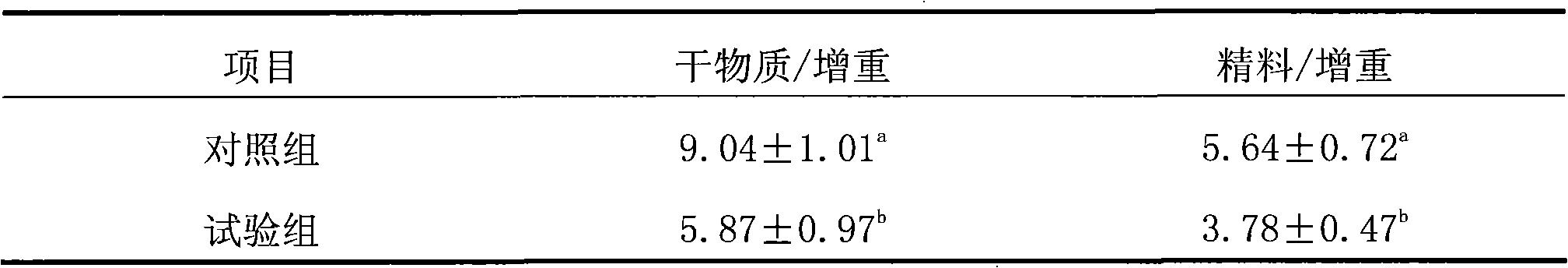

Chinese herbal medicine feed additive for lambs

InactiveCN101623055AImprove apparent digestibilityIncrease daily weight gainAnimal feeding stuffAccessory food factorsDigestionFeed additive

The invention relates to Chinese herbal medicine feed additive for lambs, which belongs to crashed mixtures and can realize rapid fattening of the lambs under the prior feeding conditions. The Chinese herbal medicine feed additive comprises the following raw materials in percent by weight: 15-20 percent of hawthorn, 15-20 percent of officinal magnolia bark, 15-20 percent of white rice stone, 10-15 percent of immature bitter orange, 10-15 percent of rhizoma atractylodis, 10-15 percent of astragalus root, 10-15 percent of fiveleaf gynostemma herb and 5-10 percent of pine needle meal. The invention has the advantages of improving nutrient apparent digestibility of lamb feed and daily gain, reducing feed-meat ratio and bringing higher economic benefits, and the like according to digestion functions.

Owner:SHANXI TEAM HORIZON AGRI & ANIMAL HUSBANDRY TECH DEV

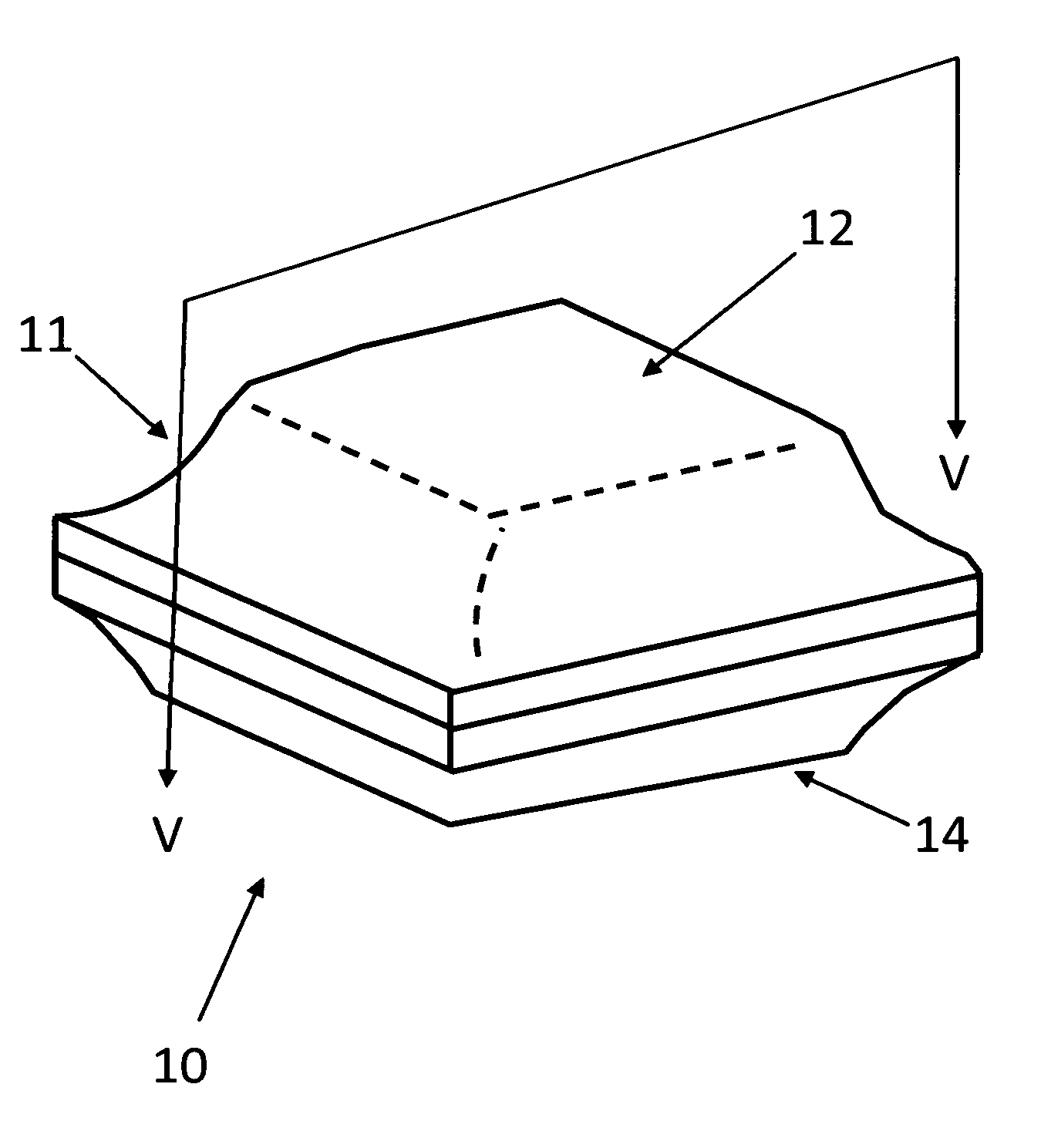

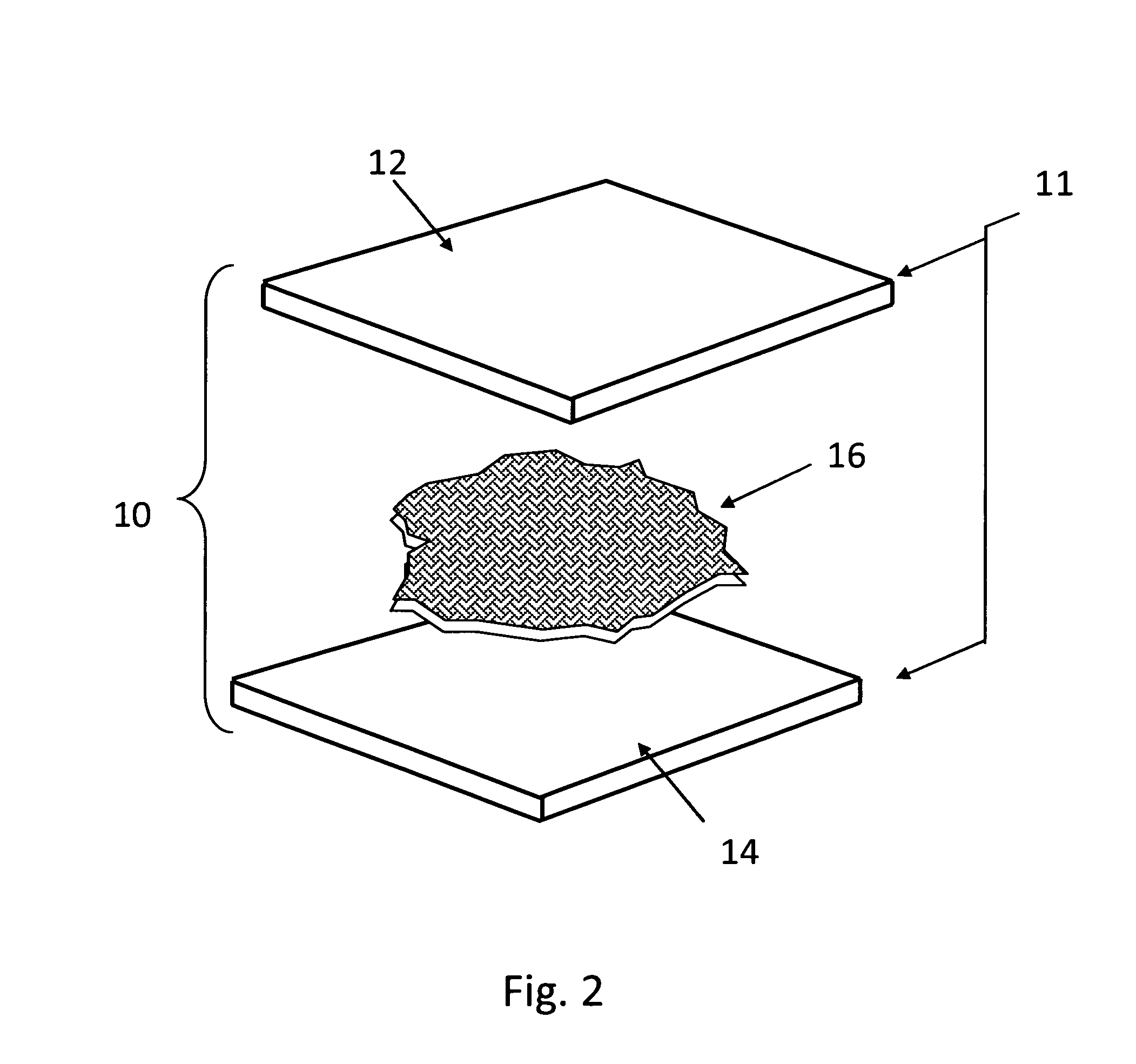

Edible pet treat packaging

ActiveUS8367130B1Promote digestionWell formedAnimal feeding stuffAccessory food factorsBiotechnologyFish oil

A pet treat is manufactured of mostly or entirely of a compressed food material or similar substance. The treat has a semi-rigid or flexible outer shell, skin, film or membrane formed of an edible paper products such as a food paper or rice paper of a type capable of being made from white rice flour, tapioca flour, salt, and water, or from a planar sheet of edible material made from, for example, ground yellow corn, or, with any material, may be used separately or together with poultry by-products, fish meal, catnip or fish oil. Catnip, alfalfa, or any other olfactory or gustative attractive material may be provided in a liquid or flake form, and may be applied integrally in the manufacture of the edible sheet, or included in a central core that is encased by the outer sheets. A method and means of packaging is also provided.

Owner:COSMIC PET LLC

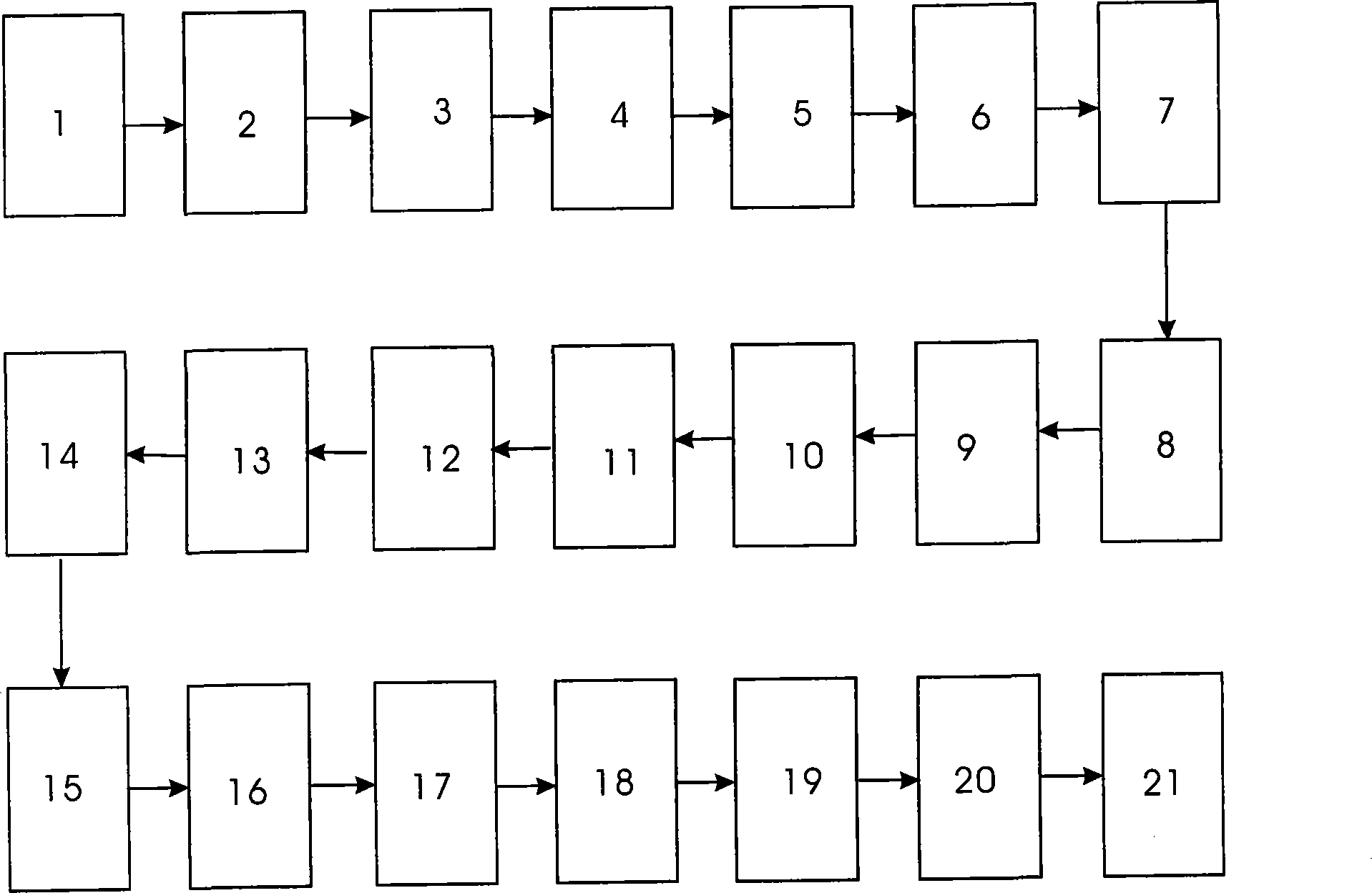

Refined rice processing method

InactiveCN104815714AGuaranteed purityHigh purityGrain huskingGrain polishingBroken riceMoisture measurement

The invention discloses a refined rice processing method. The refined rice processing method comprises the following steps of rice screening, stone removal, magnetic separation and rice shelling, rice-bran separating, secondary shelling, thickness grading, moisture measurement and drying or atomizing, rice milling and white rice grading, rice cooling, polishing, color sorting, secondary white rice grading and moisture content detection, and packaging. The refined rice processing method comprises a plurality of impurity removal steps, and consequently, the purity of rice is guaranteed, the produced rice is high in purity, and the safety and the processing efficiency in the processing process are guaranteed. In the rice shelling and rice milling steps of the refined rice processing method, the material temperature is strictly controlled so that the material can be always kept in a relative low temperature appropriate environment, and the crack ratio and the broken rice rate can be reduced and the complete particle rate can be increased; the original faint scent of rice is maintained. The refined rice processing method is used for solving the problems of surface damage and uneven polishing in the rice polishing process by controlling the polishing water temperature and the dampening amount; as a result, the surfaces of all the rice grains polished can be kept smooth and clean, and the quality guarantee period of the rice can be prolonged.

Owner:ANHUI YOUYUAN FOOD

Special formulation fertilizer for rice

ActiveCN101054326APromote growthIn line with the law of absorptionSuperphosphatesUrea compound fertilisersFiberProcess quality

The invention belongs to fertilizer technical field, more particularly relates to a rice special formula fertilizer, which is characterized in that effective elements of the fertilizer are calculated by weight percent of pure nutrient are nitrogen 25-15, phosphorus pentoxide 15-9, potassium oxide 20-12, silicon dioxide 5-0, calcium 8-0, sulphur 5-1 and zinc 2-1. Compared with the present technique, the rice special formula fertilizer of the invention has reasonable match, accords with the nutrient absorption law of rice, can promote rice growth obviously and raise rough rice output, increase economic benefits and improve rice nutriment quality. In application test, the rice special formula fertilizer of the invention increases the rice yield by 660-820 kg per hectare, increases income 756-146 RMB, increases crude protein, raw fat, crude fiber, nitrogenfree extract and crude ash by 4.1-8.6, 0.14-0.80, 0.4-0.8, 0.1-3.0, 0.4-1.0 percentage points respectively, increases brown rice rate, integral white rice rate, white rice rate of rice processed quality by 1.4%, 1.7% and 1.8% respectively, reduces chalkiness granule rate, chalkiness by 3.2% and 1.9% respectively, reduces content of amylose by 1.0%. In the meanwhile, the fertilizer utilization efficiency is raised by 5.1%-13.8%.

Owner:HUBEI YISHIZHUANG AGRI TECH

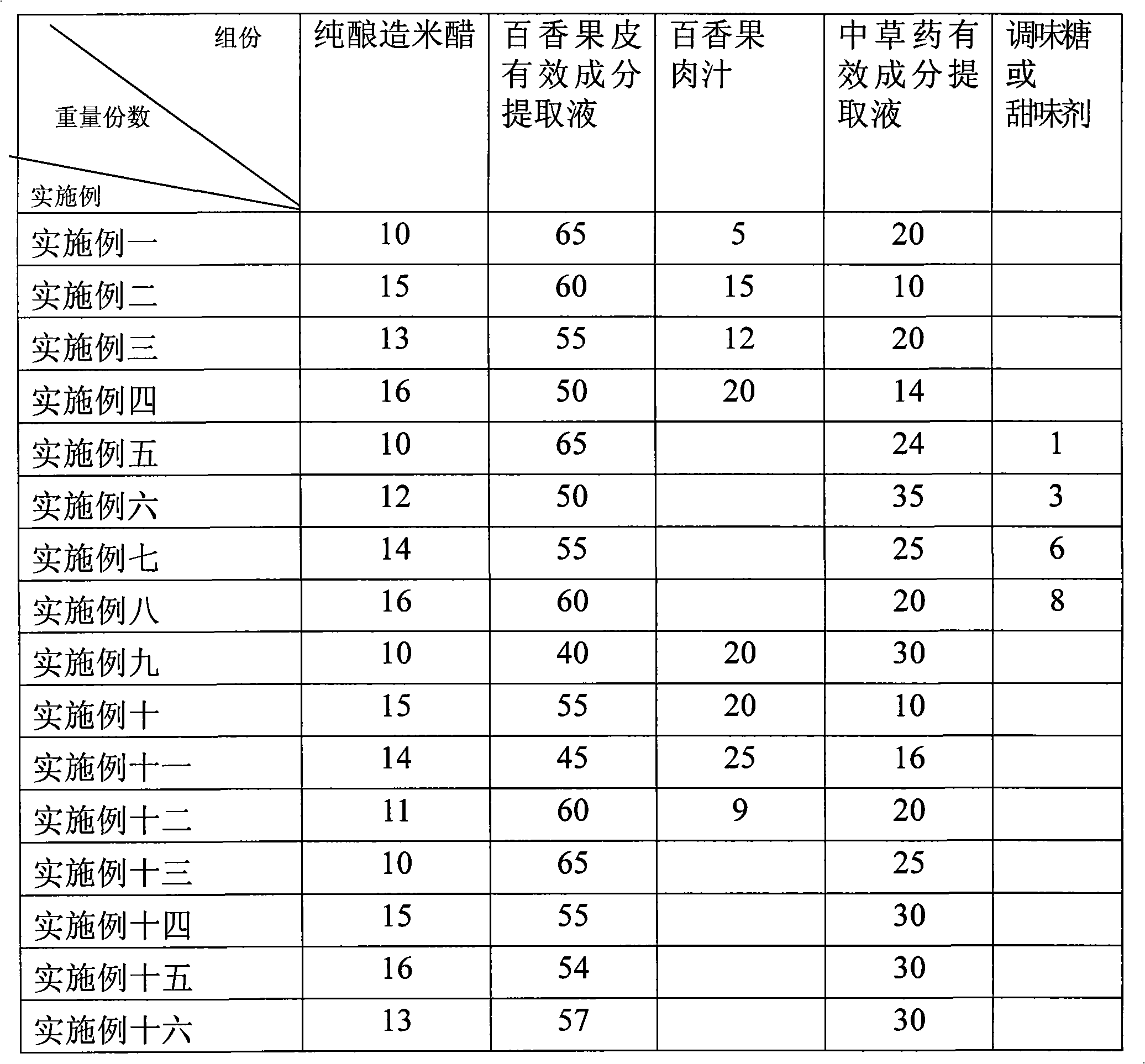

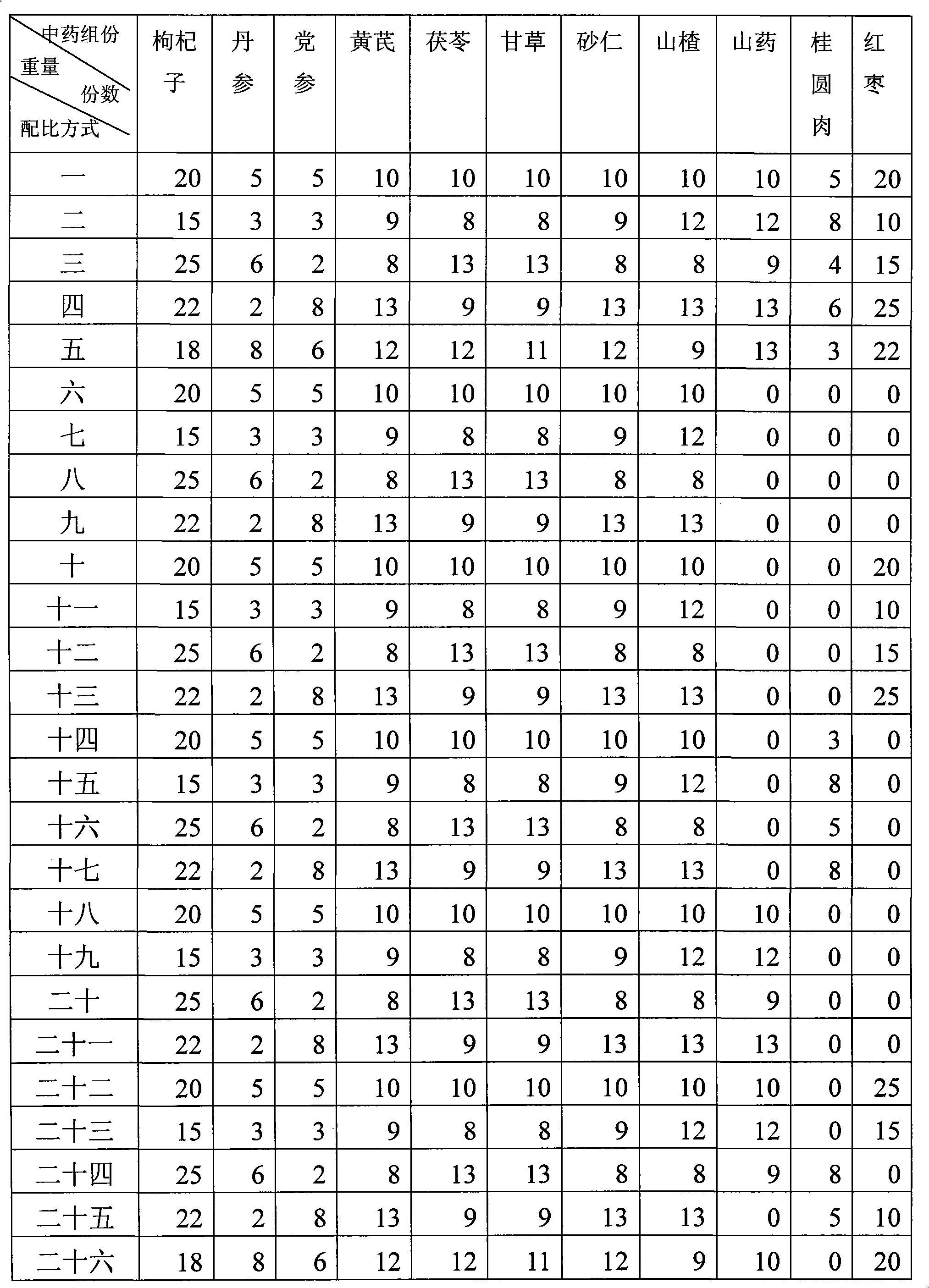

Passion fruit vinegar healthcare liquid and preparation method thereof

InactiveCN101570724AEfficient health functionIncrease profitVinegar preparationHerb medicineMedicine

The invention relates to a passion fruit vinegar healthcare liquid which is a mixture comprising 10-16 of 3-6-degree brewed white rice vinegar, 40-65 of effective component extract of passion fruit peel, 5-25 of passion fruit pulp with a concentration of 15-35 percent, and 10-35 of effective component extract of Chinese herbal medicines according to parts by weight, as well as table sugar with an appropriate amount. The effective component extract of the passion fruit peel is juice extracted by steaming and boiling the passion fruit peel with water. The passion fruit vinegar healthcare liquid fully takes the functions of vinegar and passion fruit and has the functions of the Chinese herbal medicines which promote flow of qi and blood circulation, stimulate the appetite, promote digestion and nourish and strengthen body; and the passion fruit vinegar healthcare liquid has a highly-efficient healthcare function and is favorable for adjusting the balance of the body mechanism. Meanwhile, the passion fruit vinegar healthcare liquid maintains the pure natural characteristics of the passion fruit in terms of color, aroma and taste; and the preparation method of the passion fruit vinegar healthcare liquid improves the effective utilization rate of the passion fruit from about 40 percent to over 90 percent, greatly improves the utilization rate of the effective components of the passion fruit, solves a great problem in the storage of fresh passion fruit and can generate good economic benefit.

Owner:韦裕明 +1

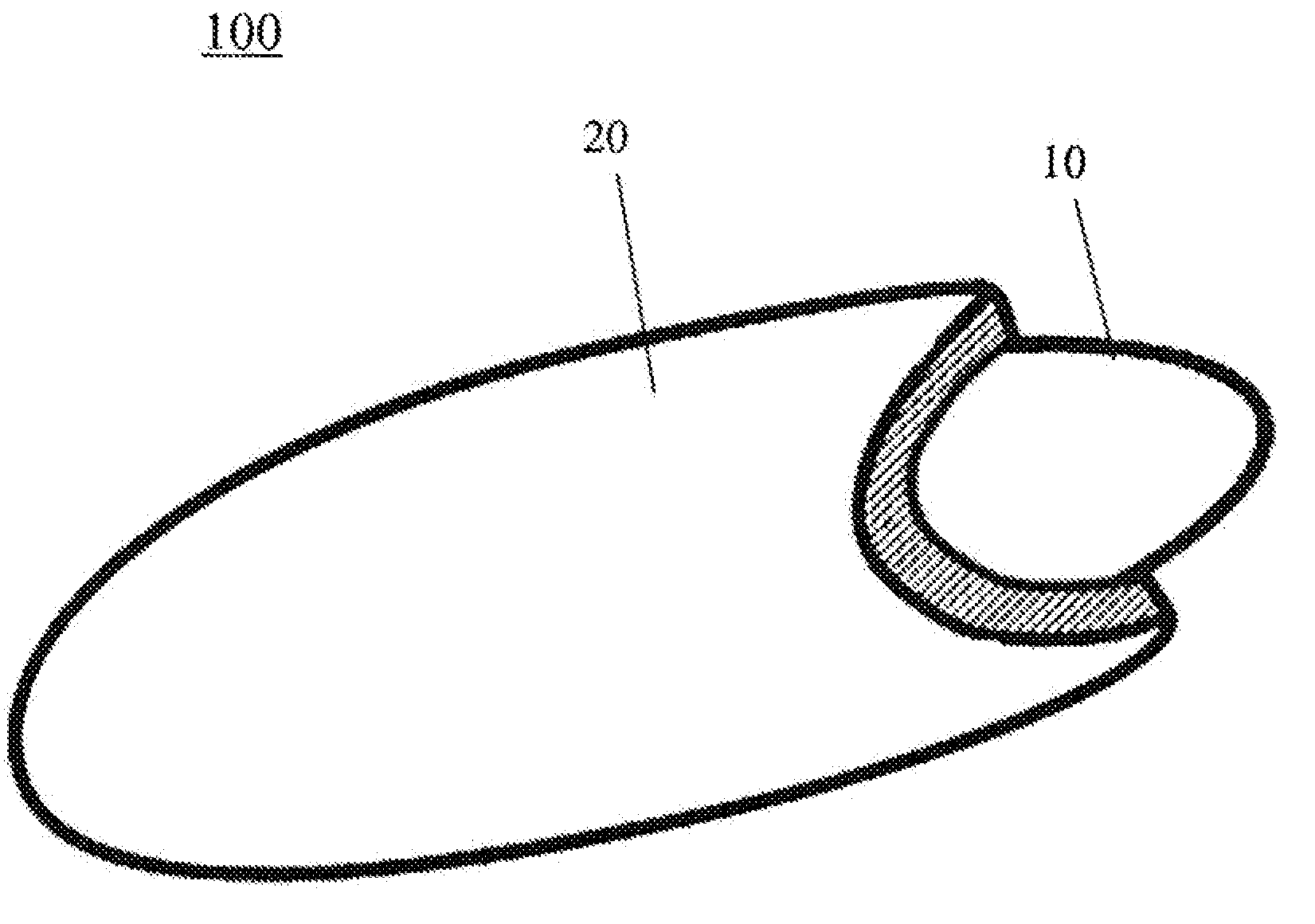

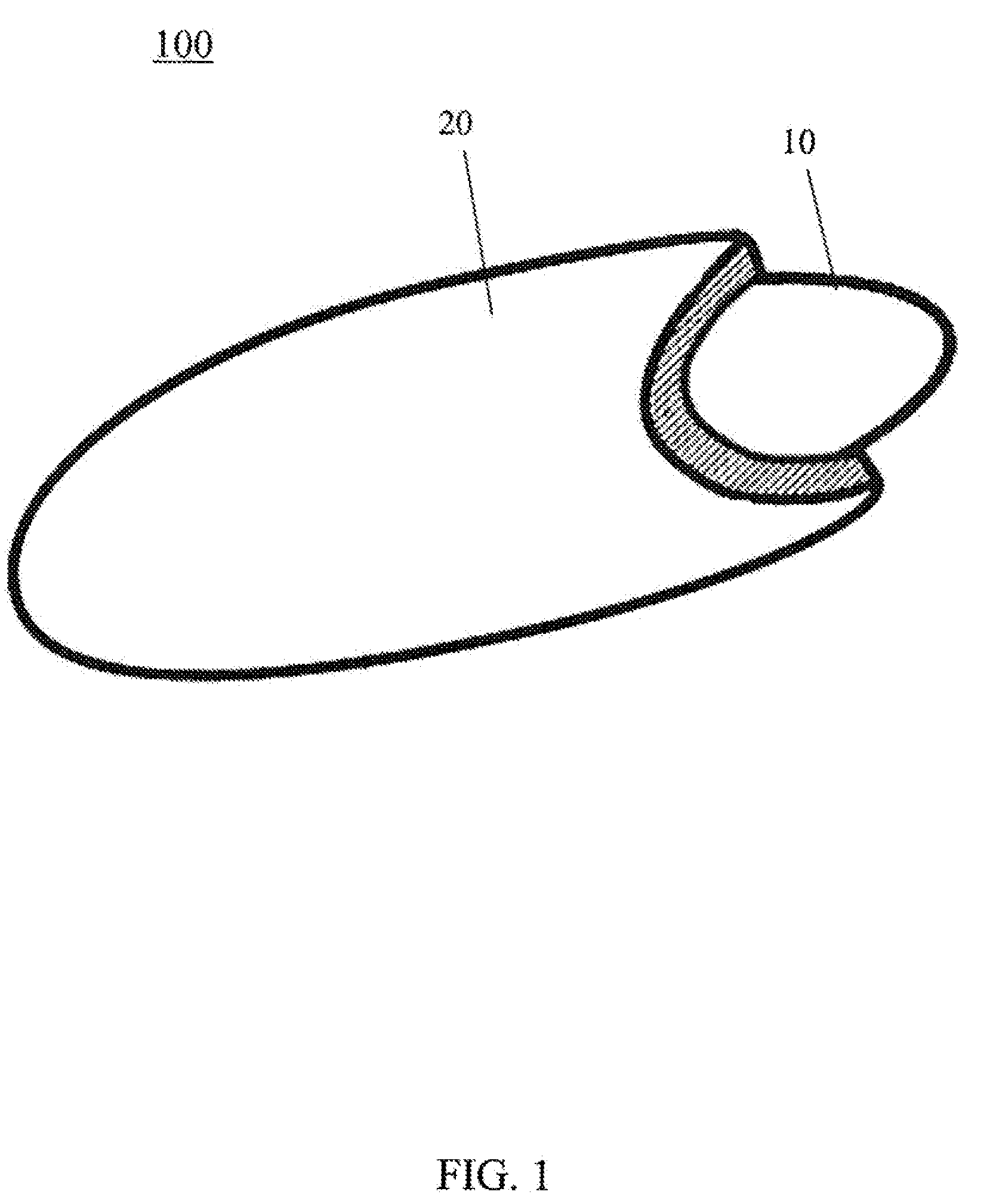

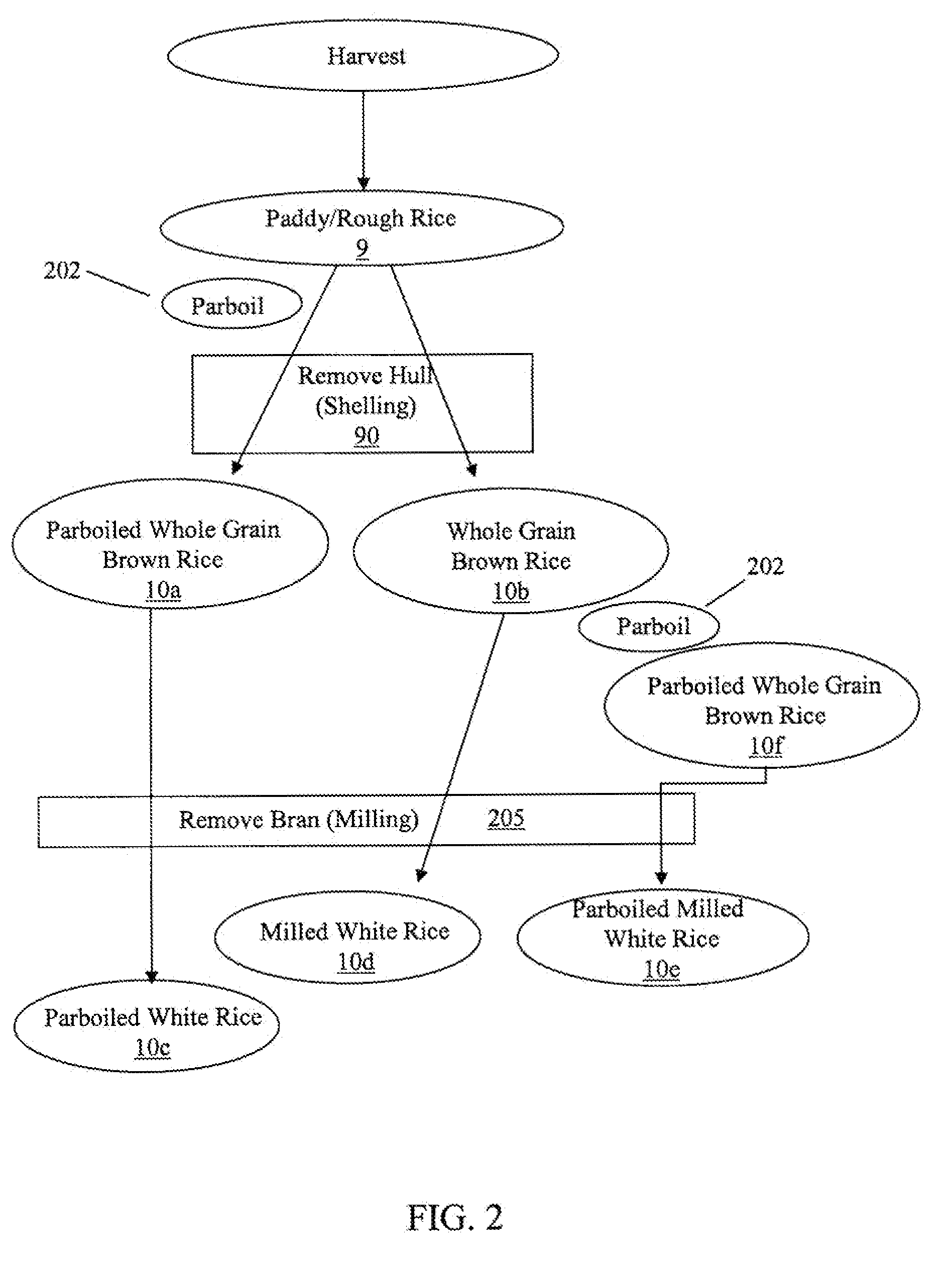

Whole Grain Rice Compositions and Coating Methods

The present invention relates to compositions of matter comprising a rice grain, which has been at least partially milled, and, on the surface of the rice grain, a coating comprising bran, a material which increases the fiber value of the composition, or a combination thereof. The present invention provides for compositions that may have the benefits of traditional white rice, i.e., soft mouth feel, short cook times, easy to digest, white appearance, long shelf-life, etc., with the benefits of brown rice, i.e., high nutritional value and enhanced flavor. Indeed, the nutritional value of the compositions of the present invention may be equal to or better than that of wholegrain brown rice. The present invention further relates to methods for the preparation of a whole grain rice composition. In one embodiment the methods comprises at least partially milling rice grains, and coating on the surface of the rice grains, a coating comprising bran, a material which increases the fiber value of the composition, or a combination thereof.

Owner:MARS INC

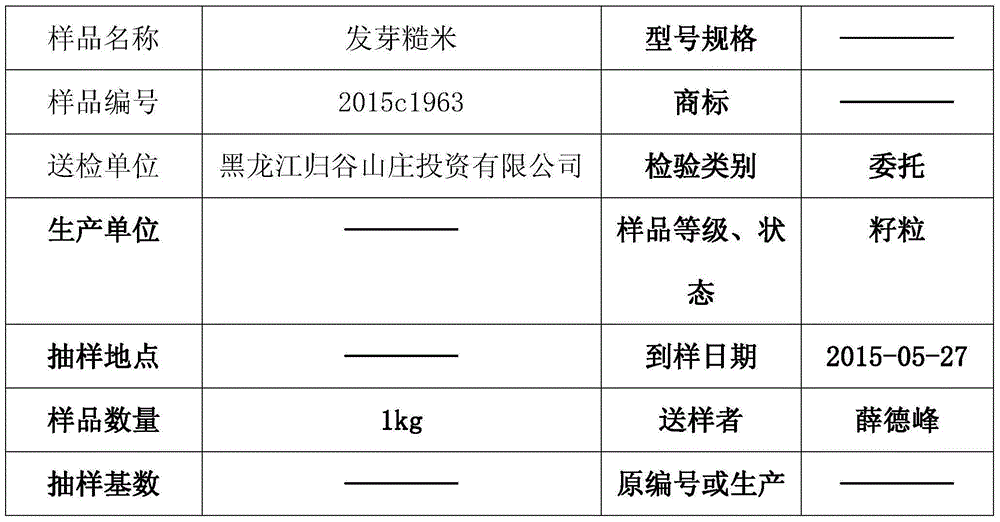

Method for processing fast cooking germination husked rice and germination dehusked rice maded thereout

The invention relates to a processing method of quick cooking germinated brown rice and the germinated brown rice made by the method. The control starts from paddy which is stored in a cryogenic thermostat warehouse after the dried in a drying tower. Afterward, the paddy was processed into brown rice which is used as raw material by cleaning, stoning, deshelling, rolling by a vertical rice mill, polishing and color-selecting. The brown rice is processed in sequence in the steps as follows: preparing phytase operating fluid, adding the brown rice in accordance with a particularly mixture of 1 to 1 brown rice and phytase pressure fluid, immersing the mixed liquid of brown rice in an ultrasonic field for 45 to 75 minutes; the brown ice germinates on a tunnel germinating bed in the temperature of 30 to 35 DEG C, which needs to be sprayed automatically with the gibberellin liquid every two hours; the germinated brown rice which is cooked in the high temperature for 30 minutes and then is dried in low temperature for 4 to 6 hours, after microwave sterilizing and subpackaging, is formed into the finished products of germinated brown rice. The invention particularly relates to that the germinated brown rice has better taste by the control of the germinating, is easier for cooking in the home and boiled with the rice simultaneously, and has higher safety for the microbial contamination.

Owner:刘来法

Production process of parboiled rice

InactiveCN105558783AHigh nutritional valueHigh meal rateFood thermal treatmentNutritive valuesEconomic benefits

The invention relates to a production process of parboiled rice and belongs to the technical field of grain fine and profound processing. According to the production process, pollution-free, environment-friendly or organic rice is selected as the raw material, no additive is added, and a parboiled rice product is obtained through such processing technologies as cleaning and preliminary classification, soaking, steaming, drying, tempering and cooling, rice with huller and husked rice separation, rice milling, polishing, color sorting and packaging. The product is nutrient-enriched food and easy to store and eat and has the advantages of being high in nutritive value, high in rice cooking rate, high in oil extraction rate, long in storage life, short in cooling time and the like; economic benefits are remarkable, the formula is reasonable, the production process is simple, energy consumption is low, processing time is short, the process is safe and sanitary, investment is little, and on the basis of original common rice production equipment, only soaking and steaming equipment is added, and then the product can be produced on a large scale.

Owner:江苏奕帆农业科技有限公司

Method for processing and purifying rice

InactiveCN105013553AQuality improvementNo pollution in the processGrain huskingGrain polishingEconomic benefitsBroken rice

The invention provides a method for processing and purifying rice. The processing technology of the method is completed by thirteen technological processes as follows: unhulled rice screening, drying, stone removing, magnetic separating, rice hulling, husked rice separating, thickness grading, rice milling, white rice grading, color sorting, polishing, white rice grading and finished product packaging. According to the method for processing and purifying rice, impurities are removed through screening; after drying, the finished product rate can be increased in subsequent processing; the quality of rice can be improved through grading for multiple times; the processing course is pollution-free; and a low-temperature rice-rubbing and rice-milling mode is adopted, so that the broken rice rate is reduced, and the economic benefit is increased.

Owner:GUIZHOU PROVINCE SHIBING COUNTY QIANXIANG RICE CO LTD

Process for preparing nutritional and delicious rice medium

The invention relates to a process for preparing a nutritional and delicious rice medium. The process is characterized by comprising the following steps of: fully mixing walnut paste, white fungus plasmagel, tuckahoe, hawthorn, sealwort, white mulberry mixed extract, fresh yam paste, fresh mushroom (or other mushrooms) paste, maize paste, green tea powder, fresh cedrela sinensis paste, bee honey and chicken extract; adding 4 percent of citric acid for decoloring; adding black sesame ground sesameseed oil, ramie seed onion oil, white rice vinegar and dextrin; stirring uniformly to obtain fine particles; and drying, sterilizing, sealing and packaging.

Owner:王跃进

Low-sugar black garlic flower beverage and preparation method thereof

ActiveCN103960729AReduce heatEasy to drinkFood ingredient as taste affecting agentNatural extract food ingredientsFiltrationStamen

The invention discloses a low-sugar black garlic flower beverage and a preparation method thereof. The low-sugar black garlic flower beverage is prepared from the following raw materials: a black garlic extract, a honeysuckle extract, a peony stamen extract, a rose extract, a chrysanthemum extract, a maca extract, bee honey, white rice vinegar, maltodextrin, xylitol, malic acid, citric acid, beta-cyclodextrin, sodium carboxymethylcellulose and sodium tripolyphosphate. The preparation method comprises the technological steps of preparation of a water extraction solution, batching of the raw materials, homogenization, filtration, canning and sterilization. The beverage is rich in nutrients, has low sugar and low heat and has a relatively good health care effect. The preparation method is simple in process as well as simple and convenient to operate.

Owner:潘炳永

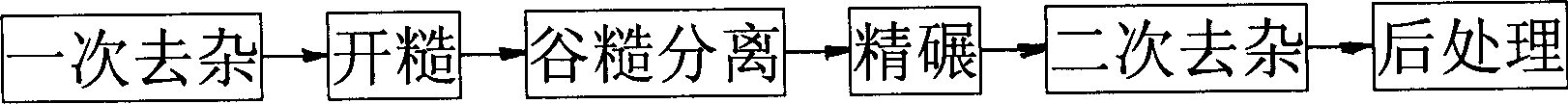

Rice fine-processing technique

InactiveCN1806923AIncrease roughnessIncrease profitCombination devicesGrain huskingBroken riceWhite rice

The invention relates the rice fine finishing technique. The technique comprises the primary rouging which removes non-metallic impurity, separating grain, fine rolling, second rouging which removes metal impurities and final treatment comprising selecting color which removes other color grain with inductor, polishing which makes the surface of rice form film by heating rice with saturated vapor at a short time, classifying which is length classifier and thickness classifier with many sifters. The technique improves the rate of husked rice, reduces the broken rice and the waste of grain and increases the grain availability ratio.

Owner:刘益民

Special-flavor rice processing method

A special-flavor rice processing method comprises the following steps that 1, unhusked rice is subjected to direct drying, dehumidification and impurity removal after being harvested till the moisture content is lower than 18%, storage is performed after warehousing, the temperature of a warehouse is controlled to be 10 DEG C, and the relative humidity is controlled to be 40%; 2, the unhusked rice in the warehouse is quickly frozen in a quick freezing device for 30 minutes, and the quick freezing temperature is -10 DEG C; 3, the quickly-frozen unhusked rice is fed into a fumigating bin to be subjected to fumigation; 4, the fumigated unhusked rice is subjected to rice-husk separation and rice separation and then is milled and grading to obtain white rice, the white rice is delivered to the warehouse to be stored, the temperature of the warehouse is controlled to be 10 DEG C, and the relative humidity is controlled to be 40%; 5, finish machining is performed, and polishing, color sorting, grading and finished product package are conducted on the white rice obtained in the step 4 in the month before selling; 6, storage is performed, namely packaged finished products obtained in the step 5 are delivered to the warehouse to be stored, the temperature of the warehouse is controlled to be 10 DEG C, the relative humidity is controlled to be 40% for selling.

Owner:ANHUI BRIGHT HUAIXIANG IND TRADE GRP

Rice drink and preparation method thereof

ActiveCN101703291AGood health effectSupplementary source is goodFood preparationWheat germWhite rice

The invention discloses a rice drink and a preparation method thereof. The drink uses brown rice and white rice as main raw materials, and wheat germ as auxiliary materials. The drink is prepared by the following steps of baking, partially baking, cooking, enzymic hydrolyzing, mixing, homogenizing, filling, sterilizing and packaging. The rice drink is white or creamy yellow, with rich nutrition. The rice drink of the invention adopts the brown rice and the white rice as the main raw materials, and the wheat germ as the auxiliary materials, so that the loss of vitamin B caused by eating fine-finished rice for long time can be supplemented from the nutrition side, simultaneously, rich fibers, vitamins and various mineral elements are contained in the brown rice and the wheat germ so as to provide the excellent supplement source for necessary nutrient substances needed by human body, while the rice is the main source of energy substances, so that the rice drink has the nutrition needed in main food and can supplement the necessary nutrient substances for the human body with good health function.

Owner:湖南金健乳业股份有限公司

Method for processing fast cooking edible husked rice and edible husked rice maded thereout

The invention relates to a processing method of edible brown rice and the edible brown rice made by the method. The control starts from paddy which is stored in a cryogenic thermostat warehouse after the drying in a drying tower. Afterward, the paddy was processed into brown rice which is used as raw material by cleaning, stoning, deshelling, rolling by a vertical rice mill, polishing and color-selecting. The brown rice is processed in sequence in the steps as follows: after water flushing, draining, adding with the enzyme complex liquid, the brown rice is immersed in the mixed liquor in an ultrasonic field; the PH of the immersed brown rice is adjusted to neutrality, then the brown rice is cleaned by water; the brown rice which is added with the enzyme complex liquid is cooked in a continuous cooking machine, by which the cooked brown rice is dried in the recirculation ventilation continuous dryer; after microwave sterilizing and subpackaging, the brown rice is formed into the finished products of quick-cooking edible brown rice. The invention more particularly relates to that the edible brown rice has better taste by the control of the processing process, is easier for cooking at home and boiled with the rice simultaneously, and has higher safety for the microbial contamination.

Owner:刘来法

Rice fine processing technology

InactiveCN106391168AImprove drying efficiencyThe processing procedure is simpleGrain huskingGrain polishingBroken riceWhite rice

The invention discloses a rice fine processing technology which comprises the following steps of unhusked rice screening, stone removal, magnetic separation, soaking in a dietary alkali solution, washing, drying and moisture removal, rice husking, husked rice separation, thickness classification, rice milling, soaking in a soaking solution, drying and moisture removal, white rice classification, rice cooling, polishing, color sorting, secondary white rice classification, sterilization and packaging. According to the method, processing technological procedures are simple, the milled rice rate is high, the production cost of rice processing enterprises can be reduced, and the rice produced through the method is clean, good in degree of finish and low in broken rice rate.

Owner:金健粮食(益阳)有限公司

Method for separating brown rice peel layer

InactiveCN103506176AGentle rubbingImprove integrityGrain huskingGrain polishingWater vaporWhite rice

The invention relates to a method for separating a brown rice peel layer. The method comprises the first step of cleaning the rice, namely, large, small and light impurities and the like easy to clean are cleaned from unprocessed grain, the magnetic impurity in the rice is removed, rice particles are separated from barnyard grass particles, and the rice is separated from stones; the second step of rice hulling, namely, rice hulls are removed through a rice huller, the rice hulls are separated out from the rice processed by the rice huller, and brown rice and the rice are sorted from the brown rice mixture through a brown rice screen sieve; the third step of dampening, namely, the content of the moisture of the brown rice is adjusted into 14%-15% of the total weight through the water mist or the water vapor, and the dampening time duration ranges from 6 minutes to 18 minutes; the fourth step of rice milling, namely, an emery roll rice husking machine is used for removing outer bran layers of the rice particles and an iron roll air blast rice husking machine is used for removing the brown rice peel layer; the fifth step of brown rice peel layer collecting, the grinded white rice is separated from the brown rice peel layer, and the brown rice peel layer is collected. The accurate dampening moisture part and dampening time control are carried out on hulled clean brown rice through a water atomizing method, the emery roll rice husking machine arranged in the middle of a first rice machine and the iron roll air blast rice husking machine arranged in a tail rice machine are selected in a combined mode to be connected in series for grinding, the brown rice is subjected to soft grinding force, the integrity of the peel layer is kept high, the effect of high peel producing ratio is achieved when the brown rice peel layer is separated, and the technique is simple and easy to control.

Owner:HUNAN AGRICULTURAL UNIV

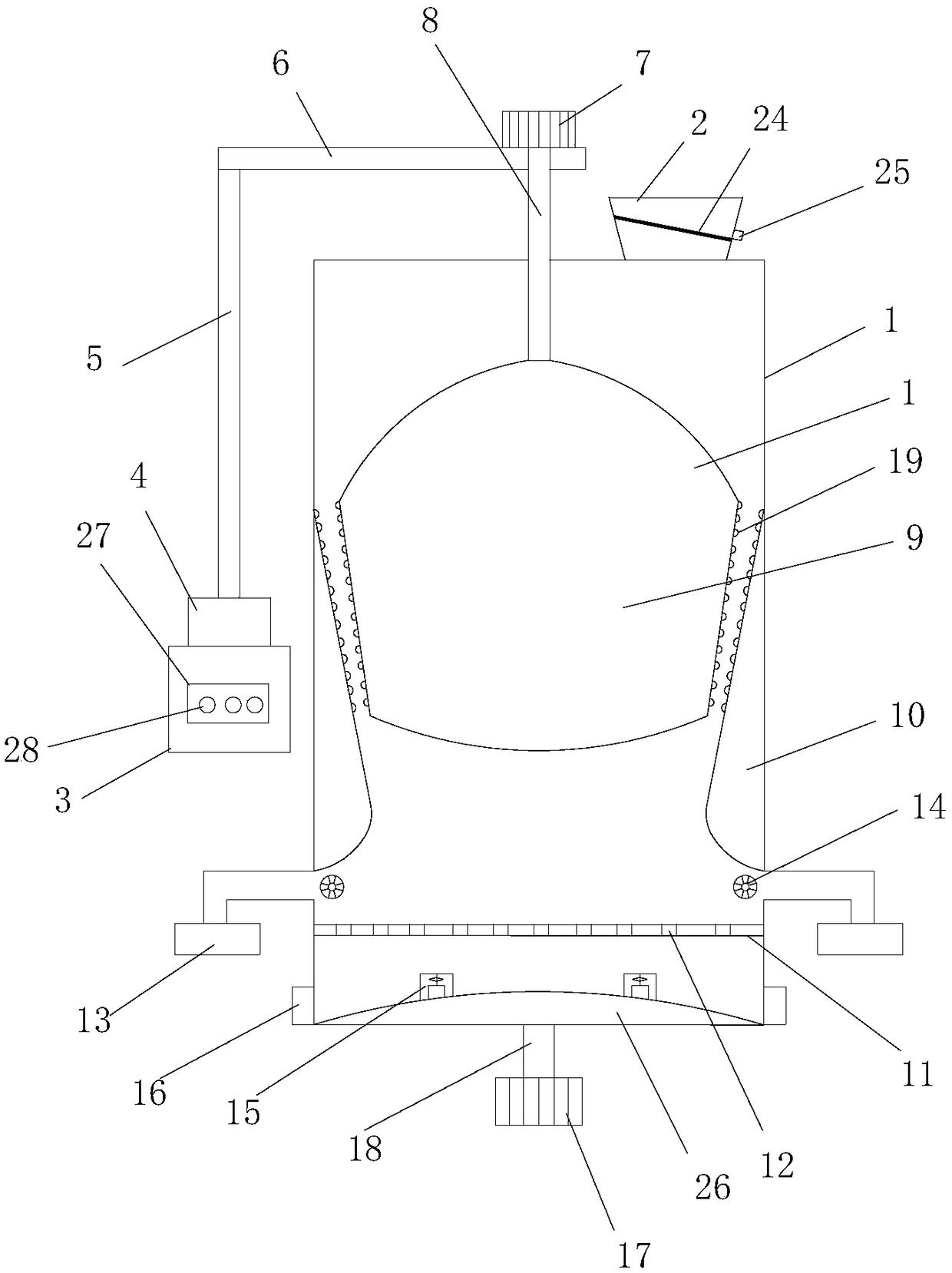

Multifunctional efficient rice husking machine

InactiveCN108160146ALow frictionLess corrosiveGrain huskingGrain polishingHydraulic cylinderPulp and paper industry

The invention discloses a multifunctional efficient rice husking machine and relates to the field of cereal processing equipment. The multifunctional efficient rice husking machine comprises a rice husking machine body, a feeding hopper, a control box and a hydraulic cylinder, wherein the hydraulic cylinder is arranged above the control box, the top of the hydraulic cylinder is connected to a telescopic rod, the upper end of the telescopic rod is connected to a platform plate, a first motor is arranged on the platform plate, a first rotating shaft is arranged below the first motor, the upper end of the first rotating shaft penetrates through the platform plate and is connected to the output end of the first motor, the lower end of the first rotating shaft extends into the rice husking machine, a grinding cone is arranged in the rice husking machine, a grinding disc matched with the grinding cone is arranged on the inner wall of the rice husking machine, and discharge ports are formed in the side walls of the left and right sides of the bottom of the rice husking machine. The rice husking machine disclosed by the invention is high in grinding efficiency and good in grinding effect,and the degree of purity of ground white rice meets the using demand. The multifunctional efficient rice husking machine has a function of adjusting the grinding strength, and is simple to operate andhigh in working reliability.

Owner:马斌祥

Rice deep processing technology and characteristic

InactiveCN107282166AQuality improvementNo pollution in the processGrain treatmentsGrazingEconomic benefits

The invention discloses a process and characteristics of deep processing of rice, comprising the following steps: rice screening, drying, stone removal, magnetic separation, rice hulling, paddy separation, thickness grading, moisture measurement, rice milling and white rice grading, cold rice , Polishing, color sorting, secondary white rice grading, moisture content testing, packaging fifteen processes. The technology and characteristics of the deep processing of rice in the present invention can improve the quality of finished rice through multiple classifications. The processing process of the present invention is environmentally friendly and pollution-free, adopts a low-temperature light rubbing rice milling mode, reduces the broken rice rate, and improves economic benefits.

Owner:安徽联邦农业科技有限公司

Rice dumpling made of unpolished rice or malted unpolished rice and processing method thereof

ActiveCN101849640AHigh nutritional valueImprove health benefitsFood preparationMonosodium glutamateNutritive values

The invention relates to a rice dumpling made of unpolished rice or malted unpolished rice and a processing method thereof, which belong to the technical field of food processing. The invention adopts unpolished rice or malted unpolished rice as major raw materials to be matched with one or several kinds of materials in sweetened bean paste, jujube, meal, egg yolk, vegetables and nuts for making the rice dumpling, the nutritive value and the health care effect of the rice dumpling are greatly improved, in addition, the cost is saved, and the utilization ratio of unhulled rice and the added value of the rice are improved. In addition, the husk flavor of the ordinary unpolished rice is covered by the fragrance of reed leaves, and the mouth feeling of the rice dumpling made of unpolished rice is similar to or even superior to that of the rice dumpling made of refined sticky rice as major raw materials. The color of the rice dumpling made of unpolished rice is similar to the color of the rice dumpling made of white rice with the addition of coloring seasoning such as soy sauce and the like, so the meal rice dumpling made of unpolished rice reaches the attractive color of the meal ricedumpling made of white rice after the addition of the seasoning without adding the soy sauce and monosodium glutamate. Besides the advantages, the rice dumpling made of malted unpolished rice as major raw materials has better mouth feeling and stronger nutritive and health care function.

Owner:无锡市嘟嗳吃食品有限公司

Instant fruit rice noodles

The invention relates to instant fruit rice noodles, which belong to the technical field of instant foods, namely rice noodles. The instant fruit rice noodles are characterized in that rice and fruit juice, fruit powder or fruit spice are used as main raw materials and are prepared into the instant fruit rice noodles by the following process method: selecting high-quality white rice, and soaking the rice with clear water; pulping the rice after the soaking by a pulping machine, and squeezing the rice pulp by a filter press; adding starch to rice flour blocks, stirring the mixture evenly, and cooking the mixture; cooling the cured raw material, adding the fruit powder, the fruit juice or the fruit spice to the raw material, and mixing the mixture sufficiently; extruding the raw material obtained in the step into threads by using a single-screw extrusion machine; aging the prepared threadlike rice noodles continuously by a mesh belt aging machine; and cutting and forming the aged rice noodles with fixed lengths by a cutting machine, drying the rice noodles by introducing hot-blast air, and packaging the rice noodles with seasoning packets to obtain finished products. Through the method, the rice noodles not only have the nutrition of fruits, but also have the tastes of the fruits. Besides, the manufacturing process does not damage the nutrition of the fruits.

Owner:ZHEJIANG CHENYUN IND

Honey, bean sprout and black fungus fermented drink

InactiveCN104621661AImprove stabilityRich in vitaminsFood ingredient functionsFood preparationAgaricWhite rice

The invention relates to a honey, bean sprout and black fungus fermented drink. The honey, bean sprout and black fungus fermented drink is prepared from the following raw materials in parts by weight: 200-205 parts of soybean sprouts, 85-100 parts of honey, 100-105 parts of green tea juice, 5-7 parts of black fungus, 60-70 parts of white rice vinegar, 60-70 parts of ginseng fruits and the like. Because of being prepared from soybean sprouts, honey and the like, the honey, bean sprout and black fungus fermented drink disclosed by the invention is rich in vitamins and dietary fibre and low in calorie; matched with black fungus and grouting rice milk, the honey, bean sprout and black fungus fermented drink is capable of maintaining beauty, keeping young and slimming; furthermore, the stability of the honey, bean sprout and black fungus fermented drink is good; and in addition, by means of addition of extracts, such as forget-me-not, dandelion, maca and sanchi flower, the honey, bean sprout and black fungus fermented drink has a certain effects of clearing away heart-fire, improving eyesight and increasing immunity.

Owner:FENGYANG RUICHENG FOOD TECH

Pure natural colorful sausage powder and its preparation method

The present invention discloses one kind of naturally colored salad sausage jelly and its production process. The salad sausage jelly consists of at least one kind of color rice slurry and proper amount of stuffing, and the color rice slurry is produced with rice 50 weight portions, glutinous rice 10 weight portions, water 100 weight portions and color vegetable juice 50 weight portions. The production process includes the following steps: washing rice and glutinous rice and soaking for 8 hr; squeezing fresh vegetable to obtain color vegetable juice; mixing color vegetable juice and rice soaking water and milling to produce color rice slurry; spreading color rice slurry in 0.8-1.0 mm thickness on wet cloth inside tray and adding proper amount of stuffing; high temperature steaming for 90 sec; scraping off the rice jelly and winding. The naturally colored salad sausage jelly has rich nutrients and different colors.

Owner:庞兆广

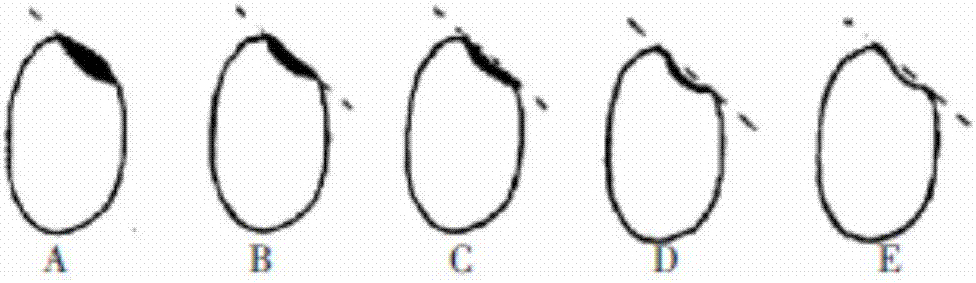

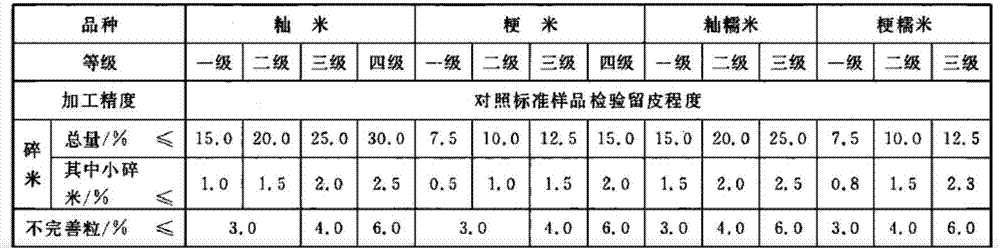

Co-production machining method of germ-remaining rice and multi-grade rice

ActiveCN106881171AHigh retention rateImprove the rice yieldSortingGrain treatmentsRice grainMagnetic separation

The invention discloses a co-production machining method of germ-remaining rice and multi-grade rice. The method comprises the steps of rice cleaning, rice shelling, rice grinding, polishing, sorting, grading, magnetic separation and packaging. According to the rice grinding technology, a sand roller rice grinding machine is selected, and multi-machine light grinding is adopted; the specification of 600-500 / micrometers, 425-355 / micrometers and 355-250 / micrometres is adopted in the granularity of diamond sand rollers of the rice grinding machine; the rotating speed is controlled to range from 840 to 1040 r / min. According to the sorting technology, a color sorting machine is adopted to judge the shape and the color of rice, through separation, germ-remaining rice and white rice are obtained. According to the proportion of the germ projection area to the whole rice grain projection area, the full-germ or half-germ or flat-germ or incomplete-germ germ-remaining rice with the purity of 85% or above is obtained; according to the grading technology, through the judgment of rice grain skin leaving degree and the broken rice by the color sorting machine, first-stage (second-stage or third-stage) rice is obtained. The method has the beneficial effects that the germ-remaining rice and multi-grade rice co-production technology is provided for the rice machining industry, the rice germ retention rate is improved, production energy consumption is reduced, and the rice is nutritional and sanitary.

Owner:国粮武汉科学研究设计院有限公司

Rice-based snack chip and method of making same

InactiveUS7189424B2Desirable flavorImprove abilitiesAnimal feeding stuffBakery productsAdditive ingredientRice dishes

A rice-based snack chip made from a dough including the dry ingredients of bumped rice kernels, long-grain pregelatinized rice flour, medium-grain course white rice flour and in which the bumped rice kernels are partially hydrated, bumped, partially dehydrated and fried as the chip is made.

Owner:WHOLESOME GOODNESS LLC +1

Five-color rice and breeding method of five-color rice

ActiveCN102715076AAchieve the same field plantingPlanting costs are the samePlant genotype modificationBiotechnologyPollination

The invention relates to a breeding method of five-color rice. According to the breeding method, indica type white rice variety type A or Deyou 17 is used as female parents, stem type colorful rice variety Lijiang small millet is used as male parents, artificial castration pollination and hybridization is carried out, according to the seedling target, pedigree method breeding and color mode RBG (red, blue and green) selection are combined, indica and stem subspecies colorful rice with the basically identical agronomic characters including the strain height, the growth period and the like and different rice seed coat colors are obtained through seven-year and six-generation breeding, and the coarse rice colors of the five-color rice are respectively the black, the sepia, the red, the yellow and the white. The same-field planting of the rice with five colors is realized, the labor and the time are saved, the planting cost is identical to that of the conventional rice, and the yield is higher than that of other colorful rice. The five-color rice is used as the special rice, the nutrition value of the five-color rice is much higher than the ordinary rice, the market value is higher than that of the ordinary rice, and better industrial development prospects are realized.

Owner:FOOD CROPS RES INST YUNNAN ACADEMY OF AGRI SCI

Production method for processing total-nutrient germinated brown rice and germinated milled rice

ActiveCN105080636AAffect germination rateAffect qualityGrain millingContinuous/uninterruptedWhite rice

The invention provides a production method for processing total-nutrient germinated brown rice and germinated milled rice. The production method includes the steps that new unhusked rice with the water content being below 15% is selected as raw materials and then put into an open container after being sieved and subjected to impurity removal; water is added to immerse the unhusked rice by above 10 cm; ozone with the concentration of 0.5-1.5 mg / L is introduced continuously into the water from the bottom of the container; the water is controlled to be at the constant temperature of 32+ / -1 DEG C for 36-48 hours for seed soaking and pregermination, and the water is not changed halfway; after the germinated rice with the germination length being 0.5-1 mm is obtained, the ozone supply is stopped, steam at the temperature of 80 DEG C is introduced for 4 min, and then rapid inactivation treatment is carried out; and the unhusked rice is then rapidly dried at the temperature of 50-52 DEG C until the water content is below 17%. After the unhusked rice is hulled according to a common method, the germinated brown rice is obtained. Then separation, rice milling, color sorting, polishing and grading are carried out, so that the germinated milled rice is obtained. The production method for processing the total-nutrient germinated brown rice and germinated milled rice is uniform in germination, is high in germination speed and keeps the nutrient in the unhusked rice as much as possible.

Owner:刘毅 +2

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com