Patents

Literature

106results about How to "Improve shelling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method allowing lower broken rice rate

The invention relates to a processing method allowing lower broken rice rate and belongs to the technical field of rice processing. The processing method includes the steps of rice screening, stone removal, magnetic separation, moisture measurement and drying or atomizing, hulling, husked rice separation, thickness classification, moisture measurement and drying or atomizing, rolling, white rice classification, cooling, polishing, color sorting, water content detection, and sterilizing and packaging. The rice processed by the processing method is low in broken rice rate, long in shelf life and good in glossiness, and flavor of the rice is rarely lost.

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

Compound vitamin nanoemulsion

ActiveCN101797276AGood dispersion and stabilityImprove solubilityHydroxy compound active ingredientsMetabolism disorderOil phaseVitamin B6 synthesis

The invention relates to compound vitamin nanoemulsion belonging to the technical field of pharmacy. Every 1000 ml of nanoemulsion is prepared by the method comprising the following steps of: fully mixing 35-50g of AEO-9 or AEO-4, 150-200g of tween-80, 16-22g of phenylcarbinol and fat-soluble active ingredients at 30-60 DEG C to prepare an oil phase; adding water to dilute the oil phase; adding water-soluble active ingredients; evenly mixing; adding water to dilute and confirm solution contents and adding water to dilute to a volume, wherein the fat-soluble active ingredients comprise 6-18 million IU of vitamin A, 1.8-4.8 million IU of vitamin D3 and 2.5-7.5g of vitamin E, and the water-soluble active ingredients comprise 1-4g of vitamin B1, 0.2-1.0g of vitamin B2, 1.6-4.2g of vitamin B6, 5-25g of barberry extractive and 30-60g of amino acid. The product is clear and transparent, has good stability, slow-release effect, persistent drug effect, great specific surface area of nanoemulsion particles and good system compatibility, can obviously improve the drug absorption rate and the bioavailability and can be compounded with various useful elements besides vitamins.

Owner:山东恩诺基生物工程有限公司

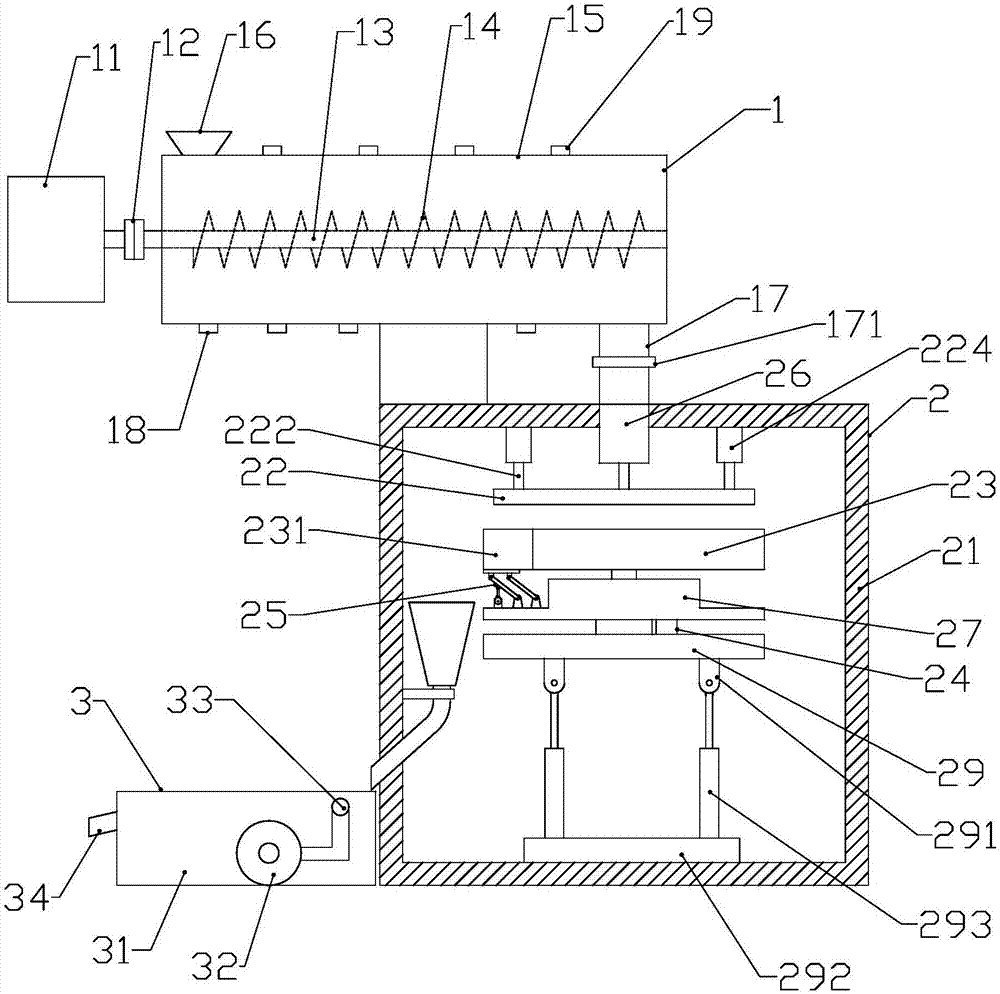

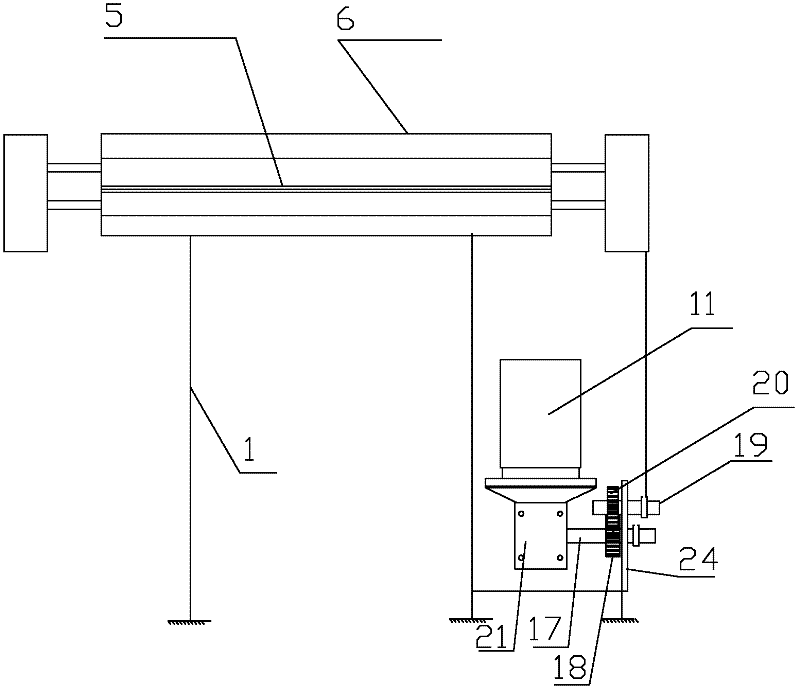

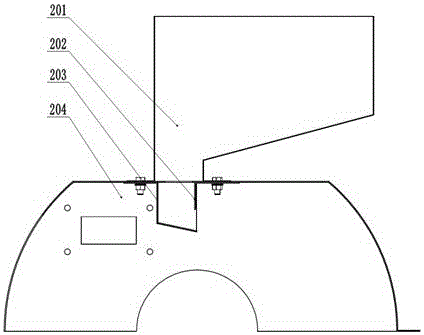

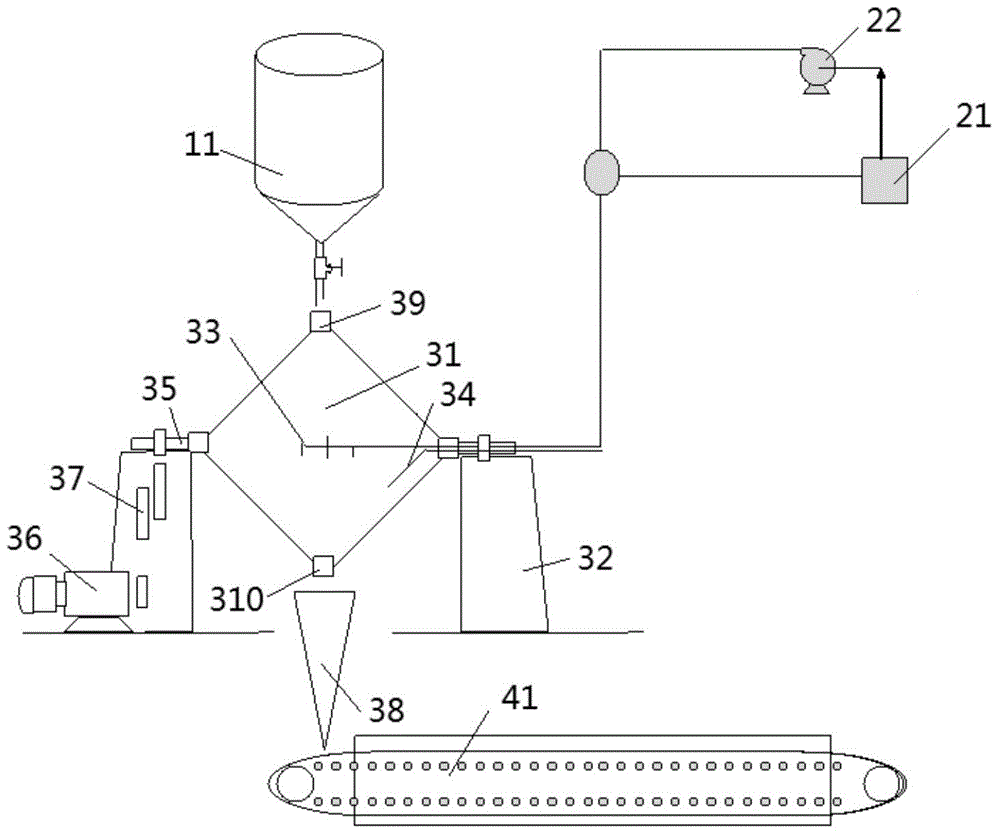

Castanea mollissima shelling device

The present invention discloses a castanea mollissima shelling device and belongs to shelling devices. A structure comprises a conveying heating mechanism, an extruding mechanism and a separating mechanism. The extruding mechanism is arranged at a lower part of the conveying heating mechanism, the separating mechanism is arranged at a lower part of the extruding mechanism, the conveying heating mechanism comprises a motor, a coupling, a rotation shaft, screw blades and a shell body, the rotation shaft and screw blades are arranged in the shell body, a material inlet is arranged at a left side of an upper part of the shell body, a material outlet is arranged at a right side of a lower part of the shell body, a material outlet valve is arranged on the material outlet, a plurality of hot air inlets are arranged at the lower part of the shell body, a plurality of moisture extraction outlets are arranged at the upper part of the shell body, and the material outlet is connected with the extruding mechanism. The castanea mollissima shelling device has characteristics of saving time and effort, not causing harms to human body, being high in shelling efficiency and suitable for large-scale processing and production of the castanea mollissima, etc.

Owner:INST OF QUALITY STANDARDS & TESTING TECH FOR AGRO PROD OF SHANDONG ACADEMY OF AGRI SCI

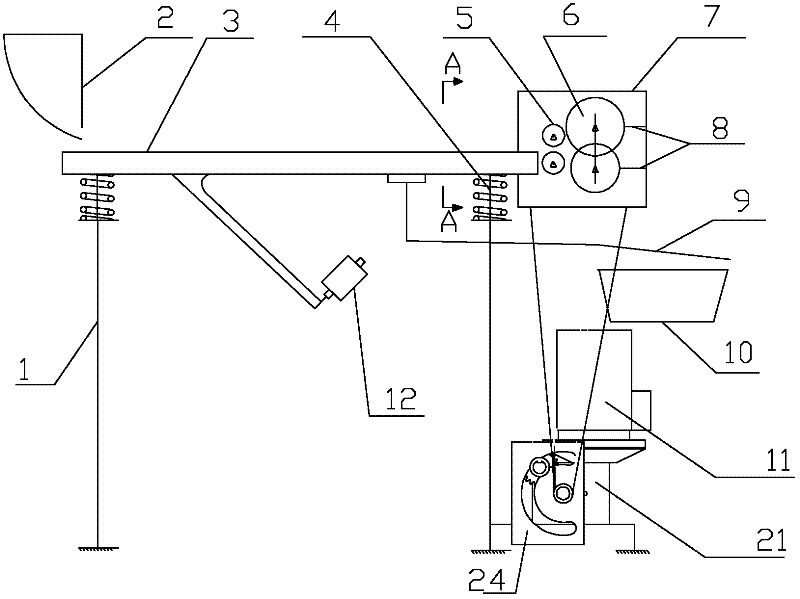

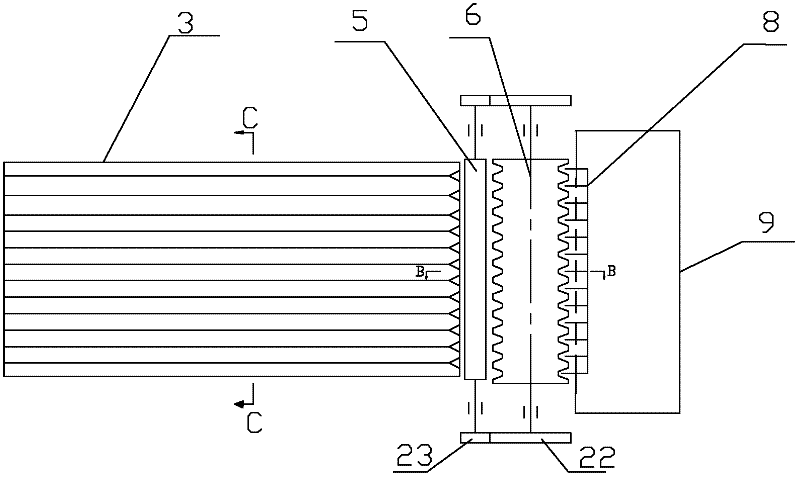

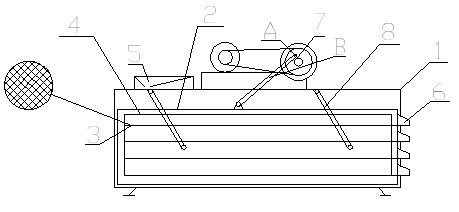

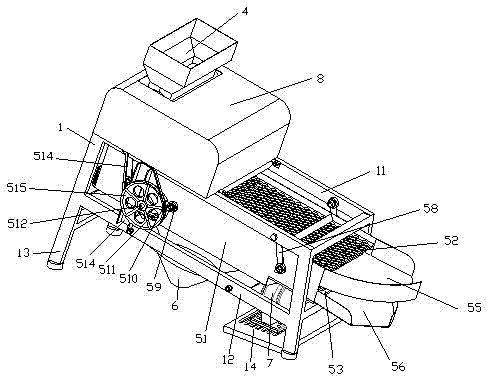

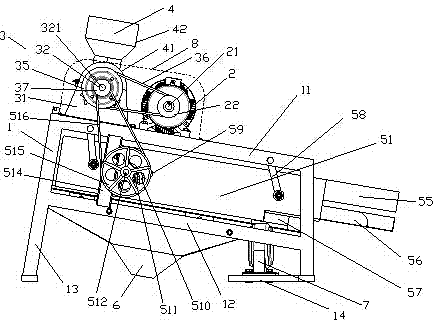

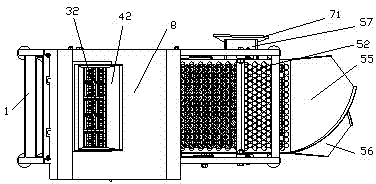

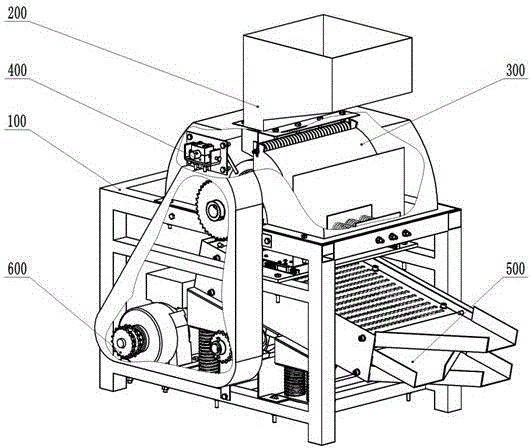

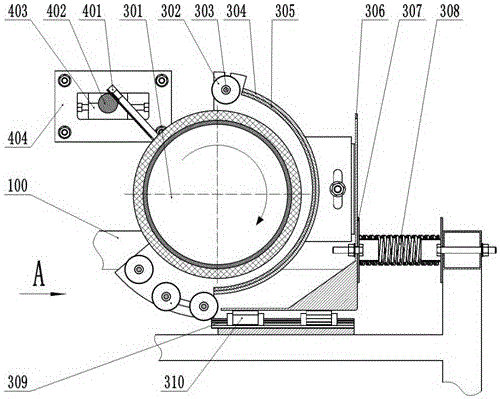

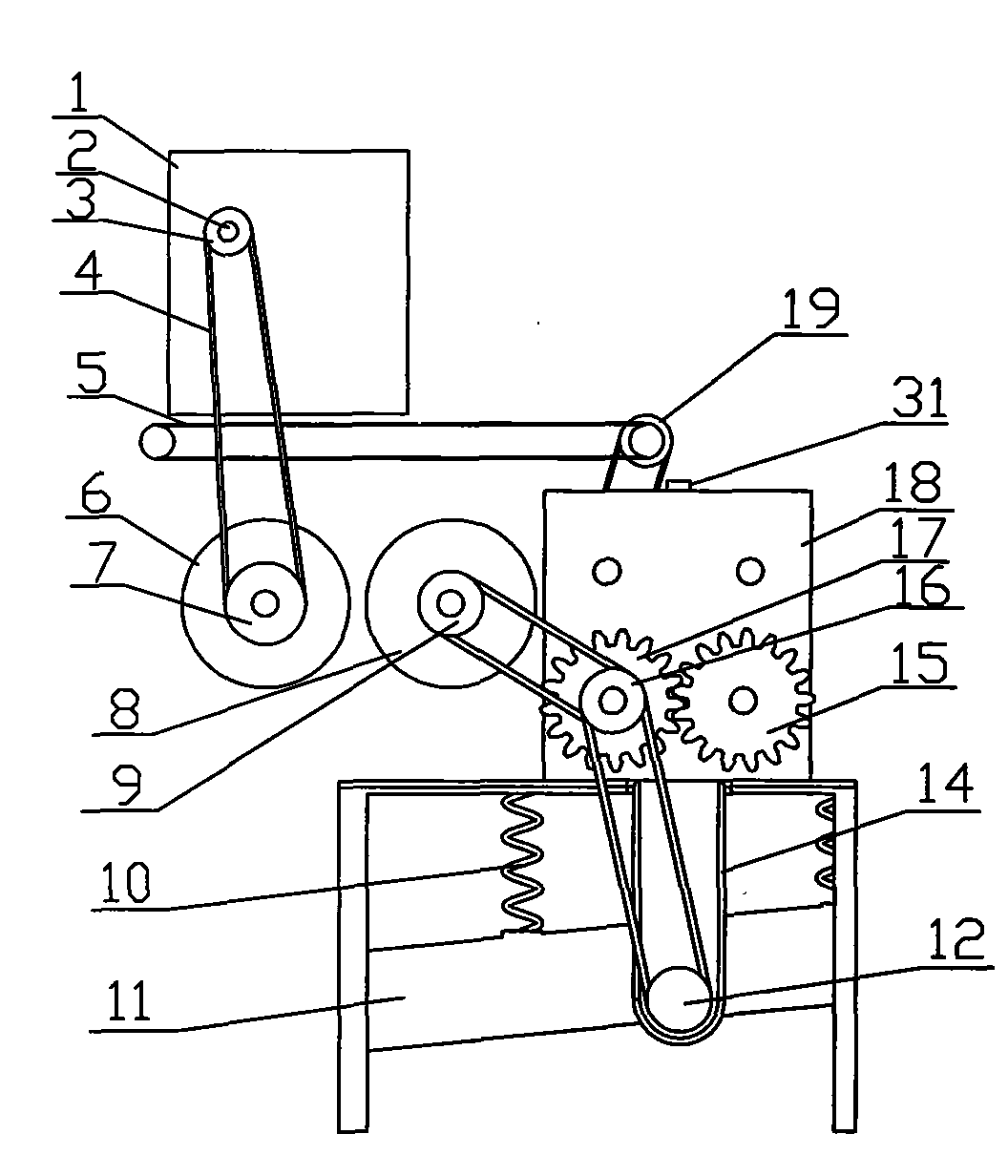

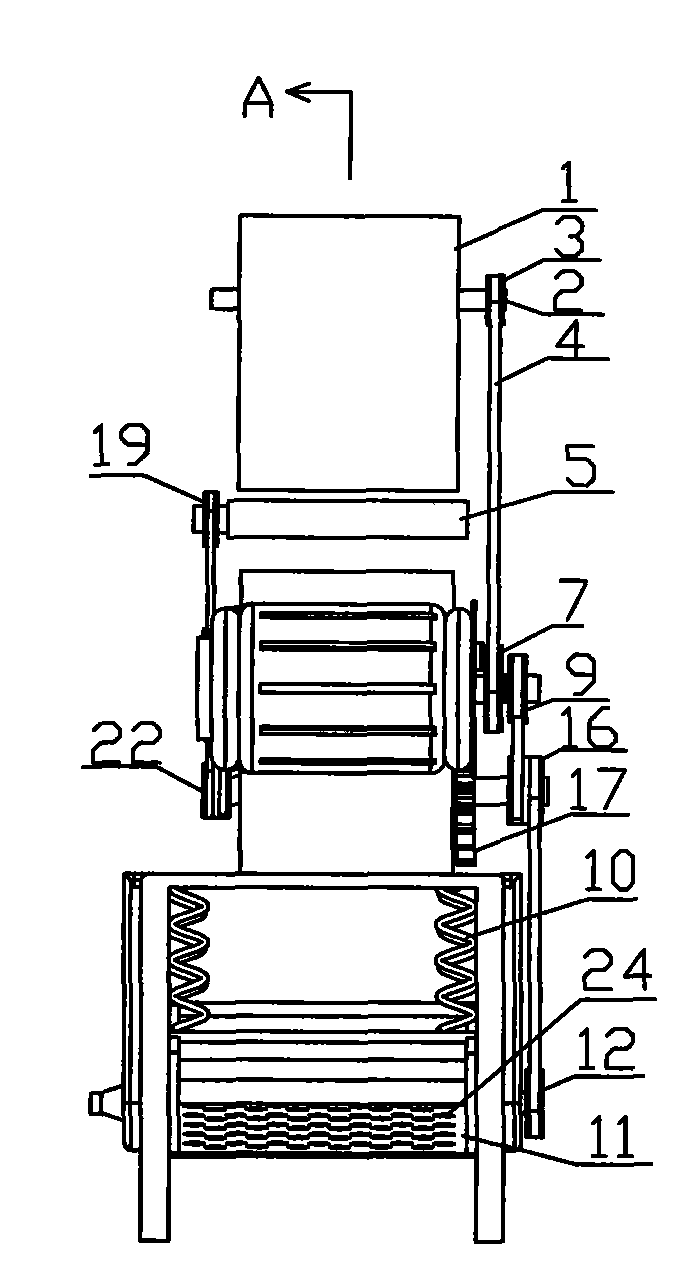

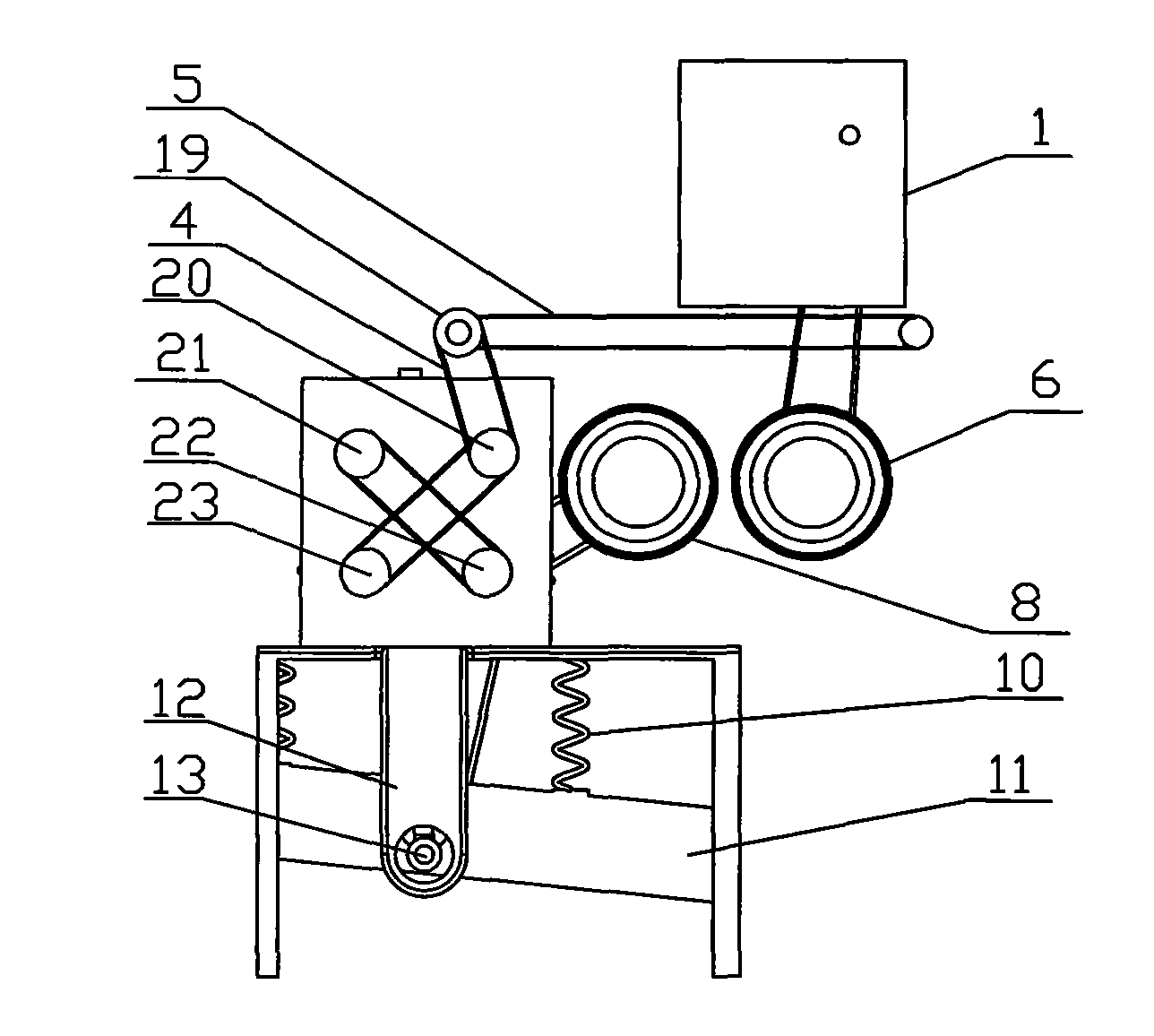

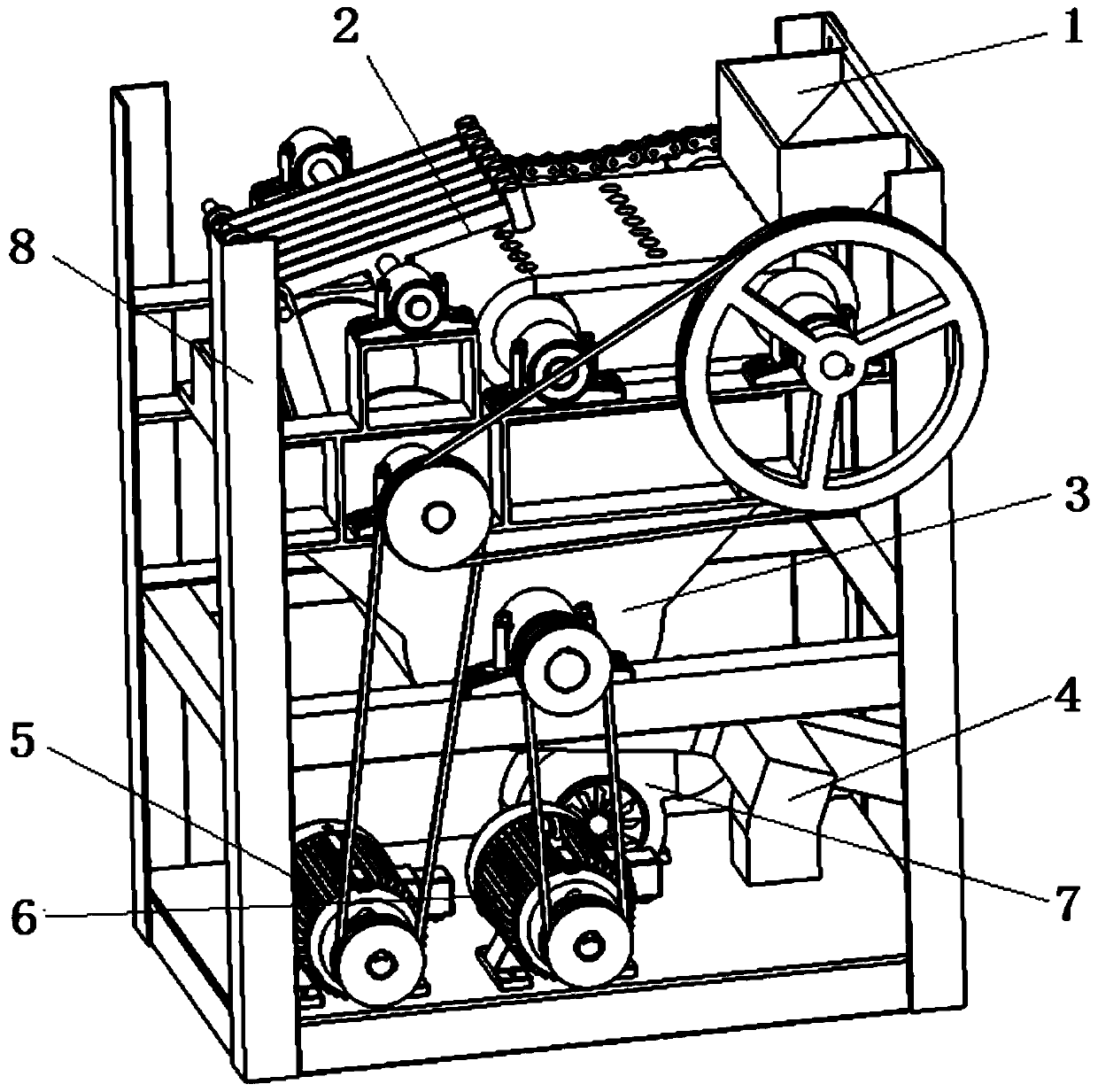

Sword bean sheller and sword bean shelling method

InactiveCN102326853AAchieve clean separationImprove shelling rateHuskingHullingElectric machinerySword beans

The invention provides a sword bean sheller and a sword bean shelling method. The sword bean sheller comprises a rack, a feed hopper, a vibration bed body, a vibration driving mechanism, a clamping roller pair, a shelling roller pair, a roller bearing seat, a roller box body, a transmission mechanism, a main motor, a cleaning comb, a separation screen and a material receiving box, wherein the vibration bed body is fixed on the rack, the feed hopper and the roller box body are respectively fixed on the head end and tail end of the vibration bed body; the clamping roller pair and the shelling roller pair are connected to the roller bearing seat and connected with the transmission mechanism; the clamping roller pair is provided with a clamping opening, the shelling roller pair is provided with a shelling cavity, and the upper surface of the vibration bed body, the central line of the clamping opening and the central line of the shelling cavity are in the same horizontal plane; the transmission mechanism is connected with the main motor; the cleaning comb is arranged on the side of the shelling roller pair; the vibration driving mechanism is connected with the vibration bed body; the separation screen is arranged below the shelling roller pair; and the material receiving box is arranged below the separation screen. The sword bean sheller is high in shelling rate and low in labor intensity.

Owner:SOUTH CHINA AGRI UNIV

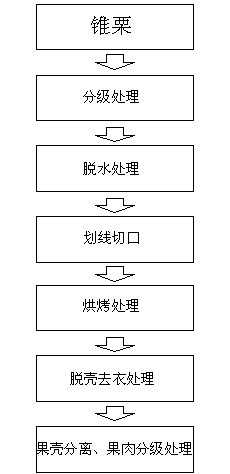

Processing method for shelling castanea henryi

The invention relates to a processing method for shelling a castanea henryi, which is characterized by comprising the following steps of: 1, carrying out stage treatment on the castanea henryi; 2. carrying out dewatering treatment on the castanea henryi; 3. carrying out tangential cutting treatment on the castanea henryi; 4. carrying out baking treatment on the castanea henryi; 5. carrying out shelling treatment on the castanea henryi; and 6. carrying out separating treatment on the shell of the castanea henryi and grading treatment on the pulp of the castanea henryi. The invention can improve the processing efficiency and lower the processing cost, the method has simple flow, and the used equipment has simple structure and is convenient to operate.

Owner:FUJIAN QINGRAN FOOD

Storing and processing method of rice

InactiveCN103053685AImprove freshnessIncrease elasticitySeed preservation by freezing/coolingRice dishesAgricultural engineering

The invention relates to a storing and processing method of rice and belongs to the technical field of crop processing. The process disclosed by the invention comprises the following steps: feeding into a warehouse: feeding wet rice into the warehouse; removing water: controlling the water content of the rice to 15-16% in a manner of warehouse ventilation; storing at low temperature: reducing the temperature of the warehouse to 18-25 DEG C to carry out low-temperature storage; and carrying out low-temperature and high-humidity processing. According to the process disclosed by the invention, the water content and the temperature of processing and storing the rice are controlled and the low-temperature and high-humidity processing is carried out at the water content and the temperature, so that the oxidation degree of fatty acid is low and the water absorbing speed in a process of immersing the rice to make rice is low; and the rice has the characteristics of small cracks in the water, good elasticity, good appearance and high freshness, and the rice has good edible quality, good mouth feel and good taste.

Owner:银尧明

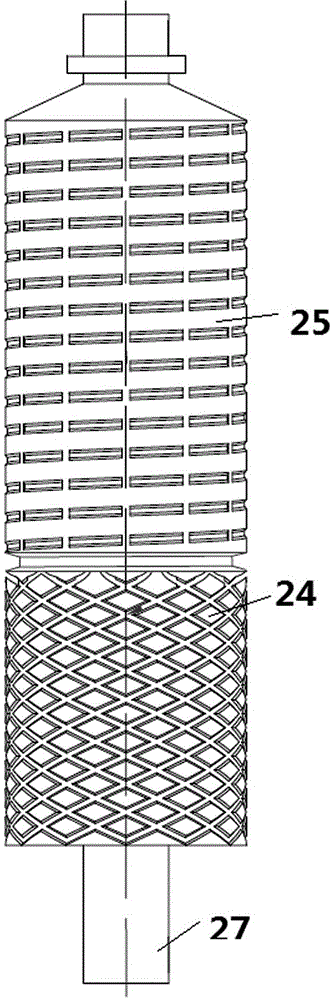

Tartary buckwheat non-thermal shucking method and Tartary buckwheat shucking device

InactiveCN103920555AThe shelling process is simpleSave energyGrain huskingGrain polishingComposite materialFagopyrum tataricum

The invention discloses a Tartary buckwheat non-thermal shucking method which includes the steps: removing impurities in raw materials; grinding the Tartary buckwheat raw materials by the aid of small contact force, grinding off protruding corner angle portions on Tartary buckwheat shells, and sufficiently grinding the corner angle portions on the Tartary buckwheat shells but not grinding endosperms and conical surface ventral groove recesses; enabling the shells to slightly deform by twisting, grinding or slightly striking, further fracturing the shells and finally separating the shells from kernels by an airflow cleaning method. By the novel method including non-thermal shucking, non-pressure grinding and the like, nutritional components are kept, shucking cost is low, shucking rate is high, and kernel breaking rate is low.

Owner:NORTHWEST A & F UNIV

Camellia fruit huller

The invention discloses a camellia fruit huller, which comprises a rack, an electromotor, a hulling device, a material inlet and a screening device, wherein the rack comprises an upper cross bar frame, a lower cross bar frame and supporting legs, wherein the upper side of one end of the upper cross bar frame of the rack is provided with the electromotor and the hulling device; the hulling device comprises a shell and a central hulling mechanism, wherein the top and the bottom of the shell are respectively provided with an opening; the upper end of the shell is seamlessly connected with the material inlet; two sides of the shell are respectively provided with a bearing pedestal; the central hulling mechanism is arranged on the bearing pedestals; the screening device is arranged between the upper cross bar frame and the lower cross bar frame and comprises a shell, a first-level screening net, a second-level screening net and a third-level screening net. The camellia fruit huller has a firm and stable structure, husks can be prevented from falling, safety is improved, the hulling ratio is higher than 98%, a breakage rate is lower than 1.1%, husk seed screening efficiency is improved, the purity of the hulled tea seed is higher than 97%, the use ratio of the electromotor is improved, a power loss rate is lower than 3%, and electricity energy is saved.

Owner:ZHONGKAI UNIV OF AGRI & ENG

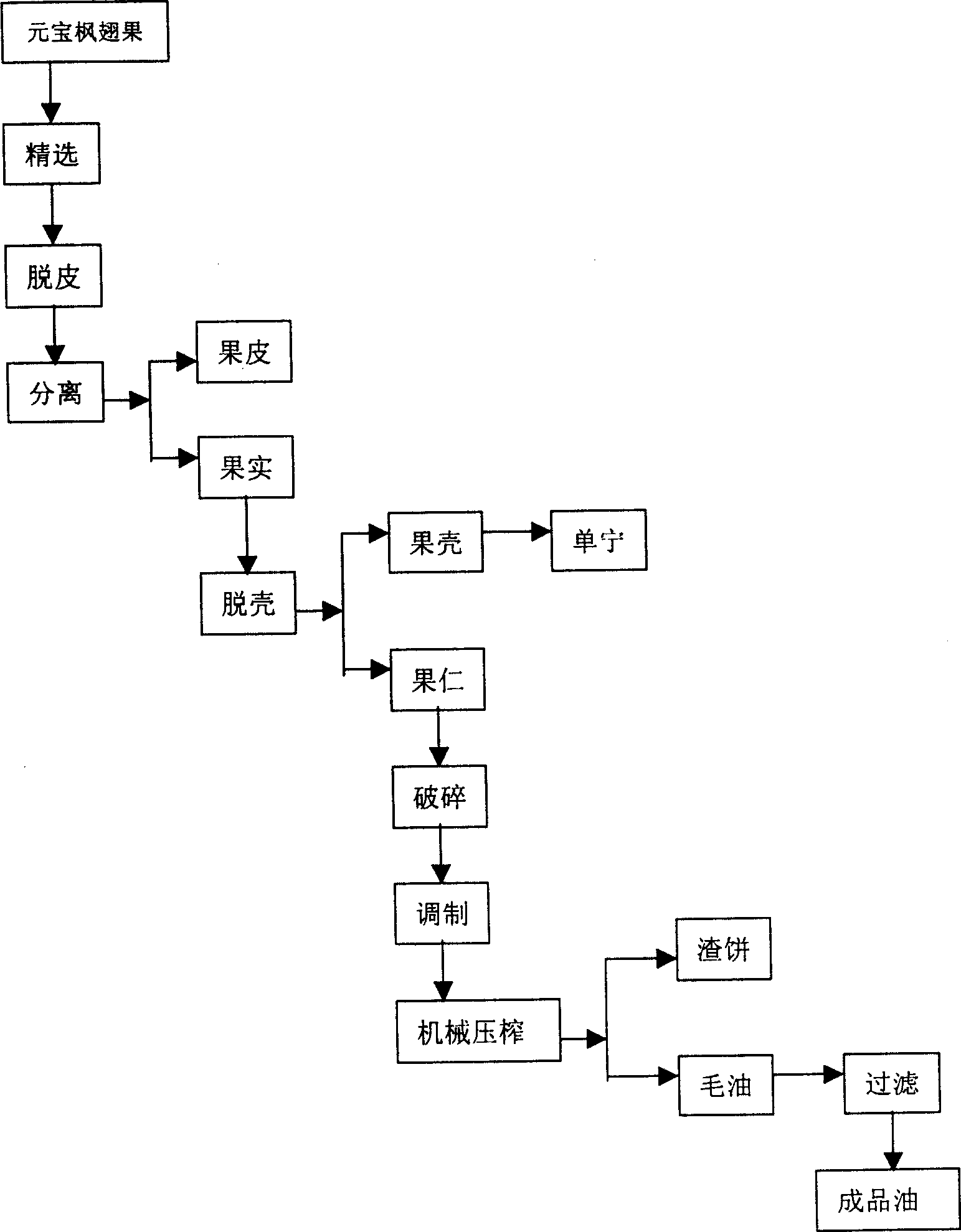

Five-split maple oil preparation process

The invention relates to a preparation method for Acer Truncatum Buge Oil, which comrpsies: fine selecting, peeling, separating, shelling, breaking, concocting, mechanical expressing, and filtering. The advantages of this invention include: improving oil quality, reducing product cost, needs no chemical treatment, and ensuring high yield and protection to benefit nutrition.

Owner:陕西宝枫科技股份有限公司

Automatic purification husking device for rice processing

InactiveCN108855305AImprove the rice yieldEffective tearing and peelingGrain huskingGrain polishingEngineeringUltimate tensile strength

The invention provides an automatic purification husking device for rice processing. The automatic purification husking device comprises a device shell and a feeding hopper. The feeding hopper is connected to the upper end of the device shell in an inserted and penetrating mode, and the lower end of the feeding hopper reaches an inner cavity of the device shell and is connected to the upper end ofa cleaning device in a penetrating mode. The upper end of the cleaning device is fixedly connected to the inner top wall of the device shell, and a motor is welded to the upper end of the outer sidewall of one side of the device shell through a first bracket. The automatic purification husking device overcomes the deficiencies of the prior art, has reasonable design and a compact structure, effectively purifies dried-up seed and grass seed in rice, improves the milled rice rate of the rice and can timely and effectively transport the processed brown rice; and the labor intensity of rice processing personnel is reduced, and the quality of the brown rice is improved.

Owner:怀宁县谷丰米业有限公司

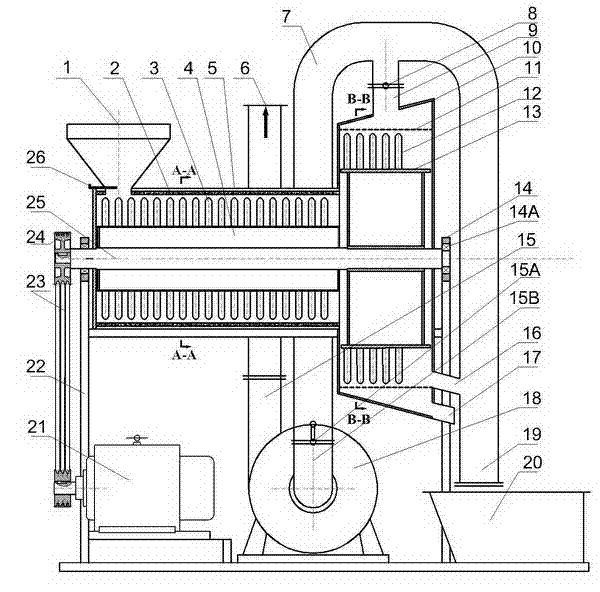

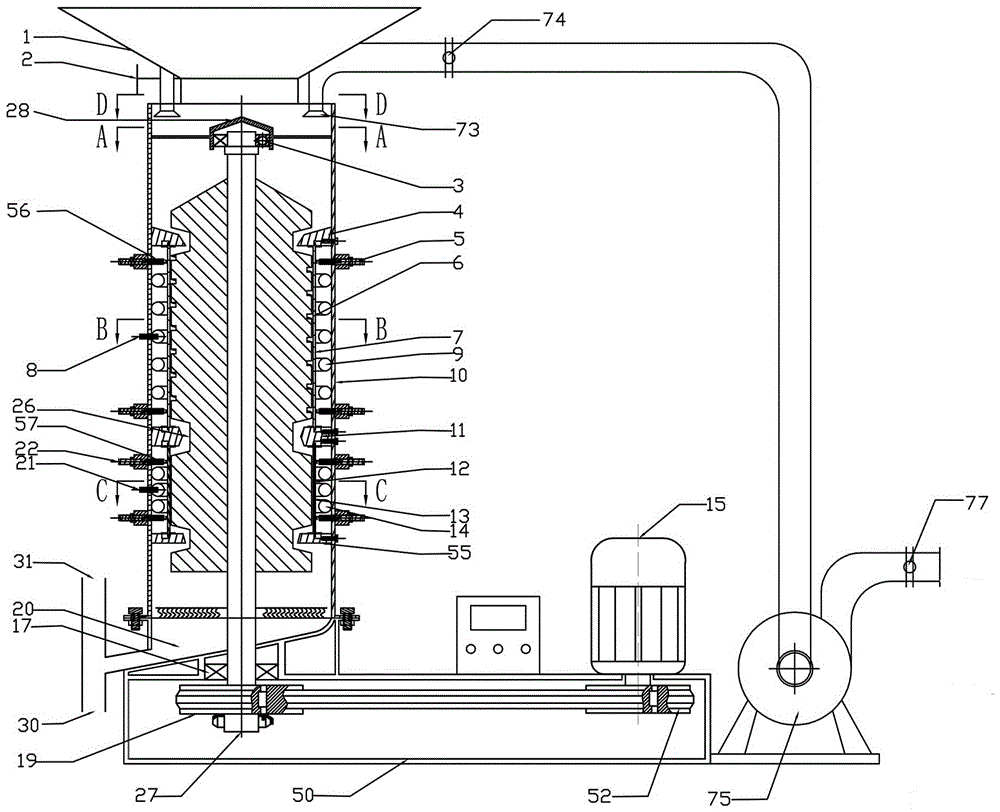

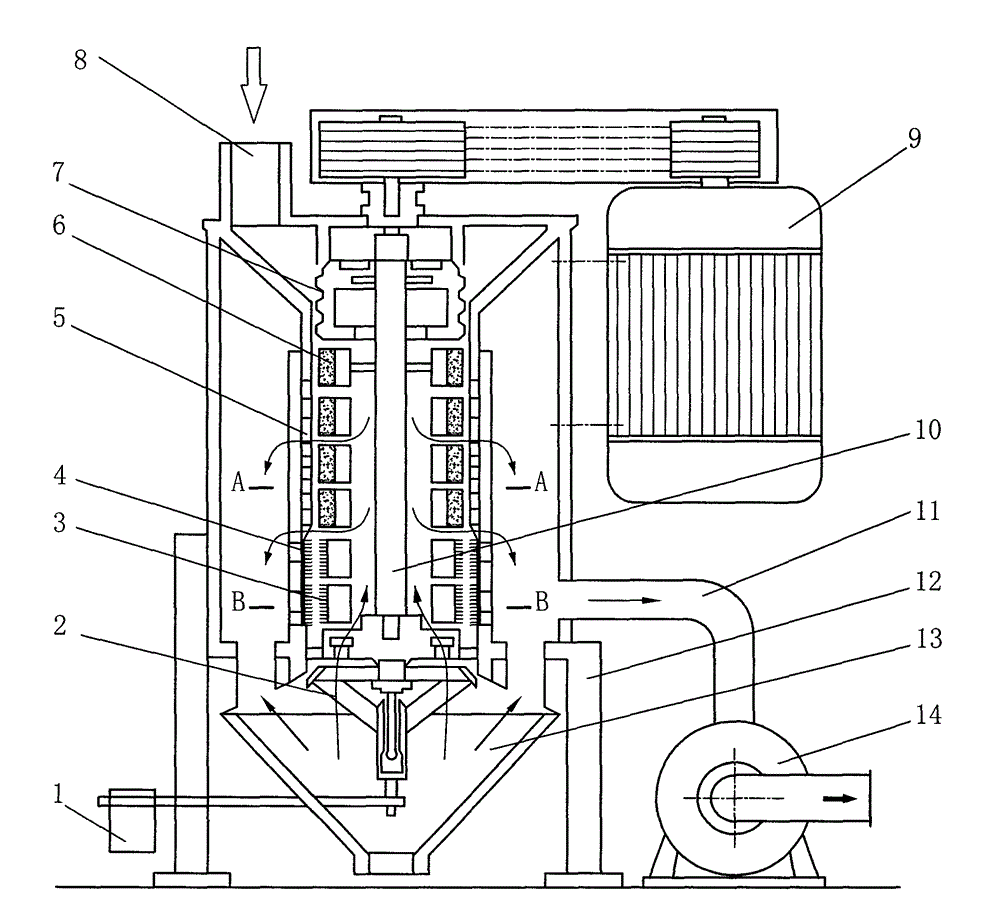

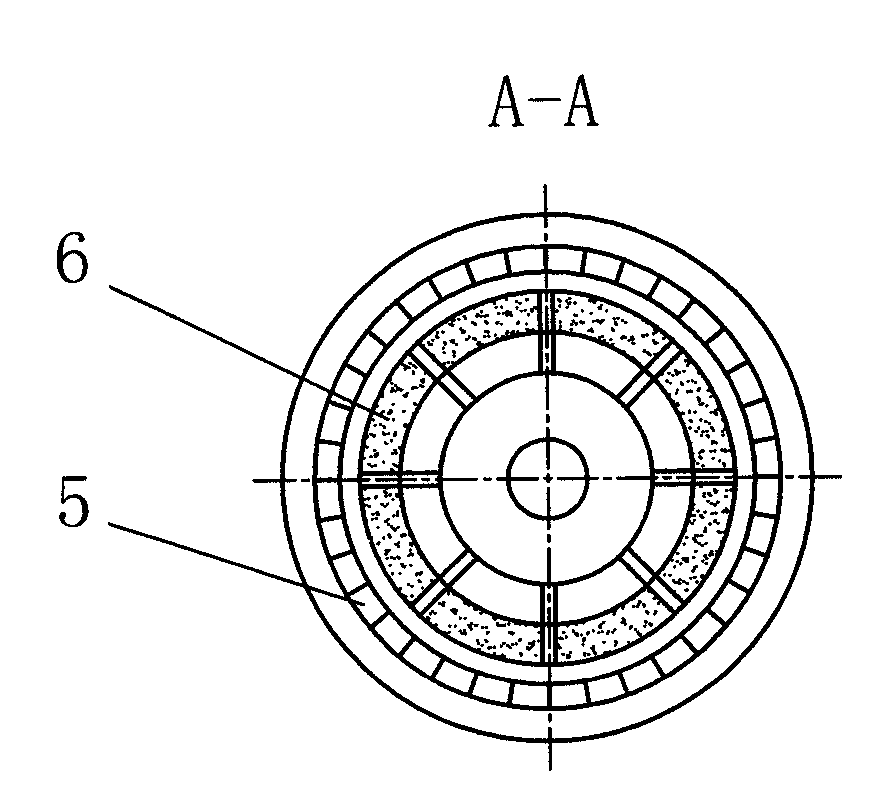

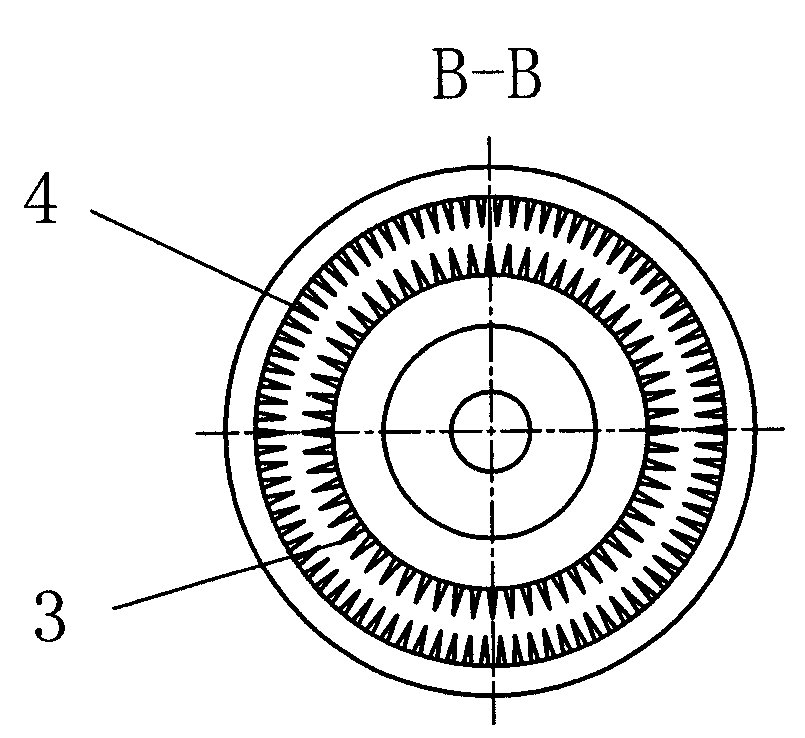

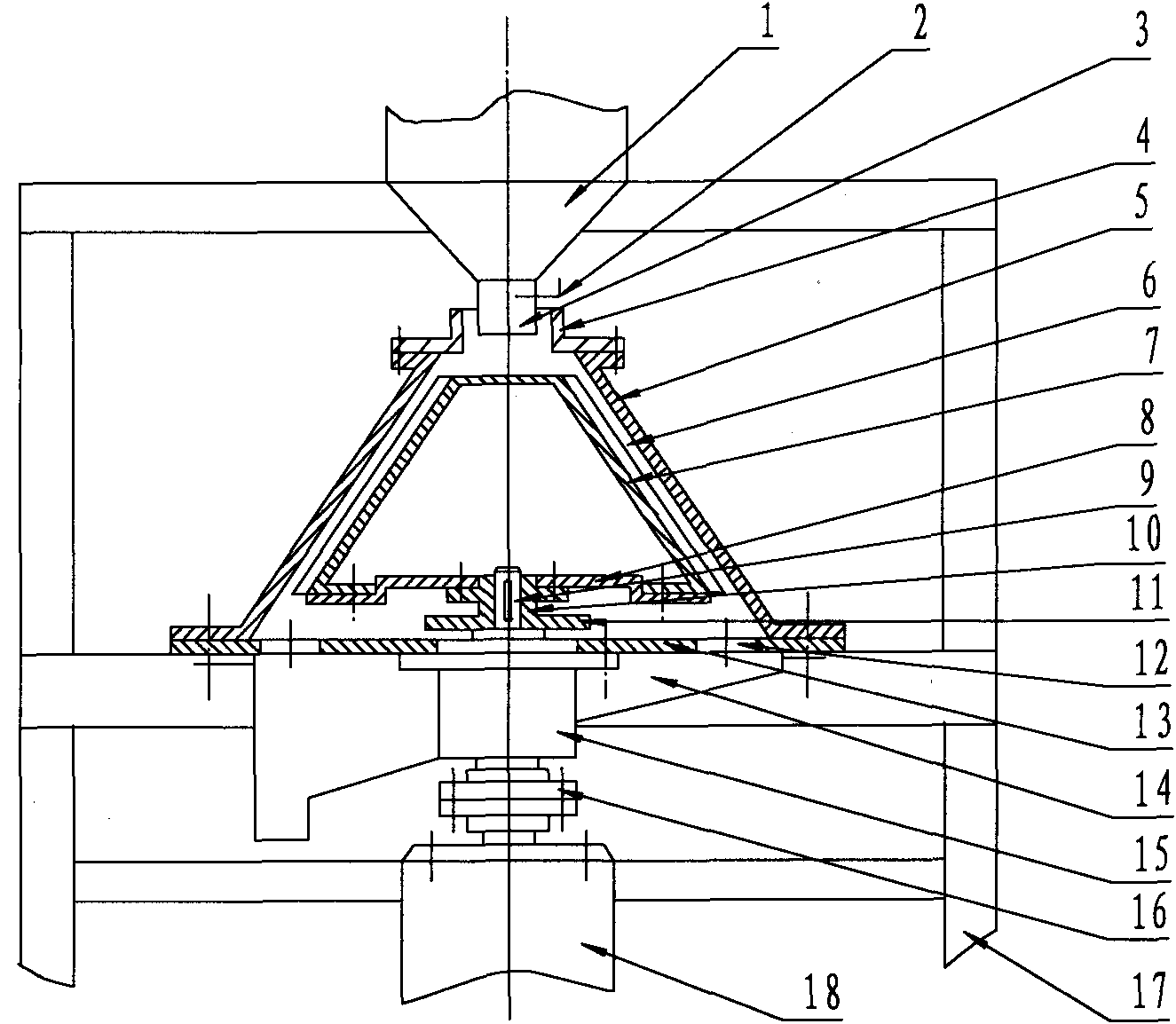

Air-breathing type tartary buckwheat low-pressure grinding huller

ActiveCN106391173AGrind fullyReduce wrapping forceGrain huskingGrain polishingPolygonum fagopyrumWorking pressure

The invention discloses an air-breathing type tartary buckwheat low-pressure grinding huller, and belongs to the field of grain hulling machines. The huller comprises a machine shell, a grinding cylinder is vertically fixed at the center of the machine shell, a grinding air bag is mounted between the grinding cylinder and the side wall of the machine shell, and grinding rollers are concentrically mounted in the grinding cylinder; a feed hopper is mounted at the top of the grinding cylinder, and a feed control door is arranged at the bottom of the feed hopper; a kneading cylinder is arranged just below the grinding cylinder, a kneading air bag is mounted between the kneading cylinder and the machine shell, and kneading rollers are concentrically mounted in the kneading cylinder; a material flowing groove is formed below the kneading cylinder, and a hulled material outlet and a cleaning device connector are arranged obliquely below the material flowing groove. An air suction pipe is mounted at the top of the machine shell and is connected with a fan. In the whole hulling process, due to the buffering effect of the grinding air bag and the kneading air bag, the working pressure of tartary buckwheat is very low and is dynamically regulated; and meanwhile, an air suction component can immediately clean dusts, cool down and dehumidify, prolong the grinding process, and effectively improve the complete kernel yield of the tartary buckwheat during hulling.

Owner:NORTHWEST A & F UNIV

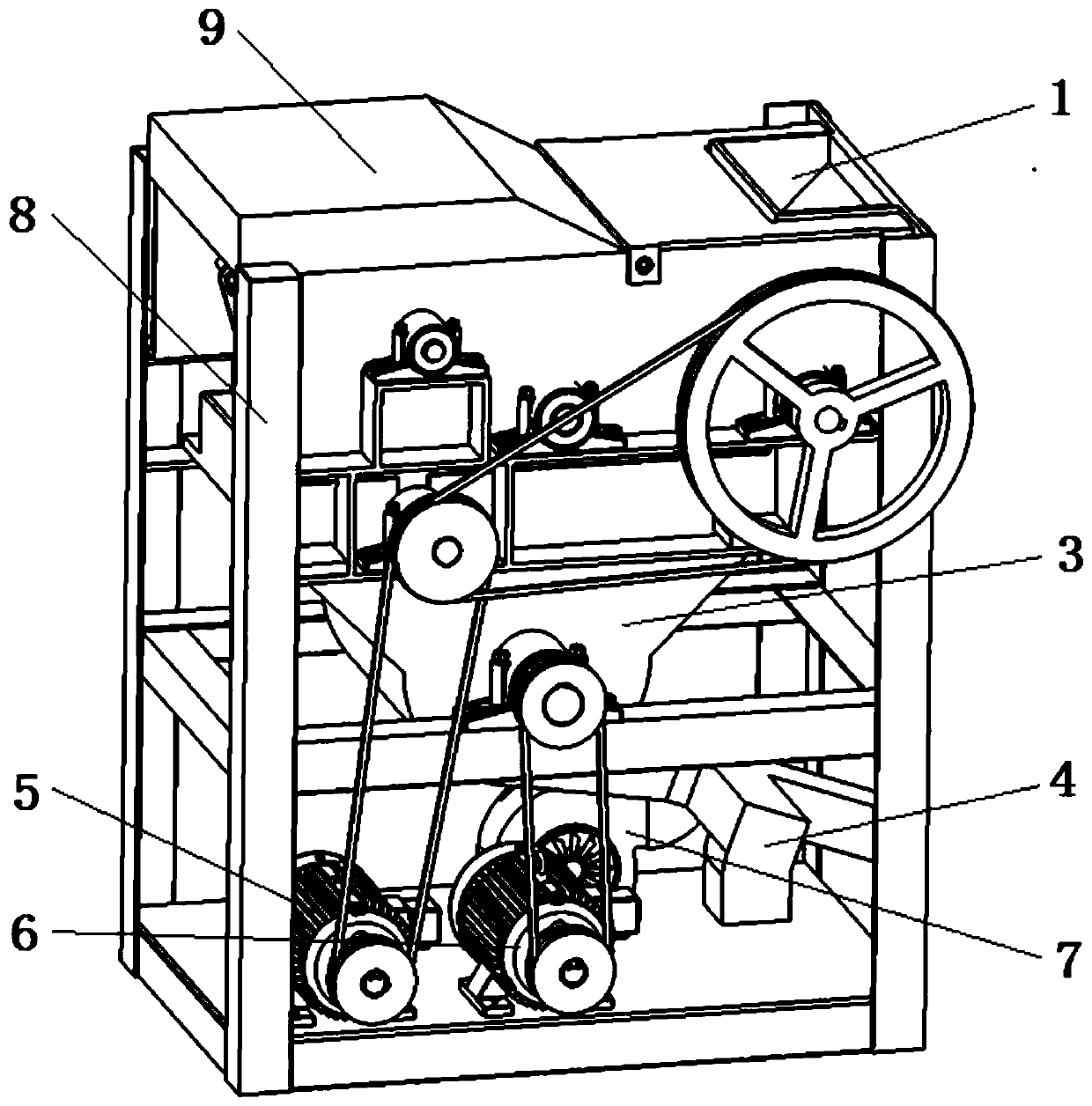

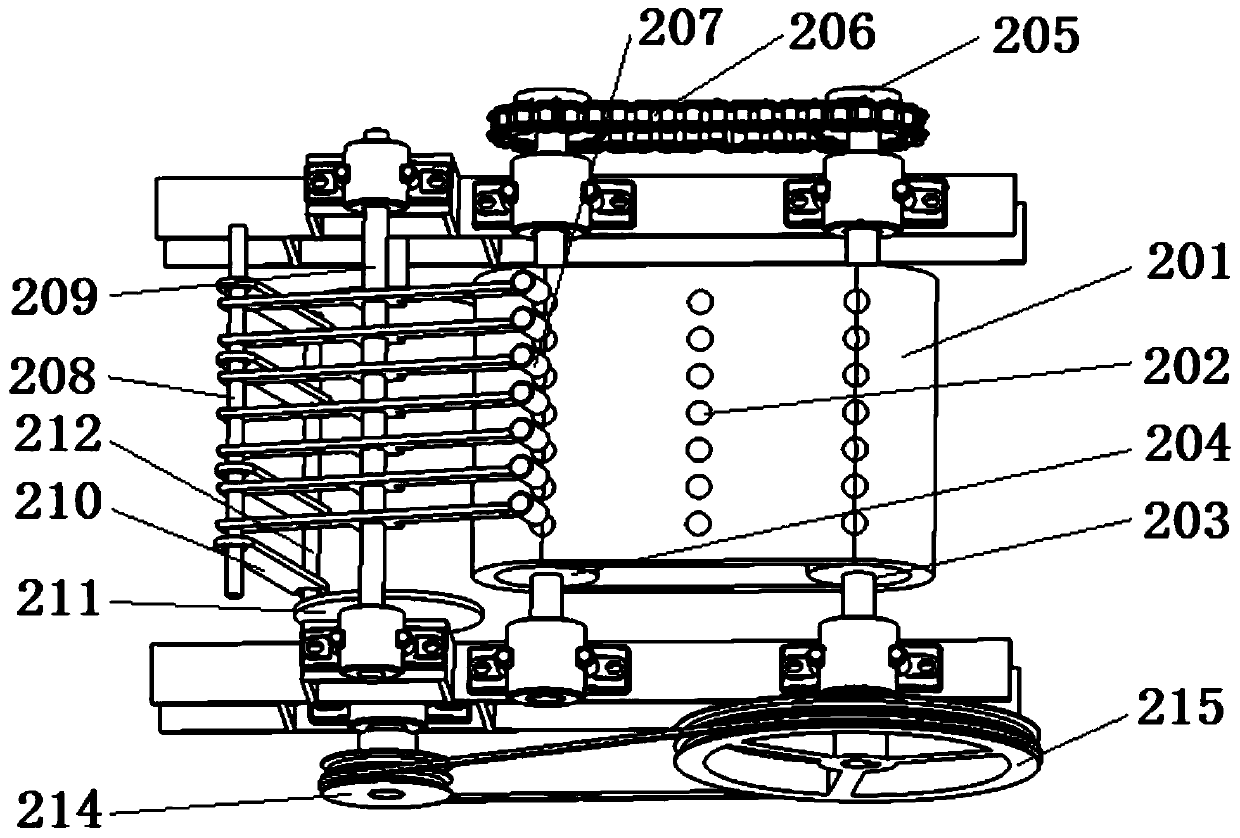

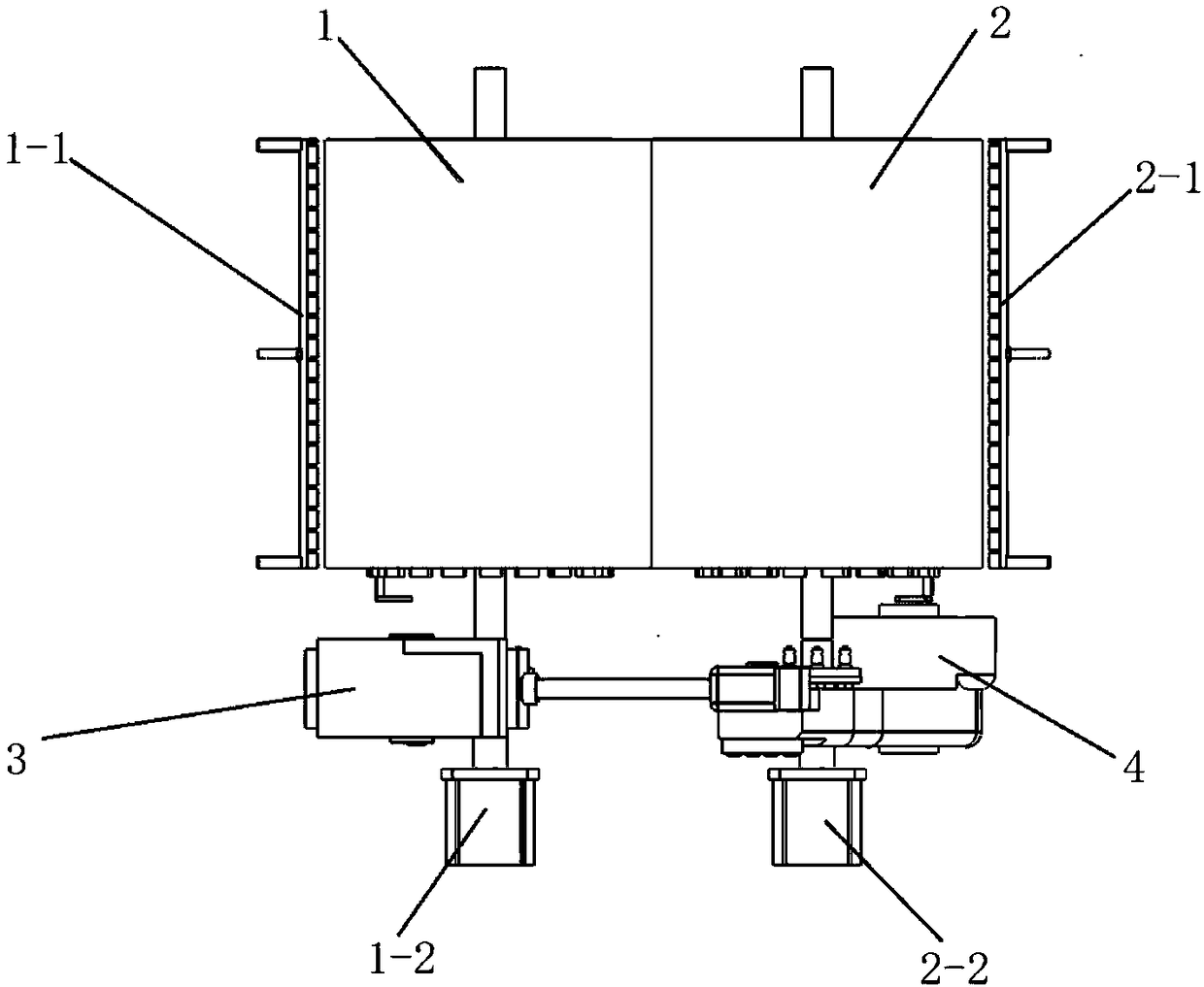

Circulating gap-changeable cutting and rubbing type soapberry husking device

The invention relates to the technical field of forestry machinery, and discloses a circulating gap-changeable cutting and rubbing type soapberry husking device. The circulating gap-changeable cutting and rubbing type soapberry husking device comprises a rack, a feeding device, a flexible extrusion cutting and rubbing device, a vibrating screen and a power transmission device, wherein the rack is used for supporting the feeding device, the flexible extrusion cutting and rubbing device, the vibrating screen and the power transmission device; the power transmission device is used for providing power for the flexible extrusion cutting and rubbing device and the vibrating screen respectively; soapberry enters the flexible extrusion cutting and rubbing device through the feeding device, and husking is realized after the soapberry is cut, extruded, ground and rubbed, so that seeds, relatively large peels and finely ground peels are obtained; and the vibrating screen is used for screening out the seeds, the relatively large peels and the finely ground peels. According to the circulating gap-changeable cutting and rubbing type soapberry husking device, circulating gap-changeable cutting and rubbing type husking can be performed on the soapberry, and the seeds and the peels are screened out, so that the device is simple in integral structure, reliable in function and high in efficiency.

Owner:BEIJING FORESTRY UNIVERSITY

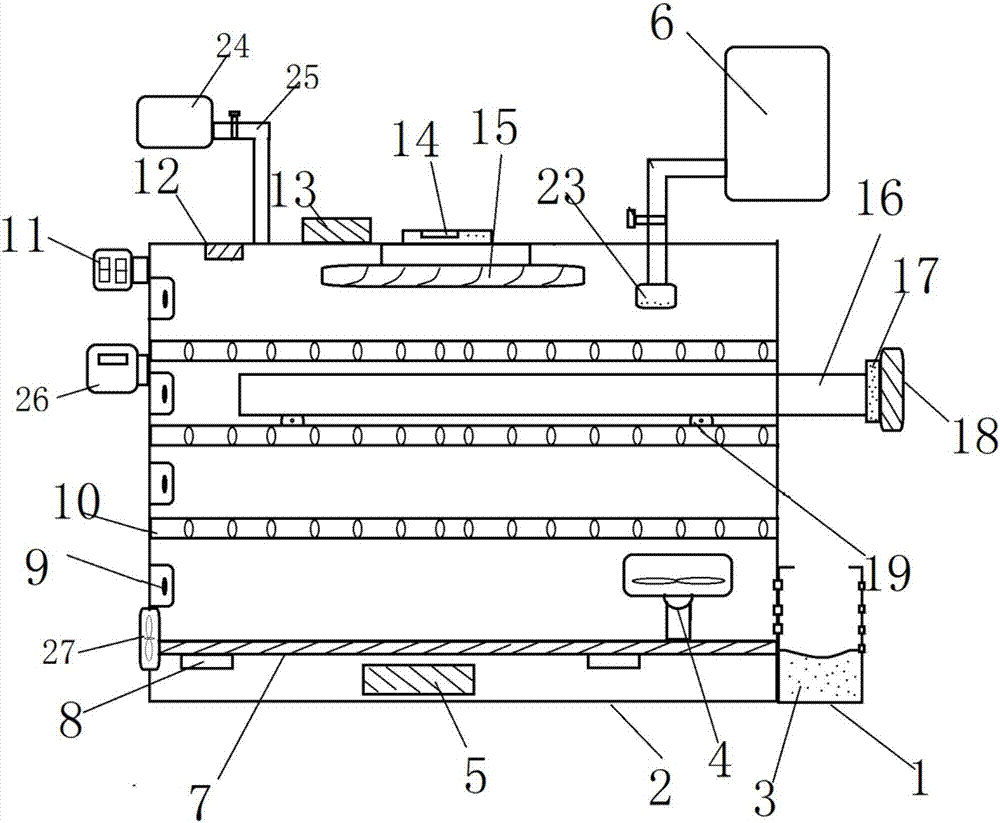

Intelligent poultry breeding sterilization incubator

InactiveCN106900596AGuarantee unimpededEasy dischargePoultry incubationUltraviolet lightsIncubation temperature

The invention discloses an intelligent poultry breeding disinfection incubator, which includes an air-drying box, a box body, a fan, a heater, a water tank, a camera, a partition board, a microprocessor, an ultraviolet light lamp, a hatching board, a groove and a partition bar. The box is provided with a guide plate, a heater is provided under the guide plate, an air-drying box is provided at the bottom of the side wall of the box body, a timer is provided on the outer wall of the box body, a radio transmitting device and a microprocessor are provided on the box body, The inner wall of the top of the box is equipped with ultraviolet light lamps. There are atomizing nozzles in the box. Divider, divider The Jiangnan Incubation Board is divided into multiple empty cabinets. There are grooves in the empty cabinets, and a camera is installed on one side of the partition board. The invention avoids the breeding of harmful bacteria from affecting the hatching rate and the health of chickens, ducks and other poultry, ensures suitable incubation humidity and temperature, has simple structure, is convenient to use, and is beneficial to popularization.

Owner:合肥红蔻健康管理有限公司

Processing technology for camellia oil

InactiveCN109593598AImprove shelling ratePure tasteFatty-oils/fats refiningFatty-oils/fats productionBranFood processing

The invention provides a processing technology for camellia oil and relates to the technical field of food processing. By taking camellia seeds, the oil content of which is 28-30%, as a raw material,the processing technology comprises the following steps: drying the camellia seeds and quick-freezing the camellia seeds; shelling the quick-frozen camellia seeds to obtain camellia seed kernels; mixing the micro-roasted camellia seed kernels with fresh bran coats uniformly, and carrying out low-temperature squeezing to obtain squeezed oil; and carrying out centrifugal filtration and distillationto obtain the camellia oil. The processing technology for camellia oil prevents generation of B(a)P in the processing course, is high in oil yield, and keeps the inherent smells and taste of the camellia oil. The camellia oil is pure in taste and natural nutritional components are kept intactly.

Owner:湖南泥头山油茶开发有限公司

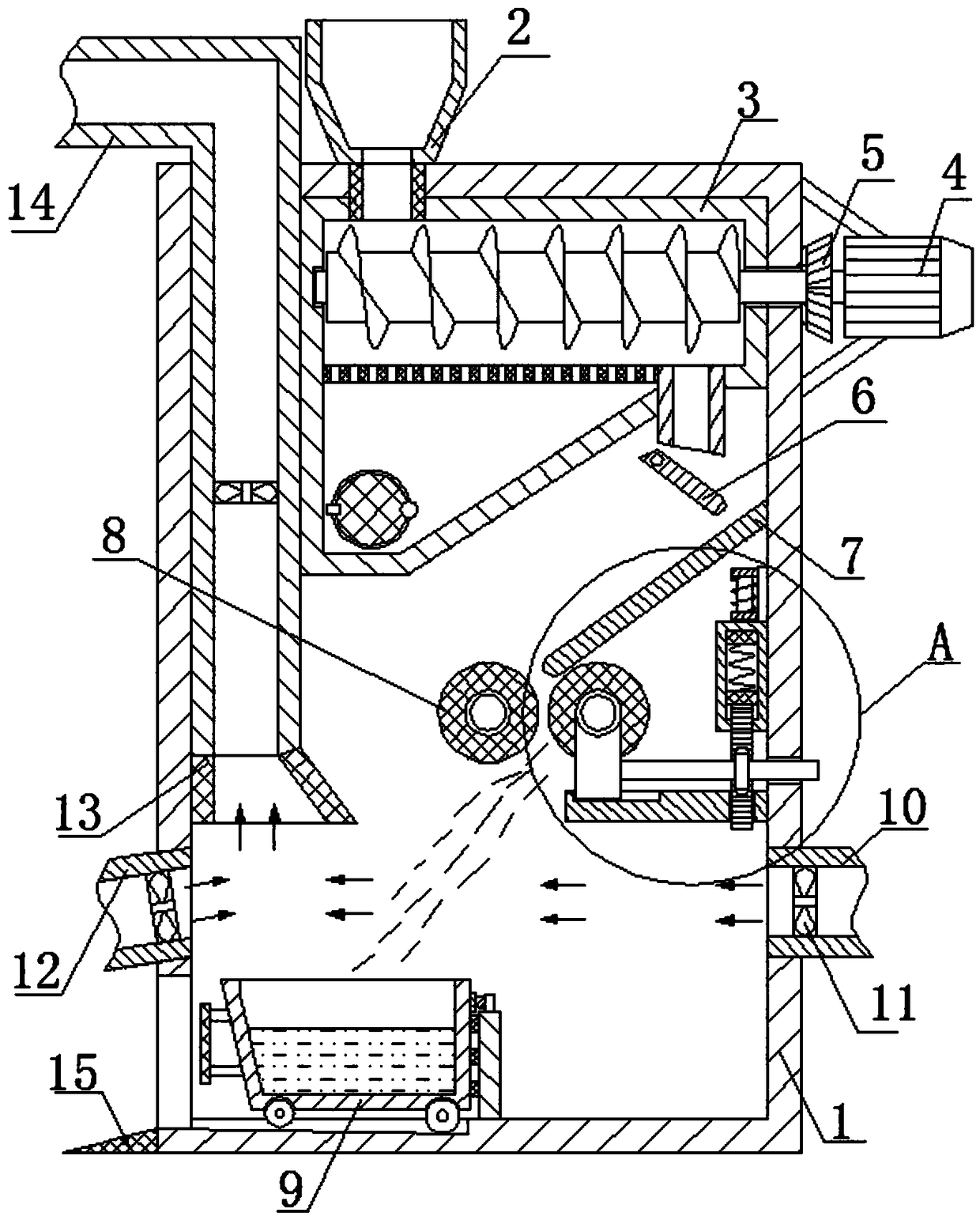

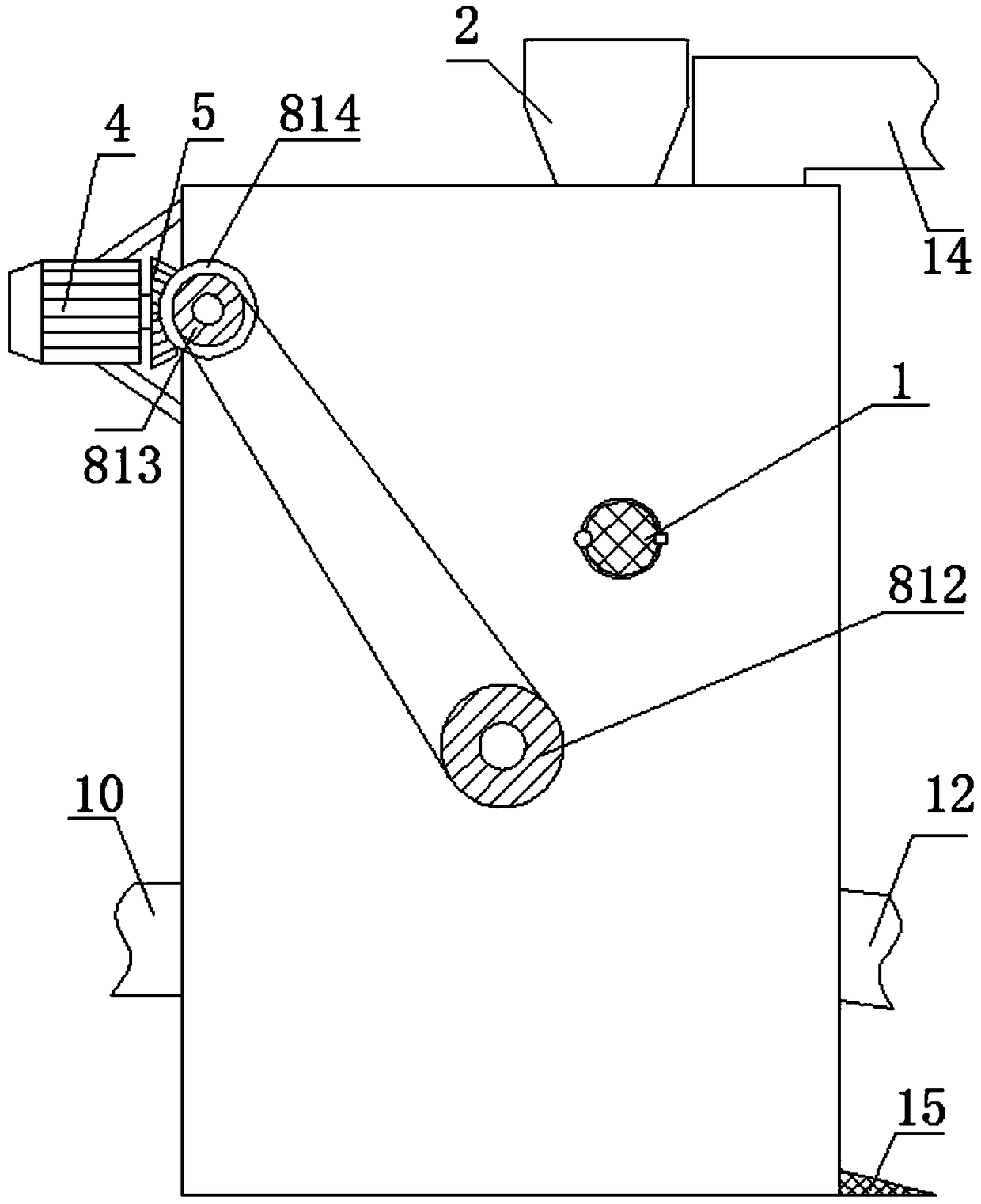

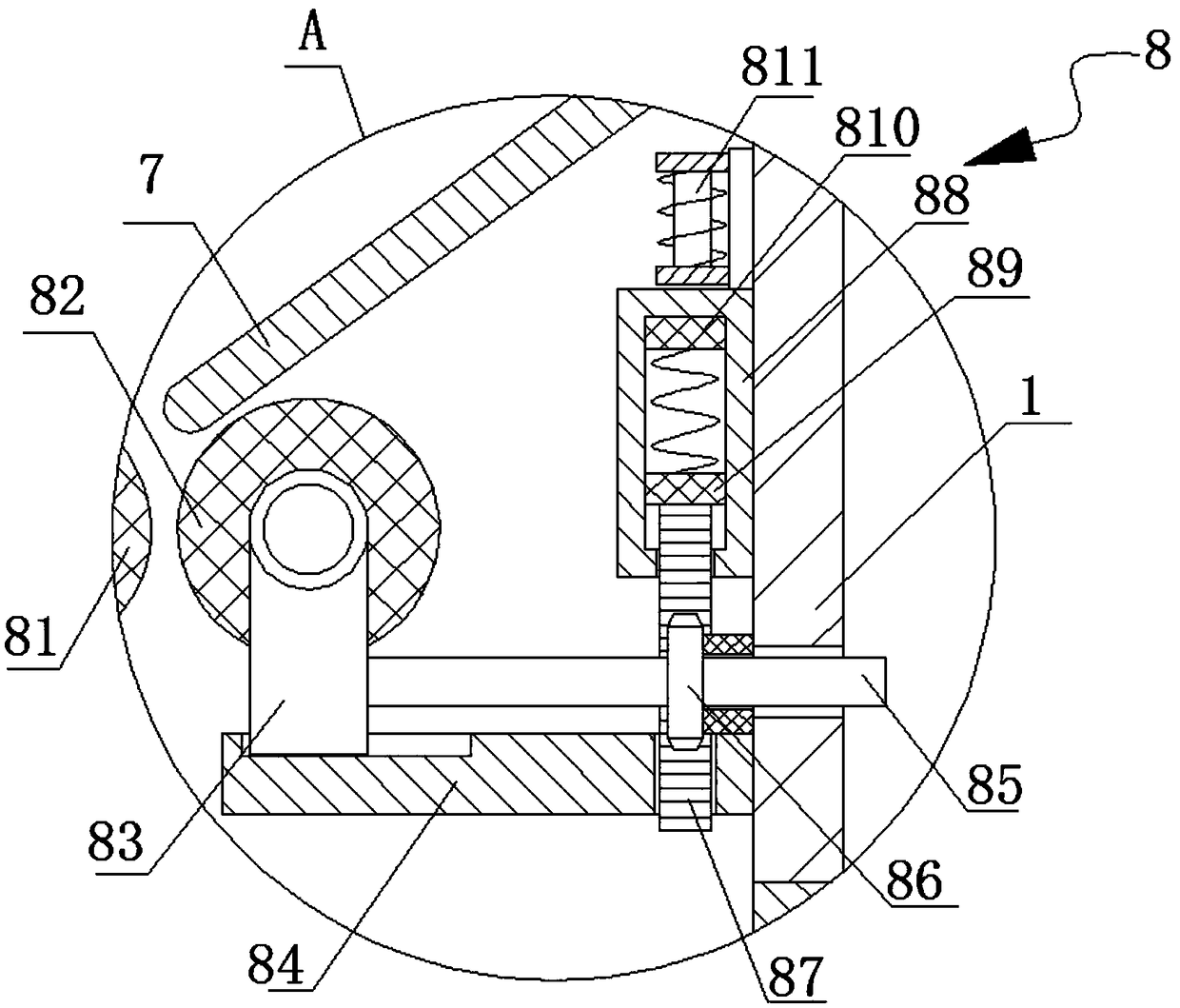

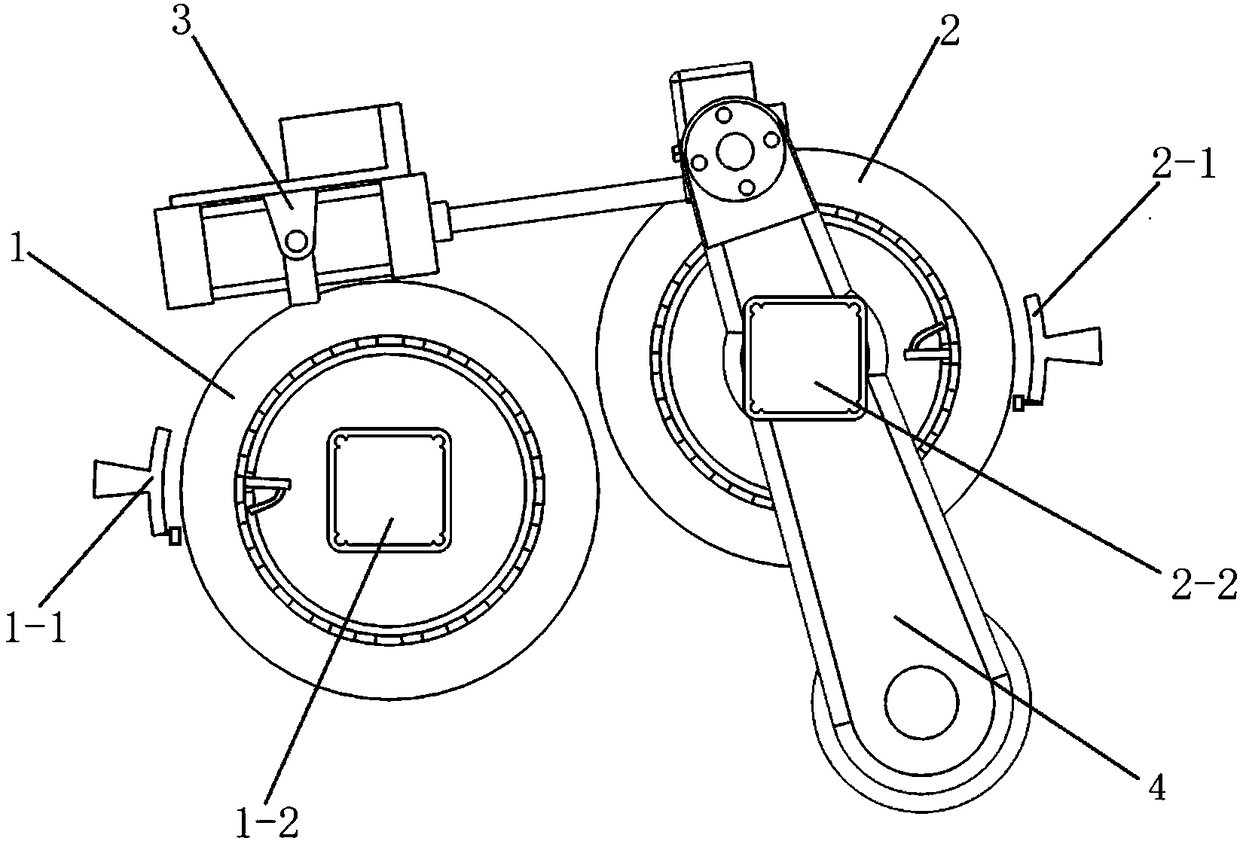

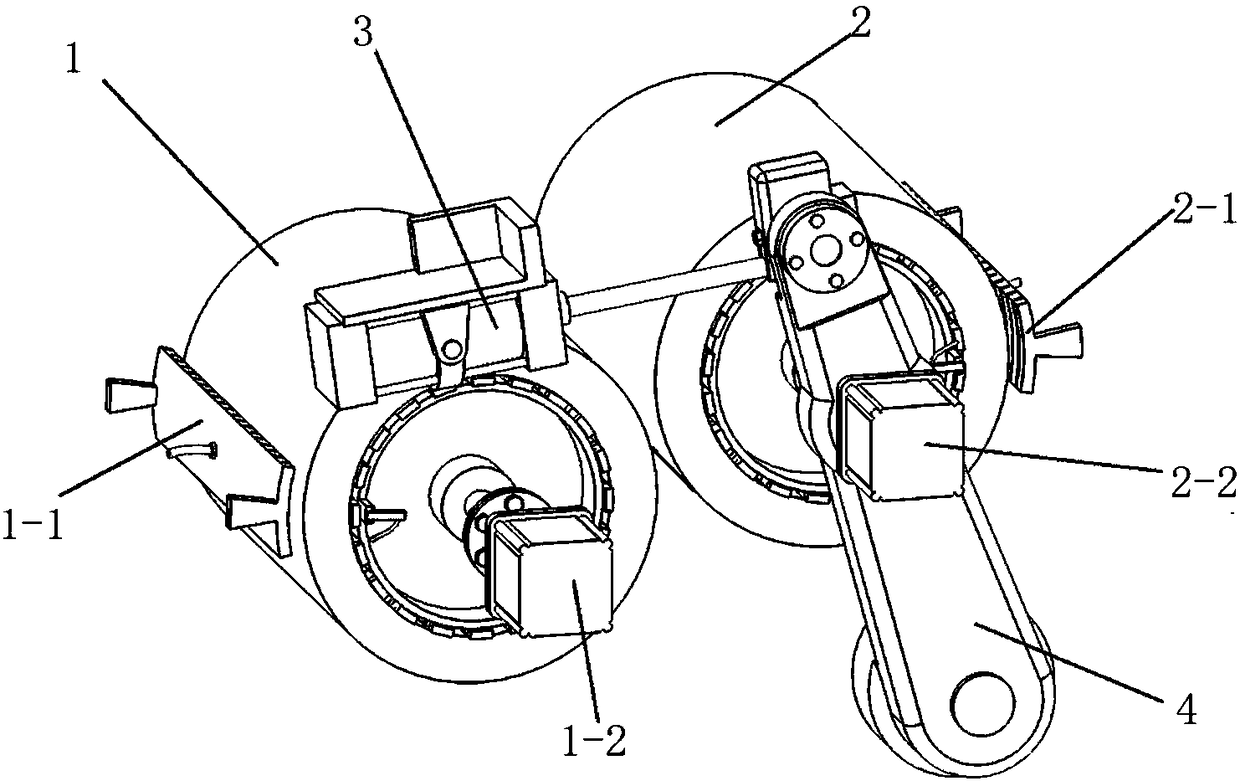

Walnut shell breaking device and application method thereof

The invention relates to a walnut shell breaking device and an application method thereof, belonging to the technical field of agricultural product processing. The shelling device of the present invention makes the water content of the walnut shells low enough to have the difference between the maximum elastic deformation and plastic deformation by controlling the freezing time, produces the maximum brittleness, is beneficial to shelling, greatly improves the shelling rate, and makes the shelling rate reach More than 98%; the flexible shear extrusion belt used for shelling of the present invention has low wear to the walnut kernel, so that the whole kernel rate reaches more than 90%, and the elastic force of the powerful spring can be adjusted to control the flexible shear in the device of the present invention. The wedge angle between the extrusion belt and the power grinding wheel can adapt to walnuts of different shapes and sizes, and has broad application prospects.

Owner:丁玉琴

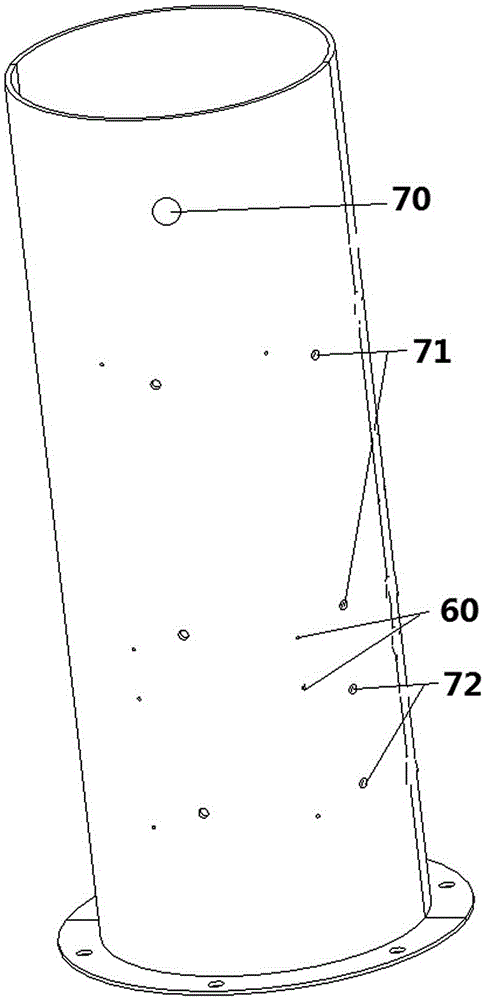

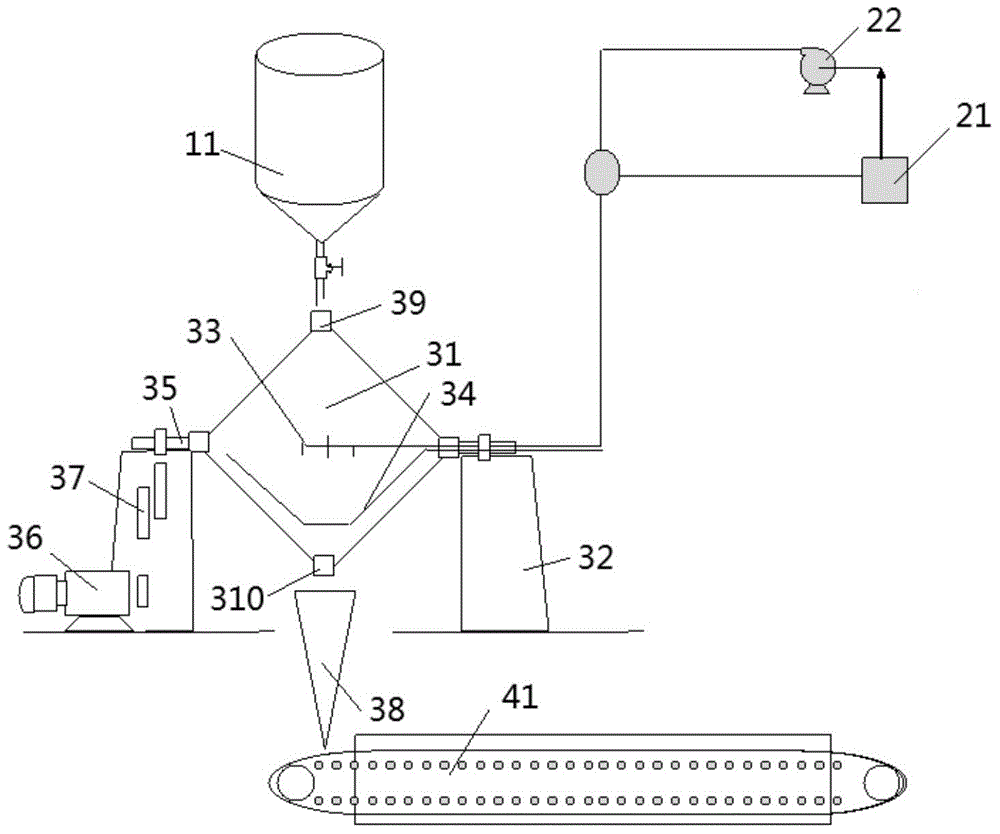

Vertical tartary buckwheat huller

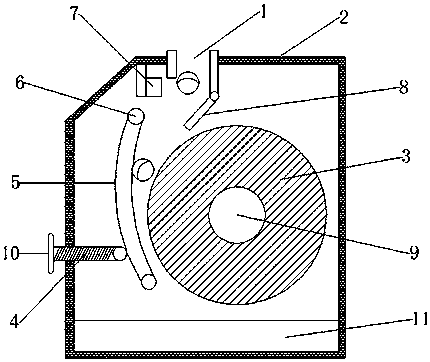

InactiveCN103599819AContinuously workingImprove shelling rateGrain huskingGrain polishingEngineeringSieve

The invention discloses a vertical tartary buckwheat huller. The huller comprises a rack, a feeding port is formed in the upper left corner of the rack, a rice sieve is arranged in the middle of the rack, and the upper end of the rice sieve is connected with the upper end of the rack. The upper end of the rice sieve is trumpet-shaped, and sieve holes are formed in the inner side of the lower end. The outside of the portion of the side wall of the lower end of the rice sieve, where the sieve hole is formed, is connected with a circular retaining plate with a fixed brush. A spindle penetrates centers of the rice sieve and the circular retaining plate perpendicularly, one end penetrates and is mounted on a bearing mounted on the rack, and the other end is connected with the lower end of the circular retaining plate with the fixed brush through a bearing block. A spiral conveyor is connected with the spindle and corresponding to the trumpet portion of the rice sieve, a sand ring is connected with the spindle and corresponding to the sieve hole portion in the side wall of the lower end, and a movable brush is connected with the spindle and corresponding to the fixed brush portion. A motor is fixed at the right corner of the rack and is connected with one end of the spindle, which penetrates the rack, through a rotation wheel and a belt. By means of the huller, the operation efficiency and the operation quality of tartary buckwheat hulling are improved.

Owner:NORTHWEST A & F UNIV +1

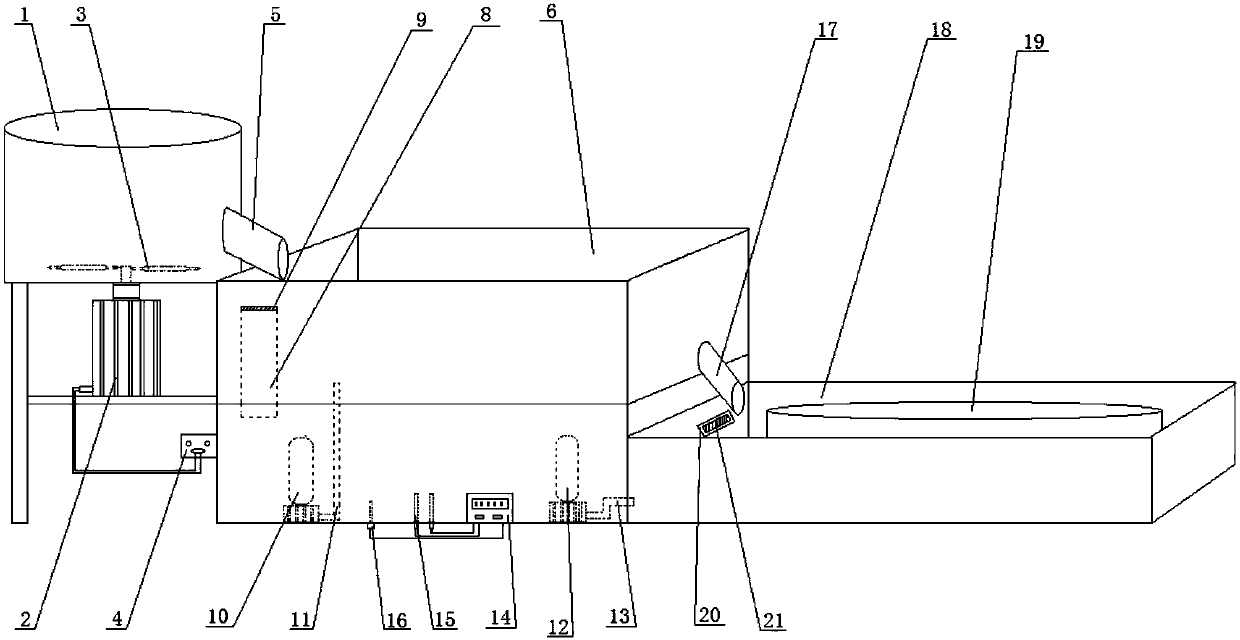

Refining method for rice processing

InactiveCN109954535AReduce moisture contentReduce extrusion pressureGrain treatmentsEconomic benefitsMagnetic separator

The invention discloses a refining method for rice processing, and belongs to the field of rice processing. The method comprises the steps that unhusked rice is tedded, specifically, the unhusked riceis tedded in a cement floor in a clear weather with sufficient sunlight; impurities in the unhusked rice are removed, specifically, the unhusked rice is conveyed to a vibrating screen and a magneticseparator in sequence; husked rice is wetted and dried, specifically, the unhusked rice is conveyed into an atomizing device through a conveyor belt, is wetted and then is heated by adopting an automatic constant-temperature heating device; husking is carried out, specifically, the unhulled rice is conveyed into a rice huller for husking treatment; paddy separation is carried out, specifically, the husked rice is conveyed to a specific gravity paddy separator through a conveyor belt for paddy separation; the husked rice is wetted and dried, specifically, the husked rice is conveyed into the atomizing device through the conveyor belt and is wetted; rice milling is carried out, specifically, a rice mill is adopted, it is guaranteed that the stone content of cleaned grains is smaller than 1 grain / kg; milled rice is wetted; the milled rice is polished; color sorting is carried out; sterilizing is carried out; and packaging is carried out. The method has the advantages that the broken ricerate is lower, the appearance quality of the rice is good, the edible quality is high, and the economic benefits of rice processing enterprises are increased.

Owner:安徽宏虎粮油股份有限公司

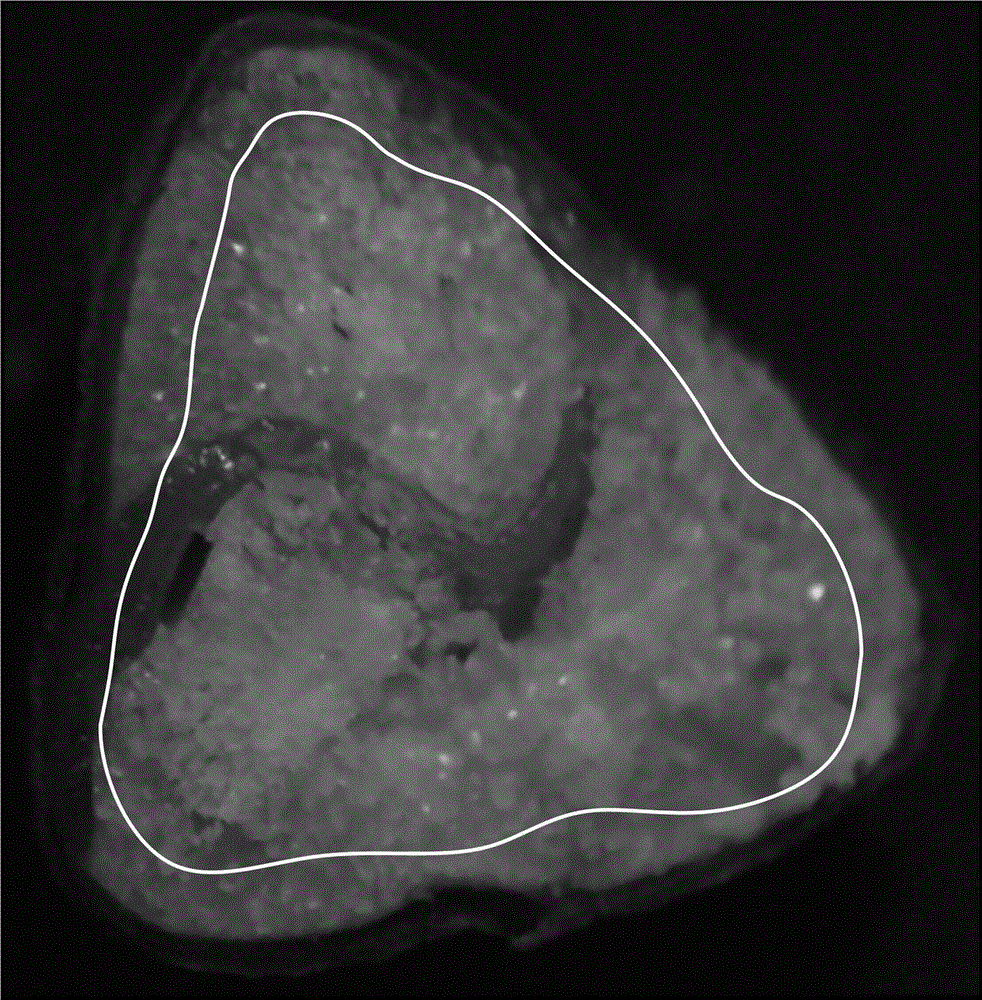

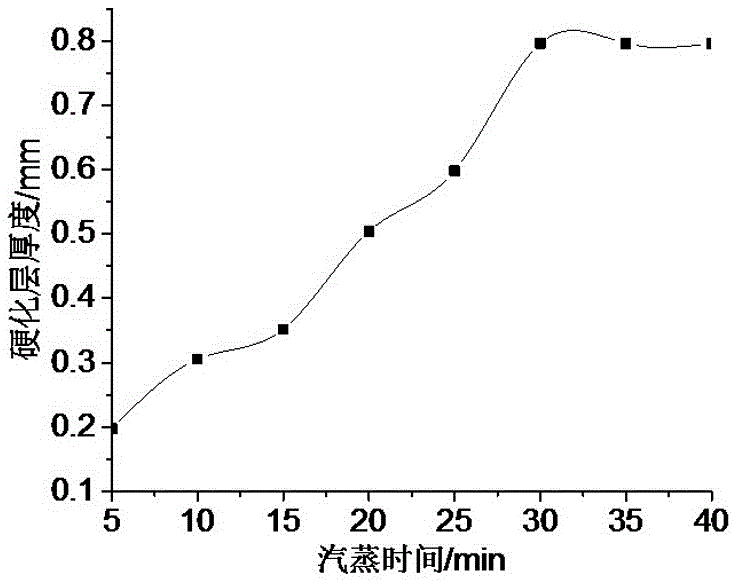

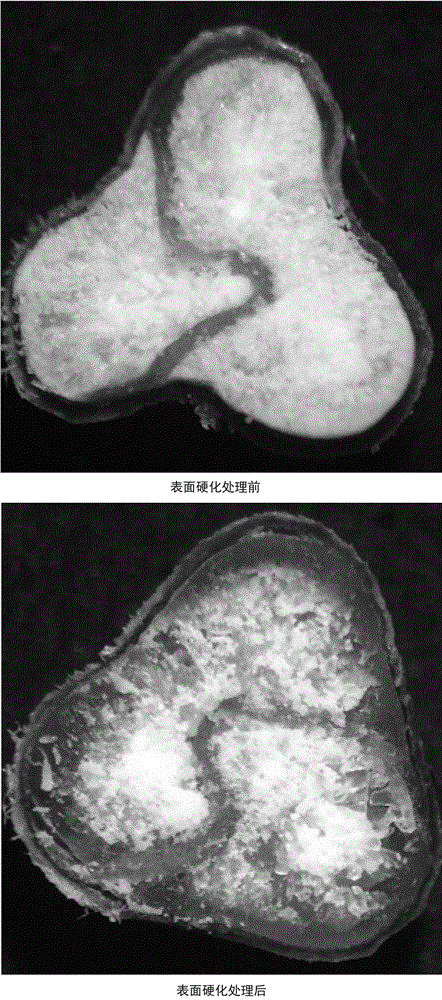

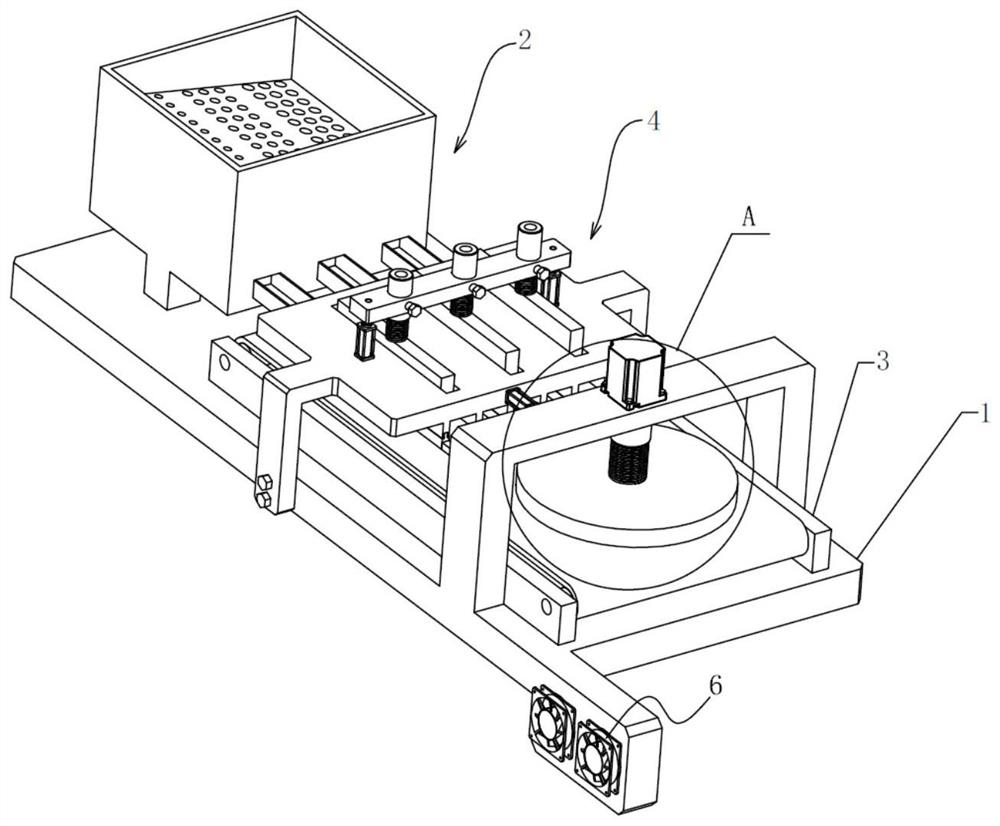

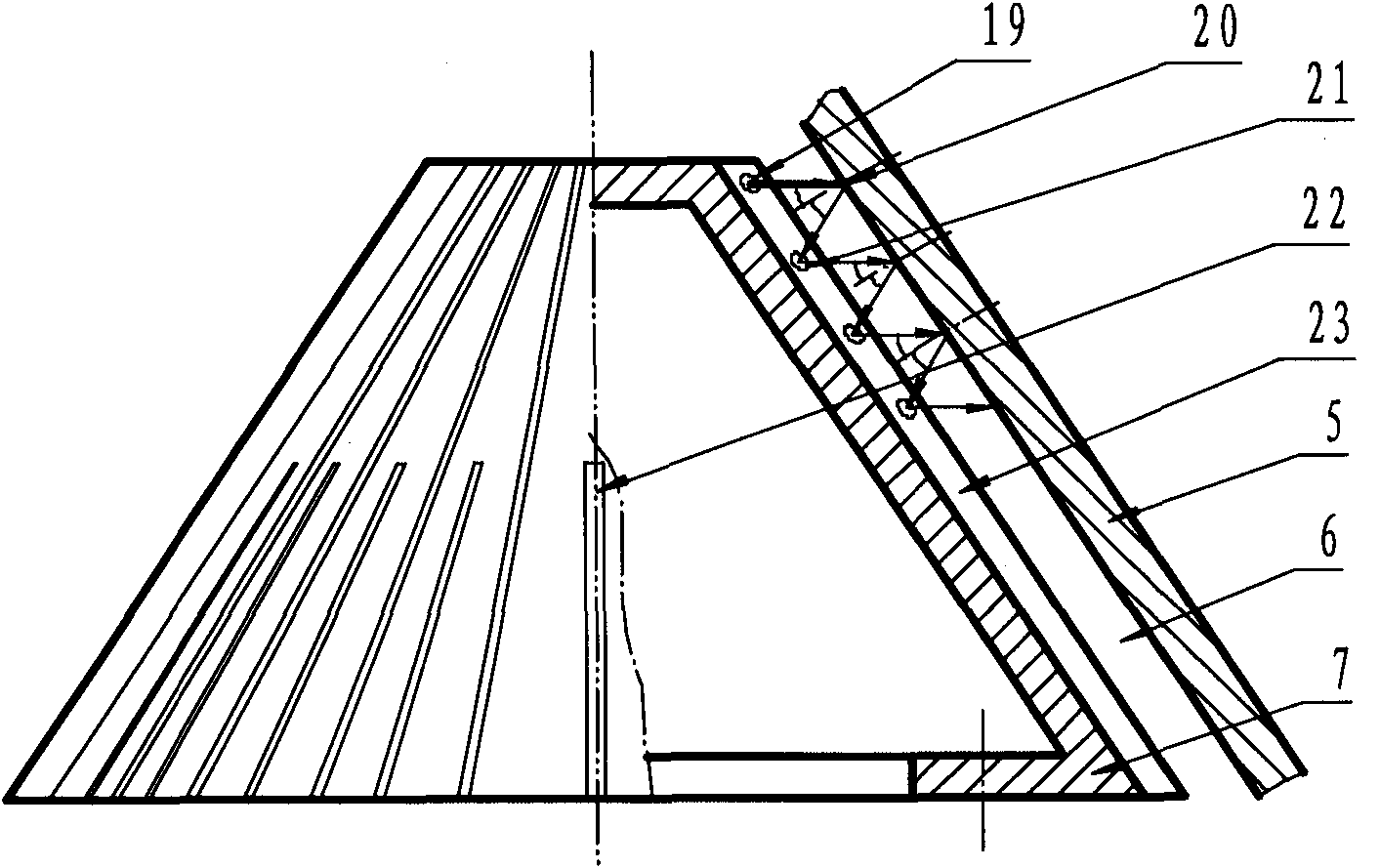

Tartary buckwheat case-hardening and hulling method

ActiveCN106391171AImprove shelling rateImprove whole kernel rateGrain huskingGrain polishingPolygonum fagopyrumHigh energy

The invention relates to the technology of grain hulling, in particular to a tartary buckwheat case-hardening and hulling method, which comprises the following steps of (1) purifying, dedusting and staged treating tartary buckwheat raw materials; (2) at the temperature of 20 DEG C to 50 DEG C, soaking the tartary buckwheat with clear water, and enabling the surface infiltration depth of tartary buckwheat kernels to achieve 0.2mm to 0.6mm; (3) at the temperatue being less than or equal to 160 DEG C, carrying out fast case hardening treatment on the tartary buckwheat, and enabling the thickness of a case hardening layer of a kernel to achieve 0.2mm to 0.6mm; (4) enabling the moisture content of the tartary buckwheat to be within 15 percent to 28 percent; (5) grinding the tartary buckwheat at low pressure; (6) kneading the tartary buckwheat at low pressure so as to separate shells and the kernels; (7) air flow cleaning and screening the fully kneaded tartary buckwheat so as to thoroughly separate the shells and the kernels so as to obtain the tartary buckwheat kernels and the shells respectively. The tartary buckwheat case-hardening and hulling method provided by the invention adopts new technologies such as case hardening, and low-pressure grinding and kneading, so that the problems of low hulling rate, low rate of perfect kernels, high nutrition loss, high energy consumption and high water consumption in the prior art can be solved.

Owner:NORTHWEST A & F UNIV

Device for classifying, shelling and sorting camellia oleifera fruits

PendingCN111869886AGuaranteed cutImprove shelling rateGas current separationHuskingCamellia oleiferaAgronomy

The invention provides a device for classifying, shelling and sorting camellia oleifera fruits. The device comprises a rack, a camellia oleifera fruit screening mechanism, a conveying belt, an openingmechanism, a rubbing mechanism and a fan, wherein a support frame in the opening mechanism is positioned above the conveying belt, and the bottom of the support frame is divided into three conveyingchannels; three discharging ports of the camellia oleifera fruit screening mechanism are in butt joint with the conveying channels in the bottom of the support frame; a bottom plate is mounted on thesupport frame through a hydraulic cylinder I, three sleeves are movably mounted on the bottom plate, and three notching cutters are movably mounted in the three sleeves respectively; and three friction plates are movably mounted in baffles at the bottom of the support frame respectively and located on the three material conveying channels respectively. The camellia oleifera fruit screening mechanism is used for screening camellia oleifera fruits, the camellia oleifera fruits of different sizes can enter the conveying channels in the bottom of the support frame, at the moment, the notching cutters cut the camellia oleifera fruits of different sizes, and then the subsequent shelling rate is increased.

Owner:ANHUI YUMIN ECOLOGICAL AGRI

Method for separating shell and meat of small crustacean

ActiveCN102792997ARealize continuous productionImprove shelling rateShellfish processingCrustaceanFishing

The invention relates to a method for separating shell and meat of small crustacean, which comprises the following steps: performing heat-treatment on the small crustacean at the temperature of 50-150 DEG C for 0.5-15 minutes; then cooling the temperature of the small crustacean to a proper temperature, employing enzyme to perform enzymolysis on the small crustacean after heat treatment; then separating the shell and meat of the small crustacean through centrifuging, and respectively collecting the shell and meat. The method provided in the invention enables realization of continuous production, the shelling rate is high, the obtained small crustacean meat can be used for producing feeds or further producing high quality food, the shell can be used for producing chitosan and the like, and the method can be directly used for separating the shell and meat of the small crustacean which enables on-line processing in a fishing ship, and the method for separating shell and meat of small crustacean has good application prospect.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Animal andrographolide powder

InactiveCN108853026AHigh antibody titerHigh in nutrientsAntibacterial agentsOrganic active ingredientsCurative effectSodium bisulfite

The invention discloses animal andrographolide powder which is prepared from the following raw materials: 3wt% of andrographolide, 0.9wt% of sodium bisulfite and the balance of starch auxiliary material. The animal andrographolide powder is prepared by the following steps of performing reaction on the andrographolide and the sodium bisulfite to form a mixture of the sodium bisulfite and the andrographolide, and matching with the starch auxiliary material to prepare the animal andrographolide powder. A product provided by the invention has the effects of resisting bacteria and diminishing inflammation, has special curative effect to bacillary dysentery and can effectively solve the problem of intestinal tracts of livestock.

Owner:WUXI ZHENGDA POULTRY

Rice processing method with low broken rice rate

InactiveCN110860324AImprove shelling rateReduce broken rice rateGrain treatmentsAgricultural engineeringBroken rice

The invention discloses a rice processing method with a low broken rice rate, and belongs to the field of rice processing. The rice processing method includes the steps of rice screening, stone removal, magnetic separation, rice moisture measurement, rice moisture control, hulling, husked rice separation, brown-rice selection, brown-rice moisture measurement, brown-rice moisture control, multi-stage milling, white-rice grading, cooling, atomizing, multi-stage polishing, color sorting and purifying, sterilization and packaging. The rice processing method has the advantages that the broken ricerate is low, the appearance quality and eating quality of rice are high, and economic benefits of rice processing enterprises are improved.

Owner:寿县永良粮油食品有限公司

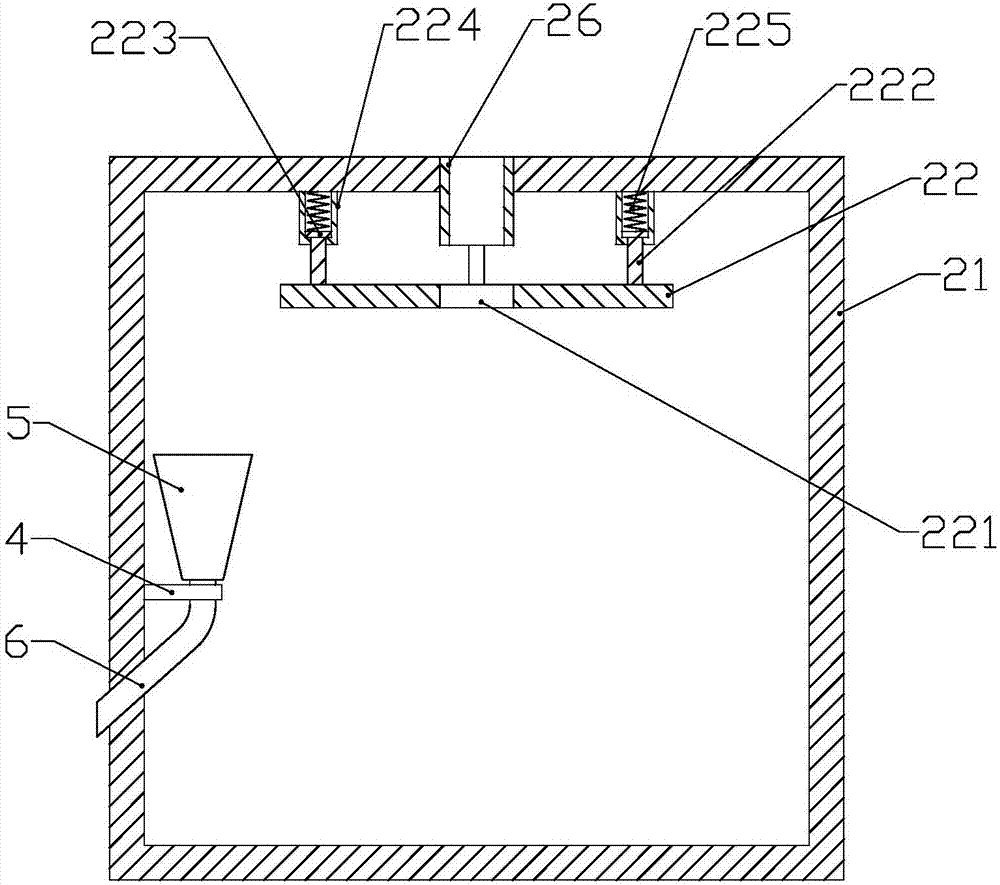

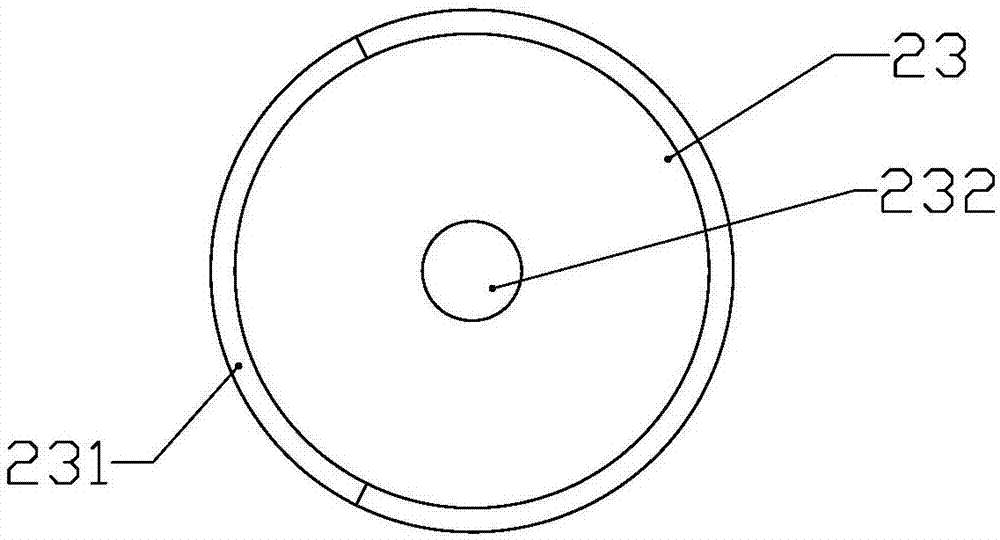

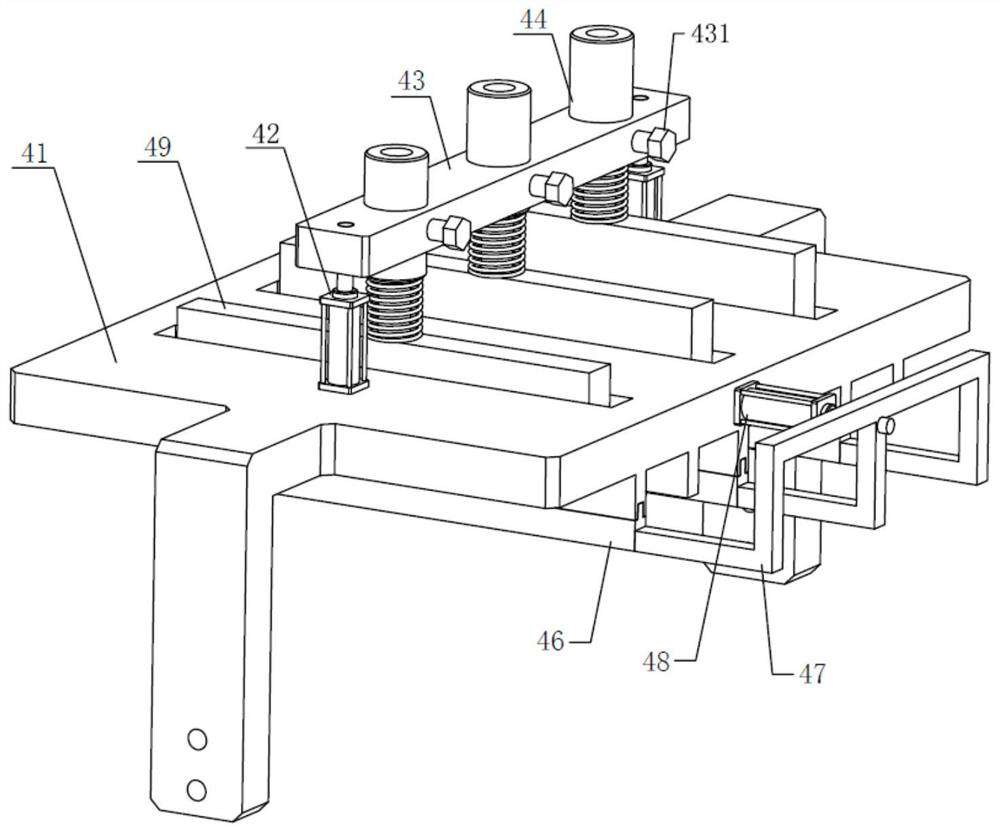

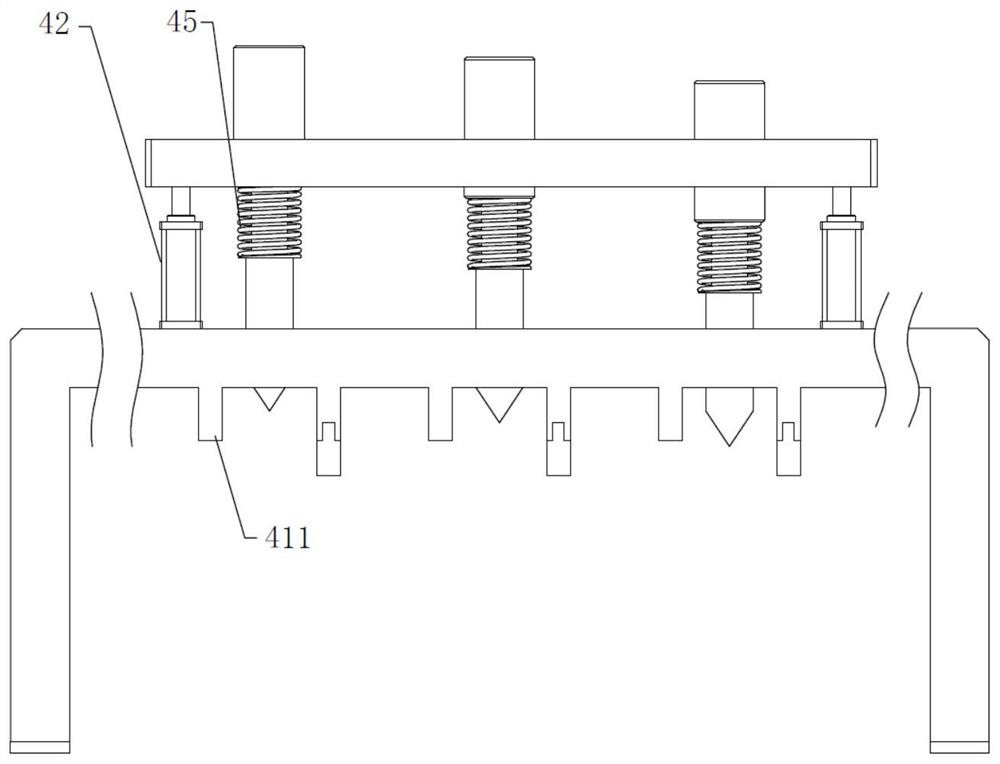

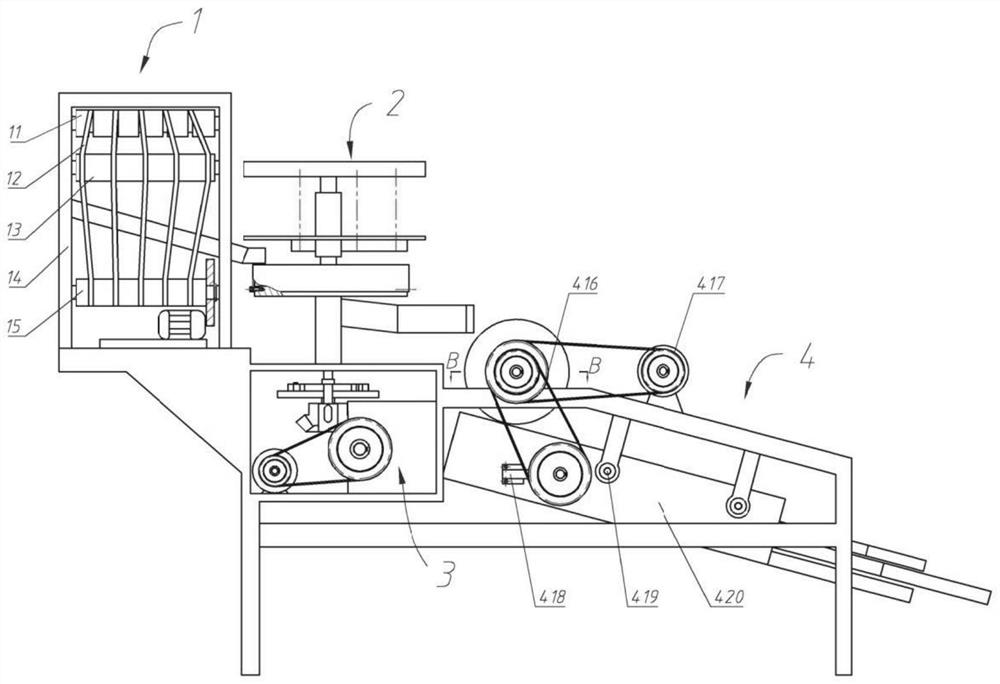

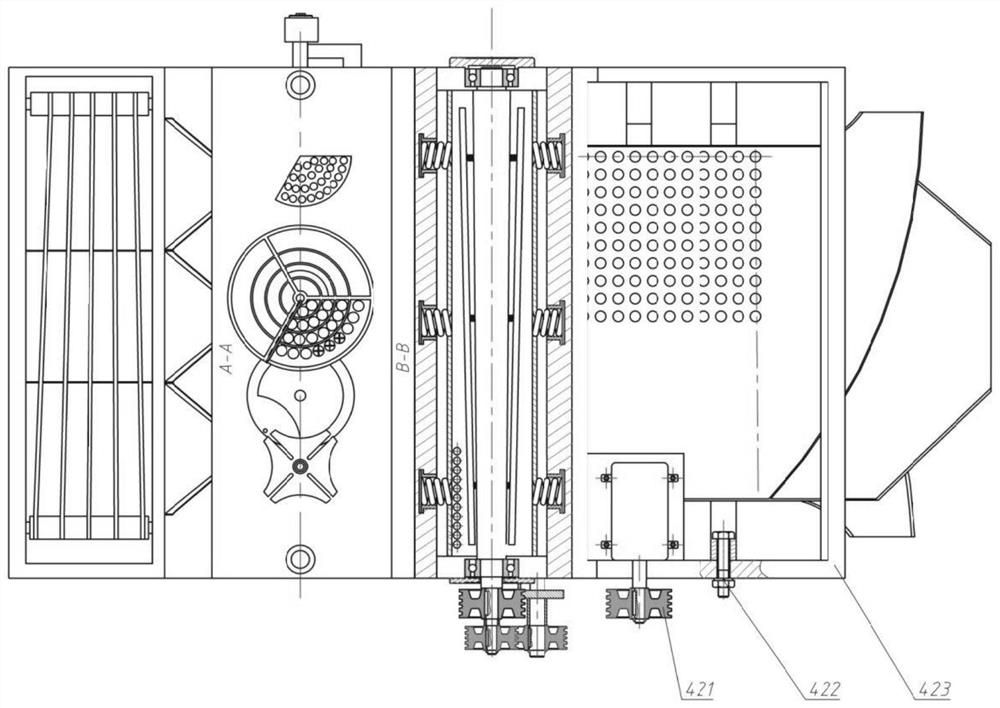

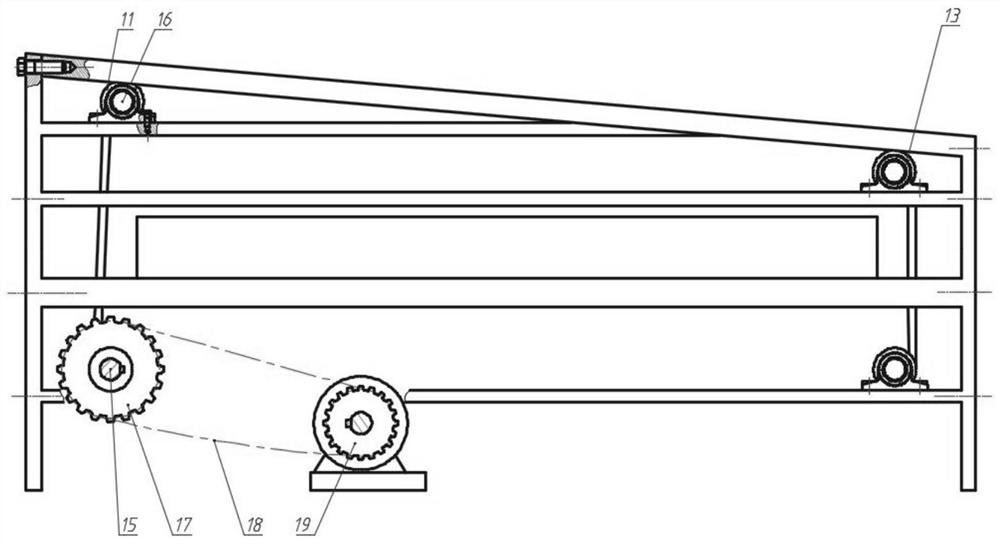

Camellia oleifera fruit shell breaking, extruding and separating device

ActiveCN113974174AReduce the rate of seed damageImprove shelling rateSievingScreeningCamellia oleiferaEngineering

The invention discloses a camellia oleifera fruit shell breaking, extruding and separating device. The device comprises a rack, a grading system installed on the upper left portion of the rack, a shell breaking system, a shell breaking transmission system, and a shell removing and separating system, wherein the shell breaking system and the shell breaking transmission system are installed in the middle of the rack, and the shell removing and separating system installed on the lower right portion of the rack; and the shell breaking transmission system comprises a crank sliding block transmission system and a grooved wheel transmission system which respectively control the vertical line motion of an upper cutter head and the intermittent rotation of a transposition disc. The camellia oleifera fruit shell breaking, extruding and separating device can complete diameter grading, cutting hull breaking, extrusion and hulling, vibration separation and other work at a time, efficient hulling and separation can be achieved for camellia oleifera fruits subjected to natural airing pretreatment or freshly picked camellia oleifera fruits, and the seed damage rate is reduced. By adopting the shell breaking, extruding and separating device, high shelling rate, low seed damage rate and mechanical shelling for camellia oleifera green fruits are realized through four processes of grading, cutting shell breaking, extrusion and shelling and vibration separation, and the camellia oleifera green fruits can be effectively and mechanically shelled without long-time pretreatment.

Owner:HUAZHONG AGRI UNIV

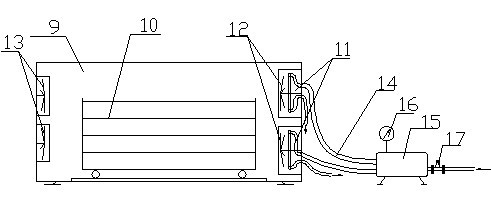

Mussel shell removing machine

InactiveCN101642158BImprove processing efficiencyIncrease profitBivalves processingTransmission beltElectric machinery

Owner:朱雅光

Knocking type rubber fruit sheller

ActiveCN109757738AImprove shelling rateImprove purityGas current separationHuskingForest industryEconomic benefits

The invention belongs to the technical field of forestry product machining machines, and relates to a knocking type rubber fruit sheller. The knocking type rubber fruit sheller completes the rubber fruit knocking hull breaking process, the fruit shell and fruit kernel separating process after rubber fruits are broken and the fruit kernel scrap removal and collecting separation process through a hull breaking unit, a separating unit and a separating unit respectively. By means of the imitated manual type impact rubber fruit breaking impact principle method, due to cooperation of a knocking hammer and a conveying device, the knocking hammer knocks and shells rubber fruits, then, fruit shells and fruit kernels of the shelled rubber fruits are separated through a separation roller of the separating unit, and the rubber fruit shelling rate is increased; by adopting a wind power separation unit and arranging separated fruit shell and fruit kernel discharging outlets, the fruit kernel puritydegree is increased. Rubber fruit processing and comprehensive utilization economic benefits are improved, and the shell is applicable to a rubber fruit comprehensive utilization enterprise.

Owner:HAINAN UNIVERSITY

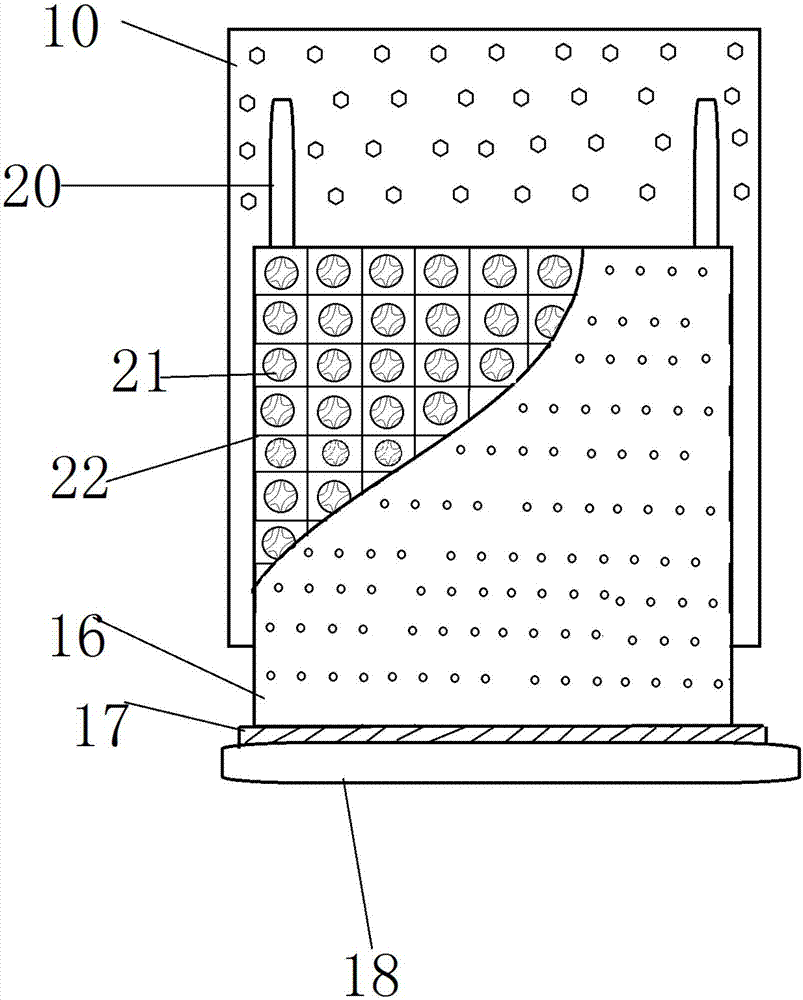

Non-contact type measuring method and structure for rubber covered roller of rice huller, and rice huller

PendingCN108514907AAffects the electric field distributionGuaranteed parallelGrain huskingGrain polishingCapacitanceContact type

The invention provides a non-contact type measuring method for a rubber covered roller of a rice huller. The non-contact type measuring method comprises the following steps that capacitance is calculated and measured, a PLC acquires the measured current of a current loop formed by unit fixing pole plates and corresponding unit movable pole plates, the capacitance is calculated between the unit fixing plates and the corresponding unit movable pole plates according to the measuring current, and a measuring capacitor is obtained; and the thickness of a rubber layer is calculated, and the PLC calculates the thickness of the rubber layer according to the dielectric constant of the air containing chaff dust which is monitored by an air capacitance monitor, the measuring capacitor, and the distances between the unit fixing pole plates and the corresponding unit movable pole plates. The invention further relates to a rubber covered roller non-contact type measuring structure and the rice huller. According to the measuring method, two rubber covered roller shafts are ensured to be parallel, the optimal distance and the optimal speed difference of the two rubber covered rollers are achieved,the measuring error is small, the precision is high, and the unshelling rate and the yield are effectively improved.

Owner:王立宗

Silybum mariamum seed huller

InactiveCN101816452AAchieve full utilizationReduce energy consumptionHuskingHullingEngineeringSilybum

The invention discloses a silybum mariamum seed huller, which comprises a bracket and an inner rotating cone, wherein the inner rotating cone is coaxial with the bracket and is positioned inside an outer conical cylinder, and tines are distributed on the surface of the inner rotating cone; a clearance is formed between the inner wall of the outer conical cylinder and the top surface of the tines of the inner rotating cone; the inner rotating cone is rotationally connected with the bracket and driven by a motor fixed on the bracket; the upper end of the clearance is connected with a feed hopper through a feed neck, and the lower end of the clearance is connected with a discharge hopper through a discharge hole on an outer conical cylinder flange. The silybum mariamum seed huller has simple structure and convenient operation, and can hull silybum mariamum seeds; and the core of the huller is to gradually break and hull the silybum mariamum seeds by adopting a short throwing distance and multi-throwing principle, and the throwing energy of every time is relatively low so as to avoid rolling and kneading; therefore, broken hulls and broken kernels are few, the hulling rate is high and the energy consumption is low.

Owner:JIANGSU UNIV

Shell distribution catalyst and preparation method thereof and Fischer-Tropsch synthetic method

ActiveCN105833869AImprove shelling rateReduced tendency to migrateHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionVacuum pumpingHydrocarbon

The invention discloses a shell distribution catalyst and a preparation method thereof. The method comprises: (1) disposing a porous support in a hollow container, and spraying a solution containing components with catalytic activity on the surface of the porous support, wherein the total spray amount of the solution is less than the total pore volume of the porous support, and during the spraying process, the hollow container is subjected to vacuum pumping, and an air-pumping port for vacuum pumping is arranged in the layer formed by the porous support; and (2) performing drying and optional roasting of the porous support loaded with the solution and obtained from the step (1). The invention further provides a Fischer-Tropsch synthetic method. In the conditions of a Fischer-Tropsch synthetic reaction, synthesis gas is connected with the shell distribution catalyst having a catalytic action on the Fischer-Tropsch synthetic reaction. Through the method, the shell distribution catalyst can be repeatedly stably produced. The shell distribution catalyst is used for the Fischer-Tropsch synthetic reaction, and is relatively high in C5+ hydrocarbon selectivity and comparatively low in methane selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyodontidae fry breeding device

InactiveCN107549066ANovel structureScientific and reasonable designClimate change adaptationPisciculture and aquariaEngineeringTemperature control

The invention discloses a polyodontidae fry breeding device, which is composed of a cylindrical placenta isolating pond, a motor, a mixer, a motor front and back direction controller, a first linkingpipe, a spawn incubation pond, a constant temperature pond, a second linking pipe, a first filter, a first water pump, a first water guide pipe, a second water pump, a second water guide pipe, a temperature control meter, a heating pipe, a temperature probe, a third link pipe, and a fry breeding slot. The polyodontidae fry breeding device can rapidly separate and demould the placenta of the wholepolyodontidae and form a single spawn without hurting the unshelled spawn; the spawn is cultivated under the best temperature and environment, the fry cultivating cycle is short, and the fry hatchingspeed is over one-time faster than that of the traditional method; besides, the fry quality is good. When the fry is bred by the polyodontidae fry breeding device, the polyodontidae fry breeding device with high degree of automation has the advantages of greatly reducing the labor intensity, reducing the fry malformation and improving the unshelling rate and the hatching rate.

Owner:何翔

Method for preventing and curing prawn virus damage and improving prawn farming yield

InactiveCN103651201AReduce the prevalenceTo prevent the boring pond from stealing deathClimate change adaptationPisciculture and aquariaAnti virusYolk

The invention discloses a method for preventing and curing prawn virus damage and improving prawn farming yield. The method is characterized by comprising the steps of pond disinfection treatment, natural bait cultivation, mixed cultivation, fertilization and pond water quality management. According to the method, dissolved oxygen is improved ceaselessly and substantially, hazardous substances like ammonia nitrogen, hydrogen sulfide and nitrite in water can be effectively degraded, microorganism ATP bacteria can maintain pond ecological environment, and it can be guaranteed that farming water quality is friendly to environment; immunoglobulin of yolk is fed reasonably to stimulate prawn organisms repeatedly, and the anti-virus and antibacterial ability of hepatopancreas can be improved; thus, the anti-virus and antibacterial ability of the whole organisms can be greatly improved, the development of aquaculture can be promoted, farmers can be driven to get rich, and rural ecological environment can be improved.

Owner:BEIHAI CITY HAICHENG DISTRICT JINHAIAN FISHERIES RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com