Tartary buckwheat non-thermal shucking method and Tartary buckwheat shucking device

A tartary buckwheat, non-thermal technology, applied in the field of tartary buckwheat non-thermal husking method and its husking device, can solve the problems of tartary buckwheat kernel breaking, husk cracking, etc., and achieve effective ingredient maintenance, energy saving, and husking equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

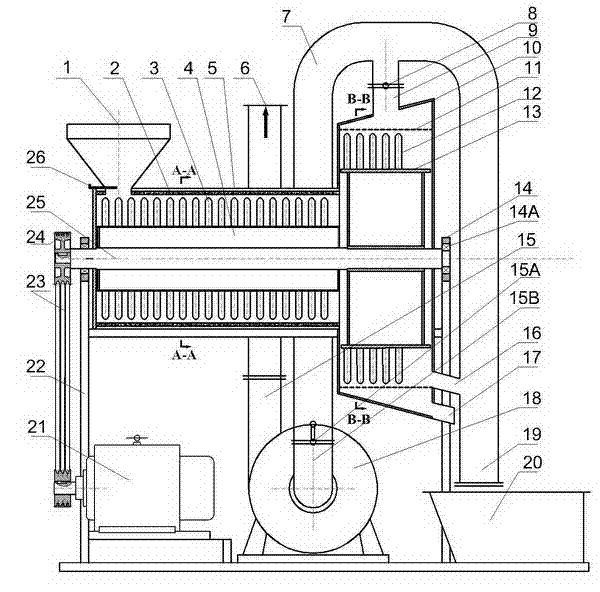

[0048] Embodiment one: a kind of tartary buckwheat non-heat shelling device

[0049] like figure 1 As shown, the device is mainly composed of feed hopper 1, flow control door 26, grinding cylinder 5, grinding rotor 4, rod-shaped grinding teeth 3, shelling rotor 13, shelling teeth 12, shelling chamber 10, tartary buckwheat Renji hopper 20, motor 21, V-belt 23, pulley 24, blower fan 18, winnowing pipe 7, shell discharge pipe 6, frame 22 etc. are formed. The feed hopper 1 is installed on the upper left side of the horizontally arranged grinding cylinder 5 and communicates with the inside of the grinding cylinder 5 . A flow control gate 26 is provided at the bottom of the feed hopper 1 . The inner wall of the grinding cylinder 5 is fixed with an abrasive inner sleeve 2, and a shelling chamber 10 is arranged at the right end. Grinding cylinder 5 is concentric with shelling chamber 10, and the two insides are straight through. The grinding rotor 4 and the shelling rotor 13 are...

Embodiment 2

[0059] Embodiment two: a kind of non-heat shelling method of tartary buckwheat

[0060] 1. The technological process of the method is:

[0061] Raw material cleaning → pressureless grinding → shell peeling → shell and kernel separation

[0062] 2. Tartary buckwheat shelling steps

[0063] (1) Raw material cleaning: the raw material is tartary buckwheat produced in Yan'an, Shaanxi, and the impurities in the raw material have been removed, and the moisture content is 13%.

[0064] (2) Pressureless grinding: After the tartary buckwheat is added to the shelling device, the grinding parts such as the rod-shaped grinding teeth 3 and the abrasive inner sleeve 2 grind the tartary buckwheat raw materials with a small contact force, so that the shell on the shell is more prominent. The edges and corners of the buckwheat shell are ground, and the corners and corners of the tartary buckwheat shell are fully ground, while the endosperm and the concave part of the cone surface are not g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com