Patents

Literature

53results about How to "Improve whole kernel rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

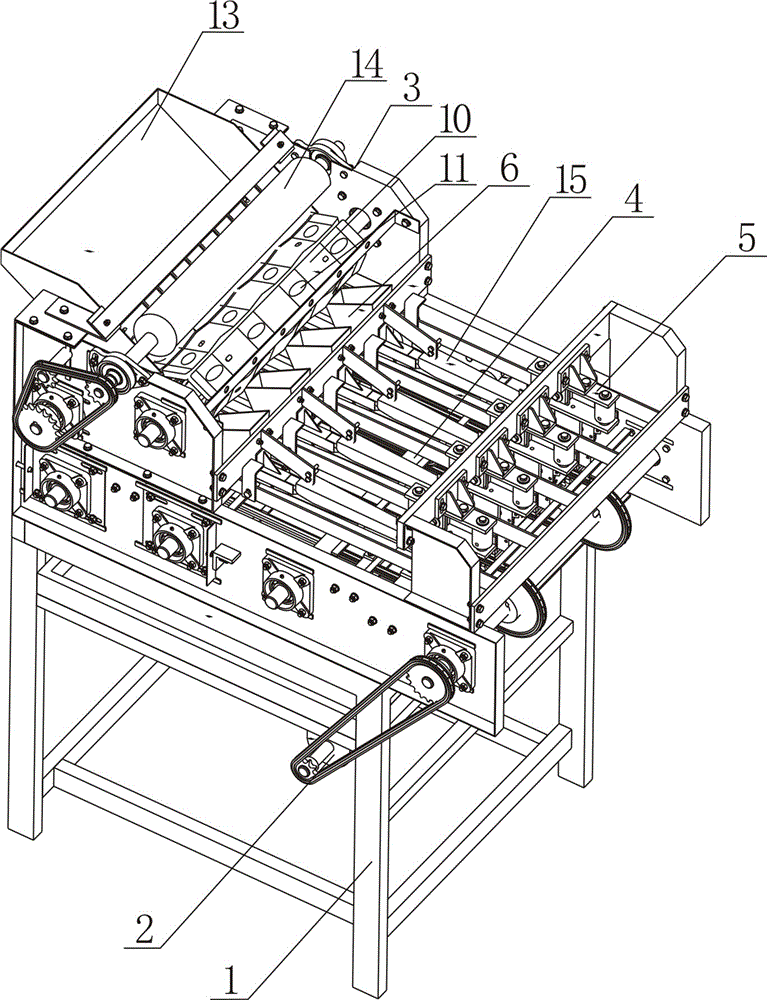

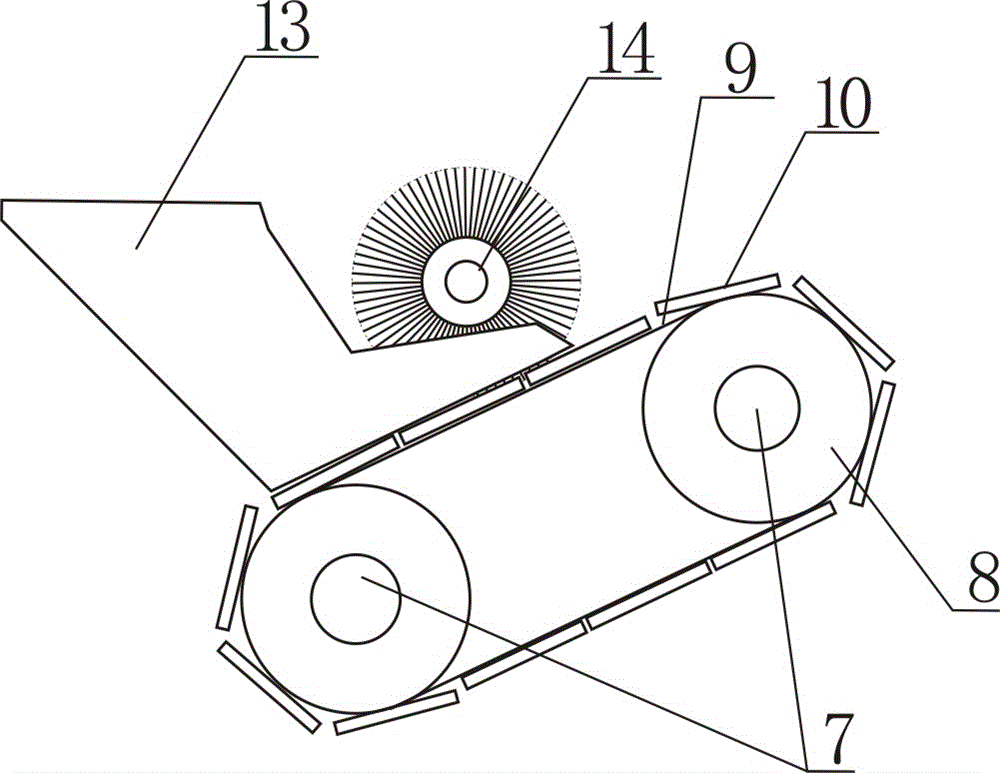

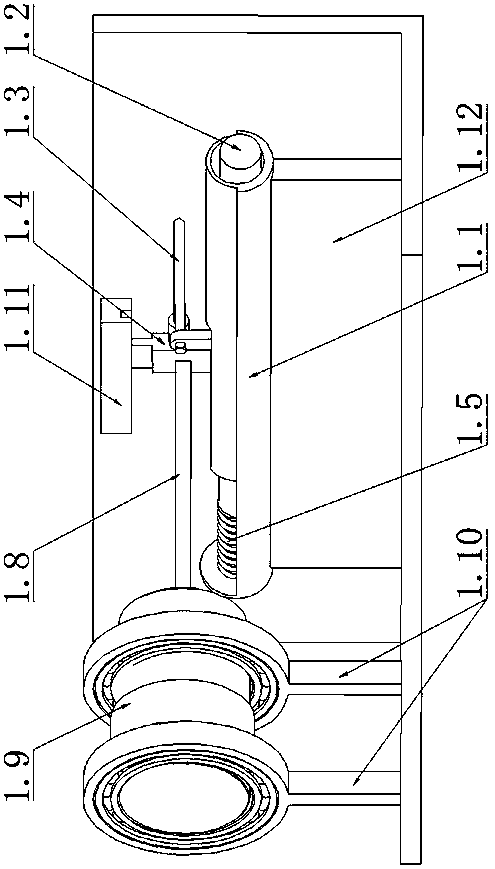

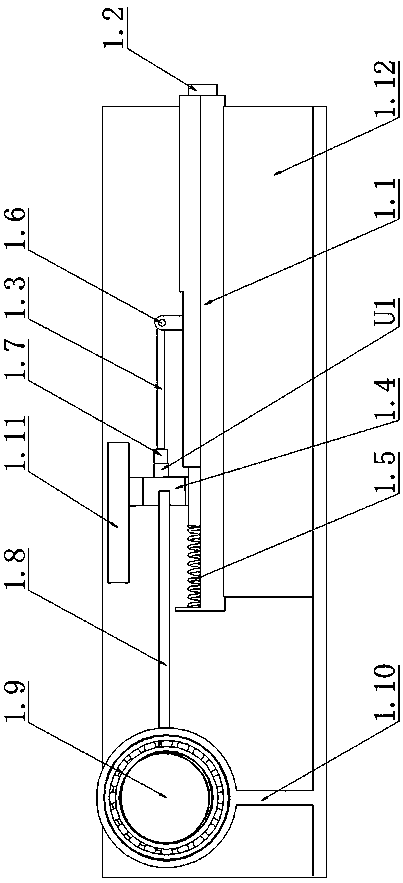

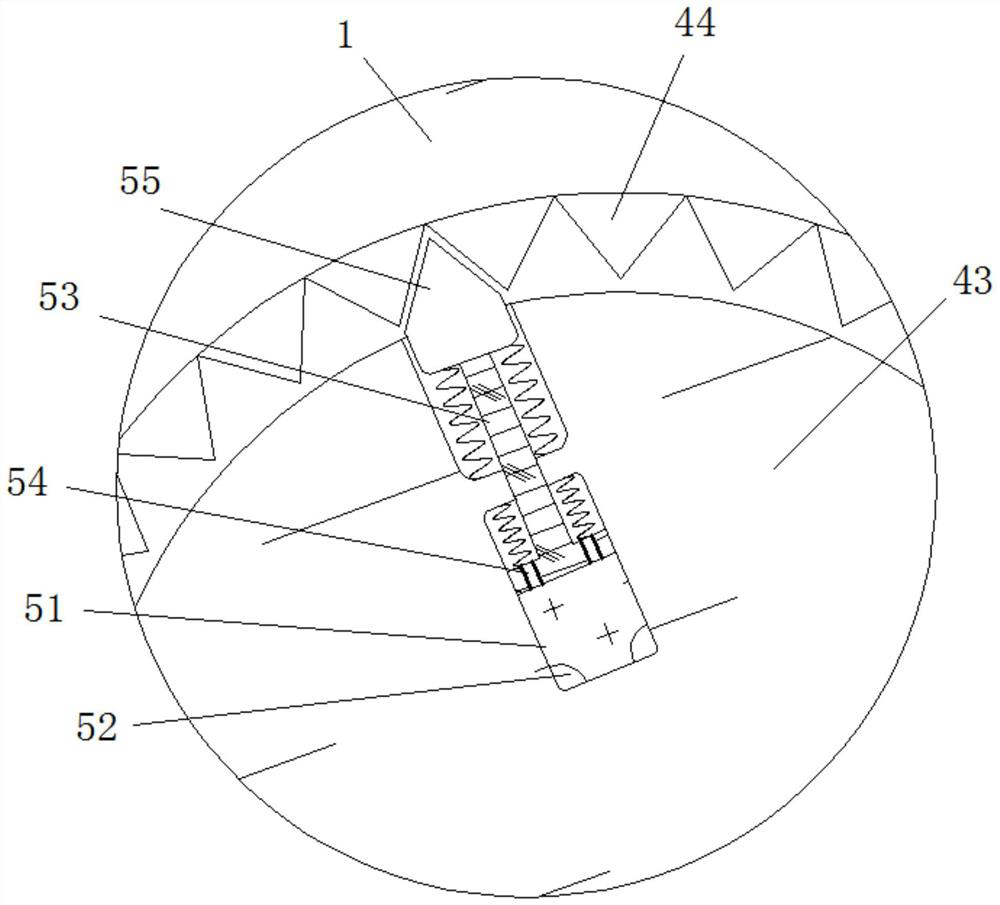

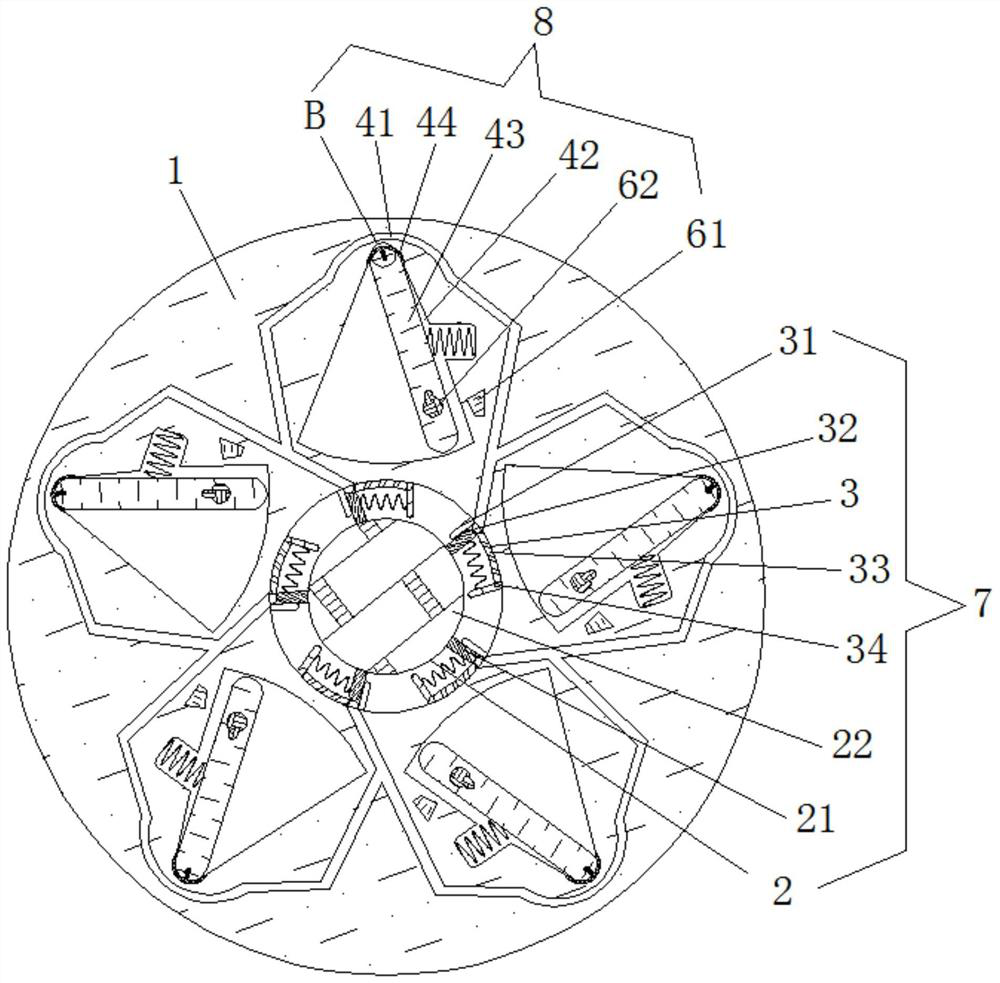

Device for breaking walnut shells and taking walnut kernels, having functions of self-positioning, pre-breaking shells, equidirectional spiral self-grading and flexible extrusion

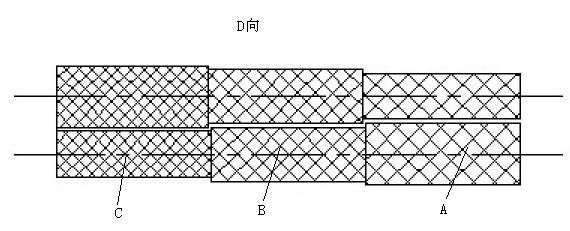

ActiveCN106473167AReduce grading processPrecise pre-crackingHuskingHullingWalnut NutReciprocating motion

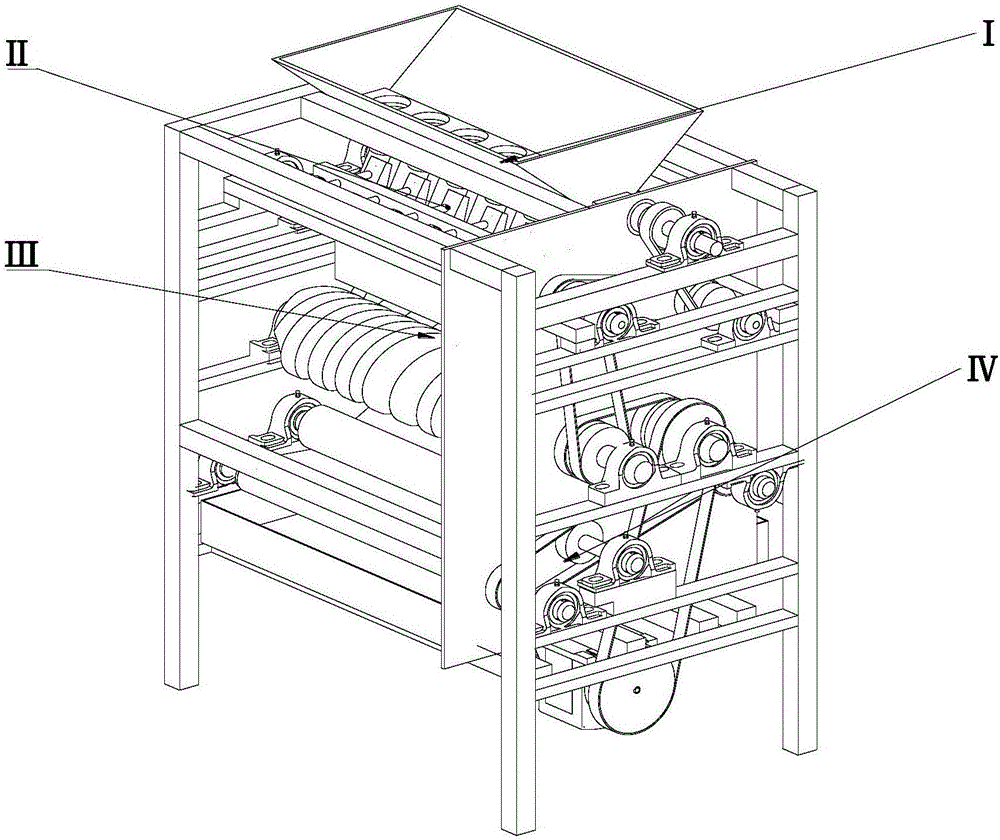

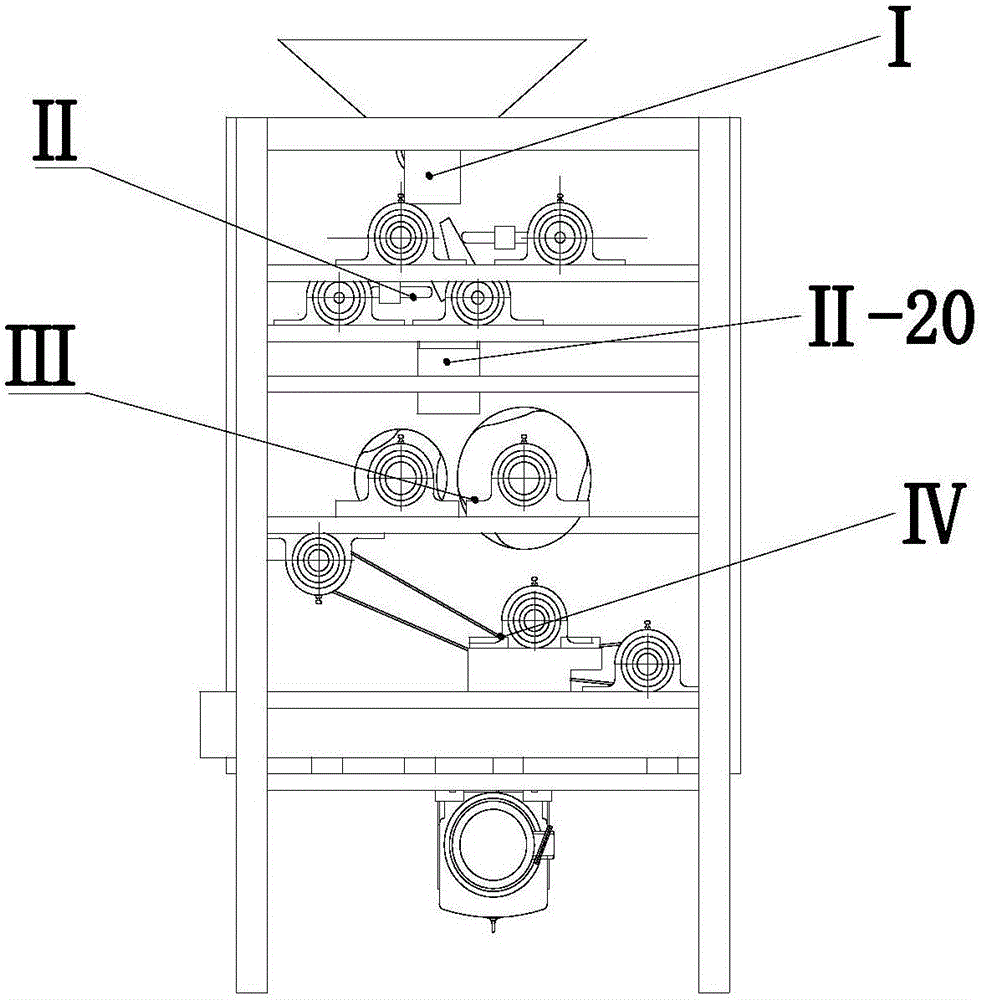

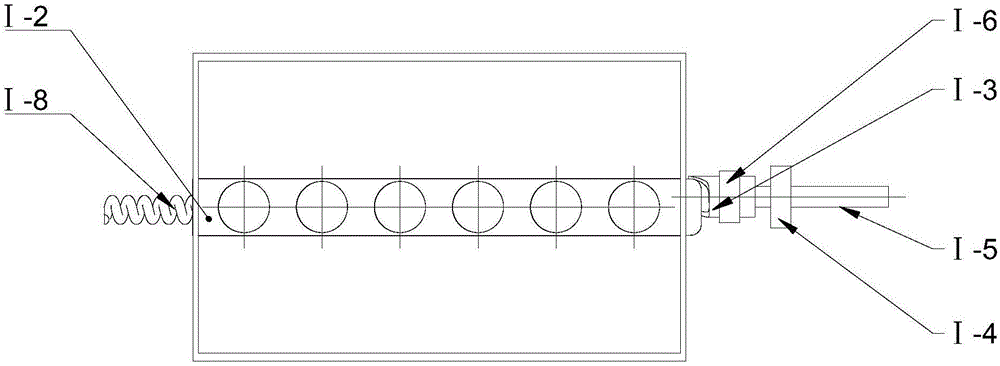

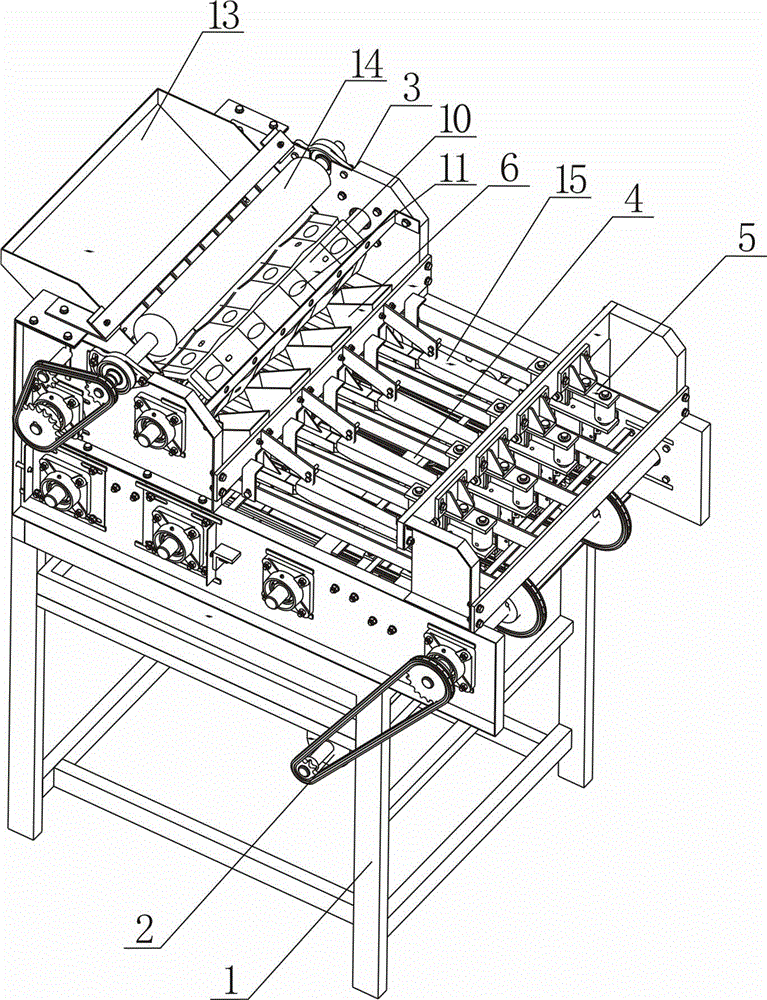

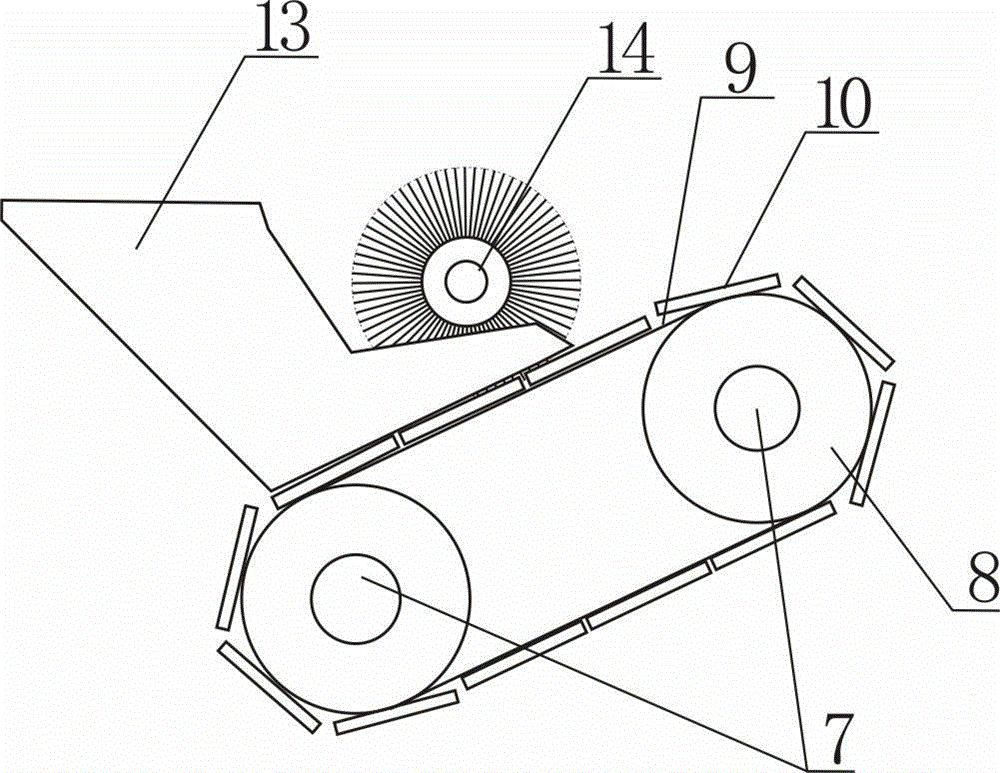

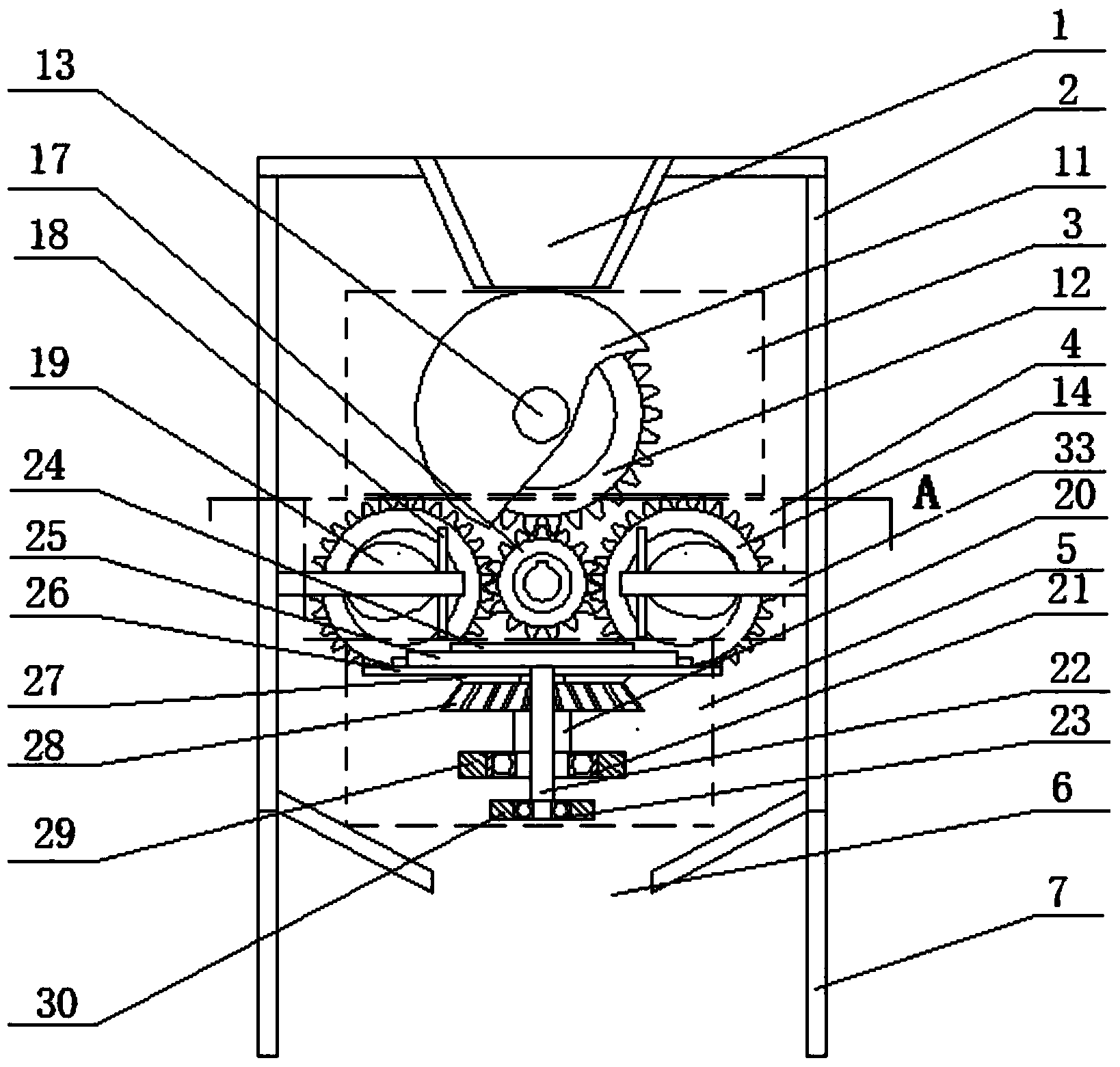

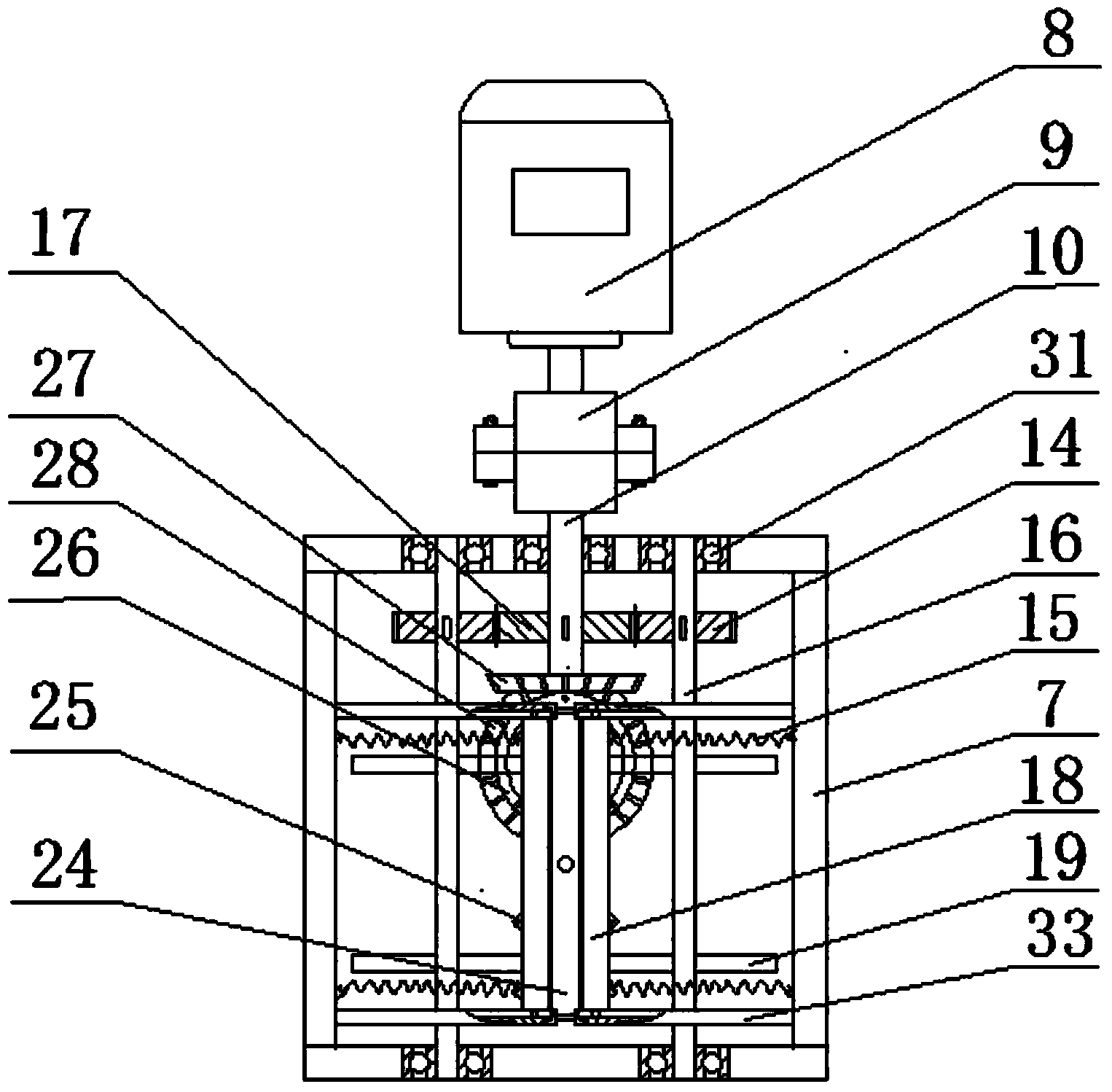

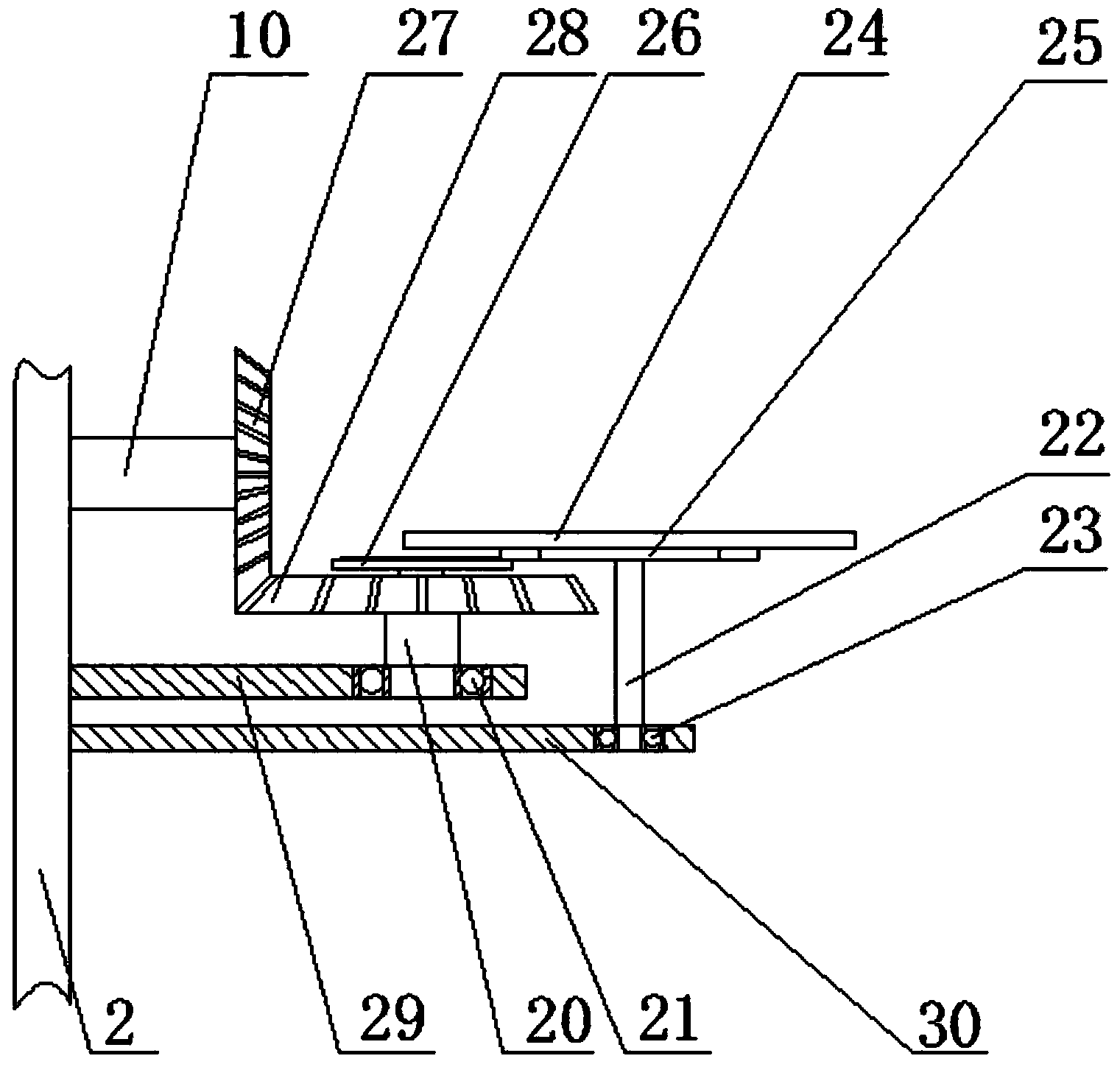

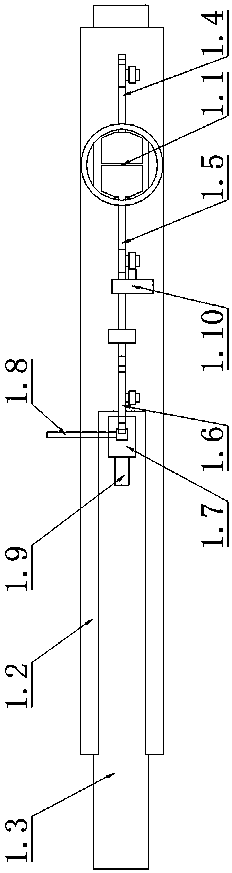

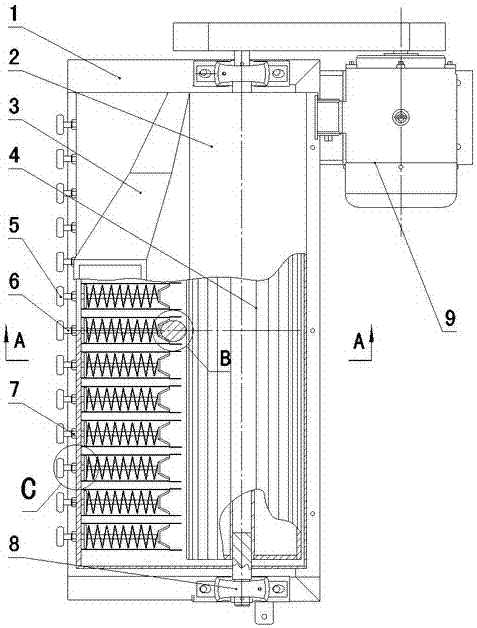

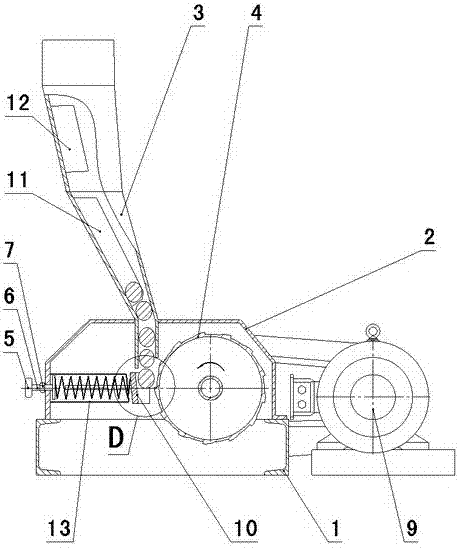

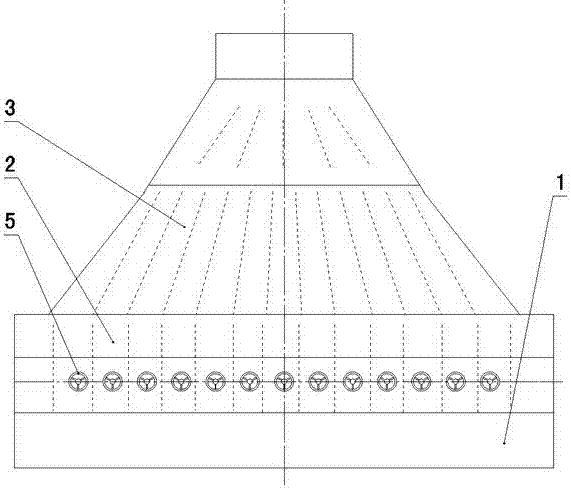

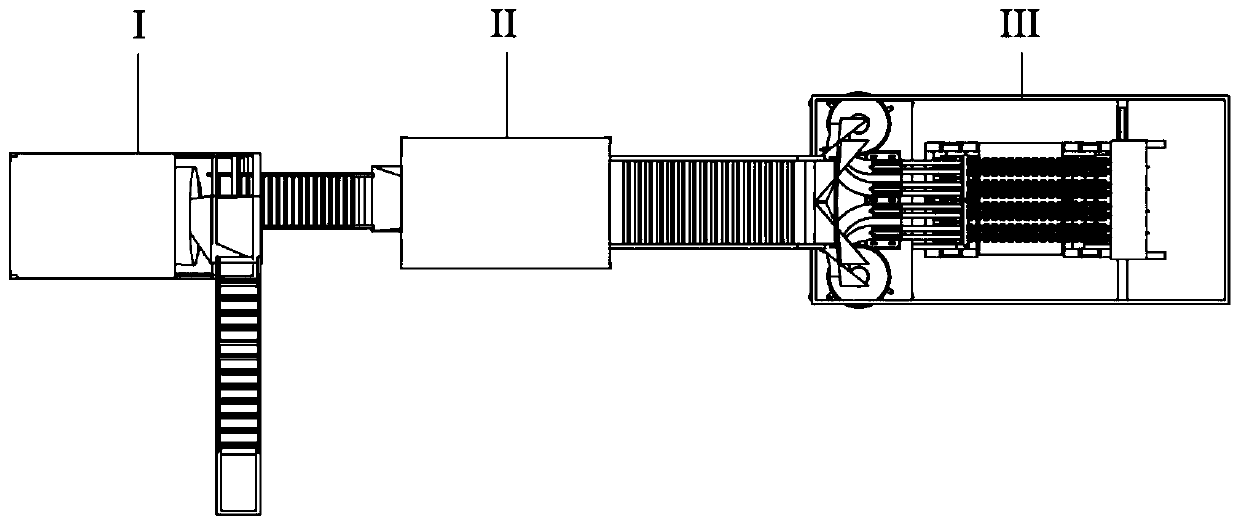

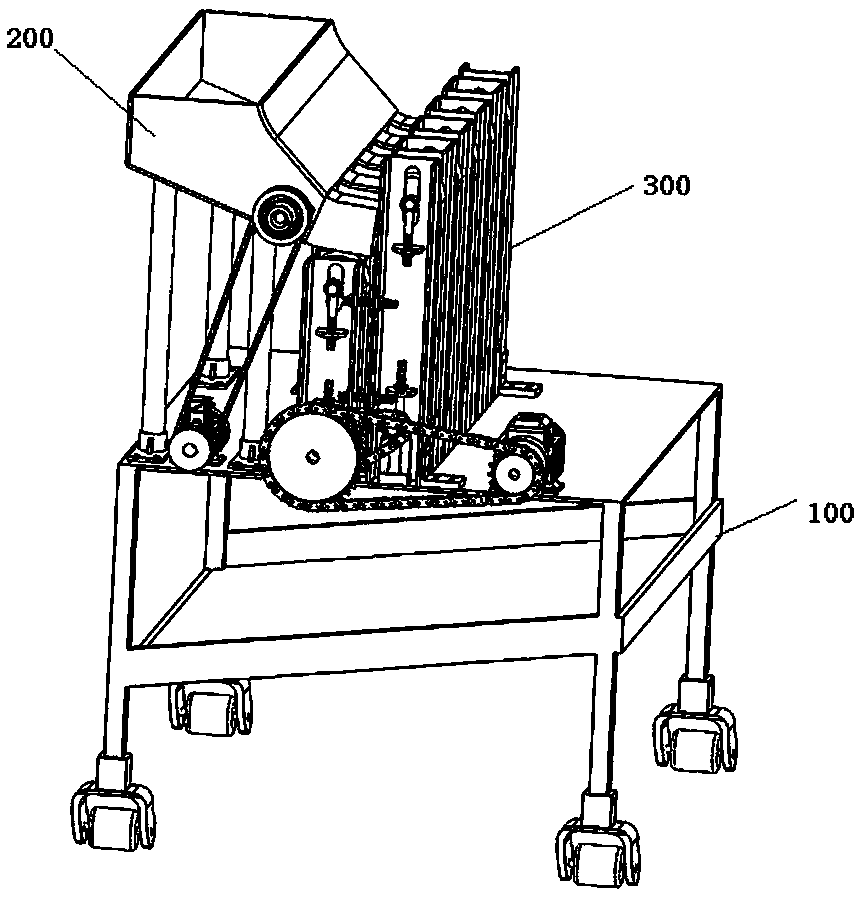

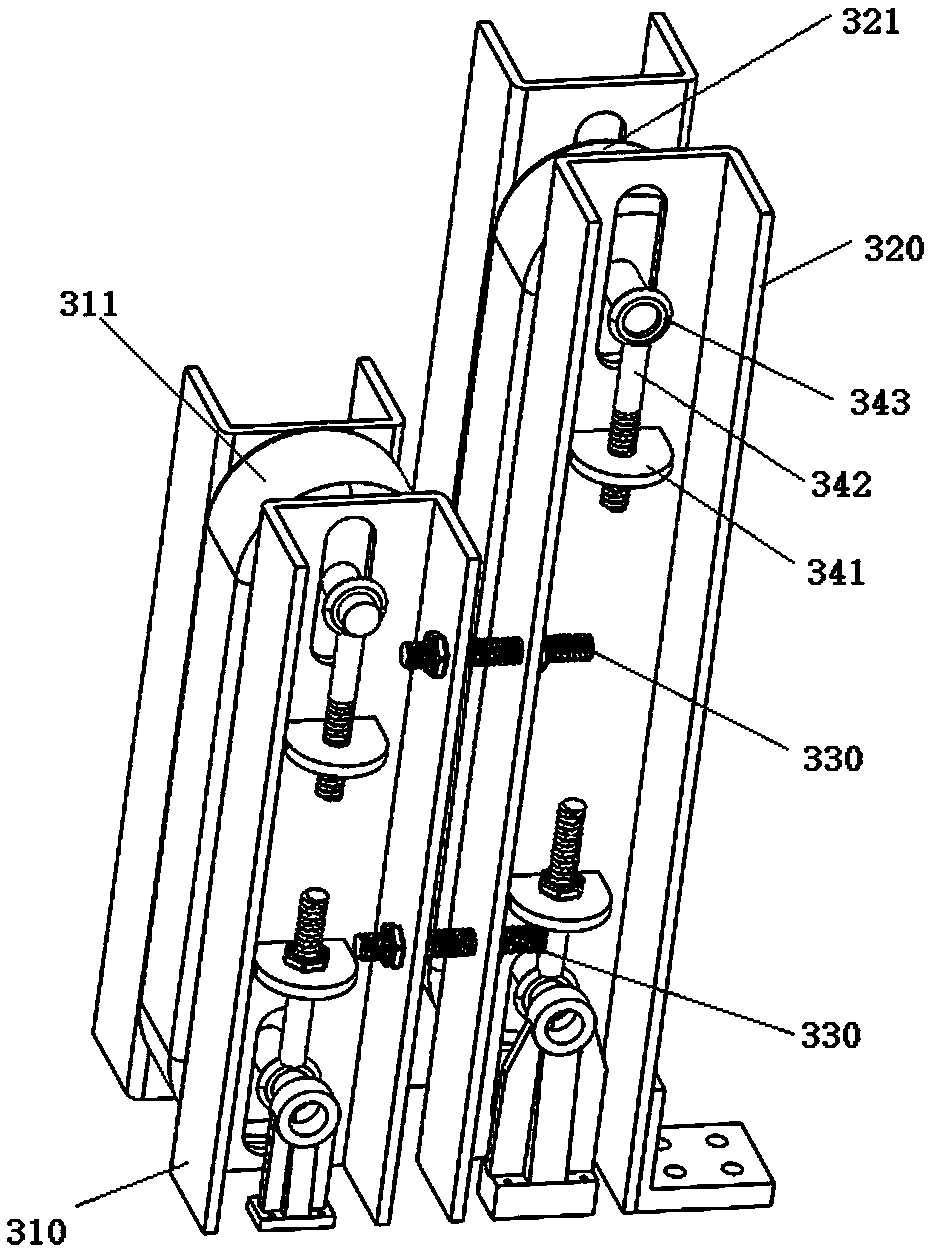

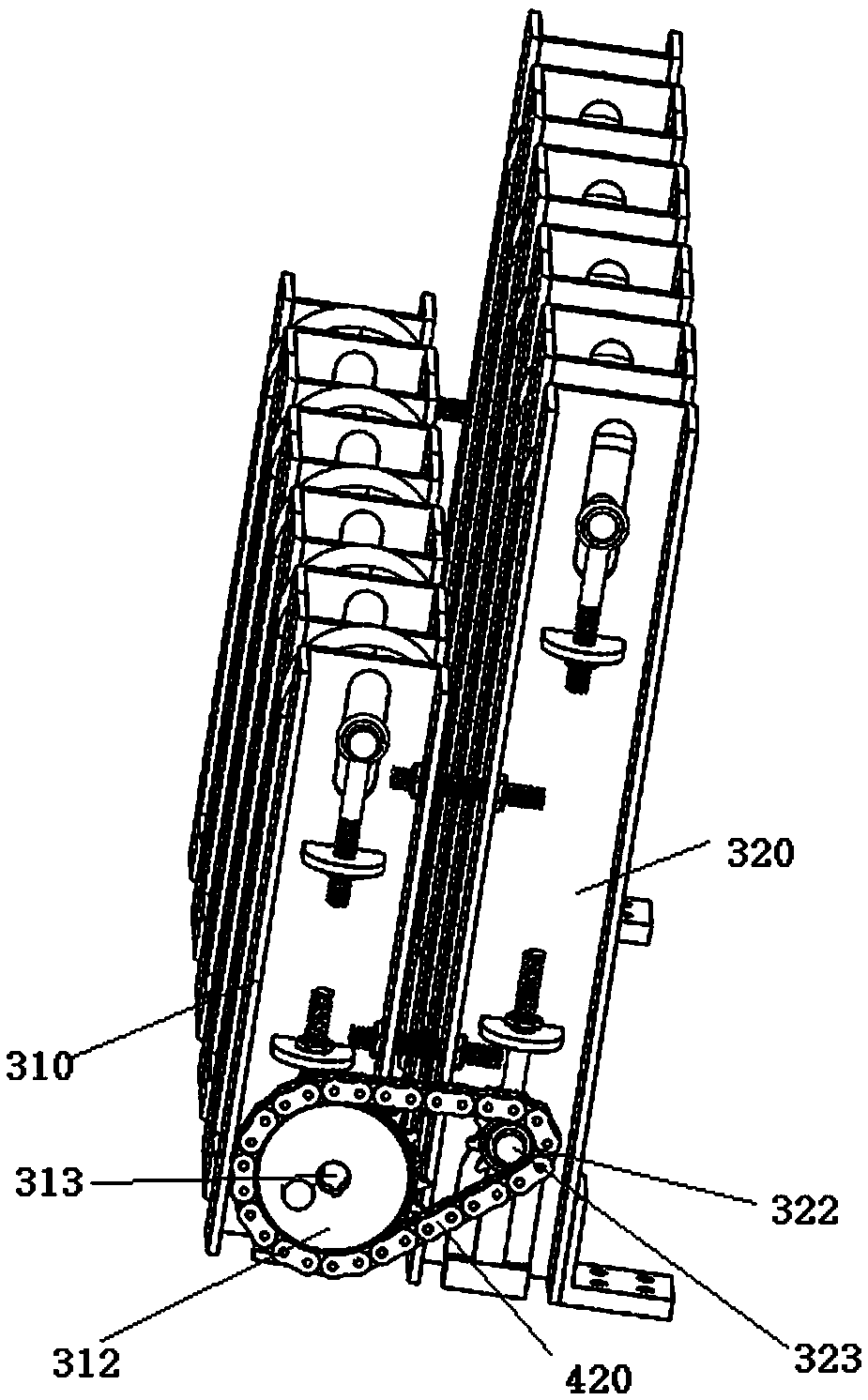

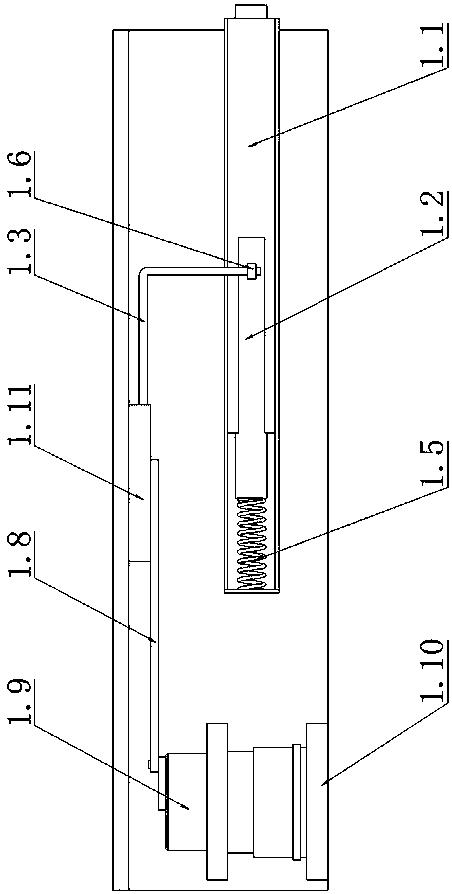

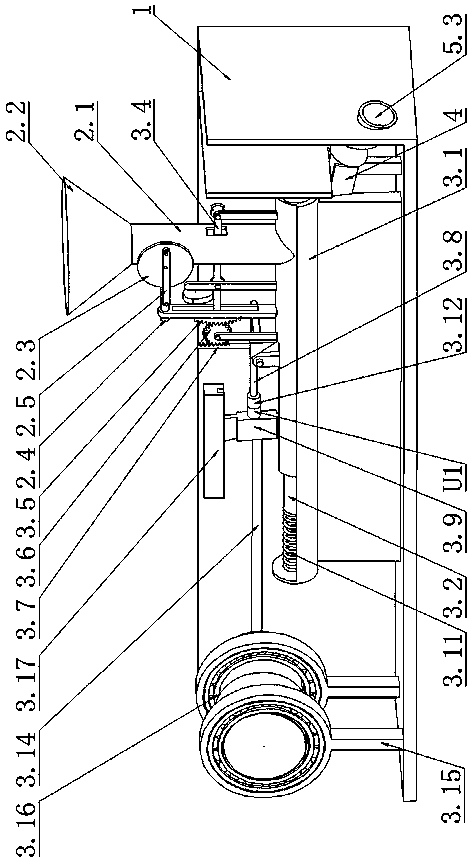

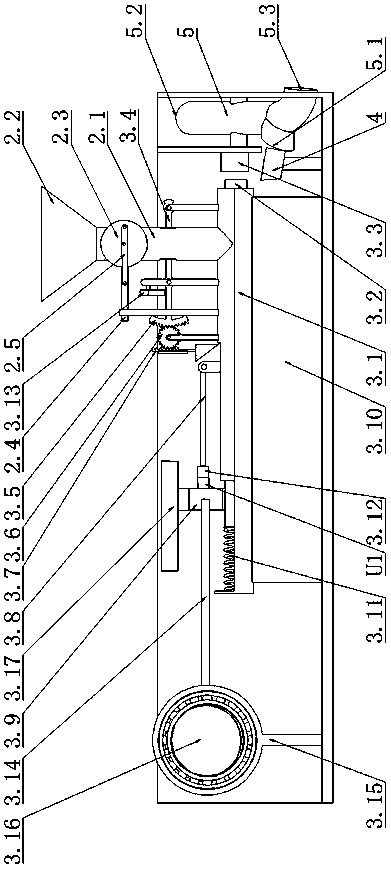

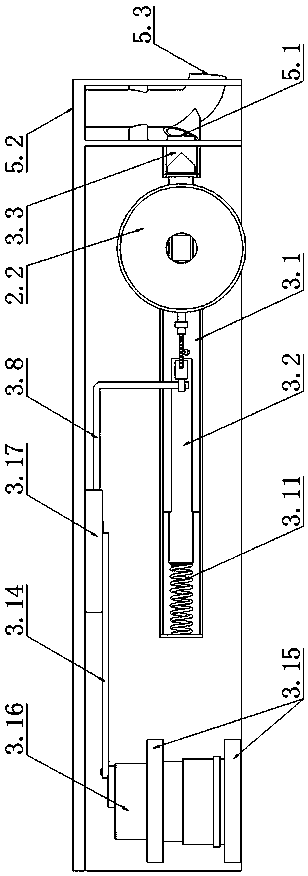

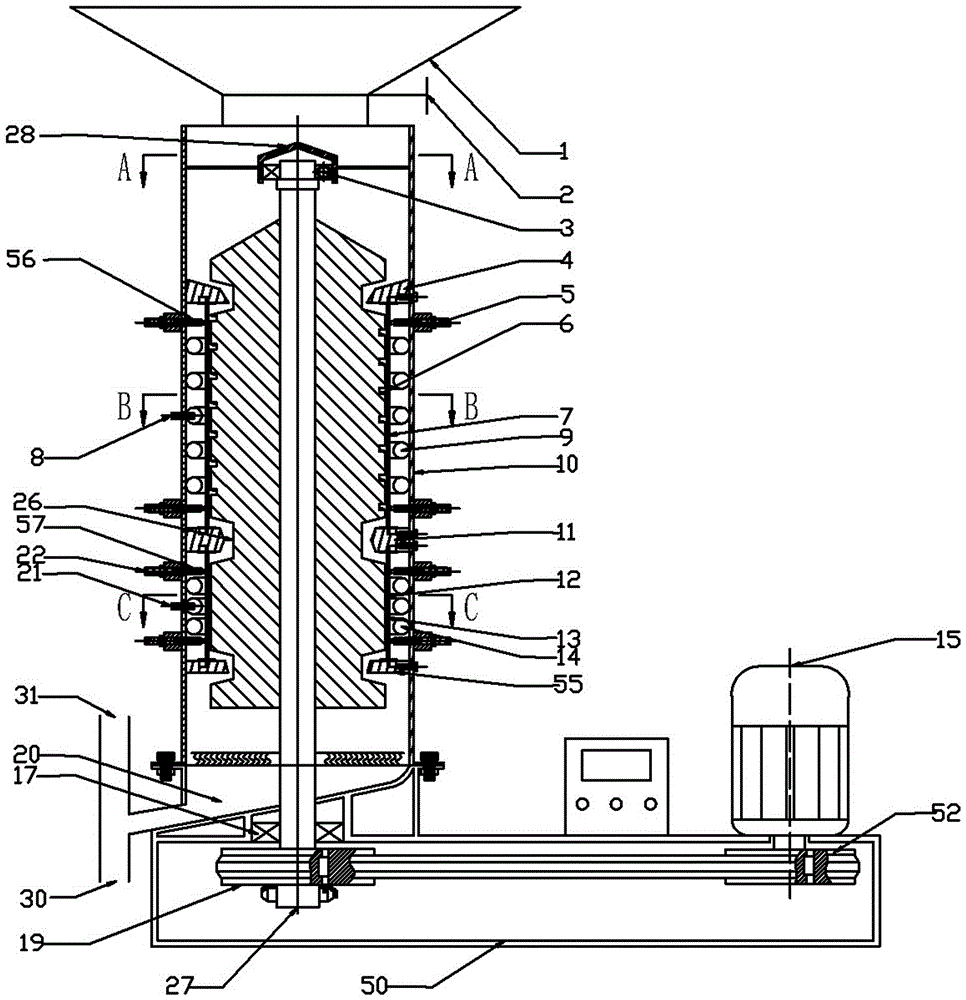

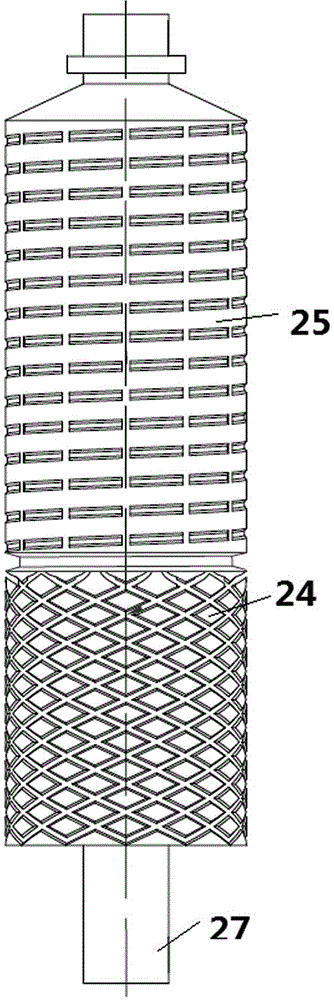

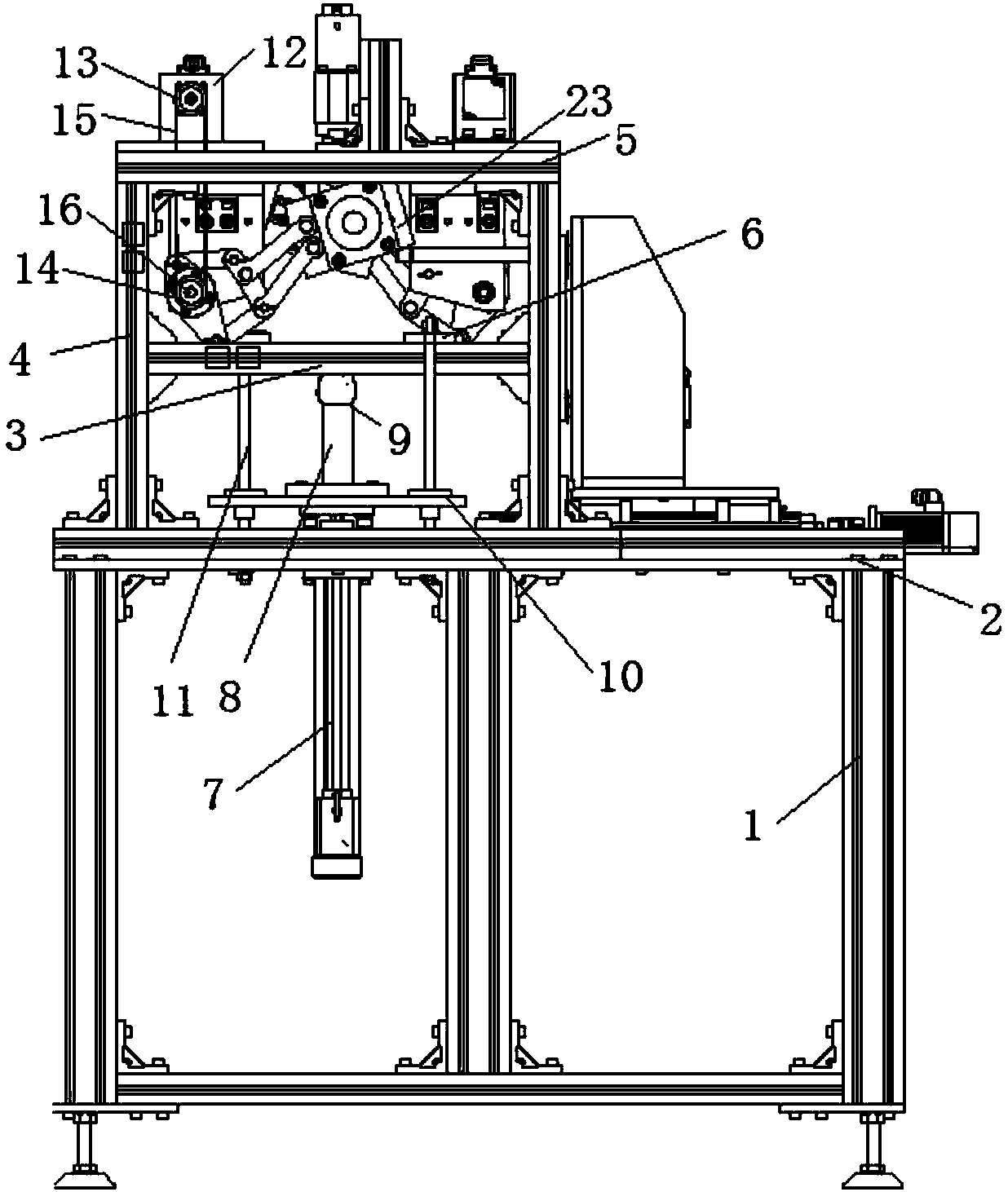

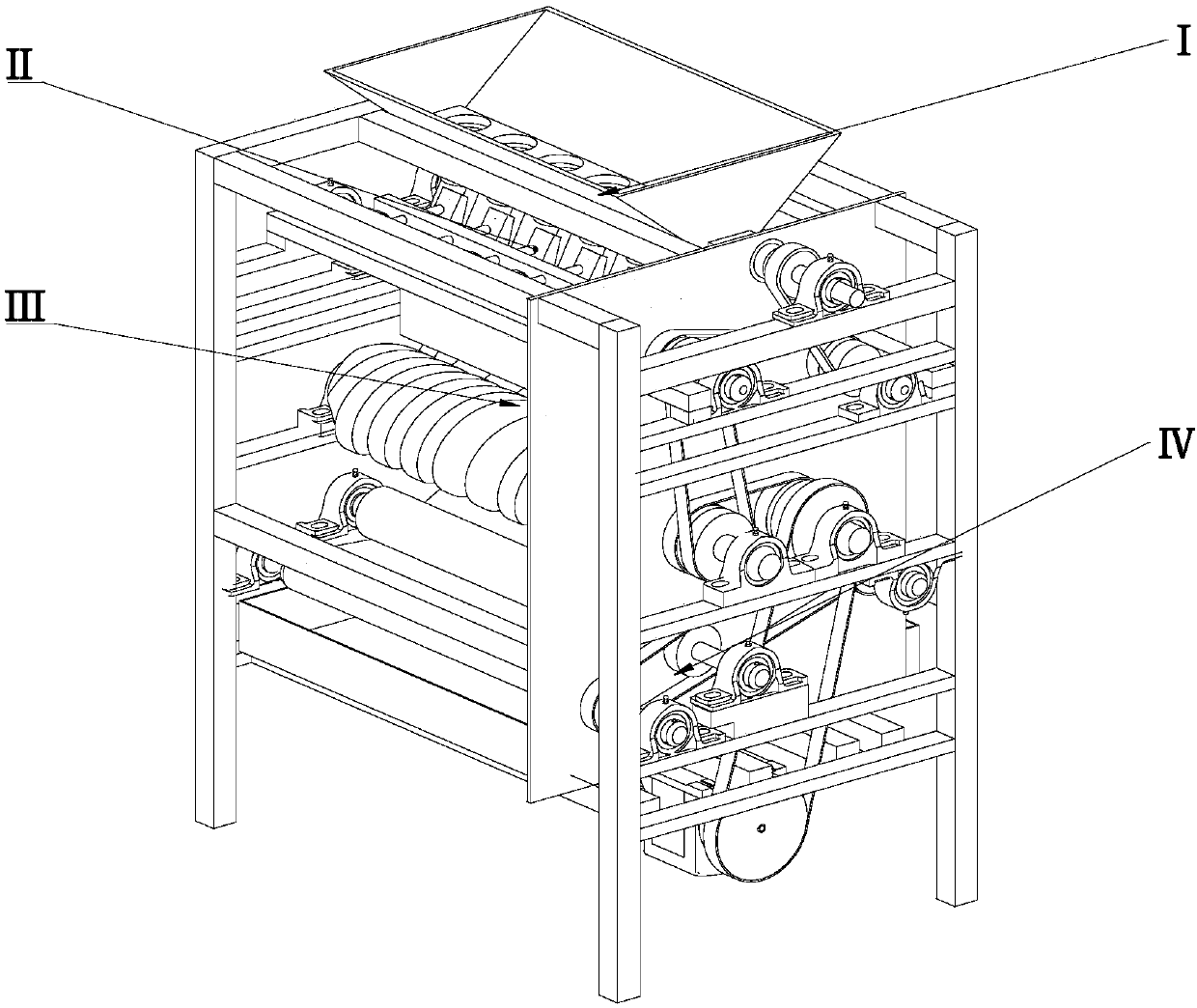

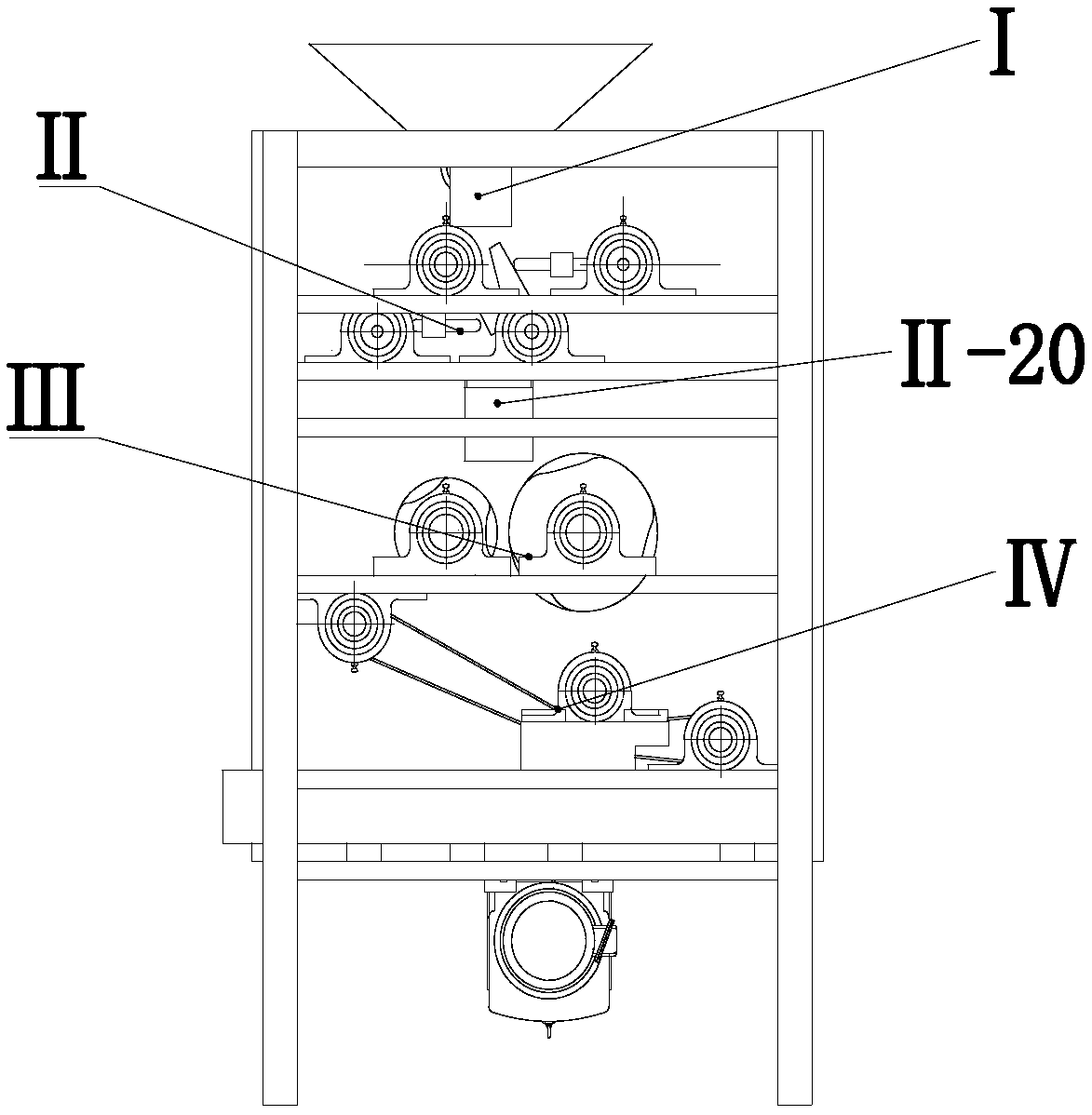

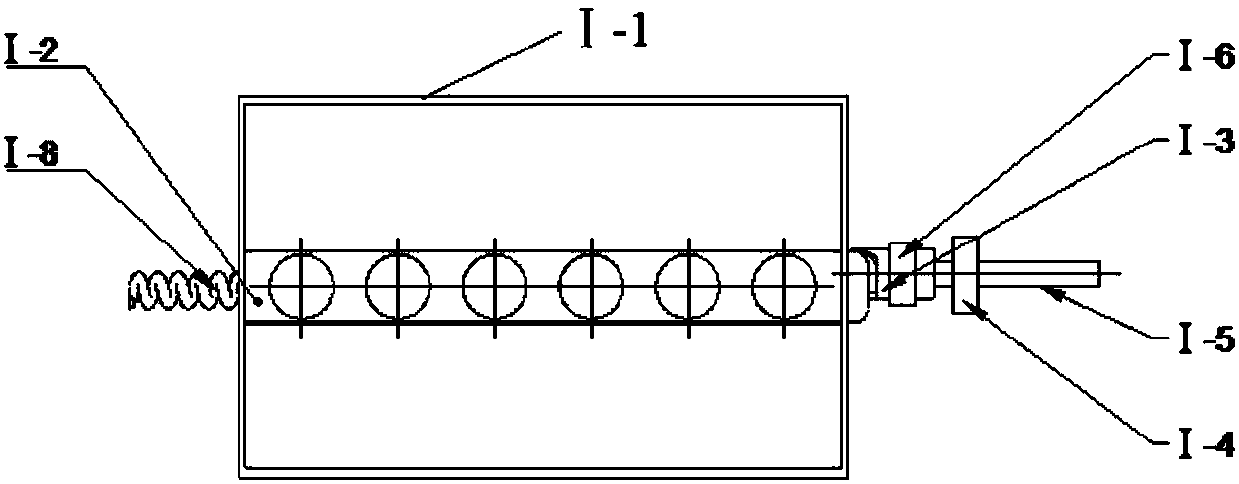

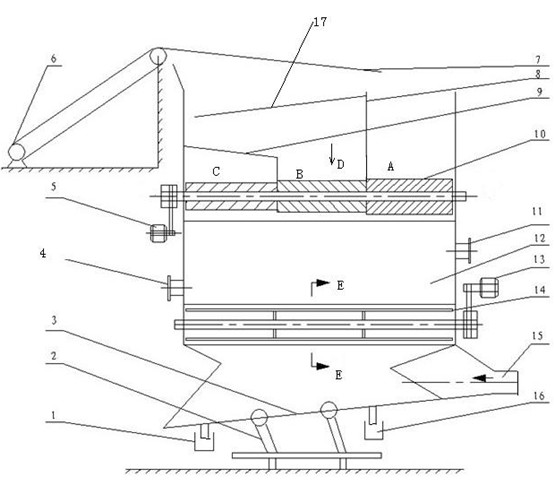

The invention discloses a device for breaking walnut shells and taking walnut kernels, having functions of self-positioning, pre-breaking shells, equidirectional spiral self-grading and flexible extrusion. The device comprises an intermittent feeding device, the a shell pre-breaking device, a flexible shell breaking device and a separating device, which are fixed on a machine frame, wherein the intermittent feeding device is used for performing intermittent batch feeding for the shell pre-breaking device; the shell pre-breaking device comprises an extruding part and a blanking part which are mutually matched; the extruding part is in reciprocating movement, and is matched with the blanking part for extruding walnuts, so that cracks are generated in the walnuts; the blanking part is in reciprocating movement, so that the extruded walnuts fall off to the flexible shell breaking device; the flexible shell breaking device is used for breaking walnut shells; and shells and kernels of the walnuts after shell breaking are separated for storage through the separating device. The device disclosed by the invention integrates a plurality of systems, and is compact in structure, the manufacturing cost of a machine is reduced, the occupied space for the operation of the machine is also reduced, and the miniaturization and the high efficiency of the machine are facilitated; in structure design, multiple connections including splicing, combining and the like for cooperating work can be realized; and the requirements of various production scales and the requirements of various production sites can be met, and the device is also suitable for families, and is widely applied.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +2

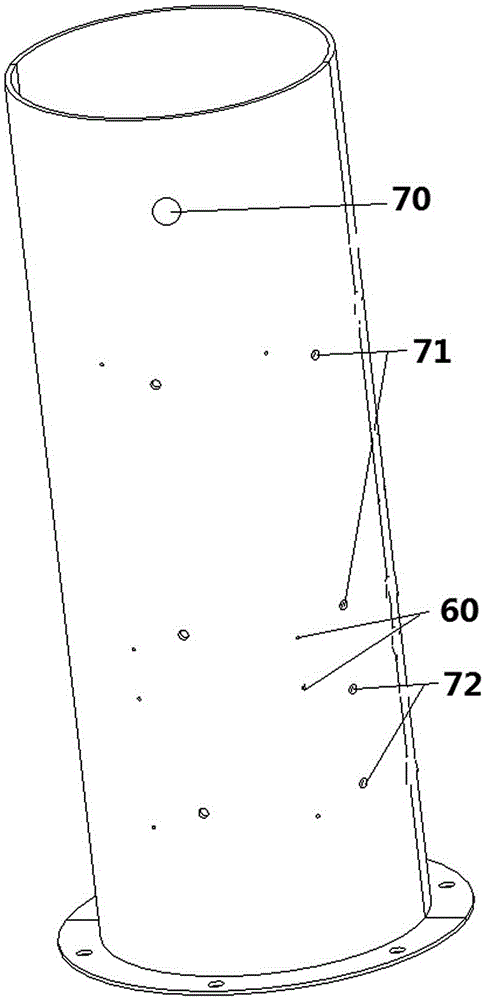

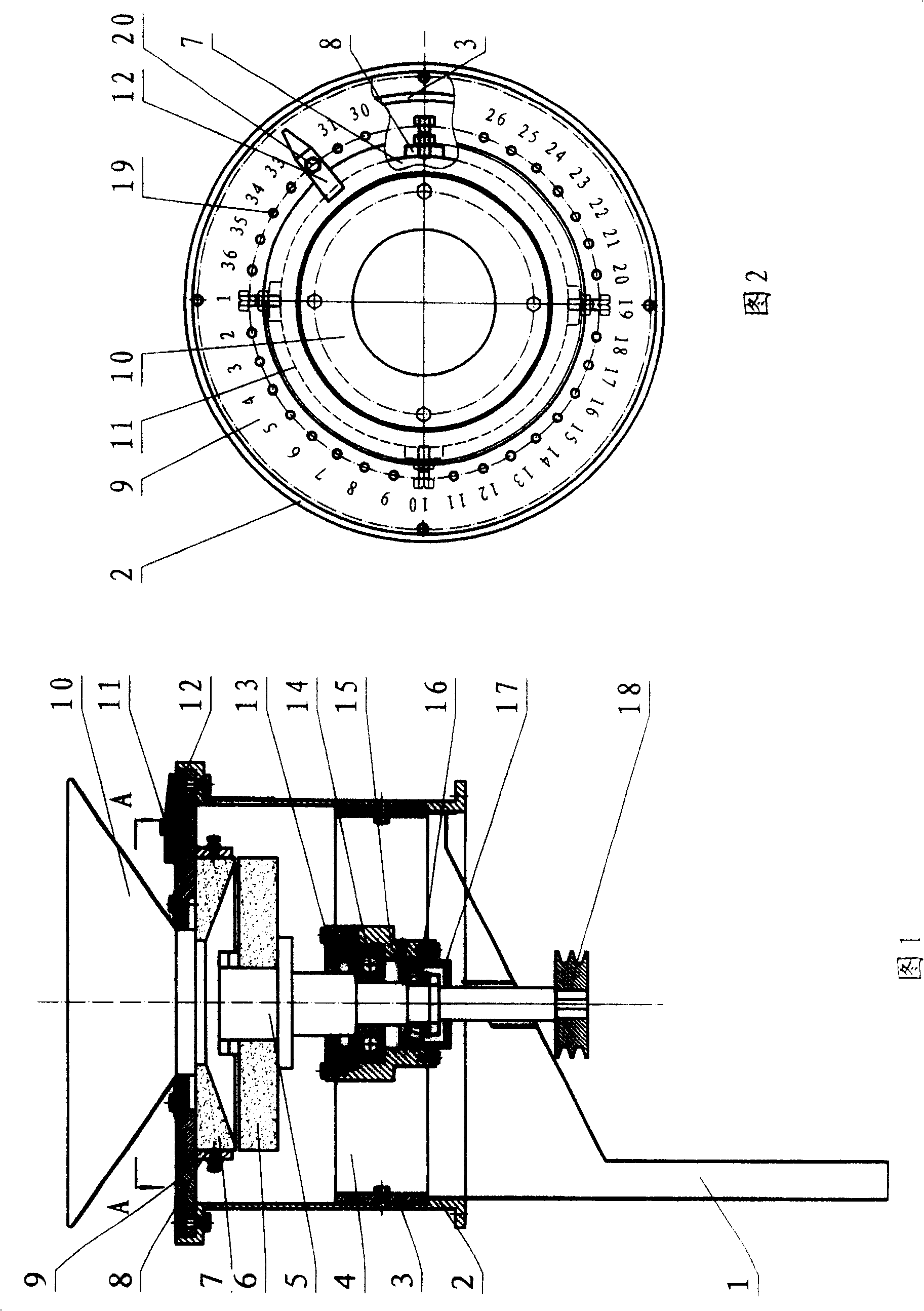

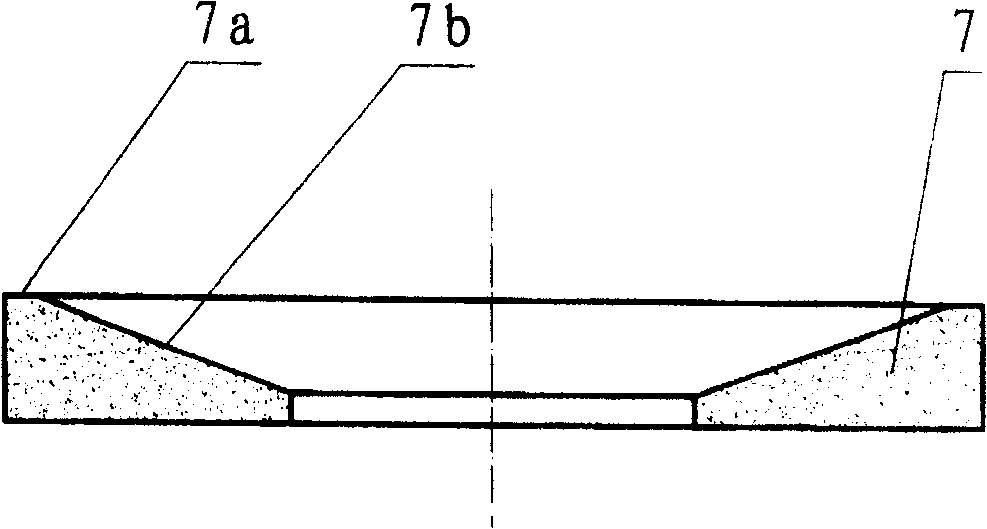

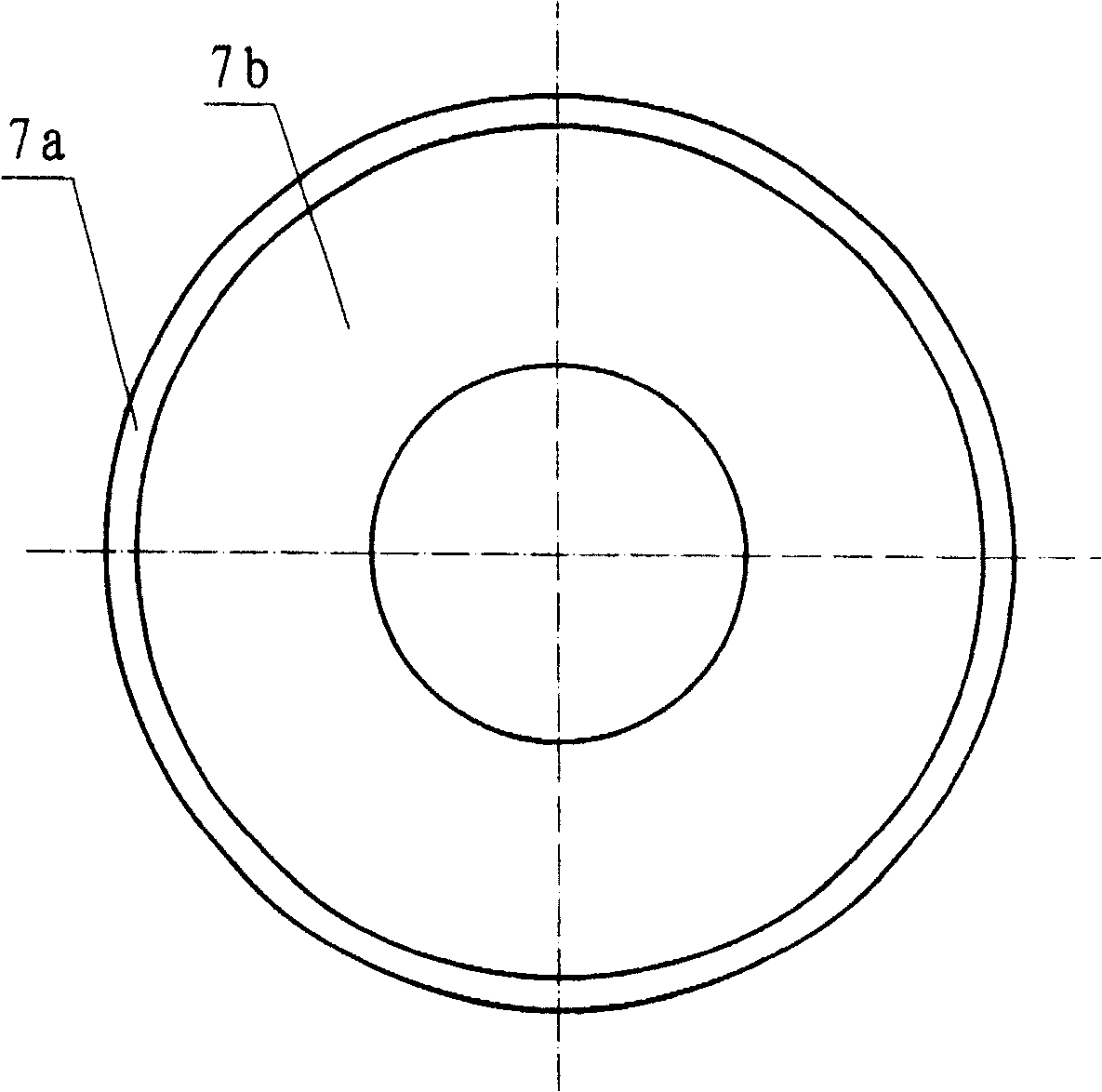

Micro regulating buckwheat sheller

ActiveCN1986062AAchieve fine-tuningHigh precisionGrain huskingGrain polishingPolygonum fagopyrumEngineering

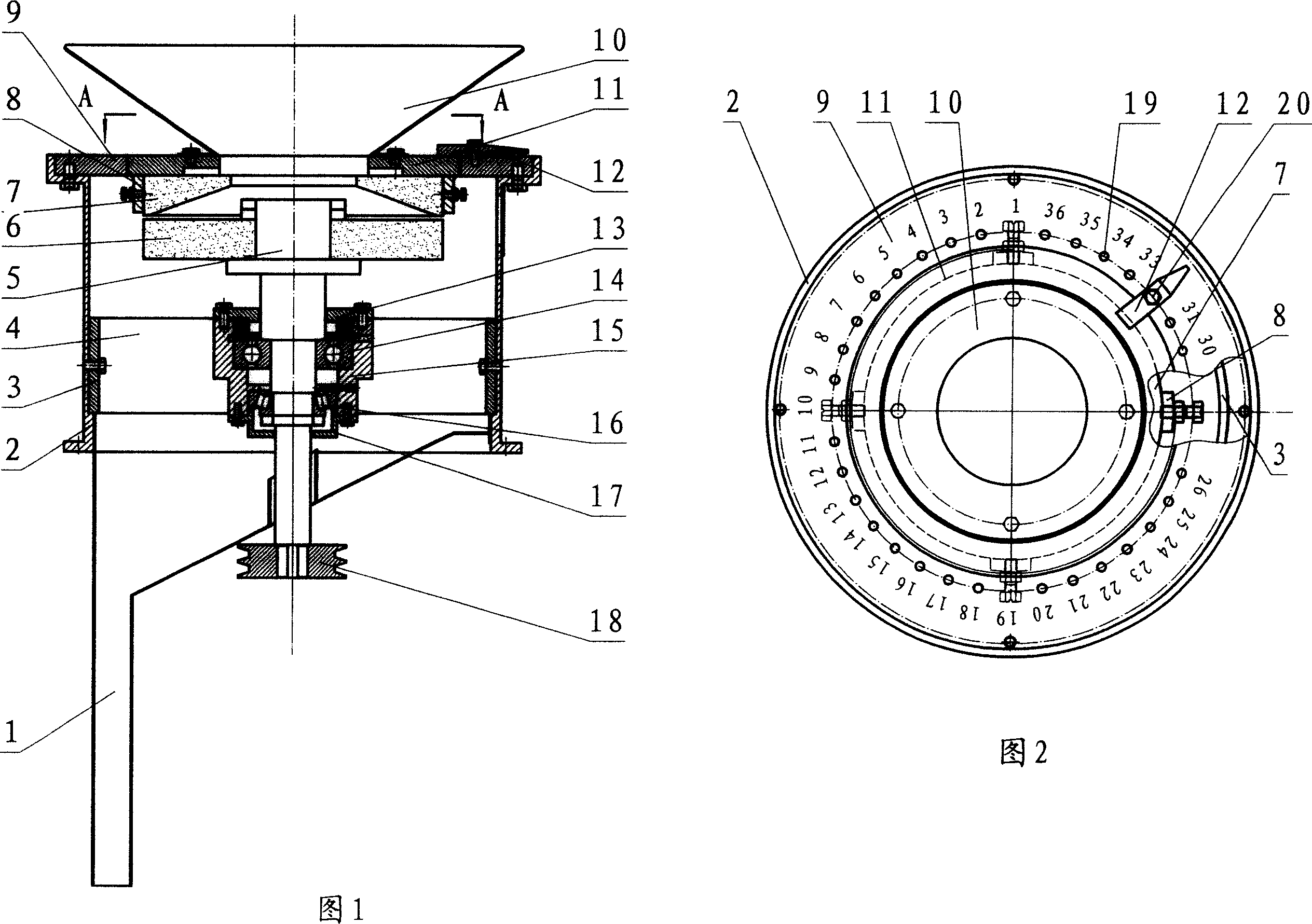

The trimmed buckwheat sheller includes one outer barrel serving as the casing, one inner bushing, one bearing seat with one rotating shaft, one movable wheel on the shaft, one upper cover, one fixed wheel fitting the movable wheel. It features the upper cover comprising one inner ring and one outer ring connected through threads for easy interval regulating and trimming. The present invention has the advantages of high regulating precision, simple and fast regulation, high production efficiency and capacity of processing buckwheat in different plumpness.

Owner:JINZHOU QIAOPAI MACHINERIES

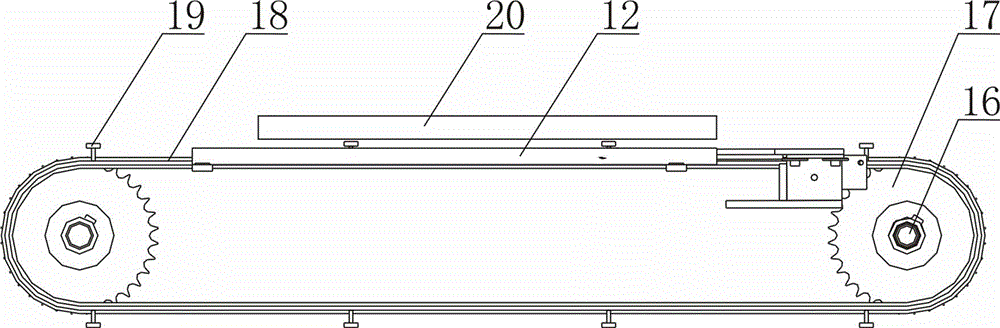

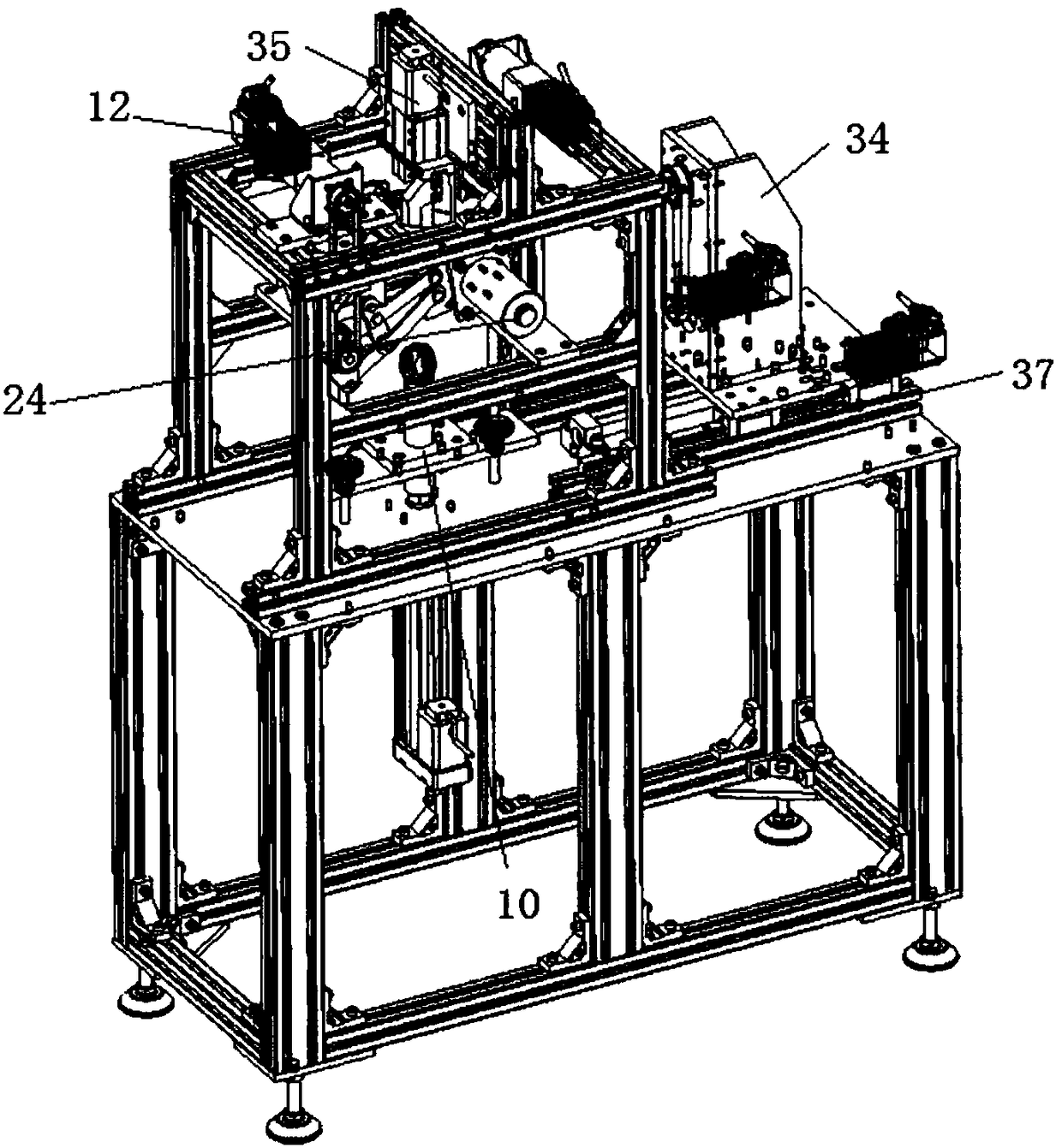

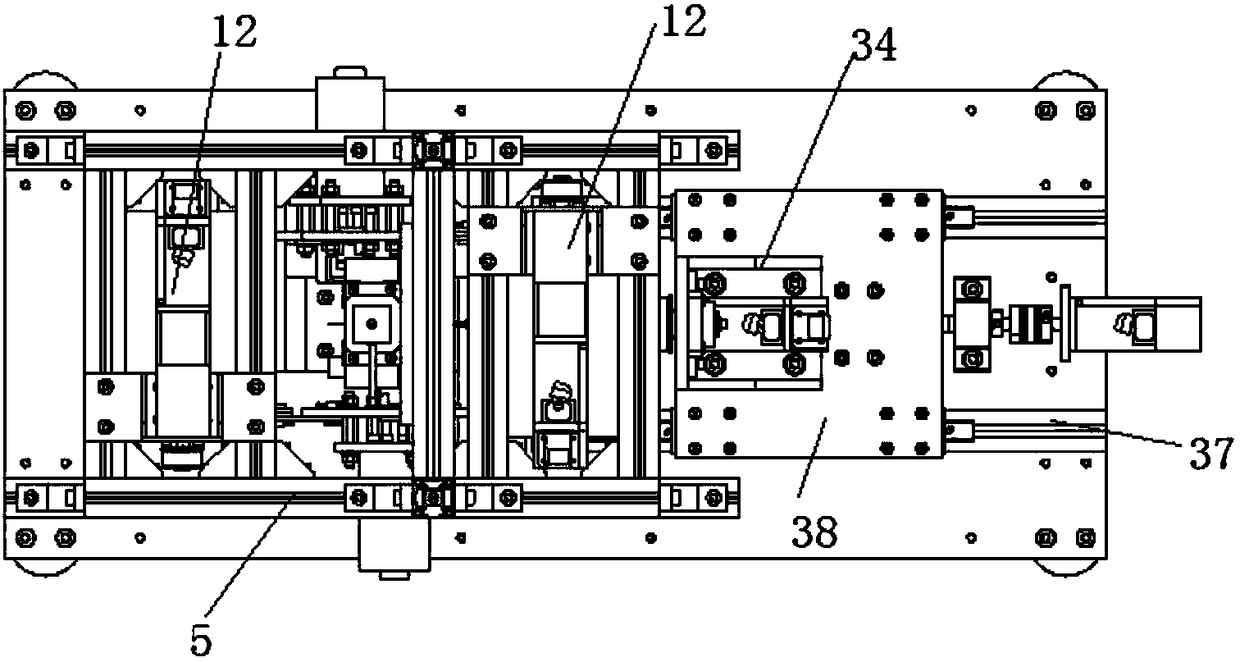

Full automatic cashew nut hull breaking machine

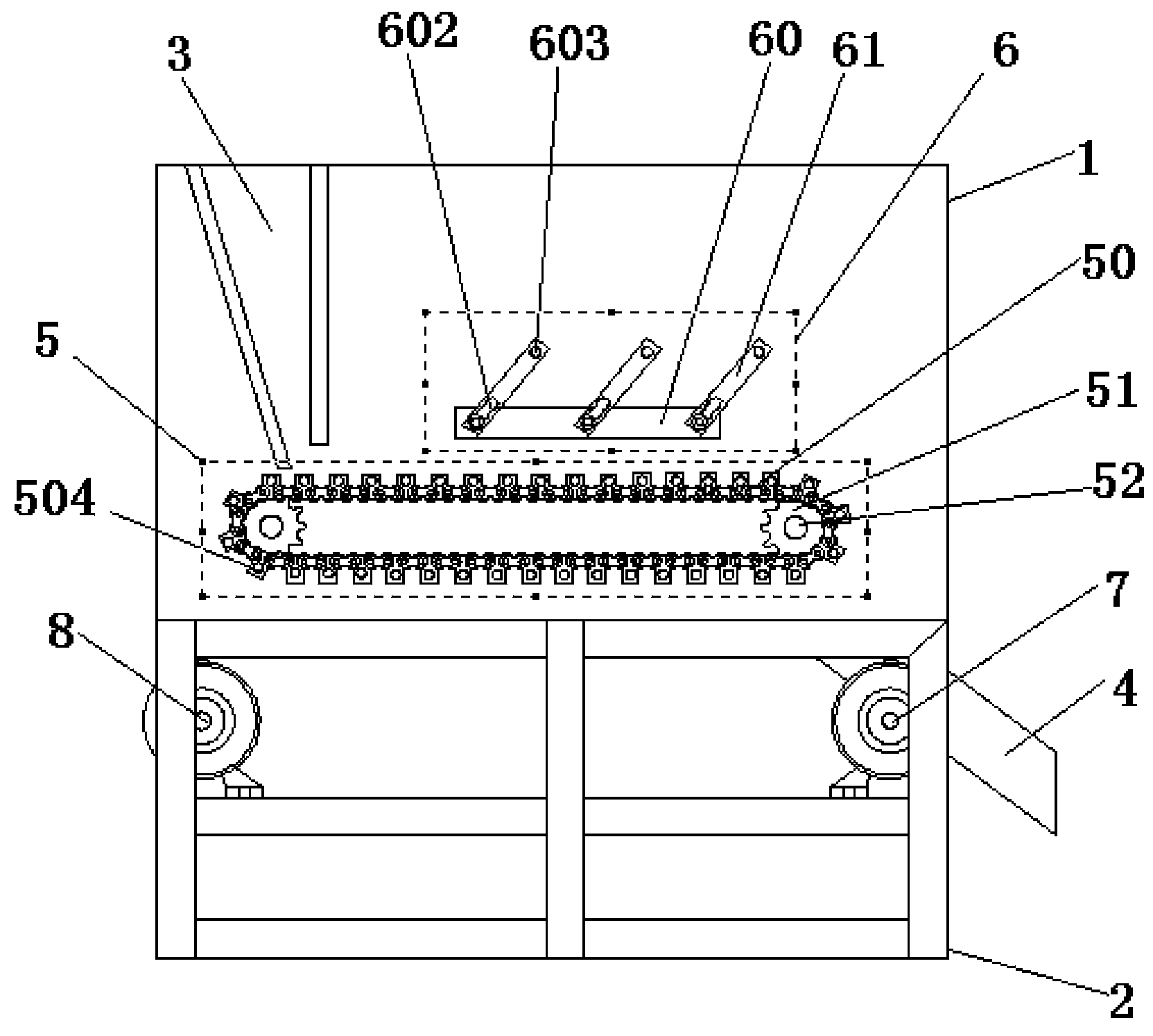

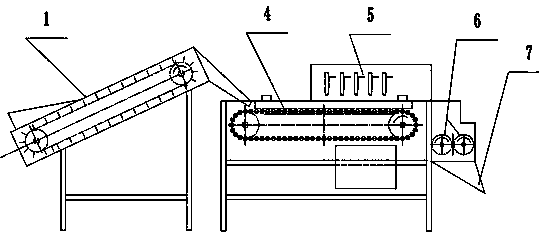

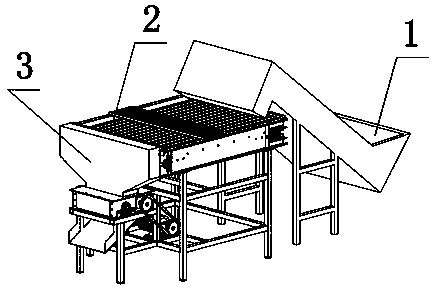

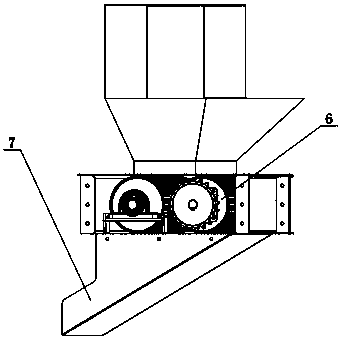

The invention discloses a full automatic cashew nut hull breaking machine which is mainly composed of a machine frame, a motor, a feeding mechanism, a conveying mechanism, a fruit picking mechanism and a cutting mechanism. The conveying mechanism is mainly formed by guide rails, a transmission shaft, a transmission chain wheel, a transmission chain and a fruit pushing plate. The guide rails are formed by an upper guide rail and a lower guide rail, the transmission chain drives the fruit pushing plate to penetrate a gap between the upper guide rail and the lower guide rail, the feeding mechanism is located at one end of the guide rail, and the cutting mechanism is located at the other end of the guide rail. The lower guide rail is formed by a left half portion and a right half portion. The fruit picking mechanism is mainly formed by two transmission shafts, a transmission chain wheel, two transmission chains and more than two fruit poking plates, and the transmission chains drive the fruit poking plates to enable poking pieces on the fruit poking plates to penetrate a gap between the left half portion and the right half portion. The full automatic cashew nut hull breaking machine is capable of achieving automatic feeding, conveying and centralizing, can improve the production efficiency, reduce labor intensity and reduce production cost, and is high in safety. The rate of perfect kernel can reach 50%-70%.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Extruding and rubbing type walnut shell breaking device

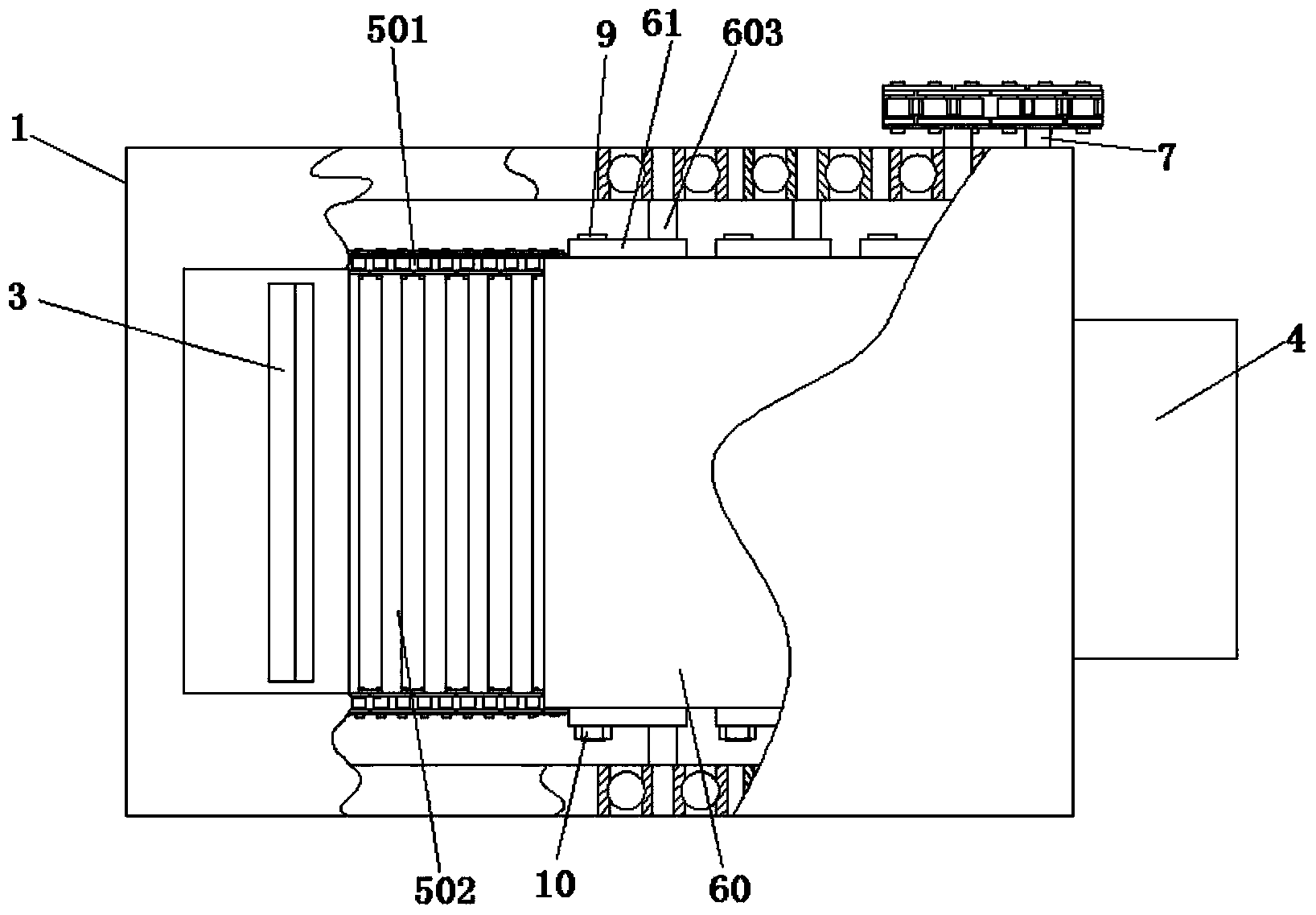

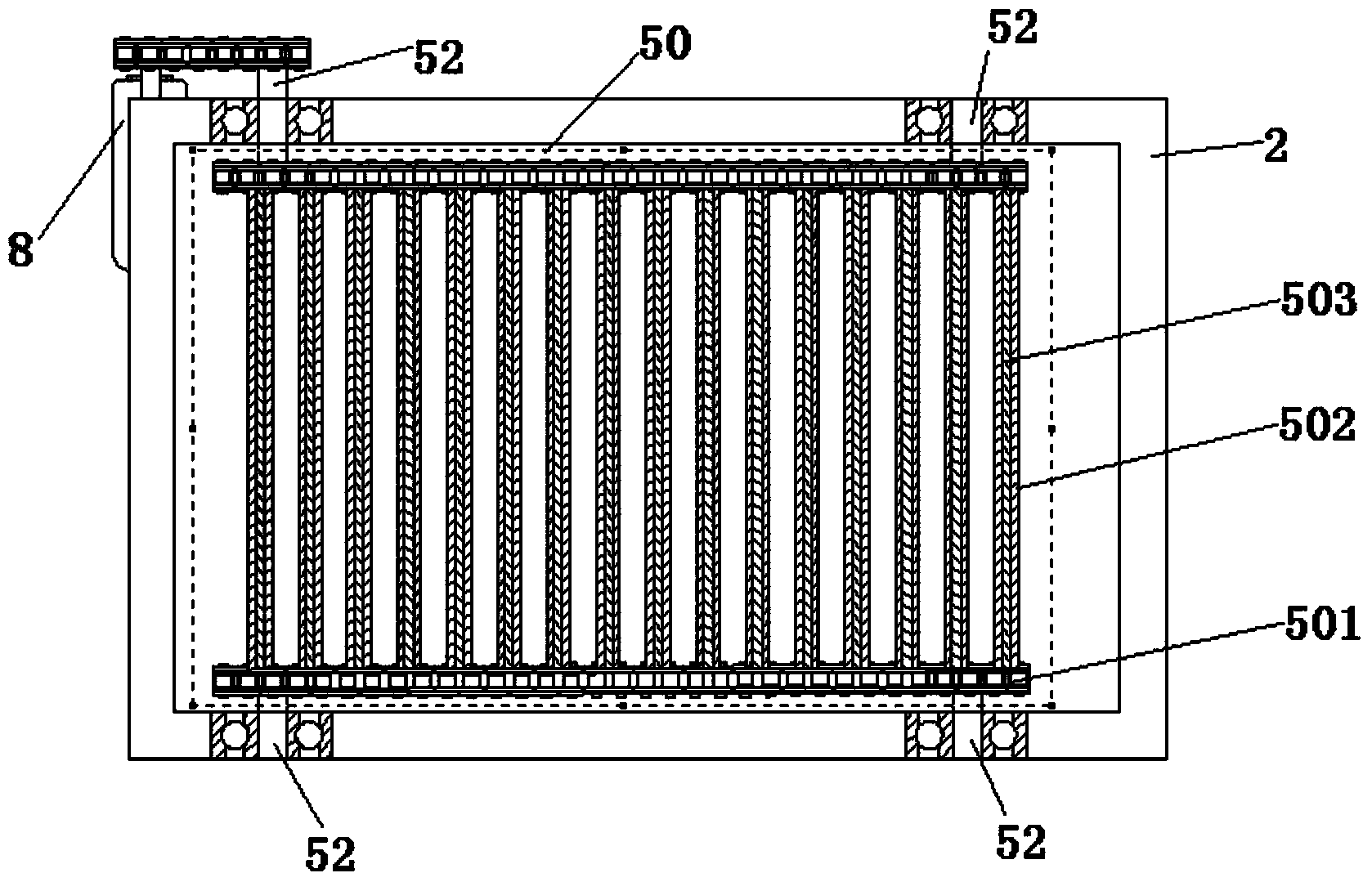

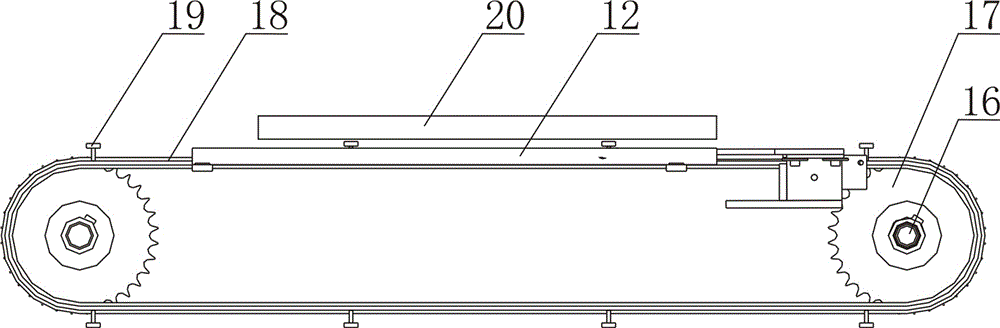

The invention provides an extruding and rubbing type walnut shell breaking device which comprises a box body and a rack. The box body is arranged on the rack. A feeding port is arranged on the top surface of one side of the box body. A discharging port is arranged on the bottom surface of the other side of the box body. A conveyer and a shell breaker are arranged inside the box body. The conveyer is located at a horizontal position between the feeding port and the discharging port and used for conveying walnuts which fall into the conveyer from the feeding port to the discharging port. The shell breaker is located above the conveyer and used for breaking shells of the walnuts conveyed by the conveyer. When the extruding and rubbing type walnut shell breaking device is used, the walnuts are placed into the feeding port, fall onto a conveying chain due to gravity, and rotate along with the conveying chain; the walnuts are extruded by a pressing plate and rubbed by rollers, so that it is guaranteed that the shells of the walnuts are completely broken. According to the extruding and rubbing type walnut shell breaking device, the distance between the pressing plate and the conveying chain can be adjusted according to the sizes of the walnuts, the walnuts are rubbed in the extrusion process so that the shells of the walnuts are completely broken, and therefore the extruding and rubbing type walnut shell breaking device has the advantages of being high in work efficiency, shell breaking rate and perfect kernel rate, low in cost and convenient to use.

Owner:SHAANXI UNIV OF SCI & TECH

Dual-directional extrusion-type hull breaking equipment for walnuts

The invention discloses dual-directional extrusion-type hull breaking equipment for walnuts. A feeding hole is formed in the top face of a box; a discharge hole is formed in the bottom face of the box; a feeding device, an extrusion device and a supporting device are arranged in the box in sequence from top to bottom; the feeding device is located right below the feeding hole; the extrusion device is located right below the feeding device; the supporting device is located right below the extrusion device; the walnuts falling into the feeding device from the feeding hole are conveyed into the extrusion device through the feeding device and extruded for hull breaking; during an extrusion process, the supporting device plays a supporting role on the walnuts; after extrusion is finished, the walnuts fall into the discharge hole from the supporting device; the hull breaking equipment also comprises an electric motor and a coupling, wherein the electric motor is used for providing energy for the equipment; the coupling is used for transmitting the energy; the electric motor and the coupling are located outside the box. According to the dual-directional extrusion-type hull breaking equipment disclosed by the invention, directional extrusion can be performed on the walnuts, and enough power can be provided during the extrusion process, so that hulls of the walnuts are fully broken; the dual-directional extrusion-type hull breaking equipment has the characteristics that the work efficiency is high, the hull breaking rate is high, the rate of perfect kernel is high, the cost is low, and the use is convenient.

Owner:SHAANXI UNIV OF SCI & TECH

Tartary buckwheat non-thermal shucking method and Tartary buckwheat shucking device

InactiveCN103920555AThe shelling process is simpleSave energyGrain huskingGrain polishingComposite materialFagopyrum tataricum

The invention discloses a Tartary buckwheat non-thermal shucking method which includes the steps: removing impurities in raw materials; grinding the Tartary buckwheat raw materials by the aid of small contact force, grinding off protruding corner angle portions on Tartary buckwheat shells, and sufficiently grinding the corner angle portions on the Tartary buckwheat shells but not grinding endosperms and conical surface ventral groove recesses; enabling the shells to slightly deform by twisting, grinding or slightly striking, further fracturing the shells and finally separating the shells from kernels by an airflow cleaning method. By the novel method including non-thermal shucking, non-pressure grinding and the like, nutritional components are kept, shucking cost is low, shucking rate is high, and kernel breaking rate is low.

Owner:NORTHWEST A & F UNIV

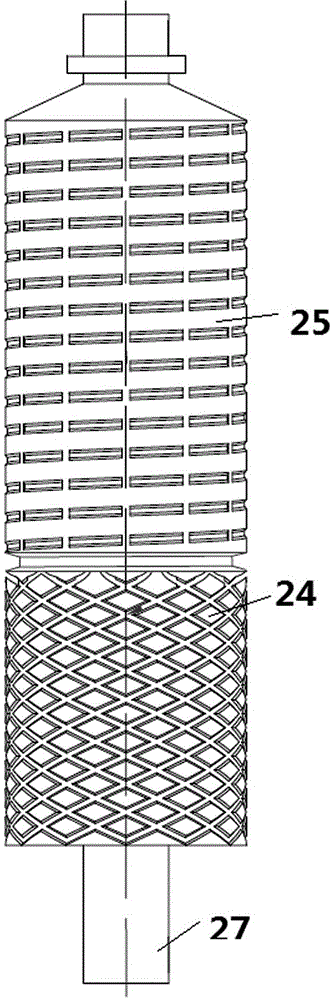

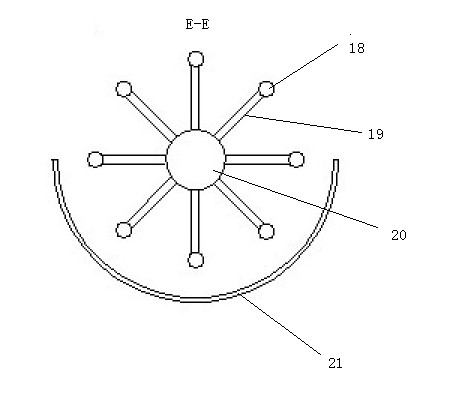

Air-breathing type tartary buckwheat low-pressure grinding huller

ActiveCN106391173AGrind fullyReduce wrapping forceGrain huskingGrain polishingPolygonum fagopyrumWorking pressure

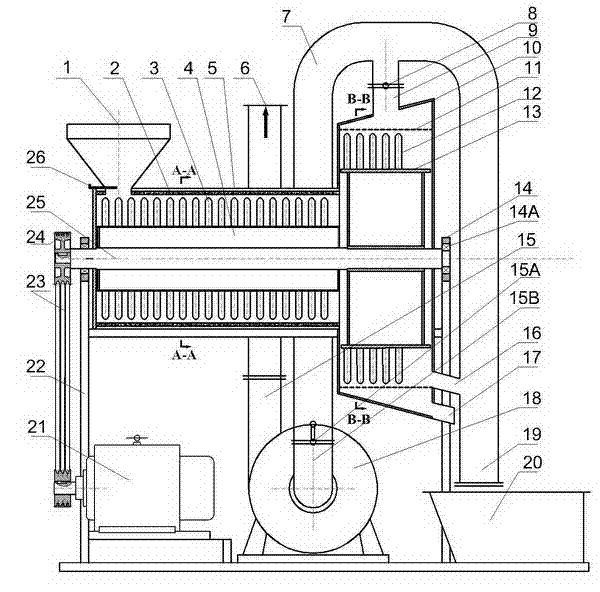

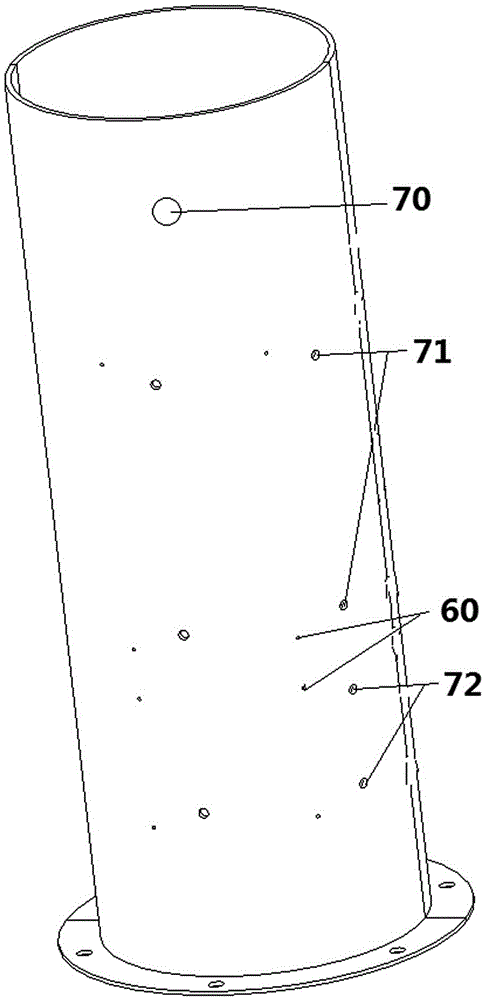

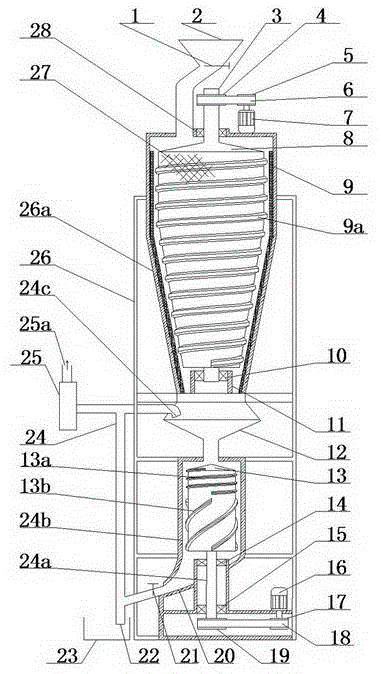

The invention discloses an air-breathing type tartary buckwheat low-pressure grinding huller, and belongs to the field of grain hulling machines. The huller comprises a machine shell, a grinding cylinder is vertically fixed at the center of the machine shell, a grinding air bag is mounted between the grinding cylinder and the side wall of the machine shell, and grinding rollers are concentrically mounted in the grinding cylinder; a feed hopper is mounted at the top of the grinding cylinder, and a feed control door is arranged at the bottom of the feed hopper; a kneading cylinder is arranged just below the grinding cylinder, a kneading air bag is mounted between the kneading cylinder and the machine shell, and kneading rollers are concentrically mounted in the kneading cylinder; a material flowing groove is formed below the kneading cylinder, and a hulled material outlet and a cleaning device connector are arranged obliquely below the material flowing groove. An air suction pipe is mounted at the top of the machine shell and is connected with a fan. In the whole hulling process, due to the buffering effect of the grinding air bag and the kneading air bag, the working pressure of tartary buckwheat is very low and is dynamically regulated; and meanwhile, an air suction component can immediately clean dusts, cool down and dehumidify, prolong the grinding process, and effectively improve the complete kernel yield of the tartary buckwheat during hulling.

Owner:NORTHWEST A & F UNIV

Microwave hull breaking method for walnuts

The invention discloses a microwave hull breaking method for walnuts. The microwave hull breaking method comprises the following steps of: cooking the walnuts and maintaining proper water content of the cooked walnut kernels; feeding the cooked walnuts in microwave equipment; carrying out microwave treatment at a certain temperature and power for a period of time; and breaking the walnut hulls and finishing the microwave hull breaking of the walnuts. The water content of the cooked walnut kernel is not lower than 15 percent. The temperature for microwave treatment is medium baking temperature, medium-high baking temperature or high baking temperature; the power is at least 500-700W; and the time is at least 4-6 minutes. The microwave hull breaking method of the walnuts, which is provided by the invention, has the advantages of low kernel breaking rate and high rate of perfect kernel.

Owner:ANHUI ZHANSHI FOOD

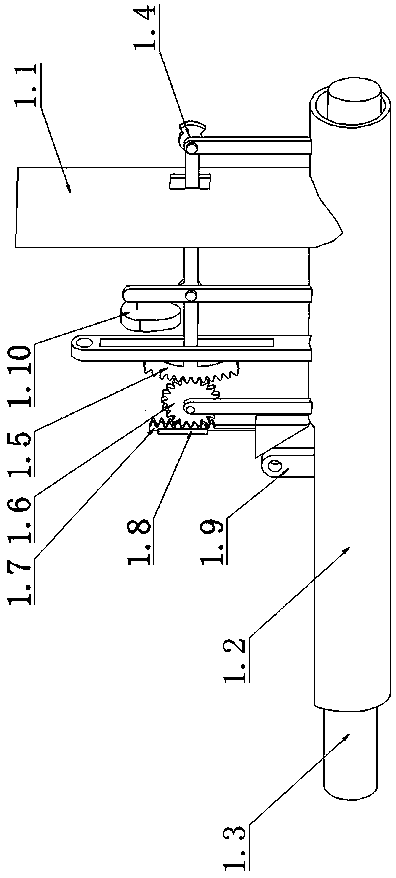

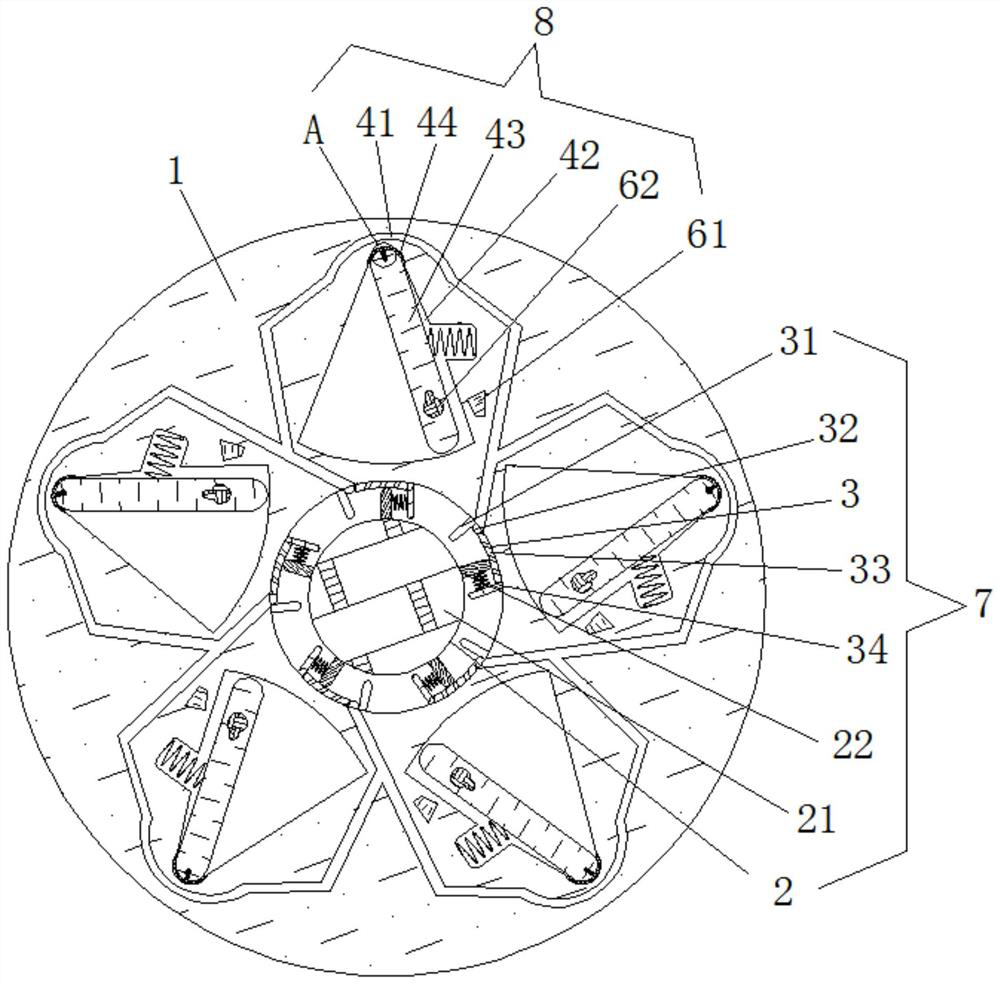

Mechanism capable of controlling nut impacting space and nut shell breaking device

ActiveCN109007869AControllable impact distanceControl Impact SpacingHuskingHullingGear wheelEngineering

The invention provides a mechanism capable of controlling the nut impacting space and a nut shell breaking device, and belongs to the technical field of nut processing. The mechanism comprises a nut falling pipe, an impact rod sleeve, an impact rod, a first connecting rod, a second connecting rod, a gear and a rack with the bottom end provided with a wedge block; the nut falling pipe is perpendicular to and communicated with the impact rod sleeve, and a first open groove is formed in the wall of the nut falling pipe; the impact rod is sleeved with the impact rod sleeve; a first end of the first connecting rod is hinged to a first supporting rod on the impact rod sleeve, and a second end of the first connecting rod is a baffle plate penetrating through the first open groove into the nut falling pipe; a second connecting rod is hinged to a second supporting rod on the impact rod sleeve, a first end of the second connecting rod is a radial incomplete gear, and a second end of the second connecting rod is a baffle plate penetrating through the first open groove into the nut falling pipe; the gear is rotatably connected to a third supporting rod on the impact rod sleeve; the rack is arranged above the impact rod sleeve through a rack supporting frame. The device can control the impact space according to the size of a single nut, and the rate of perfect kernel is improved.

Owner:SHANXI UNIV

Roller walnut shell breaking machine based on laser pretreatment

InactiveCN108113016AImprove the efficiency of breaking upLow kernel rateHuskingHullingLaser probeEngineering

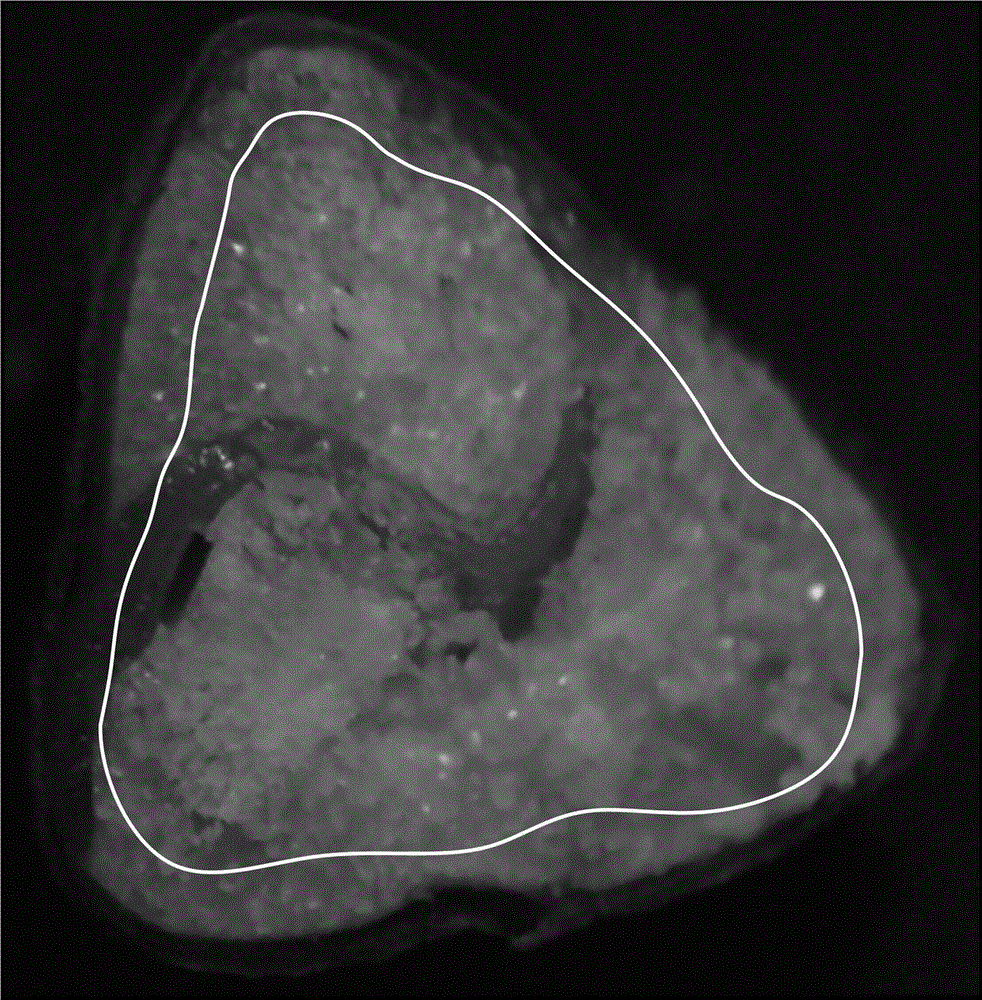

The invention relates to a roller walnut shell breaking machine based on laser pretreatment. The machine is characterized by comprising a feeding device, a laser pretreatment device and a shell breaking device; walnuts are conveyed to a rolling bar sorting device through the feeding device and evenly sorted and then roll forwards, when the walnuts pass through a laser probe mounted on a suspensionbeam, the surfaces of shells are cut, then the walnuts are conveyed to a shell-breaking working area of a roller device through a rolling bar, extruding shell-breaking is achieved, and the walnuts are conveyed out from a discharge port; the walnuts after cutting pretreatment are subjected to extruding shell-breaking by rollers, so that the shell breaking rate of the walnuts is ensured, and the damage to walnut kernels is greatly reduced at the same time; the roller walnut shell breaking machine achieves the purposes that by cutting the walnuts with laser, the structural stress on the surfacesof the walnut shells is released in advance, and the shell breaking rate and the high kernel exposure rate are ensured when the walnut shells are broken and the kernels are taken out; the equipment has the advantages of being cable of achieving batched shell breaking, high in shell breaking rate, low in crushed kernel rate, high in automation degree and controllability and the like.

Owner:SHIHEZI UNIVERSITY

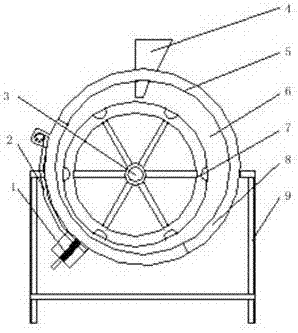

Flexible walnut shell breaking machine

The invention relates to a flexible walnut shell breaking machine. The flexible walnut shell breaking machine comprises one machine base, wherein a machine cover is arranged on the machine base, a shell breaking roller is arranged in the machine cover, shell breaking pressure heads in a plurality of axis directions are arranged on the surface of the shell breaking roller, the shell breaking rolleris connected with a motor by virtue of a belt transmission device, one feeding hopper is arranged on the machine cover, a plurality of material distributing plates are arranged in the feeding hopper,a plurality of feeding channels are formed in the feeding hopper, one shell breaking supporting plate matched with the shell breaking roller is arranged below each feeding channel, and the shell breaking supporting plate is arranged on an elasticity adjusting device. The flexible walnut shell breaking machine provided by the invention has the advantages that the shell breaking supporting plate isarranged on the elasticity adjusting device, walnuts receive elastic acting forces when being extruded, and each shell breaking supporting plate is a U-shaped trihedron which is big end down, so thatthe walnuts are stressed at multiple points; the surface of each shell breaking pressure head on the shell breaking roller is arc-shaped, force is gradually applied to the walnuts during shell breaking, and flexible multi-point extrusion is formed, so that perfect kernel rate of the walnuts after the shell breaking is greatly improved, and end product quality is improved; and meanwhile, both large walnuts and small walnuts are considered, classification does not need to be carried out, and production processes are simplified.

Owner:JINZHOU QIAOPAI MACHINERIES

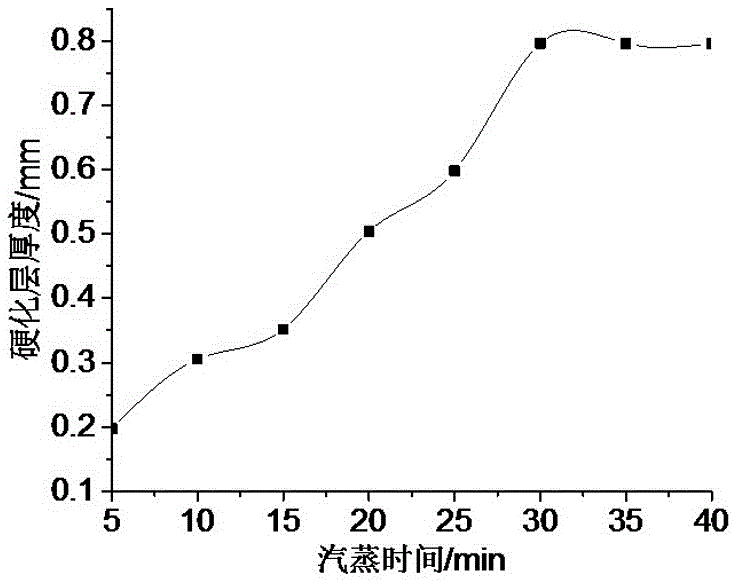

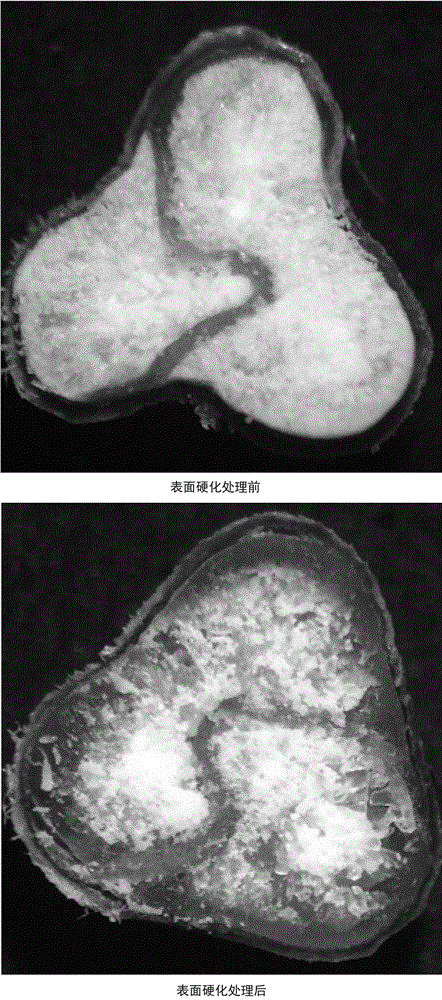

Tartary buckwheat case-hardening and hulling method

ActiveCN106391171AImprove shelling rateImprove whole kernel rateGrain huskingGrain polishingPolygonum fagopyrumHigh energy

The invention relates to the technology of grain hulling, in particular to a tartary buckwheat case-hardening and hulling method, which comprises the following steps of (1) purifying, dedusting and staged treating tartary buckwheat raw materials; (2) at the temperature of 20 DEG C to 50 DEG C, soaking the tartary buckwheat with clear water, and enabling the surface infiltration depth of tartary buckwheat kernels to achieve 0.2mm to 0.6mm; (3) at the temperatue being less than or equal to 160 DEG C, carrying out fast case hardening treatment on the tartary buckwheat, and enabling the thickness of a case hardening layer of a kernel to achieve 0.2mm to 0.6mm; (4) enabling the moisture content of the tartary buckwheat to be within 15 percent to 28 percent; (5) grinding the tartary buckwheat at low pressure; (6) kneading the tartary buckwheat at low pressure so as to separate shells and the kernels; (7) air flow cleaning and screening the fully kneaded tartary buckwheat so as to thoroughly separate the shells and the kernels so as to obtain the tartary buckwheat kernels and the shells respectively. The tartary buckwheat case-hardening and hulling method provided by the invention adopts new technologies such as case hardening, and low-pressure grinding and kneading, so that the problems of low hulling rate, low rate of perfect kernels, high nutrition loss, high energy consumption and high water consumption in the prior art can be solved.

Owner:NORTHWEST A & F UNIV

Automatic cashew nut shelling machine

The invention discloses a full automatic cashew nut hull breaking machine which is mainly composed of a machine frame, a motor, a feeding mechanism, a conveying mechanism, a fruit picking mechanism and a cutting mechanism. The conveying mechanism is mainly formed by guide rails, a transmission shaft, a transmission chain wheel, a transmission chain and a fruit pushing plate. The guide rails are formed by an upper guide rail and a lower guide rail, the transmission chain drives the fruit pushing plate to penetrate a gap between the upper guide rail and the lower guide rail, the feeding mechanism is located at one end of the guide rail, and the cutting mechanism is located at the other end of the guide rail. The lower guide rail is formed by a left half portion and a right half portion. The fruit picking mechanism is mainly formed by two transmission shafts, a transmission chain wheel, two transmission chains and more than two fruit poking plates, and the transmission chains drive the fruit poking plates to enable poking pieces on the fruit poking plates to penetrate a gap between the left half portion and the right half portion. The full automatic cashew nut hull breaking machine is capable of achieving automatic feeding, conveying and centralizing, can improve the production efficiency, reduce labor intensity and reduce production cost, and is high in safety. The rate of perfect kernel can reach 50%-70%.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Cashew shell breaking method

The invention relates to a cashew shell breaking method and belongs to the technical field of nut shell breaking processing. The method includes the steps of first removing impurities of harvested cashews with shells through vibration, winnowing, soaking in water and mixing, performing grading, steam heating, rapid cooling and the like processing, breaking shells of the cashews with the shells through a homemade cashew shell breaking machine, and finally separating cashew kernels from the cashew shells through a winnowing machine and a vibrating screen. By means of the cashew shell breaking method, the whole kernel rate is high, and the process is easy to operate, high in practicability, low in energy consumption, good in stability and suitable for bulk industrial production.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

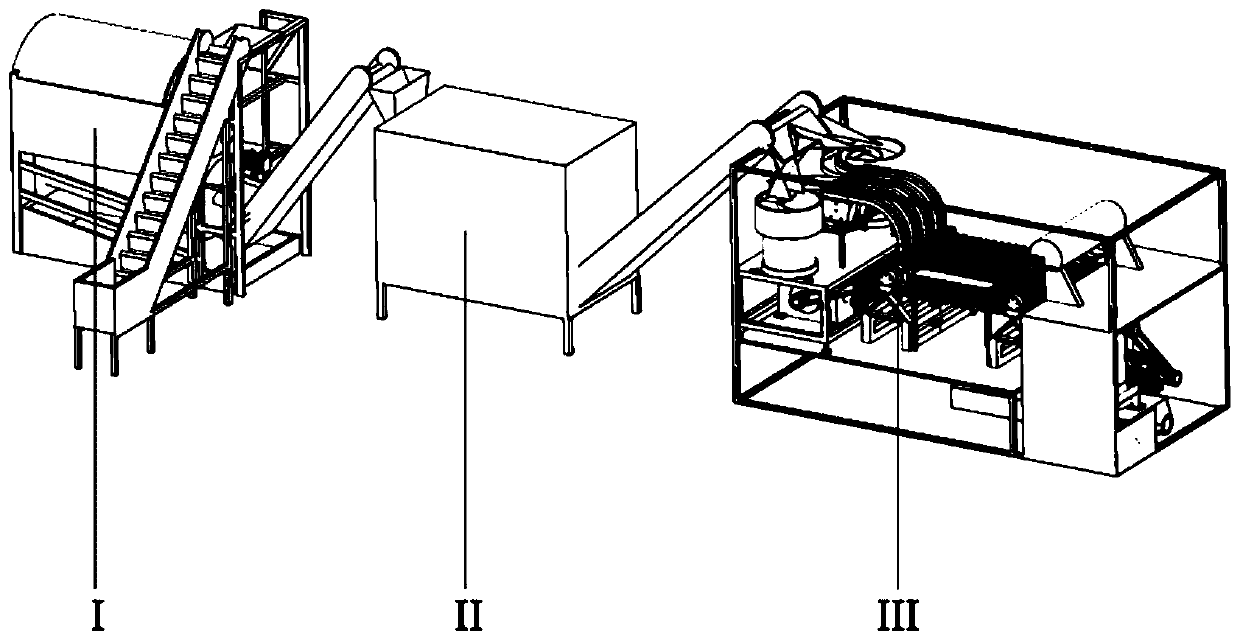

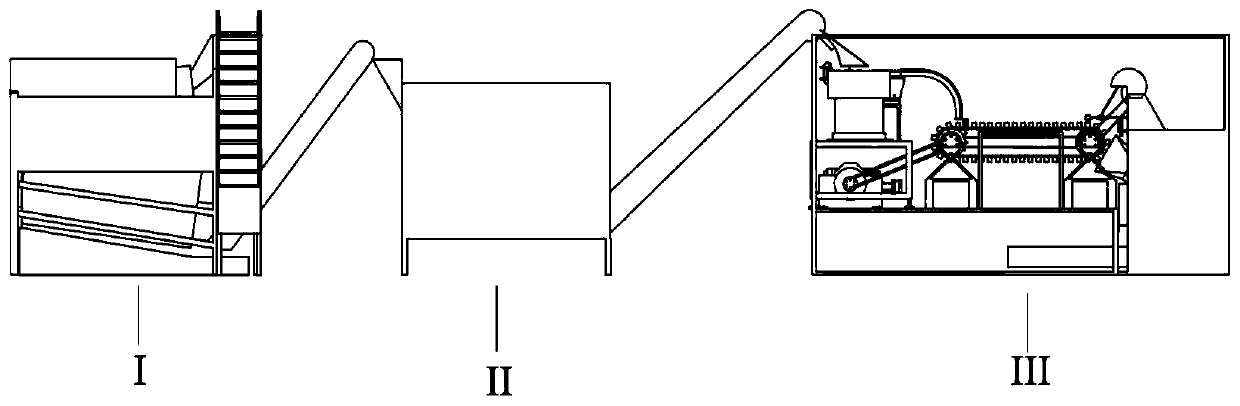

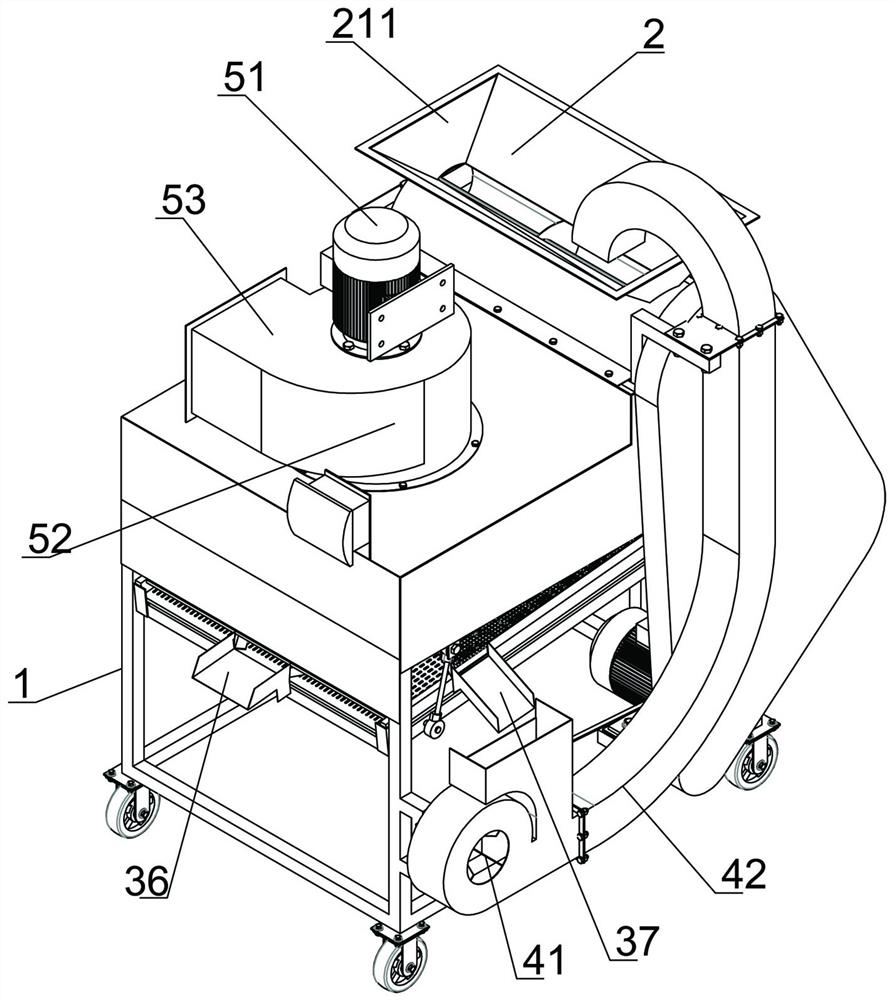

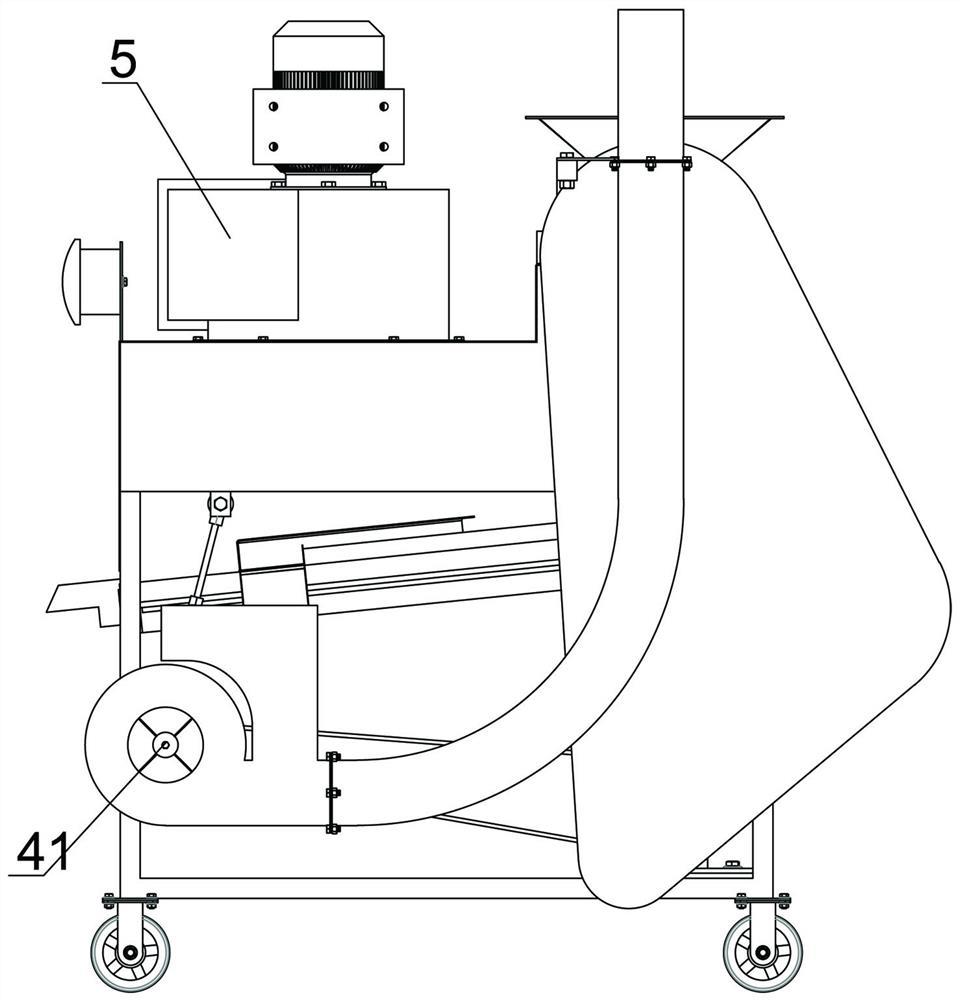

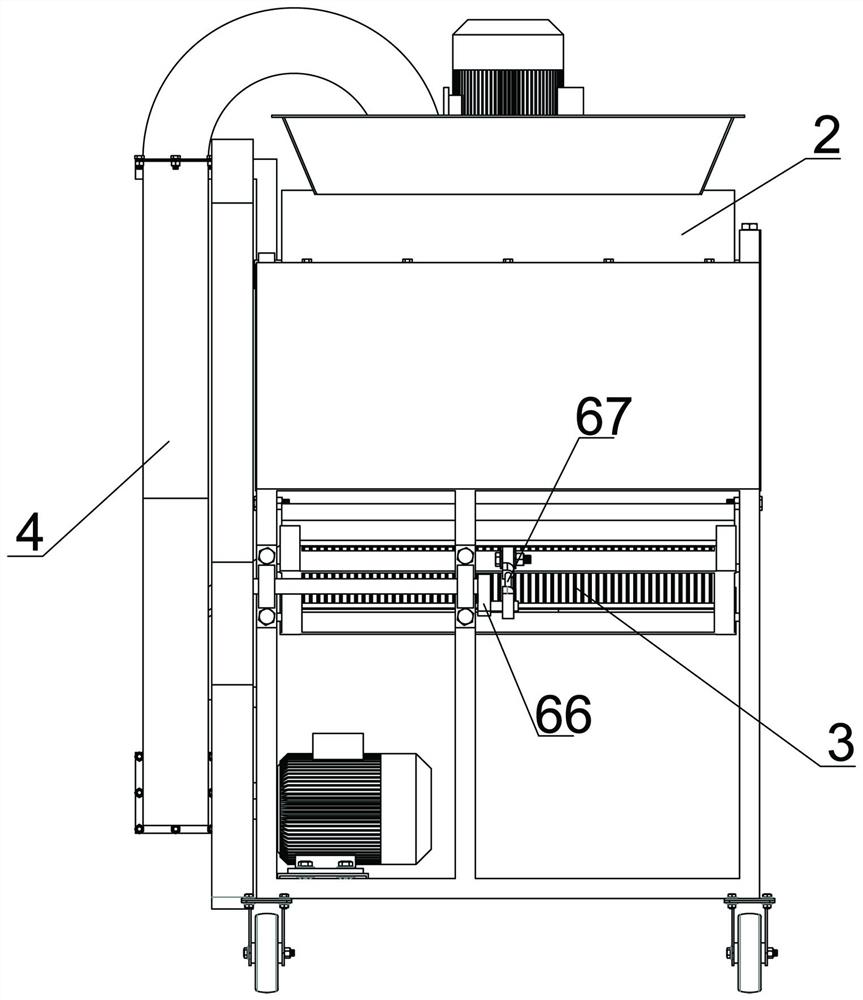

Walnut green husk removing, cleaning, drying, cracking and kernel extracting all-in-one processing production device and method

InactiveCN111567820ARealize processing integrationHigh stripping rateGas current separationHuskingWalnut NutEngineering

The invention discloses a walnut green husk removing, cleaning, drying, cracking and kernel extracting all-in-one processing production device and method. According to the technical scheme, the walnutgreen husk removing, cleaning, drying, cracking and kernel extracting all-in-one processing production device comprises a green husk removing and cleaning device, a microwave electrothermic drying device and a cracking and kernel extracting device, wherein the green husk removing and cleaning device comprises a green husk stripping device employing an opposite diagonal extrusion mode and a frictional cleaning device at the lower part of the green husk stripping device; a microwave transmitter is arranged in the microwave electrothermic drying device and an air supply heating device is arranged at the bottom of the microwave electrothermic drying device; the cracking and kernel extracting device comprises a feeding positioning device, a cracking device and a husk and kernel separation device; walnuts are discharged through vibration of the feeding positioning device and conveyed to the cracking device through a chain plate feeding device; the cracking device comprises a primary cracking device and a secondary cracking device; the primary cracking device comprises a knocking hammer; the secondary cracking device comprises a helical drum; and the cracked walnuts achieve husk and kernel separation under negative pressure of the husk and kernel separation device. The walnut green husk removing, cleaning, drying, cracking and kernel extracting all-in-one processing production deviceintegrates the functions, such as walnut feeding, husk removing, cleaning, drying, cracking and kernel extracting into a whole, thereby improving the walnut processing efficiency.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Self-adapting-based walnut kneading type shell breaker

The invention discloses a self-adapting-based walnut kneading type shell breaker, and relates to the technical field of walnut shell breaking. The self-adapting-based walnut kneading type shell breaker comprises a shell breaking device, wherein the shell breaking device comprises a shell breaking mechanism; the shell breaking mechanism comprises a first belt, a second belt and an adjusting device;the first belt is inclined to the second belt; a wedge-shaped shell breaking channel is formed between the first belt and the second belt; the speed of the first belt is different from that of the second belt; and the adjusting device is used for adjusting the distance and the inclination angle between the first belt and the second belt. The invention aims to overcome the defects in the prior art, and provides the self-adapting-based walnut kneading type shell breaker. Shearing force and extrusion force which are periodic are provided to walnuts between the two belts through the two belts atdifferent speeds so as to break shells of the walnuts, the distance and inclination angle between the two belts are adjustable to adapt to the walnuts in different sizes and different types, and the requirements of high shell breaking rate and low kernel breaking rate are met simultaneously.

Owner:SHIHEZI UNIVERSITY

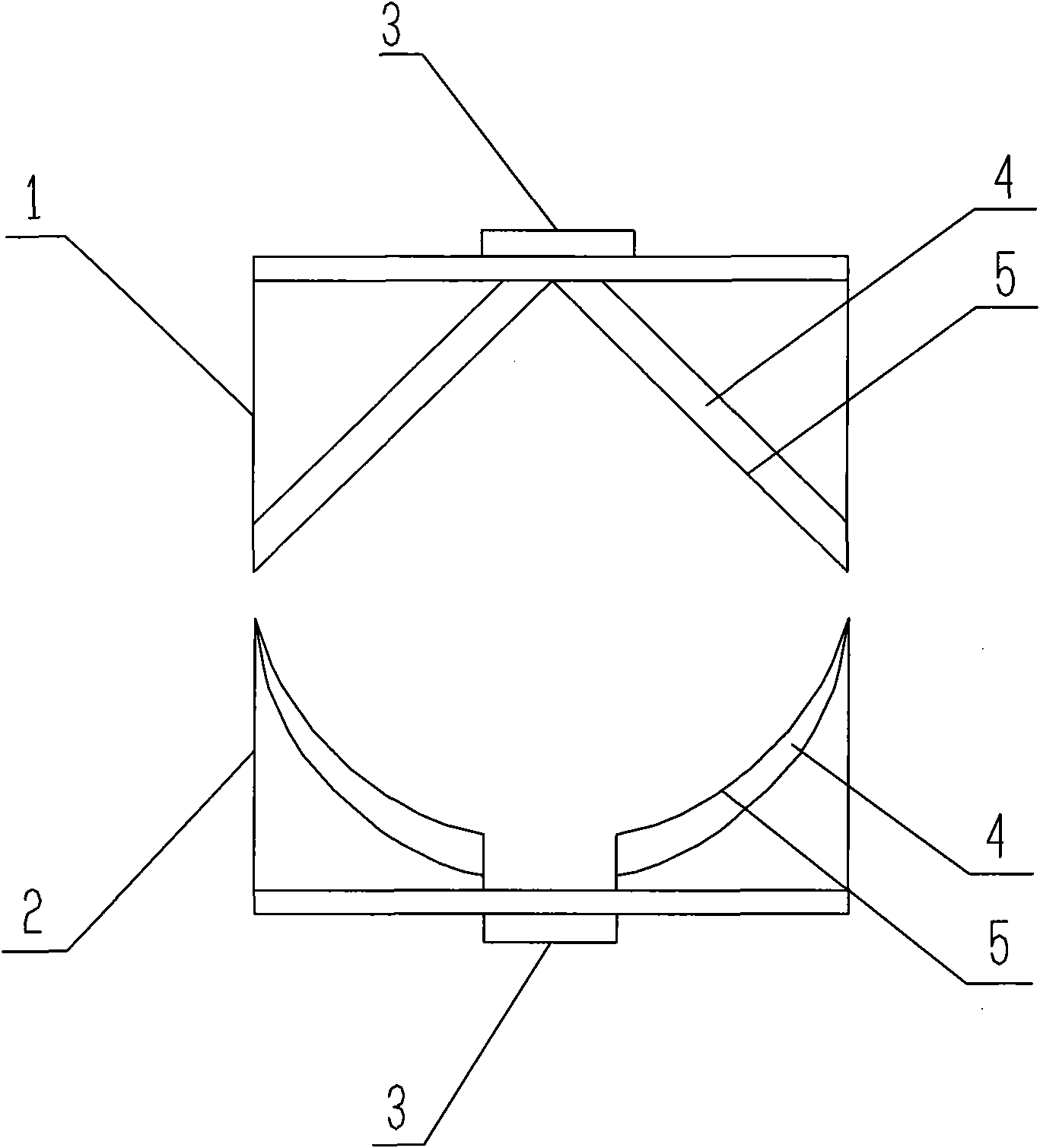

Nut shelling tool

The invention discloses a nut shelling tool, which comprises an upper tool holder and a lower tool holder, wherein the upper and lower tool holders are matched by a positioning pin; a plurality of blades are arranged in both the upper tool holder and the lower tool holder; the cutting edges of the blades in the upper tool holder are straight; and the cutting edges of the blades in the lower tool holder are arc-shaped. The nut shelling tool of the invention has the advantages that: the structure is simple; the manufacturing is easy; forces applied onto all parts of a nut shell are uniformed and does not damage a nut; the shelling efficiency is high; and the breakage rate of nut is low and the rate of compute nut is high.

Owner:KUANG BASKETRY DEV NINGGUO COUNTY ANHUI PROV

Processing method of cream flavor macadamia nuts

The invention relates to a processing method of cream flavor macadamia nuts. The method is characterized in that the method comprises the steps that the nuts pass through a certain guiding device before shell breaking, so that the loading direction is the horizontal direction, the loading rate and the moisture content of the nuts are controlled, and the kernel rate and the kernel integrity degree are improved. According to the processing method, through the difference between the nut densities and the difference between friction coefficients of shells and kernel, and by the adoption of a vibration method, the efficiency of kernel husk separation is obviously improved.

Owner:安徽亮中亮食品有限公司

Mechanism capable of controlling nut impacting strength and a nut shell breaking device

The invention provides a mechanism capable of controlling the nut impacting strength and a nut shell breaking device, and belongs to the technical field of nut processing. The mechanism comprises an impact rod sleeve, an impact rod, a first connecting rod, a sliding block, a transmission assembly capable of driving the sliding block to reciprocatingly slide, a first power source providing power for the transmission assembly and an impact force control circuit; the impact rod sleeve is communicated with a nut falling control mechanism conveying single nuts, the first end of the impact rod sleeve cylinder is an opening end, the second end of the impact rod sleeve cylinder is a closing end, and a strip groove extending to the closing end is formed in the impact rod sleeve; the impact rod is slidably sleeved with the impact rod sleeve and can extend from the opening end of the impact rod sleeve cylinder, an impact spring is arranged between the opening end and the closing end of the impactrod sleeve, and a connecting handle with the strip groove extending out is arranged on the impact rod body; the first end of the first connecting rod is connected with the connecting handle, and an armature is arranged at the second end of the first connecting rod; an electromagnetic switch cooperating with the armature is installed on the sliding block. The device can control the impacting strength according to the nut variety, and the rate of perfect kernel and the nut shell breaking rate are improved.

Owner:SHANXI UNIV

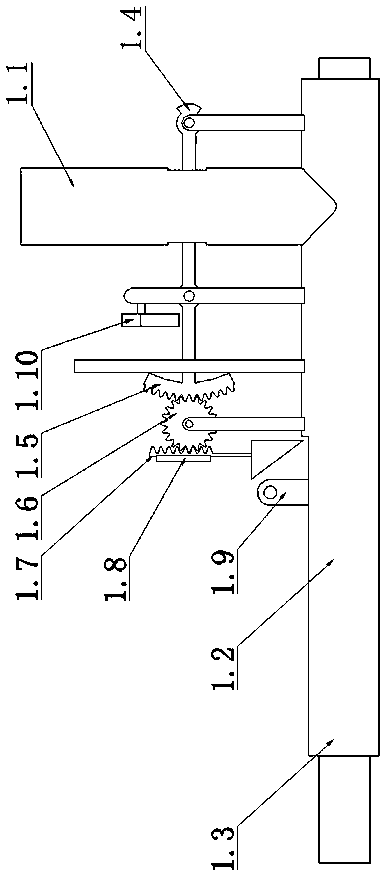

Automatic walnut shell breaking, separating, kernel taking machine and use method thereof

The invention provides an automatic walnut shell breaking, separating, kernel taking machine and a use method thereof, and belongs to the technical field of walnut processing. The machine comprises afruit dropping control mechanism, a breaking mechanism and a machine shell. The fruit dropping control mechanism is used for conveying walnuts to the breaking mechanism, and comprises a fruit droppingpipe with two first grooves in the pipe wall, and the two first grooves are oppositely formed. The breaking mechanism comprises a hitting rod sleeve, a hitting rod, a hit block, a first connecting rod, a second connecting rod, a gear with a damp, a rack with a wedge-shaped block at the bottom end, a third connecting rod, a slider, a transmission assembly for driving the slider to horizontally reciprocate and slide, a first power source for providing power for the transmission assembly, and a hitting force control circuit. By means of the machine, the hitting force can be controlled accordingto the types of the walnuts, the hitting distance is controlled according to the size of each single walnut, and the kernel integrity is improved.

Owner:SHANXI UNIV

Grinding type tartary buckwheat huller with dynamic pressure regulation

ActiveCN106391174AGrinding pressure is low and adjustableUnbreakableGrain huskingGrain polishingPolygonum fagopyrumWorking pressure

The invention discloses a grinding type tartary buckwheat huller with dynamic pressure regulation, which belongs to the field of grain hulling machines. The huller comprises a shell, wherein a grinding cylinder is vertically fixed in the middle of the shell; grinding air bags are arranged between the grinding cylinder and the side wall of the shell; a grinding roller is concentrically arranged in the grinding cylinder; a feed hopper is arranged on the top part of the grinding cylinder; a feed control gate is arranged on the bottom part of the feed hopper; a kneading cylinder is arranged right under the grinding cylinder; kneading air bags are arranged between the kneading cylinder and the shell; a kneading roller is concentrically arranged in the kneading cylinder; a draining slot is arranged under the kneading cylinder; a hulling discharge hole and a cleaning device connector are arranged under the draining slot. During the whole hulling process, with the buffer functions of the grinding air bags and the kneading air bags, the working pressure on tartary buckwheat is less and can be dynamically regulated, and the rate of perfect kernels of tartary buckwheat hulling is effectively improved.

Owner:NORTHWEST A & F UNIV

Micro regulating buckwheat sheller

ActiveCN100423842CAchieve fine-tuningHigh precisionGrain huskingGrain polishingPolygonum fagopyrumEngineering

The trimmed buckwheat sheller includes one outer barrel serving as the casing, one inner bushing, one bearing seat with one rotating shaft, one movable wheel on the shaft, one upper cover, one fixed wheel fitting the movable wheel. It features the upper cover comprising one inner ring and one outer ring connected through threads for easy interval regulating and trimming. The present invention has the advantages of high regulating precision, simple and fast regulation, high production efficiency and capacity of processing buckwheat in different plumpness.

Owner:JINZHOU QIAOPAI MACHINERIES

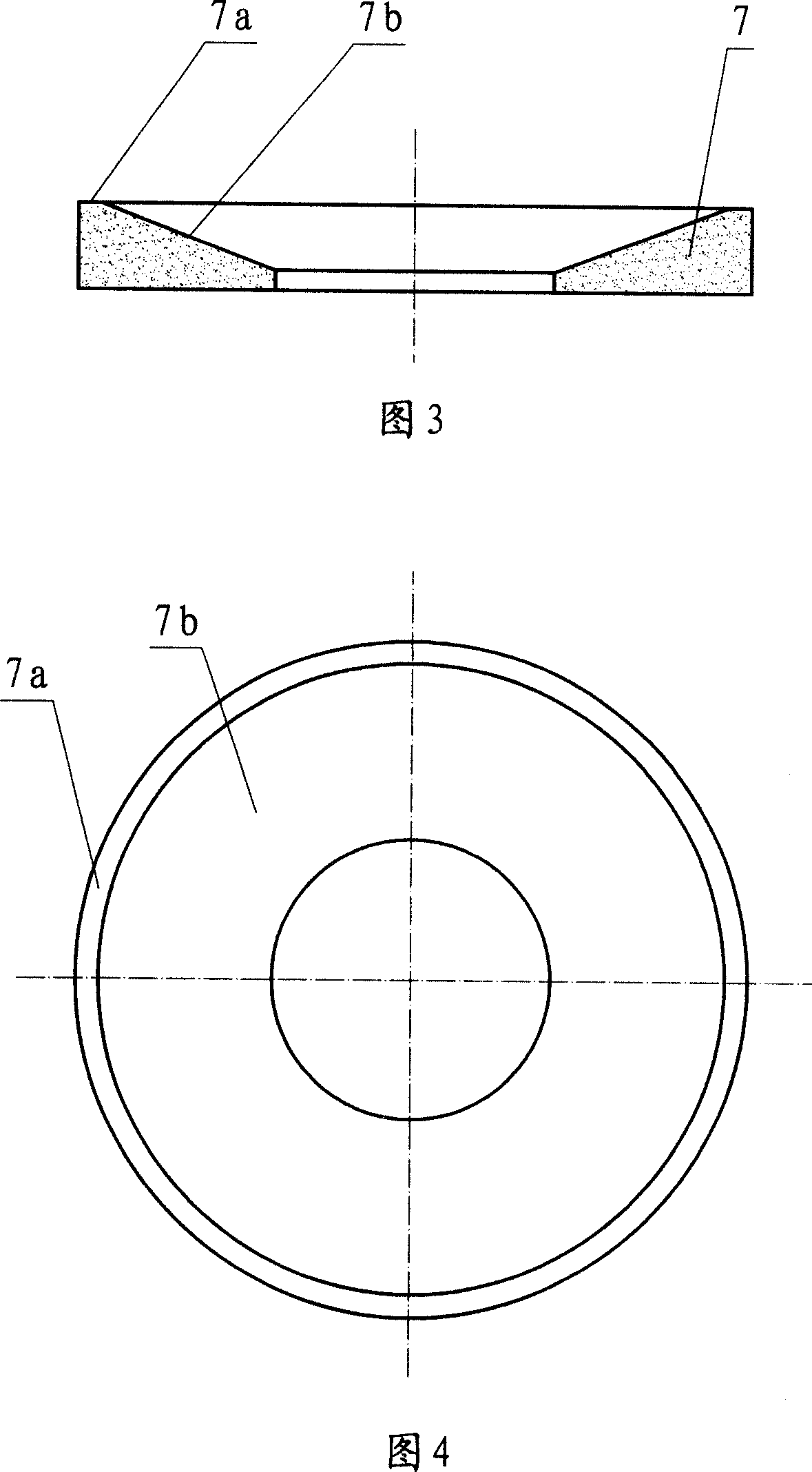

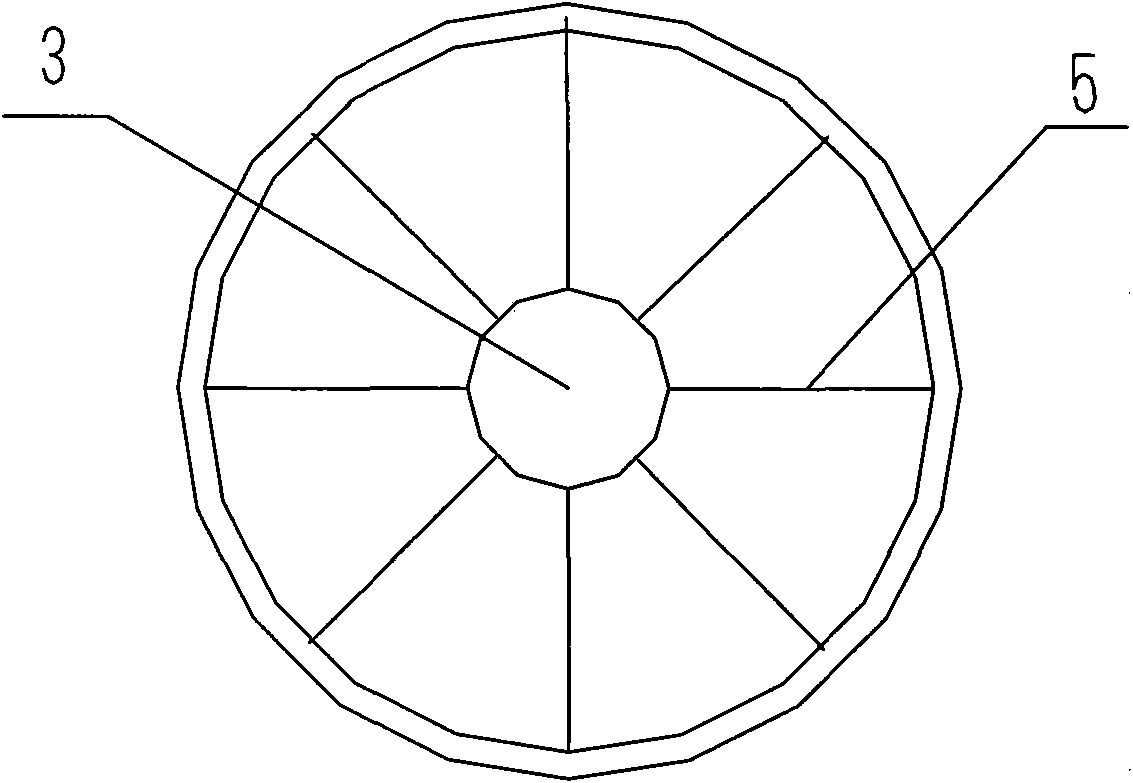

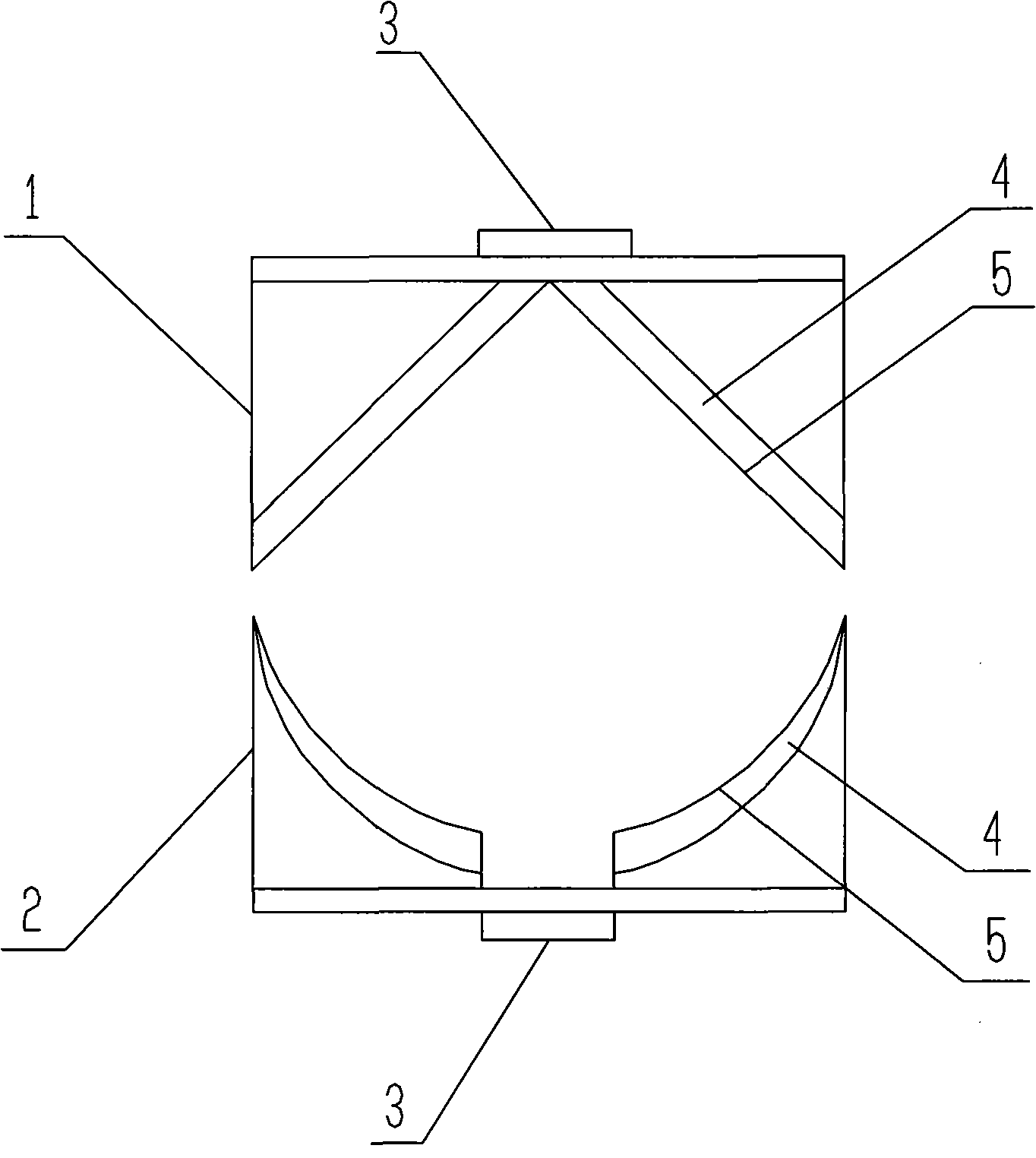

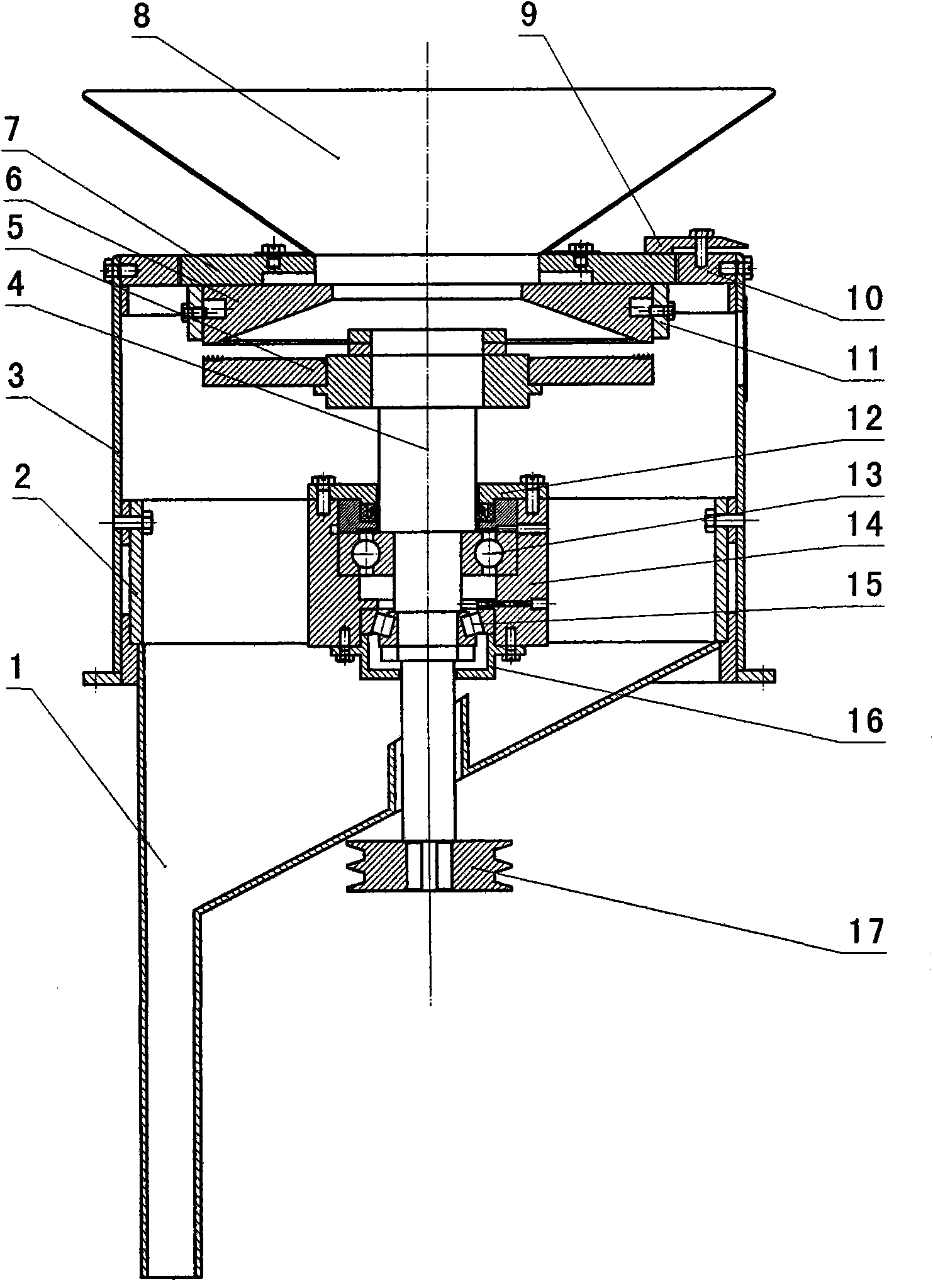

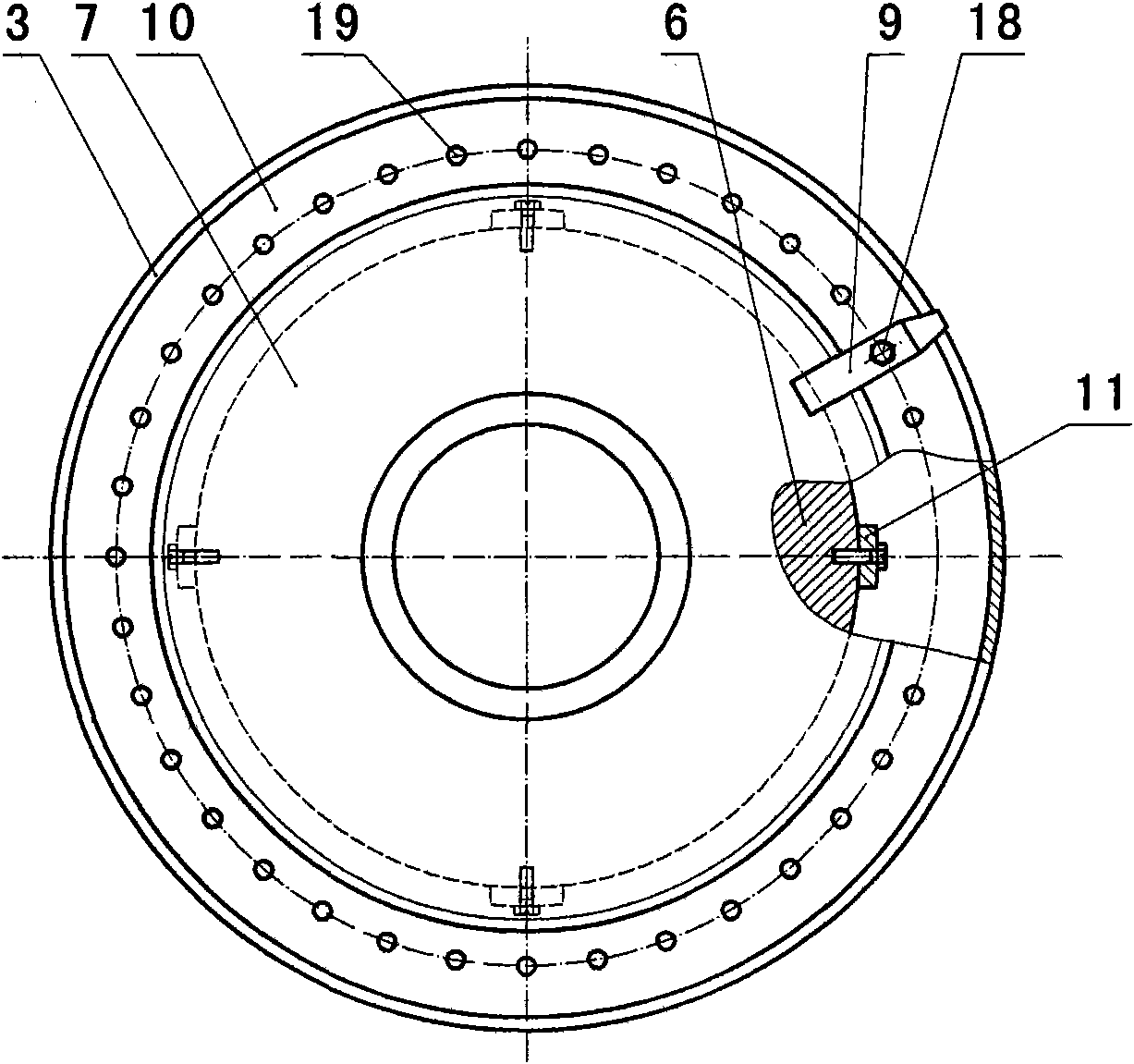

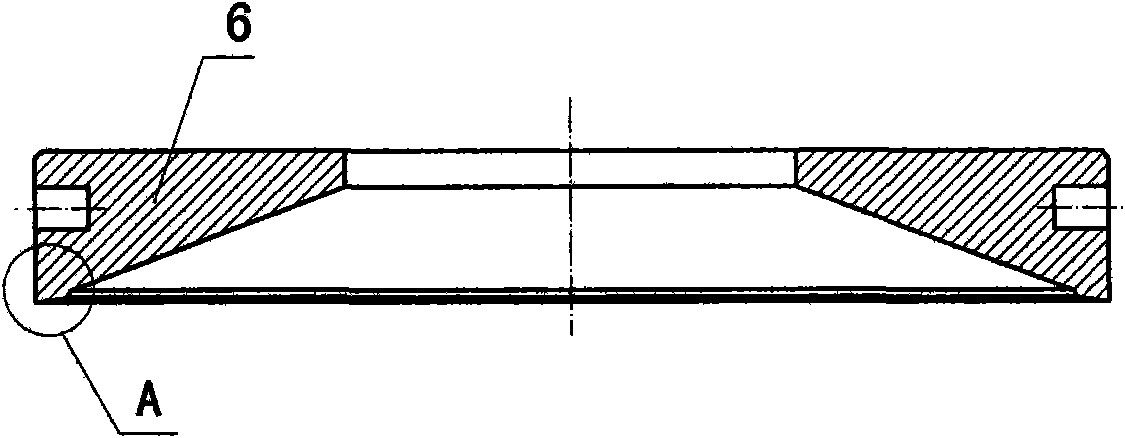

Disk type gordon euryale seed sheller

InactiveCN101564194BImprove shell opening efficiencyImprove finished product qualityHuskingHullingEconomic benefitsEngineering

The invention relates to a disk type gordon euryale seedsheller, which solves a problem of gordon euryale seed shelling. The sheller is provided with an outer cylinder in which an inner sleeve is arranged; the center of the inner sleeve is provided with a bearing block in which a rotation shaft is arranged; the rotation shaft is provided with a movable disk; the upper part of the outer cylinder isprovided with an upper cover; and the lower part of the upper cover is provided with a fixed disk matched with the movable disk. The sheller is characterized in that: the fringe of the upper surfaceof the movable disk is provided with a shell opening blade; the lower surface of the fixed disk is provided with a subuliform inclined plane matched with the shell opening blade of the movable disk; the subuliform inclined plane and the shell opening blade form a working face for processing gordon euryale seeds; endothelium of the gordon euryale seeds is broken under the coaction of the shell opening blade and the subuliform inclined plane, and the aim of shelling the gordon euryale seeds is achieved. The sheller has the advantages that the sheller breaks the endothelium of the gordon euryaleseeds by the interaction of the subuliform inclined plane and the shell opening blade of the movable disk, has the rate of perfect kernel of processed gordon euryale seeds of 70 percent, greatly improves the end product quality and economic benefit of the gordon euryale seeds, has the once shell opening rate of the endothelium of the gordon euryale seeds of 56 percent, improves the production efficiency of processing the gordon euryale seeds, and improves the production efficiency of processing the gordon euryale seeds.

Owner:JINZHOU QIAOPAI MACHINERIES

Manipulator for shelling walnuts

PendingCN108354191ADestruction will not be easyImprove whole kernel rateHuskingHullingManipulatorEngineering

The invention discloses a manipulator for shelling walnuts. The manipulator comprises a machine frame assembly, a transporting mechanism, a clamping mechanism, two cutting mechanisms and a rotating jimmying mechanism, wherein the transporting mechanism comprises a vertical reciprocating driver and a walnut fixer; the vertical reciprocating driver is used for driving a walnut placer to be in vertical reciprocating motion; the clamping mechanism is located above the walnut placer; each cutting mechanism comprises a swinging reciprocating driving mechanism, a cutting arm and a cutting machine; each swinging reciprocating driving mechanism is used for driving a corresponding linkage mechanism to rotate; each cutting arm is fixedly connected with the corresponding cutting machine; each cuttingmachine comprises a saw piece; the rotating jimmying mechanism comprises a rotating jimmying machine, a rotating driving mechanism and a horizontal reciprocating driving mechanism; the rotating jimmying machine comprises a long-handle blade and a rotating jimmying arm; the tail of the long-handle blade is mounted on the rotating jimmying arm through a bearing; the rotating jimmying arm is fixed tothe horizontal reciprocating driving mechanism; and the rotating driving mechanism is mounted on the rotating jimmying arm, and is used for driving the long-handle blade to rotate. The manipulator disclosed by the invention is used for circularly cutting a kernel crack of each walnut, so that the integrity of taken kernels can be improved.

Owner:HUAZHONG AGRI UNIV

Self-positioning pre-shell breaking and co-directional spiral self-grading flexible extrusion walnut shell breaking and kernel extraction device

ActiveCN106473167BReduce manufacturing costSmall footprintHuskingHullingMachine buildingReciprocating motion

The invention discloses a self-positioning, pre-shell breaking, co-directional spiral self-grading flexible extrusion walnut shell breaking and kernel extraction device, which includes an intermittent feeding device, a pre-breaking shell device, a flexible shell breaking device and a separation device fixed on a frame , the intermittent feeding device is intermittent batch feeding of the pre-cracking device. The pre-cracking device includes an extruding part and a blanking part that cooperate with each other. The reciprocating movement of the material part makes the extruded walnuts fall to the flexible shell breaking device, which breaks the shells of the walnuts, and then separates and stores the broken shells and kernels through the separation device. It is integrated by multiple systems and has a compact structure, which not only reduces the manufacturing cost of the machine, but also reduces the footprint of the machine operation, which is conducive to the miniaturization and high efficiency of the machine. The structural design can realize multiple connection and cooperation work such as splicing and combination, which can meet the needs of various production scales and production sites, and is also suitable for families, with wider applications.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +2

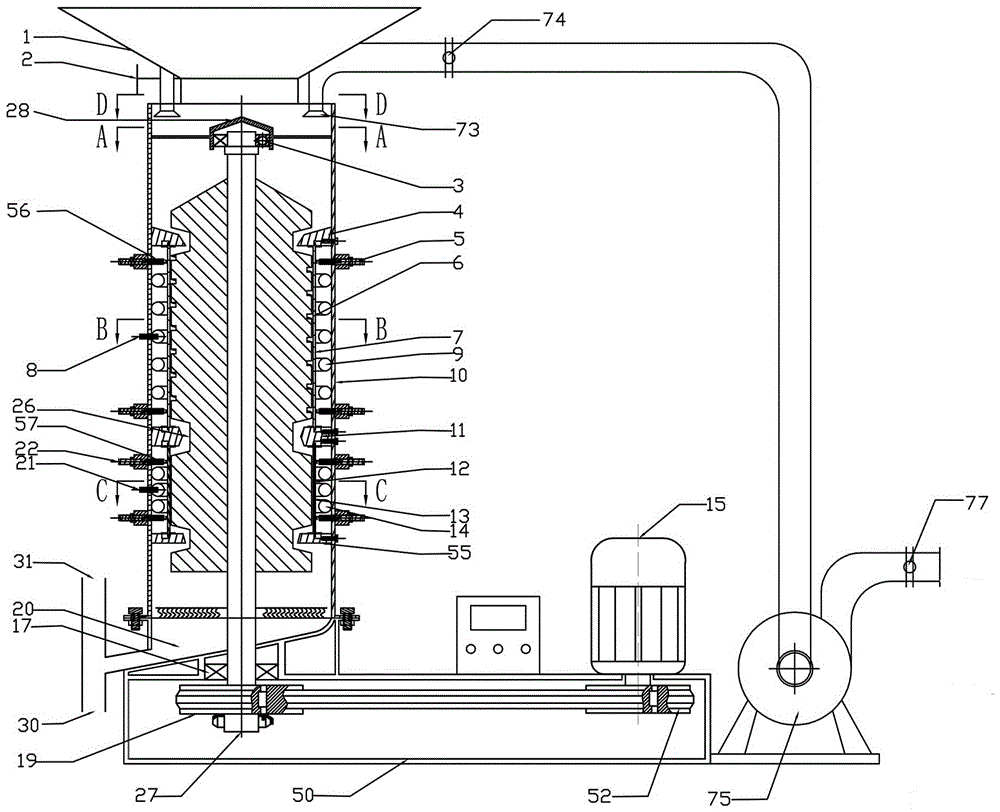

A cone type tartary buckwheat hulling device

The invention discloses a cone cylinder type tartary buckwheat dehulling device, which comprises a machine frame, wherein the middle part of the machine frame is vertically and fixedly provided with a cone mill cylinder, the interior of the cone mill cylinder is concentrically provided with a cone mill roller, the top of the cone mill cylinder is provided with a feeding hopper, a receiving hopper and a dehulling cylinder are sequentially arranged just below the cone mill cylinder and are fixedly arranged on the machine frame, the interior of the dehulling cylinder is concentrically provided with an iron roller with screws, a material flowing groove is arranged under the dehulling cylinder, a material outlet valve, a material outlet and a material receiving box are arranged under the material flowing groove, the upper part of the material outlet is connected with a vertical hull discharge pipeline, and the upper part of the hull discharge pipeline and a light slag pipe from the receiving hopper are connected into a fan. The device has the advantages that the dehulling rate and the whole kernel rate are higher; the structure is simple; and the device is suitable for the dehulling operation of grains, especially tartary buckwheat.

Owner:NORTHWEST A & F UNIV

Peanut husking and cleaning all-in-one machine

PendingCN113040399AStrong peeling abilityEasy to operateSievingScreeningPeanut hullStructural engineering

The invention belongs to the technical field of husking and cleaning machines, and particularly relates to a peanut husking and cleaning all-in-one machine. The peanut husking and cleaning all-in-one machine comprises a rack, a husking mechanism, a husking power structure, a cleaning mechanism, a vibration driving structure and a feedback mechanism; the husking mechanism comprises a combined shell, coaxial double rollers and a concave grid; and the coaxial double rollers comprise a main rolling shaft, a middle partition plate, an inlet kneading batten and a feedback kneading batten. The inlet kneading batten, the middle partition plate and the feedback kneading batten are sequentially and fixedly arranged on the main rolling shaft in a sleeving mode, the middle partition plate is sleeved with a partition plate groove in a matched mode, so that an inlet husking area and a feedback husking area which are independent of each other are formed in a husking area, the peanut husking and cleaning functions are achieved at the same time, self-adaptive husking, circulating husking and grading cleaning of peanut pods are achieved, output of large peanut pods, fine sand impurities and the like which are not completely husked is reduced, and the purposes that the husking rate of peanut husks is high and the net kernel rate of peanut kernels is high in the peanut husking and cleaning process are achieved.

Owner:河南省农业科学院长垣分院

Rubber seed shelling equipment

The invention discloses rubber seed shelling equipment, which consists of a belt elevator, primary and secondary grading sieves, a cone pulley shelling teeth roller, a rolling plate device, primary and secondary winnowing machines, a crank frame, and a power device, wherein the belt elevator is connected with the primary grading sieve; the secondary grading sieve is arranged below the primary grading sieve; the cone pulley shelling teeth roller is arranged below the secondary grading sieve; the primary winnowing machine is arranged below the cone pulley shelling teeth roller; the rolling plate device is arranged below the primary winnowing machine; the secondary winnowing machine is arranged below the rolling plate device; the crank frame is connected with the secondary winnowing machine; and the cone pulley shelling teeth roller and the rolling plate device are respectively connected with the power device. The equipment has scientific structure and high shelling rate and whole kernel rate, the mechanization efficiency is greatly improved, the operating cost is low, the production environment is clean, and the equipment is easy and convenient to operate, high in practicability and can meet industrial application.

Owner:王云

Walnut shell breaking machine

InactiveCN107495397AImprove processing qualityIncrease export rateHuskingHullingWalnut NutEngineering

A walnut shelling machine, comprising an extruding device and an extruding plate, the extruding device is placed on the extruding plate, a shaft is arranged in the middle of the extruding plate, the shaft is fixed on the frame, and the outer surface of the shaft is evenly divided Roller, the upper part of the extrusion plate is provided with a feeding port, the feeding port is placed on the upper cover, the lower part of the upper cover is provided with an end cover, and the lower part is provided with a lower cover; the advantages of the present invention are: The advantages are: simple structure, realizing mechanized processing, liberating productivity, improving efficiency, improving walnut processing quality and export rate, improving shell breaking rate and whole kernel rate, and good shell breaking performance.

Owner:李颂

Peony seed husking device

InactiveCN113430049AAvoid breakingAvoid peeling and non-composition phenomenonFatty-oils/fats productionElectric machineryEngineering

The invention relates to the technical field of peony seed husking, and discloses a peony seed husking device. The device comprises a shell, a triggering mechanism and an adjusting mechanism, wherein the inner wall of the shell is movably connected with the trigger mechanism; the trigger mechanism is used for controlling connection of a circuit; the inner wall of the shell is movably connected with the adjusting mechanism; the adjusting mechanism is used for adjusting the collision angle of peony seeds; a QMJ-30MD motor is fixedly connected to the outer side of the shell. According to the peony seed husking device, a circuit in the triggering mechanism is switched on, so that the adjusting machine moves, and the angle of blades is further adjusted; According to the device, the situation that large peony seeds and small peony seeds bear different acting forces when colliding with the blades 43 can be avoided, and the phenomenon that the large peony seeds are damaged is prevented; in addition, the device can avoid the phenomenon that small-particle peony seeds do not have ingredients during husking, the completity of peony seed production is increased, and the product quality of peony seed production is improved.

Owner:JIANGSU HONGBO MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com