Mechanism capable of controlling nut impacting strength and a nut shell breaking device

A shell breaking device and walnut technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of incomplete shell breaking, control of impact force, and inability to break walnuts, etc., to achieve a high degree of automation, ensure integrity, and be practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

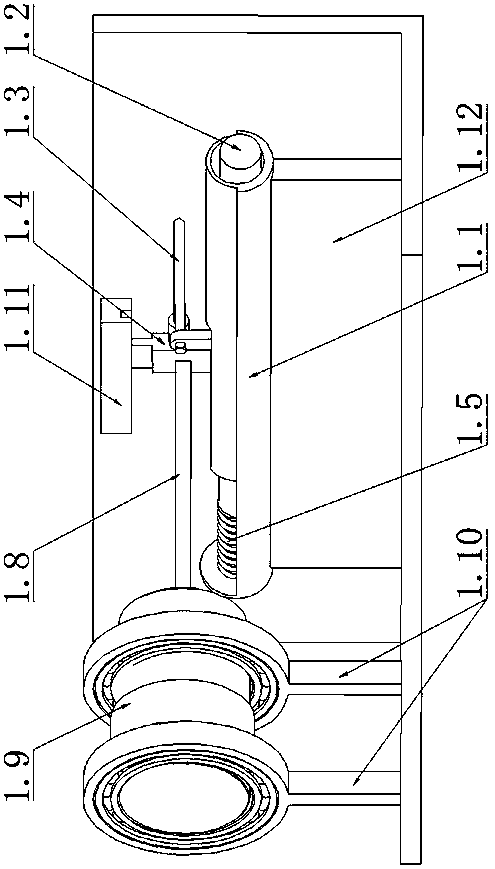

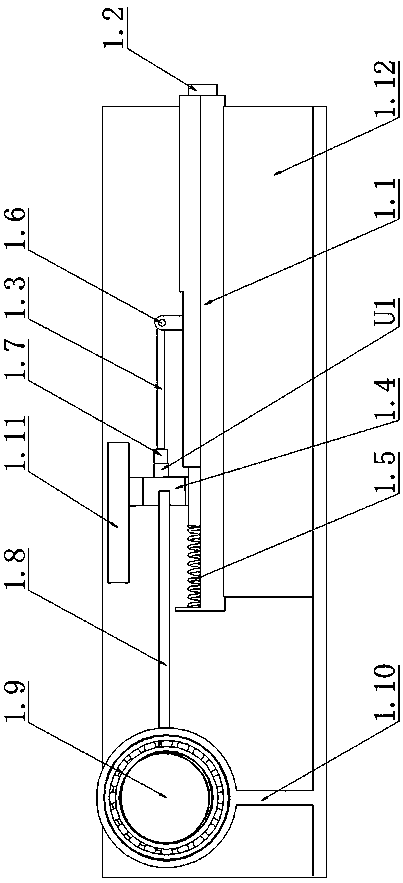

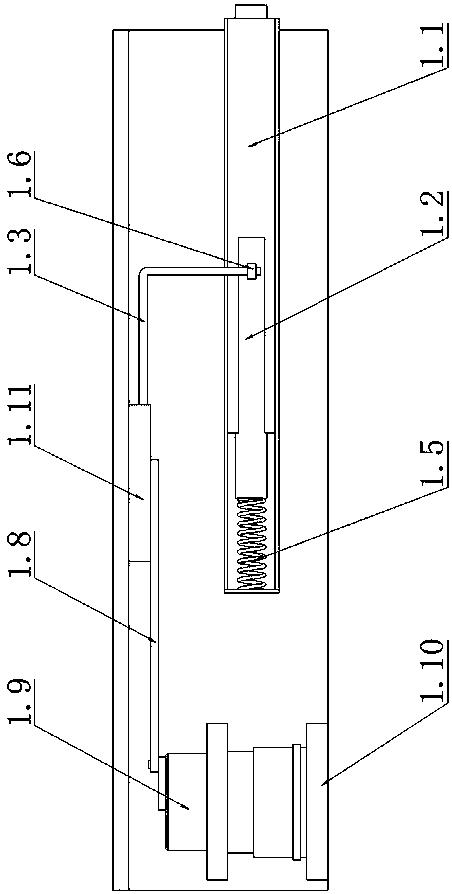

[0033] Such as Figure 1 to Figure 4 As shown, the present embodiment provides a mechanism that can control the impact force of walnuts, including a striking rod sleeve 1.1, a striking rod 1.2, a first connecting rod 1.3, a slider 1.4, and a transmission assembly that drives the sliding block 1.4 to reciprocate horizontally. The transmission assembly provides the first power source and the impact force control circuit; the impact rod sleeve 1.1 is connected with the fruit drop control mechanism for conveying a single walnut, the first end is an open end, the second end is a closed end, and the impact rod sleeve 1.1 is on A bar-shaped groove extending toward the closed end is provided; the striking rod 1.2 is slidably set in the striking rod sleeve 1.1, can protrude from the opening end of the striking rod sleeve 1.1, and is set between the closed end of the striking rod sleeve 1.1 There is an impact spring 1.5, and the rod body is provided with a connecting handle 1.6 protrudi...

Embodiment 2

[0050] Such as Figure 6 to Figure 10 As shown, the present embodiment provides a device for cracking walnut shells, including the bumped block 2 arranged outside the opening end of the striking rod sleeve 1.1 and the mechanism described in Embodiment 1 that can control the impact force of the walnut. The impact rod 1.2 promotes the walnut to impact on the bumped block 2, and the walnut shell is smashed into pieces.

[0051] Further, as Figure 7 As shown, the side of the struck block 2 towards the open end of the striking rod sleeve 1.1 has a V-shaped groove, so as to clamp the walnut.

[0052] Further, as Figure 11 As shown, the above-mentioned walnut shell breaking device also includes a fruit drop control mechanism; the fruit drop control mechanism includes a fruit drop tube 3.1 perpendicular to and communicated with the impact rod sleeve 1.1, a feed port 3.2 arranged at the top of the fruit drop tube 3.1, and a rotating device on the fruit drop tube 3.1. 3.1 The disc ...

Embodiment 3

[0067] This embodiment provides a method for using the device for cracking walnut shells, implemented based on the device for cracking walnut shells described in Example 2, comprising the following steps:

[0068] S1, input a preset value in the electronic controller according to the impact force required for the type of walnut to be processed, the first power supply supplies power to the electromagnetic switch U1, and the electromagnetic switch U1 generates magnetism at this time;

[0069] S2, a plurality of walnuts enter the fruit drop tube 3.1 from the feeding port 3.2, the second power source drives the disc 3.3 to rotate according to a predetermined frequency, and the third connecting rod 3.4 connected with the fourth connecting rod 3.5 through the fifth connecting rod 3.6 is fixed The reciprocating motion of the frequency makes a single walnut fall on the baffle plate of the sixth connecting rod 4.1 and the baffle plate of the seventh connecting rod 4.2 at a fixed frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com