Patents

Literature

168 results about "Drop tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics and materials science, a drop tower or drop tube is a structure used to produce a controlled period of weightlessness for an object under study. Air bags, polystyrene pellets, and magnetic or mechanical brakes are sometimes used to arrest the fall of the experimental payload. In other cases, high-speed impact with a substrate at the bottom of the tower is an intentional part of the experimental protocol.

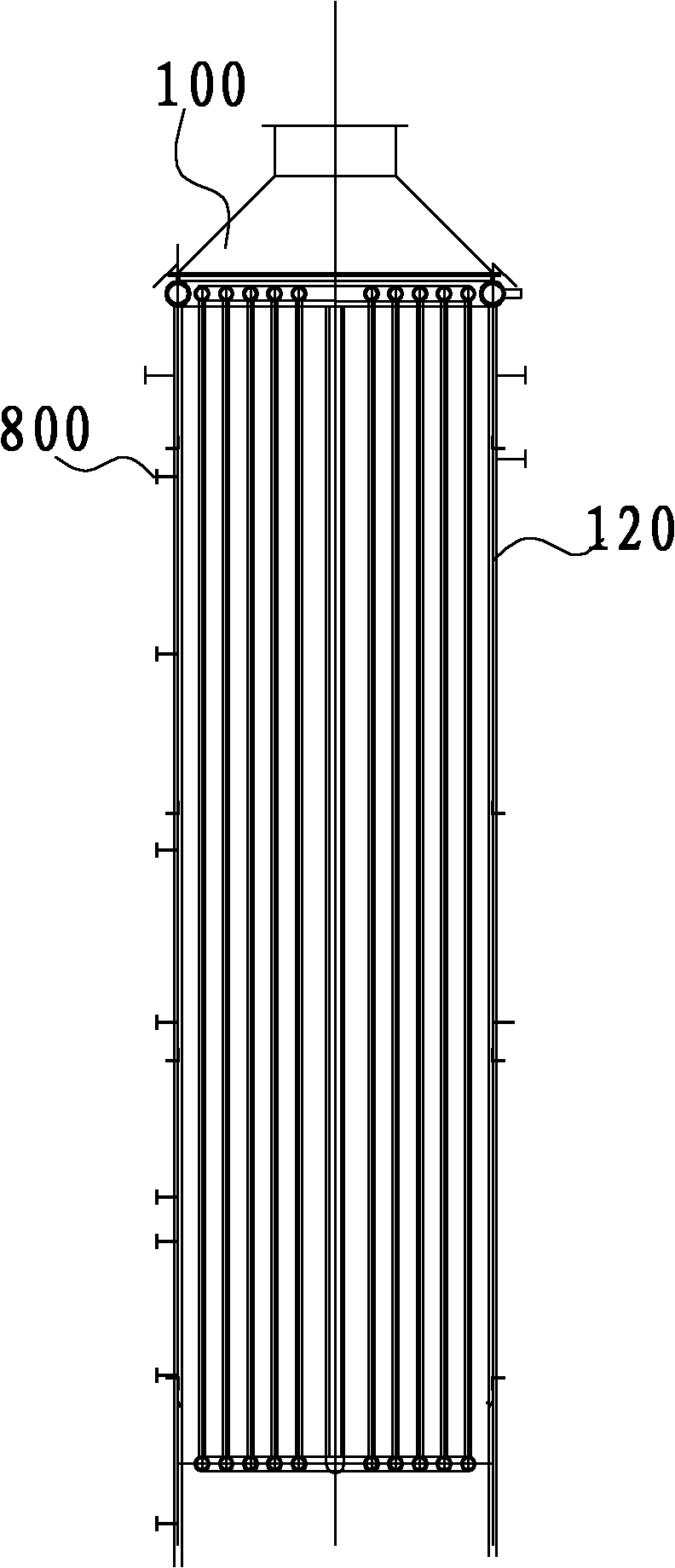

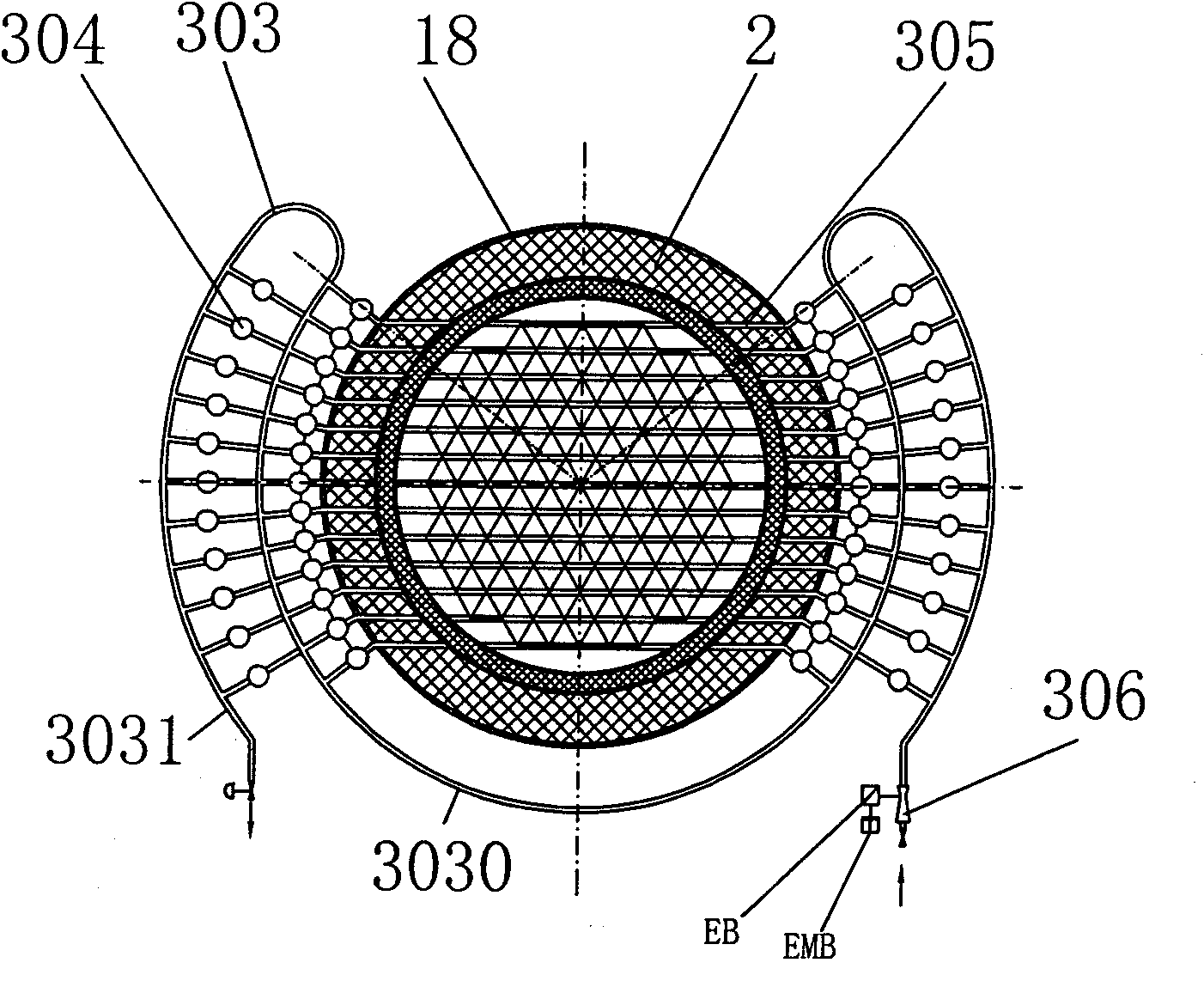

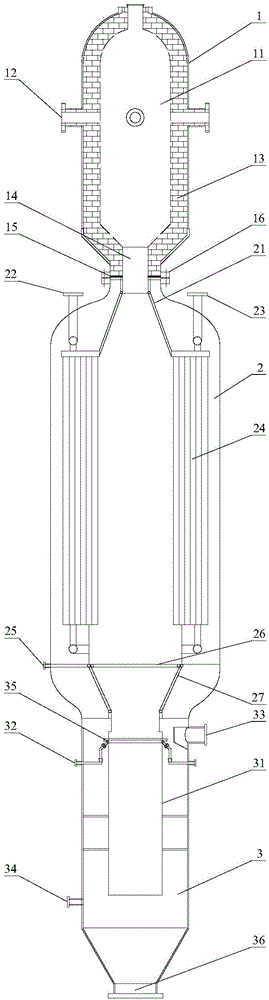

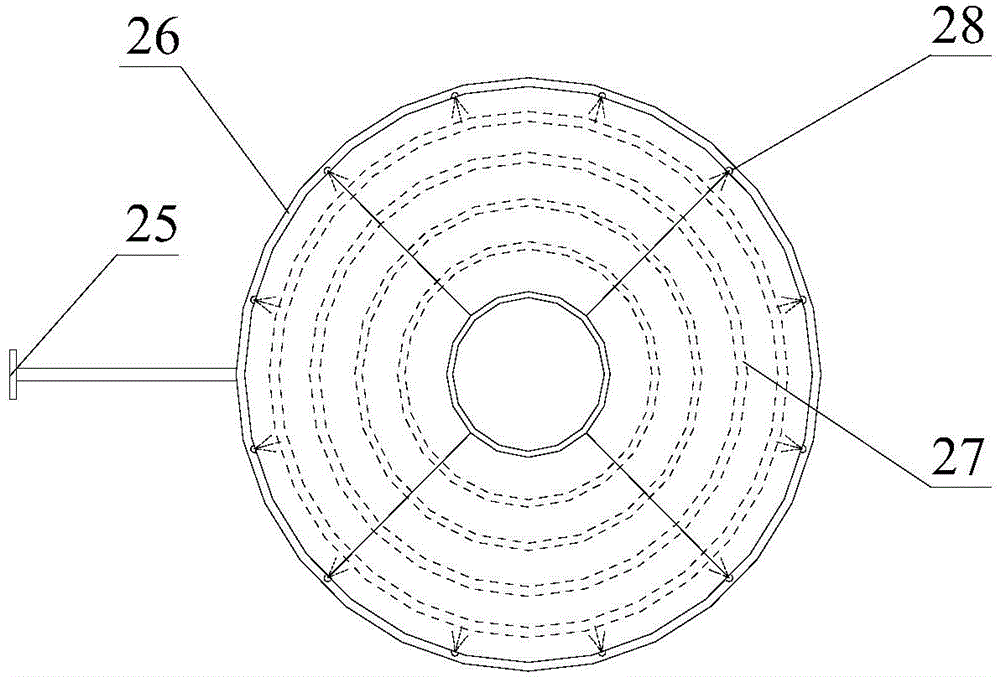

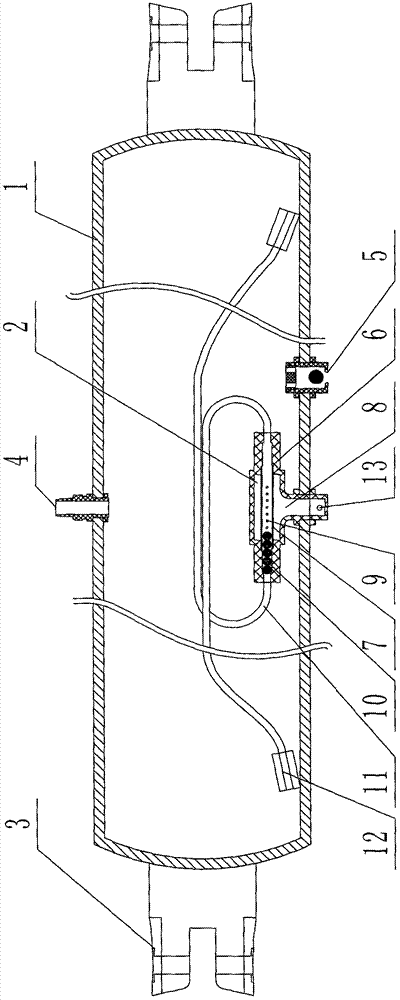

Double-circulation biological membrane anaerobic ammonia oxidation reactor

InactiveCN101767875AStart fastIncrease contactWater contaminantsTreatment with anaerobic digestion processesLow loadSludge

The invention discloses a double-circulation biological membrane anaerobic ammonia oxidation reactor. The lower part of the reactor is provided with a unique cyclone water distributor; a soft filler, a screen, a floating ball, a three-phase separator and a down pipe are arranged in the reactor; and a reflux water outlet pipe, a reflux water inlet pipe and an overflow weir are arranged outside the reactor. The reactor has the advantages that: 1) the cyclone water distributor can produce tangential flow to ensure uniform water distribution and facilitate reinforcing mass transfer; 2) the soft filler arranged in the reactor can retain the sludge, reinforce the treating effect and shorten the starting time; 3) the screen and the floating ball can eliminate gas surge phenomenon and relieve the interference of rising bubbles to a settling region; and 4) the reflux of the down pipe can reinforce the mixing of a reaction region, improve the mass transfer effect, meanwhile dilute the inlet water and improve the impact load resistance of the reactor; the refluxes of the reflux water inlet pipe and the reflux water outlet pipe can maintain the normal operation of the reactor at the starting stage and the low load stage; and the internal and external refluxes can ensure that the reactor can efficiently and stably run under low load and high load.

Owner:ZHEJIANG UNIV

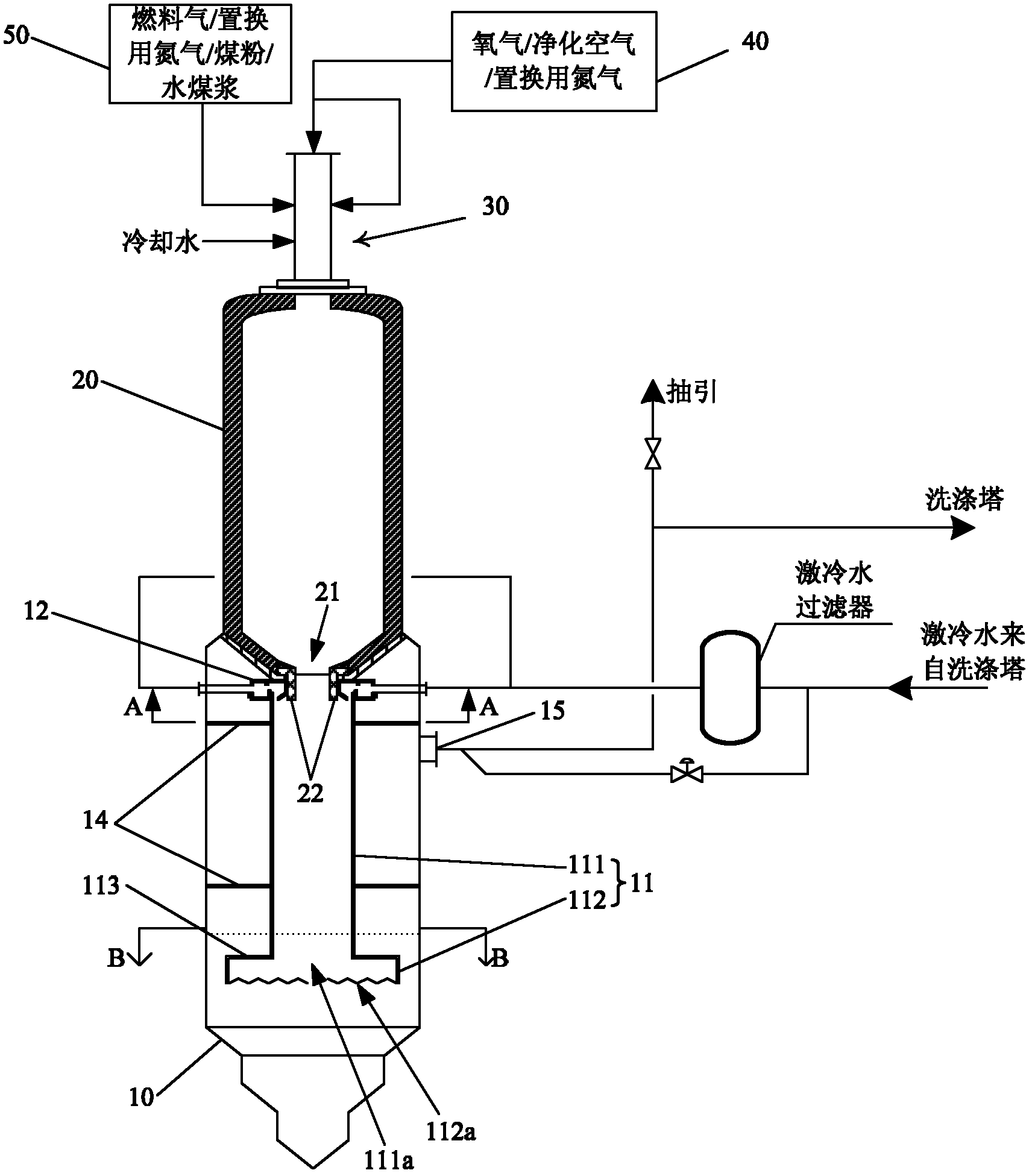

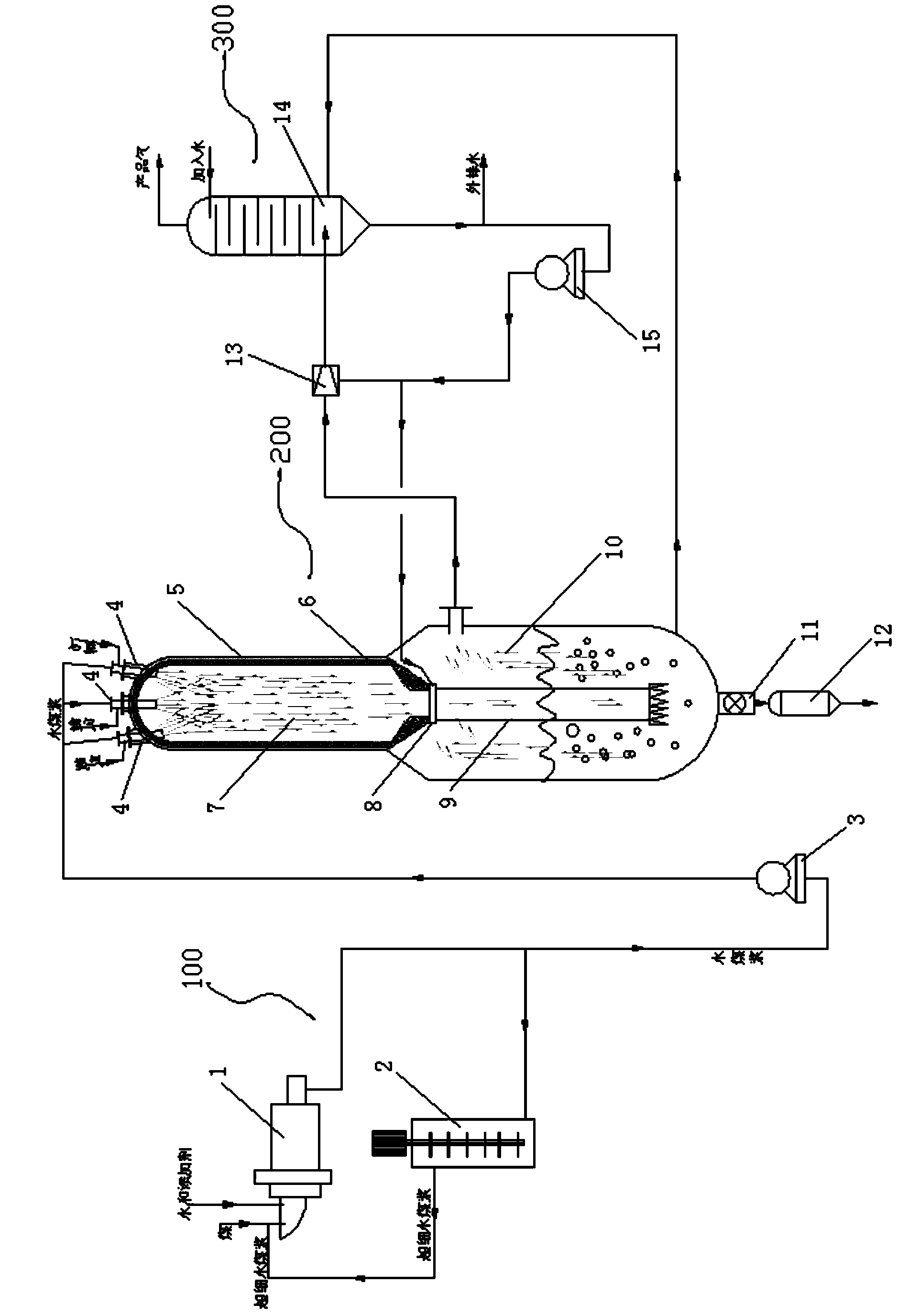

Pulverized coal or water coal slurry gasification furnace system

ActiveCN102643678AExtended operating cycleAvoid enteringGranular/pulverulent flues gasificationSyngasCombustor

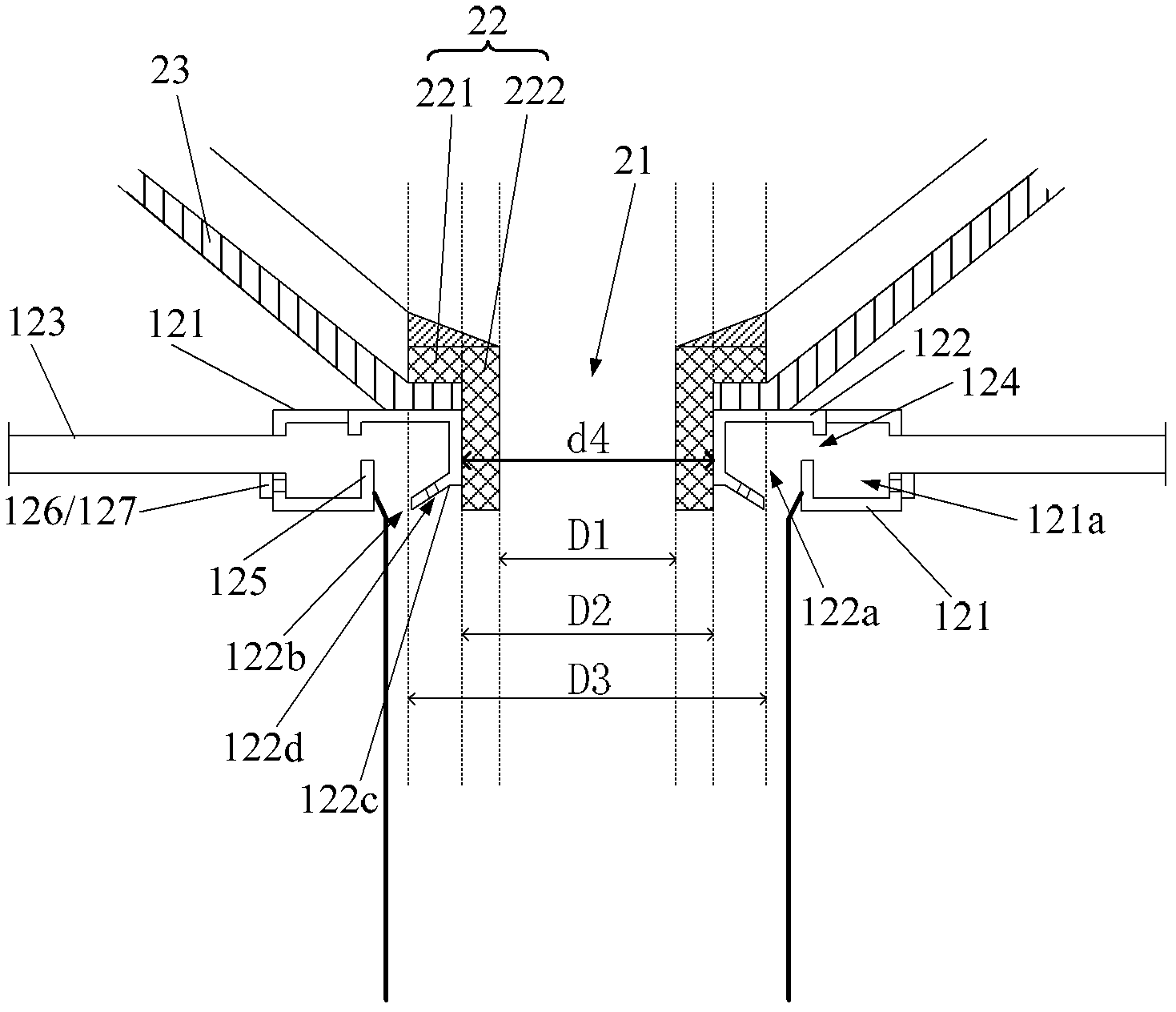

The invention discloses a pulverized coal or water coal slurry gasification furnace system which comprises a gasification furnace, a feeding system for feeding the gasification furnace and a follow-up treatment system of a discharge compound gas, wherein the gasification furnace comprises a combustor and a quench chamber positioned below the combustor; the quench chamber is provided with a downcomer and a quench ring; the quench ring is arranged at the top part of the downcomer and provides quench water; the downcomer comprises an air reduction barrel and an air distribution barrel; the lower end of the air reduction barrel extends to the air distribution barrel; an air diffusion mesh is arranged on a ring-shaped cross section between the air distribution barrel and the air reduction barrel; and the lower edge of the air reduction barrel is in a sawtooth shape. According to the pulverized coal or water coal slurry gasification furnace system, water and ash containing in a synthetic gas in the quench chamber are lightened; the service lives of the quench ring and the downcomer are prolonged; the stable production is kept; the operation period of the gasification furnace is prolonged; and the continuous operation of over baking and chemical engineering feeding.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

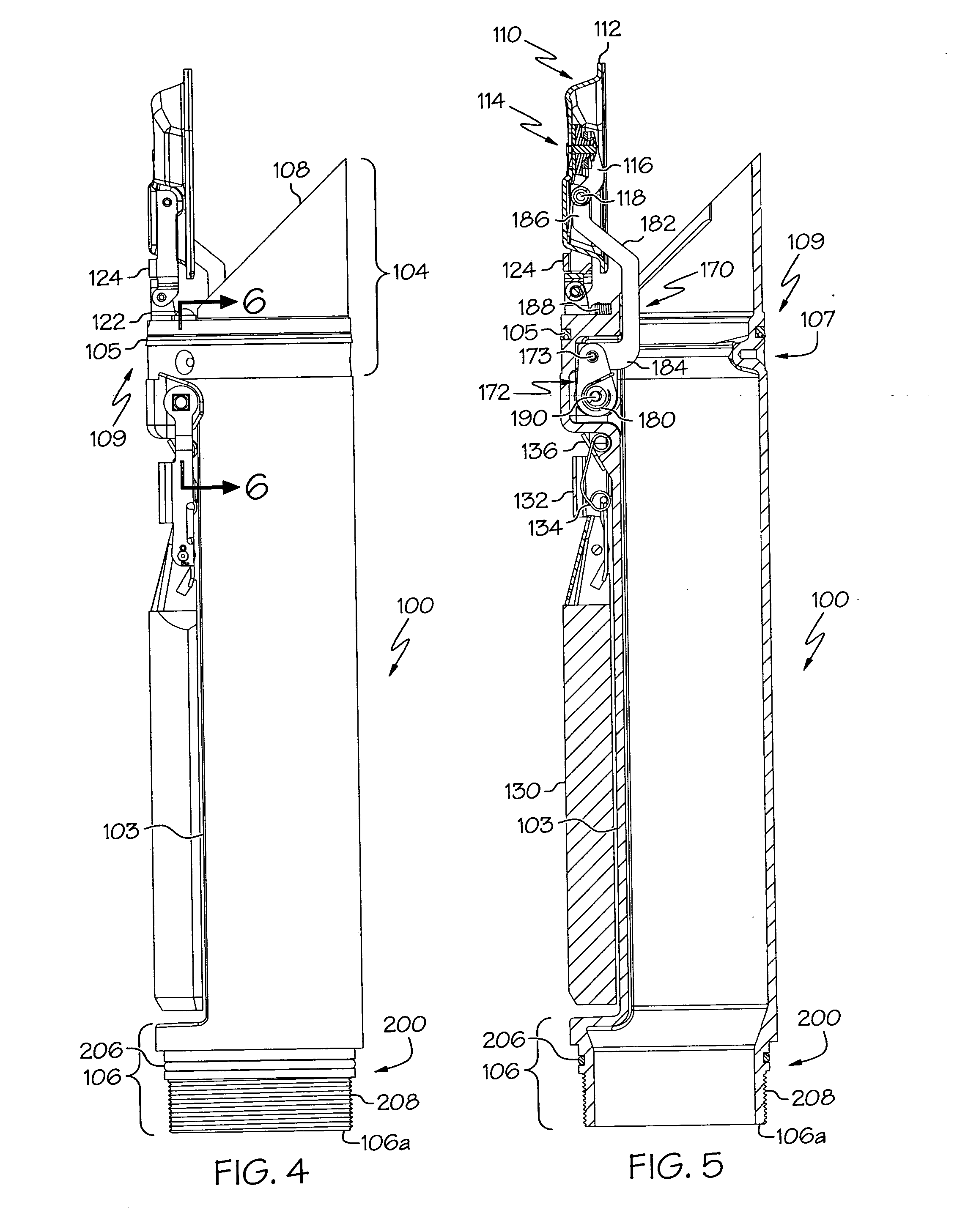

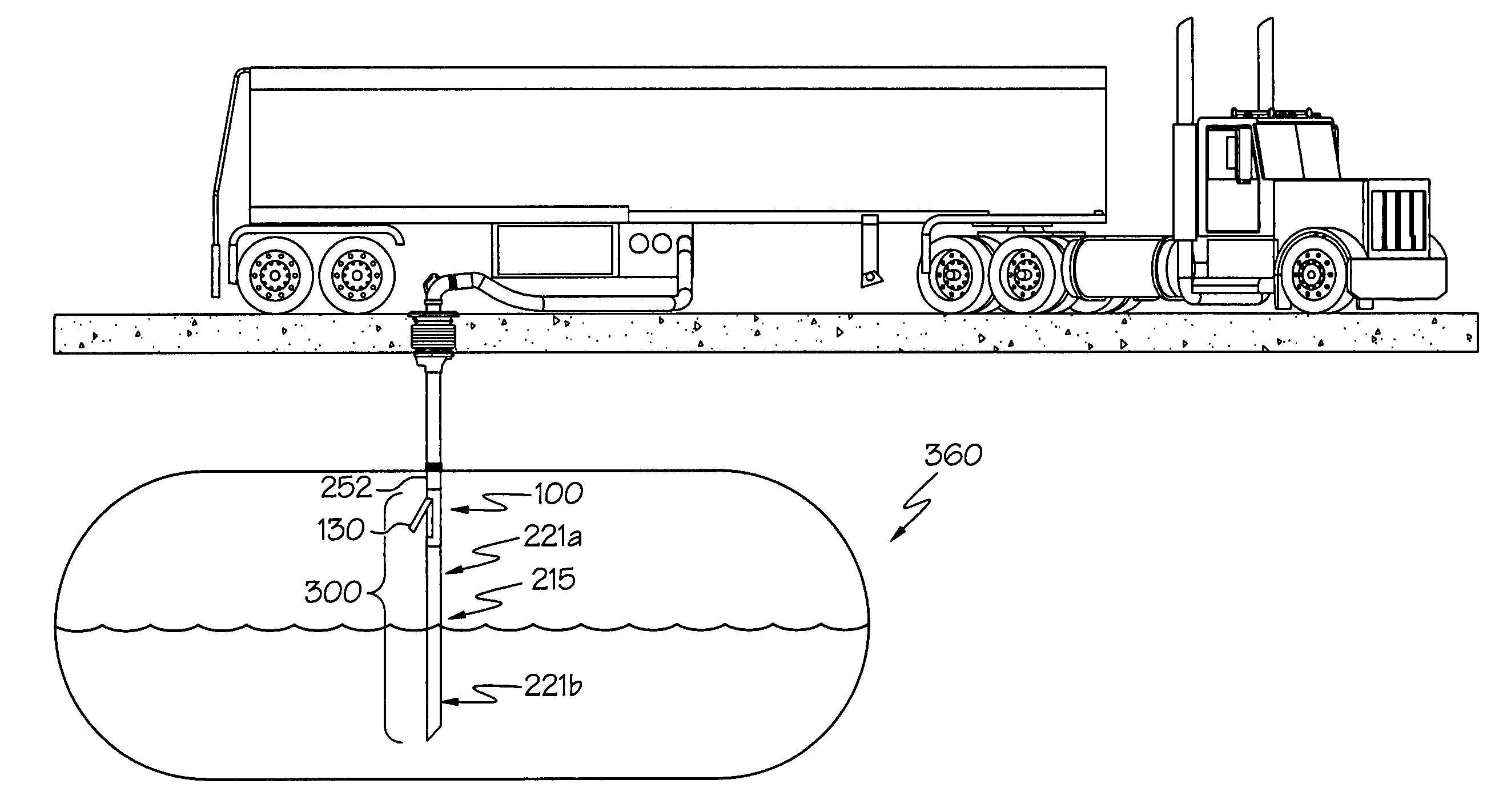

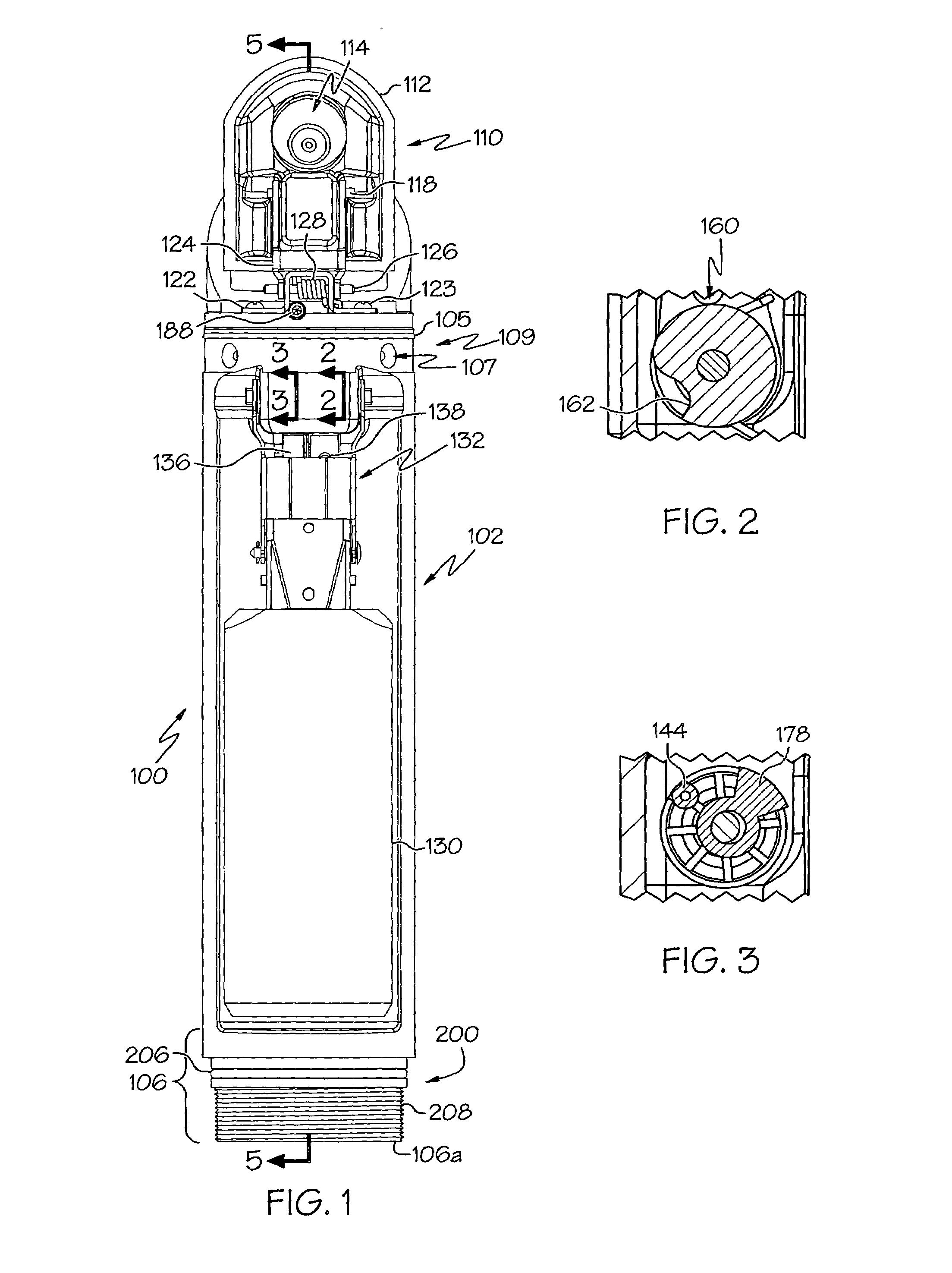

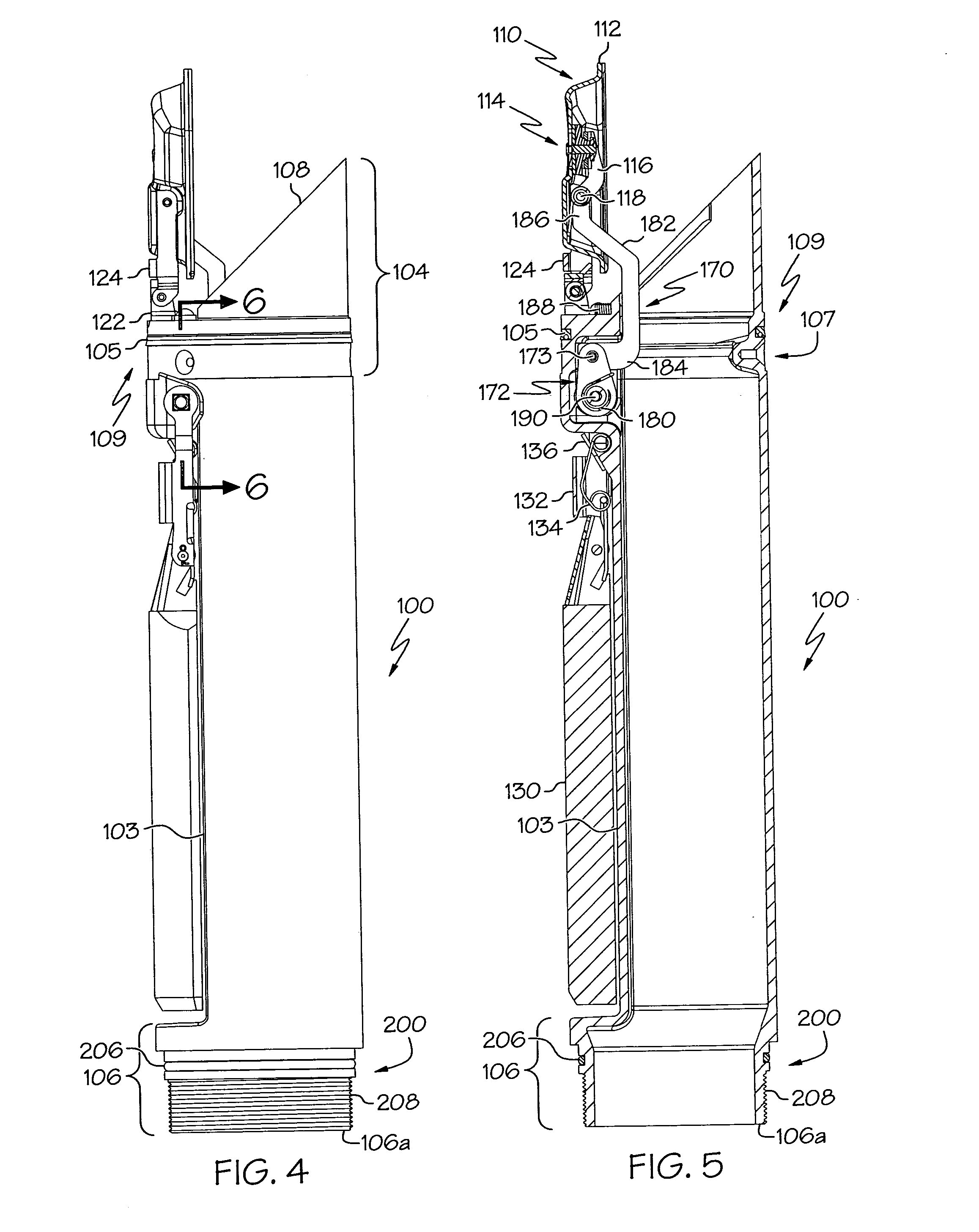

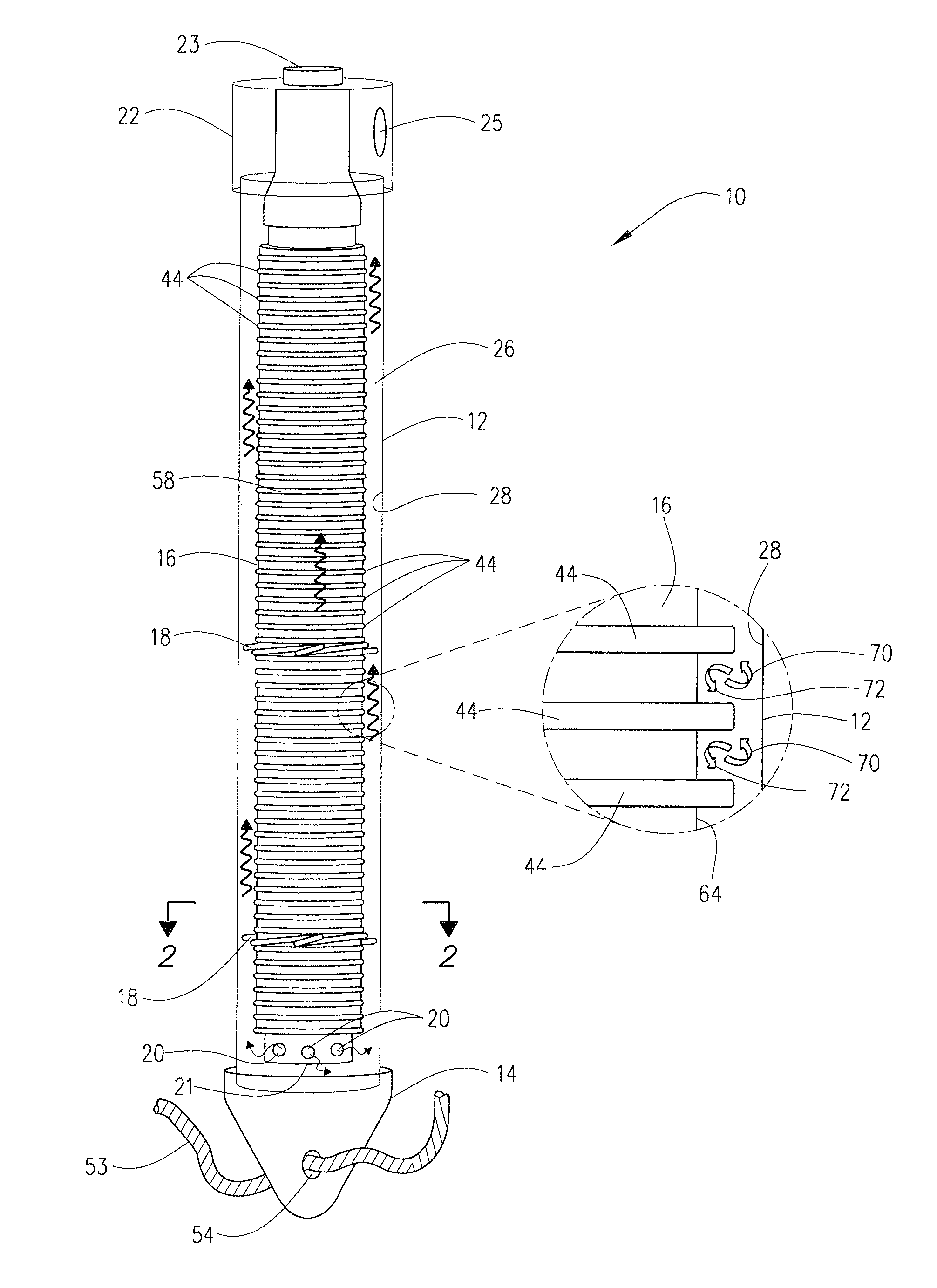

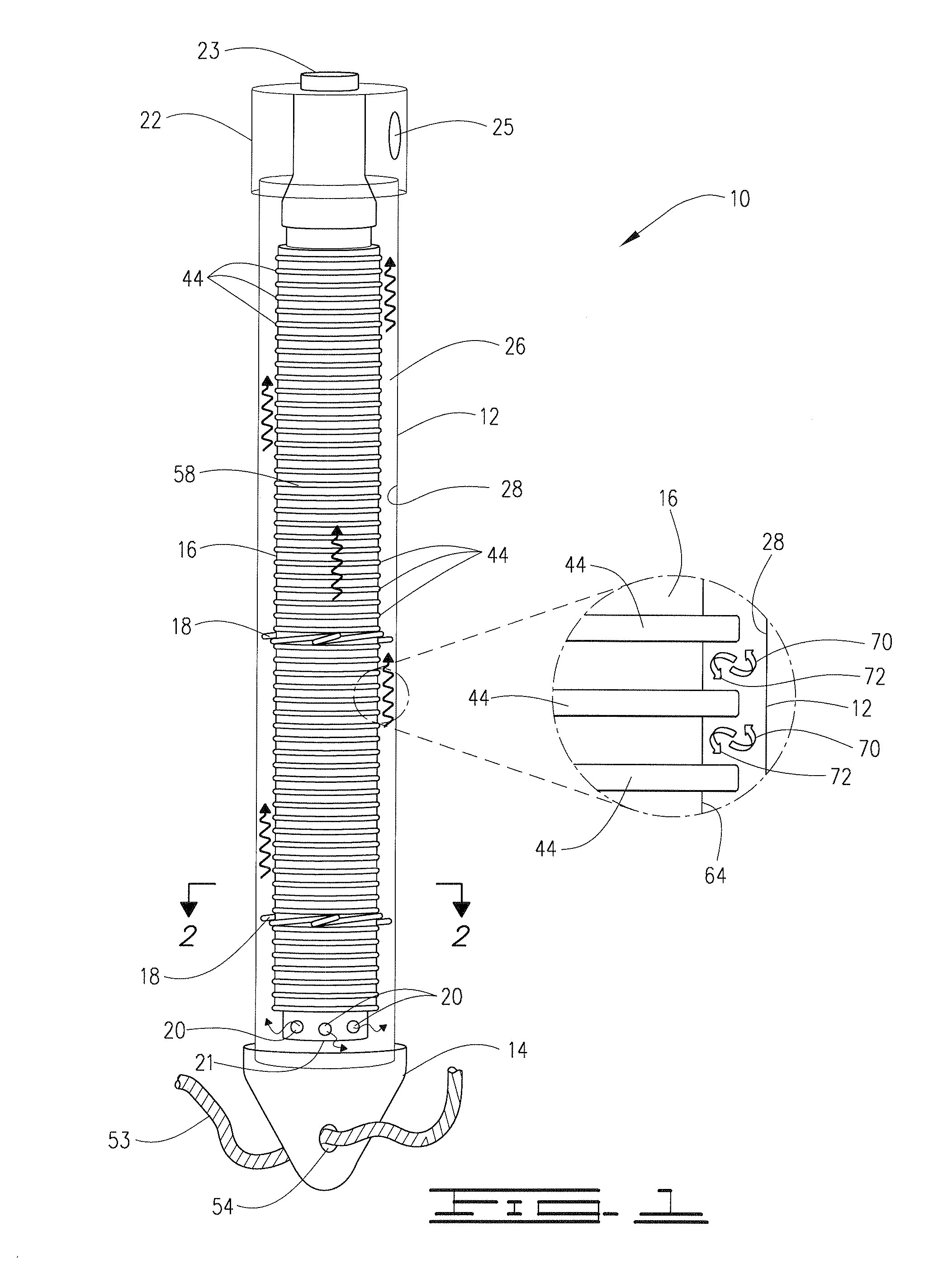

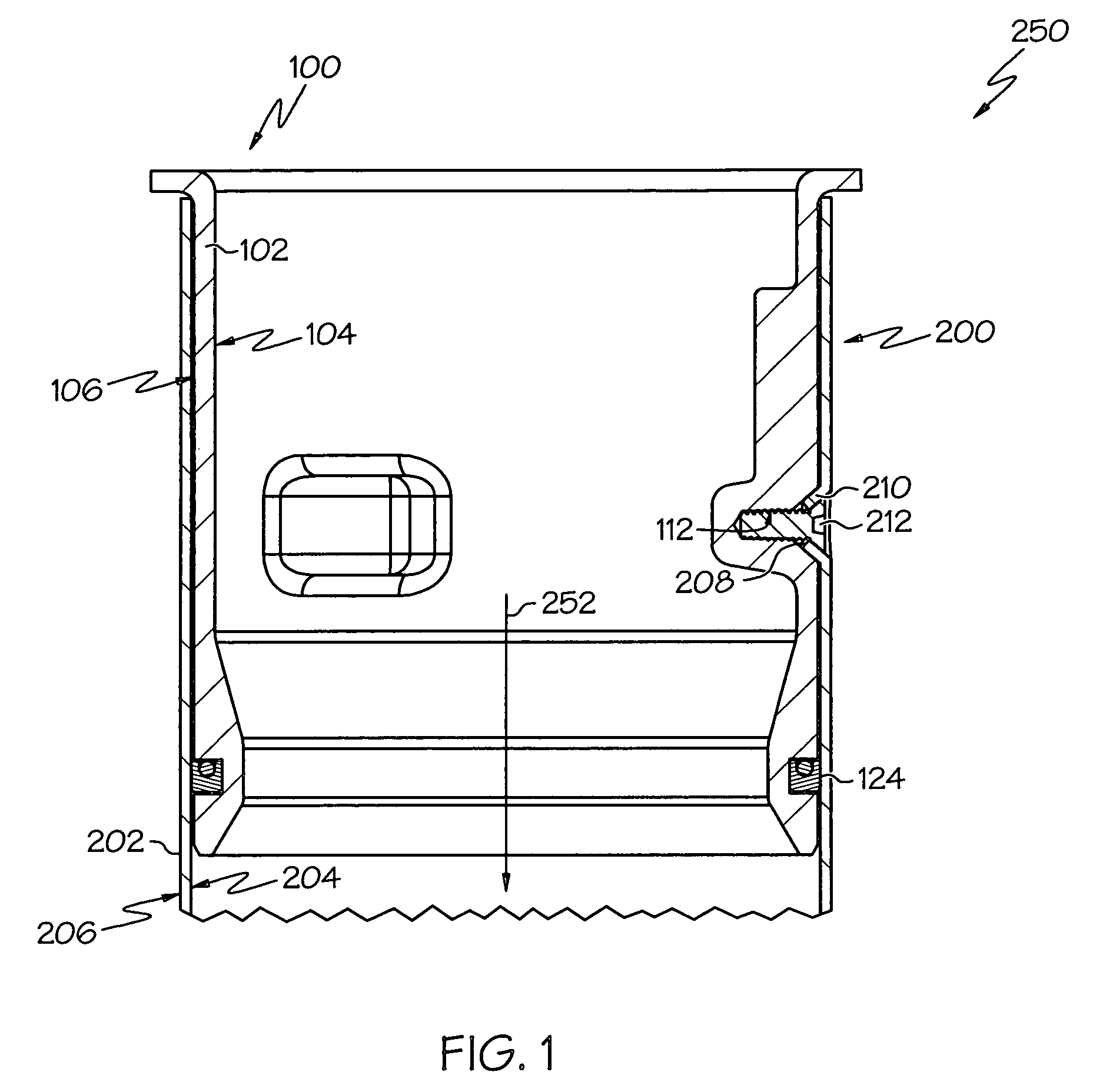

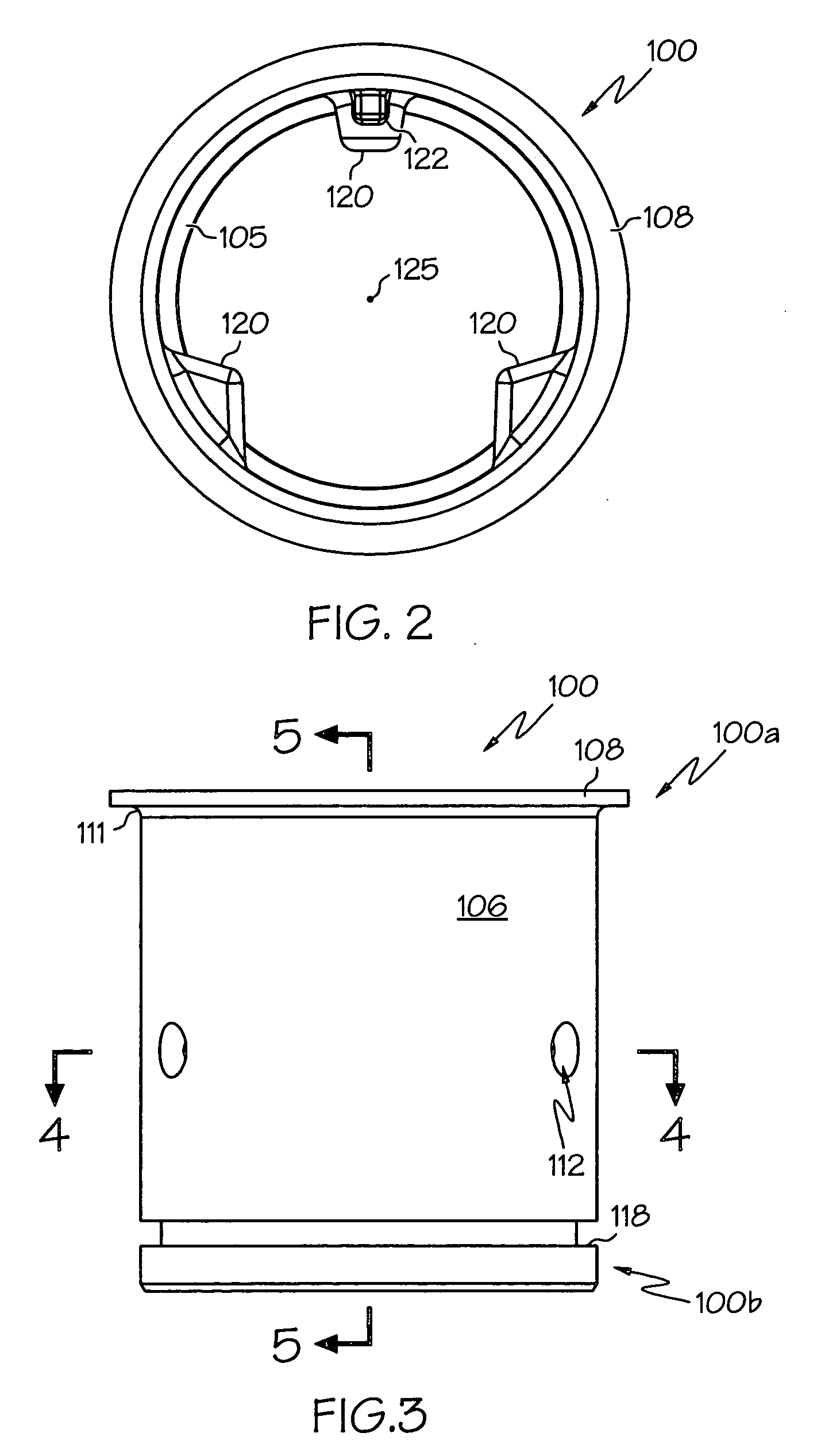

Drop tube segments adapted for use with a liquid reservoir

ActiveUS20050241722A1Extensive curing timeEasy to adjust the positionOperating means/releasing devices for valvesCheck valvesDrop tubeScrew thread

A drop tube segment includes a conduit with a first end portion and a second end portion. The drop tube segment further comprises a valve assembly with a valve member associated with the first end portion, a float, and a linkage device pivotally connected with respect to the valve member. The linkage device is adapted for communication with the float such that the float may facilitate in adjusting the position of the valve member with respect to the first end portion of the conduit in response to a liquid level in a liquid reservoir. The drop tube segment further includes a fastening section located at the second end portion of the conduit for fluid tight fastening with an end portion of another drop tube segment. The fastening section comprises a sealing surface and a threaded portion adapted for threaded engagement with a threaded portion of another drop tube segment. The drop tube segment still further includes a sealing member that engages the sealing surface of the fastening section and is adapted to engage a sealing surface of another drop tube segment.

Owner:OPW FUELING COMPONENTS LLC

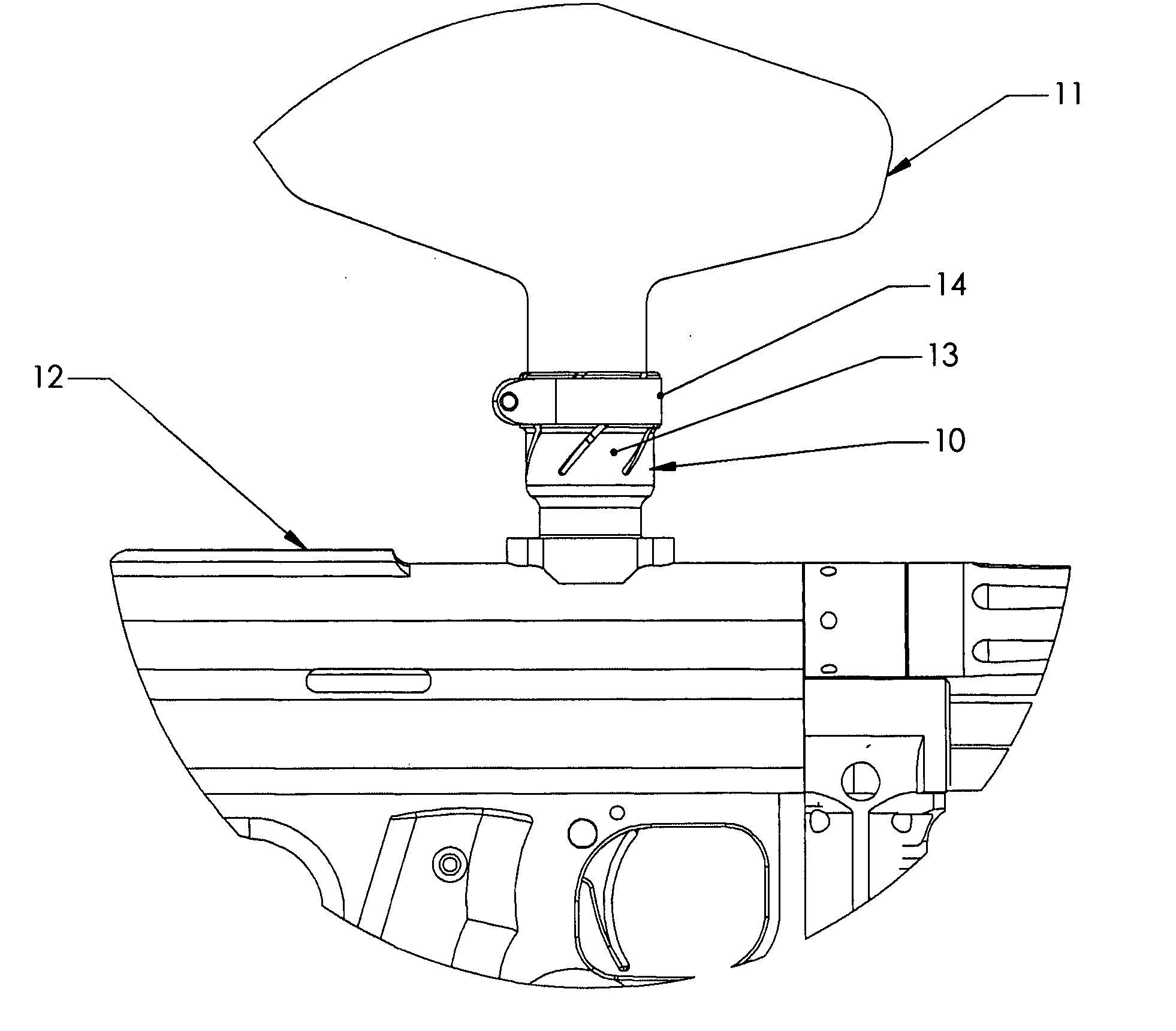

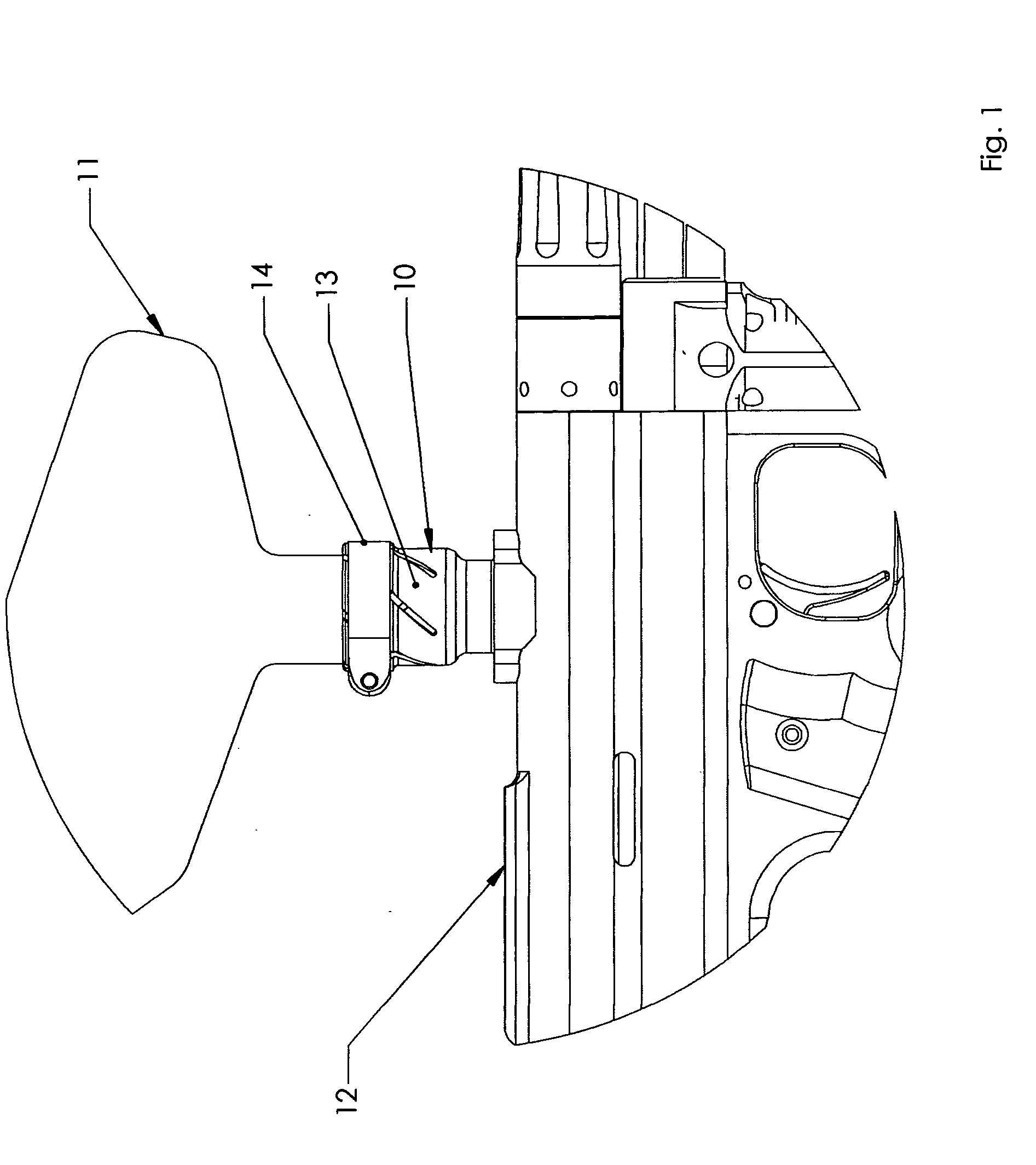

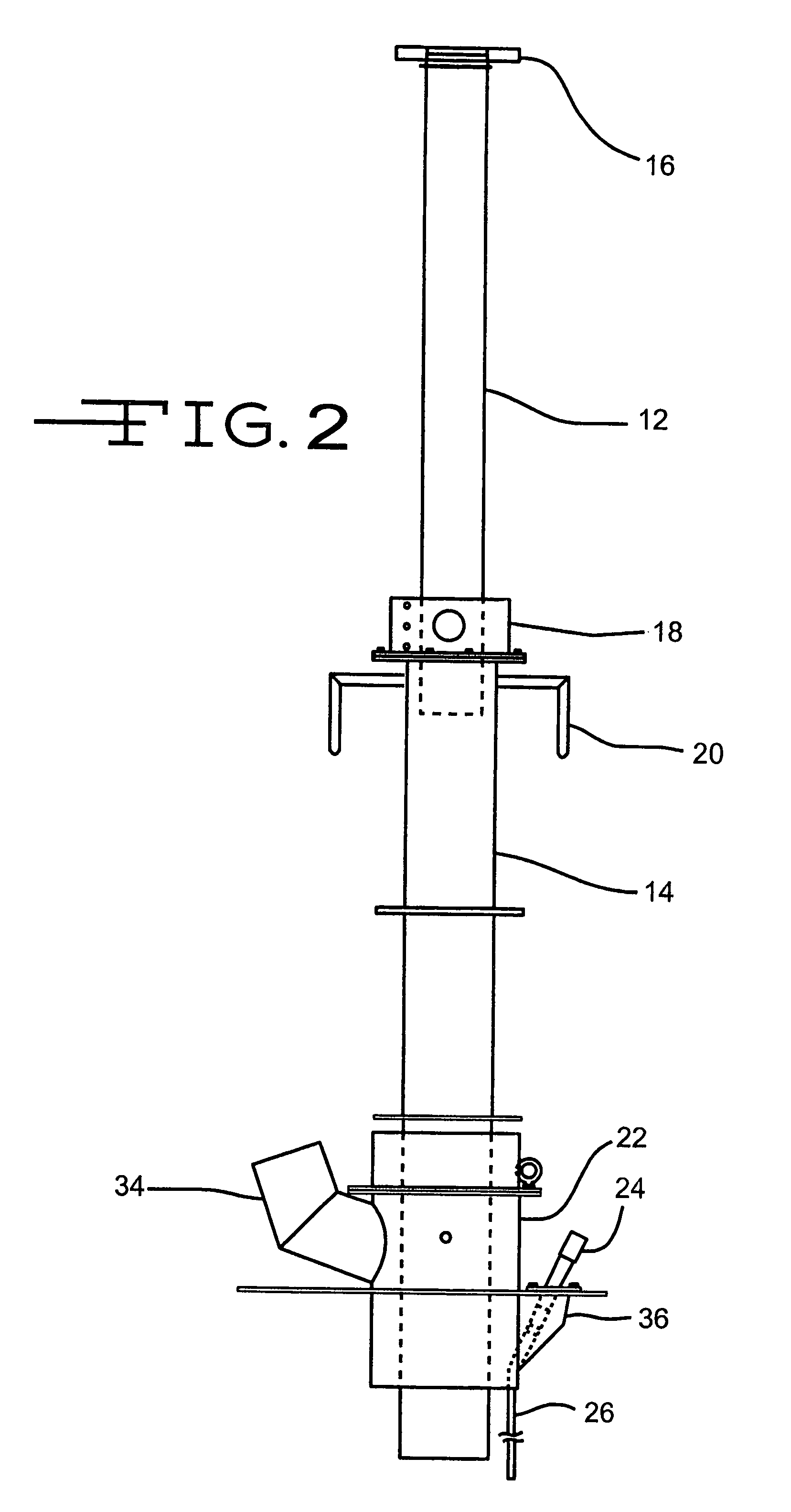

Adjustable paintball drop tube

InactiveUS20050284456A1Optimization rangeCompressed gas gunsLaunching weaponsCombined useEngineering

A improved adjustable paintball drop tube for use in conjunction with paintball guns and paintball loaders in paintball games and sports, wherein the improved adjustable paintball drop tube enables any of a variety of loaders to be adapted to any of a variety of paintball guns. Through the use of heliacal retention segments, the improved adjustable paintball drop tube also enables the user to more effectively retain paintball loaders throughout the vigorous activity inherent in the sport of paintball without said loader separating from the improved adjustable paintball drop tube, and thereby maintain a source of paintball ammunition for the paintball gun. The improved adjustable paintball drop tube can be formed of any of a variety of materials including molded plastic, aluminum or steel commonly used for such applications and known within the art.

Owner:CHIPLEY JASON

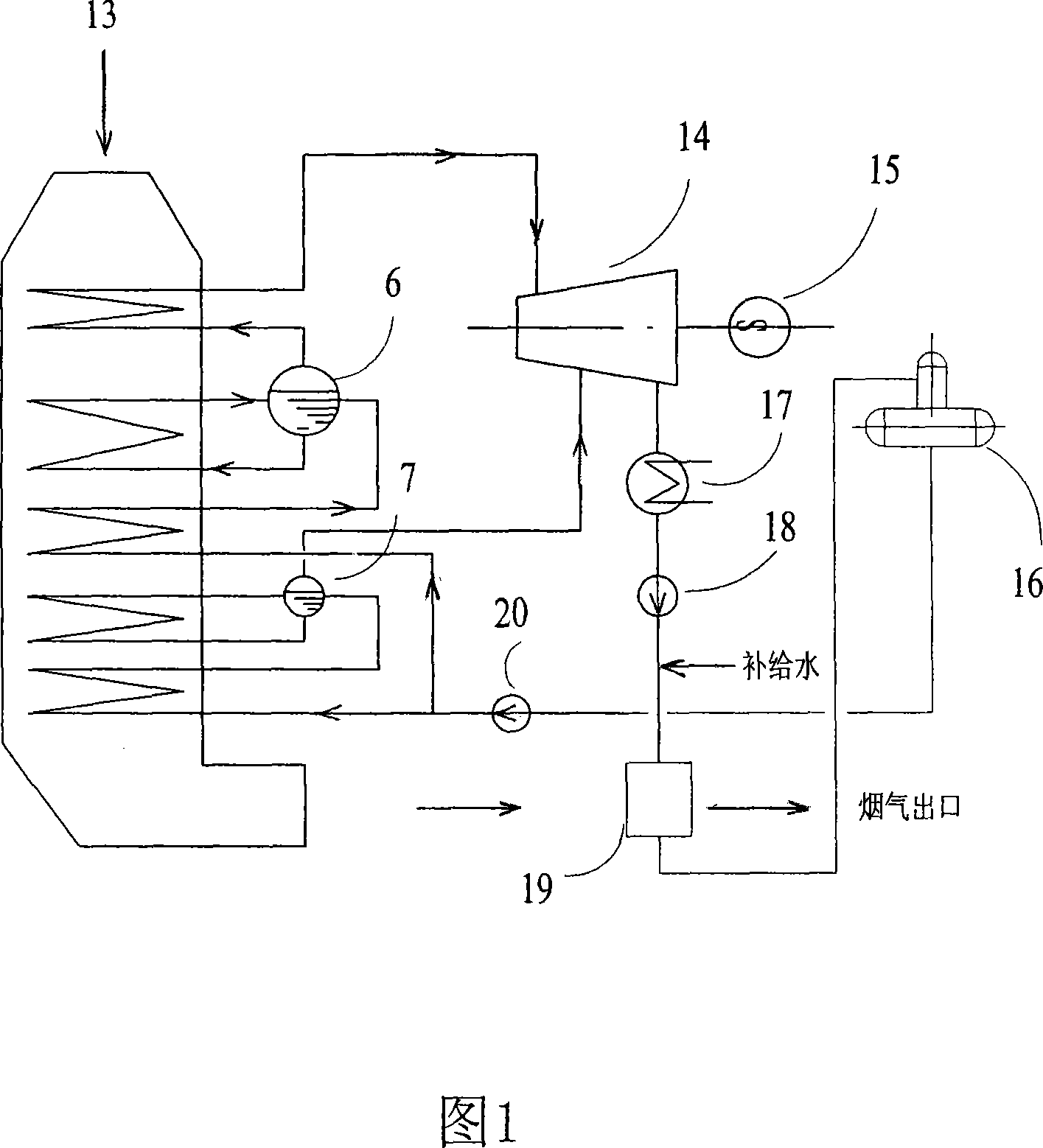

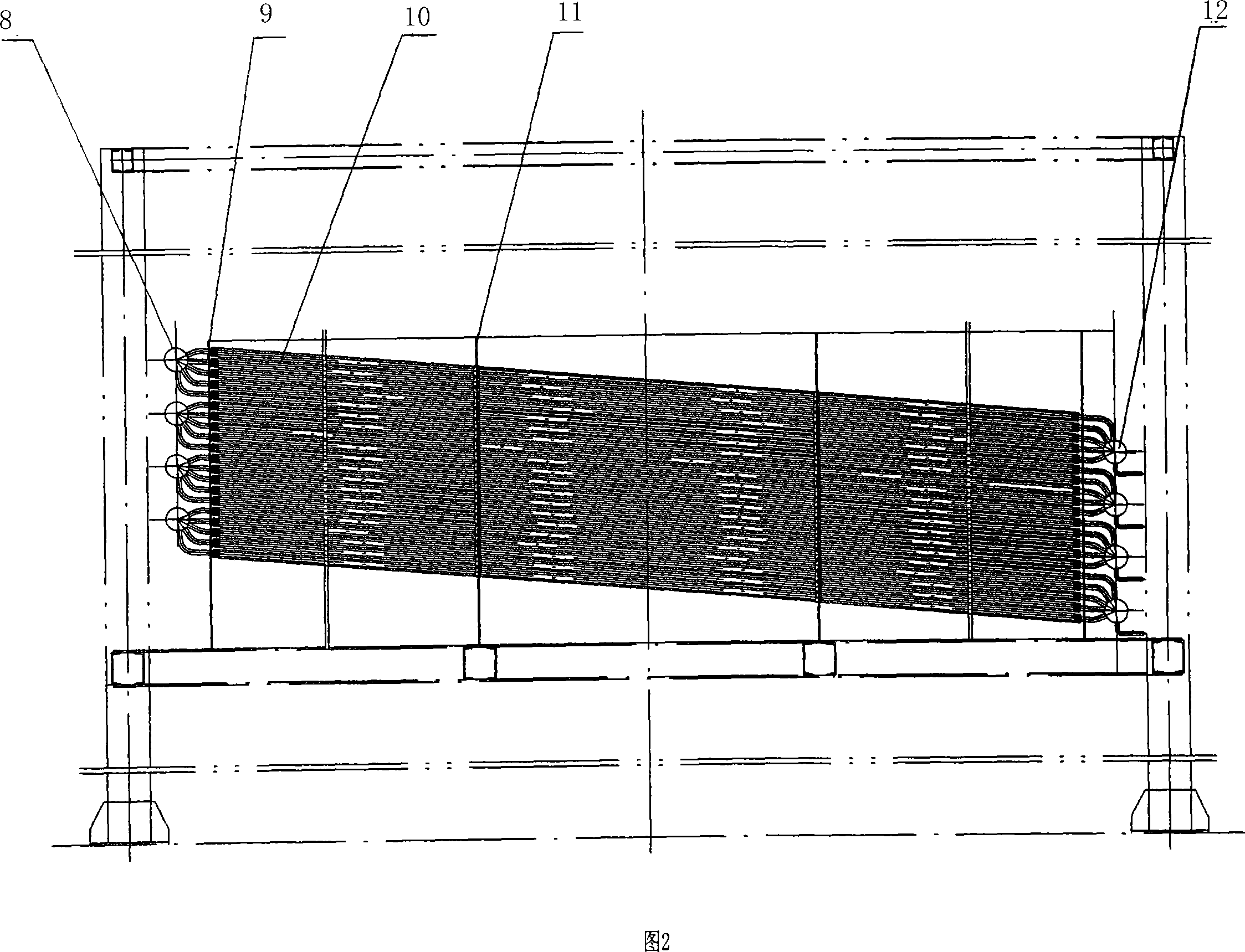

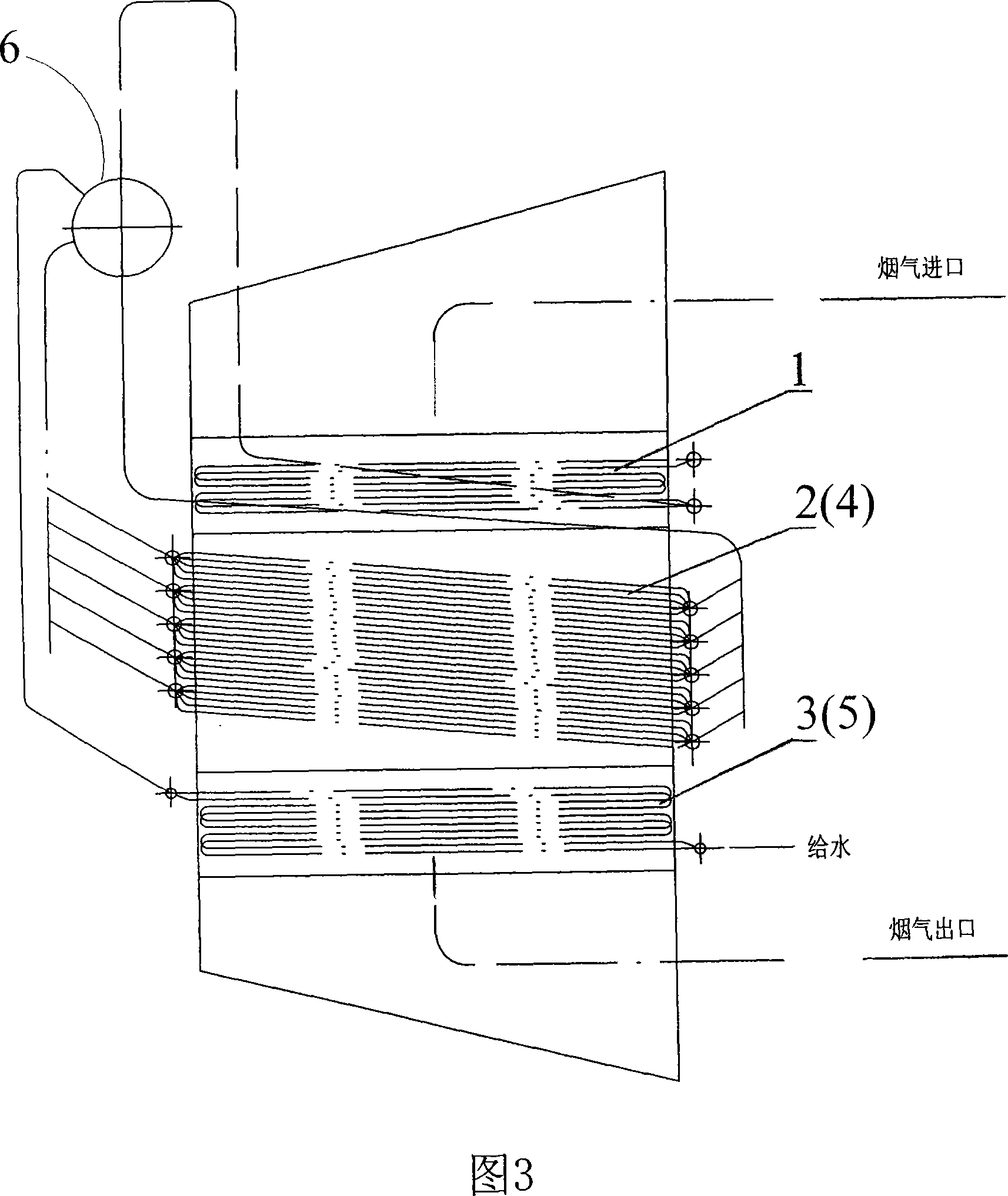

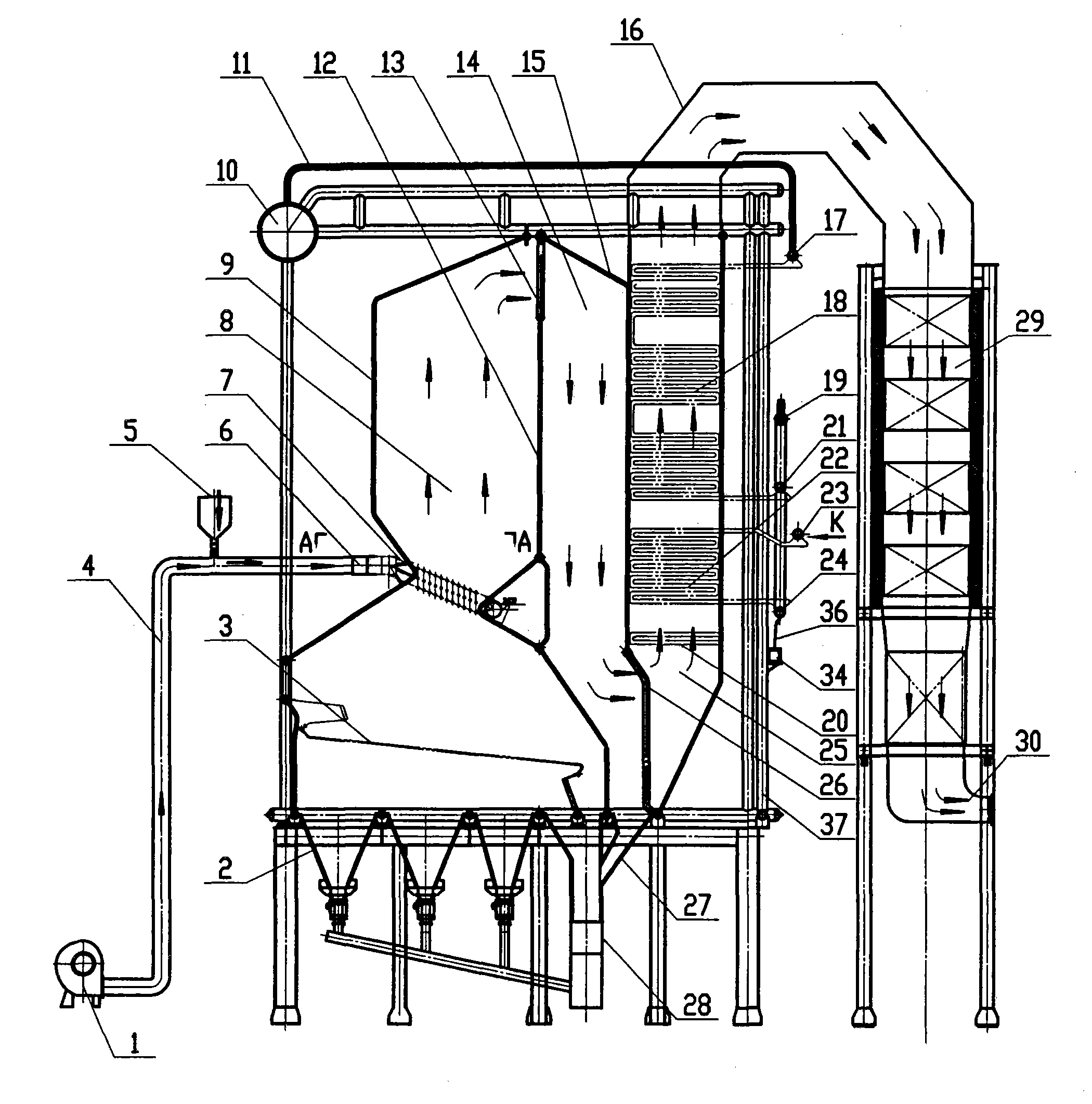

Sinter cooler low temperature waste gas residual heat boiler and power generating system thereof

InactiveCN101021305AEasy to discharge ashSmall footprintSteam boilersSteam boilers componentsWhole bodyEvaporation

The present invention provides an exhaust-heat boiler capable of effectively utilizing low-temperature heat transmission to make power generation and its power generation system. Said exhaust-heat boiler whole body adopts vertical type arrangement and tube-box type structure, in the boiler tube-box interior are successively set super heater, evaporation zone, low-pressure evaporation zone, coal economizer and low-pressure coal economizer from top to bottom, in which the evaporation zone and low-pressure evaporation zone have several groups of evaporators, these evaporators are obliquely placed in smoke flue, their inclination angle is 5 deg-15 deg. Said invention also provides the concrete structure of every evaporator, and provides the working principle of said exhaust-heat boiler and its power generation system and their concrete operation method.

Owner:JIANGSU DONGJIU HEAVY IND

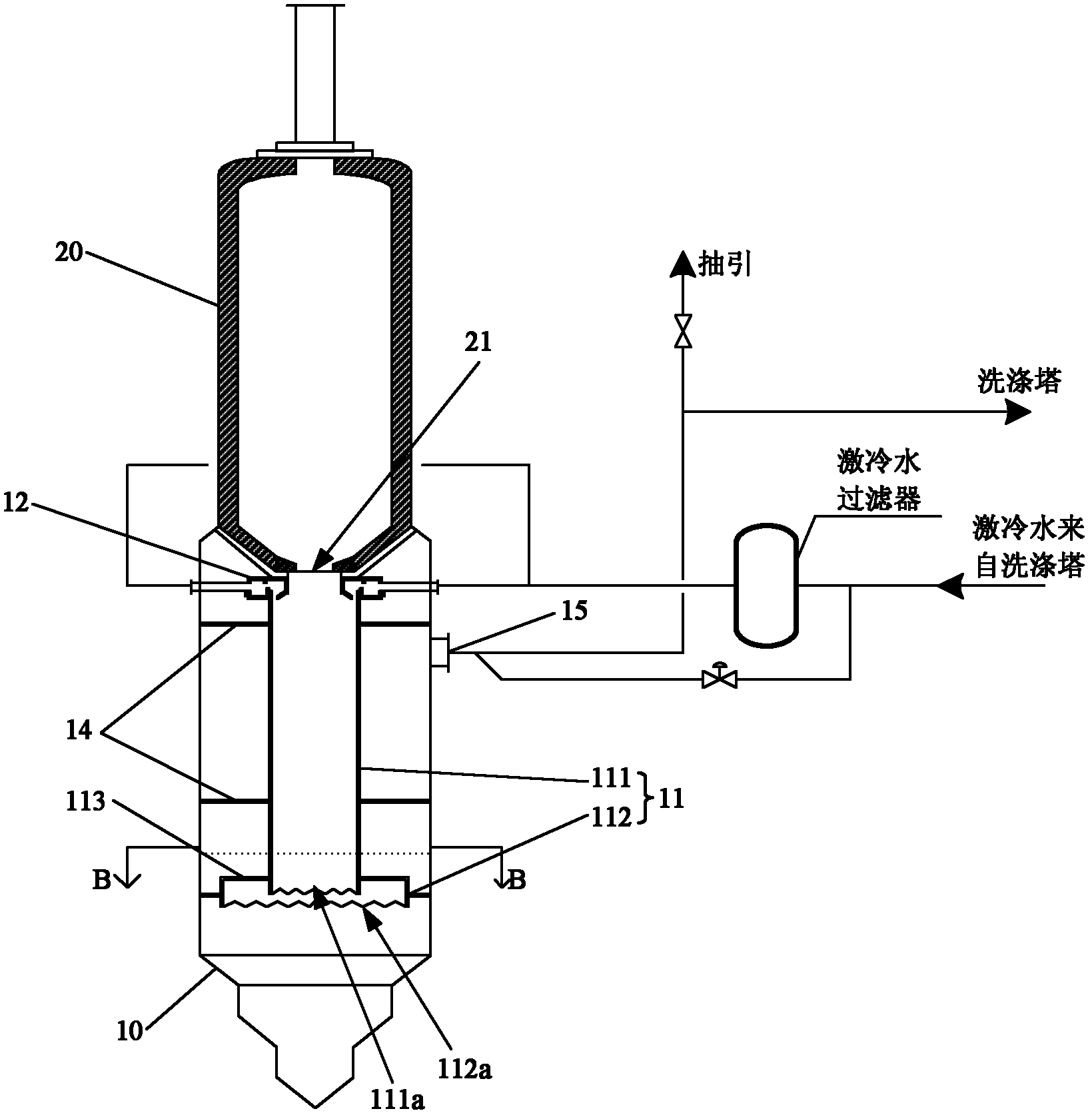

Low-pressure gasification system and gas making method

The invention discloses a low-pressure gasification system, which comprises a coal slurry supply unit, a low-pressure water-cooled wall gasifier and a synthesis gas washing unit, wherein the low-pressure water-cooled wall gasifier comprises a gasification chamber used for gasifying water coal slurry and a quenching chamber adjacently arranged below the gasification chamber to quench combustion products produced in the gasification chamber and obtain crude synthesis gas; the synthesis gas washing unit is connected to the quenching chamber and is used for washing the crude synthesis gas to generate synthesis gas; the gasification chamber is communicated with the quenching chamber through a downcomer; an ascending pipe sleeve is arranged on an outer wall of the downcomer; and quenching wateris introduced into the ascending pipe sleeve and sprays from the upper end of the ascending pipe sleeve so as to cool the combustion products. Due to the low-pressure gasification system, the carbon dioxide content in the generated synthesis gas is greatly reduced, so that decarbonizing equipment in a synthesis ammonia device can be reduced when the synthesis gas enters a downstream process. Therefore, the energy consumption in the whole downstream process is greatly reduced, the cost is reduced, and the coal types are little limited. The invention also provides a gas making method.

Owner:TSINGHUA UNIV +1

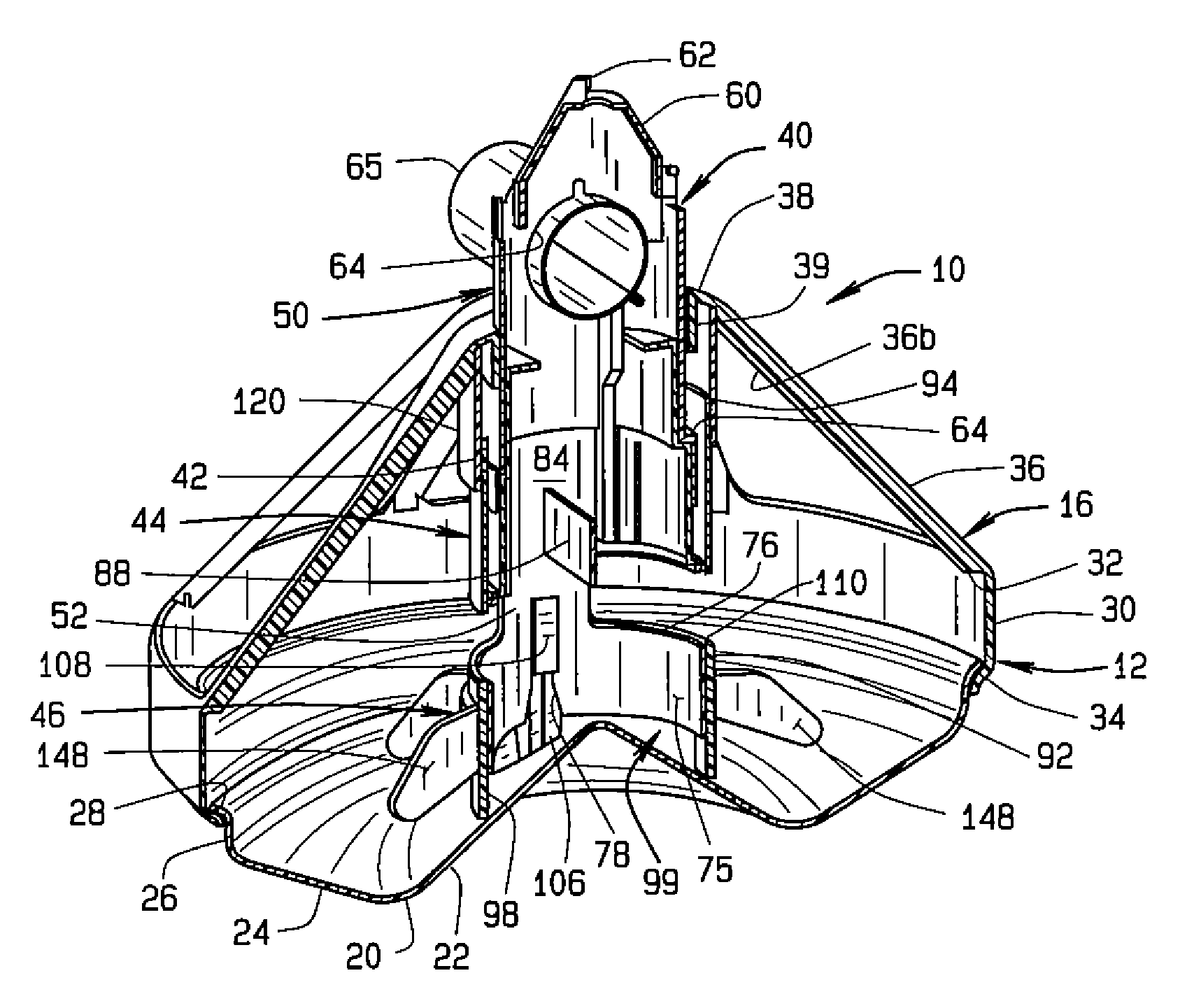

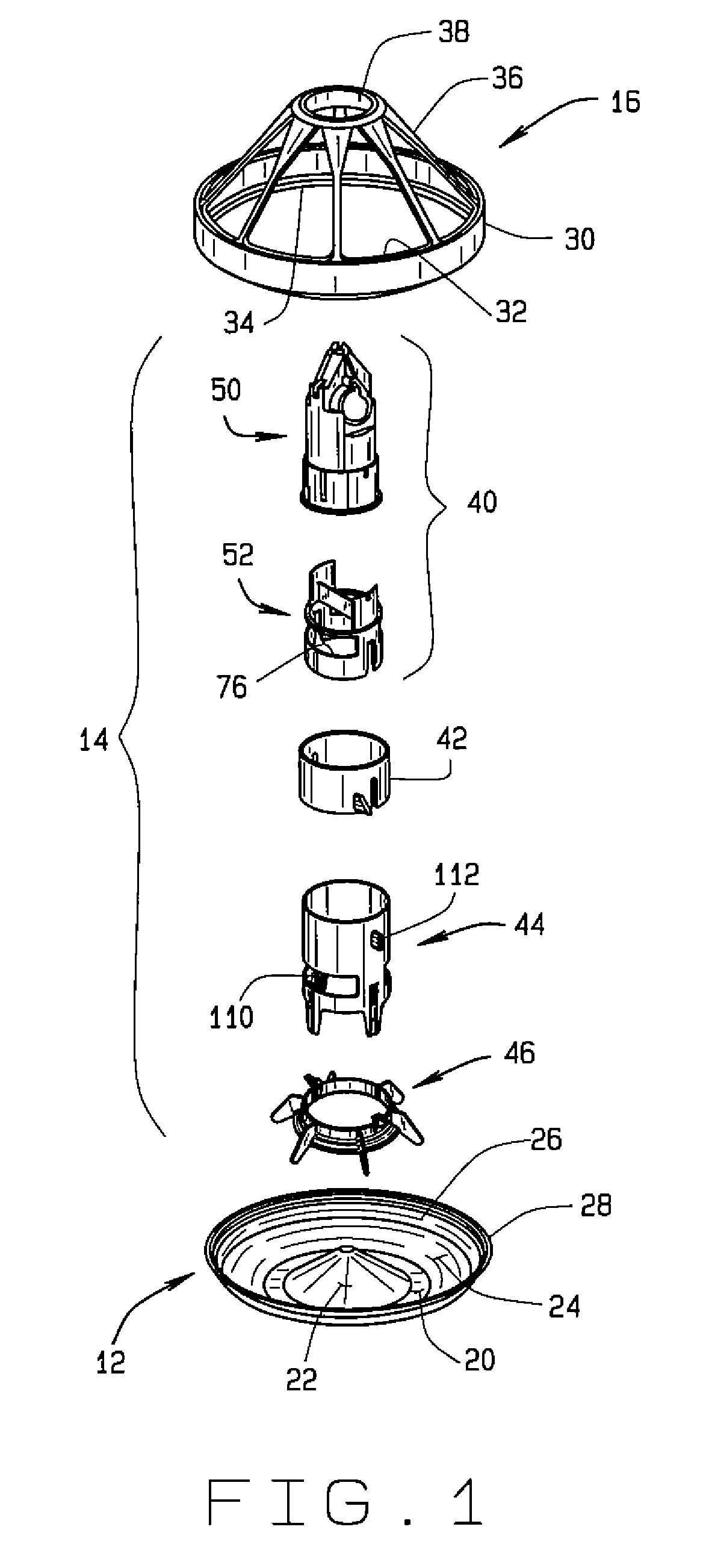

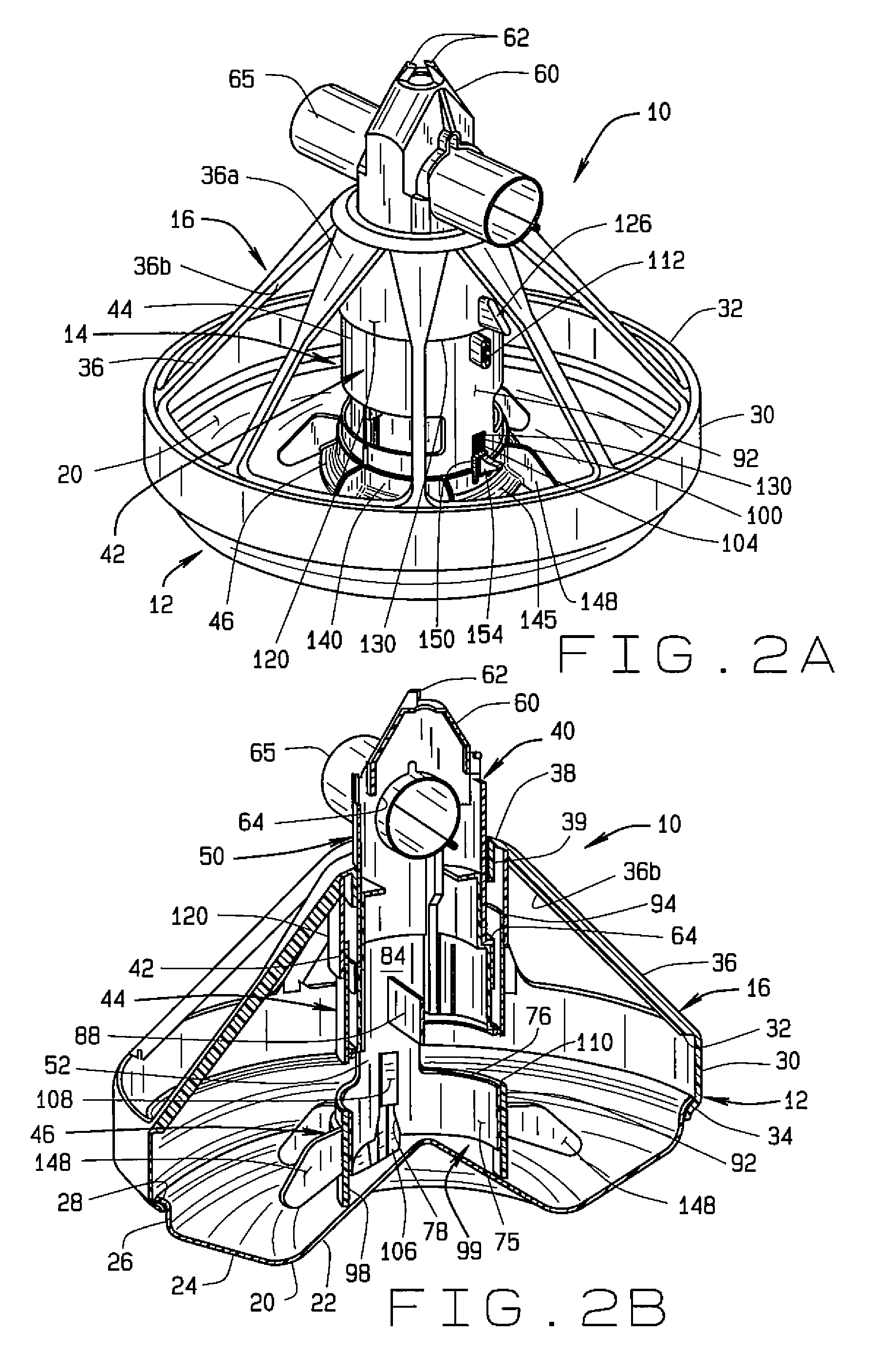

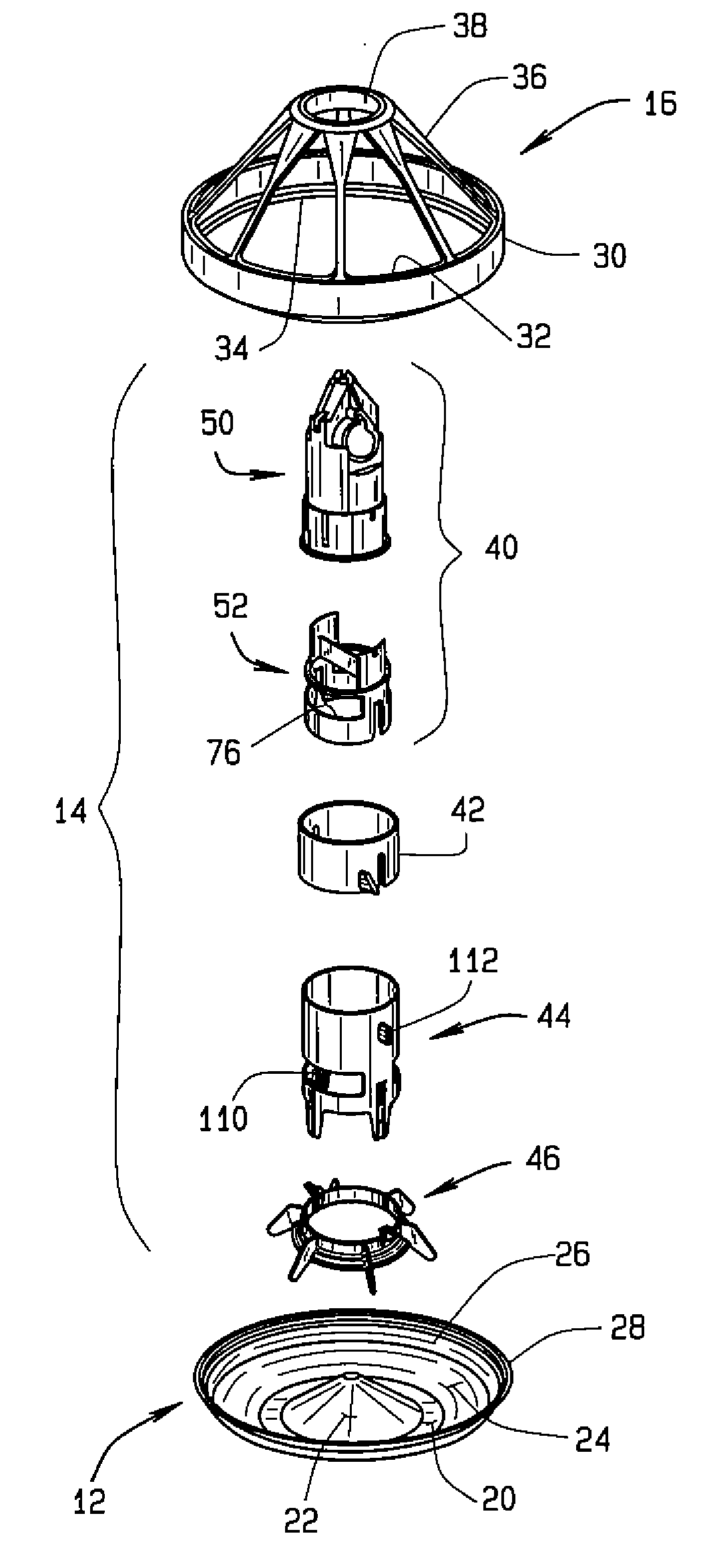

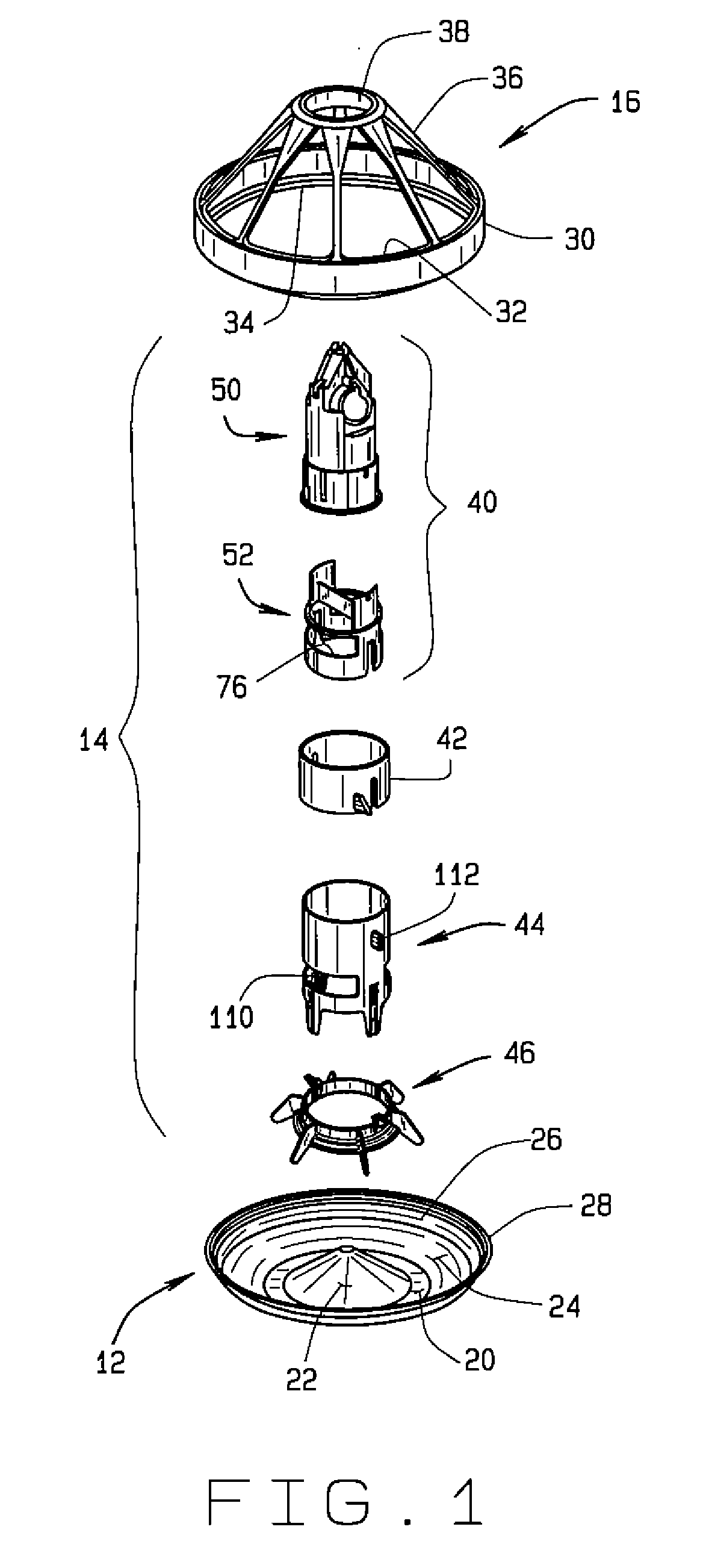

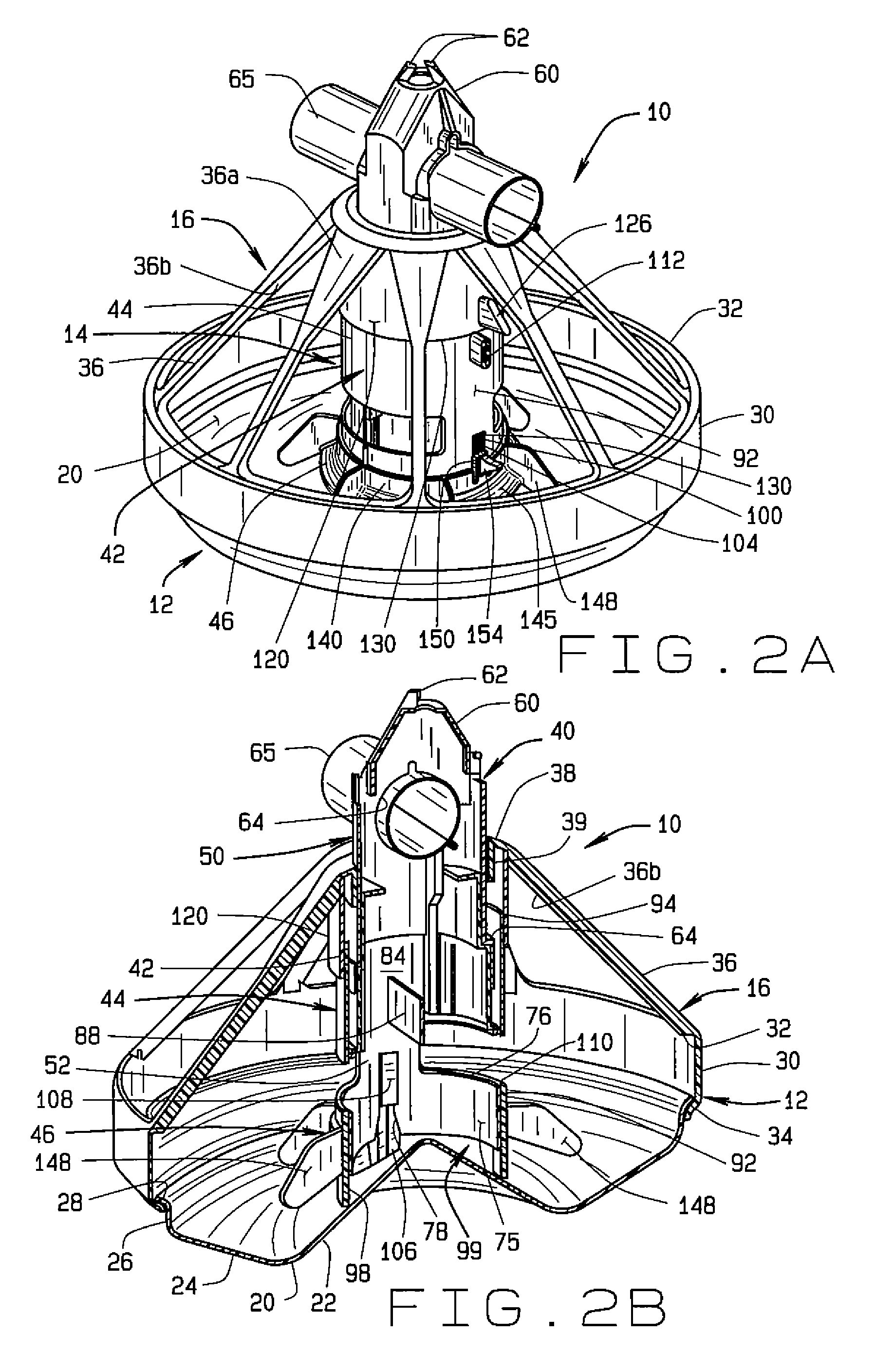

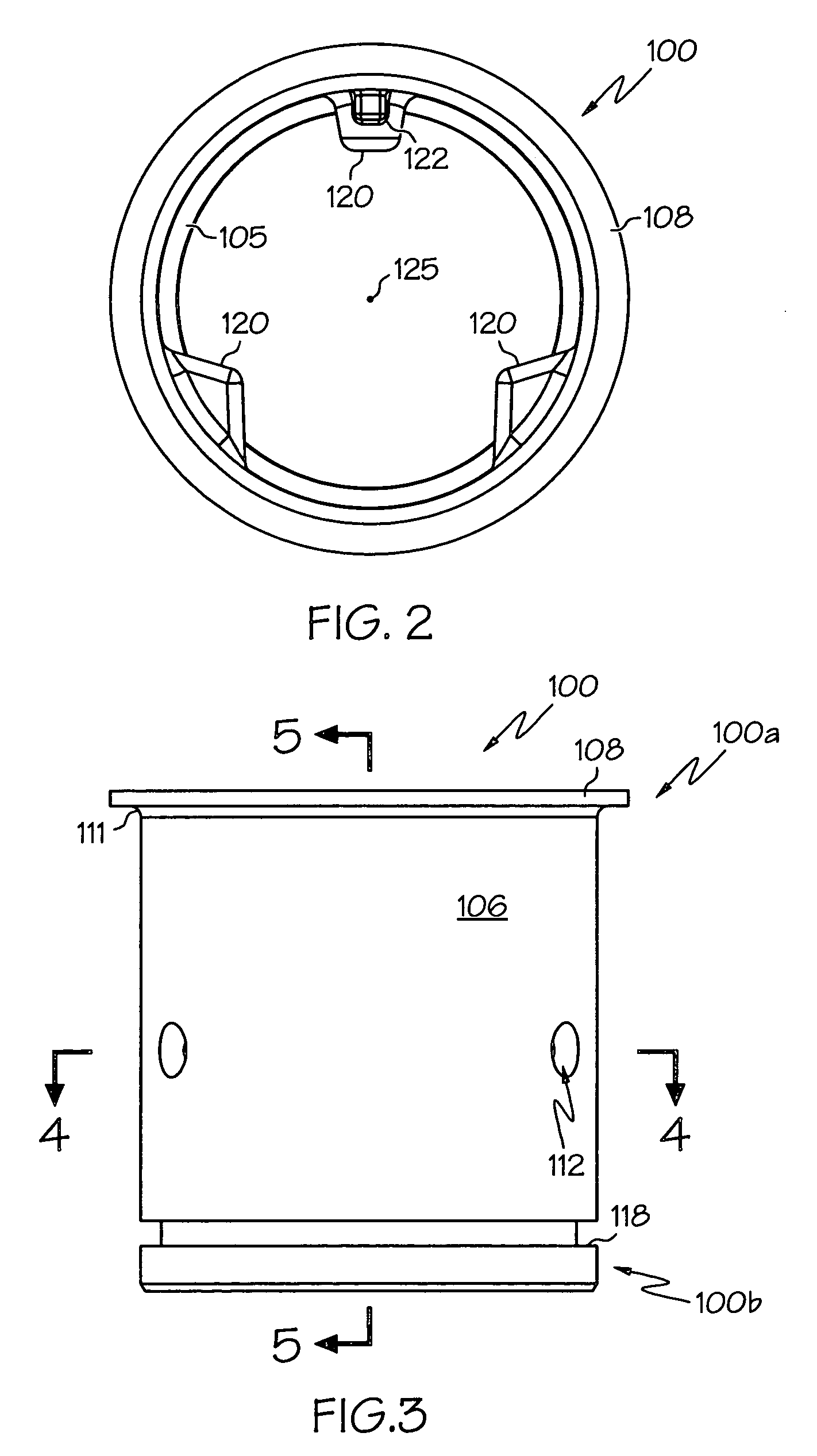

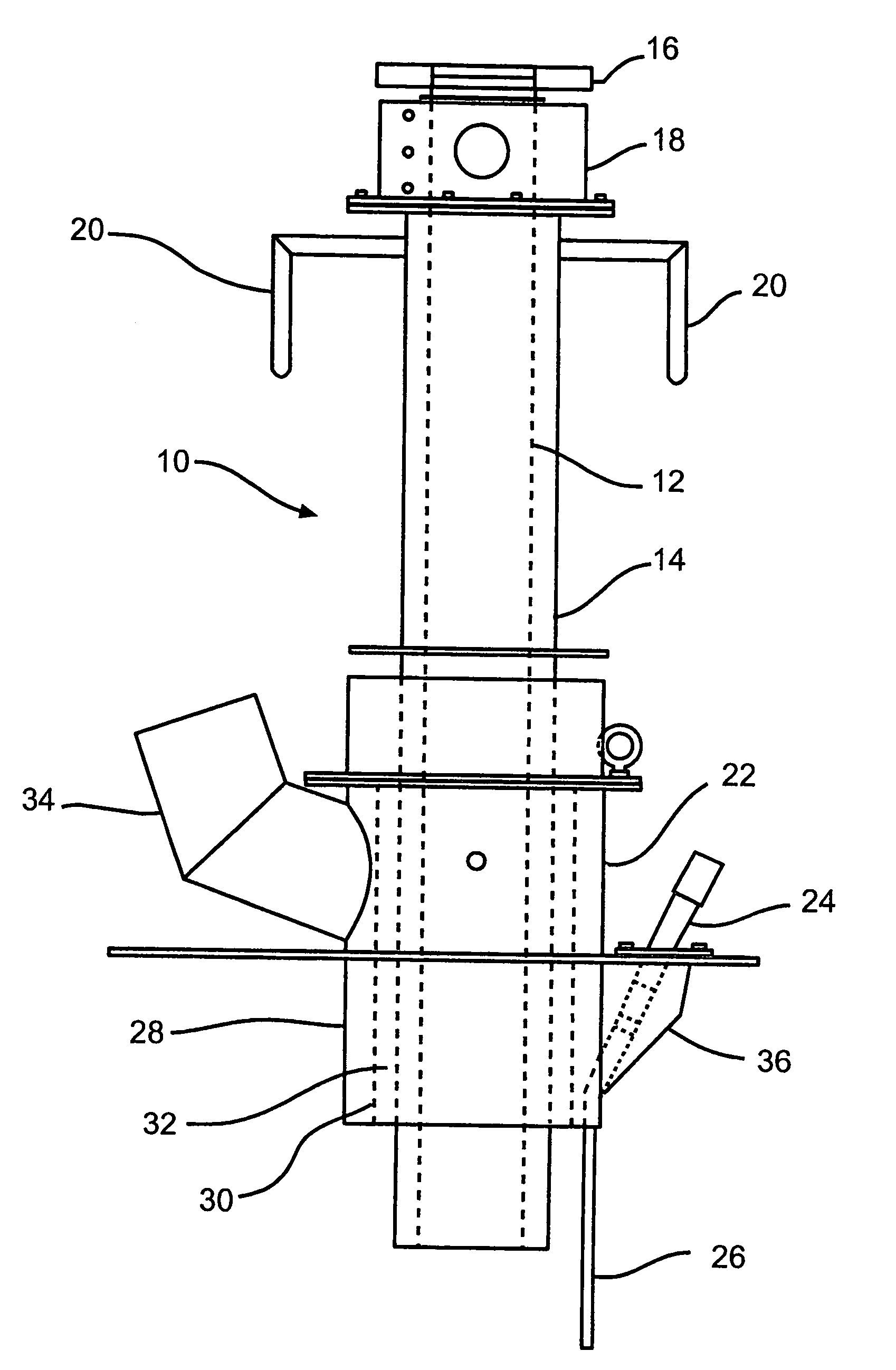

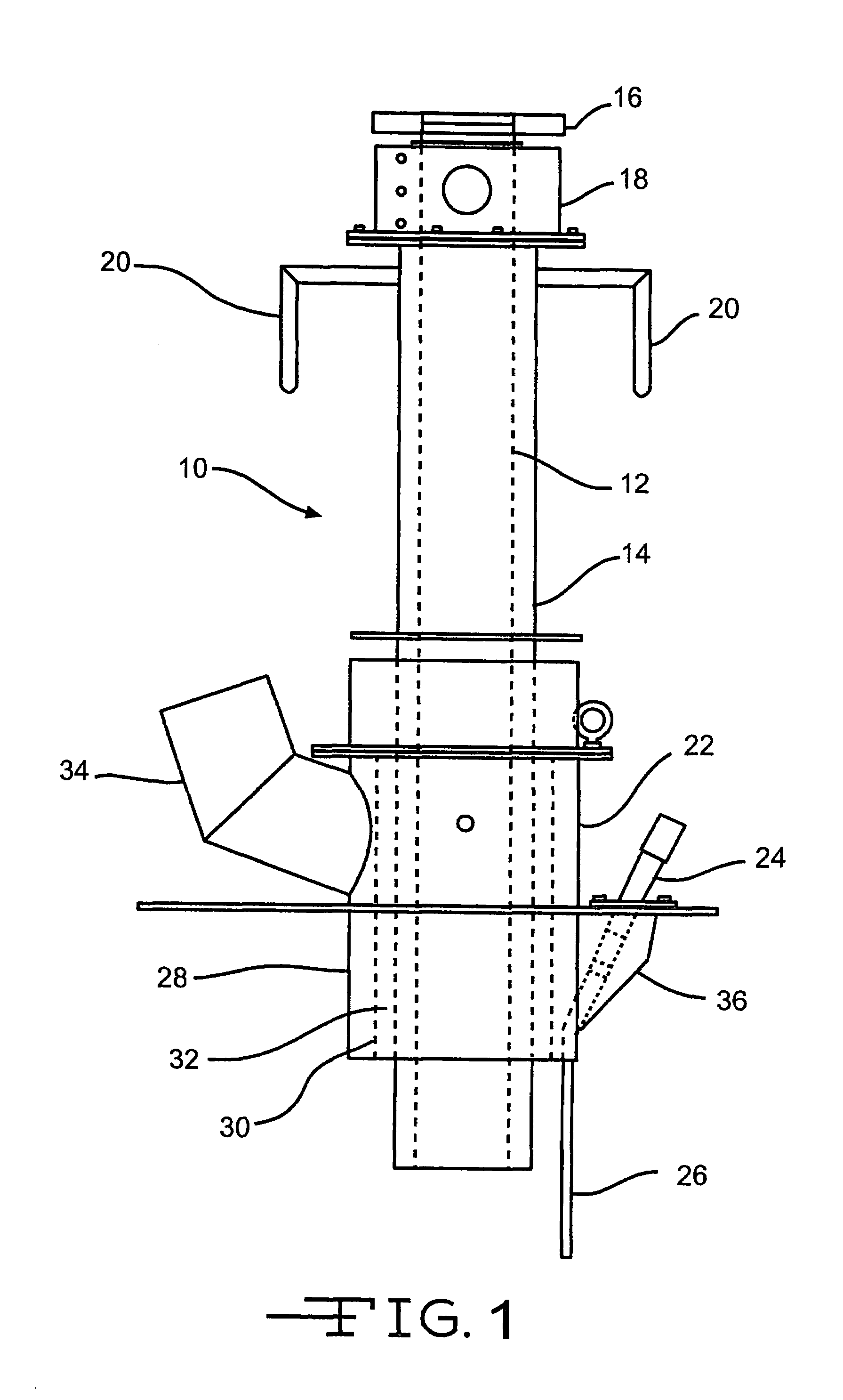

Poultry feeder

ActiveUS7647888B2Extended range of motionPrecise positioningAnimal feeding devicesAnimal housingEffective heightEngineering

A poultry feeder is provided which can be selectively switched between a mode in which it operates as a flood-type feeder and a mode in which it operates as a shallow-fill type feeder with adjustable height pan walls. The feeder includes a feed tube assembly comprising a drop tube and a feed flooding tube. The drop tube is movable axially relative to the feed flooding tube, which rests on the feed pan. The drop tube and feed flooding tube have windows which are brought into and out of alignment by raising and lowering the drop tube. When the feed flooding tube window is opened, the feeder operates in a flood mode and when the feed flooding tube is closed, the feeder operates in a shallow-fill mode. In this second mode, the effective height of the pan wall can be adjusted to allow chicks and chickens access to the feed.

Owner:THE GSI GRP LLC

Drop tube segments adapted for use with a liquid reservoir

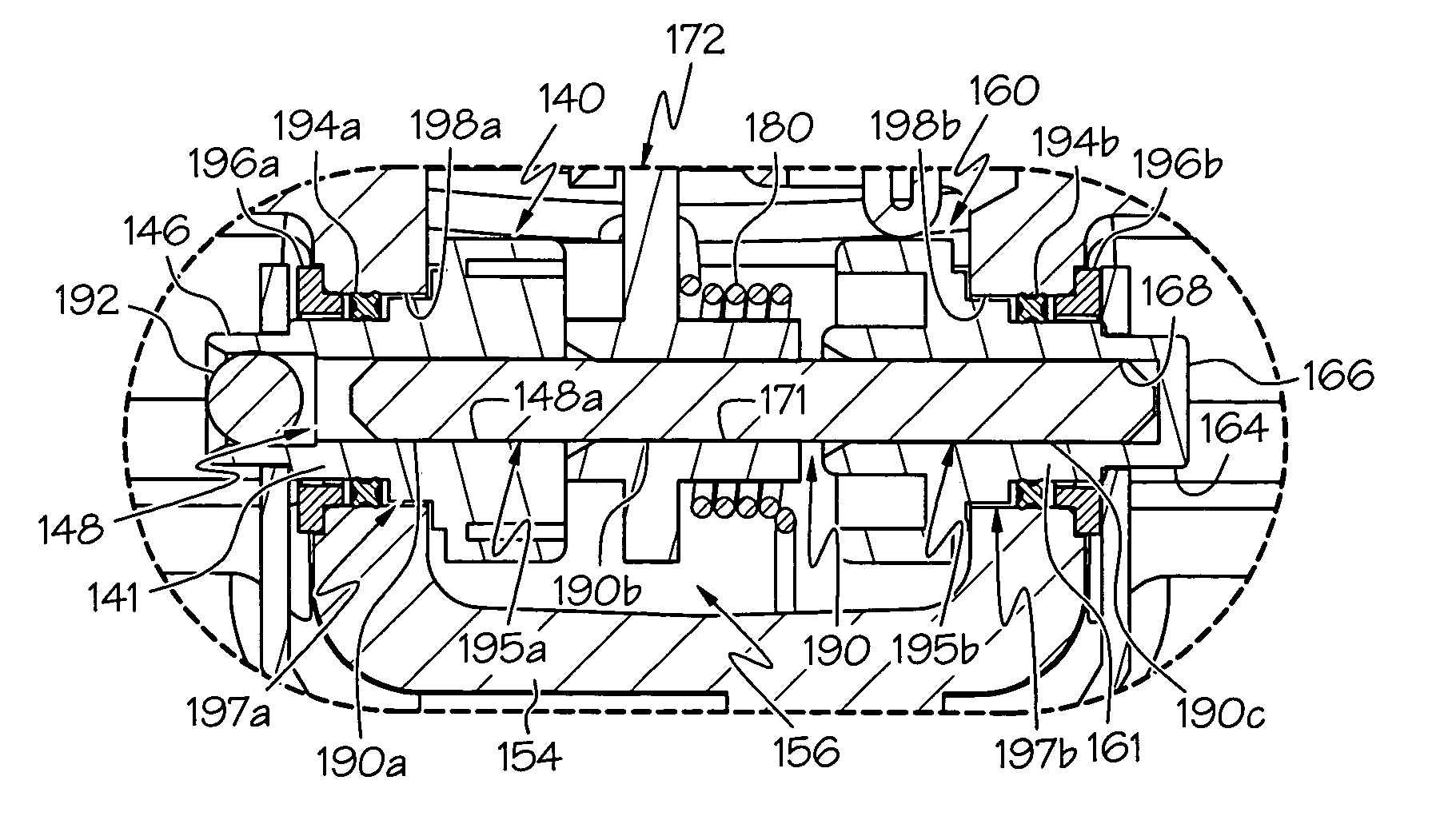

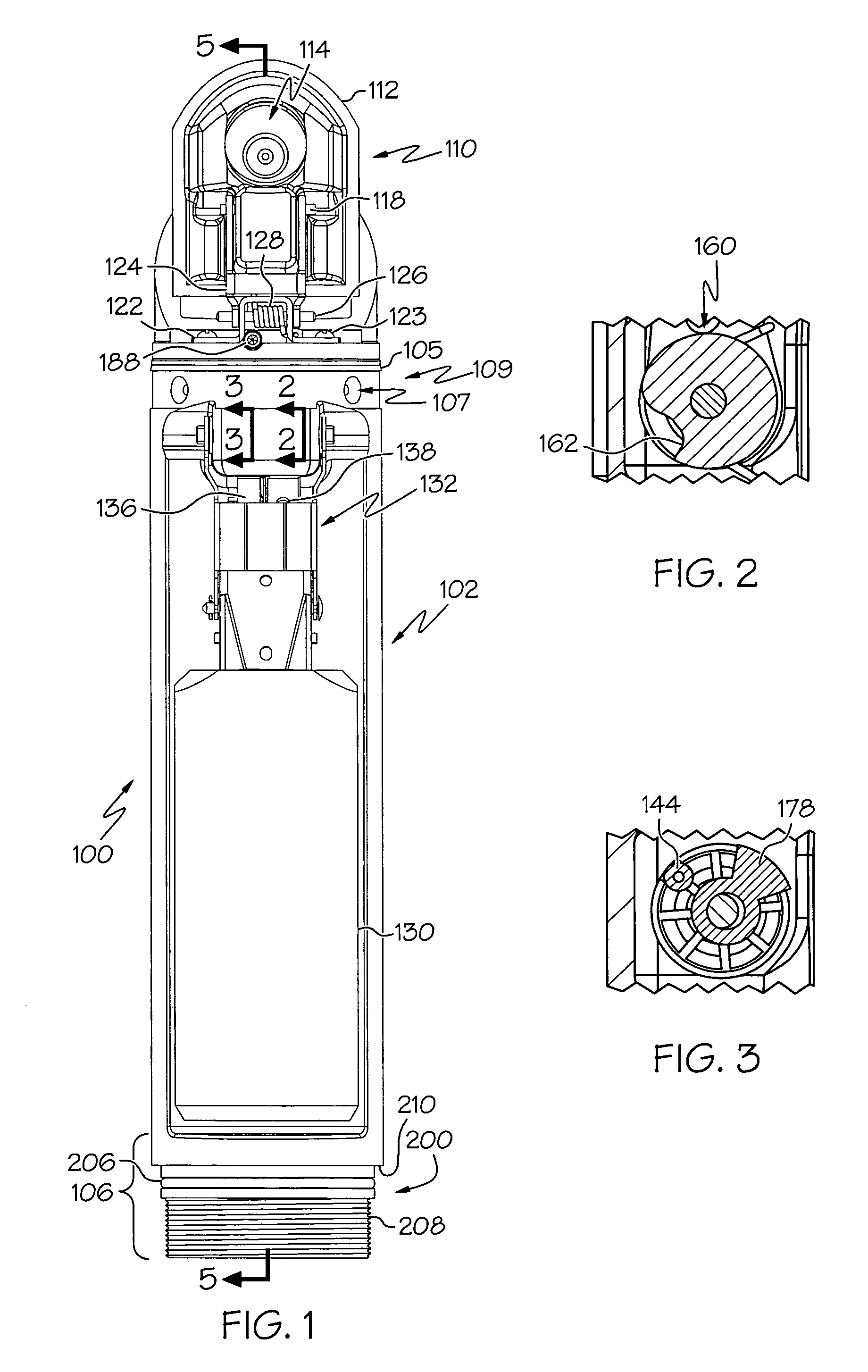

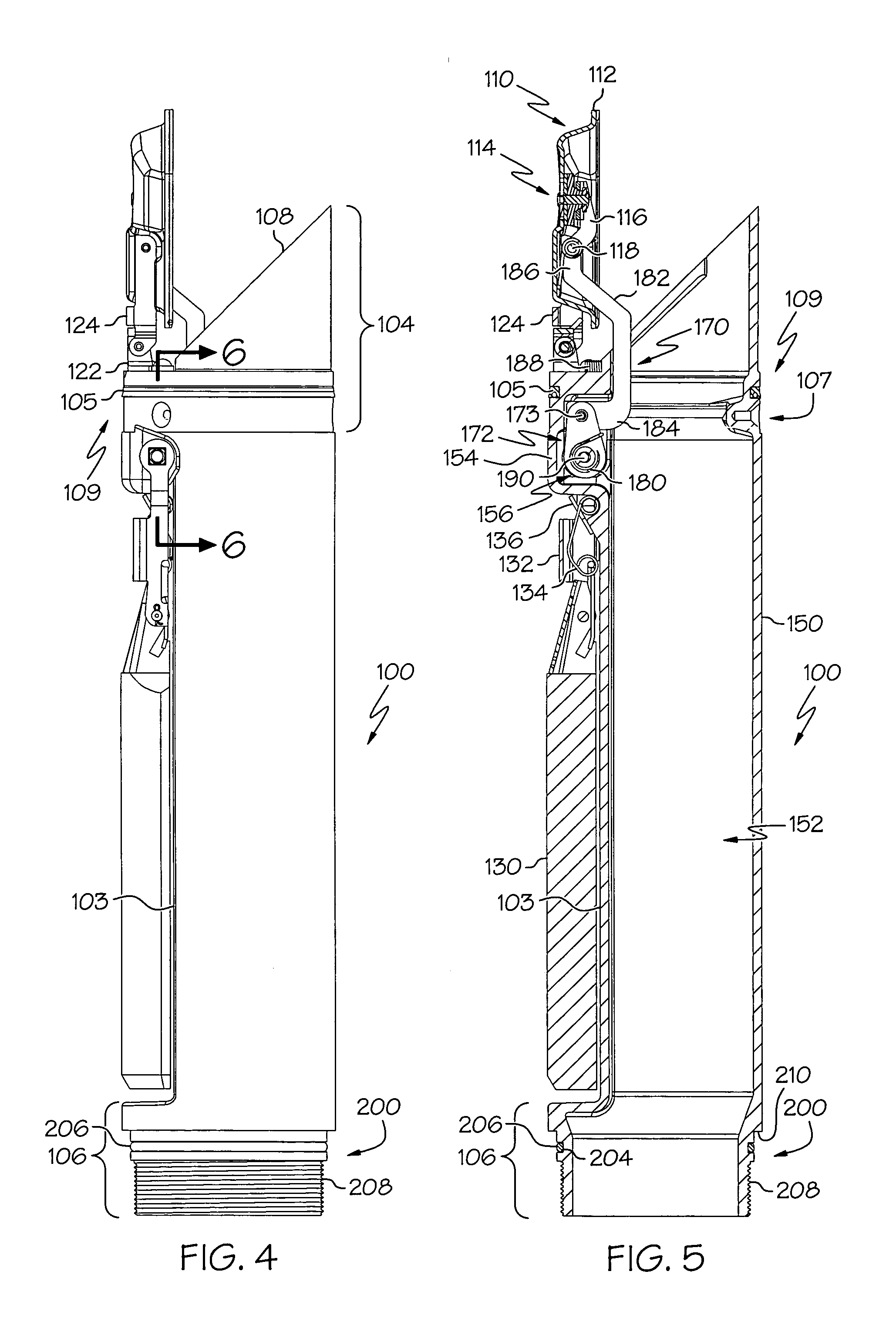

ActiveUS7128102B2Extensive curing timeEasy to adjust the positionOperating means/releasing devices for valvesCheck valvesEngineeringDrop tube

A drop tube segment includes a conduit with a first end portion and a second end portion. The drop tube segment further comprises a valve assembly with a valve member associated with the first end portion, a float, and a linkage device pivotally connected with respect to the valve member. The linkage device is adapted for communication with the float such that the float may facilitate in adjusting the position of the valve member with respect to the first end portion of the conduit in response to a liquid level in a liquid reservoir. The drop tube segment further includes a fastening section located at the second end portion of the conduit for fluid tight fastening with an end portion of another drop tube segment. The fastening section comprises a sealing surface and a threaded portion adapted for threaded engagement with a threaded portion of another drop tube segment. The drop tube segment still further includes a sealing member that engages the sealing surface of the fastening section and is adapted to engage a sealing surface of another drop tube segment.

Owner:OPW FUELING COMPONENTS LLC

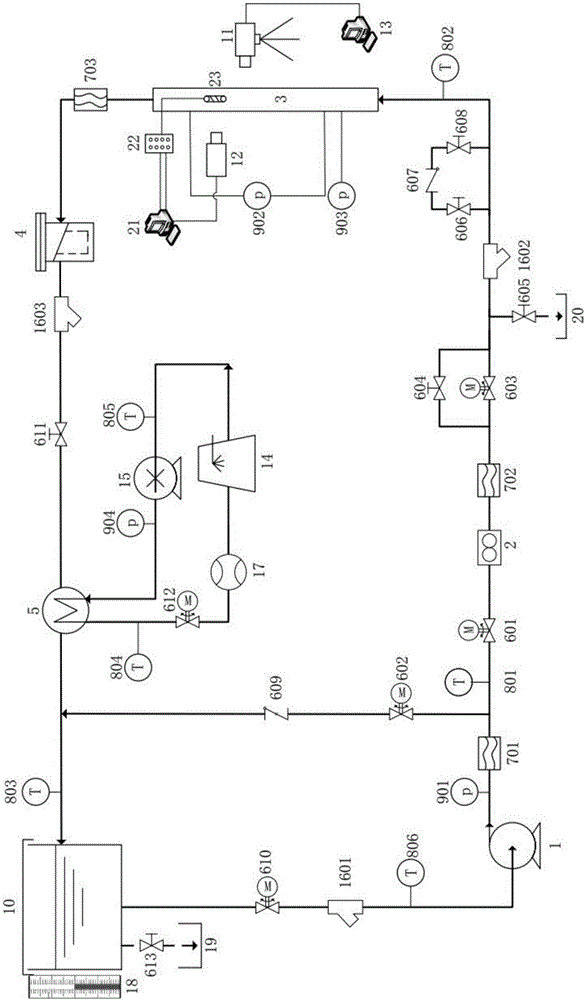

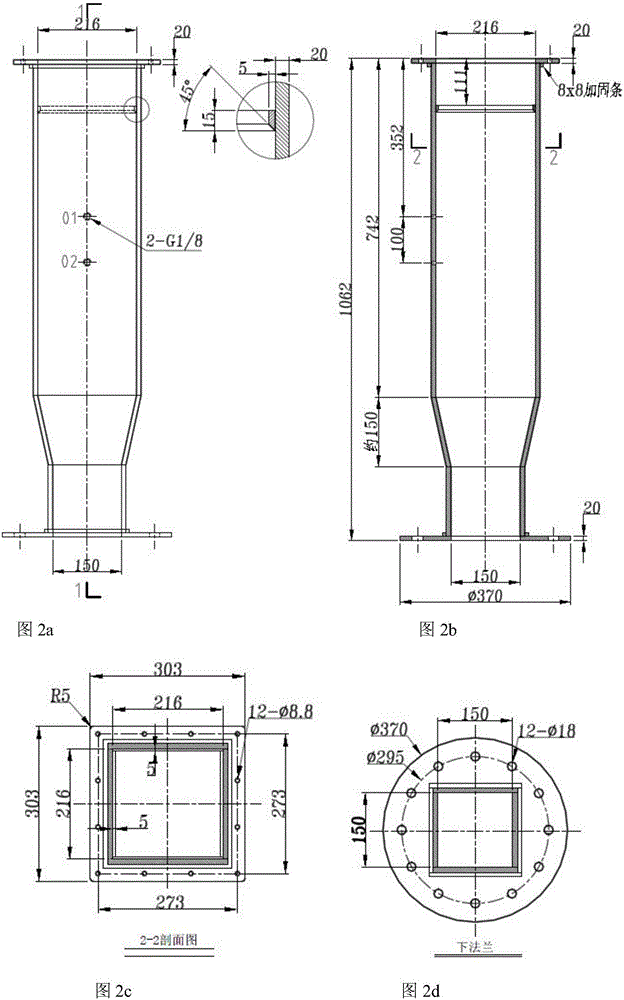

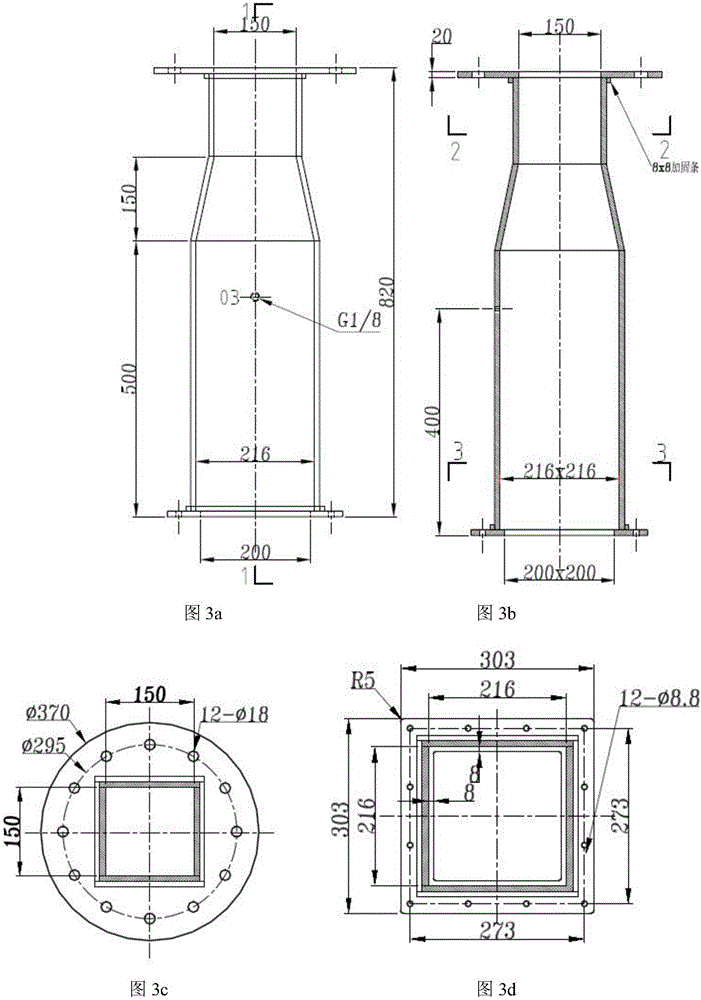

Nuclear reactor fuel assembly bottom nozzle hydraulic scouring test system and test method thereof

ActiveCN105938074AImplement testRealize evaluationInvestigating abrasion/wear resistanceStationary filtering element filtersForeign matterCooling tower

The invention relates to a nuclear reactor fuel assembly bottom nozzle hydraulic scouring test system and a test method thereof. The system comprises: a circulation system composed of a double suction pump and a closed loop pipeline; a test segment module composed of a foreign matter dropping tube segment, a test segment, a foreign matter collector and relevant devices; a flow field information acquisition module composed of a PIV device, flow field processing software and a local area network computer; an image acquisition module composed of a high speed camera and a local area network computer; an adjusting and monitoring module before pump, composed of a water tank, a filter, and relevant pipelines and meters; a cooling module composed of a cooling pump, a cooling tower, a condenser, a closed pipeline, a valve and a meter; and a remote control module composed of all electric valves, water pumps and relevant devices through a programmable logic controller. The invention also provides the test method of the system. The system and the method can meet needs of large-flow reactor bottom nozzle hydraulic scouring visual test researches, and also can realize simple and rapid adjustment of system parameters.

Owner:XI AN JIAOTONG UNIV

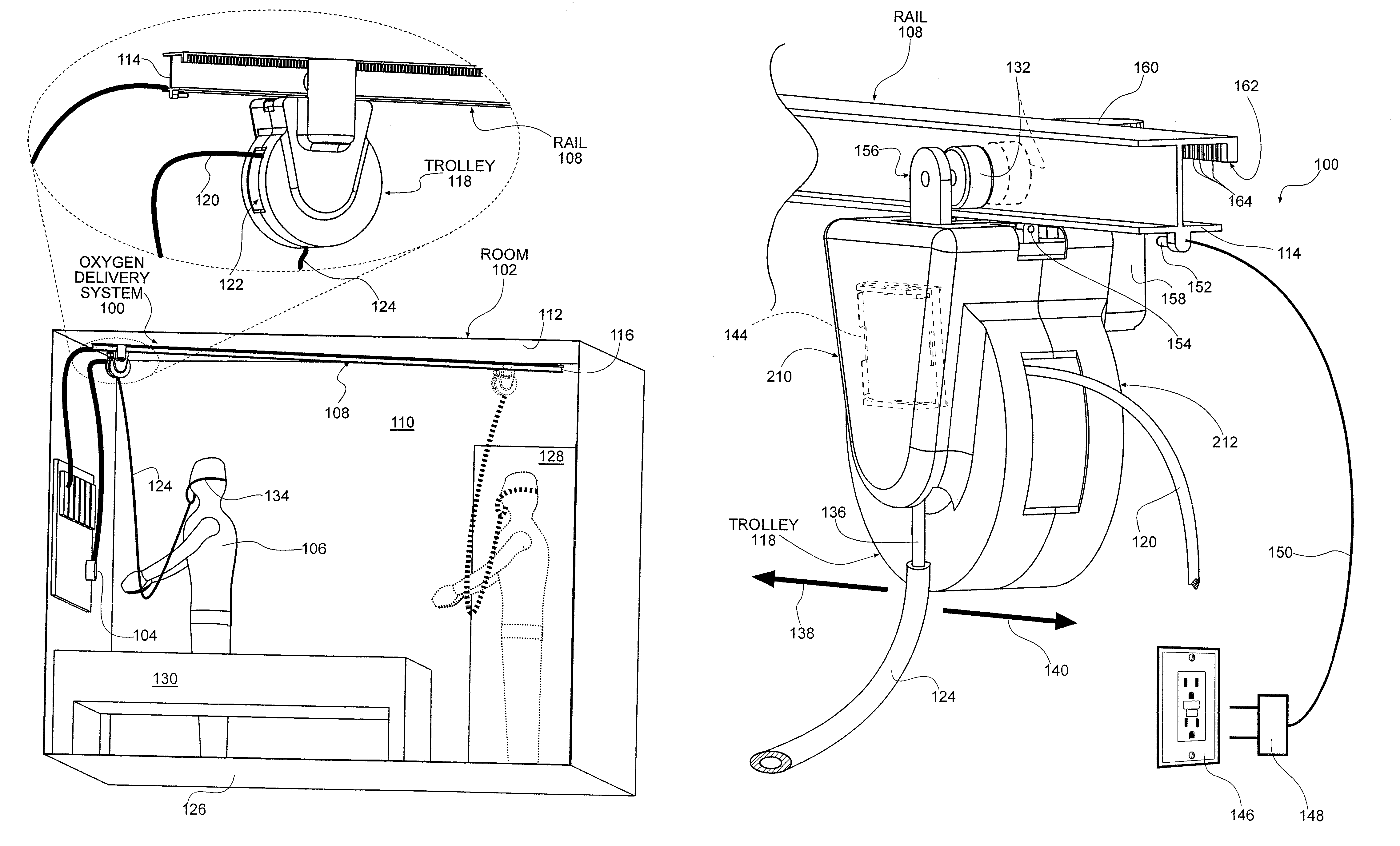

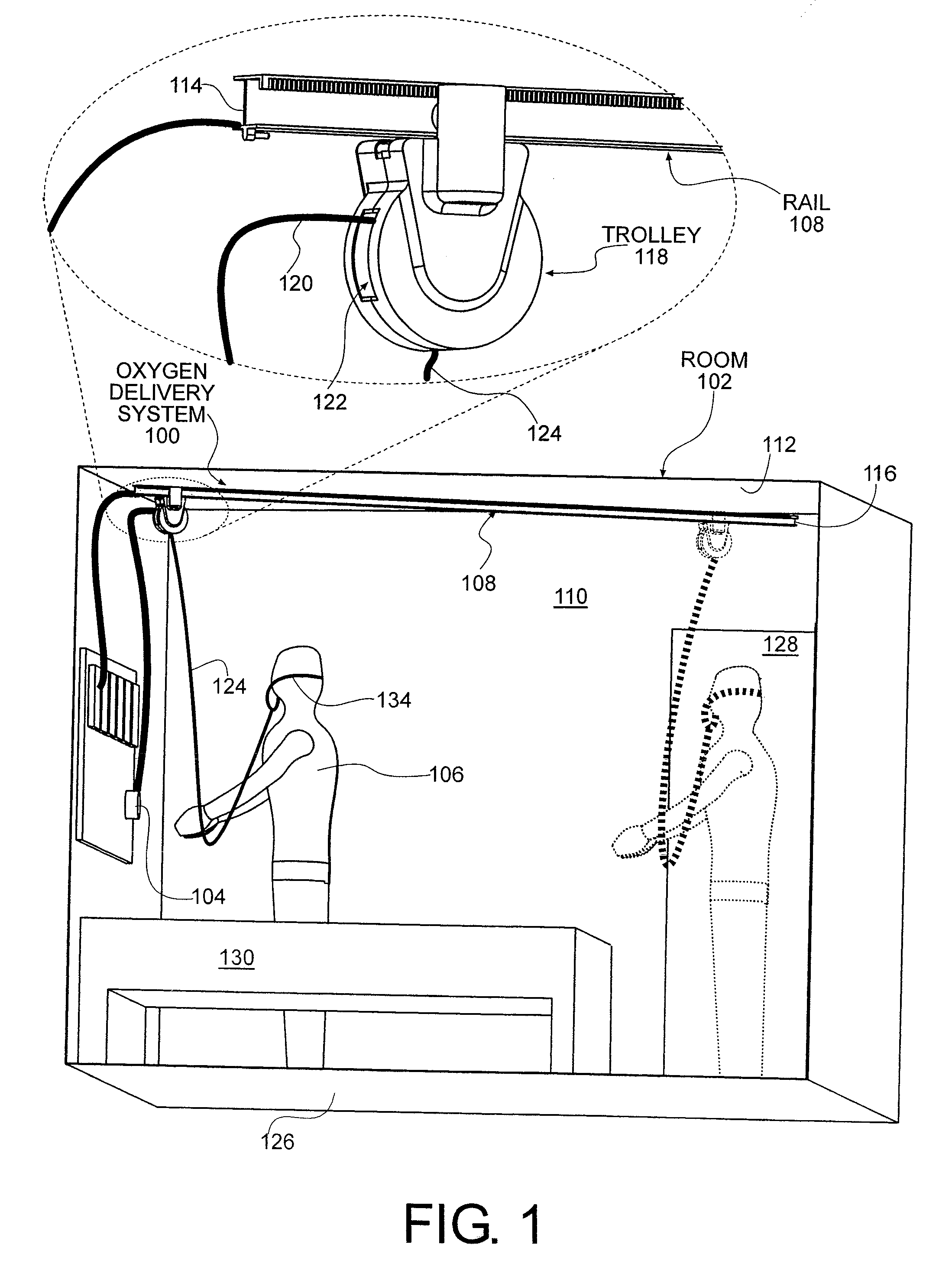

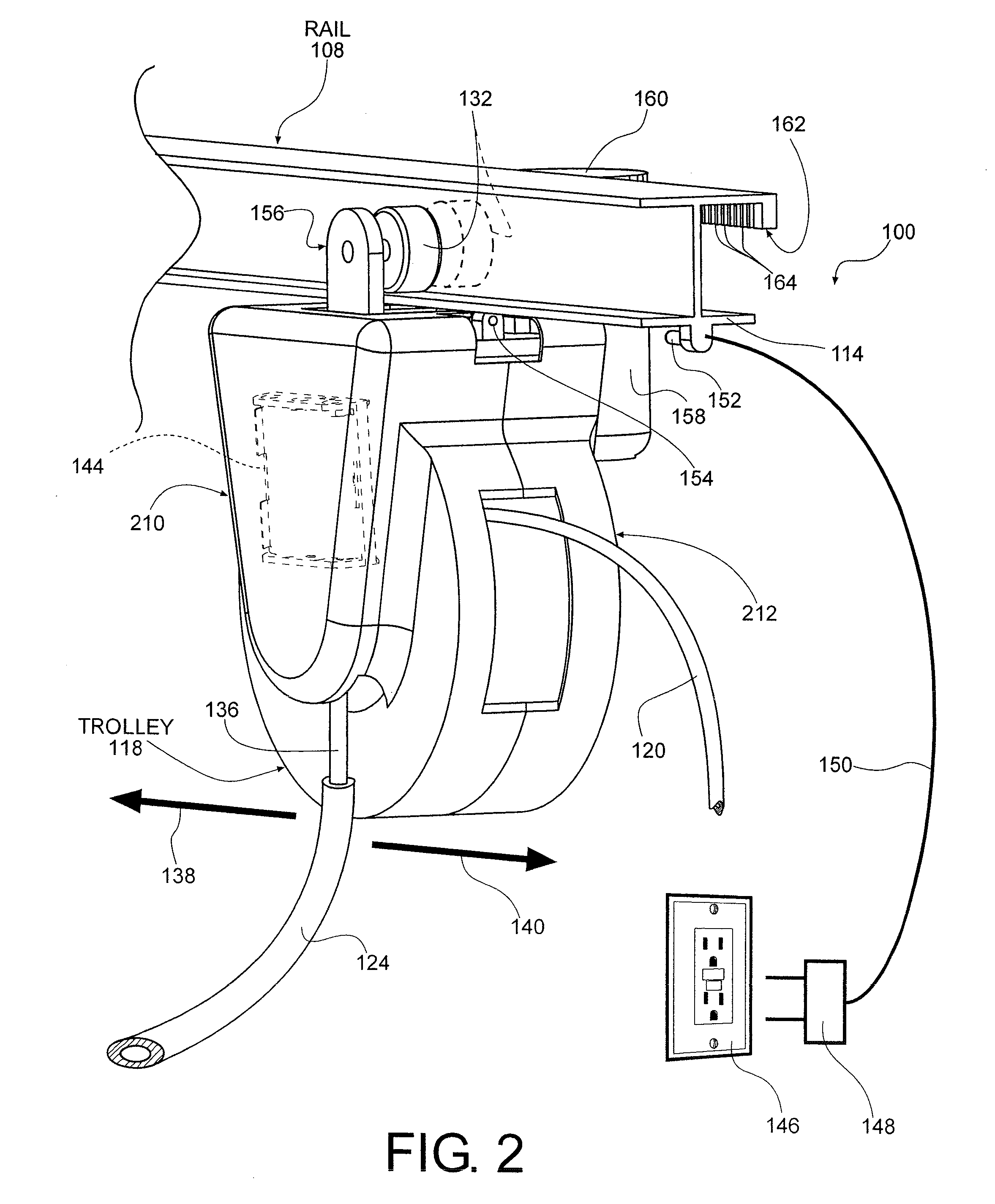

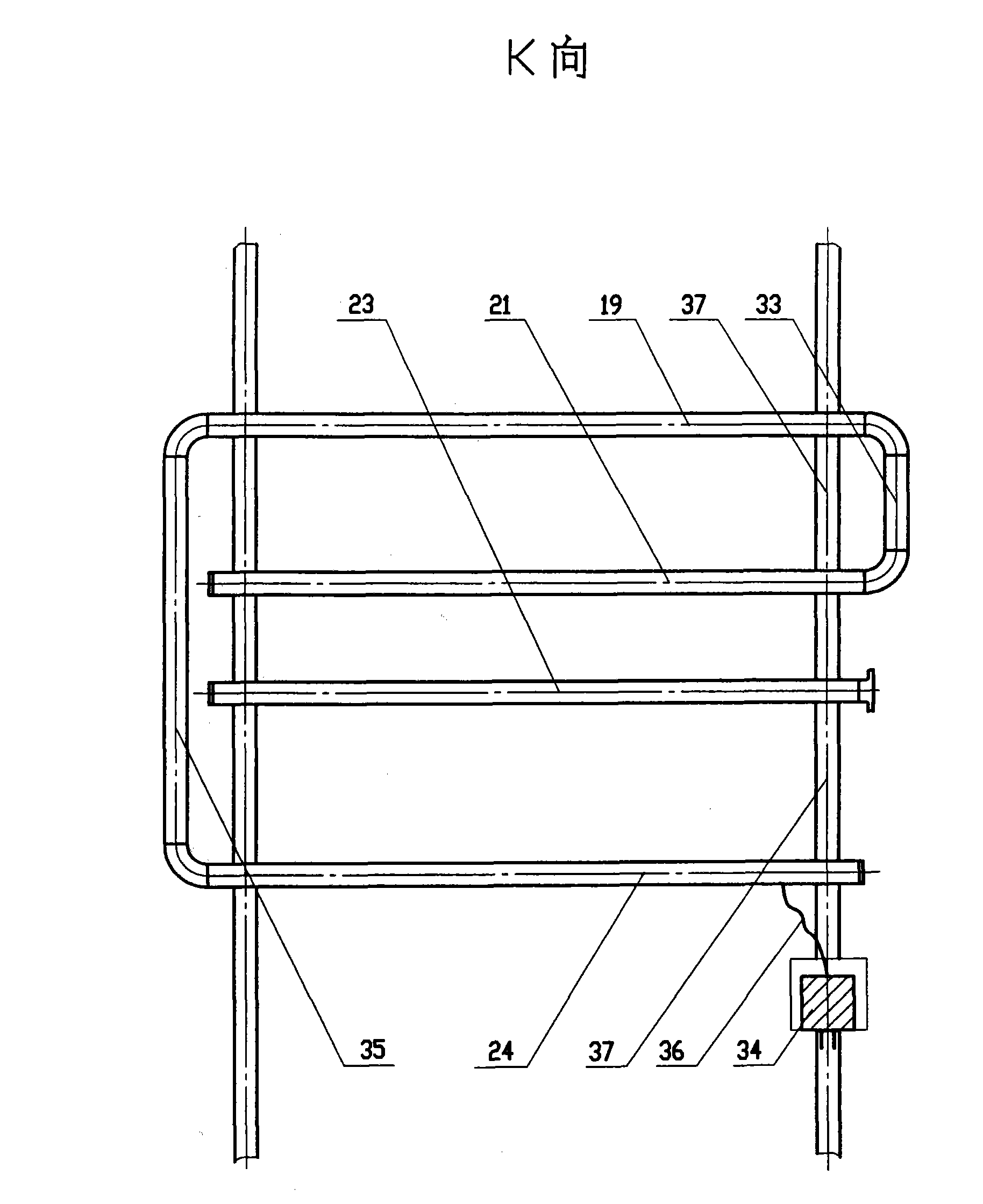

Oxygen delivery system

Disclosed are apparatus and method for delivering oxygen from an oxygen supply to a person in a convenient, sanitary and organized manner. The oxygen delivery system includes a rail attached to a surface of the room and a sliding trolley attached to the rail. An oxygen supply tube is attached to the oxygen supply and the trolley for transferring oxygen from the oxygen supply to the trolley. The system enables the person to move to various locations in the room while receiving oxygen from the oxygen supply through the oxygen supply tube, the trolley, a drop tube and a nasal cannula, or other breathing device connected to the trolley. The person may guide the trolley around the room by pulling the drop tube in the desired direction of travel.

Owner:SKOVGARD JOAN

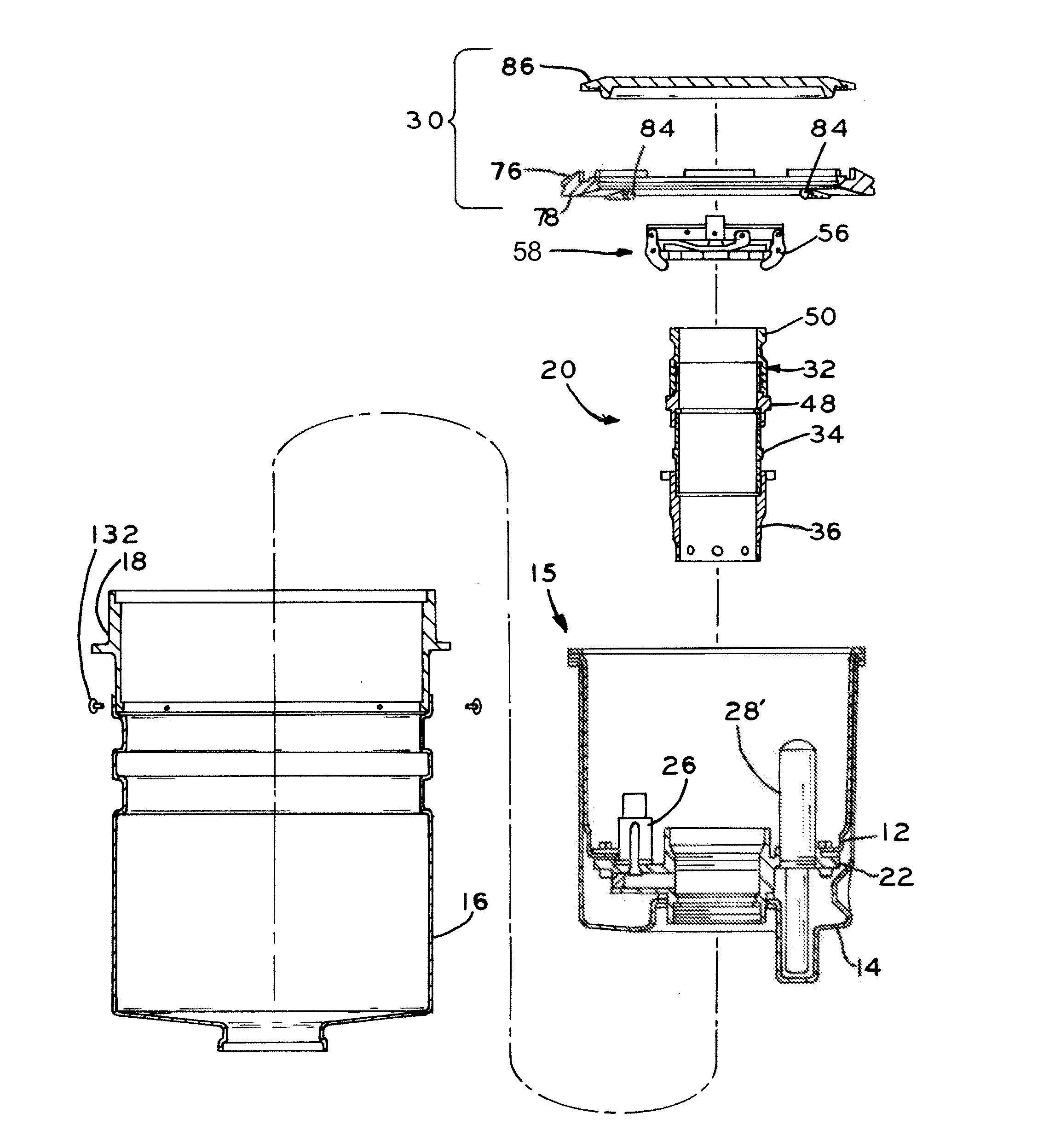

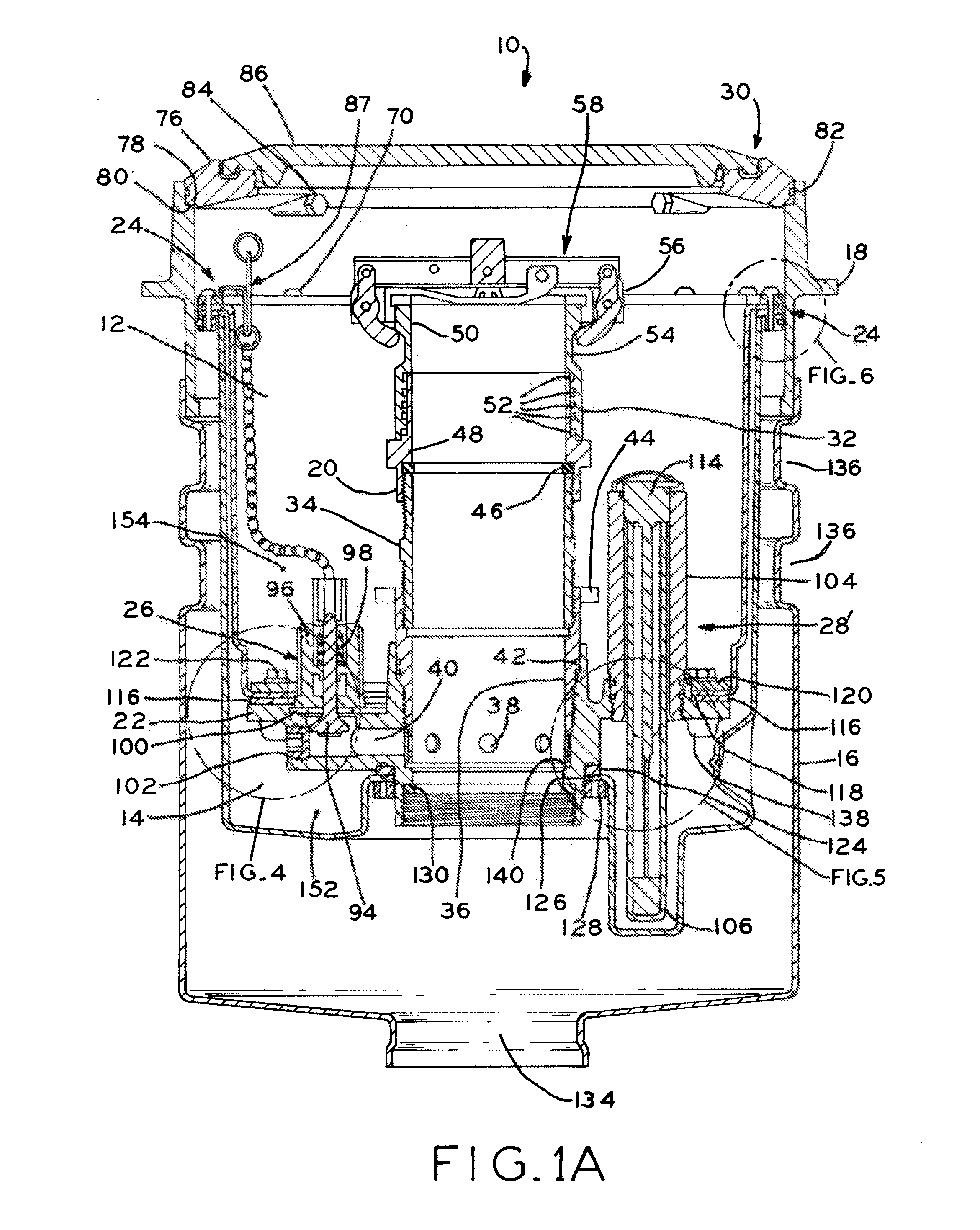

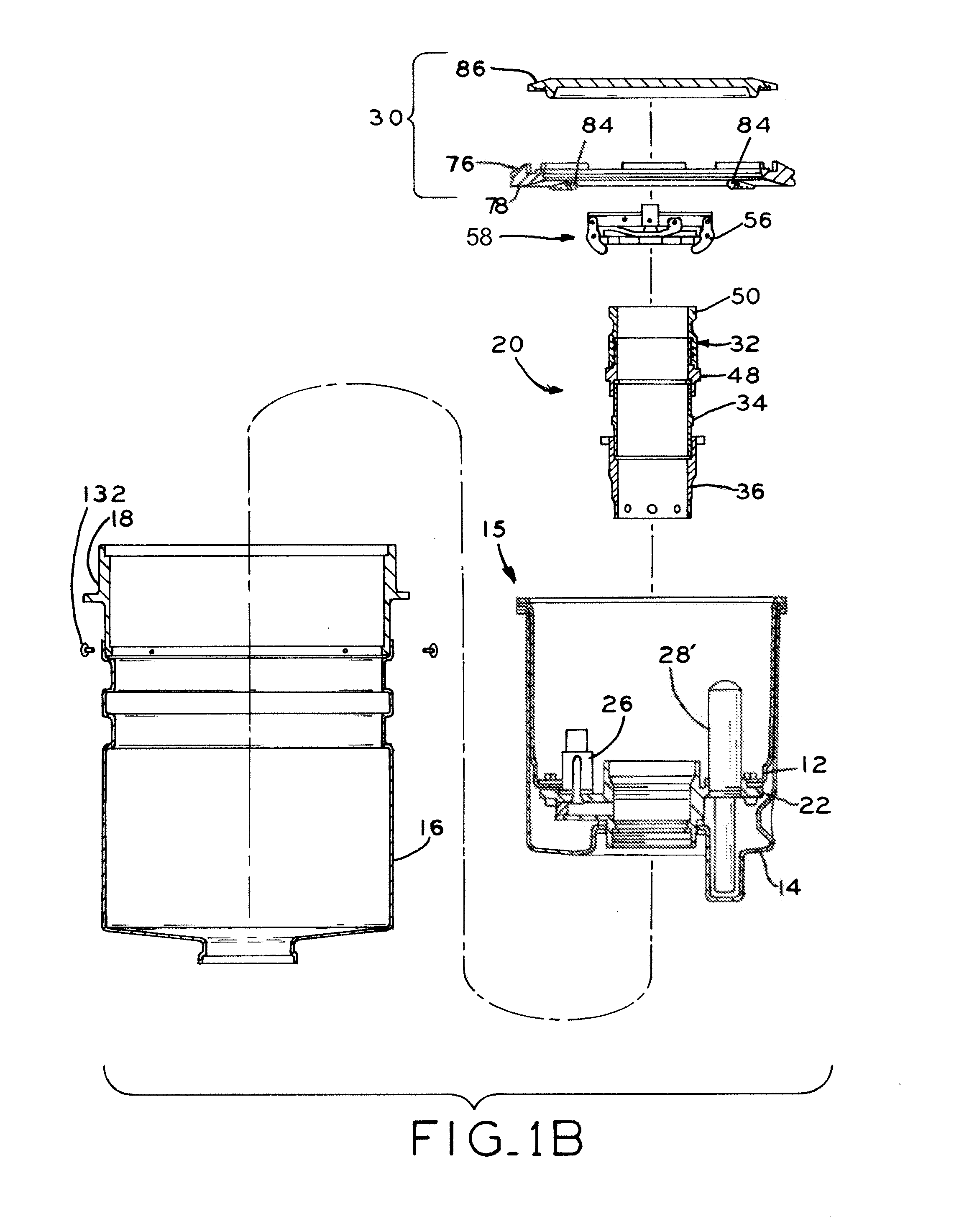

Poultry feeder

ActiveUS20080257270A1Extended range of motionPrecise positioningAnimal feeding devicesAnimal housingEffective heightEngineering

A poultry feeder is provided which can be selectively switched between a mode in which it operates as a flood-type feeder and a mode in which it operates as a shallow-fill type feeder with adjustable height pan walls. The feeder includes a feed tube assembly comprising a drop tube and a feed flooding tube. The drop tube is movable axially relative to the feed flooding tube, which rests on the feed pan. The drop tube and feed flooding tube have windows which are brought into and out of alignment by raising and lowering the drop tube. When the feed flooding tube window is opened, the feeder operates in a flood mode and when the feed flooding tube is closed, the feeder operates in a shallow-fill mode. In this second mode, the effective height of the pan wall can be adjusted to allow chicks and chickens access to the feed.

Owner:THE GSI GRP LLC

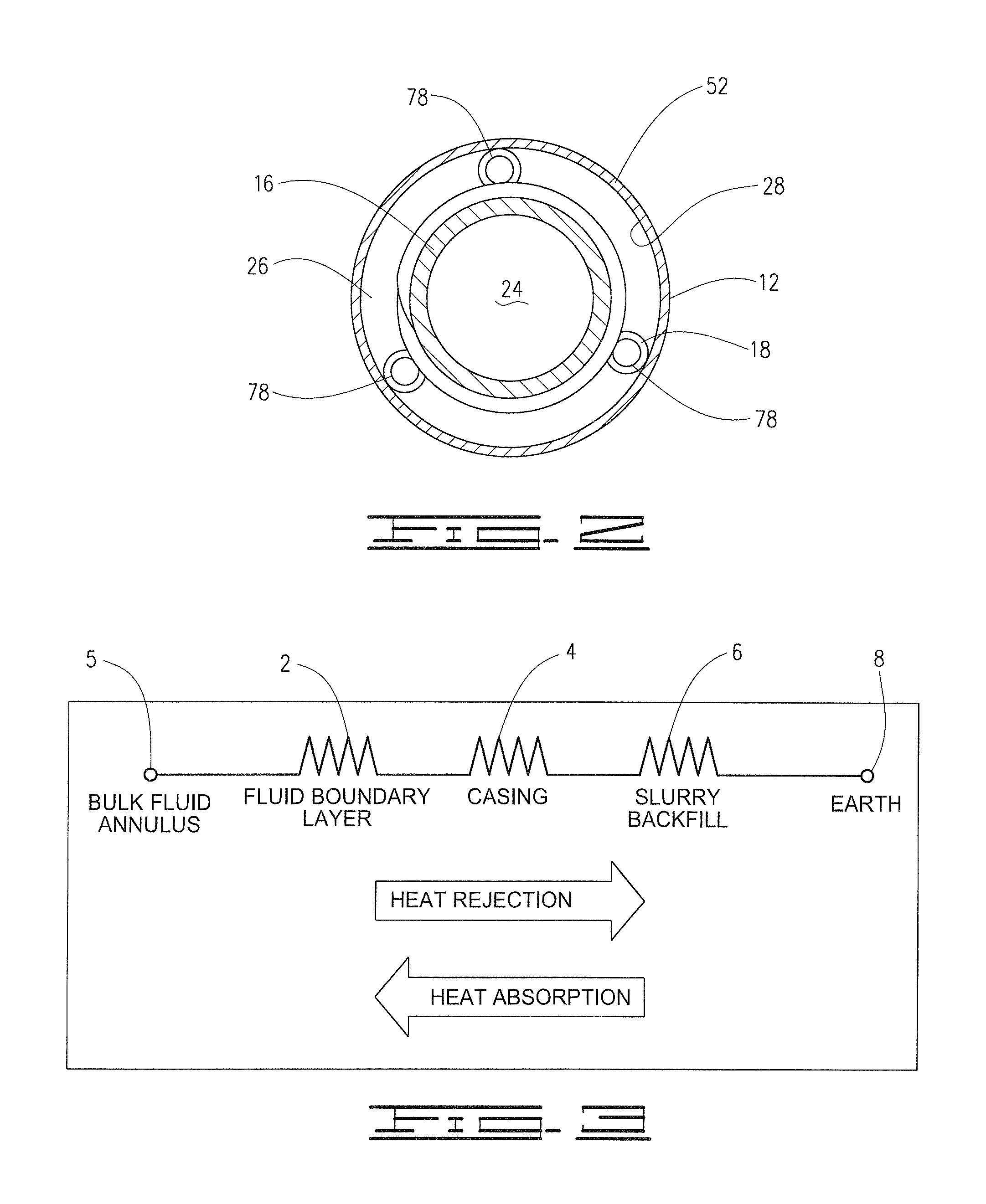

Method, apparatus, conduit, and composition for low thermal resistance ground heat exchange

ActiveUS9121630B1Minimize pressureMinimize transferSpacing meansGeothermal energy generationFiberGraphite

A method, apparatus, conduit, and composition for low thermal resistance ground heat exchange which preferably comprise, include, and / or use one or more of: a thin-walled, highly conductive filament wound conduit / casing formed using a thermosetting plastic composition containing a thermal conductivity enhancer; a grout backfill preferably including a sufficient amount of graphite, coke, or similar additive to provide a thermal conductivity of 3 Btu / hr-ft-° F. and higher; and a drop tube delivery conduit within the casing, the drop tube having radial exterior ribs which extend into the fluid return annulus formed between the interior wall of the casing and the exterior of the drop tube.

Owner:RYGAN CORP

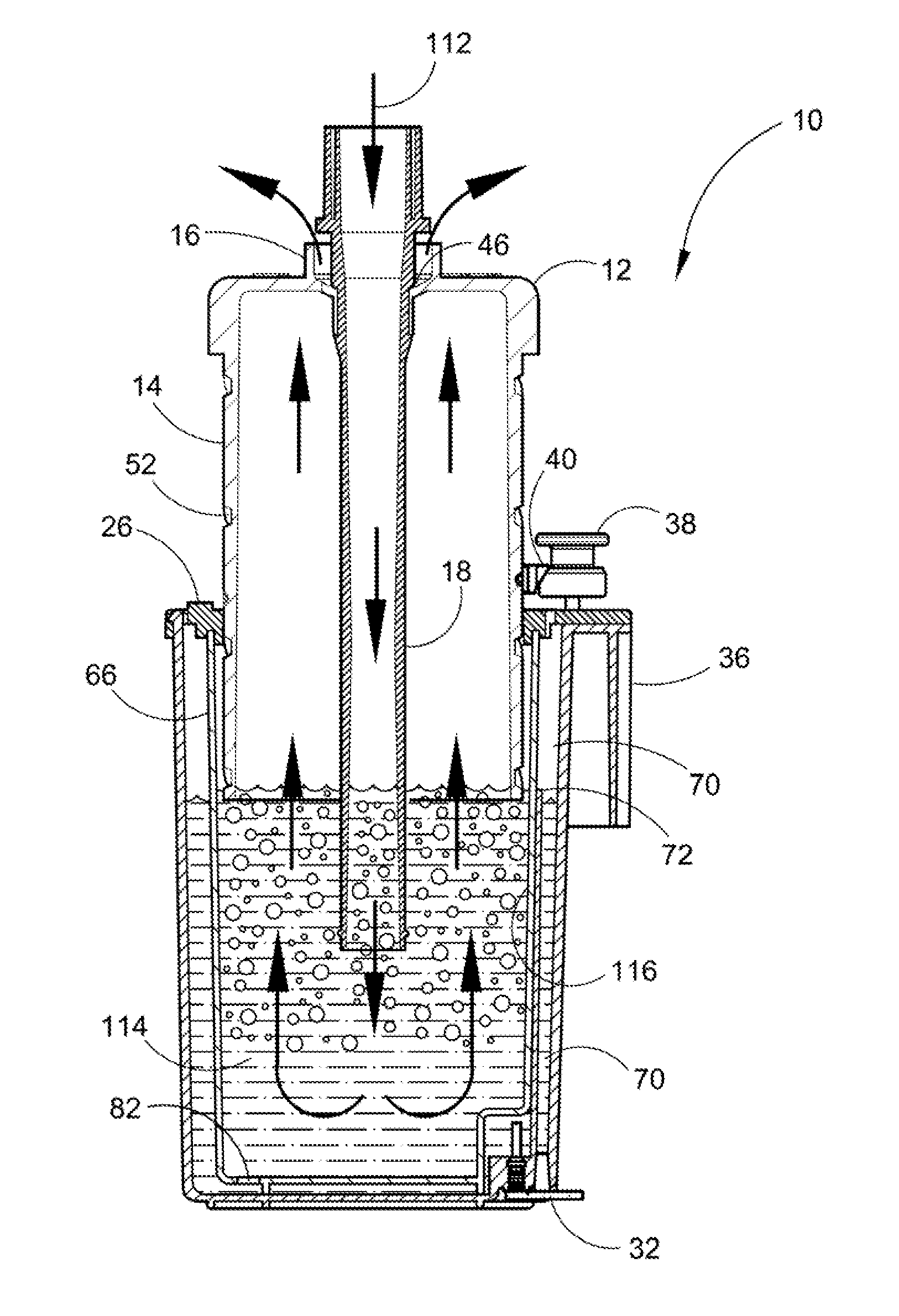

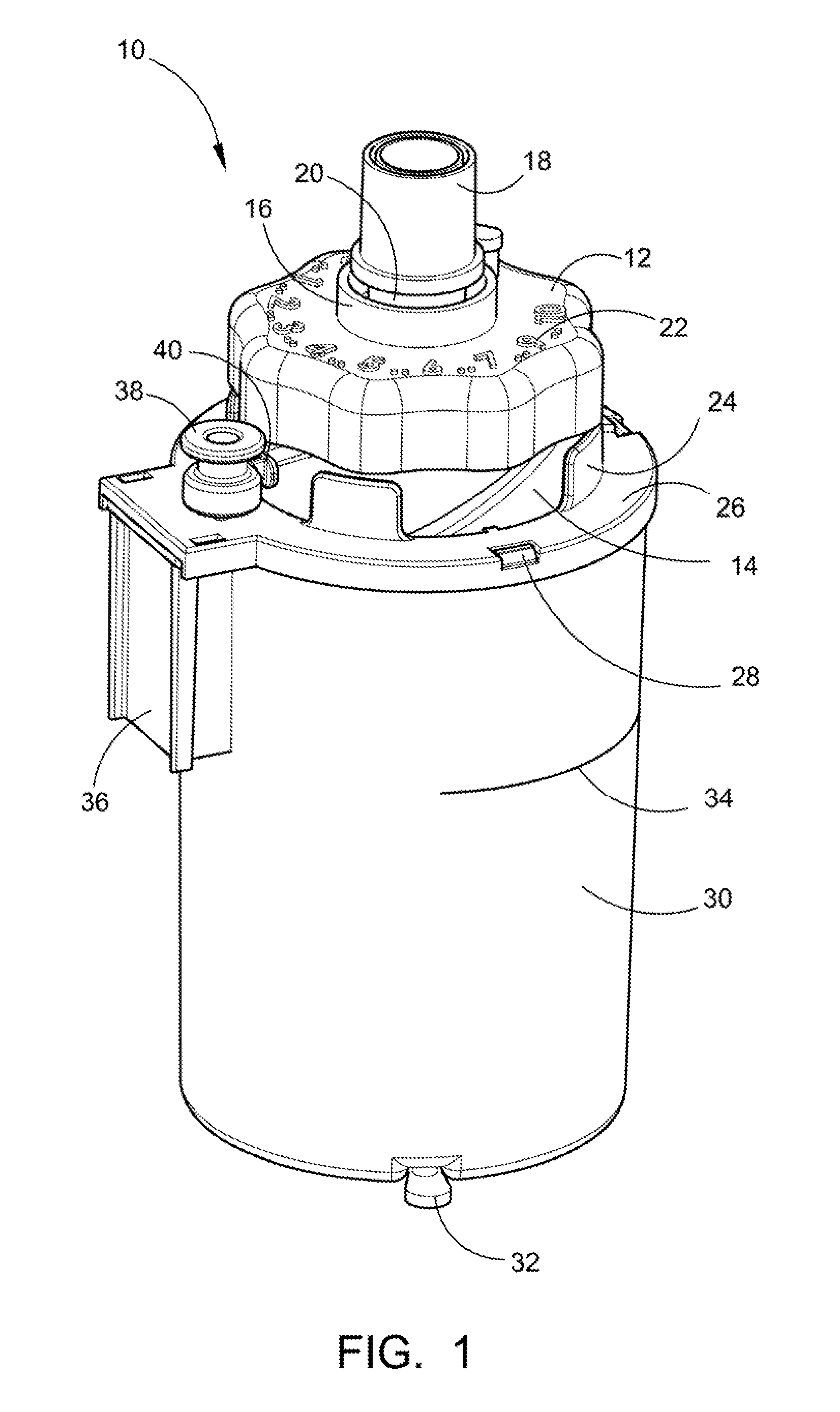

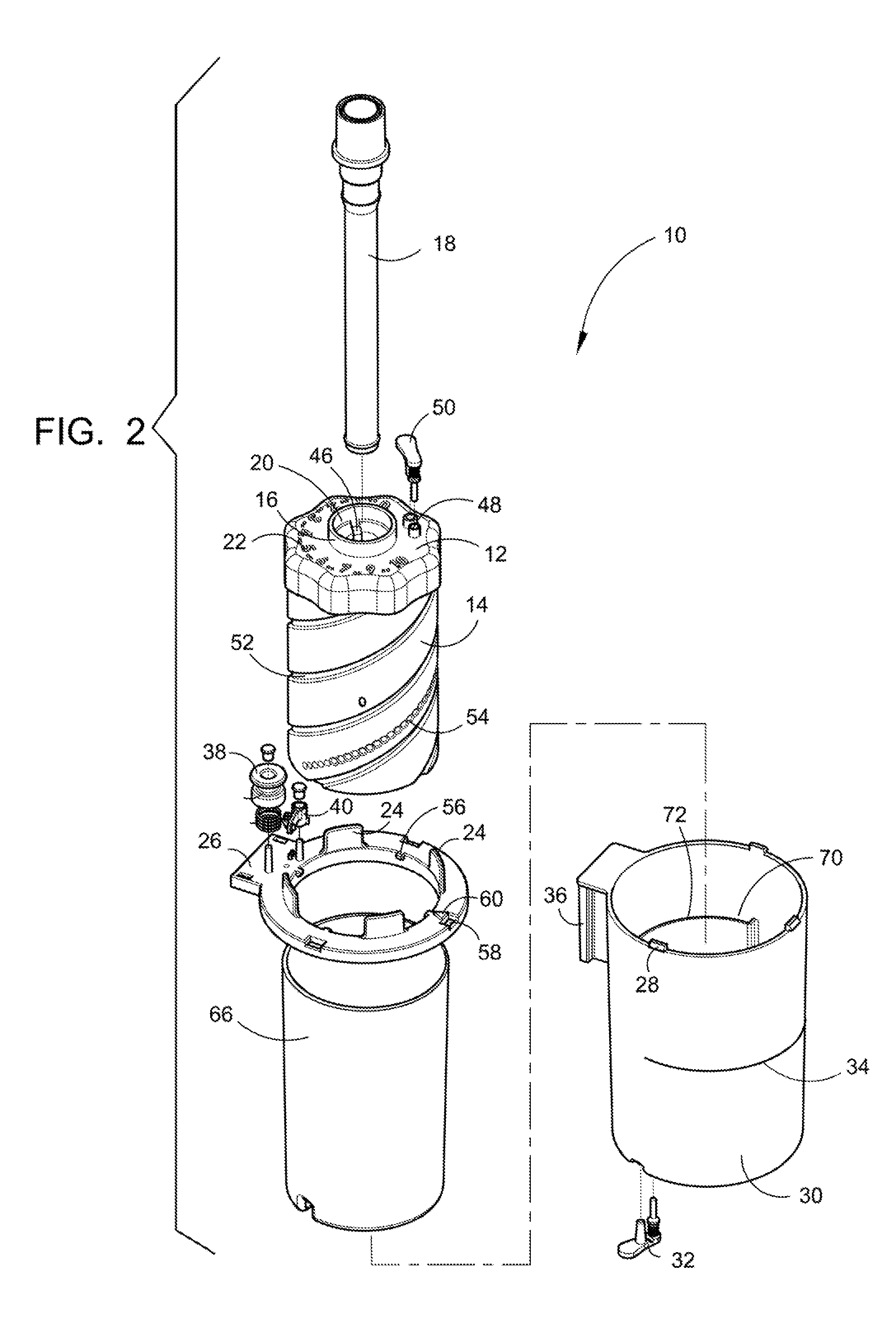

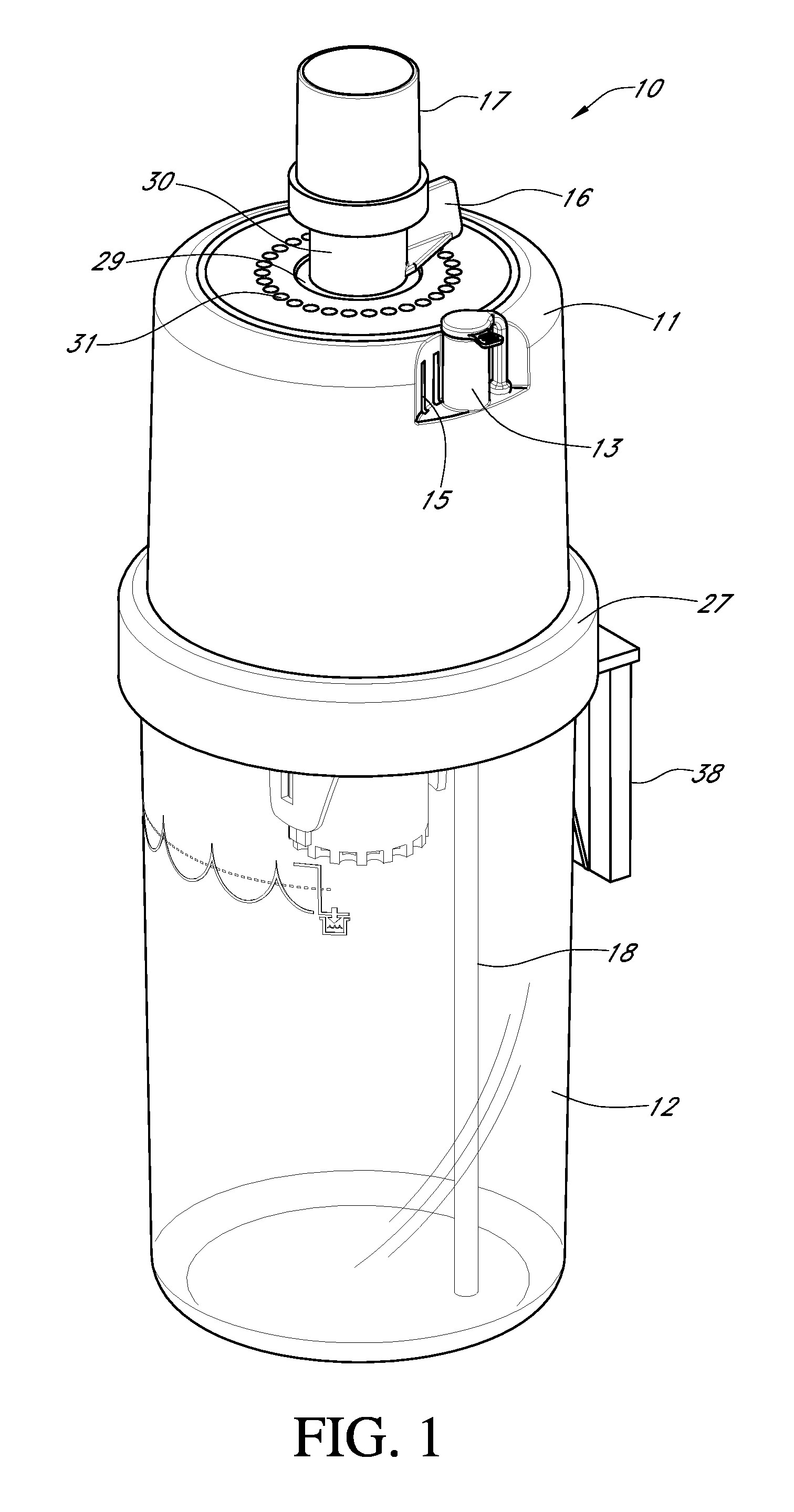

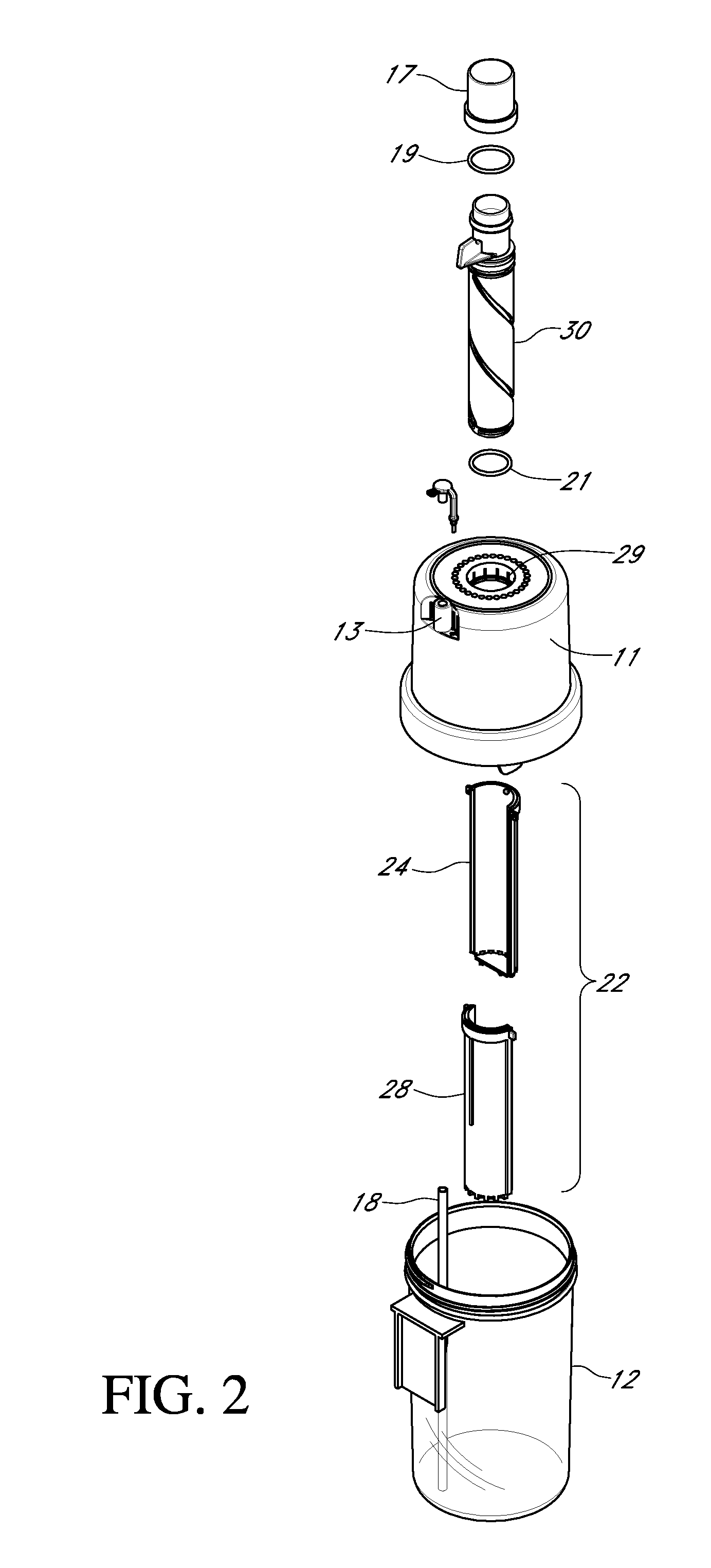

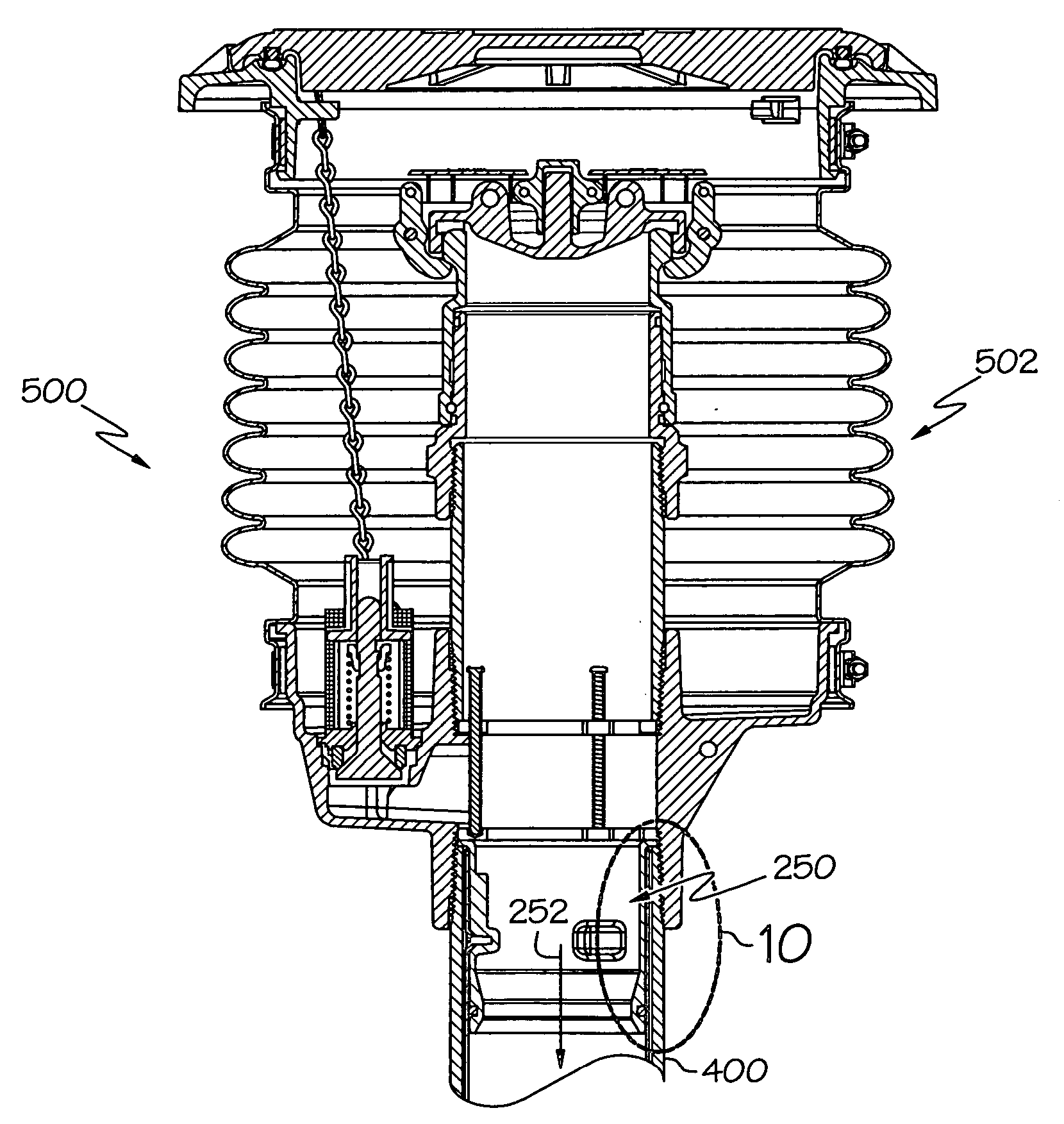

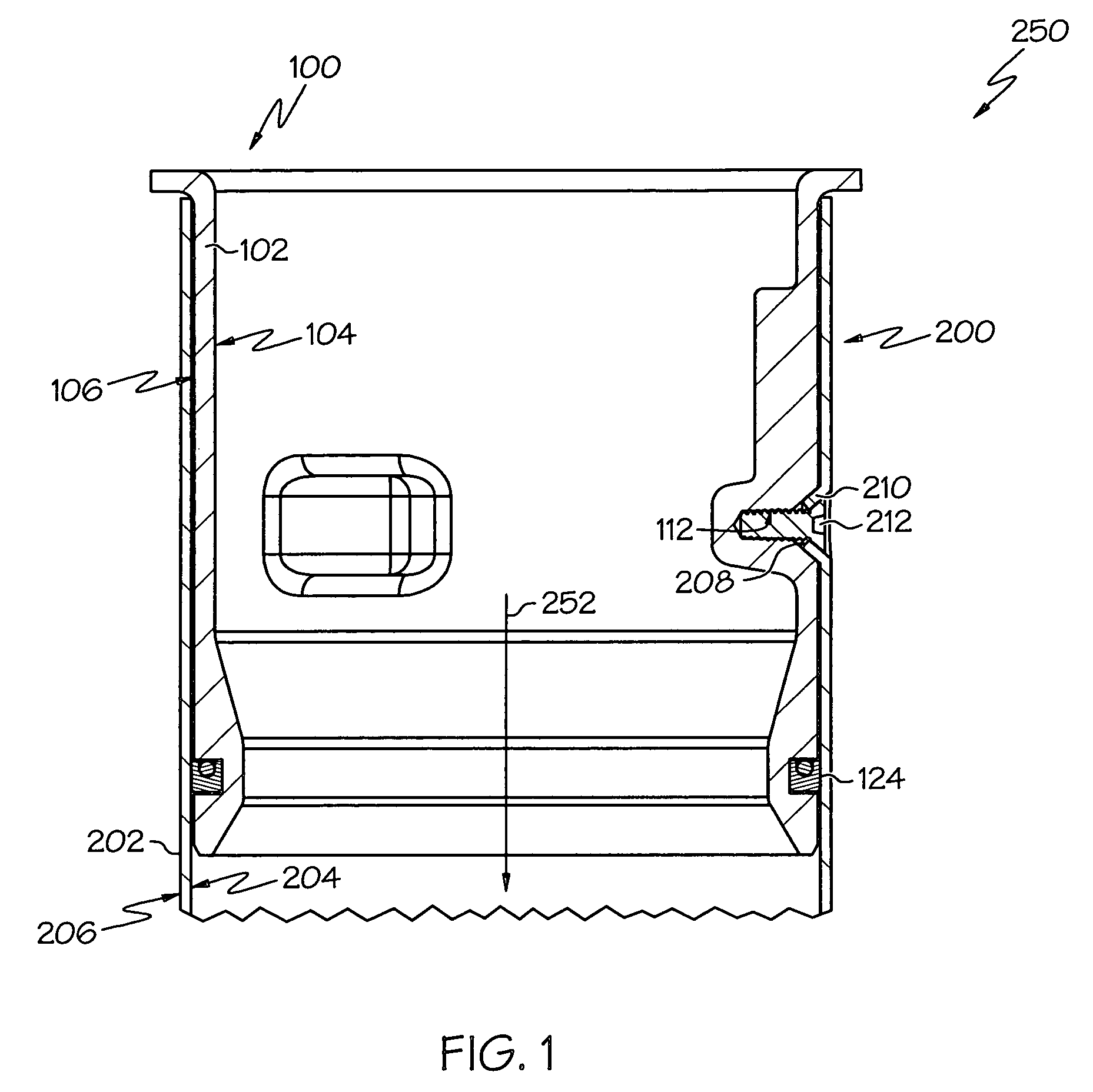

Continuous positive airway pressure device

ActiveUS20140166013A1Avoid accidental movementEasy to installRespiratorsMedical devicesPositive airway pressurePositive pressure

The present invention is directed to a Continuous Positive Airway Pressure Device as an apparatus configured to provide positive airway pressure in a respiratory circuit that comprises a container configured to be filled to a preselected level with liquids; a drop tube assembly comprising a hollow gas tube rotatably mounted in said container having an upper end extending a static distance outwardly of the container and connected to a respiratory circuit downstream of a user, and a hollow drop tube reciprocally movable upwardly and downwardly in the liquid in response to rotational movement of the gas tube. The container is provided with a gas vent and a liquid fill port.

Owner:S&T MEDICAL TECH

Bubble continuous positive airway pressure device

ActiveUS9108008B2Easy to adjustLarge dialRespiratorsMedical devicesPositive pressurePositive airway pressure device

The present invention is directed to a Continuous Positive Airway Pressure Device as an apparatus configured to provide positive airway pressure in a respiratory circuit that comprises a container configured to be filled to a preselected level with liquids; a drop tube assembly comprising a hollow gas tube rotatably mounted in said container having an upper end extending a static distance outwardly of the container and connected to a respiratory circuit downstream of a user, and a hollow drop tube reciprocally movable upwardly and downwardly in the liquid in response to rotational movement of the gas tube. The container is provided with a gas vent and a liquid fill port.

Owner:S&T MEDICAL TECH

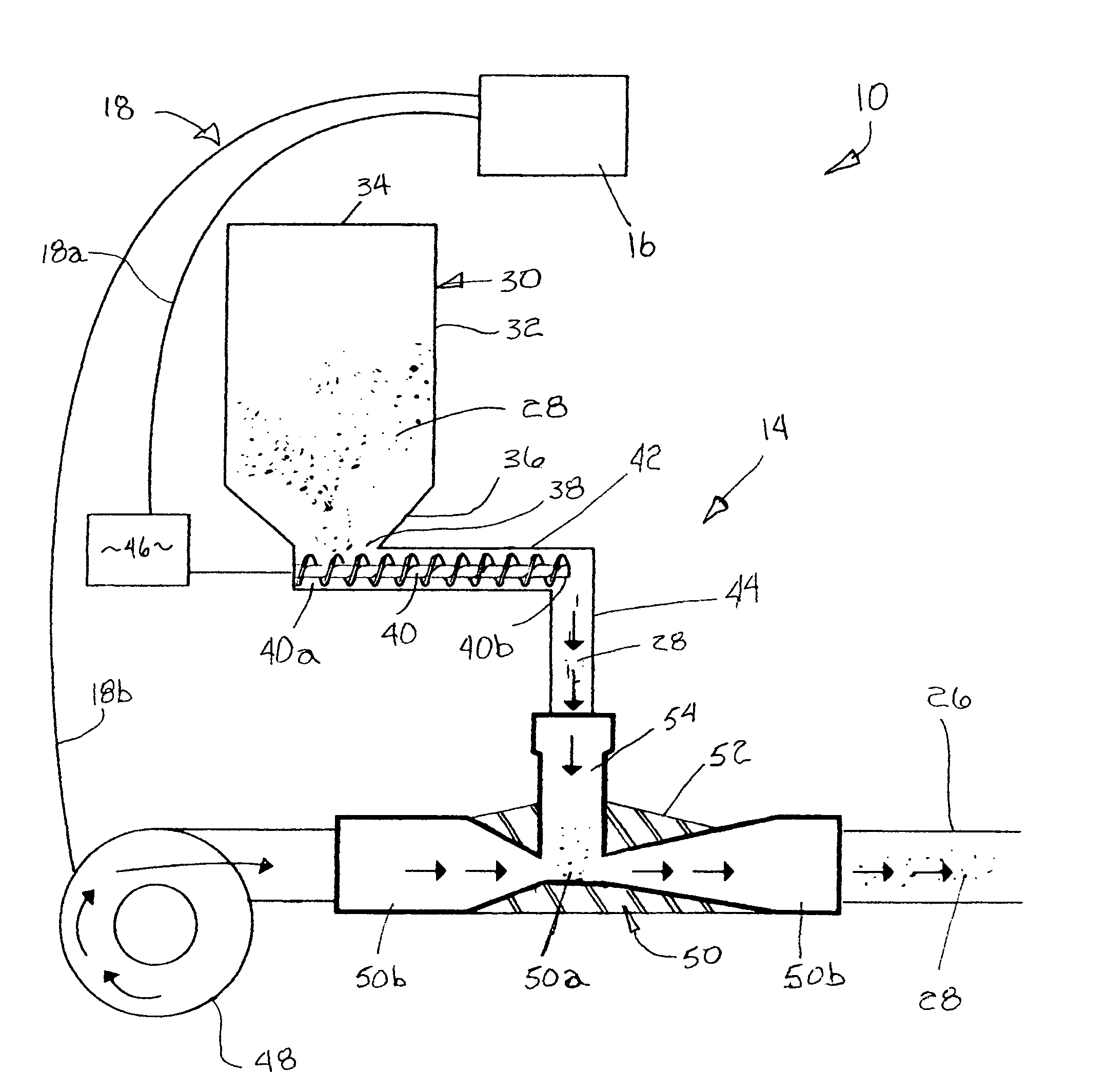

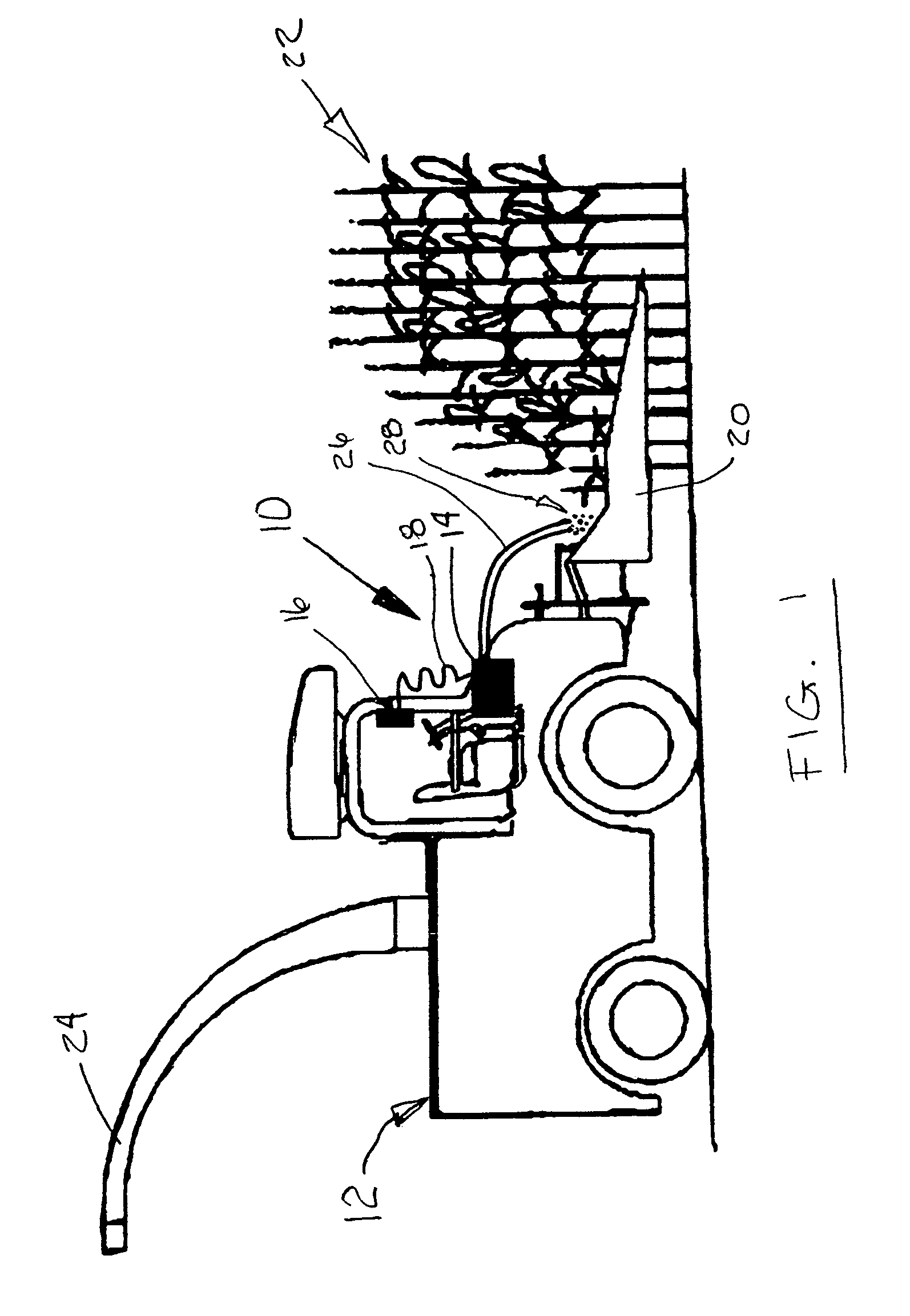

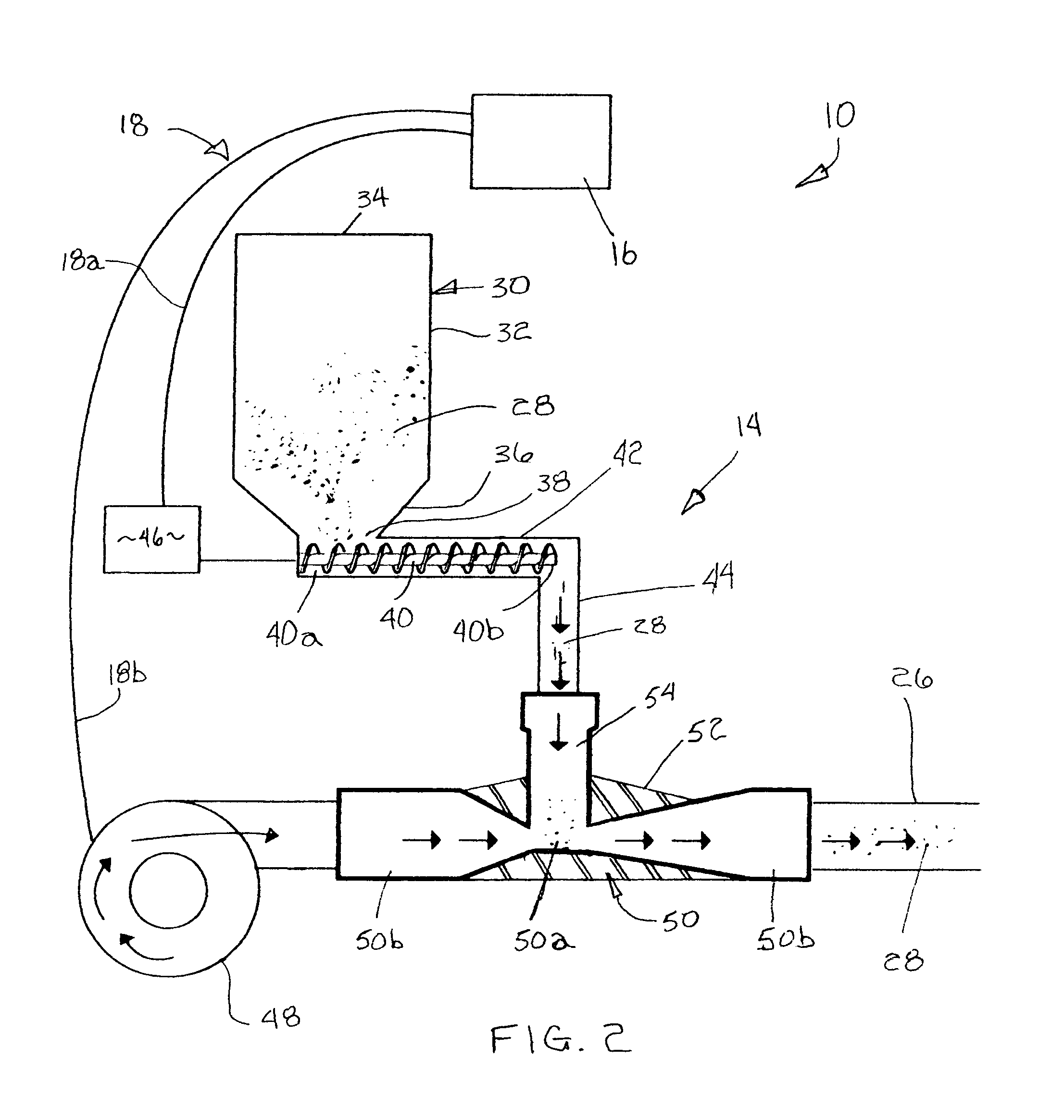

Apparatus and method for applying dry inoculant to forage material

A dry inoculant dispenser includes a hopper with dry inoculant therein, and a conveyor for carrying dry product to a vertical drop tube. The drop tube is connected to a dispenser tube that will direct the inoculant to the forage material. A flow of air is created in the dispenser tube to carry inoculant therethrough, and a vacuum is created in the drop tube such that dry inoculant within the drop tube is sucked into the dispenser tube and dispensed from the distal end thereof.

Owner:KREIKEMEIER KELLY

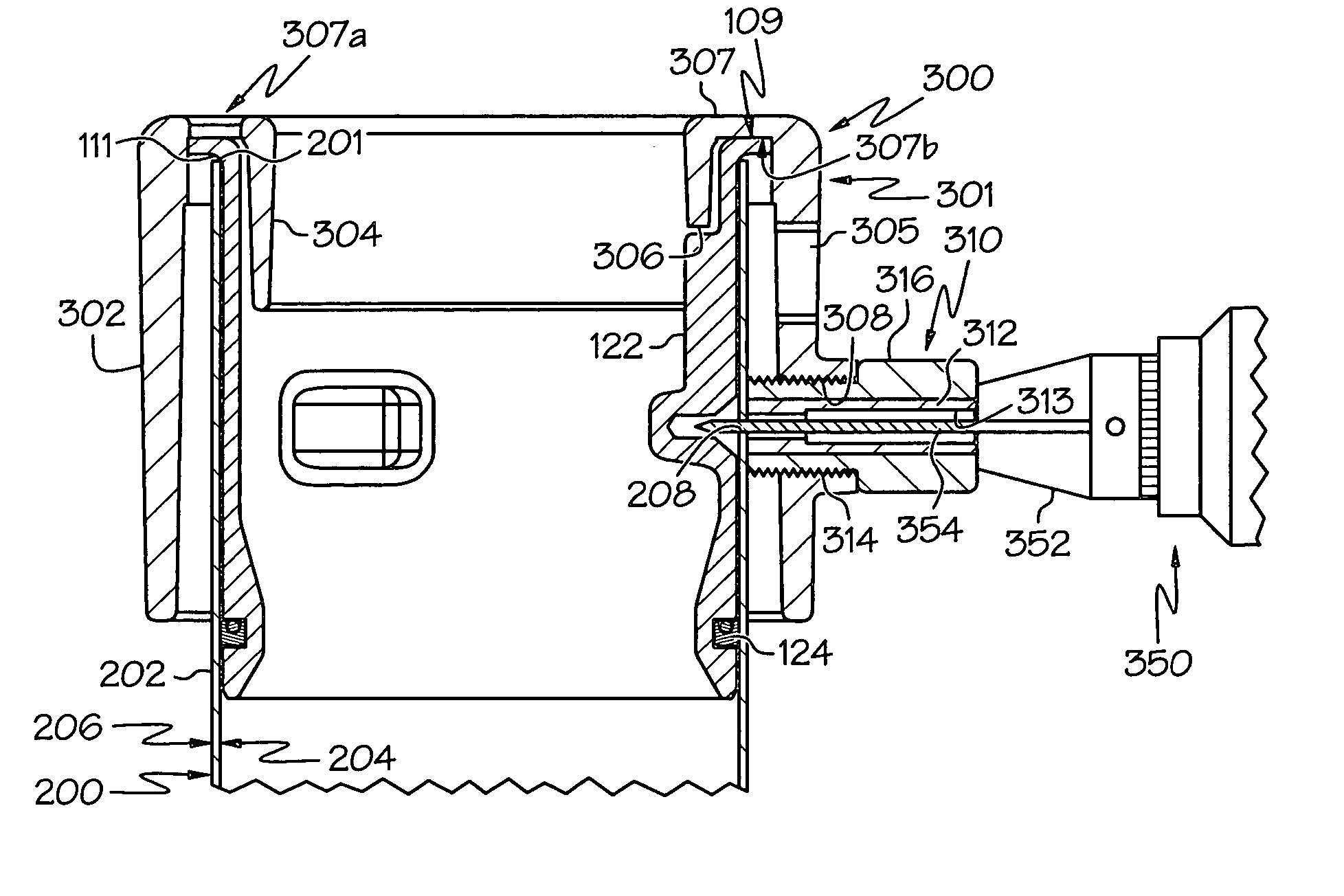

Spill containment system

ActiveUS20110089071A1Avoid replacementLarge containersLiquid transferring devicesControl systemEngineering

A spill containment system is attachable to a riser pipe with an axially moveable seal. The spill containment system allows access to a drop tube in the riser pipe via a removable liquid communication assembly. The spill containment system includes a sealed interstitial space, which remains sealed during installation, service and use of the system. The spill containment system is protected by a weather resistant cover assembly.

Owner:FRANKLIN FUELING SYST

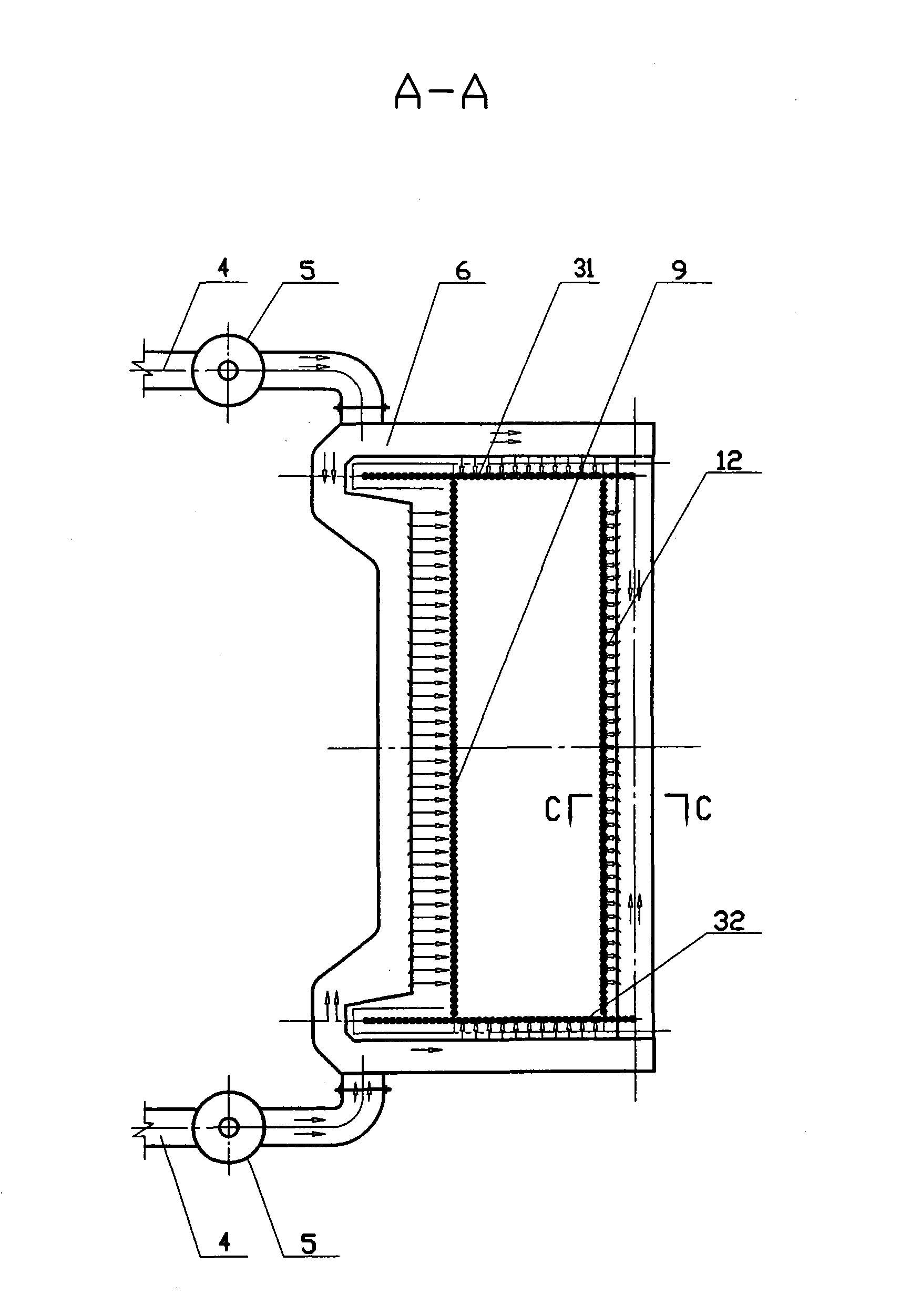

High temperature and high dusty burner gas quencher

The invention provides a high temperature and high dusty burner gas quencher which relates to a novel heat exchanger and is an important device for recovering afterheat of high temperature and high dusty burner gas from various industrial stoves. The body structure of the quencher includes a double-sleeve water / steam natural circulation primary cooling structure and a tube casing air secondary cooling structure, wherein double sleeves are respectively connected with two opposite elliptic tube plates to form a waist-shaped collecting tube box together with expansion sections, integral enhanced rings, inner linings and the like. A layer of cobalt fire-resistant casting materials is covered on the elliptic tube plates connected with inner tubes, and the inner tubes of the double sleeves are provided with fire and abrasion resistant inner lining sleeves on tube ends. The body of the quencher is connected with steam pockets through an ascending tube and a descending tube to form a water / steam natural circulation system.

Owner:NANJING UNIV OF TECH +1

Positive airway pressure apparatus

An apparatus configured to provide positive airway pressure in a respiratory circuit comprises a container configured to be filled to a preselected level with liquids; a drop tube assembly comprising a hollow gas tube rotatably mounted in said container having an upper end extending a static distance outwardly of the container and connected to a respiratory circuit downstream of a user, and a hollow drop tube reciprocally movable upwardly and downwardly in the liquid in response to rotational movement of the gas tube. The container is provided with a gas vent and a liquid fill port.

Owner:GALEMED

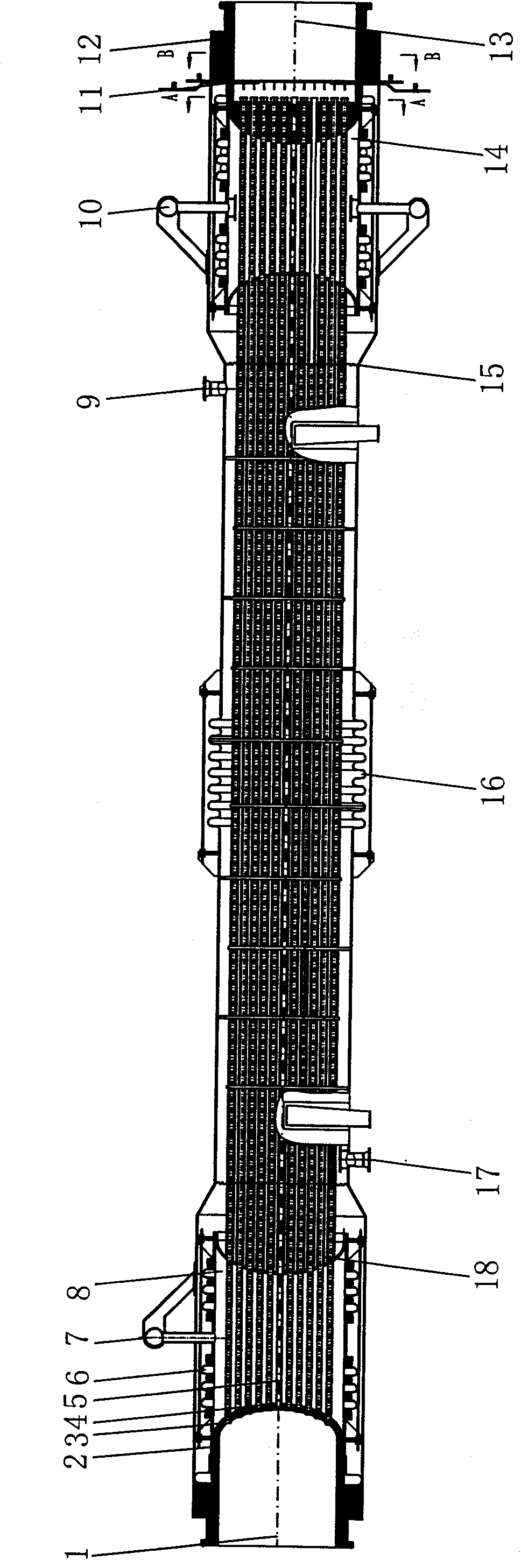

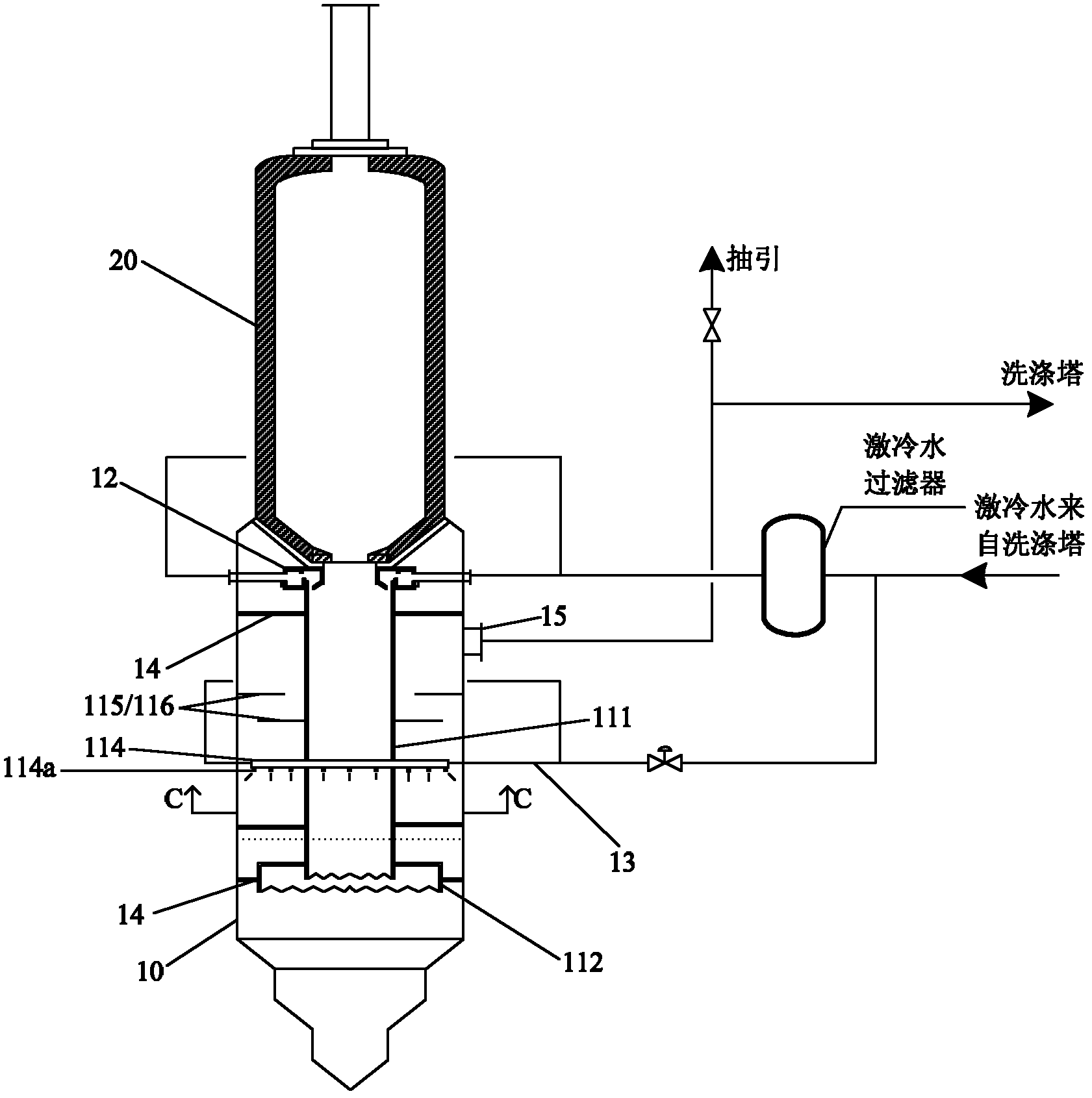

Chilling process gasifier with high-temperature heat recovery unit

InactiveCN104629807AMeet the requirements of the transformationApplicableEnergy inputCombined combustion mitigationCombustion chamberCooling chamber

The invention discloses a chilling process gasifier with a high-temperature heat recovery unit, which comprises an upper gasification / combustion chamber, a middle radiation waste pot with high-temperature heat recovery function and a bottom washing and cooling chamber, wherein the top of the gasification / combustion chamber furnace body or a certain plane on the periphery of the furnace body or a plurality of planes is / are provided with one or a plurality of nozzles; the radiation waste pot is composed of a flange connected with the gasification / combustion chamber, an interface water cooling coil pipe, a single-channel water cooling wall, a water cooling coil pipe connected with the washing and cooling chamber, and the like; the washing and cooling chamber is mainly composed of a chilling water ring and a down pipe; and the upper part of the side surface of the washing and cooling chamber is provided with a synthetic gas outlet. The chilling process gasifier can enhance the adaptability to coal types, effectively recovers the high-position sensible heat of the gasification product, and is suitable for a process unit for preparing synthetic gas and an integral coal gasification combined cycle generation system. Compared with the traditional waste-pot process gasifier, the chilling process gasifier is simpler in structure and convenient for manufacturing and maintenance, and has higher popularization and application values.

Owner:EAST CHINA UNIV OF SCI & TECH

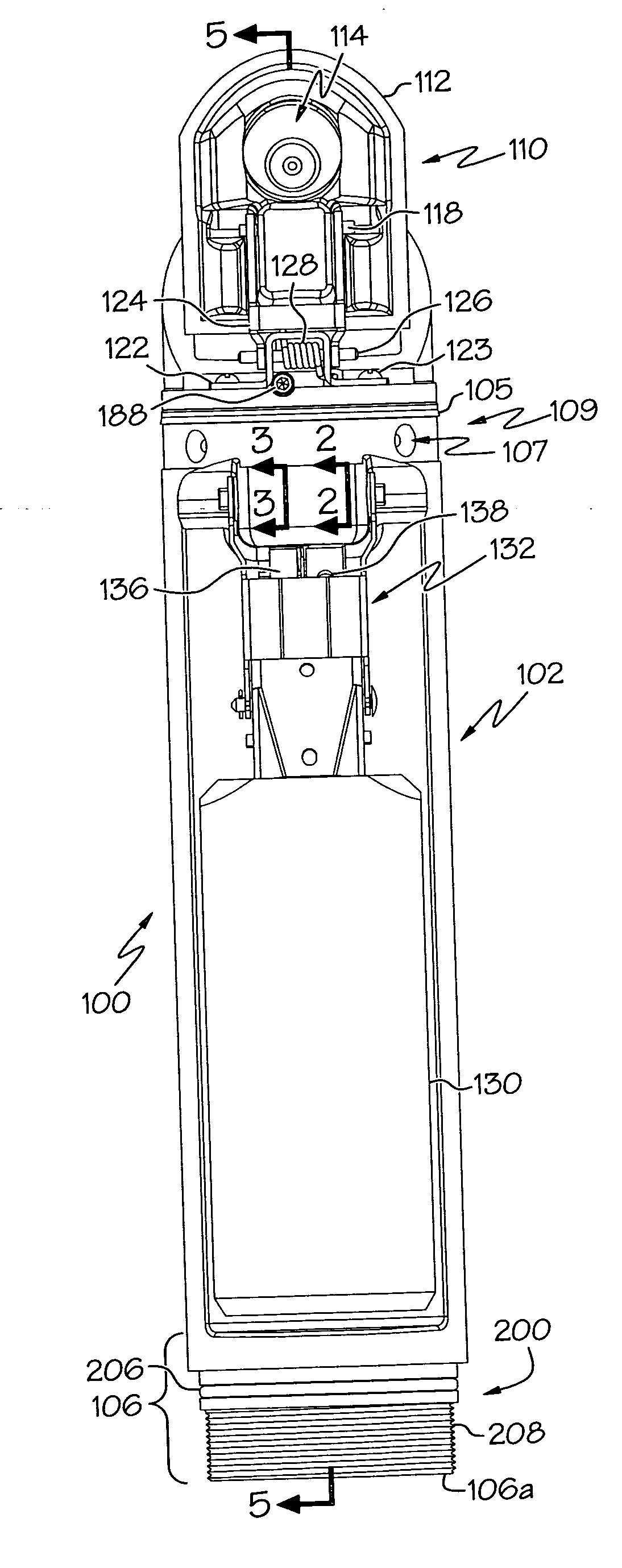

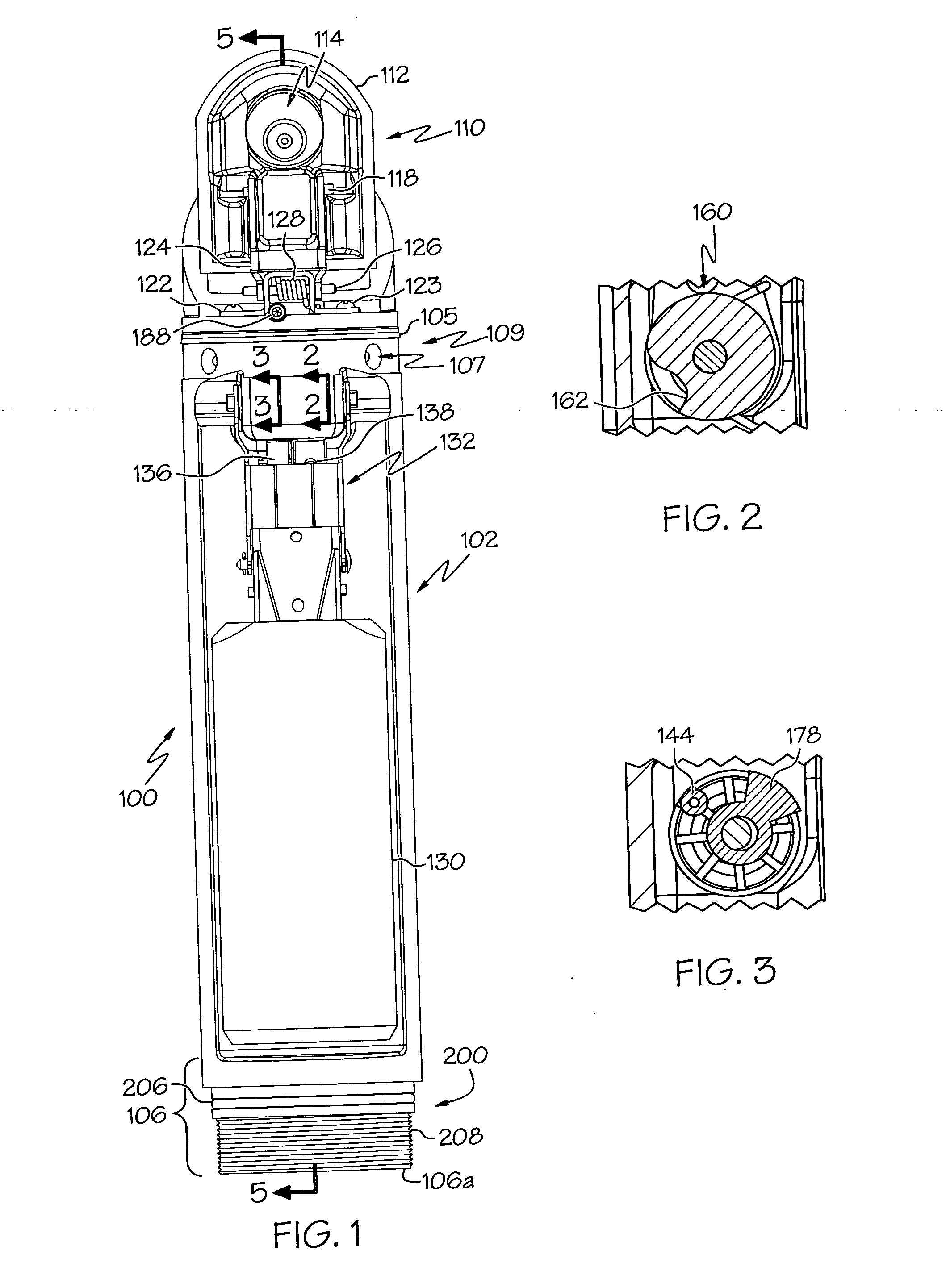

Drop tube segments adapted for use with a liquid reservoir

ActiveUS7243675B2Easy to adjust the positionPrevent leakageSleeve/socket jointsOperating means/releasing devices for valvesEngineeringDrop tube

A drop tube segment is adapted for use with a liquid reservoir. The drop tube segment includes a conduit with an end portion and a sidewall including a sidewall portion at least partially defining an interior housing area. The drop tube segment further includes a valve assembly comprising a valve member attached to the end portion of the conduit, a float, and a linkage device pivotally connected to the valve member. The valve assembly further includes a driver member at least partially disposed in the interior housing area. An adjustment of the float may rotate the driver member to engage the linkage device to facilitate in adjusting the position of the valve member with respect to the end portion of the conduit. The valve assembly further includes a structure adapted to inhibit, such as prevent, fluid from leaking into the interior housing area.

Owner:OPW FUELING COMPONENTS LLC

Drop tube inserts and apparatus adapted for use with a riser pipe

ActiveUS7069965B2Minimize and prevent vapor releaseLiquid fillingLarge containersEngineeringDrop tube

Drop tube inserts and apparatus adapted for use with a riser pipe of a liquid reservoir are provided. Apparatus include a drop tube insert at least partially disposed within an end portion of a drop tube. The drop tube insert includes a wall with inner and outer surfaces wherein the wall of the drop tube insert is devoid of any opening extending between its inner and outer surfaces.

Owner:OPW FUELING COMPONENTS LLC

Biomass preventing corrosion of superheater and garbage power generation boiler

The invention discloses a biomass preventing the corrosion of superheater and a garbage power generation boiler, belonging to power generation equipment using renewable sources as fuel. The garbage power generation boiler comprises a boiler body, characterized in that: a circular secondary air box is arranged around a furnace arc part of a hearth and the spacing between a front arc and a rear arc is appropriately shortened; a limestone powder funnel is arranged at a secondary air main, limestone powder is fully mixed with smoke gas under the driving of secondary air so as to reduce the content of chlorine in the smoke gas; a shaft flue I, a shaft flue II and a shaft flue III are arranged sequentially at a high-temperature smoke gas outlet of the hearth, a superheater pipe is arranged inside the shaft flue II and controlled within 800 DEG C; a box body for fixing a zinc spelter is arranged at a descending pipe wall which is adjacent to a high-temperature superheater inlet header and a low-temperature superheater outlet header, and the zinc spelter is connected with the high-temperature superheater inlet header or the low-temperature superheater outlet header via conducting wires; the garbage power generation boiler has obvious effect in preventing the corrosion of the superheater, prolongs the service life of the superheater and includes low cost, simple and convenient construction and maintenance.

Owner:朴显泽 +2

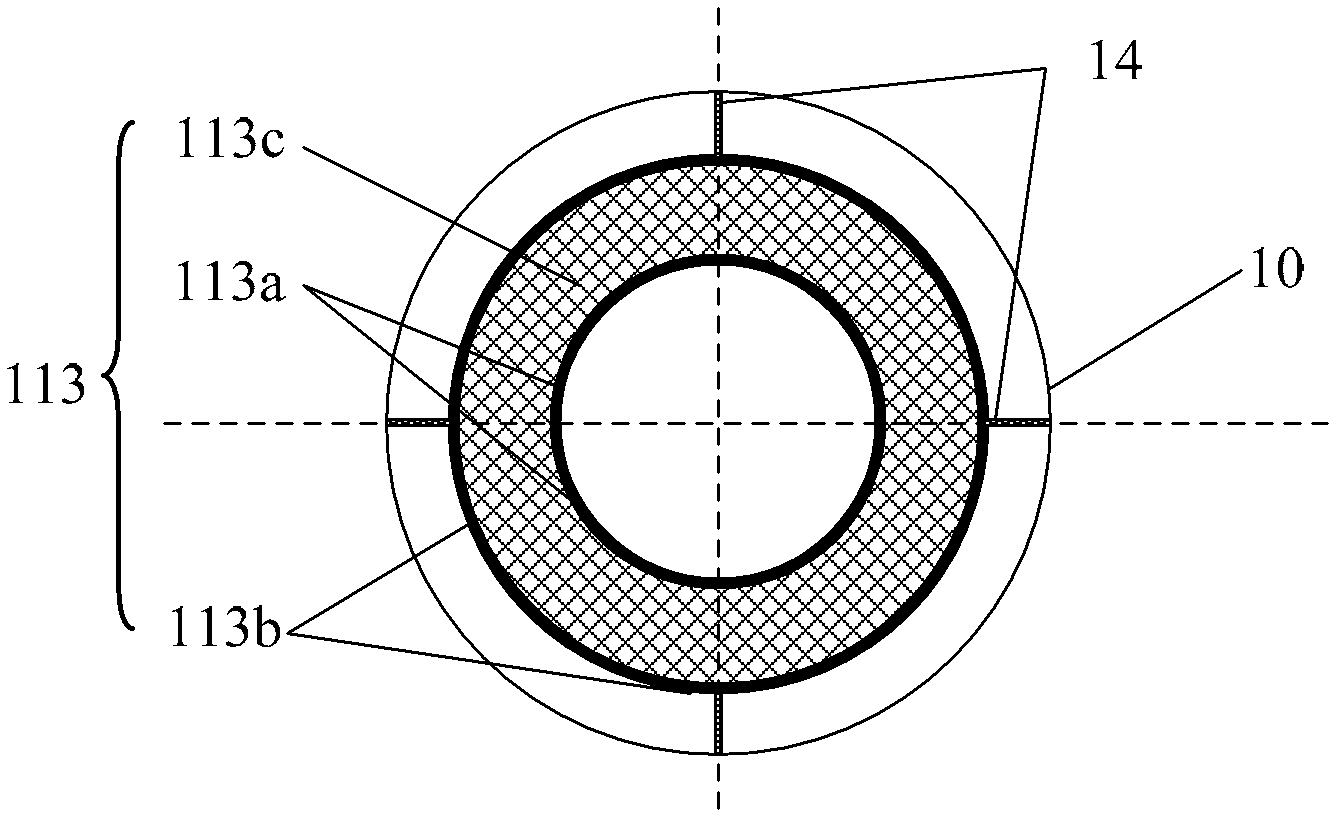

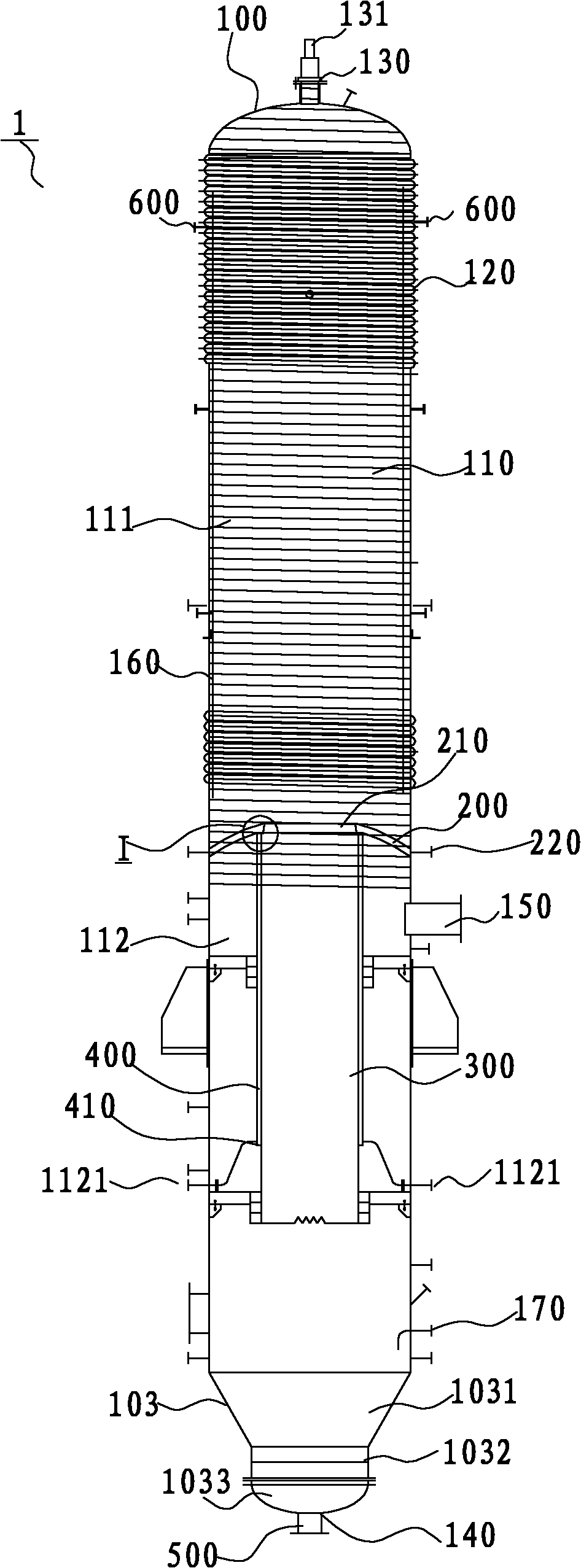

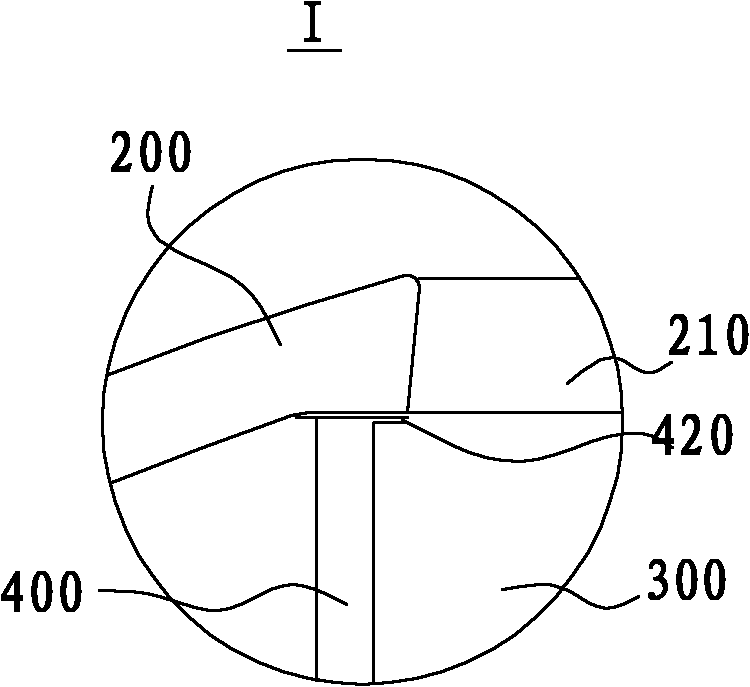

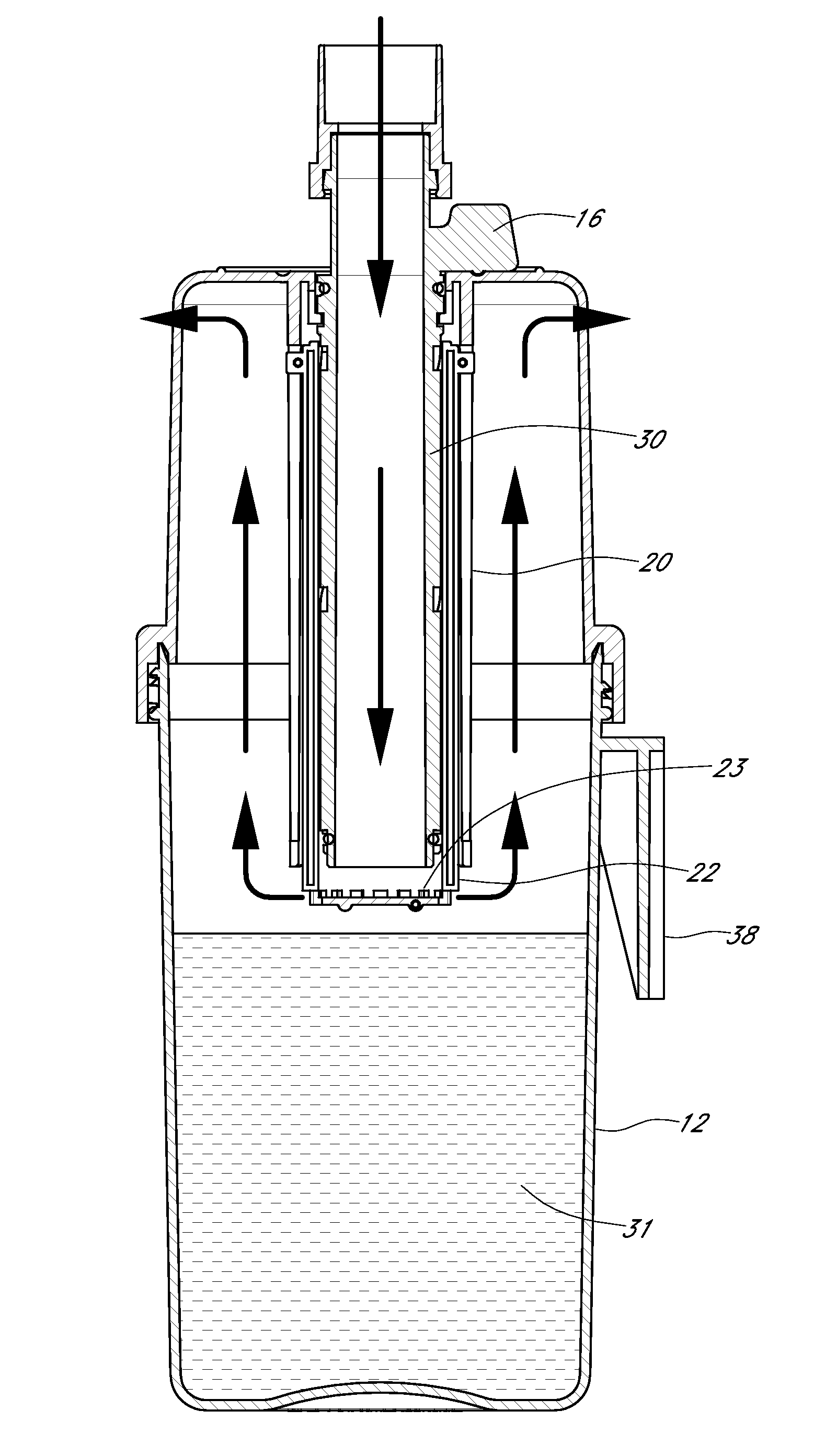

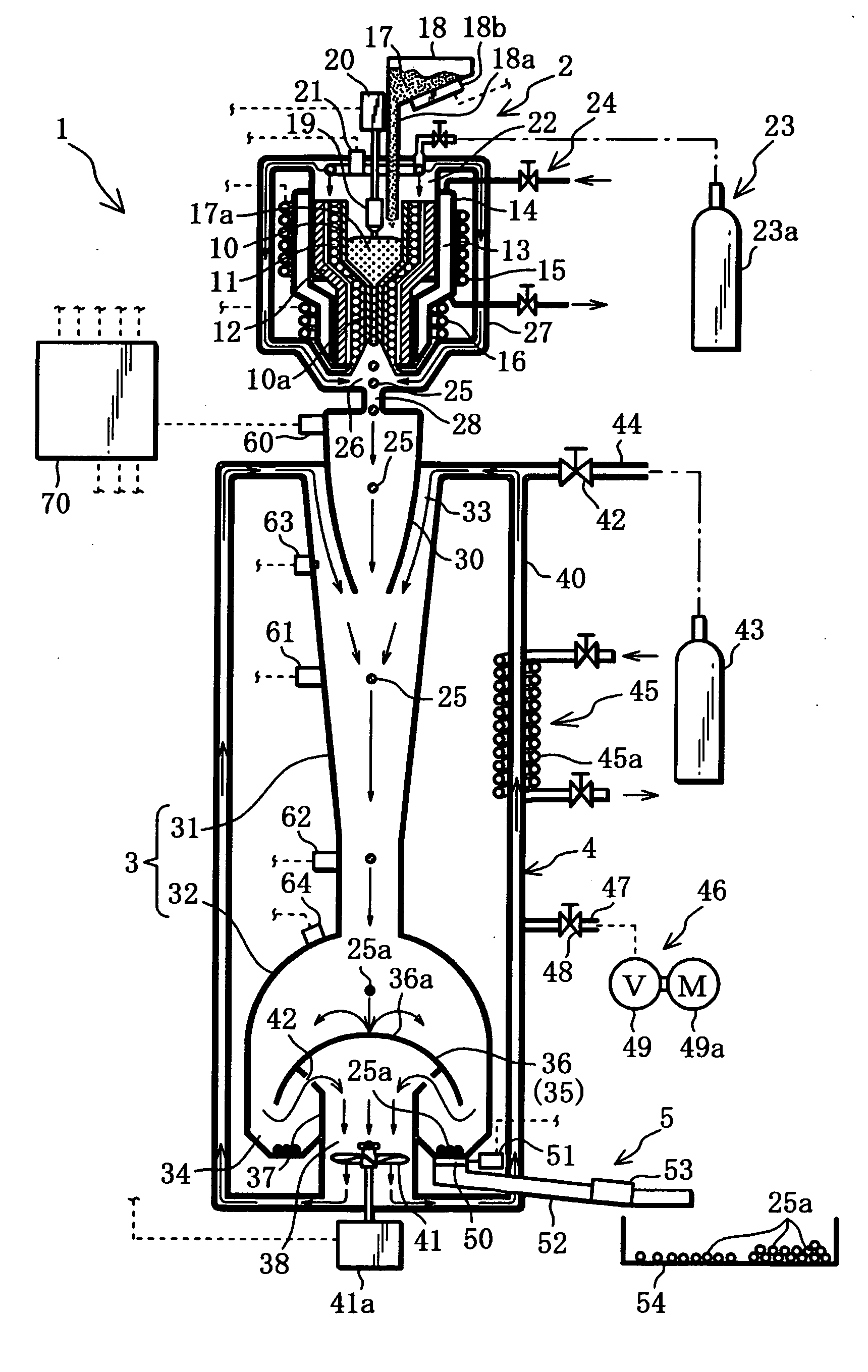

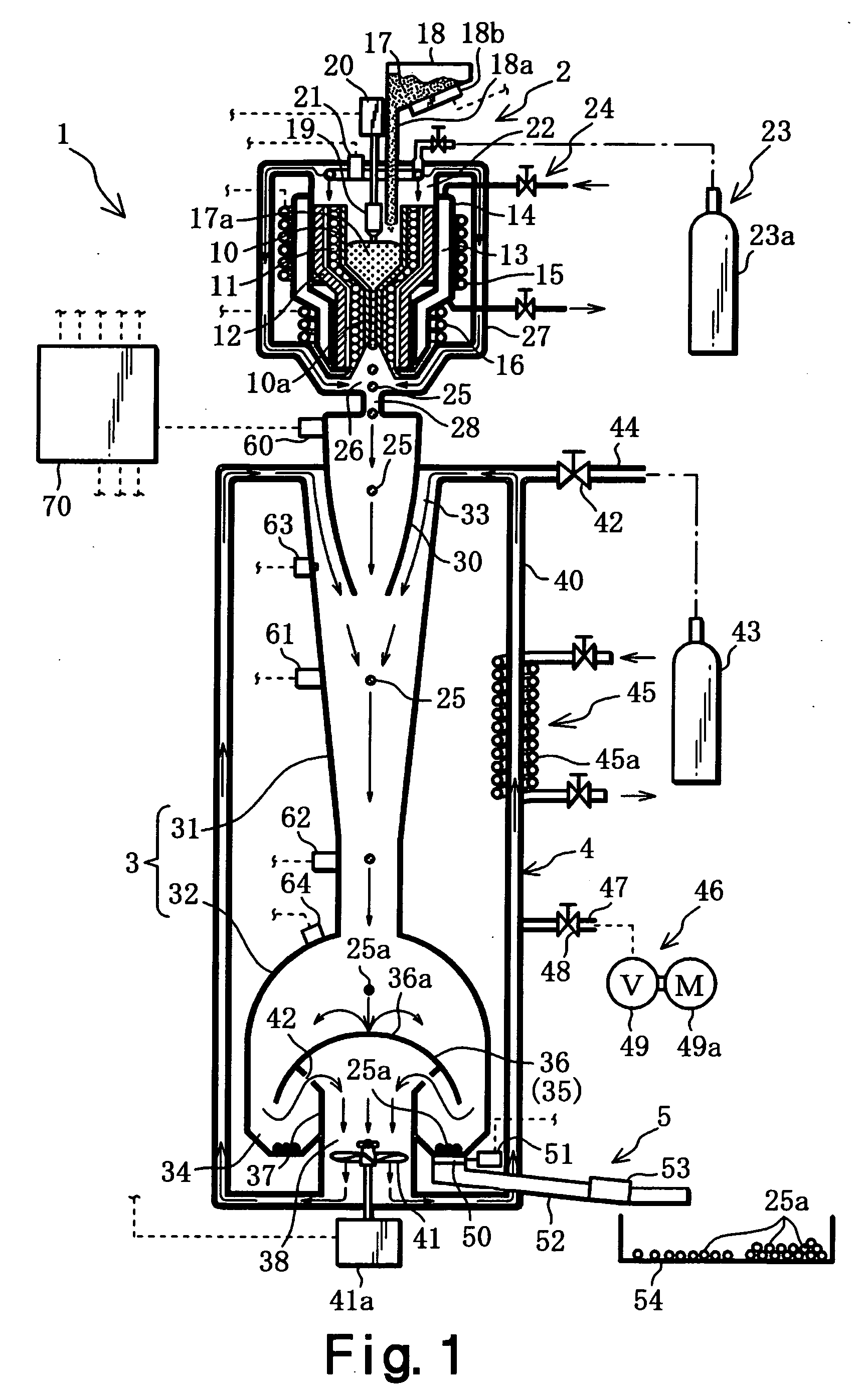

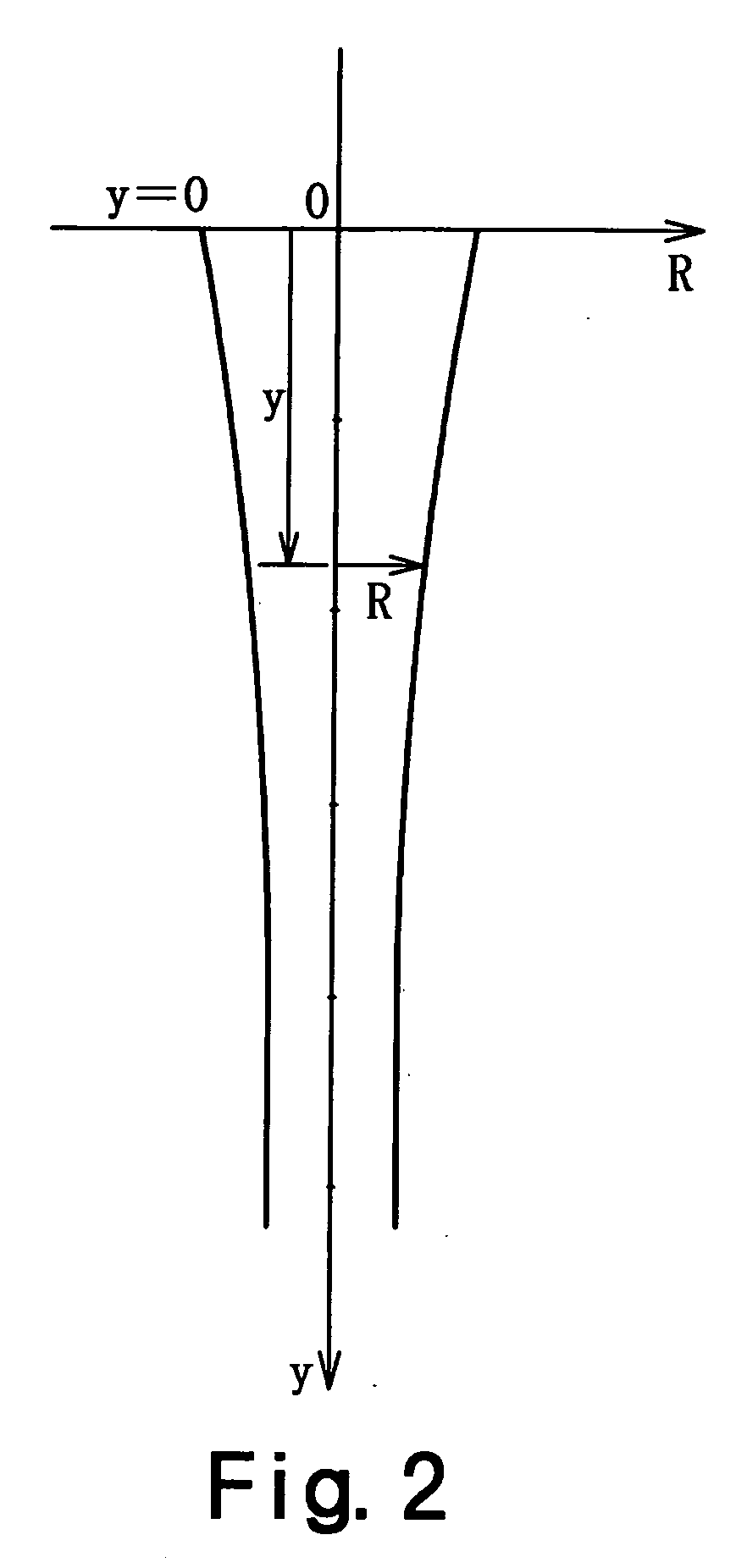

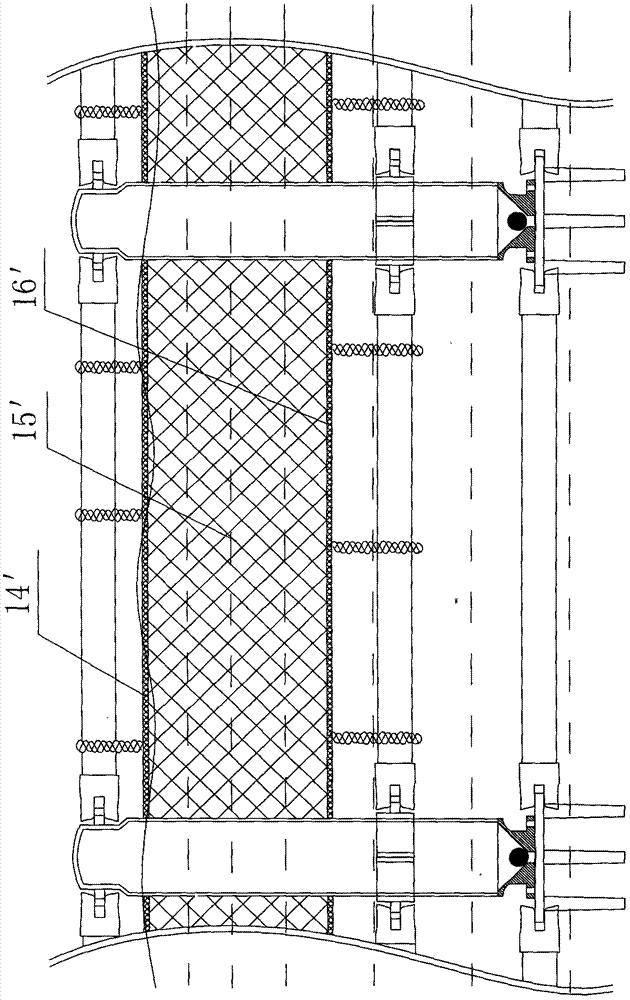

Drop tube type granular crystal producing device

InactiveUS20060070652A1Reduce drop heightEffectively cool the meltAfter-treatment apparatusPolycrystalline material growthParticulatesFree falling

A drop tube type particulate crystalline body producing device is a device for creating a substantially spherical crystalline body by solidifying a particulate melt of an inorganic material while allowing it to free-fall inside a drop tube. This device 1 has a melt formation device 2, drop tube 3, gas flow formation means for forming inside the drop tube 3 a gas flow of cooling gas, and recovery mechanism 5 for recovering a crystalline body 25a from the lower end of the drop tube 3. The drop tube 3 comprises an introducing tube 30, cooling tube 31, and solidification tube 32, where the cooling tube 31 is configured such that the cross sectional area thereof becomes smaller toward the bottom such that the cooling gas flow speed becomes substantially equal to the free fall speed of the particulate melt, and the solidification tube 32 is connected to the lower end of the cooling tube 31 and has a cross sectional area enlarged discontinuously from the lower end of the cooling tube 31. In a proximity of the upper end of the solidification tube 32, the flow speed of the cooling gas is rapidly reduced and the gas pressure increases, whereby a crystal nucleus is generated in the melt in a supercooled state, and the melt is crystallized at once.

Owner:SPHELAR POWER

Nest floating method

InactiveCN103535300AEasy maintenanceImprove efficiencyClimate change adaptationPisciculture and aquariaEngineeringSteel ball

The invention discloses a net floating method. The net floating method includes that 1), a net floats in a horizontal state: stainless steel balls in an inner tube of a T-shaped drainage valve are positioned in the center of the inner tube, and water in a buoyancy tube flows into the inner tube of the T-shaped drainage valve via two U-shaped PE (polyethylene) hoses connected with metal drop tubes, and is sequentially drained out of the T-shaped drainage valve and the buoyancy tube via inner drainage holes in the inner tube, so that the transverse buoyancy tube ascends to drive a net top, a net enclosure and a net bottom of the net to float; 2), the net floats in a non-horizontal state: the stainless steel balls in the T-shaped drainage valve automatically roll to a lower side of the inner tube of the T-shaped drainage valve and plug an orifice of the U-shaped PE hose on the lower side of the inner tube, and under the effect of air pressure, the water is sequentially drained out of the T-shaped drainage valve and the buoyancy tube via the U-shaped PE hose which is arranged on the other side of the inner tube and is connected with the inner tube of the T-shaped drainage valve, so that the transverse buoyancy tube ascends to drive the net top, the net enclosure and the net bottom of the net to float. The net floating method has the advantages that the net can completely float on a water surface, so that the fishing efficiency can be improved, and maintenance on the net can be facilitated.

Owner:青岛利东海洋网箱科技有限公司

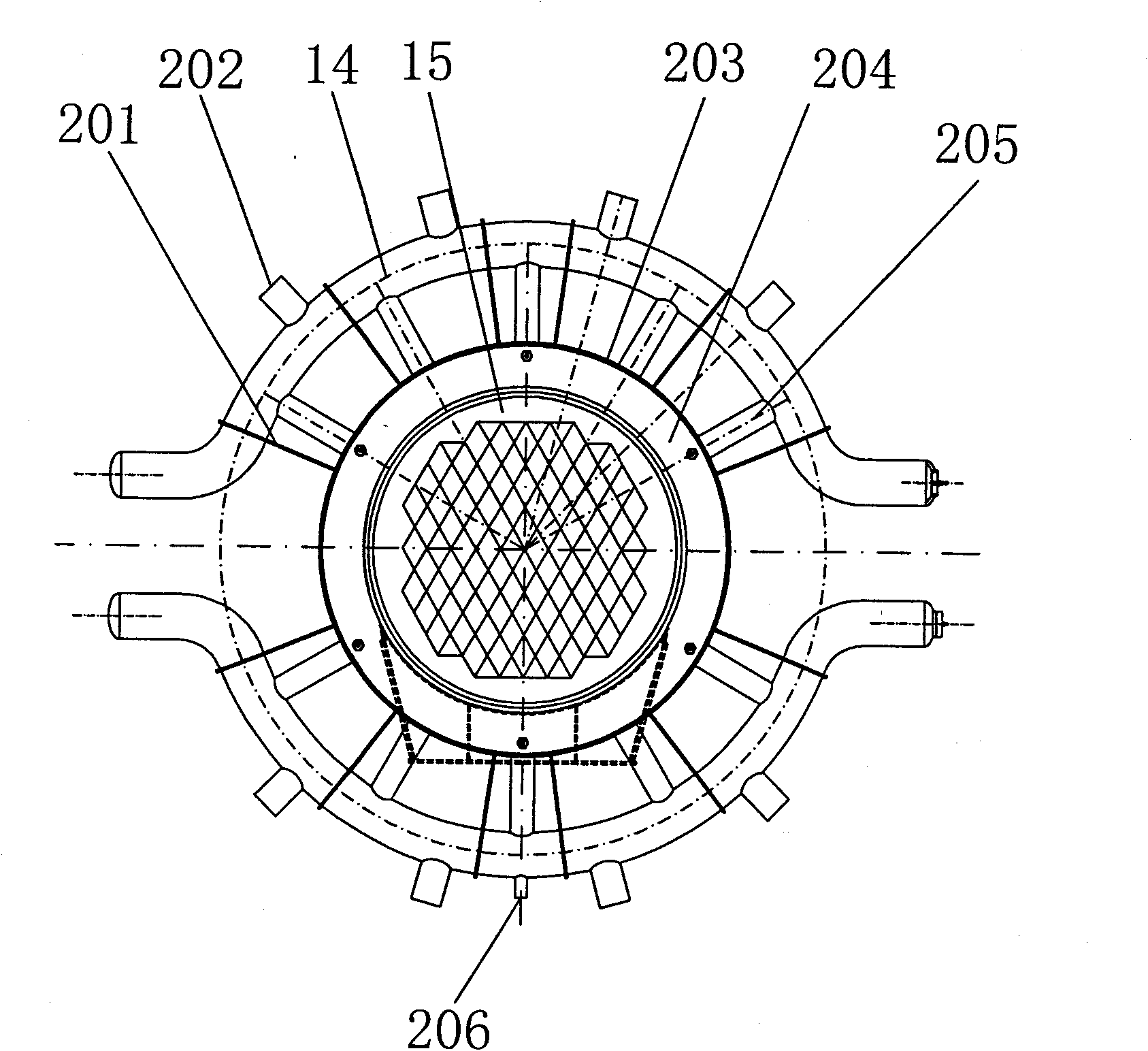

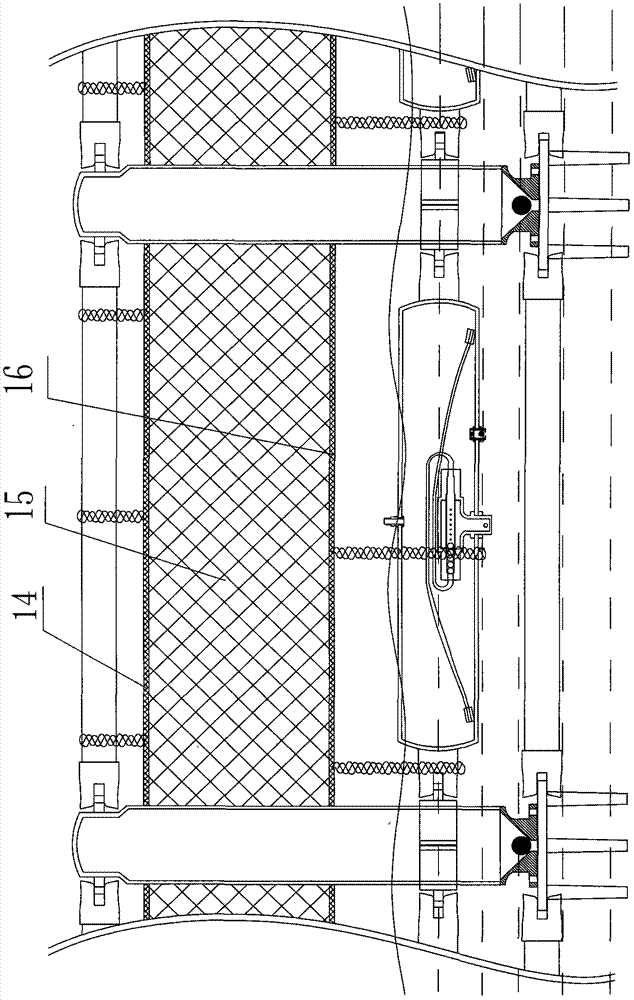

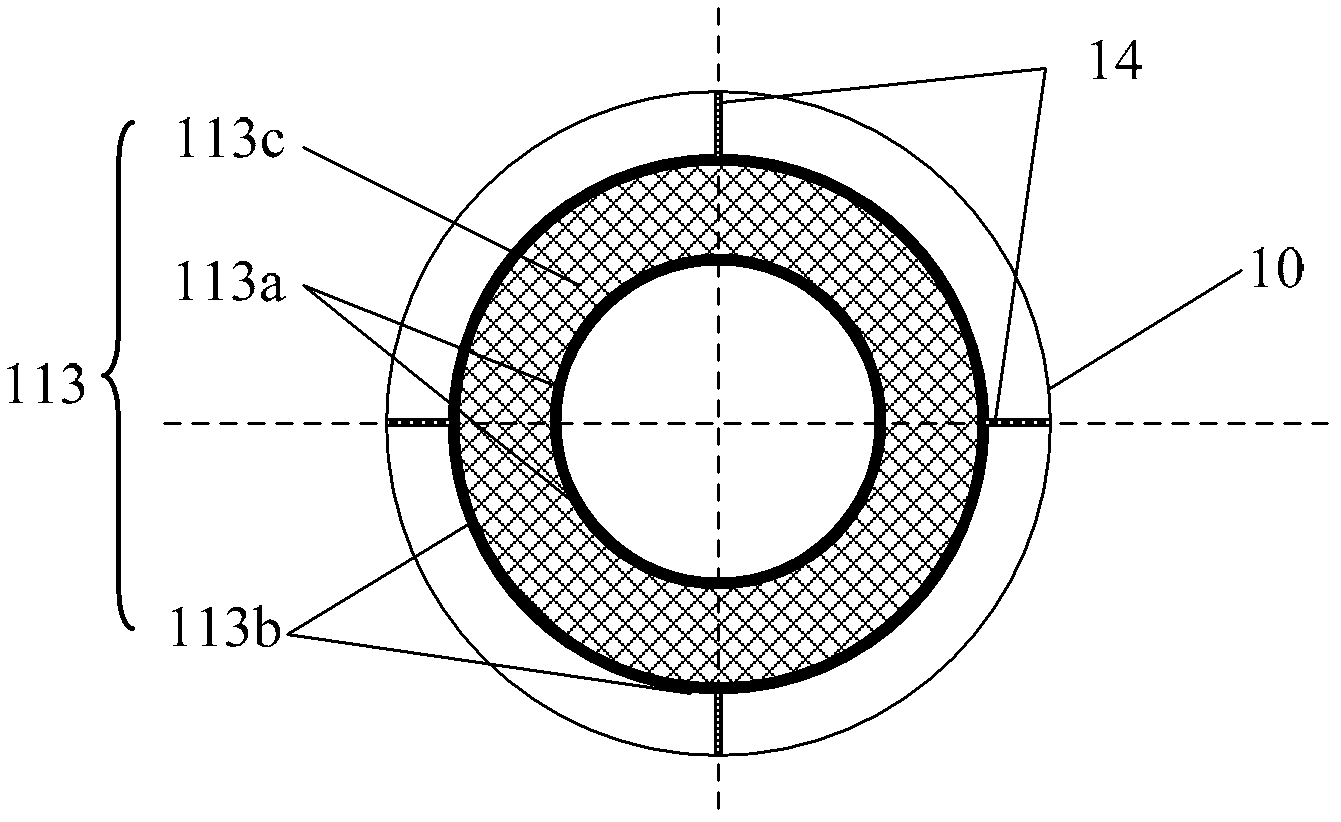

Gasification furnace and chilling chamber thereof

ActiveCN102634378AInhibition of water phenomenonIncrease the washing areaGranular/pulverulent flues gasificationSyngasWater baths

The invention discloses a gasification furnace and a chilling chamber of the gasification furnace of the gasification furnace. The chilling chamber of the gasification furnace comprises a downcomer consisting of a gas reduction tube and a gas distribution tube, wherein the lower end of the gas reduction tube extends into the gas distribution tube, a gas exhausting net is arranged in a circular space between the gas distribution tube and the gas reduction tube, the lower edge of the gas reduction tube is lower than the plane where the gas exhausting net is positioned, and a plane where the gas exhausting net is positioned is lower than the liquid level of the chilling chamber. Compared with the prior art, for the gasification furnace provided by the invention, an ascending pipe is removed, the water-bringing phenomenon of the synthesis gas of the chilling chamber is effectively inhibited, and the water bath humidifying, dedusting, desmutting and temperature reduction effects of the synthesis gas are improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Drop tube assembly

ActiveUS7225840B1Increase radial clearanceImprove the problemLiquid fillingLiquid transferring devicesControl systemSpray nozzle

This drop tube loading arm assembly is adaptable for loading asphalt into tank trailers at marketing terminals. The telescoping drop tube employs guides made of steel rollers of polymers such as fluorocarbon polymers and aluminum. The guides are located in the annular space between the tubes in combination with increased radial clearance between the tubes or sleeves and in combination with protection for the overfill probe. With the addition of vapor control systems and overfill protection probes, the telescoping drop loading spouts are less susceptible to cold weather sticking problems.

Owner:MARATHON PETROLEUM

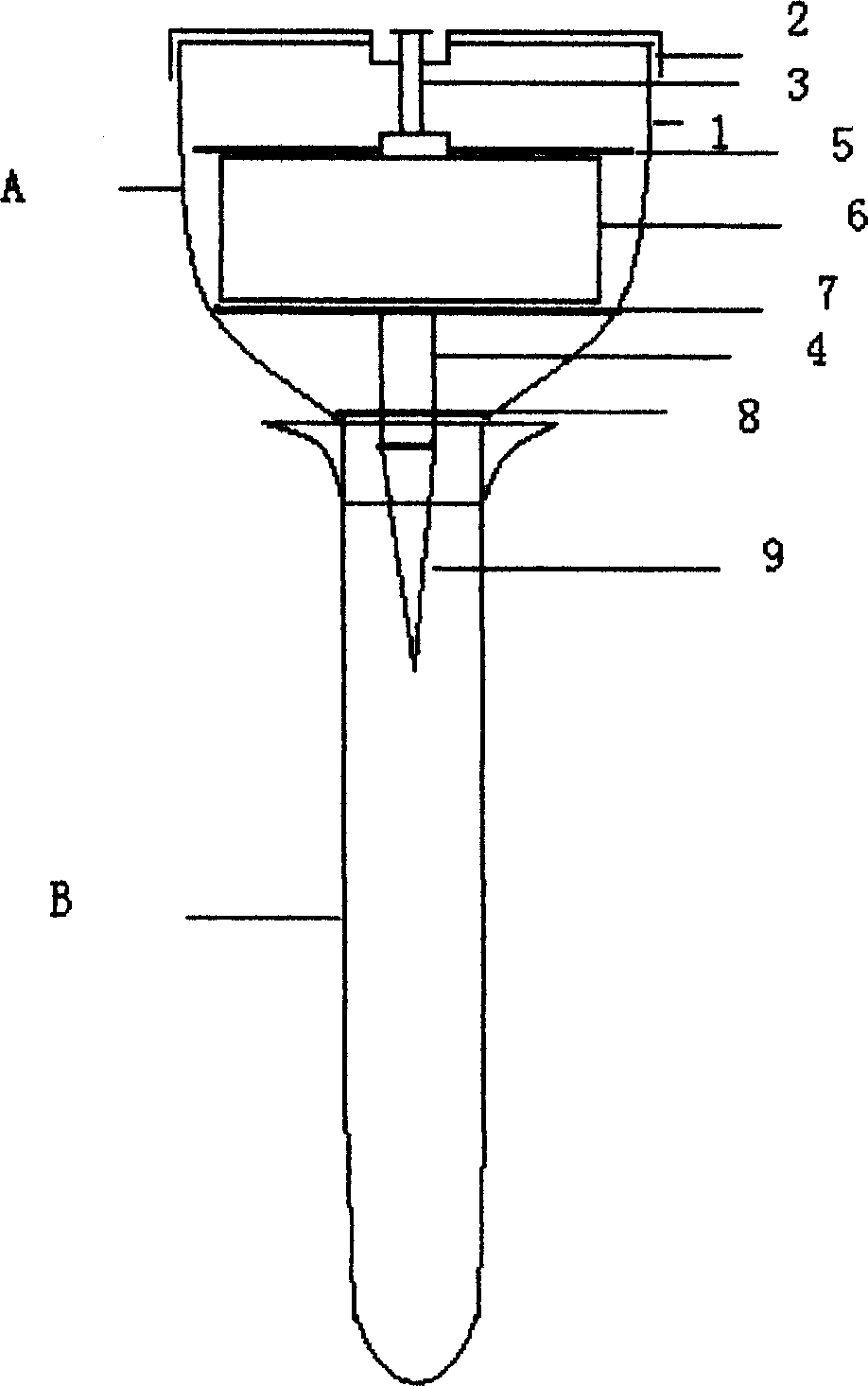

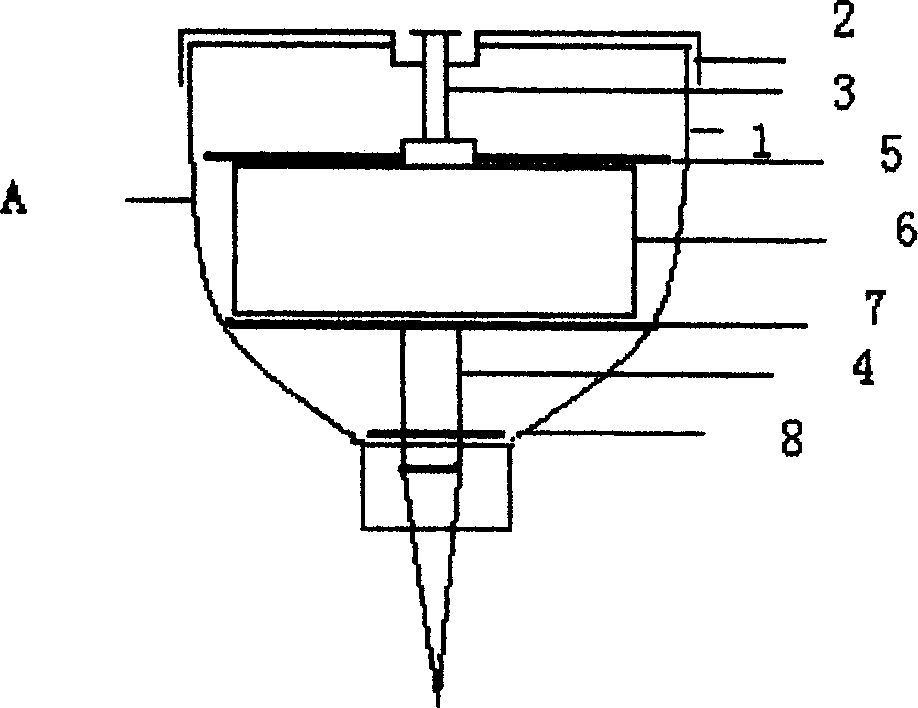

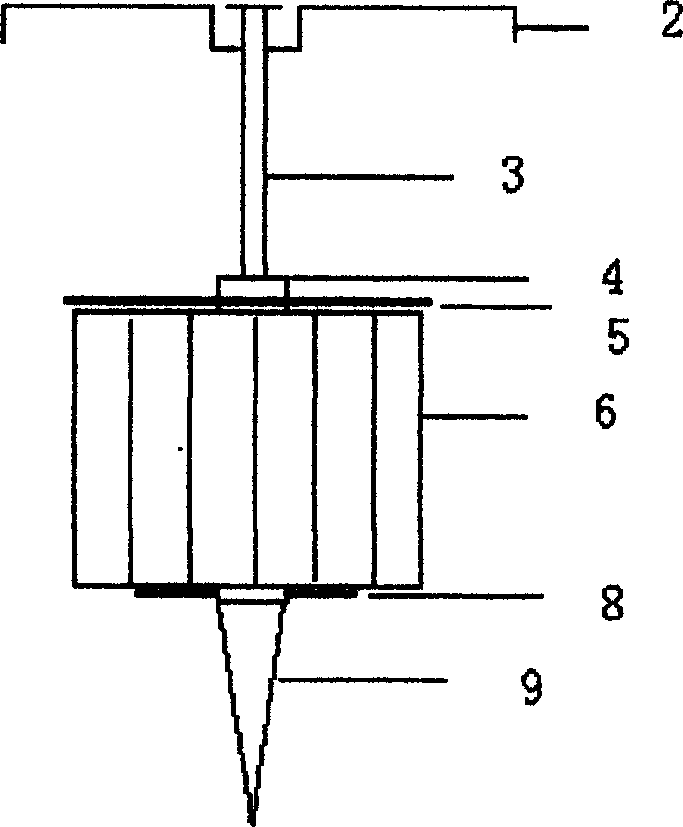

Integrated multifunctional urine sample collecting apparatus

The invention discloses a device for collecting urine specimen. The device comprises a collect canister A and a standard centrifuge tube B. The collect canister A includes a hopper collect canister 1, a collect canister cover 2, an extensible arm 3, an extensible pipe 4, a butterfly-shape compression board 5, a spongy mass 6, a lower baffle plate 7, a sealed baffle plate 8, a dropping tube 9; the standard centrifuge tube B is a private plastic container, which has screw-thread on the inner wall of the tube opening to connect with the collect canister A.

Owner:徐双苗

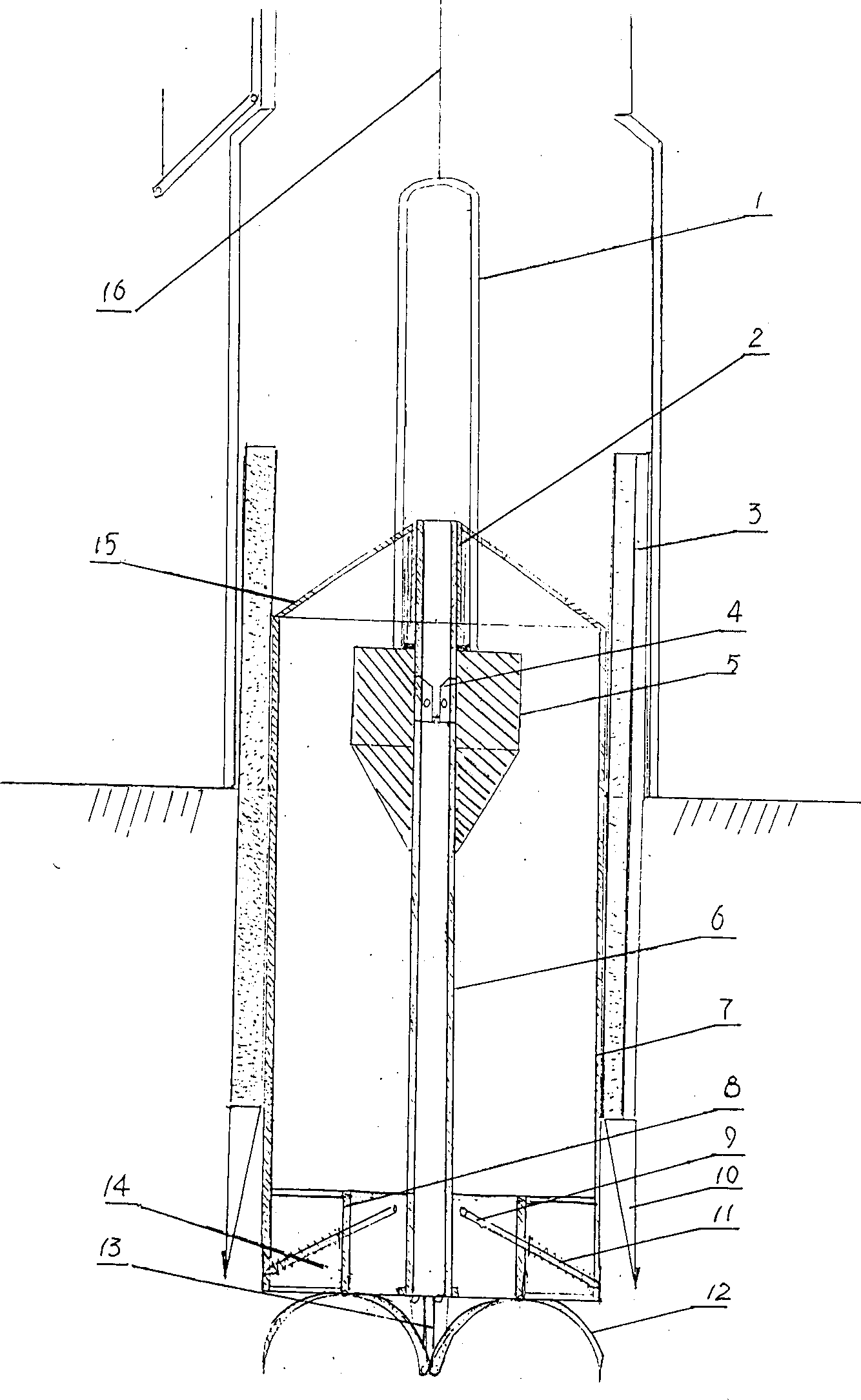

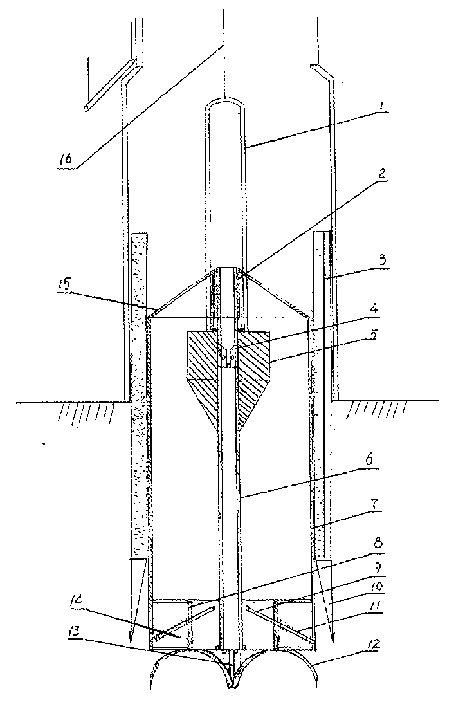

Well drilling machine with shocking, grabbing, spading, planing and drilling heads

InactiveCN1374438AGood technical effectImprove drilling efficiencyReciprocating drilling machinesSoil-shifting machines/dredgersWell drillingDrop tube

The present invention is one well drilling machine including winder and frame. The present invention features that there are movable impact tube connected to the lower end of the hanging ring of the winder steel cable, movable shaft matched with the impact tube, chuck in the upper end of the shaft, balance weight in the lower end of the shaft, planing and grasping shovel connected via push rod tothe shaft, and impact shovel fixed to the lower end of the balance weight. During drilling well, the machine can drop tube while drilling.

Owner:秦孝成

Drop tube inserts and apparatus adapted for use with a riser pipe

ActiveUS20050241723A1Minimize and prevent vapor releaseLiquid fillingLarge containersEngineeringDrop tube

Drop tube inserts and apparatus adapted for use with a riser pipe of a liquid reservoir are provided. Apparatus include a drop tube insert at least partially disposed within an end portion of a drop tube. The drop tube insert includes a wall with inner and outer surfaces wherein the wall of the drop tube insert is devoid of any opening extending between its inner and outer surfaces.

Owner:OPW FUELING COMPONENTS LLC

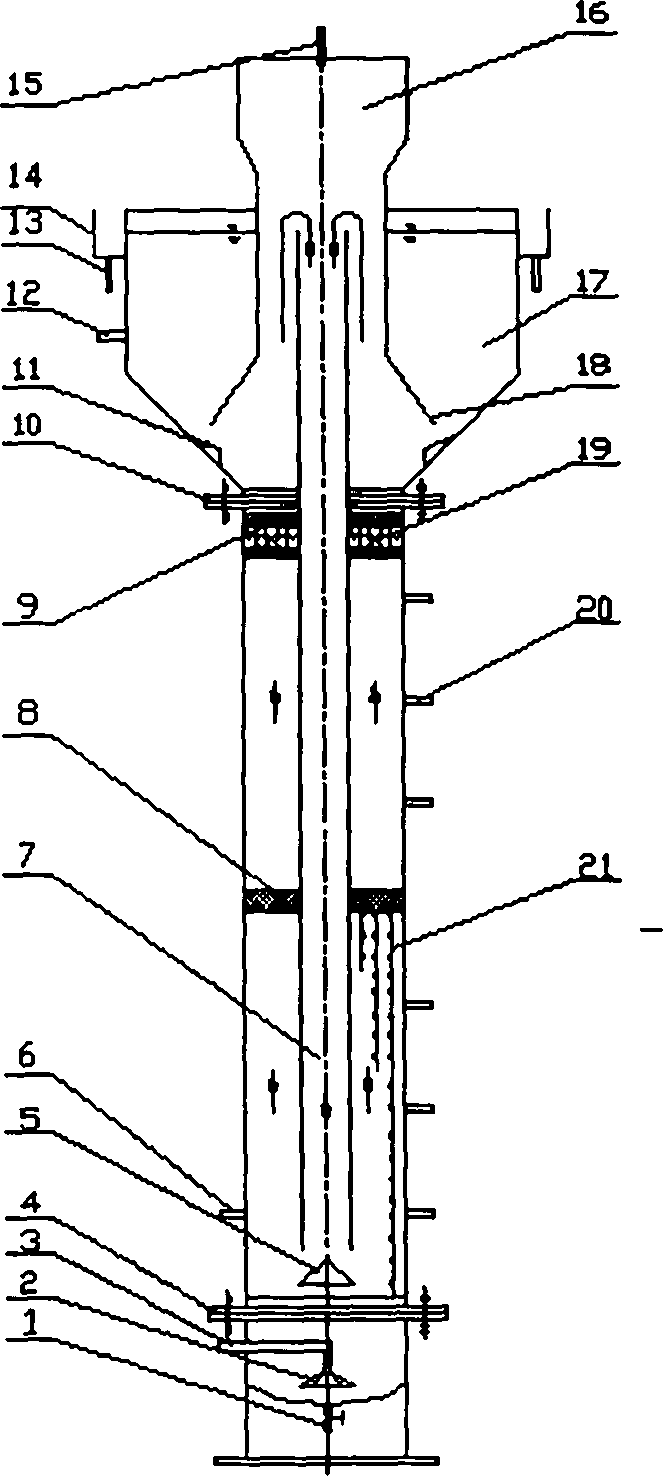

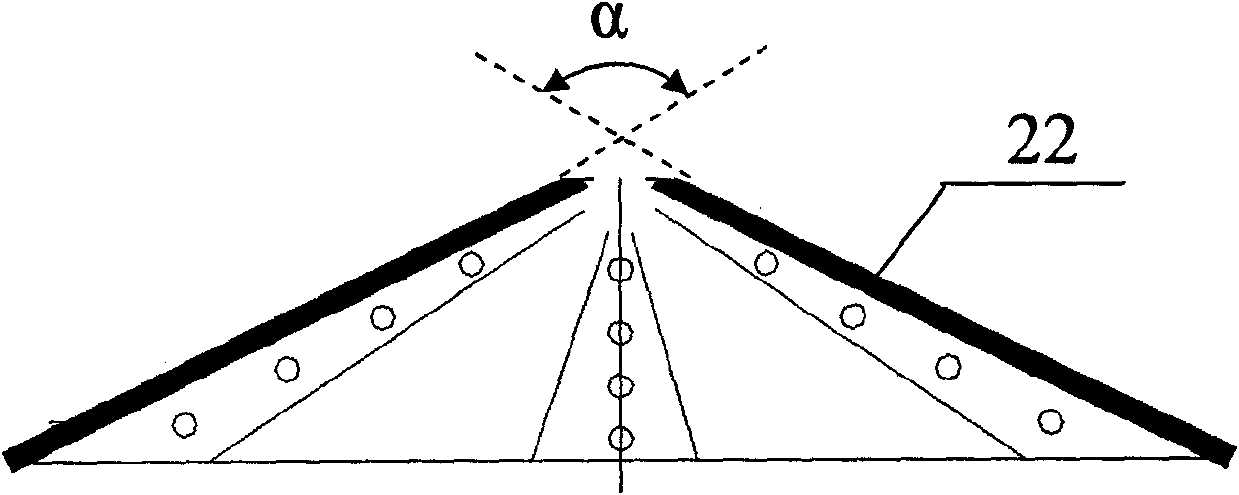

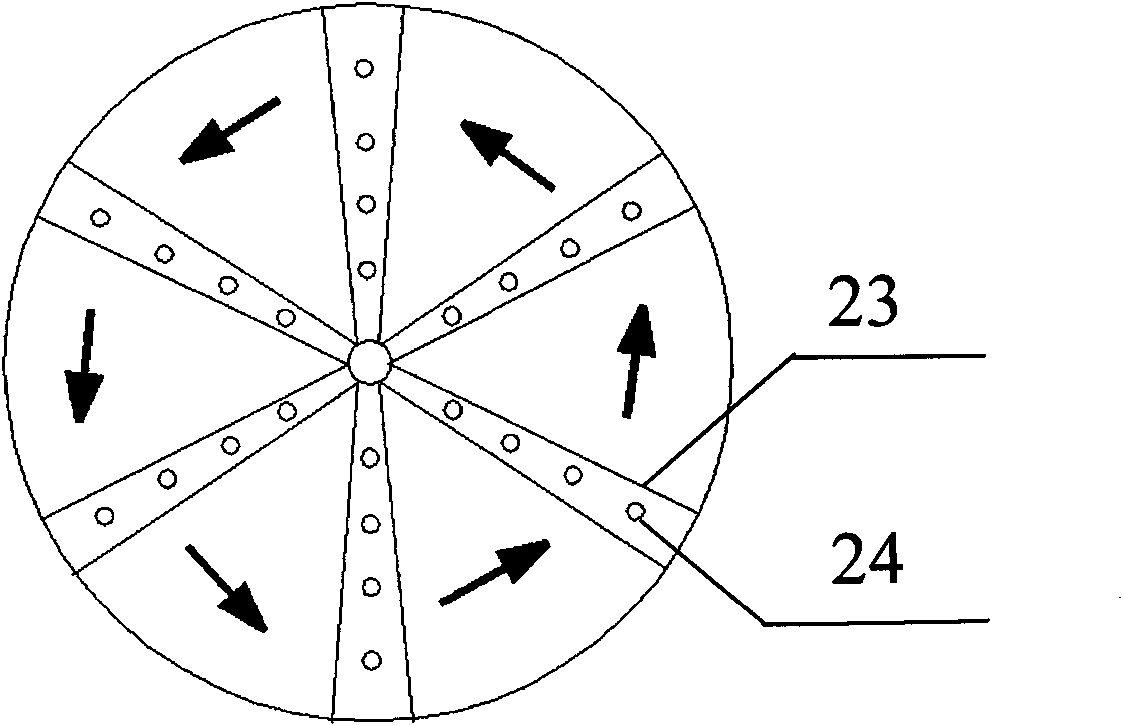

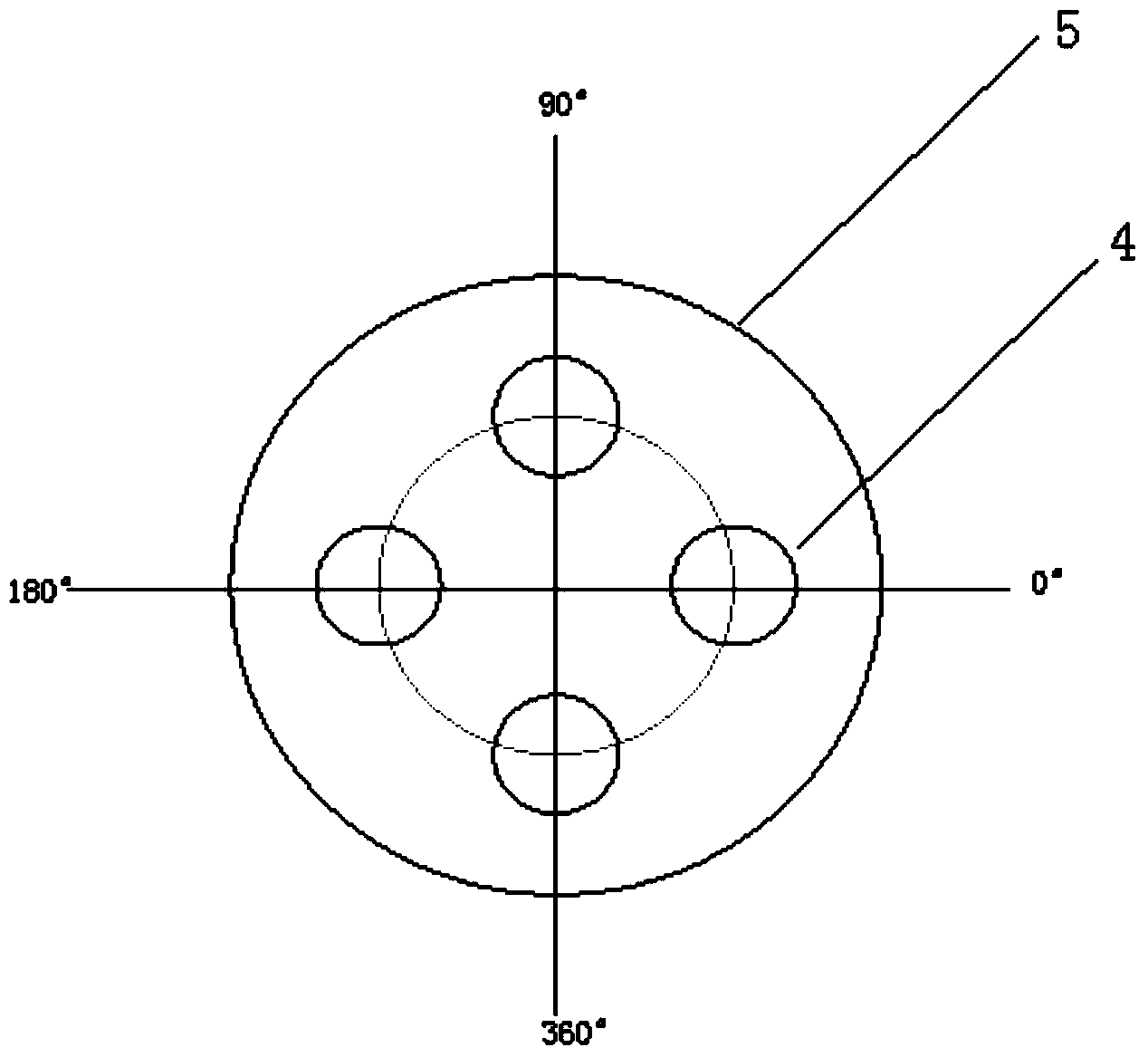

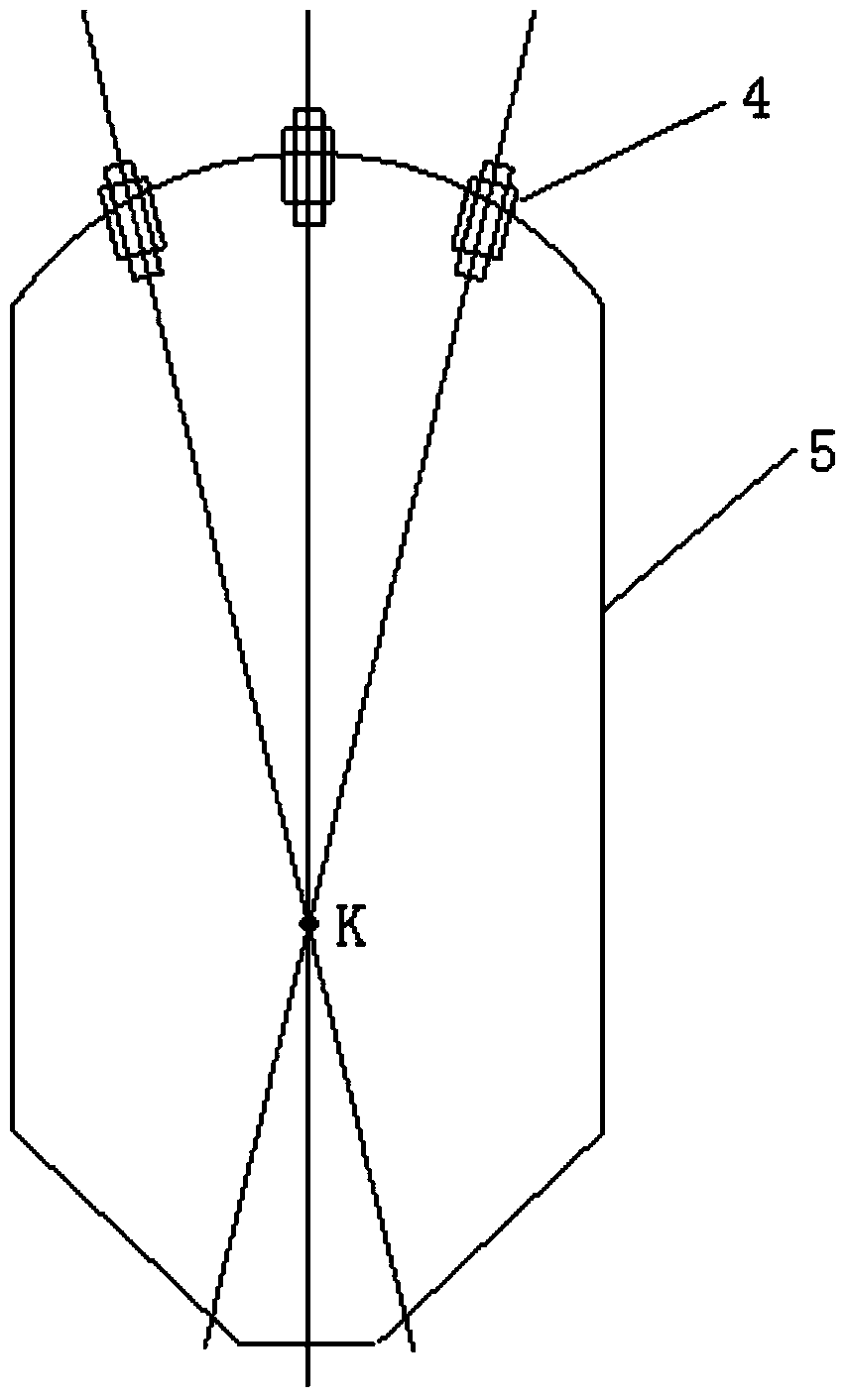

Synclastic multi-shaft gasification device

ActiveCN103525470AReduce joinSolving Ablation ProblemsGranular/pulverulent flues gasificationBrickEngineering

The invention relates to a synclastic multi-shaft gasification device. The gasification device comprises a feed mechanism, a gasification mechanism and a washing mechanism, wherein the gasification mechanism comprises a gasification furnace consisting of a gasification chamber and a shock chamber; a plurality of burners communicated with the feed mechanism are uniformly arranged on the top of the gasification chamber, and a conical outlet extending into the shock chamber is formed in the bottom of the gasification chamber; a coal gas outlet is formed in the upper part of the shock chamber, and chilled water with a certain liquid level is filled in the lower part of the shock chamber; a chilling ring and a down pipe are sequentially arranged in the lower part of the conical outlet of the gasification chamber; a plurality of water outlets with a certain tilting angle are uniformly formed in the periphery of the upper edge of the inner ring wall of the chilling ring; the outlet end of the down pipe extends below the liquid surface of the shock chamber; the washing mechanism comprises a washing tower which is communicated with the coal gas outlet of the shock chamber through a washer, the water outlet of the washing tower is respectively communicated with the washer and the chilling ring through a chilling water pump. The synclastic multi-shaft gasification device solves the problems of low pulping concentration, crown brick erosion, poor coal slurry atomization effect, uneven flow field of gasification furnace and the like in the prior art.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com