Well drilling machine with shocking, grabbing, spading, planing and drilling heads

A technology of drilling equipment and cone head, which is applied to drilling equipment, impact drilling, reciprocating drilling rigs, etc., can solve the problems of affecting the drilling efficiency, the failure of the well wall to be shaped and solidified in time, and the single function of the drilling equipment. The effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

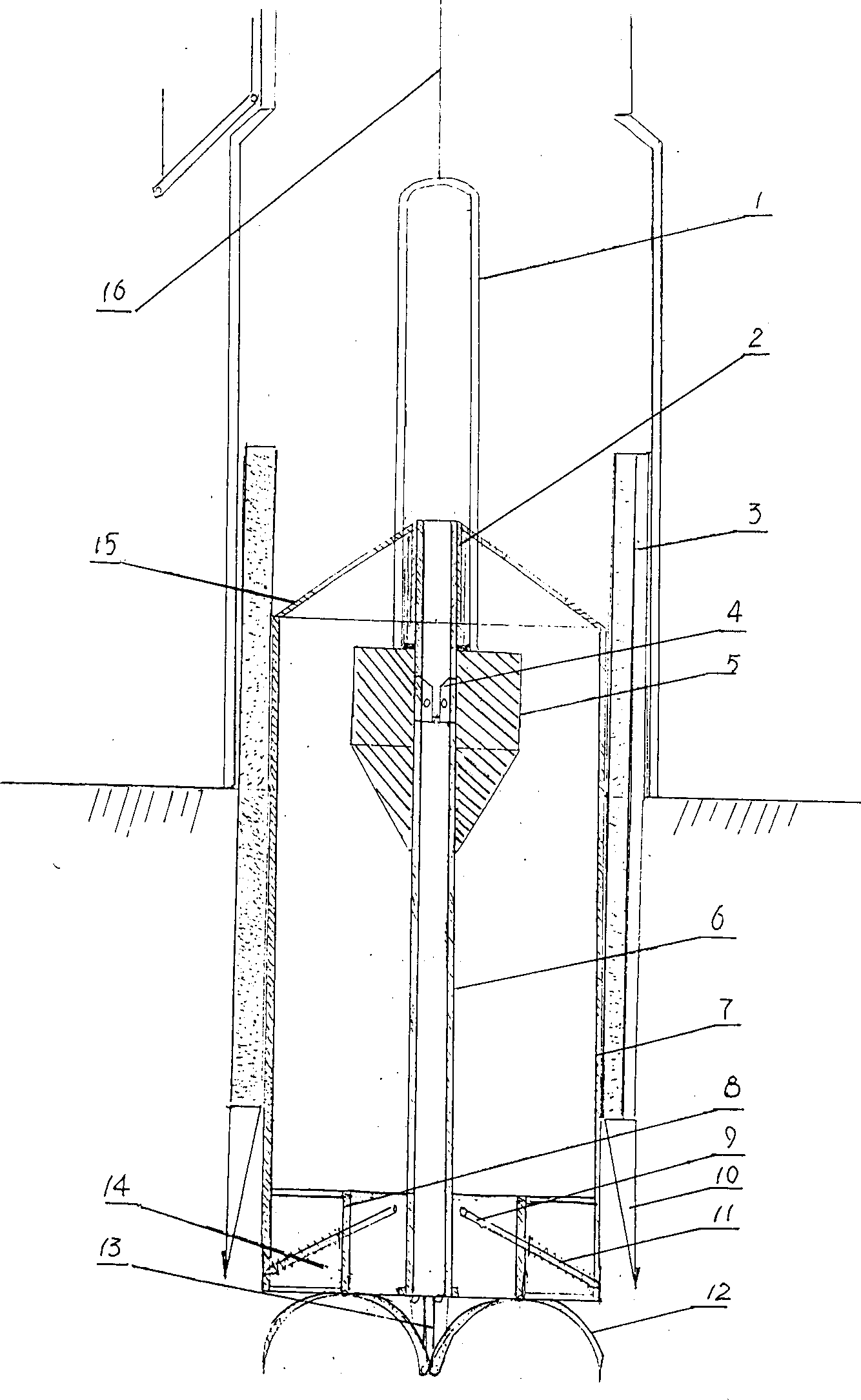

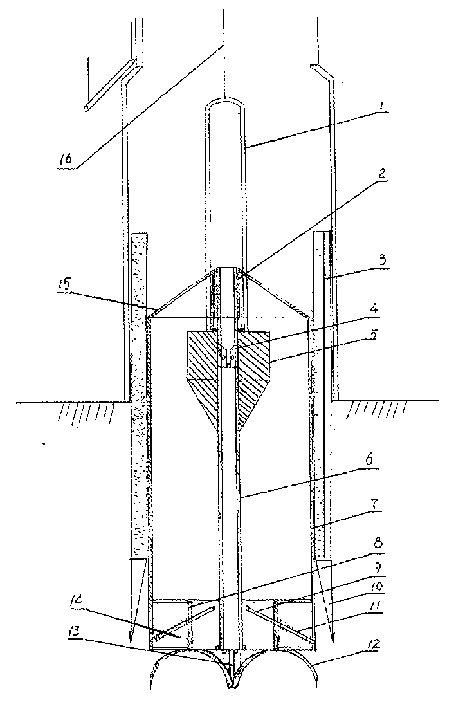

[0009] The punching, grabbing, shoveling, and cone-head drilling equipment includes a hoist and a frame. The lower end of the suspension ring (1) connected with the wire rope of the hoist is connected with the movable impact cylinder (5), and the movable impact cylinder (5) is slidingly matched with the movable shaft (6). The upper end of the movable shaft (6) is provided with a chuck (4), and the lower end Set in the base (14) of the counterweight body (7), and connected with the planer grab shovel (12) through the pull rod (13), the movable impact cylinder (5) and the movable shaft (6) are placed in the counterweight body (7) On the axis line, the inner lower part of the counterweight body (7) is fixed with an impact shovel (9). The impact shovel (9) is evenly distributed and fixed on the circumference of the inner ring (8). The claw petal of planing and grabbing shovel (12) is four petals.

[0010] Its working process is like this. Wire rope (16) connects movable impact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com