Catalyst for directly preparing low-carbon olefin from microspherical synthesis gas, as well as preparation method thereof

A technology of low-carbon olefins and catalysts, which is applied in the field of catalysts and preparations for direct preparation of low-carbon olefins from microspherical syngas, which can solve the problems of wide product distribution and achieve reasonable particle size distribution, high specific surface area, uniform and stable distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

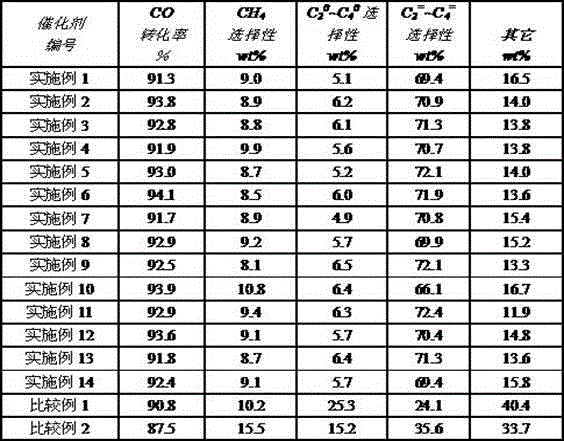

Examples

Embodiment 1

[0029] 1.96g of barium nitrate and 218.3g of cobalt nitrate hexahydrate were dissolved in water to make a solution, then the solution was precipitated in parallel with 450g of 6% by weight ammonia solution, the precipitate was filtered, and washed repeatedly with deionized water to obtain a fresh and clean solution. Mixed oxide I of barium oxide and cobalt oxide; take 606.03g of ferric nitrate nonahydrate dissolved in water to make solution II, take 0.084g of potassium hydroxide to make solution III; mix solution II and solution III and 49.3g weight 40% SiO 2 The sol was sequentially added to the mixed oxide I and stirred in a boiling water bath at 100°C. At the same time, the pH value of the slurry was adjusted to 5 with ammonia water, and peptized to obtain a sol IV with a solid content of 15% by weight. The sol was spray-dried and formed. The inlet temperature of the sprayer is 380°C, the outlet temperature is 230°C, and then roasted at a temperature of 750°C and roasted fo...

Embodiment 2

[0033] The copper nitrate trihydrate of 81.6g titanyl sulfate and 724.8g and the calcium nitrate tetrahydrate of 1.77g are dissolved in water and make solution, then this solution and the 20% by weight solution that contains the salt of wormwood of 560g co-current precipitation, will The precipitate was filtered and washed repeatedly with deionized water to obtain fresh and clean mixed oxide I of titanium oxide, copper oxide and calcium oxide; 606.03g of ferric nitrate nonahydrate was dissolved in water to form solution II, and 8.4g of hydrogen Potassium oxide was made into solution III; solution II and solution III were sequentially added to mixed oxide I and stirred in a water bath at 50°C, while dilute nitric acid was used to adjust the pH value of the slurry to 1, and peptized to obtain a solid content of 45% by weight The sol body IV, the sol is spray-dried and molded, the inlet temperature of the sprayer is 200°C, the outlet temperature is 100°C, and then roasted, the roa...

Embodiment 3

[0037] 813.6g of zirconium nitrate pentahydrate and 2.7g of 50% manganese nitrate and 38.5g of magnesium nitrate hexahydrate are dissolved in water to make a solution, and then the solution is cocurrently precipitated with a 20% by weight solution containing 530g of sodium carbonate, The precipitate was filtered and washed repeatedly with deionized water to obtain fresh and clean mixed oxide I of zirconia, manganese oxide and magnesium oxide; 606.03g of ferric nitrate nonahydrate was dissolved in water to form solution II, and 0.6g of Potassium hydroxide was made into solution III; solution II and solution III were sequentially added to mixed oxide I and stirred in an ice-water bath at 0°C. At the same time, the pH value of the slurry was adjusted to 4.5 with dilute ammonia water, and the solid content of 30 was obtained by peptization. % by weight of the sol body IV, the sol is spray-dried and molded, the inlet temperature of the spray machine is 280°C, the outlet temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com