Three-layer non-mixed bottom net papermaking press felt

A technology for pressing felt and bottom wire, applied in textiles and papermaking, papermaking, papermaking, etc., can solve the problems of uneven pressure distribution in the nip, reduce the compaction resistance and dewatering performance of the felt, and reduce the wear of the felt, etc. The effect of improving wear resistance, wear resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

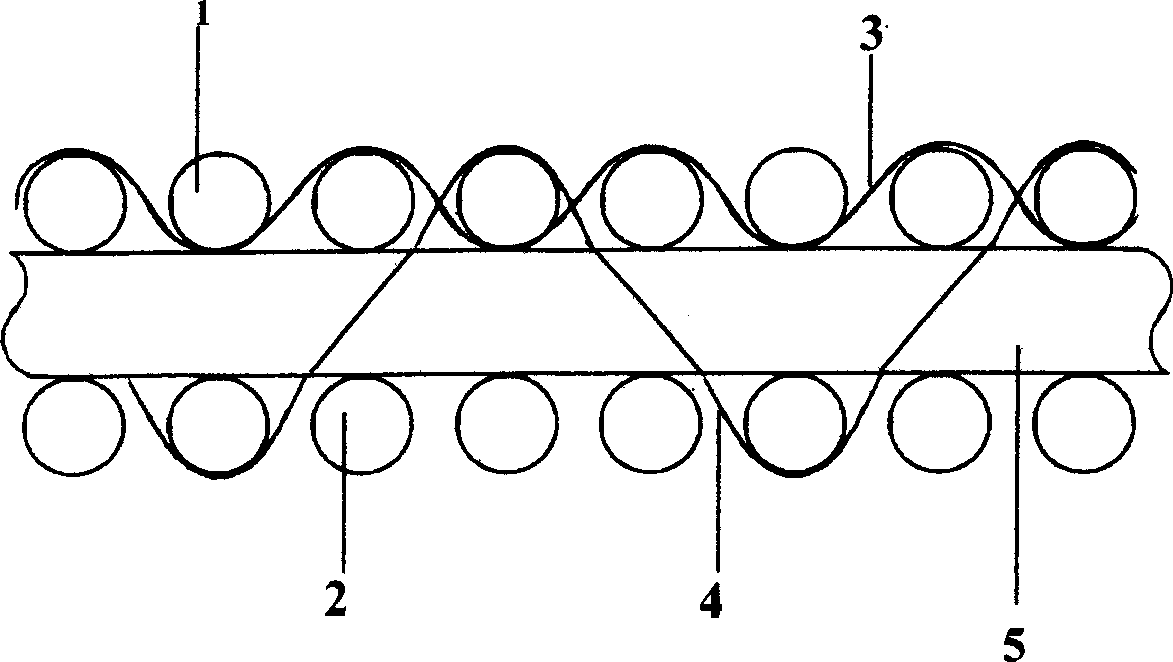

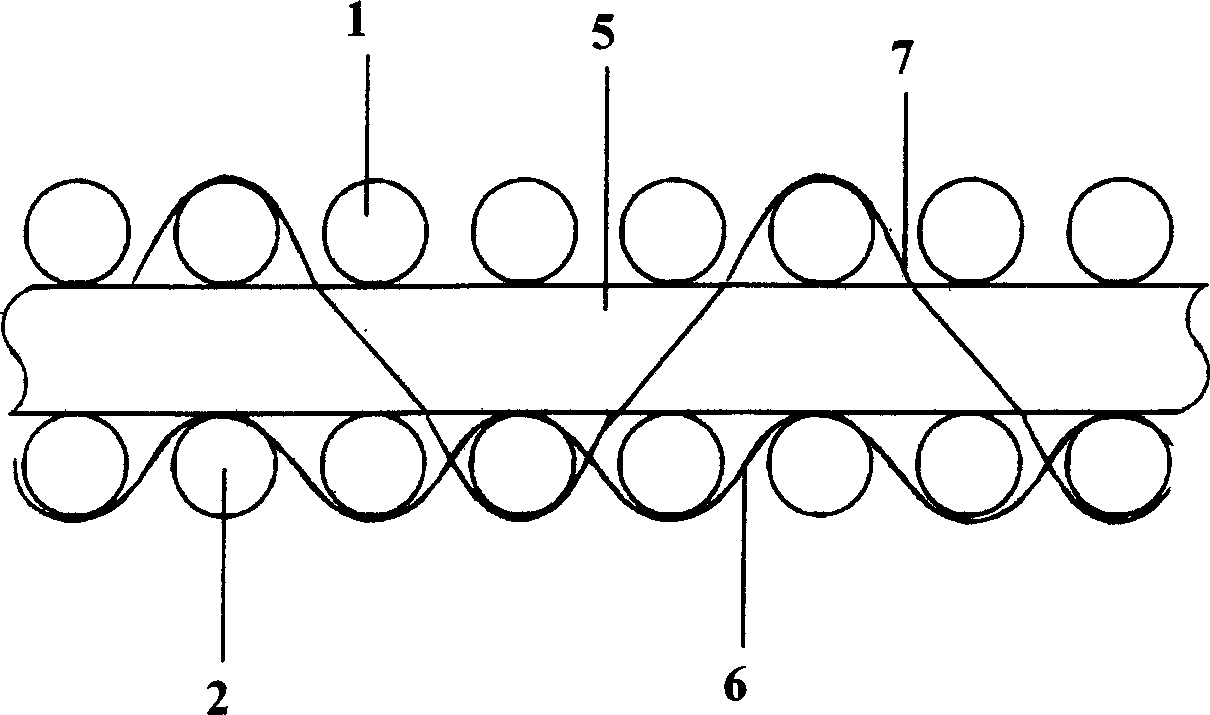

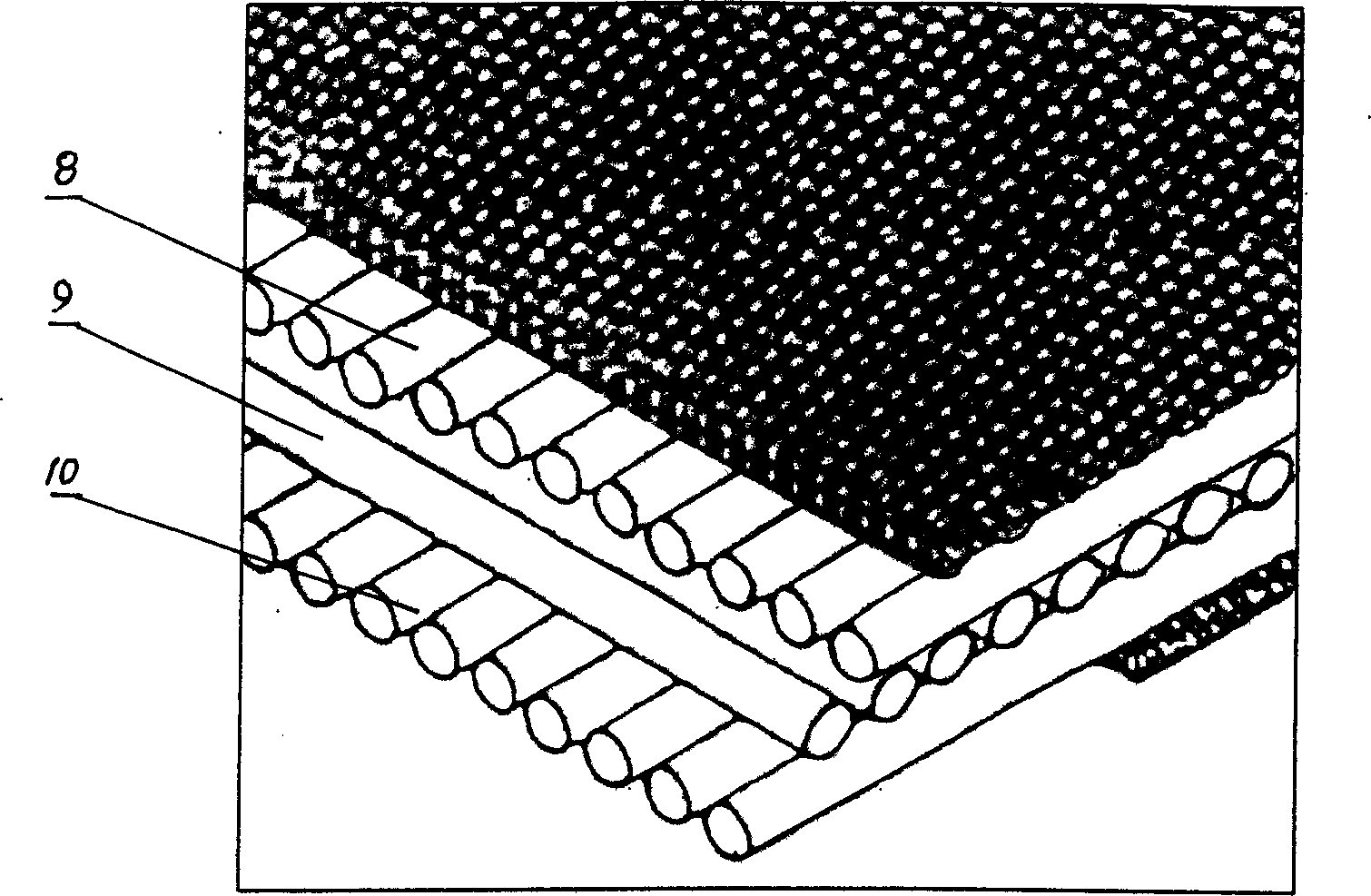

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment: the bottom net of this blanket is made up of altogether three layers of woven fabrics of upper layer 8, middle layer 9 and lower layer 10. Wherein the upper layer 8 is woven by warp threads 1 and weft threads 3 . Likewise, the lower layer 10 is also woven by warp threads 2 and weft threads 6 . And the used weft 2 and weft 6 of upper layer 8 and lower layer 10 are polyvinyl formal fiber filaments of 100d. Simultaneously part warp thread 1 and warp thread 2 of upper strata 8 and lower floor 10 also will connect them with connecting wire 4,7, and used connecting wire 4,7 is also the polyvinyl formal fiber filament of 100d. And the middle layer 9 between the upper layer 8 and the lower layer 10 is to use 0.8mm nylon monofilament as only the weft yarn layer of the weft 5; The warp threads 1 and weft threads 3 of 8 are braided together, and then part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com