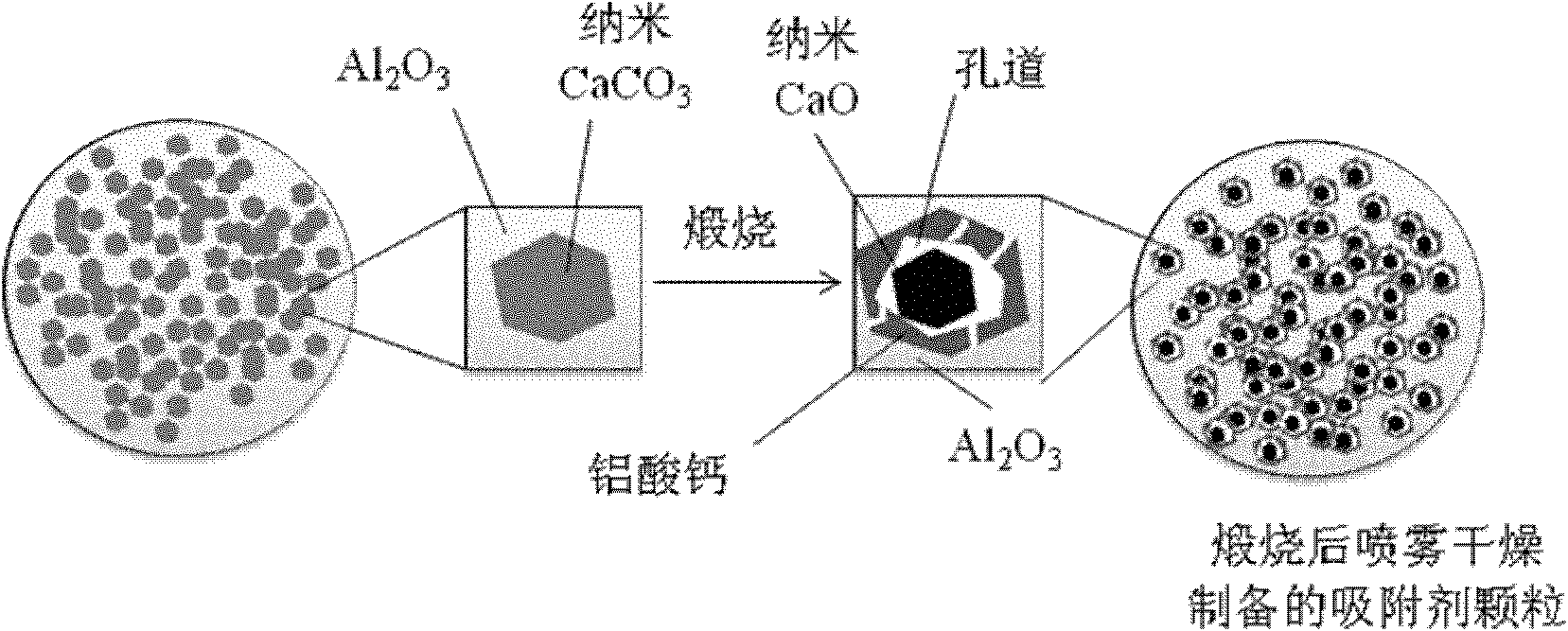

Method for preparing wear-resistant nano calcium oxide-based carbon dioxide reaction adsorbent

A technology of nano-calcium oxide and adsorbent, which is applied in the field of material manufacturing to achieve the effect of improving wear performance, high stability, and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

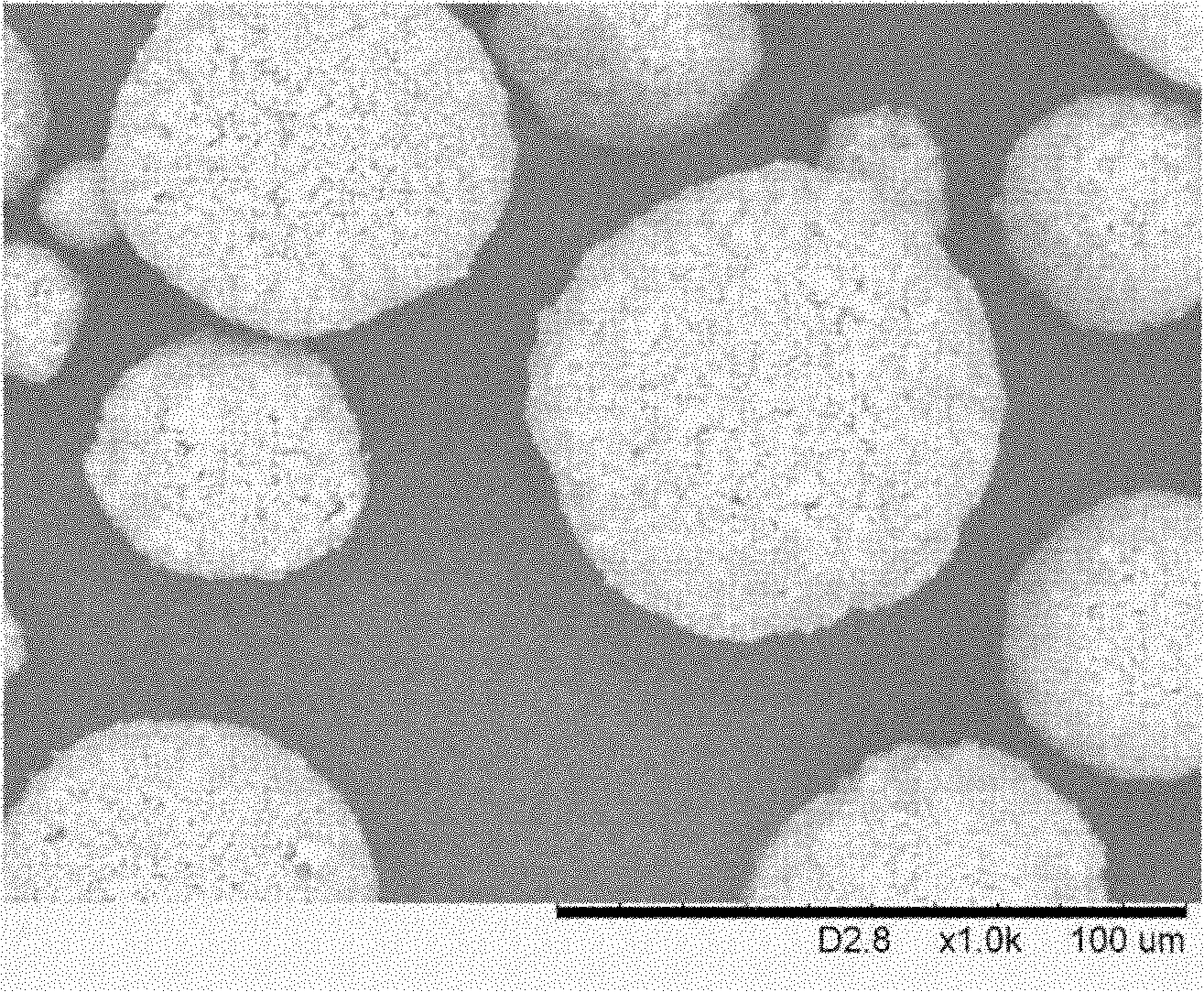

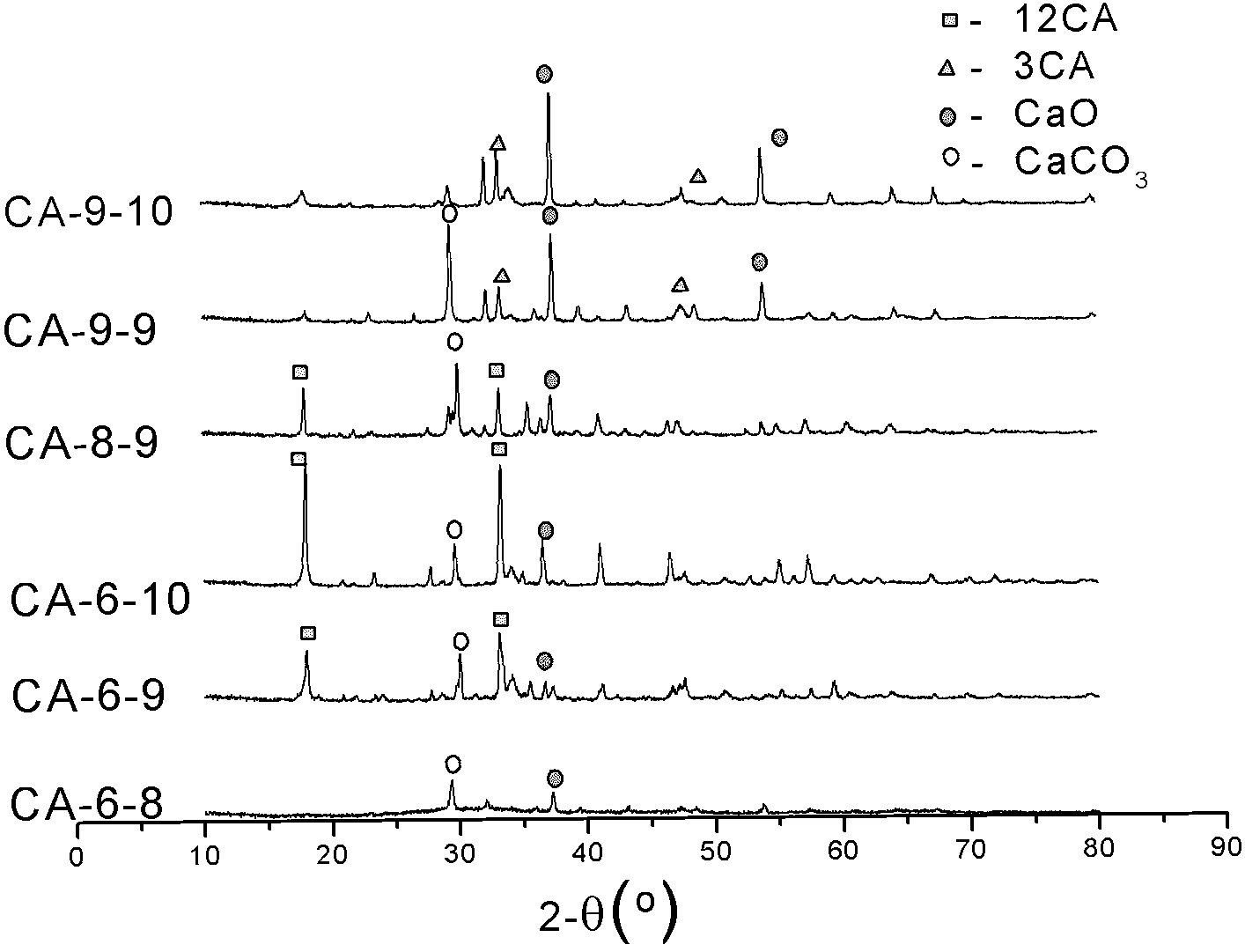

[0048] CaCO 3 50g of particles are dispersed in water by ultrasonic waves, adding 15% 225g of aluminum sol, stirring until a uniform slurry, and spray granulation to obtain microsphere particles with a particle size of 20-250μm, which are calcined at 900°C to prepare spherical wear-resistant nano CaO-based CO 2 Reactive sorbent.

Embodiment 2

[0050] CaCO 3 200g of particles are dispersed in water by ultrasonic wave, adding 15% 590g of aluminum sol, stirring until uniform slurry, spray granulation to obtain microsphere particles with a particle size of 20-250μm, and calcining at 850°C to prepare spherical wear-resistant nano CaO-based CO 2 Reactive sorbent.

Embodiment 3

[0052] CaCO 3 80g of particles are dispersed in water by ultrasonic wave, adding 15% 234g of aluminum sol, stirring until uniform slurry, and spraying granulation to obtain microsphere particles with a particle size of 20-250μm, which are calcined at 900°C to prepare spherical wear-resistant nano CaO-based CO 2 Reactive sorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com