Preparation and application of composite CoP/g-C3N4 photocatalyst

A technology of g-c3n4 and complexes, which is applied in the field of nanomaterials and photocatalysis, can solve the problems of expensiveness, wide application limitation, and rare price of precious metals, and achieve the effects of avoiding pollution, economical and easy-to-obtain raw materials, and simple and convenient experimental procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] g-C 3 N 4 preparation of

[0033] 5 g of melamine and 5 g of ammonium chloride were ground and mixed uniformly in a mortar, then the uniformly mixed powder was placed in a crucible with a cover, and placed in a muffle furnace at a rate of 5 °C / min. to 300°C, then raised to 520°C at a rate of 2°C / min, and then kept at this temperature for 4 hours. After the temperature dropped to room temperature, it was taken out to obtain light yellow g-C 3 N 4 , ground into powder for later use.

[0034] The following cases are CoP and CoP / g-C 3 N 4 The preparation steps:

Embodiment 2

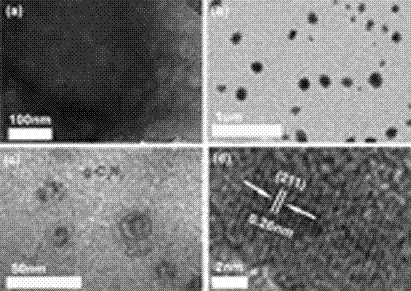

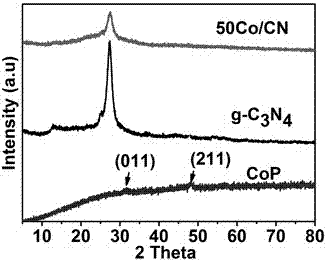

[0036] Weigh 200 mg of cobalt nitrate hexahydrate and 200 mg of hexamethylenetetramine into 50 ml of water in sequence, stir magnetically for 10 min, and sonicate for 10 min, then place the solution in an oil bath at 90°C for 6 hours, the solution was cooled to room temperature, washed by centrifugation, washed three times with water, washed three times with alcohol, and then dried in a vacuum oven at 60°C to obtain Co(OH) 2 . Then take out 50 mg of this compound and place it on one end of the porcelain ark, then place 500 mg of sodium hypophosphite on the other end, place the porcelain ark in a tube furnace, and place the end with sodium hypophosphite near the air inlet At 1°C / min, the temperature was raised to 300°C and kept for 2 hours. The black solid collected after cooling to room temperature is the CoP.

Embodiment 3

[0038] Weigh 0.2 g of g-C 3 N 4 Place it in 50 ml of water and ultrasonically disperse it for 2 hours, which is called solution A. Another 30 mg of cobalt nitrate hexahydrate and an equivalent amount of hexamethylenetetramine were dissolved in 10 ml of deionized water in turn, and magnetically stirred to form a homogeneous solution, called solution B. Then solution B was slowly added dropwise to solution A under magnetic stirring (one drop per second), then magnetic stirring for 10 min, and ultrasonication for 10 min. Place the above solution in an oil bath at 90°C to react for 6 hours. After cooling, wash by centrifugation, wash three times with water, and wash three times with alcohol. Then dry the solid in a vacuum oven to obtain Co(OH) 2 / g -C 3 N 4 Complex. Take out 50 mg Co(OH) 2 / g -C 3 N 4 Compound, then weigh 500 mg of sodium hypophosphite, place the two parts of the drug on the two ends of the porcelain ark, place the porcelain ark in a tube furnace, and plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com