Patents

Literature

231 results about "Pulp bleaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of pulp bleaching: Removal of colored substance or alter the coloring material from chemical pulp to increase its brightness and cleanliness, without deleterious effect on the physical and chemical properties of the pulp.

Bleaching stage using xylanase with hydrogen peroxide, peracids, or a combination thereof

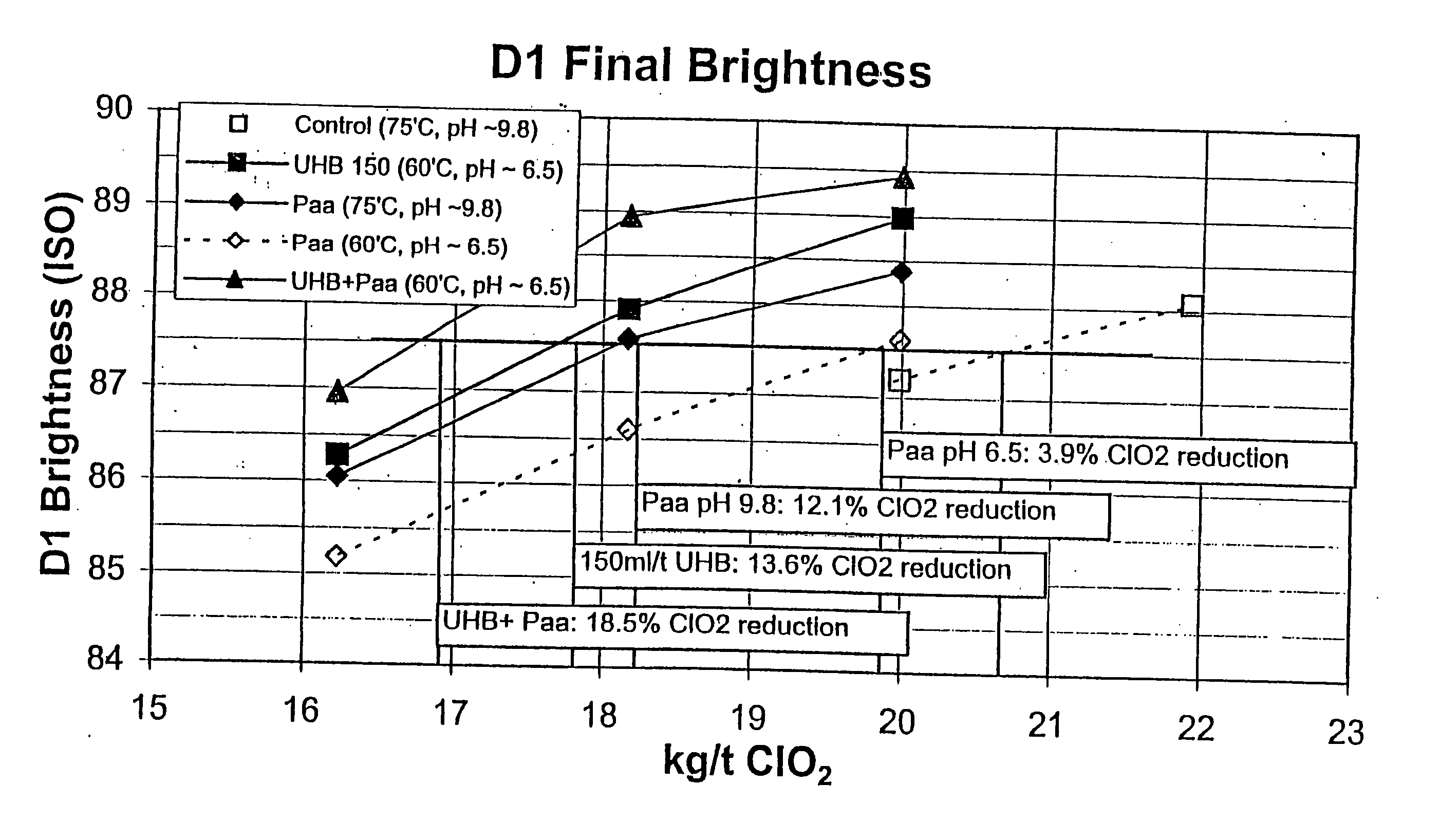

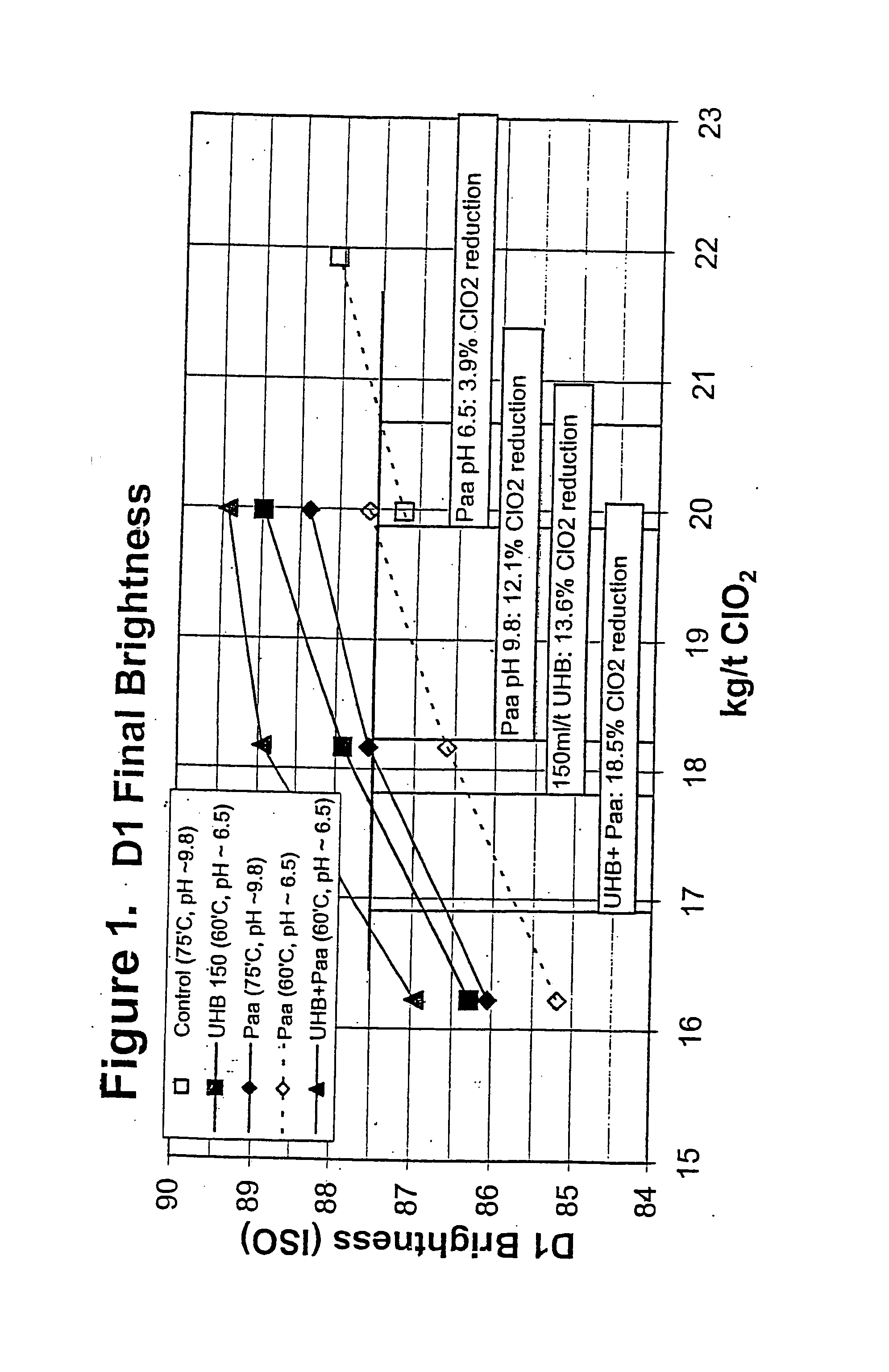

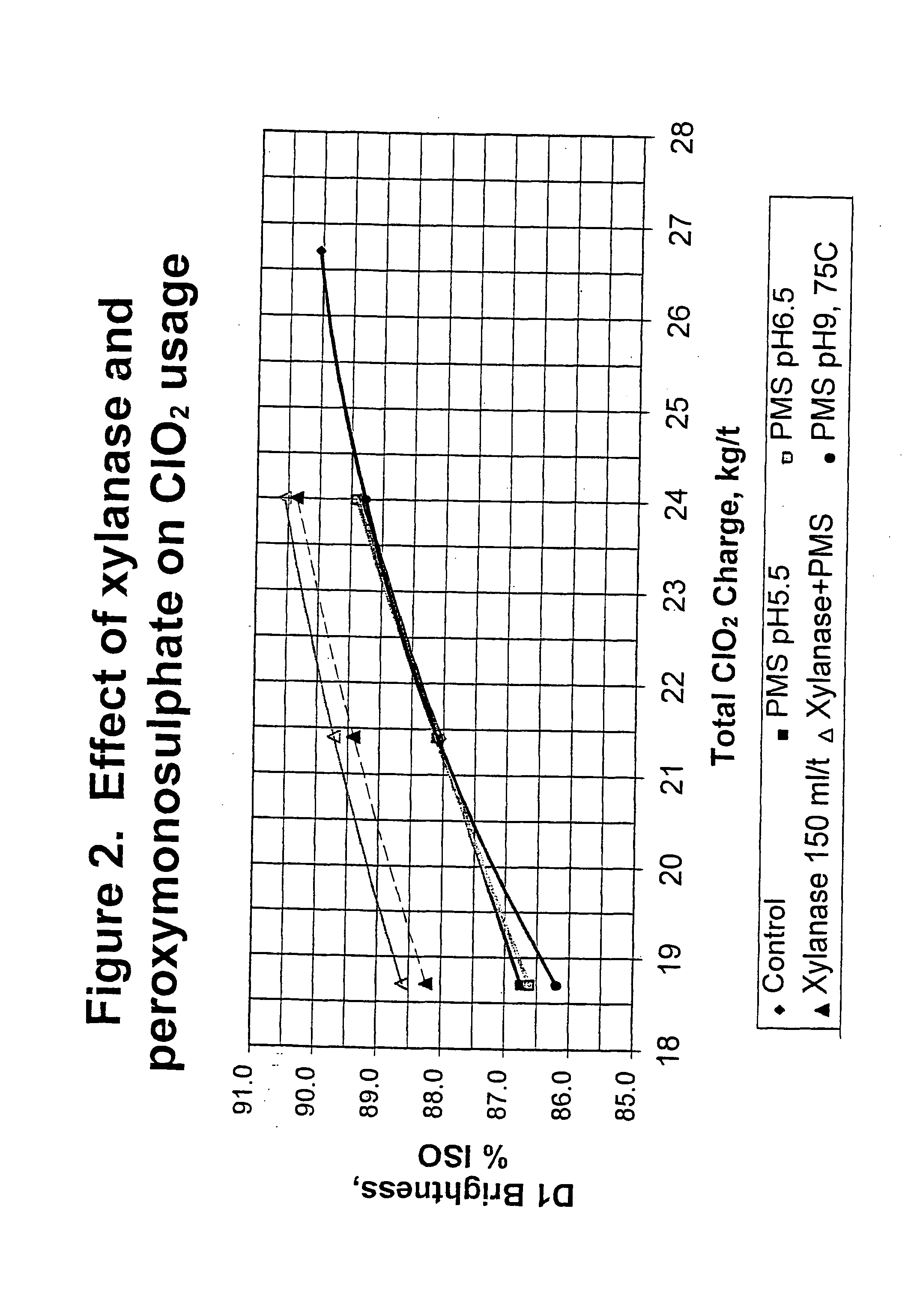

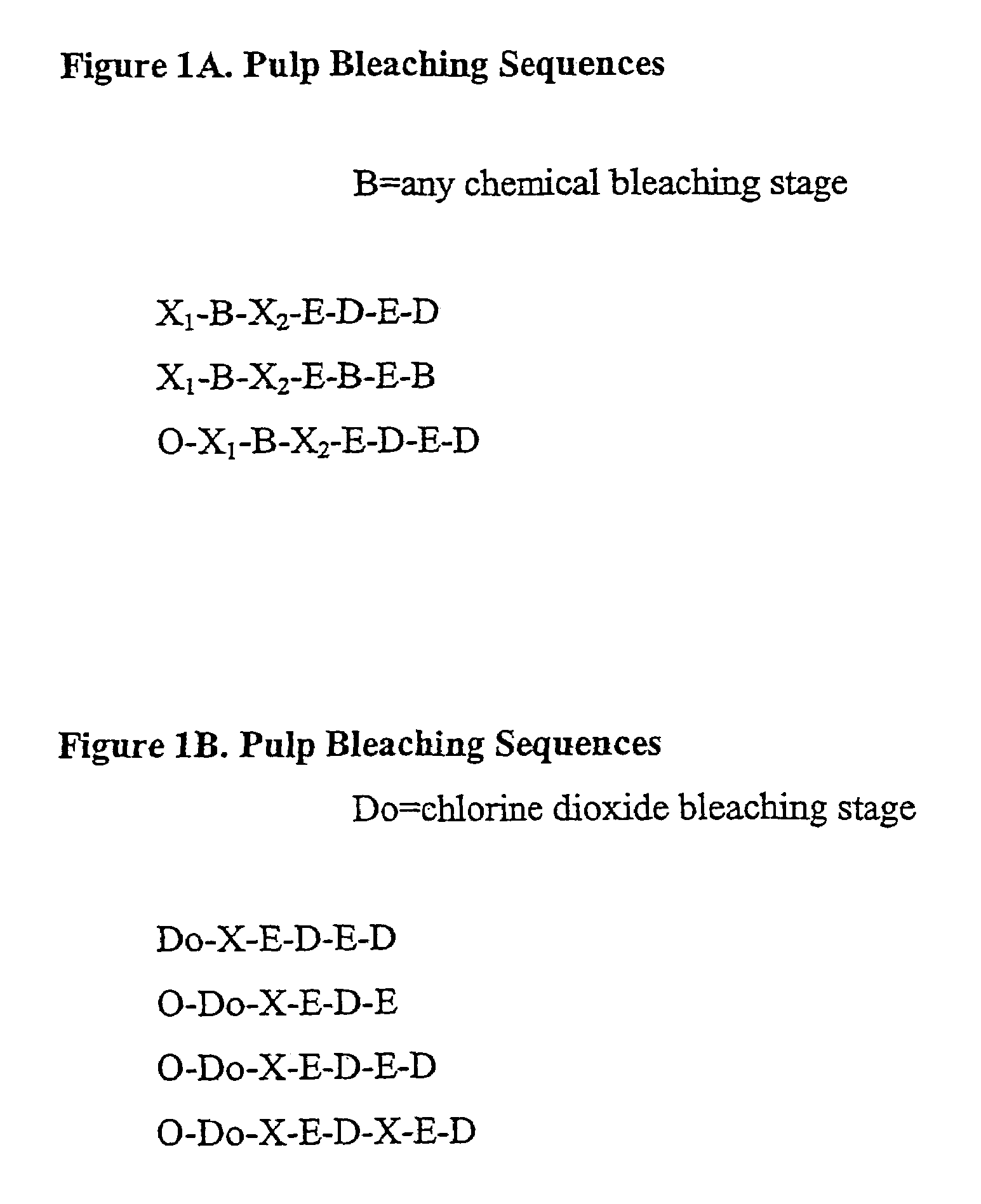

InactiveUS20040112555A1Less-costly bleaching operationReduce usagePulp bleachingPulping with inorganic basesChlorine dioxideXylanase Y

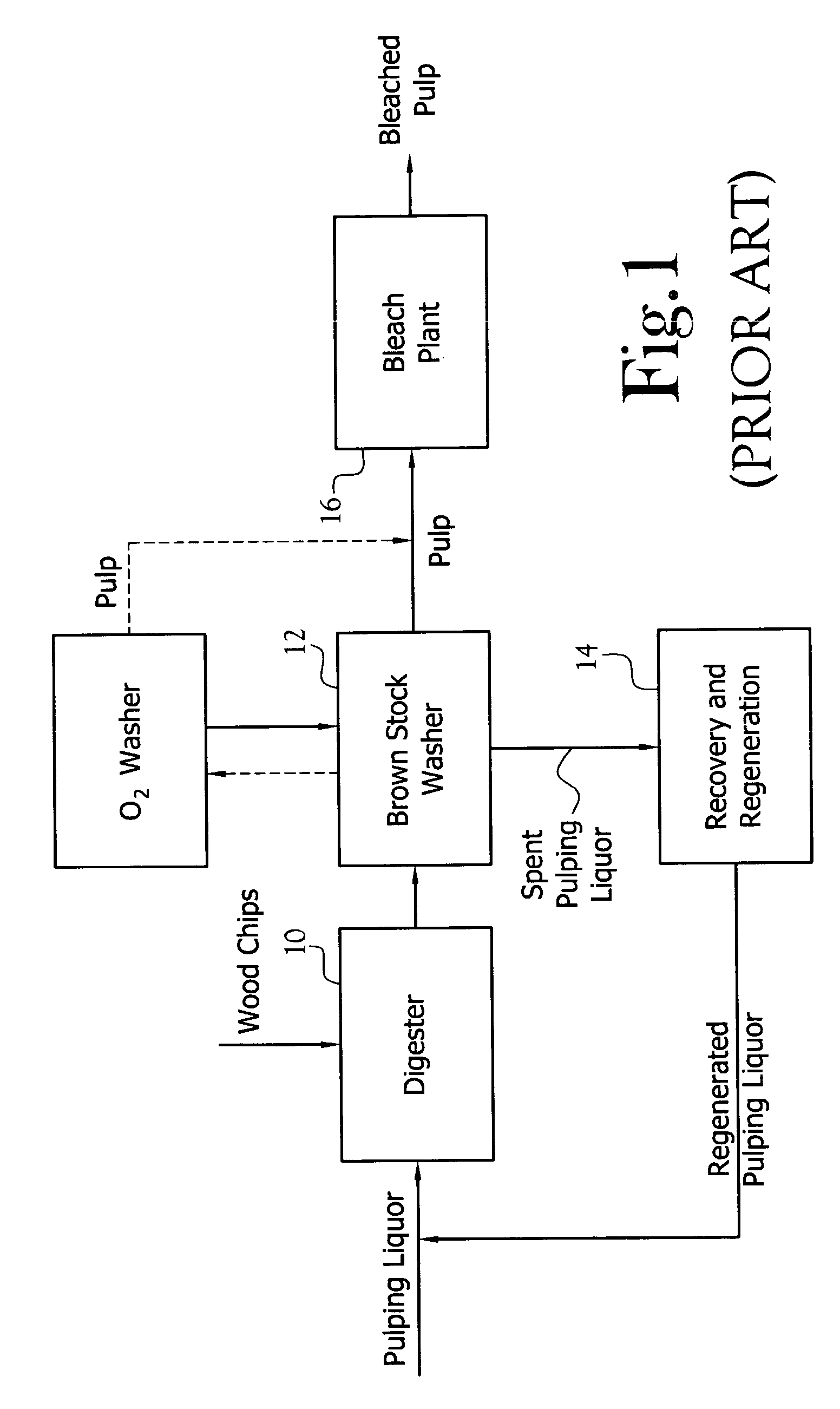

The present invention discloses methods of bleaching chemical pulp that combine xylanase enzymes with hydrogen peroxide, peracids, or a mixture. The method comprises the steps of carrying out a chemical pulping operation, optionally followed by delignifying the pulp with oxygen, then combining xylanase enzymes with hydrogen peroxide, peracids, or a mixture to bleach the pulp. The method allows the mill to use both xylanase and peracids in a single bleaching tower to decrease the usage of chlorine dioxide and other bleaching chemicals. The pulp bleaching method of the present invention may be performed in a pulp mill as part of a complex pulp bleaching process.

Owner:IOGEN BIO PRODUCKTS CORP

Apparatus for making carboxylated pulp fibers

InactiveUS7001483B2Little additional equipmentDelay transitionNon-fibrous pulp additionSpecial paperFiberBleach

Owner:WEYERHAEUSER CO

Xylanase treatment of chemical pulp

InactiveUS20050150619A1Reduce usageHigh strengthPulp bleachingPulping with organic solventsChlorine dioxidePulp mill

The present invention discloses methods of bleaching chemical pulp that use xylanase enzymes after chemical bleaching. The method comprises the steps of carrying out a chlorine dioxide stage to produce a partially bleached pulp, treating the partially bleached pulp with a xylanase enzyme, optionally in the presence of oxygen and hydrogen peroxide, in a mild extraction stage, then bleaching the pulp with a second chlorine dioxide stage. The method allows the mill to decrease the usage of sodium hydroxide or other alkali, while decreasing the use of chlorine dioxide, and possibly improving the yield and strength of the pulp, while maintaining a similar level of bleached brightness of the pulp. The pulp bleaching method of the present invention may be performed in a pulp mill as part of a complex pulp bleaching process.

Owner:NOVOZYMES AS

Extended retention and medium consistency pulp treatment

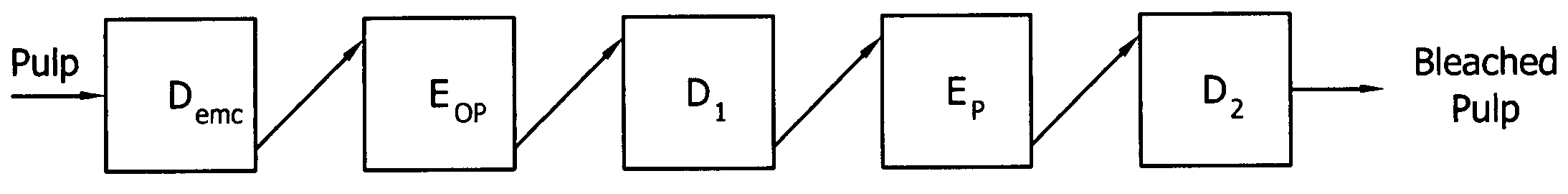

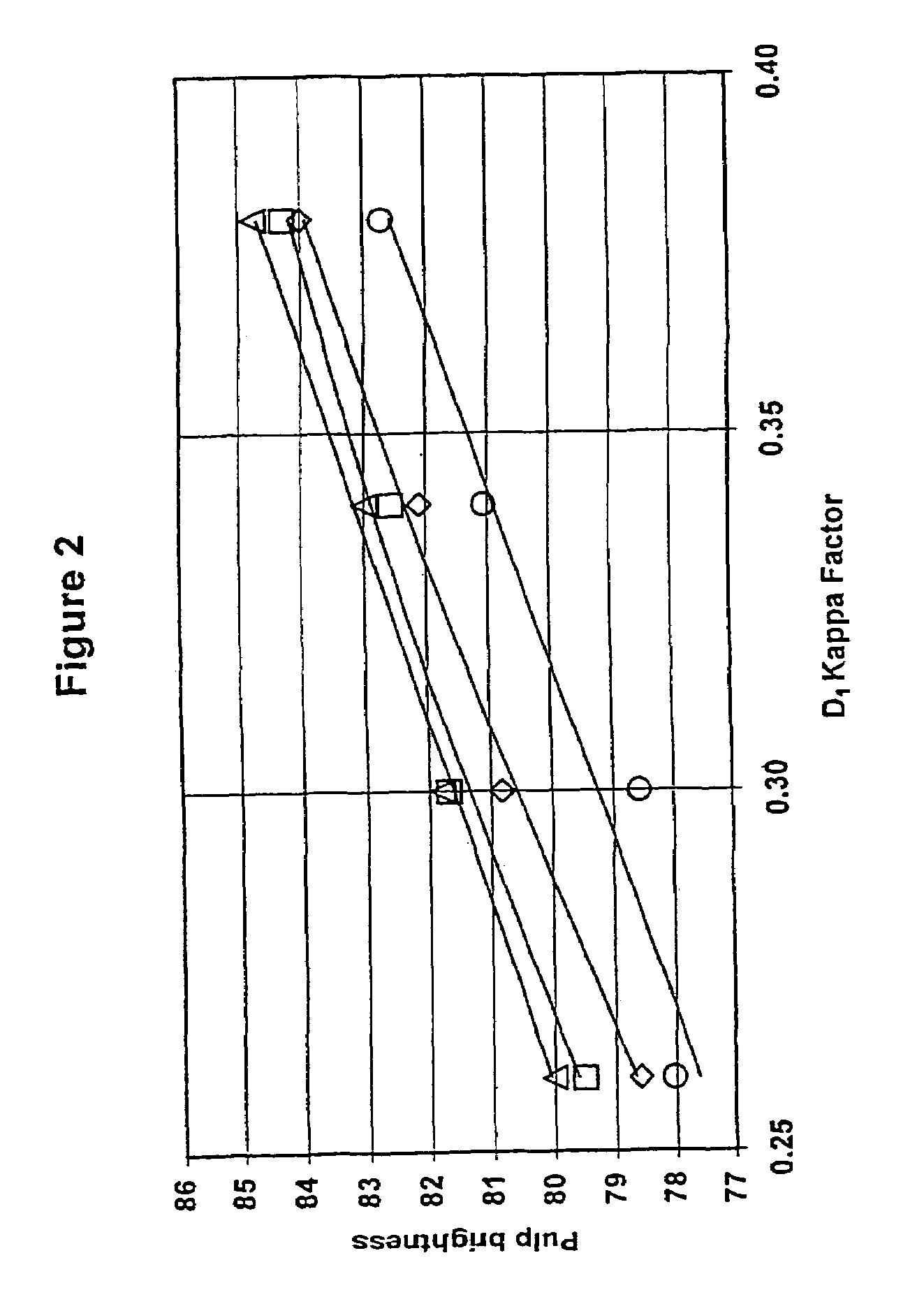

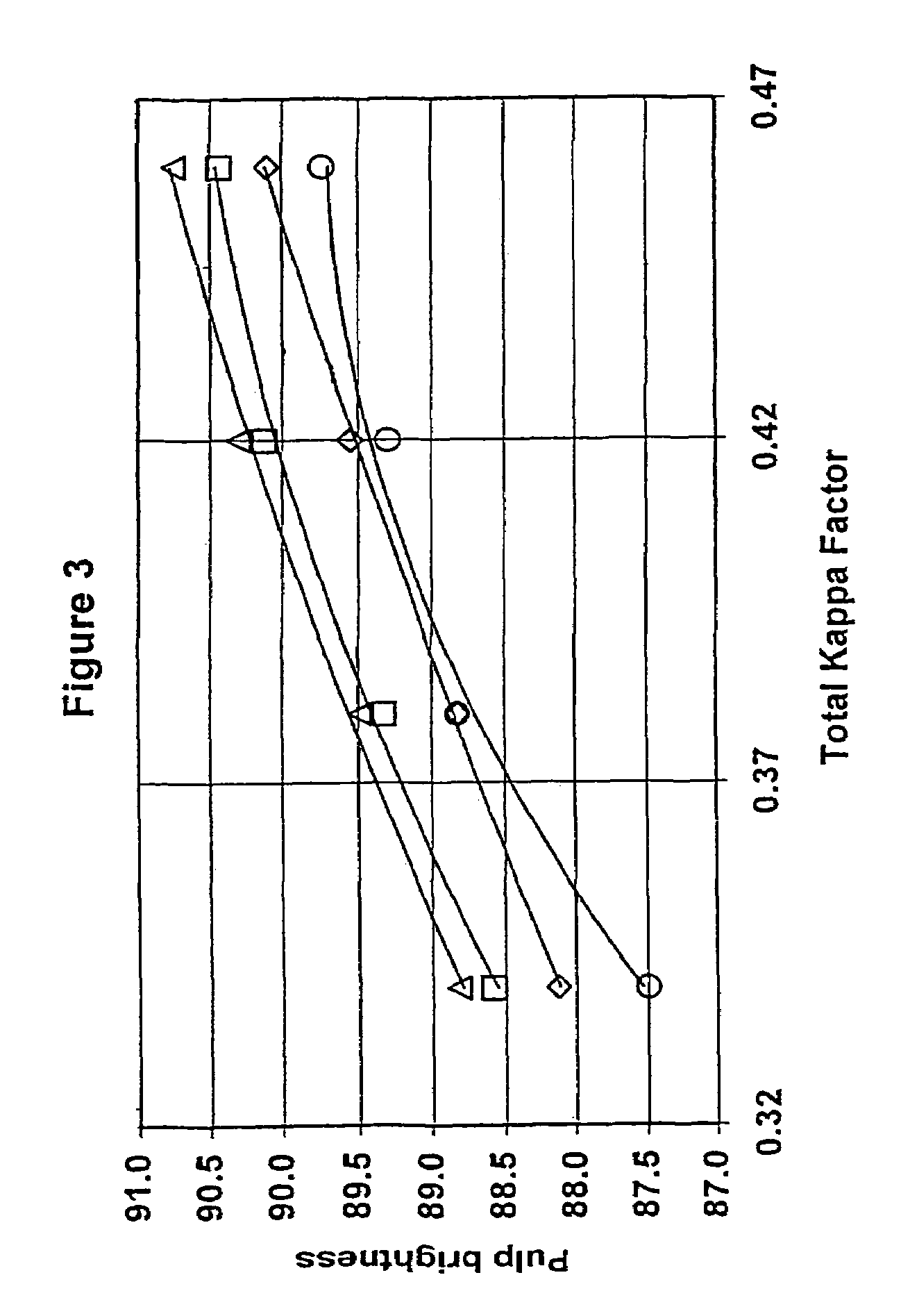

InactiveUS20050051288A1Improve efficiency and selectivityLowering of chlorine dioxide consumptionPulp bleachingPulping with inorganic basesPulp treatmentChemistry

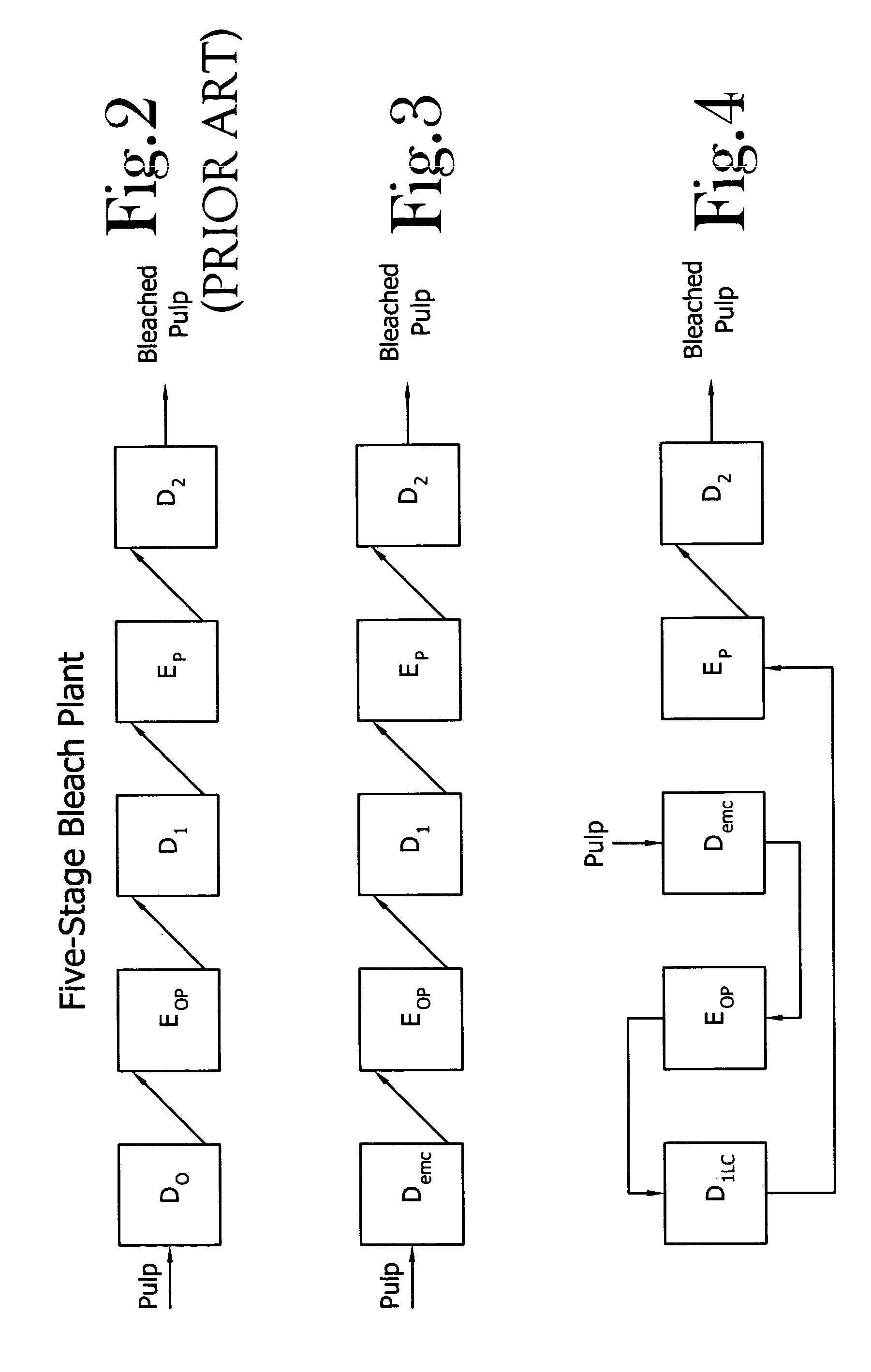

Treatment of digested or O2 delignified cellulosic pulp in a chlorine dioxide (Do) delignification stage, preceding bleaching of the pulp, at a medium pulp consistency for an extended period of time. Unexpected benefits include improvement in the delignification efficiency and selectivity, a lowering of the chlorine dioxide consumption in the overall post-digestion or post-O2 delignification and bleaching process, a reduction in the filtrate volume, a reduction of COD / AOX from an ECF bleaching plant, improved pulp properties, and enhanced removal of Hex-A. The process may be implemented in existing three, four or five-stage bleaching plants.

Owner:INT PAPER CO

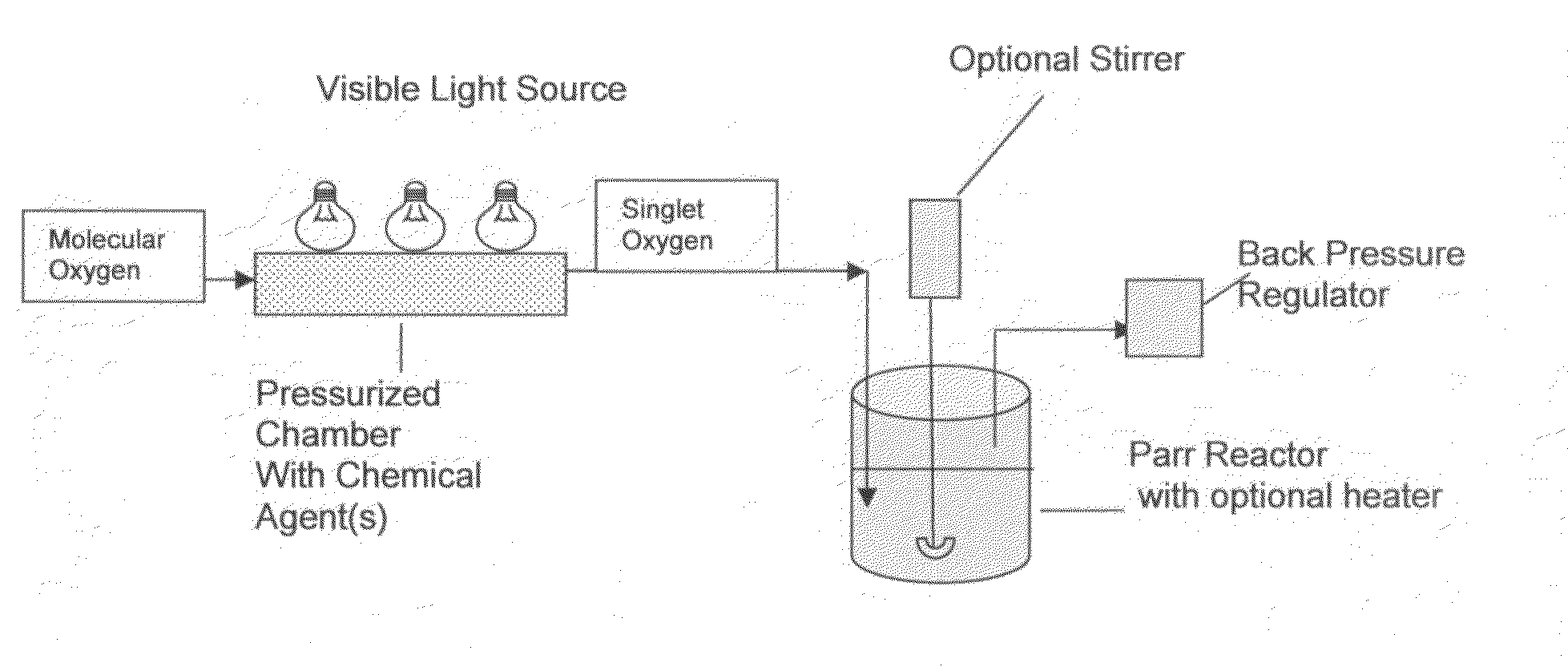

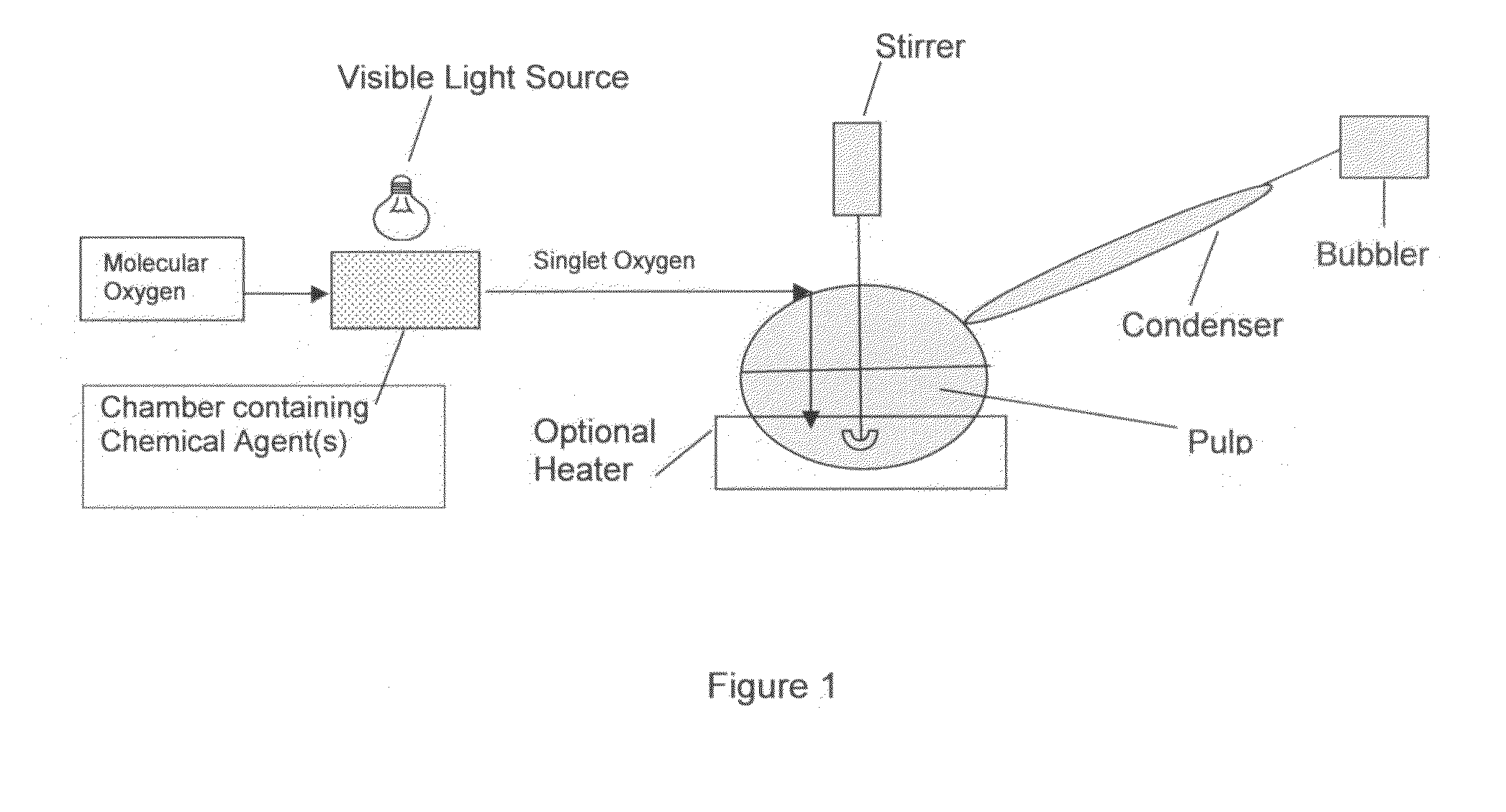

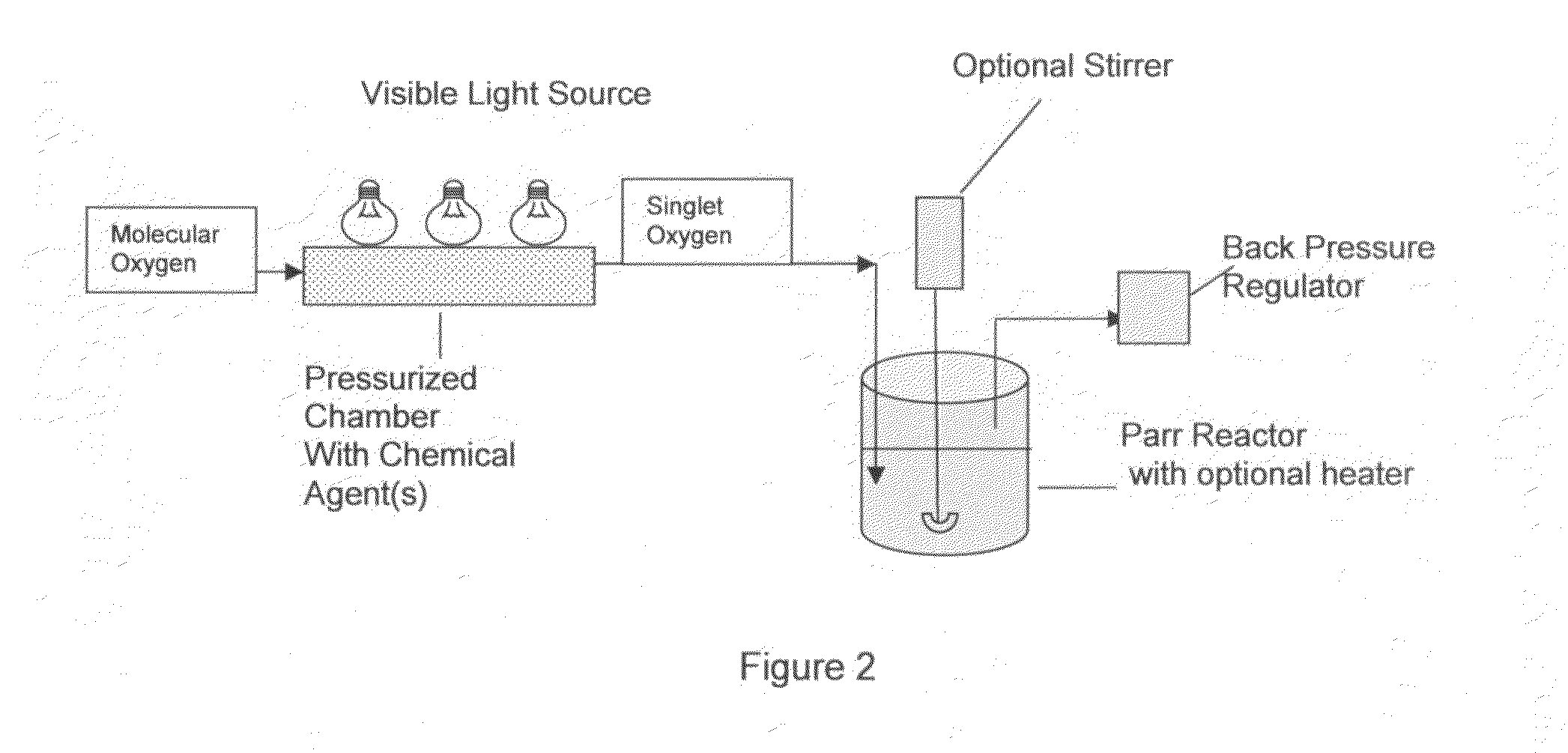

Selectivity improvement in oxygen delignification and bleaching of lignocellulose pulp using singlet oxygen

A process to enhance delignification or bleaching in chemical or mechanical pulps comprising generation of singlet oxygen as a separate step and subsequent transport of singlet oxygen to pulp to effect bleaching or brightening of the pulp.

Owner:ROSSI JOANNE MARY FOBARE

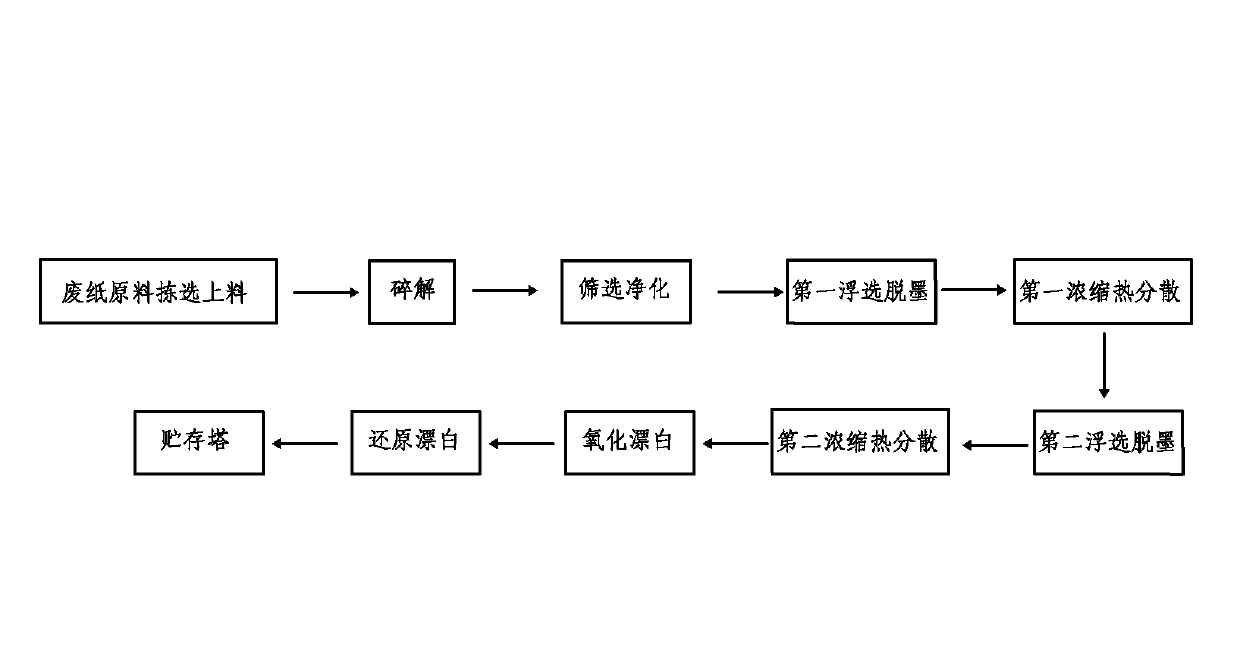

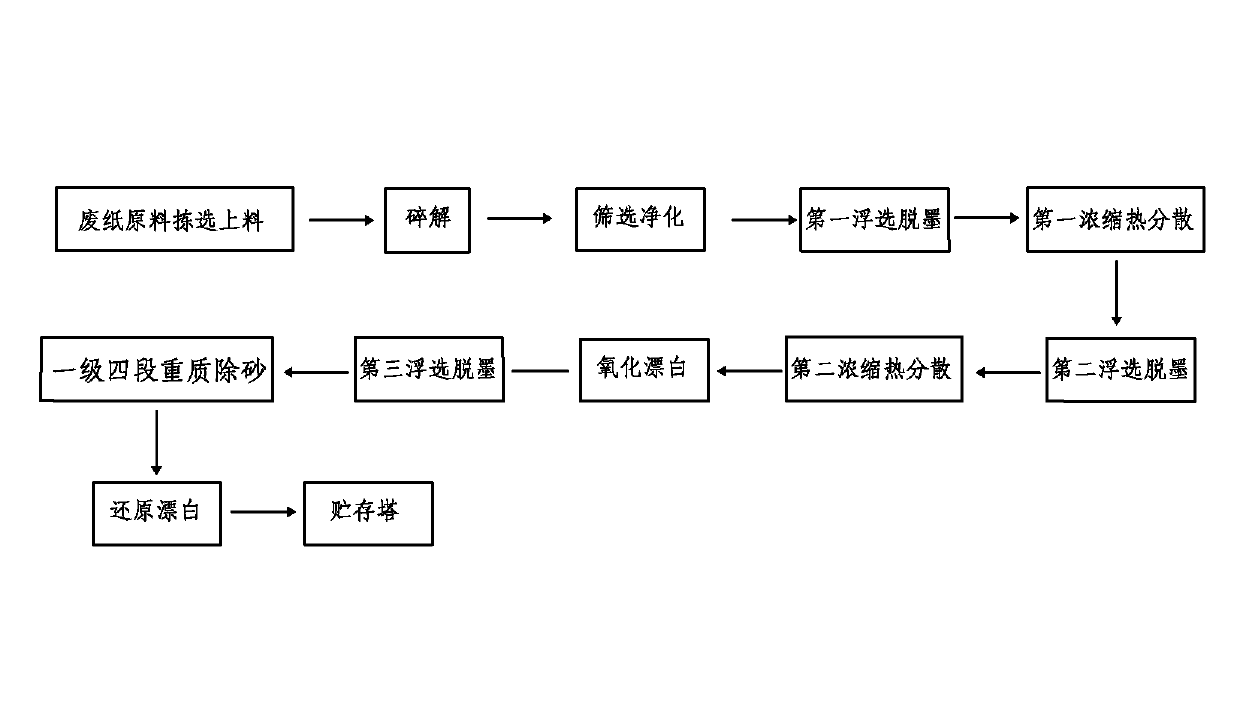

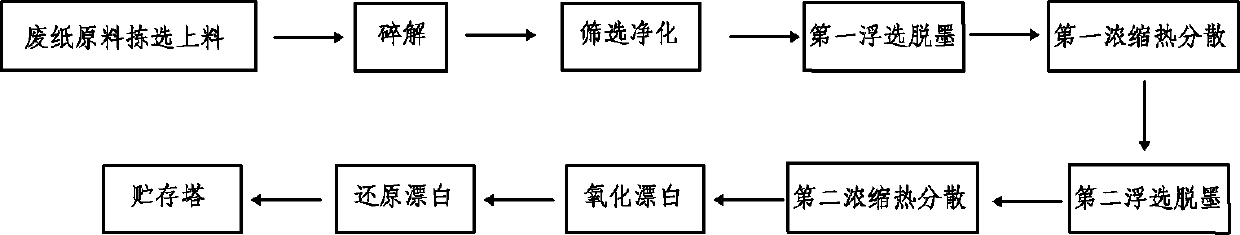

Process for preparing recovered pulp with high whiteness and high cleanliness

InactiveCN102677515ALow costHigh whitenessCellulosic pulp after-treatmentPaper recyclingDeinkingProduction line

The invention relates to the technical field of papermaking raw material processing, in particular to a process for preparing recovered pulp with high whiteness and high cleanliness in a papermaking industry. The process comprises the following steps of: selecting and feeding of waste paper raw materials; disintegration; screening purification; first flotation deinking; first concentrated heat dispersion; second flotation deinking; second concentrated heat dispersion; oxidation bleaching; reduction bleaching; and storage in a storage tower. According to the process, 20-30 percent of high-quality office waste paper and 70-80 percent of other low-quality waste paper raw materials are matched, so that the cost of the waste paper raw materials is effectively reduced, and the corporate profit is increased. An advanced rotary drum pulper, a pulping machine and a production line of office waste paper screening purification, flotation deinking, concentrated heat dispersion and pulp bleaching are introduced, and the recovered pulp is prepared through the efficient use of chemicals and an effective production control process. The whiteness of the recovered secondary pulp achieves 90 percent ISO, and the cleanliness is high. The whiteness and the cleanliness of finished culture paper are increased.

Owner:DONGGUAN NINE DRAGONS PAPER IND

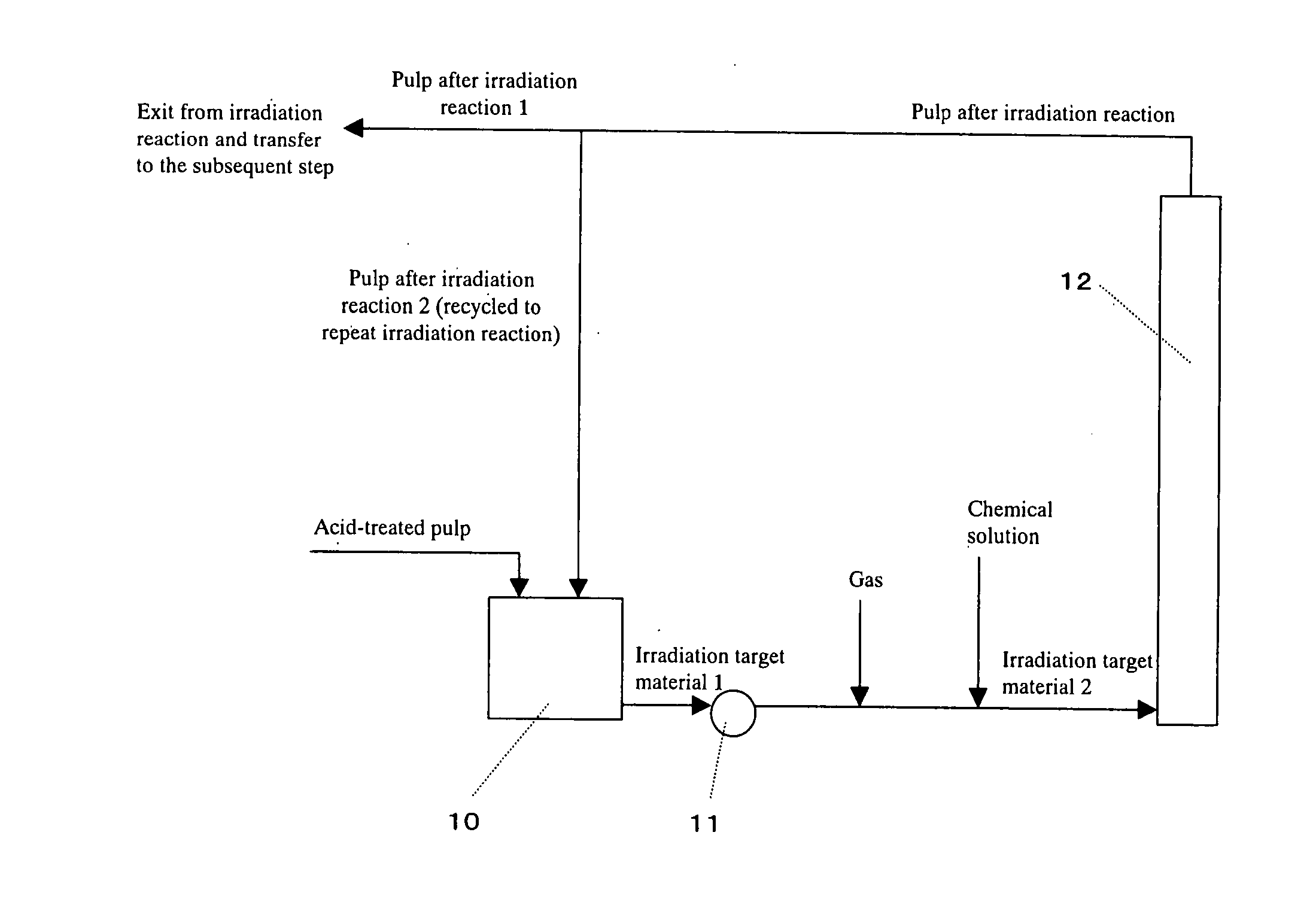

Pulp Bleaching Processes

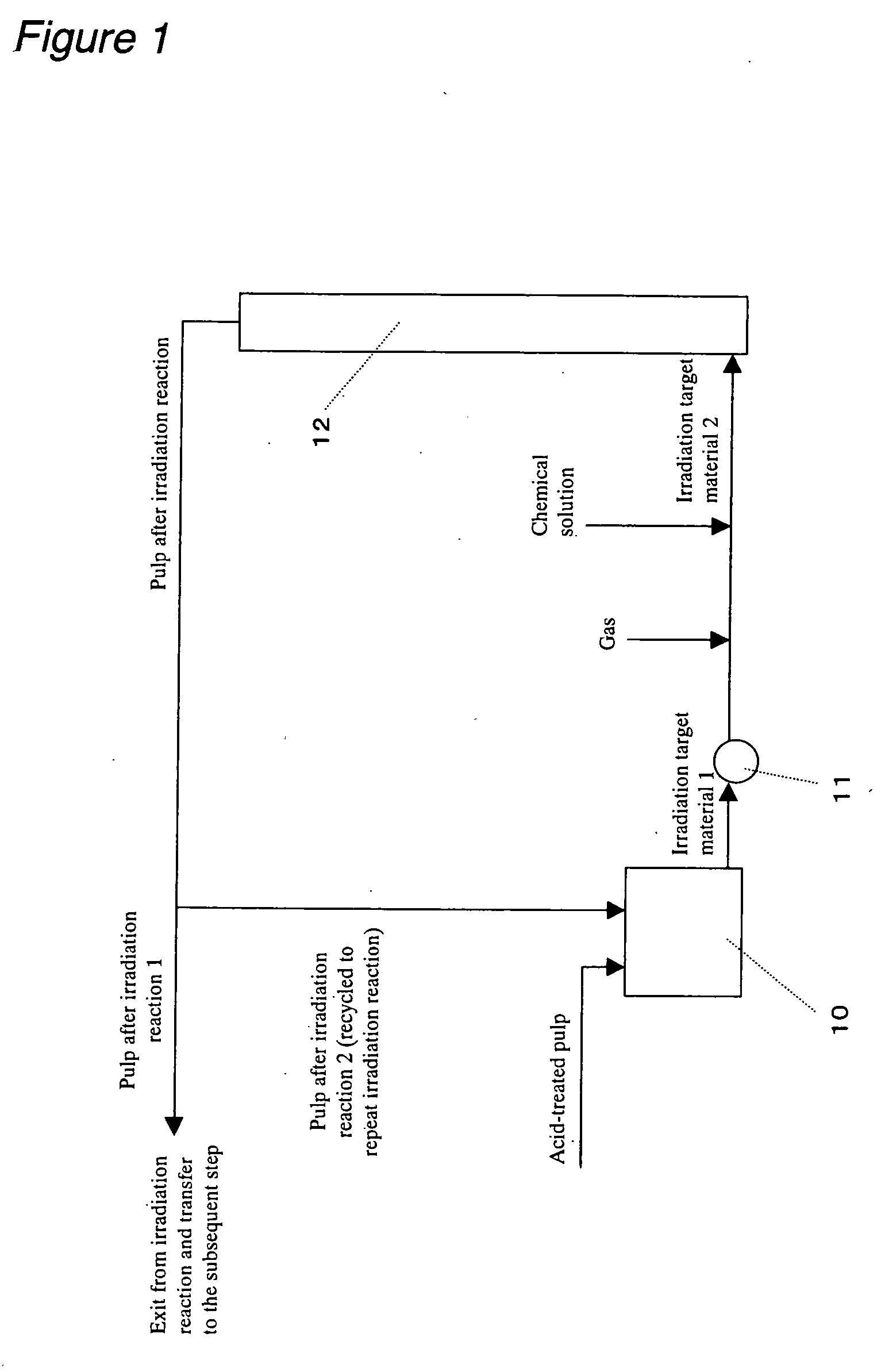

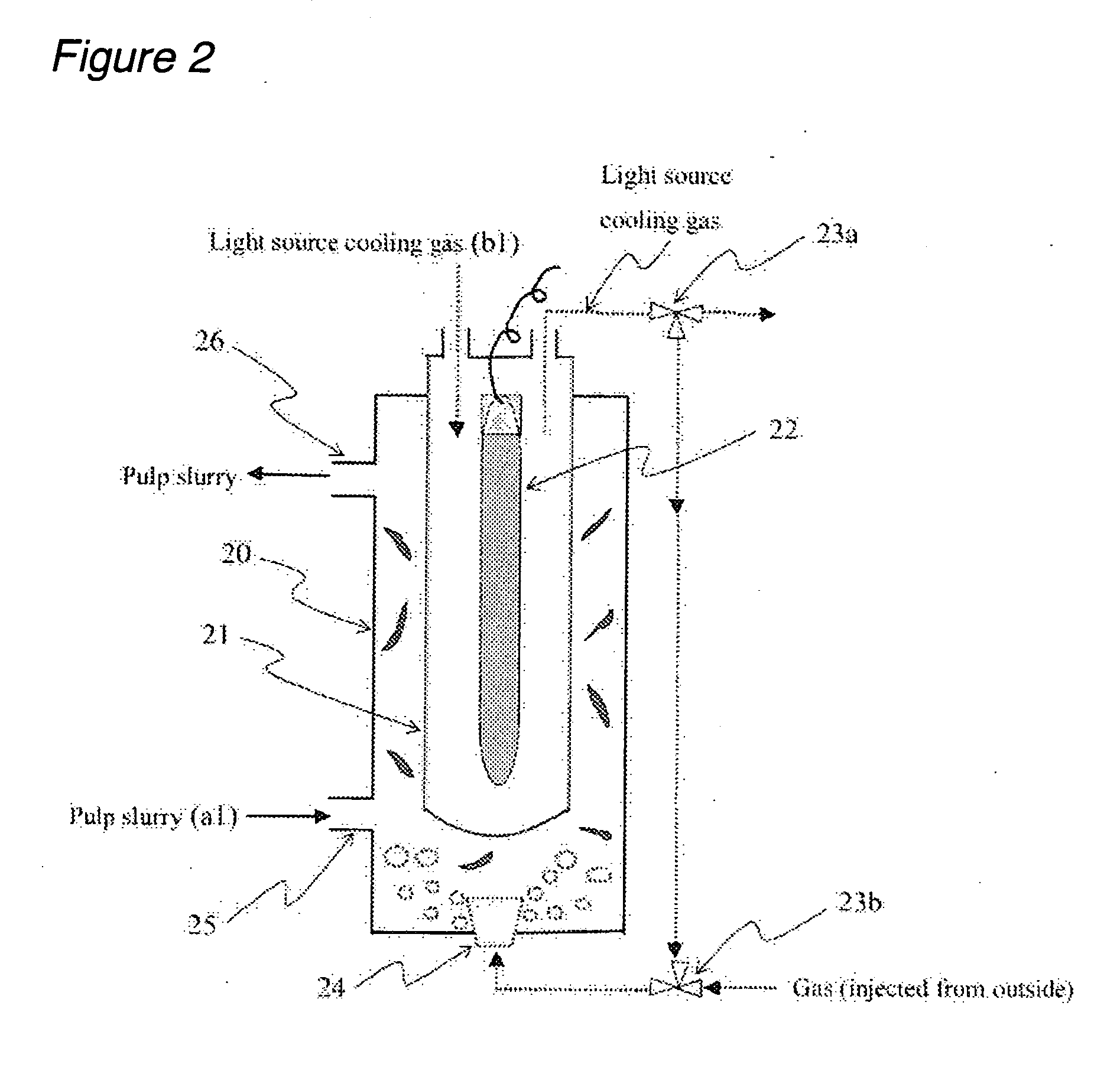

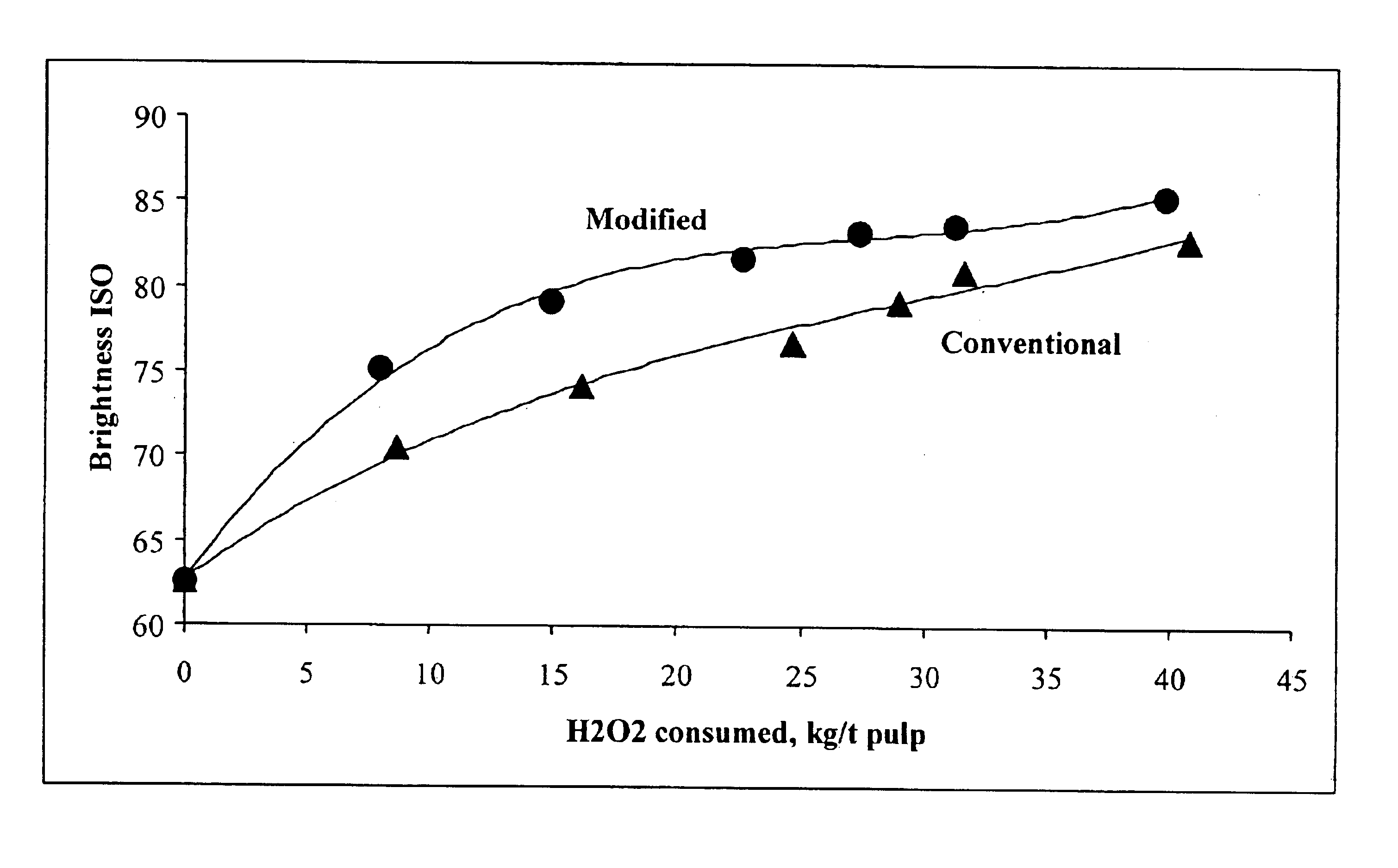

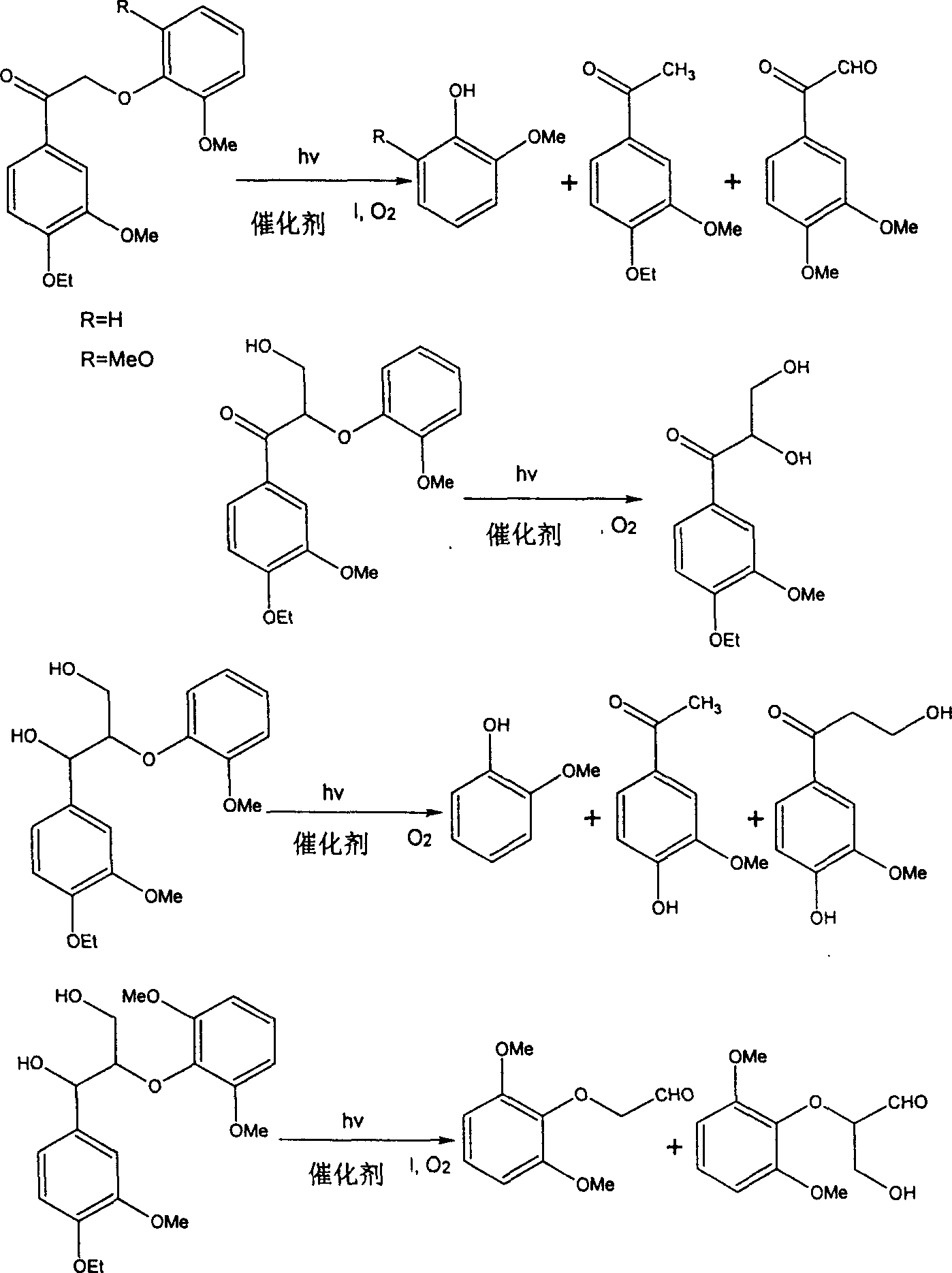

InactiveUS20070246176A1Improve bleaching efficiencyHigh ozone-generating efficiencyPulp bleachingEnergy based chemical/physical/physico-chemical processesOrganic compoundPhotochemistry

The present invention aims to further advance the acid treatment or irradiation technology for pulp to develop a bleaching process using smaller amounts of chlorine chemicals with higher efficiency as compared with conventional bleaching processes. It also aims to provide an excellent high brightness pulp having a low environmental impact and no discoloration as well as a paper containing it. The present invention provides a chlorine-free bleaching process with very high efficiency by irradiating a pulp washed after an acid treatment with UV light and / or visible light at a wavelength of 100-400 nm under alkaline conditions, preferably in a pH range of 10-13. The acid treatment can be performed under conditions of pH 1-6 and a temperature of 80° C. or more. The irradiation treatment can be performed in the presence of at least one compound selected from the group consisting of reducing agents, peroxides, and hydrogen-donating organic compounds. The present invention also provides a high brightness chemical pulp having an ISO brightness of 88% or more and a brightness loss of 1.0% or less in a specific fading test.

Owner:NIPPON PAPER IND CO LTD

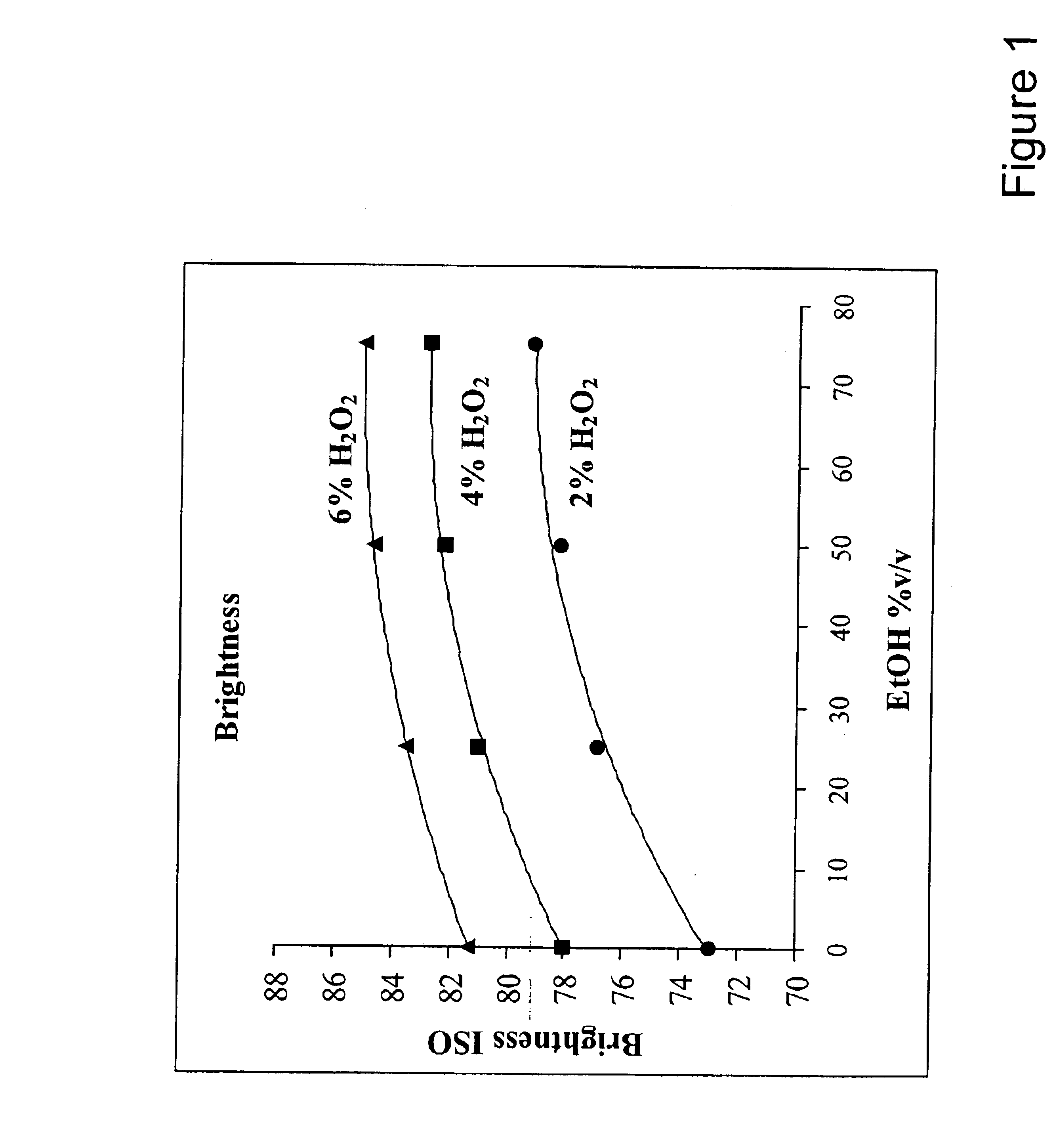

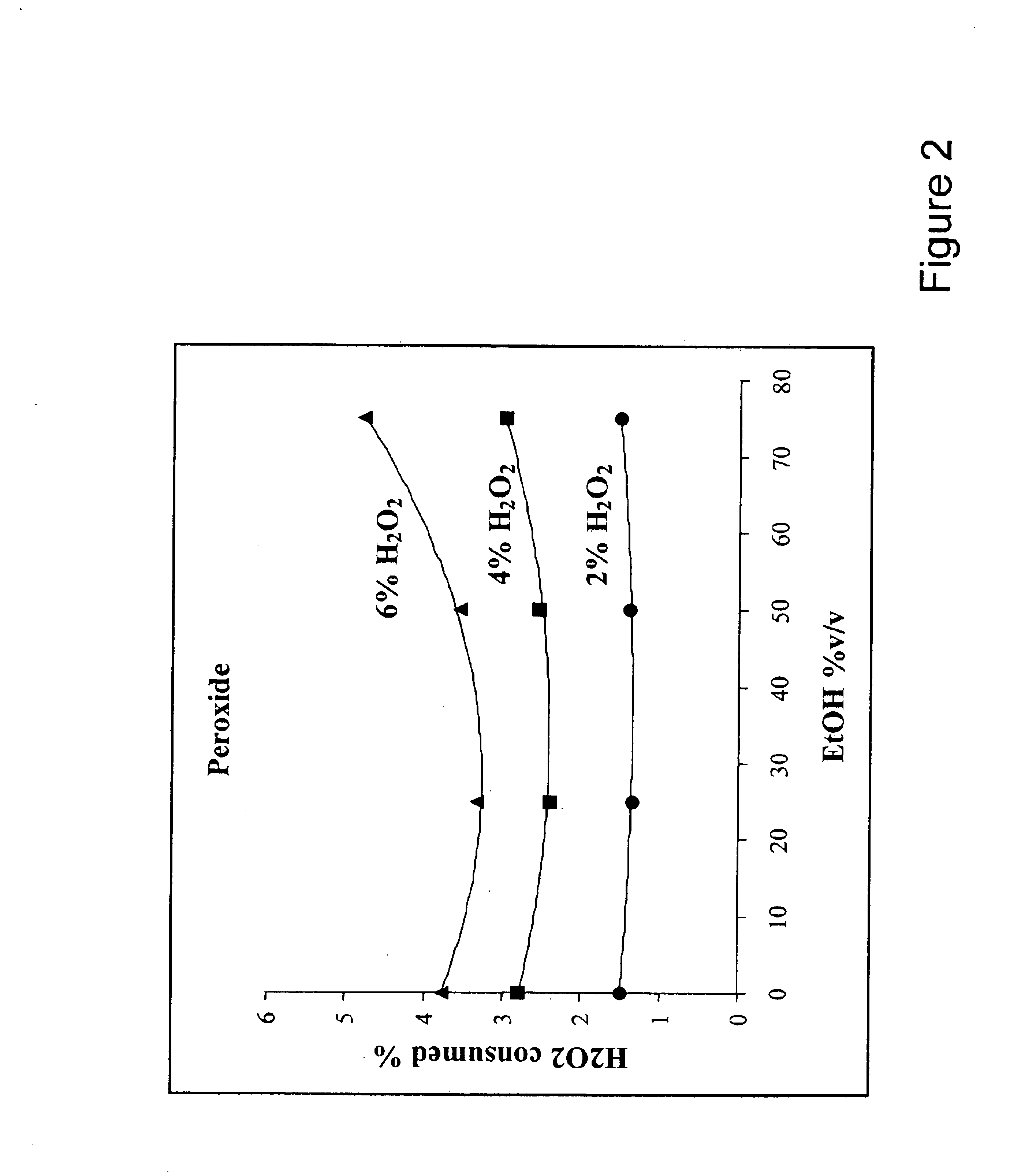

Method for hydrogen peroxide bleaching of pulp using an organic solvent in the bleaching medium

Disclosed is a method for pulp bleaching. The method comprises the steps of providing a pulp sample for bleaching, the pulp sample stemming from a pulp producing process, providing a bleaching liquor comprising water and an organic component as solvent components constituting a bleaching medium, dissolved within are at least a bleaching agent, and a basic agent; and subjecting the pulp sample to the bleaching liquor for a predefined amount of time at predefined bleaching conditions. A preferred bleaching agent is hydrogen peroxide. The organic component amounts to at least 5% in weight of the bleaching medium.

Owner:ALBERTA RES COUNCIL INC

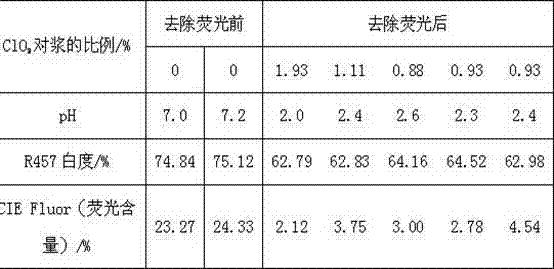

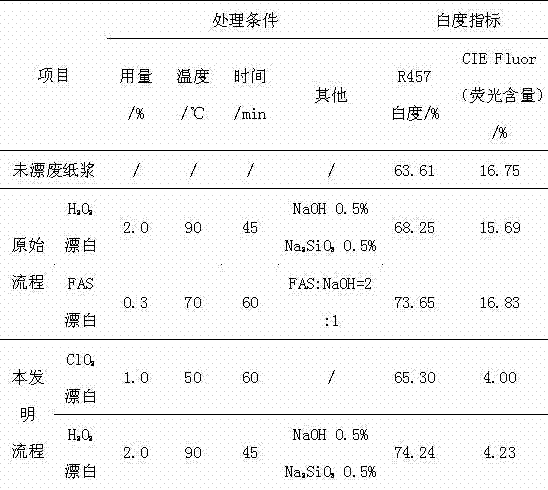

Method for removing fluorescent substance in waste paper pulp

InactiveCN102230291AHas a bleaching effectEliminate the effects ofPulp bleachingLuminophoreChlorine dioxide

The invention provides a method for removing fluorescent substances in waste paper pulp, which relates to improvement of the waste paper pulping bleaching technology and more specifically to bleaching treatment on waste paper pulp using a chemical approach. The method can remove fluorescent substances in waste paper pulp. According to the invention, the processes of bleaching and fluorescence removal are carried out simultaneously; chlorine dioxide is used as a fluorescence remover to destroy luminophores and molecular structures of fluorescence, which not only radically eradicates fluorescence, but also eliminates influence of fluorescent substances on human health; chlorine dioxide also has an effect of bleaching, which compensates for and gets rid of the defect of decreased whiteness of paper pulp after removal of fluorescence; the method is in combined use with the waste paper bleaching technology to partially substitute conventional bleaching technology, which not only is easy to realize, but also saves investment and considerable energy and chemicals, producing the two effects of bleaching and fluorescence removal through a single technology.

Owner:黑龙江省造纸研究所有限公司

Improved paper pulp bleaching process

The invention discloses an improved pulp bleaching technique for reed pulp paper-making, which comprises: first, using deoxylignin for bleaching, wherein, slurry concentration 8-20%, temperature 85-130Deg, oxygen consumption quanity 1-4.5Kg per ton slurry, NaOH consumption quanity 1-4Kg per ton slurry, and MgSO4 consumption quantiy 0.1-1.0%; second, using biological enzyme for bleaching, wherien, enzyme adding quanity 20-80g per ton slurry, temperature 30-80Deg, slurry concentration 5-16%, pH value 5-12, slurry hardness 2-8(KMnO4), and time 0.5-4h; third, adding hypochlorite for bleaching. This invention can reduce bleachability and back-yellow value, improves yield and slurry hardness, and decreases pollution to environment.

Owner:XINJIANG BOHU REED IND

Straw pulp bleaching technique

InactiveCN101463573AReduce generationReduce pollutionPulp bleachingOrganic chloride compoundChlorine dioxide

The invention discloses a bleaching process with low pollution used for straw pulp by virtue of elemental chlorine-free bleaching agents such as oxygen, chlorine dioxide, hydrogen peroxide and the like. The invention is characterized in that the process comprises the steps as follows: (1) on oxygen delignification section, sealing, sifting and washing are carried out; (2) on chlorine dioxide delignification section, washing is carried out; (3) on alkaline extraction section, washing is carried out; (4) on chlorine dioxide whitening section, washing and papermaking are carried out. The process of the invention is simple and feasible, applicable for reed pulps and the mixed pulp thereof and anaphalis yedoensis, the final brightness of the pulp of the reed pulps (ISO) reaches 78-85%, the brightness stability and the strength are good, and tear index is more than or equal to 8.0mN.m<2> / g; as no elemental chlorine joins the bleaching process, the generation amount of organic chloride during the bleaching process is greatly lowered and the pollution to ecological environment is reduced, thus having obvious social and economic benefits.

Owner:YUANJIANG PAPER

Novel non-chlorine bleaching technique for bamboo pulp

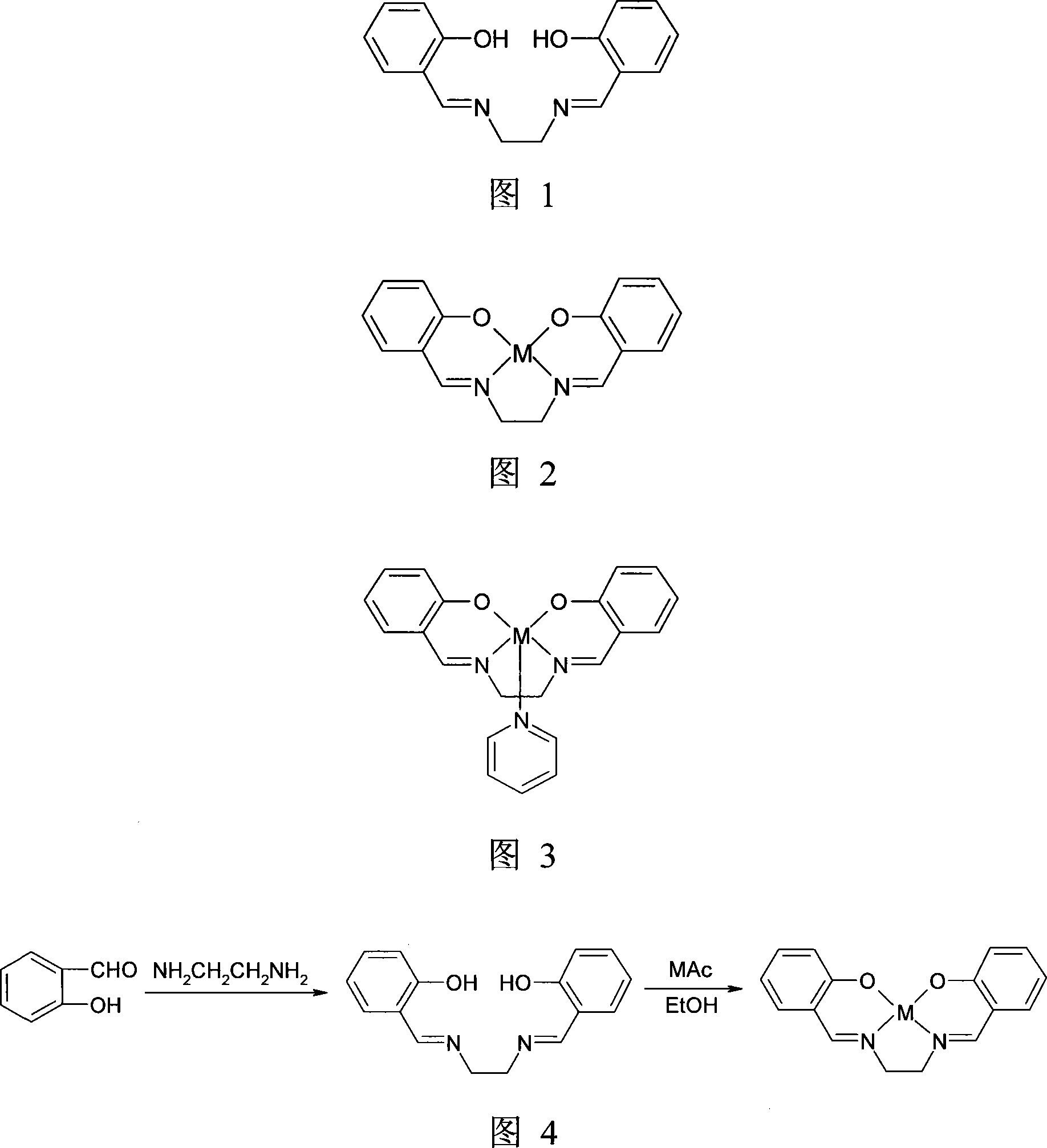

A novel totally chlorine-free bamboo-pulp bleaching process is provided. The invention relates to a novel totally chlorine free (TCF) bamboo-pulp bleaching process, is a new bionic bleaching technology for paper pulp. The invention essentially comprises the following procedures: (1) Synthesizing enzyme-imitated metal salen, using Schiff base salen to react with metallic organic acid salt to synthesize metal salen; (2) Pre-treatment bleaching bamboo pulp, carrying out bleaching pre-treatment on the oxygen delignification sulfate bamboo pulp with metal salen, NaOH, H2O2 and O2 existing; (3) Subsequent TCF bleaching, carrying out three bleaching treatments, namely, alkaline treating enhanced by hydrogen peroxide, bleaching by peroxy acid and bleaching by hydrogen peroxide the bamboo pulp pre-treated by enzyme-imitated metal salen. For the invention, the source is wide, the metal salen is easy to synthesize, the yield rate is high, the cost is low, the consumption is very low; the metal salen is easy to store, has no demanding requirement on the environment, can obviously improve the whiteness of paper pulp, reduce the load of waste water pollution in bleaching, and saves the use of bleaching chemicals.

Owner:KUNMING UNIV OF SCI & TECH

Methods for making carboxylated pulp fibers

InactiveUS20050028953A1Solve bulkyDelay transitionPulp properties modificationOrganic chemistryFiberBleach

Owner:WEYERHAEUSER CO

High water resistance straw lining paper and preparation method thereof

InactiveCN109487626AImprove water resistancePermeation barrierSpecial paperWater-repelling agents additionFiberSlag

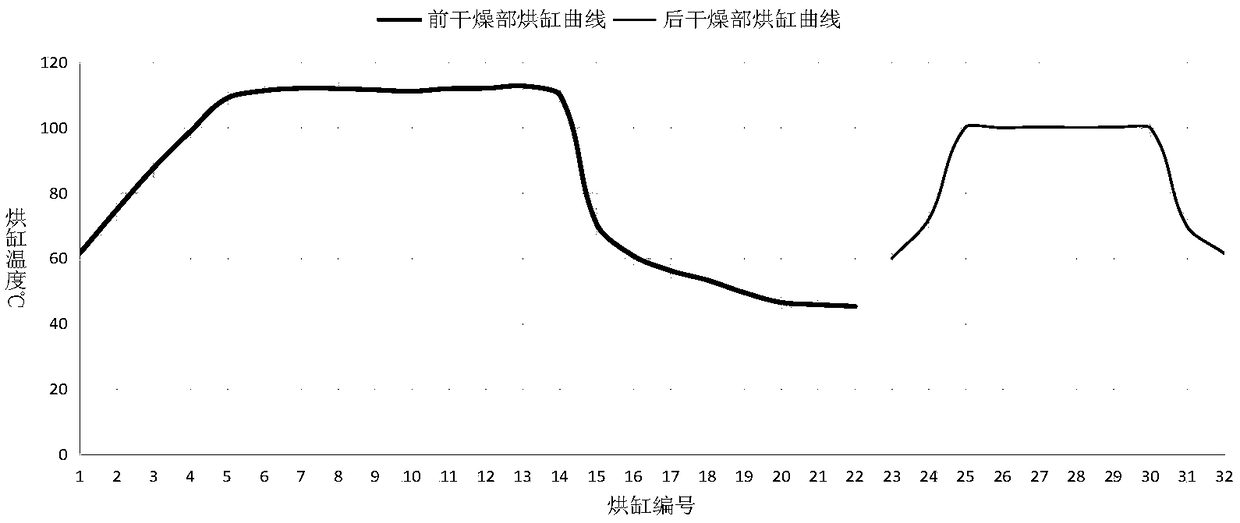

Th einvention discloses high water resistance straw lining paper and a preparation method thereof. The preparation method comprises the following steps: (1) mixing and pulping bleaching injection andhardwood pulp, adding filler, a wet strength agent, a sizing agent, retention aid and the like, and preparing fiber pulp which can be put on a net through slag removing and concentration regulating; (2) forming and squeezing the fiber pulp with a fourdrinier machine, controlling the curve of a dryer to completely cure the sizing agent, performing a surface sizing process with a three-element surface sizing agent of starch with alkyl ketene dimer and carboxymethylcellulose; and preparing the high water resistance straw lining paper through drying, press polishing and rolling. The straw lining paper has good water resistance and wet strength and can be used for effectively prevent liquid infiltration, and each index can accord with the safety standard of national food package materials.

Owner:ZHEJIANG HENGDA NEW MATERIAL CO LTD

Paper pulp bleaching process

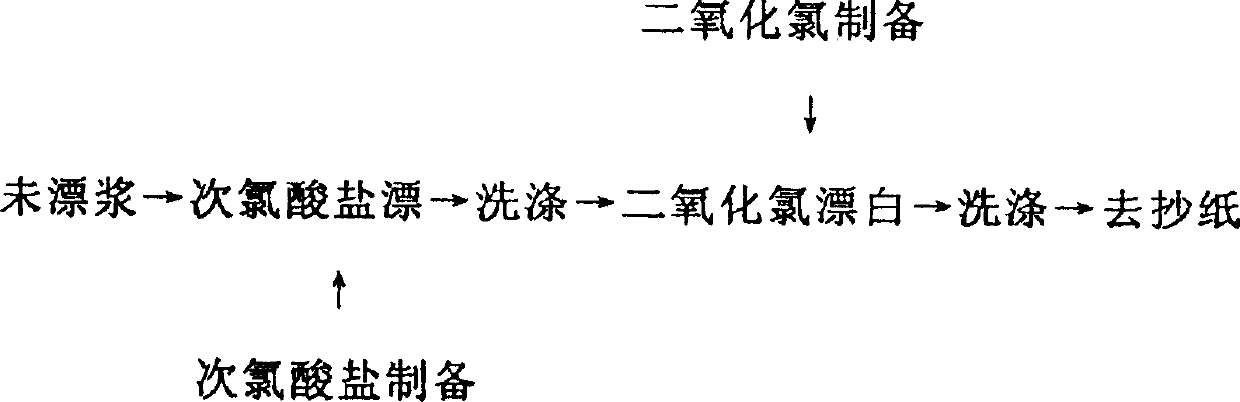

InactiveCN1401848AIncrease the breaking lengthHigh folding resistancePulp bleachingChlorine dioxideHypochlorite

A process for bleaching paper pulp includes such steps as adding hypochlorite, prebleaching at 30-60 deg.C for 30-150 min, water washing, adding ClO2, bleaching and water washing. Its advantages are low pollution and low consumption of water.

Owner:QILU UNIV OF TECH

Photochemical paper pulp bleaching method and device

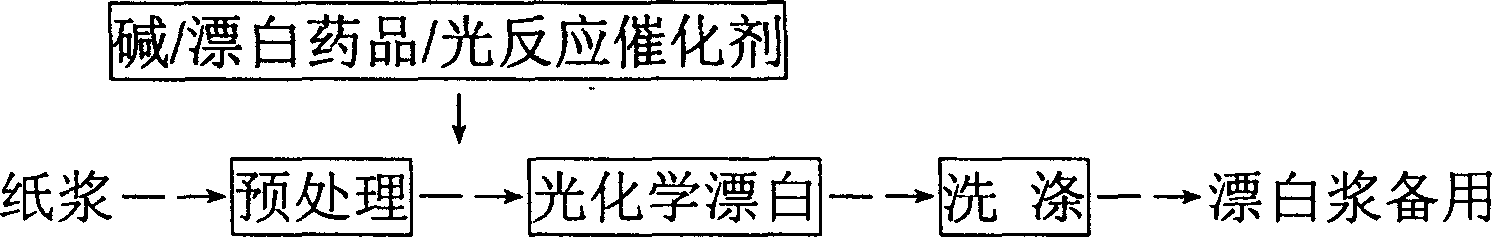

InactiveCN1554826AHigh whitenessHigh degree of delignificationPulp bleachingPlant fibrePhotochemical degradation

Based on photochemical principle, plant fiber pulp after being pre-treated is irradiated with light, and in alkali environment and under the aid of introduced oxygen or air and photobleaching catalyst, the residual lignin in pulp is degraded via photochemical reaction into leached out fragments and thus eliminated, resulting in high whiteness pulp. During the bleaching process, different shielding agent may be added to shield partial light selectively to protect the physical strength of pulp. The bleaching process is environment friendly, and has less corrosion to the apparatus and simple operation.

Owner:GUANGXI UNIV

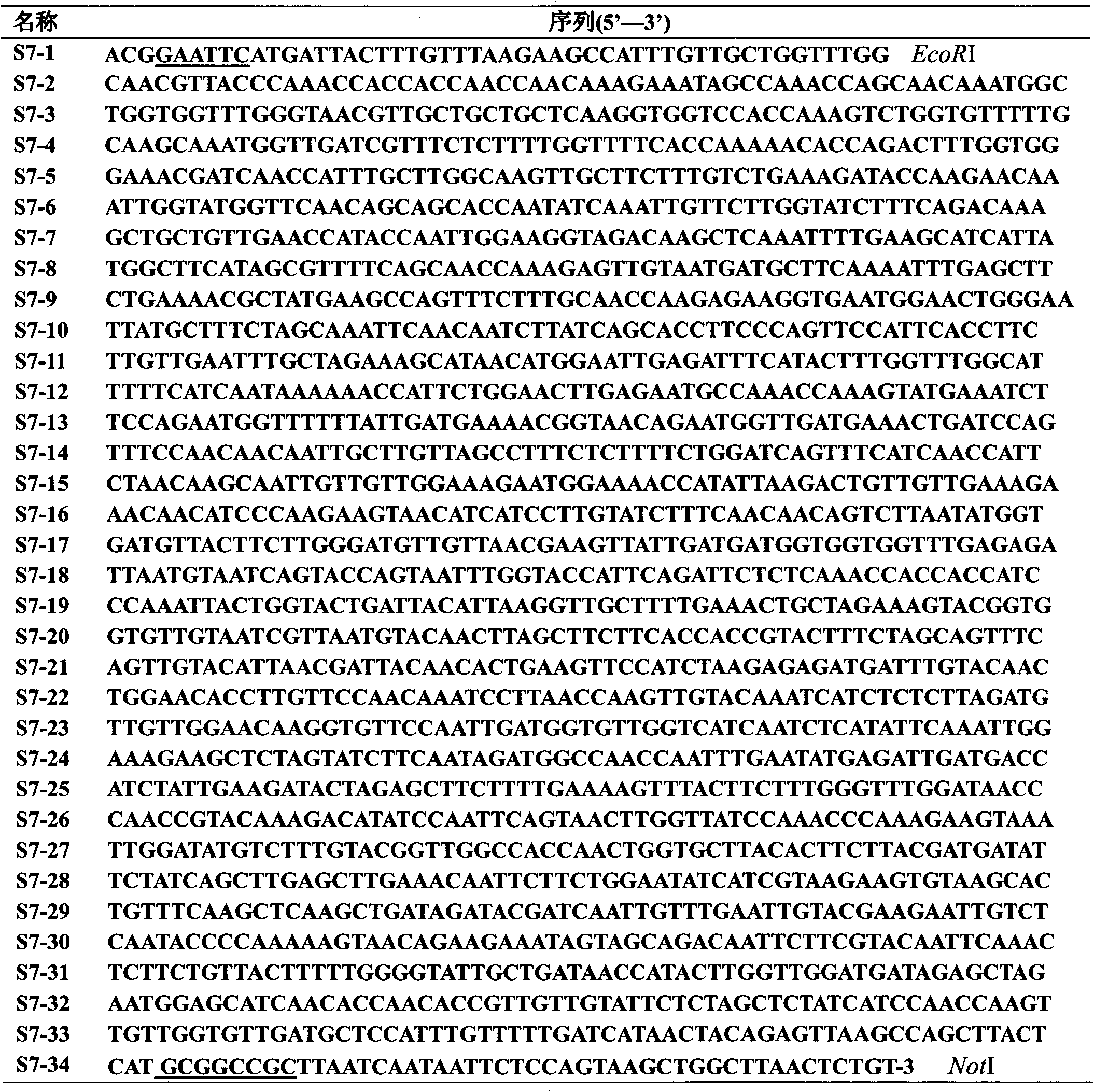

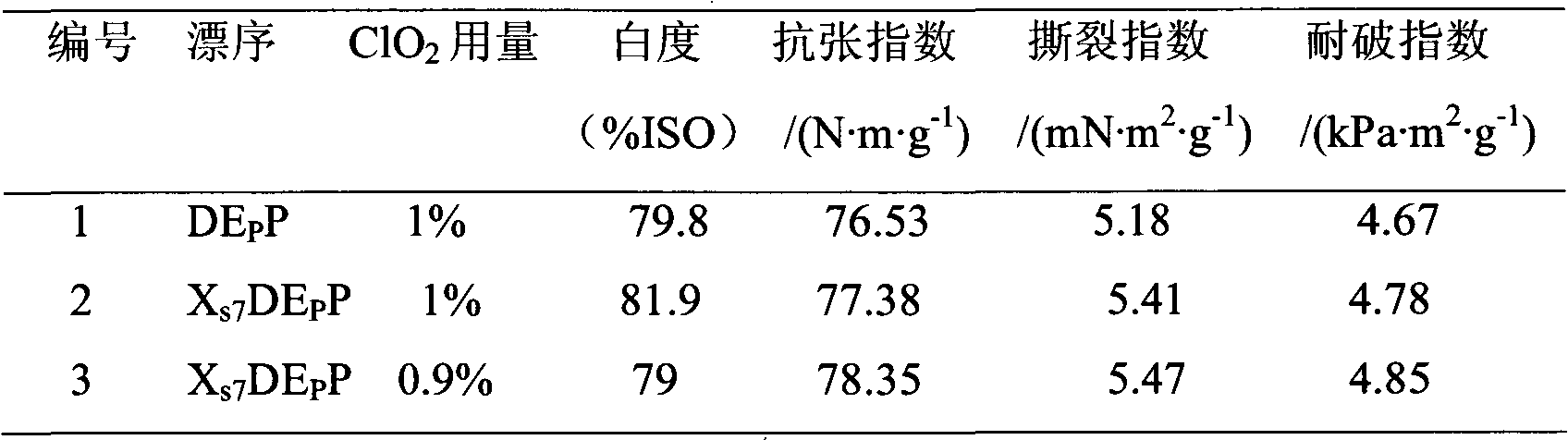

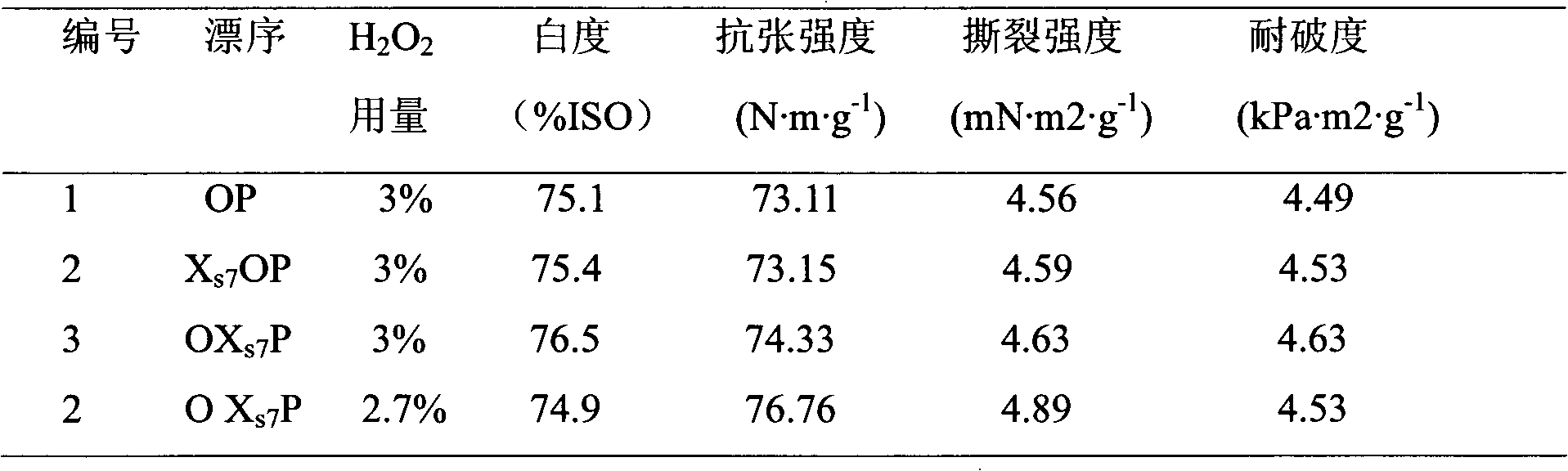

Genes, plasmid, bacterial strain and application of xylanase

The invention provides genes, an expression vector, a production bacterial strain and application of xylanase with high temperature resistance, strong base resistance, high efficiency and stability in pulp bleaching. The genes of the xylanase provided in the invention realize high expression in Pichia pastoris by utilizing a codon optimizing and multi-copy technique; the expressed xylanase has no cellulase activity, high temperature resistance and high base resistance; and the xylanase can be applied to wheat straw pulp bleaching; when applied to an elemental chlorine free (ECF) bleaching procedure, the xylanase saves chlorine dioxide by 10%; when applied to a hydrogen peroxide (OP) bleaching procedure, the xylanase saves hydrogen peroxide by 10%.

Owner:SOUTH CHINA UNIV OF TECH

Multi-step pulp bleaching

A method for bleaching cellulosic pulp is disclosed, with one embodiment revealing a three-step bleaching method for cellulosic pulp comprising an activating bleach step, an alkaline peroxide step, and a reductive bleach step. The cellulosic pulp treated according to the present invention may possess a greater GE brightness gain than if treated according to conventional methods, while not suffering a significant loss of lignin. The cellulosic pulp may comprise recycled fibers, including those with high groundwood content. The bleaching method may also decrease the pH of the pulp.

Owner:GEORGIA PACIFIC CONSUMER PRODS LP

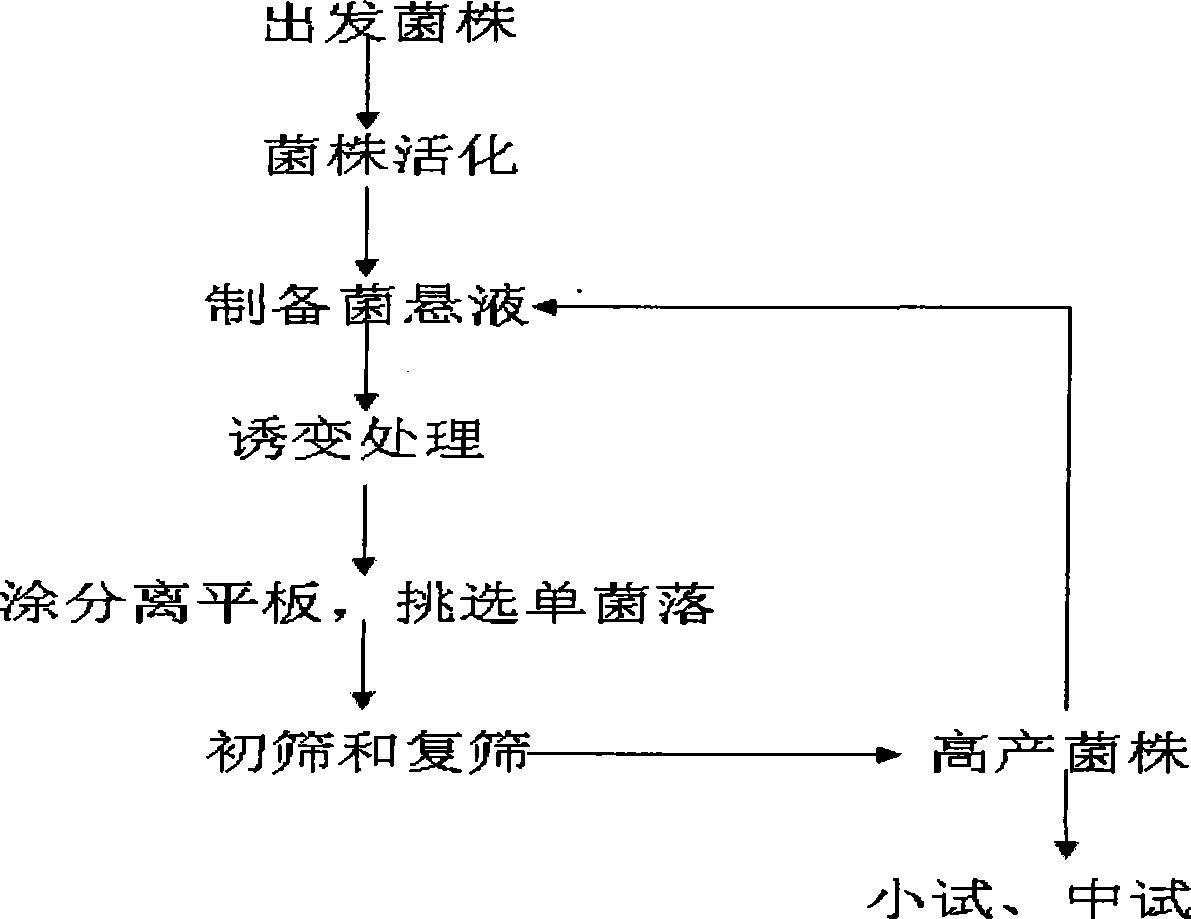

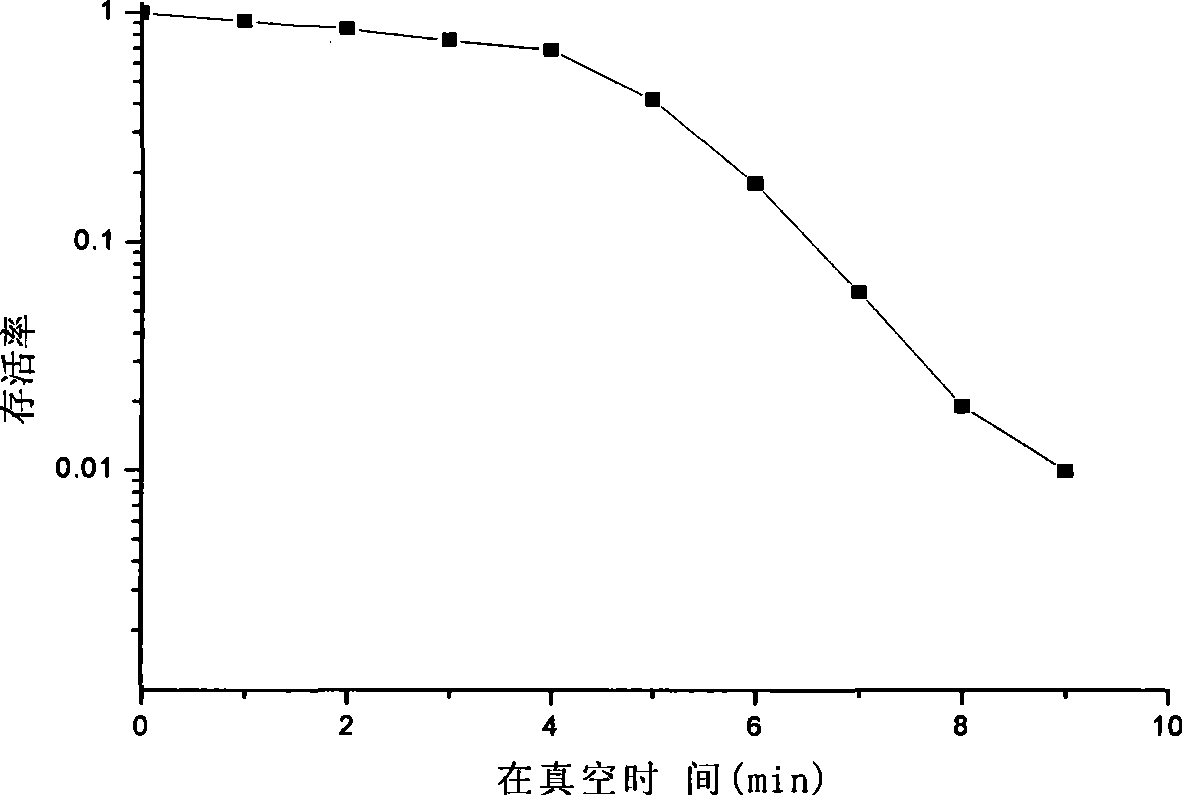

White rot fungi, breeding method and use thereof

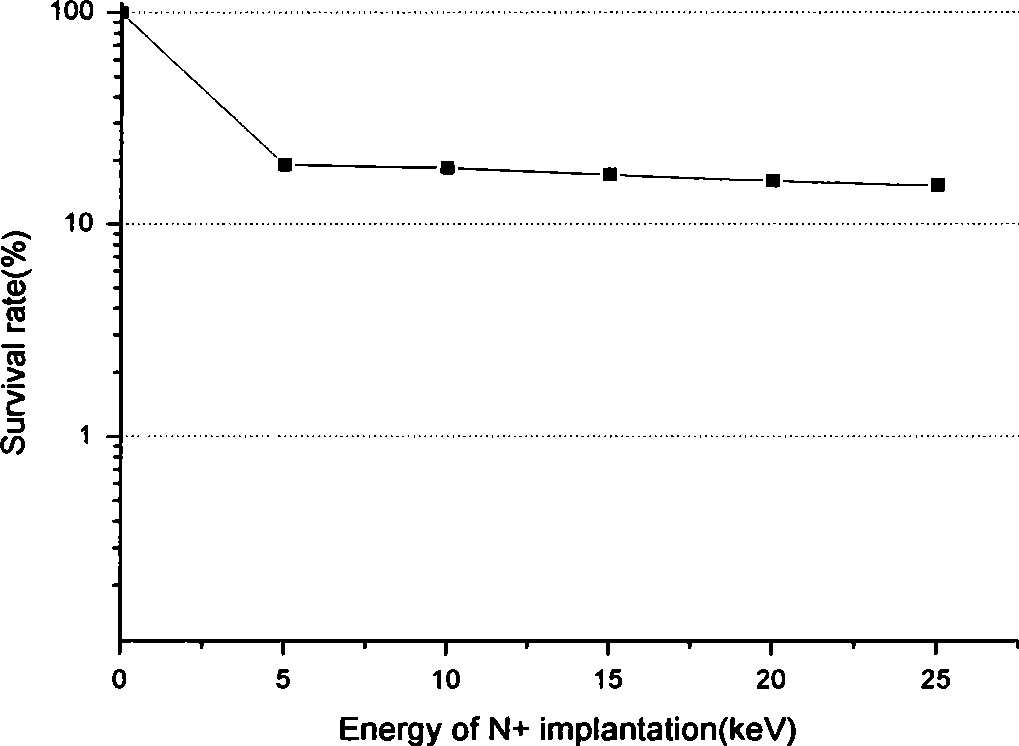

InactiveCN101469312AStable enzyme productionShort cycleFungiMutant preparationFiberAutomatic control

The invention relates to Trametes Versicolor YS-L613 and a breeding method and application thereof. The Trametes Versicolor YS-L613 is prepared by the method through mutation breeding. The breeding method is to take Trametes Versicolor as a starting strain, adopt composite mutation breeding technology which combines UV, 60 CO, ultraviolet rays, nitrosoguanidine, ion implantation and microwave treatment, and breed the YS-L613 strain for high-yield production of laccase. The invention performs breeding operation through physiochemical treatment methods such as ion implantation, the ultraviolet rays and mutagen, finally obtains the YS-L613 strain for high-yield production of the laccase, and adopts experimental automatic control technology, strain fermentation control technology and strain extraction technology to develop laccase products. As proved by experiments of the laccase in pulp bleaching, fiber modification and pulp deinking, utilization of the laccase in the paper-making industry can improve the quality of paper, reduce environmental pollution and save the cost.

Owner:HENAN YANGSHAO BIOCHEM ENG

Hydrogen peroxide stabilizer composition in paper pulp bleaching

InactiveCN101265678AReduce decomposition rateAvoid it happening againPulp bleachingBleaching agents additionFiberDecomposition

A hydrogen peroxide stabilizer composition in paper pulp bleaching contains the following materials by the weight percentages: ethylenediaminetetraacetic acid 8%-10%, polyacrylic acid 3%-5%, nitrilortiacetic acid 5%-10%, hydroxy ethylidene-1, 1-diphosphonic acid 5%-8%, sodium hydroxide in suitable amount and the rest of deionized water,. The preparation method includes: mixing the materials in the material ratio, adjusting the pH value to 6.8-7.1 with the sodium hydroxide and adding the deionized water to 100%. The inventive hydrogen peroxide stabilizer composition in the paper pulp bleaching can reduce the decomposition rate of the hydrogen peroxide to less than 20%, prevent the fouling from generating and dispersing pulp fibers and chelating metal ions.

Owner:JIANGXI SCI & TECH NORMAL UNIV

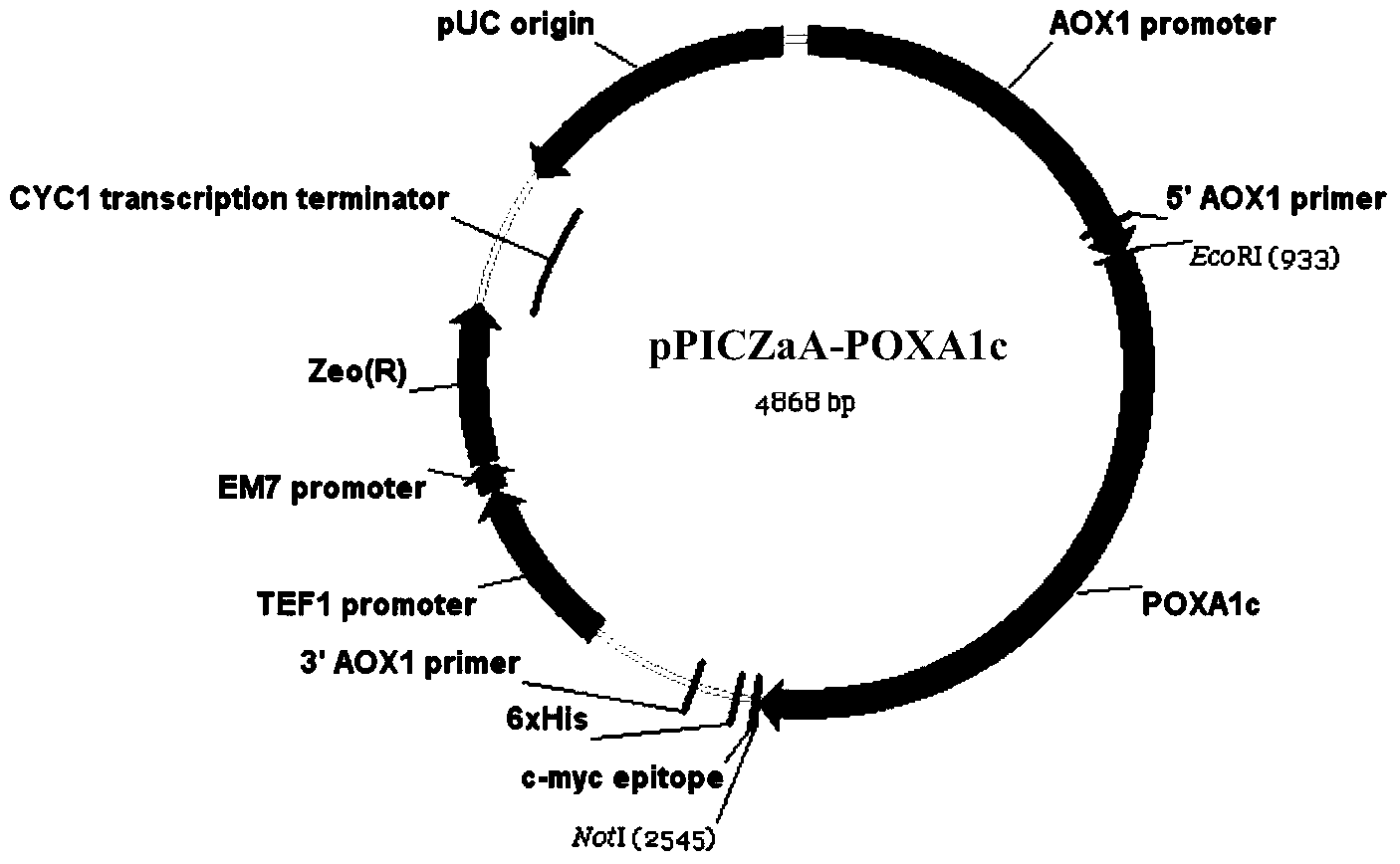

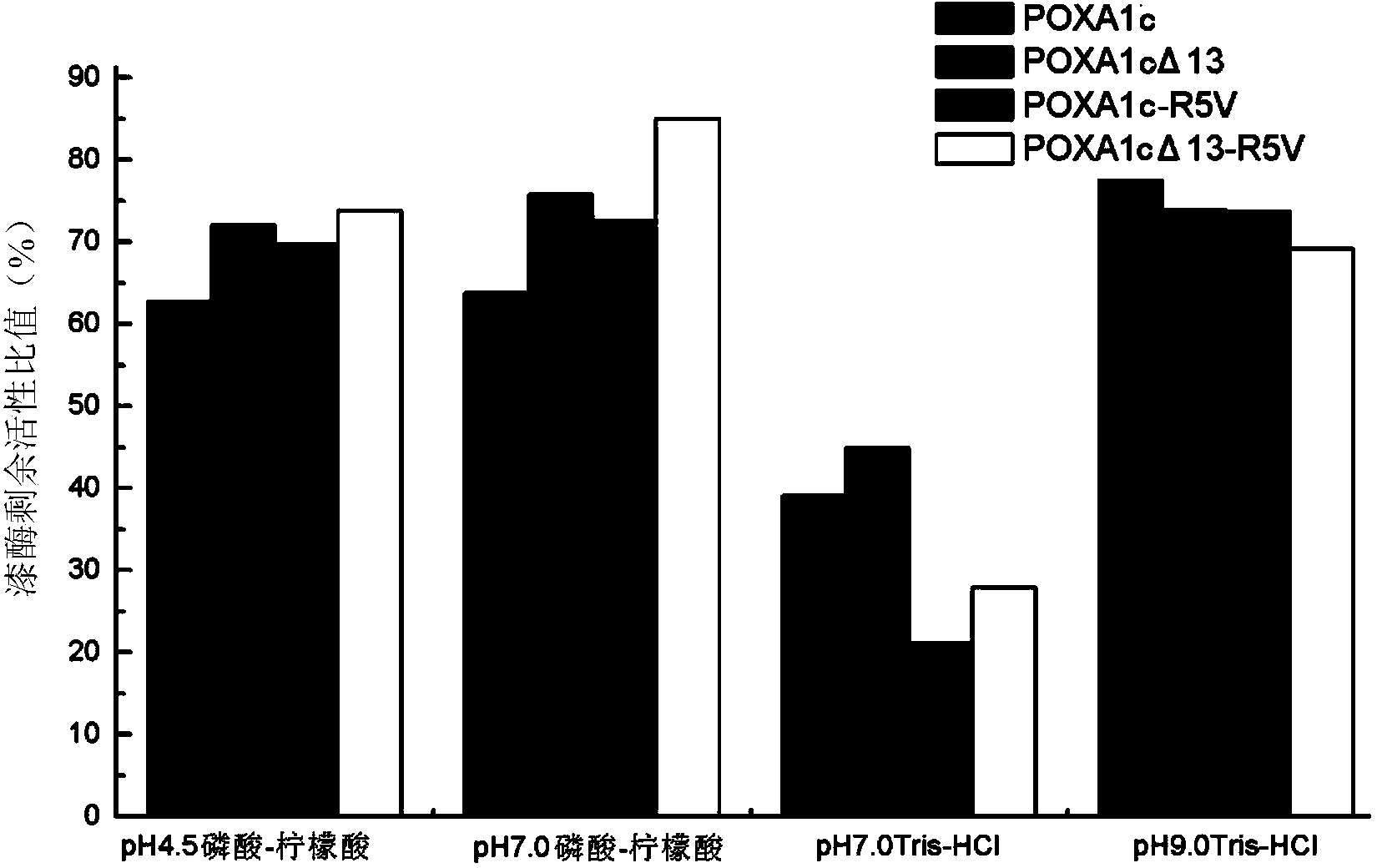

Laccase mutant and encoding gene and application thereof

The invention discloses a laccase mutant and an encoding gene and an application thereof. The laccase mutant disclosed by the invention is any one of the following protein in a) to d): a) protein as shown in a sequence 1; b) protein as shown in a sequence 3; c) protein as shown in a sequence 5; d) protein with laccase activity and obtained by substituting and / or deleting and / or adding one or multiple amino acid residues in the amino acid sequences of the proteins limited by any one of a) to c). As shown in experiments, compared with wild laccase, the laccase mutant disclosed by the invention has the advantages of high activity, wide pH tolerance range and the like. The laccase mutant disclosed by the invention is expected to be applied in such fields as wastewater treatment in pulp bleaching and dyeing and printing industry, biological detection in medicine field, food industry, organic synthesis, organic pesticide degradation, etc.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

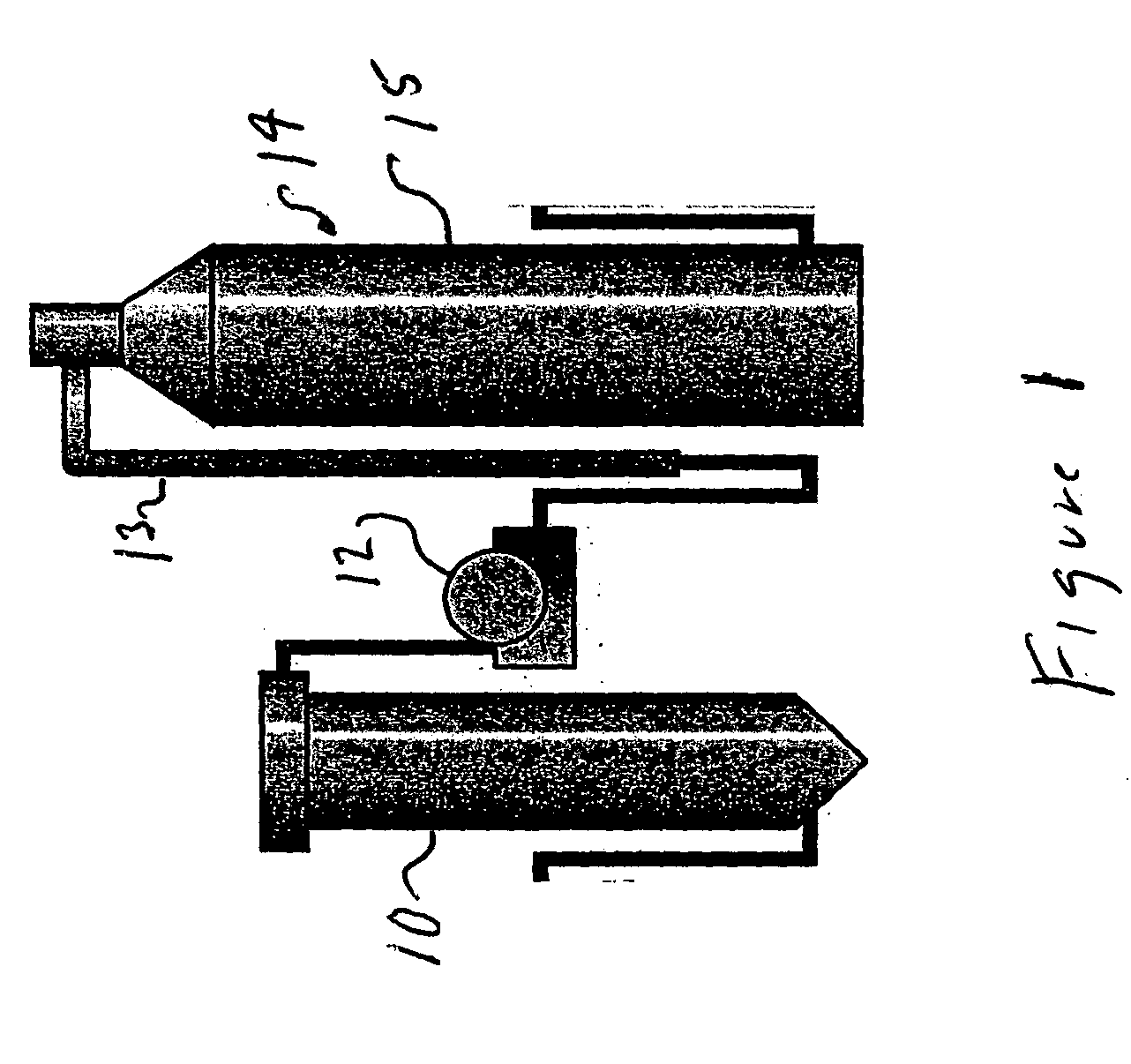

Method of xylanase treatment in a chlorine dioxide bleaching sequence

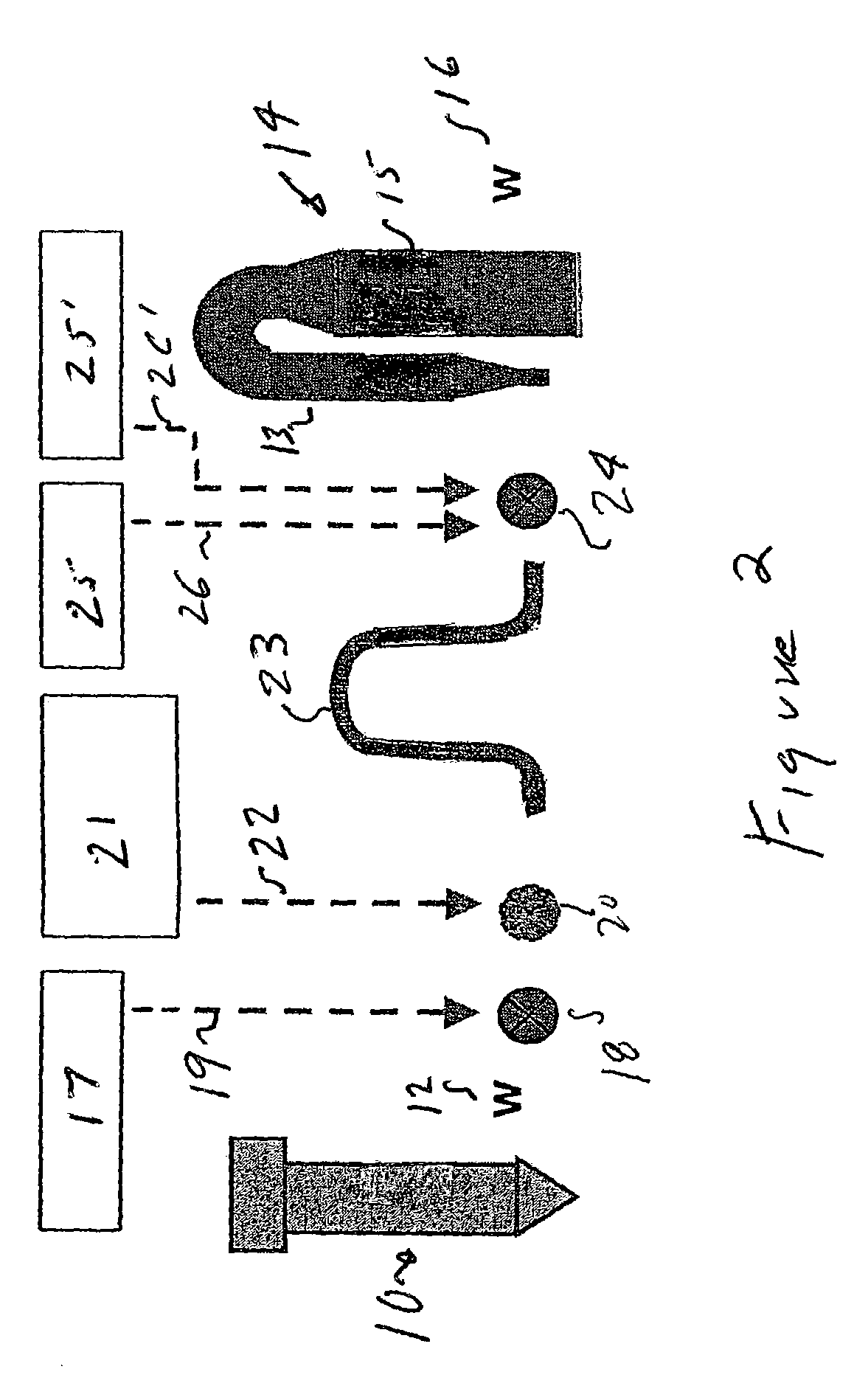

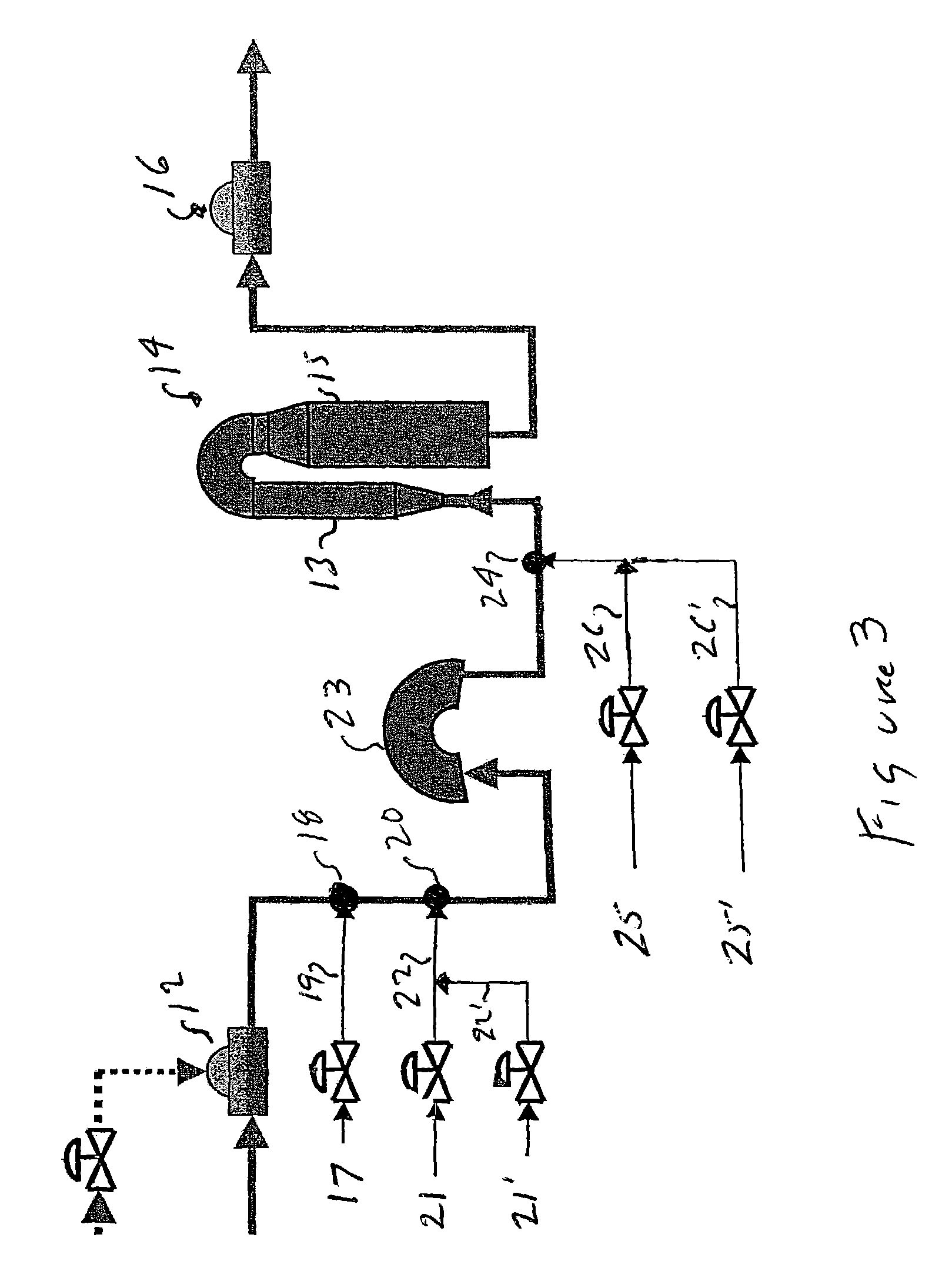

InactiveUS7320741B2Enhances pulp bleachingEasily integrated into pulp bleaching processPulp bleachingBleaching apparatusChlorine dioxidePulp mill

A method of bleaching chemical pulp with xylanase after chemical bleaching is provided. The method comprises the steps of exposing chemical pulp to a chlorine dioxide bleaching stage to produce a partially bleached pulp, treating the partially bleached pulp with a xylanase in an enzyme treatment stage at a pH of about 3 to about 8, then carrying out an alkaline extraction of the pulp. The pulp bleaching method of the present invention may be performed in a pulp mill as part of a complex pulp bleaching process.

Owner:IOGEN BIO PRODUCKTS CORP

Method for carrying out elemental chlorine free (ECF) multistage bleaching on masson pine kraft pulp by using glyoxal

The invention provides a method for carrying out elemental chlorine free (ECF) multistage bleaching on masson pine kraft pulp by using glyoxal. The method is characterized by firstly adopting chlorine dioxide to carry out delignification on the unbleached masson pine kraft pulp; then utilizing sodium hydroxide to carry out alkali extraction on the masson pine kraft pulp after delignification; then using chlorine dioxide to carry out delignification on the masson pine kraft pulp; and finally adopting hydrogen peroxide to bleach the masson pine kraft pulp to obtain the masson pine ECF pulp with high whiteness and excellent physical indexes. The method has the following beneficial effects: the whiteness of the prepared masson pine kraft pulp can reach 88.36% ISO, the Kappa number is 5.02 and the yield is about 90.28%; and the masson pine kraft pulp bleached by DEDP is used for manufacturing the handsheet and the tensile index is 40.08N.m / g, the tear index is 12.80mN.m<2> / g and the burst index is 3.45kPa.m<2> / g, thus showing that the finished paper has better physical strength.

Owner:SHAANXI UNIV OF SCI & TECH

Pulp-bleaching technique

The invention relates to a pulp-bleaching technique. 40 percent to 50 percent by weight of residual lignin of boiled pulp is removed by way of oxygen delignification, hydrogen peroxide is then utilized to further remove the lignin, and finally, calcium hypochlorite is used for supplementary bleaching. The yield of bleached pulp is high, moreover, the whiteness of bleached pulp is high, the stability of whiteness is good, and the pollution load of bleaching waste liquor is low.

Owner:WUHAN CHENMING HANYANG PAPER

Fermentation production method of fungal laccase and application of laccase

InactiveCN103571801AReduce outputReduce enzyme activityPulp bleachingMicroorganism based processesBiotechnologyFermentation broth

The invention discloses a fermentation production method of fungal laccase and an application of the laccase. The method comprises the following steps: preparing Panus conchatus suspension; inoculating the suspension into a fermentation tank containing 3-5L of fermentation medium and culturing for 10-15 days, thus obtaining fermentation liquor; and finally, filtering or centrifuging the fermentation liquor, thus obtaining a laccase preparation. The method of the invention is simple and convenient in subsequent treatment of the fermentation liquor and low in production cost, and the activity of the Panus conchatus laccase obtained through fermentation is over 200IU / mL. Compared with other domestic and overseas laccase production methods in a fermentation tank scale, the fermentation production method of the fungal laccase, which is disclosed by the invention, has the advantages that the total laccase yield and the laccase activity reach a relatively high level, and the prepared laccase preparation has a good pulp bleaching effect.

Owner:SHENZHEN LEVEKING BIOLOGY ENG

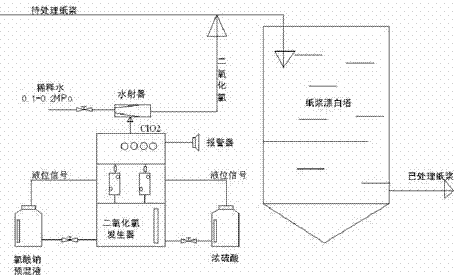

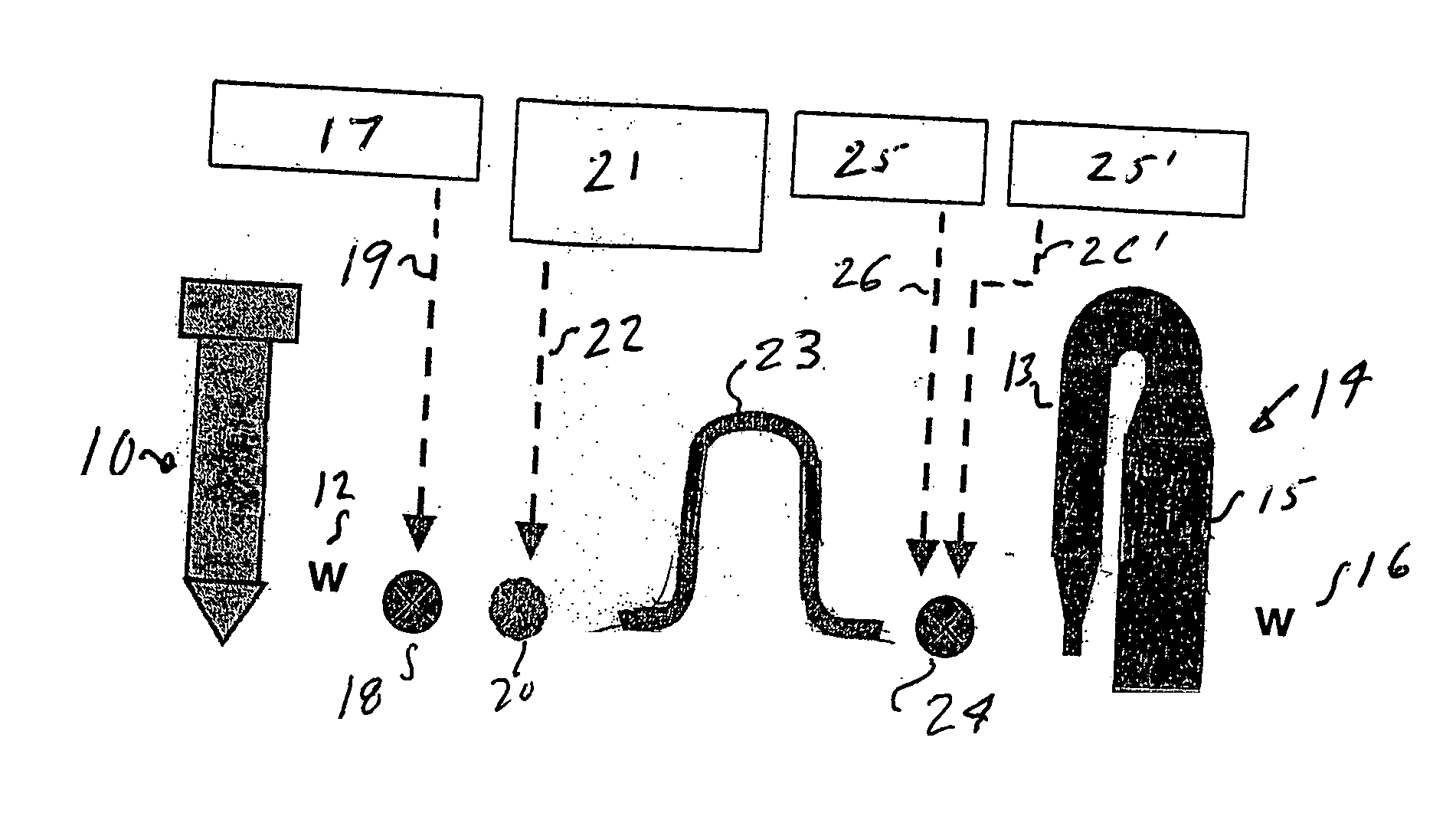

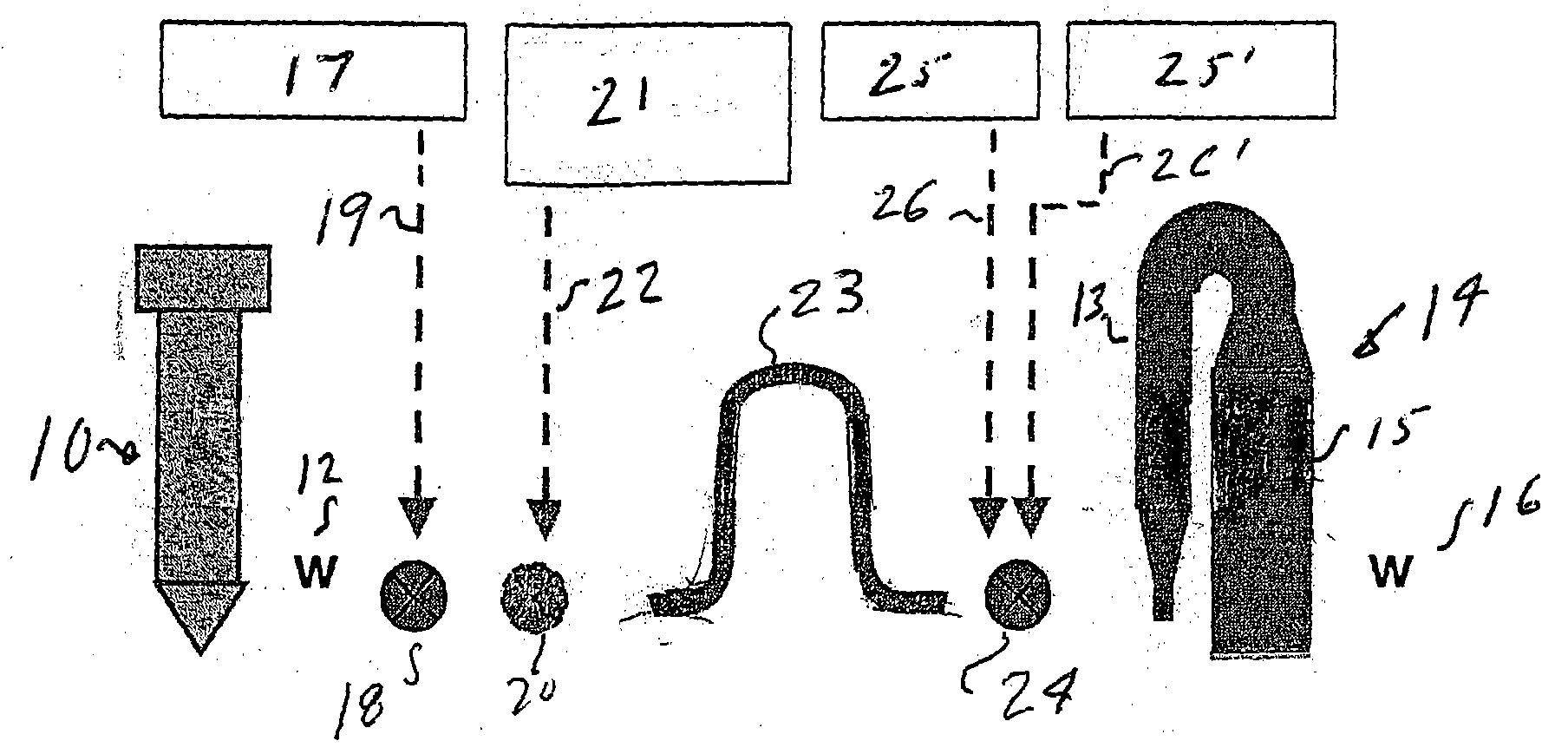

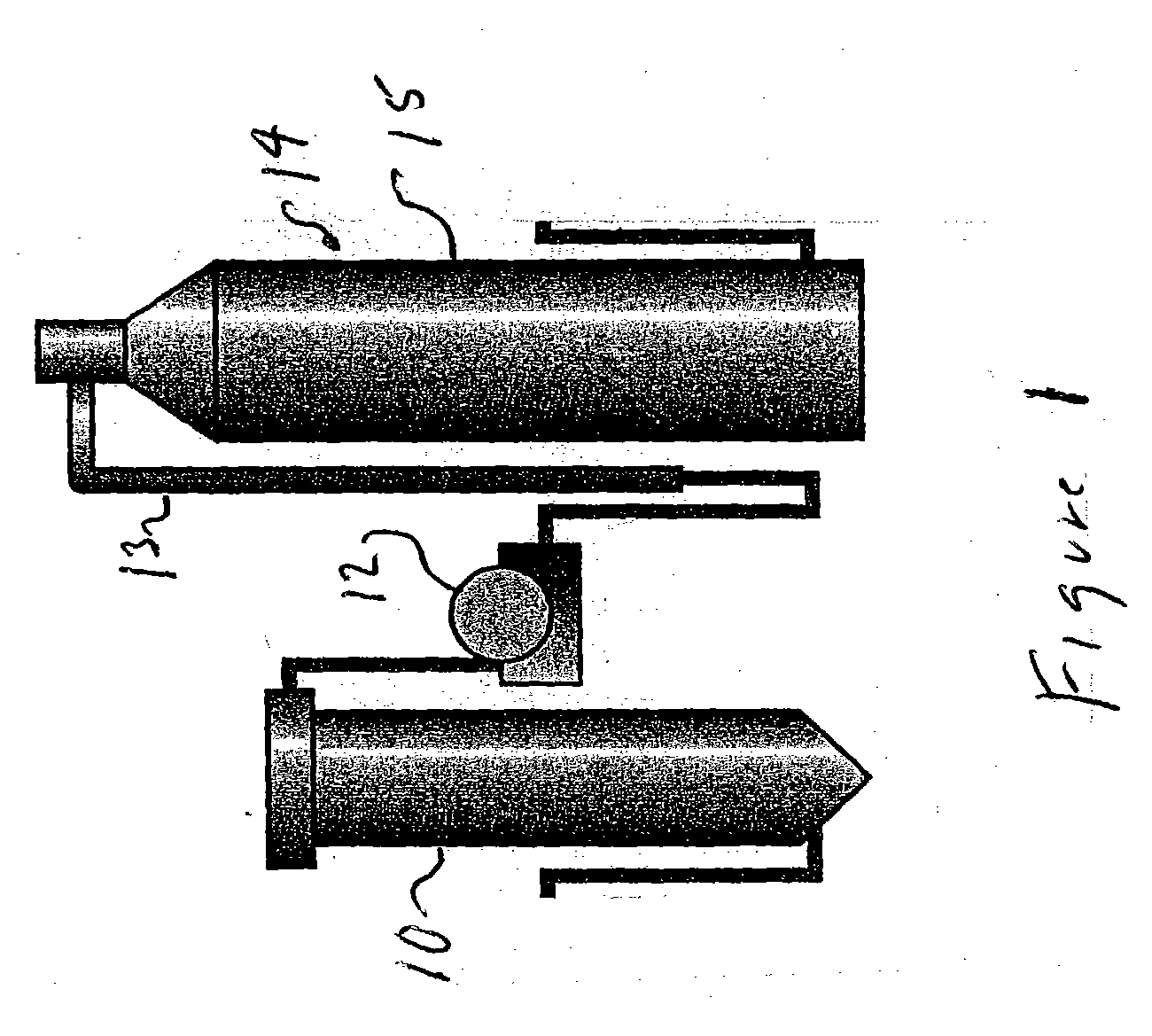

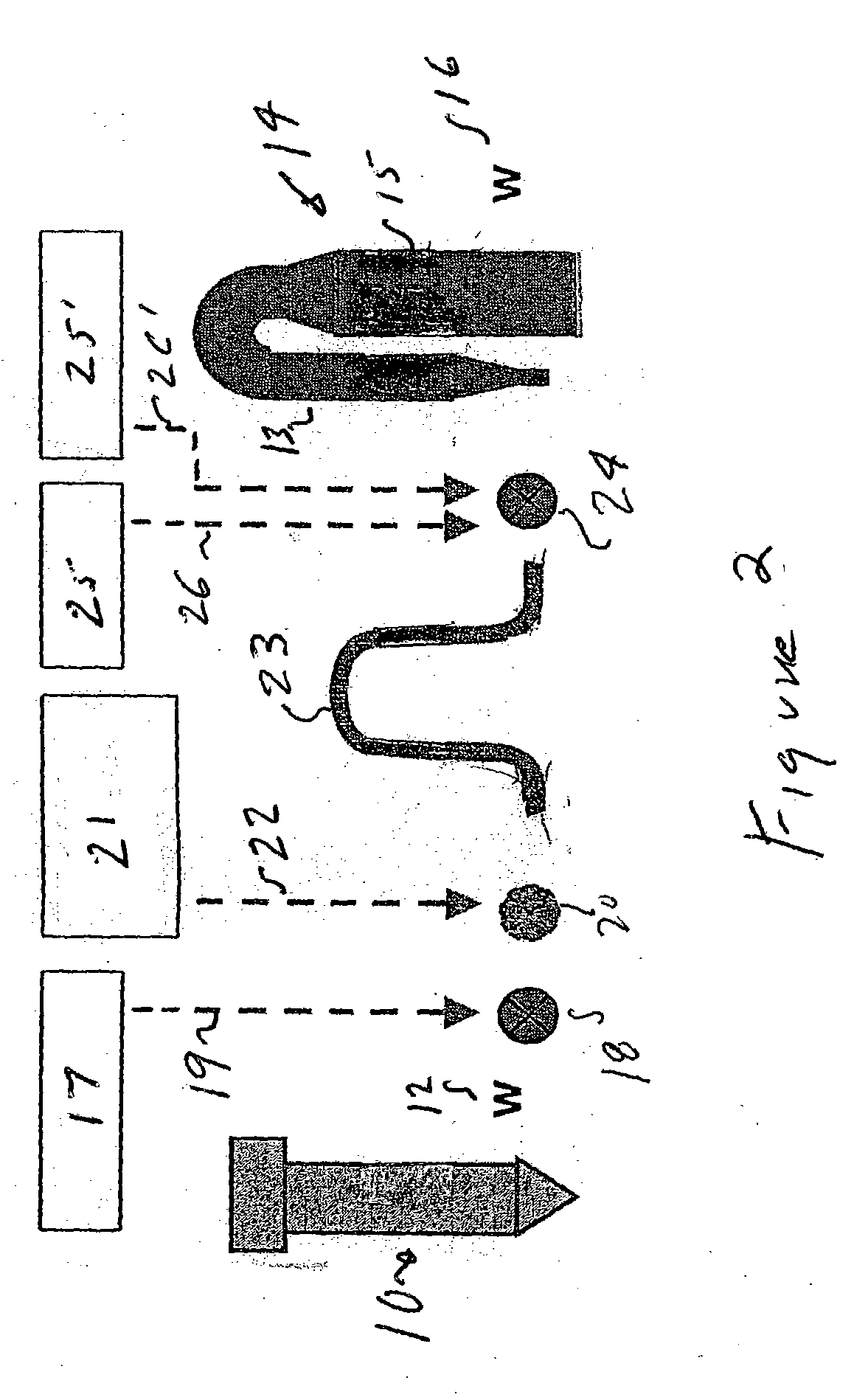

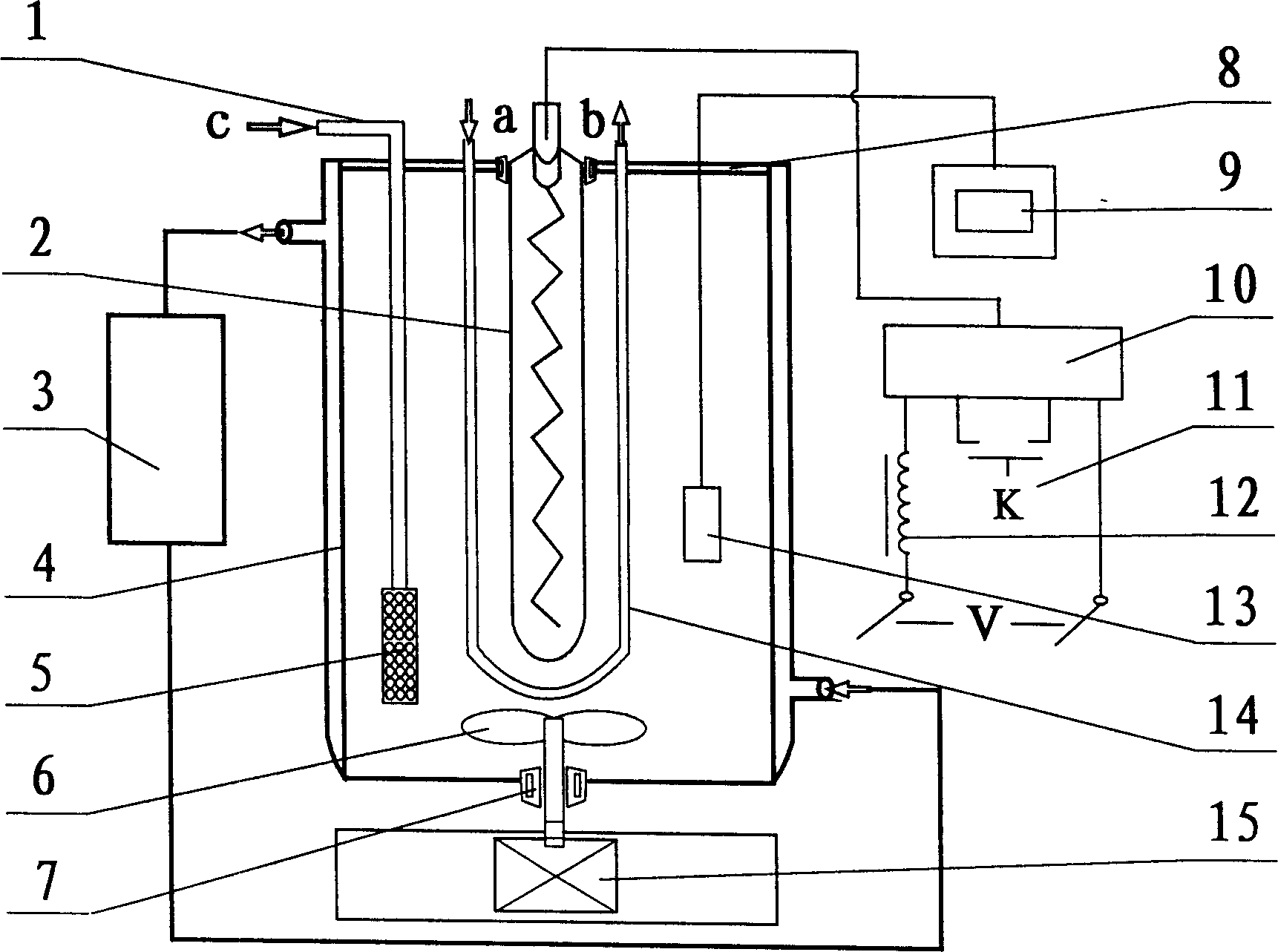

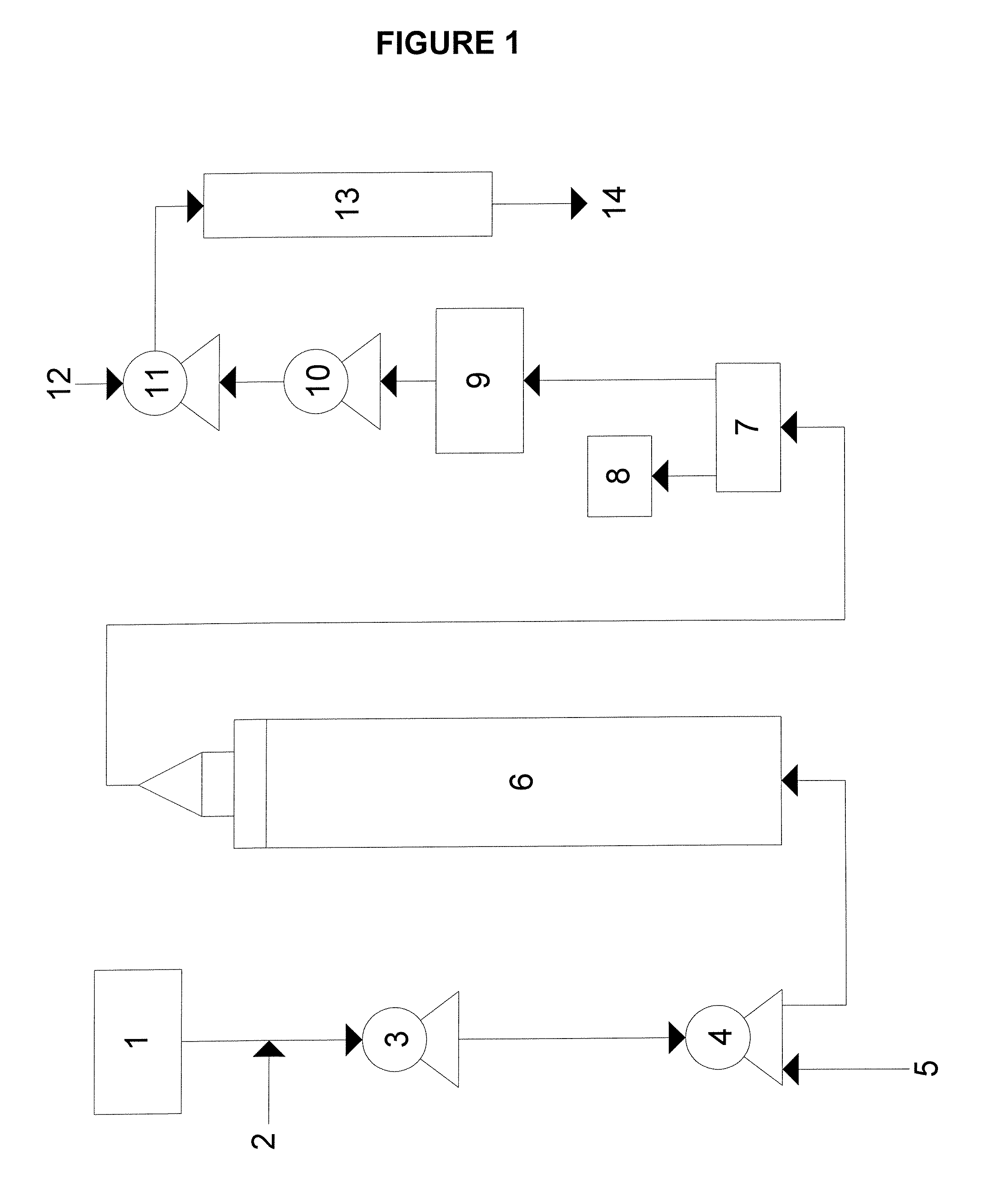

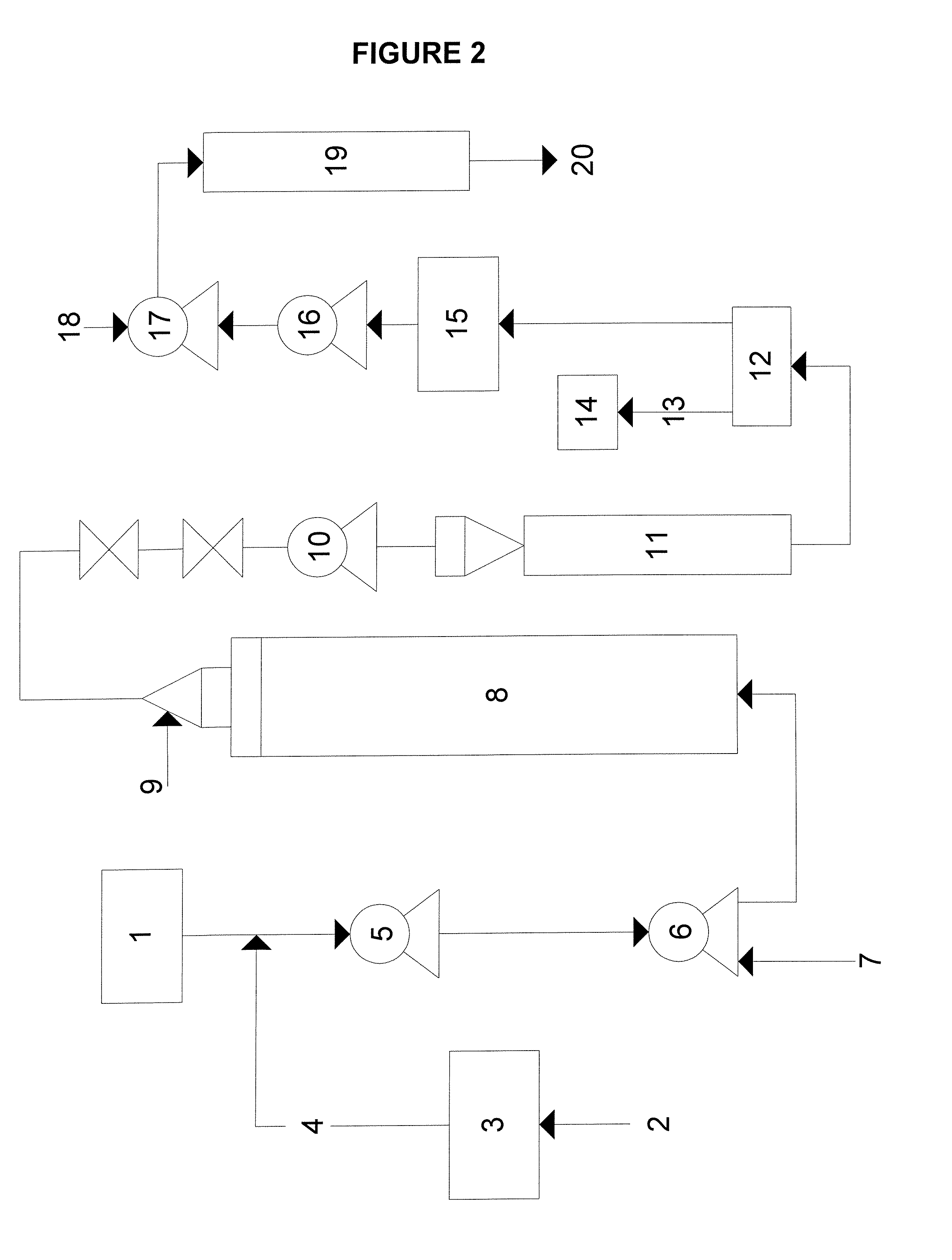

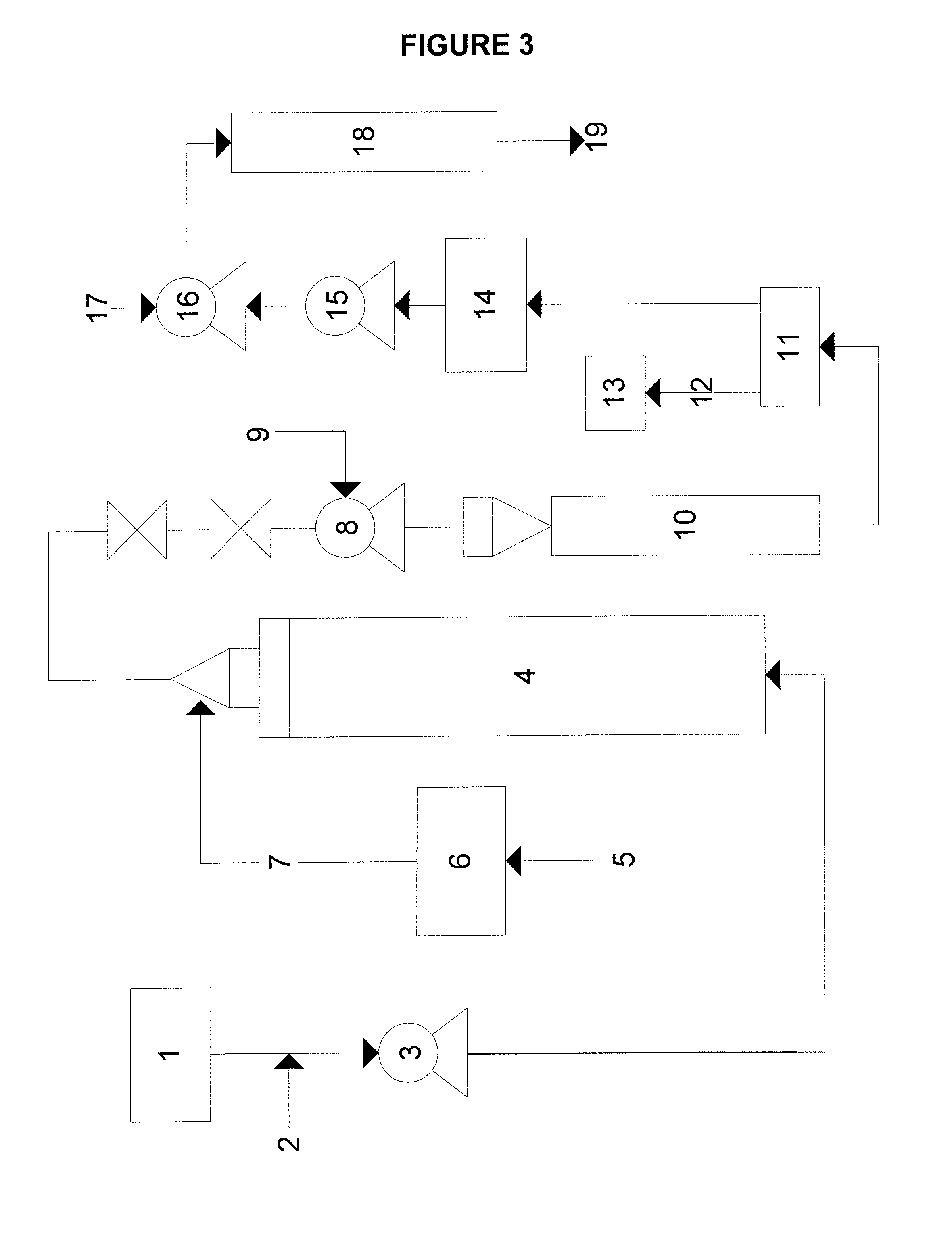

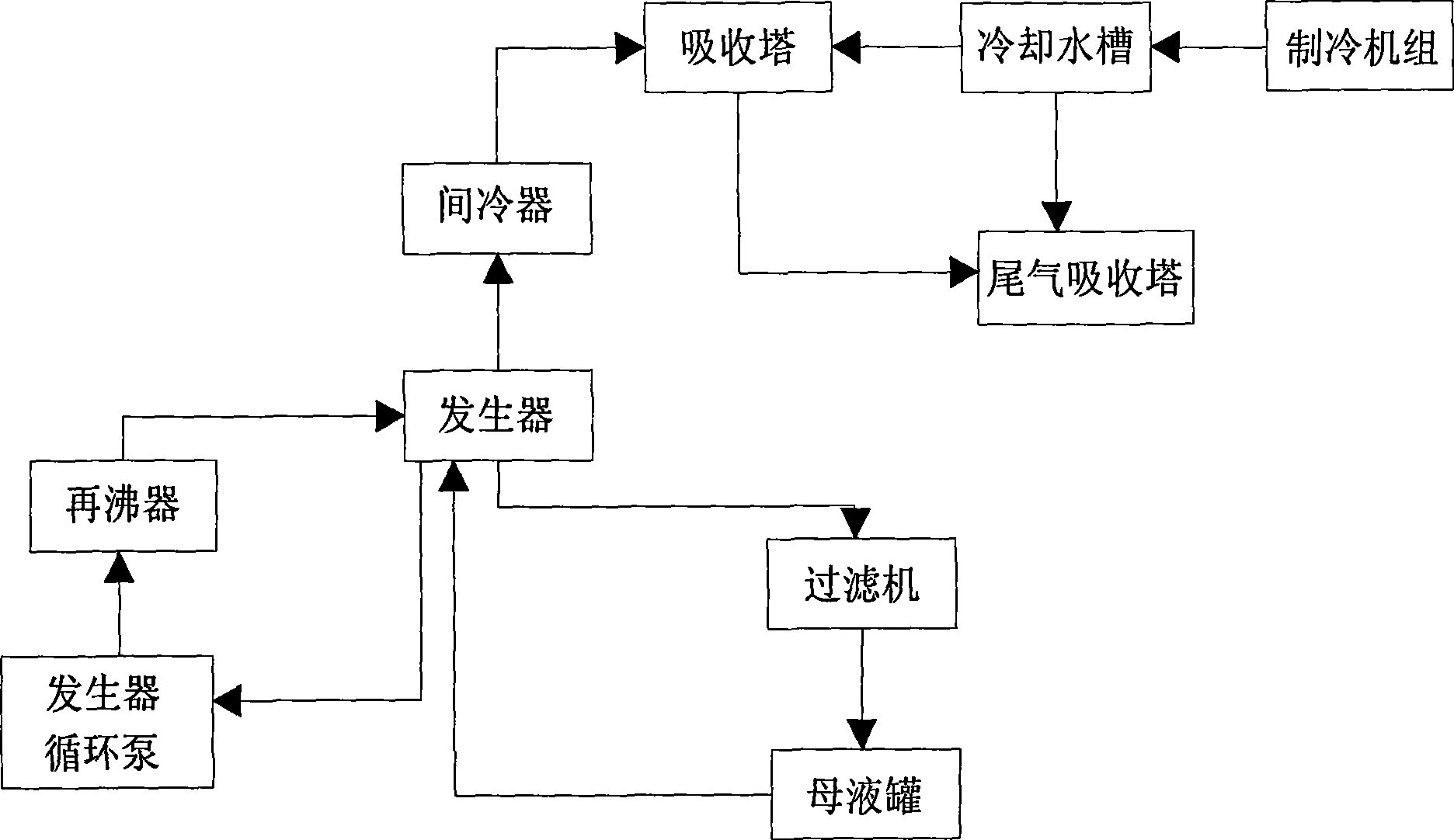

Process for preparing chlorine dioxide for pulp bleaching and apparatus thereof

The invention relates to a preparation process of chlorine dioxide used for pulp bleaching and a corresponding apparatus. The invention adopts sodium chlorate, sulfuric acid and methyl alcohol as materials which are mixed according to a certain proportion for reaction to generate chlorine dioxide and acid mirabilite. The chlorine dioxide is absorbed by iced water to generate the chlorine dioxide solution; the by-product mirabilite suspension is filtered by a rotary-drum vacuum filter to filter the mirabilite crystal out and then the mother solution and the filter solution are collected by a mother solution tank to return to the reactor for recycling use and the mirabilite crystal is directly diluted by black liquor. The invention has the beneficial effects that the process is simple; the productivity and reaction efficiency are high; the material cost is low; the productivity adaptability is high; the purity of chlorine dioxide is high; the content of chlorine is low; as the by-product of the preparation process, the mirabilite can be consumed in the paper mill so as to reduce the emission of contamination.

Owner:SICHUAN KAIWO ENVIRONMENTAL PROTECTION TECHCO

Salix mongolica sulfate pulp bleaching process

The invention relates to a salix mongolica sulfate pulp bleaching process belonging to the technical field of a paper pulp bleaching process. The process comprises the following steps: boiling and washing pulp, and carrying out AU series xylanase pretreatment at 48-50 DEG C under the condition that the pH value is 6.5-7; washing, and carrying out chlorine dioxide bleaching; washing, and carrying out cellulase treatment at 50-55 DEG C under the condition that the pH value is 5.5-6.5; and washing, carrying out hydrogen peroxide bleaching, and washing to obtain high-whiteness high-strength salix mongolica bleaching sulfate pulp. Under the short-time bleaching process conditions, the invention improves the bleaching property of the paper pulp, increases the bleaching yield and strength property of the paper pulp, reduces the consumption of bleaching chemical agent, lessens the environmental pollution, improves the utility value of the fast growing shrub salix mongolica sulfate pulp, and widens the application range of the salix mongolica sulfate pulp, thereby solving the resource and environment problems hampering the development of the paper making industry in China.

Owner:QILU UNIV OF TECH

Technology for catalyzing and bleaching paper pulp with immobilized Schiff alkali metals

InactiveCN102776796AThe implementation process is simpleReduce dosagePulp bleachingAlcoholPeroxy acid

The invention relates to a technology for catalyzing and bleaching paper pulp with immobilized Schiff alkali metals, belonging to the technology for catalyzing and bleaching paper pulp. The method provided by the invention can ensure that paper pulp is catalyzed and bleached under a condition that immobilized Schiff alkali metals exist in a paper pulp bleaching treatment; and simultaneously peroxy acid and alcohol are added. The method provided by the invention is simple, is carried out easily, and is featured with remarkably effects; and the paper pulp bleaching effect is good.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com