Novel non-chlorine bleaching technique for bamboo pulp

A completely chlorine-free, new technology, applied in the technical field of pulp bionic bleaching, can solve the problems of affecting the paper strength of pulp and the large amount of toxic substance pyridine, and achieve the effects of improving various properties, excellent pulp performance and reducing treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

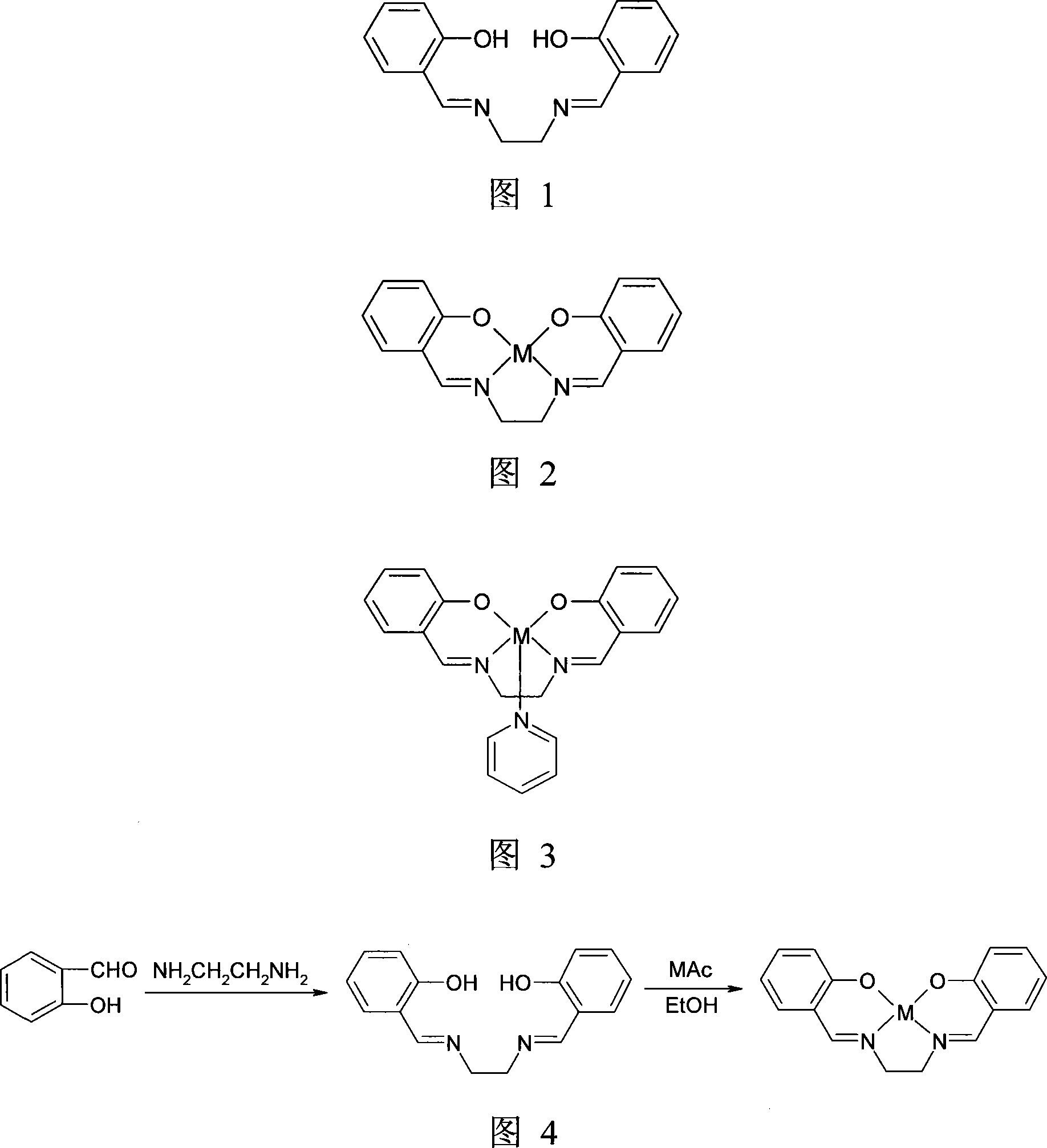

[0025] Dissolve 2.5 grams of ethylenediamine and 8.5 milliliters of salicylaldehyde in 18 milliliters of methanol, stir in an ice-water bath for 30 minutes, let stand for 15 minutes, filter under reduced pressure, wash with 1 milliliter of ether, and dry at 33°C for 6 hours , a light yellow solid was obtained. Then recrystallize with 160 ml of absolute ethanol, and dry at 33° C. for 18 hours to obtain Schiff base salen.

[0026] Dissolve 13 mmol of Schiff base salen in 150 ml of methanol, weigh another 13 mmol of cobalt acetate tetrahydrate, dissolve in warm water, quickly transfer to the above reaction bottle, and quickly form a brown precipitate, 70 ° C ~ 80 ° C Heat to reflux for 1 hour, the brown precipitate turns into dark red crystals, cool to room temperature, transfer the crystals to a sand core funnel, filter with suction, and dry to obtain Co-salen.

[0027] In bamboo pulp with a concentration of 6% by weight, the amount of NaOH is 3.0%, H 2 o 2 The consumption is...

Embodiment 2

[0029] Dissolve 2.0 g of ethylenediamine and 6.8 ml of salicylaldehyde in 14.4 ml of methanol, stir in an ice-water bath for 30 minutes, let stand for 15 minutes, filter under reduced pressure, wash with 1 ml of ether, and dry at 33°C for 6 hours , a light yellow solid was obtained. Then recrystallized with 128 ml of absolute ethanol, dried at 33° C. for 18 hours to obtain Schiff base salen.

[0030] Dissolve 10.4 mmol of Schiff base salen in 120 ml of methanol, weigh another 10.4 mmol of zinc acetate dihydrate, dissolve in warm water, quickly transfer to the above reaction bottle, and quickly form a brown precipitate, 70 ° C ~ 80 ° C Heat to reflux for 1 hour, the brown precipitate turns into dark red crystals, cool to room temperature, transfer the crystals to a sand core funnel, suction filter, and dry to obtain Zn-salen.

[0031] In bamboo pulp with a concentration of 5.0% by weight, the amount of NaOH is 2.4%, H 2 o 2 The consumption is 0.9%, the metal salen consumptio...

Embodiment 3

[0033] Dissolve 3.0 g of ethylenediamine and 10.2 ml of salicylaldehyde in 21.6 ml of methanol, stir in an ice-water bath for 30 minutes, let stand for 15 minutes, filter under reduced pressure, wash with 1.2 ml of ether, and dry at 33°C for 6 hours , a light yellow solid was obtained. Then recrystallized with 192 ml of absolute ethanol, dried at 33° C. for 18 hours to obtain Schiff base salen.

[0034] Dissolve 15.6 mmol of Schiff base salen in 180 ml of methanol, weigh another 15.6 mmol of nickel acetate tetrahydrate, dissolve in warm water, quickly transfer to the above reaction bottle, and quickly form a brown precipitate, 70 ° C ~ 80 ° C Heat to reflux for 1 hour, the brown precipitate turns into dark red crystals, cool to room temperature, transfer the crystals to a sand core funnel, filter with suction, and dry to obtain Ni-salen.

[0035] In bamboo pulp with a concentration of 4% by weight, the amount of NaOH is 2.7%, H 2 o 2 The consumption is 0.8%, the metal salen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com