Method for preparing transitional metal/active carbon catalyst

A transition metal and activated carbon technology, applied in the field of chemical treatment of combustion exhaust gas, can solve the problems of limited activity promotion space and low catalyst loading, and achieve the effect of simple operation, low cost and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

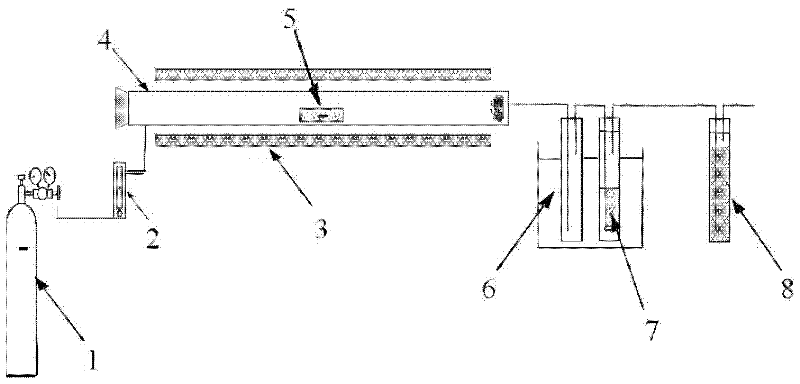

[0021] The preparation method is realized through the following steps:

[0022] The first step, the loading of ion exchange resin;

[0023] Take a certain amount of ion-exchange resin and soak it in deionized water for 4-6 hours to remove the water-soluble impurities, and then place it in the ion-exchange column to prepare an ammonia solution containing a certain amount of transition metal sulfate, with 10-50mL / The flow rate of min is to perform ion exchange on the ion exchange resin for 1 to 2 hours. After the exchange, the ion exchange resin is washed with deionized water, and then dried in an oven at 70°C for 24 hours to obtain an ion exchange resin loaded with transition metals.

[0024] Second step, carbonization of ion exchange resin;

[0025] The carbonization of the ion-exchange resin is carried out in a high-temperature carbonization device, and the high-temperature carbonization device includes a high-purity nitrogen cylinder 1, a rotameter 2, a quartz tube furnace...

Embodiment 1

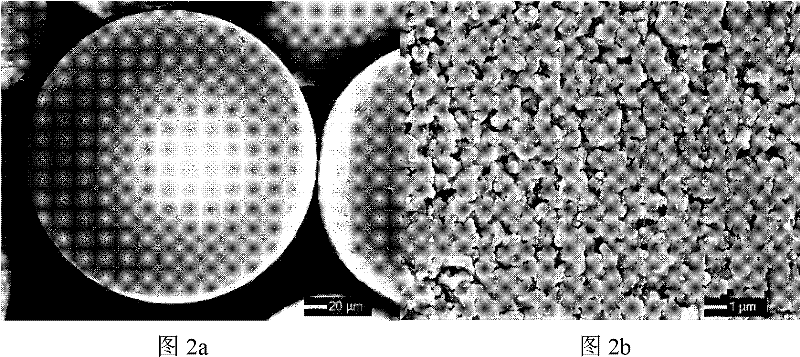

[0029] The present invention provides a kind of preparation method of transition metal / activated carbon catalyst, taking transition metal zinc / activated carbon as an example, mainly comprises the following steps to realize:

[0030] The first step, the loading of ion exchange resin, concrete steps are:

[0031] (1) Take by weighing 5g weakly acidic cation exchange resin (WK-11, Japan Mitsubishi Chemical Industry), its structural formula is as follows:

[0032]

[0033] Soak in 100mL deionized water for 4h to remove water-soluble impurities contained in the resin.

[0034] (2) Prepare an aqueous ammonia solution containing a certain amount of zinc sulfate, including 10gZnSO 4 ·7H 2 O, 100mL deionized water and 100mL mass fraction are 15% ammoniacal liquor.

[0035] (3) Fill the soaked ion-exchange resin into the ion-exchange column, and circulate and exchange the resin with an ammonia solution of zinc sulfate at a flow rate of 50 mL / min for 2 hours.

[0036] (4) After th...

Embodiment 2

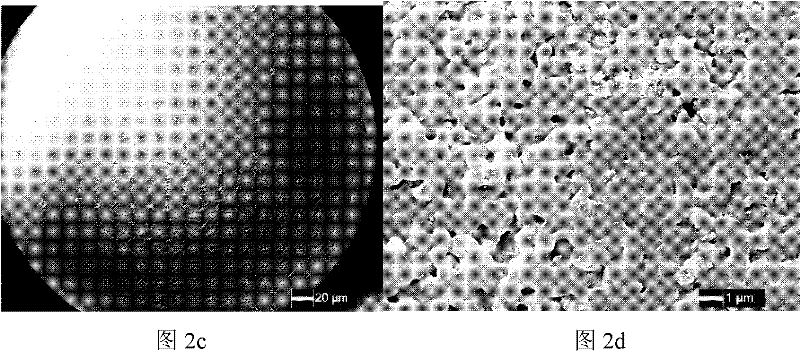

[0044] This embodiment takes the preparation of transition metal nickel / activated carbon catalyst as an example to describe in detail, mainly through the following steps:

[0045] The first step, the loading of ion exchange resin, concrete steps are:

[0046] (1) Weigh 5 g of weakly acidic cation exchange resin (WK-11, Mitsubishi Chemical Industry), the structural formula of which is the same as in Example 1, soak in 100 mL of deionized water for 4 hours to remove water-soluble impurities contained in the resin.

[0047] (2) preparation contains the ammoniacal solution of a certain amount of nickel sulfate, comprises 10.5gNiSO 4 ·6H 2 O, 100mL deionized water and 100mL mass fraction are 15% ammoniacal liquor.

[0048] (3) Fill the soaked ion-exchange resin into the ion-exchange column, and circulate and exchange the resin with an ammonia solution of nickel sulfate at a flow rate of 50 mL / min for 2 hours.

[0049] (4) After the exchange, the nickel-loaded resin was washed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com