Inorganic-organic composite flocculant, preparation method and application thereof

A compound flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, natural water treatment, etc., can solve the complex process, difficult latex wastewater treatment, wastewater pollution and other problems, to achieve the preparation of raw materials Simple and easy to obtain, low price of raw materials, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

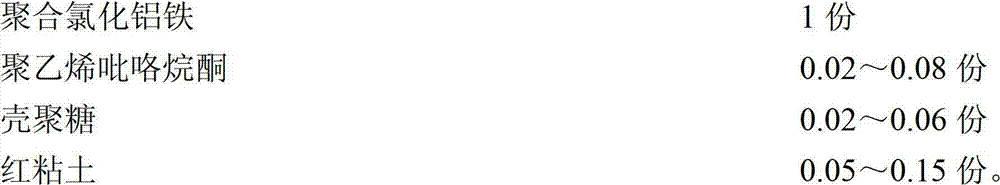

[0023] Under the condition of 35℃ and 260r / min continuous stirring, add 1g polyaluminum ferric chloride to 100g water, stir for 4 minutes; continue to add 0.02g polyvinylpyrrolidone, stir for 4 minutes; continue to add 0.02g chitosan, stir 10 minutes; finally add 0.05g of red clay and stir for 6 minutes to obtain inorganic-organic composite flocculant 1.

Embodiment 2

[0025] At 50°C and 260r / min under continuous stirring, add 1g of polyaluminum ferric chloride to 100g of water and stir for 4 minutes; continue to add 0.05g of polyvinylpyrrolidone and stir for 4 minutes; continue to add 0.04g of chitosan and stir 10 minutes; finally add 0.1 g of red clay and stir for 6 minutes to obtain inorganic-organic composite flocculant 2.

Embodiment 3

[0027] At 65°C and 260r / min under continuous stirring, add 1g of polyaluminum ferric chloride to 100g of water, and stir for 4 minutes; continue to add 0.08g of polyvinylpyrrolidone, and stir for 4 minutes; continue to add 0.06g of chitosan, and stir 10 minutes; finally add 0.15g of red clay and stir for 6 minutes to obtain inorganic-organic composite flocculant 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com