Natural high-iron albumen powder and preparation method thereof

A technology of protein powder and high iron, which is applied in food preparation, protein food ingredients, protein composition of vegetable seeds, etc., can solve the problems of increasing the risk of cancer, low iron absorption efficiency, side effects, etc., to improve the utilization value, The raw materials are easy to obtain, and the processing technology is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

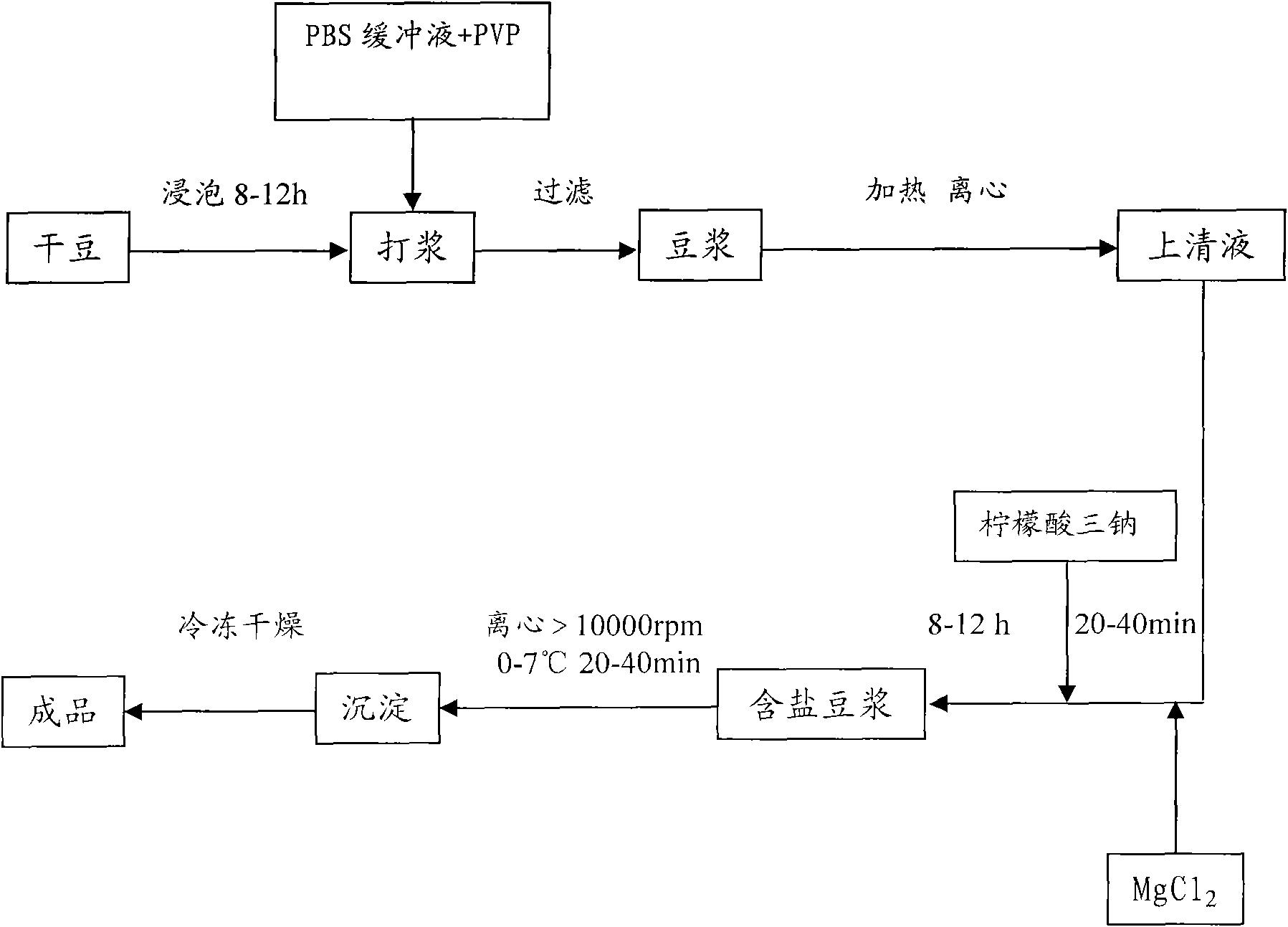

[0035] The invention discloses a preparation method of natural ferritin powder, comprising the following steps:

[0036] 1. Grind soybean milk

[0037] The raw material processed in the present invention is selected from one of soybeans, black beans or peas. Other iron-rich bean raw materials can also be used as needed.

[0038] First of all, the raw materials need to be soaked, and the required treatment time is generally 8 to 12 hours. Subsequently, beating treatment is carried out. Since the functional component of iron supplementation in the product is ferritin, and ferritin is a water-soluble protein, the pH value solution that is too high or too low in the production process will have a relatively large impact on the stability of ferritin and the iron content of the product. Therefore, the pH of the PBS buffer is 7-8. Add the PBS buffer solution (i.e. phosphate buffer solution) whose quality is 1 to 2 times of that of dry beans and whose concentration is 50 mM, and t...

Embodiment 1

[0052] The raw material is soybean, the ferritin content is about 60mg / kg, and the iron content is about 0.82mg / kg.

[0053] Weigh 2kg of dry soybeans, soak them for 10 hours, and make a slurry with PBS buffer solution whose mass is 1.5 times that of dry beans and whose concentration is 50mM. The polyvinylpyrrolidone in PBS buffer solution is 0.5-10 g / L The pH value of the PBS buffer solution is 7-8, and the bean dregs are filtered out with gauze to obtain soybean milk.

[0054] Heat the above soybean milk in a warm water bath at 55°C for 15 minutes, cool to room temperature and centrifuge at 4500rpm for 10 minutes, and take the supernatant;

[0055] Dissolve magnesium chloride in the supernatant first, dissolve trisodium citrate after 30 minutes and mix well, stir at 4°C for 10 hours to obtain salt-containing soybean milk, the concentrations of magnesium chloride and trisodium citrate are 500mM and 700mM respectively;

[0056] Centrifuge the salty soybean milk at a speed gre...

Embodiment 2

[0060] The raw material is black soybeans, the ferritin content is about 50mg / kg, and the iron content is about 0.7mg / kg.

[0061] Weigh 2kg of dry black beans, soak them for 10 hours, peel them off, and make a slurry with PBS buffer solution with a mass 1.5 times the mass of dry beans and a concentration of 50mM. The polyvinylpyrrolidone in the PBS buffer solution is 0.5-10 g / L , the pH value of the PBS buffer solution is 7-8, and the bean dregs are filtered out with gauze to obtain soybean milk.

[0062] Heat the above soybean milk in a warm water bath at 55°C for 15 minutes, cool to room temperature, centrifuge at 4500rpm for 10 minutes, and take the supernatant;

[0063] Dissolve magnesium chloride in the supernatant first, dissolve trisodium citrate after 30 minutes and mix well, stir at 4°C for 10 hours to obtain salt-containing soybean milk, the concentrations of magnesium chloride and trisodium citrate are 300mM and 450mM respectively;

[0064] Centrifuge the salty so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com