Patents

Literature

76 results about "IRON PREPARATIONS" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feed additive for improving stress resistance, meat color and meat quality of grown fattening pig and application thereof

ActiveCN102172265AImprove stress resistanceThe comprehensive effect is outstandingAnimal feeding stuffAccessory food factorsBiotechnologySide effect

The invention discloses a feed additive for improving the stress resistance, meat color and meat quality of a grown fattening pig and application thereof. The feed additive comprises the following components in parts by weight: 0.3-0.5 part of L-carnitine, 10-20 parts of betaine, 10-15 parts of electrolyte, 1-3 parts of selenium preparation, 2-5 parts of iron preparation, 3-5 parts of magnesium preparation, 0.5-1 part of chromium preparation, 1-2 parts of decavitamin, 5-10 parts of compound amino acid, 1-5 parts of tea polyphenol, 5-10 parts of isatis root and 20-61.2 parts of carrier. The feed additive provided by the invention has the following advantages: (1) the feed additive is composed of nutrient substances, Chinese herbal medicines and plant extracts, has non-toxic side effect, and is beneficial for the health of animals and human beings; (2) the raw material used by the invention is stable in resource, low in price, simple in production process, easy for industrial production; and (3) the feed additive provided by the invention can be used for rapidly supplementing various nutritive stress resisting substances, reliefing the stress of animals, improving the meat color and meat quality, and reducing the drip loss.

Owner:湖南鑫广安农牧股份有限公司

Nutrient composition

InactiveUS20090069217A1Promotes collagen productionPrevent and treat skin agingOrganic active ingredientsHeavy metal active ingredientsVitamin CAdditive ingredient

Provided is a nutrient composition for promoting collagen production, which contains vitamin C, an iron preparation, and collagen as active ingredients, promotes collagen production in a living body such as skin or bone, prevents or treats skin aging or bone and joint diseases, and is an iron preparation-containing composition having stability imparted thereto. Also provided are a food or beverage, a feed, and a medicine each containing the nutrient composition incorporated therein.

Owner:SNOW BRAND MILK PROD CO LTD

Iron preparation suitable for pharmaceutical formulation and process for the preparation thereof

Owner:ROCKWELL MEDICAL INC

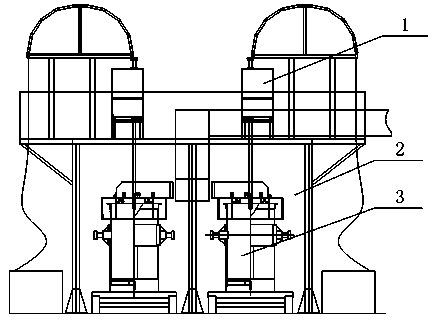

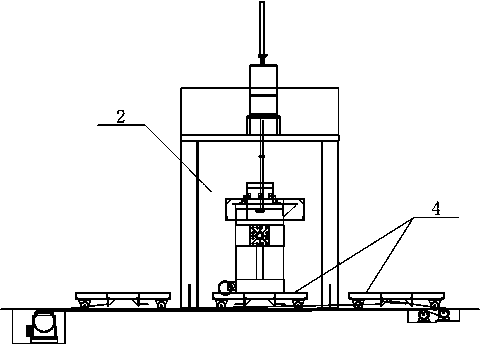

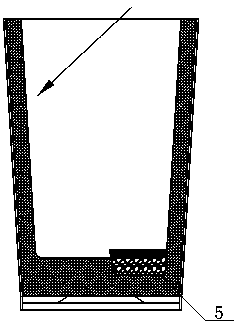

Method for preparing centrifugal nodular cast iron pipe

ActiveCN104480382AImprove appearance qualityRefining material organizationLiquid surface applicatorsCoatingsIRON PREPARATIONSCast iron pipe

The invention discloses a method for preparing a centrifugal nodular cast iron pipe. The method discloses the preparation process of the centrifugal nodular cast iron pipe of high quality, the preparation process comprises a series of operation processes of molten iron preparation, nodulizing of molten iron, centrifugal casting, annealing treatment, pipe body shaping and coating protection and the like. The method is suitable for preparation of cast iron pipes of the specification of DN 80-1000 mm, the application range is wide, and the preparation process is simple. The cast iron pipe prepared through the method has the characteristics of being high in appearance quality, fine in material structure, high in production efficiency, long in service life and the like, and compared with existing steel pipes and gray iron pipes, the cast iron pipe prepared through the method has better decay resistance and tensile property.

Owner:SICHUAN CHUANJIAN PIPES

Iron preparation suitable for pharmaceutical formulation and process for the preparation thereof

ActiveUS20110021629A1Avoid chemical changesInhibition of polymerizationBiocideHeavy metal active ingredientsFood additivePharmaceutical formulation

New iron preparations comprising stable, unpolymerized iron(III) citrate complex compositions and methods for their preparation are provided. Further, the invention involves the use stable, unpolymerized iron(III) citrate complex compositions of the invention as a food additive, nutritional supplement, dietary supplement, medical food, nutrient, iron fortificant, and source of iron in the fields of nutrition for humans, animals, fish, and birds and of diagnostics. The invention further involves the use of stable, unpolymerized iron(III) citrate complex compositions of the invention as a pharmaceutical and pharmacologically active ingredient for human clinical and veterinary applications.

Owner:ROCKWELL MEDICAL INC

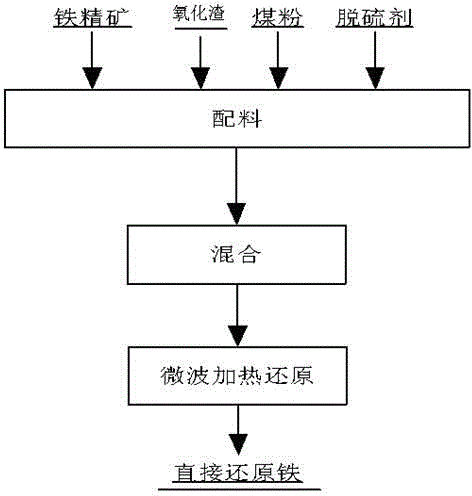

Method for preparing direct-reduction iron by reducing carbon-containing iron ore powder in microwave heating manner

The invention relates to a method for preparing direct-reduction iron by reducing carbon-containing iron ore powder in a microwave heating manner. A microwave heating manner is induced to a coal-based method direct-reduction iron preparation so as to replace the traditional coal heating manner, and high-quality direct-reduction iron is produced by utilizing self-reduction characteristics of iron ore powder, oxidizing slag and the like with coal powder. Through the method for preparing the direct-reduction iron by reducing the carbon-containing iron ore powder, the defects that the reduction time is long, the product quality is unlikely to control, the investment is large, the floor space is large and the like in a process of producing the direct-reduction iron by a coal-based tunnel kiln canning external carbon method can be effectively overcome, the production flow is simplified, the reduction time is largely shortened, the manual cost is reduced, and the certain energy-saving and emission reduction effect can be obtained.

Owner:WUKUN STEEL

Iron composition containing milk protein

InactiveUS20090081315A1Composition is stableBiocideHeavy metal active ingredientsIRON PREPARATIONSVitamin C

There are provided an iron composition including a milk protein and an iron preparation, which is stable in the presence of a substance having a property of releasing iron from the composition or reducing the released iron, and foods or drinks, animal feeds, and medicines blended with the iron composition. A milk protein such as skim milk is blended into an iron preparation, thereby producing the iron composition which is stable in the presence of a substance having a property of releasing iron from the composition or reducing the released iron (e.g., vitamin C or citric acid).

Owner:SNOW BRAND MILK PROD CO LTD

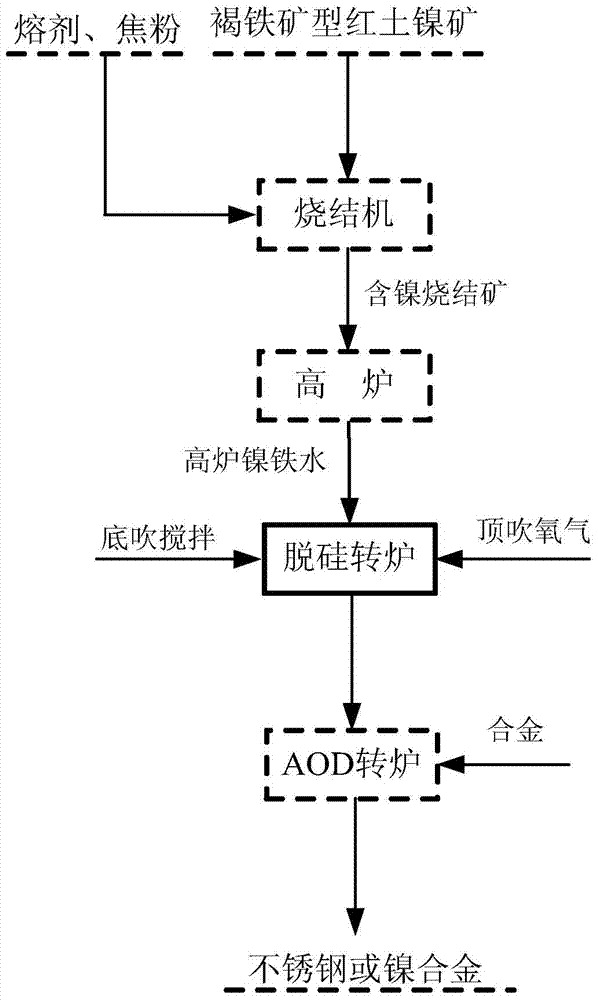

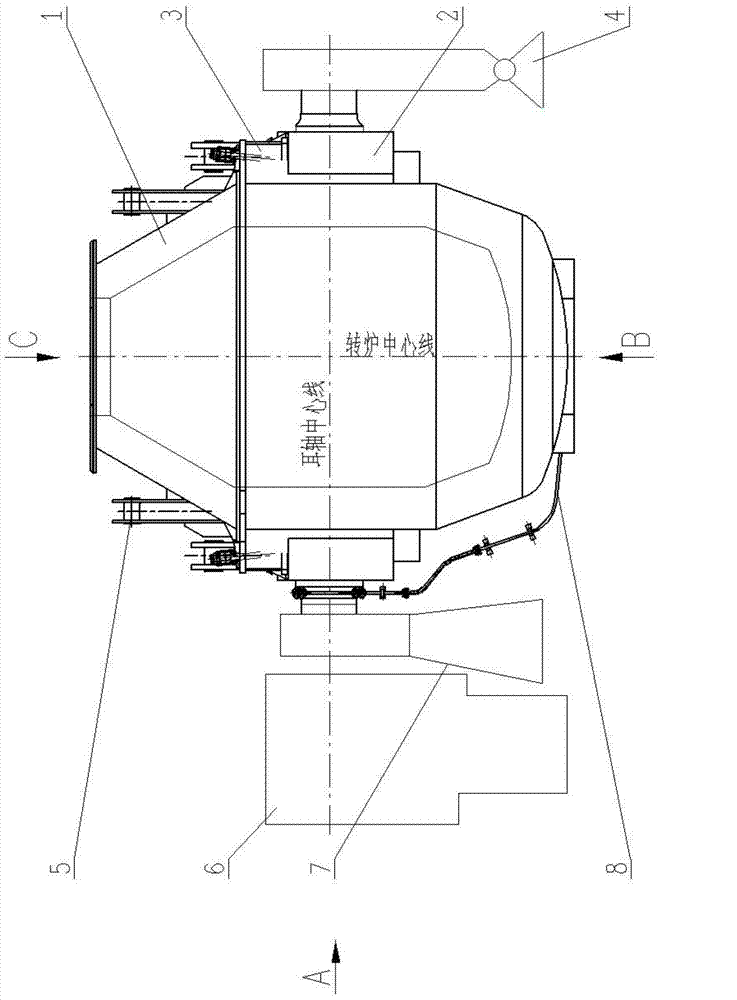

Molten iron desilication method for stainless steel smelting

ActiveCN103614609ALow Si content requirementEnough reaction spaceManufacturing convertersIRON PREPARATIONSFerrosilicon

The invention provides a molten iron desilication method for stainless steel smelting, which comprises the following steps: 1. blast furnace molten iron preparation: mixing and sintering laterite-nickel ore, adding the laterite-nickel ore into a blast furnace, and smelting while ensuring the blast furnace tapping temperature to be at least 1350 DEG C; 2. transportation: transporting the high-temperature nickeliferous high-silicon molten iron of the blast furnace to a desilication converter in the one-step or metal mixer form; 3. carrying out desilication, decarburization, dephosphorization and desulfurization on the nickeliferous high-silicon molten iron in the desilication converter, and carrying out desilication treatment on the molten iron in a top / bottom blowing mode, wherein the mass percent of silicon in the desilicated molten iron is not greater than 0.20%; and 4. final product smelting: after finishing converting, charging the semisteel from the desilication converter into an AOD (argon oxygen decarburization) furnace while adding alloy into the AOD furnace, and finishing the final smelting of stainless steel. The desilication technique has low requirements for Si content in the molten iron, provides sufficient reaction space for desilication, effectively prevents splashing, creates favorable dynamic conditions for desilication, and meanwhile, can perform dephosphorization and desulfurization.

Owner:BERIS ENG & RES CORP

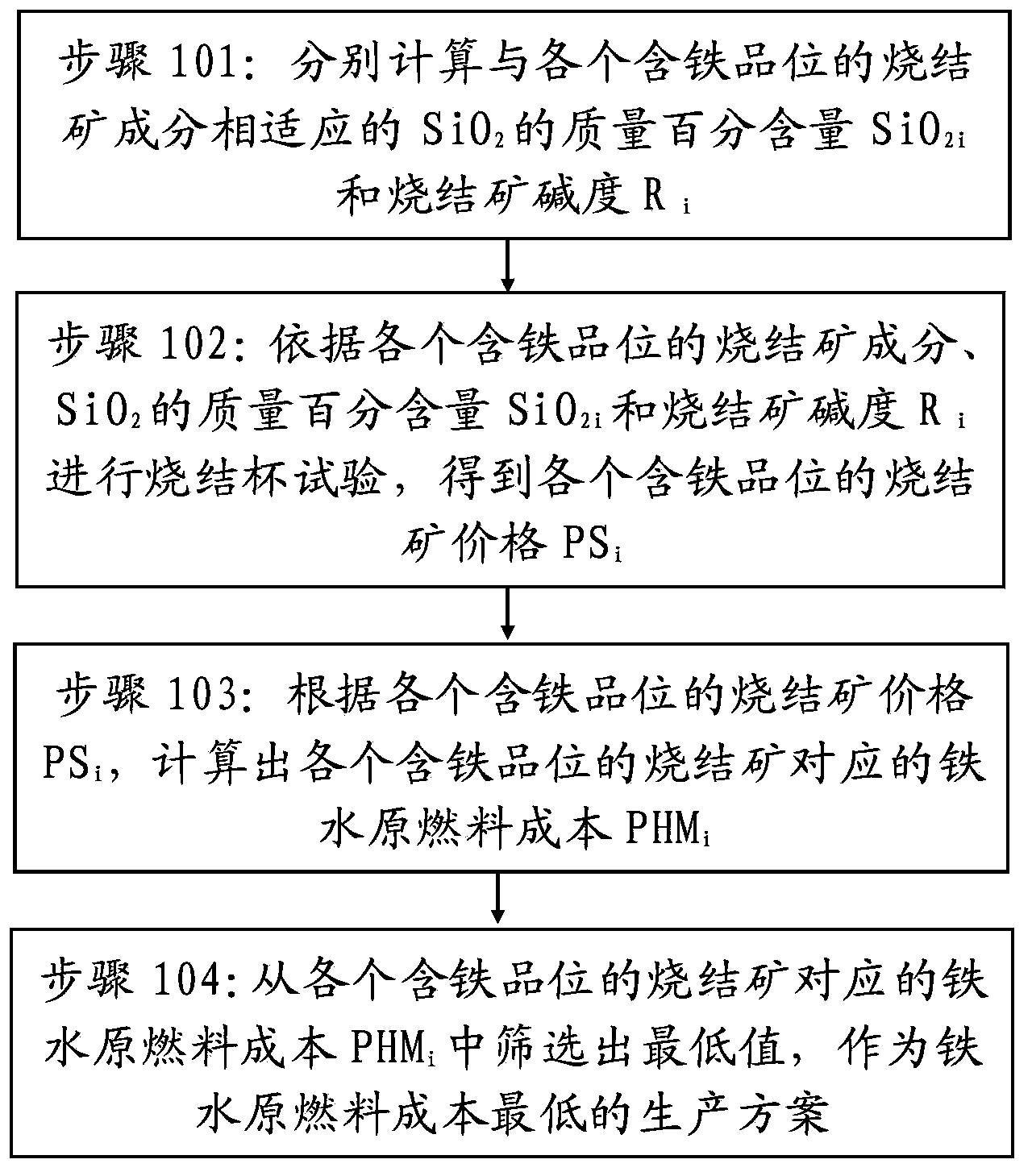

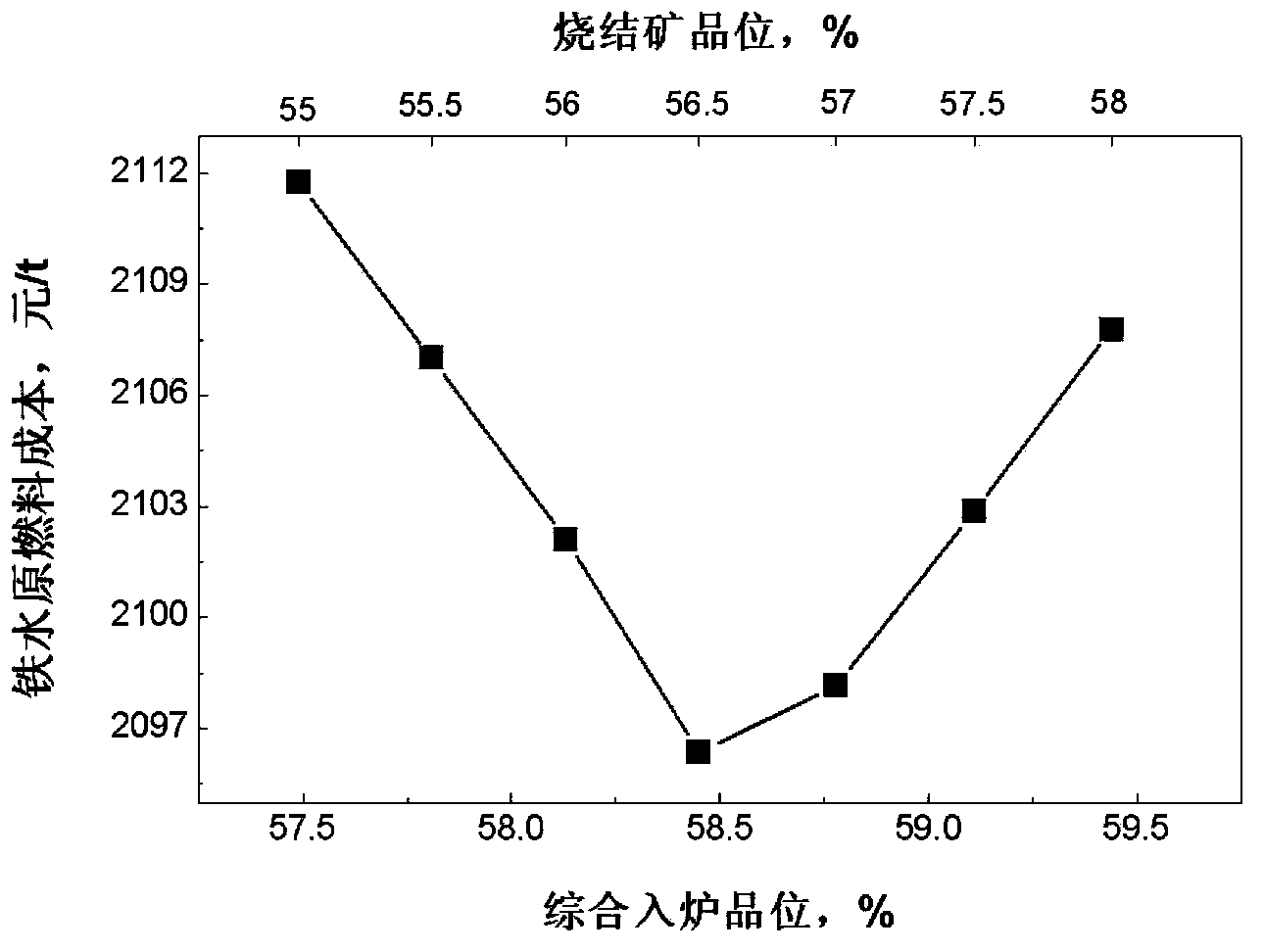

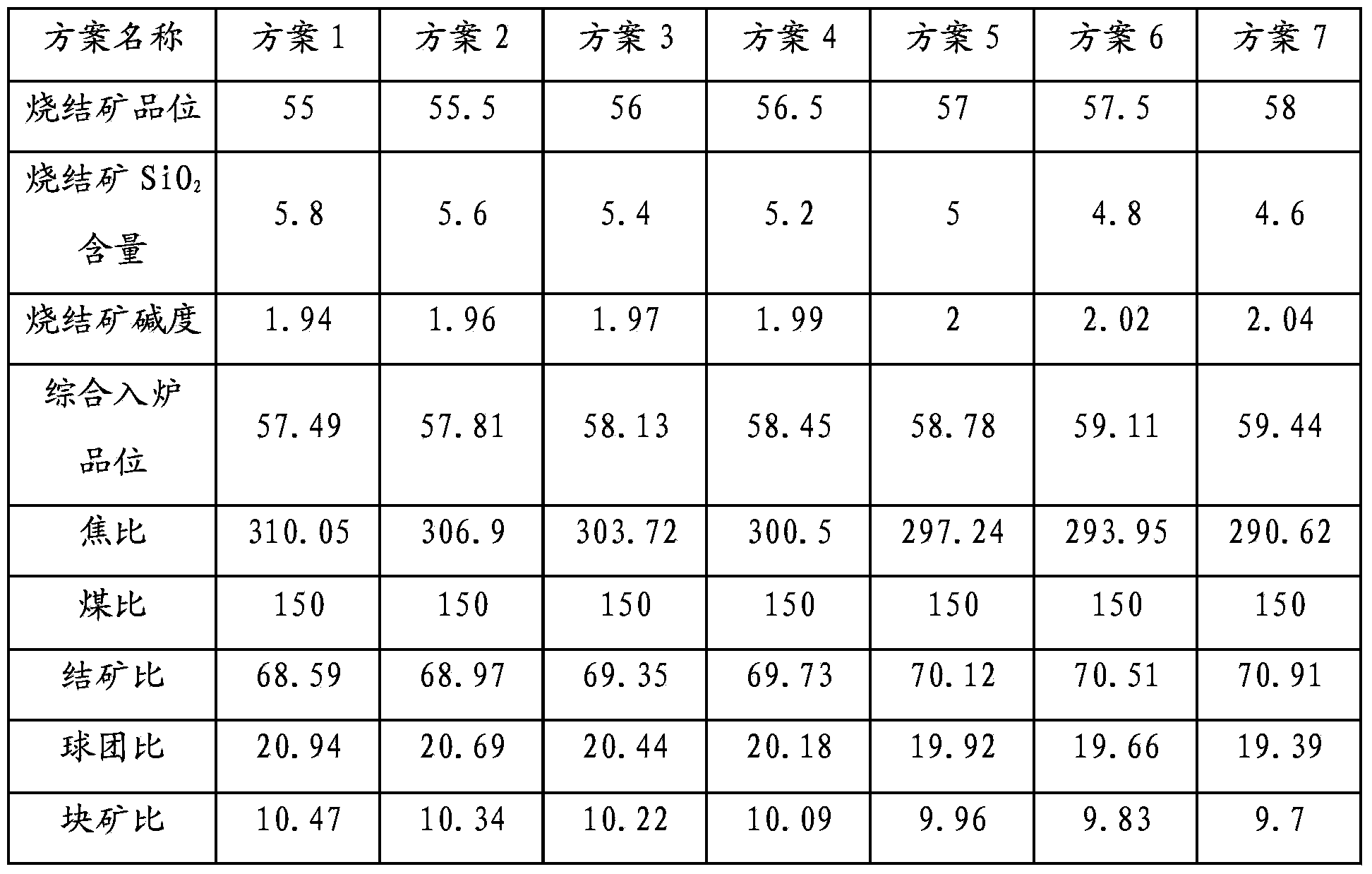

Blast furnace sintering linked low-cost molten iron preparation method

ActiveCN103382513ALow sintering ore distribution structureBlast furnace detailsAlkalinityIRON PREPARATIONS

The invention provides a blast furnace sintering linked low-cost molten iron preparation method. The blast furnace sintering linked low-cost molten iron preparation method comprises following steps: firstly, sinter SiO2 content and sinter alkalinity which match with a blast furnace burden structure are calculated according to sinter with different grades; and then, sintering cup experiment is performed based on sinter composition so as to obtain sinter prices according to experiment results; at last, the sinter prices are put into a molten iron crude fuel cost calculation formula so as to obtain the molten iron crude fuel cost of each sinter grade, and a minimum value is selected from the results so as to obtain the production scheme which possesses a lowest molten iron crude fuel cost. The blast furnace sintering linked low-cost molten iron preparation method is provided by the invention so as to obtain a sinter structure which possesses a lowest molten iron crude fuel cost, and to provide low-cost molten iron production with guarantees.

Owner:SHOUGANG CORPORATION

Ultra low silicon welding rod steel continuous casting production process

The continuously-casting production process of conventional welding electrode steel includes the following procedures: molten iron preparation, converter charging, converter smelting, deoxidization alloying, external refining and continuous casting. In the deoxidization alloying procedure, according to the total weight of molten iron the following deoxidizing agents are added, the calcium carbide, titanium-ion alloy and silicon-calcium alloy, etc. are added into the ladle, and the aluminium-manganese-iron alloy is added into the converter. Said invention implements of continuous coating production of ultralow silicon welding electrode steel, and its silicon content is less than 0.035.

Owner:新疆钢铁研究所

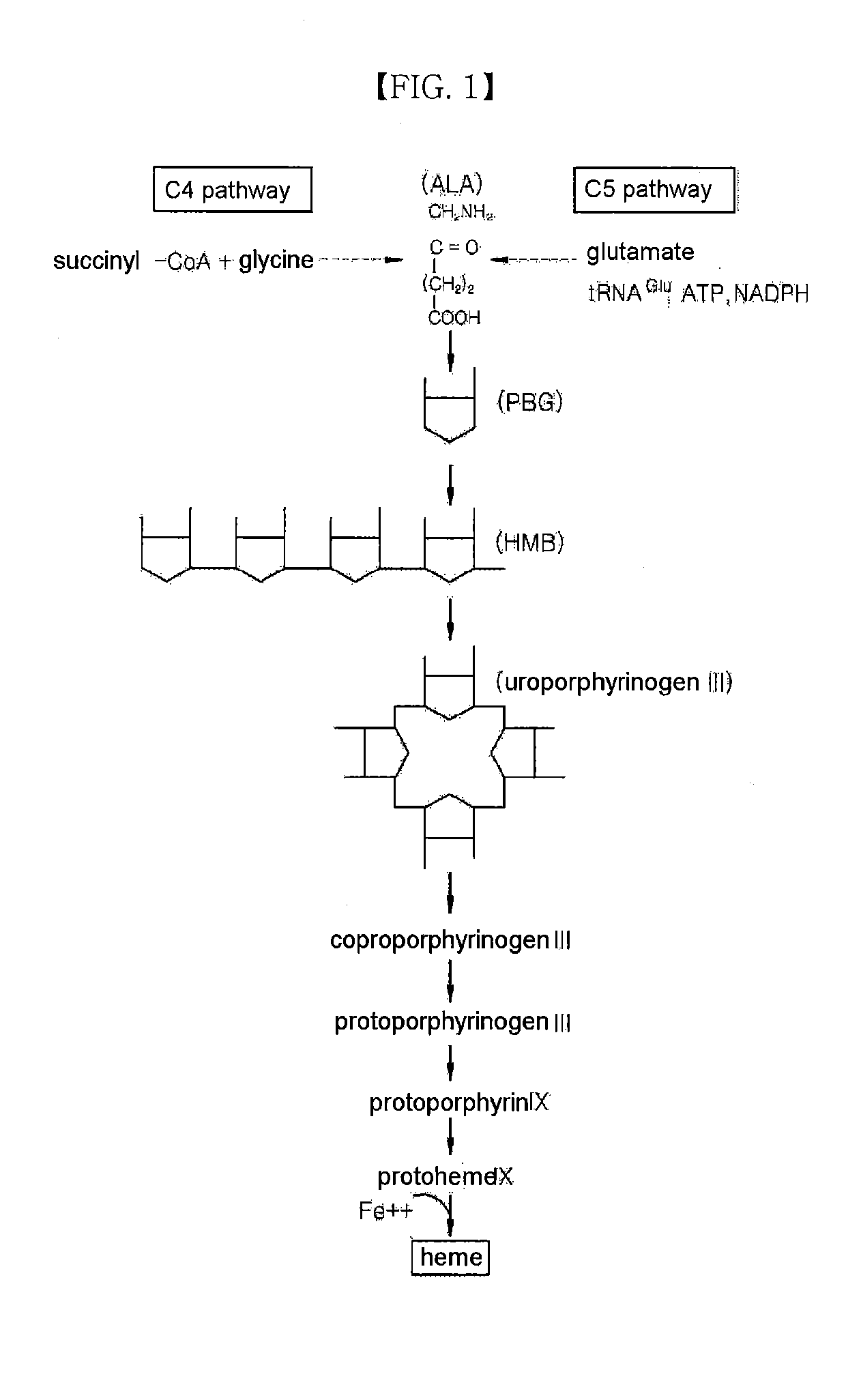

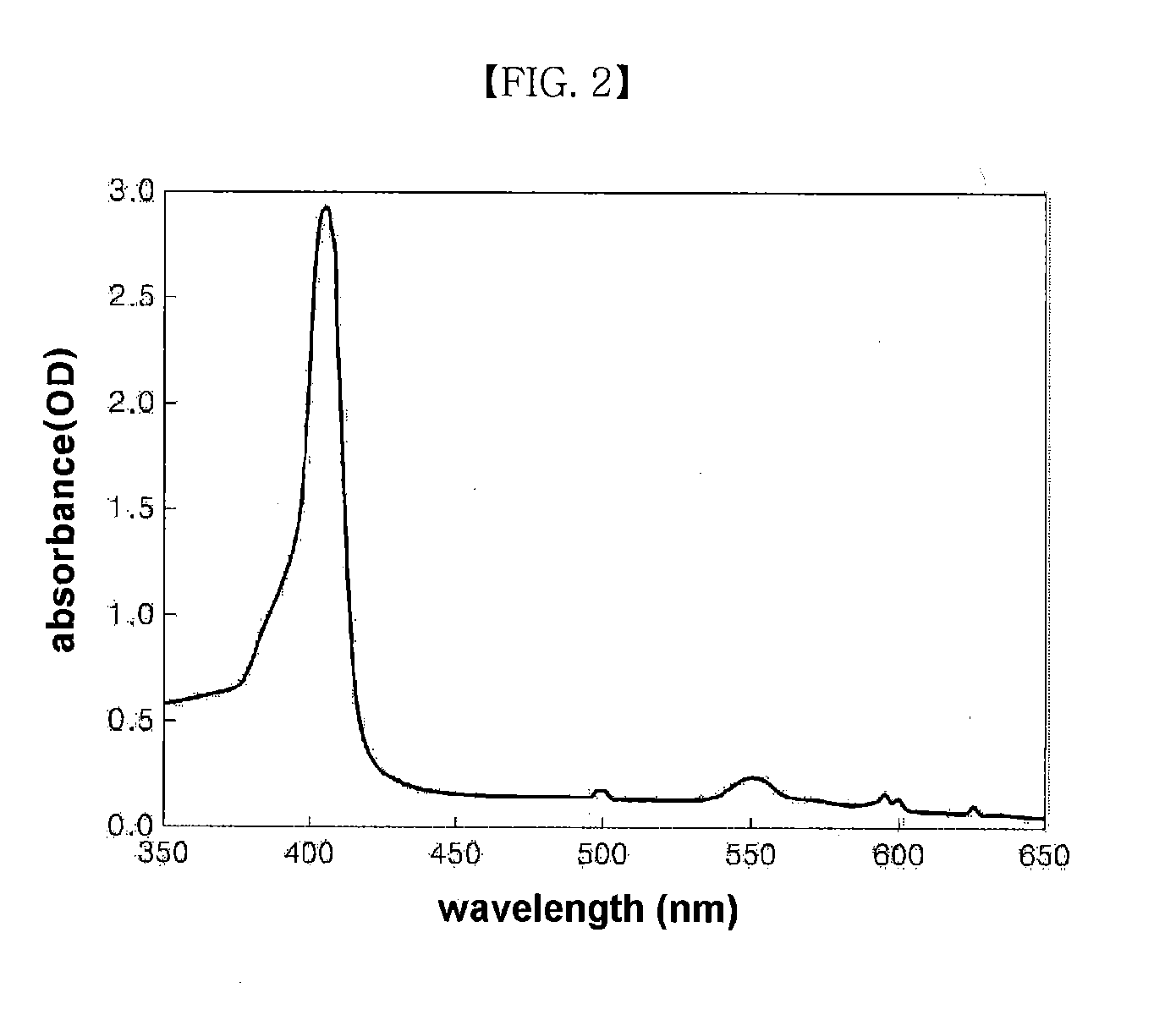

Method for Producing Biological Heme Iron, and Iron Supplementing Composition Containing the Heme Iron Produced By Same

ActiveUS20110213142A1Safely used as iron supplementProduced economicallyHeavy metal active ingredientsFungiBiotechnologyMicroorganism

The present invention relates to a method for biologically producing heme-iron through microorganism cultivation, and to an iron supplementing composition containing the heme-iron produced by the same. The present invention provides a method for biologically producing heme-iron through microorganism cultivation, making it possible to economically produce heme-iron or heme-iron preparations which can be safely used as an iron supplement.

Owner:THE CATHOLIC UNIV OF KOREA IND ACADEMIC COOPERATION FOUND +1

Method of stabilizing iron compositions with milk protein

InactiveUS20100178361A1Composition is stableHeavy metal active ingredientsBiocideIRON PREPARATIONSVitamin C

There are provided an iron composition including a milk protein and an iron preparation, which is stable in the presence of a substance having a property of releasing iron from the composition or reducing the released iron, and foods or drinks, animal feeds, and medicines blended with the iron composition. A milk protein such as skim milk is blended into an iron preparation, thereby producing the iron composition which is stable in the presence of a substance having a property of releasing iron from the composition or reducing the released iron (e.g., vitamin C or citric acid).

Owner:SNOW BRAND MILK PROD CO LTD

Complex iron preparation and preparation method thereof

InactiveCN108795525AIncrease profitIncrease oxidation rateDispersed particle separationGaseous fuelsIRON PREPARATIONSCobalt salt

The invention belongs to the field of natural gas desulfurization in the petroleum industry, and specifically discloses a complex iron preparation and a preparation method thereof. The complex iron preparation is prepared from the following raw materials: ferrite, inorganic base, cobalt salt, organic complexing agent, piperazine, polyethylene glycol and water. The preparation method of the complexiron preparation comprises the following steps: (1) mixing the cobalt salt, the inorganic base, the organic complexing agent, the ferrite and the water at normal temperature and stirring for 2-5 hours; (2) introducing air for 2-3.5 hours continuously; (3) adding the piperazine, stirring uniformly, then adding polyethylene glycol and stirring for 1-1.5 hours to obtain the complex iron preparation.The complex iron preparation has the advantages of simple preparation, high regeneration rate and low cost, and has good application prospects in the field of natural gas desulfurization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Converter steelmaking method for increasing scrap steel ratio per ton of steel

InactiveCN108103262AIncrease the amount of participationReduce adverse effectsManufacturing convertersProcess efficiency improvementMaterials preparationSteelmaking

A converter steelmaking method for increasing the scrap steel ratio per ton of steel comprises the steps of scrap steel preheating, molten iron preparation, scrap steel material preparation, converteroperation, operation after a converter, treatment outside the converter, and the like. According to the converter operation step, scrap steel molten steel, a scrap steel material and molten iron which are added into the converter comprise, by weight, 33-45% of the scrap steel molten steel, 9-12% of the scrap steel material and the balance the molten iron. According to the converter steelmaking method for increasing the scrap steel ratio per ton of the steel, the adding amount of scrap steel per ton of the steel is increased in the premises of ensuring the molten steel quality and meeting thetapping temperature requirements, and meanwhile, the adverse effect of the coal gas preheated scrap steel on the environment is eliminated, so that the scrap steel ratio per ton of the steel is further increased, and the iron loss is greatly reduced; and researches show that the scrap steel ratio per ton of the steel can reach 40% or above in the premise of ensuring normal production and the molten steel quality by adopting the converter steelmaking method.

Owner:TANGSHAN DELONG STEEL CO LTD

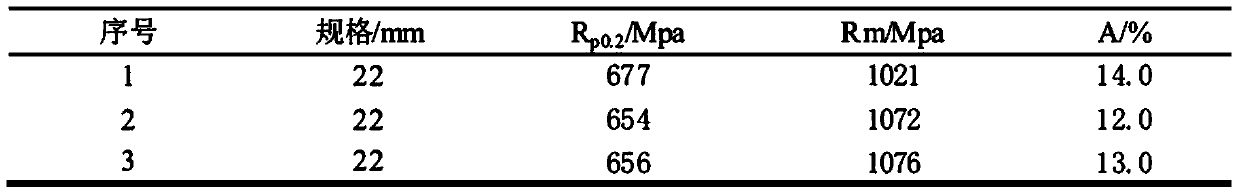

Corrosion-resistant 5Cr steel and production method thereof

ActiveCN103993229AAccelerated corrosionImprove plastic toughnessHeat treatment process controlProcess efficiency improvementWetlandImpurity

The invention discloses corrosion-resistant 5Cr steel and a production method thereof, belonging to the technical field of corrosion-resistant high-5Cr-content steel production. The steel comprises the following chemical components in percentage by mass: 0.05-0.07% of C, 0.1-0.3% of Si, 0.5-0.8% of Mn, less than or equal to 0.02% of P, less than or equal to 0.01% of S, 4.5-5.5% of Cr, 0.02-0.05% of N and the balance of Fe and unavoidable impurities. The production method of the corrosion-resistant steel comprises the steps of molten iron preparation; converter smelting; ferrochrome adding; refining; continuous casting of small square billets; heating furnace heating; controlled rolling; and controlled cooling. The corrosion-resistant 5Cr steel produced by using the method has the yield strength of 600Mpa and a thin stripped martensite. The corrosion-resistant 5Cr steel has the advantages of excellent chloride ion corrosion resistance 2-3 times as high as that of carbon steel, excellent industrial atmospheric corrosion resistance and suitability for a concrete structure with requirements for ultrahigh strength and durability design under bad conditions such as sea, wetlands and the like; and in addition, the cost of the corrosion-resistant 5Cr steel is relatively low and is far lower than the cost of stainless steel, and therefore, the corrosion-resistant 5Cr steel as structural steel for a building is easier to popularize and use.

Owner:SHOUGANG CORPORATION

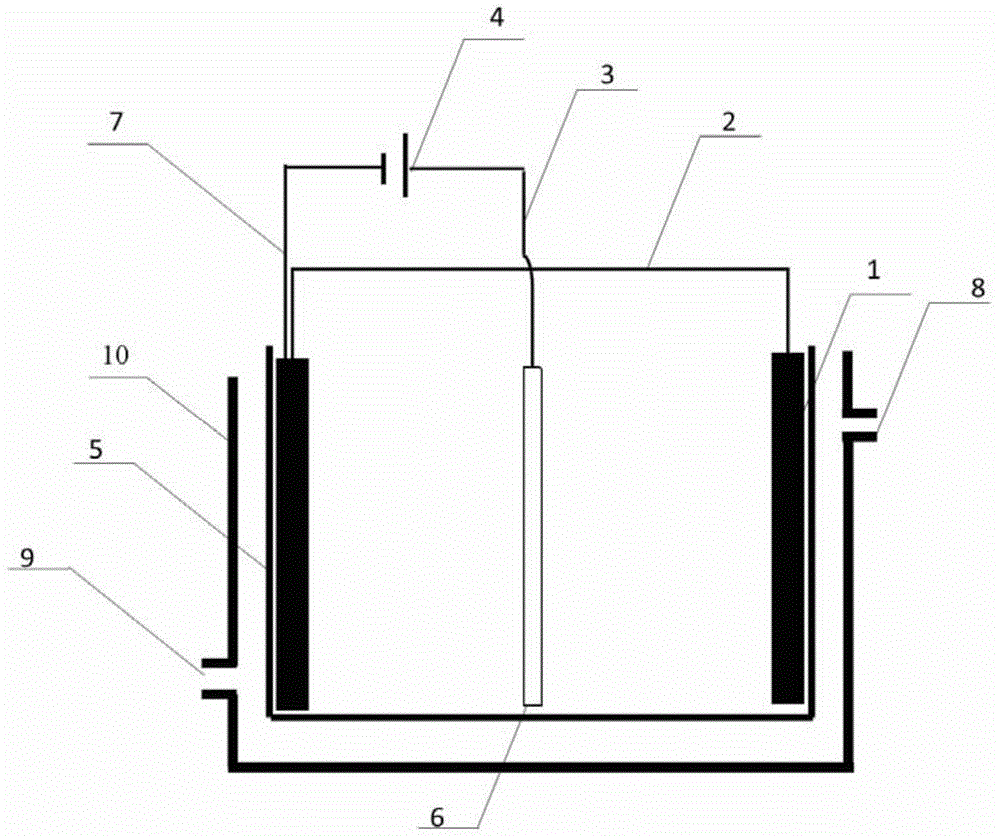

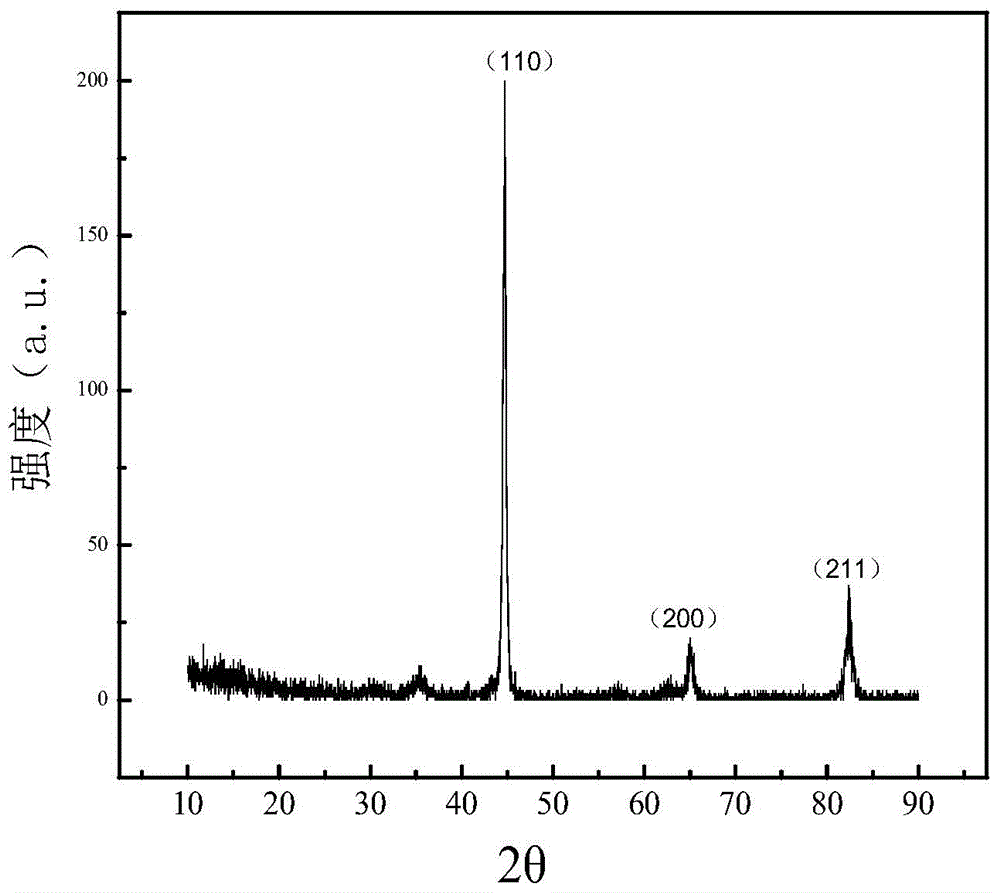

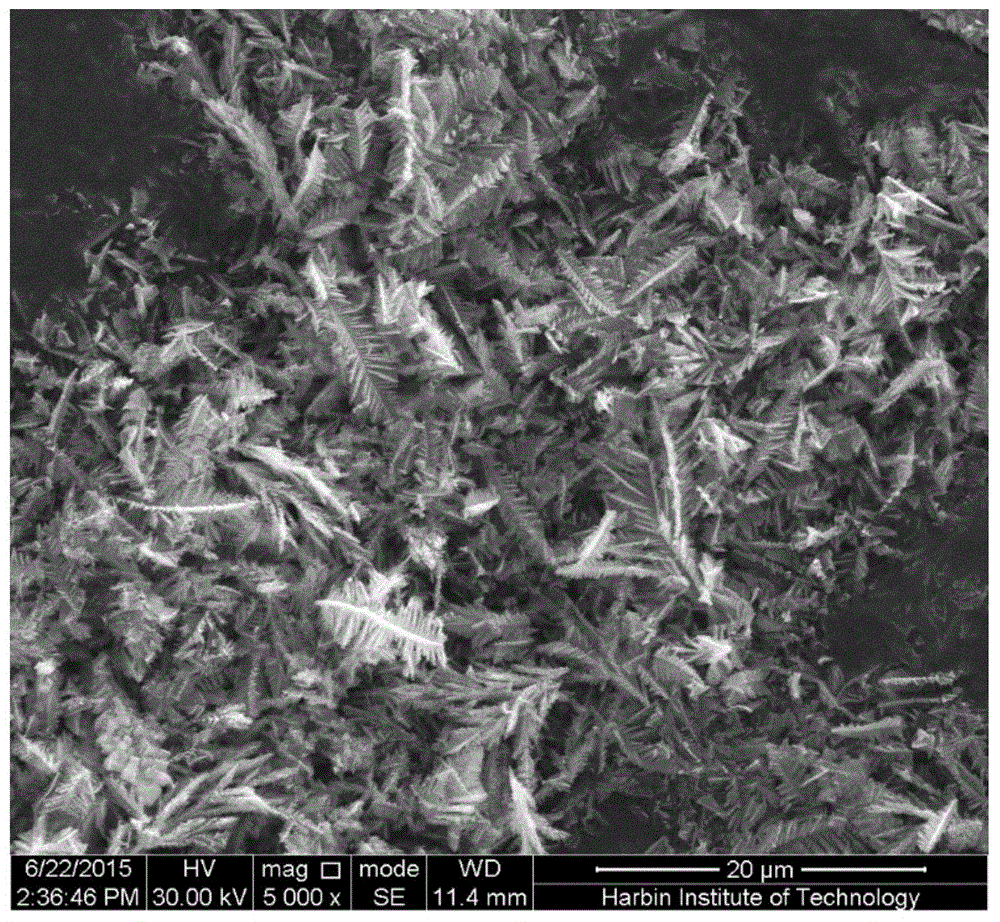

Method for preparing functional micro-nano structure dendritic alpha-Fe-based material through iron

The invention relates to a method for preparing a functional alpha-Fe material, in particular to a method for preparing a functional micro-nano structure dendritic alpha-Fe-based material through iron. The method is used for solving the problems that an existing waste iron recovery process is high in cost and causes pollution, and an existing nano-iron preparation process is complex, high in cost and low in product purity. The method includes the steps of firstly, taking a set of reaction equipment; secondly, preparing an electrolytic solution; thirdly, preparing metal powder; and fourthly, performing cleaning and drying to obtain the functional micro-nano structure dendritic alpha-Fe-based material. According to the method, waste steel is used as an anode, so that the waste steel is utilized, and the problem of steel waste is solved; the common steel is converted into dendritic alpha-Fe, and the dendritic alpha-Fe has various excellent properties and is widely applied to various fields. The method for preparing the functional micro-nano structure dendritic alpha-Fe-based material through the iron is obtained.

Owner:HARBIN INST OF TECH

Iron-dextrin long-acting injection and preparation method thereof

InactiveCN102440952ASmall toxicityFacilitated releaseOrganic active ingredientsMetabolism disorderSide effectIron supplement

The invention relates to iron-dextrin long-acting injection and a preparation method thereof. The iron-dextrin long-acting injection is used for piglet iron supplement iron, and has the advantages that the release, absorption, distribution, metabolism and excretion processes of an iron preparation can be prolonged in vivo, so that the purpose of prolonging the action of a drug can be achieved, the number of the dosing times can be reduced, the complicance of livestocks is improved, the blood concentration can be stable, the peak and valley phenomena can be avoided, the side effects of the drug can be facilitated to be reduced, the total drug dosage is reduced, and further, the maximum drug effect by the minimum dosage is achieved. Thus, the iron-dextrin long-acting injection can completely play the role of long-acting iron supplement in the prevention and the cure of piglet iron-deficiency anemia.

Owner:TIANJIN RINGPU BIO TECH

Iron replenisher with control released iron and its preparing method and use

InactiveCN1857306AGood biocompatibilityImprove convenienceHeavy metal active ingredientsPowder deliveryControlled releaseIron salts

The present invention discloses iron replenisher with control released iron and its preparation process and use. The iron replenisher is zeolite containing active iron in 1.5-10 wt%. The preparation process includes the adsorption and ion exchange reaction between bivalent iron salt and zeolite, filtering, drying and crushing to obtain zeolite containing active iron. Supporting iron onto zeolite, which possesses excellent biocompatibility, excellent gastrointestinal mucous membrane affinity, regular pore canal structures and cage spaces, high surface activity and great specific surface area, can obtain controlled releasing of iron and raise utilization of iron. The control released iron preparation may be used as iron replenisher for human body and animal.

Owner:ZHEJIANG UNIV

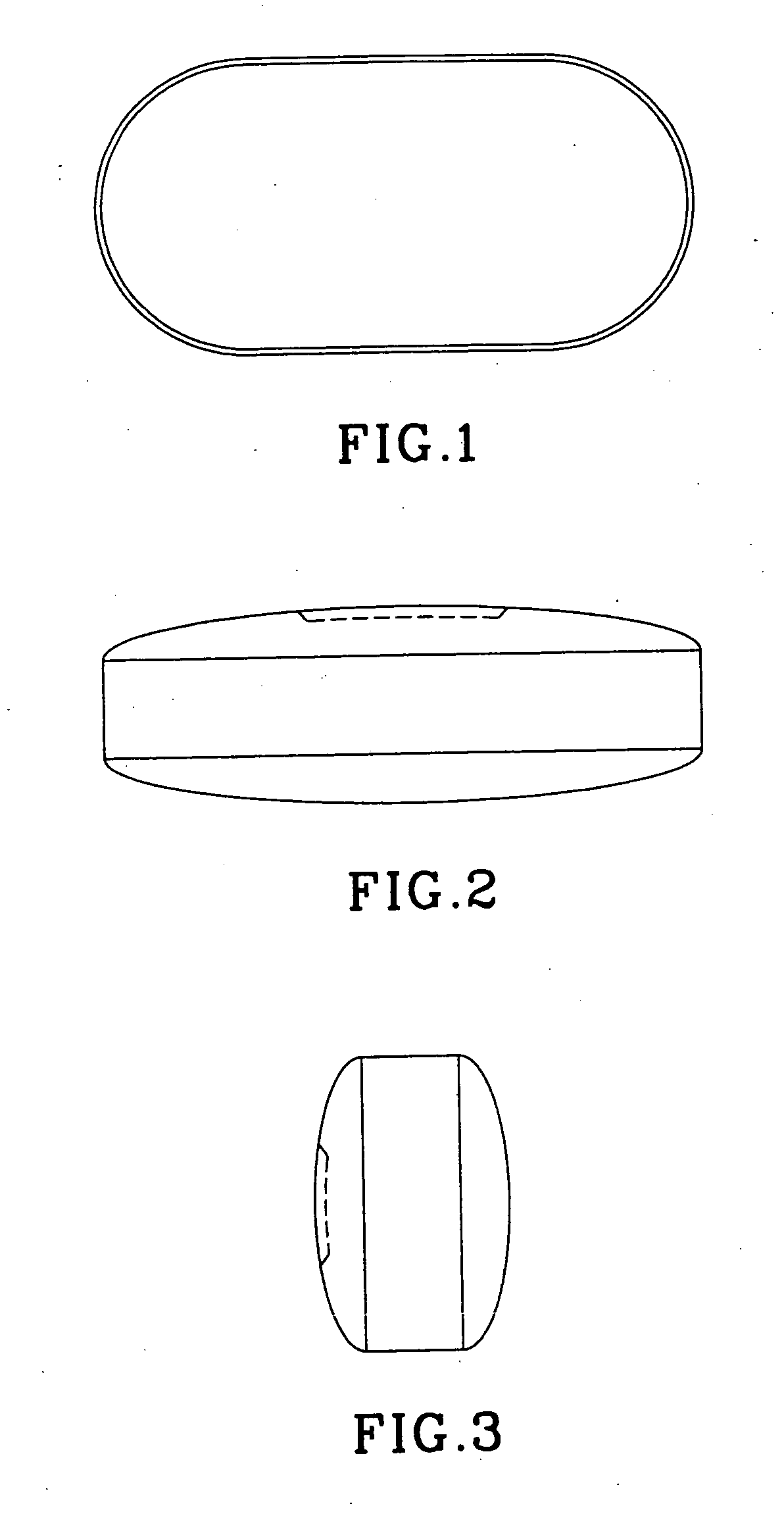

Film coated tablet for improved upper gastrointestinal tract safety

InactiveUS20070071822A1Protection is in progressInhibition releaseBiocideTetracycline active ingredientsIrritationUpper gastrointestinal

A novel oral dosage to be delivered to the stomach comprising a safe and effective amount of an active ingredient selected from the group consisting of emepronium bromidebromide, doxycycline, and other tetracyclines / antibiotics, iron preparations, quinidine, nonsteroidal anti-inflammatory drugs, alprenolol, ascorbic acid, captopril, theophylline, zidovoudine (AZT), bisphosphonates and mixtures thereof and pharmaceutically-acceptable excipients, wherein said oral dosage form is a generally oval form and film coated to facilitate rapid esophageal transit and avoid irritation in the mouth, buccal cavity, pharynx, and esophagus.

Owner:THE PROCTER & GAMBLE COMPANY

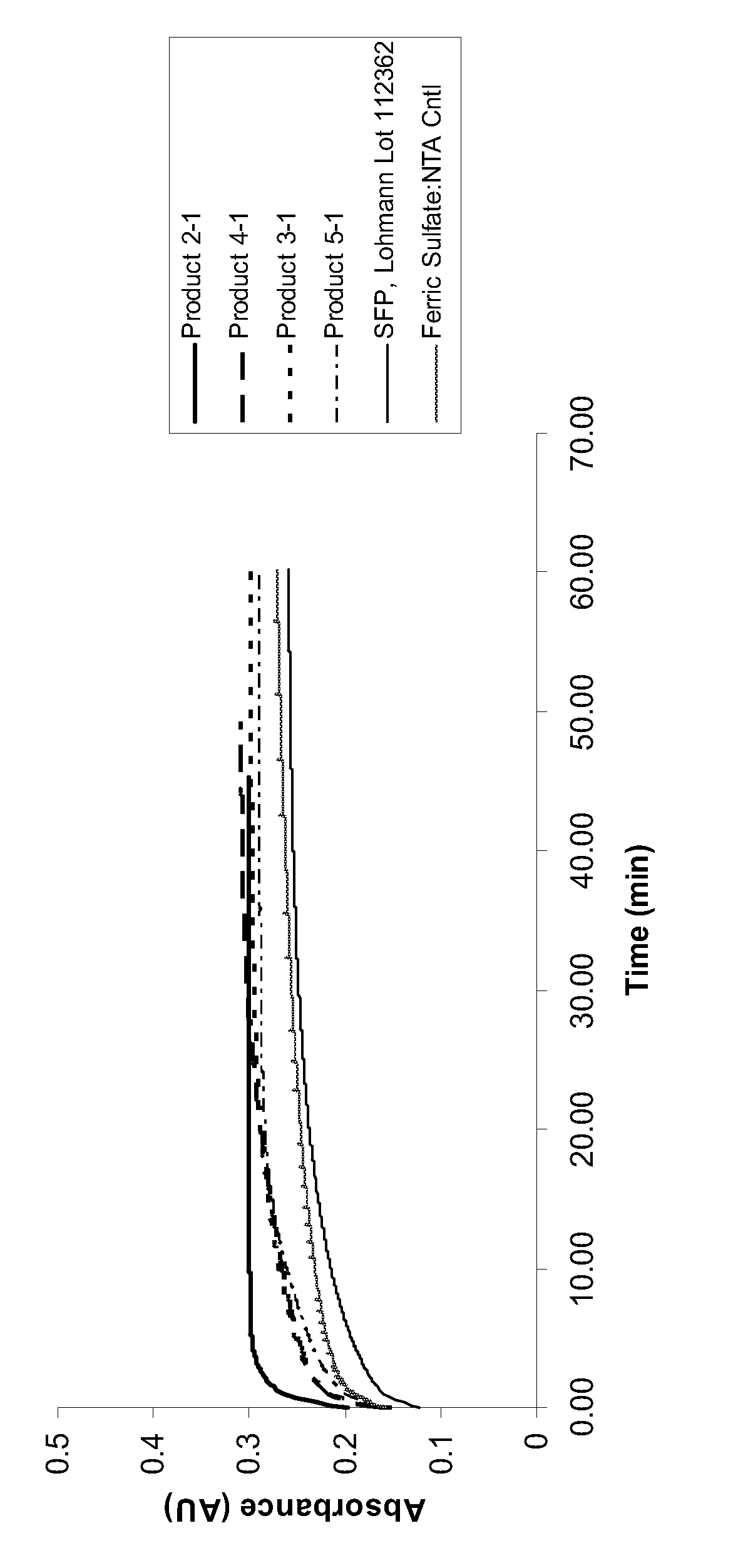

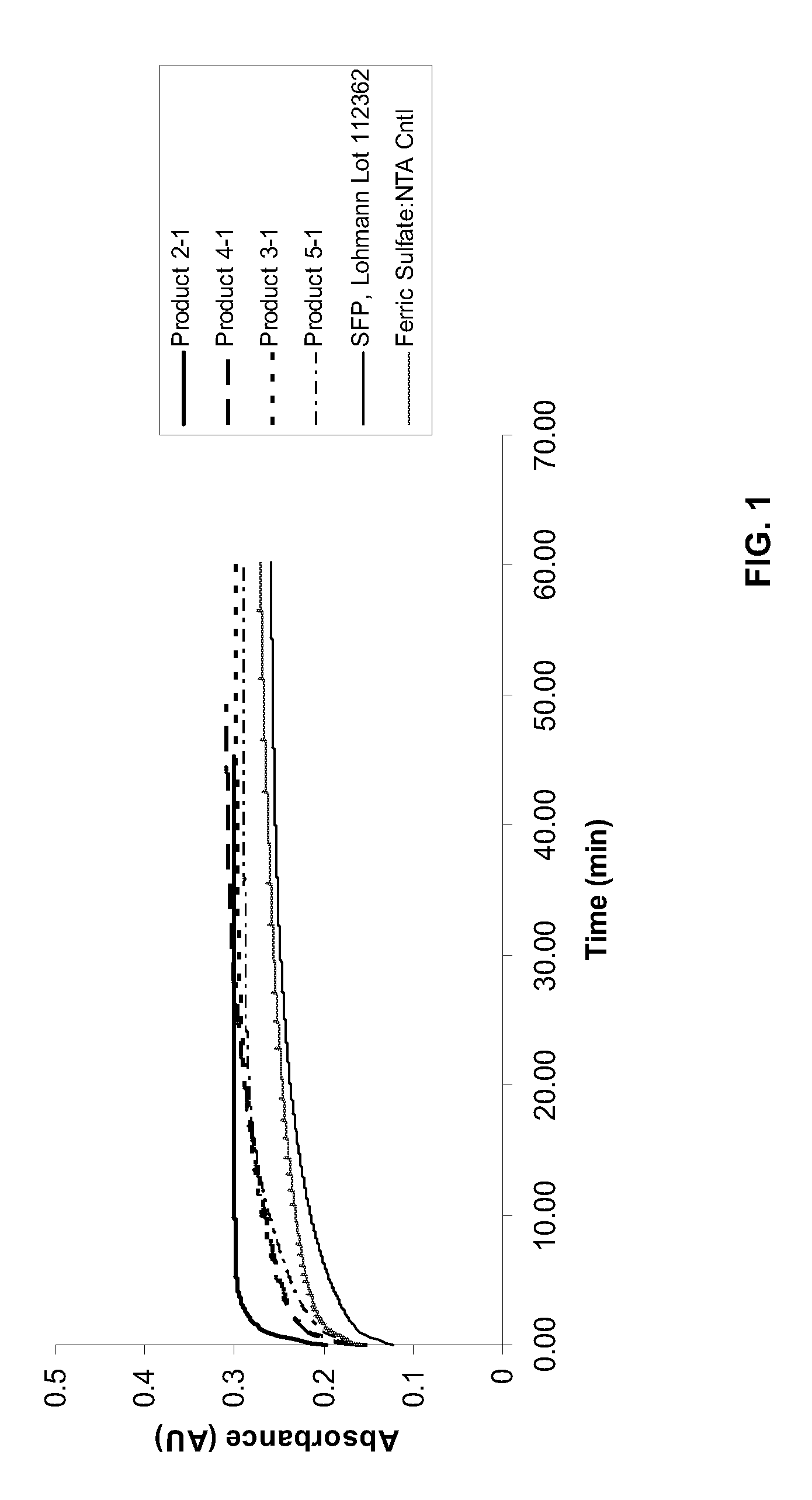

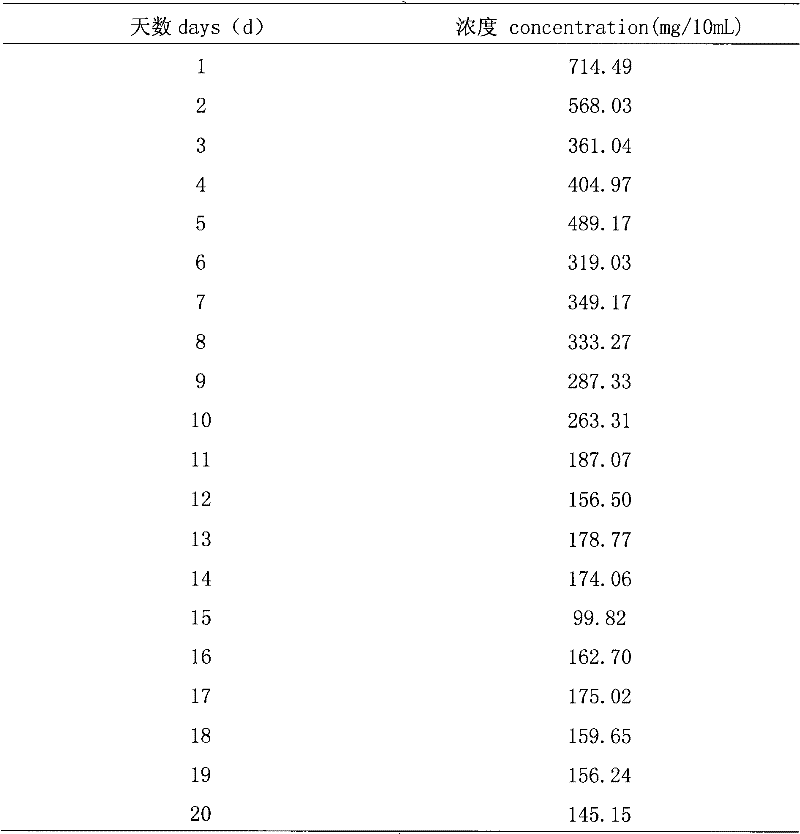

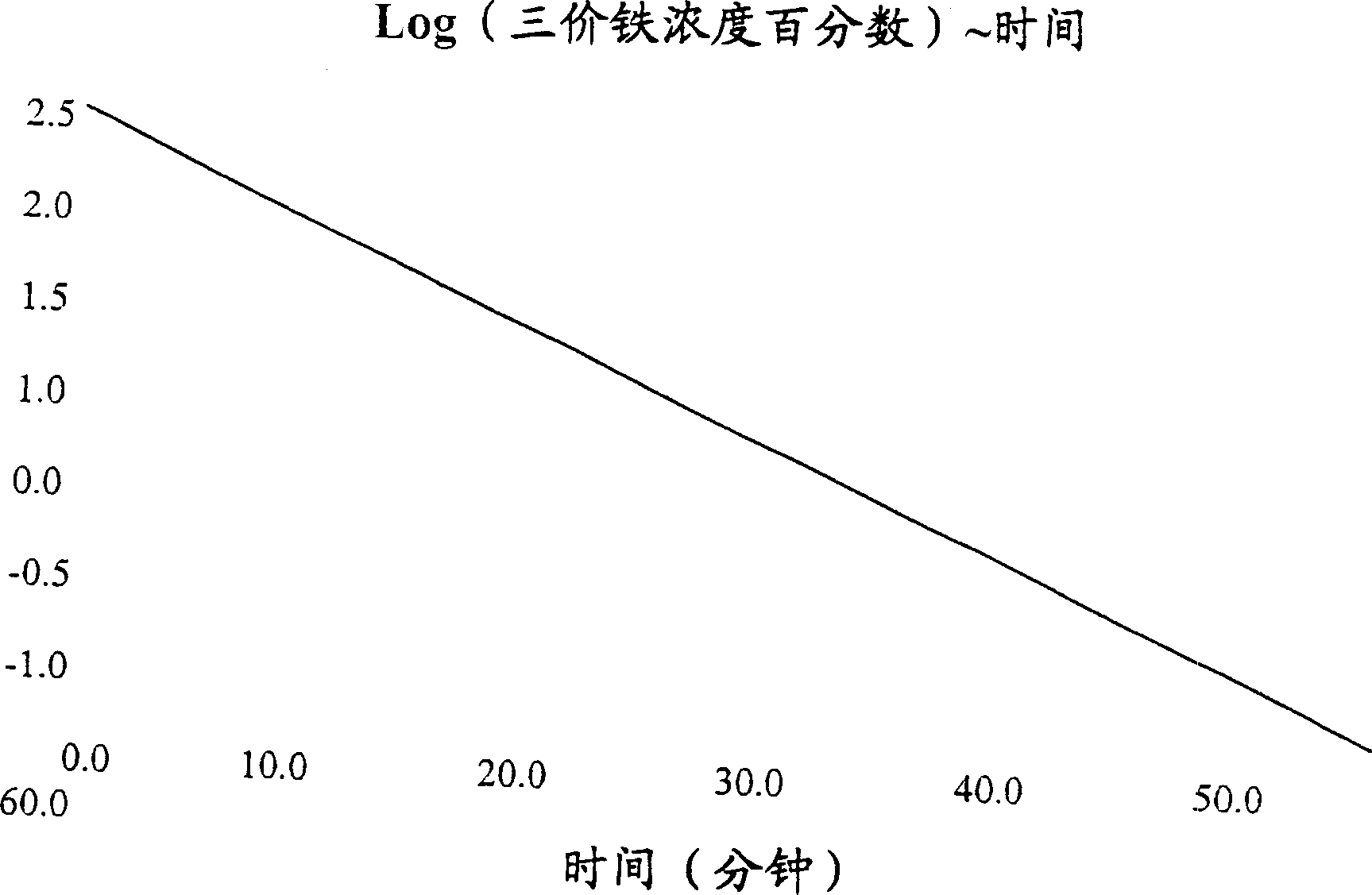

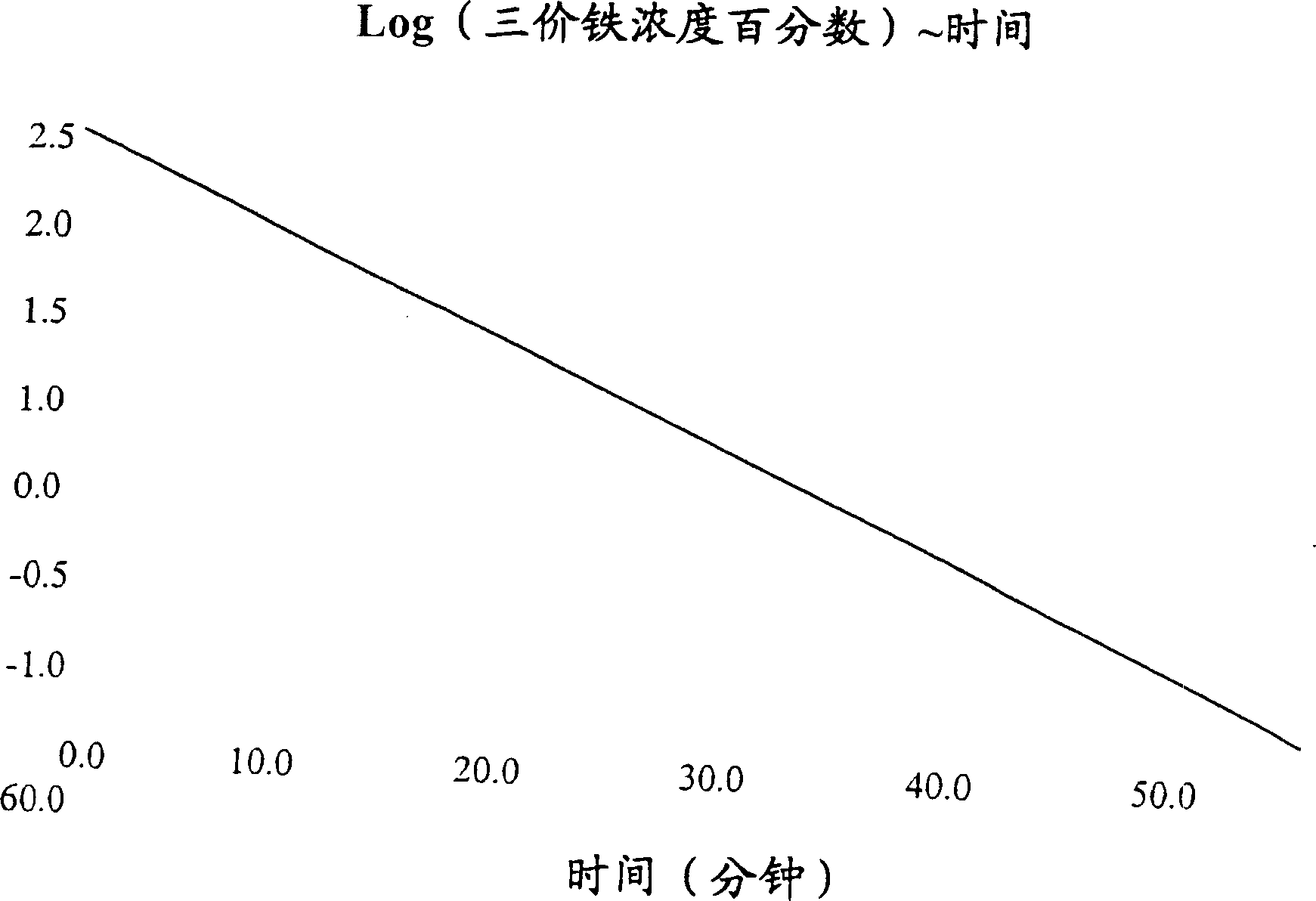

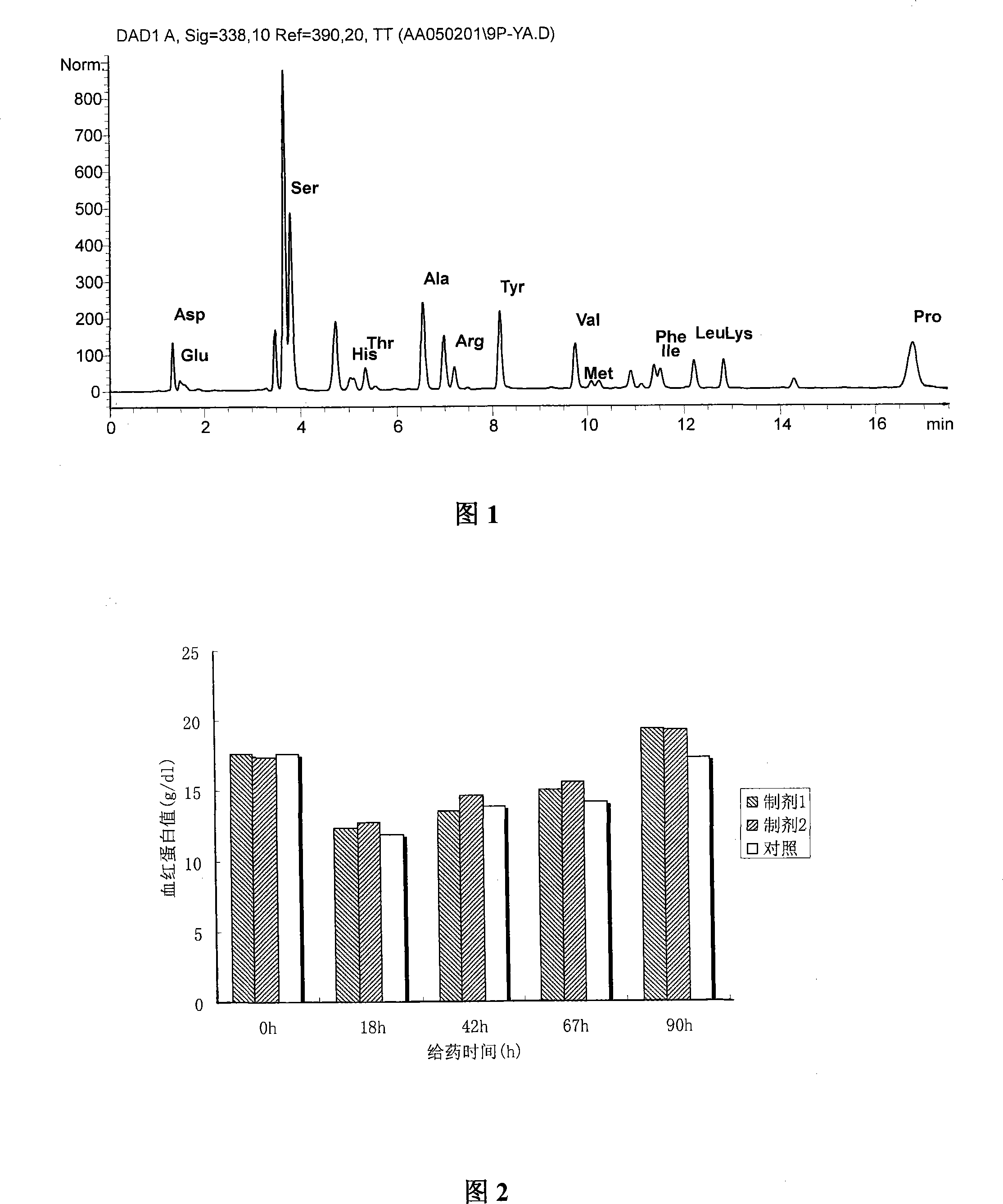

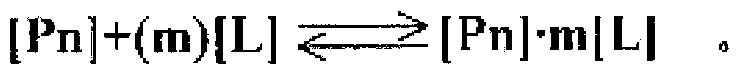

Bioequivalence test for iron-containing formulations

InactiveCN1685227AOrganic active ingredientsAnalysis using chemical indicatorsSucroseIRON PREPARATIONS

Owner:VIFOR (INT) AG

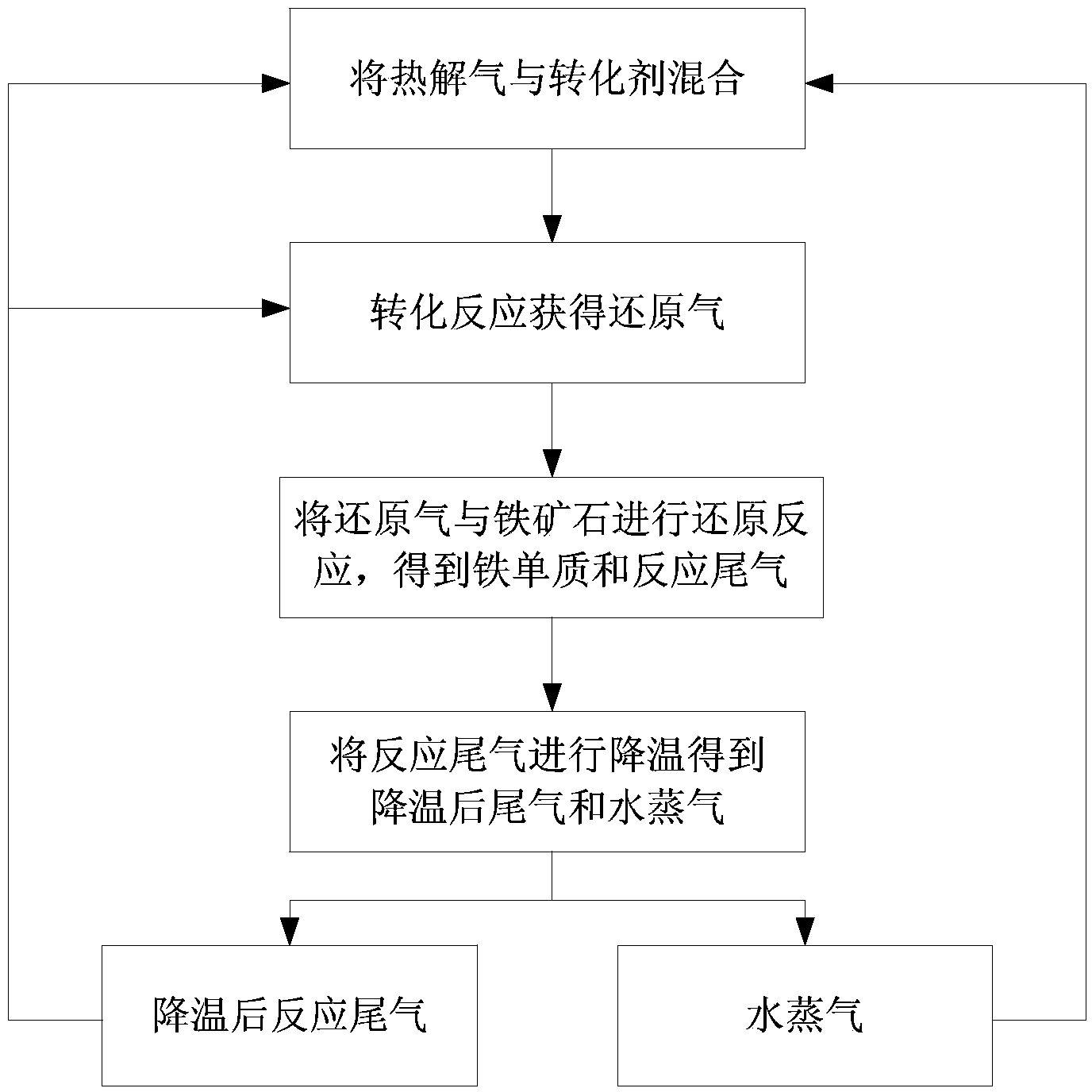

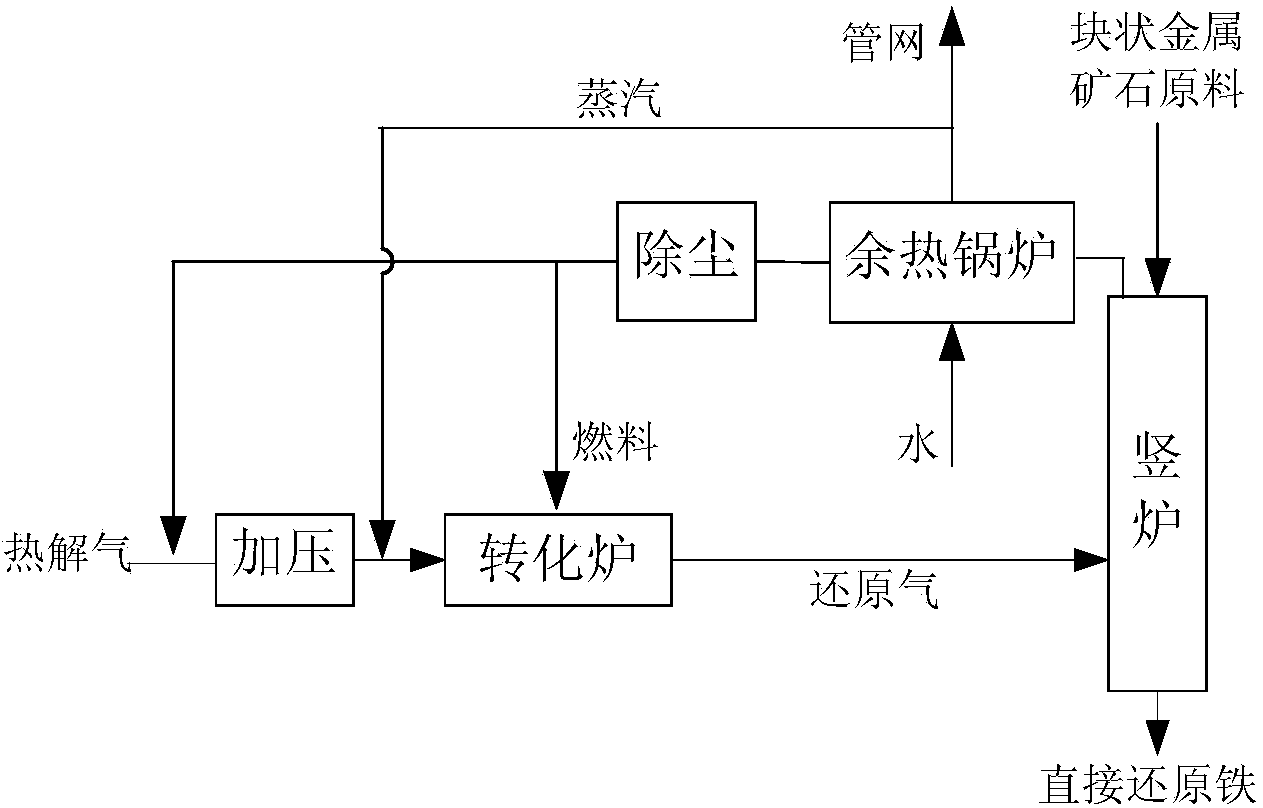

Method for preparing simple substance iron by virtue of pyrolytic gas

ActiveCN103866072ABroaden the range of gas sourcesLow costShaft furnaceGas emission reductionWaste heat recovery unitIRON PREPARATIONS

The invention discloses a method for preparing simple substance iron by virtue of a pyrolytic gas. The method comprises the steps of (1) mixing the pyrolytic gas which is obtained by performing pyrolysis treatment on middle- and low-rank coal, junked tire, biomass or garbage, with a transforming agent; (2) carrying out a transformation reaction of the mixture obtained in the step (1) in a transformation furnace so as to obtain a reducing gas; (3) reducing the iron ore in a shaft furnace by virtue of the reducing gas obtained in the step (2) so as to obtain the simple substance iron and a reaction tail gas;(4) performing waste heat recovery treatment on the reaction tail gas by using a waste heat boiler so as to obtain water vapor and the cooled reaction tail gas; and (5) returning one part of the cooled reaction tail gas and the water vapor as the transforming agent to be mixed with the pyrolytic gas in the step (1), and returning the other part of the cooled reaction tail gas to the step (2) as a fuel of the transformation furnace. Due to the method, the simple substance iron preparation cost can be remarkably reduced.

Owner:SHENWU TECH GRP CO LTD

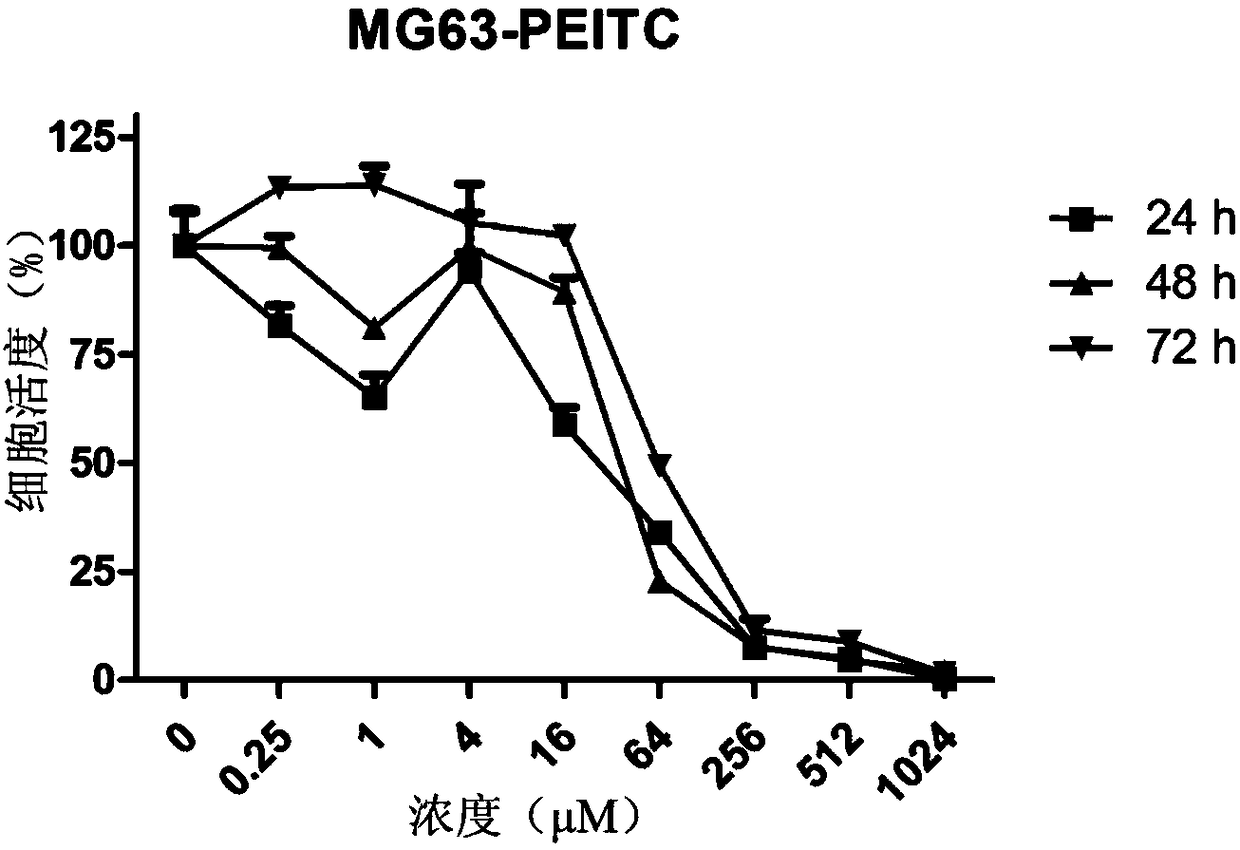

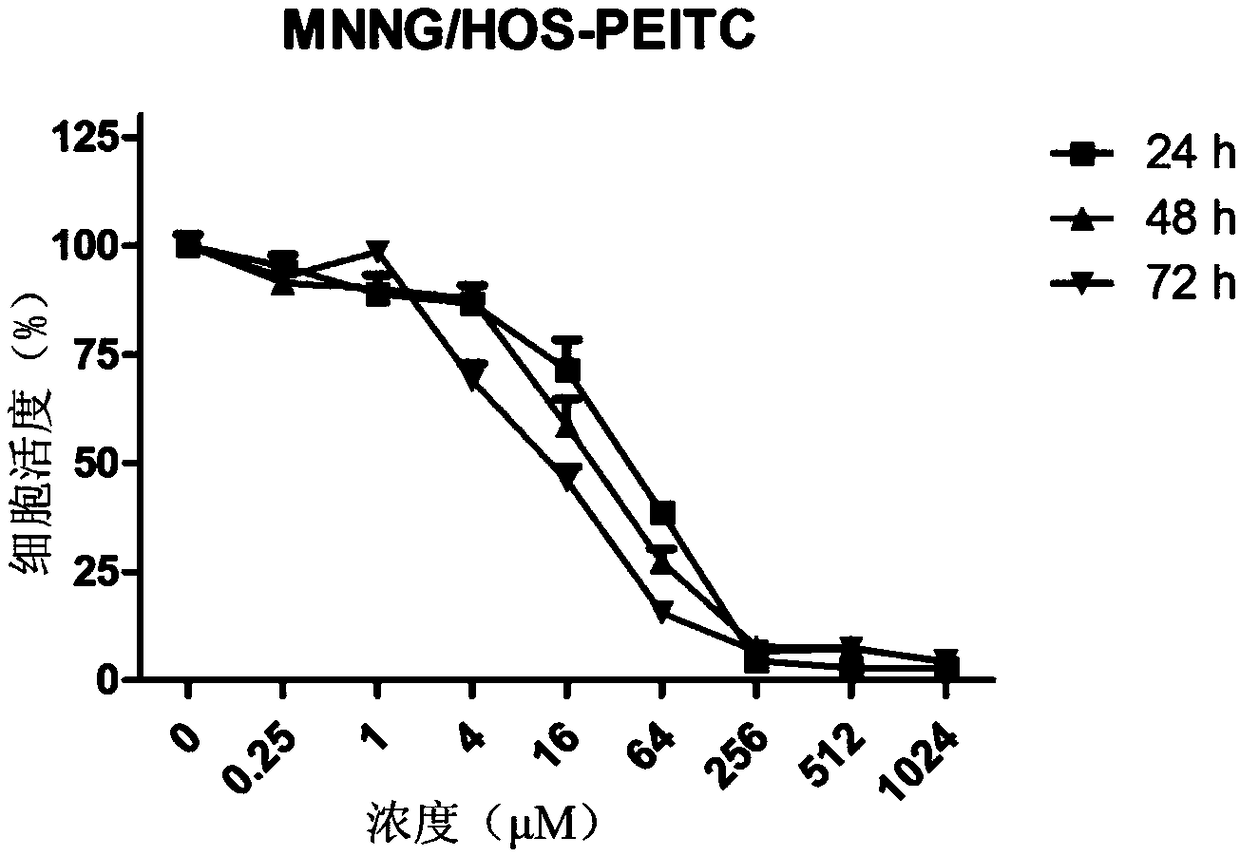

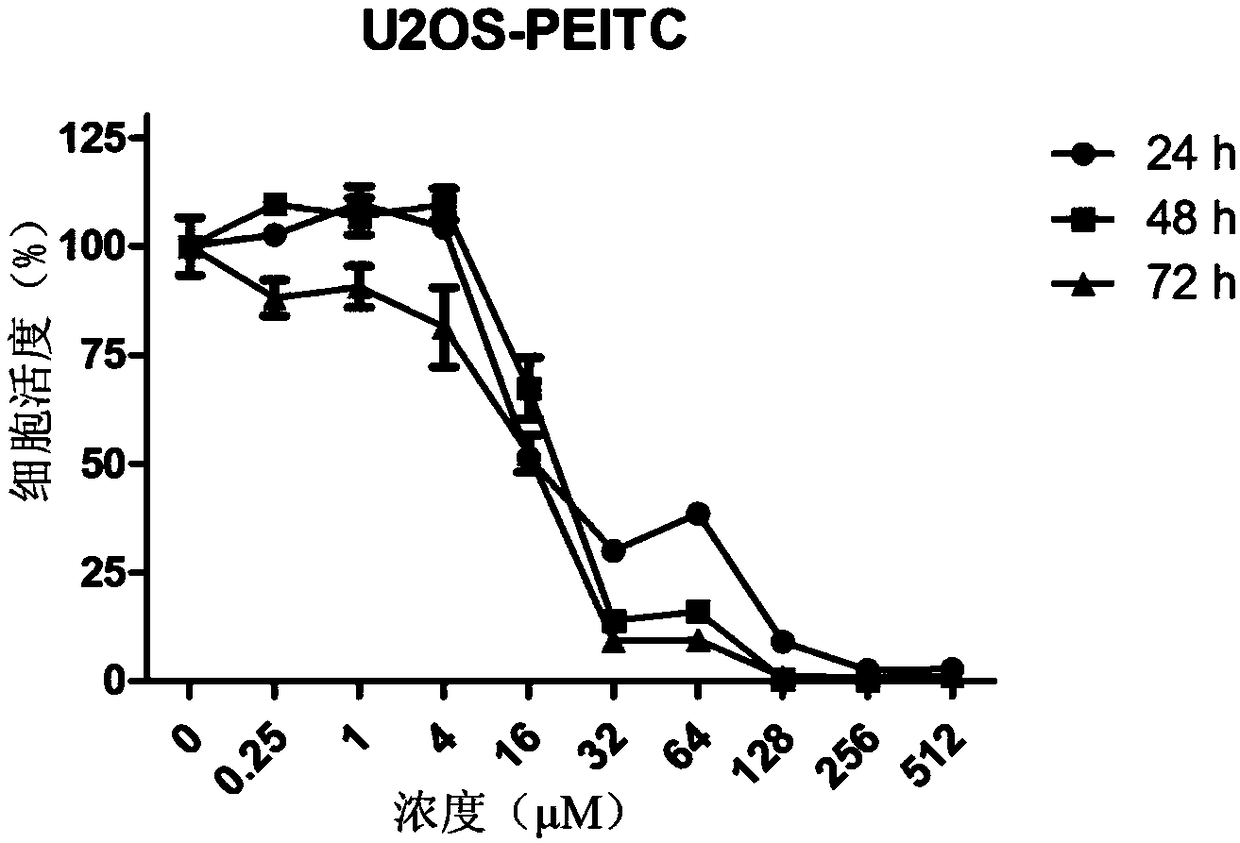

Anti-tumor medicine composition and application thereof

InactiveCN108272821ALower doseLow toxicityHeavy metal active ingredientsEster active ingredientsFenton reactionIRON PREPARATIONS

The invention provides an anti-tumor medicine composition. The medicine composition comprises at least one isothiocyanate derivative and at least one iron preparation. The anti-tumor medicine composition provided by the invention contains at least one isothiocyanate derivative and at least one iron preparation. On the premise of improving the oxidation level by combining the isothiocyanate derivative with GSH, after the iron preparation enters into the body, the content of Fe<2+> inside tumor cells can be obviously increased through the siderophilic characteristic of tumor cells, the Fe<2+> ions participate in a Fenton reaction to further produce ROS, and then a GSH anti-oxidation system inside the cells is inhibited, a stable oxidoreduction state is broken, and ROS inside the cells is maintained to a relatively high level. The ROS can perform a lipid peroxidation reaction with lipids to produce lipid ROS, and the ROS damages lipids and proteins and also cause DNA damage, so that the death of the cells is promoted.

Owner:HI MAG HEALTH TECH CO LTD SHENZHEN

Nodular cast iron foundation pile pipe and a method for preparing same

InactiveUS20150233074A1Improve mechanical propertiesHigh strengthFurnace typesHeat treatment furnacesIRON PREPARATIONSDuctile iron

Owner:YU PEI

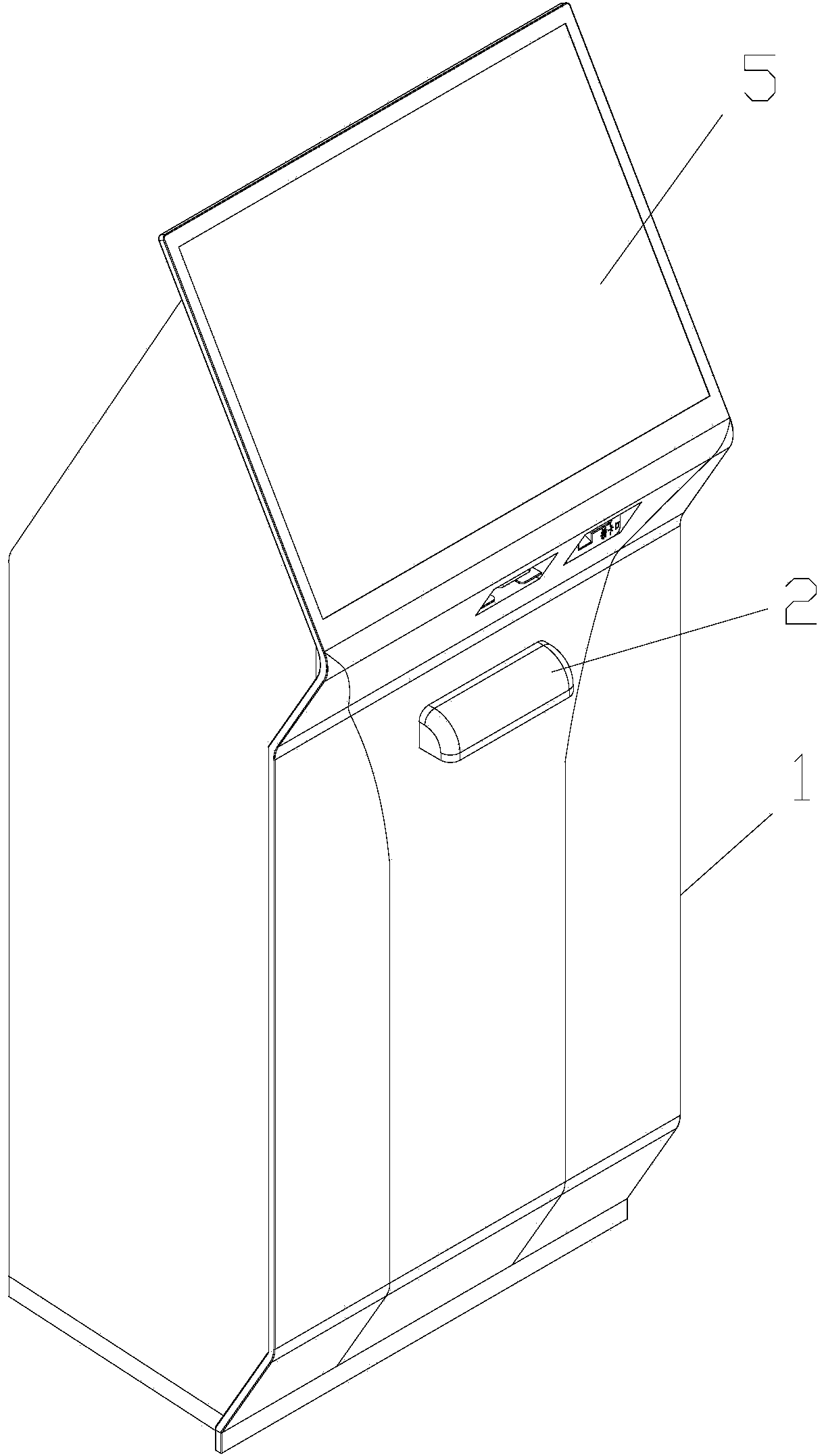

Bubble pack automatic selling all-in-one machine with combination of commercial use and industrial use

ActiveCN104112316AExtended waiting timeReduce time lossBox making operationsPaper-makingIRON PREPARATIONSControl system

The invention relates to a bubble pack automatic selling all-in-one machine with a combination of commercial use and industrial use. The bubble pack automatic selling all-in-one machine with the combination of the commercial use and the industrial use comprises a box body (1), wherein a discharge hole (2) is formed in the front end face of the box body (1), a feeding bin, an ironing preparation area, a traction motor (8) and a control system are arranged in the box body (1), the ironing preparation area is provided with an ironing mechanism (3) and an air charging system, two material rolls (4) are arranged in the feeding bin, the material rolls (4) are respectively connected with one end of the ironing mechanism (3), the other end of the ironing mechanism (3) is connected with an outlet surge bin (9), the outlet surge bin (9) is connected with the discharge hole (2), the traction motor (8) is installed on the outlet surge bin (9), an output end of the traction motor (8) is connected with thin films of the material rolls (4), and the ironing mechanism (3), the air charging system and the traction motor (8) are respectively connected with the control system through circuits. According to the bubble pack automatic selling all-in-one machine with the combination of the commercial use and the industrial use, not only is transportation cost consumed from a manufacture site to a use position reduced, but also a plurality of persons can obtain benefits brought by the bubble pack automatic selling all-in-one machine with the combination of the commercial use and the industrial use when stay in buildings. Furthermore, the bubble pack automatic selling all-in-one machine with the combination of the commercial use and the industrial use is simple and convenient to operate and practical.

Owner:上海博瑁机电科技有限公司

Bamboo shoot extract compound preparation and preparing method thereof

InactiveCN101229330ASimple processStimulate hematopoiesisOrganic active ingredientsPill deliveryAdditive ingredientBlood loss anemia

The invention discloses a composite preparation of extract of bamboo shoots which is used for improving anaemia and a preparation method thereof. The composite preparation is made from the extract of bamboo shoots, iron supplement and other accessory ingredients, wherein, the extract of bamboo shoots is solid, extract liquid or dry powder which is extracted from fresh or dried bamboo shoots by water extraction and alcohol extraction; the iron supplement is ferriporphyrin or heme iron. By adopting the design, the extract of bamboo shoots in the composite preparation of the invention comprising rich glucose, protein and multi elements can stimulate hematopoiesis and expand blood volume and the iron composite preparation thereof has better promotion effect on the recovery of blood loss anemia. By adopting the preparation method of the invention to prepare the extract of bamboo shoot, the process is simple and practical and the various beneficial components in bamboo shoots can be well kept, thus being applicable to commercial production.

Owner:FIELD OPERATION BLOOD TRANSFUSION INST OF PLA SCI ACAD OF MILITARY

Iron sucrose injection and preparation method thereof

ActiveCN103340827ALower detection rateReduce distributionOrganic active ingredientsPharmaceutical delivery mechanismSucroseBULK ACTIVE INGREDIENT

The invention relates to iron sucrose injection and a preparation method thereof. The iron sucrose injection comprises iron sucrose serving as an active ingredient, an optional acidifying or alkalizing agent and water for injection. The iron sucrose injection is characterized in that the pH value is 10.0-11.5, the osmotic pressure is 1100-1400mOsmol / L, 1ml of iron sucrose injection contains 15-25mg of iron and 240-400g of sucrose, the turbid point is in the range from 4.4-5.3 based on pH, the weight-average molecular weight (MW) is in the range from 34000-60000Da, the number-average molar mass (Mn) is no less than 24000Da, and the molecular weight distribution is less than 1.7 by Mw / Mn. The iron sucrose injection can be used for specially treating iron-deficiency anemia, can be used for intravenous administration in an instillation or slow injection manner and is suitable for patients which do not have good response to oral iron preparations and need to undergo intravenous iron preparation treatment, such as patients which cannot tolerate the oral iron preparations and cannot absorb the oral iron preparations well.

Owner:CHENGDU TIANTAISHAN PHARMA

Method for preparing Tibetan medicament seven-ingredient scrap-iron preparation for treating hepatic diseases

InactiveCN101543530AGood effectEasy to operateHeavy metal active ingredientsDigestive systemHepatic DiseasesIRON PREPARATIONS

The invention relates to a method for preparing a medicament, in particular to a method for preparing a Tibetan medicament seven-ingredient scrap-iron preparation for treating hepatic diseases. The method comprises the following steps: scrap iron preparation with myrobalan, gypsum rubrum preparation with milk, lying squirrel droppings paste extraction, mixing, drying, grinding, and capsule fabrication. The method has the advantages of simple process and convenient operation, and the prepared capsule preparation has good drug action and is suitable for popularization and application.

Owner:西藏金哈达药业有限公司

Chitosan nanoscale iron preparation method

InactiveCN108453266AOvercoming the problem of difficult sedimentation after adsorptionOvercome the problem of subsidence difficultiesTransportation and packagingMetal-working apparatusFiltrationSoil cadmium

A chitosan nanoscale iron preparation method comprises the following steps that chitosan is dissolved in an HNO3 solution, and the mixture is added into an FeSO4.7H2O aqueous solution to be evenly stirred; and a KBH4 solution is added dropwise, the mixture is stirred till no bubble exists, nano zero-valent iron particles are separated out through a magnetic separation method and washed three timeswith distilled water and ethyl alcohol, nanoscale zero-valent iron coated with the chitosan is obtained, dilution is carried out through deionized water, then bentonite is added slowly, continuous stirring, centrifugal separation, washing, suction filtration and drying are carried out successively, and chitosan nanoscale iron is obtained. The problem of settling difficulty after adsorption causedby purely using bentonite powder or chitosan is overcome through the chitosan nanoscale iron, and the method is suitable for soil cadmium pollution regulation and has the application and popularization value.

Owner:重庆智诚知识产权服务有限公司

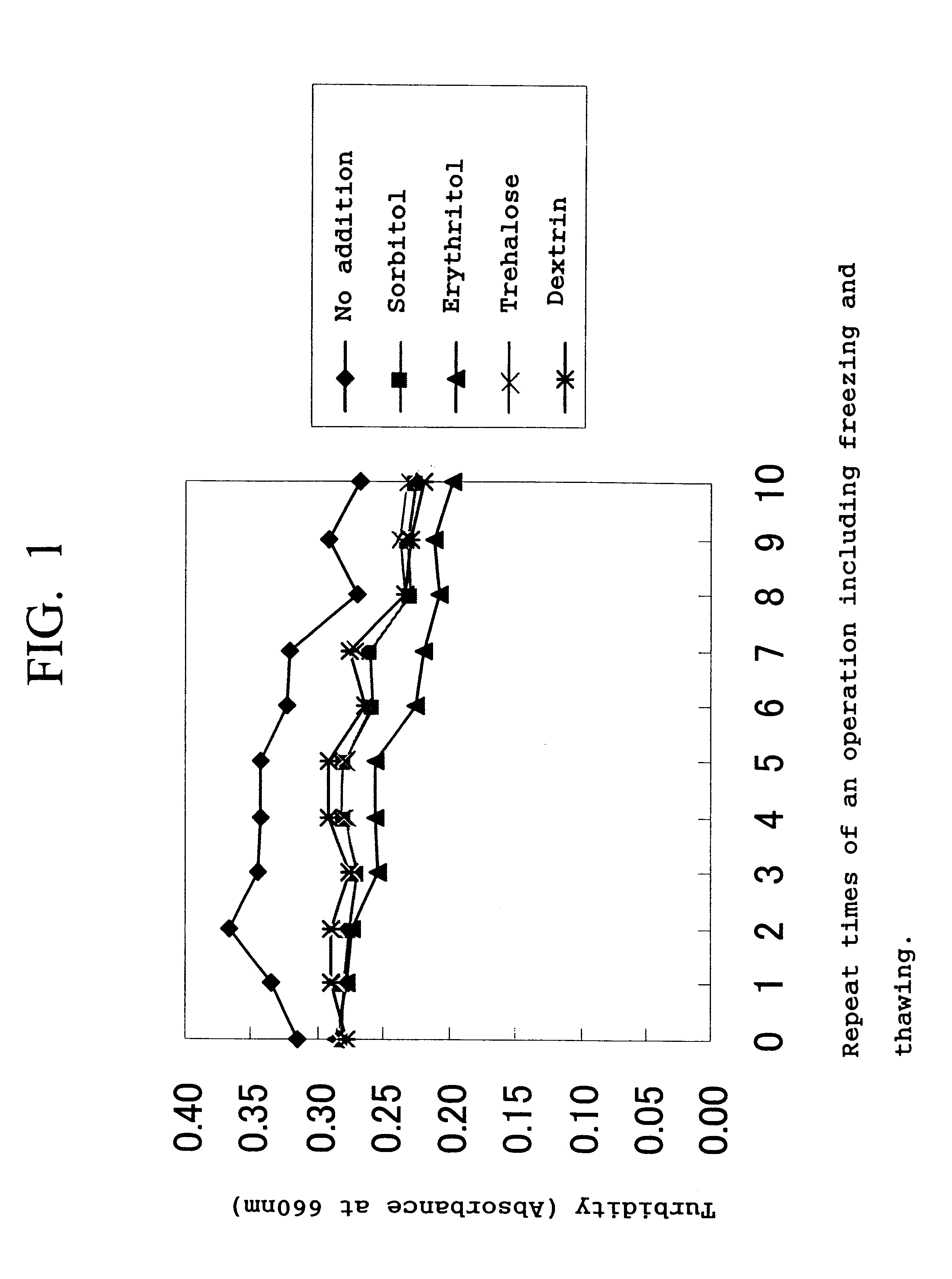

Iron-containing protein composition

InactiveUS6673382B2Loss of iron-containing protein by precipitation is suppressed effectivelyQuality improvementPowder deliveryOrganic active ingredientsProtein compositionIRON PREPARATIONS

Addition of a specific sugar compound to an iron-containing protein composition solution can provide an excellent freezing and thawing stability and restrained precipitate productivity in a thawed solution of its frozen product and increase the efficiency in the use of the iron-containing protein useful for enrichment of iron in a food or drink, production of iron preparations.

Owner:SNOW BRAND MILK PROD CO LTD

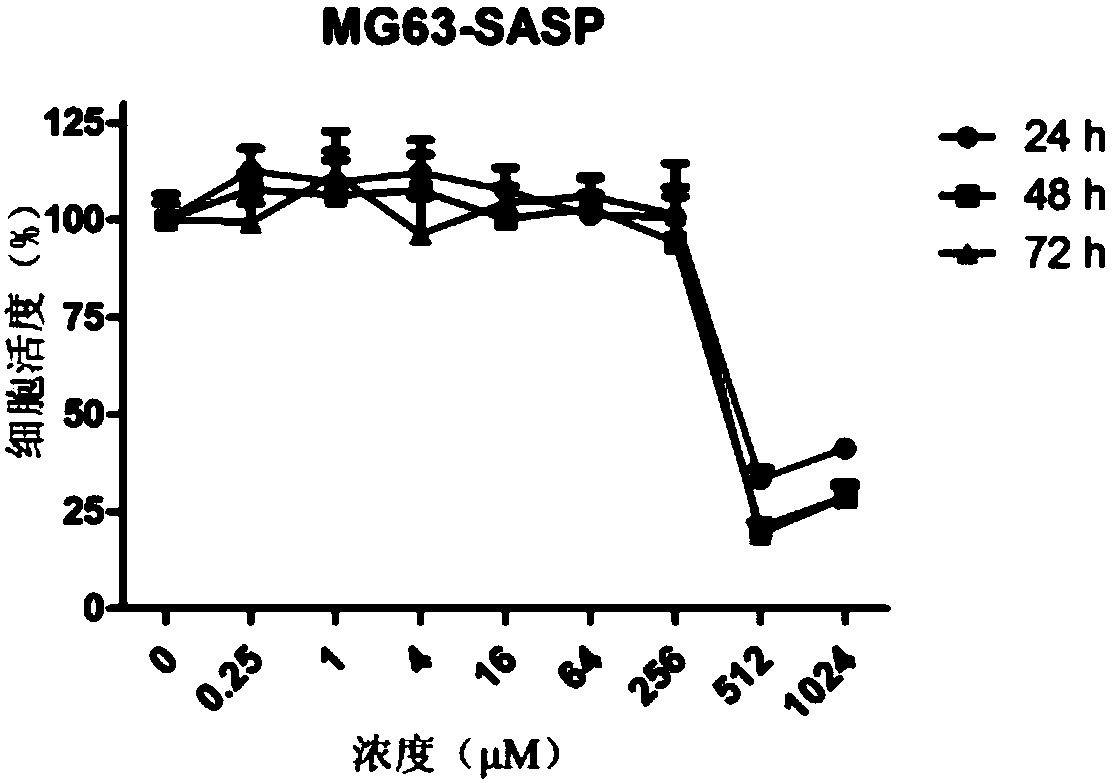

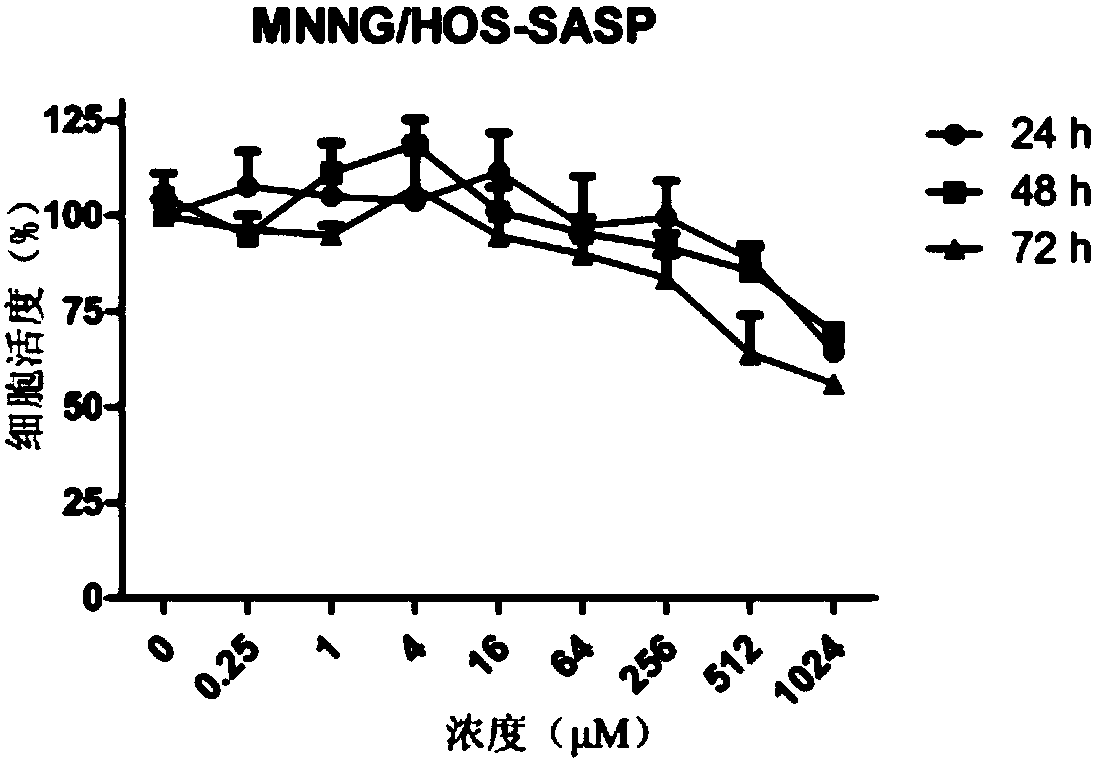

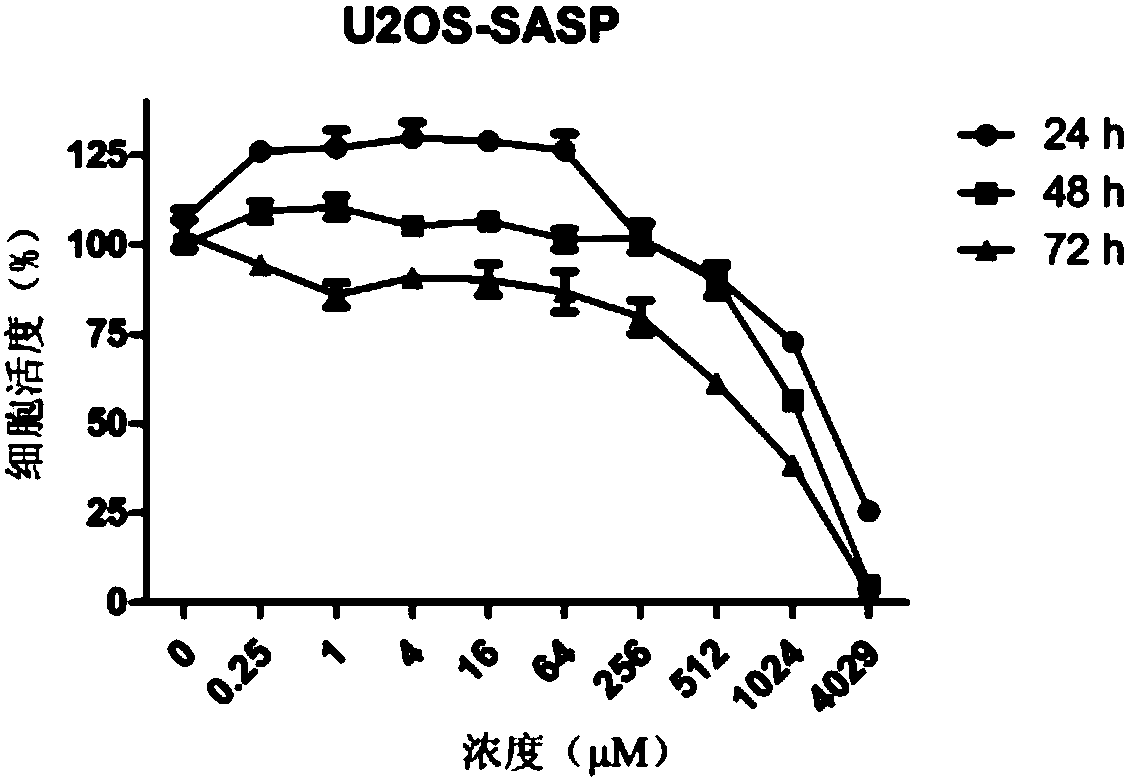

Anti-tumor medicine composition and application thereof

InactiveCN108272820AInhibit transferGrowth inhibitionOrganic active ingredientsHeavy metal active ingredientsFenton reactionIRON PREPARATIONS

The invention provides an anti-tumor medicine composition, and the medicine composition comprises salicylazosulfapyridine (SASP) and at least one iron preparation. The anti-tumor medicine compositionprovided by the invention contains at least one SASP and at least one iron preparation. The quantity of GSH is reduced indirectly by indirectly inhibiting cystine / cysteine transporter in SASP, the iron preparation can participate in a Fenton reaction on the premise of reducing the reduction level, the oxidation level is improved to further generate ROS, and then a GSH anti-oxidation system insidecells is inhibited, a stable oxidoreduction state is broken, and ROS inside the cells is maintained to a relatively high level. The ROS can perform a lipid peroxidation reaction with lipids to producelipid ROS, and the ROS damages lipids and proteins and also cause DNA damage, so that the death of the cells is promoted.

Owner:HI MAG HEALTH TECH CO LTD SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com