Patents

Literature

63results about How to "Lower detection rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

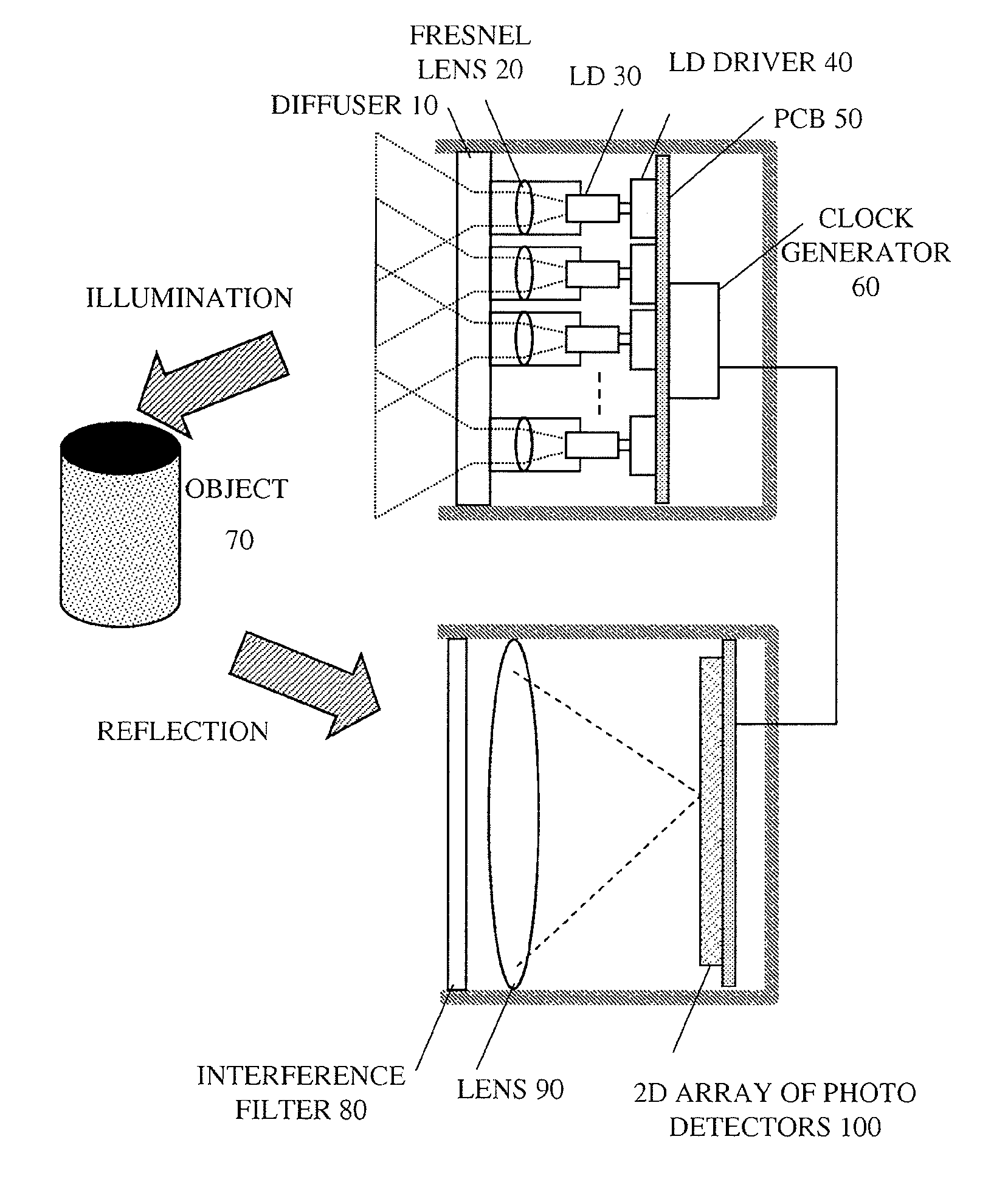

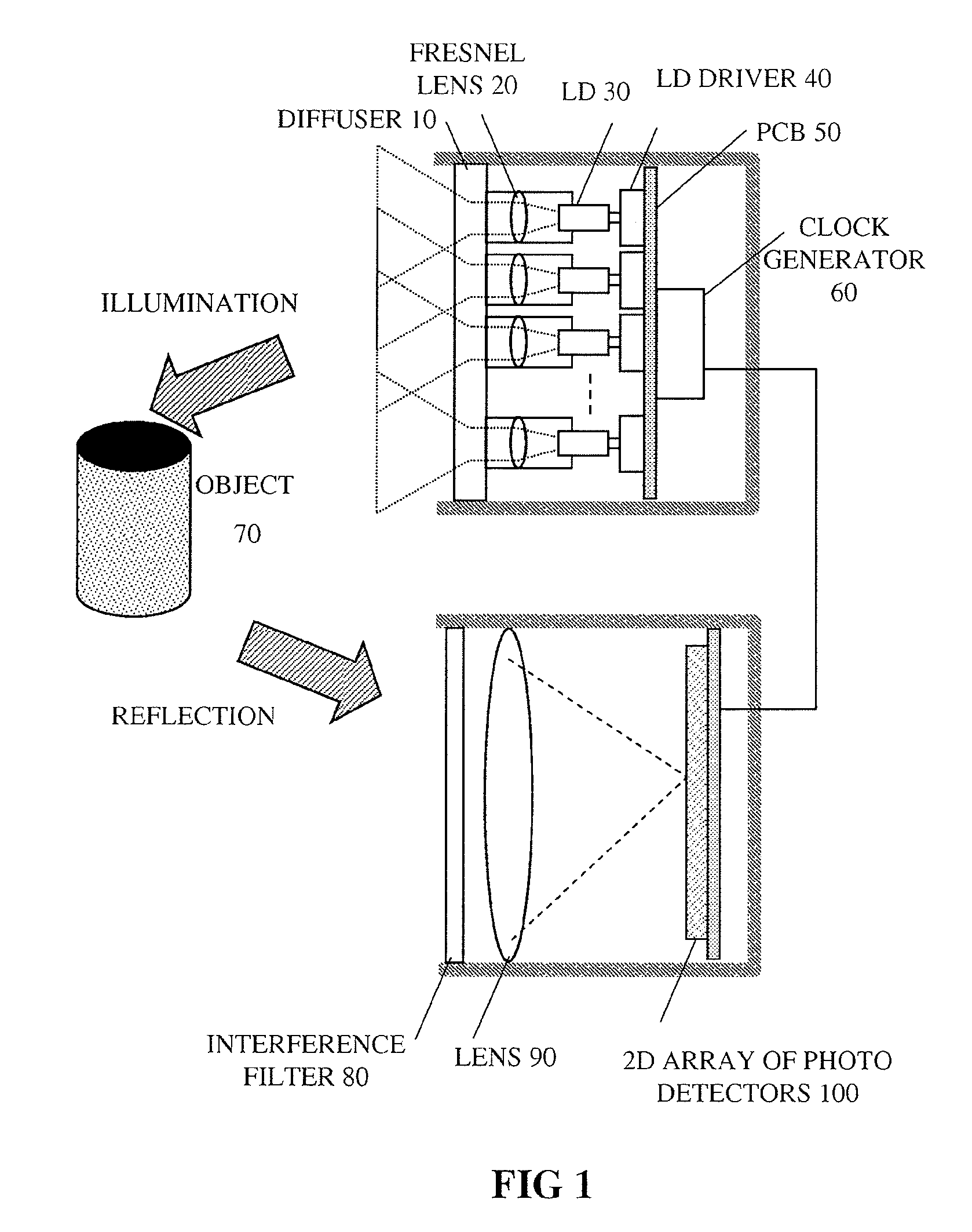

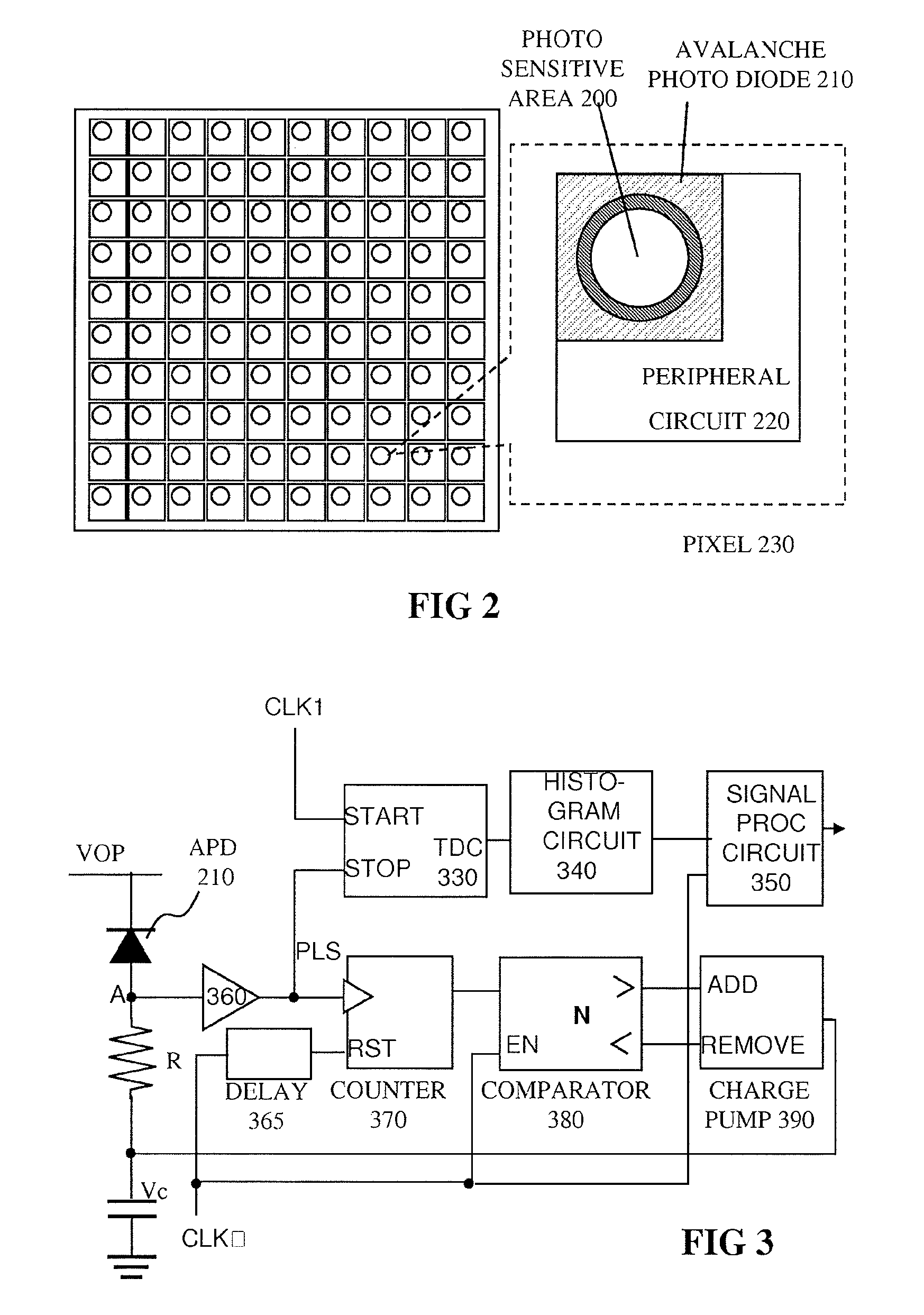

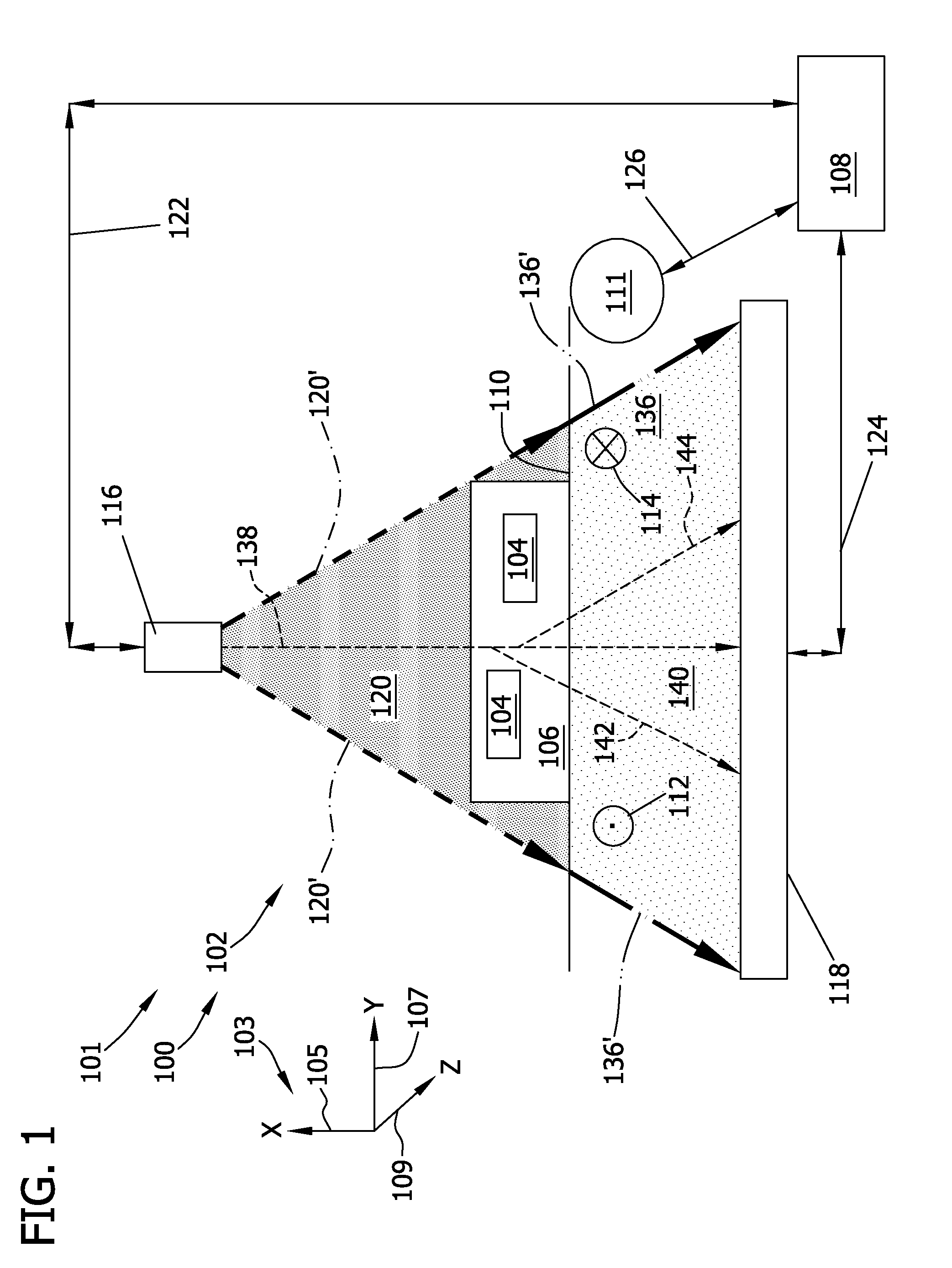

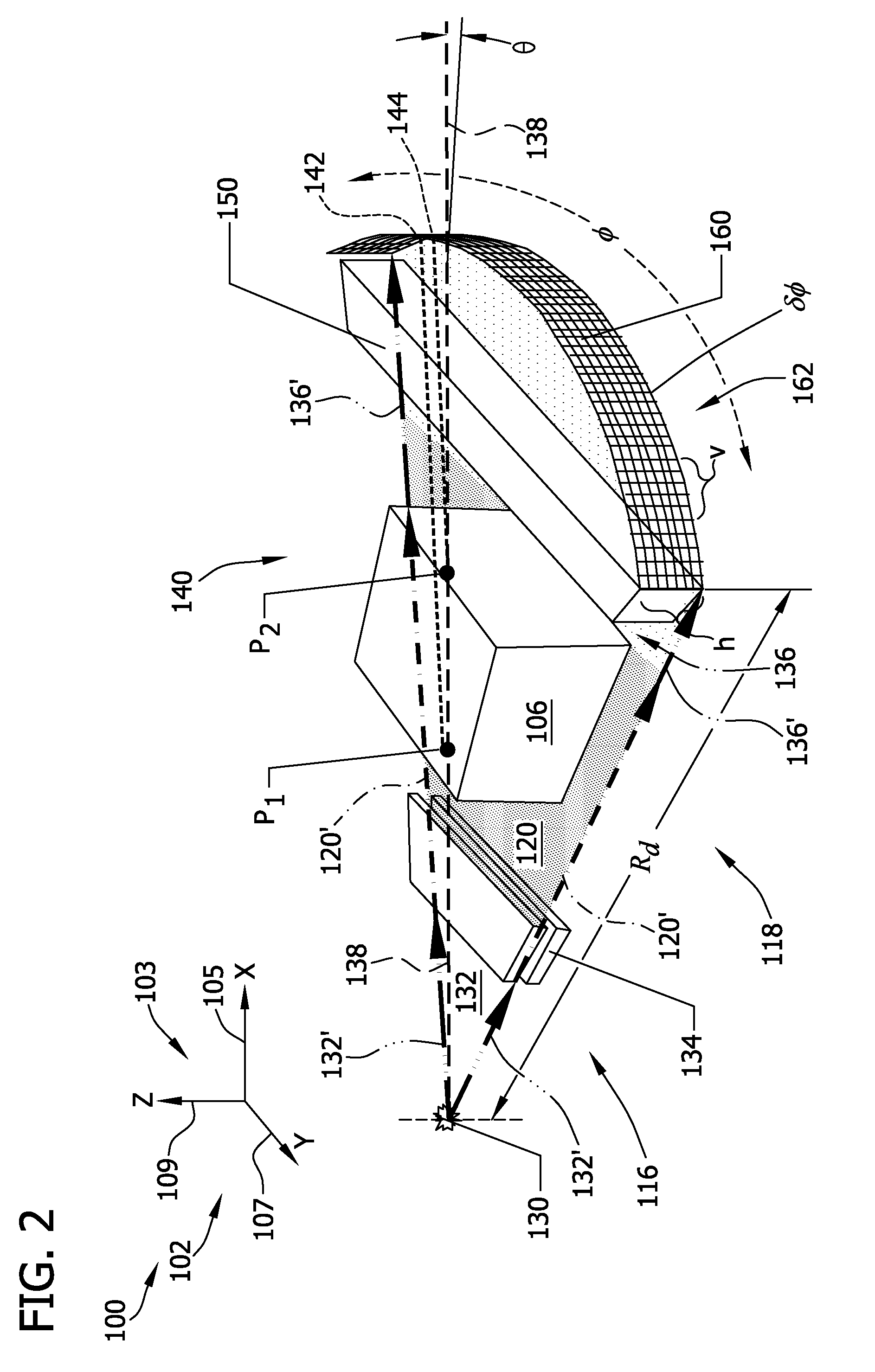

Pulsed light optical rangefinder

ActiveUS20120075615A1Improve dynamic rangeAvoid saturationOptical rangefindersElectromagnetic wave reradiationPhoton detectionTime of flight

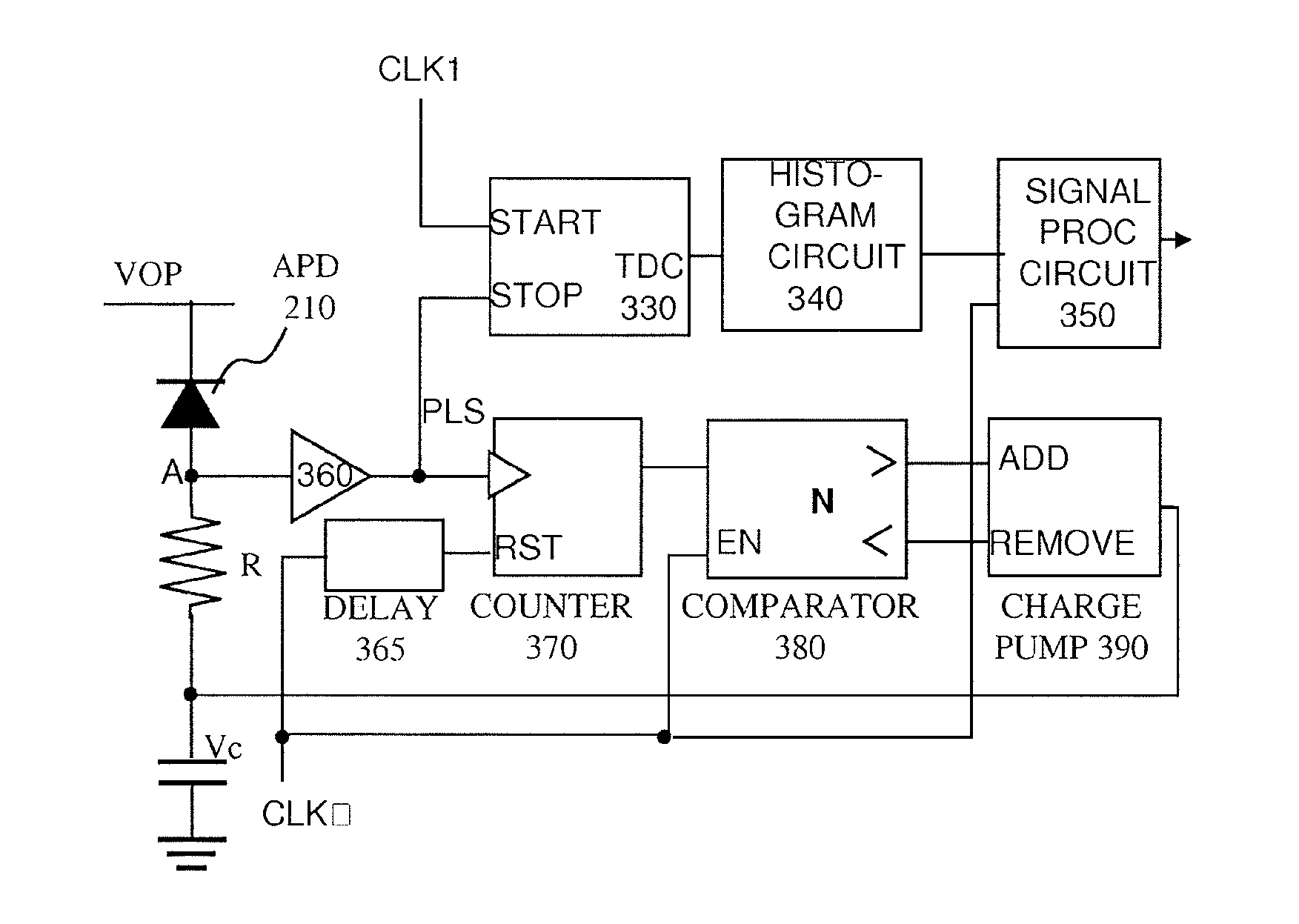

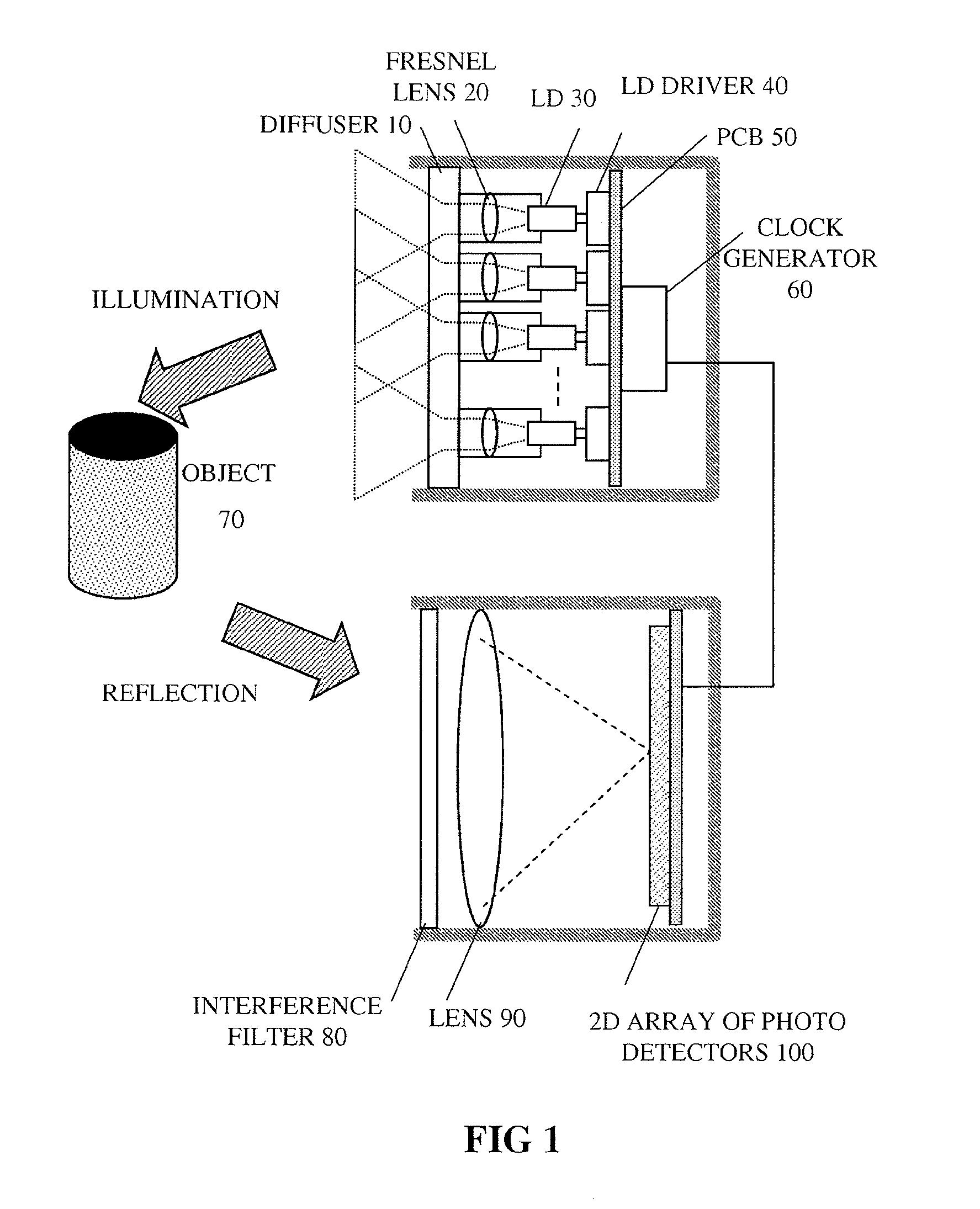

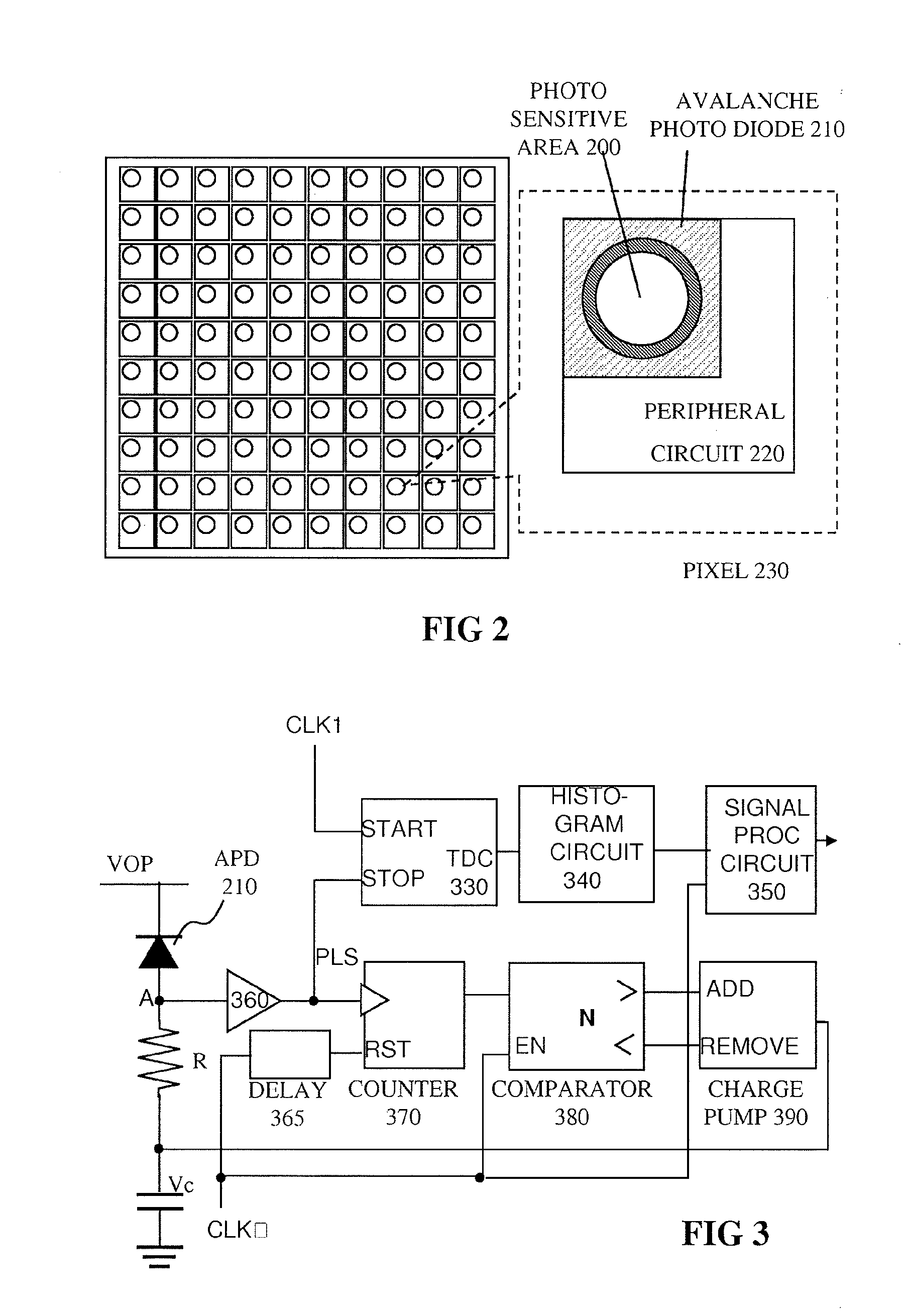

An optical rangefinder based on time-of-flight measurement, radiates pulsed light toward an object (70), and receives reflected light from the object, the receiver operating in a photon counting mode, so as to generate a pulse for a detected photon. There is a variable probability of a photon detection on the receiver, and a controller (370, 380, 390; 365, 470, 475, 380, 390; 570, 580, 590, 390) controls the photon detection probability of the receiver, based on a light level. By controlling the detection probability according to a light level, the receiver can have an increased dynamic range, and without the expense of using optical components. This can apply even while detecting very weak signals since the receiver can still be in a photon counting mode while the detection probability is controlled. The light level can be indicated by an output of the receiver itself, or by another detector external to the receiver.

Owner:TOYOTA JIDOSHA KK

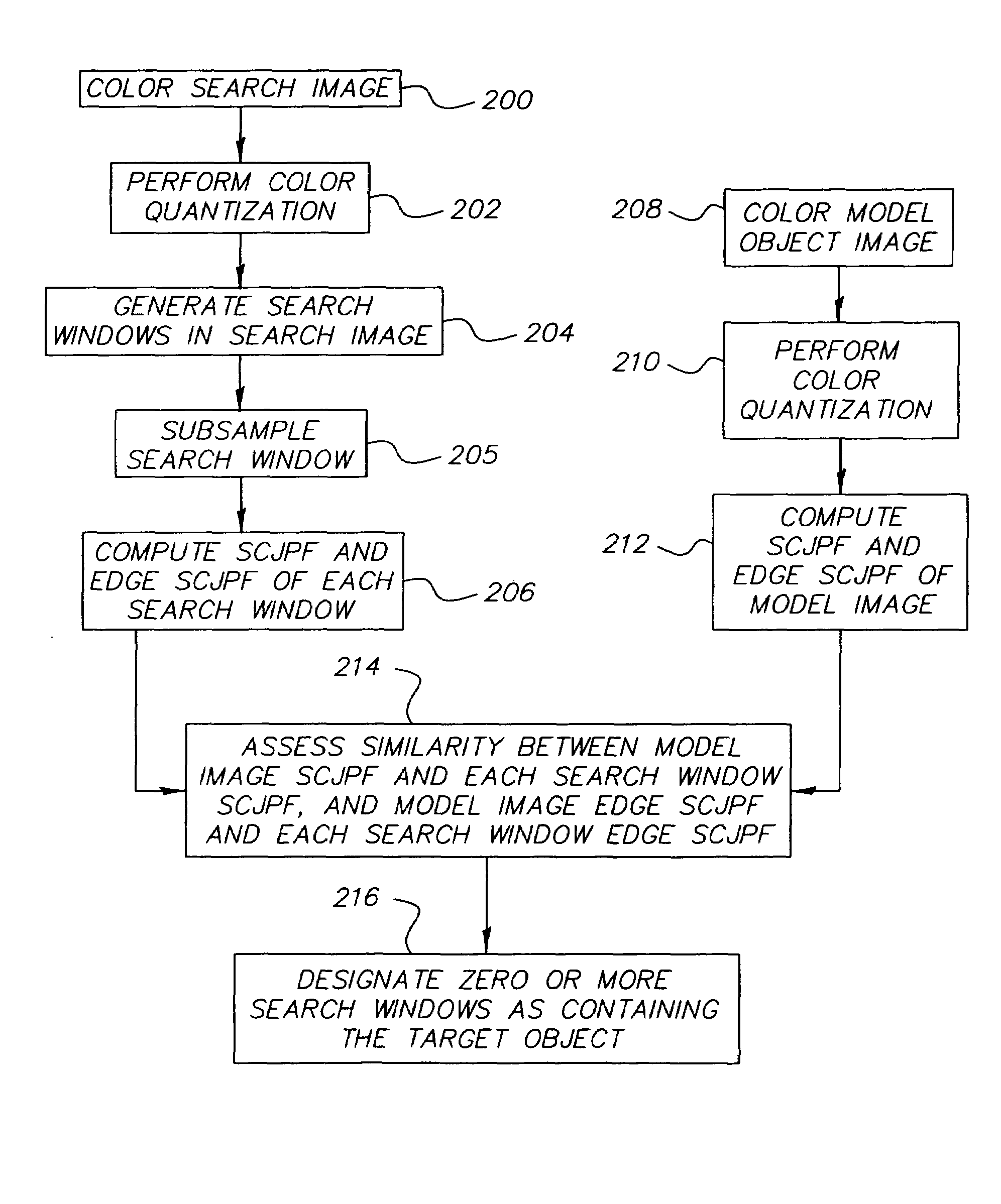

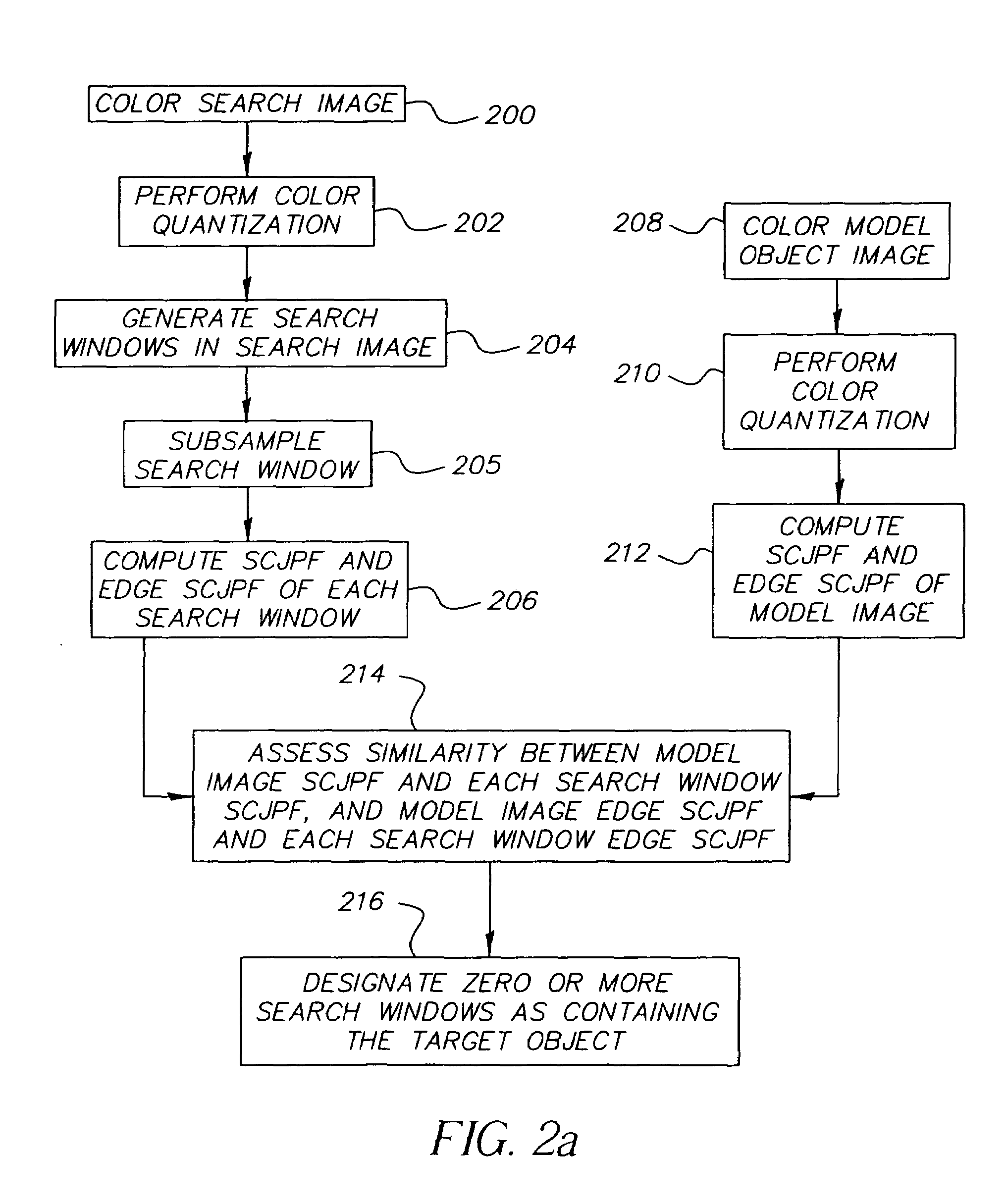

Method for detecting color objects in digital images

InactiveUS7263220B2Improve the detection rateLower detection rateImage analysisCharacter and pattern recognitionCo-occurrenceDigital image

A method for detecting an object in a digital image including the steps of performing color quantization on a model image including the object and on a search image that potentially includes the object, generating a plurality of search windows, computing spatial-color joint probability functions of each model and search image, where the color co-occurrence edge histogram is chosen to be the spatial-color joint probability function, assessing the similarity of each search image to the model, and designating search windows as containing the target object.

Owner:MONUMENT PEAK VENTURES LLC

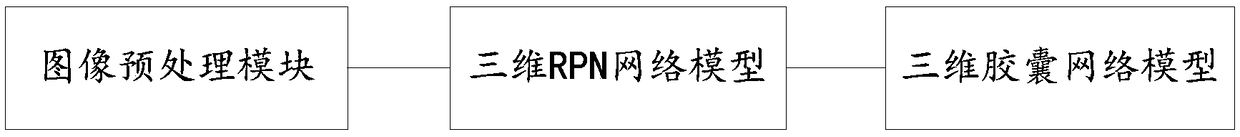

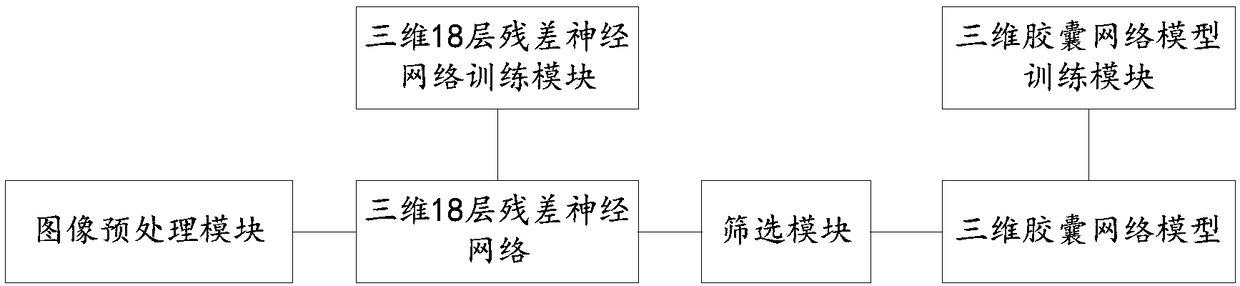

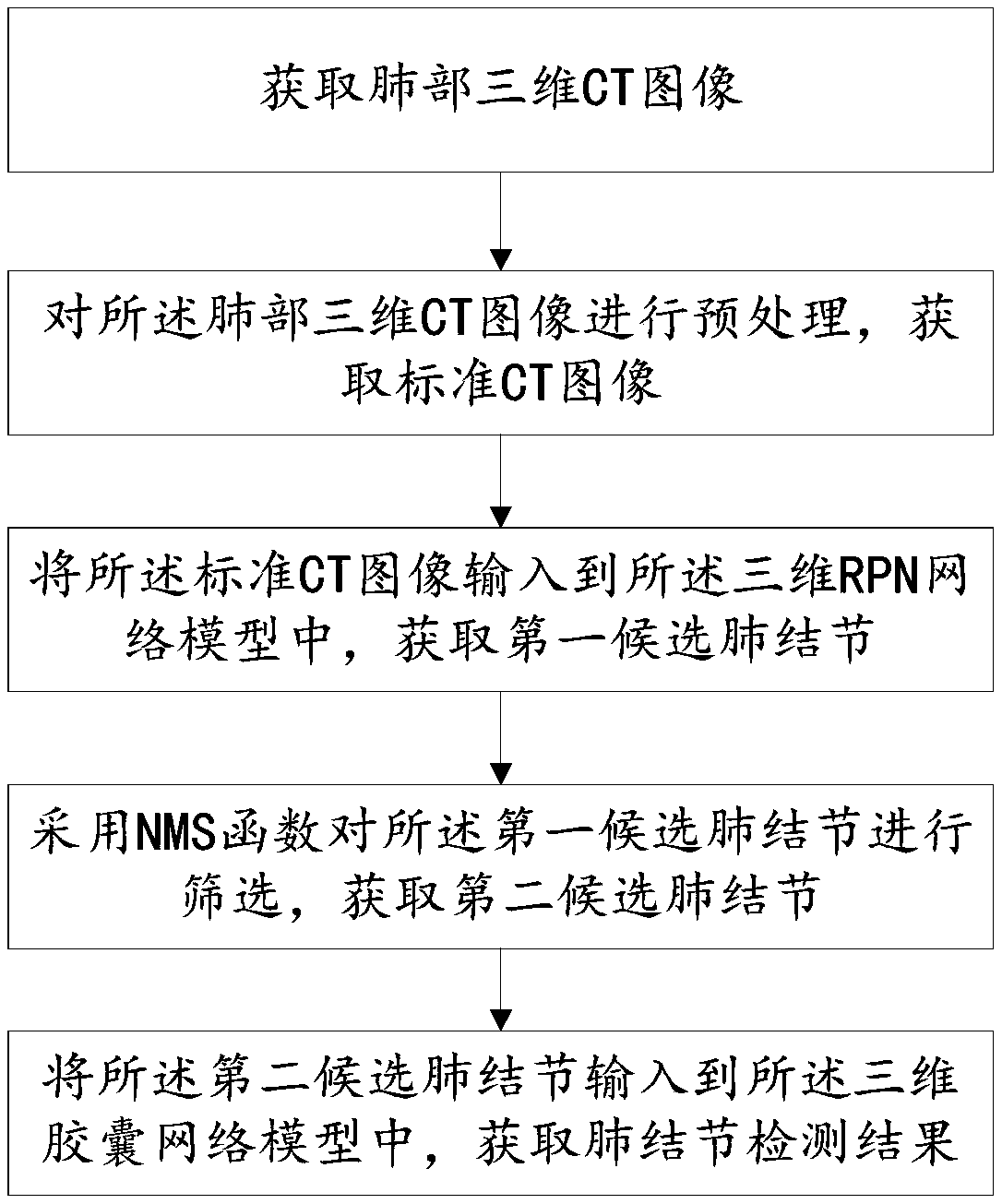

System and method of detecting pulmonary nodule

ActiveCN108830826AEasy to detectImprove recallImage enhancementImage analysisThree dimensional ctPulmonary nodule

The invention discloses a system and a method of detecting a pulmonary nodule. The system comprises an image preprocessing module, a three-dimensional RPN network model and a three-dimensional capsulenetwork model, wherein the image preprocessing module is used for preprocessing an original three-dimensional CT image to acquire a standard CT image; the three-dimensional RPN network model is usedfor detecting a first candidate pulmonary nodule from the standard CT image outputted from the image preprocessing module; and the three-dimensional capsule network model is used for carrying out false positive pulmonary nodule screening on the first candidate pulmonary nodule outputted by the three-dimensional RPN network model to acquire a pulmonary nodule detection result. According to the technical scheme provided in the invention, while the false positive pulmonary nodule detection rate is ensured to be lower, a high recall ratio is ensured to be realized for the pulmonary nodule, and thedetection method is simple and the detection speed is quick.

Owner:SICHUAN UNIV

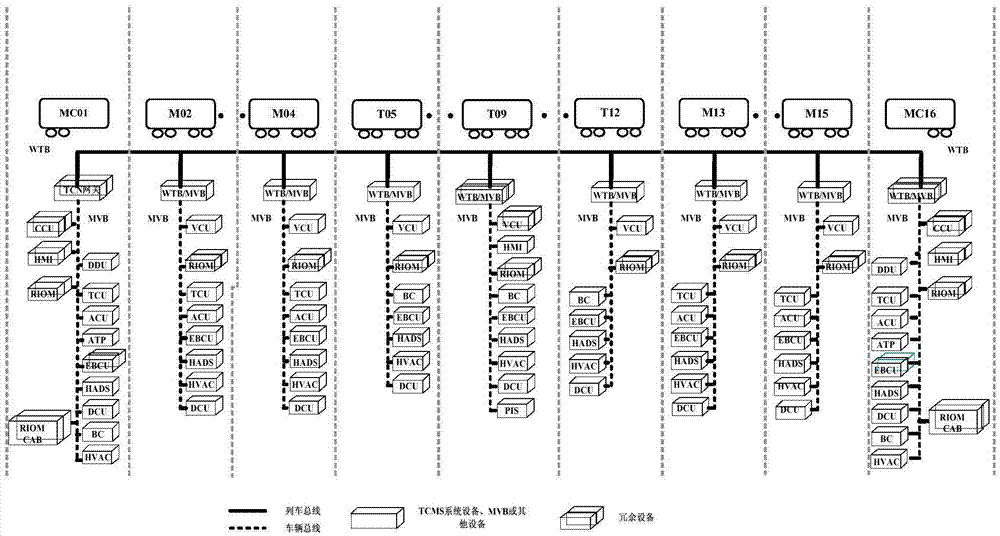

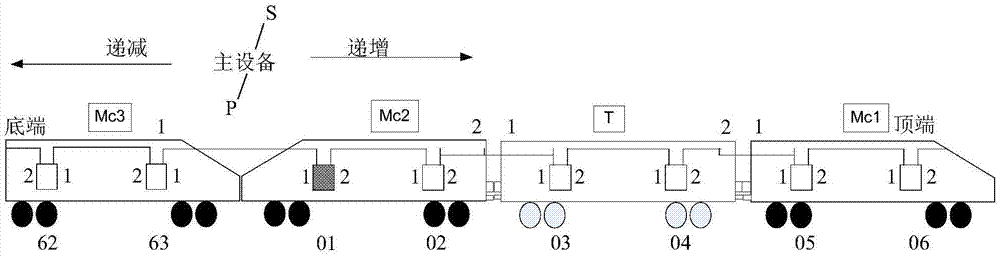

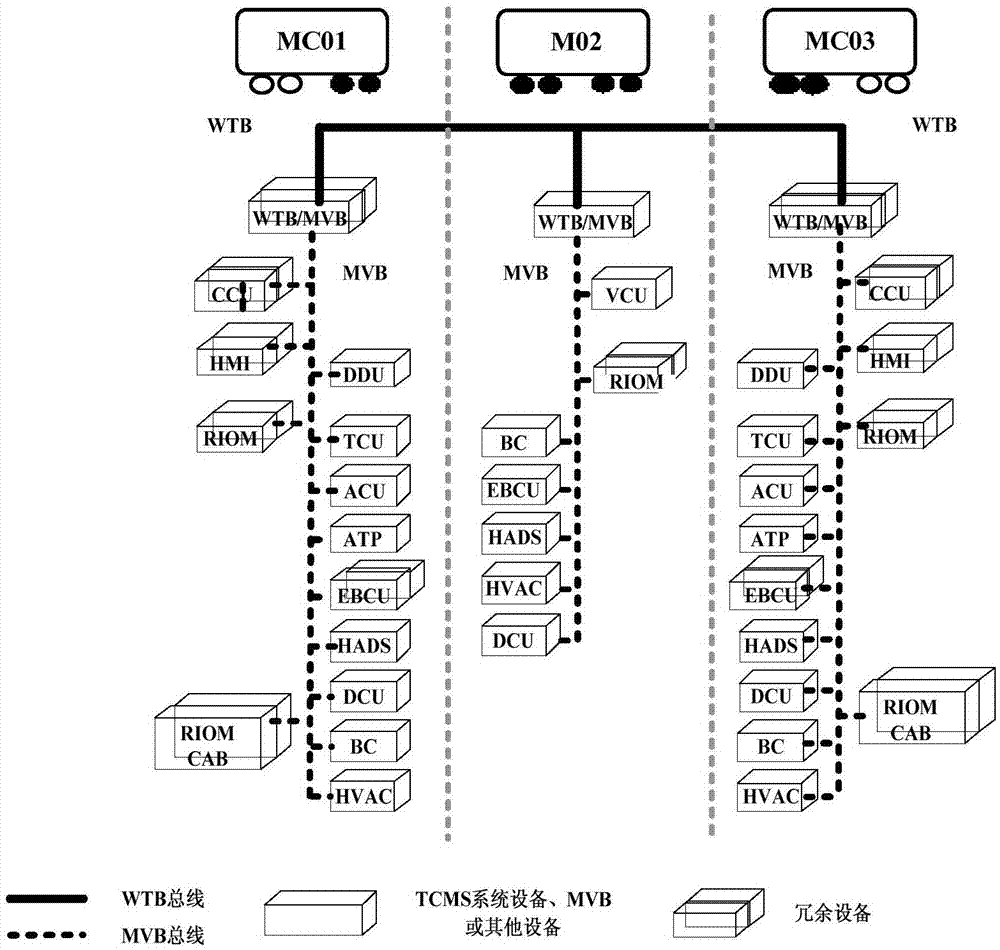

Train formation control system

InactiveCN105438222ALower detection rateIncrease profitSignalling indicators on vehicleAutomotive engineeringControl system

The invention provides a train formation control system which comprises at least one vehicle and a train bus, wherein all vehicles are communicated through the train bus and are formed into a train; each vehicle comprises a vehicle bus, a TCN gateway and a control unit, wherein the TCN gateway forms an interface between the train bus and the vehicle bus, and the control unit is used for storing the structure information of the train; and at least one vehicle system comprises a locomotive, a motor train unit and a trailer. In the system, each vehicle is internally provided with a TCN gateway so as to enable each vehicle to respectively form a set of network; when the quantity of any one of the locomotives, motor train units and trailers is changed, the TCN gateways can address nodes automatically according to the corresponding sequence through initial operation to re-allocate addresses to the vehicles so as to determine the positions of the vehicles relative to a host node and notify the directions of all node trains, so that flexible train formation can be realized; and according to the actual operation condition, the train formation quantity is adjusted so as to reduce the train inspection rate and reduce the operation and maintenance cost.

Owner:CRRC TANGSHAN CO LTD

Pulsed light optical rangefinder

ActiveUS9417326B2Improve dynamic rangeLower detection rateElectromagnetic wave reradiationPhoton detectionTime of flight

An optical rangefinder based on time-of-flight measurement, radiates pulsed light toward an object (70), and receives reflected light from the object, the receiver operating in a photon counting mode, so as to generate a pulse for a detected photon. There is a variable probability of a photon detection on the receiver, and a controller (370, 380, 390; 365, 470, 475, 380, 390; 570, 580, 590, 390) controls the photon detection probability of the receiver, based on a light level. By controlling the detection probability according to a light level, the receiver can have an increased dynamic range, and without the expense of using optical components. This can apply even while detecting very weak signals since the receiver can still be in a photon counting mode while the detection probability is controlled. The light level can be indicated by an output of the receiver itself, or by another detector external to the receiver.

Owner:TOYOTA JIDOSHA KK

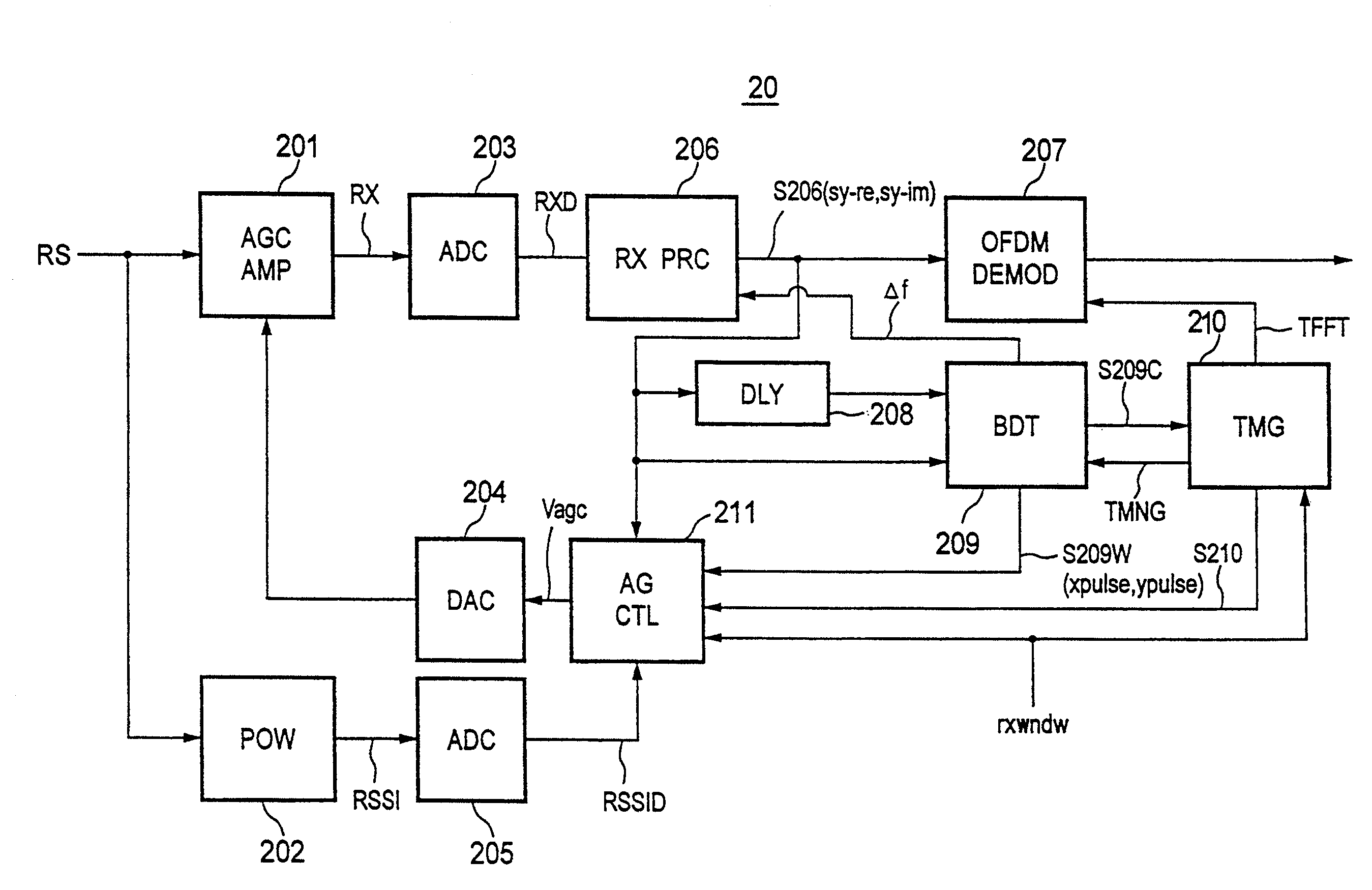

Automatic gain control circuit and method thereof and demodulation apparatus using the same

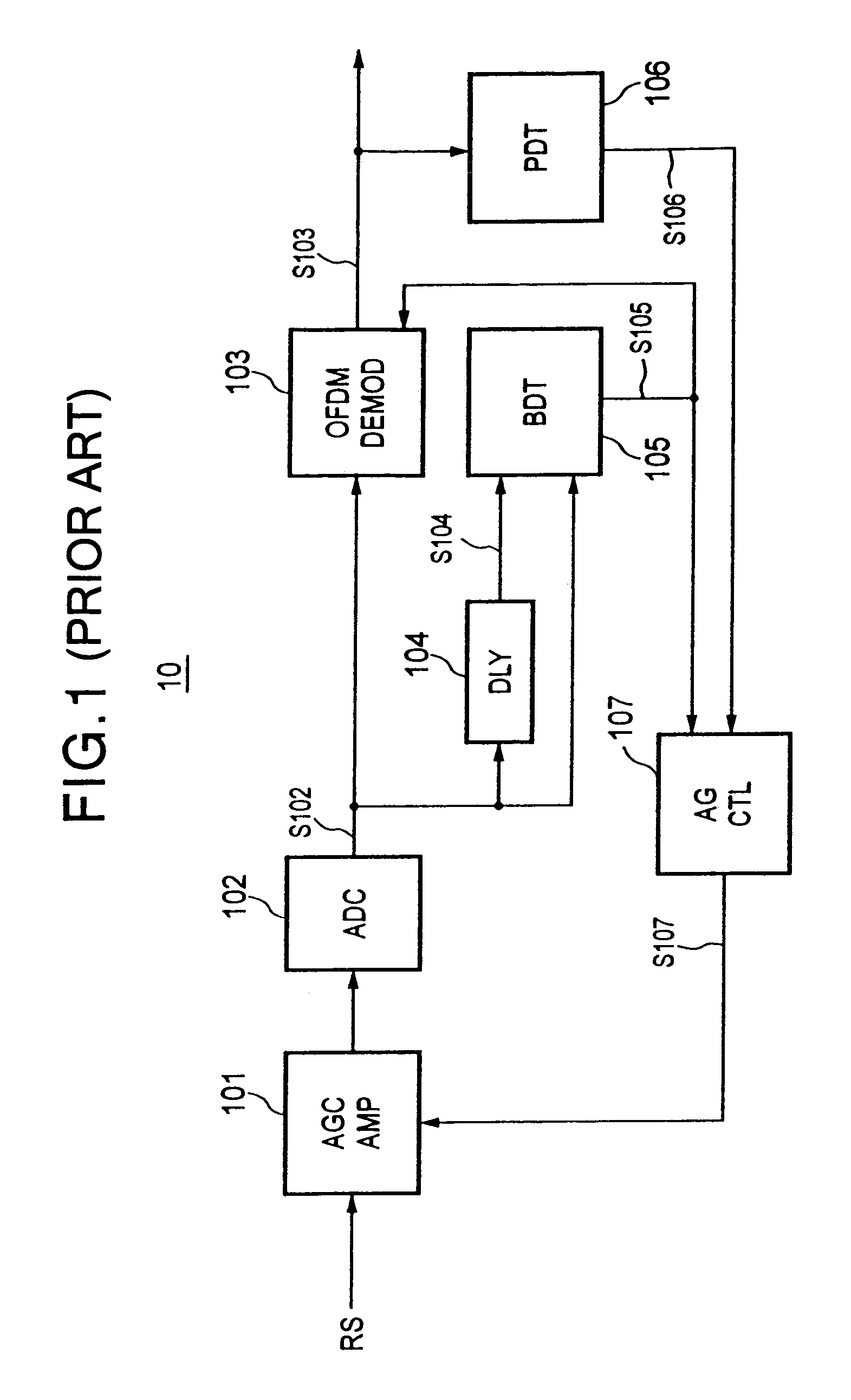

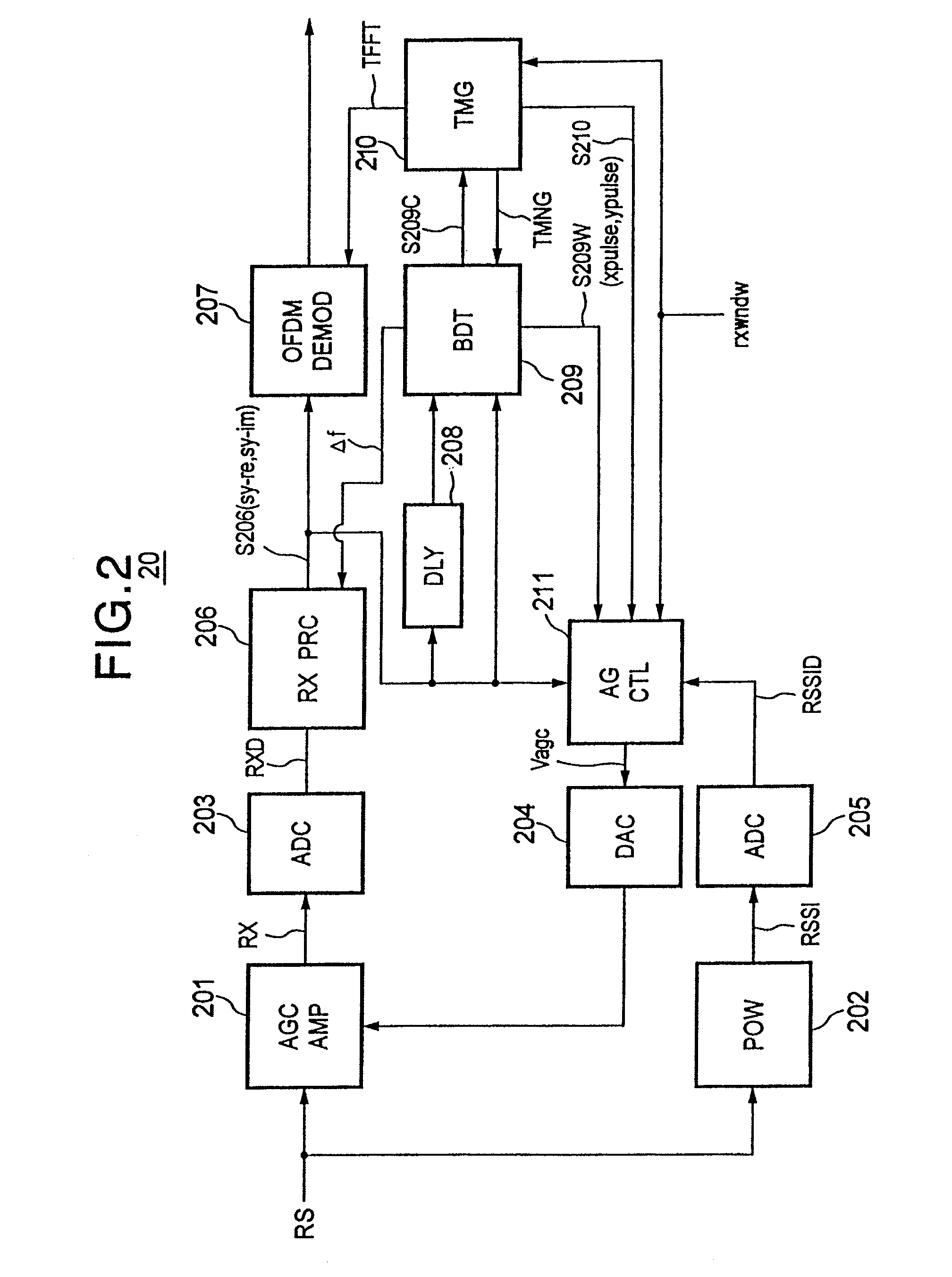

InactiveUS7397872B2Avoid mistakesIncrease speedGain controlAmplitude-modulated carrier systemsAudio power amplifierControl signal

An automatic gain control circuit able to perform high speed and correct level acquisition, able to prevent occurrence of error, and able to prevent a crash of the system. An amplification gain controller outputs a gain control signal to an automatic gain control amplifier to amplify the received signal with maximum value when receiving a burst detection trigger signal. A second gain control signal based on the detected reception signal power is calculated when receiving a first burst synchronization detection signal; and this second gain control signal is output to the automatic gain control amplifier. A received digital signal is amplified with the second gain and integrated to find the reception signal power, from which a third gain control signal is calculated and outputted to the automatic gain control amplifier to amplify the received signal with this third gain.

Owner:SONY CORP

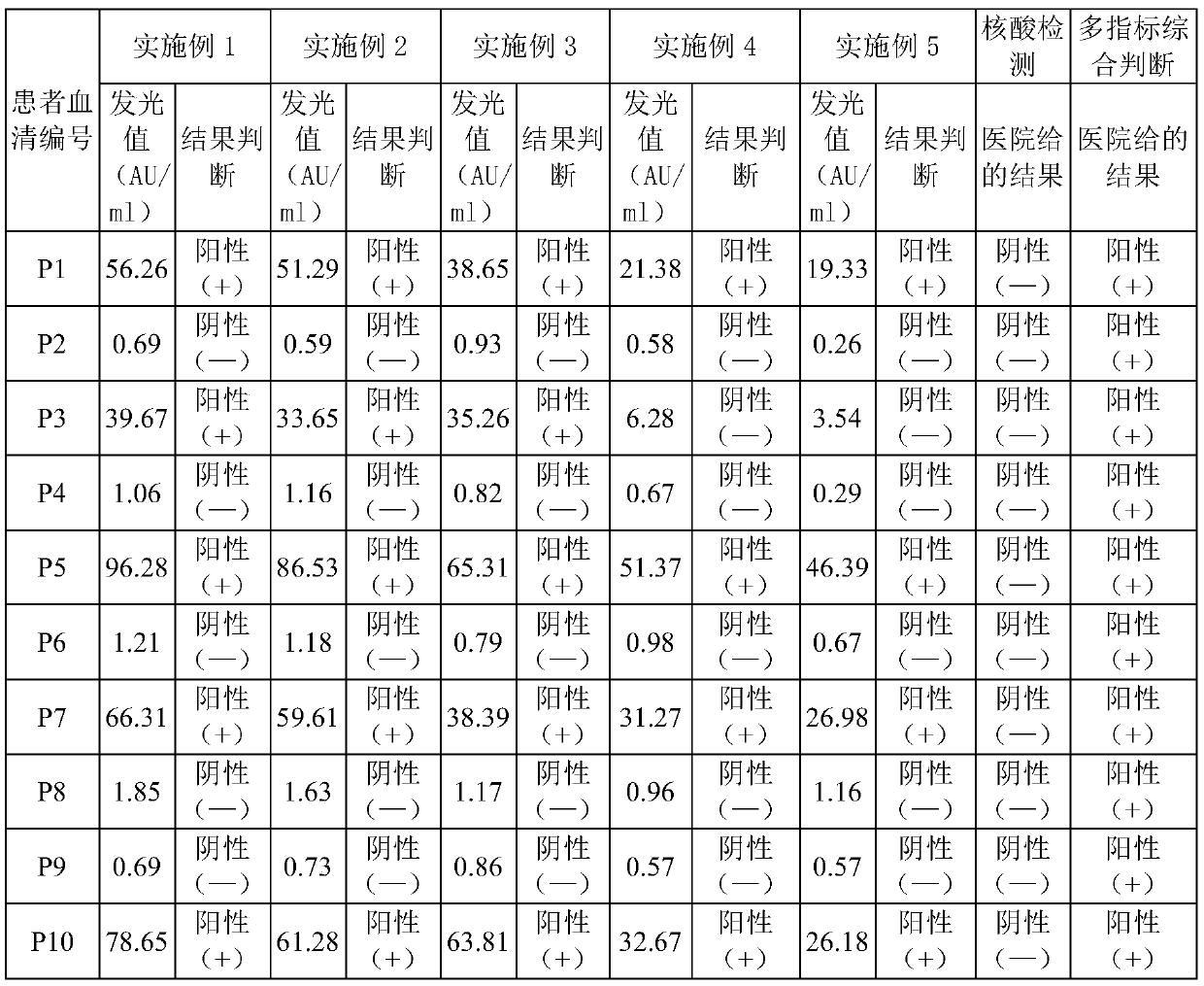

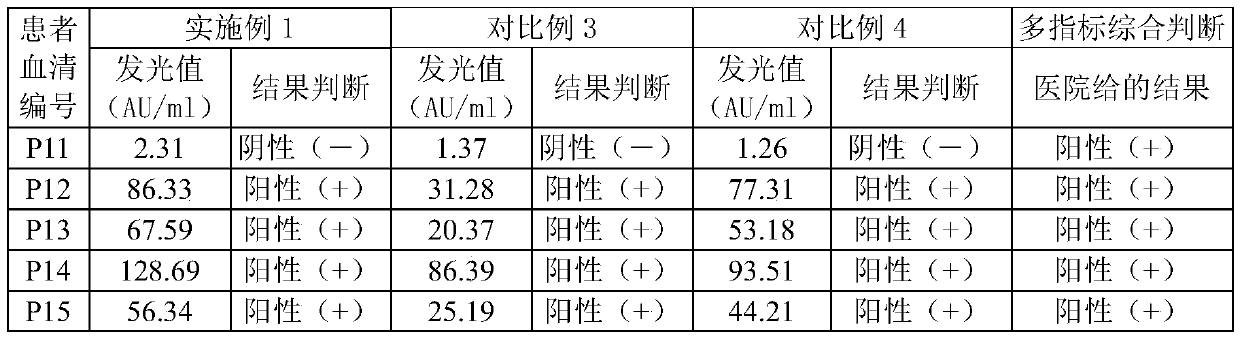

Kit for quickly and accurately detecting novel coronavirus IgM antibody and preparation method thereof

ActiveCN111551743AHigh sensitivityImprove the detection rateBiological testingImmunoassaysViral antibodyProtein Fragment

The embodiment of the invention relates to clinical in-vitro detection, in particular to a kit for quickly and accurately detecting a novel coronavirus IgM antibody and a preparation method of the kit. The kit provided by the invention comprises: a horseradish peroxidase labeled novel coronavirus antigen; and magnetic particles coupled with an anti-human IgM antibody, the novel coronavirus antigencomprises an N protein antigen derived from a novel coronavirus N protein and an S protein antigen derived from a novel coronavirus S protein. According to the kit provided by the invention, the newcoronavirus IgM antibody is used as a detection object, so that early auxiliary diagnosis on a patient is facilitated; n protein and S protein fragments are jointly used as antigens for combined use,so that the sensitivity of related products can be improved on the basis of not influencing the specificity; complementation with nucleic acid detection can be formed, and the new coronal pneumonia detection rate is increased; the positive detection rate of the kit is obviously higher than that of similar new coronavirus IgM detection products sold in the market, and the kit can more accurately serve the field of in-vitro diagnosis.

Owner:BEIJING BEIER BIOENG

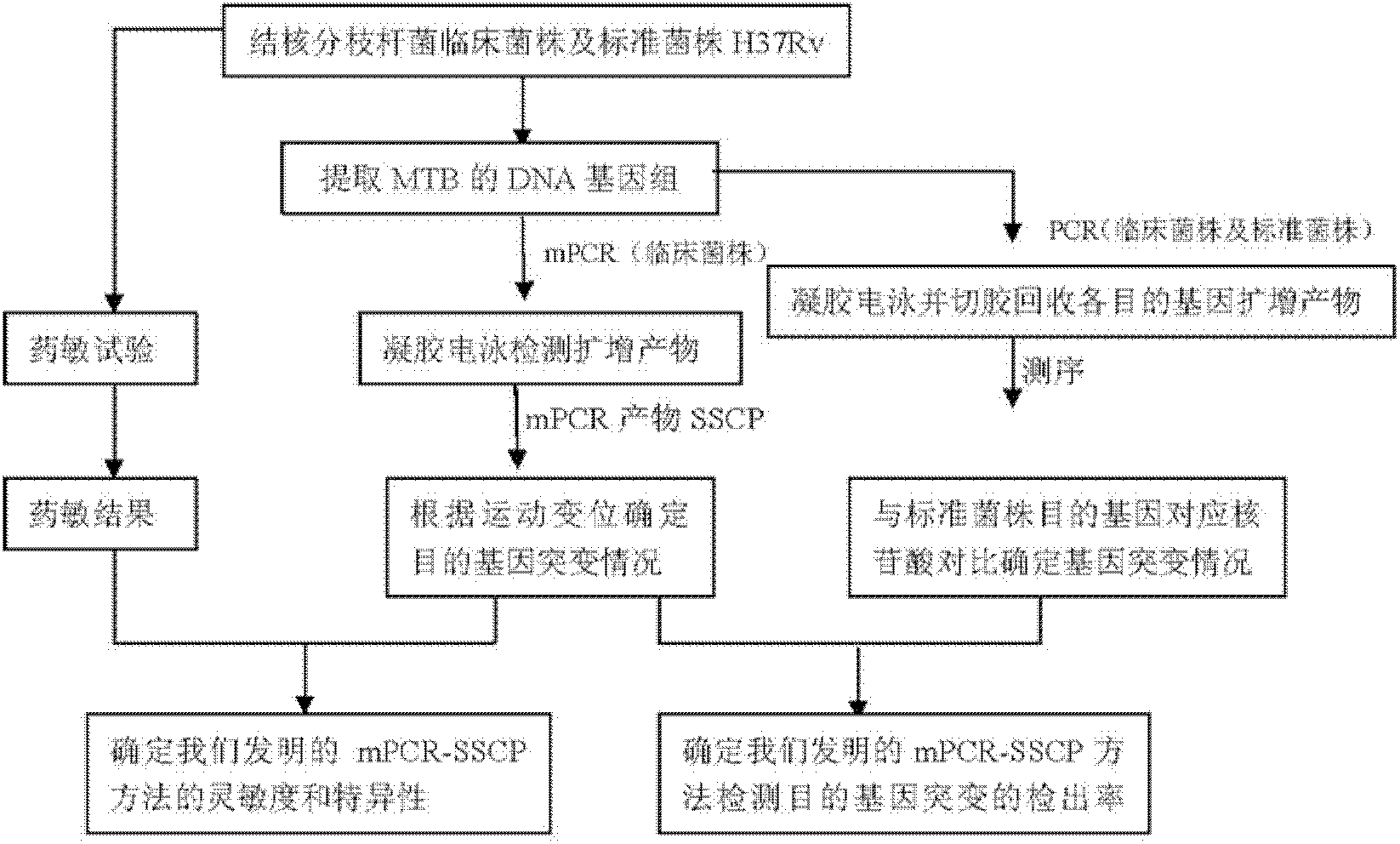

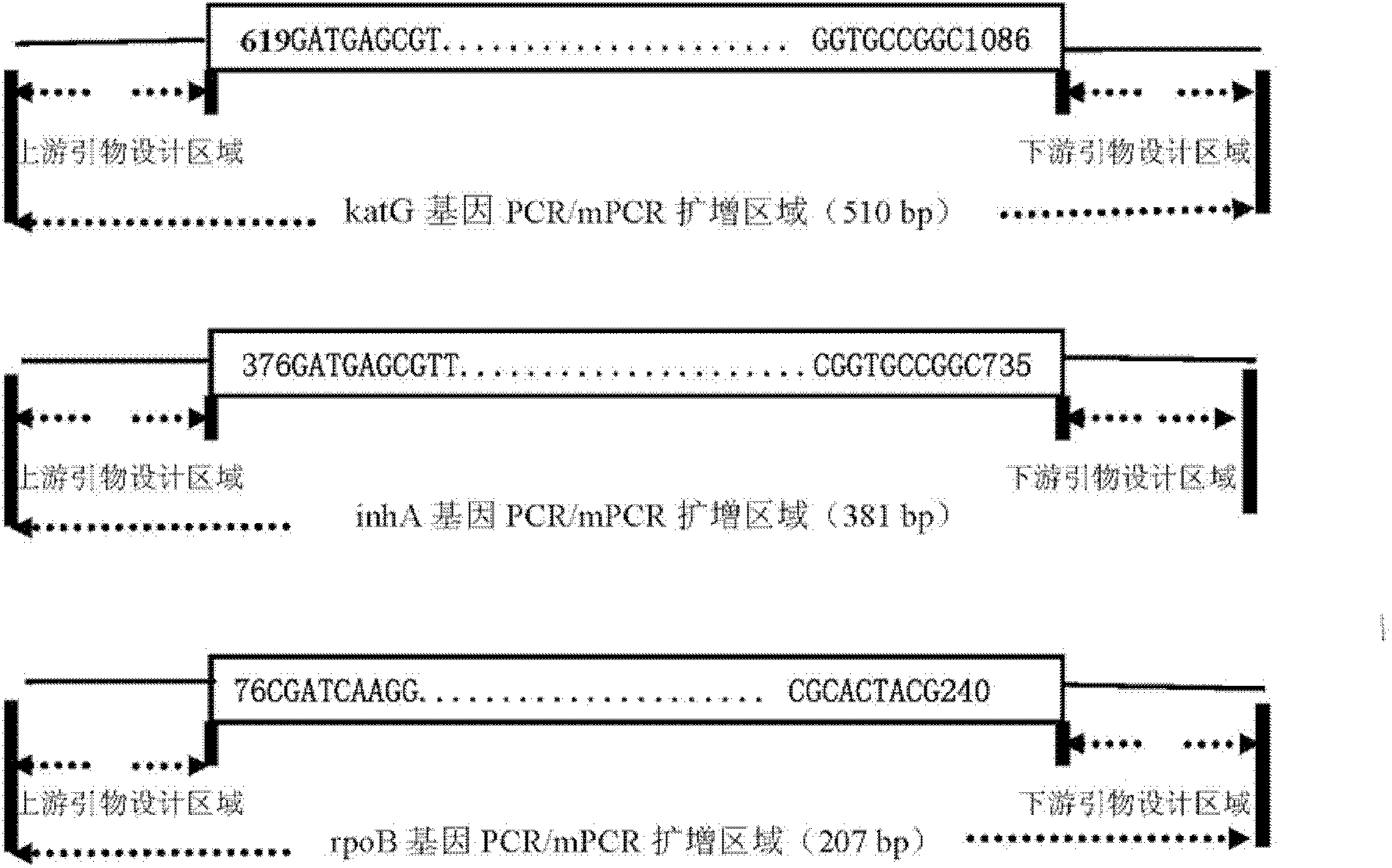

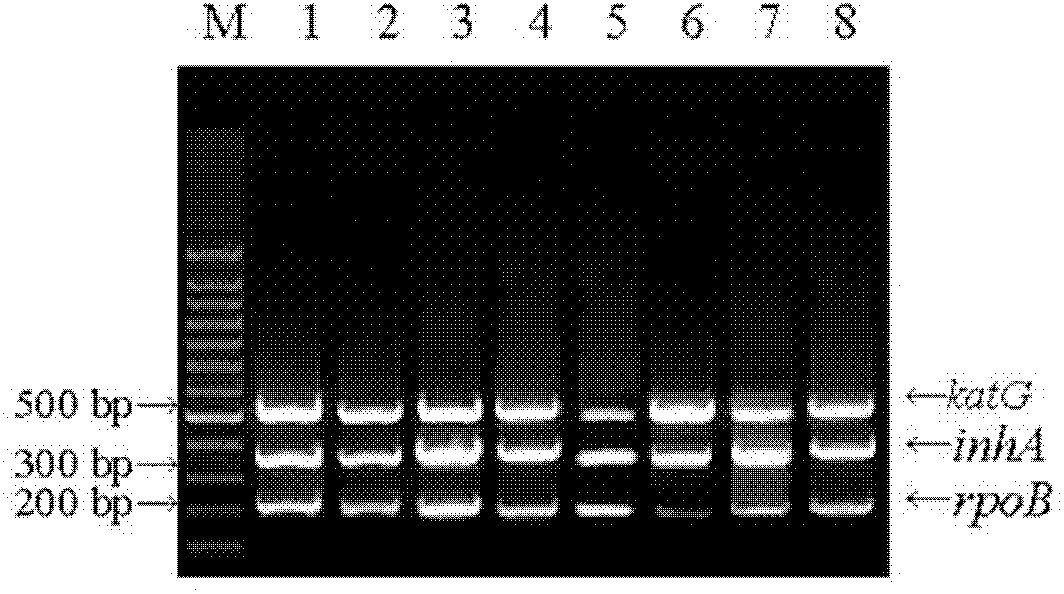

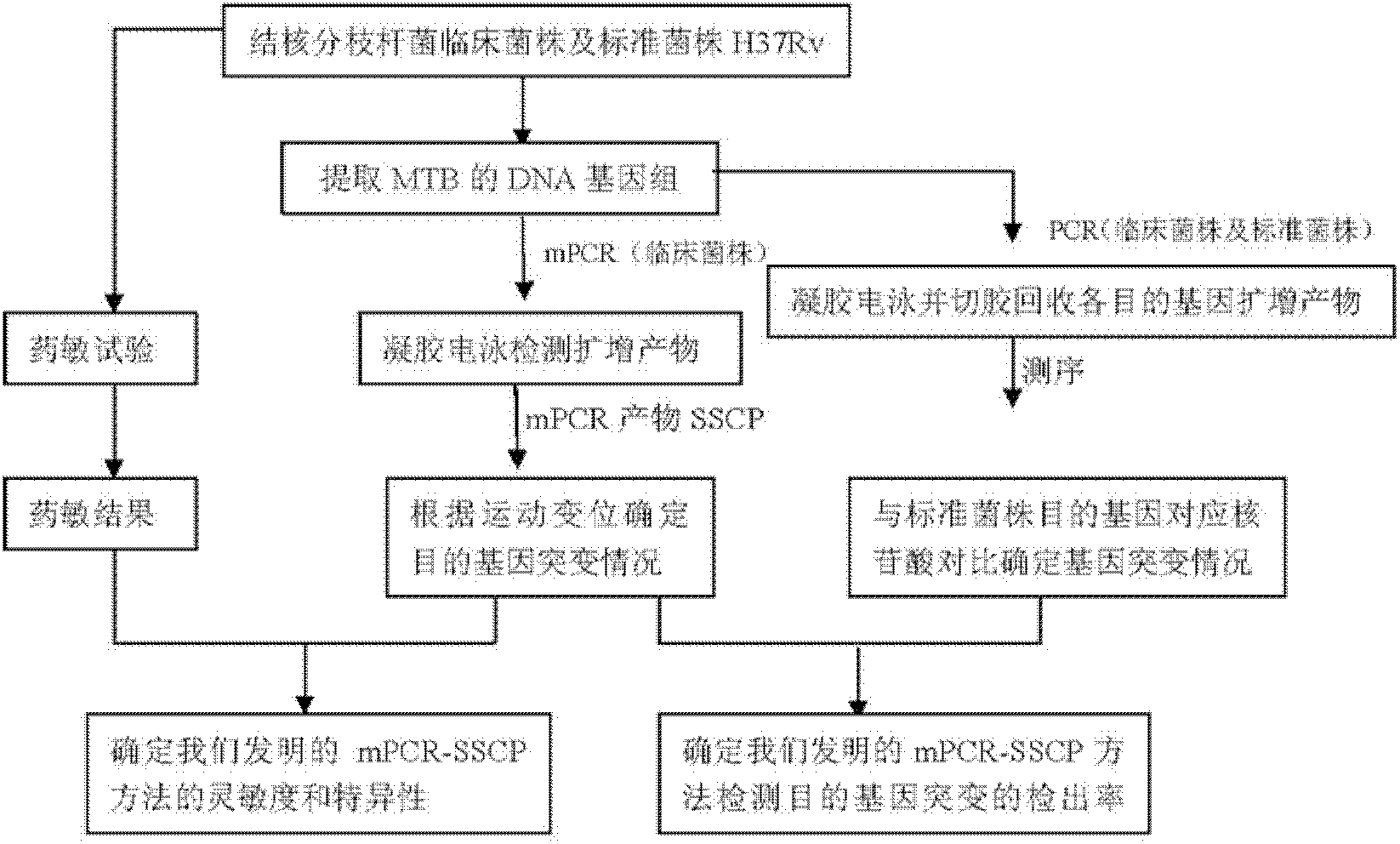

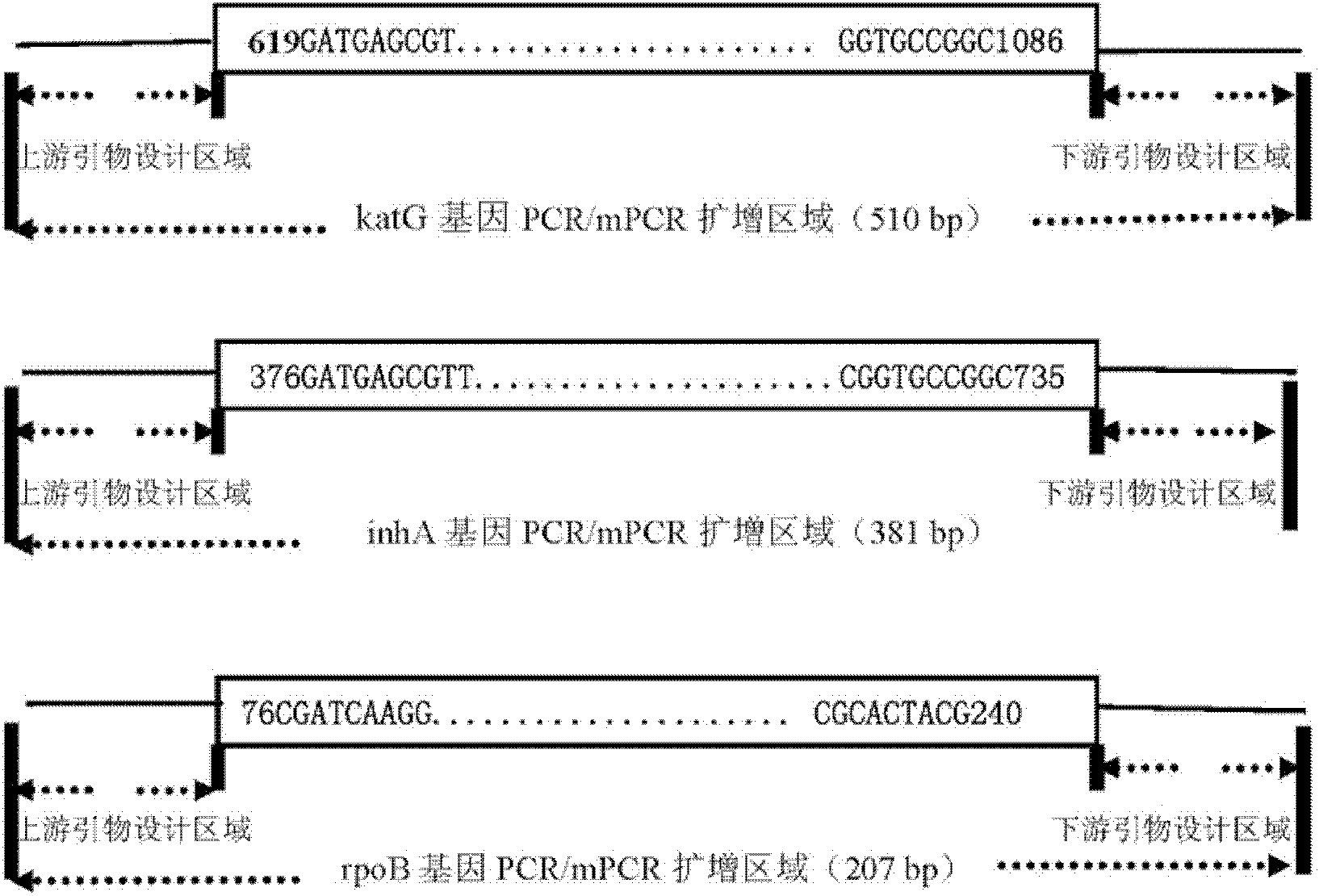

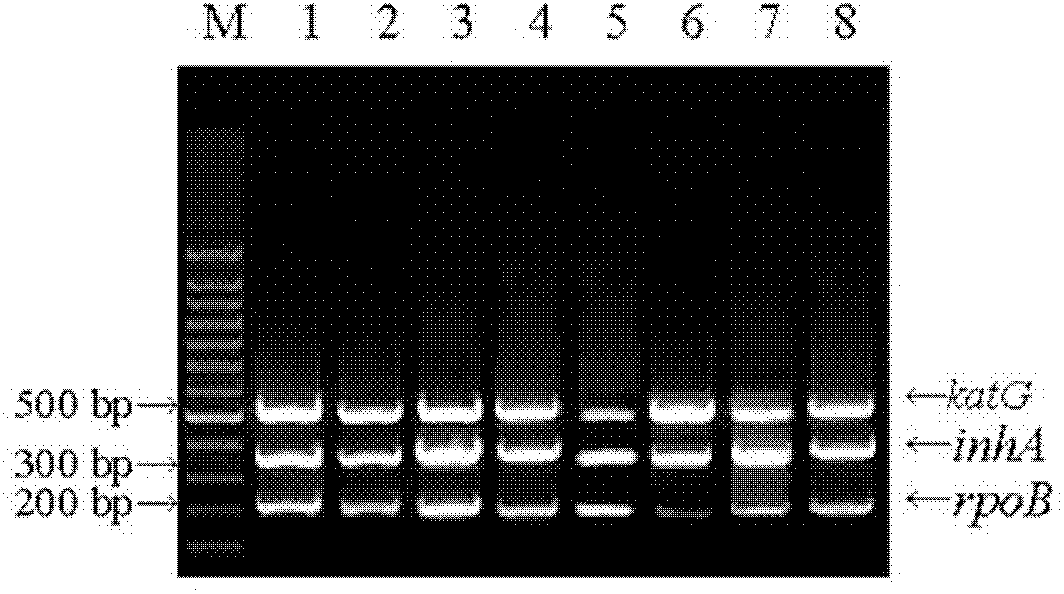

Method for detecting multi-drug resistance of Mycobacterium tuberculosis

InactiveCN102559916AVerify reliabilityExperiment operation is simpleMicrobiological testing/measurementMicroorganism based processesSingle-strand conformation polymorphismIsoniazid resistance

The invention relates to a method for detecting multi-drug resistance of Mycobacterium tuberculosis, which aims at detecting the resistance of the Mycobacterium tuberculosis to isoniazid and rifampicin at the same time and has the characteristics of high specificity and sensitivity, quickness in detection, and easiness and convenience in operation. The technical scheme is as follows: the method comprises the following steps: A, establishing PCR (polymerase chain reaction) templates of an MTB clinical strain and a standard strain H37Rv; B, designing three pairs of primers of katG, inhA and rpoB gene fragments which are closely related to the isoniazid resistance and the rifampin resistance, performing mPCR amplification on katG, inhA and rpoB genes of the clinical strain, and performing PCR amplification on katG, inhA and rpoB genes of the clinical strain and the standard strain H37Rv; and C, detecting the mutation conditions of related INH-resistant and RFP-resistant 3 genes of the clinical strain at the same time by a single-strand conformation polymorphism detection method.

Owner:孙爱华 +2

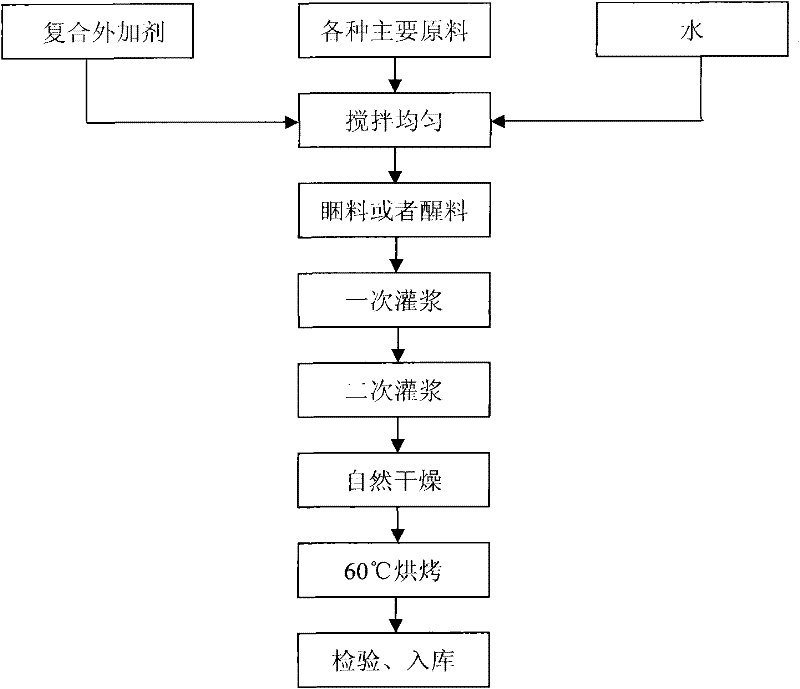

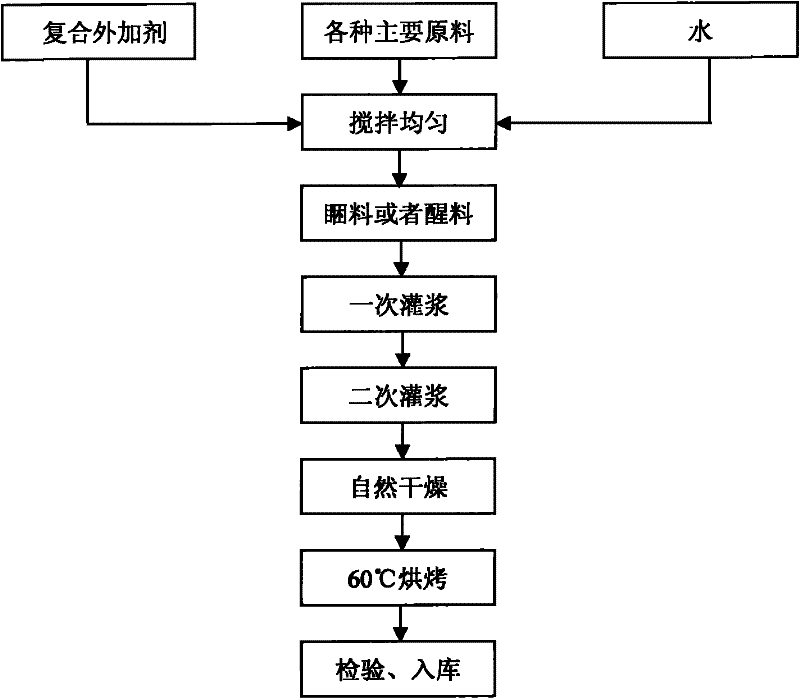

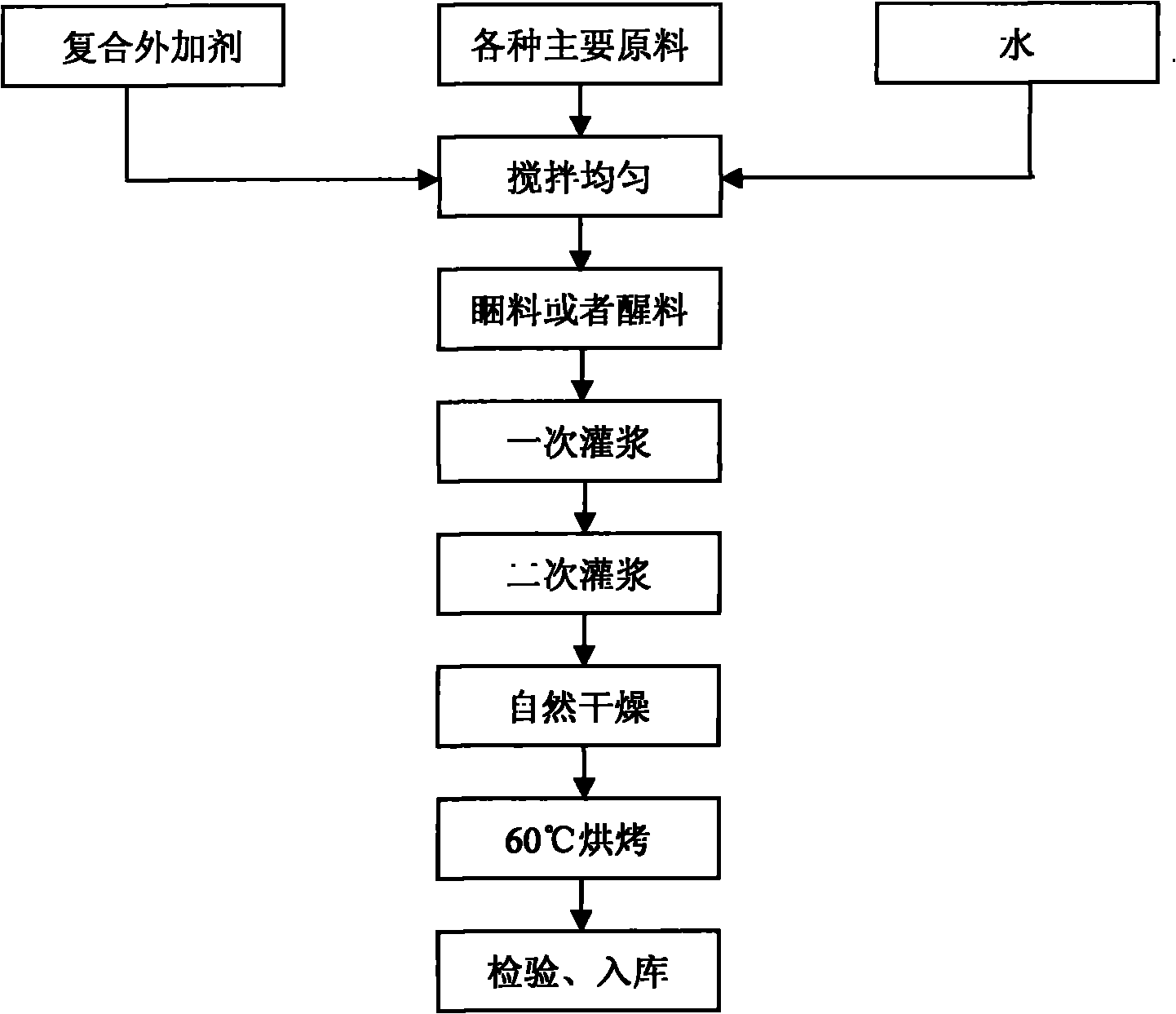

Early-strength quick-drying refractory mud filling material with good insulativity

The invention discloses an early-strength quick-drying refractory mud filling material with a good insulativity. The filling material is prepared through the following steps: adding water in 100 parts of main raw material and 1-10 parts of composite additives, mixing, ageing mixture or fermenting, grouting, naturally drying and baking, wherein the main raw material is a mixture of sintered mullite, quartz sand powder, alumina micropowder and pure calcium aluminate cement; and the composite additives are lignosulfonate, sodium carboxymethylcellulose and one substance or a mixture of two substances selected from subnano alumina micropowder with a grain size of 0.25-0.50 mu m, silicon micropowder with a grain size of 1-2 mu m, sodium tripolyphosphate, sodium hexametaphosphate and sodium polyphosphate. The filling material has good properties such as good early strength, rapid consolidation speed, no moisture regain and good insulativity, dose not corrode metals, can be widely applied to a metallurgy smelting high temperature sensor and a rapid temperature-measuring element to be used as an insulation material.

Owner:马鞍山江润冶金有限责任公司

Method for rejuvenating and detoxifying edible fungal strain by using protoplast regeneration technology

The invention relates to the domain of cell engineering, in particular to a method for rejuvenating and detoxifying an edible fungal strain by using protoplast regeneration technology. The method comprises the following steps: selecting parents, preparing protoplast, regenerating the protoplast, and establishing an evaluation standard for rejuvenating and detoxifying the edible fungal strain. The step of preparing the protoplast comprises the step of selecting steady infiltration agent solute, steady infiltration agent concentration, degrading enzyme, enzymolysis time and enzymolysis temperature; and the step of regenerating the protoplast comprises the step of selecting a pre-culture medium and a culture method. The method has the advantages that the effects of removing viable bacteria in the edible fungal and inhibiting factor accumulation are achieved by obtaining the protoplast so as to fulfill the purposes of rejuvenating and detoxifying the edible fungal and recover good properties of the edible fungal. For example, the comprehensive properties of oyster mushroom 89 and pleurotus ferulae 10 are remarkably superior to those of a contrast variety in the aspects of yield, adaptability, commercial property, impure fungal resistance and the like, and the remarkable economic benefit is produced.

Owner:TANGSHAN NORMAL UNIV

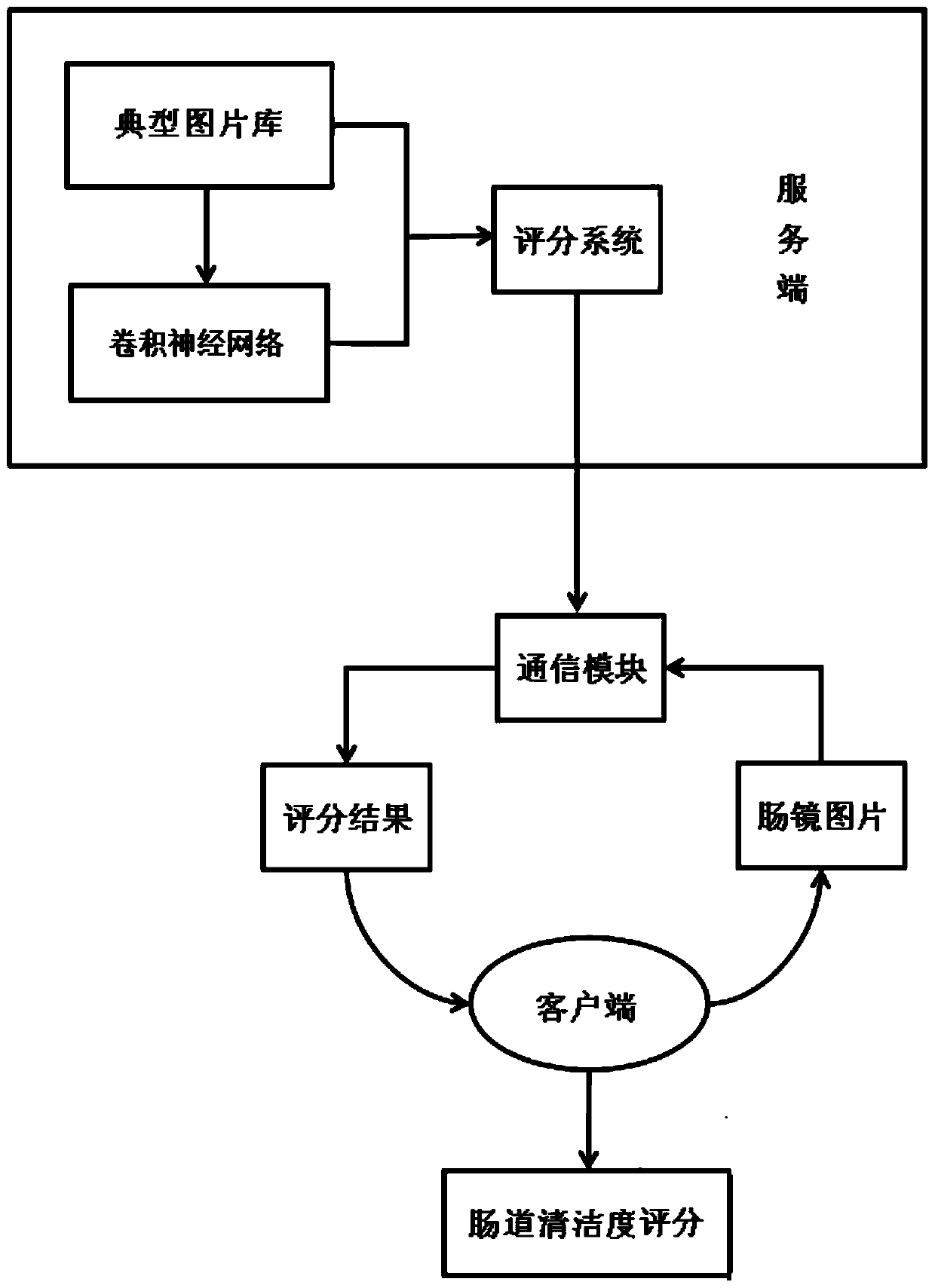

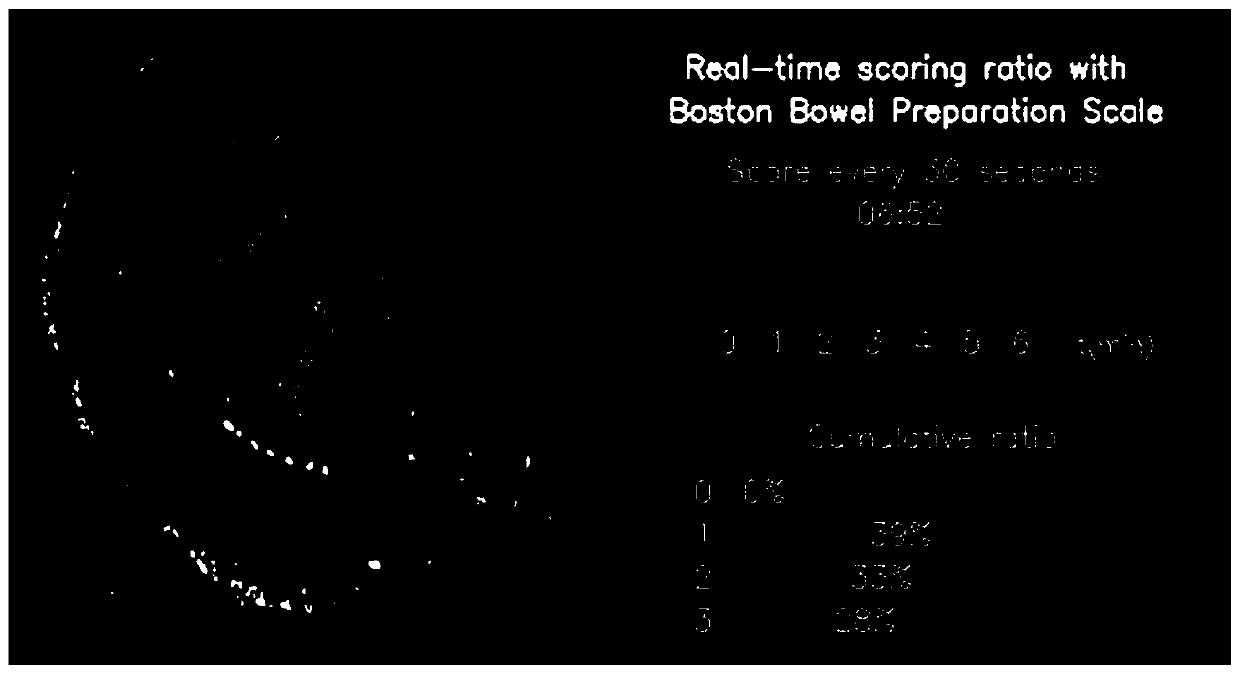

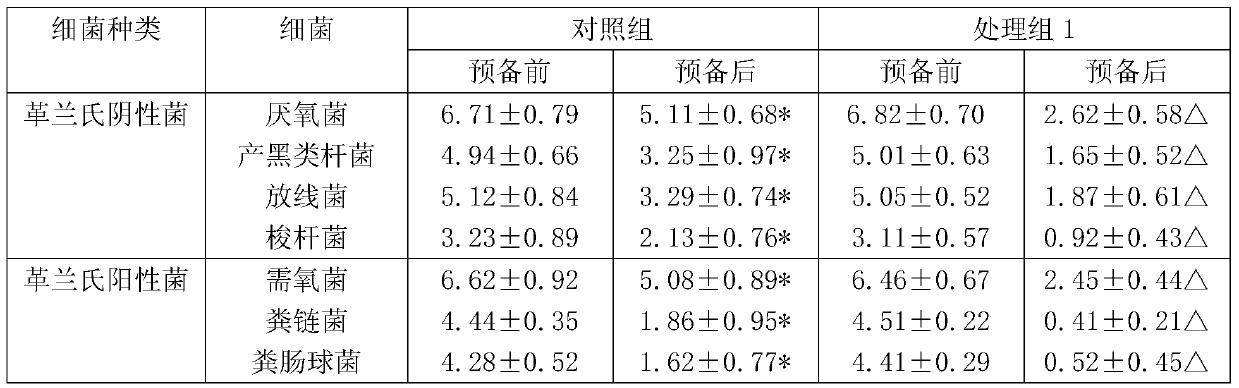

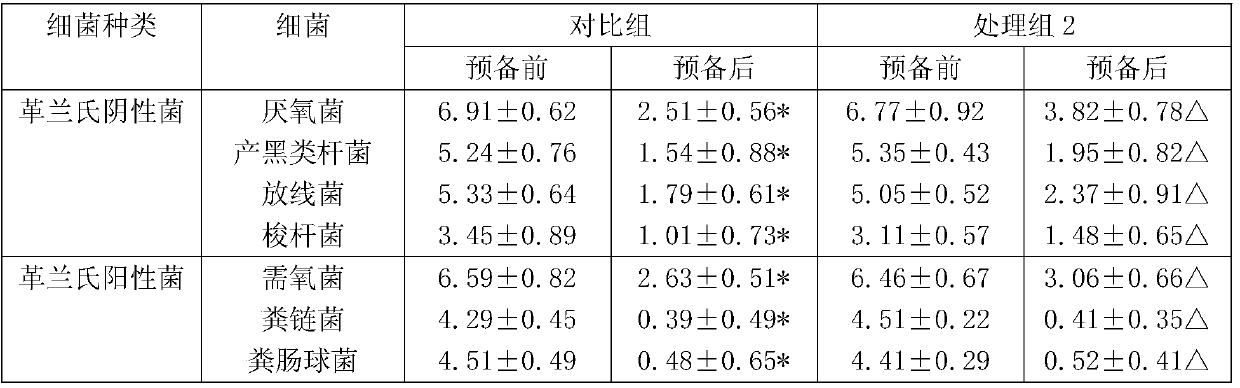

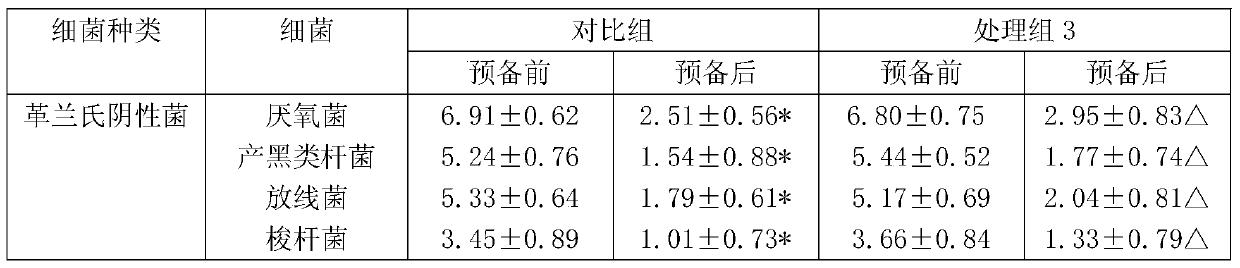

Real-time intestinal tract cleanliness scoring system and method based on artificial intelligence

InactiveCN110916606APrepare for quality understandingImprove preparation qualityEndoscopesRectum colonoscopesBowel preparationPrecancerous condition

The invention discloses a real-time intestinal tract cleanliness scoring system and method based on artificial intelligence. By adopting the system and method, bowel preparation quality examined by aclinical colonoscope is monitored in real time, and scoring display is carried out at a client; and the constituent ratio of each score and the cleanliness of an examined intestinal segment within each 30 s are represented. On one hand, the bowel preparation quality condition of a patient operated by a physician can be more objectively and directly expressed in a quantitative manner, and the workload and scoring errors of endoscopic physicians are reduced, so that the error evaluation of endoscopic examination quality is reduced and the interval of reexamination of colonoscope examination isrecommended; on the other hand, medical institutions can more objectively and directly know about the bowel preparation quality, so that the quality control work can be done effectively, the intestinal tract cleaning quality is rapidly improved, the adenoma detection rate is reduced, and early detection and early treatment of precancerous lesions of intestinal tracts are realized; and more importantly, the development of the system facilitates scientific inquiry for subsequent influences on bowel preparation schemes by different intestinal tract preparations.

Owner:WUHAN ENDOANGEL MEDICAL TECH CO LTD

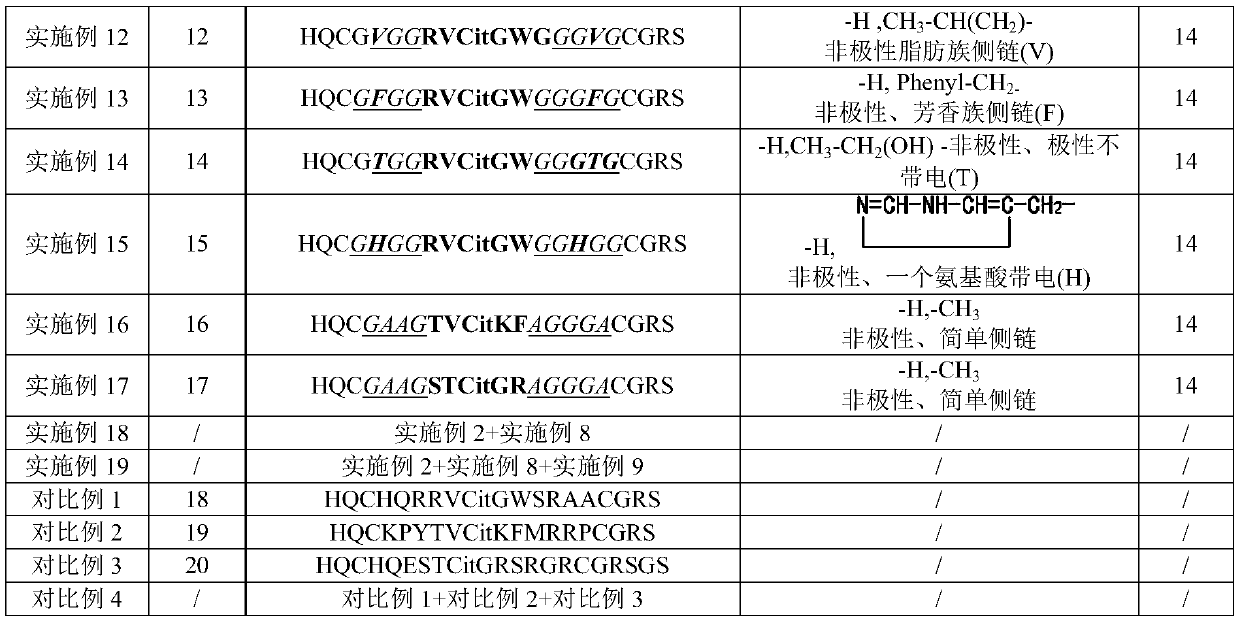

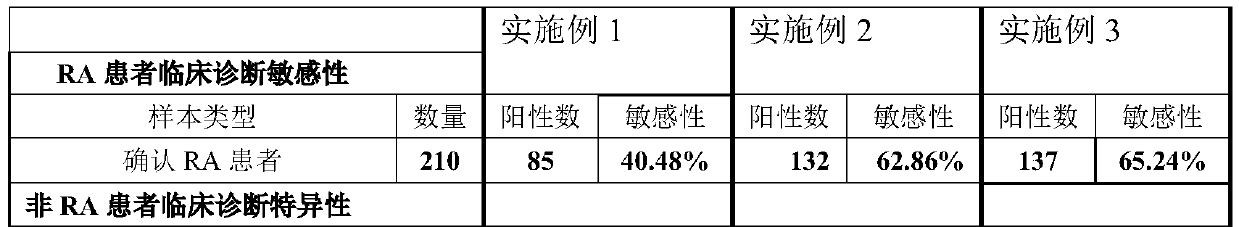

CCP peptide segment, antigen containing CCP peptide segment, reagent, kit and application

ActiveCN109929009AImprove clinical assay specificityGuaranteed clinical detection sensitivityBiological testingHybrid peptidesPeptideChemistry

The invention provides a CCP peptide segment, an antigen containing the CCP peptide segment, a reagent, a kit and an application. The CCP peptide has a structure shown as NH2-S3-S1-X-S2-S4-COOH, X isa citrulline-containing epitope region, S1 and S2 are flanking regions of the citrulline-containing epitope region, at most one of S1 and S2 is a charged amino acid residue, and S3 and S4 are amino acid residue regions connected to form a loop so as to form an amino acid residue region of the CCP peptide segment. The flanking regions of the CCP peptide segment are composed of amino acids with at most one amino acid serving as a charged amino acid, so that the intermolecular acting force can be reduced or the formation of an antigenic epitope can be avoided, the probability is reduced that thecitrulline antibody recognizes amino acid residues outside a key region to form an antigenic epitope and is recognized by other antibodies, thus the probability is reduced that the anti-cyclic citrulline peptide antibody is detected in the serum of non-RA patients, and the clinical detection specificity of the anti-cyclic citrulline peptide antibody in the diagnosis of RA diseases is improved.

Owner:SHENZHEN NEW INDS BIOMEDICAL ENG

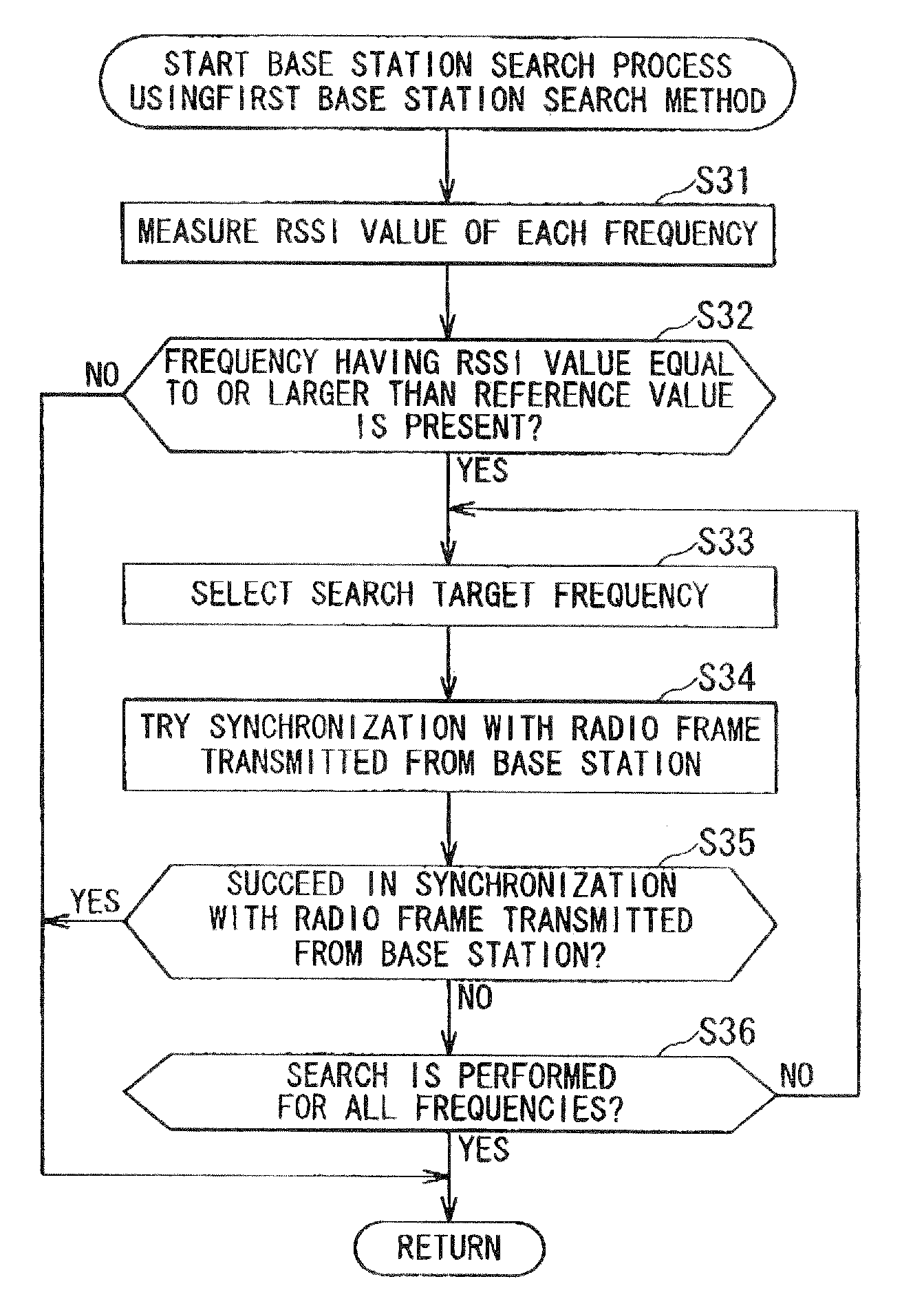

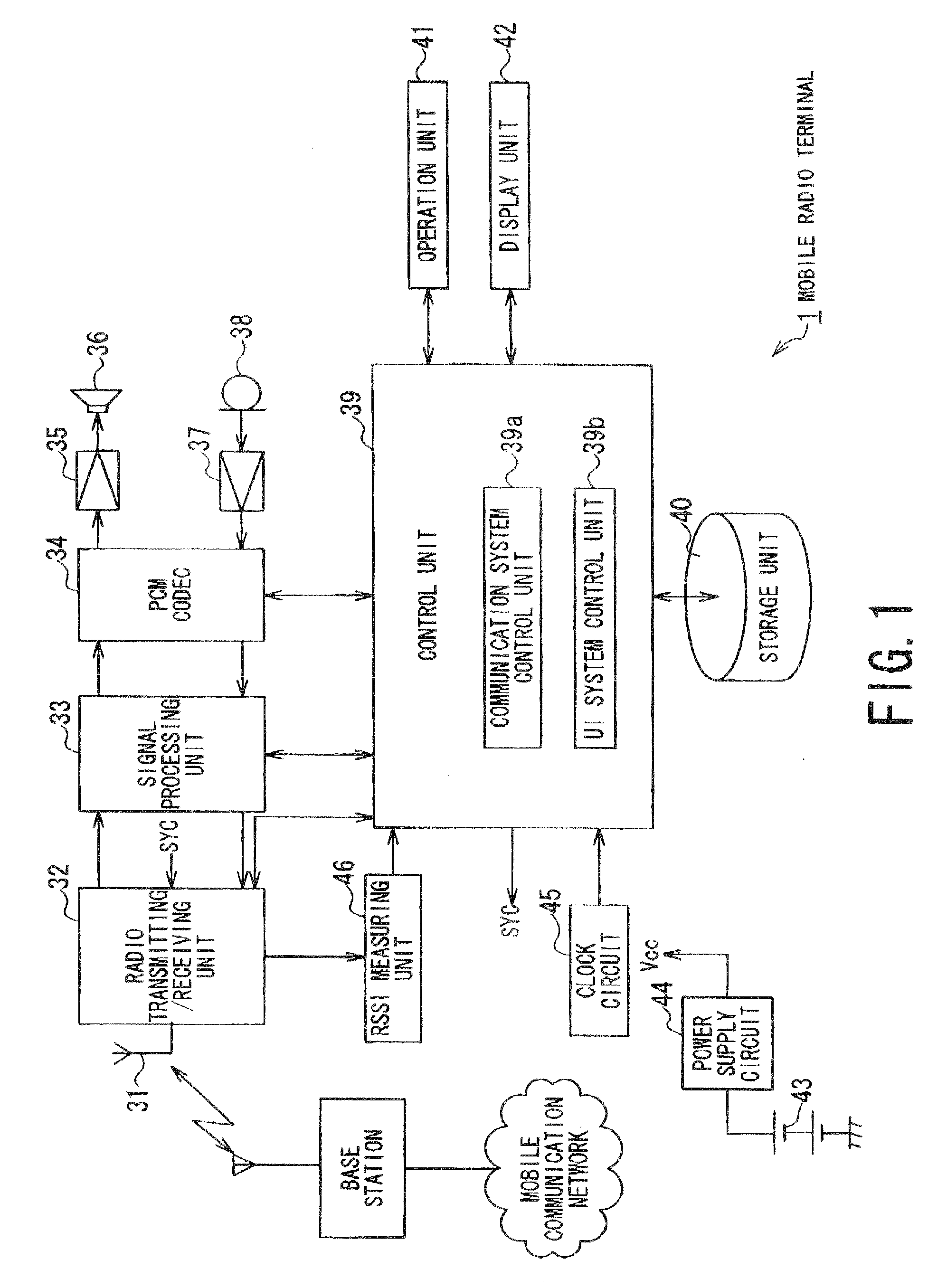

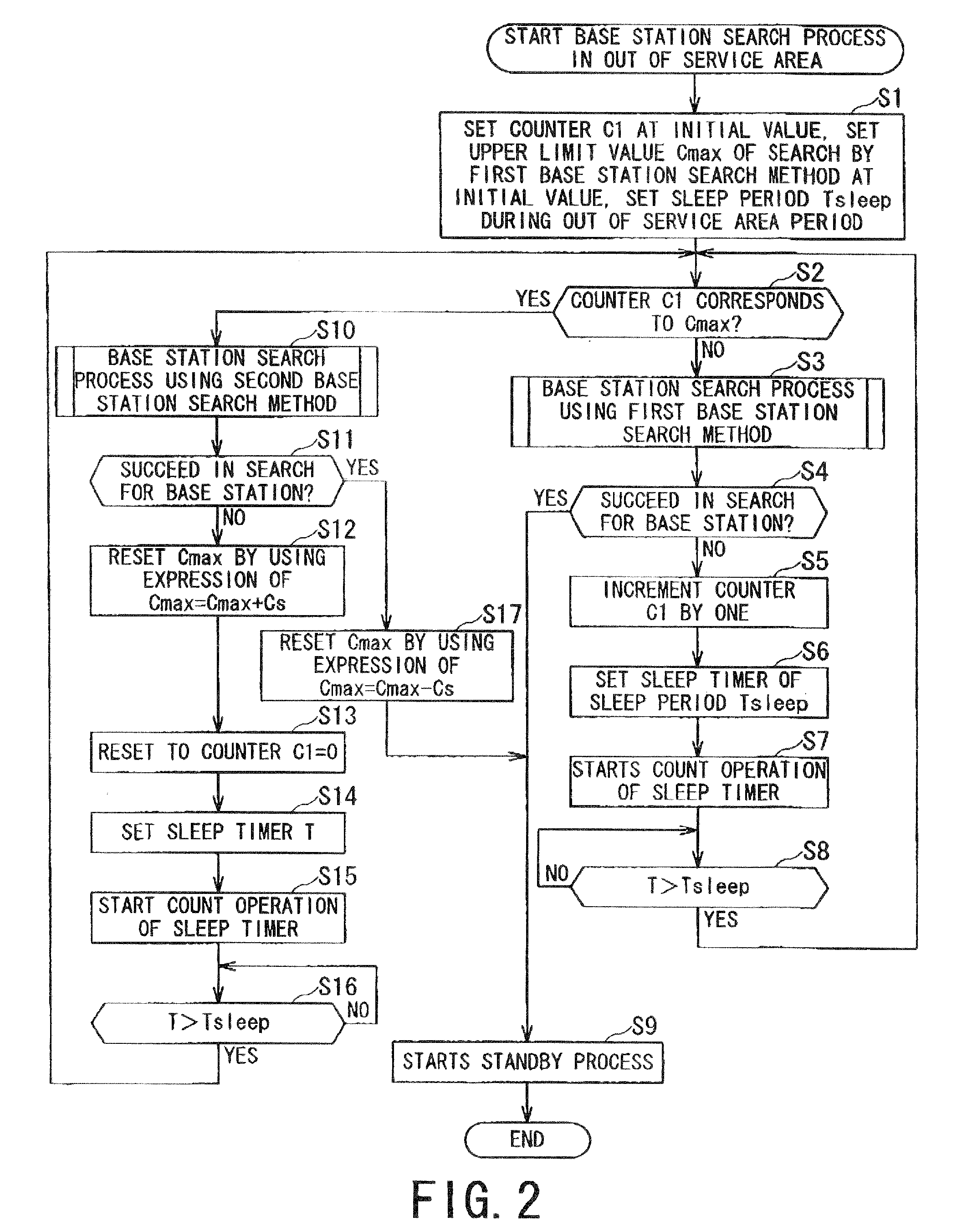

Mobile radio terminal and base station search method

InactiveUS20110045829A1Reduce power consumptionImprove the detection rateEnergy efficient ICTAssess restrictionLimit valueMobile radio

A mobile radio terminal of the present invention searches for a base station by a first search method by using a frequency at which an electric field strength of a radio signal has a reference value or more, searches for the base station by a second search method by using the frequency group usable for communication with the base station belonging to the mobile communication network, searches for the base station by the first search method until a number of searches by the first base station search method corresponds to an upper limit value of a number of searches, and searches for the base station by the second search method when the base station search by the first search method does not succeed by a time when the number of searches for the base station by the first search method corresponds to the upper limit value.

Owner:FUJITSU TOSHIBA MOBILE COMM LTD

Kit for screening and checking glucose-6-phosphate dehydrogenase (G6PD) deficiency of neonates and preparation method for kit

ActiveCN102519925AReduce false positive rateImprove the detection rateBiological testingFluorescence/phosphorescenceFull Term NeonateBiochemistry

The invention discloses a kit for screening and checking glucose-6-phosphate dehydrogenase (G6PD) deficiency of neonates and a preparation method for the kit. The kit for screening and checking the glucose-6-phosphate dehydrogenase (G6PD) deficiency of the neonates consists of substrate reagent dry powder, a substrate redissolved reagent, a copper reagent, a reaction board and filter paper dried blood spot quality control material. The detection result of the kit is high in accuracy and sensitivity, and the kit has the advantages of high stability, economy, simplicity, high efficiency and thelike; when the kit is applied to screening and checking for the neonates, the relevance ratio of heterozygote is improved; and the judgment accuracy is improved.

Owner:GUANGZHOU FENGHUA BIOENG

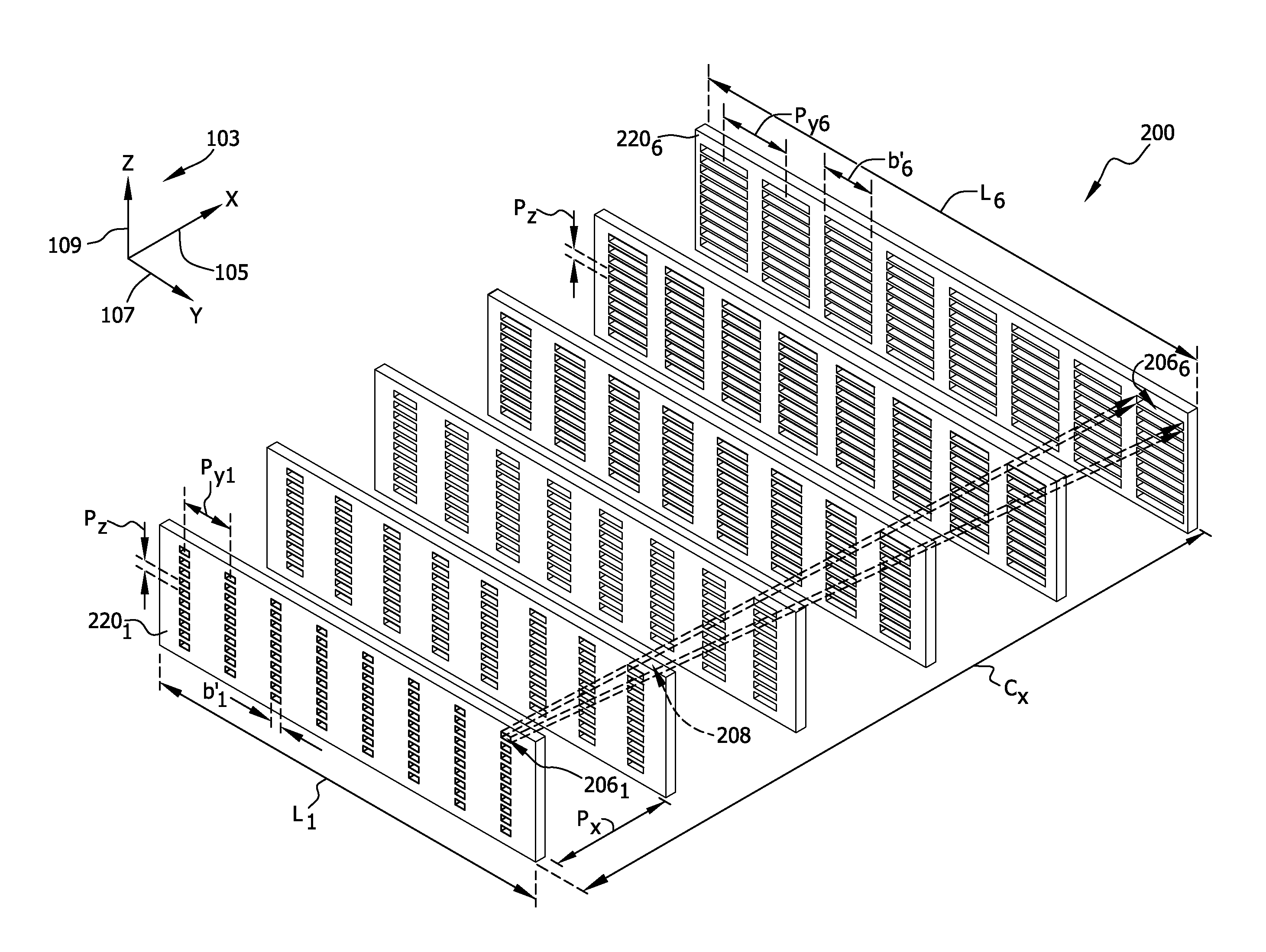

X-ray diffraction device, object imaging system, and method for operating a security system

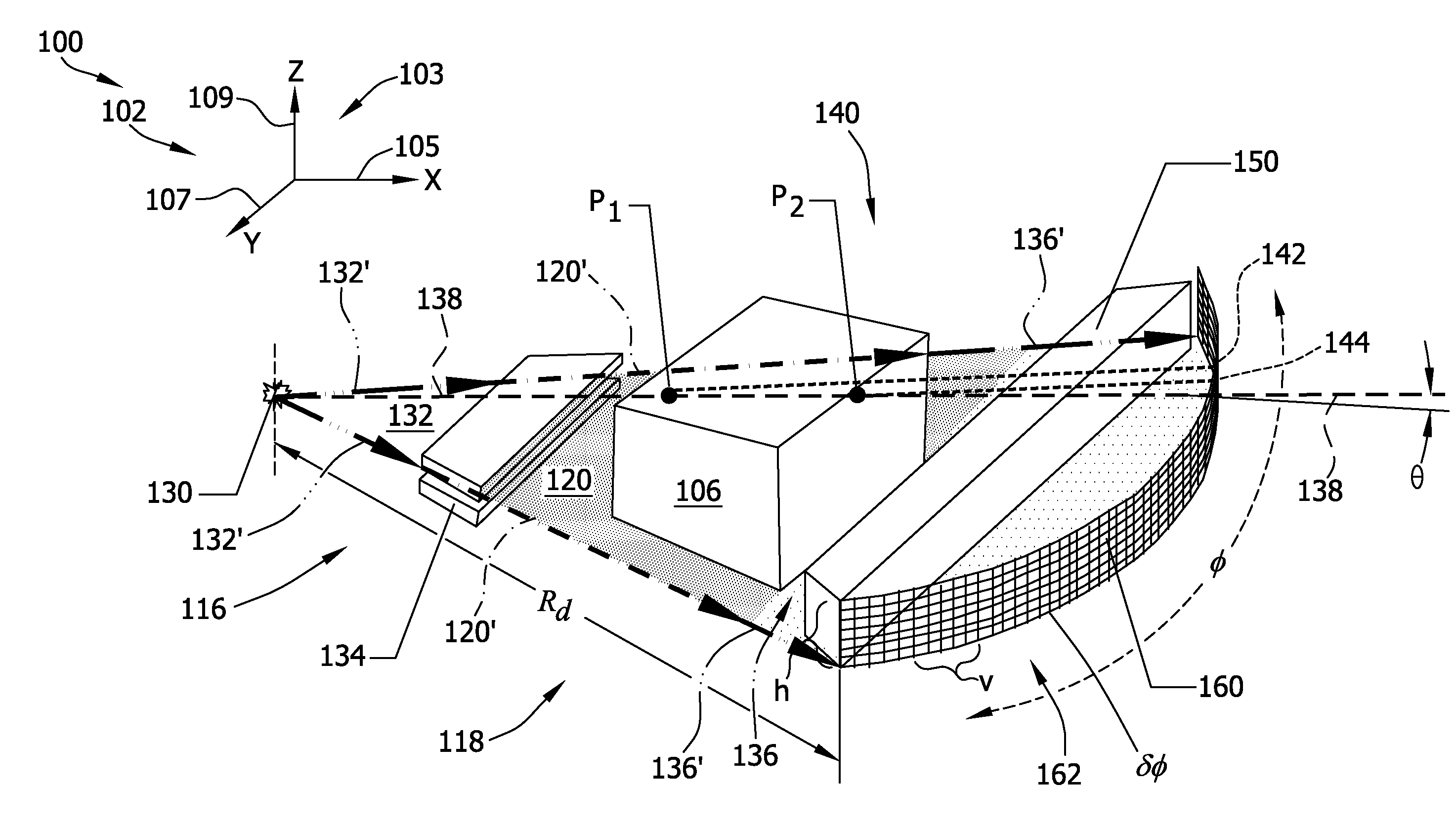

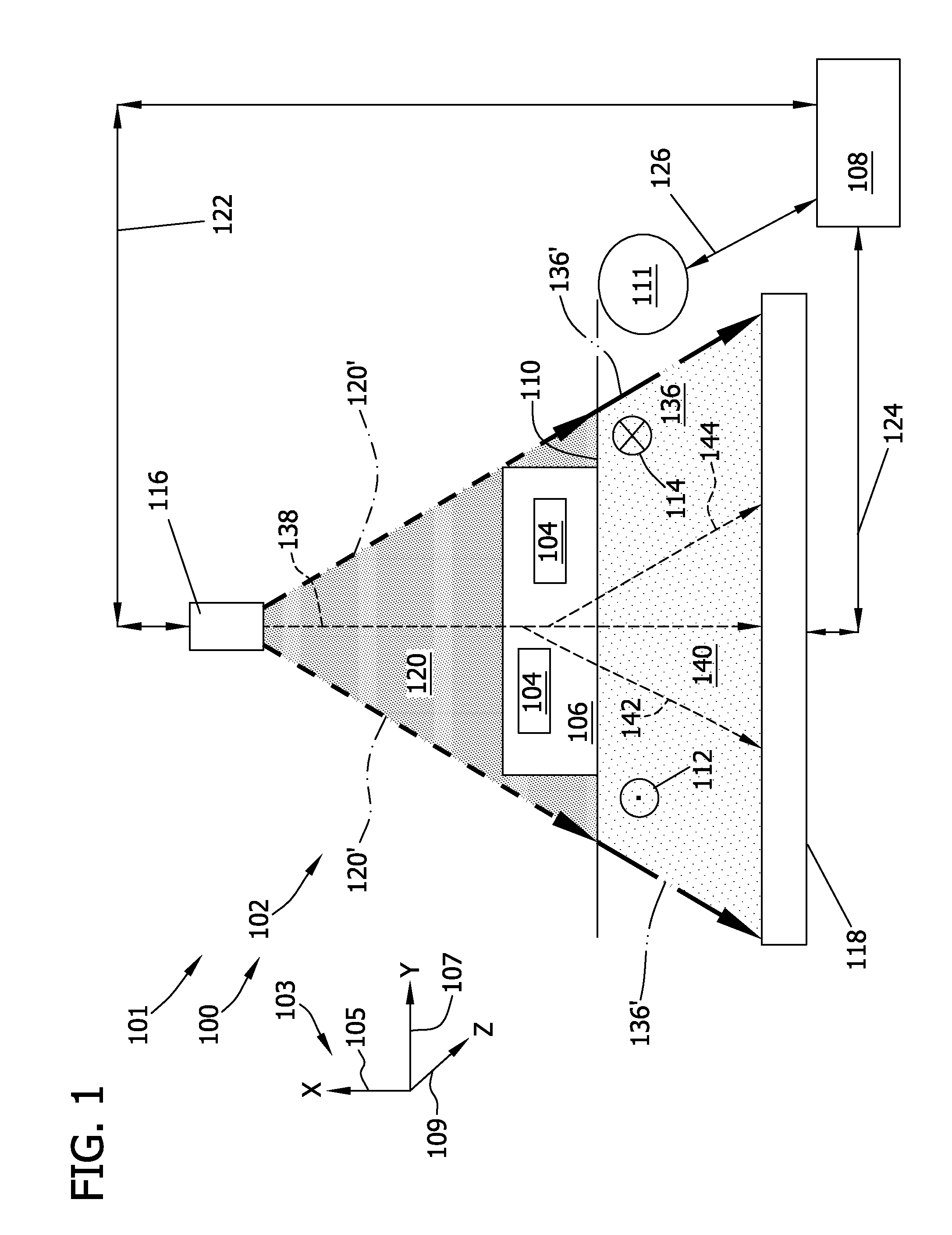

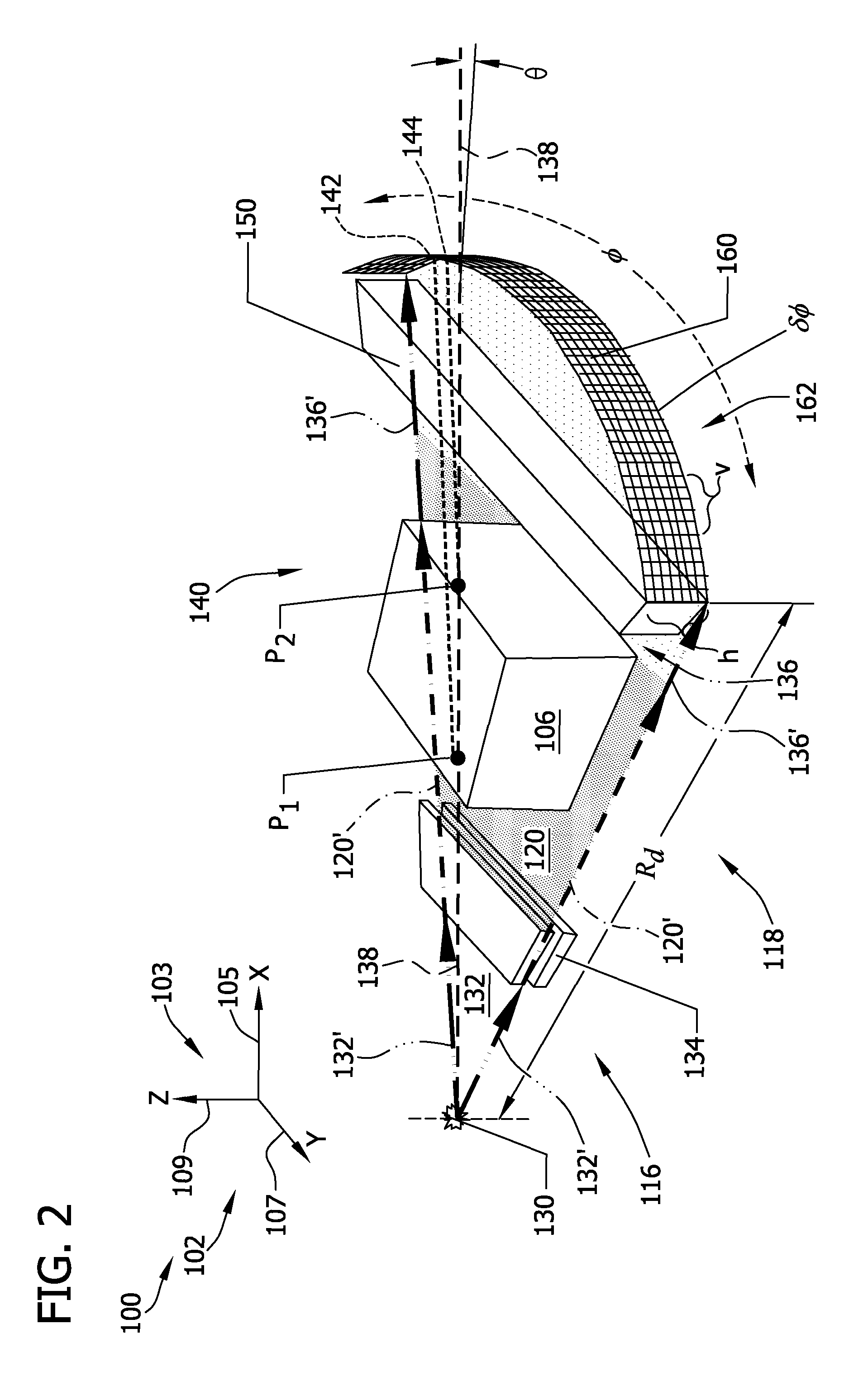

ActiveUS20100226478A1Improve the detection rateLower detection rateHandling using diaphragms/collimetersMaterial analysis using radiation diffractionSoft x rayX-ray

An x-ray diffraction imaging device includes at least one x-ray detector and at least one scatter collimator positioned upstream of the at least one x-ray detector. The at least one collimator includes a plurality of successive plates. Each of the plurality of plates defines a plurality of rectangular holes. The plurality of successive plates are arranged such that the plurality of rectangular holes define a plurality of quadrilateral passages extending through the at least one scatter collimator. Each of the plurality of quadrilateral passages is configured to increase a rate of detection of first x-rays that define an x-ray transit path enclosed within a single such quadrilateral passage. Also, the plurality of quadrilateral passages is configured to decrease a rate of detection of second x-rays that define an x-ray transit path that intersects more than one such quadrilateral passage.

Owner:MORPHO DETECTION INC

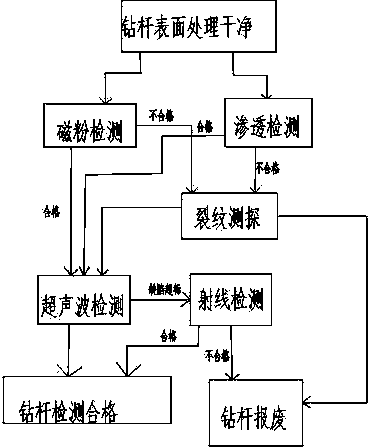

Technology for lossless drilling rod detection

InactiveCN104034797ALower detection rateHigh detection sensitivityMaterial analysis using wave/particle radiationAnalysing solids using sonic/ultrasonic/infrasonic wavesRod defectPermeation

The invention discloses a technology for lossless drilling rod detection. The technology comprises the following steps of cleaning the surfaces of drilling rods to be detected; performing magnetic powder detection or permeation detection on the surfaces of the drilling rods and near surfaces; performing ultrasonic detection on the qualified drilling rods without cracks, which are detected in the step B, and performing crack detection on the drilling rods with cracks, which are detected in the step B; polishing the drilling rods with the crack depths being not greater than 10 percent, which are subjected to crack detection in the step C, performing ultrasonic detection, and rejecting the drilling rods with the crack depths being greater than 10 percent; performing ray detection on the drilling rods with over-standard drilling rod defects, which are subjected to the ultrasonic detection in the step C and the step D, and determining that the drilling rods without the over-standard defects through the ultrasonic detection are qualified; and determining that the drilling rods passing the ray detection in the step E are qualified, and determining that the drilling rods not passing the ray detection are rejected. According to the technology, the number of structural members needing to be subjected to the ray detection is reduced, the total detection time of the drilling rods is effectively shortened, the detection sensitivity is greatly higher than that of the pure ray detection, and the detection cost is lower than that of the pure ray detection.

Owner:CHENGDU GAOPU PETROLEUM ENG TECH

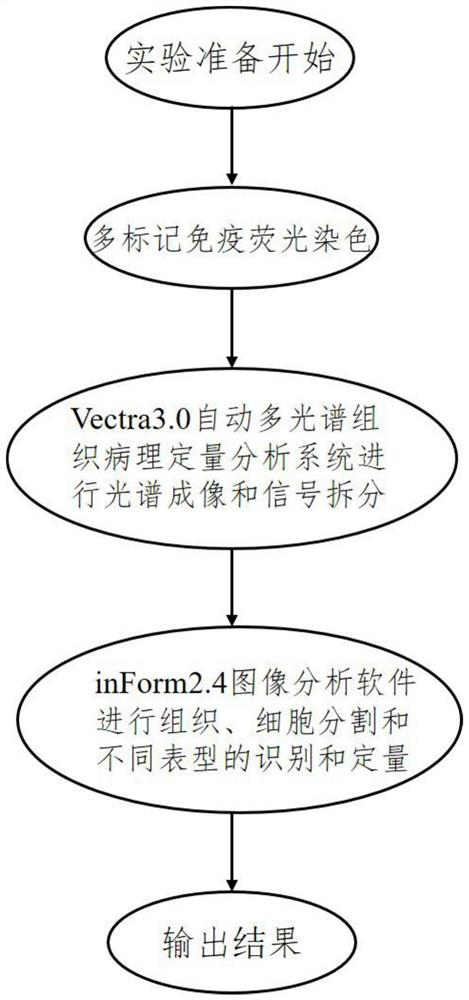

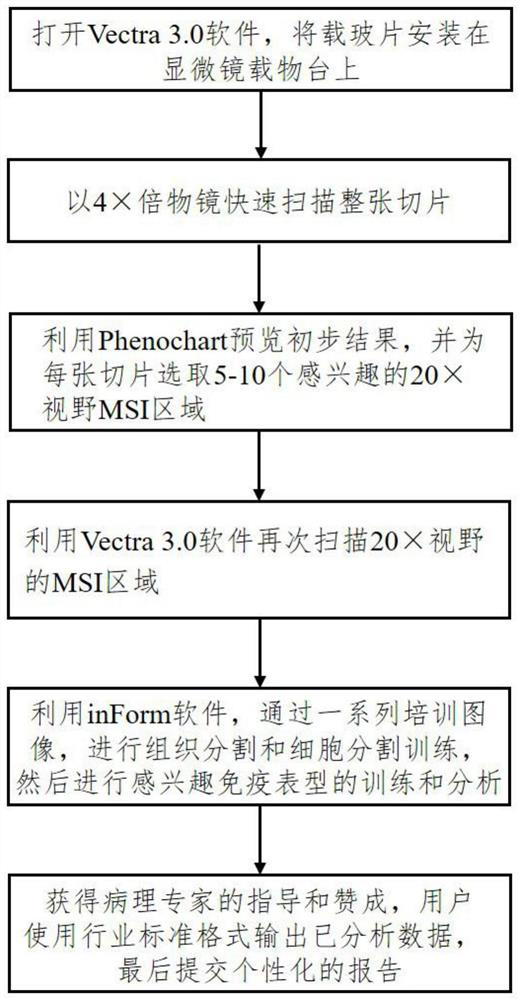

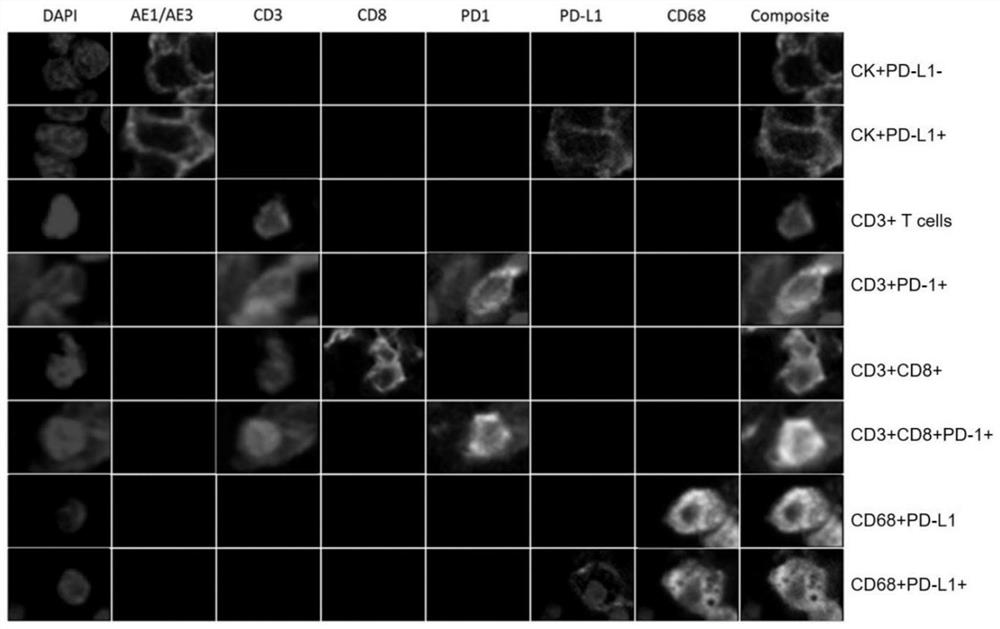

Marker combination, method, and system for immune checkpoint PD-1/PD-L1 dynamic monitoring

InactiveCN112014562AUnderstand sensitivityEnrich Extracted DataDisease diagnosisBiological testingImmune checkpointImage analysis

The invention discloses a marker combination, a method and a system for dynamically monitoring an immune checkpoint PD-1 / PD-L1. According to the method, an Opal / TSA multi-label immunofluorescence technology is adopted to simultaneously detect a plurality of markers related to tumor immunity in tumor tissues, and a Vectra automatic multispectral quantitative pathological image analysis system is combined to carry out data processing. The method disclosed by the invention can be used for guiding the actual medication of the tumor immunosuppressor; on the same tissue, different immune detection points and immune cell markers can detect signals, subtyping can be conducted on cells, cells of all phenotypes are obtained, and a theoretical basis is provided for treatment effect judgment of tumorpatients before and after treatment and guidance of tumor immunotherapy. Dynamic detection can be provided for the curative effect of tumor immunotherapy, clinical medication can be better guided, andmore tumor patients can be benefited from immunotherapy; compared with the conventional immunohistochemical detection technology, the detection target is richer and more intuitive.

Owner:WUHAN UNIV

Mycobacterium tuberculosis sputum specimen liquefier kit and application thereof

InactiveCN103555809AReduce dosageEliminate the centrifugation stepMicrobiological testing/measurementPreparing sample for investigationAcid-fastMedicine

The invention belongs to the technical field of detection of medical samples, and in particular relates to a mycobacterium tuberculosis sputum specimen liquefier kit and application thereof. The mycobacterium tuberculosis sputum specimen liquefier kit includes a liquefier R1 and a liquefier R2; and the liquefier R1 is ammonia, and the liquefier R2 is a water solution of a sulfydryl reducing agent. The invention also provides application of the above mycobacterium tuberculosis sputum specimen liquefier kit, and the kit can be applied to acid-fast staining microscopic examination of mycobacterium tuberculosis and liquefaction of sputum specimen before isolated culture. Compared with the prior art, the technical scheme provided by the invention has the following advantages: the kit helps to improve smear quality, increases positive detection rate and reading efficiency, optimizes the existing pretreatment technology for sputum specimens, satisfies requirements of multiple detection samples, and is in favor of staining microscopic examination of the sputum specimen smear and automation operation of isolated culture and inoculation.

Owner:SHANGHAI WEIYIN BIOTECH CO LTD

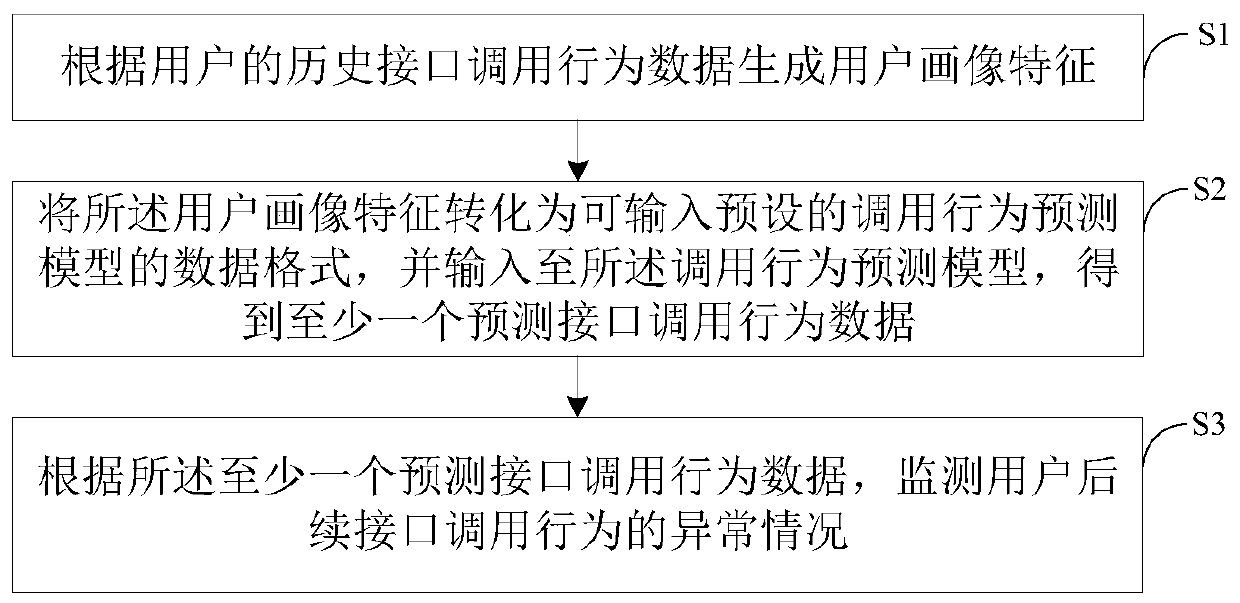

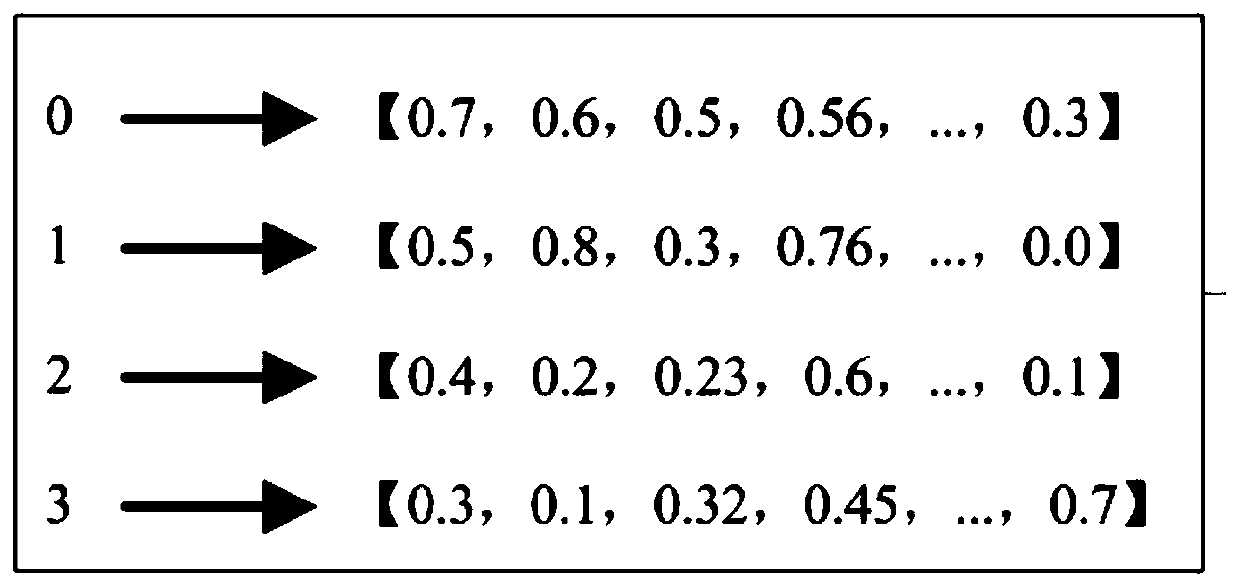

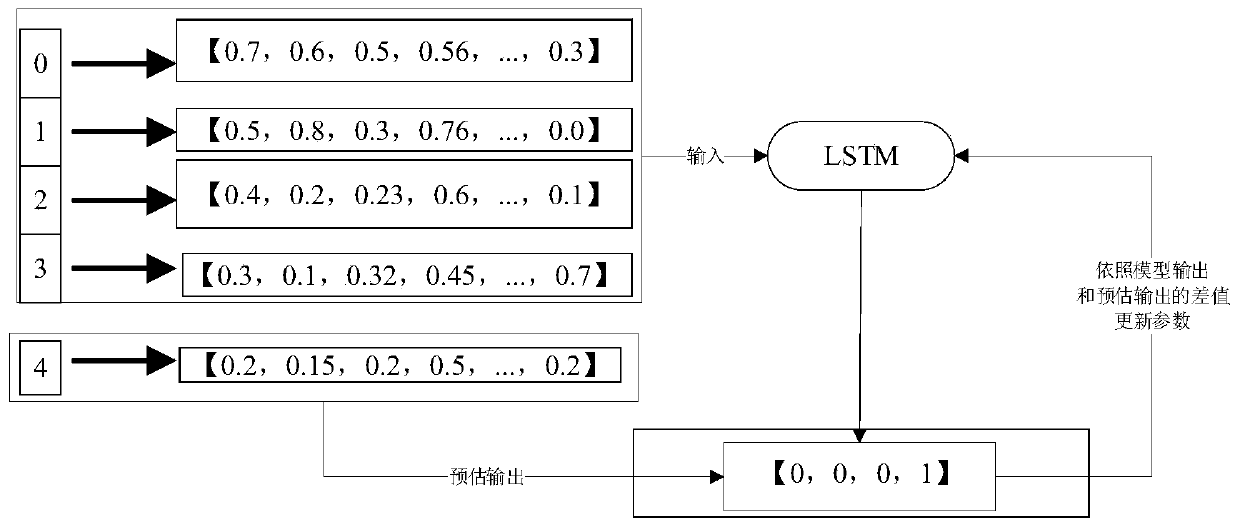

Interface abnormal call monitoring method and device

ActiveCN110489307AReduce the probability of detectionLower detection rateForecastingHardware monitoringCluster algorithmNetwork model

An interface abnormal call monitoring method and device solve the problems that an existing method based on a blacklist, rules and machine learning is low in detection rate and high in false detectionrate, and new abnormal behaviors cannot be found in time. The characteristics of the clustering algorithm are obtained by using the user portrait technology, and the users are divided into a plurality of user subclasses with comparability, so that the detection rate of abnormal interface calling is higher, and the false detection rate is lower. Learning a behavior mode of each user subclass by using a neural network model; according to the method, the envelope of the normal behavior mode is obtained, the trained neural network is used for predicting the subsequent normal API interface callingbehavior of the client, and the predicted behavior is compared with the actual API interface calling behavior of the client, so that the new abnormal behavior can be found in time.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

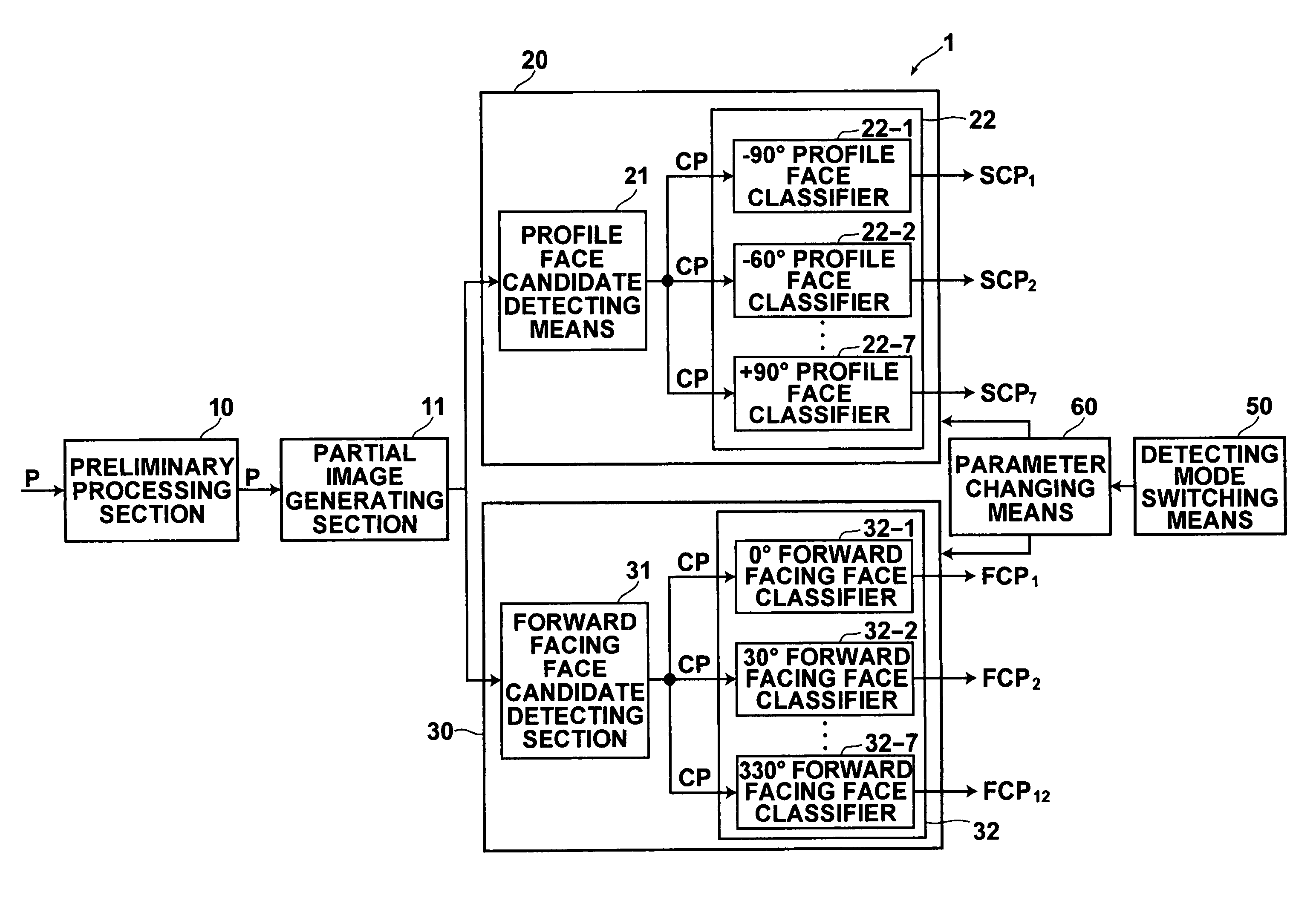

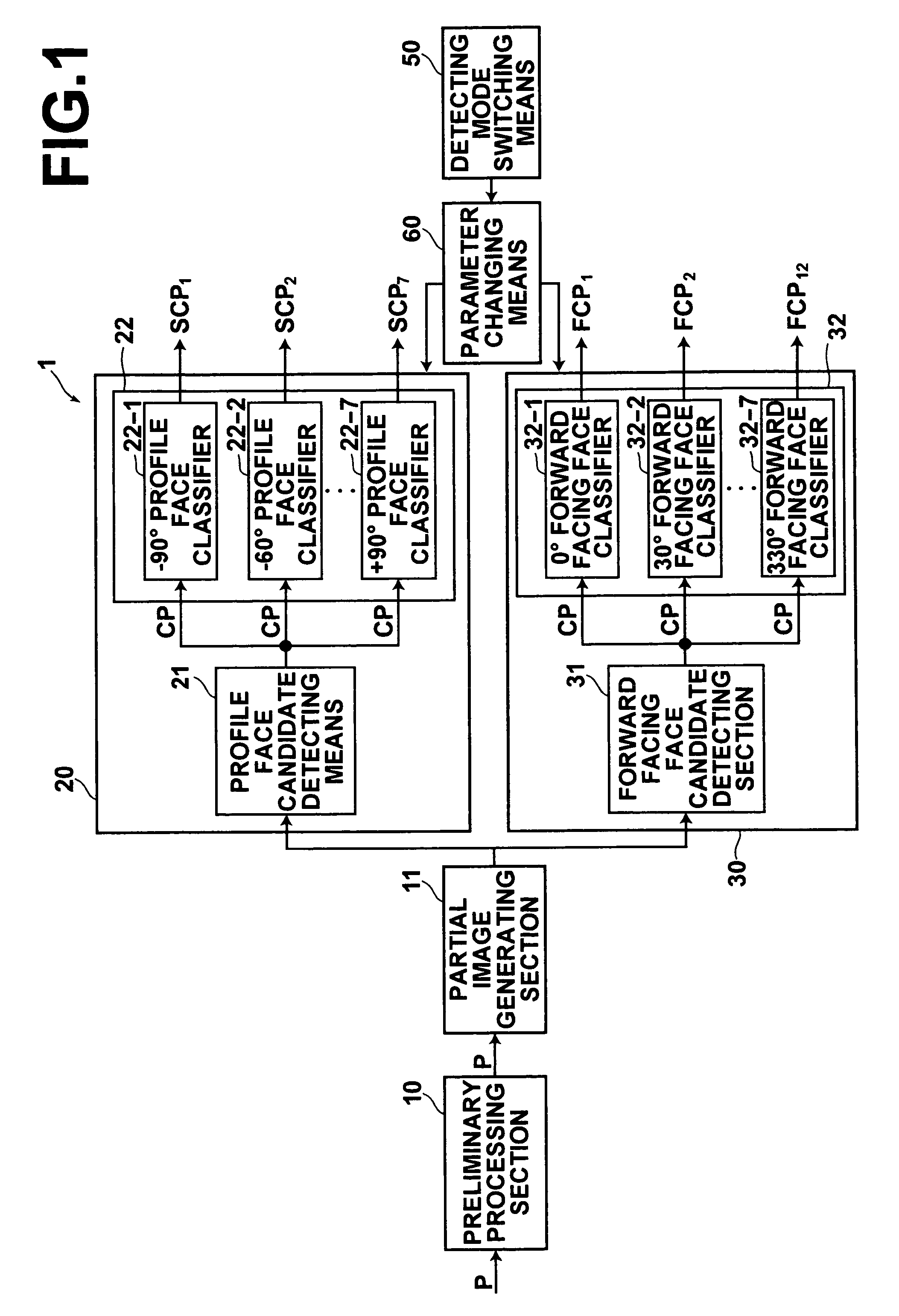

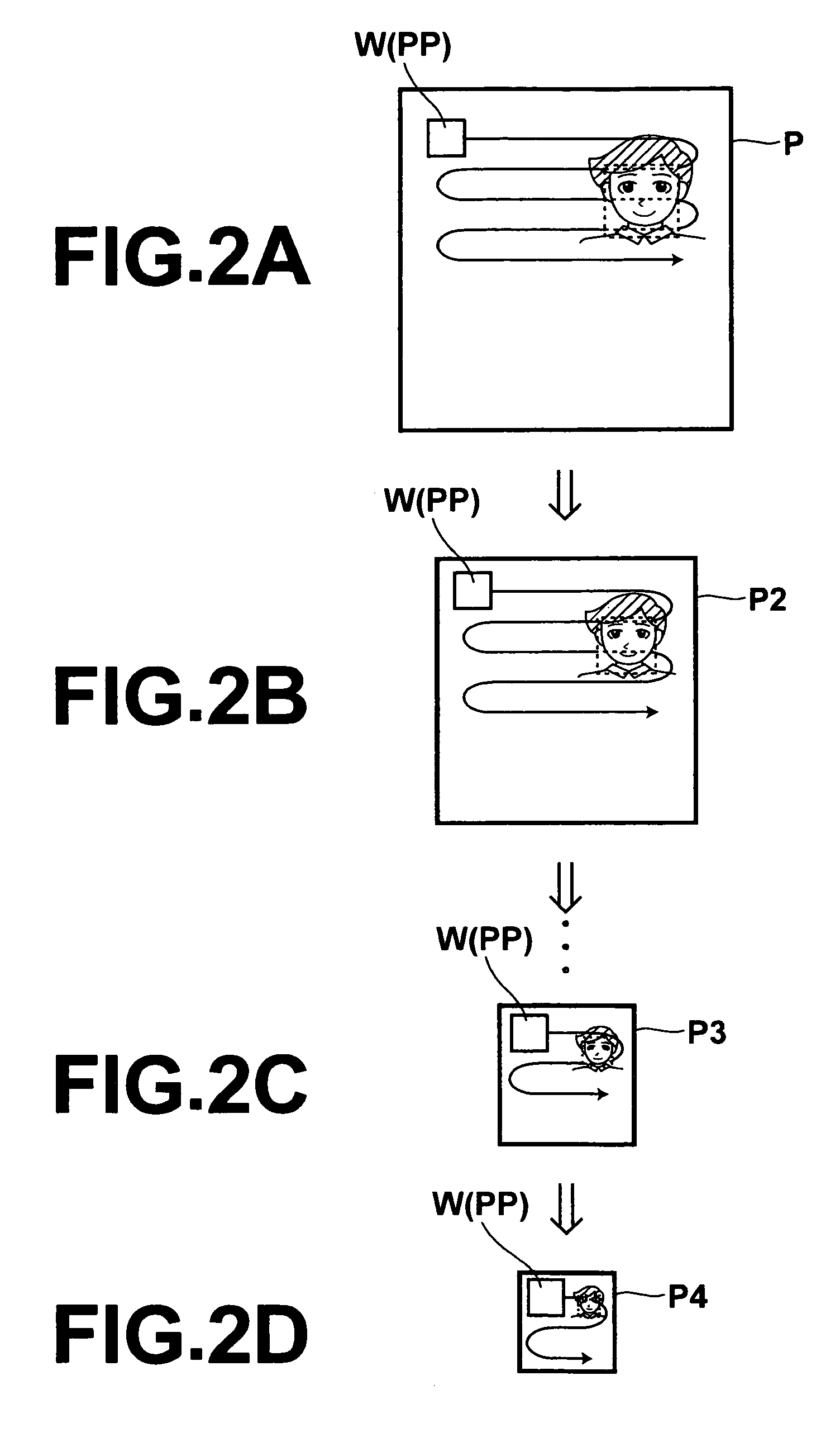

Apparatus and program for detecting faces

ActiveUS7742627B2Improve the detection rateLower detection rateCharacter and pattern recognitionPattern recognitionFace detection

Usability of a face detecting apparatus is improved, by enabling selection of a detecting mode optimal for an intended purpose, when detecting facial images from within images. During detection of images of forward facing faces, switching of the detecting mode to one of: a detection rate mode; a false positive detection rate mode; and a processing speed mode is enabled. Face detection focused on optimizing detection performance for each detecting mode is performed.

Owner:FUJIFILM CORP +1

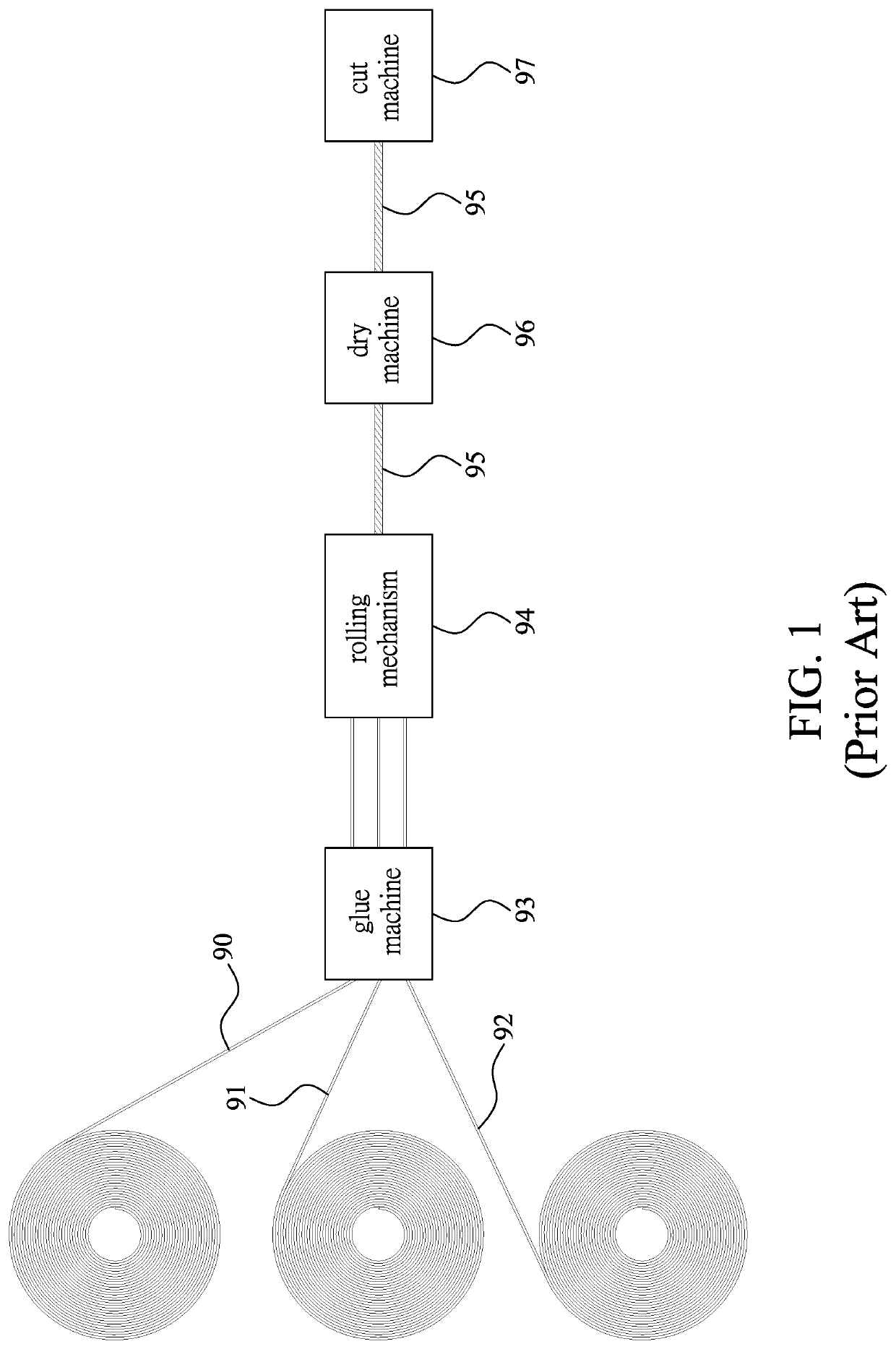

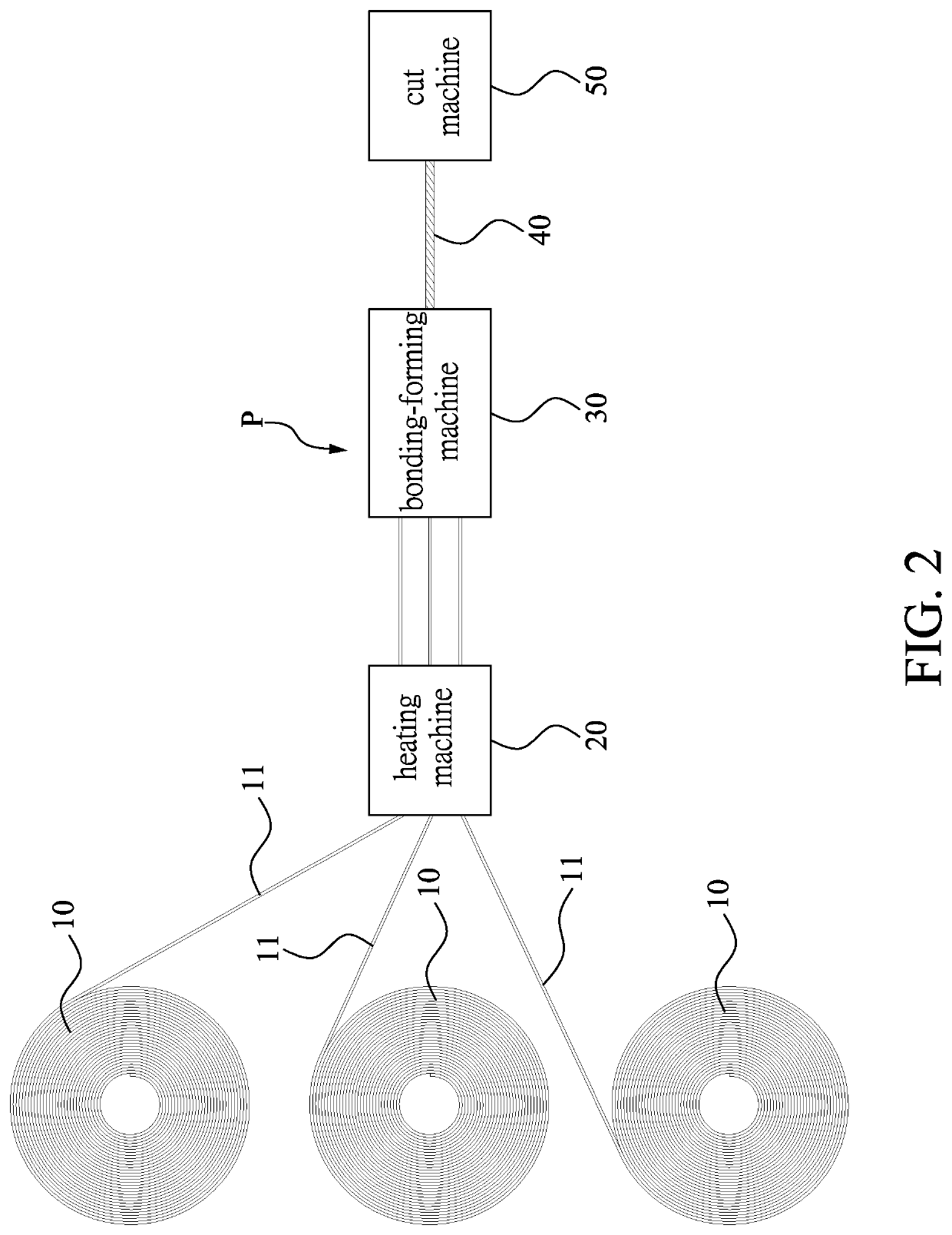

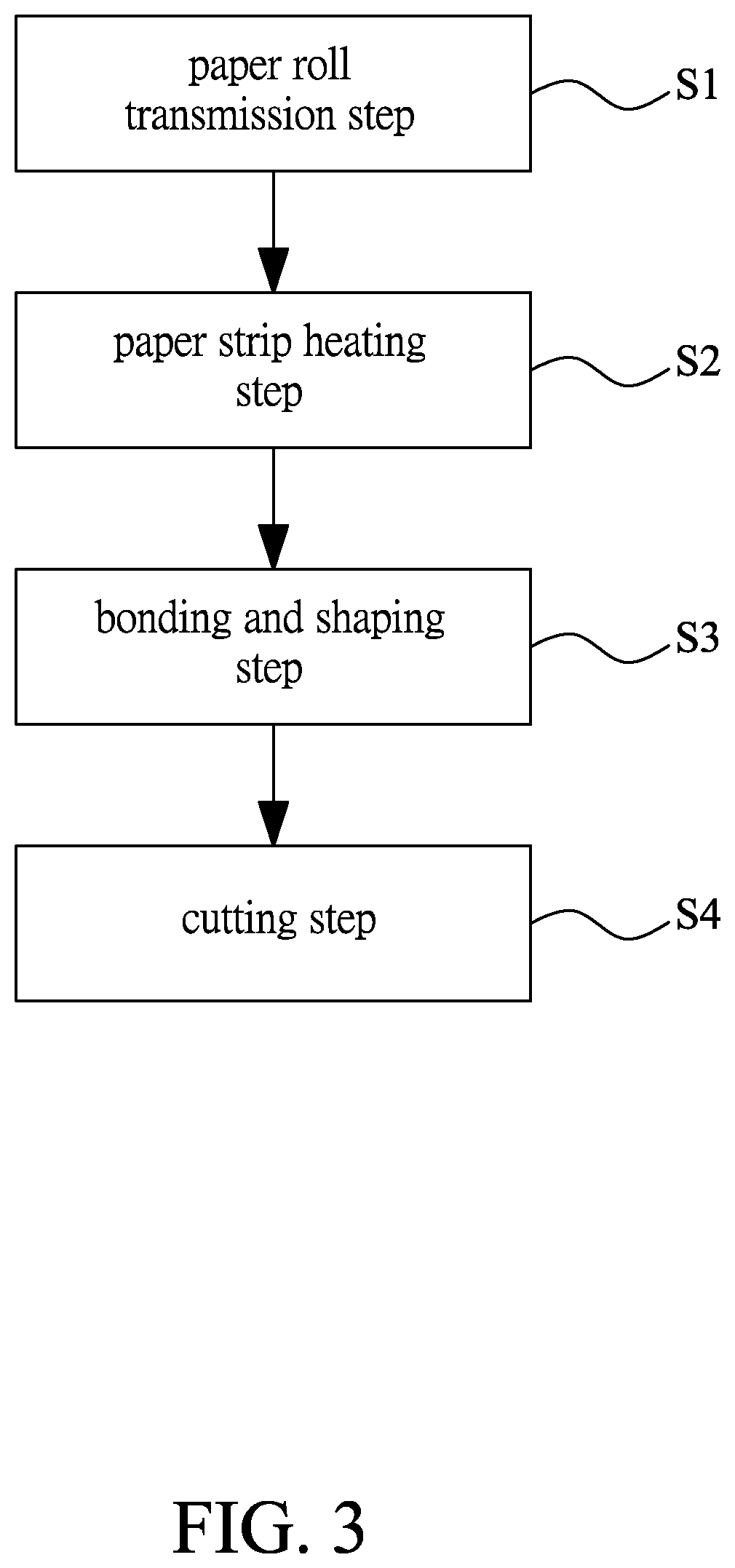

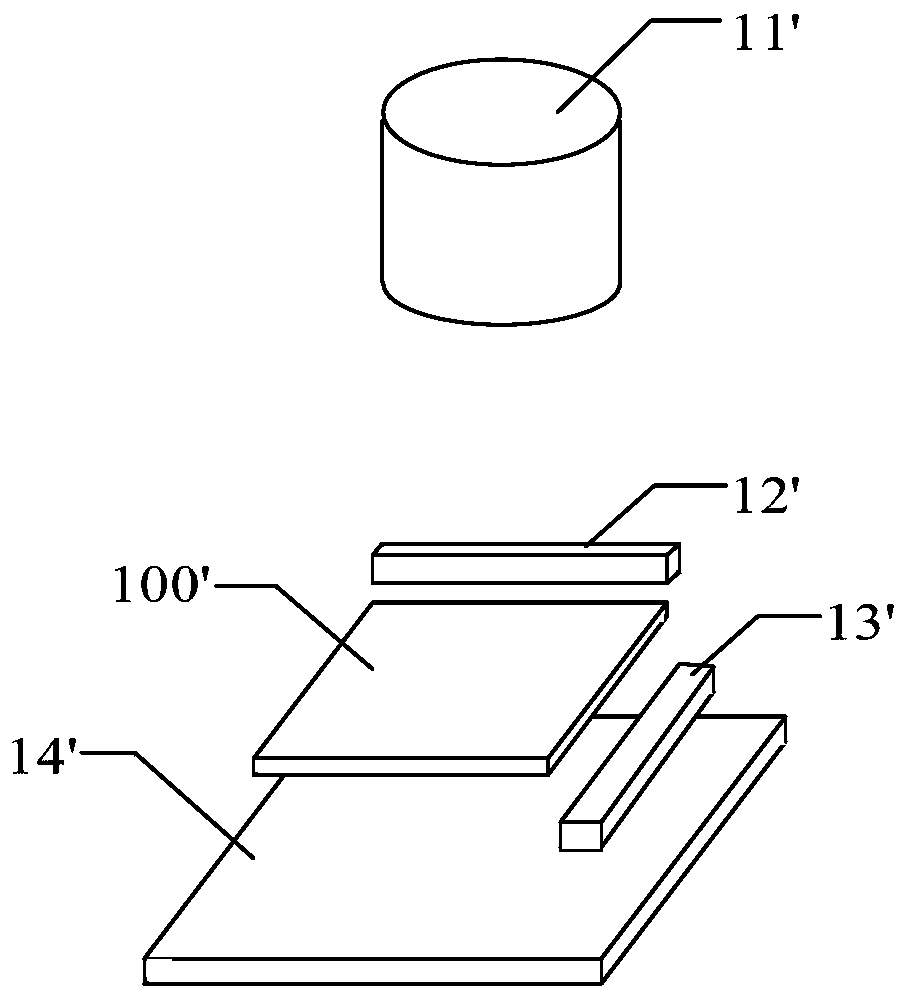

Method for manufacturing paper straw

ActiveUS20210060890A1High viscosityImprove efficiencyMechanical working/deformationPaper/cardboard articlesWet bondingAdhesive glue

The present invention relates to a method for manufacturing a paper straw, the method comprising: a paper roll transmission step, a paper strip heating step, a bonding and shaping step and a cutting step. Wherein, a plurality of raw paper rolls face a connection position jointly to transmit a raw paper strip, the raw paper strip includes a paper material and a dry hot-melt adhesive. The dry hot-melt adhesive of the raw paper rolls is heated for changing into flow hot-melt adhesive. Then the raw paper rolls is transmitted to the connection position for rolling jointly, and the flow hot-melt adhesives are bounded on another raw paper strip to form a pipe. Finally, the pipe is cut to form at least one paper straw after the pipe exceeds a setting length. The present invention uses dry adhesive to manufacture paper straw, without the excessive glue problem and mold phenomenon of the traditional wet bonding method as well as without an extra dry fixing step of traditional manufacture process, so the productivity will be raised significantly, and the defect rate will be reduced.

Owner:HOU JING SHENG JINGHUA CO LTD

Optical detection method and device for display panel

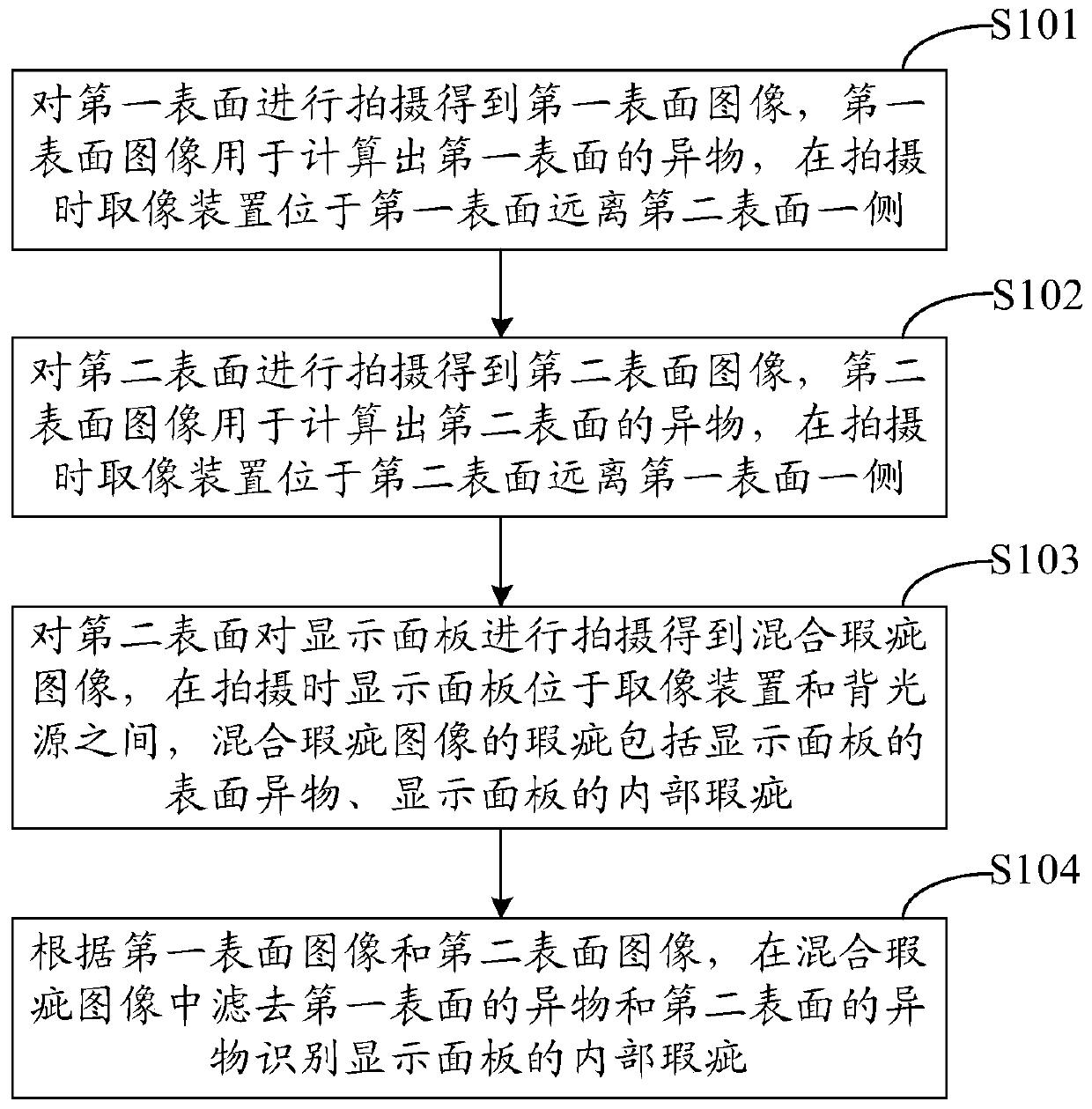

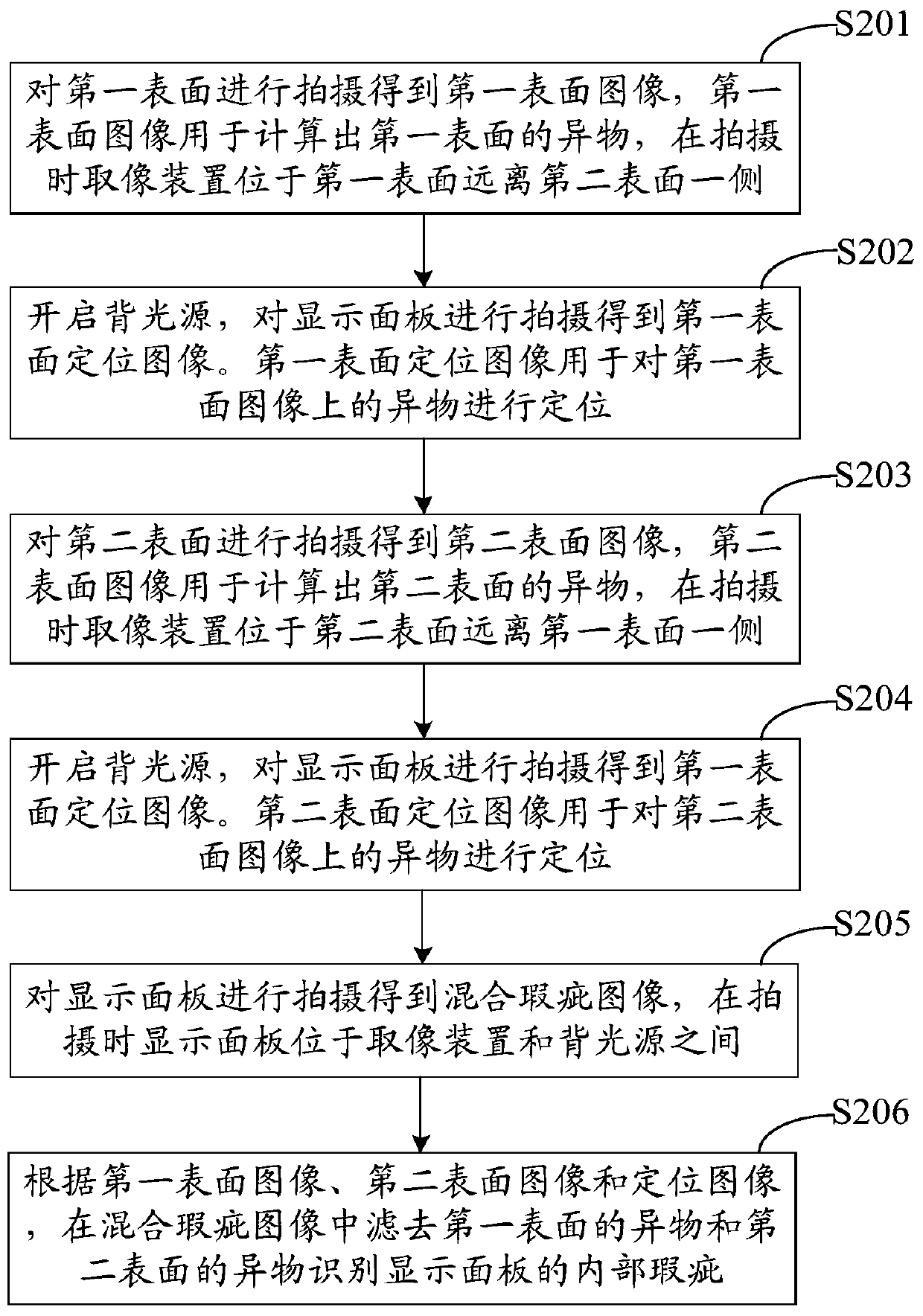

InactiveCN110286132AImprove the detection rateLower detection rateOptically investigating flaws/contaminationForeign matterComputer science

The invention discloses an optical detection method and device of a display panel. The display panel comprises a first surface and a second surface, and the first surface and the second surface are oppositely arranged, and the optical detection method comprises the following steps of shooting the first surface to obtain a first surface image, wherein an image capturing device is positioned on one side of the first surface far away from the second surface during shooting; shooting the second surface to obtain a second surface image, wherein the image capturing device is positioned on one side of the second surface far away from the first surface during shooting; shooting the display panel to obtain a mixed flaw image, wherein the display panel is positioned between the image capturing device and a backlight source during shooting, and the flaws of the mixed flaw image comprise surface foreign matters of the display panel and internal flaws of the display panel; and filtering the foreign matters on the first surface and the foreign matters on the second surface in the mixed flaw image to identify the internal flaws of the display panel according to the first surface image and the second surface image. The optical detection method and device of the display panel can improve the detection rate of the display panel and reduce the over-judgment rate.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

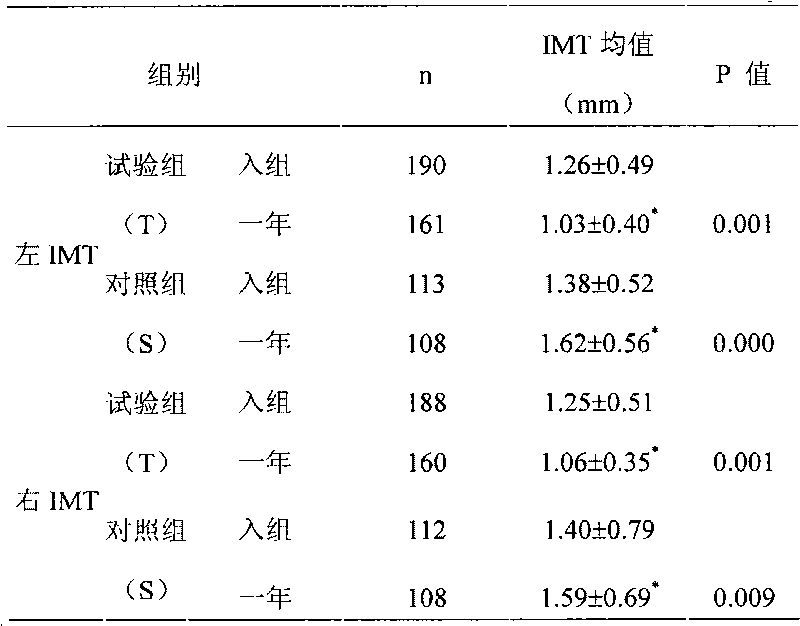

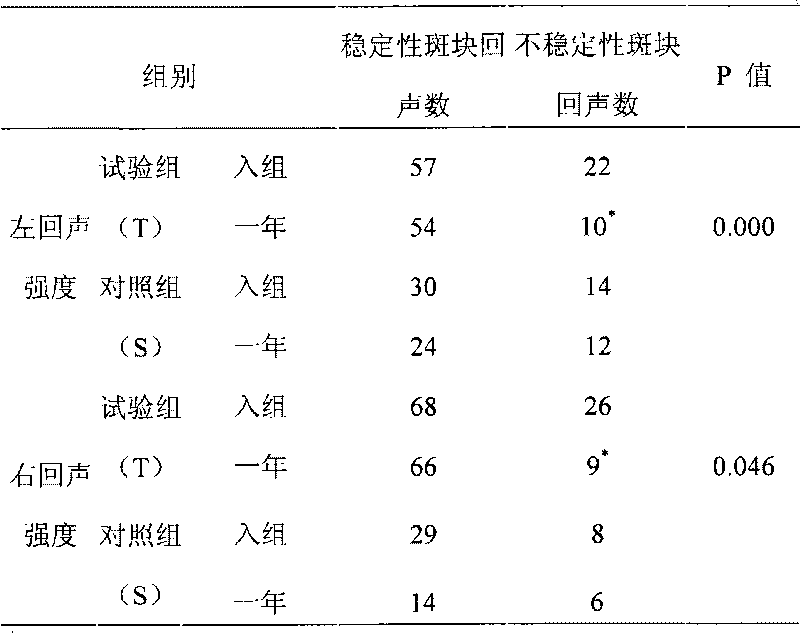

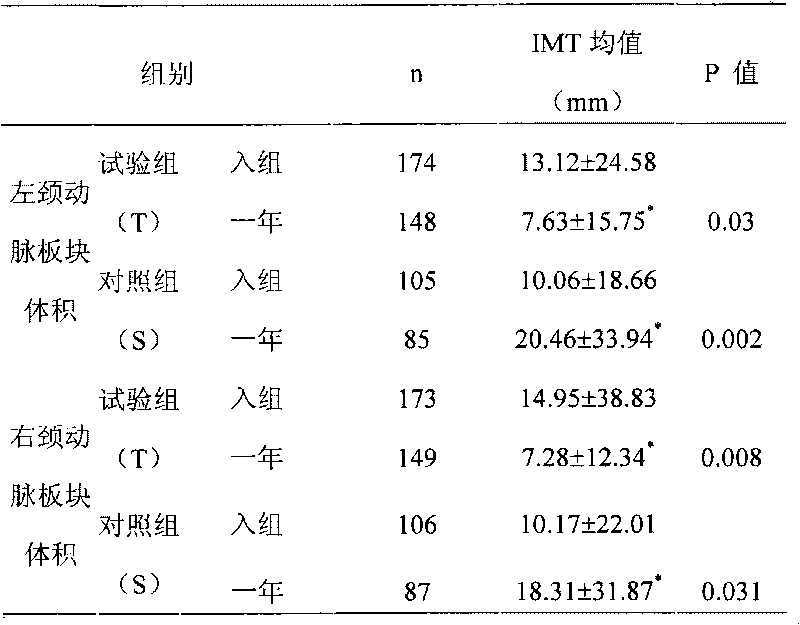

Application of lumbrukinase in treating carotid atherosclerosis

ActiveCN101717761ALower detection rateReduce in quantityPeptide/protein ingredientsHydrolasesCarotid atherosclerosisActive component

The invention provides lumbrukinase and application thereof for preparing a medicament treating carotid atherosclerosis and a medicament containing the lumbrukinase as an active component.

Owner:BEIJING BAIAO PHARMA

Method for detecting multi-drug resistance of Mycobacterium tuberculosis

InactiveCN102559916BVerify reliabilityExperiment operation is simpleMicrobiological testing/measurementMicroorganism based processesSingle-strand conformation polymorphismIsoniazid resistance

The invention relates to a method for detecting multi-drug resistance of Mycobacterium tuberculosis, which aims at detecting the resistance of the Mycobacterium tuberculosis to isoniazid and rifampicin at the same time and has the characteristics of high specificity and sensitivity, quickness in detection, and easiness and convenience in operation. The technical scheme is as follows: the method comprises the following steps: A, establishing PCR (polymerase chain reaction) templates of an MTB clinical strain and a standard strain H37Rv; B, designing three pairs of primers of katG, inhA and rpoB gene fragments which are closely related to the isoniazid resistance and the rifampin resistance, performing mPCR amplification on katG, inhA and rpoB genes of the clinical strain, and performing PCR amplification on katG, inhA and rpoB genes of the clinical strain and the standard strain H37Rv; and C, detecting the mutation conditions of related INH-resistant and RFP-resistant 3 genes of the clinical strain at the same time by a single-strand conformation polymorphism detection method.

Owner:孙爱华 +2

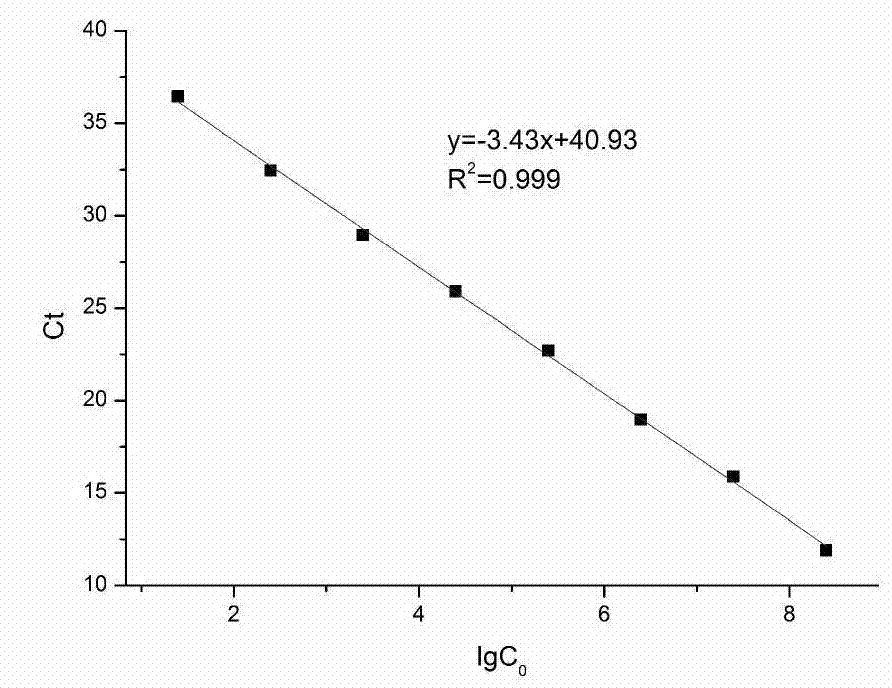

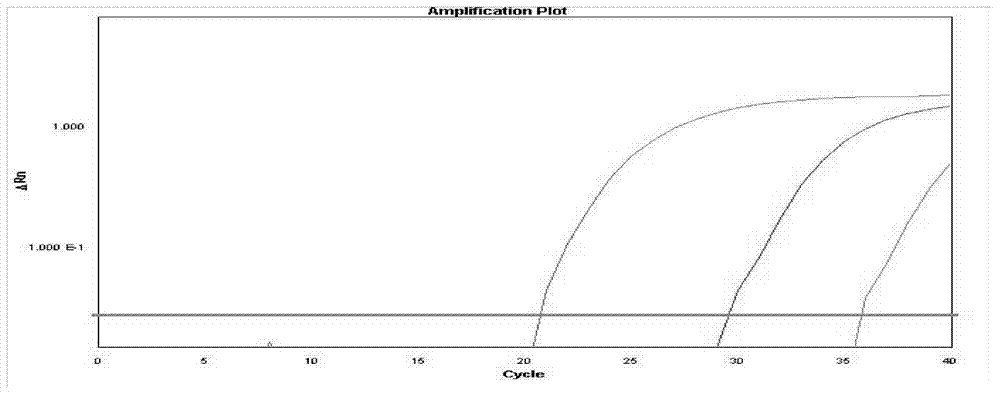

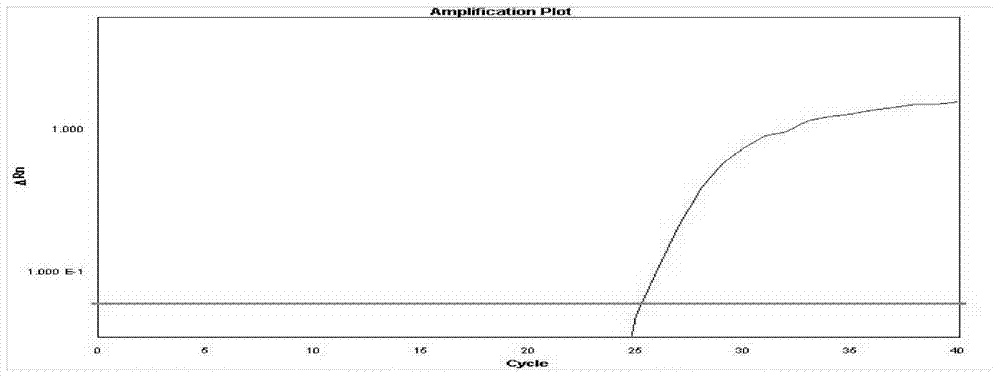

Plasmodium falci parum nano magnetic separation real-time fluorescence quantitative PCR (polymerase chain reaction) detection kit and nucleotide sequence

InactiveCN103937907AEasy to operateReduce missed detection rateMicrobiological testing/measurementAgainst vector-borne diseasesFluorescenceNucleotide

The invention relates to a plasmodium falci parum nano magnetic separation real-time fluorescence quantitative PCR (polymerase chain reaction) detection kit and a nucleotide sequence. The invention designs plasmodium falci parum-specific primers and probes, and optimizes the real-time fluorescence PCR detection system. A pair of primers for plasmodium falci parum are combined with a common PCR technique and a molecular cloning technique to construct a plasmodium falci parum plasmid standard substance, establish a standard curve about the relationship between the target gene copy number and fluoroscopic examination signals and implement real-time fluorescence quantitative detection of plasmodium falci parum. By organically combining the technique of separating plasmodium nucleic acid by nano magnetic particles with the real-time fluorescence quantitative PCR technique, the kit is convenient to operate and is cheap, quick and efficient in the aspect of specimen nucleic acid extraction, has great advantages in the aspects of filter paper dried blood spot nucleic acid extraction and trace whole blood nucleic acid extraction, and achieves the goals of widening the detection range and maximally lowering the omission factor. The detection limit of the kit is 25 copies / mu L.

Owner:PEOPLES REPUBLIC OF CHINA BEIJING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Method for expelling wood citrus lice by ultrasonic waves

The invention discloses a method for expelling wood citrus lice by ultrasonic waves, and relates to the technical field of ultrasonic application. According to the method, ultrasound equipment is arranged in a grid in a citrus orchard, and then the ultrasound equipment is automatically opened in sequence from inside to outside in the citrus orchard to carry out ultrasonic emission, with the ultrasonic frequency of each ultrasound equipment being 20kHz-10MHz, the power being 1-5kW, the single ultrasonic emission time being 1-10min, and the intermittent time being 1-15min; and ultrasonic waves are adopted to block citrus wood lice and repeat ultrasonic emission, so that the effect of long-term expelling of citrus wood lice is realized. The method has an obvious effect of expelling citrus wood lice, can reduce the detection rate of citrus wood lice in orchards by more than 90%, greatly limits the ability of wood lice to spread citrus yellow dragon disease, can effectively prevent the spread and spread of yellow dragon disease, and does not need to use chemical agents, so that the method is an ecological, environment-friendly and efficient method for expelling wood lice.

Owner:GUANGXI ACAD OF SCI +2

X-ray diffraction device, object imaging system, and method for operating a security system

ActiveUS7813477B2Improve the detection rateLower detection rateHandling using diaphragms/collimetersMaterial analysis using radiation diffractionSoft x rayX-ray

Owner:MORPHO DETECTION INC

Early-strength quick-drying refractory mud filling material with good insulativity

The invention discloses an early-strength quick-drying refractory mud filling material with a good insulativity. The filling material is prepared through the following steps: adding water in 100 parts of main raw material and 1-10 parts of composite additives, mixing, ageing mixture or fermenting, grouting, naturally drying and baking, wherein the main raw material is a mixture of sintered mullite, quartz sand powder, alumina micropowder and pure calcium aluminate cement; and the composite additives are lignosulfonate, sodium carboxymethylcellulose and one substance or a mixture of two substances selected from subnano alumina micropowder with a grain size of 0.25-0.50 mu m, silicon micropowder with a grain size of 1-2 mu m, sodium tripolyphosphate, sodium hexametaphosphate and sodium polyphosphate. The filling material has good properties such as good early strength, rapid consolidation speed, no moisture regain and good insulativity, dose not corrode metals, can be widely applied to a metallurgy smelting high temperature sensor and a rapid temperature-measuring element to be used as an insulation material.

Owner:马鞍山江润冶金有限责任公司

A lubricant for root canal treatment

ActiveCN105213200BFavorable conditions for healingReduce reserve resistanceImpression capsDentistry preparationsGlycerolClinical trial

The invention discloses a lubricant for root canal treatment, which comprises sodium edetate, citric acid, carbamide peroxide, cetyltrimethylammonium bromide, sodium carboxymethylcellulose, glycerin and water. The lubricant of the present invention can soften the root canal wall, reduce preparation resistance, and is especially suitable for the preparation of large-tapered nickel-titanium instruments. By comparing the use of root canal lubricant (experimental group) and no use of root canal lubricant (control group) two groups of experiments Similarly, the results of clinical trials show that the use of root canal lubricants in the root canal preparation process, the detection rate of bacteria in the root canal was significantly lower than that of the group without lubricants, indicating that the use of lubricants in the root canal preparation process helps to eliminate the bacteria in the root canal. Bacteria, creating conditions conducive to the healing of clinical chronic apical periodontitis.

Owner:陕西恒远生物科技有限公司

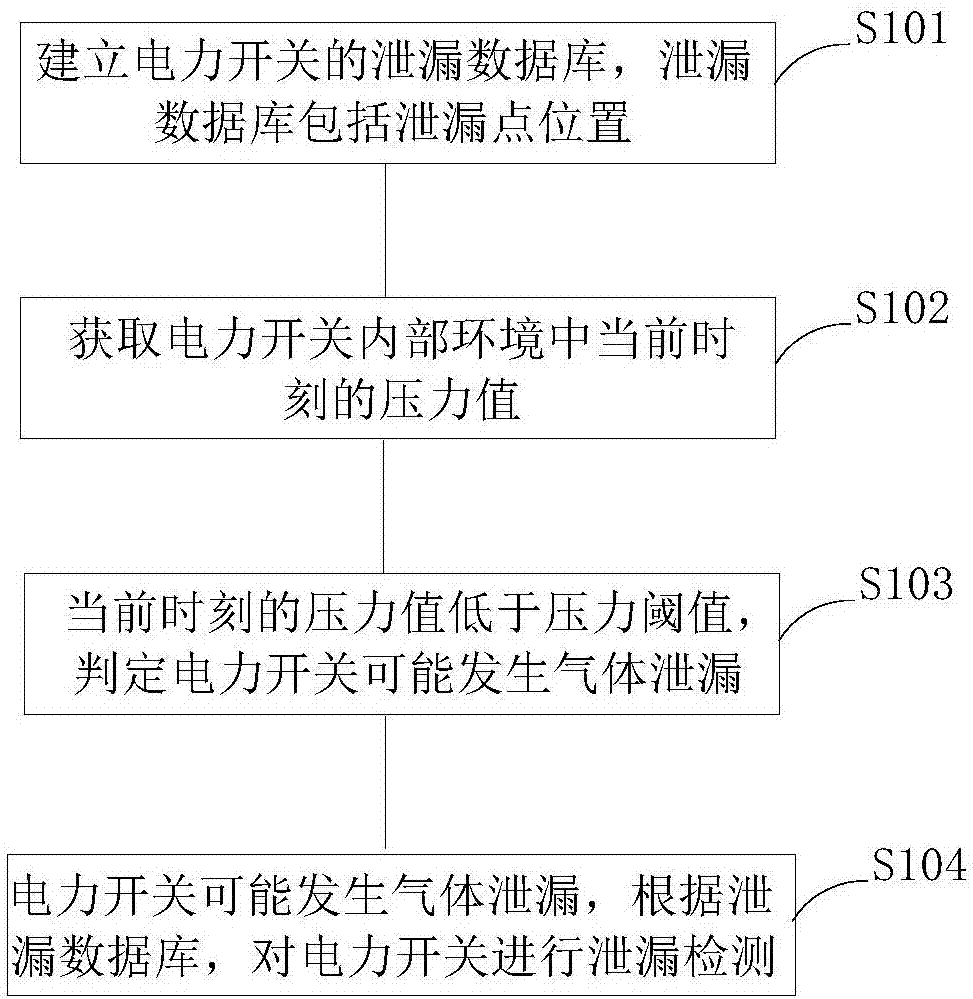

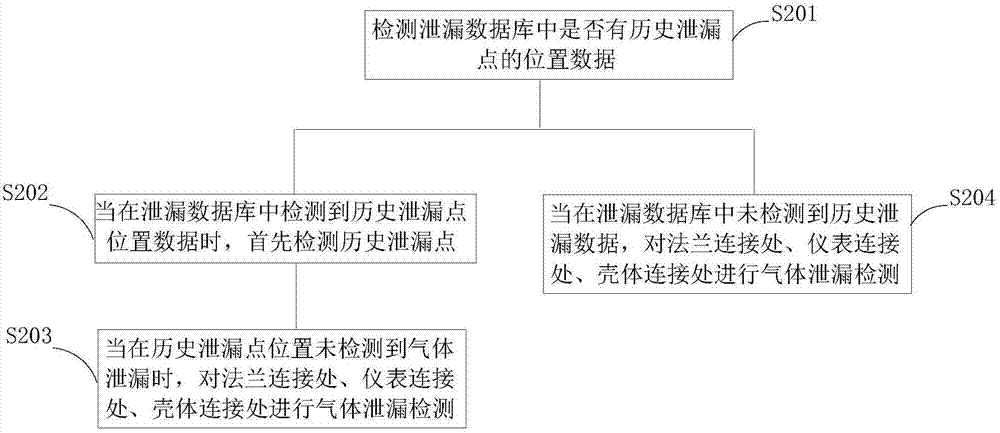

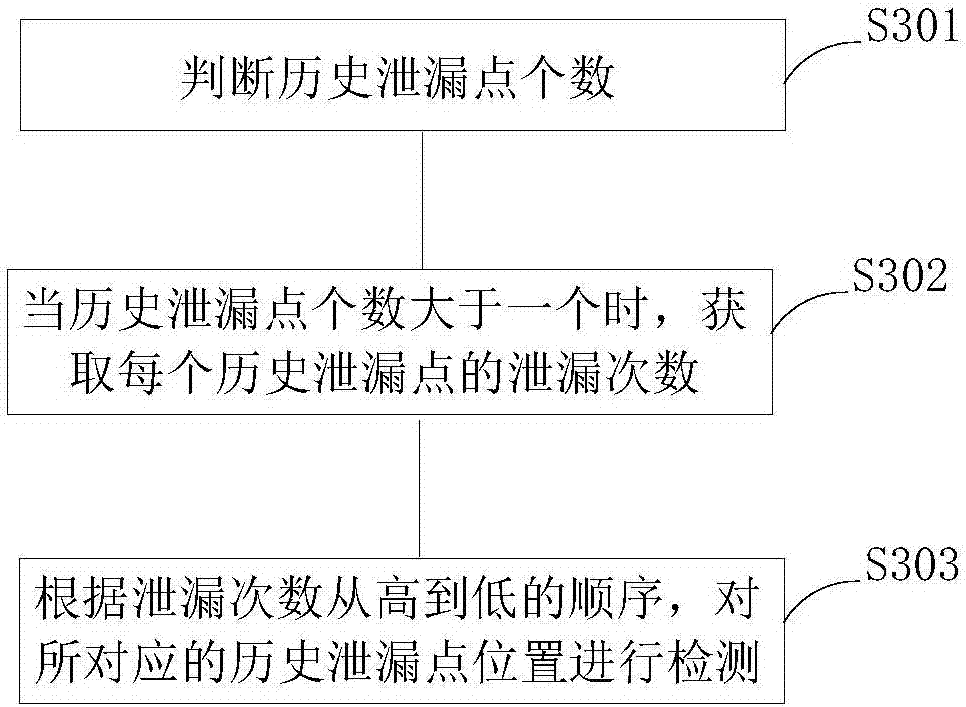

Power switch gas leakage detection method and system

InactiveCN107576456AReduce checkout timeLower detection rateMeasurement of fluid loss/gain rateFluid-tightness measurement using lightEngineeringPressure threshold

The invention provides a power switch gas leakage detection method and system. The method includes the steps: building a leakage database of a power switch; acquiring a pressure valve of the current moment in the internal environment of the power switch, and judging that the power switch possibly has gas leakage when the pressure valve of the current moment is lower than a pressure threshold value; performing leakage detection on the power switch according to the leakage database when the power switch possibly has gas leakage. The leakage database comprises history leakage point positions. Relative to the prior art, when leakage is detected by the aid of infrared imaging technology, detection is blindly disordered. According to the power switch gas leakage detection method and system, compared with a historical database, leakage detection orders in power switch gas leakage detection are optimized, leakage point detection time is shortened, and leakage detection efficiency is improved.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com