Technology for lossless drilling rod detection

A non-destructive testing and drill pipe technology, which is applied to measuring devices, using wave/particle radiation for material analysis, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of high cost of radiographic testing, shorten the detection time, and work The effect of long cycle and reduced testing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

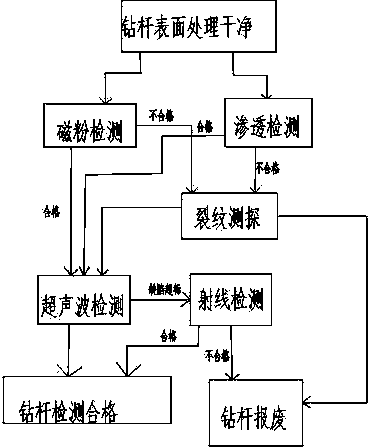

[0021] like figure 1 As shown, the present invention includes a technique for non-destructive testing of drill pipes, which is characterized in that, comprising the steps of:

[0022] A. Clean the surface of the drill pipe to be tested;

[0023] B. Carry out magnetic particle testing or penetrant testing on the surface and near surface of the drill pipe;

[0024] C, the qualified drill pipe that does not have crackle by step B detection enters ultrasonic detection, detects that crackle is carried out by step B detection and detects;

[0025] D. Through the crack detection in step C, the drill pipe with a crack depth of less than 10% is allowed to be polished and subjected to ultrasonic testing, and the drill pipe with a crack depth of more than 10% is discarded;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com