Power switch gas leakage detection method and system

A technology of gas leakage detection and gas detection system, which is applied in the direction of using liquid/vacuum degree to measure liquid tightness, measuring the rate of increase and deceleration of fluid, and testing fluid tightness by using light, etc. Time-consuming detection, equipment burnout and other problems, to achieve the effect of shortening the detection time, optimizing the sequence of leak detection, and improving the efficiency of leak detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

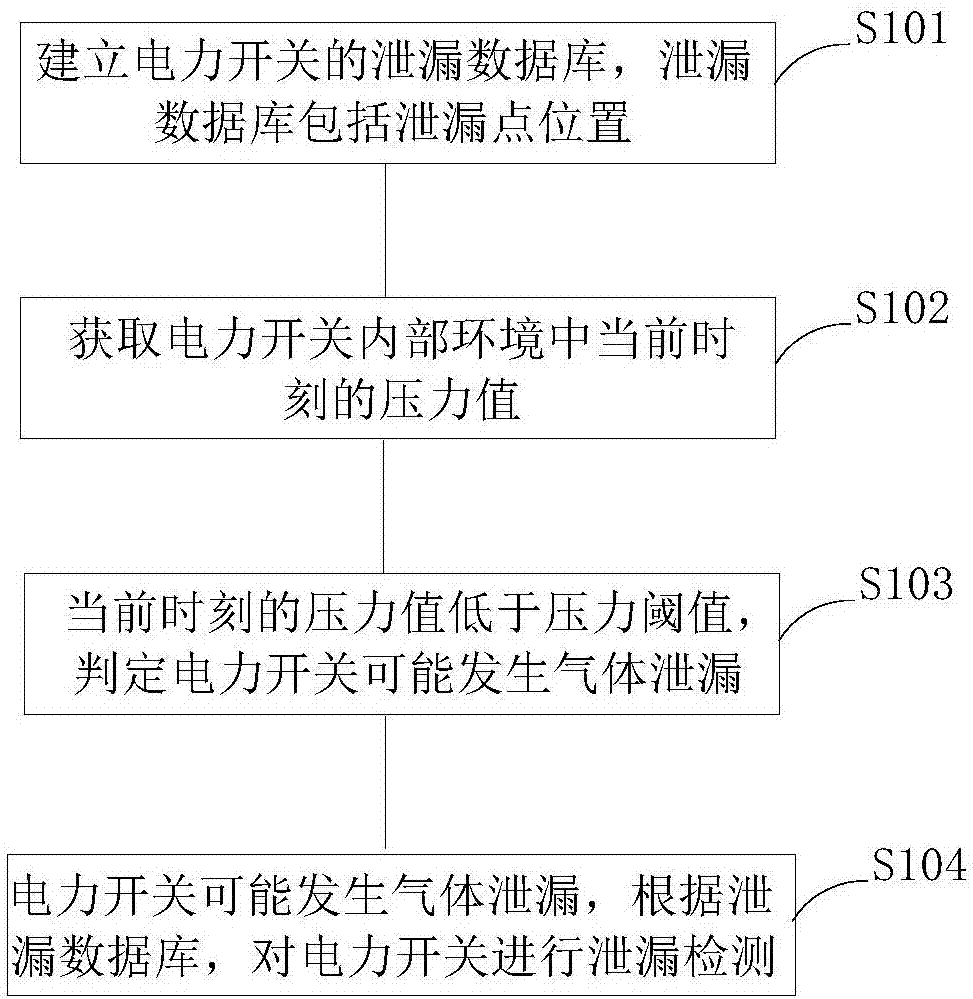

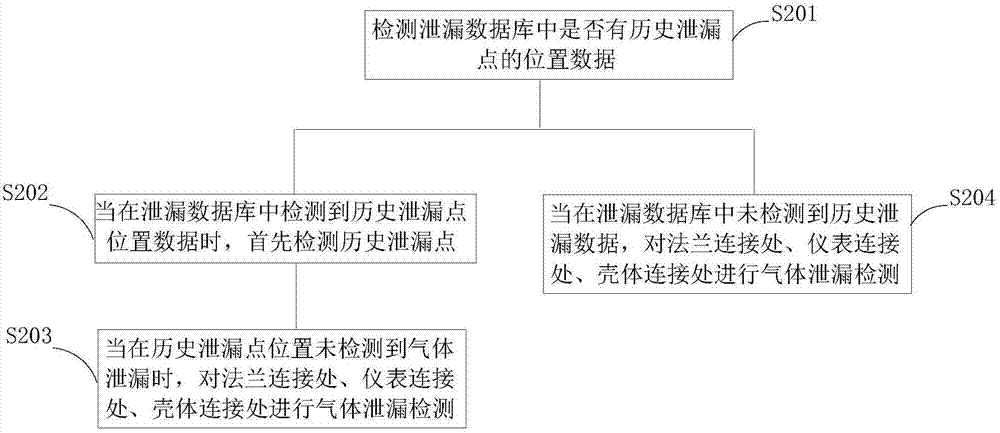

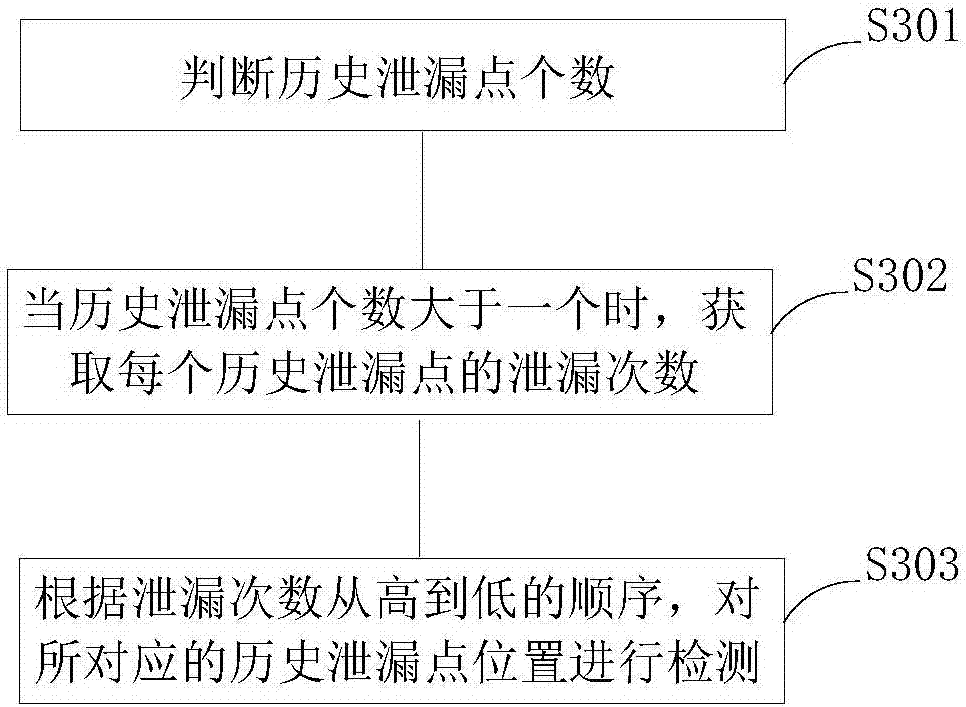

[0046] figure 1 It is a flow chart of a method for detecting gas leakage of a power switch provided in the embodiment of the present application. see figure 1 , the method includes the following steps:

[0047] S101: Establish a leakage database of the power switch, where the leakage database includes historical leakage point locations.

[0048] The leakage database is an information database of historical leakage points. When used for the first time, the information in the leakage database can be established through manual input, and then the leakage database can be established through automatic saving during use.

[0049] S102: Obtain the pressure value at the current moment in the internal environment of the power switch.

[0050] The gas volume inside the power switch is directly related to the pressure value of the power switch. If the power switch gas leaks, the gas pressure inside the power switch will decrease with the reduction of the gas volume. In a possible imp...

Embodiment 2

[0086] Please refer to the attached Figure 5 , which shows a schematic diagram of a power switch gas leakage detection system provided in this embodiment.

[0087] An embodiment of the present application provides a power switch gas leakage detection system, including:

[0088] The database establishment unit 1 is used to establish a leakage database of the power switch, and the database includes historical leakage point locations.

[0089] The pressure value acquisition unit 2 is used to acquire the current moment pressure value in the internal environment of the power switch, and the pressure value acquisition unit 2 includes a pressure sensor.

[0090] The pressure value judging unit 3 is configured to judge that gas leakage may occur in the power switch when the pressure value at the current moment is lower than the pressure threshold.

[0091] The gas leakage detection device 4 is used for performing leakage detection on the power switch according to the leakage databa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com