Early-strength quick-drying refractory mud filling material with good insulativity

A refractory mud and insulating technology, applied in the field of refractory mud filler, can solve the problems of reducing the insulation resistance of thermocouples, high dosage of magnesium phosphate solution, corrosion of metal welding points, etc. Effect of Insulation Resistance Lowering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

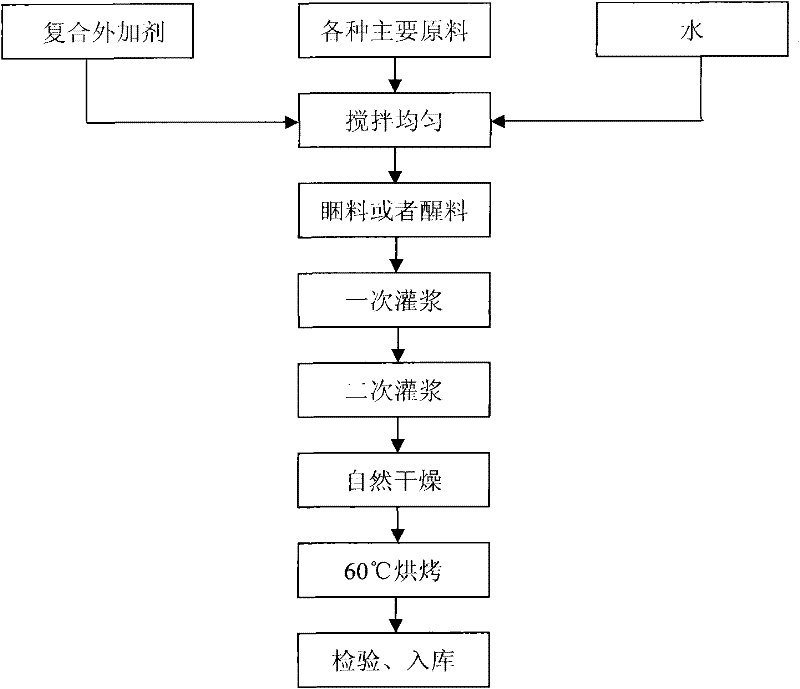

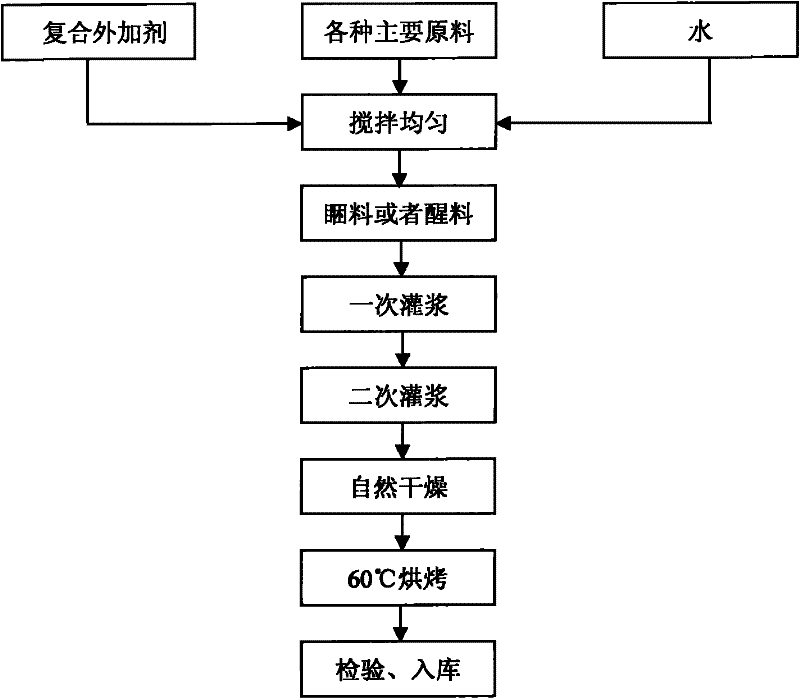

Method used

Image

Examples

Embodiment 1

[0068] 20 parts of mullite with a particle size of ≤76 μm, 5 parts of alumina micropowder with a particle size of 2 to 5 μm, 20 parts of quartz sand with a particle size of ≤76 μm, Al 2 o 3≥75% pure calcium aluminate cement 55 parts, compound admixture 1.6 parts. Among them, composite admixtures: 1 part of subnano alumina micropowder with a particle size of 0.25-0.50 μm, 0.1 part of sodium tripolyphosphate, 0.2 part of lignosulfonate, and 0.3 part of sodium carboxymethyl cellulose. Stir the dry powder in a mud mixer for 2 minutes, add water and stir for 3 minutes, and place it for 30 minutes before grouting. The semi-finished product is naturally cured for 24 hours and baked at 60°C for 48 hours to complete.

Embodiment 2

[0070] 5 parts of alumina fine powder with a particle size of 2-5 μm, 40 parts of quartz sand with a particle size of ≤76 μm, Al 2 o 3 ≥75% pure calcium aluminate cement 55 parts, compound admixture 1.6 parts. Among them, composite admixtures: 1 part of subnano alumina micropowder with a particle size of 0.25-0.50 μm, 0.1 part of sodium tripolyphosphate, 0.2 part of lignosulfonate, and 0.3 part of sodium carboxymethyl cellulose. Stir the dry powder in a mud mixer for 2 minutes, add water and stir for 3 minutes, and place it for 30 minutes before grouting. The semi-finished product is naturally cured for 24 hours and baked at 60°C for 48 hours to complete.

Embodiment 3

[0072] 40 parts of mullite with a particle size of ≤76 μm, 5 parts of alumina micropowder with a particle size of 2 to 5 μm, Al 2 o 3 ≥75% pure calcium aluminate cement 55 parts, compound admixture 1.7 parts. Among them, composite admixtures: 1 part of subnano alumina micropowder with a particle size of 0.25-0.50 μm, 0.1 part of sodium hexametaphosphate, 0.1 part of sodium tripolyphosphate, 0.2 part of lignosulfonate, and 0.3 part of sodium carboxymethylcellulose. Stir the dry powder in a mud mixer for 2 minutes, add water and stir for 3 minutes, and place it for 30 minutes before grouting. The semi-finished product is naturally cured for 24 hours and baked at 60°C for 48 hours to complete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com