Impermeable moisture-proof pre-stirring mortar and production method thereof

A ready-mixed mortar and uniform mixing technology, which is applied in the field of building materials, can solve the problems of unacceptable polymer mortar, insufficient hydrophilicity of polymer, and easy bleeding, etc., to save manpower, reduce noise and dust pollution on the construction site , The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

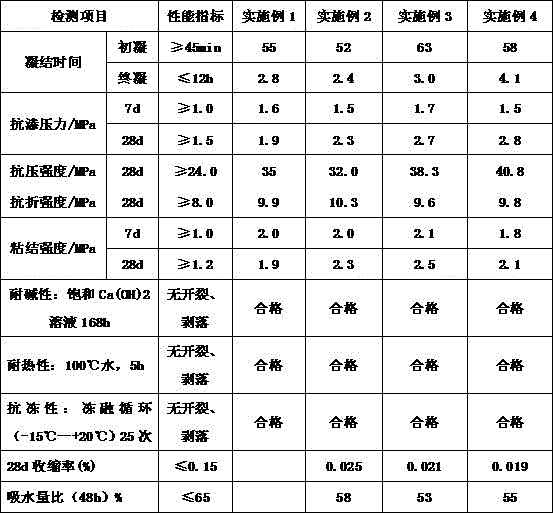

Examples

Embodiment 1

[0024] Combine 40 parts of aggregate, 40 parts of ultra-fine 52.5 Portland cement, 3 parts of highly active permeable crystallization masterbatch, 5 parts of nano calcium carbonate, 0.2 parts of water reducing agent, 0.5 parts of accelerator enhancer, and 1 part of redispersible latex powder. Parts, 0.1 part of cellulose ether, 0.02 part of defoamer, 0.2 part of polypropylene fiber, 0.1 part of zinc stearate, after weighing in proportions, the high activity permeating crystallization masterbatch, nano calcium carbonate, water reducing agent, coagulation accelerator Reinforcer, redispersible latex powder, cellulose ether, defoamer, polypropylene fiber and zinc stearate are put into the mixer for stirring and mixing, then superfine 52.5 Portland cement is added to the mixer for mixing, and finally Aggregate is added to the mixer, stirred and mixed, and then enters the finished product packaging tank, and the packaging is inspected to obtain the product.

Embodiment 2

[0026] Combine 50 parts of aggregate, 44 parts of ultra-fine 52.5 Portland cement, 4 parts of highly active permeable crystallization masterbatch, 10 parts of nano calcium carbonate, 0.4 parts of water reducing agent, 1 part of coagulation enhancer, and 2 parts of redispersible latex powder. Parts, 0.2 part of cellulose ether, 0.03 part of defoamer, 0.3 part of polypropylene fiber, and 0.15 part of zinc stearate. After weighing, the high-activity permeating crystal masterbatch, nano calcium carbonate, water reducing agent, and coagulation accelerator Reinforcer, redispersible latex powder, cellulose ether, defoamer, polypropylene fiber and zinc stearate are put into the mixer for stirring and mixing, then superfine 52.5 Portland cement is added to the mixer for mixing, and finally Aggregate is added to the mixer, stirred and mixed, and then enters the finished product packaging tank, and the packaging is inspected to obtain the product.

Embodiment 3

[0028] Combine 52 parts of aggregate, 48 parts of ultra-fine 52.5 Portland cement, 4.5 parts of highly active permeable crystallization masterbatch, 12 parts of nano calcium carbonate, 0.6 parts of water reducing agent, 1.5 parts of accelerator enhancer, and 2.5 parts of redispersible latex powder. Parts, 0.3 parts of cellulose ether, 0.04 parts of defoamer, 0.4 parts of polypropylene fiber, and 0.2 parts of zinc stearate. After weighing, the high-activity permeating crystal masterbatch, nano calcium carbonate, water reducing agent, and coagulation accelerator Reinforcer, redispersible latex powder, cellulose ether, defoamer, polypropylene fiber and zinc stearate are put into the mixer for stirring and mixing, then superfine 52.5 Portland cement is added to the mixer for mixing, and finally Aggregate is added to the mixer, stirred and mixed, and then enters the finished product packaging tank, and the packaging is inspected to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com