Environment-friendly masonry mortar and production method thereof

A masonry mortar, green and environmental protection technology, applied in the field of building materials, can solve the problems of high energy consumption of material reuse, shortage of natural river sand, and low output of river sand, etc., and achieves the effect of saving resources, low price and protecting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

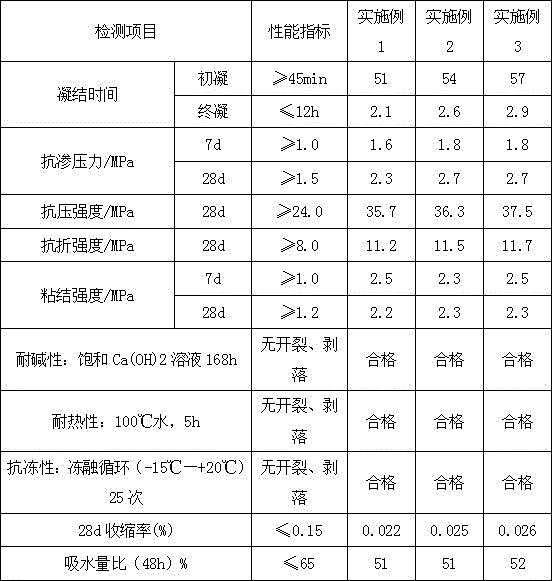

Embodiment 1

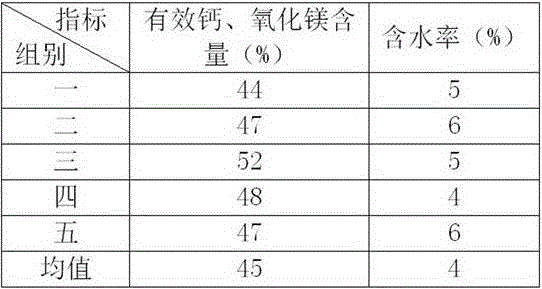

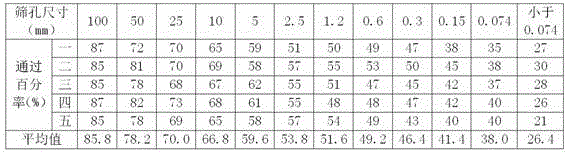

[0043] A green environment-friendly masonry mortar, comprising the following raw materials by weight: 38 parts of lime plant waste, 42 parts of sulfoaluminate cement clinker, 10 parts of steel slag micropowder, 10 parts of high-activity permeable crystallization masterbatch, and 12 parts of nano calcium carbonate parts, water reducing agent 1.0 parts, coagulation enhancer 3 parts, composite activator 0.12 parts, redispersible latex powder 5 parts, cellulose ether 1.2 parts, defoamer 0.16 parts, polypropylene fiber 1.5 parts, stearic acid Zinc 0.8 parts.

[0044] The lime plant wastes are crushed stone, flakes, cinder, slaked lime, lime clinker, unburned limestone, roasted clay and clay.

[0045] The sulfoaluminate cement clinker is a sulfoaluminate cement clinker produced by replacing bauxite with low-grade bauxite or aluminum slag at a ratio of 1:1.

[0046] The steel slag micropowder is powdered powder of converter steel slag or electric furnace steel slag of a steelmaking ...

Embodiment 2

[0060] A green and environment-friendly masonry mortar, comprising the following raw materials by weight: 40 parts of lime plant waste, 44 parts of sulfoaluminate cement clinker, 15 parts of steel slag micropowder, 11 parts of high-activity permeable crystallization masterbatch, and 13 parts of nano-calcium carbonate. parts, water reducing agent 1.1 parts, coagulation enhancer 4 parts, composite activator 0.13 parts, redispersible latex powder 6 parts, cellulose ether 1.3 parts, defoamer 0.17 parts, polypropylene fiber 1.6 parts, stearic acid Zinc 1.0 phr.

[0061] The lime plant wastes are crushed stone, flakes, cinder, slaked lime, lime clinker, unburned limestone, roasted clay and clay.

[0062] The sulfoaluminate cement clinker is a sulfoaluminate cement clinker produced by replacing bauxite with low-grade bauxite or aluminum slag at a ratio of 1:1.

[0063] The steel slag micropowder is powdered powder of converter steel slag or electric furnace steel slag of a steelmaki...

Embodiment 3

[0077] A green and environmentally friendly masonry mortar, comprising the following raw materials by weight: 42 parts of lime plant waste, 46 parts of sulfoaluminate cement clinker, 20 parts of steel slag micropowder, 12 parts of high-activity permeable crystallization masterbatch, and 14 parts of nano-calcium carbonate. parts, water reducing agent 1.2 parts, coagulation enhancer 5 parts, composite activator 0.14 parts, redispersible latex powder 7 parts, cellulose ether 1.4 parts, defoamer 0.18 parts, polypropylene fiber 1.7 parts, stearic acid Zinc 1.2 parts.

[0078] The lime plant wastes are crushed stone, flakes, cinder, slaked lime, lime clinker, unburned limestone, roasted clay and clay.

[0079] The sulfoaluminate cement clinker is a sulfoaluminate cement clinker produced by replacing bauxite with low-grade bauxite or aluminum slag at a ratio of 1:1.

[0080] The steel slag micropowder is powdered powder of converter steel slag or electric furnace steel slag of a ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com