High-precision environmental-friendly emission-reducing low-carbon dust, waste gas and lampblack collecting processor and processing method thereof

A high-precision, processor-based technology, applied in the processor field, can solve problems such as heavy economic burden and unfavorable environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

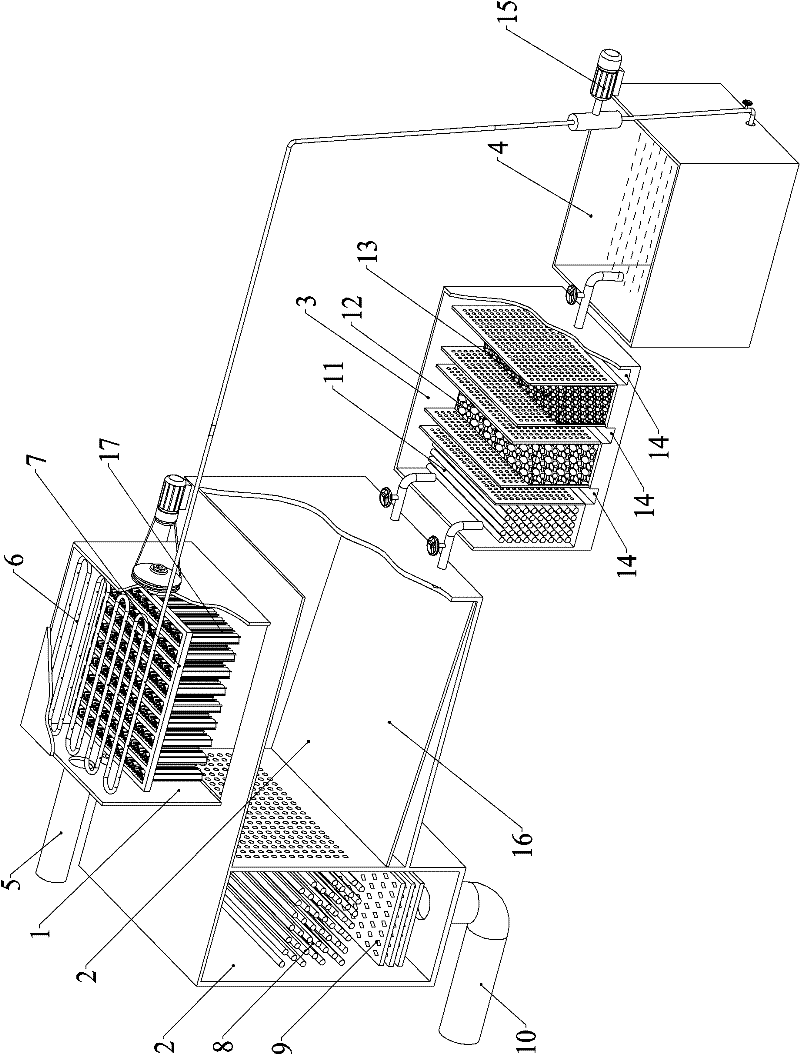

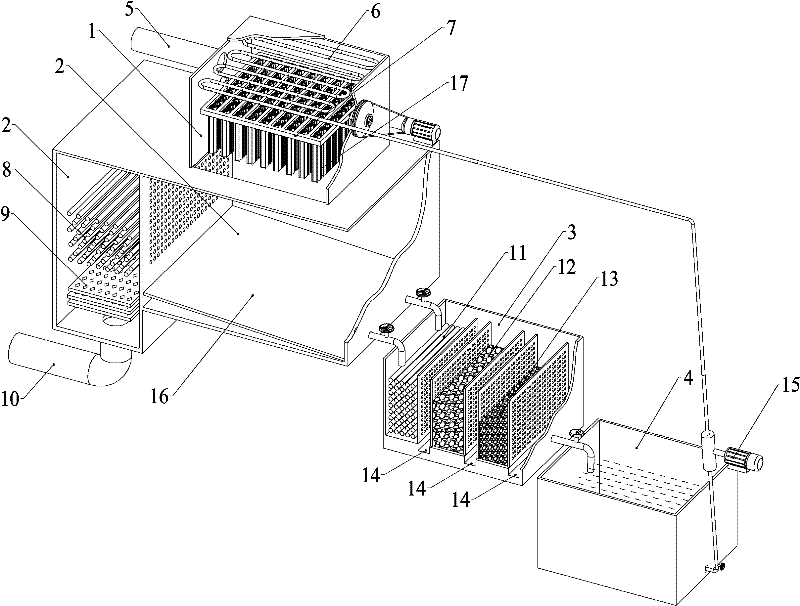

[0027] A high-precision, environmentally friendly, emission-reducing, and low-carbon dust, waste gas, and oil fume collection processor:

[0028] refer to figure 1 , the present embodiment includes a cleaning absorption area 1, a purification exhaust area 2, a filtering water purification area 3 and a water storage area 4; An automatic water spraying device 6 is provided, and a vibrating rocker 7 is arranged below the automatic water spraying device. The vibrating rocker is hoisted with a dust and oil absorption interlayer composed of vertical straw and banana bark 17 interlaced layer by layer. The straw can replace Using wheat straw, the straw and banana bark that are hoisted by the vibrating shaker vibrate and sway continuously, and the water sprayed by the automatic sprinkler device cools down the vertically staggered straw and banana bark and washes the attached dust and oil. The bottom of the cleaning absorption area is connected to the upper part of the purification exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com