Patents

Literature

762 results about "Cast iron pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cast iron pipe is a pipe which has had historic use as a pressure pipe for transmission of water, gas and sewage, and as a water drainage pipe during the 17th, 18th, 19th and 20th centuries. It comprises predominantly a gray cast iron tube and was frequently used uncoated, although later coatings and linings reduced corrosion and improved hydraulics. In cast iron pipe, the graphite forms flakes during the casting process, when examined under a microscope. Cast iron pipe was superseded by ductile iron pipe, which is a direct development, with most existing manufacturing plants transitioning to the new material during the 1970s and 1980s. Ductile iron pipe is different than cast iron, because the introduction of magnesium during the casting process causes the graphite to form spheres (graphite nodules) rather than flakes. While this allows the material to remain castable, the end product is much tougher than cast iron, and allows elastic behavior at lower stress levels. Little cast iron pipe is currently manufactured, since ductile iron pipe is widely accepted as a superior product. Many public utilities, municipalities, and private industries still have functional cast iron pipe in service to this day.

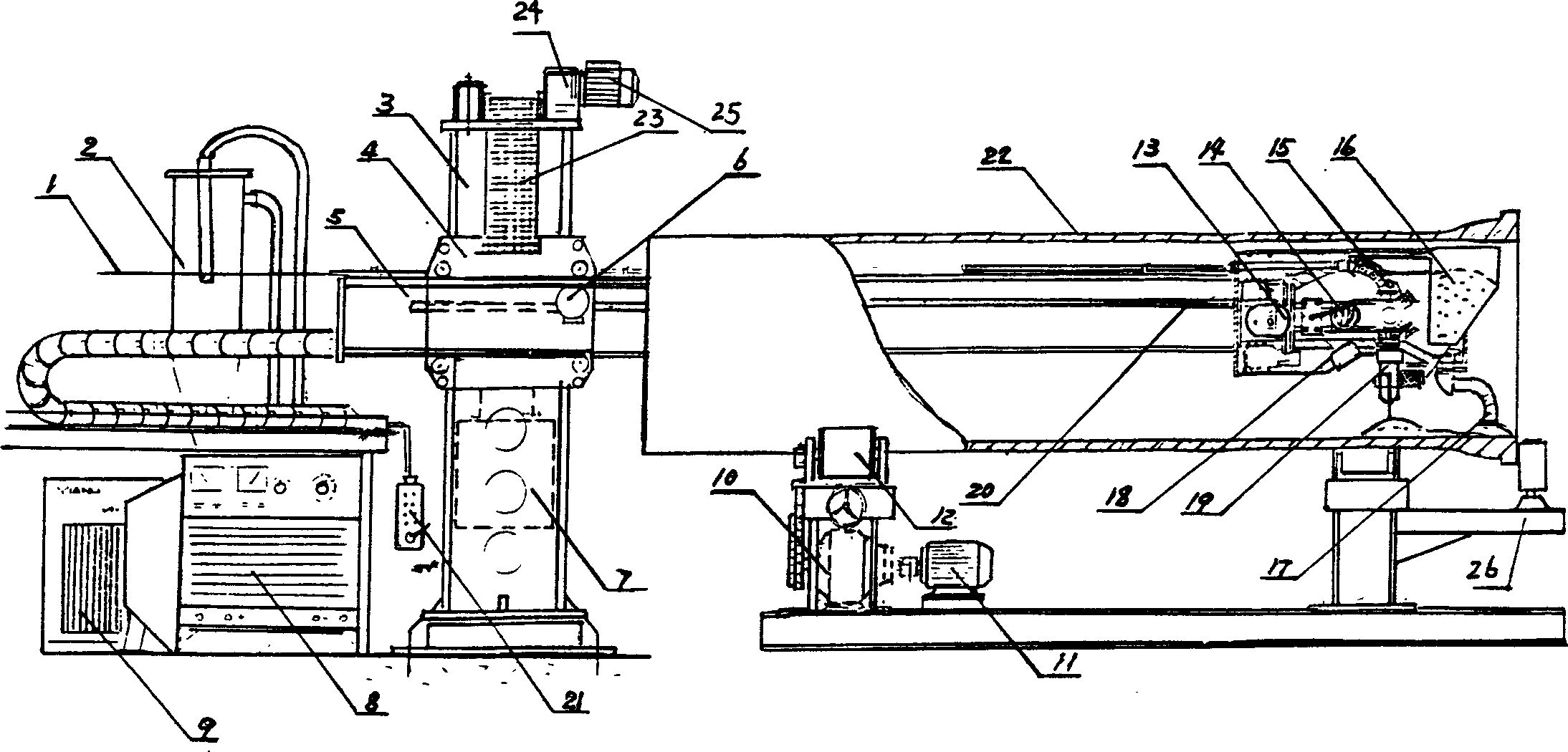

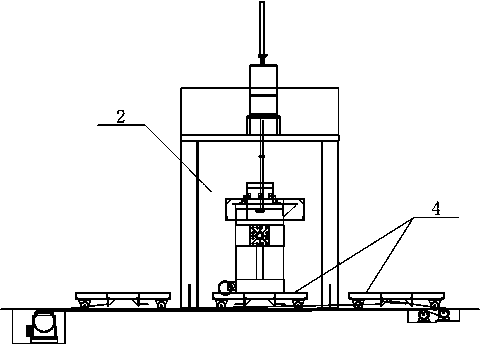

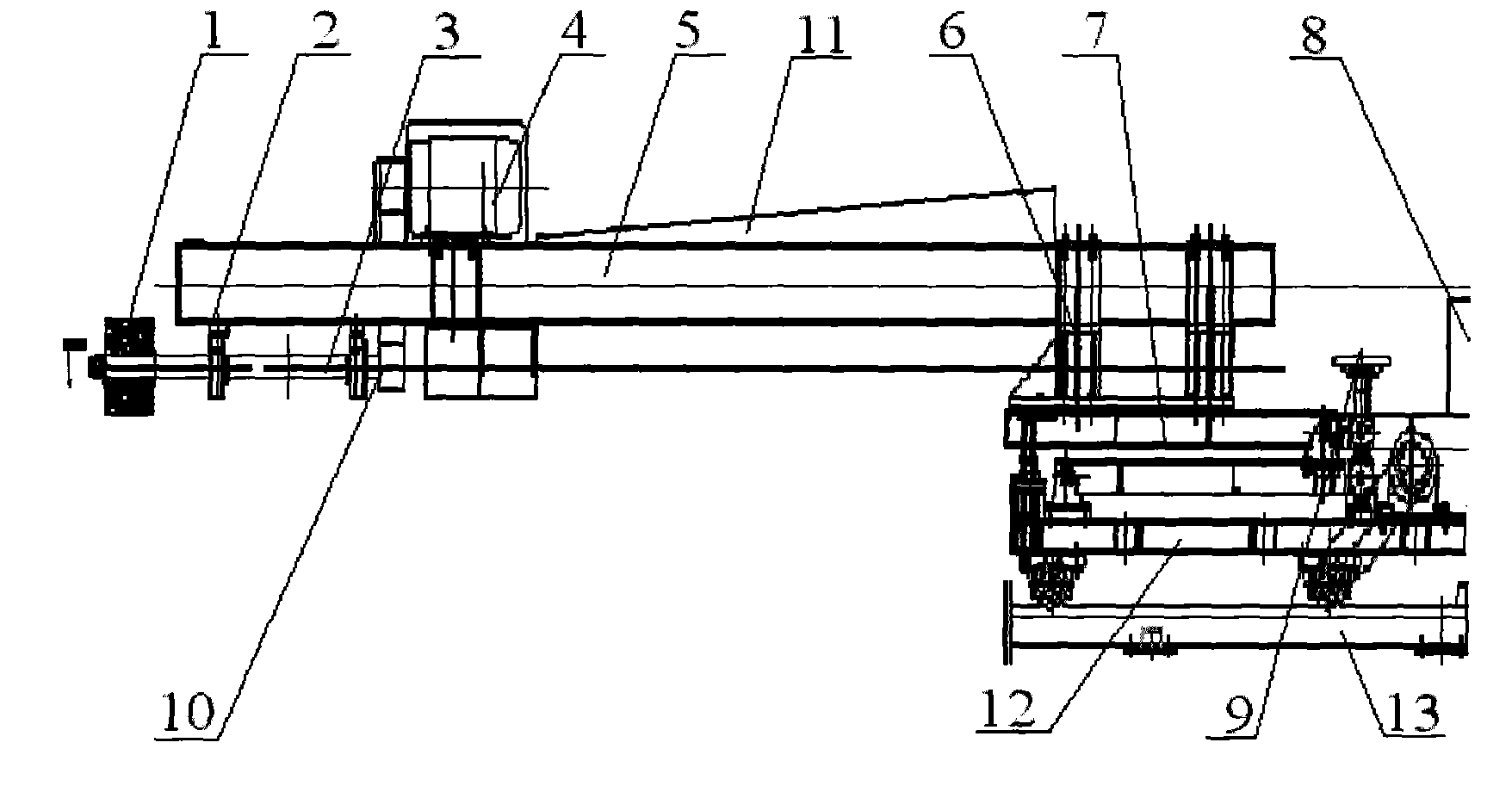

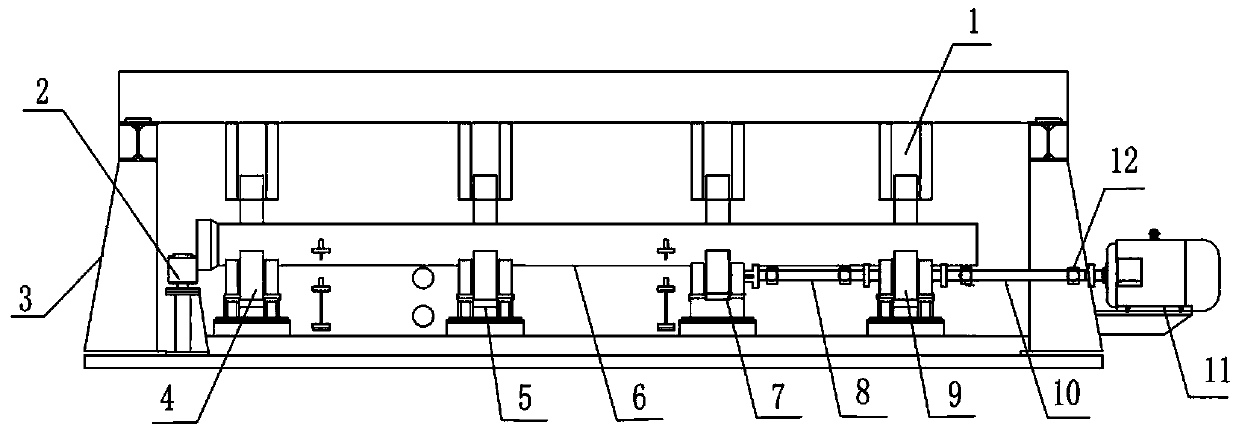

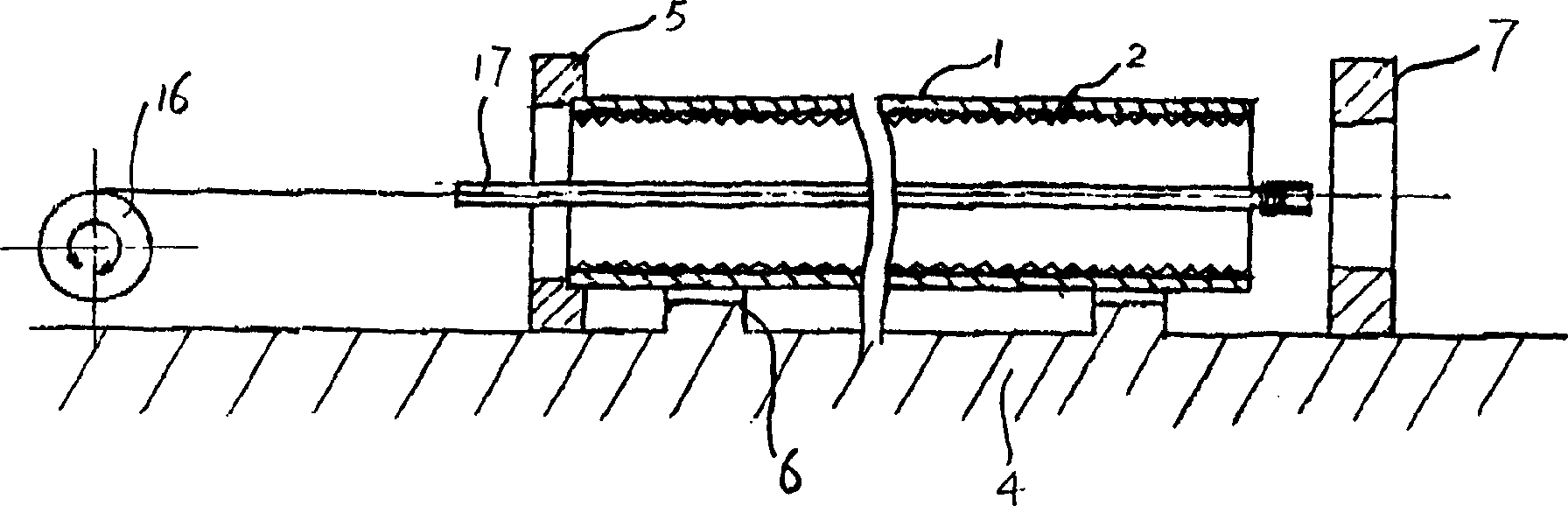

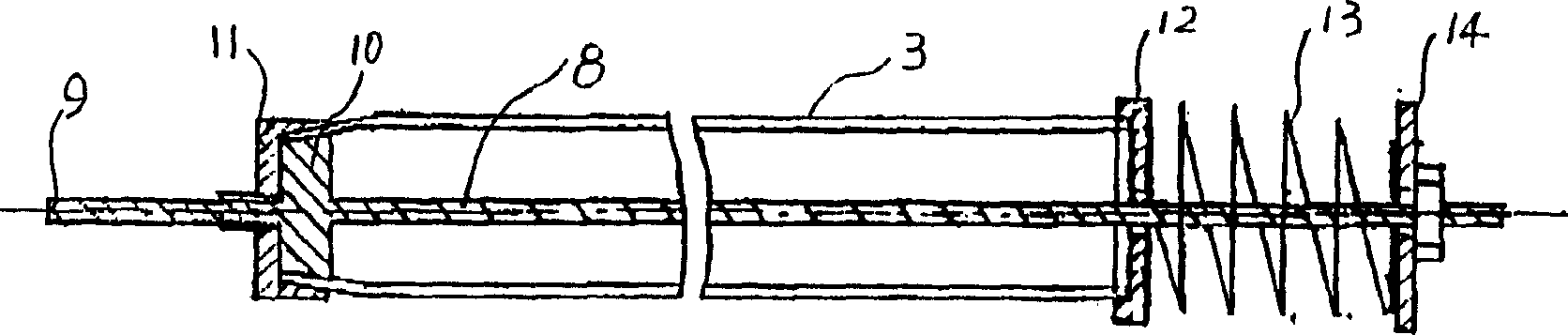

Long barrel internal and external wall spiral type helical swinging built up welding method and equipment

InactiveCN1475323AImprove corrosion resistanceWelding/cutting auxillary devicesArc welding apparatusEngineeringCast iron pipe

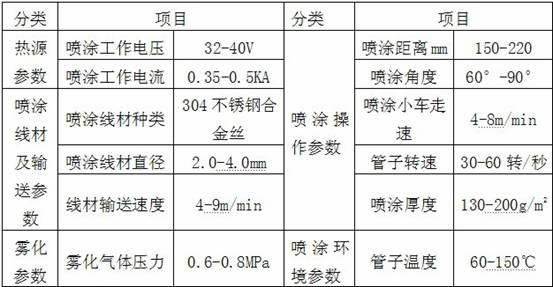

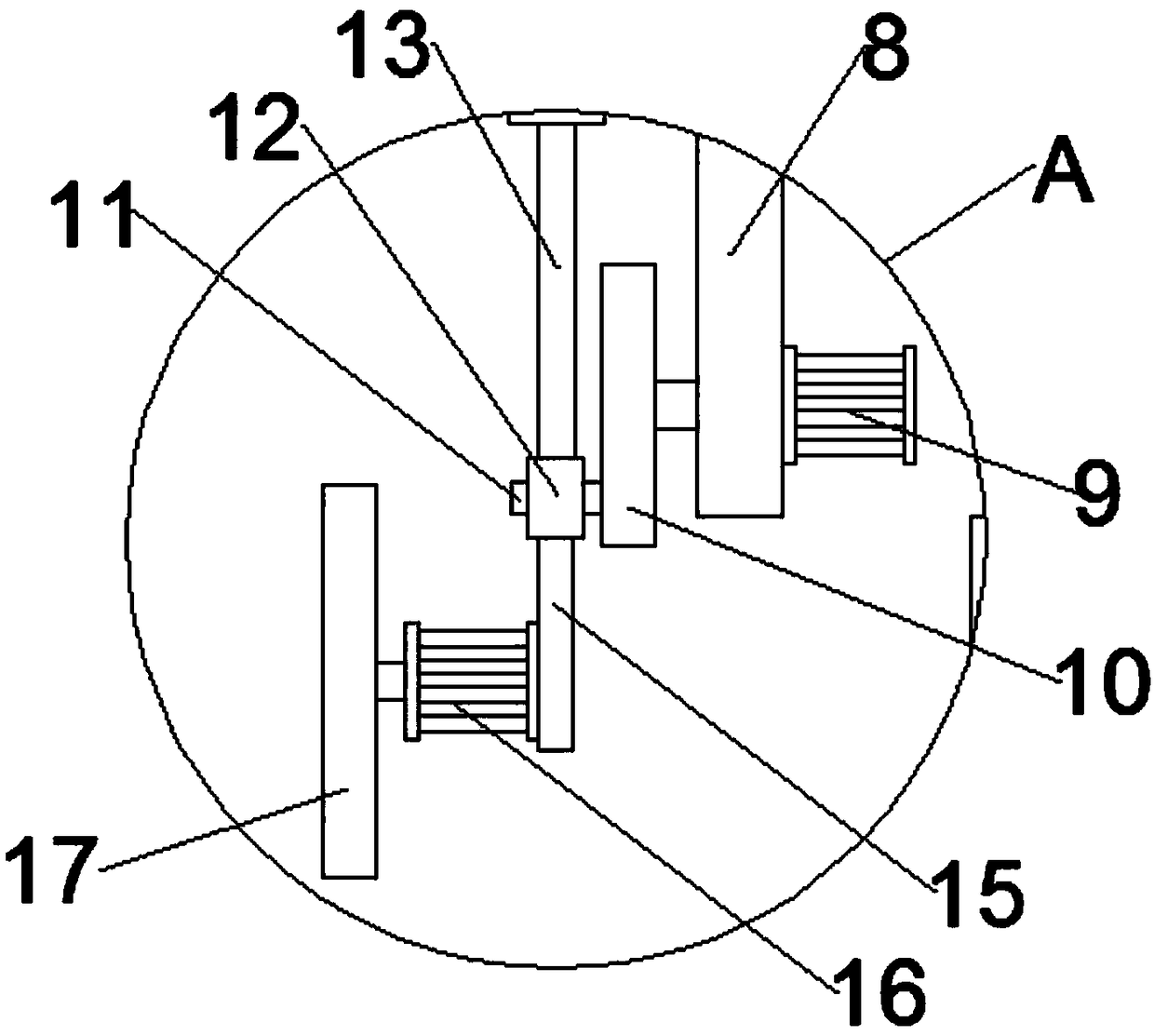

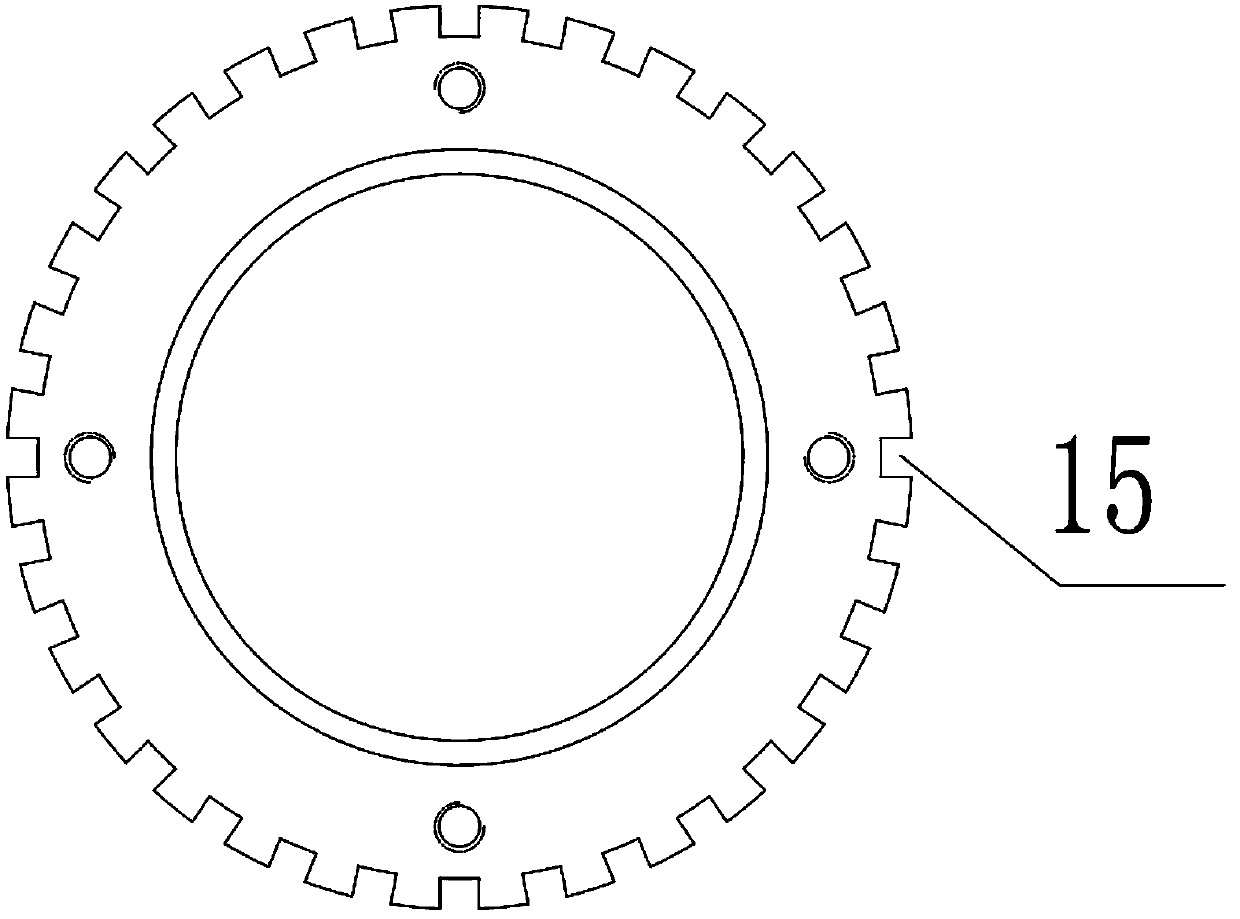

A spirally oscillating wrap build-up welding method and equipment for long cylindrical body, such as the mould of long (14m) large-diameter (500 mm) nodular cast iron pipe, rotary drum type ball grinder, cylindrical container, etc features that the included spiral angle between wide welded band and cylinder's axis is 30-60 deg, welding gun is oscillating by 30-100 mm for ampletude and 30-50 times / min for frequency, and the adjacent welded bands are overlapped by 10 mm.

Owner:傅成

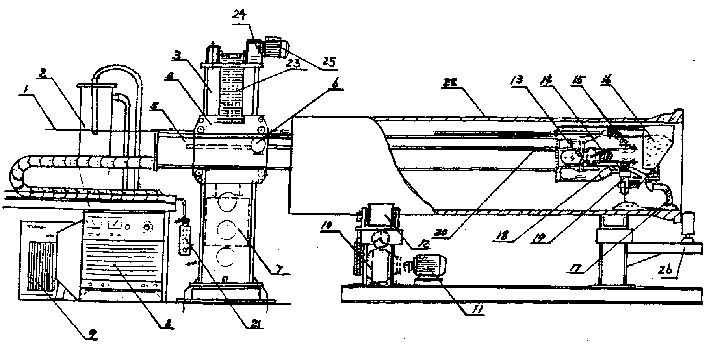

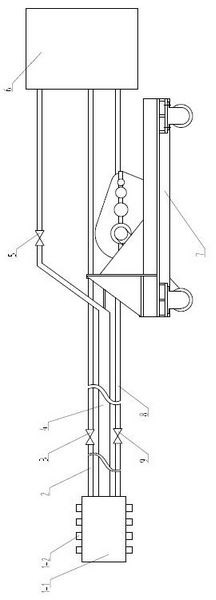

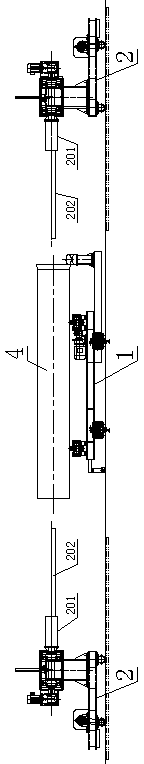

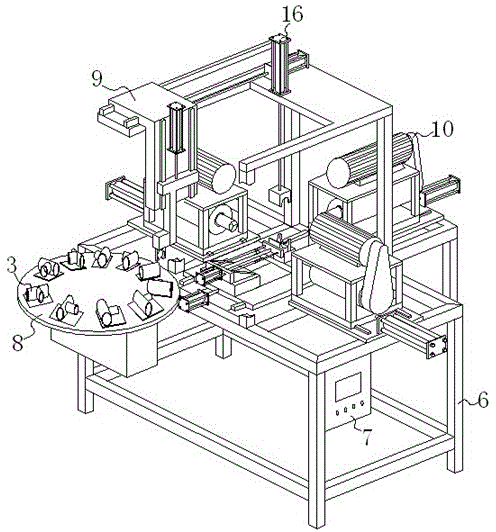

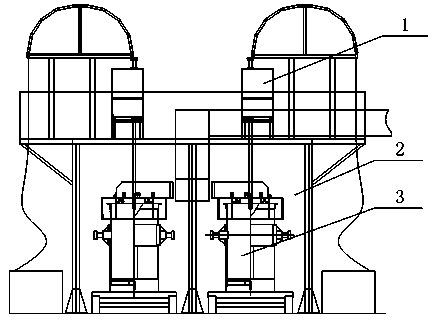

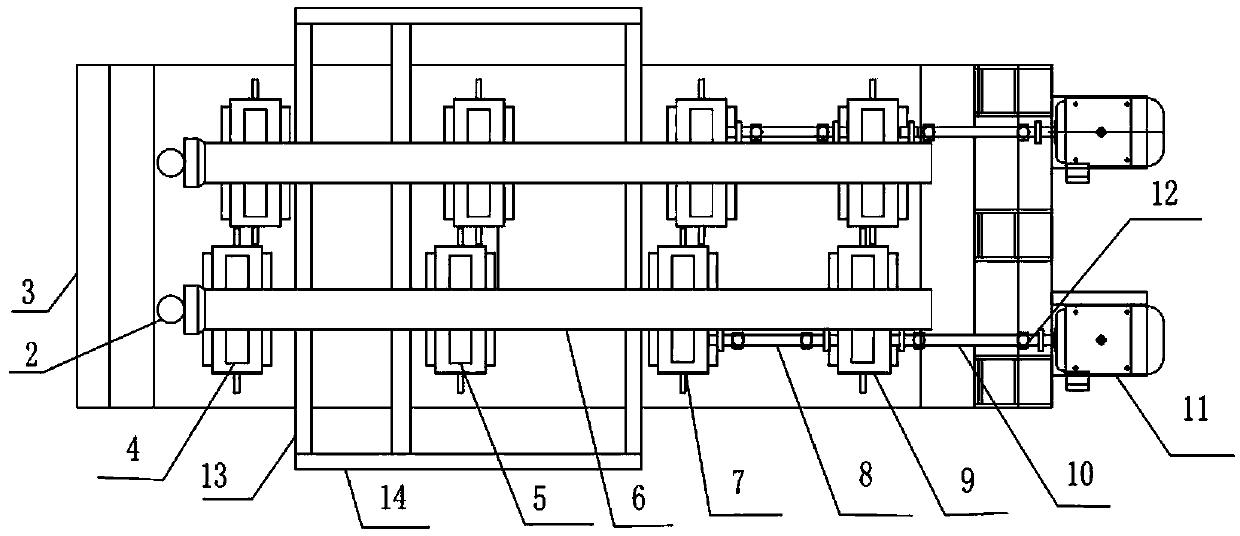

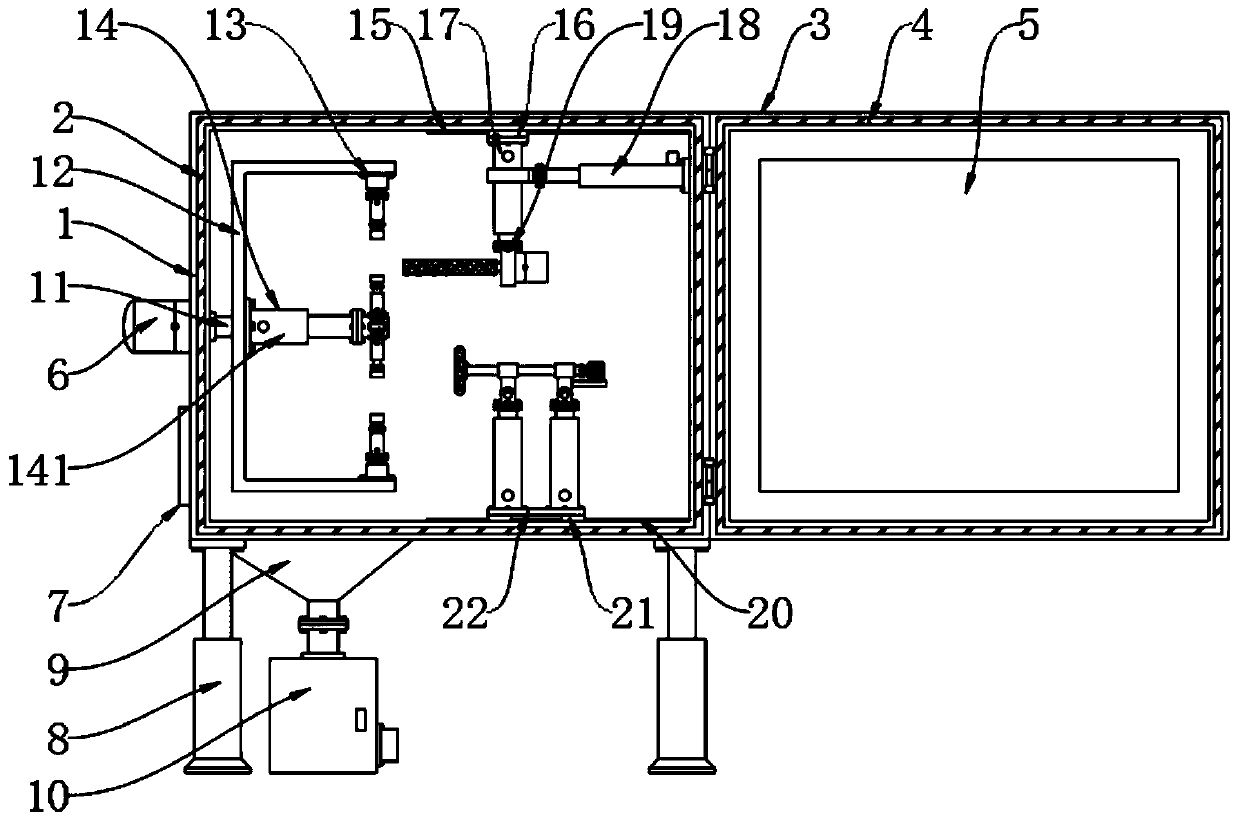

Full-automatic double-station device for spraying paint on outer surfaces of cast iron pipes

ActiveCN106111401AUniform paint thicknessQuality improvementLiquid surface applicatorsSpraying apparatusAutomatic controlEngineering

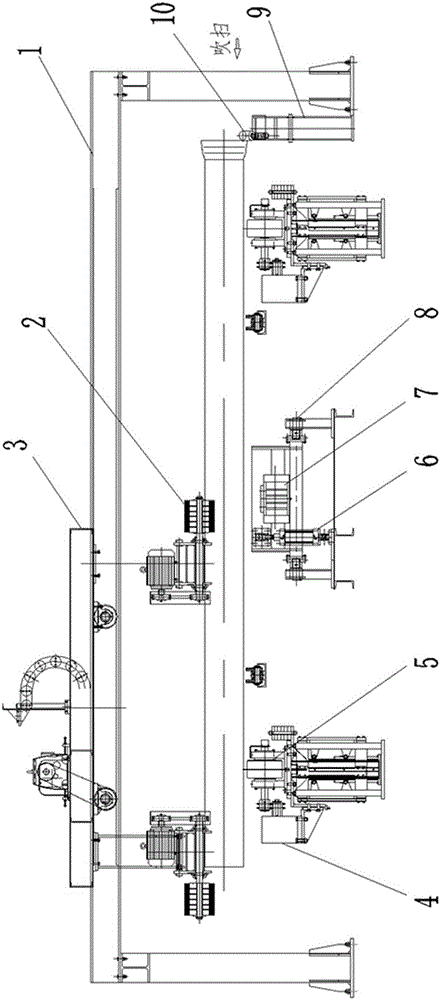

The invention relates to a full-automatic double-station device for spraying paint on the outer surfaces of cast iron pipes. A bracket is mounted on the ground. A guide rail is arranged at the upper part of the bracket. A paint spraying trolley and dust removing trolleys are mounted on the guide rail and can move along the guide rail. The paint spraying trolley is connected with the dust removing trolleys. Another guide rail used for allowing a primary tip trolley and a secondary tip trolley to travel is arranged in the middle of the bracket. Pneumatic devices are connected with the tail parts of the primary tip trolley and the secondary tip trolley. A trolley guide rail is arranged under the bracket. A pipe feeding and discharging stepping trolley is mounted on the trolley guide rail, and is connected with a stepping trolley cylinder and a duplex cylinder, which are mounted on the bracket. Automatic aligning devices are arranged in front of the bracket, are parallel to the bracket, and are connected with a pneumatic system. The full-automatic double-station device can be used for spraying paint on cast iron pipes which are 3 m long and have different external diameters, and adopts automatic control, the labor condition and the operation environment are improved, the labor intensity of workers is effectively reduced, the paint sprayed cast iron pipe is high in quality, and high in precision, and the working efficiency is improved effectively.

Owner:侯马市风雷管模制造股份有限公司

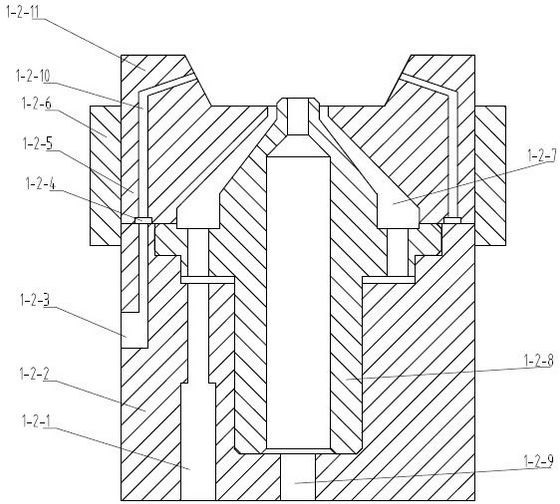

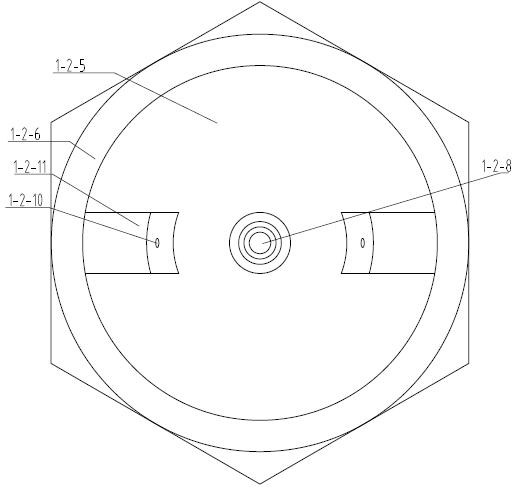

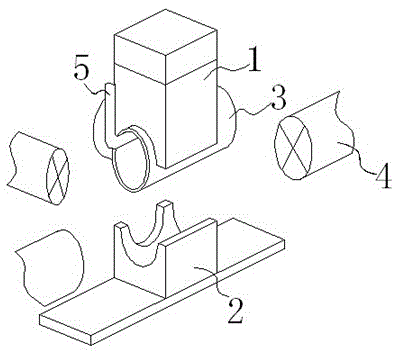

Secondary atomization fan nozzle and paint sprayer special for cast pipe

InactiveCN102139249ASmall diameterImprove spray qualityLiquid surface applicatorsSpray nozzlesAtomizer nozzleSprayer

The invention discloses a secondary atomization fan nozzle and a paint sprayer special for a cast pipe. The current primary atomization nozzle is changed into such a structure that the top is provided with a secondary atomization air outlet and the top surface of a valve core is higher than the bottom surface of an angle-shaped atomization block. The paint sprayer has the advantages that the atomization quality of the nozzle can be effectively improved, the service life of the valve core can be prolonged; the fan nozzle with the function of secondary atomization is applied to the paint sprayer special for the cast pipe, then a plurality of nozzles can be used in parallel owing to the fan-shaped spraying, and the paint sprayer also has the advantage that: the spraying efficiency of a paint special for the cast pipe on the inner wall of a pipe die can be effectively increased, the spraying quality of a paint coating special for the cast pipe can be improved, the outer wall quality of a nodular cast iron pipe is further improved and the production efficiency of the nodular cast iron pipe is increased.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Preparation method for composite coating of outer surface of nodular cast iron pipe

ActiveCN102676971APlug poresReduce porosityLiquid surface applicatorsMolten spray coatingPorosityCeramic coating

The invention discloses a preparation method for a composite coating of an outer surface of a nodular cast iron pipe, belonging to the technical field of corrosion inhibition of a metal material. The preparation method comprises the following steps of: (1) pretreating the outer surface of the nodular cast iron pipe; (2) the spray coating of a ceramic coating: uniformly mixing a ceramic coating raw material, and spraying the ceramic coating raw material on the outer surface of the nodular cast iron pipe by adopting flame spraying equipment, wherein the weight of the ceramic coating on the outer surface of the nodular cast iron pipe is 80-300g / m<2>, the diameter of the powder of the mixing ceramic coating raw material is 5-60 microns; the mixing ceramic coating raw material comprises Al2O3, TiO2 and Cr2O3; and (3) coating a hole sealing finishing coat. As the ceramic coating prepared by the invention has low porosity, the ceramic coating has better corrosion resistance performance; the ceramic coating has stronger binding capacity with a substrate and good wear resistance performance, can be suitable for severe environments and is low in manufacturing cost; and the hole sealing finishing coat can further increase the corrosion resistance performance of the ceramic coating.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Mechanical zinc-plating process

The present invention provides a mechanical galvanization process. It uses industrial zine powder (150-300 meshes) as raw material, utilizes special-purpose active dispersion galvanization adjuvant and uses glass microbeads as impact medium to implement mechanical galvanization of iron base metal workpieces of metal structure components, standard components and casting iron pipe, etc. and can obttain the uniform, compact and smooth pure galvanized layer with silver white colour. Said galvanized layer possesses good corrosion resistance and stability.

Owner:SHANDONG UNIV

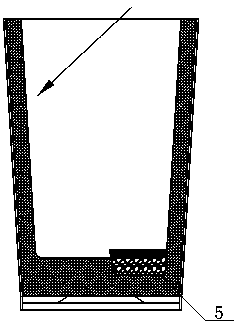

Lining coating technology for spheroidal graphite cast iron tube

ActiveCN103691625AWill not affect the formationNo shedding phenomenonLiquid surface applicatorsCoatingsPolyvinyl chlorideEngineering plastic

The invention discloses a lining coating technology for a spheroidal graphite cast iron tube. The lining coating technology is characterized by comprising the following steps of 1, polishing the inner wall of a blank tube, and performing shot blasting; 2, putting the treated tube on a riding wheel of lining coating equipment through a transferring tool, and switching on a variable-frequency motor connected with the riding wheel to drive the tube to rotate at the rotating speed of less than or equal to 50rpm; 3, switching on a heating fire gun arranged below the tube to preheat the outer wall of the tube, and controlling the temperature between 140 DEG C and 230 DEG C; 4, after preheating is finished, uniformly distributing polyvinyl chloride or polyethylene or ABS (acrylonitrile butadiene styrene) engineering plastic or polytetrafluoroethylene or polypropylene powdered substances on the inner wall of the tube through a material distribution trolley to form a lining layer, and then cooling the lining layer, wherein in the cooling process, the tube is continuously rotated until the tube is completely cooled. The problem of the influence, which is caused by a fact that the lining layer prepared by an existing lining coating technology for the spheroidal graphite cast iron tube is easy to fall off, on normal mounting, the use of metering equipment, the sanitation of water quality and the like is solved; the manufacturing cost of the lining layer is reduced.

Owner:广西安钢永通铸管管业有限公司

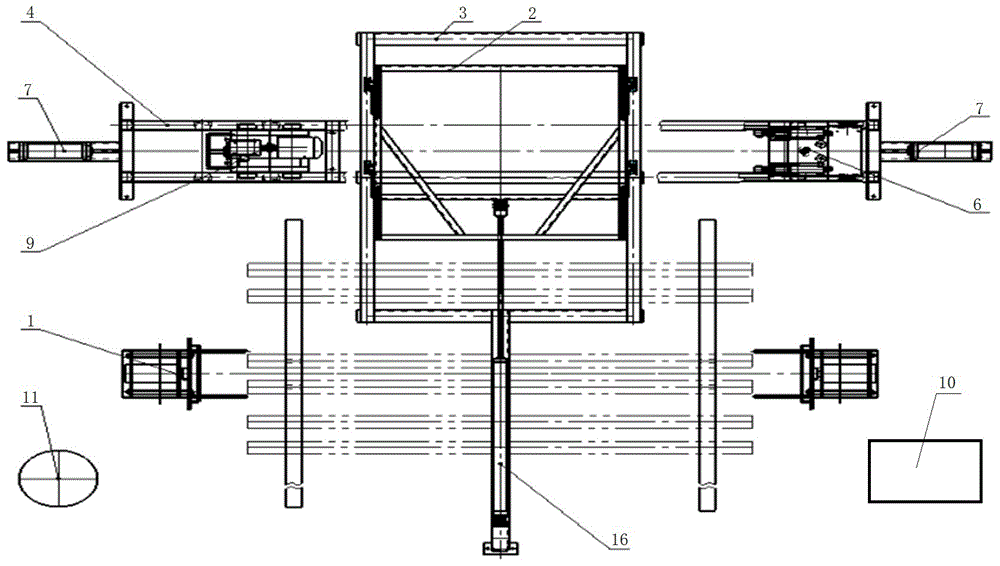

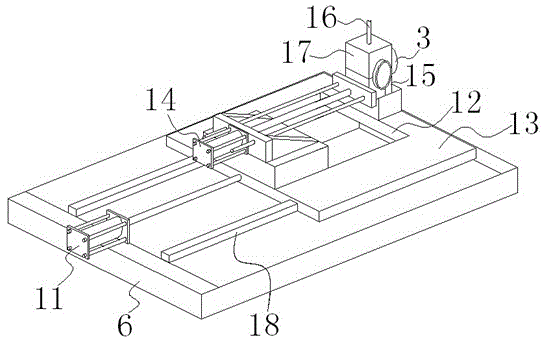

Full automatic malleable cast iron pipe fitting flat head machine and processing method thereof

ActiveCN103551639AImprove processing efficiencyAvoid waiting timeMilling equipment detailsMetal working apparatusPipe fittingProgrammable logic controller

The invention discloses a full automatic malleable cast iron pipe fitting flat head machine and a processing method thereof. The full automatic malleable cast iron pipe fitting flat head machine comprises a rack and a PLC (programmable logic controller), a material supporting device, a clamping apparatus device, a feeding device and a power head device, a clamping apparatus supporting plate with a discharge port, a lower clamping apparatus air cylinder, a lower clamping apparatus, a material pressing air cylinder and an upper clamping apparatus connected with the material pressing air cylinder, wherein the material supporting material device, the clamping apparatus device, the feeding device, the power head device and the PLC controller are connected in an electrical control manner, and the clamping apparatus device comprises a supporting plate air cylinder; the lower clamping apparatus is divided into two parts, a part of the lower clamping apparatus is connected with the lower clamping apparatus air cylinder, and the other part of the lower clamping apparatus is arranged on the clamping apparatus supporting plate; the rack is provided with a clamping apparatus device guide rail, and the clamping apparatus device and the clamping apparatus device guide rail are matched and connected in a sliding manner. The full automatic malleable cast iron pipe fitting flat head machine and the processing method provided by the invention have the advantages that the waiting time of a clamping apparatus when a workpiece is unloaded is avoided through a manner of changing the unloading workpiece, the whole processing time of a pipe fitting is reduced, and the processing efficiency of a workpiece is greatly improved.

Owner:ZHUZHOU KAIFENG IND

Nodular cast iron pipe cleaning device

InactiveCN108466178AEasy to cleanSimple structureHollow article cleaningAbrasive blasting machinesArchitectural engineeringCast iron pipe

The invention discloses a nodular cast iron pipe cleaning device which comprises a base. The base is provided with a supporting rod, the top of the base is provided with a first placing rod, the top of the first placing rod is connected with a placing ring, the top of the base is provided with a second placing rod, the top of the second placing rod is provided with a placing plate, the right sideof the second placing rod is provided with a motor, the motor is connected with a clamping device through a rotating shaft, the clamping device clamps a nodular cast iron pipe, the left end of the nodular cast iron pipe is provided with a limiting part, the limiting part is connected with a fixing plate, the top of the supporting rod is connected with an adjusting plate, a hand turning handle penetrates through the adjusting plate to be connected with a lead screw, the lead screw is in threaded connection with a sliding sleeve, a polishing part is connected with the bottom end of the sliding sleeve, the bottom end of the sliding sleeve is connected with a cleaning brush, the upper portion of the supporting rod is provided with a transverse rod, and the transverse rod is provided with a sliding groove. The structure is simple, shot blasting is adopted for removing rust on the outer wall of the nodular cast iron pipe, the rust removal effect is good, the cleaning brush is arranged so asto remove impurities attached to the outer wall of the nodular cast iron pipe conveniently, the rust and impurity removal speed can be manually controlled, and the cleaning effect is better.

Owner:HANSHAN DONGSHAN DEYU SPHERULITIC GRAPHITE CASTING FACTORY

Special coating of hot-mould centrifugal casting mould for flexible joint ferrosteel pipe

InactiveCN1775415AImprove the level ofImprove liquidityFoundry mouldsFoundry coresSodium BentoniteColloid

The present invention relates to a soft joint grey cast-iron pipe hot-mould centrifugal casting special-purpose adhering moulding material. It includes fire-resisting aggregate, bonding agent, suspension agent and water. The described fire-resisting aggregate includes diatomite powder, perlite powder, vermiculite powder and silica flour, and the described bonding agent and suspension agent include sodium base bentonite and sodium cellalose glycollate. Said invention also provides its preparation method and concrete steps.

Owner:张鑫

Large-area or large-volume concrete pre-buried blast hole arrangement method and blasting demolition method

Disclosed are a large-area or large-volume concrete pre-buried blast hole arrangement method and a blasting demolition method. A plurality of high-heat-conductivity HDPE plastic pipes or steel pipes or cast iron pipes are pre-buried in concrete, can be used as cooling water pipes in the large-volume concrete construction process, and can also be used as blast holes for blasting demolition in the future. In the blasting demolition construction process, through the technical means of binding continuous or discontinuous cartridge bags and detonating cords through ropes for traction power charging and the like, stable explosion propagation and a good crushing effect are guaranteed. The life cycle design philosophy is applied, meanwhile, temperature control in the large-area and large-volume concrete construction process and blasting demolition in the future are considered, and revolutionary technical progress is achieved. Good economic and social benefits can be brought.

Owner:叶建军

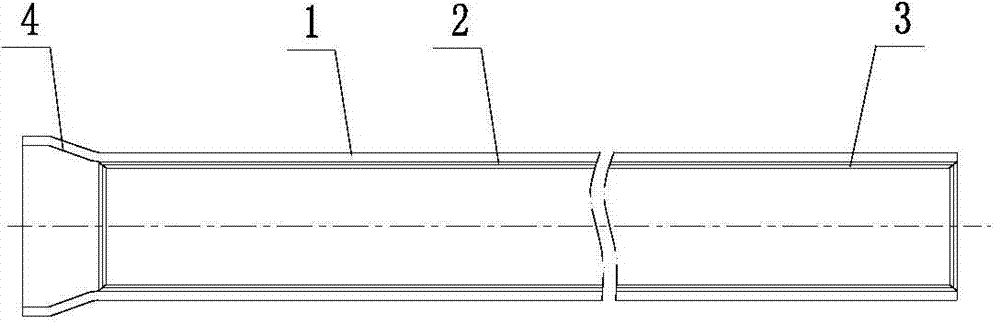

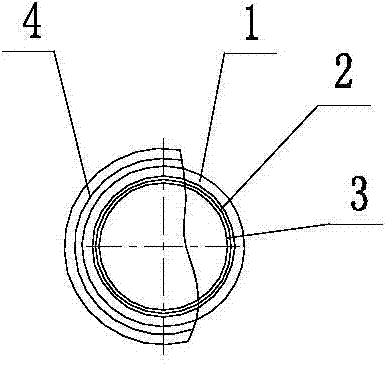

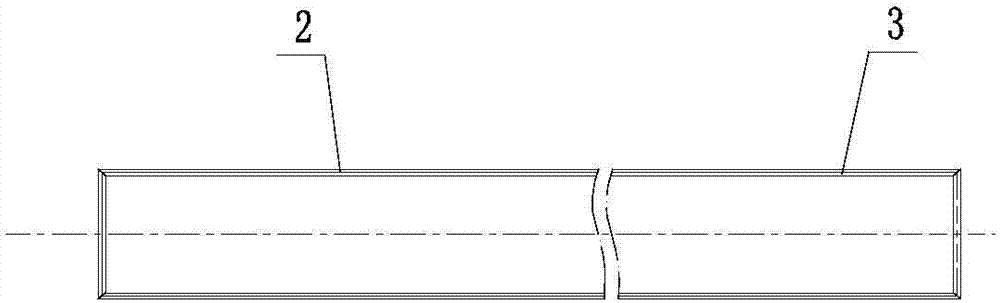

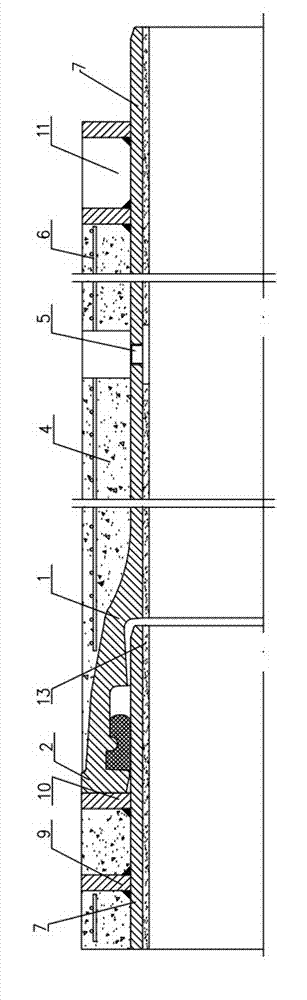

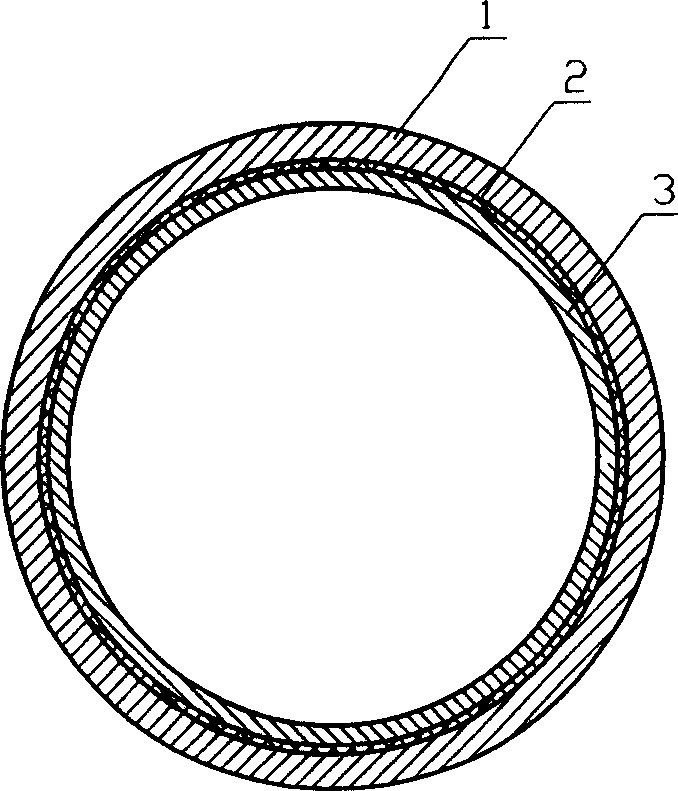

Plastic-lined socket and spigot coast iron pipe and manufacturing process thereof

Disclosed are a plastic-lined socket and spigot coast iron pipe and a manufacturing process of the plastic-lined socket and spigot coast iron pipe. The plastic-lined socket and spigot coast iron pipe comprises a cast iron pipe, a glue layer and a lining. A blank is manufactured in an on-line mode through the lining and the glue layer and is then subjected to on-line operation through deformation, stretching, heating and expansion, and therefore the technical scheme of integral bonding of the cast iron pipe and lined plastic is achieved, and the defects that because a cement mortar lining or an epoxy ceramic lining is adopted for an existing ordinary cast iron pipe, the inner wall of the existing ordinary cast iron pipe is not smooth, water flow resistance is large, scaling can happen easily, water quality is affected by reaction objects generated by cement hardening, the lining is large in thickness, water conveying efficiency is low, installing and construction are difficult, manufacturing difficulty is large, equipment is complex and cost is high are overcome; the plastic-lined socket and spigot coast iron pipe is suitable for water, gas and oil conveying of all municipal engineering and industrial and mining enterprises, is particularly suitable for water supply in municipal engineering and is a preferential water conveying pipe product.

Owner:HUNAN ZHENHUI PIPE IND

Products for the protection of continuous cast moulds for cast-iron pipes

ActiveUS20050066771A1Speed up the restore processBlast furnace componentsFoundry mouldsMetal alloyCasting mold

A powder product for the protection of centrifugal casting molds for cast iron pipes includes an inoculating metal alloy and possibly mineral powders, and a strongly reducing metal that is volatile at the temperature of the liquid cast iron. The use of products according to the invention prevents accumulation of dirt on molds and improves the surface condition of the cast iron pipes.

Owner:FERROPEM SAS

Method for preparing centrifugal nodular cast iron pipe

ActiveCN104480382AImprove appearance qualityRefining material organizationLiquid surface applicatorsCoatingsIRON PREPARATIONSCast iron pipe

The invention discloses a method for preparing a centrifugal nodular cast iron pipe. The method discloses the preparation process of the centrifugal nodular cast iron pipe of high quality, the preparation process comprises a series of operation processes of molten iron preparation, nodulizing of molten iron, centrifugal casting, annealing treatment, pipe body shaping and coating protection and the like. The method is suitable for preparation of cast iron pipes of the specification of DN 80-1000 mm, the application range is wide, and the preparation process is simple. The cast iron pipe prepared through the method has the characteristics of being high in appearance quality, fine in material structure, high in production efficiency, long in service life and the like, and compared with existing steel pipes and gray iron pipes, the cast iron pipe prepared through the method has better decay resistance and tensile property.

Owner:SICHUAN CHUANJIAN PIPES

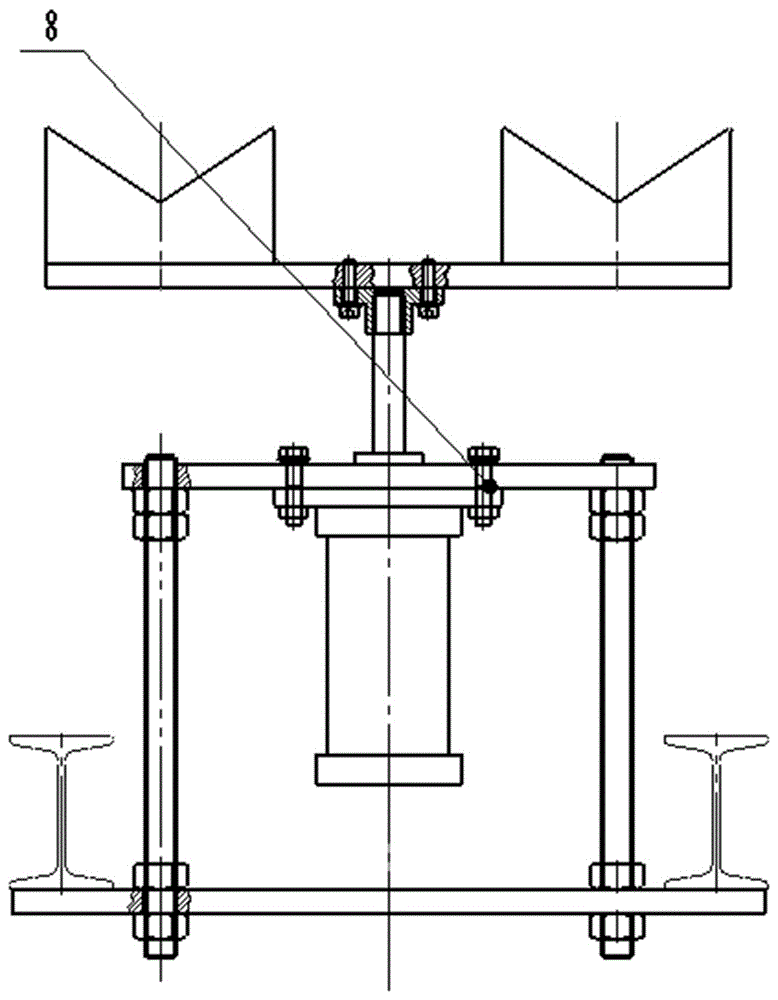

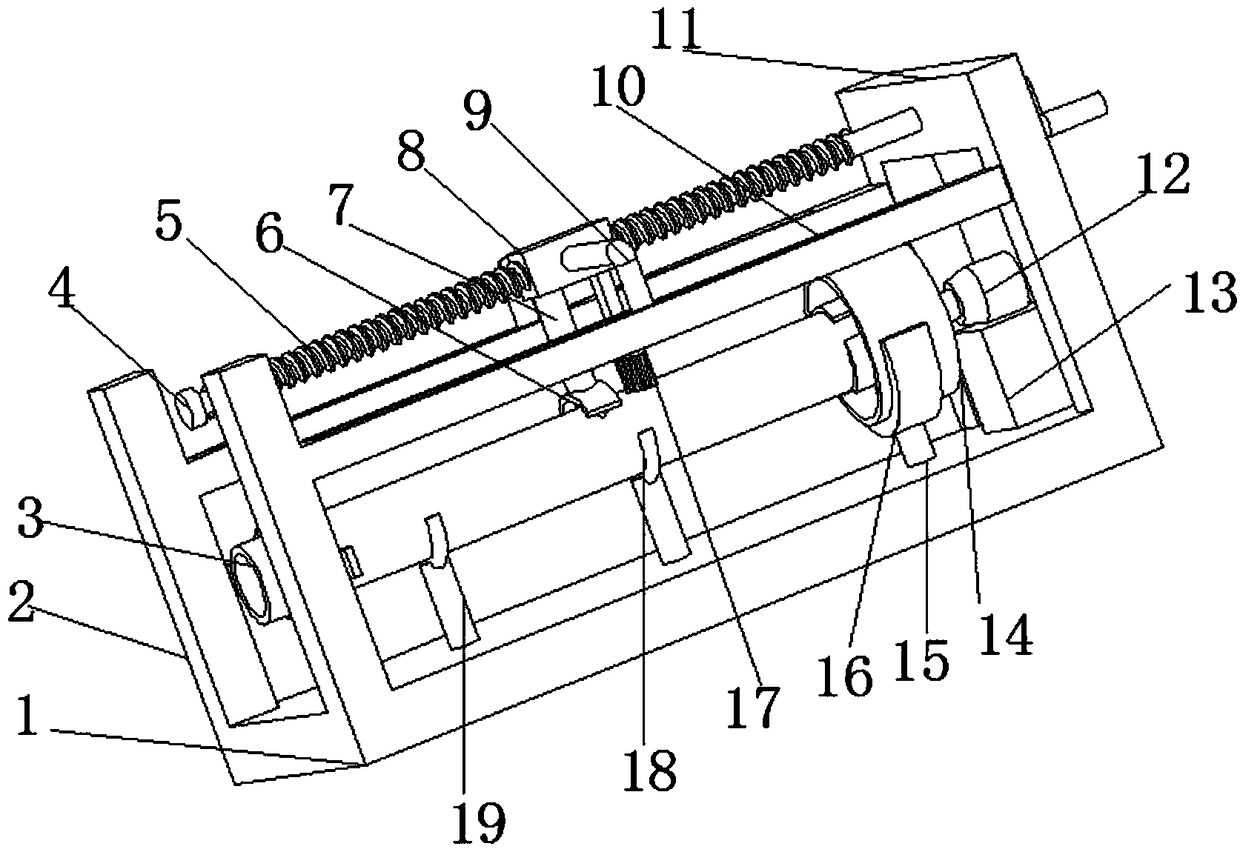

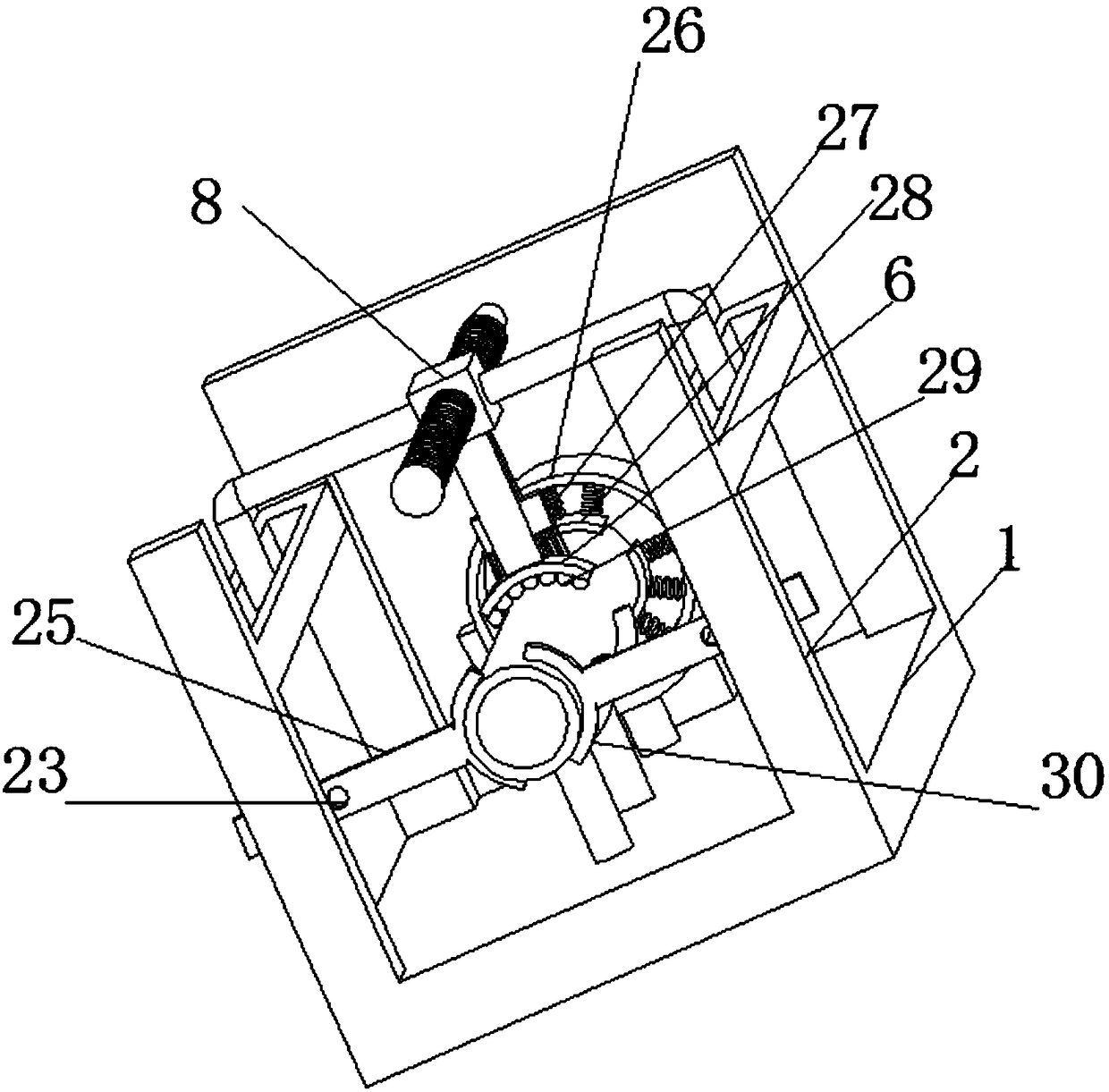

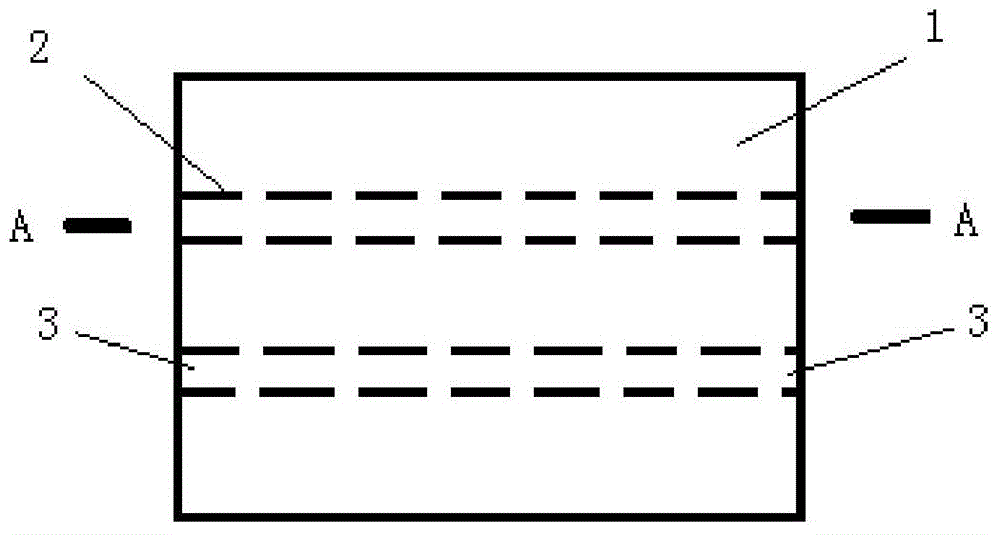

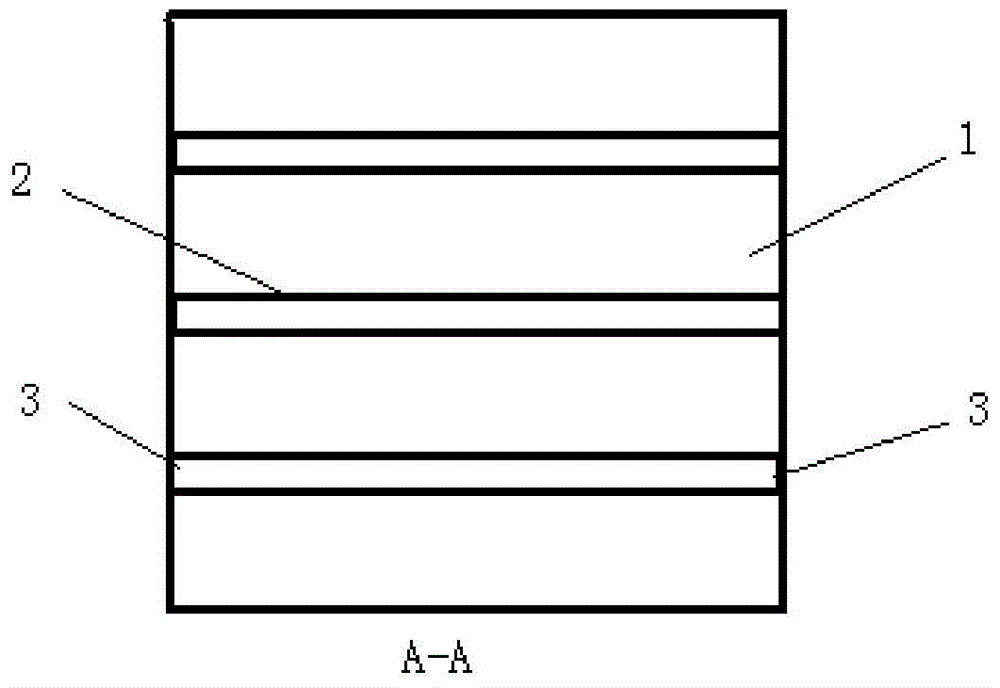

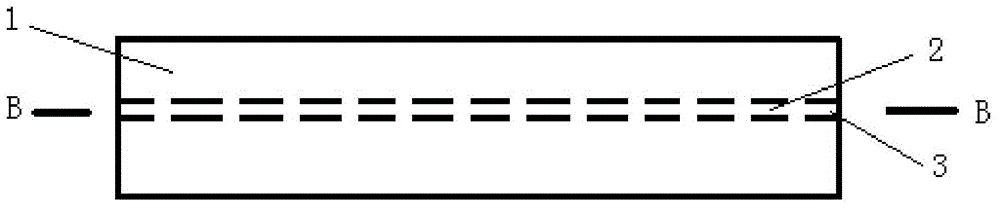

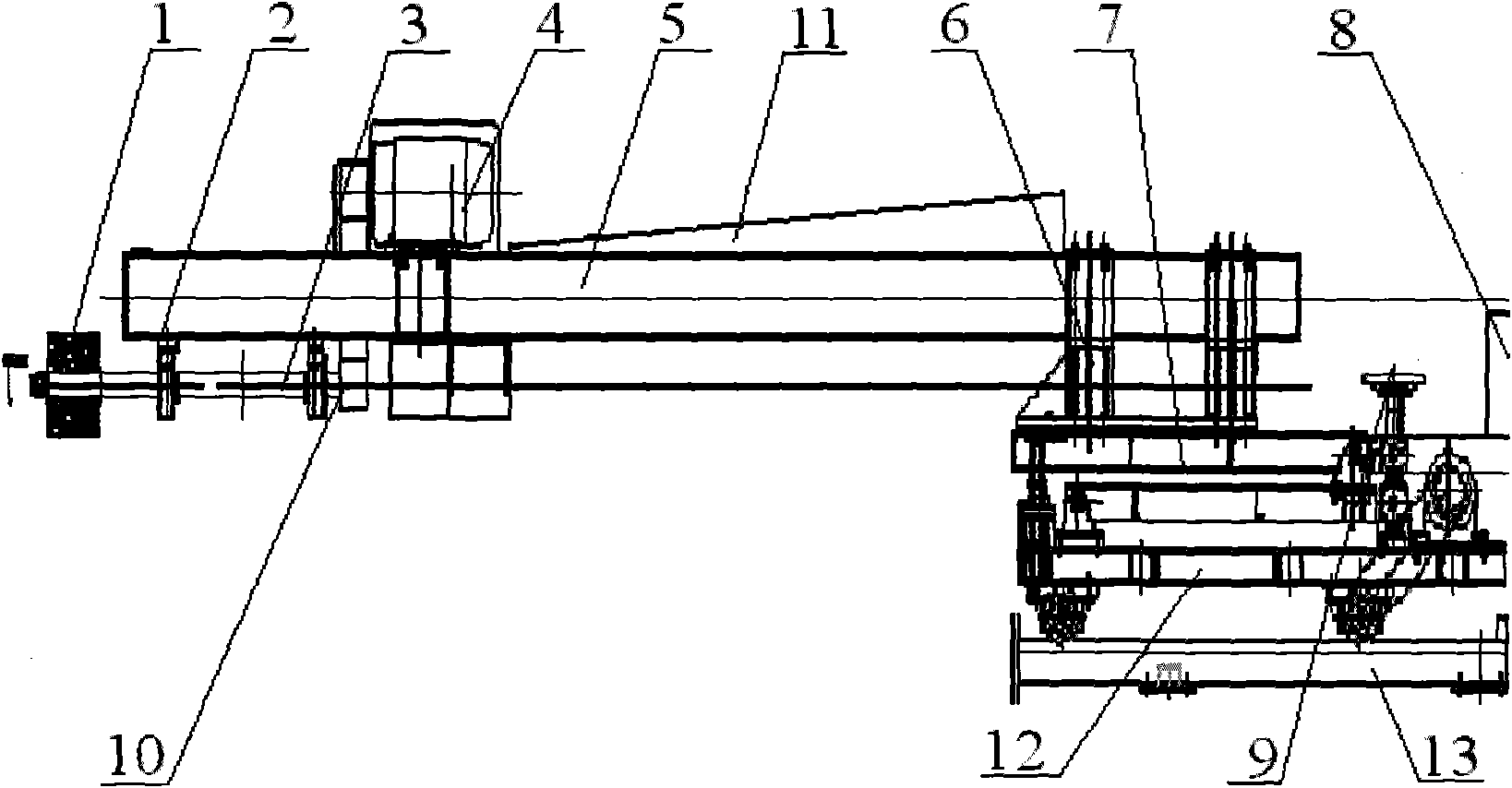

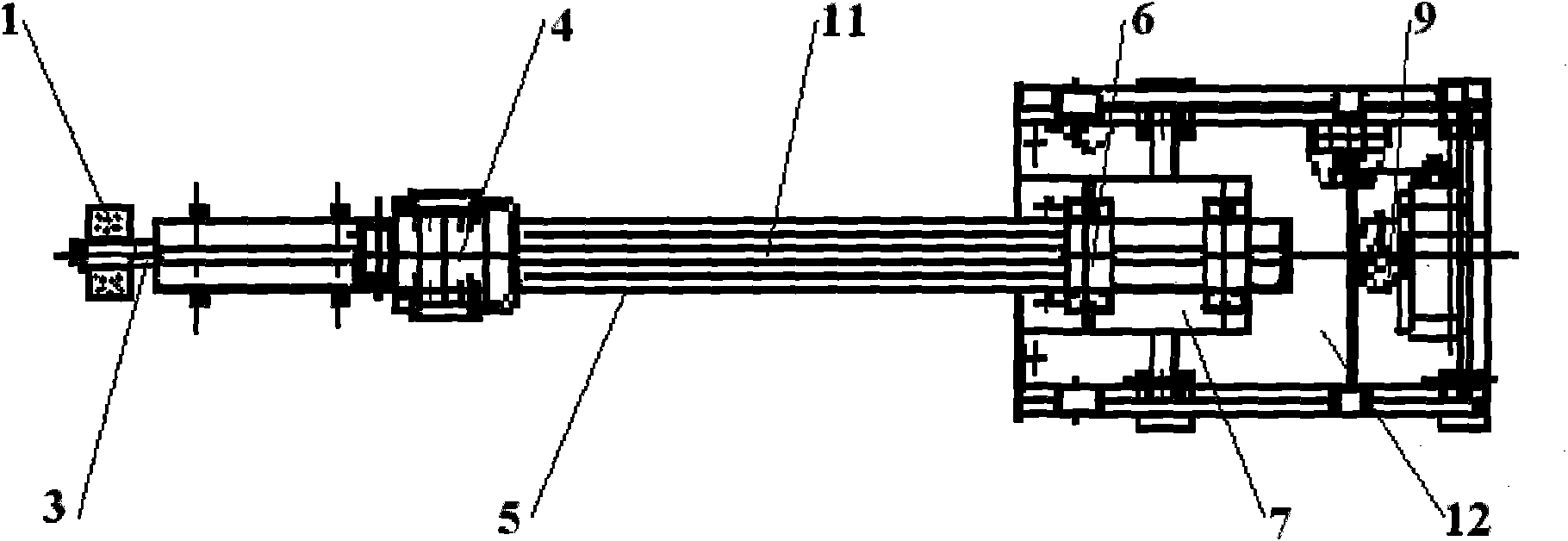

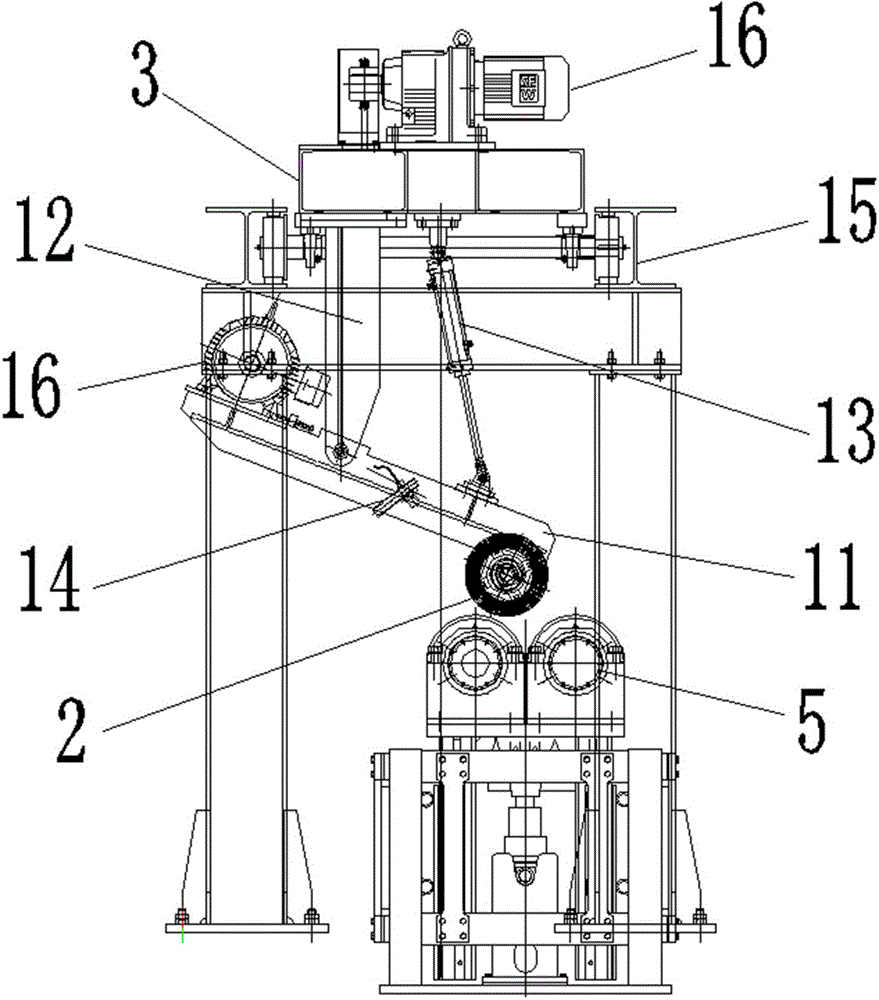

Grinding and driving mechanism of inner grinder of large-diameter cast iron pipe production line

ActiveCN101797706ASimple structureShorten the lengthRevolution surface grinding machinesEngineeringCast iron pipe

The invention discloses a grinding and driving mechanism of an inner grinder of a large-diameter cast iron pipe production line. The mechanism is provided with a grinding rod shaft bracket connected to a connecting seat of the inner grinder, and a grinding rod shaft is arranged on the front part of the grinding rod shaft bracket extending into a cast iron pipe through a bearing block, wherein the axis of the grinding rod shaft is longitudinally parallel to the grinding rod shaft bracket; and a driving motor is fixed on the grinding rod shaft bracket and connected with the grinding rod shaft through a belt transmission mechanism. The adoption of the technical scheme simplifies the structure of the inner grinder, decreases the length of the grinding rod shaft and reduces the number of supporting bearing blocks of the grinding rod shaft; in addition, the weight of the equipment mechanism is lightened, and under the condition that the power of a grinding electromotor keeps unchanged, the grinding time is reduced, and the replacement period of the grinding rod shaft is prolonged, thereby reducing the inventory of spare parts, greatly improving the production efficiency and reducing the production cost.

Owner:WUHU XINXING DUCTILE IRON PIPES

Hot mould centrifugal cast iron pipe mold paint and preparation method thereof

ActiveCN101693281AImprove breathabilityGood heat insulationFoundry mouldsFoundry coresSodium BentoniteEconomic benefits

The invention relates to a hot mould centrifugal cast iron pipe mold paint and a preparation method thereof. The invention mainly solves the technical difficulties of poor quality and low yield and poor economic benefit of a cast iron pipe produced by the traditional paint. The technical scheme is achieved as follows: the hot mould centrifugal cast iron pipe mold paint comprises the following components in percentage by weight: 14-16 percent of kaoline, 14-16 percent of burned diatomite, 2-4 percent of sodium base bentonite, 2-3.5 percent of talcpowder and 64-68 percent of water. The preparation method comprises the following steps: firstly, adding the kaoline, the burned diatomite, the sodium base bentonite and the talcpowder in percentage by weight into a mixing pan for dry mixing; secondly, adding 1 / 4 of water with weight percentage of 64-68 percent into the mixing pan; thirdly, mixing and rolling into a hard paste material for storage for later use; fourthly, when in use, putting the material into a wheel-rolling mixer, adding the left 3 / 4 of water into the wheel-rolling mixer for mixing-rolling and obtaining the mold paint when the concentration reaches 1.2.

Owner:绛县恒通铸造有限公司

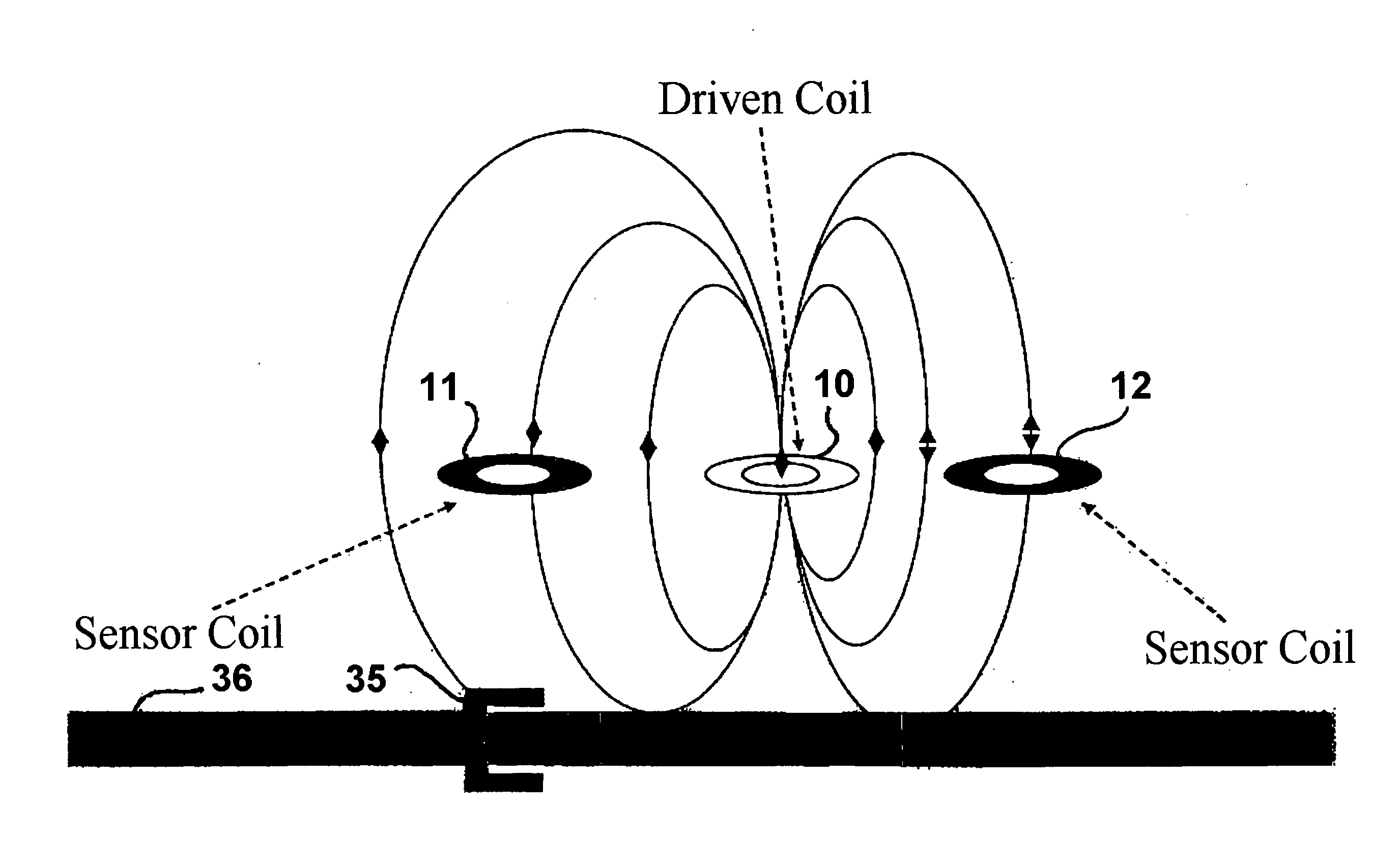

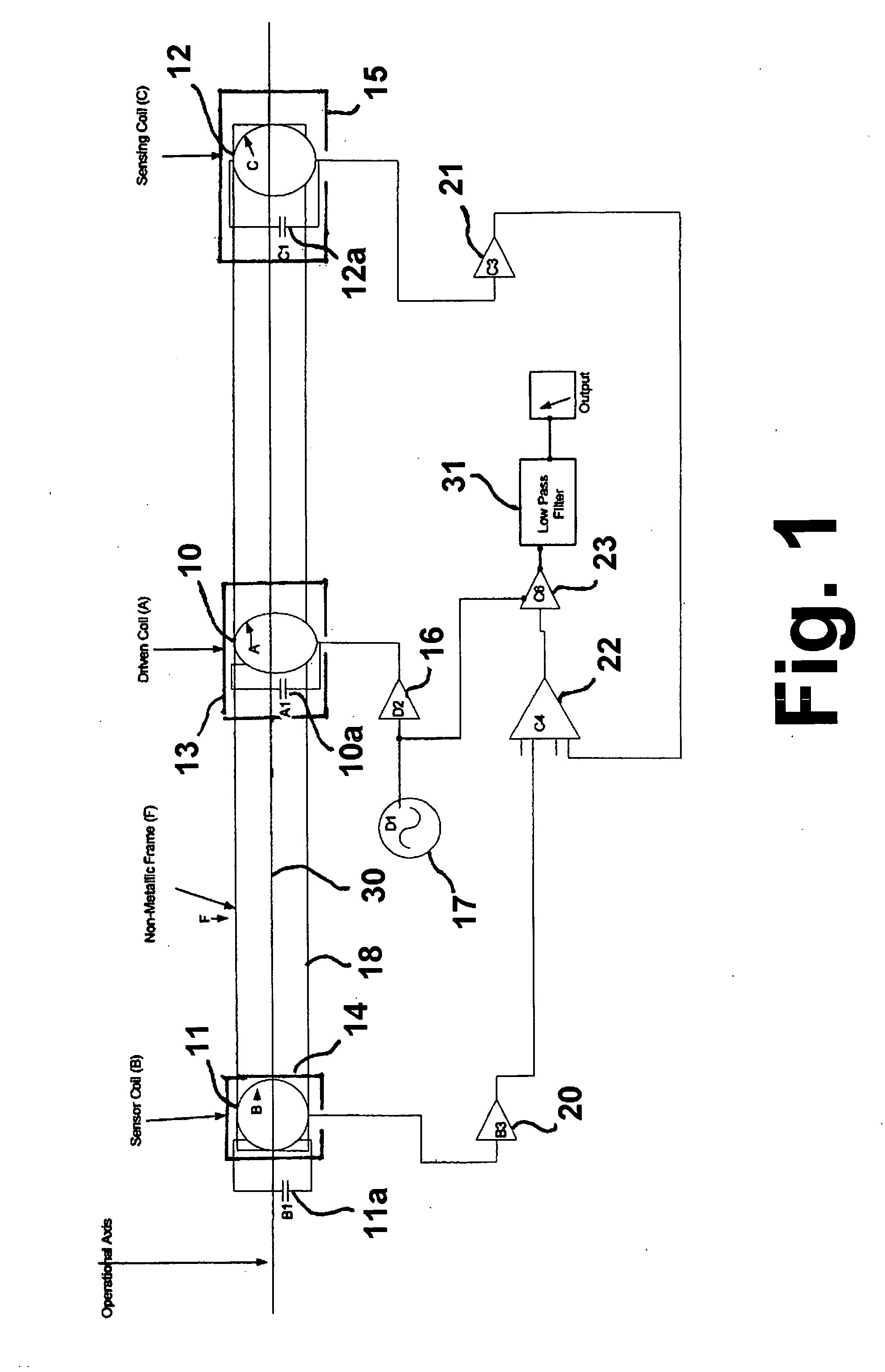

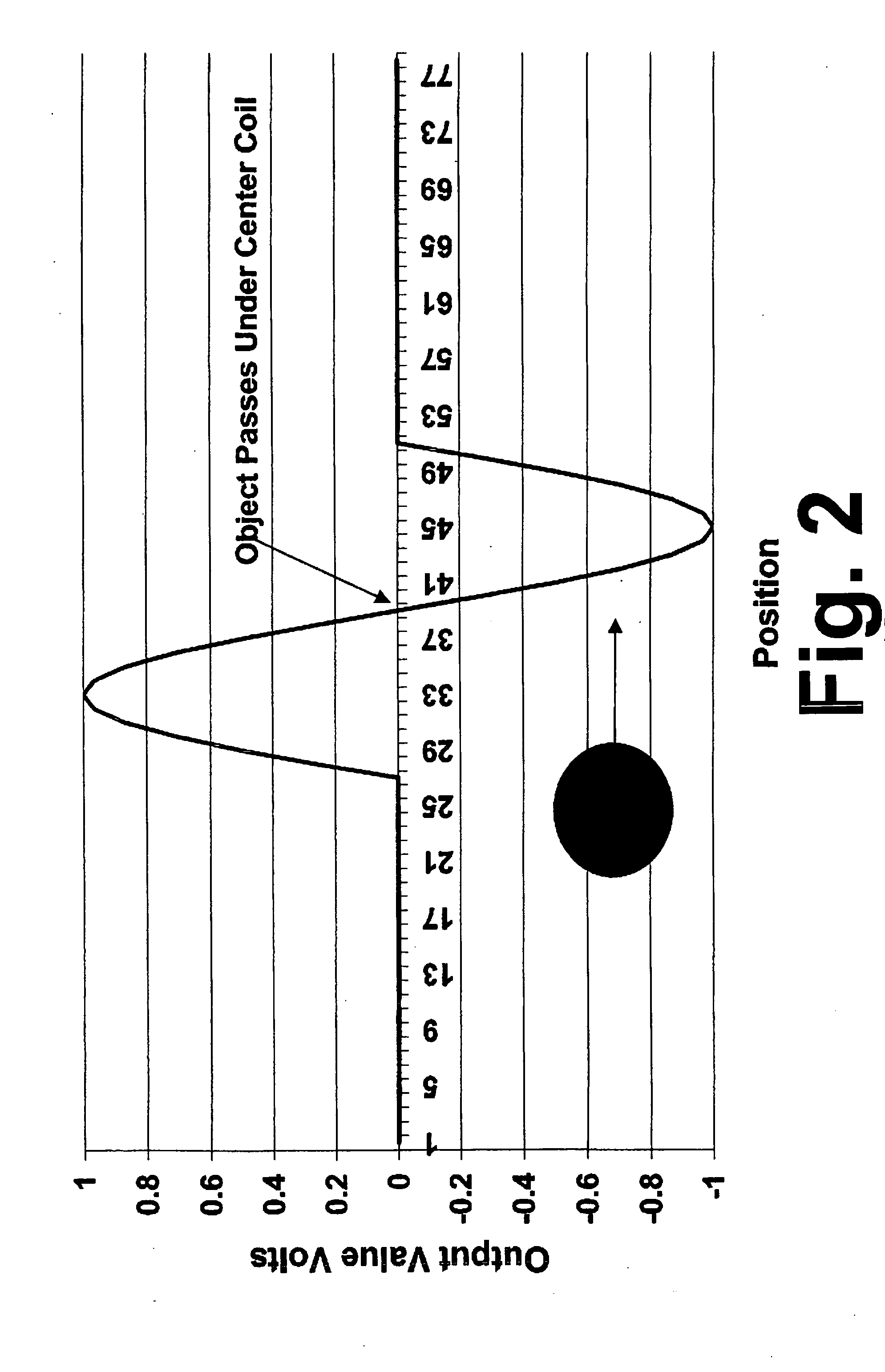

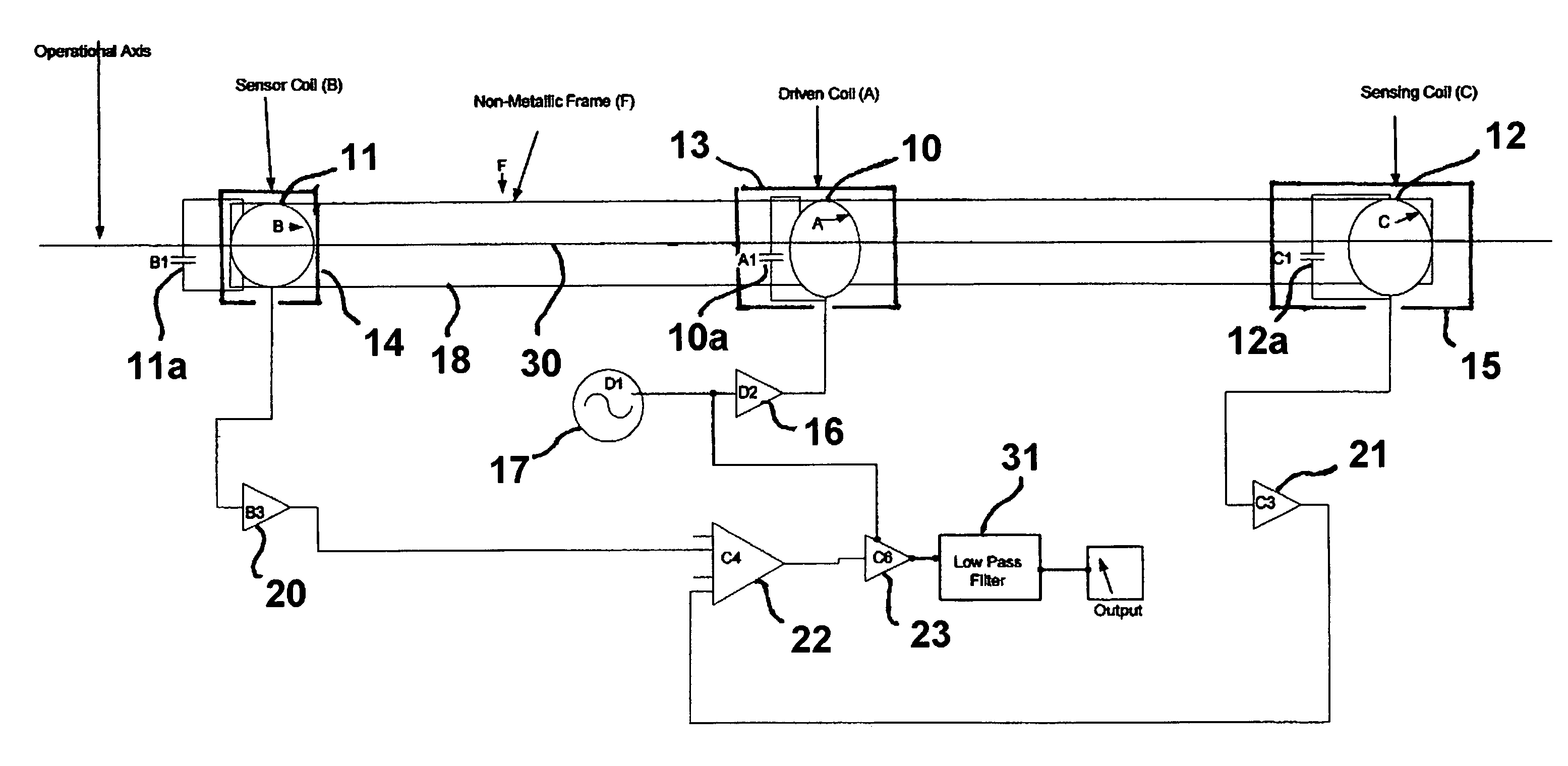

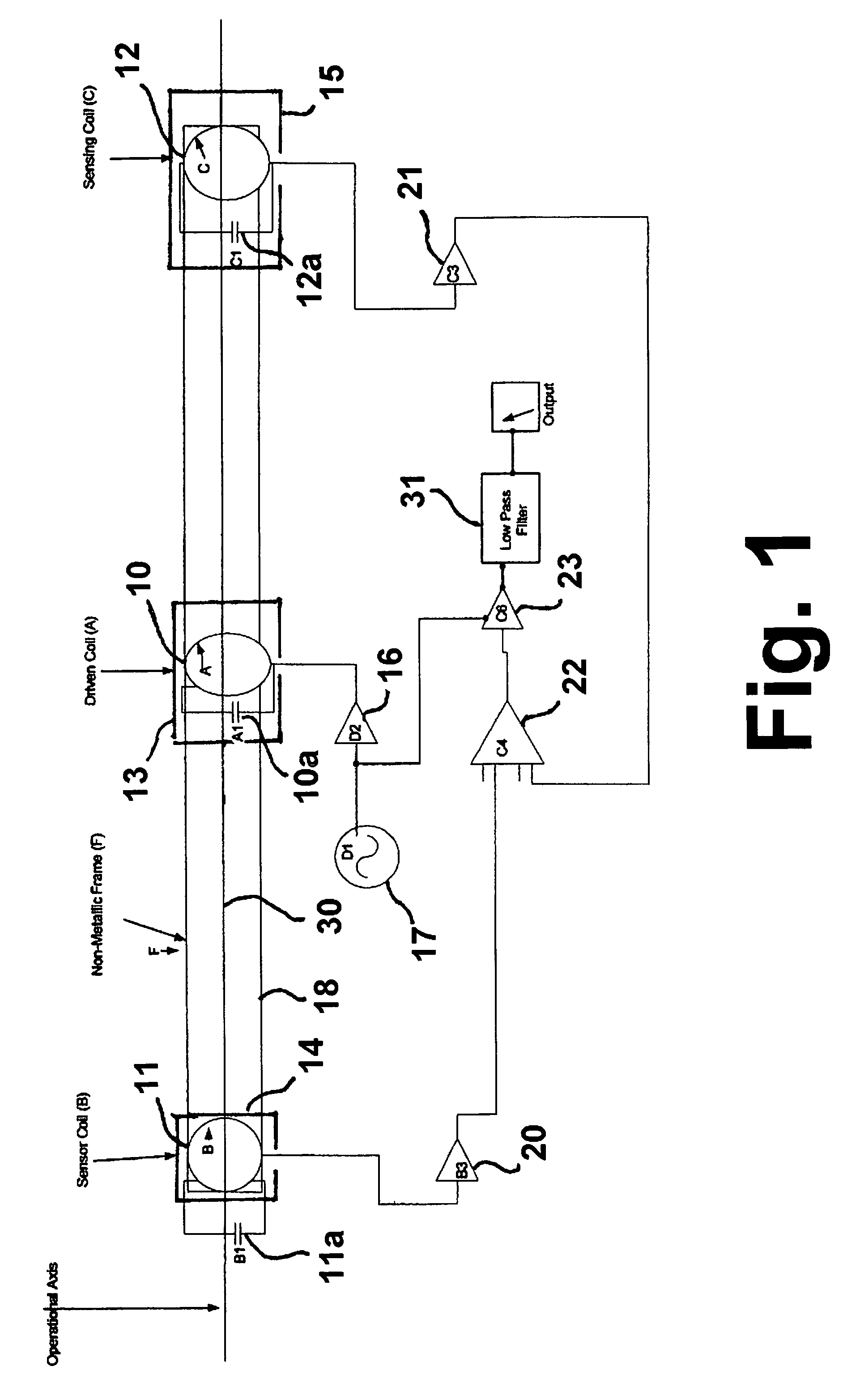

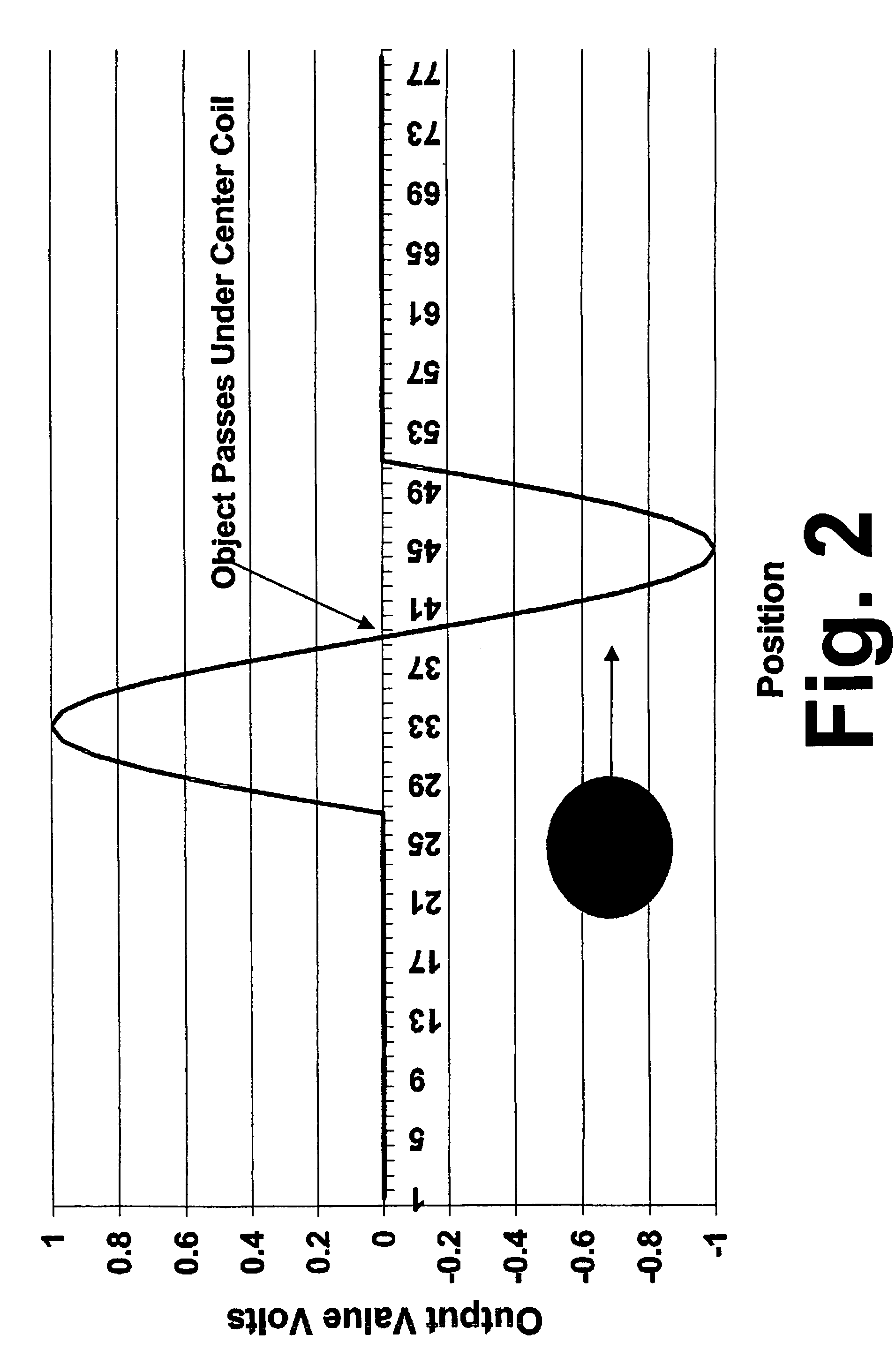

Method and apparatus for locating underground cast iron pipe joints

ActiveUS20080030189A1Accurate locationMagnetic property measurementsElectric/magnetic detectionElectricityRelative magnitude

An apparatus for locating underground cast iron pipe joints having an electrically driven resonant coil generating an alternating magnetic field and two resonant sensor coils disposed within the alternating magnetic field, each of the resonant sensor coils having an independent magnetic reluctance circuit. A device is provided for comparing electrical currents induced in each of the resonant sensor coils and a device is provided for indicating a relative magnitude of the electrical currents.

Owner:GAS TECH INST

A kind of nodular cast iron pipe with waterproof protective layer and its production process

ActiveCN102278568AImprove corrosion resistanceNeat appearanceCorrosion preventionPipe protection against corrosion/incrustationWear resistanceZinc

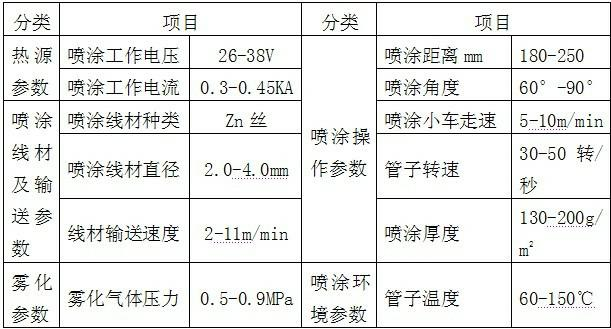

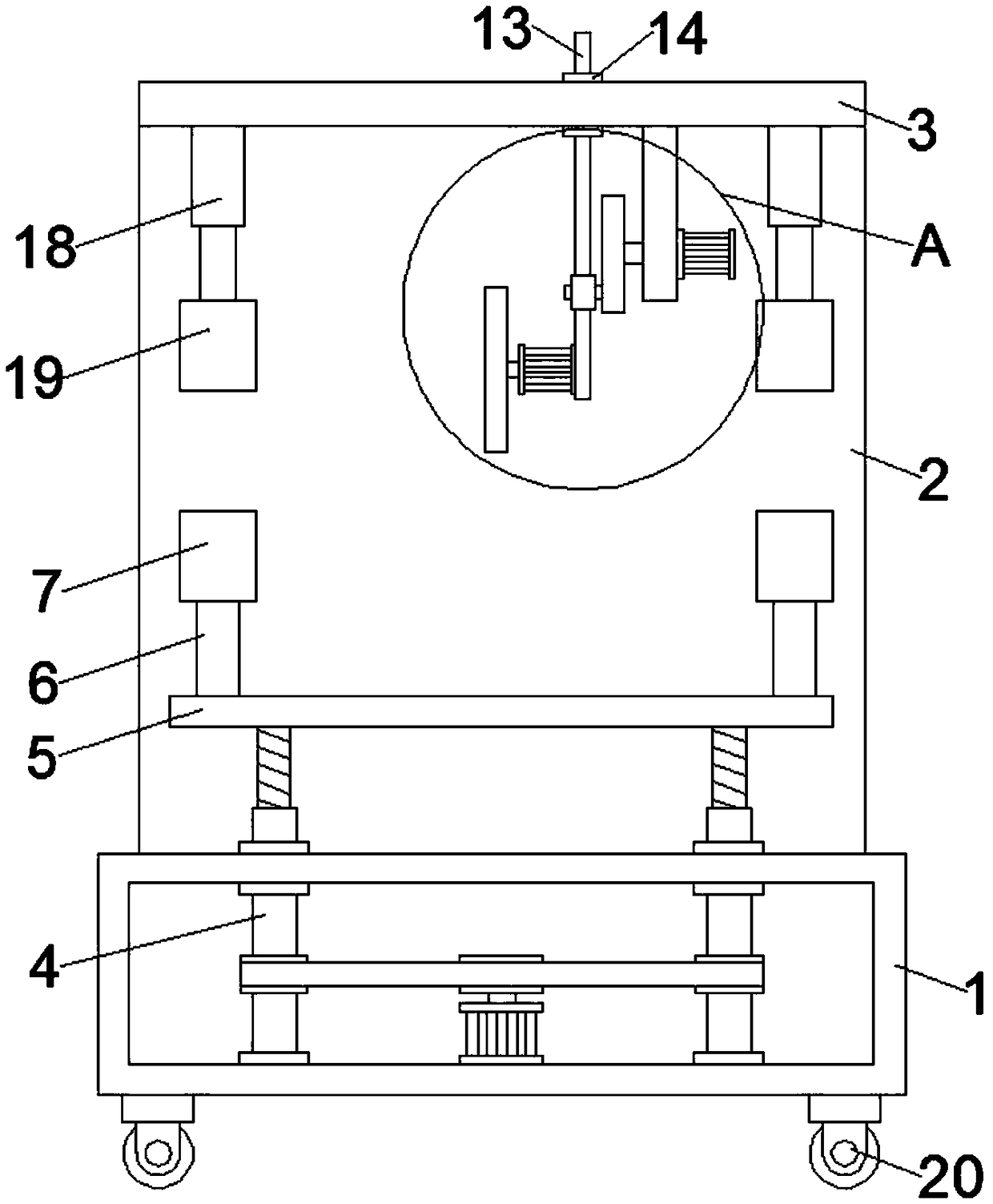

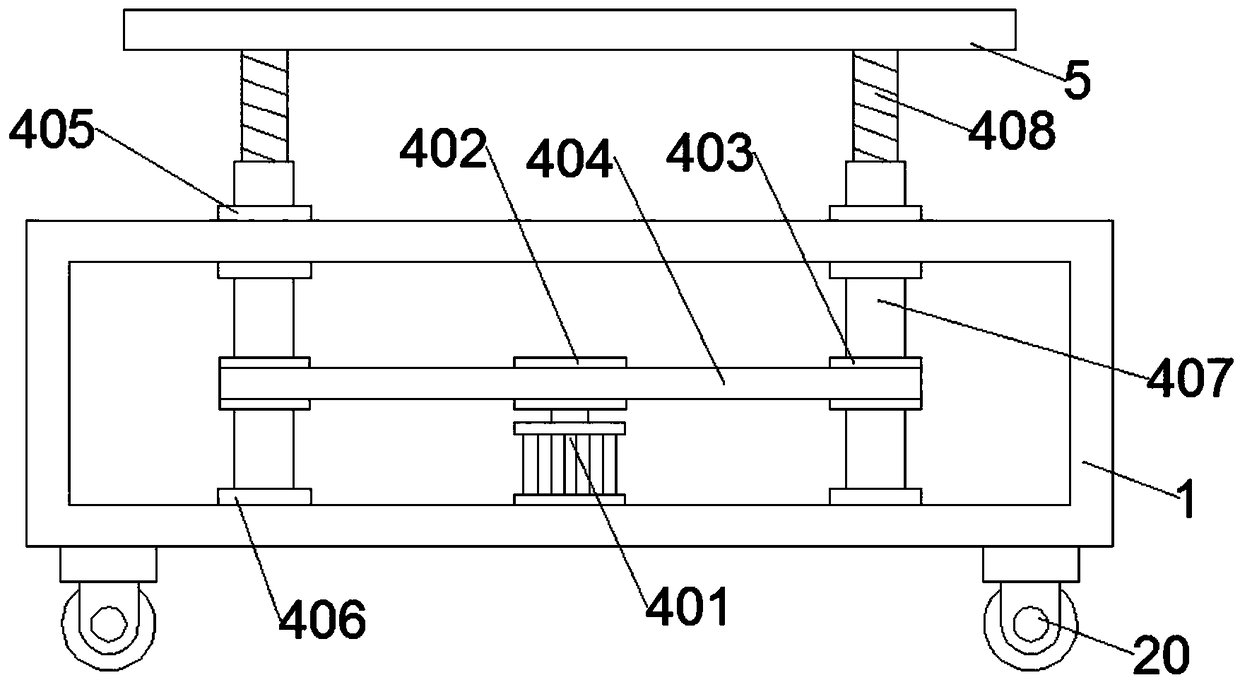

The invention discloses a ductile cast iron pipe with a waterproof protective layer and a production process thereof. The method comprises the following steps of: (1) performing surface treatment on the ductile cast iron pipe to remove surface oxides thereof; (2) spraying a zinc protective layer; (3) spraying a stainless steel protective layer; and (4) coating an enclosed corrosion-resistant protective layer. The invention has the advantages that: the zinc protective layer, the stainless steel protective layer and the enclosed corrosion-resistant protective layer are sequentially sprayed at the periphery of the ductile cast iron pipe through an arc spraying method, and a sacrificial anode protection function of the zinc protective layer, the wear resistance and corrosion resistance of thestainless steel coating and the hole-sealing corrosion inhibition performance of the enclosed coating can be cooperatively exerted, so that the ductile cast iron pipe is well protected. The ductile cast iron pipe with the coating structure has high corrosion resistance in a hydraulic environment, the waterproof protective layer has a neat appearance, covers uniformly and densely, has long protection period, high corrosion resistance and high damage resistance, secondary excavation construction is not needed, and the life cycle cost of a project is obviously reduced.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Mute drainage pipe

ActiveCN102002970AChemically resistantHeat resistantDomestic plumbingSewer pipelinesHeat resistanceUltraviolet

The invention relates to a mute drainage pipe, which effectively solves the problems of large noise, poor high temperature resistance and poor chemical corrosion resistance of the traditional drainage pipe. In the technical scheme for solving the problems, a multi-layer compound is made of a polypropylene material inner layer, a middle packing layer and a polypropylene material outer layer, wherein the thickness ratio of the polypropylene material inner layer to the middle packing layer to the polypropylene material outer layer is 1:5:1; the polypropylene material inner layer and the polypropylene material outer layer are made by mixing the following components: 17-87wt% of polypropylene random copolymer, 11-80wt% of packing, 0.5-3wt% of color master batch, 0.5-3wt% of antioxygen, 0.5-2wt% of ultraviolet absorber and 0.1-2wt% of fire retardant, wherein the total amount is 100 percent. Except the characteristics of chemical corrosion resistance, heat resistance and impact resistance just like a common plastic pipe, the drainage pipe also has the biggest characteristic of good muting effect, the noise is reduced by 20dB in comparison with the common plastic pipe, the noise is reduced by 10dB in comparison with a cast iron pipe.

Owner:康泰塑胶科技集团(郑州)有限公司

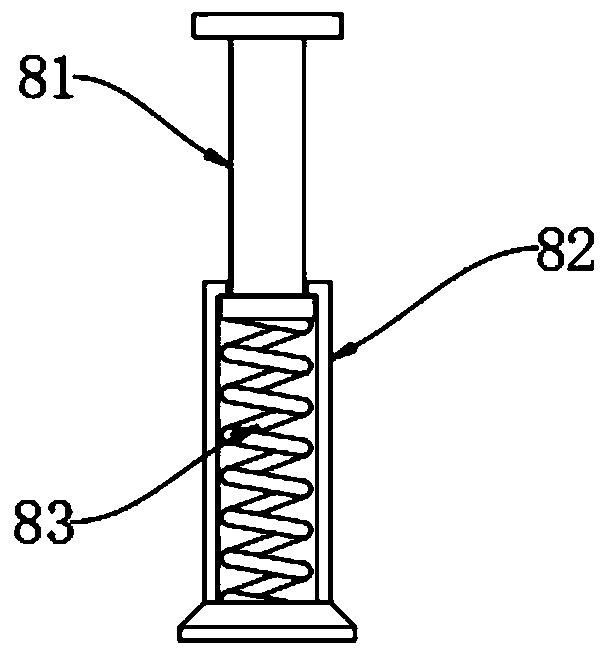

Cutting device for processing of nodular cast iron pipe

InactiveCN108788277ARealize up and down reciprocating motionFast cutting speedTube shearing machinesShearing machine accessoriesReciprocating motionCast iron pipe

The invention relates to the technical field of processing of nodular cast iron pipes, particularly to a cutting device for processing of the nodular cast iron pipe. The cutting device comprises a base, a side plate and a top plate, wherein the base is provided with an inner cavity; a lifting mechanism is arranged at the bottom of the inner cavity of the base; the lifting mechanism penetrates through the top of the base to be connected with a workbench; supporting rods are symmetrically arranged at the two ends of the top of the workbench; lower clamping plates are arranged at the upper ends of the supporting rods; the side plate is arranged at the back side of the top of the base; the top plate is arranged on the front side of the upper end of the side plate; a mounting plate is arrangedat the bottom of the top plate; a rotating motor is mounted on the right side of the lower end of the mounting plate; and an output shaft of the rotating motor penetrates through the mounting plate tobe connected with a disc. According to the cutting device for processing of the nodular cast iron pipe provided by the invention, up-down reciprocating motion of a cutting blade is achieved while thenodular cast iron pipe is cut, cutting speed is increased, and cutting quality and cutting efficiency are improved; and the structure is novel, design is reasonable, operation is convenient and quick, and the requirement of production utilization is met.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

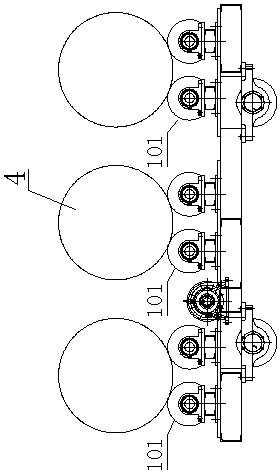

Cast iron pipe outer wall grinding device

ActiveCN104985494AReduce loadImprove stabilityRevolution surface grinding machinesGrinding work supportsUltimate tensile strengthCast iron pipe

The invention relates to the technical field of cast iron pipe machining and particularly discloses a cast iron pipe outer wall grinding device. The cast iron pipe outer wall grinding device comprises a supporting frame. The supporting frame is provided with at least one pipe grinding mechanism capable of walking on the supporting frame. The pipe grinding mechanism is used for grinding the outer wall of a cast iron pipe. A rotary carrier roller set is arranged below the supporting frame, and comprises a plurality of pairs of carrier rollers arranged in parallel. The portion between each pair of carrier rollers is used for bearing the cast iron pipe. The carrier rollers are driven by a drive mechanism to rotate to drive the cast iron pipe to rotate. The cast iron pipe outer wall grinding device further comprises a vibrating device and a blowing device. The vibrating device is arranged below the supporting frame and used for making the cast iron pipe vibrate on the carrier rollers. The blowing device is arranged on one side of the supporting frame and used for blowing the inner surface and the outer surface of the cast iron pipe. The pipe wall of the cast iron pipe can be effectively ground and cleaned, efficiency is high, the quality of the surface of the outer wall of the formed cast pipe can be improved, adhesive force of a paint film is improved, and the labor intensity of workers is relieved.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Powder product to protect moulds for the centrifugal casting of cast iron tubes and method of preparing this product

Powder product for the protection of molds for centrifugal casting of cast iron tubes, and a method for its production. The powder contains a mixture of a silicon-based inoculating agent and a mineral powder, the silicon-based inoculating product comprising waste masses from synthesis of alkyl- or aryl- halosilanes, from which tin and optionally copper has been removed. The mineral powder may contain at least one material selected from the group consisting of carbon and a fluoride.

Owner:PECHINEY ELECTROMETALLURGIE

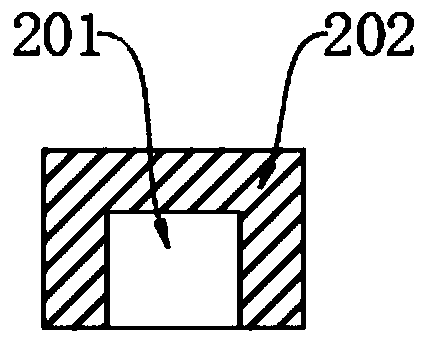

Encased concrete nodular cast iron pipe

InactiveCN102777706AEasy for jacking constructionShorten the construction periodRigid pipesCast iron pipeFlange

The invention discloses an encased concrete nodular cast iron pipe and relates to the technical field of a socket-type nodular cast iron pipe. The encased concrete nodular cast iron pipe comprises a socket-type nodular cast iron pipe body; both ends of the socket-type nodular cast iron pipe body are respectively provided with a socket and a spigot; the outer wall of the socket-type nodular cast iron pipe body is coated with a concrete layer for ensuring the continuous lengths of the socket-type nodular cast iron pipe body equal; a cylindrical reinforcing mesh is sandwiched in the concrete layer; a connecting flange set is arranged at the outer end of the spigot; a ring-shaped boss is arranged outside the end part of the socket; and the outer diameter of the ring-shaped boss is the same with that of the concrete layer. The encased concrete nodular cast iron pipe has the advantages that (1) the concrete layer is coated on the outer wall of the socket-type nodular cast iron pipe body, so that the diameters of both ends of the socket-type nodular cast iron pipe body are ensured equal, the jacking construction is convenient to carry out, the construction period is shortened, the engineering cost is reduced, concrete on the outer layer of the socket-type nodular cast iron pipe body can also protect the socket-type nodular cast iron pipe body and the service life is prolonged; and (2) flanges and reinforcement plates are arranged at the end of the spigot of the socket-type nodular cast iron pipe coated with the concrete layer and the end of the spigot is used as a bearing end in the jacking construction, so that the construction is convenient to carry out.

Owner:XINXING DUCTILE IRON PIPES CO LTD +1

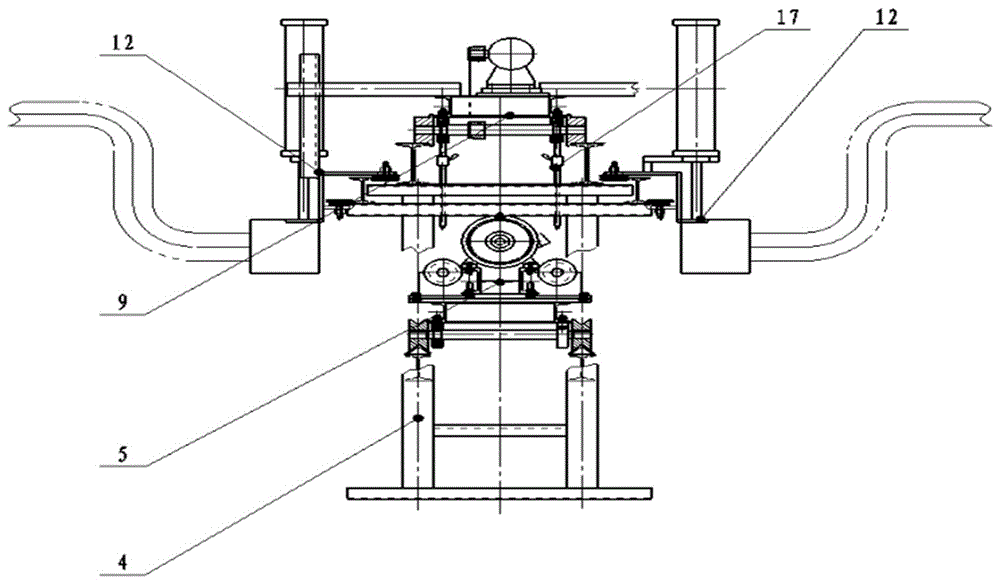

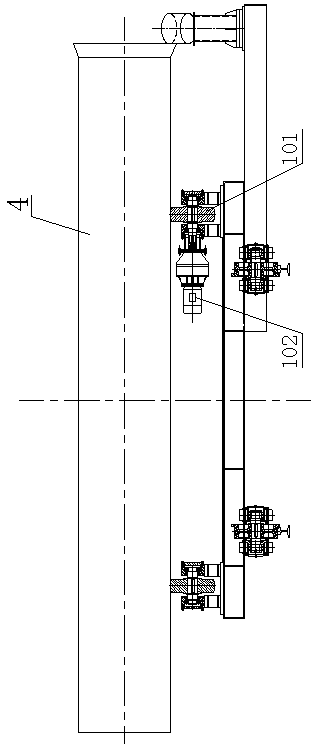

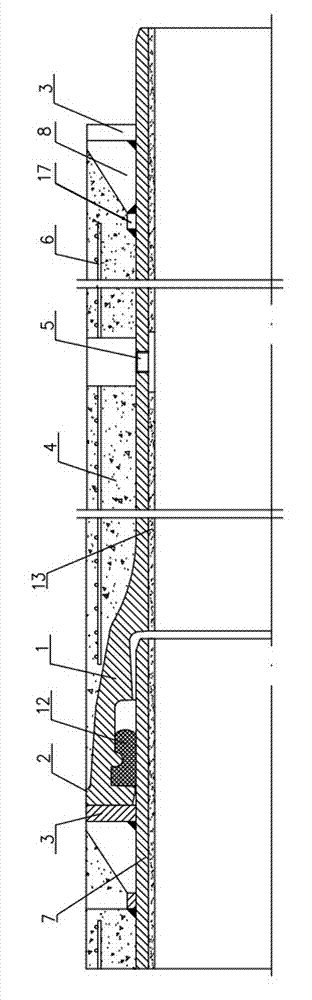

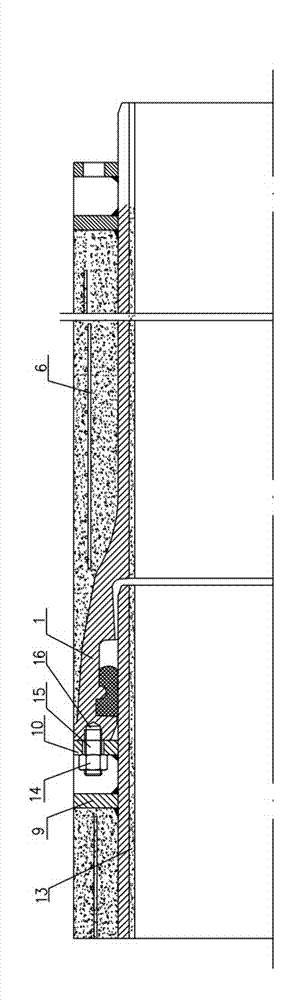

Cement lining device of centrifugal spherical graphite cast-iron pipe

The invention discloses a cement lining device of a centrifugal spherical graphite cast-iron pipe, and relates to the technical field of cement lining of the spherical graphite cast-iron pipe. The cement lining device mainly comprises a frame, a pressing wheel set, a first drive riding wheel set, a second drive riding wheel set, a first driven riding wheel set, a second driven riding wheel set, and a baffle wheel. A drive motor is mounted on one side of the second drive riding wheel set of the frame, the drive riding wheels of the second drive riding wheel set is connected with the drive motor through a second transmission shaft, and the drive riding wheels of the first drive riding wheel set is connected with the drive riding wheels of the second drive riding wheel set through a first transmission shaft. Elongated grooves are uniformly and axially distributed on an outer periphery face on which the baffle wheel is in contact with a spherical graphite cast-iron pipe end. By the aid of the cement lining device, uniformity and stability of rotation speed of the spherical graphite cast-iron pipe can be guaranteed, a uniform and tight cement layer is formed on the inner wall of the spherical graphite cast-iron pipe, quality of cement lining of the spherical graphite cast-iron pipe is effectively improved, and production efficiency is improved.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Process for spraying polyurethane on inner wall of nodular cast iron pipe

InactiveCN101758013APrecise proportionWell mixedPretreated surfacesCoatingsStress relievingHigh pressure

The invention relates to a process for spraying polyurethane on the inner wall of a nodular cast iron pipe, in particular to the process for spraying the polyurethane on the inner wall of the DN100-DN300 nodular cast iron pipe. The steps of the process are as follows: 1. processing the inner surface: (1) removing rust and oxide skins; (2) shot-blasting, further removing the rust on the surface of the nodular cast iron pipe, and eliminating stress; (3) removing floating dust; 2. heating and drying; 3. preparing for the spraying: (1) storing coatings; (2) stirring the coatings; (3)_heating and heat-preserving the coatings; (4)_spraying for trial; 4. spraying the polyurethane: polyurethane components A and B are heated, filtered and heat-preserved according to the volume ratio of 1:1, are conveyed into a special mixer under high pressure for high-speed collision mixing or spiral mixing, and are then sprayed onto the surface of the nodular cast iron pipe by a spray gun or a spray cup at high speed in an atomized manner; 5. cleaning the mixer and the spray gun or the spray cup. The thickness of a film formed in one step can be up to 3mm and the adhesive power of the coatings is high, so that the invention can meet the demand for spraying the polyurethane on the inner wall of the small-caliber nodular cast iron pipe.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Production technology for nodular cast iron pipe lining epoxy ceramic

InactiveCN104728557ANo leakageNo segregationCorrosion preventionPipe protection against corrosion/incrustationCeramic coatingFirming agent

The invention belongs to the field of nodular cast iron pipe corrosion prevention, and particularly relates to a production technology for nodular cast iron pipe lining epoxy ceramic. The production technology comprises the steps that after being preheated, a nodular cast iron pipe metal base body rotates at high speed under the drive of a carrier roller, a coating machine coats the interior of the pipe body with liquid A and liquid B at uniform speed, an antifoaming agent with the weight being 3% of the total weight of the liquid A and the liquid B is added into the liquid A and the liquid B for synchronous coating, and an epoxy ceramic coating layer is formed on the inner surface of the pipe body after cooling and solidification. The liquid A is formed by mixing, by mass, 20-30% of quartz powder and 70-80% of epoxy resin. The liquid B is formed by mixing, by mass, 20-30% of quartz powder and 70-80% of polyamide curing agent. The weight ratio of the liquid A to the liquid B ranges from 1:1 to 1:1.2. By the adoption of the production technology, pin hole and bubble phenomena produced on the surface of epoxy ceramic are avoided, the surface of the epoxy ceramic is smooth and flat, and no electric leakage phenomenon exists through electric spark detection.

Owner:BENGANG STEEL PLATES +1

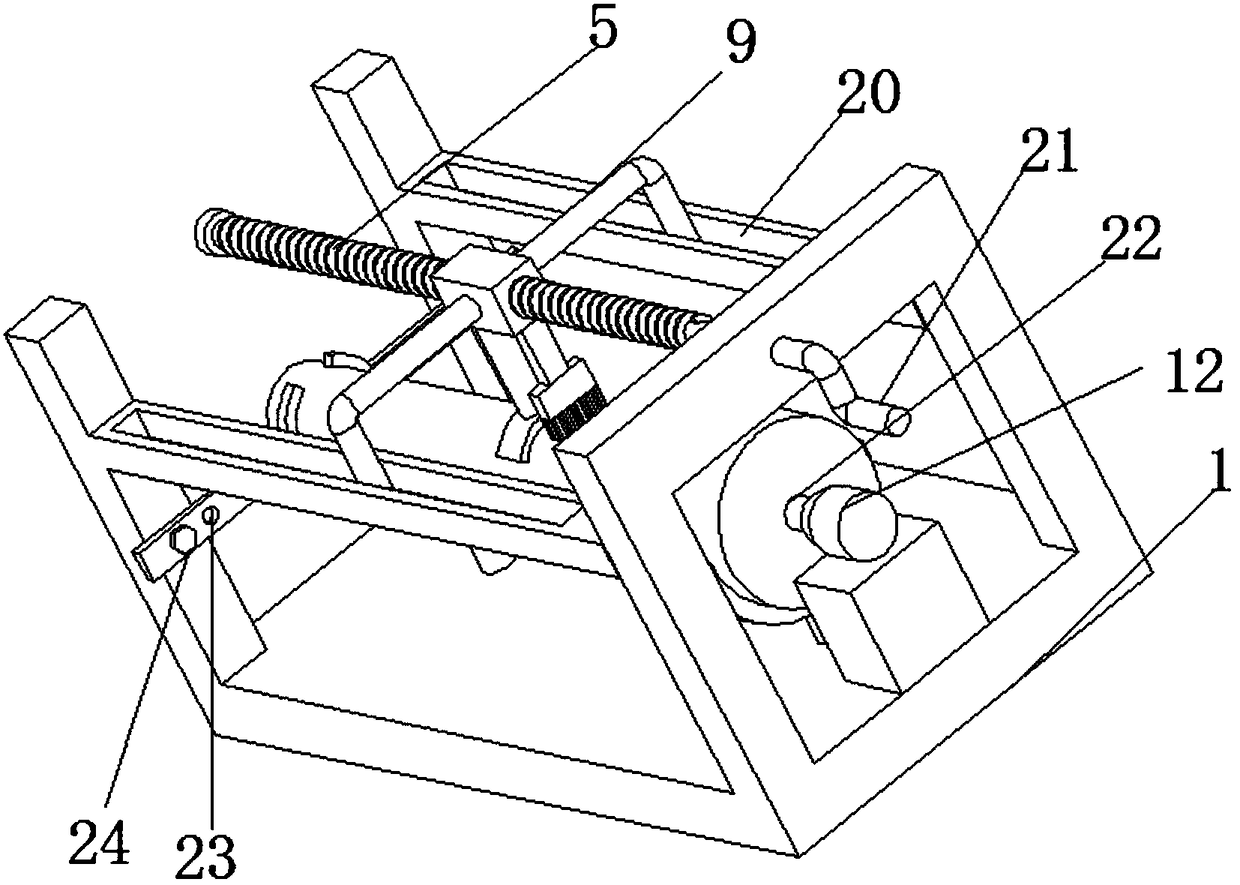

Centrifugal spheroidal cast iron pipe with plastic lining

The invention discloses a plastic lining eccentric spheroidal graphite, which includes a spheroidal graphite body and a inner lining pipe, the inner lining pipe is high molecular poly resin pipe, the two arrange with banding layer; it also discloses the manufacturing method for above mentioned plastic lining spheroidal graphite, the inner wall is pasted with banding agent, the pipe is assembled onto the frame of the extension mechanism; the grip holder core pole is penetrated through the plastic lining pipe, the cone core and the cone grip holder nut on the front part of the grip holder core pole of the grip holder core pole clamp the cone end of the plastic lining; then adjusts the adjusting nut back of the grip holder core pole, the spring penetrating on back of the grip holder core pole is supported by another end of the plastic lining; the extension mechanism pulls the inner lining pipe through the diameter shrinkage model and pulls it into the spheroidal graphite; when the inner lining pipes all goes into the spheroidal graphite and is amended, carries on thermal process to the spheroidal graphite.

Owner:CHEUNG KAY PLASTIC LINED STEEL PIPE MFG

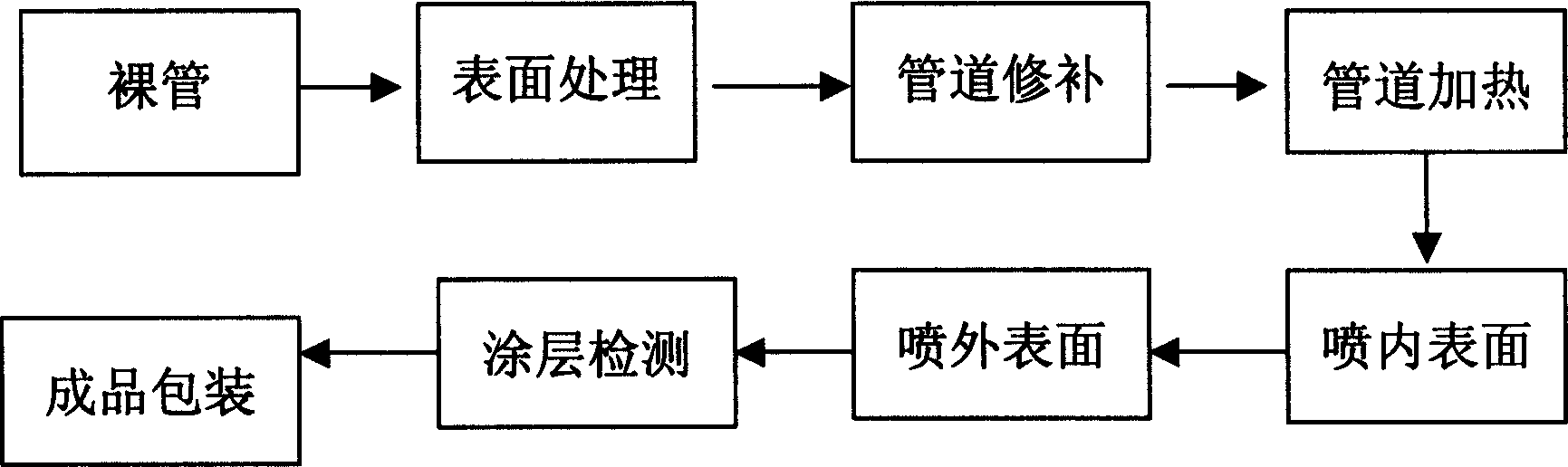

Process for coating polyurethane on inner and outer surface of nodular graphite cast iron pipe

The technological process of painting polyurethane to inner and outer surface of nodular cast iron pipe includes the successive steps of: surface treatment comprising outer surface shot blast and inner surface polishing; surface repairing including filling the notches with putty; heating to temperature of 20-80 deg.c; spraying inner surface with high pressure air-free spraying machine, spraying bogie and spraying gun; spraying outer surface with high pressure air-free spraying machine, spraying bogie and spraying gun; coating detection comprising detecting coating thickness and electric spark detection; and product packing. The present invention has the advantages of simple construction, wide coating application temperature range, high coating mechanical strength, stable chemical performance and no environmental pollution.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Mother for preparing a lifting tube through counter-gravity casting

InactiveCN102925945AImprove air tightnessHigh strengthAnodisationHot-dipping/immersion processesEconomic benefitsAlloy

The invention discloses a method for preparing a lifting tube through counter-gravity casting, which uses a stainless steel tube or a cast iron pipe as a matrix tube, wherein a layer of aluminum oxide (Al2O3) ceramic layer which endures erosion and is not wetted in alloy liquid such as aluminum (Al) liquid and the like, the Al2O3 ceramic layer and a ferrum (Fe) matrix layer have strong binding power, and the Al2O3 ceramic layer is also not easy to fall even in a collision situation. Because of adopting the Fe matrix tube, the formed lifting tube by adopting the method for preparing the lifting tube through counter-gravity casting is high in air tightness and strength. The formed lifting tube adopting the method for preparing the lifting tube through counter-gravity casting is high in reliability, simple in process and low in cost, and can generate huge economic benefits.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

Production device for ductile iron pipe fittings

ActiveCN110695825AIncrease costEasy to grind separatelyEdge grinding machinesRevolution surface grinding machinesHydraulic cylinderPipe fitting

The invention discloses a production device for ductile iron pipe fittings, relates to the technical field of production of ductile iron pipe fittings, and solves the problems that the cost of grinding devices is increased, the time spent on installing the pipe fittings twice is long, and the grinding efficiency of the pipe fittings is reduced as the surface and the mouth of the ductile iron pipefittings are ground by two types of grinding devices respectively. A first sealing strip is fixedly connected to the mouth of a grinding box, and a first driving motor and a control panel are sequentially arranged on the other side of the grinding box from top to bottom. A supporting column is fixedly connected to the side of the lower end of the grinding box. A dust collector is fixedly connectedto the lower end of a collecting cover. Outer clamping mechanisms are arranged at both ends of a mounting rod, and an inner clamping mechanism is arranged in the middle of the mounting rod. A first grinding mechanism is arranged at the lower end of a first hydraulic cylinder, an electric slider is arranged at the upper end of an electric slide rail, and a second grinding mechanism is arranged atthe upper end of the electric slider.

Owner:HUBEI ZHENGXIN TUBE

Method and apparatus for locating underground cast iron pipe joints

ActiveUS7466134B2Accurate locationMagnetic property measurementsElectric/magnetic detectionRelative magnitudeElectricity

An apparatus for locating underground cast iron pipe joints having an electrically driven resonant coil generating an alternating magnetic field and two resonant sensor coils disposed within the alternating magnetic field, each of the resonant sensor coils having an independent magnetic reluctance circuit. A device is provided for comparing electrical currents induced in each of the resonant sensor coils and a device is provided for indicating a relative magnitude of the electrical currents.

Owner:GAS TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com