Secondary atomization fan nozzle and paint sprayer special for cast pipe

A secondary atomization and fan-shaped nozzle technology, which is applied in the direction of coating, spraying device, spraying device, etc., can solve the problems of unsatisfactory atomization effect, unsuitable side-by-side arrangement, poor coating quality, etc., so as to improve the spraying quality, Improve the quality of the outer wall and production efficiency, and improve the effect of spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

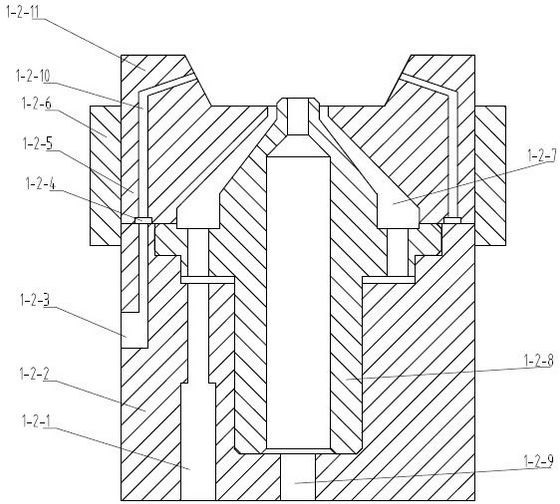

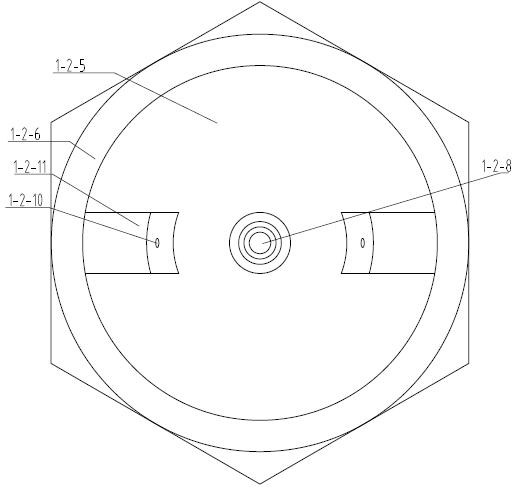

[0014] Such as figure 1 and figure 2 The secondary atomization fan nozzle shown includes a base 1-2-2, a valve core 1-2-8, an atomizing cap 1-2-5, and a locking atomizing cap 1-2-5 and a base 1 - 2-2 lock nut 1-2-6, the atomizing cap 1-2-5 is a ring-shaped structure, the middle part is provided with a conical through hole, the conical through hole and the cone at the top of the valve core The surface constitutes a primary atomization air channel 1-2-7; the top of the atomization cap 1-2-5 is also symmetrically provided with an angular atomization block 1-2-11, the key improvement of which is: the atomization cap 1- Two eccentric secondary atomization air passages 1-2-10 are symmetrically arranged in the middle of 2-5, and the outlets of the secondary atomization air passages 1-2-10 are respectively located in the angular atomization block 1-2-11 Two slopes; the bottom surface of the atomizing cap 1-2-5 is also provided with an annular groove 1-2-4, and the two secondary ato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com