Patents

Literature

518 results about "Ductile iron pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ductile iron pipe is a pipe made of ductile cast iron commonly used for potable water transmission and distribution. This type of pipe is a direct development of earlier cast iron pipe, which it has superseded. The ductile iron used to manufacture the pipe is characterized by the spheroidal or nodular nature of the graphite within the iron. Typically, the pipe is manufactured using centrifugal casting in metal or resin lined moulds. Protective internal linings and external coatings are often applied to ductile iron pipes to inhibit corrosion: the standard internal lining is cement mortar and standard external coatings include bonded zinc, asphalt or water-based paint. In highly corrosive environments loose polyethylene sleeving (LPS) to encase the pipe may also be used. Life expectancy of unprotected ductile iron pipes depends on the corrosiveness of soil present and tends to be shorter where soil is highly corrosive. However, a lifespan in excess of 100 years has been estimated for ductile iron pipelines installed using "evolved laying practices", including use of properly installed LPS (polyethylene encasement). Studies of ductile iron pipe's environmental impact have differing findings regarding emissions and energy consumed. Ductile iron pipe manufactured in the United States has been certified as a sustainable product by the Institute for Market Transformation to Sustainability.

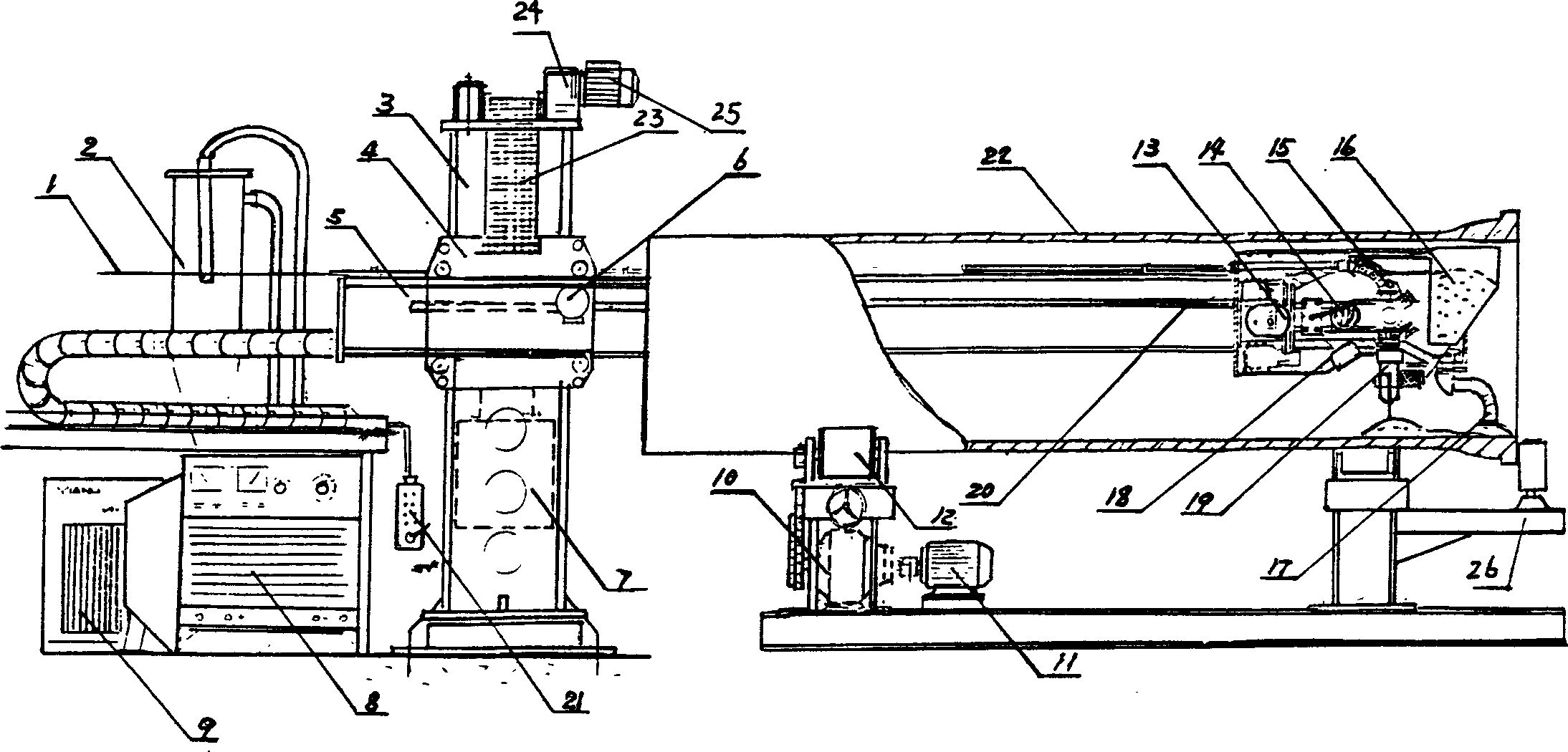

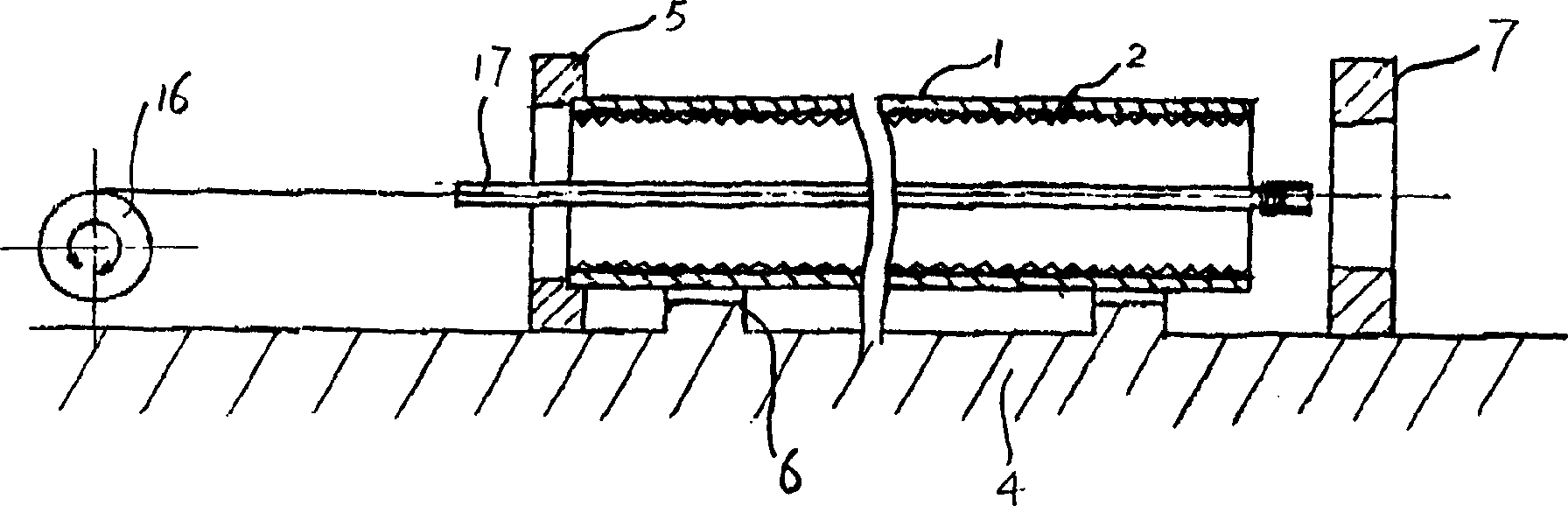

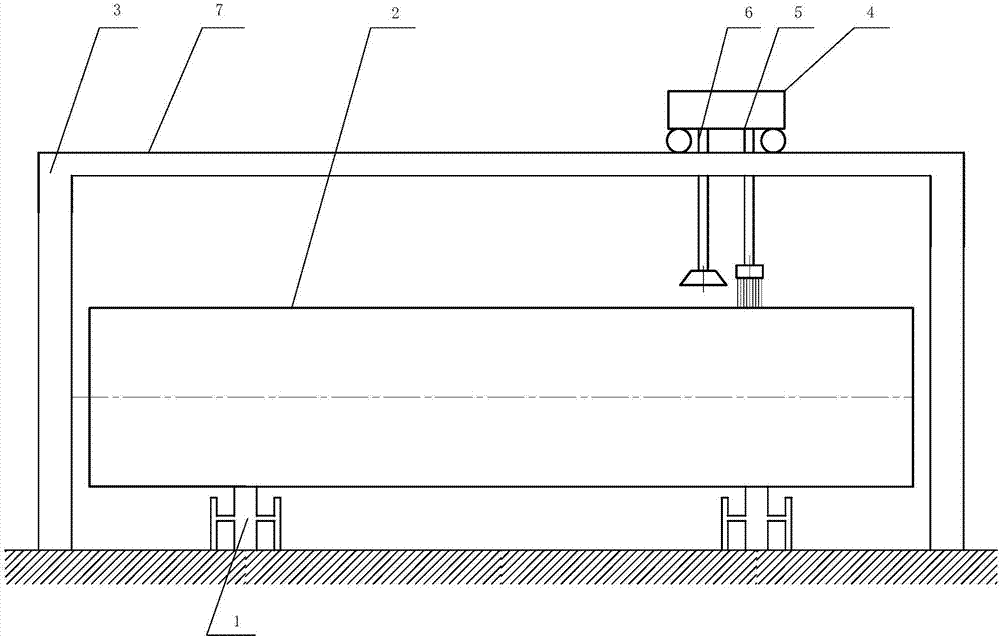

Long barrel internal and external wall spiral type helical swinging built up welding method and equipment

InactiveCN1475323AImprove corrosion resistanceWelding/cutting auxillary devicesArc welding apparatusEngineeringCast iron pipe

A spirally oscillating wrap build-up welding method and equipment for long cylindrical body, such as the mould of long (14m) large-diameter (500 mm) nodular cast iron pipe, rotary drum type ball grinder, cylindrical container, etc features that the included spiral angle between wide welded band and cylinder's axis is 30-60 deg, welding gun is oscillating by 30-100 mm for ampletude and 30-50 times / min for frequency, and the adjacent welded bands are overlapped by 10 mm.

Owner:傅成

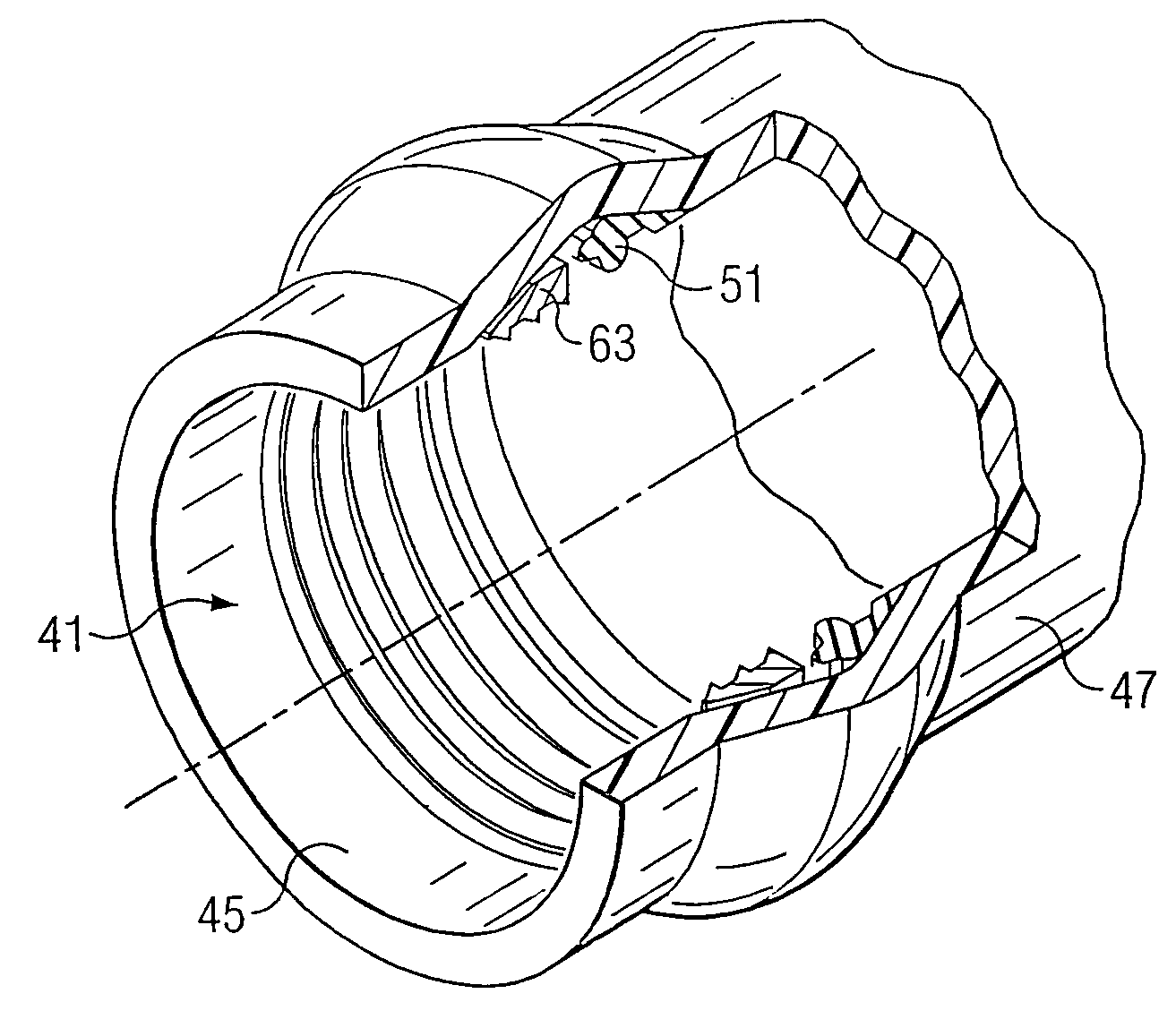

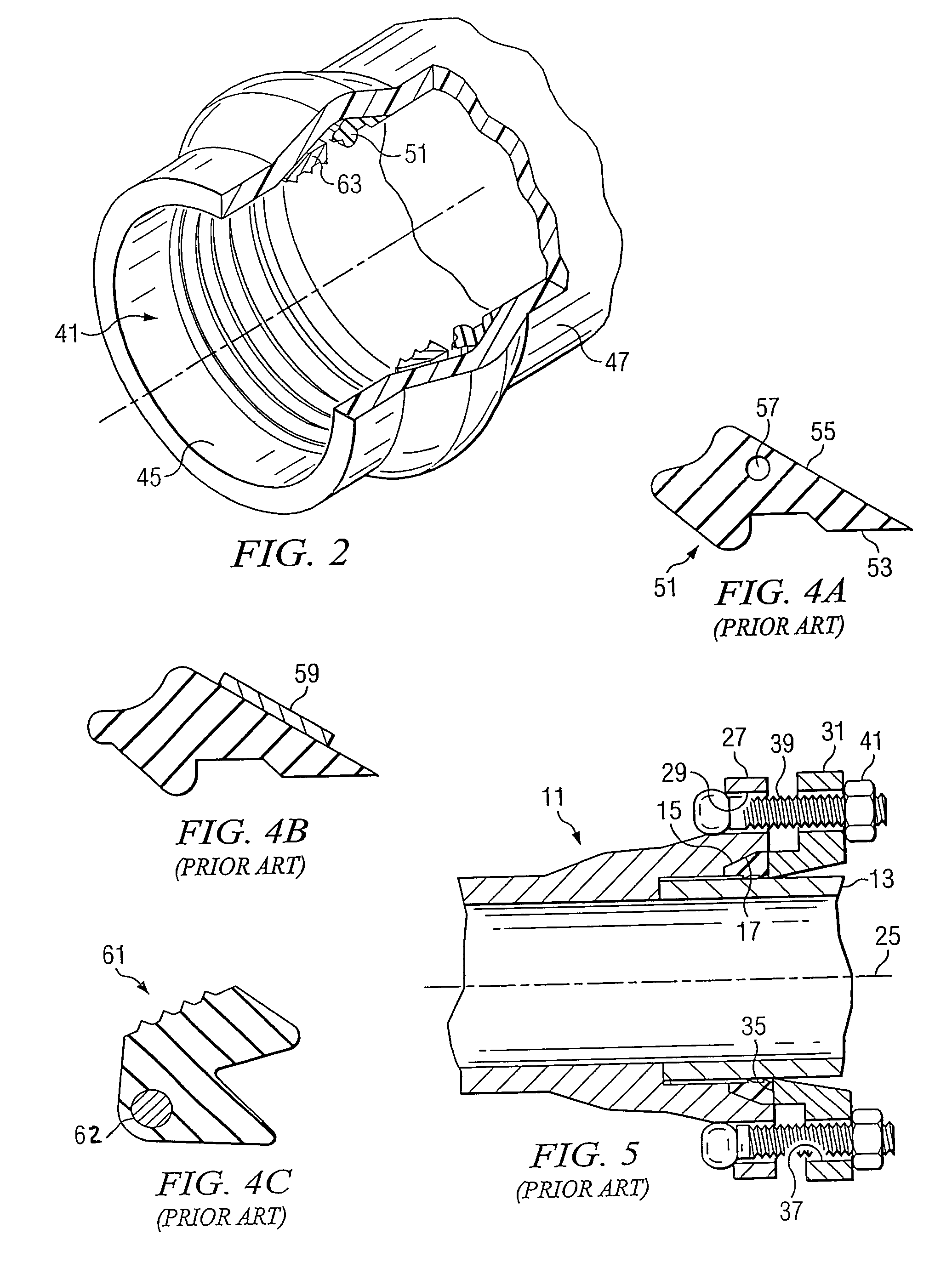

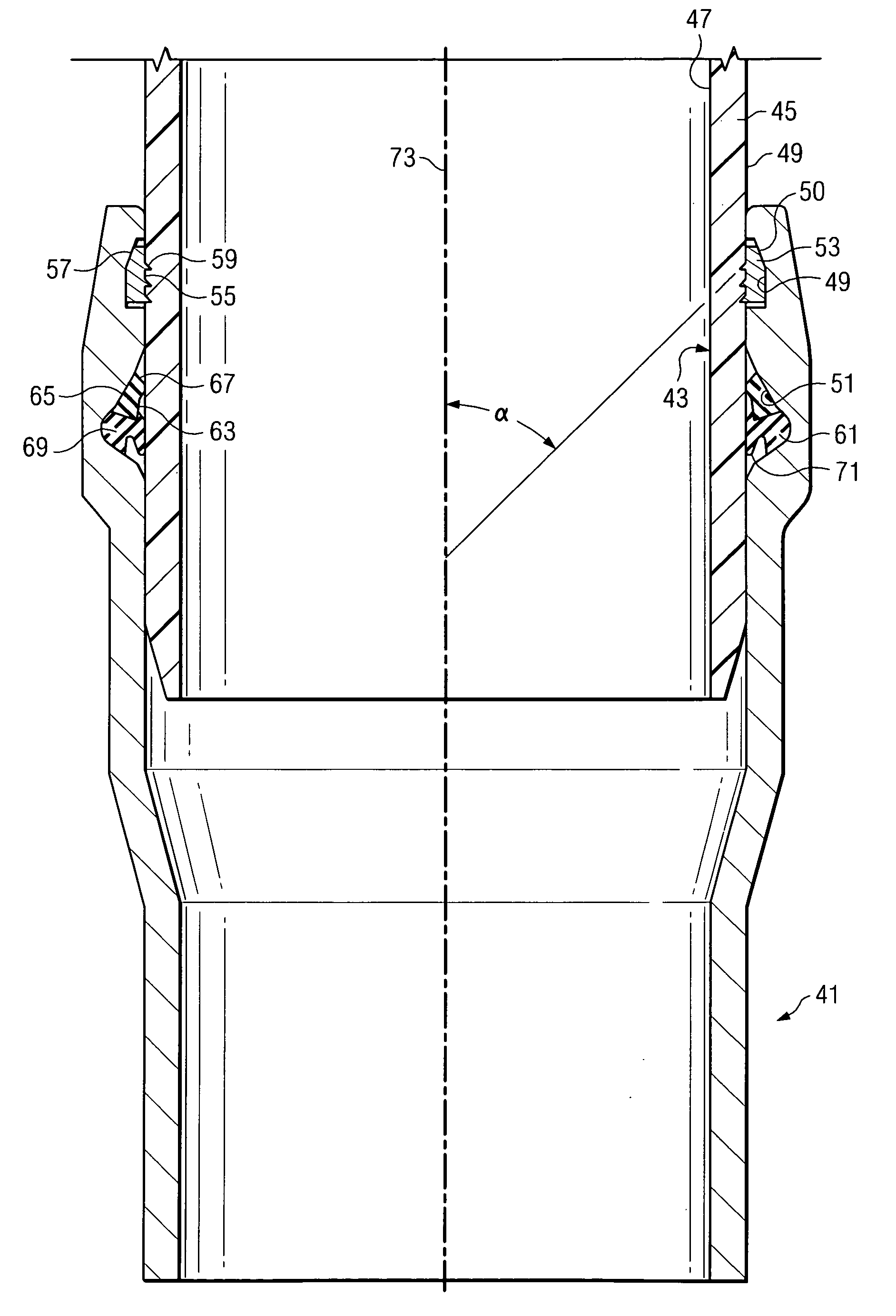

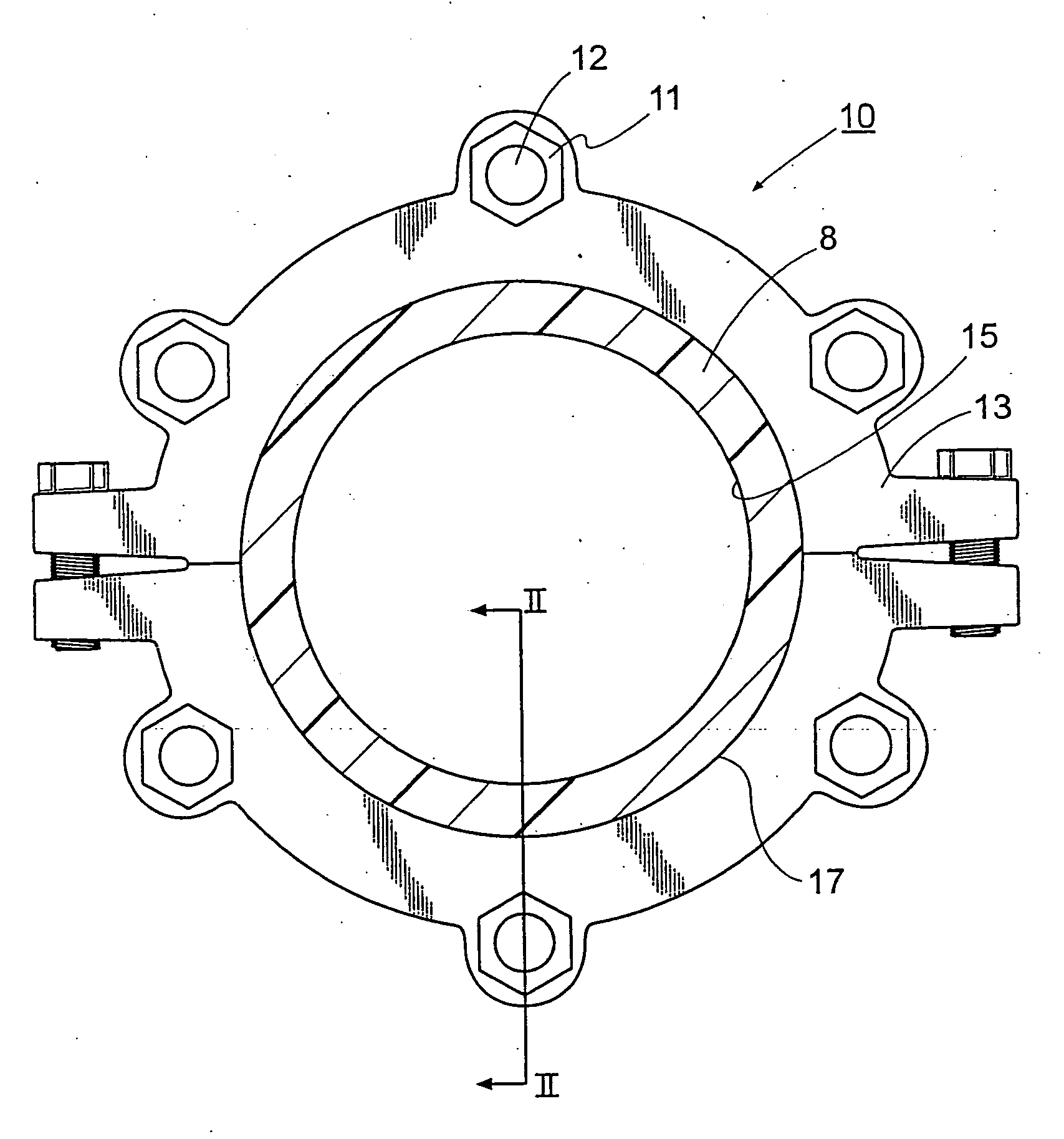

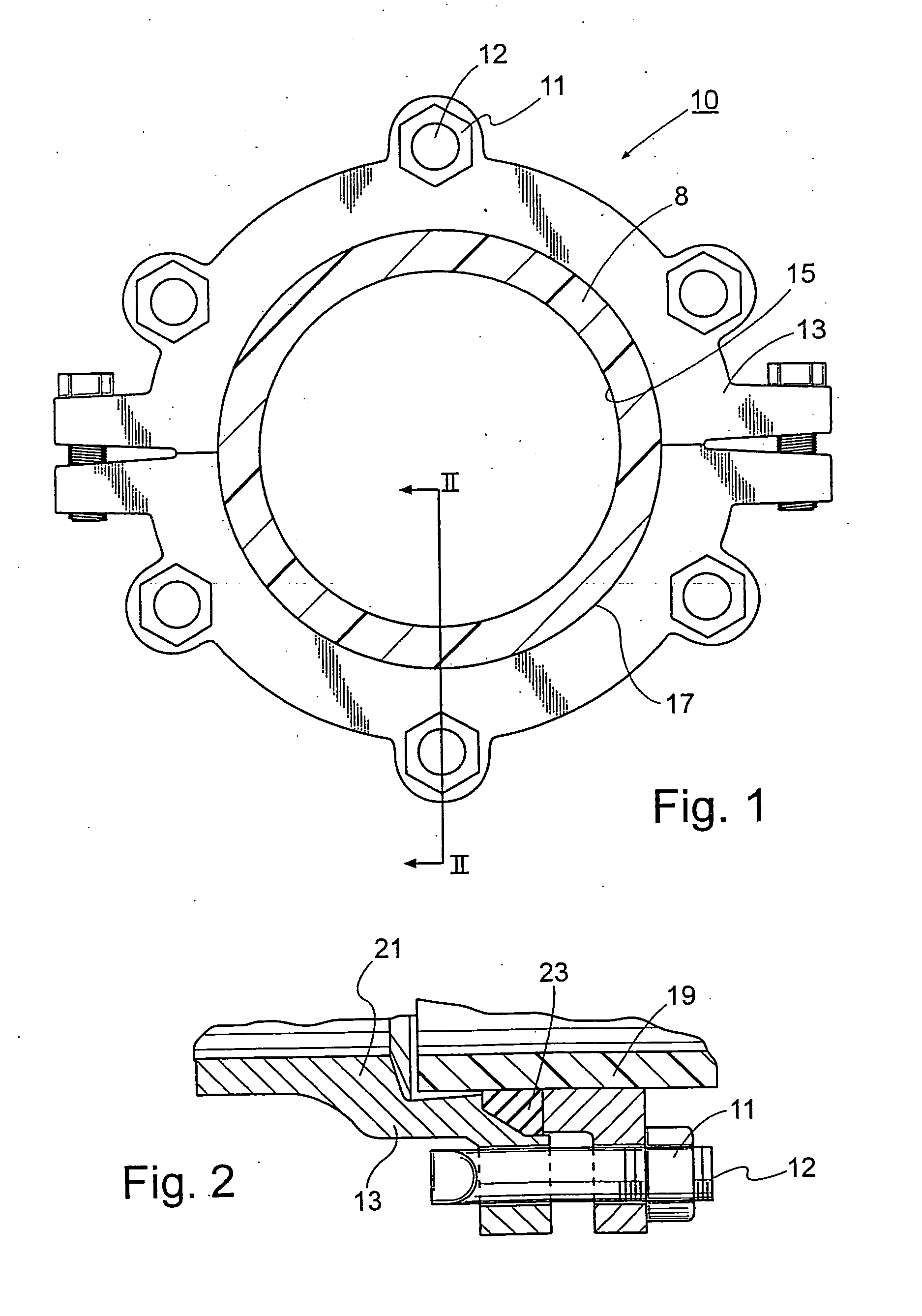

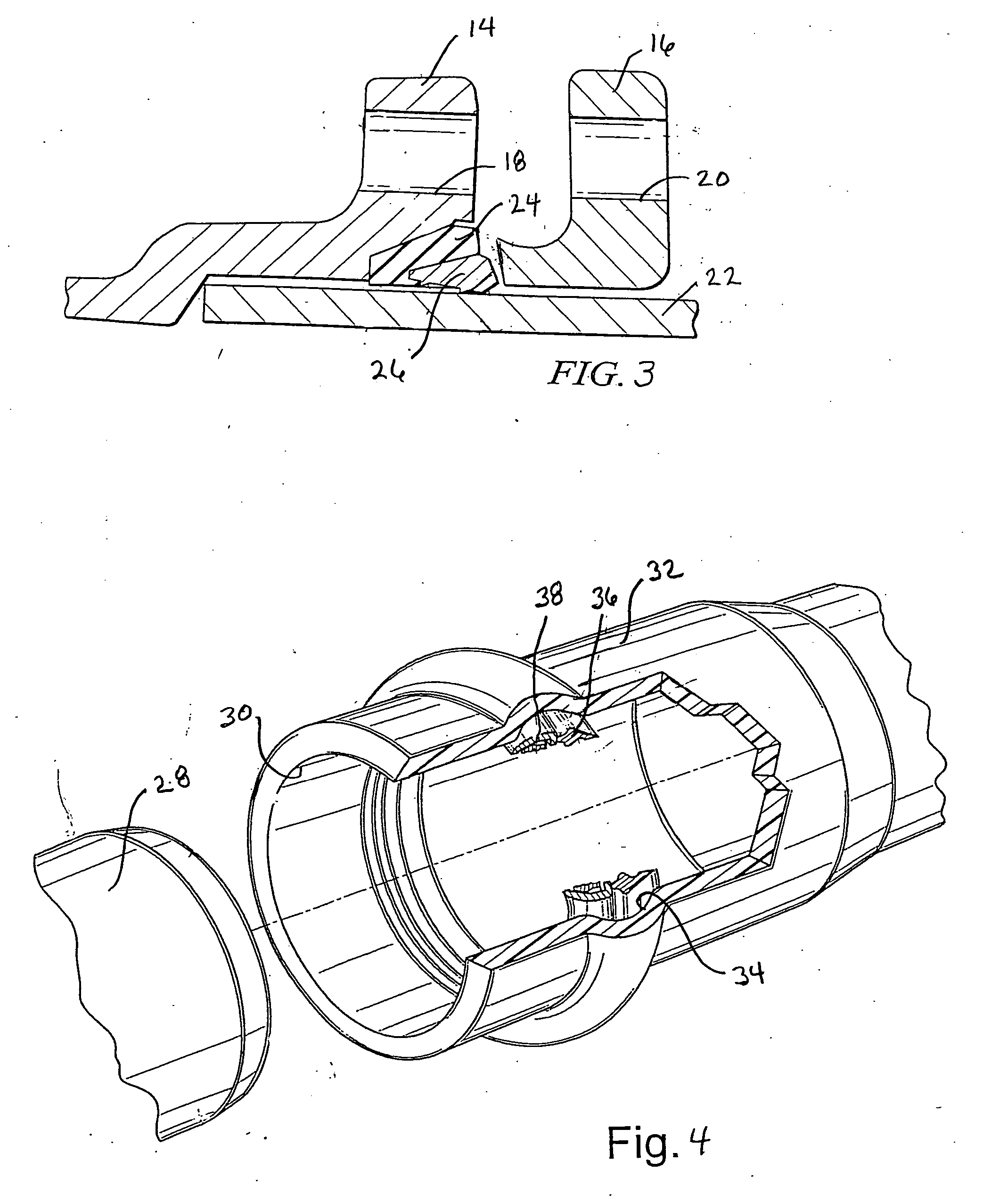

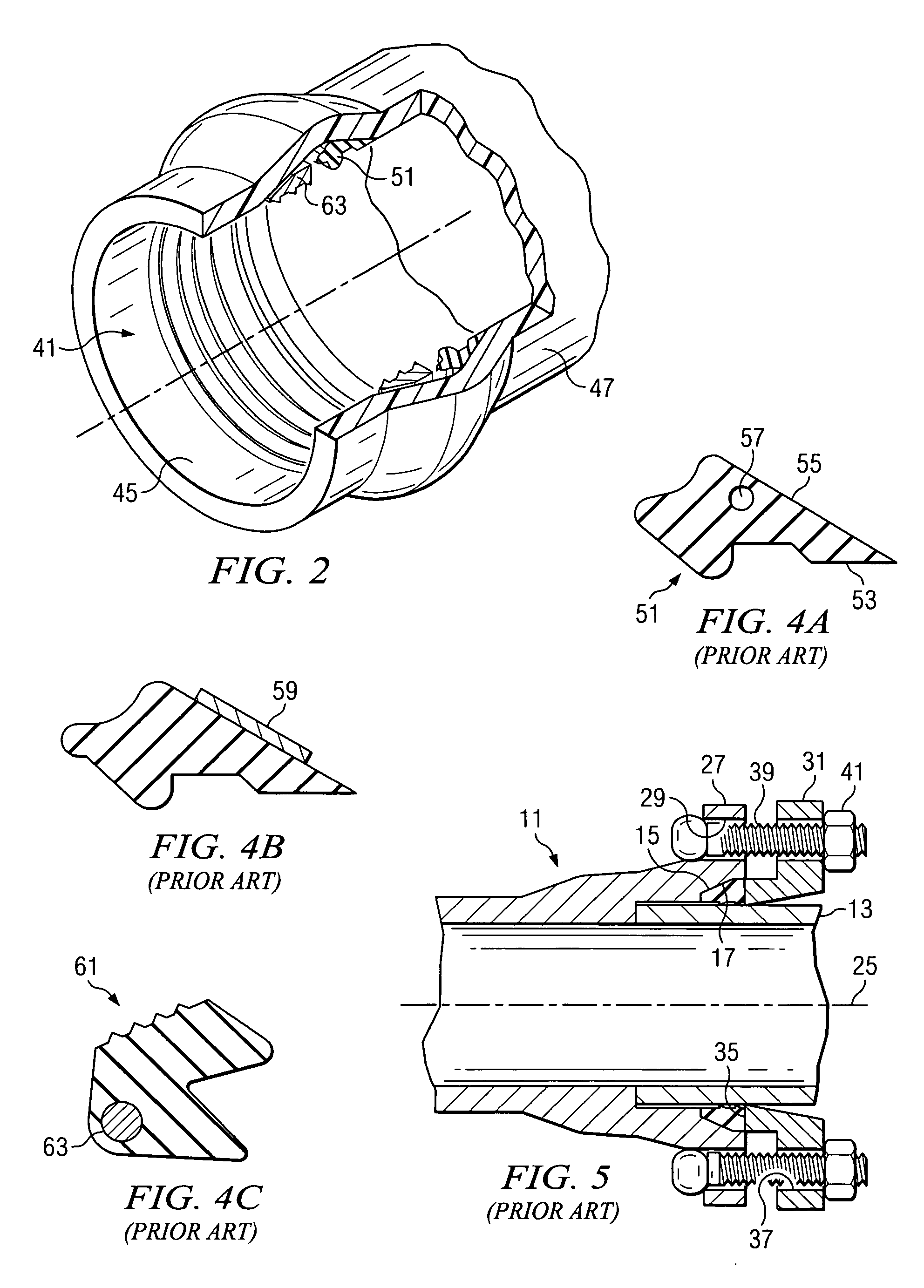

Self restrained fitting for PVC and ductile iron pipe

InactiveUS7328493B2Not easily bent and flexedSleeve/socket jointsFluid pressure sealed jointsPipe fittingEngineering

Owner:S & B TECHN PRODS

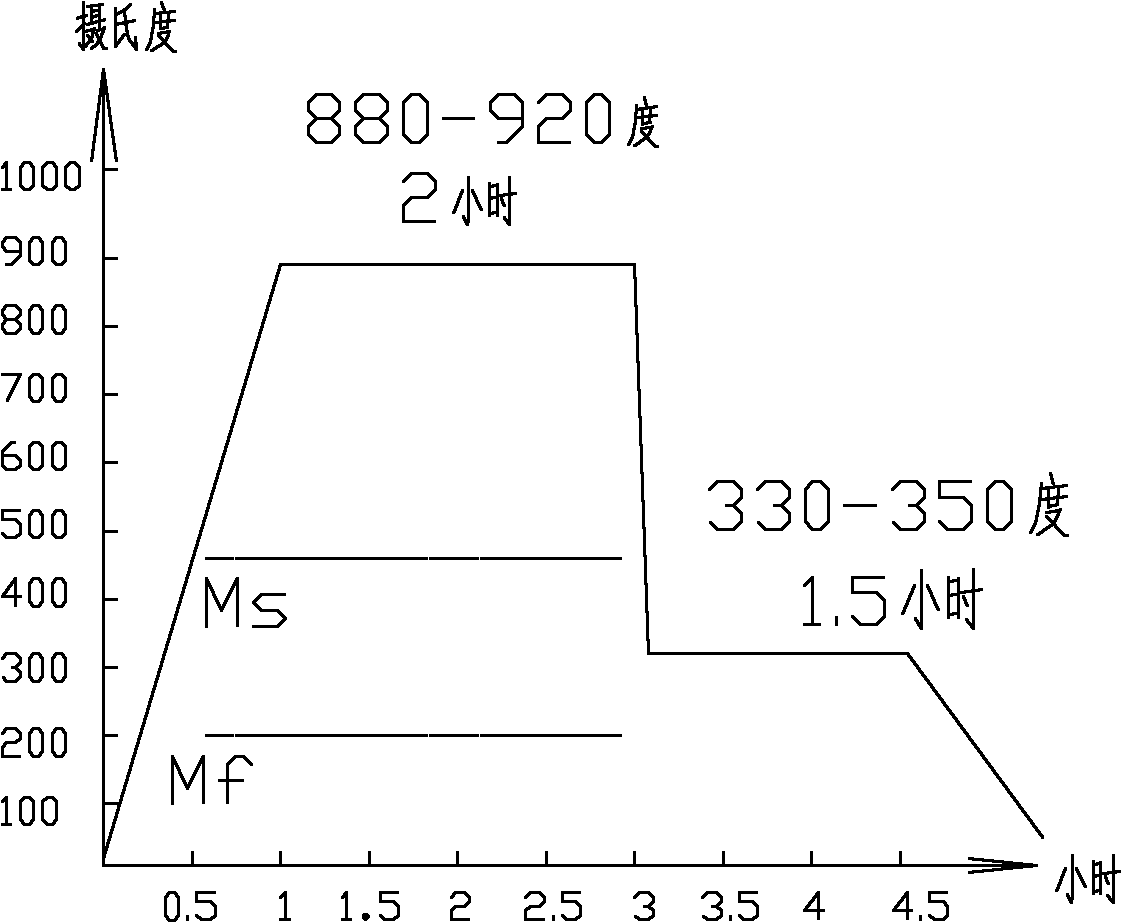

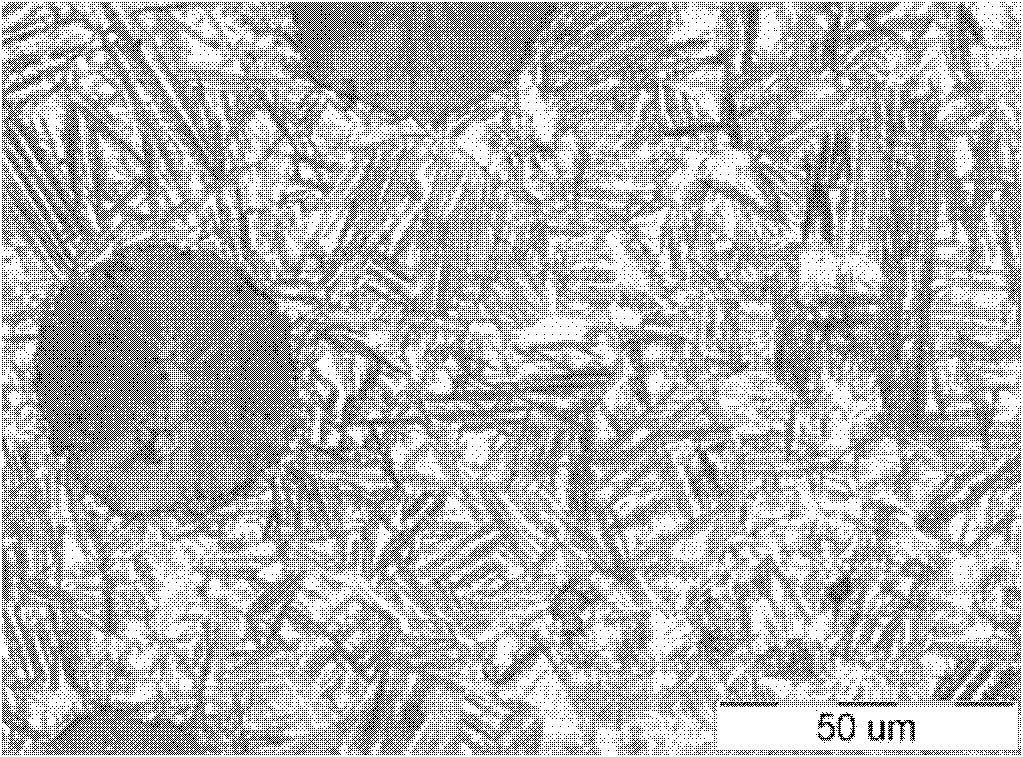

Method for manufacturing austempered ductile iron (ADI) front axle of heavy truck by sand casting

InactiveCN102218504AImprove integrityImprove fatigue lifeFoundry mouldsFurnace typesVolumetric Mass DensityQuenching

The invention discloses a method for manufacturing an austempered ductile iron (ADI) front axle of a heavy truck by sand casting. By the method, nickel molybdenum copper austempered ductile iron (ADI) front axle of the heavy truck is produced by a furane resin sand molding process, and the problems that the internal density and the performance reliability of ADI products are difficult to guarantee and the mechanical properties of the ADI products are low are solved. The method has the following steps of: firstly, casting a blank of the nickel molybdenum copper alloyed spheroidal graphite cast iron front axle by the furane resin sand molding process; secondly, performing the surface shot peening strengthening and isothermal quenching heat treatment; and finally machining the front axle parts. By the method, casting is replaced by forging, and the iron is replaced by steel, the comprehensive mechanical properties are obviously higher than those of common spheroidal graphite cast iron and forged steel, the weight of truck parts is reduced, the investment of heavy forging equipment and dies is saved, the cost is reduced, the production cycle is shortened, energy is saved, the emission is reduced, and the economic benefit and the social benefit are obvious.

Owner:DALIAN XINZHONG GRP +1

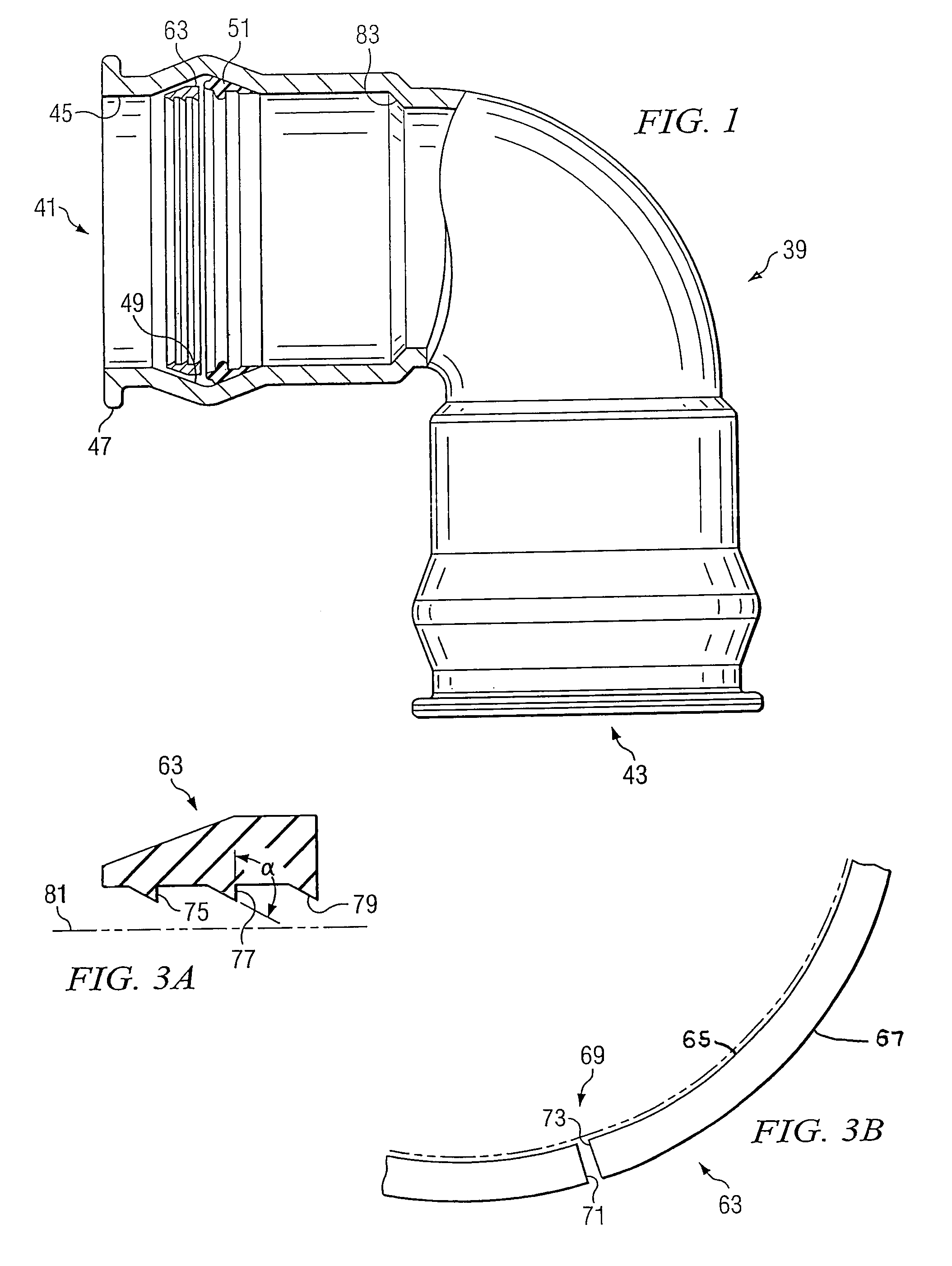

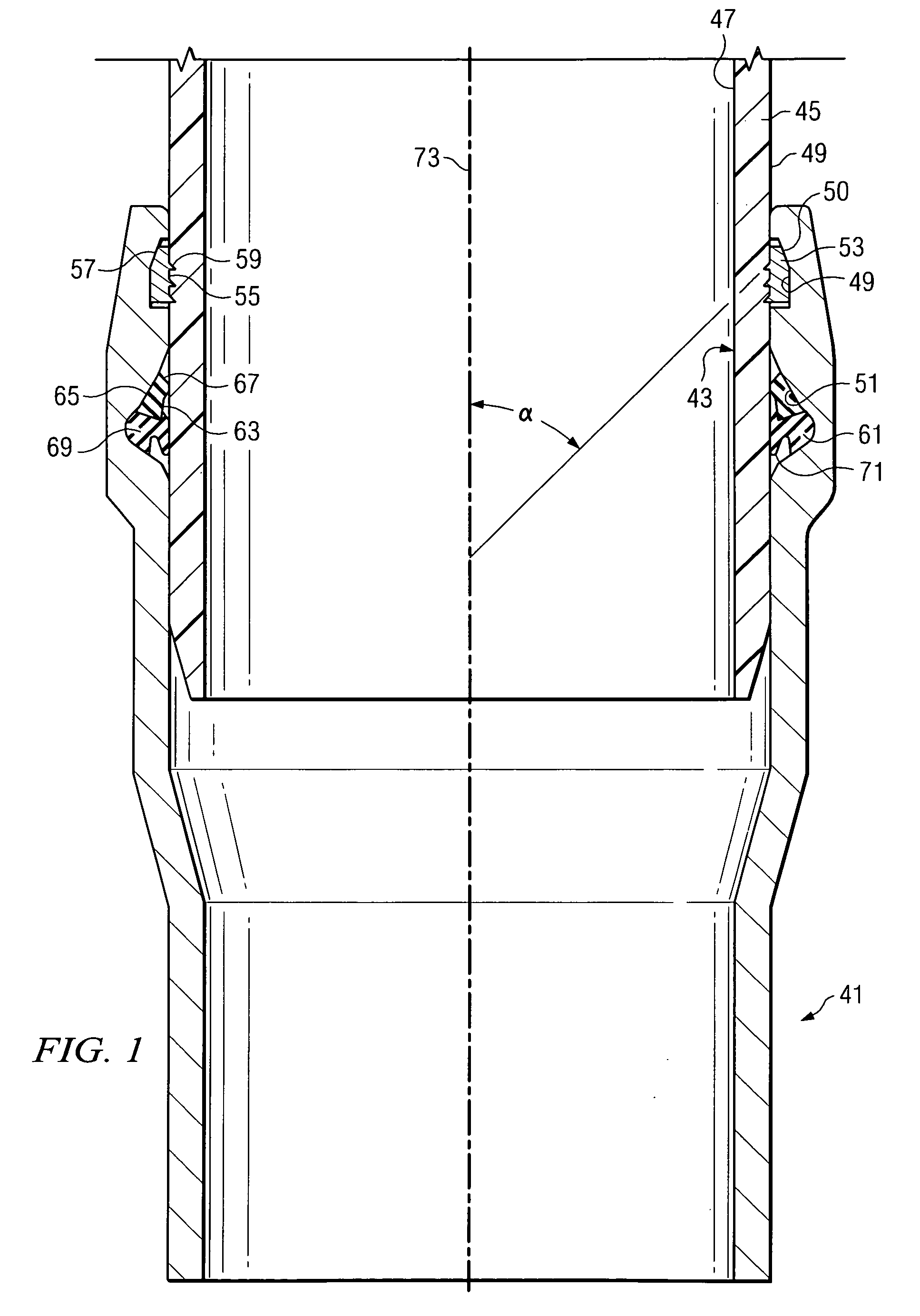

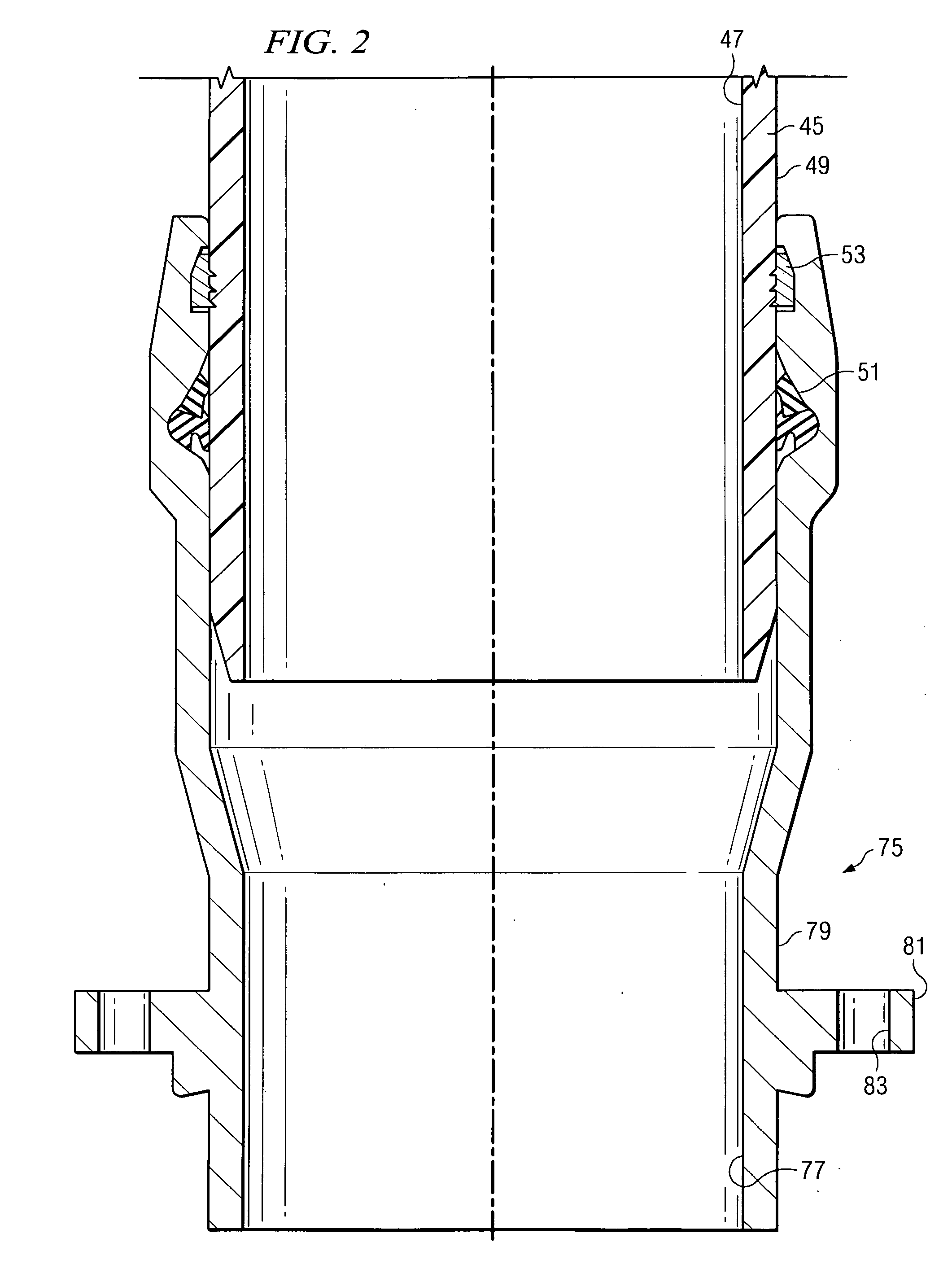

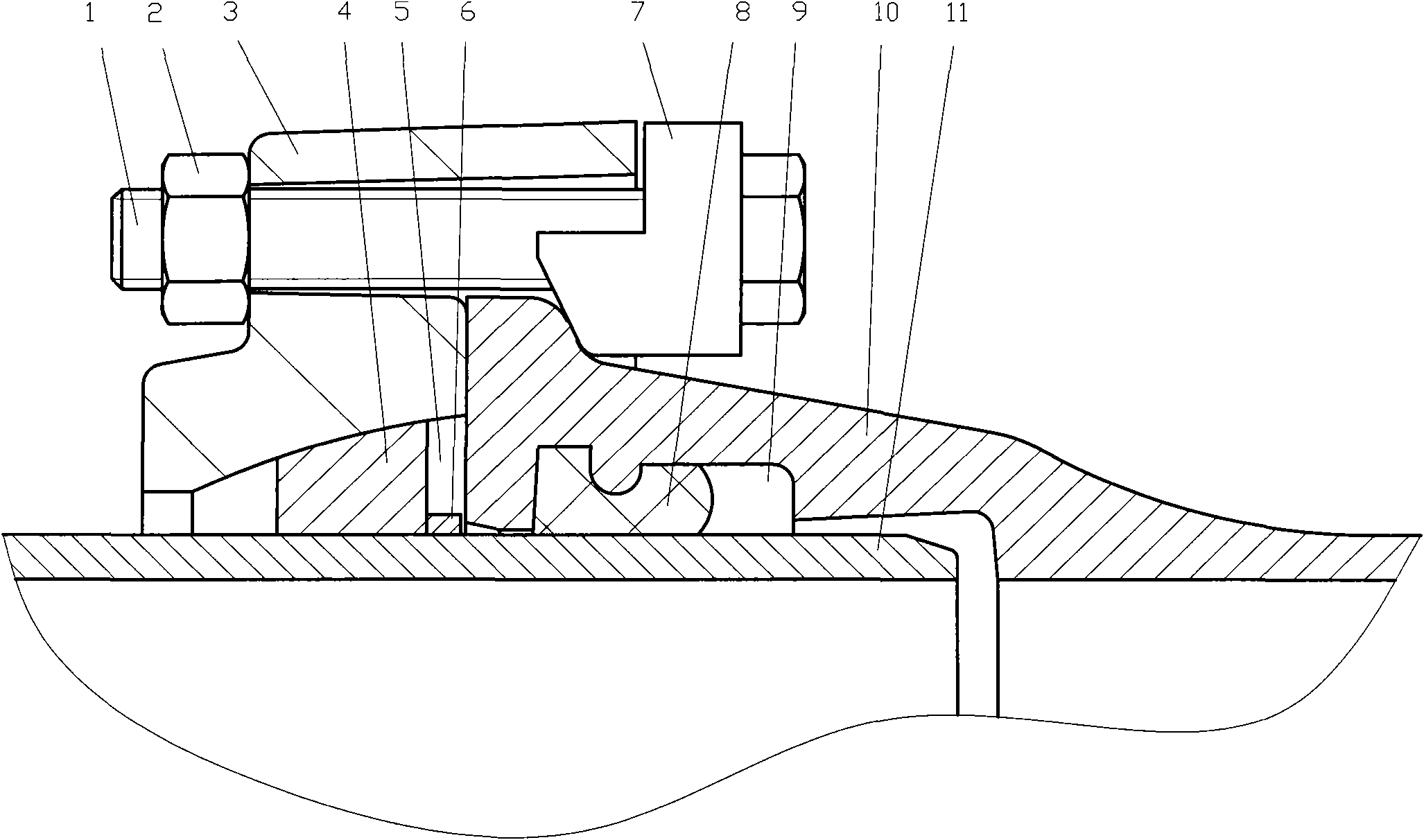

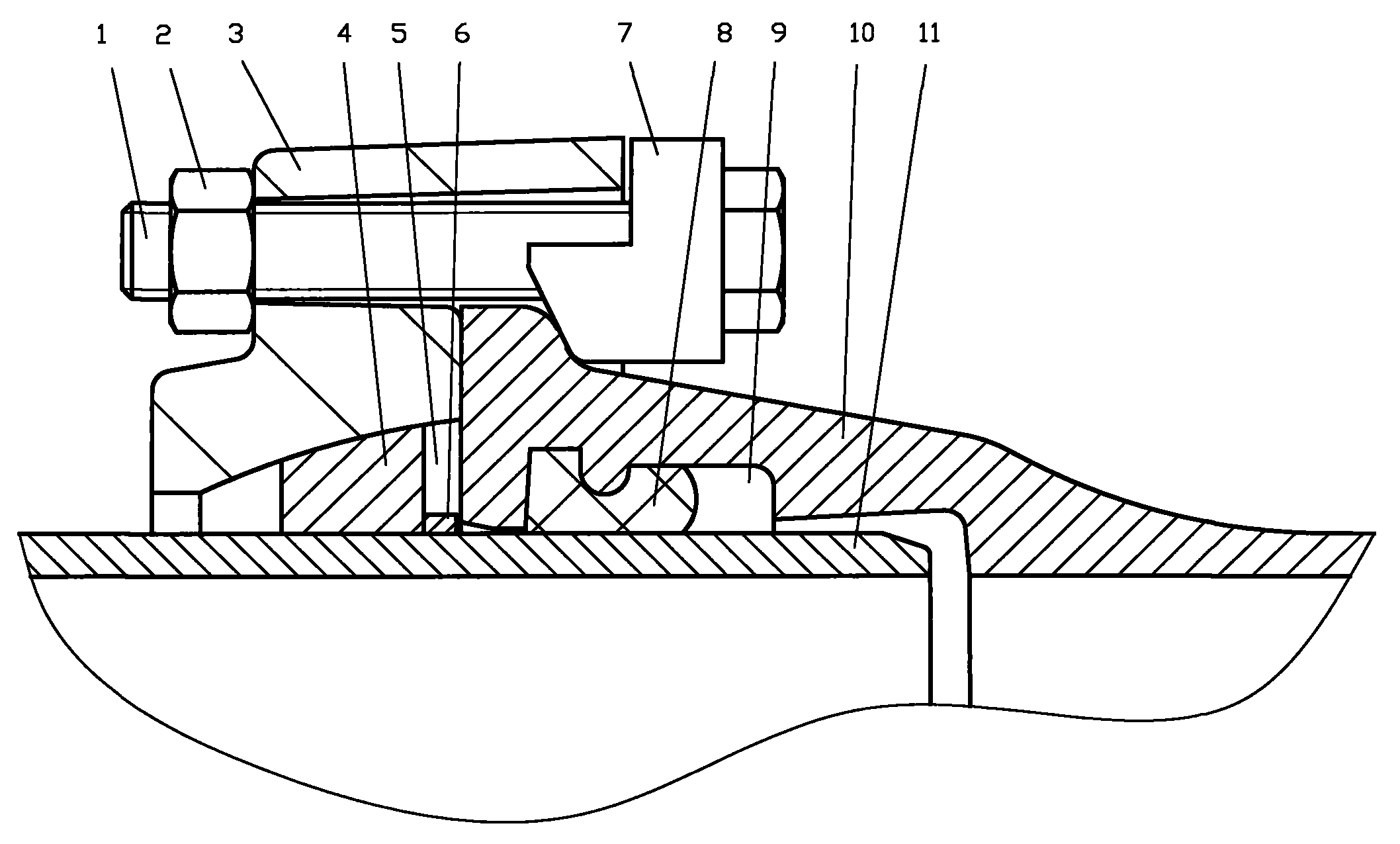

Self restrained joint for ductile iron pipe and fittings

InactiveUS20090273184A1Easily bentEasily flexedSleeve/socket jointsFluid pressure sealed jointsEngineeringSacroiliac joint

A combination sealing and restraint system for an as-cast ductile iron pipe systems. A ductile iron pipe / fitting with a bell end has an as-cast profile formed therein for receiving both a gripping ring and a sealing ring in spaced apart locations. The gripping ring is installed within a first recess provided as a part of the as-cast profile in a post-casting step. The sealing ring is also installed within a second, spaced recess after the casting operation is complete. The sealing ring can be a dual durometer gasket which can be flexed and inserted into the profile. The same type bell end can be provided as an adapter which converts a traditional mechanical joint restraint to an internal gripping and restrain system.

Owner:S & B TECHN PRODS

Secondary atomization fan nozzle and paint sprayer special for cast pipe

InactiveCN102139249ASmall diameterImprove spray qualityLiquid surface applicatorsSpray nozzlesAtomizer nozzleSprayer

The invention discloses a secondary atomization fan nozzle and a paint sprayer special for a cast pipe. The current primary atomization nozzle is changed into such a structure that the top is provided with a secondary atomization air outlet and the top surface of a valve core is higher than the bottom surface of an angle-shaped atomization block. The paint sprayer has the advantages that the atomization quality of the nozzle can be effectively improved, the service life of the valve core can be prolonged; the fan nozzle with the function of secondary atomization is applied to the paint sprayer special for the cast pipe, then a plurality of nozzles can be used in parallel owing to the fan-shaped spraying, and the paint sprayer also has the advantage that: the spraying efficiency of a paint special for the cast pipe on the inner wall of a pipe die can be effectively increased, the spraying quality of a paint coating special for the cast pipe can be improved, the outer wall quality of a nodular cast iron pipe is further improved and the production efficiency of the nodular cast iron pipe is increased.

Owner:XINXING DUCTILE IRON PIPES CO LTD

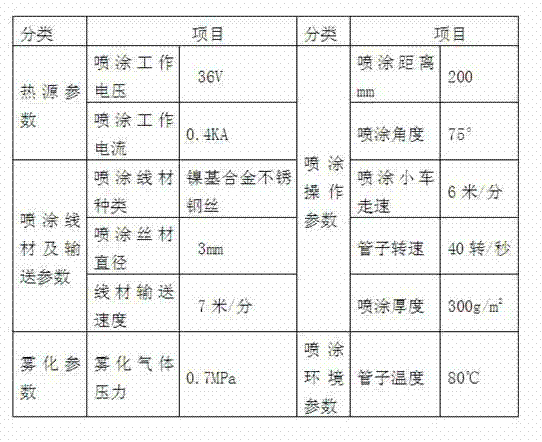

Preparation method for composite coating of outer surface of nodular cast iron pipe

ActiveCN102676971APlug poresReduce porosityLiquid surface applicatorsMolten spray coatingPorosityCeramic coating

The invention discloses a preparation method for a composite coating of an outer surface of a nodular cast iron pipe, belonging to the technical field of corrosion inhibition of a metal material. The preparation method comprises the following steps of: (1) pretreating the outer surface of the nodular cast iron pipe; (2) the spray coating of a ceramic coating: uniformly mixing a ceramic coating raw material, and spraying the ceramic coating raw material on the outer surface of the nodular cast iron pipe by adopting flame spraying equipment, wherein the weight of the ceramic coating on the outer surface of the nodular cast iron pipe is 80-300g / m<2>, the diameter of the powder of the mixing ceramic coating raw material is 5-60 microns; the mixing ceramic coating raw material comprises Al2O3, TiO2 and Cr2O3; and (3) coating a hole sealing finishing coat. As the ceramic coating prepared by the invention has low porosity, the ceramic coating has better corrosion resistance performance; the ceramic coating has stronger binding capacity with a substrate and good wear resistance performance, can be suitable for severe environments and is low in manufacturing cost; and the hole sealing finishing coat can further increase the corrosion resistance performance of the ceramic coating.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Method of applying a phenolic resin corrosion protective coating to a component used in a fluid conveyance system

InactiveUS20070190244A1Corrosion resistanceEffective protectionElectric shock equipmentsPretreated surfacesResin coatingDelivery system

Owner:TERRAMIX

Lining coating technology for spheroidal graphite cast iron tube

ActiveCN103691625AWill not affect the formationNo shedding phenomenonLiquid surface applicatorsCoatingsPolyvinyl chlorideEngineering plastic

The invention discloses a lining coating technology for a spheroidal graphite cast iron tube. The lining coating technology is characterized by comprising the following steps of 1, polishing the inner wall of a blank tube, and performing shot blasting; 2, putting the treated tube on a riding wheel of lining coating equipment through a transferring tool, and switching on a variable-frequency motor connected with the riding wheel to drive the tube to rotate at the rotating speed of less than or equal to 50rpm; 3, switching on a heating fire gun arranged below the tube to preheat the outer wall of the tube, and controlling the temperature between 140 DEG C and 230 DEG C; 4, after preheating is finished, uniformly distributing polyvinyl chloride or polyethylene or ABS (acrylonitrile butadiene styrene) engineering plastic or polytetrafluoroethylene or polypropylene powdered substances on the inner wall of the tube through a material distribution trolley to form a lining layer, and then cooling the lining layer, wherein in the cooling process, the tube is continuously rotated until the tube is completely cooled. The problem of the influence, which is caused by a fact that the lining layer prepared by an existing lining coating technology for the spheroidal graphite cast iron tube is easy to fall off, on normal mounting, the use of metering equipment, the sanitation of water quality and the like is solved; the manufacturing cost of the lining layer is reduced.

Owner:广西安钢永通铸管管业有限公司

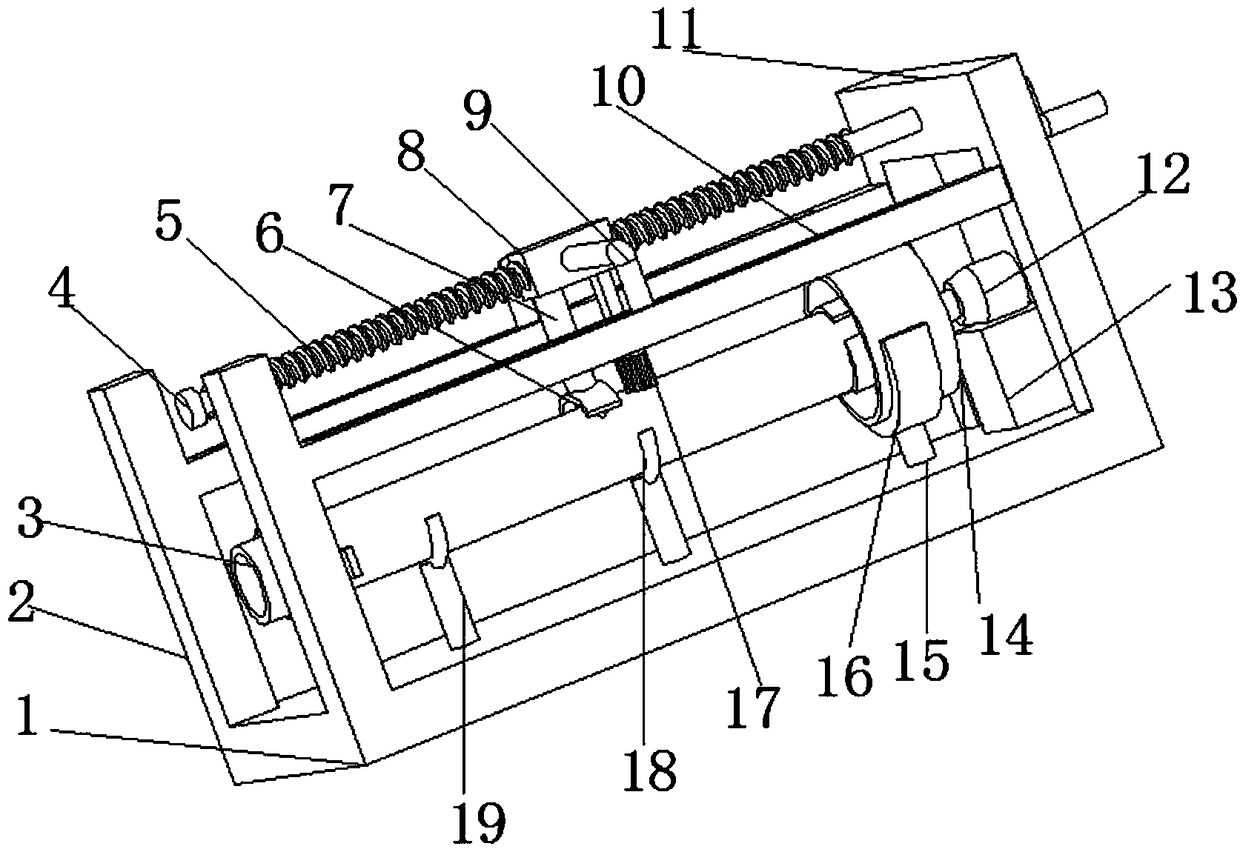

Nodular cast iron pipe cleaning device

InactiveCN108466178AEasy to cleanSimple structureHollow article cleaningAbrasive blasting machinesArchitectural engineeringCast iron pipe

The invention discloses a nodular cast iron pipe cleaning device which comprises a base. The base is provided with a supporting rod, the top of the base is provided with a first placing rod, the top of the first placing rod is connected with a placing ring, the top of the base is provided with a second placing rod, the top of the second placing rod is provided with a placing plate, the right sideof the second placing rod is provided with a motor, the motor is connected with a clamping device through a rotating shaft, the clamping device clamps a nodular cast iron pipe, the left end of the nodular cast iron pipe is provided with a limiting part, the limiting part is connected with a fixing plate, the top of the supporting rod is connected with an adjusting plate, a hand turning handle penetrates through the adjusting plate to be connected with a lead screw, the lead screw is in threaded connection with a sliding sleeve, a polishing part is connected with the bottom end of the sliding sleeve, the bottom end of the sliding sleeve is connected with a cleaning brush, the upper portion of the supporting rod is provided with a transverse rod, and the transverse rod is provided with a sliding groove. The structure is simple, shot blasting is adopted for removing rust on the outer wall of the nodular cast iron pipe, the rust removal effect is good, the cleaning brush is arranged so asto remove impurities attached to the outer wall of the nodular cast iron pipe conveniently, the rust and impurity removal speed can be manually controlled, and the cleaning effect is better.

Owner:HANSHAN DONGSHAN DEYU SPHERULITIC GRAPHITE CASTING FACTORY

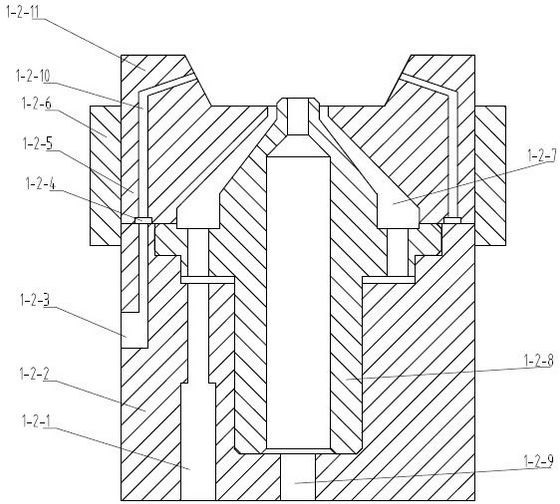

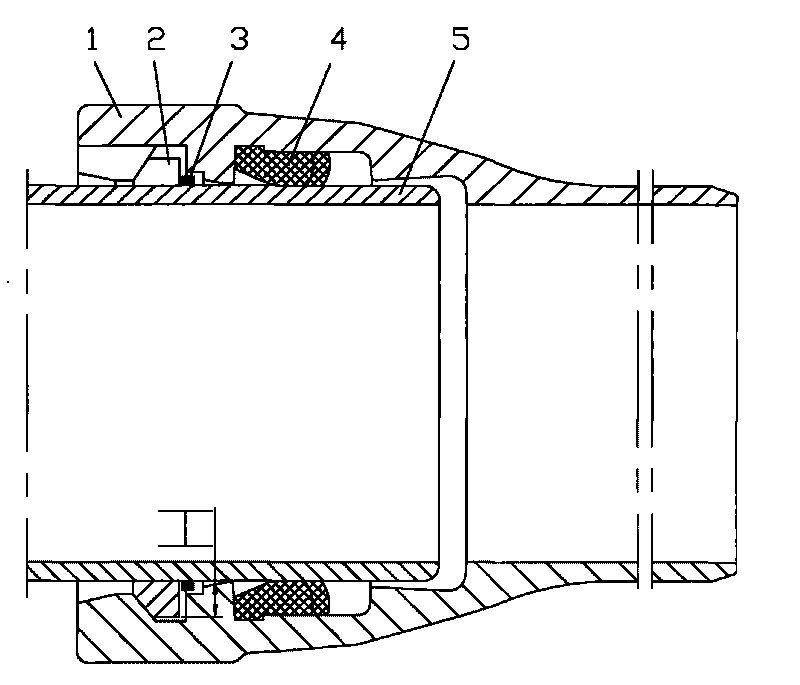

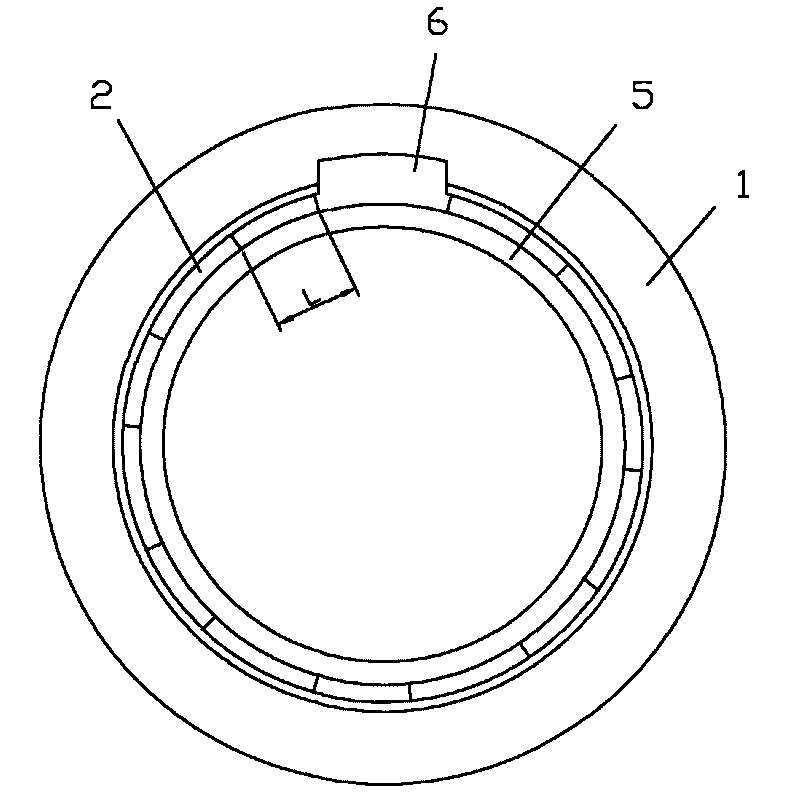

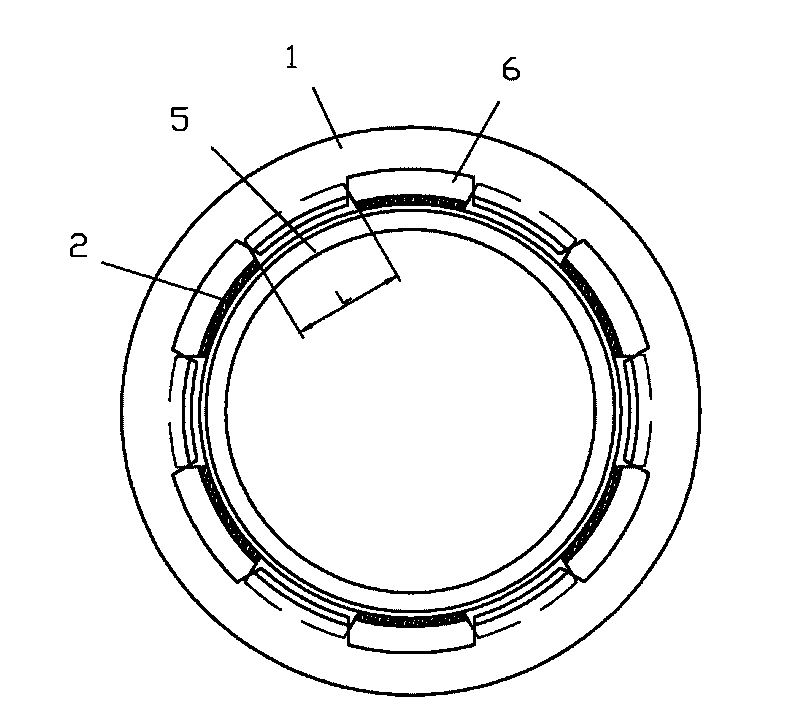

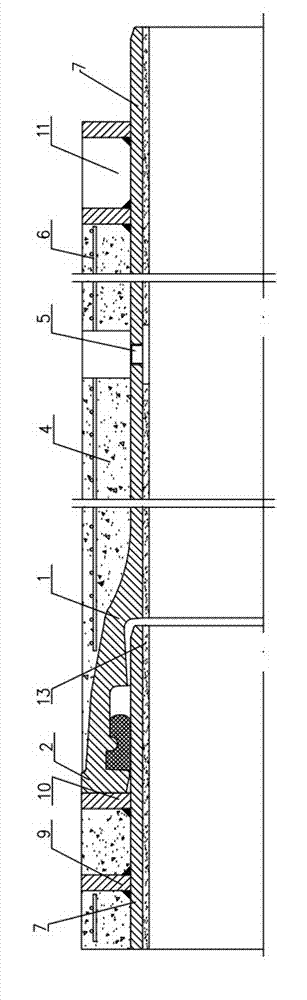

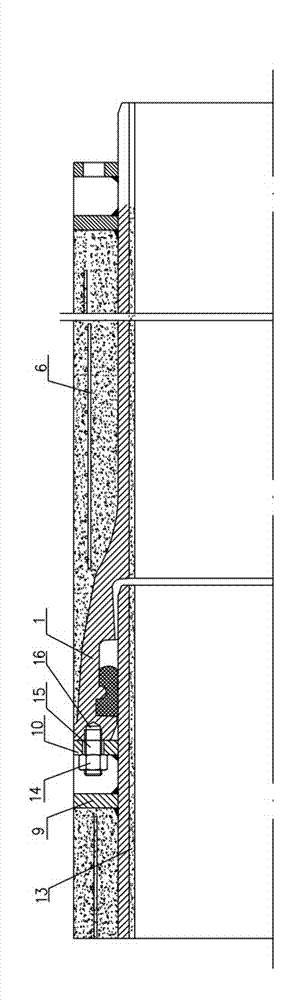

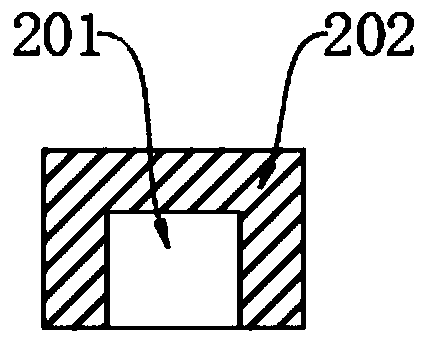

Interface structure of ductileiron pipe

The invention relates to a pipeline interface structure, in particular to an interface structure of a ductileiron pipe. A baffle ring mounting groove and a sealing ring mounting groove are arranged on the inner cylindrical surface of a bellmouth of the ductileiron pipe, and a sealing ring is embedded in the sealing ring mounting groove. An anchoring ring is arranged on the outer cylindrical surface of a socket and is positioned between the baffle ring mounting groove and the sealing ring mounting groove a well as is close to the baffle ring mounting groove. A baffle ring mounting hole is arranged on the end face of the socket and communicated with the baffle ring mounting groove, and a baffle ring is embedded in the baffle ring mounting groove from the baffle ring mounting hole, wherein the right end face of the baffle ring is abutted against the anchoring ring, and the left end face is abutted against the left ring surface of the baffle ring mounting groove. The interface structure of a ductileiron pipe has simple structure and firm connection and can be suitable for pipelines with various calibers and pressures.

Owner:XINXING DUCTILE IRON PIPES CO LTD

A kind of nodular cast iron pipe with waterproof protective layer and its production process

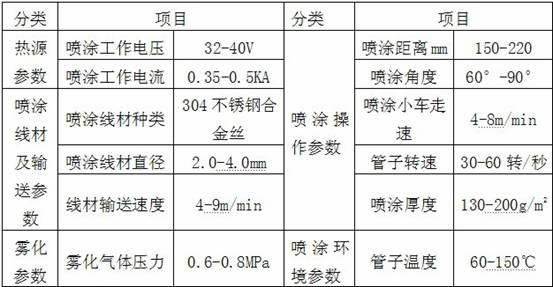

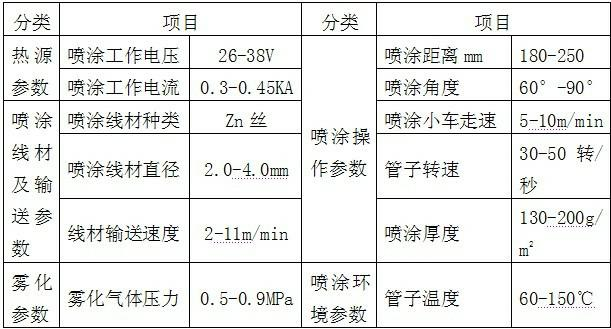

ActiveCN102278568AImprove corrosion resistanceNeat appearanceCorrosion preventionPipe protection against corrosion/incrustationWear resistanceZinc

The invention discloses a ductile cast iron pipe with a waterproof protective layer and a production process thereof. The method comprises the following steps of: (1) performing surface treatment on the ductile cast iron pipe to remove surface oxides thereof; (2) spraying a zinc protective layer; (3) spraying a stainless steel protective layer; and (4) coating an enclosed corrosion-resistant protective layer. The invention has the advantages that: the zinc protective layer, the stainless steel protective layer and the enclosed corrosion-resistant protective layer are sequentially sprayed at the periphery of the ductile cast iron pipe through an arc spraying method, and a sacrificial anode protection function of the zinc protective layer, the wear resistance and corrosion resistance of thestainless steel coating and the hole-sealing corrosion inhibition performance of the enclosed coating can be cooperatively exerted, so that the ductile cast iron pipe is well protected. The ductile cast iron pipe with the coating structure has high corrosion resistance in a hydraulic environment, the waterproof protective layer has a neat appearance, covers uniformly and densely, has long protection period, high corrosion resistance and high damage resistance, secondary excavation construction is not needed, and the life cycle cost of a project is obviously reduced.

Owner:XINXING DUCTILE IRON PIPES CO LTD

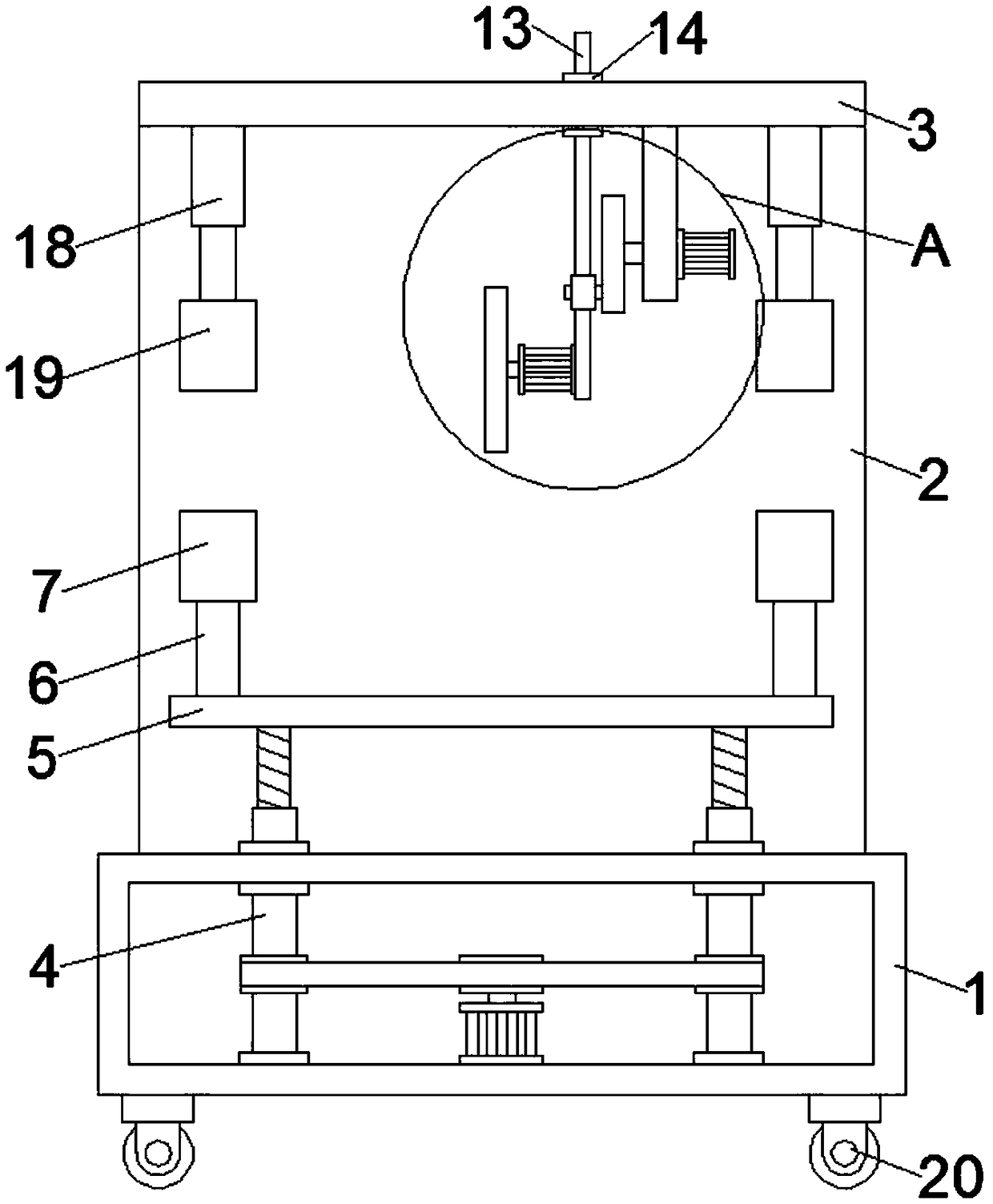

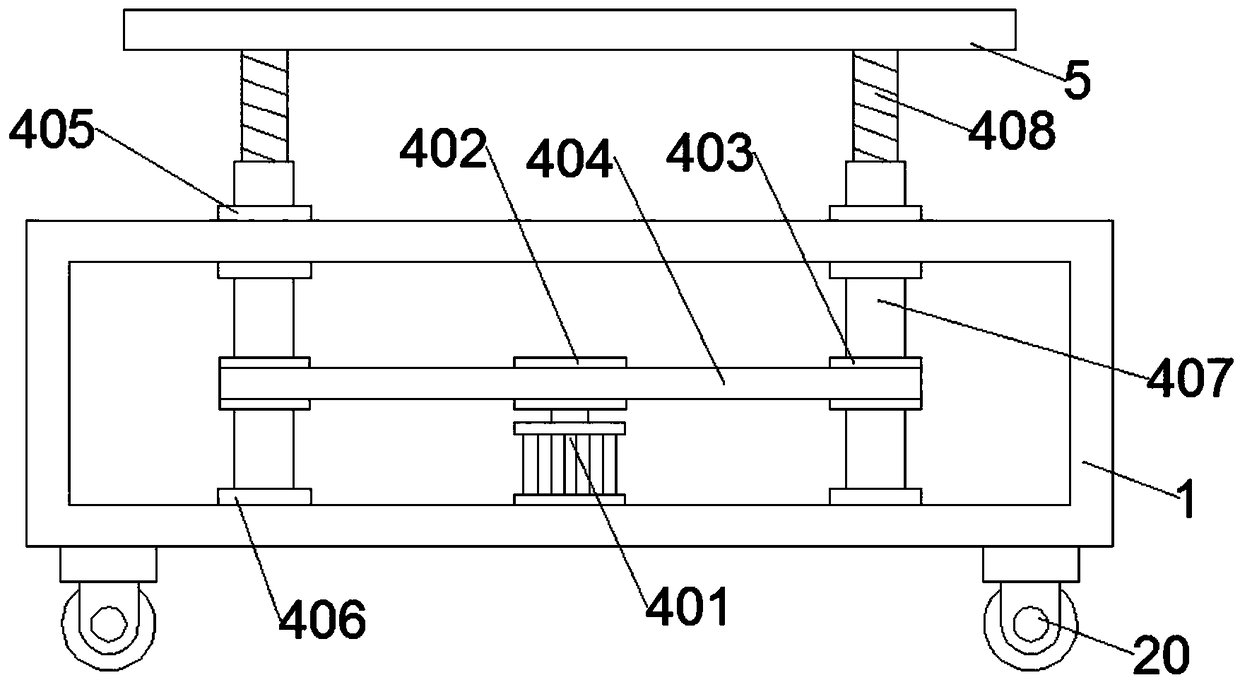

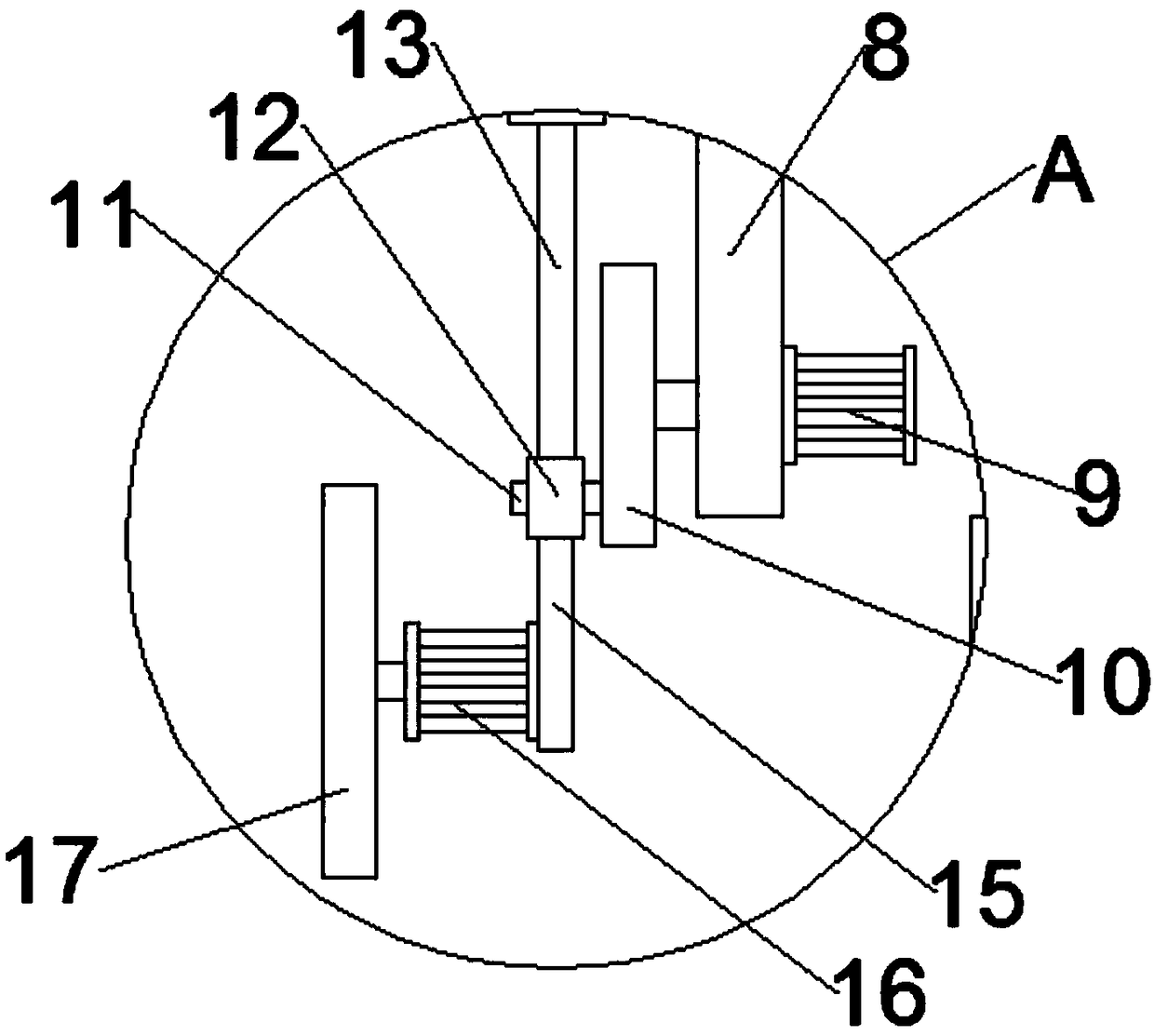

Cutting device for processing of nodular cast iron pipe

InactiveCN108788277ARealize up and down reciprocating motionFast cutting speedTube shearing machinesShearing machine accessoriesReciprocating motionCast iron pipe

The invention relates to the technical field of processing of nodular cast iron pipes, particularly to a cutting device for processing of the nodular cast iron pipe. The cutting device comprises a base, a side plate and a top plate, wherein the base is provided with an inner cavity; a lifting mechanism is arranged at the bottom of the inner cavity of the base; the lifting mechanism penetrates through the top of the base to be connected with a workbench; supporting rods are symmetrically arranged at the two ends of the top of the workbench; lower clamping plates are arranged at the upper ends of the supporting rods; the side plate is arranged at the back side of the top of the base; the top plate is arranged on the front side of the upper end of the side plate; a mounting plate is arrangedat the bottom of the top plate; a rotating motor is mounted on the right side of the lower end of the mounting plate; and an output shaft of the rotating motor penetrates through the mounting plate tobe connected with a disc. According to the cutting device for processing of the nodular cast iron pipe provided by the invention, up-down reciprocating motion of a cutting blade is achieved while thenodular cast iron pipe is cut, cutting speed is increased, and cutting quality and cutting efficiency are improved; and the structure is novel, design is reasonable, operation is convenient and quick, and the requirement of production utilization is met.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

Liquid iron inoculation process for ductile iron pipes

ActiveCN101921945AAchieve long-term pregnancyReduce residual magnesium contentLong actingInoculation

The invention discloses a liquid iron inoculation process for ductile iron pipes, which comprises the following steps of: (1) inoculating in a spheroidizing ladle, and adding an inoculator accounts for 0.4 to 0.6 weight percent of the liquid iron into the spheroidizing ladle; (2) performing stream inoculation, adding an inoculator in an amount which is 0.1 to 0.25 weight percent of the liquid iron into a pouring ladle; and (3) performing pipe powder inoculation, spraying pipe powder on the inner surface of a pipe die before pouring and during pipe drawing in a ratio of 20-30g / m<2>. The key improvement is that: a tundish inoculation step is added between the step (1) and the step (2), wherein an inoculator in an amount which is 0.15 to 0.25 weight percent of the liquid iron is added into the tudish, and after the inoculator is completely melted, the liquid iron is transferred into the pouring ladle for stream inoculation. The liquid iron inoculation process has the advantages that: a tundish inoculation process is added between the spheroidizing ladle inoculation and the stream inoculation to realize long-acting inoculation of the liquid iron; the residual magnesium in the spheroidizing liquid iron can be effectively reduced; the tensile strength and the yield strength are improved; and meanwhile, conditions are created for reducing high-temperature annealing temperature and stabilizing the size of the ductile iron pipe finished products.

Owner:河北新兴铸管有限公司

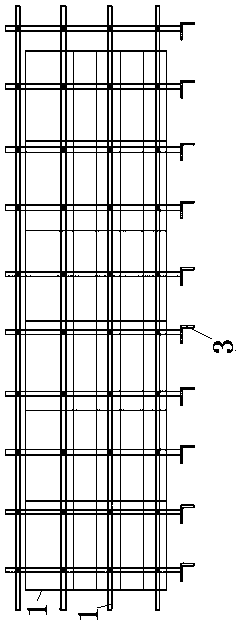

Encased concrete nodular cast iron pipe

InactiveCN102777706AEasy for jacking constructionShorten the construction periodRigid pipesCast iron pipeFlange

The invention discloses an encased concrete nodular cast iron pipe and relates to the technical field of a socket-type nodular cast iron pipe. The encased concrete nodular cast iron pipe comprises a socket-type nodular cast iron pipe body; both ends of the socket-type nodular cast iron pipe body are respectively provided with a socket and a spigot; the outer wall of the socket-type nodular cast iron pipe body is coated with a concrete layer for ensuring the continuous lengths of the socket-type nodular cast iron pipe body equal; a cylindrical reinforcing mesh is sandwiched in the concrete layer; a connecting flange set is arranged at the outer end of the spigot; a ring-shaped boss is arranged outside the end part of the socket; and the outer diameter of the ring-shaped boss is the same with that of the concrete layer. The encased concrete nodular cast iron pipe has the advantages that (1) the concrete layer is coated on the outer wall of the socket-type nodular cast iron pipe body, so that the diameters of both ends of the socket-type nodular cast iron pipe body are ensured equal, the jacking construction is convenient to carry out, the construction period is shortened, the engineering cost is reduced, concrete on the outer layer of the socket-type nodular cast iron pipe body can also protect the socket-type nodular cast iron pipe body and the service life is prolonged; and (2) flanges and reinforcement plates are arranged at the end of the spigot of the socket-type nodular cast iron pipe coated with the concrete layer and the end of the spigot is used as a bearing end in the jacking construction, so that the construction is convenient to carry out.

Owner:XINXING DUCTILE IRON PIPES CO LTD +1

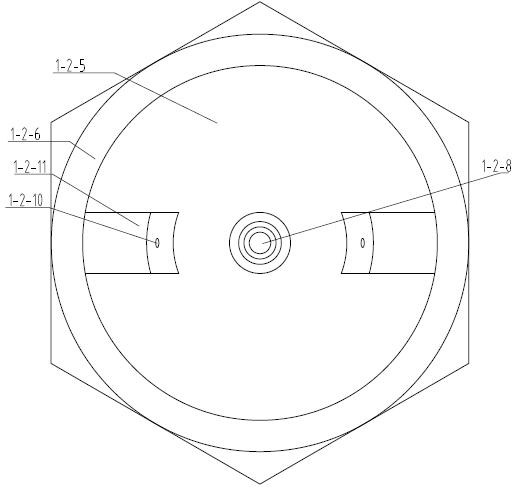

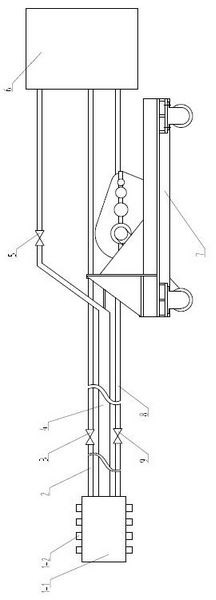

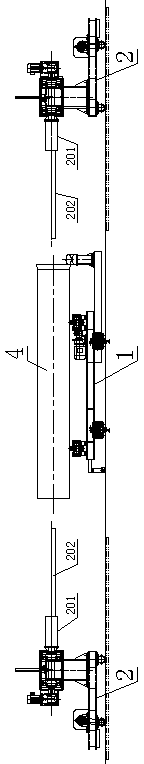

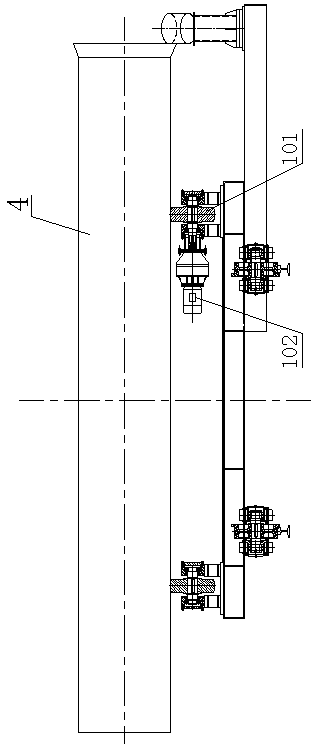

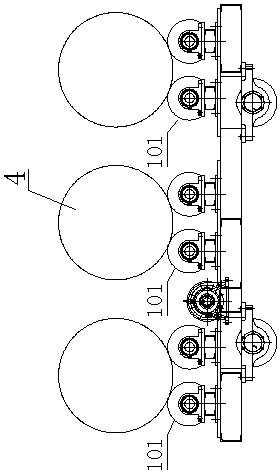

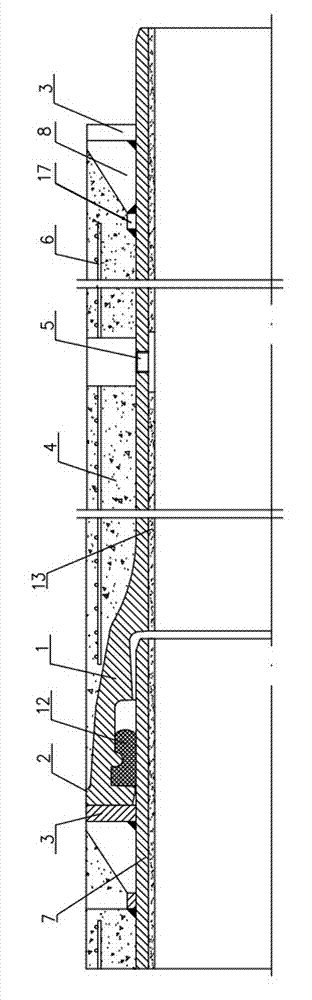

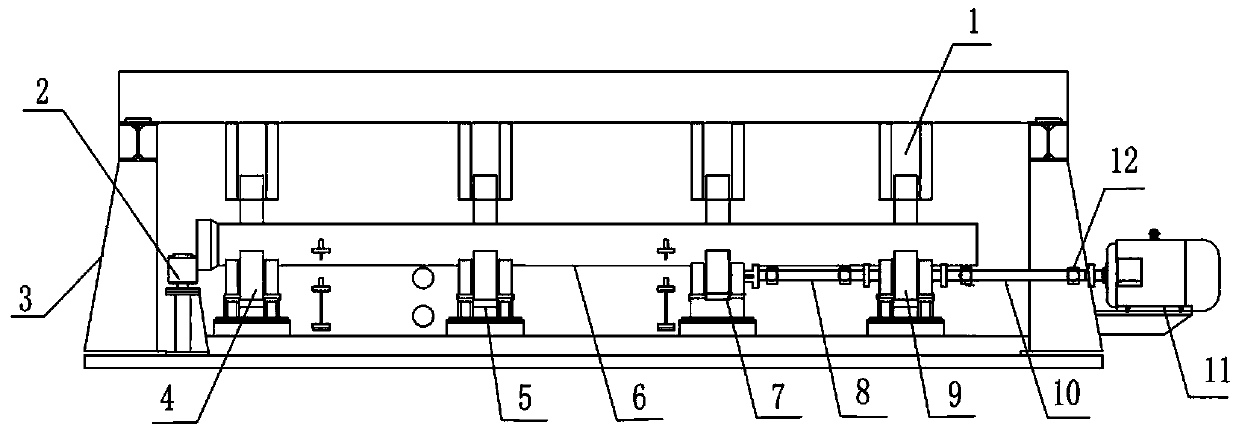

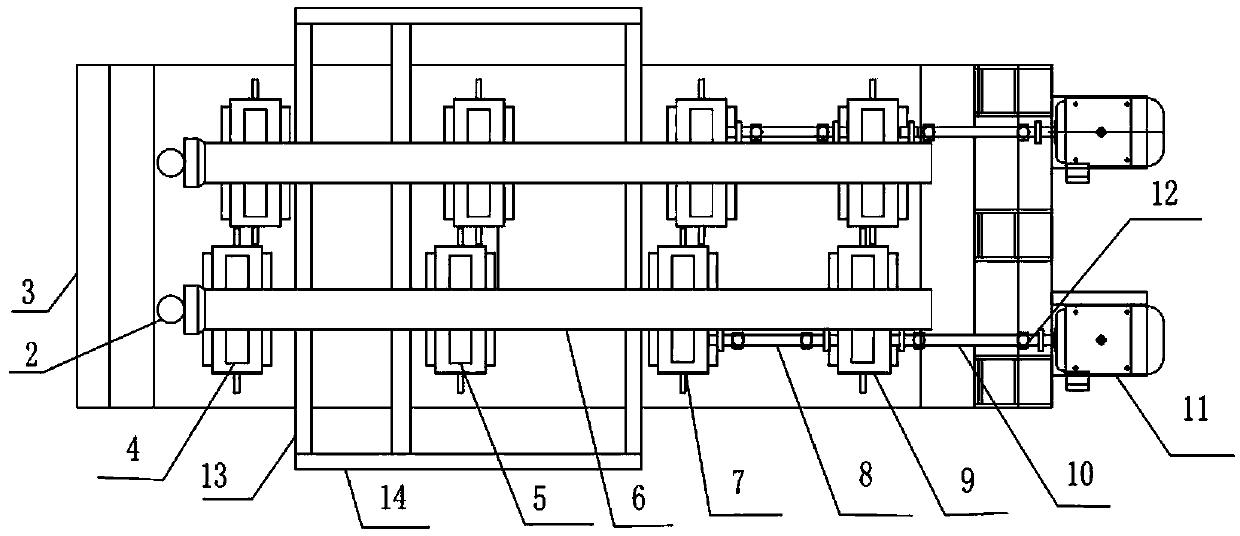

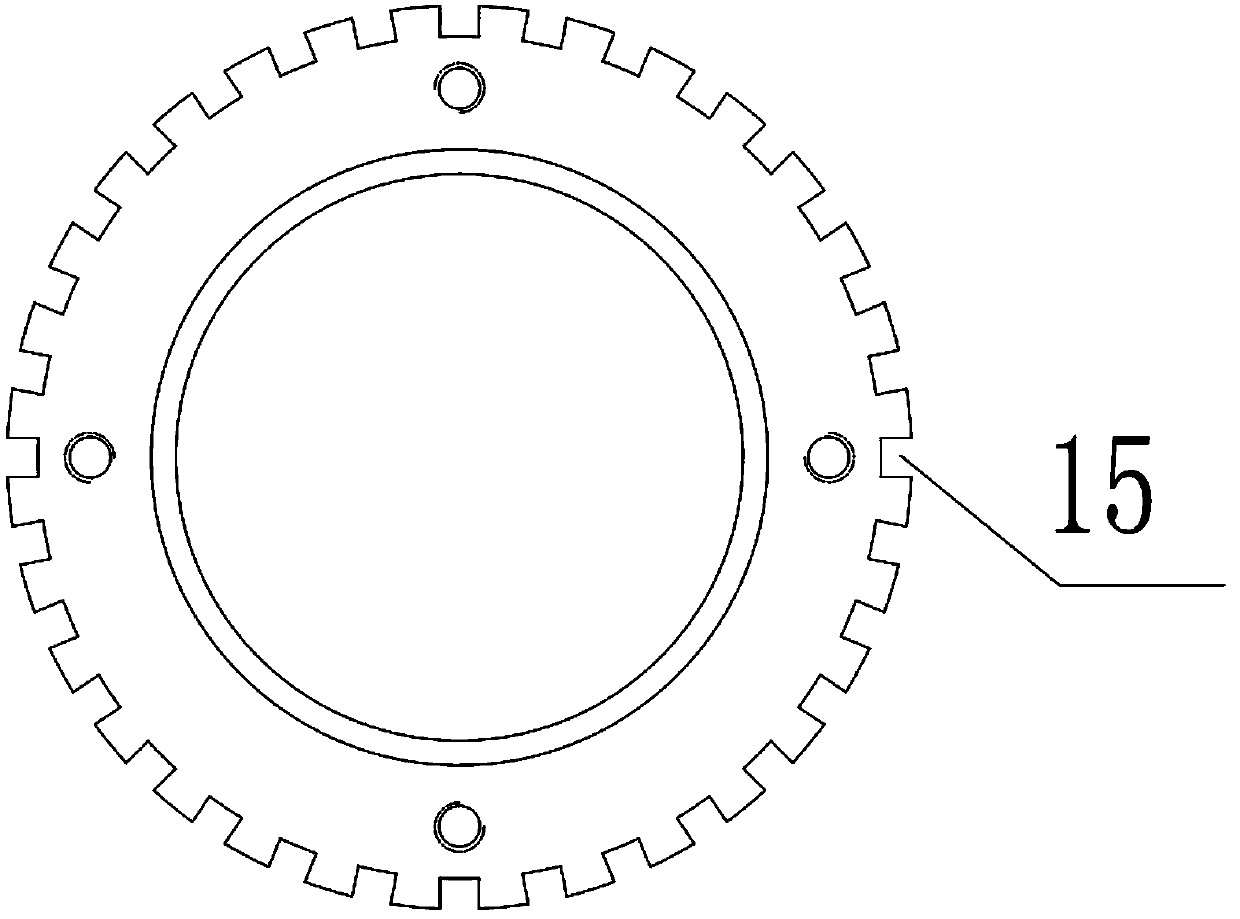

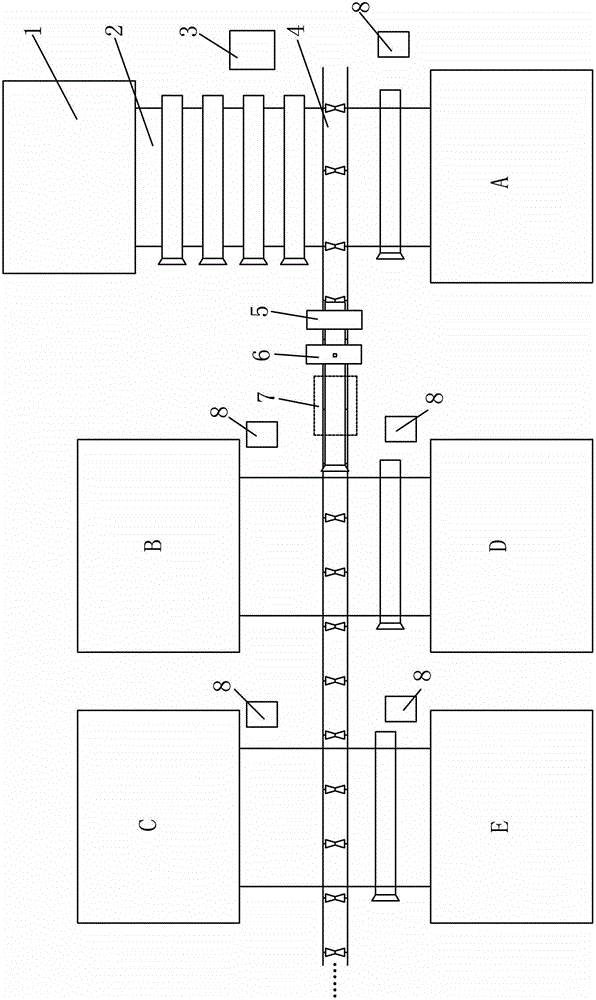

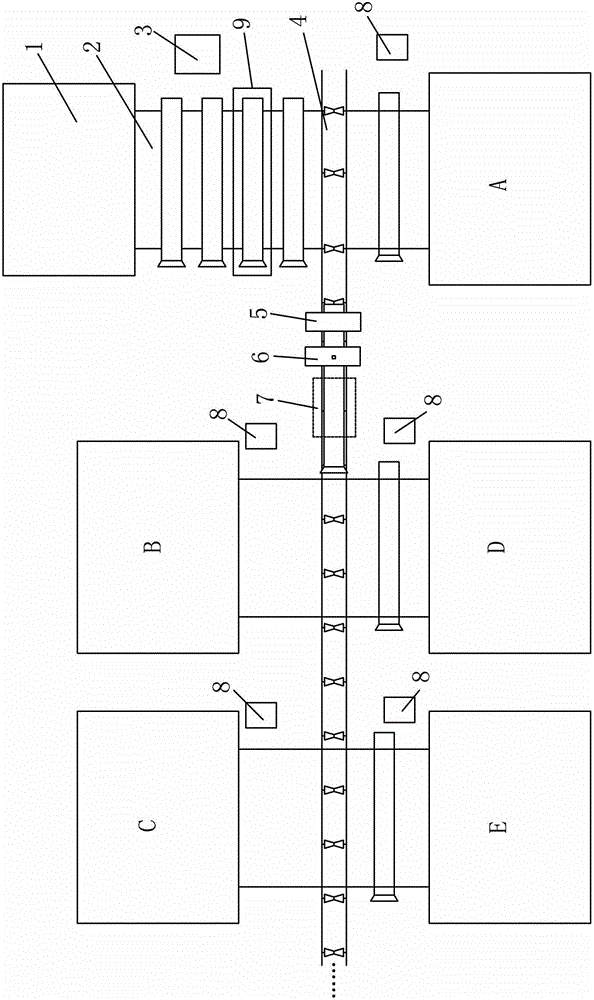

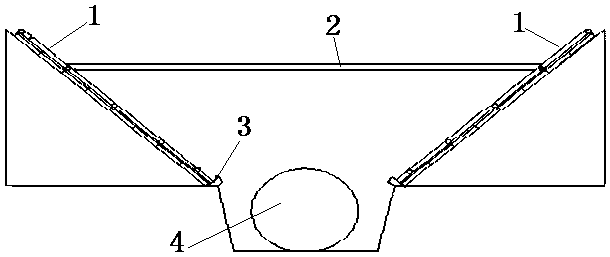

Cement lining device of centrifugal spherical graphite cast-iron pipe

The invention discloses a cement lining device of a centrifugal spherical graphite cast-iron pipe, and relates to the technical field of cement lining of the spherical graphite cast-iron pipe. The cement lining device mainly comprises a frame, a pressing wheel set, a first drive riding wheel set, a second drive riding wheel set, a first driven riding wheel set, a second driven riding wheel set, and a baffle wheel. A drive motor is mounted on one side of the second drive riding wheel set of the frame, the drive riding wheels of the second drive riding wheel set is connected with the drive motor through a second transmission shaft, and the drive riding wheels of the first drive riding wheel set is connected with the drive riding wheels of the second drive riding wheel set through a first transmission shaft. Elongated grooves are uniformly and axially distributed on an outer periphery face on which the baffle wheel is in contact with a spherical graphite cast-iron pipe end. By the aid of the cement lining device, uniformity and stability of rotation speed of the spherical graphite cast-iron pipe can be guaranteed, a uniform and tight cement layer is formed on the inner wall of the spherical graphite cast-iron pipe, quality of cement lining of the spherical graphite cast-iron pipe is effectively improved, and production efficiency is improved.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Treating technology for ductile iron pipes after annealing

ActiveCN102981492AAutomate managementRealize automatic identificationTotal factory controlProgramme total factory controlComputer control systemProduction line

The invention discloses a treating technology for ductile iron pipes after annealing. The treating technology comprises the following steps that a mapping table of a production line and relative positions of the on-line ductile iron pipes on the production line are preset in a computer control system; the mapping tablet records information, such as appearances, pipe diameters, ovality, wall thicknesses of the ductile iron pipes respectively, and number the ductile iron pipes respectively according to a sequence of the ductile iron pipes out of an annealing furnace; orders of the ductile iron pipes on the production line are set; the ductile iron pipes enter a first transportation line and a second transportation line in sequence after the annealing; the ductile iron pipes of which the diameters, the ovality, the wall thicknesses and the appearances are all qualified enter a subsequent finishing operation procedure; the ductile iron pipes with the unqualified ovality enter an ovality correction area; and the ductile iron pipes with the unqualified pipe diameters, wall thicknesses and appearances enter a waste pipe area. The treating technology is simple and precision in process; pipe sizes can be managed automatically; a quality control level of products can be raised; the traceability of the products can be improved; the efficiency can be improved; and the labor intensity of workers can be reduced.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Process for spraying polyurethane on inner wall of nodular cast iron pipe

InactiveCN101758013APrecise proportionWell mixedPretreated surfacesCoatingsStress relievingHigh pressure

The invention relates to a process for spraying polyurethane on the inner wall of a nodular cast iron pipe, in particular to the process for spraying the polyurethane on the inner wall of the DN100-DN300 nodular cast iron pipe. The steps of the process are as follows: 1. processing the inner surface: (1) removing rust and oxide skins; (2) shot-blasting, further removing the rust on the surface of the nodular cast iron pipe, and eliminating stress; (3) removing floating dust; 2. heating and drying; 3. preparing for the spraying: (1) storing coatings; (2) stirring the coatings; (3)_heating and heat-preserving the coatings; (4)_spraying for trial; 4. spraying the polyurethane: polyurethane components A and B are heated, filtered and heat-preserved according to the volume ratio of 1:1, are conveyed into a special mixer under high pressure for high-speed collision mixing or spiral mixing, and are then sprayed onto the surface of the nodular cast iron pipe by a spray gun or a spray cup at high speed in an atomized manner; 5. cleaning the mixer and the spray gun or the spray cup. The thickness of a film formed in one step can be up to 3mm and the adhesive power of the coatings is high, so that the invention can meet the demand for spraying the polyurethane on the inner wall of the small-caliber nodular cast iron pipe.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Production technology for nodular cast iron pipe lining epoxy ceramic

InactiveCN104728557ANo leakageNo segregationCorrosion preventionPipe protection against corrosion/incrustationCeramic coatingFirming agent

The invention belongs to the field of nodular cast iron pipe corrosion prevention, and particularly relates to a production technology for nodular cast iron pipe lining epoxy ceramic. The production technology comprises the steps that after being preheated, a nodular cast iron pipe metal base body rotates at high speed under the drive of a carrier roller, a coating machine coats the interior of the pipe body with liquid A and liquid B at uniform speed, an antifoaming agent with the weight being 3% of the total weight of the liquid A and the liquid B is added into the liquid A and the liquid B for synchronous coating, and an epoxy ceramic coating layer is formed on the inner surface of the pipe body after cooling and solidification. The liquid A is formed by mixing, by mass, 20-30% of quartz powder and 70-80% of epoxy resin. The liquid B is formed by mixing, by mass, 20-30% of quartz powder and 70-80% of polyamide curing agent. The weight ratio of the liquid A to the liquid B ranges from 1:1 to 1:1.2. By the adoption of the production technology, pin hole and bubble phenomena produced on the surface of epoxy ceramic are avoided, the surface of the epoxy ceramic is smooth and flat, and no electric leakage phenomenon exists through electric spark detection.

Owner:BENGANG STEEL PLATES +1

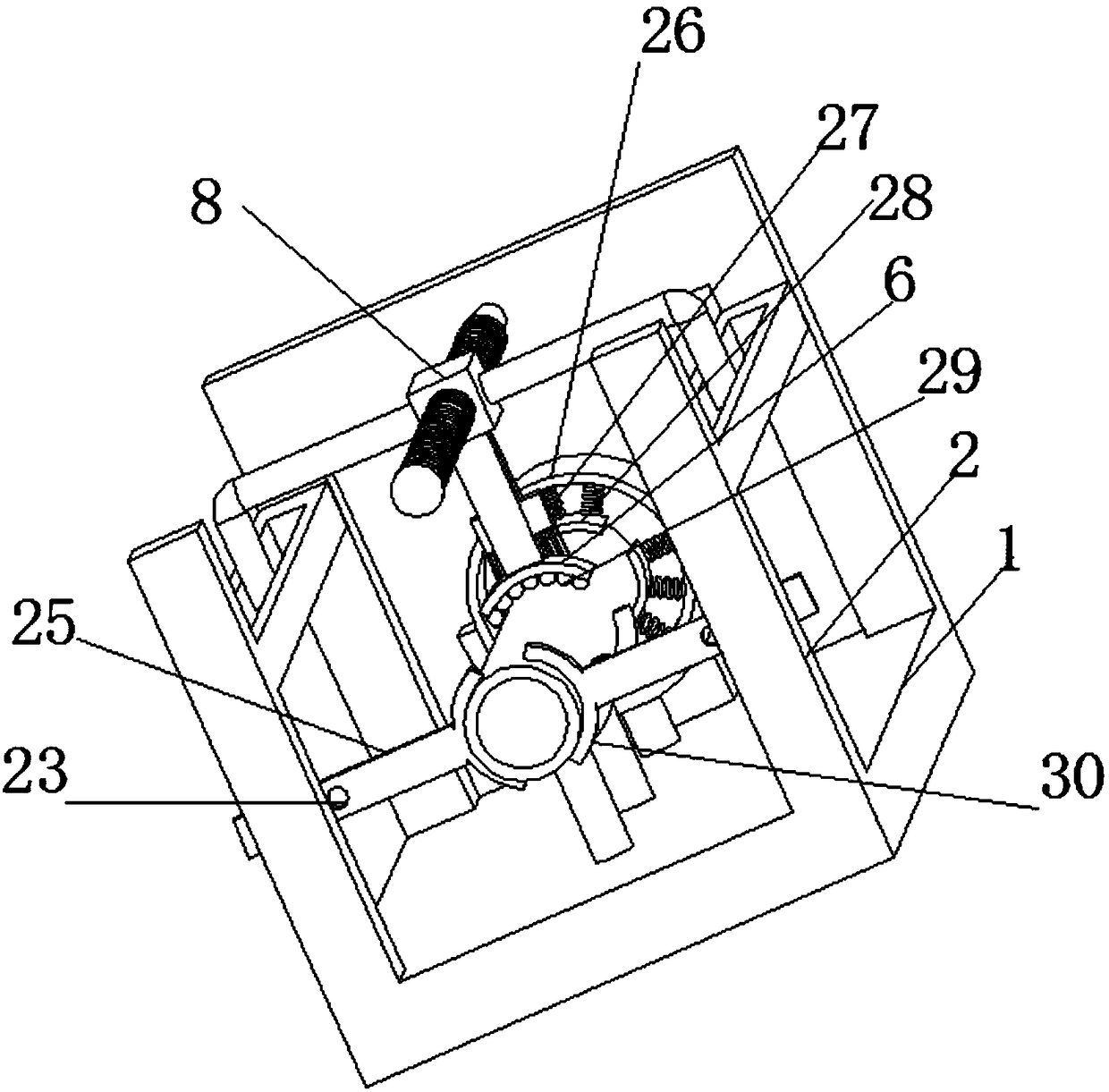

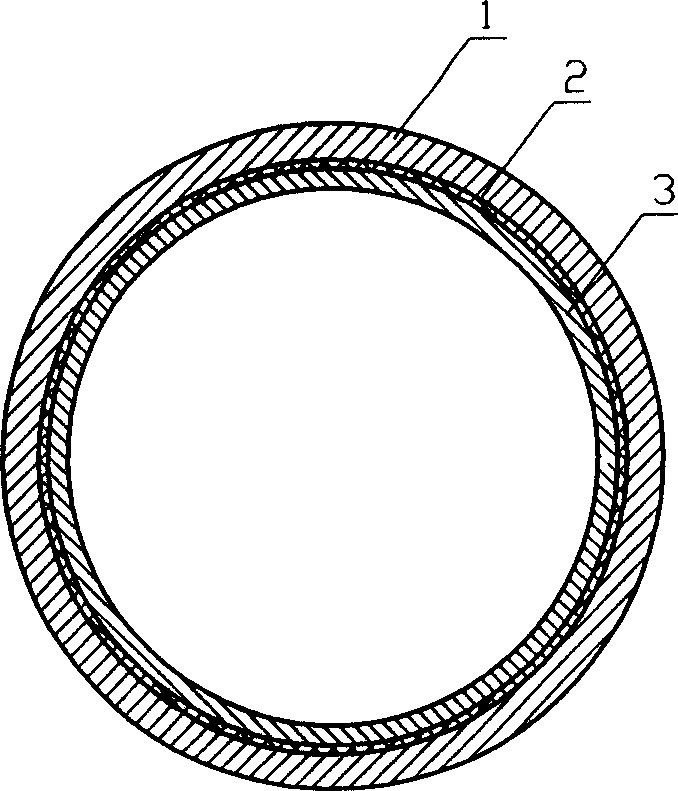

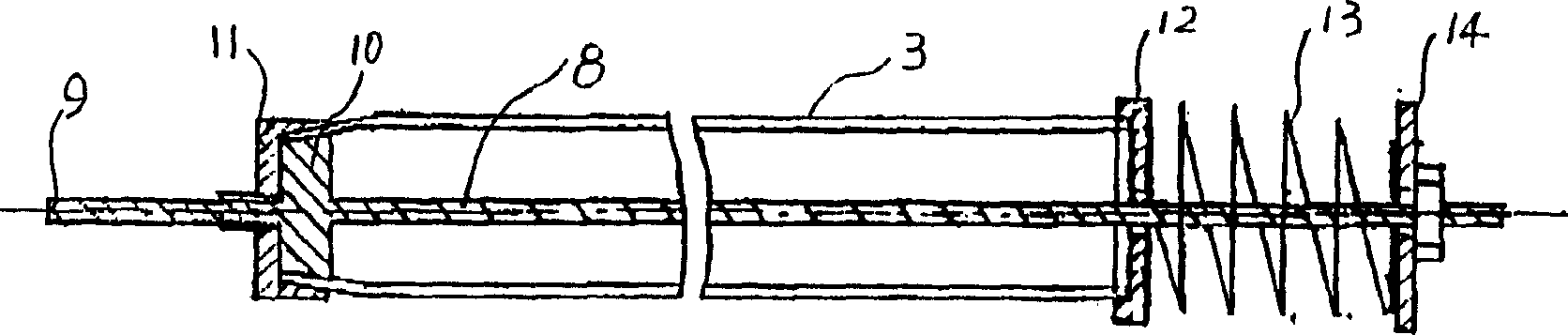

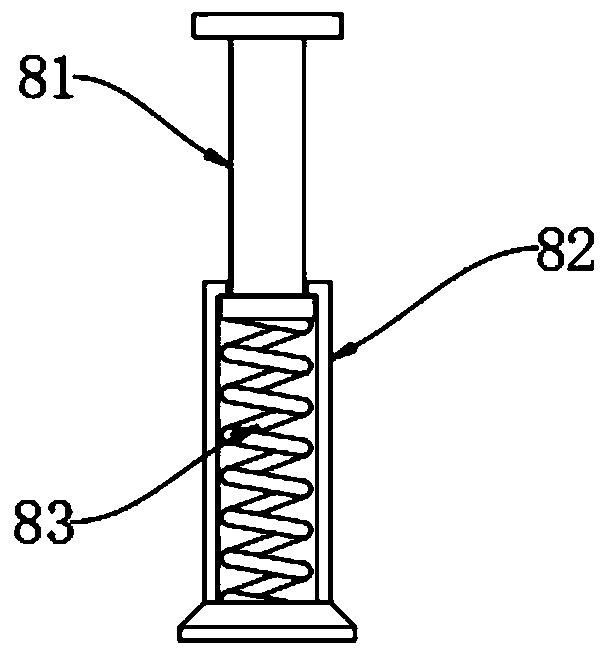

Centrifugal spheroidal cast iron pipe with plastic lining

The invention discloses a plastic lining eccentric spheroidal graphite, which includes a spheroidal graphite body and a inner lining pipe, the inner lining pipe is high molecular poly resin pipe, the two arrange with banding layer; it also discloses the manufacturing method for above mentioned plastic lining spheroidal graphite, the inner wall is pasted with banding agent, the pipe is assembled onto the frame of the extension mechanism; the grip holder core pole is penetrated through the plastic lining pipe, the cone core and the cone grip holder nut on the front part of the grip holder core pole of the grip holder core pole clamp the cone end of the plastic lining; then adjusts the adjusting nut back of the grip holder core pole, the spring penetrating on back of the grip holder core pole is supported by another end of the plastic lining; the extension mechanism pulls the inner lining pipe through the diameter shrinkage model and pulls it into the spheroidal graphite; when the inner lining pipes all goes into the spheroidal graphite and is amended, carries on thermal process to the spheroidal graphite.

Owner:CHEUNG KAY PLASTIC LINED STEEL PIPE MFG

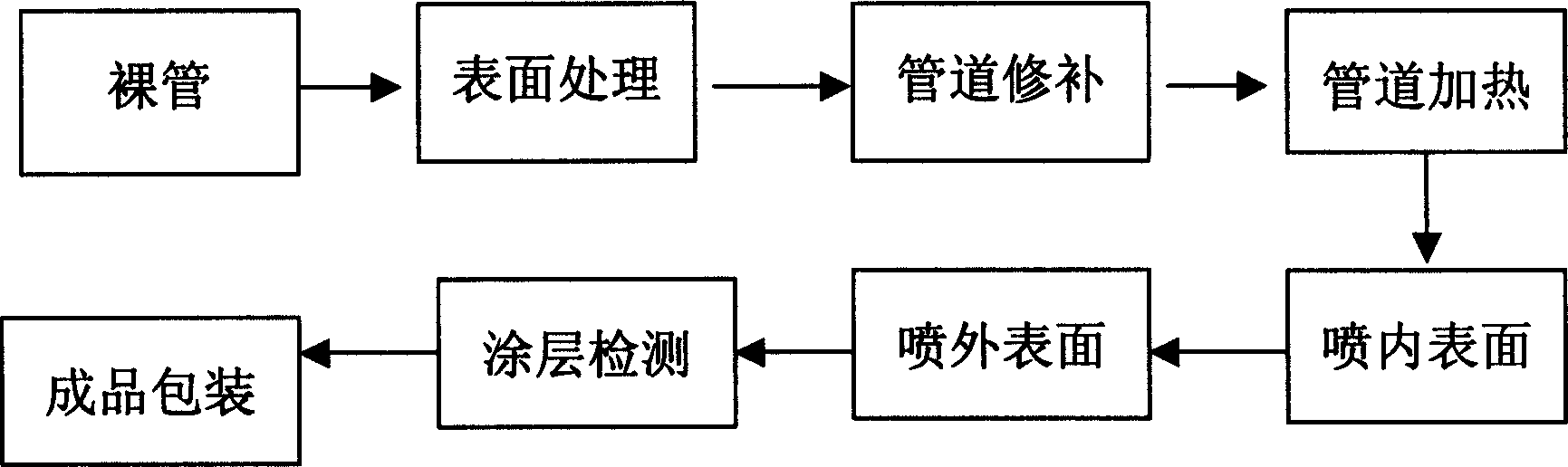

Process for coating polyurethane on inner and outer surface of nodular graphite cast iron pipe

The technological process of painting polyurethane to inner and outer surface of nodular cast iron pipe includes the successive steps of: surface treatment comprising outer surface shot blast and inner surface polishing; surface repairing including filling the notches with putty; heating to temperature of 20-80 deg.c; spraying inner surface with high pressure air-free spraying machine, spraying bogie and spraying gun; spraying outer surface with high pressure air-free spraying machine, spraying bogie and spraying gun; coating detection comprising detecting coating thickness and electric spark detection; and product packing. The present invention has the advantages of simple construction, wide coating application temperature range, high coating mechanical strength, stable chemical performance and no environmental pollution.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Production device for ductile iron pipe fittings

ActiveCN110695825AIncrease costEasy to grind separatelyEdge grinding machinesRevolution surface grinding machinesHydraulic cylinderPipe fitting

The invention discloses a production device for ductile iron pipe fittings, relates to the technical field of production of ductile iron pipe fittings, and solves the problems that the cost of grinding devices is increased, the time spent on installing the pipe fittings twice is long, and the grinding efficiency of the pipe fittings is reduced as the surface and the mouth of the ductile iron pipefittings are ground by two types of grinding devices respectively. A first sealing strip is fixedly connected to the mouth of a grinding box, and a first driving motor and a control panel are sequentially arranged on the other side of the grinding box from top to bottom. A supporting column is fixedly connected to the side of the lower end of the grinding box. A dust collector is fixedly connectedto the lower end of a collecting cover. Outer clamping mechanisms are arranged at both ends of a mounting rod, and an inner clamping mechanism is arranged in the middle of the mounting rod. A first grinding mechanism is arranged at the lower end of a first hydraulic cylinder, an electric slider is arranged at the upper end of an electric slide rail, and a second grinding mechanism is arranged atthe upper end of the electric slider.

Owner:HUBEI ZHENGXIN TUBE

Self-anchoring port fixedly-connecting structure

InactiveCN102003584AImprove pressure bearing capacityPrevent mutual disengagementSleeve/socket jointsFlanged jointsAxial forceCast iron pipe

The invention relates to a self-anchoring port fixedly-connecting structure of nodular cast iron pipes for a water pipe. A port of one nodular cast iron pipe is inserted into a bell mouth of the other nodular cast iron pipe, a sealing groove is arranged in the inner wall of the bell mouth, a sealing ring is embedded in the sealing groove, a press flange is supported against the left end face of the bell mouth, the press flange is fixed with the bell mouth through a bolt, a nut and a press block, the press flange is provided with a tapered inner hole, a port in the tapered inner hole is sleeved with a baffle ring, and a port at the right end of the baffle ring is fixed with a welding ring. Axial force generated by water pressure is resisted by using interaction among the port parts of the welding ring, the baffle ring, the press flange, the high-strength bolt and the press block, the nodular cast iron pipes can be prevented from mutually separating under a higher pipe operation pressure, setting of rest piers is avoided, thus the construction cost of the pipe is greatly lowered.

Owner:XINXING HEBEI ENG & RES INC

A kind of preparation method of strong acid and strong alkali resistant nodular cast iron pipe

ActiveCN102266847AExtended service lifeReduce corrosion rateLiquid surface applicatorsMolten spray coatingStrong acidsAlloy

The invention discloses a method for preparing a ductile cast iron tube with strong acid and alkali resistance. The method comprises the following steps: (1) performing ball blast treatment on the surface of a ductile cast iron tube substrate; (2) spraying a stainless steel alloy bottom layer; and (3) coating an anti-corrosion coating layer on the outer surface of the ductile cast iron tube with the stainless steel alloy bottom layer. The method provided by the invention is used for reducing the uniform corrosion speed of the stainless steel alloy. on the basis of a formed synergetic anti-corrosion system of the stainless steel alloy bottom layer and the anti-corrosion coating layer, the ductile cast iron tube still has excellent anti-corrosion property under the conditions of lower pH value (PH<4) and higher PH value (PH<12), thereby greatly prolonging the service life of the ductile cast iron tube under strong acid and alkali conditions.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Device capable of cleaning outer wall of nodular cast iron pipe or pipe mold

InactiveCN107234106AImprove cleaning qualityReduce consumptionHollow article cleaningEngineeringCast iron pipe

Disclosed is a device capable of cleaning the outer wall of a nodular cast iron pipe or pipe mold. The device comprises at least two supporting wheels, a support, a rail, a trolley and a laser cleaning machine; the rail is arranged above the support, the at least two supporting wheels are mounted under the rail, the nodular cast iron pipe or pipe mold is placed on at least two supporting wheels, the trolley is arranged on the rail, and can walk on the rail, the laser cleaning machine is arranged on the trolley, and the laser cleaning machine is aligned at the outer wall of the nodular cast iron pipe or pipe mold to emit lasers. According to the device, in the production process of the nodular cast iron pipe, due to rust removal of the outer wall of the nodular cast iron pipe or descaling of the outer wall of the pipe mold, quick-wear part consumption is reduced, the wear of other descaling and rust removal manners to the outer wall of the nodular cast iron pipe or pipe mold is completely eradicated, the quality of nodular cast iron pip finished products can be improved, and the cleaning device can be used for carrying out rust removal treatment on the nodular cast iron pipe, and also can be used for descaling treatment of the pipe mold.

Owner:XINXING DUCTILE IRON PIPES CO LTD

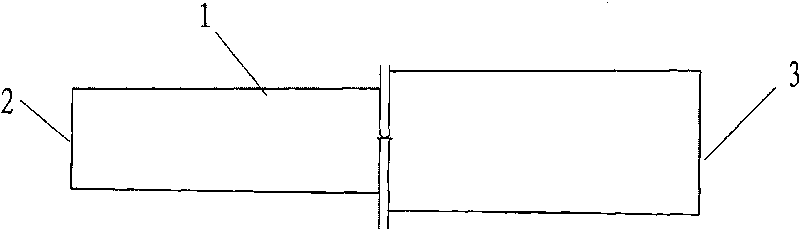

Drawing process of conical ductile cast-iron pipe

The invention discloses a drawing process of a conical ductile cast-iron pipe cast by devices, including a sand mold core, a cast-iron core frame, pipe-drawing calipers, a casting mold and a centrifugal pipe-casting machine. The drawing process comprises the following steps: firstly, putting the dotted casting mold in the centrifugal pipe-casting machine; leading cooling water to the outer wall of the casting mold; mounting the casting mold in the centrifugal pipe-casting machine; mounting the sand mold core on the cast-iron core frame; arranging the cast-iron core frame in the bearing port of the casting mold; pouring molten iron in the fan-shaped ladle of the centrifugal pipe-casting machine; then, starting the automatic pipe-drawing system of the centrifugal pipe-casting machine; drawing to mold; and drawing out the conical ductile cast-iron pipe with the pipe-drawing calipers. In the pipe-drawing process, the drawing speed curve of the automatic pipe-drawing system of the centrifugal pipe-casting machine adopts segmental control, and the rotating speed of a casting rotating DC (Direct Current) motor gradually increases and ranges from 800r / min to 1700r / min. The process enables the pipe body of the conical ductile cast-iron pipe to have even wall thickness and internal compact structure and accord with the use performance requirements.

Owner:ANYANG IRON & STEEL

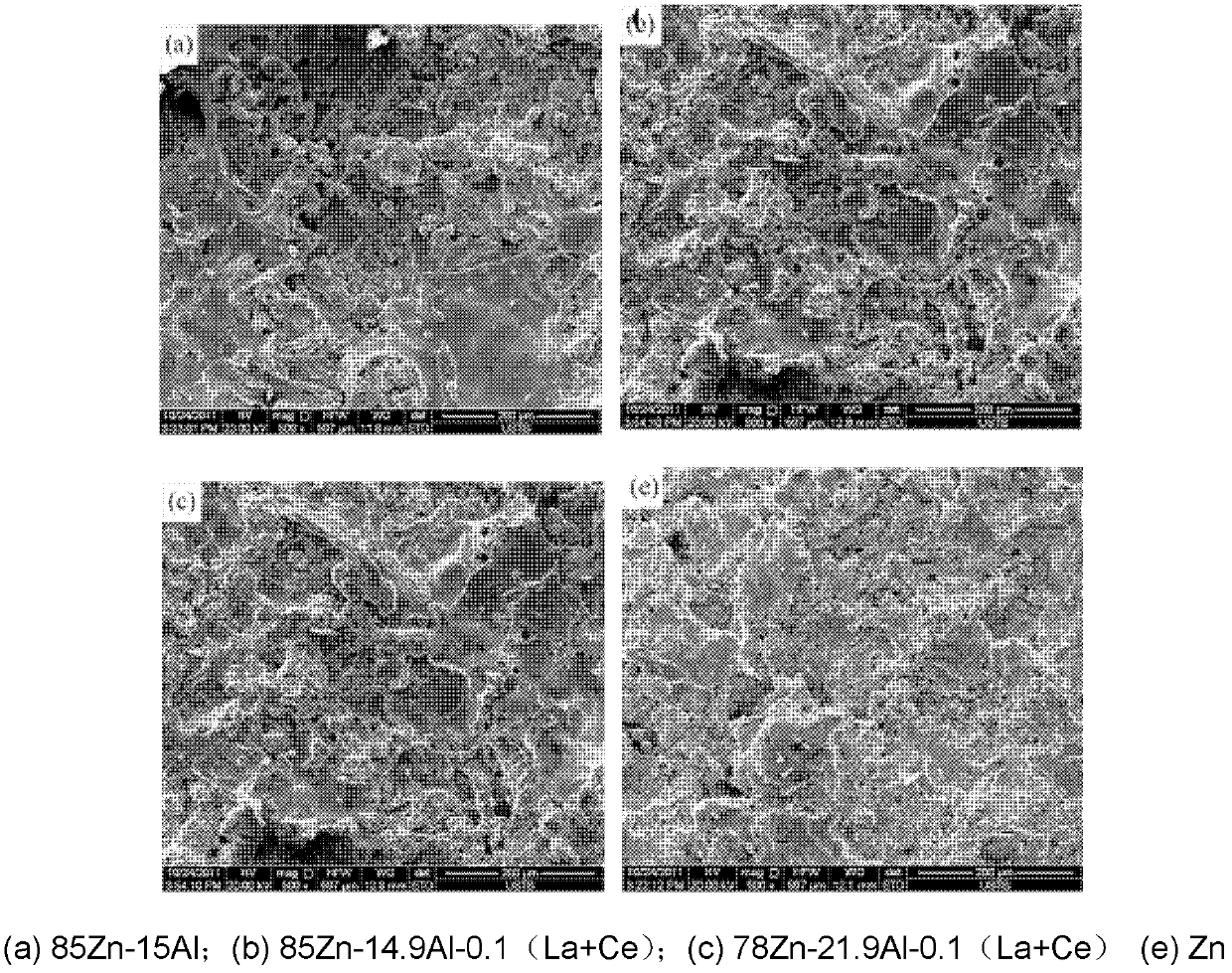

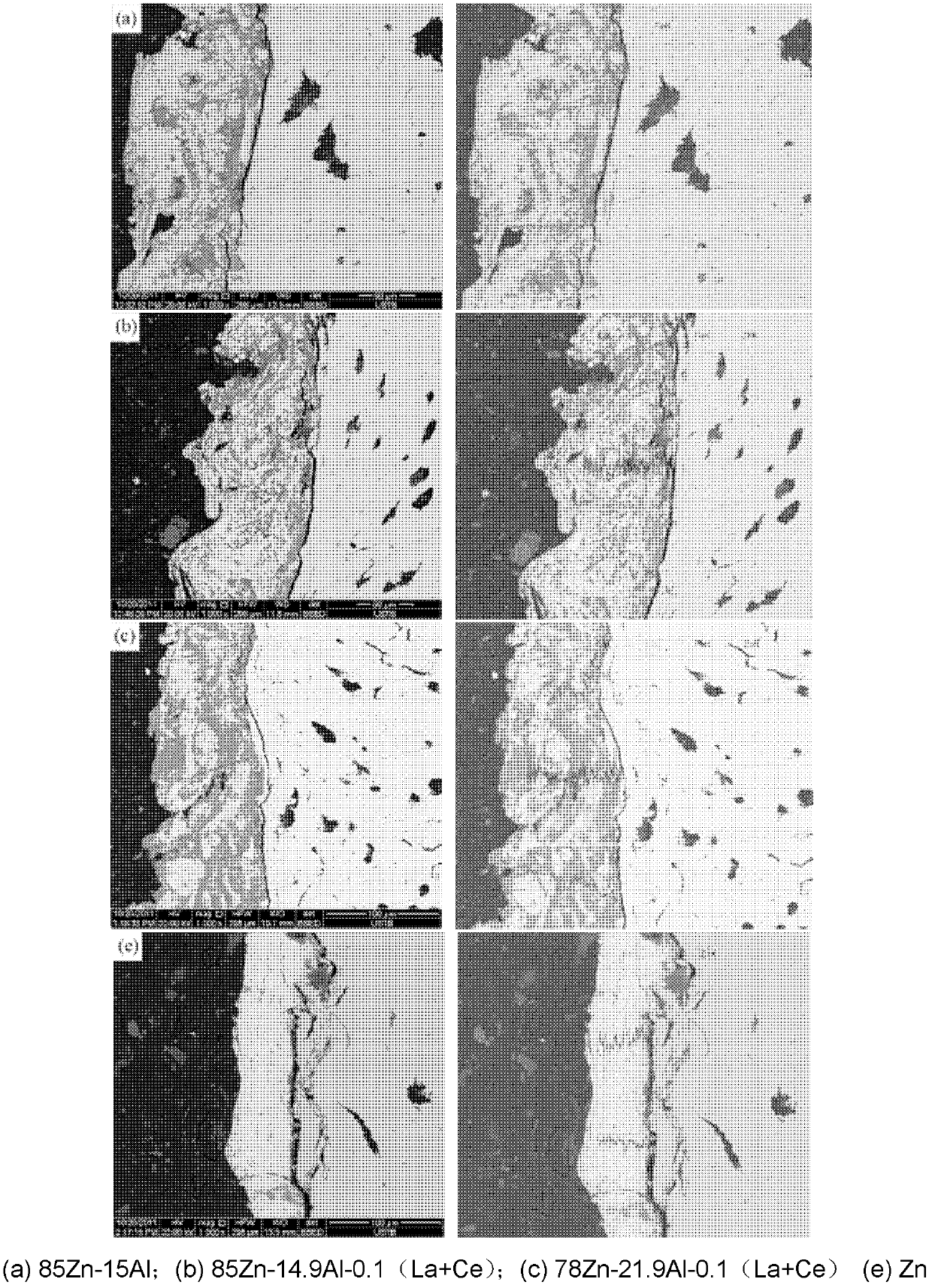

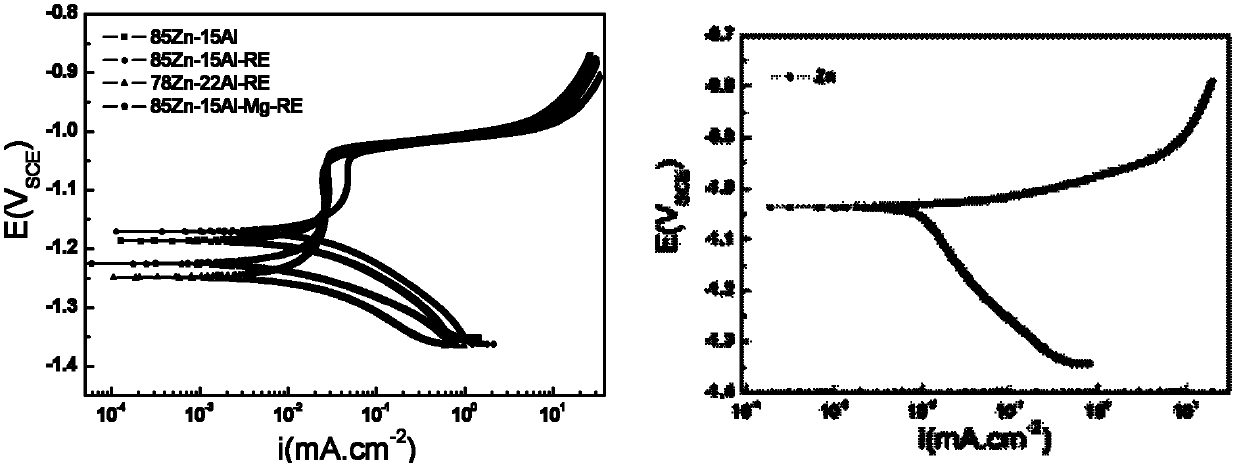

Iron-based pipe comprising anticorrosive coating

ActiveCN103375657AImprove corrosion resistanceReduce porosityCorrosion preventionPipe protection against corrosion/incrustationPorosityAlloy

The invention discloses an anticorrosive coating of a nodular cast iron pipe fitting and a nodular cast iron pipe comprising the coating. The anticorrosive coating comprises a ZnAlRE alloy layer and a hole sealing layer, the ZnAlRE alloy layer comprises, by weight, 4.7-60% of Al, 0.02%-5% of RE and the balance Zn, porosity of the coating is 1.0-2.0%, Ecorr is -1.26--1.17V, and Icorr is 1.0-1.1x10<-5>A.cm<2>. The anticorrosive coating and the nodular cast iron pipe have the advantages of environmental protection, low alloy consumption, high corrosion resistance and the like.

Owner:XINXING DUCTILE IRON PIPES CO LTD

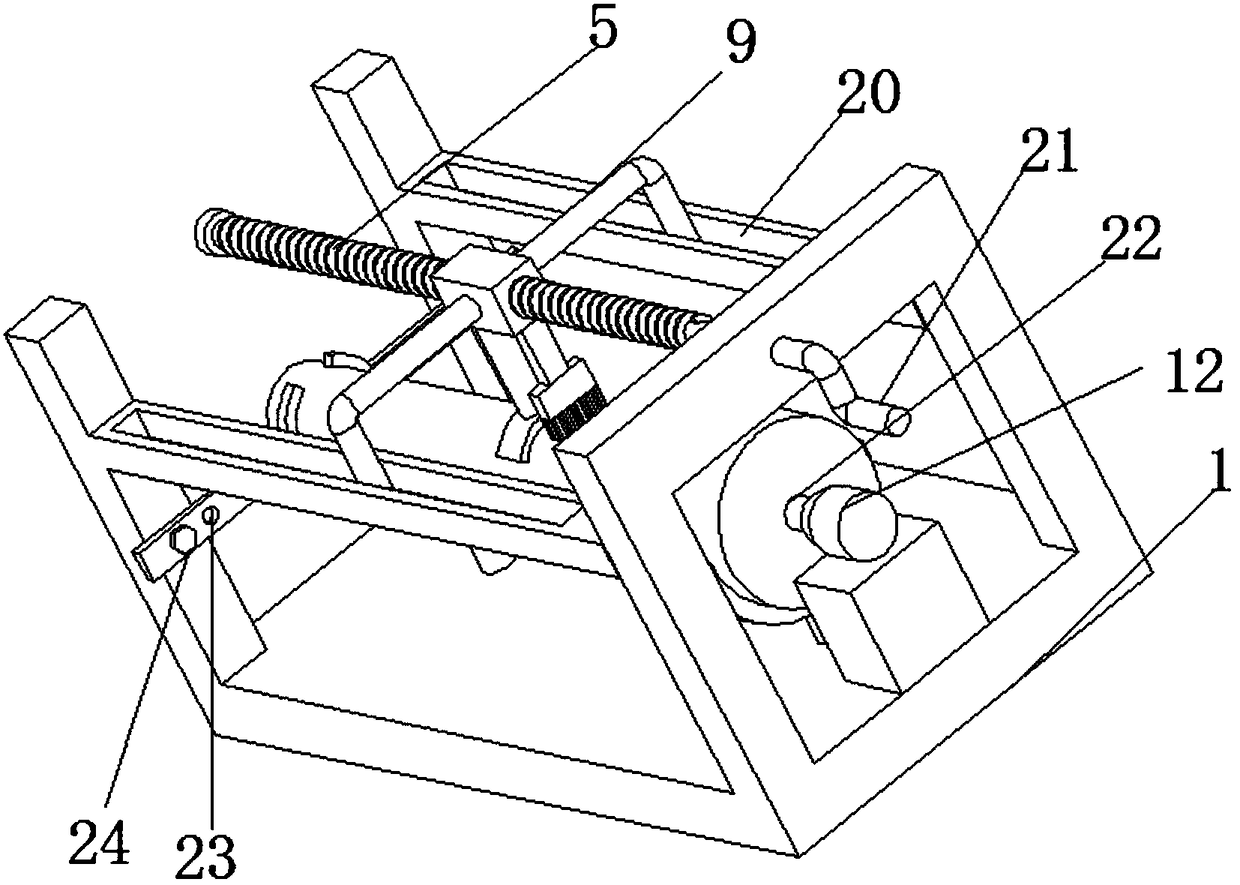

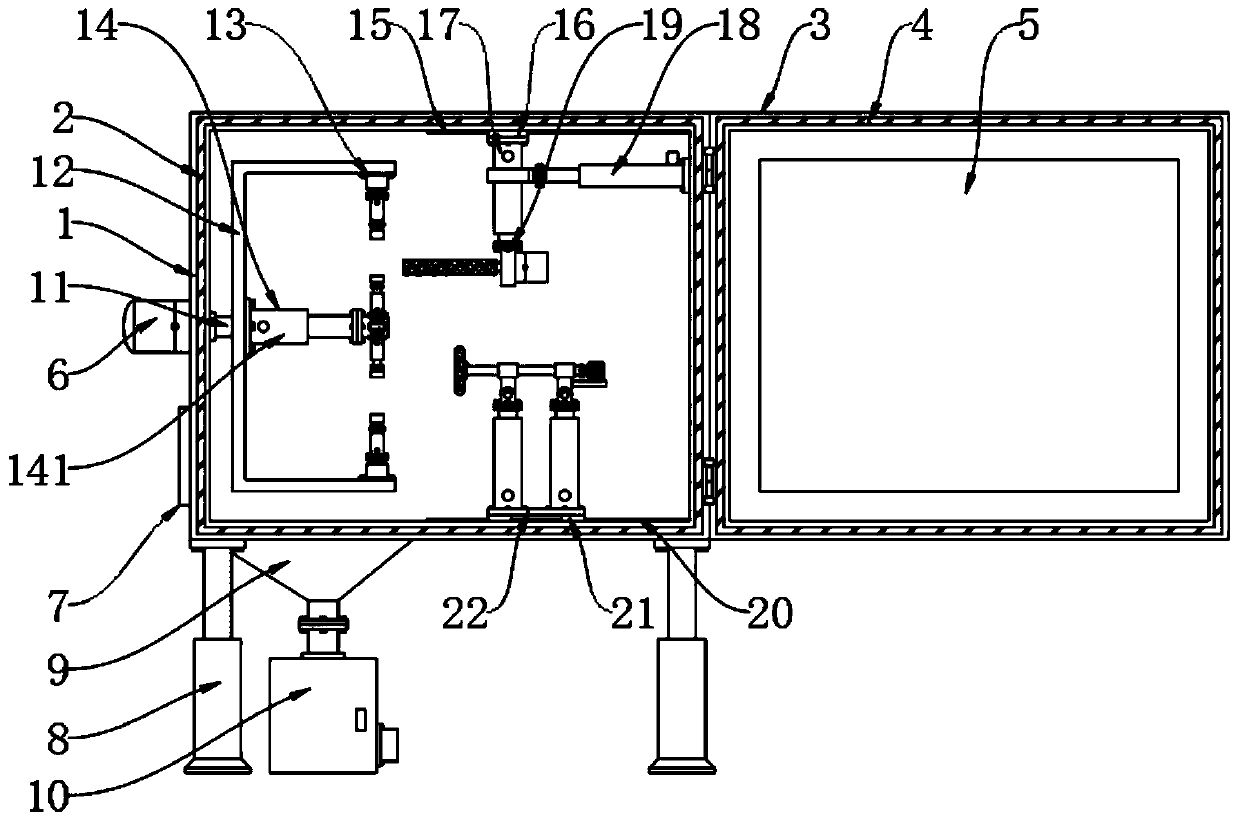

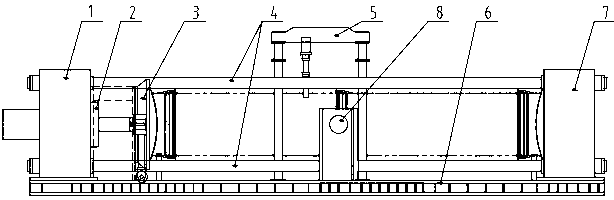

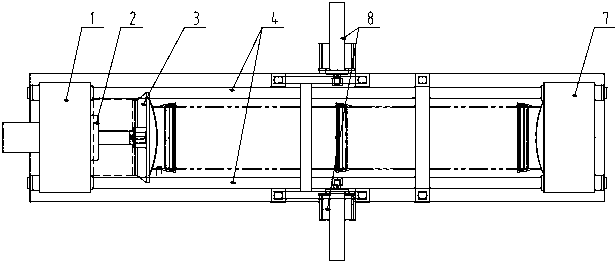

Comprehensive test device for joint sealing and hydraulic circulating of pipe body

ActiveCN103278394AIncrease the lengthImprove the forceMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumHydraulic cylinderEngineering

The invention discloses a comprehensive test device for joint sealing and hydraulic circulating of a pipe body, and belongs to the field of pipe body detection equipment. The comprehensive test device specifically comprises a square base, wherein a front baffle wall and a rear baffle wall are fixedly arranged at the two ends of the base; the front baffle wall is connected with the rear baffle wall through a pull rod; a pushing hydraulic cylinder is arranged in the middle of the front baffle wall; a movable end plug is mounted at the extension end of the pushing hydraulic cylinder; a press-down mechanism and a deflection hydraulic cylinder are arranged in the middle of the base; and the press-down mechanism and the deflection hydraulic cylinder are arranged between the front baffle wall and the rear baffle wall. The comprehensive test device can be used for carrying out joint sealing detection and hydraulic circulating tests on a nodular cast iron pipe at the same time, so that the defect of one device for one test is avoided, the utilization rate of the equipment is increased and the convenience is provided for staffs in operation.

Owner:XINXING HEBEI ENG & RES INC

Construction method allowing nodular cast iron pipe to penetrate water-containing soil layer

InactiveCN108223910AOvercome exclusion difficultiesPrevent collapse accidentsPipe laying and repairLandslideWater table

The invention relates to a construction method allowing a nodular cast iron pipe to penetrate a water-containing soil layer, relates to a method allowing the nodular cast iron pipe to penetrate the water-containing soil layer to be laid, and is suitable for laying construction of the soil layer with the higher underground water level. The construction method is characterized in that the construction process comprises the steps of groove excavation, underground water drainage, pipe ditch landslide treatment, pipe installation, pipe ditch backfill and hydrostatic testing. According to the method, the groove excavation cross section adopts a manner combining a straight groove and a dovetail groove, the water level height of the underground water is effectively controlled, a sloping bamboo diving board hack lever supporting scheme is adopted for strengthening, the groove collapse accident is prevented, the pipe installing and hydrostatic testing technology is reasonable, the problems thatthe difficulty of water removal can be overcome, and the pipe ditch landslide and pipe installing difficulties are large are solved, construction allowing the nodular cast iron pipe to penetrate the water-containing soil layer is achieved, and effective water supply guarantees are provided for production.

Owner:JINCHUAN GROUP LIMITED

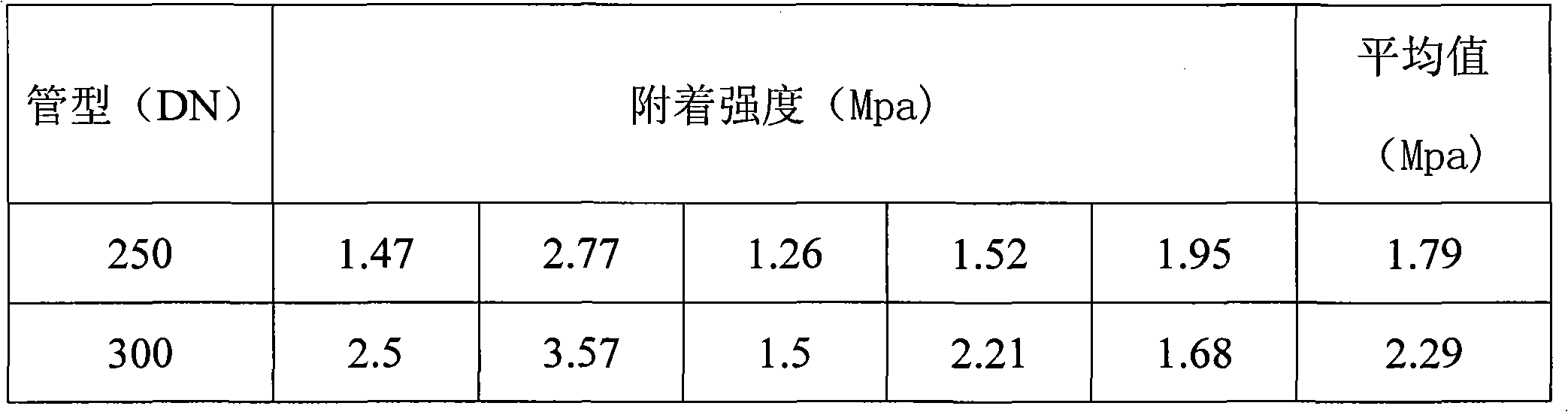

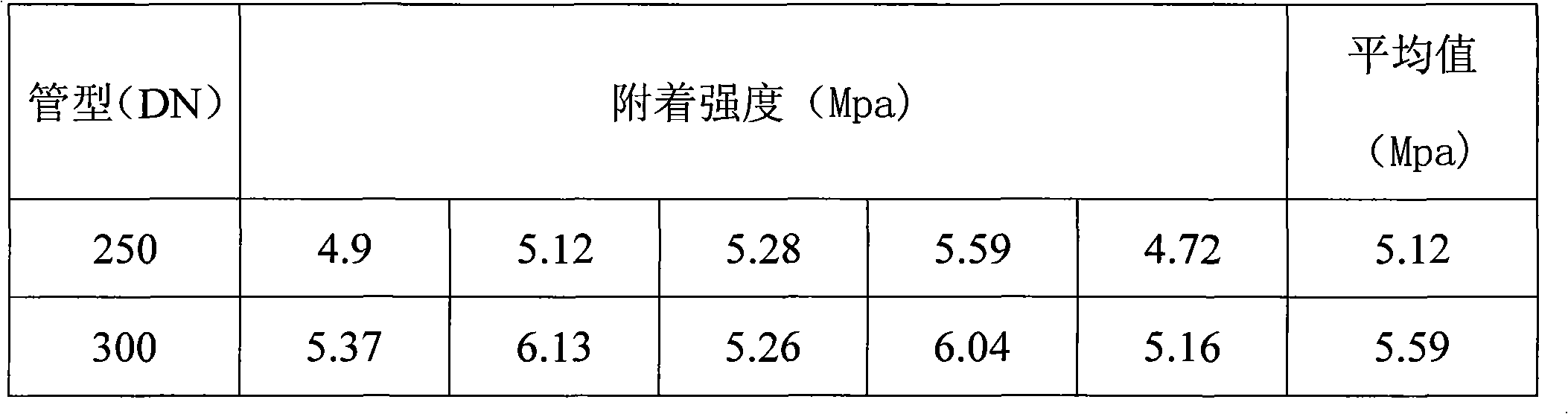

Cement mortar for inner liner of centrifugal ductile iron pipe

The invention discloses cement mortar for an inner liner of a centrifugal ductile iron pipe, which comprises the following components in parts by weight: 1 part of cement, 1.0-1.5 parts of sand, 0.25-0.35 parts of water and 0.0075-0.035 part of a water reducing agent. The cement mortar of the invention improves the strength of the inner liner of the centrifugal ductile iron pipe, the peel strength of the inner liner and the adhesive strength between the inner liner and the inner wall of the ductile iron pipe.

Owner:XINXING DUCTILE IRON PIPES CO LTD

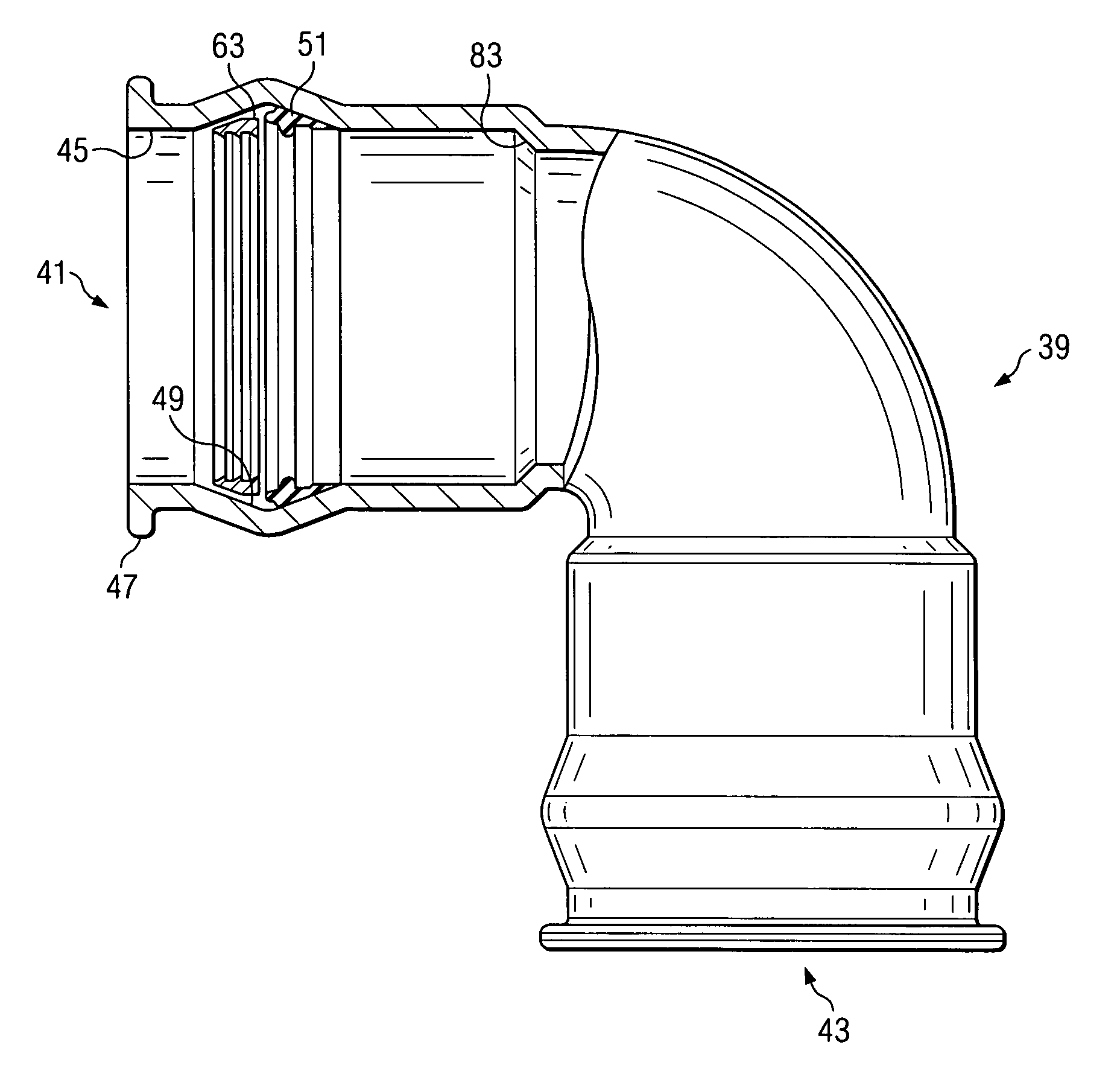

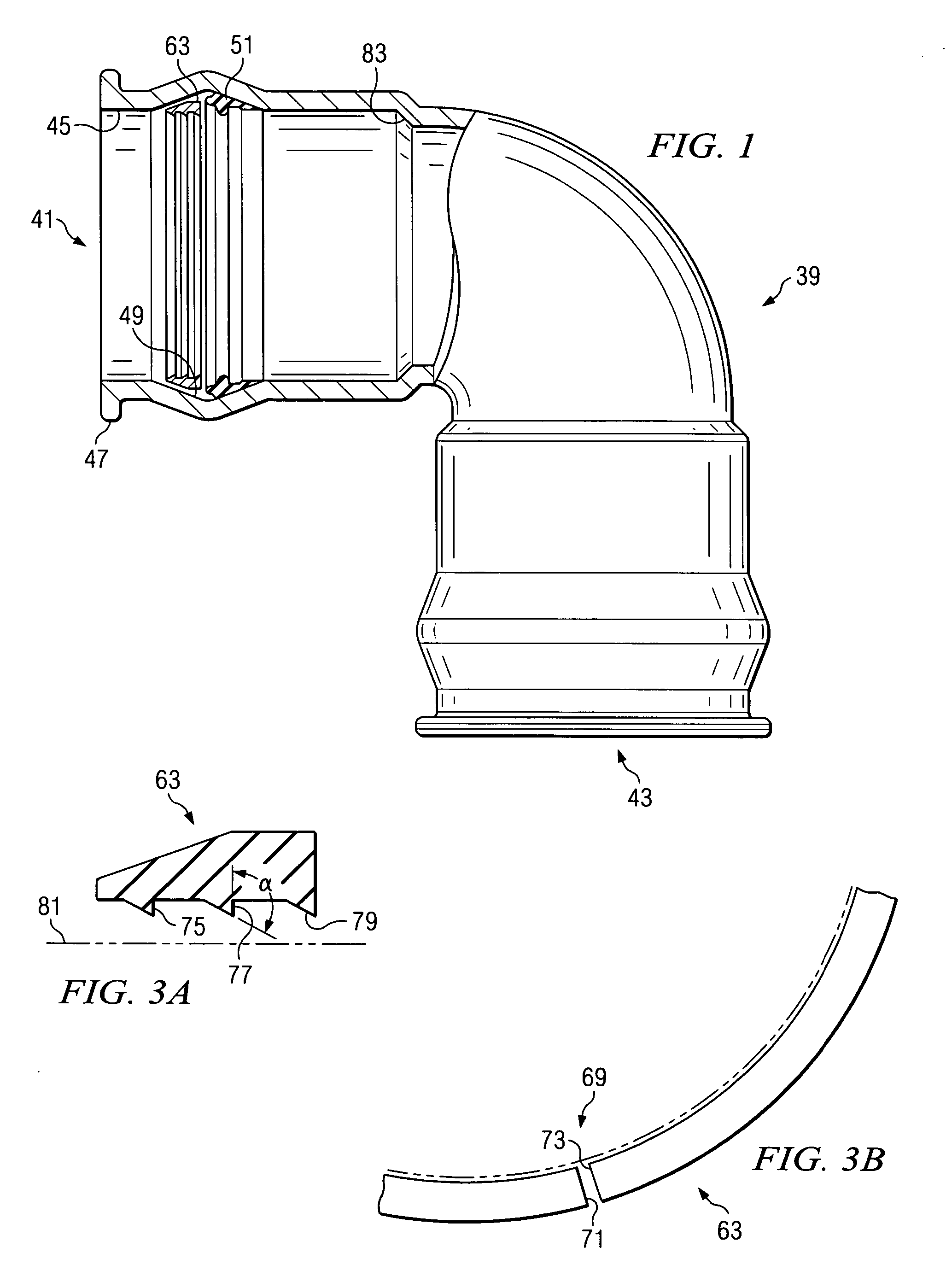

Self restrained fitting for PVC and ductile iron pipe

InactiveUS20060279080A1Easily bentEasily flexedSleeve/socket jointsFluid pressure sealed jointsPipe fittingEngineering

A combination sealing and restraint system for an as-cast ductile iron fitting is shown for both sealing and preventing separation of an iron pipe fitting and a mating male pipe. The restraint system includes both a sealing ring and a combination gripping ring which are installed in a groove provided in a mouth region of the iron fitting. The gripping ring has teeth on an inner surface which are initially angled away from an outer surface of the male pipe. The teeth are forced into engagement with the exterior surface of the mating male pipe as the pipe joint at the fitting is assembled. The teeth are oriented to allow movement of the male pipe in a first direction relative to an end opening of the fitting during assembly, but to resist movement in a opposite direction after the fitting joint has been assembled. The sealing ring and gripping ring are installed in the annular groove of the as-cast iron fitting after the iron casting operation at the factory.

Owner:S & B TECHN PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com