Iron-based pipe comprising anticorrosive coating

An anti-corrosion coating and pipeline technology, applied in the field of anti-corrosion coating of iron-based pipelines, pipelines and coatings, ductile iron pipelines and pipe fittings, can solve the problems of weakening anti-corrosion performance, reducing coating adhesion, shortening anti-corrosion life, etc. Achieve the effect of reducing coating porosity, reducing surface active points, and reducing corrosion channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

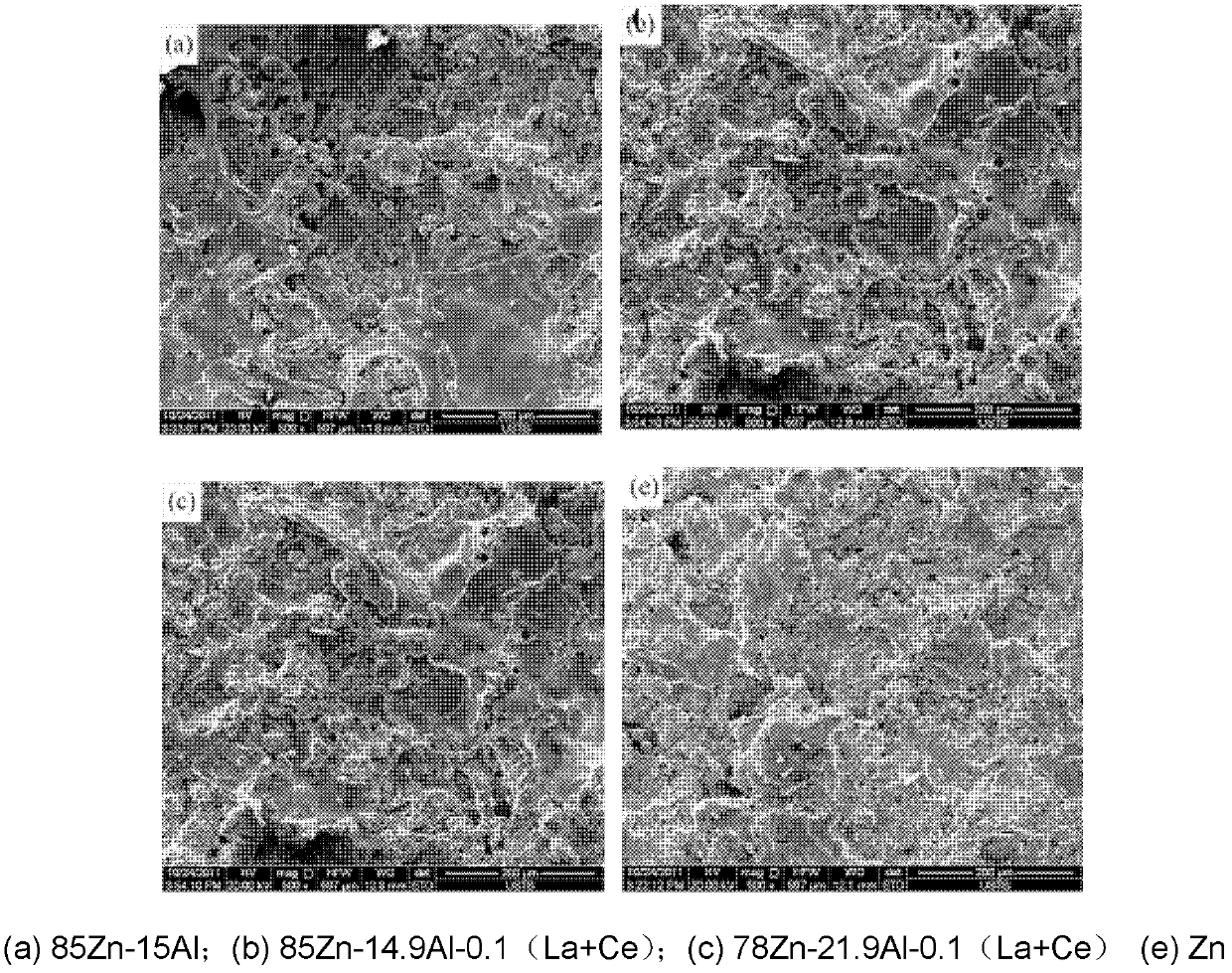

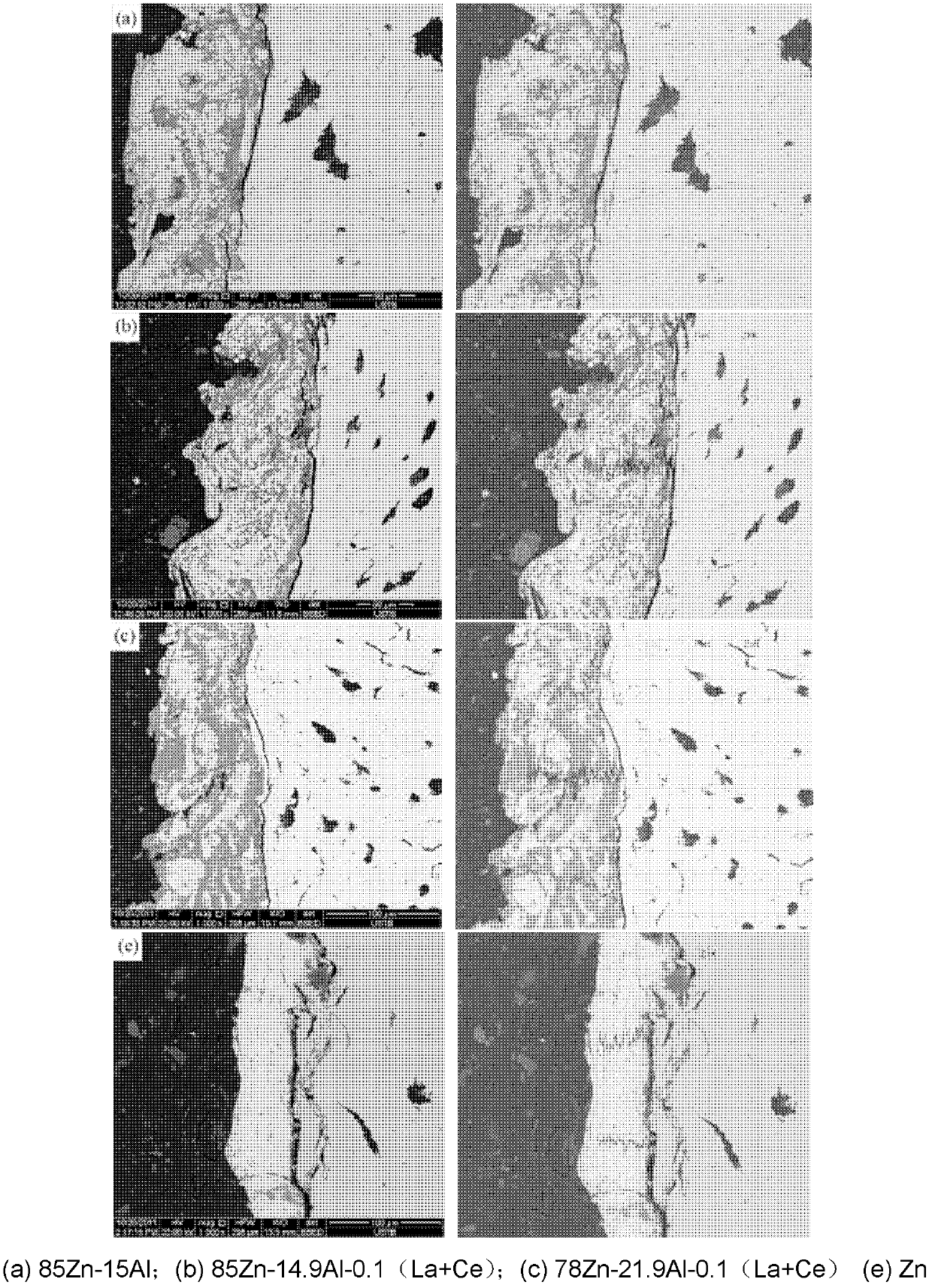

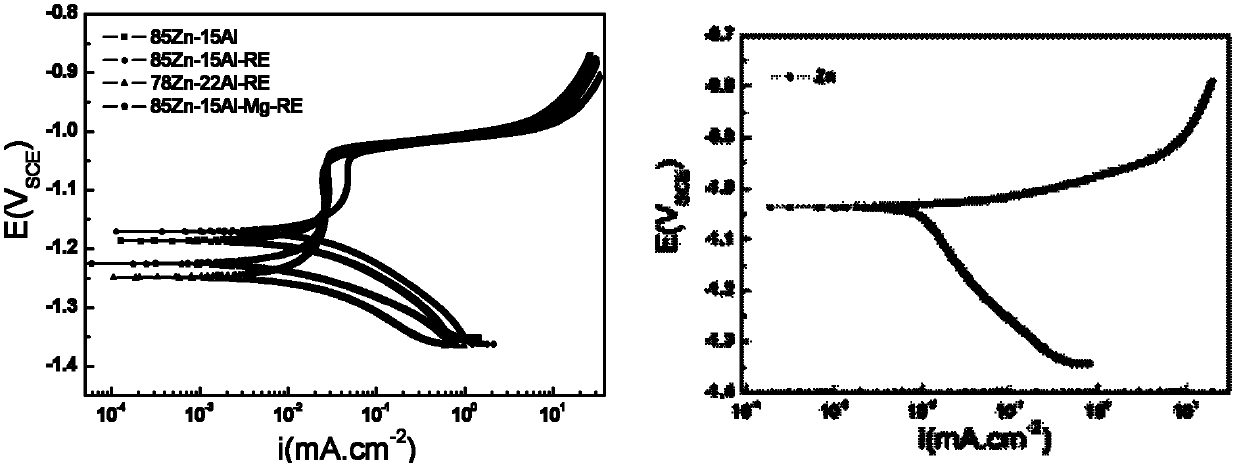

[0047] 1. Spray ZnAlLaCe alloy layer

[0048] Spraying wire type: two ZnAlLaCe alloy wires are used, and the diameter of the alloy wire is 4.0mm.

[0049] By arc spraying, ZnAlLaCe alloy wire is used to deposit ZnAlLaCe alloy coating on the ductile iron pipe substrate. The composition content of each element of the coating is: Al: 14.9%, La+Ce: 0.1%, and the rest is Zn.

[0050] 2. Coating the sealing layer

[0051] Spray the sealing layer with epoxy resin paint, and the coating thickness is 150 microns.

[0052] (1) Adhesion test results

[0053] Table 1 Adhesion of pure zinc coating, zinc-aluminum alloy coating, zinc-aluminum rare earth alloy coating

[0054] type

[0055]

[0056] It can be seen from Table 1 that the adhesion of zinc-aluminum rare earth alloy coating is significantly higher than that of pure zinc coating and zinc-aluminum alloy coating.

[0057] (2) Porosity test results

[0058] Table 2 Porosity of pure zinc coating, zinc-aluminum...

Embodiment 2

[0085] The content of the alloy layer is: Al: 21.9%, La+Ce: 0.1%, the rest is Zn, and the rest is the same as in Example 1.

[0086] (1) Adhesion test results

[0087] Table 8 Adhesion of pure zinc coating, zinc-aluminum alloy coating, zinc-aluminum rare earth alloy coating

[0088]

[0089] It can be seen from Table 8 that the adhesion of zinc-aluminum rare earth alloy coating is higher than that of pure zinc coating and zinc-aluminum alloy coating.

[0090] (2) Porosity test results

[0091] The porosity of table 9 pure zinc coating, zinc-aluminum alloy coating, zinc-aluminum rare earth alloy coating

[0092]

[0093] It can be seen from Table 9 that the porosity of zinc-aluminum rare-earth alloy coating is significantly lower than that of pure zinc coating and zinc-aluminum alloy coating, which is more conducive to preventing external corrosive media from contacting the metal substrate, thereby improving the corrosion resistance of the coating.

[0094] (3) The ini...

Embodiment 3

[0116] 1. Spray ZnAlLa alloy layer

[0117] Spraying wire type: two ZnAlLa alloy wires are used, and the diameter of the alloy wire is 2.0mm.

[0118] By arc spraying, ZnAlLa alloy wire is used to deposit ZnAlLa alloy coating on the ductile iron pipe substrate. The composition content of each element of the coating is: Al: 4.7%, La: 0.3%, and the rest is Zn.

[0119] 2. Coating the sealing layer

[0120] The sealing layer is sprayed with epoxy resin paint, and the thickness of the coating is 60 microns.

[0121] (1) Adhesion test results

[0122] Table 15 Adhesion of pure zinc coating, zinc aluminum alloy coating, zinc aluminum rare earth alloy coating

[0123]

[0124] It can be seen from Table 15 that the adhesion of zinc-aluminum rare earth alloy coating is higher than that of pure zinc coating and zinc-aluminum alloy coating.

[0125] (2) Porosity test results

[0126] The porosity of table 16 pure zinc coating, zinc-aluminum alloy coating, zinc-aluminum rare earth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com