Patents

Literature

12168results about "Corrosion prevention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

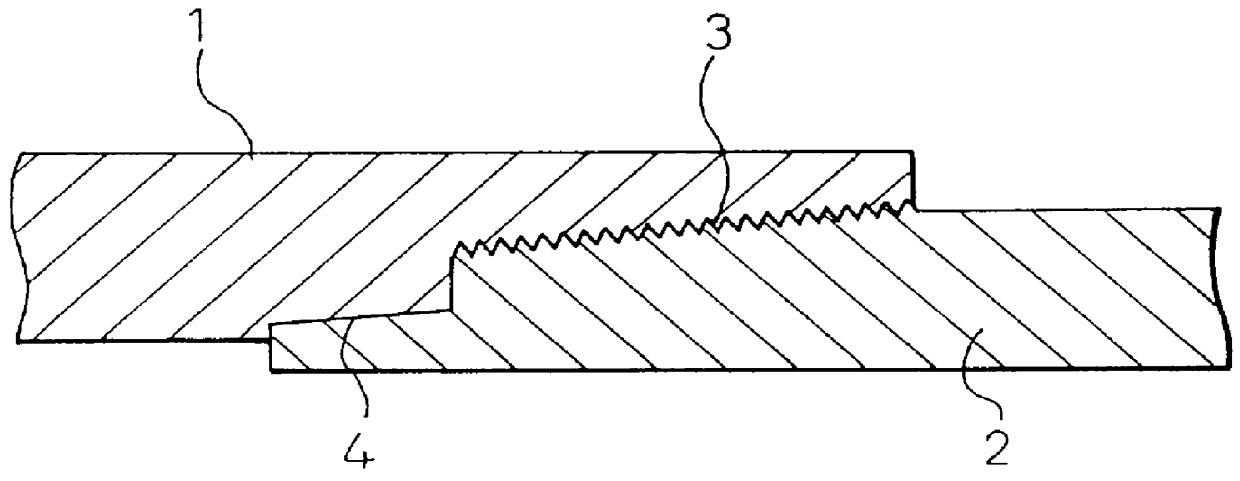

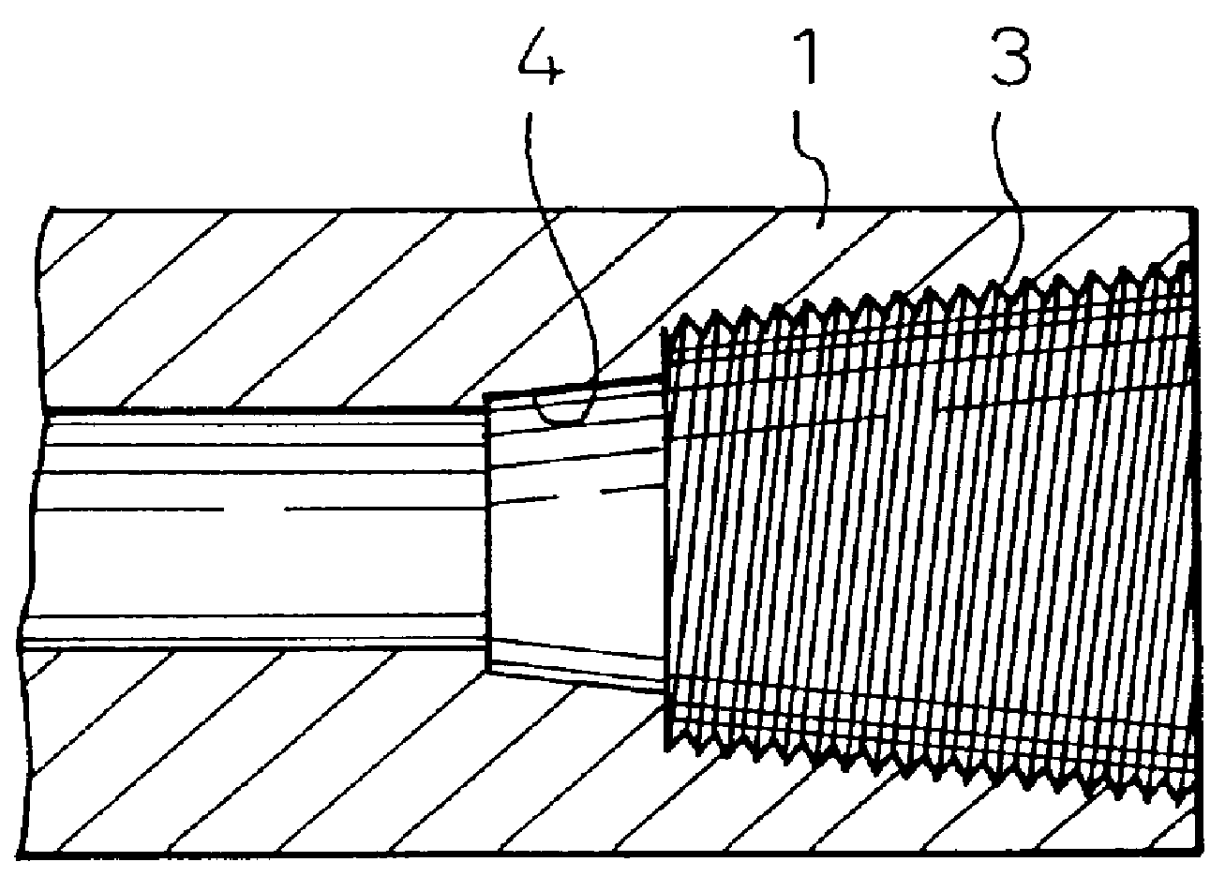

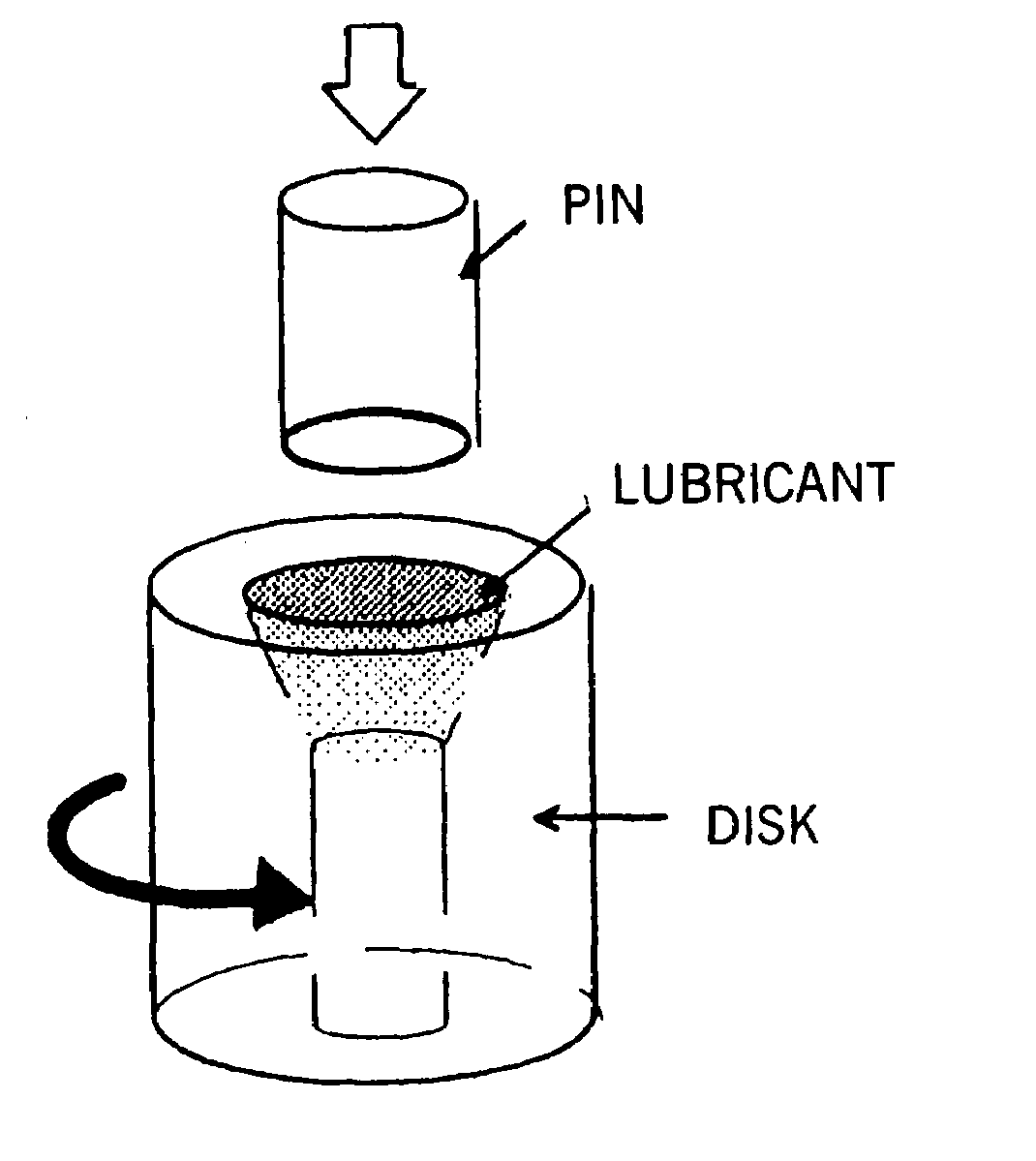

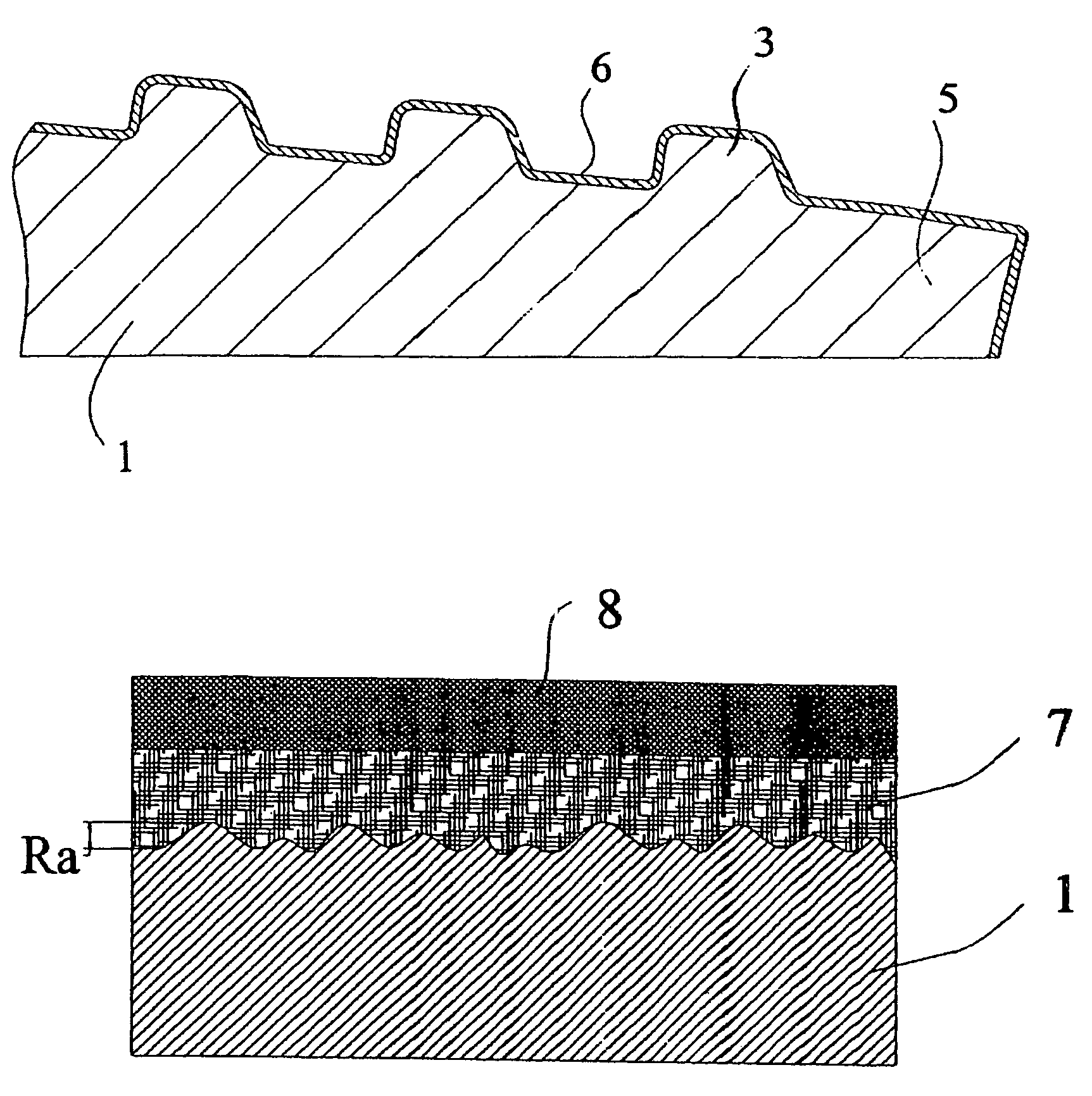

Joint for steel pipe having high galling resistance and surface treatment method thereof

InactiveUS6027145AShorten heating timeImprove the lubrication effectDrilling rodsPretreated surfacesEpoxyPolyamide

PCT No. PCT / JP95 / 02034 Sec. 371 Date May 23, 1997 Sec. 102(e) Date May 23, 1997 PCT Filed Oct. 4, 1995 PCT Pub. No. WO96 / 10710 PCT Pub. Date Apr. 11, 1996An object of the present invention is to provide galling resistance to a threaded joint used for an oil well pipe. On a thread portion and a metallic sealing portion of the joint, there is provided a manganese phosphate chemical formation coating layer, or alternatively there are provided a nitriding layer of 1 to 20 mu m thickness and a manganese phosphate chemical formation coating layer of 5 to 30 mu m thickness, and also there is coated a solid lubricant which contains powder of molybdenum disulfide or tungsten disulfide and also contains one of epoxy resin, furan resin and polyamide resin as an essential component, and a ratio of composition is maintained at a specific value, so that a solid lubricant coating layer of 10 to 45 mu m thickness can be formed by heating. Due to the above surface treatment, even when the frequency of repetition of fastening and unfastening of the joint is increased, the occurrence of galling can be prevented over a long period of time.

Owner:NSCT PREMIUM TUBULARS

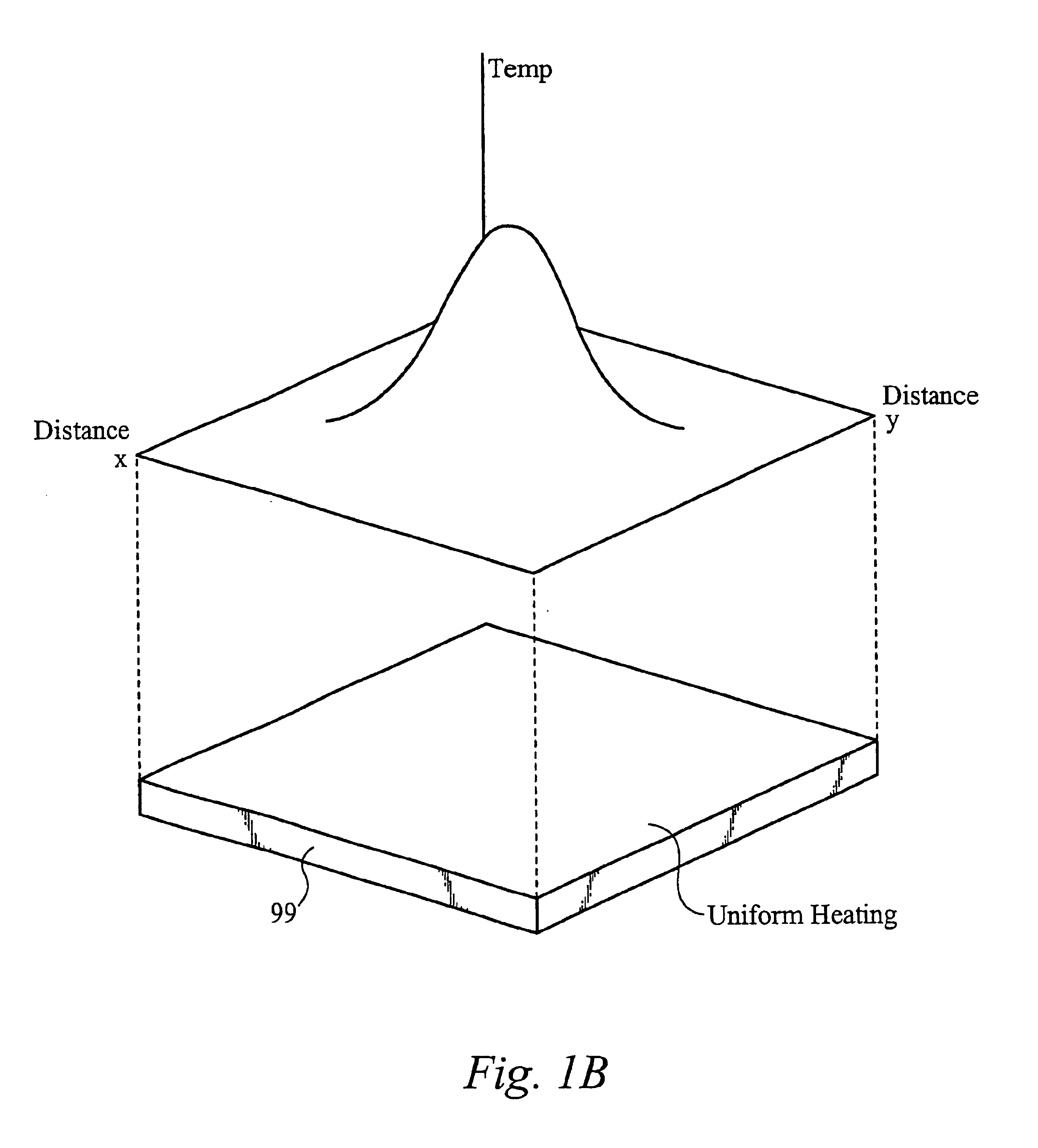

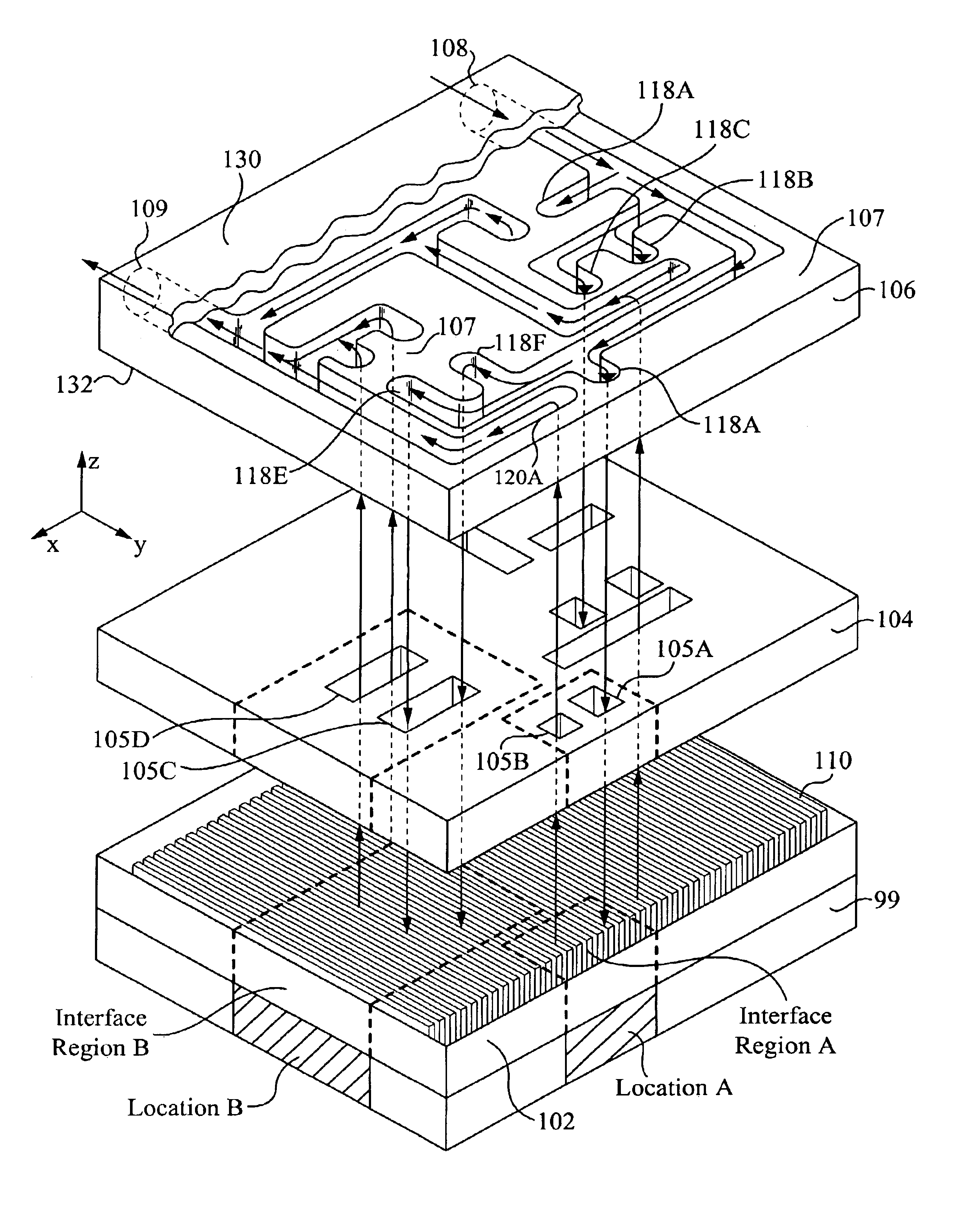

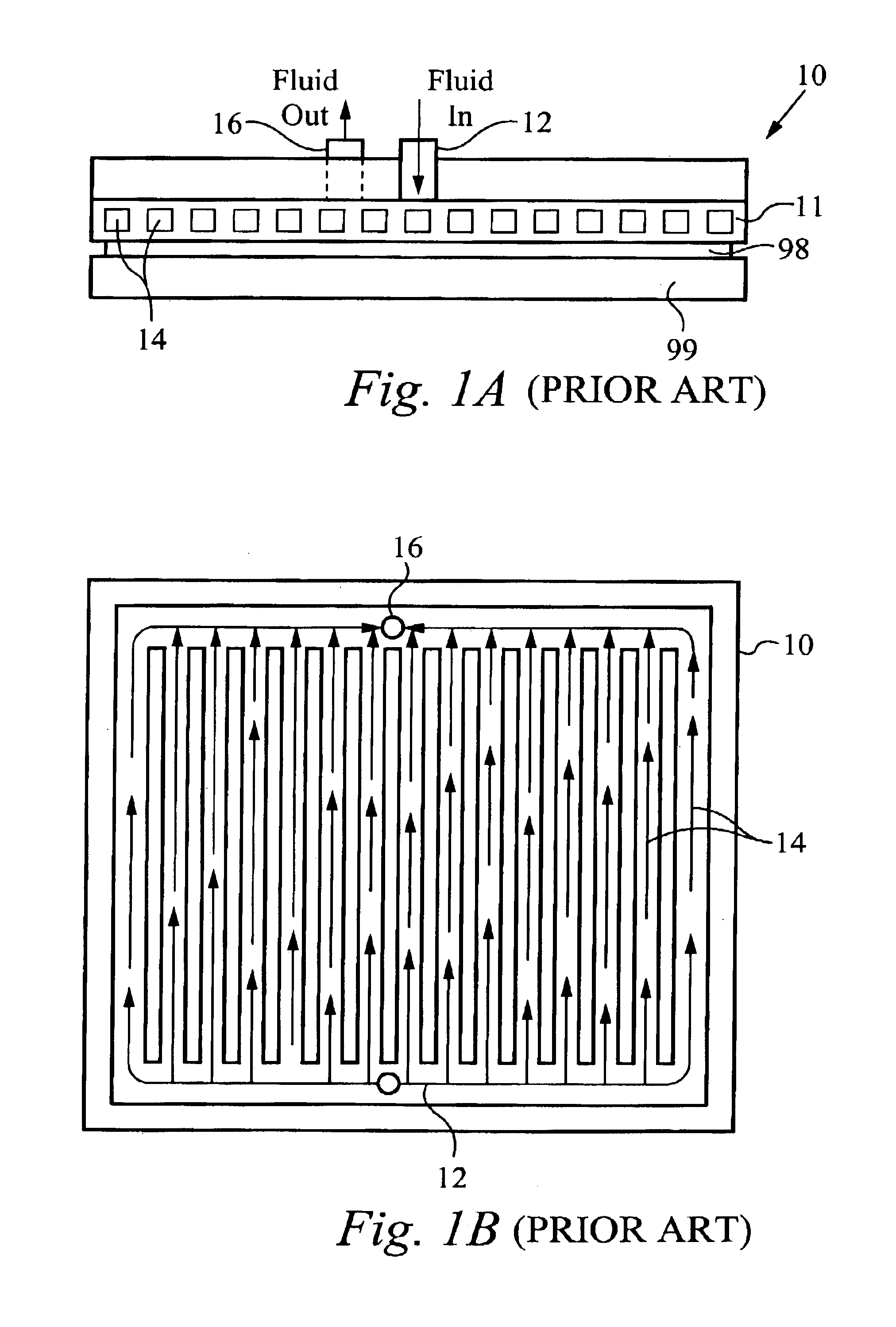

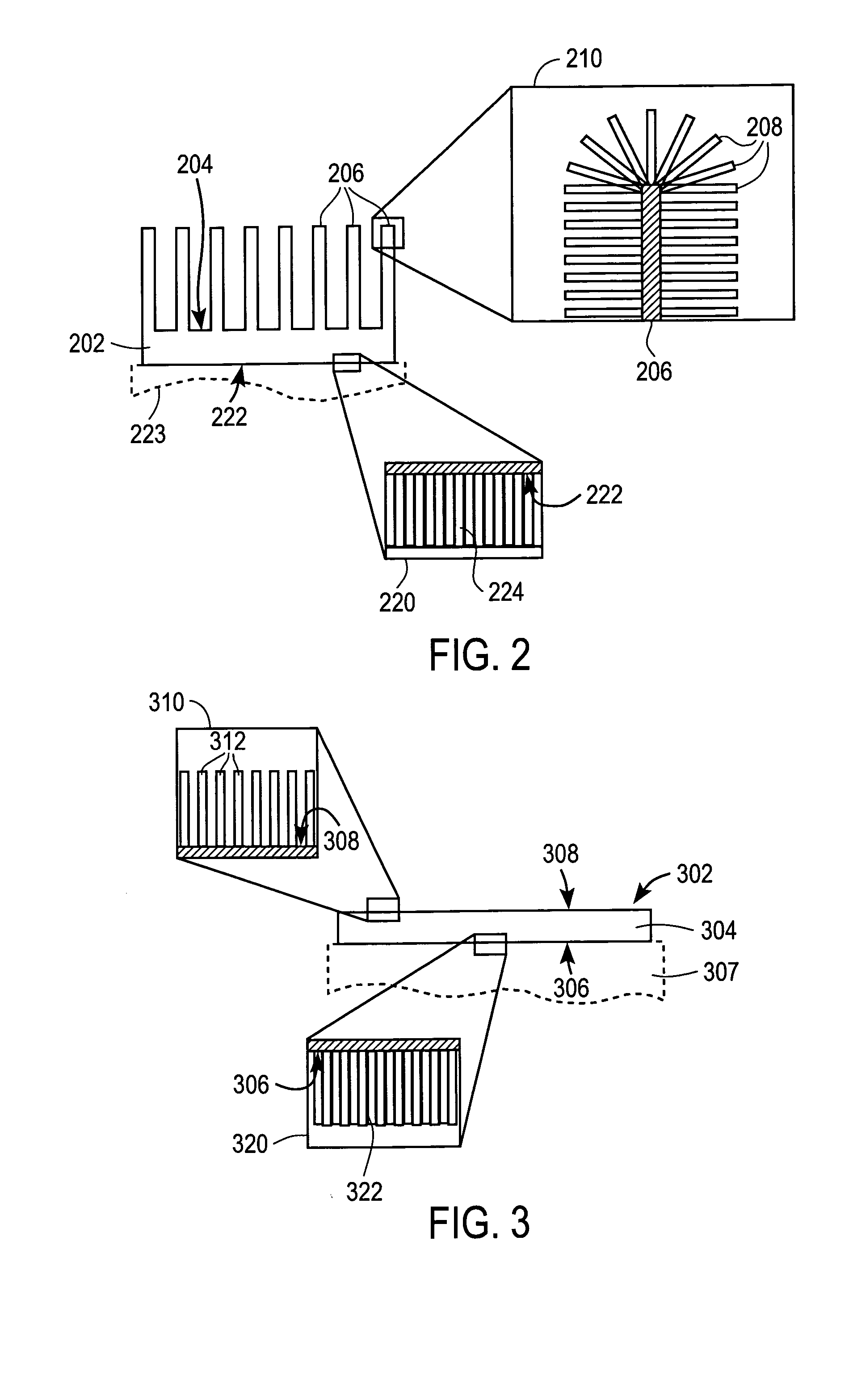

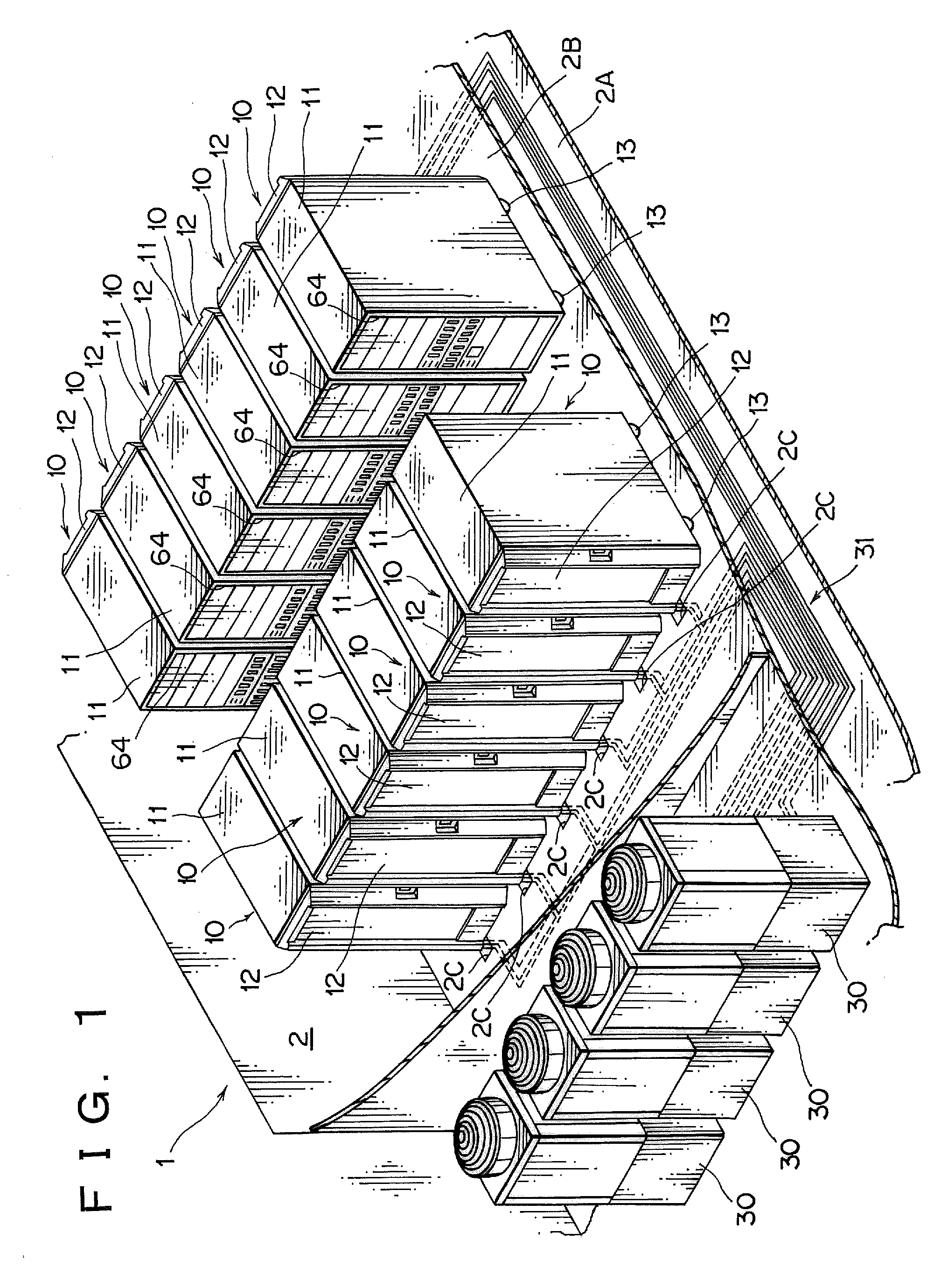

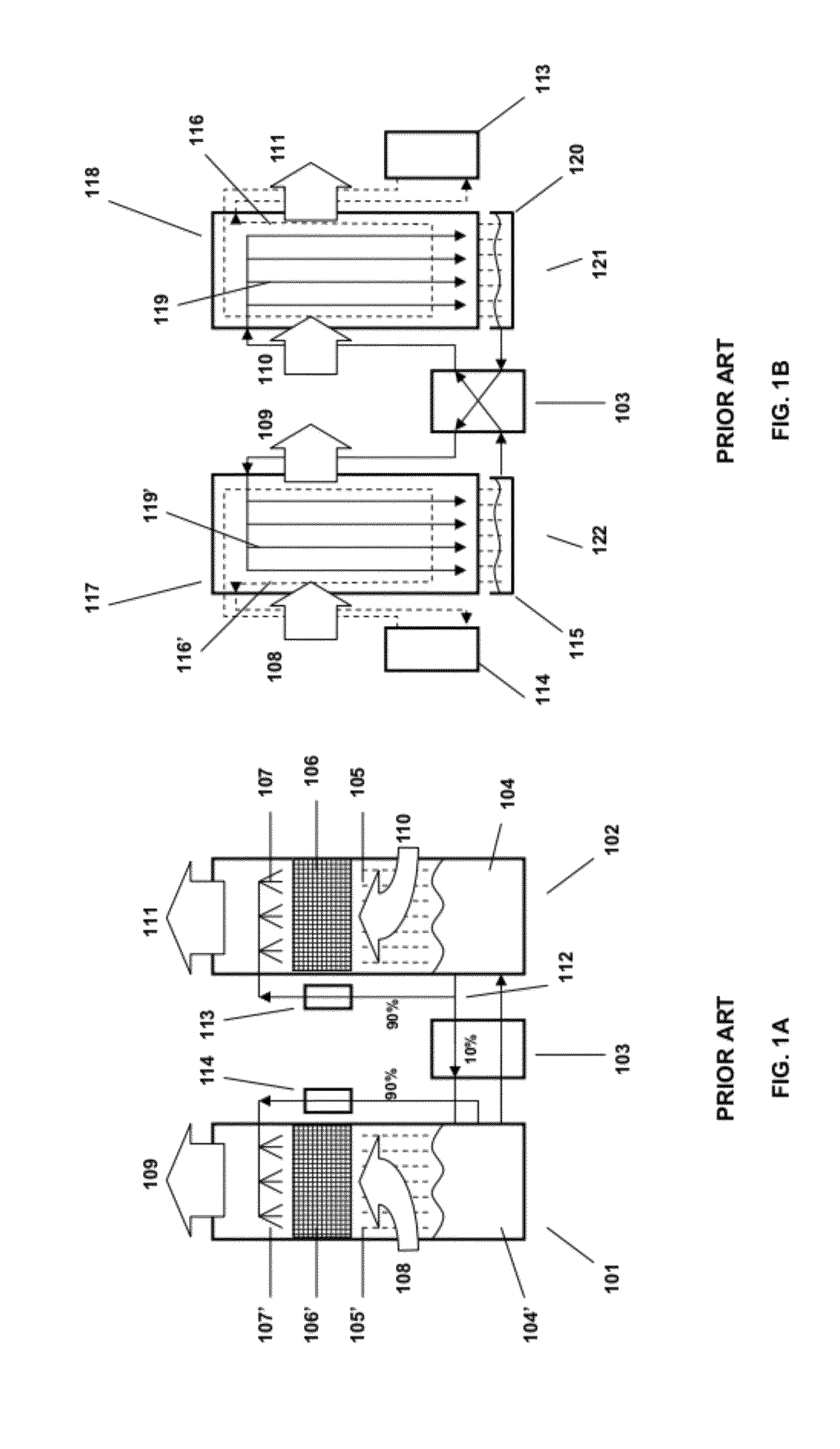

Method and apparatus for achieving temperature uniformity and hot spot cooling in a heat producing device

ActiveUS7104312B2Minimize temperature differenceTemperatue controlSemiconductor/solid-state device detailsTemperature differenceEngineering

A method of controlling temperature of a heat source in contact with a heat exchanging surface of a heat exchanger, wherein the heat exchanging surface is substantially aligned along a plane. The method comprises channeling a first temperature fluid to the heat exchanging surface, wherein the first temperature fluid undergoes thermal exchange with the heat source along the heat exchanging surface. The method comprises channeling a second temperature fluid from the heat exchange surface, wherein fluid is channeled to minimize temperature differences along the heat source. The temperature differences are minimized by optimizing and controlling the fluidic and thermal resistances in the heat exchanger. The resistances to the fluid are influenced by size, volume and surface area of heat transferring features, multiple pumps, fixed and variable valves and flow impedance elements in the fluid path, pressure and flow rate control of the fluid, and other factors.

Owner:VERTIV CORP

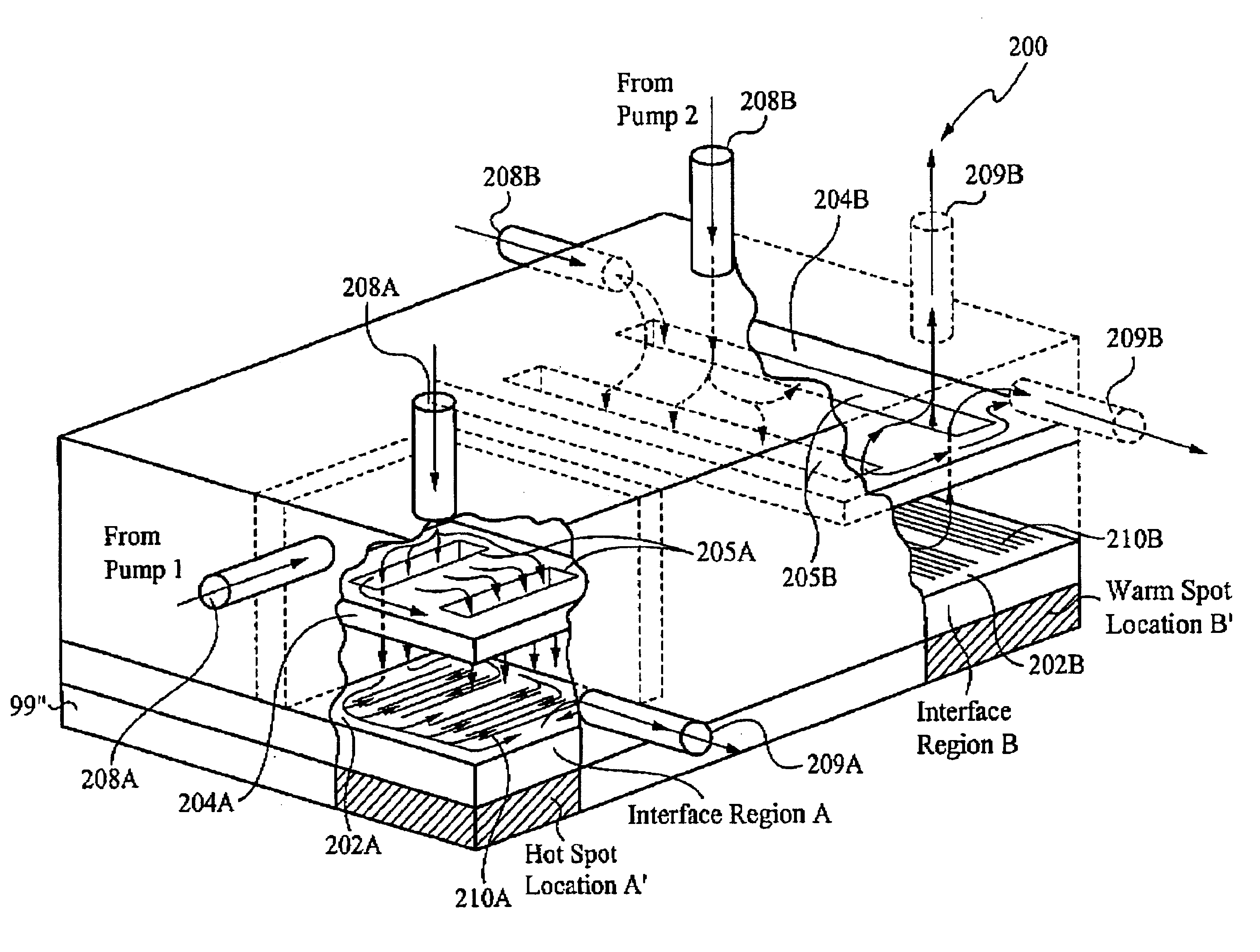

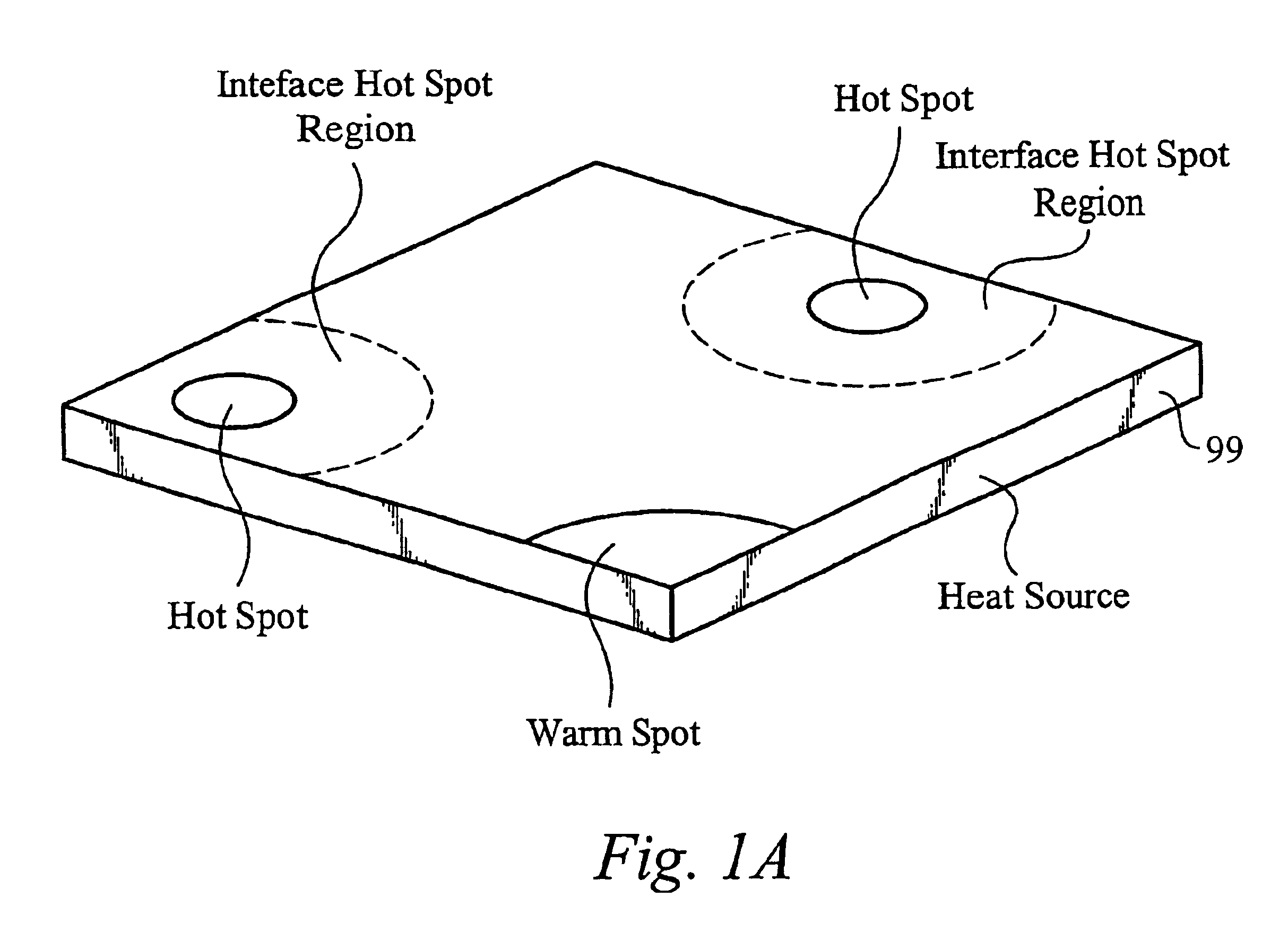

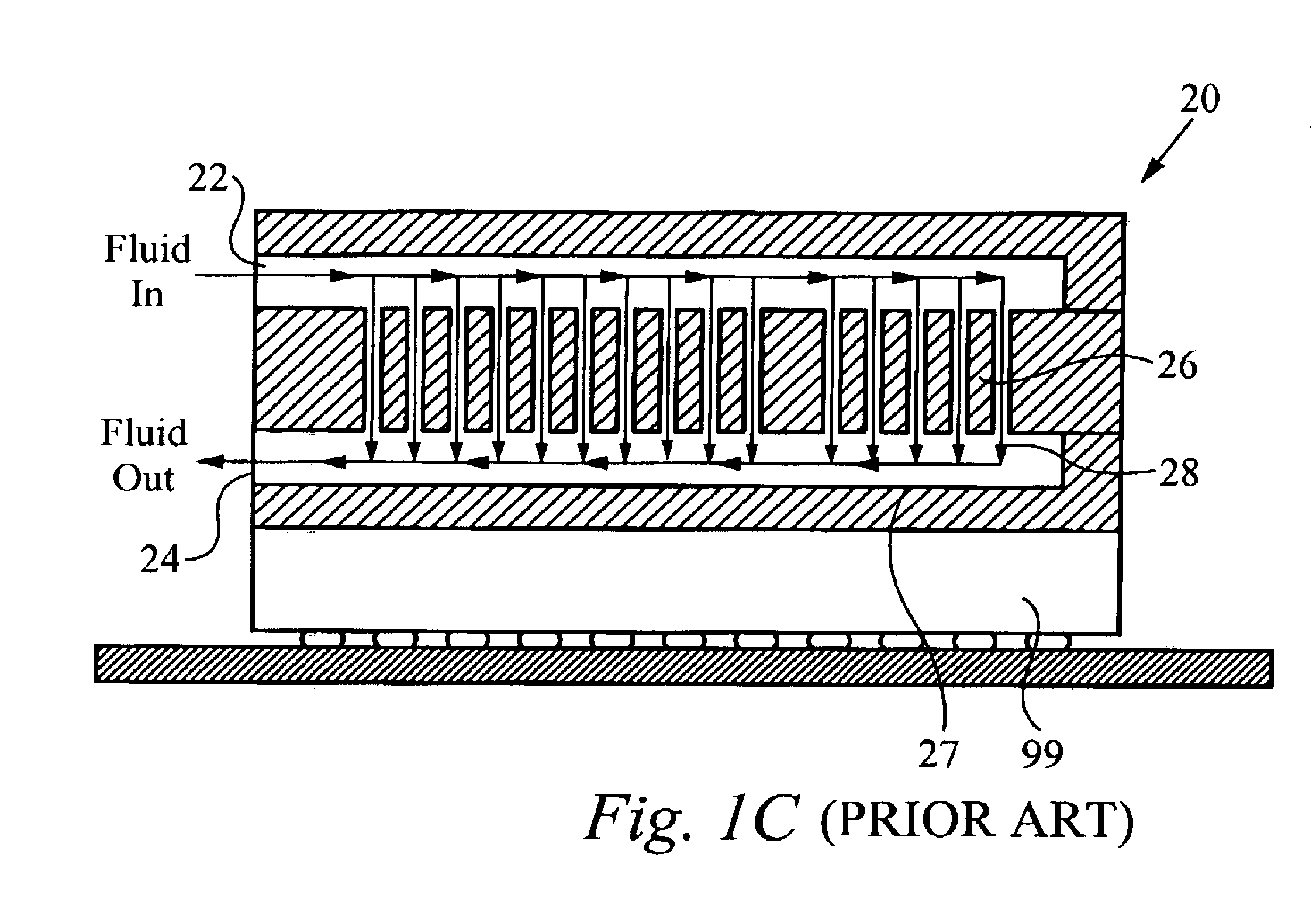

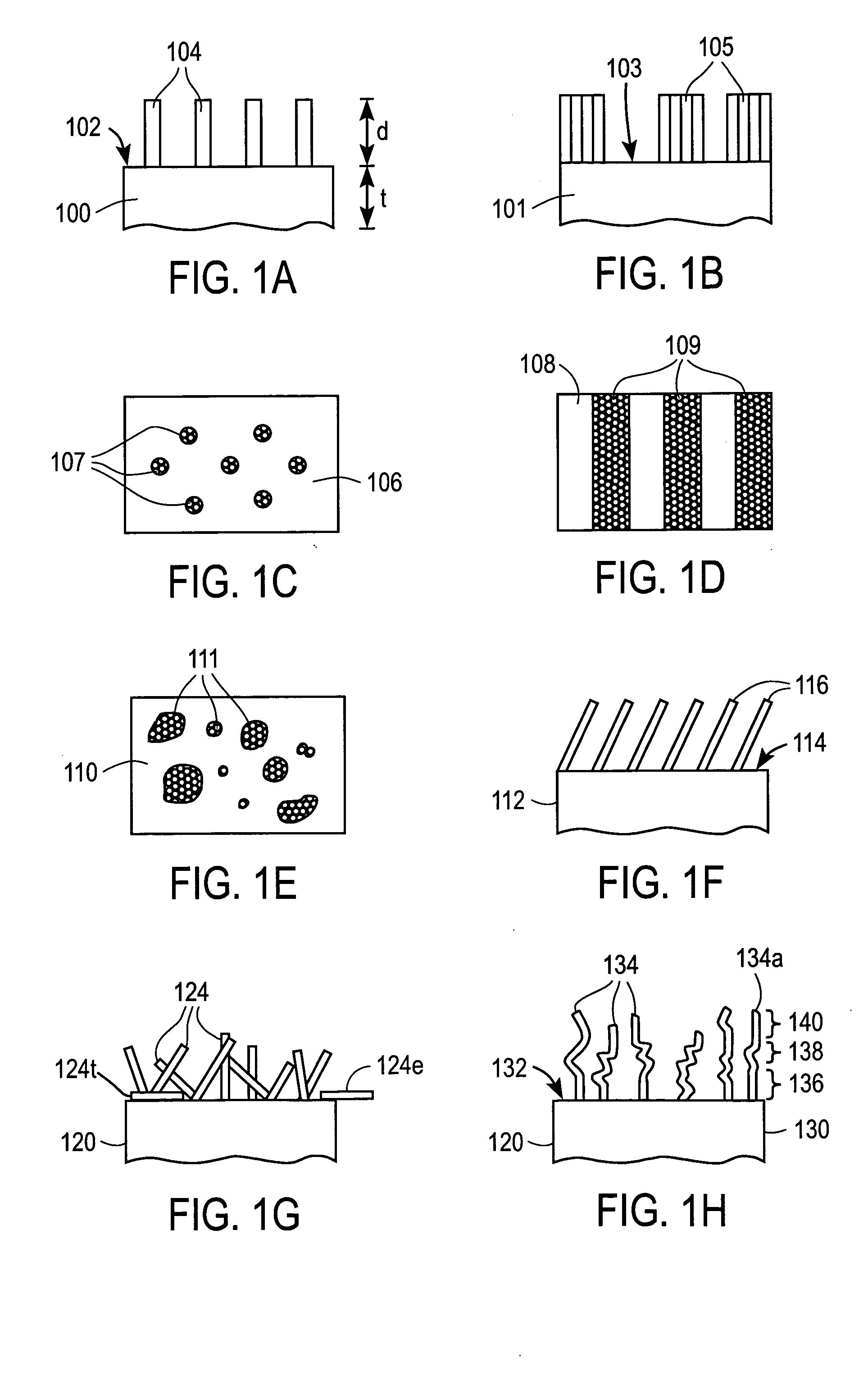

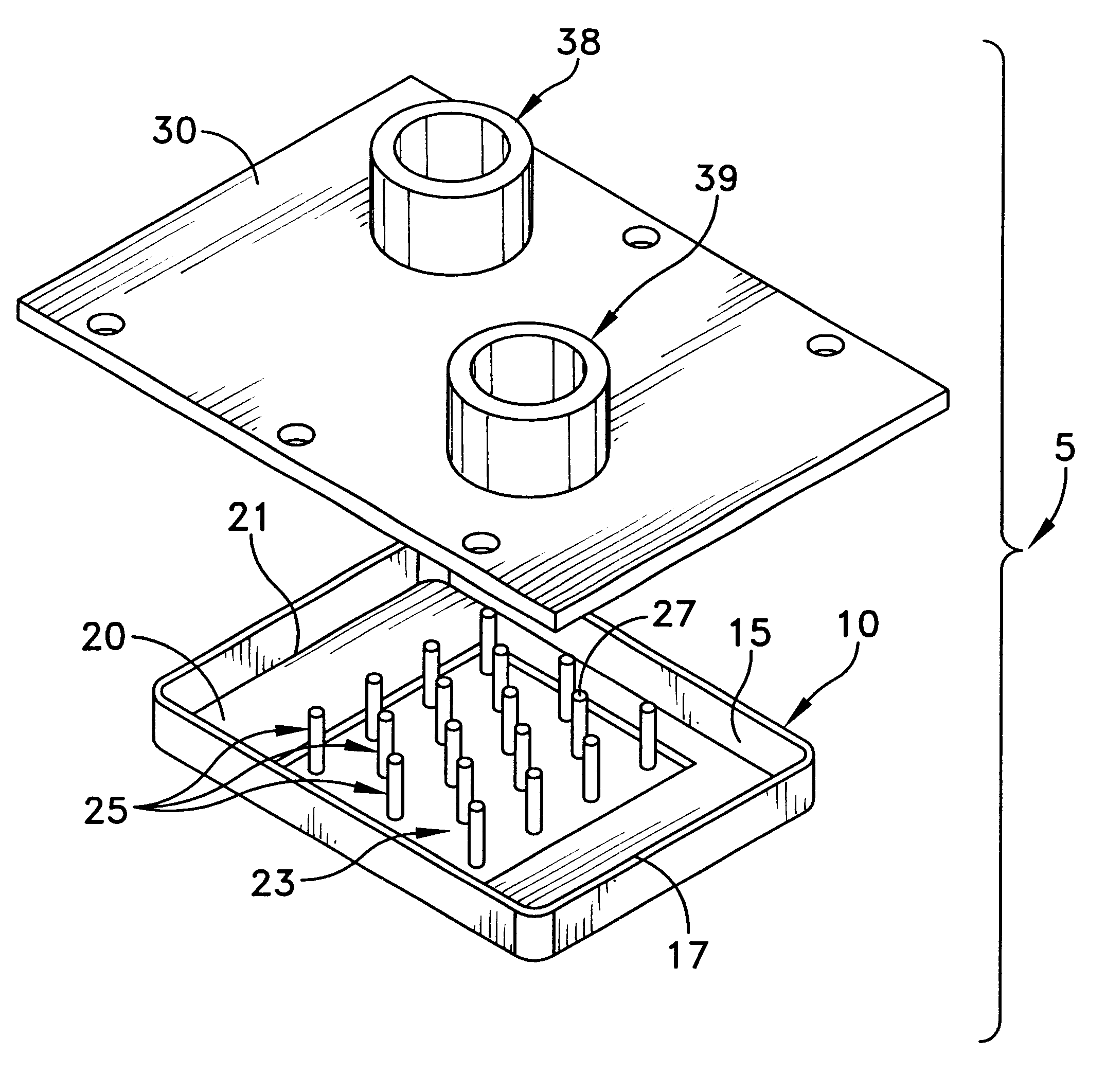

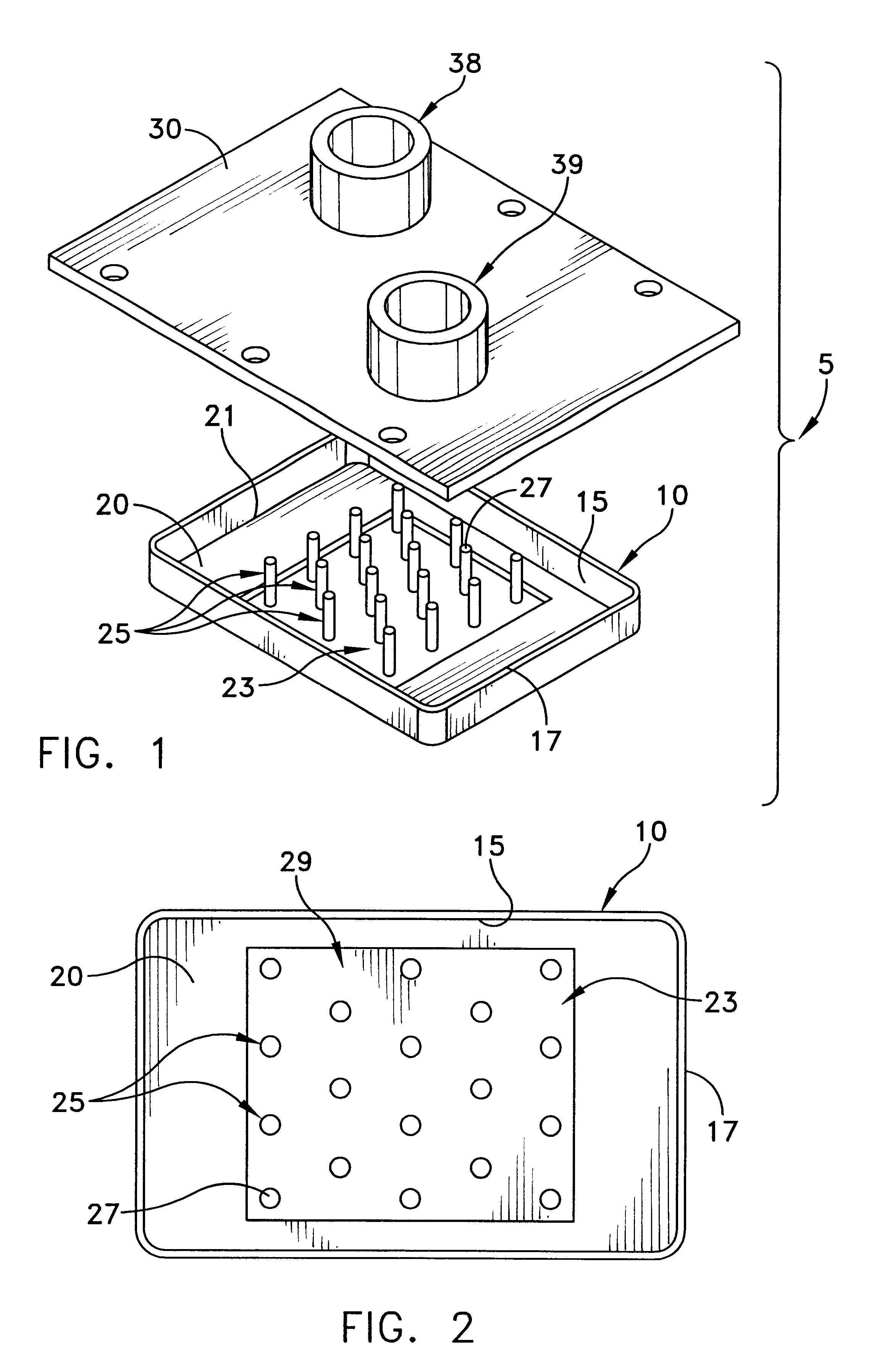

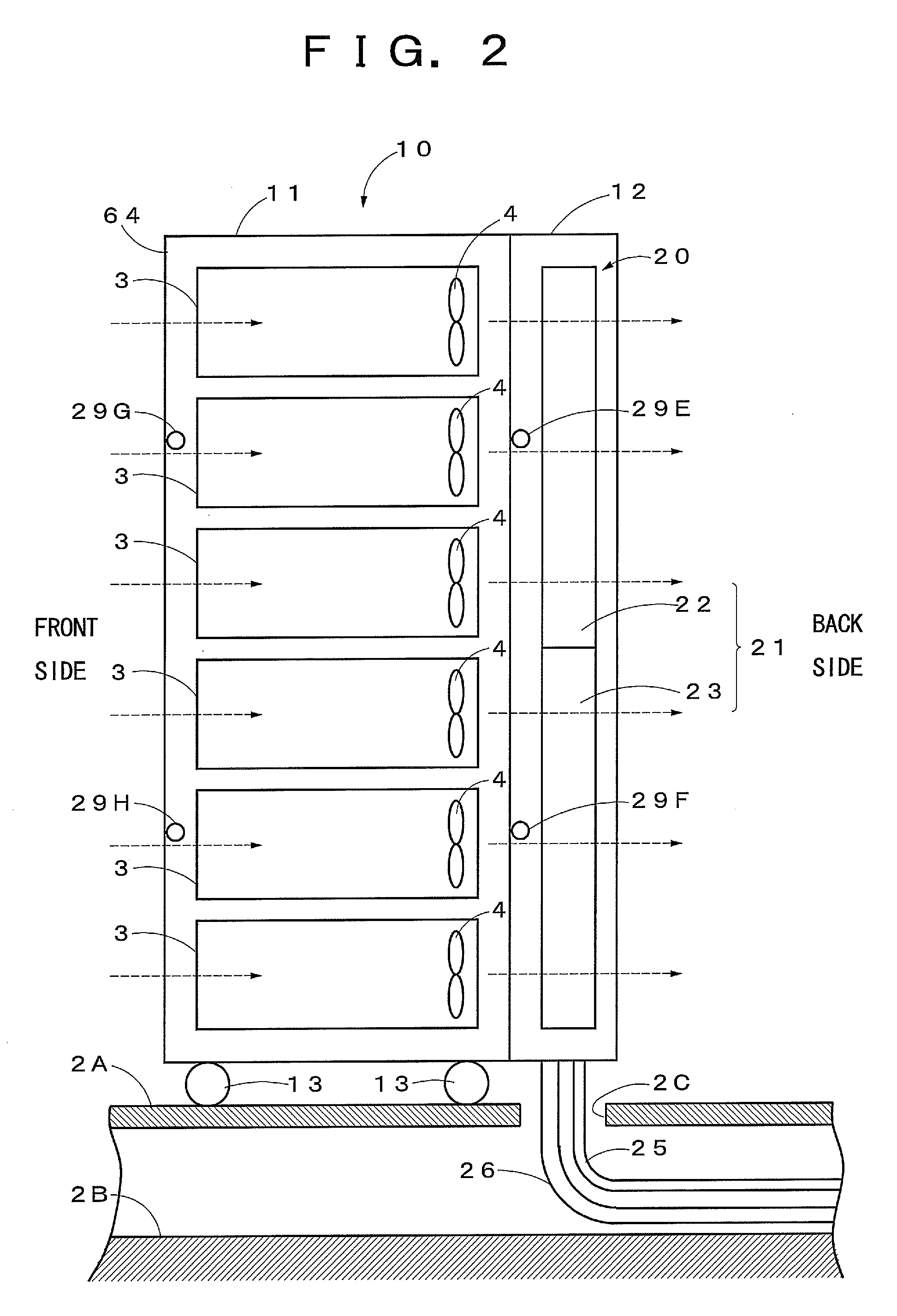

Method and apparatus for flexible fluid delivery for cooling desired hot spots in a heat producing device

InactiveUS6988534B2Temperatue controlSemiconductor/solid-state device detailsInter layerInterface layer

A heat exchanger apparatus and method of manufacturing comprising: an interface layer for cooling a heat source and configured to pass fluid therethrough, the interface layer having an appropriate thermal conductivity and a manifold layer for providing fluid to the interface layer, wherein the manifold layer is configured to achieve temperature uniformity in the heat source preferably by cooling interface hot spot regions. A plurality of fluid ports are configured to the heat exchanger such as an inlet port and outlet port, whereby the fluid ports are configured vertically and horizontally. The manifold layer circulates fluid to a predetermined interface hot spot region in the interface layer, wherein the interface hot spot region is associated with the hot spot. The heat exchanger preferably includes an intermediate layer positioned between the interface and manifold layers and optimally channels fluid to the interface hot spot region.

Owner:VERTIV CORP

Metal material having good resistance to metal dusting

InactiveUS6623869B1Excellent in metal dusting resistanceIncreased durabilityChemical industryCorrosion preventionMetal dustingMetallic materials

A metallic material of the invention which comprises, in mass %, C: not more than 0.2%, Si: 0.01-4%, Mn: 0.05-2%, P: not more than 0.04%, S: not more than 0.015%, Cr: 10-35%, Ni: 30-78%, Al: not less than 0.005% but less than 4.5%, N: 0.005-0.2%, and one or both of Cu: 0.015-3% and Co: 0.015-3%, with the balance substantially being Fe, and of which the value of 40Si+Ni+5Al+40N+10 (Cu+Co), wherein the symbols of elements represent the contents of the respective elements, is not less than 50 and has excellent corrosion resistance in an environment in which metal dusting is ready to occur and, therefore, can be utilized as or in heating furnace pipes, piping systems, heat exchanger pipes and so forth to be used in a petroleum refinery or in petrochemical plants, and can markedly improve the equipment durability and safety.

Owner:NIPPON STEEL CORP

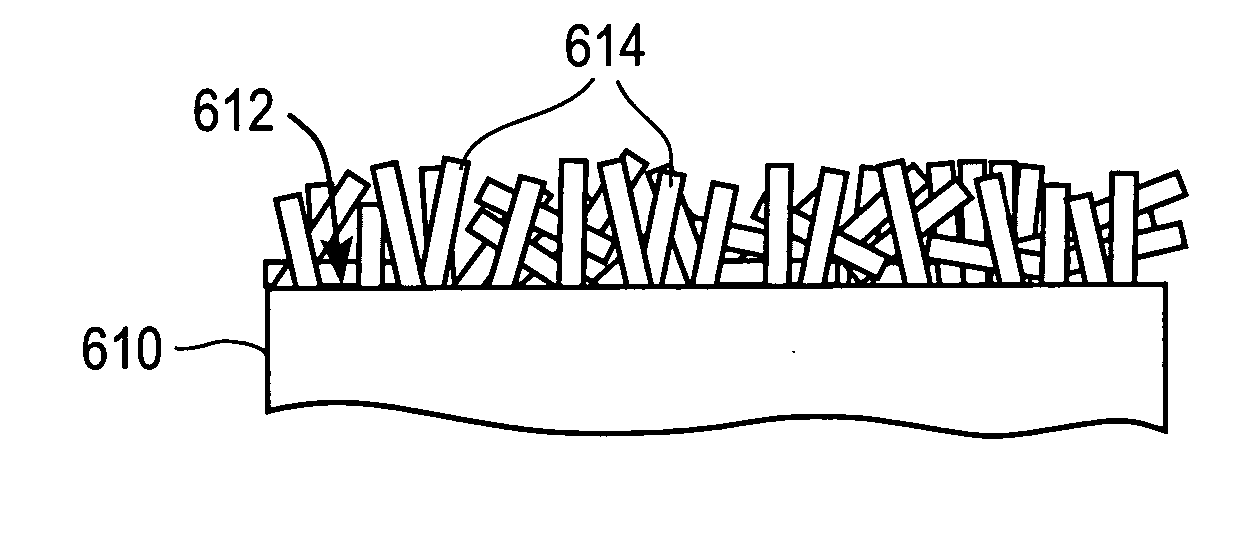

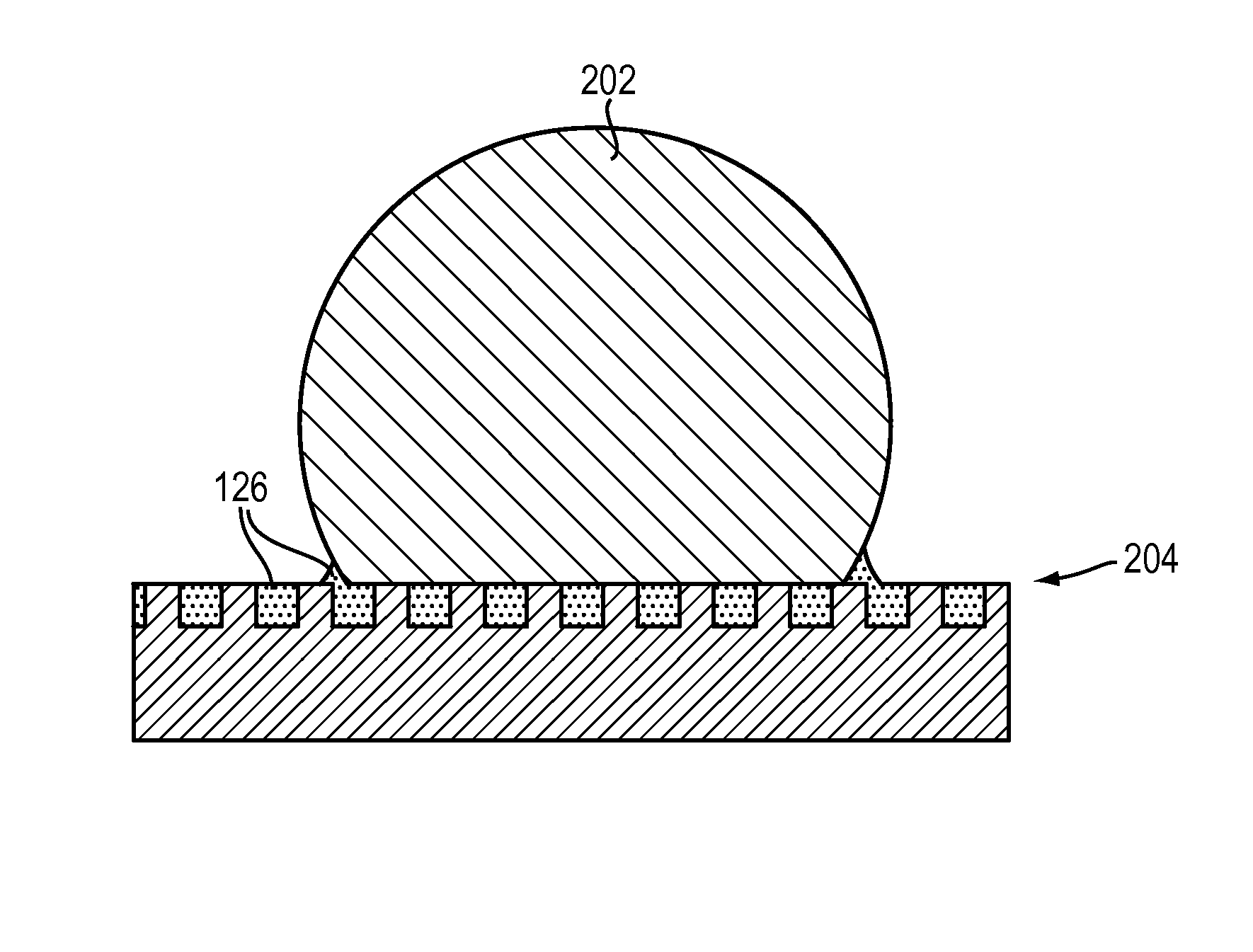

Nanostructure augmentation of surfaces for enhanced thermal transfer with improved contact

InactiveUS20050126766A1Increase surface areaGood thermal contactSemiconductor/solid-state device detailsNanoinformaticsBoron nitrideNanostructure

Nanostructures provide improved contact to augment heat-exchange surfaces of various devices or structures. In one embodiment, an article of manufacture has a body having a heat-exchanging surface and nanostructures disposed on the heat-exchanging surface. The nanostructures are arranged to enhance thermal transfer between said body and an object distinct from said body and may be arranged to form a substantially continuous film. Examples of suitable nanostructures include carbon and / or boron nitride nanotubes, which may be grown on the heat-exchanging surface.

Owner:NASREEN CHOPRA

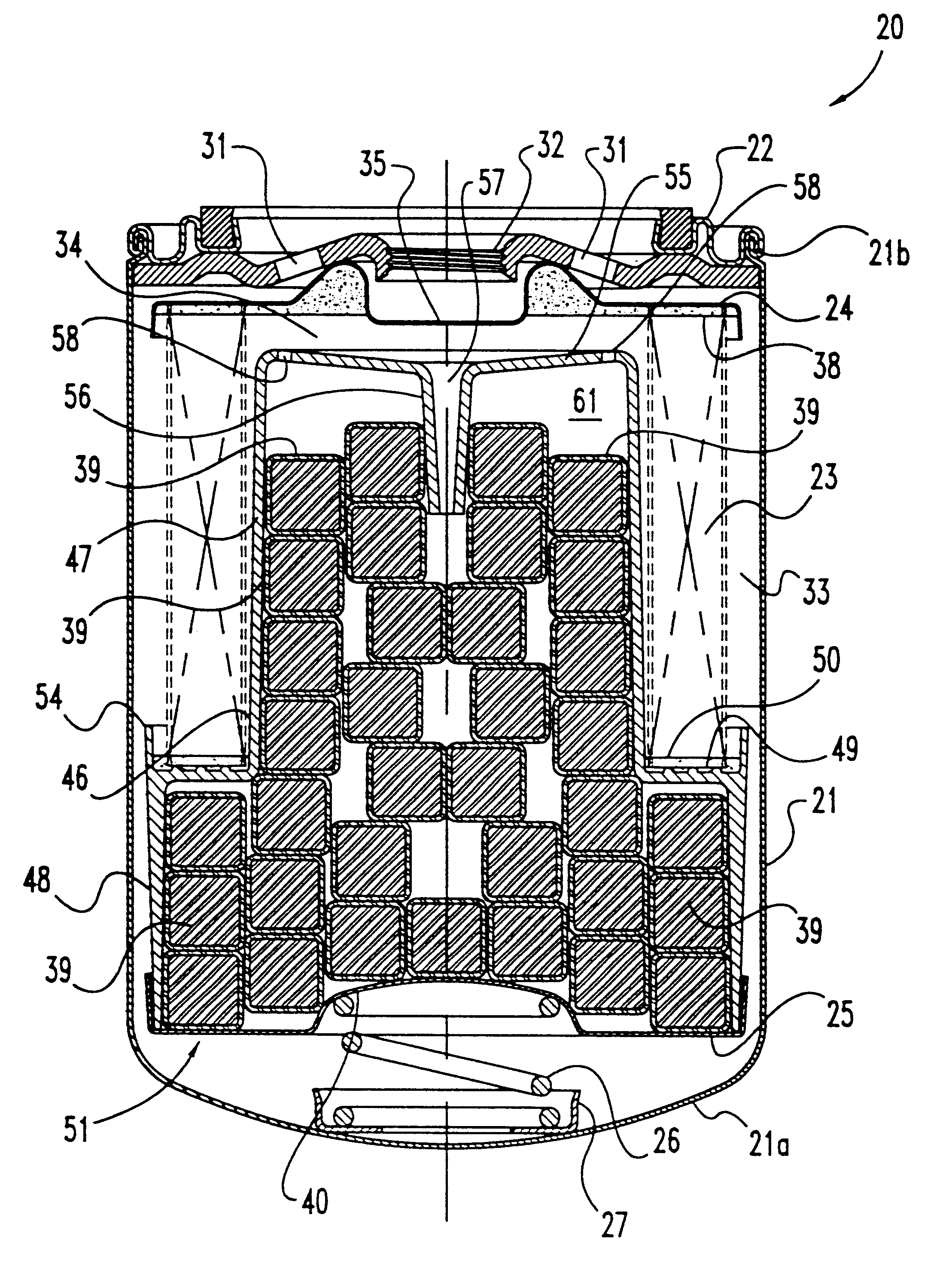

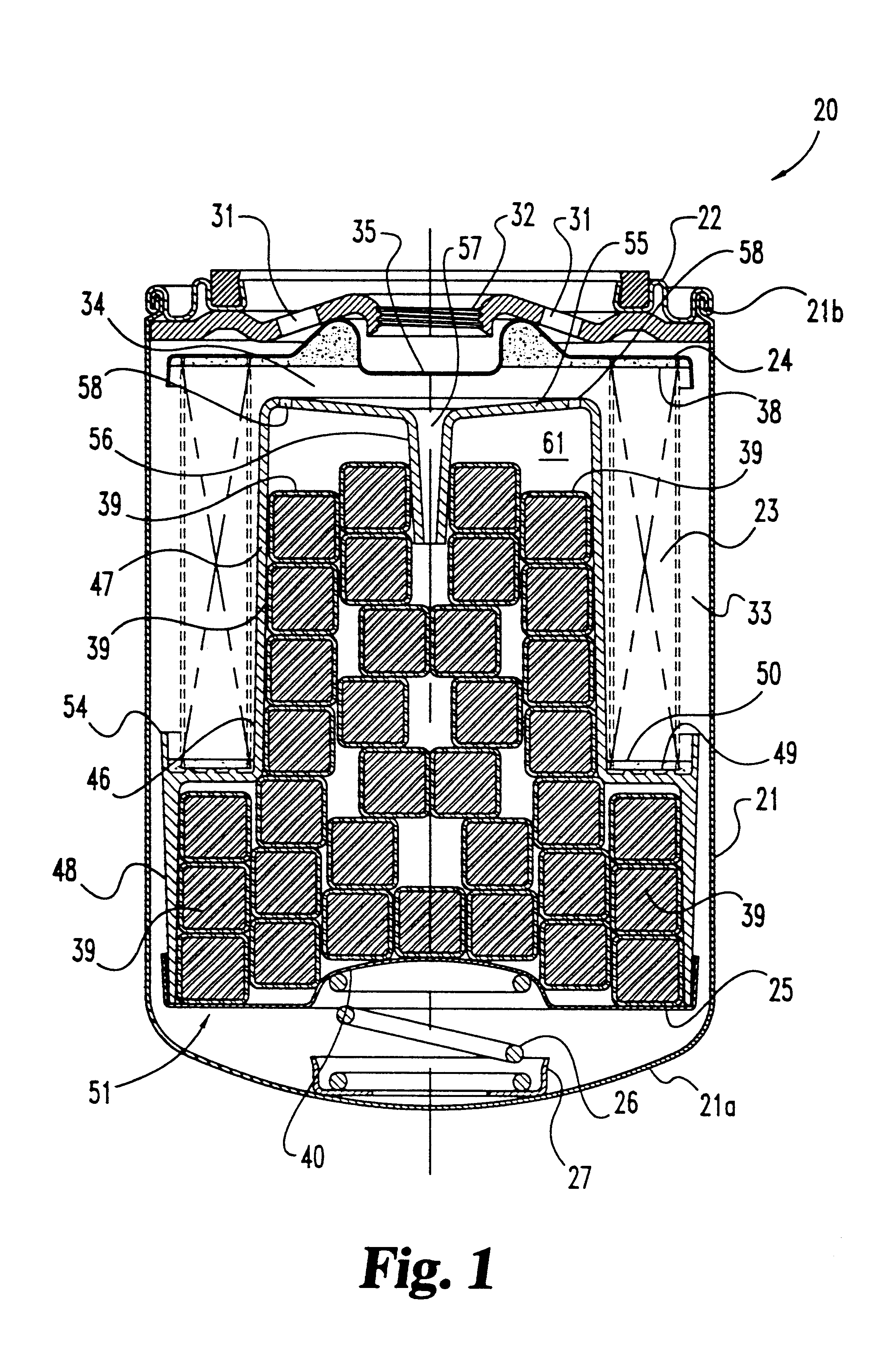

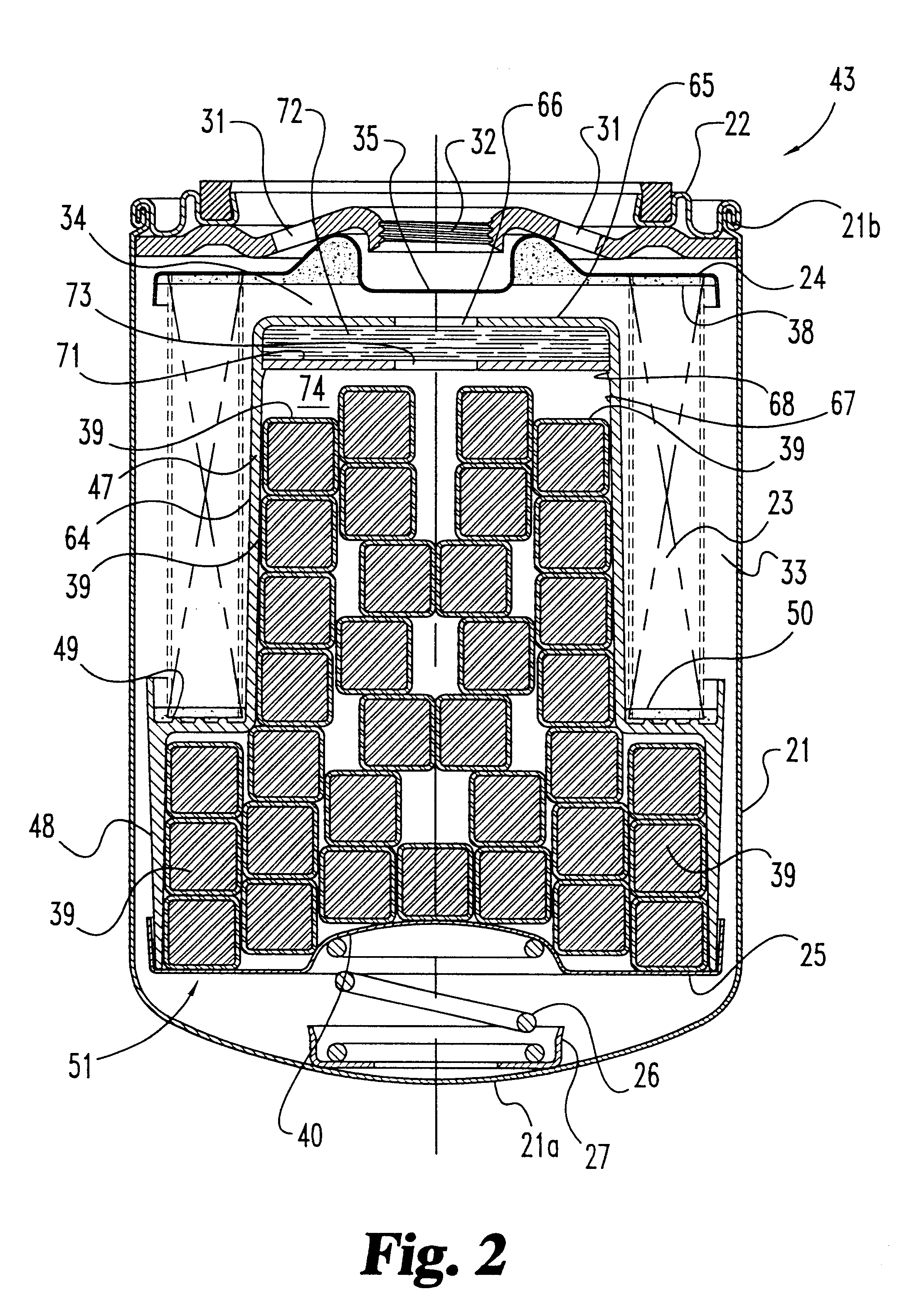

Liquid-cooled heat sink with thermal jacket

A liquid-cooled heat sink is provided having a cooling housing including a peripheral side wall extending from the perimeter of a bottom wall and a lid sized to engage the peripheral side wall so as to form a chamber. A fluid inlet port and a fluid outlet port are defined through the lid, and disposed in fluid communication with the chamber. In one embodiment, a plurality of pins project outwardly from the bottom wall so as to be positioned within the chamber and arranged in a staggered pattern. The pins include an end that engages the undersurface of the lid. In an alternative embodiment, a corrugated fin having a plurality of corrugations is positioned within the chamber so that at least one of the corrugations engages the bottom wall and at least one of the corrugations engages the under surface of the lid.

Owner:THERMAL

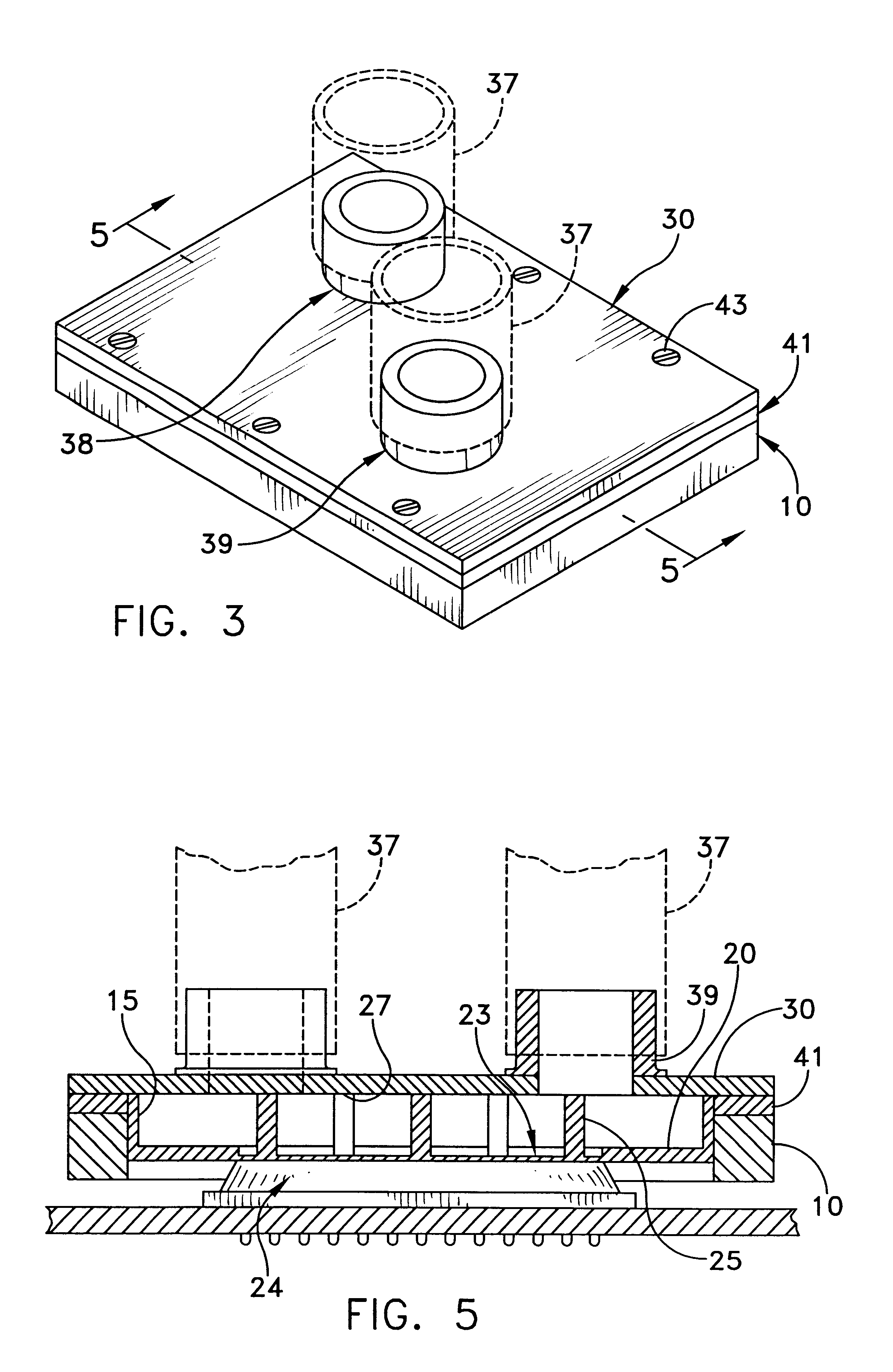

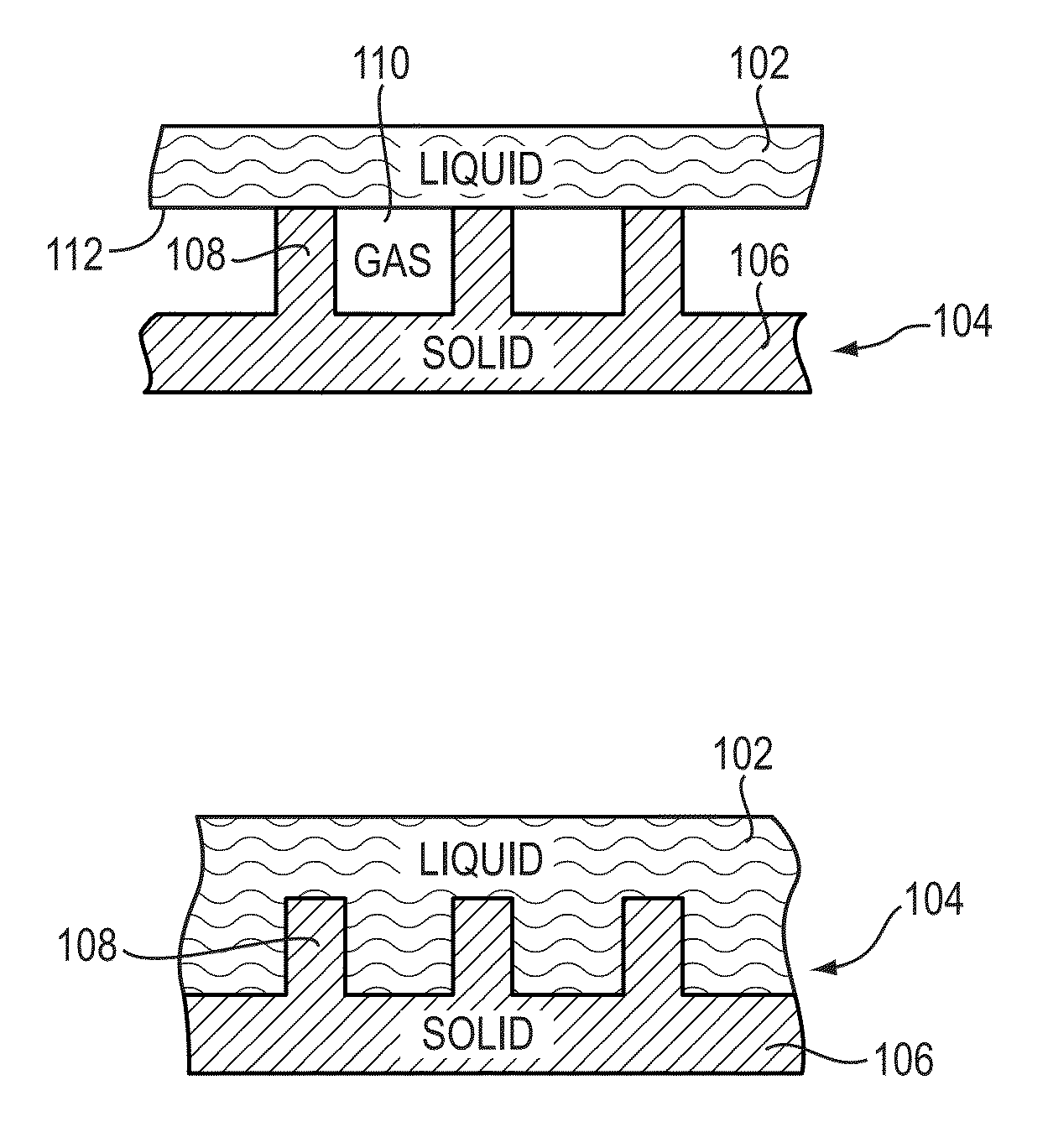

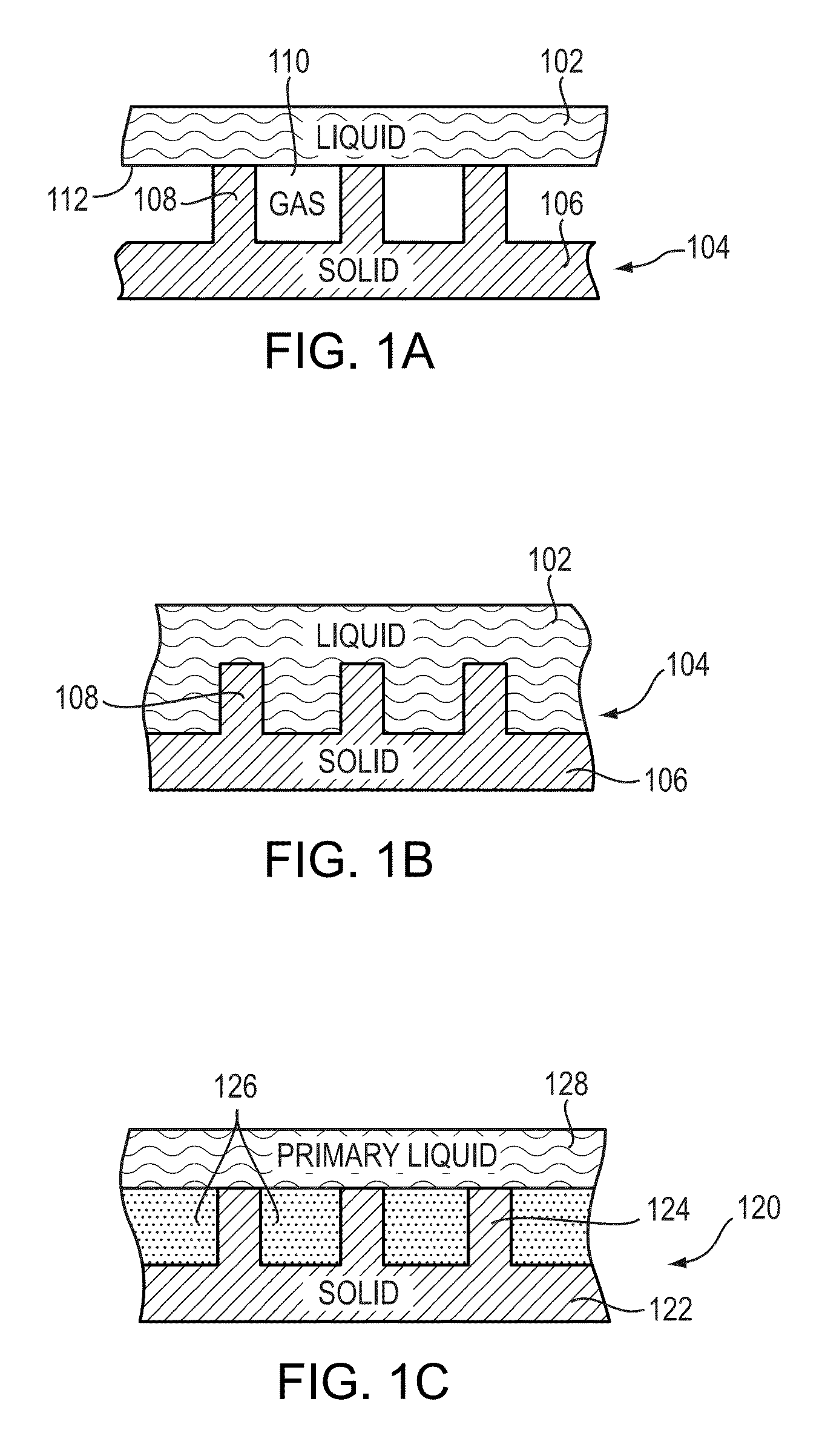

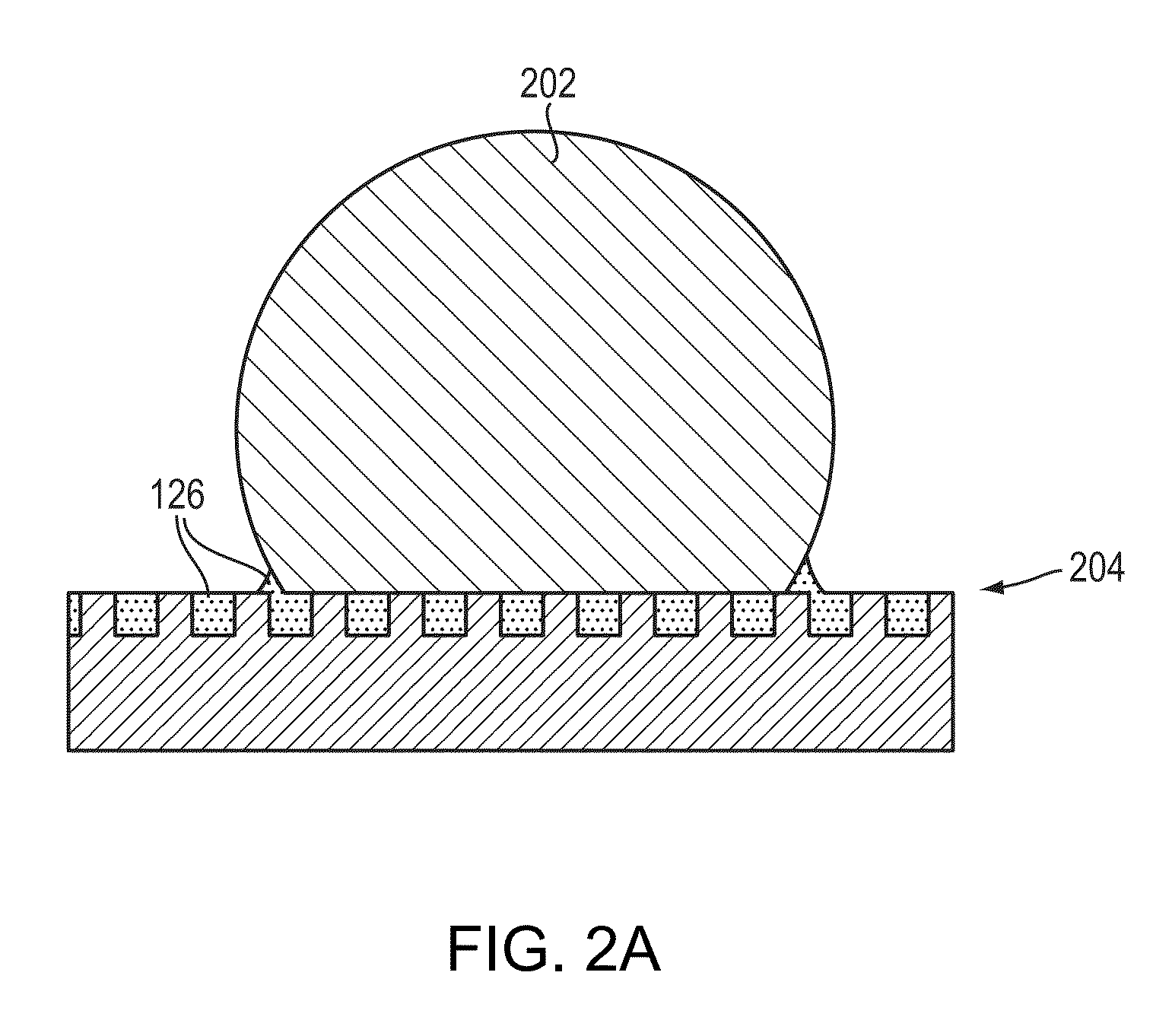

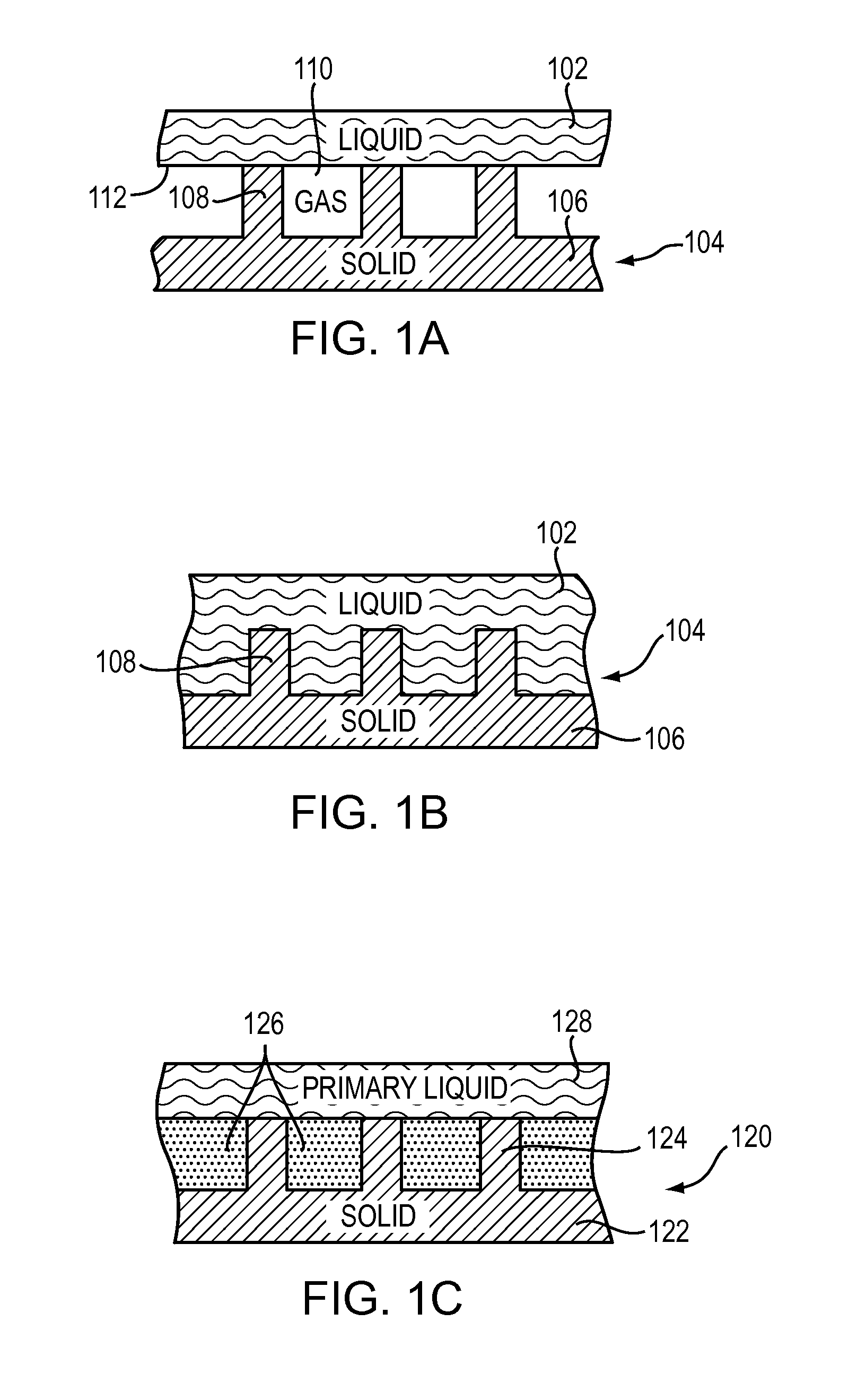

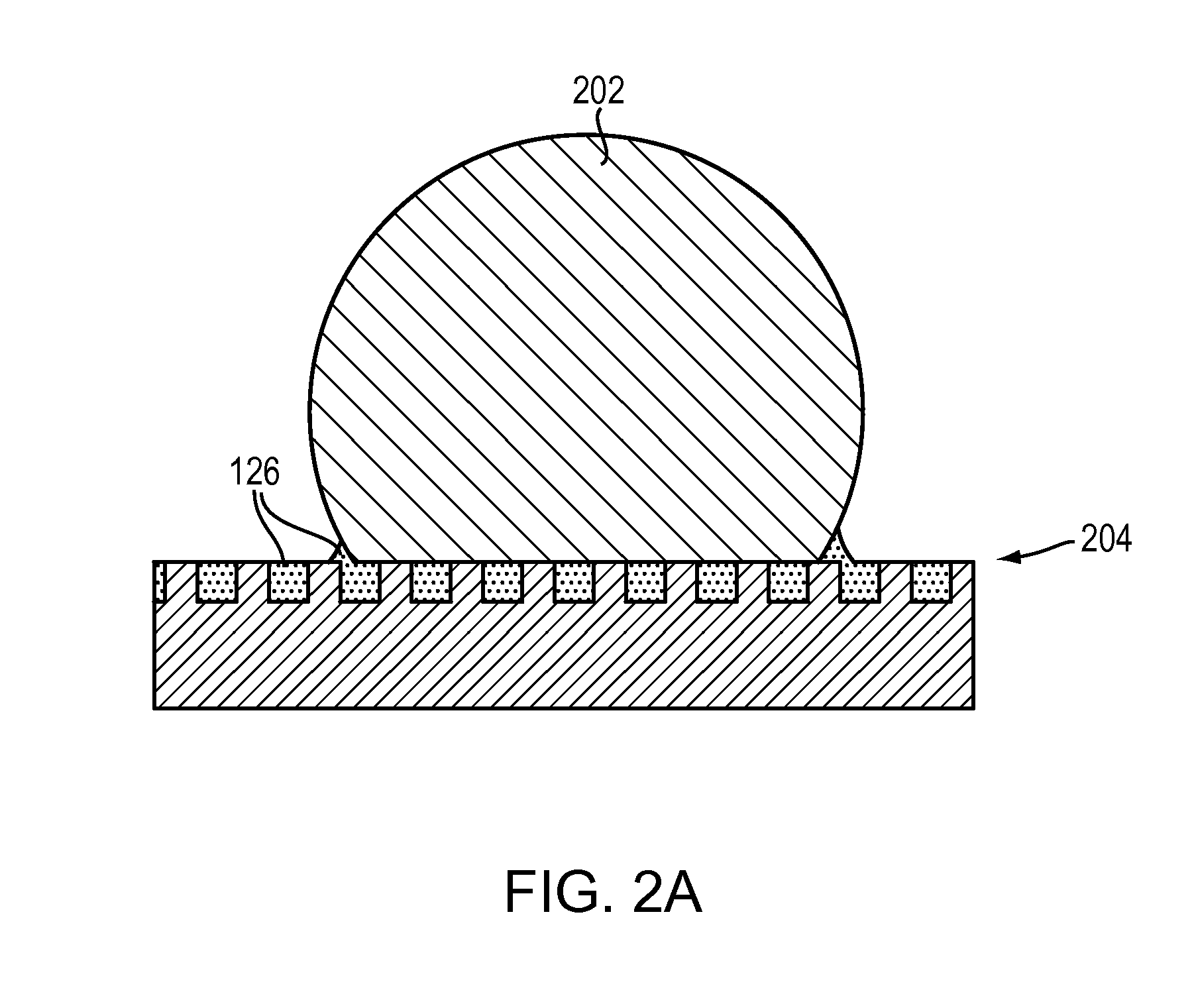

Liquid-Impregnated Surfaces, Methods of Making, and Devices Incorporating the Same

InactiveUS20130032316A1Improve skidReduce resistanceFouling preventionDe-icing equipmentsNon wettingFrost

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

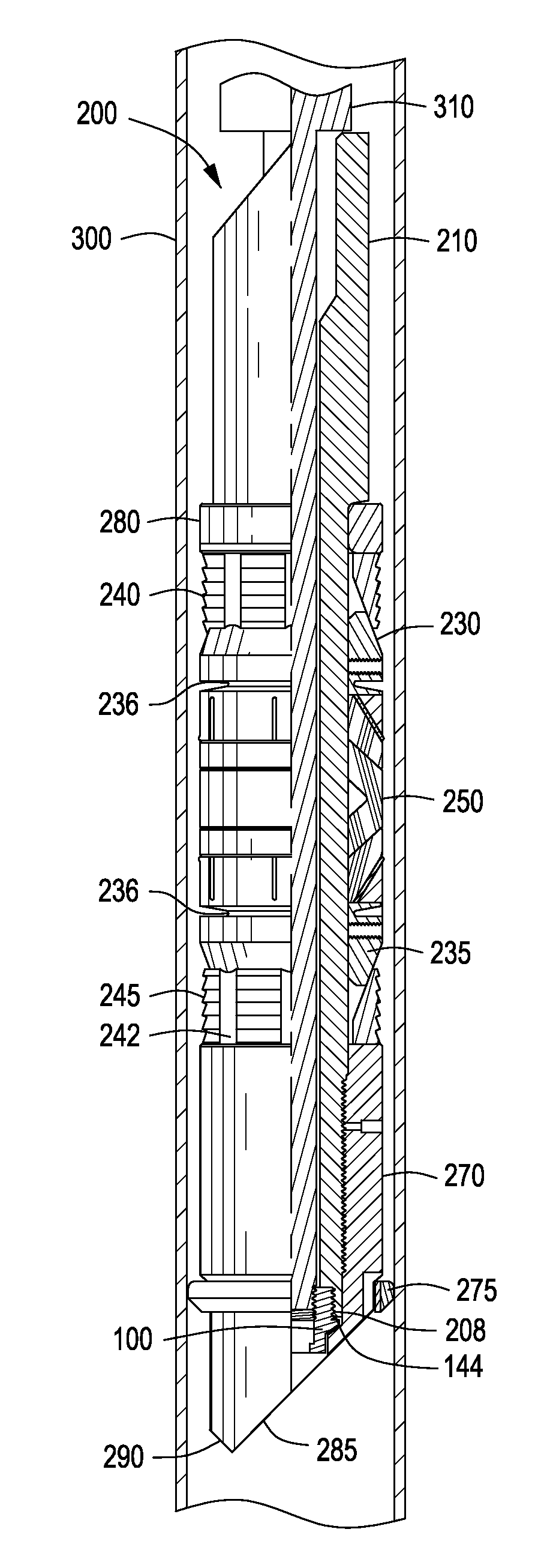

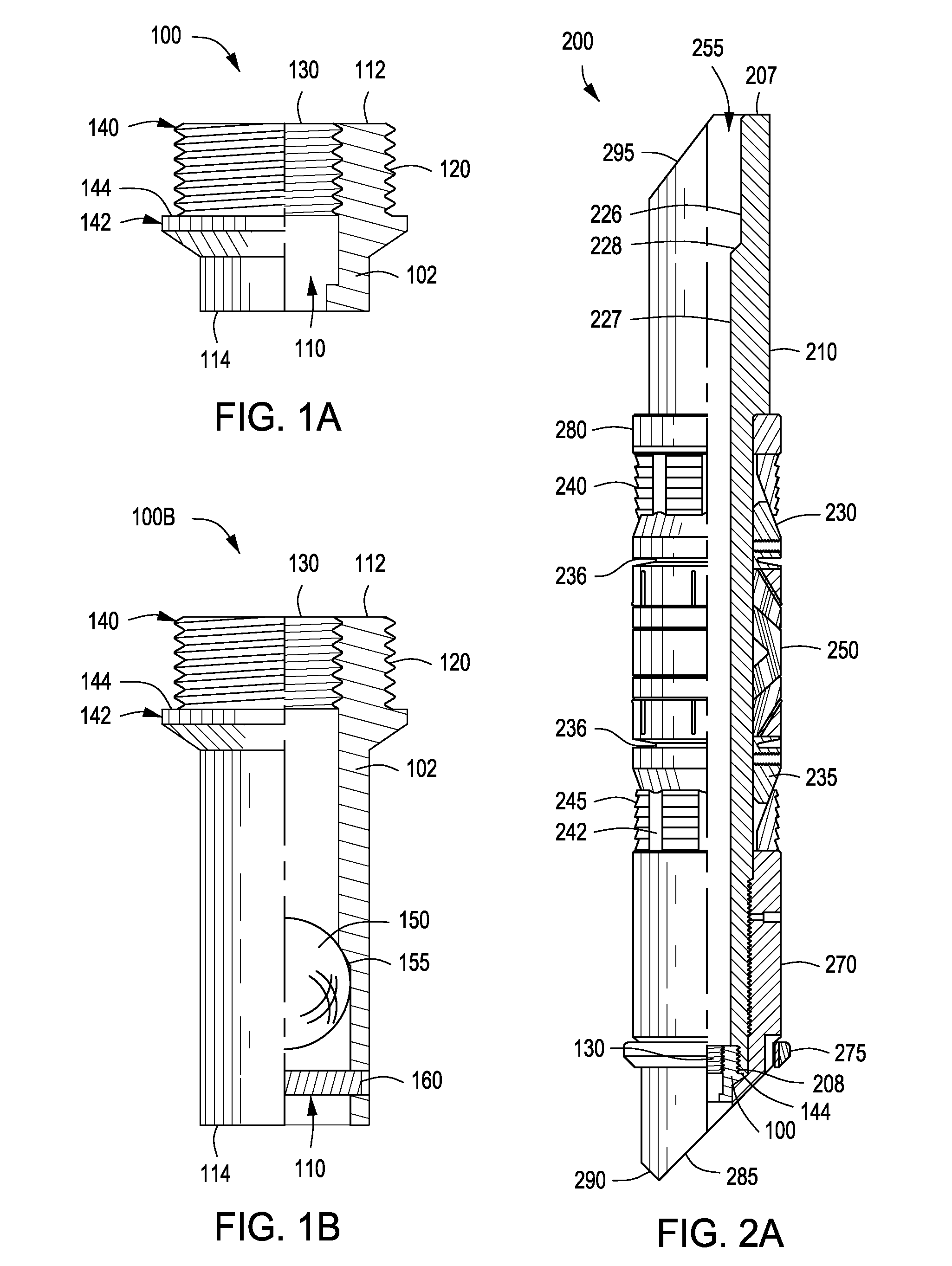

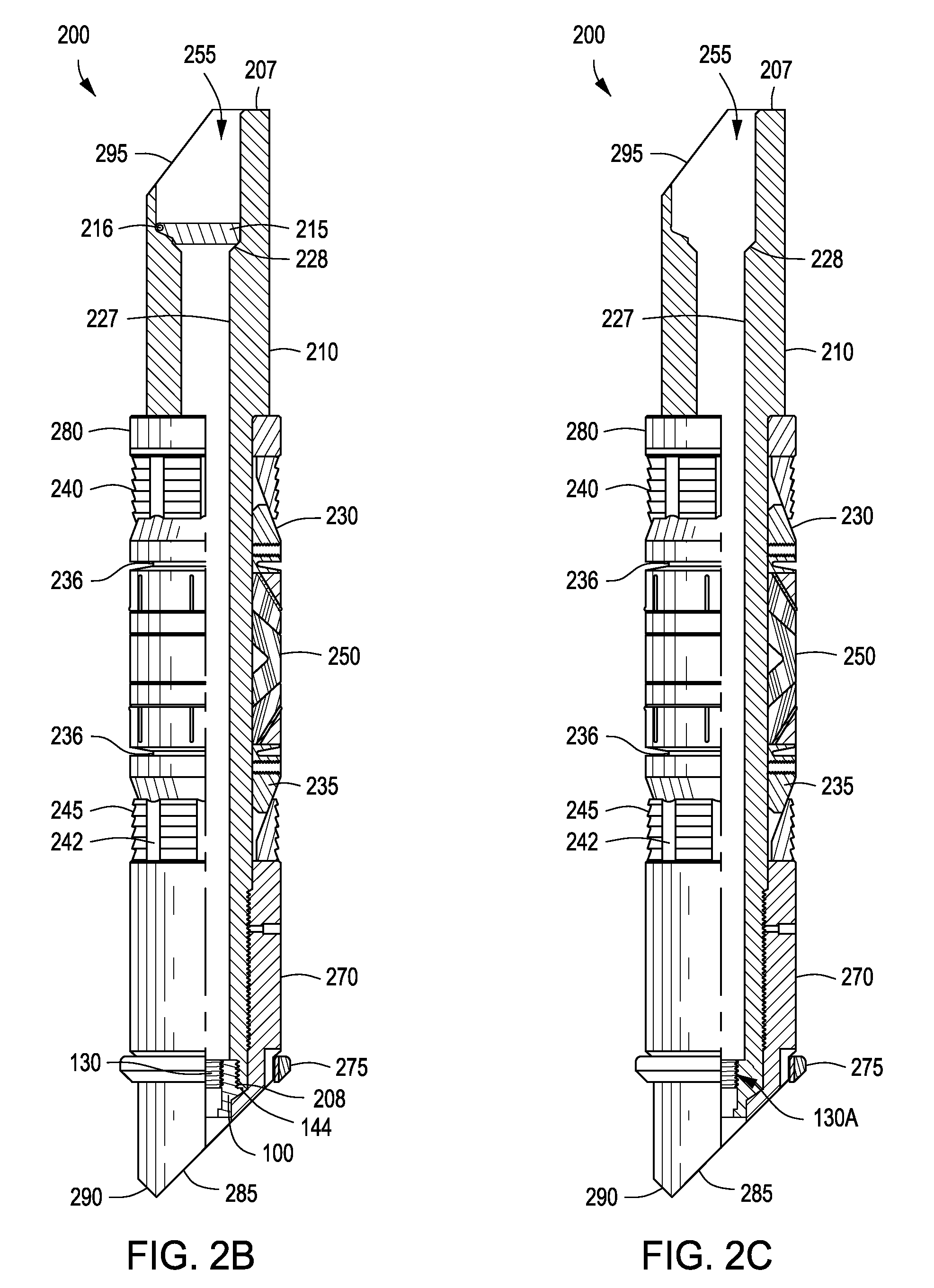

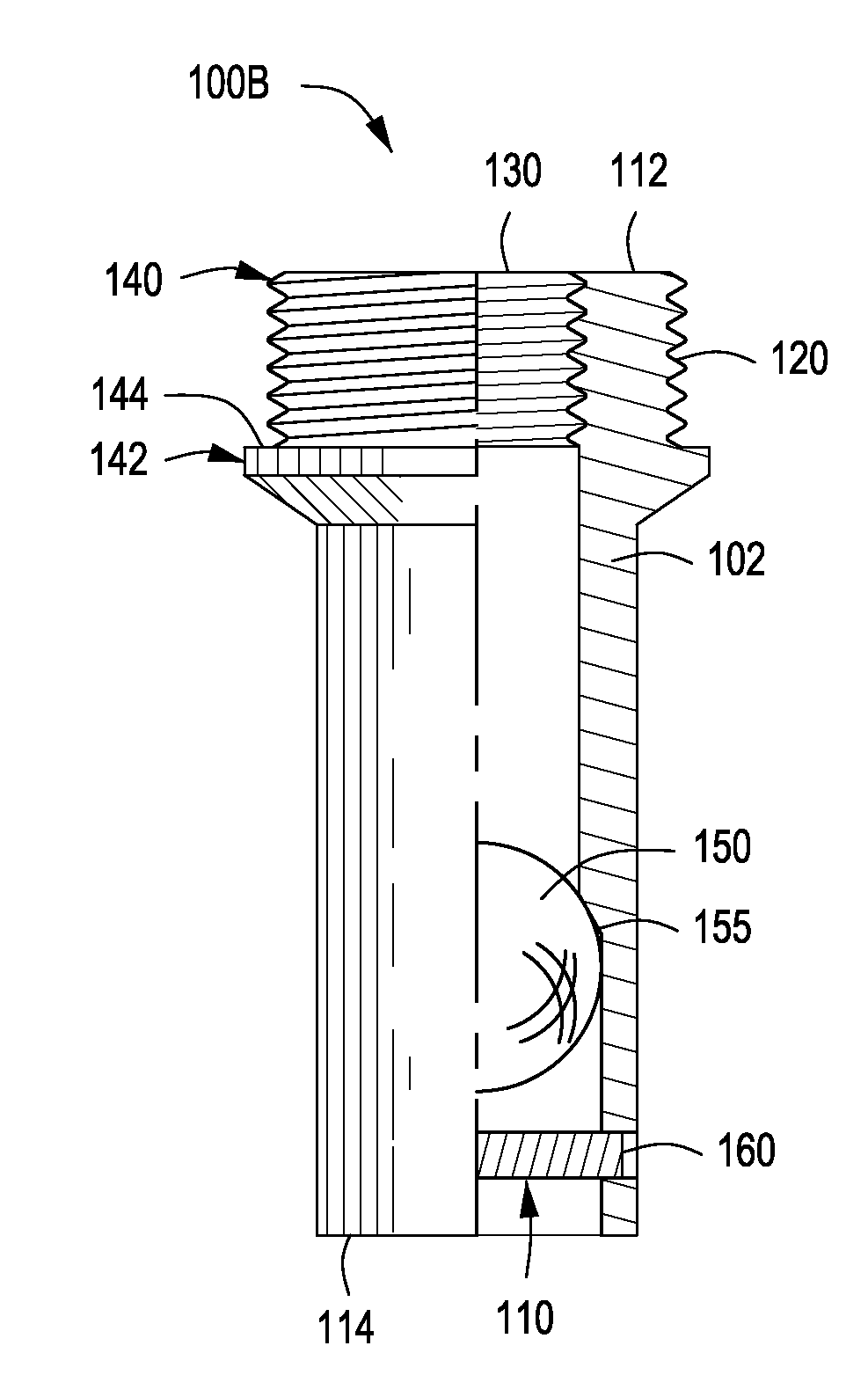

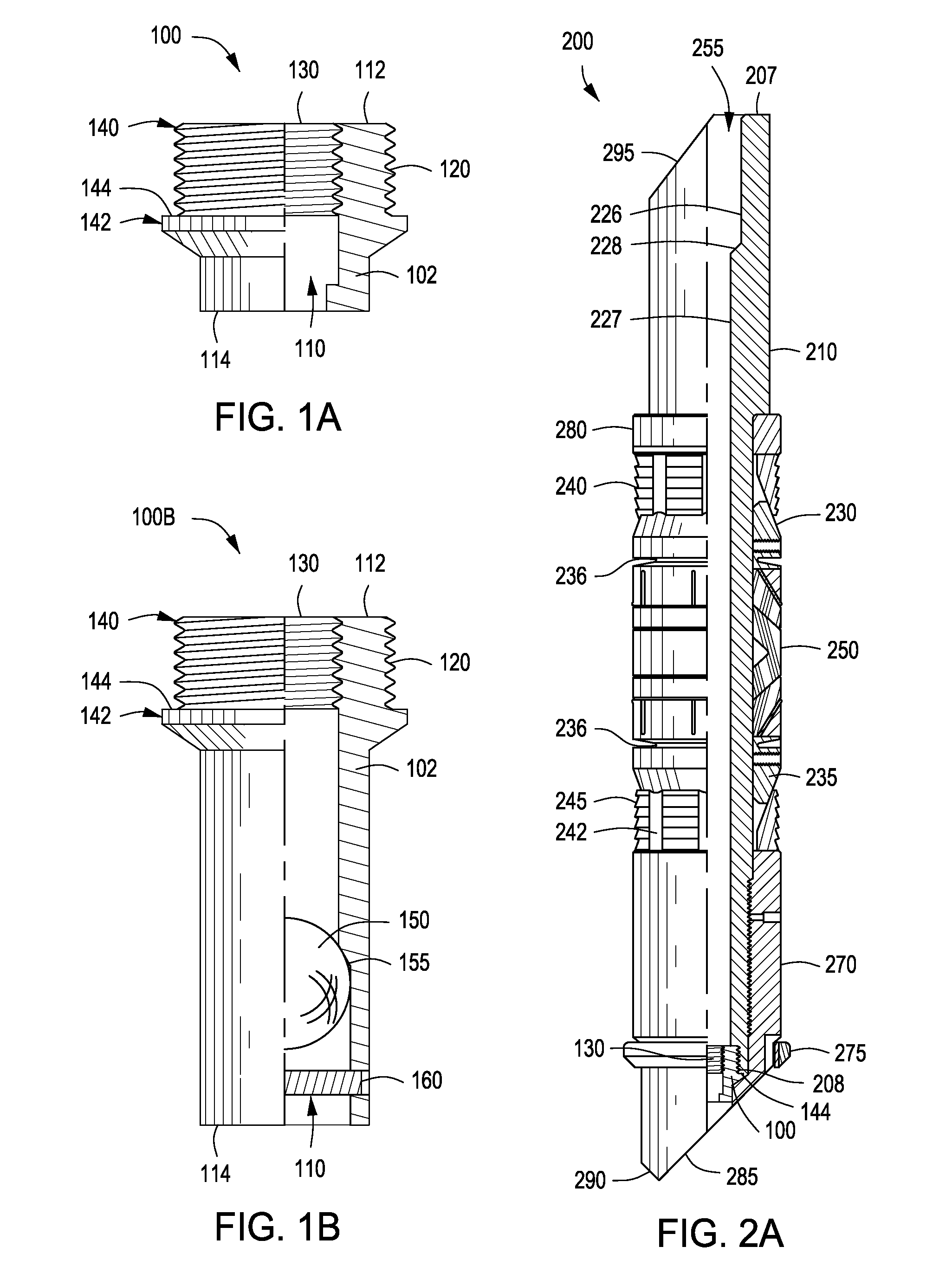

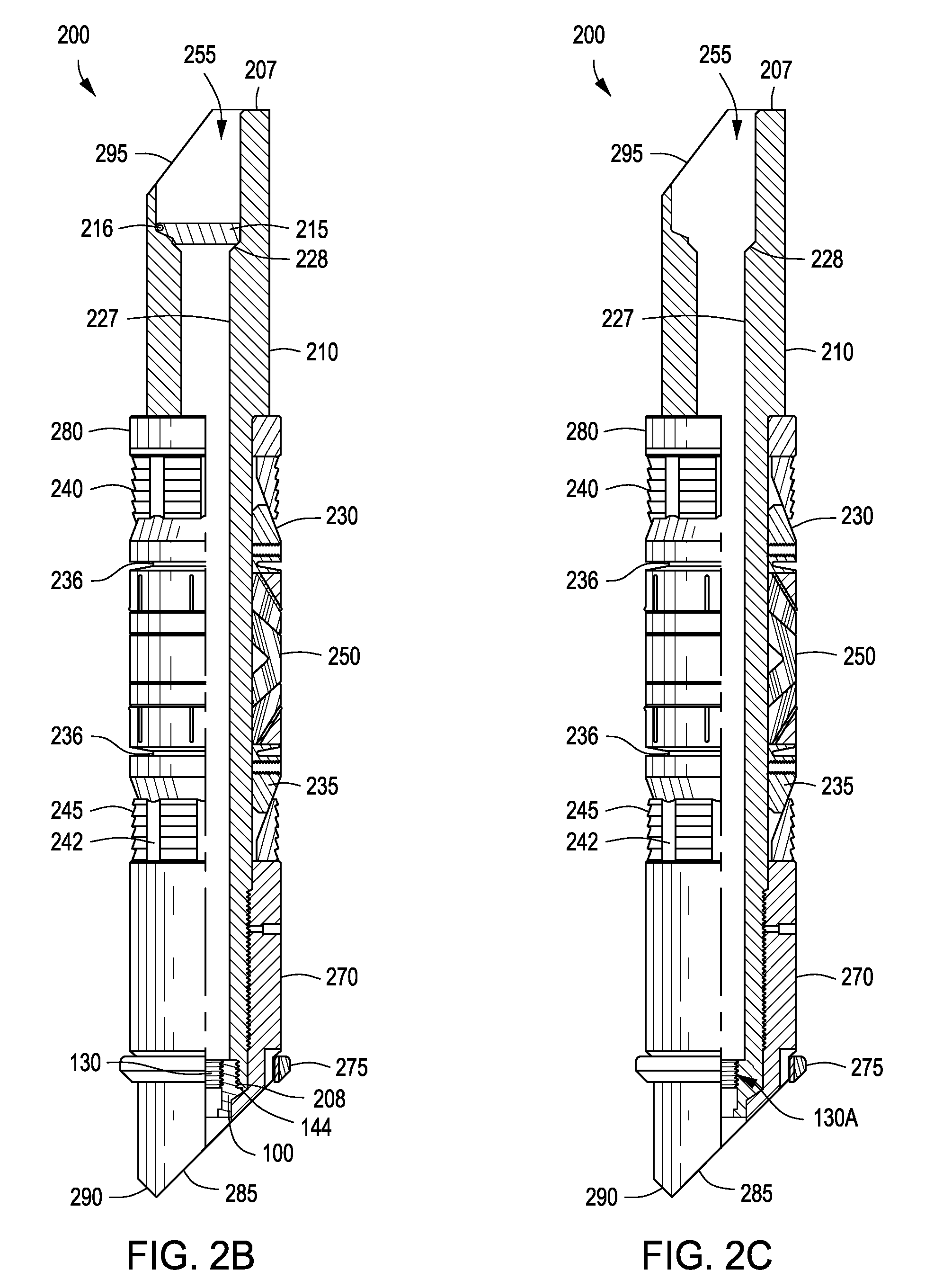

Bottom set downhole plug

A plug for isolating a wellbore. The plug can include a body having a first end and a second end, wherein the body is formed from one or more composite materials and adapted to receive a setting tool through the first end thereof, at least one malleable element disposed about the body, at least one slip disposed about the body, at least one conical member disposed about the body, and one or more shearable threads disposed on an inner surface of the body, adjacent the second end thereof, wherein the one or more shearable threads are adapted to receive at least a portion of a setting tool that enters the body through the first end thereof, and wherein the one or more shearable threads are adapted to engage the setting tool when disposed through the body and adapted to release the setting tool when exposed to a predetermined axial force.

Owner:NINE DOWNHOLE TECHNOLOLGIES LLC

Bottom set downhole plug

A plug for isolating a wellbore. The plug can include a body having a first end and a second end, wherein the body is formed from one or more composite materials and adapted to receive a setting tool through the first end thereof, at least one malleable element disposed about the body, at least one slip disposed about the body, at least one conical member disposed about the body, and one or more shearable threads disposed on an inner surface of the body, adjacent the second end thereof, wherein the one or more shearable threads are adapted to receive at least a portion of a setting tool that enters the body through the first end thereof, and wherein the one or more shearable threads are adapted to engage the setting tool when disposed through the body and adapted to release the setting tool when exposed to a predetermined axial force.

Owner:NINE DOWNHOLE TECHNOLOLGIES LLC

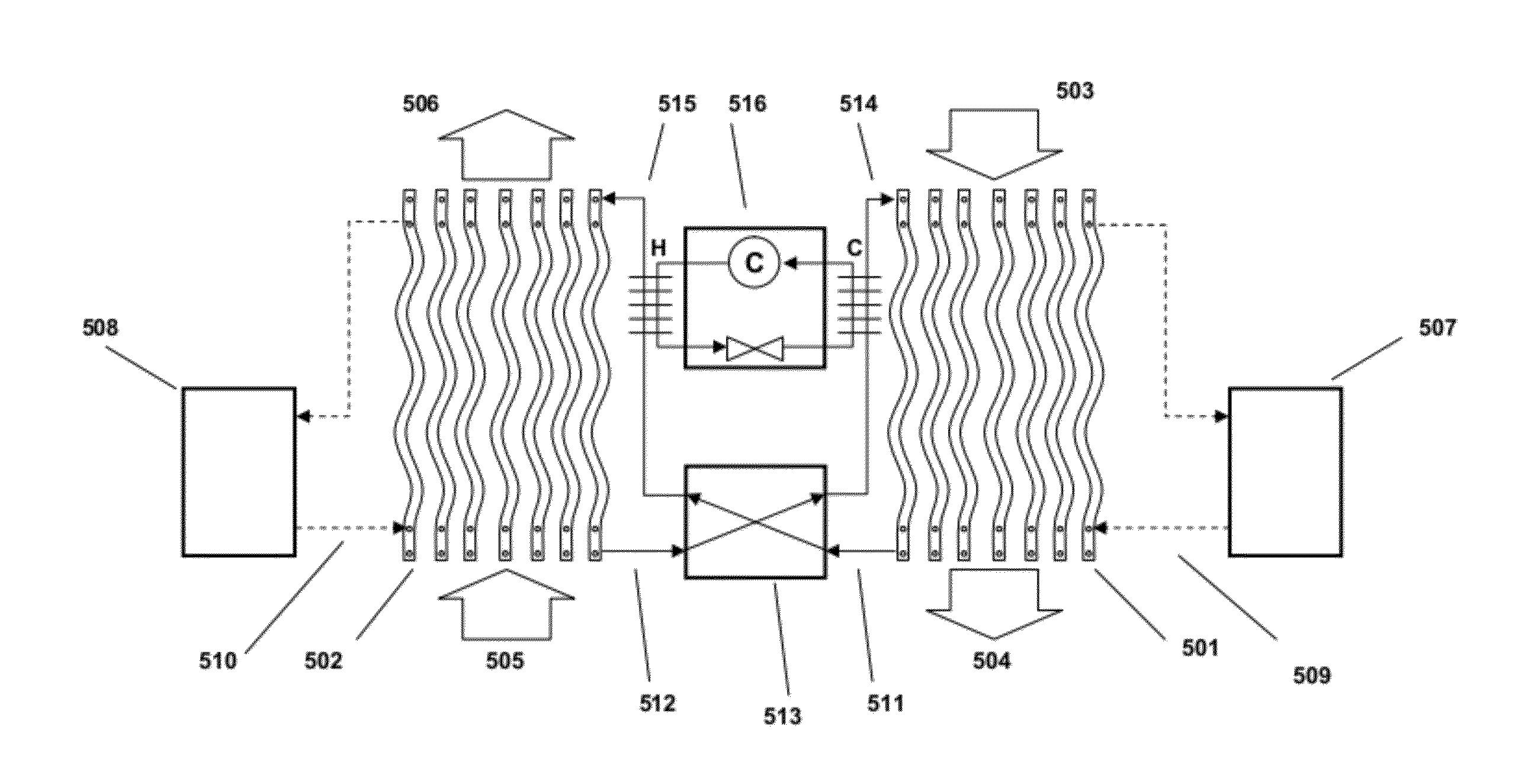

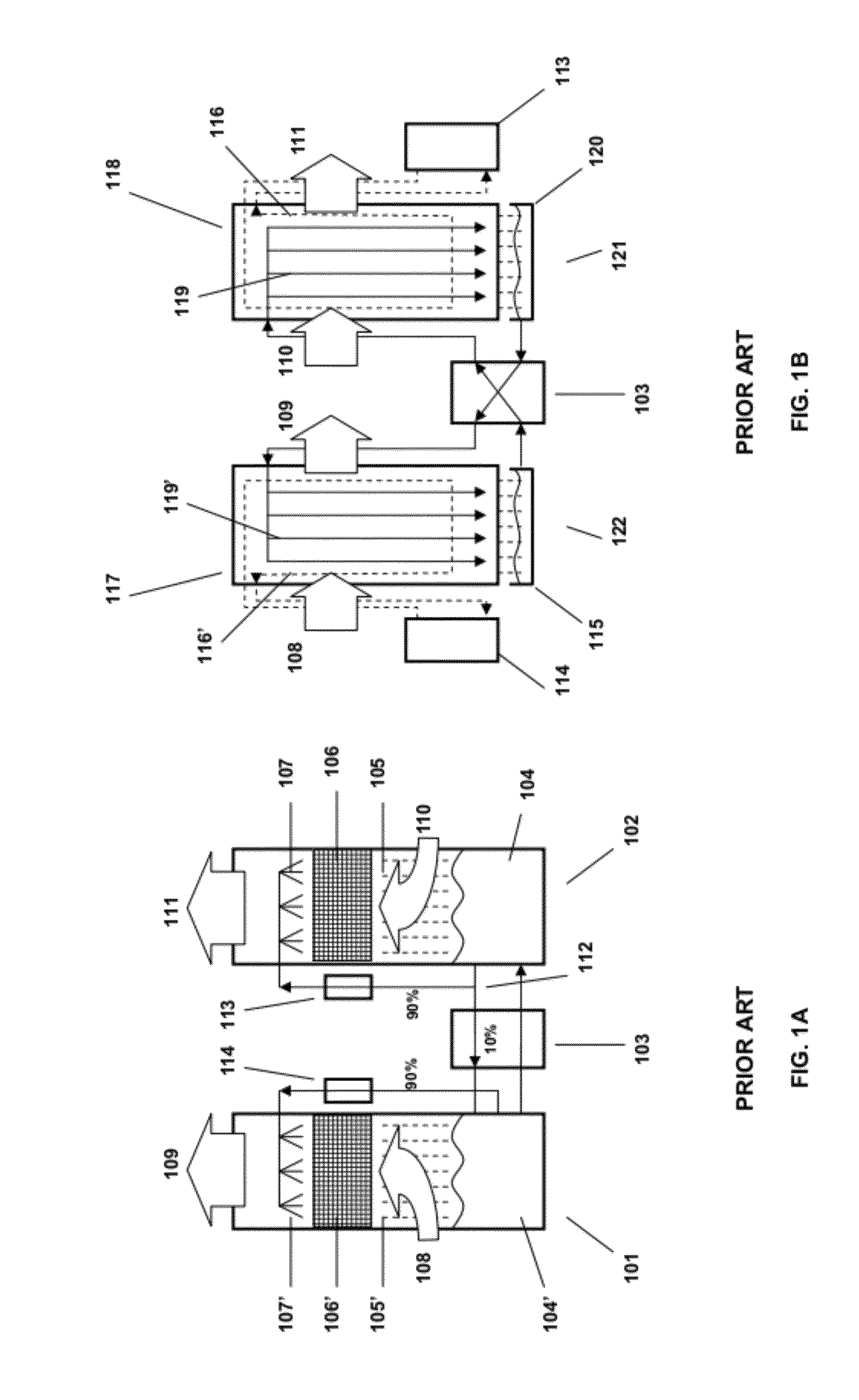

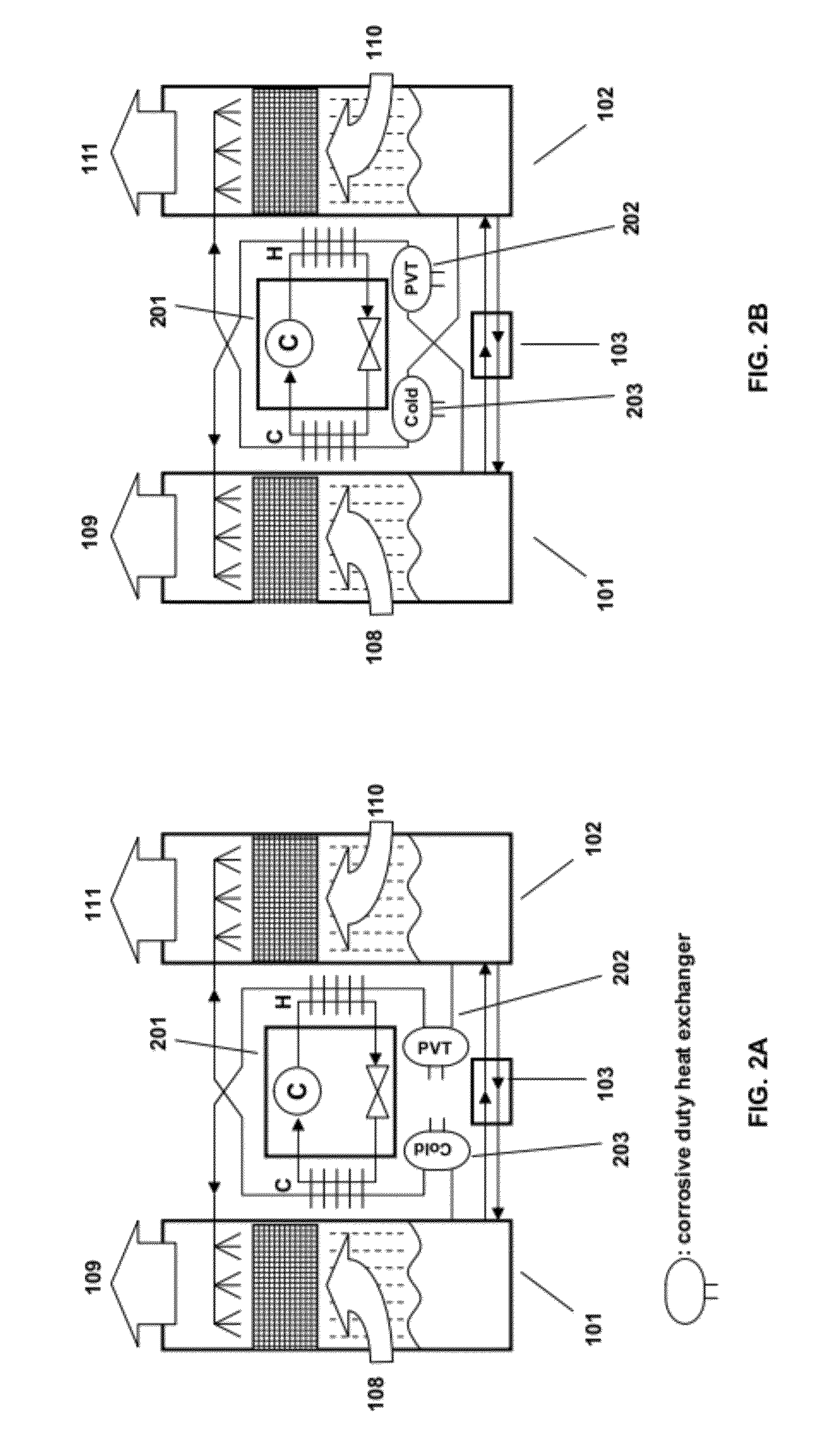

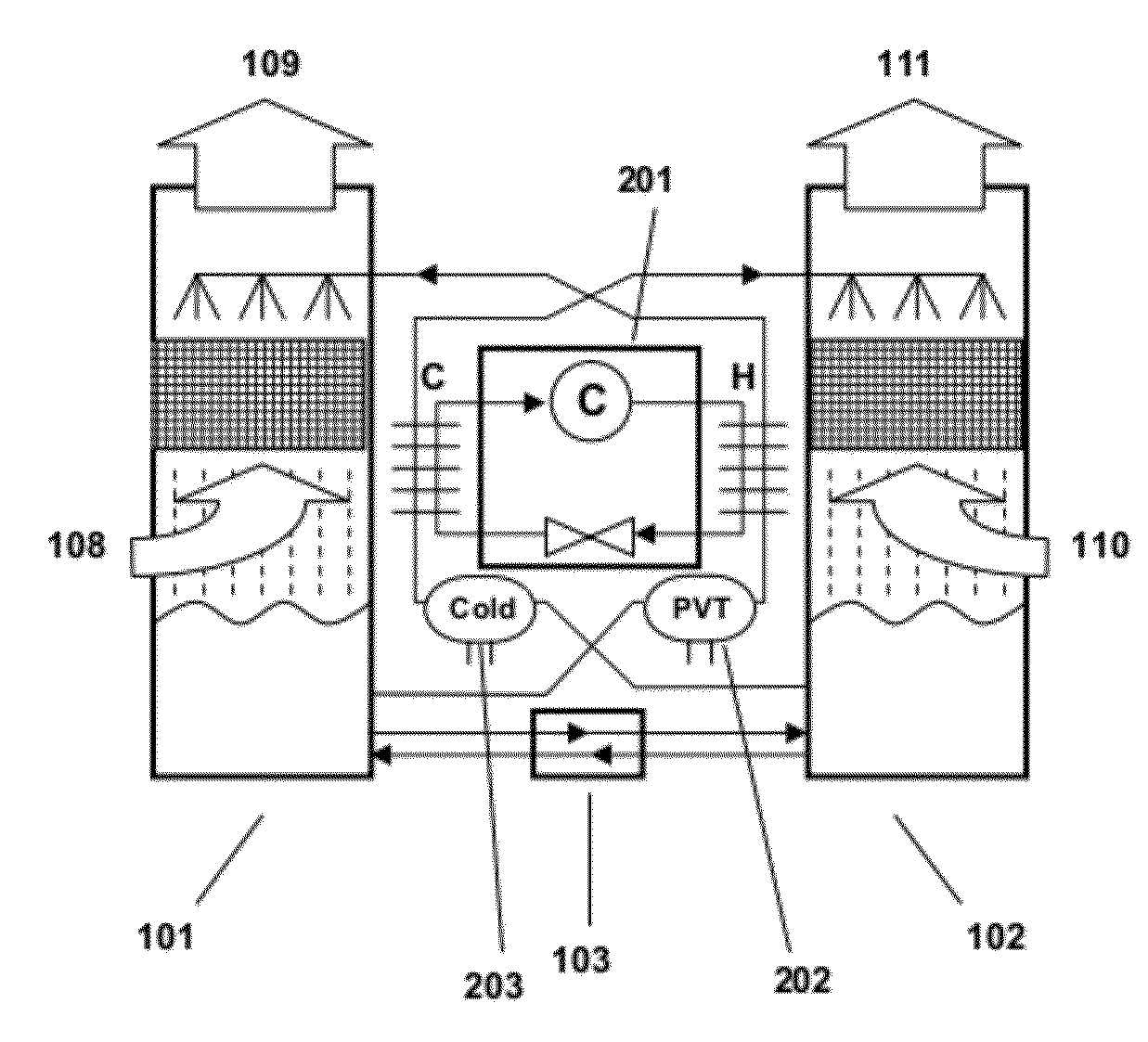

Desalination methods and systems

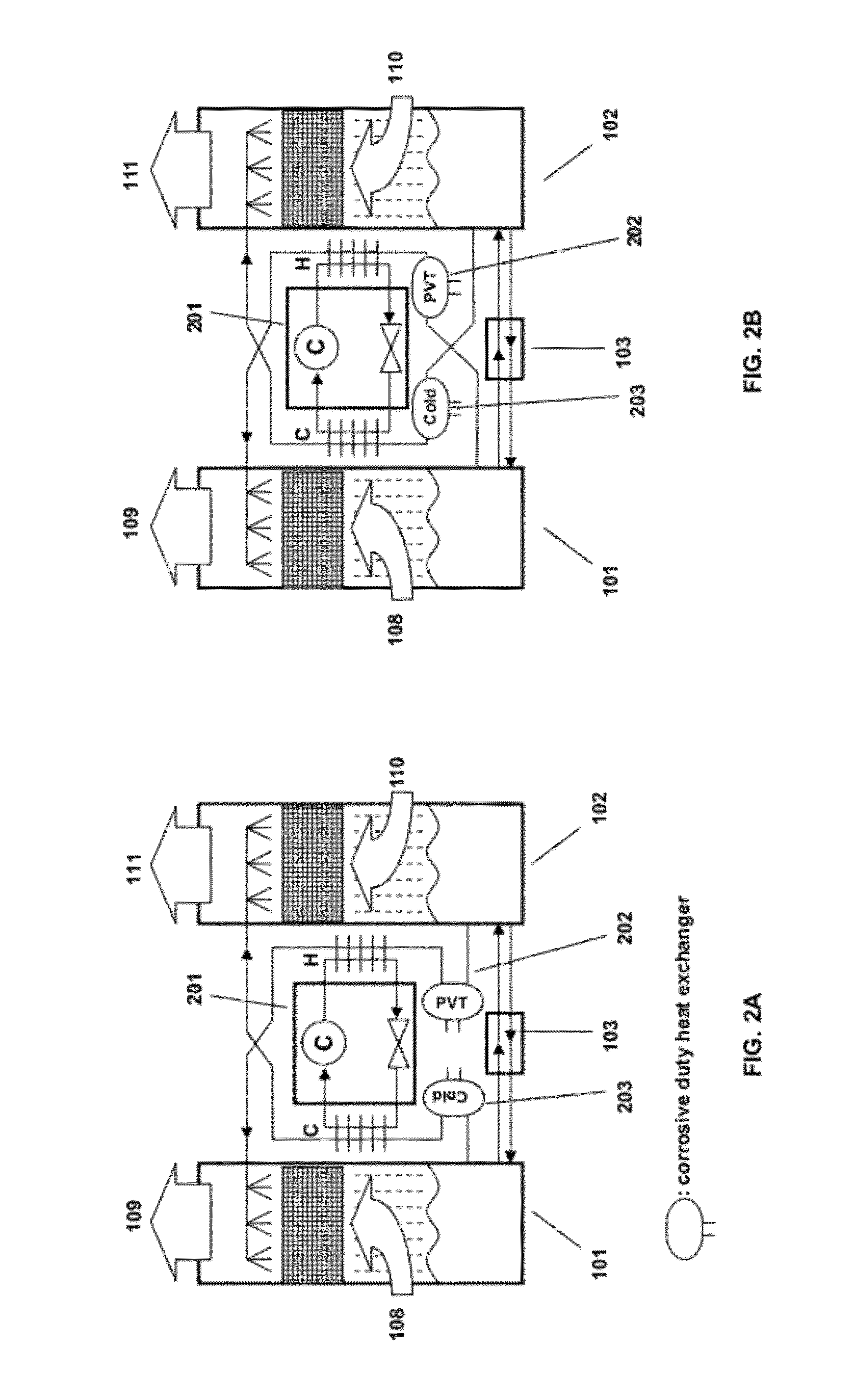

Methods and systems are provided for air conditioning, capturing combustion contaminants, desalination, and other processes using liquid desiccants.

Owner:EMERSON CLIMATE TECH INC

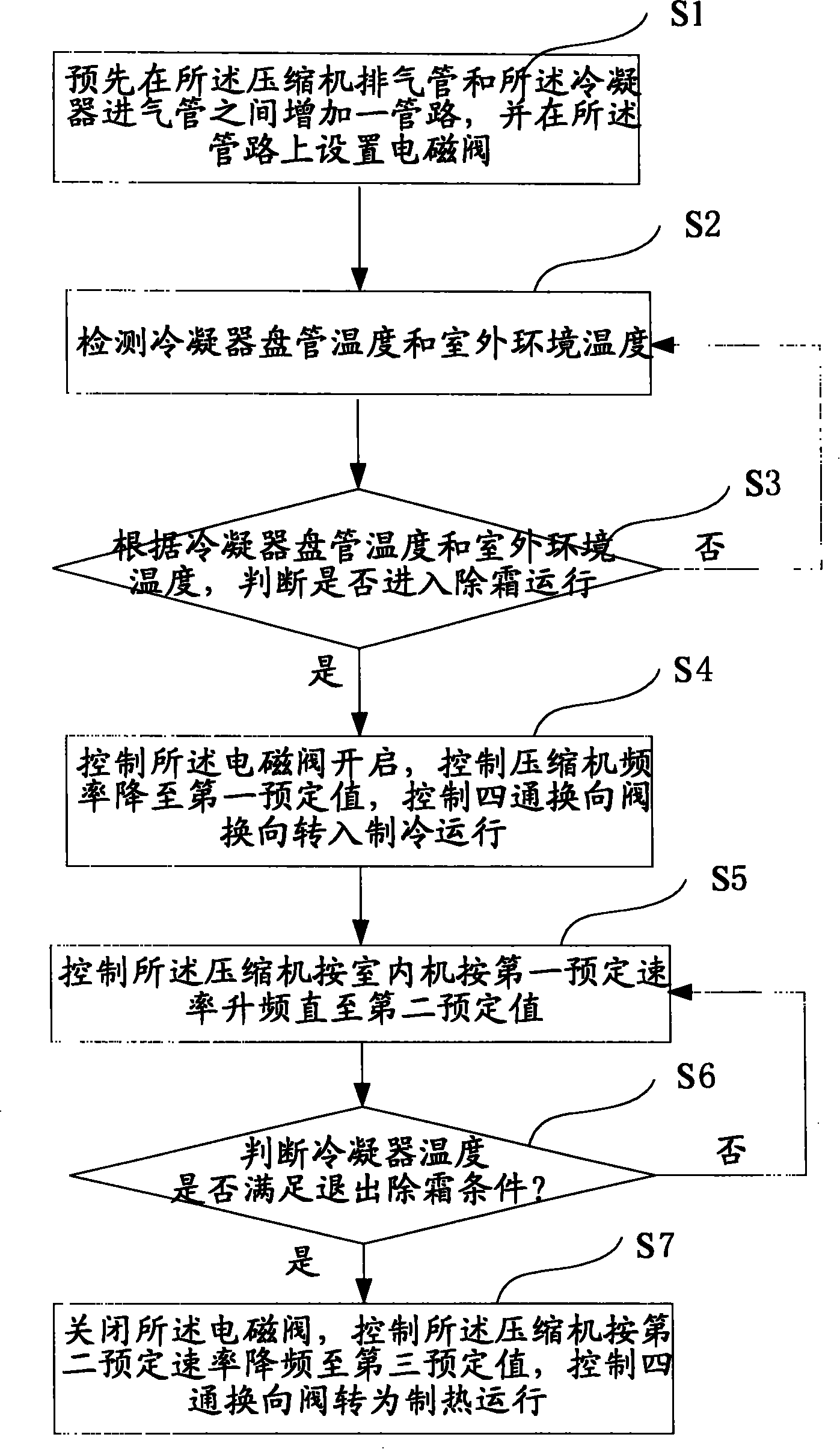

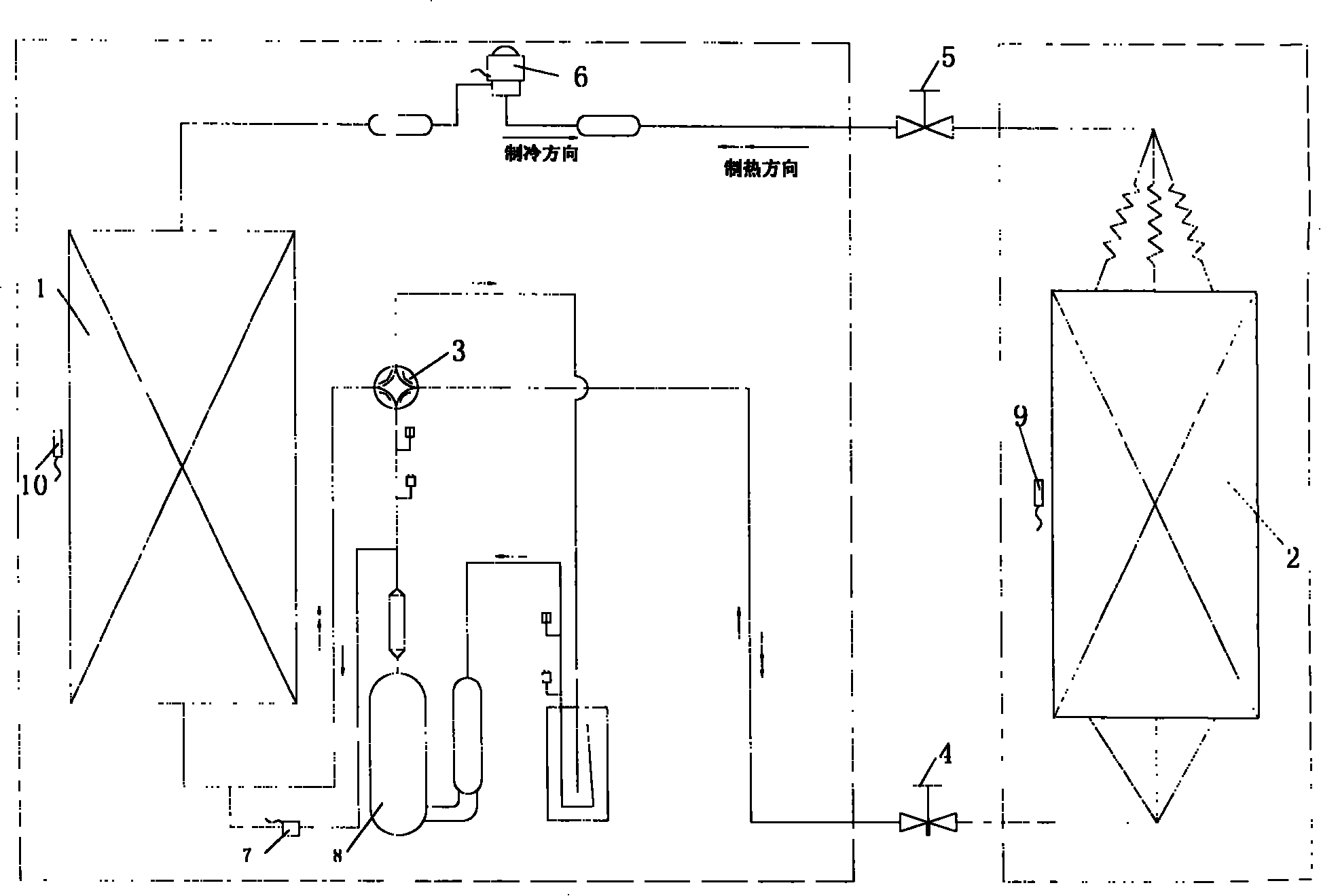

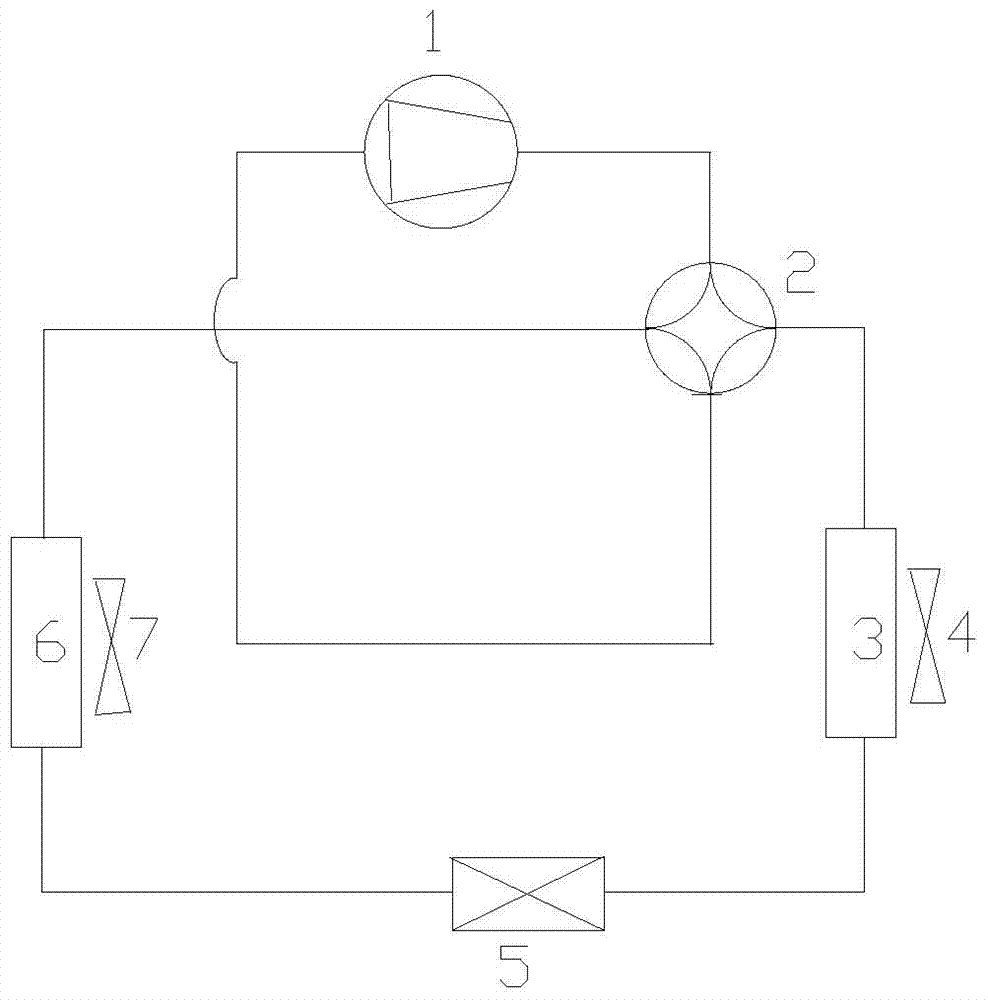

Air-conditioner defrosting method

InactiveCN101187516AImprove defrosting efficiencyImprove defrosting effectSpace heating and ventilation safety systemsSpace heating and ventilation control systemsMagnetic valveDefrosting

The invention discloses a method for air conditioner defrosting, which comprises the following steps, first, a pipeline is added between an air discharge pipe of a compressor and an air inlet pipe of a condensator in advance, and a magnetic valve is arranged on the pipeline, second, the temperature of a coil pipe of the condensator and temperature of outdoor environment are detected, third, a defrosting operation is judged to be operated or not according to the temperature of the coil pipe of the condensator and the outdoor environment, if the defrosting operation is needed, the fourth step is executed, otherwise the second step is executed, fourth, the magnetic valve is controlled to open, the frequency of the compressor is controlled to reduce to a first predetermined value, a four-way change-over valve is controlled to change into a refrigerating operation, fifth, the compressor is controlled to make an indoor set convert up to a second predetermined value according to the first predetermined speed, sixth, the temperature of the condensator is judged to detect whether the temperature is satisfied for a condition of the defrosting withdrawal, if satisfied, the seventh step is operated, otherwise, the fifth step is operated, seventh, the magnetic valve is closed, the compressor is controlled to convert down to a third predetermined value according to the second predetermined speed, and the four-way change-over valve is controlled to change to a heat-producing operation. The invention provides a method for air conditioner defrosting, which solves the problem that the period of defrosting for an air conditioner is longer, and defrosting effect of the air conditioner is influenced.

Owner:HAIER GRP CORP +1

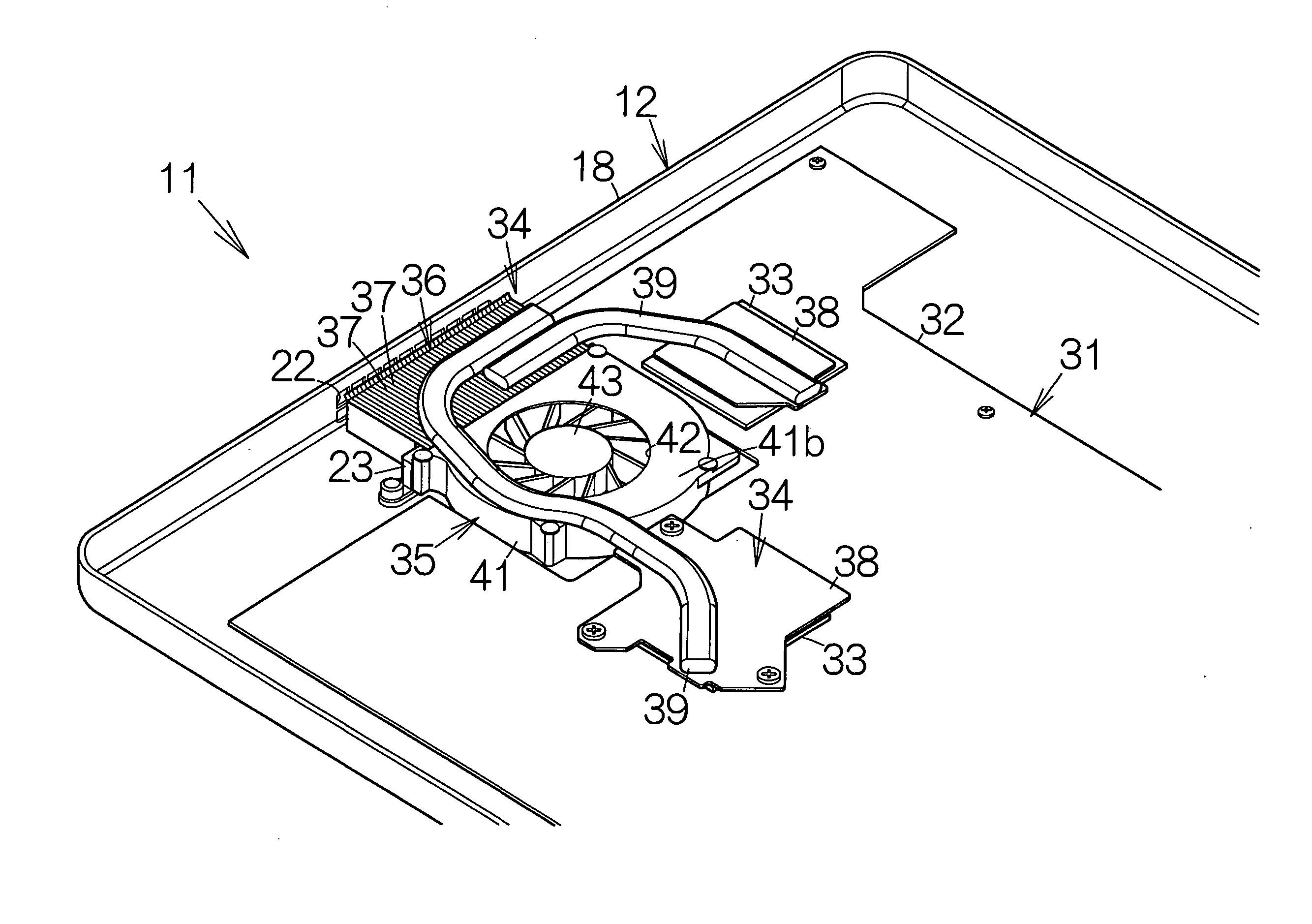

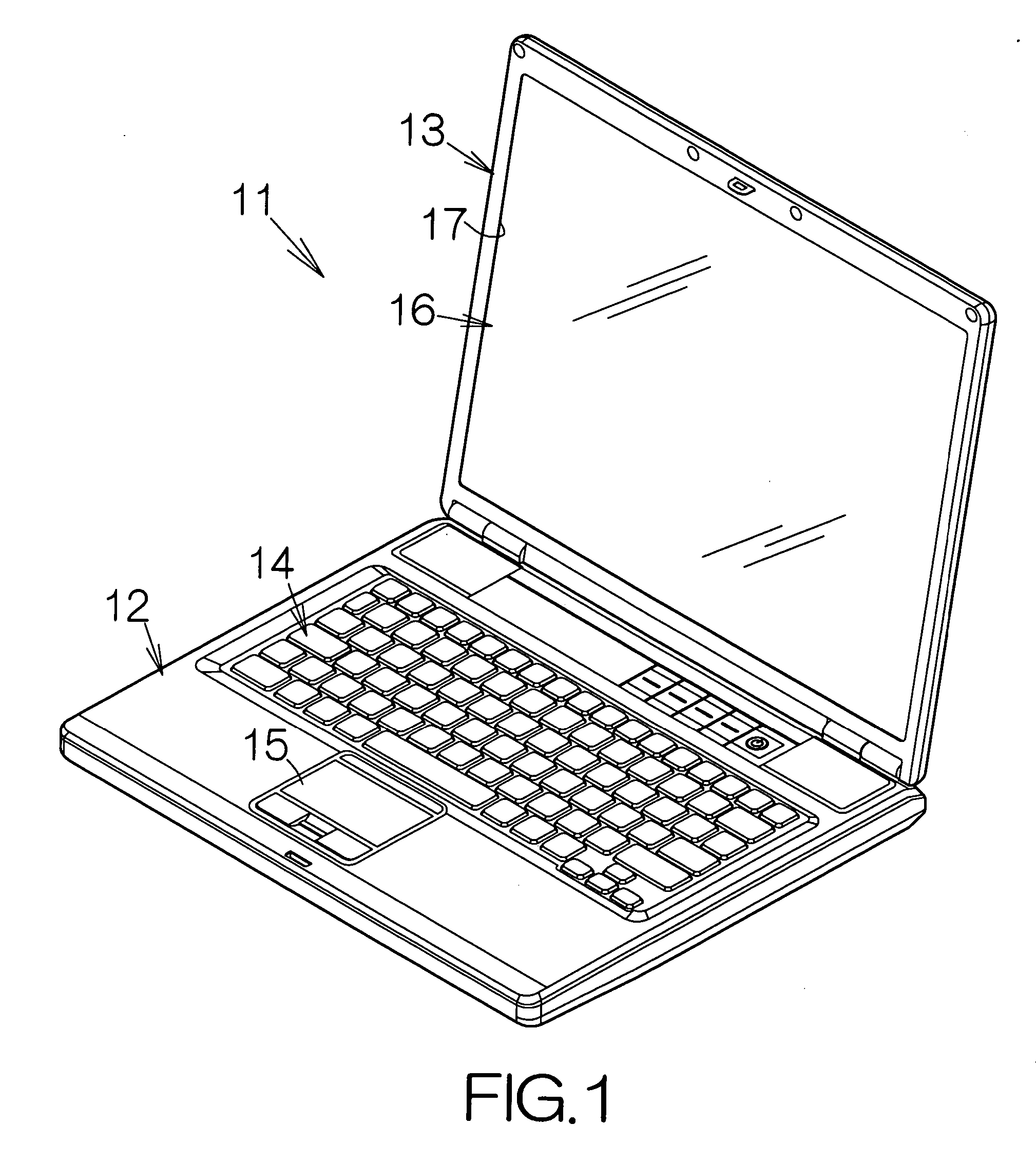

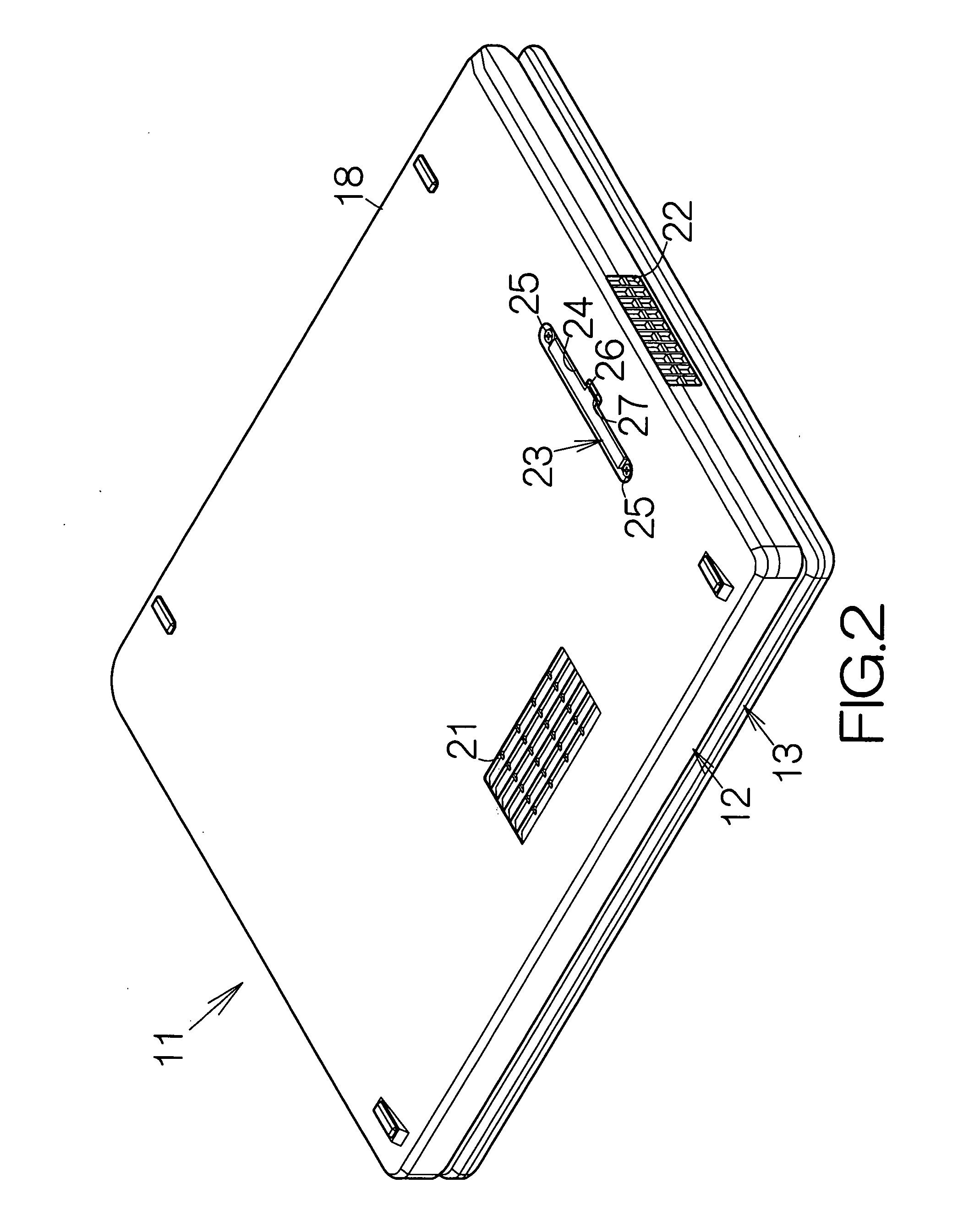

Electronic apparatus including removable dust catcher

InactiveUS20070131383A1Effective radiationAvoid painCombination devicesDispersed particle filtrationEngineeringHeat sink

A fan is enclosed in the enclosure of an electronic apparatus. The fan discharges air out of a ventilation opening of the fan itself. Heat radiating fins are located in an air passage extending from the ventilation opening. A dust catcher is removably mounted in an opening of the enclosure from the outside of the enclosure. The dust catcher is located in the air passage between the heat radiating fins and the ventilation opening. The dust catcher serves to catch the dust in the air passage. The dust catcher is removed from the enclosure along with the dust. The dust is thus reliably cleared from the air passage. The dust catcher can then be cleaned. The cleaned dust catcher can again be set in the opening of the enclosure. Airflow of a sufficient amount is in this manner always kept in the air passage.

Owner:FUJITSU CLIENT COMPUTING LTD

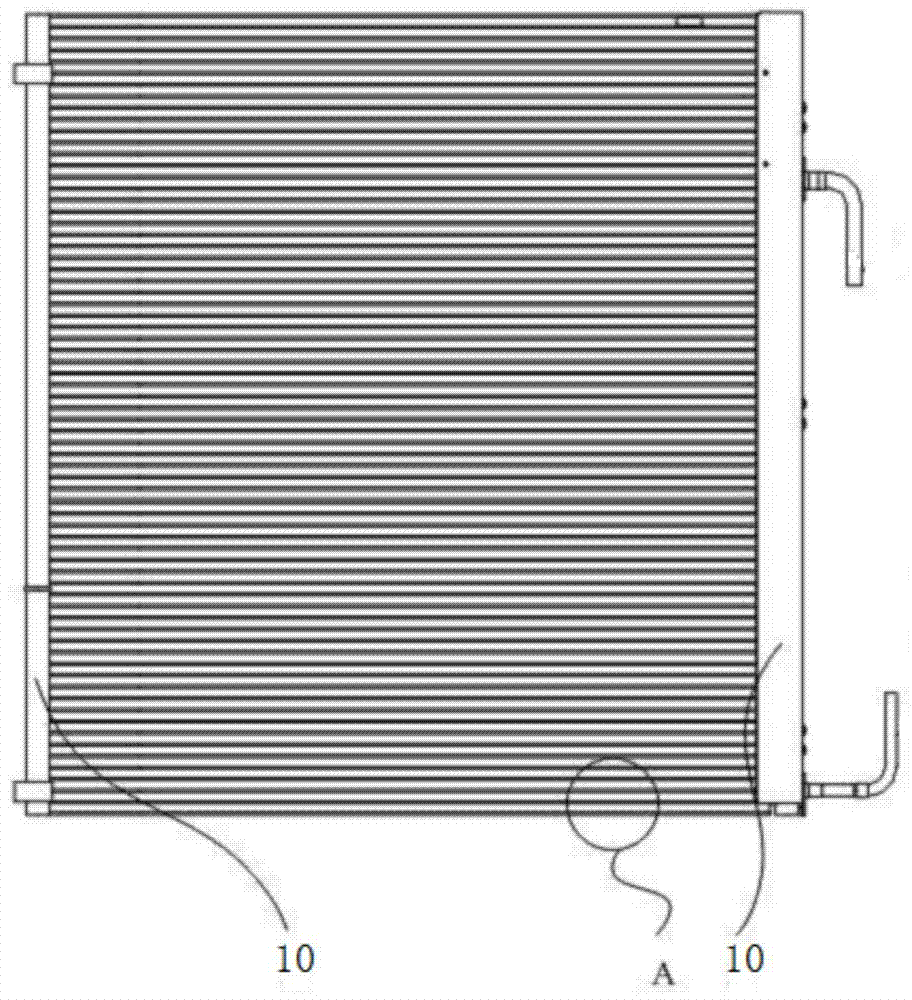

Method for controlling defrosting operation of air-conditioner

InactiveCN104515330AMechanical apparatusSpace heating and ventilation safety systemsEngineeringTubes types

The invention relates to a method for controlling defrosting operation of an air-conditioner; when one defrosting operation period is completed or one defrosting operation period is divided into a plurality of stages, an outdoor condensate fan is controlled to operate reversely for a certain time t at the end of each stage and blows off defrosted water on a condenser. The method for controlling defrosting operation of the air-conditioner is particularly applicable to the air-conditioner with the condenser using a micro-channel special structure; the fan of the outdoor unit is utilized sufficiently; during the defrosting operation, the condensate fan of the outdoor unit is controlled to operate reversely within a short time and blows off the defrosted water on the condenser, so that the purpose of completely defrosting is achieved; and the method is also applicable to other air conditioners with finned tube type condensers.

Owner:HAIER GRP CORP +1

Liquid-impregnated surfaces, methods of making, and devices incorporating the same

ActiveUS8574704B2Reduce viscous dragMinimizes accumulationLayered productsDe-icing equipmentsNon wettingFrost

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

Slow release coolant filter

InactiveUSRE37369E1Transportation and packagingSolid sorbent liquid separationEngineeringCooling fluid

A coolant filter for use in filtering a coolant solution which flows through the coolant filter includes a filter housing assembly which is made up of an outer housing which is crimped to a nutplate which defines an internally threaded flow outlet. A generally cylindrical filter element is positioned inside of the filter housing assembly and a first endplate is bonded to the end of the filter element which is adjacent to the nutplate. An endplate member is provided for attachment to the opposite end of the filter element and is configured in such a way so as to define an interior chamber where supplemental coolant additive pellets are stored. A closing plate is applied across the open end of the interior chamber so as to create an enclosed chamber for the supplemental coolant additive pellets. A slow release mechanism is provided for controlling the rate of release of the supplemental coolant additive from the enclosed chamber into the coolant solution. In one embodiment of the present invention, the slow release mechanism includes a diffusion tube which defines a diffusion orifice. In another embodiment of the present invention, the slow release mechanism includes a semipermeable (or osmotic) membrane wafer. In both instances, the slow release mechanism is positioned between the source of supplemental coolant additive and the flow outlet in the nutplate.

Owner:FLEETGUARD INC

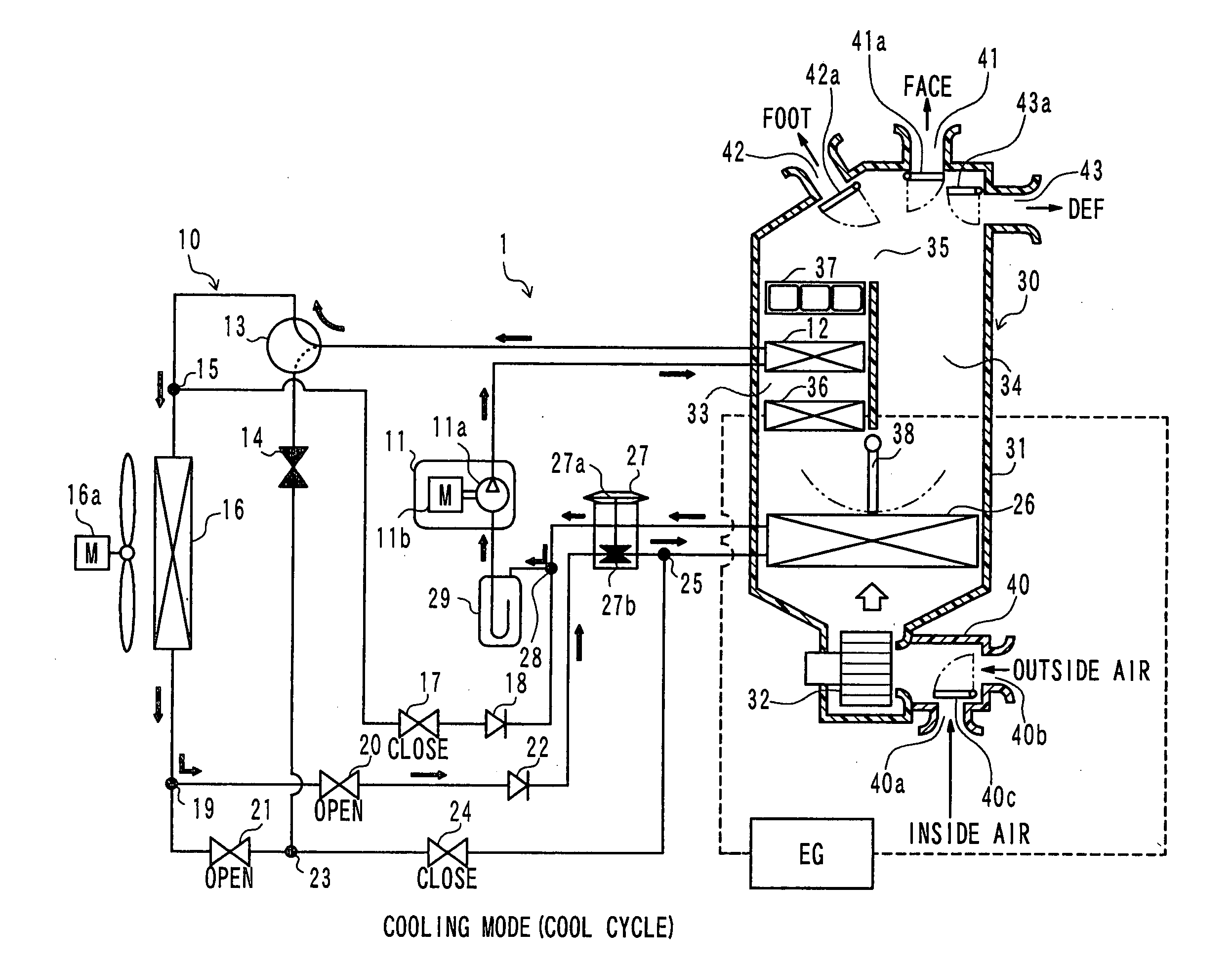

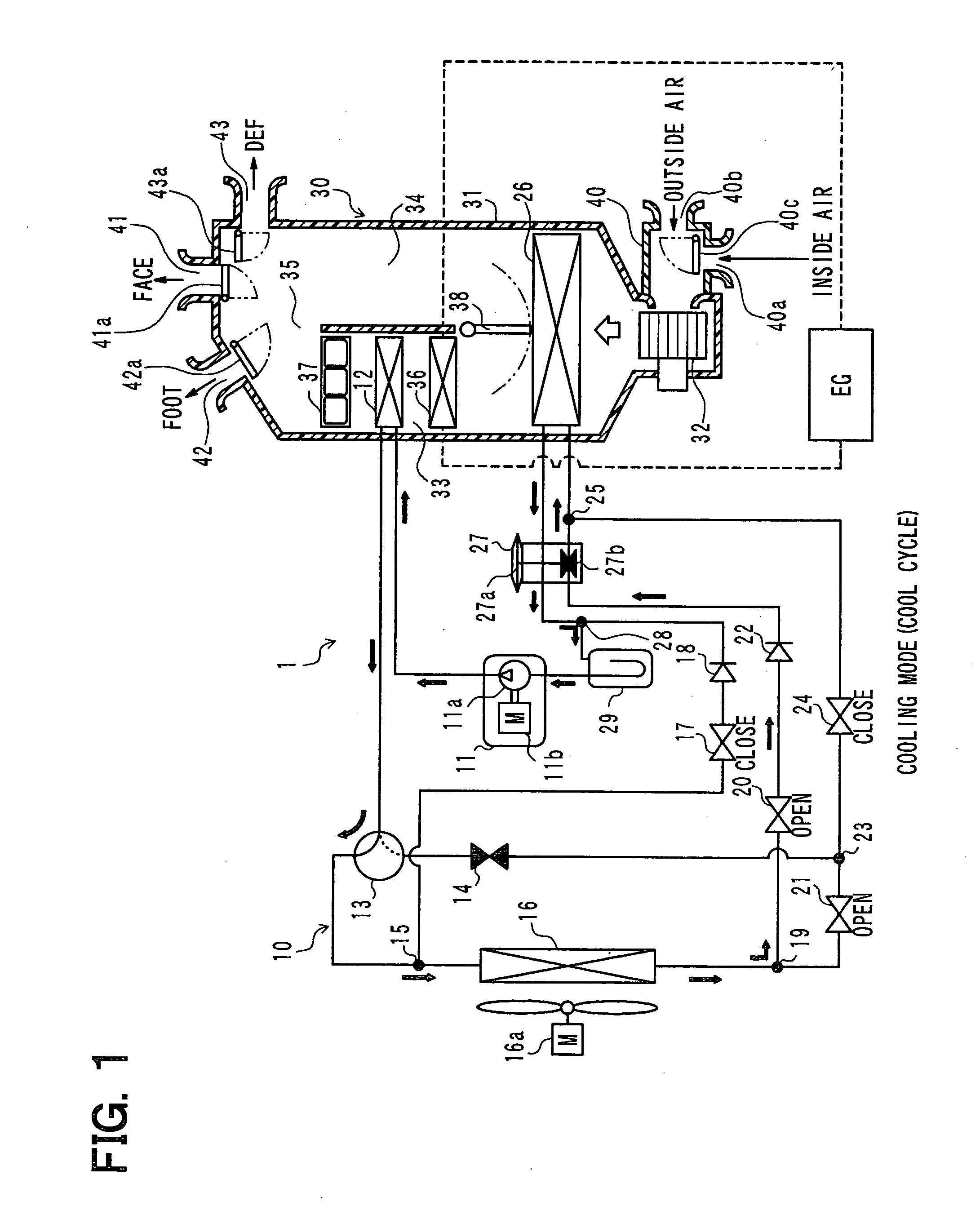

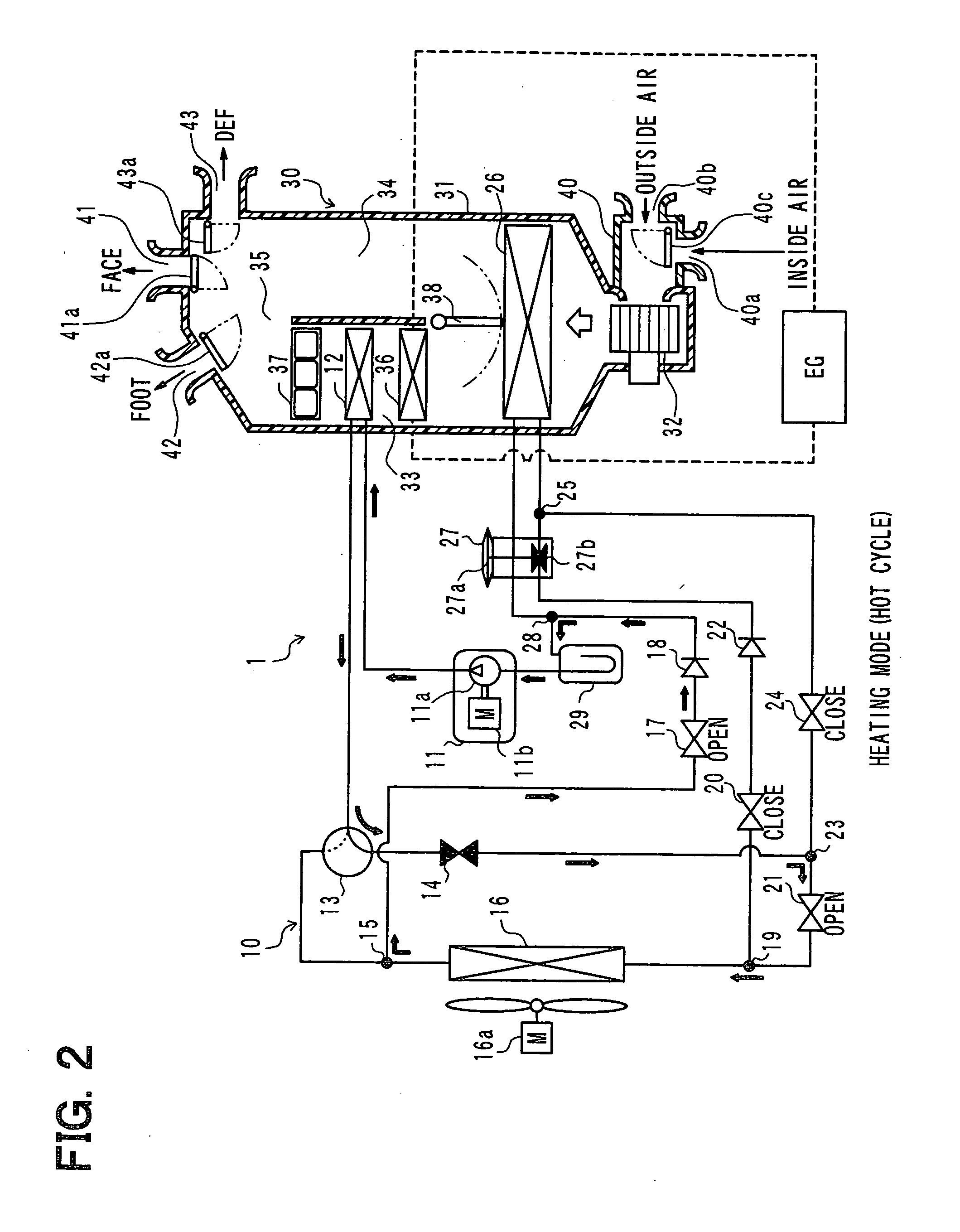

Air conditioner for vehicle with heat pump cycle

InactiveUS20100326127A1Effectively reducing fuel consumptionPrevent heating capacity being excessiveMechanical apparatusCompression machines with non-reversible cycleEngineeringInternal combustion engine

An air conditioner for a vehicle includes a vapor compression refrigeration cycle configured to have a heat pump cycle for heating air to be blown into an interior of a vehicle compartment, and a heating member for heating the air using a coolant of an internal combustion engine of the vehicle as a heat source. In the air conditioner, an operation request signal is output by an air conditioning controller to the internal combustion engine when an outside air temperature is lower than a predetermined threshold.

Owner:DENSO CORP

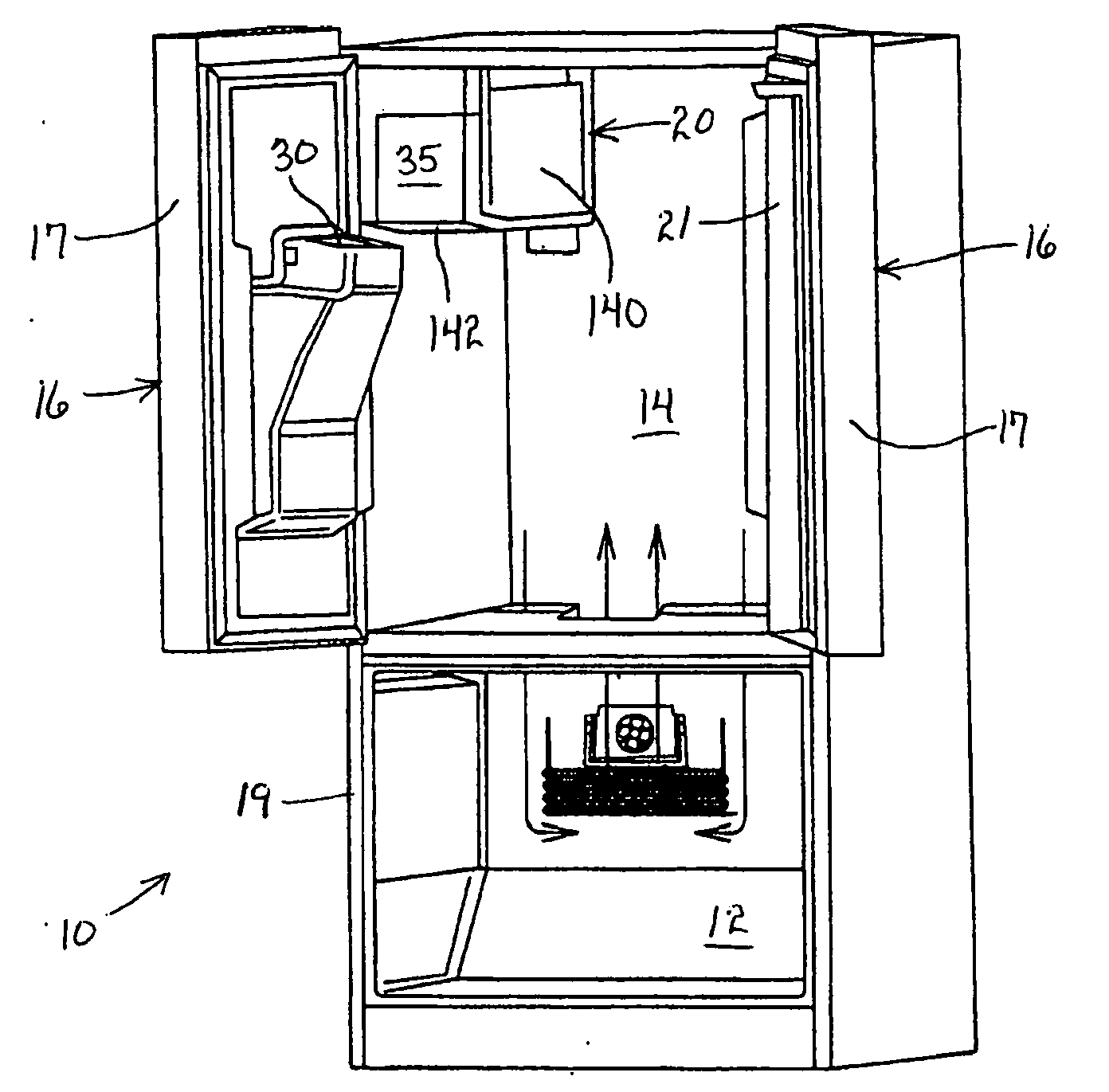

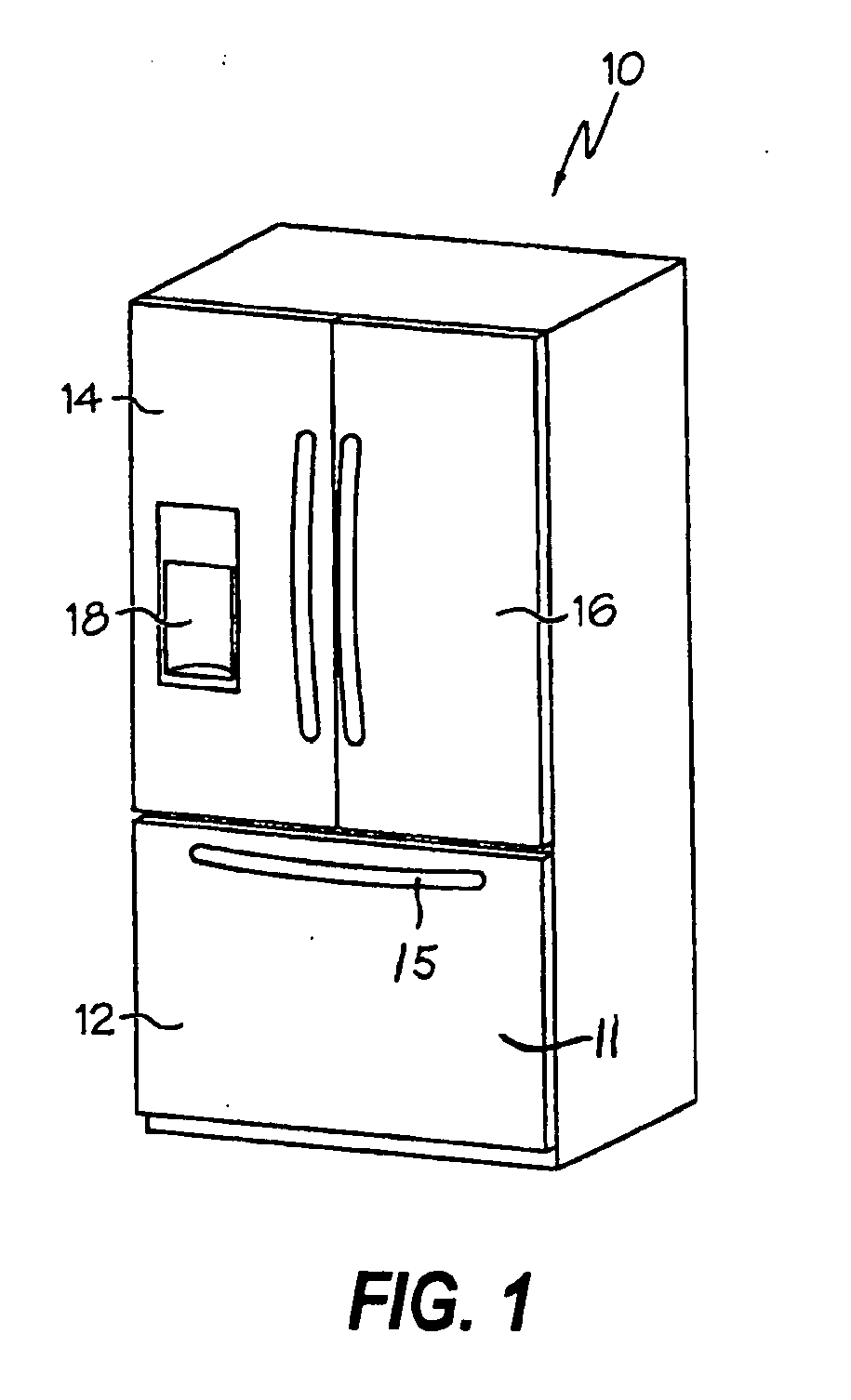

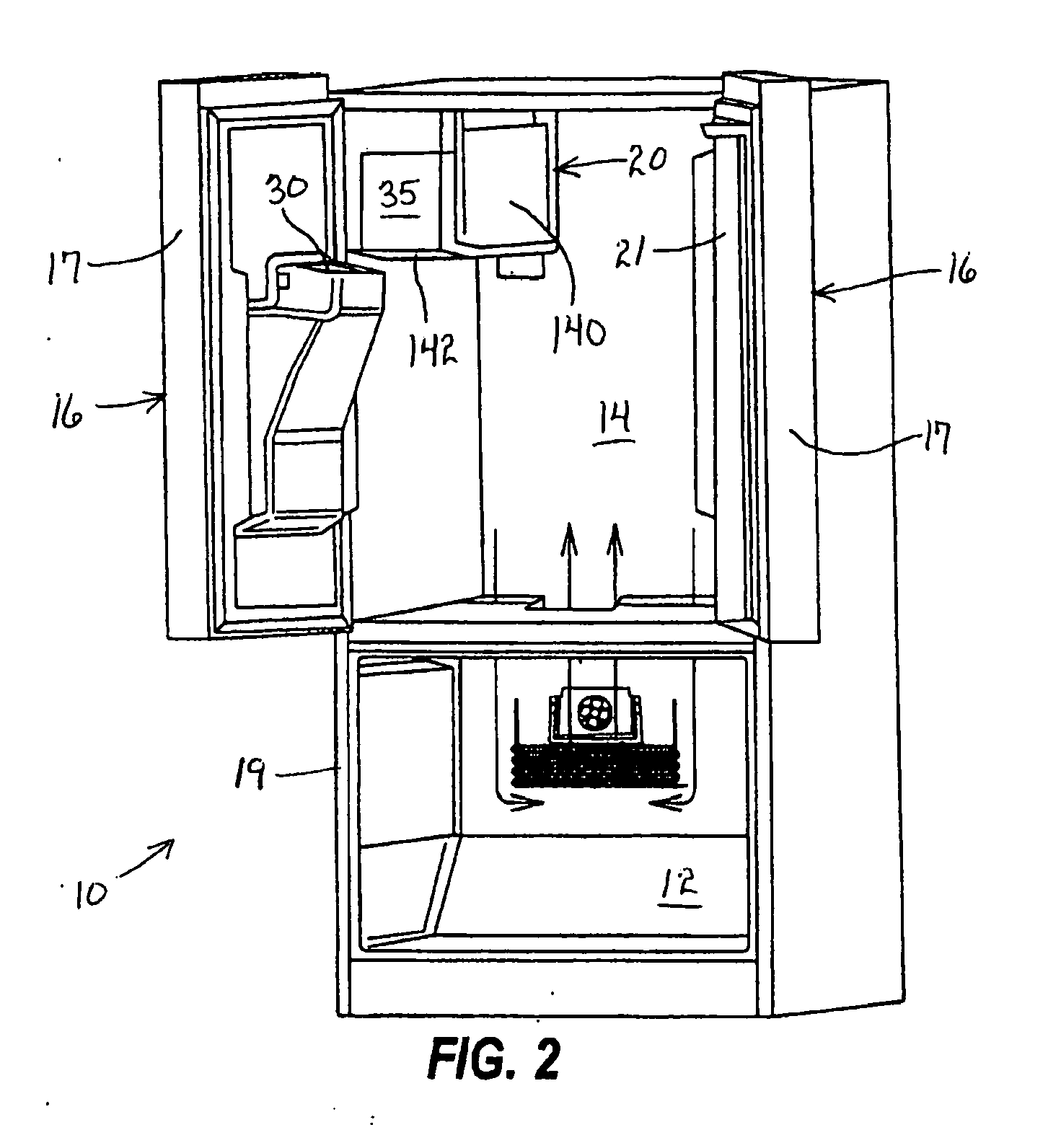

Ice maker control system and method

Provided is an ice maker that includes a mold including a plurality of cavities for receiving water to be frozen into ice pieces, a driver operatively connected to the mold for adjusting a position of the mold to a plurality of different locations during an ice making cycle, and a controller. A limit switch is located at a plurality of different positions along a range of travel of the mold to be actuated and transmit a signal indicative of the mold's arrival at the different locations. The mold can travel along path including first portion having a first axis of rotation and a substantially vertical portion, and can be driven by a motor with a drive shaft rotatable about a single axis of rotation. The motor can drive both the mold and a bail arm, and the mold can be leveled upon reaching a predetermined location. The ice maker can perform a Dry Cycle in response to detecting an anomaly during ice making.

Owner:ELECTROLUX HOME PROD CORP NV

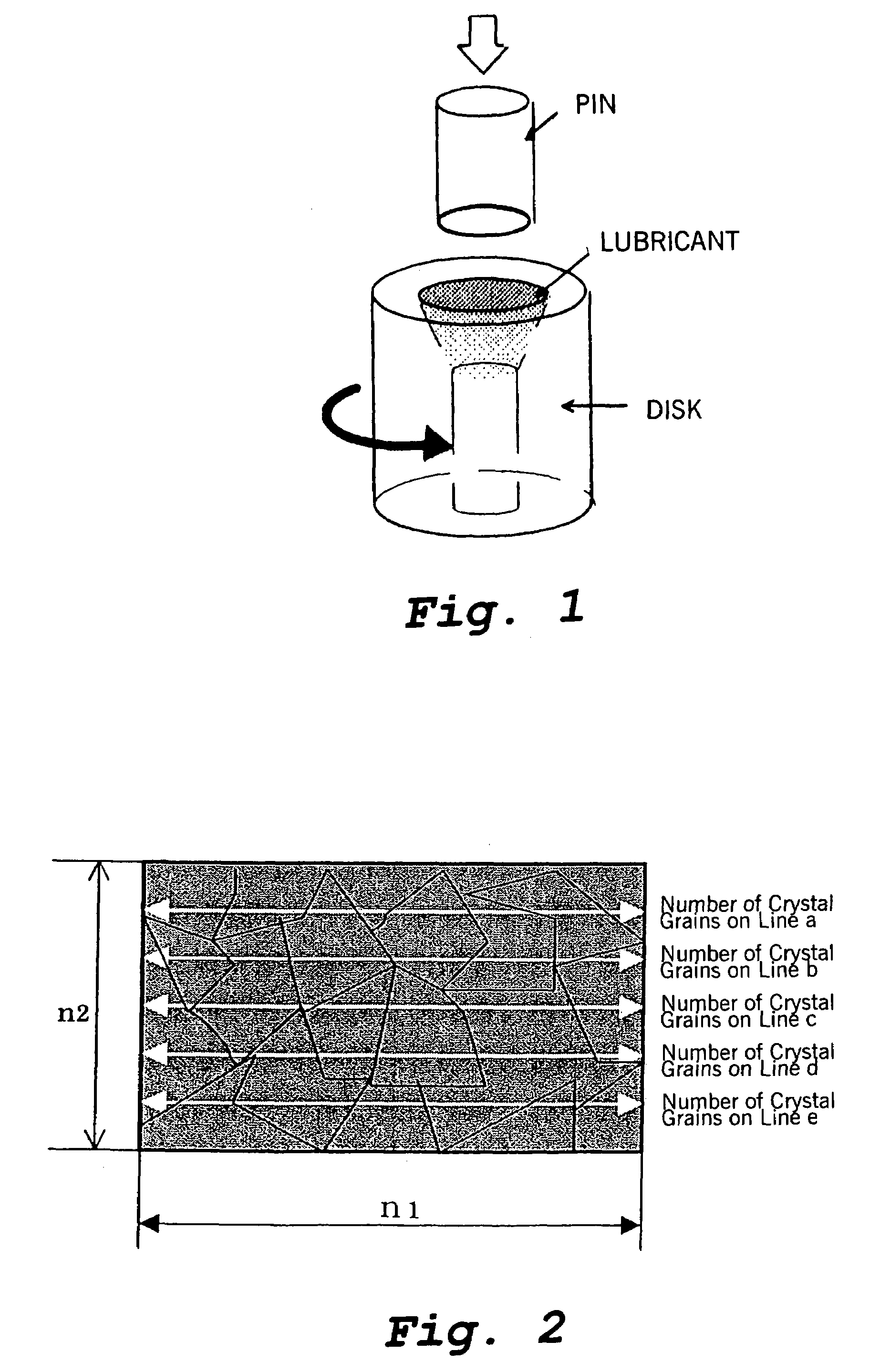

Surface conditioning prior to chemical conversion treatment of a steel member

ActiveUS7666266B2Optimized diameterShort timeOther chemical processesCorrosion preventionPotassiumMaterials science

By subjecting a threaded joint for OCTG (oil country tubular goods) to surface conditioning with an aqueous solution of potassium tetraborate or sodium tetraborate prior to manganese phosphate chemical conversion treatment, a manganese phosphate chemical conversion coating having coarse crystal grains with an average crystal grain diameter of 10-110 micrometers is formed on the surface of the steel member which may be any steel including a high Cr steel. This manganese phosphate chemical conversion coating can hold a large amount of a liquid lubricant, and it is effective at preventing the occurrence of galling at the time of makeup of a threaded joint for OCTG.

Owner:NIPPON STEEL CORP

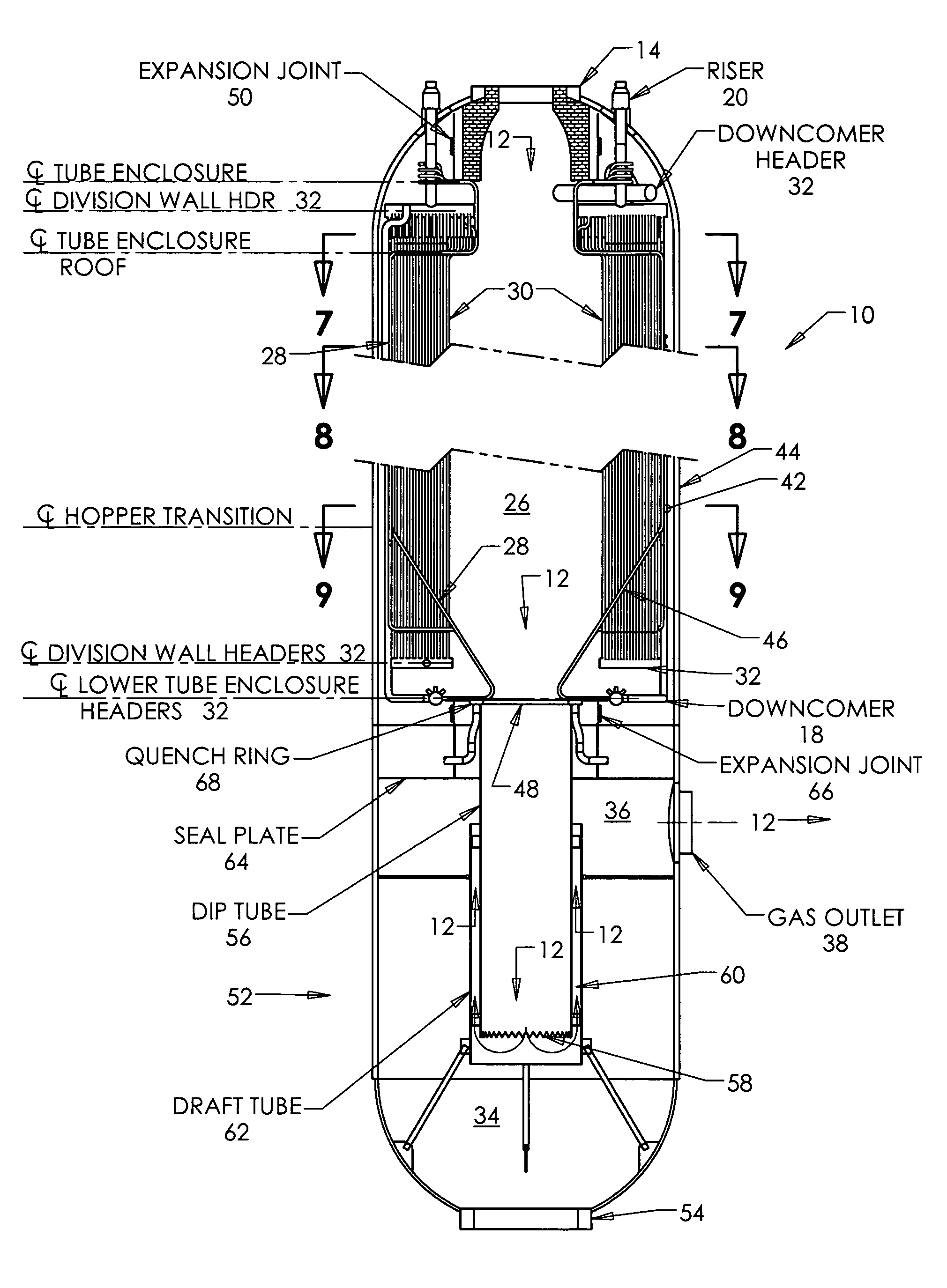

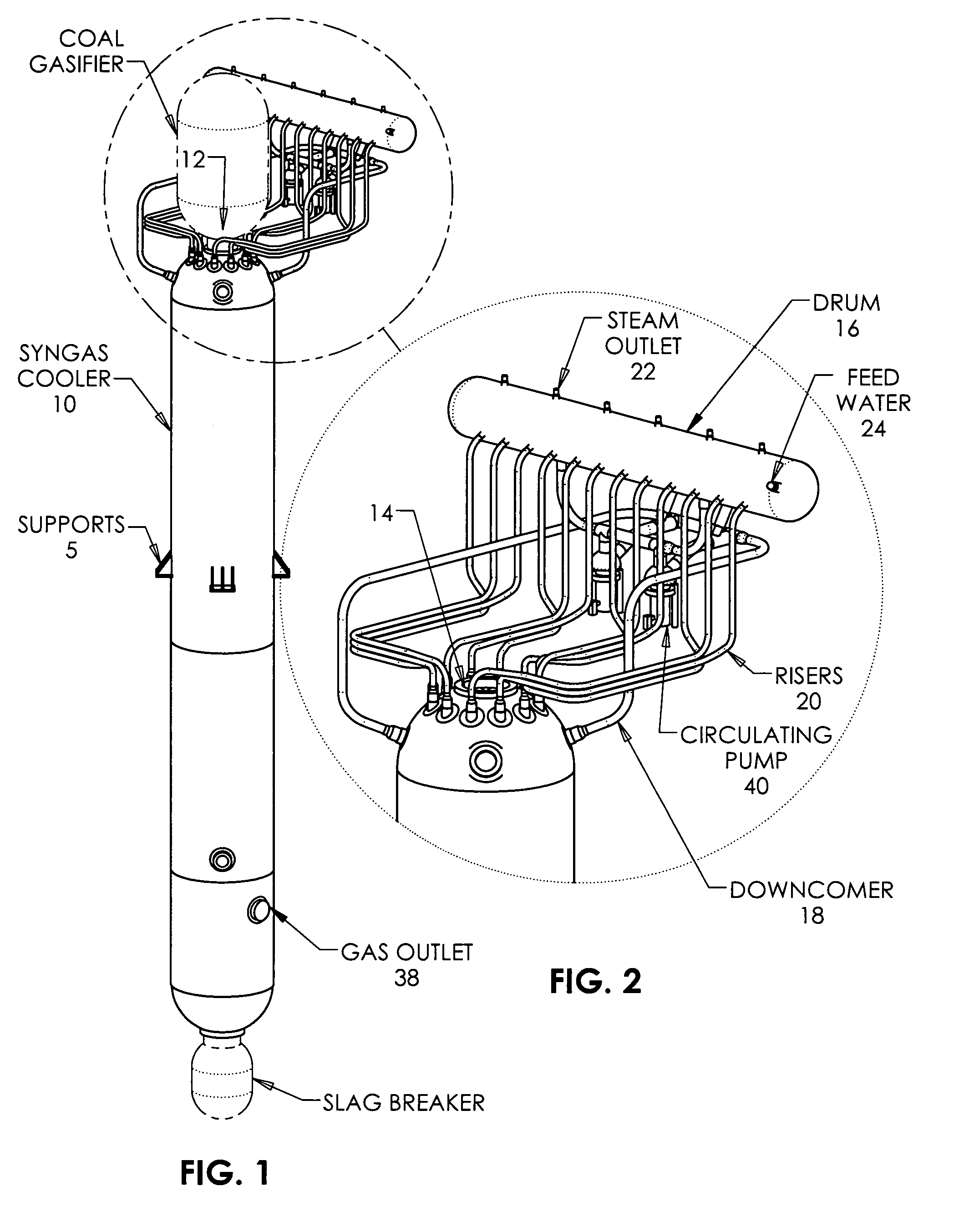

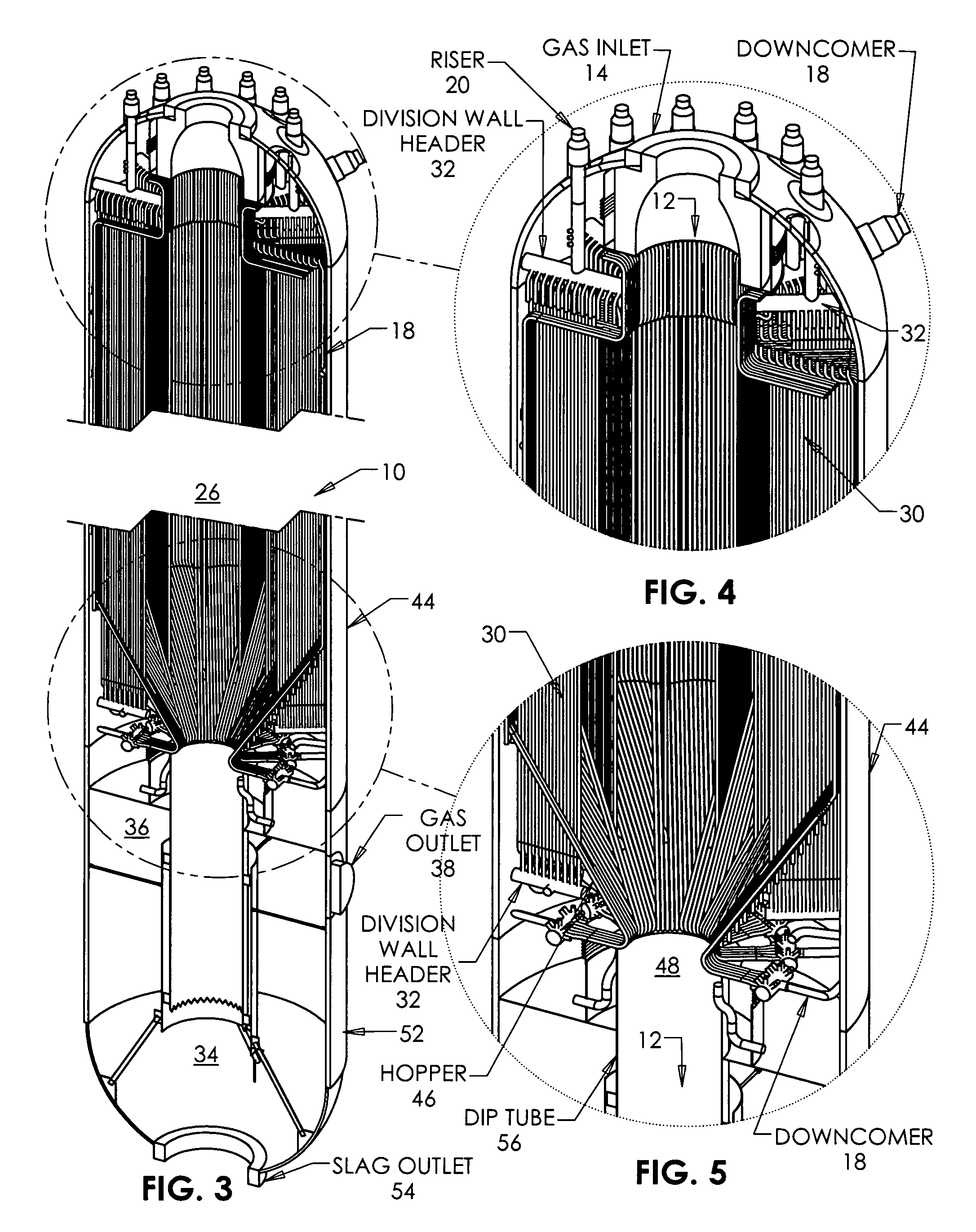

Radiant syngas cooler

A radiant syngas cooler used to contain and cool the synthesis gas produced by coal gasification processes employs radiant and convection surfaces in a specific arrangement to achieve a cost-effective, compact design.

Owner:THE BABCOCK & WILCOX CO

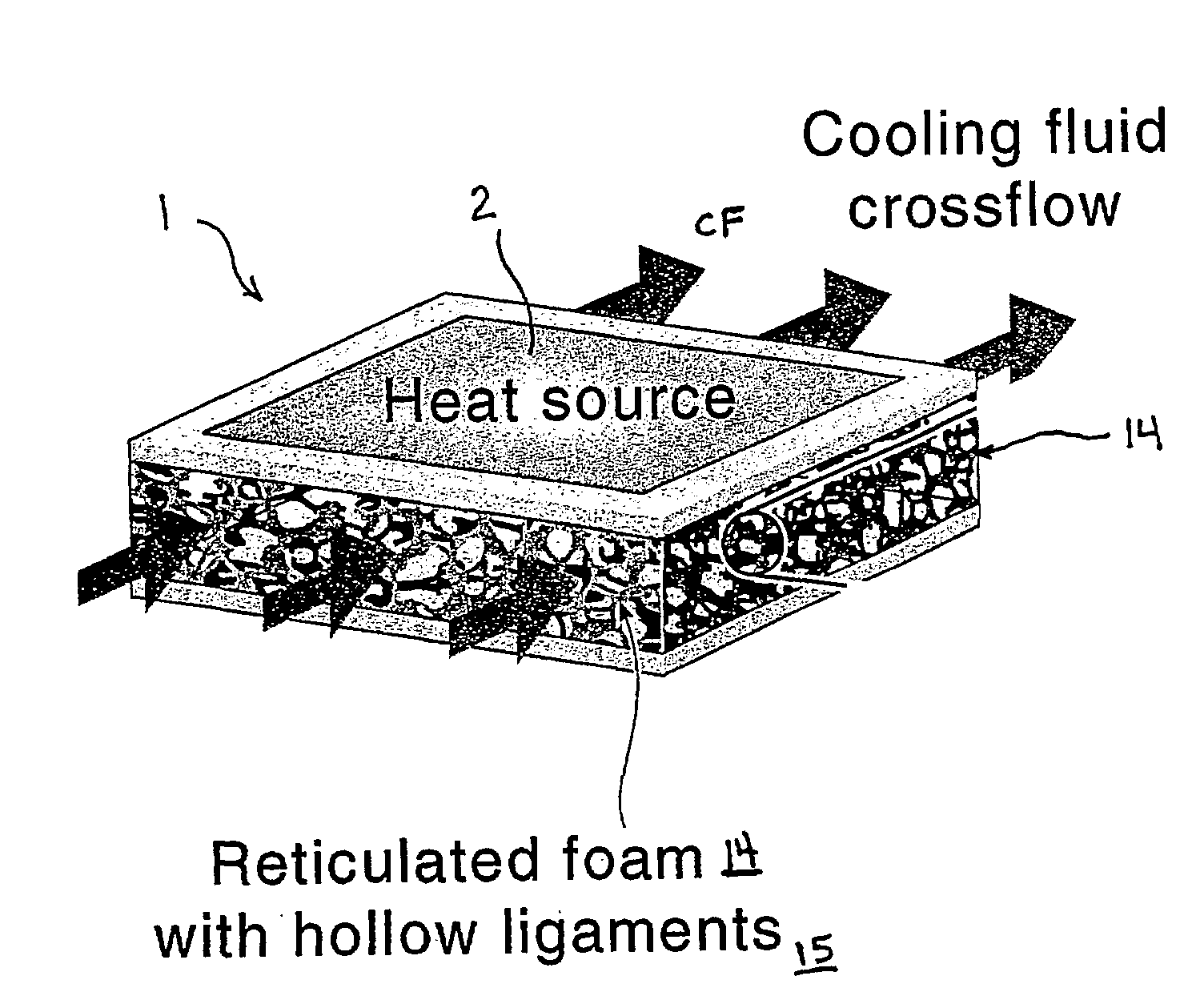

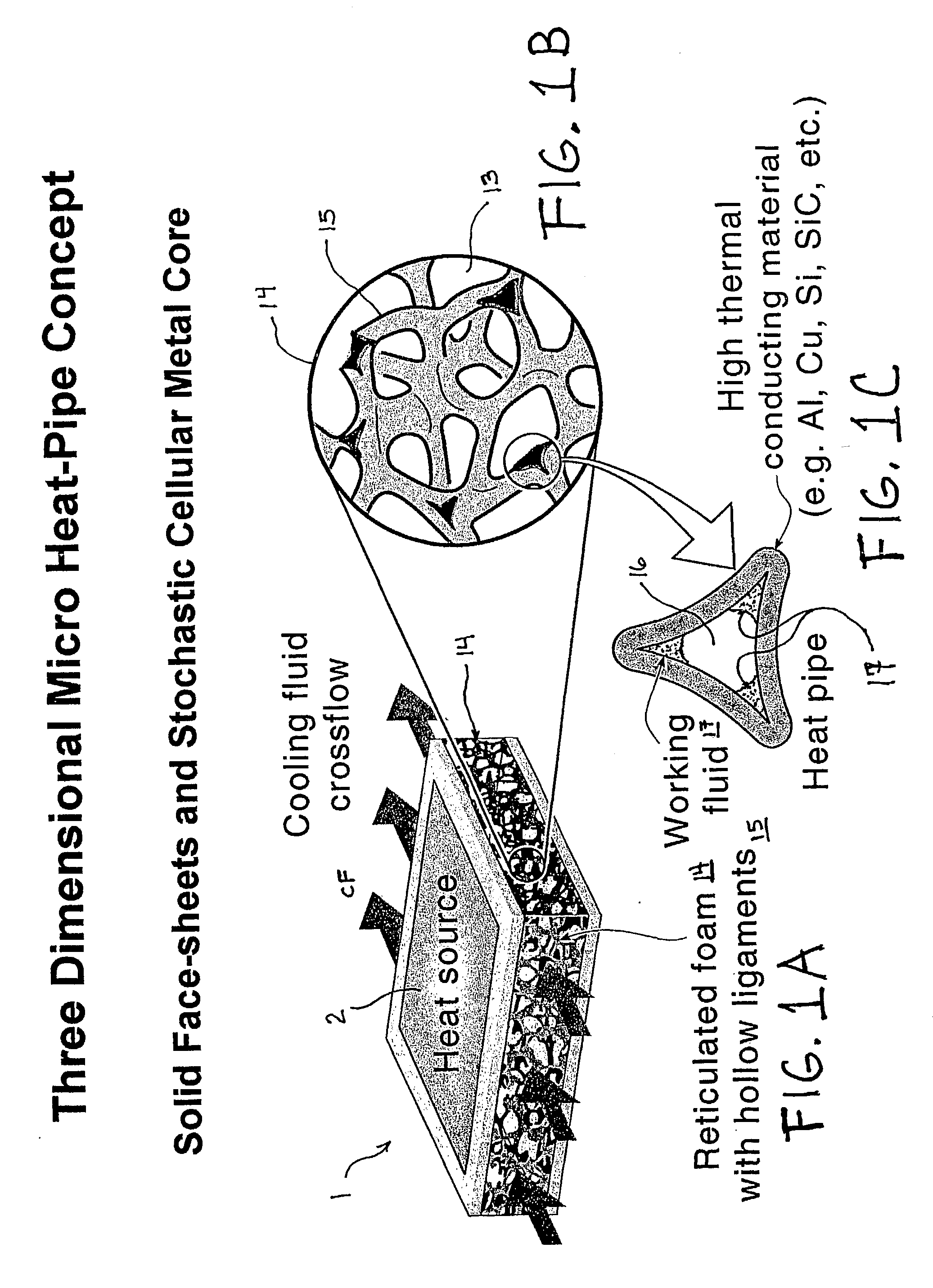

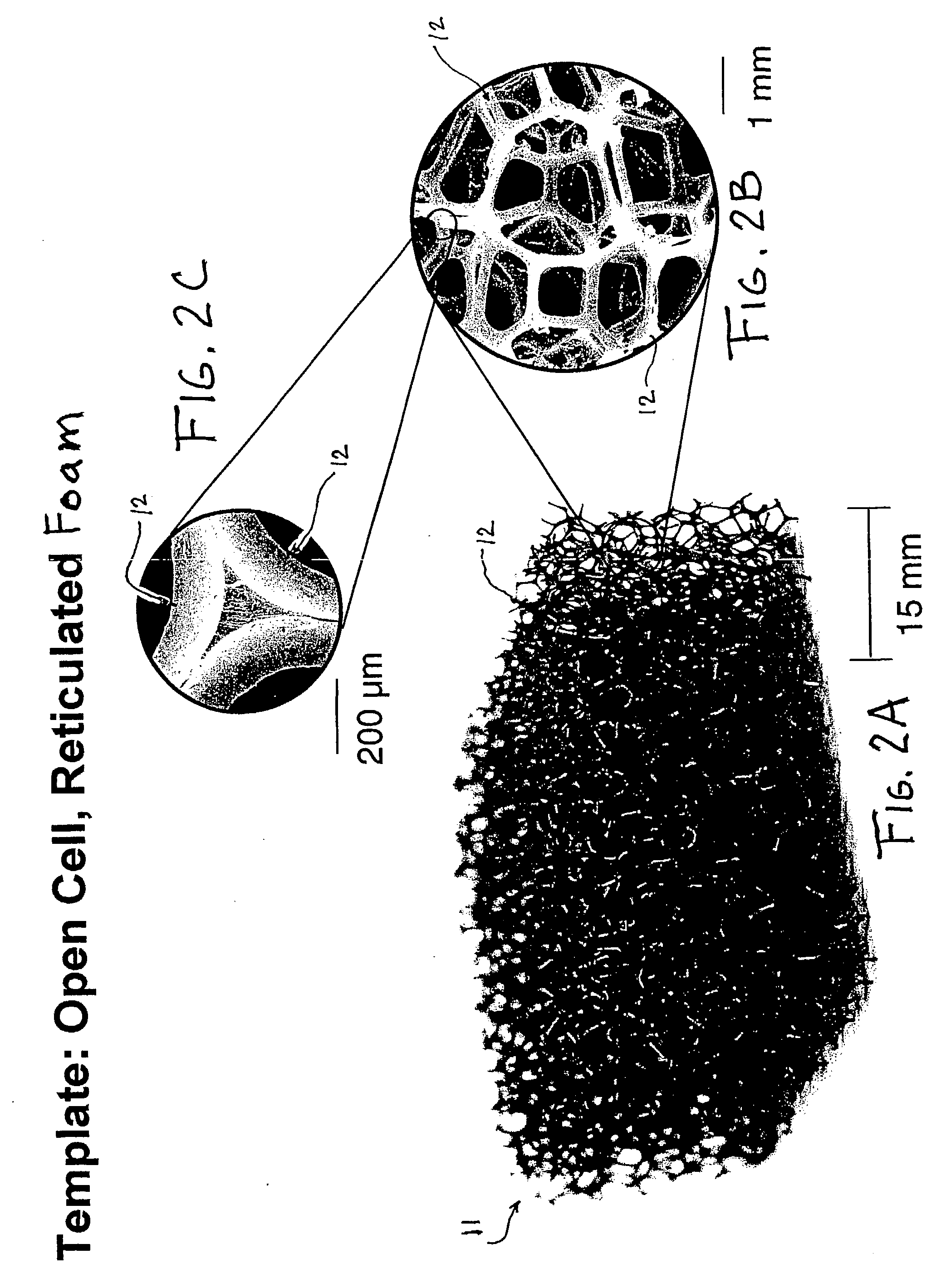

Heat exchange foam

InactiveUS20040123980A1Improve efficiencyReduce temperature gradientVacuum evaporation coatingSputtering coatingEngineeringHeat exchanger

A heat exchanger (1) including a foam (14) having hollow ligaments (15) and an interstital volume (13).

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Intelligent defrosting method for air onditioner

ActiveCN101256045ADoes not affect the heating effectThe process method is reasonableSpace heating and ventilation safety systemsSpace heating and ventilation control systemsTransducerEngineering

The invention relates to an intelligent defrosting method of an air conditioner. The air conditioner judges whether one of the seven conditions is satisfied according to a series of integral elements such as indoor coil pipe temperature transducer variable quantity, environment temperature variable quantity, indoor wind velocity variable quantity, heat-production runtime accumulation quantity, and whether an outdoor fan and a compressor are overcurrent protected, to determine whether an outdoor set is defrosted or whether defrosting is needed or not, so that intelligent defrosting is performed without using an outdoor coil pipe temperature transducer. The outdoor coil pipe temperature transducer and related signal lines are saved on the base of traditional air conditioners. Intelligent defrosting can be performed without human interference and only operation according to a preset program is needed. Clean outdoor defrosting is provided, heat quantity is not affected, and international specified requirements are satisfied.

Owner:安徽奥克斯智能电气有限公司

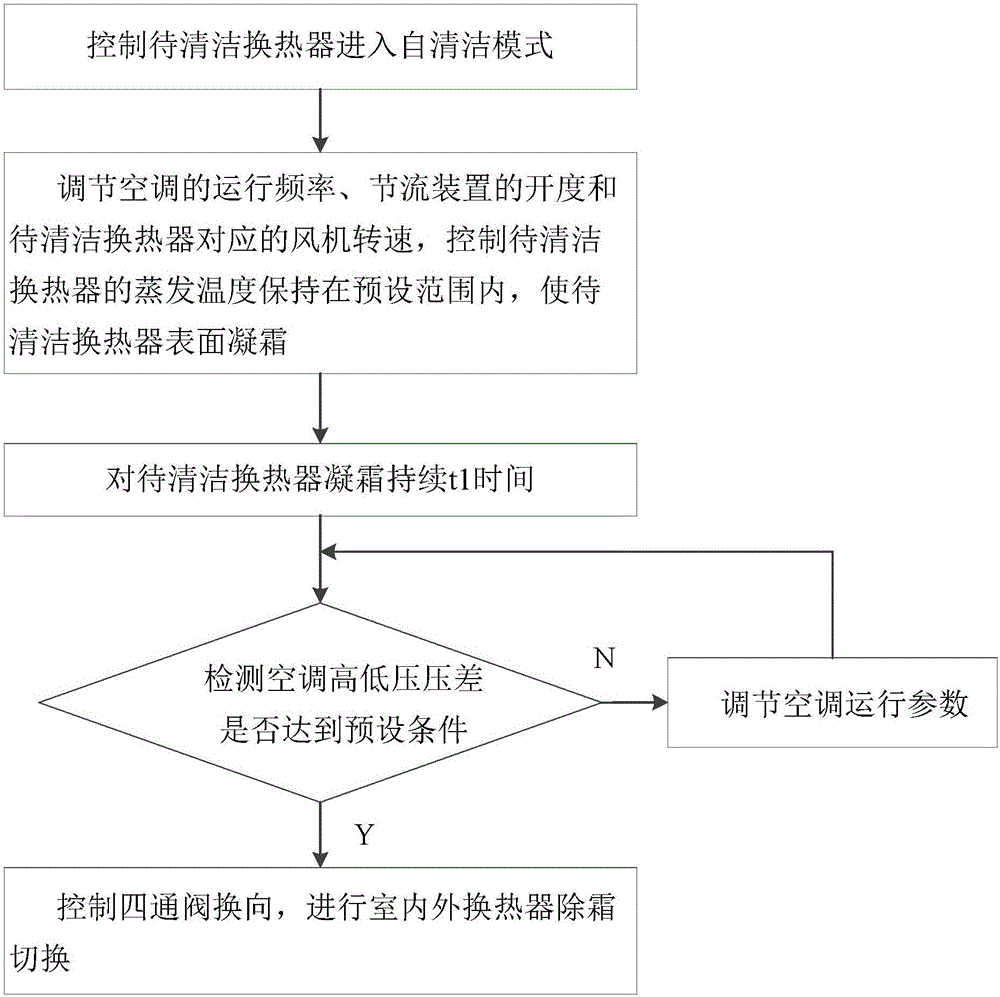

Air conditioner indoor/outdoor unit cleaning method

ActiveCN106594976AGuaranteed uptimeFrosting evenlyMechanical apparatusSpace heating and ventilation safety systemsFour-way valveEngineering

The invention discloses an air conditioner indoor / outdoor unit cleaning method. The method comprises the steps of: controlling a heat exchanger to be cleaned to enter a self-cleaning mode; adjusting the operation frequency of an air conditioner, the openness of a throttling device and the rotating speed of a fan corresponding to the heat exchanger to be cleaned, and controlling the evaporation temperature of the heat exchanger to be cleaned to keep in a preset range to condense the surface of the heat exchanger to be cleaned; condensing the heat exchanger to be cleaned by t1 time; detecting if the high / low pressure difference of the air conditioner reaches preset conditions; controlling a four-way valve to change the direction to perform the defrosting switching of indoor and outdoor heat exchangers when the high / low pressure difference of the air conditioner reaches the preset conditions; and adjusting air conditioner operation parameters when the high / low pressure difference of the air conditioner dose not reach the preset conditions, and then, controlling the four-way valve to change the direction to perform the defrosting switching of the indoor and outdoor heat exchangers when the high / low pressure difference of the air conditioner reaches the preset conditions. As the direction change of the four-way valve can be controlled through detecting if the high / low pressure difference of the air conditioner reaches the preset conditions, the higher shock on the compressor caused by excessive high / low pressure difference of the air conditioner can be prevented.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

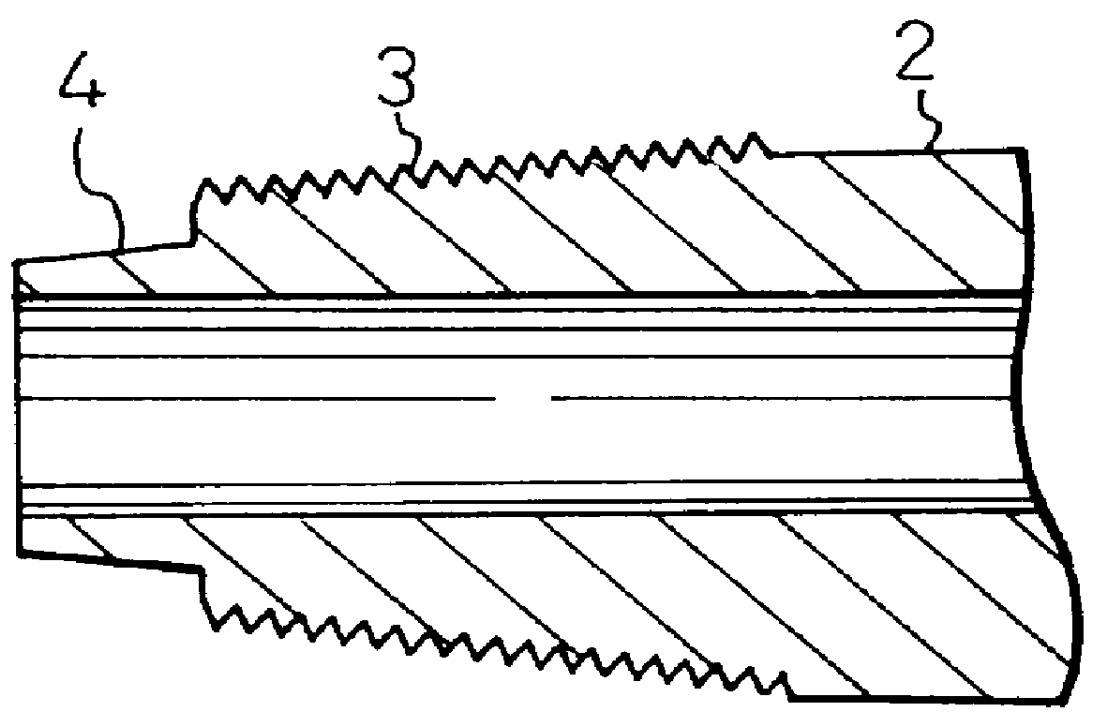

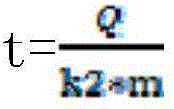

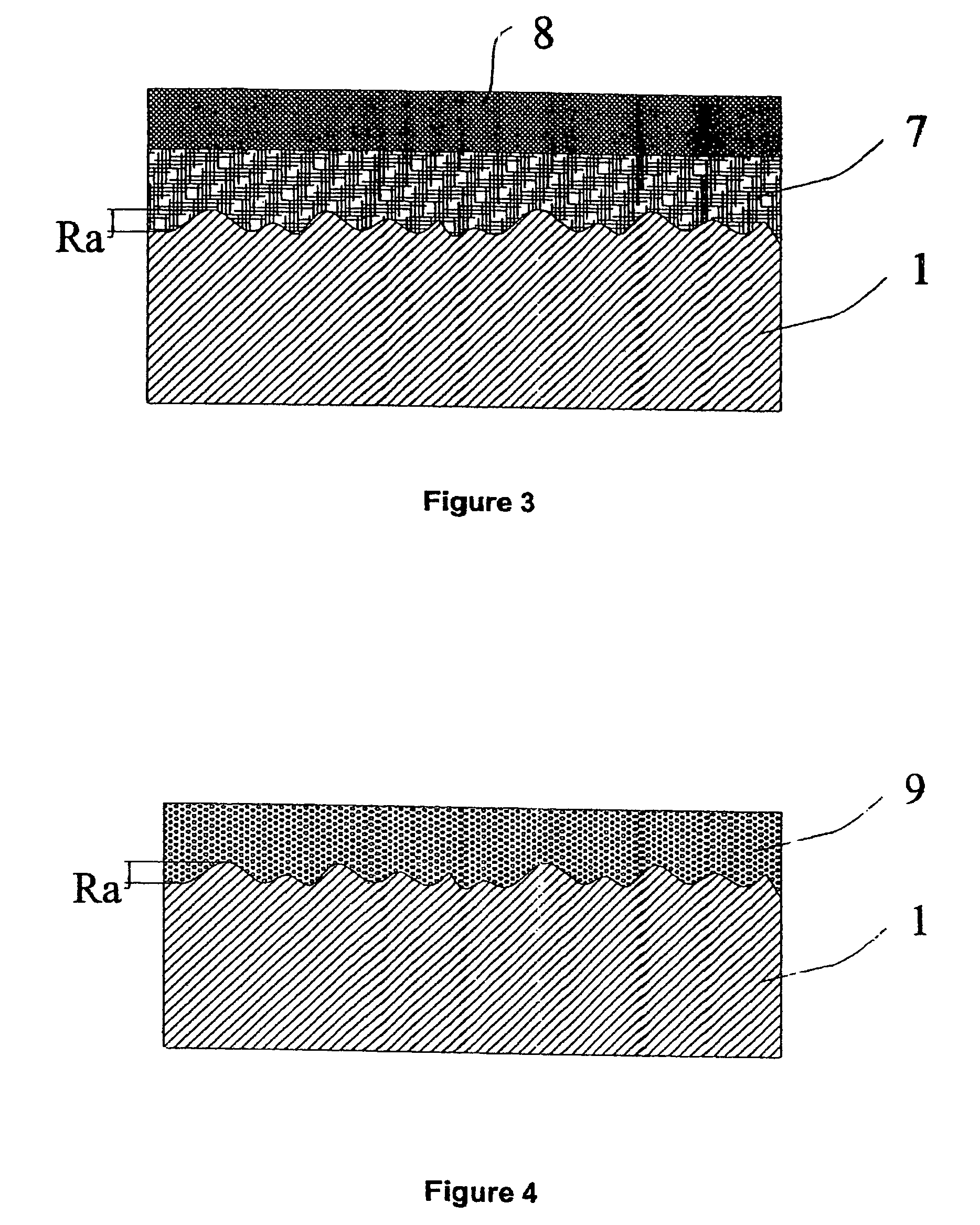

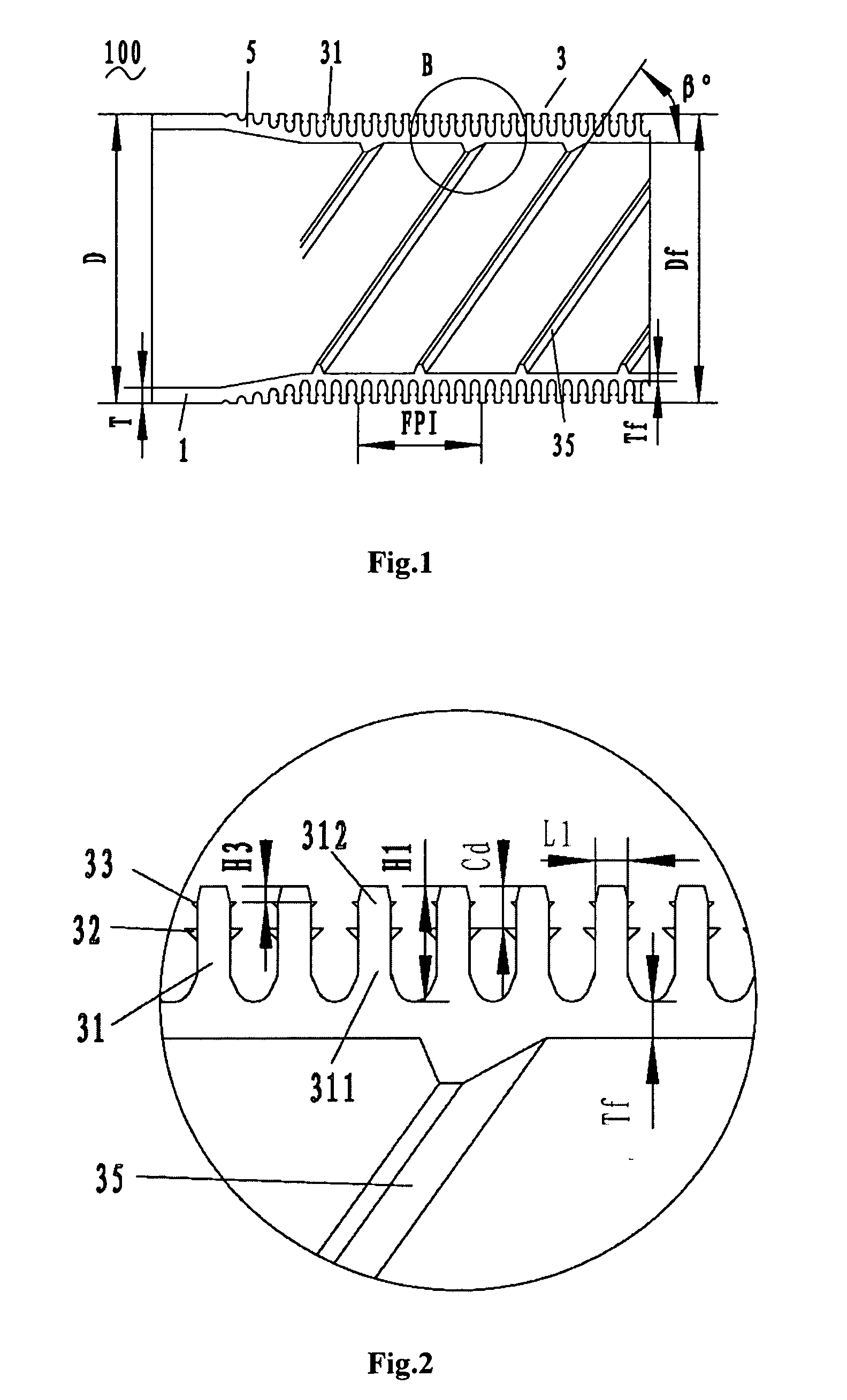

Threaded pipe with surface treatment

InactiveUS6971681B2Maintain good propertiesIncrease resistanceDrilling rodsPipe elementsThreaded pipeDry lubricant

A threaded metallic pipe for oil extraction industry has a threaded end portion with treated surface in which the metal surface has a roughness (Ra) comprised of 2.0 μm and 6.0 μm, which is covered by a uniform layer (7) of a dry corrosion inhibiting coating and a second uniform layer (8) of dry lubricant coating. Alternatively the layers (8, 9) combined into one uniform layer (9) of a dry corrosion inhibiting coating containing a dispersion of particles of solid lubricant.

Owner:TENARIS CONNECTIONS

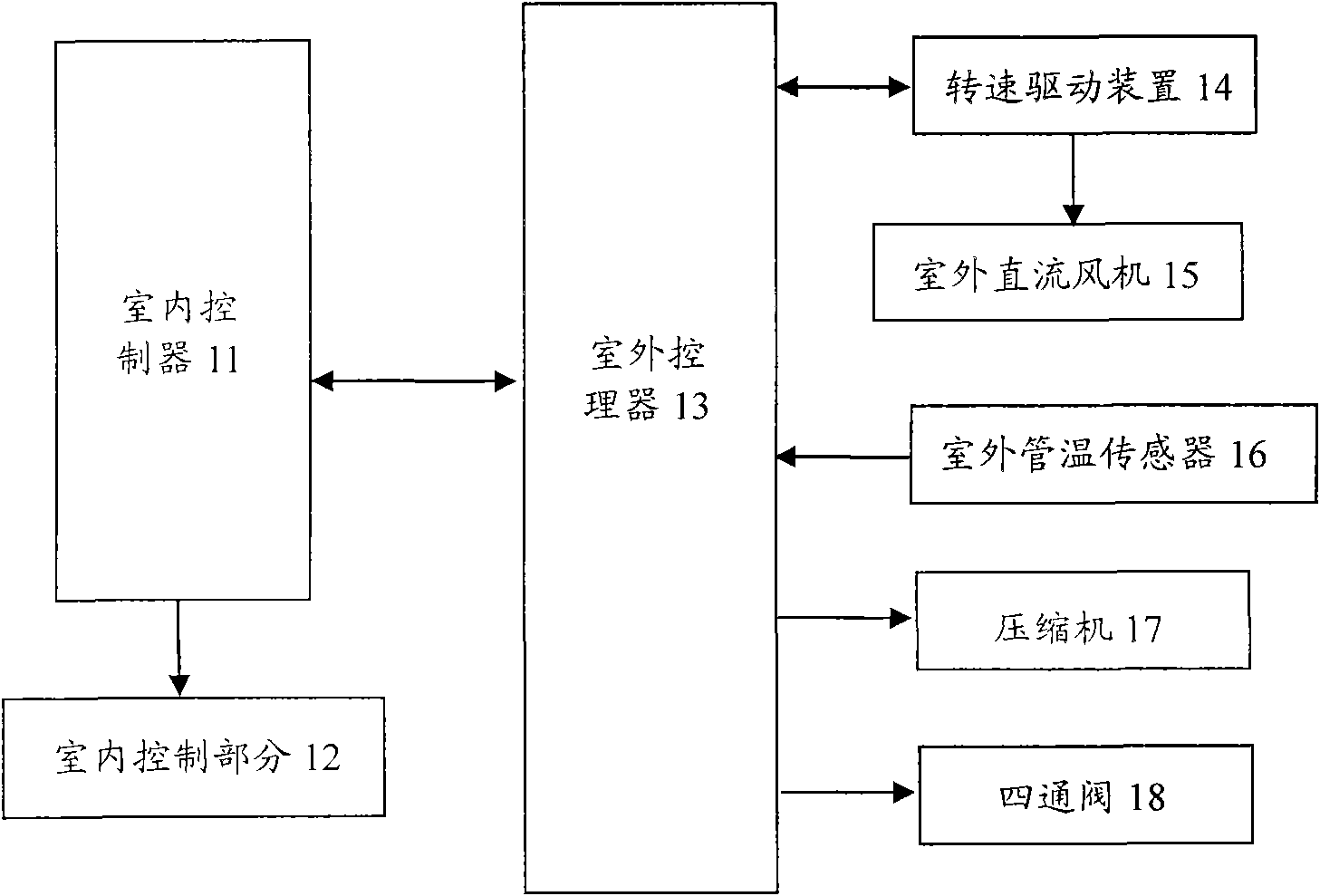

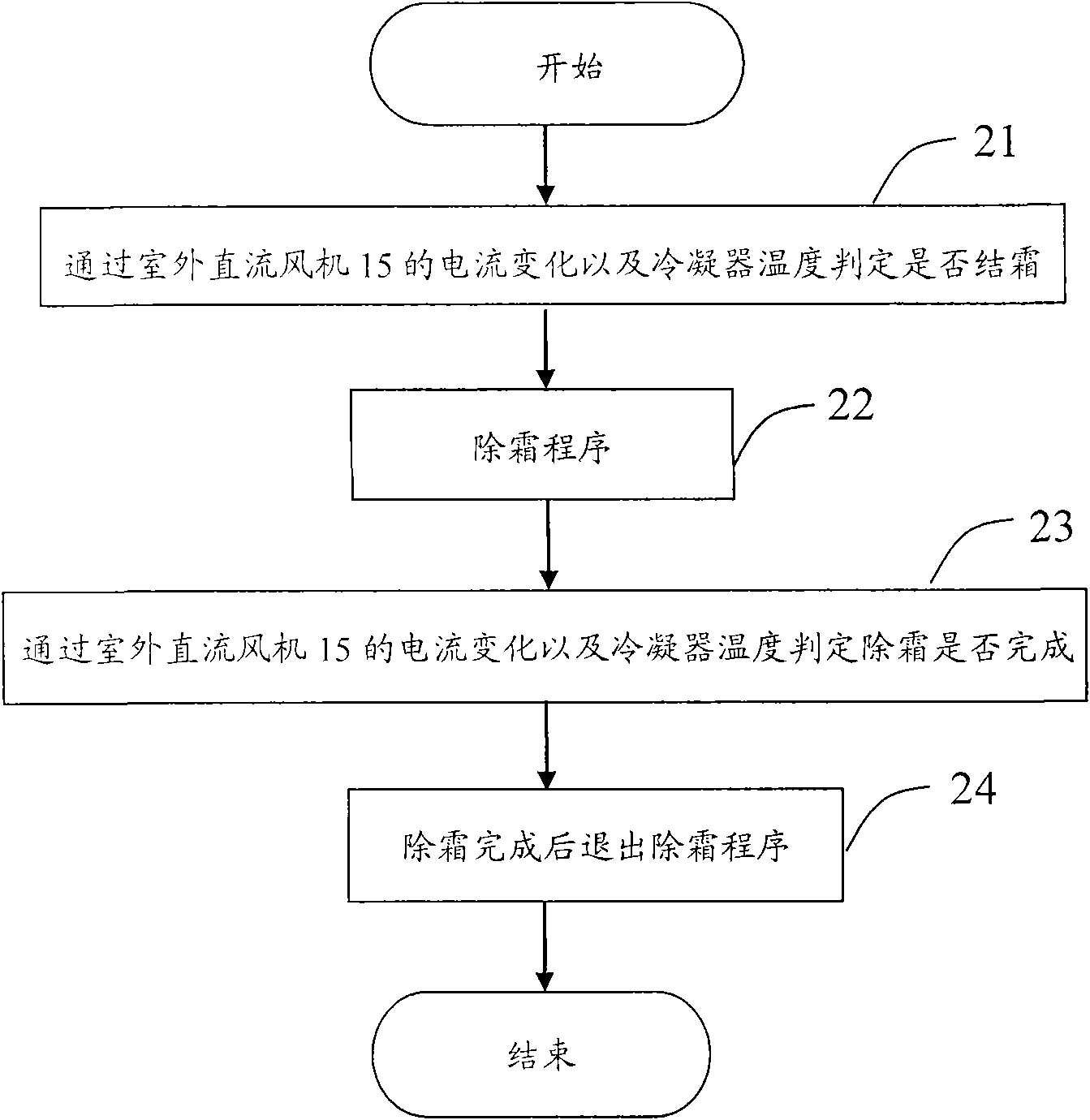

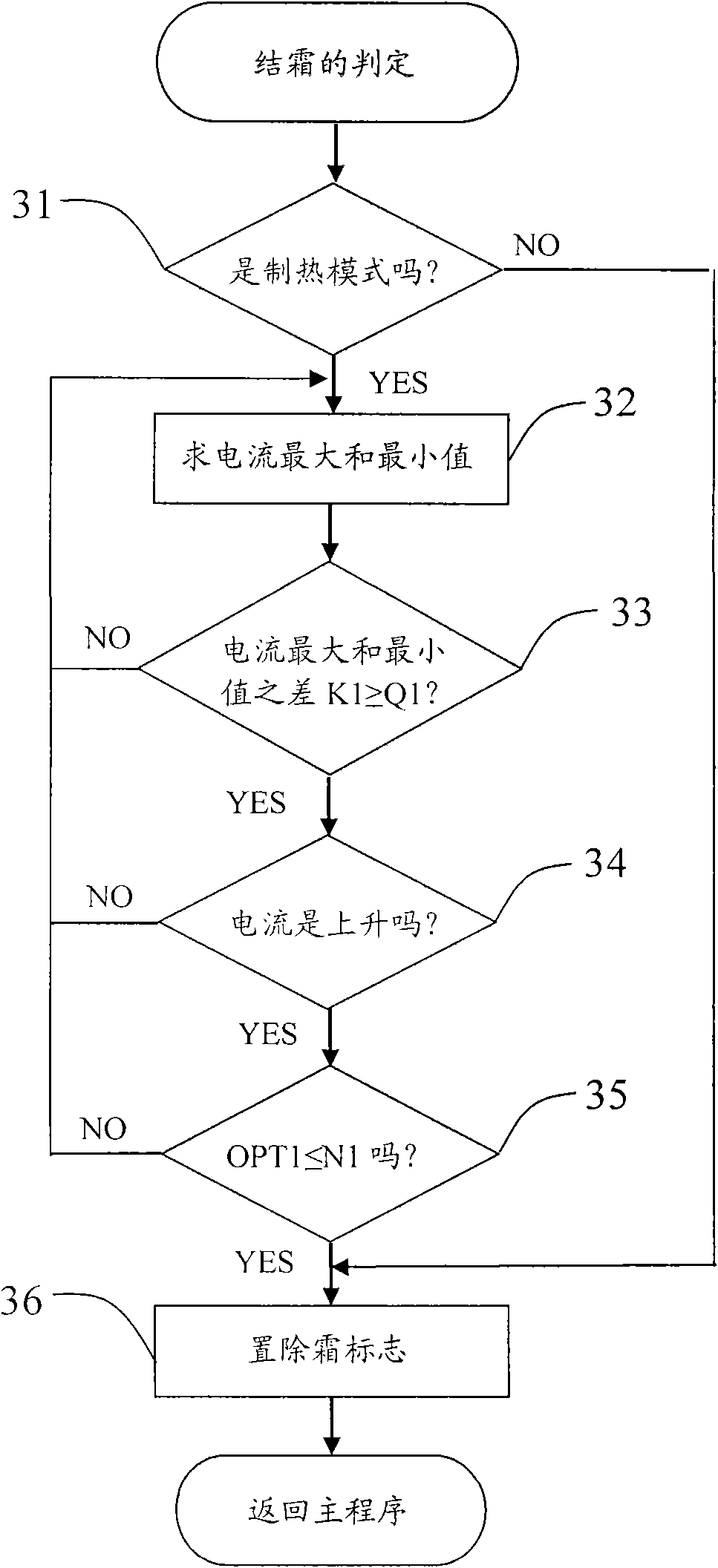

Air conditioner and frost removal control method thereof

InactiveCN101660808AAccurate and smart defrostingThermometers using value differencesCurrent/voltage measurementFrostPower flow

The invention provides an air conditioner and a frost removal control method of the air conditioner. The air conditioner comprises a controller, an outdoor direct current fan, a condenser and a current detecting unit which detects the current changes of the outdoor direct current fan and feeds the detection result back to the controller. The frost removal control method of the air conditioner comprises the following steps: a, judging whether the air conditioner is frosted through the current changes of the outdoor direct current fan and the temperature of the condenser; and b, judging whetherthe frost removal is finished through the current changes of the outdoor direct current fan and the temperature of the condenser. The conditioner and the frost removal control method of the air conditioner can judge whether the condenser of the air conditioner is frosted and whether the frost removal is finished together by combining the temperature of the condenser with the current changes of theoutdoor direct current fan, and have the advantage of accurate and intelligent frost removal.

Owner:TCL CORPORATION

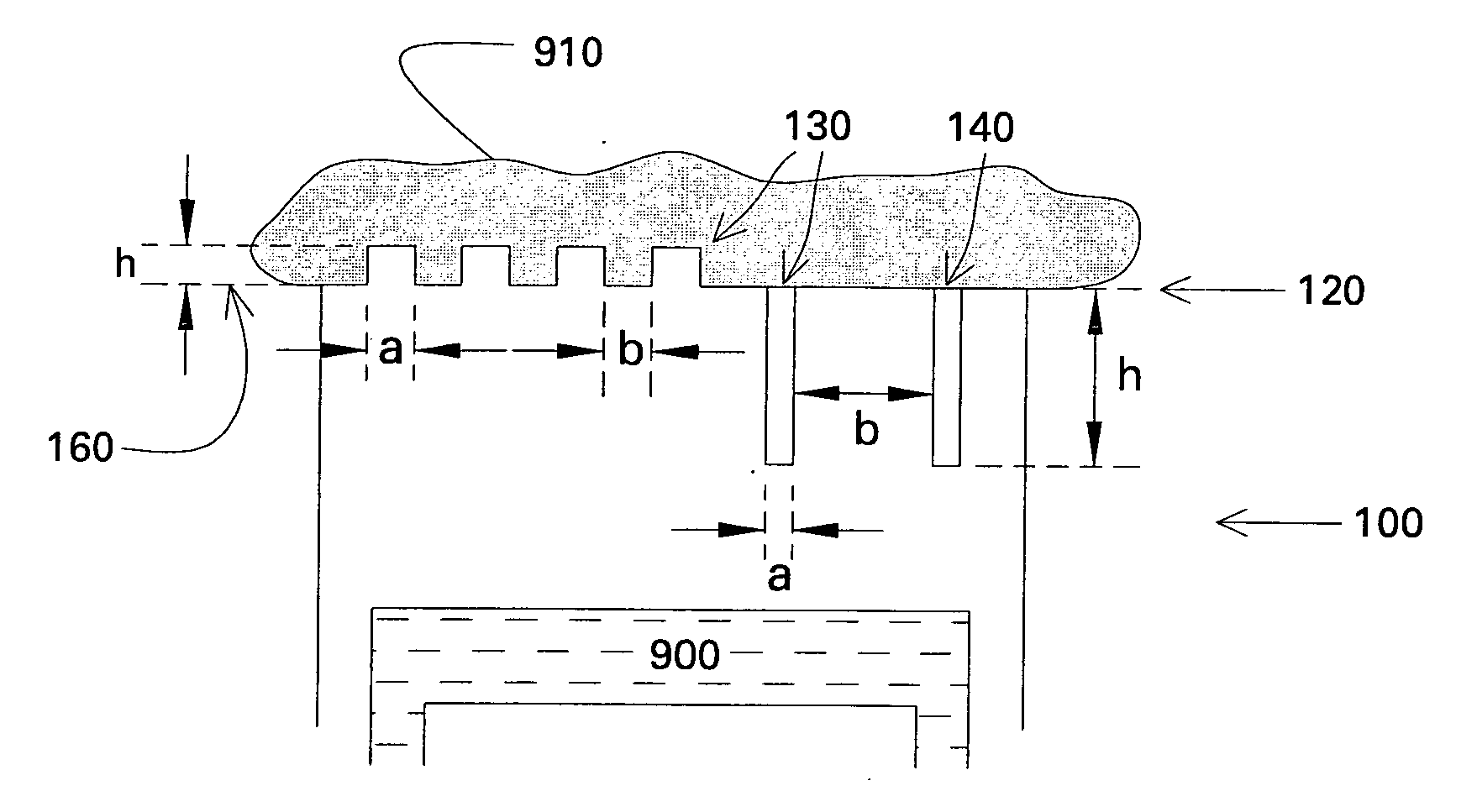

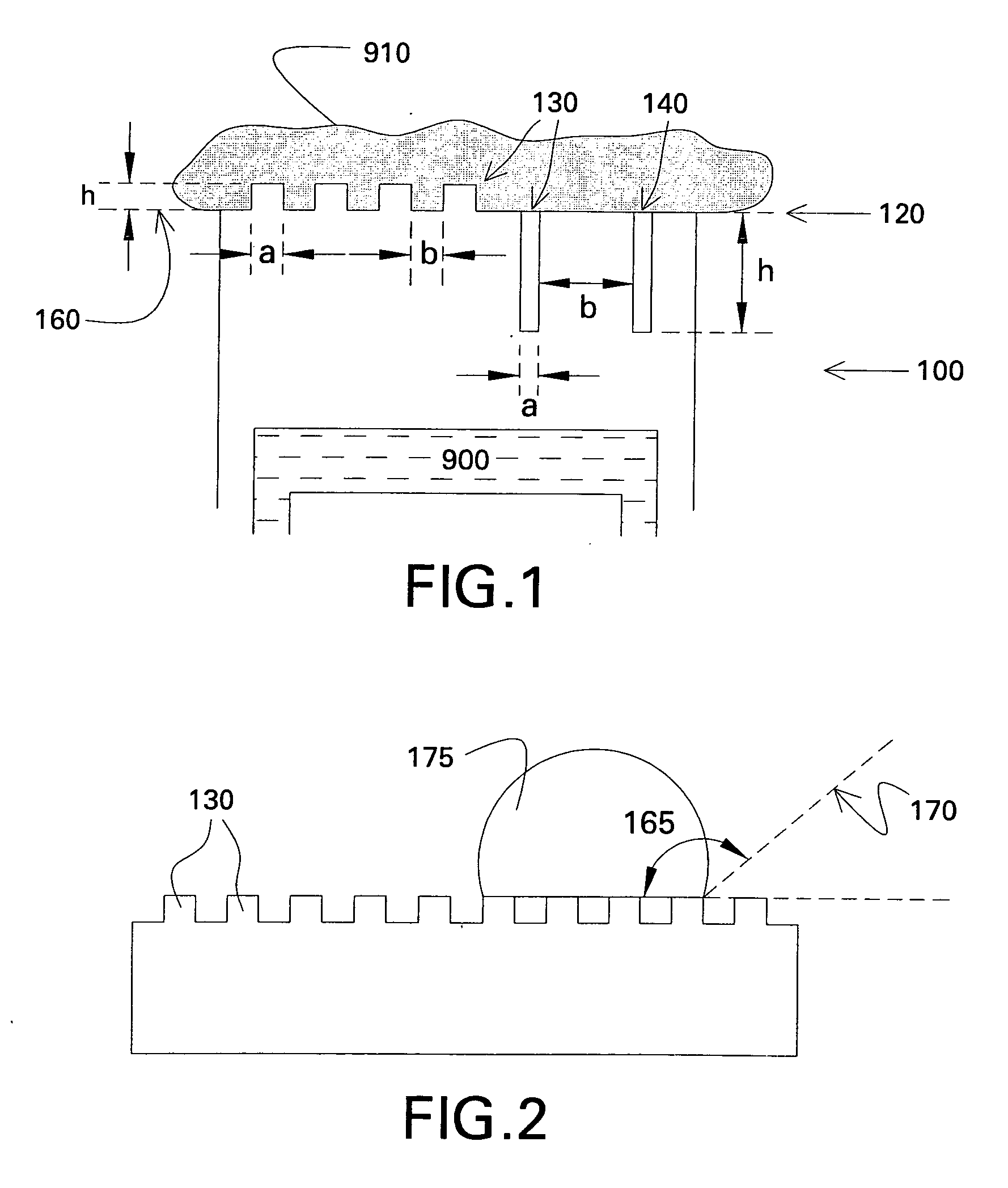

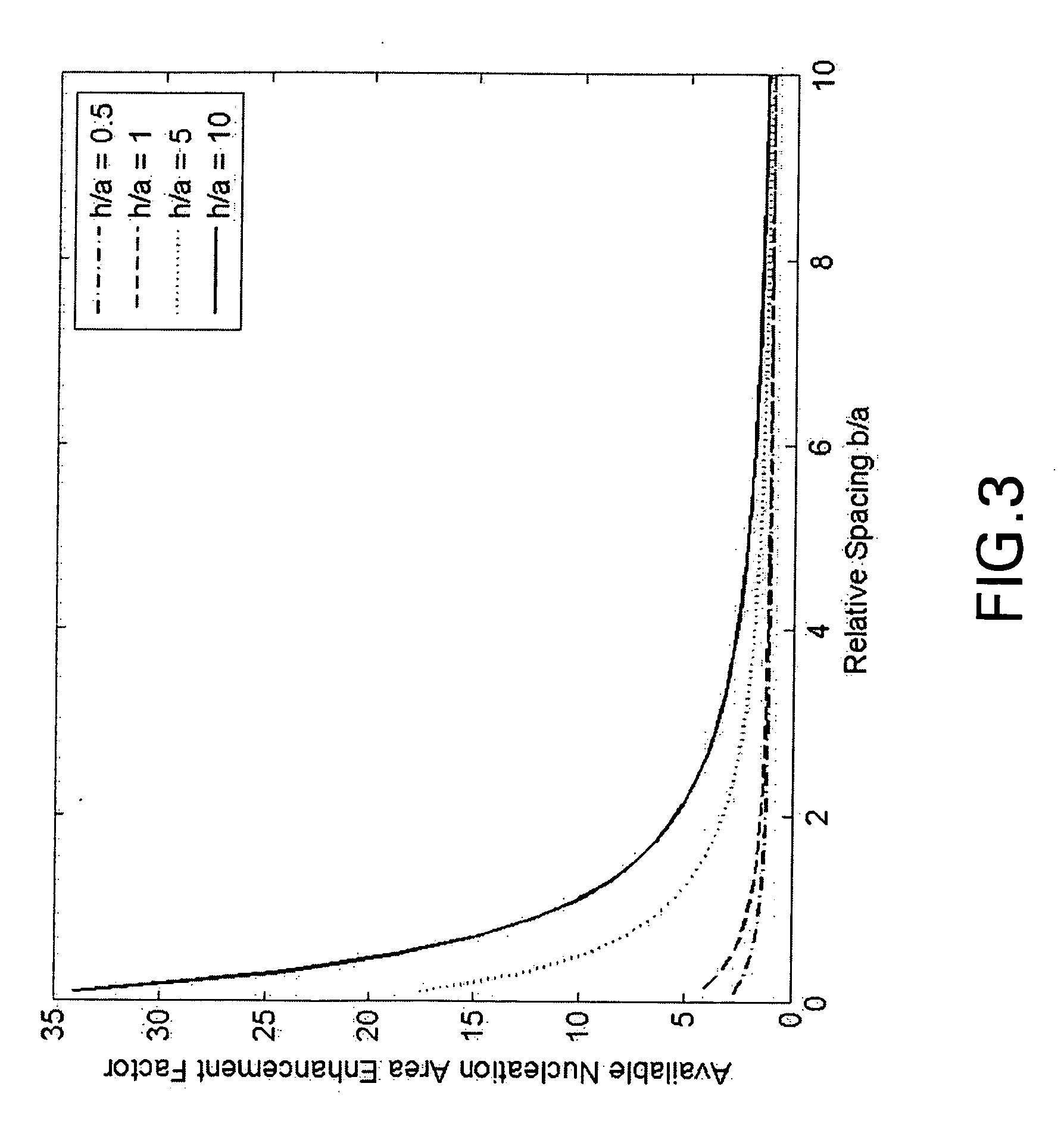

Heat transfer apparatus and systems including the apparatus

InactiveUS20070028588A1Promote and stabilize dropwise condensationGas turbine plantsCorrosion preventionDistillationEngineering

An apparatus for the transfer of heat is presented. The apparatus comprises a textured heat transfer surface disposed to promote condensation of a vapor medium to a liquid condensate, the surface comprising a plurality of surface texture features disposed on the heat transfer surface. The plurality of features has a median size, a median spacing, and a median height displacement such that the force exerted by the surface to pin a drop of condensate to the surface is equal to or less than an external force acting to remove the drop from the surface. Also included are heat pumps, systems for power generation, and distillation systems comprising the apparatus.

Owner:GENERAL ELECTRIC CO

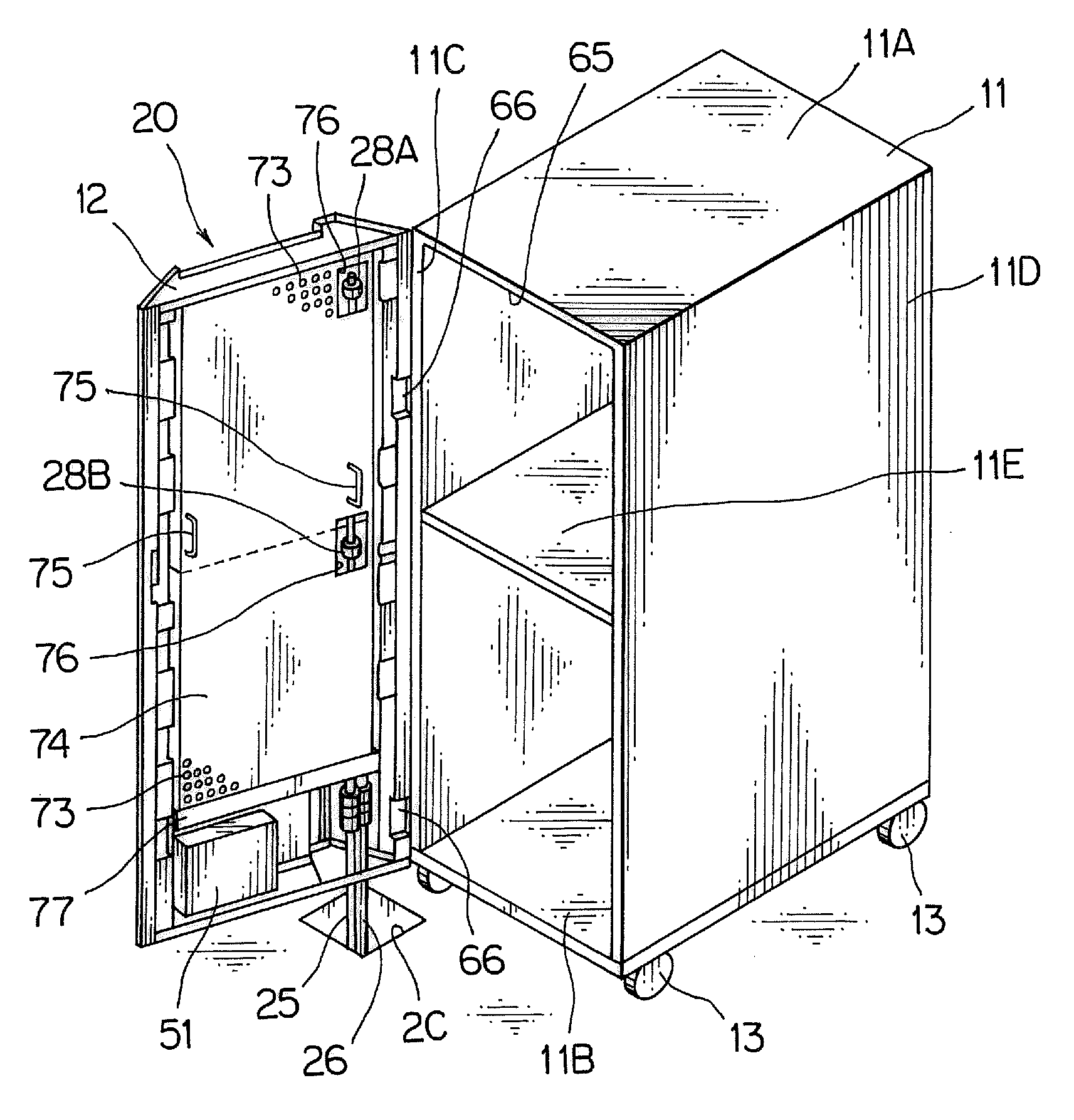

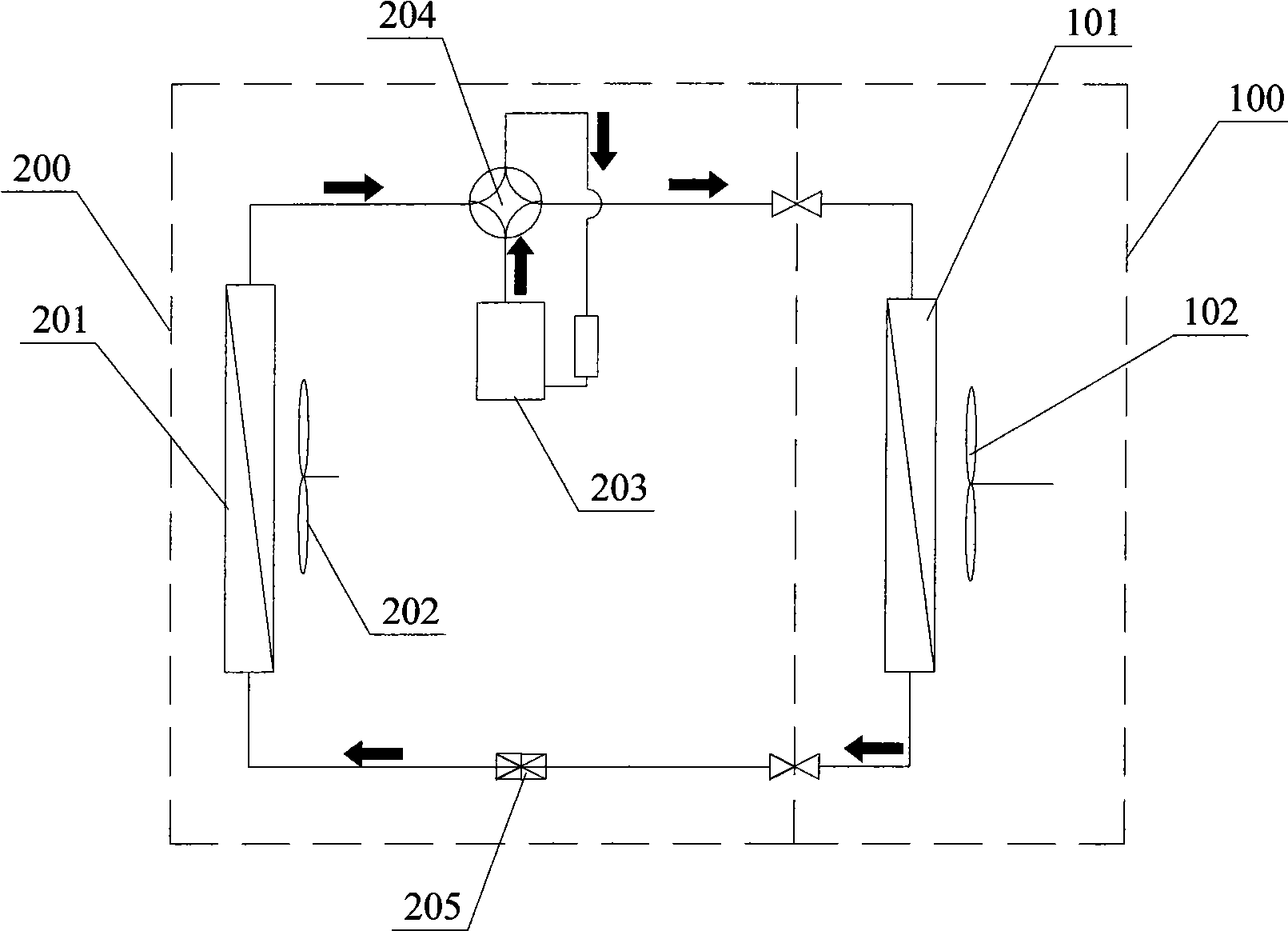

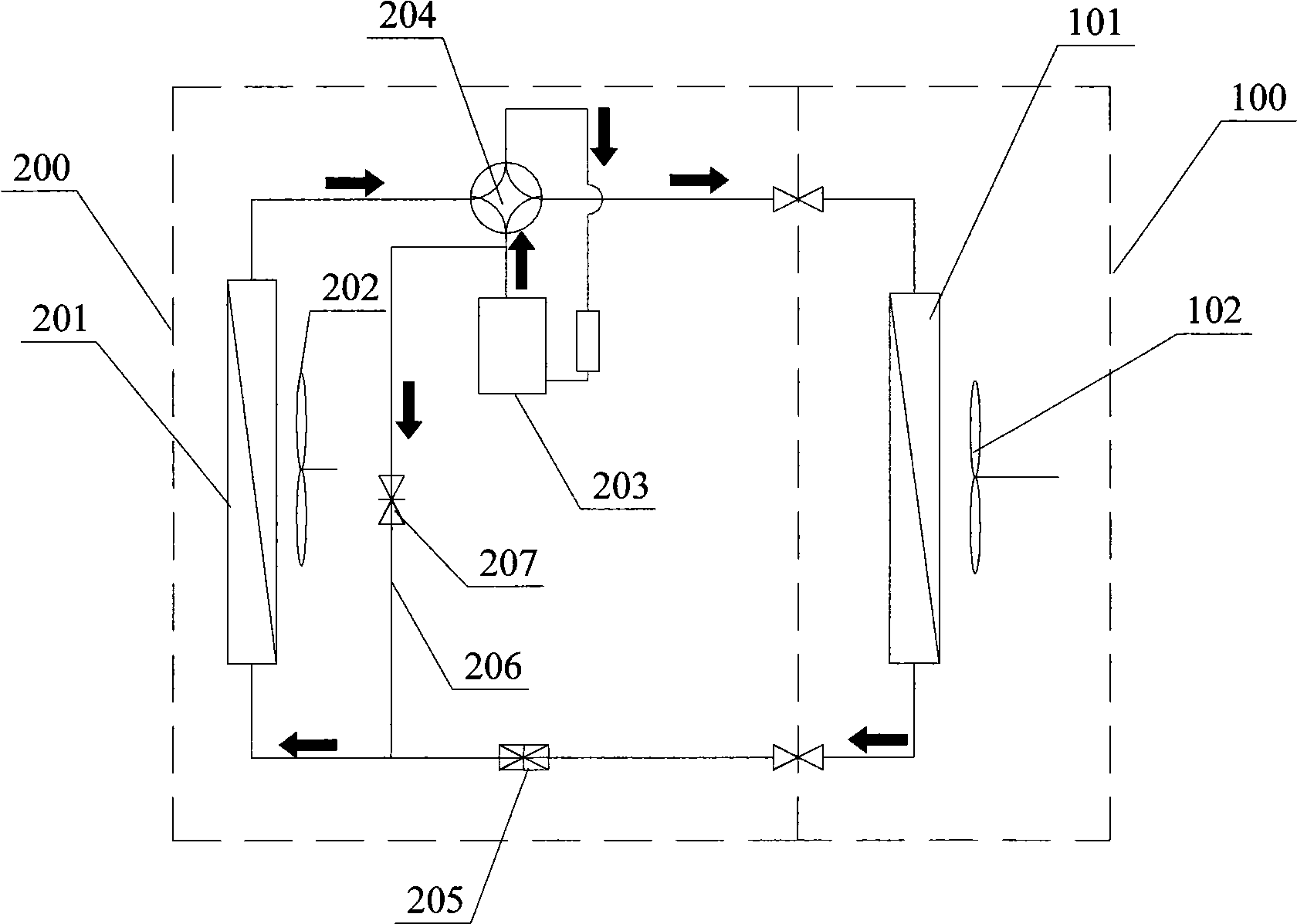

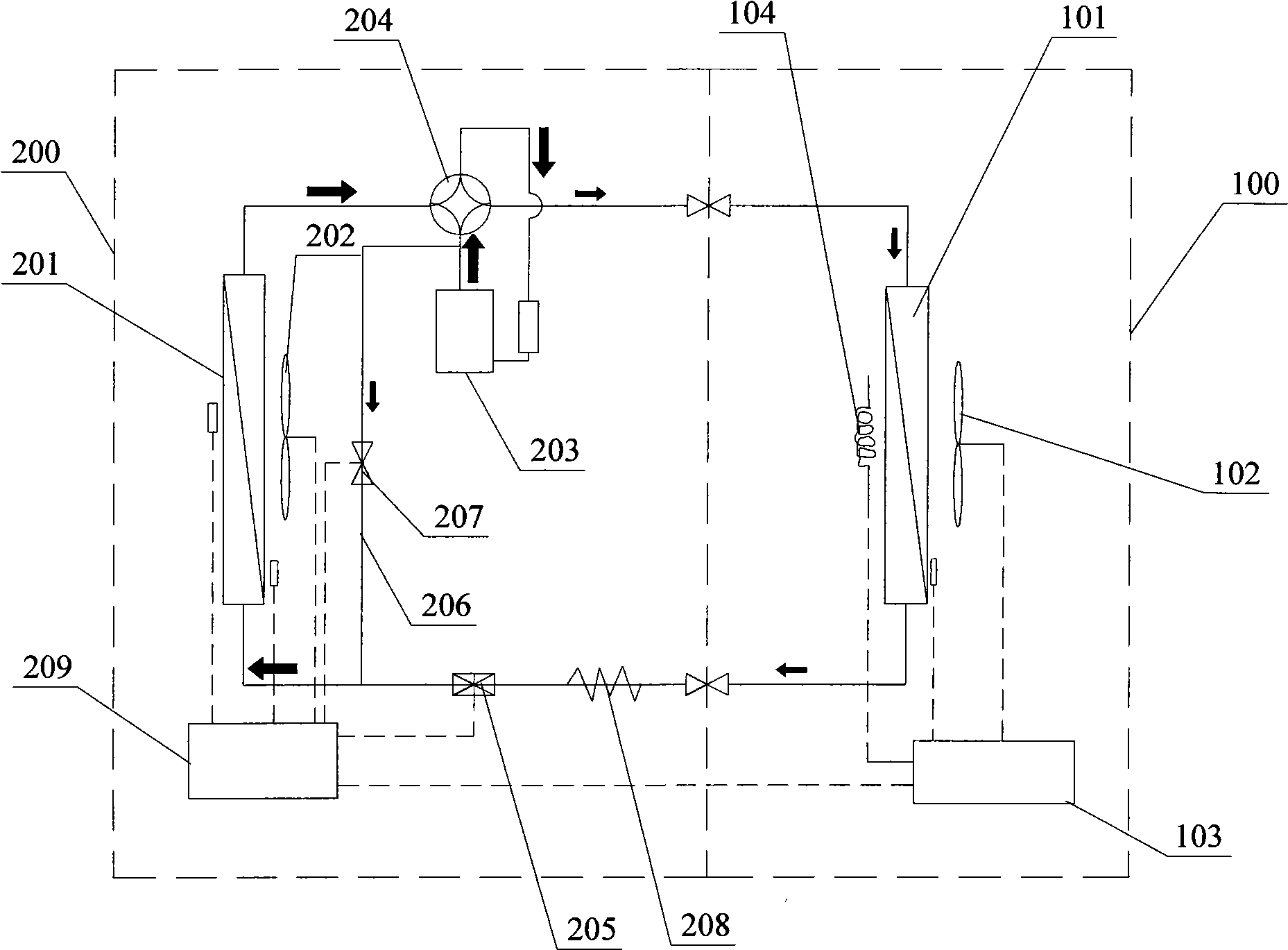

Electronic device cooling system and electronic device cooling apparatus

InactiveUS20090100848A1Avoid condensationEasy constructionCompression machines with non-reversible cycleEvaporators/condensersElectronics coolingRefrigerant

An electronic cooling apparatus has a cabinet which is open at the front and rear sides thereof and accommodates plural electronic devices each having a fan, and a rear door which is provided with an evaporator. Air blown by the fan is cooled by the evaporator and then returned to a room. An expansion valve and control. A drain pan with an extension portion having hole portions through which refrigerant pipes extend is provided. A drain hose discharges drain water from the drain pan. An exhaust heat temperature detecting unit and a control for controlling the refrigerant supply to the evaporator are provided. When the exhaust heat temperature is equal to or less than a set exhaust temperature, the controller stops the refrigerant supply to the evaporator. When the exhaust heat temperature exceeds the set temperature, the controller starts the refrigerant supply.

Owner:SANYO ELECTRIC CO LTD

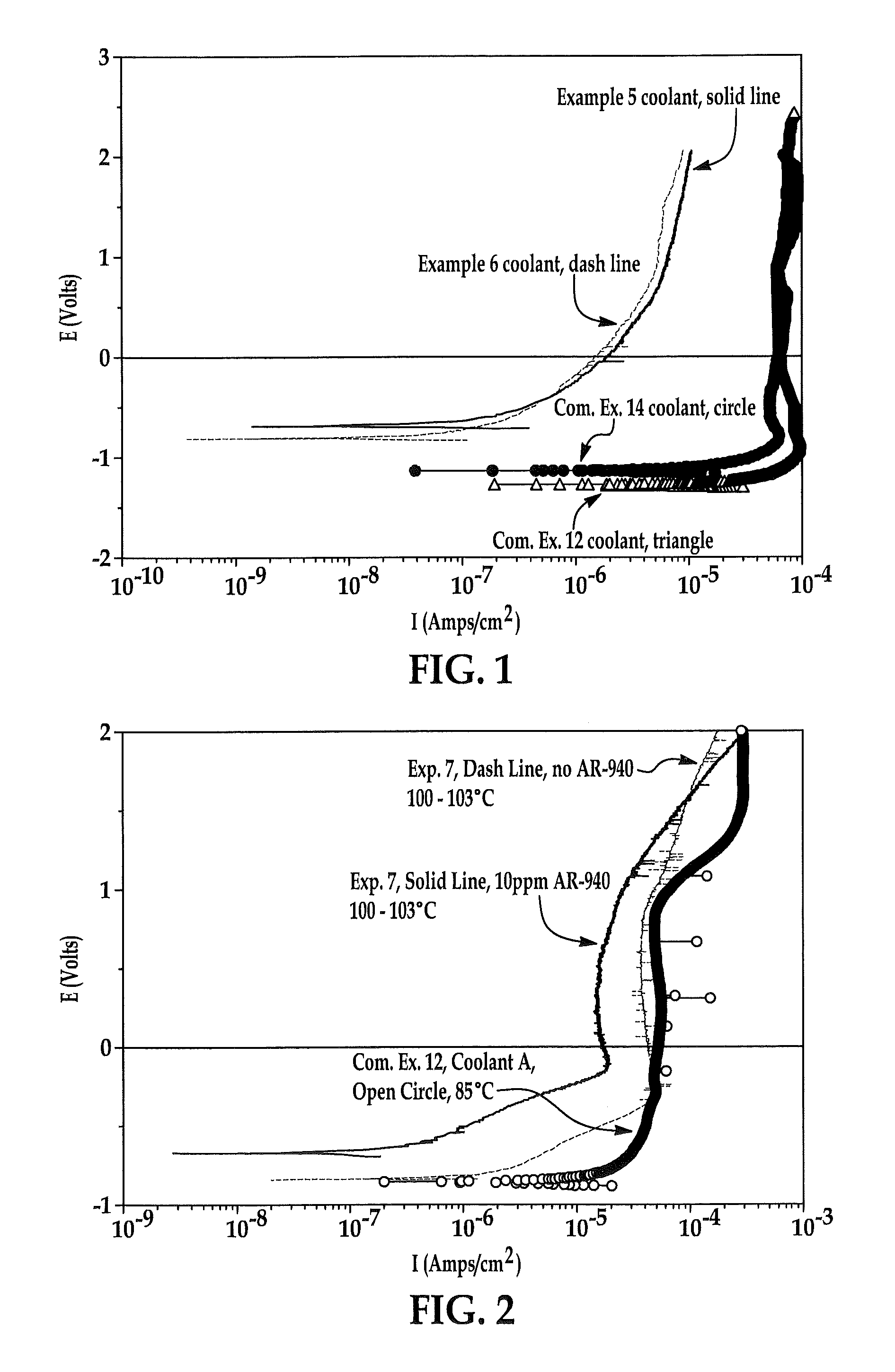

Heat transfer fluids and corrosion inhibitor formulations for use thereof

ActiveUS20100116473A1Corrosion protection is enhancedImprove anti-corrosion performanceLiquid coolingCorrosion preventionIonMagnesium

Disclosed herein is a heat transfer fluid comprises: a freezing point-depressant; an aliphatic carboxylic acid, a salt thereof, or a combination of the foregoing; an inorganic phosphate; a magnesium compound; deionized water; and a component selected from the group consisting of azole compounds, copper alloy corrosion inhibitors, phosphonocarboxylates, phosphinocarboxylates, and combinations of two or more of the foregoing components. Also described is a heat transfer system comprising the heat transfer fluid.

Owner:PRESTONE PROD CORP

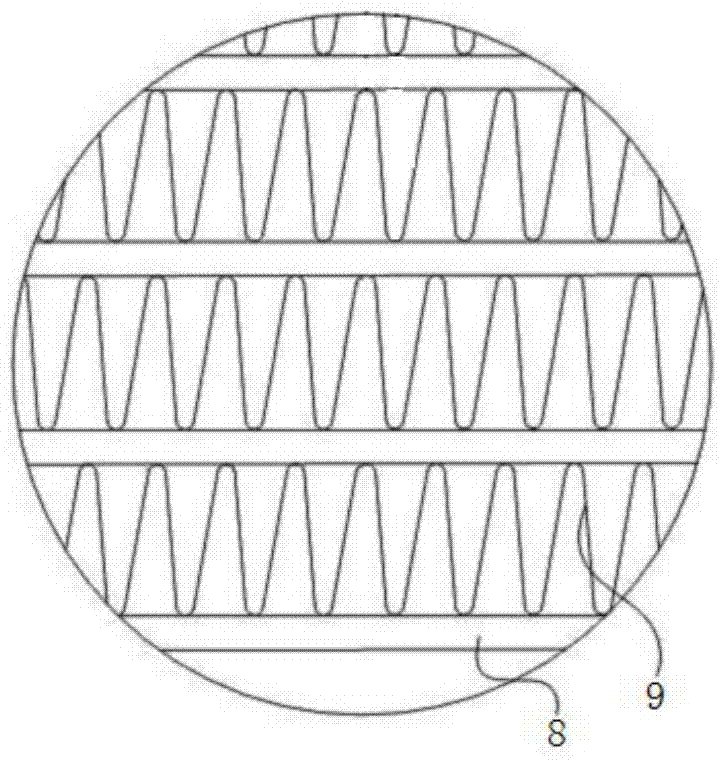

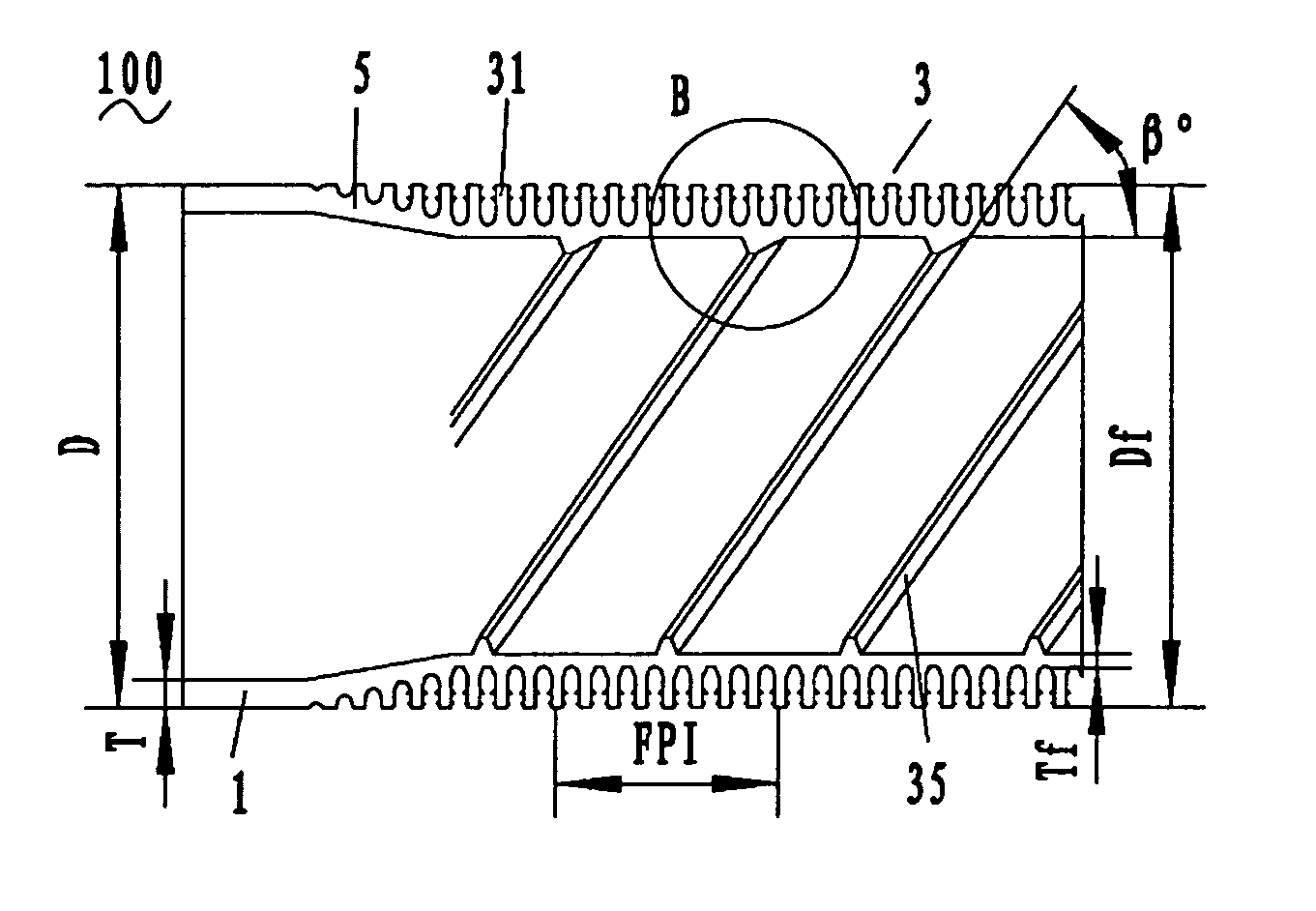

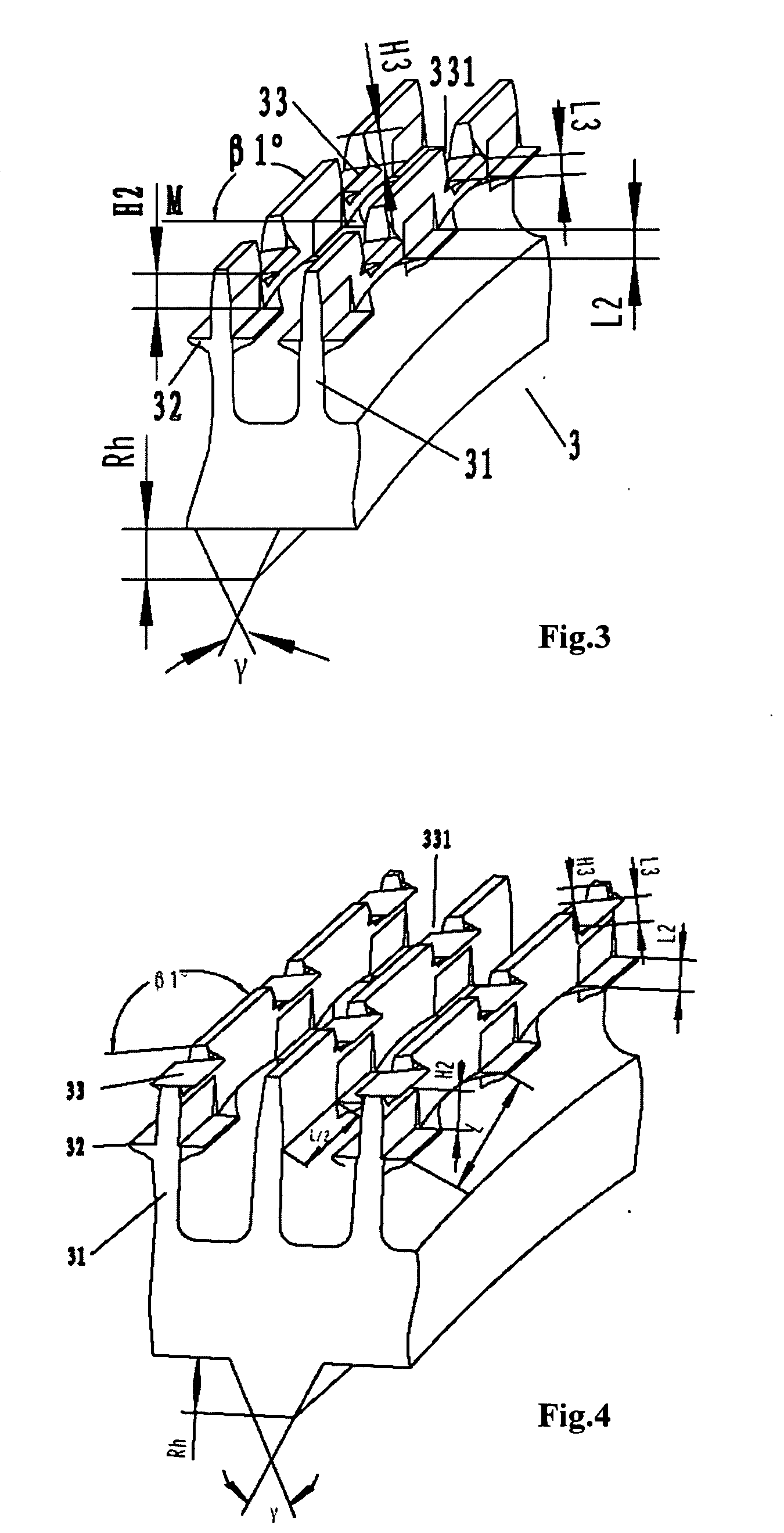

Condensing heat-exchange copper tube for an flooded type electrical refrigeration unit

ActiveUS20070131396A1Large heat transfer coefficientImprove heat transfer efficiencyEvaporators/condensersCorrosion preventionElectricityHeat resistance

The present invention discloses a condensing heat-exchange copper tube for a flooded type electrical refrigeration unit, which comprises a smooth surface portion, a finned portion provided with plurality of fins and a transitional portion connecting the smooth surface portion to the finned portion. Said fin includes a fin base close to the outer surface of the heat-exchange tube and a fin top away from the outer surface. Said fin is further provided with a secondary fin at the central portion of the fin and a third fin at the top portion of the fin, wherein a certain distance is provided between two axially adjacent secondary fins or two axially adjacent third fins. Secondary fins as well as third fins according to the invention further increase the heat transfer area for the heat-exchange tube. Meanwhile, secondary fins and third fins help to attenuate the condensate film such that the condensate film is substantially eliminated, and vapor condensation and heat transfer may be carried out in a better way. At the same time, secondary fins and third fins help to guide the condensate film away from the surface of the heat-exchange tube such that heat resistance may be reduced. Thus, the overall efficiency of heat transfer through condensation is enhanced, and the property of the condenser is improved.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

Desiccant air conditioning methods and systems using evaporative chiller

Methods and systems are provided for air conditioning, capturing combustion contaminants, desalination, and other processes using liquid desiccants.

Owner:COPELAND LP

Cold and warm type frequency conversion air conditioner and defrosting method thereof

ActiveCN101532705AGuaranteed comfortPrevent indoor temperature from droppingCorrosion preventionCompression machines with reversible cycleType frequencyFour-way valve

The invention discloses a cold and warm type frequency conversion air conditioner and a defrosting method thereof. The air conditioner comprises an indoor machine and an outdoor machine, wherein the outdoor machine is provided with a frequency conversion compressor, a four-way valve, a throttling element and an outdoor heat exchanger which are communicated through a connecting pipeline, and the connecting pipeline of the outdoor machine is also provided with a by-pass loop; and the indoor machine is internally provided with an electric heating device which is at least turned on to operate in the defrosting process of the air conditioner. The defrosting method for the air conditioner comprises that when a defrosting condition is reached, the electric heating device is turned on, and a by-pass defrosting process is carried out by the by-pass loop. The air conditioner and the defrosting method not only can guarantee the using comfort of users, but also can improve the defrosting efficiency of the air conditioner, and cannot influence the using reliability of the frequency conversion compressor of the air conditioner.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com