Patents

Literature

51 results about "Metal dusting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal dusting is "a catastrophic form of corrosion that occurs when susceptible materials are exposed to environments with high carbon activities." The corrosion manifests itself as a break-up of bulk metal to metal powder. The suspected mechanism is firstly the deposition of a graphite layer on the surface of the metal, usually from carbon monoxide (CO) in the vapour phase. This graphite layer is then thought to form metastable M₃C species (where M is the metal), which migrate away from the metal surface. However, in some regimes no M₃C species are observed indicating a direct transfer of metal atoms into the graphite layer.

Metal material having good resistance to metal dusting

InactiveUS6623869B1Excellent in metal dusting resistanceIncreased durabilityChemical industryCorrosion preventionMetal dustingMetallic materials

A metallic material of the invention which comprises, in mass %, C: not more than 0.2%, Si: 0.01-4%, Mn: 0.05-2%, P: not more than 0.04%, S: not more than 0.015%, Cr: 10-35%, Ni: 30-78%, Al: not less than 0.005% but less than 4.5%, N: 0.005-0.2%, and one or both of Cu: 0.015-3% and Co: 0.015-3%, with the balance substantially being Fe, and of which the value of 40Si+Ni+5Al+40N+10 (Cu+Co), wherein the symbols of elements represent the contents of the respective elements, is not less than 50 and has excellent corrosion resistance in an environment in which metal dusting is ready to occur and, therefore, can be utilized as or in heating furnace pipes, piping systems, heat exchanger pipes and so forth to be used in a petroleum refinery or in petrochemical plants, and can markedly improve the equipment durability and safety.

Owner:NIPPON STEEL CORP

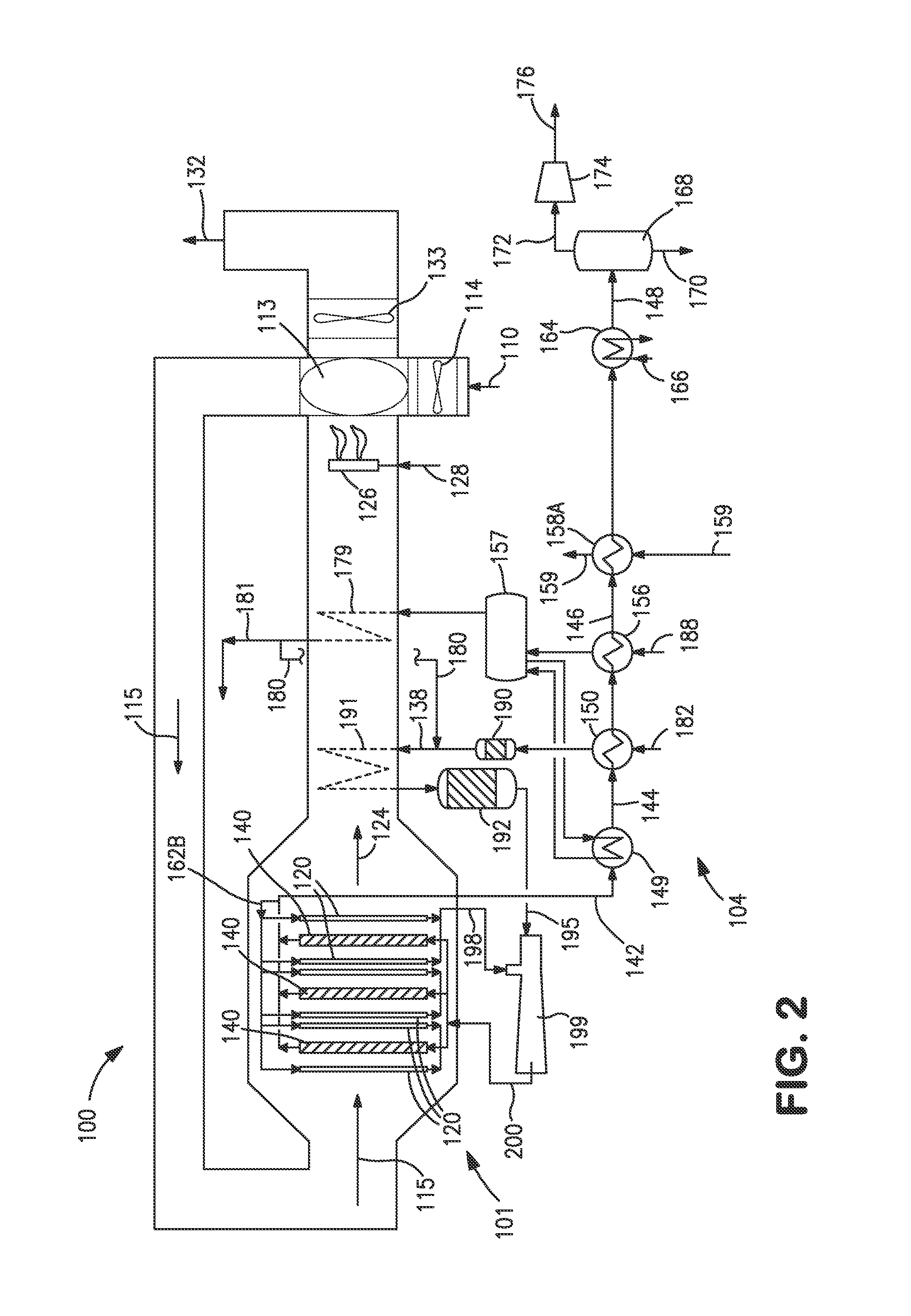

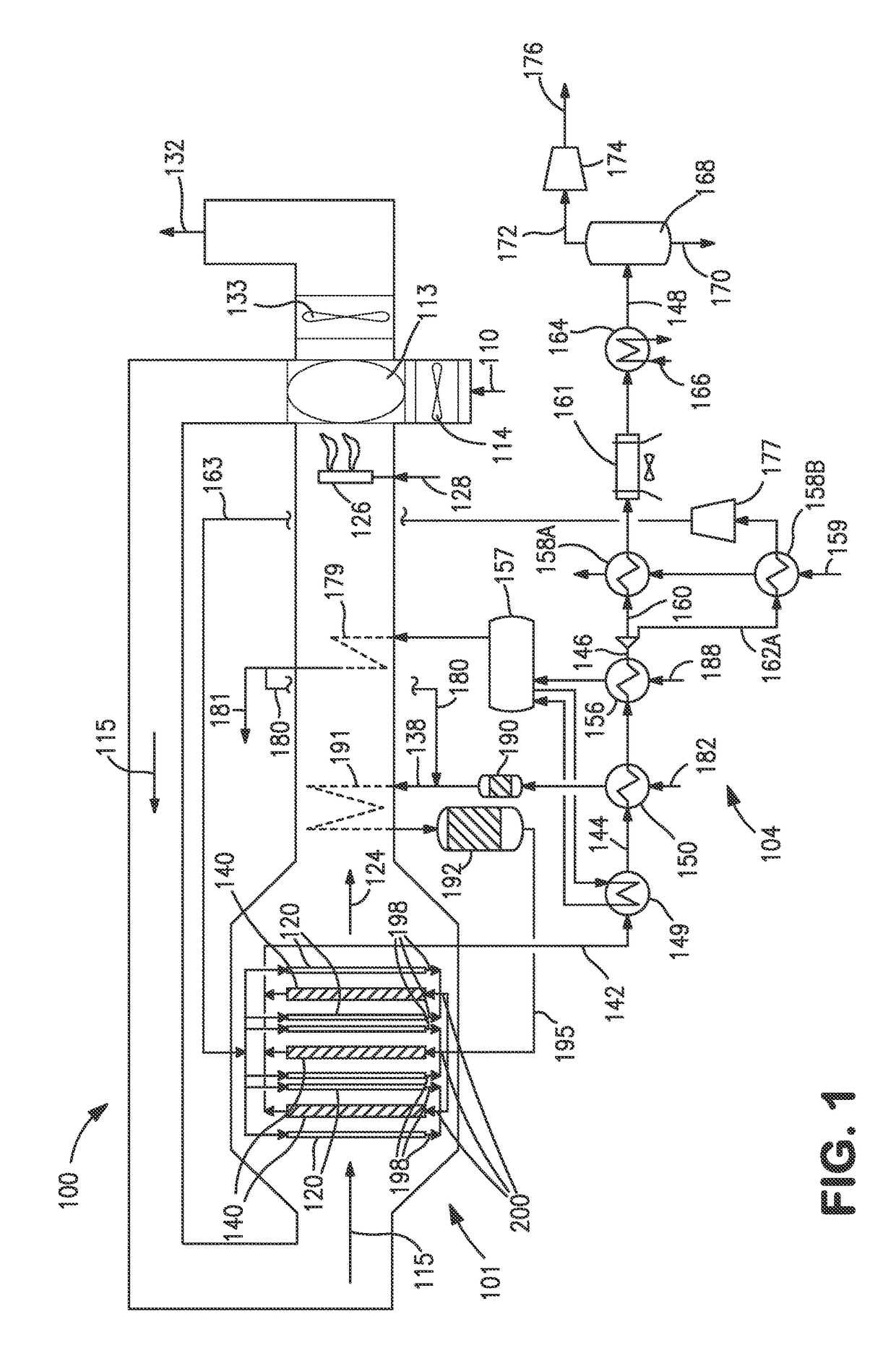

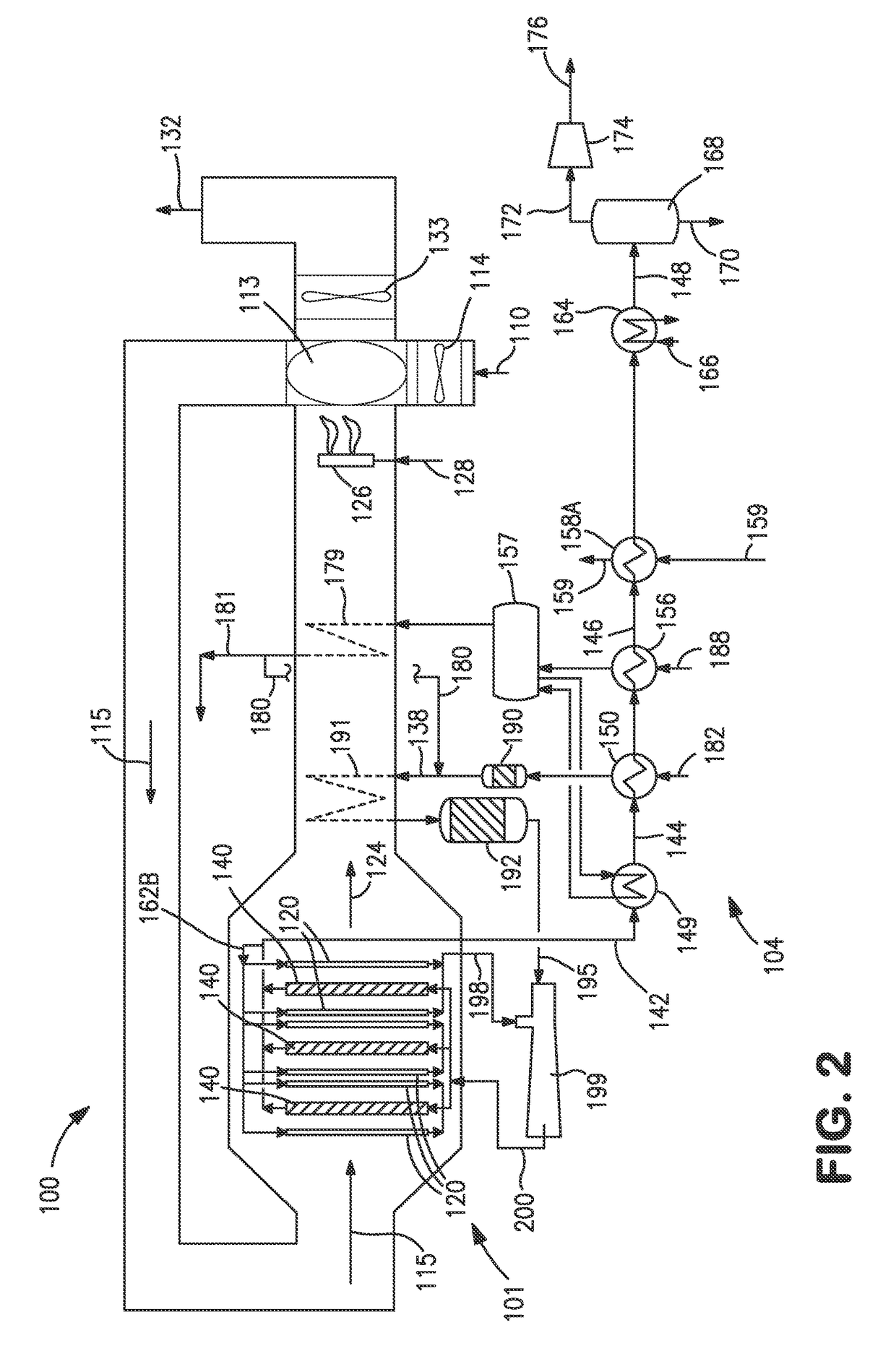

Reforming apparatus and method

ActiveUS20080244975A1Avoid adjustmentMultiple metal hydridesHigh temperature gas-gas reactionSyngasMetal dusting

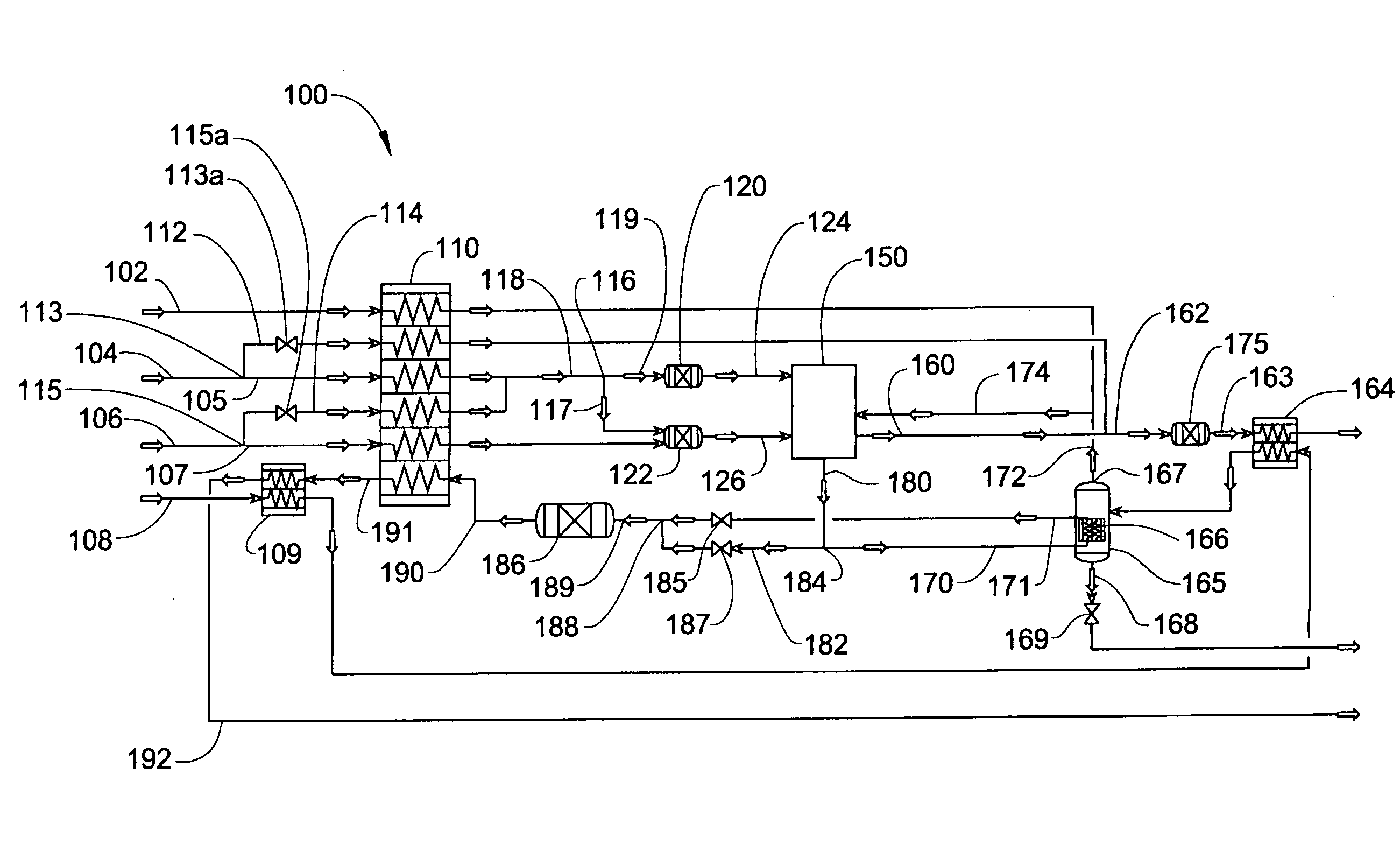

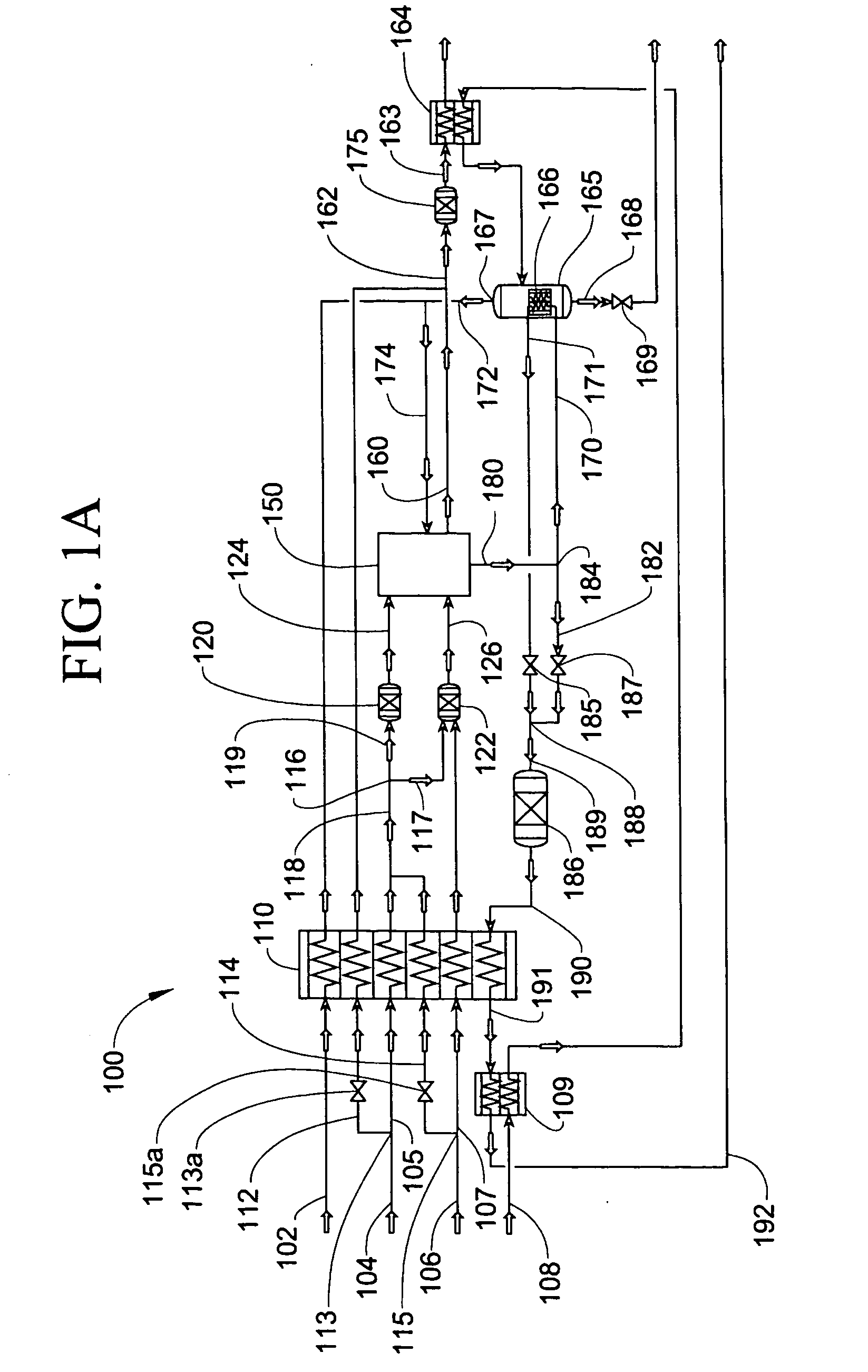

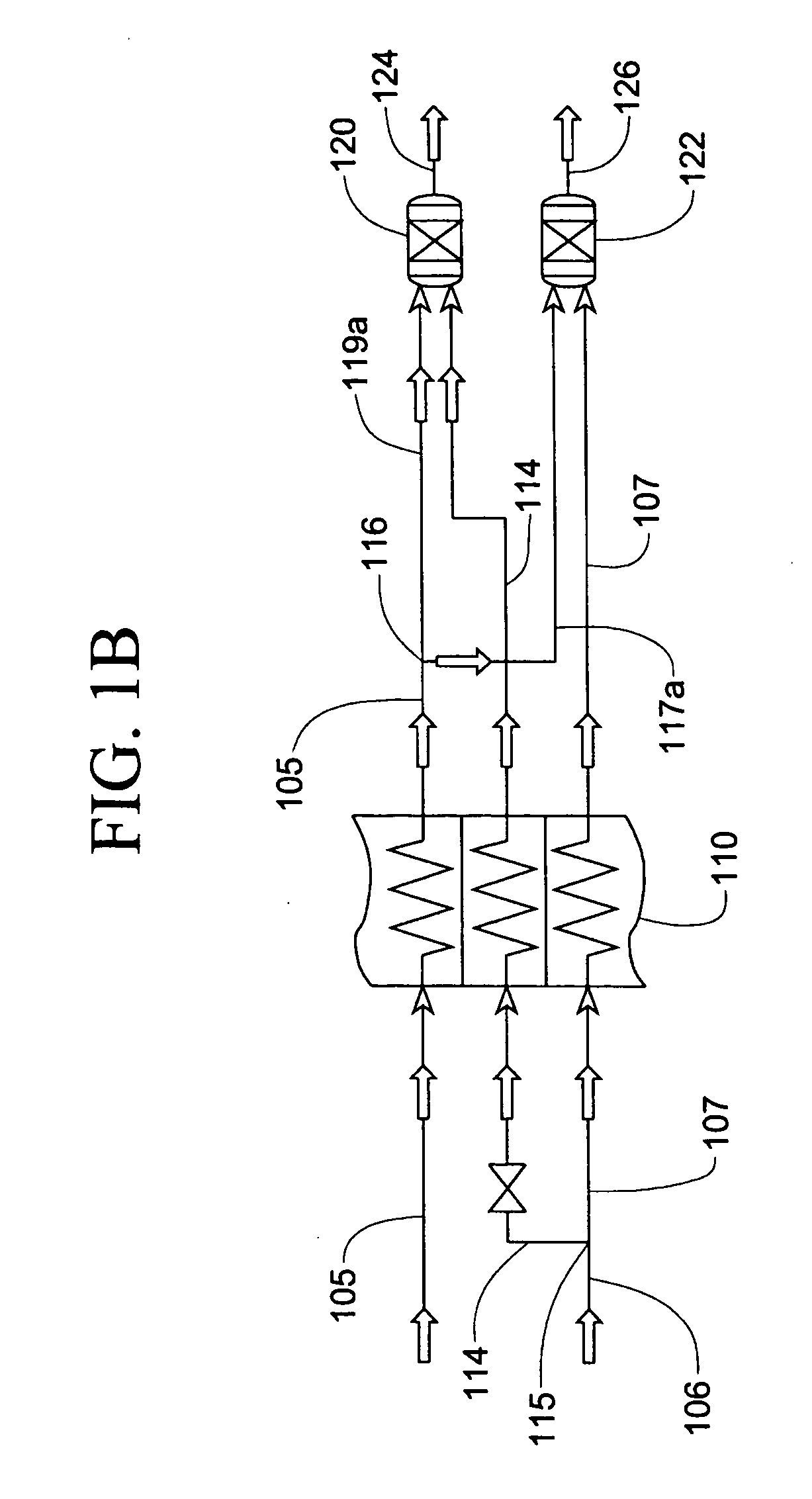

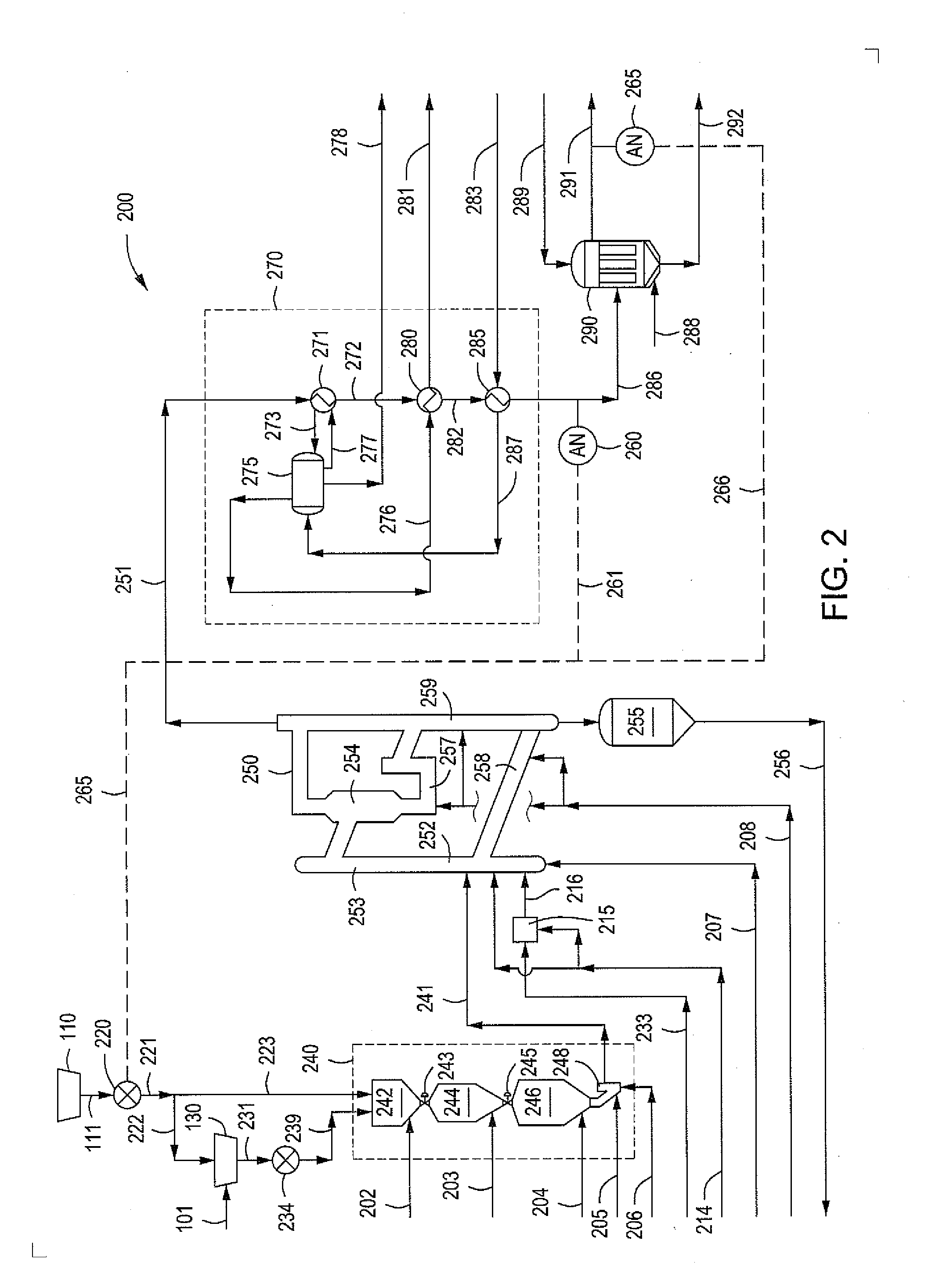

A multiple adiabatic bed reforming apparatus and process are disclosed in which stage-wise combustion, in combination with multiple reforming chambers with catalyst, utilize co-flow and cross-flow under laminar flow conditions, to provide a reformer suitable for smaller production situations as well as large scale production. A passive stage by stage fuel distribution network suitable for low pressure fuel is incorporated and the resistances in successive fuel distribution lines control the amount of fuel delivered to each combustion stage. The fuel distribution system allows relatively constant fuel and air flow during turn up or turn down conditions. High efficiency is achieved by capturing heat from reforming syngas product to preheat gases before entering the reformer. Conditions that would produce unwanted coking or metal dusting are also eliminated or localized to locations within the apparatus outside the heat exchangers, but which locations can be cost effectively protected. Also, a chemical reactor is disclosed and which has a core composed of a stack of metal plates that are diffusion bonded in face-to-face relationship. A plurality of reaction zones are located within the core, as are a plurality of catalyst receiving zones, and both the reaction zones and the catalyst receiving zones are defined by respective aligned apertures in the plates. First and second channel arrangements are provided in the plates for transporting first and second reactants to reaction zones. Portions of the first channel arrangement that interconnect the reaction zones are formed as heat exchange channels. A third channel arrangement is provided in the plates for transporting a third reactant to catalyst receiving zones. Portions of the third channel arrangement are formed as heat exchange channels in proximity to the heat exchange channels of the first channel arrangement.

Owner:MEGGIT (UK) LTD

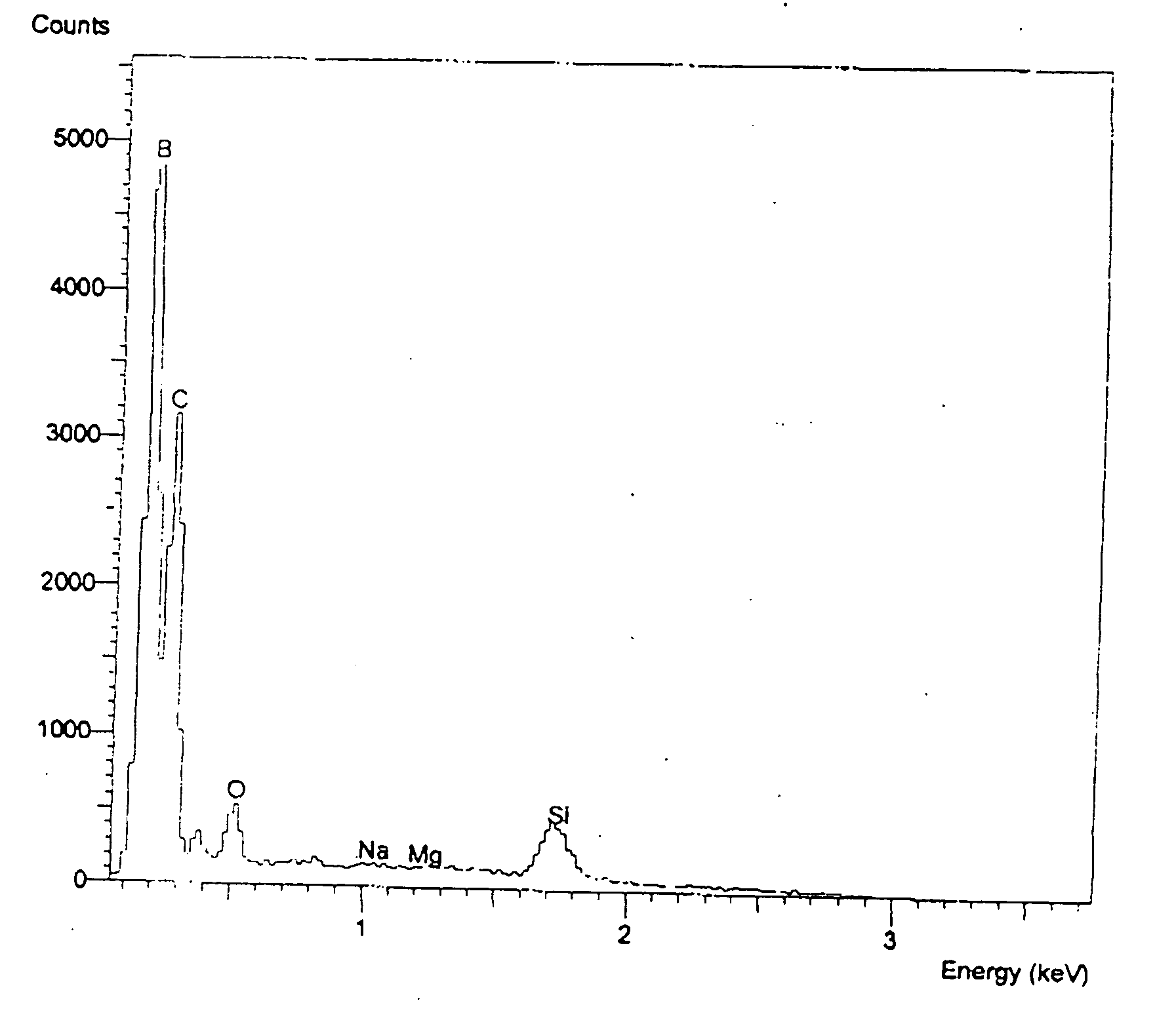

Method for depositing boron-rich coatings

InactiveUS20050208218A1Not readyReduce usageSpark gapsLiquid surface applicatorsLutetiumControl manner

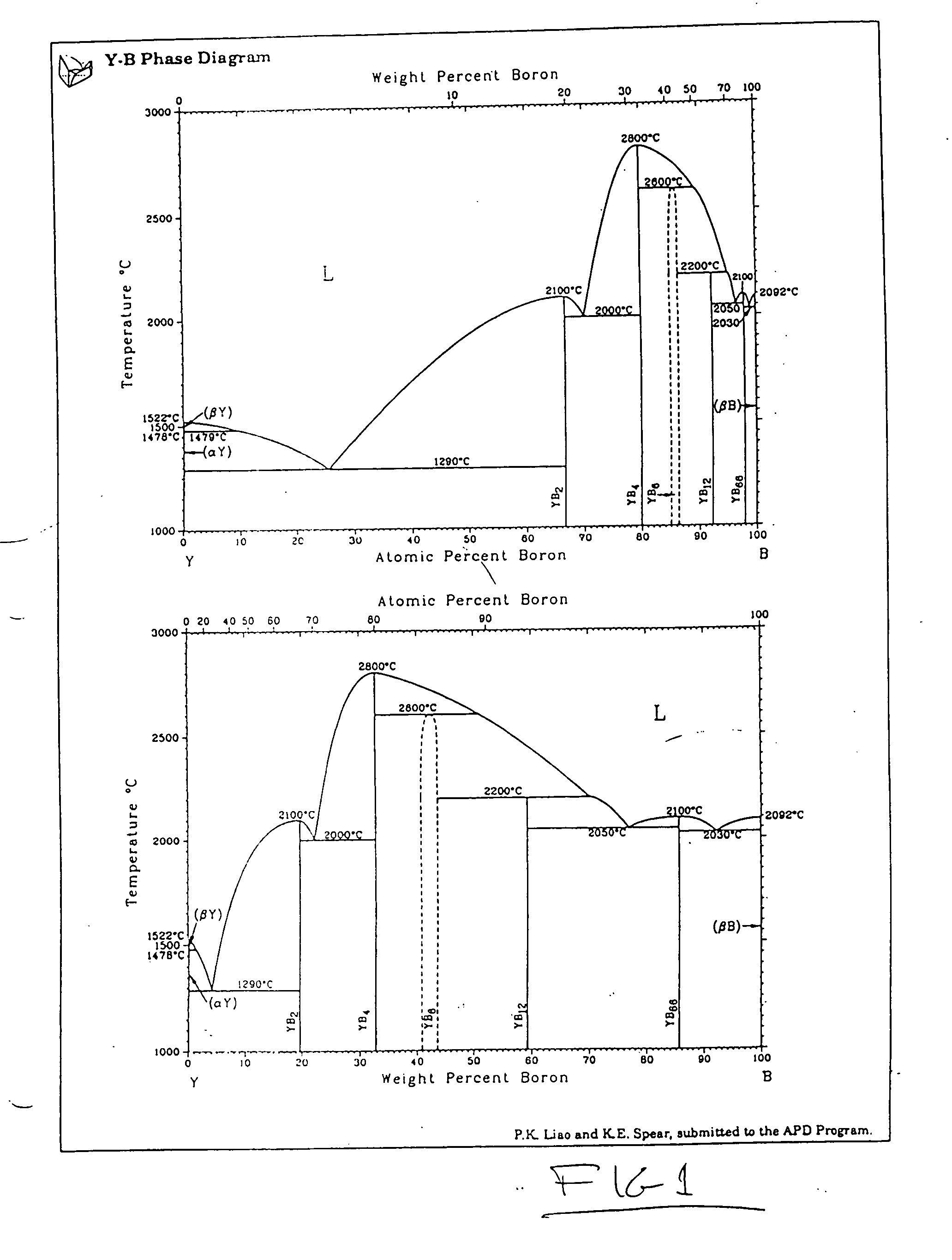

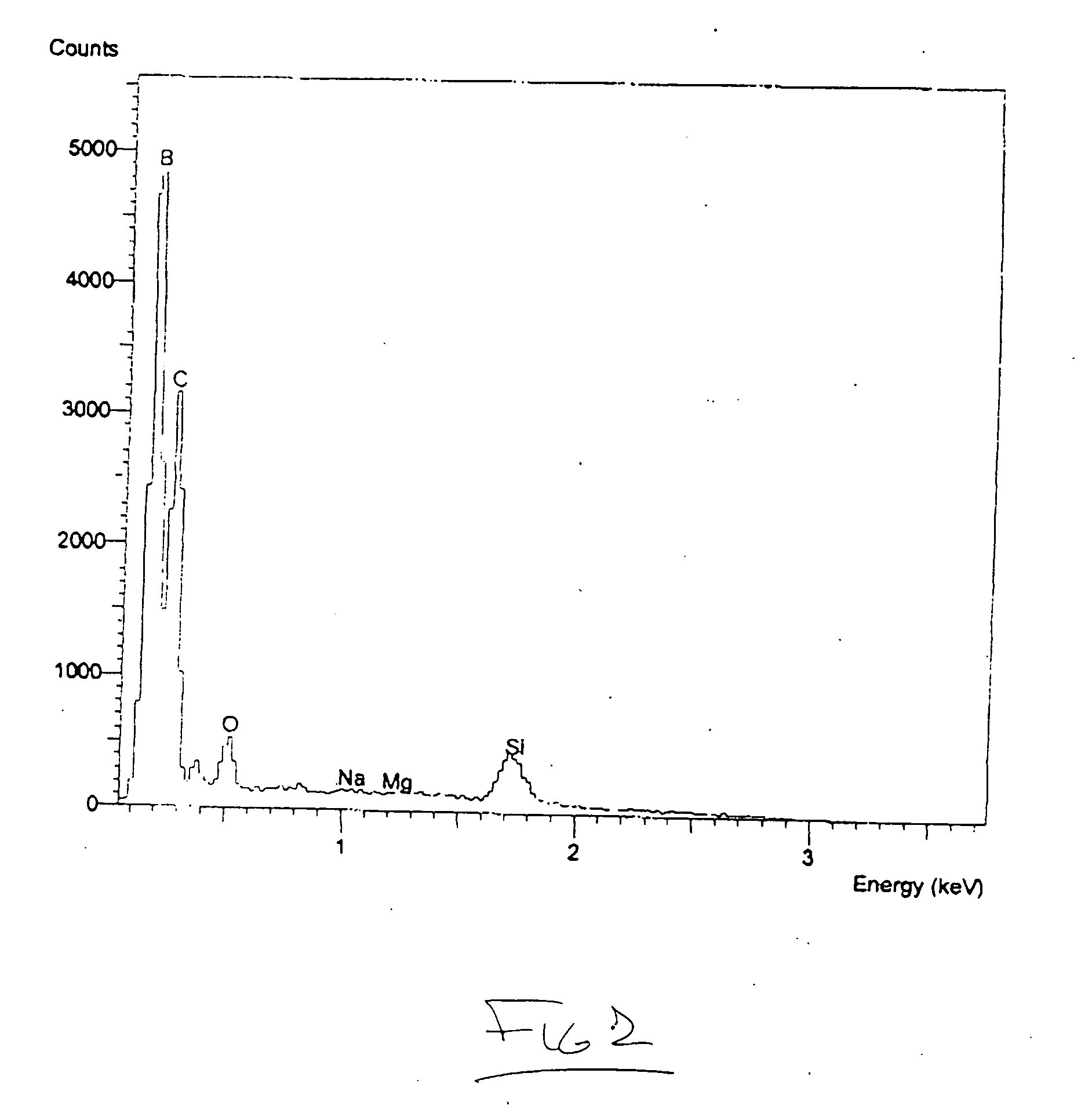

A method is disclosed for coating substantially pure boron or highly boron-rich borides in a controlled manner. Such a method of coating of boron has a variety of applications, including surface chemical and wear protection, neutron absorption, prevention of impurity emission from heated filaments and ion beams, elimination of metal dust from vacuum systems, boridizing, boron cluster emission, and reactive chemistry. Borides with a boron-to-metal ratio of 20 or more are known to exist and may be used as a feedstock for substantially pure boron coatings for deposition processes requiring feedstock electrical conductivity, and / or enhanced reactivity. While most metal borides coincidentally produce significant metal vapor as a by-product, certain borides of yttrium, holmium, erbium, thulium, terbium, gadolinium, and lutetium have been identified as capable of producing substantially pure boron vapor.

Owner:IBADEX

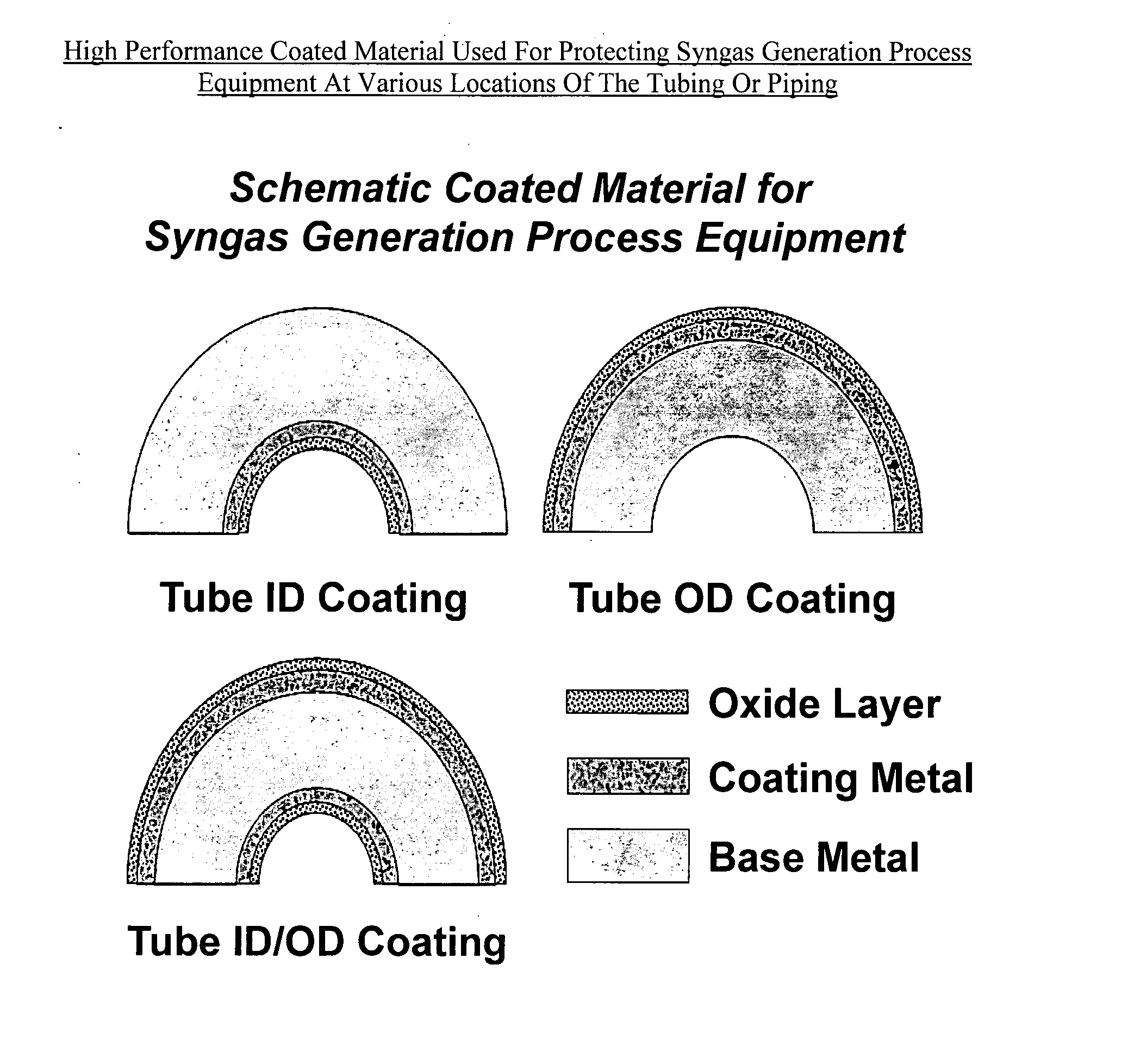

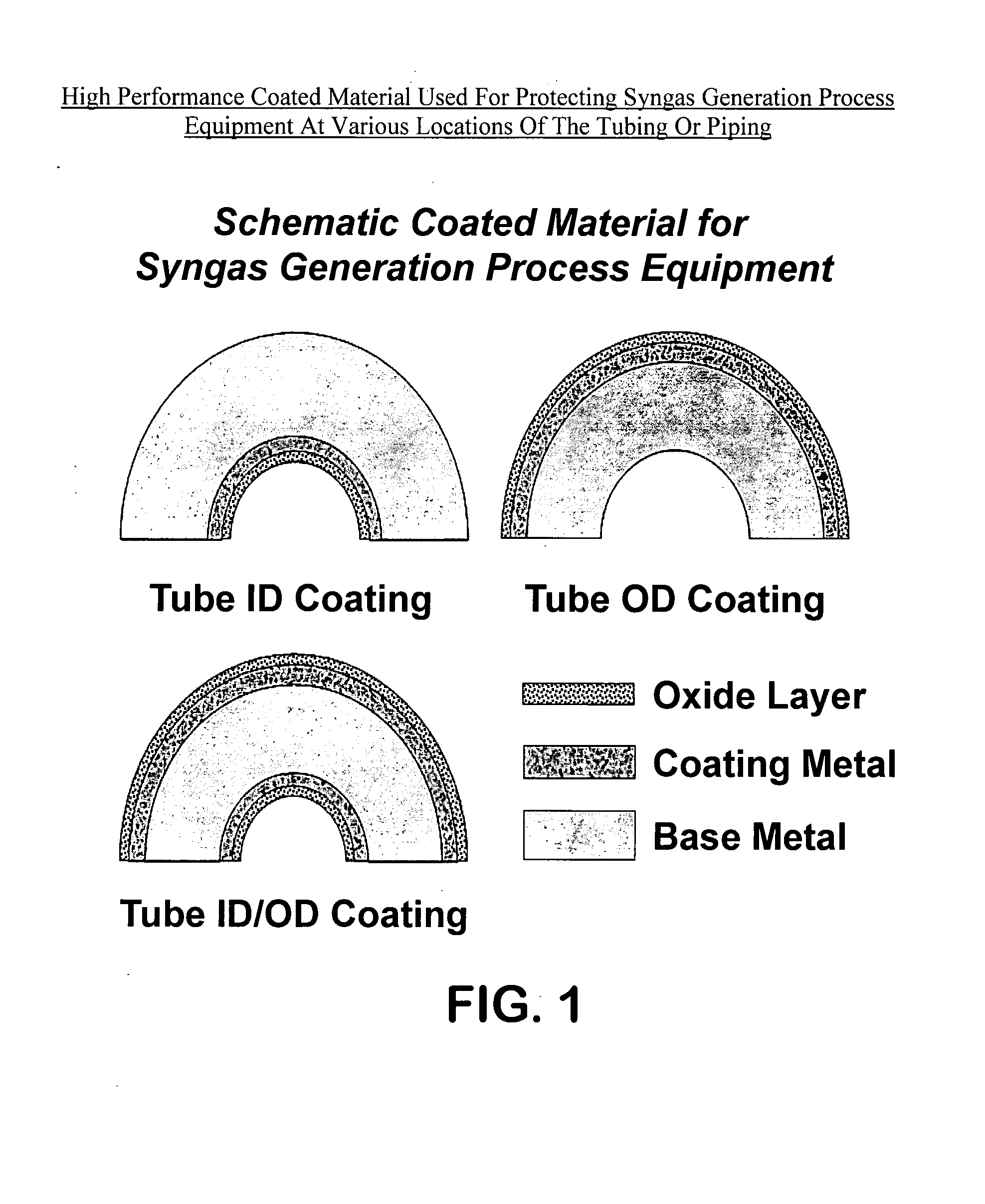

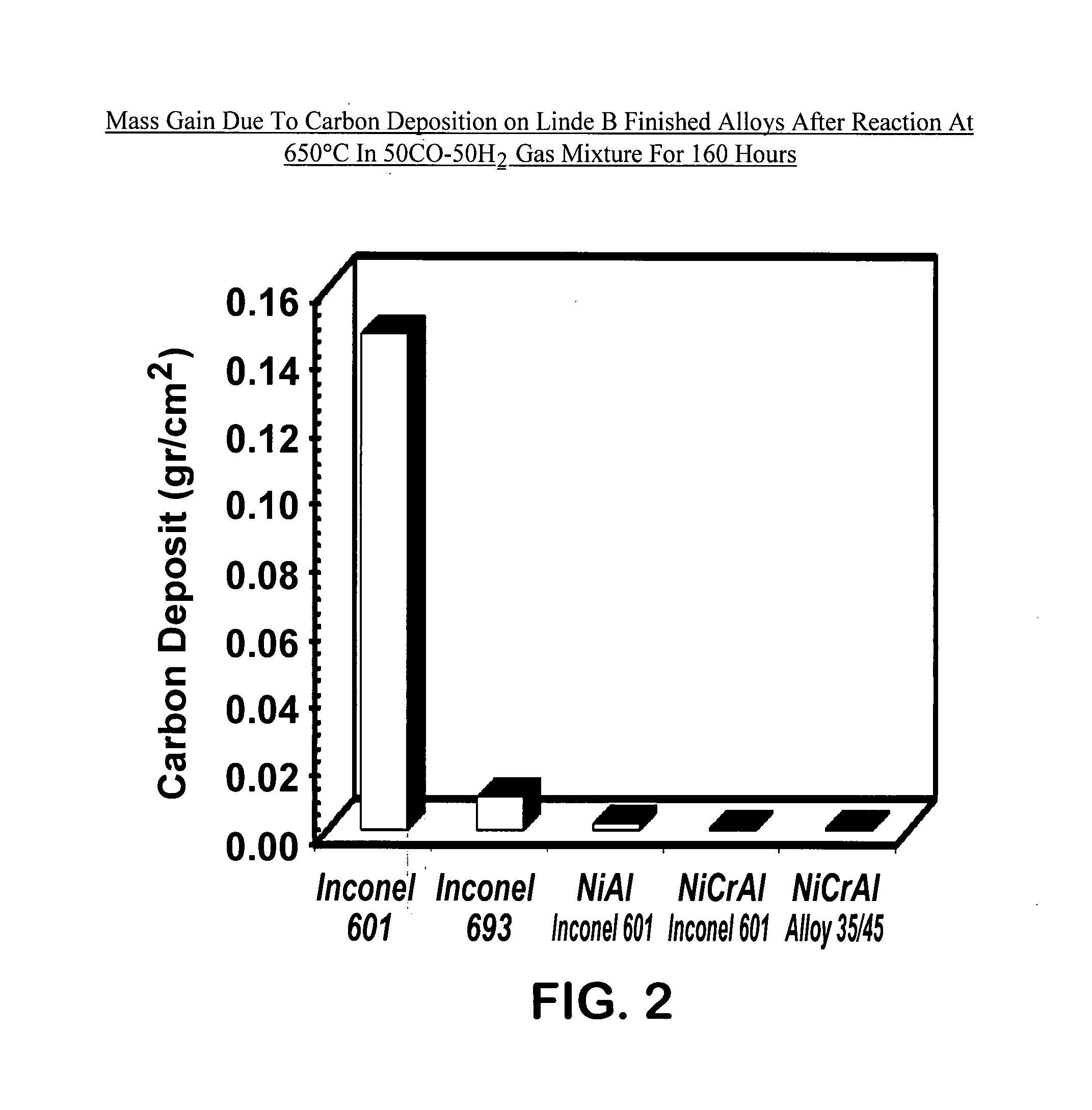

High performance coated material with improved metal dusting corrosion resistance

InactiveUS20080020216A1Improve the immunityReduce carbon depositionAnodisationLiquid surface applicatorsMulliteInconel

High performance coated metal compositions resistant to metal dusting corrosion and methods of providing such compositions are provided by the present invention. The coated metal compositions are represented by the structure (PQR), wherein P is an oxide layer at the surface of (PQR), Q is a coating metal layer interposed between P and R, and R is a base metal. P includes alumina, chromia, silica, mullite or mixtures thereof. Q includes Ni and Al, and at least one element selected from the group consisting of Cr, Si, Mn, Fe, Co, B, C, N, P, Ga, Ge, As, In, Sn, Sb, Pb, Sc, La, Y, Ce, Ti, Zr, Hf, V, Nb, Ta, Mo, W, Ru, Rh, Ir, Pd, Pt, Cu, Ag, Au and mixtures thereof. R is selected from the group consisting of carbon steels, low chromium steels, ferritic stainless steels, austenetic stainless steels, duplex stainless steels, Inconel alloys, Incoloy alloys, Fe—Ni based alloys, Ni-based alloys and Co-based alloys. Advantages exhibited by the disclosed coated metal compositions include improved metal dusting corrosion resistance at high temperatures in carbon-supersaturated environments having relatively low oxygen partial pressures. The coated metal compositions are suitable for use in syngas generation process equipment.

Owner:EXXON RES & ENG CO

Metal material having good resistance to metal dusting

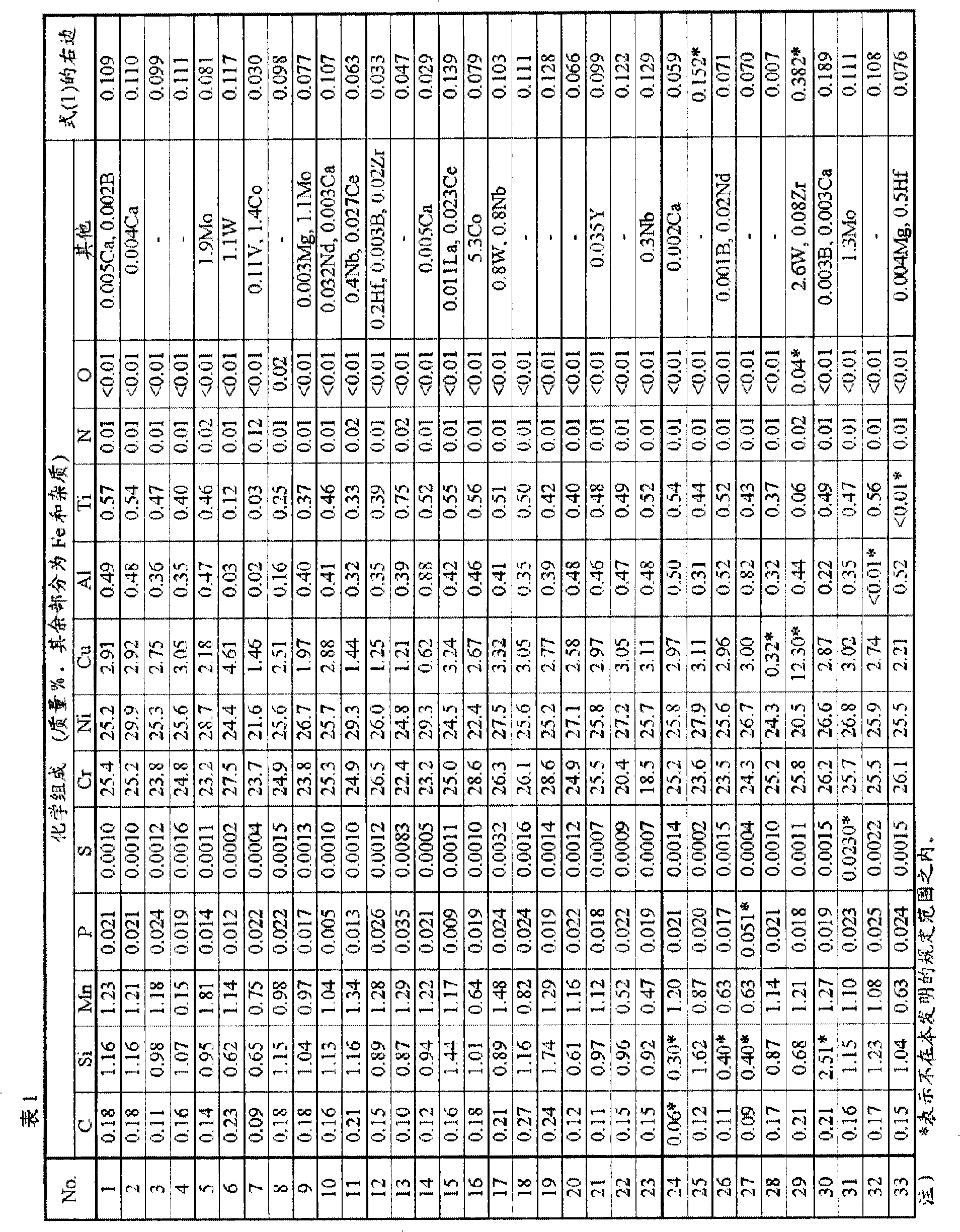

InactiveCN1463296AHas anti-metal dusting propertiesIncreased durabilityChemical industryCoatingsChemical compositionMetal dusting

A metal material, which has a chemical composition in mass %; C: 0.2 % or less, Si: 0.01 to 4 %, Mn: 0.05 to 2 %, P: 0.04 % or less, S: 0.015 % or less, Cr: 10 to 35 %, Ni: 30 to 78 %, Al: not less than 0.005 % and less than 4.5 %, N: 0.005 to 0.2 %, at least one of Cu: 0.015 to 3 % and Co: 0.015 to 3 % and balance: substantially Fe, wherein the value of [40S + Ni + 5Al + 40N + 10(Cu + Co)] is 50 or more where an elemental symbol represents the content in mass % of each element. The metal material exhibits excellent corrosion resistance in a circumstance wherein a conventional material is prone to metal dusting, and thus can be used for a heating furnace tube, a piping, a heat exchanger tube and the like in a petroleum refiner, a petrochemical plant and the like, and can significantly improve the durability and safety of an apparatus.

Owner:NIPPON STEEL CORP

Metal material having excellent metal dusting resistance

InactiveUS20080279716A1Inhibition of surface reactionsExcellent in metal dusting resistanceFurnace typesEngine componentsMetal dustingMetallic materials

[Objective] To provide a metal material having excellent metal dusting resistance which is suited for using cracking furnaces, reforming furnaces, heating furnaces or heat exchangers, in petroleum refining, petrochemical plants, etc.[Means for Solution] A metal material having excellent metal dusting resistance, characterized in comprising, by mass %, C: 0.01 to 0.4%, Si: 0.01 to 2.5%, Mn: 0.01 to 2.5%, Cr: 15 to 35%, Ni: 20 to 65%, Cu: 0.05 to 20%, S: not more than 0.1%, N: not more than 0.25% and O (oxygen): not more than 0.02% and the balance Fe and impurities, and also containing, by mass %, one or more selected among the elements of P: more than 0.05% and not more than 0.3%, Sb: 0.001 to 1% and Bi: 0.001 to 0.5. It may further contain one or more selected among the elements of Nd: 0.001 to 0.15%, Co: not more than 10%, Mo: not more than 3%, W: not more than 6%, Ti: not more than 1%, Nb: not more than 2%, B: not more than 0.1%, Zr: not more than 1.2%, Hf: not more than 0.5%, Mg: not more than 0.1%, Ca: not more than 0.1%, Al: not more than 0.8%, Y: not more than 0.15%, La: not more than 0.15% and Ce: not more than 0.15%.

Owner:SUMITOMO METAL IND LTD

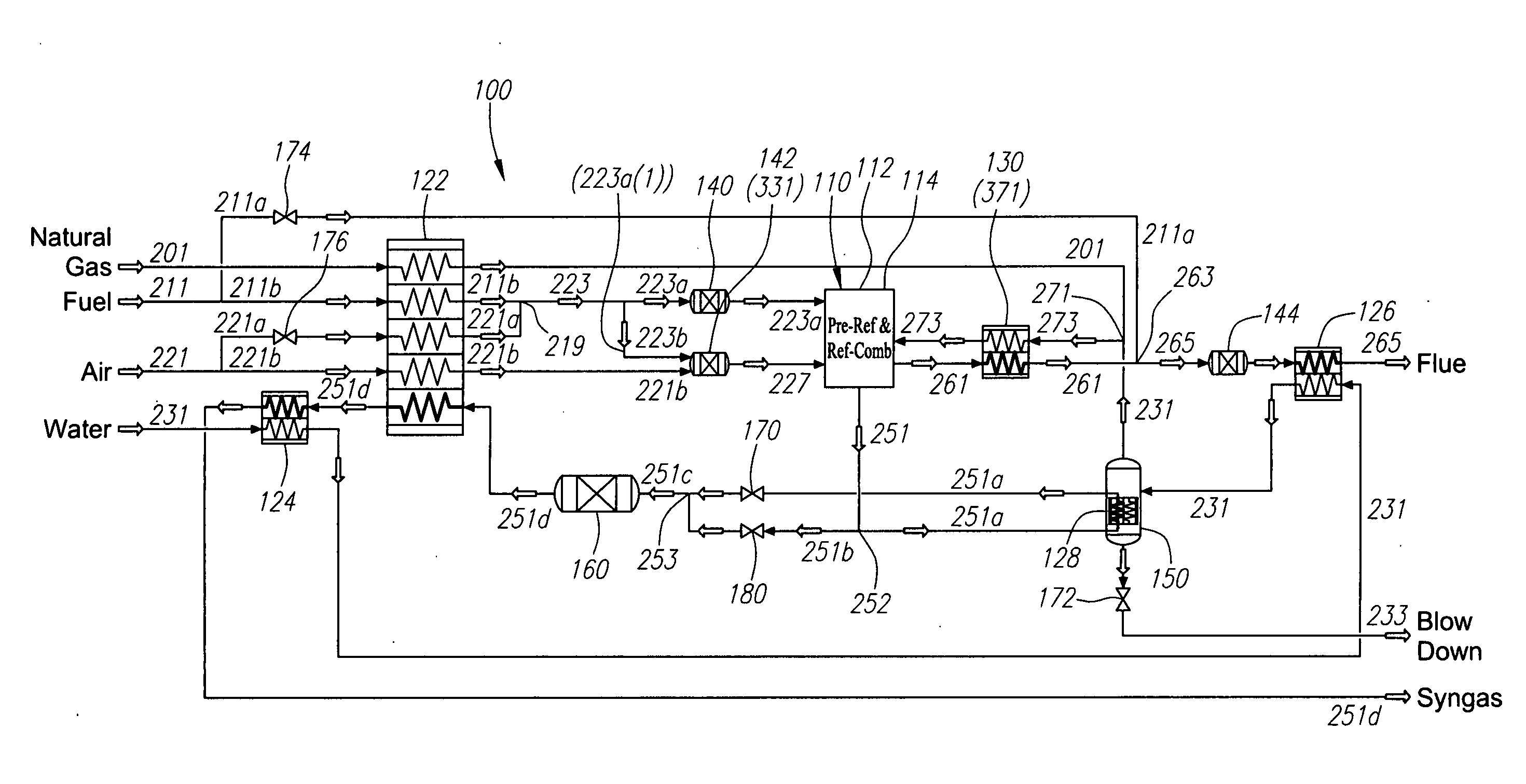

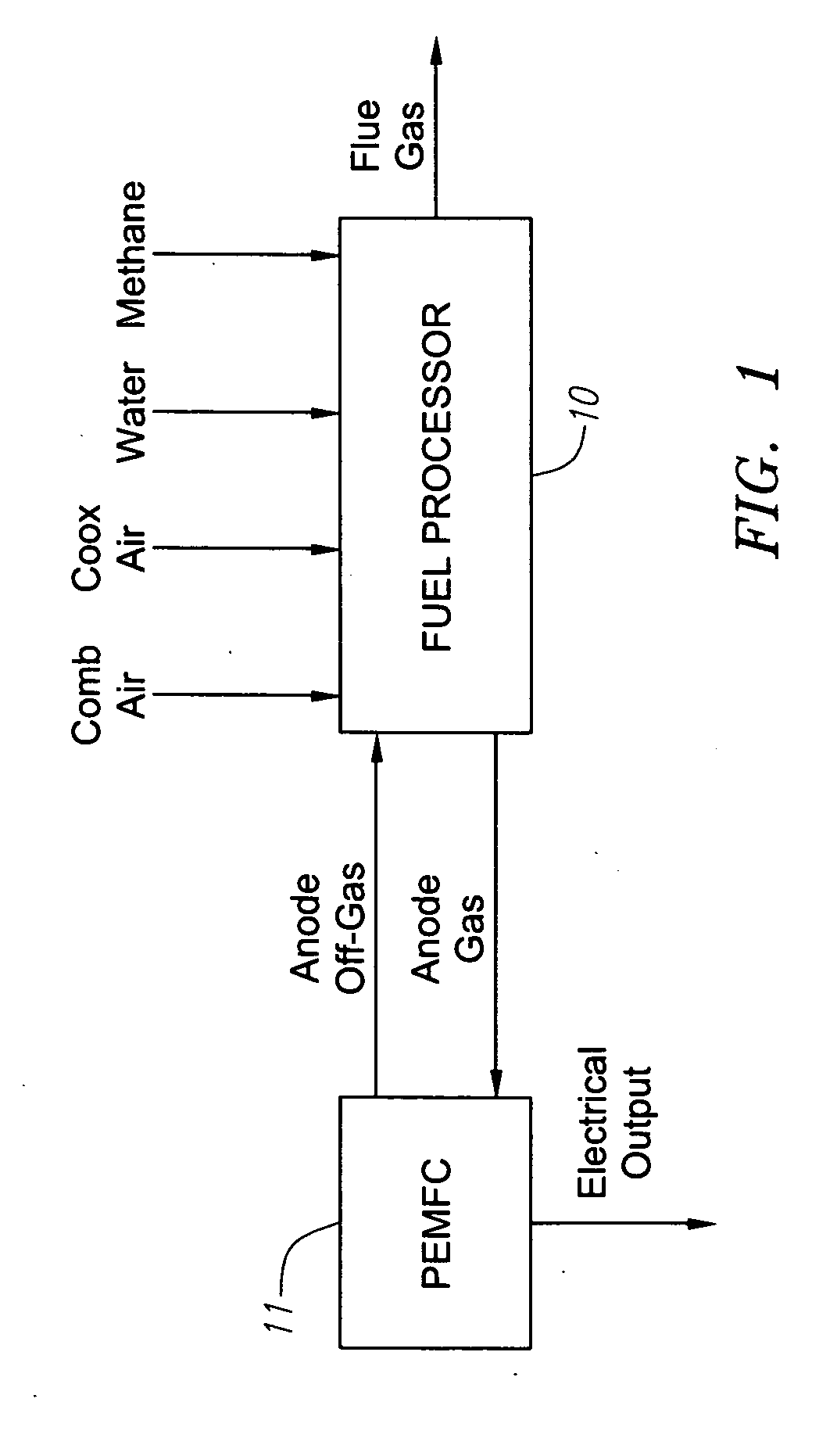

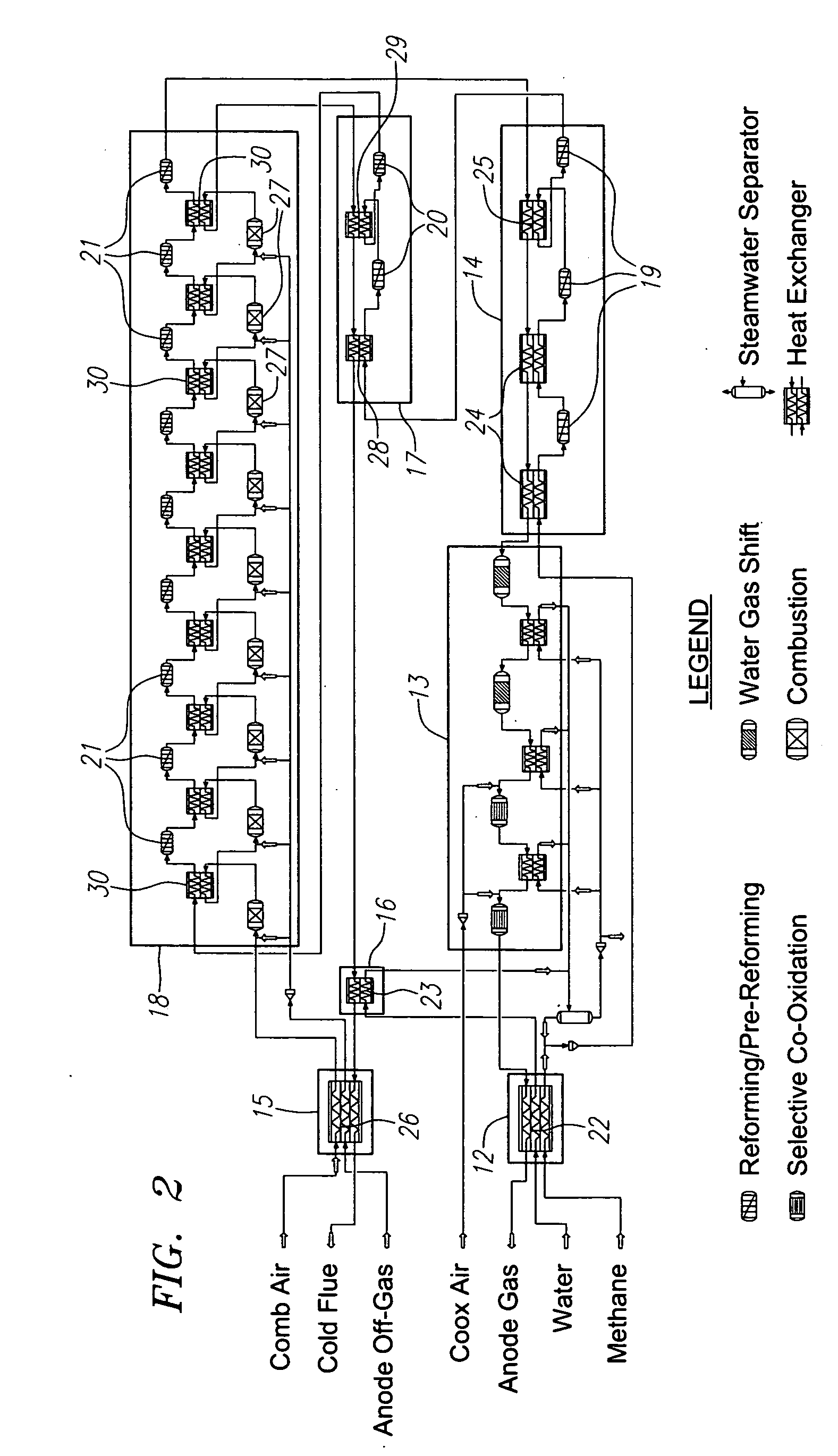

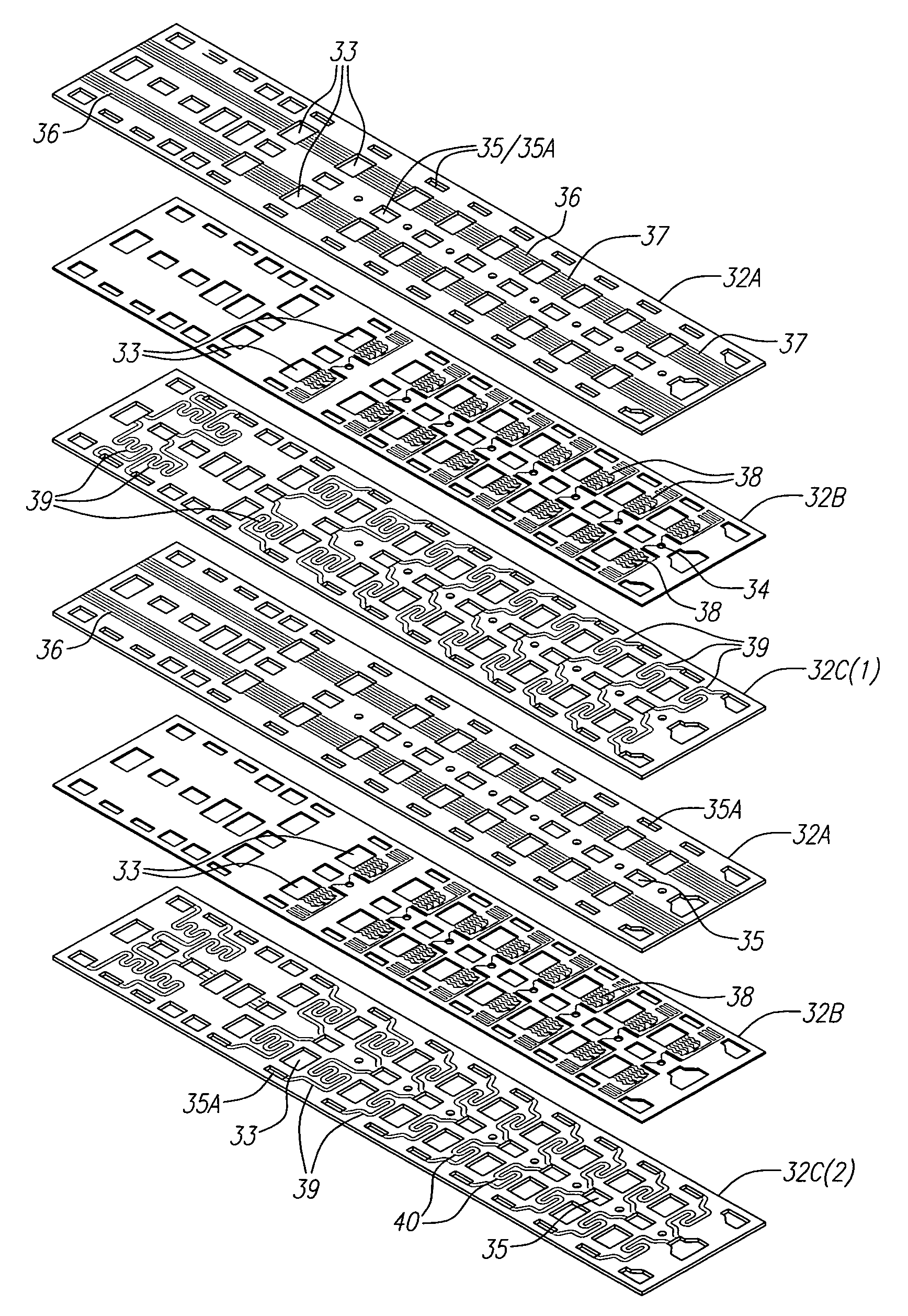

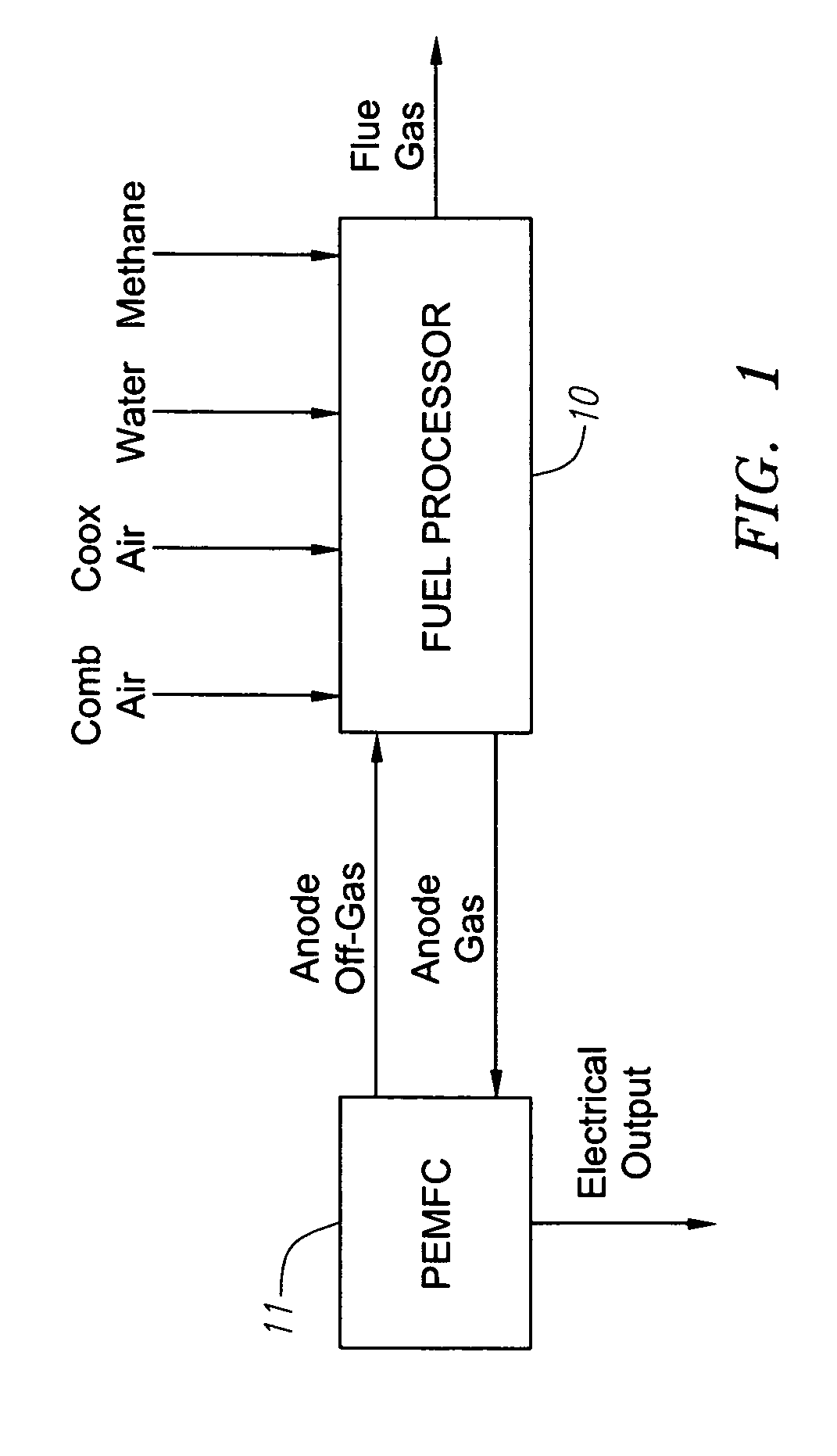

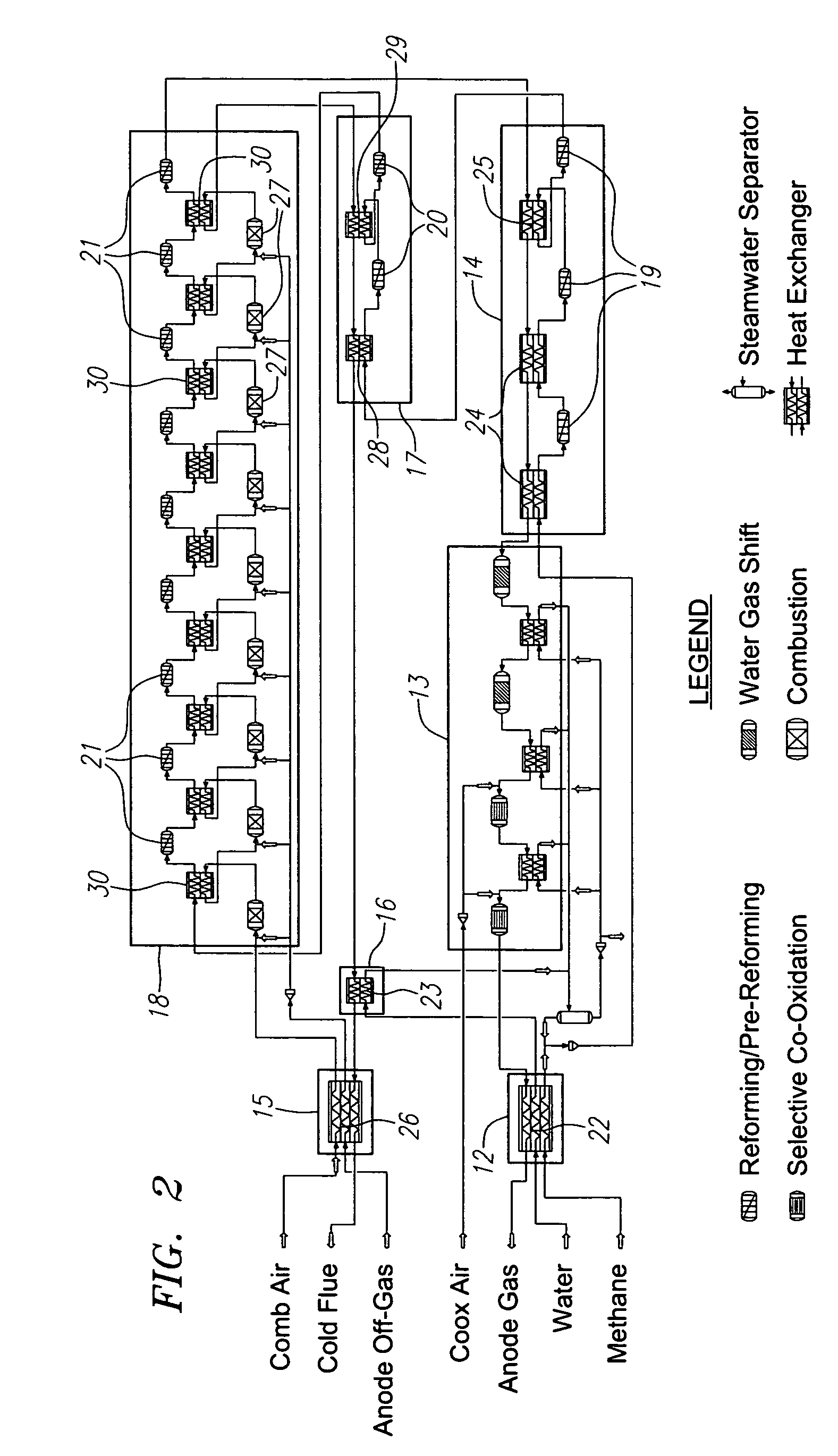

Reformer apparatus and method

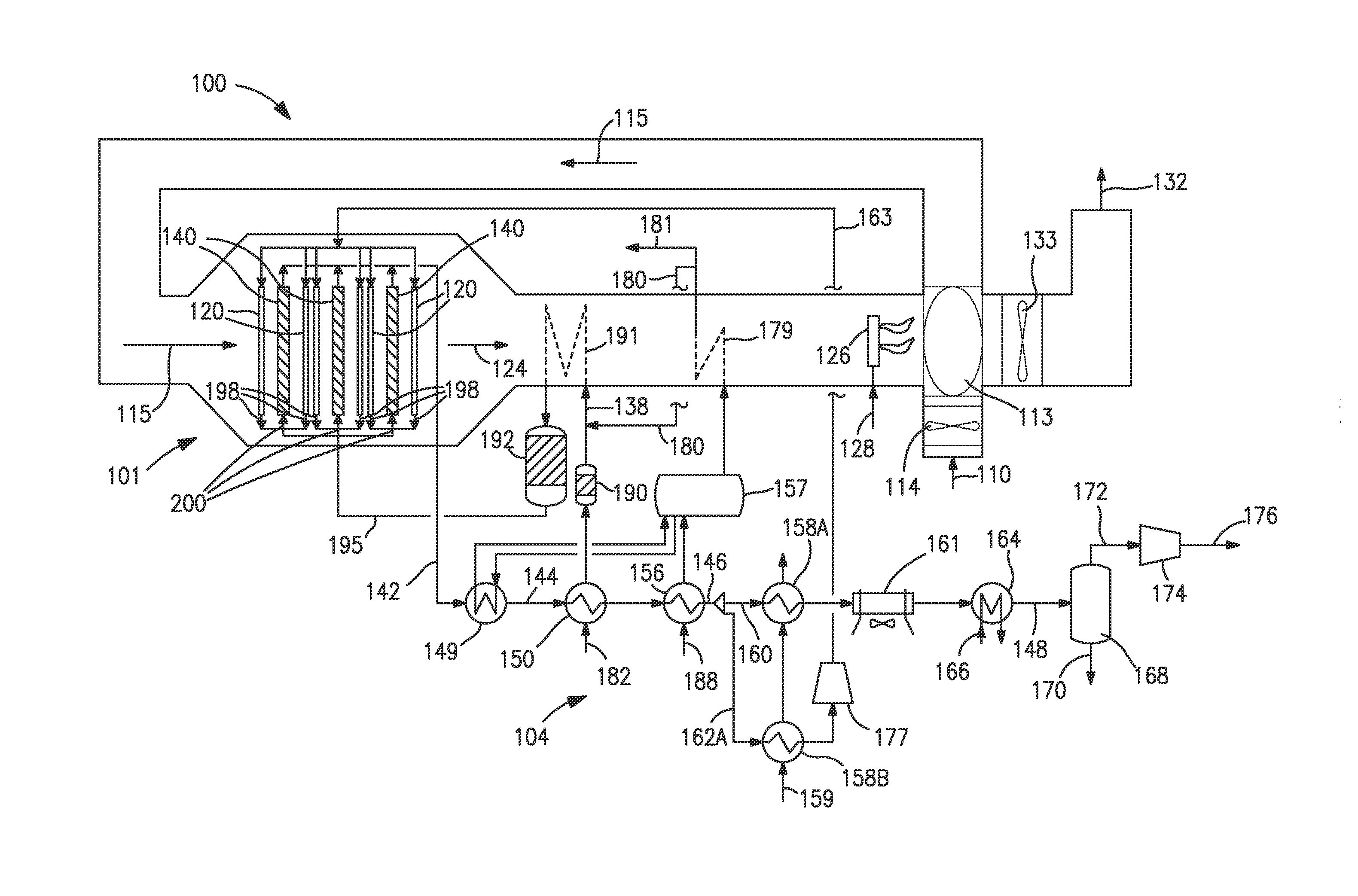

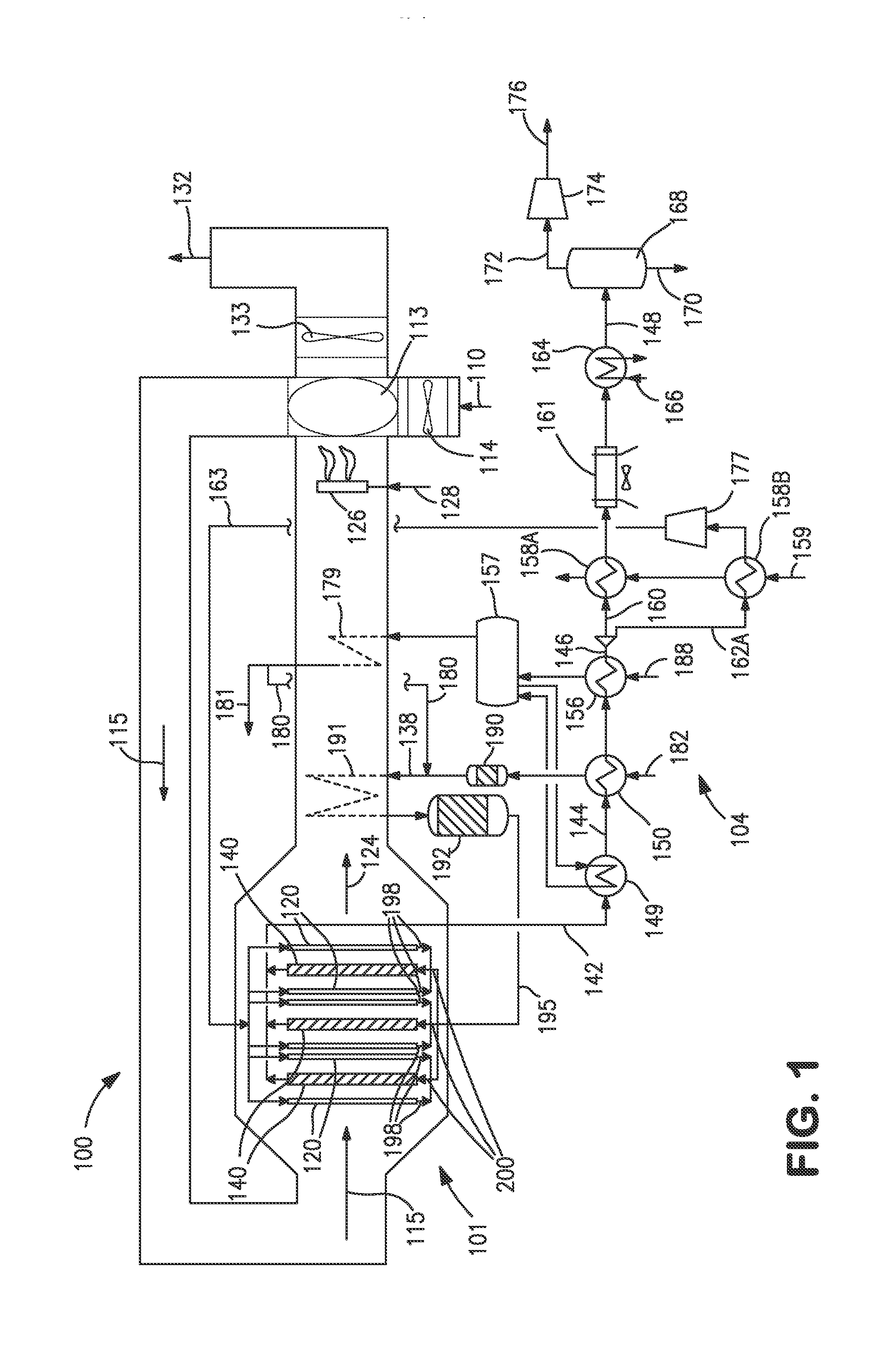

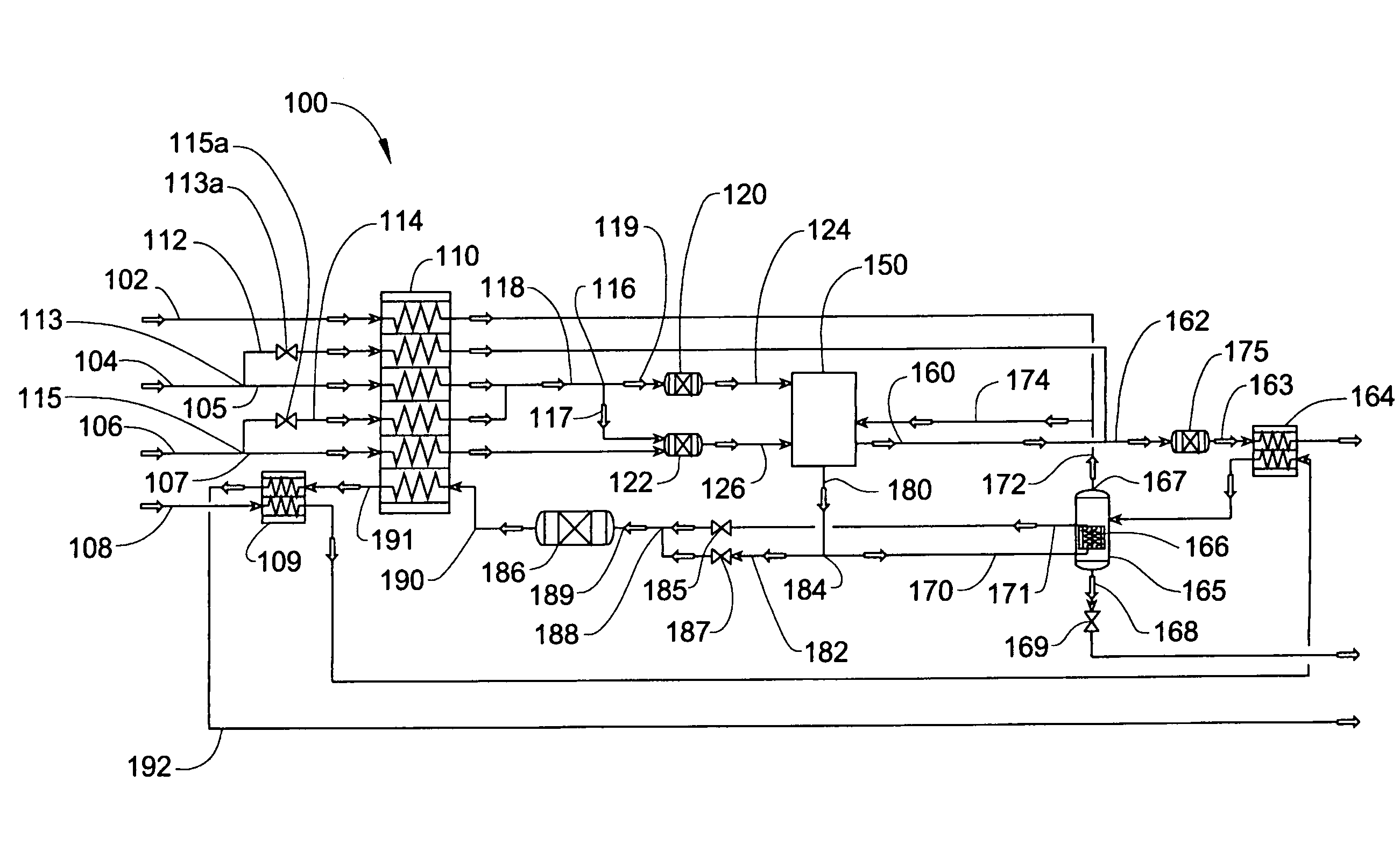

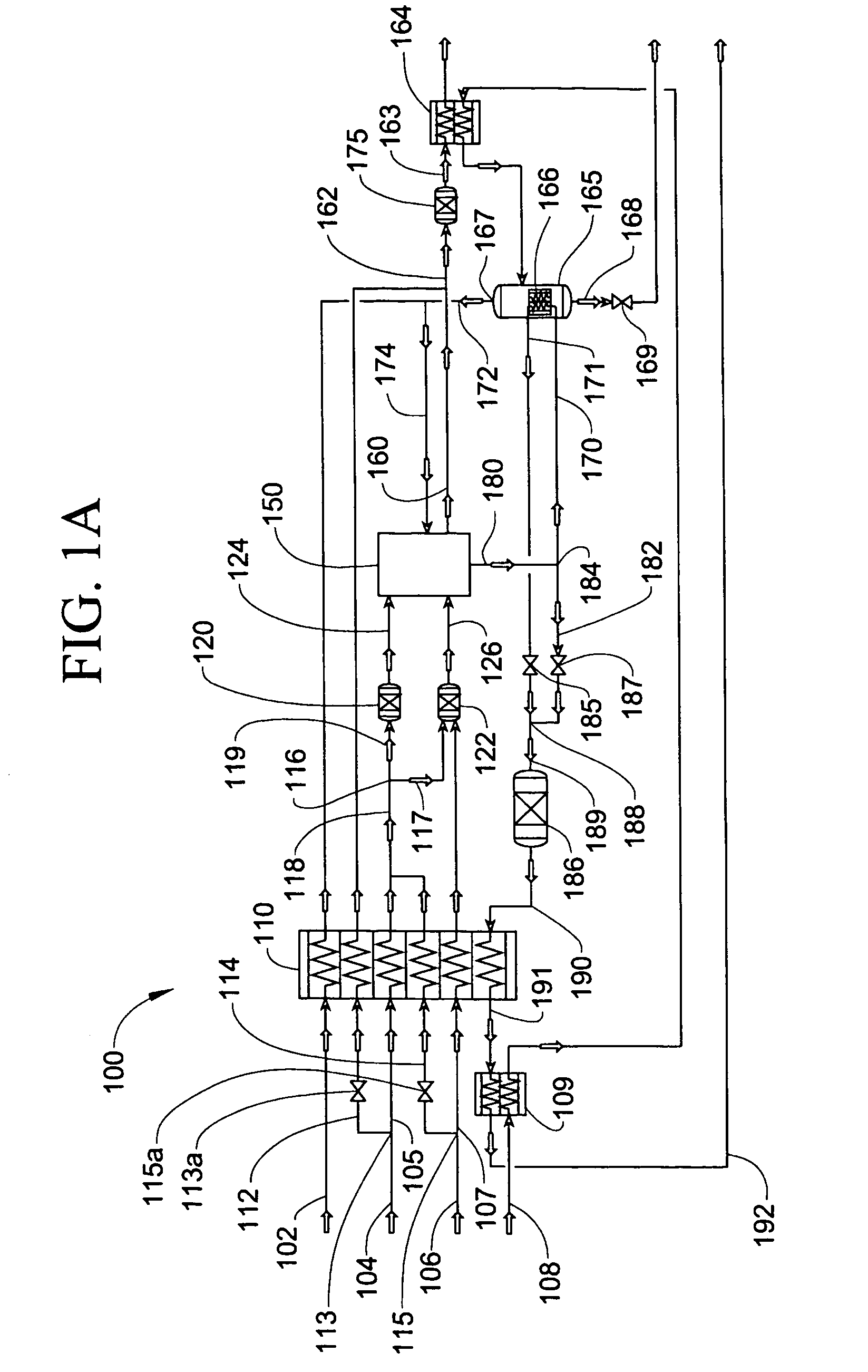

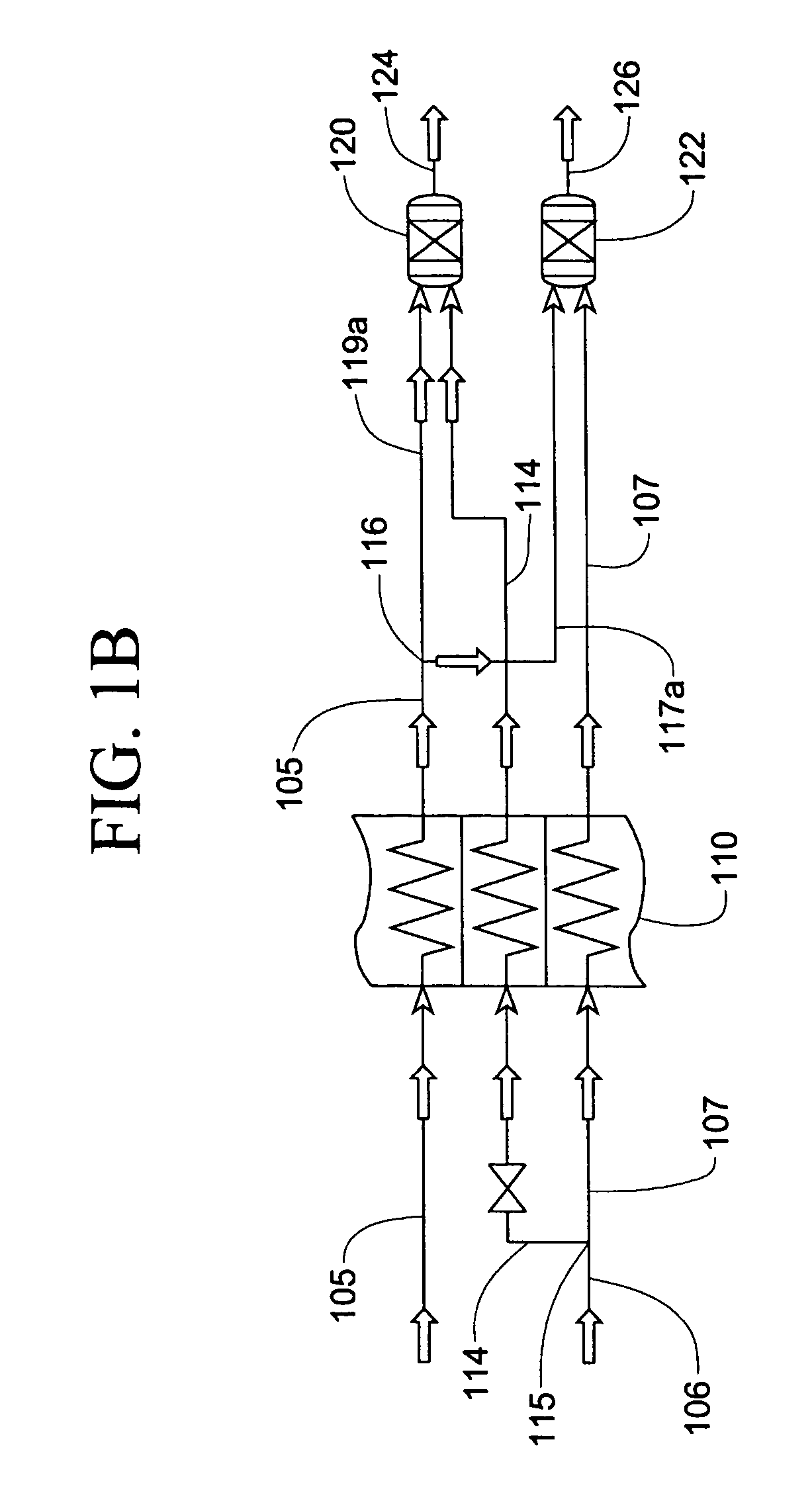

ActiveUS20080124255A1Reduce the amount requiredEliminate needHydrogenFinal product manufactureSyngasMetal dusting

A multiple adiabatic bed reforming apparatus and process involving stage-wise combustion and multiple reforming chambers. Co-flow and cross-flow occurs under laminar flow conditions. A reformer suitable for small scale production as well as large scale production. A passive stage-by-stage fuel distribution network suitable for low pressure fuel wherein the resistances in successive fuel distribution lines control the amount of fuel delivered to each combustion stage. Heat is captured from reforming syngas product to preheat gases before entering the reformer. Conditions that would produce unwanted coking or metal dusting are avoided or localized away from the heat exchangers to locations which can be cost effectively protected. A chemical reactor which has a core composed of a stack of metal plates that are diffusion bonded in face-to-face relationship.

Owner:MEGGIT (UK) LTD

Carburization resistant metal material

ActiveCN101946016AExcellent resistance to metal dustingImprove carburization resistanceMetal dustingMetallic materials

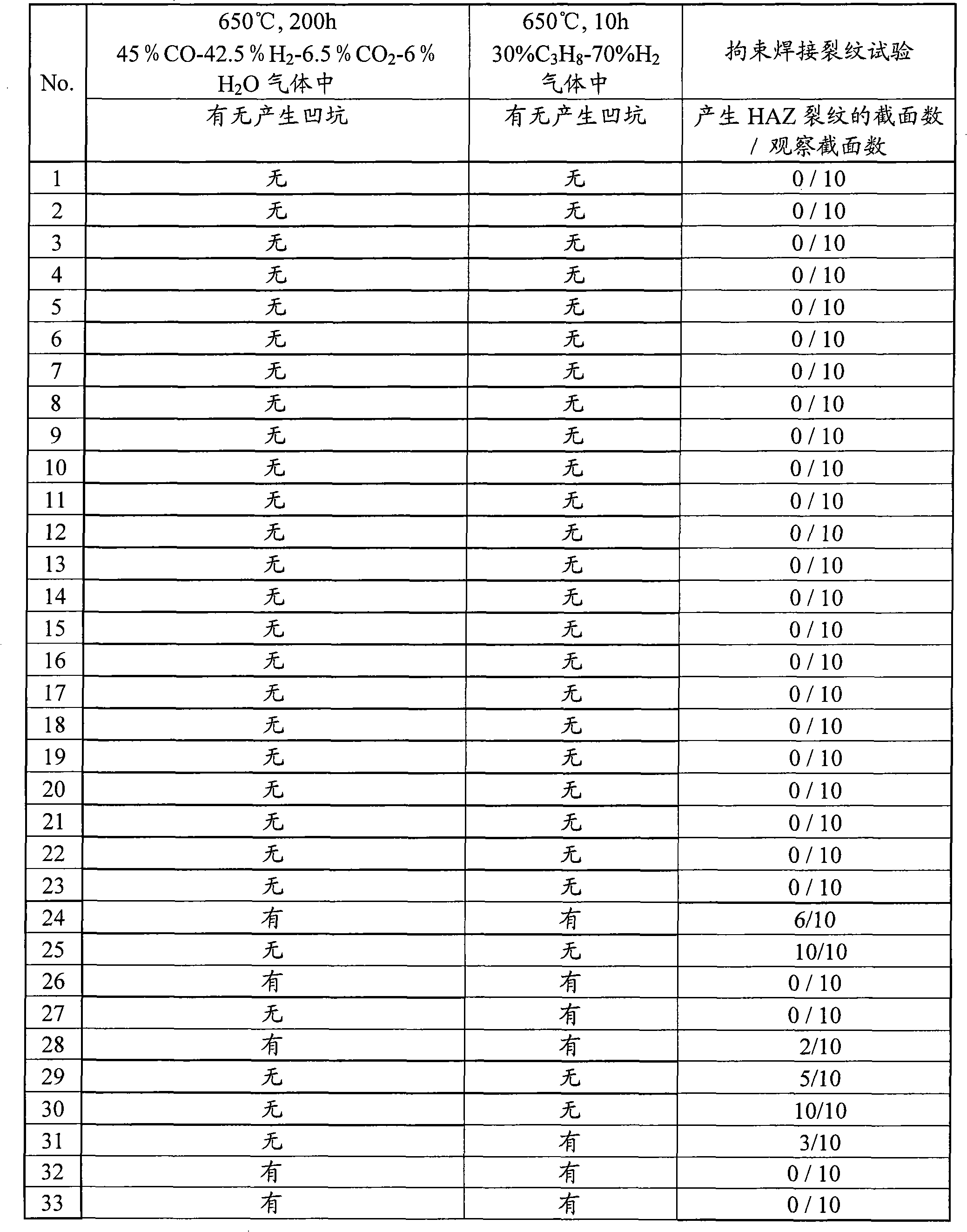

A metal material which exhibits both excellent workability and excellent metal dusting resistance and which is suitable for use as the material in a cracking furnace, a reforming furnace, a heating furnace, or a heat exchanger in petroleum refining or petrochemical plants or the like. A carburization-resistant metal material characterized by containing by mass C: 0.08 to 0.4%, Si: 0.6 to 2.0%, Mn: 0.05 to 2.5%, P: 0.04% or less, S: 0.015% or less, Cr: 18 to 30%, Ni: 20 to less than 30%, Cu: 0.5 to 10.0%, Al: 0.01 to 1%, Ti: 0.01 to 1%, N: 0.15% or less, O (oxygen): 0.02% or less with the balance consisting of Fe and impurities and by satisfying relationship (1). The material may further contain one or more of Co, Mo, W, B, V, Zr, Nb, Hf, Mg, Ca, Y, La, Ce and Nd. C > 0.062Si + 0.033Cu - 0.004Cr + 0.043 (1) (wherein each symbol of element represents the content of the element in mass%).

Owner:NIPPON STEEL CORP

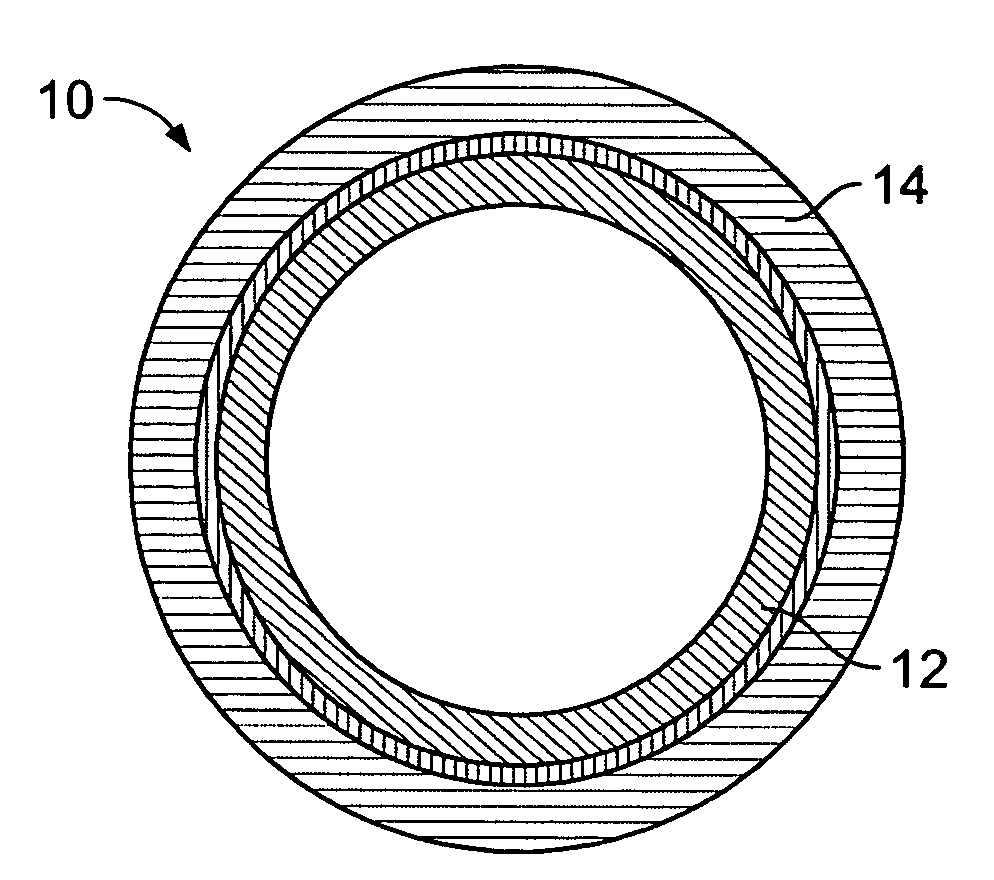

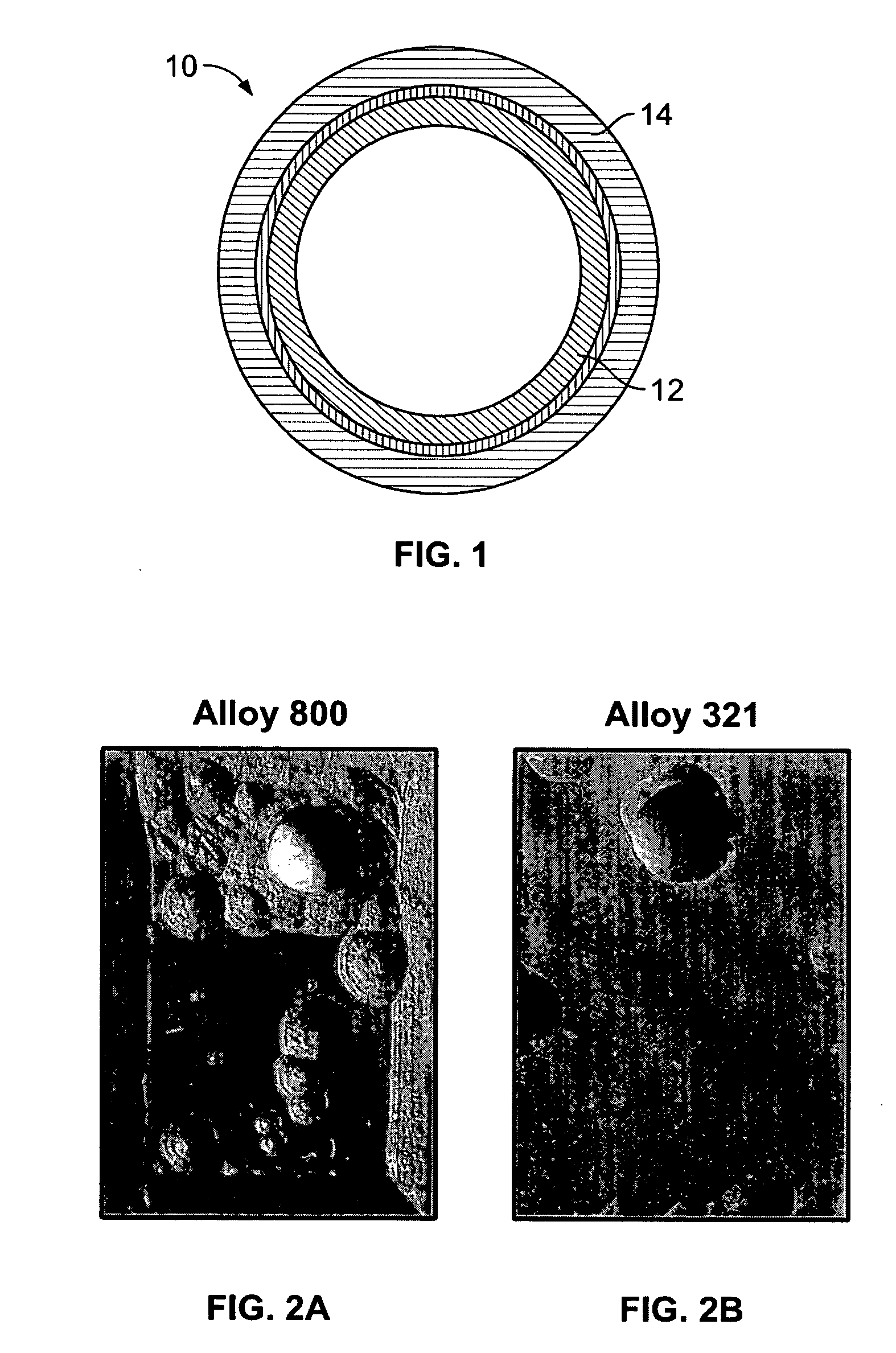

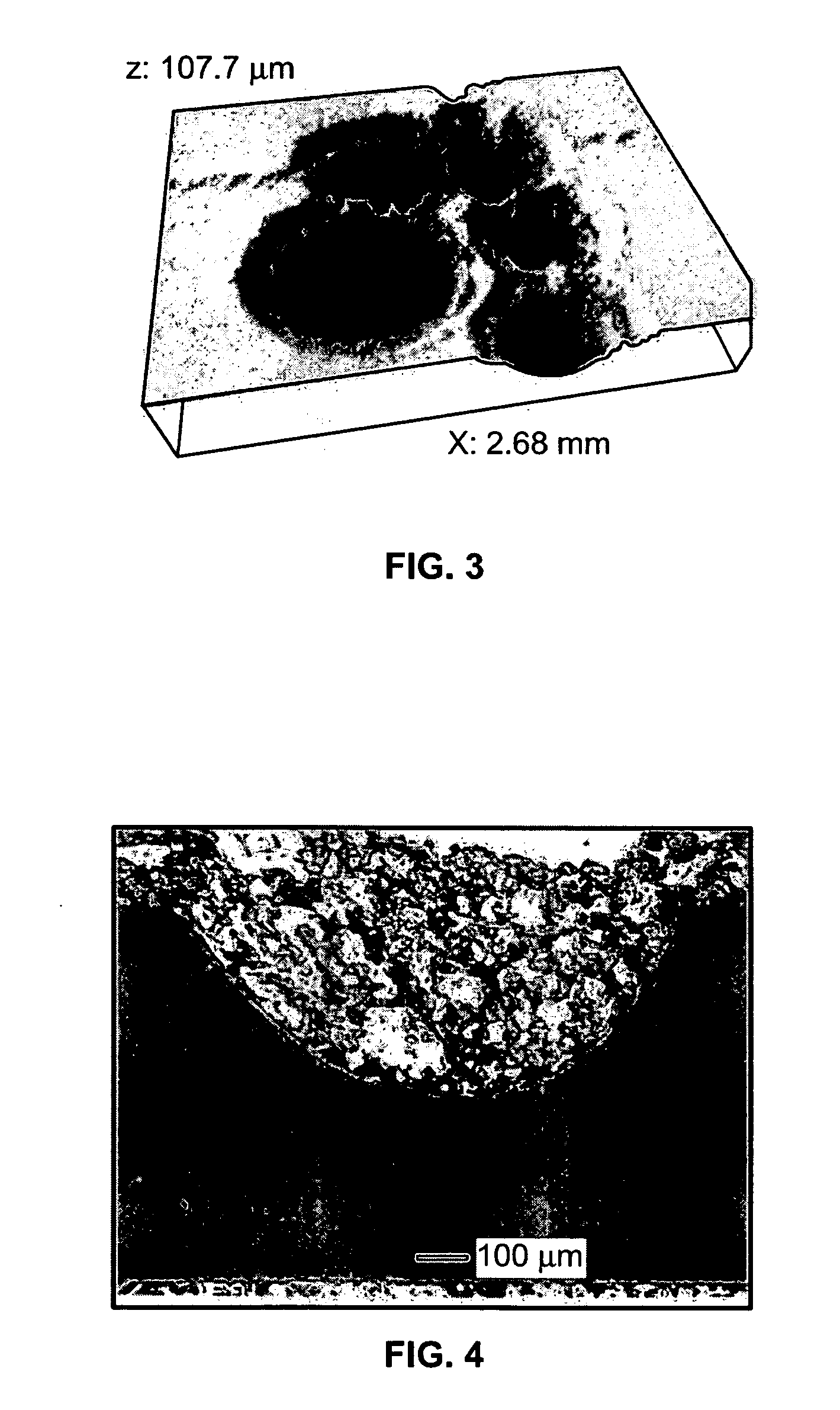

High performance alloys with improved metal dusting corrosion resistance

InactiveUS20060257675A1Molten spray coatingDistillation corrosion inhibitionReactor systemMetal dusting

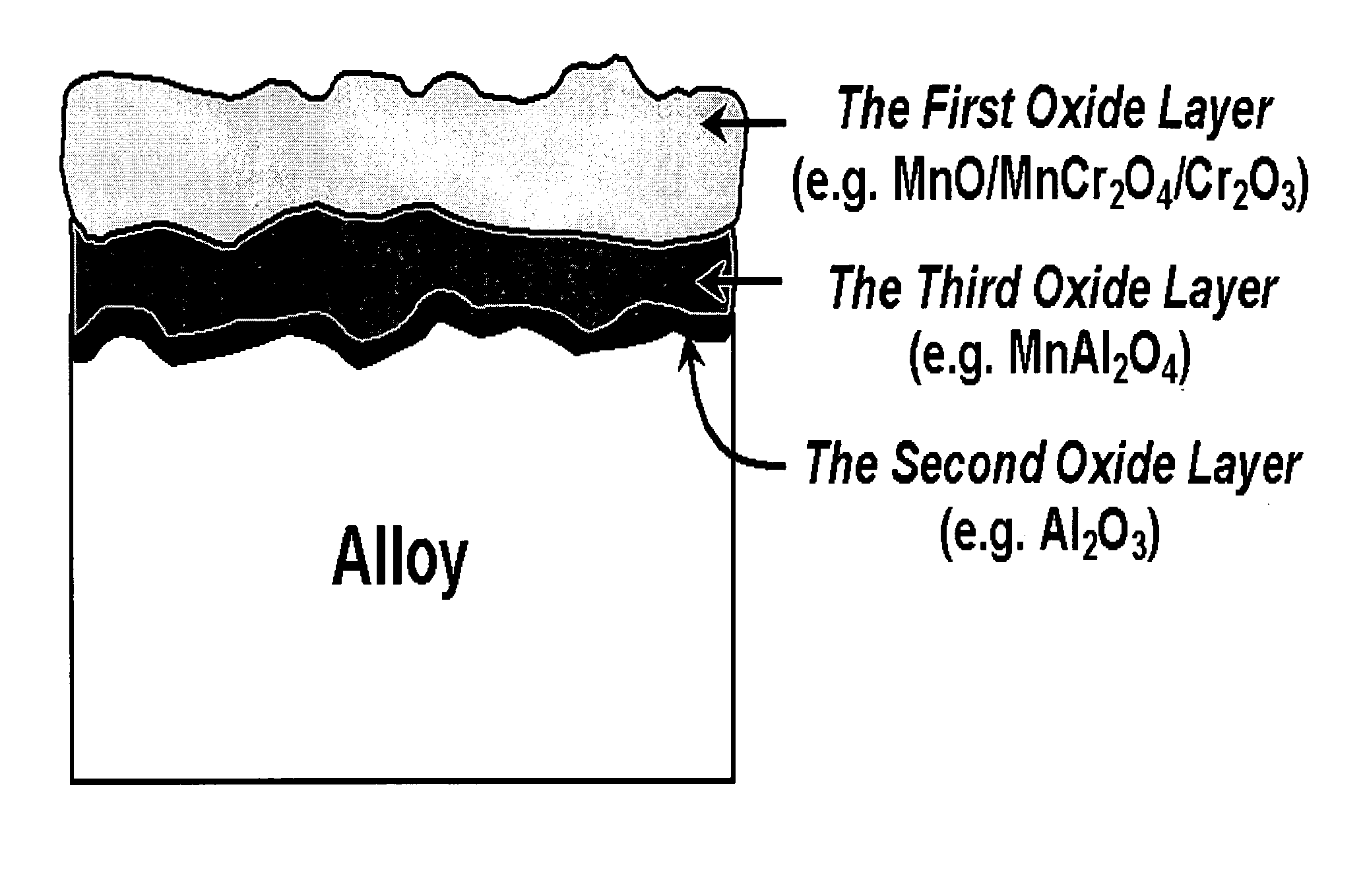

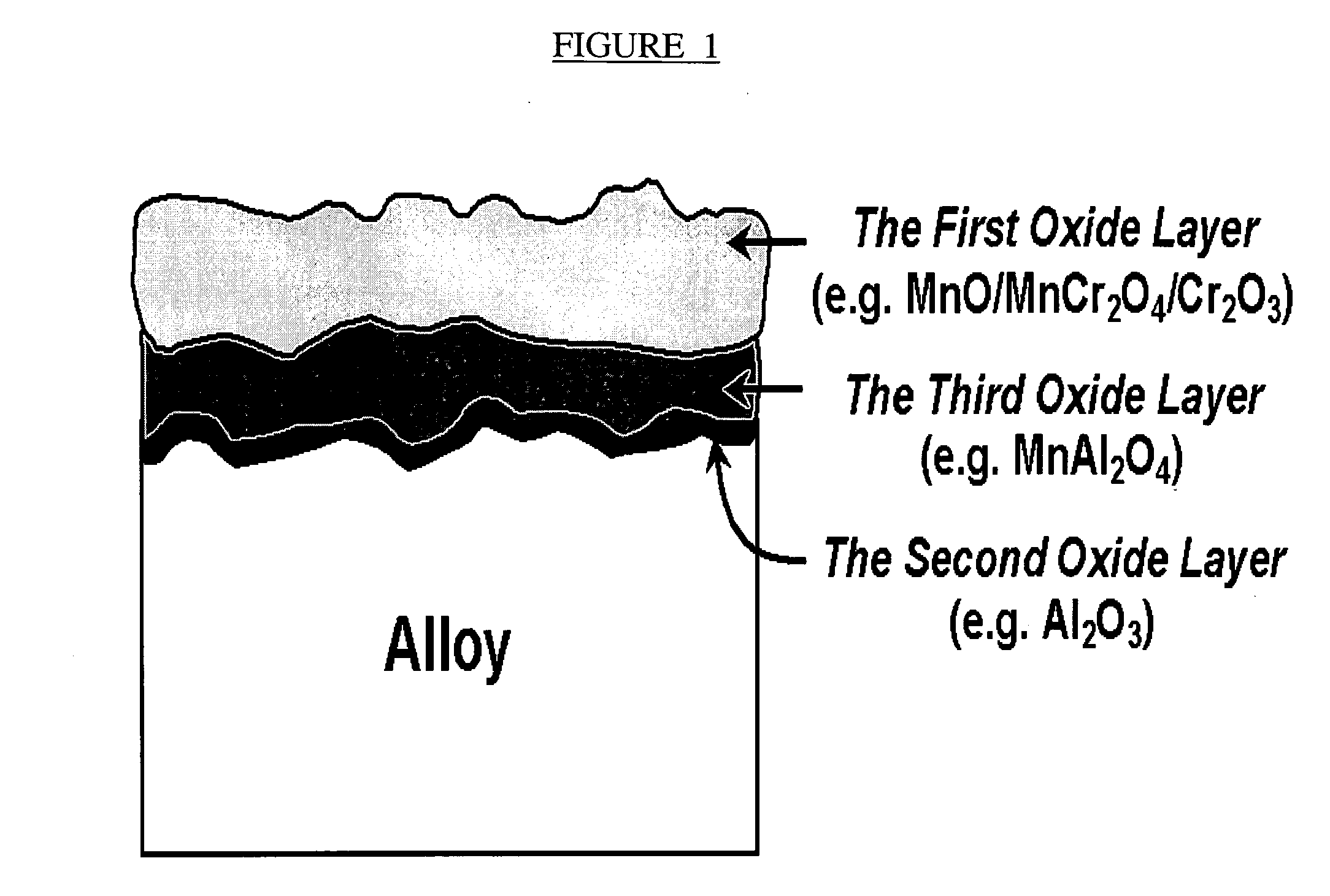

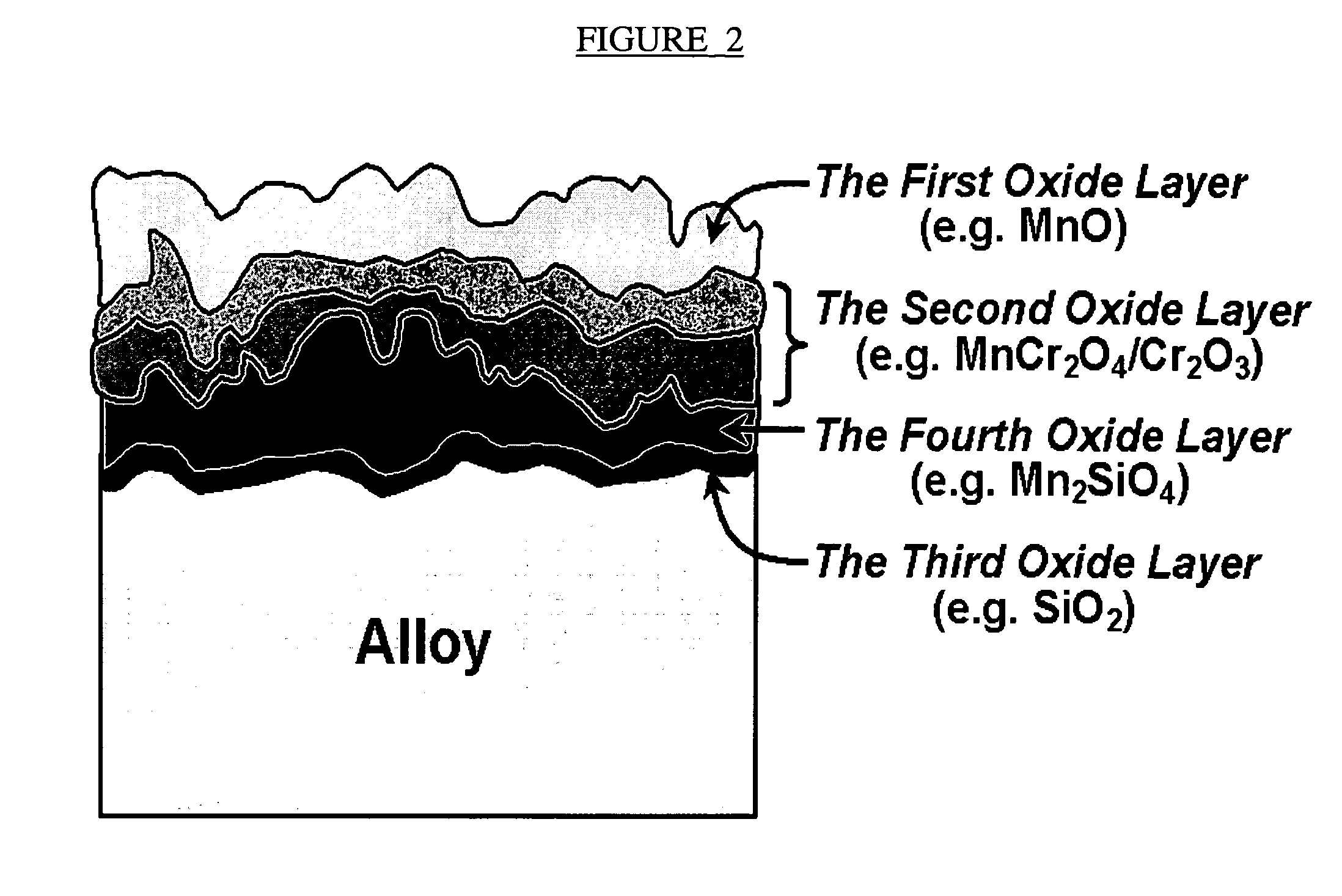

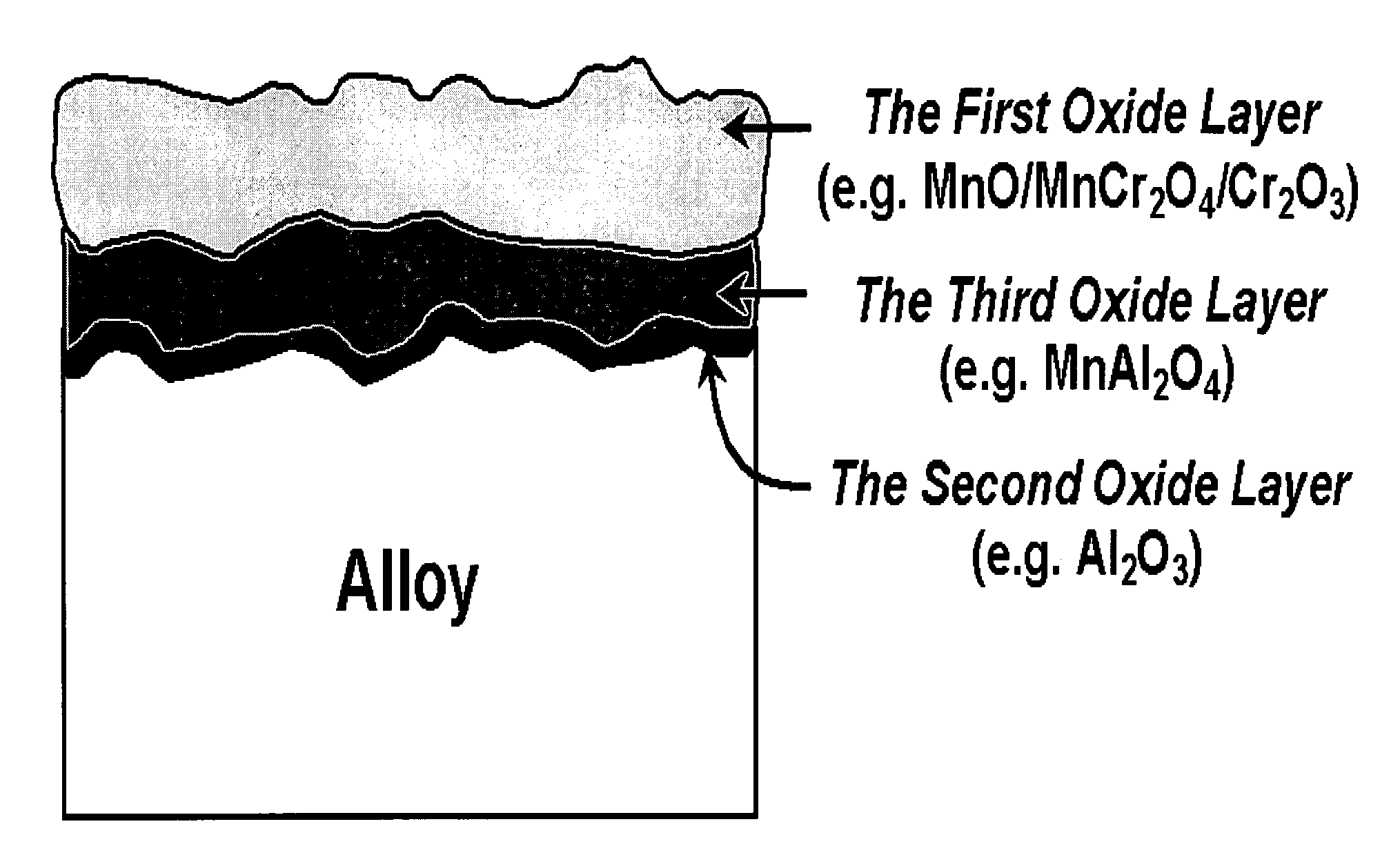

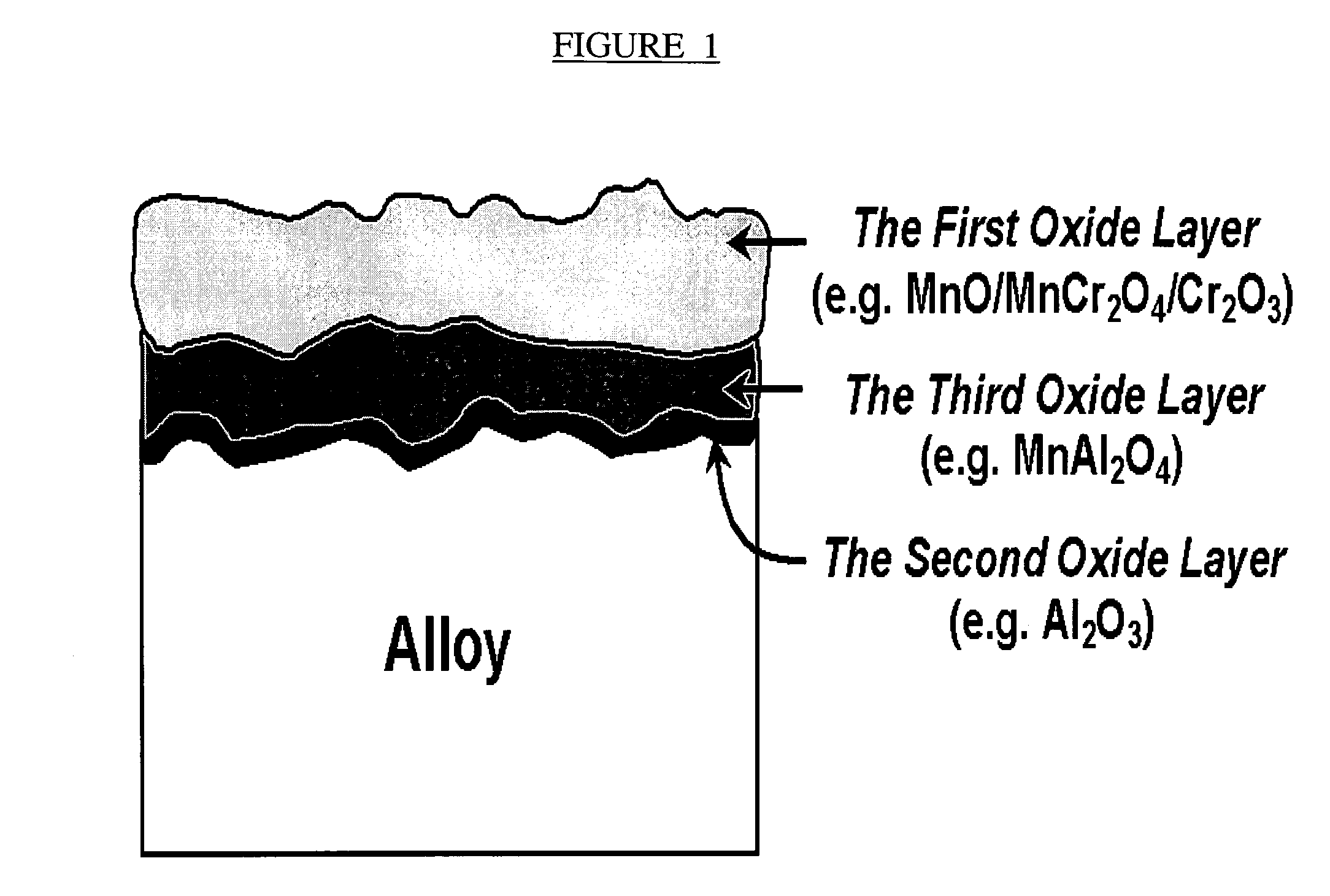

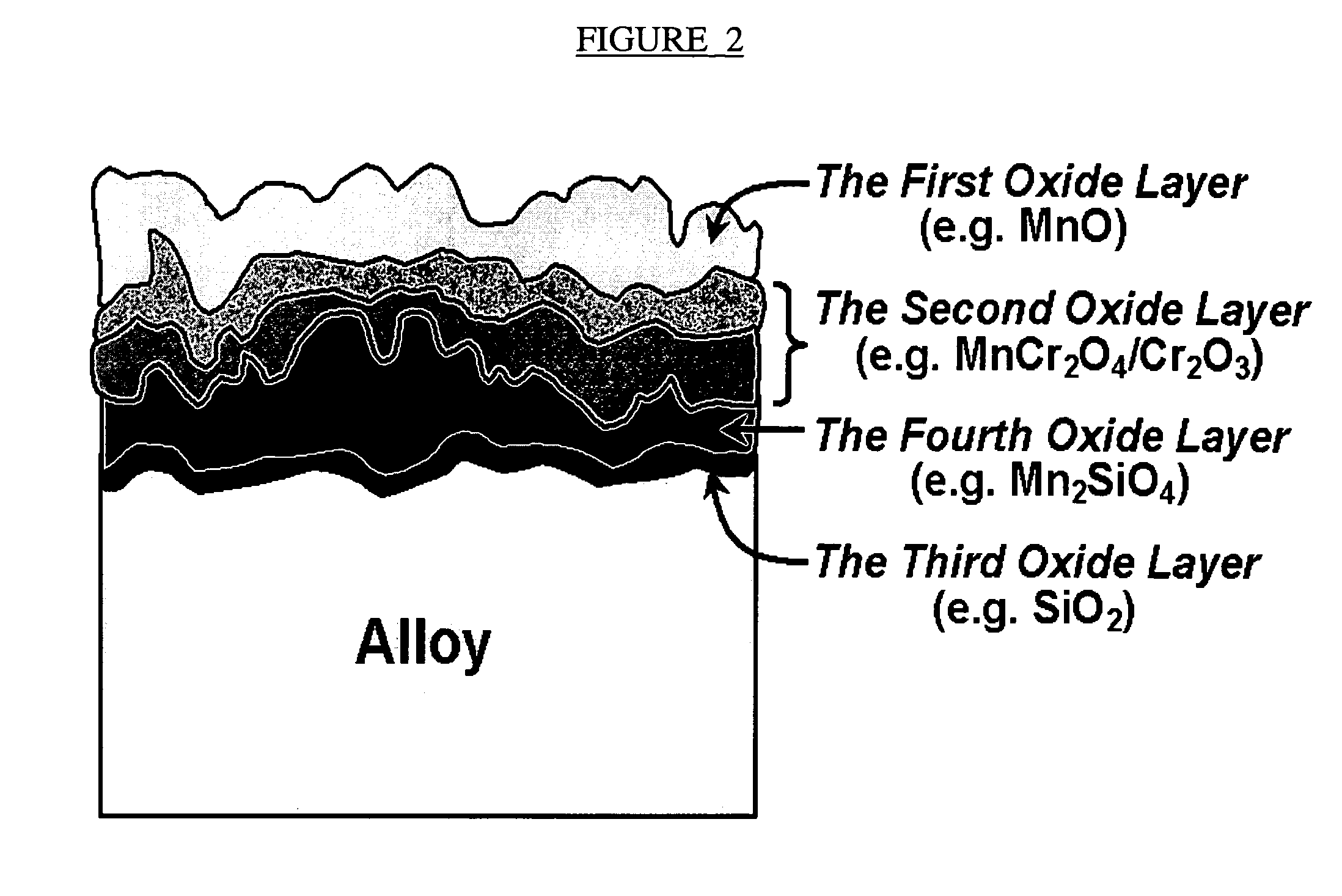

Alloy compositions which are resistant to metal dusting corrosion are provided by the present invention. Also provided are methods for preventing metal dusting on metal surfaces exposed to carbon supersaturated environments. The alloy compositions include an alloy (PQR), and a multi-layer oxide film on the surface of the alloy (PQR). The alloy (PQR) includes a metal (P) selected from the group consisting of Fe, Ni, Co, and mixtures thereof, an alloying metal (Q) comprising Cr, Mn, and either Al, Si, or Al / Si, and an alloying element (R). When the alloying metal (Q) includes Al, the multi-layer oxide film on the surface of the alloy includes at least three oxide layers. When the alloying metal (Q) includes Si, the multi-layer oxide film on the surface of the alloy (PQR) includes at least four oxide layers. When the alloying metal (Q) includes Al and Si, the multi-layer oxide film on the surface of the alloy (PQR) includes at least three oxide layers. The multi-layer oxide film is formed in situ during use of the alloy composition in a carbon supersaturated metal dusting environment. Advantages exhibited by the disclosed alloy compositions include improved metal dusting corrosion resistance at high temperatures in carbon-supersaturated environments having relatively low oxygen partial pressures. The disclosed alloy compositions are suitable for use as the inner surfaces in reactor systems and refinery apparatus.

Owner:EXXON RES & ENG CO

Thermally insulated metal surface protected against metal dusting corrosion

The metal surface protected against metal-dusting corrosion has an insulating layer of a gas-permeable, thermally insulating material. The side of the thermal insulating layer that is colder during operation is in direct vicinity of the metal surface, and the side of the insulating layer that is hotter during operation is heated by a gas stream containing carbon monoxide, which in addition contains hydrogen and / or steam and has a temperature in the range from 300 to 1700 DEG C. In the region between the metal surface to be protected and the hot side of the insulating layer a catalyst is provided for reacting carbon monoxide with hydrogen and / or steam.

Owner:METALLGESELLSCHAFT AG

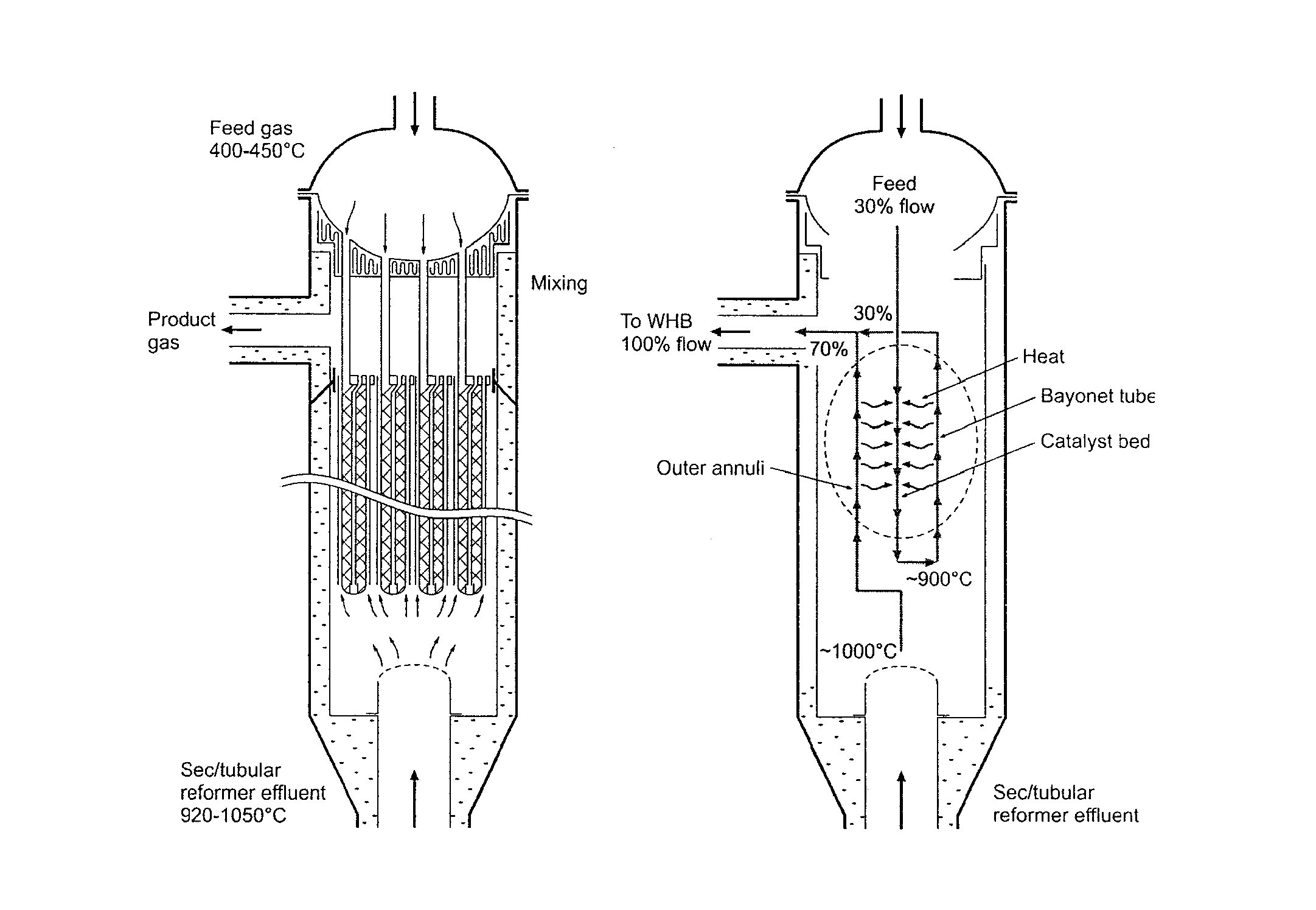

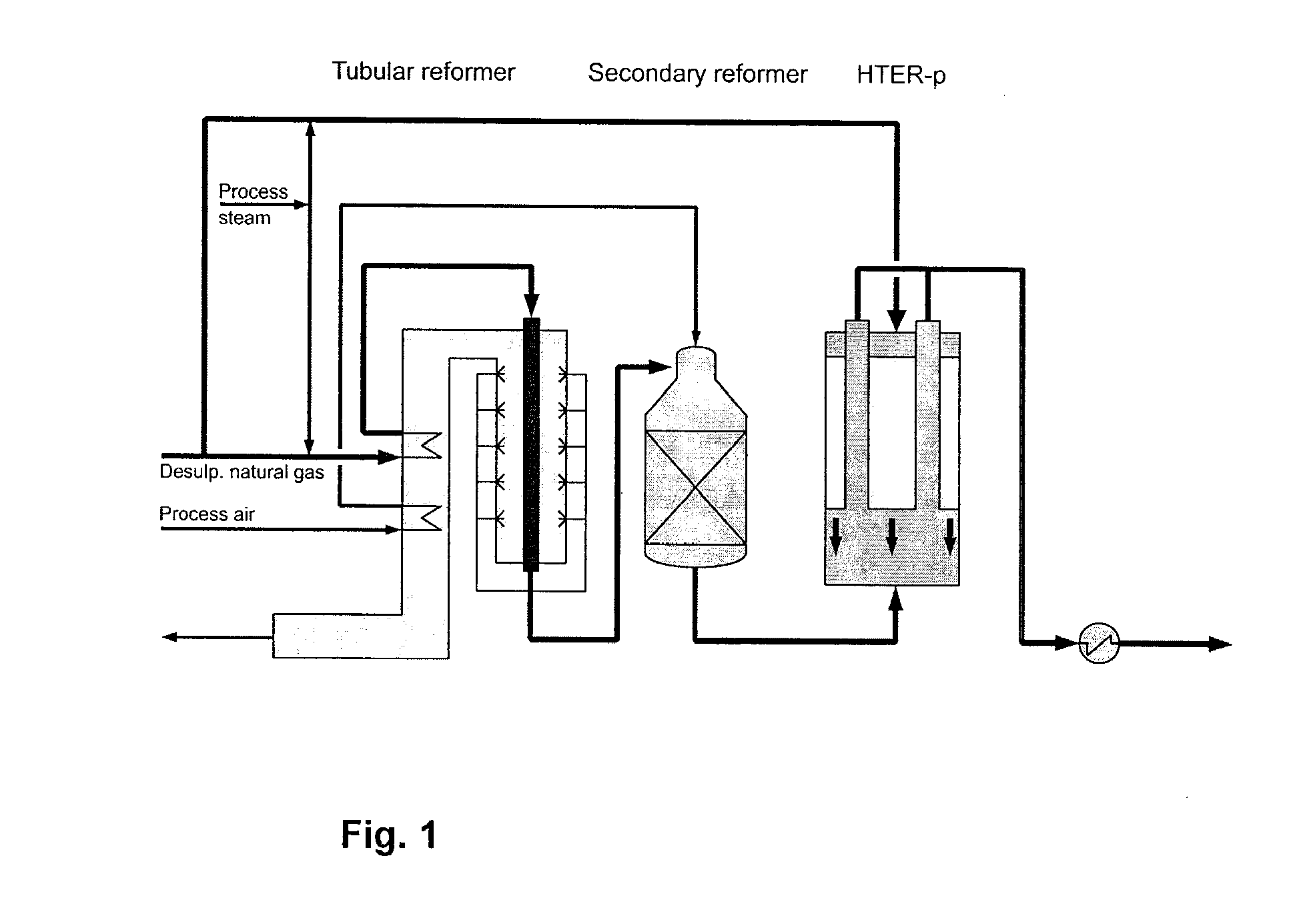

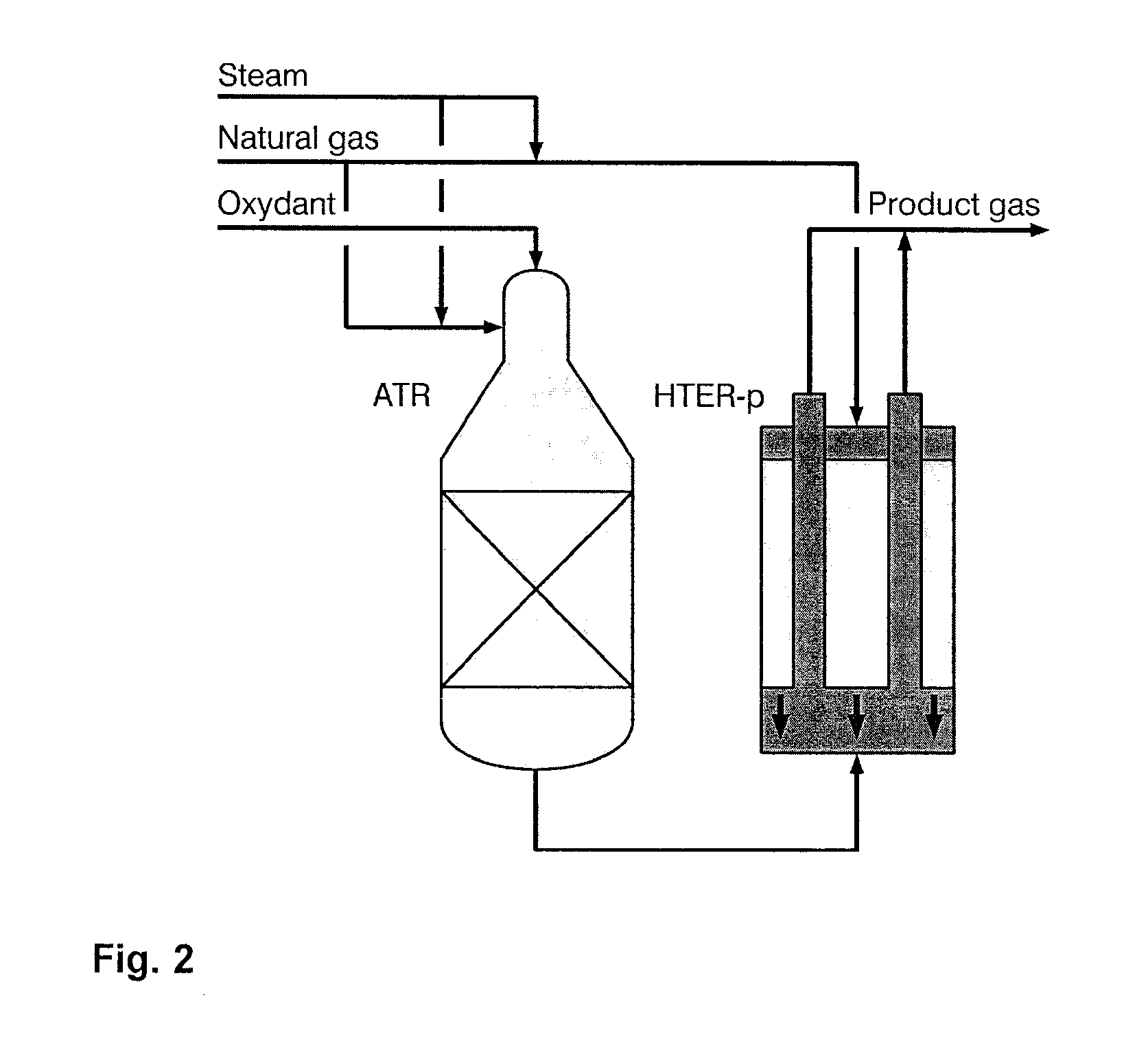

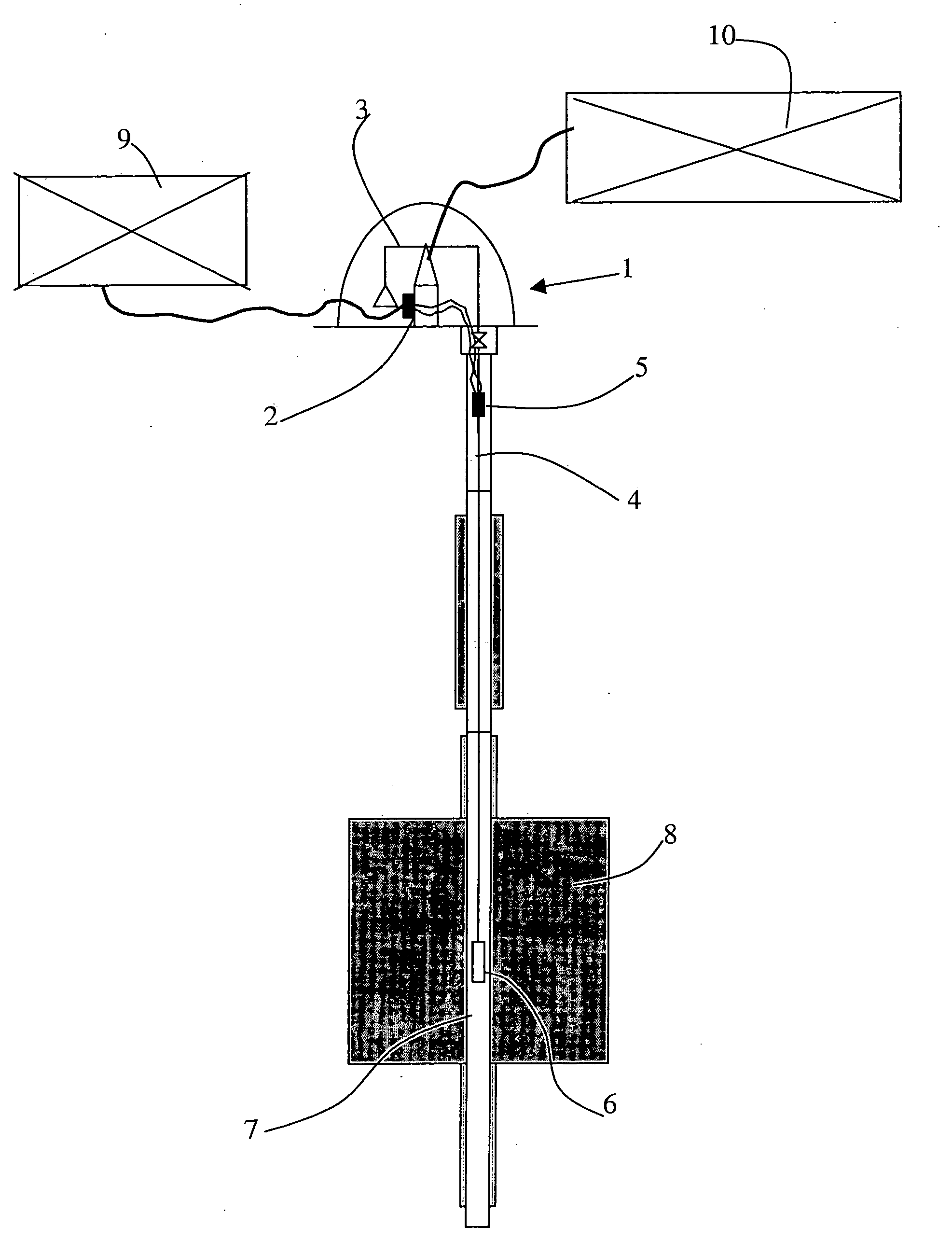

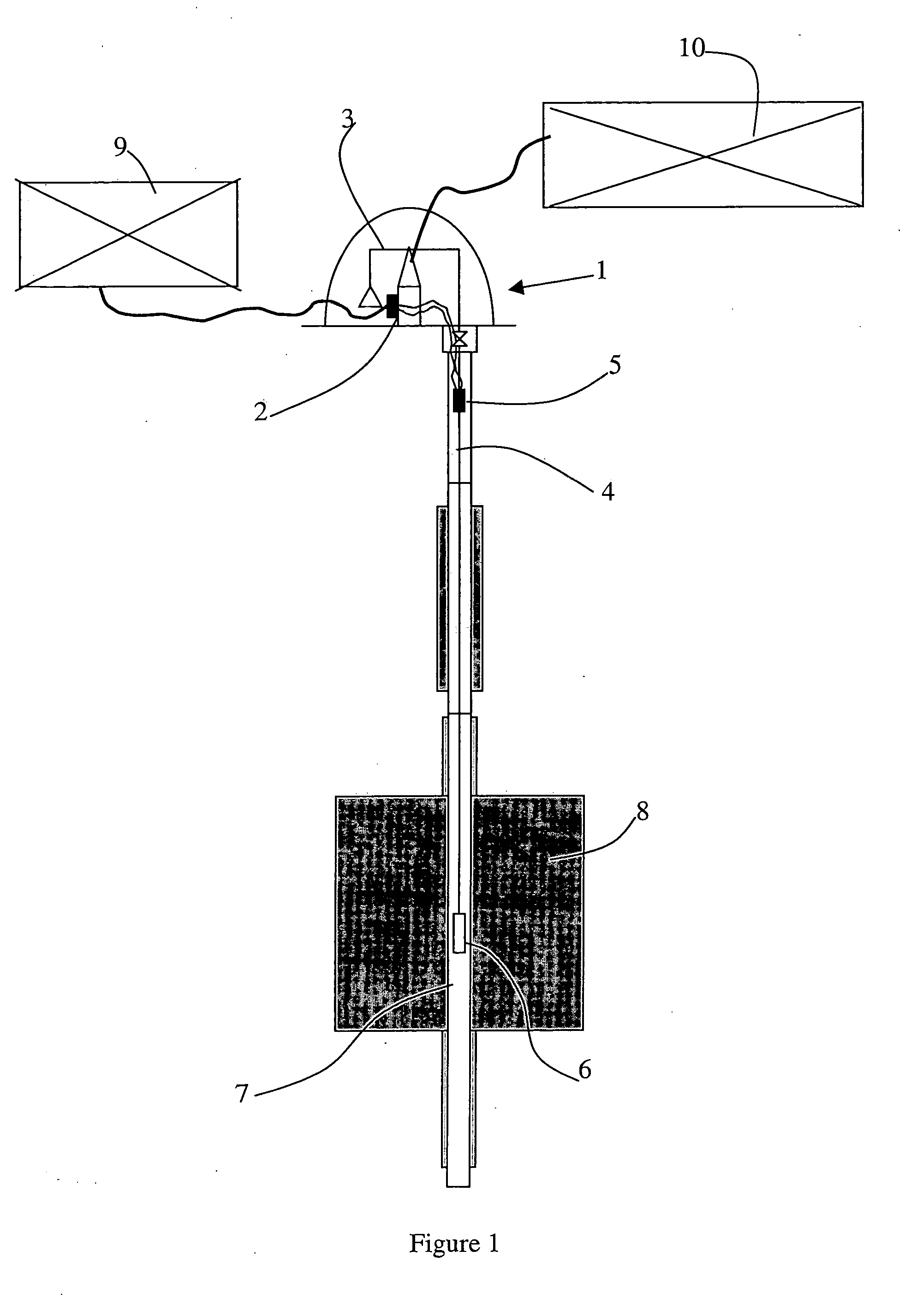

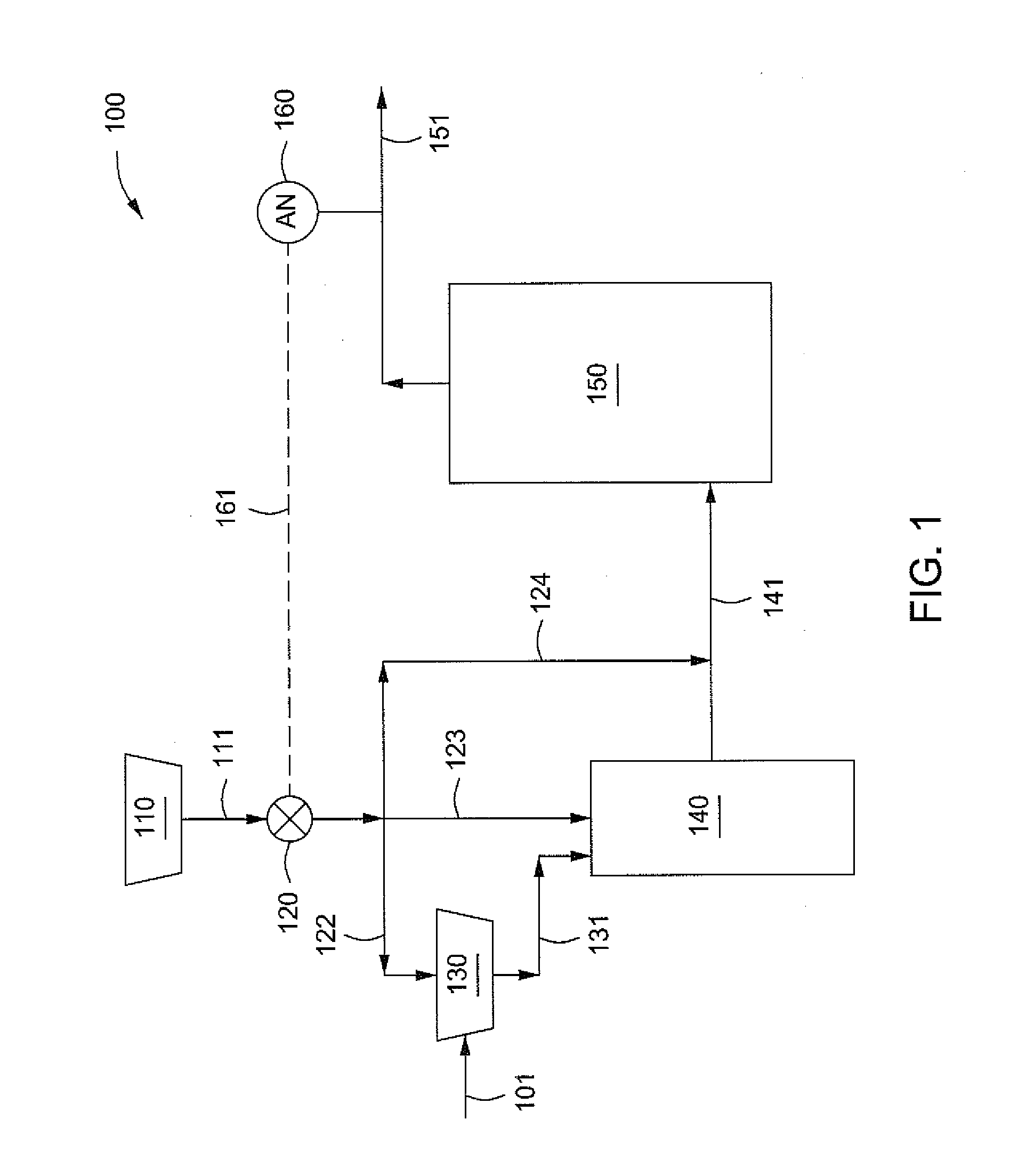

Feed ratio control for hter

The invention provides a Heat Exchange Reformer (HER) arranged to be part of a synthesis gas production unit and comprising at least a first and a second metal in order to minimise metal dusting. The invention moreover relates to a method for improved thermal control in a Heat Exchange Reformer (HER) and a computer readable storage medium. The invention provides improved thermal control and reduced metal dusting of the Heat Exchange Reformer.

Owner:HALDOR TOPSOE AS

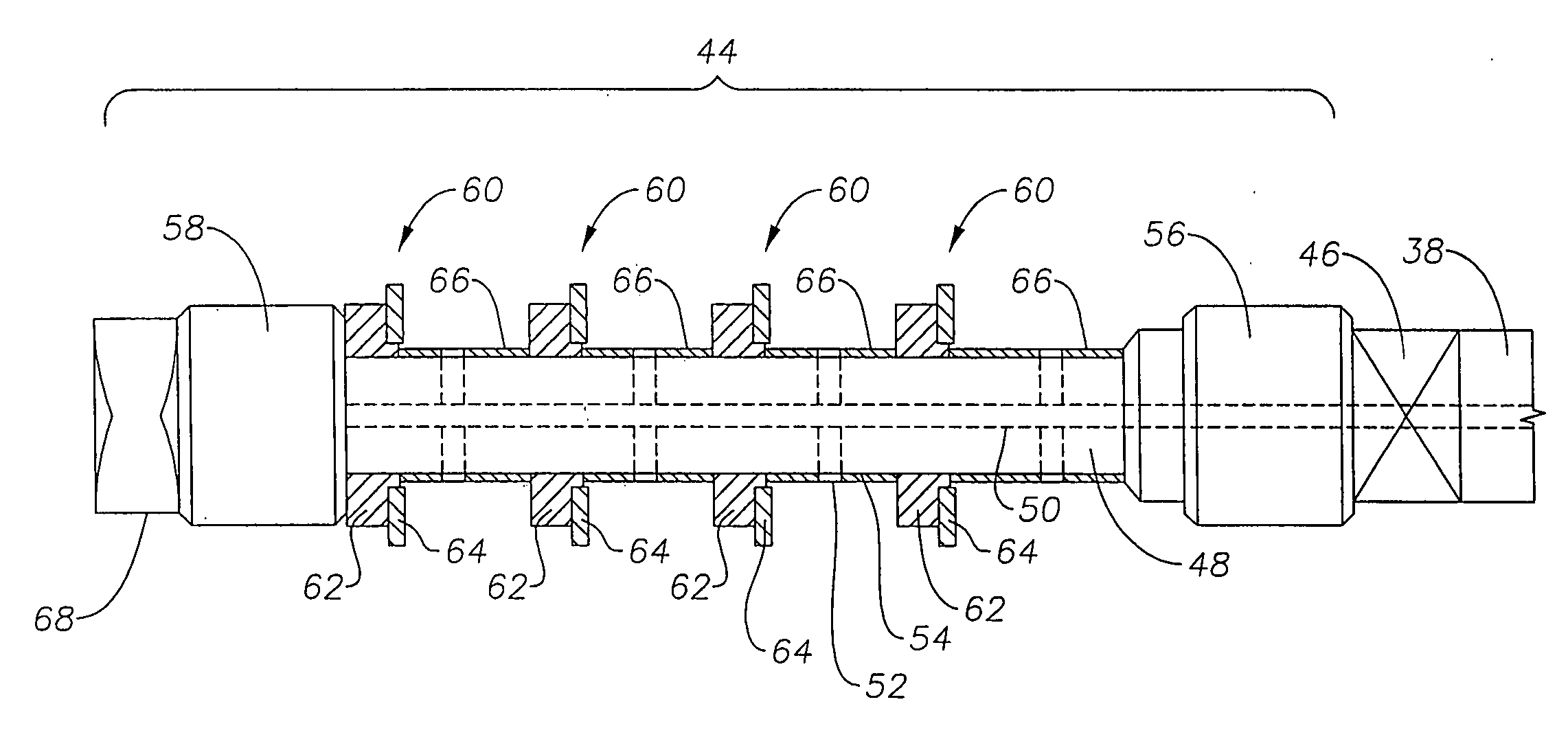

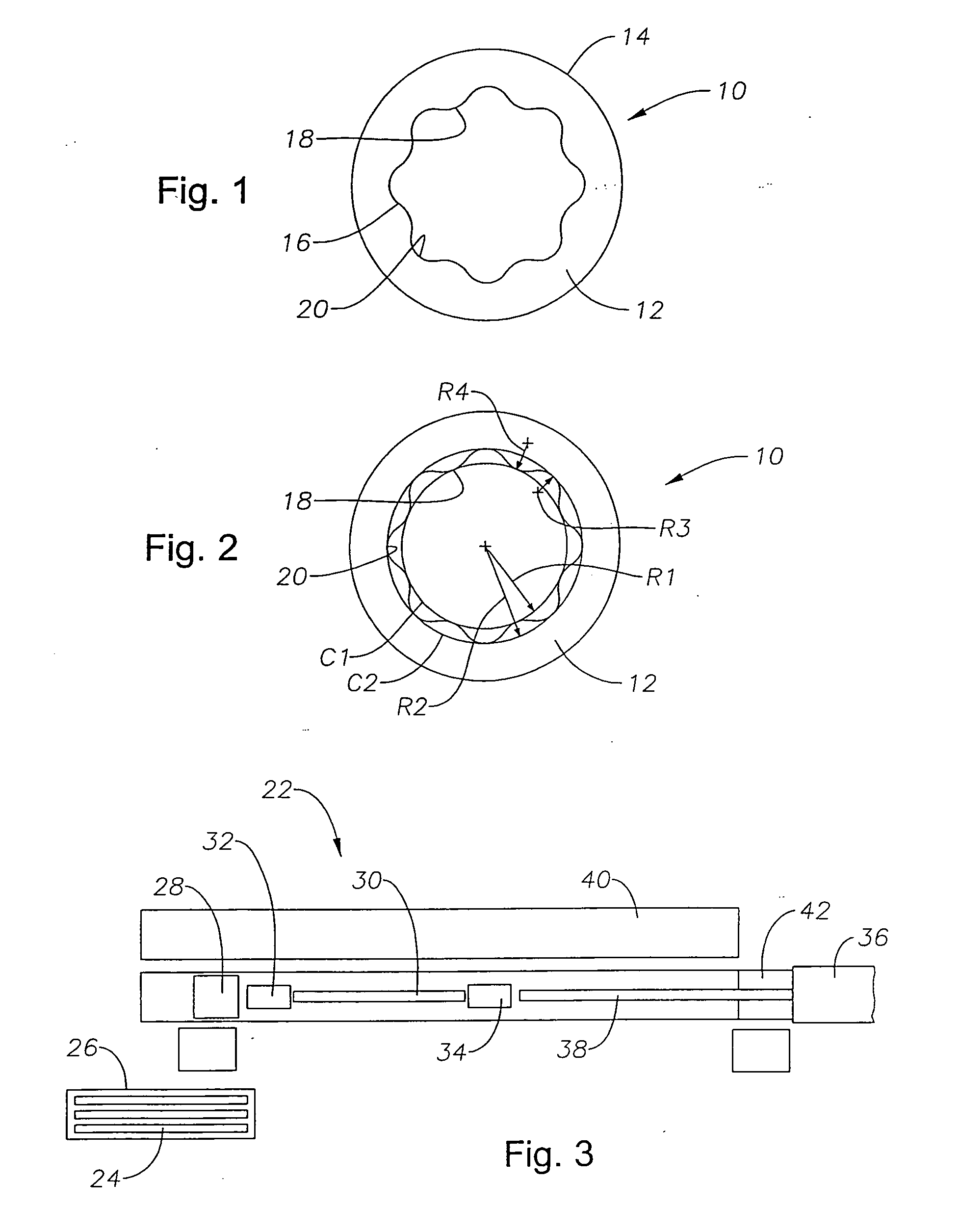

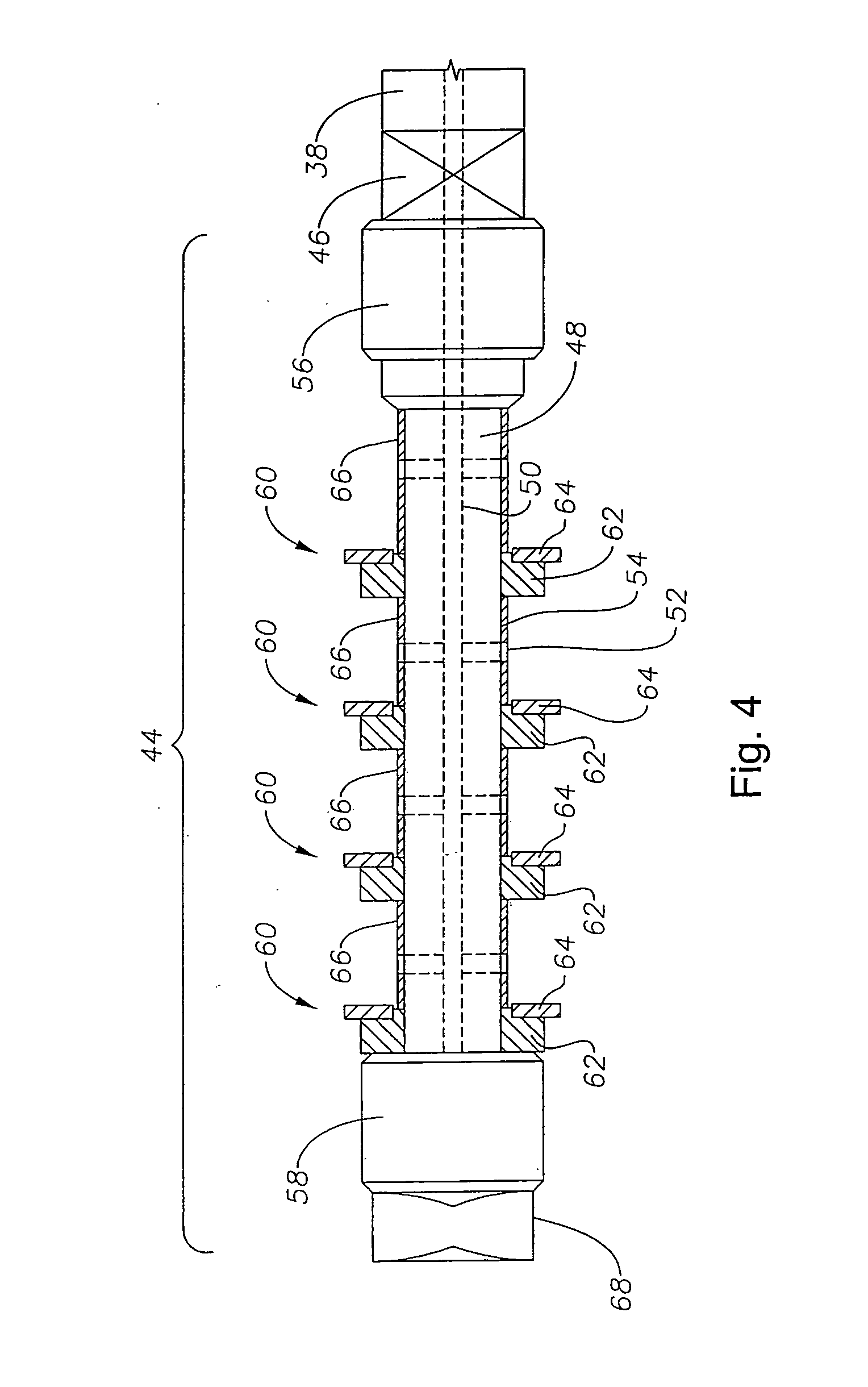

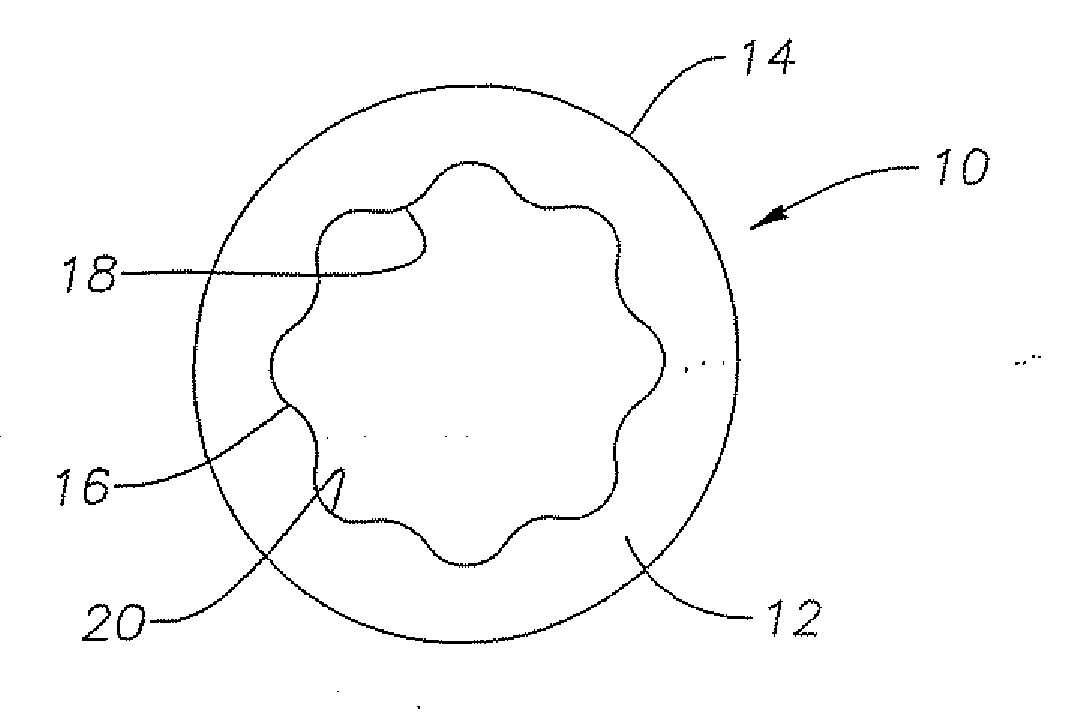

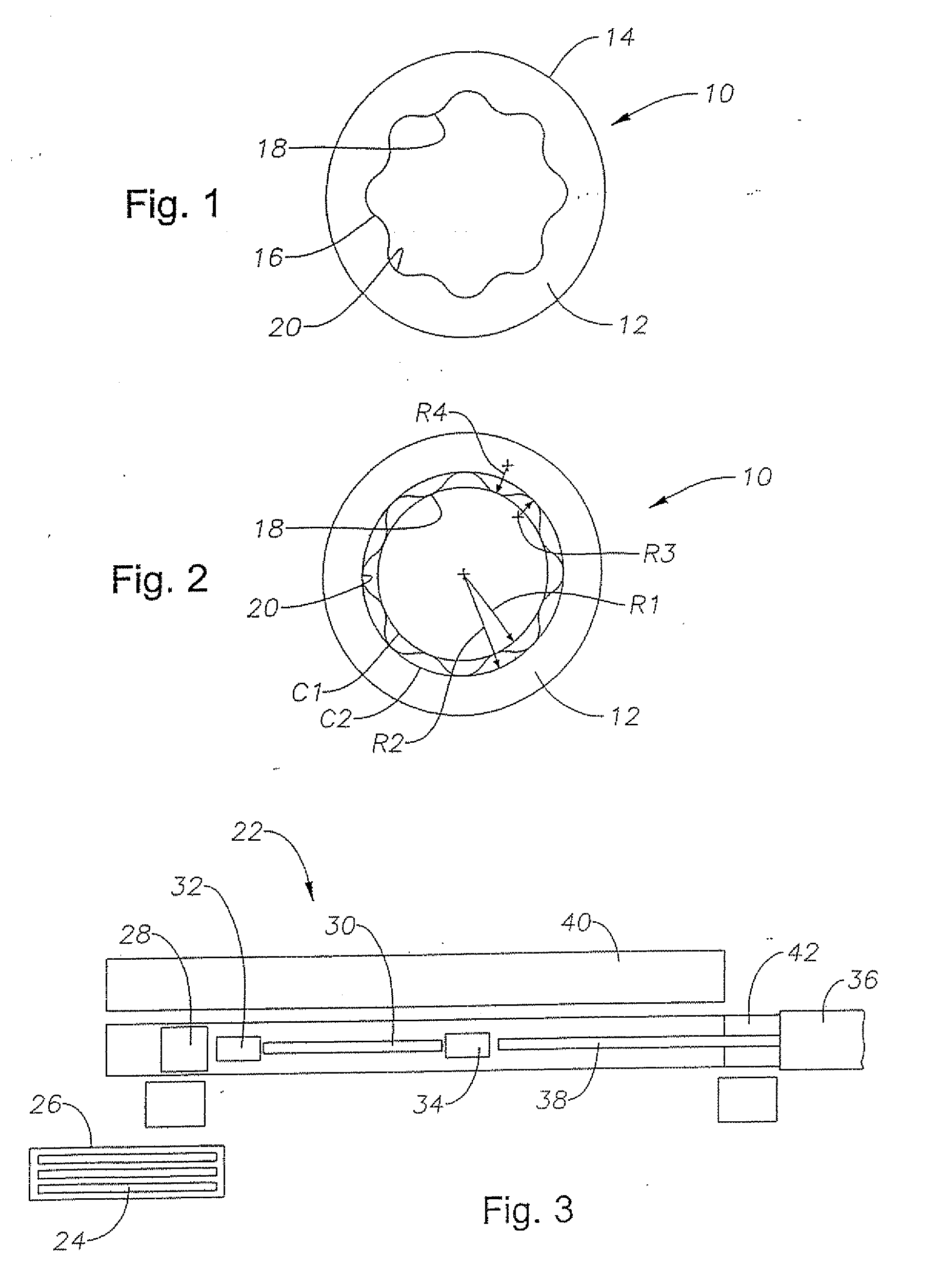

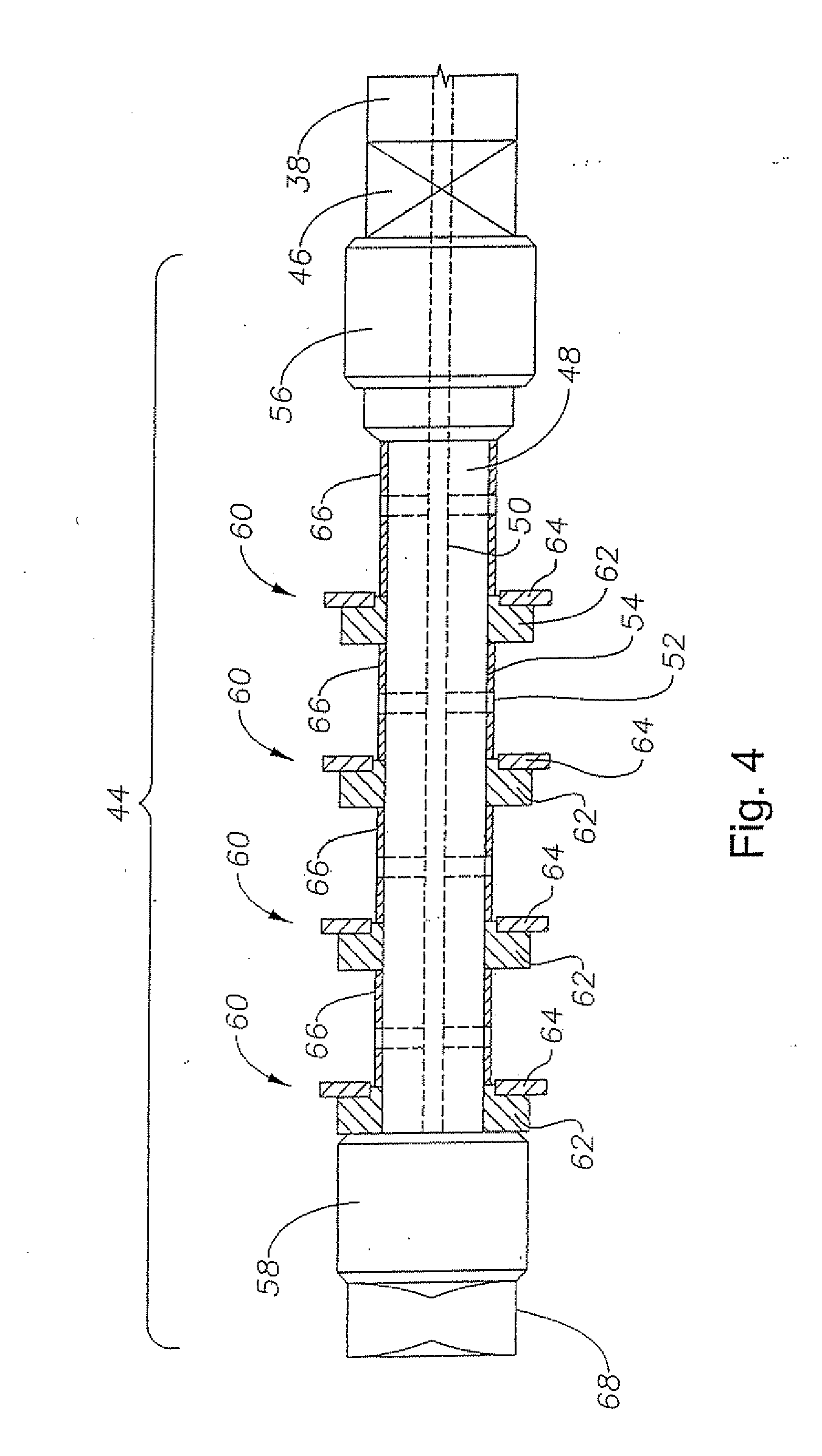

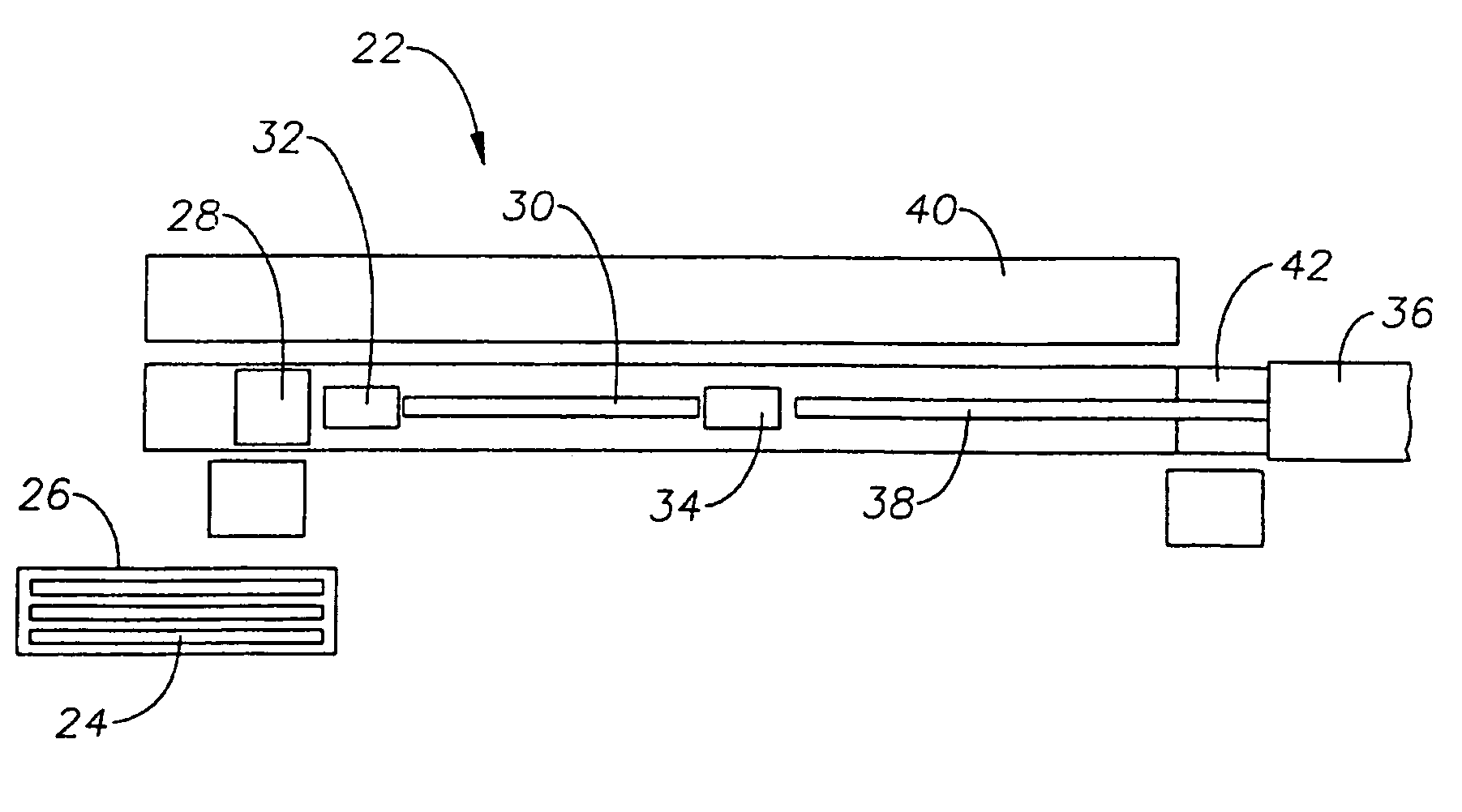

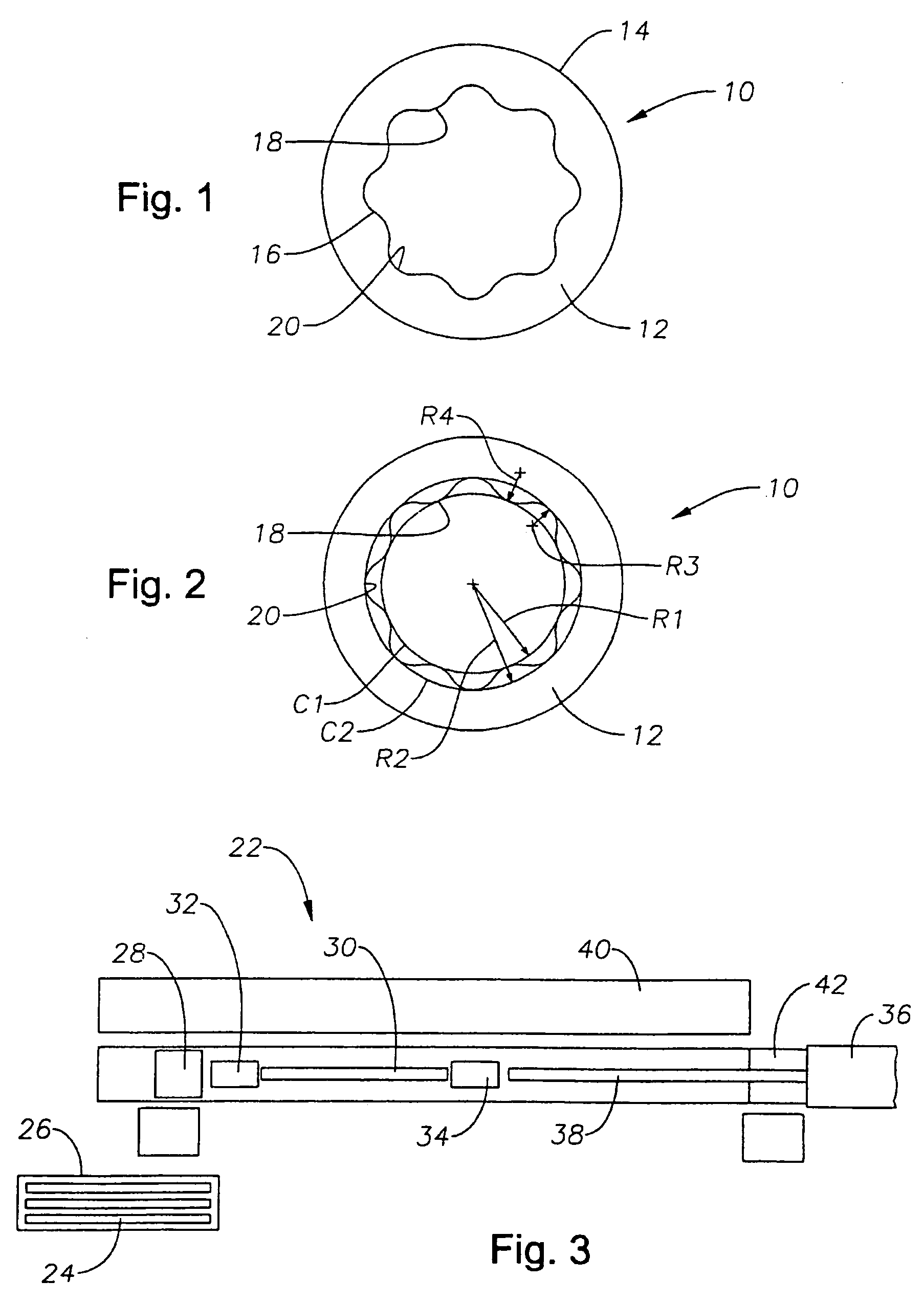

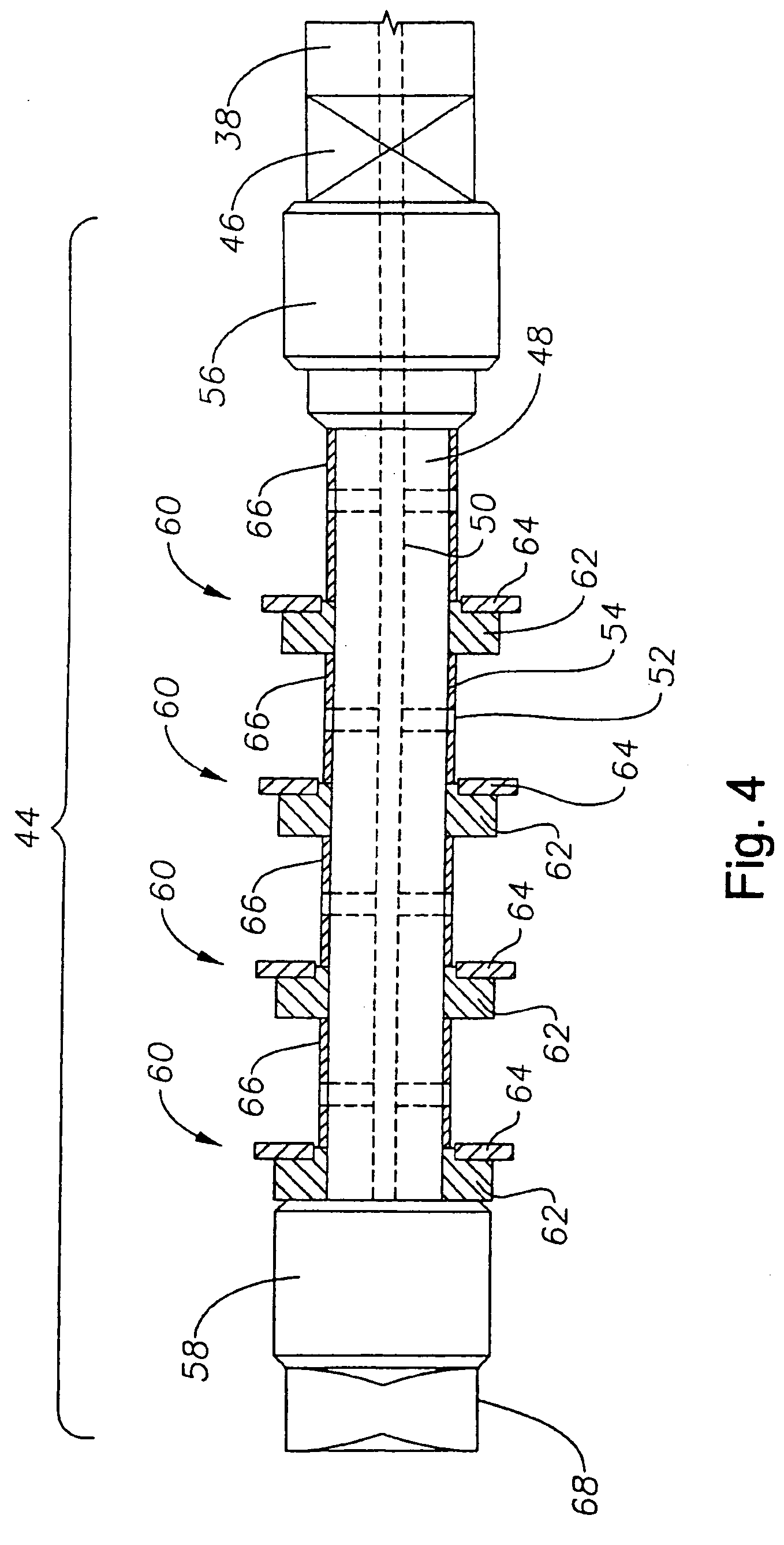

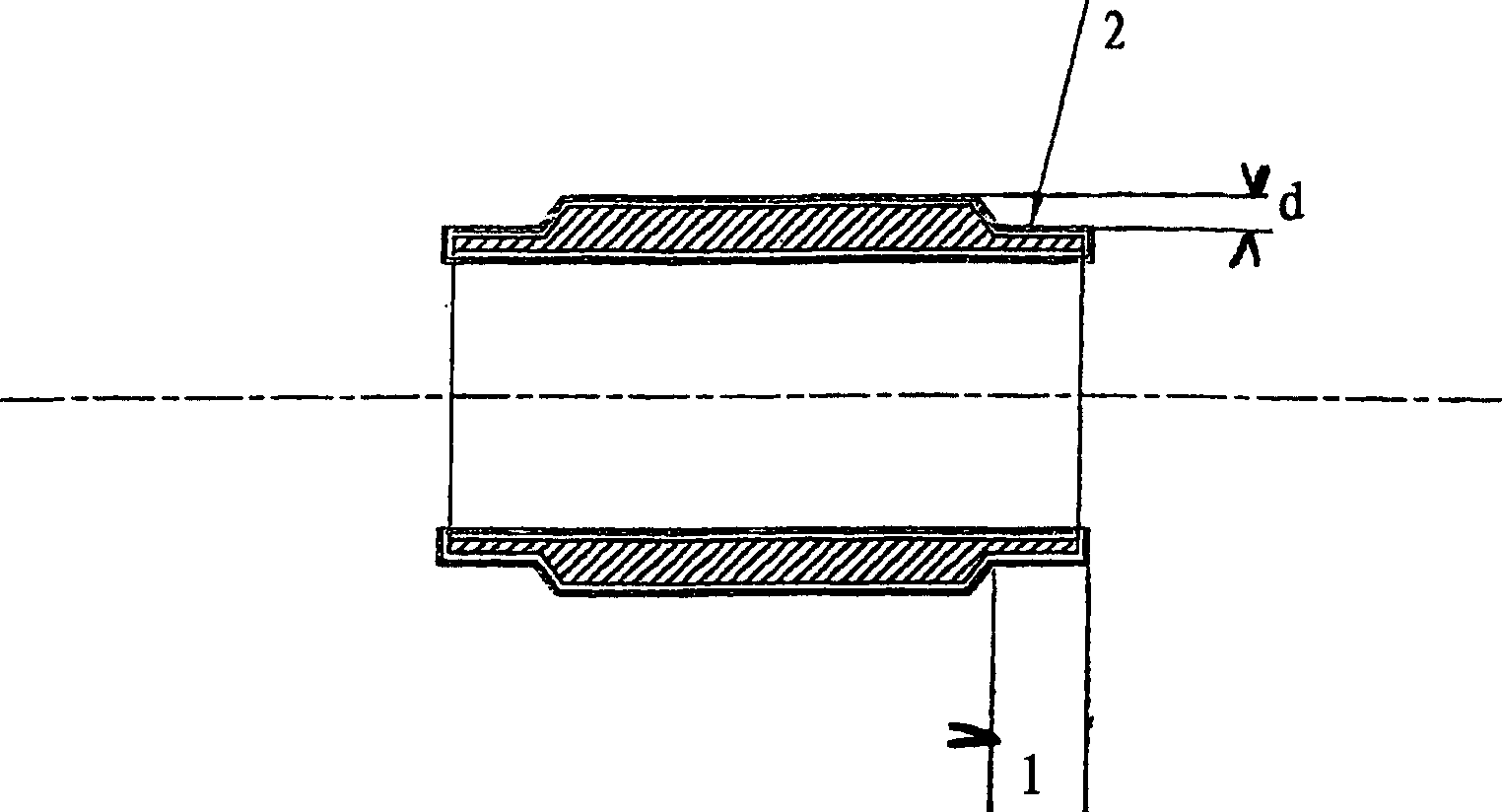

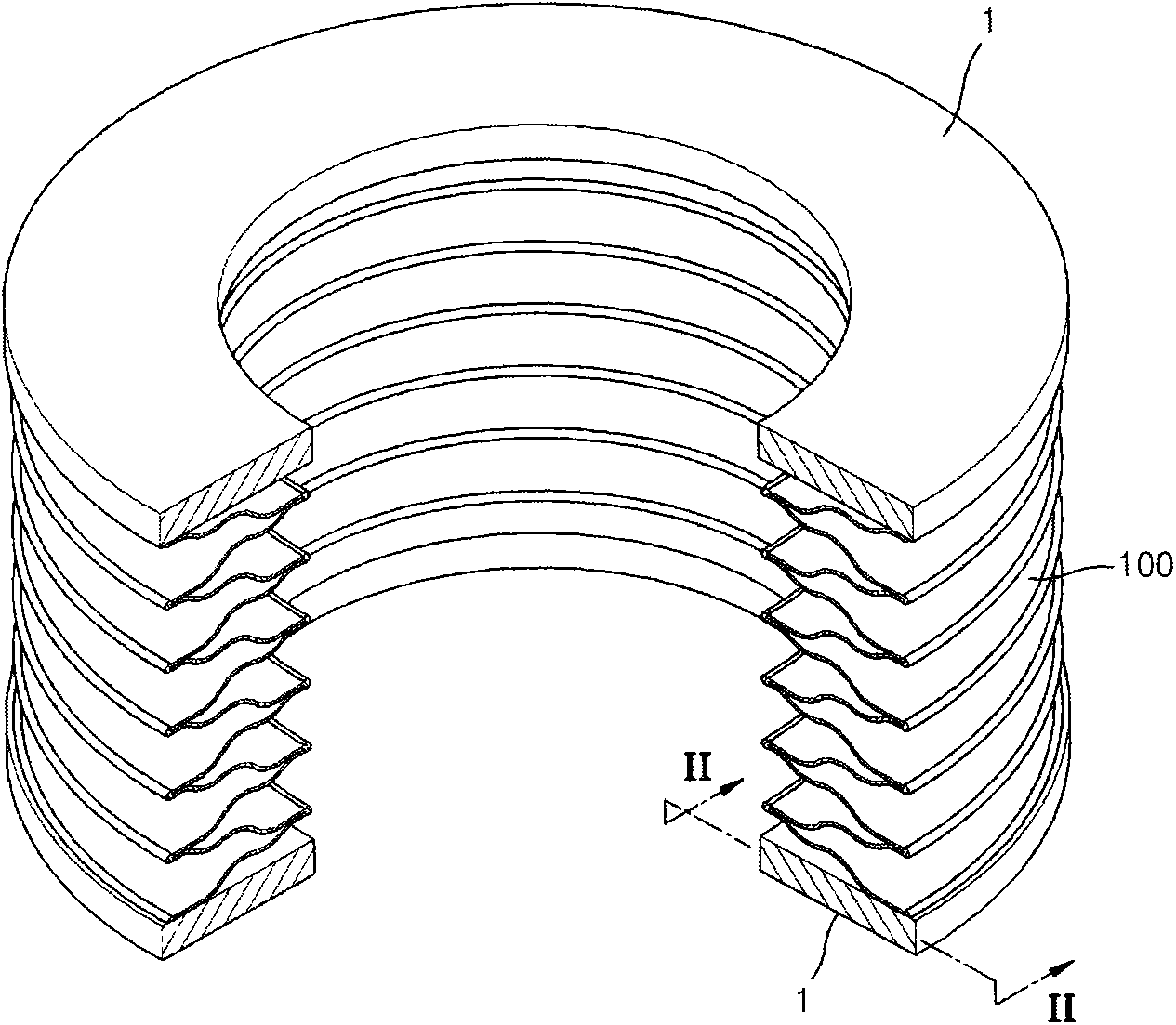

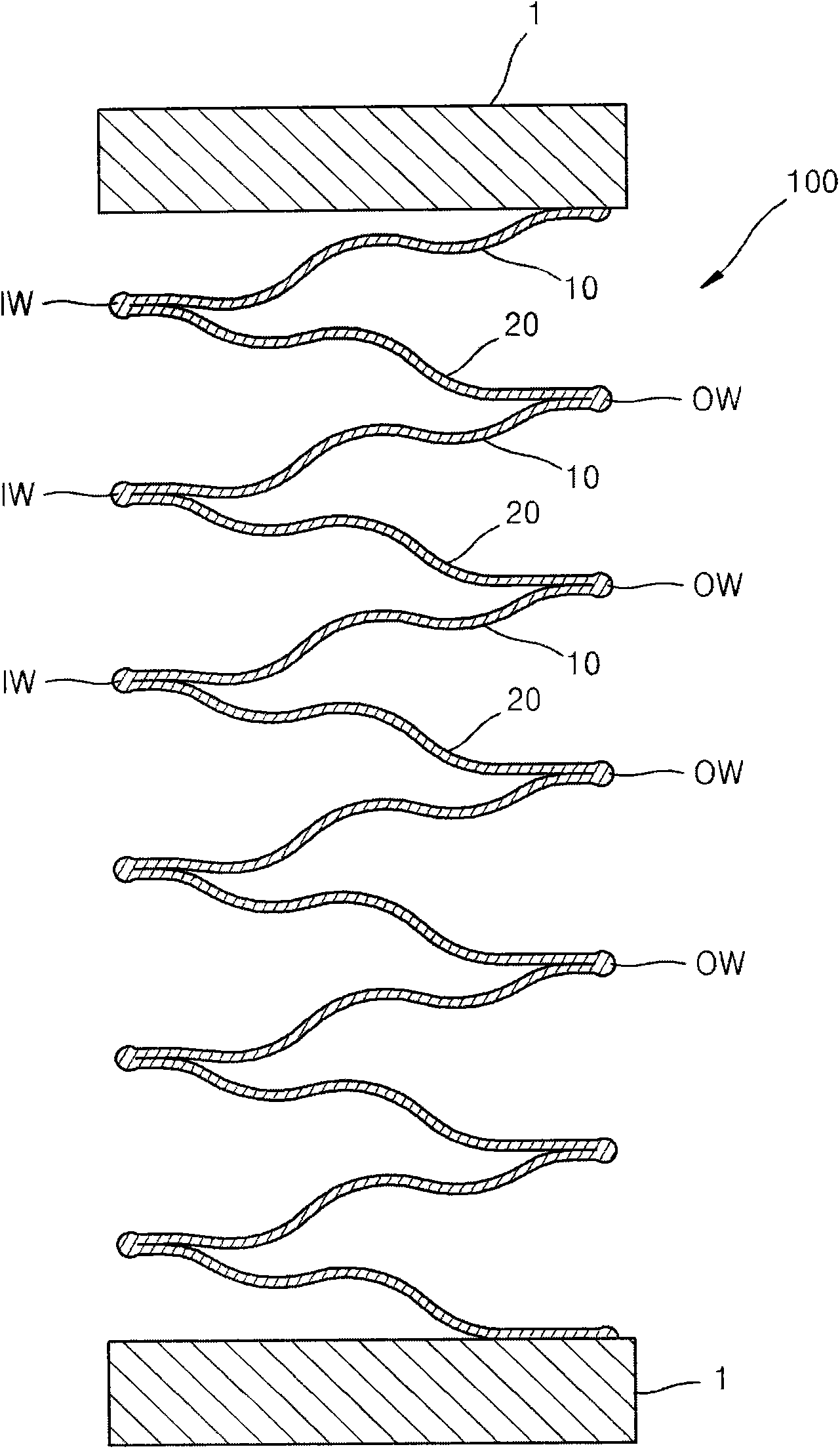

Centrifugally-cast tube and related method and apparatus for making same

InactiveUS20060056934A1High dimensional accuracyImprove roughness accuracyBroaching accessoriesRectilinear broachMetal dustingEnhanced heat transfer

An improved centrifugally-cast tube is provided, along with a related method and apparatus of making the tube. The tube includes a plurality of grooves and bosses that are mechanically machined into an interior surface of the tube, such as by a broaching process. The profile of grooves and bosses may be defined by a plurality of intersecting concave and convex radii. The tube is resistant to creep, carburization and metal dusting. The tube also has an enhanced heat transfer rate, and a desirable surface roughness. A method of making the tube is also provided. The method essentially consists of mechanically deforming the interior surface of the tube by passing a series of cutting inserts on support rings having incrementally-differing dimensions over the interior surface. An apparatus is also provided which includes a telescoping shaft upon which is mounted at least one cutting tool that has a plurality of cutting inserts and is adapted to form a plurality of grooves and bosses in the interior surface of the tube. The grooves and bosses may be straight or spiraled.

Owner:DEMAREST JOEL +1

Centrifugally-cast tube and related method and apparatus for making same

An improved centrifugally-cast tube is provided, along with a related method and apparatus of making the tube. The tube includes a plurality of grooves and bosses that are mechanically machined into an interior surface of the tube, such as by a broaching process The profile of grooves and bosses may be defined by a plurality of intersecting concave and convex radii. The tube is resistant to creep, carburization and metal dusting. The table also has an enhanced heat transfer rate, and a desirable surface roughness. A method of making the tube is also provided. The method essentially consists of mechanically deforming the interior surface of the tube by passing a series of cutting inserts on support rings having incrementally-differing dimensions over the interior surface. An apparatus is also provided which includes a telescoping shaft upon which is mounted at least one cutting tool that has a plurality of cutting inserts and is adapted to form a plurality of grooves and bosses in the interior surface of the tube. The grooves and bosses may be straight or spiraled.

Owner:MANOIR INDUSTRIES

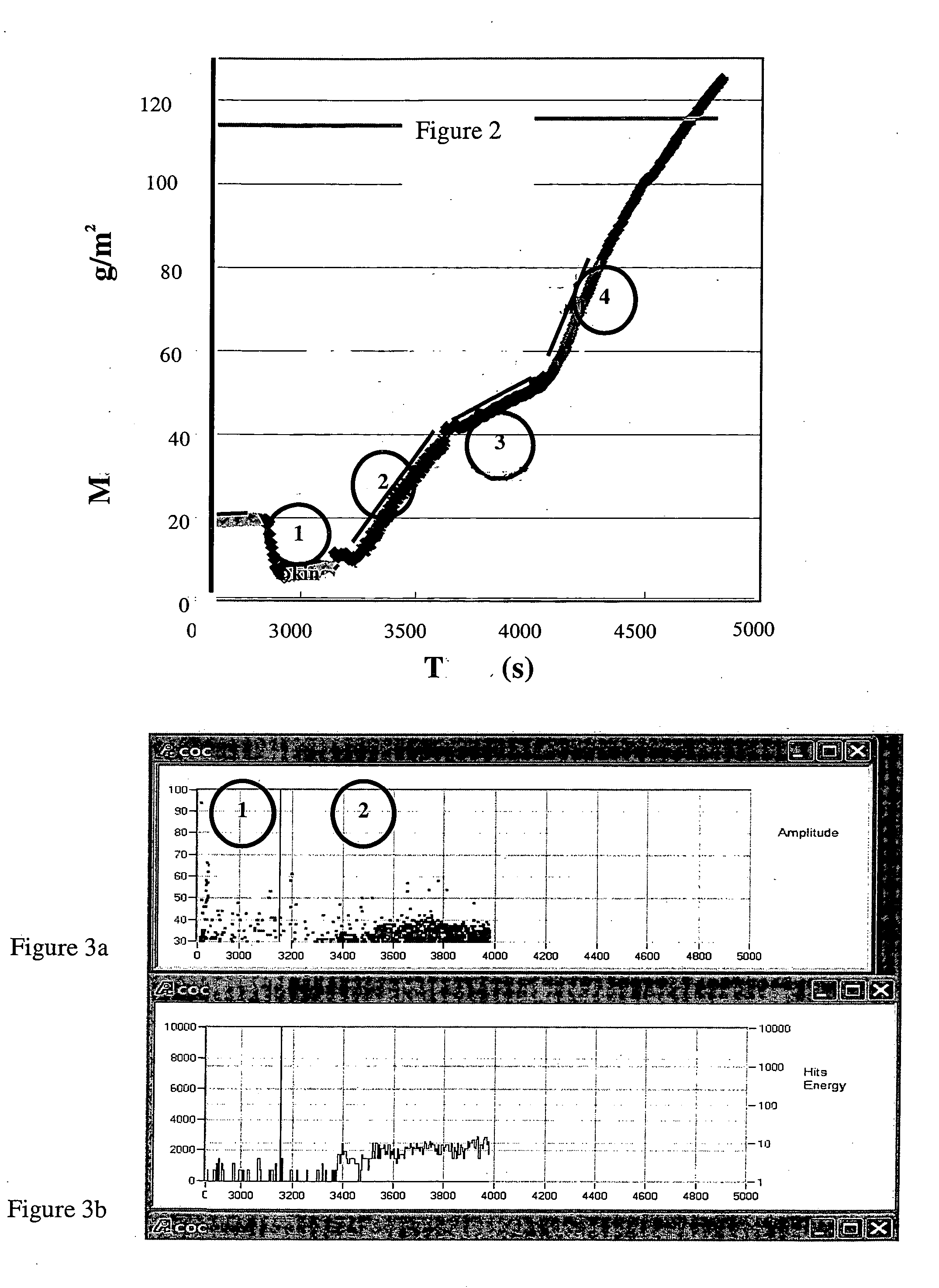

Device for coupling thermogravimetric analyses and acoustic emission measurements

InactiveUS20060037386A1Vibration measurement in solidsMaterial analysis using acoustic emission techniquesMetal dustingAudio power amplifier

Owner:INST FR DU PETROLE

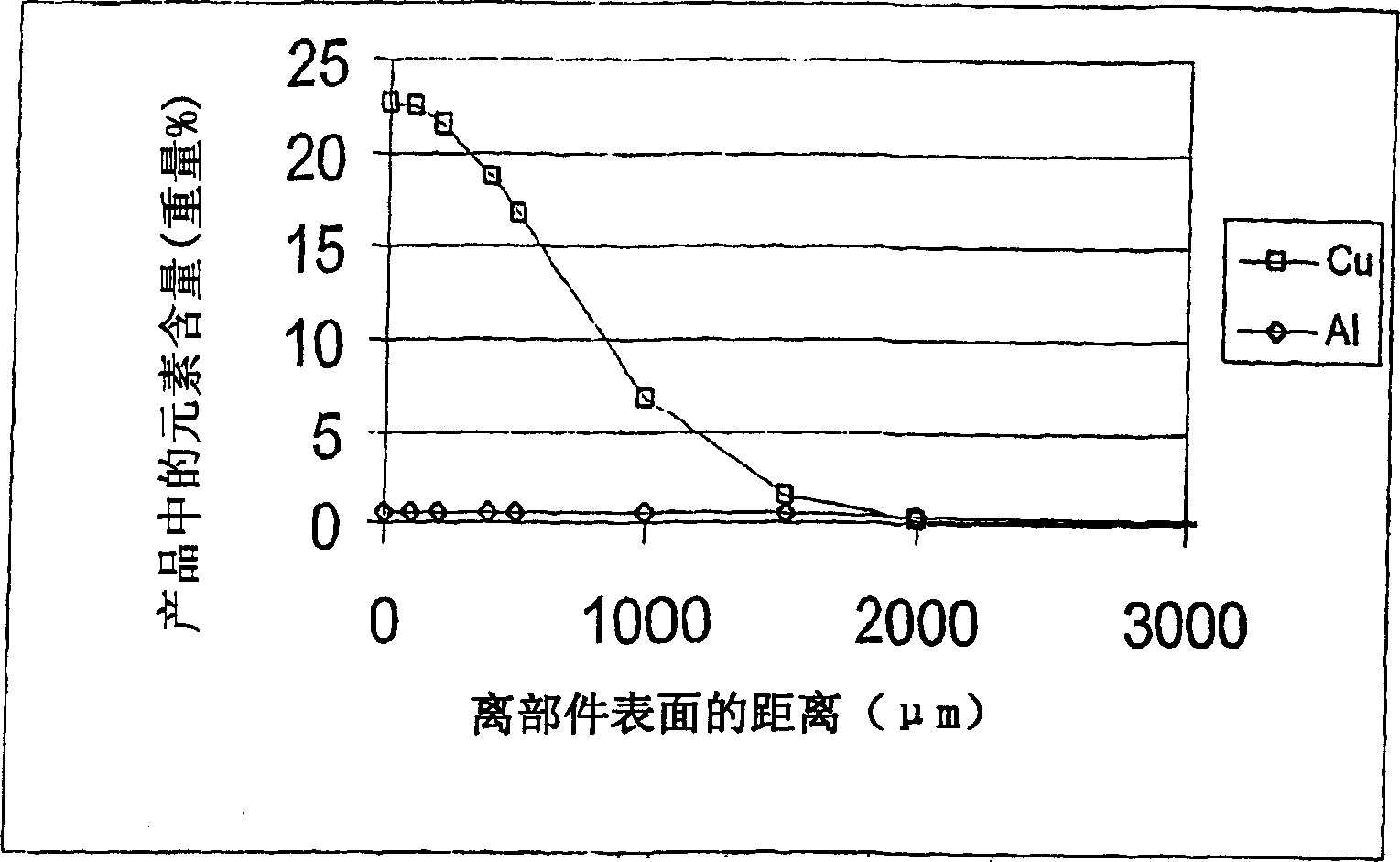

Metal dusting resistant product

A product is disclosed which is resistant or immune to carburization, metal dusting, coking, oxidation, and has sufficient mechanical strength for use at temperatures greater than 400 DEG C. The product consist of a load-bearing member and a corrosion resistant member, wherein the corrosion resistant member is a Cu-Al-alloy comprising Si. Furthermore, the use of the product in CO-containing atmospheres, and / or hydrocarbon containing atmospheres or solid carbon containing processes is disclosed, as well as a method of resisting carburization, metal dusting, coking and oxidation.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Centrifugally-cast tube and related method and apparatus for making same

An improved centrifugally-cast tube is provided, along with a related method and apparatus of making the tube. The tube includes a plurality of grooves and bosses that are mechanically machined into an interior surface of the tube, such as by a broaching process. The profile of grooves and bosses may be defined by a plurality of intersecting concave and convex radii. The tube is resistant to creep, carburization and metal dusting. The tube also has an enhanced heat transfer rate, and a desirable surface roughness. A method of making the tube is also provided. The method essentially consists of mechanically deforming the interior surface of the tube by passing a series of cutting inserts on support rings having incrementally-differing dimensions over the interior surface. An apparatus is also provided which includes a telescoping shaft upon which is mounted at least one cutting tool that has a plurality of cutting inserts and is adapted to form a plurality of grooves and bosses in the interior surface of the tube. The grooves and bosses may be straight or spiraled.

Owner:MANOIR INDUSTRIES

Systems and methods for maintaining sulfur concentration in a syngas to reduce metal dusting in downstream components

Systems and methods for maintaining a sulfur concentration in a syngas are provided. The method can include combining sulfur and a carbonaceous material to produce a sulfur containing carbonaceous feed. The method can also include gasifying at least a portion of the sulfur containing carbonaceous feed to produce a syngas and detecting a sulfur concentration in the syngas. The method can further include adjusting an amount of the sulfur combined with the carbonaceous material based on the detected sulfur concentration.

Owner:KELLOGG BROWN & ROOT LLC

High performance alloys with improved metal dusting corrosion resistance

Alloy compositions which are resistant to metal dusting corrosion are provided by the present invention. Also provided are methods for preventing metal dusting on metal surfaces exposed to carbon supersaturated environments. The alloy compositions include an alloy (PQR), and a multi-layer oxide film on the surface of the alloy (PQR). The alloy (PQR) includes a metal (P) selected from the group consisting of Fe, Ni, Co, and mixtures thereof, an alloying metal (Q) comprising Cr, Mn, and either Al, Si, or Al / Si, and an alloying element (R). When the alloying metal (Q) includes Al, the multi-layer oxide film on the surface of the alloy includes at least three oxide layers. When the alloying metal (Q) includes Si, the multi-layer oxide film on the surface of the alloy (PQR) includes at least four oxide layers. When the alloying metal (Q) includes Al and Si, the multi-layer oxide film on the surface of the alloy (PQR) includes at least three oxide layers. The multi-layer oxide film is formed in situ during use of the alloy composition in a carbon supersaturated metal dusting environment. Advantages exhibited by the disclosed alloy compositions include improved metal dusting corrosion resistance at high temperatures in carbon-supersaturated environments having relatively low oxygen partial pressures. The disclosed alloy compositions are suitable for use as the inner surfaces in reactor systems and refinery apparatus.

Owner:EXXON RES & ENG CO

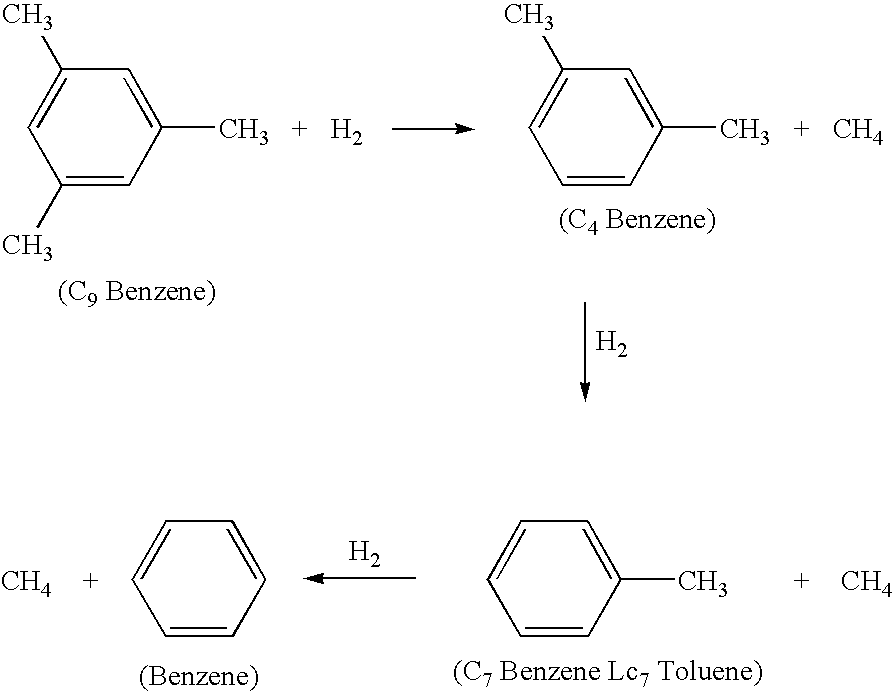

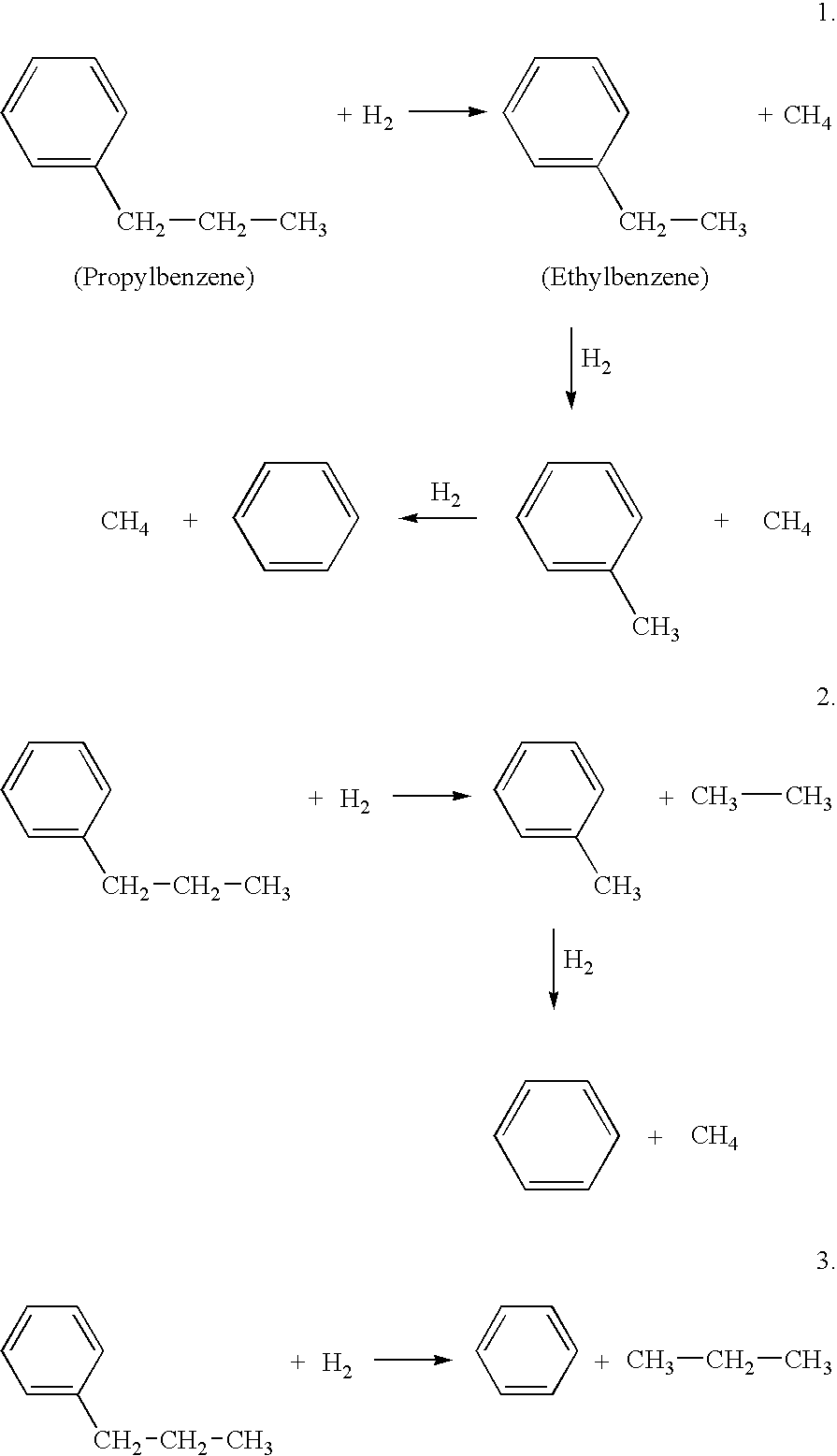

Hydrodealkylation processes

InactiveUSRE38532E1Reduce sulfide corrosionImprove product valueHydrogenOrganic compound preparationMetal dustingEngineering

Carburization and metal-dusting while hydrodealkylating a hydrodealkylatable hydrocarbon are reduced even in the substantial absence of added sulfur.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Reformer apparatus and method

ActiveUS7967878B2Reduce the amount requiredEliminate needHydrogenFinal product manufactureSyngasMetal dusting

A multiple adiabatic bed reforming apparatus and process involving stage-wise combustion and multiple reforming chambers. Co-flow and cross-flow occurs under laminar flow conditions. A reformer suitable for small scale production as well as large scale production. A passive stage-by-stage fuel distribution network suitable for low pressure fuel wherein the resistances in successive fuel distribution lines control the amount of fuel delivered to each combustion stage. Heat is captured from reforming syngas product to preheat gases before entering the reformer. Conditions that would produce unwanted coking or metal dusting are avoided or localized away from the heat exchangers to locations which can be cost effectively protected. A chemical reactor which has a core composed of a stack of metal plates that are diffusion bonded in face-to-face relationship.

Owner:MEGGIT (UK) LTD

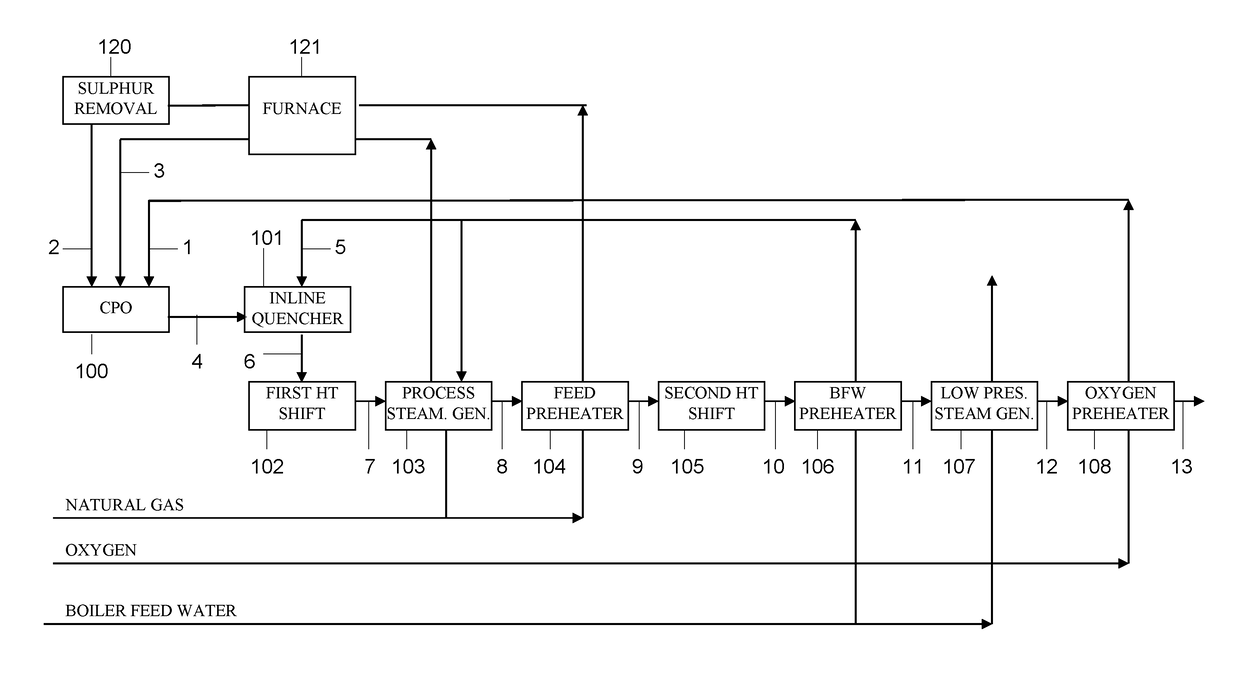

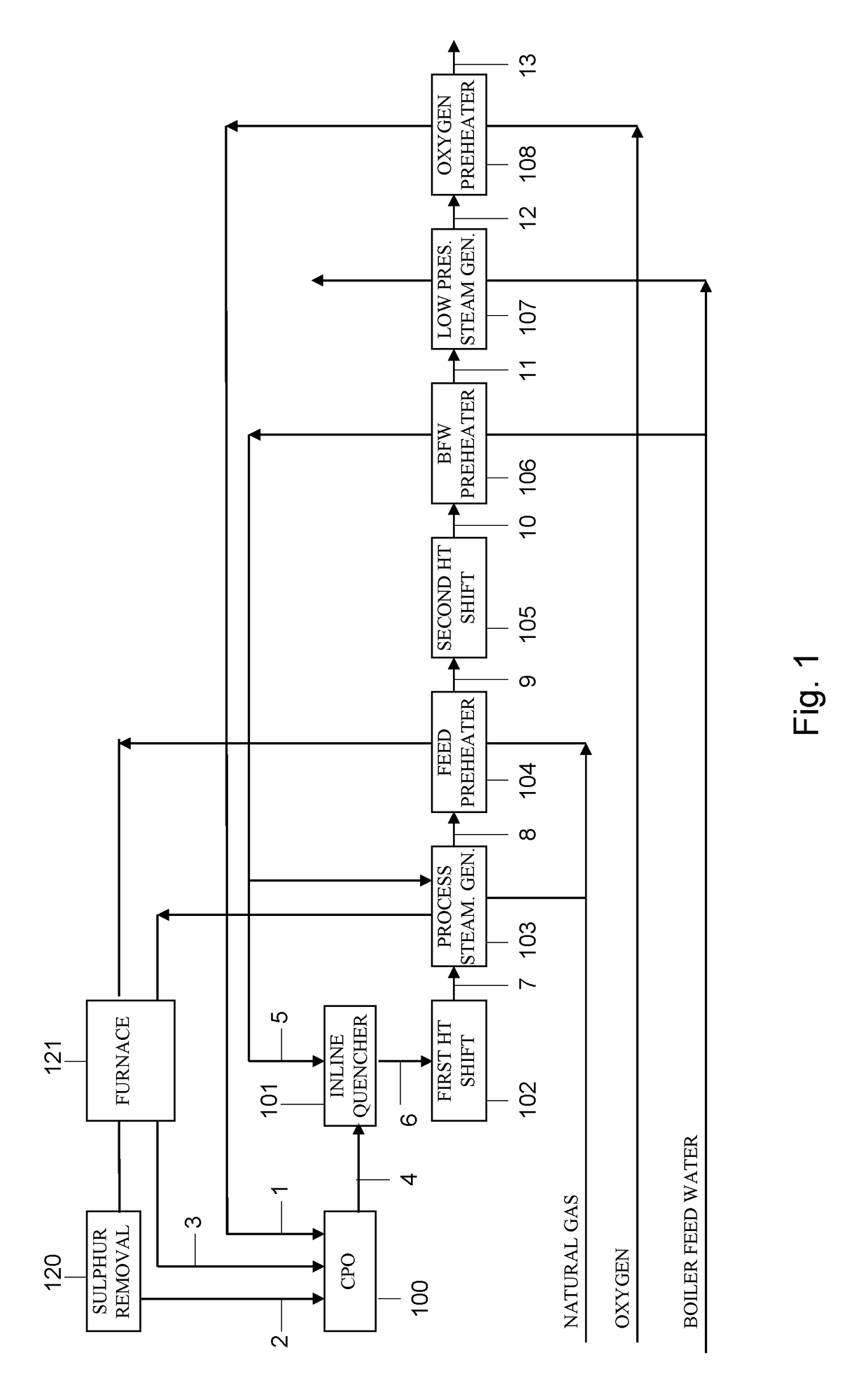

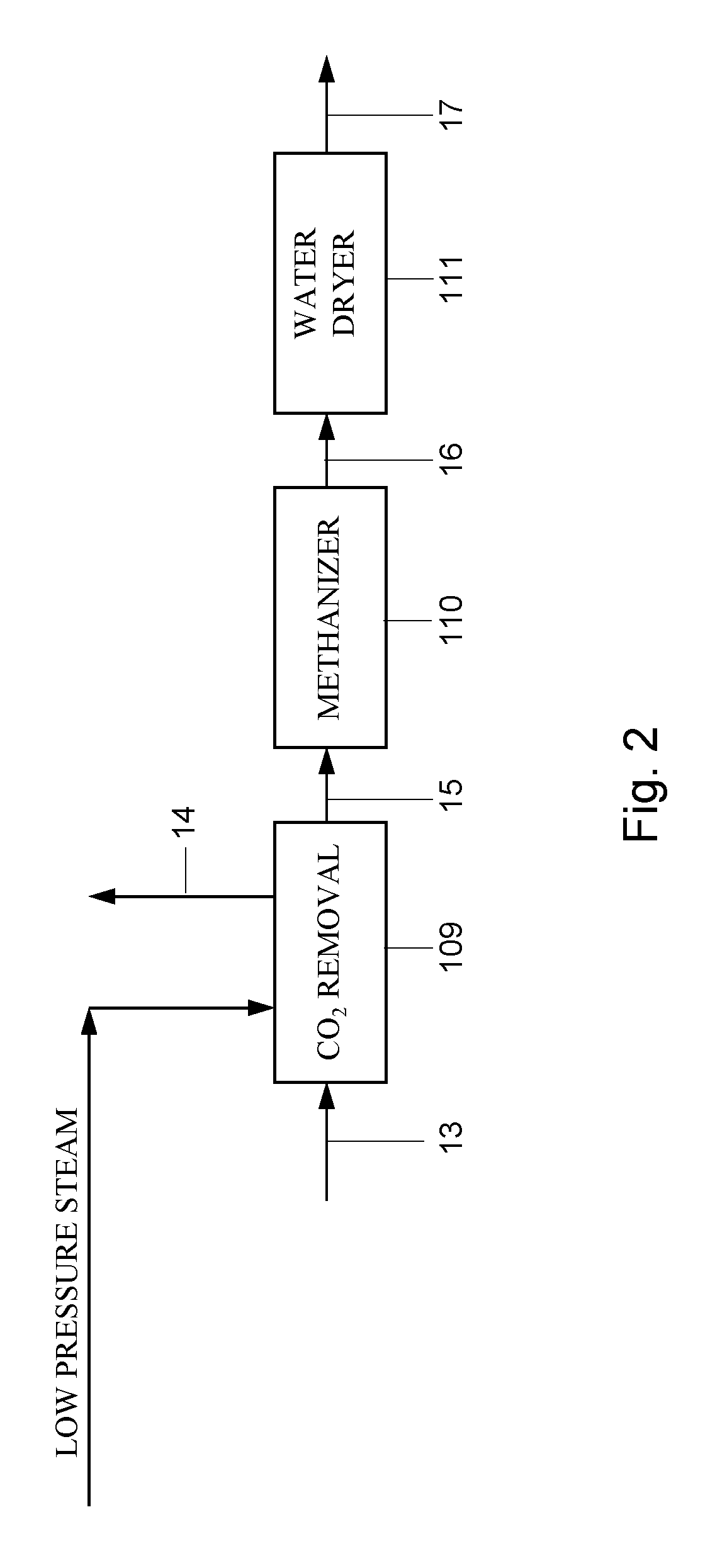

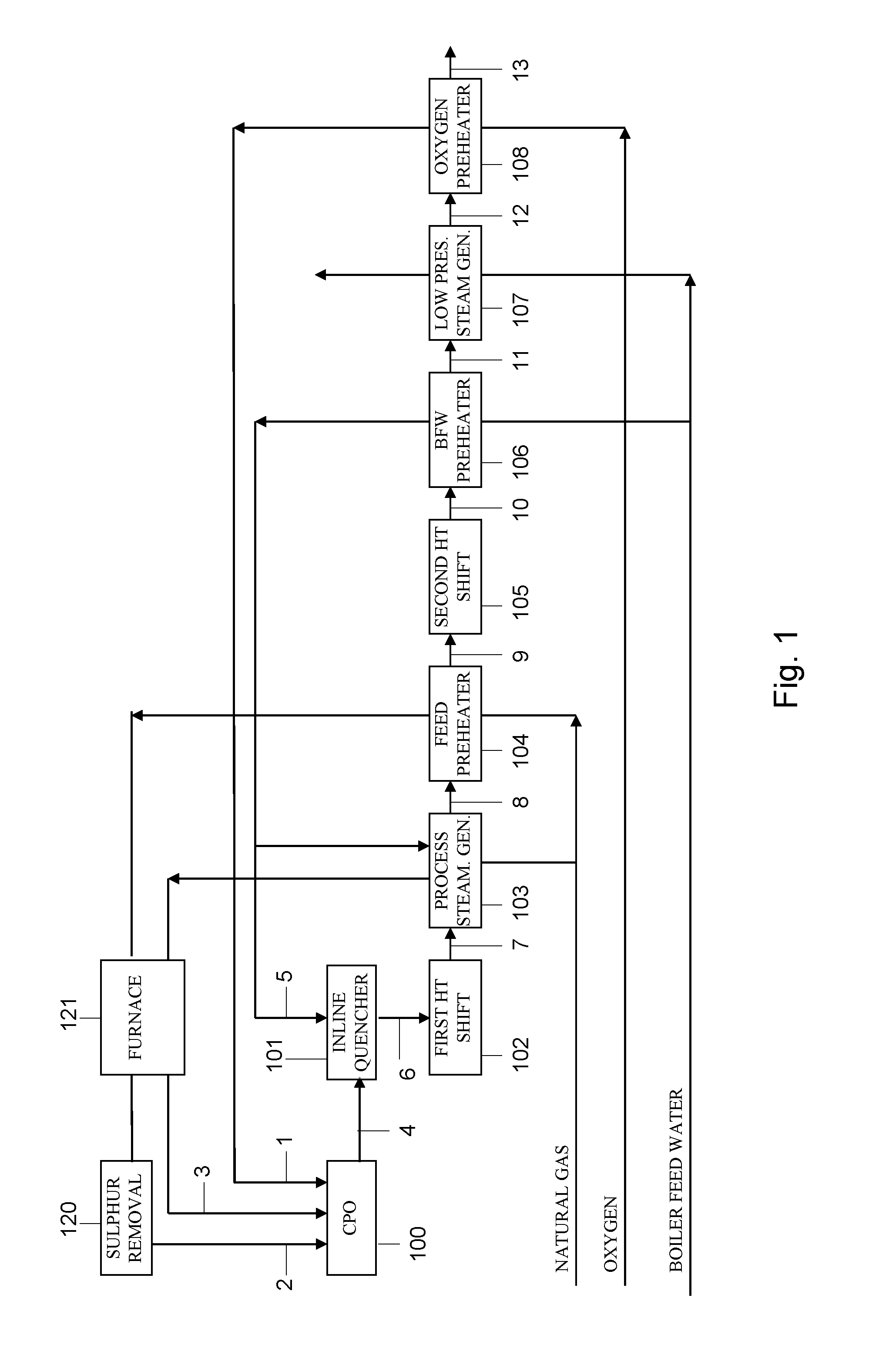

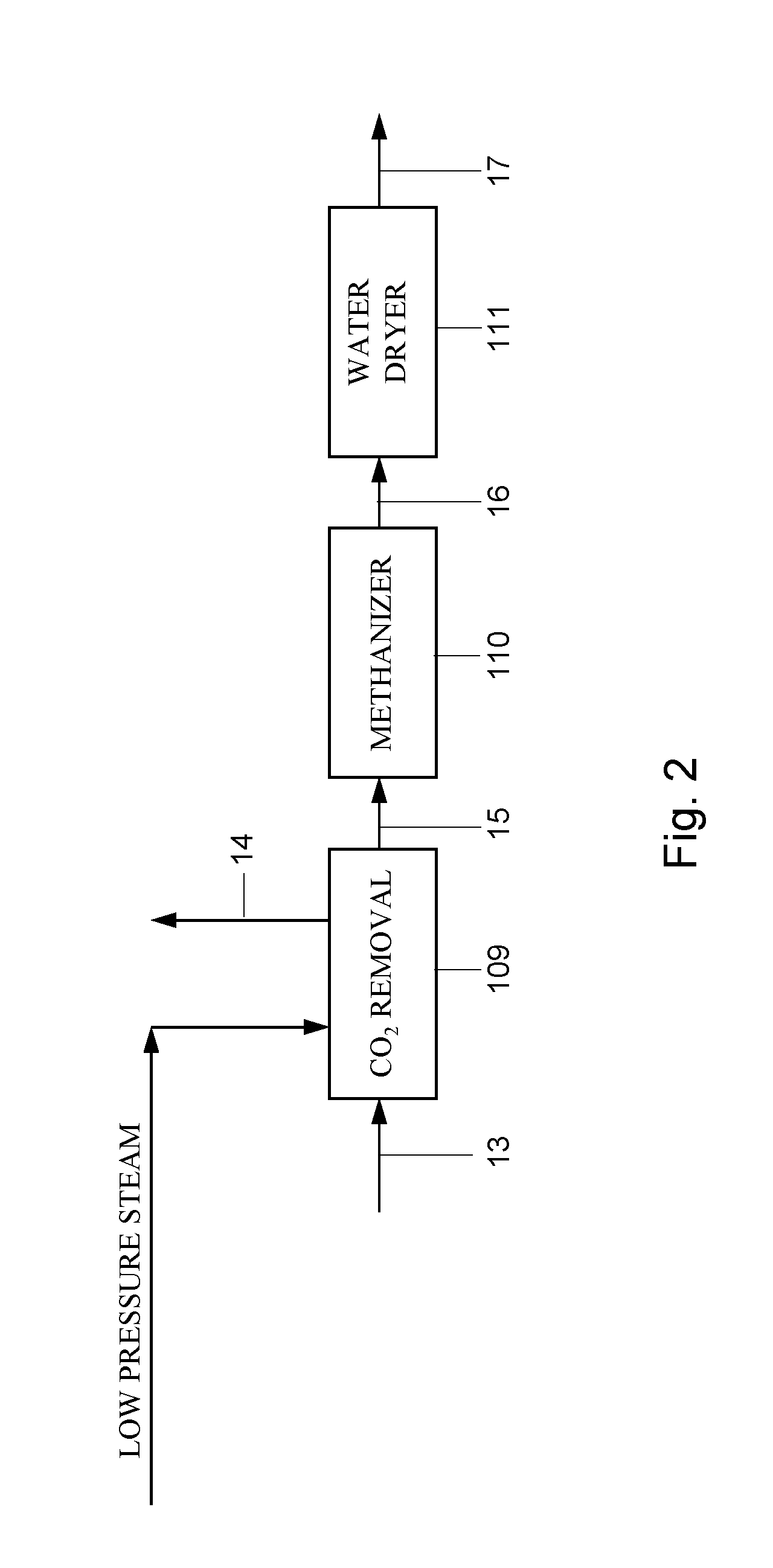

Process for producing a syngas intermediate suitable for the production of hydrogen

Disclosed is a process for the production of a syngas mixture by catalytic partial oxidation. The syngas mixture is suitable as an intermediate in the production of hydrogen. According to the invention, the syngas is cooled, prior to a water gas shift reaction, with liquid water. This has the advantage of avoiding the problem of metal dusting, and it presents a gas mixture comprising water vapor that is particularly suitable for a water gas shift reaction in the production of hydrogen.

Owner:STAMICARBON ACTING UNDER THE NAME OF MT INNOVATION CENT

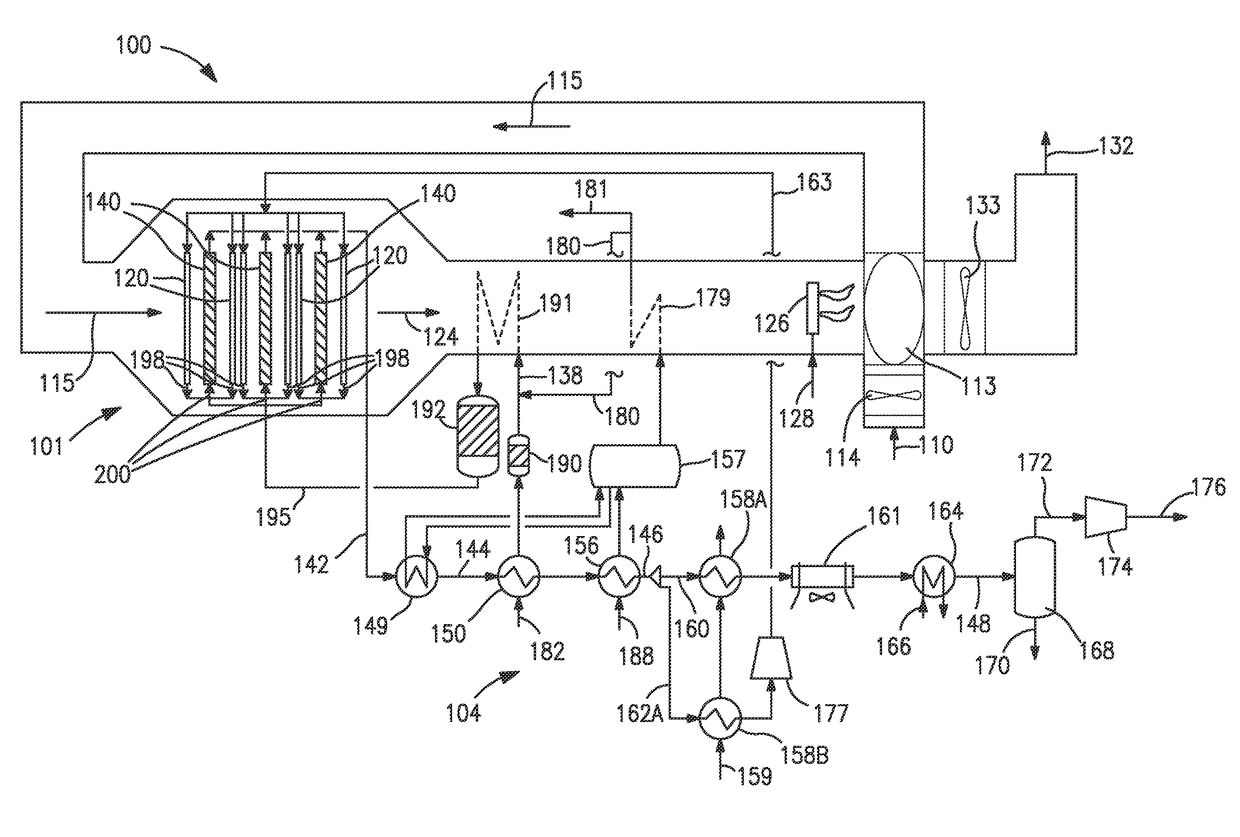

Method and system for producing a synthesis gas in an oxygen transport membrane based reforming system that is free of metal dusting corrosion

A method and system for producing a synthesis gas in an oxygen transport membrane based reforming system that utilizes a combined feed stream having a steam to carbon ratio between about 1.6 and 3.0 and a temperature between about 500° C. and 750° C. The combined feed stream is comprised a pre-reformed hydrocarbon feed, superheated steam, and a reaction product stream created by the reaction of a hydrogen containing stream reacted with the permeated oxygen at the permeate side of the oxygen transport membrane elements and wherein the oxygen transport membrane based reforming system and associated synthesis production process equipment are substantially free of carbon formation and metal dusting corrosion.

Owner:PRAXAIR TECH INC

Reforming apparatus and method

ActiveUS8177868B2Avoid adjustmentMultiple metal hydridesHigh temperature gas-gas reactionElectrical resistance and conductanceSyngas

A multiple adiabatic bed reforming apparatus and process are disclosed in which stage-wise combustion, in combination with multiple reforming chambers with catalyst, utilize co-flow and cross-flow under laminar flow conditions, to provide a reformer suitable for smaller production situations as well as large scale production. A passive stage by stage fuel distribution network suitable for low pressure fuel is incorporated and the resistances in successive fuel distribution lines control the amount of fuel delivered to each combustion stage. The fuel distribution system allows relatively constant fuel and air flow during turn up or turn down conditions. High efficiency is achieved by capturing heat from reforming syngas product to preheat gases before entering the reformer. Conditions that would produce unwanted coking or metal dusting are also eliminated or localized to locations within the apparatus outside the heat exchangers, but which locations can be cost effectively protected.

Owner:MEGGIT (UK) LTD

Method and system for producing a synthesis gas in an oxygen transport membrane based reforming system that is free of metal dusting corrosion

A method and system for producing a synthesis gas in an oxygen transport membrane based reforming system that utilizes a combined feed stream having a steam to carbon ratio between about 1.6 and 3.0 and a temperature between about 500° C. and 750° C. The combined feed stream is comprised a pre-reformed hydrocarbon feed, superheated steam, and a reaction product stream created by the reaction of a hydrogen containing stream reacted with the permeated oxygen at the permeate side of the oxygen transport membrane elements and wherein the oxygen transport membrane based reforming system and associated synthesis production process equipment are substantially free of carbon formation and metal dusting corrosion.

Owner:PRAXAIR TECH INC

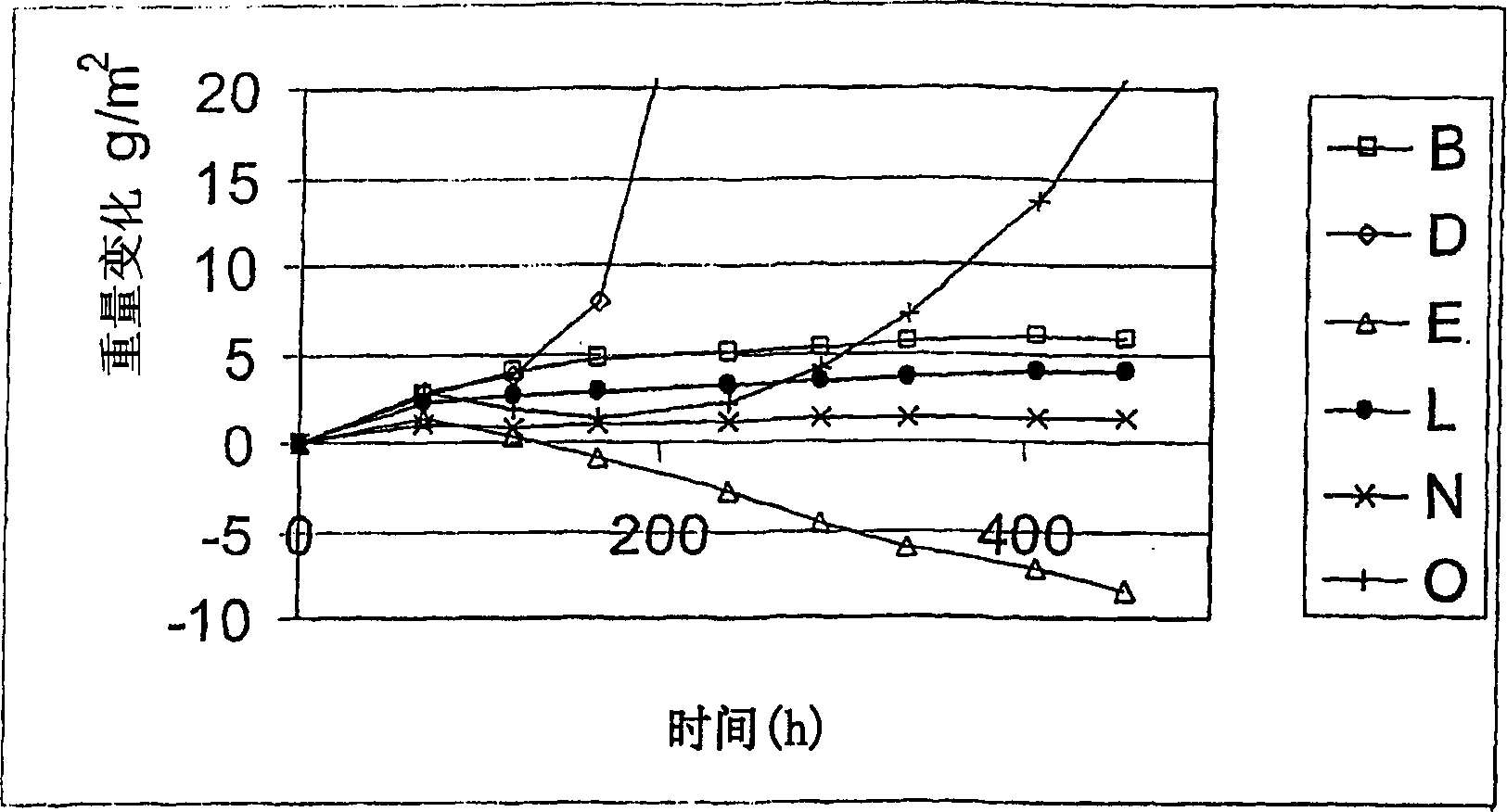

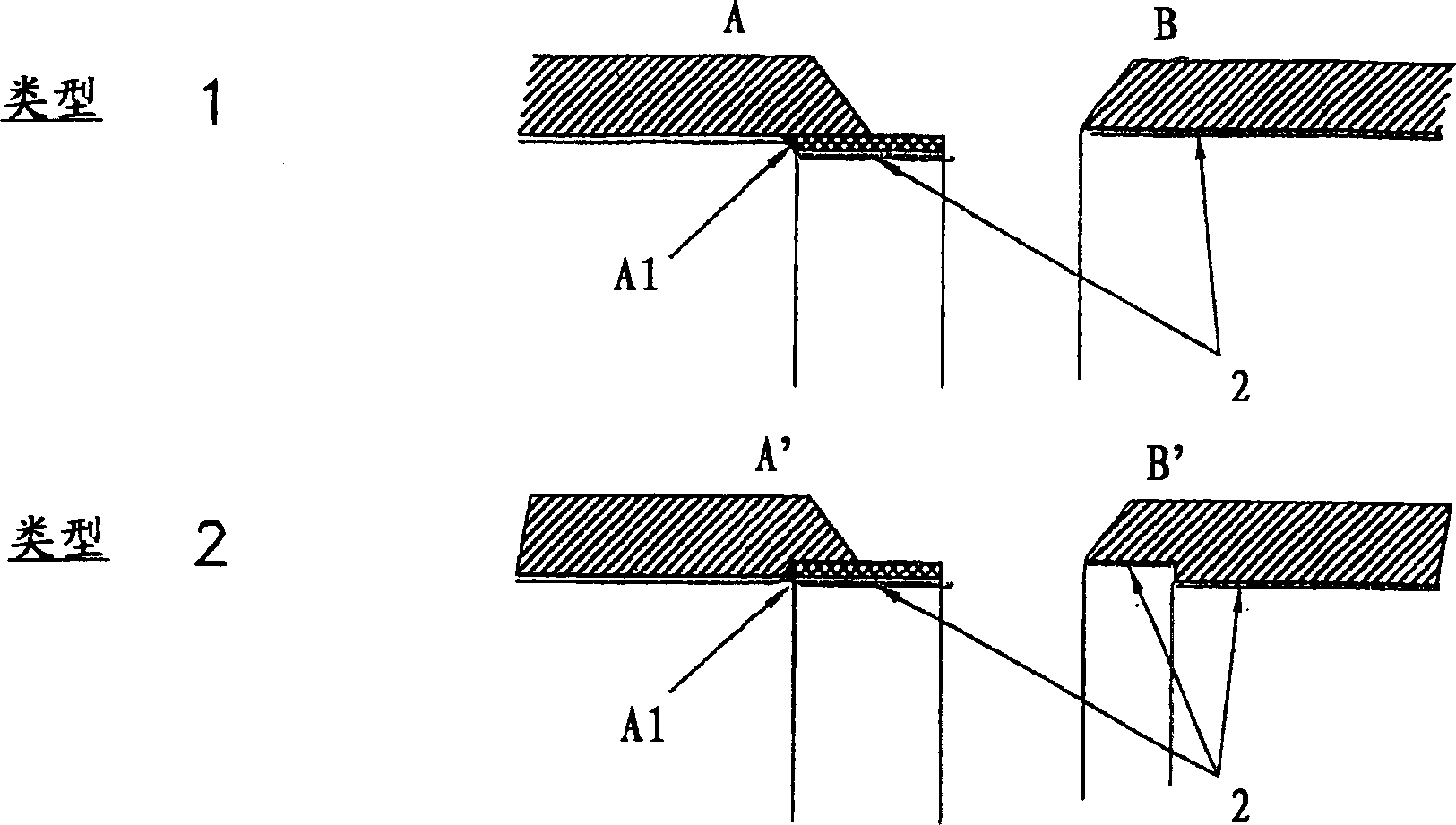

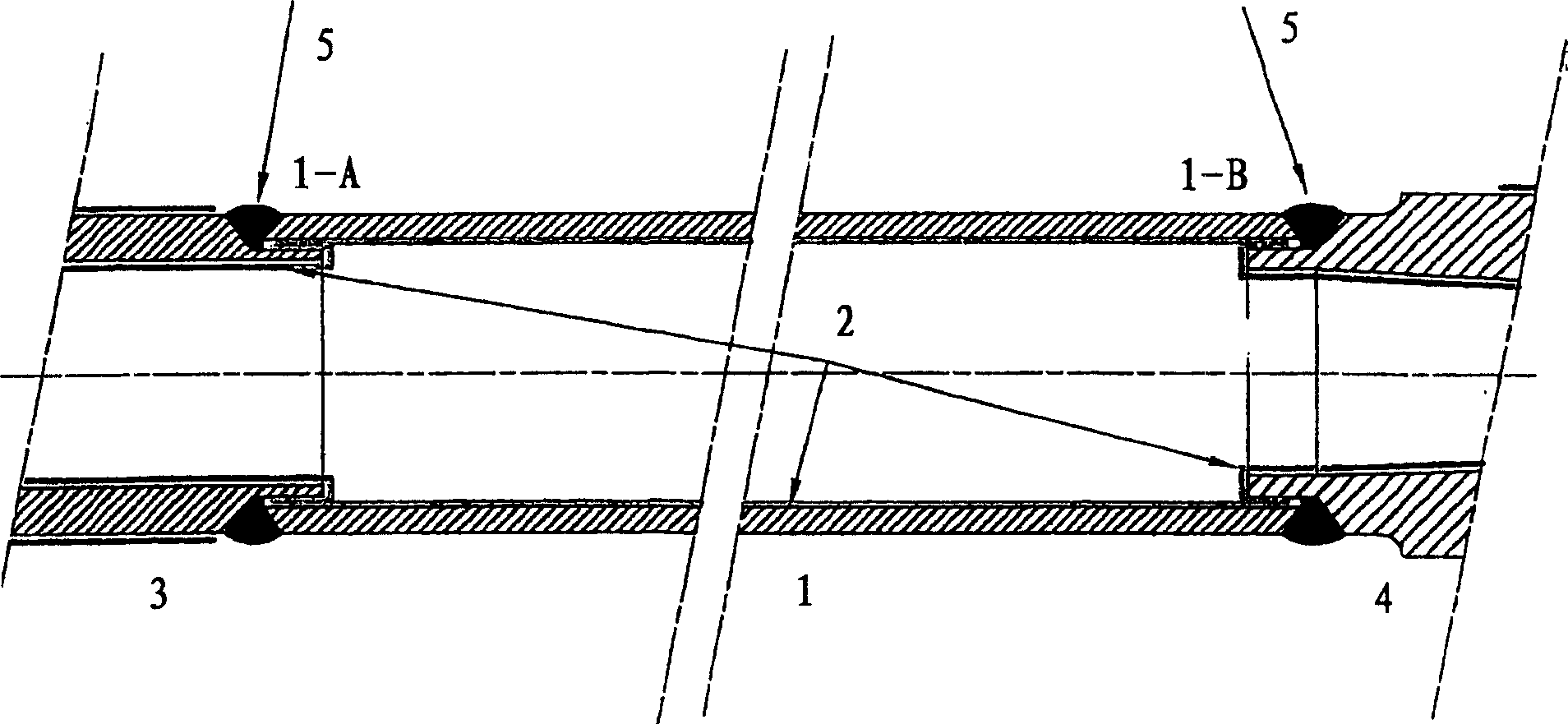

Method of protecting equipment against corrosion at high temperature

ActiveCN1761519ASolve localized corrosion problemsCorrosion preventionPipe protection against corrosion/incrustationMetal dustingCopper

The invention relates to a method of protecting equipment intended to operate at high temperature in the presence of a fluid containing at least one hydrocarbon and / or carbon monoxide against corrosion by metal dusting and / or carburization, method in which pieces of the equipment are made from an alloy containing nickel, iron, chromium and / or aluminum, and / or copper and in which said pieces of the equipment are protected from said corrosion by a protective coating. This method is characterized in that said equipment pieces protected in this way are connected to each other by means of joining pieces, said joining pieces being protected beforehand over at least part of their surface intended to be brought into contact with said fluid at high temperature, and in that each of the connections intended to be subjected to said corrosion is produced by external welding of the ends of the joining piece with said pieces of equipment.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

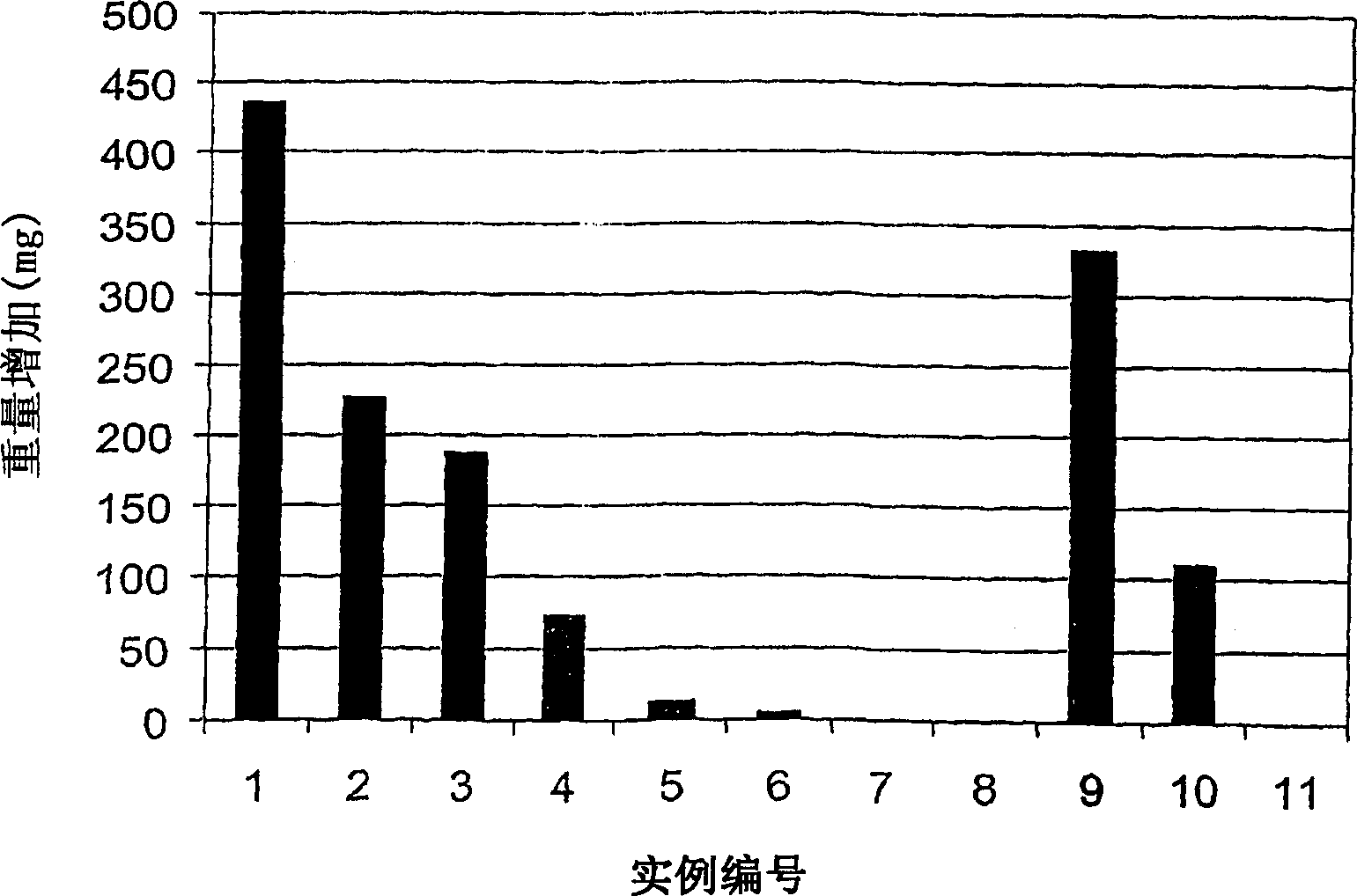

Nickel based alloys to prevent metal dusting degradation

InactiveUS20070104974A1Diffusion of in lowReduce solubilityBlade accessoriesMachines/enginesMetal dustingSpinel

An article of manufacture for reducing susceptibility of a metal pipe to metal dusting degradation. The article includes a multi-layer tubing having an alloy layer and a copper layer. The alloy layer can include a Ni based, an Al based and an Fe based alloy layer. In addition, layers of chrome oxide, spinel and aluminum oxide can be used.

Owner:UCHICAGO ARGONNE LLC

High-strength metal material

The invention relates to a metal material, in particular to a high-strength metal material, and belongs to the technical field of metal alloy materials. The high-strength metal material comprises, byweight, 2-8 parts of Mo, 1-2 parts of Po, 1-3 parts of Ir, 1-2 parts of Os, 1-2 parts of Pd, 1-3 parts of Zr, 1-4 parts of Y, 1-2 parts of Cu, 1-3 parts of Sc, 1-4 parts of P, 1-3 parts of Te, 1-2 parts of Si and 100 parts of Fe. According to the metal material, the Mo, the Po, the Ir, the Os, the Pd, the Zr, the Y, the Cu, the Sc, the P, the Te, the Si and the Fe are compounded, and the synergistic effect of the raw materials is utilized so that the strength of the metal material can be high, and the requirement of a specific place for the strength of the metal material can be met; and meanwhile, the metal material also has excellent metal dusting resistance, carburization resistance and coking resistance.

Owner:江苏晶王新材料科技有限公司

Process for producing a syngas intermediate suitable for the production of hydrogen

ActiveUS20140103260A1Urea derivatives preparationHydrocarbon from carbon oxidesSyngasPartial oxidation

Disclosed is a process for the production of a syngas mixture by catalytic partial oxidation. The syngas mixture is suitable as an intermediate in the production of hydrogen. According to the invention, the syngas is cooled, prior to a water gas shift reaction, with liquid water. This has the advantage of avoiding the problem of metal dusting, and it presents a gas mixture comprising water vapor that is particularly suitable for a water gas shift reaction in the production of hydrogen.

Owner:STAMICARBON ACTING UNDER THE NAME OF MT INNOVATION CENT

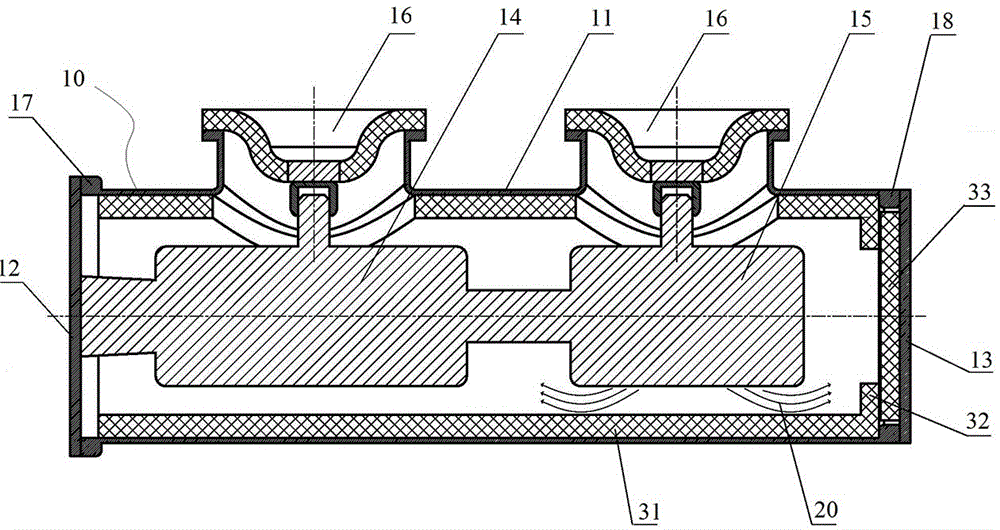

Cooling ring for welding bellows generating less metal powder

ActiveCN103857492AImprove conductivityWelding/cutting auxillary devicesAuxillary welding devicesMetal dustingEngineering

The present invention pertains to a cooling ring for welding bellows, a cooling ring for welding used in the manufacture of bellows, which include multiple pairs of diaphragms, wherein a pair of diaphragms are formed of a first diaphragm and a second diaphragm disposed to face the first diaphragm. The cooling ring includes: an arc-shaped main body which is disposed to bring the first diaphragm and the second diaphragm into contact with each other in the state in which the main body is in contact with the first diaphragm and / or the second diaphragm, and includes copper; and a plating layer which is plated on the main body, wherein the plated layer includes at least one selected from the group consisting of nickel and chromium. Since the present invention is provided with the arc-shaped main body, which includes copper, and with the plating layer, which is plated on the main body, the present invention does not generate, during welding, the powder of metals such as copper, aluminum, gold, silver or the like, which have high electric conductivity.

Owner:KOREA SHEET METAL

Arc-extinguishing chamber, arc-extinguishing chamber tank and high-voltage switching equipment applying this arc-extinguishing chamber

InactiveCN106328435AReduce axial sizeAvoid damageSwitchgear arrangementsHigh-tension/heavy-dress switchesMetal dustingInsulation layer

The invention relates to arc-extinguishing chamber, arc-extinguishing chamber tank and high-voltage switching equipment applying this arc-extinguishing chamber. The arc-extinguishing chamber comprises main part of tank which consists of barrel and end cap mounted on the barrel with axis stretching to both sides; the inner wall of barrel is covered with solid insulation layer and at least one end of the end cap is covered with solid insulation layer on its inner wall, thus a complete blocked layer is jointly formed through interconnection of solid insulation layer on both barrel and end cap. Just as the fixed insulation layer on barrel can act as protection, that on end cap can also be the protection, avoiding the damage from high-temperature airflow and also benefiting to shorten axial dimension of the tank, at the same time, the complete blocked layer jointly formed through interconnection of the solid insulation layer on both barrel and end cap can improve the condition of metallic dust depositing on end cap, thus to achieve better protective effect and ideal insulating property.

Owner:PINGGAO GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com