Patents

Literature

45results about "Rectilinear broach" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

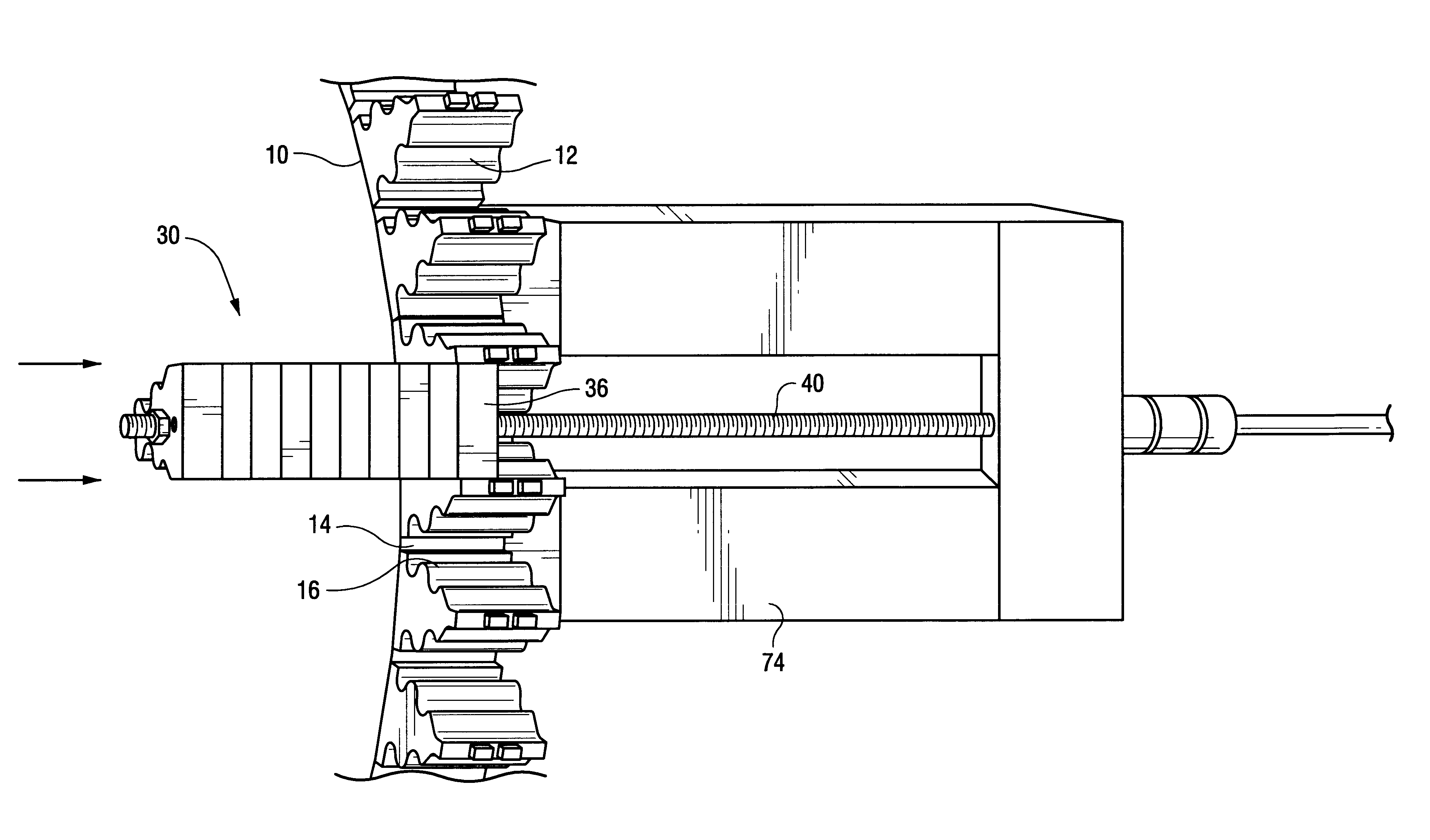

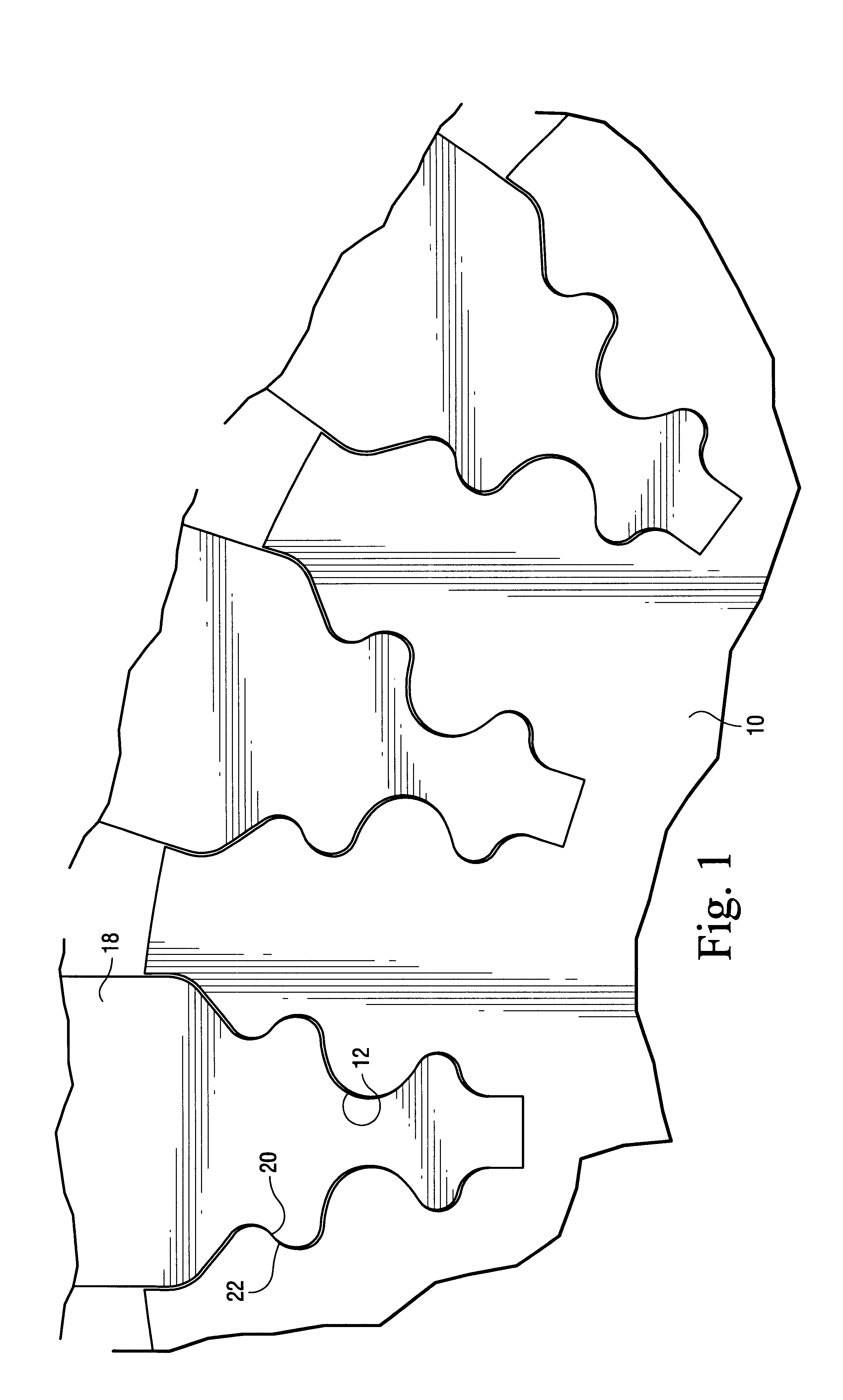

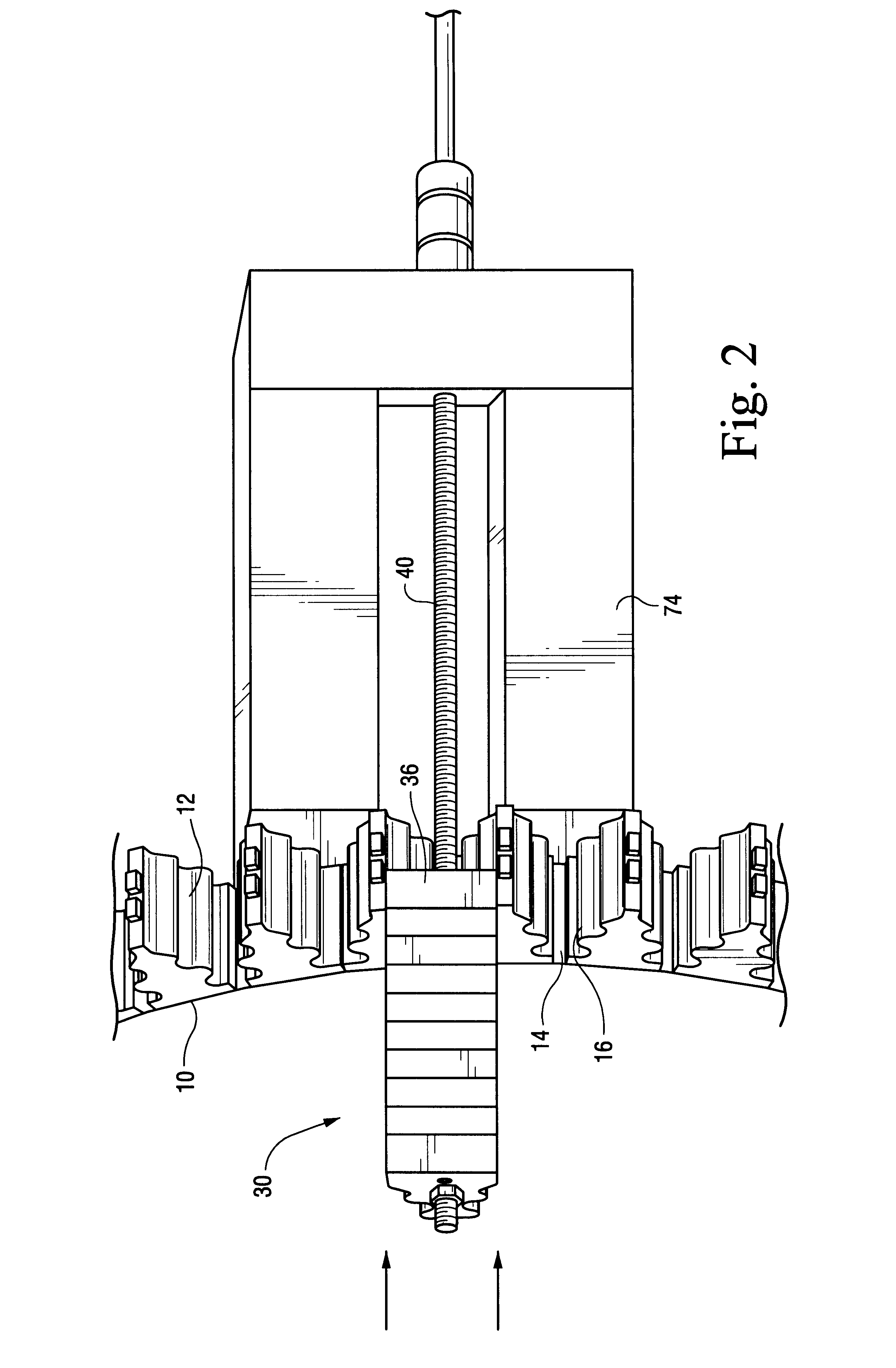

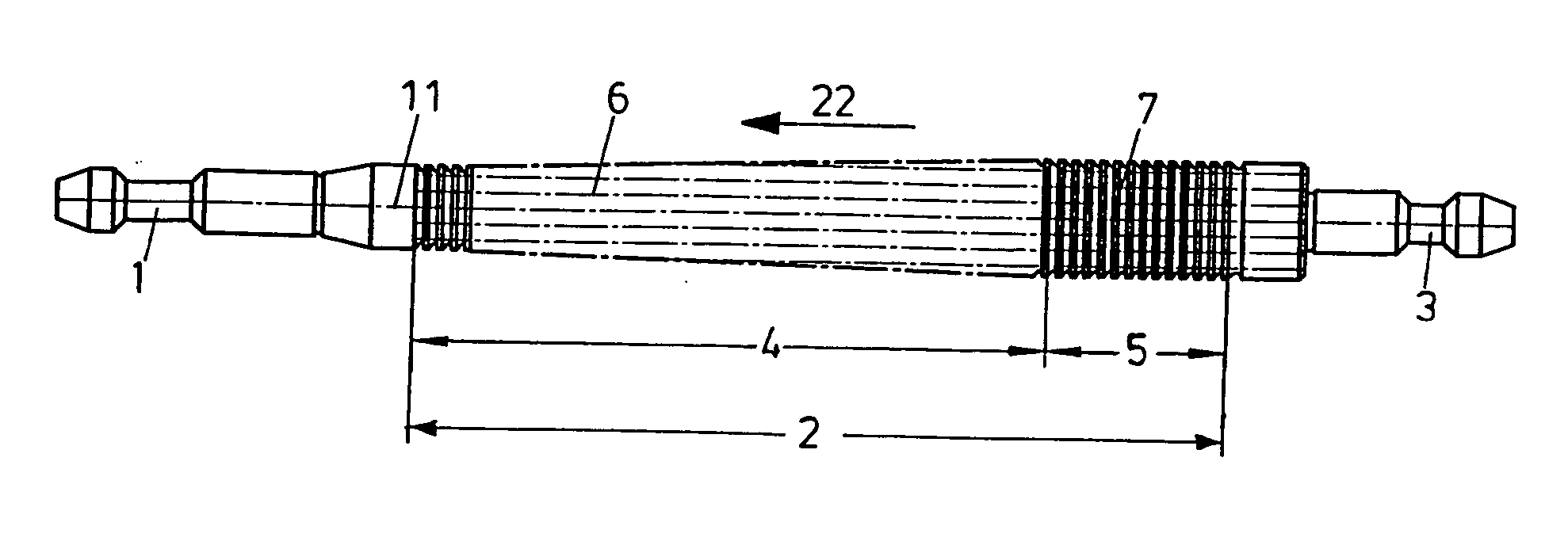

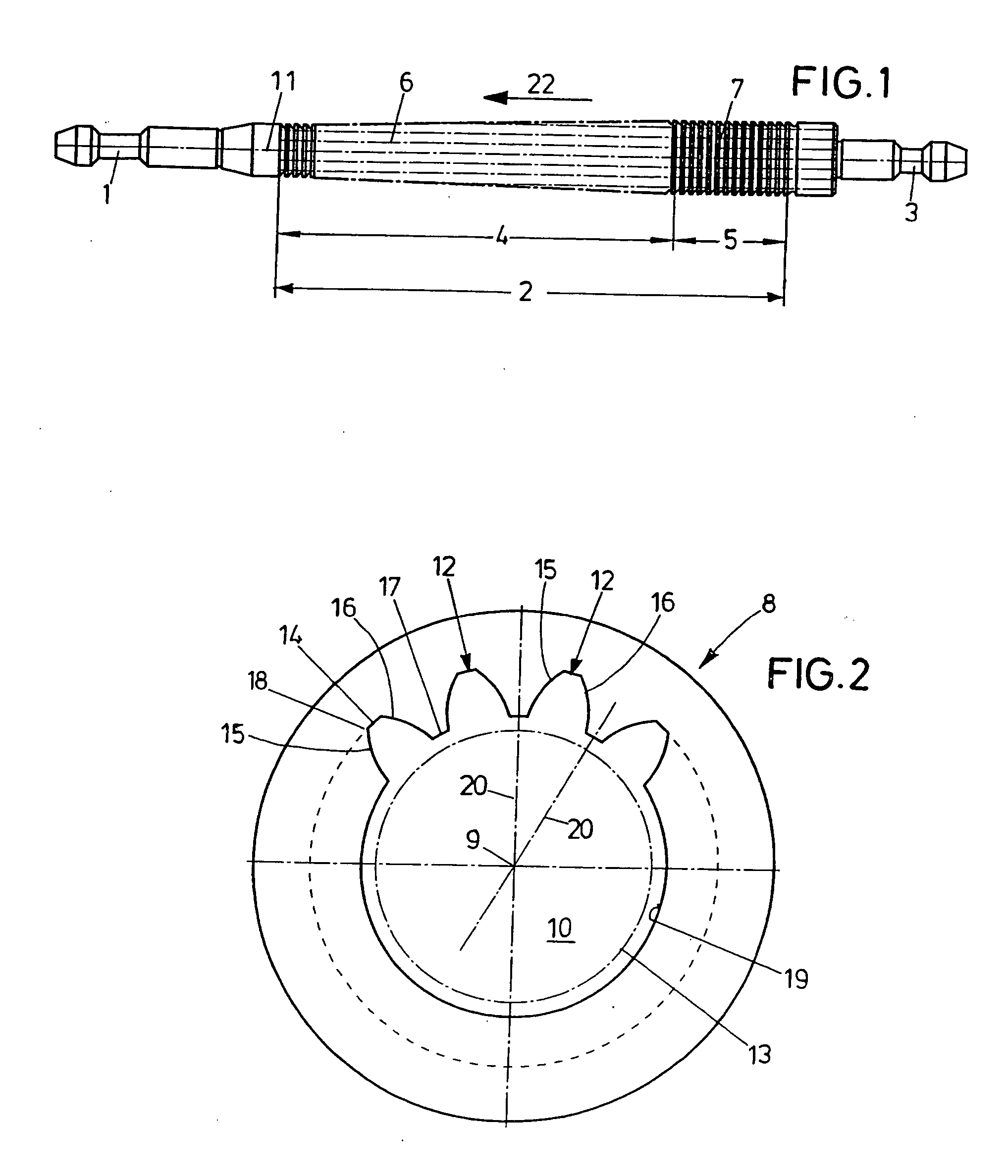

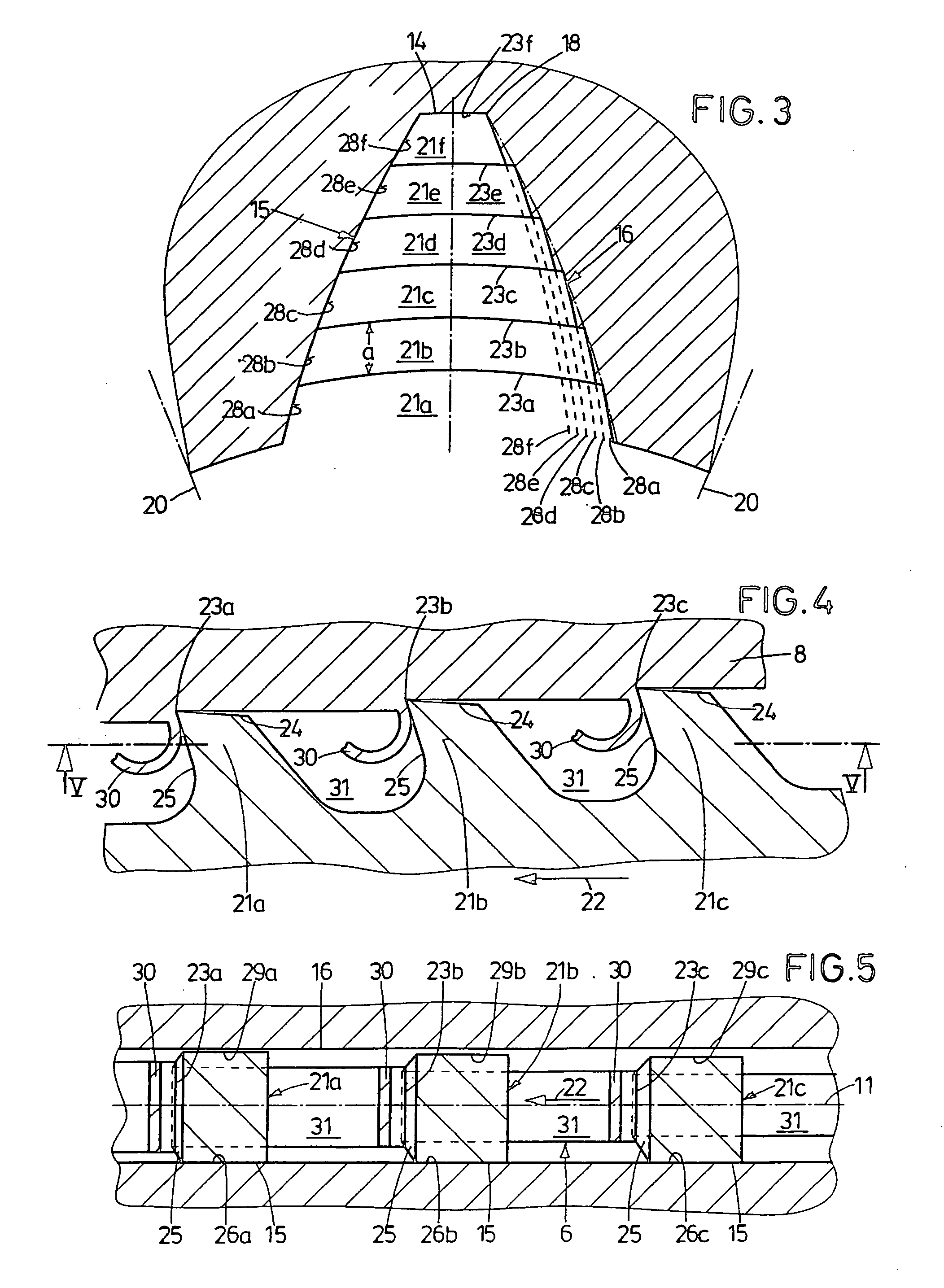

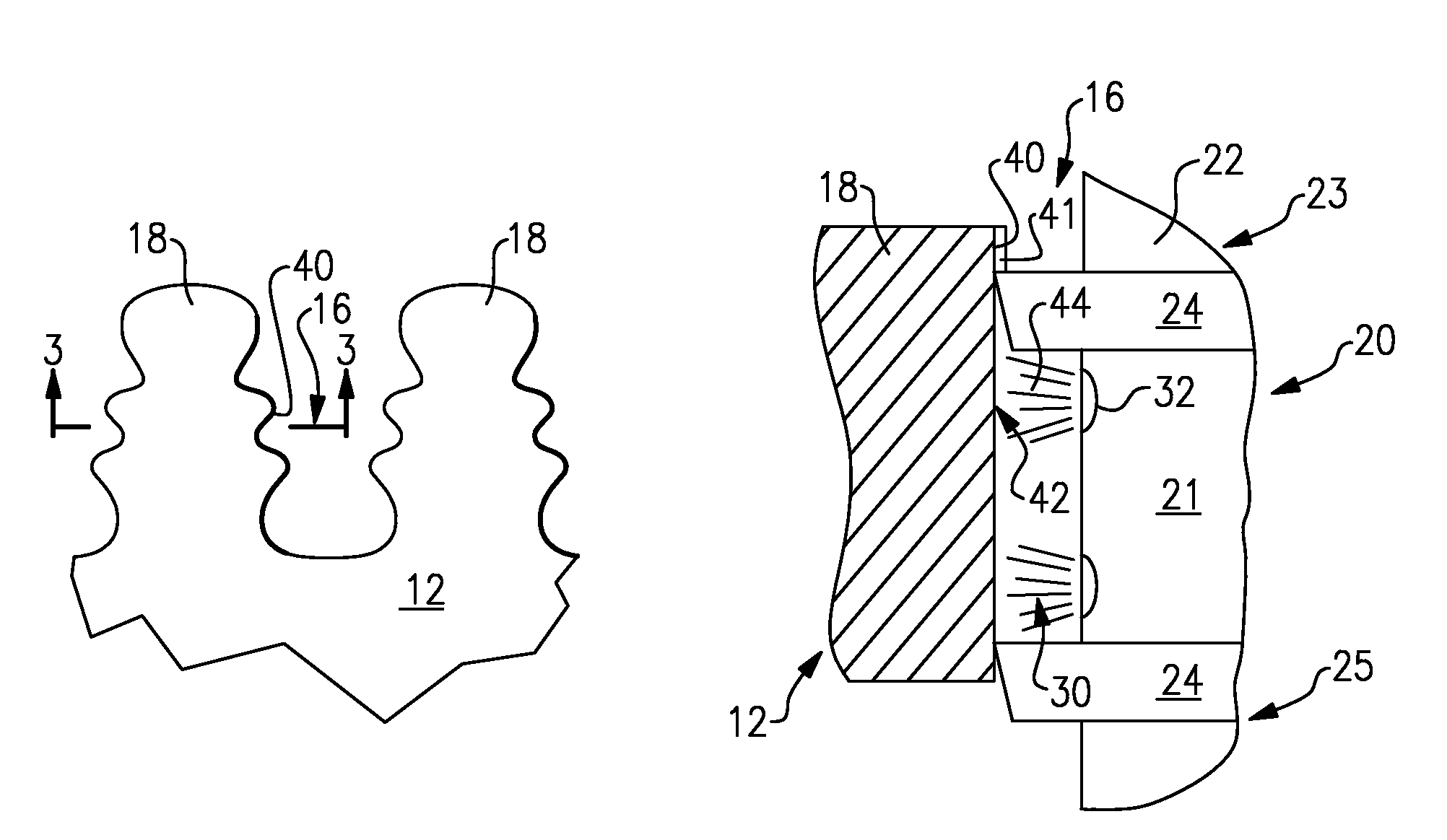

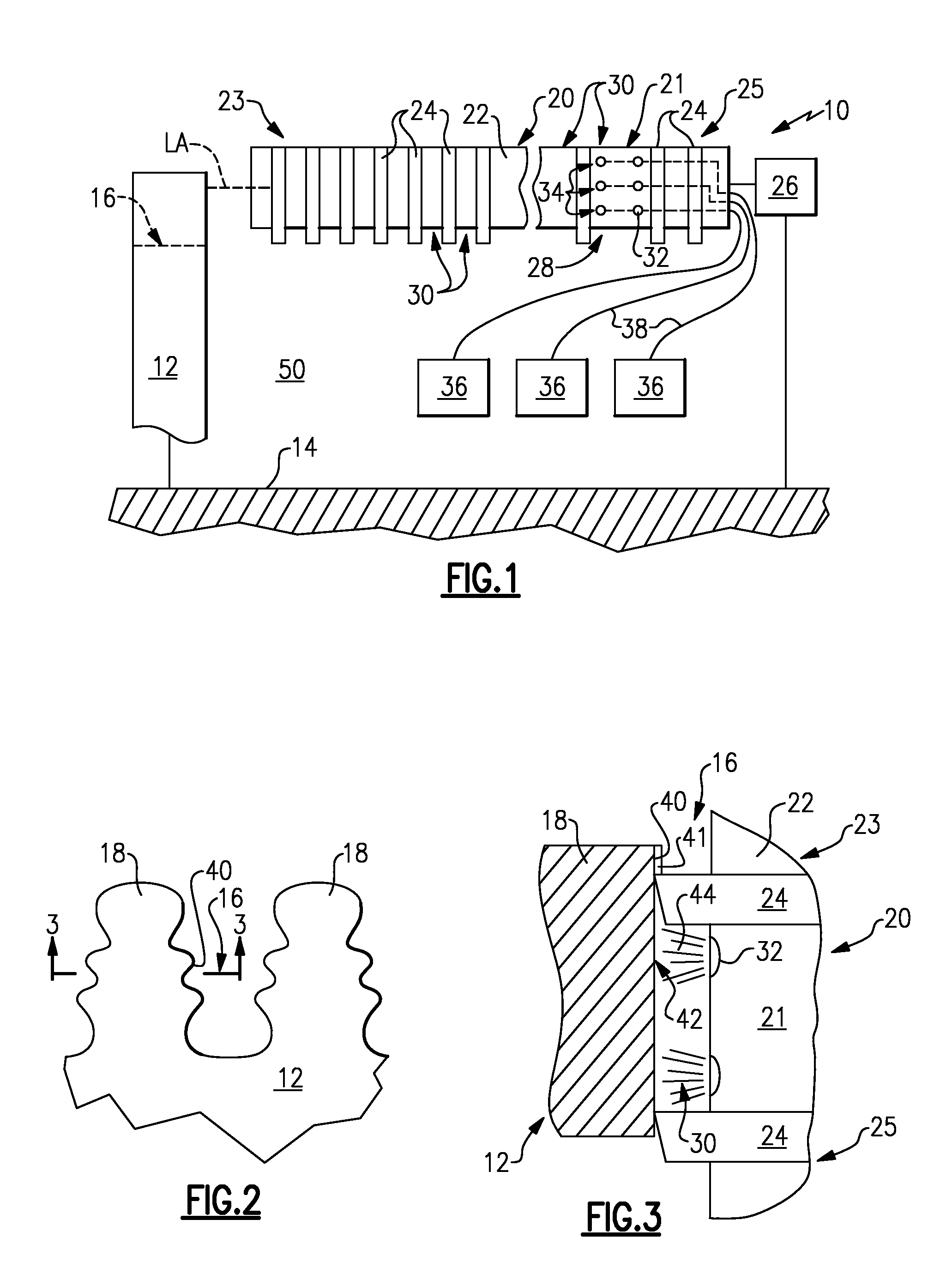

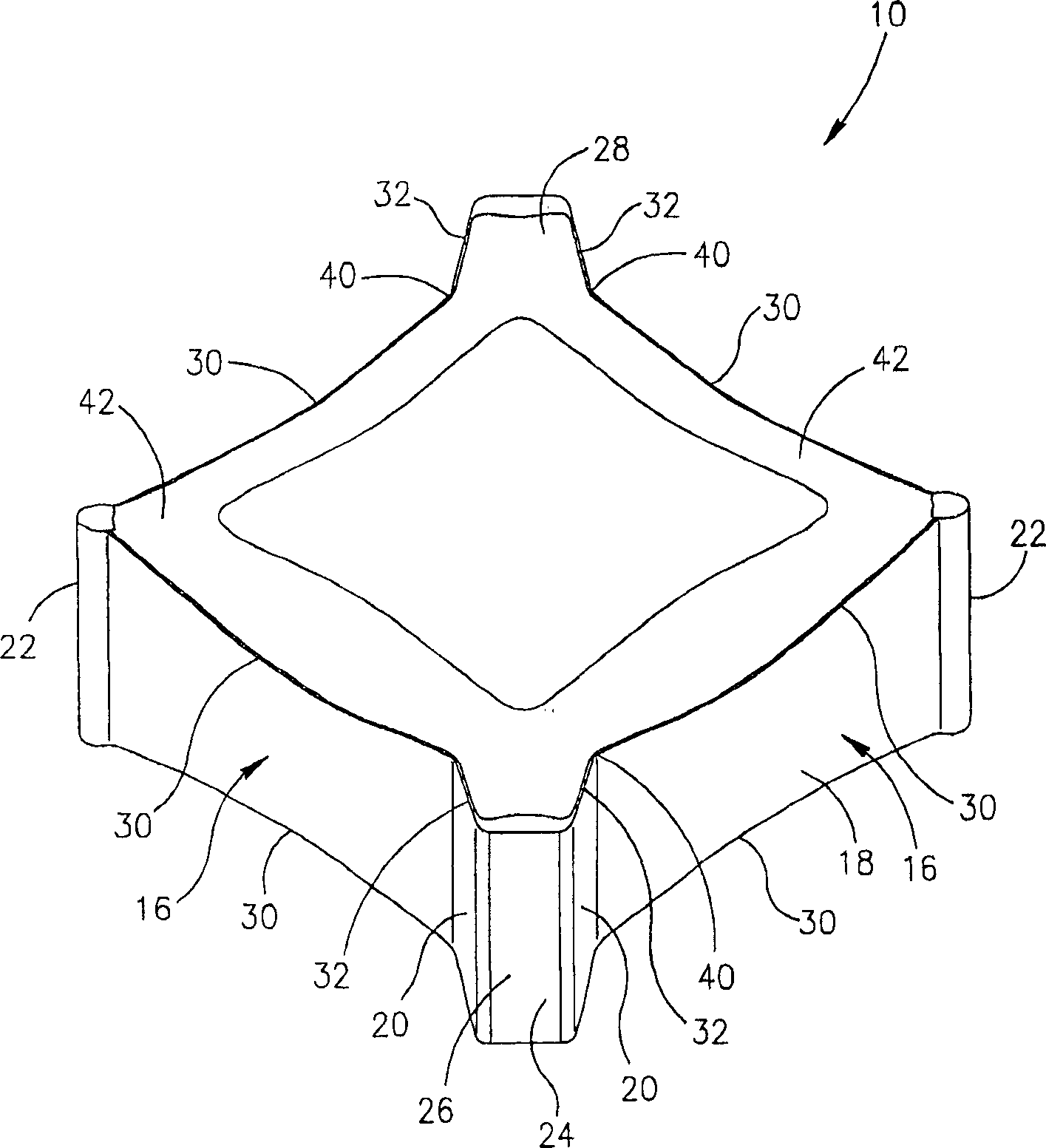

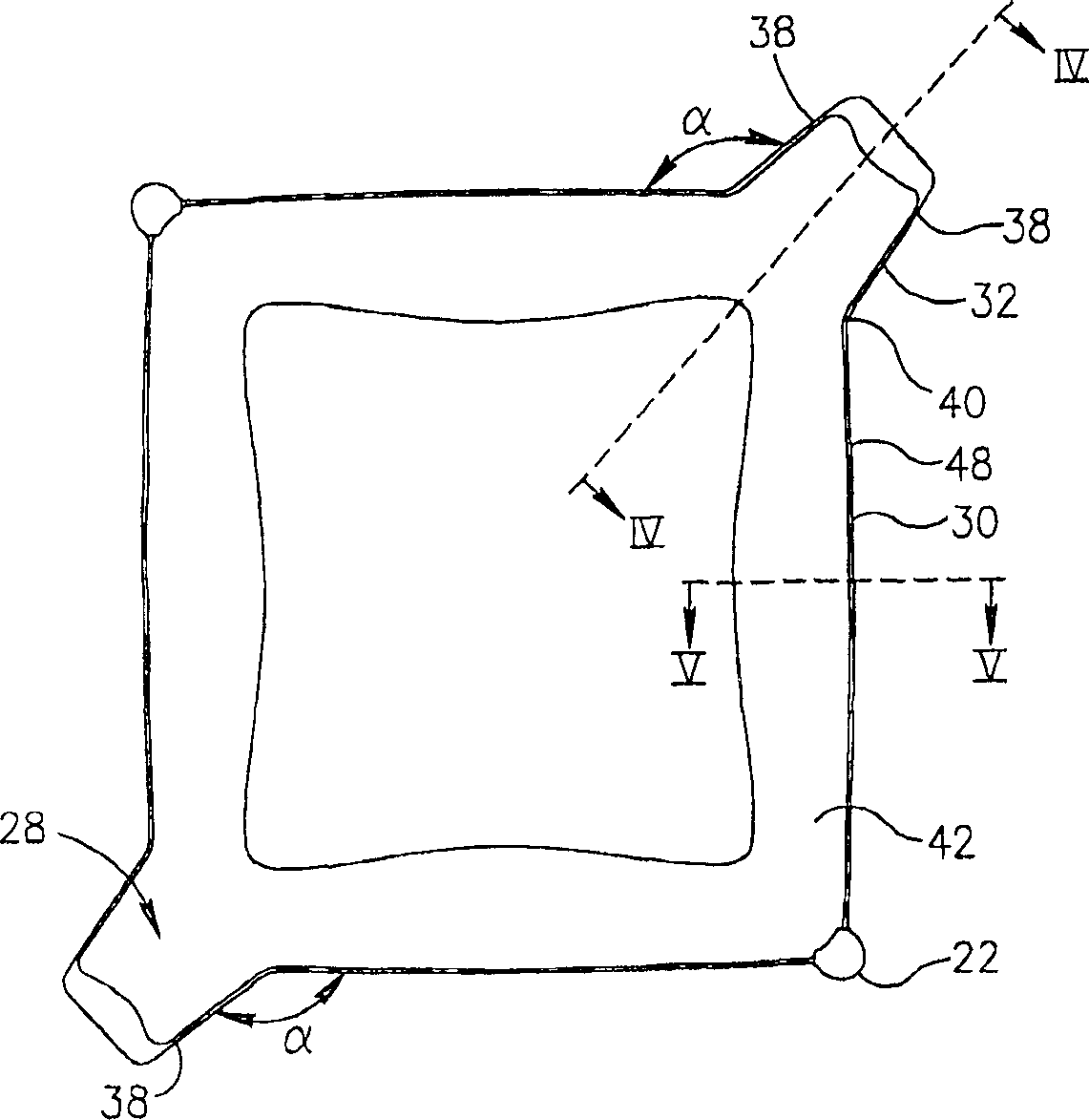

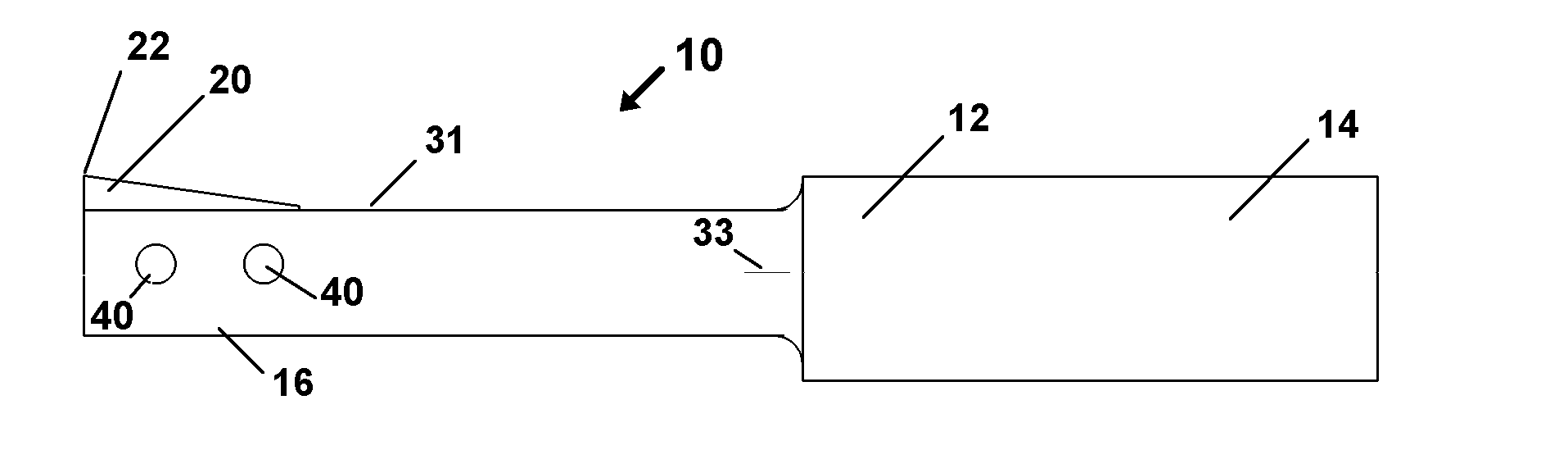

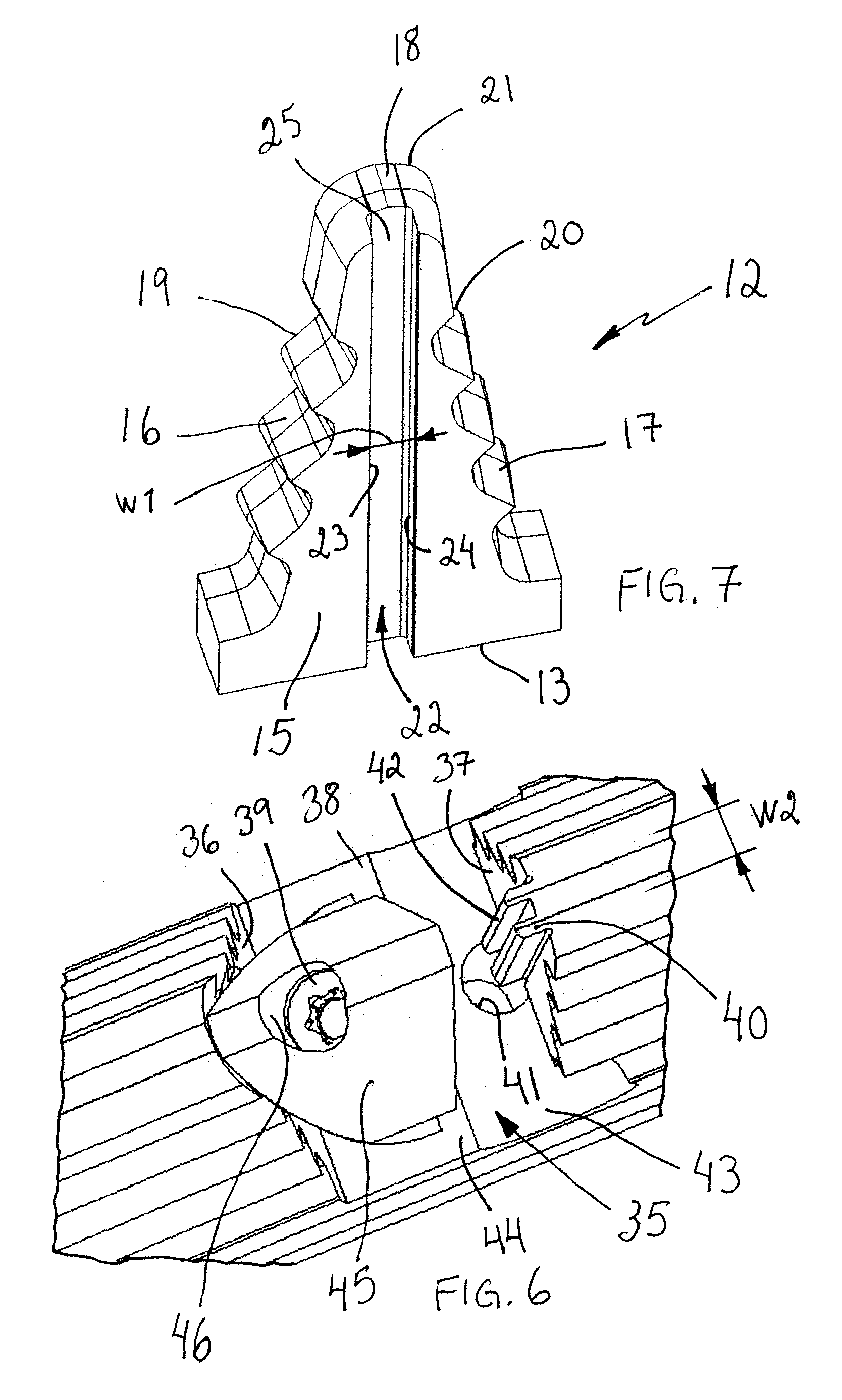

Multi-part dovetail repair broach assembly and methods of use

InactiveUS6676336B2Easy to importInexpensive to fabricateRectilinear broachBroaching toolsImpellerTurbine wheel

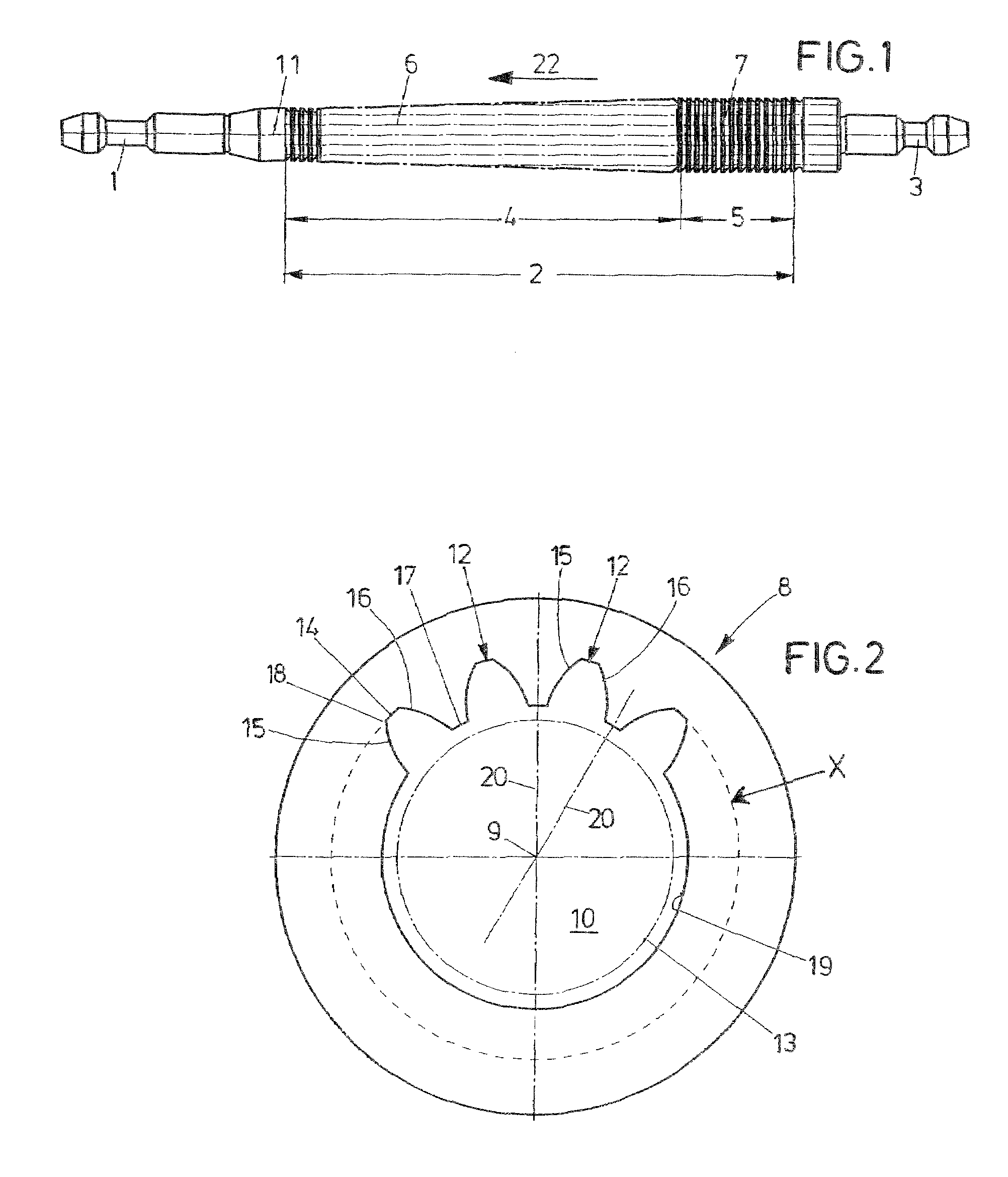

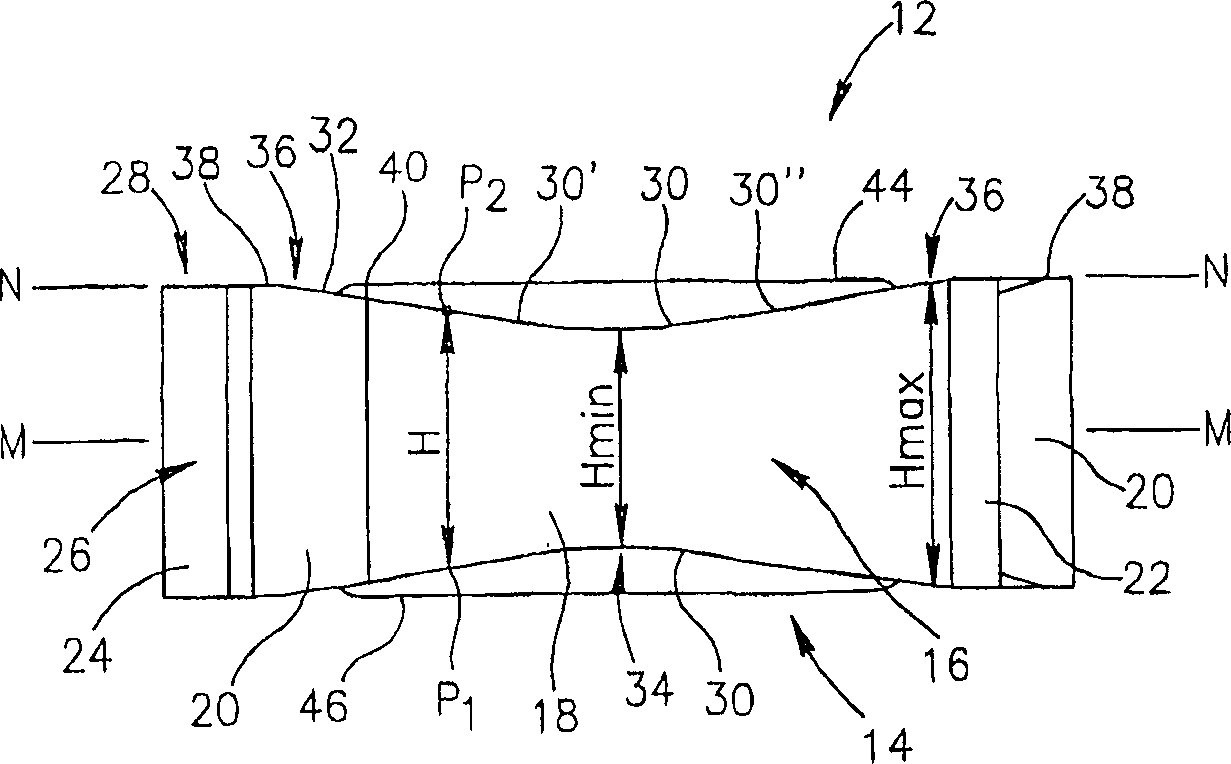

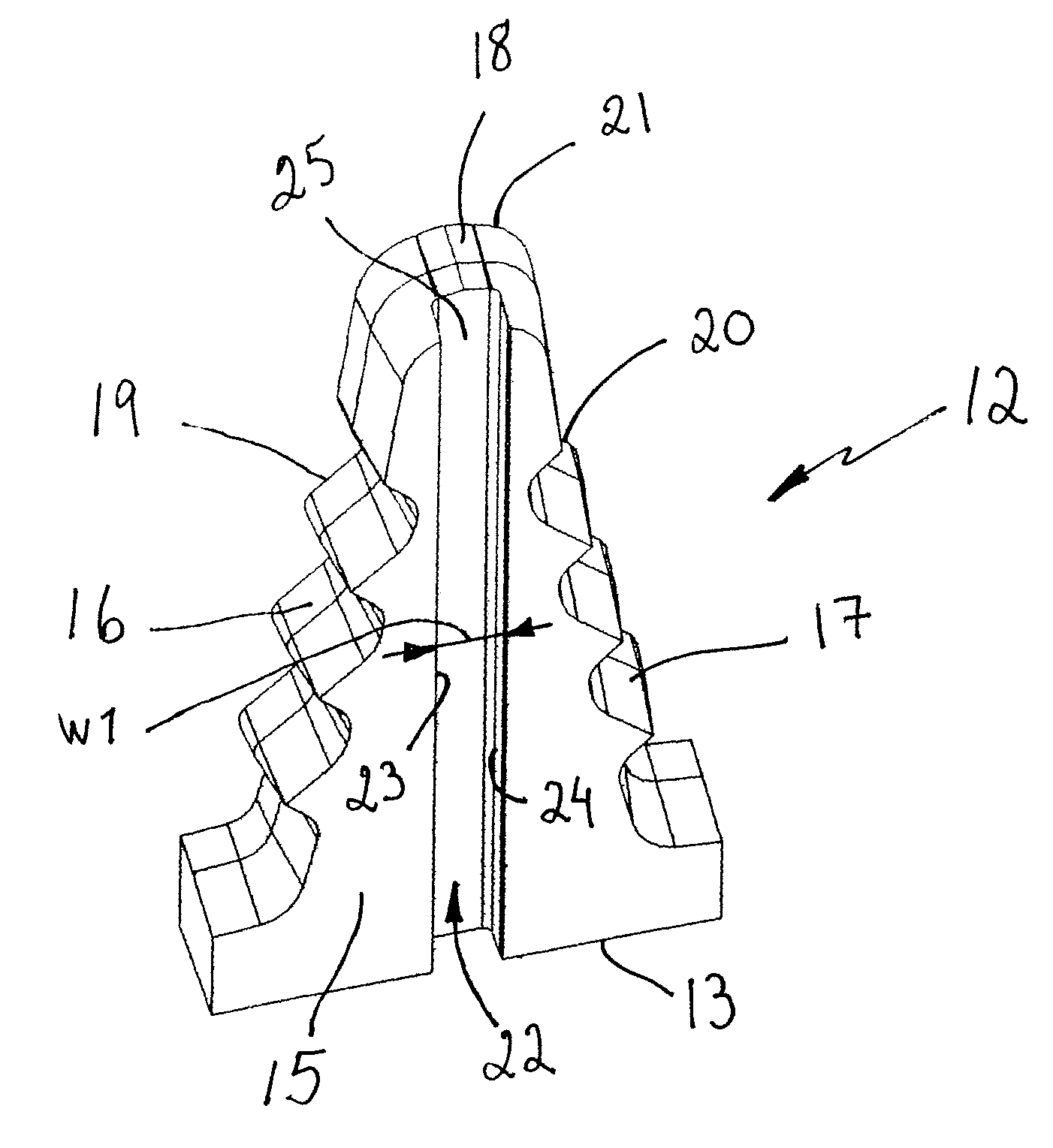

The broach assembly includes alternate spacers and cutters arranged in a sub-assembly having a lead at a leading end and a lag at a trailing end. The cutters have side margins in excess of the margins of the spacers for cutting material from the dovetail slots of the turbine wheel as the broach assembly passes through the slots. The bottom or apices of each spacer and cutter are tapered to form a continuously tapered surface along the bottom of the broach assembly. Upon passing the broach assembly through the slot, the assembly is progressively displaced in a radial outward direction to progressively cut the active dovetail slot surfaces. Shims may be disposed in the bottom of the slot to further displace the broach assembly radially outwardly in multiple passes.

Owner:GENERAL ELECTRIC CO

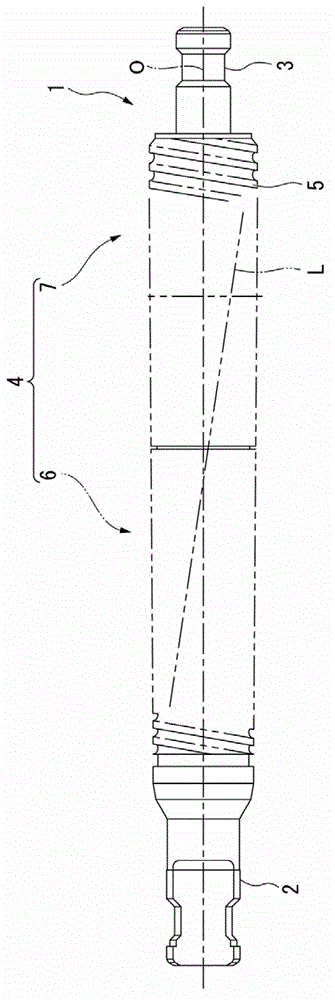

Internal broach

Owner:FORST TECH

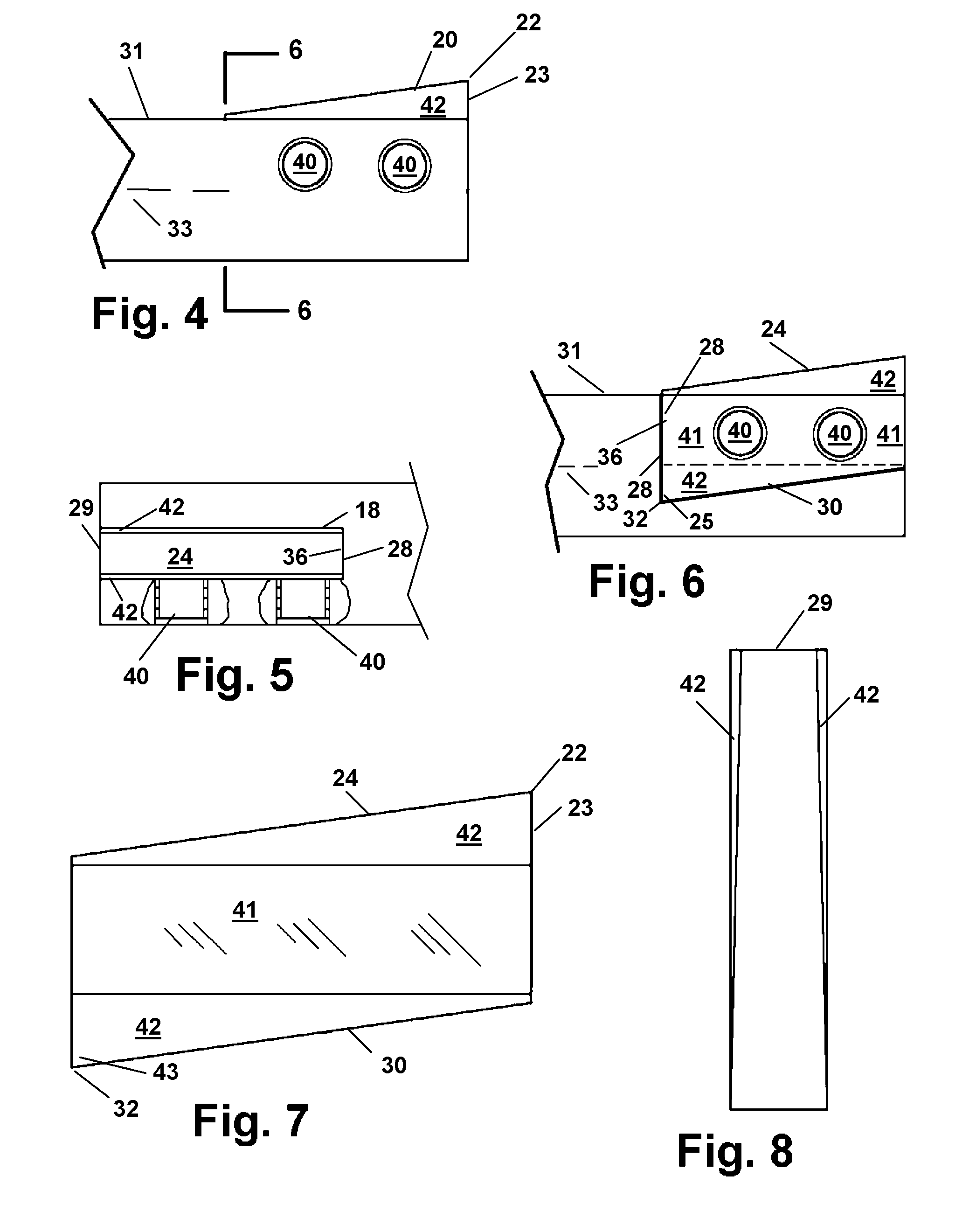

Helical broach for roughing

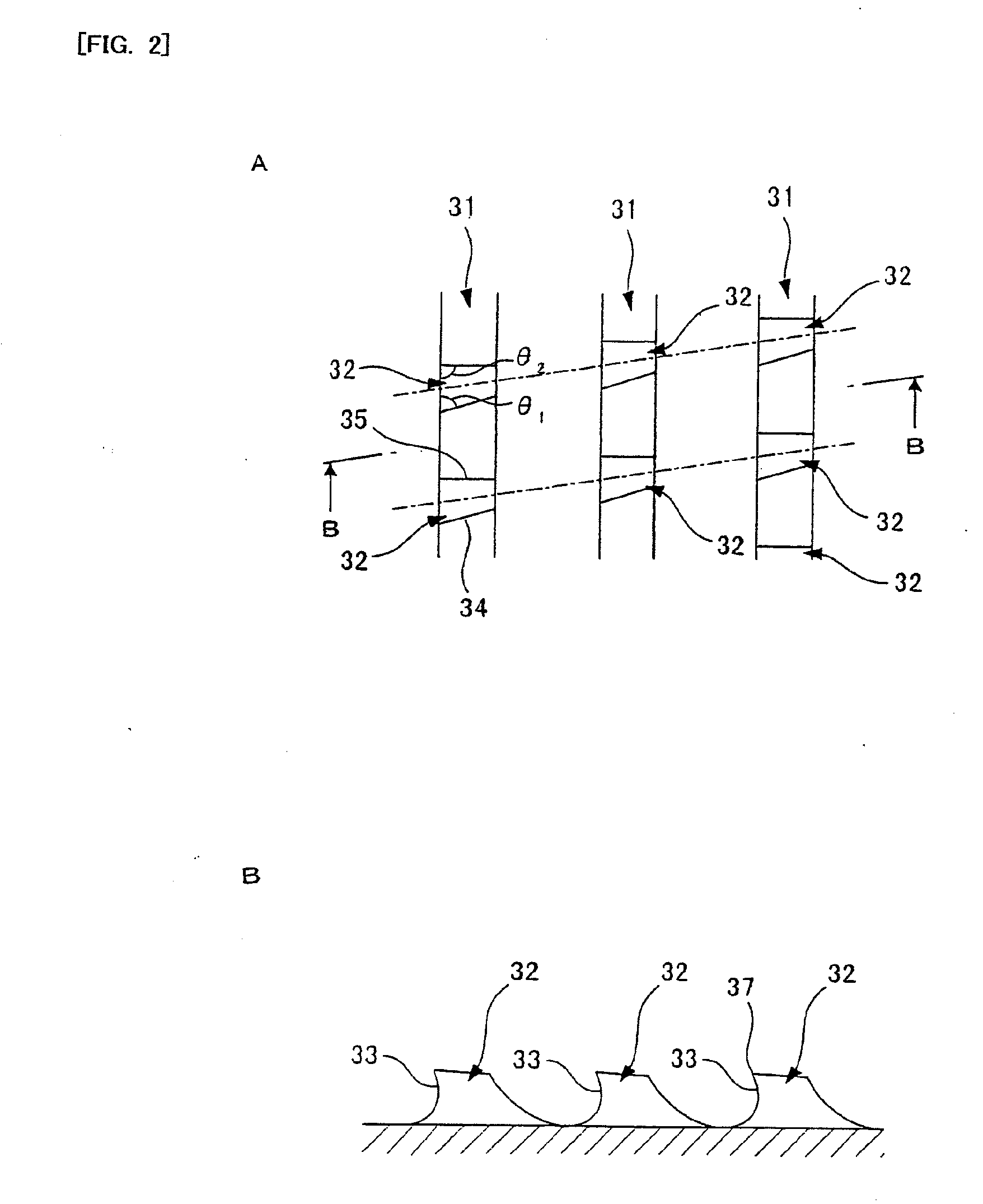

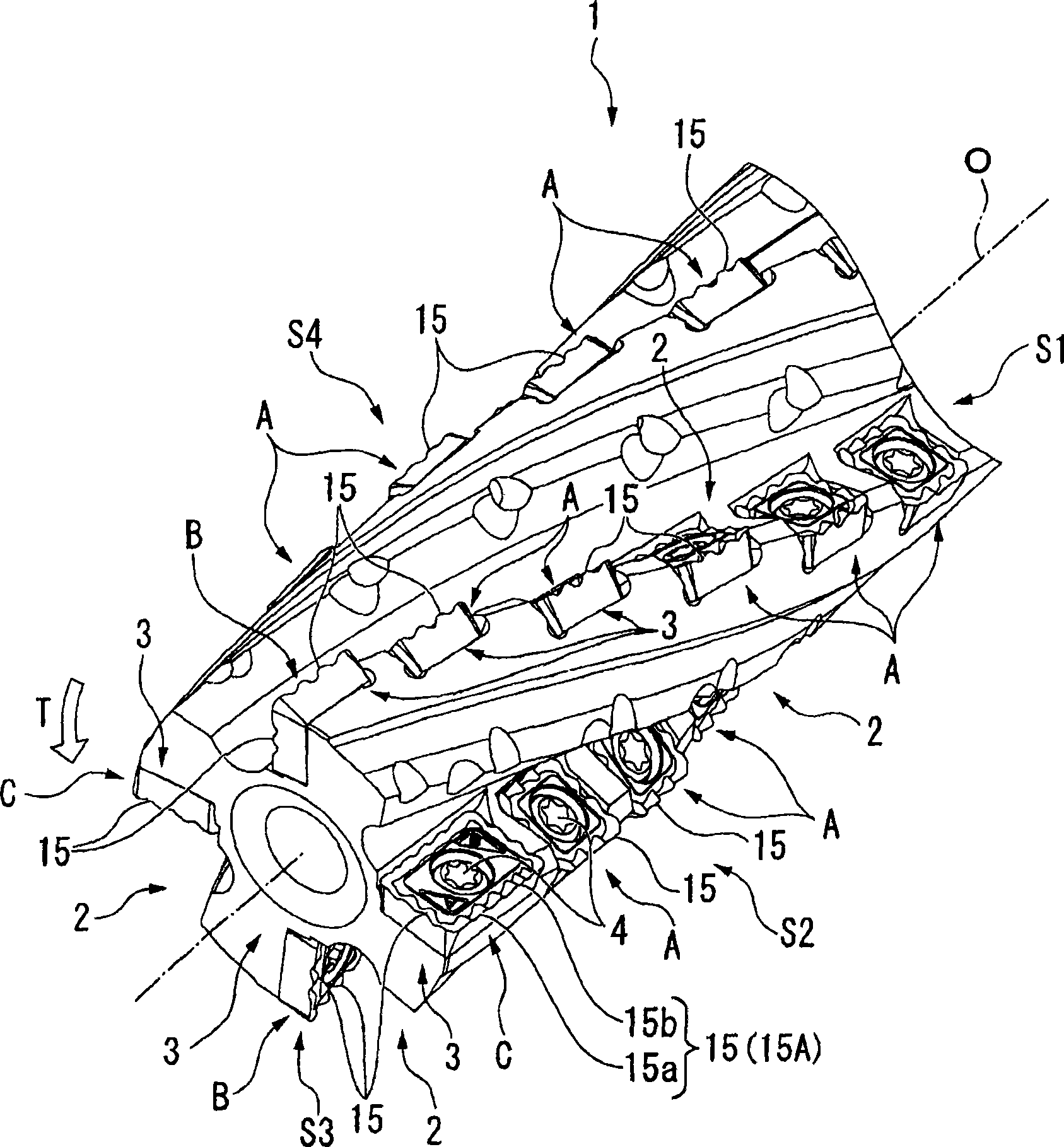

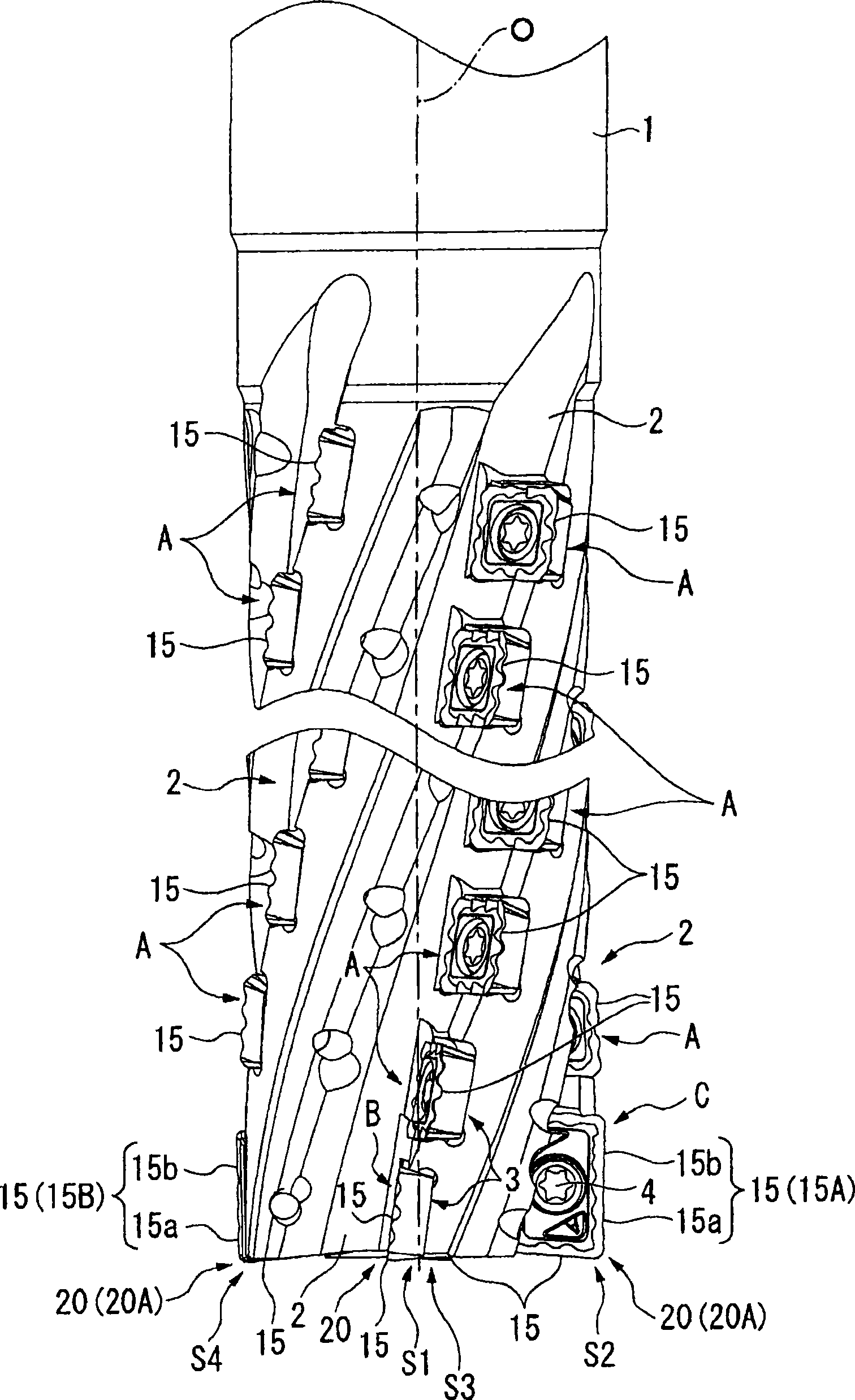

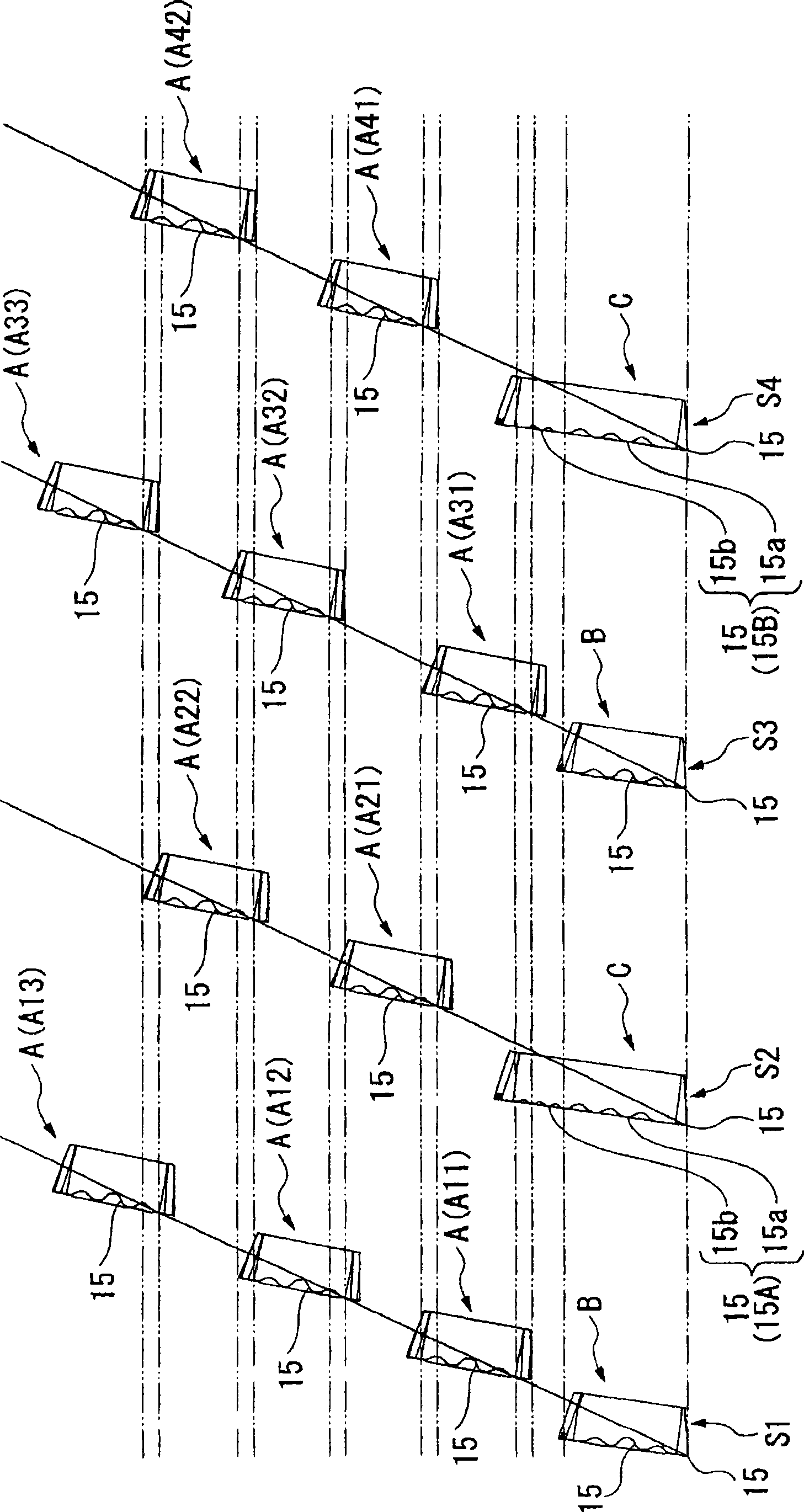

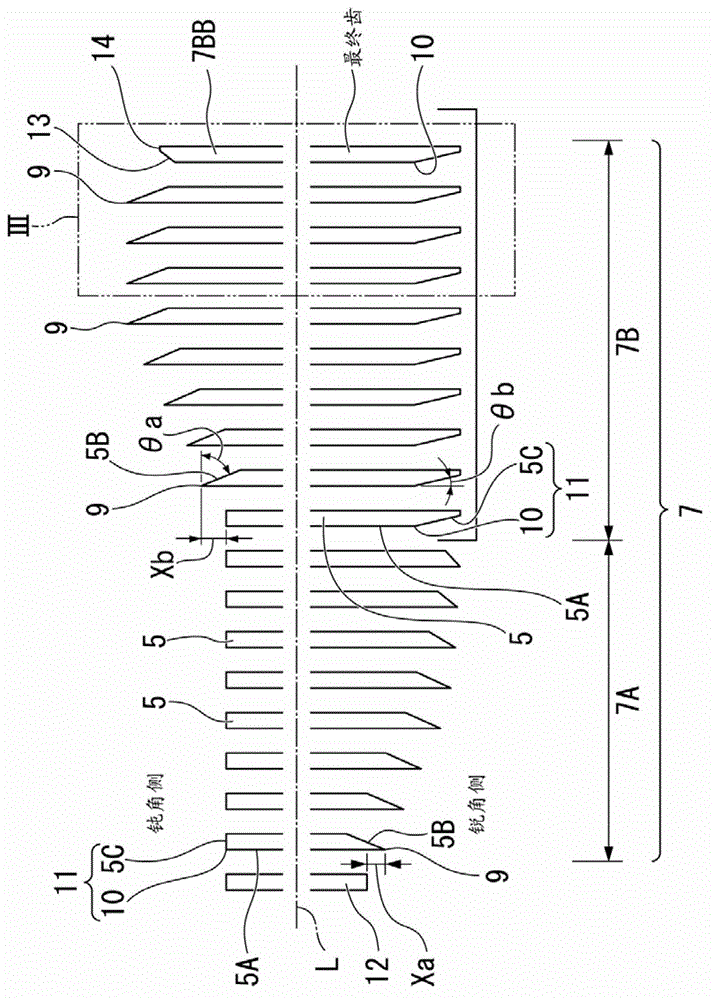

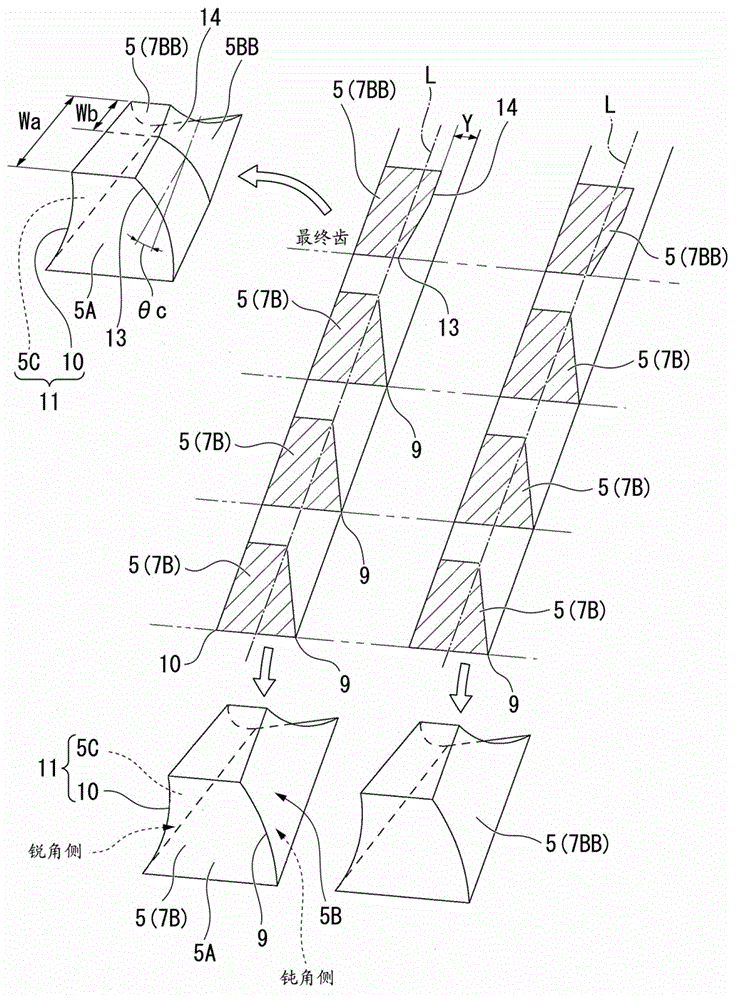

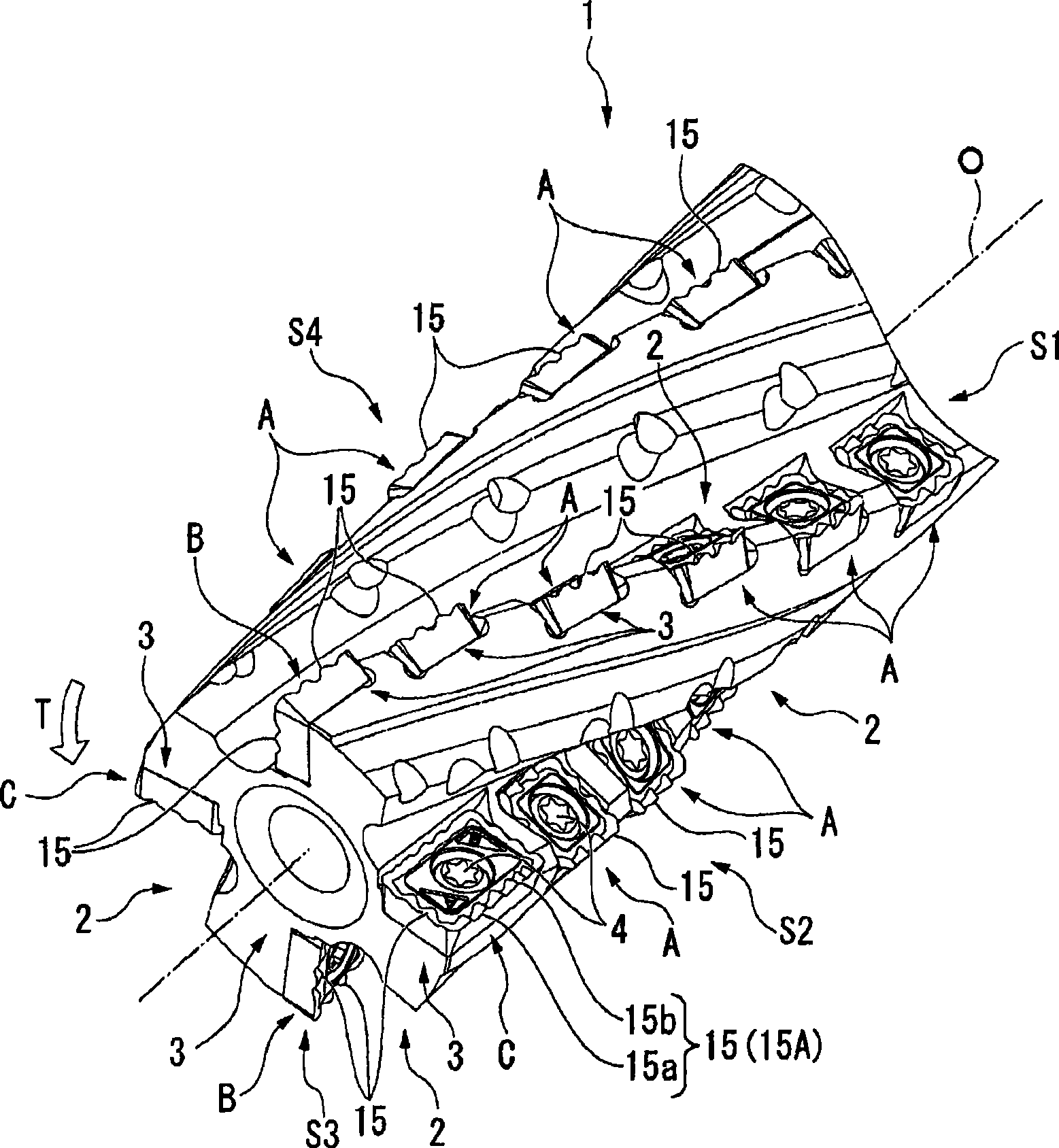

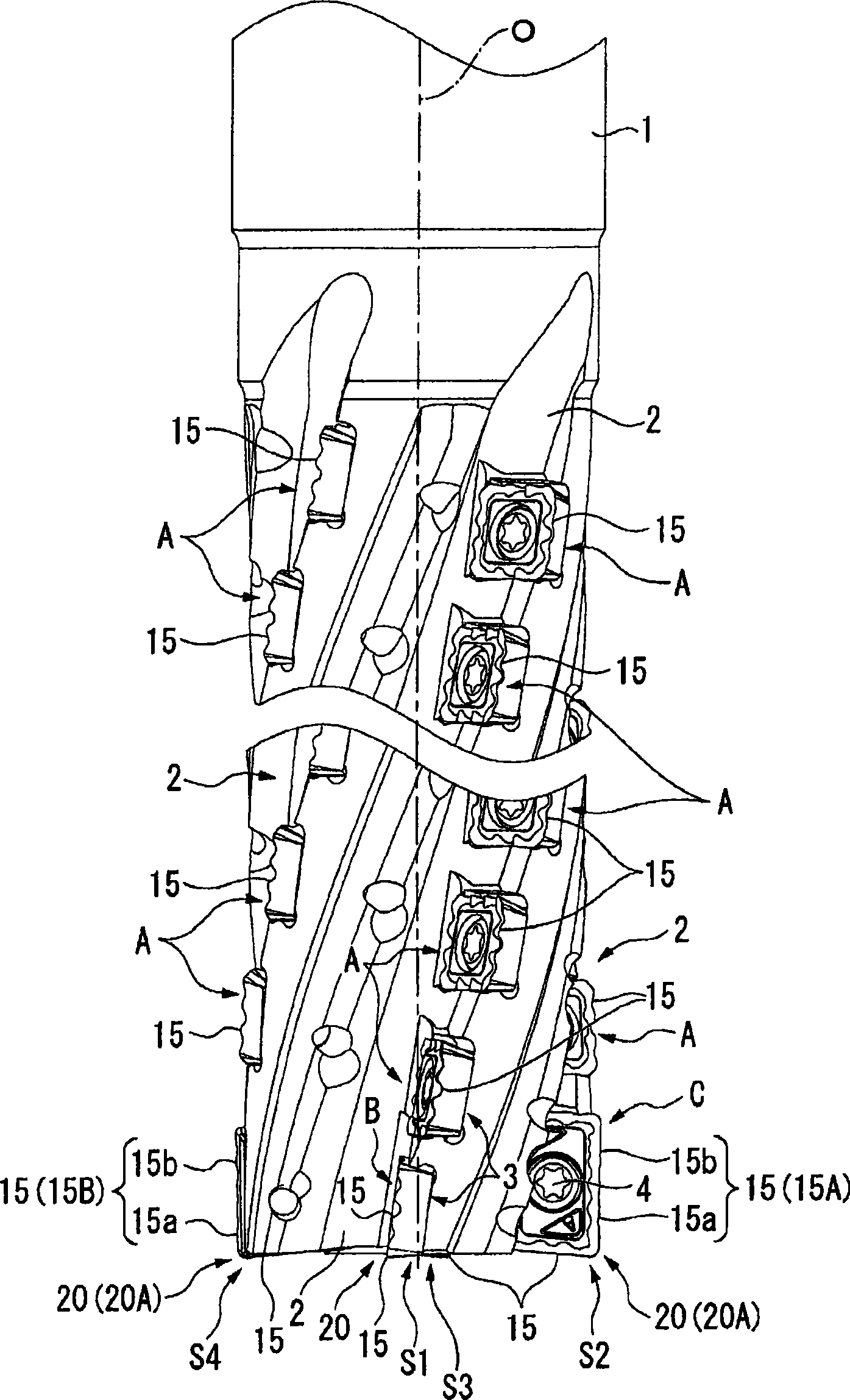

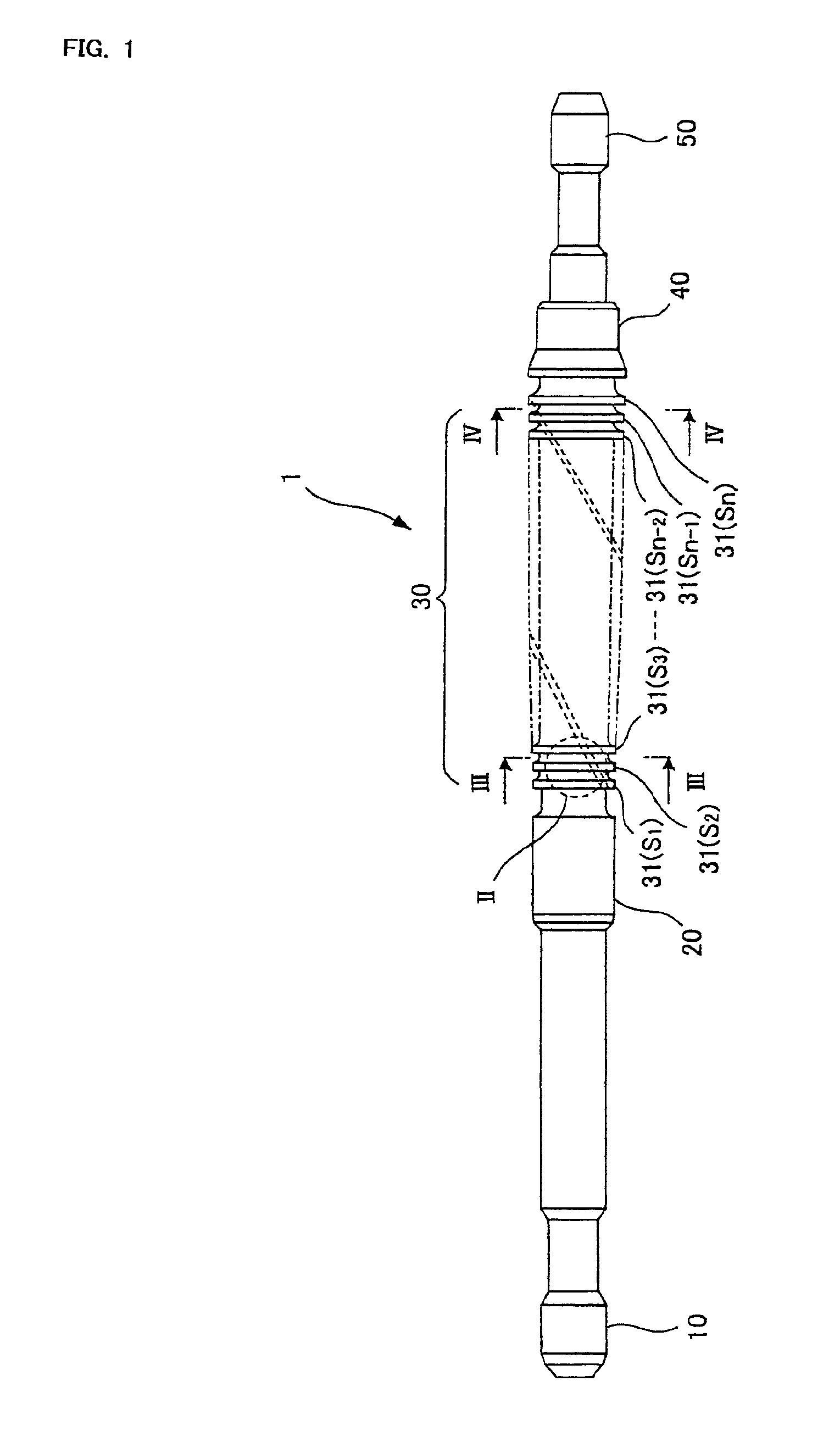

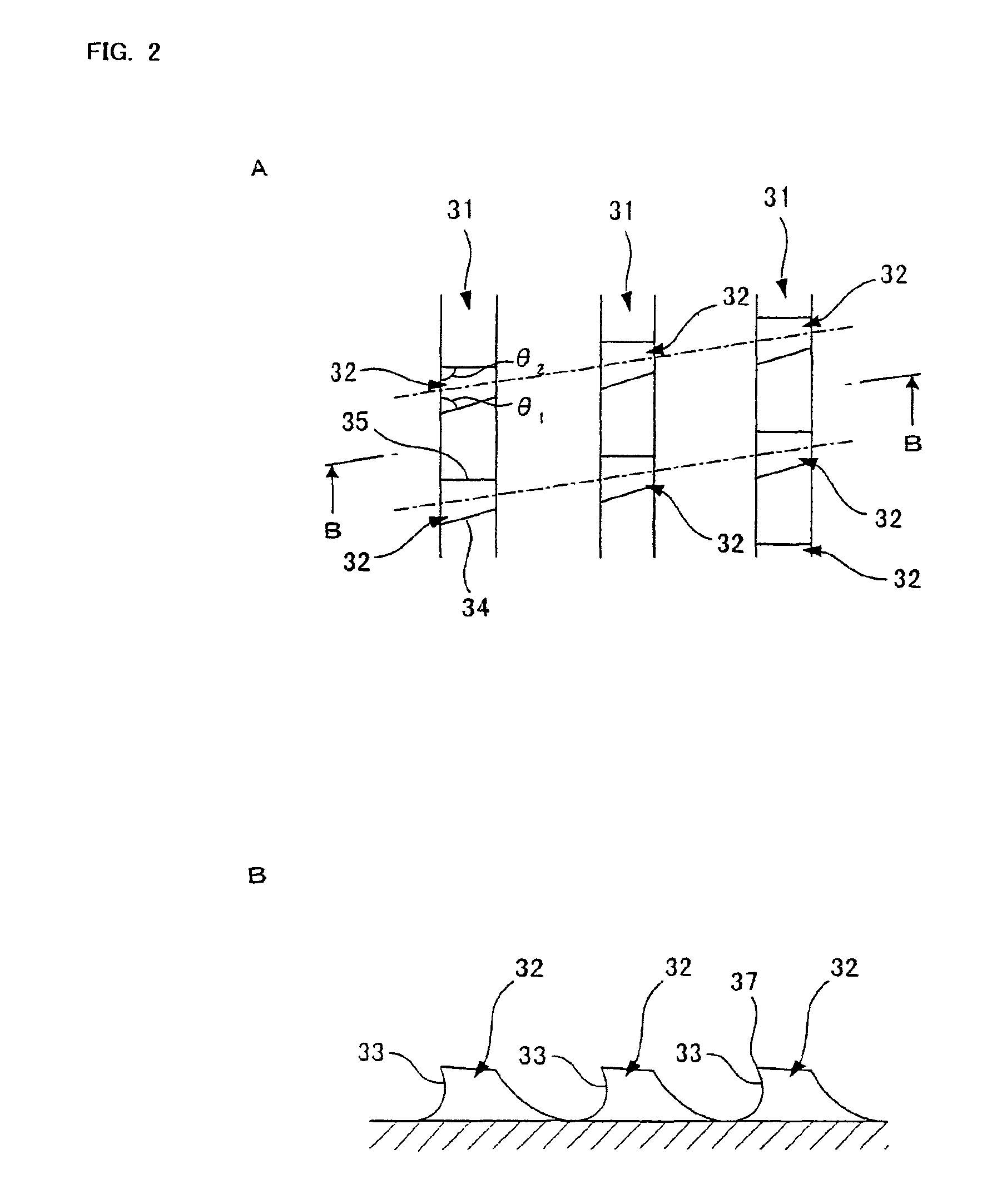

InactiveUS20110020078A1Reduce the balanceReduce the differenceRectilinear broachBroaching toolsAcute angleEngineering

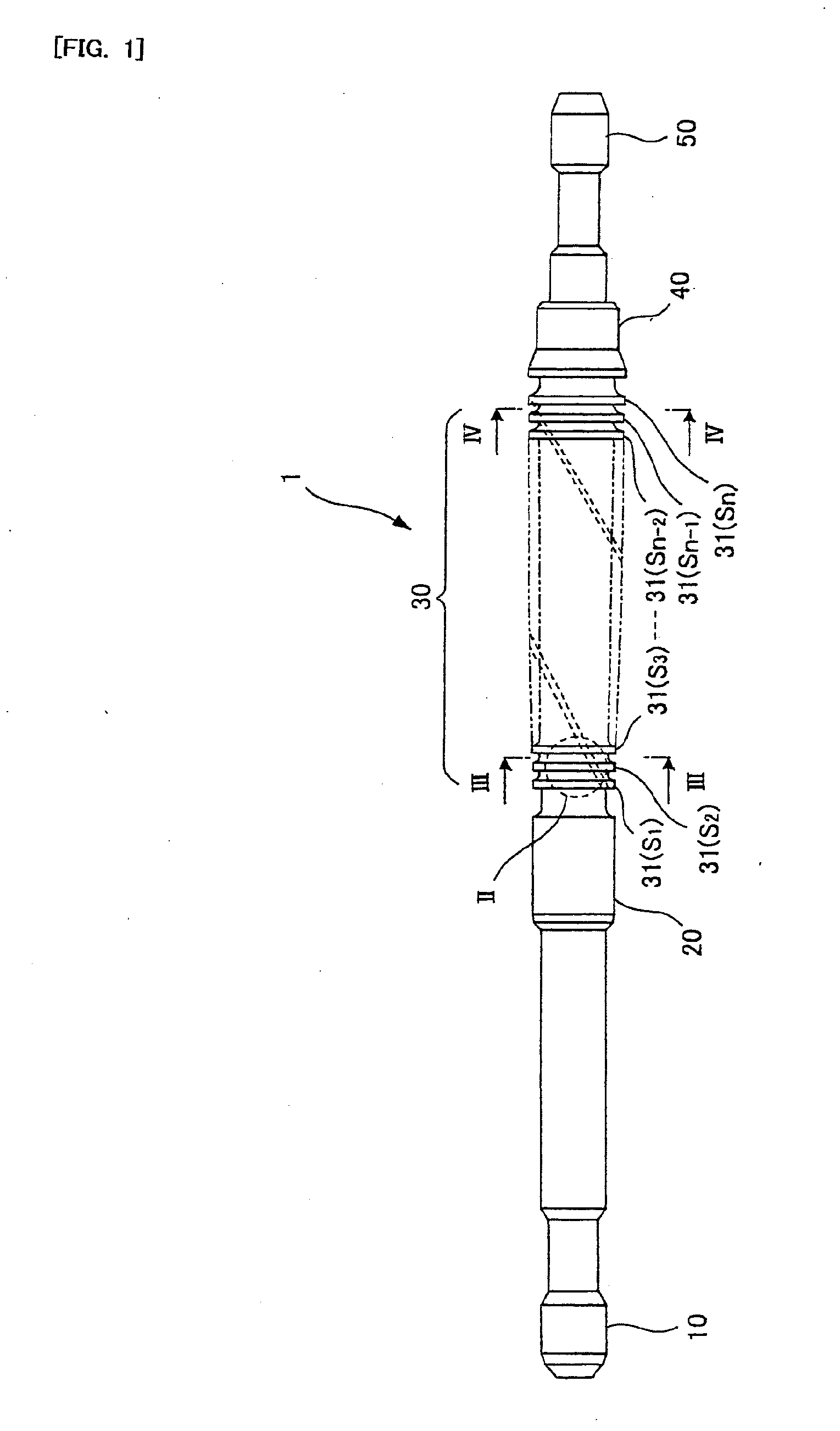

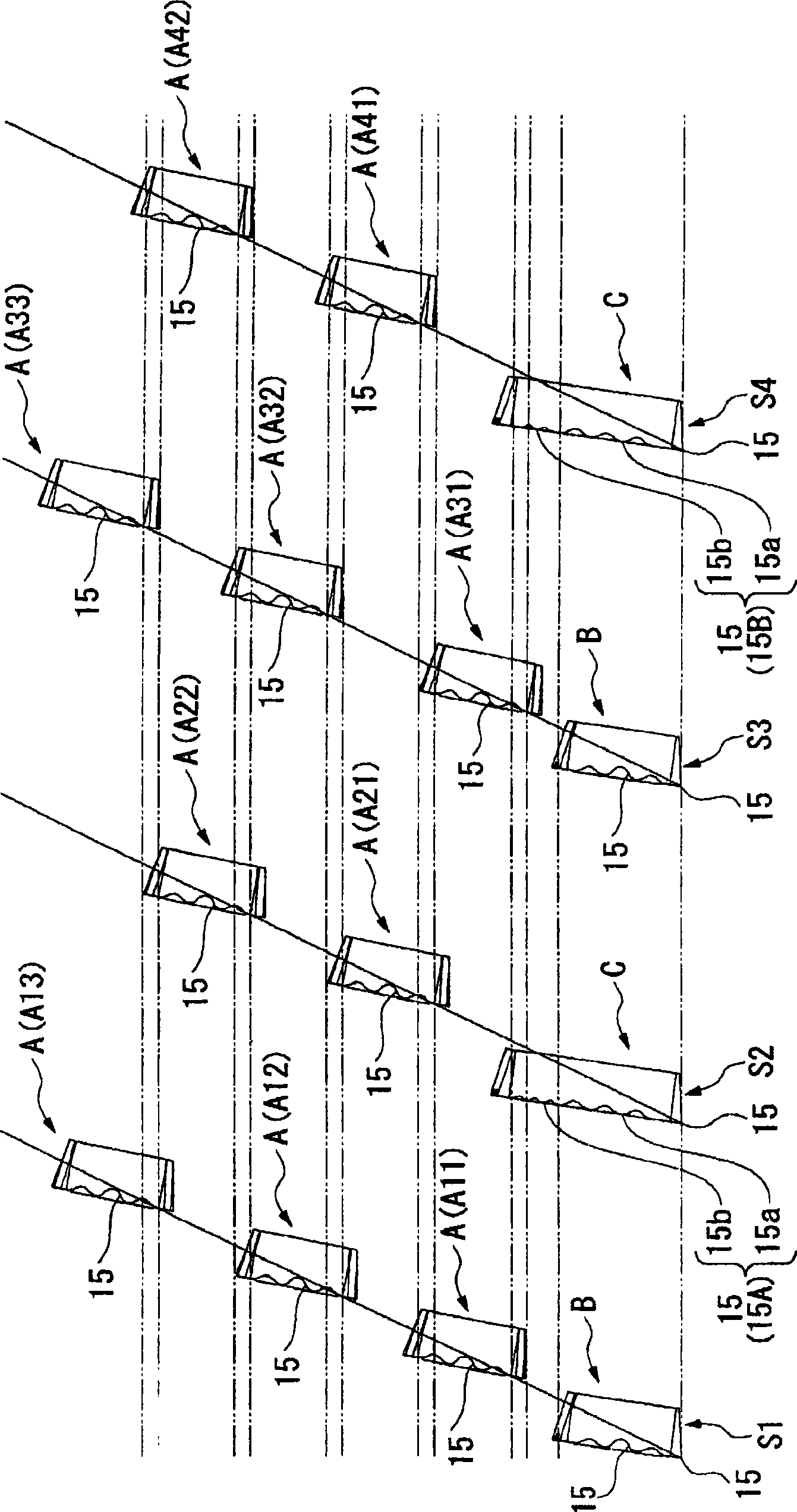

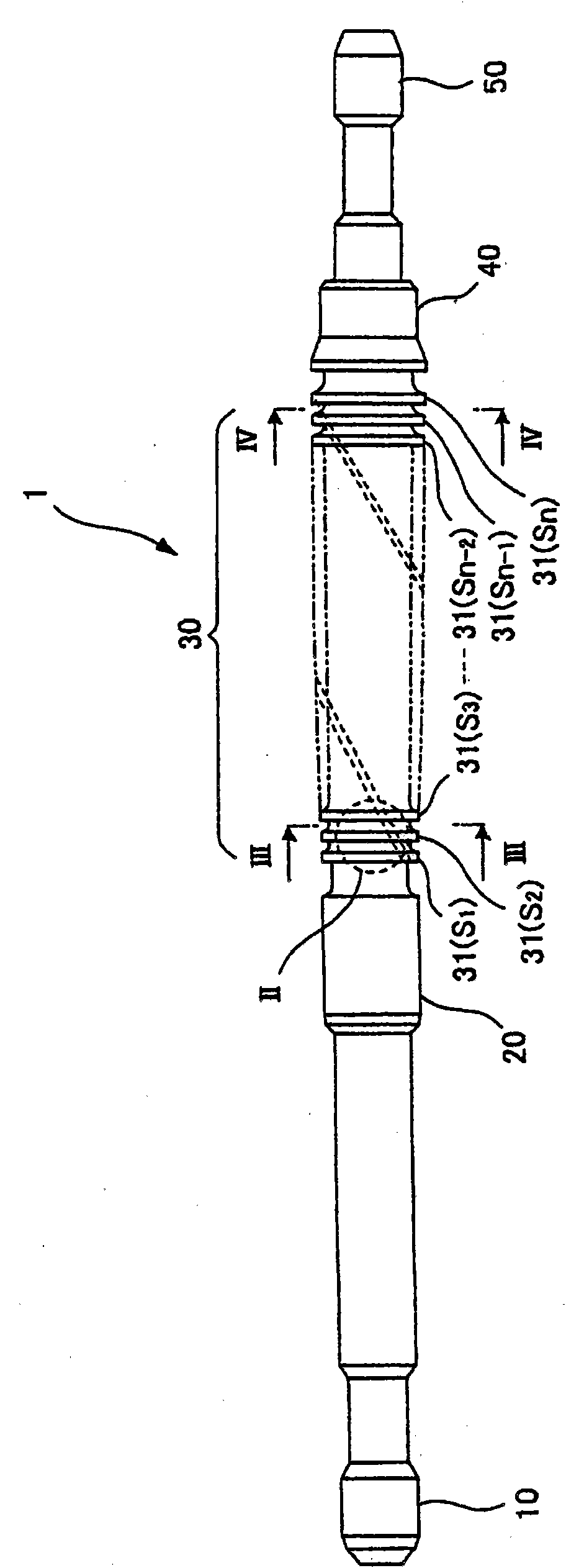

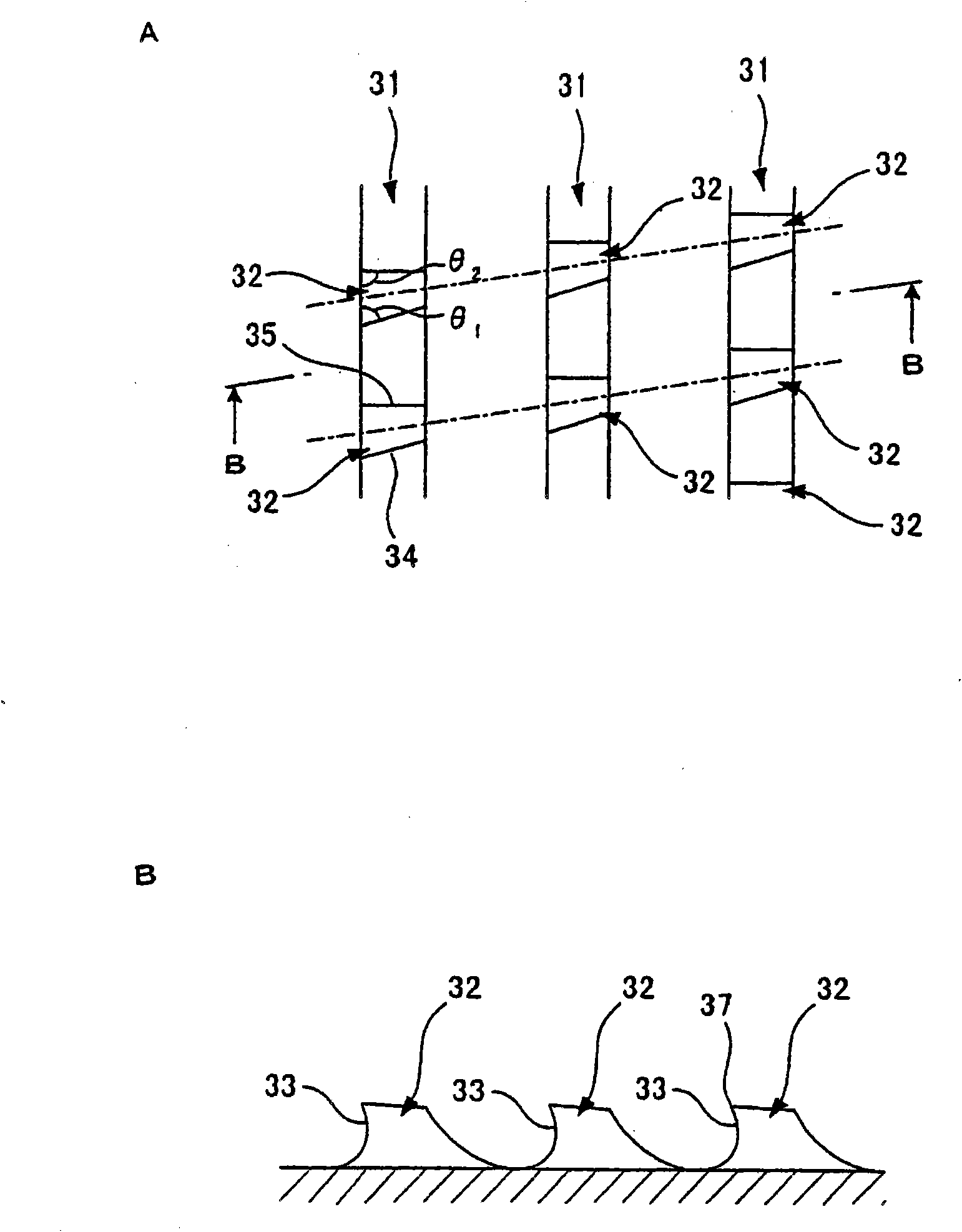

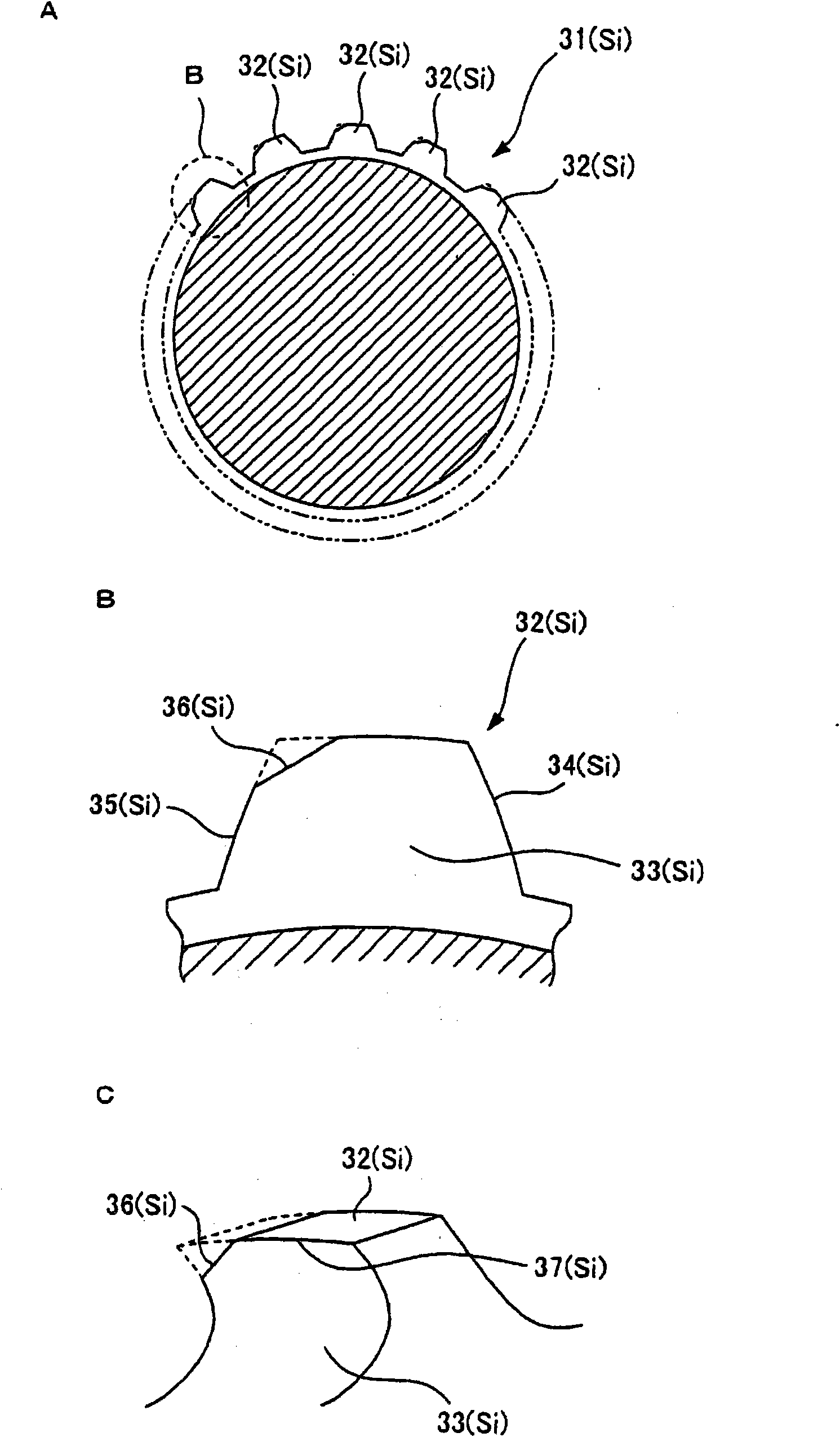

A helical broach 1 for roughing includes a cutting tooth part 30 in which n spline teeth 31 are arranged side by side in an axial direction. The spline teeth 31 each include cutting teeth 32 which are arranged at a predetermined helix angle. The cutting teeth 32 each have an acute angle portion and an obtuse angle portion on both sides thereof in a circumferential direction. The cutting teeth disposed on the first to n−1th spline teeth 31 (S1 to Sn−1) in the circumferential direction are each formed in such a way that its height on the acute angle portion side differs from that on the obtuse angle portion side. The cutting teeth (Sn) of the nth spline tooth (Sn) are each formed in such a way that its height stays constant in the circumferential direction.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

Internal broach

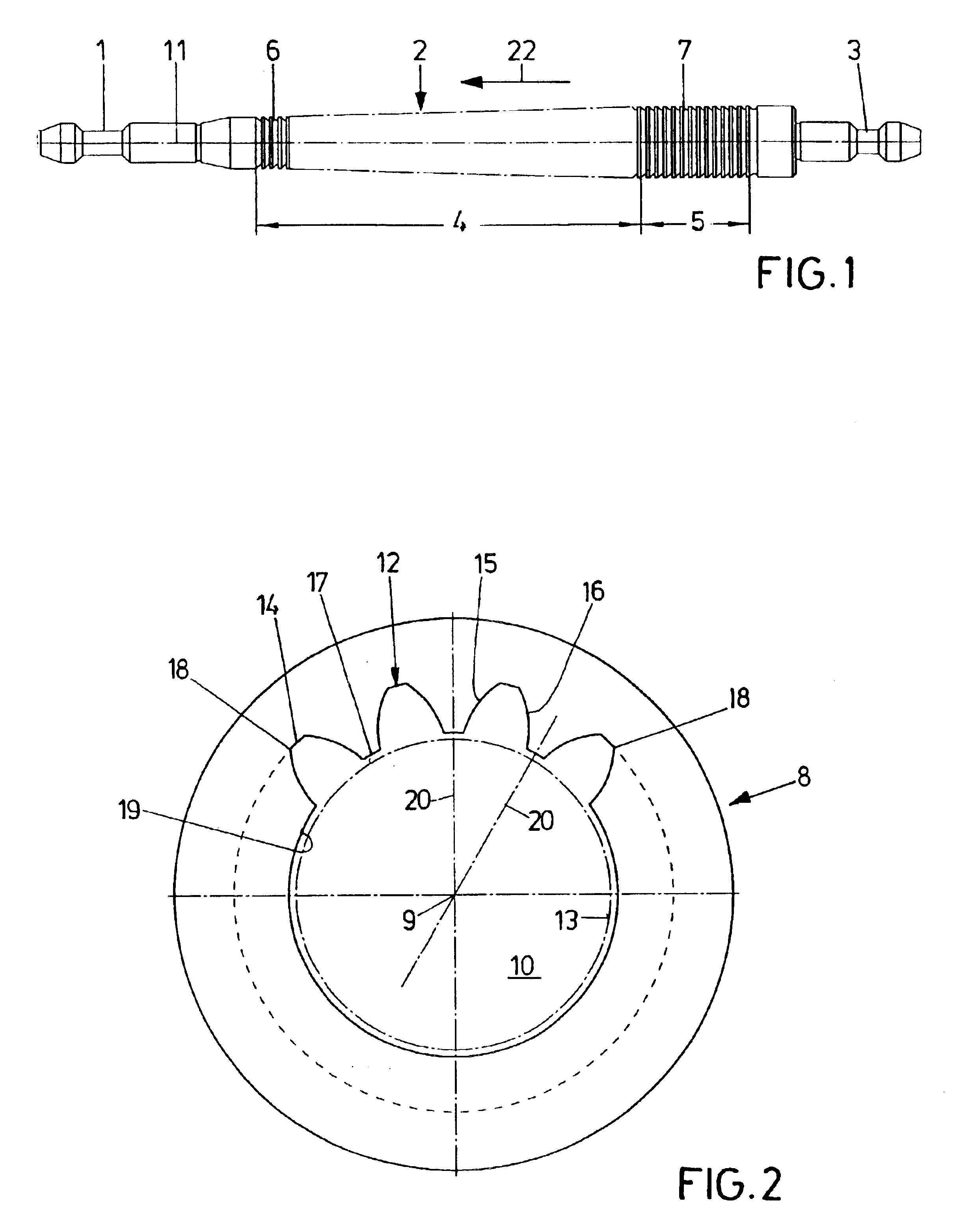

InactiveUS6918716B2Reduce capacityAvoid pinchingRectilinear broachBroaching toolsEngineeringMechanical engineering

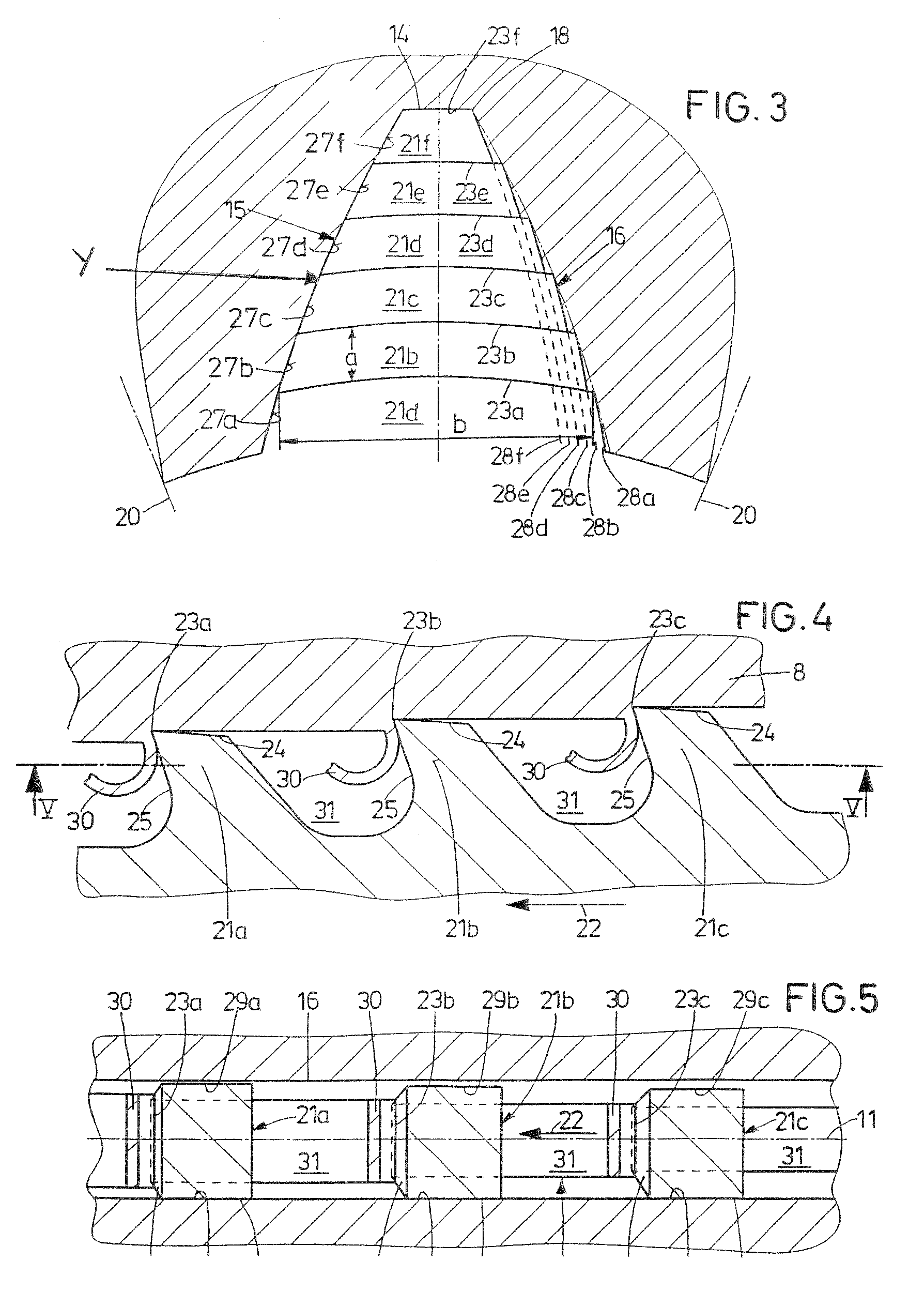

An internal broach for internally broaching profiles, defined by a bottom and flanks, of female serrations of a work piece, comprises a toothed portion with several rows of broach cutting teeth disposed successively counter to a direction of broaching, successive broach cutting teeth being allocated to each other for broaching a profile. The broach cutting teeth have bottom cutting blades and first and second sides. The first sides are guide flanks, the edges of which are guide edges without cutting ability. The second sides are flank-cutting-blade relief surfaces, the edges of which are designed as flank blades with cutting ability.

Owner:FORST TECH

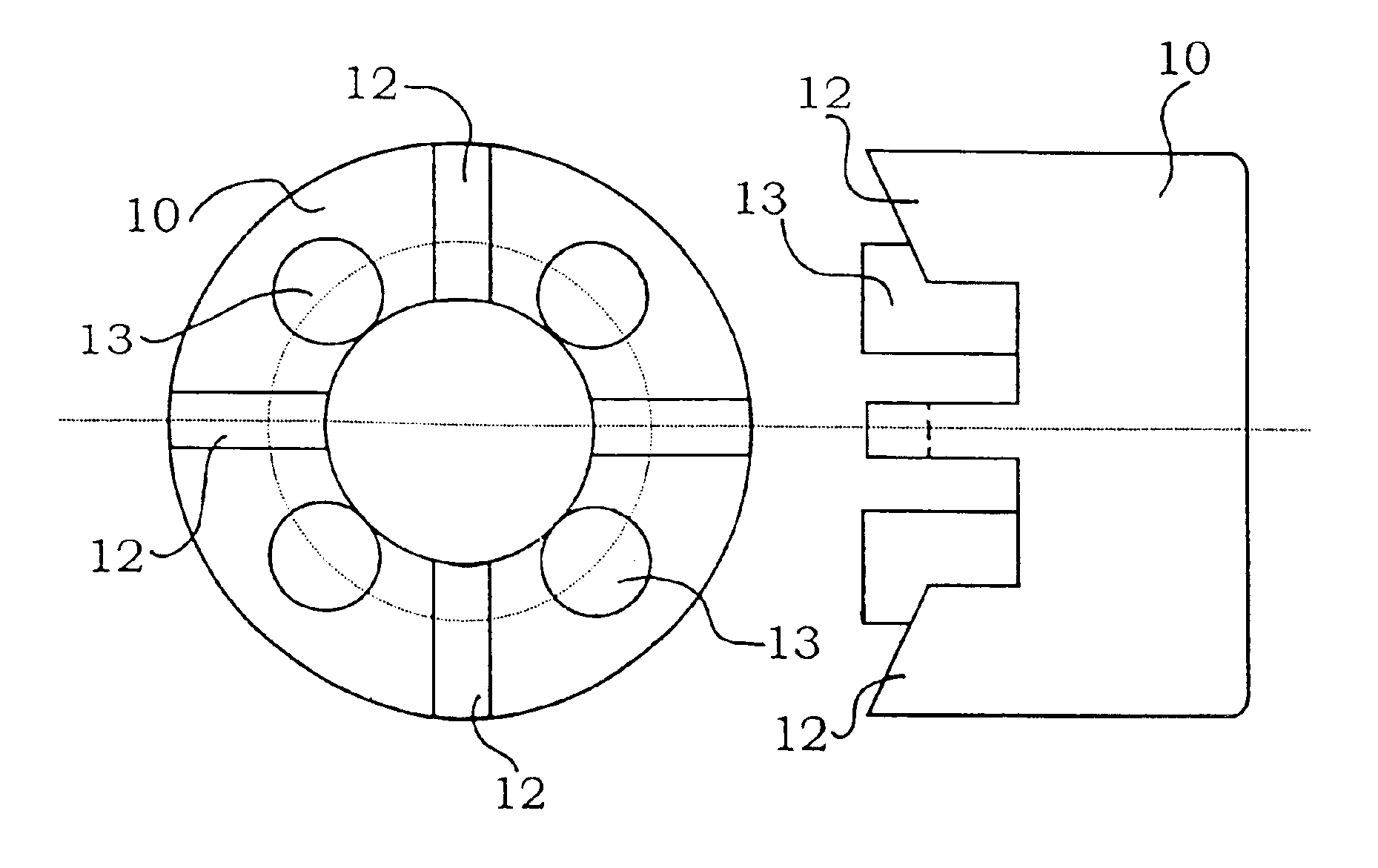

Wheel bearing assembly for motor vehicles

InactiveUS6935026B2Reduced mechanical stabilityLow costRoller bearingsBearing assemblyMobile vehicleEngineering

The invention relates to a wheel bearing assembly for motor vehicles with a bearing provided with an inner ring and an outer ring, the bearing being fitted with its outer ring into a bearing casing and the outer ring being mechanically supported in axial direction on a first side by a supporting surface provided on the bearing casing. Discrete and preferably evenly arranged stop protrusions are formed on the inner circumference of the bearing casing, the outer ring abutting thereon in axial direction on its second side, and the stop protrusions being formed by locally plastic forming the bearing casing.

Owner:VISTEON GLOBAL TECH INC

Cemented carbide broach and broaching machine

InactiveCN1550278AEasy to cutWon't breakRectilinear broachBroaching toolsEngineeringCemented carbide

A broach has a main body of a cemented carbide material. On this main body, a front grip portion, a cylindrical portion following the front grip portion and provided with a plurality of guide parts in its outer periphery, a broach cutting edge portion following an end of the cylindrical portion and having a number of cutting edges, and a cylindrical extension following the broach cutting edge portion and having a maximum outer periphery dimension to such an extent that the extension does not interfere with a work are integrally provided. On an end surface of the cylindrical extension, a load receiving shoulder is formed, which leads to a rear grip portion including a small-diameter part and is orthogonal to or inclined with respect to a broach axis. The load receiving shoulder has a sufficient area to bear a cutting load. A broaching machine grips the rear grip portion with its load receiving surface abutting against the load receiving shoulder of the cemented carbide broach. The broach, even when having a small diameter, does not suffer from an insufficient tensile strength of the front grip portion.

Owner:NACHI-FUJIKOSHI

Insert for roughing and roughing end mill

InactiveCN101511514ASmooth cutInconsistent rotation trajectoryRectilinear broachMilling cuttersEngineeringReference line

This roughing insert is provided with an insert body, and a waveform cutting edge which is formed on an intersecting ridge line portion between a rake face and a flank face of the insert body, and which undulates along this intersecting ridge line portion. The waveform cutting edges are formed on the insert body respectively at positions which are rotationally symmetrical at predetermined angularintervals around a reference line of the insert bodies. These waveform cutting edges which are positioned rotationally symmetrically to each other are formed such that, when the insert bodies are rotated by the predetermined angle around the reference line, one or more portions of the waveform cutting edges do not match each other and are mutually asymmetrical.

Owner:MITSUBISHI MATERIALS CORP

Broaching apparatus and method for producing a gear member with tapered gear teeth

Owner:GM GLOBAL TECH OPERATIONS LLC

Helical broach

ActiveCN103068509ASmooth movementGood precisionRectilinear broachBroaching toolsGroove widthEngineering

This helical broach forms a twisted groove at the inner periphery of a machined hole of a work by means of a plurality of cutting blades. The plurality of cutting blades have: a plurality of groove depth-expanding blades that are arrayed towards the tip of a broach body; and a plurality of groove width-expanding blades that are arrayed towards the base of the broach body. The plurality of groove width-expanding blades have a cutting blade and a guiding blade. The groove width-expanding blade positioned furthest towards the base of the broach body is formed with a guiding blade instead of a cutting blade at the edge of intersection of a scooping surface and the lateral surface that faces one of the wall surfaces from among both groove wall surfaces of the twisted groove of the work.

Owner:MITSUBISHI MATERIALS CORP

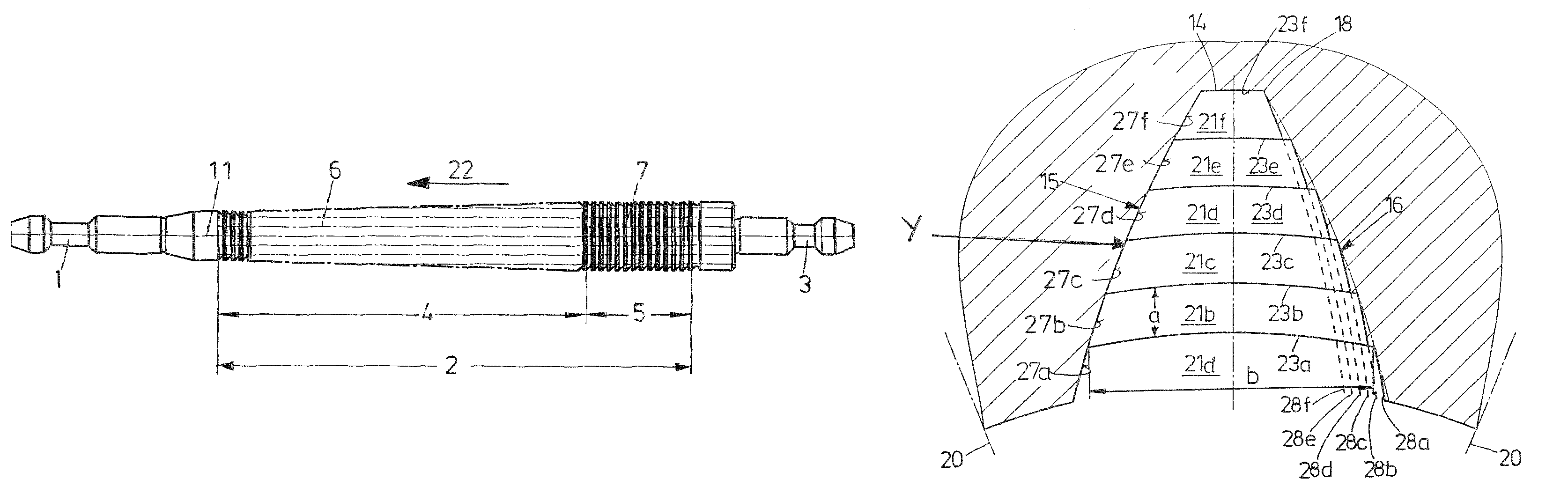

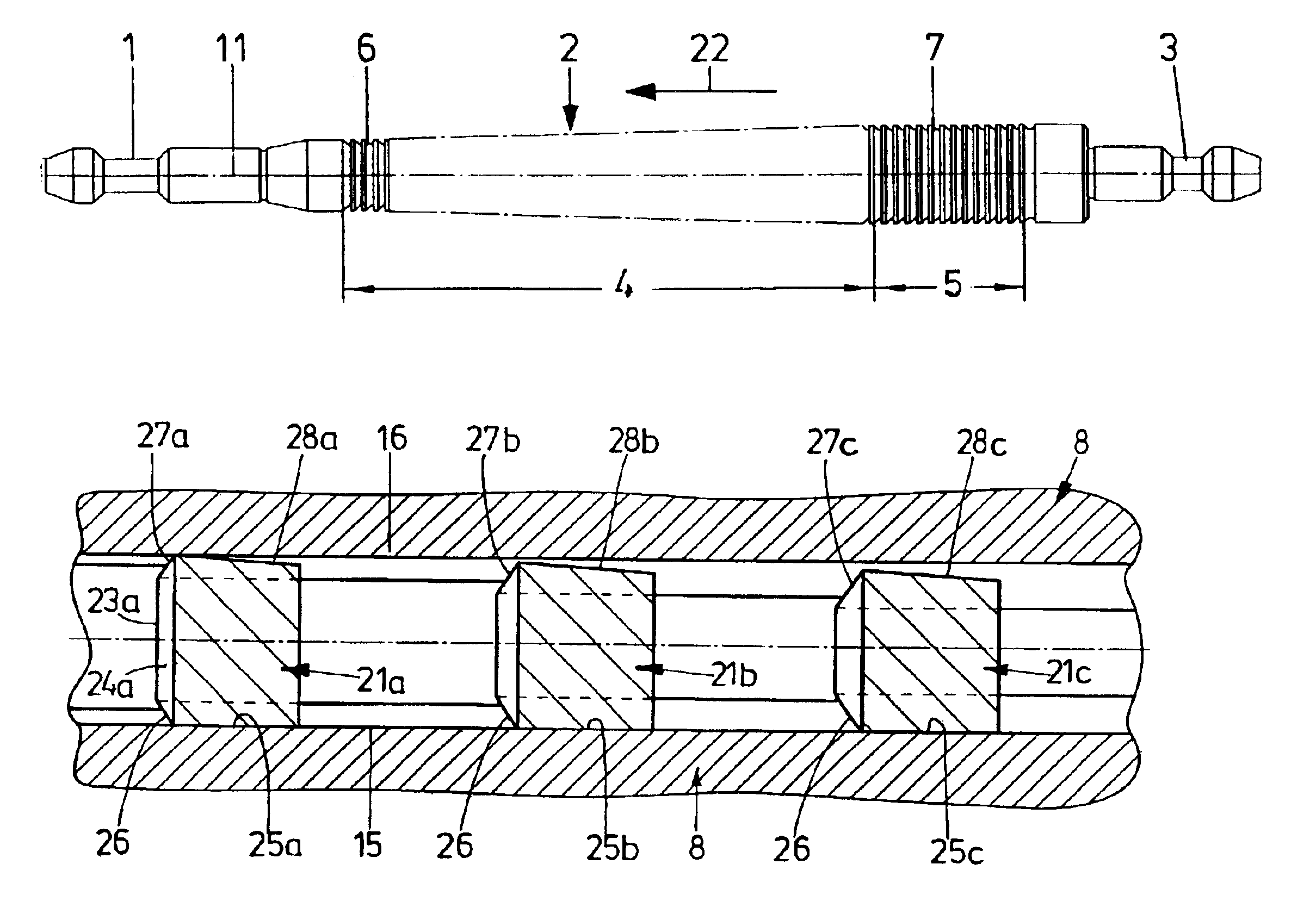

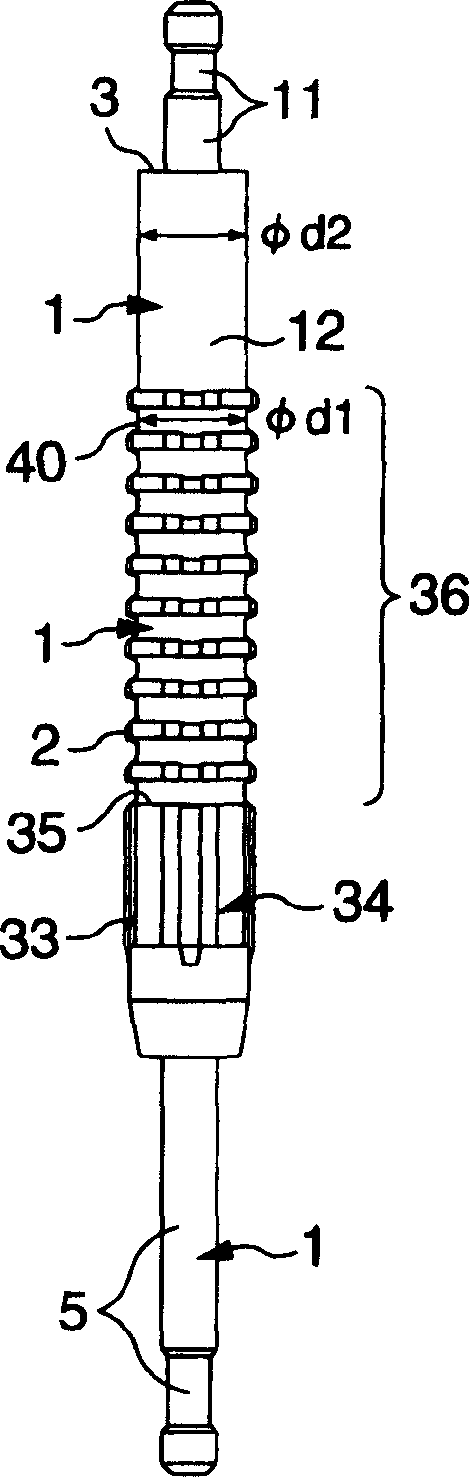

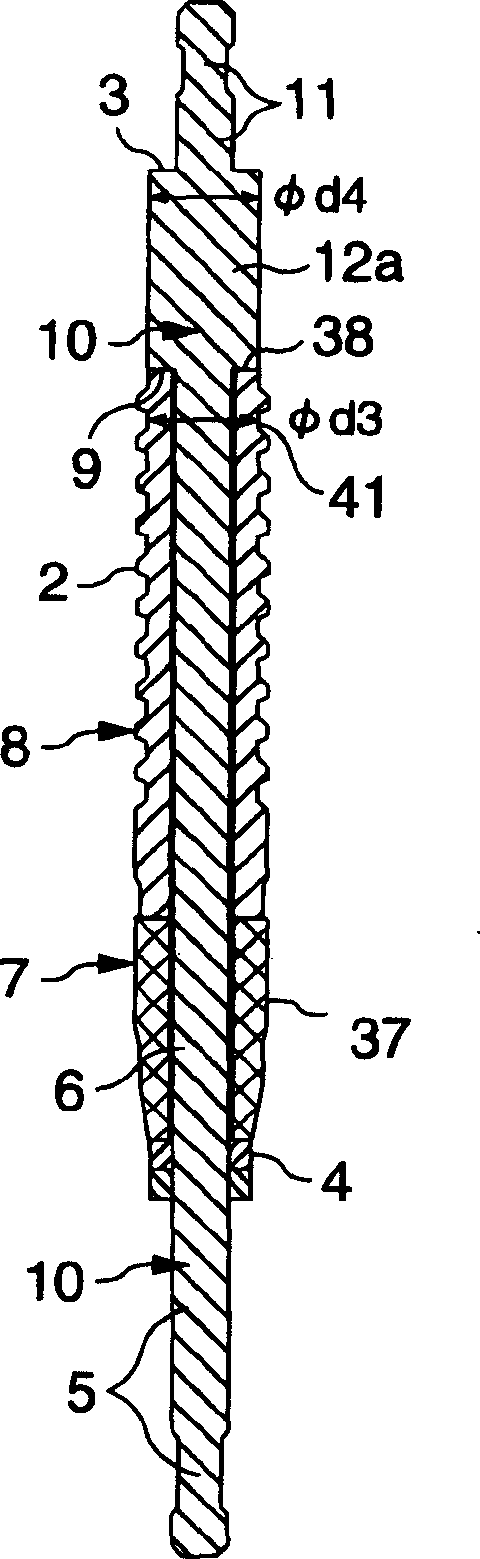

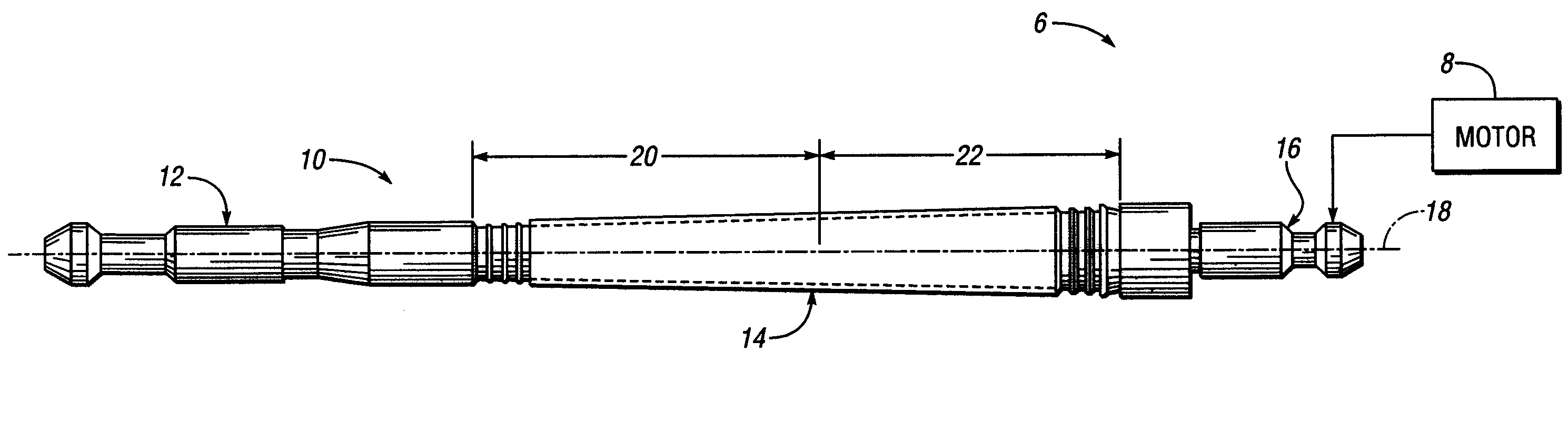

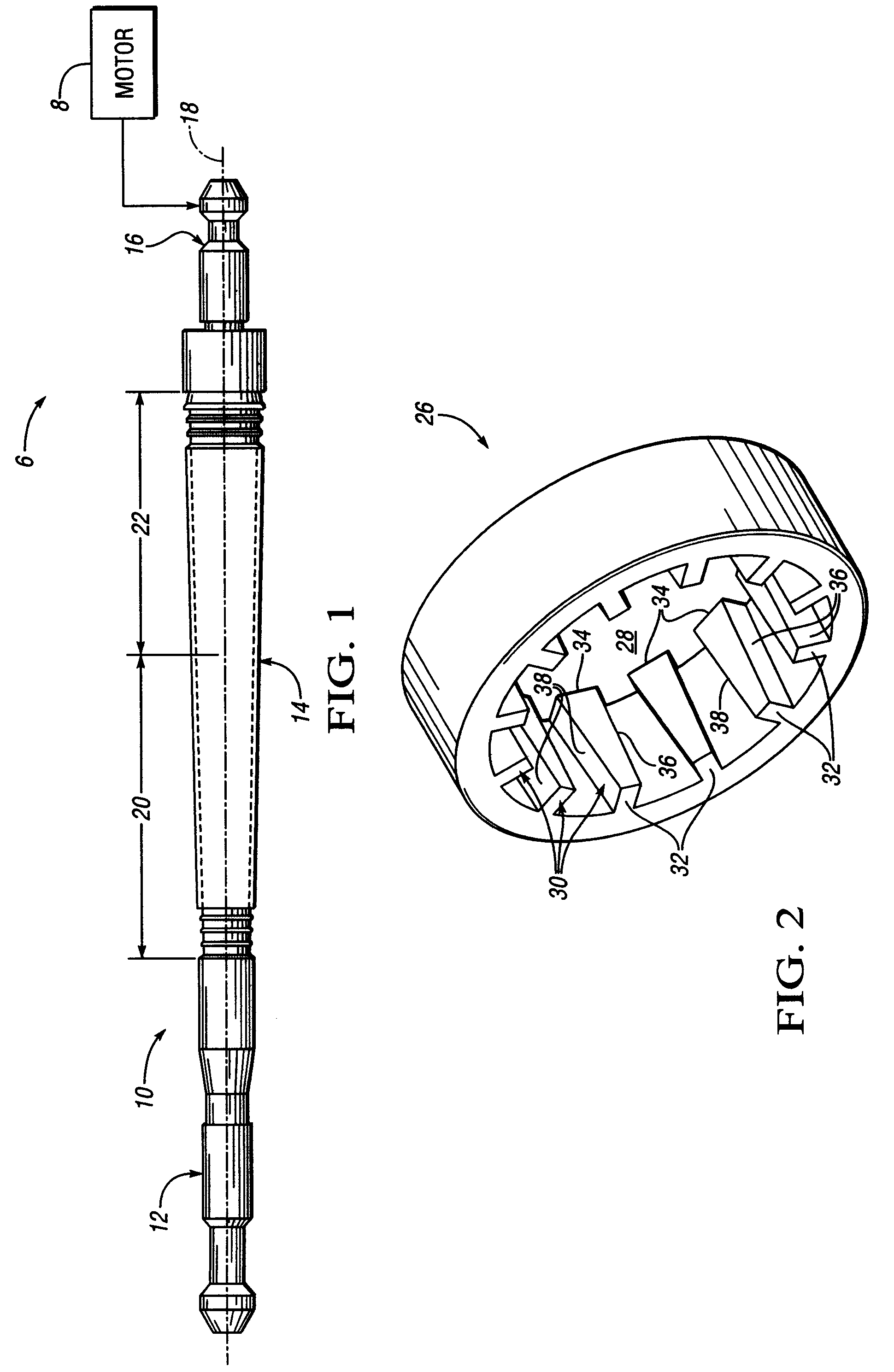

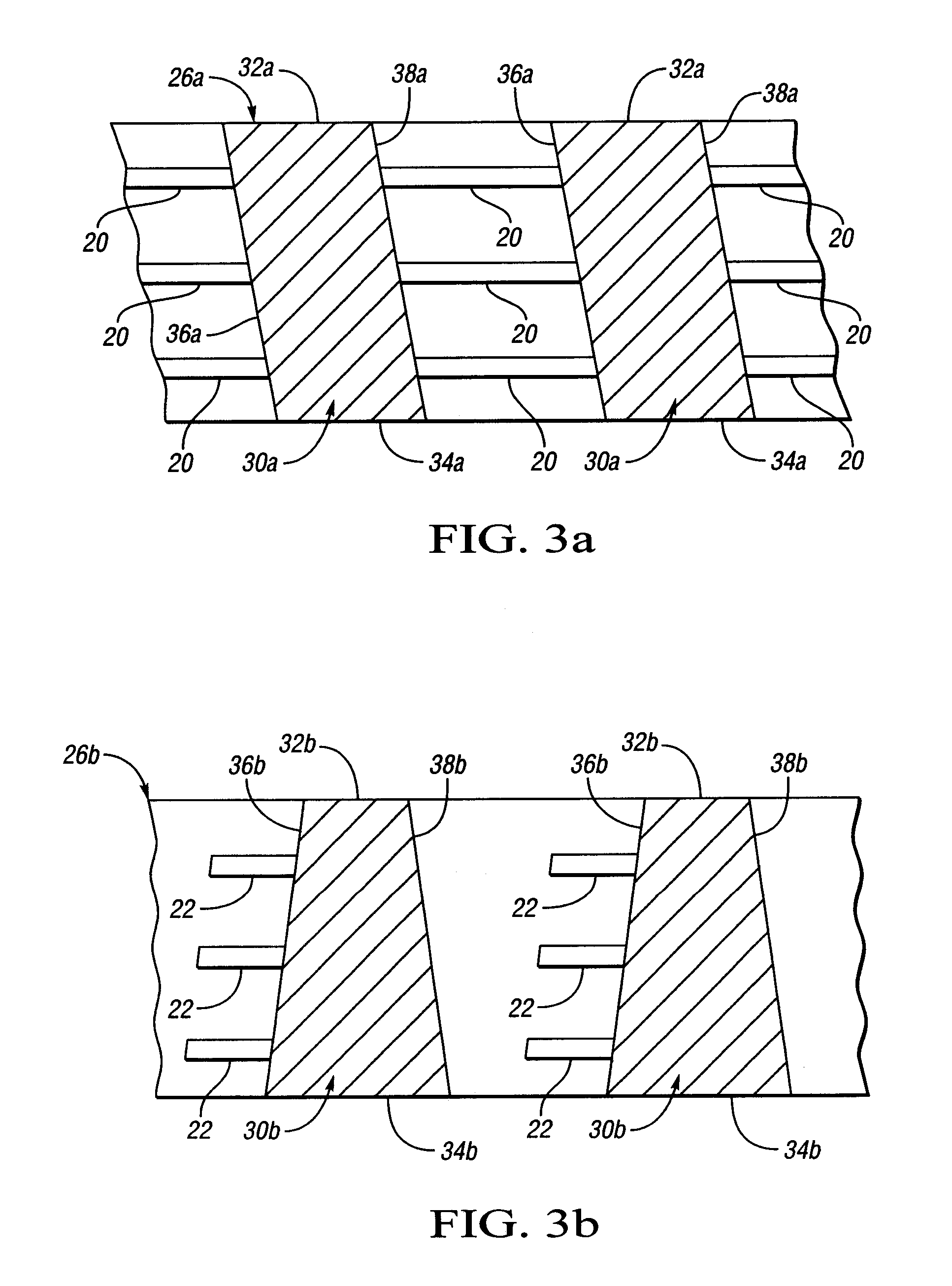

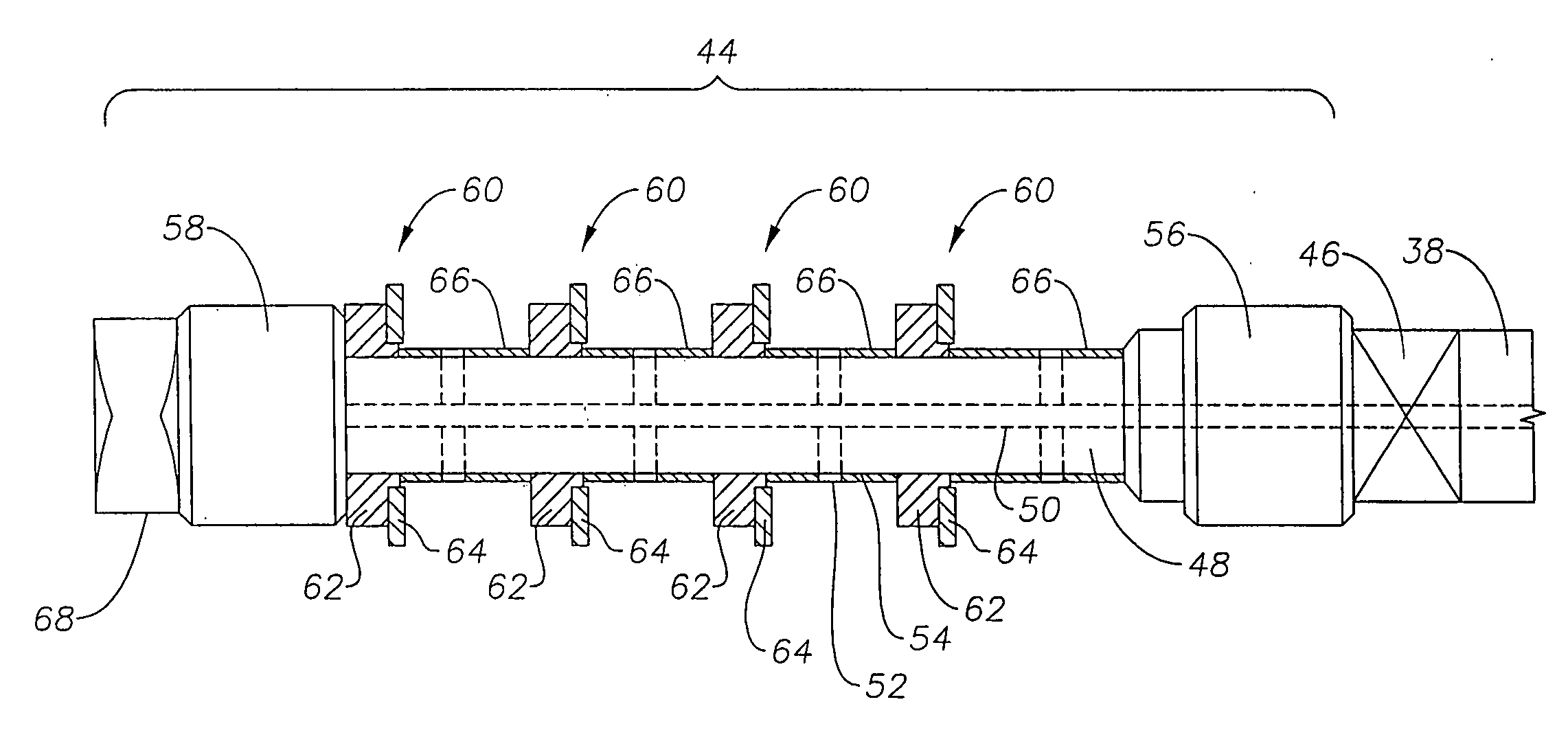

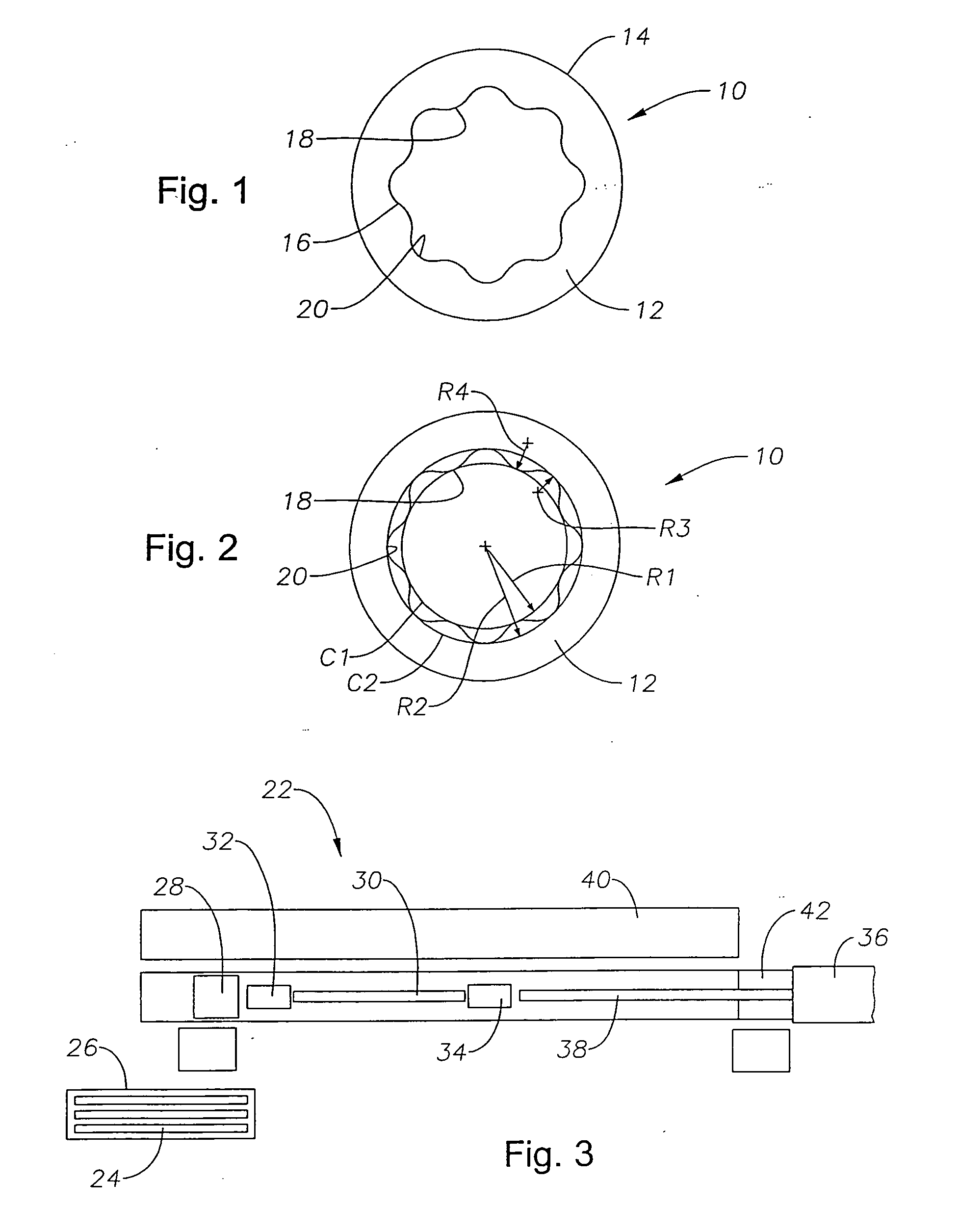

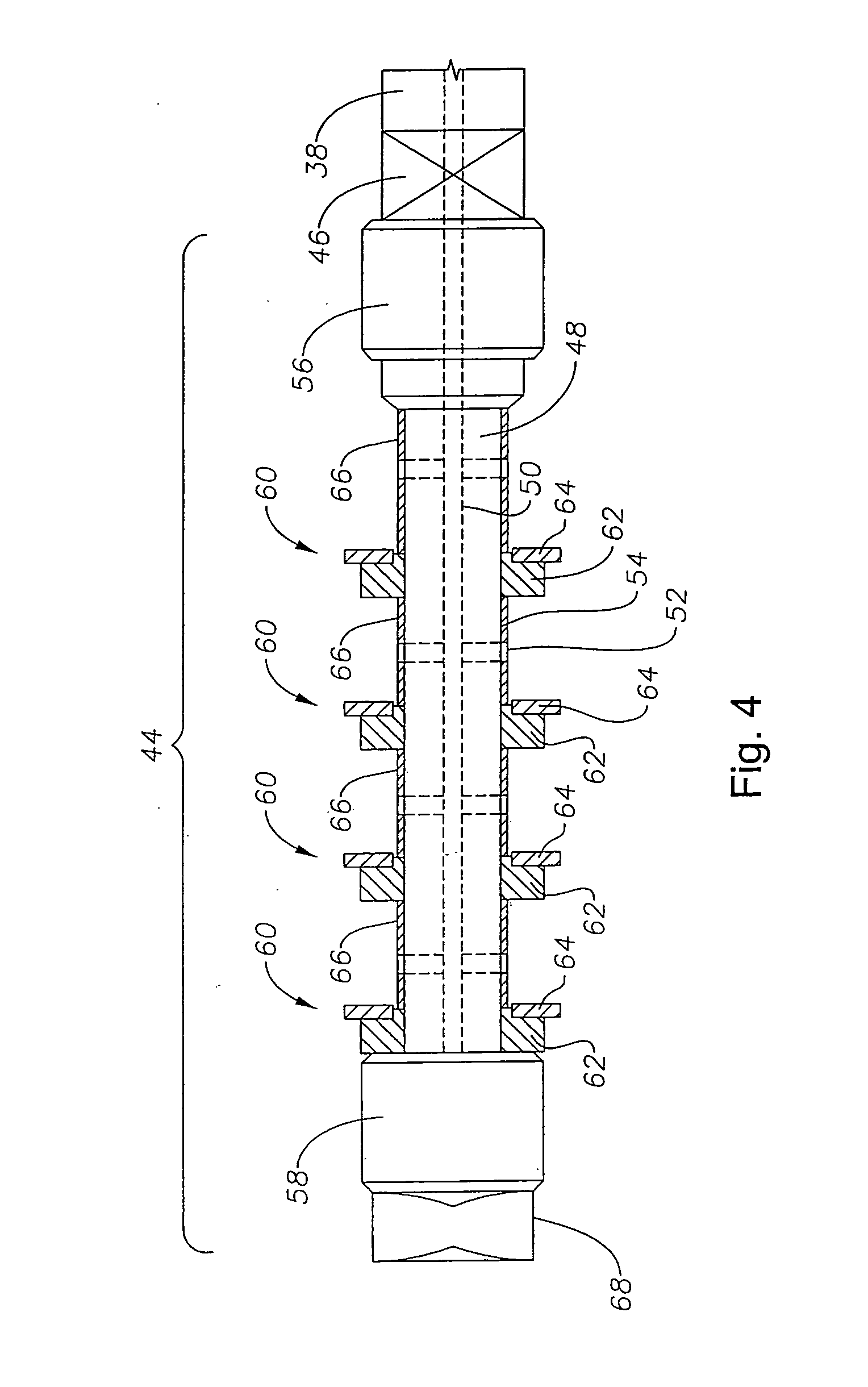

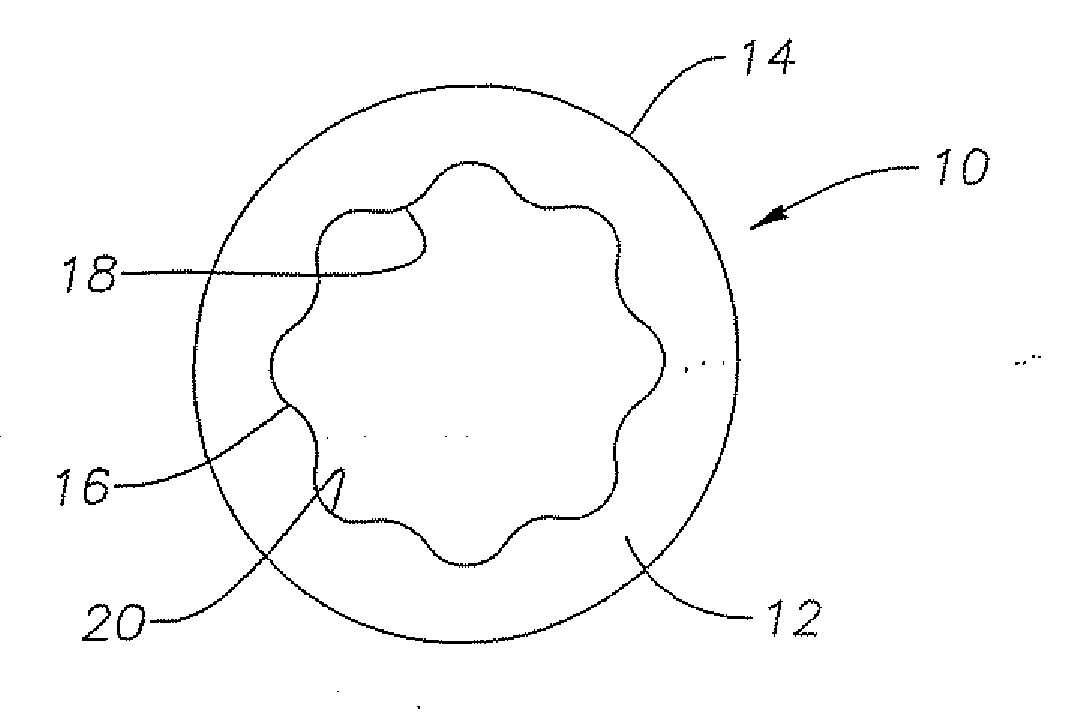

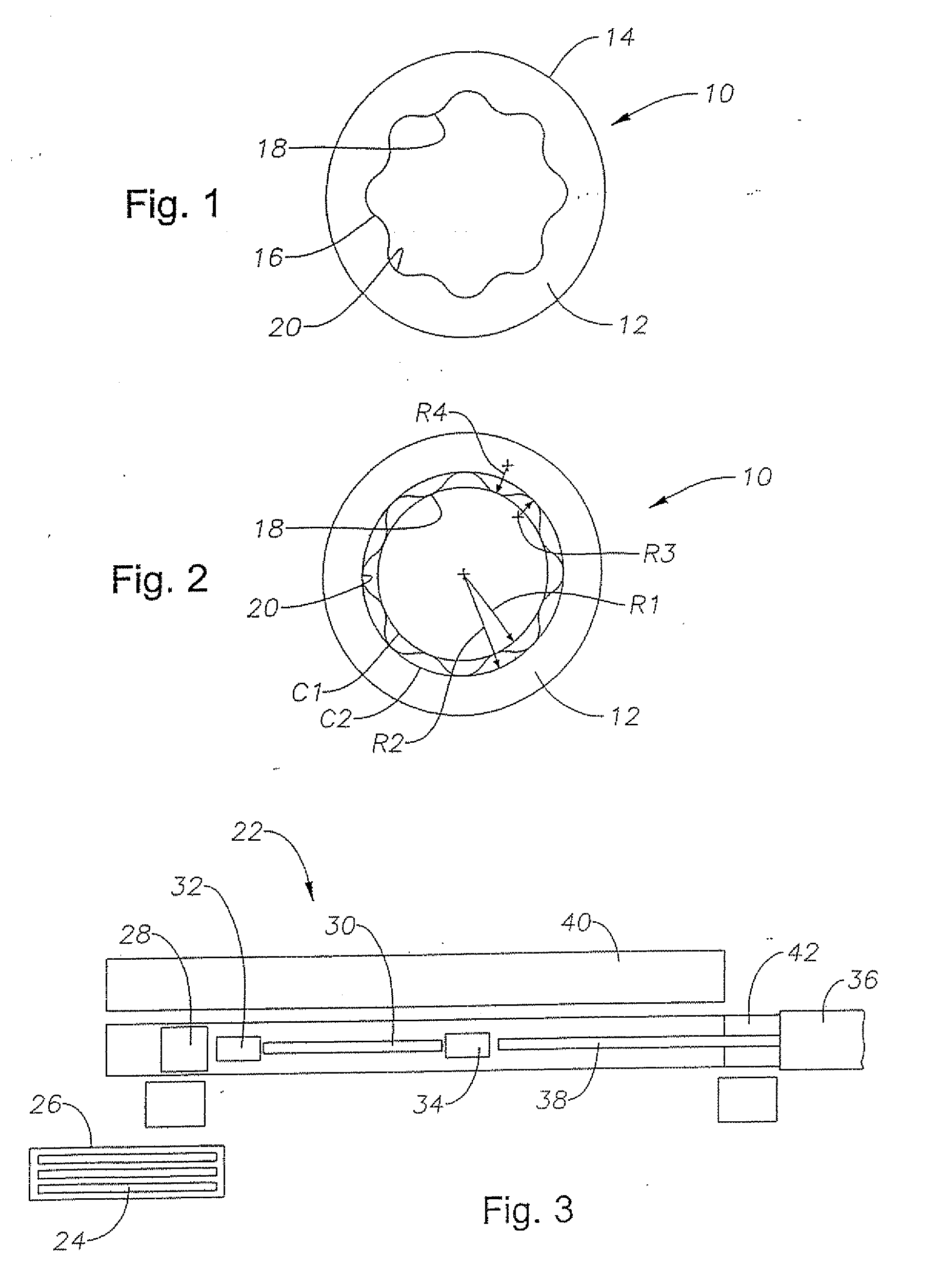

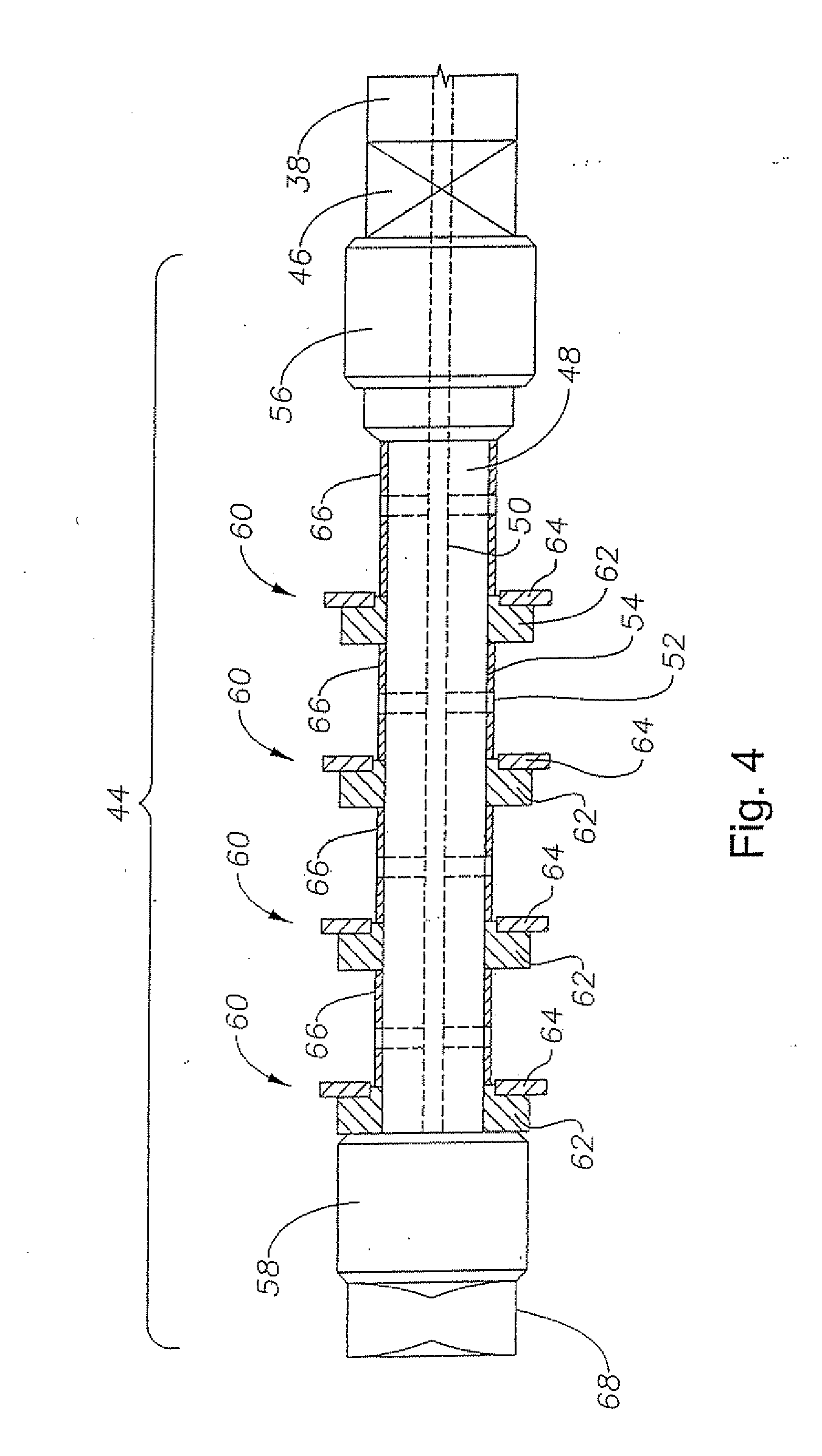

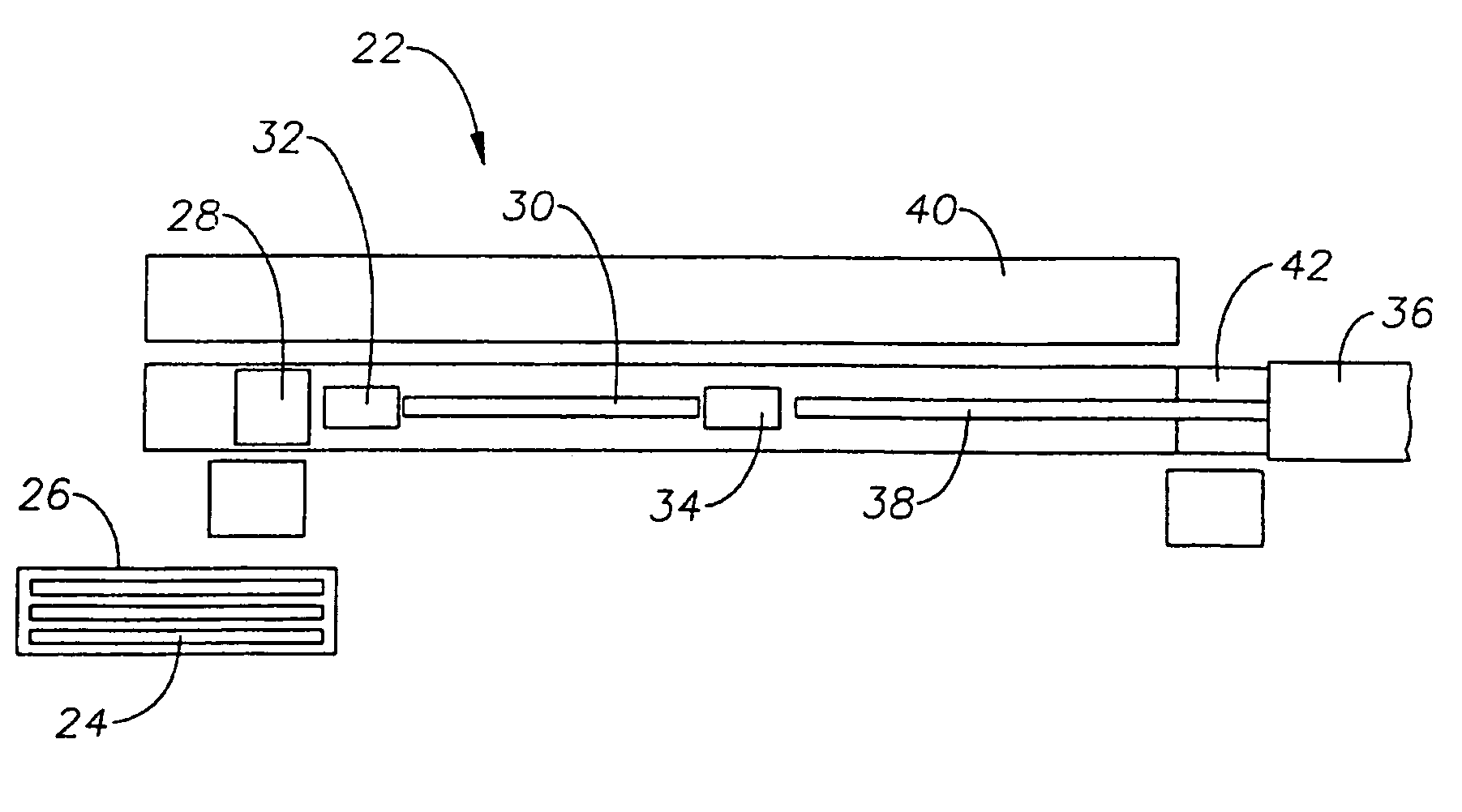

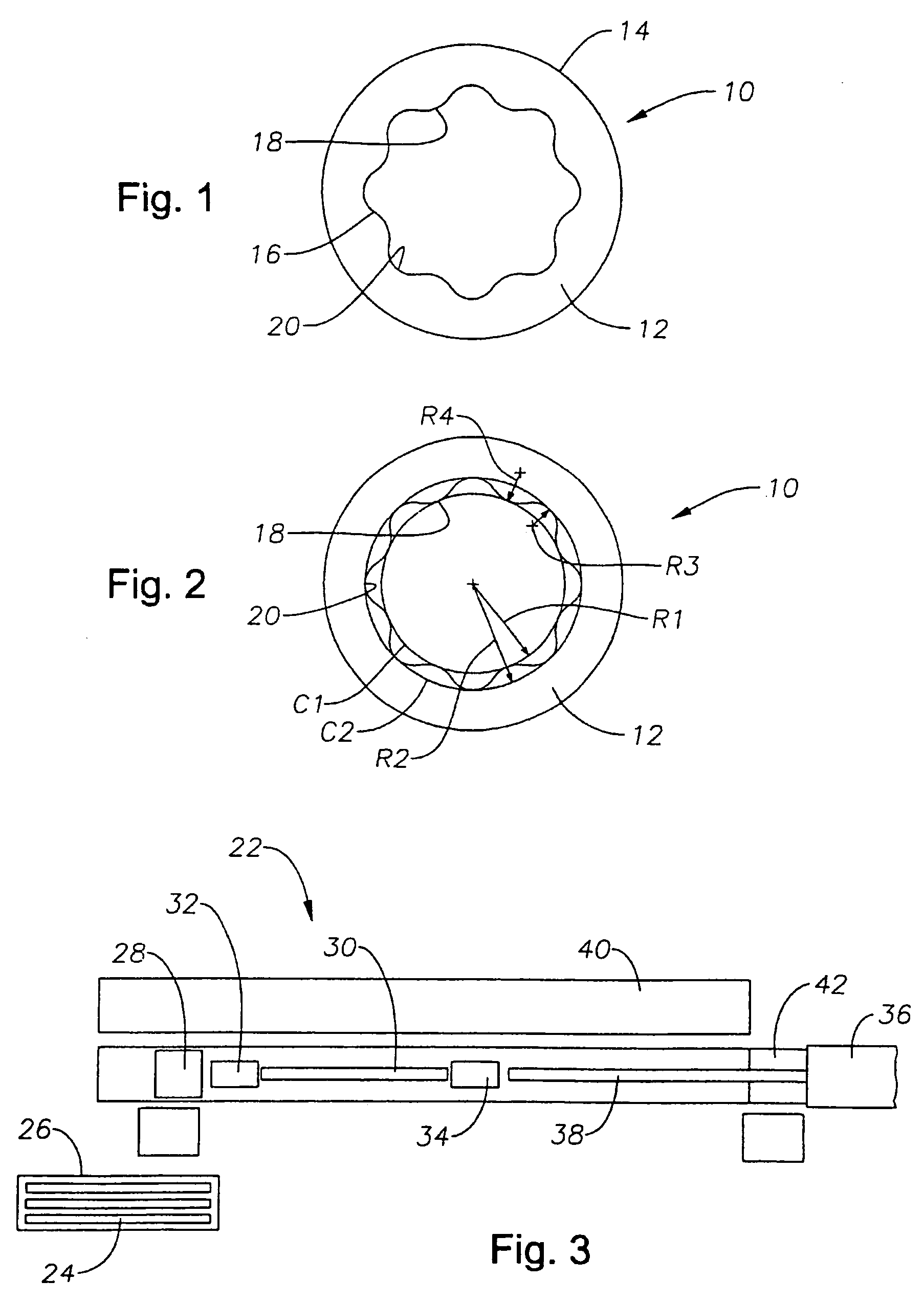

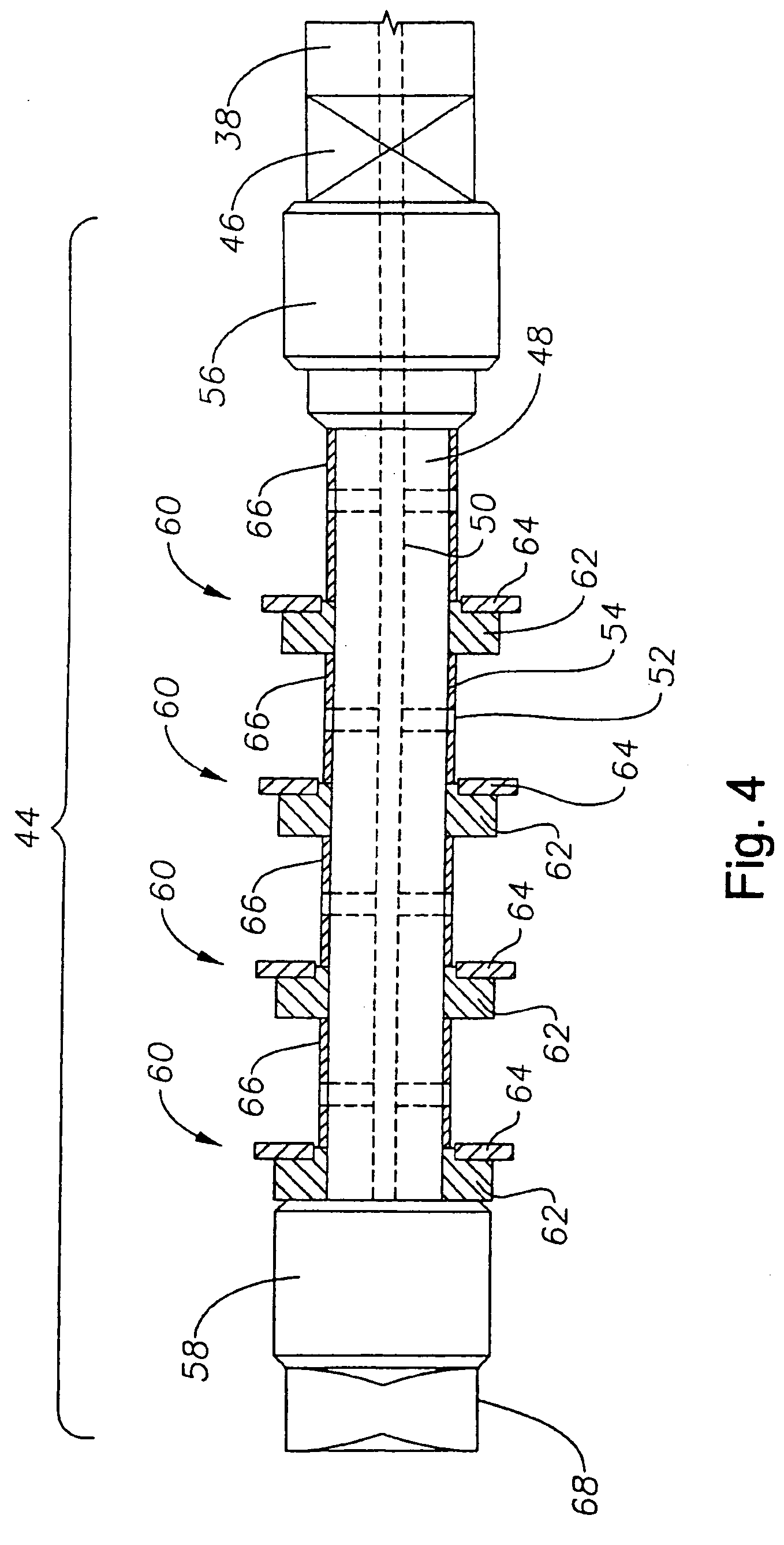

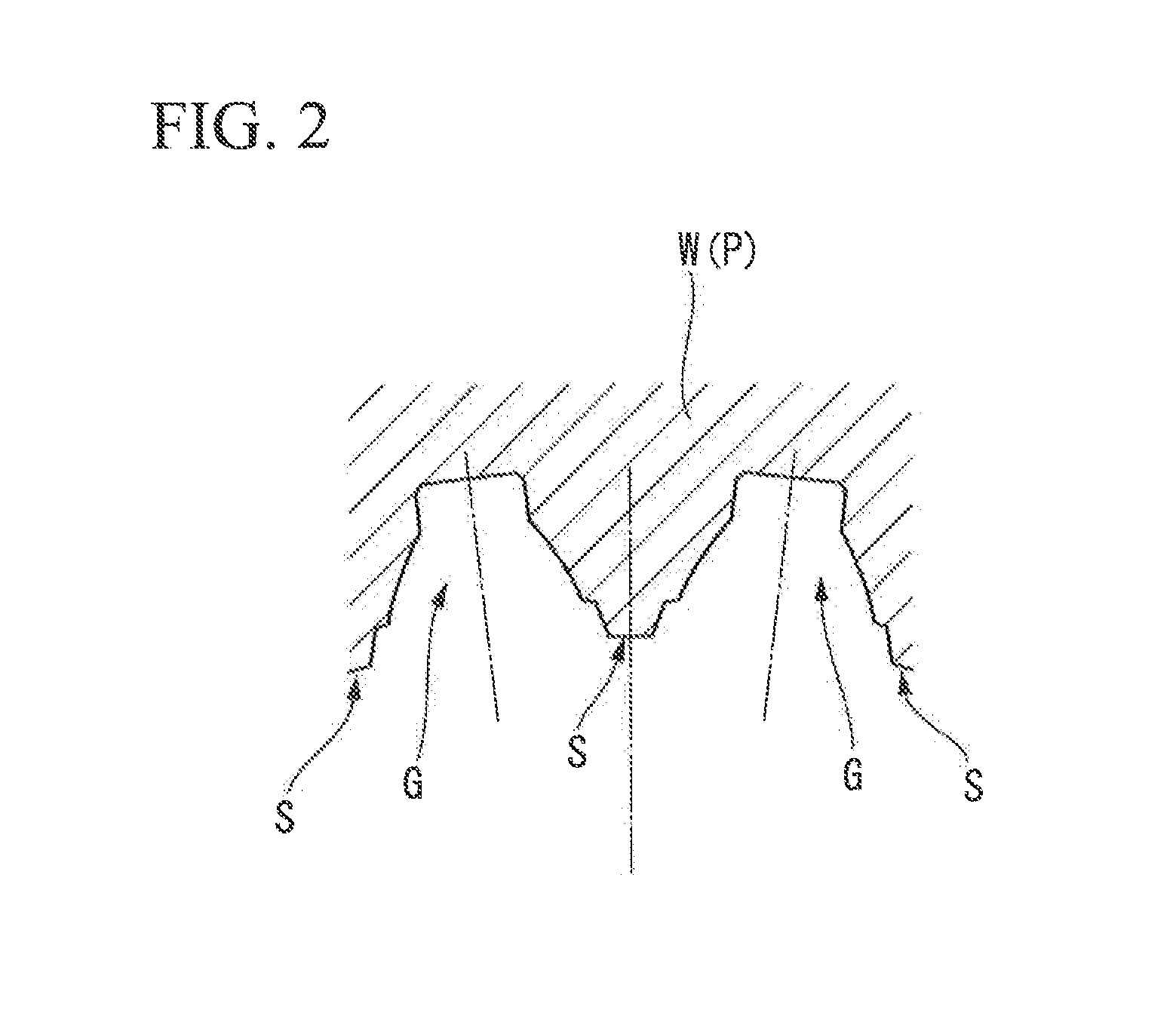

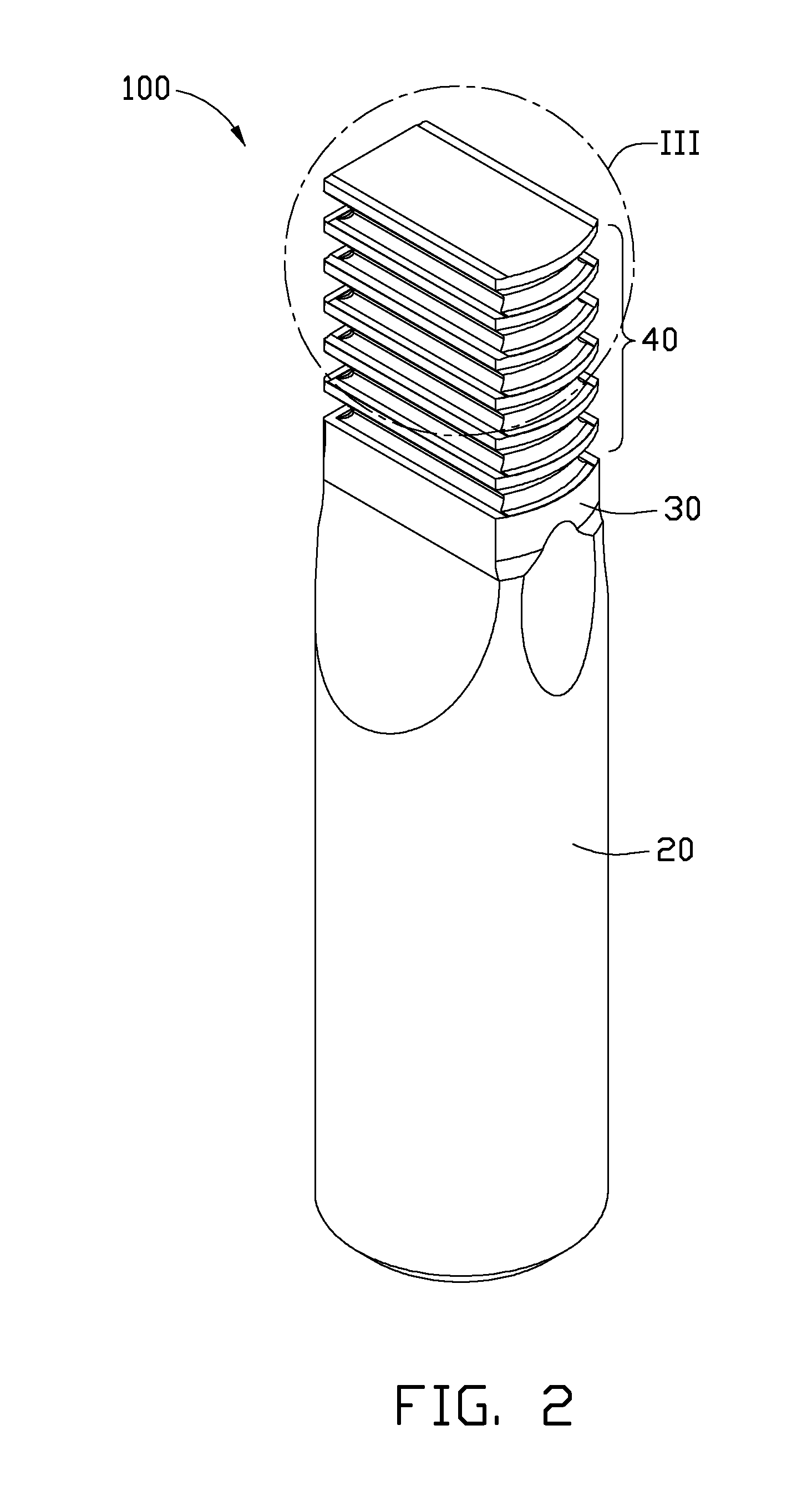

Centrifugally-cast tube and related method and apparatus for making same

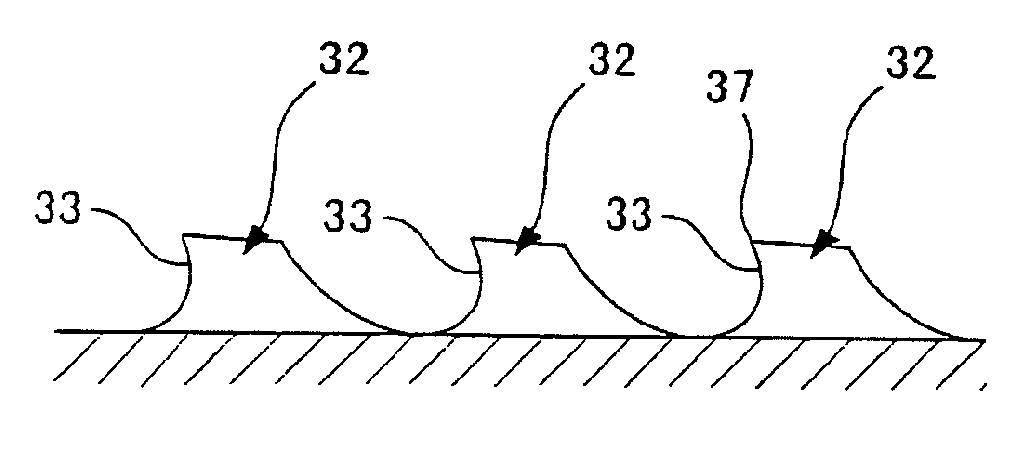

InactiveUS20060056934A1High dimensional accuracyImprove roughness accuracyBroaching accessoriesRectilinear broachMetal dustingEnhanced heat transfer

An improved centrifugally-cast tube is provided, along with a related method and apparatus of making the tube. The tube includes a plurality of grooves and bosses that are mechanically machined into an interior surface of the tube, such as by a broaching process. The profile of grooves and bosses may be defined by a plurality of intersecting concave and convex radii. The tube is resistant to creep, carburization and metal dusting. The tube also has an enhanced heat transfer rate, and a desirable surface roughness. A method of making the tube is also provided. The method essentially consists of mechanically deforming the interior surface of the tube by passing a series of cutting inserts on support rings having incrementally-differing dimensions over the interior surface. An apparatus is also provided which includes a telescoping shaft upon which is mounted at least one cutting tool that has a plurality of cutting inserts and is adapted to form a plurality of grooves and bosses in the interior surface of the tube. The grooves and bosses may be straight or spiraled.

Owner:DEMAREST JOEL +1

Centrifugally-cast tube and related method and apparatus for making same

An improved centrifugally-cast tube is provided, along with a related method and apparatus of making the tube. The tube includes a plurality of grooves and bosses that are mechanically machined into an interior surface of the tube, such as by a broaching process The profile of grooves and bosses may be defined by a plurality of intersecting concave and convex radii. The tube is resistant to creep, carburization and metal dusting. The table also has an enhanced heat transfer rate, and a desirable surface roughness. A method of making the tube is also provided. The method essentially consists of mechanically deforming the interior surface of the tube by passing a series of cutting inserts on support rings having incrementally-differing dimensions over the interior surface. An apparatus is also provided which includes a telescoping shaft upon which is mounted at least one cutting tool that has a plurality of cutting inserts and is adapted to form a plurality of grooves and bosses in the interior surface of the tube. The grooves and bosses may be straight or spiraled.

Owner:MANOIR INDUSTRIES

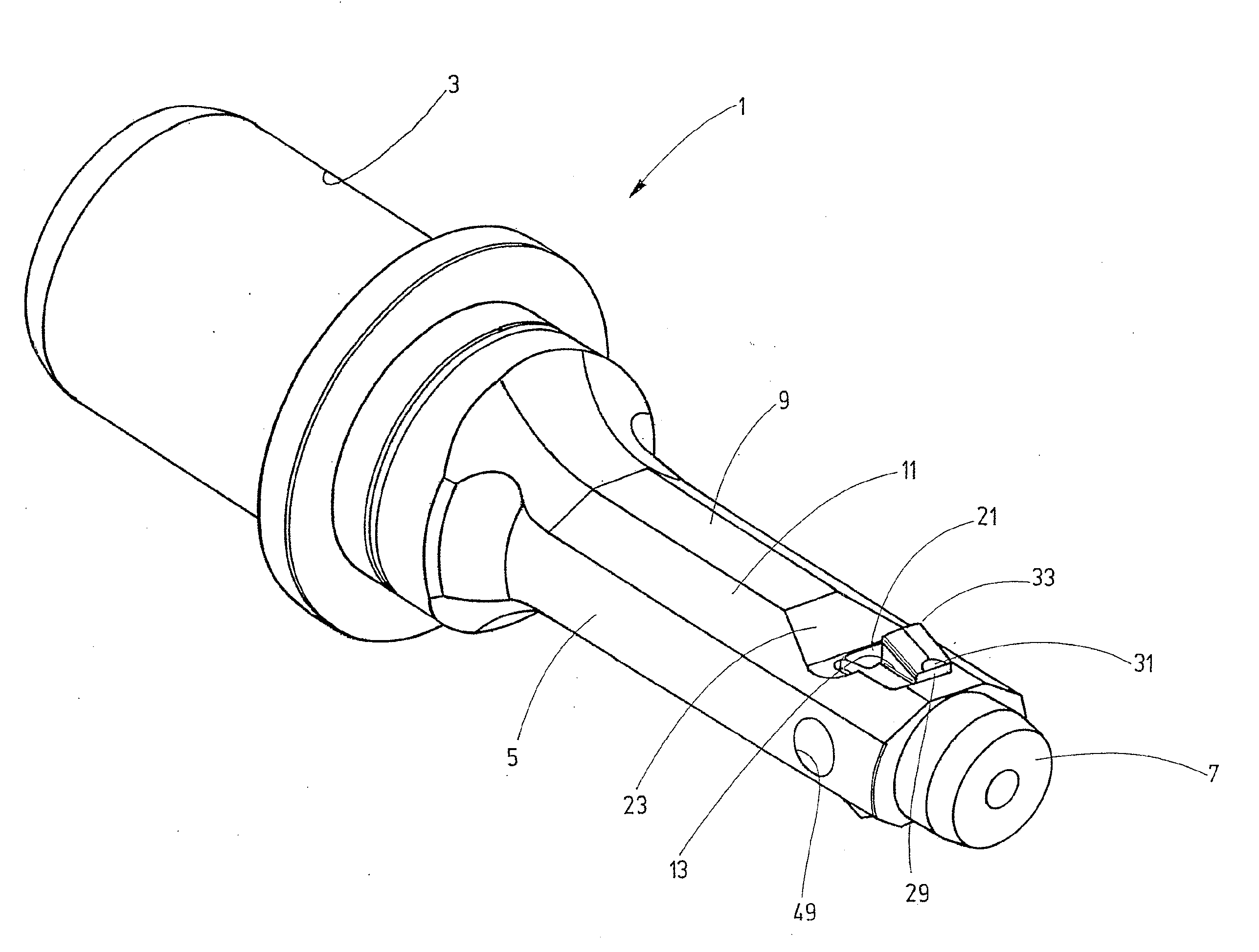

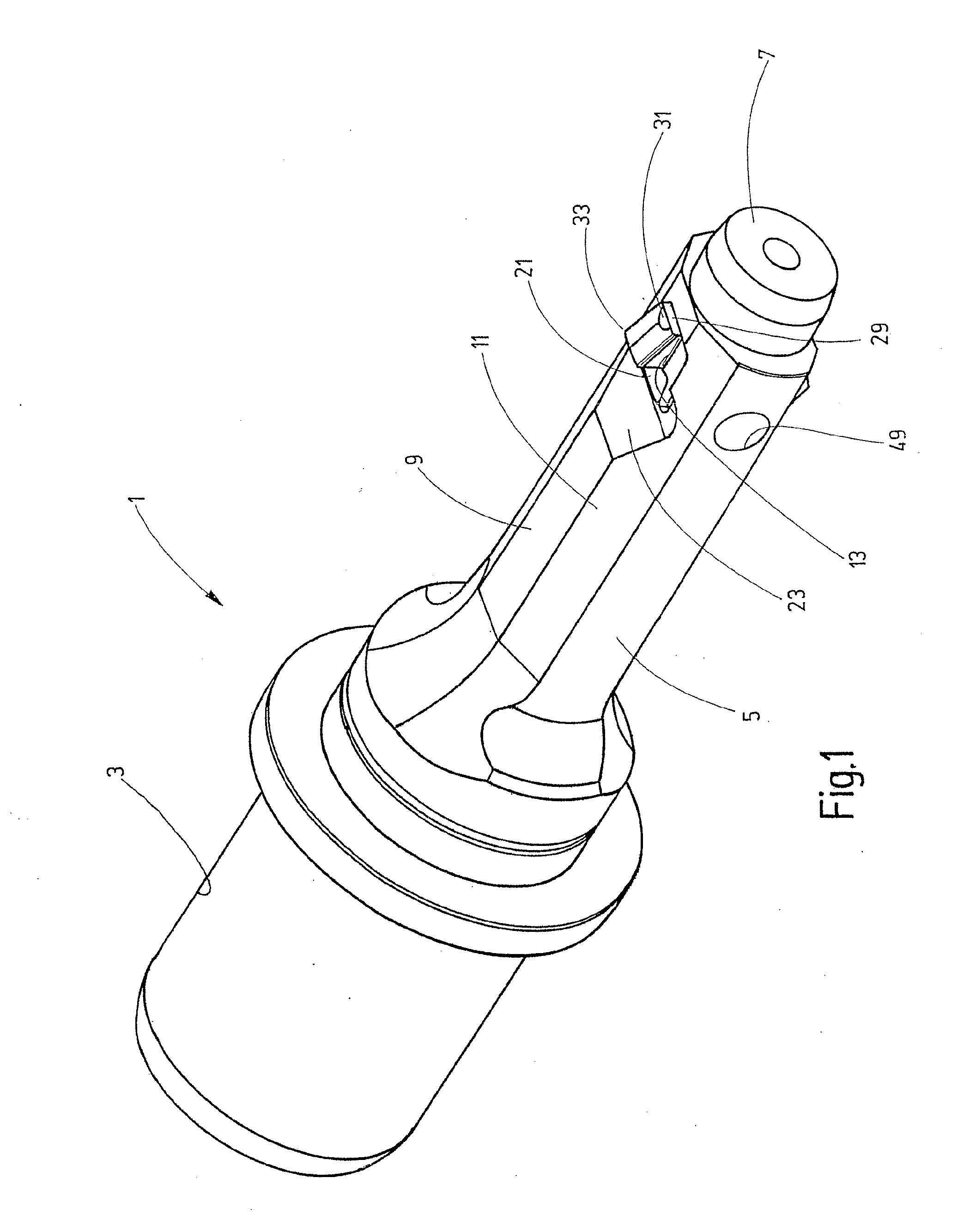

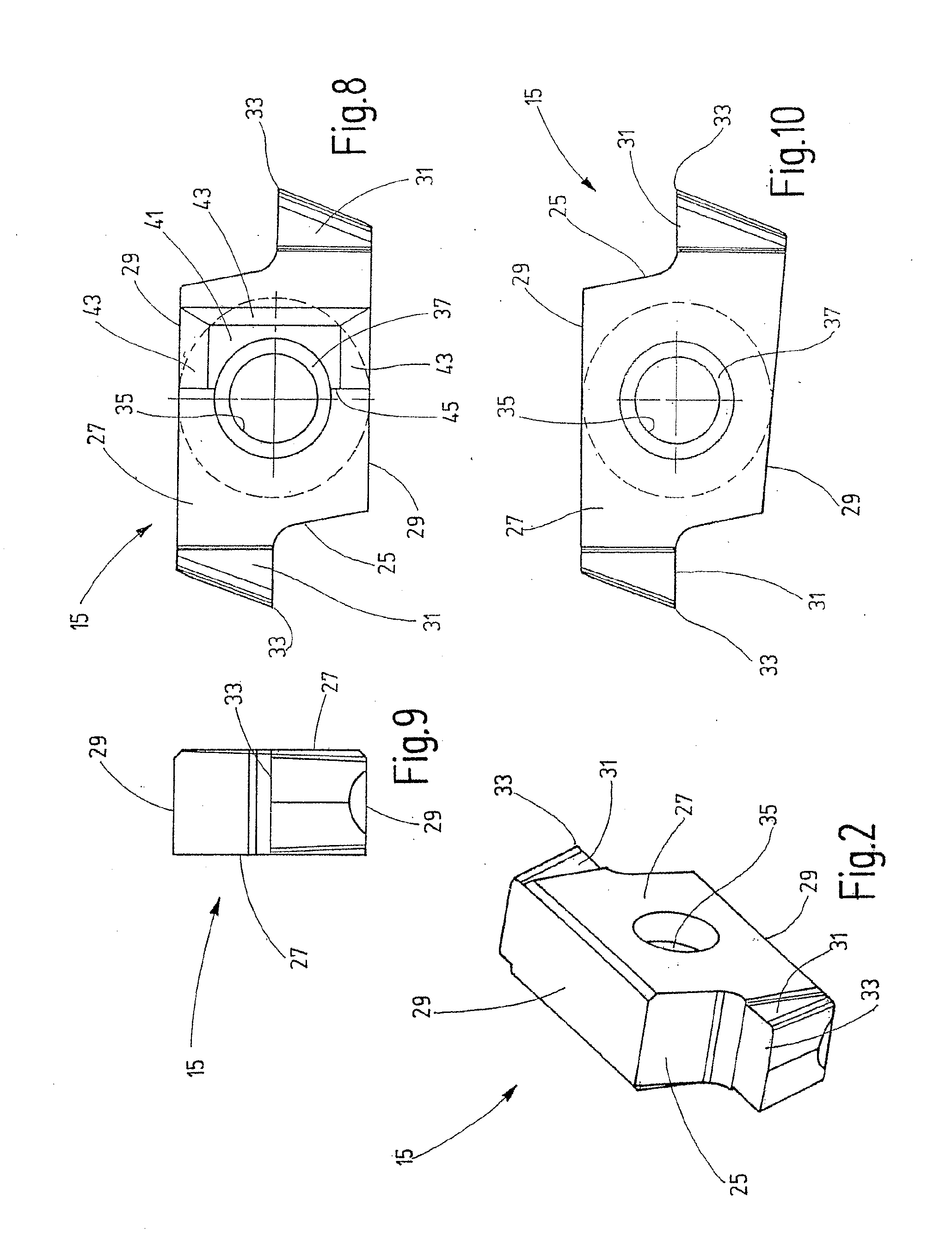

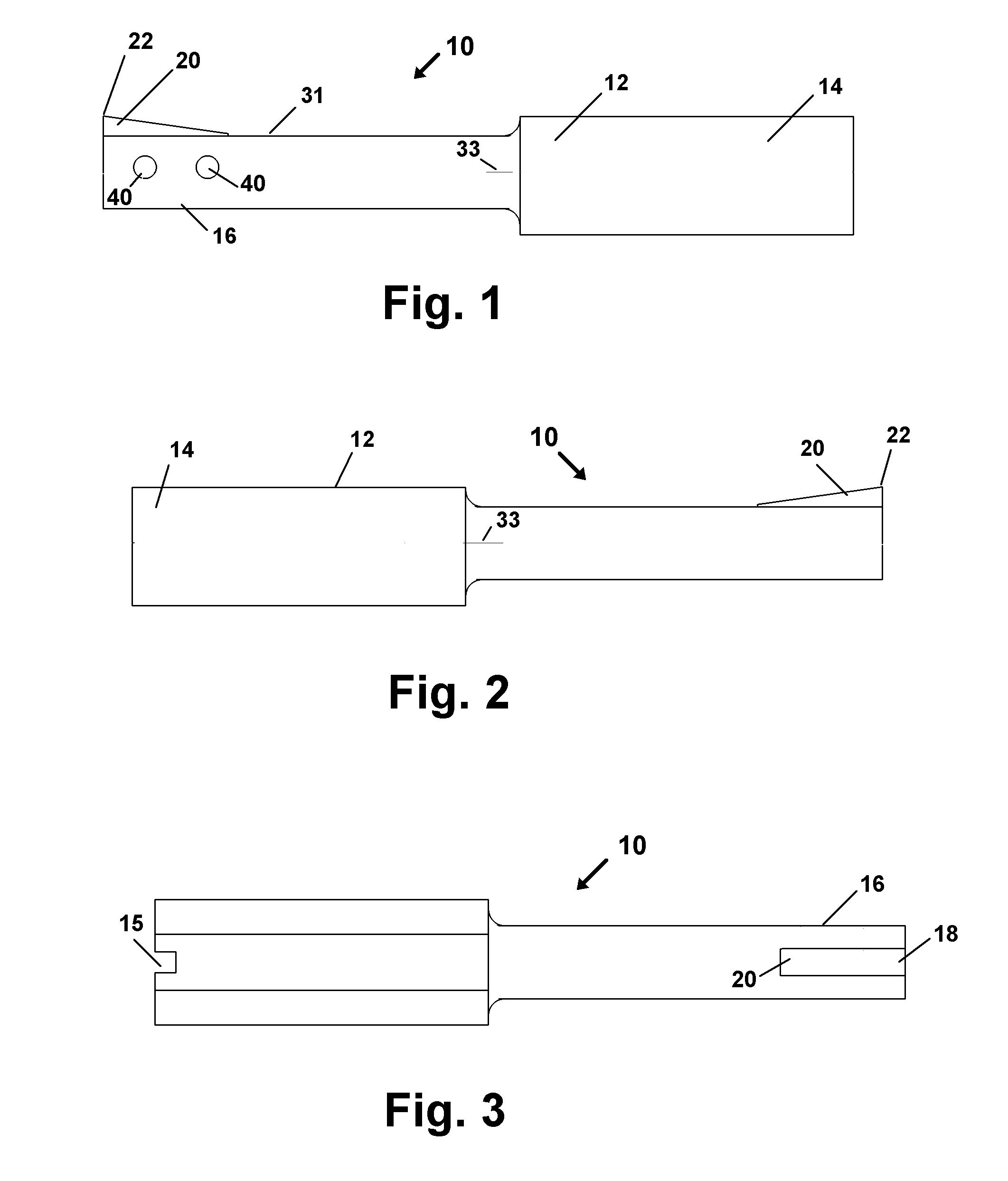

Broaching tool, in particular keyway broaching tool

ActiveUS20100104390A1Simple structureRectilinear broachPlaning/slotting toolsEngineeringBearing surface

The invention relates to a broaching tool, in particular a keyway broaching tool, comprising a holder which defines a longitudinal axis and has a shank, extending in the longitudinal direction, as support for a cutting body which can be fixed in a seat of the shank by means of a clamping device. The seat has a passage which is at a distance from the free end of the shank and extends transversely to the longitudinal axis and the inside of which forms guide surfaces for bearing surfaces of the cutting body, which can be inserted into the passage in an insertion direction. An end-position limit for the inserted cutting body is formed on guide surfaces and on associated bearing surfaces. The clamping device produces a force component on the cutting body which presses the latter against the end-position limit.

Owner:HARTMETALL WERKZEUGFAB PAUL HORN

Internal broach

An internal broach for internally broaching profiles, defined by a bottom and flanks, of female serrations of a work piece comprises a toothed section with several rows of broach cutting teeth, the rows being disposed successively counter to a direction of broaching, with successive broach cutting teeth being allocated to each other for broaching a profile. The broach cutting teeth have bottom cutting blades and first and second sides. The first sides are guide flanks, the edges of which are guide edges without cutting ability. The second sides are relieved flanks, the edges of which are relieved edges without cutting ability.

Owner:FORST TECH

Centrifugally-cast tube and related method and apparatus for making same

An improved centrifugally-cast tube is provided, along with a related method and apparatus of making the tube. The tube includes a plurality of grooves and bosses that are mechanically machined into an interior surface of the tube, such as by a broaching process. The profile of grooves and bosses may be defined by a plurality of intersecting concave and convex radii. The tube is resistant to creep, carburization and metal dusting. The tube also has an enhanced heat transfer rate, and a desirable surface roughness. A method of making the tube is also provided. The method essentially consists of mechanically deforming the interior surface of the tube by passing a series of cutting inserts on support rings having incrementally-differing dimensions over the interior surface. An apparatus is also provided which includes a telescoping shaft upon which is mounted at least one cutting tool that has a plurality of cutting inserts and is adapted to form a plurality of grooves and bosses in the interior surface of the tube. The grooves and bosses may be straight or spiraled.

Owner:MANOIR INDUSTRIES

Roughing end mill and roughing end mill

ActiveCN101511516ADeterioration of small surface roughnessReduce deteriorationRectilinear broachMilling cuttersEngineeringMechanical engineering

This roughing insert is provided with an insert body, and a waveform cutting edge which is formed on an intersecting ridge line portion between a rake face and a flank face of the insert body, and which undulates along this intersecting ridge line portion. The waveform cutting edges are formed such that a portion thereof has a smaller wavelength than the remaining portion thereof.

Owner:MITSUBISHI MATERIALS CORP

Helical broach for roughing

InactiveCN101959636AAchieving Balanced CutsImprove machining accuracyRectilinear broachBroaching toolsAcute angleEngineering

A helical broach (1) for roughing comprises a cutting edge (30) where n spline teeth (31) are arranged along the axial direction, and each cutting edge (32) of the spline teeth (31) is arranged along a desired helix angle and has an acute angle portion and an obtuse angle portion, respectively, on the opposite sides of the cutting edge (32) in the circumferential direction, wherein the cutting edges (32)(S1-Sn-1) arranged in the circumferential direction of the first through (n-1)th spline teeth (31)(S1-Sn-1) are formed so that the height is different on the side of the acute angle portion and the obtuse angle portion, and the cutting edges (32)(Sn) of the n-th spline tooth (31)(Sn) is formed to have a constant height over the circumferential direction.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

Control of white-etched layer during machining

A machining system includes a support configured to retain an article, such as a rotor disk, having an area, such as a surface of a slot in the disk. A cutting tool, for example, a broach, is movable relative to the support to cut the area. A heating member, such as a laser, is configured to locally heat the area of the article. In one example, the cutting tool includes a body having a cutting edge. The heating member is supported by the body and is configured to provide heat adjacent to the cutting edge. The cutting edge cuts the locally heated area while the area is still heated.

Owner:RAYTHEON TECH CORP

Milling cutter and cutting insert therefor

An indexable cutting insert for use in a milling cutter. The cutting insert having four identical side surfaces extending between generally square shaped top and bottom surfaces with two diametrically opposite protuberances extending away from each other in a top or bottom view of the cutting insert. The cutting insert has eight identical major and minor cutting edges. The milling cutter having the general form of a circular disk with a plurality of the cutting inserts releasably mounted in insert pockets angularly around the periphery of the cutter. The cutting inserts are arranged to produce a profile on a workpiece having a central straight section and two beveled sections on either side of the central straight section.

Owner:ISCAR LTD

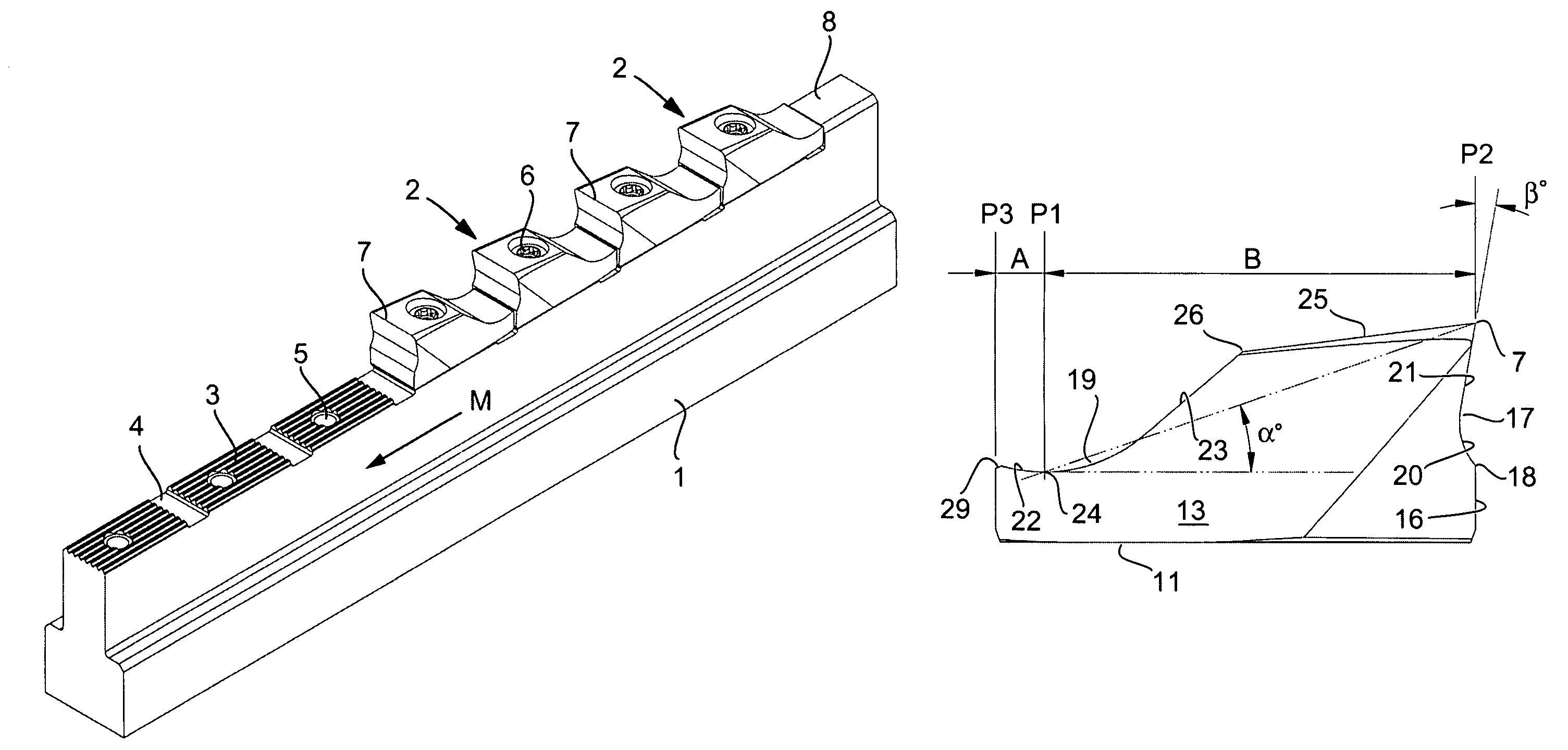

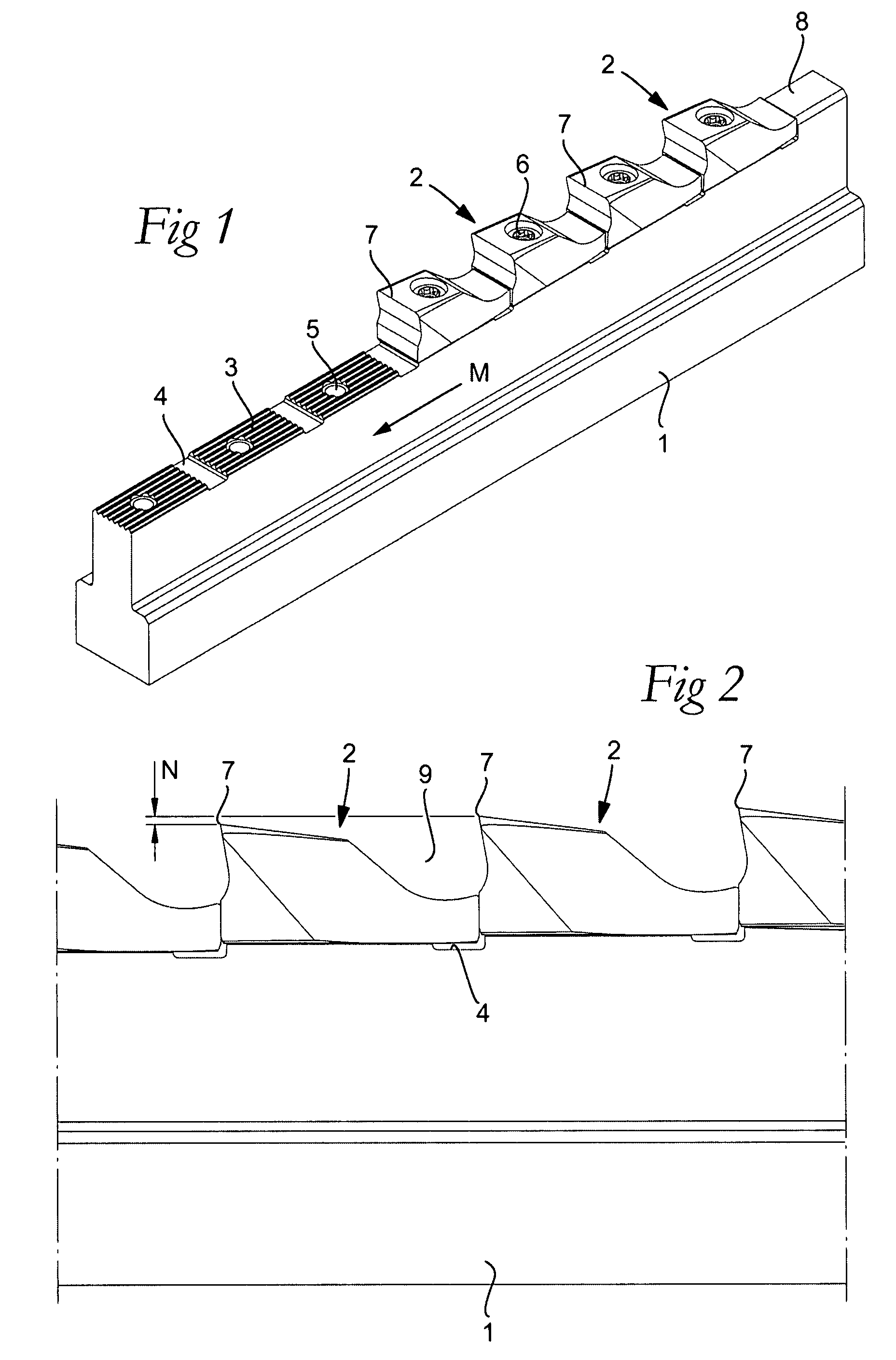

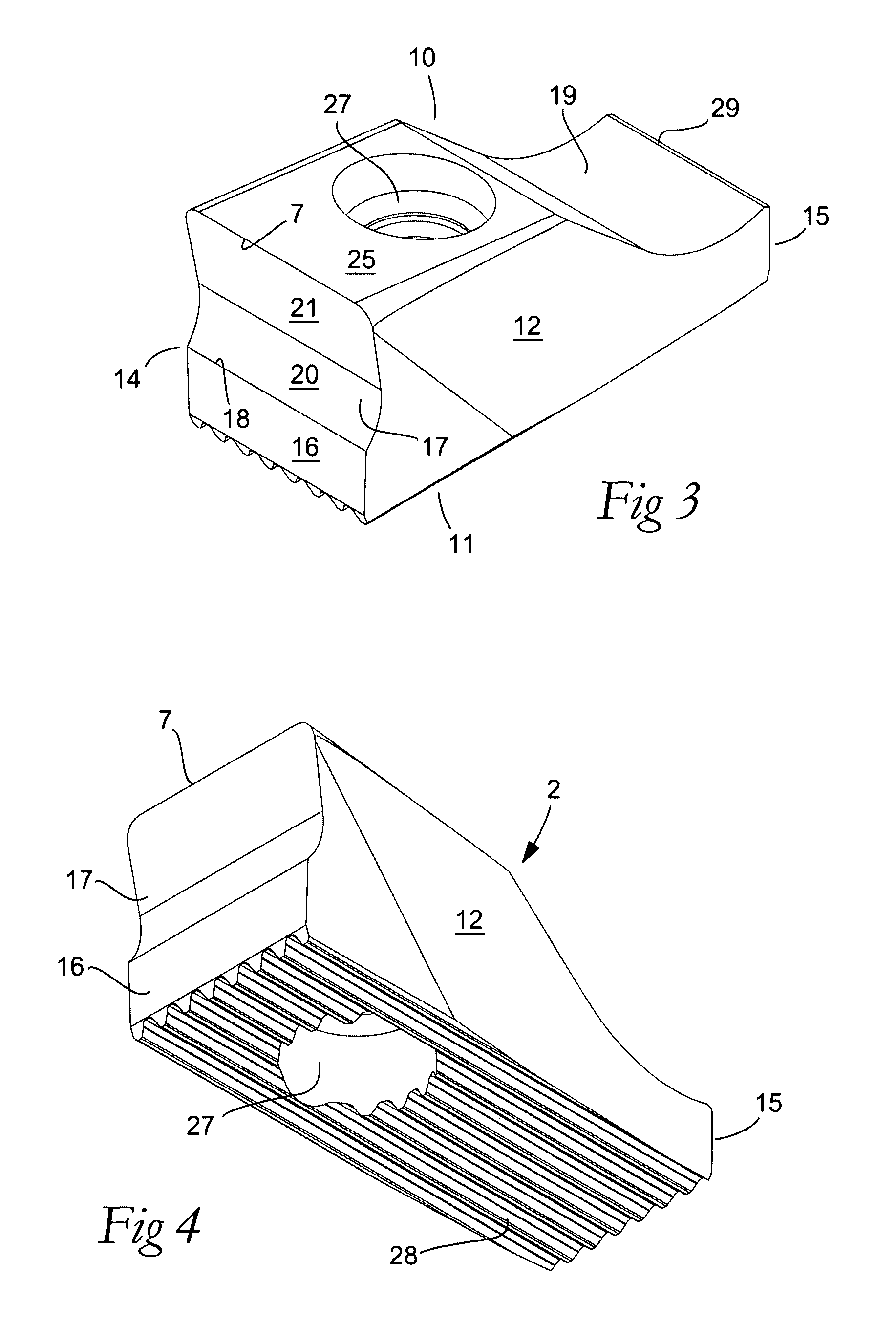

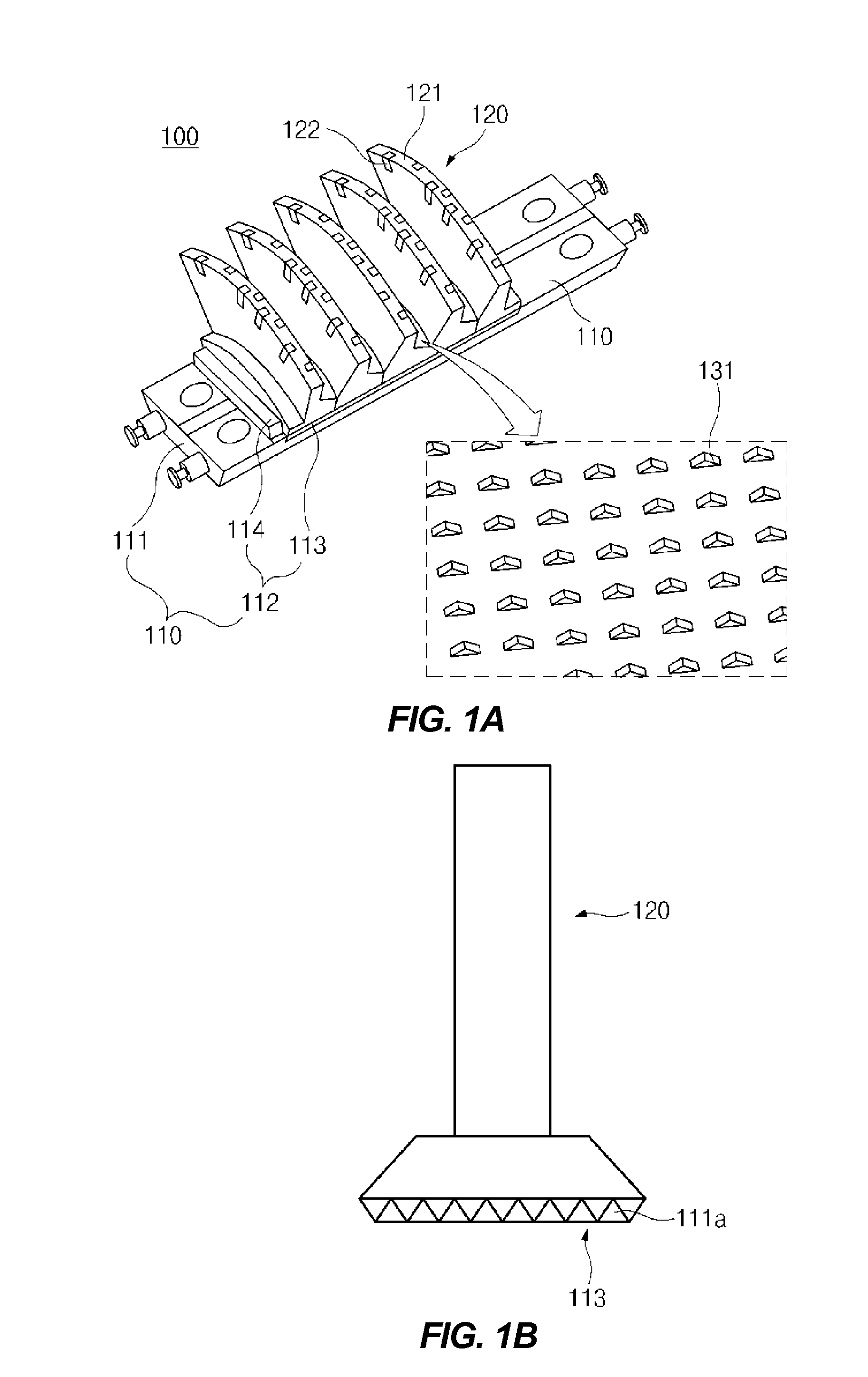

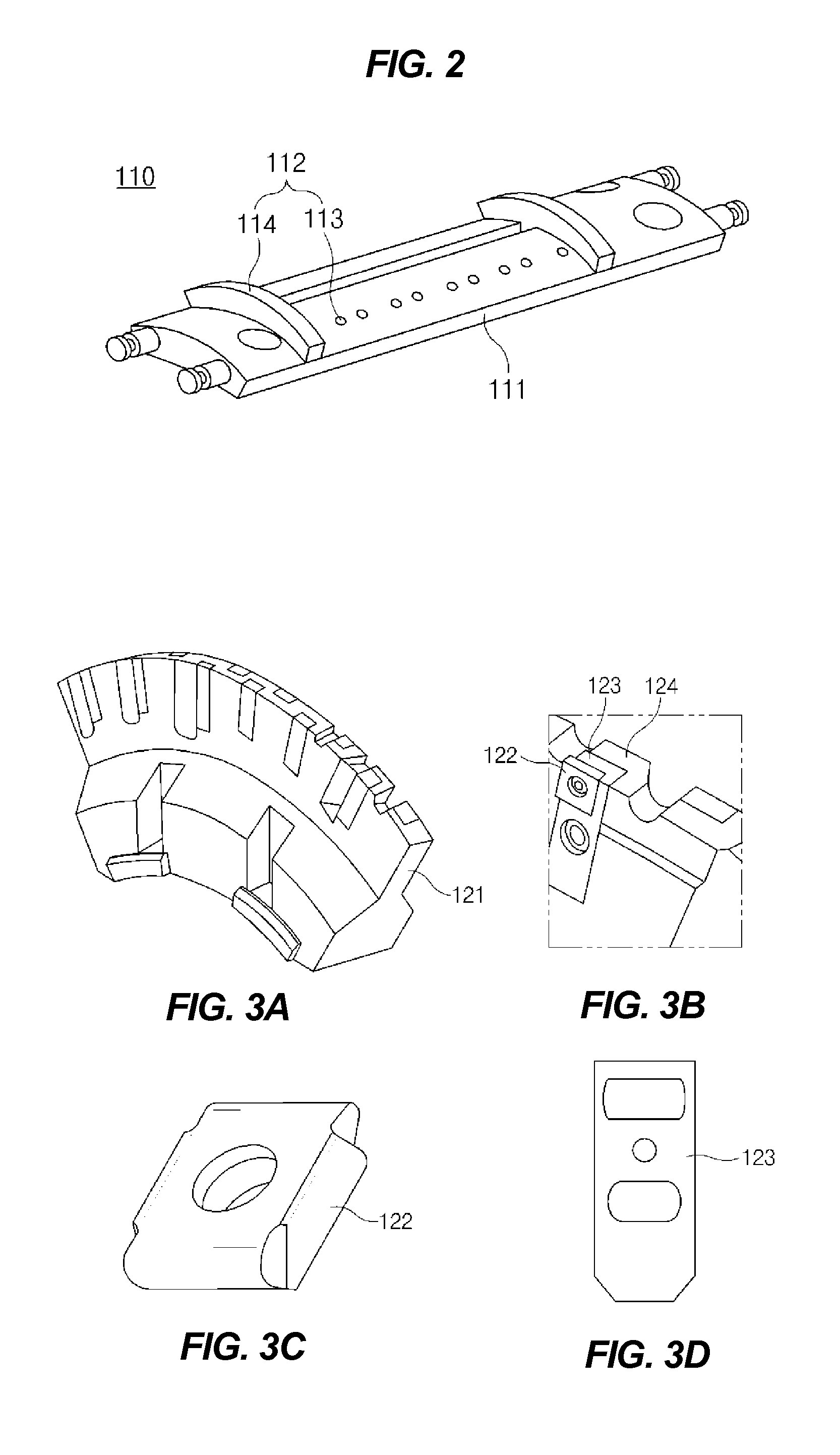

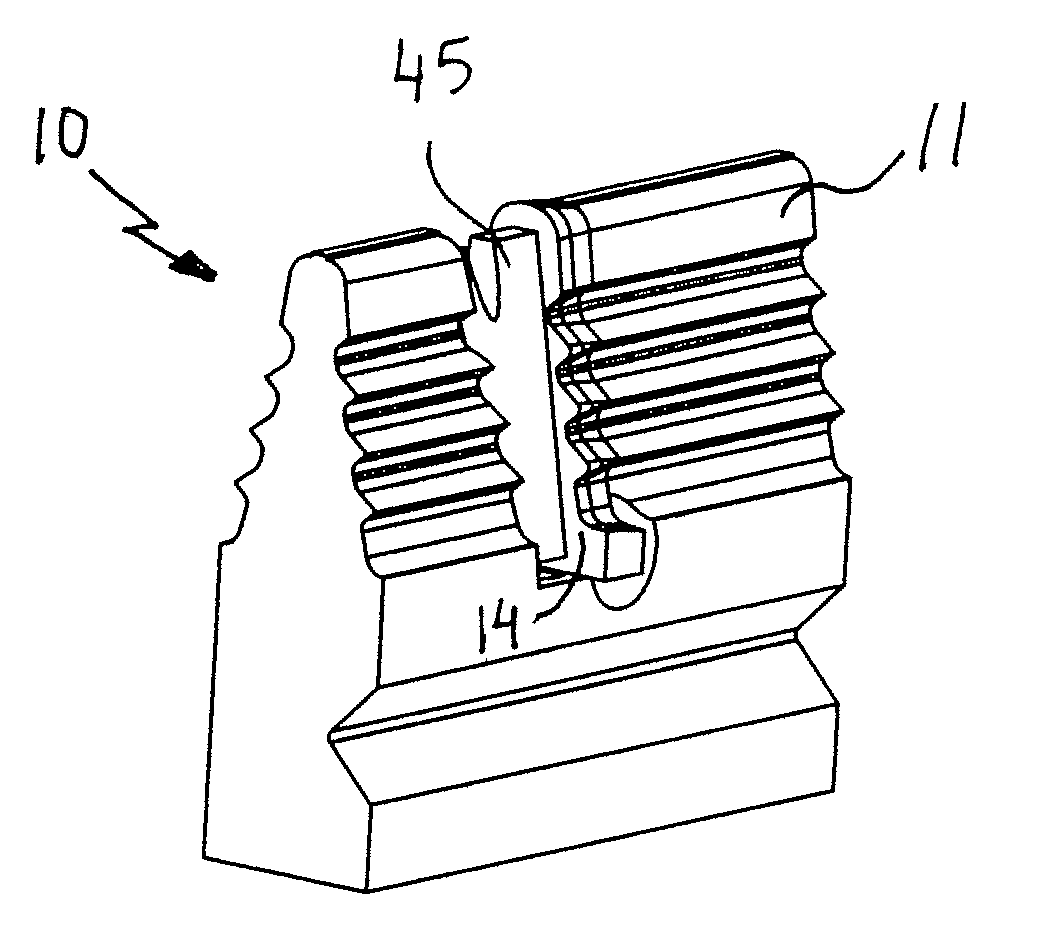

Broach tool and a broach insert

InactiveUS8070396B2Easy to replaceGood precisionRectilinear broachBroaching toolsEngineeringMachining

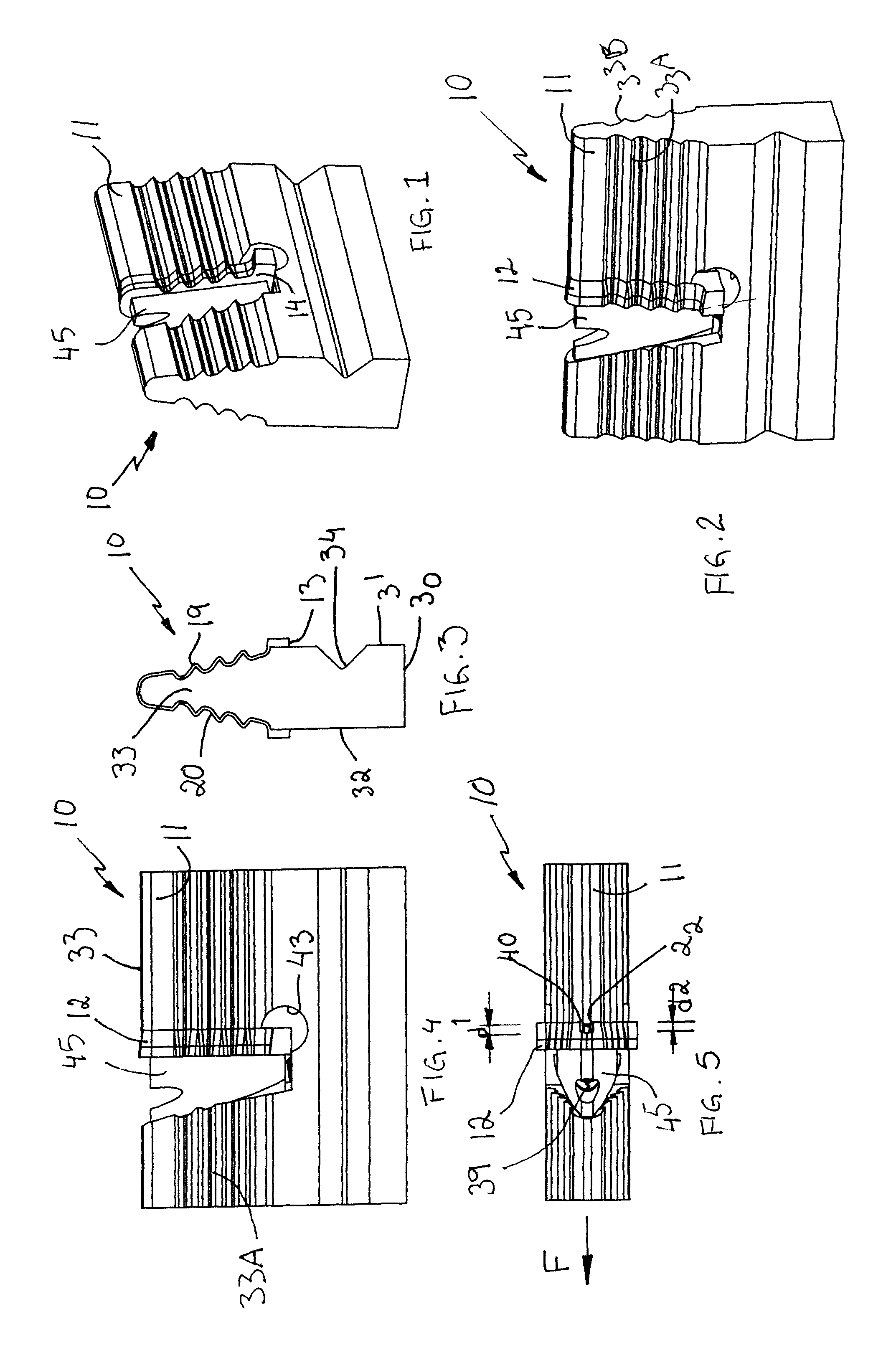

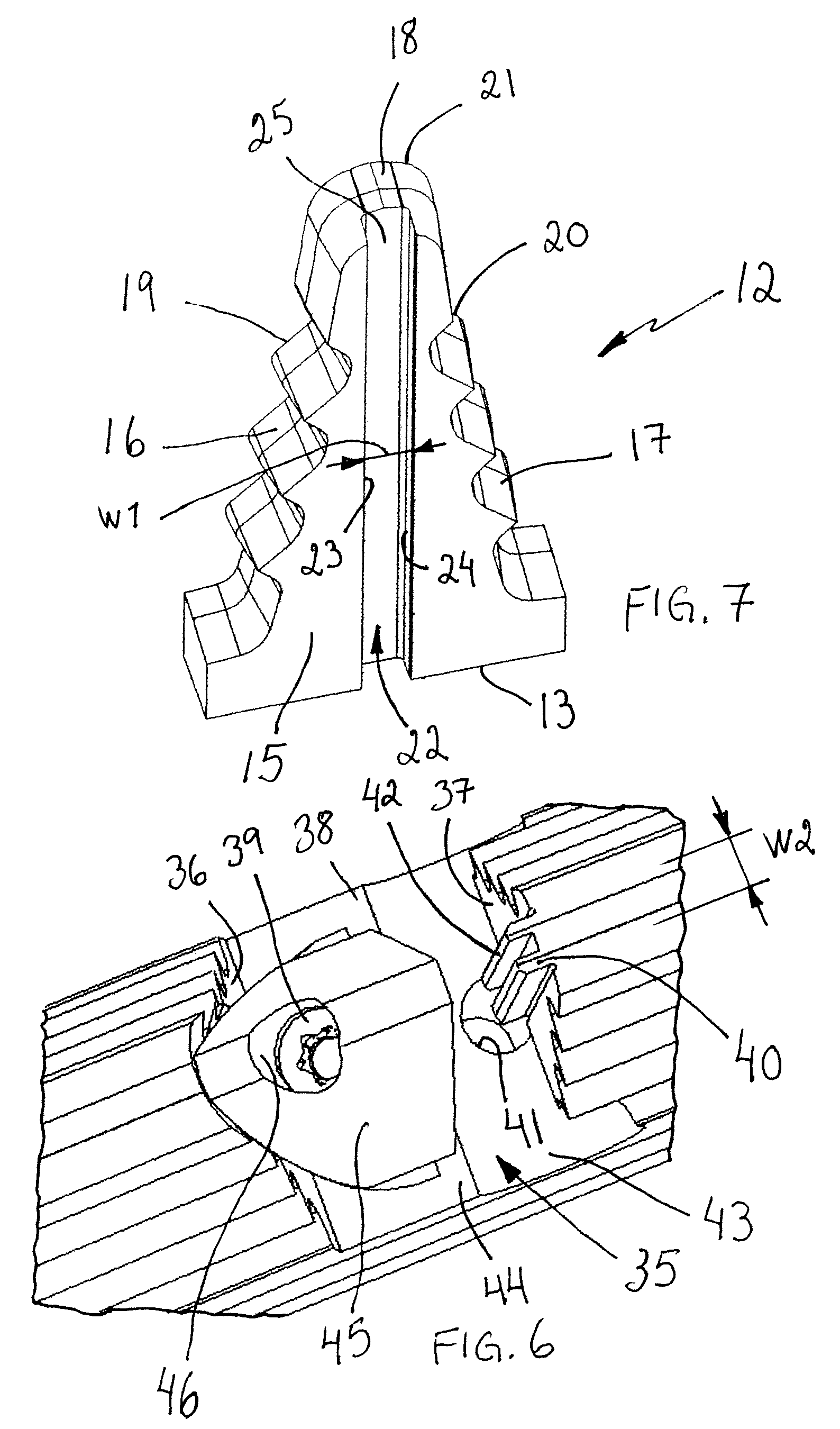

A broach tool and a broach insert for chip removing machining of metals are provided. The broach tool includes an elongate holder and at least one cutting unit. The holder comprises at least one recess for the receipt of the cutting unit. The broach tool has a feeding direction. The broach tool includes clamping members for each cutting unit. Each clamping member is arranged in front of the cutting unit in the feeding direction. The cutting unit is a replaceable broach insert including a base part and a cutting part. A notch is formed centrally in a rear side surface of the broach insert. The recess includes a rear wall formed with a projection, the cross section of which is U-shaped and includes arms. The arms are arranged to be elastically deformed by the notch.

Owner:SECO TOOLS AB

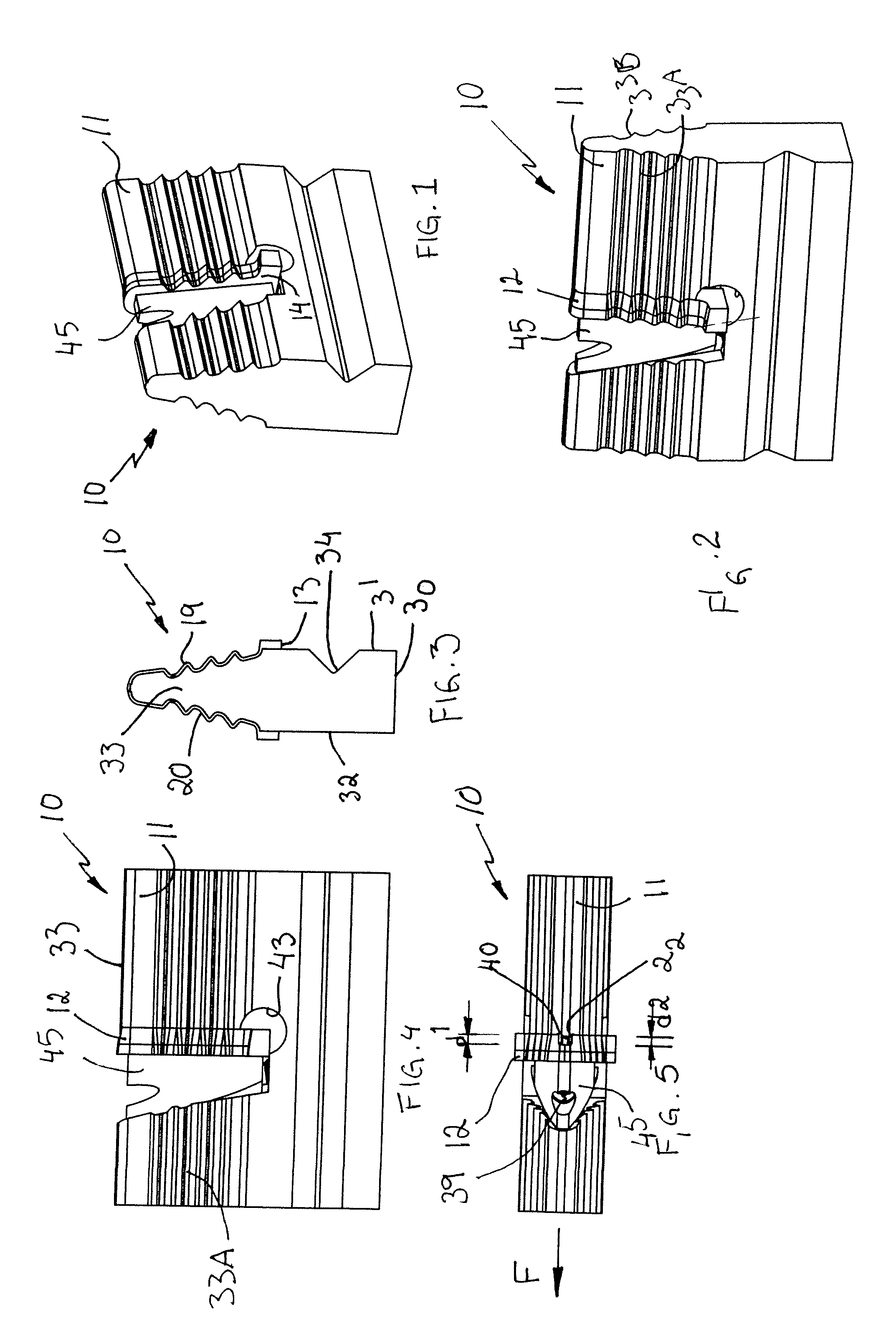

Tool and a cutting insert for chip removing machining

InactiveUS7578638B2Improve abilitiesEliminate shortcomingsRectilinear broachBroaching toolsEngineeringChip formation

A cutting tool including a basic body and a plurality of cutting inserts arranged in series one after the other. Each insert includes a topside, an underside, two opposite side surfaces, front and rear ends, and a cutting edge adjacent to the front end. The rear end of a first cutting insert faces the front end of a second cutting insert disposed rearward of the first insert, and a chip space forward of the cutting edge of the second cutting insert is delimited by a chip-forming surface extending in the forward direction from the rear end of the first cutting insert, and a chip-forming surface extending downward from the cutting edge of the second cutting insert.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

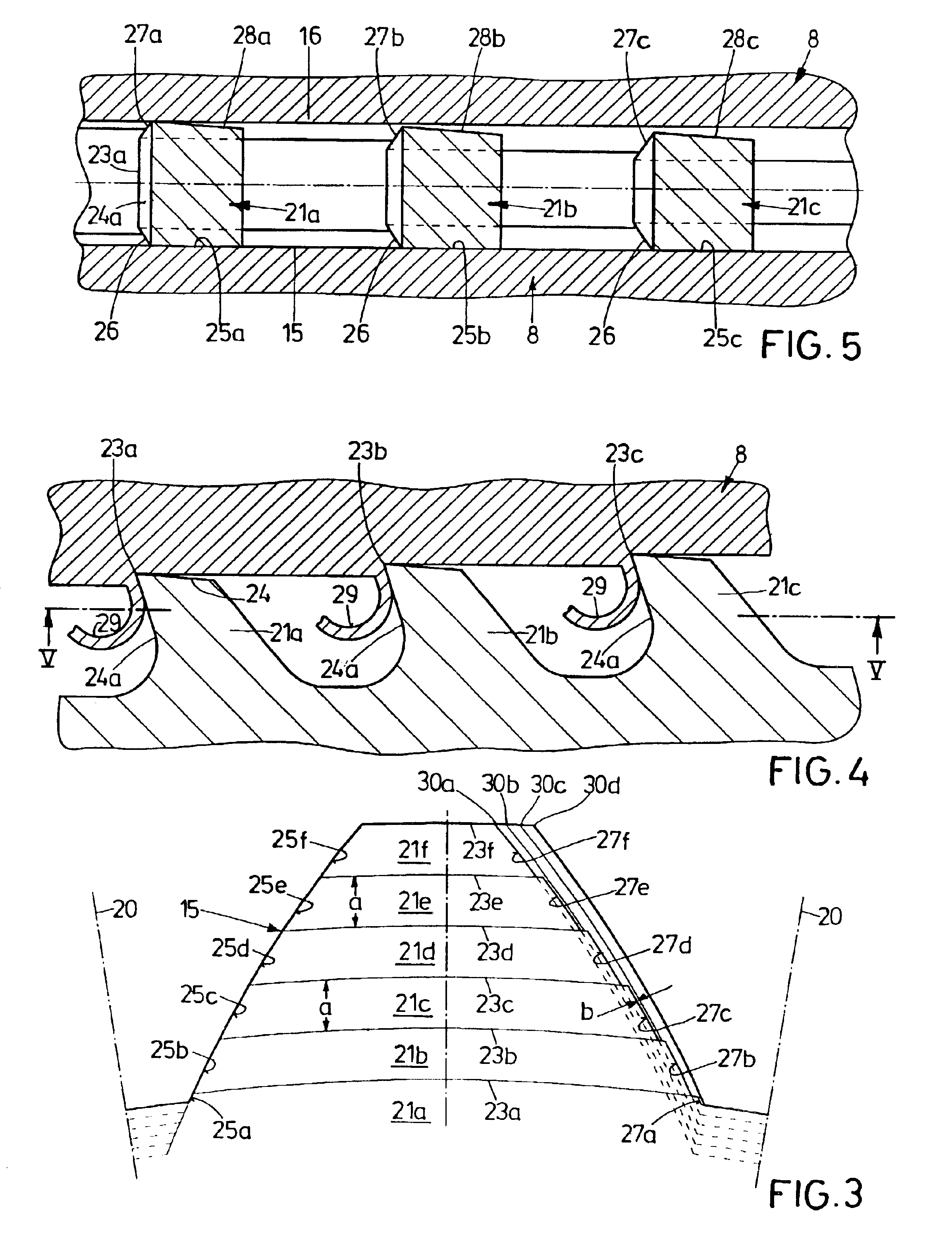

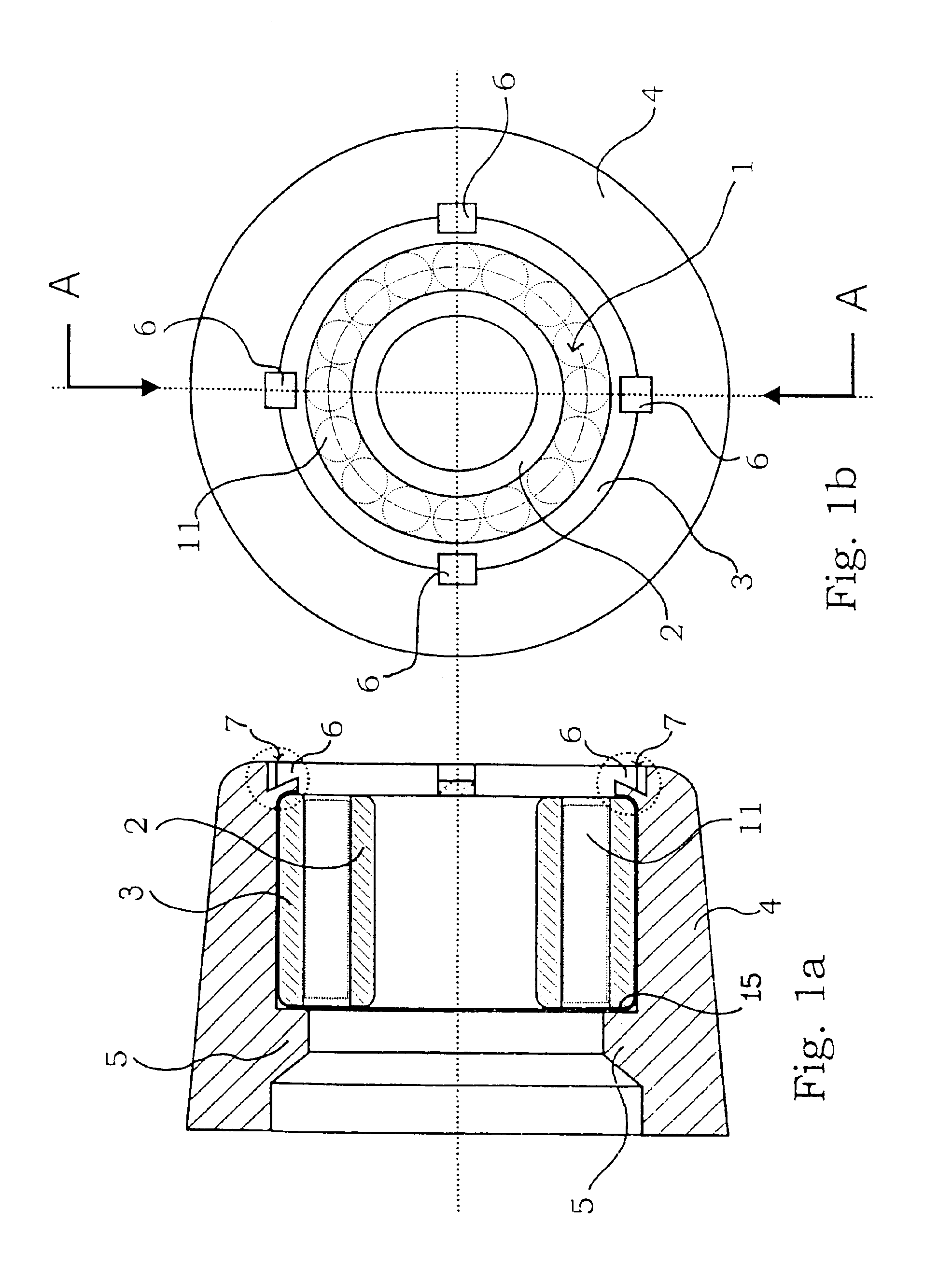

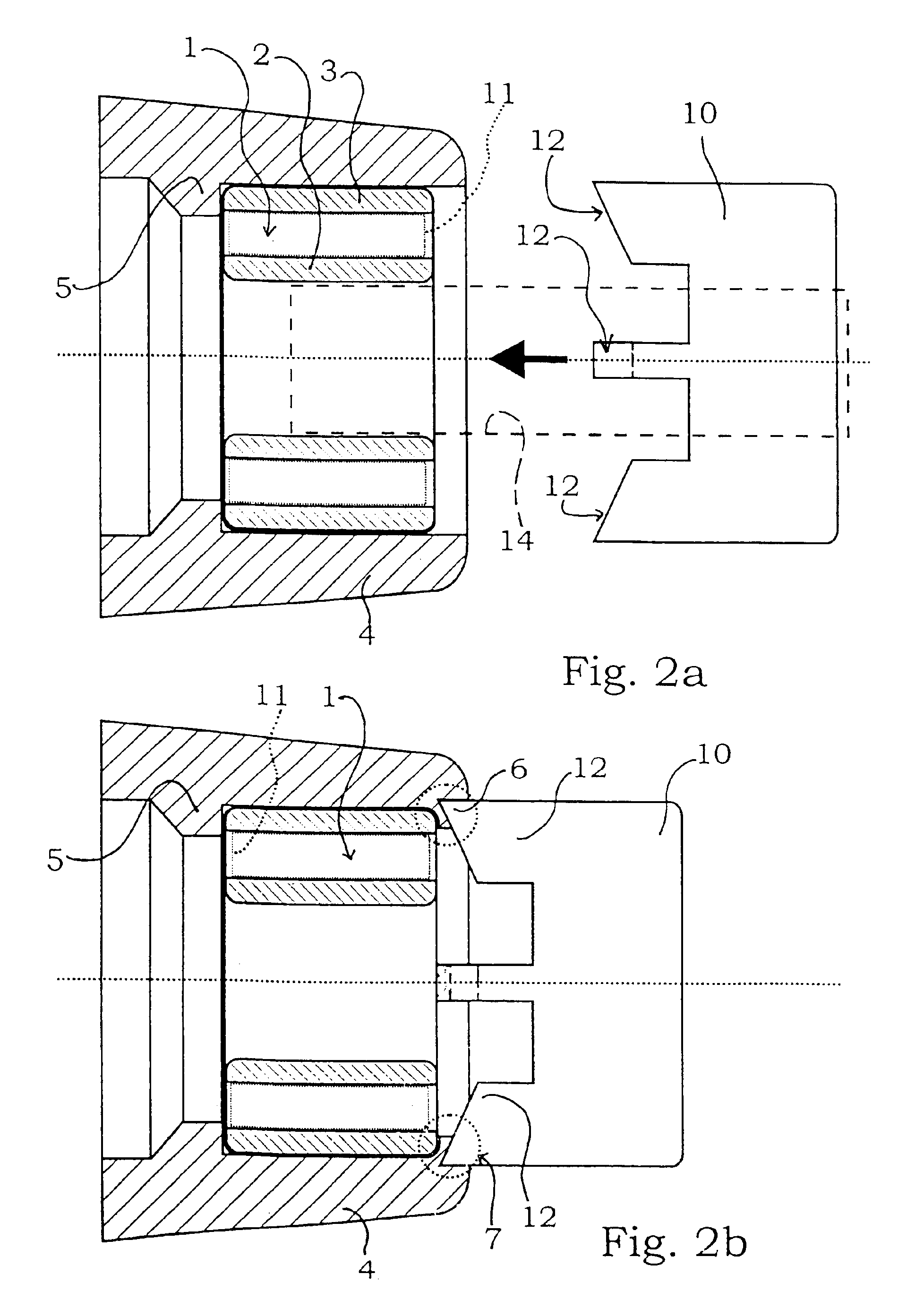

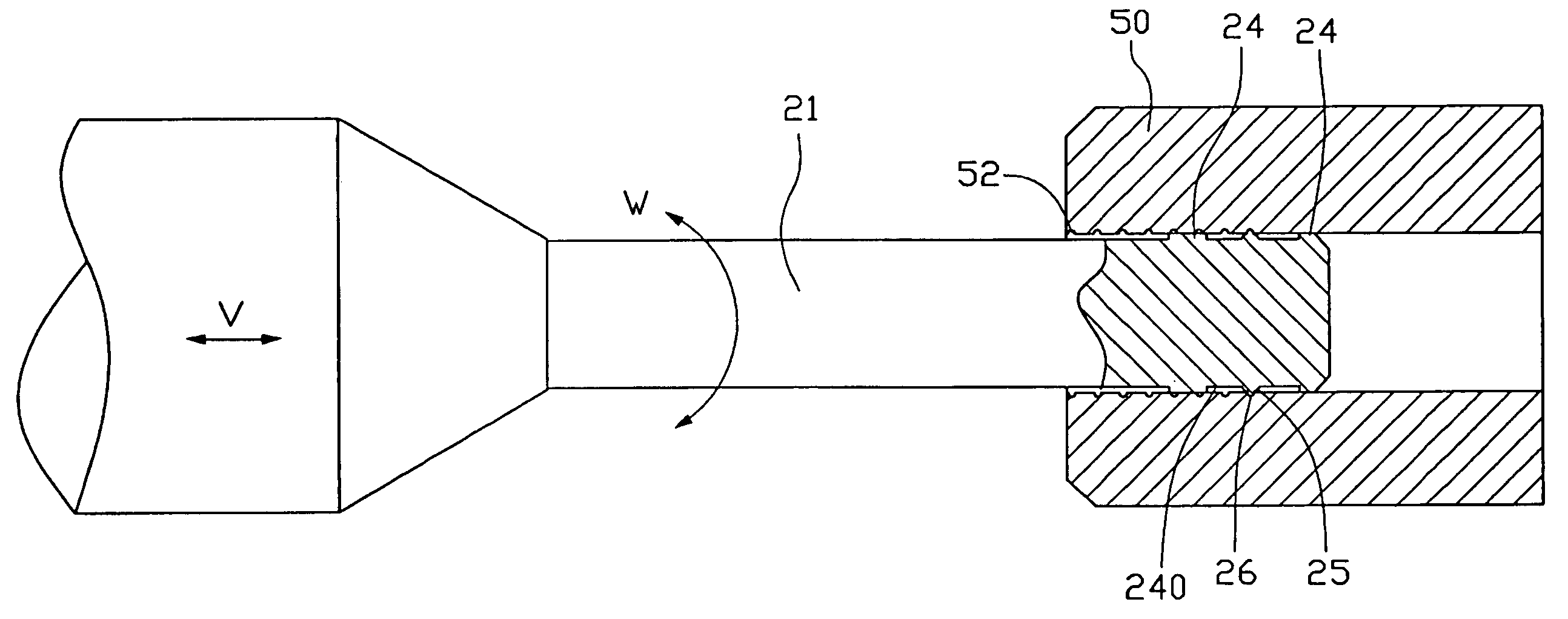

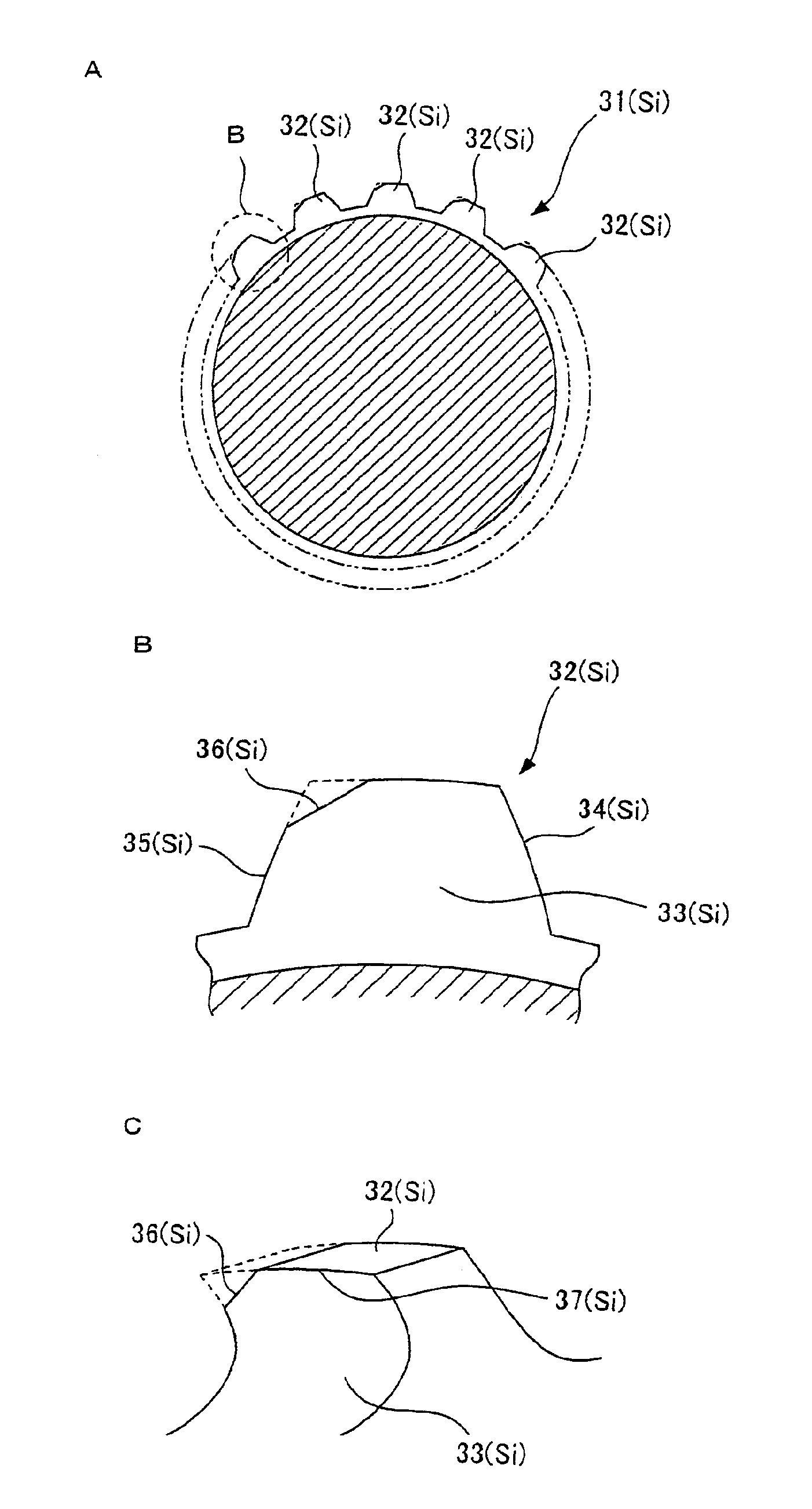

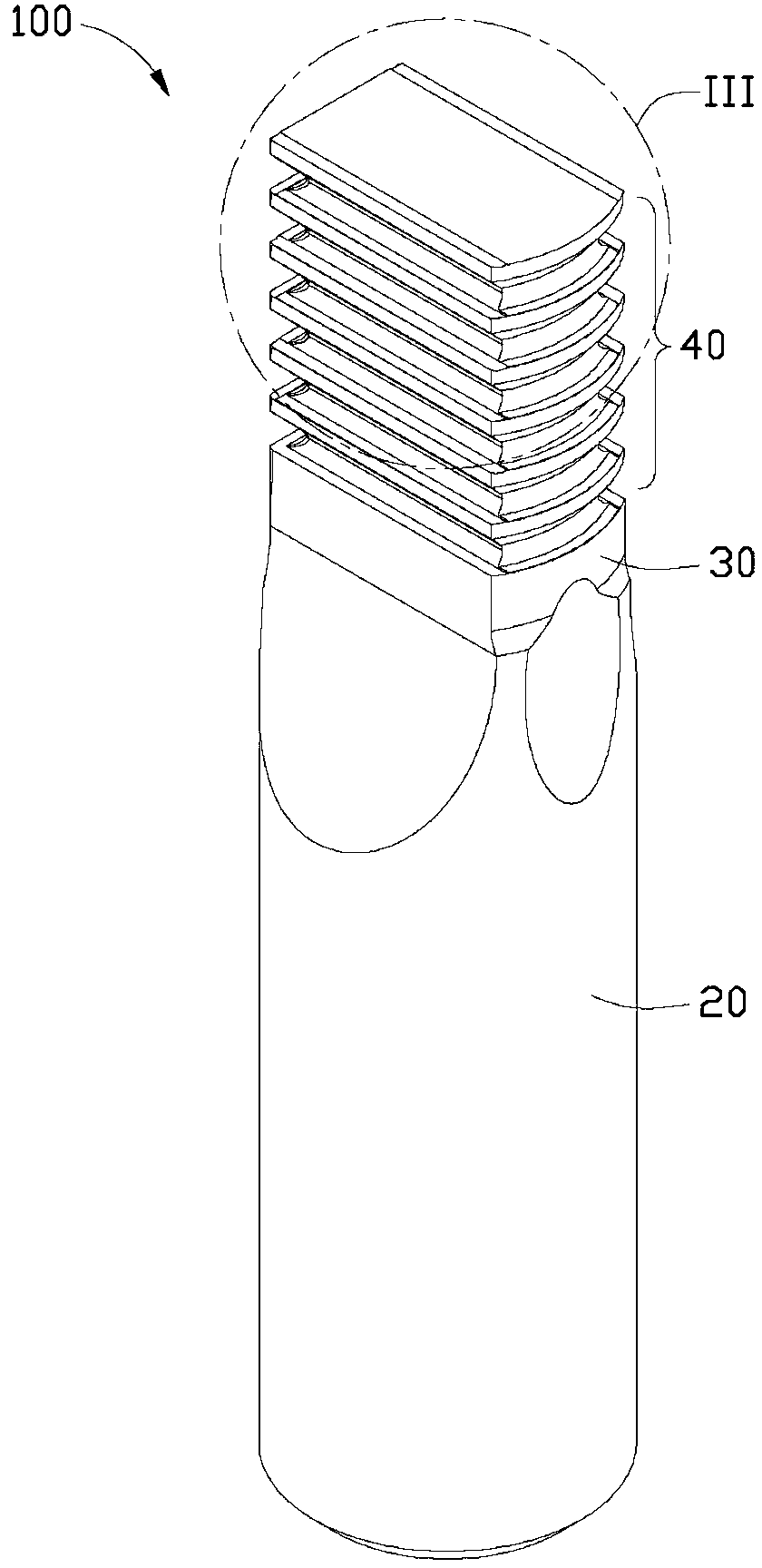

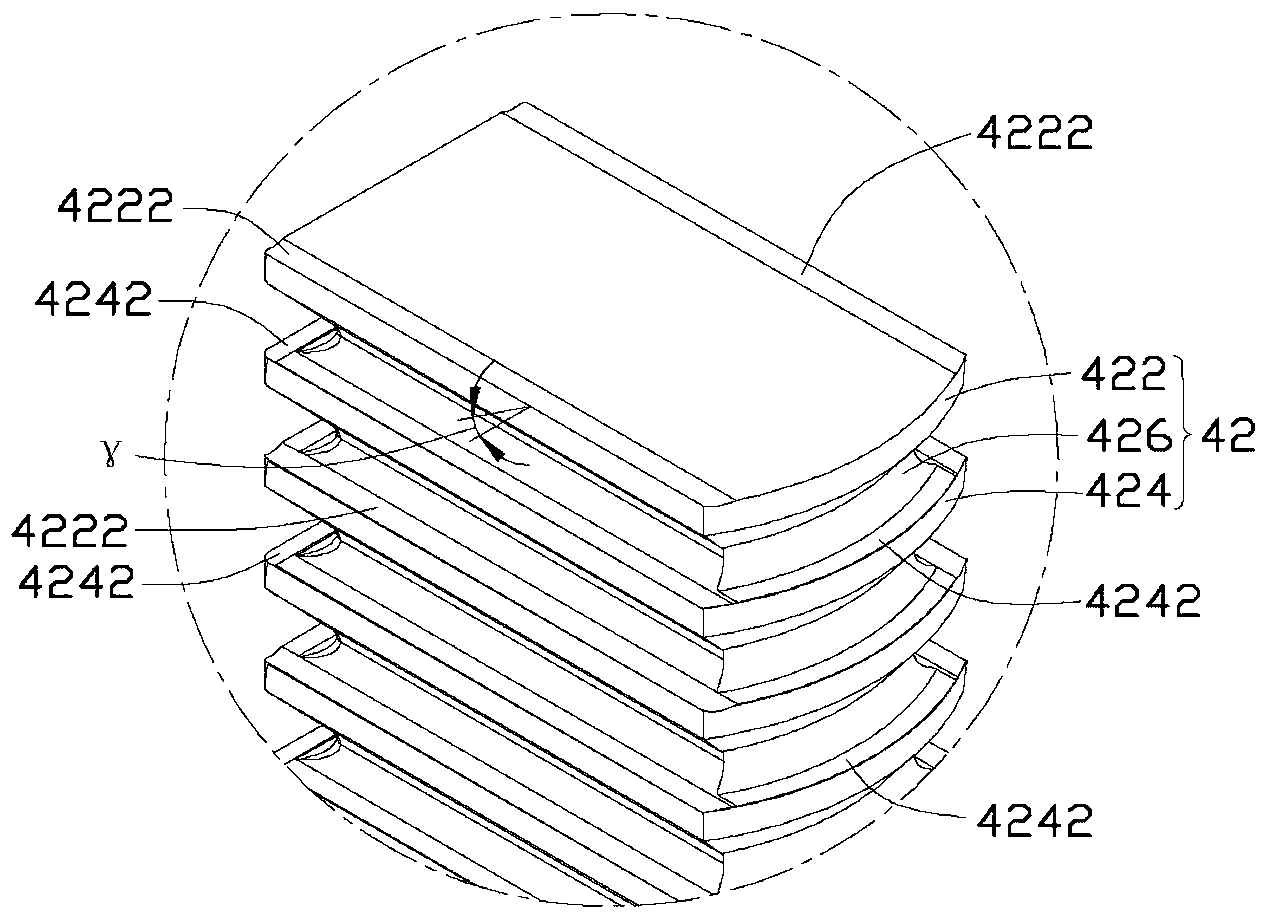

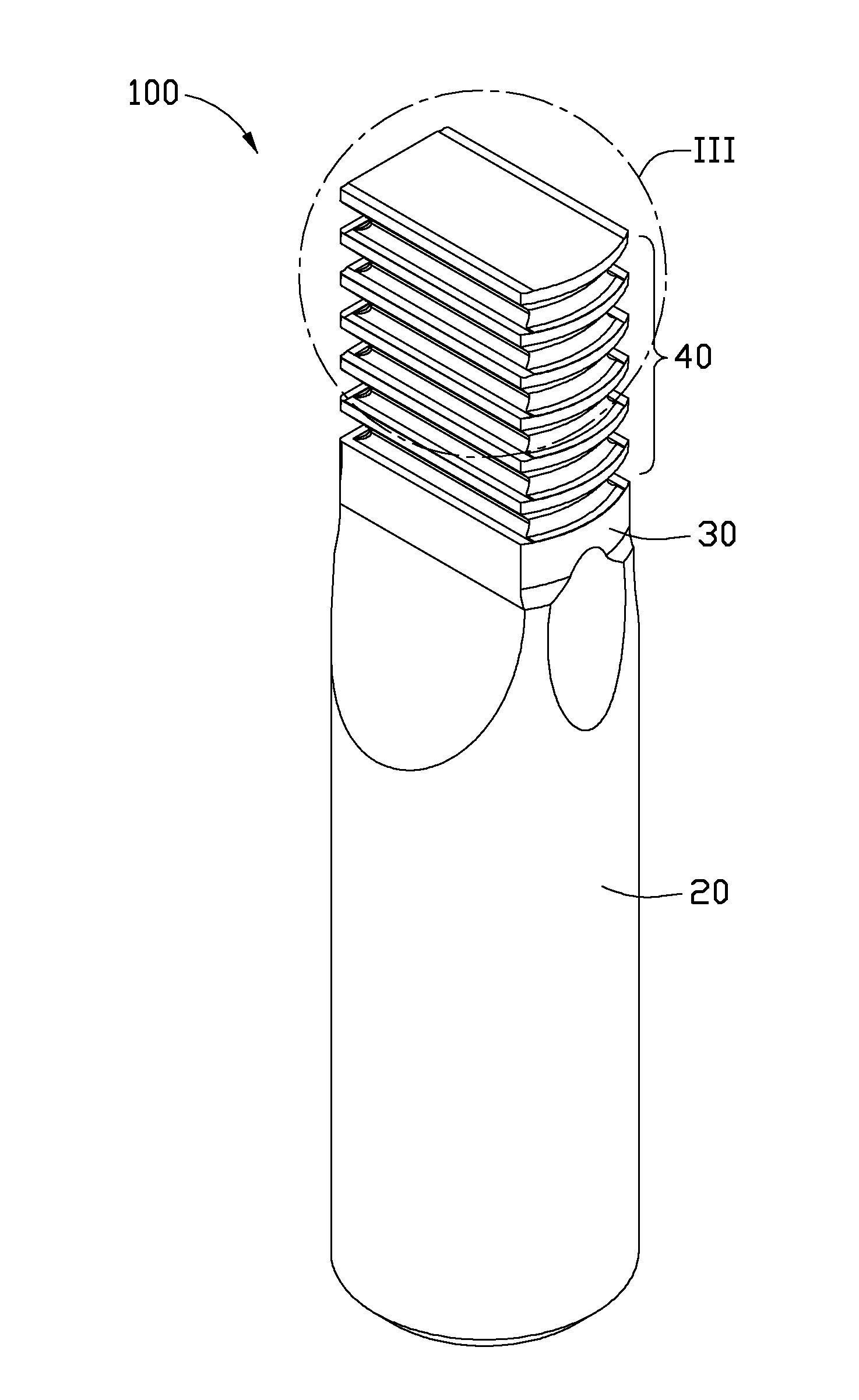

Manufacturing tool for fluid dynamic bearing

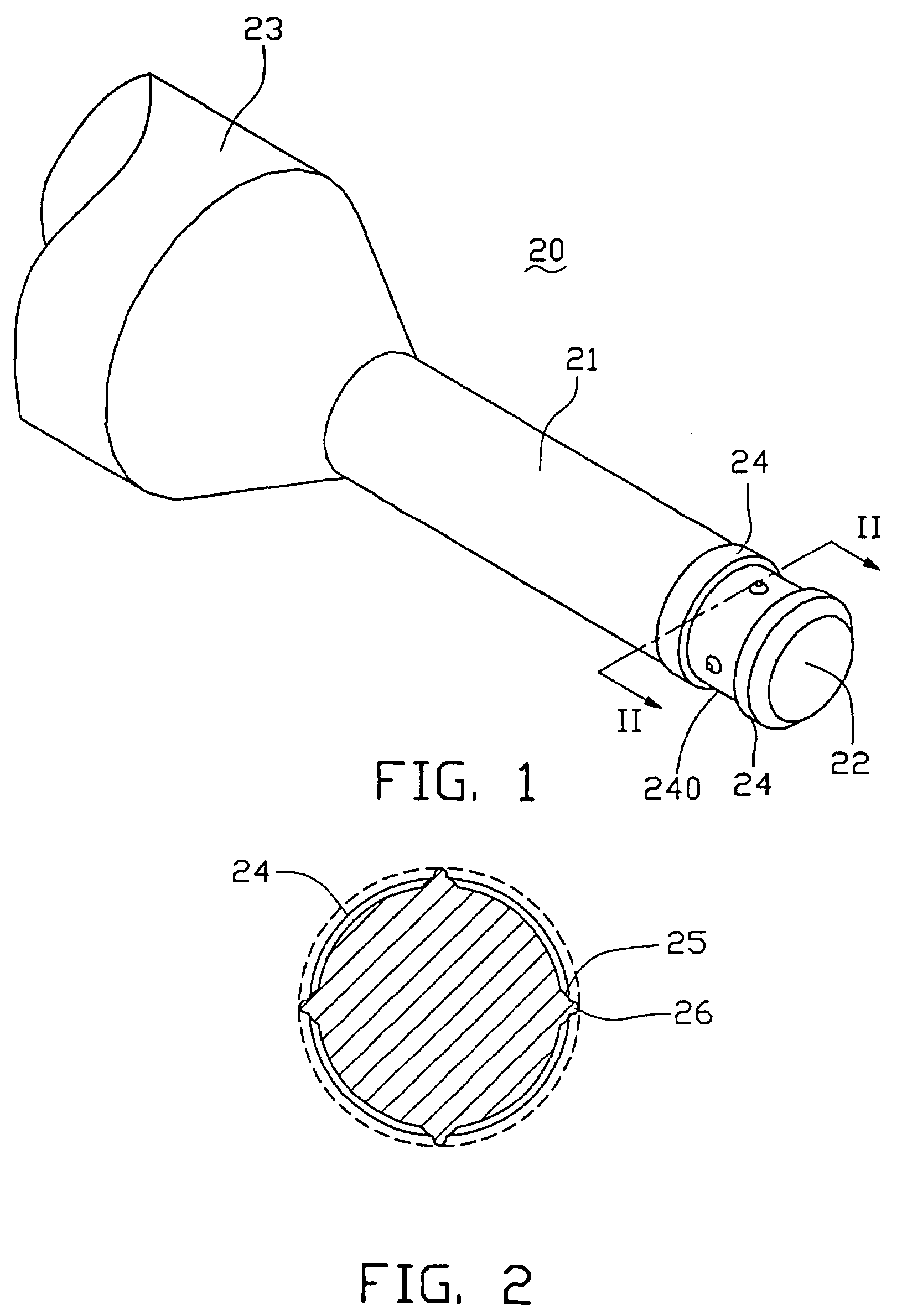

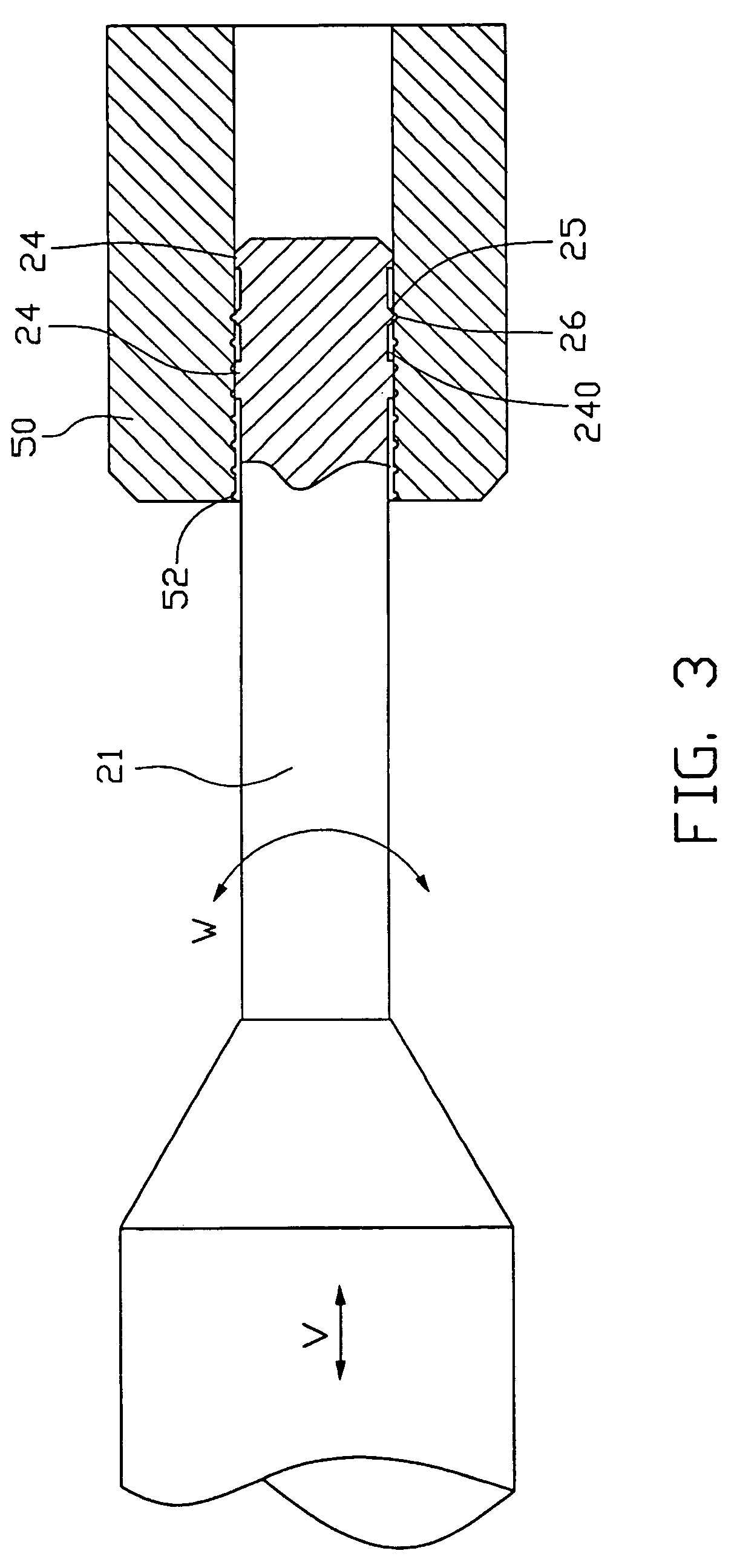

InactiveUS7251975B2Improve accuracyEasy to manufactureRectilinear broachShaftsEngineeringMechanical engineering

A manufacturing tool (20) for forming a dynamic pressure groove (52) in an inner peripheral surface of a bearing sleeve (50) includes a tool shaft (21) for being rotated in a bore of the bearing sleeve while being moved in an axial direction thereof. Protrusions (25) are integrally and circumferentially arranged on an outer periphery of the tool shaft near a leading end (22) thereof. Machining tips (26) are integrally formed on outmost ends of the protrusions for machining the inner peripheral surface of the bearing sleeve to form the dynamic pressure groove therein.

Owner:HON HAI PRECISION IND CO LTD

Broach

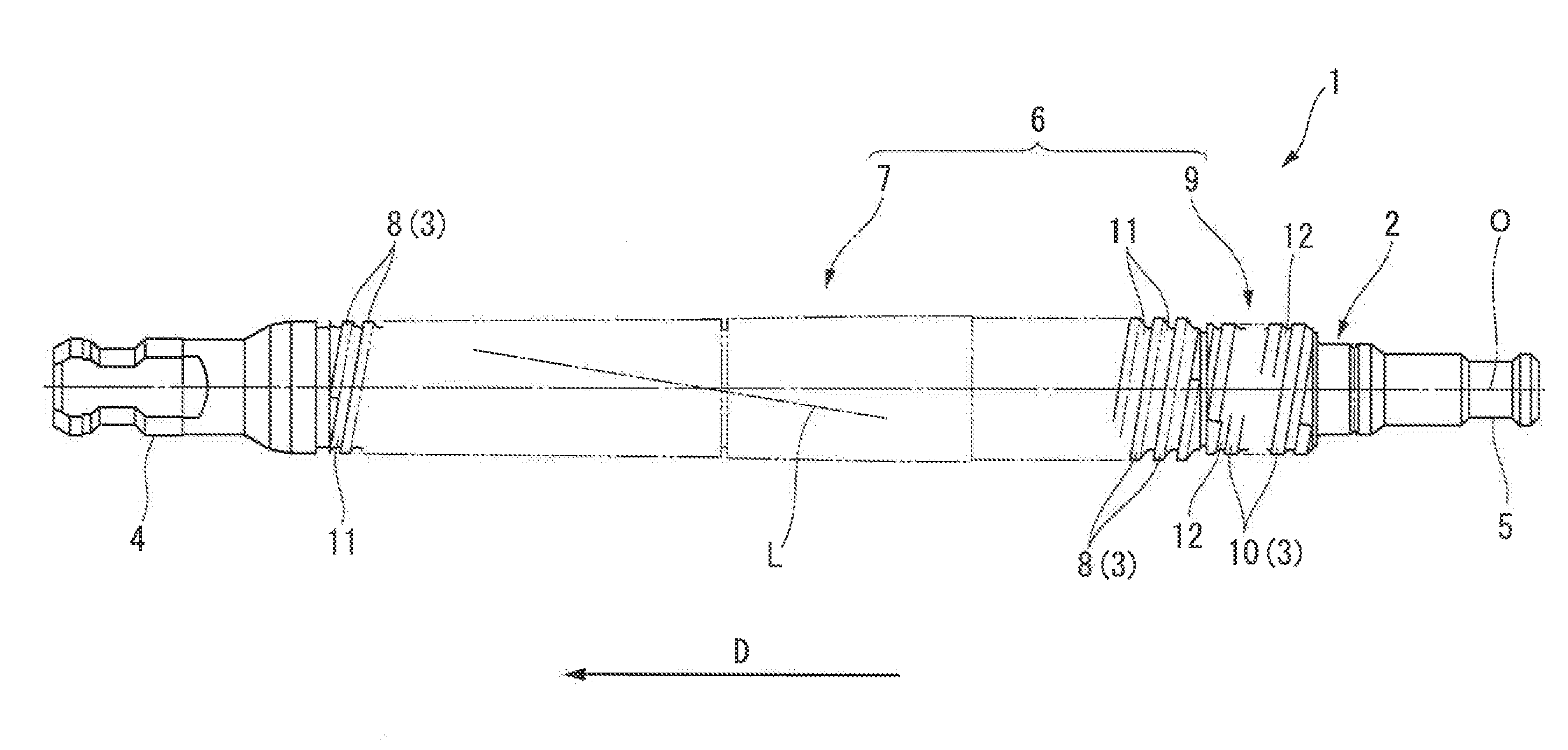

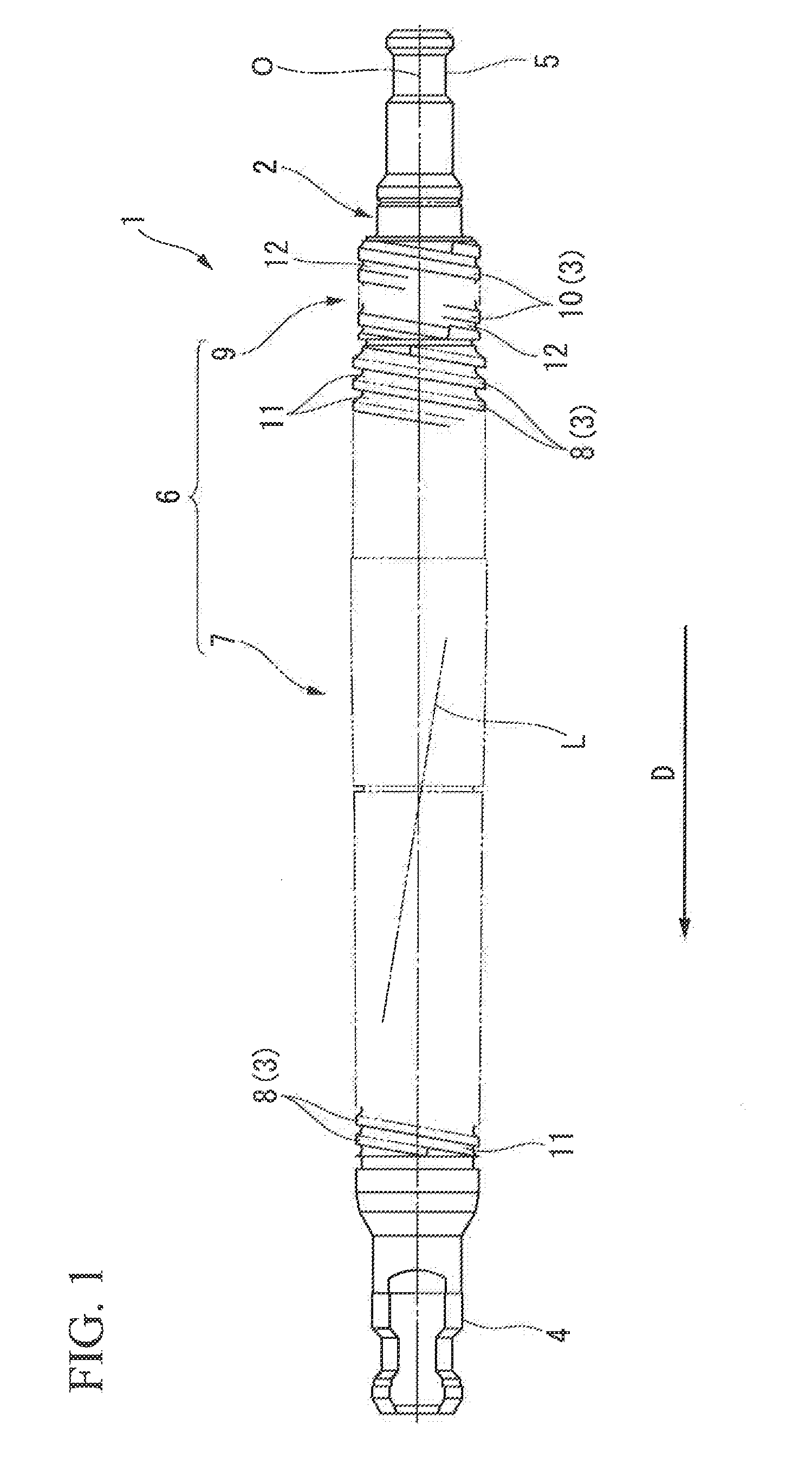

ActiveUS20140294521A1Easy to manufactureInternal diameter can be increasedRectilinear broachBroaching toolsEngineering

A plurality of cutting edges that are arranged on an outer circumference of a shaft-shaped broach body are provided with a spline teeth group, which contains a plurality of spline teeth 8 that groove a prepared hole of a work material, and a round teeth group, which is disposed in a different position from the spline teeth group along an axis direction and contains a plurality of round teeth that machine an inner circumference of the prepared hole. At least one gullet is formed to extend along the outer circumference of the broach body in a circumferential direction around the axis between the round teeth that are adjacent to one another in the axis direction in the round teeth group. The gullet extends toward the axis direction, gradually twisting toward the circumferential direction. The spline teeth group and the round teeth group are formed integrally on the outer circumference of the broach body.

Owner:MITSUBISHI MATERIALS CORP

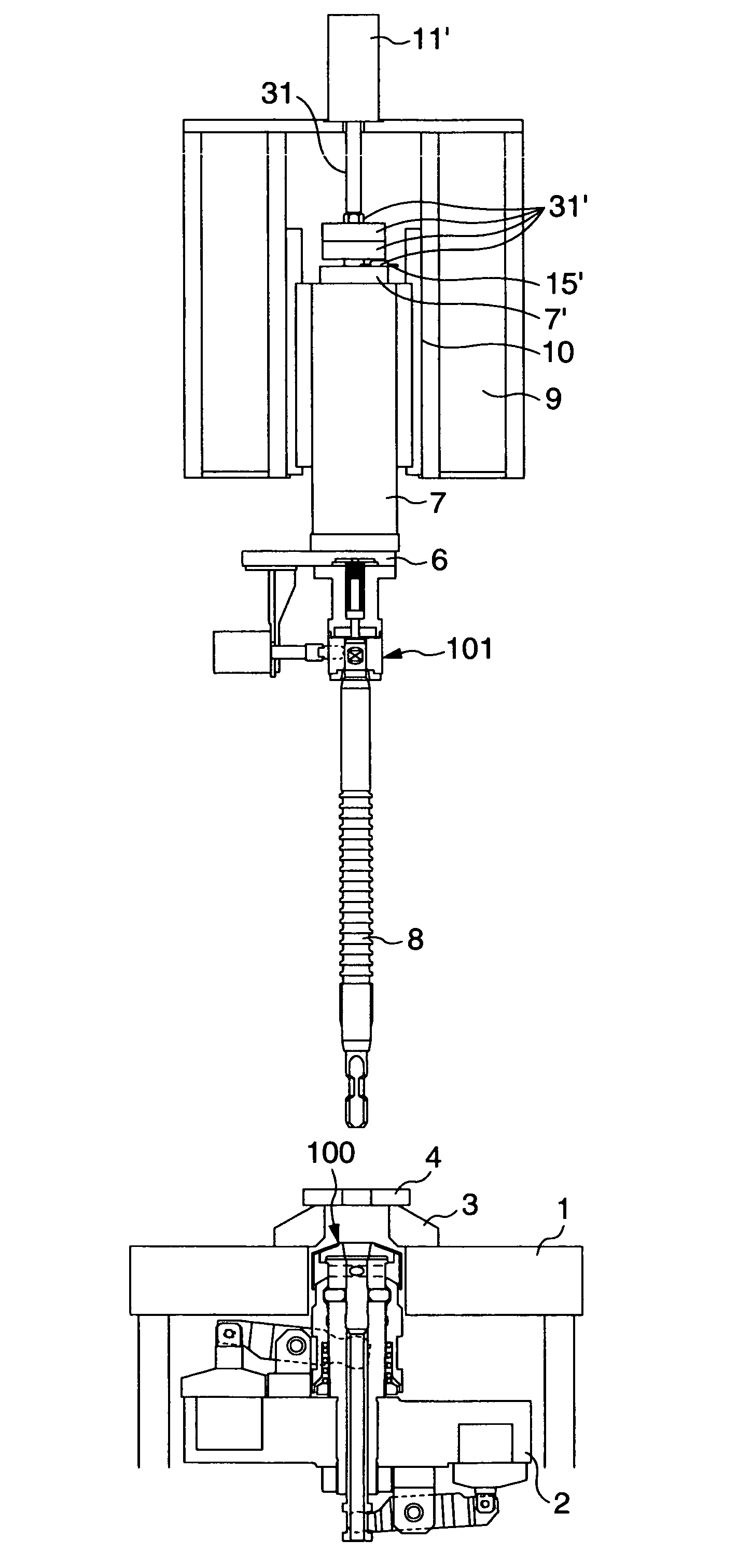

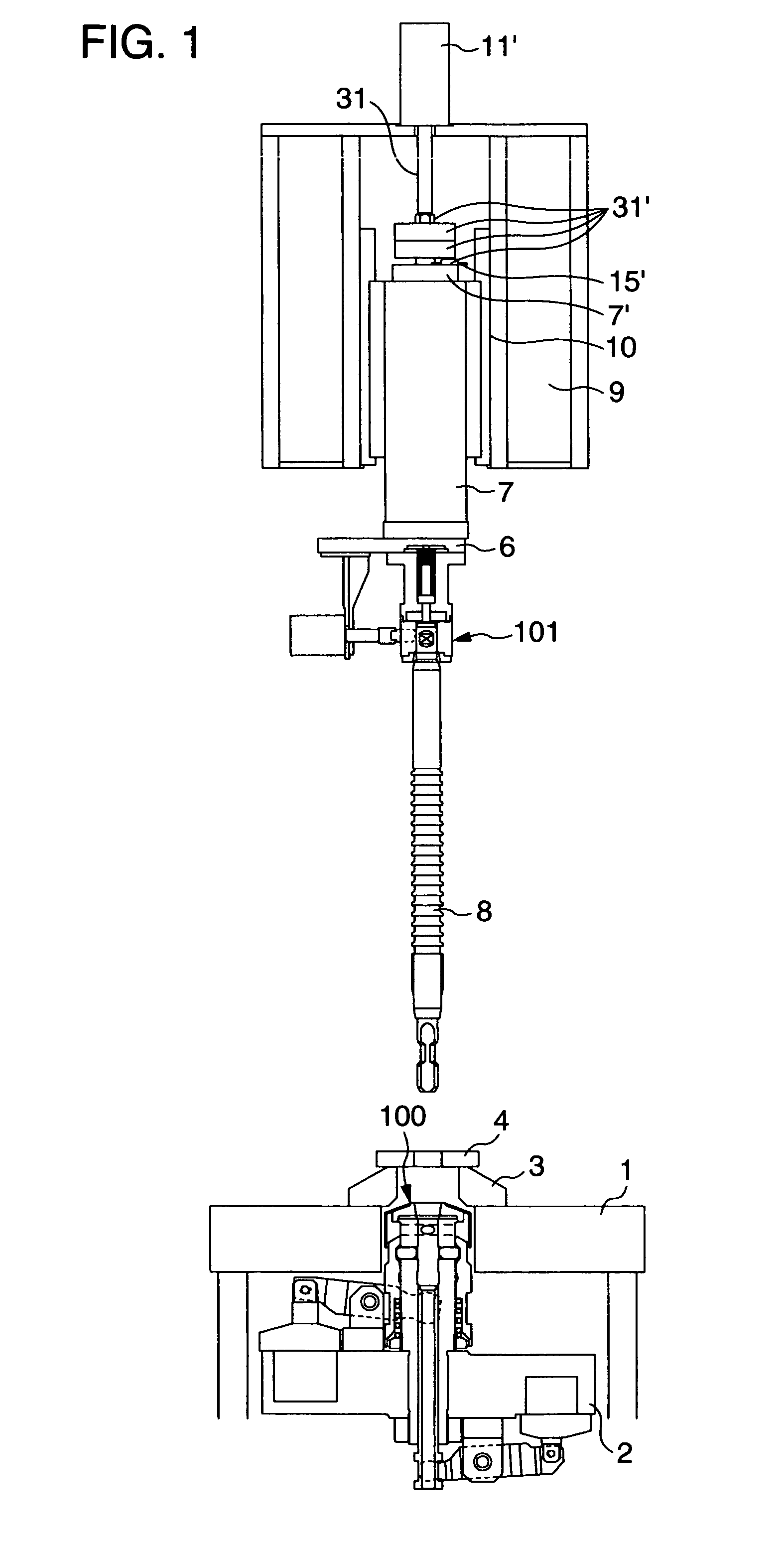

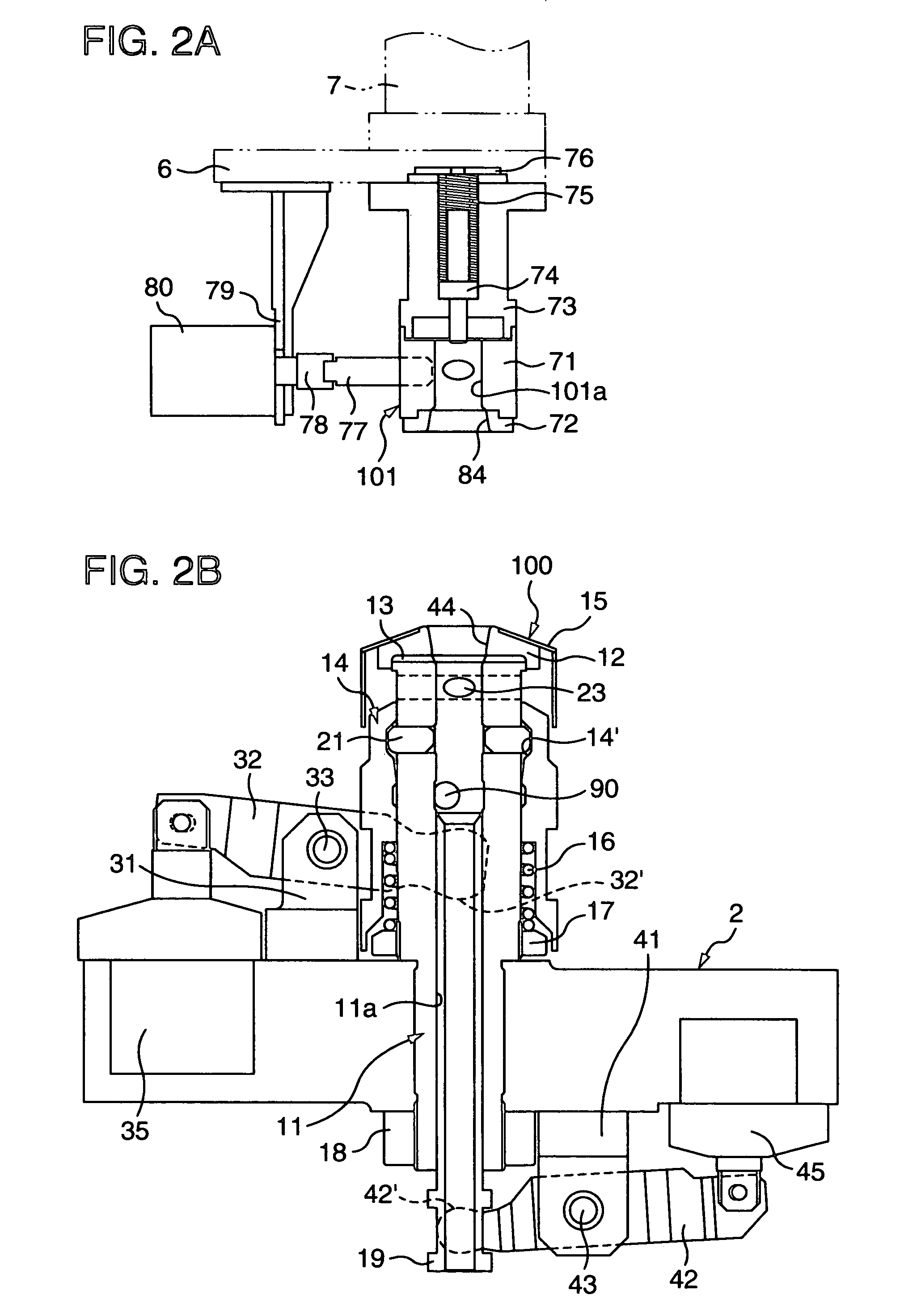

Internal broaching machine and internal broach

ActiveUS7021874B2Highly accurate broachingHigh concentricityRectilinear broachBroaching toolsEngineeringMechanical engineering

A broach for internal broaching is formed on its pull end and / or follower end with a tapered surface machined with high accuracy. A pull head and / or a retrieving head of a broaching machine, which drivingly grip the pull end and the follower end the broach, is formed with a tapered inner surface complementary to the tapered surface of the broach. The pull head and the retrieving head grip the broach while pressing and clamping their tapered inner surface against the tapered surface, and these heads and the broach are firmly connected together. Clearances or gaps between the heads and the broach are thus eliminated, concentricity between the heads and the broach is significantly improved, and broaching can be performed with high accuracy.

Owner:NACHI-FUJIKOSHI +1

Broaching Tool

ActiveUS20090297281A1Minimize chatterHigh repeat positioning accuracyRectilinear broachBroaching toolsEngineeringMechanical engineering

A broaching tool for machining a workpiece formed of a parallelogram shaped insert which fits within a slot formed in a body member. The insert has two juxtaposed corners either of which may be oriented at the distal end of the body member to function as a cutting edge. Repositioning of the insert to place either cutting edge in place is provided by flipping it over in its engagement within the slot. The inserts may be provided in a kit of differently configured inserts to yield different cutting widths.

Owner:GARDNER LARRY JOHN

Helical broach for roughing

InactiveUS8485763B2Reduce the balanceReduce the differenceRectilinear broachBroaching toolsAcute angleEngineering

A helical broach 1 for roughing includes a cutting tooth part 30 in which n spline teeth 31 are arranged side by side in an axial direction. The spline teeth 31 each include cutting teeth 32 which are arranged at a predetermined helix angle. The cutting teeth 32 each have an acute angle portion and an obtuse angle portion on both sides thereof in a circumferential direction. The cutting teeth disposed on the first to n−1th spline teeth 31 (S1 to Sn−1) in the circumferential direction are each formed in such a way that its height on the acute angle portion side differs from that on the obtuse angle portion side. The cutting teeth (Sn) of the nth spline tooth (Sn) are each formed in such a way that its height stays constant in the circumferential direction.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

Push-type broach

InactiveCN103157852AReduce manufacturing costWill not cause interferenceRectilinear broachBroaching toolsMechanical engineering

A push-type broach is used for processing quadrilateral holes or quadrilateral grooves. The push-type broach comprises a handle portion and a cutting portion, wherein the cutting portion comprises more than one gear pair, the gear pair comprises a first gear and a second gear which are arranged adjacent, two opposite sides of the first gear respectively form a first cutting blade, two opposite sides, stagger with the first cutting blades, of the second gear from a second cutting blade, the first cutting blades and the second cutting blades are respectively formed on different gears of the gear pair, no interference is caused between different cutting blades, and therefore forming of the first cutting blades and the second cutting blades is facilitated, and production cost of the push-type broach is reduced.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

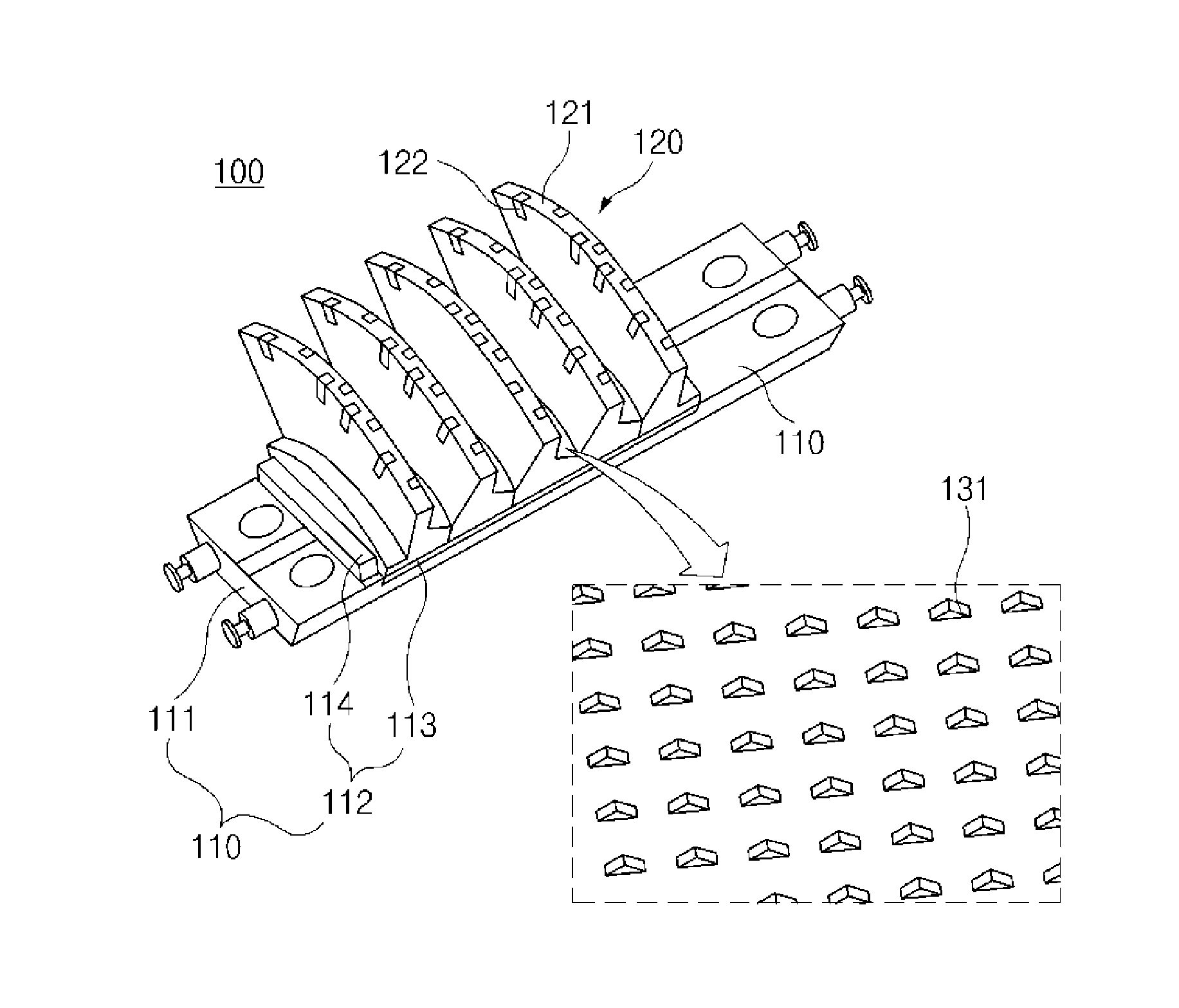

Turn broach machine

ActiveUS20150147126A1Enhanced couplingAdjustable positionRectilinear broachBroaching toolsWork timeEngineering

A turn broach machine includes: a machining member machining a target to be cut; and an adaptor provided under the machining member, supporting the machining member, and adjusting a position of the machining member. At the time of adjusting a position of a segment of the machining member from a plate provided in an adapter, the segment does not manually move, but moves on an adjusting plate that is mechanically defined, such that work accuracy may be improved to increase marketability and a work time may be decreased to improve work convenience and productivity.

Owner:HYUNDAI MOTOR CO LTD

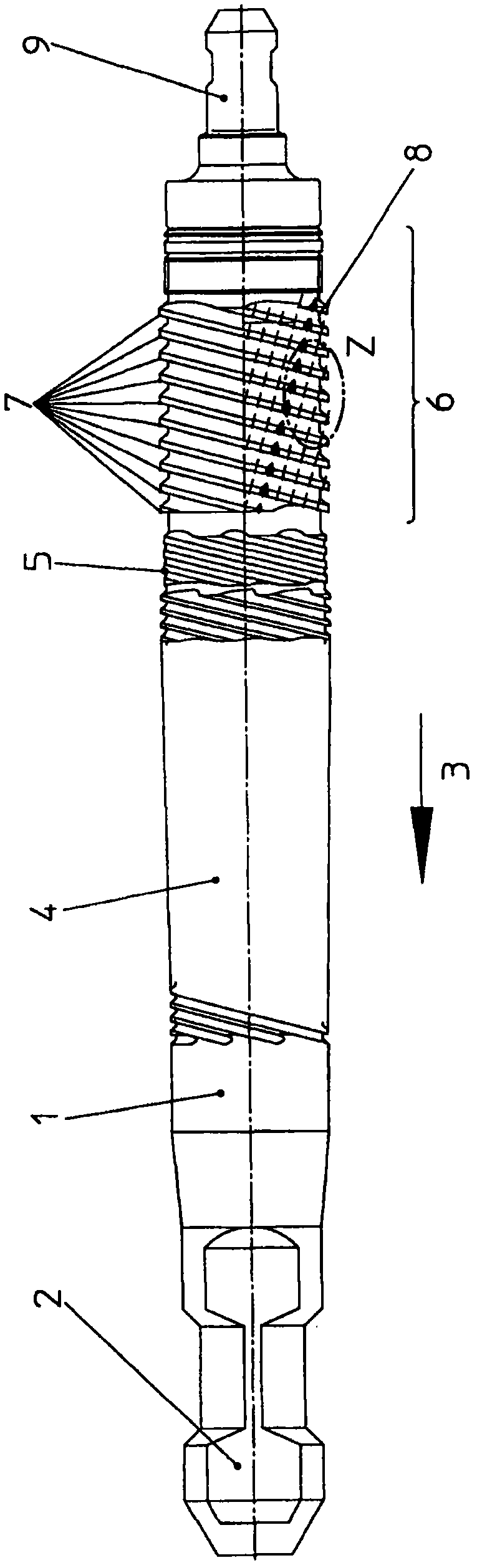

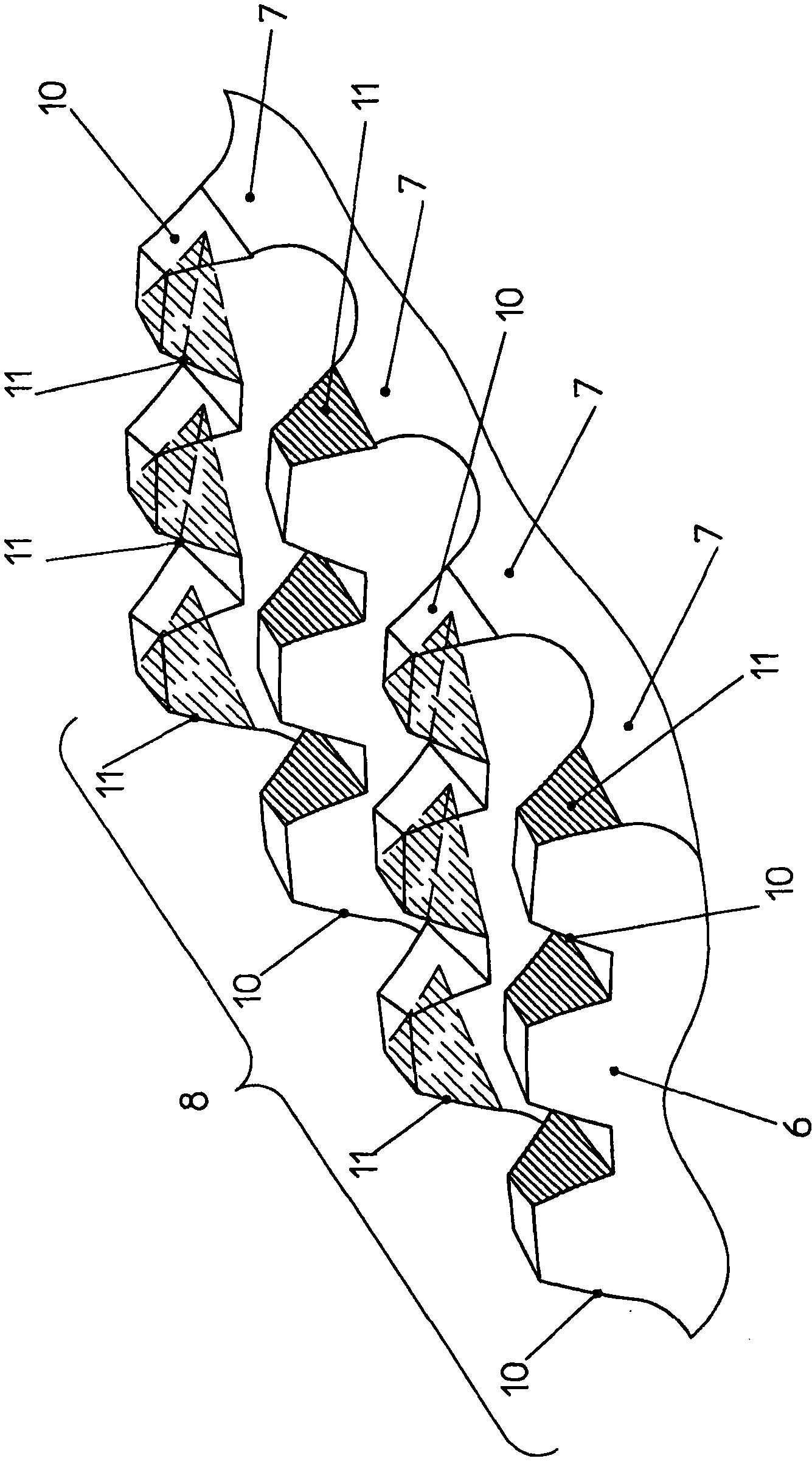

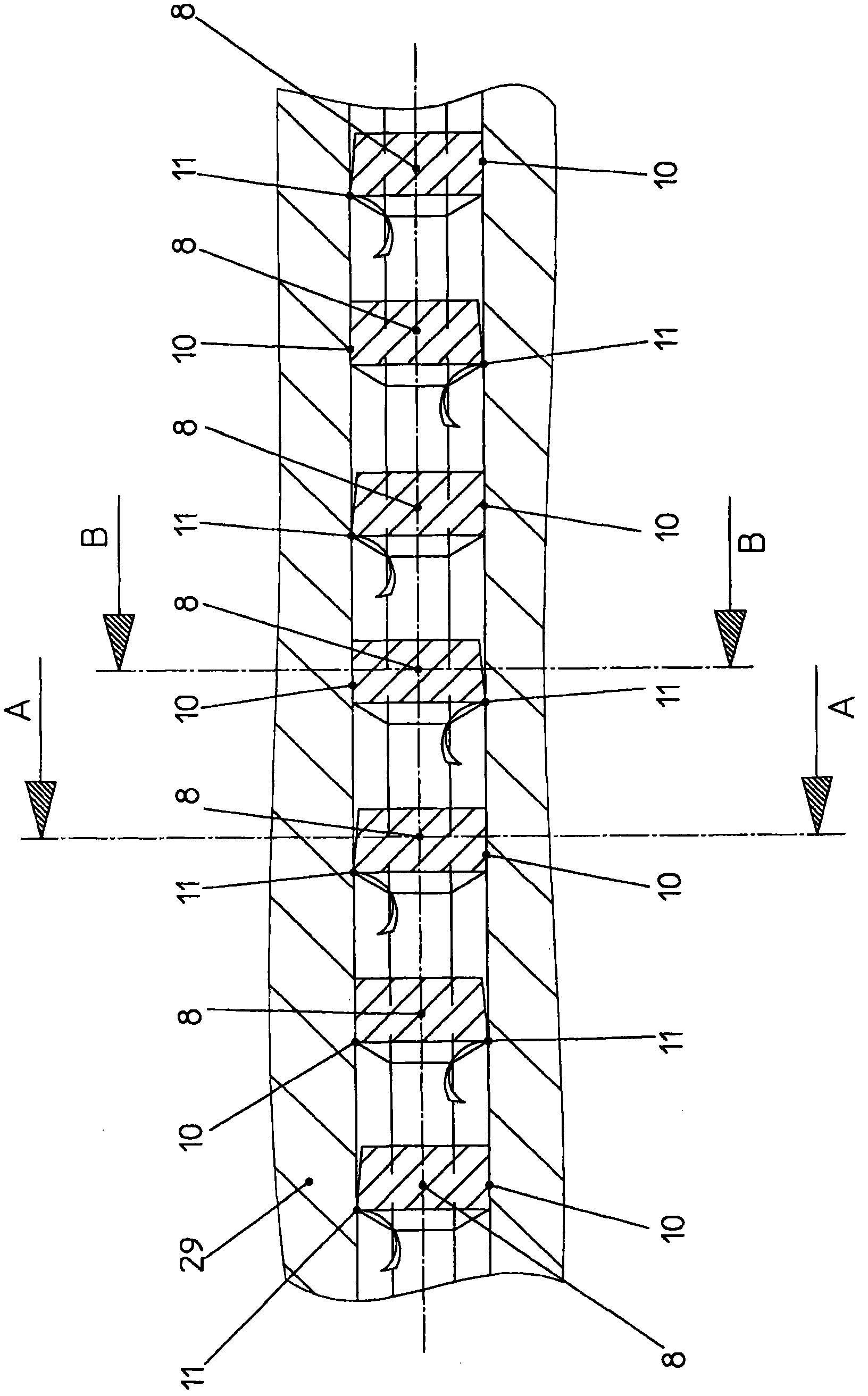

Internal broaching tools

The invention relates to an internal broaching tool for broaching profiles delimited by a root and flanks. The aim of the invention is to design an internal broaching tool for broaching profiles that allows a workpiece to be broached in an inexpensive, robust, simple, functionally safe, and reliable manner without requiring a machining allowance while ensuring great accuracy of the shape and flanks of the profile on the broached workpiece even when the material strength of the workpiece changes, such that the actually broached profile exactly matches the desired profile. The internal broaching tool as per the invention is characterized in that a relief part (5) is arranged between the toothed part (4) and the calibration part (6), and the calibrating broaching teeth (8) in adjacent rows (7) on the calibration part (6) are designed such that said teeth (8) have a guiding flank (10) (without a clearance angle or with a maximum negative clearance angle of 0.1 DEG ) and a cutting flank (11) (with a positive clearance angle), and the guiding flanks (10) and the cutting flanks (11) on the calibrating broaching teeth (8) located behind each other in the direction opposite the broaching direction are alternately offset relative to each other in adjacent rows (7). The position, shape, and size of each guiding flank (10) located downstream in relation to the direction opposite the broaching direction are associated with the position, shape, and size of the associated cutting flank (11) (or the flank of the broaching tooth) in the preceding row (7). Alternatively, a relief part (5) is arranged between the toothed part (4) and the calibration part (6), and broaching cutting teeth (12) (the two flanks of which have a positive clearance angle) and broaching guiding teeth (13) (the two flanks of which have no clearance angle or a maximum negative clearance angle of 0.1 DEG ) are disposed on the calibration part (6) as broaching teeth (8) in such a way that a broaching guiding tooth (13) is always located next to a broaching cutting tooth (12) in a row (7). The position, shape, and size of each broaching guiding tooth (13) located downstream in relation to the direction opposite the broaching direction (3) are associated with the position, shape, and size of the associated broaching cutting tooth (12) (or the broaching tooth) in the preceding row (7).

Owner:德国采拉梅里斯特殊刀具有限公司

Push broach

A push broach, for machining a quadrilateral hole or quadrilateral groove, includes a shank portion and a cutting portion connected to the shank portion. The cutting portion includes at least one pair of cutting teeth including a first cutting tooth and a second cutting tooth arranged substantially parallel to the first cutting tooth, the first cutting tooth includes a pair of first cutting edges at two opposite edges thereof, the second cutting tooth includes a pair of cutting edges at two opposite edges thereof, when viewed from an end of the shank portion, each second cutting edge interconnects the pair of first cutting edge, and the pair of the first cutting edges and the pair of second cutting edges cooperatively form a quadrangle enclosing a periphery of the first cutting tooth.

Owner:JIZHUN PRECISION IND HUIZHOU

Broach tool and a broach insert

InactiveUS20070065238A1Easy to replaceGood precisionRectilinear broachBroaching toolsEngineeringMachining

A broach tool and a broach insert for chip removing machining of metals are provided. The broach tool includes an elongate holder and at least one cutting unit. The holder comprises at least one recess for the receipt of the cutting unit. The broach tool has a feeding direction. The broach tool includes clamping members for each cutting unit. Each clamping member is arranged in front of the cutting unit in the feeding direction. The cutting unit is a replaceable broach insert including a base part and a cutting part. A notch is formed centrally in a rear side surface of the broach insert. The recess includes a rear wall formed with a projection, the cross section of which is U-shaped and includes arms. The arms are arranged to be elastically deformed by the notch.

Owner:SECO TOOLS AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com