Centrifugally-cast tube and related method and apparatus for making same

a centrifugally cast tube and tube body technology, applied in the direction of hydrocarbon oil treatment, gear teeth, rectilinear broach, etc., can solve the problems of not providing adequate deformation and/or orientation of the subsurface or material lattice of the inner surface of the tube, electropolished surface is not resistant to corrosion, carburization or metal dusting, etc., to achieve superior surface roughness and dimensional accuracy of the interior surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

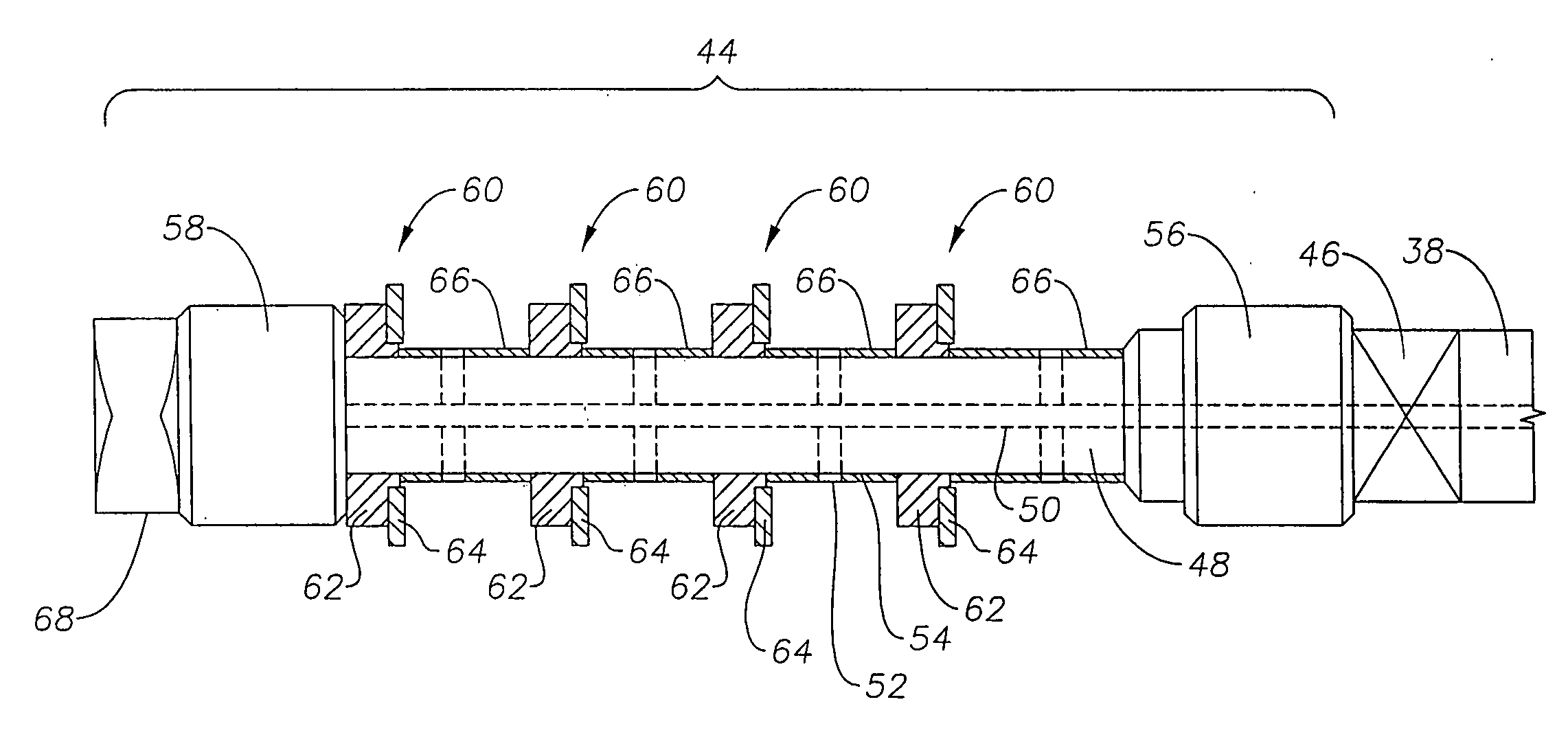

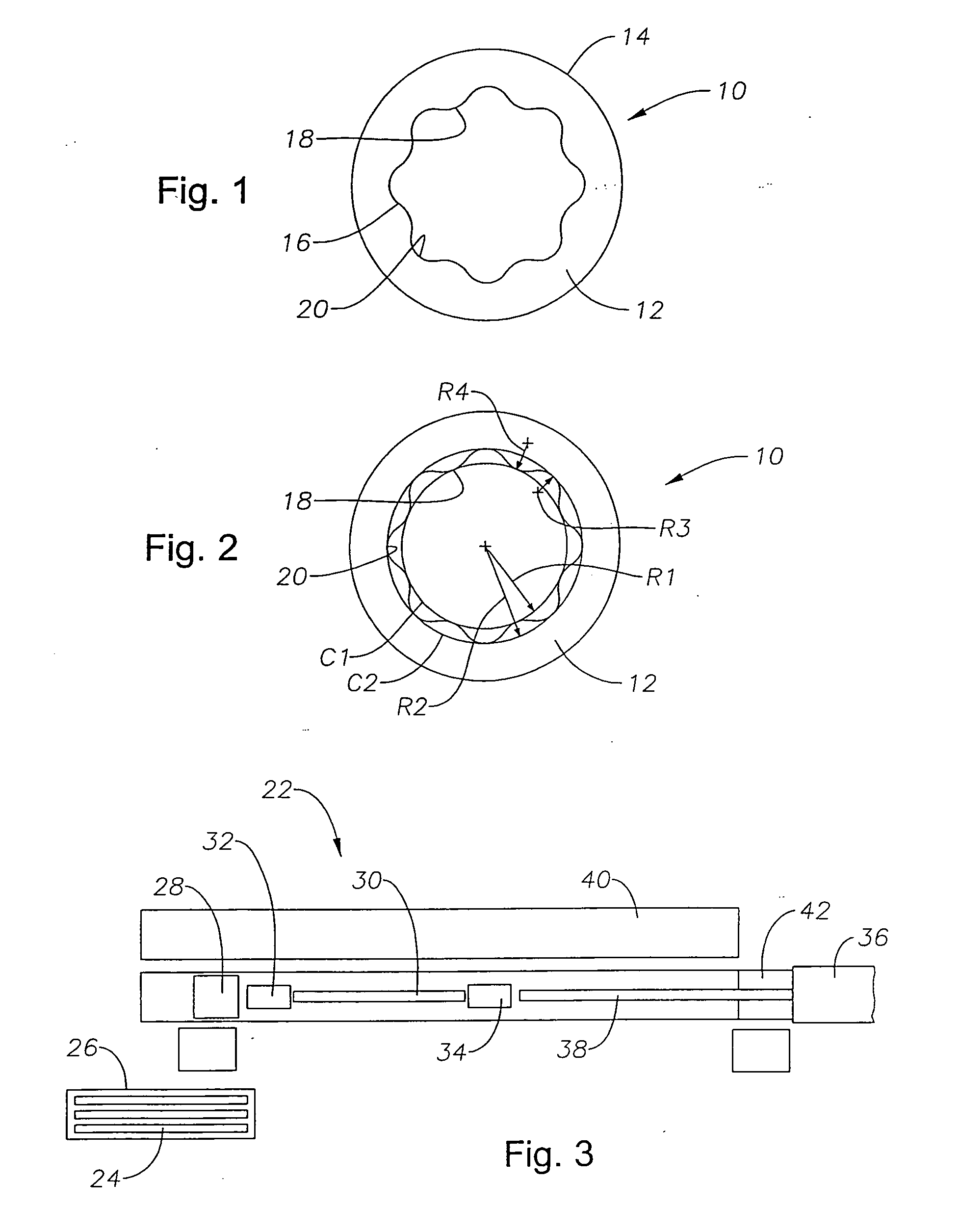

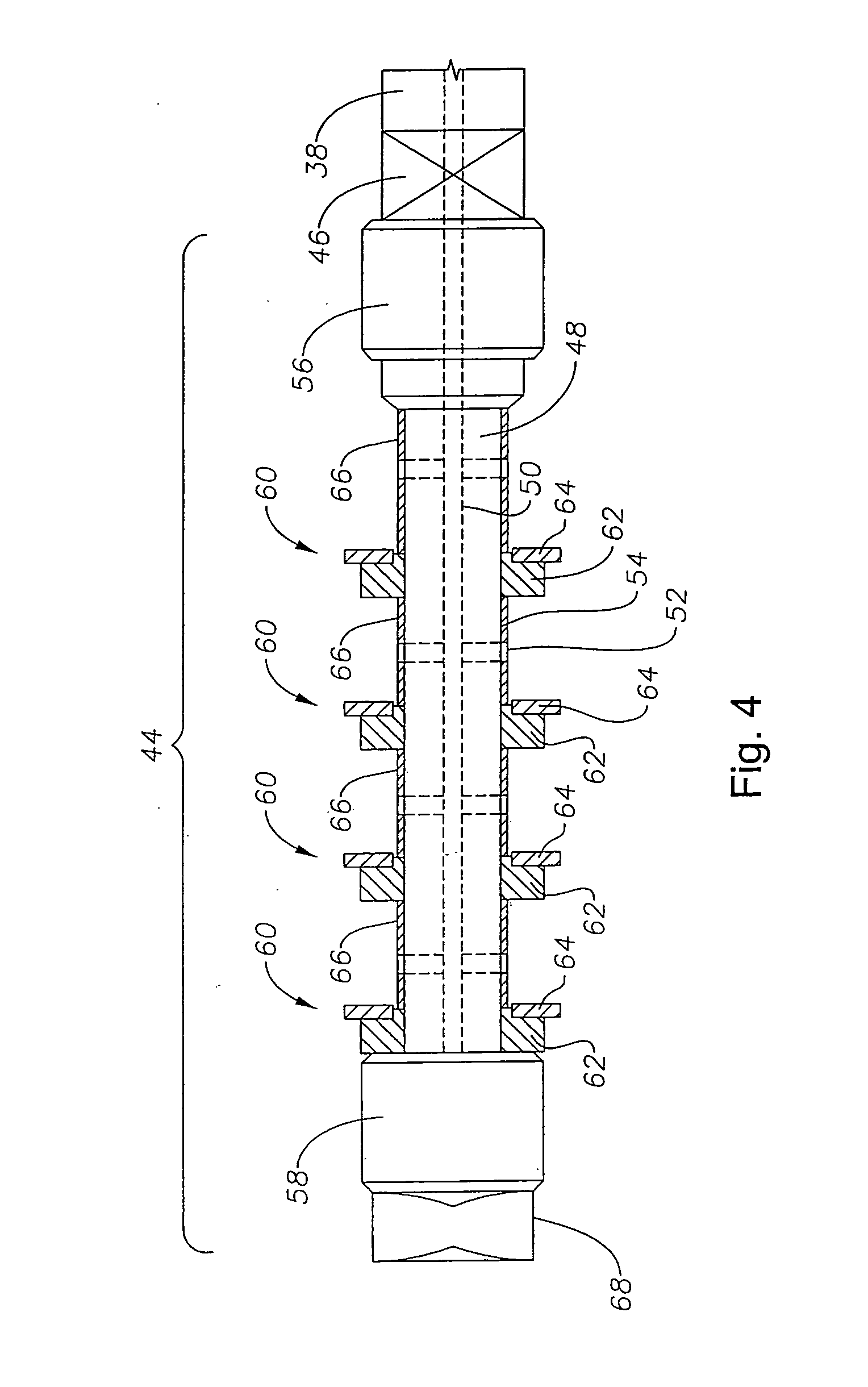

[0036] Referring to the drawings in detail, wherein like numerals denote identical elements throughout the several views, there is shown in FIG. 1 a specific embodiment of a centrifugally-cast tube 10 constructed in-accordance with the present invention. In a specific embodiment, the tube 10 may include a body 12 made from a creep-resistant alloy, such as, for example, Manaurite 36X. The body 12 may include an exterior surface 14 and an interior surface 16. The interior surface 16 may include a plurality of bosses 18 and a plurality of grooves 20 disposed therebetween. While the specific embodiment shown in FIG. 1 illustrates a tube 10 having eight bosses 18 and eight grooves 20, those numbers should not be taken as a limitation, but, instead, the present invention covers any number of bosses 18 and grooves 20. In a specific embodiment, as shown in FIG. 2, the peaks of the bosses 18 may intersect a circle C1 having a radius R1. In a specific embodiment, the radius R1 may be 19 milli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com