Patents

Literature

588results about "Broaching machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

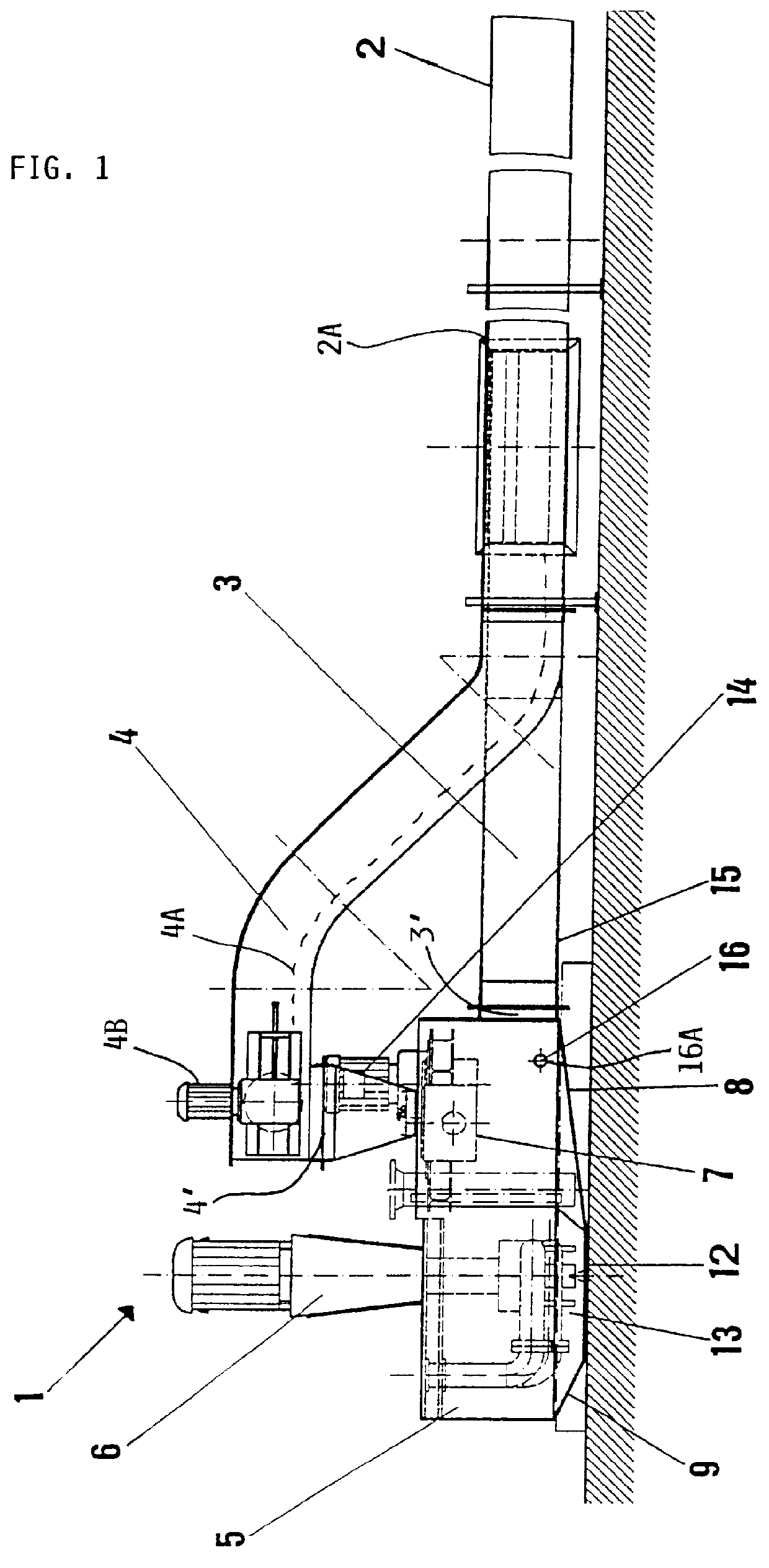

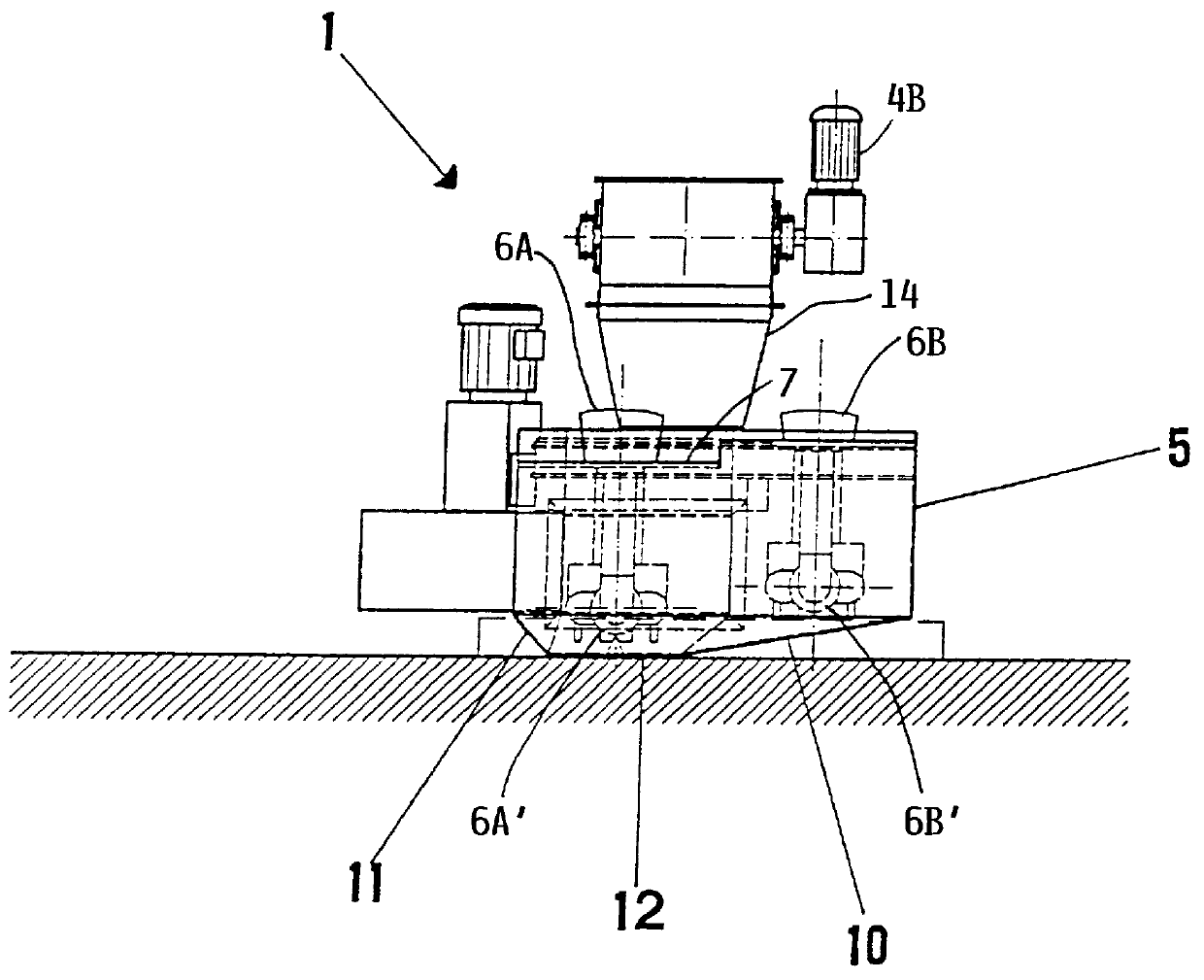

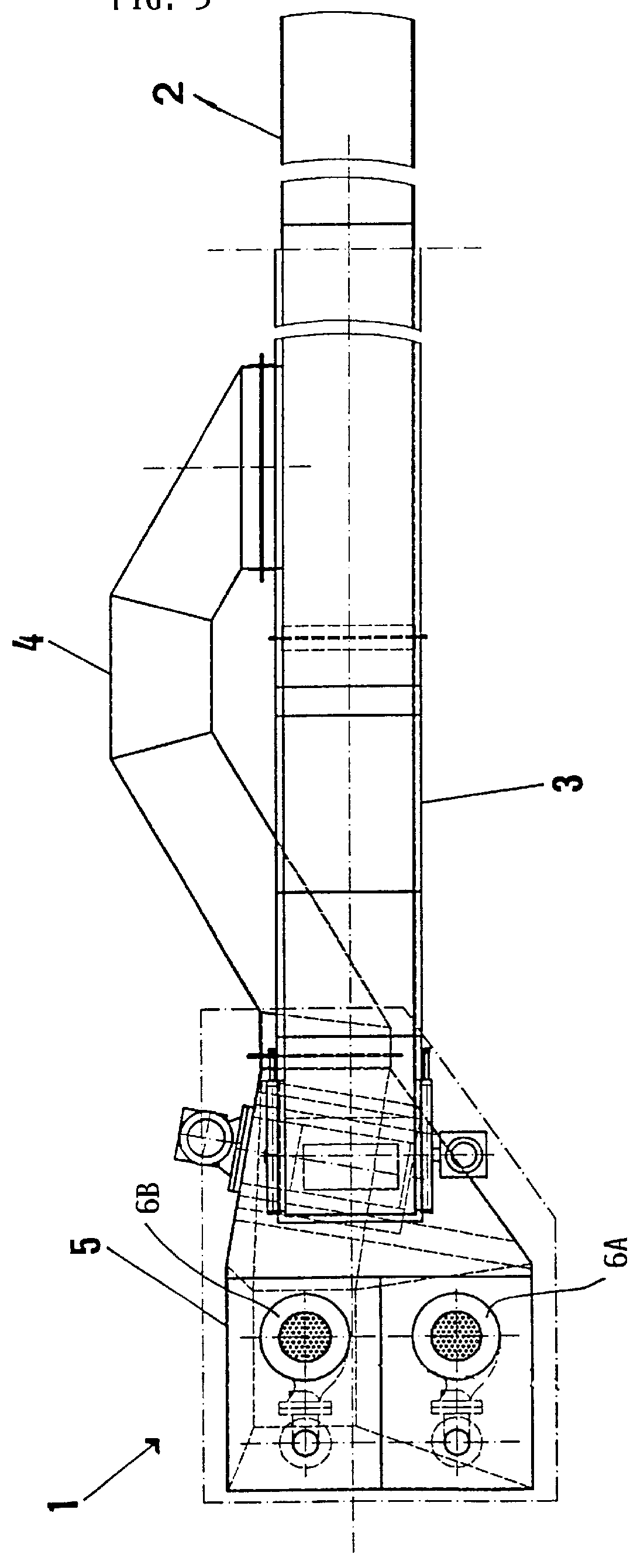

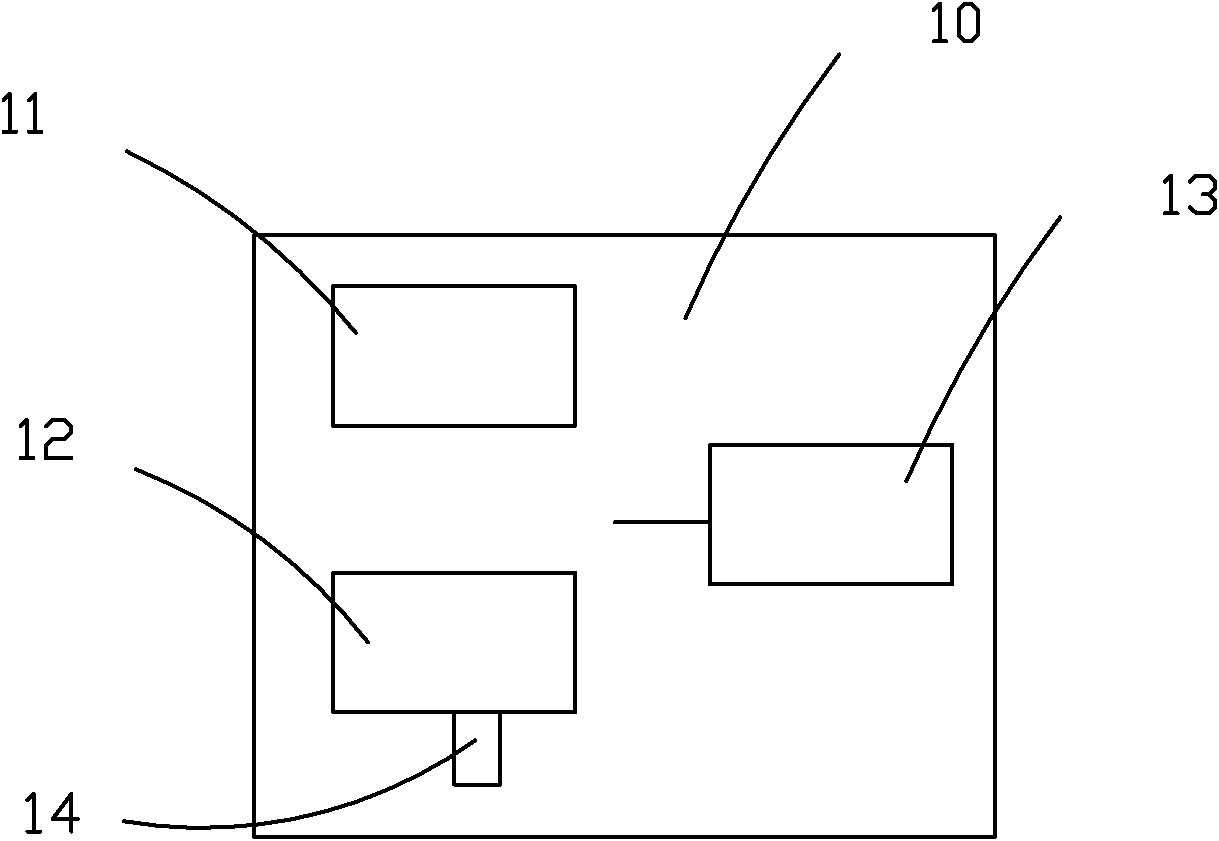

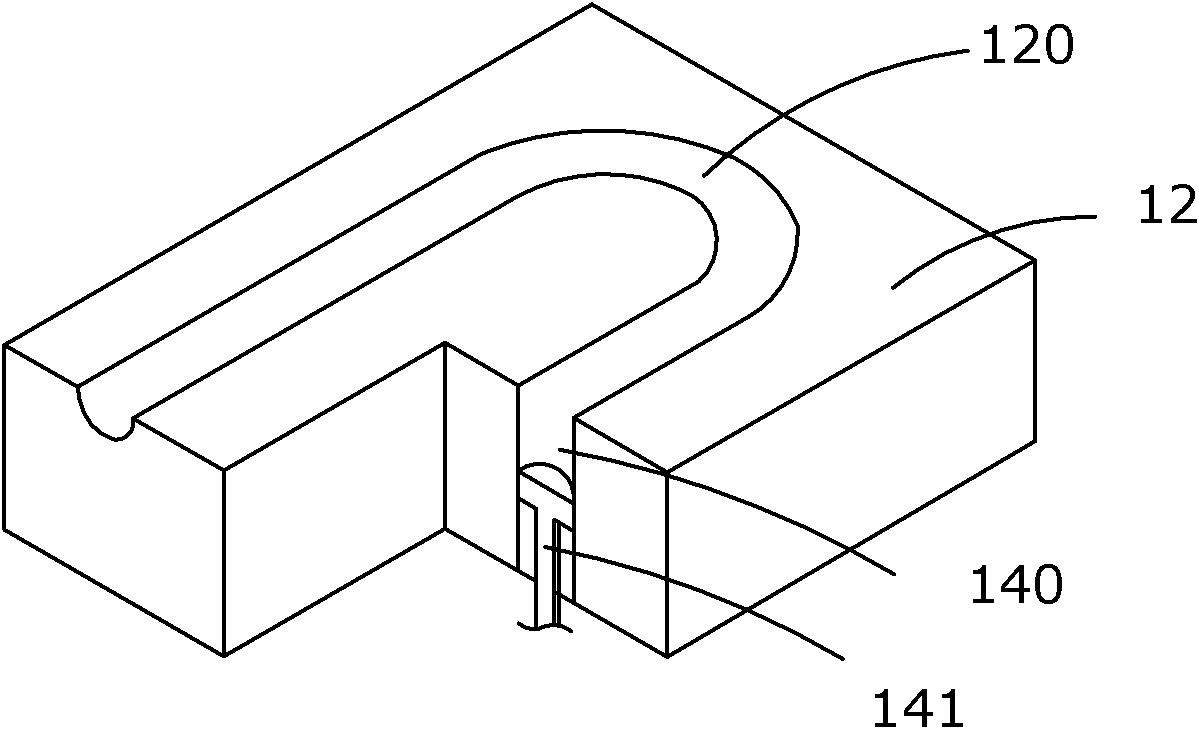

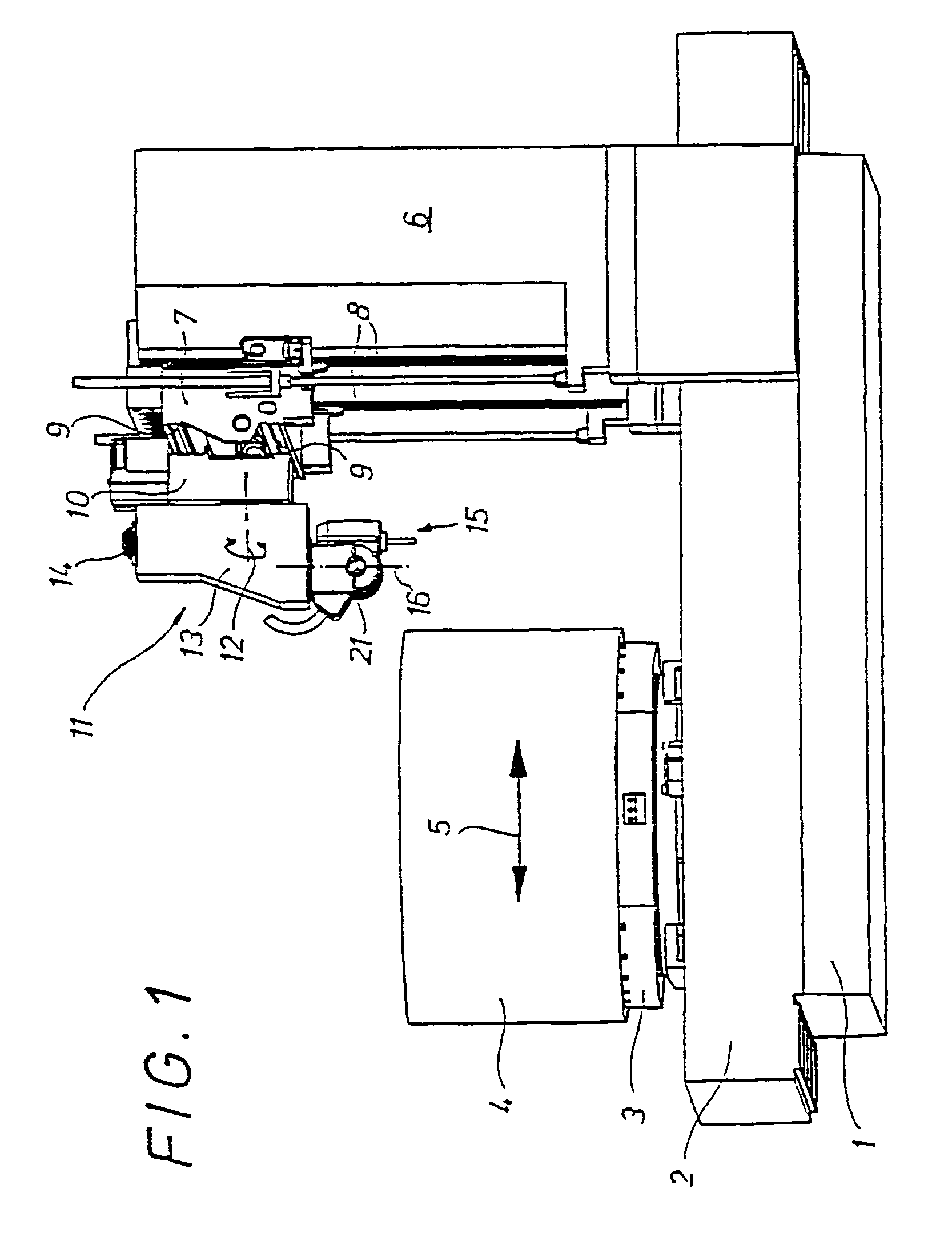

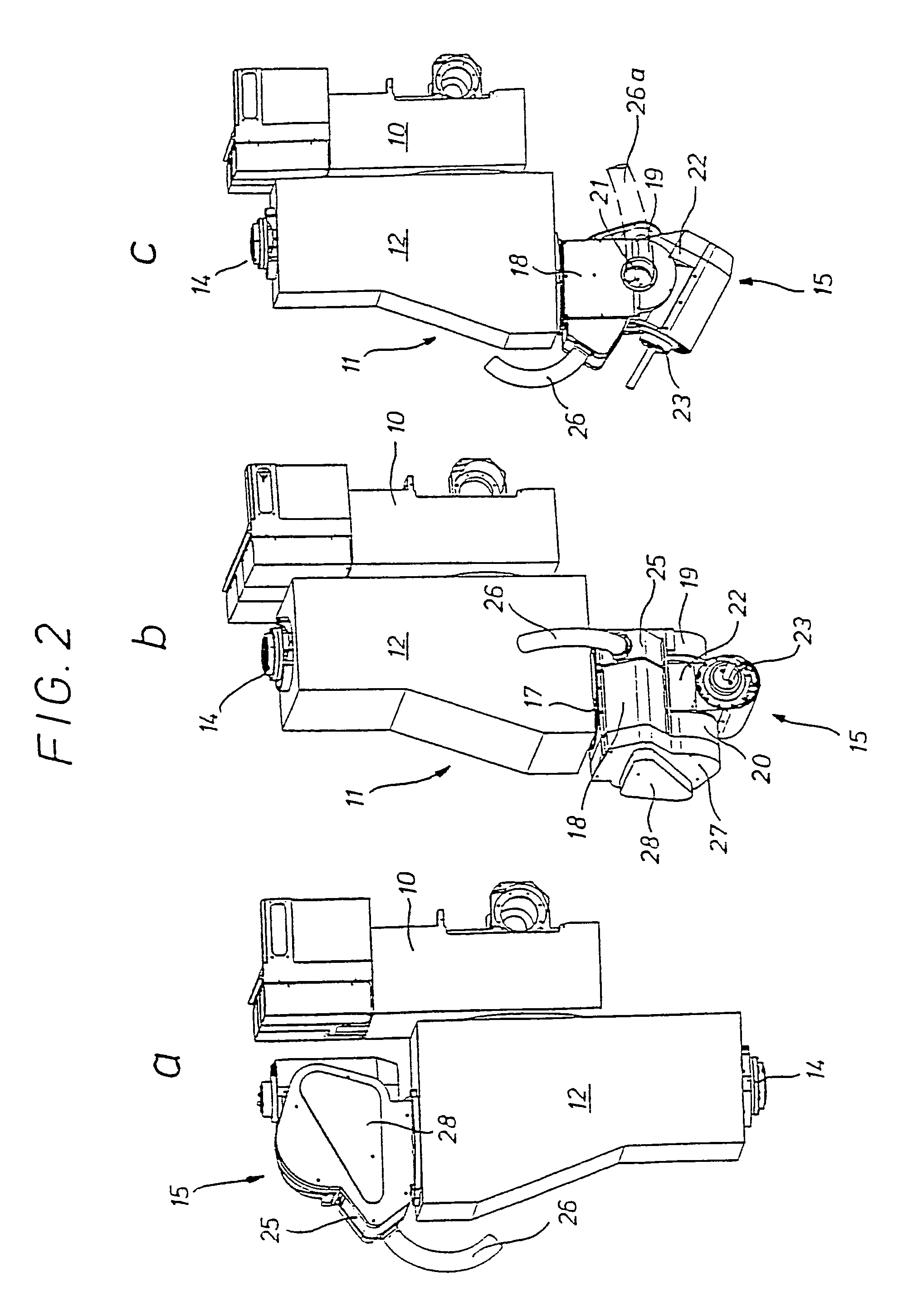

Pumping station for a cooling and lubricating fluid containing particulate matter

A pumping station for pumping a cooling and lubricating fluid containing particulate matter such as machining chips has a compact structure with a relatively low total structural height, while still assuring that the chips are conveyed with the fluid to the pump suction inlet, without settling-out or accumulating in the apparatus. The pumping station (1) includes a collecting container (5) with at least one pump (6) arranged therein, a chip breaker (7) and a supply conduit arrangement. The supply conduit arrangement includes a supply line (2) through which the cooling and lubricating fluid containing the machining chips is received from a machining tool or transfer station. Furthermore, two branch lines (3) and (4) are interposed and connected between the supply line (2) and the collecting container (5). A first branch line (3) conveys the fluid, from which the chips have been removed, with a slight downward slope toward the collecting container (5). The second branch line (4) conveys the chips that have been removed from the fluid flow. A scraper conveyor or the like conveys the chips upward through the second branch line (4), and the outlet end of the branch line (4) is arranged directly above the chip breaker (7), which in turn is arranged above the outlet end of the fluid conveying branch line (3). The comminuted chips thus fall from the breaker (7) directly into the flow of fluid, in which the chips are then entrained and carried along into the sump (13) of the collecting container (5), where the chips and fluid are sucked and pumped away by the pump (6).

Owner:MANN HUMMEL GMBH +1

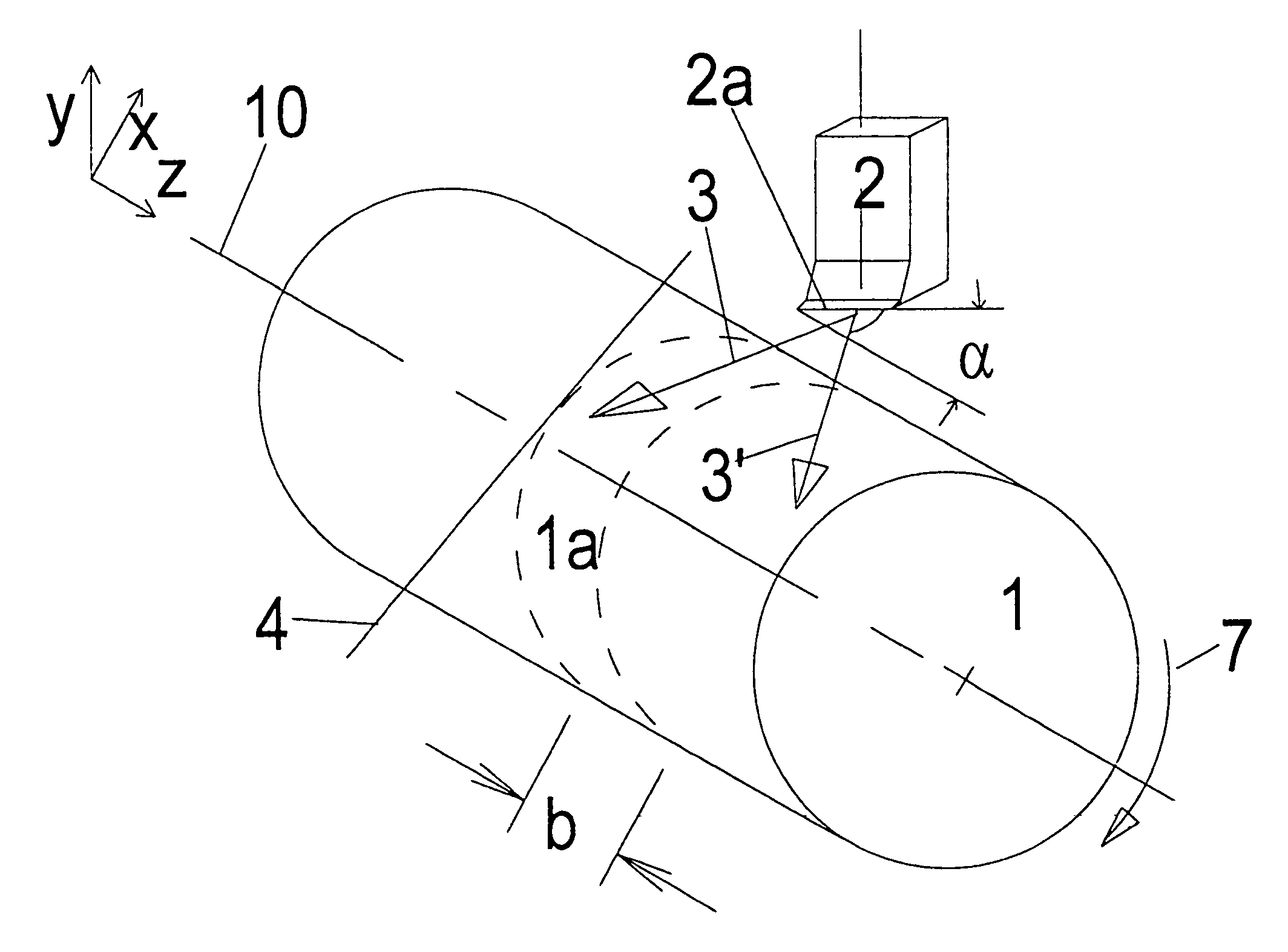

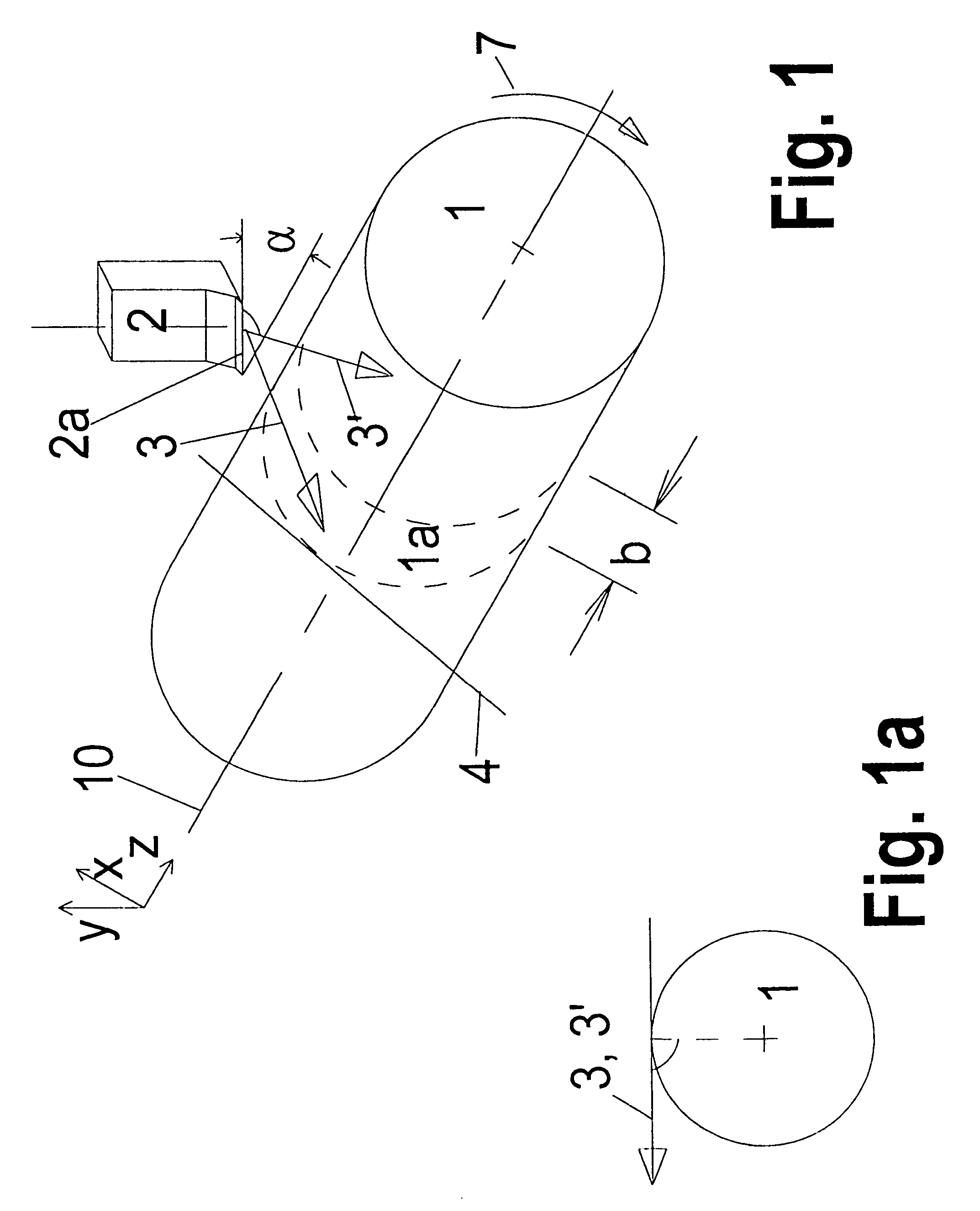

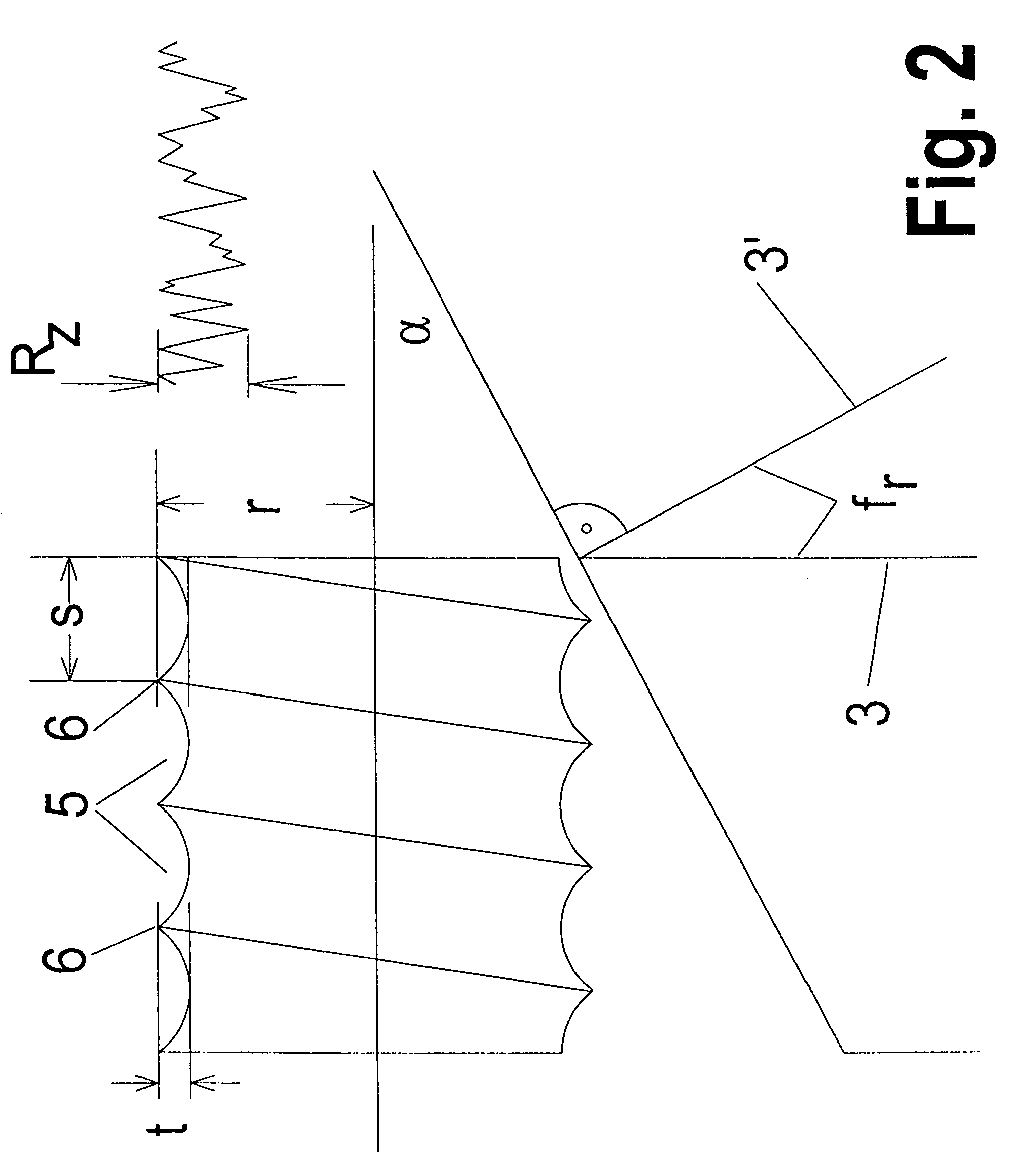

Process for twist-free steel cutting of rotational symmetrical surfaces

The invention relates to the cutting of rotating surfaces, especially centric symmetric surfaces (1a) of a metal workpiece (1), especially one made of steel or gray cast iron, also when said workpiece is in hardened state, by means of a geometrically determined cutter (2a) or cutters, wherein the axial extension and the material of the surface to be machined are hardly limited or not limited at all and / or the operating time during machining is reduced according to said method and / or the service life of the tool is enhanced and / or the effect of the twist-free condition is achieved, wherein at least one cutter (2a) that is skewed relative to the rotational axis (10) of the workpiece is guided during a feeding motion (3,3′) in a contacting manner on the rotating workpiece and wherein the machining parameters of the rotational axis, especially the forward feed motion in the direction of feeding and the skewed position (x) of the cutter (2a) relative to the longitudinal direction (z), are chosen in such a way that twisting in terms of the degree of twisting (s) and / or the depth of twisting (t), more particularly the depth of twisting, on the surface being machined is minimized, wherein the forward feed motion includes an axial movement.

Owner:BOEHRINGER WERKZEUGMASCHEN

Tee joint forming die and tee joint forming method

InactiveCN102198467AImprove appearance qualityImprove consistencyBroaching machinesEngineeringHydraulic action

The invention provides a tee joint forming die. The tee joint forming die comprises an upper die and a lower die which are combined together, wherein semi-circular groove-shaped cavities for accommodating a tee joint workpiece are symmetrically arranged on the upper die and the lower die; openings of the cavity are formed on lateral sides of the upper die and the lower die; the cavity is communicated with a tee joint branch pipe cavity; a support rod capable of reciprocating displacement is arranged in the tee joint branch pipe cavity; the support rod is connected with a support cylinder and transfers pressure by the support cylinder; and a tee joint branch pipe is filled with medium in the tee joint workpiece, and is formed in the tee joint branch pipe cavity in the hydraulic action of a hydraulic cylinder. By the tee joint forming die, a tee joint finished product has higher appearance quality and excellent uniformity; the U-shaped bend of the tee joint has smooth transition, the outer diameter of each position of the tee joint can achieve the requirement of equal diameter; and the current problem that the bend is flat after lead is filled can be solved.

Owner:李镇南

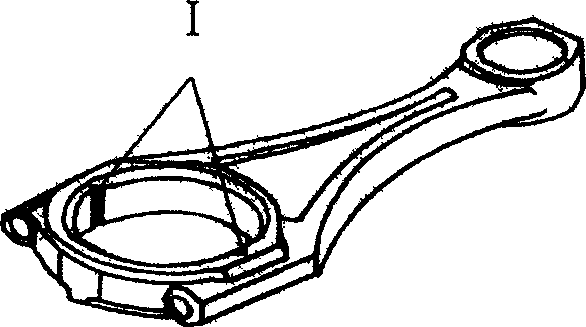

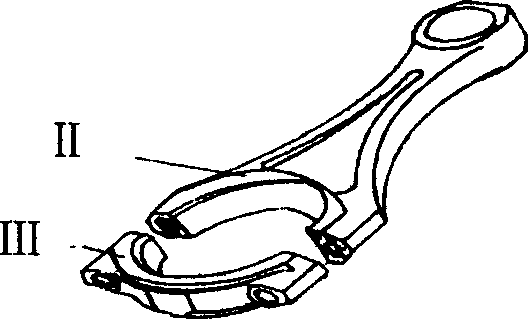

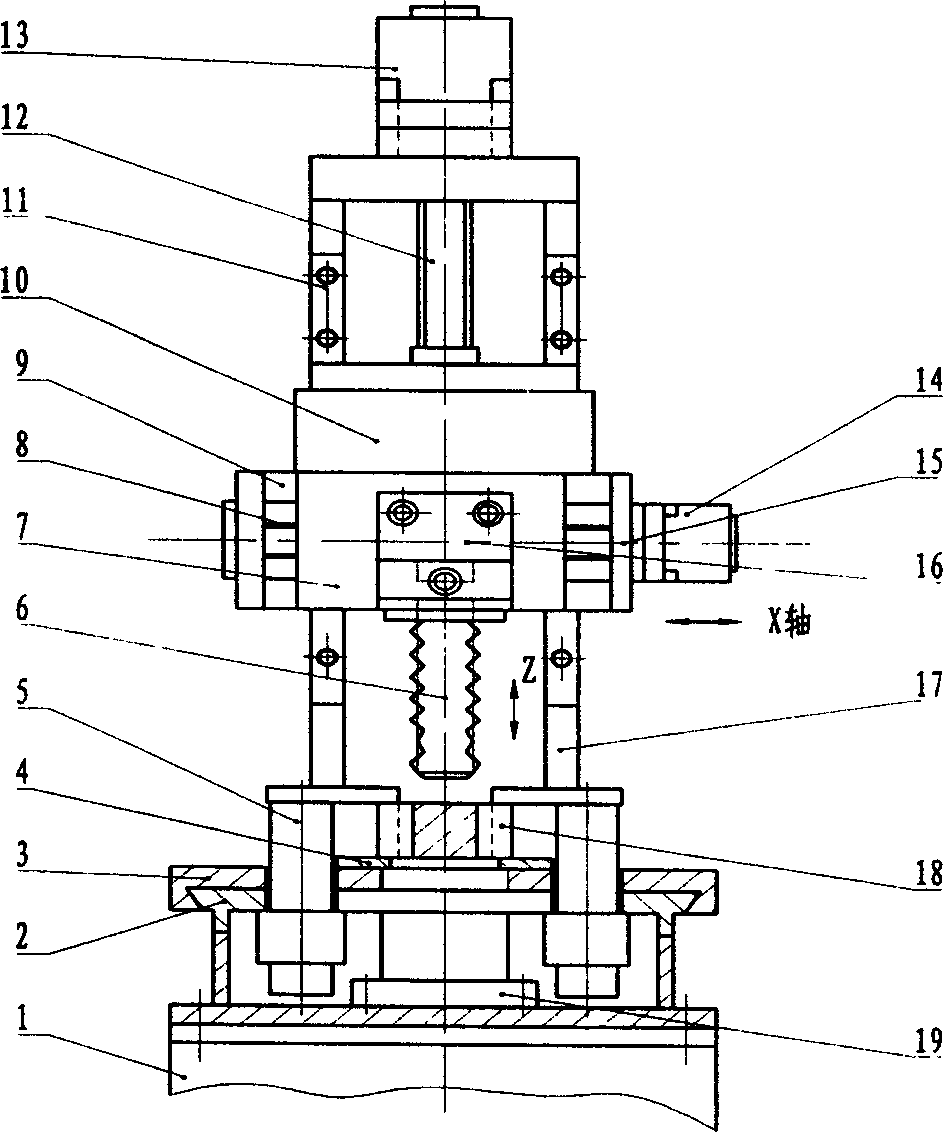

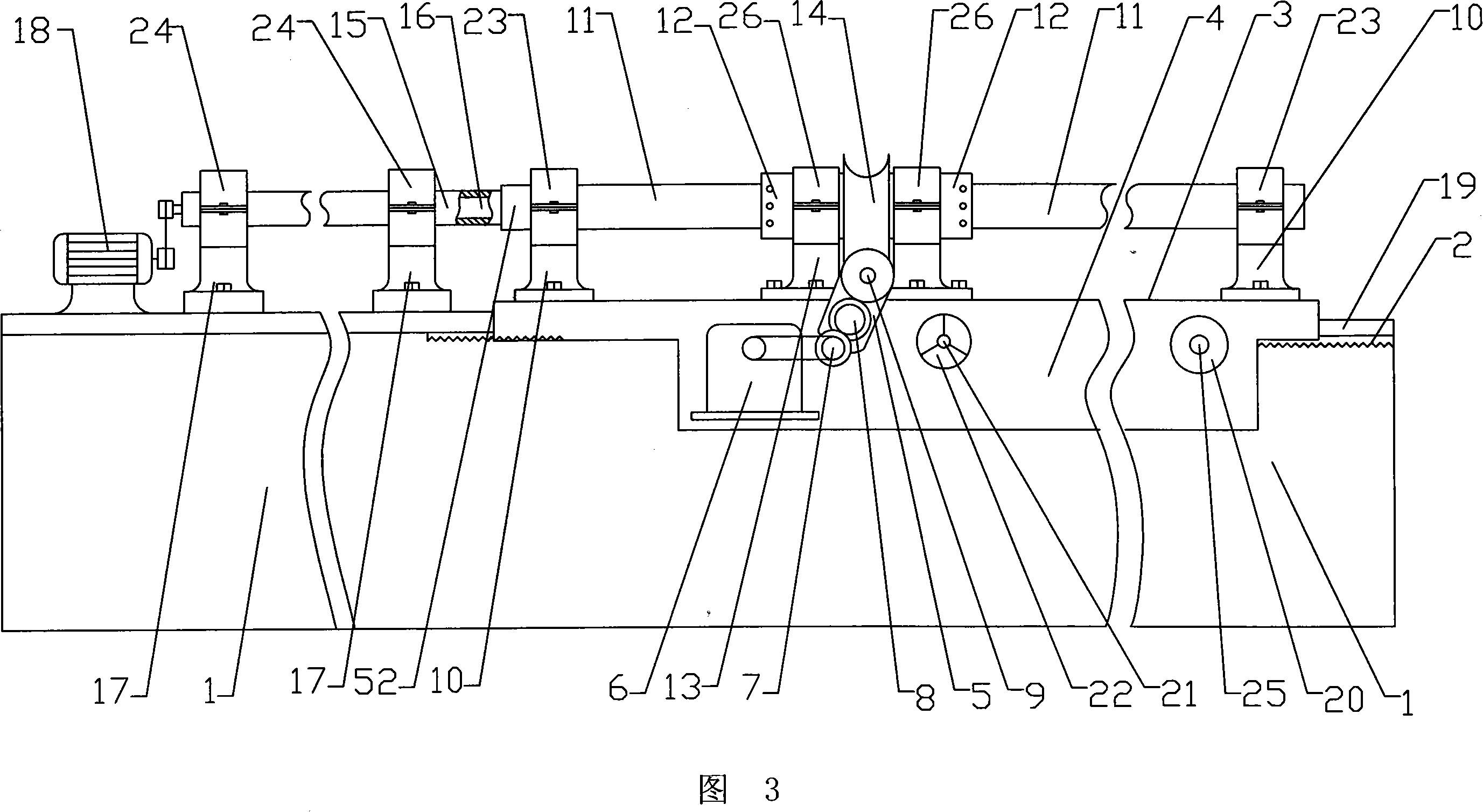

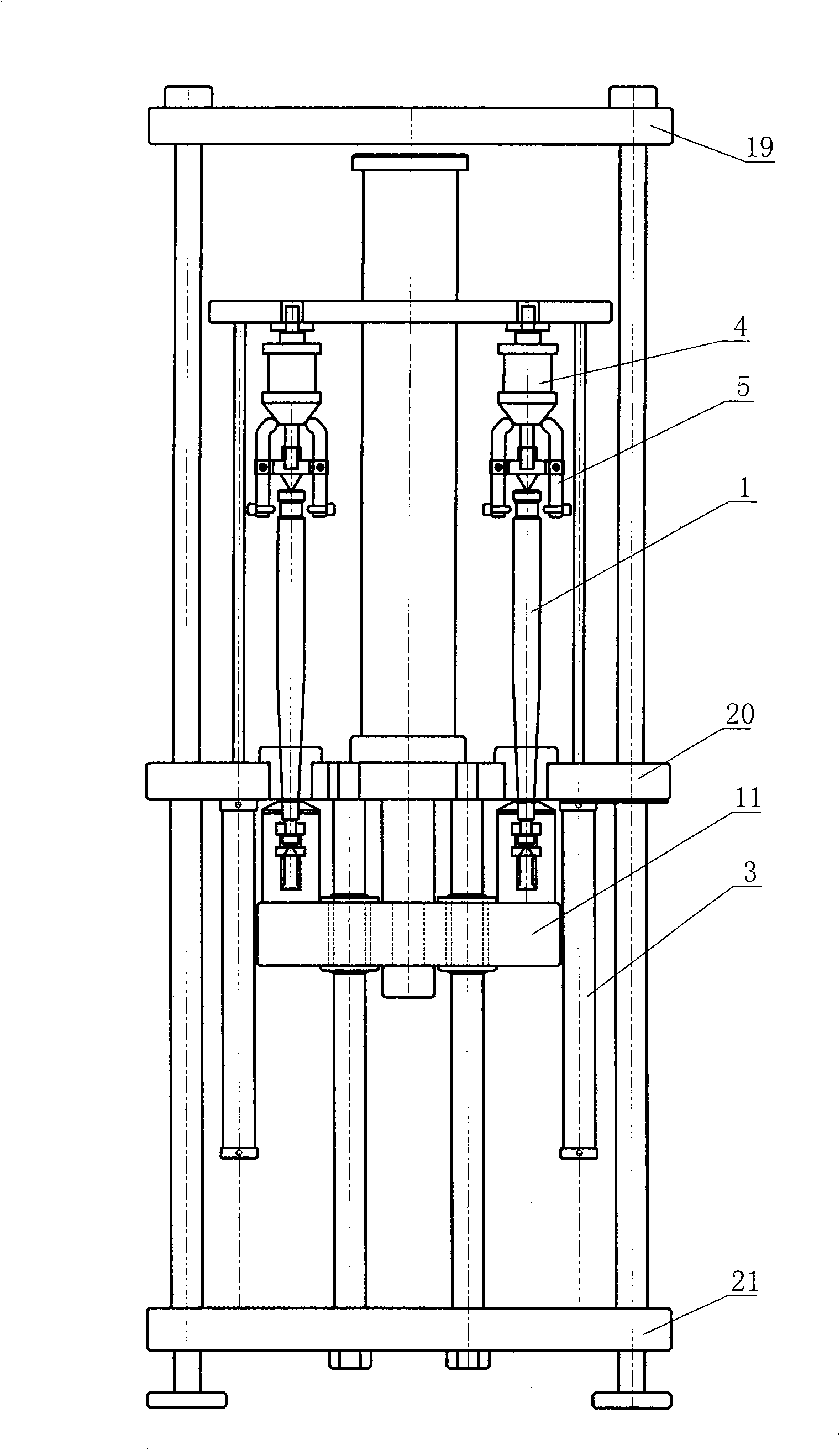

Processing apparatus for initial cracking tank for engine connecting rod

InactiveCN1569373AQuality improvementPrevent slaggingBroaching machinesEngineeringMechanical engineering

The invention relates to special device for motor link decomposing slot. The device mainly includes a host machine and piece clamping platform. . the host machine is assembled according to following meanings: there arranges with guiding track and sliding blocks along Z axis direction and X axis direction, the sliding block moves linearly on the guiding track; the platform is assembled according to following meanings: there has a sliding block which can moves linearly along y direction, the sliding block is arranged with three rotation pressing cylinders, and it has permutable fixing board.

Owner:JILIN UNIV

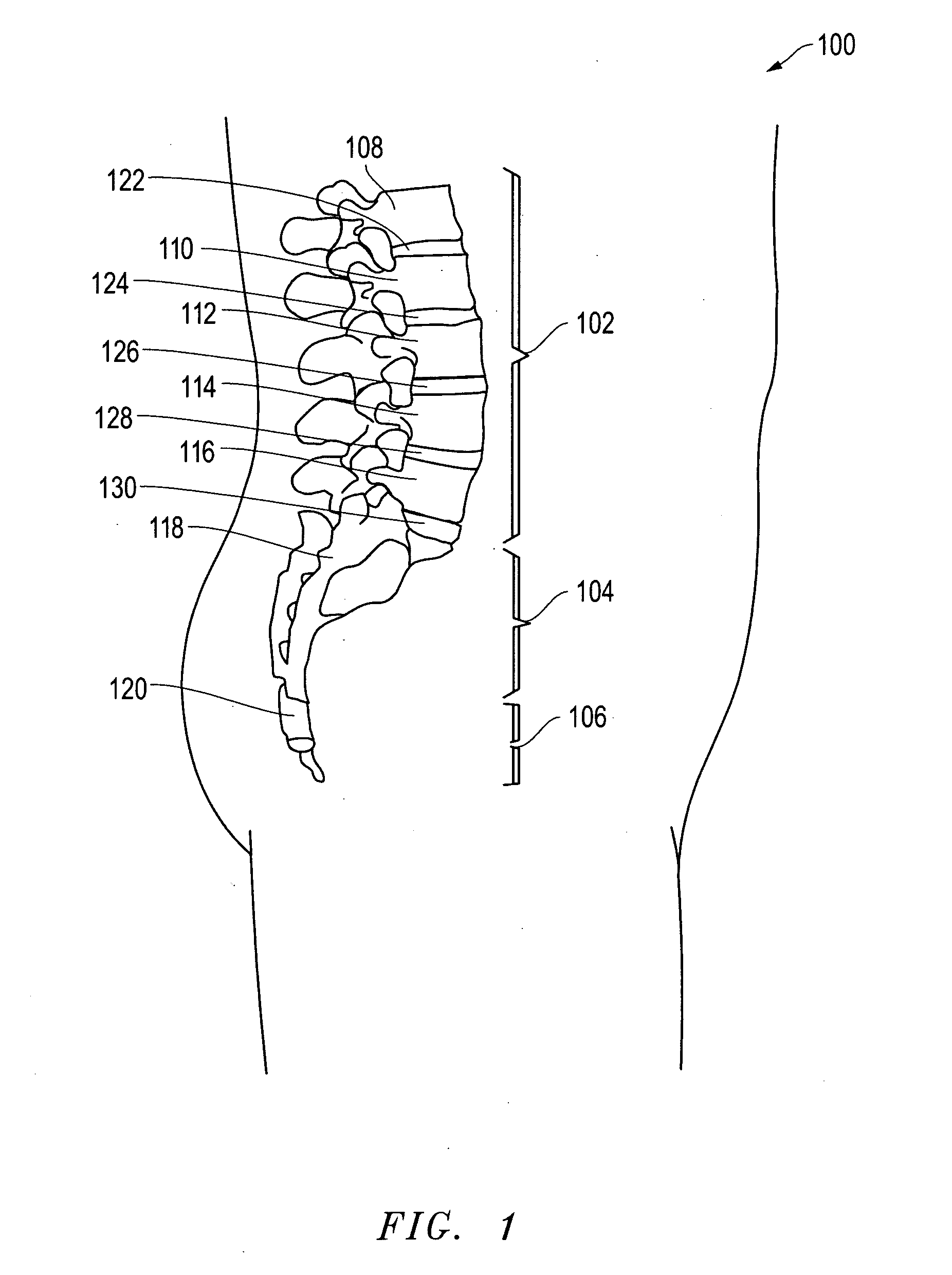

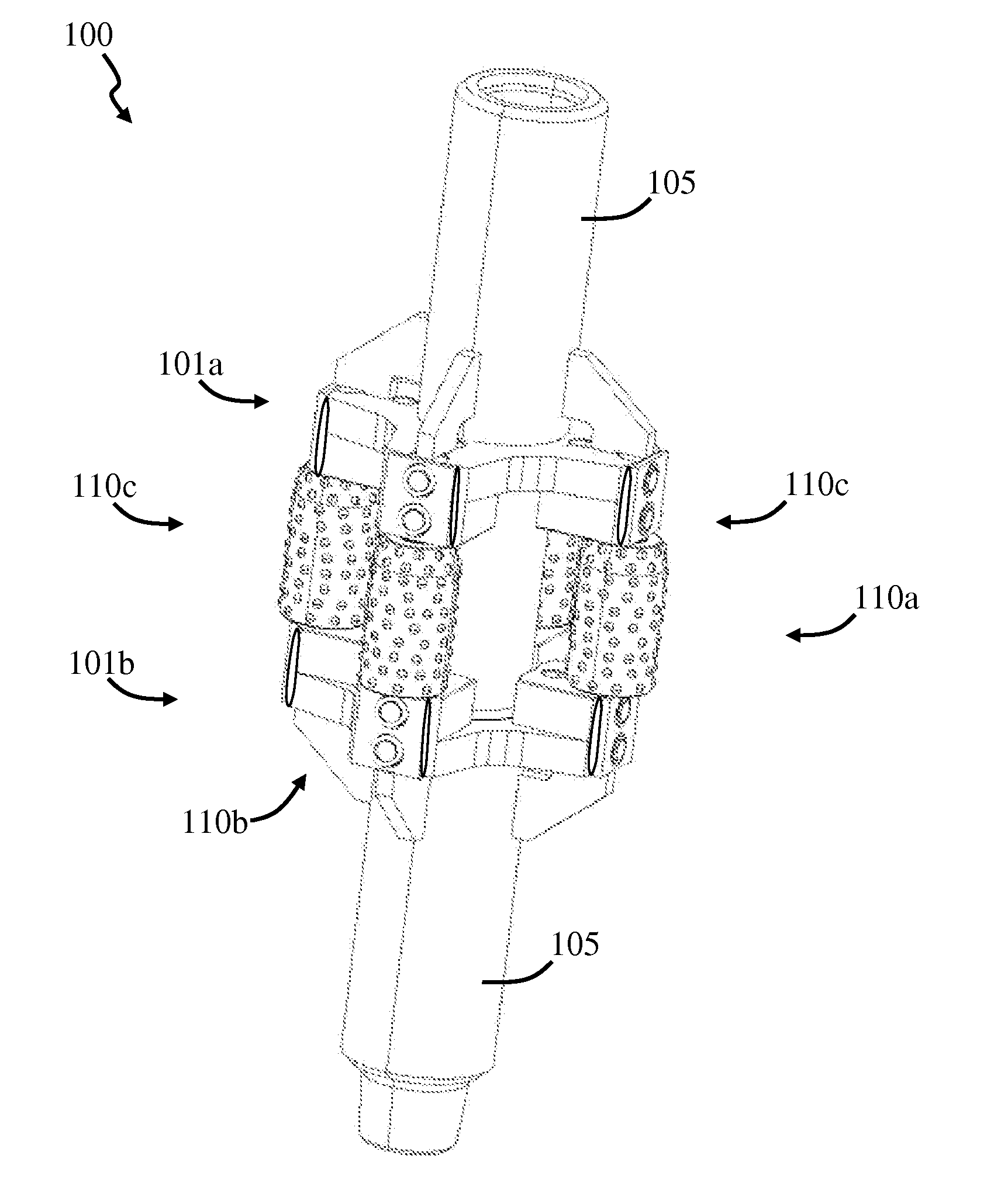

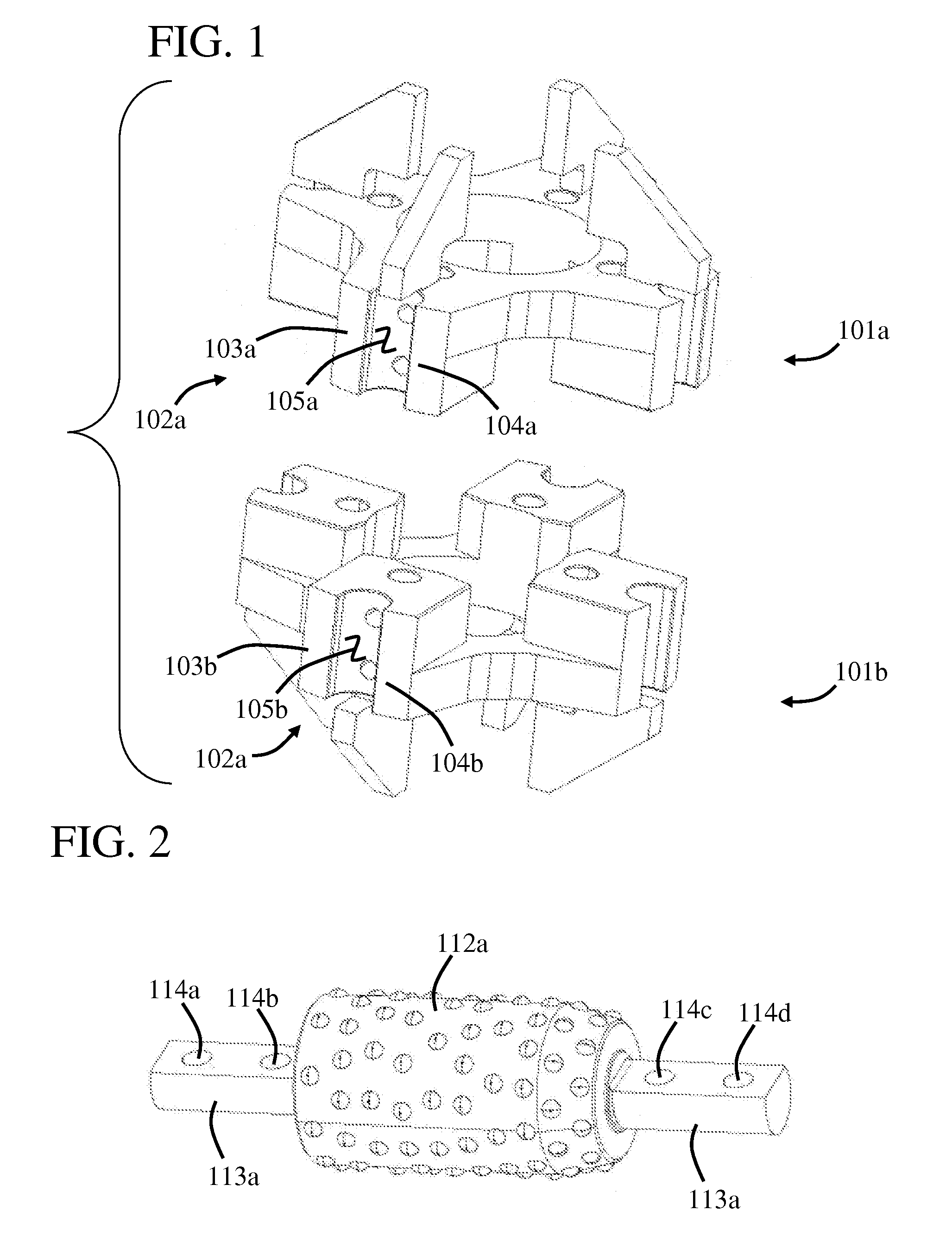

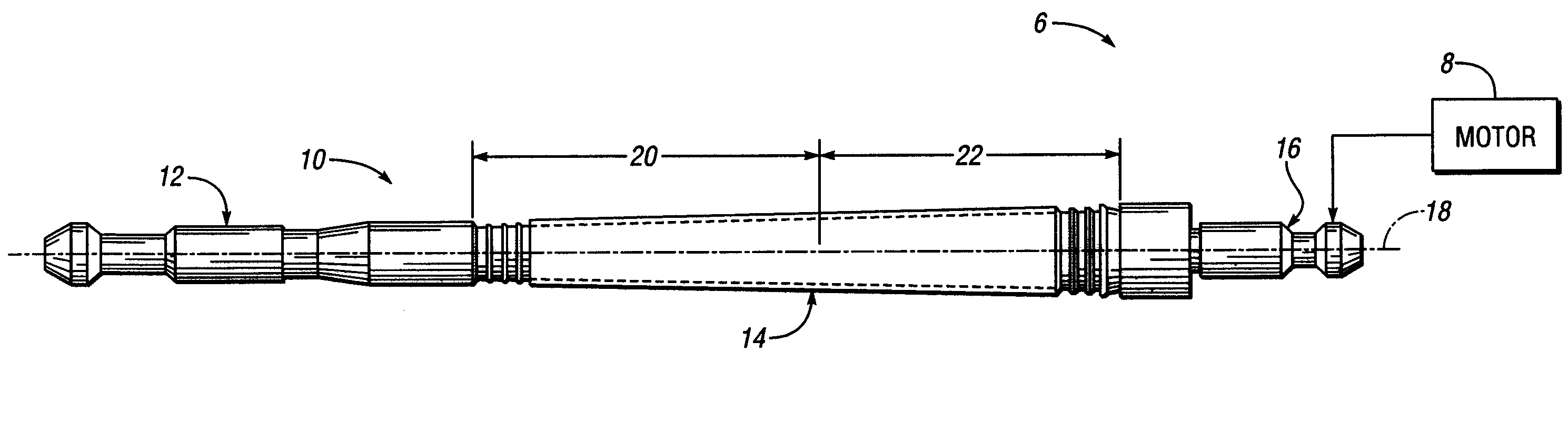

Tool for Finishing the Ends of Surgical Rods and Methods of Use

An apparatus for finishing an end of a rod including a shaping tool comprising a shaping assembly having a shaping housing and a shaping surface within the housing configured to engage an end of a rod and form a shaped rod end. The apparatus further including a finishing tool comprising a finishing assembly having a finishing surface for changing the contour of the shaped rod end to form a finished rod end.

Owner:WARSAW ORTHOPEDIC INC

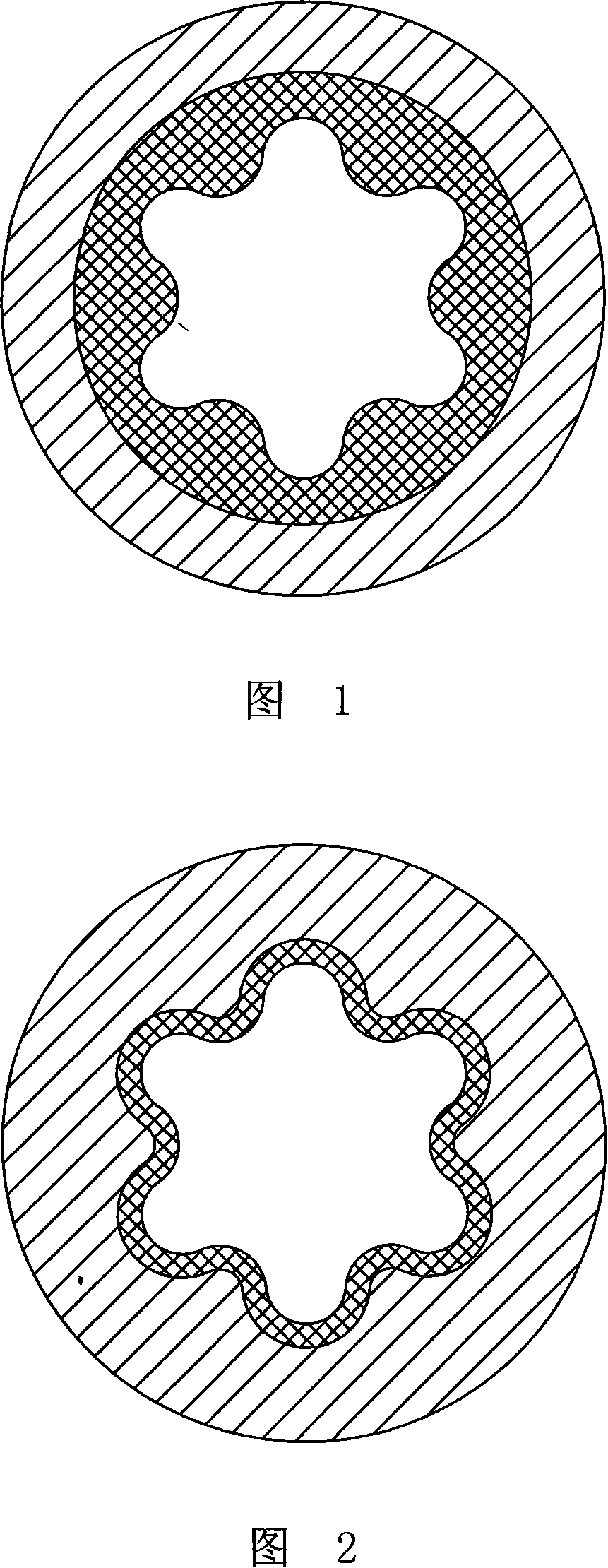

Internal spiral face processing equipment and its processing technology

InactiveCN101147989AImprove adhesionConsistent shrinkageMilling equipment detailsBroaching machinesDrive shaftEngineering

The present invention discloses one kind of inner helical surface machining apparatus and process. The machining apparatus includes one milling machine and one broaching machine. The milling machine for rough machining includes one machine body, one cutter bar with cutter and driving shaft connected to the cutter, one first driving mechanism connected to the driving shaft, one turbine with one through hole for the workpiece to penetrate through coaxially with the cutter bar and one second driving mechanism connected to the turbine. The broaching machine is for the finish machining of the inner helical surface. The present invention has high inner helical surface machining precision, and high machining efficiency.

Owner:WEIFANG LUTAI MACHINERY

Downhole tool

A downhole tool includes a cutter rotatably mounted to a journal. The journal is fastened to a downhole tool frame with a fastener. The fastener is engaged by an insert and retainer so it is restricted from rotating. The insert extends over a head of the fastener, and the retainer extends over the insert.

Owner:ATLAS COPCO SECOROC LLC

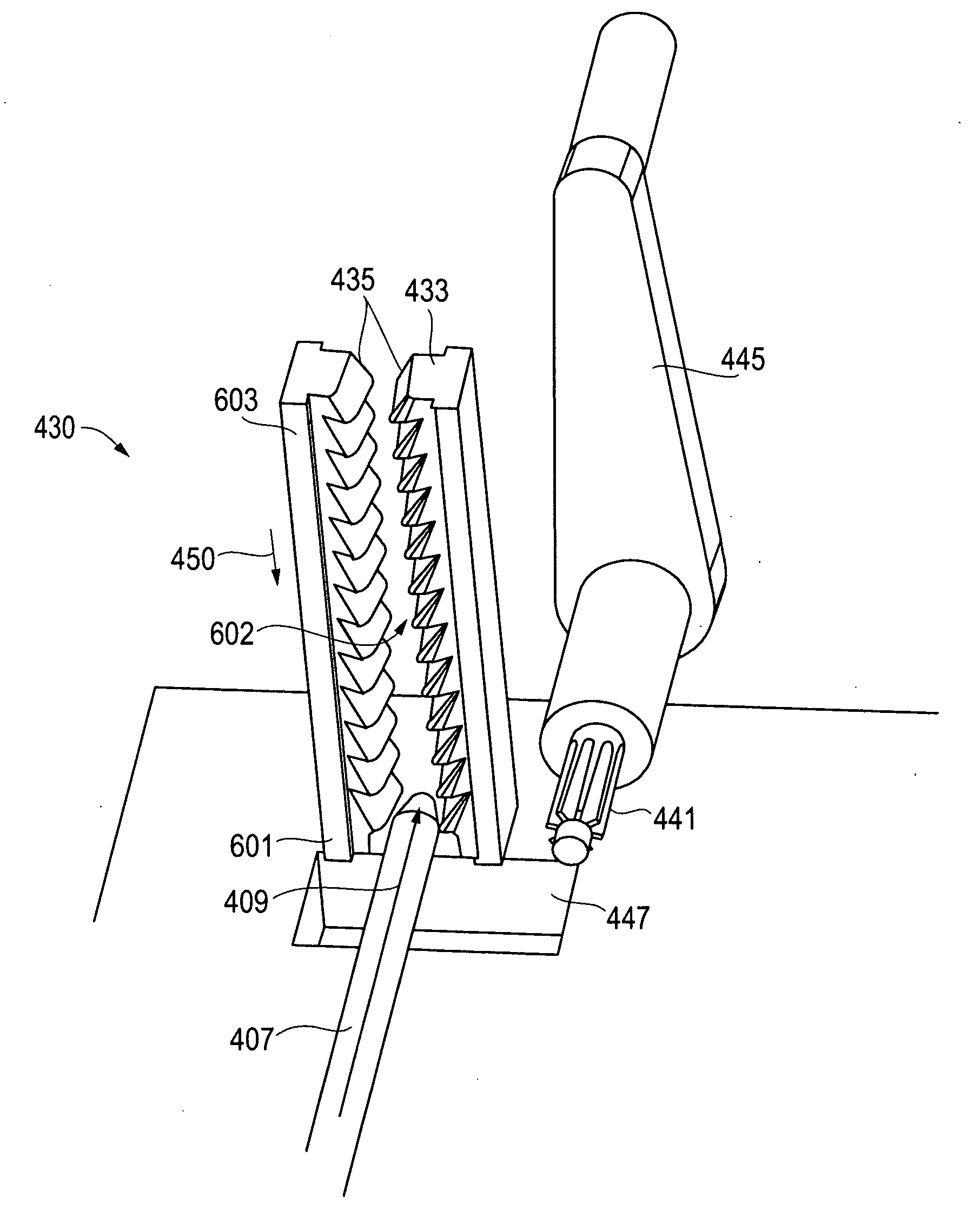

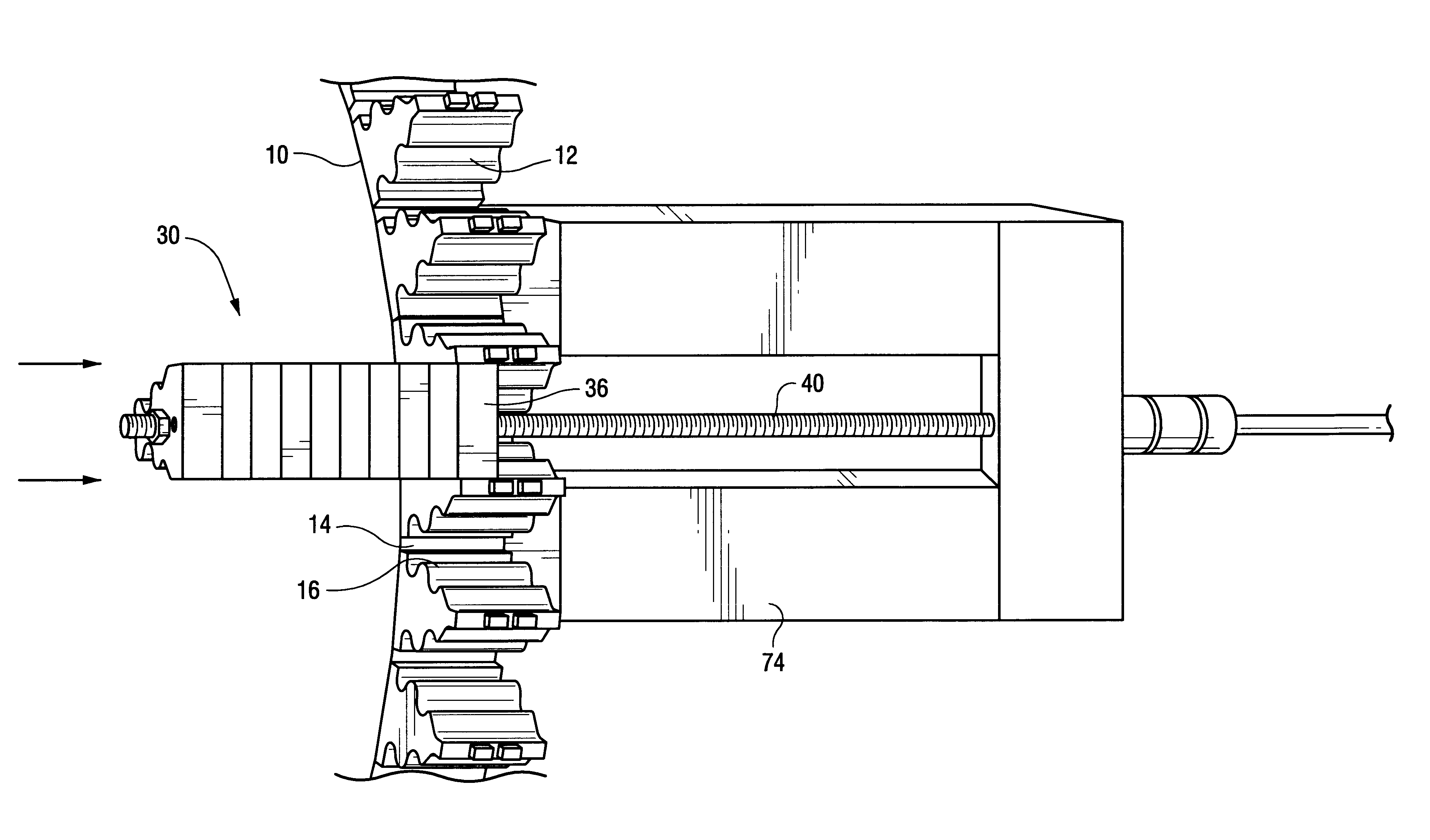

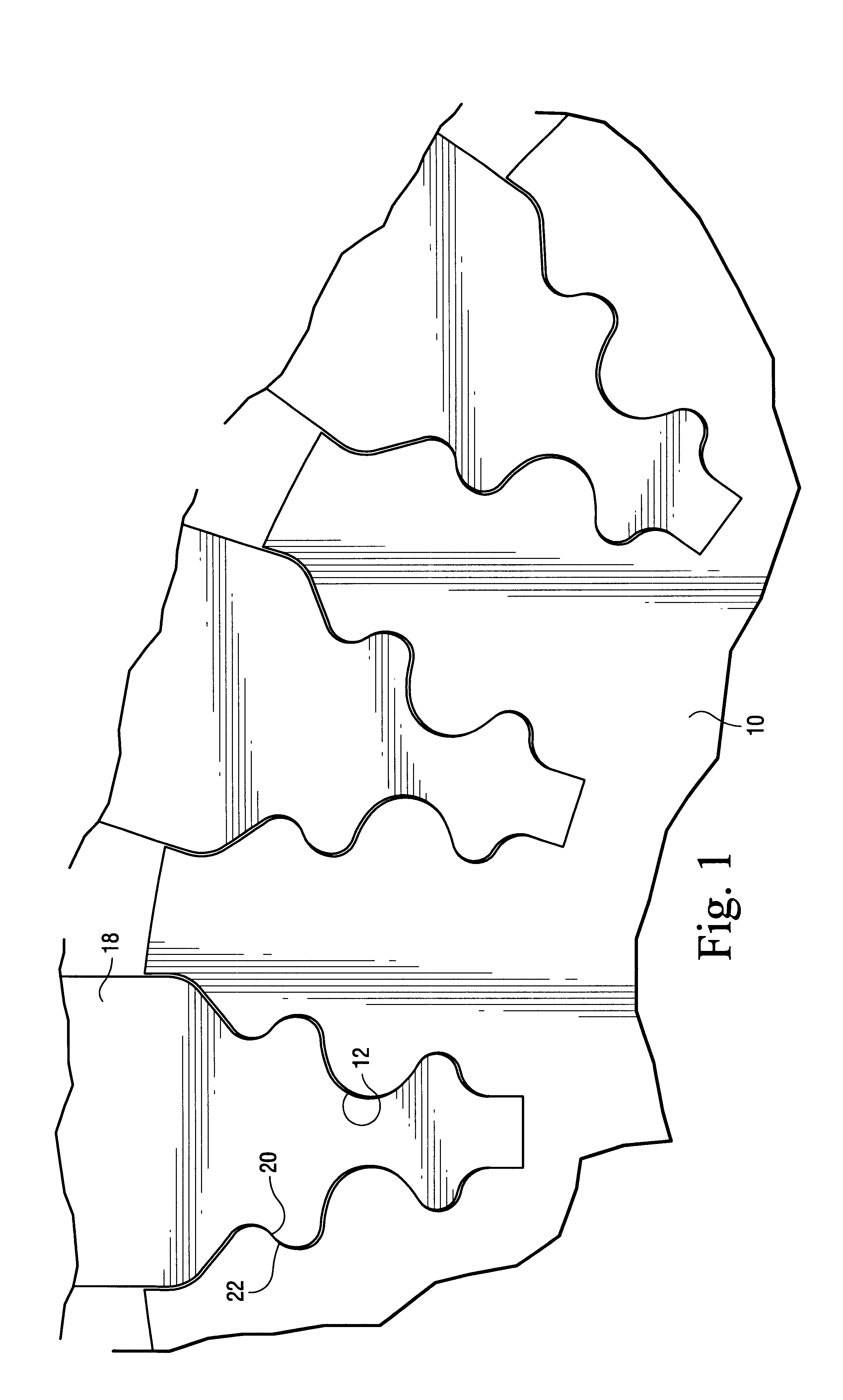

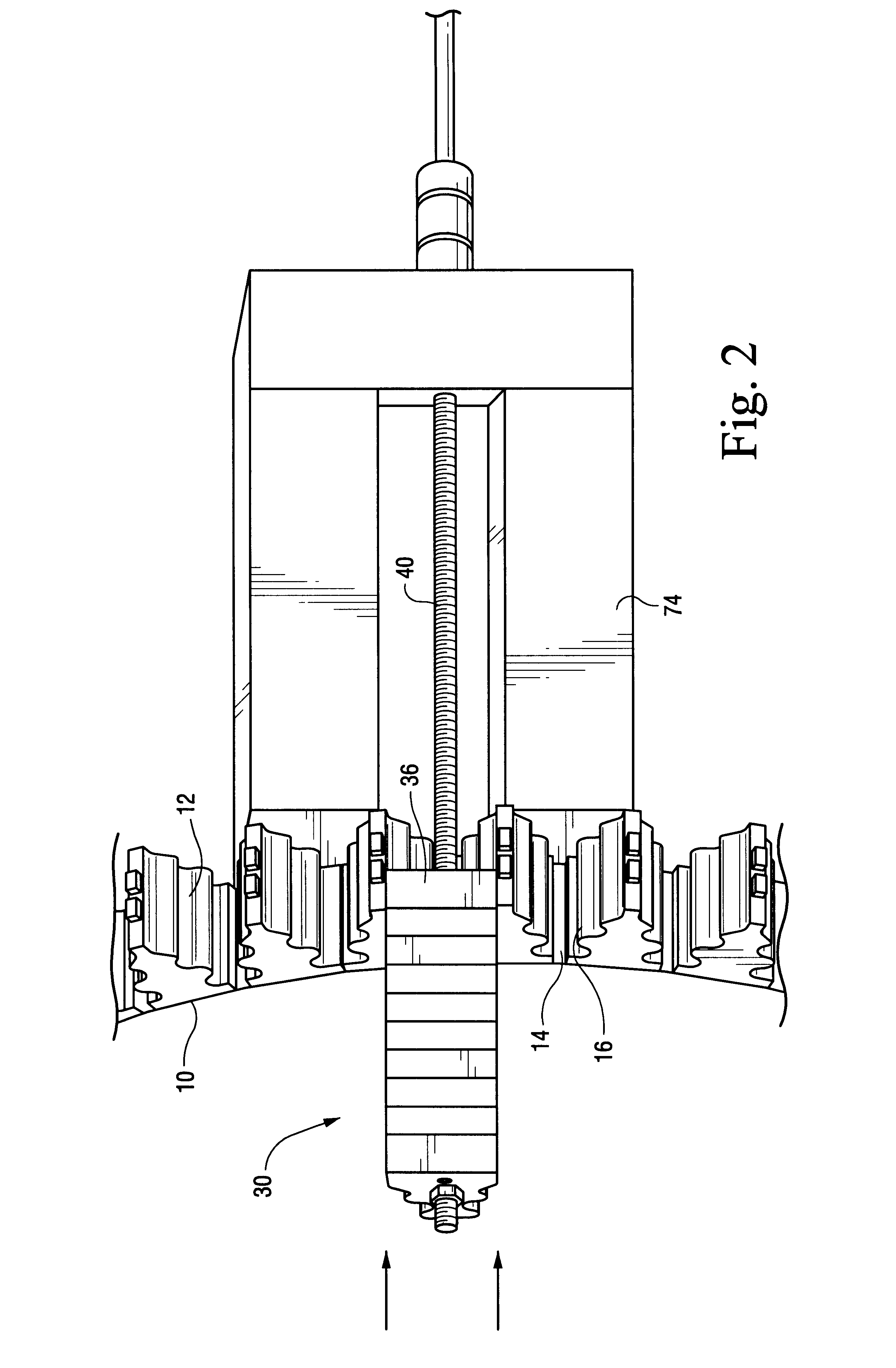

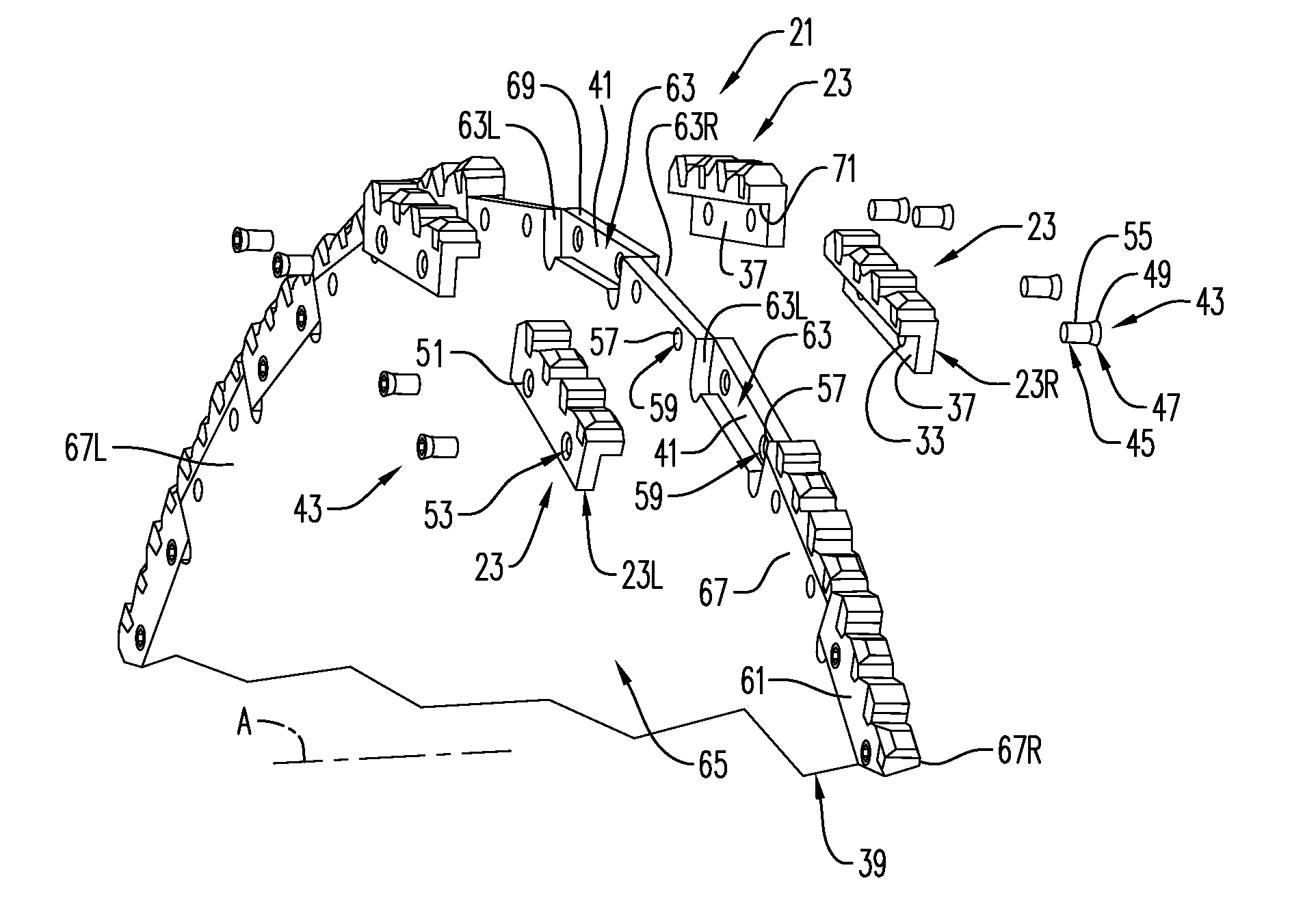

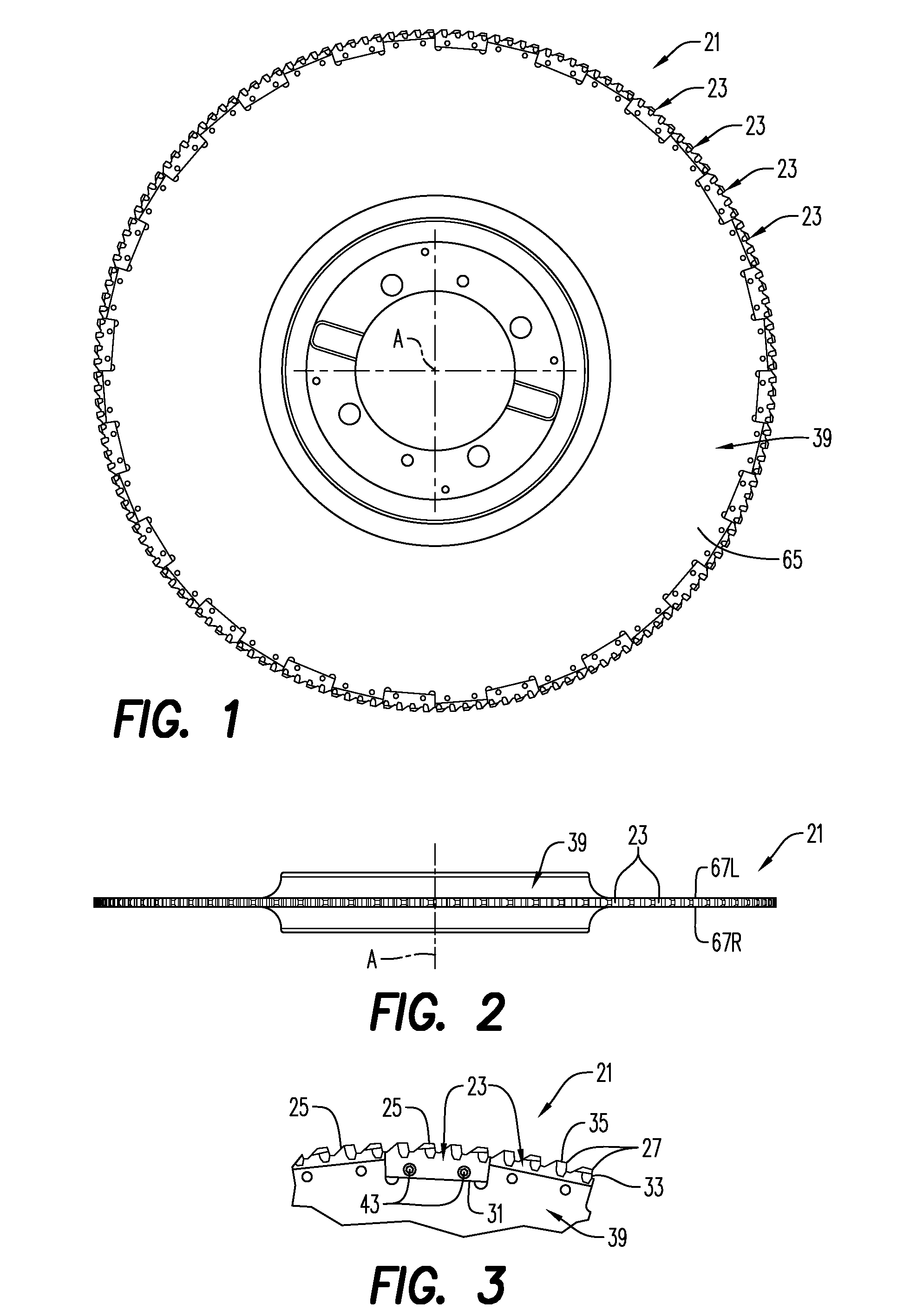

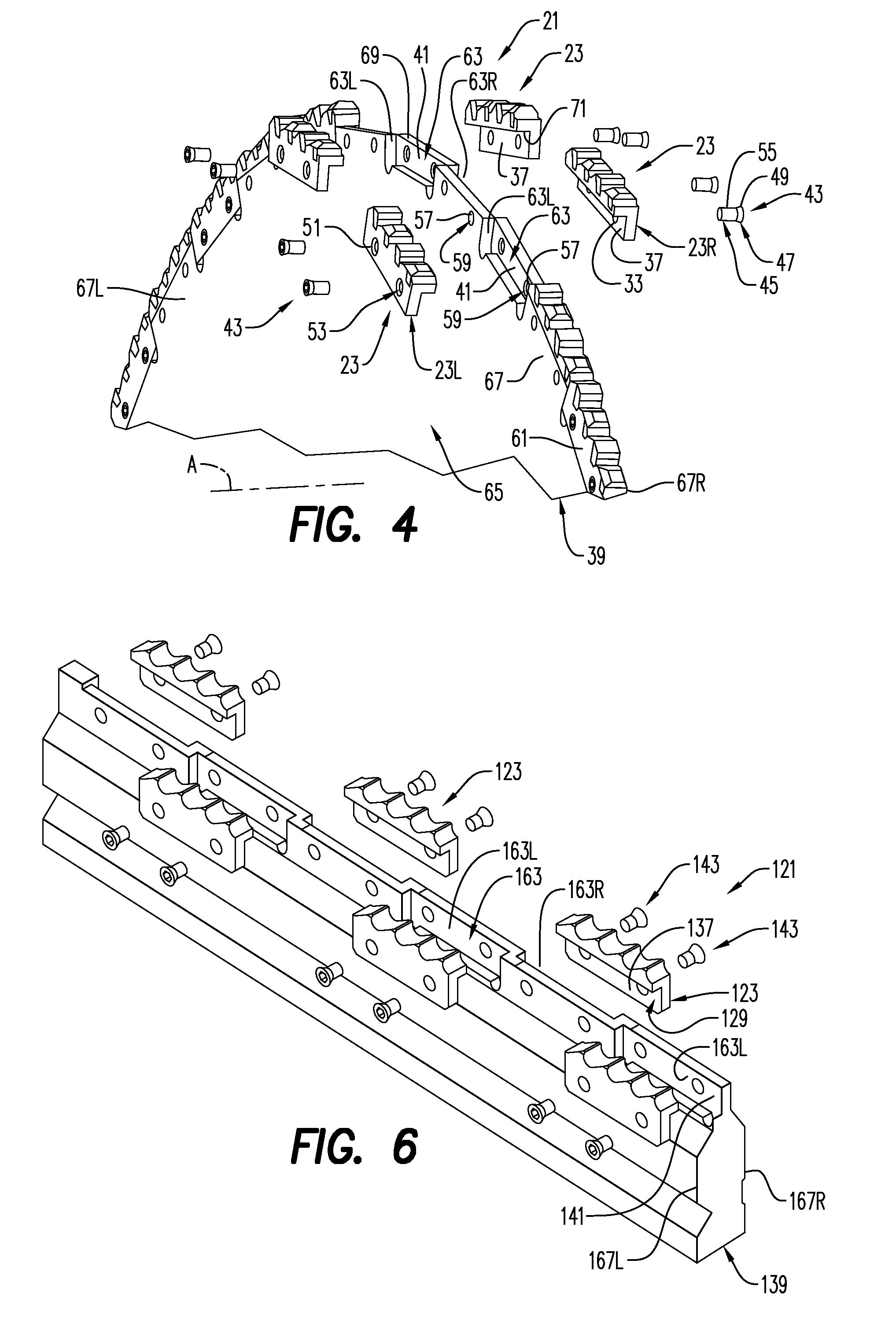

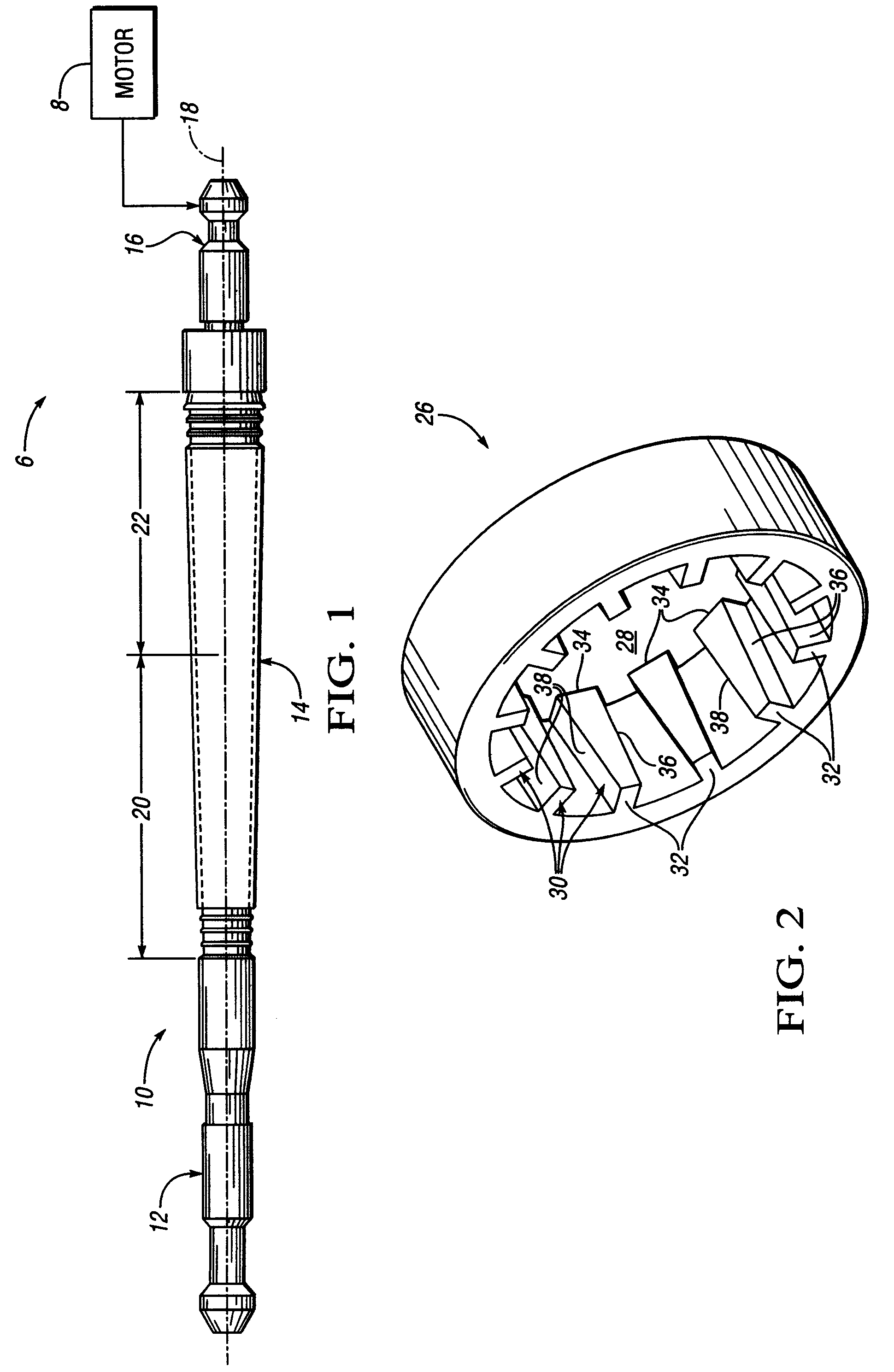

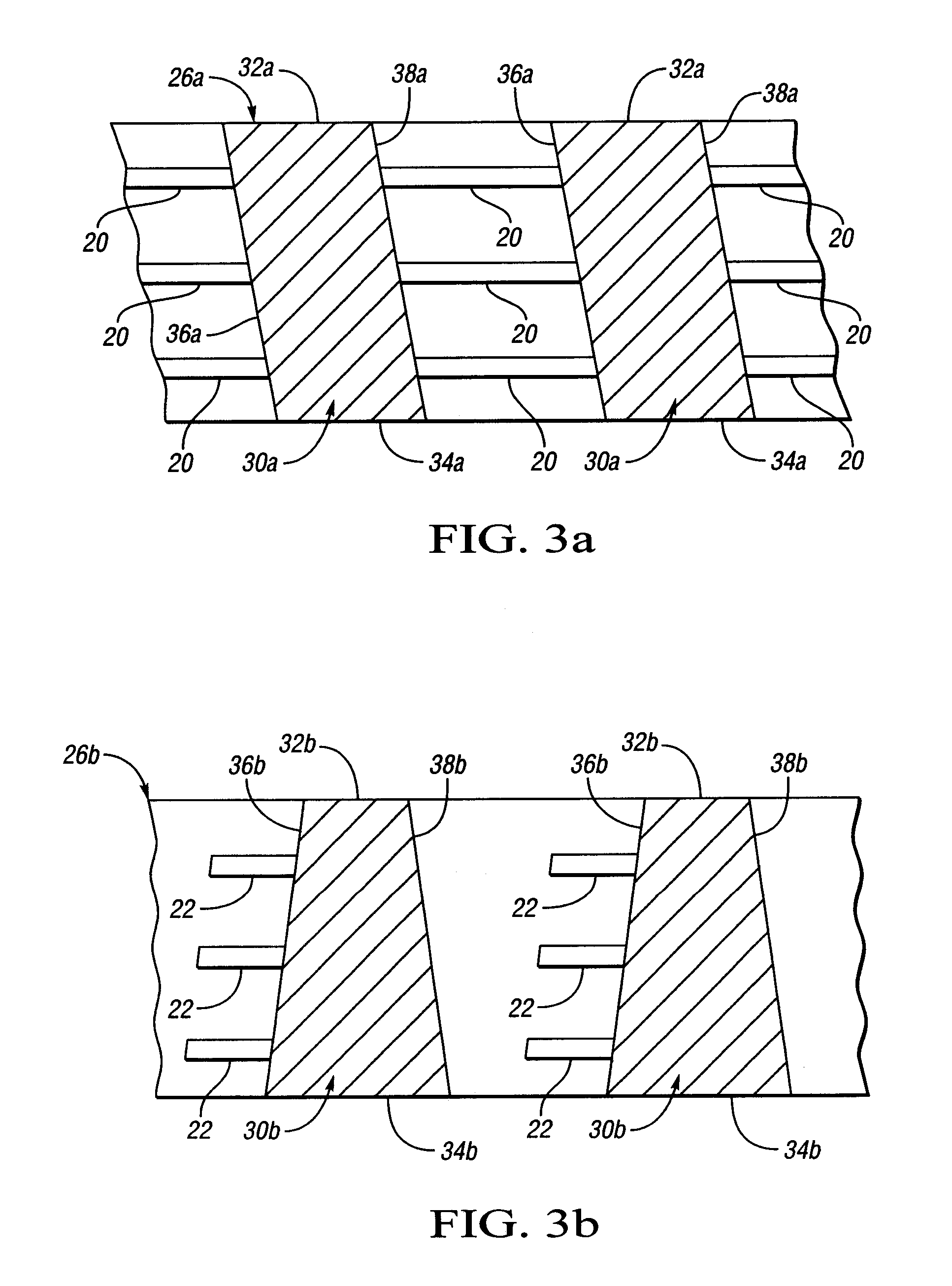

Multi-part dovetail repair broach assembly and methods of use

InactiveUS6676336B2Easy to importInexpensive to fabricateRectilinear broachBroaching toolsImpellerTurbine wheel

The broach assembly includes alternate spacers and cutters arranged in a sub-assembly having a lead at a leading end and a lag at a trailing end. The cutters have side margins in excess of the margins of the spacers for cutting material from the dovetail slots of the turbine wheel as the broach assembly passes through the slots. The bottom or apices of each spacer and cutter are tapered to form a continuously tapered surface along the bottom of the broach assembly. Upon passing the broach assembly through the slot, the assembly is progressively displaced in a radial outward direction to progressively cut the active dovetail slot surfaces. Shims may be disposed in the bottom of the slot to further displace the broach assembly radially outwardly in multiple passes.

Owner:GENERAL ELECTRIC CO

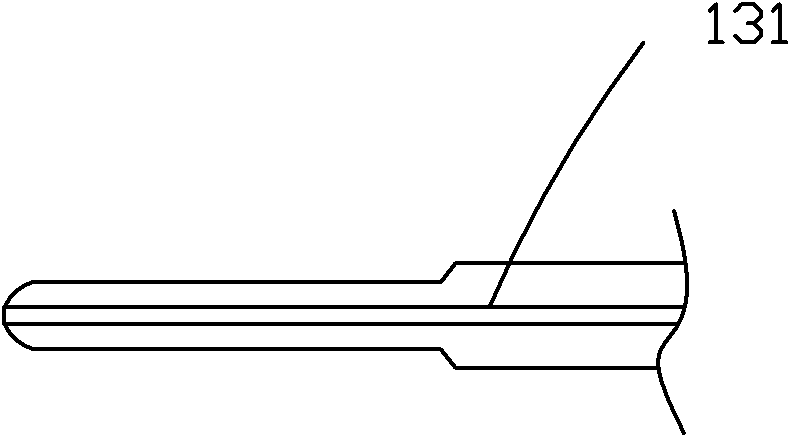

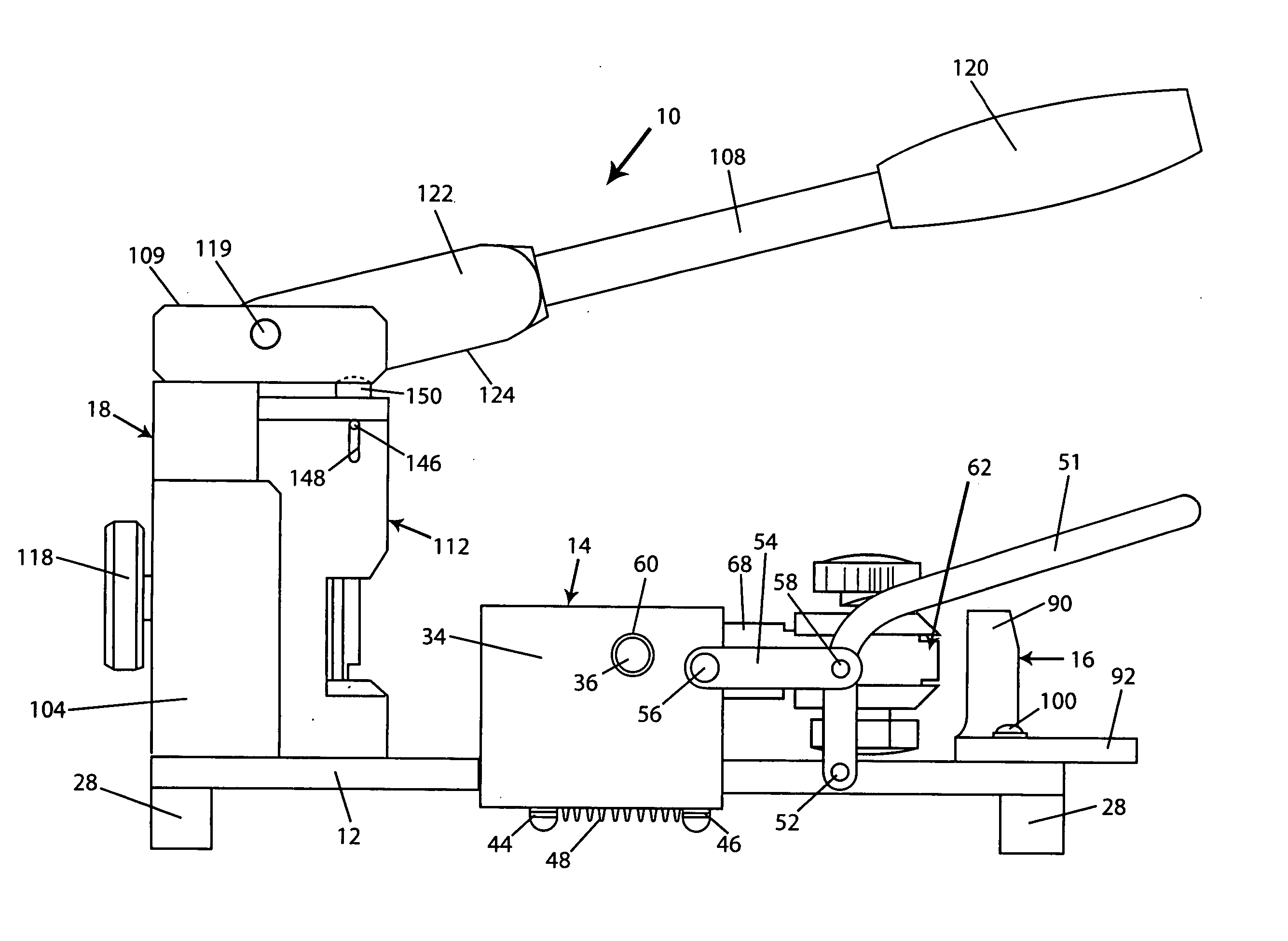

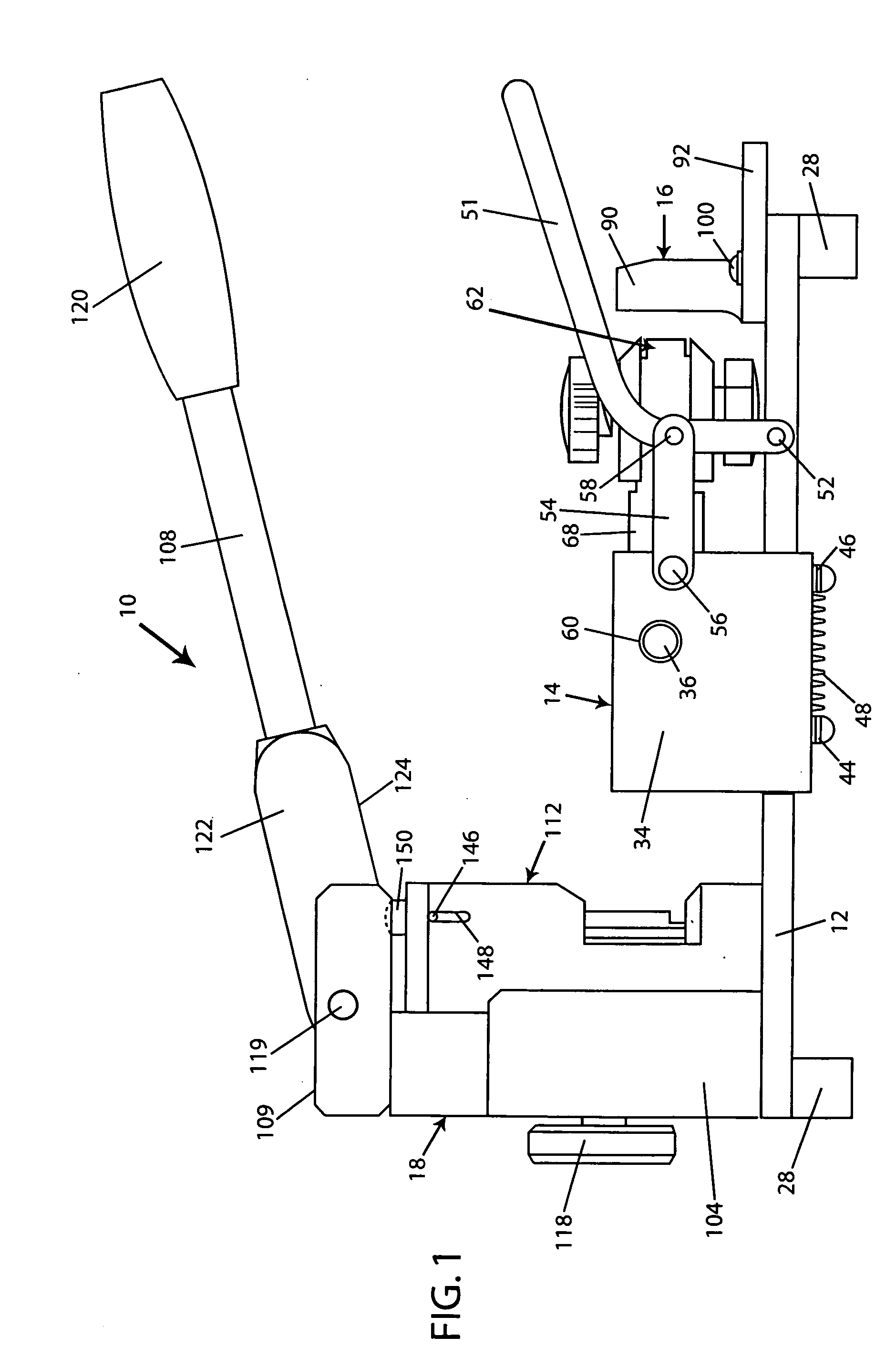

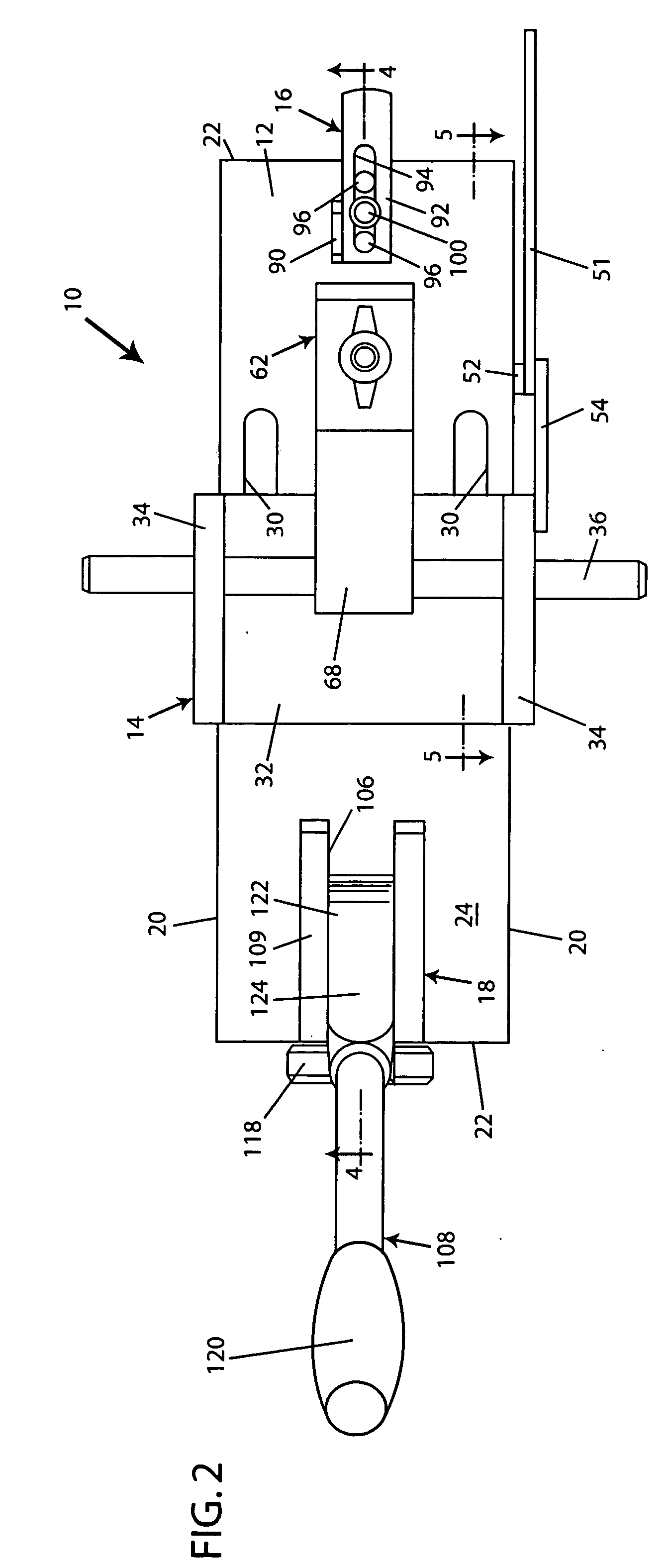

Key duplicating machine

A portable, mechanically operated, key-duplicating machine that relies on a punch-cutting system that selectively punches out the particular notches or “bittings” of a key blank in response to the details of an adjacent and aligned master key. The duplicating machine comprises a frame having cutting end and an alignment end. The frame defines a longitudinal axis. A carriage is movable along the longitudinal axis and includes a transverse axis. A key clamping assembly has a first key clamp for holding the key blank and a second key clamp for holding the master key. The key assembly is selectively slidable along the transverse axis. A cutting assembly is located at the cutting end and includes a punch-type cutter pin that is adapted to selectively cut pre-shaped notches from the held key blank. The cutter pin includes a guide section that aligns with the notch-profile of the held master key. The key clamping assembly is rotatable about the transverse axis and with respect to the carriage so that the mounted keys face either the cutting end or the alignment end of the frame.

Owner:JET HARDWARE MFG CORP

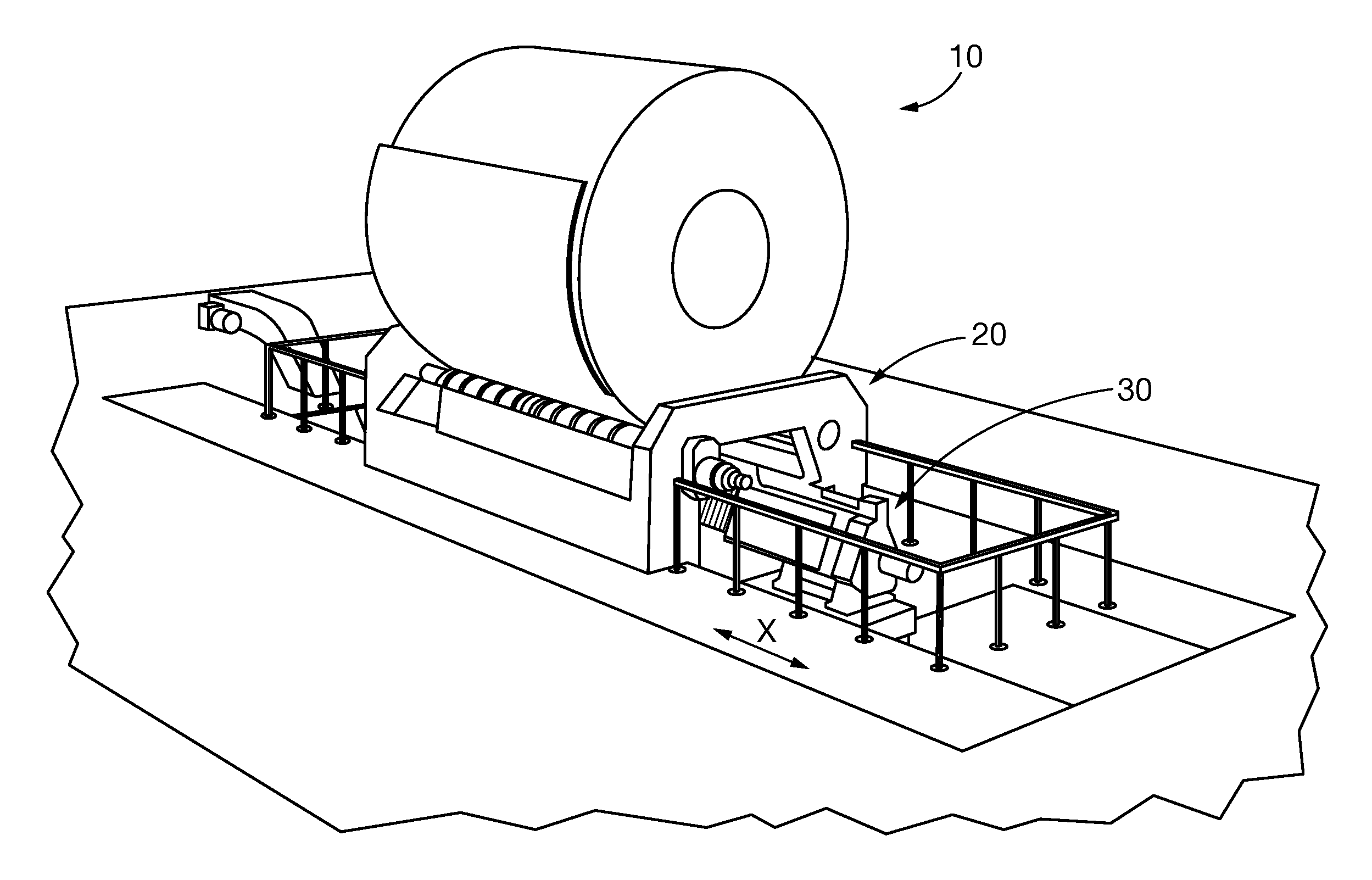

Method and apparatus for trimming a sample from a coiled metal web

ActiveUS20120187091A1Facilitates rebandingPrevent materialWithdrawing sample devicesArc welding apparatusMechanical engineeringMetal

Sample extraction or trimming from an end strip of an elongated formed metal that is coiled in layers within a tensioned metal coil resting on driven rollers. A cut channel is formed across the material width. In some embodiments the cut channel is formed between the rollers and by cutting at an angle relative to the coil outer surface. Coil weight and / or a coil tensioner mechanism inhibits coil relaxation along the cut channel by maintaining tension on wrapped layers against each other when the coil is unbanded for sample extraction. The coil is rotated so that the cut channel clears the rollers laterally. Material downstream the cut is then separated from the coil. After trimming and / or sample extraction the coil maintains rolled tautness for ease of rebanding.

Owner:PRIMETALS TECH USA

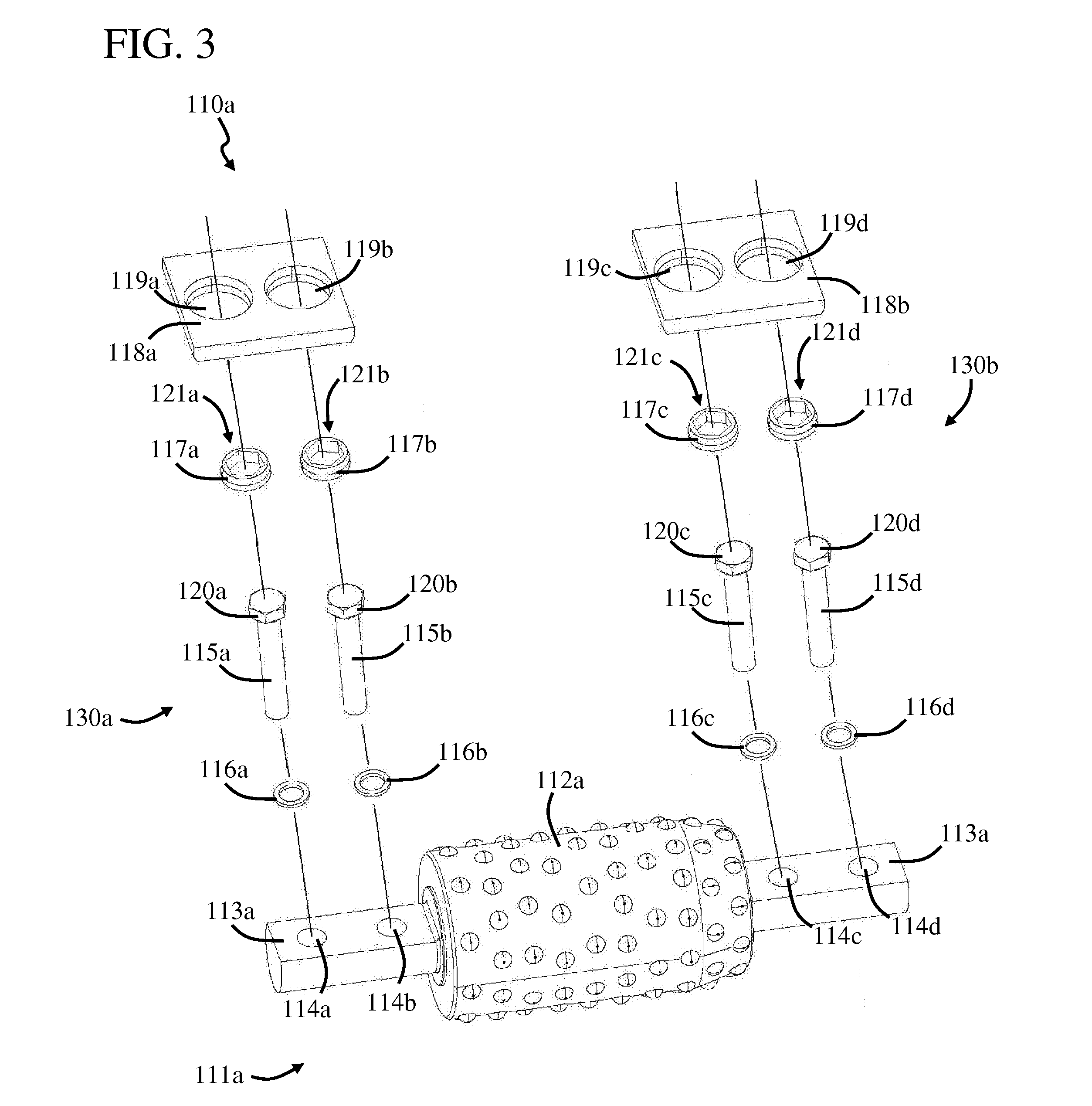

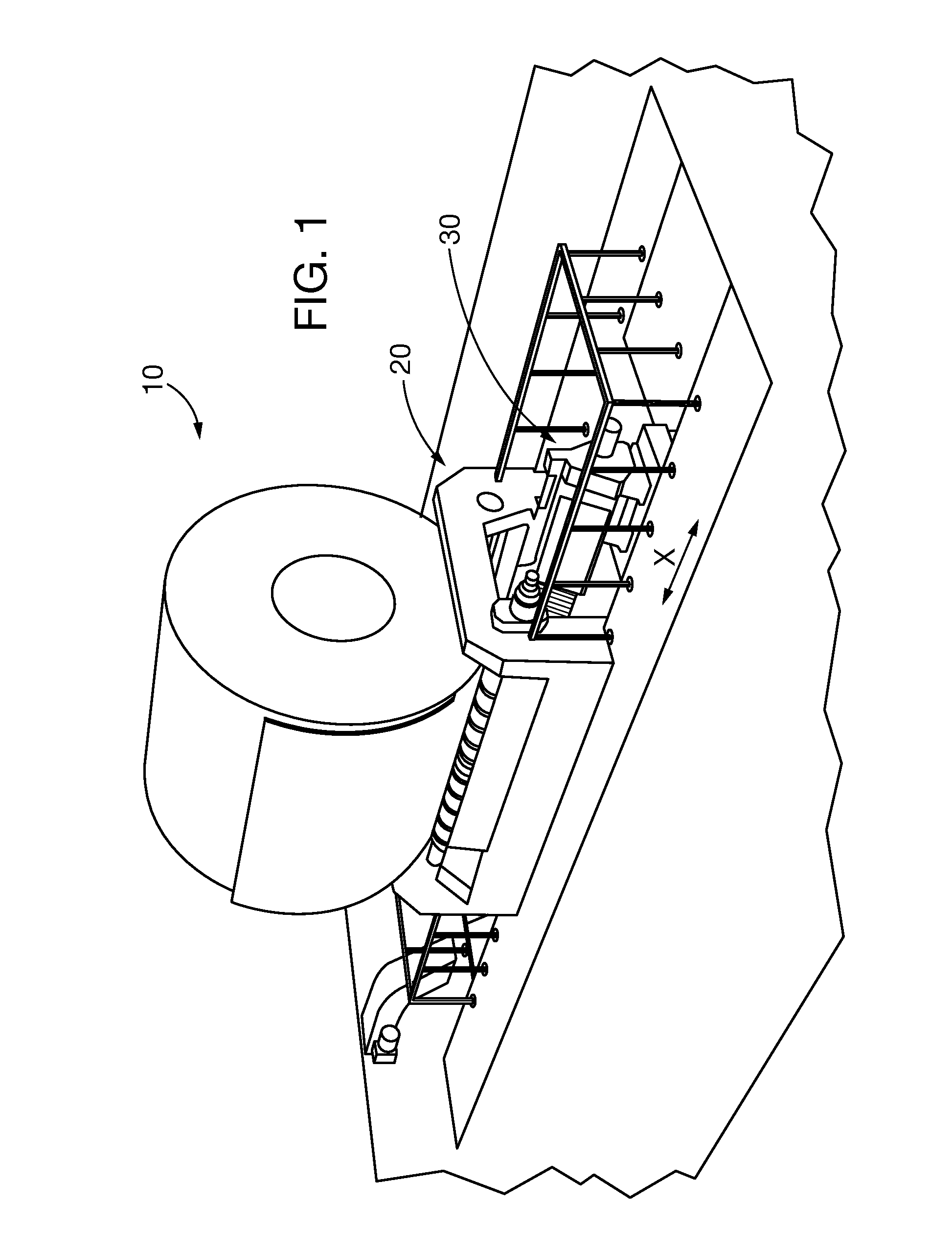

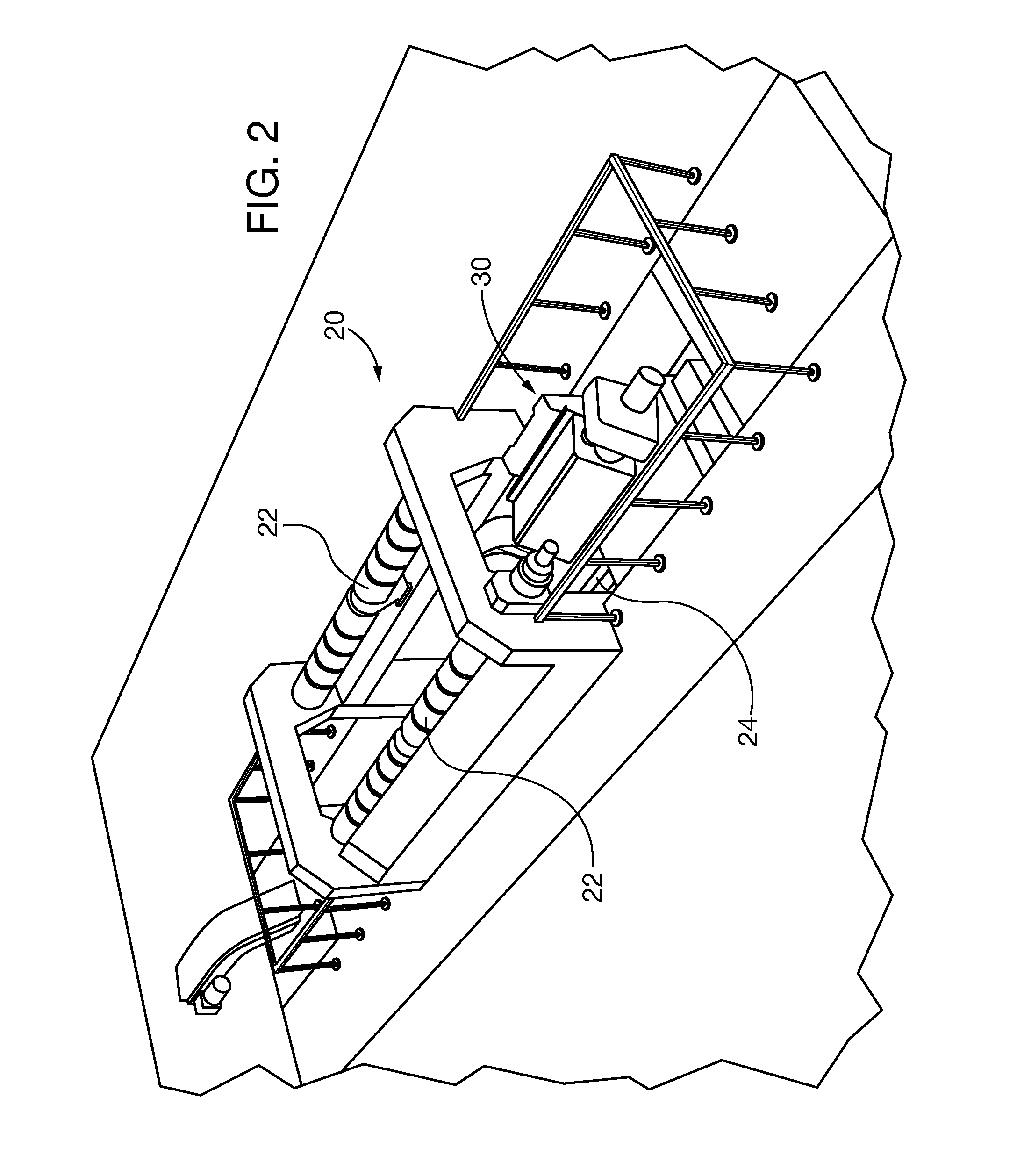

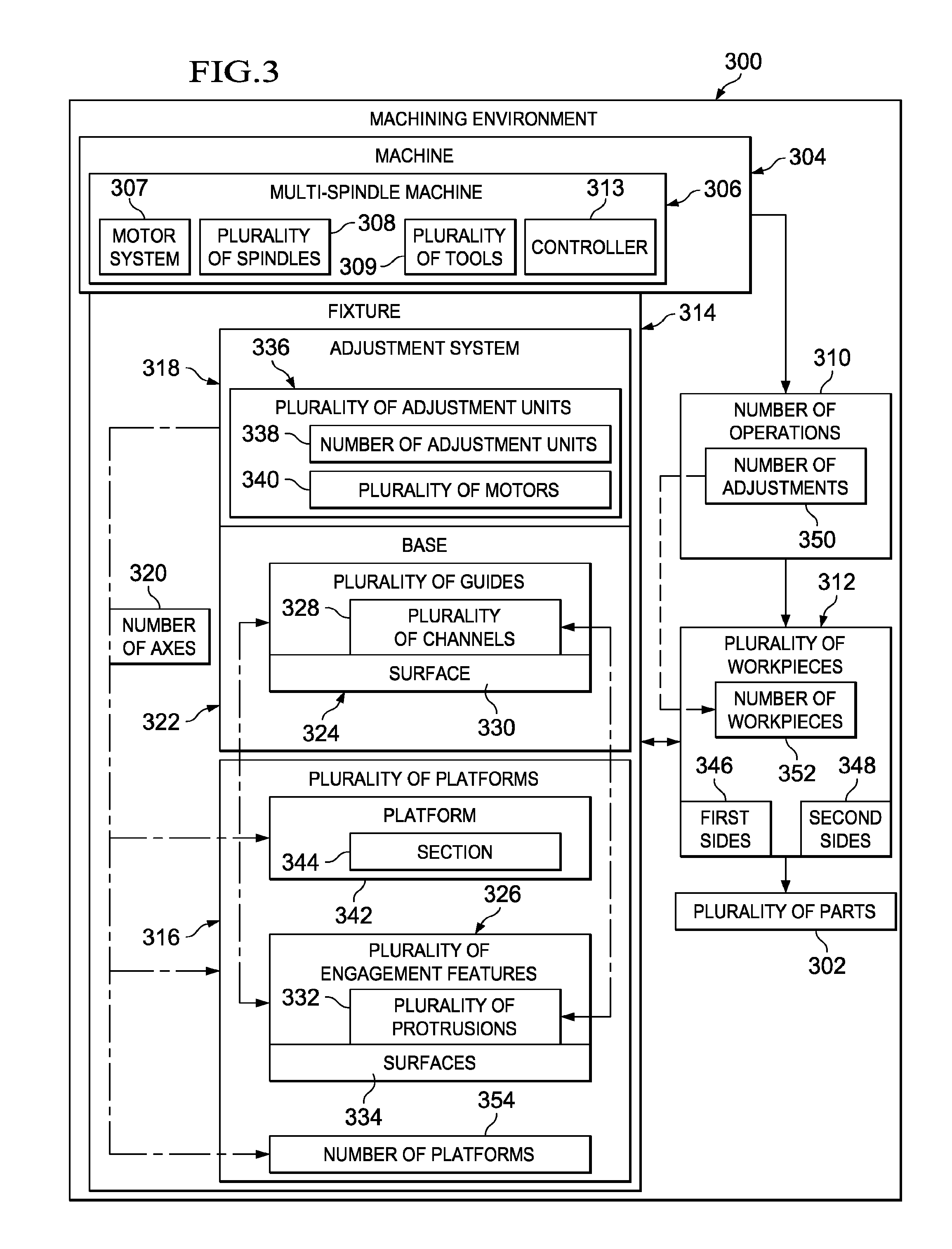

Adjustable Fixture for a Multi-Spindle Machine

A method and apparatus for processing workpieces to form parts. Tools associated with a multi-spindle machine may be positioned with respect to a plurality of workpieces on a fixture comprising a plurality of platforms and an adjustment system. Each platform may be individually moveable with respect to others in the plurality of platforms about a number of axes. The plurality of platforms may be configured to hold the plurality of workpieces in which each platform may be configured to hold a workpiece in the plurality of workpieces during operations performed by the multi-spindle machine. The adjustment system may be configured to move each of the plurality of platforms about the number of axes independently from the others in the plurality of platforms. The operations may be performed on the plurality of workpieces using the multi-spindle machine and the fixture to form a plurality of parts.

Owner:THE BOEING CO

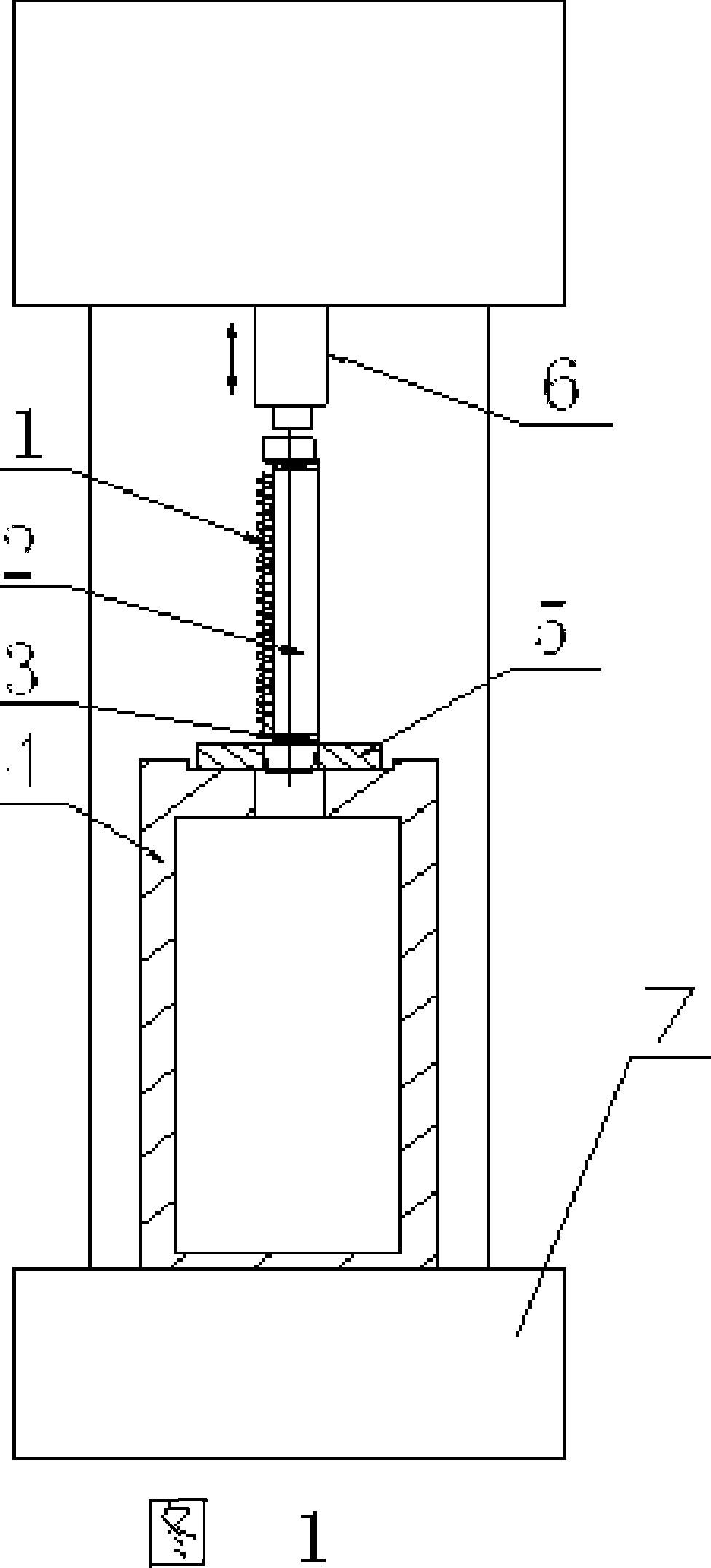

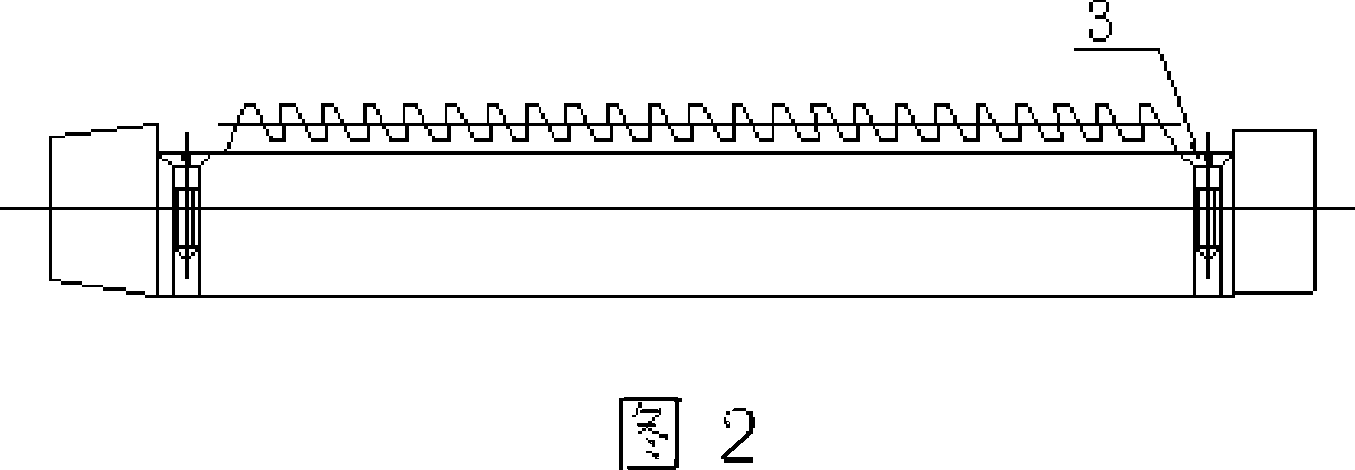

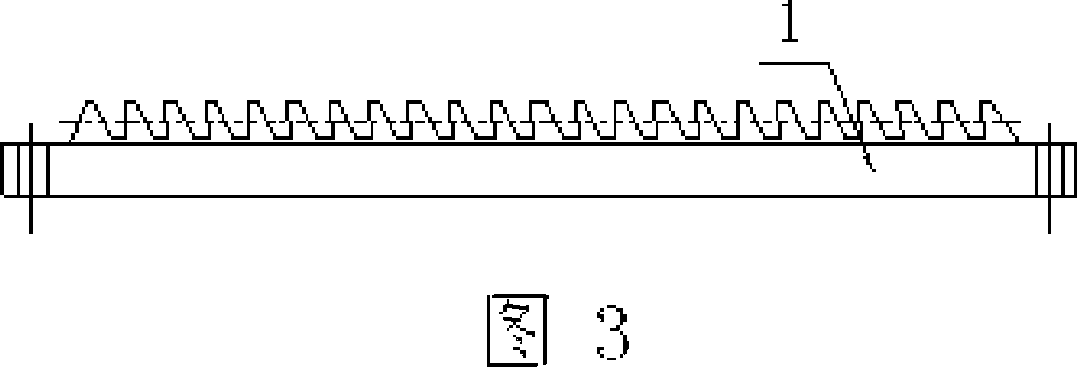

Method for processing gear inner hole key slot and special device

InactiveCN1943940ASimple and fast operationIncrease productivityBroaching toolsBroaching machinesGear wheelMachining

The present invention discloses method and device for machining key slot in gear inner hole. The method includes fixing one support on the press bench, setting the workpiece on the support, inserting the conical guide part of the combined tool into the inner hole of the workpiece, pressing the combined tool to pass through the inner hole with pressure mandrel, cutting the key slot with the pushing broach in the combined tool, and loosening the mandrel to unload the workpiece and the combined tool to complete the machining. The device specially for machining key slot in gear inner hole includes a pressure mandrel on a press, a support on the bench of the press, and a combined tool. The combined tool consists of a pushing broach, a broach pouch and a locking screw for connection. The present invention is used in cutting single key slot in inner hole of gear of non-ferrous metal and plastic.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

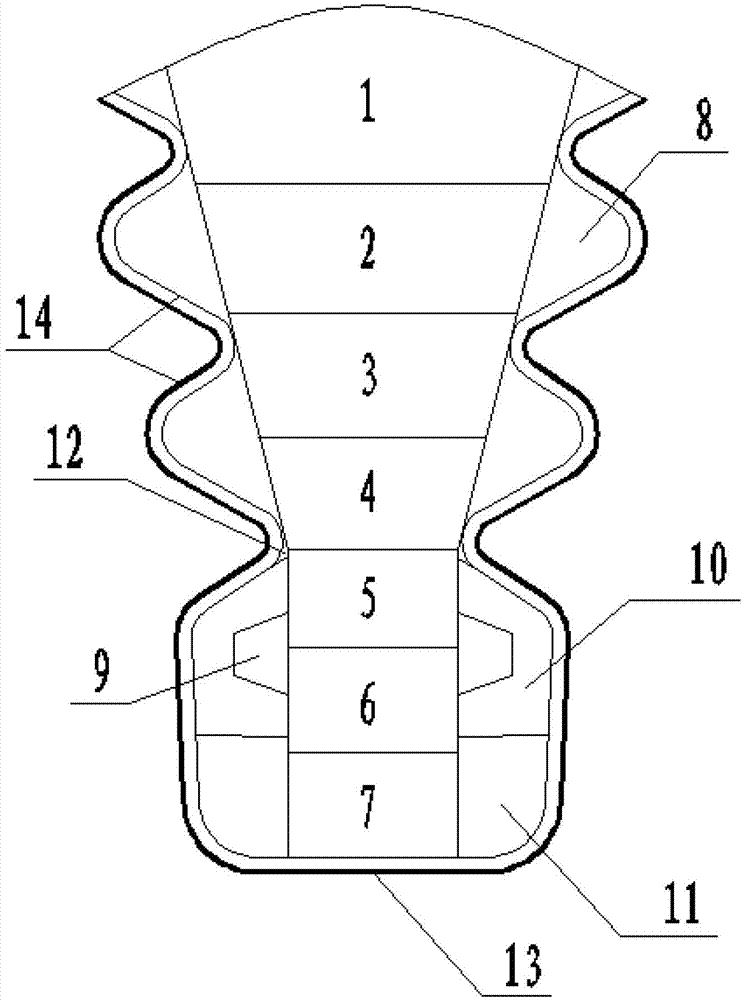

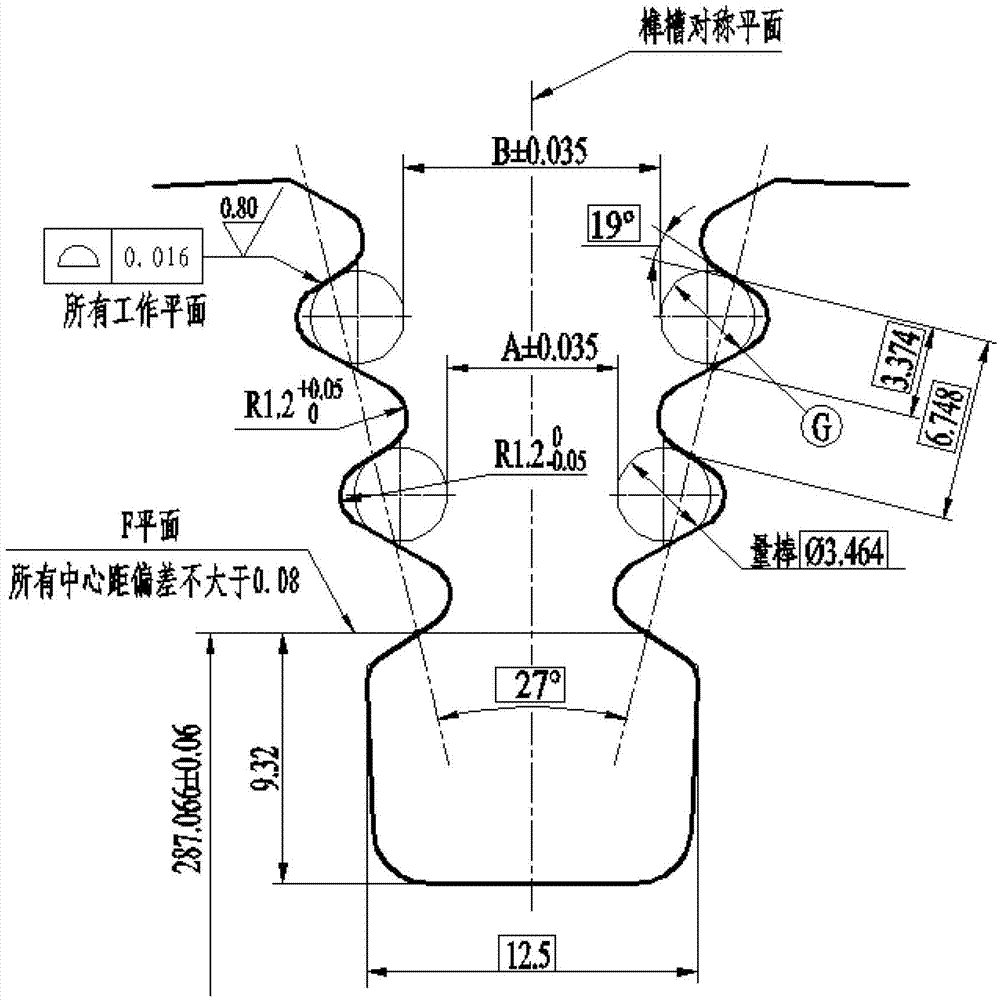

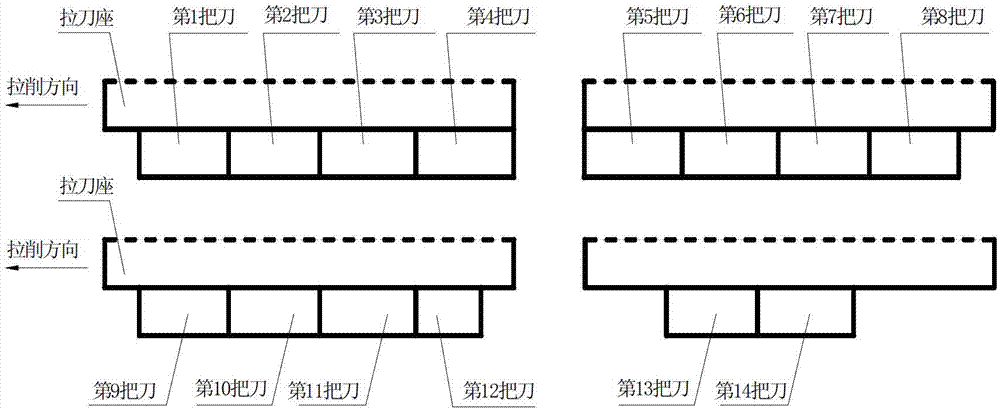

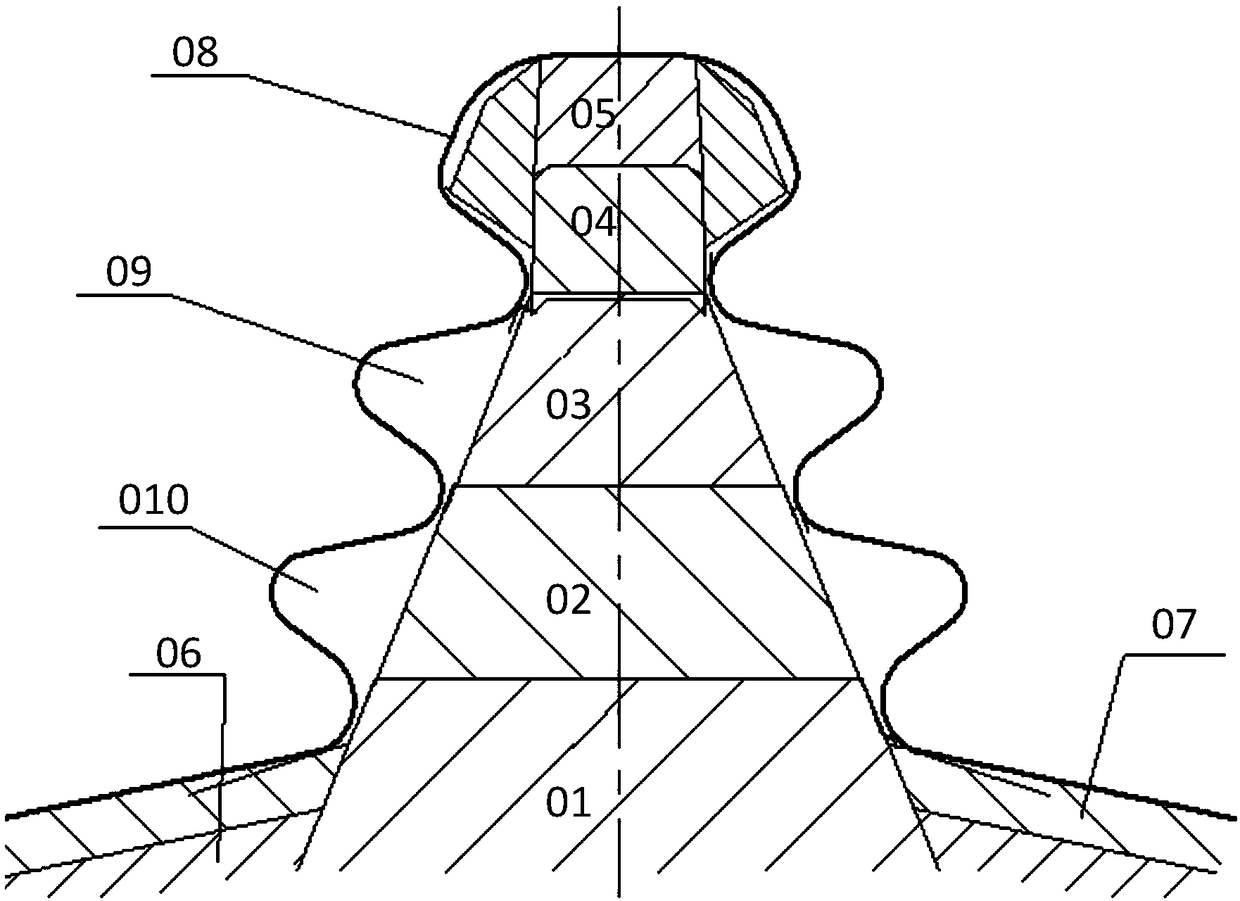

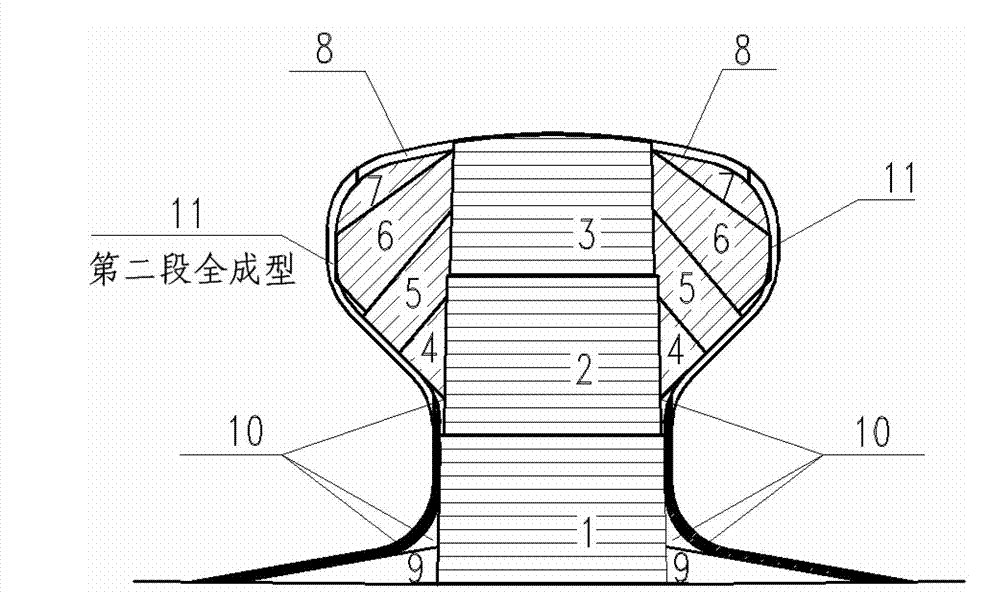

High-accuracy mortise broaching processing method for turbine disk made of powder high-temperature alloy material

InactiveCN102962513AControl and reduce broaching distortionMeet processing needsBroaching toolsBroaching machinesHardnessSuperalloy

The invention discloses a high-accuracy mortise broaching processing method for a turbine disk made of a powder high-temperature alloy material. Broaching tools made of an imported powder high-speed steel material ASP2060 are adopted; the hardness HRC of the broaching tools is 66-68; 14 fourteen broaching tools in a complete set are adopted; first to seventh broaching tools are necking tools; an eighth broaching tool is a roughing tooth type tool; ninth to eleventh broaching tools are roughing tooth bottom cut tools; a twelfth broaching tool is a roughing tooth top circular arc tool; a thirteenth broaching tool is a finish broaching tank bottom circular arc tool; a fourteenth broaching tool is a finish broaching tooth type tool; the broaching tools are made of an ASP2060 powder high-temperature alloy material; the front angles of the broaching tools are 15 degrees; the back angles of the broaching tools are 3 degrees; the rise per teeth of the rough necking tools are 0.045-0.06 millimeters; the rise per tooth of the roughing tooth type tool is 0.02-0.035 millimeters; the rise per tooth of the finish broaching tank bottom circular arc tool is 0.02 millimeters; the rise per tooth of the finish broaching tooth type toolfourteenth broaching tool is 0-0.03 millimeters; gradual cutting and complete molding are adopted in a broaching way; the rough broaching speed is 1 meter per minute; and the finish broaching speed is 1-1.5 meters per minute. The high-accuracy mortise broaching processing method has the advantages that: broaching deformation of parts is controlled and reduced effectively, the processing requirements of a high-accuracy powder metallurgy disk are met, and the requirement of a high-accuracy mortise on size accuracy on a high-accuracy mortise is met effectively.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

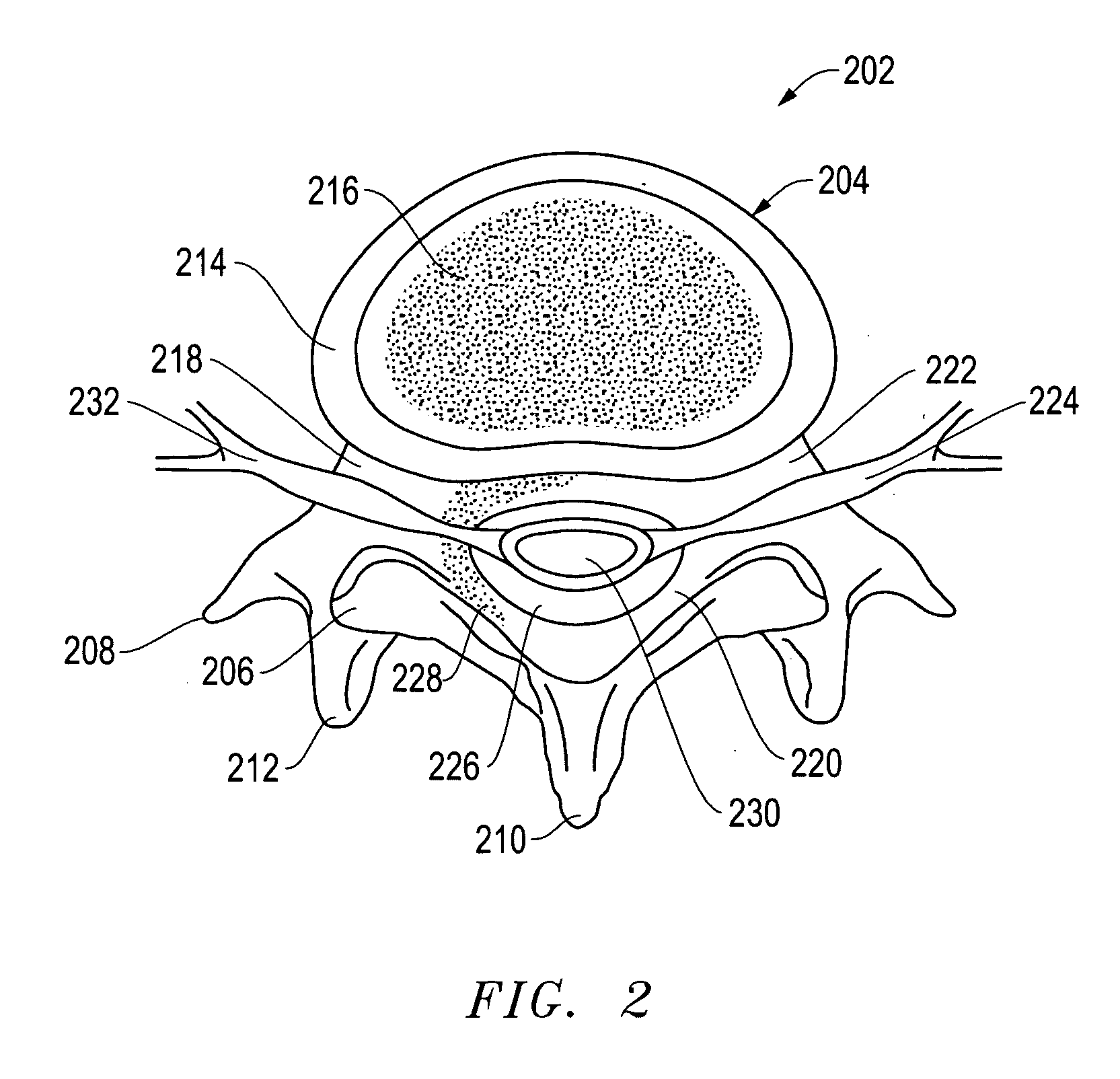

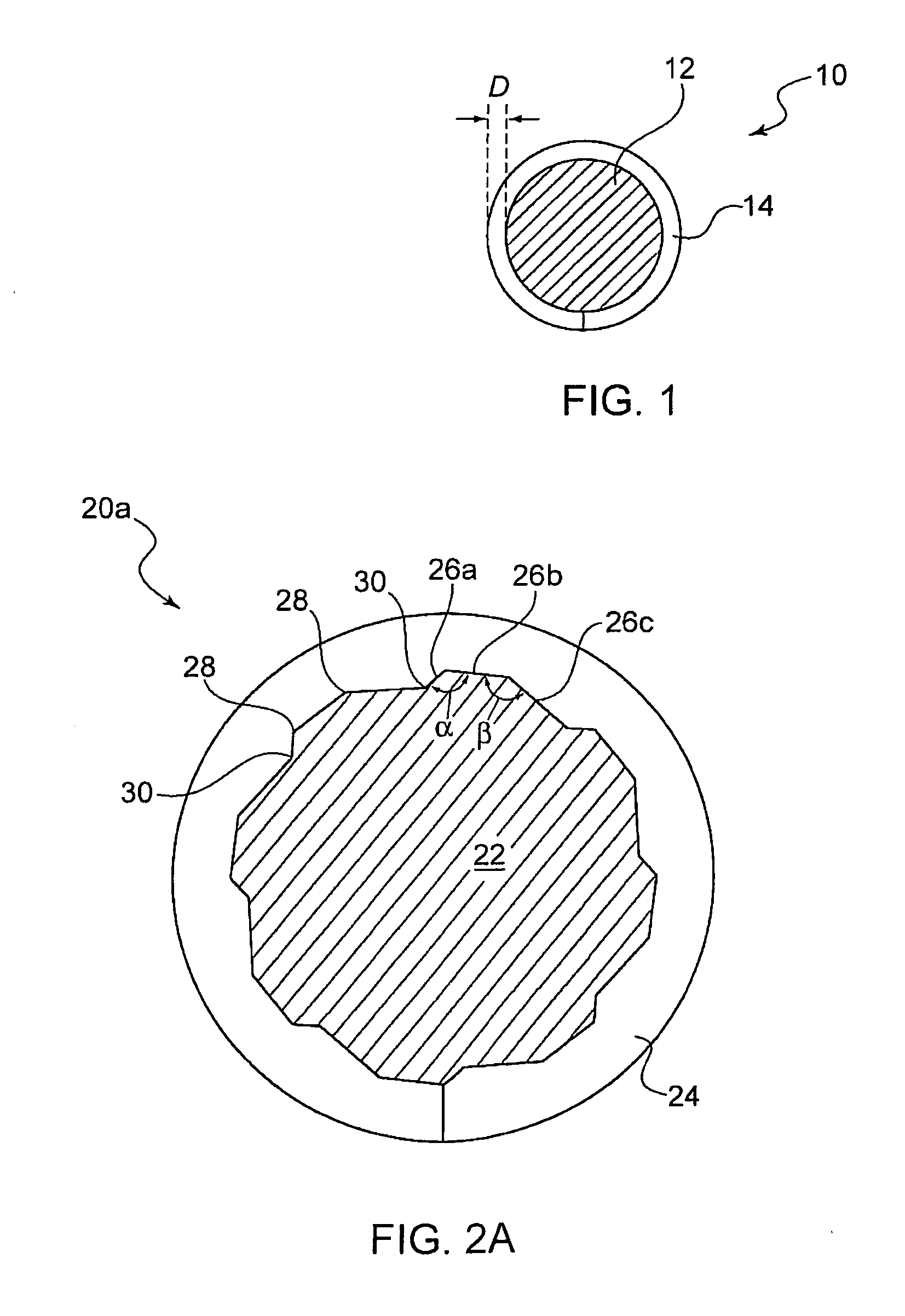

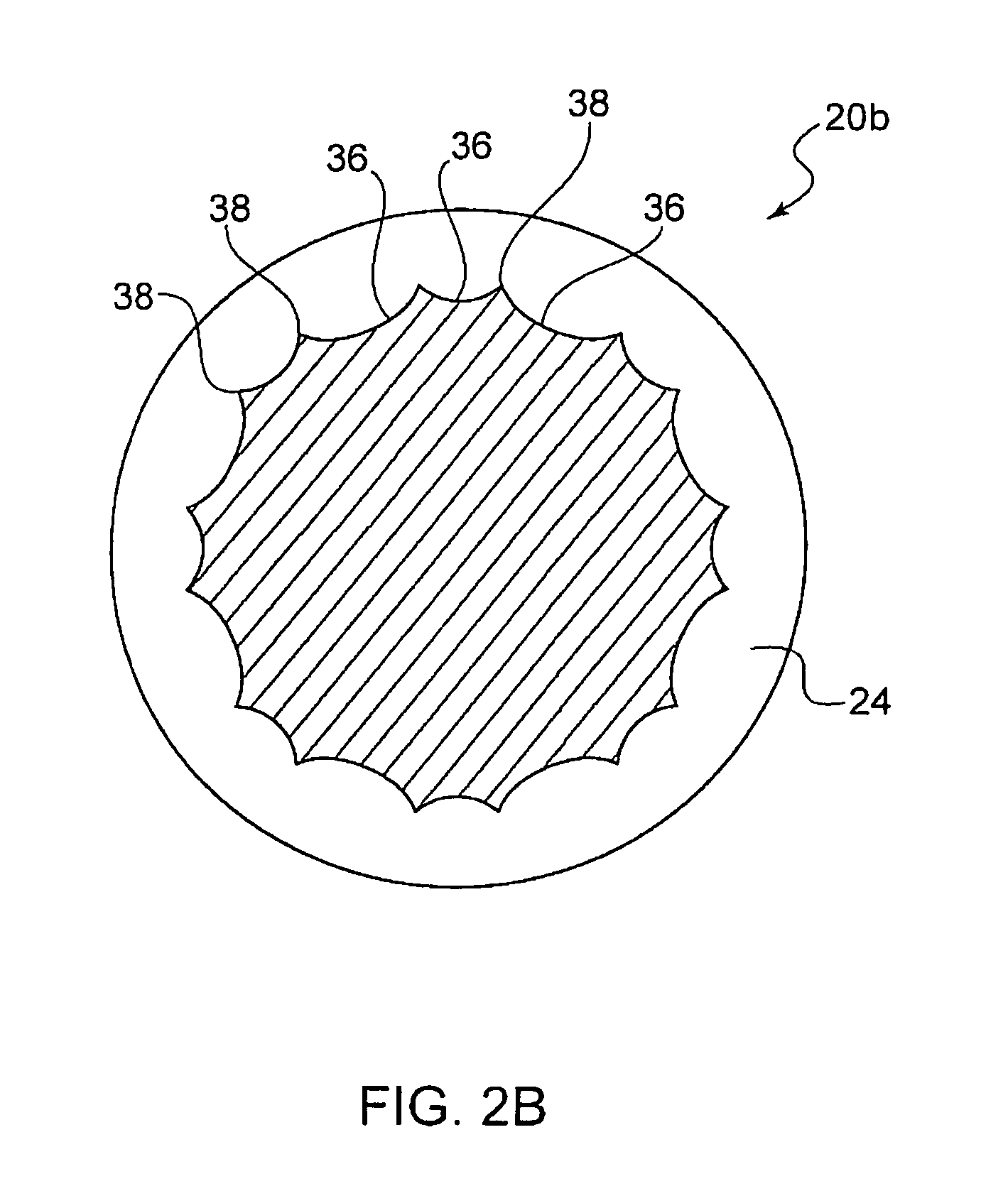

Bone screw and method for manfacturing the same

ActiveUS20090131989A1Reduce frictionReduce probabilitySuture equipmentsLigamentsScrew threadBiomedical engineering

A faceted bone screw and a method for manufacturing the same includes a screw thread configuration having facets that are substantially transverse to the thread. The facets are generally made up of a plurality of transitioning peaks and valleys which vary the depth of the thread and are disposed in one or more locations throughout the threaded portion of the bone screw. The facets operate to reduce the torque required to drive the bone screw into bone, while at the same time operate to assist in anchoring the bone screw within the bone once inserted therein, and thereby reduce the possibility for the screw backing out after insertion.

Owner:MEDICAL FACETAB

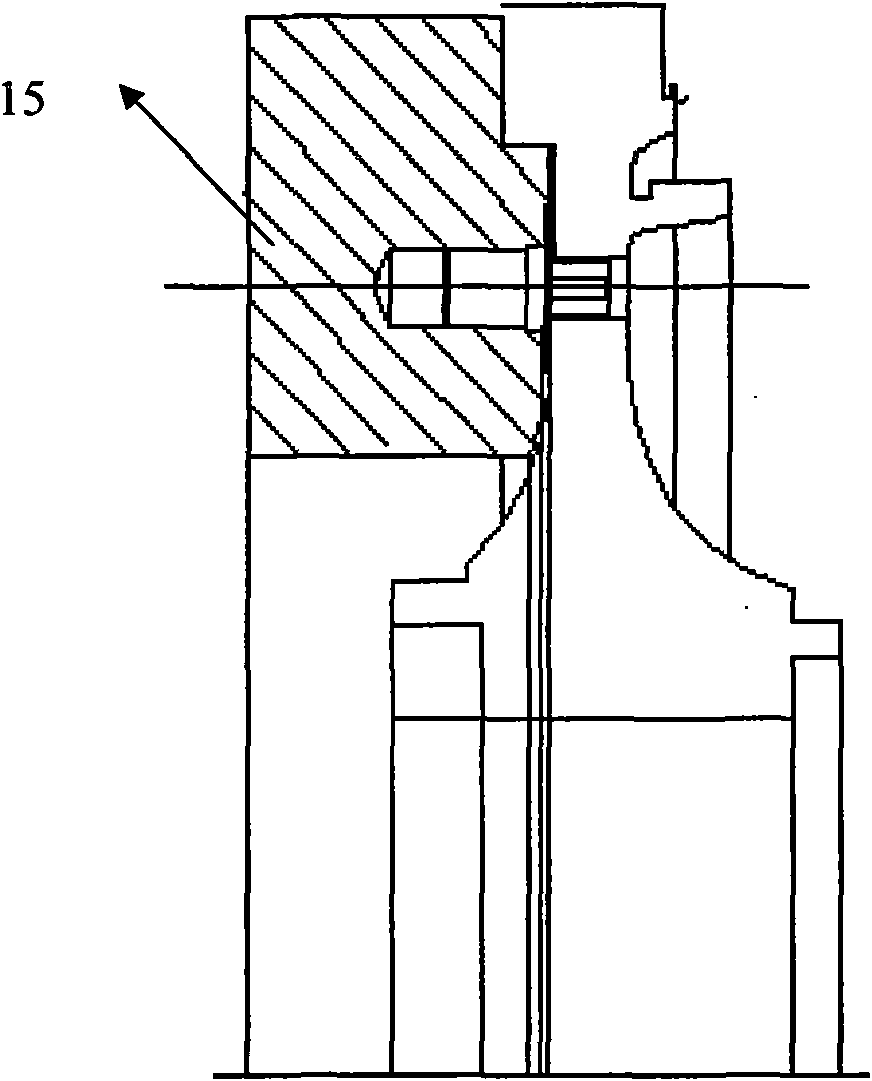

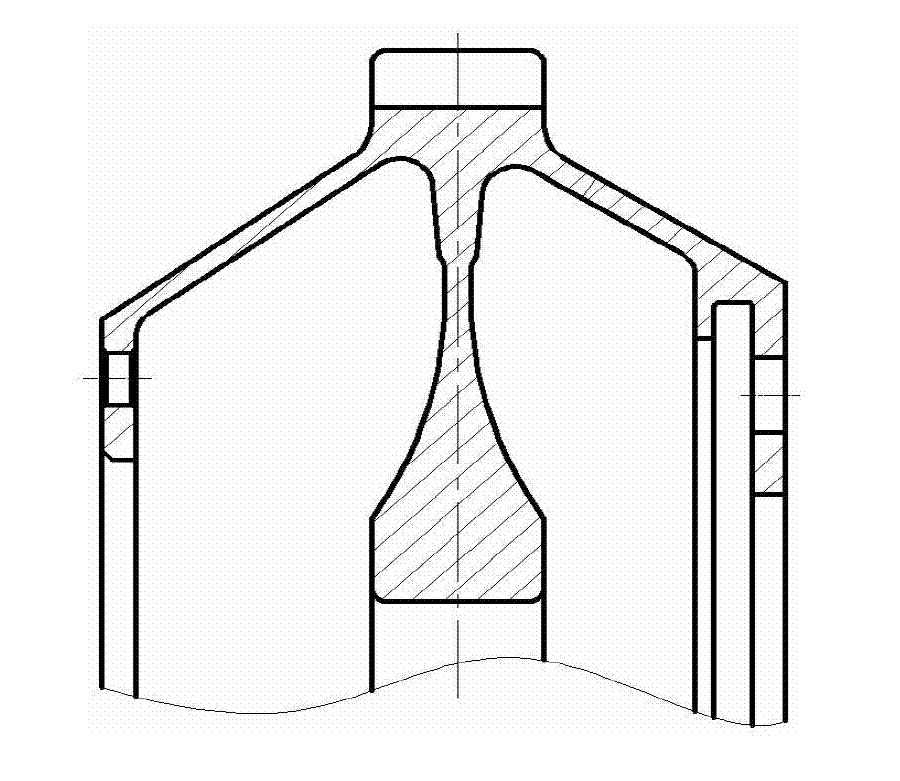

Fixture special for mortise of broaching disc type part

InactiveCN101664883AEliminate radial playIncrease productivityPositioning apparatusBroaching machinesPass rateScrew thread

The invention relates to a fixture special for a mortise of a broaching disc type part, belonging to the technical field of fixture machinery. The fixture comprises a base, an angular positioning pin,a press cover, a compression nut, a compression screw, a gasket, a screw-thread bush, a lock screw, a positioning mandrel and radial gap elimination mechanisms, wherein each radial gap elimination mechanism comprises a positioning end surface ring, a positioning stop opening ring, a radial positioning gap regulation top block, a tightening screw and a spring. By uniformly distributing the radialgap elimination mechanisms on the circumferences of two layers of positioning rings, the fixture can eliminate the positioning radial gap of the part also enable the part to be coaxial with a positioning stop opening of a puller and enhance the production efficiency and the product qualification rate of the part and the qualification rate from original 10 percent to 95 percent and directly enhancethe economic efficiency by 50 percent.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

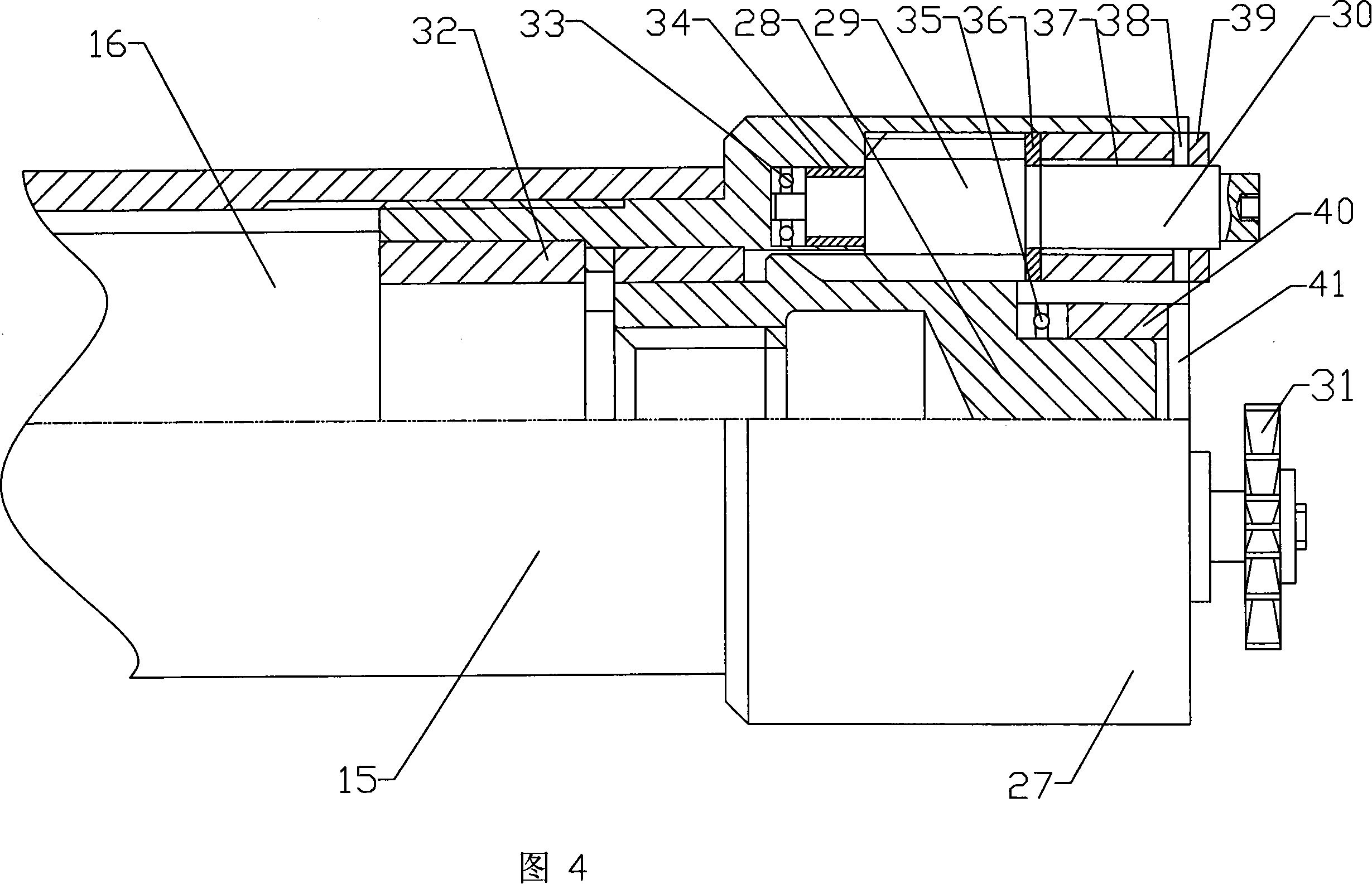

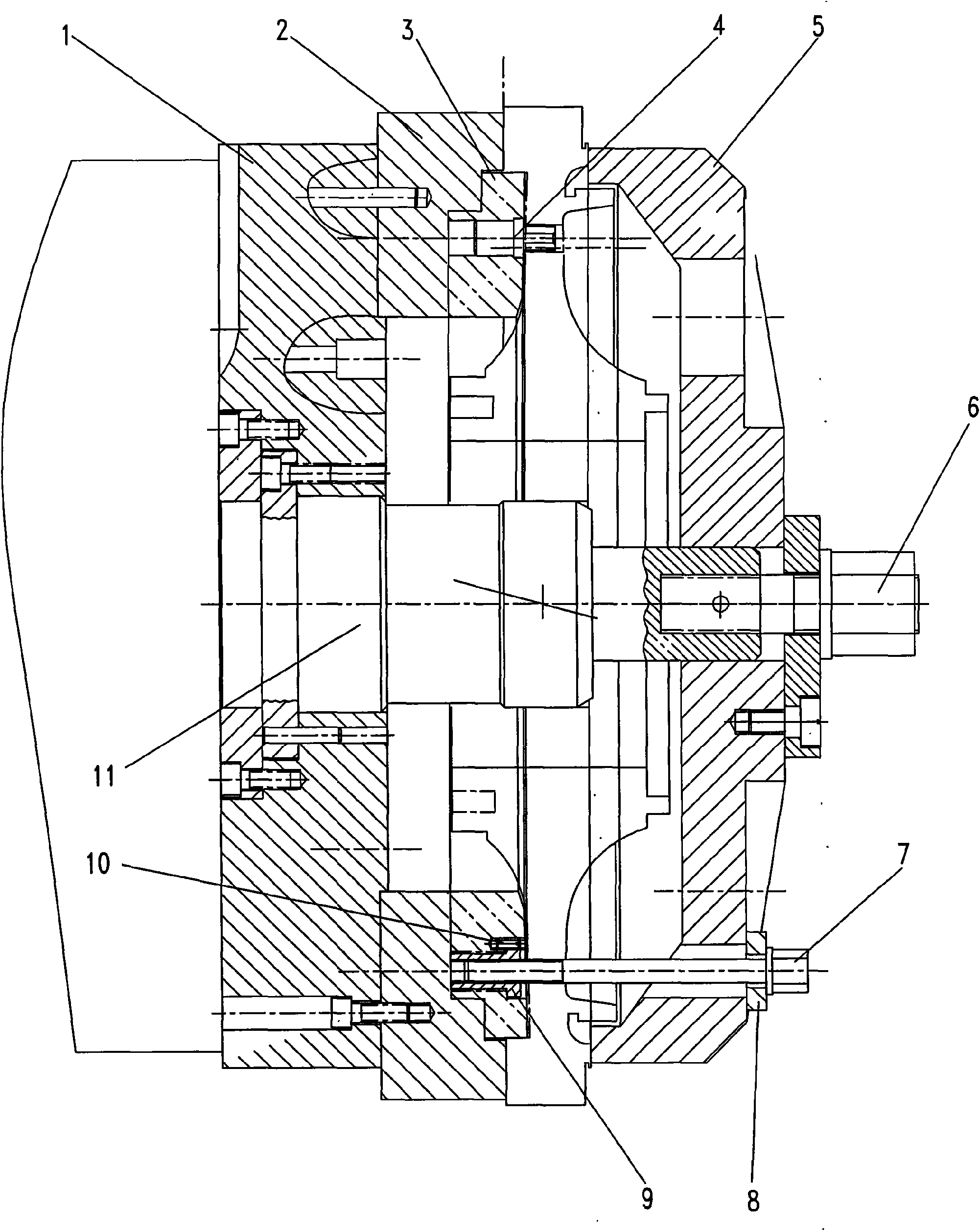

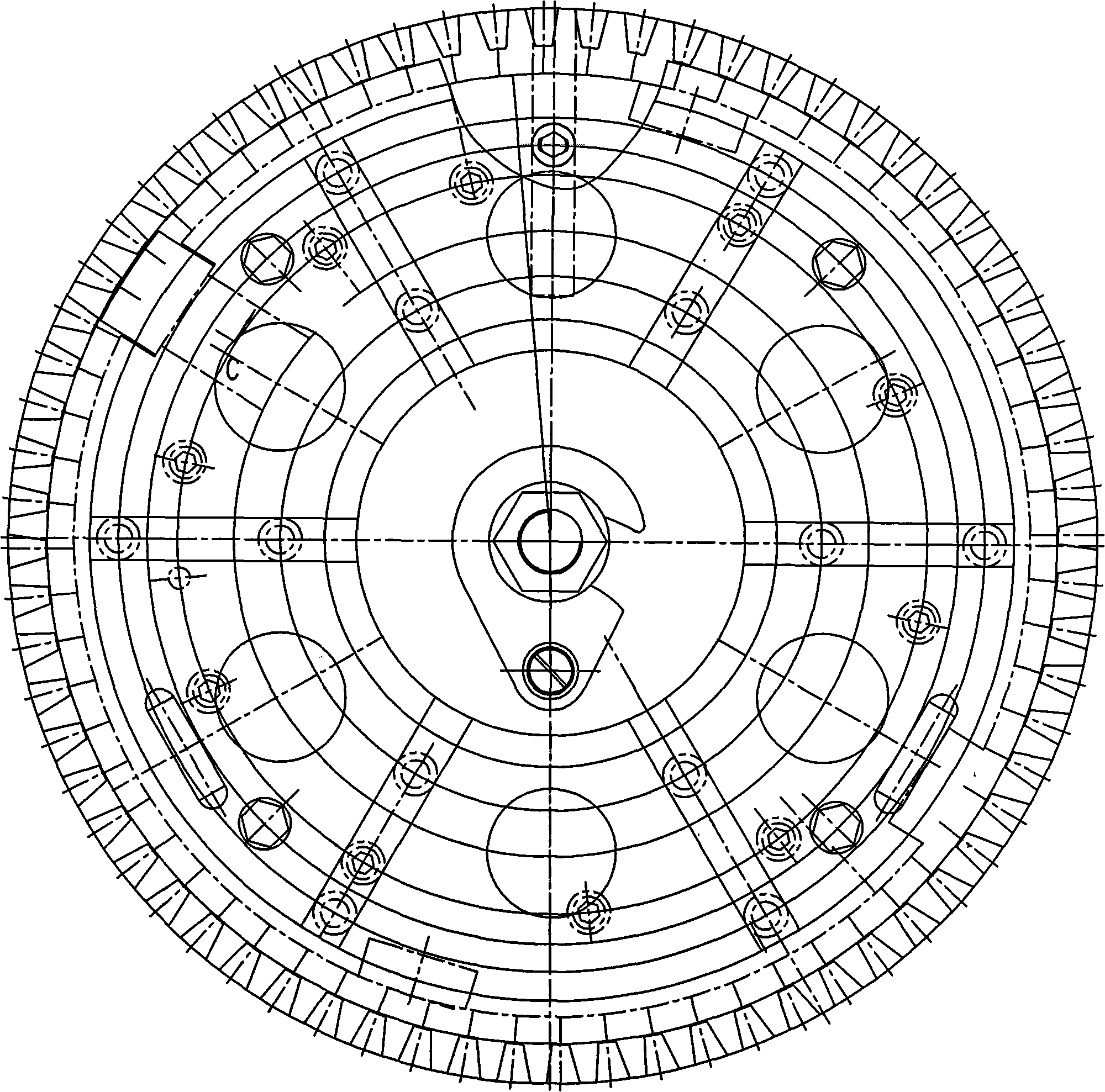

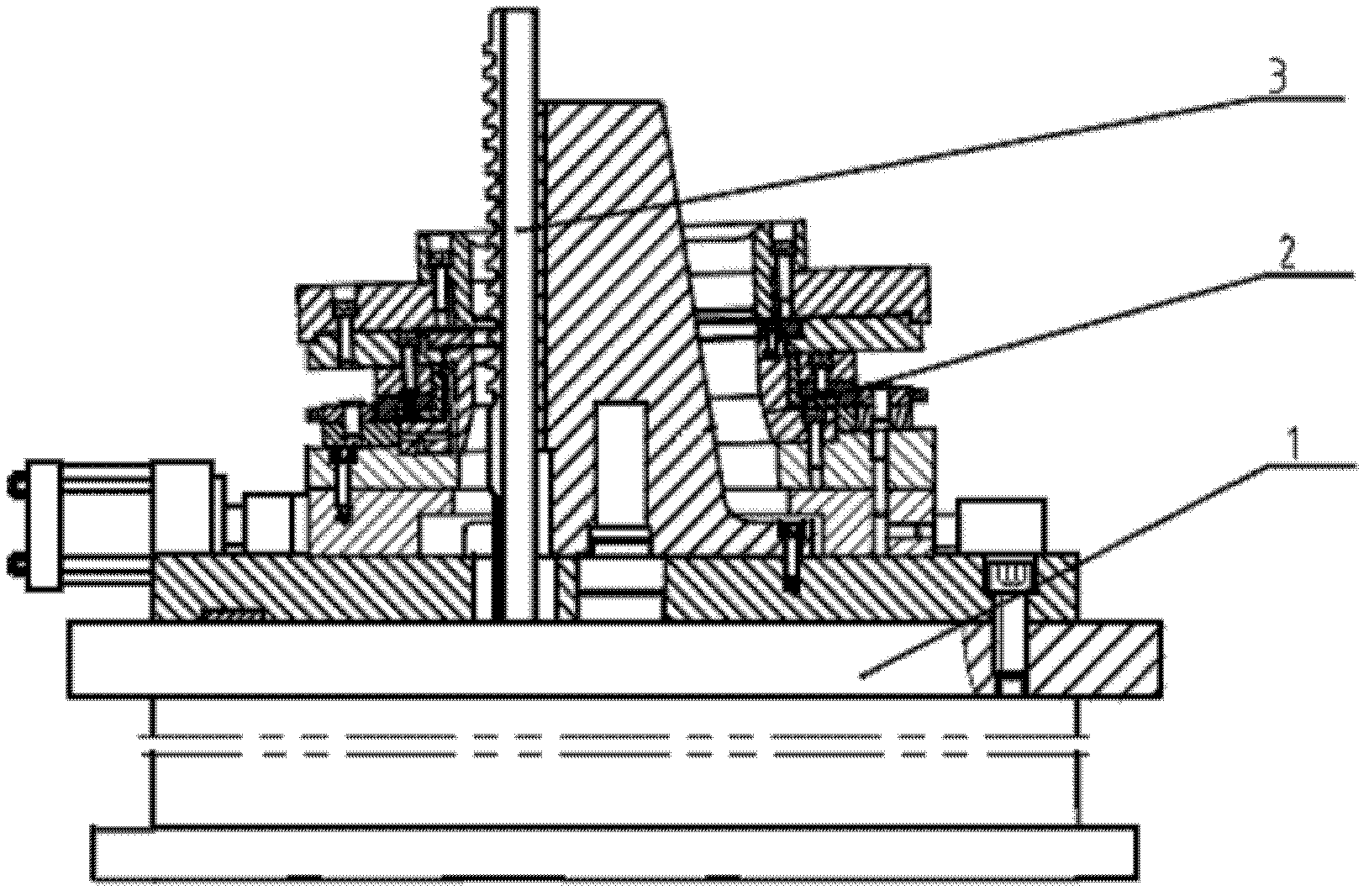

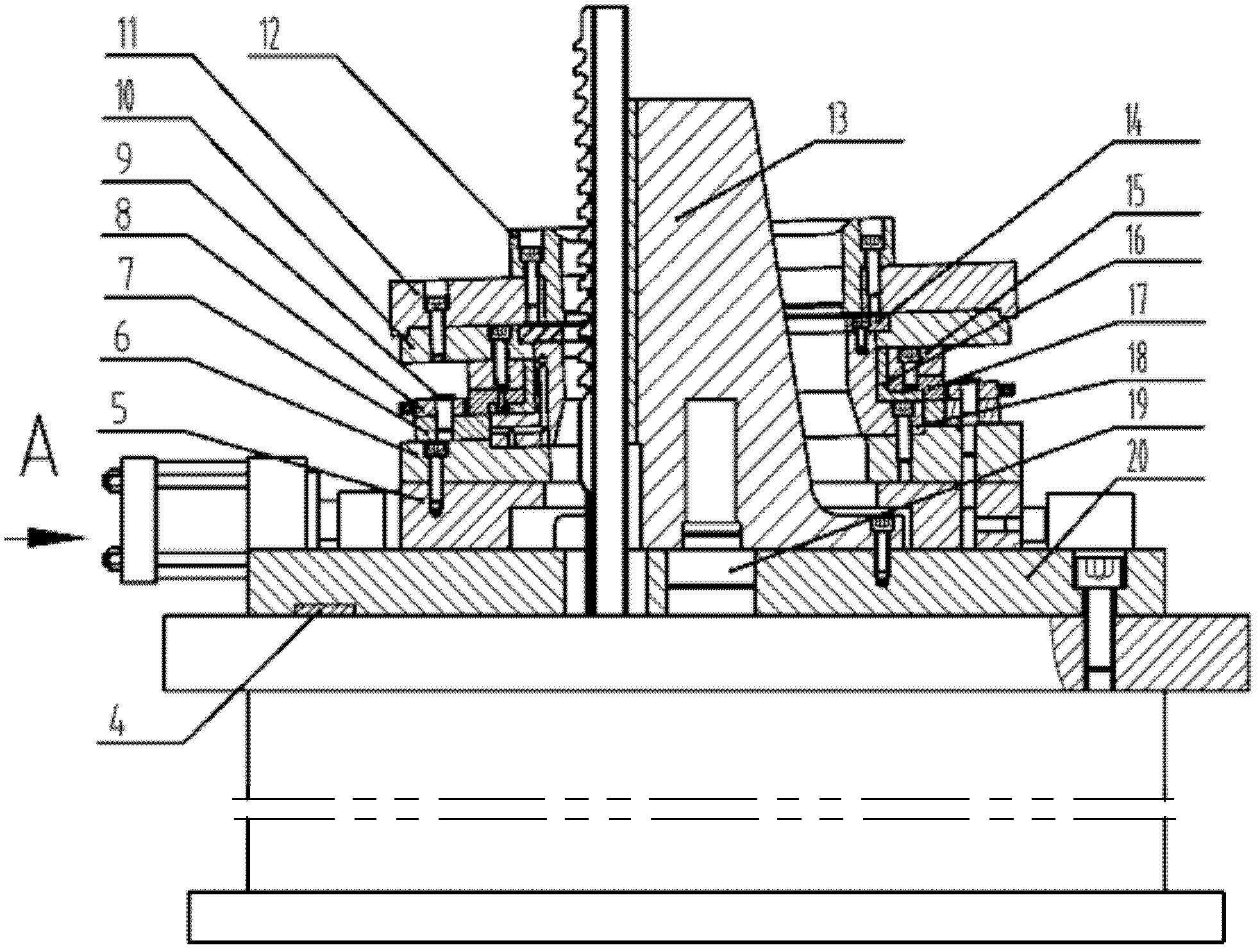

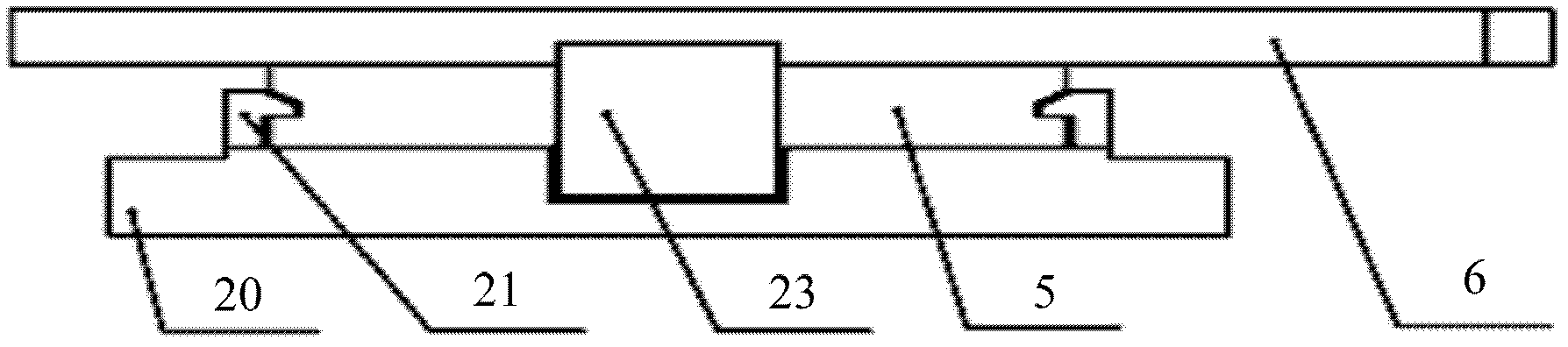

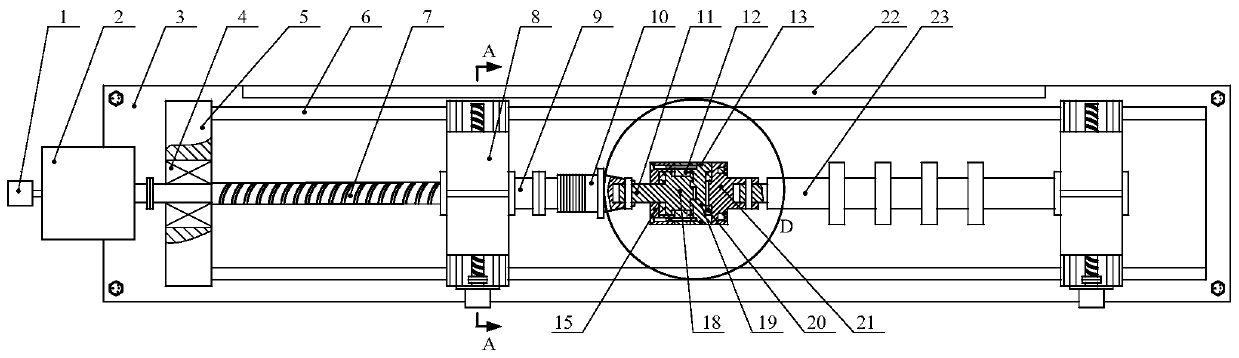

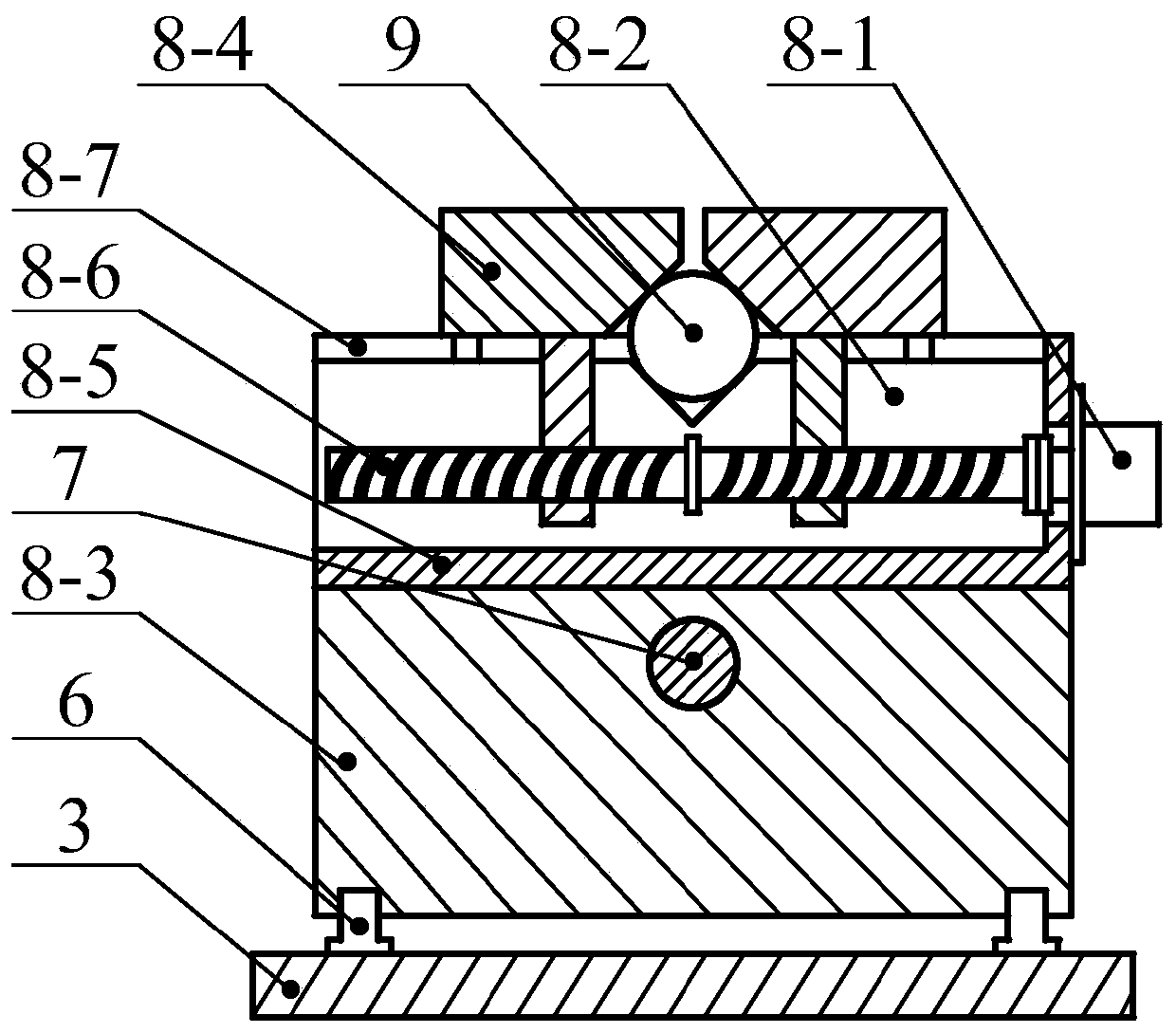

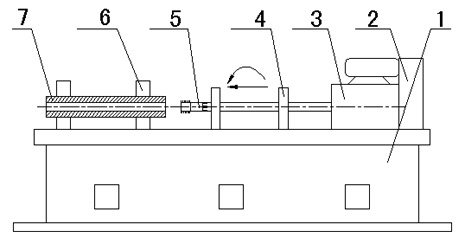

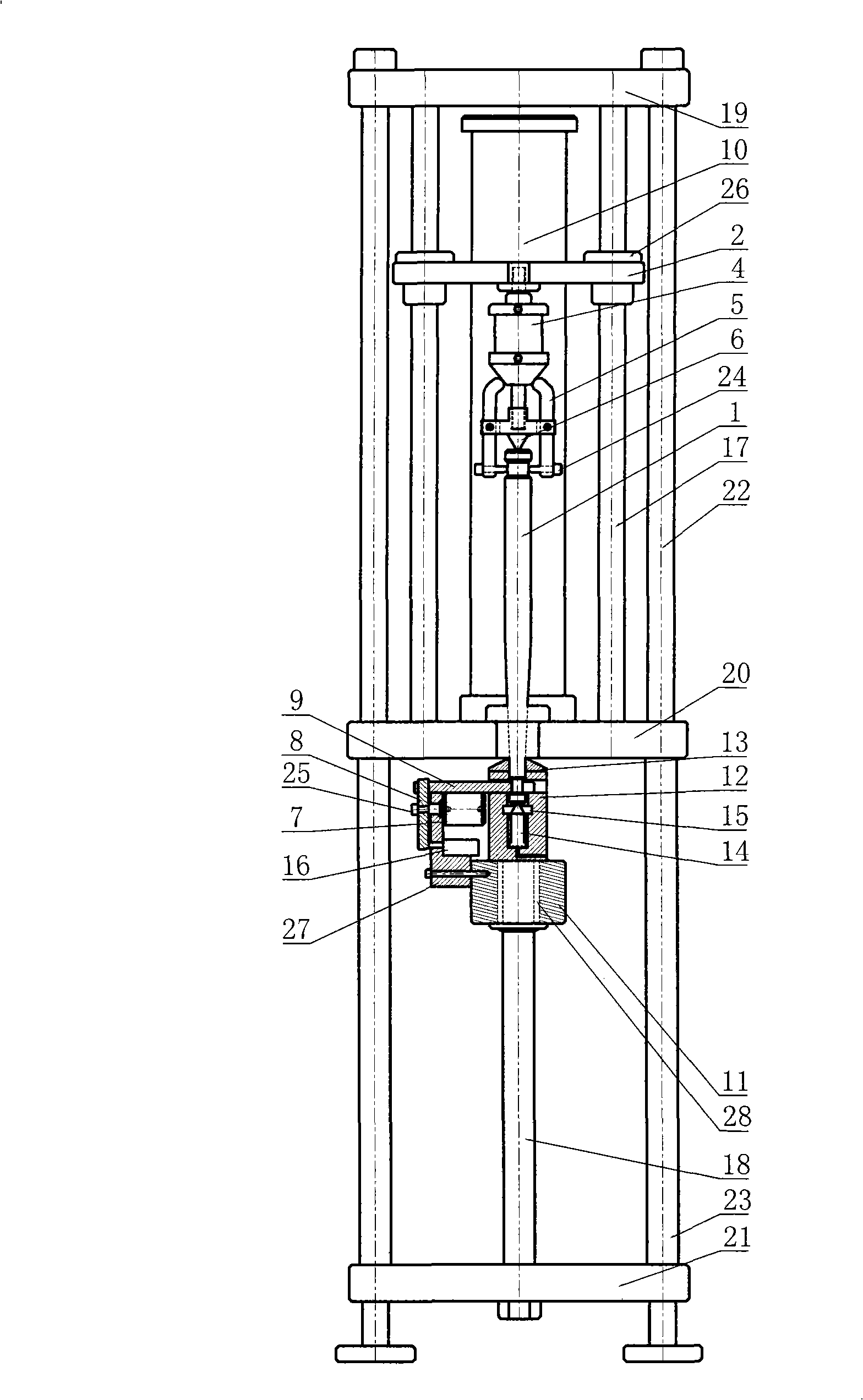

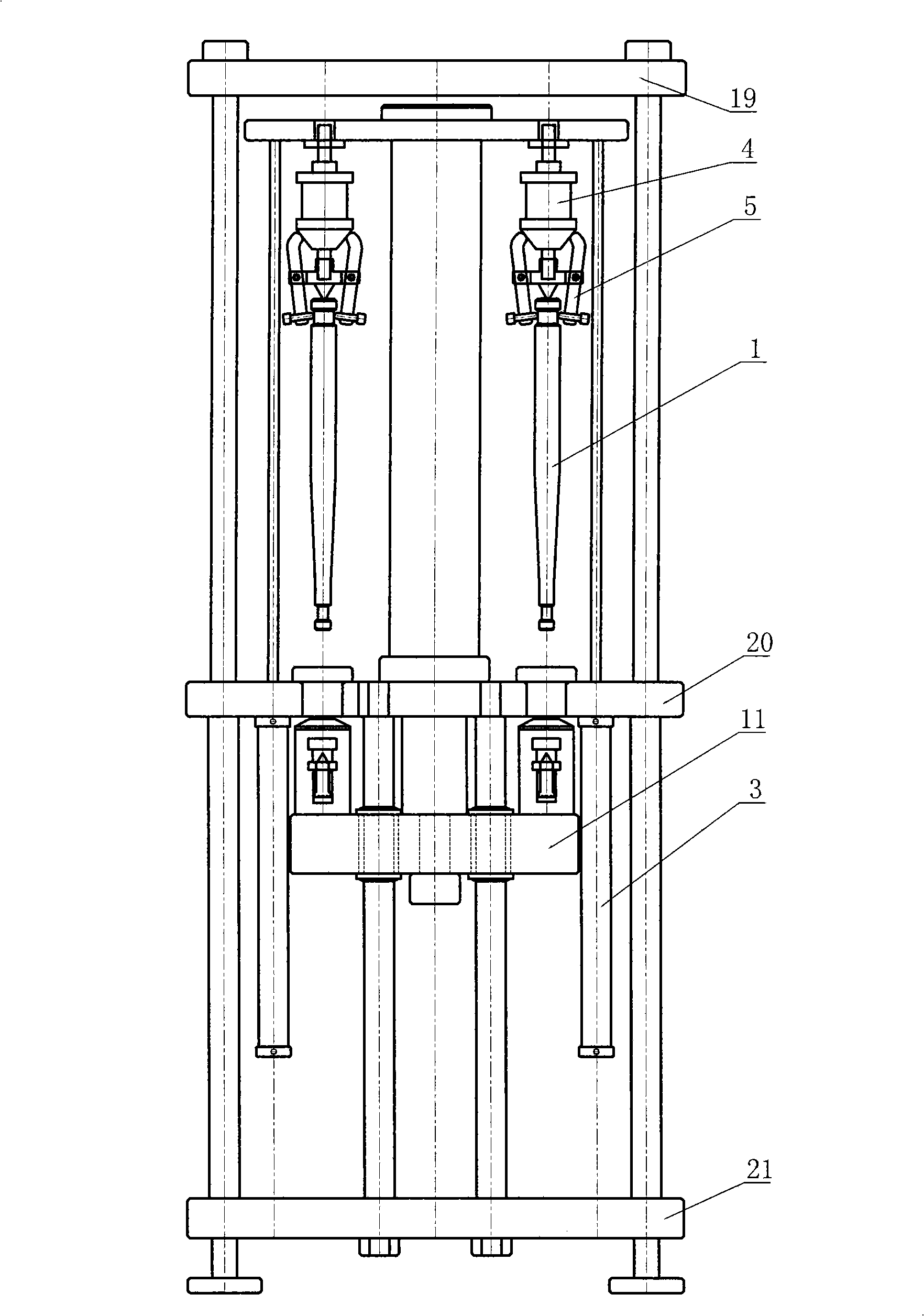

Inner-cone spline broaching machine tool

ActiveCN102407379AEasy to adjust processing sizeExcellent quality and efficiencyPrecision positioning equipmentBroaching machinesSlide plateMachine tool

The invention discloses an inner-cone spline broaching machine tool, which comprises a base, a broaching tool, a sliding plate, a cutter relieving cylinder assembly, a working device and a driving device. The base is arranged on a machine tool body and is provided with a guiding seat thereon; one end of the broaching tool extends into the machine tool body, and the broaching tool is connected with a stretching cylinder in the machine tool body and can be vertically and slidably arranged on the guiding seat; the sliding plate is sleeved on the guiding seat and is slidably arranged on the base;the cutter relieving cylinder assembly is arranged on the base, and an extending end of the cutter relieving cylinder assembly is connected with the sliding plate; the working device is arranged on the sliding plate and is used for fixing inner-cone splines; and the driving device is arranged on the sliding plate and is used for driving the working device to rotate one indexing unit each time. According to the inner-cone spline broaching machine tool disclosed by the invention, the inner-cone splines are machined by a broaching tool in a broaching manner, the precision by adopting the broaching tool is higher than the precision by adopting gear planning, and the efficiency by adopting the broaching tool is higher the efficiency by adopting the gear shaping and the gear planning; the working device carries out operations, such as automatic indexing, automatic broaching tool feeding, retracting and the like, by the driving device, thus the indexing operation is uniform and reliable, andthe degree of automation is high; and the inner-cone spline broaching machine tool disclosed by the invention is convenient to be detached, and can carry out multiple specifications of inner-cone spline operations by replacing the working device.

Owner:SHANTUI CONSTR MASCH CO LTD

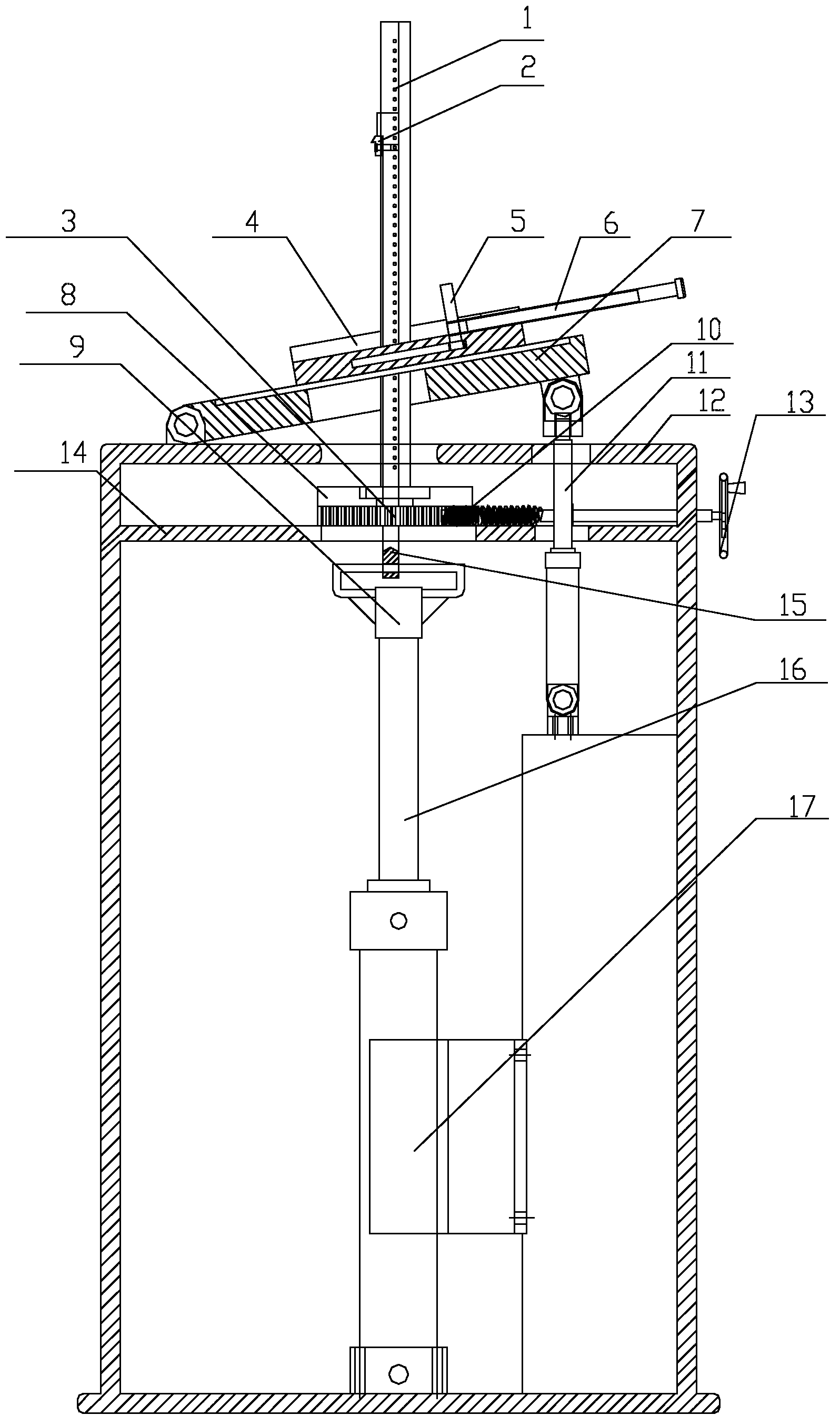

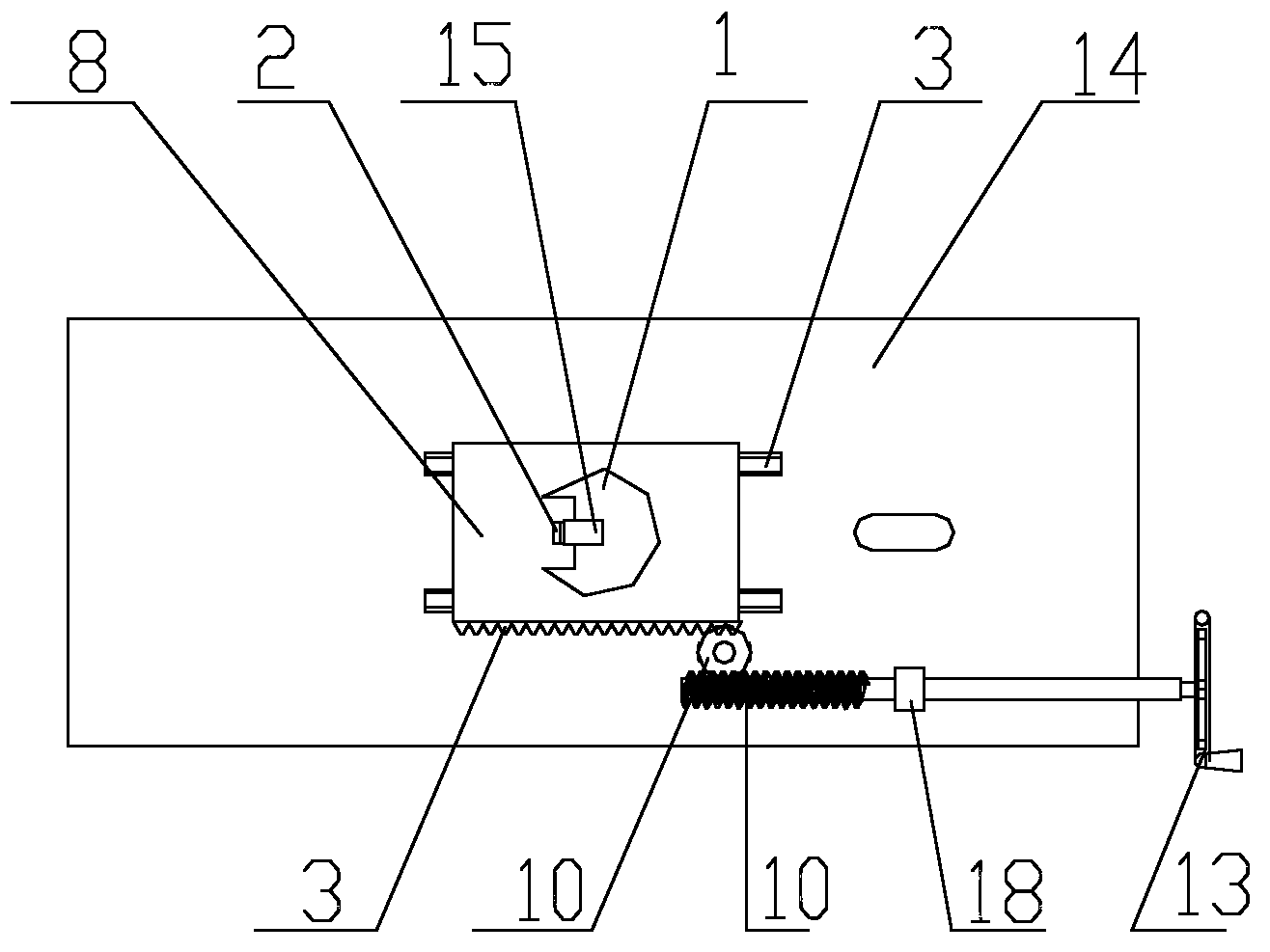

Processing device of internal keyway of tapered hole of large workpiece

InactiveCN103240460AImprove machining accuracyHigh precisionLarge fixed membersBroaching machinesHydraulic cylinderEngineering

The invention discloses a processing device of an internal keyway of a tapered hole of a large workpiece. The processing device comprises a guide rod, a broach sheet, rack guide rails, a fixture body, a locating pin, a locating rod, a worktop, a feed workbench, a coupling mechanism, a worm and gear, a hydraulic cylinder, a machine tool body, a hand feed device, a broach rod, a primary motion hydraulic cylinder, a fixing device and a bearing pedestal, wherein one end of the worktop used for placing and locating the workpiece is connected with the machine tool body by a fixed hinged support, and the upper end of the hydraulic cylinder is articulated with the other end of the worktop. The processing device can process the internal keyway of the tapered hole of the large workpiece, is simple in structure, convenient to mount and high in practicability, and has the characteristics that a small mechanism can process the large workpiece and the processing precision is high; and parts and components are high in standardization degree and universalization degree.

Owner:JIANGSU UNIV OF SCI & TECH

Cutting tool with cutting insert having multiple cutting edges, and cutting insert therefor

A cutting tool includes a cutting insert. The insert includes a top side including a plurality of cutting edges, the cutting edges being arranged one after another in a longitudinally direction of the insert and extending substantially perpendicularly to a longitudinal, vertical axial plane of the insert. The insert includes a side wall extending downwardly relative to a plane of the top side of the insert, the side wall including a side supporting surface. The cutting tool includes a toolholder. The toolholder includes a side abutment surface against which the side supporting surface of the insert is adapted to be supported. A clamp is provided for clamping the side supporting surface of the insert against the side abutment surface of the toolholder.

Owner:SECO TOOLS AB

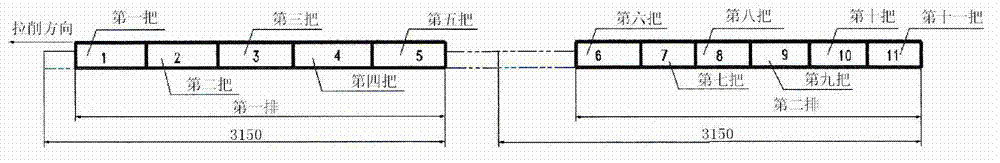

Method for machining tongues and grooves of turbine discs

InactiveCN108723481AReduce marginImprove processing qualityBroaching machinesTongue and grooveEngineering

The invention discloses a method for machining tongues and grooves of turbine discs. The method includes steps of 1), forming section grooves in turbine disc blanks along reference lines of tooth crests of tongue teeth in rough broaching stroke; 2), cutting preset tongue tooth groove locations on the side walls of the section grooves to form tongue tooth rough grooves in semi-finish broaching stroke; 3), continuing to carry out cutting on the basis of the tongue tooth rough grooves to obtain tongue tooth grooves. The method for machining the tongues and grooves of the turbine discs has the advantages that the semi-finish broaching stroke is added between the rough broaching stroke and the finish broaching stroke, the partial tongue tooth rough grooves in allowance stroke can be removed bythe aid of the semi-finish broaching stroke, then the remaining tongue tooth grooves in the allowance stroke can be removed by the aid of the finish broaching stroke, finish broaching tools and semi-finish broaching tools are jointly responsible for tongue tooth groove allowance cutting, accordingly, allowance required to be cut by the various broaching tools can be reduced, broaching force in broaching procedures can be reduced, tool damage phenomena can be prevented, and the purposes of protecting the broaching tools, prolonging the service lives of the broaching tools and improving the component machining quality can be achieved.

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

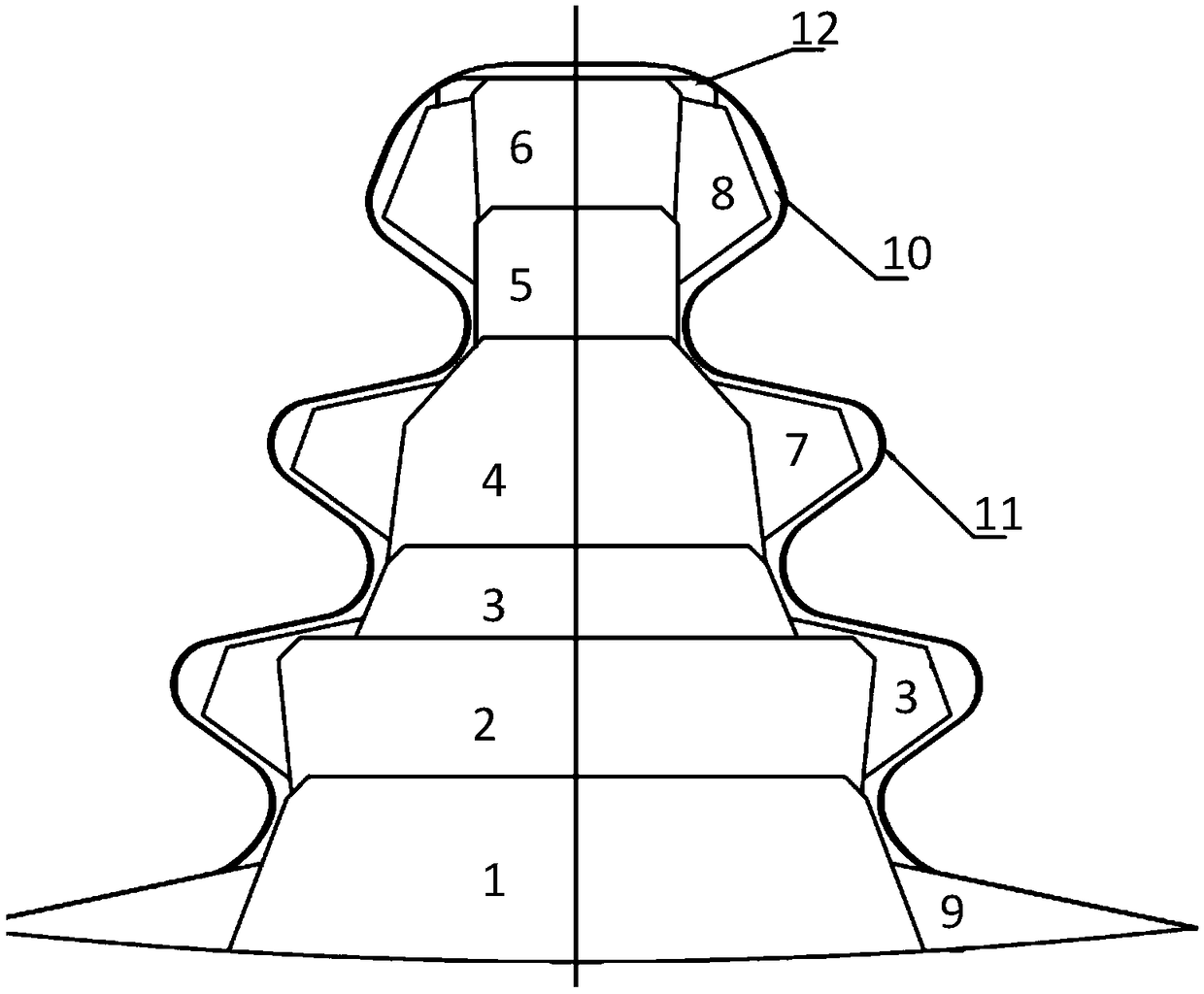

Broaching method and special tool for high-accuracy small-sized mortises

InactiveCN103071853AGuaranteed lifeGuaranteed durabilityBroaching toolsBroaching machinesAir compressorTurbine

The invention discloses a broaching method and a special tool for high-accuracy small-sized mortises. A special broaching tool is used for machining a to-be-machined workpiece. The structure of the special broaching tool meets the requirement that straight chamfers or / and round chamfers capable of participating in broaching are arranged on tooth crests of the broaching tool. The broaching method for the high-accuracy small-sized mortise meets the requirements that a broaching machining allowance elimination mode comprises the step of machining the workpiece by using main blades on the tooth crests of the broaching tools or / and the chamfer parts of the broaching tools, and the chamfer parts of the broaching tool are the straight chamfers or / and the round chamfers on the two sides of blades on the tooth crests; and totally 11 broaching tools are formed into a complete set, and are sequentially used for machining all the contour shapes of the mortises. The method and the special tool are mainly applied to the broaching machining of mortises of core parts of aero-engines and gas turbines such as turbine disks and air compressor disks, can be popularized and used for like parts, and have broad application prospect in a series of new-generation aero-engines and gas turbines, and a technical bottleneck in the broaching of specially-structured high-accuracy small-sized mortises is solved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

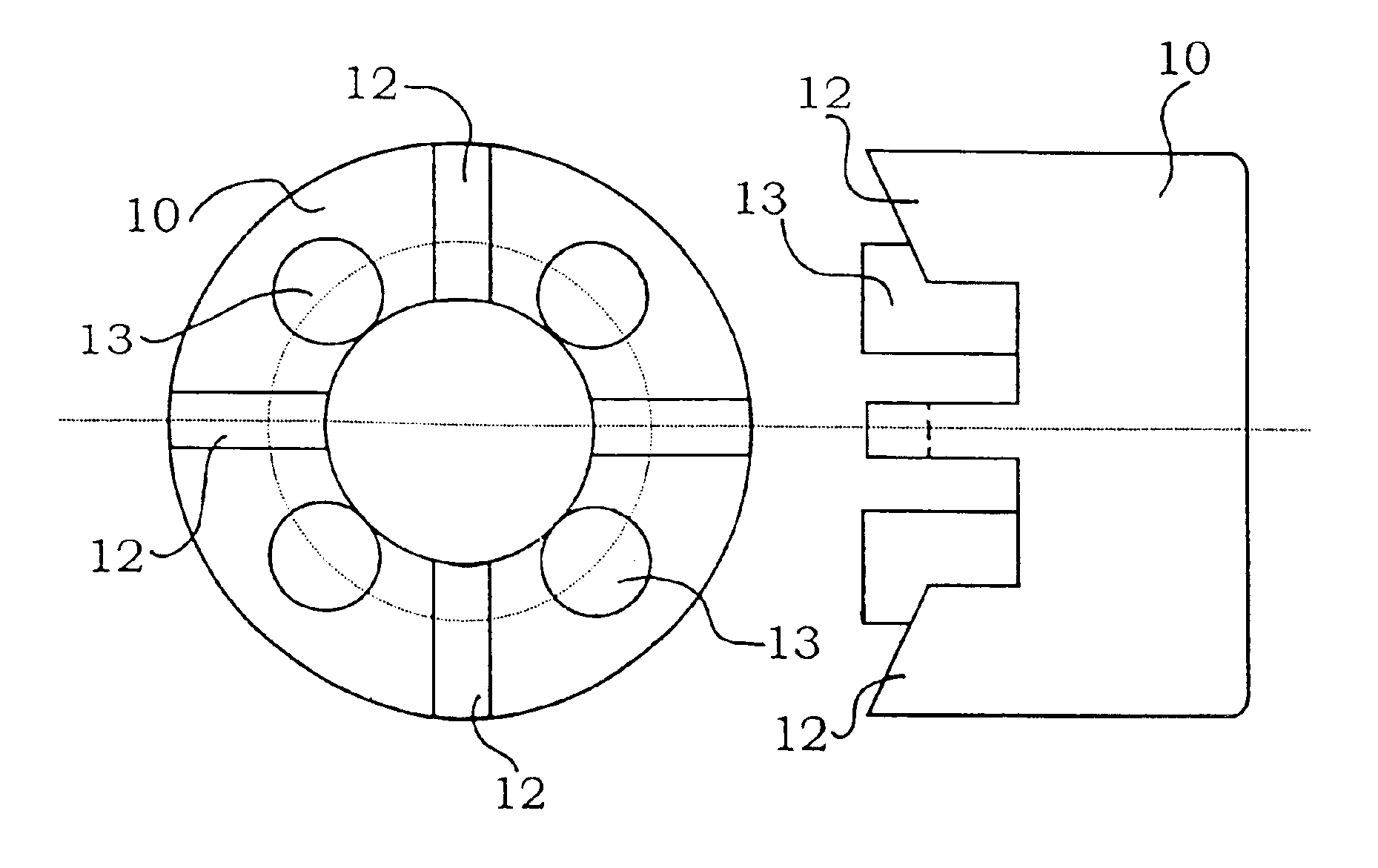

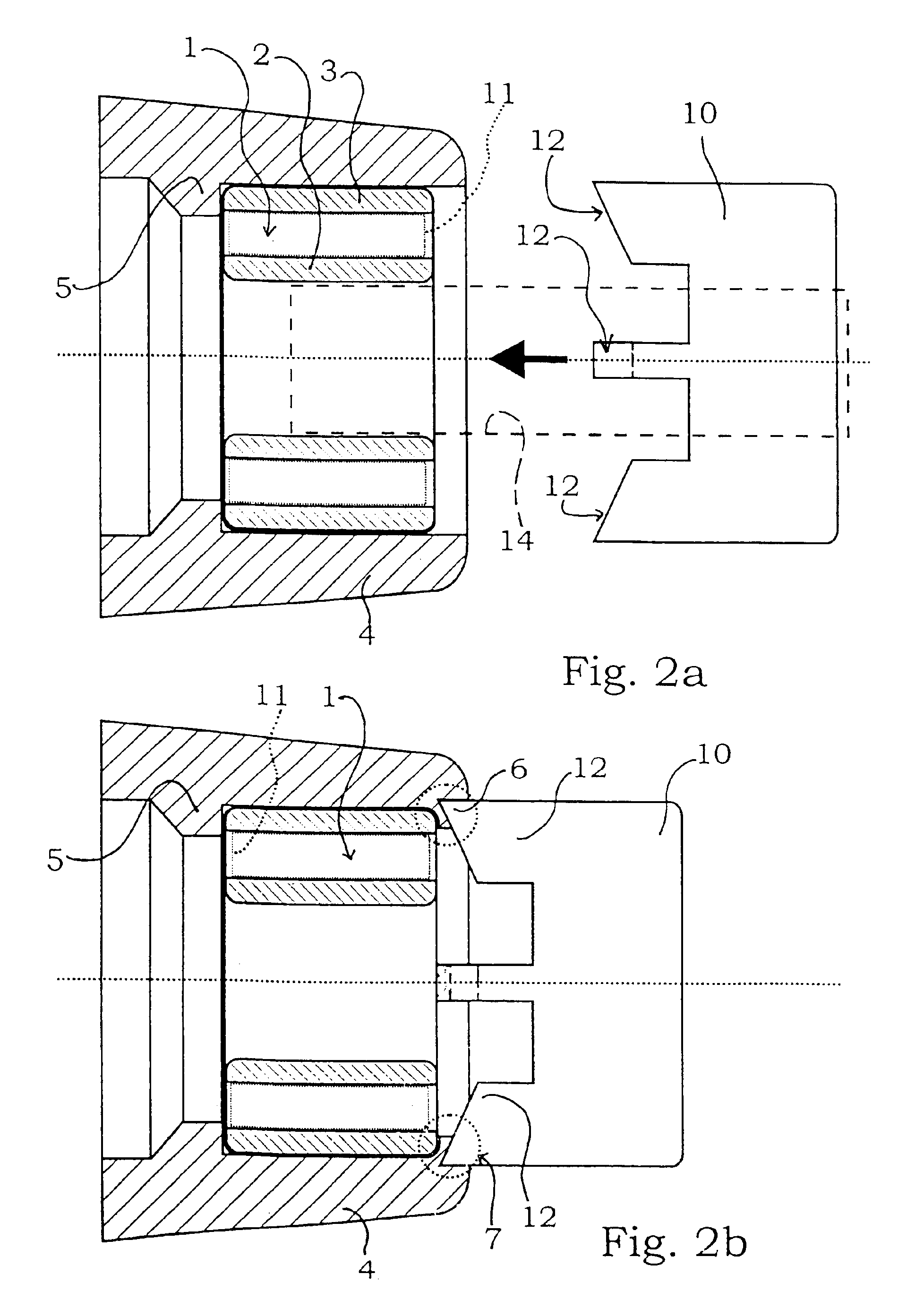

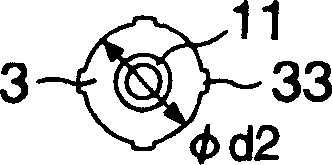

Wheel bearing assembly for motor vehicles

InactiveUS6935026B2Reduced mechanical stabilityLow costRoller bearingsBearing assemblyMobile vehicleEngineering

The invention relates to a wheel bearing assembly for motor vehicles with a bearing provided with an inner ring and an outer ring, the bearing being fitted with its outer ring into a bearing casing and the outer ring being mechanically supported in axial direction on a first side by a supporting surface provided on the bearing casing. Discrete and preferably evenly arranged stop protrusions are formed on the inner circumference of the bearing casing, the outer ring abutting thereon in axial direction on its second side, and the stop protrusions being formed by locally plastic forming the bearing casing.

Owner:VISTEON GLOBAL TECH INC

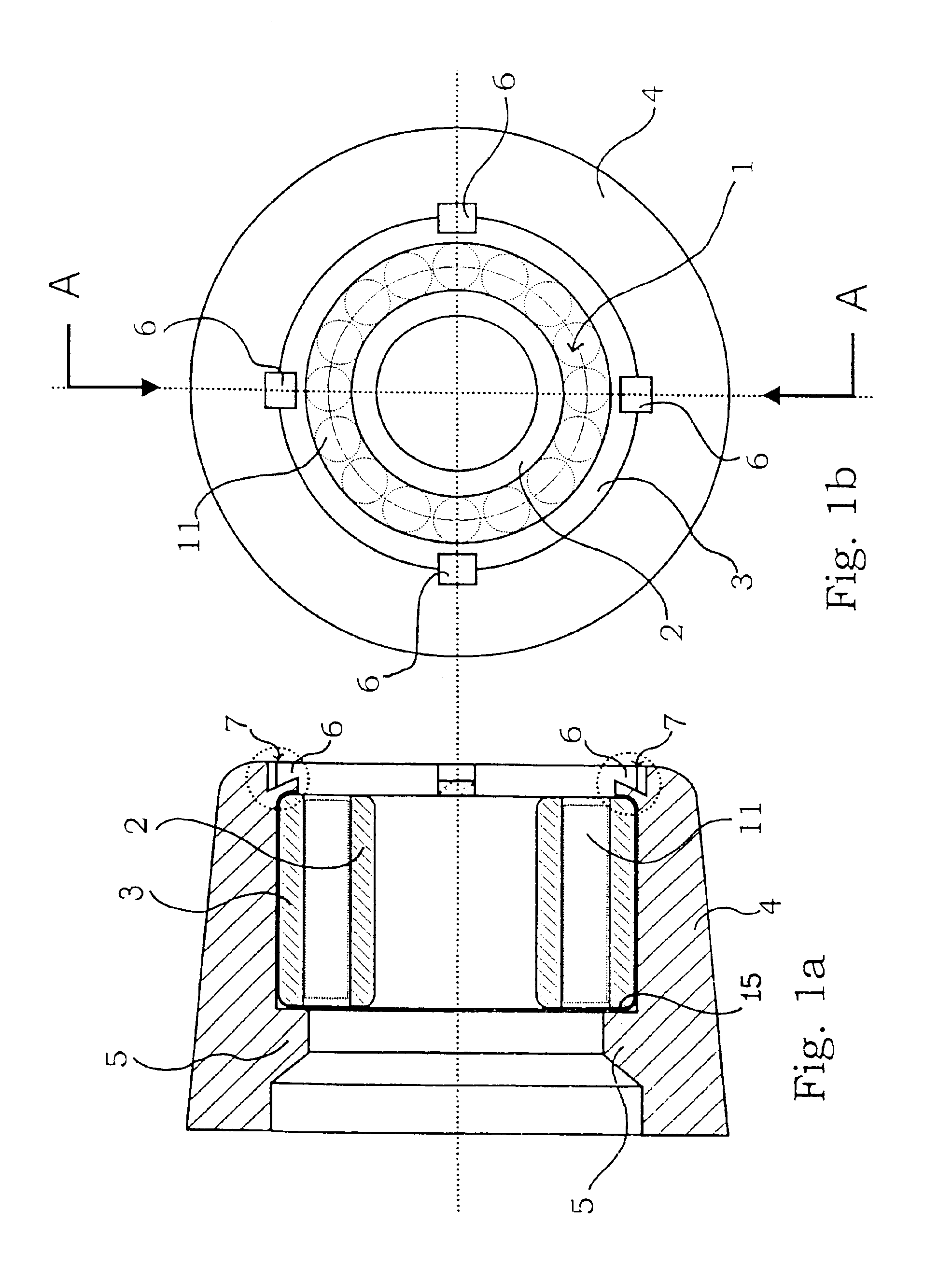

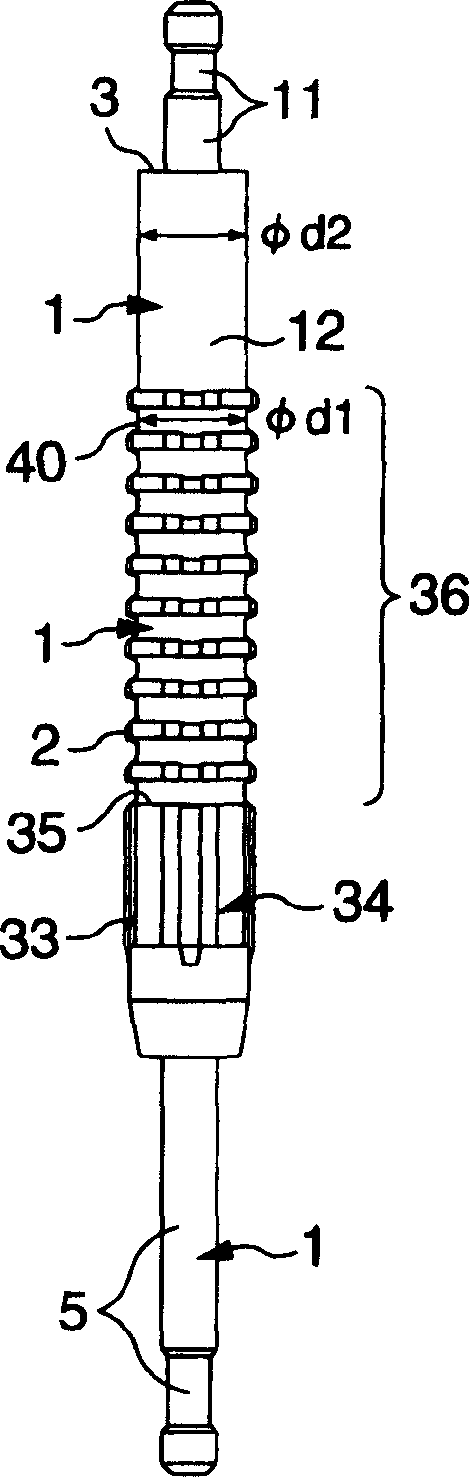

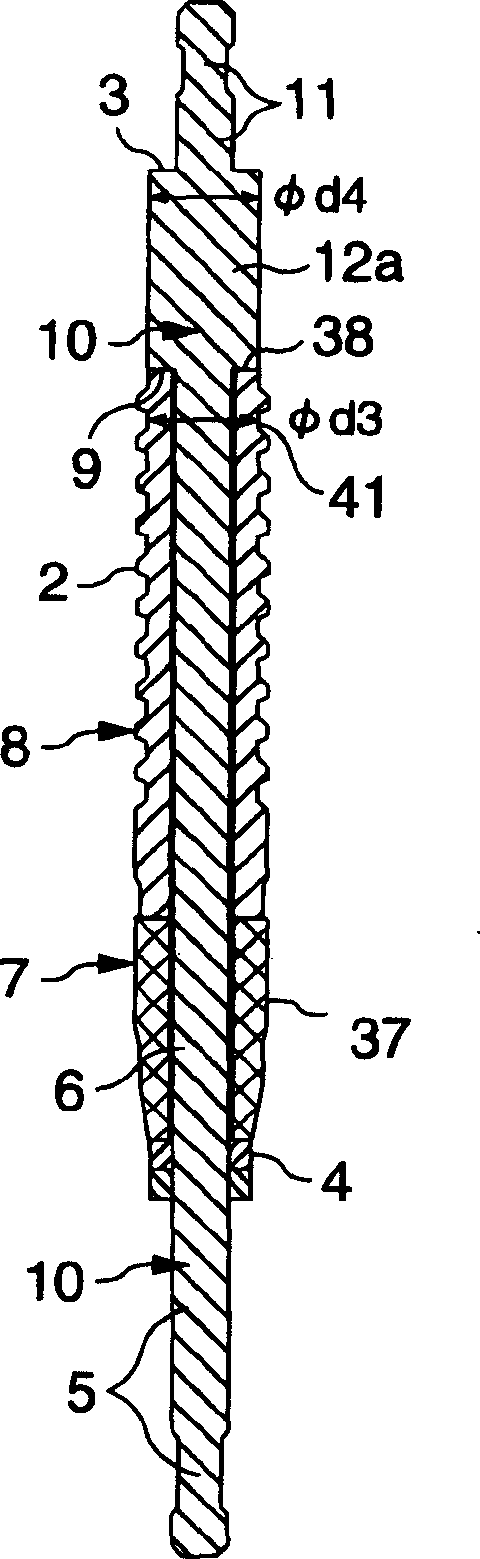

Cemented carbide broach and broaching machine

InactiveCN1550278AEasy to cutWon't breakRectilinear broachBroaching toolsEngineeringCemented carbide

A broach has a main body of a cemented carbide material. On this main body, a front grip portion, a cylindrical portion following the front grip portion and provided with a plurality of guide parts in its outer periphery, a broach cutting edge portion following an end of the cylindrical portion and having a number of cutting edges, and a cylindrical extension following the broach cutting edge portion and having a maximum outer periphery dimension to such an extent that the extension does not interfere with a work are integrally provided. On an end surface of the cylindrical extension, a load receiving shoulder is formed, which leads to a rear grip portion including a small-diameter part and is orthogonal to or inclined with respect to a broach axis. The load receiving shoulder has a sufficient area to bear a cutting load. A broaching machine grips the rear grip portion with its load receiving surface abutting against the load receiving shoulder of the cemented carbide broach. The broach, even when having a small diameter, does not suffer from an insufficient tensile strength of the front grip portion.

Owner:NACHI-FUJIKOSHI

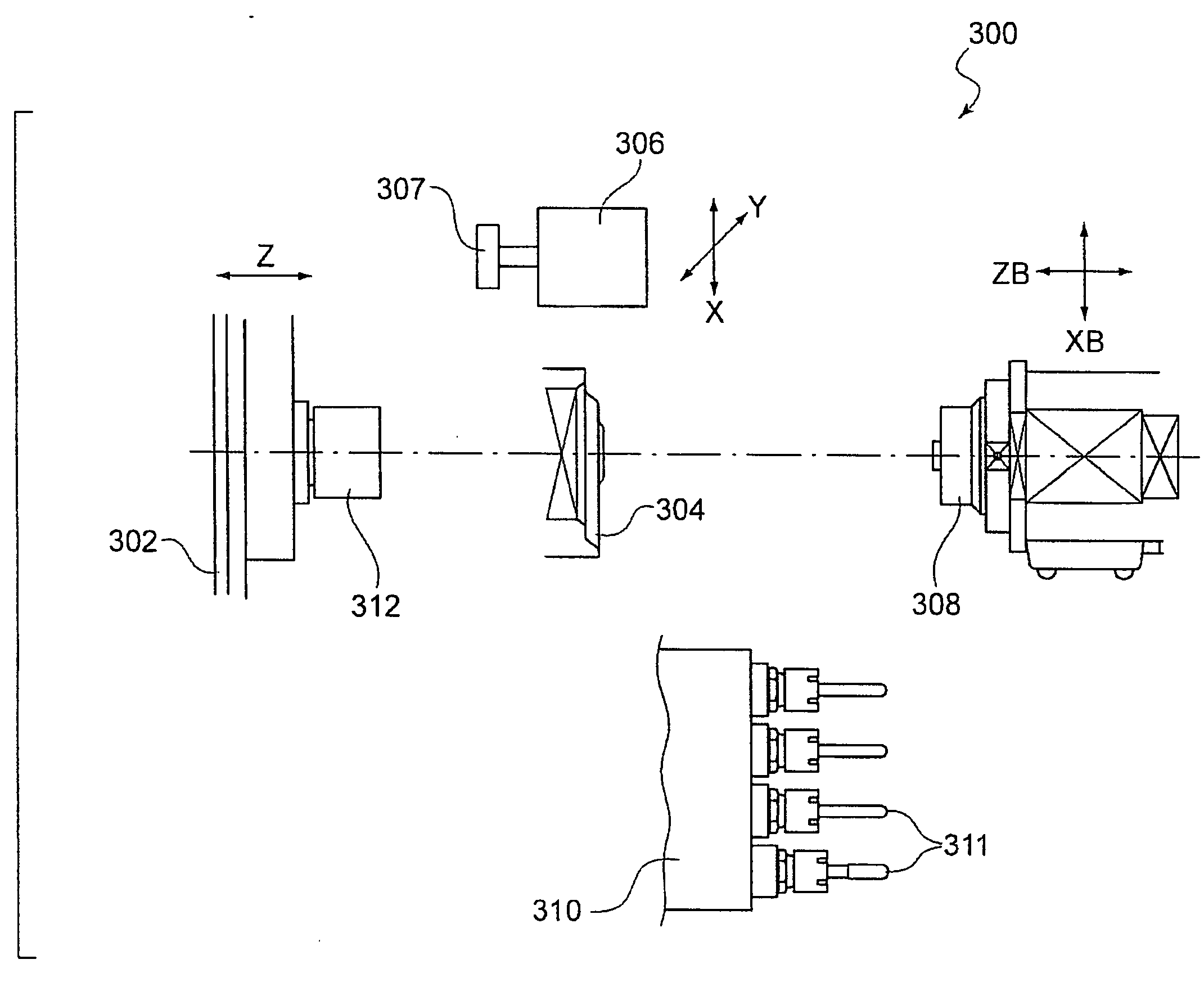

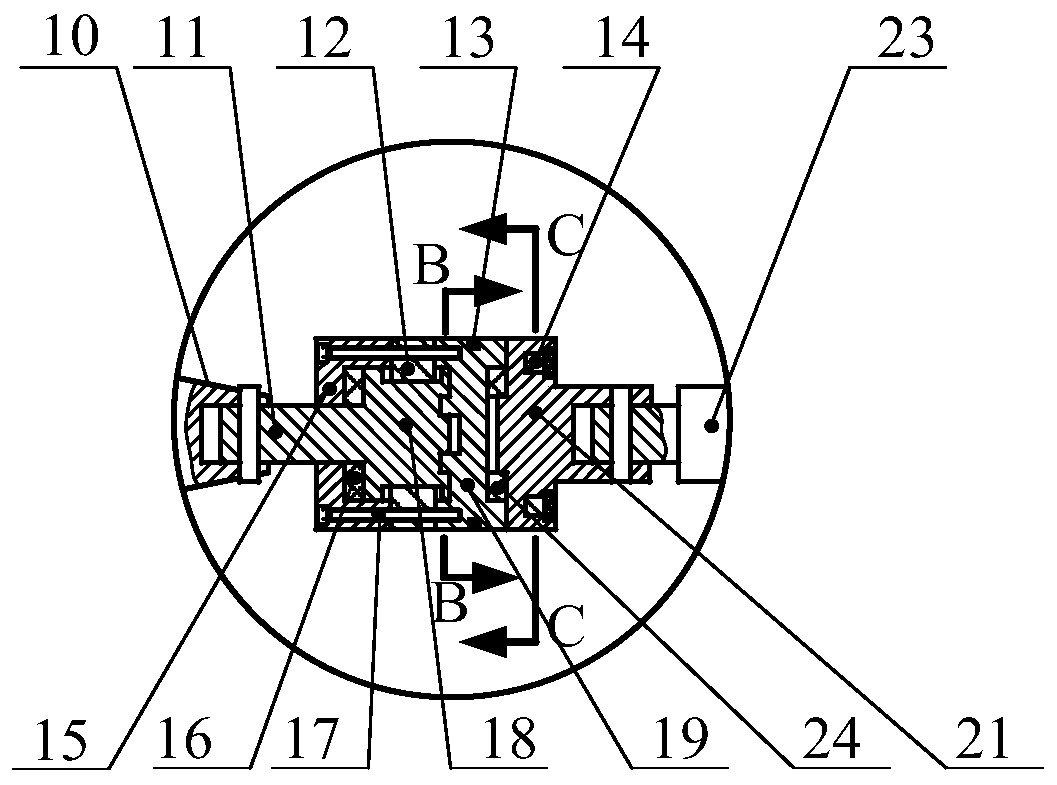

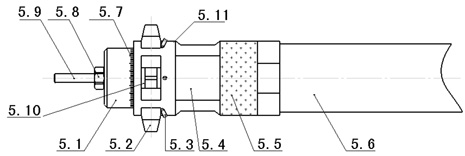

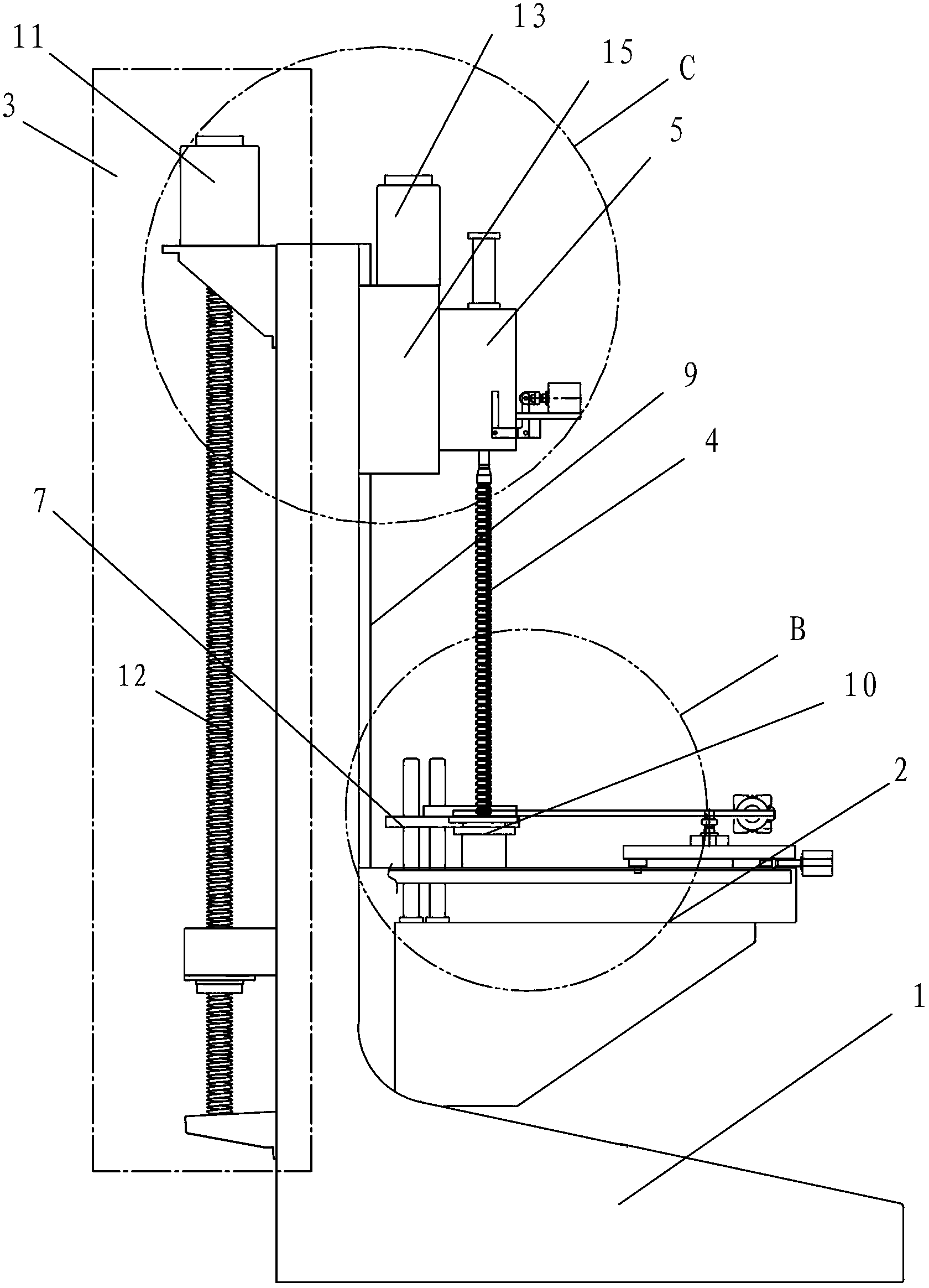

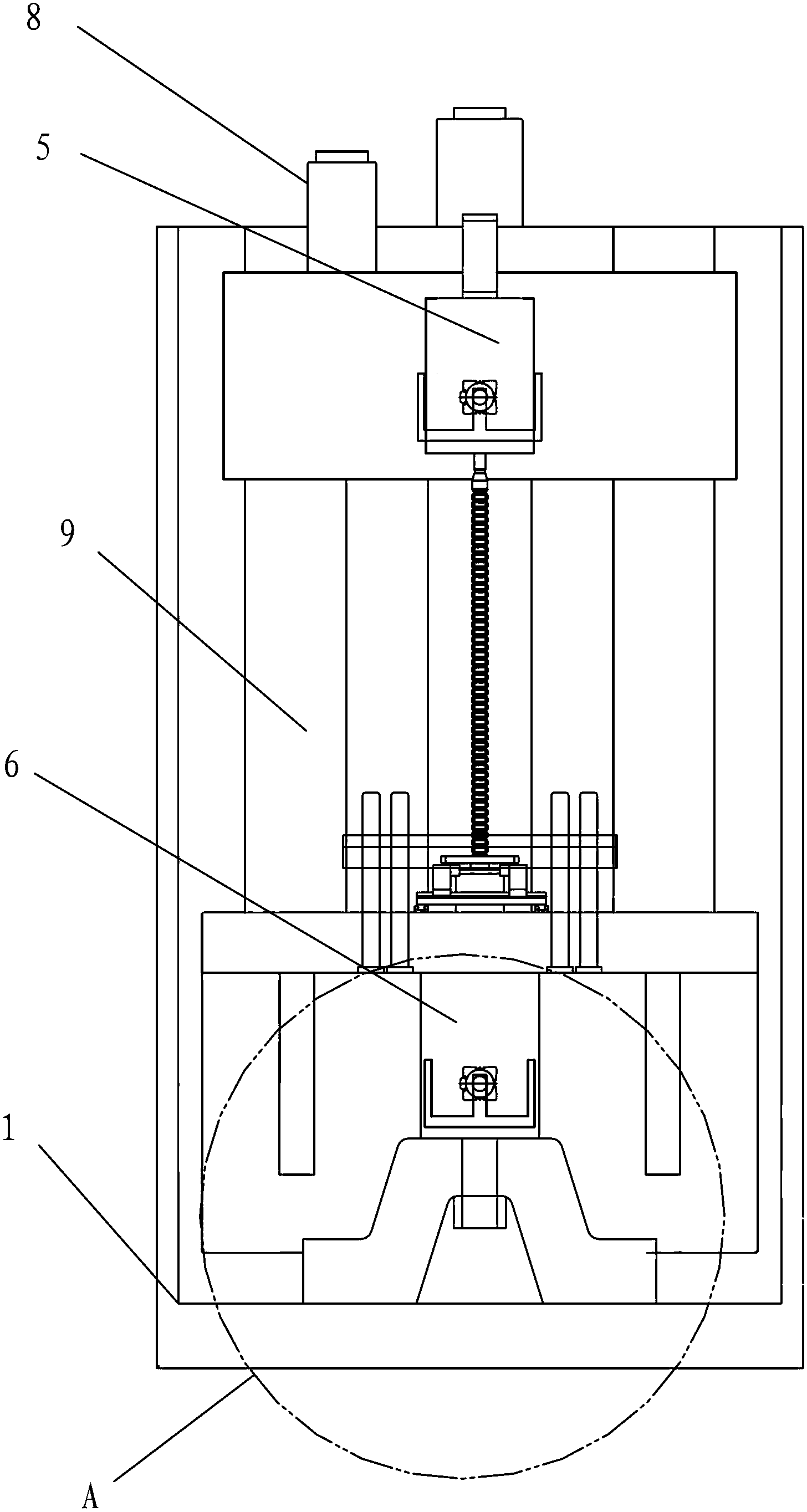

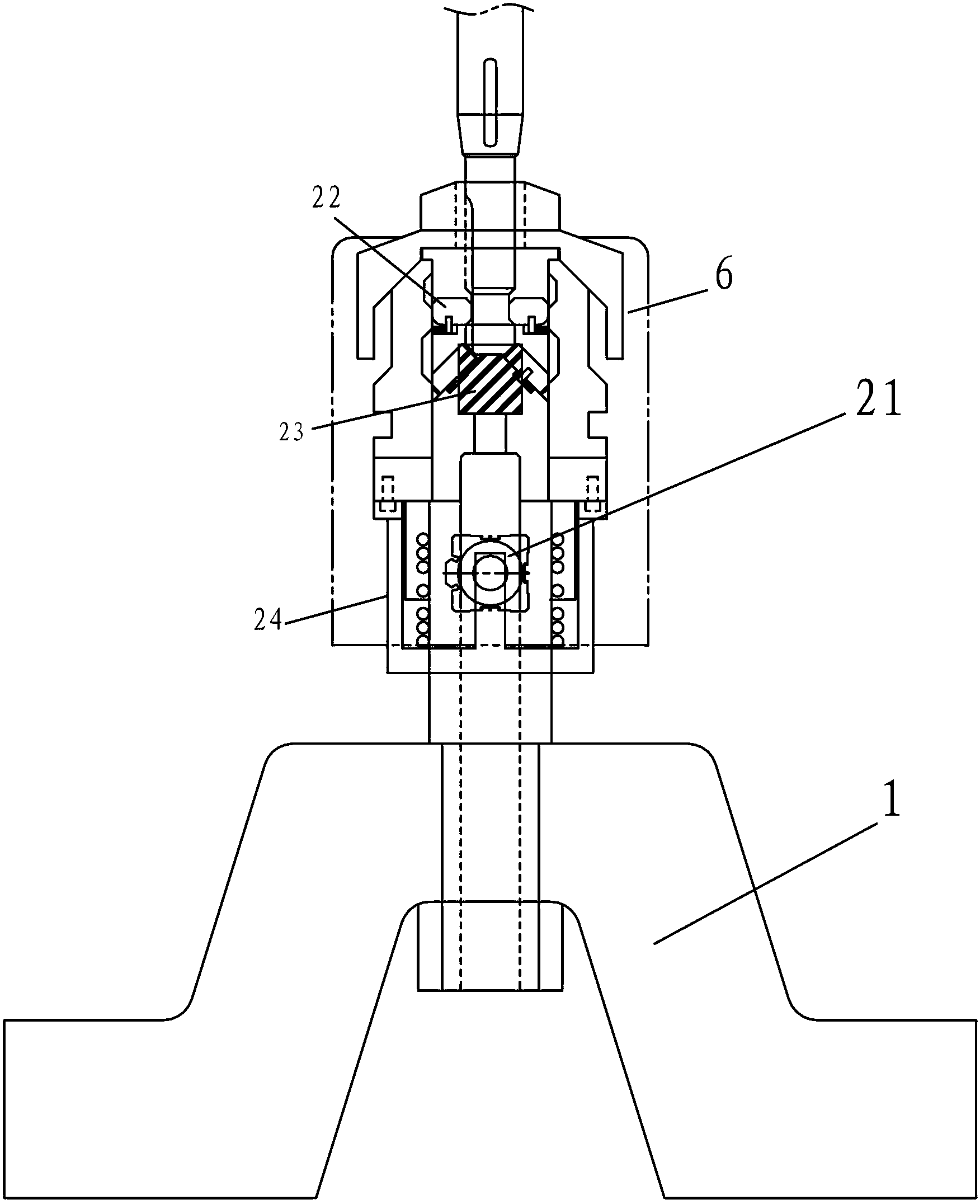

Ultrasonic broaching tool, high-efficiency precise ultrasonic broaching device and broaching process thereof

ActiveCN109967789AExtended service lifeImprove broaching efficiencyBroaching accessoriesBroaching toolsGratingUltrasonic sensor

The invention discloses an ultrasonic broaching tool, a high-efficiency precise ultrasonic broaching device and a broaching process thereof. An existing broaching tool and an existing broaching machine are not provided with integrated information acquisition devices and are short in service life. The ultrasonic broaching tool comprises an ultrasonic transducer, a detection assembly and a broachingtool body. The detection assembly comprises a detection substrate, a laser transceiving belt, an image sensor, an axial pressure sensor, a first radial pressure sensor and a second radial pressure sensor. The high-efficiency precise ultrasonic broaching device comprises a broaching machine body, an optical grating and the ultrasonic broaching tool. The broaching machine body comprises a broachingmachine drive assembly, a broaching machine body, a broaching machine guide rail and a fast positioning and clamping device. A broaching tool three-directional vibration value, a broaching tool axialtensile force, a broaching tool displacement value, and a workpiece dimension based on an image are measured. Real-time detection data is provided for a working condition feedback loop and a stop control loop of a control system. The service life of the broaching tool can be effectively prolonged.

Owner:HANGZHOU DIANZI UNIV

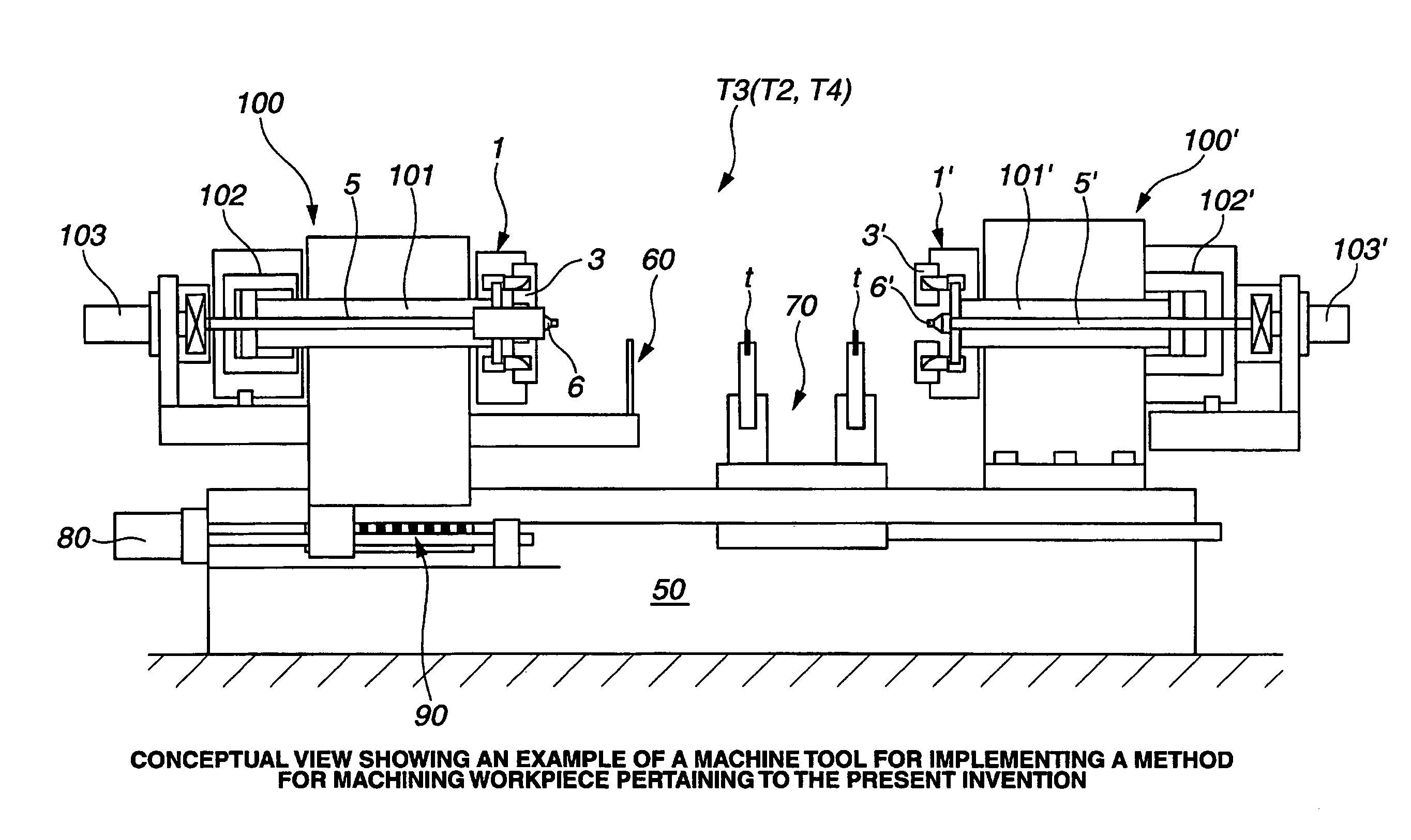

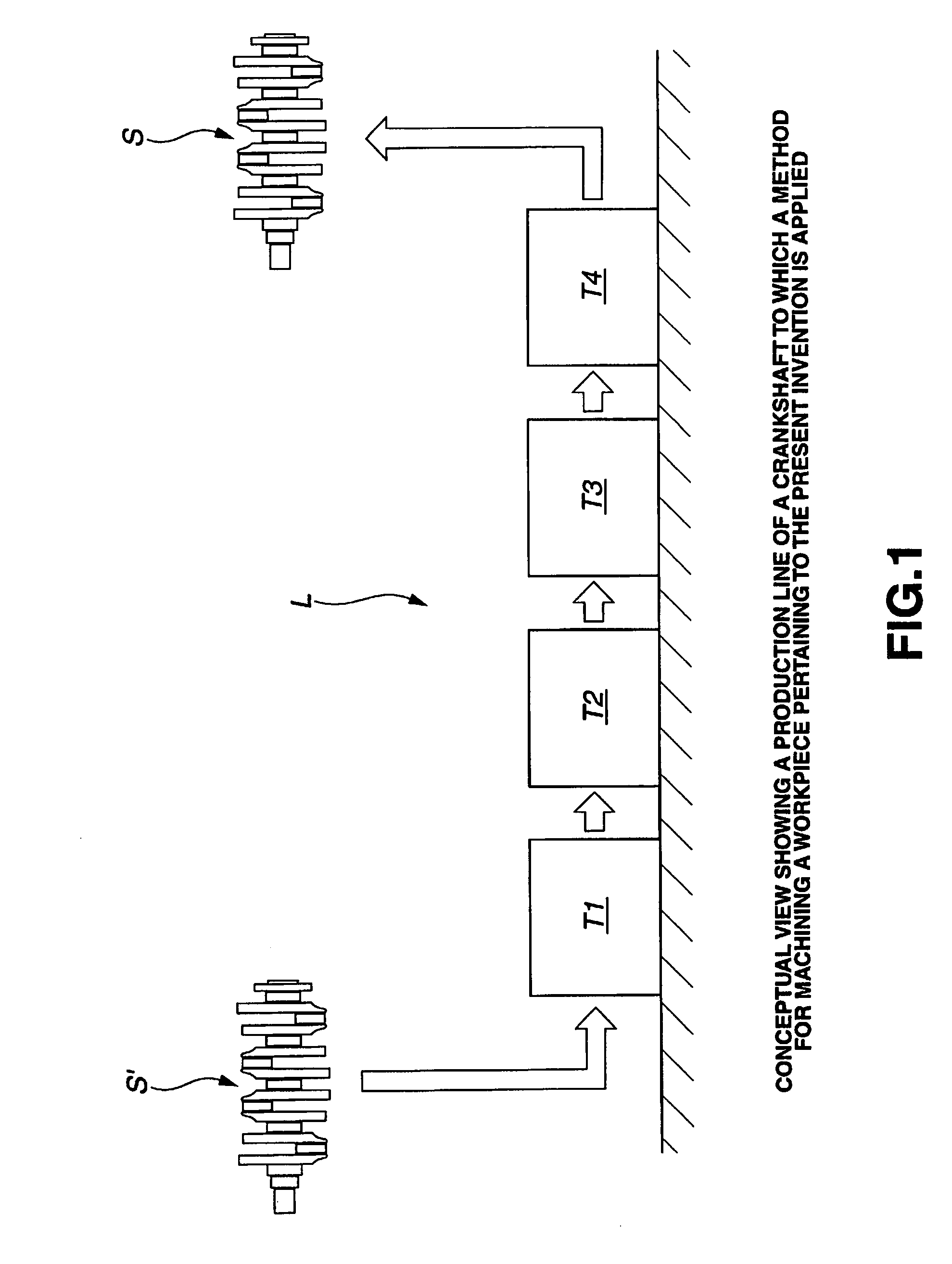

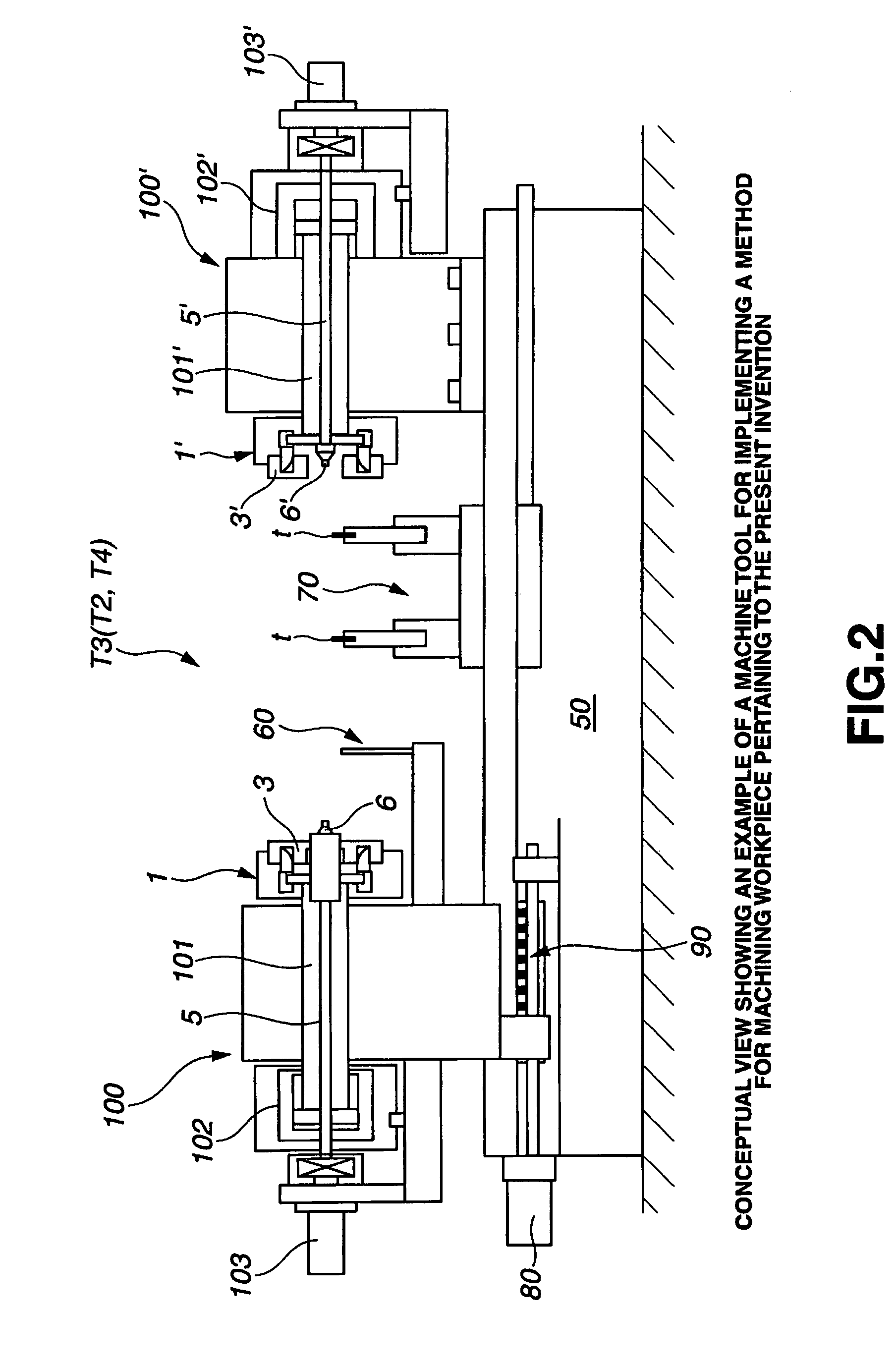

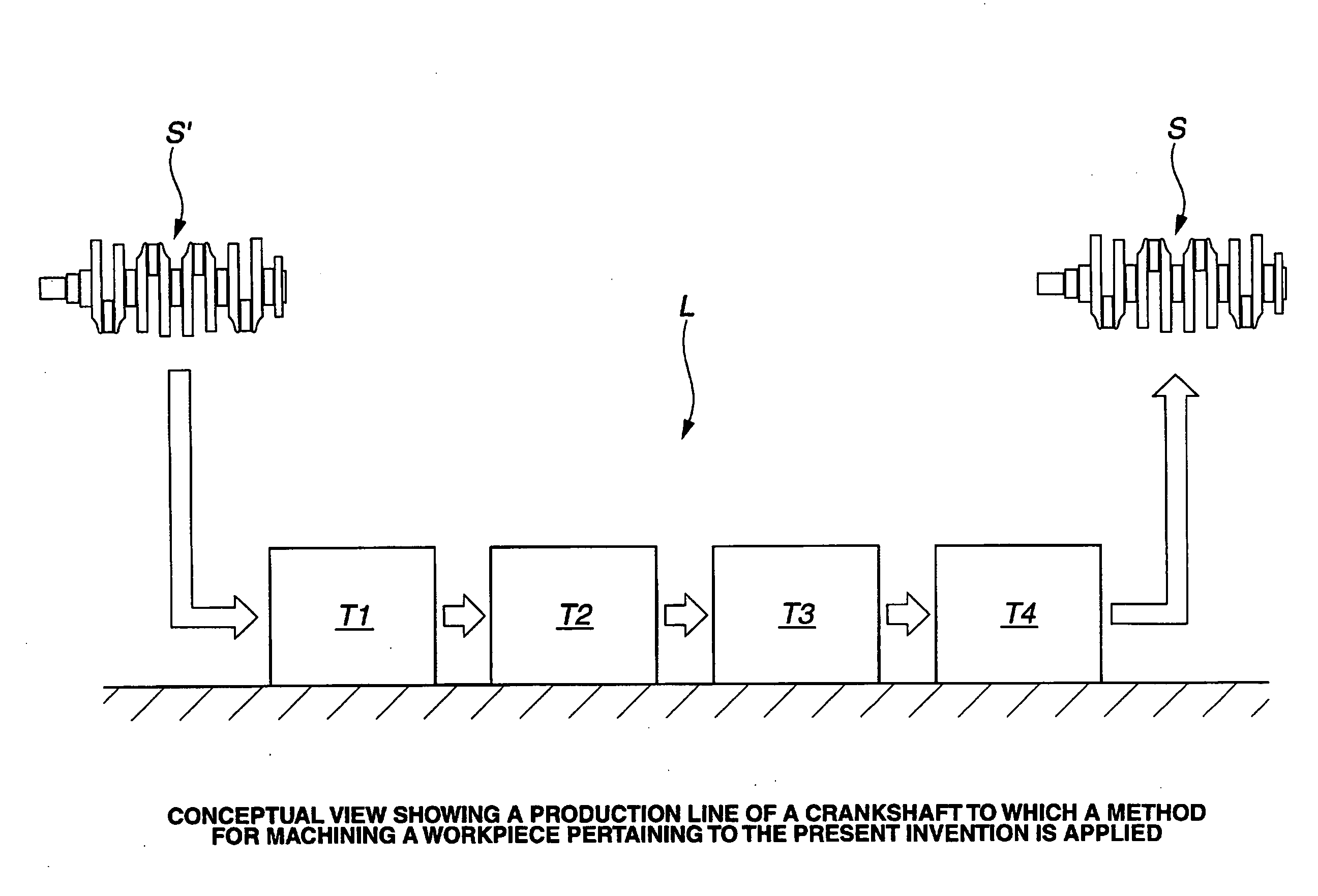

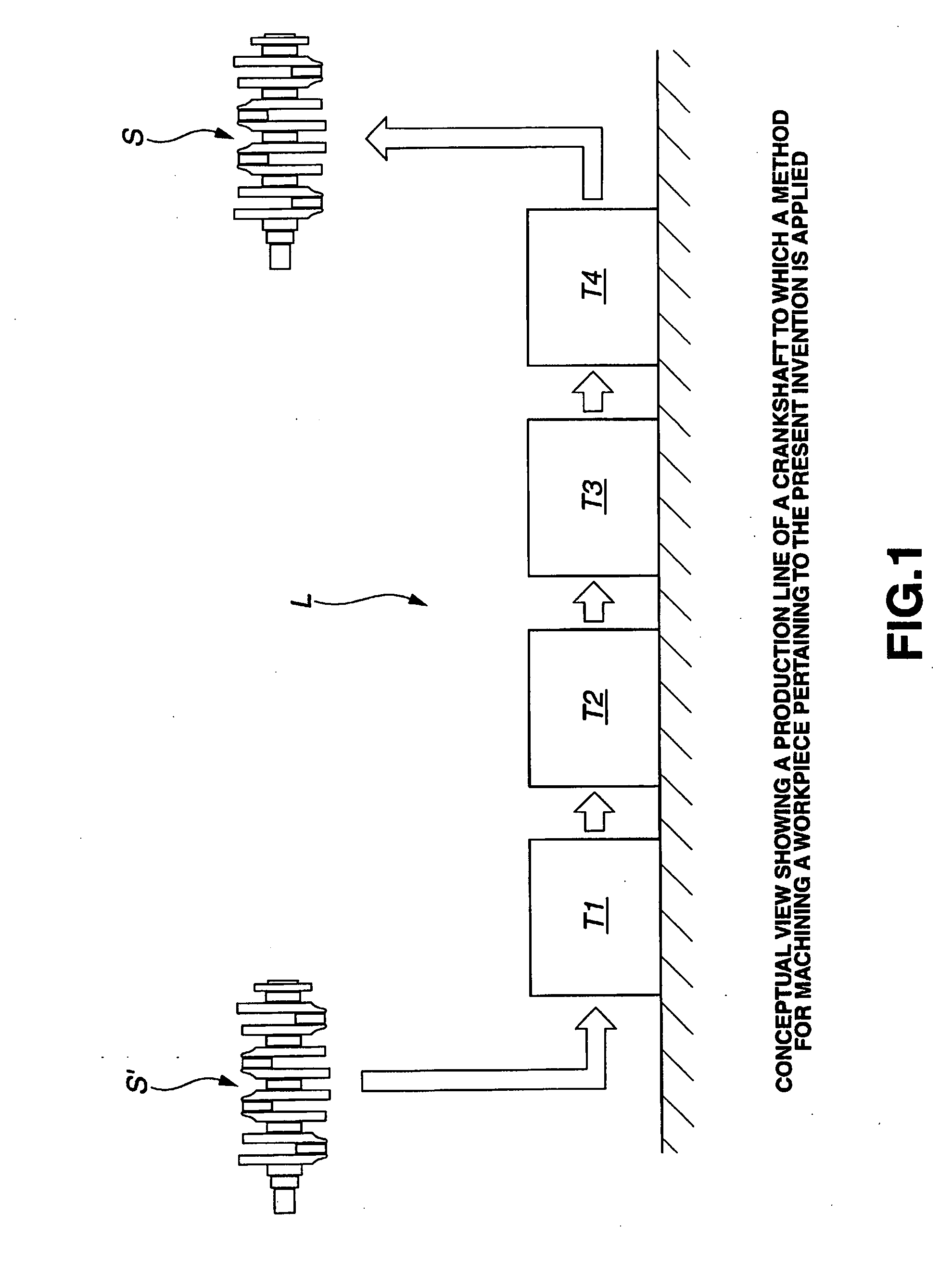

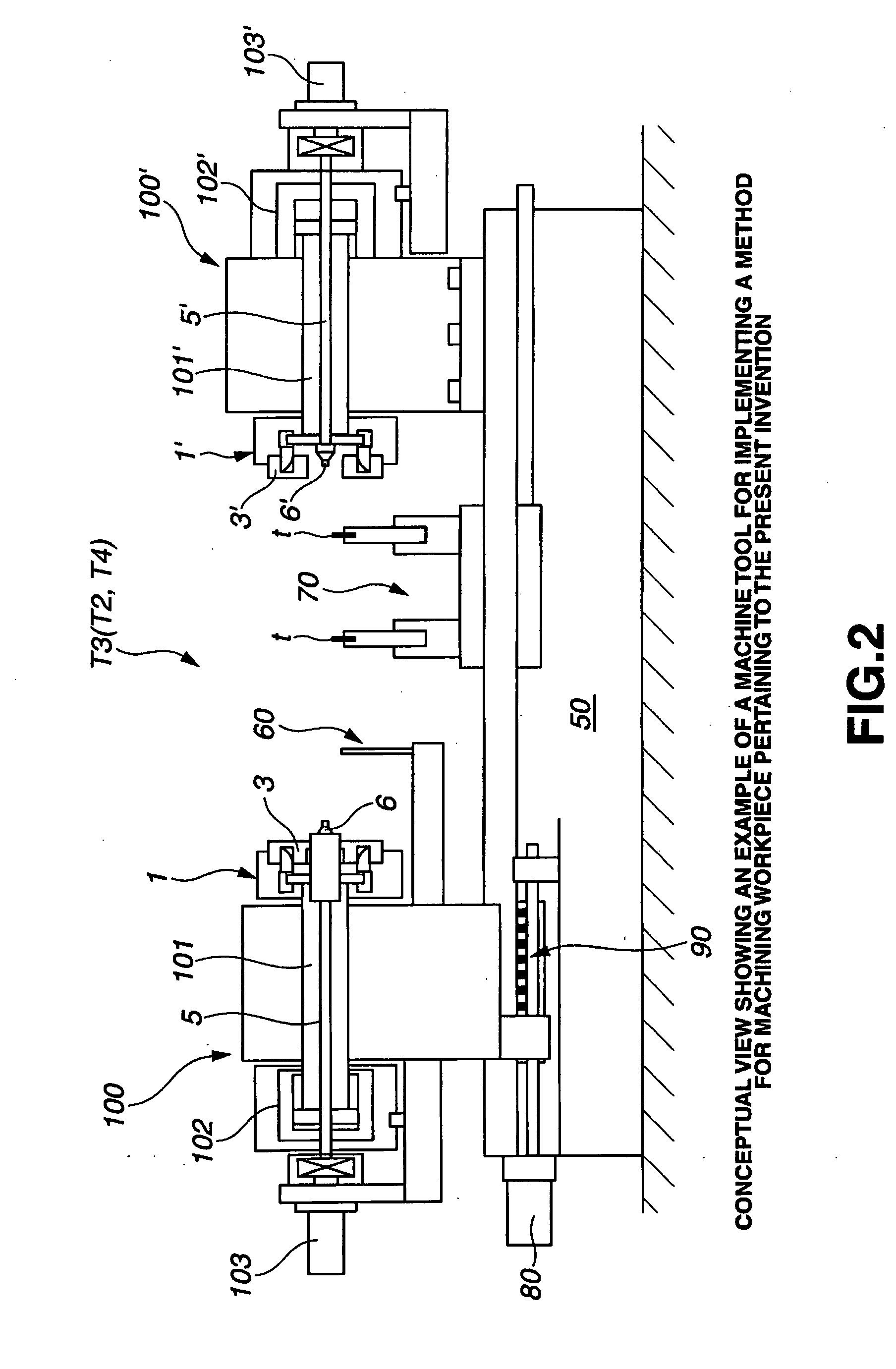

Method for machining a workpiece

A method for machining a workpiece in which a machine tool comprising a first and a second chuck devices is employed to machine the workpiece, the machine tool being used in which the first and the second chuck devices comprise a chuck main body, plural chuck jaws, a chuck jaw drive body, and a pressing member, the method comprising: machining a clamp part of the other end part of the workpiece in a state where one end part of the workpiece is clamped by the first chuck device; machining a clamp part of the one end part of the workpiece in a state where the clamp part of the other end part of the workpiece is clamped by the second chuck device; and executing desired machining on the workpiece in a state where each of the clamp parts are clamped by each of the chuck devices.

Owner:KOMATSU NTC LTD

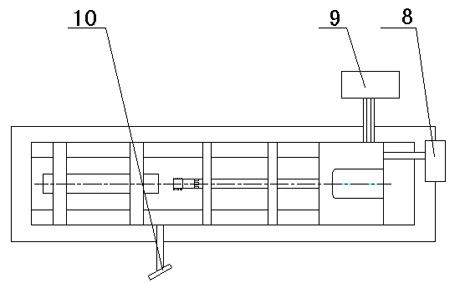

Numerical control machine for contour broach of internal screw of constant-wall-thickness stator and use method

InactiveCN102430798AFix production issuesMeet processing technical requirementsBroaching machinesNumerical controlPush and pull

The invention relates to a numerical control machine for contour broach of an internal screw of a constant-wall-thickness stator and a use method. In a technical scheme, the numerical control machine mainly comprises a machine body, a push-and-pull system, a rotating system, a cutter system, a hydraulic system, an electrical control cabinet and a control system, wherein the cutter system mainly comprises a cutter blade, a cutter body and a cutter bar, the cutter body is provided with a cuttings accommodating slot for accommodating cuttings produced by the cutter, a clamping slot for the cutter blade is arranged at the front part of the cuttings accommodating slot and is used for installing and adjusting the cutter blade, and a metal hair brush is arranged on the cutter body and rotates along with the cutter bar to clean away cuttings; and the cutter body is connected with the cutter bar and is hollow, and cooling fluid can be transferred through the hollow portion during machining. Inthe invention, the mature deep hole machining technology and equipment are used as a platform, the gun barrel rifling and broaching equipment and process technology are combined, the machining mannerof workpiece fixation as well as cutter rotation and feeding is adopted, and a special numerical control contour broach machine is designed and manufactured.

Owner:DONGYING BOSUN GASOLINEEUM MACHINERY

Hard broaching finish machining process for surface of internal keyway and device

InactiveCN102699419AGuaranteed stabilityOvercoming the challenges of broachingBroaching toolsBroaching machinesMachining processMachine tool

The invention relates to a hard broaching finish machining process for a surface of an internal keyway. The internal keyway of a part is sleeved at one end of a cutter which is same with the internal keyway in shape to fix both ends of the cutter so that the part moves along the cutter axially at a speed of 4-10m / s. During movement, deviation of the center of the internal keyway in the part and the axis of the cutter is maintained smaller than or equal to 0.01mm. The cutter is of a sectionally differential stepped structure. The blade hardness is greater than or equal to HRC67. The invention further provides a hard broaching finish machining device for the surface of the internal keyway. Both ends of the cutter are respectively fixed on an upper tool apron and a lower tool apron which are located above and below a work table and installed coaxially. A work table drive device drives the work table to move along a guide rail on a machine tool body to realize high speed machining of an internal spline of a workpiece to be machined. The hard broaching finish machining process for the surface of the internal keyway and the device provided by the invention are simple in process method and reasonable in structure of the device, and has high machining precision and efficiency for internal keyways, and low cost and energy consumption, and industrialized production can be realized in a large scale.

Owner:尹时中

Method for machining a workpiece

A method for machining a workpiece in which a machine tool comprising a first and a second chuck devices is employed to machine the workpiece, the machine tool being used in which the first and the second chuck devices comprise a chuck main body, plural chuck jaws, a chuck jaw drive body, and a pressing member, the method comprising: machining a clamp part of the other end part of the workpiece in a state where one end part of the workpiece is clamped by the first chuck device; machining a clamp part of the one end part of the workpiece in a state where the clamp part of the other end part of the workpiece is clamped by the second chuck device; and executing desired machining on the workpiece in a state where each of the clamp parts are clamped by each of the chuck devices.

Owner:KOMATSU NTC LTD

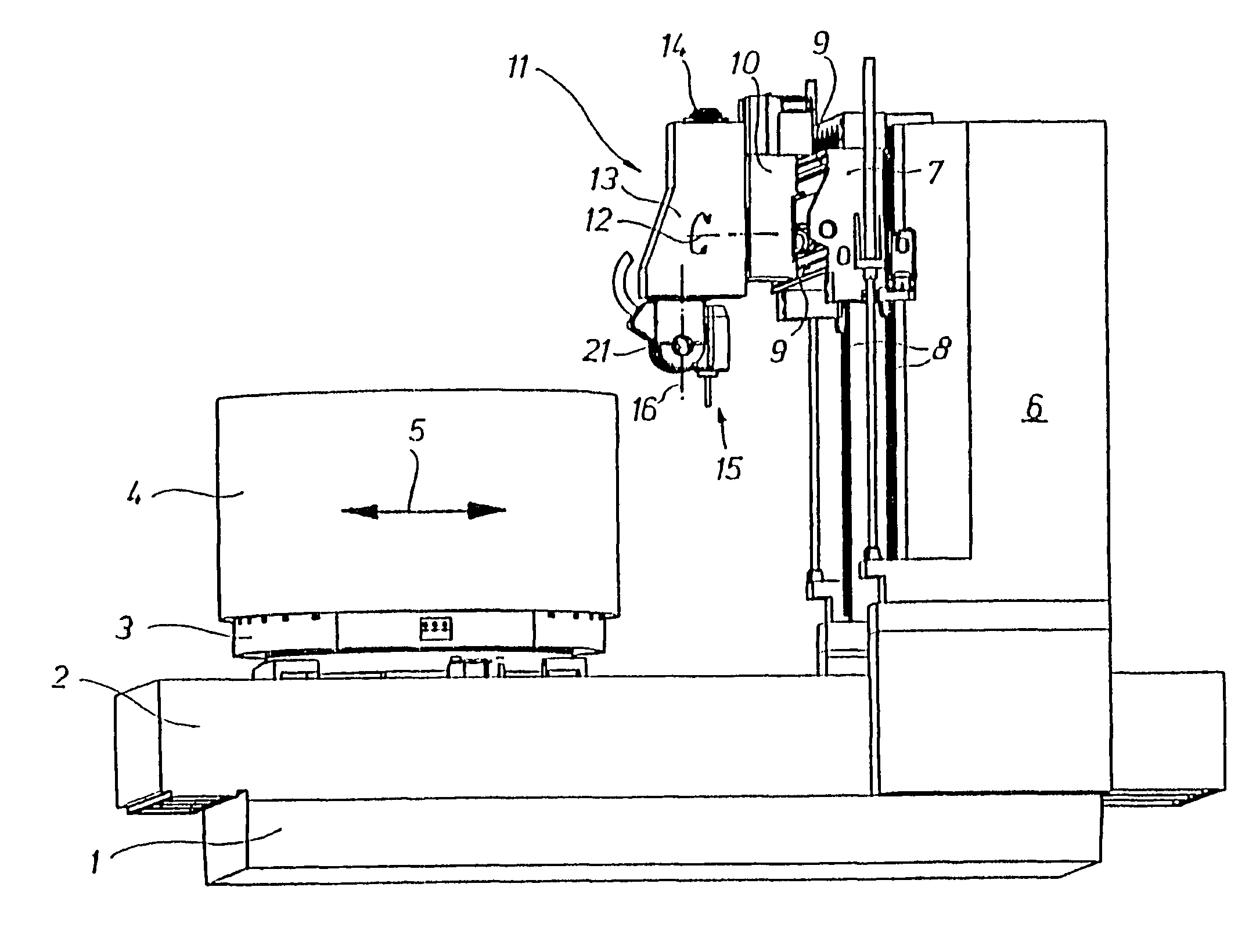

Spindle head for a universal milling machine

InactiveUS7134173B2Increase in sizeReduce delaysMachine tool componentsMilling machinesMachine parts

Owner:DECKEL MAHO PFRONTEN GMBH

Vertical type internal broaching machine

InactiveCN101337291AAvoid bendingExtended service lifePositioning apparatusBroaching machinesEngineeringMechanical engineering

The invention discloses a vertical internal broaching machine, which comprises a vertical frame, a broaching tool and a main fluid drive component, wherein the main fluid drive component is mounted on the vertical frame. The vertical internal broaching machine further comprises a pneumatic clamping mechanism, a griffe movable plate, a griffe cylinder, a guide pole of the griffe movable plate, and a pneumatic flashboard mechanism. The pneumatic clamping mechanism can clamp the tail part of the broaching tool; the pneumatic flashboard mechanism can clamp the head part of the broaching tool; the pneumatic clamping mechanism is fixed on the griffe movable plate; the griffe movable plate is arranged on the guide pole of the griffe movable plate; the griffe cylinder is connected with the guide pole of the griffe movable plate, and can control the guide pole of the griffe movable plate to move upwards and downwards; and the pneumatic flashboard mechanism is fixed on the main fluid drive component. The vertical internal broaching machine adopts pneumatic power to perform assistant actions, enables rapid clamping and back stroke, optimizes the product structure, increases the production efficiency, reduces the manufacture cost, and lowers the consumption of production energy.

Owner:庄全林

Broaching apparatus and method for producing a gear member with tapered gear teeth

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com