Patents

Literature

328results about How to "Fix production issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

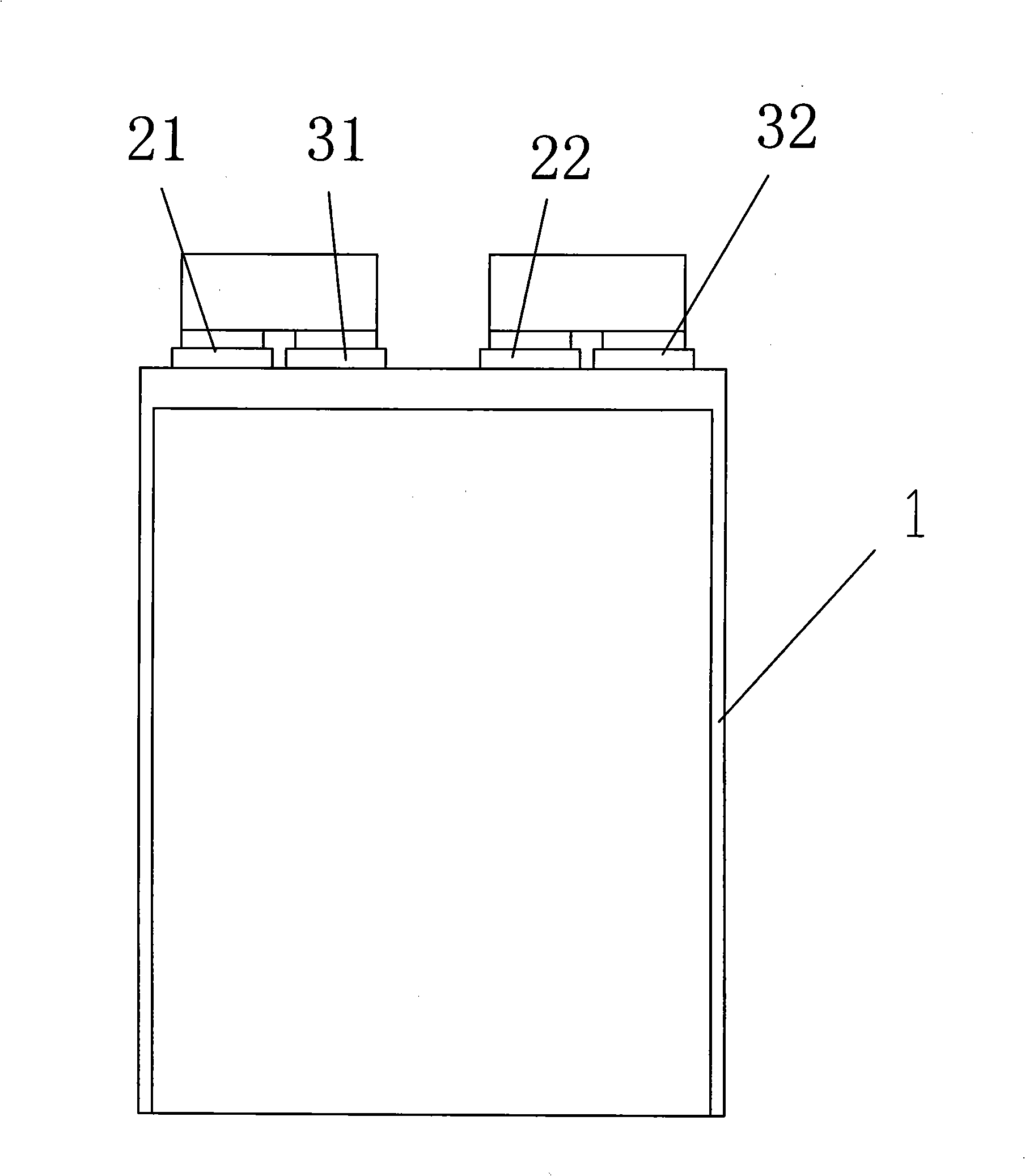

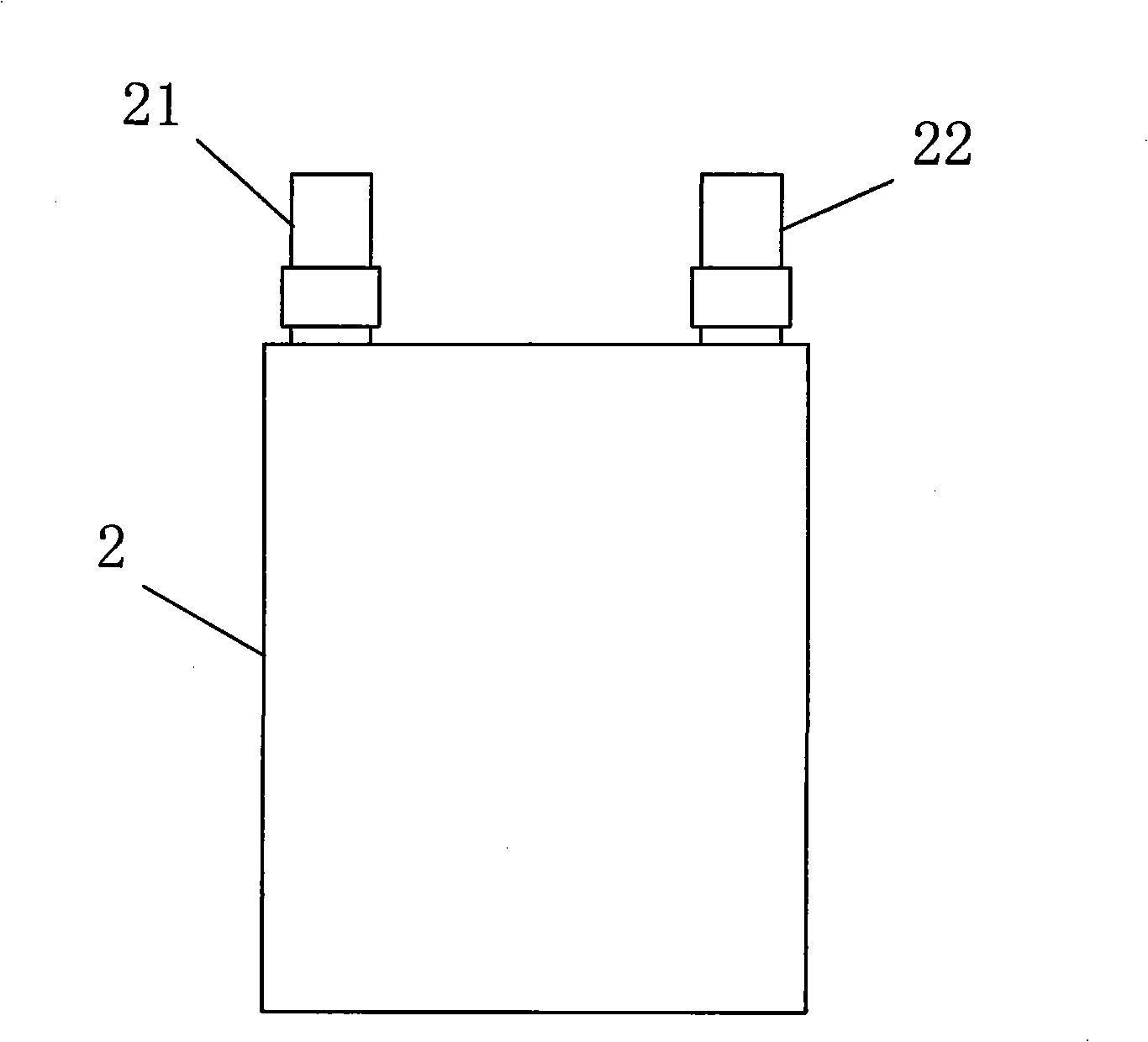

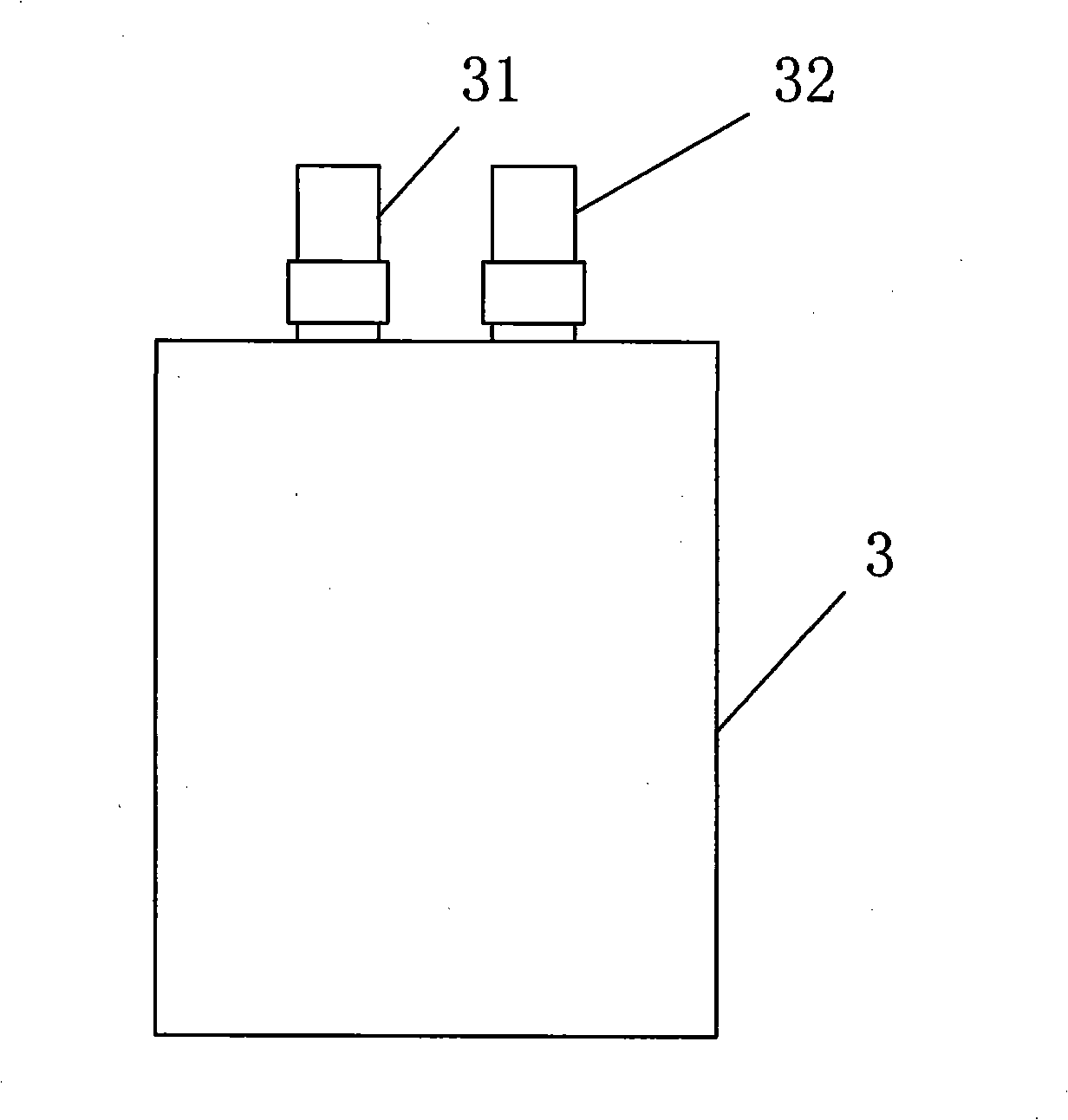

Large-capacity high power polymer ferric lithium phosphate power cell and preparation method thereof

InactiveCN101409369AImprove securityIncrease capacityElectrode manufacturing processesFinal product manufactureSlurryElectric vehicle

The invention discloses a large-capacity high-power polymer lithium iron phosphate power battery. The weight ratio of anode slurry is as follows: 81 to 85 percent of lithium iron phosphate, 1 to 5.5 percent of superconduction carbon, 0 to 2.5 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 0 to 2.5 percent of crystalline flake graphite, 0 to 2 percent of carbon nanometer tube as well as 6 to 7.5 percent of polyvinylidene fluoride; the weight ratio of cathode slurry is as follows: 89 to 91 percent of cathode material, 1 to 3.5 percent of superconduction carbon, 0 to 2 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 2.5 to 3.5 percent of styrene-butadiene rubber as well as 1.5 to 2 percent of sodium carboxymethyl cellulose; the steps for preparing the battery are as follows: preparing slurry, coating the anode and the cathode, rolling and pressing a polar plate, transversely and separately cutting the polar plate, baking the polar plate, welding the polar ears of the anode and the cathode, preparing a battery cell, putting the electric core into a shell and sealing, baking the electric core, injecting liquid into the battery as well as forming the battery and dividing the volume of the battery. The invention relates to a lithium-ion secondary battery which can provide drive energies for electric tools, electric bicycles, motor cars and electric vehicles.

Owner:MCNAIR TECH

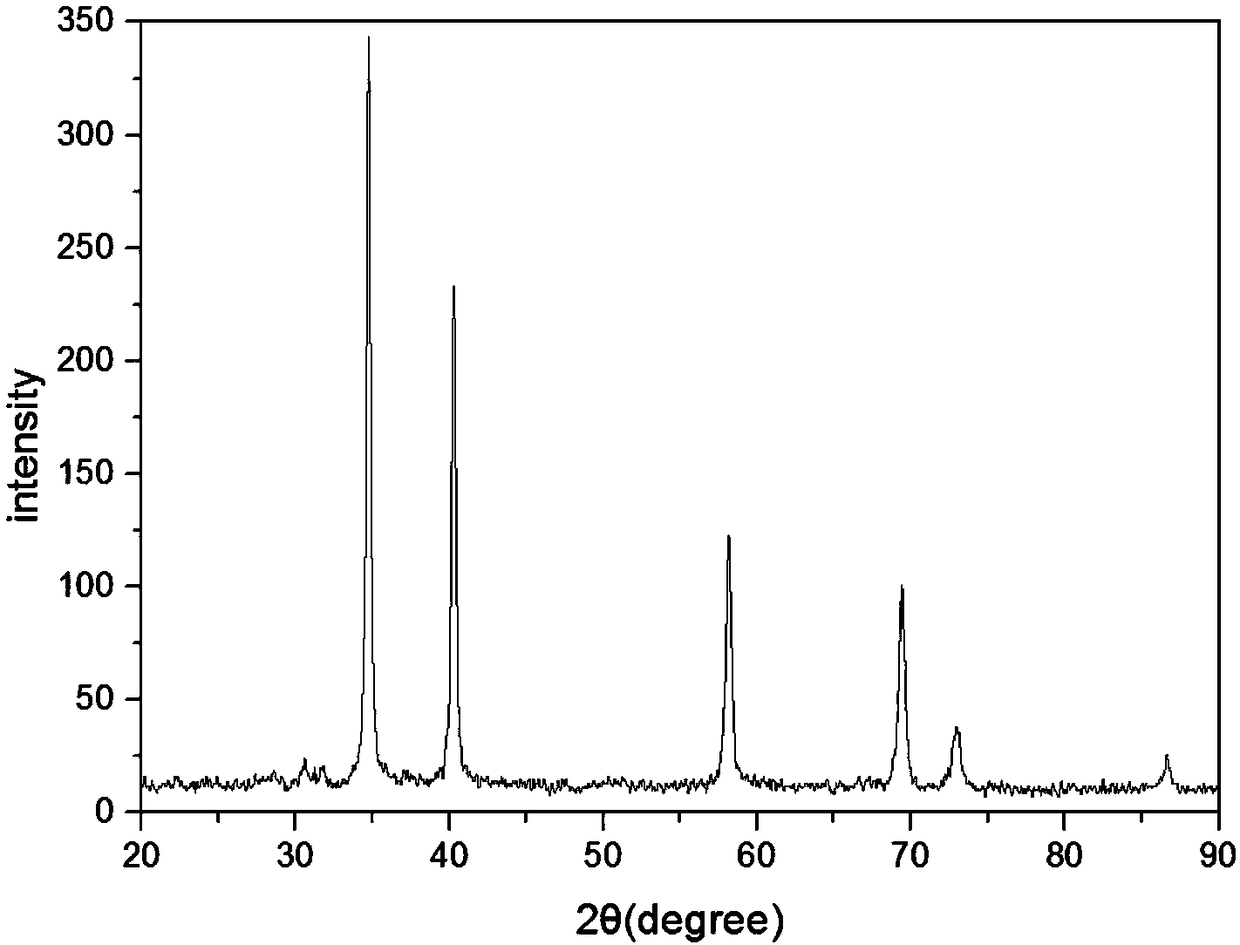

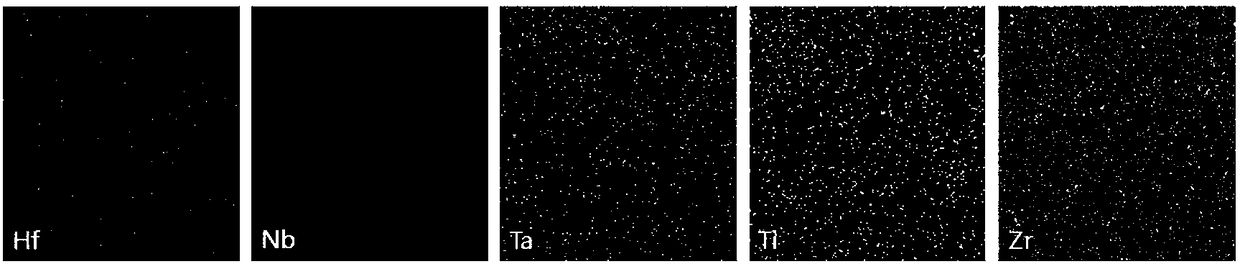

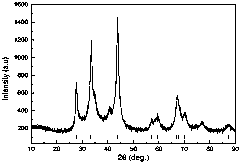

(HfTaZrTiNb) C high-entropy ceramic powder and preparation methods of high-entropy ceramic powder and high-entropy ceramic blocks

The invention relates to (HfTaZrTiNb) C high-entropy ceramic powder and preparation methods of the high-entropy ceramic powder and high-entropy ceramic blocks. Five-face centered cube (FCC) carbonizedpowder is made into ceramic powder through a high-energy ball milling method, then a discharging plasma method is adopted to realize preparation of the high-entropy ceramic blocks, and quick sintering of ceramic within a temperature range of 1700-2350 DEG C can be realized to obtain high-entropy ceramic with single-phase-face centered cube (FCC) structure. The preparation method of (HfTaZrTiNb) Chigh-entropy block ceramic is solved; the high-entropy ceramic with the FCC structure is finally obtained by strictly controlling parameters of a discharging plasma sintering furnace or a hot press furnace and characterizing XRD, so that the ceramic material system is enriched.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

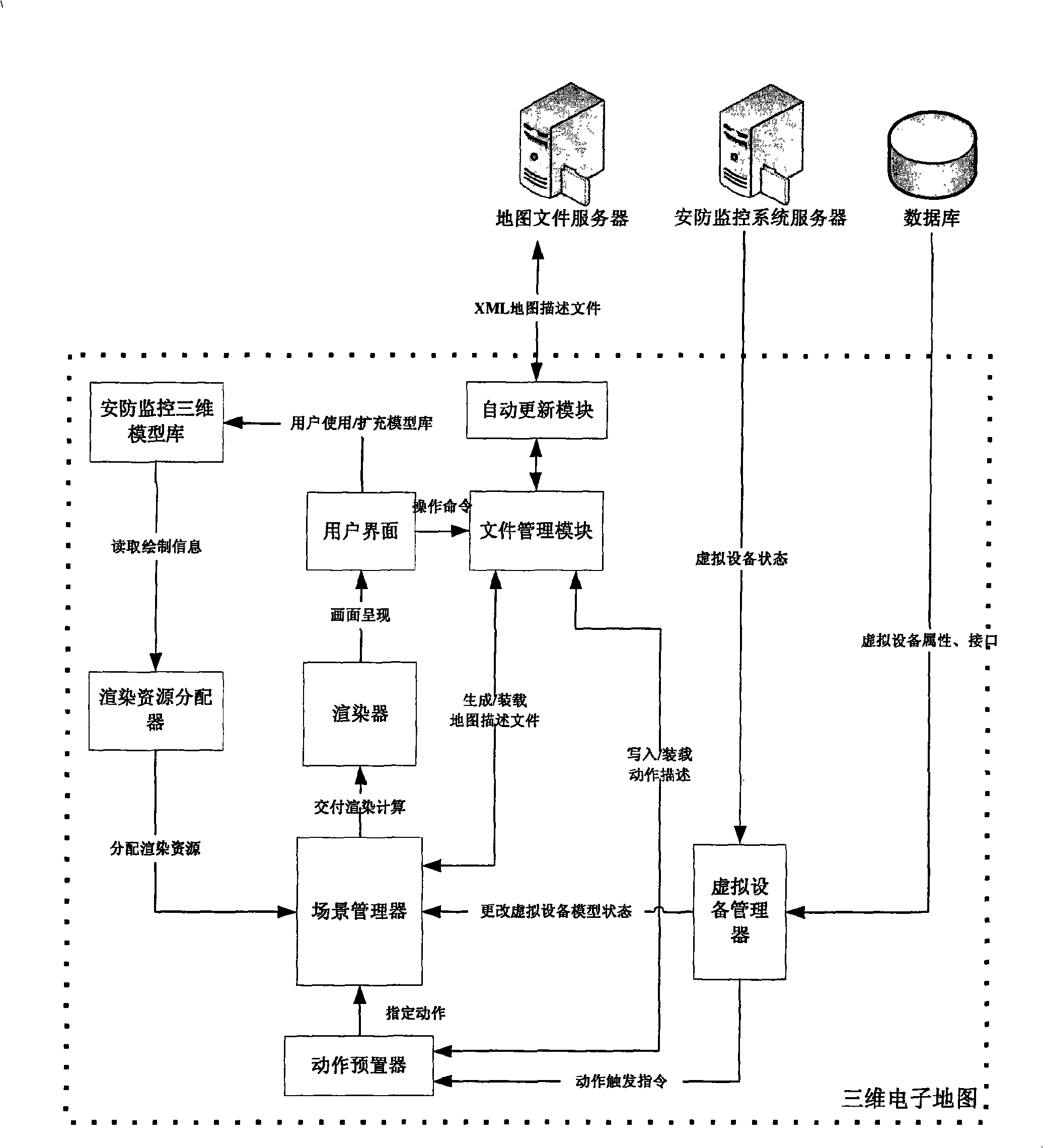

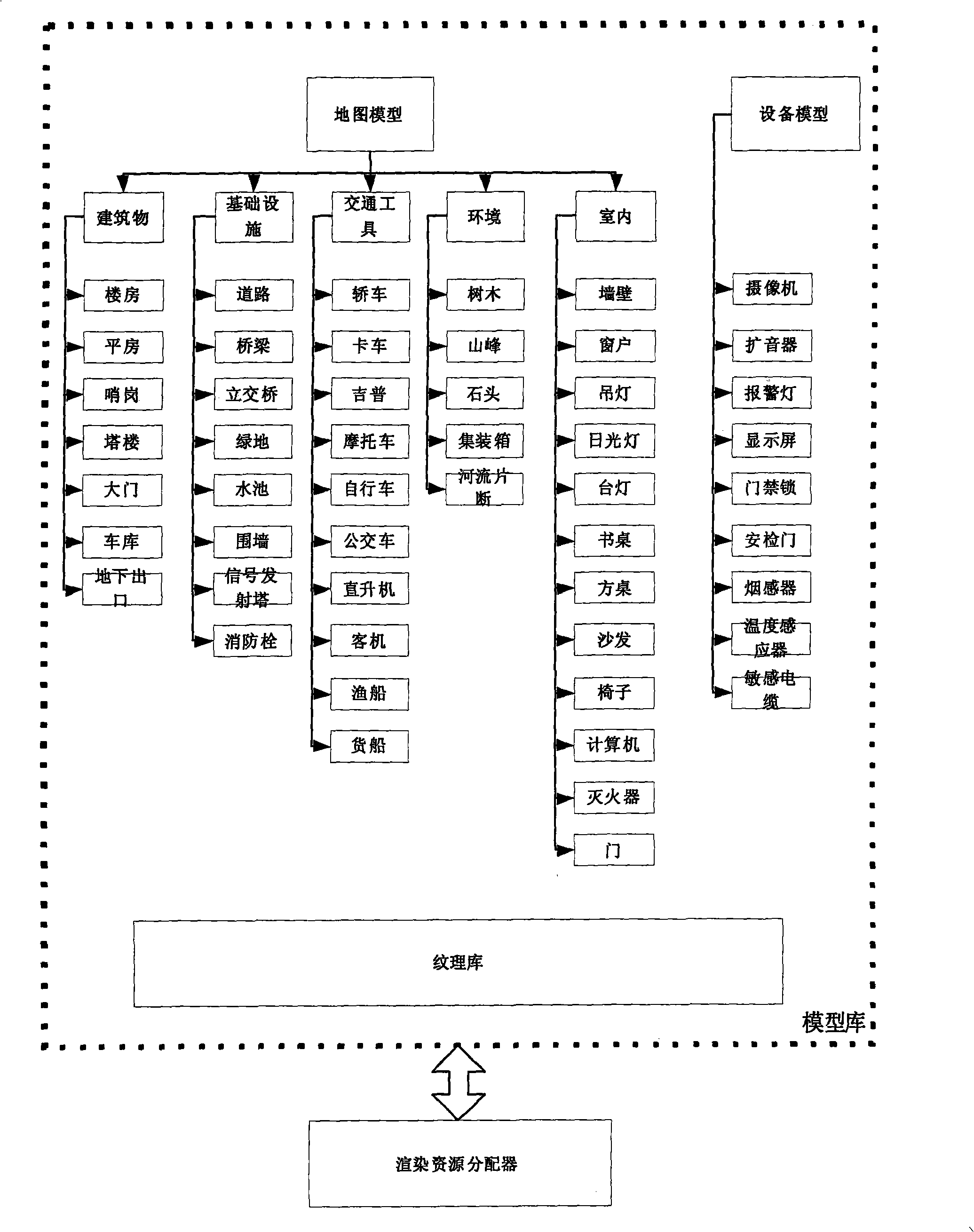

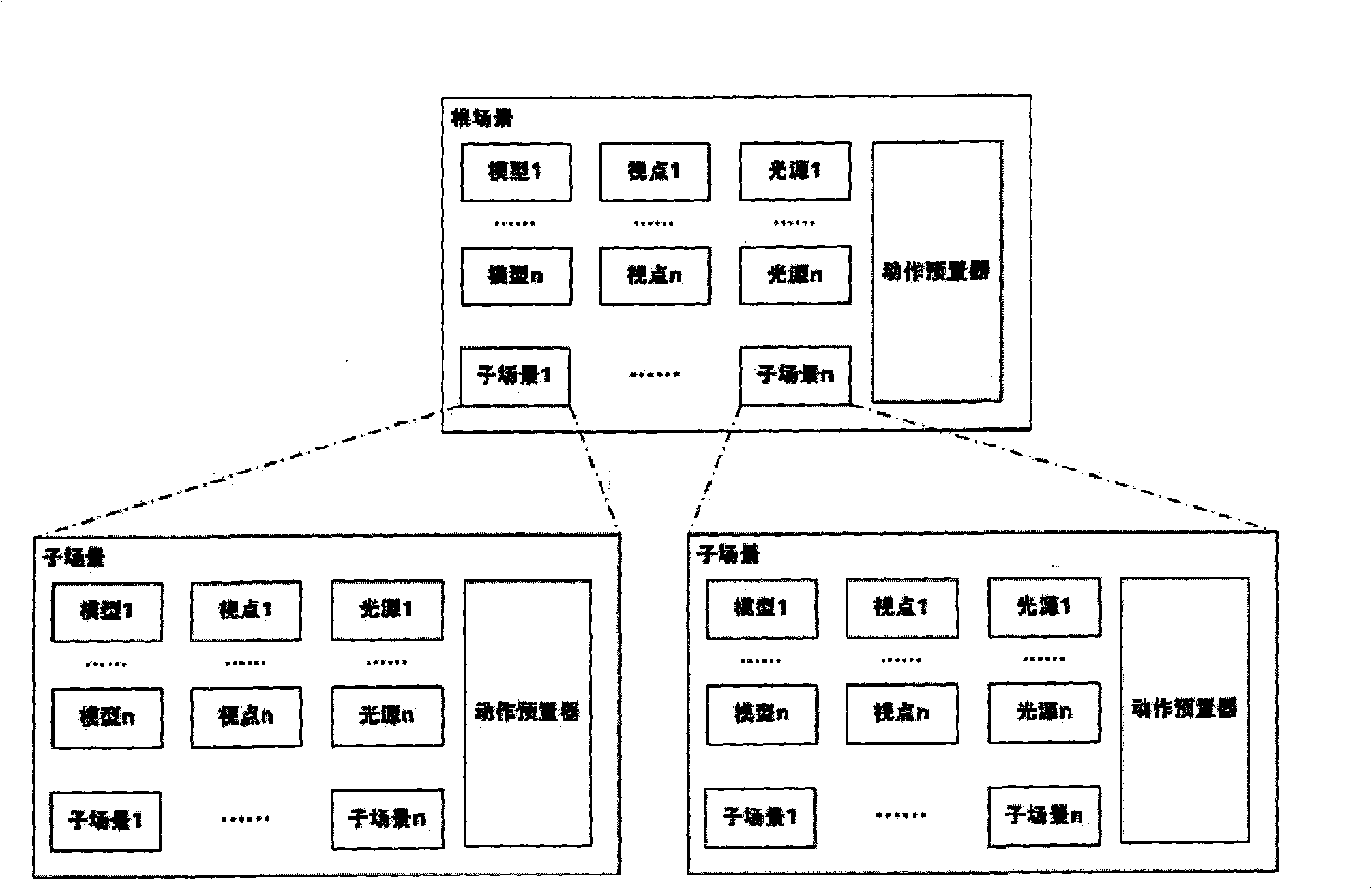

Quickly configurable and real time rendering safety protection three-dimensional electronic map

InactiveCN101286240ARich means of operationIntuitive and vivid monitoring sceneMaps/plans/charts3D-image renderingVirtual deviceSecurity monitoring

The invention relates to a security three-dimensional electronic map for rapid deployment and real-time rendering, comprising a virtual device manager, an action pre-setter, a field manager, a renderer, a rendering resource distributor, a security monitoring three-dimensional model library and a user interface. The map applies a three-dimensional field map in the security monitoring system to replace the traditional two-dimensional electronic map and the expandable model library is designed according to the characteristics of the security monitoring system, thus realizing the rapid deployment of the electronic map. The models in the model library carry out the control on the complexity of the structure and the texture against the specific needs of the security monitoring, sharing of the rendering resources, rendering, reducing and other means are simultaneously adopted to realize the aim of real-time rendering. The map is in line with the application requirements on district division rendering, detail control and all-direction roaming of the security monitoring field. The concept of the virtual device is introduced, the expansion and compatibility of the device can be realized by the deployment of a database; the map can rapidly set up various fields, provide the real-time rendering performance, thus improving the visualization and the modernization level of the security monitoring system.

Owner:BEIHANG UNIV

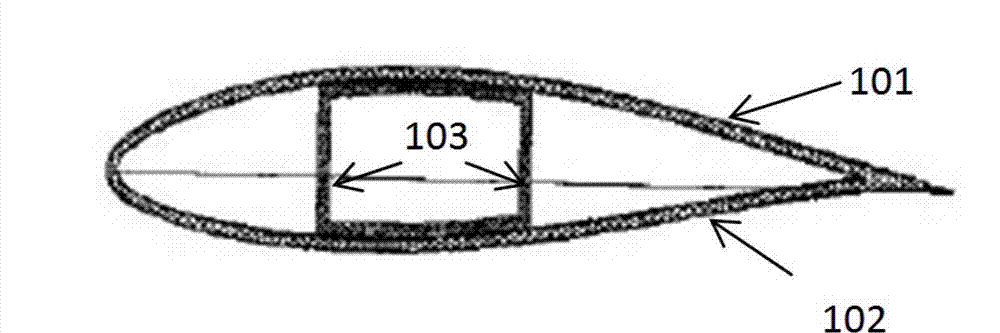

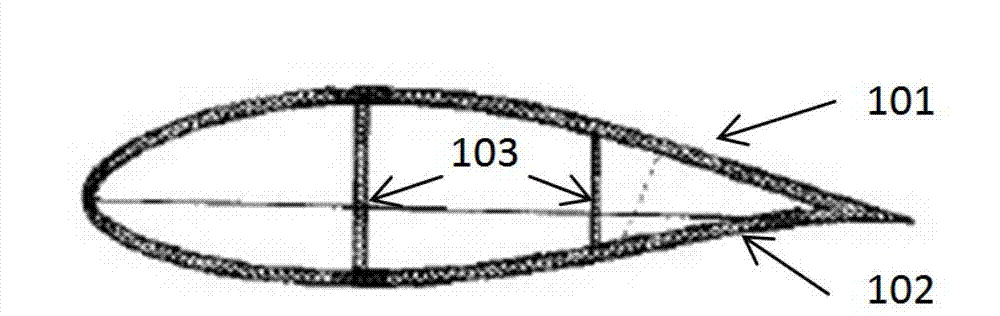

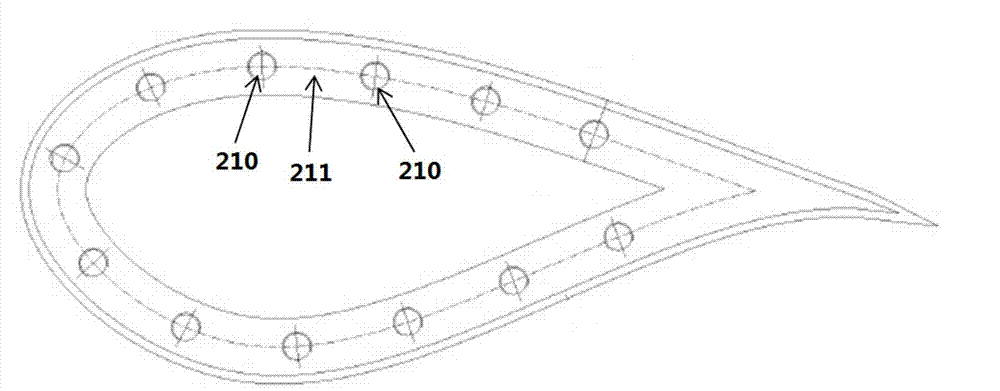

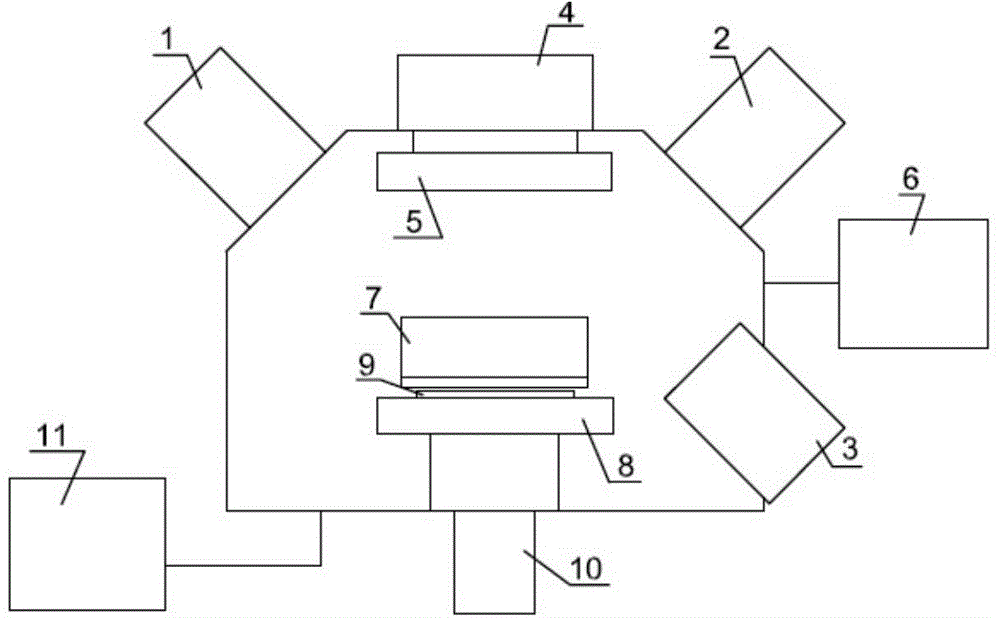

Integrated forming method and device for segmented blade

ActiveCN103042700ASolve the problem of integrated moldingImprove finished product qualityDomestic articlesElectricityPositive pressure

The invention relates to a manufacturing process method for integrated formation of a horizontal shaft segmented wind power blade and an integrated device applicable to the method. The wind power blade at least comprises two segments of composite material blade segments. A metal bolt sleeve is embedded into the connecting part of the two adjacent segments during manufacturing, and integrated formation is realized by a positive pressure auxiliary vacuum perfusion mode, so the defects of the traditional perfusion process are overcome, and the manufacturing problem of the segmented blade is solved. In addition, the integrated formation process avoids various disadvantages and risks caused by that the traditional process shell adopts adhesive to adhere.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

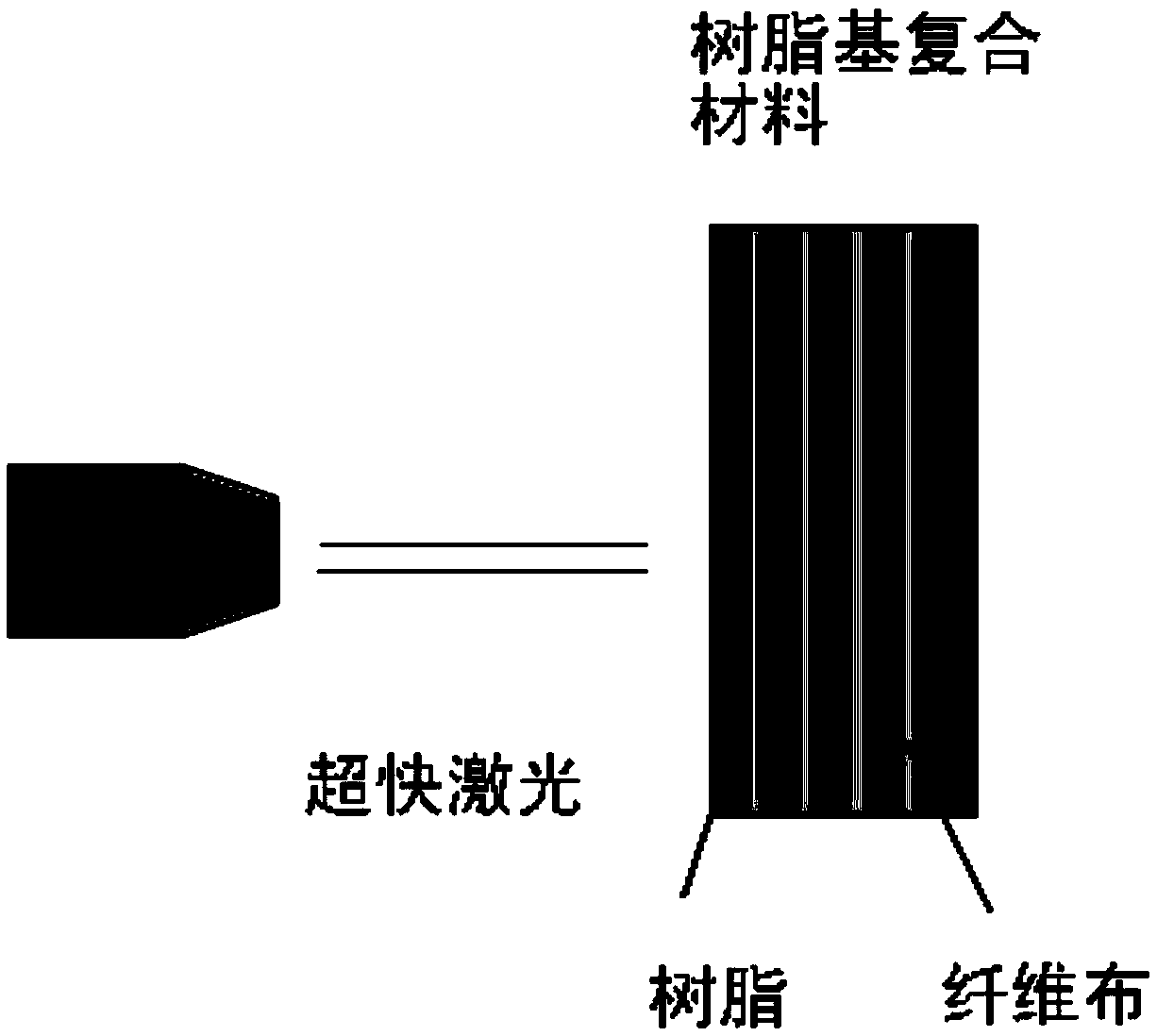

Resin matrix composite with super-hydrophobic bionic surface and preparation method of resin matrix composite

ActiveCN105504324AImprove environmental adaptabilityAvoid heat damageCoatingsMicrostructureResin matrix

The invention provides a resin matrix composite with a super-hydrophobic bionic surface and a preparation method of the resin matrix composite. The method comprises steps as follows: the surface of a matrix of the resin matrix composite is polished until the surface turns white; the matrix of the resin matrix composite is processed through ultrafast laser, and a microstructure is formed on the surface; a first coating is sprayed on the microstructure surface of the matrix of the resin matrix composite through a pneumatic type paint spray gun to form a bonding layer, a second coating containing nanosilicon dioxide particles is sprayed to form a surface hydrophobic function layer, and the resin matrix composite with the super-hydrophobic bionic surface is obtained. The preparation method is simple to operate and facilitates production, the prepared resin matrix composite with the super-hydrophobic bionic surface can allow water drops to freely slip off, and the real self-cleaning super-hydrophobic function is realized.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

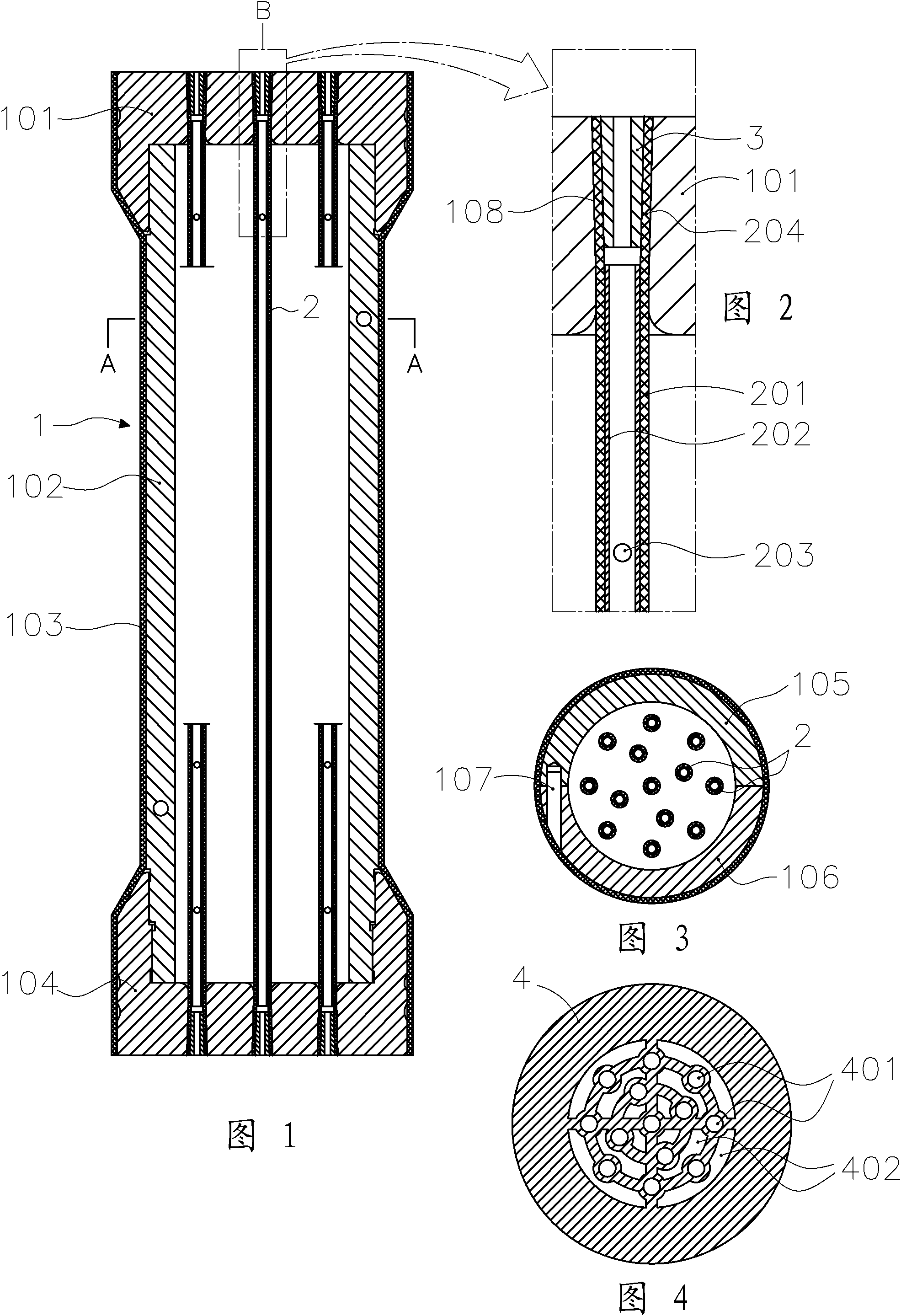

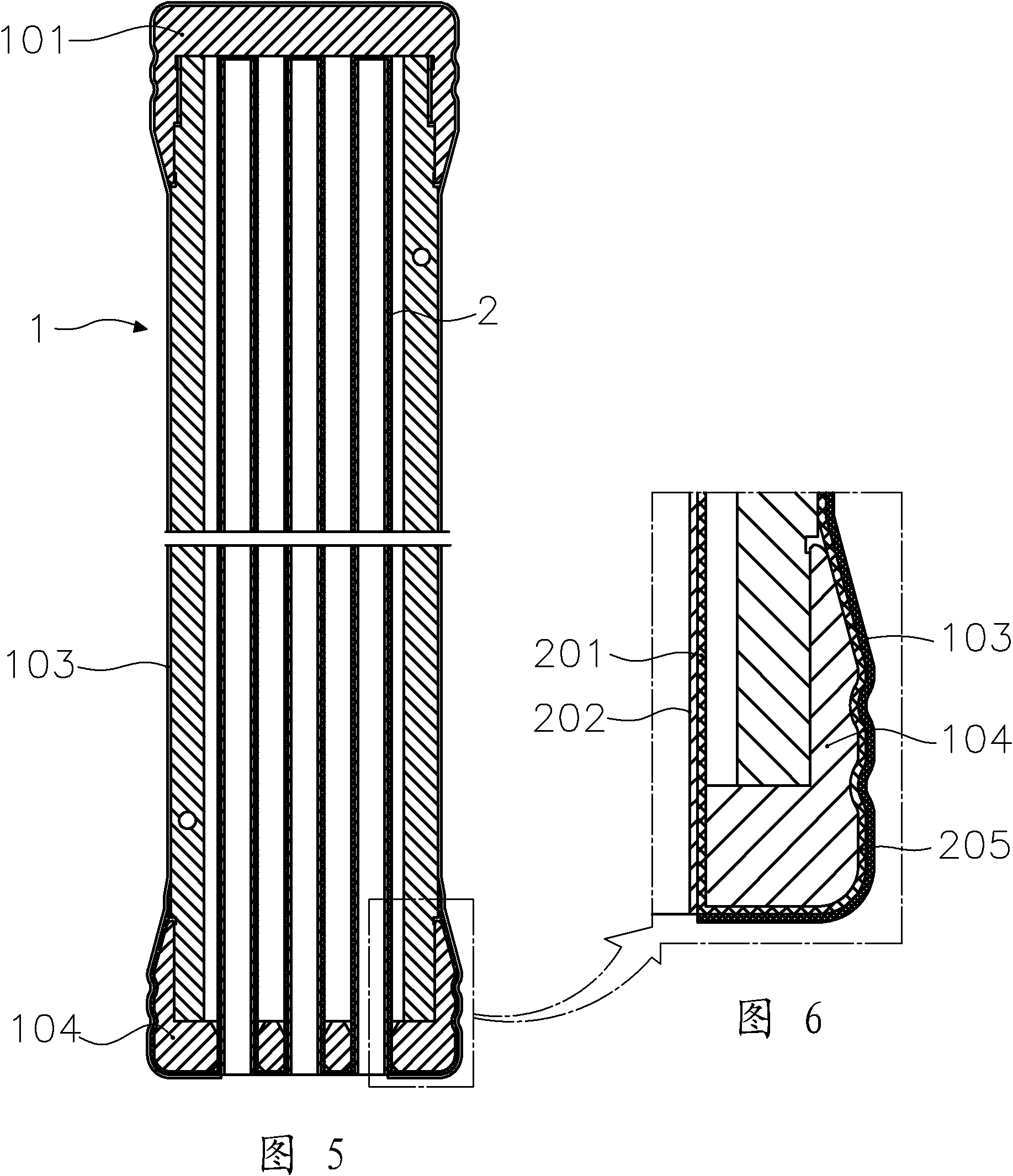

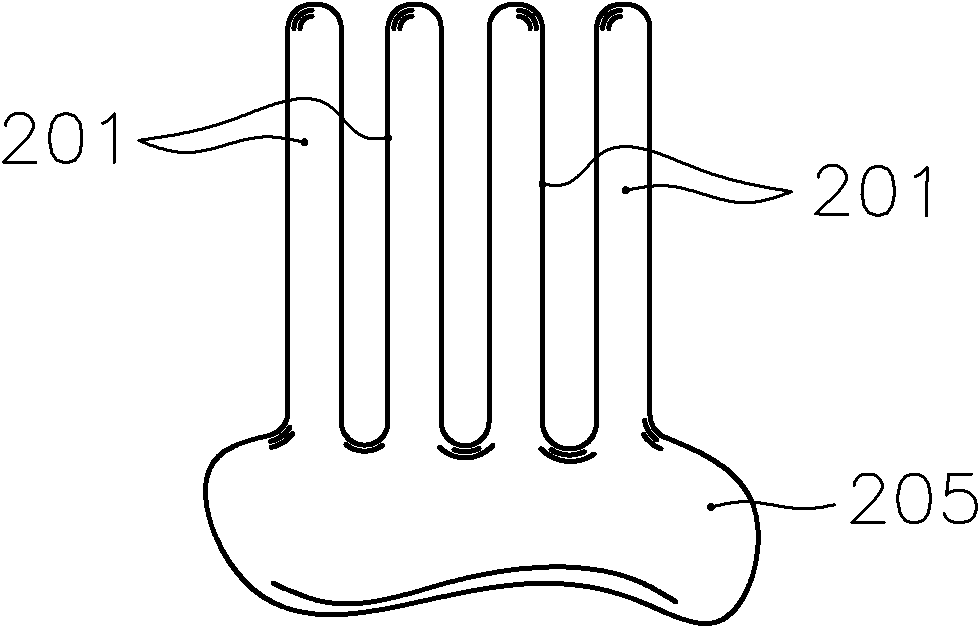

Mould for forming multi-channel filter element and method for forming intermetallic compound multi-channel filter element

The invention discloses a mould which is easy to demould a core rod and used for forming a multi-channel filter element. The mould comprises an outer mould and multiple core rods mounted in the outer mould, wherein each core rod is composed of a support tube and an elastic sleeve sleeved on the support tube; multiple through holes are formed on the wall, on which the elastic sleeve is sleeved, ofeach support tube; and at least one end of each core rod is an open end communicated with the exterior of the mould. The support tubes can support the core rods so as to accurately position the core rods in the outer mould, thereby basically ensuring the true position after inner bores of a filter element are formed and improving the entire quality of the filter element; when the elastic sleeve is formed, the elastic sleeve extrudes powder filled between the outer mould and the core rods from inside to outside so as to carry out compression moulding on the powder; and during demoulding, the elastic sleeve retracts so as to demould the core rods. The invention also discloses a method for forming an intermetallic compound multi-channel filter element, wherein an intermetallic compound material filled in the cavity of the mould is pressed into the multi-channel filter element by use of an isostatic pressing technology. By utilizing the method, the cold isostatic pressing manufacturing ofthe intermetallic compound multi-channel filter element is achieved.

Owner:CHENGDU INTERMENT TECH

Composite nanostructure based on three-dimensional porous transition metal carbide Ti3C2MXene and general preparation method thereof

InactiveCN110589786AFix production issuesSolve application problemsTitanium carbideNickel oxides/hydroxidesChemical reactionMetal-organic framework

The invention discloses a composite nanostructure based on a three-dimensional porous transition metal carbide Ti3C2MXene and a general preparation method thereof, and belongs to the field of nanomaterials. The three-dimensional composite structure is composed of a three-dimensional porous Mxene-supported inorganic nanostructure, and has a honeycomb hierarchical porous structure. A precursor of atwo-dimensional transition metal carbide and a metal-organic framework compound is subjected to high-temperature pyrolysis or a chemical reaction in an inert or reactive atmosphere to prepare the composite nanostructure with a controllable size. According to the composite nanostructure, stacking of MXene itself is inhibited, an active surface area, porosity, and ion permeability of MXene are increased, and thereby a surface interface of MXene is efficiently used. At the same time, introduction of the metal-organic framework compound realizes uniform and stable compounding of the three-dimensional porous MXene and an inorganic nanomaterial, the fundamental difficult problem that plagues exerting and application of inorganic nanomaterial performance is solved, and the composite nanostructurehas wide application prospects in the fields such as catalysis, energy, photo-electricity, space technology, and military industry.

Owner:DALIAN UNIV OF TECH

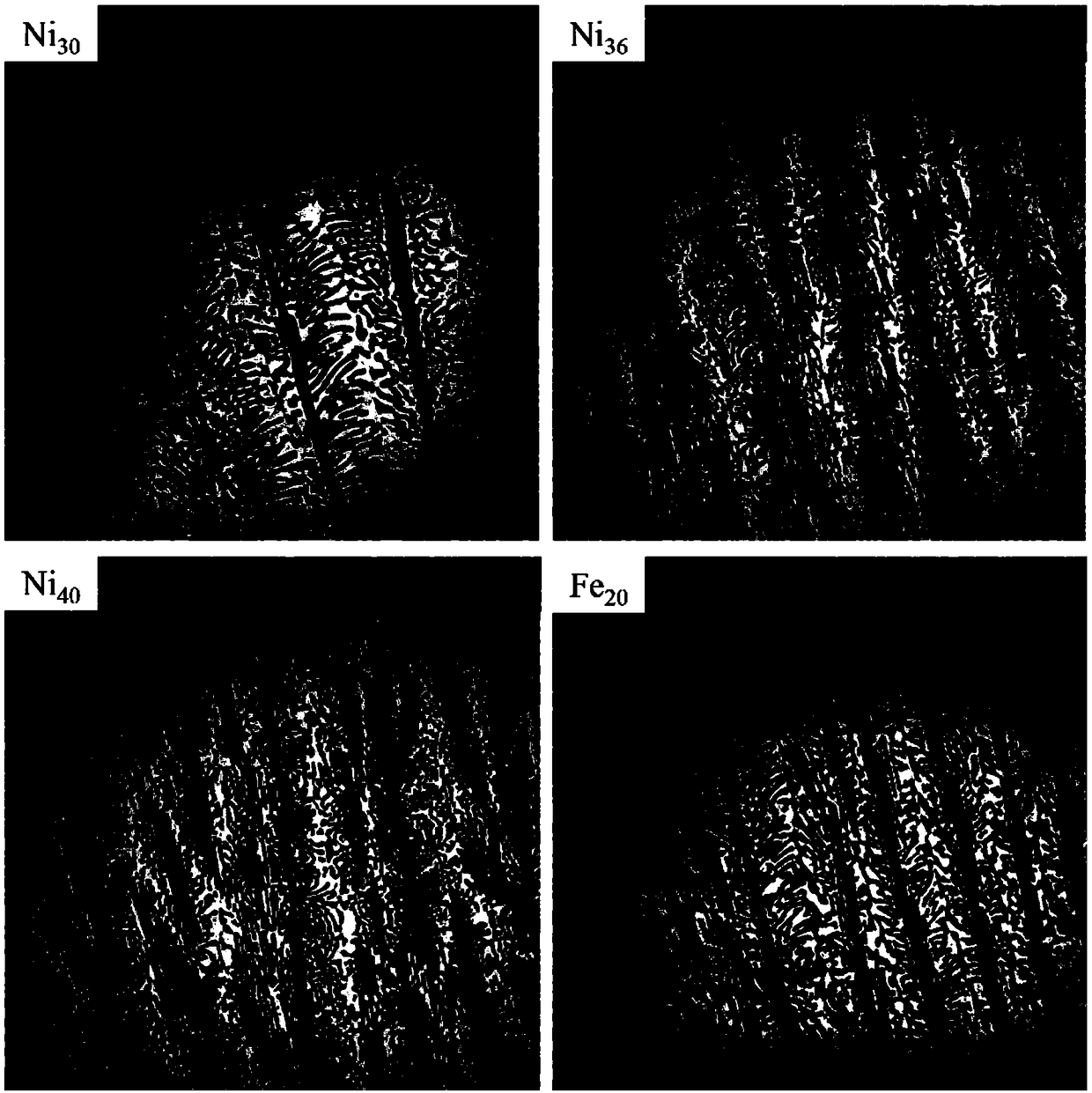

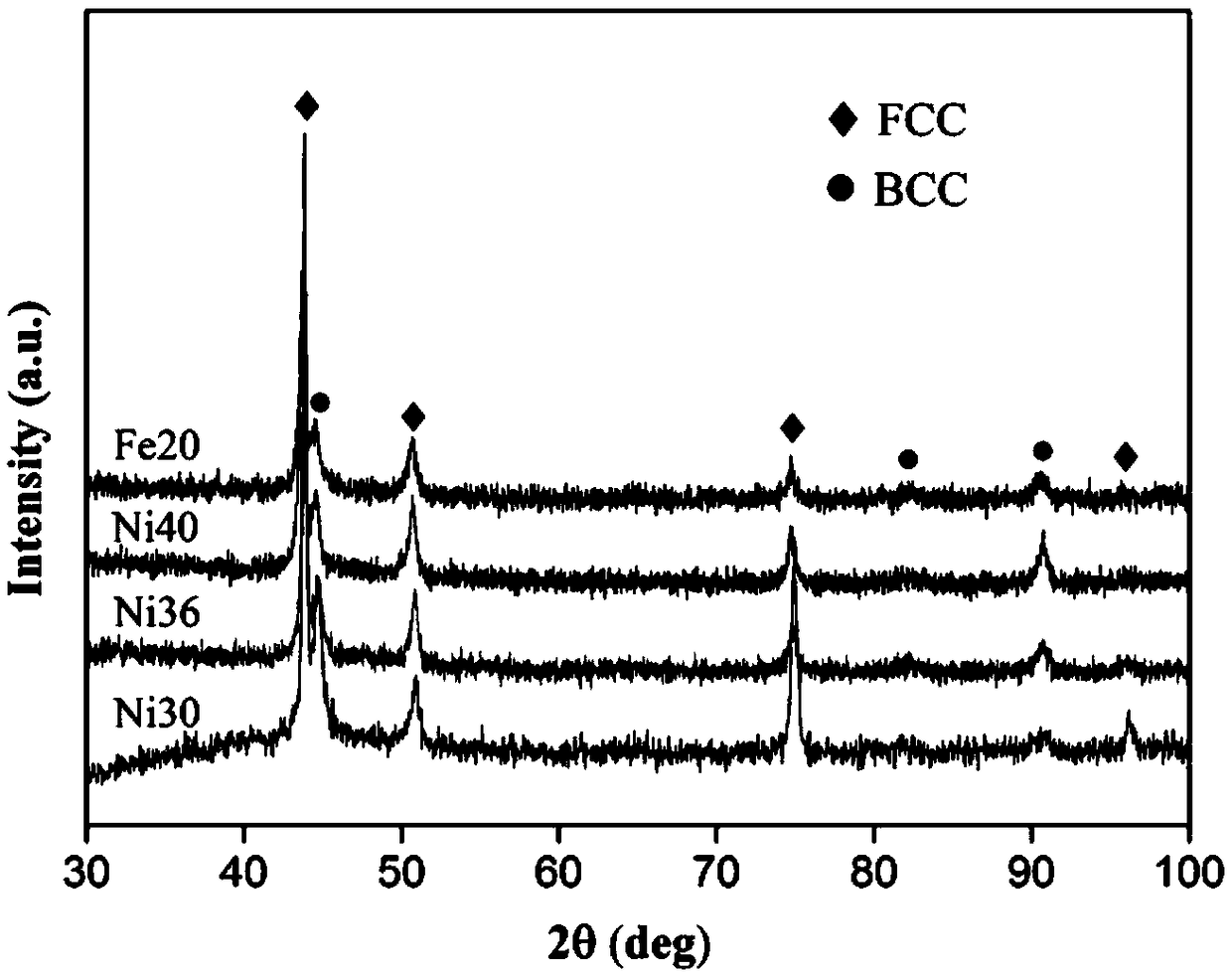

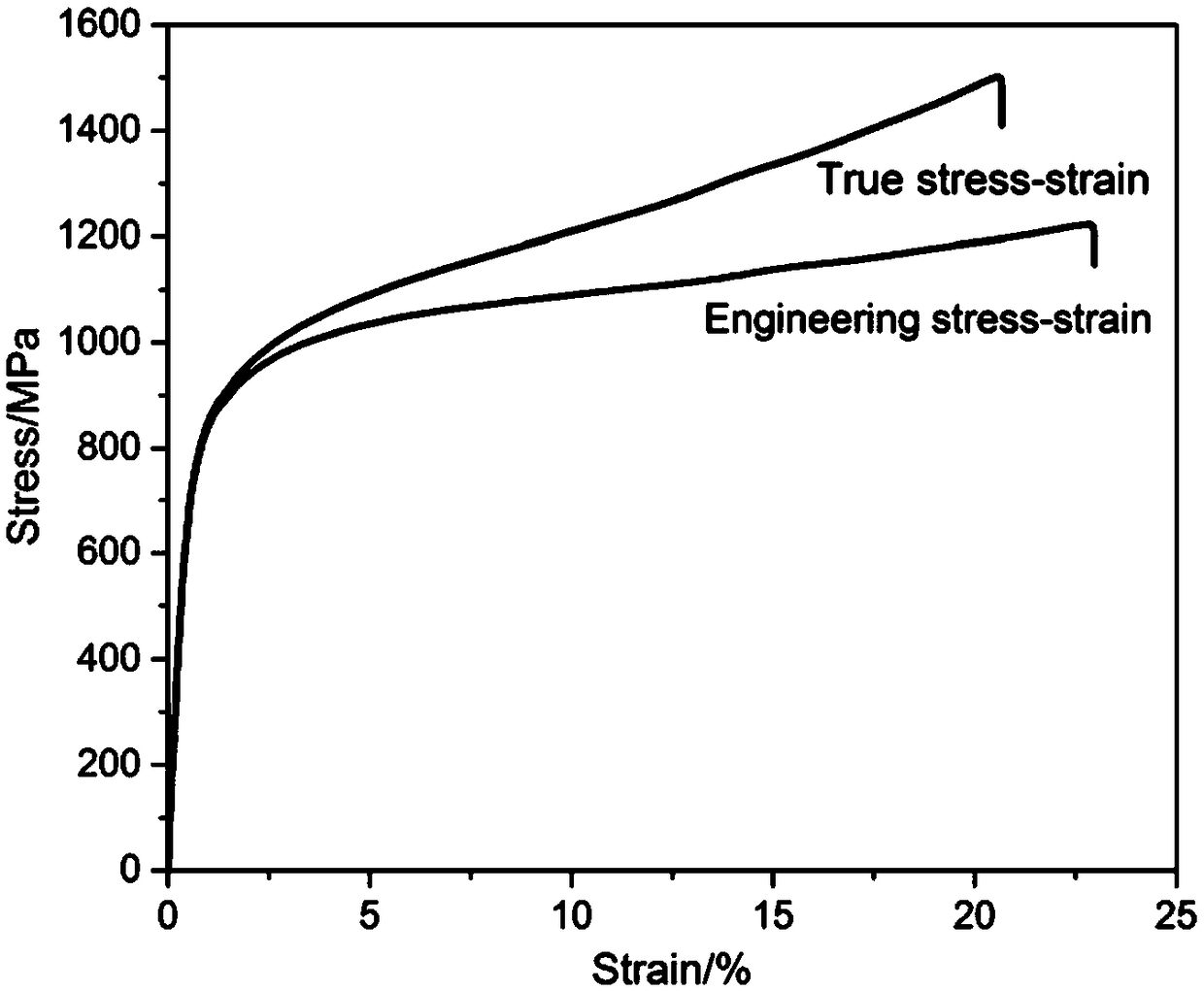

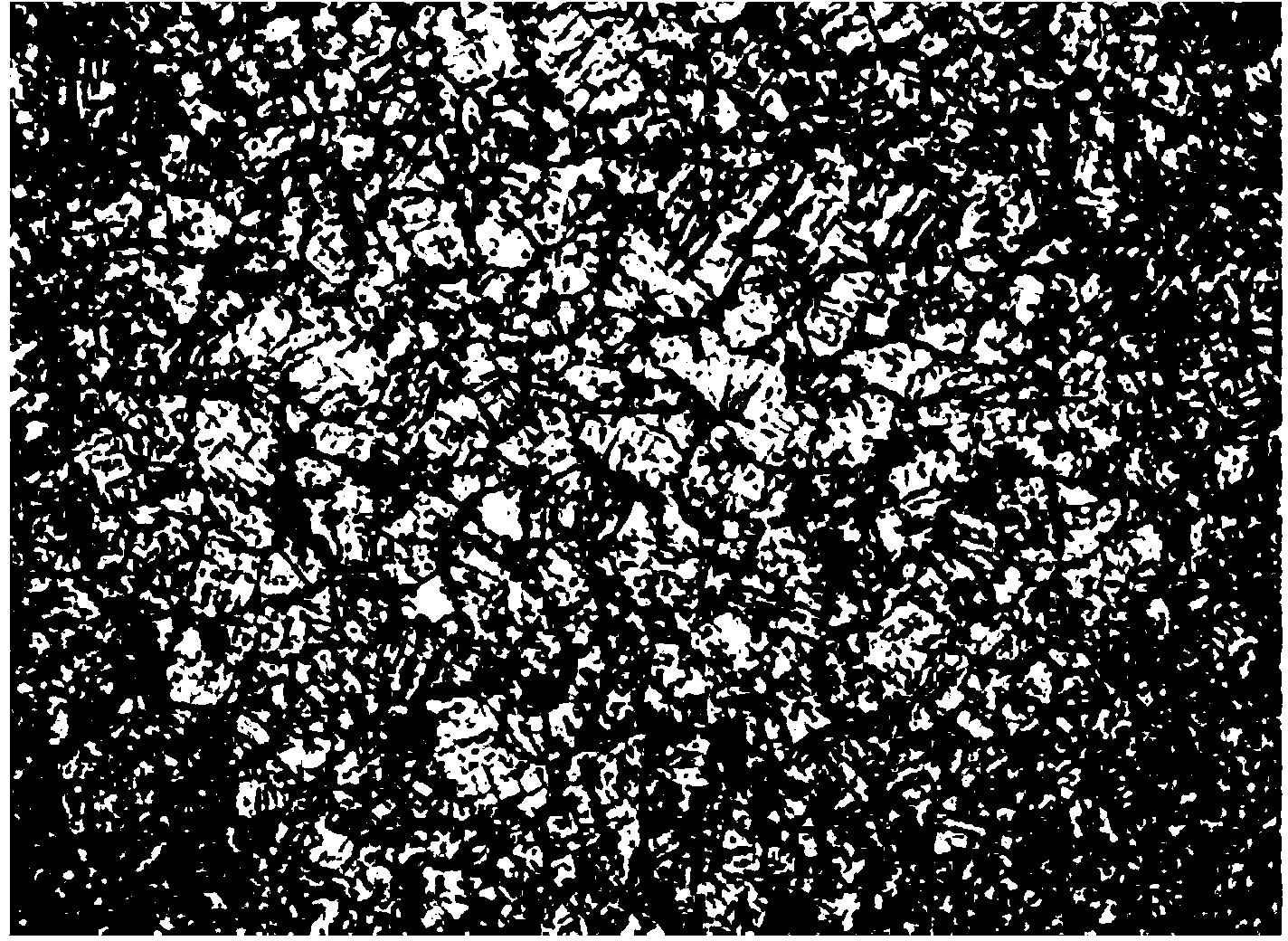

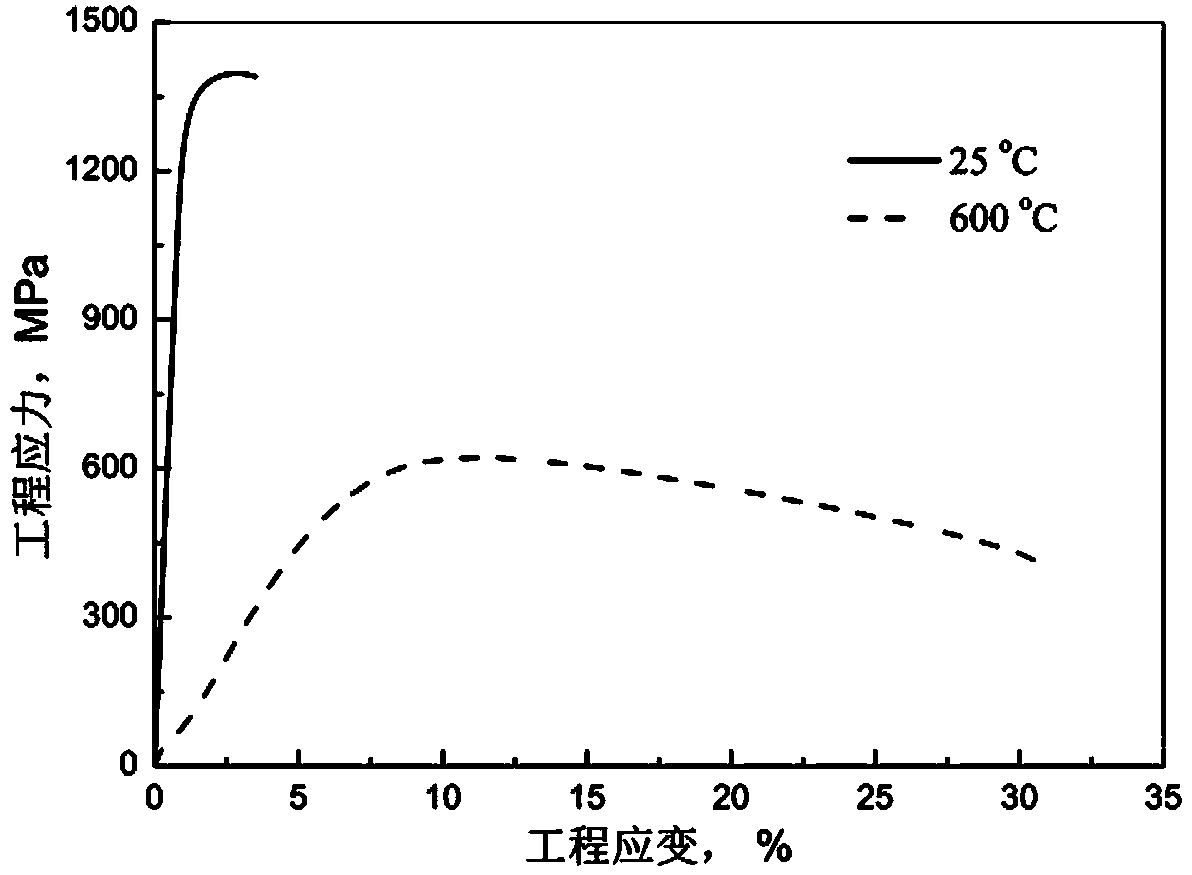

High-strength and high-plasticity eutectic high-entropy alloy and preparation method thereof

The invention discloses a high-strength and high-plasticity eutectic high-entropy alloy and a preparation method thereof. The high-strength and high-plasticity eutectic high-entropy alloy is preparedfrom the major elements of Ni, Co, Fe, Cr, Al and the trace elements X; the alloy composition is NiaCobFecCrdAleXf, wherein a, b, c, d, e and f represent the molar percentages of the corresponding elements, a+b is greater than or equal to 58 and less than or equal to 62, a is greater than or equal to b, c+d is greater than or equal to 18 and less than or equal to 22, c is greater than or equal tod, e is greater than or equal to 17 and less than or equal to 19, and f is less than or equal to 5.3; and the trace elements X comprise the following elements of W, Nb, Mo, B and C. The preparation method for the eutectic high-entropy alloy comprises the following steps that firstly, the alloying elements of the Ni, the Co, the Fe, the Cr, the Al and the X are descaled and cleaned and are weighedand mixed according to a certain molar ratio, a mother alloy is smelted, and finally suction casting is carried out so as to obtain the eutectic high-entropy alloy. The alloy combines the face-centered cubic phase and the body-centered cubic phase and has the advantages of being high in strength and high in plasticity, the elements such as the Al, the Cr and the W are beneficial to the improvementof the oxidation resistance, the corrosion resistance and the high-temperature stability of the alloy, and the comprehensive performance of the alloy is quite excellent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

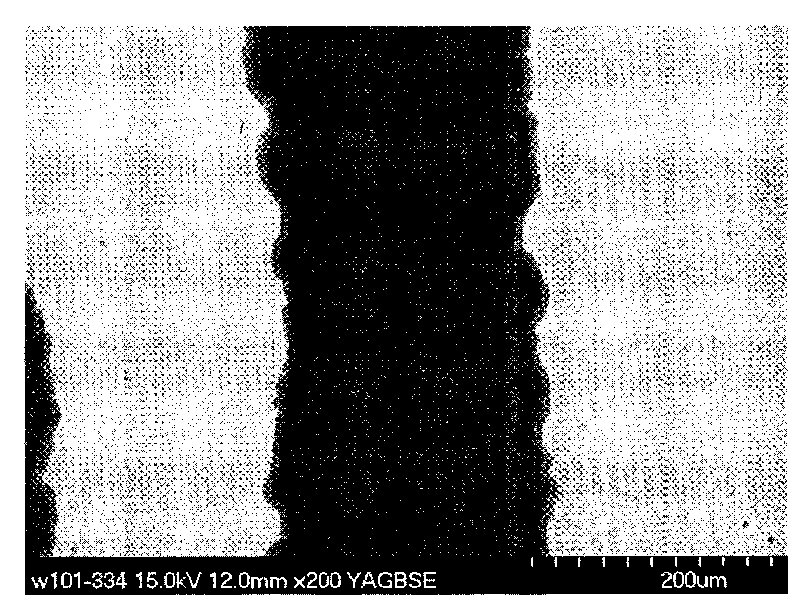

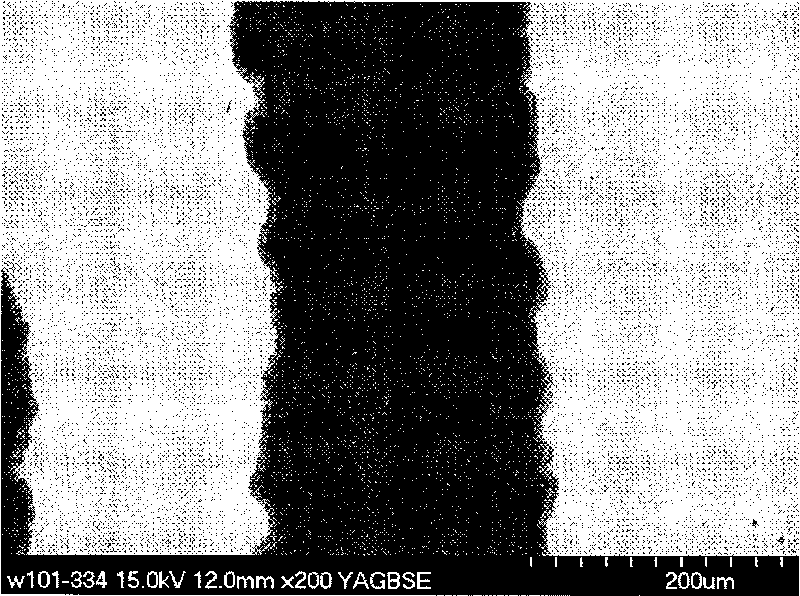

Preparation method of TiBw/Ti-6Al-4V composite bar adopting quasi-continuous reticular structure

The invention relates to a preparation method of a TiBw / Ti-6Al-4V composite bar adopting a quasi-continuous reticular structure and solves problems that existing Ti-6Al-4V composites are harsh in technological condition, high in equipment requirement, low in production efficiency, difficult to produce on a large scale and the like. The method comprises steps as follows: low-energy ball milling and mixing are performed on spherical Ti-6Al-4V powder and TiB2 powder firstly; then TiB2 / Ti-6Al-4V mixed powder is placed in a metal sheath for cold press molding, and vacuum degassing and sheath sealing welding are performed to obtain an extrusion billet; finally, short-time pre-sintering is performed on the obtained extrusion billet, and hot extrusion deformation is performed on the pre-sintered extrusion billet to obtain a required material. The method can be applied to preparation of a TiBw / Ti-6Al-4V composite adopting the quasi-continuous reticular structure.

Owner:HARBIN INST OF TECH AT WEIHAI

Roll forming technique of board made of NiAl-based composite material

InactiveCN101760674AFix production issuesSolve deformation coordination problemsMetal rolling arrangementsRoll formingAluminum composites

The invention relates to a preparation process of a novel composite material, in particular to a roll forming technique of a board made of an NiAl-based composite material, which comprises the following steps of: (1) preparing a board made of an aluminium base composite material reinforced by ceramic particles; (2) preparing a nickel-aluminum composite board; and (3) carrying out heat treatment on the nickel-aluminum composite board. The invention solves the preparation problem of the board of the NiAl-based composite material and is mainly applied to the roll forming of the board made of the NiAl-based composite material.

Owner:HARBIN INST OF TECH

Method for performing powder material surface modification through plasma

InactiveCN105312554AComposite functionIncrease surface specific surface areaVacuum evaporation coatingSputtering coatingPlasma technologyNew materials

The invention discloses a method for performing powder material surface modification through plasma. According to powder material surface modification, under a vacuum environment condition, one or more plasma technologies are used for combination to deposit one or more different characteristic materials on the surfaces of powder materials in different types. Meanwhile, one ore more gases can be selected for combination for micro-etching on the surface of powder in different materials according to the plasma appearance. Powder manufactured and processed through the technology is a novel modified powder material with one or more functional characteristics. The modified powder is changed into a single-metal or multiple-metal combined surface from a non-metal surface, vice versa, the metal surface can be modified into a non-metal ceramic surface. Meanwhile, the smooth powder surface can be subjected to micro roughening.

Owner:ZHANGJIAGANG ULTRASONIC & ELECTRIC +2

Oxygen evolution reaction (OER) catalyst based on composite structure of MXene and metal-organic frameworks (MOFs) and synthesis method of catalyst

ActiveCN110038634AOvercome the basic problem that the catalytic performance of the oxygen evolution reaction cannot be exertedHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsElectrolysisSynthesis methods

The invention discloses an oxygen evolution reaction (OER) catalyst based on a composite structure of MXene and metal-organic frameworks (MOFs) and a synthesis method of the catalyst and belongs to the fields of nano materials, energy and catalysis. The catalyst is prepared from MXene two-dimensional nanosheets uniformly loaded with MOFs nanoparticles on the surfaces, and has a two-dimensional structure. The preparation method comprises the following steps: dissolving and uniformly mixing MXene, metal salt, an organic ligand and an acid-binding agent, then centrifuging, washing, and carrying out vacuum drying to obtain an electrocatalyst with a two-dimensional nanostructure with finely-adjustable structure and components. The oxygen evolution reaction catalyst and the synthesis method of the catalyst disclosed by the invention have the beneficial effects that the basic difficulty of failed catalytic property of an oxygen evolution reaction due to poor conductivity and stability of theMOFs can be effectively overcome; the obtained oxygen catalyst shows excellent catalytic activity and stability to the oxygen evolution reaction in alkaline electrolyte and lays a foundation for wideapplication of new-energy technologies such as fuel cells, metal-air batteries and electrolytic water.

Owner:DALIAN UNIV OF TECH

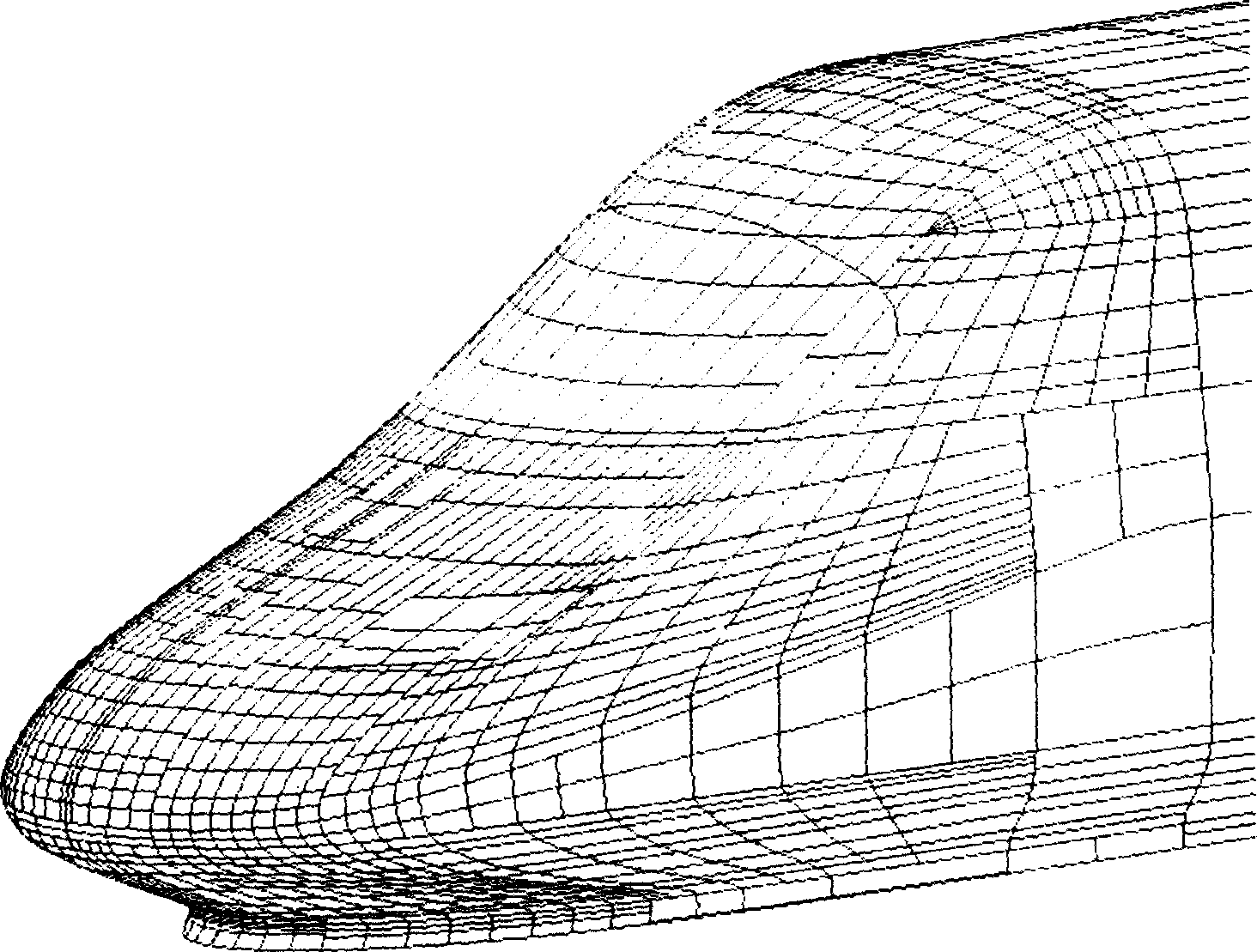

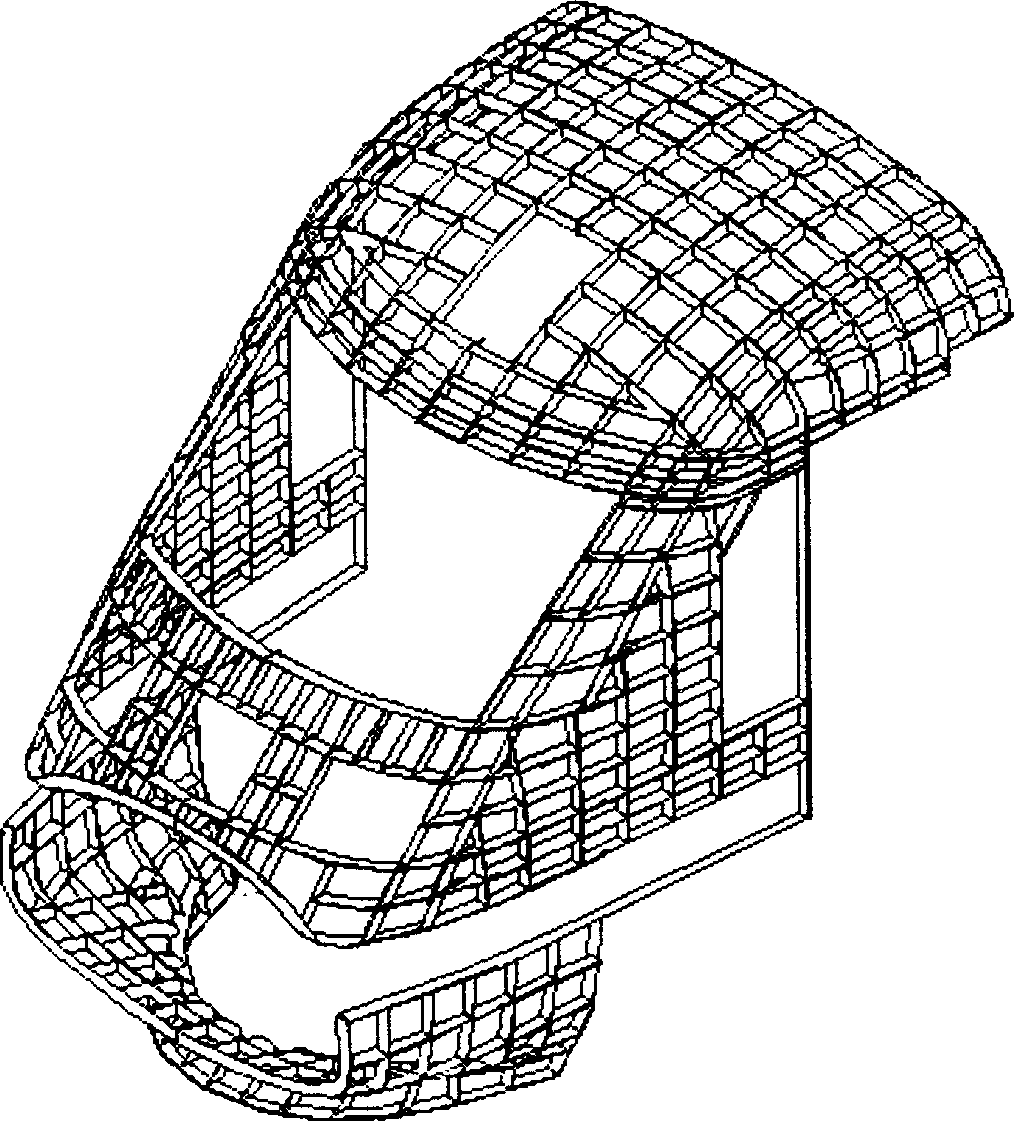

Design and process method for profile and structure of streamline locomotive

InactiveCN1634735AReduce labor intensityRealize shape designRailway transportAxle-box lubricationIntermediate typeCoating

This invention relates to train body parts kinds in railway trains and especially to streamline trains, which comprises railway speeding train, speeding gas train set and speeding automobiles or high speed magnetic floating train head part or structure design. The invention is characterized by the following: the streamline train head is composed of multiple NUBRS curved pieces to form the train head outline through dynamic automatic generation or piece adjusting; then welding the space net structure plane of the head structure with the coating iron into the streamline train head.

Owner:CENT SOUTH UNIV

Preparation method of thin-wall tubular product of particle-reinforced aluminum-based composite material

ActiveCN101737574AReduce plasticityFix production issuesRigid pipesSolution treatmentRoom temperature

The invention relates to a preparation method of a thin-wall tubular product of a particle-reinforced aluminum-based composite material, which comprises the steps of: 1, preparing a tube blank by adopting a mixing and casting process and a powder metallurgy process; 2, homogenizing the tube blank, turning and stripping, carrying out a high-temperature compression deformation test to obtain a suitable processing deformation condition; 3, spinning the tube blank for finite element number value simulation, optimizing process parameters, and thermally spinning and warmly spinning; and 4, carrying out solution treatment on the obtained tubular product, and ageing after water hardening at room temperature. The tubular product prepared by the invention has larger diameter wall thickness ratio, smooth internal surface and outer surface without defects, uniform wall thickness and better interface combination between reinforced particles and a base body of the thin-wall tubular product. The method has short procedure, labor saving of the processing mode, energy saving and environmental protection, simple process, low raw material cost, suitability for large-scale production and better popularization value, and can be widely applied to the preparation of high-strength light tubular products in the fields of aerospace, vehicles, advanced weapons and the like.

Owner:有研金属复材技术有限公司

Transition metal diboride high-entropy ceramic and preparation method thereof

The invention discloses a transition metal diboride high-entropy ceramic and a preparation method thereof, mainly relates to a high-entropy ceramic material with excellent performance, and belongs tothe field of high-temperature ceramics. At least five IVB, VB and VIB groups of transition metal boride powder is mixed according to the same mole ratio, high-energy ball milling and vacuum treatmentof mixture are implemented, the mixture is packaged and pre-pressed by high-melting-point packaging material, and the packaged mixture is sintered at the pressure of 4-10GPa and at the temperature of1000-1800 DEG C to form the diboride high-entropy ceramic. The diboride high-entropy ceramic is firstly prepared by a high-temperature and high-pressure method and has the advantages of high breakingtenacity, compactness and hardness, small grain size, excellent oxidation resistance and the like. the method has the advantages that the method is low in cost, environmentally friendly, simple in sintering process, good in product performance and high in finished product ratio, and raw materials are easily acquired. Industrial production is facilitated.

Owner:SICHUAN UNIV

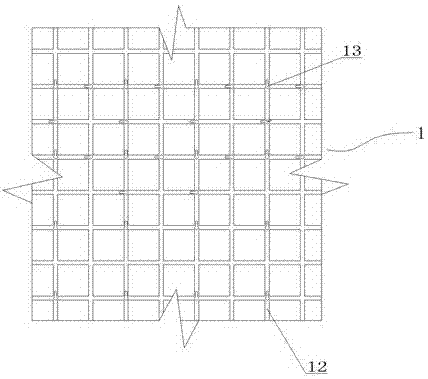

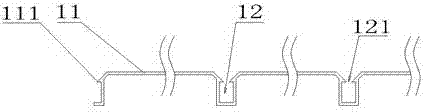

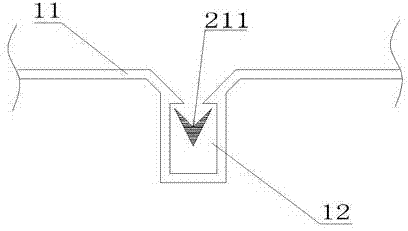

A kind of soft package wall decoration profile and its production method

The invention relates to a soft package wall decoration profile and a production method thereof, belonging to the technical field of wall decorations. The soft package wall decoration profile is characterized by comprising a baseplate, a soft package material and a plurality of bulges uniformly arranged on the baseplate, wherein cap-like convex lugs are arranged at the upper parts of the bulges, grooves are formed between the adjacent two bulges respectively, an opening is formed between the adjacent two cap-like convex lugs at the upper part of each groove, and the soft package material is coated on the baseplate and tightly locked in the grooves of the baseplate through fasteners. The soft package wall decoration profile has the characteristics of being simple in structure, being convenient to use and mount, being high in production efficiency and being capable of constituting or transforming various styles at random.

Owner:SHAOXING UNIVERSITY +1

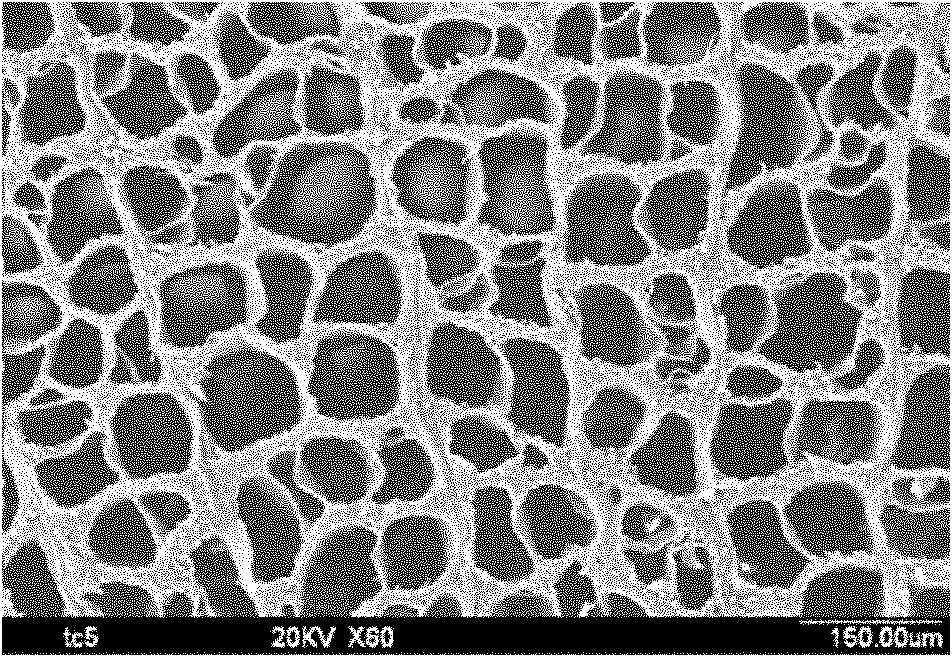

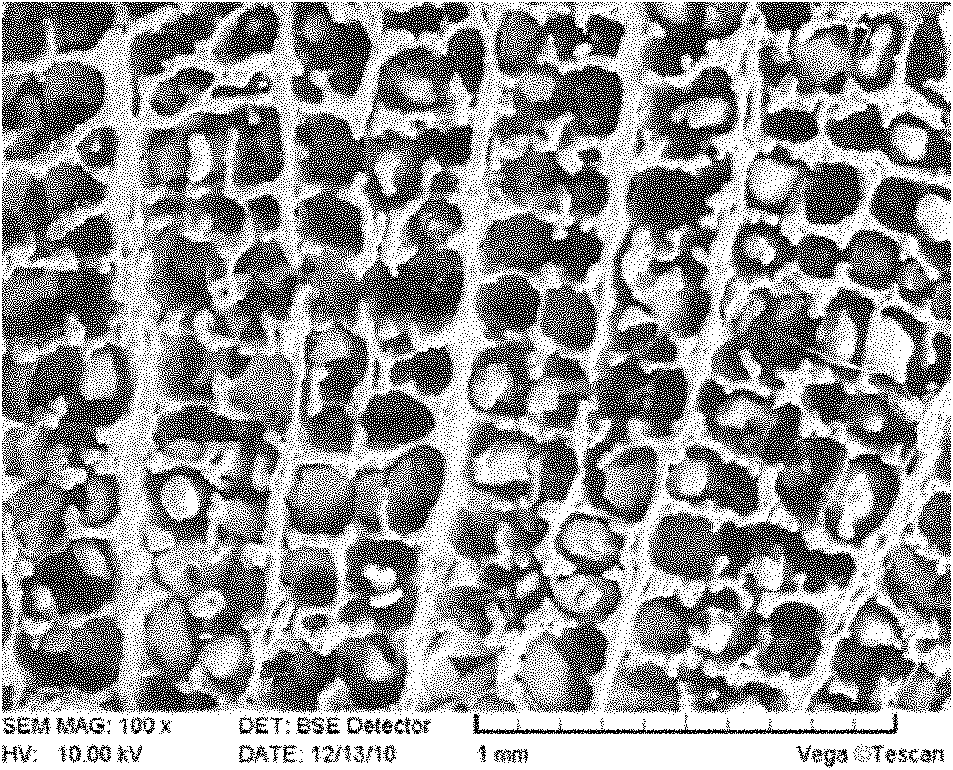

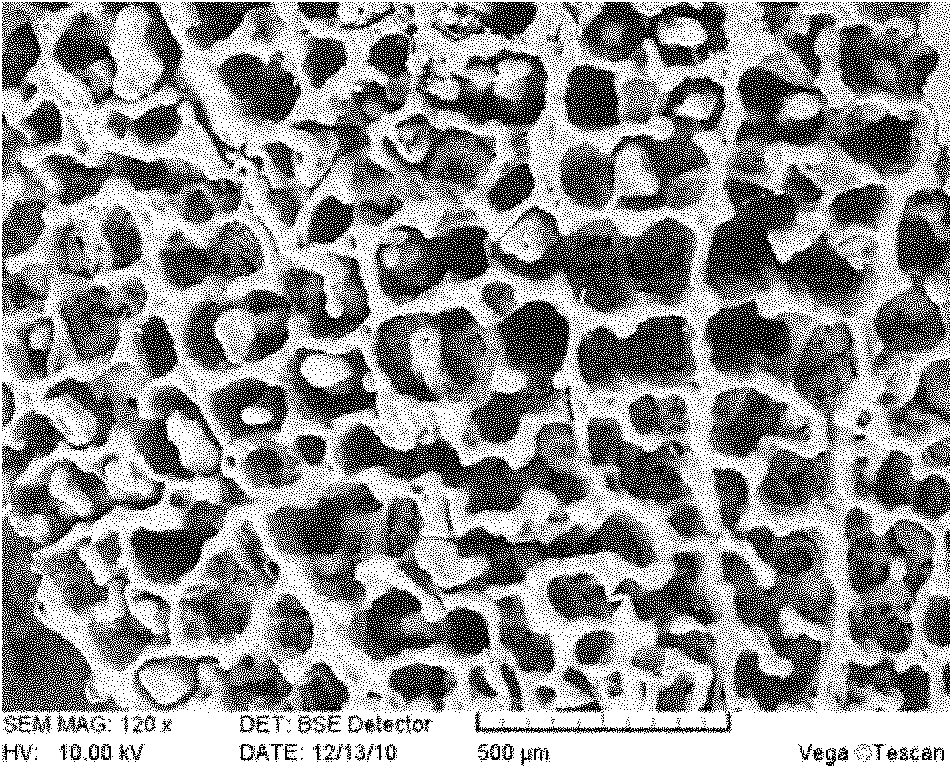

Honeycomb polymer-based bionic porous scaffold material and preparation method thereof

The invention discloses a honeycomb polymer-based bionic porous scaffold material and a preparation method thereof. Natural plant tissues are used as templates. The method comprises the following steps of: performing vacuum carbonation, melting, permeating in water-soluble salt, performing oxidation and carbon removal on the templates to obtain template carrying porous salt, and finally performing the processes of vacuum / pressure biological macromolecular solution soaking, vacuum drying, desalting treatment and the like to prepare the honeycomb polymer-based bionic porous scaffold material. The prepared bionic porous scaffold material has a honeycomb porous structure based on the plant tissues, the porosity is 70 to 95 percent, and the aperture is 10 to 160 microns. The preparation methodis widely applied to water-insoluble biological macromolecular materials, and is easy to realize regulation and control of physicochemical, mechanical and biological properties of porous scaffolds. The honeycomb polymer-based bionic porous scaffold material and the preparation method thereof have special significance for realizing regenerative repair of defective tissues of peripheral nerves, muscle tendons, ligaments and the like with longitudinal morphology by using tissue engineering technology, and have broad practical application prospect.

Owner:XI AN JIAOTONG UNIV

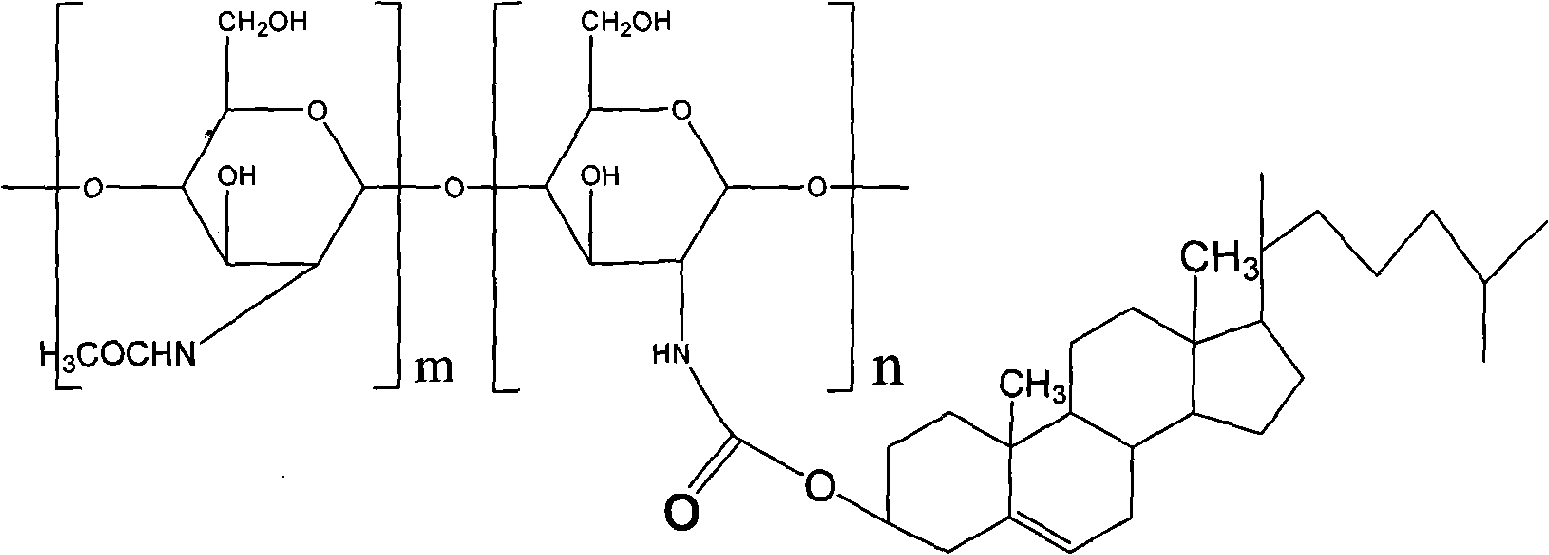

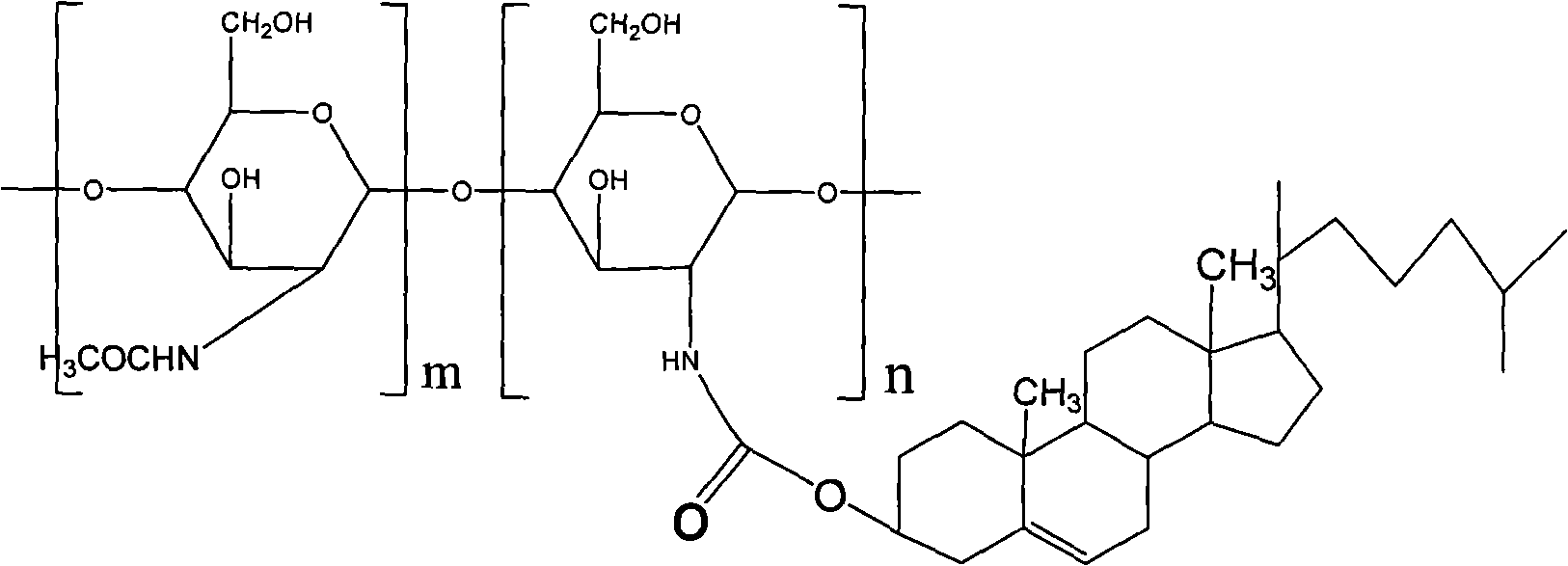

Preparation method and application of chitosan copolymer carrier micelle modified by cholesterol formyl chloride

InactiveCN101658484AFix production issuesEasy to makePharmaceutical delivery mechanismUnknown materialsCholesterolChloride

The invention relates to a preparation method and an application of chitosan copolymer carrier micelle modified by cholesterol formyl chloride, which can effectively solve the preparation problem of chitosan copolymer carrier micelle modified by cholesterol formyl chloride. The technical scheme comprises the steps of: 1. purifying chitosan; 2. preparing the chitosan copolymer modified by cholesterol formyl chloride; 3. separating and purifying the chitosan copolymer modified by cholesterol formyl chloride; and 4 preparing the chitosan copolymer carrier micelle modified by cholesterol formyl chloride. The method has the characteristic of preparing a colloid solution with stable thermodynamics by self-assembling in a water medium, has simple preparation process and good effect and is an innovation in the medical field.

Owner:ZHENGZHOU UNIV

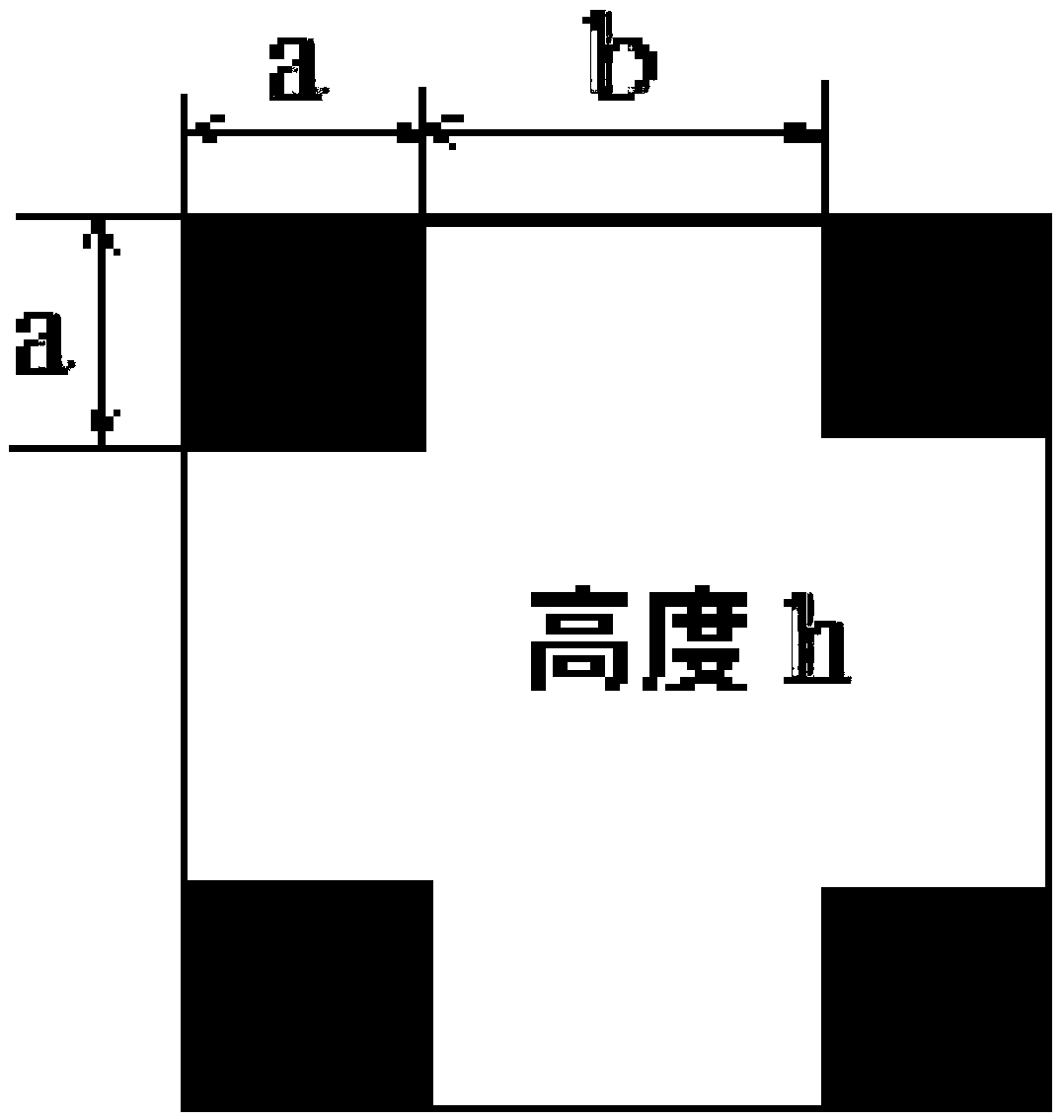

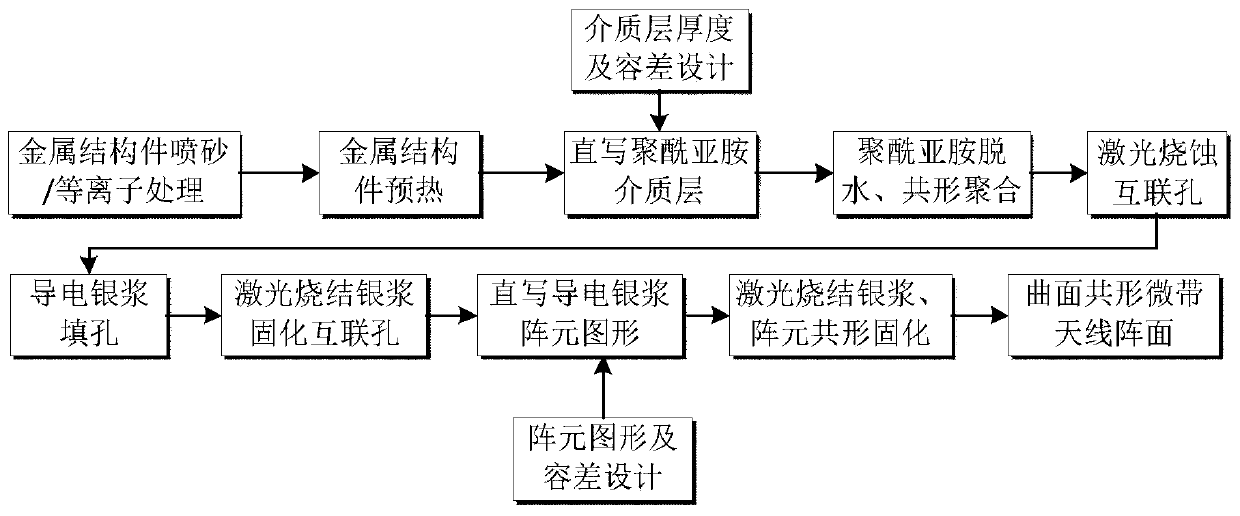

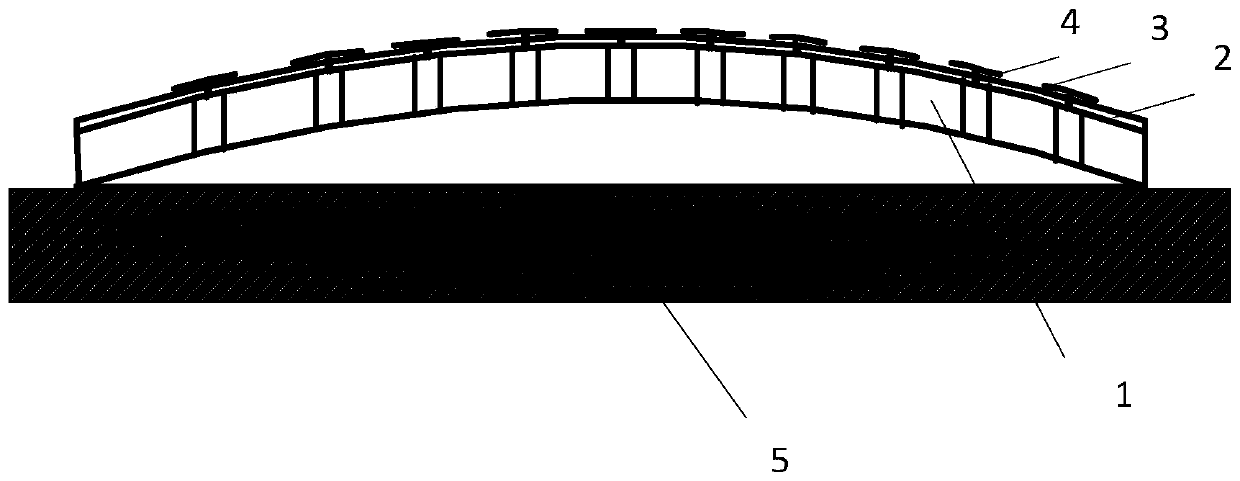

Preparation method of curved conformal microstrip antenna array surface

ActiveCN109755760AAvoid quality risks of electrical performance deteriorationAvoid quality risksIndividually energised antenna arraysSilver pasteMicrostrip antenna array

The invention discloses a preparation method of a curved conformal microstrip antenna array surface and aims to provide a technological method of a microstrip antenna completely conformal to a metal structural part. According to the technical scheme, microstrip patches selected to serve as antenna conformal array units, and a curved antenna array surface is directly printed on the metal structuralpart; sand-blasting roughening processing is performed first, wherein a direct writing pen A is adopted to spread a polyimide precursor solution in a layered mode on a sand-blasting surface of a metal carrier according to the shape and size of a dielectric layer of the microstrip antenna array surface till the requirement of total thickness is met, and after surface drying, temperature is raisedthrough a heating substrate for dehydration, and a conformal dielectric layer of the microstrip antenna array surface is formed through aggregation on the surface of the metal carrier; pulse lasers are adopted to ablate bottom holes of vertical interconnected holes in the array units of the polyimide dielectric layer, the bottom holes are filled with conductive silver paste to serve as the vertical interconnected holes, and sintering is performed to solidify the conductive silver paste; and a conductive silver paste array unit pattern is spread on the conformal dielectric layer and is solidified onto the surface of the dielectric layer after surface drying, so that the curved conformal microstrip antenna array surface is formed.

Owner:10TH RES INST OF CETC

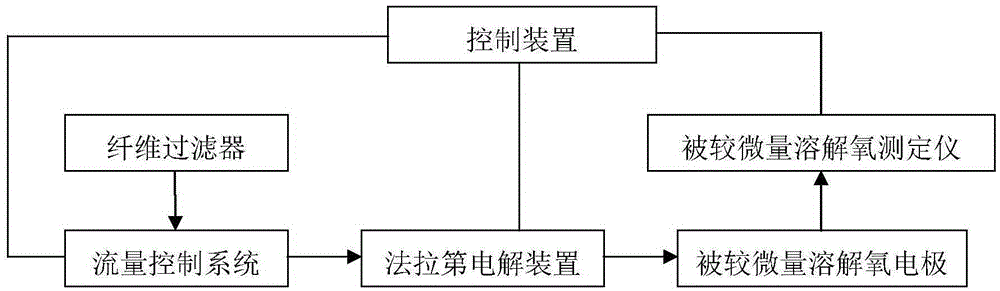

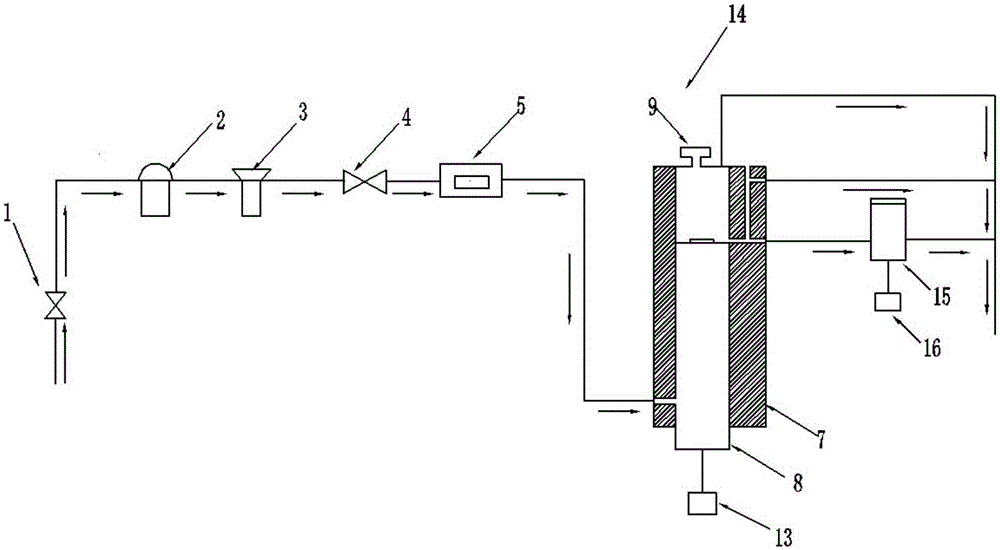

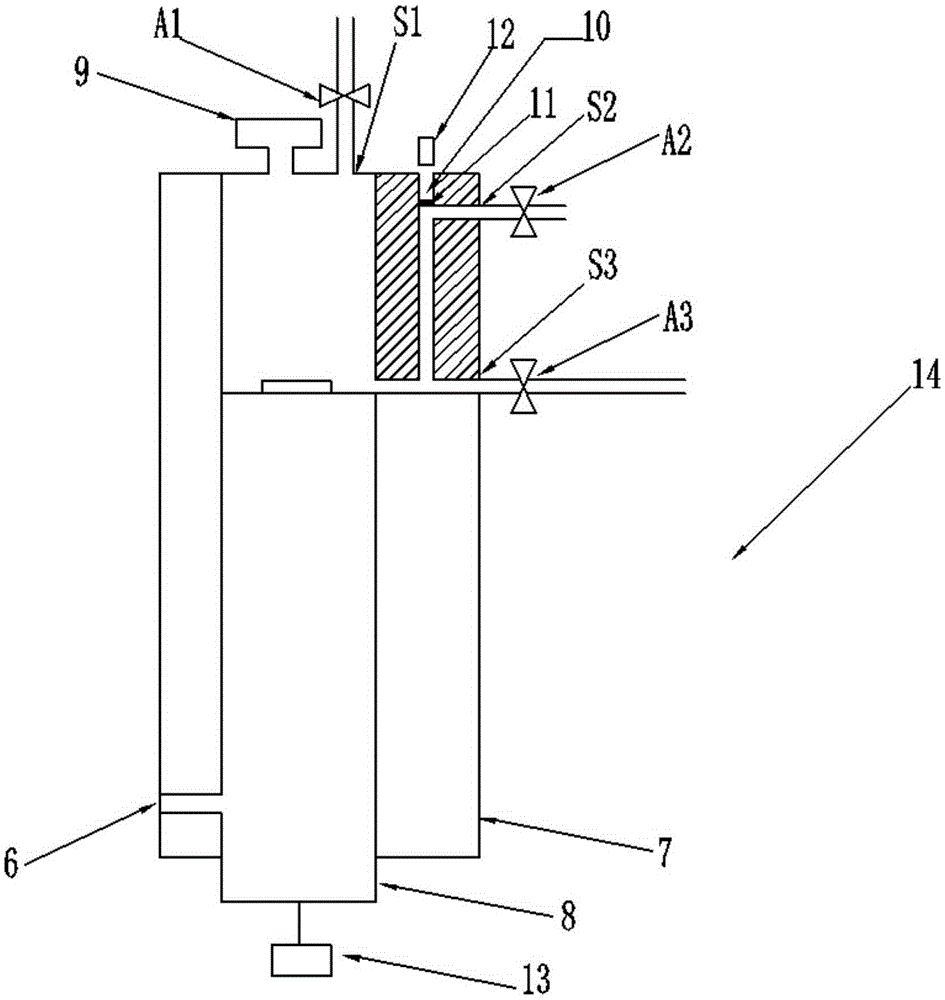

Trace dissolved oxygen tester on-line calibrating device and calibration method thereof

ActiveCN105424769ASimple structureEasy to operateMaterial electrochemical variablesSample waterInstability

The invention relates to a trace dissolved oxygen tester on-line calibrating device and a calibration method thereof. The method is based on the Faraday's law of electrolysis, and the device comprises a fiber filter, a flow control system, a Faraday electrolysis device, dissolved oxygen measurement equipment and a control device. The trace dissolved oxygen tester on-line calibrating device and the calibration method thereof are reliable in design theory, simple and convenient in method and great in operability. According to the trace dissolved oxygen tester on-line calibrating device and the calibration method thereof, field sample water is used, the process of preparing ultra-pure water is omitted, and the process of taking out an oxygen electrode is avoided through on-line calibration. Water electrolysis efficiency is measured on line, so that electrolysis efficiency variation caused by water sample variation and instability of an electrode can be tracked, and the calibration result can be more accurate and reliable. Calculation of electrolysis efficiency of the field sample water is applied to a high precision gauge pressure sensor, and accuracy of electrolysis efficiency calculation is guaranteed.

Owner:HKY TECH

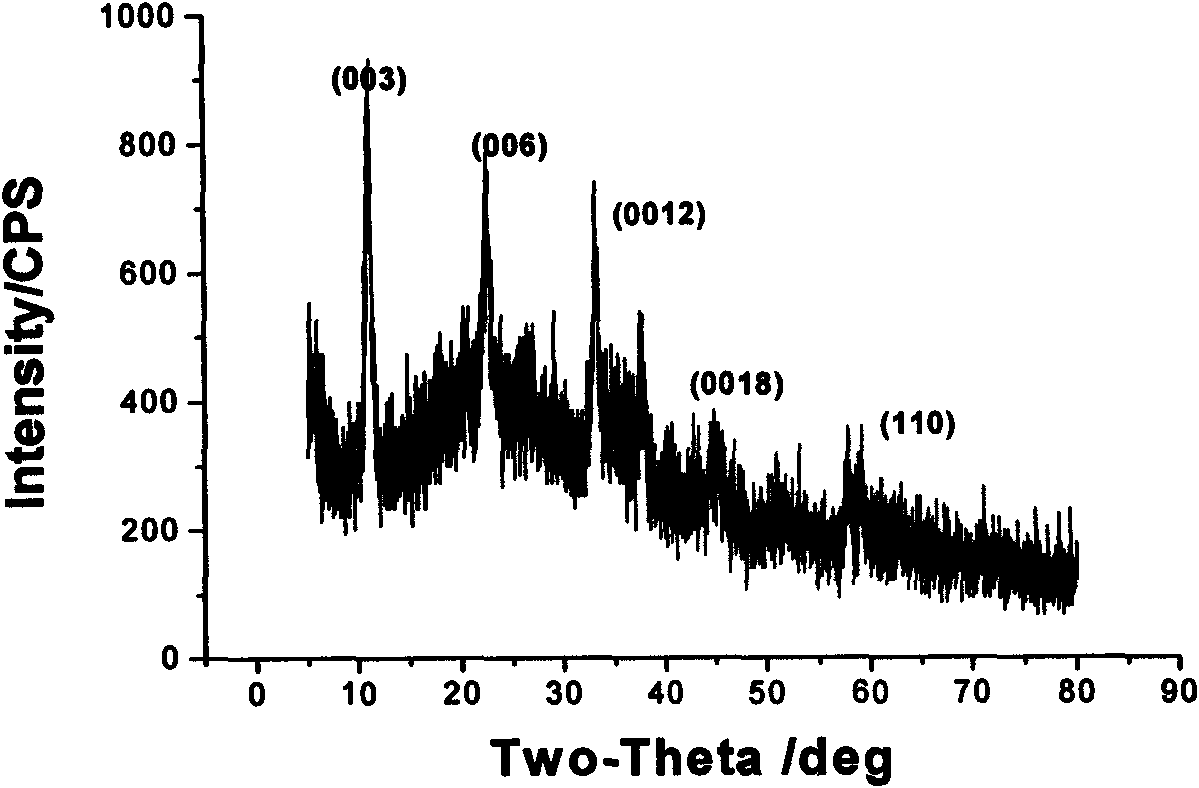

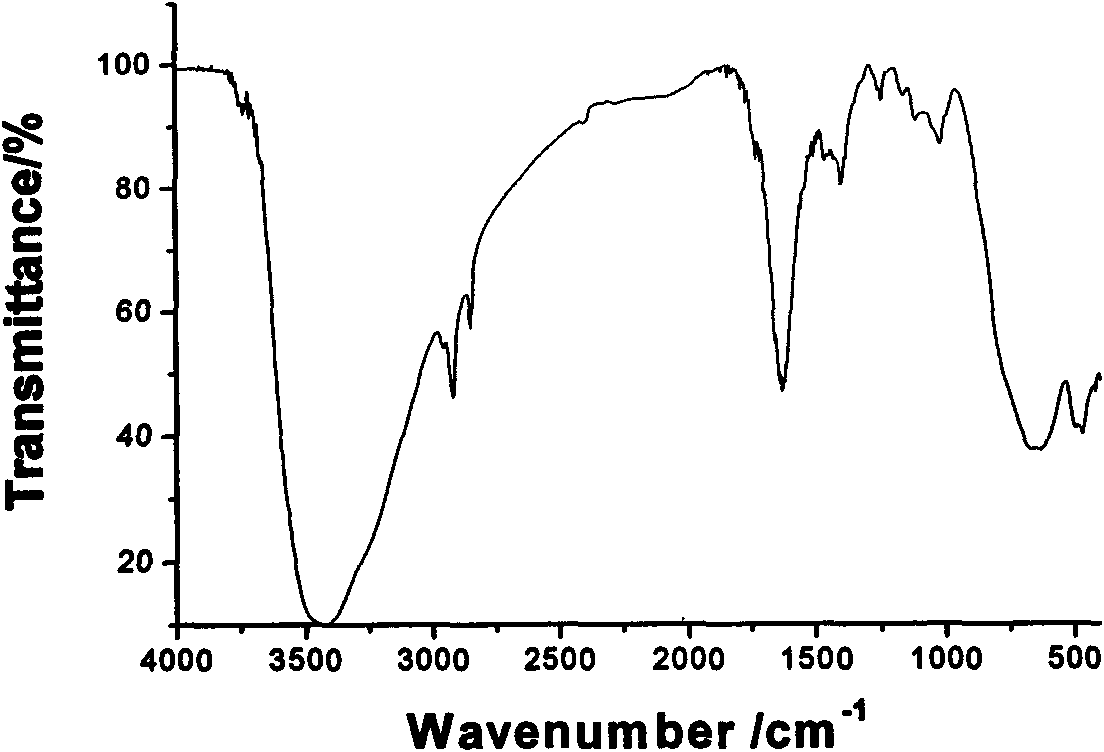

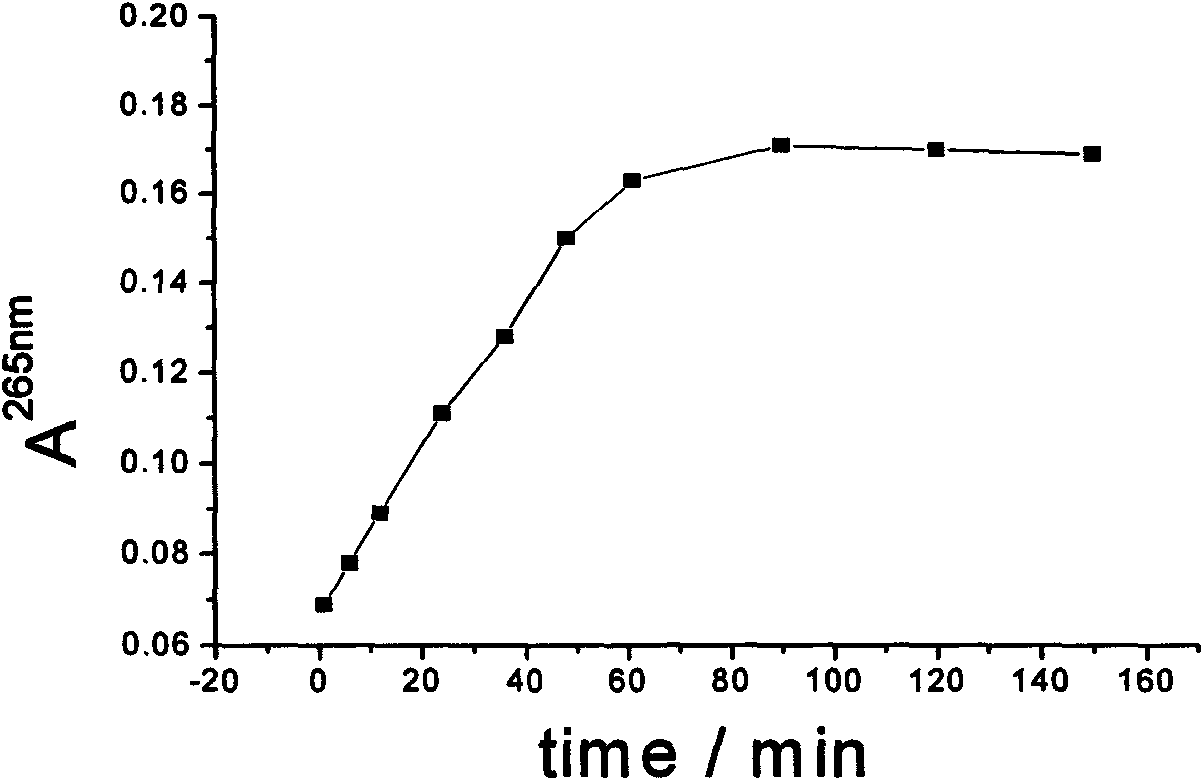

Method for synthesizing dextran-magnetic LDH-fluorouracil magnetic targeting sustained and controlled release tripolymer

ActiveCN101607091ASolve the problems of preparation and antioxidant protectionGood biocompatibilityOrganic active ingredientsInorganic non-active ingredientsSolventChemistry

The invention relates to a method for synthesizing dextran-magnetic LDH-fluorouracil magnetic targeting sustained and controlled release tripolymer, comprising the following steps of: finishing the synthesis of magnetic layered composite hydroxide and the intercalation assembly of fluorouracil to the magnetic layered composite hydroxide under the condition of nitrogen protection; performing the in-situ composite process of magnetic LDH-fluorouracil under the condition of nitrogen protection with the dextran as the wrapping material; and finally separating the product through the solvent conversion technology. The invention realizes the merging and unification of the targeting and the sustained release of a magnetic targeting drug, thereby solving the problems of the preparation of magnetic LDH-Drugs and protection against oxidation, and synthesizing a magnetic targeting sustained and controlled release drug delivery system which has good biocompatibility and high storage stability and fits for transport in vivo; and the invention is suitable for the chemical synthesis of various magnetic targeting sustained and controlled release drugs, and has the advantages of simple and rapid preparation technology, high product purity, energy consumption saving, no environment pollution, wide application range and the like.

Owner:NINGXIA MEDICAL UNIV

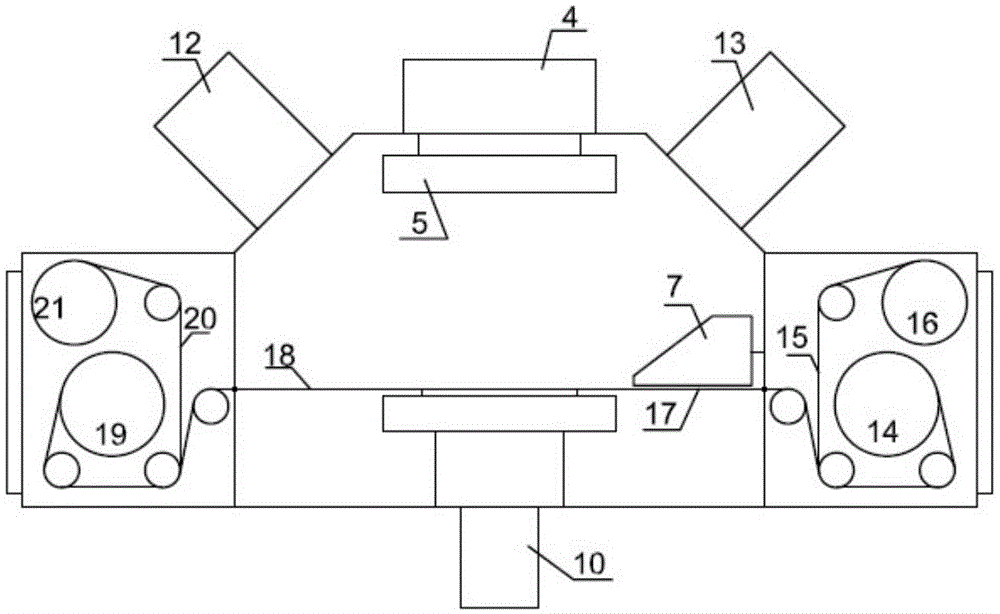

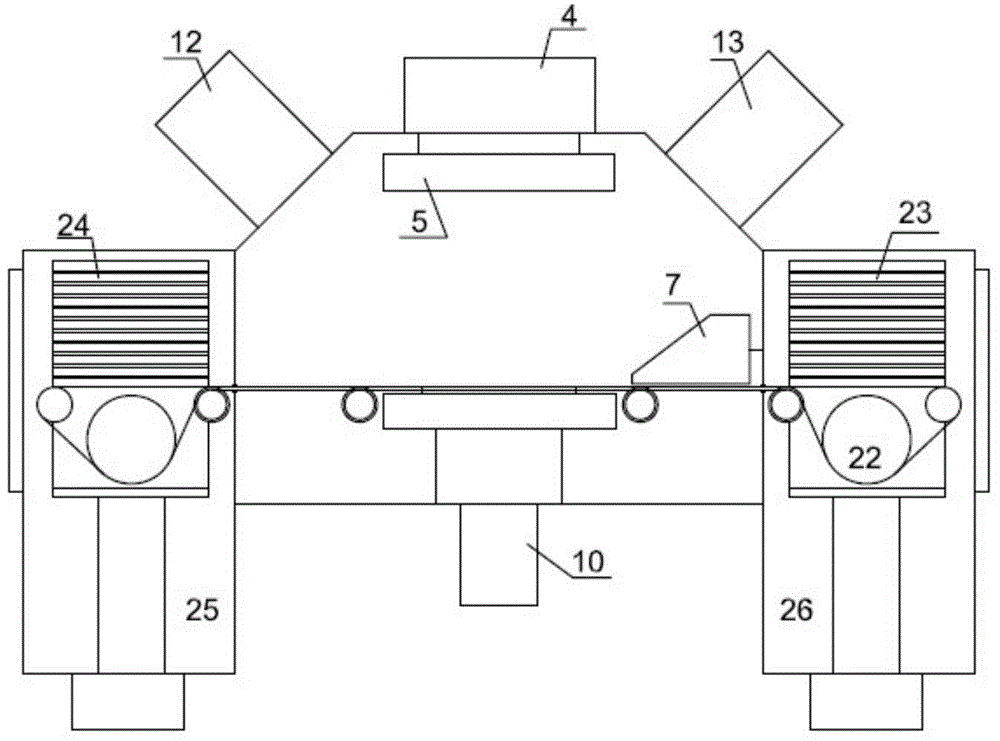

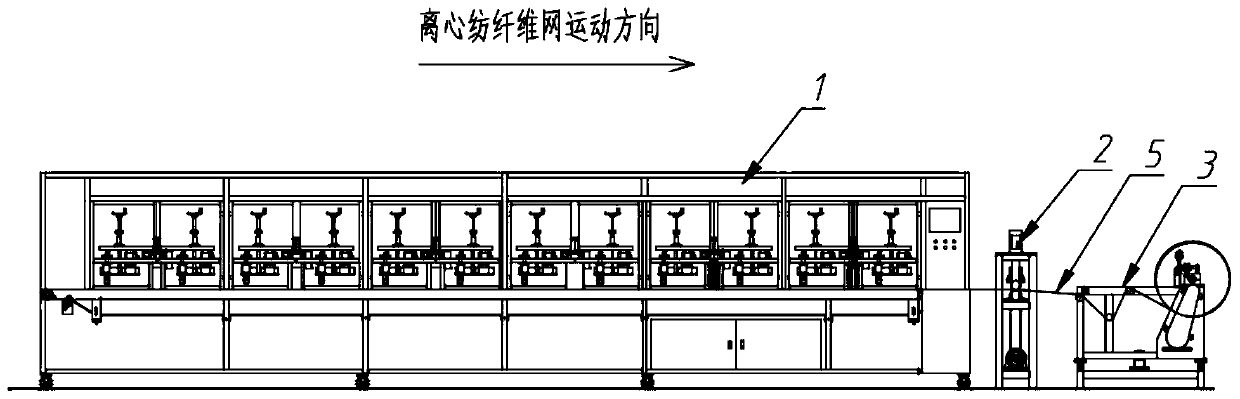

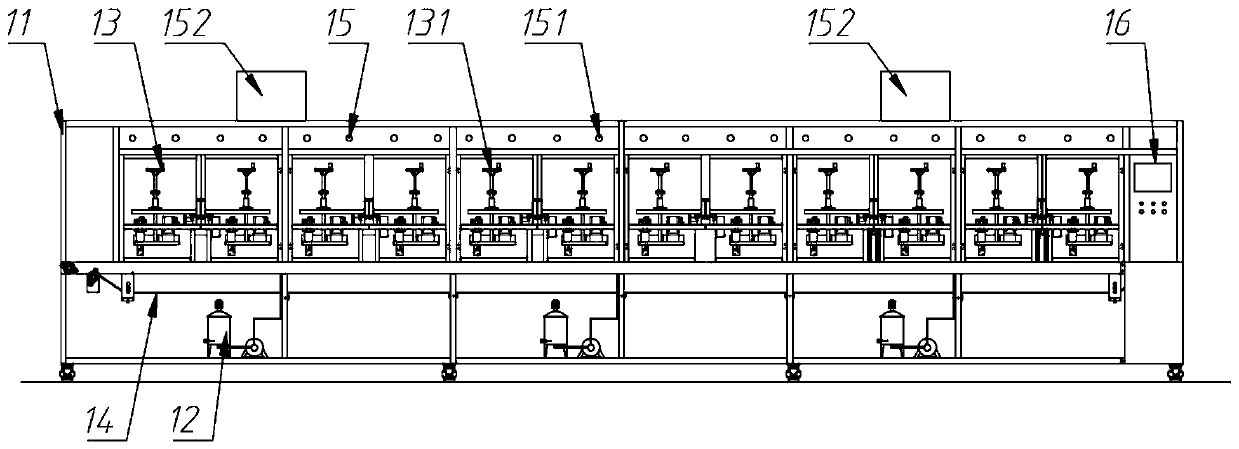

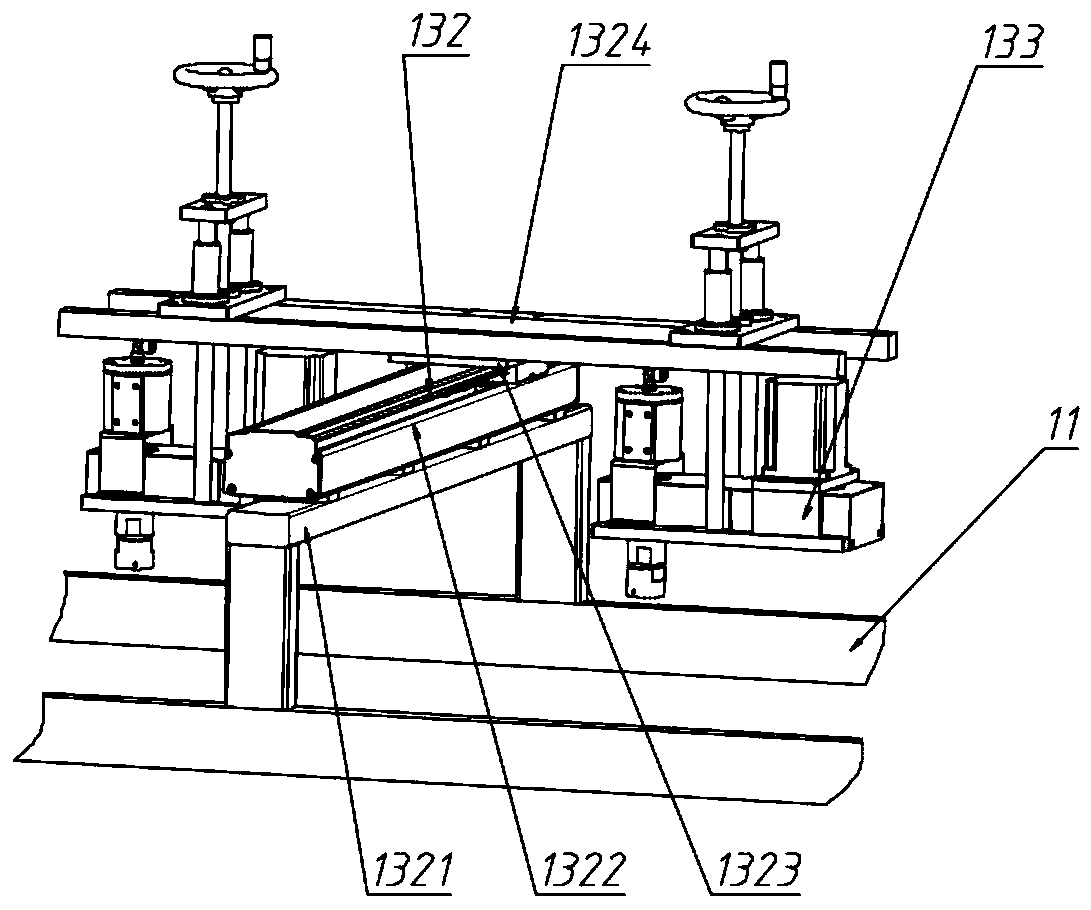

Planar receiving type centrifugal-spinning automatic production equipment and method

ActiveCN110295404ARealize mass productionFix production issuesFilament/thread formingNon-woven fabricsNanofiberNonwoven fabric

The invention discloses a planar receiving type centrifugal-spinning automatic production equipment and method. A continuously moving collection belt is arranged under spinnerets, and after proper height adjustment, spinning solution ejected by the spinnerets in high-speed rotation forms fibers instantly, and the fibers spirally fall down to be collected on the collection belt to finally form a continuous centrifugally-spun fiber net. The centrifugally-spun fiber net is compacted by a compacting device and wound in a winding device to finally form a centrifugally-spun fiber net roll. A whole production process is completed automatically without manual intervention. By the planar receiving type centrifugal-spinning automatic production equipment and the method, the problem of preparation ofcentrifugally-spun continuous filaments is solved, batch production in centrifugal spinning is realized, and the planar receiving type centrifugal-spinning automatic production equipment and the method are applicable to wide nonwoven fabric surface nanofiber or submicron fiber compounding or wide nano or submicron nonwoven fabric production.

Owner:WUHAN TEXTILE UNIV +1

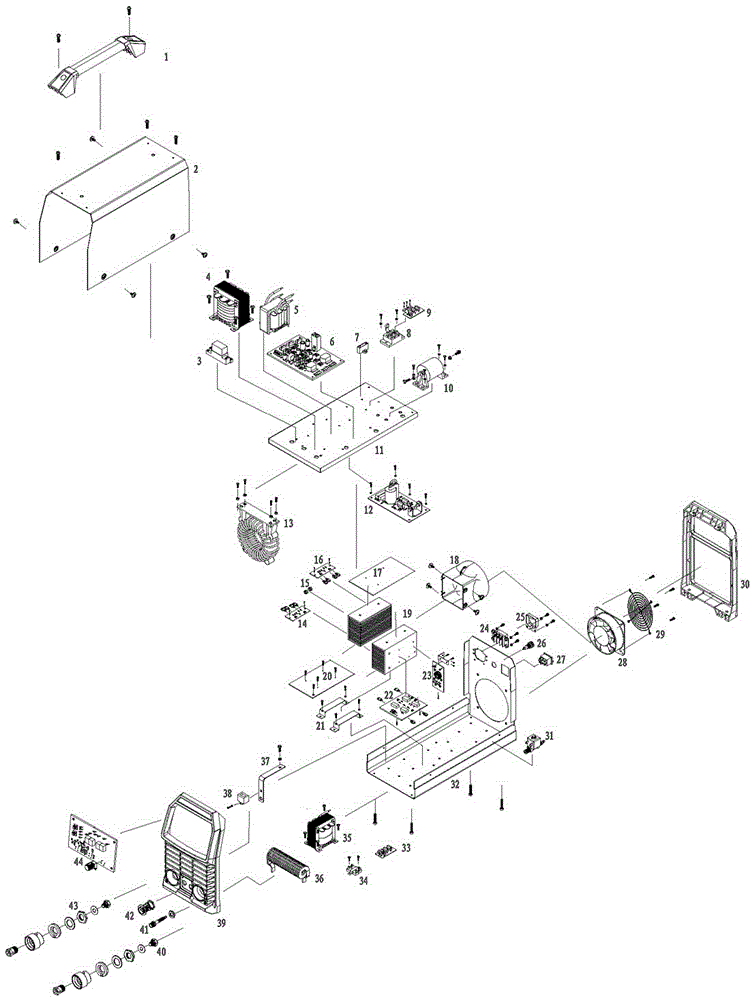

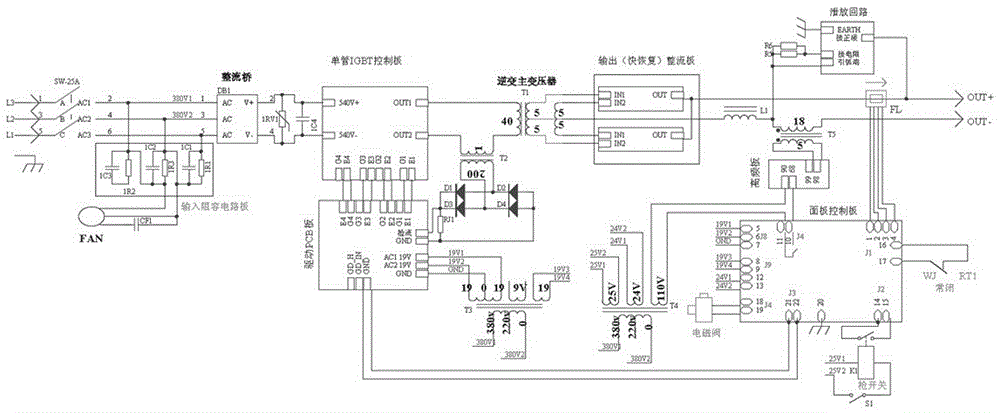

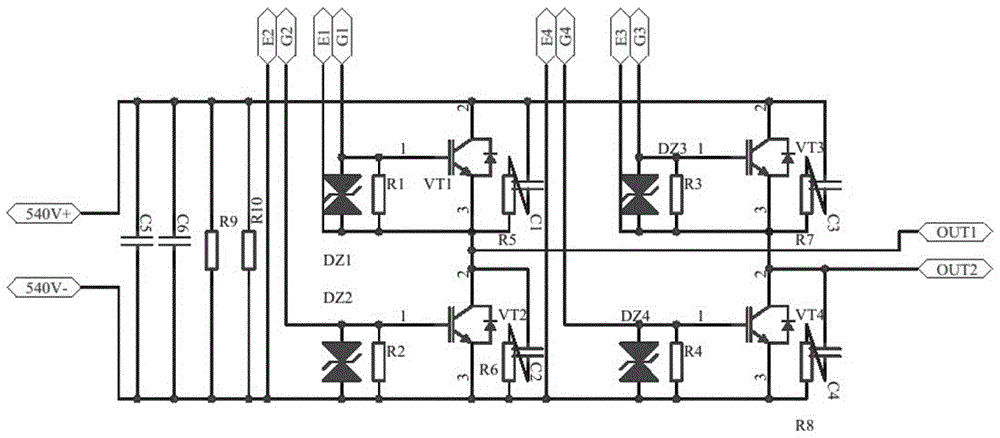

Microprocessor controlled contravariant multifunctional argon arc welding machine

ActiveCN106041267ASimple structural designFix performance issuesWelding accessoriesShielded metal arc weldingControl circuit

The invention relates to a microprocessor controlled contravariant multifunctional argon arc welding machine which comprises a shell part, a front panel part, a rear panel part and an internal control part; the internal control part comprises a contravariant main circuit, a monotube IGBT control circuit, a driving circuit, a rectification output circuit, a tapping loop circuit, a high-frequency circuit and a panel control circuit; the monotube IGBT control circuit and the rectification output circuit are connected in series onto the contravariant main circuit; the driving circuit is connected with the monotube IGBT control circuit and the panel control circuit; the driving circuit controls on-off of the monotube IGBT control circuit under the control of the panel control circuit; the high-frequency circuit is connected with the panel control circuit and the contravariant main circuit and realizes high-frequency or non-contact arc strike during argon arc welding under the control of the panel control circuit; and the tapping loop circuit is connected with the high-frequency circuit and the contravariant main circuit. The microprocessor controlled contravariant multifunctional argon arc welding machine has three functions of pulse argon arc welding, DC argon arc welding and manual arc welding and the characteristic of multiple purposes.

Owner:ZHEJIANG KENDE MECHANICAL & ELECTRICAL

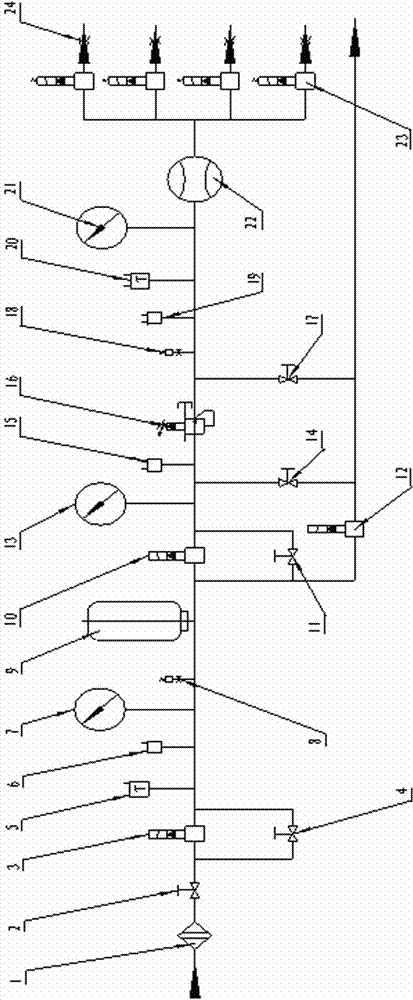

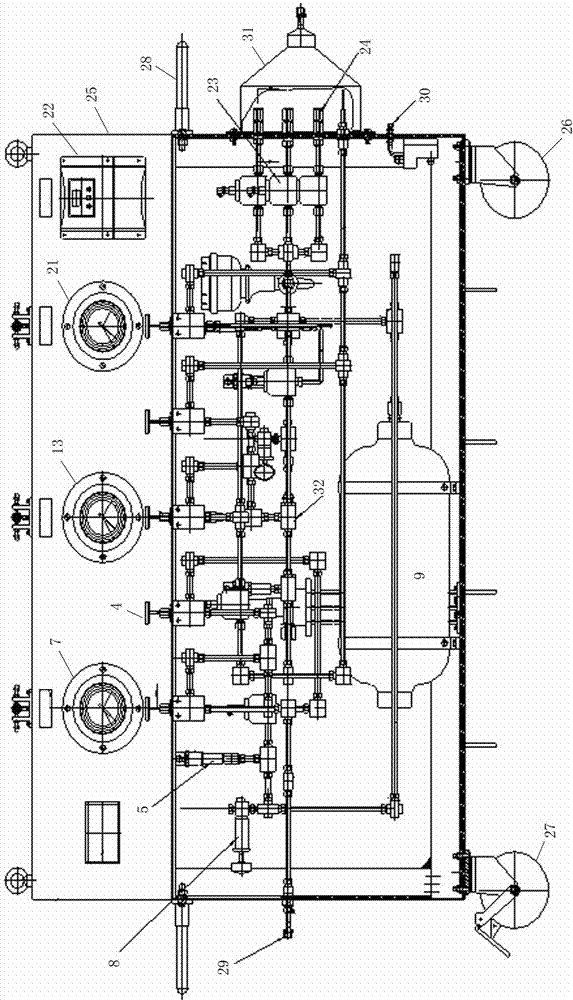

Superhigh-pressure pressure-reducing valve performance testing bench

ActiveCN103674510ASolve design problemsFix production issuesMachine part testingMeasurement of fluid loss/gain rateVena contracta diameterGas cylinder

The invention relates to a superhigh-pressure pressure-reducing valve performance testing bench. The structure is as follows: in a casing, a filter is connected with the inflation port of a gas cylinder through a pipeline; the inflation port of the gas cylinder is connected with the air inlet of a pressure-reducing valve through the pipeline; the air outlet of the pressure-reducing valve is connected with a gas flowmeter; and the gas flowmeter is connected with a damping orifice plate through a pneumatic valve. The superhigh-pressure pressure-reducing valve performance testing bench solves the problems of designing, manufacturing and installing of a testing bench in a large-flow pressure-reducing valve performance testing system with gas medium pressure reaching superhigh pressure of 60 MPa and a pressure-reducing valve maximum flow being 120 L / min.

Owner:SHENYANG AEROSPACE XINGUANG GRP

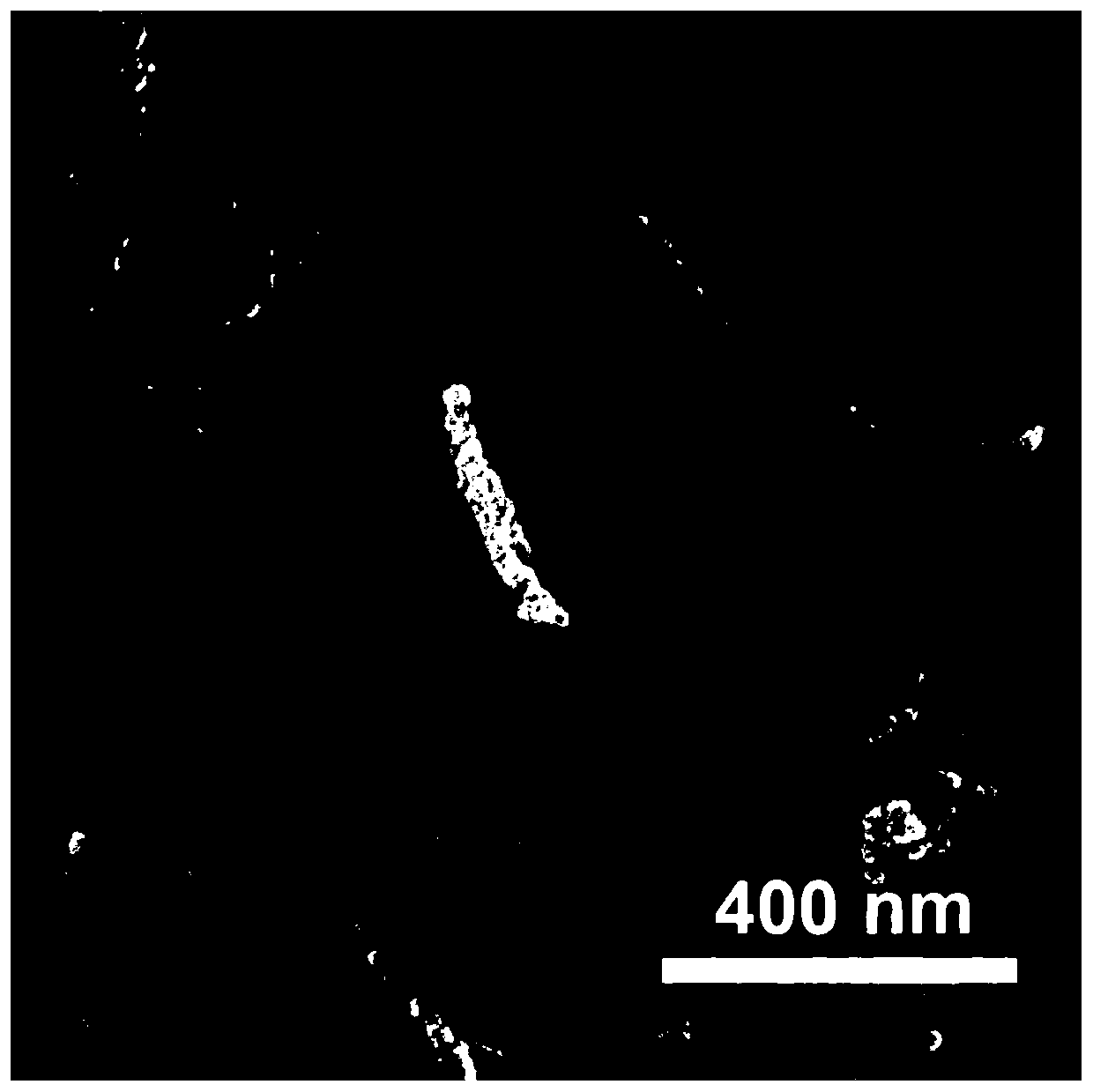

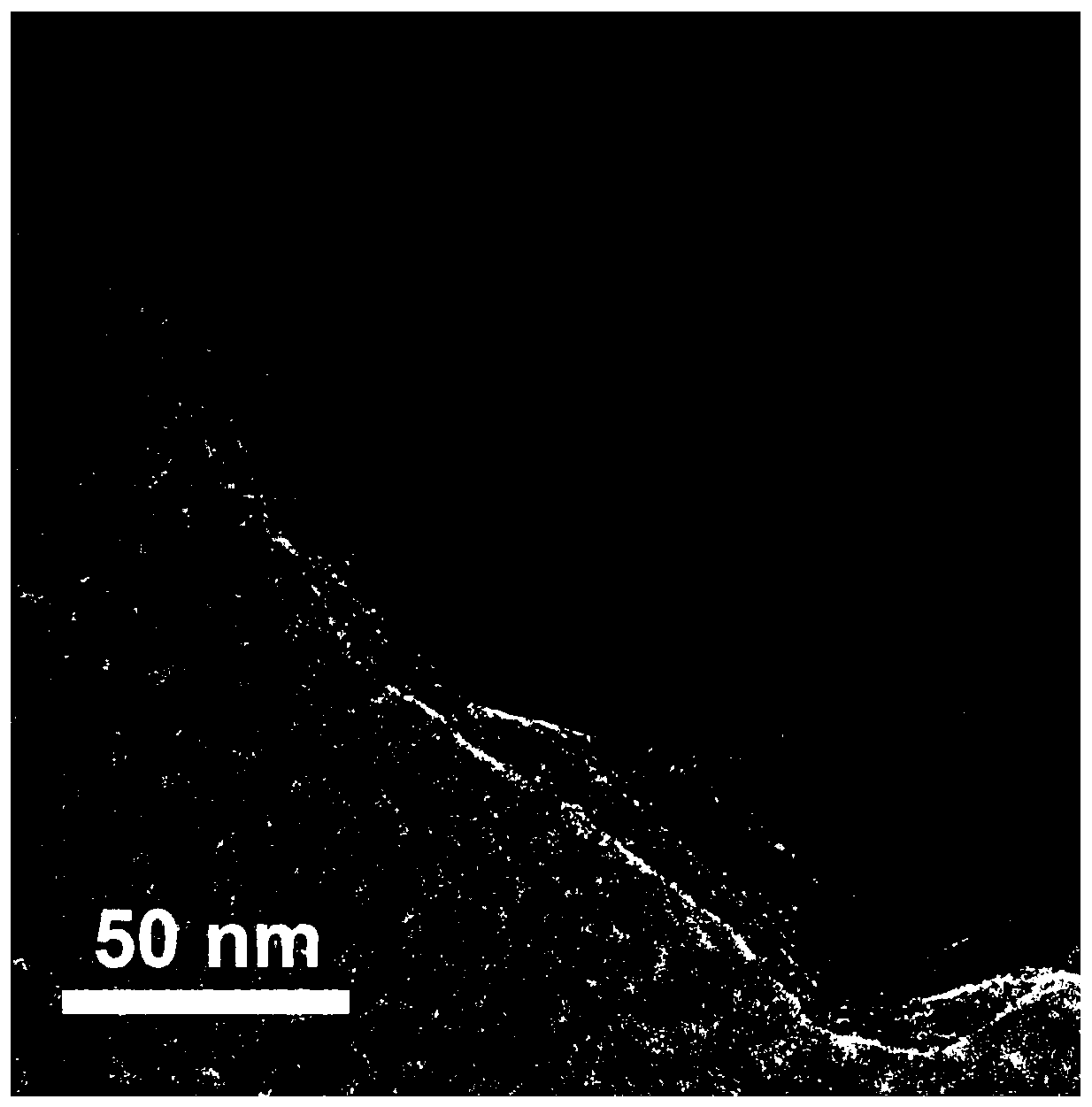

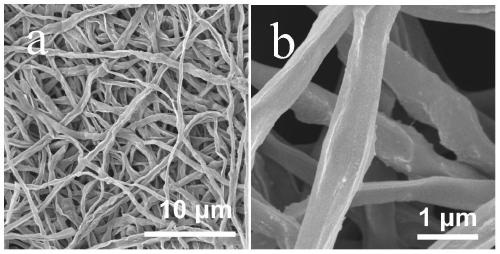

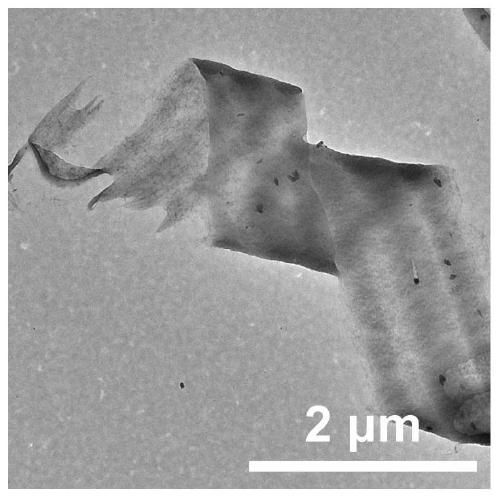

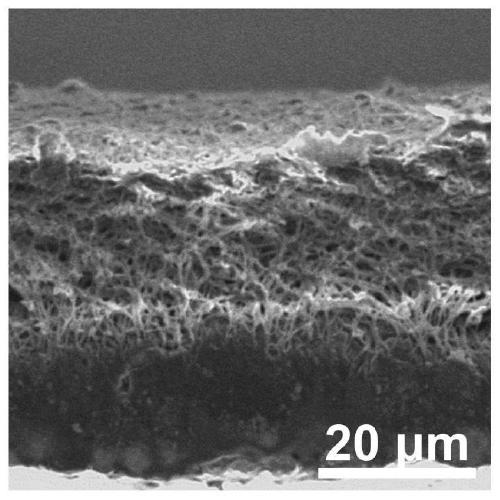

Composite lithium metal negative electrode based on MXene nanoribbon and general synthesis method of composite lithium metal negative electrode

ActiveCN111293276AFix production issuesSolve application problemsElectrochemical processing of electrodesElectrode carriers/collectorsPolymer dissolutionMetallic lithium

The invention discloses a composite lithium metal negative electrode based on an MXene nanoribbon and a general synthesis method of the composite lithium metal negative electrode, and belongs to the field of lithium batteries. The MXene nanoribbon is formed by overlapping two-dimensional MXene nanosheets in a staggered manner along the axial direction. The preparation method comprises the steps ofpreparing MXene / polymer composite fibers with a core-shell structure by utilizing an electrostatic spinning machine, selectively removing the high-molecular polymer of the core by utilizing the difference of the solubility of different polymers and adopting a water solvent, and expanding the shell layer at the same time to obtain an MXene nanoribbon structure with controllable structure and size;and depositing lithium metal into pores or cavities of a three-dimensional current collector formed by the MXene nanoribbon through an electro-deposition method to obtain the composite lithium metalnegative electrode. The MXene nanoribbon structure prepared by the invention can effectively reduce the local current density of the electrode and inhibit the volume expansion of metal lithium. Meanwhile, rich lithium-philic functional groups on the surface of MXene can be specifically combined with lithium ions, uniform nucleation of lithium is achieved, generation of lithium dendrites is inhibited, the safety of the lithium metal battery is improved, and the basic problem puzzling large-scale production of the lithium metal battery is solved.

Owner:DALIAN UNIV OF TECH

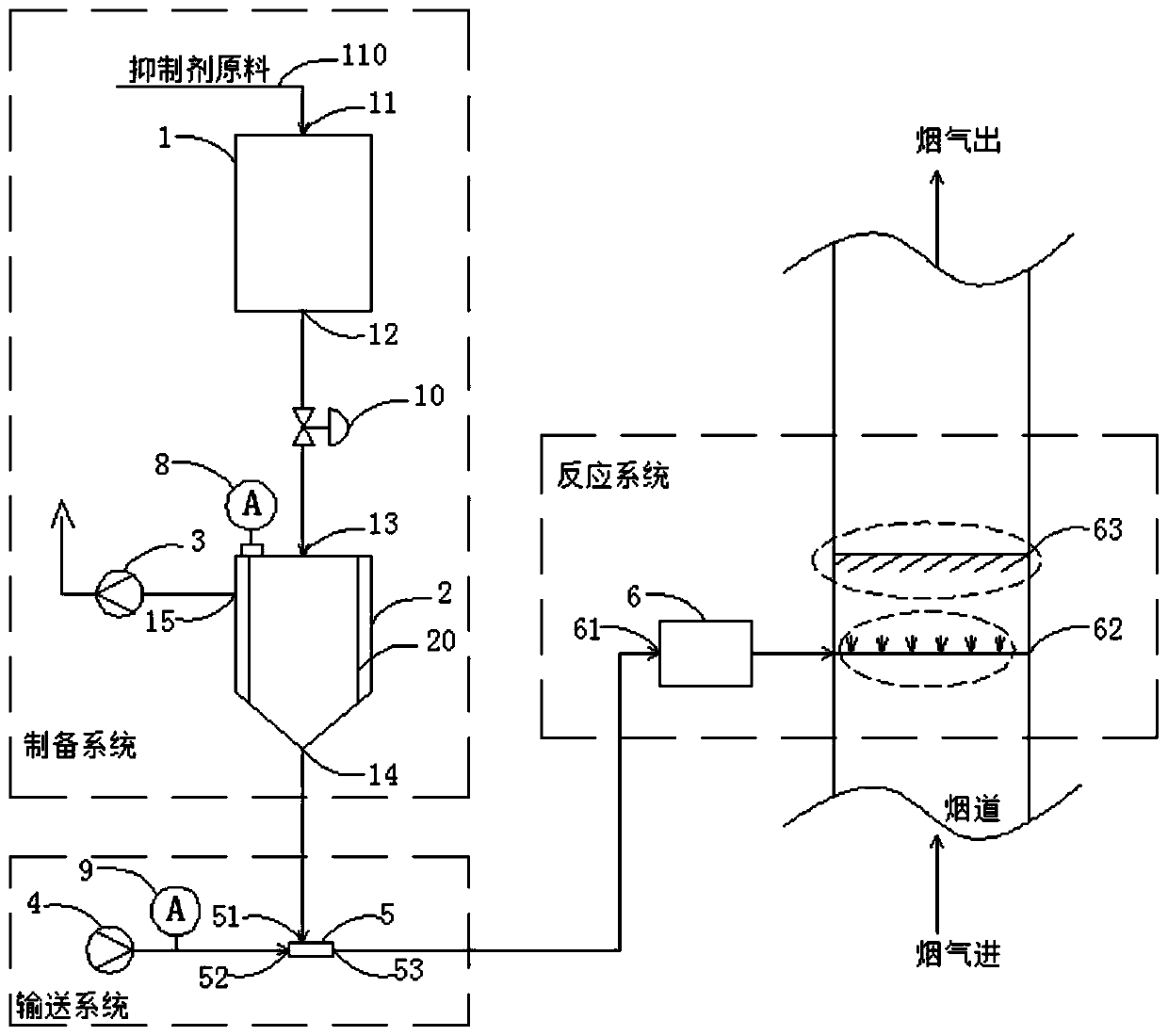

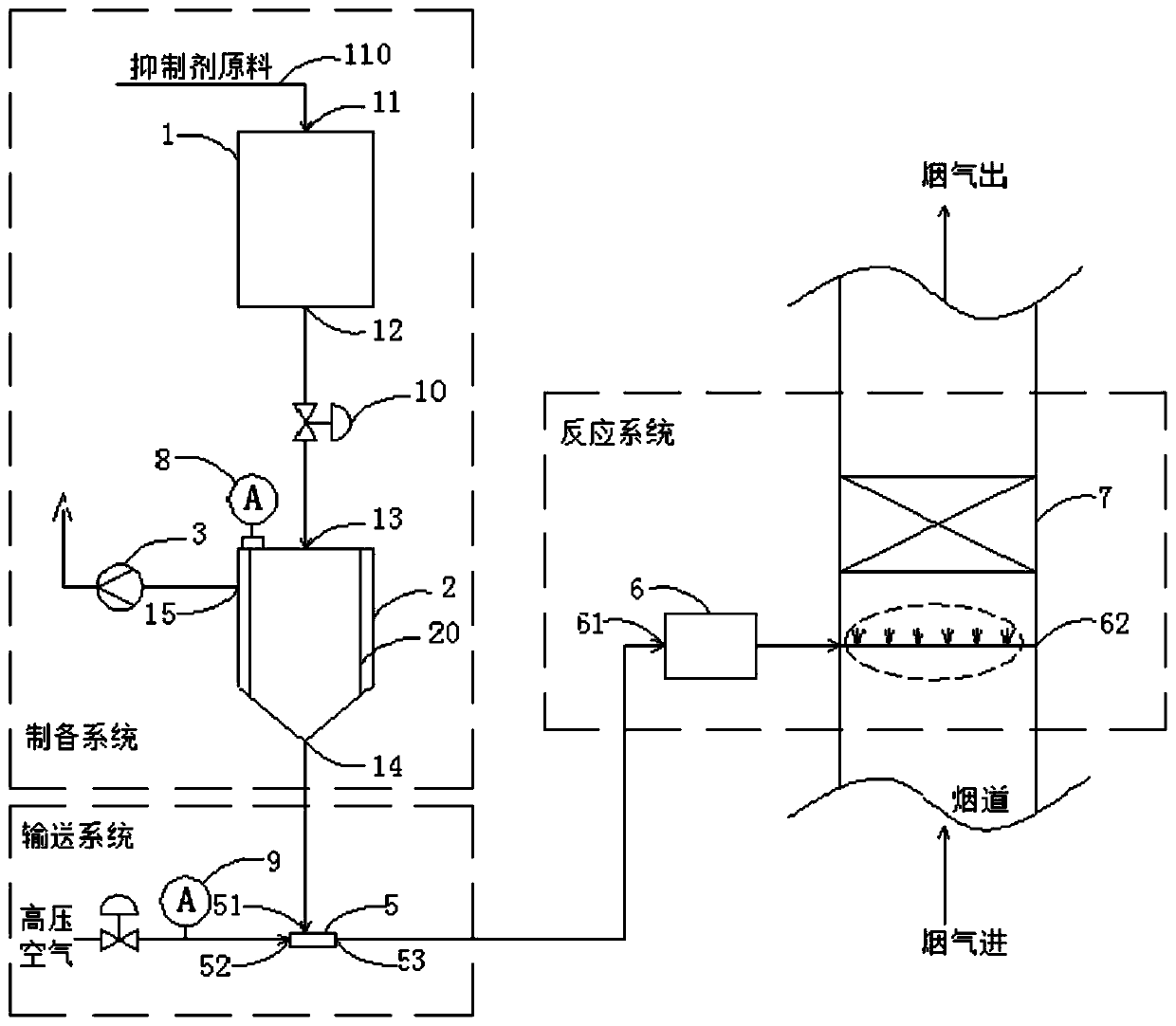

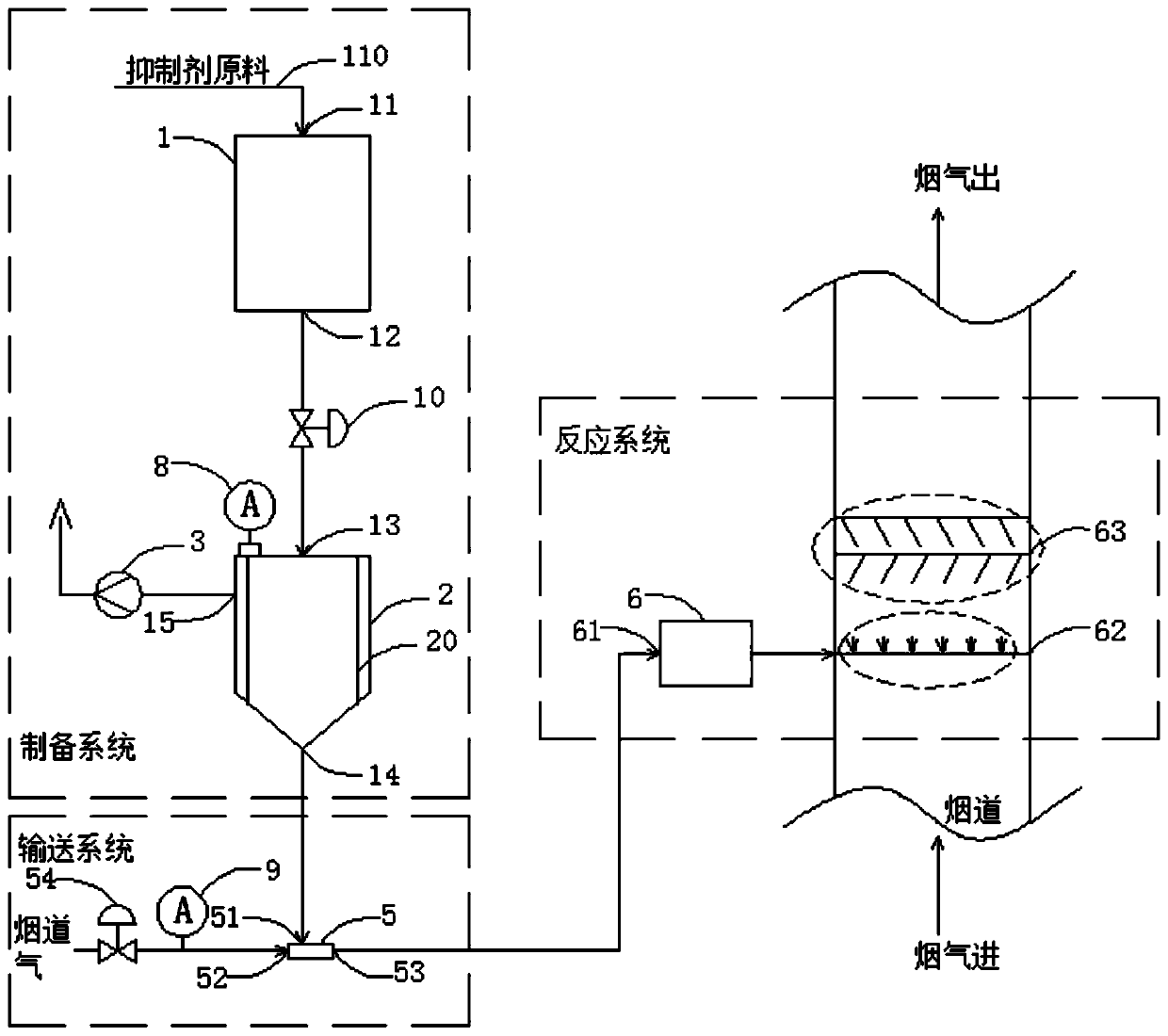

Equipment inhibiting generation of dioxin in incineration flue gas and use method of equipment

InactiveCN109908741ASuppress generationUniform responseDispersed particle separationThermodynamicsFlue gas

The invention relates to equipment inhibiting generation of dioxin in incineration flue gas and a use method of the equipment. The equipment comprises a micropowder inhibitor preparation system, a micropowder inhibitor conveying system and a reaction system, wherein the micropowder inhibitor preparation system comprises a micron-sized solid inhibitor production device and a micropowder inhibitor storage tank that are sequentially connected; the micropowder inhibitor storage tank is connected with a gas extractor; the micropowder inhibitor conveying system comprises a pneumatic conveying sourceand a gas-solid mixing device that are sequentially connected; a feed port of the gas-solid mixing device is connected with a discharge port of the micropowder inhibitor storage tank; the reaction system comprises a gas-solid mixing and distributing device and a gas-solid spray device that are sequentially connected; a feed port of the gas-solid mixing and distributing device is connected with adischarge port of the gas-solid mixing device; and the gas-solid spray device is arranged in a flue gas pipeline and performs distribution through the gas-solid mixing and distributing device. The equipment can improve an inhibition effect on the generation of dioxin in the incineration flue gas and reduce influence on conveying of the incineration flue gas.

Owner:上海环保工程成套有限公司

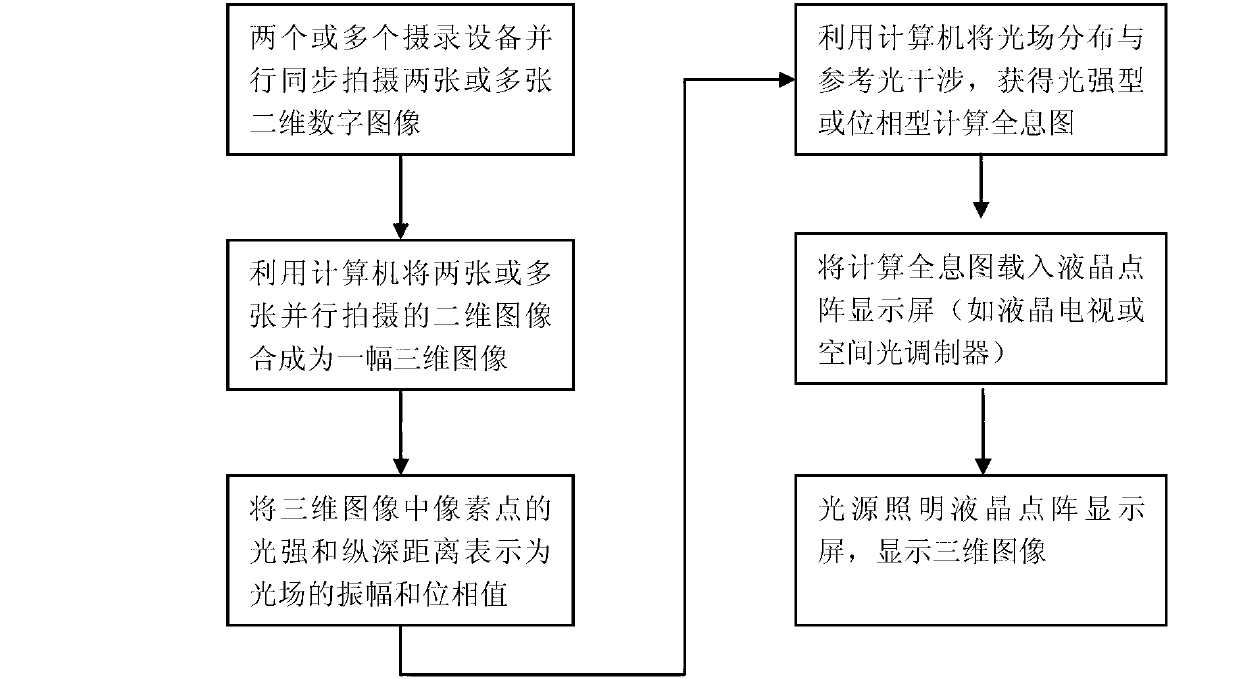

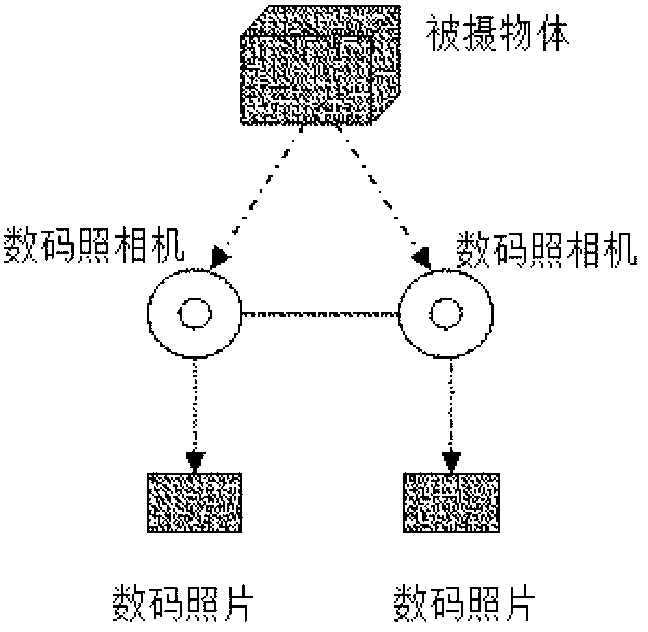

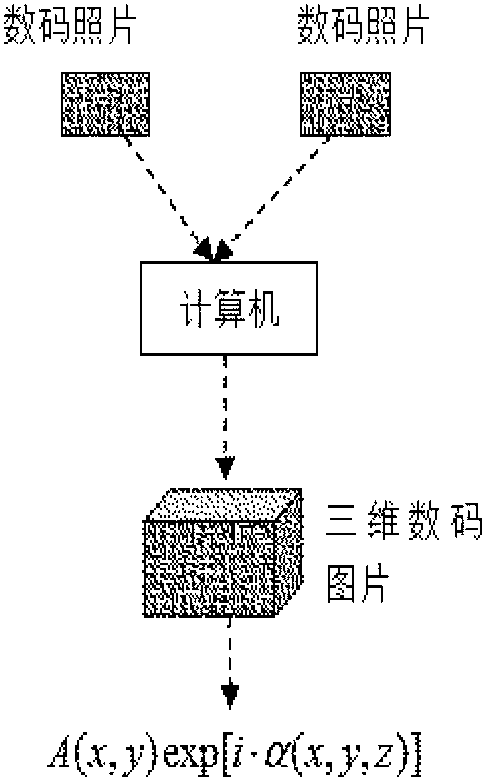

Method of manufacturing and displaying three-dimensional image

InactiveCN103106686AEasy to watchFix production issuesImage enhancement3D modellingDot matrixLight beam

The invention discloses a method of manufacturing and displaying a three-dimensional image. The method comprises the following steps: combining two two-dimensional images into a three-dimensional image using a three-dimensional image combining algorithm, acquiring optical field distribution of the three-dimensional image based on light intensity of the three-dimensional image and depth distance, generating a light intensity type or phase type computer generated hologram of the light intensity of the three-dimensional image, controlling voltage of liquid crystal dot matrixes according to light intensity or phase of pixel points of the light intensity type or phase type computer generated hologram, and displaying the three-dimensional images by the liquid crystal dot matrixes using light beams shining the liquid crystal dot matrixes. The method can use an existing device to acquire a two-dimensional image simply, and meet the needs that material objects need to be recorded by holographic records in an optical holographic method. Due to the fact that the holographic method is used for reproducing the three-dimensional image, and the reproduced three-dimensional image is similar to a real three-dimensional image which can be observed by human eyes, so observers can observe the three-dimensional image conveniently without wearing any special glasses, and the problems of manufacturing and display of the three-dimensional image are solved effectively.

Owner:CENT SOUTH UNIV

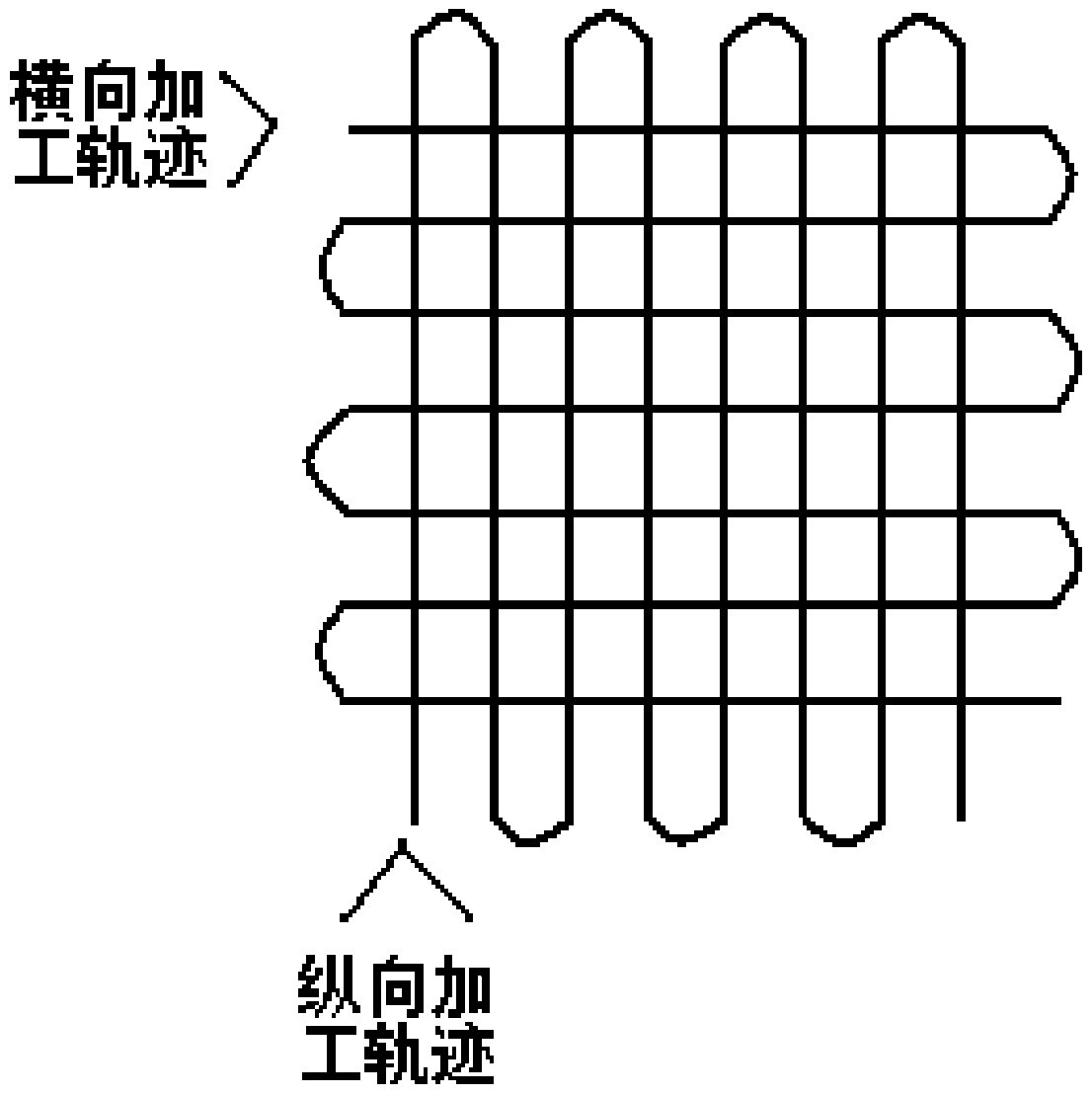

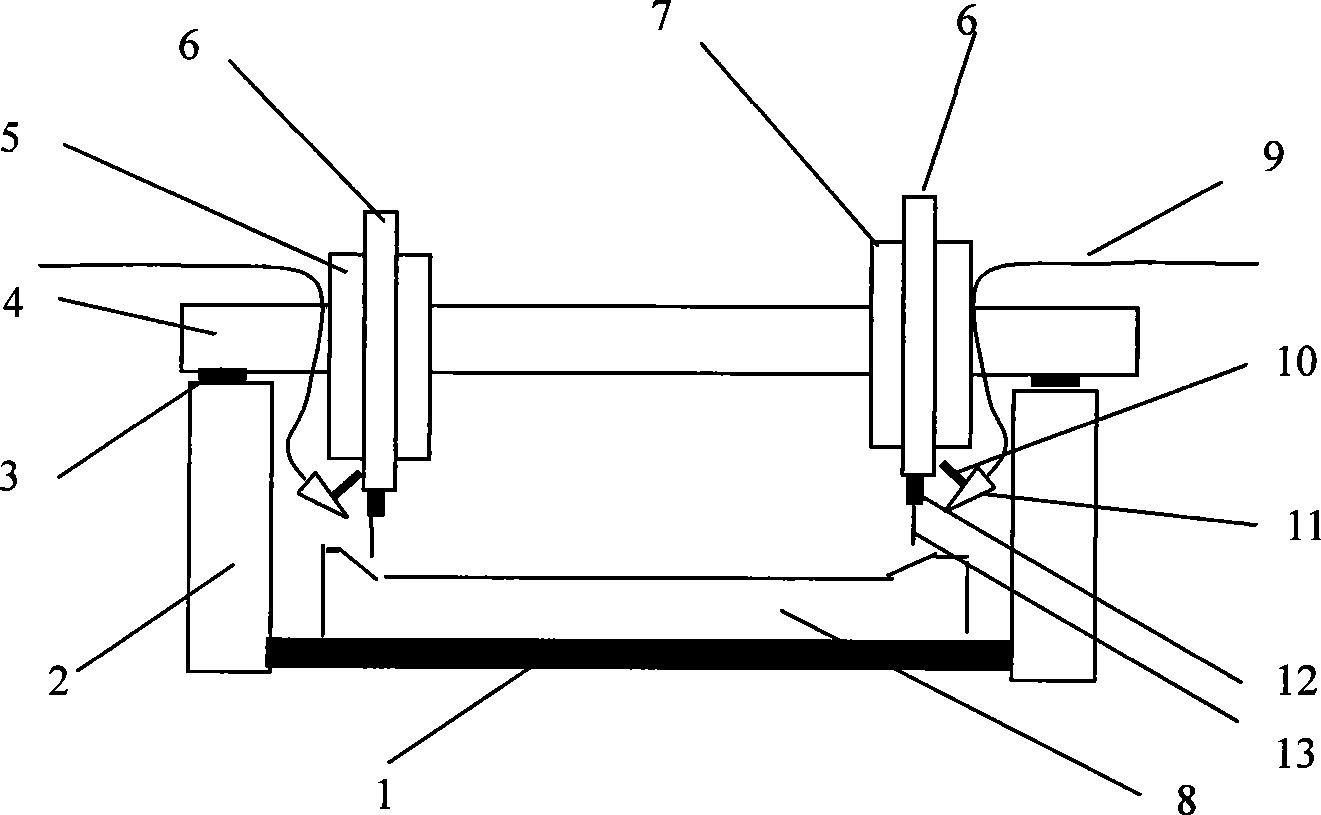

Sand mold milling method and apparatus based on double-processing primary shaft

InactiveCN101367113AFix production issuesImprove processing efficiencyFoundry mouldsMilling machinesMachine toolMaterials science

The invention discloses a sand mould milling method based on a double processing main shaft and a device adopting the method. The method comprises the following steps: according to a cast drawing, a three dimensional solid model of the part is established, and according to the solid model, a cast mould cavity is reversely worked out; according to the size and the number of the processing sand moulds, the cutter selection, the path planning and the milling parameter set are performed; NC codes are generated; the sand moulds which are cured to form in advance are fixed on a worktable; according to driving codes, a double main shaft machine tool is control to carry out the milling process of the sand moulds; and the processed sand moulds are subjected to post treatment. The used devices comprises a machine tool body provided with a worktable, the machine body is provided with a guide rail, the guide rail is provided with a cross beam, the cross beam is provided with a left slide frame and a right slide frame respectively provided with z shafts capable of moving up and down, the processing main shafts are fixed on the z shafts, and the lower surfaces of the processing main shafts are provided with cutter heads. The processing method has the wider processing range and higher processing efficiency, and is particularly applied to the manufacturing of large-sized sand moulds in single piece and small batch.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

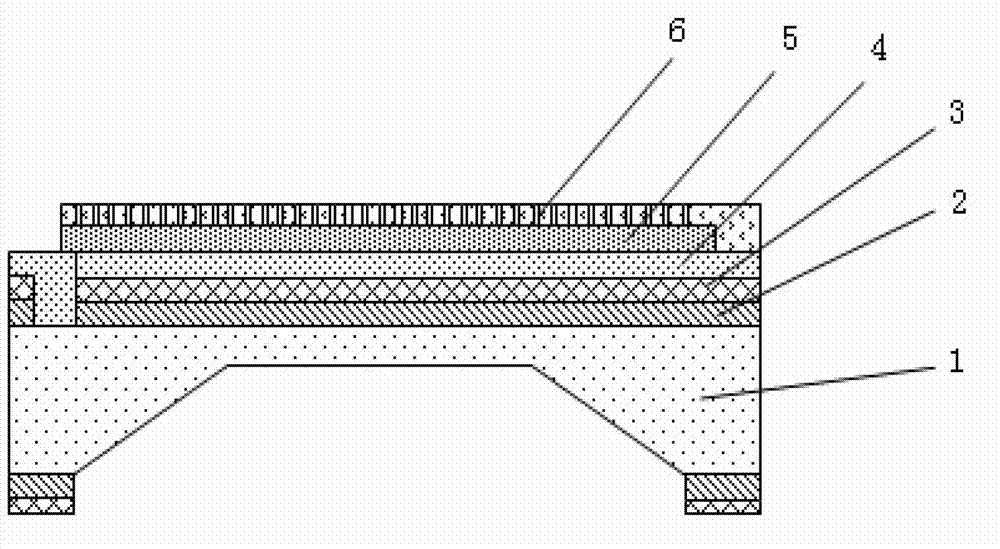

Capacitive high polymer humidity sensor with micron gridded porous electrode and manufacturing method thereof

InactiveCN102890106AIncreased Thickness RedundancyReduced solderabilityMaterial capacitanceElectricityPorous electrode

The invention discloses a capacitive high polymer humidity sensor with a micron gridded porous electrode and a manufacturing method thereof, relates to a capacitive high polymer humidity sensor and a manufacturing method thereof and aims to solve the problem that the capacitive high polymer humidity sensor with the unchanged size is low in reliability at present. The sensor comprises a substrate, a lower electrode, a dielectric layer and an upper electrode, wherein the upper electrode is a micron gridded porous electrode; a plurality of holes are through holes which are formed in an array way; and the lower electrode comprises a transitional metal thin layer and a metal film. The manufacturing method comprises the following steps of: employing a method compatible with a high polymer humidity-sensitive material, forming a metal film with a plurality of gridded holes which are formed in the array way and have the overall thickness of 0.5 to 1mu m, wherein the width of each hole gap and each line of the gridded holes is in a micron order of magnitude; and welding a lead at a pad position of the metal film with the thickness of 0.5 to 1mu m. The capacitive high polymer humidity sensor is used for a sensor for detecting the humidity.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP

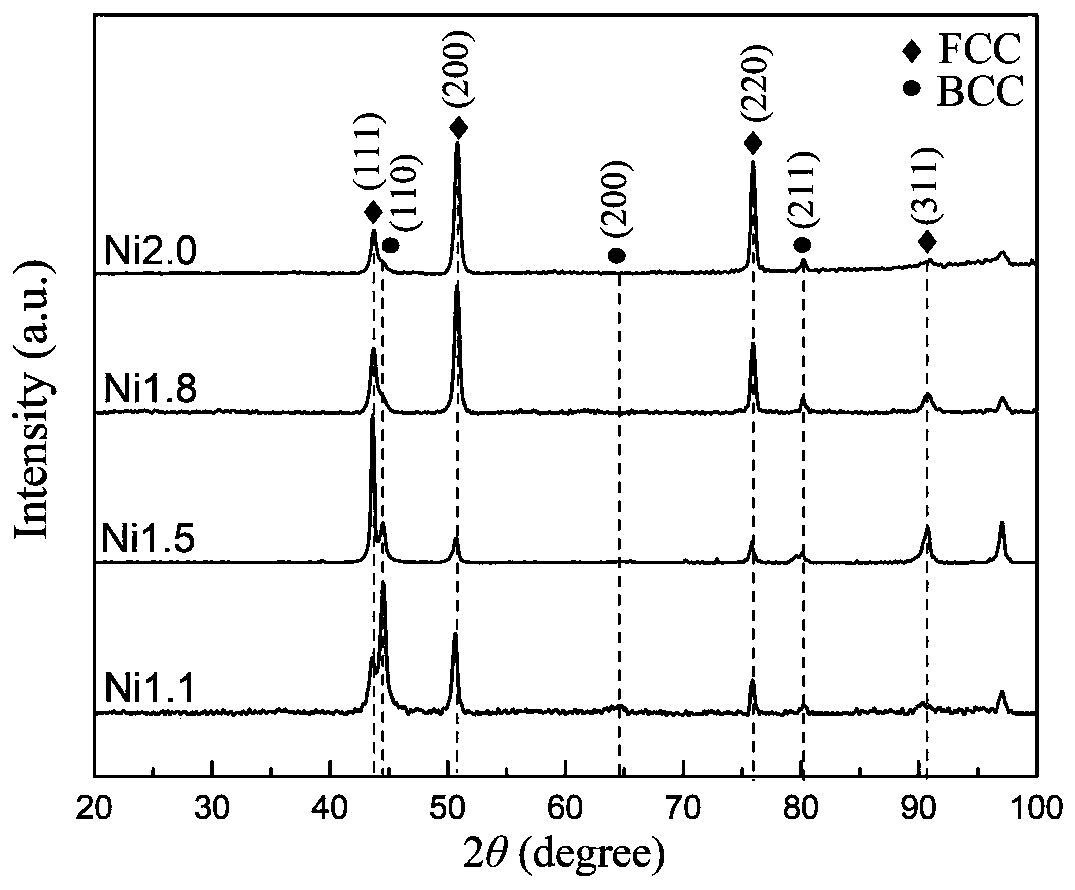

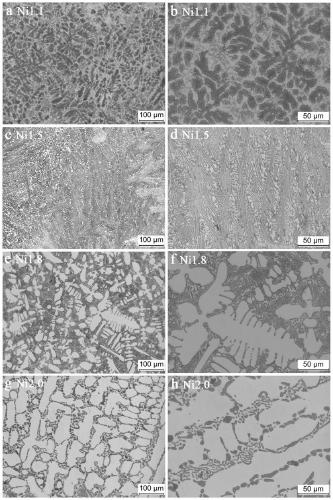

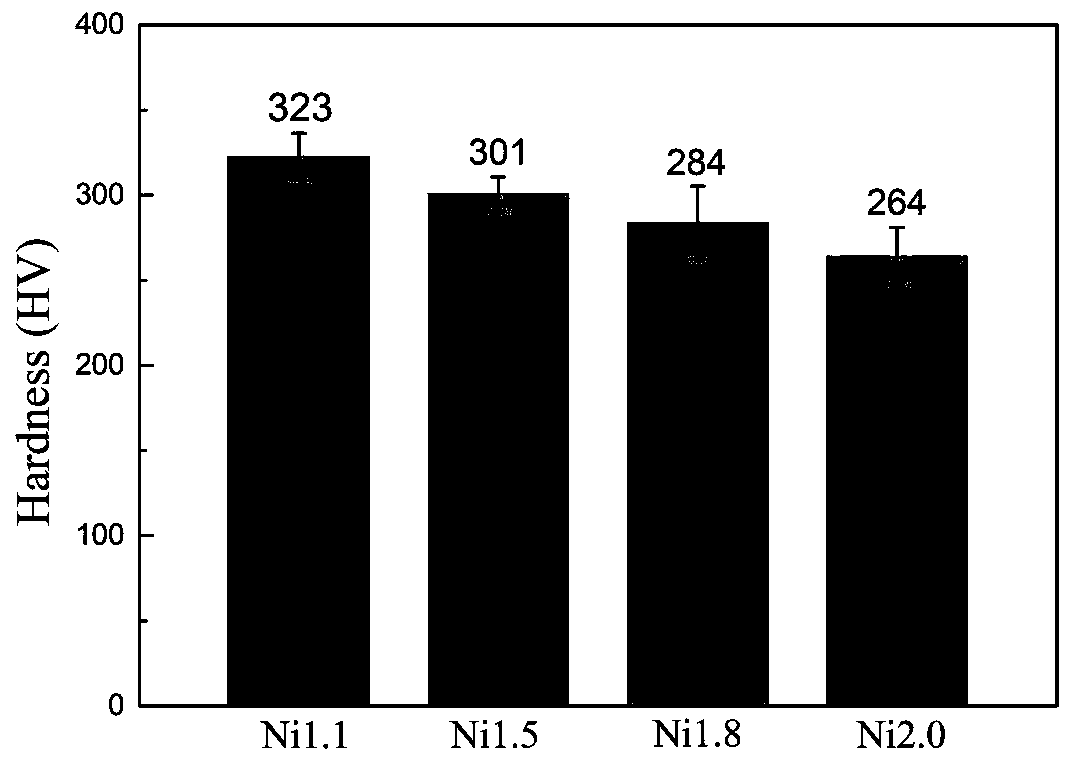

High-entropy quinary alloy with good high strength and high plasticity matching performance and preparation method thereof

ActiveCN110229991ANot prone to segregationNarrow crystallization rangeHigh entropy alloysHigh intensity

The invention discloses a high-entropy quinary alloy with good high strength and high plasticity matching performance. The chemical formula of the high-entropy quinary alloy is AlaCobCrcFedNie (a-e are molar ratios), wherein 1>=a>=0.5, 1.2>=b>=0.7, 1>=c>=0.4, 1>=d>=0.4, and 2.2>=e>=0.8. Furthermore, a:e is 1:1.2-2.5. Furthermore, a is 0.8, b is 1, c is 0.6, d is 0.7, and e is 1.1-2.0. Furthermore,the chemical formula of the alloy is Al0.8CoCr0.6Fe0.7Ni1.1, Al0.8CoCr0.6Fe0.7Ni1.5, Al0.8CoCr0.6Fe0.7Ni1.8, or Al0.8CoCr0.6Fe0.7Ni2.0. The high-entropy quinary alloy has high strength and high plasticity, and the problem that the strength-plasticity matching performance of a high-entropy alloy in the prior art is poor is solved. The invention further provides a preparation method of the high-entropy quinary alloy with the good high strength and high plasticity matching performance. The preparation method is simple, safe and stable.

Owner:QINGHAI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com