Transition metal diboride high-entropy ceramic and preparation method thereof

A diboride and transition metal technology, applied in the field of ultra-high temperature structural ceramic materials, can solve the problems of poor oxidation resistance, low sample toughness, and difficulty in densification, and achieve the effects of high density, good product performance and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

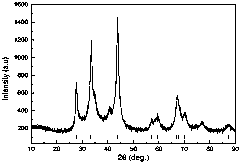

Image

Examples

Embodiment 1

[0024] Embodiment 1: select vanadium diboride, niobium diboride, tantalum diboride, molybdenum diboride and tungsten diboride powder as initial raw materials, vanadium diboride, niobium diboride, tantalum diboride, Molybdenum diboride and tungsten diboride are configured according to the molar ratio of 1:1:1:1:1. The above raw materials were subjected to high-energy ball milling, the grinding balls were WC-8wt%Co cemented carbide balls, the ball-to-material ratio was 10:1, the ball milling rate was 400 r / min and the ball milling time was 24 hours. The powder after ball milling is treated with dilute pickling, and the treated powder is placed in a high-temperature vacuum furnace for vacuum treatment at 800 °C, with a vacuum degree of 1×10 -2 Pa, holding time 60 minutes. Then put it into a high-melting-point wrapping material for encapsulation and pre-press under a pressure of 580 MPa to obtain a cylindrical inclusion, and then put it into a salt tube in a pyrophyllite synthet...

Embodiment 2

[0025] Embodiment 2: select vanadium diboride, niobium diboride, tantalum diboride, molybdenum diboride and tungsten diboride powder as initial raw materials, vanadium diboride, niobium diboride, tantalum diboride, Molybdenum diboride and tungsten diboride are configured according to the molar ratio of 1:1:1:1:1. The above raw materials were subjected to high-energy ball milling, the grinding balls were WC-8wt%Co cemented carbide balls, the ball-to-material ratio was 10:1, the ball milling rate was 400 r / min and the ball milling time was 24 hours. The powder after ball milling is treated with dilute pickling, and the treated powder is placed in a high-temperature vacuum furnace for vacuum treatment at 800 °C, with a vacuum degree of 1×10 -2Pa, holding time 60 minutes. Then put it into a high-melting-point wrapping material for encapsulation and pre-press under a pressure of 580 MPa to obtain a cylindrical inclusion, and then put it into a salt tube in a pyrophyllite synthetic...

Embodiment 3

[0026] Embodiment 3: select vanadium diboride, niobium diboride, tantalum diboride, molybdenum diboride and tungsten diboride powder as initial raw materials, vanadium diboride, niobium diboride, tantalum diboride, Molybdenum diboride and tungsten diboride are configured according to the molar ratio of 1:1:1:1:1. The above raw materials were subjected to high-energy ball milling, the grinding balls were WC-8wt%Co cemented carbide balls, the ball-to-material ratio was 8:1, the ball milling rate was 450 r / min, and the ball milling time was 24 hours. The powder after ball milling is treated with dilute pickling, and the treated powder is placed in a high-temperature vacuum furnace for vacuum treatment at 800 °C, with a vacuum degree of 1×10 -2 Pa, holding time 60 minutes. Then put it into a high-melting-point wrapping material for encapsulation and pre-press under a pressure of 580 MPa to obtain a cylindrical inclusion, and then put it into a salt tube in a pyrophyllite synthet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com