Patents

Literature

60results about How to "Not prone to segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formula and preparation process of alcohol group nanometer composite and surface modified dry powder mold paint

The invention relates to an auxiliary material for casting and moulding, in particular to a formula of alcohol group dry powder mold paint for sand mold casting. The dry powder mold paint comprises surface modifier, suspending agent, binder and refractory powder, wherein the surface modifier is 0.6-4.2wt% of refractory powder, the suspending agent is 4.0-8.0wt% of refractory powder and the binderis 4.0-6.2wt% of refractory powder. The alcohol group nanometer composite and surface modified dry powder mold paint of the invention adopts nanometer layered clay and nano-SiO2 to form composite suspending agent so that the controllability of operation technological parameters of the alcohol group dry powder mold paint is good and the process performance and operating performance of the obtainedpulp-type paint can both meet the demand of the casting factory.

Owner:深圳市景鼎现代科技有限公司

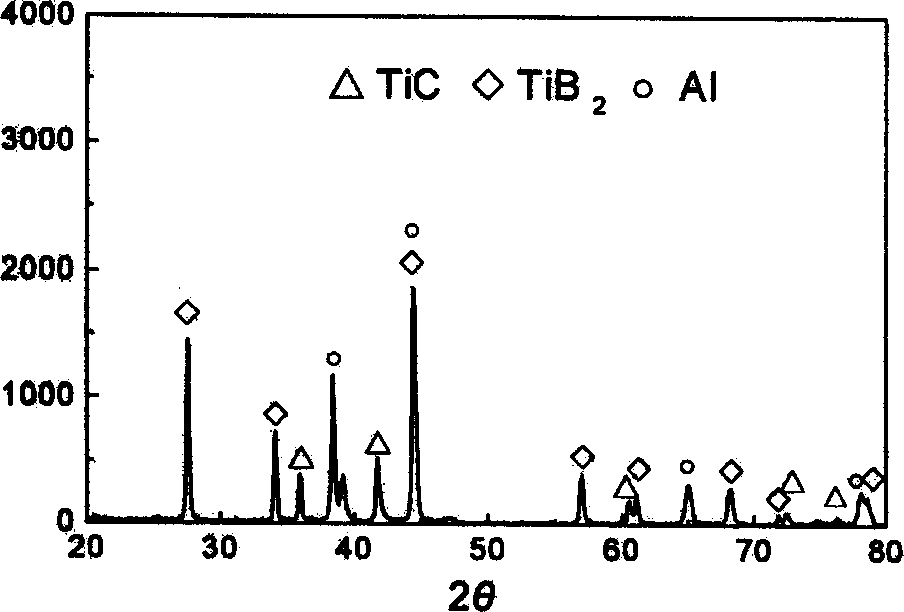

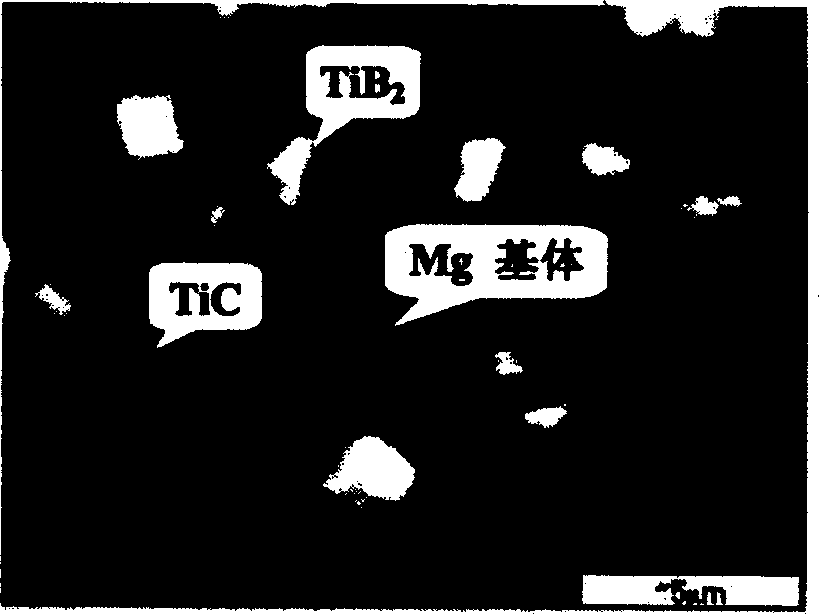

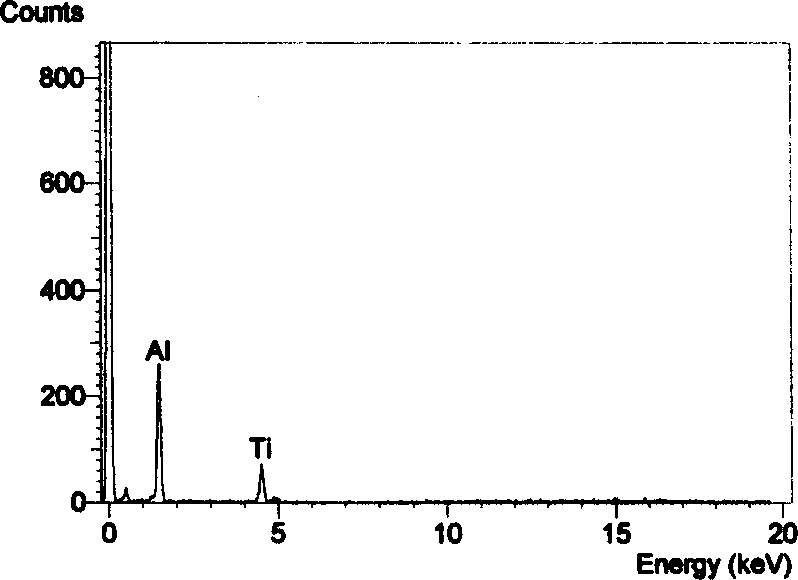

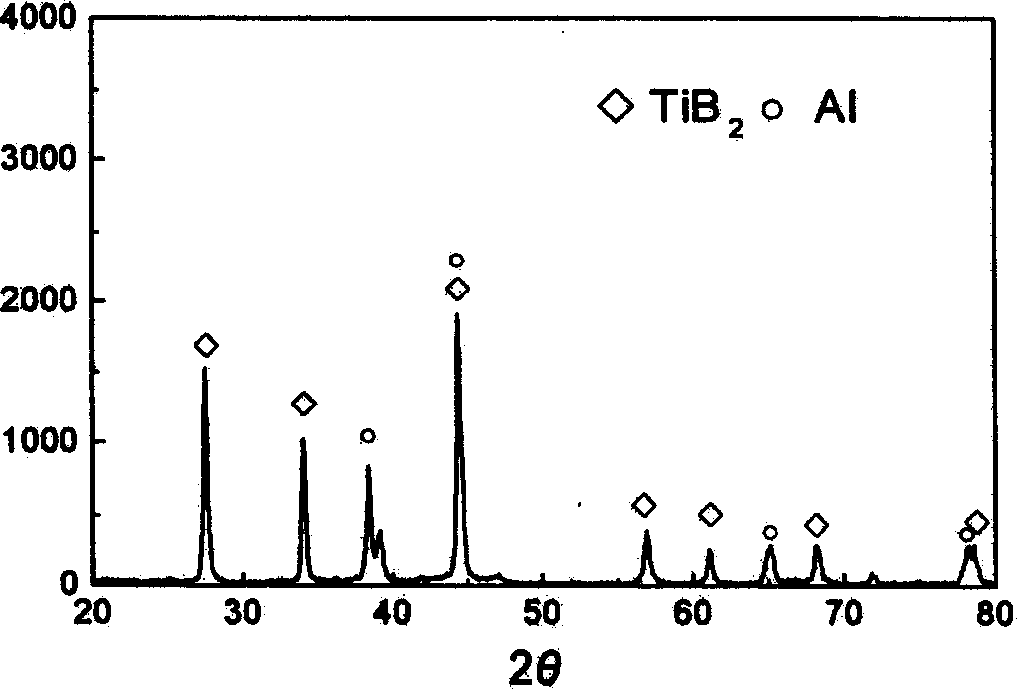

Method for preparing two-phase granular mixed reinforced magnesium alloy based composite material

The new process for preparing TiB2 and TiC double-phase mixed hybridization reinforced magnesium alloy base composite material is characterized by that it adopts Al-Ti-B-C system reaction prefabricated block and makes it produce chemical synthesis reaction under the condition of vacuum or inert gas protection to prepare (TiB2+TiC) / Al intermediate phase carrier, then adds the intermediate phase carrier into molten magnesium alloy to make dissolution and diffusion, and fully stirs them to make said intermediate phase carrier be uniformly distributed in molten magnesium alloy to obtain the invented product in which the TiB2 is formed into block form and the TiC is formed into ball form, so that the comprehensive performance of said composite can be obviously raised.

Owner:JILIN UNIV

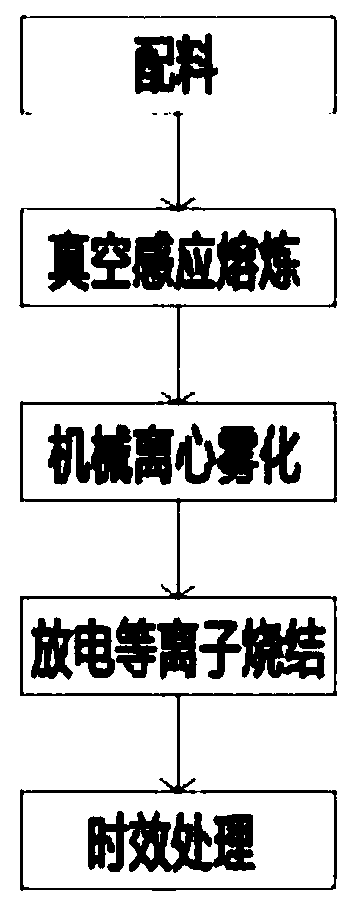

Method of copper and iron alloy materials for novel motor rotors

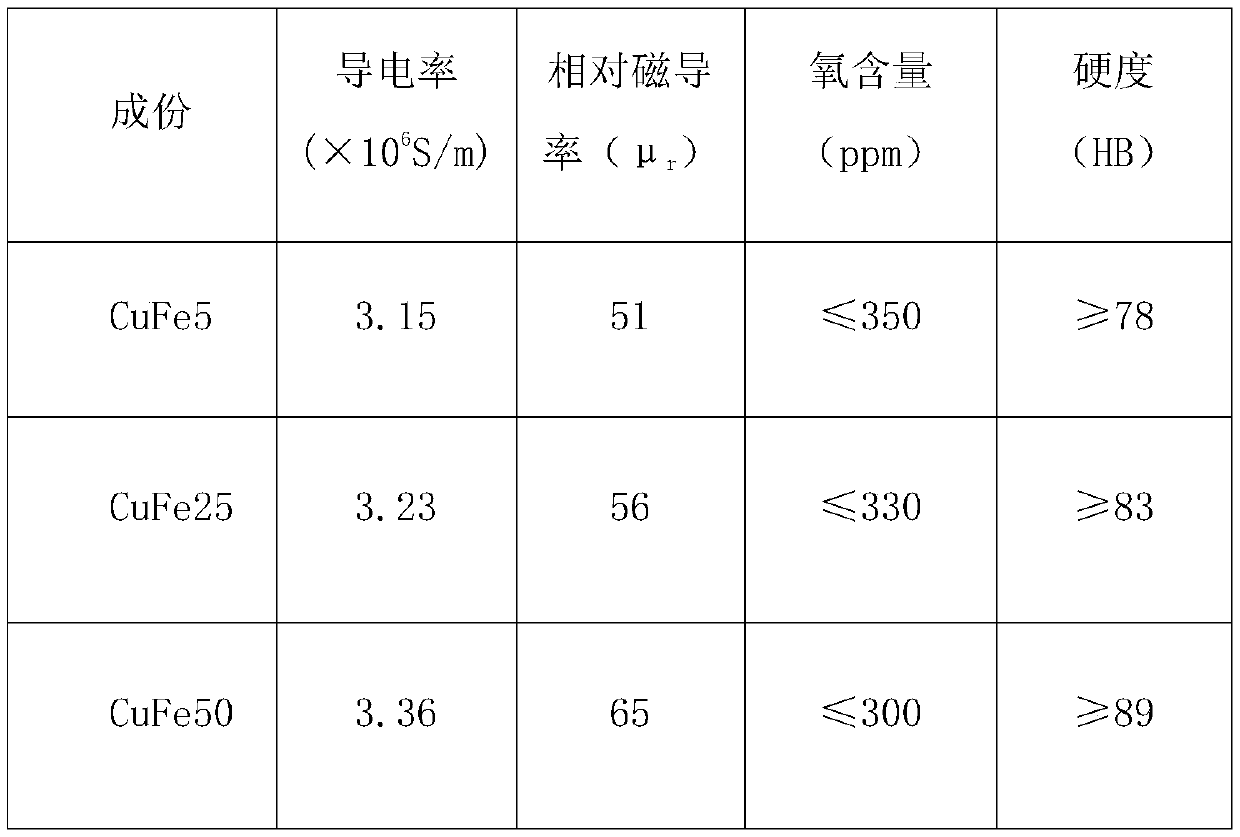

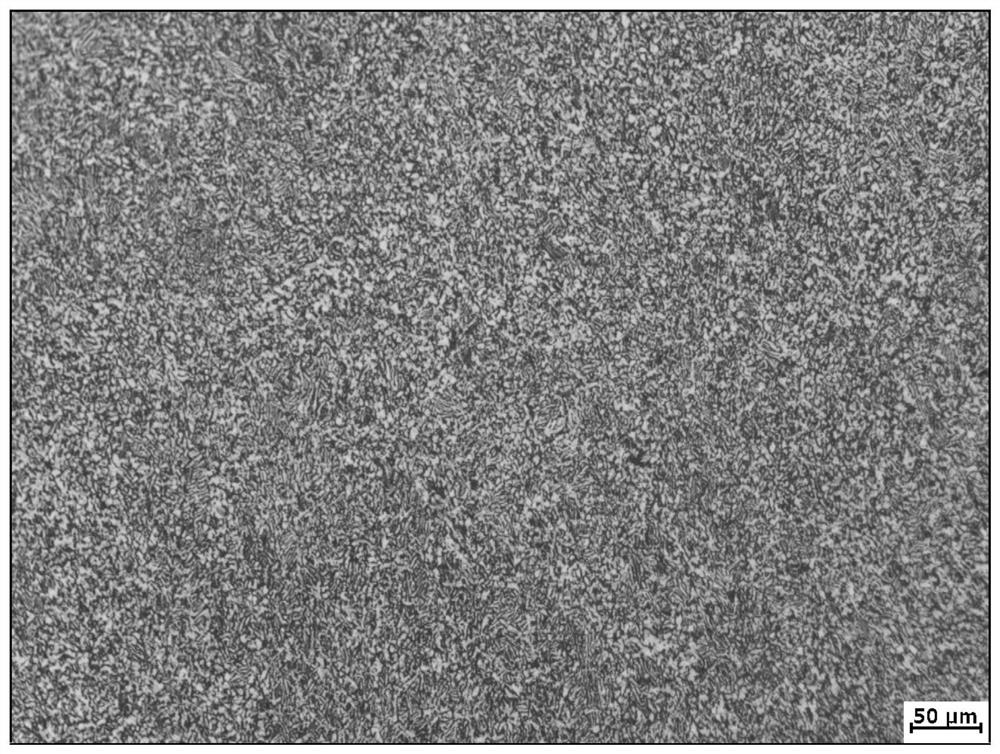

ActiveCN110484762AIncrease cooling rateOvercoming the problem of prone to macro segregationMagnetic/electric field screeningElectromagnetic shieldingSolid solubility

The invention discloses a method of copper and iron alloy materials for novel motor rotors, and belongs to the technical field of nonferrous metal material manufacturing. The method mainly comprises the steps of (1) burdening, (2) vacuum induction smelting, (3) mechanical centrifugal atomization, (4) discharge plasma sintering and (5) aging. Cu and Fe raw materials with higher purity are selected,fed silver is excellent in electric conductivity, and meanwhile, iron, silicon and copper are lower in solid solubility, so that the influence on electricity and heat conductivity of copper rods is lower, the solid solubility cannot be changed along with the temperature change, and alloys formed by Cu and Fe achieve higher electric conductivity; and through the mechanical centrifugal atomizationmode, Cu-Fe alloys are atomized as drops, and the drops are quickly condensed through low-temperature and high-purity argon, so that the cooling speed of the alloy drops can be accelerated, the macroscopic segregation of the alloys is overcome, and the electromagnetic shielding performance of the alloys is further improved.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Medium-strength nitric acid corrosion-resistant titanium alloy

The invention discloses a medium-strength nitric acid corrosion-resistant titanium alloy. The titanium alloy is composed of the following components of, in percentage by mass, 5.0-7.0% of Ta, 0.7-1.5%of Al, 0.2-2% of Zr, 0.6-1.5% of Mo, 0.2-2% of Nb, and the balance Ti and inevitable impurities. The tensile strength of the annealed titanium alloy subjected to annealing treatment is 670-750 MPa, the yield strength of the annealed titanium alloy is 520-650 MPa, and the corrosion rate of the annealed titanium alloy in a boiling nitric acid solution with the concentration of 6 mol / L is not higherthan 0.08 mm / a. According to the medium-strength nitric acid corrosion-resistant titanium alloy, through adjusting the content of each element in the titanium alloy, the medium-strength nitric acid corrosion-resistant titanium alloy has excellent tensile strength, yield strength, corrosion resistance and impact toughness, also has excellent cold and hot processing properties, can be prepared intovarious processed products, and is suitable for manufacturing related equipment in the fields of nuclear industry and chemical industry.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

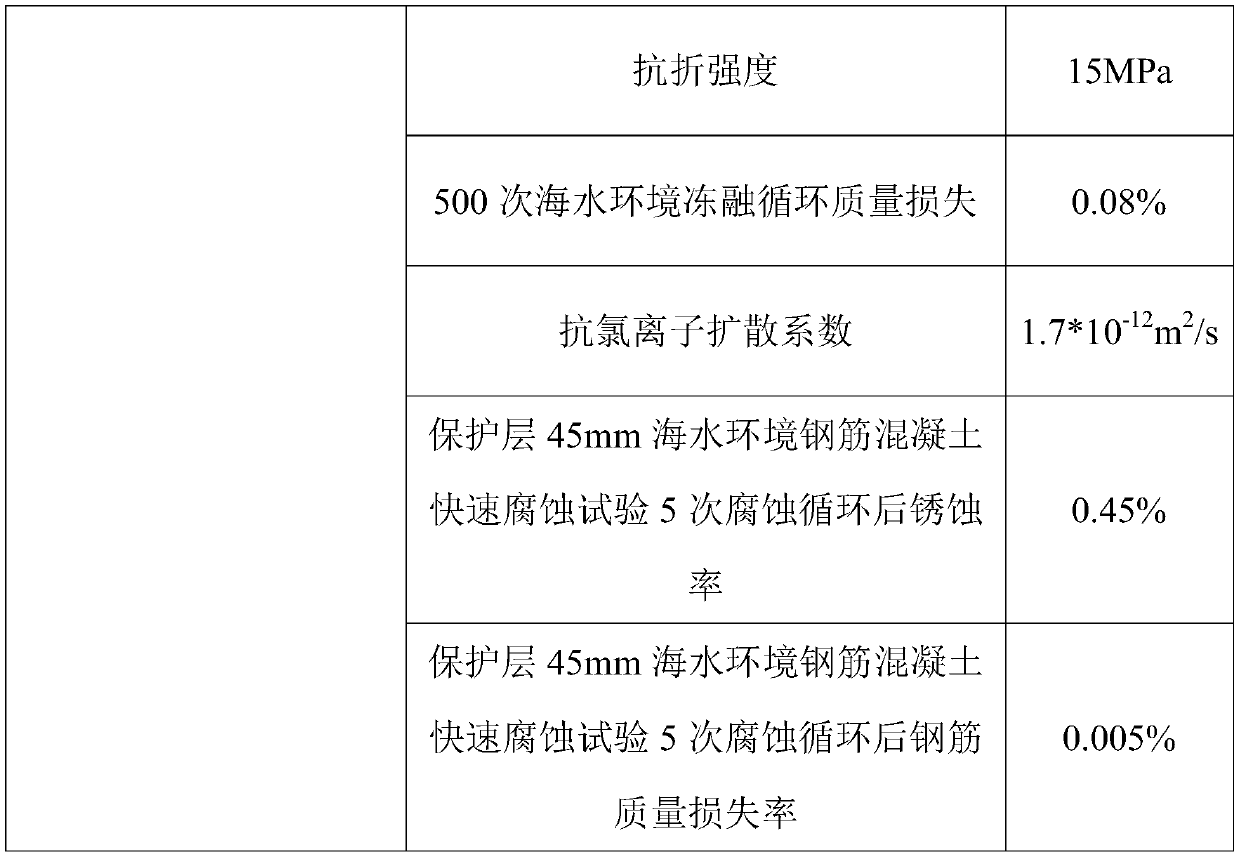

Ecological dustproof type seawater sea-sand anti-corrosion marine concrete and preparation method thereof

The invention discloses an ecological dustproof type seawater sea-sand anti-corrosion marine concrete and a preparation method thereof. The concrete comprises the following raw materials: cement, silica fume, coal ash beads, blast furnace slag powder, corroding ion inhibitors, sea sand, steel fibers, a water reducing agent and seawater. The preparation method comprises the following steps: mixingcement, silica fume, coal ash beads, blast furnace slag powder, corroding ion inhibitors and steel fibers and then uniformly stirring with a stirrer; adding sea sand and continuing to uniformly stir;adding seawater and the water reducing agent; mechanically stirring till uniformly stirring, thereby acquiring a concrete slurry; pouring and then removing a mold and maintaining for 48h at 80 DEG C under the condition of humidity of 95%, thereby acquiring the marine concrete. The concrete disclosed by the invention has the advantages of high curing rate of chloride ions, excellent working performances, high durability, lower cost, locally acquired raw materials, short construction period and suitability for popularization and application.

Owner:HOHAI UNIV

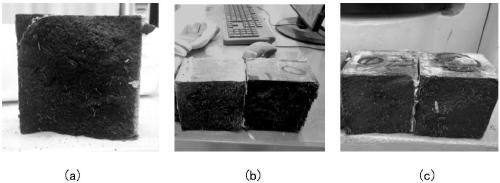

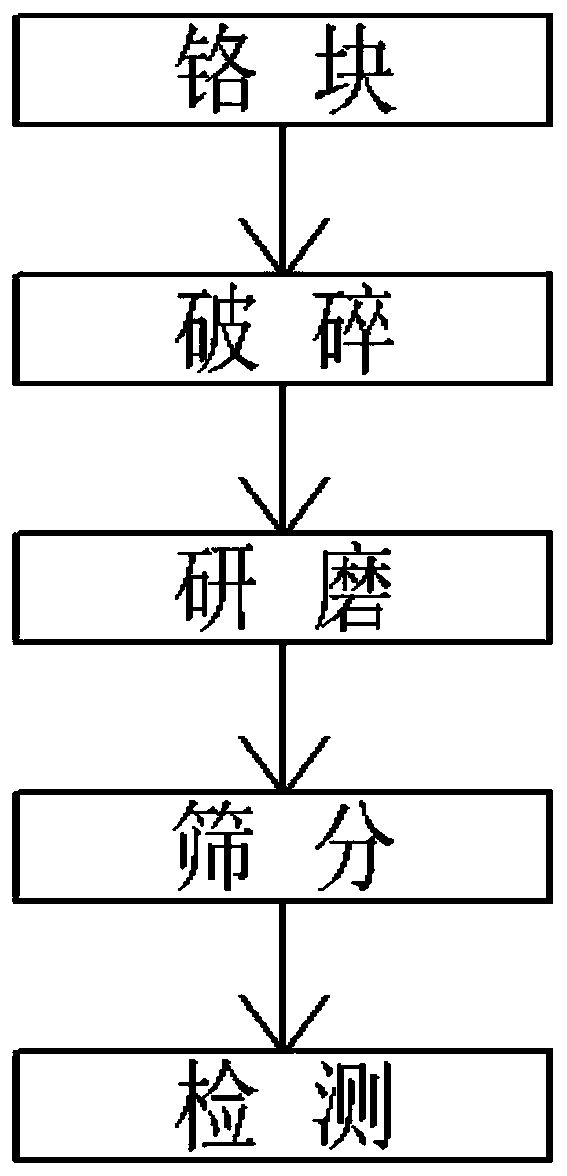

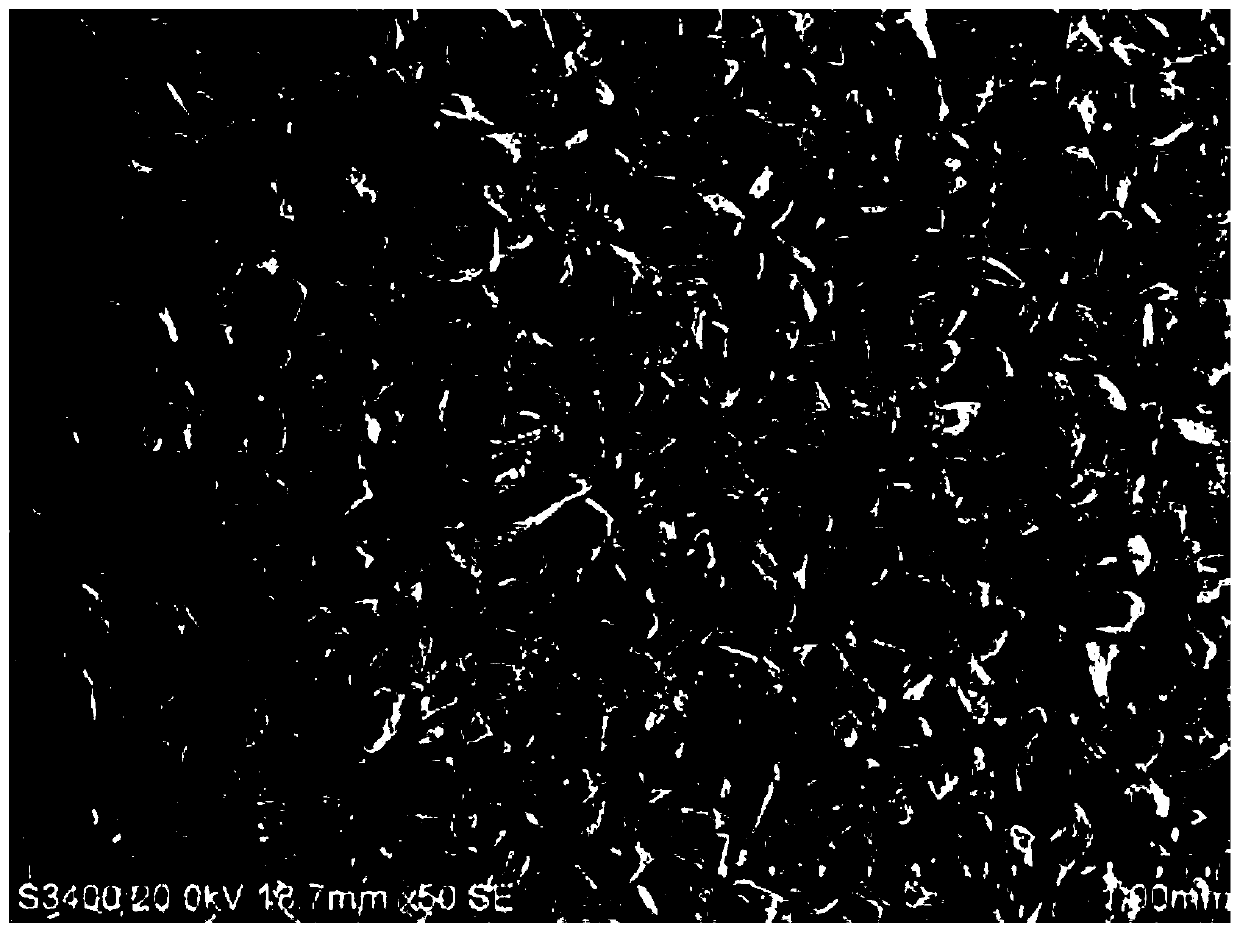

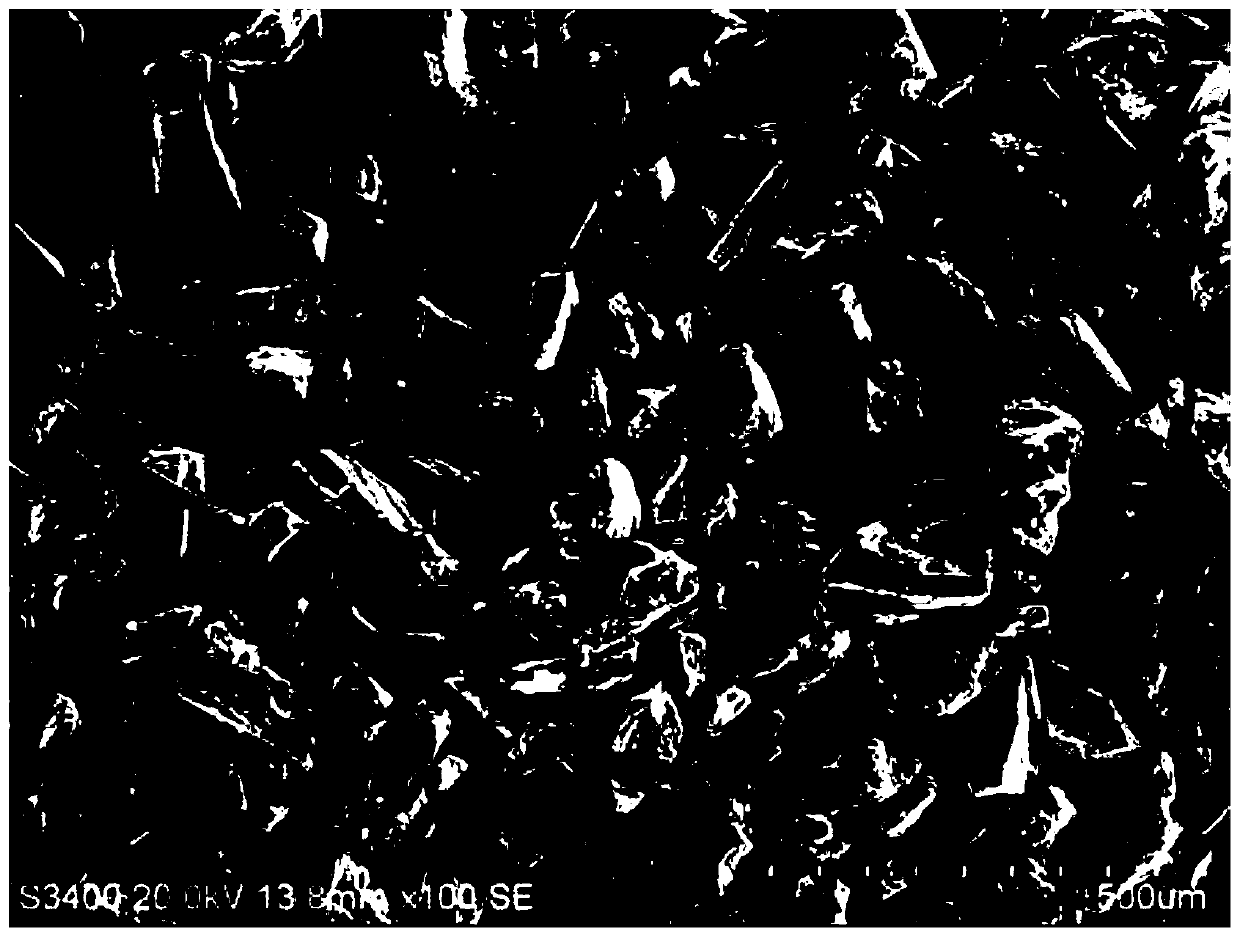

Preparation method of metal chromium powder special for high-performance CuCr electrical contact

ActiveCN110202159AImprove wettabilityGuaranteed oxygen contentTransportation and packagingMetal-working apparatusNitrogenCrusher

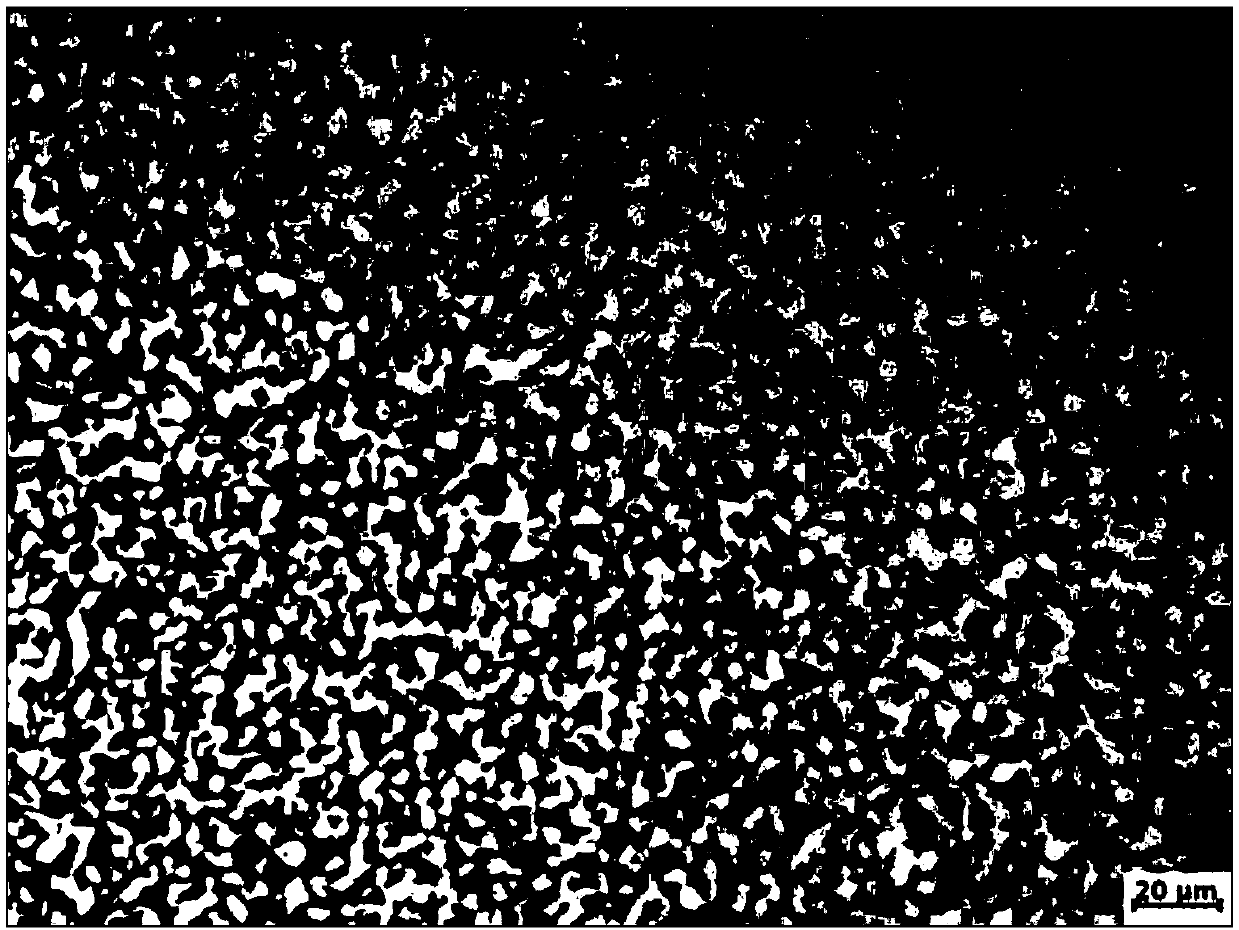

The invention discloses a preparation method of metal chromium powder special for a high-performance CuCr electrical contact. The preparation method comprises the steps of crushing, specifically, a chromium block is placed into a crusher and crushed into granules; screening the granulated chromium block by using a 10-mm aperture screen, and selecting undersize chromium particles; grinding, specifically, the chromium particles are added into low-temperature grinding powder manufacturing equipment, and a cooling medium is introduced to obtain the metal chromium powder; screening again, specifically, the metal chromium powder is respectively screened by using a 200-mesh screen, a 240-mesh screen and a 320-mesh screen; and detecting, specifically, oxygen content in the metal chromium powder isanalyzed by using a nitrogen-oxygen analyzer and is required to be no greater than 600 ppm. According to the preparation method of the metal chromium powder, the oxygen content in the chromium powdercan be effectively controlled; and the chromium powder is not prone to segregation after being mixed with Cu powder, has good formability, and has good wettability of Cr and Cu after sintered.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

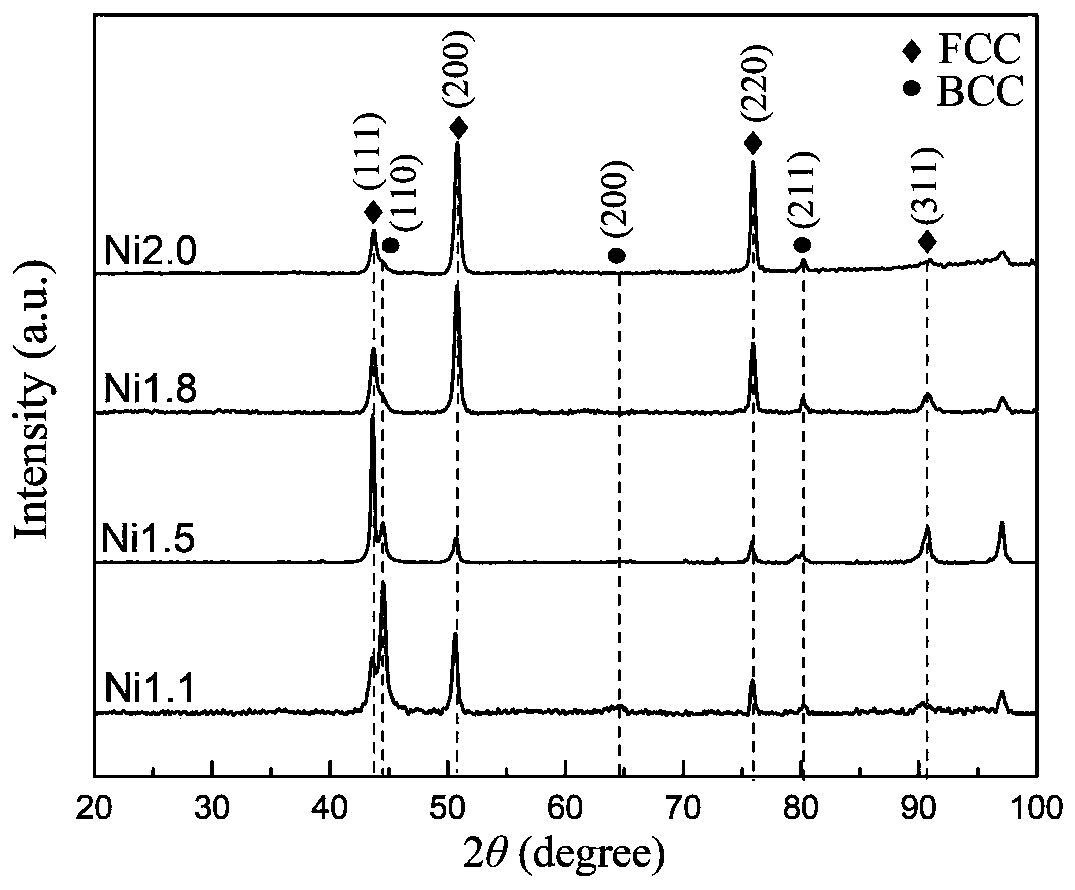

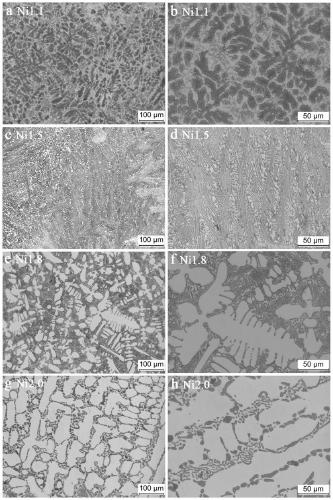

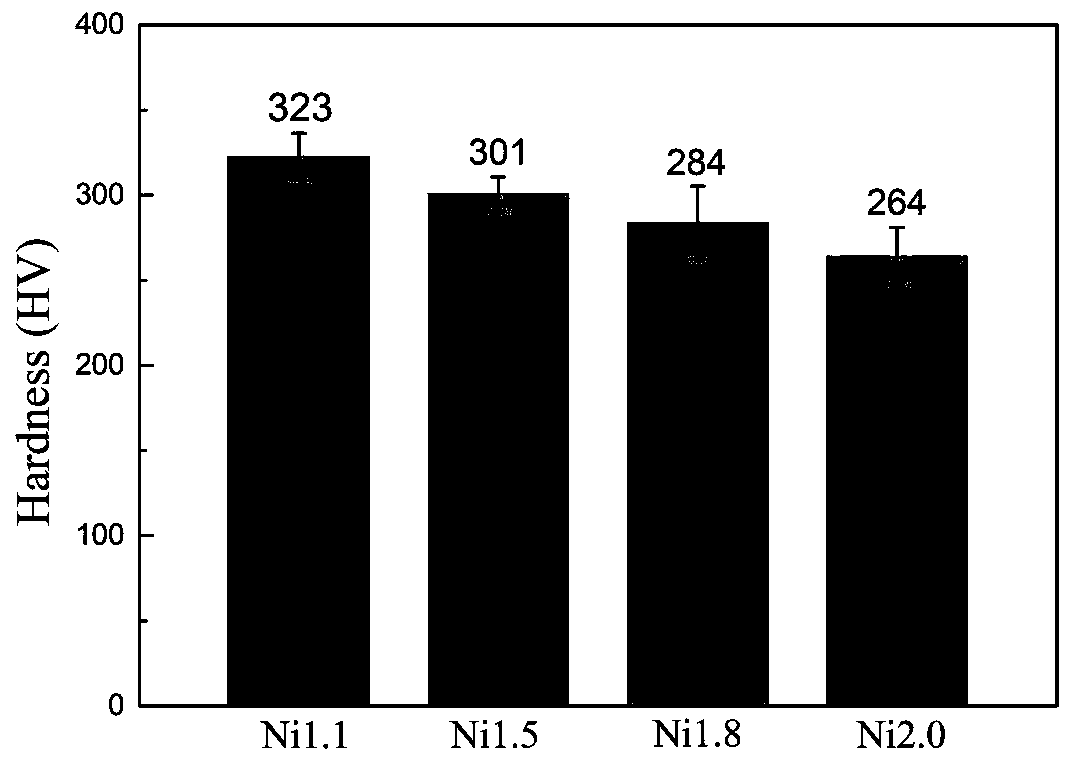

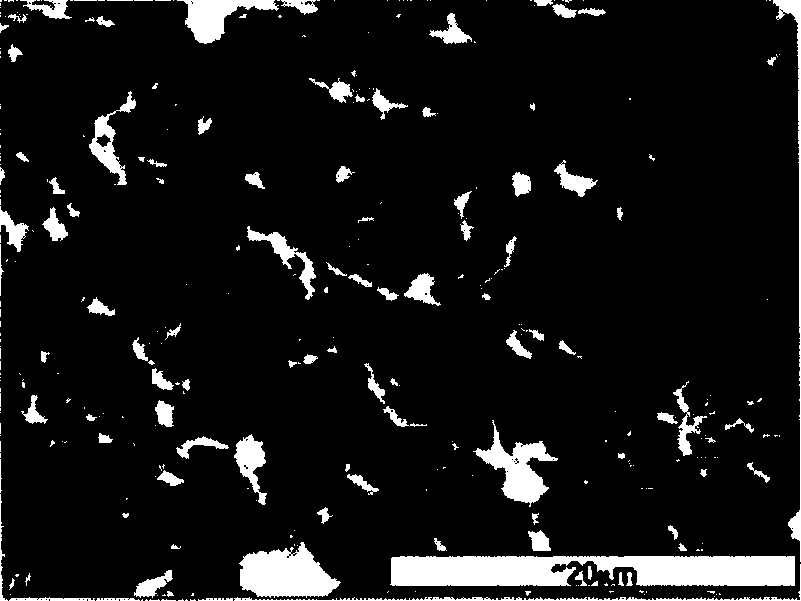

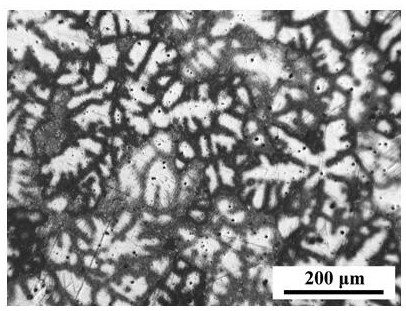

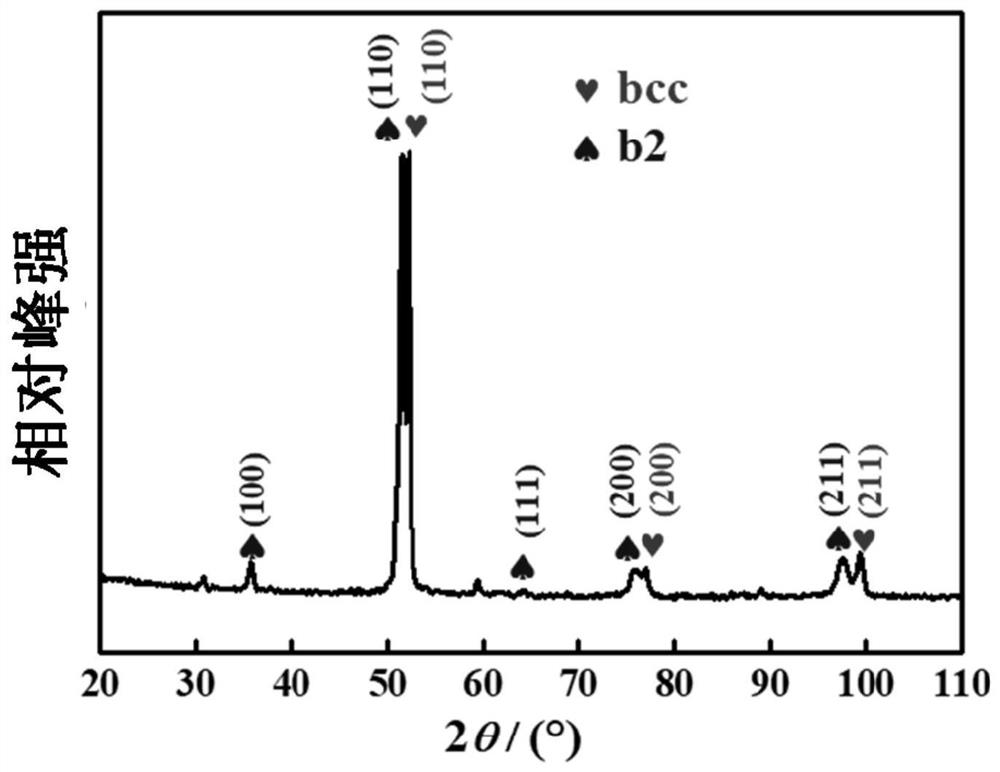

High-entropy quinary alloy with good high strength and high plasticity matching performance and preparation method thereof

ActiveCN110229991ANot prone to segregationNarrow crystallization rangeHigh entropy alloysHigh intensity

The invention discloses a high-entropy quinary alloy with good high strength and high plasticity matching performance. The chemical formula of the high-entropy quinary alloy is AlaCobCrcFedNie (a-e are molar ratios), wherein 1>=a>=0.5, 1.2>=b>=0.7, 1>=c>=0.4, 1>=d>=0.4, and 2.2>=e>=0.8. Furthermore, a:e is 1:1.2-2.5. Furthermore, a is 0.8, b is 1, c is 0.6, d is 0.7, and e is 1.1-2.0. Furthermore,the chemical formula of the alloy is Al0.8CoCr0.6Fe0.7Ni1.1, Al0.8CoCr0.6Fe0.7Ni1.5, Al0.8CoCr0.6Fe0.7Ni1.8, or Al0.8CoCr0.6Fe0.7Ni2.0. The high-entropy quinary alloy has high strength and high plasticity, and the problem that the strength-plasticity matching performance of a high-entropy alloy in the prior art is poor is solved. The invention further provides a preparation method of the high-entropy quinary alloy with the good high strength and high plasticity matching performance. The preparation method is simple, safe and stable.

Owner:QINGHAI UNIVERSITY

N-doped crystalline silicon and preparation method thereof

InactiveCN101845666AHigh mechanical strengthHigh nitrogen doping concentrationPolycrystalline material growthFrom frozen solutionsHigh concentrationDopant

The invention discloses a preparation method of an N-doped polysilicon ingot, which comprises the following steps that: the mixture of polysilicon material, silicon nitride nano powder with the grain size of 1 to 100nm and electrically active dopant is put into a quartz crucible and is loaded into a furnace; a furnace chamber is vacuumized and heated to 1420 to 1550DEG C, the temperature is insulated until the mixture is fully melted, to obtain molten silicon mixture; and then the molten silicon mixture is solidified to obtain the polysilicon ingot, wherein the electrically active dopant is any one type of B, P or Ga and the added amount makes the concentration of the electrically active dopant in the polysilicon ingot be 0.02 to 2ppm, and the added amount of the silicon nitride nano powder makes the nitrogen concentration in the polysilicon ingot be 0.0002 to 1ppm. The preparation method of N-doped polysilicon can dope nitrogen with existing equipment, and has the advantages of uniform nitrogen doping, high concentration of doped nitrogen, simple and easily controllable process and low cost. In addition, the invention also discloses a preparation method of an N-doped mono-crystalline ingot.

Owner:王敬 +1

Preparation method of epoxy resin coated ceramic powder

The invention discloses a preparation method of epoxy resin coated ceramic powder, which comprises the following steps: ceramic powder, an epoxy resin and an acetone solvent are proportionally added into a reaction kettle, the sealed reaction kettle is heated and mechanically stirred, and the acetone is directly volatilized and recovered in the thermal insulation process; in the cooling process, the epoxy resin crystal is coated on the surface of the ceramic powder; and the powder is taken out of the reaction kettle, naturally dried, ground and screened to obtain the final epoxy resin coated ceramic powder material. The method is beneficial to enhancing the strength of the initial blank, lowers the adhesive content, has the advantages of favorable coating effect, simple technique and low facility request, and can not pollute the environment.

Owner:HUAZHONG UNIV OF SCI & TECH

N-doped crystalline silicon and preparation method thereof

InactiveCN101864593AUniform nitrogen dopingNitrogen doping concentration is easy to controlPolycrystalline material growthFrom frozen solutionsFurnace roomSilicon nitride

The invention discloses a preparation method of an N-doped polysilicon ingot. The preparation method comprises the following steps of: putting polysilicon and silicon nitride nanopowder with the grain size of 1 to 100nm in a quartz crucible and charging, vacuumizing a furnace room and heating to 1420 to 1550 DEG C, and preserving the temperature till mixture is fused completely; gradually reducing the cooling speed in 1 to 10 DEG C / min in a furnace till reaching 1350 to 1420 DEG C; then naturally cooling the temperature in the furnace room to the room temperature; taking the silicon ingot out and crushing into small pieces to obtain master alloy silicon blocks; putting mixture of the master alloy silicon blocks, the polysilicon material and electrical activity dopants in the quartz crucible, vacuumizing the furnace room and heating to 1420 to 1550 DEG C to obtain a fused silicon material mixture; and enabling the fused silicon material mixture to solidify to obtain the polysilicon ingot. According to the preparation method of the N-doped polysilicon, the invention can carry out N-doping by adopting conventional devices and has even N-doping, high N-doping concentration, simple entire process and low cost. In addition, the invention also discloses a preparation method of an N-doped monocrystalline silicon ingot.

Owner:王敬 +1

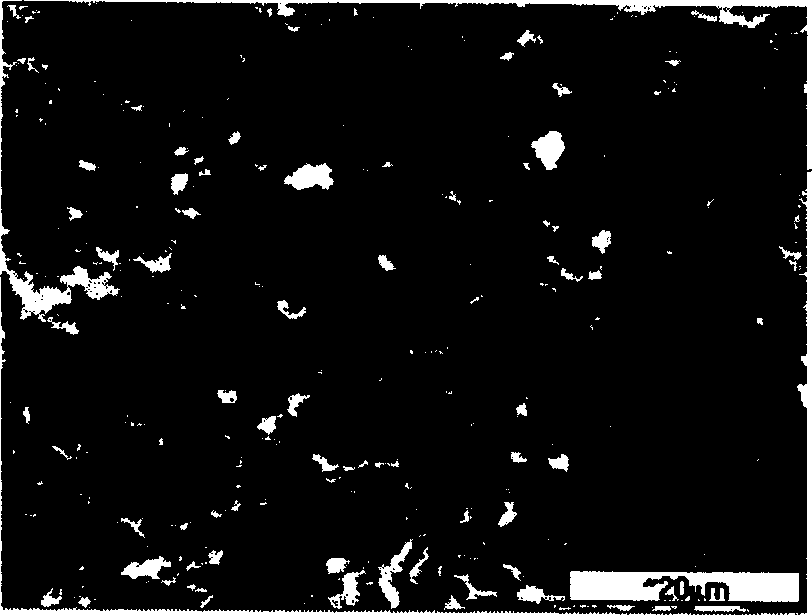

Magnesium alloy bused composite material and preparing method thereof

InactiveCN1470663AImprove mechanical propertiesImprove wear resistanceMaterials scienceMagnesium alloy

The present invention relates to a magnesium alloy base composite material, and is characterized by that it is a reinforced composite material obtained by making TiB2 granules be dispersed and uniformly distributed in the magnesium alloy base body. Its preparation includes the following processes: preparing reaction prefabricated block, preparing intermediate phase carrier containing reinforcement granules, dissolving and diffusing the intermediate phase carrier in magnesium alloy base body and dispersing and distributing the reinforcement granules in the magnesium alloy base body. Said composite material has good comprehensive performance, so that it has extensive application range.

Owner:JILIN UNIV

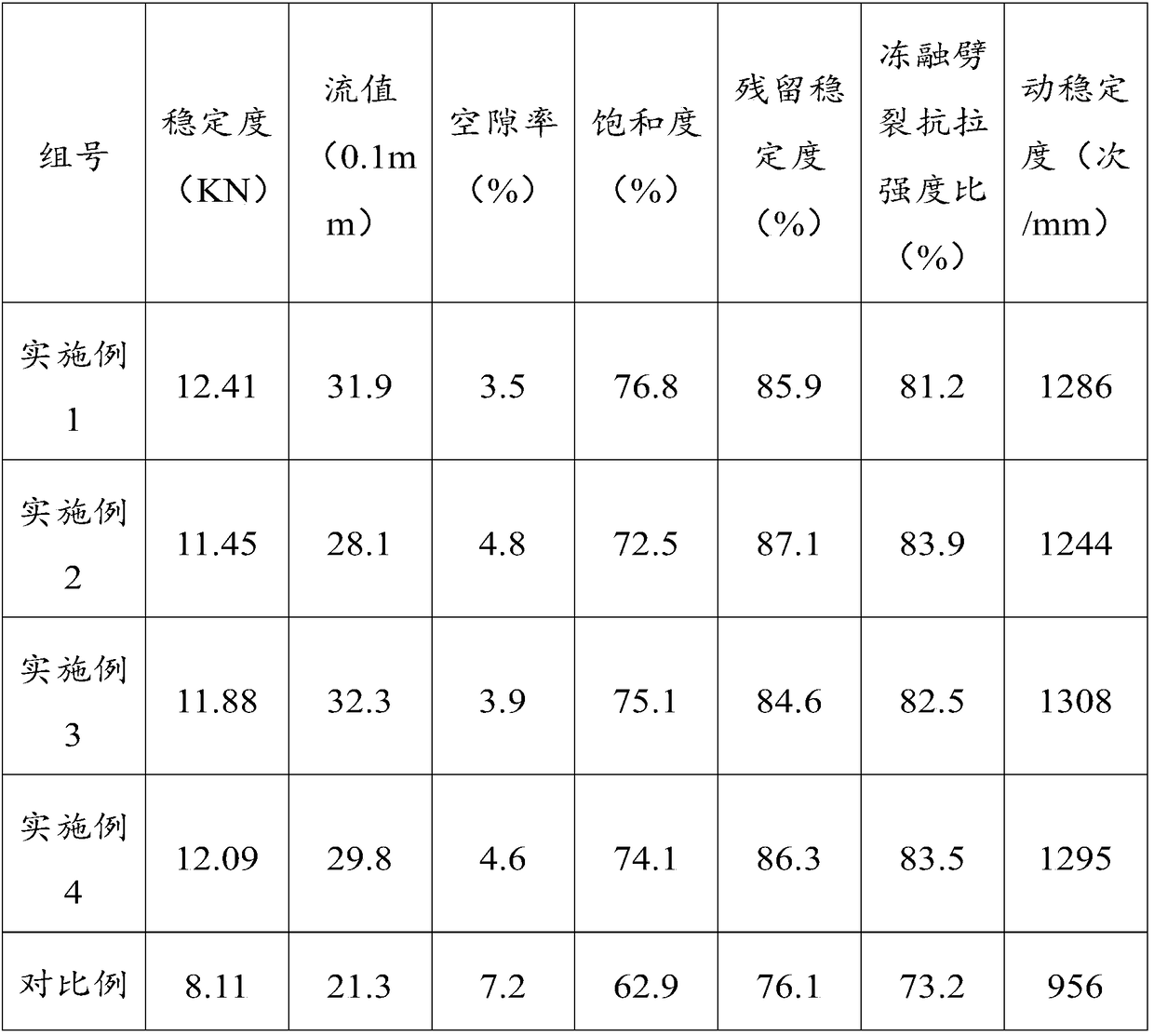

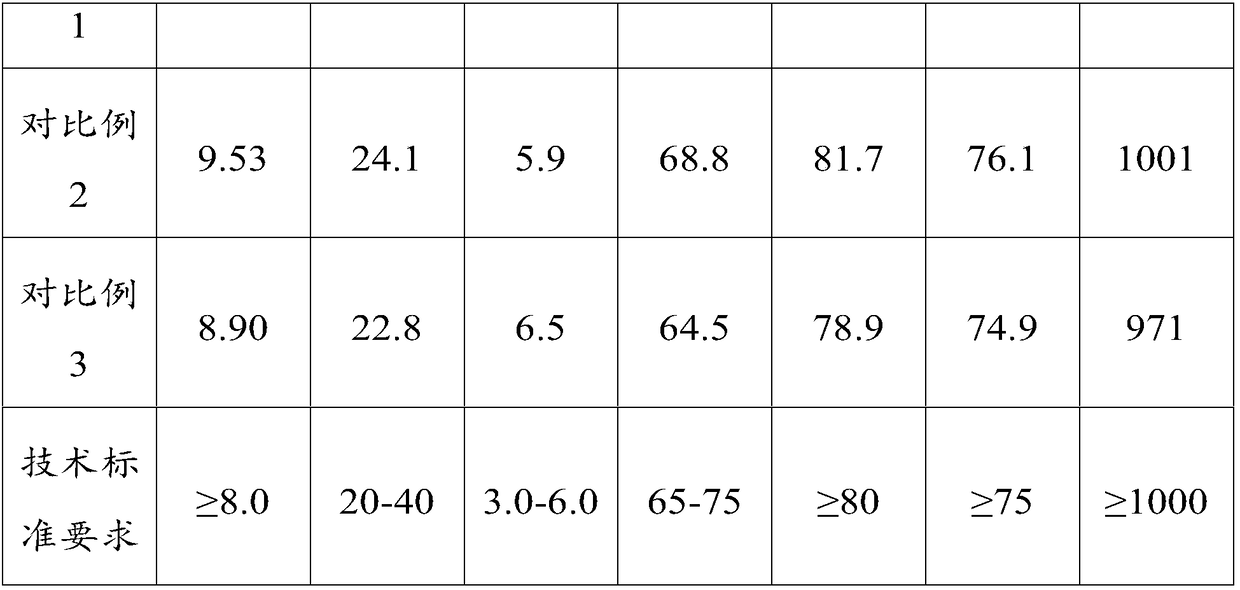

Asphalt mixture and preparation method thereof

The invention relates to the technical field of road engineering, in particular to an asphalt mixture and a preparation method thereof. The preparation method comprises the following steps: preparingmaterials and performing hot melting, wherein the step of preparing the materials comprises a substep of preparing asphalt, rubber, water-soluble silicate, ceramsite, perlite, slag and river sand; thestep of performing hot melting comprises the substeps of performing hot melting for the first time, performing hot melting for the second time, performing hot melting for the third time and performing hot melting for the fourth time; the substep of performing hot melting for the first time further comprises the substeps of adding asphalt into a preheated hot melting tank, heating at 150-160 DEG Cfor 20-30 min, and then heating to 170-185 DEG C; the substep of performing hot melting for the second time further comprises the substeps of adding the water-soluble silicate and the ceramsite to the hot-melt asphalt, and performing hot stirring together; the substep of performing hot melting for the third time further comprises the substeps of adding the rubber into a mixture obtained after hotmelting for the second time, heating and stirring; the substep of performing hot melting for the fourth time further comprises the substeps of adding the perlite, the slag and the river sand into a mixture obtained after hot melting for the third time, and performing hot stirring. By the preparation method, the performance of the asphalt mixture can be improved, and the prepared asphalt mixture has improved cracking resistance after being paved.

Owner:CHINA FIRST HIGHWAY ENG +1

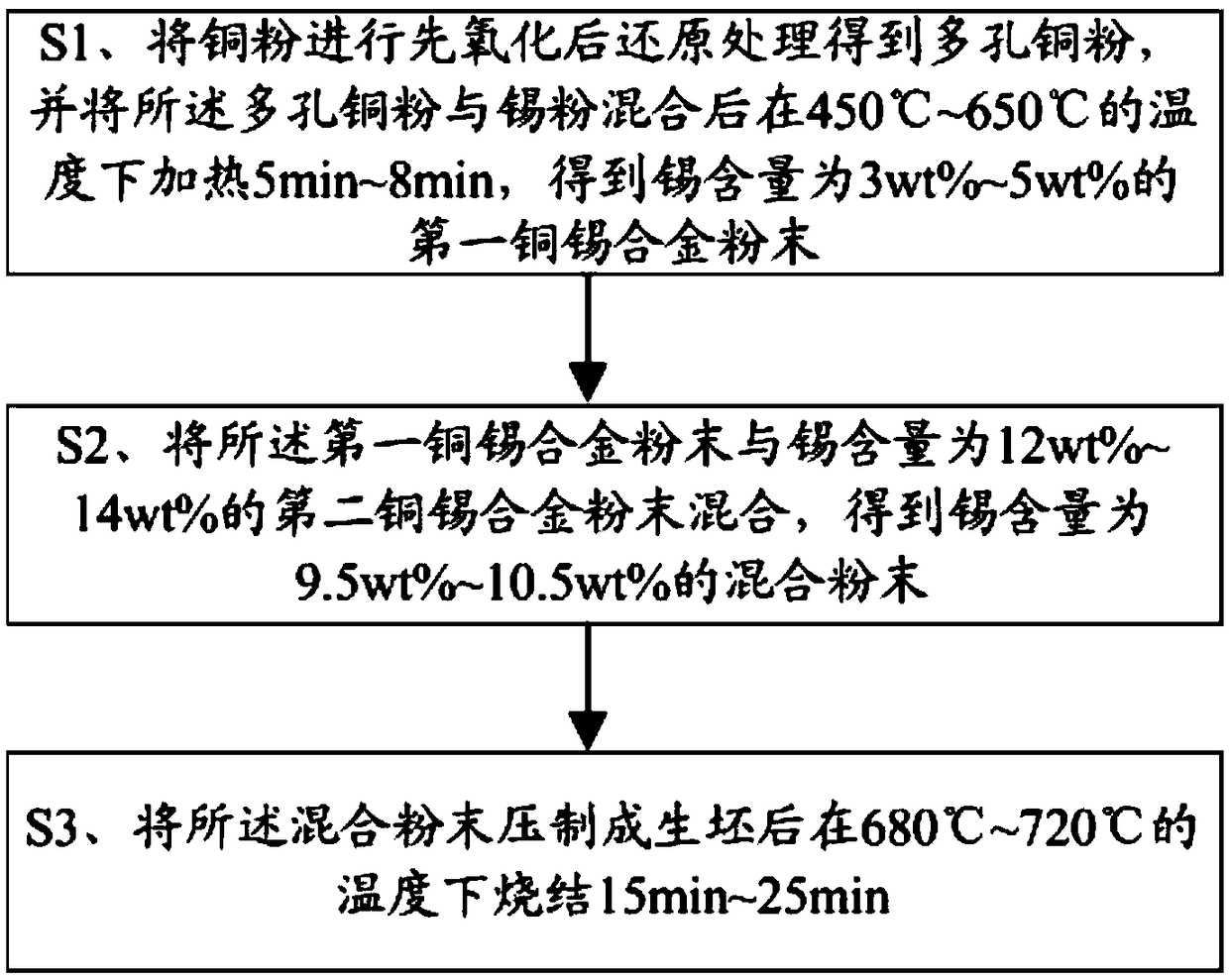

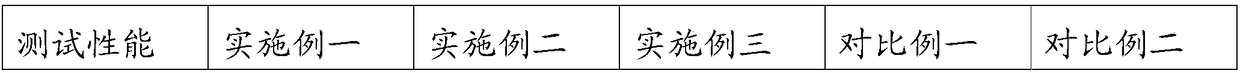

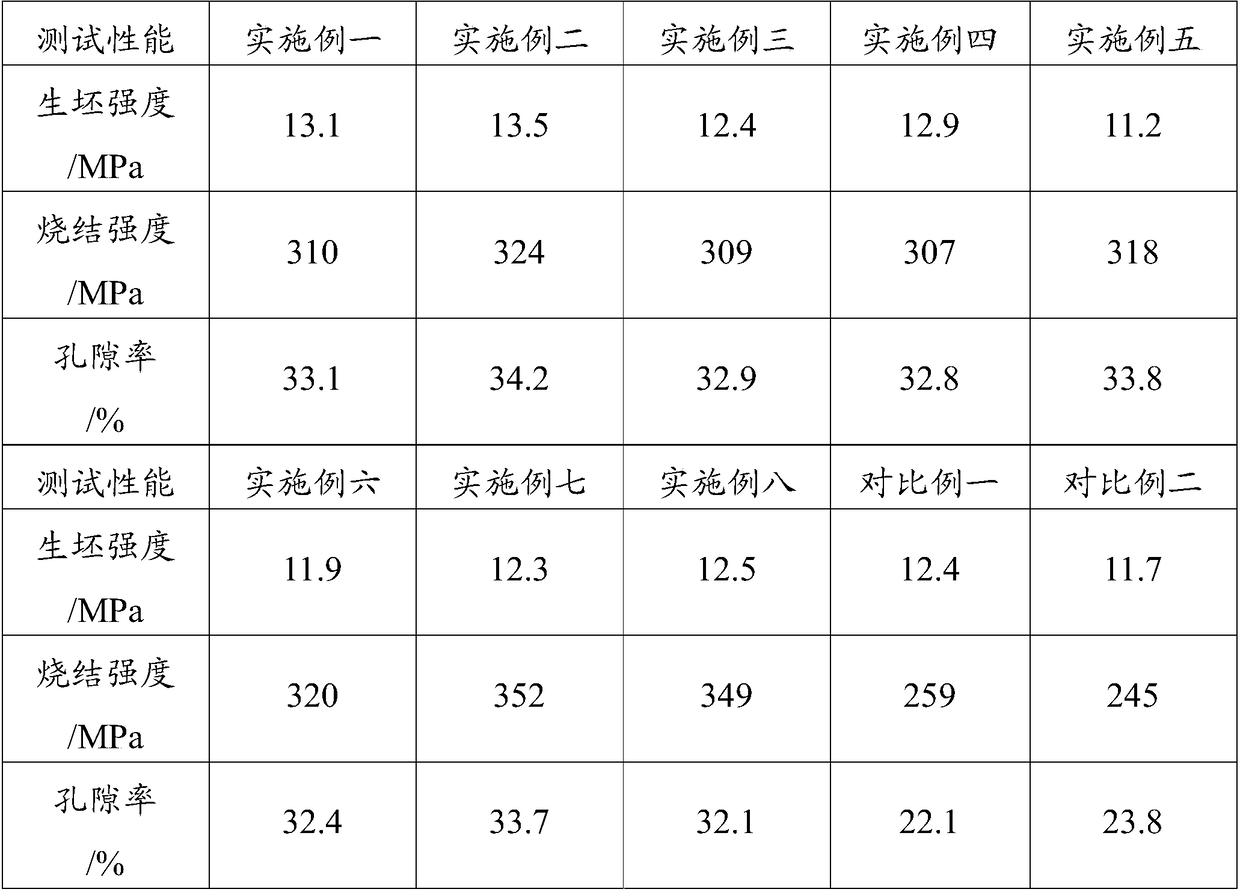

Preparation method of copper-tin alloy oil-containing bearing

ActiveCN109128140AEvenly distributedLow particle densityTransportation and packagingMetal-working apparatusPorosityAlloy

The invention relates to a preparation method of a copper-tin alloy oil-containing bearing. The preparation method includes the following steps that S1, copper powder is firstly oxidized and then reduced to obtain porous copper powder, the porous copper powder is mixed with tin powder, then the product is heated for 5-8 min under the temperature of 450 DEG C-650 DEG C, and first copper-tin alloy powder with the tin content being 3wt%-5wt% is obtained; S2, the first copper-tin alloy powder is mixed with second copper-tin alloy powder with the tin content being 12 wt%-14 wt% to obtain mixed powder with the tin content being 9.5 wt%-10.5 wt%; and S3, the mixed powder is sintered for 15-25 min under the temperature of 680 DEG C-720 DEG C after being pressed into green bodies. The made oil-containing bearing is not prone to generating unfilled corners, and has high porosity.

Owner:罗源县凤山镇企业服务中心

Composite powder material for making high-performance abrasion resistant exhaust valve seat, and its application

InactiveCN103882325AHigh technical contentThe method flow is simpleTurbinesOther manufacturing equipments/toolsExhaust valveDecomposition

The invention discloses a composite powder material for making a high-performance abrasion resistant exhaust valve seat, and its application, and belongs to the technical field of making of exhaust valve seats. The composite powder material comprises, by mass, 8-12% of Mo, 4-8% of Ni, 0.5-2.5% of Cr, 1-3% of V, 0-2.5% of Cu, 0.5-2.0% of C, 1% or less of impurities, and the balance Fe. A making method of the exhaust valve seat comprises the following steps: 1, powder preparation: preparing iron-based pre-alloy powder with the granularity of 100 meshes through a pre-alloy diffusion process; 2, compacting: adding graphite having an amount accounting for 0.5-2.0% of the mass of the composite powder material and zinc stearate having an amount accounting for 0.5-1.0% of the mass of the composite powder material, and compacting under a pressure of 600-800Mpa; and 3, sintering: sintering in ammonia decomposition atmosphere for 0.5-1h to make the high-performance abrasion resistant exhaust valve seat. The method has the advantages of simple flow and high technical content, and the made exhaust valve seat has the advantages of unlikely segregation and good abrasion resistance, and is suitable for the automobile industry.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

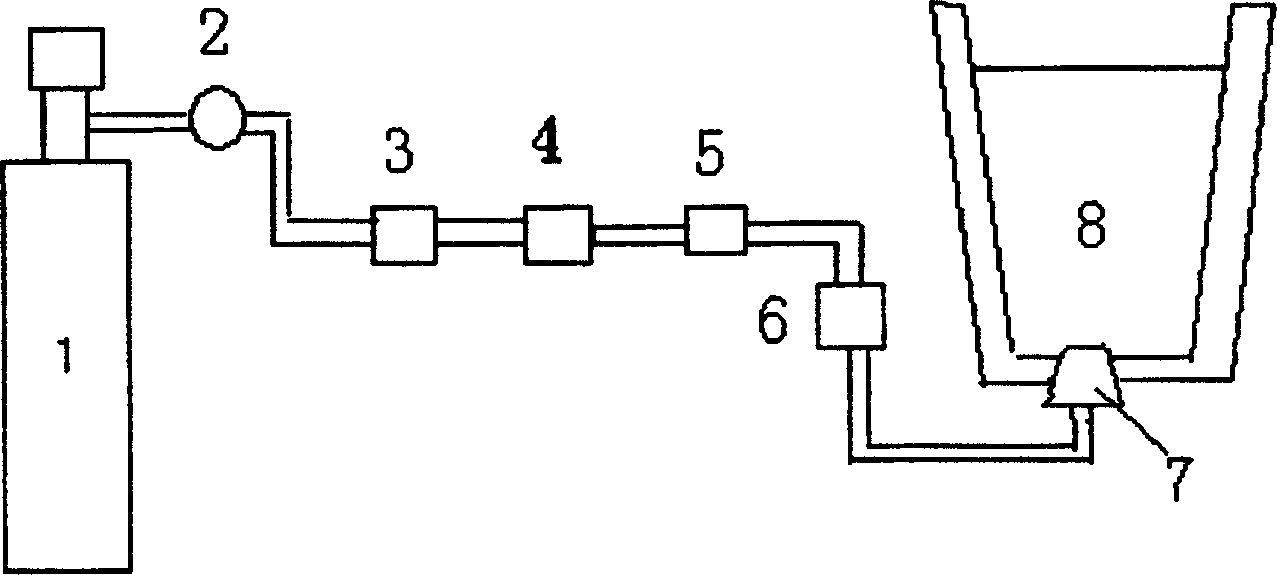

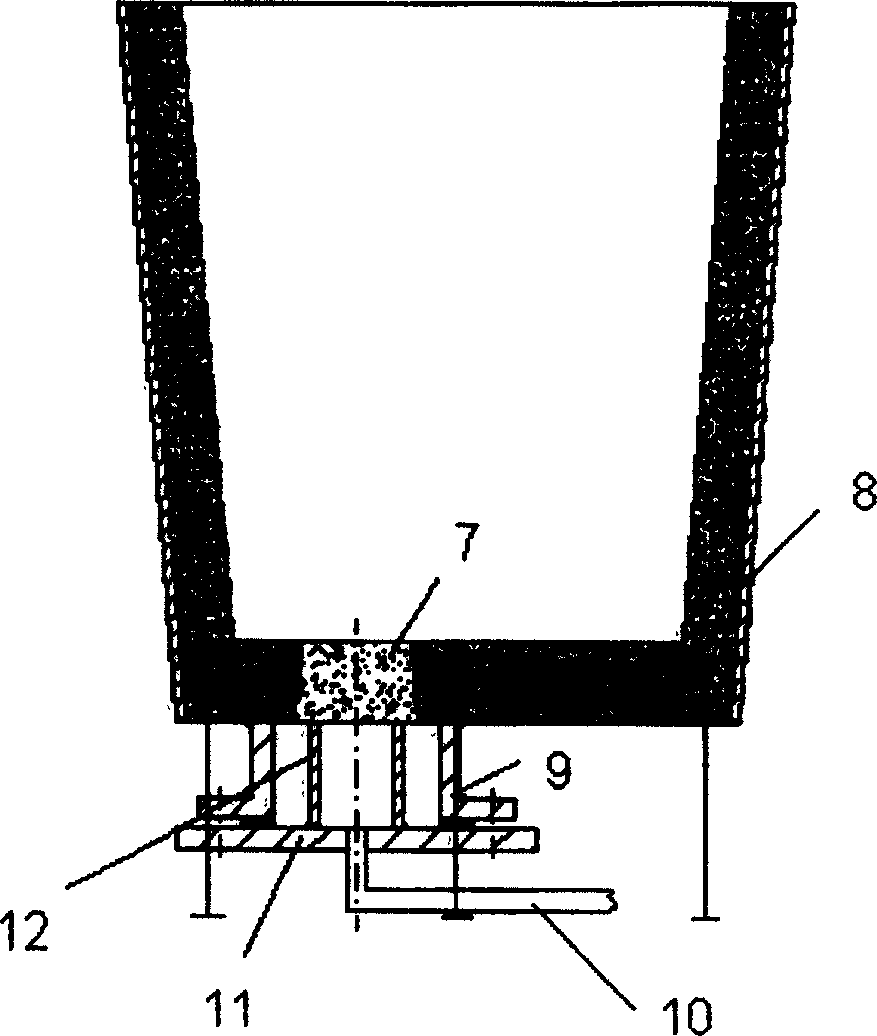

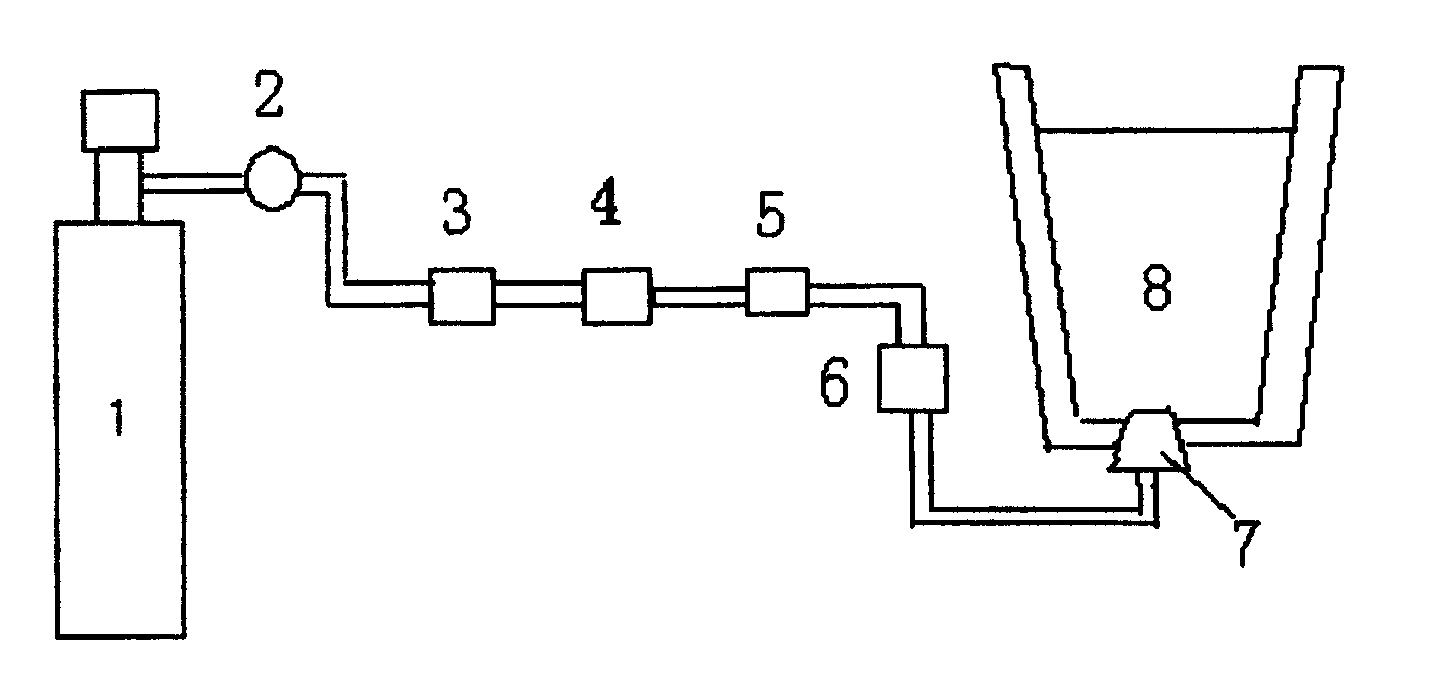

Blowing purifying method for casting ladle

InactiveCN1219081CIncrease the probability of collisionEasy to excludeMelt-holding vesselsGas cylinderProduct gas

The present invention relates to a gas-blowing cleaning method of pouring ladle and its equipment. Said method can effectively reducing harmful gas and impurity in the molten metal and can more fully implement inoculation, modification and microalloying process of the molten steel in the pouring ladle, at the same time can more effectively make the cleaning agent produce action, so that it can raise the mechanical property of casting, its cold and heat fatigue property and service life. Said equipment is formed from gas permeation plug set on the bottom portion of ladle and pressure gas cylinder. The pressure gas cylinder is connected with ais permeation plug yas circuit successively by means of pressure gauge, gas flow meter, fitering dewatering agent and quick-switch connector.

Owner:JILIN UNIV

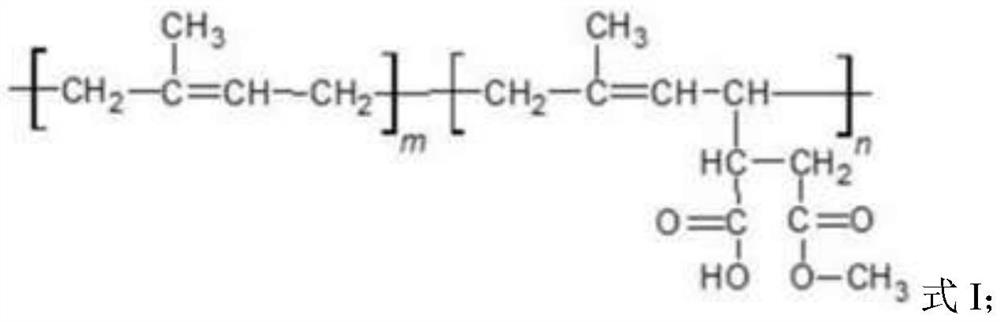

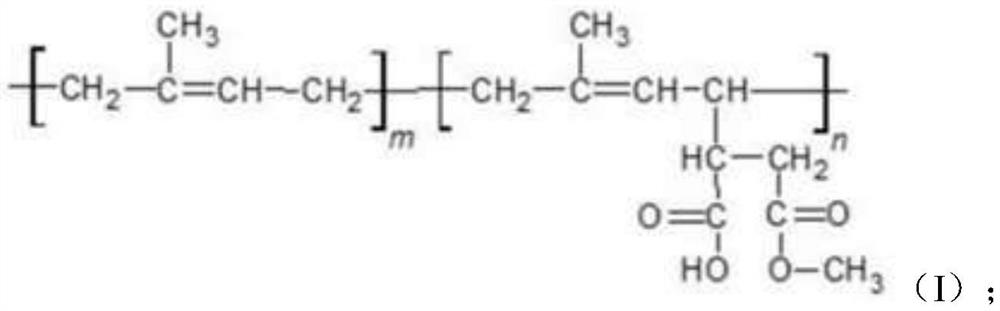

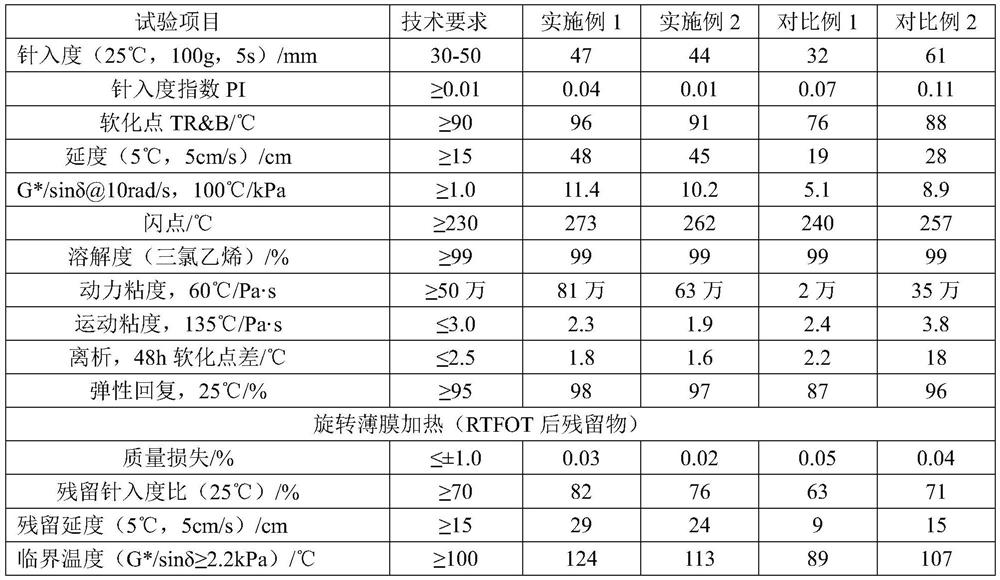

Composite modified asphalt and preparation method thereof

ActiveCN113136109AStable storageNot prone to segregationBuilding insulationsElastomerPolymer science

The invention discloses composite modified asphalt which comprises the following components in parts by weight: 85-95 parts of matrix asphalt, 4-6 parts of a thermoplastic elastomer, 5-8 parts of a modifier, 2-4 parts of a compatilizer and 1-2 parts of a stabilizer, wherein the thermoplastic elastomer is a styrene-butadiene-styrene block copolymer, and the modifier is a polyisoprene copolymer. The dynamic viscosity of the obtained composite modified asphalt at 60 DEG C can reach 7 million Pa.s, the ductility of the composite modified asphalt at the low temperature of 5 DEG C is 35 cm or above, and the composite modified asphalt has good viscosity and toughness; meanwhile, the high-temperature rotary viscosity is low, the mixing difficulty and the construction difficulty are reduced, and the composite modified asphalt is suitable for application and popularization.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Bi-metal composite high-vanadium high-speed steel roller sleeve for hot rolling

InactiveCN109898021AHigh hardness and impact toughnessNot easy to segregateRollsMetal rolling arrangementsHigh-speed steelMetal

The invention provides a bi-metal composite high-vanadium high-speed steel roller sleeve for hot rolling. The composite high-speed steel roller sleeve comprises an outer layer and an inner layer. Theouter layer is a high-vanadium high-speed steel wear-resisting layer, and comprises, by mass percentage, 1.8%-2.8% of C, 0.2%-1.0% of Si, 0.3%-0.8% of Mn, 4%-10% of V, 4%-8% of Cr, 3%-6% of Mo, 1.0%-4.0% of Nb, 2.0%-5.0% of Co, smaller than or equal to 1.0% of W, smaller than or equal to 0.03% of S, smaller than or equal to 0.04% of P and the balance Fe and inevitable impurities. According to thebi-metal composite high-vanadium high-speed steel roller sleeve for hot rolling, the alloy component of the roller sleeve is optimized, the organization structure of the roller sleeve is improved, andtherefore the performance such as the strength of the roller sleeve is improved. In addition, the problems that in the existing process of centrifugal casting of high-speed steel roller sleeves, segregation is prone to existing, and an integral roller is not prone to being subjected to thermal treatment can be effectively solved.

Owner:HUNAN 3T NEW MATERIAL

C35 low-gel-material self-compacting water-tolerant concrete and preparation method thereof

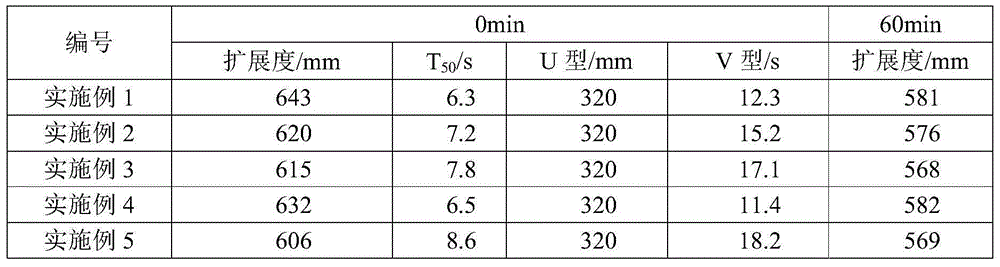

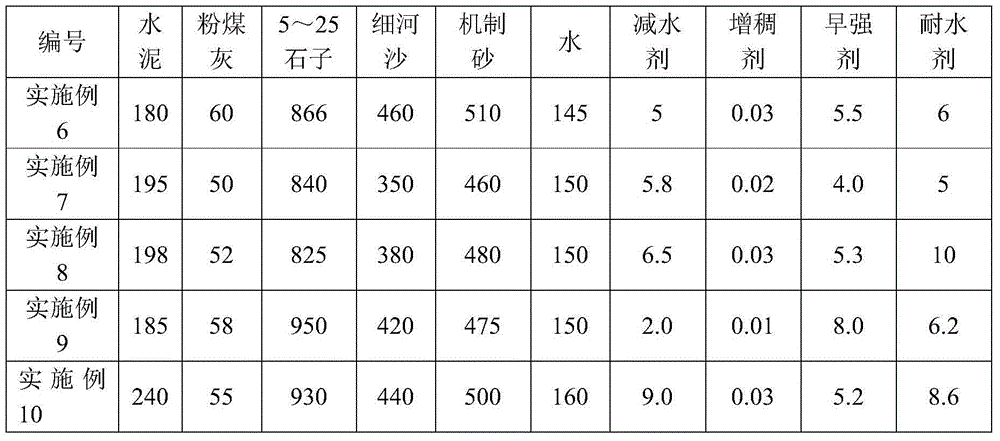

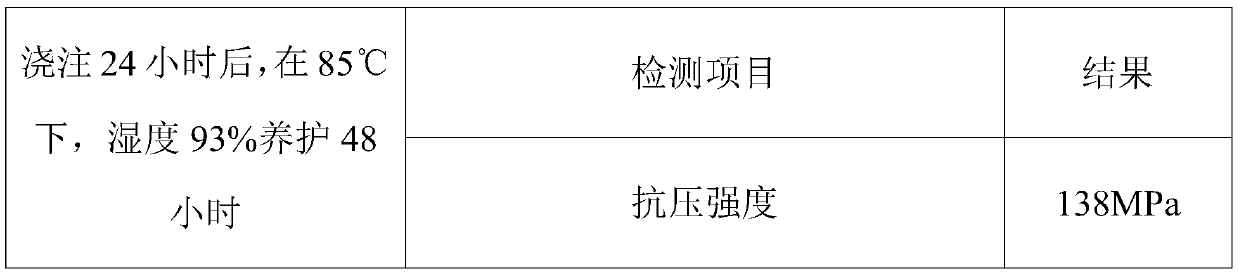

The invention relates to concrete, and specifically relates to C35 low-gel-material self-compacting water-tolerant concrete and a preparation method of the water-tolerant concrete. The scheme of the invention is that the C35 low-gel-material self-compacting water-tolerant concrete comprises the following raw materials, by mass: 180-300 kg / m3 of cement, 30-80 kg / m3 of coal ash, 220-640 kg / m3 of fine river sand, 300-600 kg / m3 of machine-made sand, 600-1100 kg / m3 of cobblestone with a diameter of 5-25 mm, 2-10 kg / m3 of a polycarboxylic acid water reducer, 0.01-0.03 kg / m3 of a thickening agent, 4-8 kg / m3 of an early strength agent, and 2-10 kg / m3 of a water-tolerant agent. The C35 low-gel-material self-compacting water-tolerant concrete provided in the invention is less in use amount of materials, has better fluidity, early strength, and water-tolerant property, and plays an important part in accelerating popularization of application of C35 self-compacting concrete.

Owner:CHINA MINSHENG ZHUYOU

Method for extracting vanadium efficiently from vanadium slag by controlling particle diameter of additive

InactiveCN103421959AReduce cakingReduce stickingProcess efficiency improvementSlagSingle factor analysis

The invention discloses a method for extracting vanadium efficiently from vanadium slag by controlling the particle diameter of additive. A sodium salt roasting vanadium extraction technology is adopted in the method, and when the additive is added in the vanadium slag, the particle diameter of the additive is determined through the following steps of (1) calculating the ratio between the particle number of the vanadium slag and the particle number of the additive based on the stacking density of the vanadium, the stacking density of the additive and the dosage of the additive to obtain an ideal particle diameter of the additive, and (2) taking the particle diameter of the vanadium slag, an original particle diameter of the additive, the ideal particle diameter of the additive and a final particle diameter of the additive as boundary points to obtain the ranges of the three sections of the particle diameters of the additive, taking the particle diameter of the additive as a variable, carrying out comparison on sodium salt roasting leaching based on a single factor analysis method, and taking the particle diameter range with the optimal result as the final particle diameter of the additive. The method for extracting the vanadium efficiently from the vanadium slag by controlling the particle diameter of the additive can reduce the caking phenomenon of the additive, materials are mixed more evenly, and the utilization efficiency of the additive and the roasting conversion rate of the vanadium slag are improved.

Owner:CHONGQING UNIV

High-performance concrete and preparation method thereof

InactiveCN111548114AImprove stabilityIncreased durabilitySolid waste managementMelt spinning methodsPolyvinyl alcoholSlag

The invention discloses high-performance concrete and a preparation method thereof. The high-performance concrete comprises the following raw materials in parts by weight: 100 to 110 parts of machine-made sand, 130 to 140 parts of macadam, 30 to 45 parts of sea sand, 30 to 45 parts of seawater, 25 to 35 parts of Portland cement, 30 to 32 parts of silica fume, 25 to 30 parts of polypropylene fibers, 20 to 28 parts of steel slag powder, 20 to 25 parts of a shrinkage compensation agent, 20 to 22 parts of polystyrene foam particles, 16 to 20 parts of silica sand particles, 15 to 20 parts of steelfibers, 15 to 18 parts of desulfurized gypsum, 15 to 18 parts of red mud particles, 15 to 18 parts of mineral slag powder, 12 to 16 parts of fly ash, 10 to 15 parts of nano dolomite particles, 10 to 15 parts of phosphorus slag powder, 8 to 10 parts of aluminate cement, 8 to 10 parts of reef powder, 8 to 10 parts of ceramic particles, 8 to 10 parts of sodium alginate, 5 to 8 parts of calcium formate, 5 to 7 parts of calcium nitrite, 4 to 5 parts of pyridine-3-formic acid, 2 to 5 parts of a polycarboxylate water-reducer, 2 to 3 parts of white carbon black, 1 to 1.5 parts of sodium silicate, 0.8to 1.2 parts of caustic soda, 1 to 2 parts of crystalline wax, 1 to 1.5 parts of polyvinyl alcohol, 0.5 to 1 part of diethylene glycol monobutyl ether, 0.3 to 0.7 part of a defoaming agent and 0.2 to0.5 part of azodicarbonamide. The high-performance concrete disclosed by the invention is high in stability, good in durability, excellent in segregation resistance and filling property and stable inconcrete quality. The manufacturing method is simple in process, low in energy consumption, low in investment cost and high in production efficiency.

Owner:北京启顺京腾科技有限责任公司

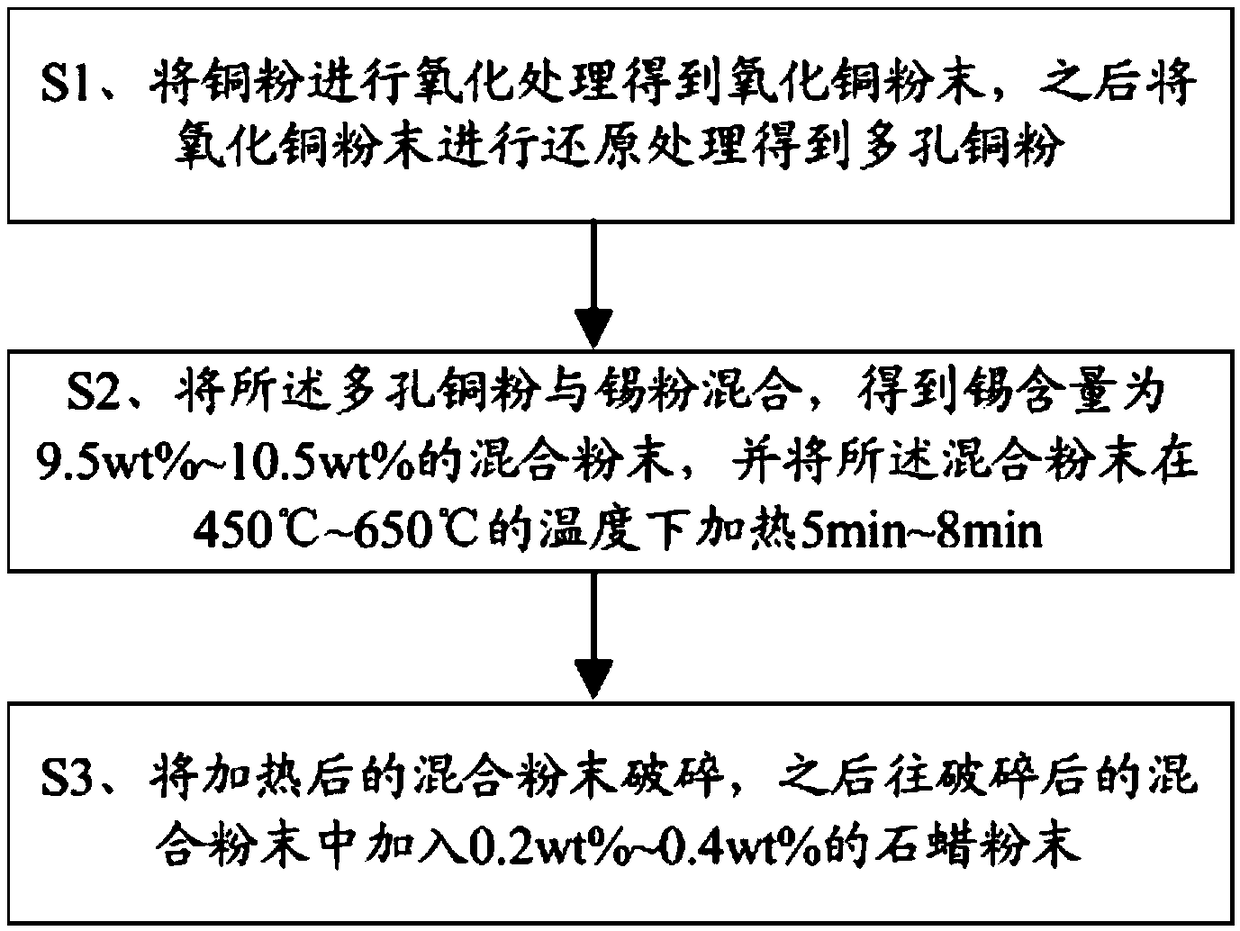

Preparation method of copper-tin local alloy powder for oil-containing bearing

InactiveCN109382509AEvenly distributedIncrease frictionTransportation and packagingMetal-working apparatusParaffin waxPorosity

The invention relates to a preparation method of copper-tin local alloy powder for an oil-containing bearing. The method includes the following steps that S1, oxidation is carried out on copper powderto obtain copper oxide powder, and then reduction treatment is carried out on the copper oxide powder to obtain porous copper powder; S2, the porous copper powder is mixed with tin powder to obtain the mixed powder with the tin content of 9.5-10.5%, and the mixed powder is heated at the temperature of 450-650 DEG C for 5-8 minutes; S3, the heated mixed powder is crushed, and then 0.2-0.4% of paraffin powder is added into the crushed mixed powder. The copper-tin local alloy powder uniform in tin distribution can be obtained, and meanwhile, the prepared oil-containing bearing has high porosity.

Owner:罗源县凤山镇企业服务中心

Manufacturing process of bimetallic sliding bearing

InactiveCN103899650ANot prone to segregationQuality assuranceBearing componentsMasterbatchSlider bearing

The invention discloses a manufacturing mould and manufacturing method of a bimetallic composite sliding bearing. The mould comprises an upper mould (1), a lower mould (4), a cavity (2), and a bearing (3). The manufacturing method is characterized by comprising the following steps: preparing an inner sleeve material according to the mass percentage of the following components, pre-mixing the prepared components in a high-speed mixer; further granulating and granulating in a granulation extruder to obtain the inner sleeve material masterbatch; and finally conducting curing heat treatment on a metal injection molding bearing to obtain a finished product. The mold provided by the invention is reliable in operation, has the advanategs of less energy consumption of the equipment, high speed, mass production, good product consistency, few personnel, raises the utilization rate of materials, and can effectively improve the production efficiency and reduce the manufacturing cost.

Owner:DALIAN HONGRUN COMPOSITE BEARING

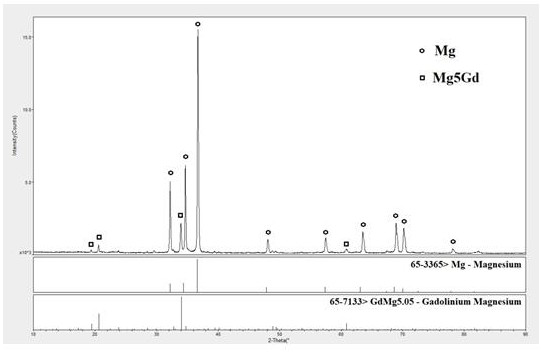

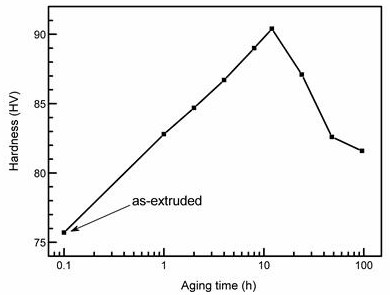

Mg-Gd alloy with low Gd content and preparation and heat treatment method thereof

ActiveCN113403515ALow densityReduce contentNuclear energy generationFurnace typesChemical compositionCrucible

The invention discloses a low-Gd-content Mg-Gd alloy and a preparation and heat treatment method thereof. The Mg-Gd alloy with the low Gd content is prepared from the following chemical components in percentage by mass: 2-5% of Gd, 2-5% of Li, 1-3% of Y, 1-2% of Nd, 0.2-0.6% of Zr and the balance of magnesium and inevitable impurities. The preparation method comprises the following steps of S1, preparing materials according to the proportion of the Mg-Gd alloy with the low Gd content; and S2, under the protection of SF6+CO2 gas, melting the alloy material in a resistance furnace and then refining for 2-4 minutes, then standing for 25-30 minutes in the resistance furnace and then casting into a metal mold to obtain a casting. The heat treatment method comprises the steps that the casting is put into a crucible, the crucible is put into a muffle furnace, the temperature is increased to 480-500 DEG C, then heat preservation treatment is conducted, and the heat preservation time is 2-4 hours; and after heat preservation is completed, the crucible is taken out and immediately quenched in water, and heat treatment is completed. The Li in the solid solution state is used for promoting the formation of an MgGd phase under the condition of low alloy content, and the content of Gd in the Mg-Gd alloy is reduced.

Owner:CHONGQING UNIV OF ARTS & SCI

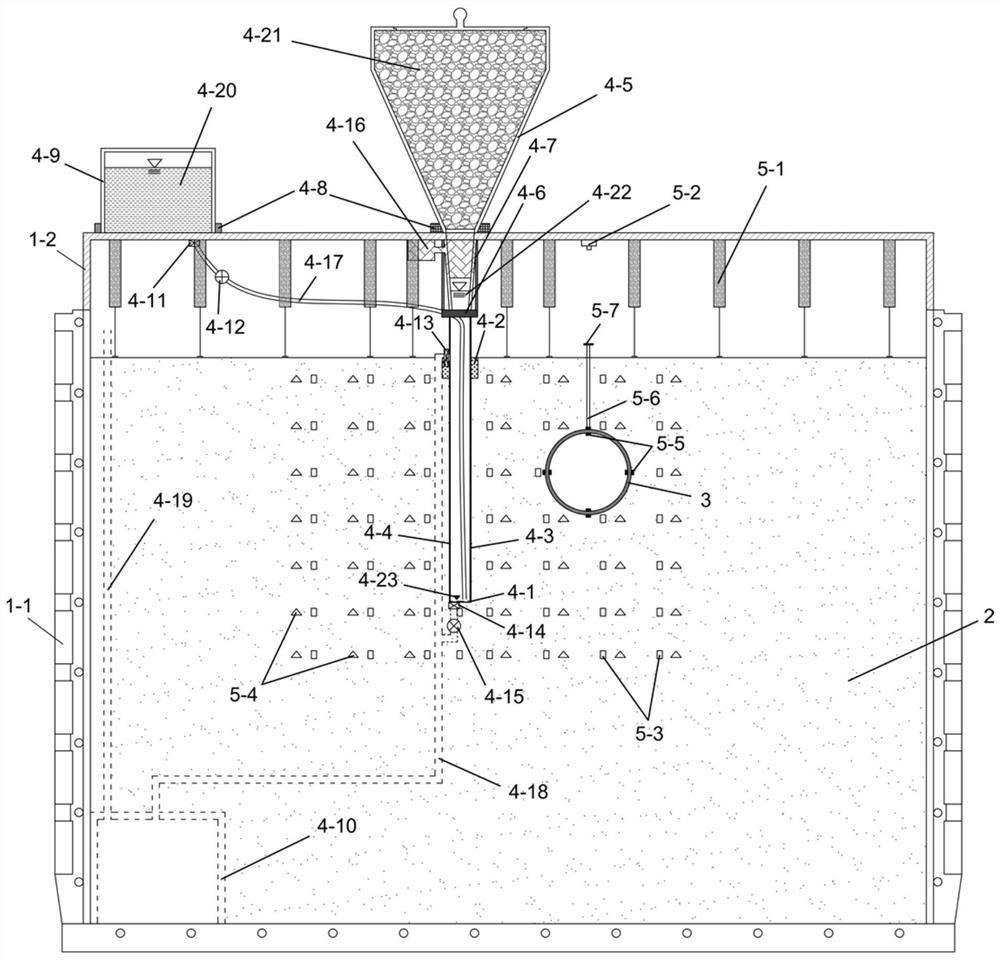

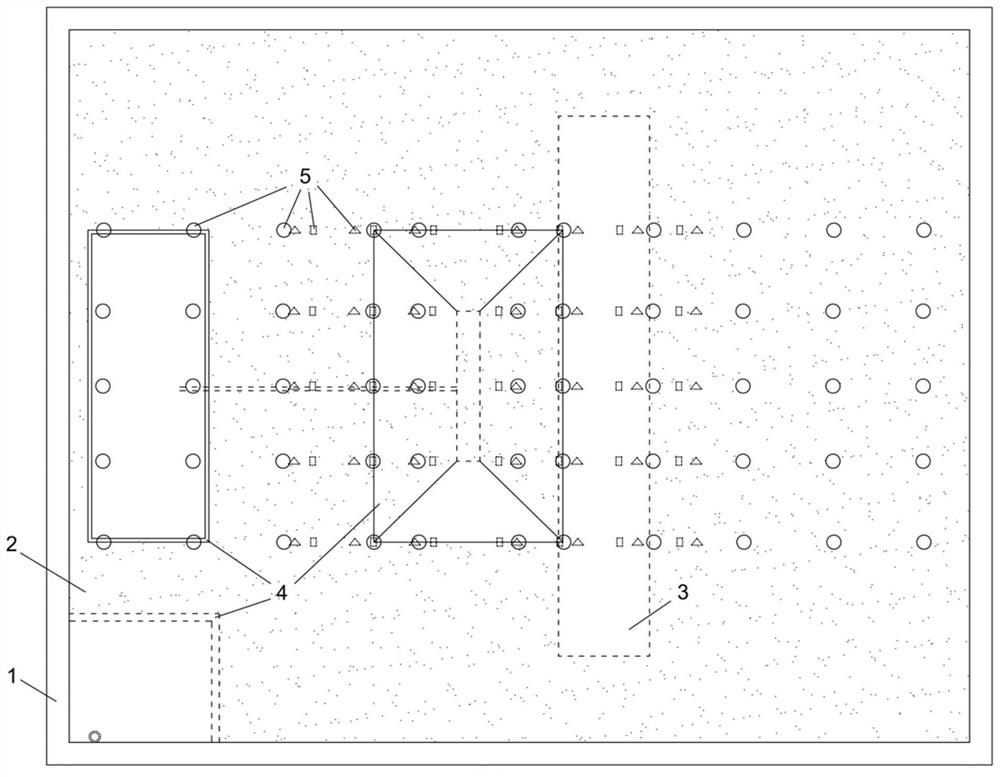

Centrifugal model test device and method for researching underground diaphragm wall construction environment effect

ActiveCN112816660AAvoid strong corrosive problemsMaterials are readily availableEarth material testingSlurry wallChloride

Owner:ZHEJIANG UNIV

1000MPa-grade nitric acid corrosion resistant titanium alloy

ActiveCN113444918AExcellent nitric acid corrosion resistanceEasy to manufactureTitanium alloyUltimate tensile strength

The invention discloses a 1000MPa-grade nitric acid corrosion resistant titanium alloy. The alloy comprises the following components of, by mass, 4%-6% of Ta, 4%-6% of V, 7%-9% of Cr, not larger than 1.5% of Al and the balance Ti and inevitable impurities, wherein the tensile strength of the titanium alloy subjected to solution aging treatment is not less than 1000 MPa, the yield strength is not less than 900 MPa, and the corrosion rate in a boiling nitric acid solution with the concentration of 6 mol / L is not higher than 0.1 mm / a. The novel titanium alloy designed by optimizing the beta stable element and the proportion thereof is simple in composition, not prone to segregation, uniform and stable in structure, excellent in cold and hot workability and easy to prepare; compared with an existing titanium alloy, the nitric acid corrosion resistance is improved, meanwhile, the tensile strength and the yield strength are greatly improved; and the alloy is applied to nuclear power and chemical engineering equipment and has a good application prospect.

Owner:西安稀有金属材料研究院有限公司

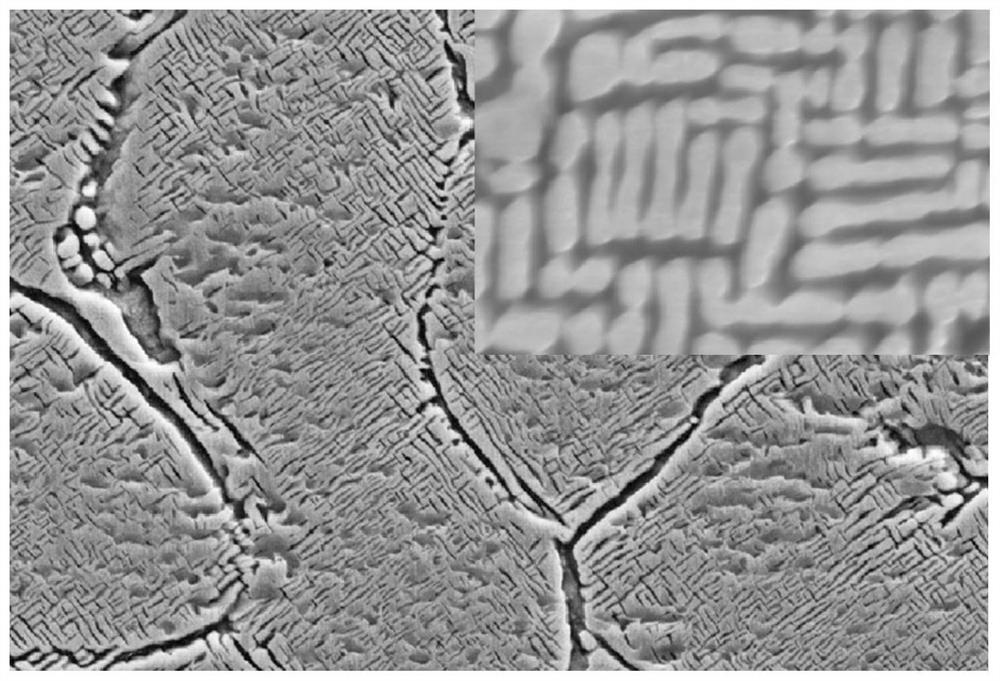

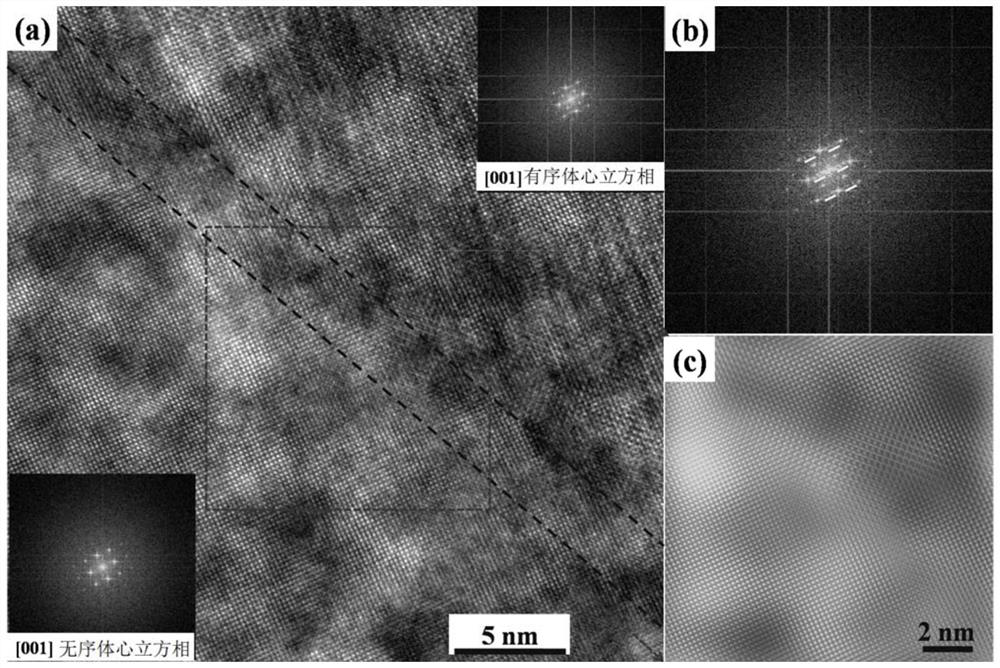

A high-performance low-density dual-phase high-entropy alloy and its preparation method

ActiveCN112831711BHigh strengthGuaranteed plasticityIncreasing energy efficiencyHigh entropy alloysOxidation resistant

Owner:DALIAN UNIV OF TECH

Method for preparing polymer modified asphalt

The invention discloses a method for preparing polymer modified asphalt. The method for preparing polymer-modified asphalt provided by the present invention is to mix molten matrix asphalt and polymer modifier to form a uniformly molten polymer-modified asphalt system, and then add it to a twin-screw extruder, Perform extrusion reaction in the extruder to obtain polymer modified asphalt; among them, the temperature range of the first zone of the twin-screw extruder is 90-190°C, the temperature range of the second zone is 100-250°C, and the temperature range of the third zone is 120-220°C ℃, the temperature range of four zones is 120-220℃. The production process of the invention is simple and convenient to operate, the production time is short, a production cycle is 0.5-1 hour, and the intermediate control process is reduced to realize continuous industrial production.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for preparing high-magnetic-property powder silicon steel sheet

The invention discloses a method for preparing a high-magnetic-property powder silicon steel sheet, and belongs to the field of powder metallurgy. According to the method, electrolytic iron powder, pure silicon powder and ferrophosphorus alloy powder are evenly mixed according to Fe-(3-4) wt.% Si -(0.05-0.3) wt.% P, a thick plate blank is formed through isostatic cool pressing, multi-pass hot rolling is carried out after metallurgical bonding of the thick plate blank is achieved through sintering, cold rolling is carried out for 2-4 times, and finally heat treatment is carried out to obtain the silicon steel sheet with excellent performance. Compared with low-silicon steel, a small amount of P element is added into the silicon steel, so that the resistivity can be effectively improved, andthe iron loss is greatly reduced; compared with high-silicon steel, the Si content is greatly reduced, the iron loss can be slightly increased by slightly increasing the P content, meanwhile, the saturation magnetization intensity is improved, and the formability and the subsequent hot working performance of a powder system are obviously improved; in addition, the P element is added, activated sintering can be promoted, the sintering temperature is remarkably reduced, and the plate blank brittleness is reduced; and the method has the advantages of simple steps, high preparation efficiency, high product precision, no pollution and inclusion, excellent magnetic performance and the like.

Owner:UNIV OF SCI & TECH BEIJING

Formula and preparation process of alcohol group nanometer composite and surface modified dry powder mold paint

The present invention relates to an auxiliary material for casting and moulding, in particular to a formula of alcohol group dry powder mold paint for sand mold casting. The dry powder mold paint comprises surface modifier, suspending agent, binder and refractory powder, wherein the surface modifier is 0.6-4.2wt% of refractory powder, the suspending agent is 4.0-8.0wt% of refractory powder and the binder is 4.0-6.2wt% of refractory powder. The alcohol group nanometer composite and surface modified dry powder mold paint of the invention adopts nanometer layered clay and nano-SiO2 to form composite suspending agent so that the controllability of operation technological parameters of the alcohol group dry powder mold paint is good and the process performance and operating performance of the obtained pulp-type paint can both meet the demand of the casting factory.

Owner:深圳市景鼎现代科技有限公司

A titanium alloy with medium strength and high impact toughness for marine engineering

The invention provides a moderate-intensity and high-impact-toughness titanium alloy in ocean engineering. The moderate-intensity and high-impact-toughness titanium alloy is prepared from the following components in percentage by mass: 1.5 percent to 3.5 percent of Al, 0.5 percent to 3 percent of Zr, 0.5 percent to 2 percent of Mo, 0.5 percent to 3 percent of Nb and the balance of Ti and unavoidable impurities. After the titanium alloy provided by the invention is simply annealed or subjected to dual annealing treatment, the yield strength is 450MPa to 550MPa and the impact toughness is not lower than 780kJ / m<2>. According to the titanium alloy provided by the invention, the yield strength can reach the grade of 450MPa to 550MPa under the condition that an element Ni is not added, and the titanium alloy has plasticity and toughness, which are equivalent to those of pure titanium; meanwhile, the titanium alloy has good seawater corrosion resistance and cold and hot machinability, and is applicable to manufacturing of related equipment of ocean engineering and shipping industry.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com